Carbon nanotube modified lithium-rich manganese-based positive electrode material and preparation method thereof

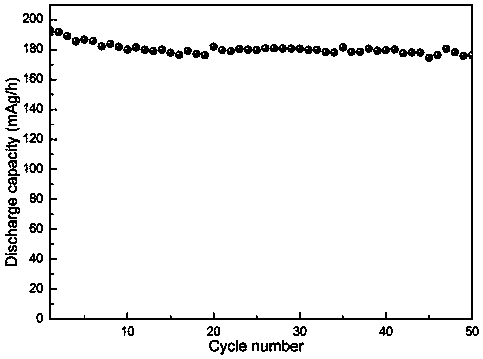

A carbon nanotube modification, lithium-rich manganese-based technology, applied in battery electrodes, electrical components, electrochemical generators, etc. Nanotube agglomeration is difficult to disperse uniformly, etc., to achieve excellent rate performance, stable cycle performance, and high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Press Li 1.2 [Mn 0.54 Ni 0.13 co 0.13 ]O 2 The ratio of the amount of each metal element in the material takes nickel sulfate, manganese sulfate and cobalt sulfate and dissolves them in deionized water to form a solution A with a metal ion concentration of 0.5mol / L;

[0029] (2) Aqueous ammonia solution B is configured, and the concentration of aqueous ammonia is 0.2mol / L;

[0030] (3) Sodium carbonate solution C is configured, and the concentration of sodium carbonate is 0.1mol / L;

[0031] (4) Use a constant flow pump to add solutions A, B, and C dropwise to the beaker and stir continuously at 50°C, pass in nitrogen, and adjust the pH value with ammonia water and maintain it at 7.5. After the reaction is complete, the precipitation continues at 50°C After aging for 10 hours, the resulting precipitate was filtered and washed several times with deionized water, and dried in an oven at 105°C to obtain a carbonate precursor;

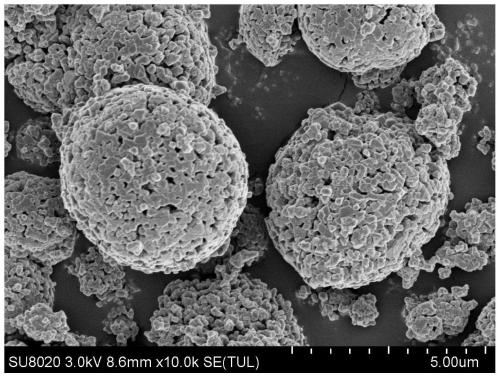

[0032] (5) Airflow pulverize the pre...

Embodiment 2

[0038] (1) Press Li 1.12 [Mn 0.48 Ni 0.16 co 0.16 ]O 2 The ratio of the amount of each metal element in the material takes nickel sulfate, manganese sulfate and cobalt sulfate and dissolves them in deionized water to form a solution A with a metal ion concentration of 0.5mol / L;

[0039] (2) Aqueous ammonia solution B is configured, and the concentration of aqueous ammonia is 0.5mol / L;

[0040] (3) Sodium carbonate solution C is configured, and the concentration of sodium carbonate is 0.2mol / L;

[0041] (4) Use a constant flow pump to add solutions A, B, and C dropwise to the beaker and stir continuously at 50°C, pass in nitrogen, and adjust the pH value with ammonia water and maintain it at 7.5. After the reaction is complete, the precipitation continues at 50°C After aging for 10 hours, the resulting precipitate was filtered and washed several times with deionized water, and dried in an oven at 105°C to obtain a carbonate precursor;

[0042] (5) Airflow pulverize the pr...

Embodiment 3

[0047] (1) Press Li 1.2 [Mn 0.52 Ni 0.13 co 0.13 Al 0.02 ]O 2 The ratio of the amount of each metal element in the substance is taken by weighing nickel nitrate, manganese nitrate, cobalt nitrate and aluminum nitrate and dissolved in deionized water to form a solution A with a metal ion concentration of 1.0mol / L;

[0048] (2) Aqueous ammonia solution B is configured, and the concentration of aqueous ammonia is 0.5mol / L;

[0049] (3) Sodium carbonate solution C is configured, and the concentration of sodium carbonate is 0.2mol / L;

[0050] (4) Use a constant flow pump to add solutions A, B, and C dropwise to the beaker and stir continuously at 50°C, pass in nitrogen, and adjust the pH value with ammonia water and maintain it at 7.5. After the reaction is complete, the precipitation continues at 50°C After aging for 12 hours, the resulting precipitate was filtered and washed several times with deionized water, and dried in an oven at 105°C to obtain a carbonate precursor; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com