Self-bacterial lactic acid-based waterborne polyurethane, its preparation method and its emulsion

A water-based polyurethane and lactic acid-based technology, applied in the field of functional polymer materials, can solve the problems that water-based polyurethane has no antibacterial effect, destroy the antibacterial effect of cell surface structure, hinder the action of cell lysozyme, etc., and achieve significant antibacterial performance, and Good stability and long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

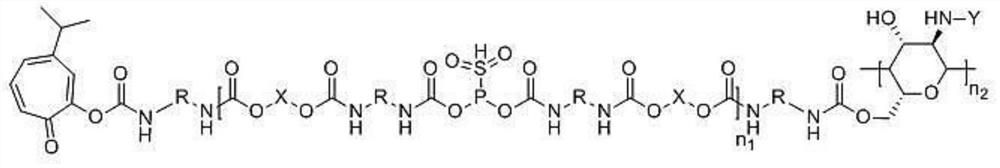

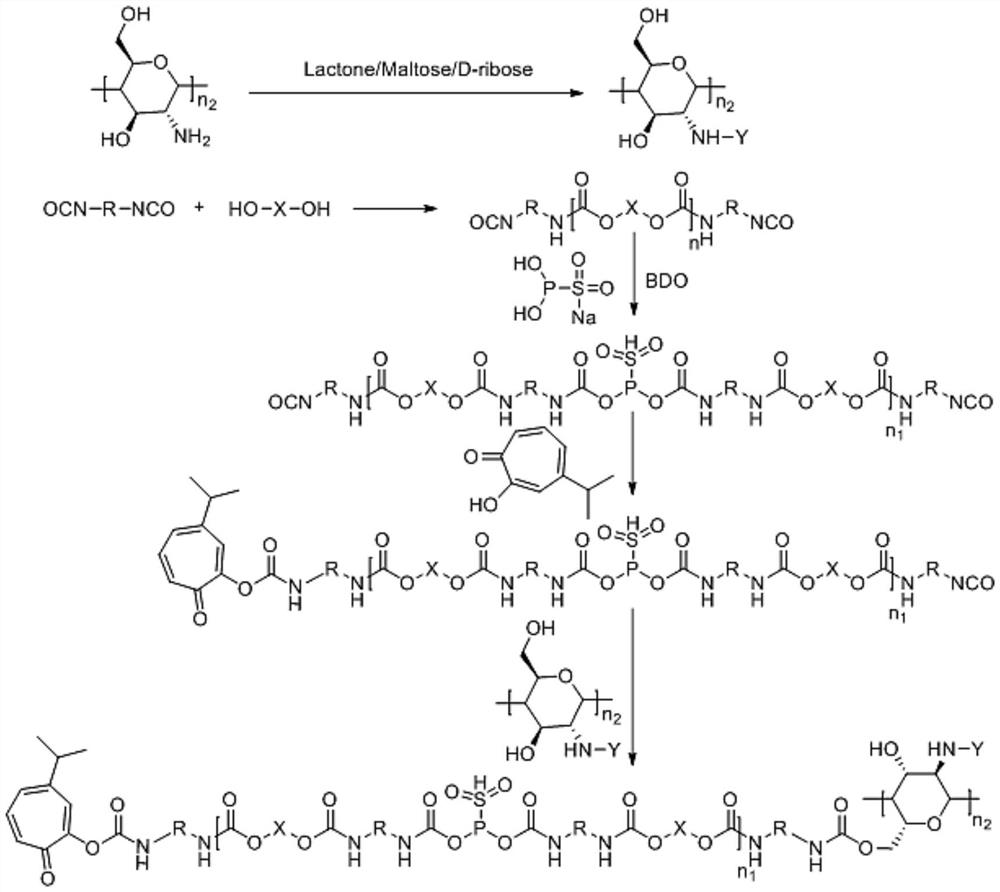

[0048] Preparation of Chitosan-lactone-BT-PU Self-bacterial Lactic Acid-Based Waterborne Polyurethane Emulsion

[0049] Step 1. Preparation of Chitosan-lactone

[0050] Weigh 17.52g of chitosan and dissolve it in DCM solvent containing 0.5% acetic acid. After the solution is clarified, add 51.34g of lactose, stir at room temperature for 6h, and then add 6.59g of NaBH. 3 CN continued to react for 48h. After the reaction was over, the solid was filtered out, washed with MeOH and dried to finally obtain the water-soluble chitosan Chitosan-lactone. The specific synthetic route is as follows:

[0051]

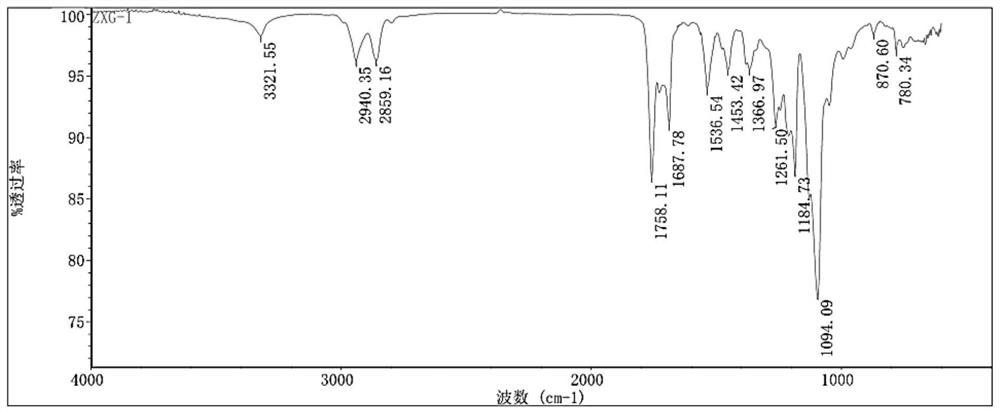

[0052] Step 2. Preparation of BT-PU

[0053] Weigh 20.88g of lactic acid-based polyol (hydroxyl value 53.72mgKOH / g) in a reaction flask, heat to 100°C for vacuum dehydration for 45min, then cool to 70°C, add 0.014g of stannous octoate, and slowly dropwise add 11.99 g diphenylmethane diisocyanate, after the dropwise addition, react at this temperature for 2 hours to reach the t...

Embodiment 2

[0056] Example 2 Preparation of Chitosan-maltose-BT-PU Self-Bacterial Lactic Acid-Based Waterborne Polyurethane Emulsion

[0057] Step 1. Preparation of Chitosan-maltose

[0058] 17.52g of chitosan was weighed and dissolved in THF solvent containing 0.5% acetic acid. After the dissolution was clarified, 51.34g of maltose was added. The reaction was stirred at room temperature for 6h, and then 3.97g of NaBH was added. 4 The reaction was continued for 48 hours, and after the reaction was over, the solid was filtered out, washed with MeOH and dried to finally obtain the water-soluble chitosan Chitosan-maltose. The specific synthetic route is as follows:

[0059]

[0060] Step 2. Preparation of BT-PU

[0061] Weigh 20.46g of lactic acid-based polyol (hydroxyl value is 54.83mgKOH / g) in a reaction flask, heat to 100°C for vacuum dehydration for 45min, then cool to 70°C, add 0.014g of dibutyltin dilaurate, and slowly dropwise add ,8.06g hexamethylene diisocyanate, after the dro...

Embodiment 3

[0065] Example 3 Preparation of Chitosan-D-ribose-BT-PU Self-Bacterial Lactic Acid-Based Waterborne Polyurethane Emulsion

[0066] Step 1. Preparation of Chitosan-D-ribose

[0067] Weigh 17.52g of chitosan and dissolve it in MeCN solvent containing 0.5% acetic acid. After the solution is clarified, add 22.51g of D-ribose, stir at room temperature for 6h, and then add 22.22g of NaB(OAc) 3 H continued the reaction for 48h. After the reaction, the solid was filtered out, washed with MeOH and dried to finally obtain the water-soluble chitosan Chitosan-D-ribose. The specific synthetic route is as follows:

[0068]

[0069] Step 2. Preparation of BT-PU

[0070] Weigh 19.90g of lactic acid-based polyol (hydroxyl value is 56.38mgKOH / g) in a reaction flask, heat to 100°C for vacuum dehydration for 45min, then cool to 70°C, add 0.014g of bis(dodecyl sulfide) dibutyltin , and slowly added dropwise, 10.65g of isophorone diisocyanate, after the dropwise addition, reacted at this temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com