Nano-silver antibacterial fabric and preparation method thereof

A nano-silver antibacterial and fabric technology, applied in physical treatment, plant fibers, textiles and papermaking, etc., can solve the problems of graphite pneumoconiosis and silicosis, biosafety needs to be investigated, carbon materials and silicon materials are difficult to degrade, etc. Efficiency improvement, avoidance of biosafety issues, effect of improving antibacterial capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

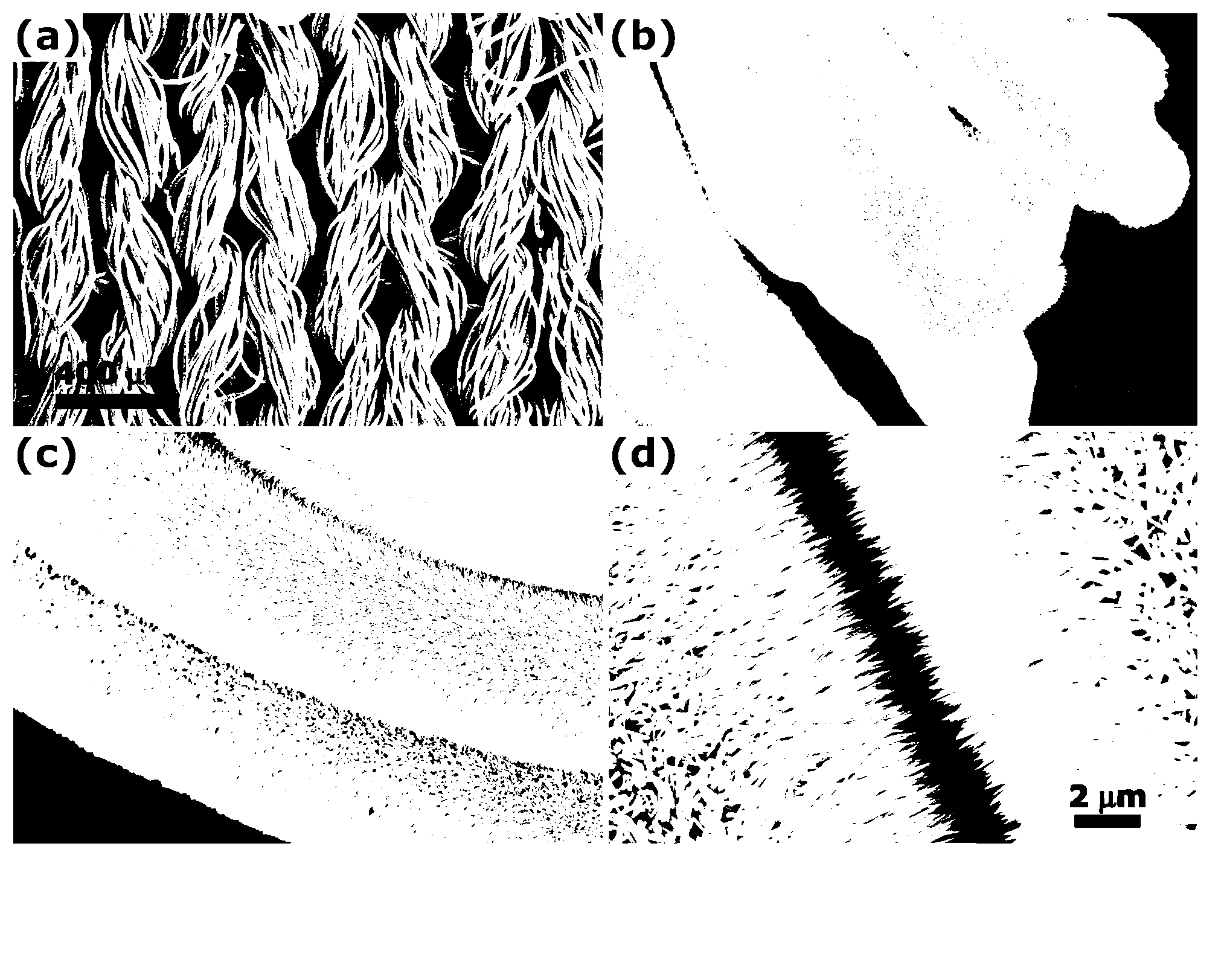

[0039] In the first step, after the polyester fiber fabric is sequentially cleaned in acetone and ethanol, it is treated with oxygen plasma to obtain a hydrophilic surface;

[0040] The second step is to prepare a solution containing zinc oxide nanoparticles, and transfer the solution containing zinc oxide nanoparticles to the surface of the polyester fiber fabric by drip coating. In order to ensure uniform coating, each side of the fabric is drip coated 3-5 times;

[0041] The 3rd step, preparation zinc nitrate concentration is that 25mM, hexamethylenetetramine concentration are 12.5mM, polyethyleneimine concentration is the aqueous solution of 5mM;

[0042] In the fourth step, ammonia water is added to the aqueous solution obtained in the third step to obtain a mixed aqueous solution with an ammonia concentration of 0.35 mM;

[0043] In the fifth step, the polyester fiber fabric obtained in the second step is immersed in the solution obtained in the fourth step, and reacted ...

Embodiment 2

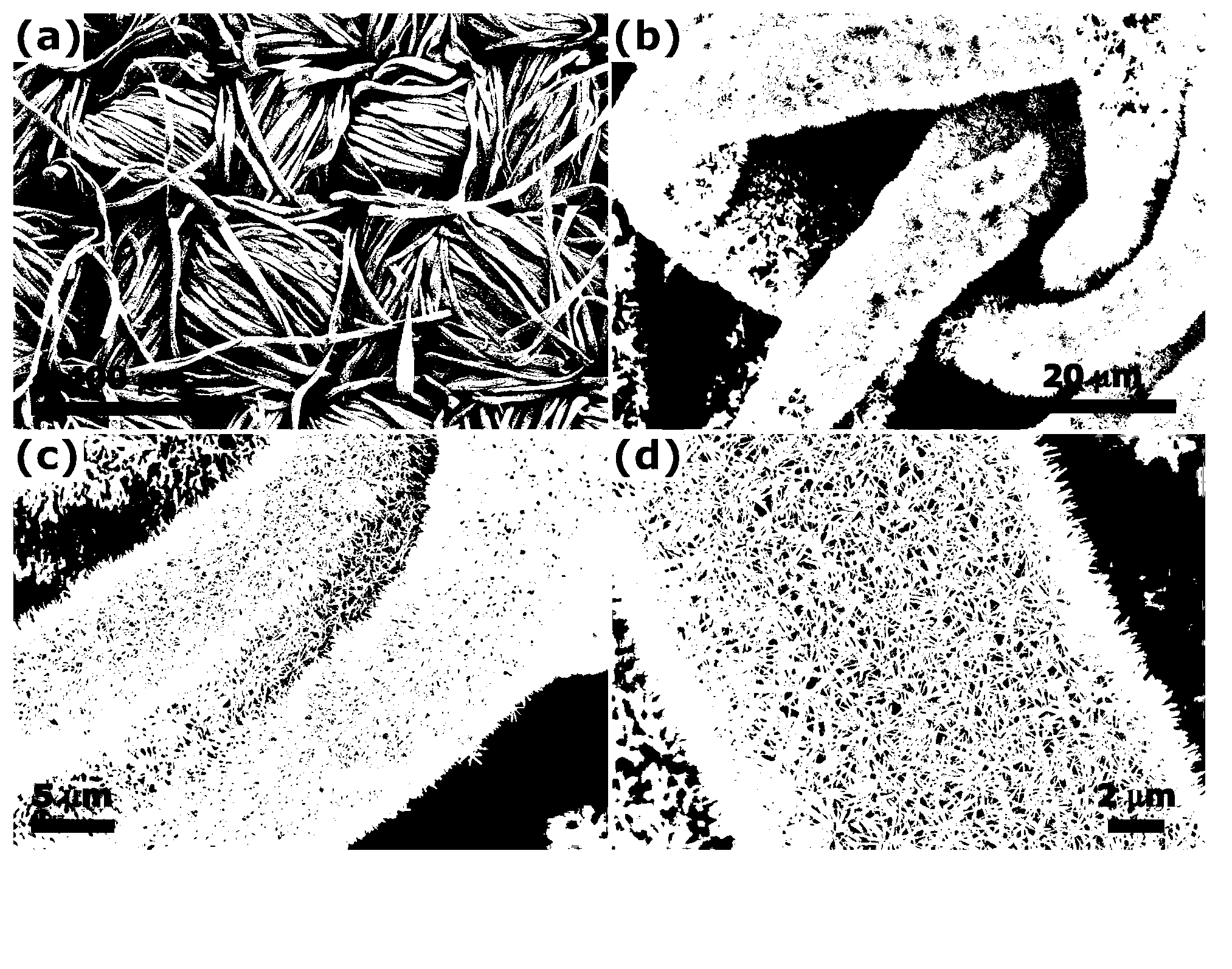

[0056] In the first step, after the cotton fabric is washed sequentially in acetone and ethanol, it is cleaned with ultraviolet ozone to obtain a hydrophilic surface;

[0057] The second step is to prepare a solution containing zinc oxide nanoparticles, and transfer the prepared solution containing zinc oxide nanoparticles to the surface of the cotton fabric by pulling. Zinc oxide nanoparticles attached to the surface;

[0058] The 3rd step, preparation zinc sulfate concentration is that 10mM, hexamethylenetetramine concentration are 10mM, polyethyleneimine concentration is the aqueous solution of 1mM;

[0059] The 4th step, add ammoniacal liquor in the aqueous solution of the 3rd step and obtain the mixed aqueous solution that ammoniacal liquor concentration is 0.35mM;

[0060] In the fifth step, the cotton fabric obtained in the second step is immersed in the solution obtained in the fourth step, and reacted for 5 hours at 65° C. to obtain zinc oxide nanowires grown on the ...

Embodiment 3

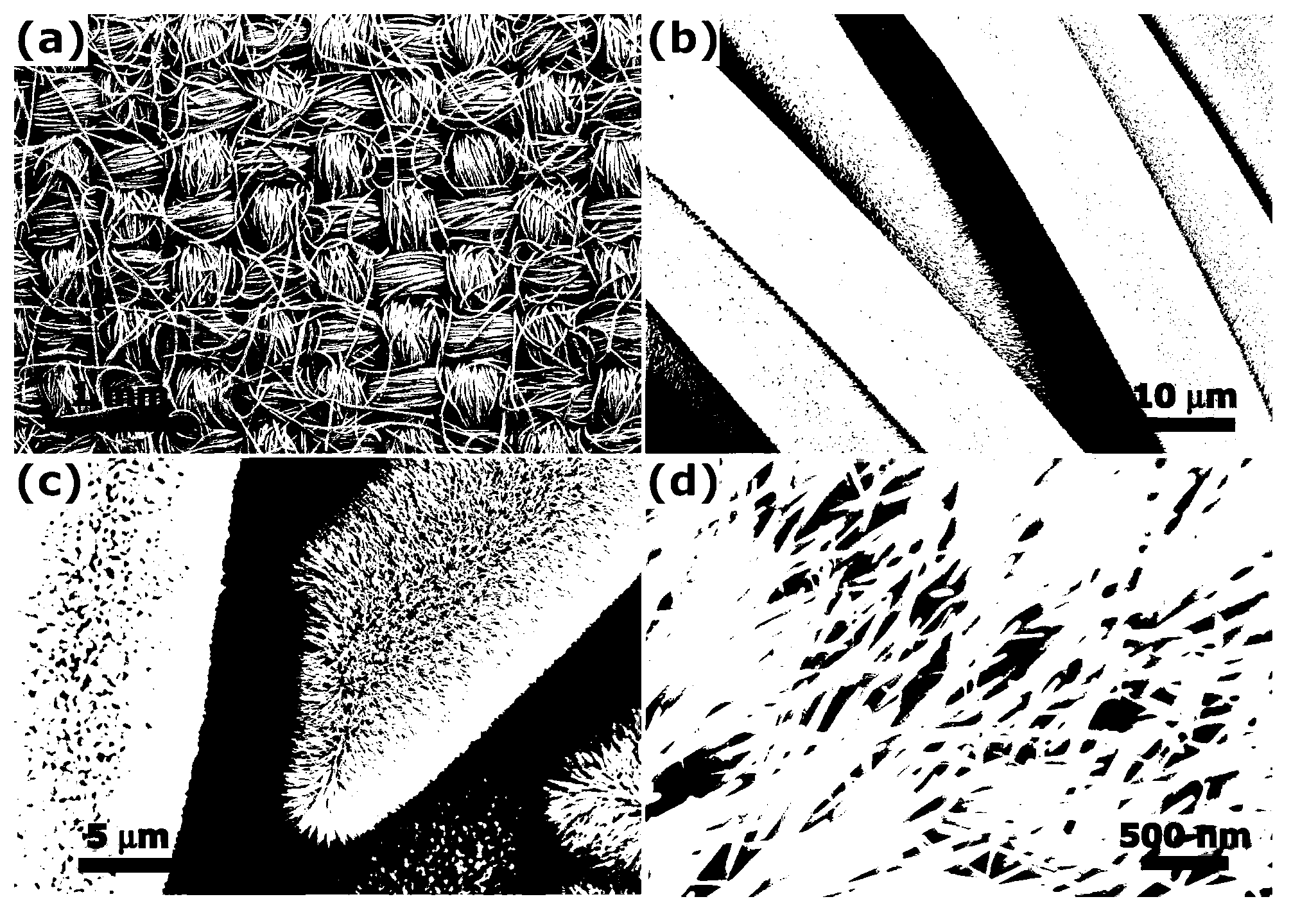

[0066] In the first step, after the carbon fiber fabric is sequentially cleaned in acetone and ethanol, it is treated with oxygen plasma to obtain a hydrophilic surface;

[0067] The second step is to prepare a solution containing zinc oxide nanoparticles; transfer the zinc oxide nanoparticles to the surface of the carbon fiber fabric by spin coating. In order to ensure uniform coating, the carbon fiber fabric is spin-coated 3-5 times on both sides;

[0068] The 3rd step, preparation zinc acetate concentration is that 100mM, hexamethylenetetramine concentration are 100mM, polyethyleneimine concentration is the aqueous solution of 20mM;

[0069] The fourth step is to add ammonium salt and sodium hydroxide to the aqueous solution of the third step until the ammonium salt concentration in the solution is 0.2M, and the concentration of sodium hydroxide is 100mM to form a mixed aqueous solution;

[0070] In the fifth step, the carbon fiber fabric obtained in the second step is imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com