Patents

Literature

352 results about "Chemical used" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

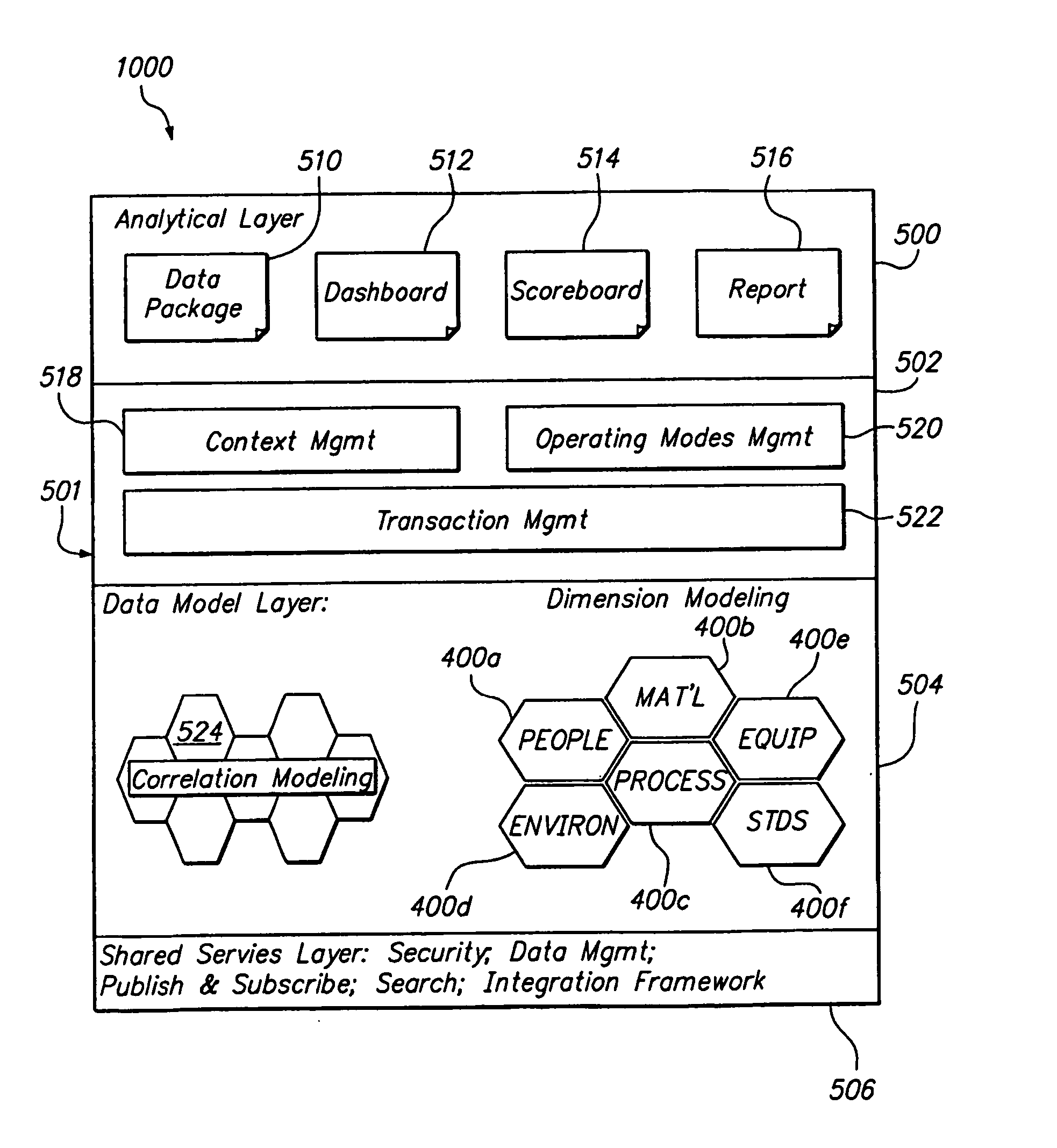

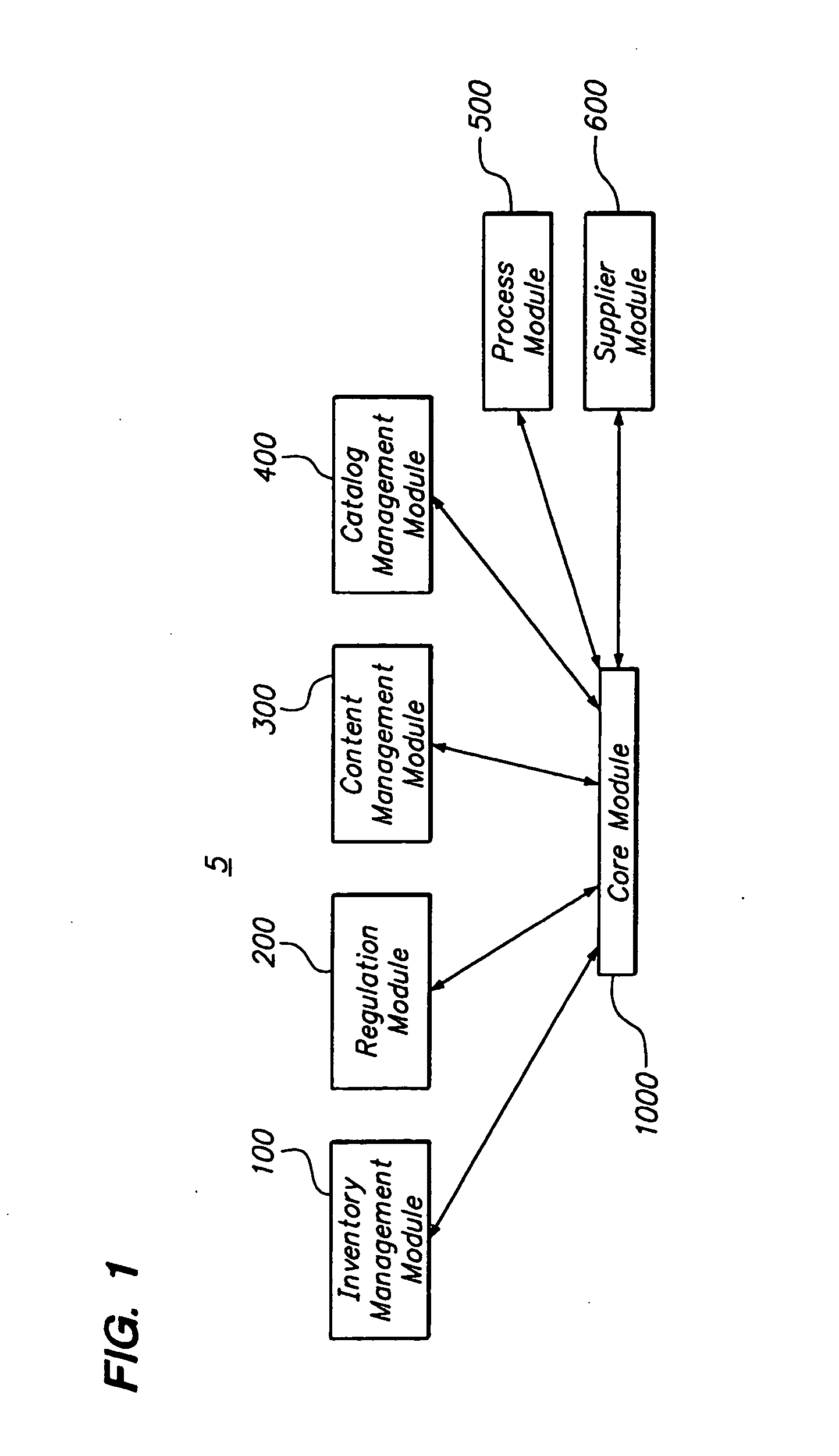

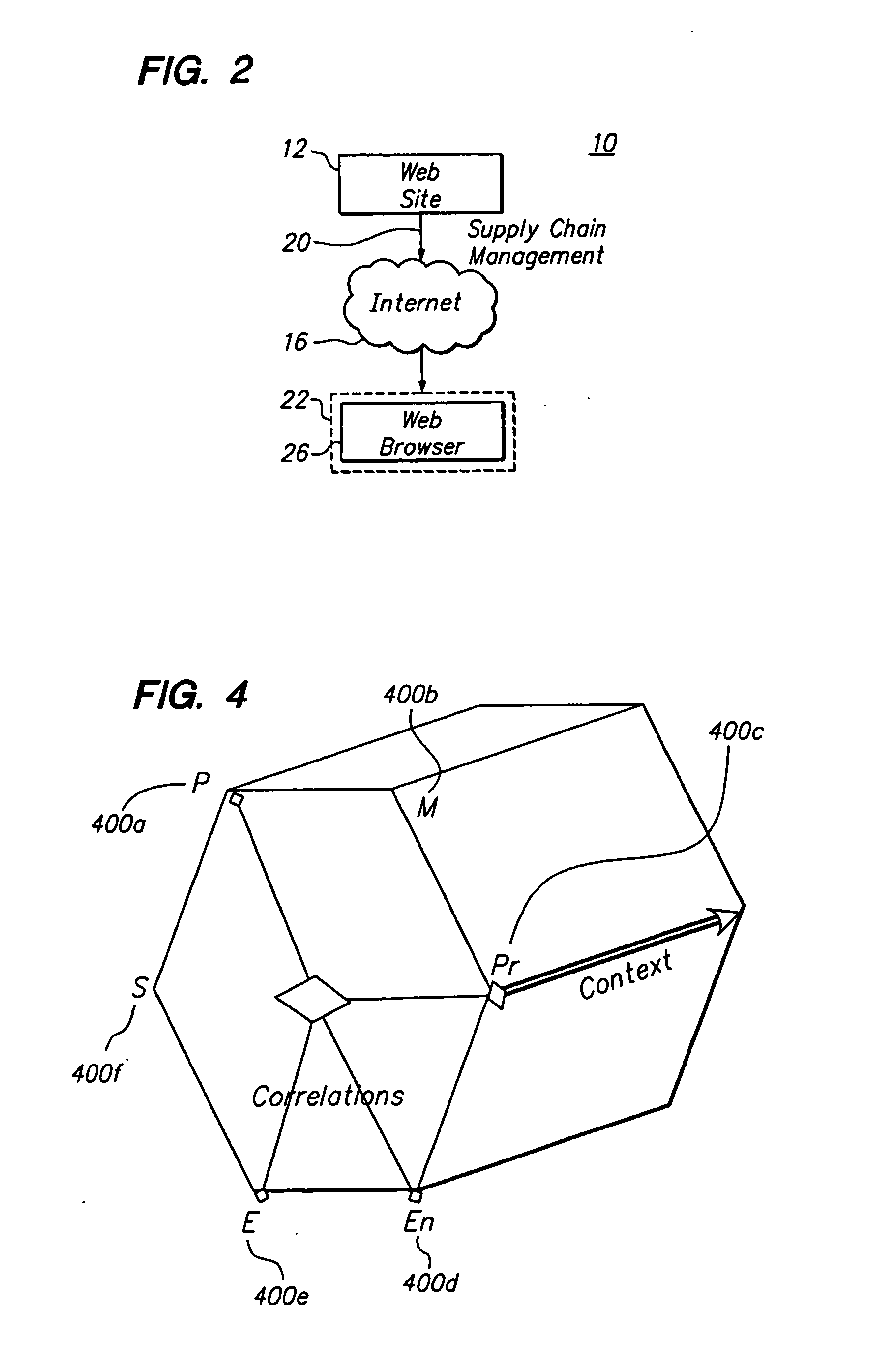

Systems and methods for managing the development and manufacturing of a drug

InactiveUS20070192715A1Easy to optimizeManagement complexityComputer-assisted medical data acquisitionTechnology managementGraphicsChemical reaction

Graphical user interfaces, computer readable media, and computer systems for monitoring a chemical process. An administration module sets a plurality of user preferences associated with the chemical process. A people management module defines a user role in the chemical process. An organization module defines an organizational structure of an organization that runs the chemical process. An equipment module defines equipment used in the chemical process. A material module controls a chemical used in the chemical process. A process module defines a chemical reaction in the chemical process.

Owner:ORACLE INT CORP

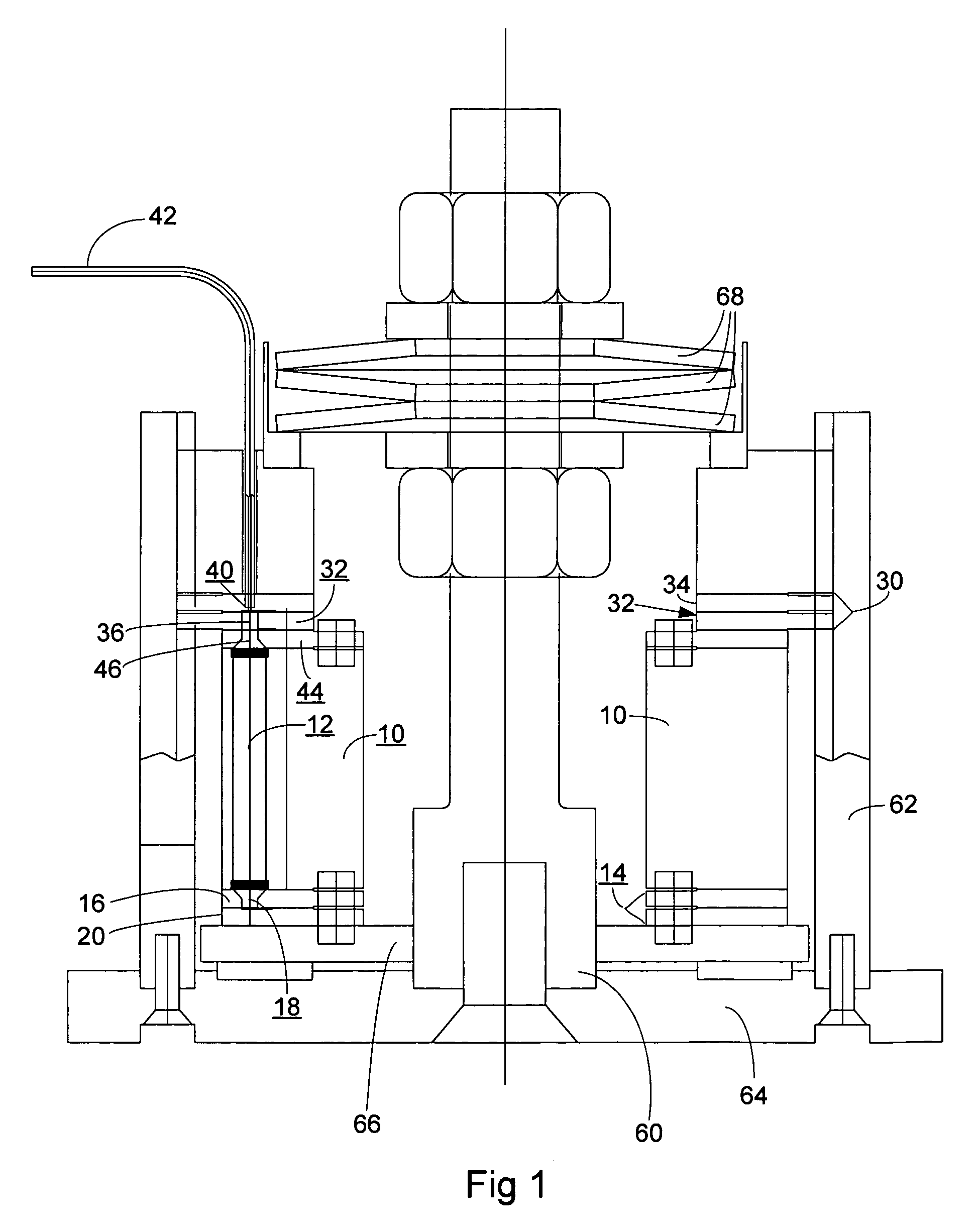

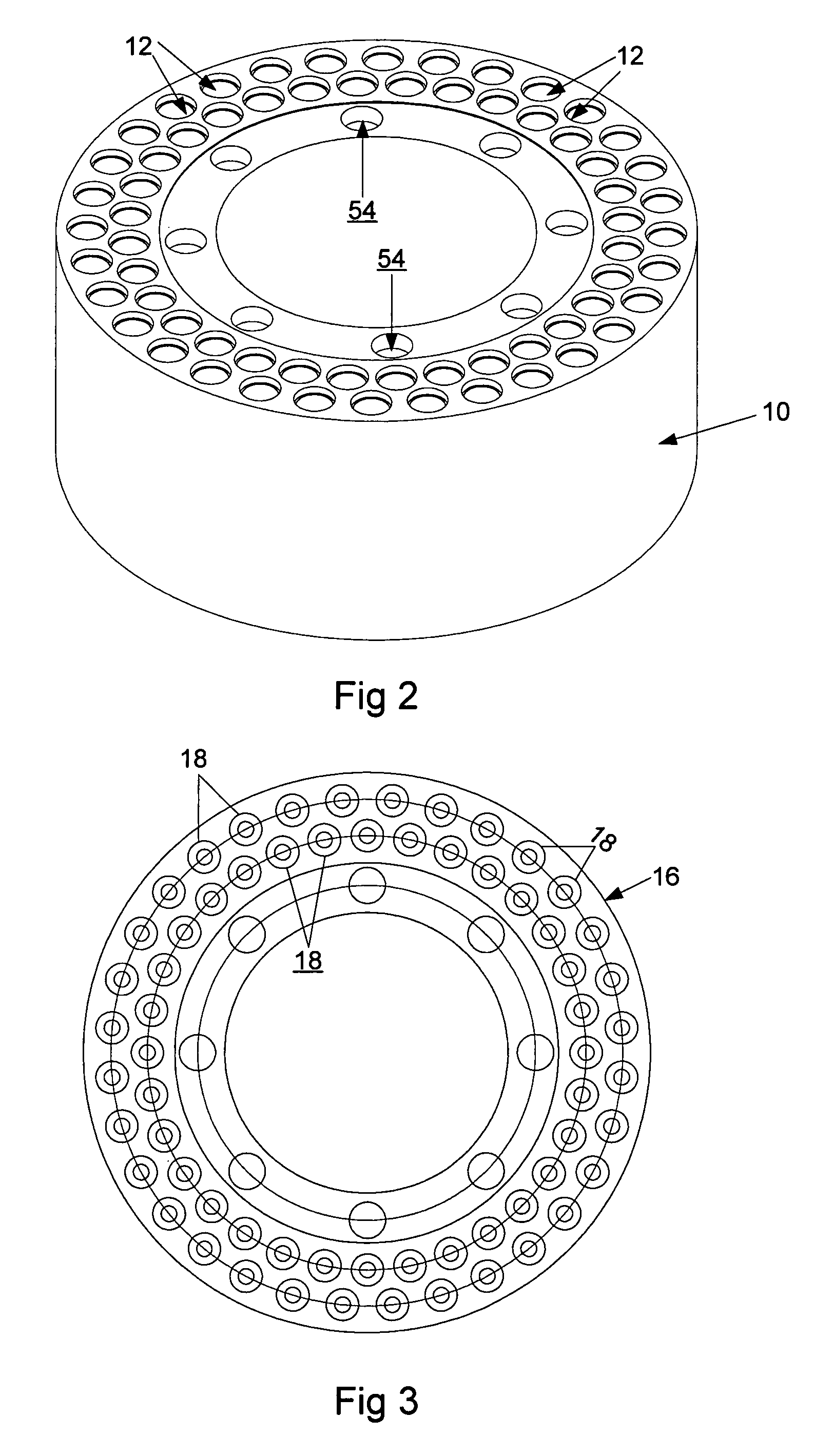

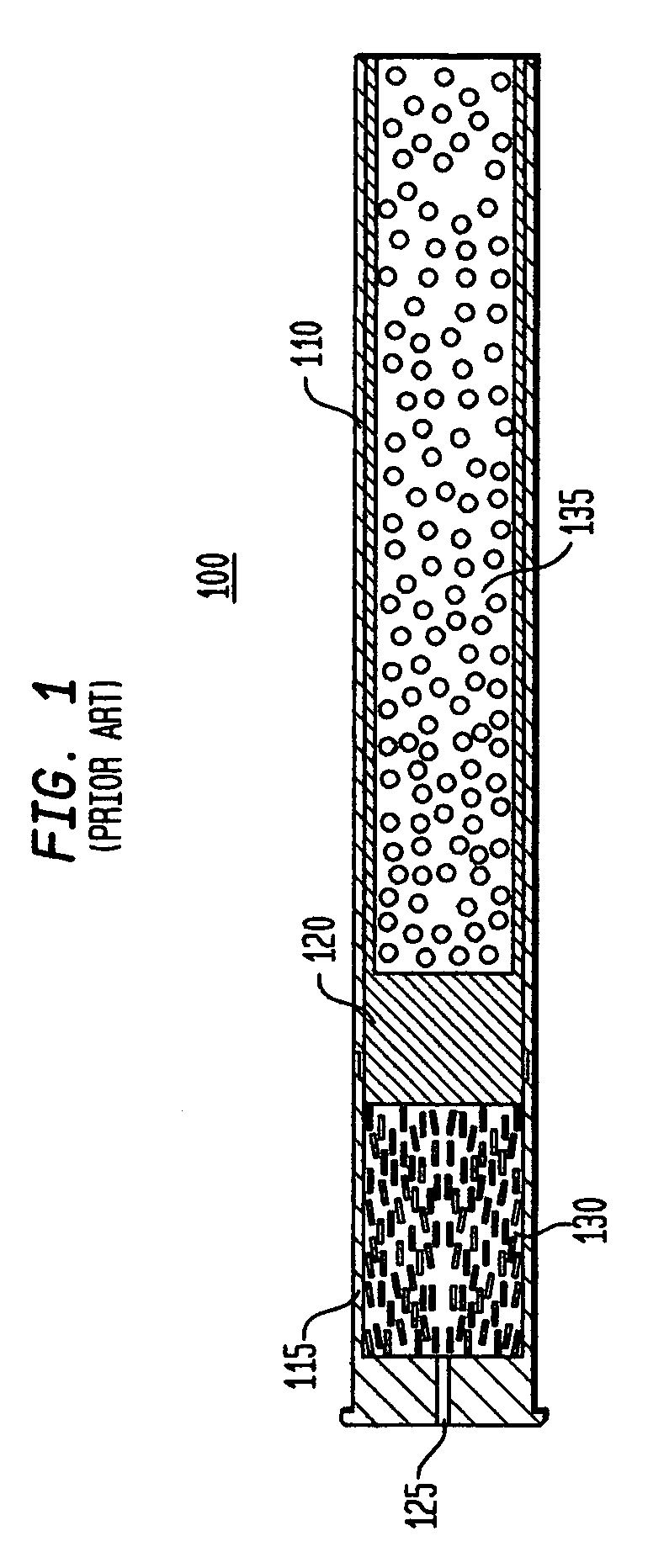

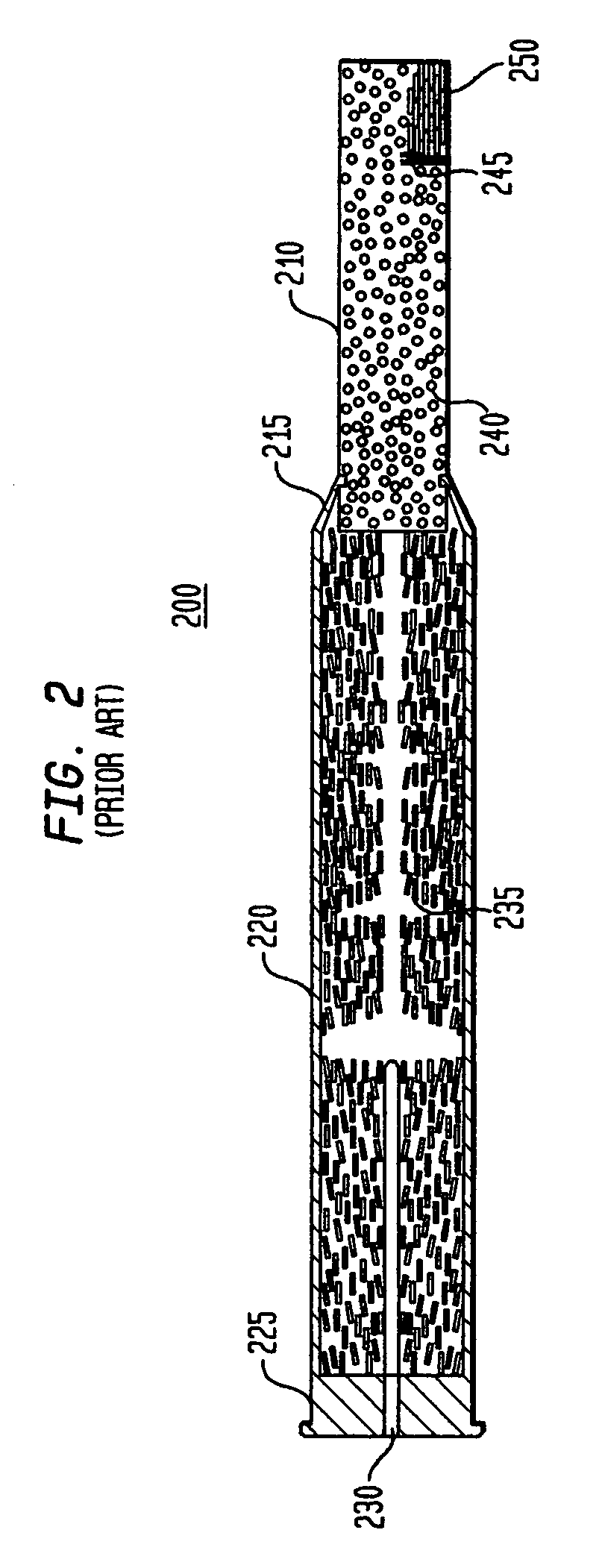

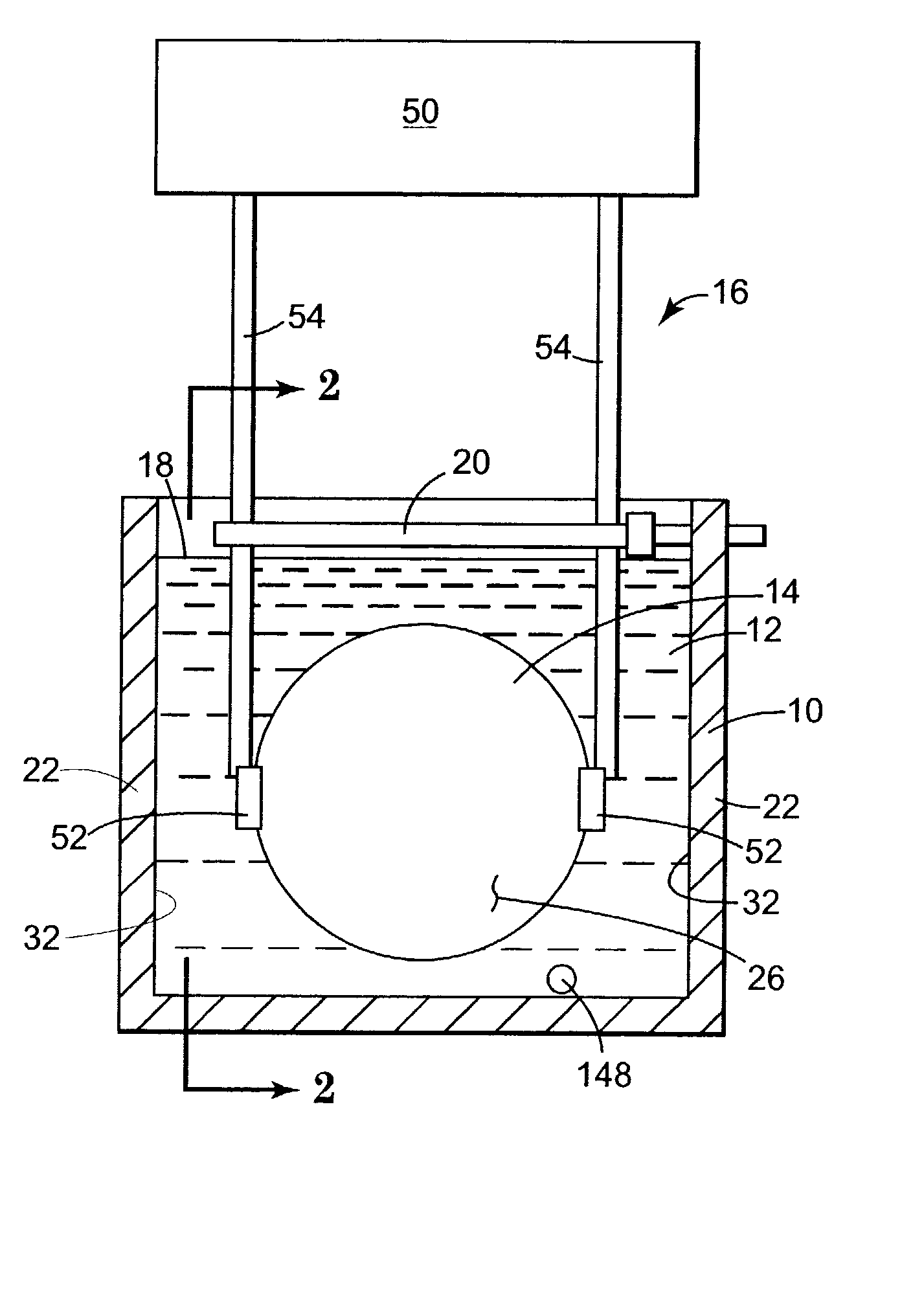

Miniature actual moving bed assembly

An apparatus is presented for separating chemicals using adsorption separation methods. The apparatus uses a plurality of adsorption units holding adsorbent, where the adsorption units positioned in a cylindrical spool, are serially connected and the spool is rotated to shift the relative position of the feeds and drawoffs to the apparatus.

Owner:UOP LLC

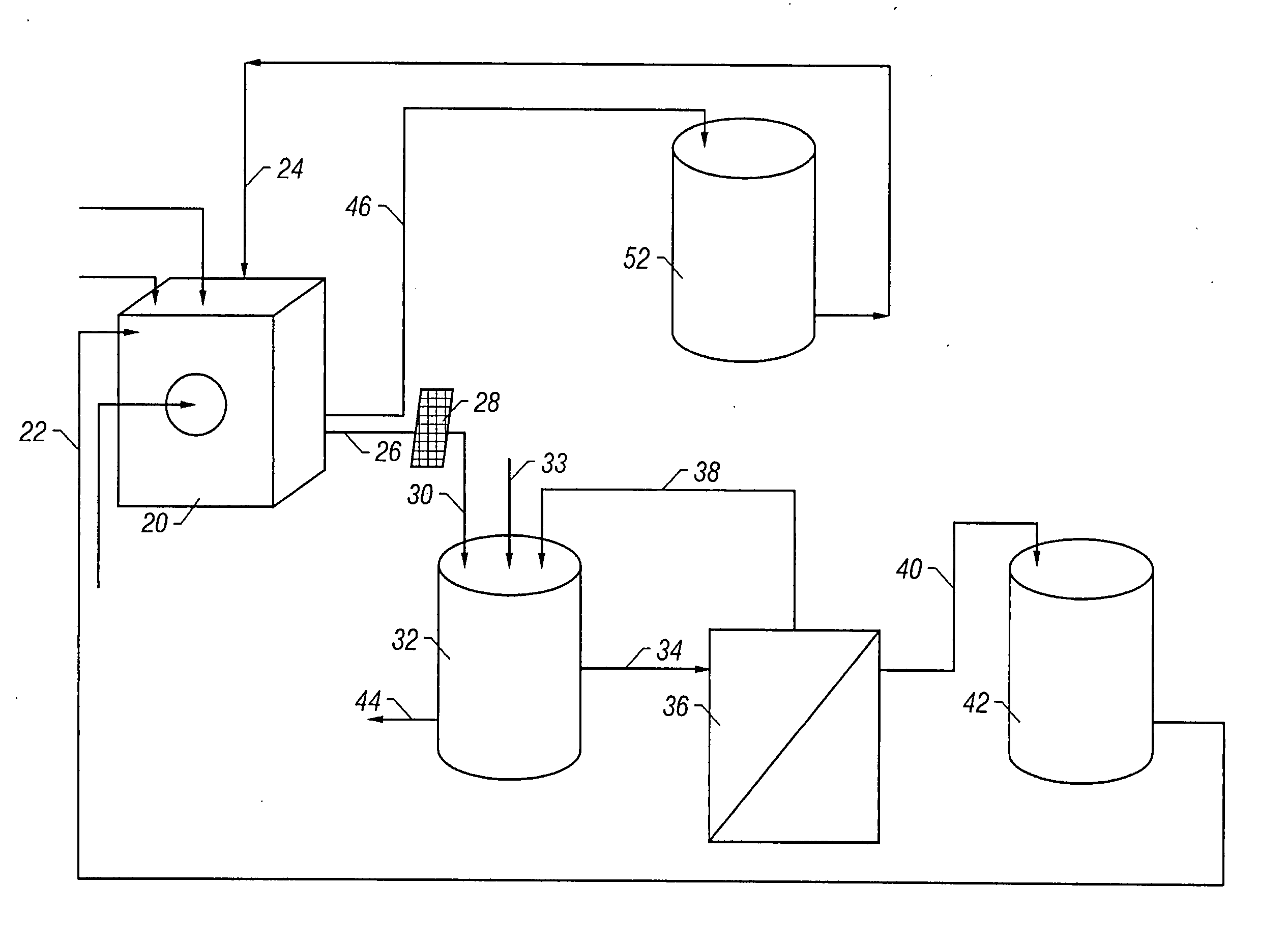

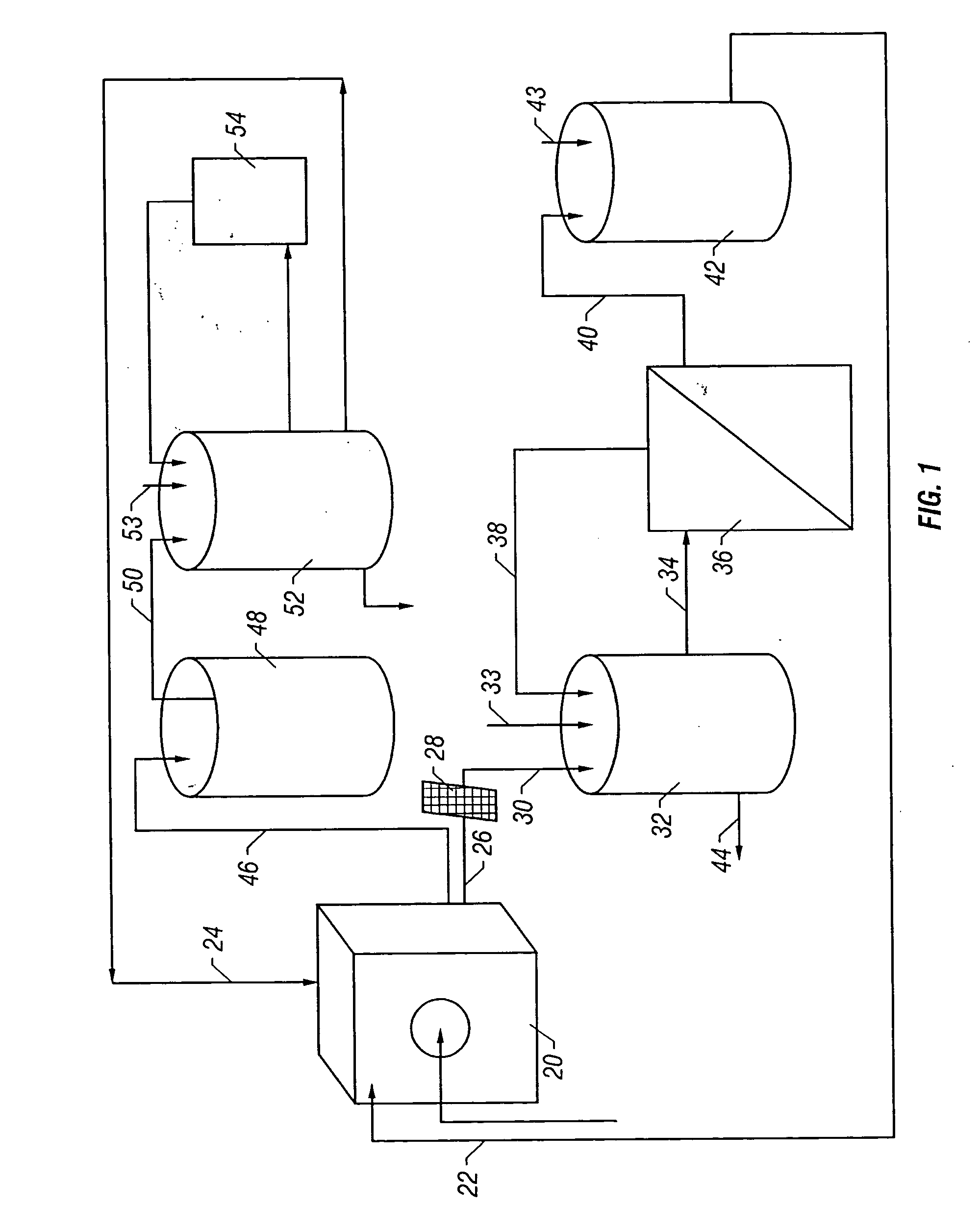

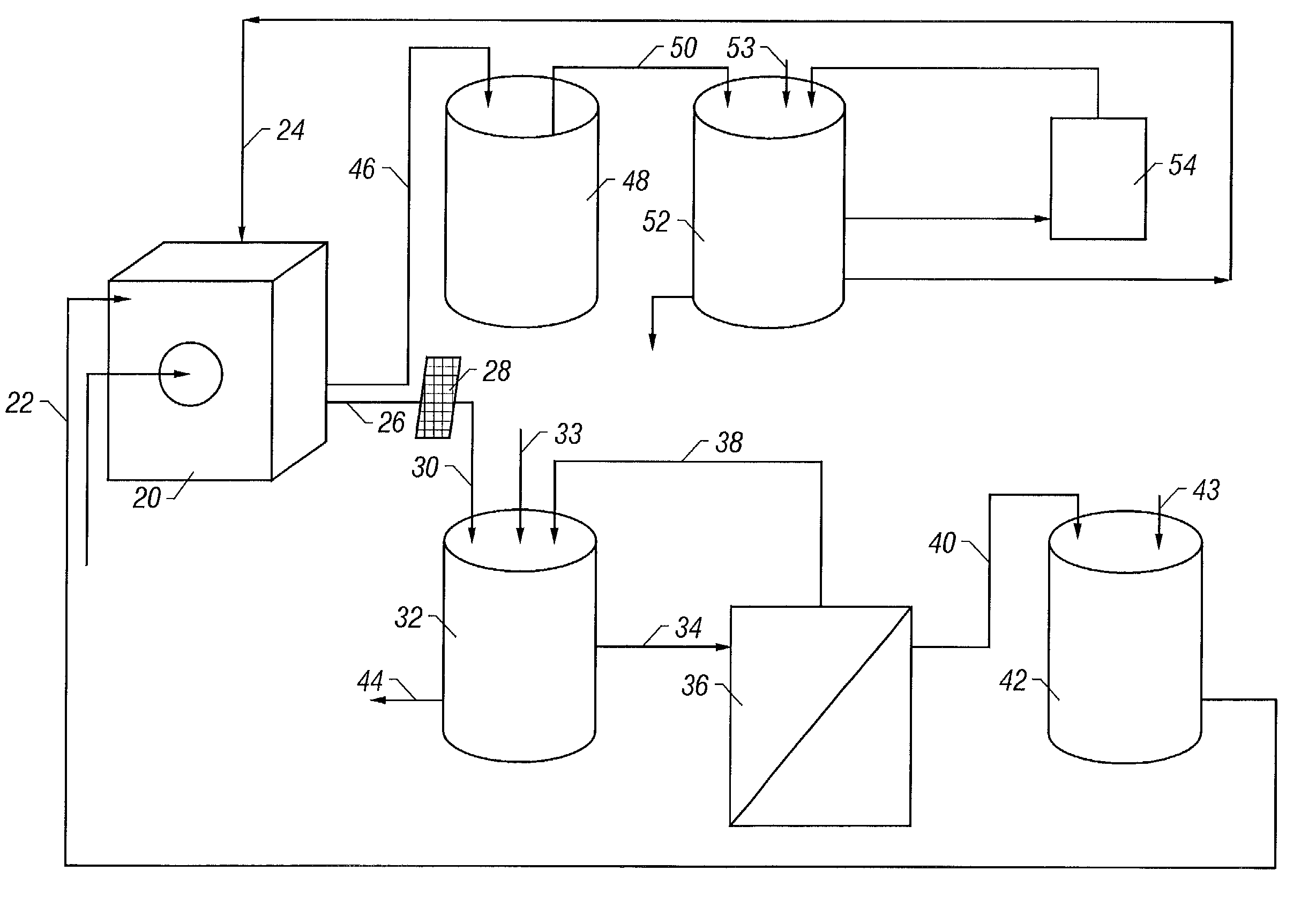

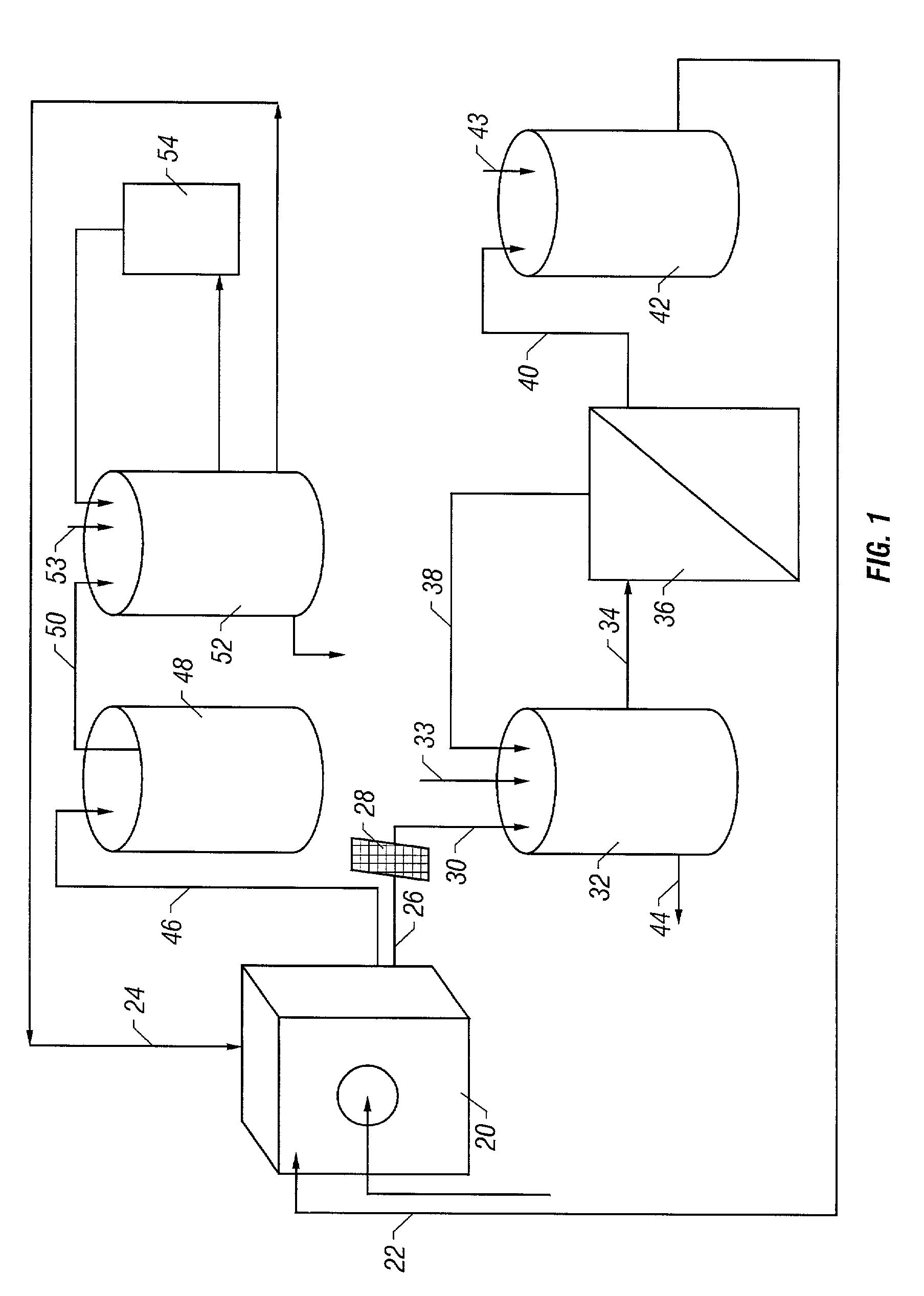

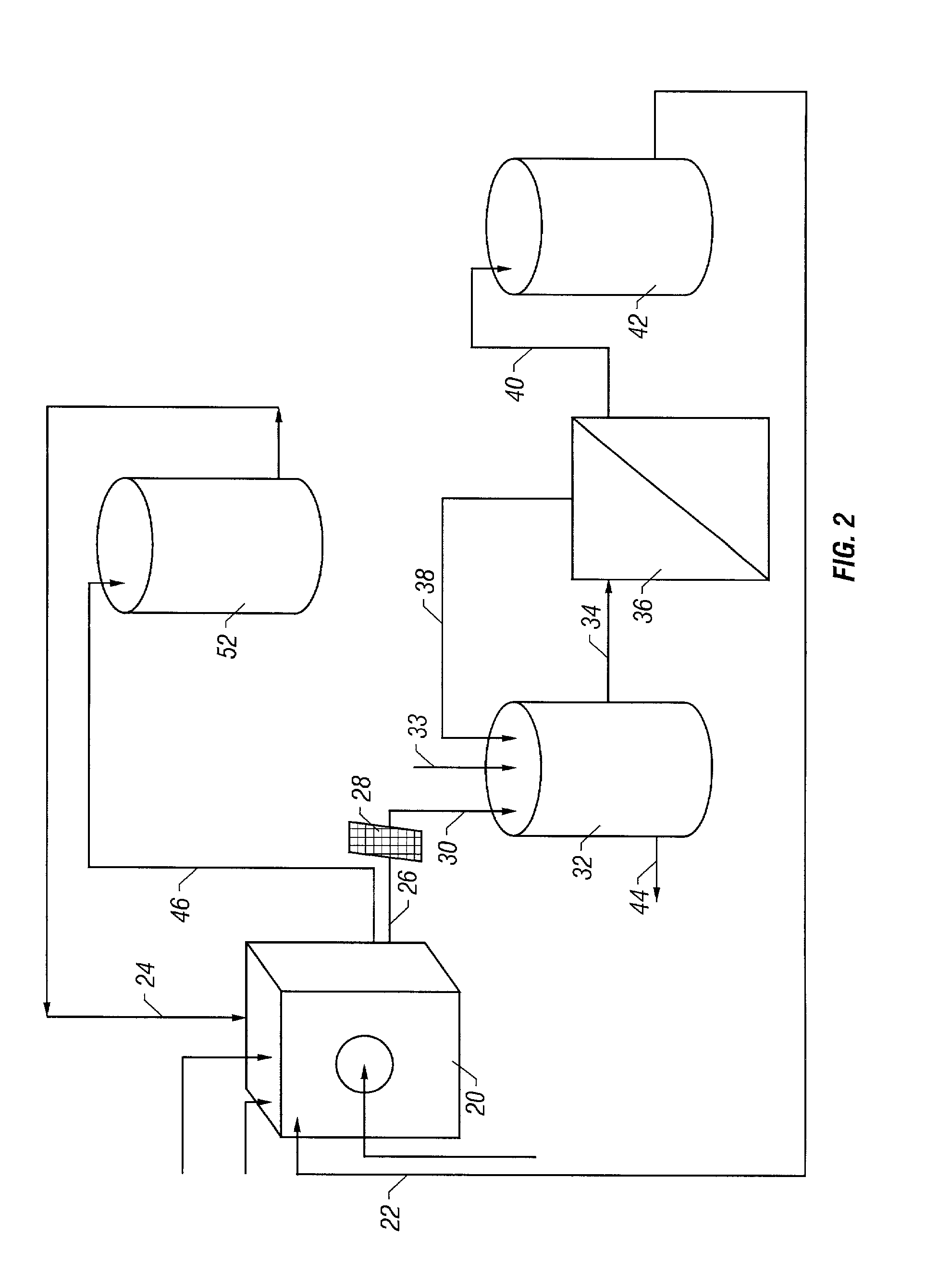

Method for economically viable and environmentally friendly central processing of home laundry

InactiveUS20060123563A1Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesEnvironmental effectWash water

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:RANEY KIRK HERBERT +5

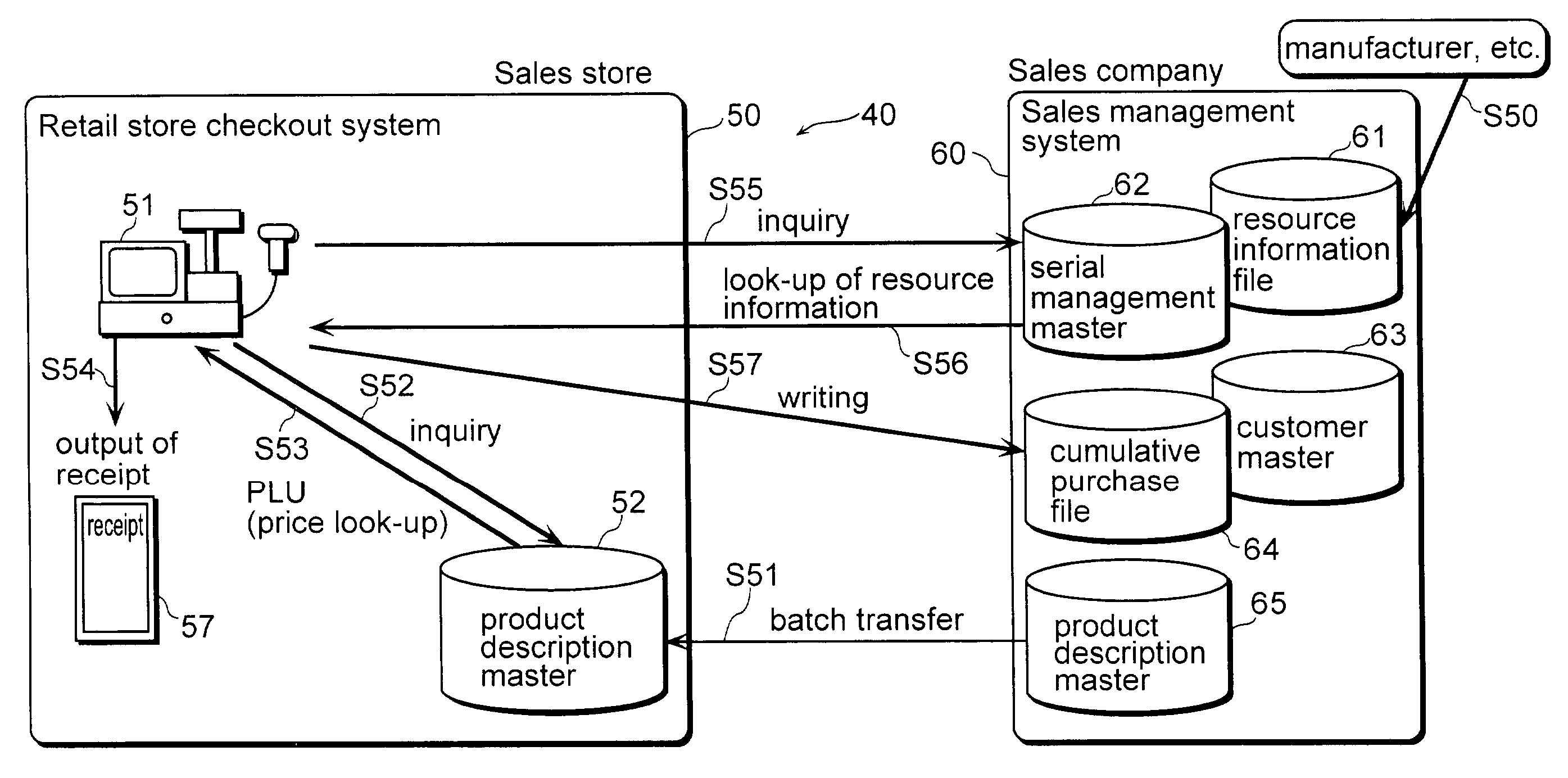

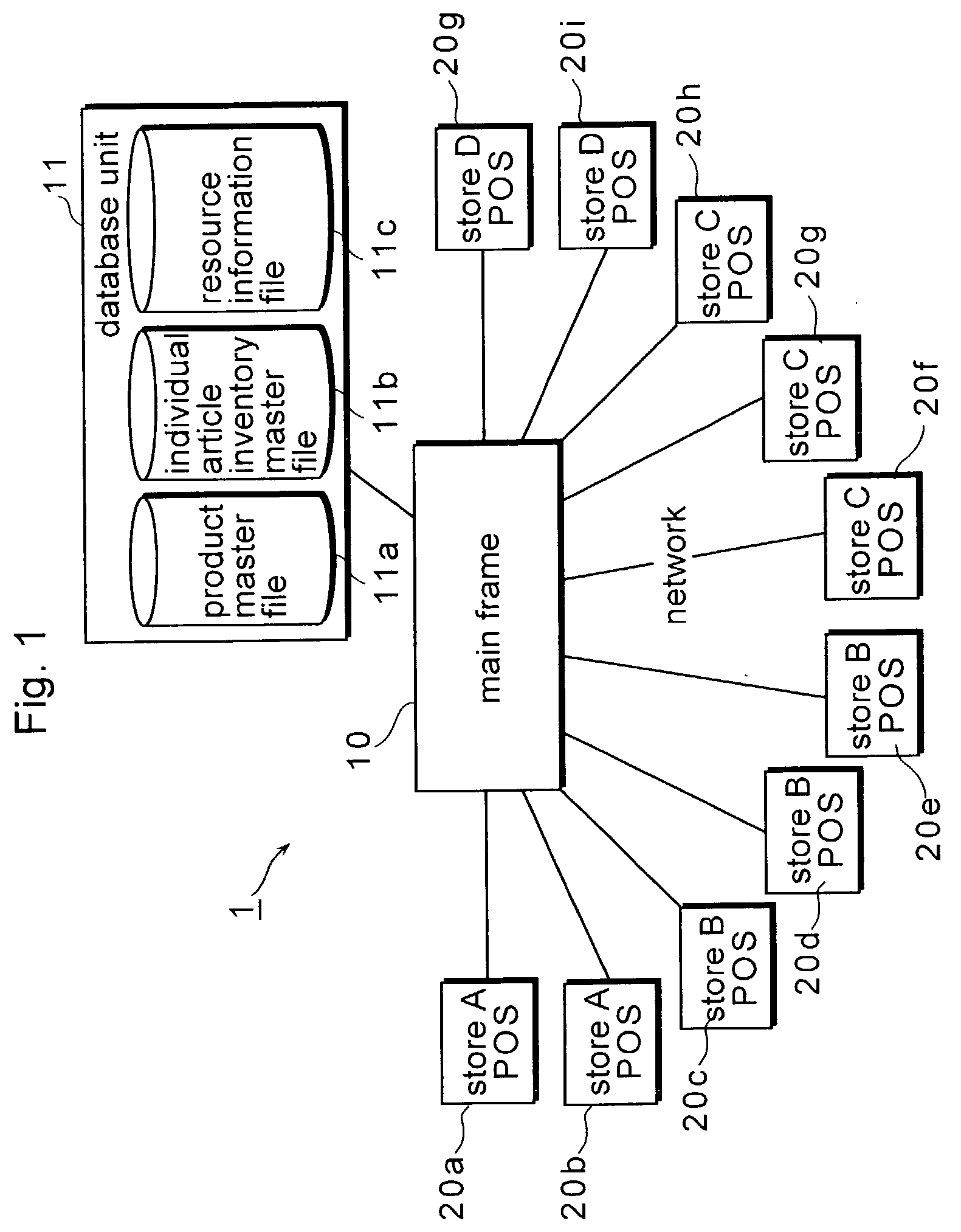

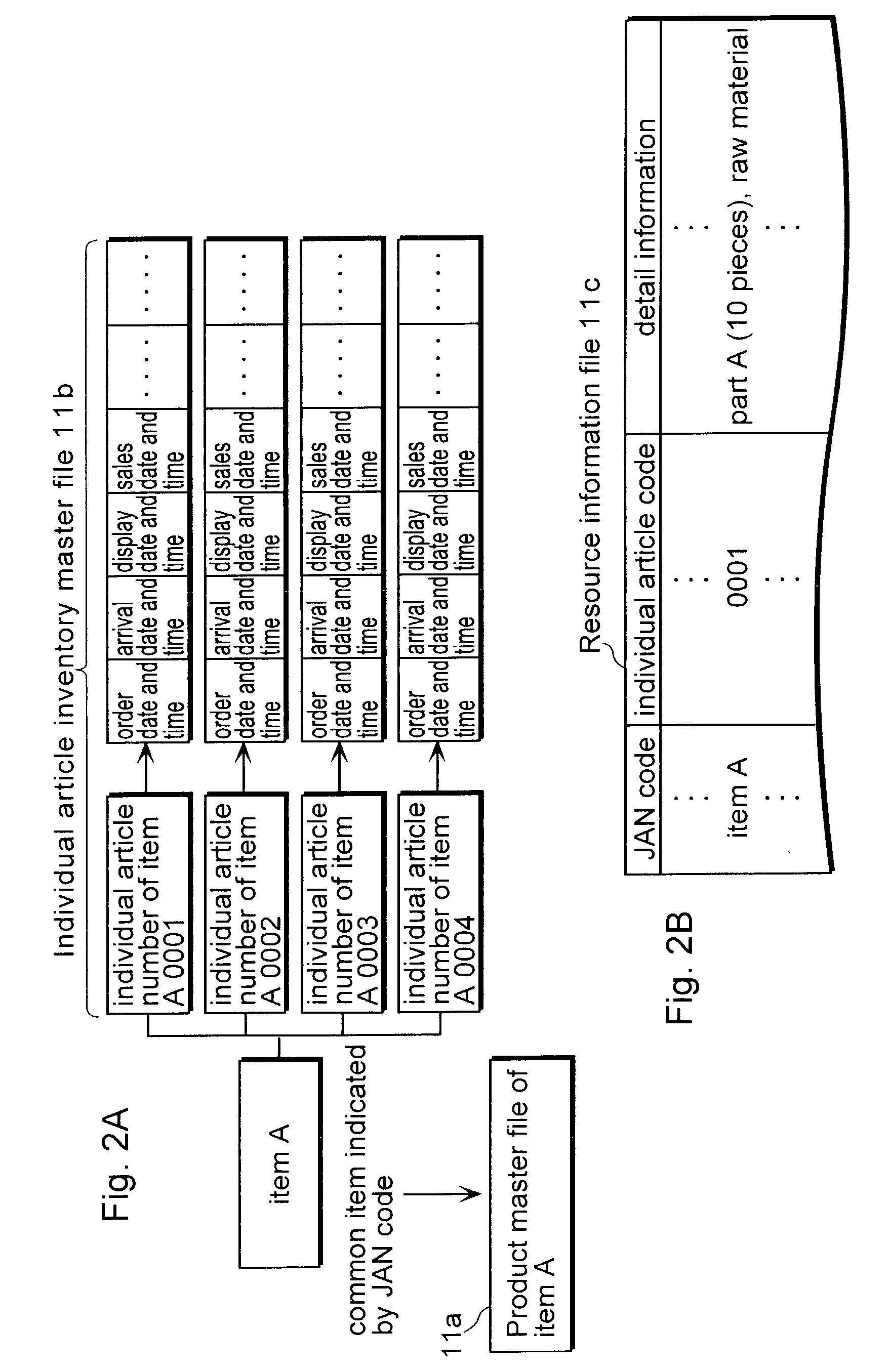

Product marked with product code, product information inquiry system, product information inquiry device and POS system

InactiveUS20030213844A1Extend product lifeEasy maintenanceCo-operative working arrangementsCash registersAdditive ingredientWorld Wide Web

A product code includes an item code 30a, an individual article code 30b and a detail code 30c. The item code 30a is a code specifying an item to which the product belongs, such as a JAN code. The individual article code 30b is a code identifying the product uniquely, such as a bar code indicating a lot number or a serial number marked on the product at the time of manufacturing. The detail code 30c is a code indicating detail information of the product including information about the sources of the product, and component parts, raw materials or ingredients of the product. The detail code 30c is, for example, a two-dimensional code describing parts and raw materials, a production place and feed and chemicals used in the raising process if the product is livestock meat or cultivated fish, etc., and chemical fertilizers and pesticides used for the ingredients if the product is food, as the detail information of the product according to MRP.

Owner:SYST RES +2

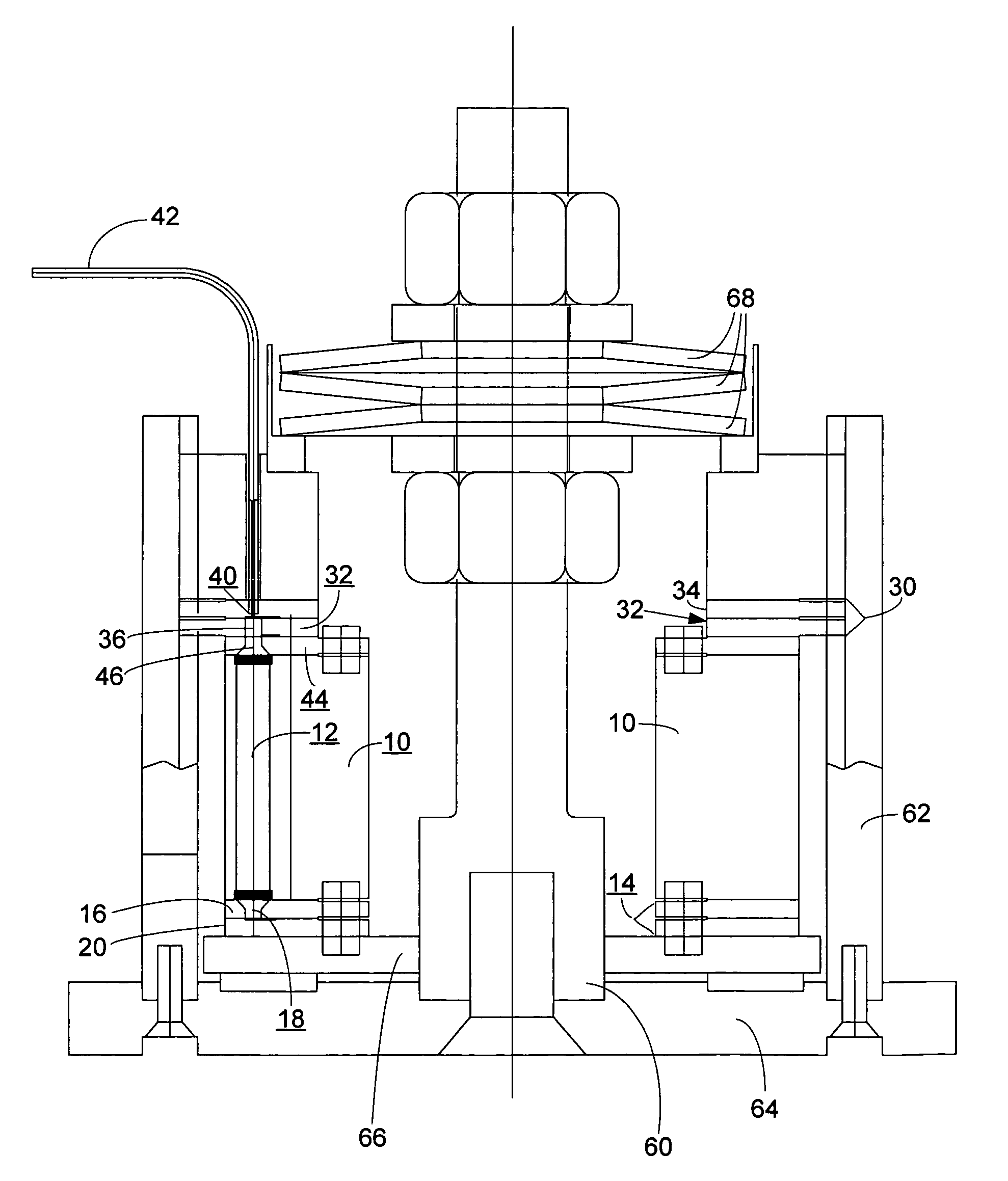

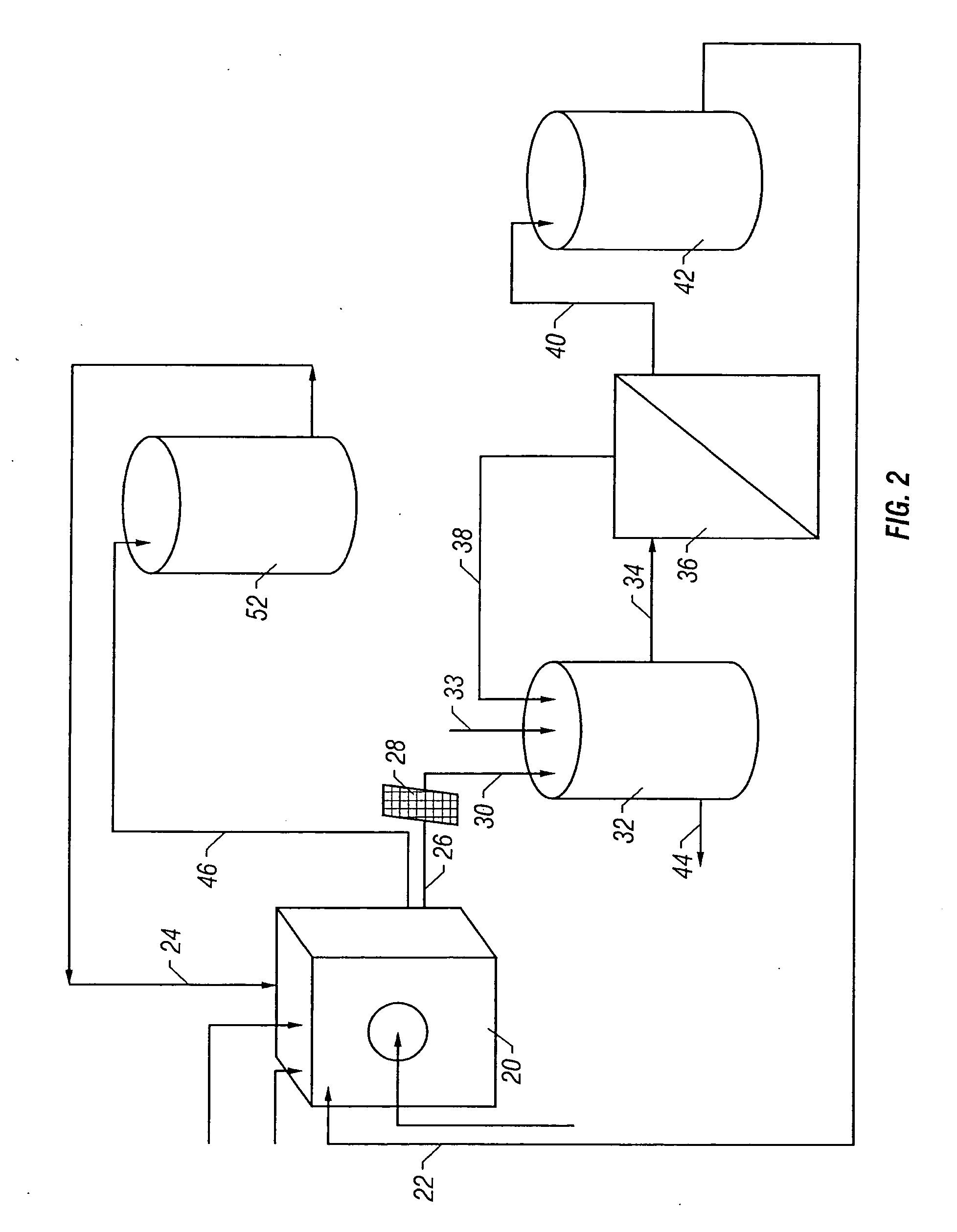

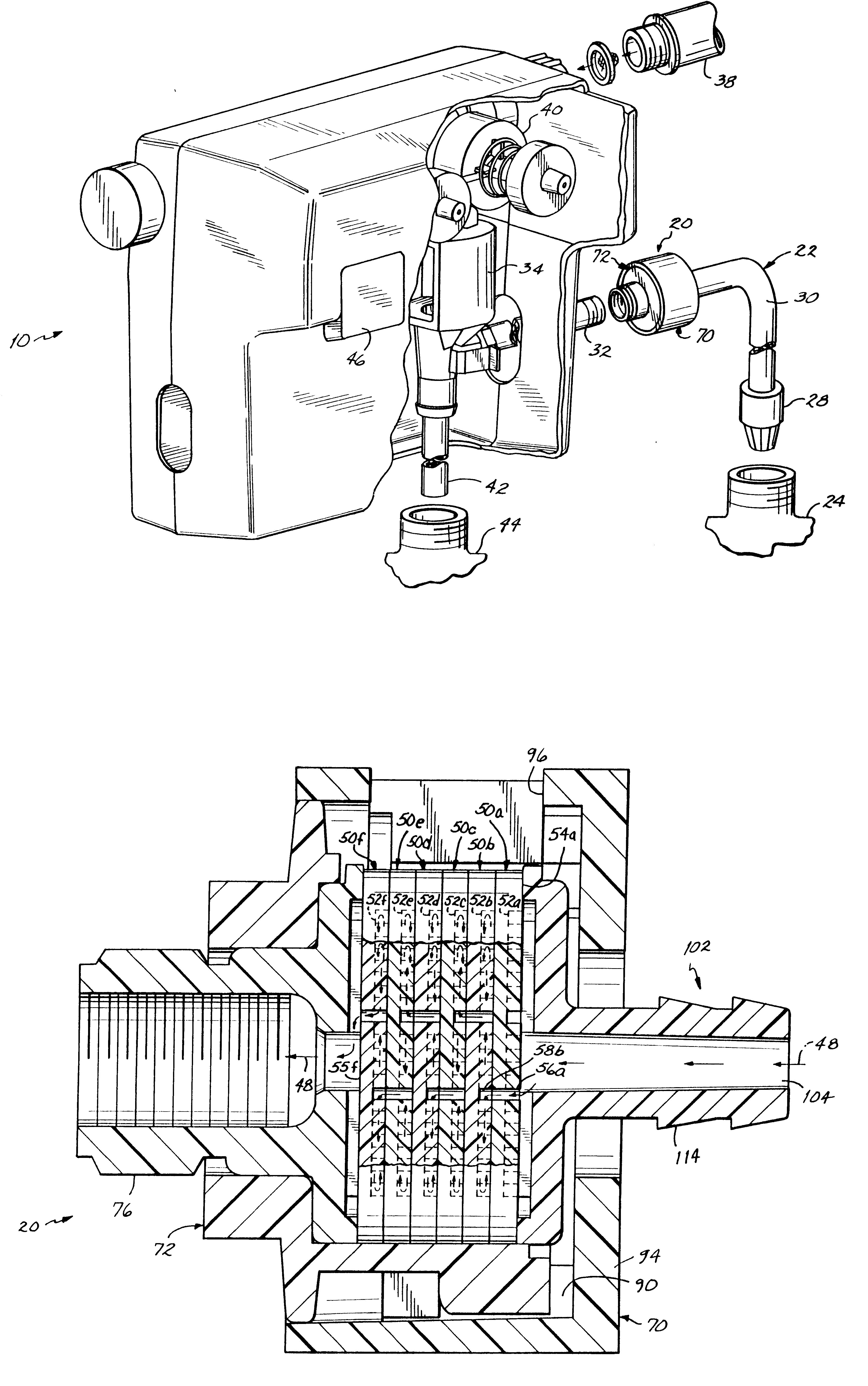

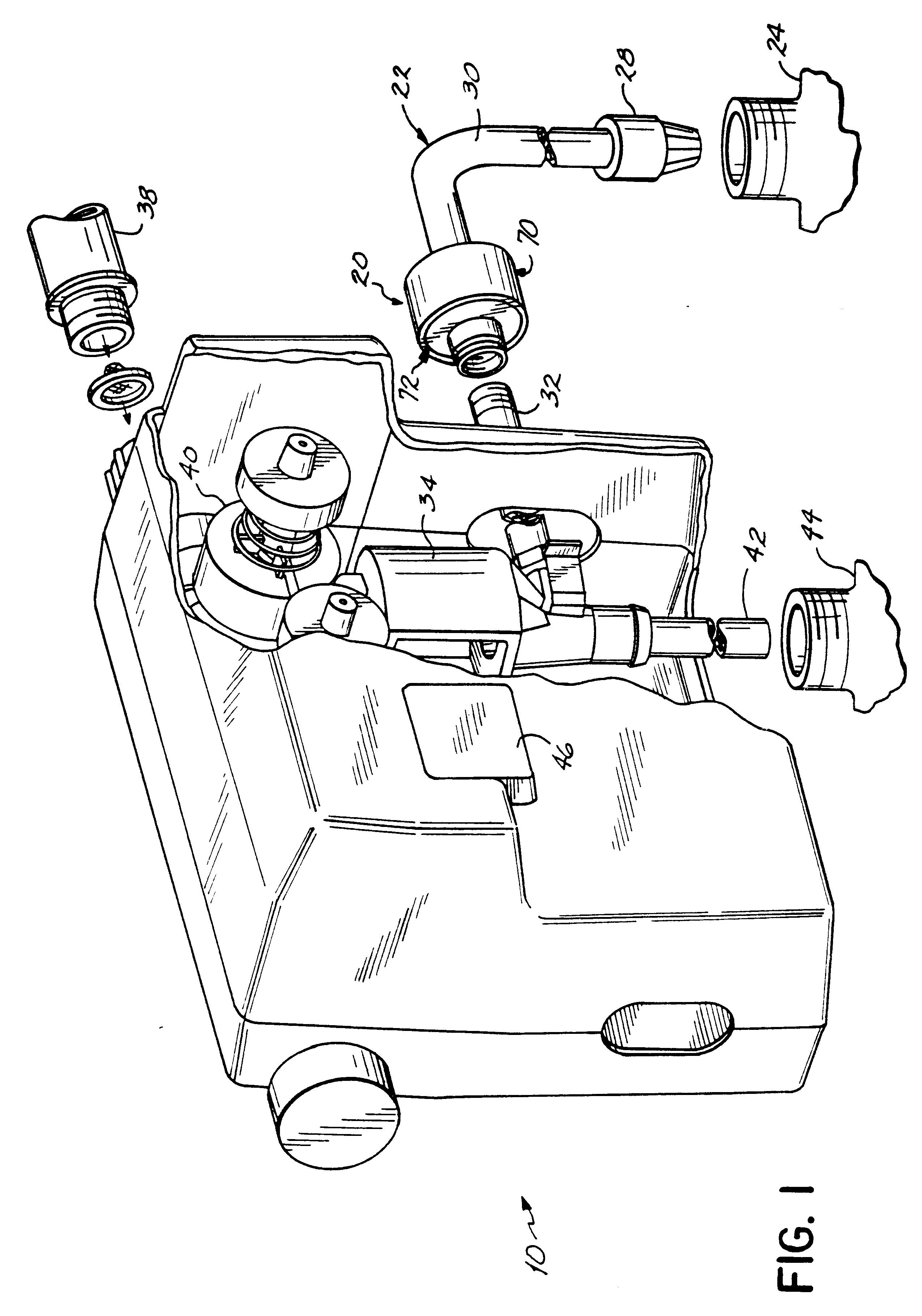

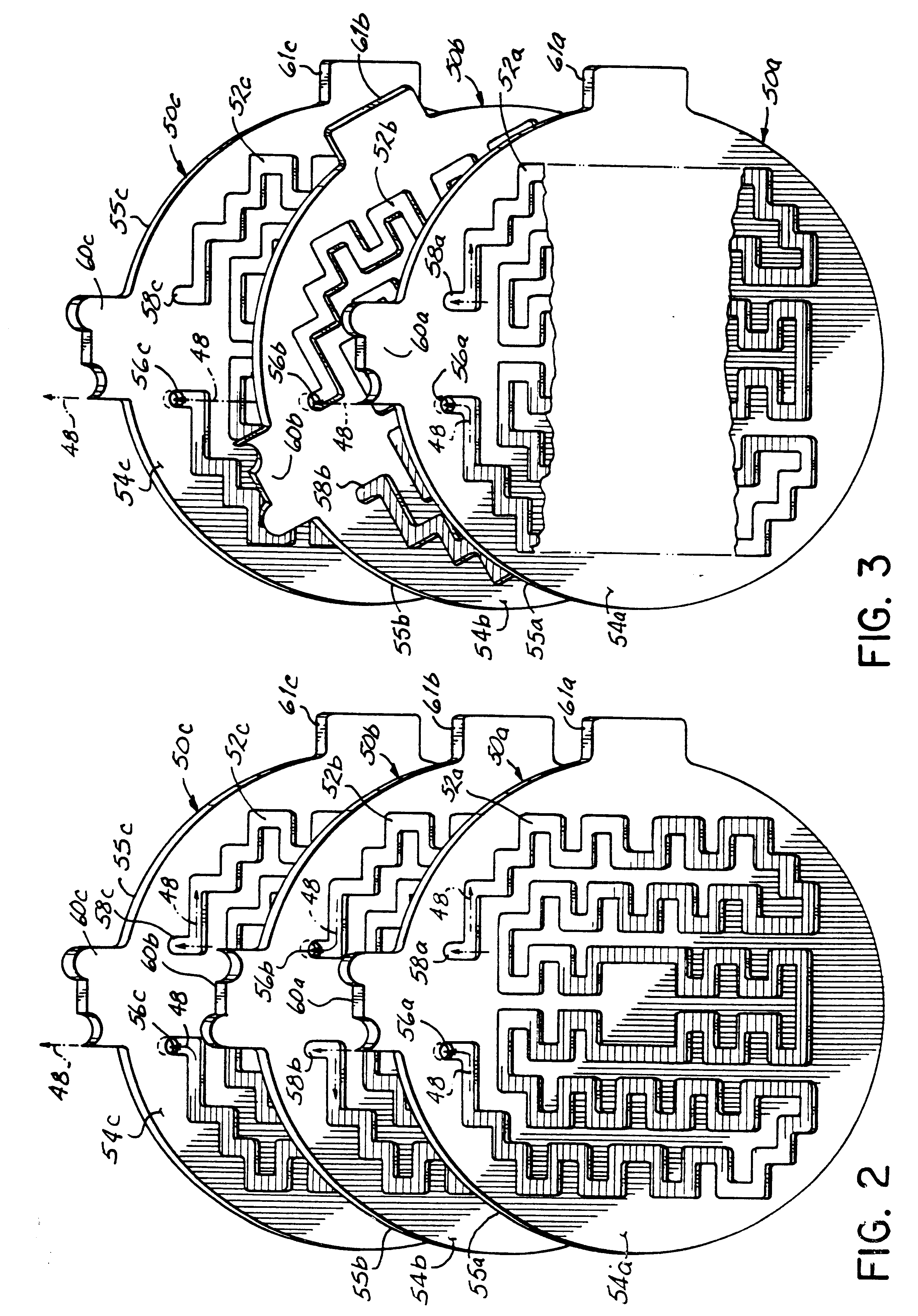

Ultra-lean dilution apparatus

InactiveUS6499872B2Prevent movementImprove performanceFlow mixersWatering devicesChemical usedEngineering

An ultra-lean dilution apparatus is provided for proportioning minute quantities of a first fluid, such as a concentrated cleaning solution, for mixing into a second fluid, such as tap water, which provides improved performance and which can be manufactured by assembling several molded components with little or no machining. The dilution apparatus (20) provides a selective pressure drop in a conduit (22) by including a plurality of dilution disks (50a-50f), each dilution disk (50a-50f) having a tortuous path (52a-52f) of sufficient cross-sectional area to be resistant to clogging and having a sufficient number of sharp turns to create a desired pressure drop. While each disk (50a-50f) produces a predetermined drop, the serial configuration of the tortuous paths of the plurality of dilution disks is additive to produce a range of dilution suitable for the chemicals used. Advantageously, the tortuous path of a first of the plurality of dilution disks (50a) is recessed into a front face so that bringing the front face (54a) of the first dilution disk (50a) in contact with a back face (55b) of a second dilution disk (50b) completes the tortuous path (52a). Furthermore, a blind intake (58a) of the tortuous path (52a) of the first dilution disk (50a-50f) selectively communicates with an output port (56b) of another tortuous path (52b) on a front face (54b) the second dilution disk (50b).

Owner:DELAWARE CAPITAL FORMATION

System and method for a flameless tracer / marker for ammunition housing multiple projectiles utilizing chemlucent chemicals

InactiveUS6931993B1Evaluate effectivenessAmmunition projectilesShotgun ammunitionSteel ballEngineering

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

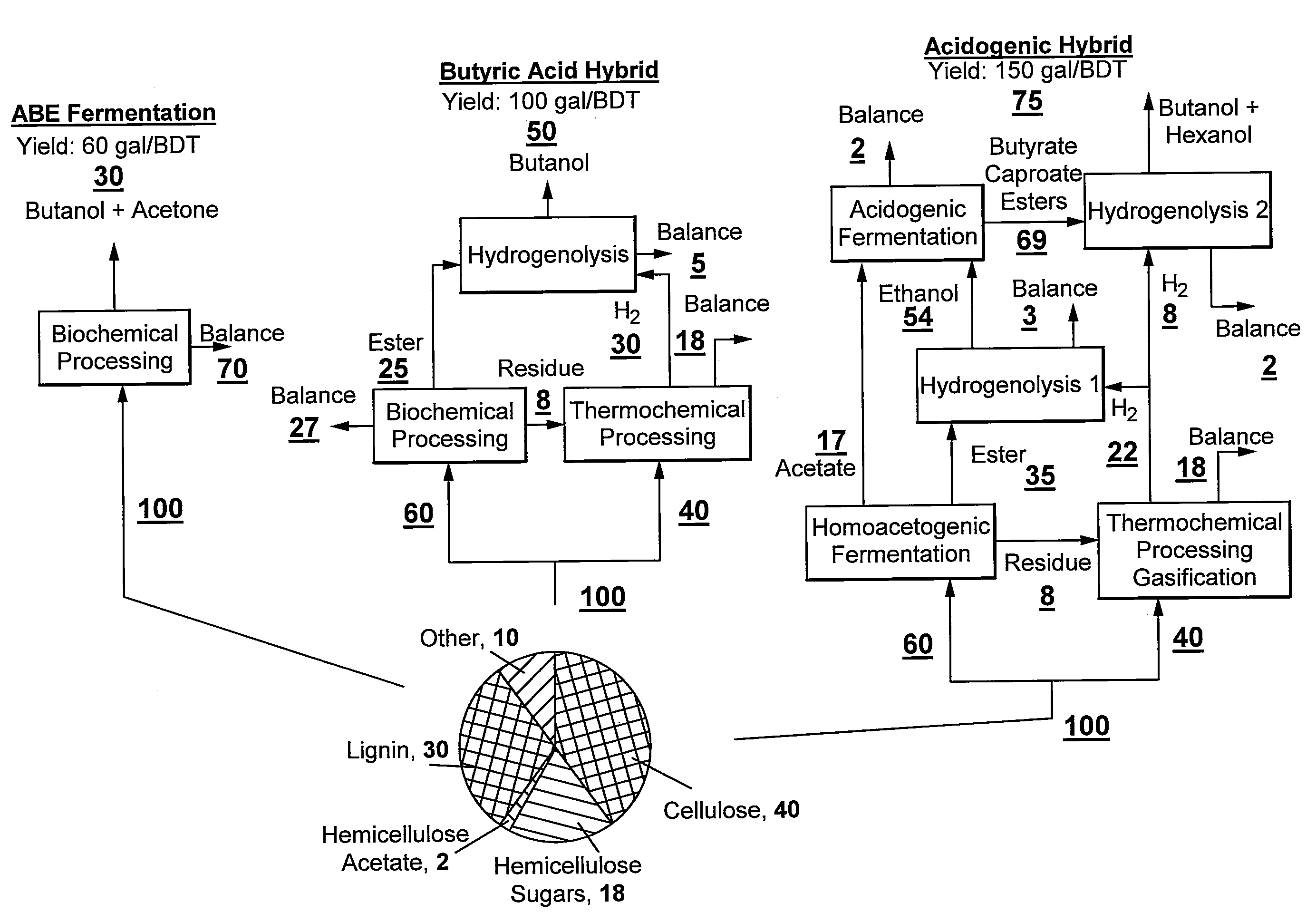

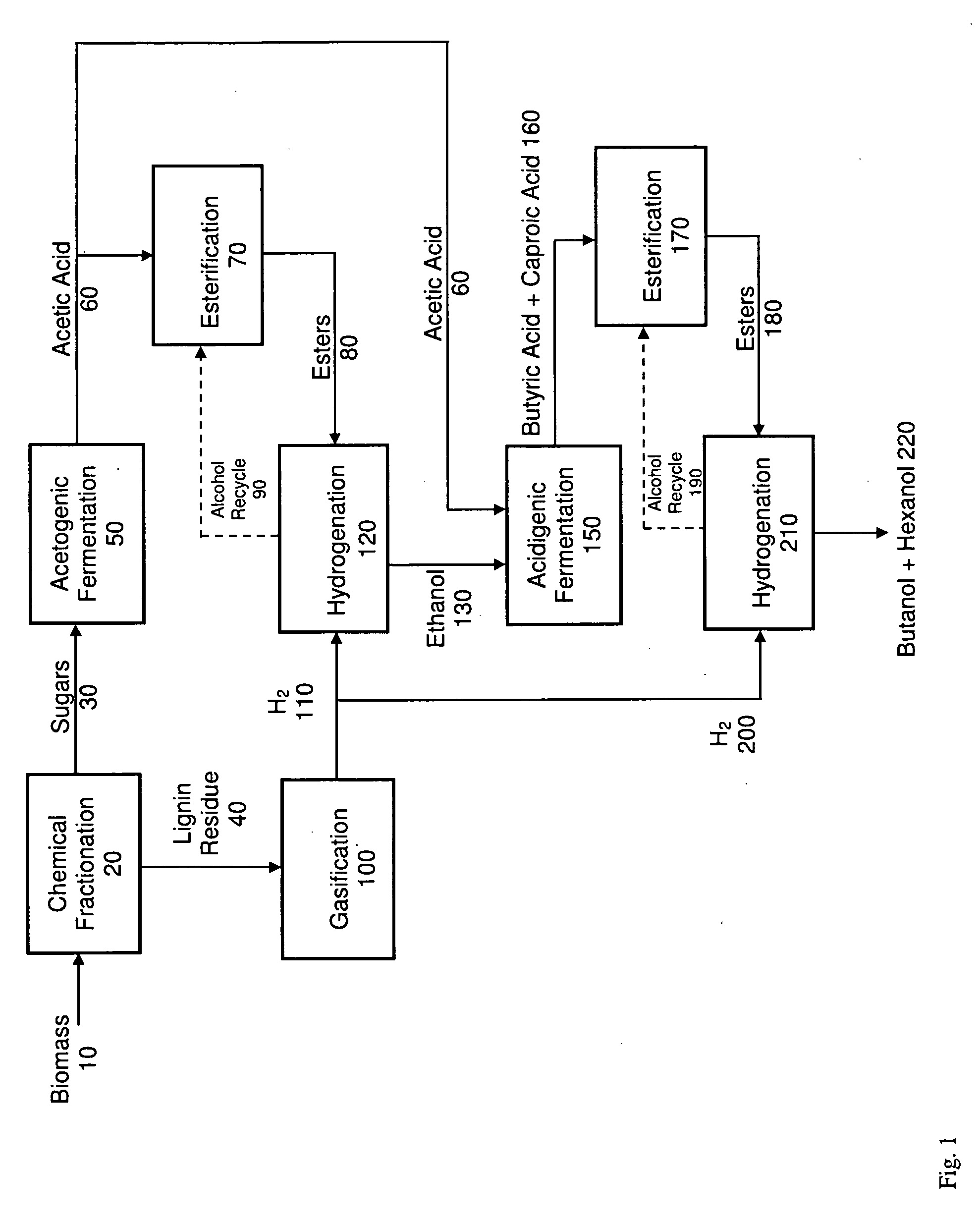

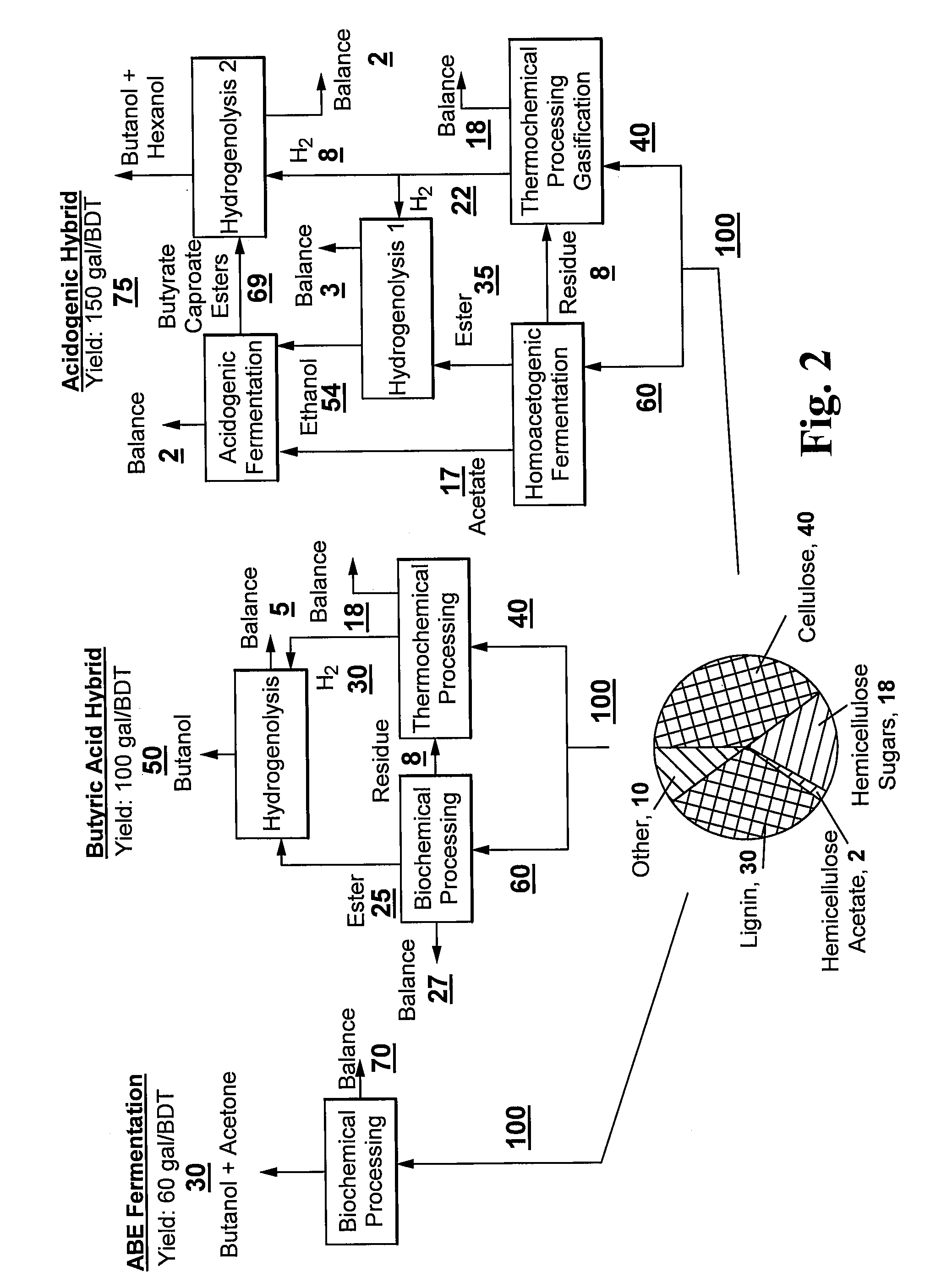

Indirect production of butanol and hexanol

InactiveUS20090203098A1Organic compound preparationHydroxy compound preparationAcetic acidButyric acid

A process for the conversion of carbohydrates from any of a number of sources into butanol and hexanol for fuel or chemical use is disclosed. The process includes conducting a homoacetogenic fermentation to produce an acetic acid intermediate which is chemically converted to ethanol. The ethanol and a remaining portion of the acetic acid intermediate are used as a substrate in an acidogenic fermentation to produce butyric and caproic acid intermediates which are then chemically converted to butanol and hexanol.

Owner:ZEACHEM

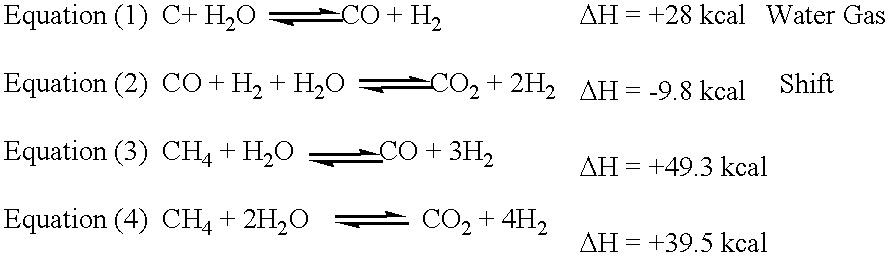

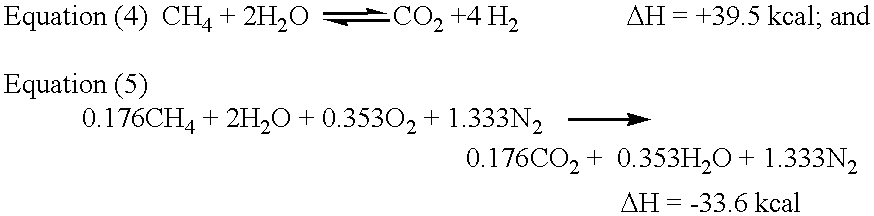

Method and apparatus for total energy fuel conversion systems

InactiveUS6350394B1Thermal non-catalytic crackingInternal combustion piston enginesPeak loadElectric power

An independent and conserved source of fuel and / or power comprises a top stage rocket engine firing up to 5000 F. at very high pressures, delivering jet flows up to transonic velocities into a near adiabatic tunnel for mixing in general and / or for transforming reactants introduced to suit specific objectives. The related compression is supplied by an independent prime mover which compresses its exhaust and other recoverable fluids. Low grade flows, thereby upgraded in temperature and pressure, are adiabatically contained, are further upgraded in the tunnel to become part of the prescribed fuel for export at the tunnel ends; or fuel to be fired in a prime mover for electric or other power, or hydrogen for chemical use. Expansion turbines for this purpose are relieved of the load used to compress the excess air in standard gas turbines thus increasing export power. A portion of the expansion turbine's exhaust becomes part of recoverable fluids. When oxygen is used instead of air, the gases through turbines are nitrogen-free with more heat capacity reducing turbine inlet temperatures for the same power. When reactant transformation is specified, the larger water vapor content in the cycle enhances the water gas / shift autothermally for ammonia and / or power and alternatively for pyrolysis cracking for olefins and diolefins. Further, staging rocket engine reactors increases efficiency in boilers and steam turbines; and staging can produce sponge iron and / or iron carbide as well as expansion turbine power and fuel cells for peak and off-peak loads.

Owner:EGT ENTERPRISES

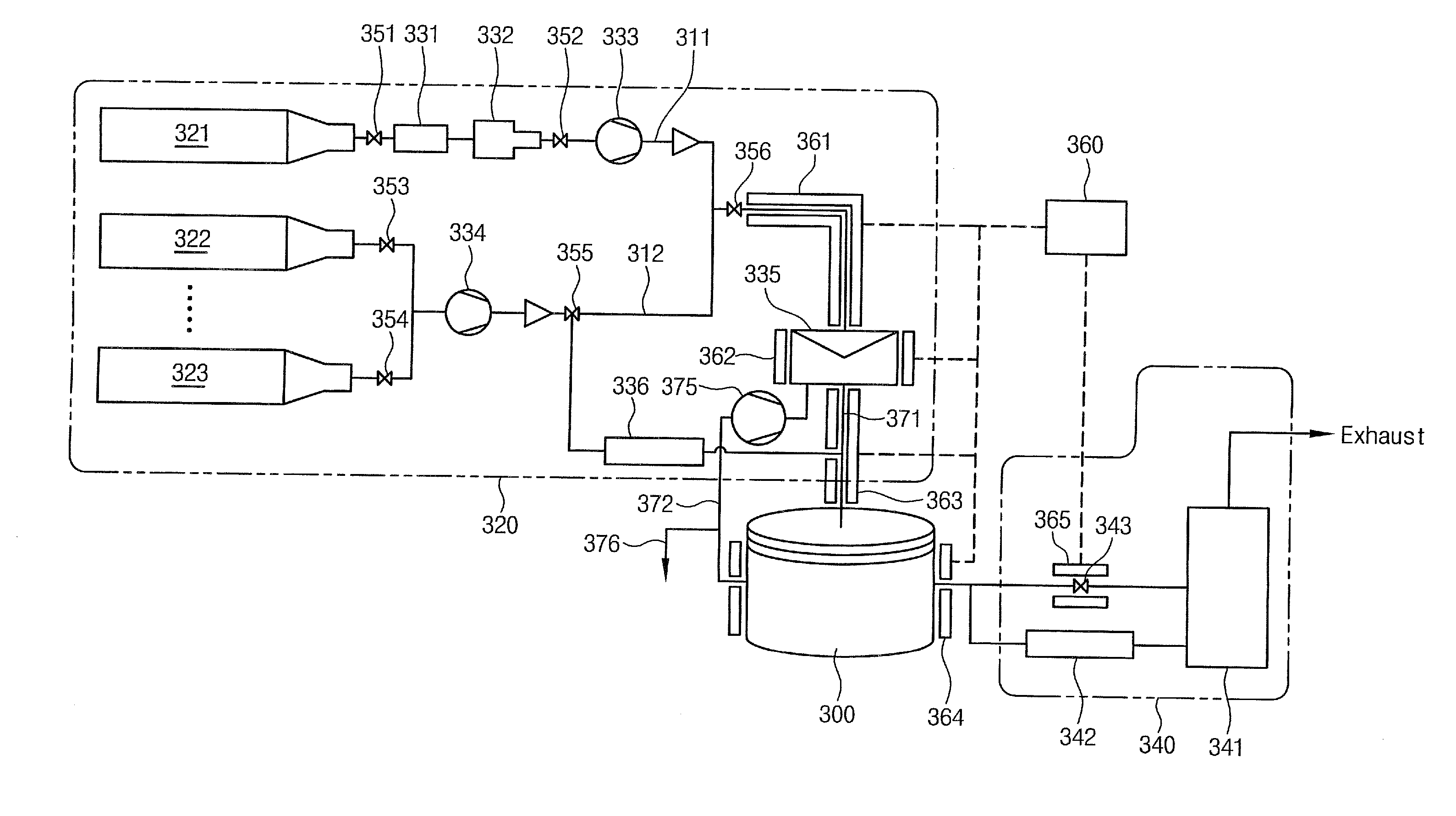

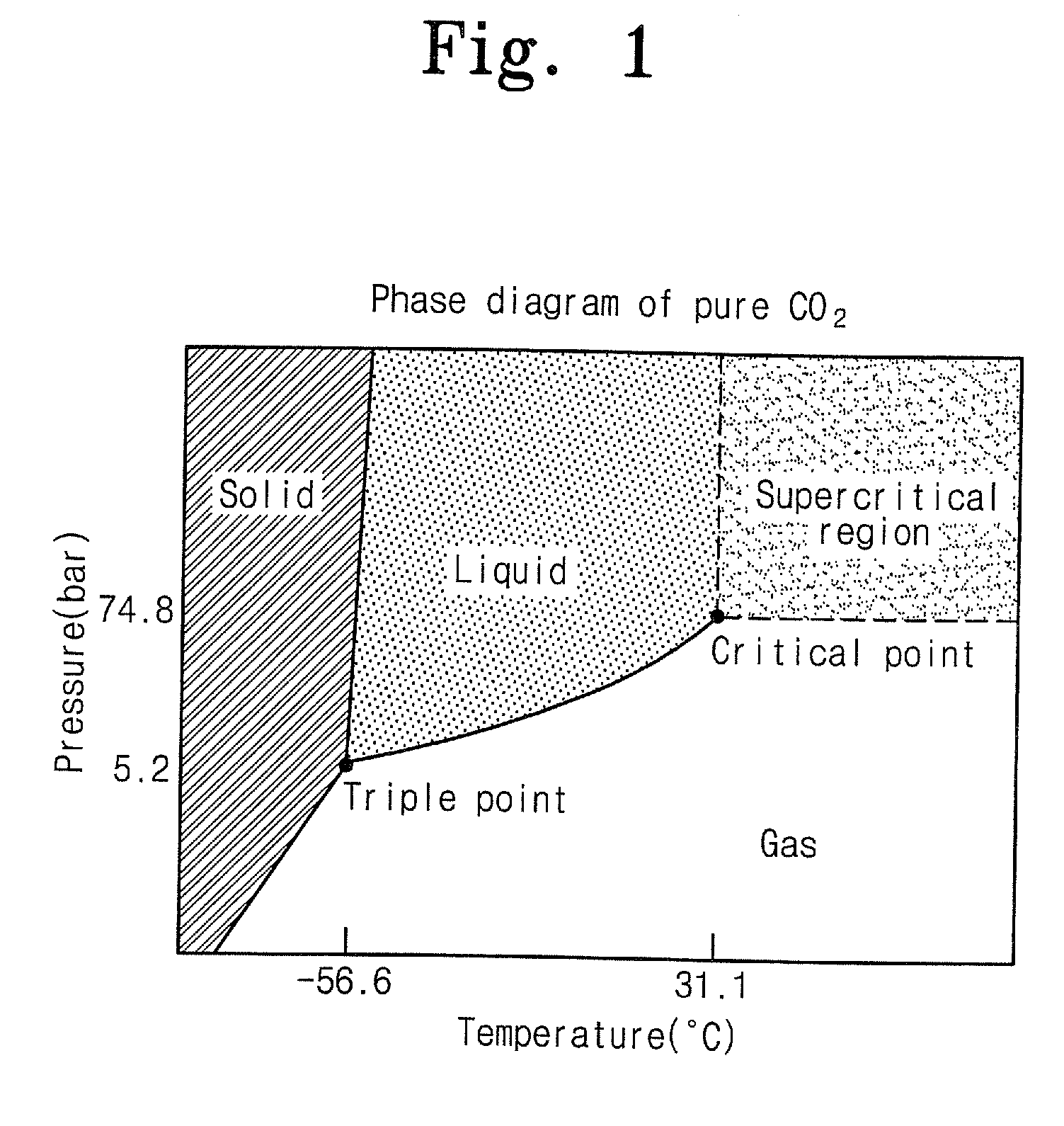

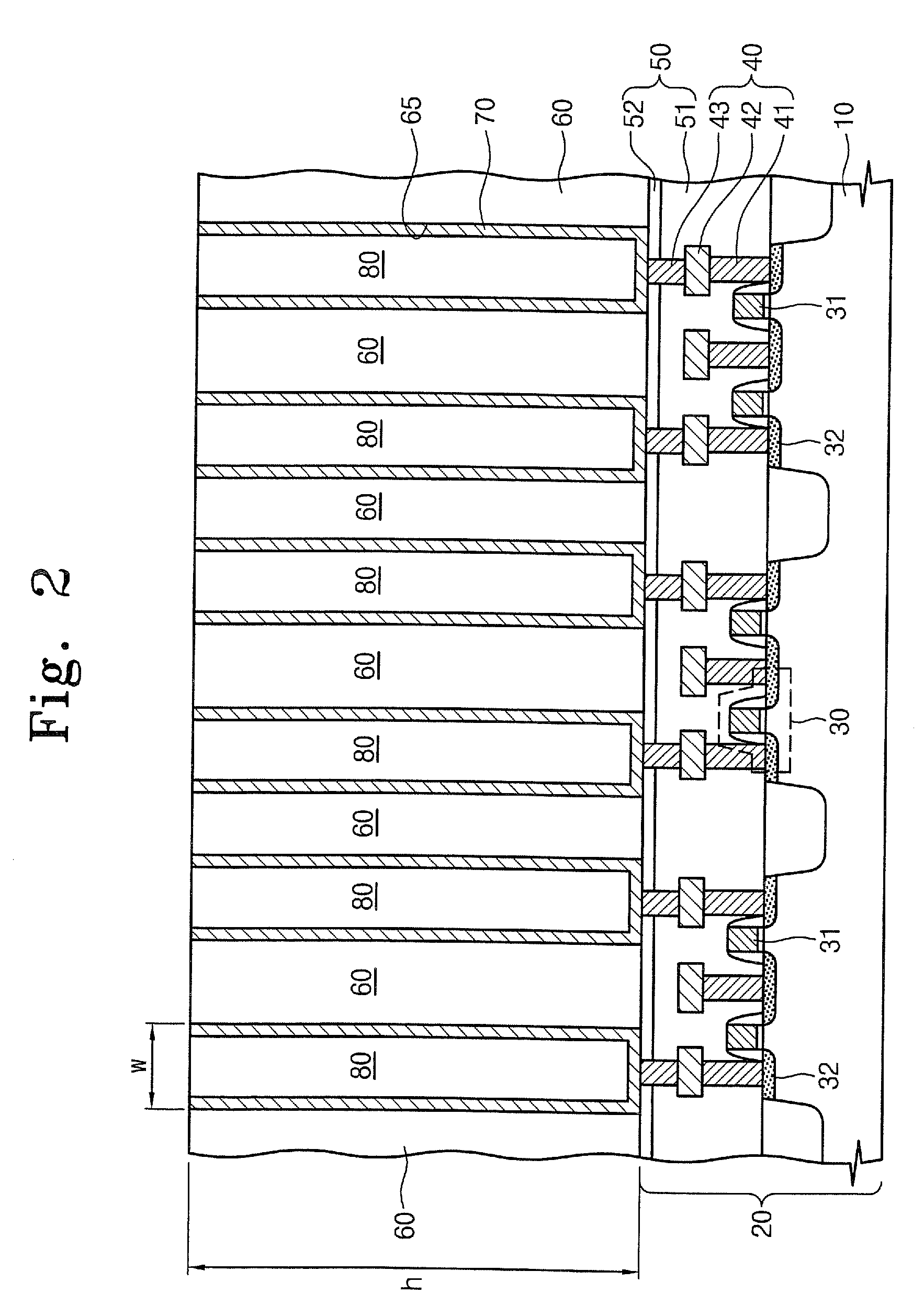

Etching, cleaning and drying methods using supercritical fluid and chamber systems using these methods

ActiveUS20070293054A1Solid-state devicesSemiconductor/solid-state device manufacturingEtchingDevice material

Provided herein are etching, cleaning and drying methods using a supercritical fluid, and a chamber system for conducting the same. The etching method includes etching the material layer using a supercritical carbon dioxide in which an etching chemical is dissolved, and removing an etching by-product created from a reaction between the material layer and the etching chemical using a supercritical carbon dioxide in which a cleaning chemical is dissolved. Methods of manufacturing a semiconductor device are also provided.

Owner:SAMSUNG ELECTRONICS CO LTD +1

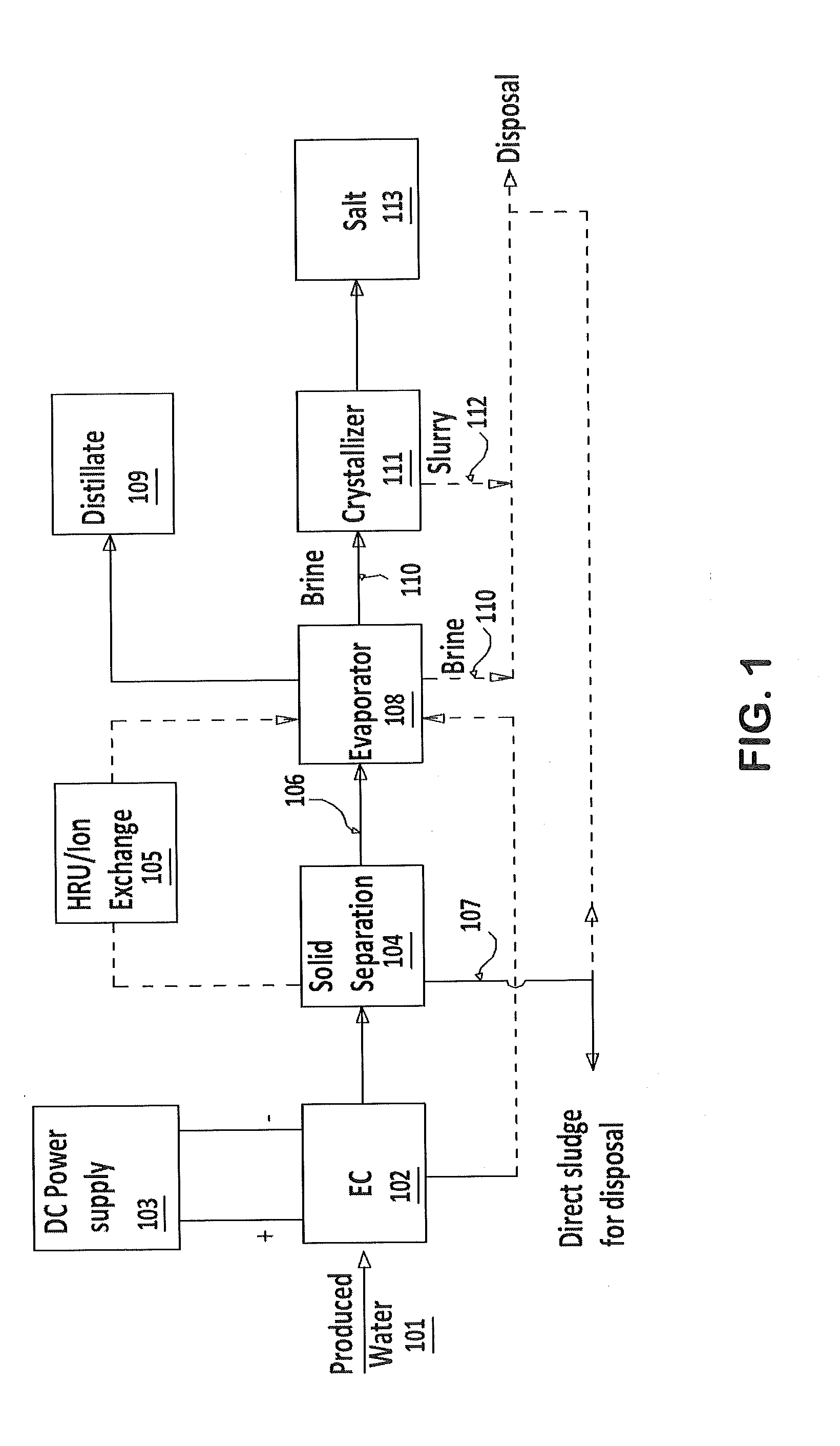

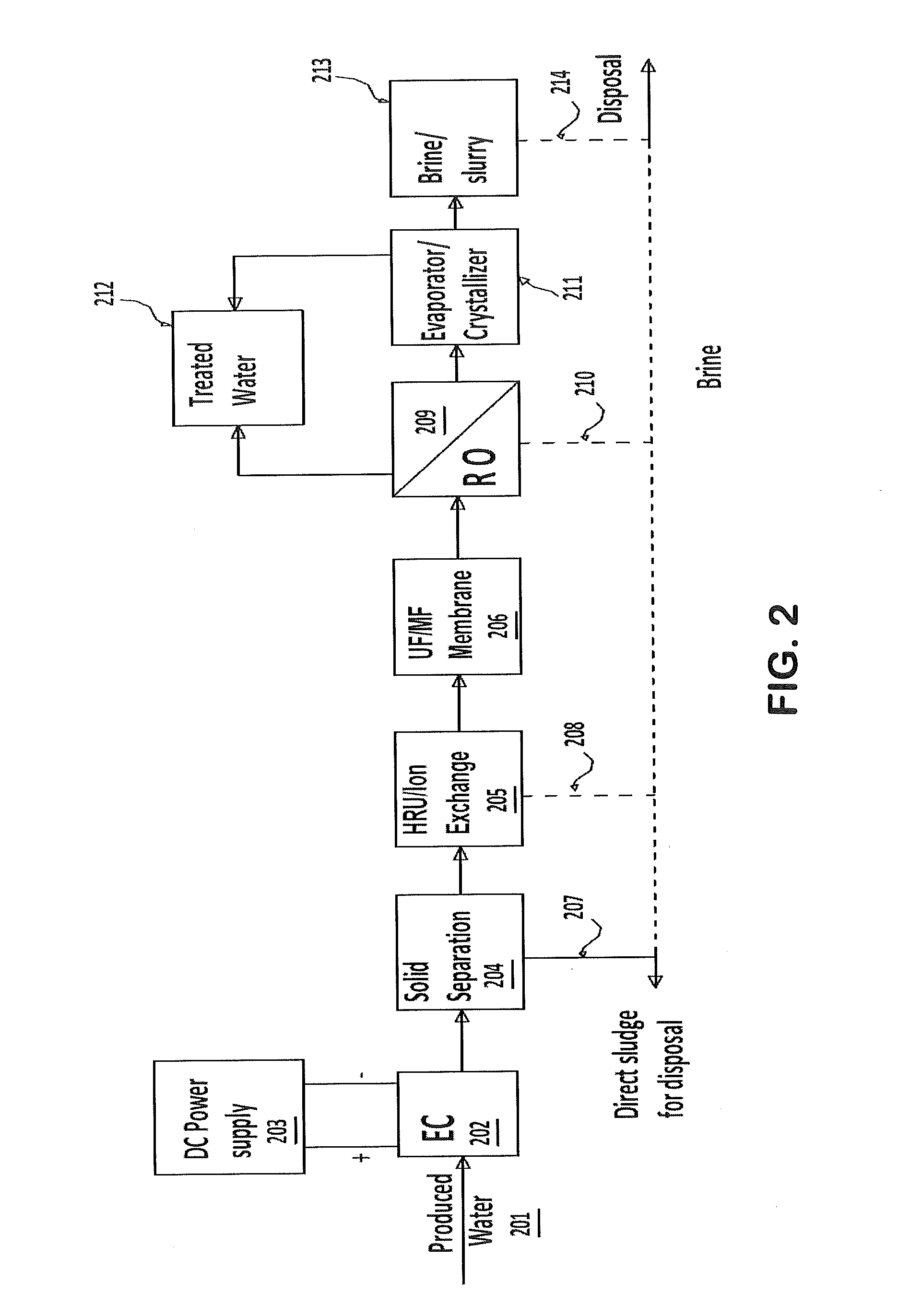

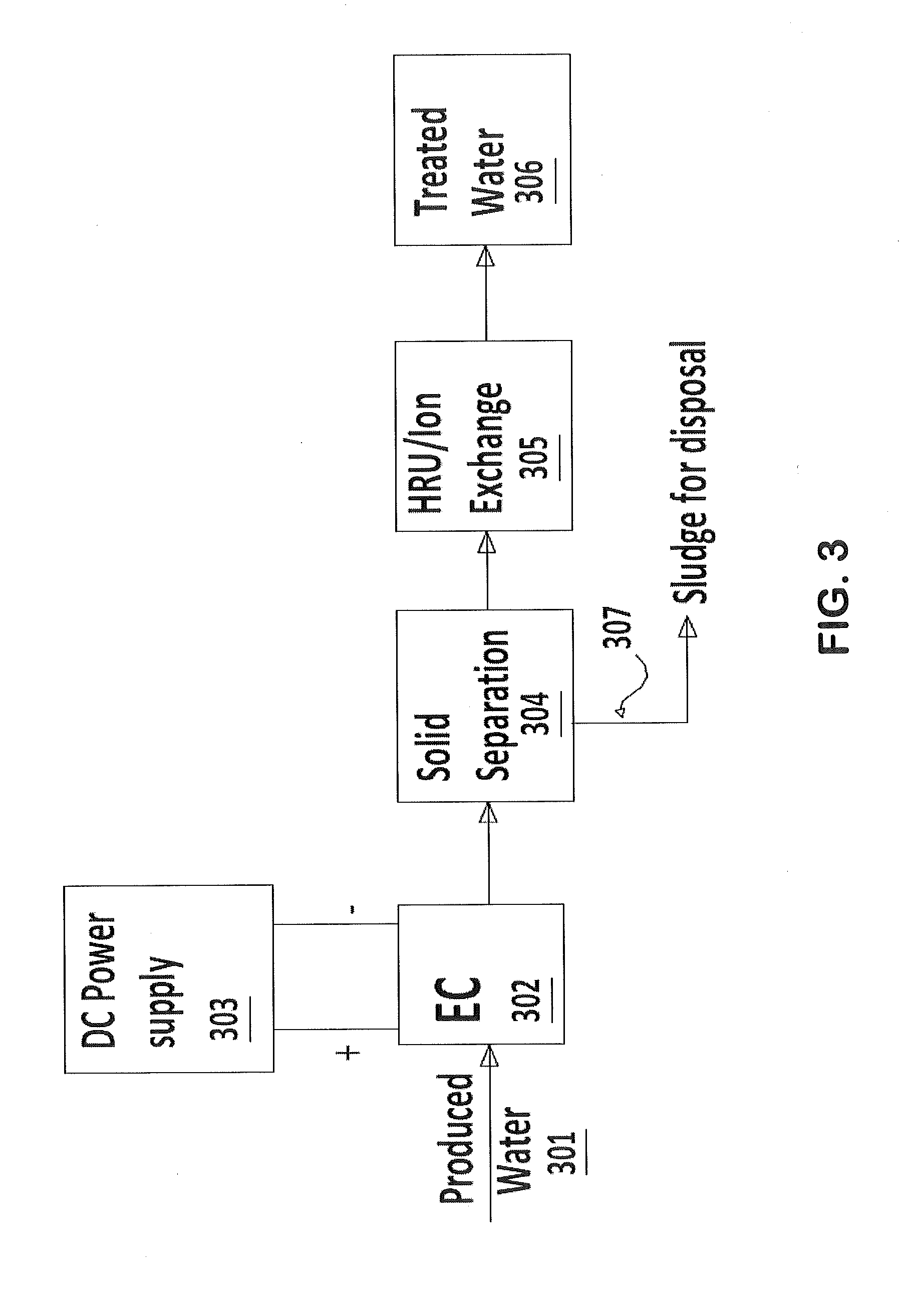

Water Treatment Process

InactiveUS20150315055A1Minimal environmental impactLow costWaste water treatment from quariesWater contaminantsElectrocoagulationHardness

A process for enhanced removal of impurities from water by an enhanced multi-step electrocoagulation process including electrocoagulation, solids separation, hardness removal, crystallization, and, optionally, reverse osmosis and evaporative purification. Embodiments of the invention may remove multiple impurities at substantial savings in time, energy, and chemical use. Zero liquid discharge options are also reported.

Owner:AQUATECH INT LLC

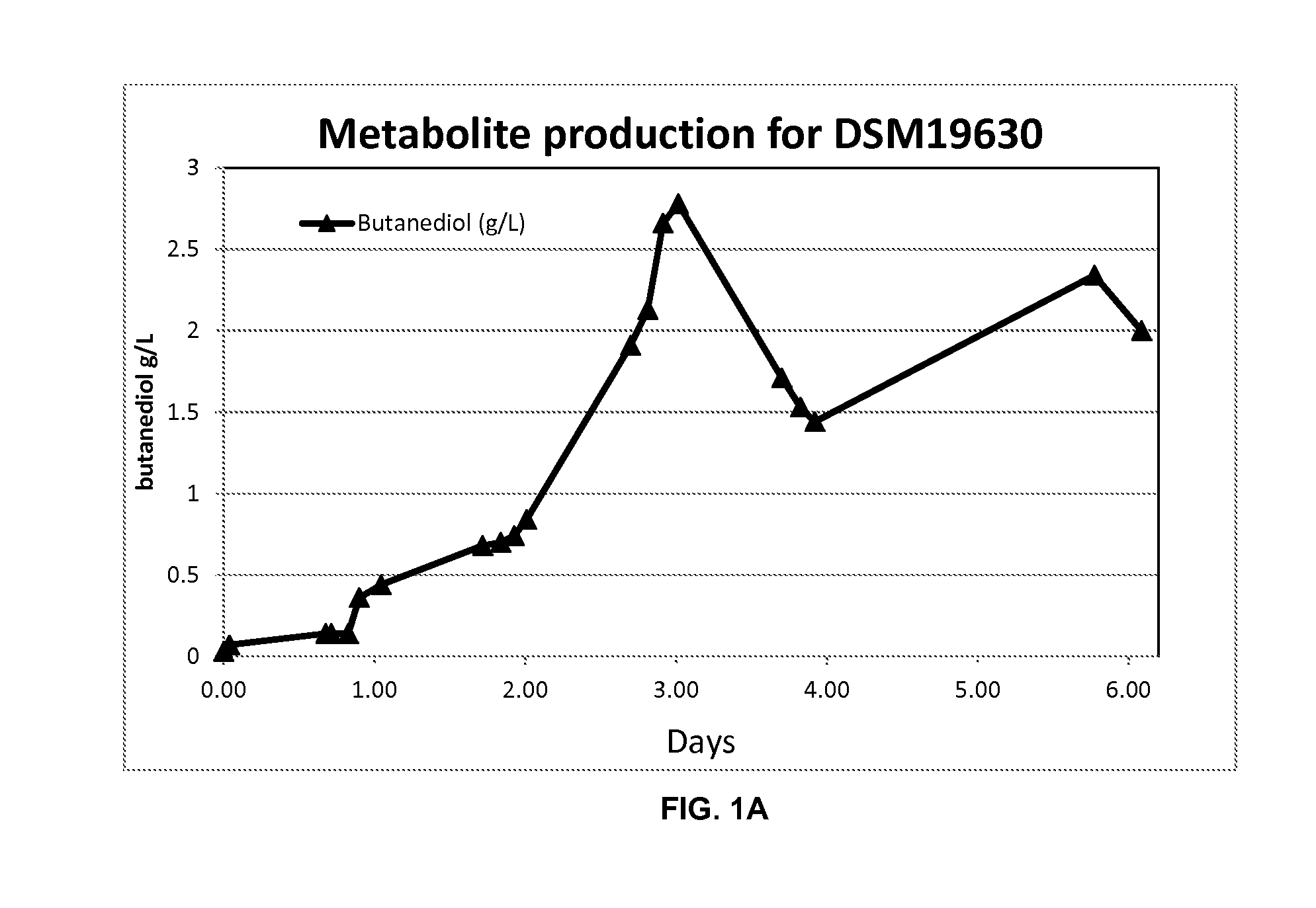

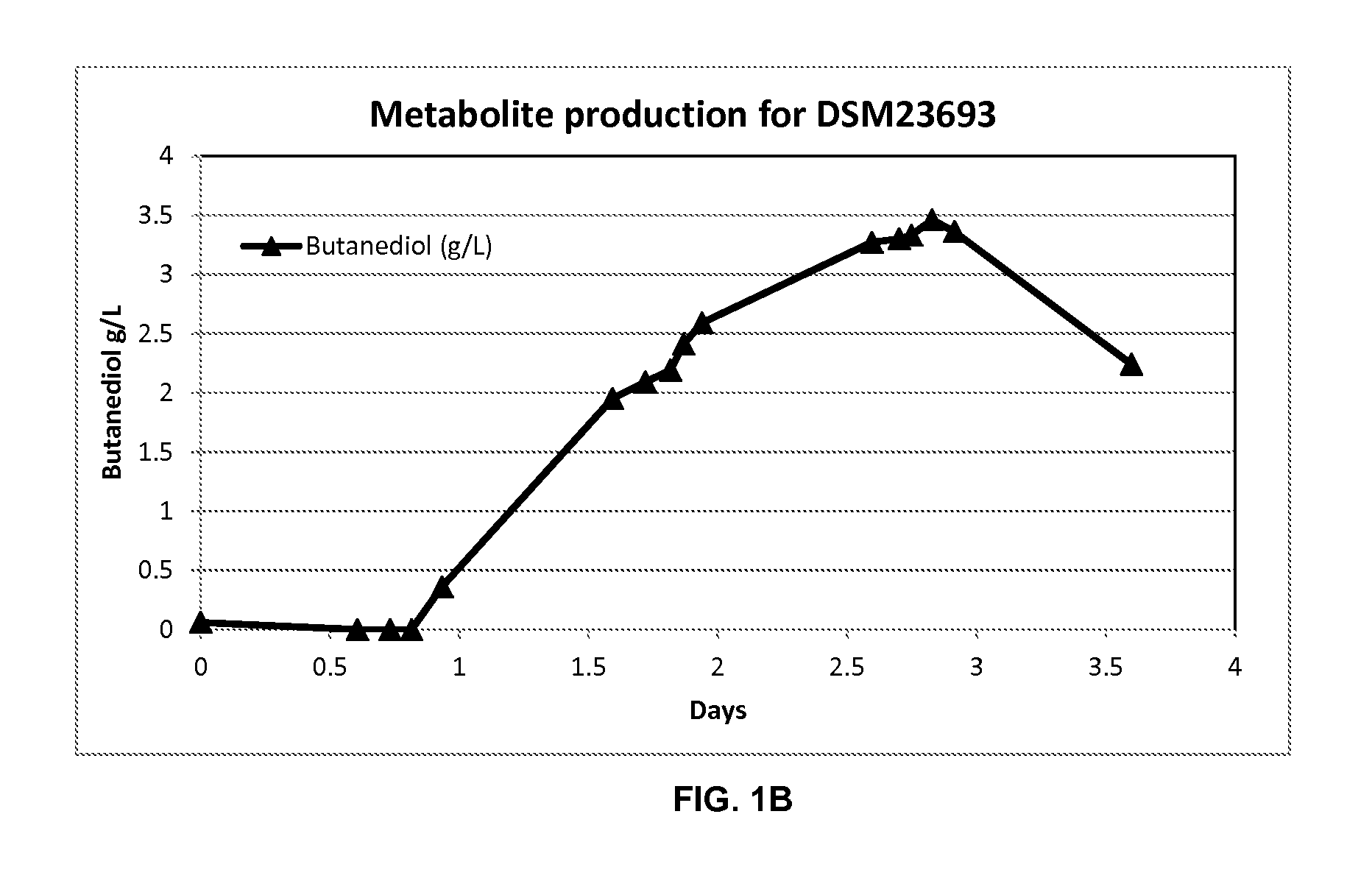

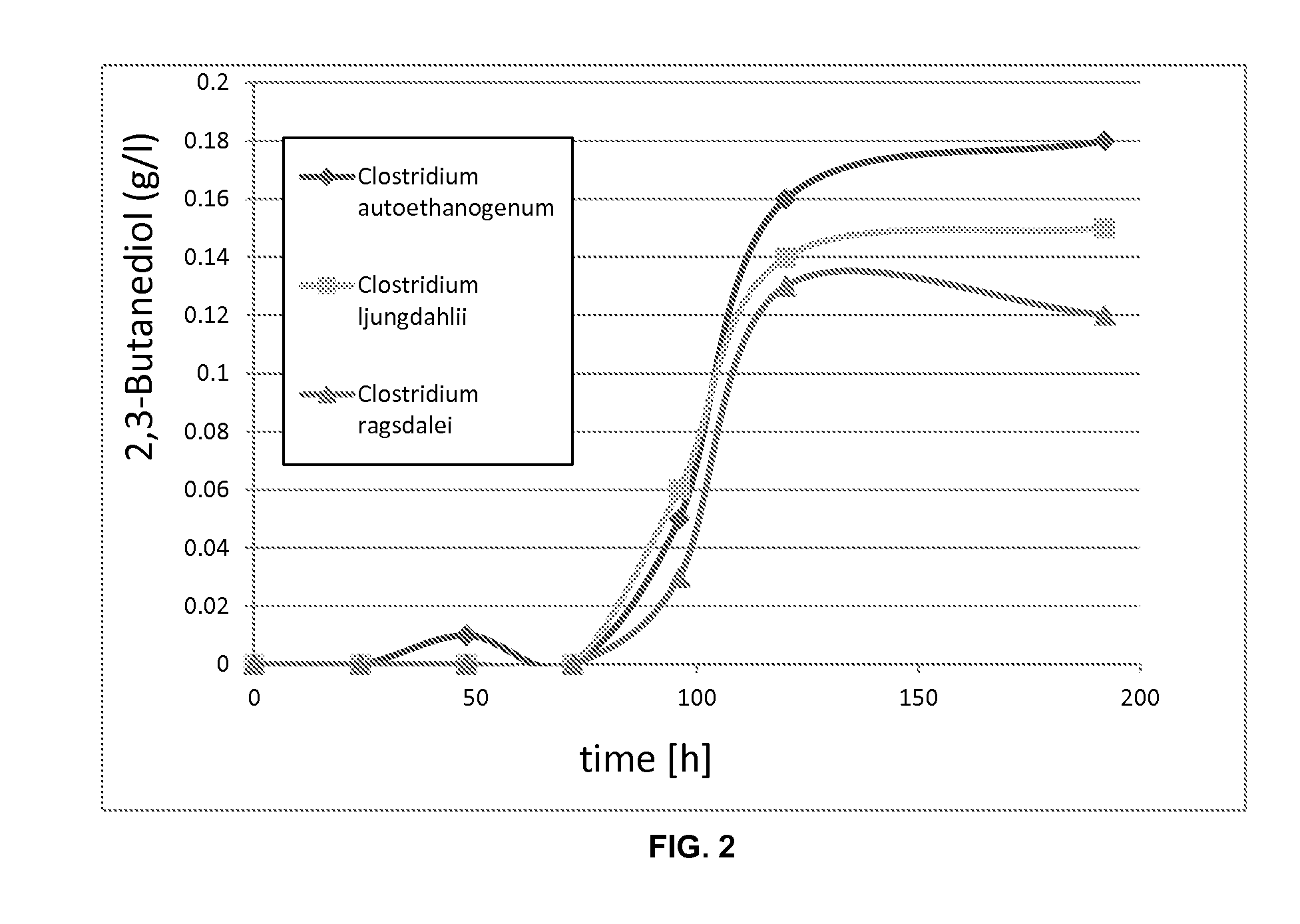

Process for producing chemicals using microbial fermentation of substrates comprising carbon monoxide

InactiveUS20120045807A1Organic compound preparationMicroorganismsClostridium ragsdalei2,3-Butanediol

A process for converting a substrate such as carbon monoxide to useful chemicals has been developed. The process involves providing a substrate comprising CO to a bioreactor which contains a culture of one or more micro-organisms and anaerobically fermenting the substrate to produce 2,3-butanediol (BDO). The BDO is next converted to one or more of butane, butadiene and / or methyl ethyl ketone which in turn can be converted to other compounds. The source of the CO can be an industrial process such as the ferrous metal products manufacturing. The microorganism can be Clostridium autoethanogenum, Clostridium ljundahlii or Clostridium ragsdalei.

Owner:LANZATECH NZ INC

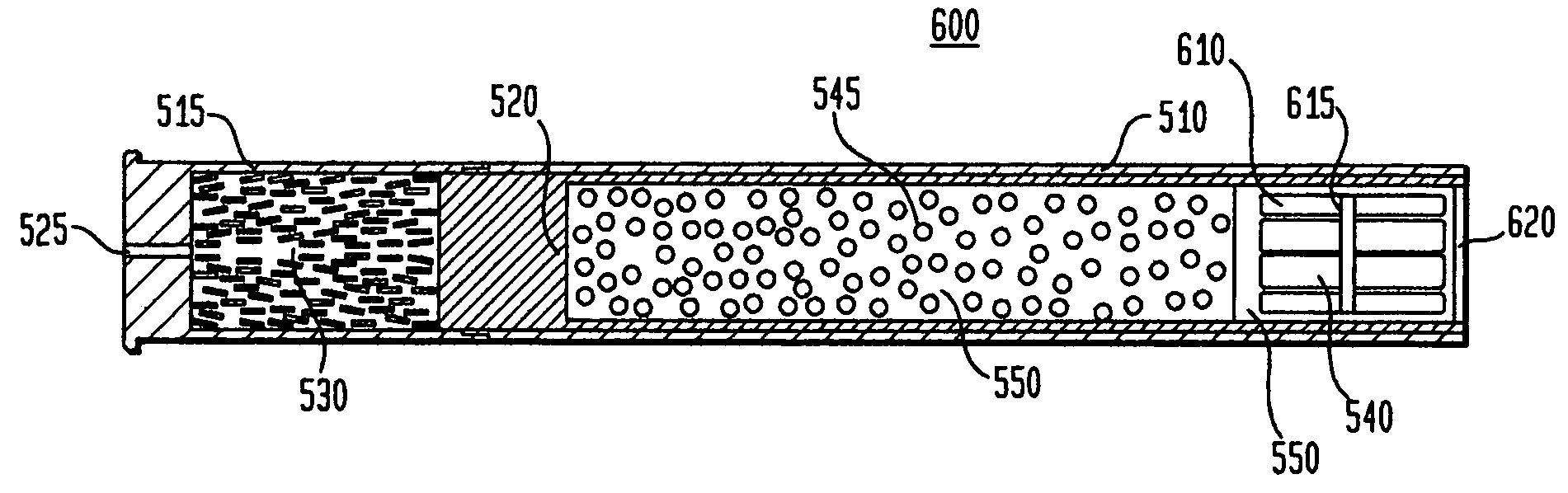

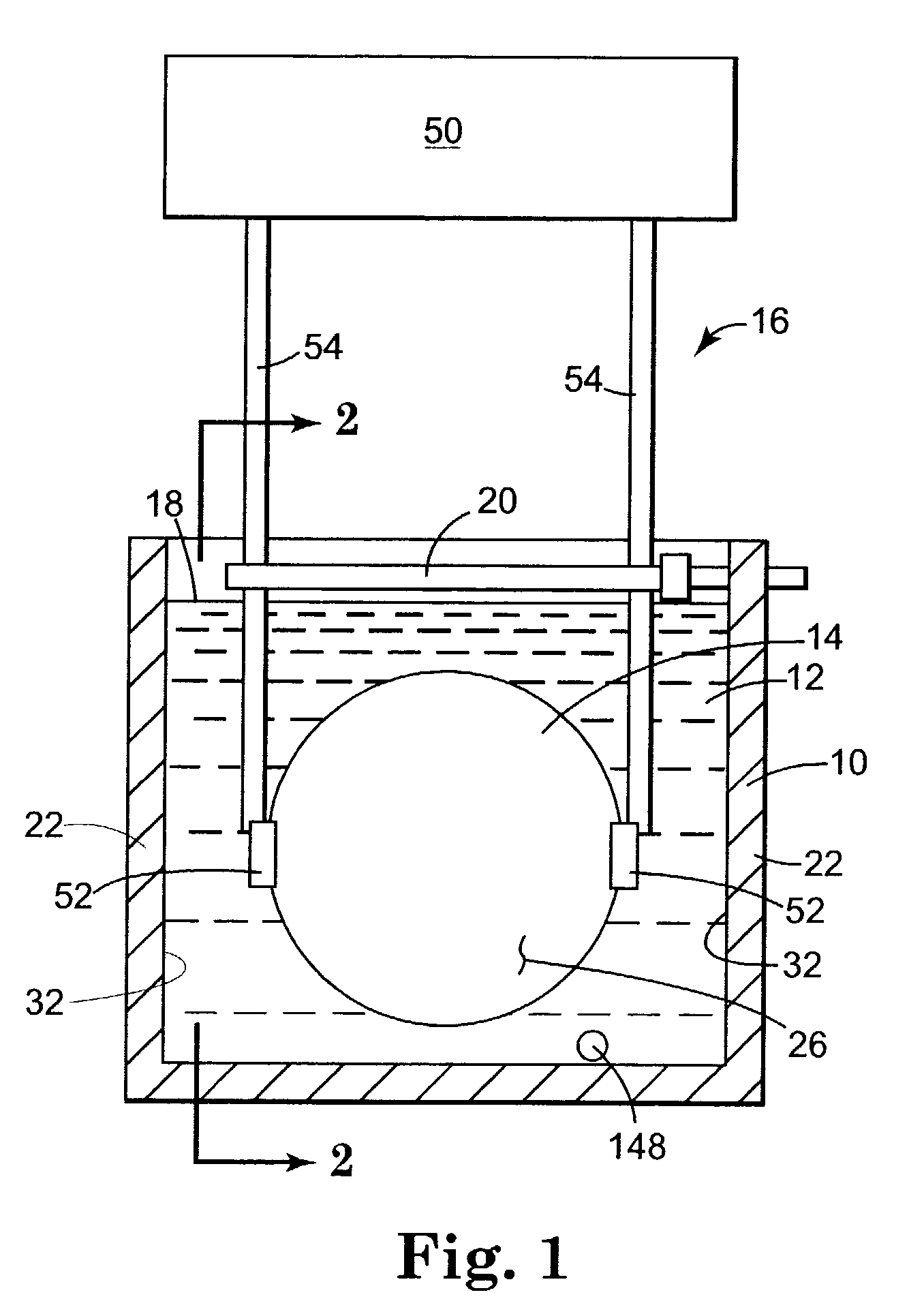

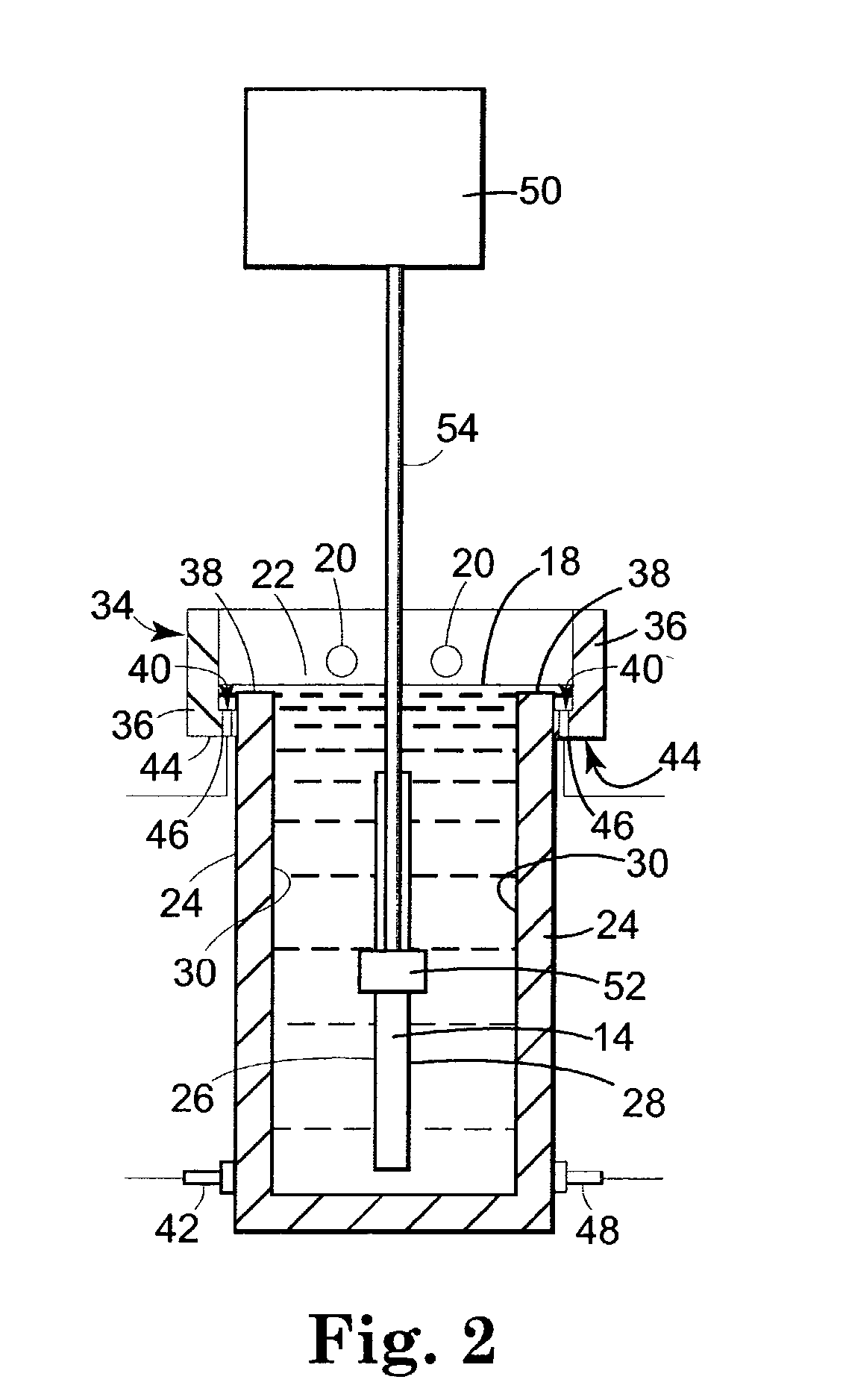

Semiconductor wafer cleaning systems and methods

InactiveUS6875289B2Improve efficiencySubstance may accumulateDrying solid materials with heatReconditioning/cleaning record carriersEngineeringDelivery system

An immersion processing system is provided for cleaning wafers with an increased efficiency of chemical use. Such a system advantageously uses less cleaning enhancement substance that may be provided as gas, vapor or liquid directly to a meniscus or wafer / liquid / gas bath interface so as to effectively modify surface tensions at the meniscus with minimized chemical usage. Such a delivery system design may be applied for single wafer processing or for processing multiple wafers together within a single liquid bath vessel. For single wafer processing, in particular, cleaning enhancement substance can be delivered along one or both major sides of the wafer, preferably at the meniscus that is formed as the wafer and liquid are relatively moved, while a processing vessel usable for such single wafer processing may itself be designed with a minimized size to accommodate a single wafer. By reducing the vessel volume, chemical usage for any processing chemicals that are to be provided within a liquid bath may also be advantageously reduced.

Owner:TEL EPION

PVC material and preparation thereof

InactiveCN101486820AReduce foulingHigh low temperature impact resistanceProcedure AgentsFood sanitation

The invention discloses a PVC material and a preparation method thereof. The PVC material comprises the following substances according to parts by weight: 100 parts of PVC, 2-8 parts of stabilizer, 2-6 parts of processing agent, 1.5-2.5 parts of lubricants, 4-12 parts of filler, and 0.05-1 part of colorant. Compared with the prior art, the invention adopts food sanitation-level or nontoxic raw materials; the mobility of the manufactured material is good, and the molding temperature and molding pressure of tubular products and pipe fittings can be reduced, thus preventing the PVC material from pyrolyzing. The PVC-U water supply tubular products, pipe fittings and pressure-proof ball valves made from the material have good acid and alkali resistance, inoxidability and ageing resistance, and the pressure resistance of the pressure-proof ball valve is more than or equal to 2.5MPa (the pressure resistance of similar products is only more than 1.6MPa), thus fully meeting food and chemical use requirements.

Owner:黄山琦源塑管阀门有限公司

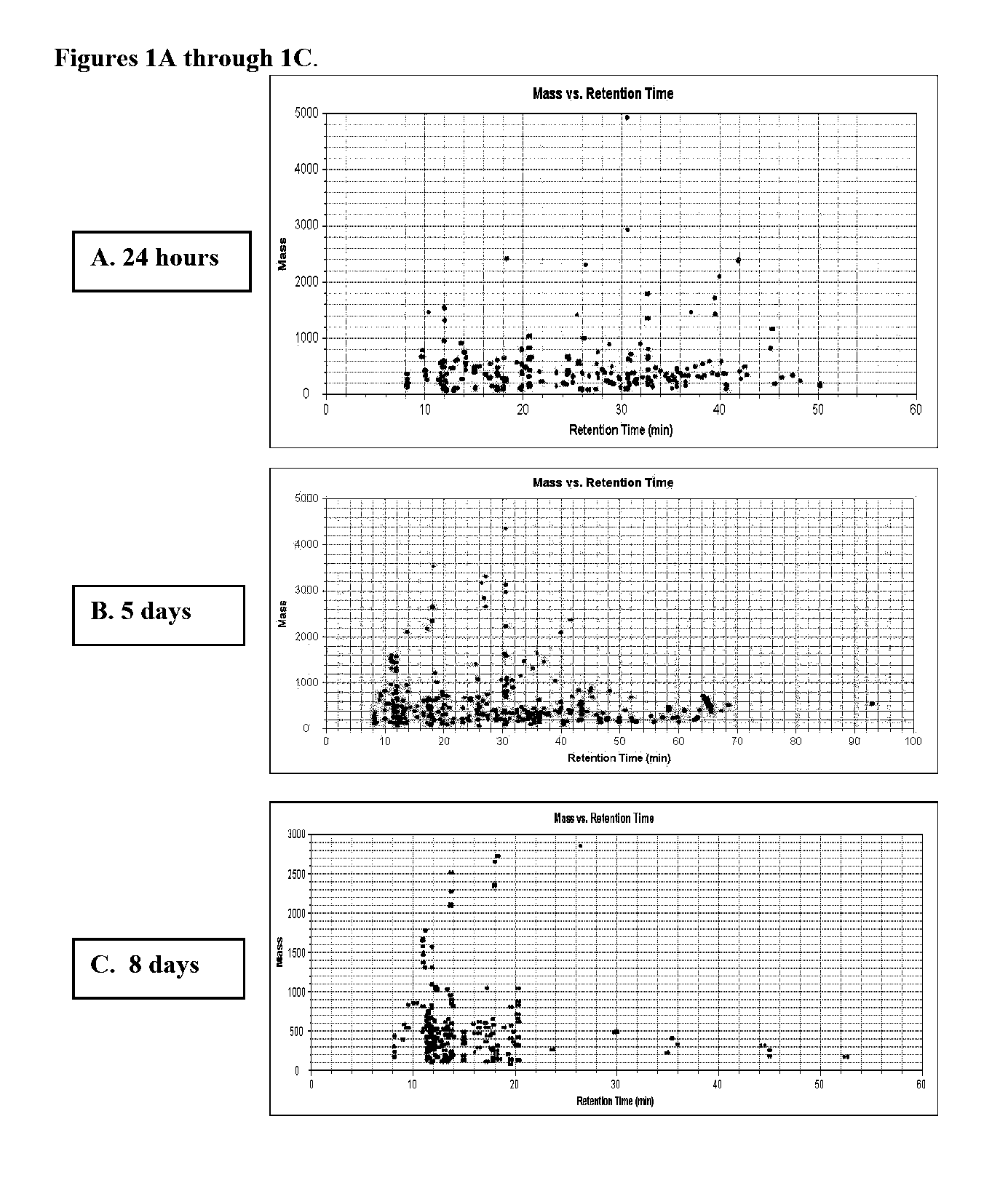

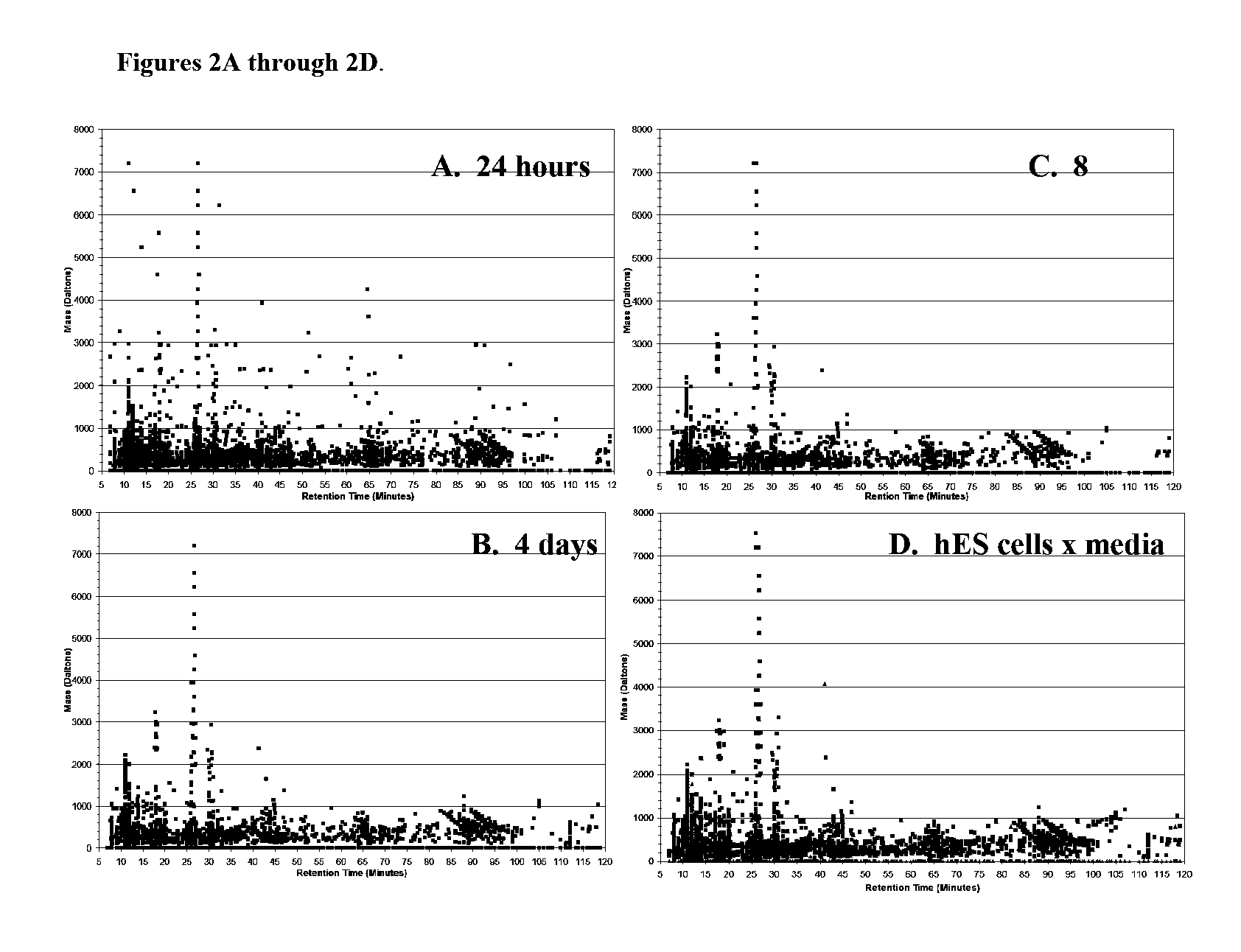

Reagents and Methods for Using Human Embryonic Stem Cells to Evaluate Toxicity of Pharmaceutical Compounds and Other Chemicals

ActiveUS20070248947A1Reliably determinedPotential for false negatives is reducedCompound screeningApoptosis detectionTesting toxicityChemical compound

The invention provides biomarker profiles of cellular metabolites and methods for screening chemical compounds including pharmaceutical agents, lead and candidate drug compounds and other chemicals using human embryonic stem cells (hESC) or lineage-specific cells produced therefrom. The inventive methods are useful for testing toxicity, particularly developmental toxicity and detecting teratogenic effects of such chemical compounds.

Owner:WISCONSIN ALUMNI RES FOUND

Semiconductor wafer cleaning systems and methods

InactiveUS20040050405A1Improve efficiencyMinimized chemical usageDrying solid materials with heatReconditioning/cleaning record carriersEngineeringDelivery system

An immersion processing system is provided for cleaning wafers with an increased efficiency of chemical use. Such a system advantageously uses less cleaning enhancement substance that may be provided as gas, vapor or liquid directly to a meniscus or wafer / liquid / gas bath interface so as to effectively modify surface tensions at the meniscus with minimized chemical usage. Such a delivery system design may be applied for single wafer processing or for processing multiple wafers together within a single liquid bath vessel. For single wafer processing, in particular, cleaning enhancement substance can be delivered along one or both major sides of the wafer, preferably at the meniscus that is formed as the wafer and liquid are relatively moved, while a processing vessel usable for such single wafer processing may itself be designed with a minimized size to accommodate a single wafer. By reducing the vessel volume, chemical usage for any processing chemicals that are to be provided within a liquid bath may also be advantageously reduced.

Owner:TEL EPION

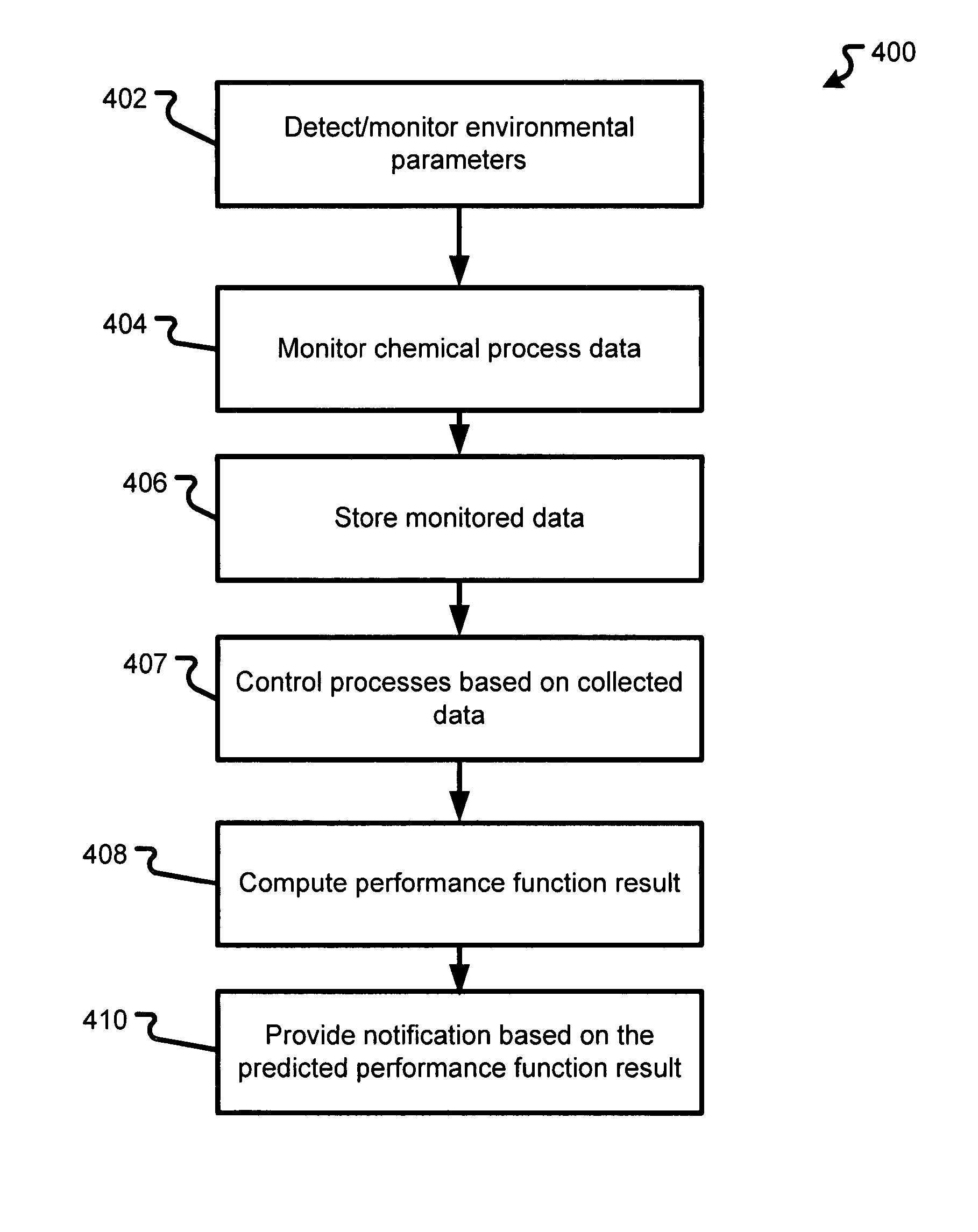

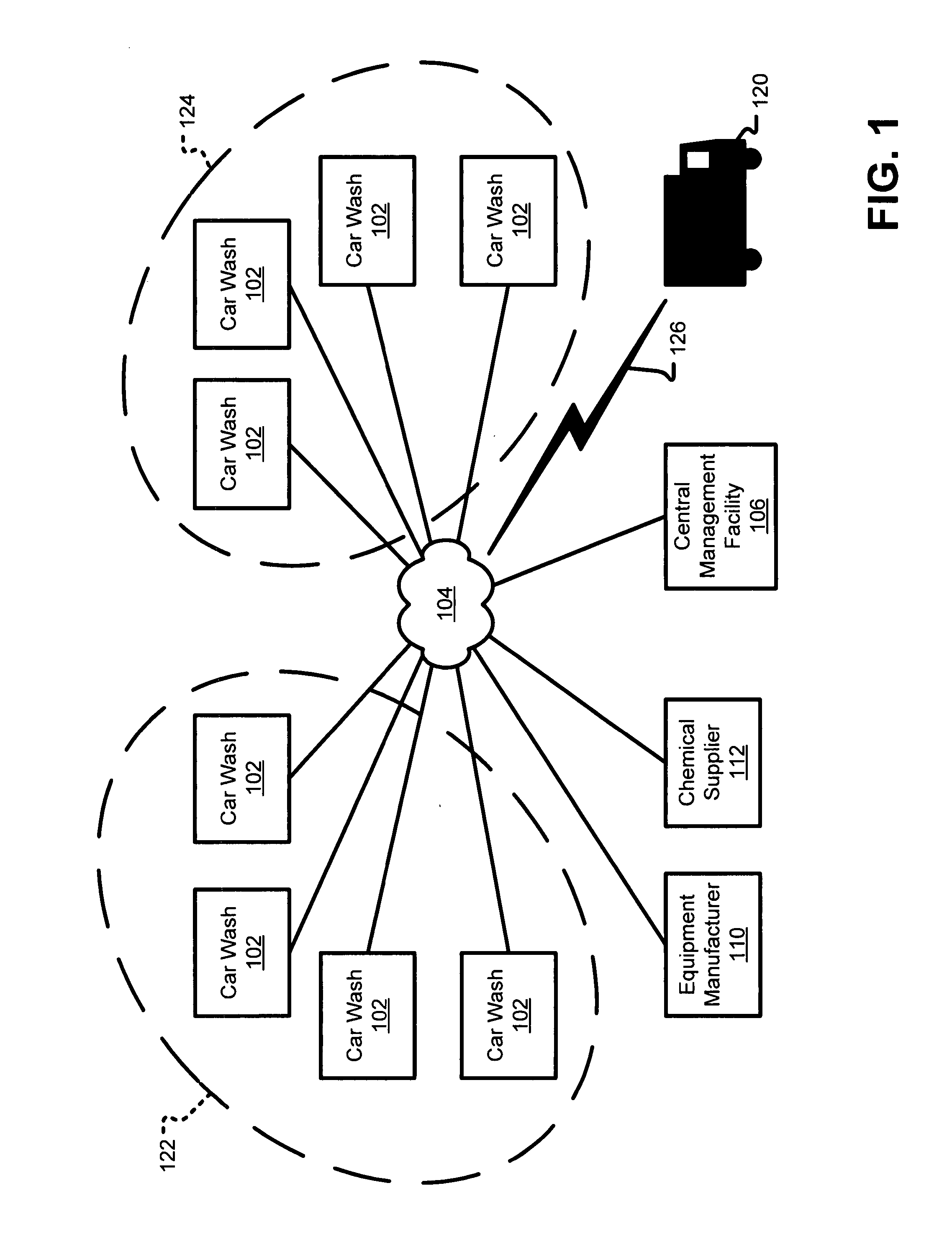

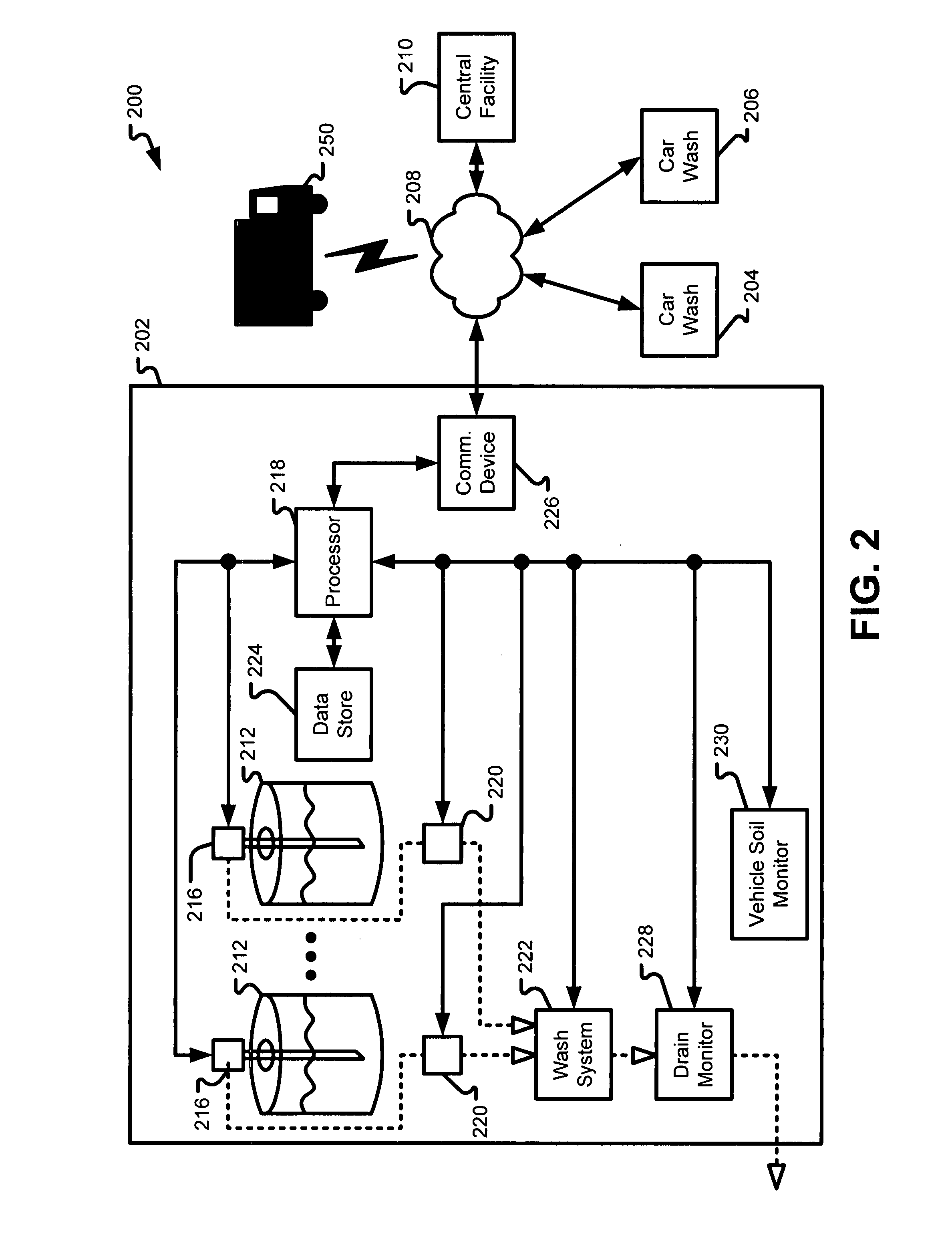

Monitoring and controlling processes at a vehicle wash facility

InactiveUS20080046278A1Maximize cleaning processVehicle cleaning apparatusResourcesEngineeringRoad condition

Remote monitoring of vehicle washing facilities allows a facility operator to more efficiently manage each site, particularly when combined with environmental conditions that influence the rate at which individual chemicals are used. Accurate chemical exhaustion times can therefore be predicted and communicated to the operator, and wash sequences and parameters may be altered in accordance with such environmental parameters. For example, information related to the composition of soil on a car may be monitored and used to alter the chemicals used in the wash cycle for that car. Other environmental conditions may include without limitation weather conditions, road conditions, types of vehicles, mechanical system status, vehicle temperature, etc.

Owner:ZEP IP HLDG LLC

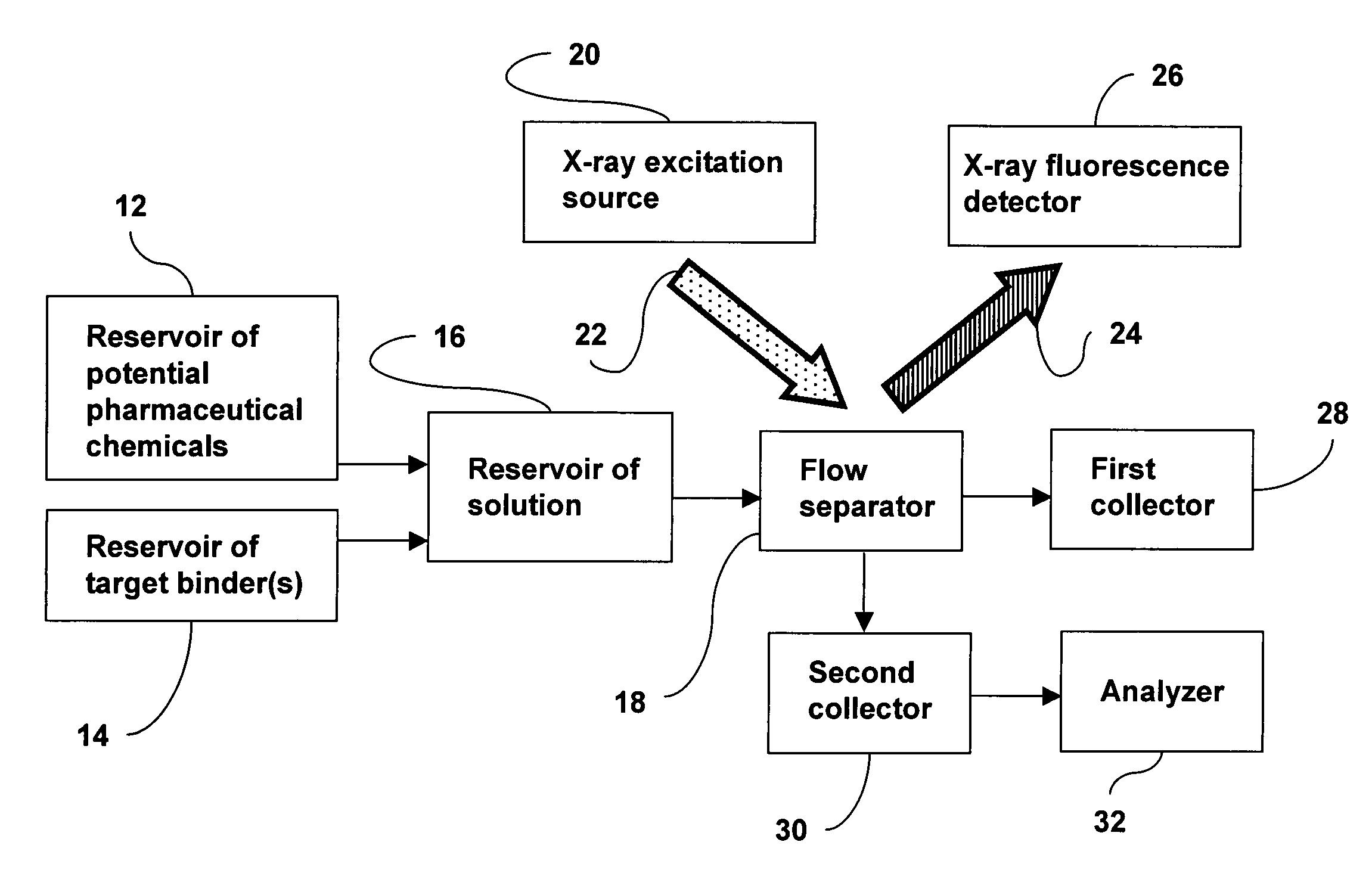

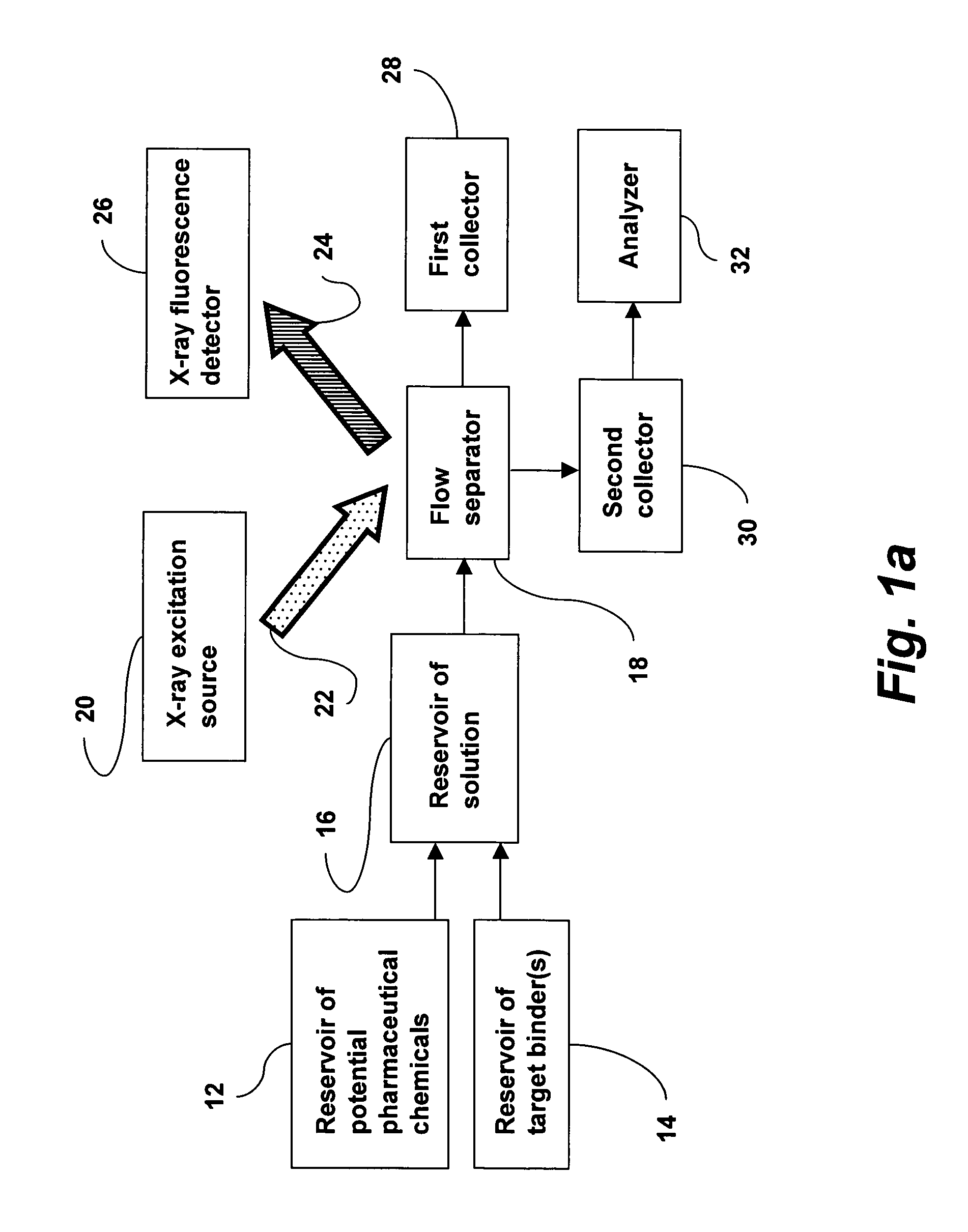

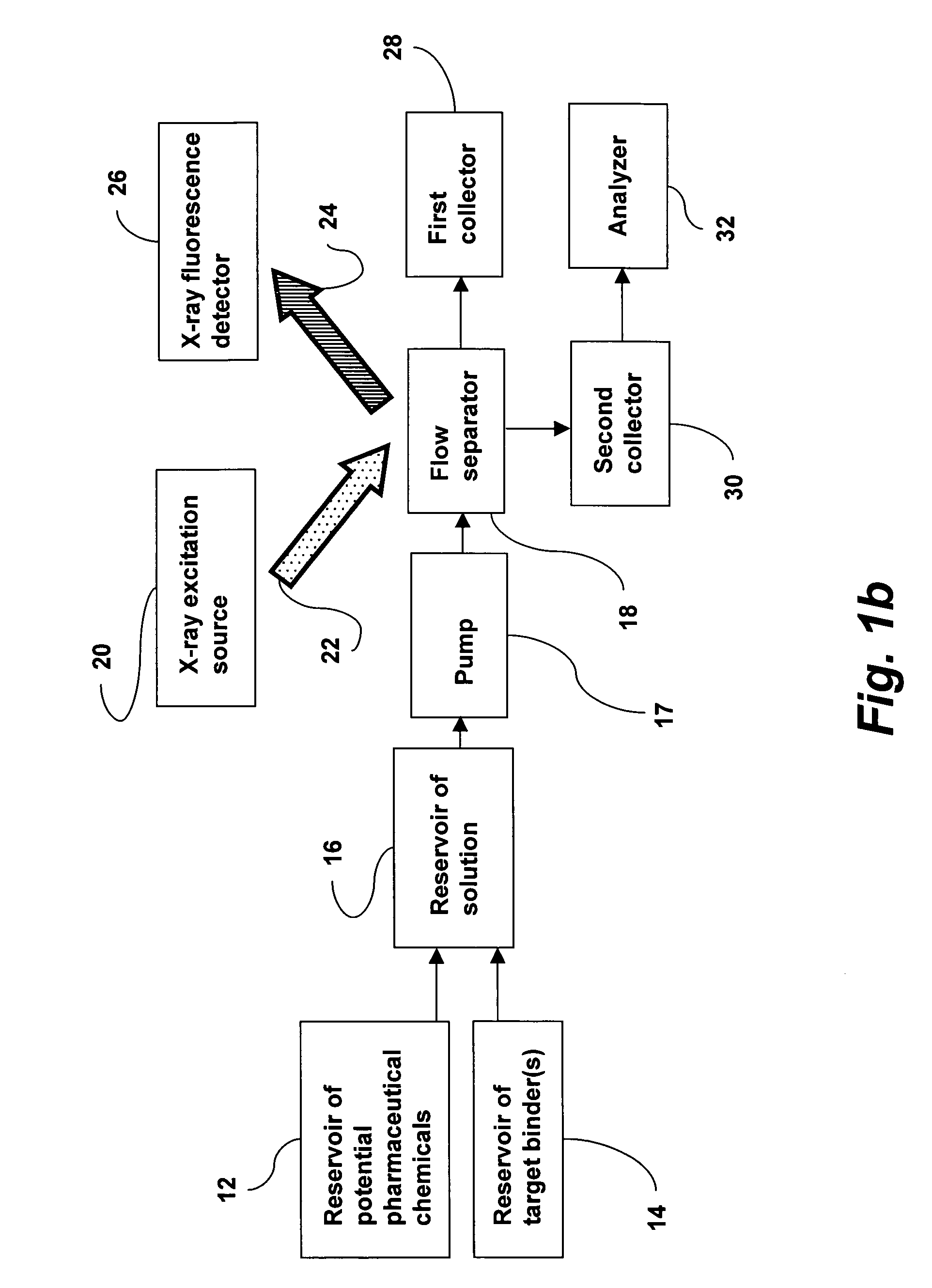

Flow method and apparatus for screening chemicals using micro x-ray fluorescence

InactiveUS7519145B2X-ray spectral distribution measurementMaterial analysis using wave/particle radiationExcitation beamX-ray

Method and apparatus for screening chemicals using micro x-ray fluorescence. A method for screening a mixture of potential pharmaceutical chemicals for binding to at least one target binder involves flow-separating a solution of chemicals and target binders into separated components, exposing them to an x-ray excitation beam, detecting x-ray fluorescence signals from the components, and determining from the signals whether or not a binding event between a chemical and target binder has occurred.

Owner:ICAGEN LLC

System and method for economically viable and environmentally friendly central processing of home laundry

InactiveUS7000437B2Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesWash waterChemical recovery

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:SHELL OIL CO

Coating compositions having extended pot life and shortened cure time and combination of chemicals used therein

InactiveUS6084026AExtension of timeRaise the ratioSynthetic resin layered productsPolyurea/polyurethane coatingsCarbamateDibutyl tin dilaurate

A combination of chemicals suitable for extending pot life and shortening cure time of a pot mix of a thermosetting composition is disclosed. The combination of chemicals includes a catalyst, such as, dibutyl tin dilaurate; carboxylic or sulfonic acid; and an extender compound, such as 2,4 pentanedione. The combination is generally included in a polymeric component of the urethane composition. The extended pot life provides the user with longer open time during which to efficiently apply a coating of the pot mix over a wide variety of substrate surfaces while still producing coatings that cure quickly upon application.

Owner:ROHM & HAAS CO

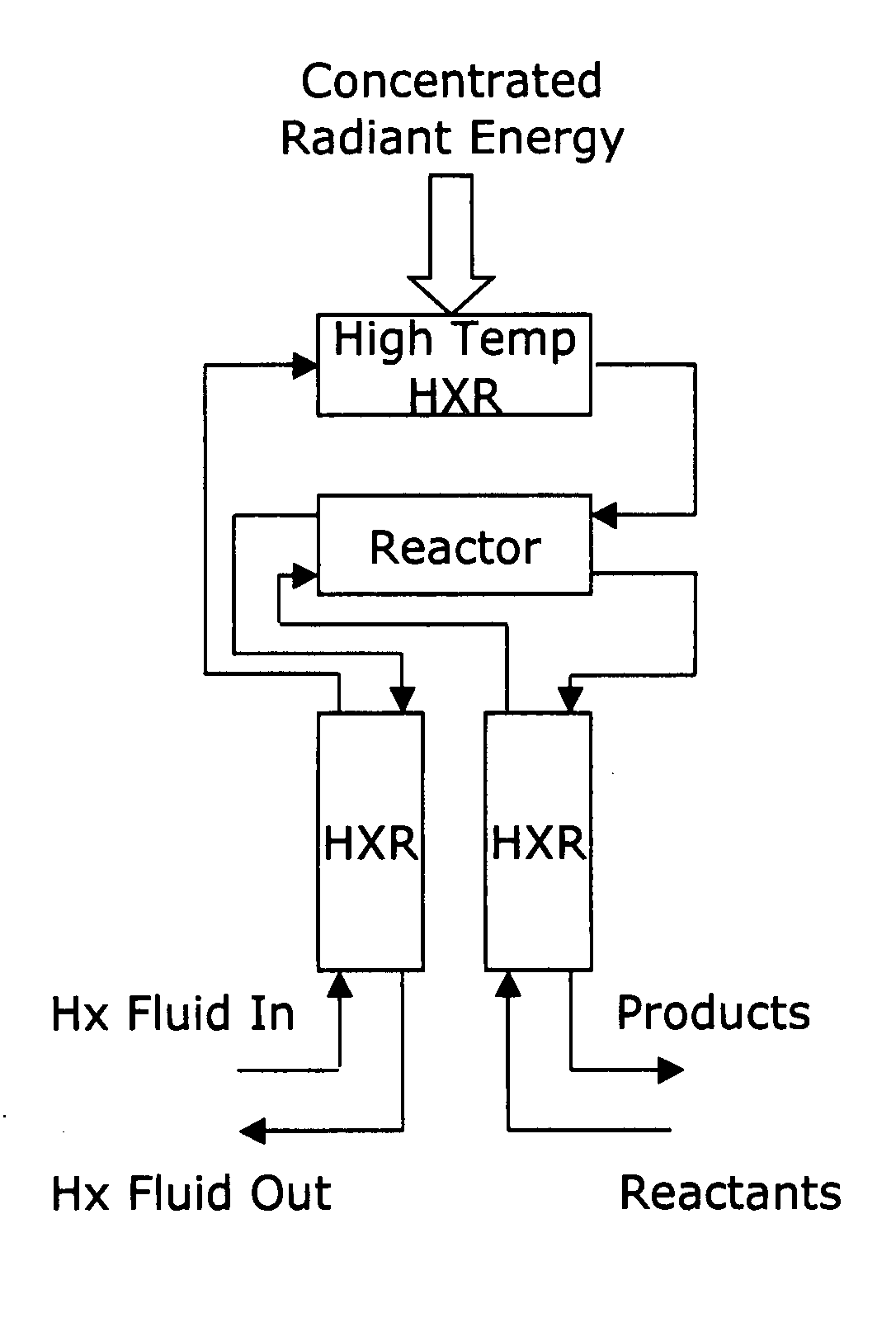

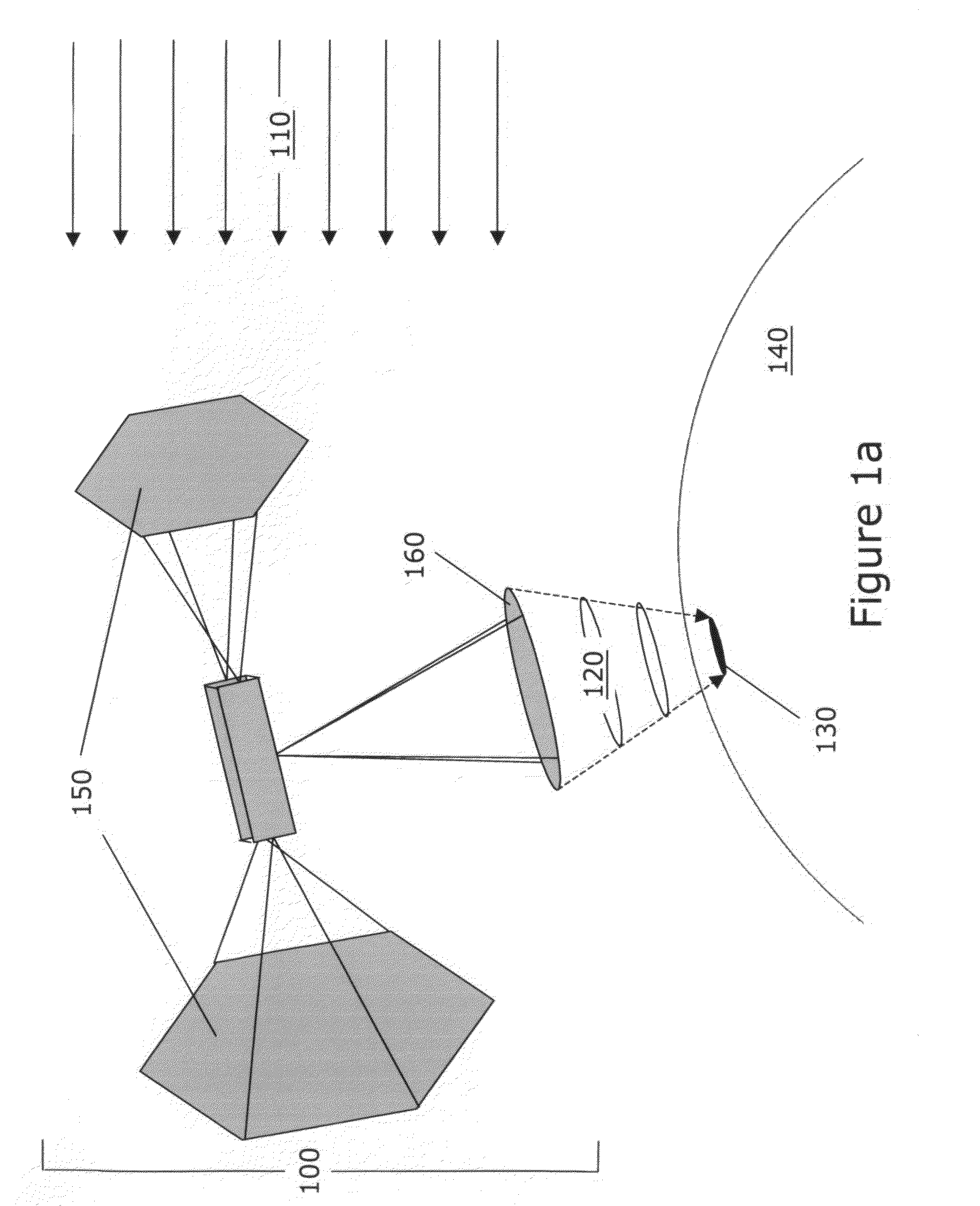

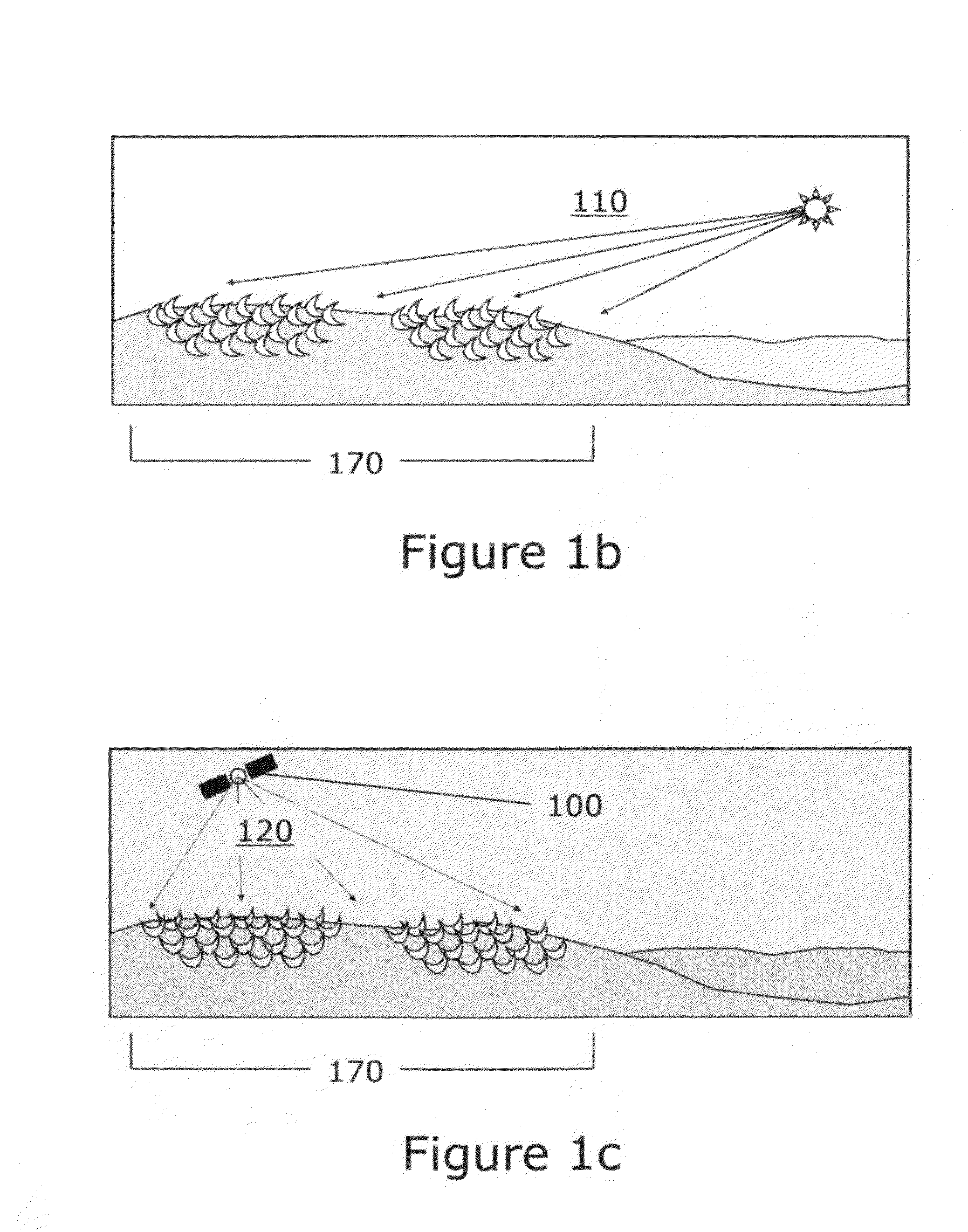

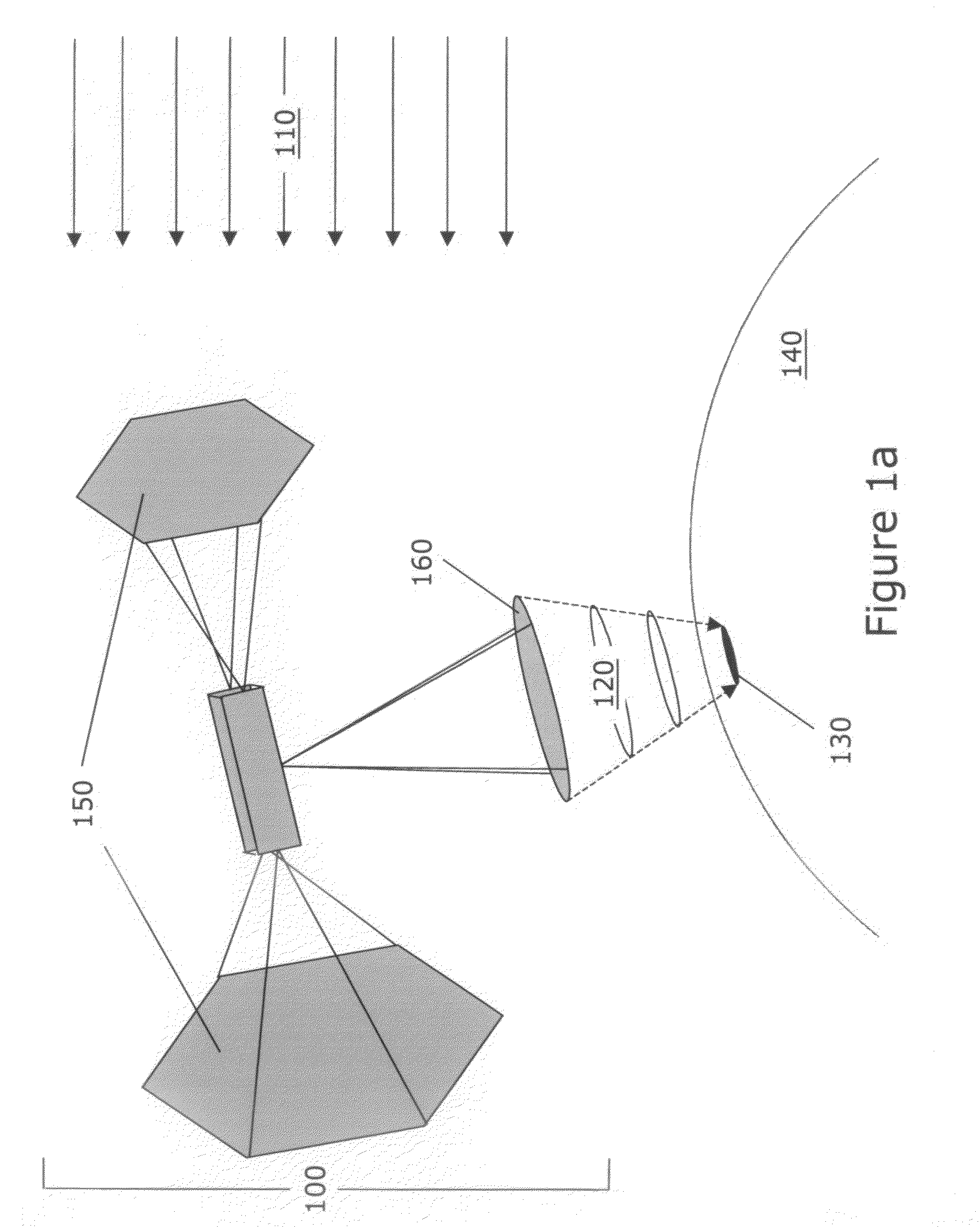

Radiant energy thermochemical processing system

InactiveUS20100098599A1Promote absorptionImprove abilitiesSolar heating energySolar heat devicesChemical treatmentChemical reaction

Thermochemical processing systems for the production of chemicals using solar (110) or other radiant energy as the heat source for chemical reactions and separations. Radiant energy receivers (310) operating in conjunction with concentrator systems (300), heat exchangers, chemical reactors and chemical separators. Systems and applications include the concentration of radiant energy in support of a moderate- and / or high-temperature, endothermic chemical reaction followed by downstream reactions and separations so that a chemical fuel is produced. Efforts are made to match concentrator types with need; for example, parabolic trough concentrators may be used to produce steam at low- to moderate-temperatures and parabolic dish concentrators may be used to drive moderate- to high-temperature chemical reactions such as methane reforming, and hybrid concentrators (400) may be used to concentrate radiant energy from multiple energy sources.

Owner:MANKINS JOHN CARLTON +1

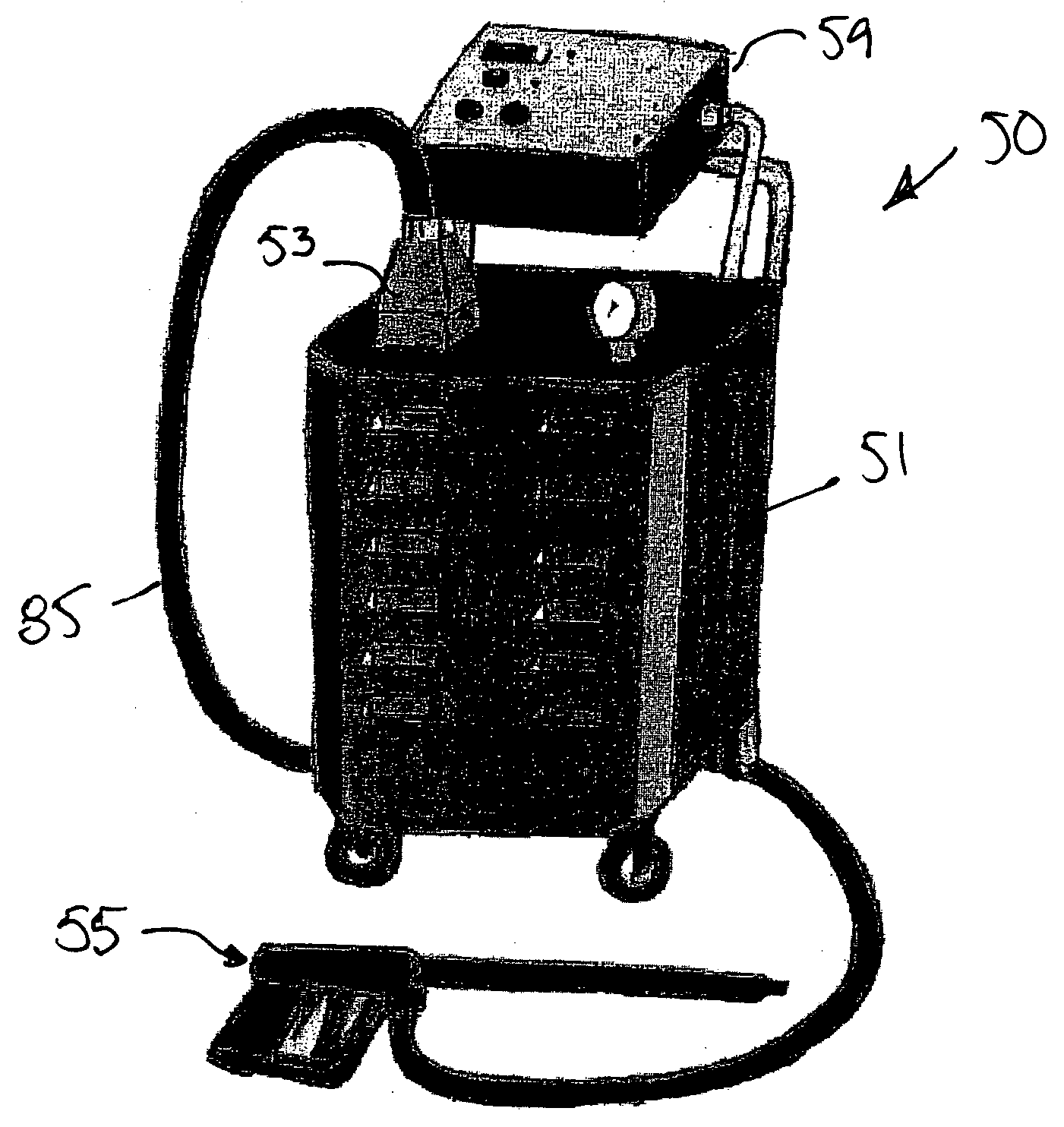

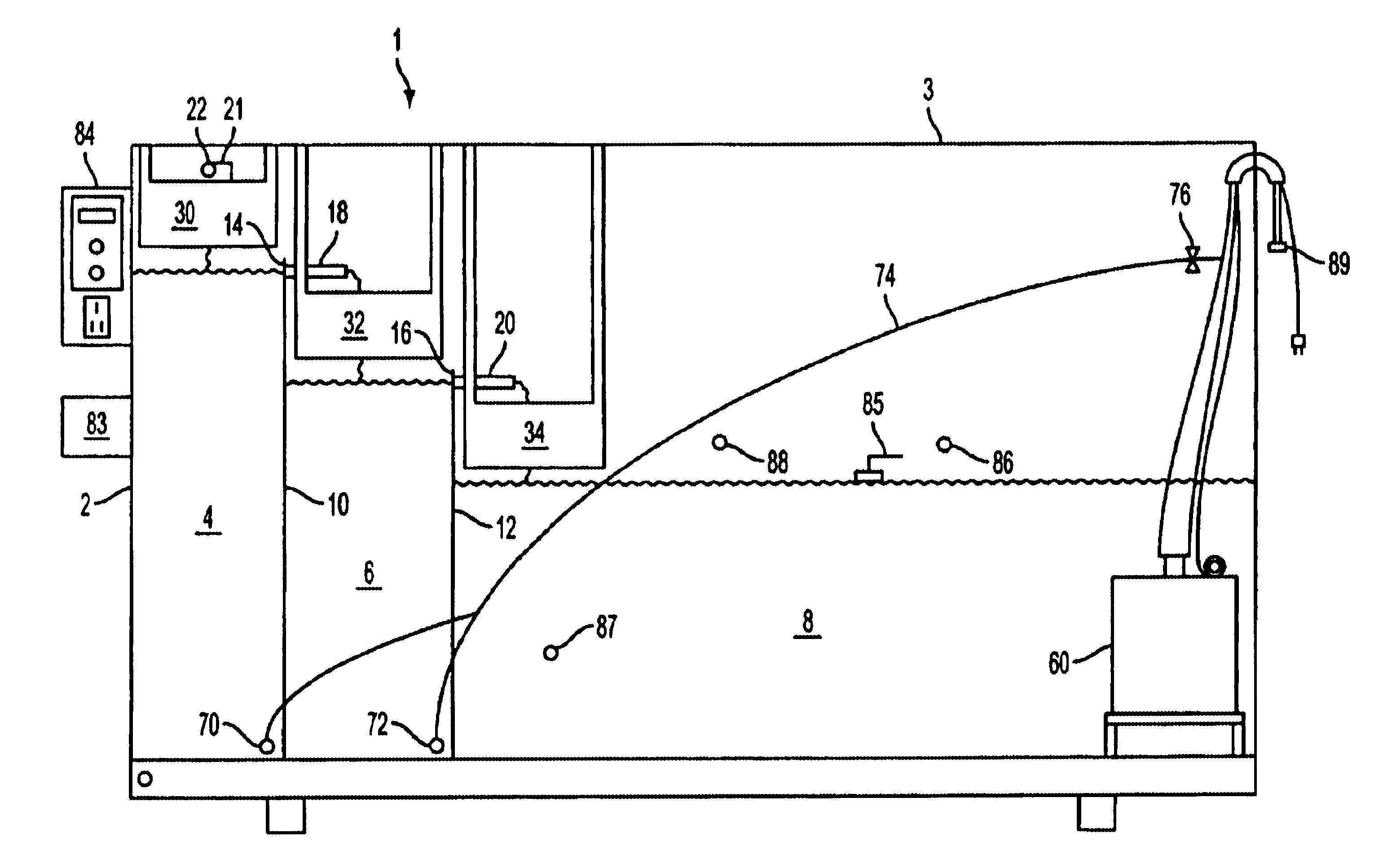

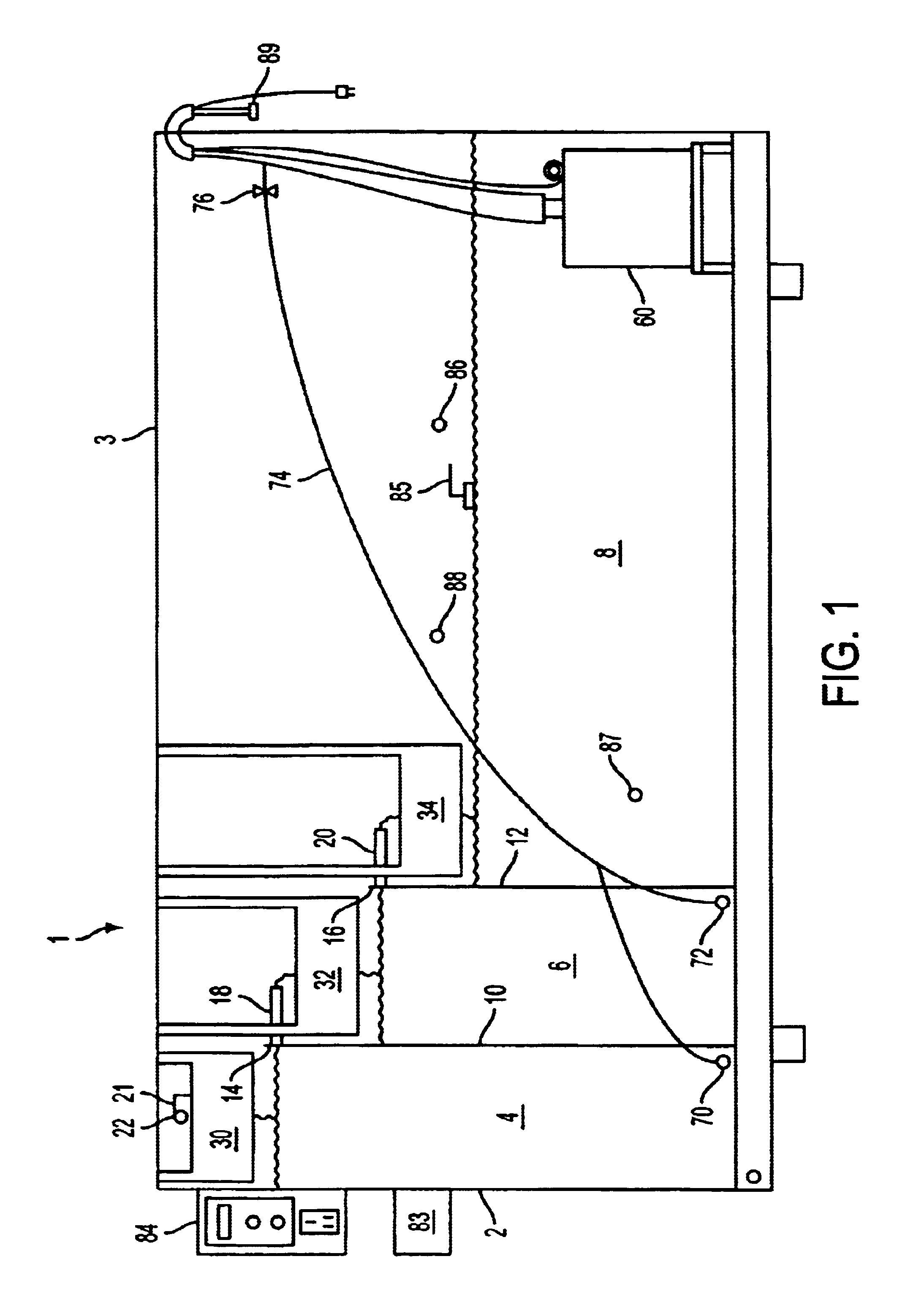

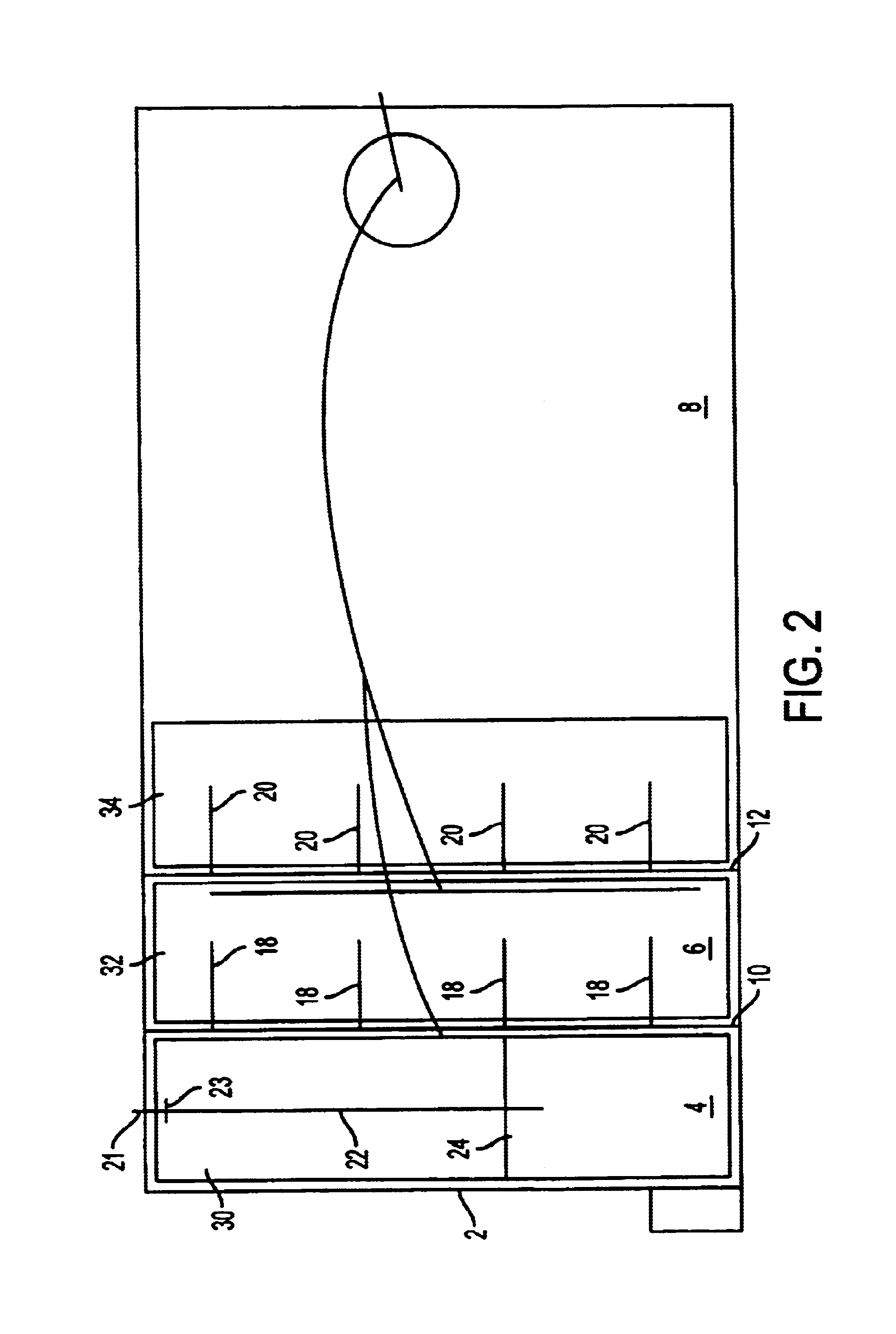

Low pressure saturated steam cleaning assembly with chemical delivery system

InactiveUS20050178410A1Low volumeAvoid collateral damageElectrostatic cleaningCleaning using liquidsSurface cleaningHigh pressure

The present invention provides a steam cleaning system comprising a housing and a steam generating system for producing a low pressure, superheated saturated steam. A steam dispensing system comprising a water reservoir and a pump feeding the water into a steam producing boiler, is coupled thereto for dispensing the steam from the system to at least one first outlet port. A cleaning solution dispensing system is provided, having at least one reservoir for a cleaning solution, and a pump system for dispensing a predetermined amount of a cleaning solution from said at least one reservoir to at least one second outlet port. The at least one first and second outlet ports are positioned adjacent one another, such that a mixture of cleaning solution and saturated steam at a low pressure and low volume of steam and cleaning solution is dispensed from the system. The present invention is particularly suited to clean objects off the floor, vertical surfaces such as glass, and small areas of floor. Because of the small volume of water and chemicals used, it can be used indoors, as well as mounted on mobile platforms such as trucks, buggies, utility vehicles, automatic floor scrubbers or the like. The system also provides for cleaning of roads, sidewalks, exterior structures, or for spot cleaning or cleaning of surfaces in difficult environments. The low pressure, superheated, saturated steam cleaning assembly of the present invention provides low pressure (10 Bar) operation, and relies upon superheated steam temperatures coupled with environmentally friendly chemicals as an abrasive force, thus avoiding any collateral damage usually caused by the high pressure output. The present invention only applies 3 to 10 gallons of water an hour, depending on the size of the machine, while a conventional high-pressure washer / steamer will use 240 gallons per hour.

Owner:LEVY MOISE MAURICE

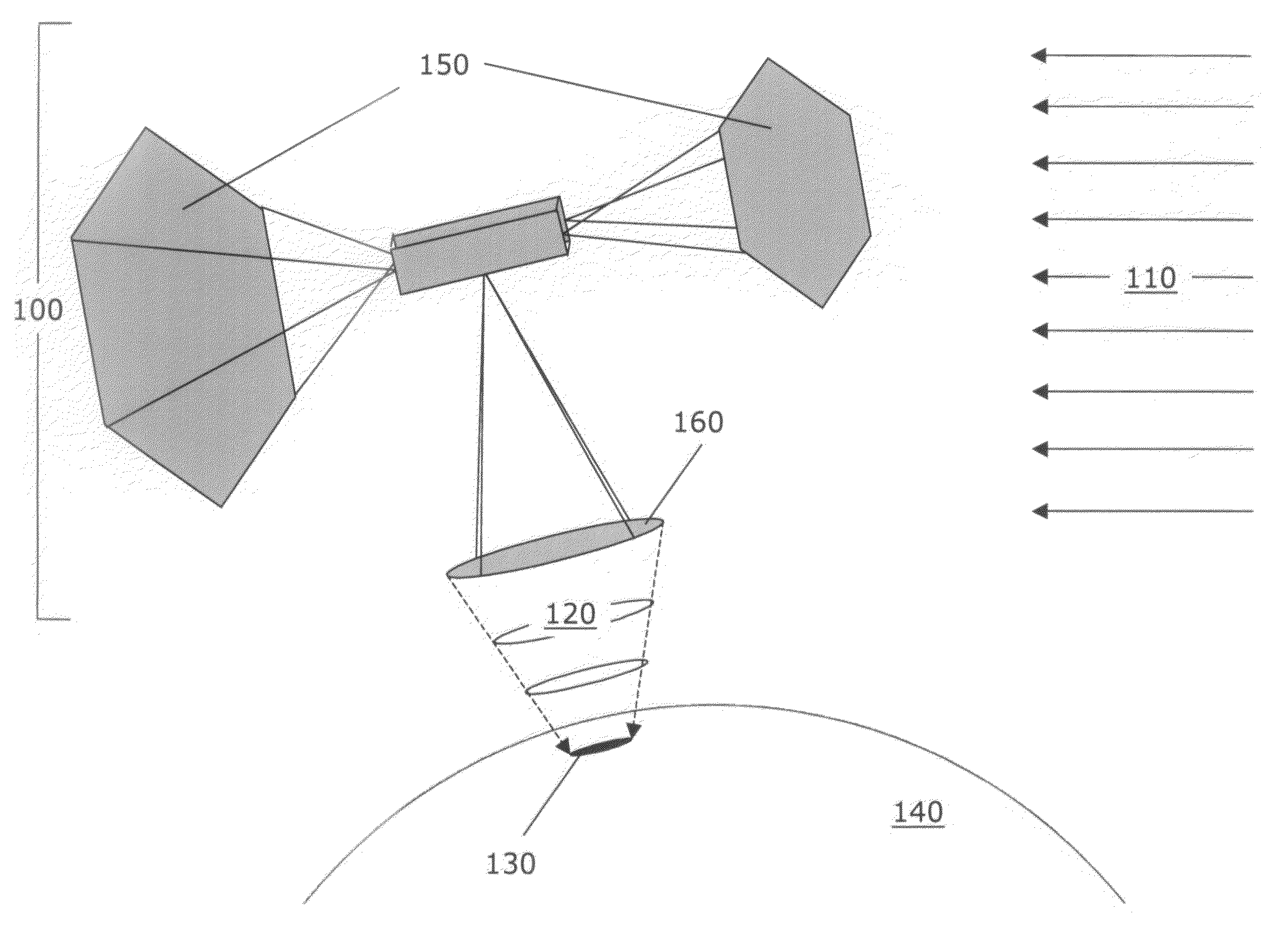

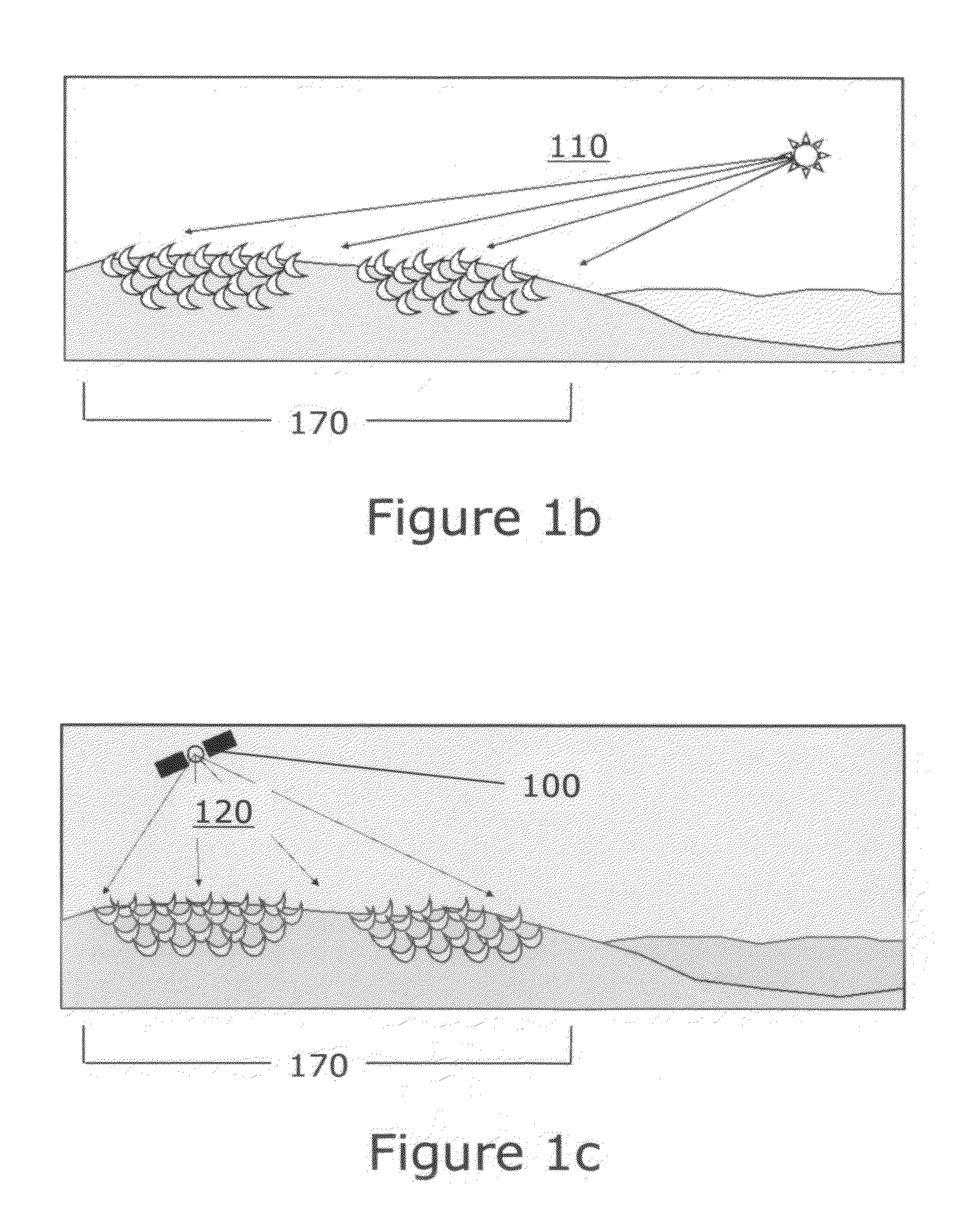

Space solar power system for thermochemical processing and electricity production

InactiveUS20080283109A1Promote absorptionImprove abilitiesSolar heating energyThermoelectric device manufacture/treatmentProcess systemsElectricity

Thermochemical processing systems for the production of electricity and chemicals using energy from an orbiting space solar power satellite (100). Methods of producing electricity and chemicals using the powerbeam (120). Systems and applications include the orbiting satellite, which intercepts solar energy (110) and directs a powerbeam to a lunar or planetary surface or a receiving system in space; rectennas (220) for the production of electricity; and concentrators (300), receivers (310) and thermochemical process systems for the production of fuels and other chemicals. Efforts are made to optimize the operation of the system through the utilization of solar energy, when available, plus the powerbeam from the satellite.

Owner:MANKINS JOHN CARLTON +1

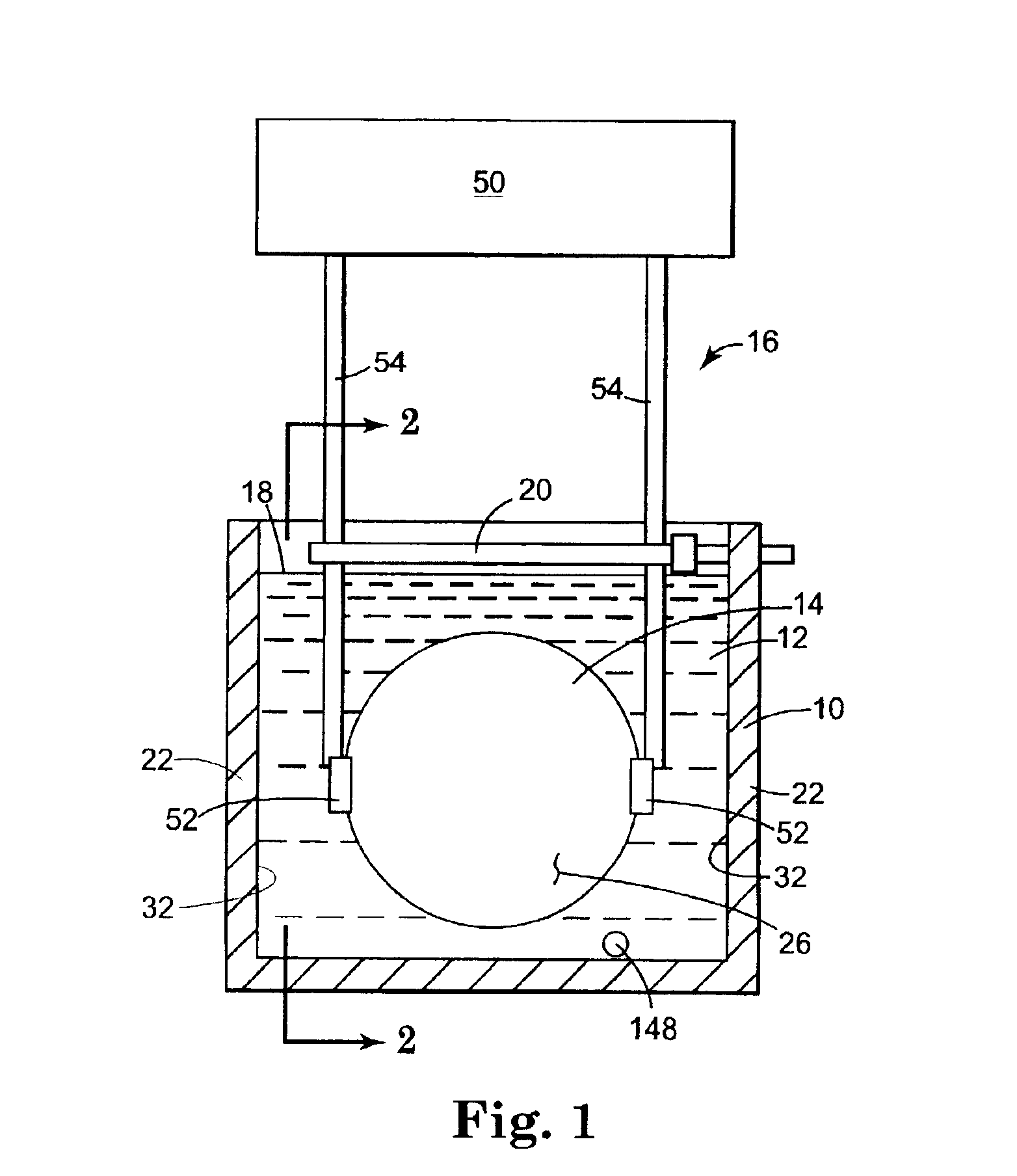

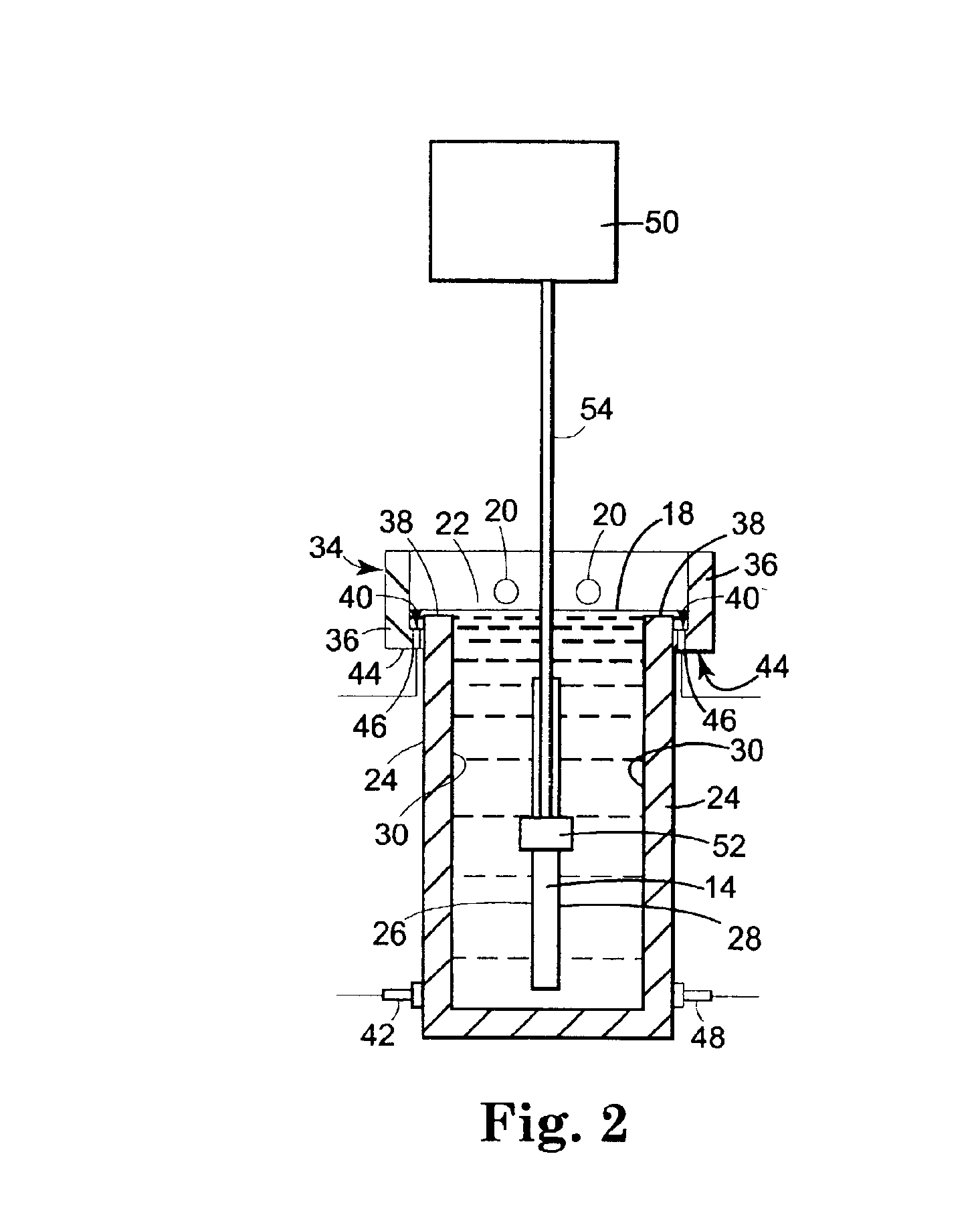

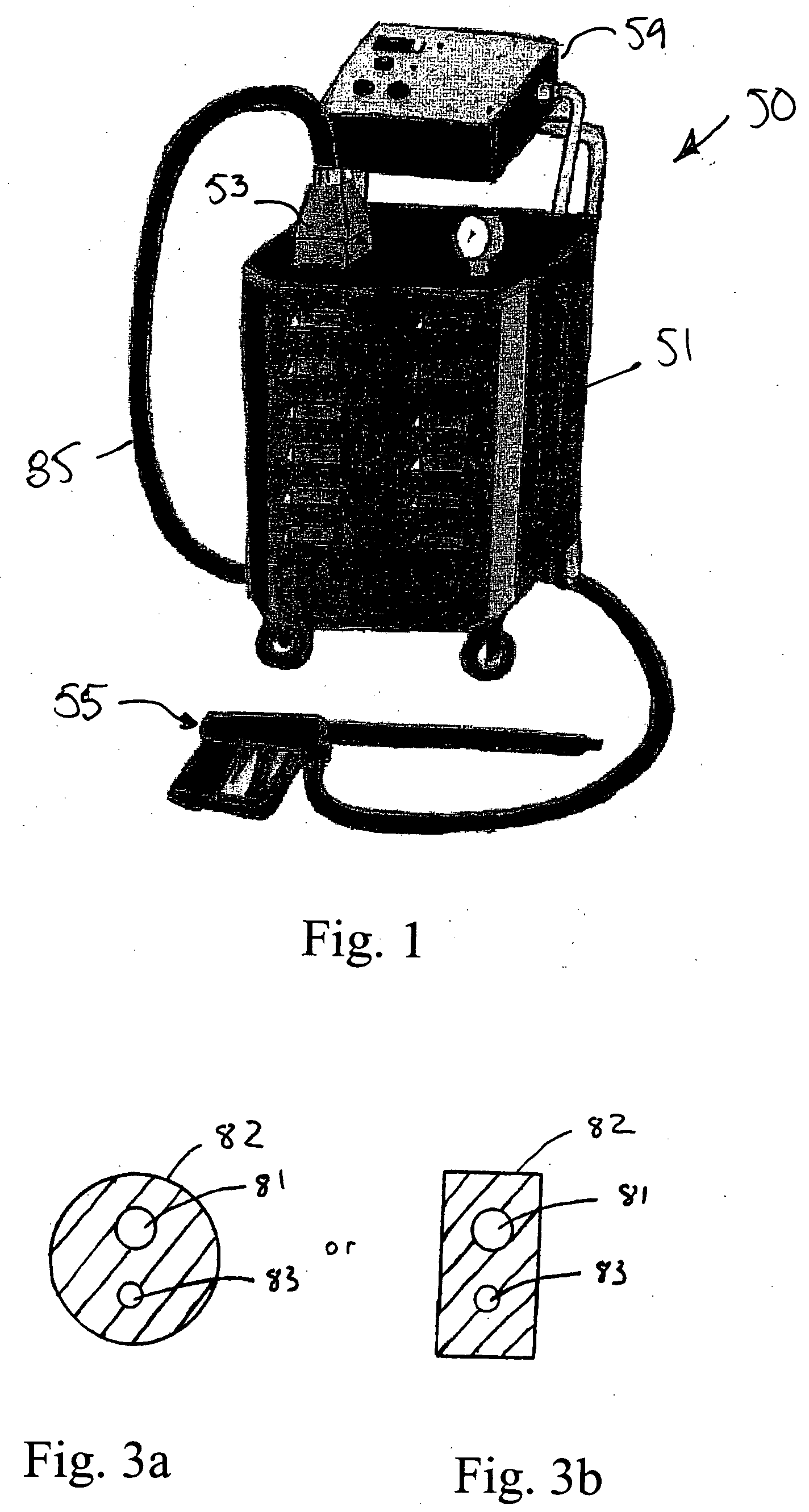

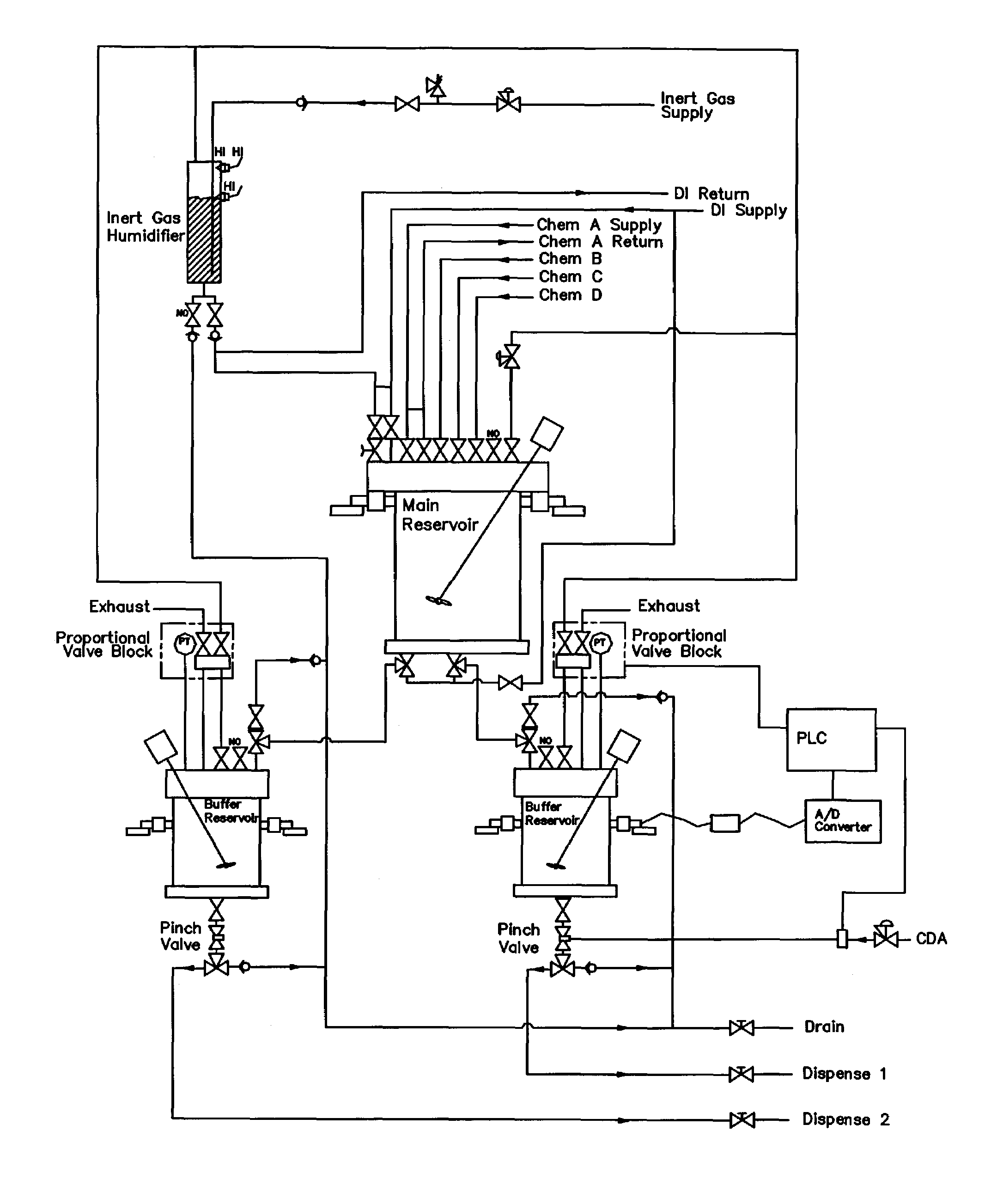

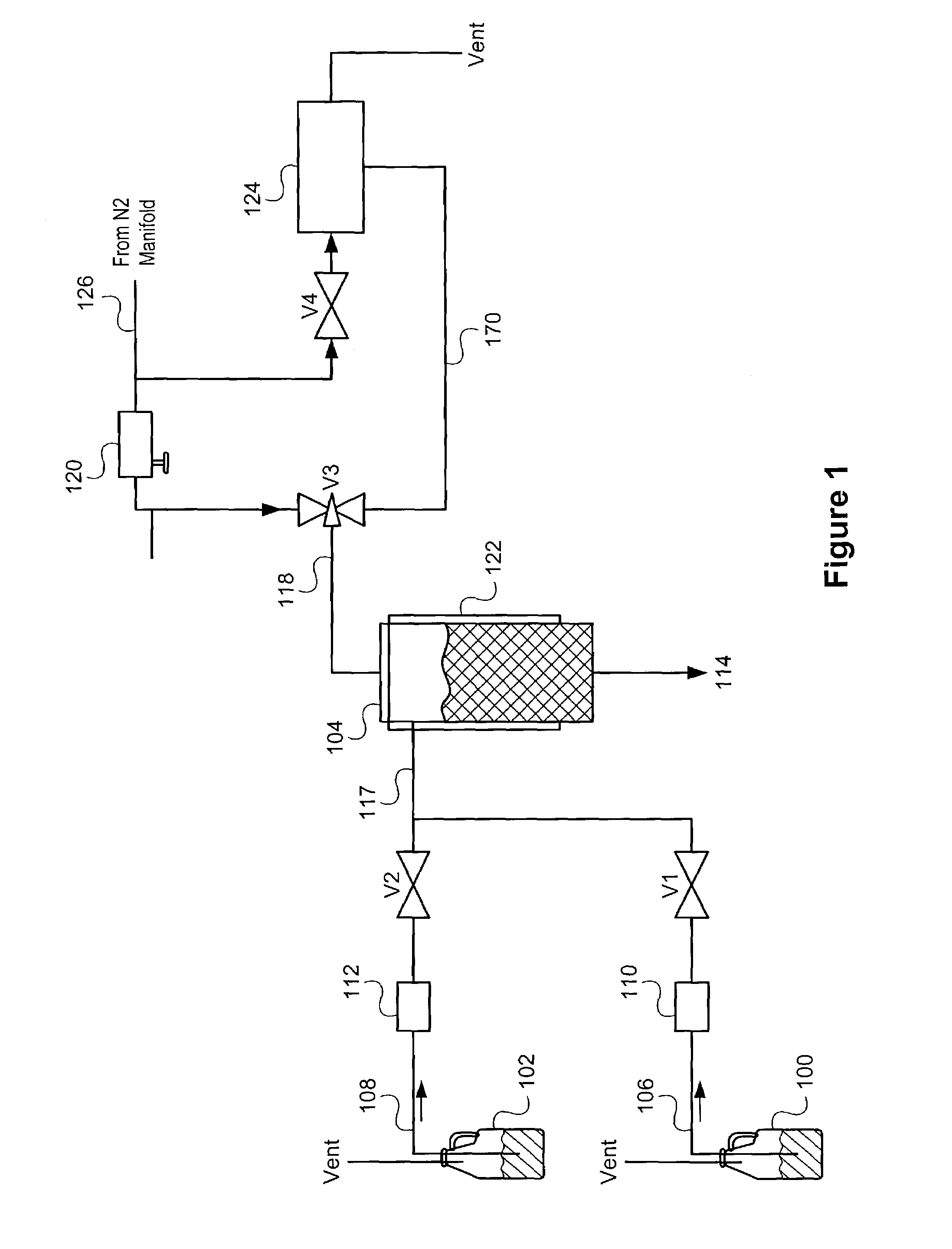

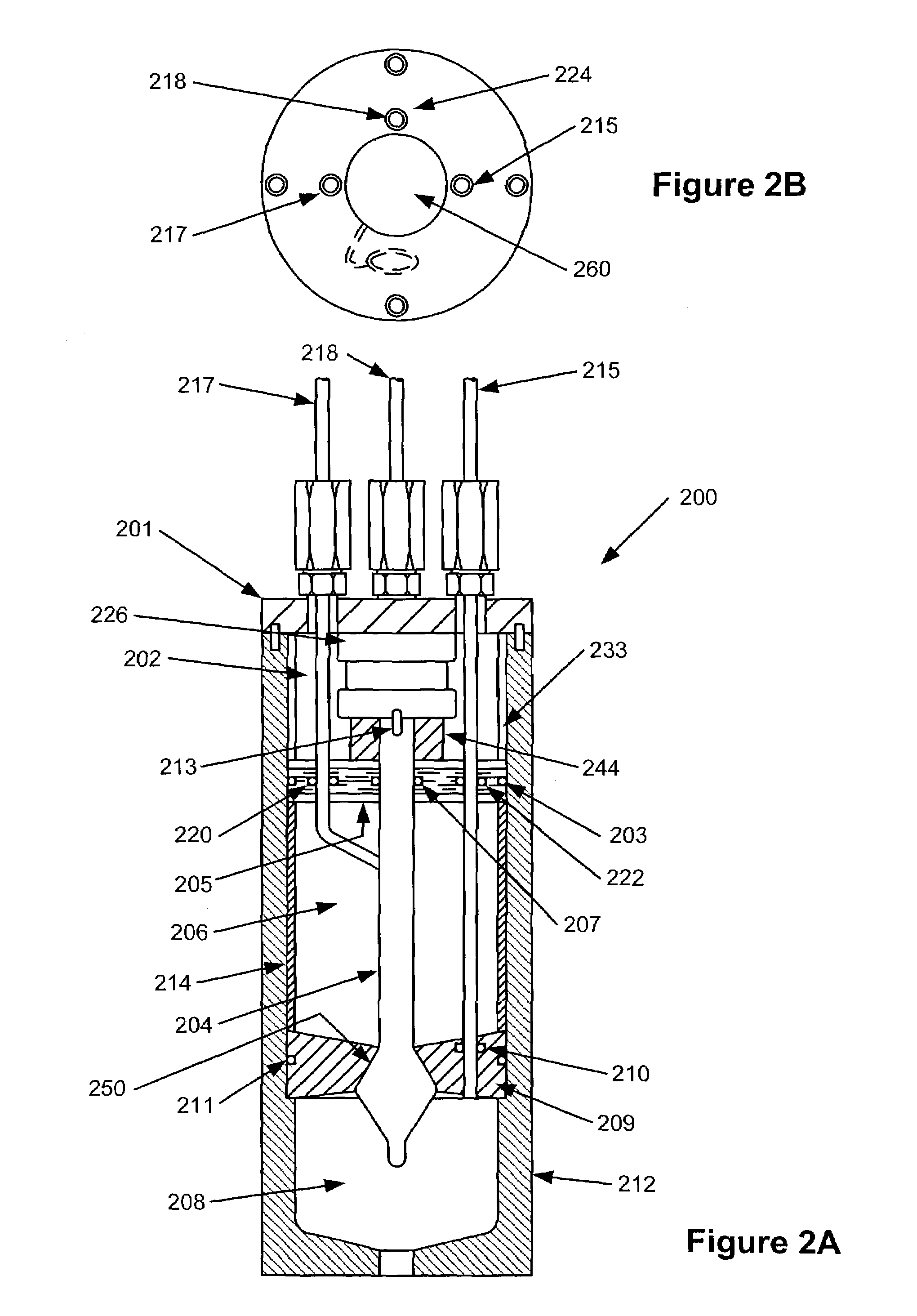

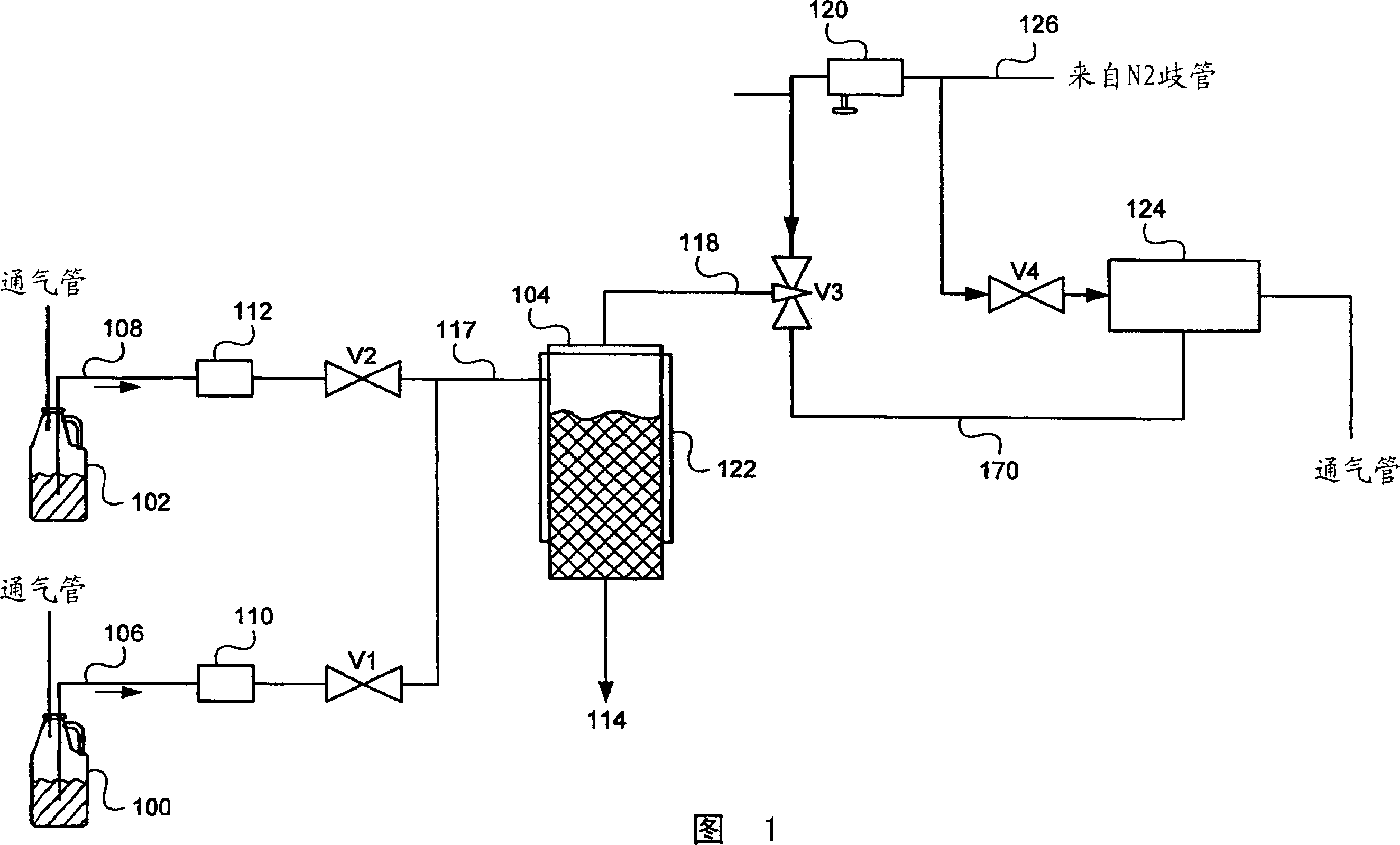

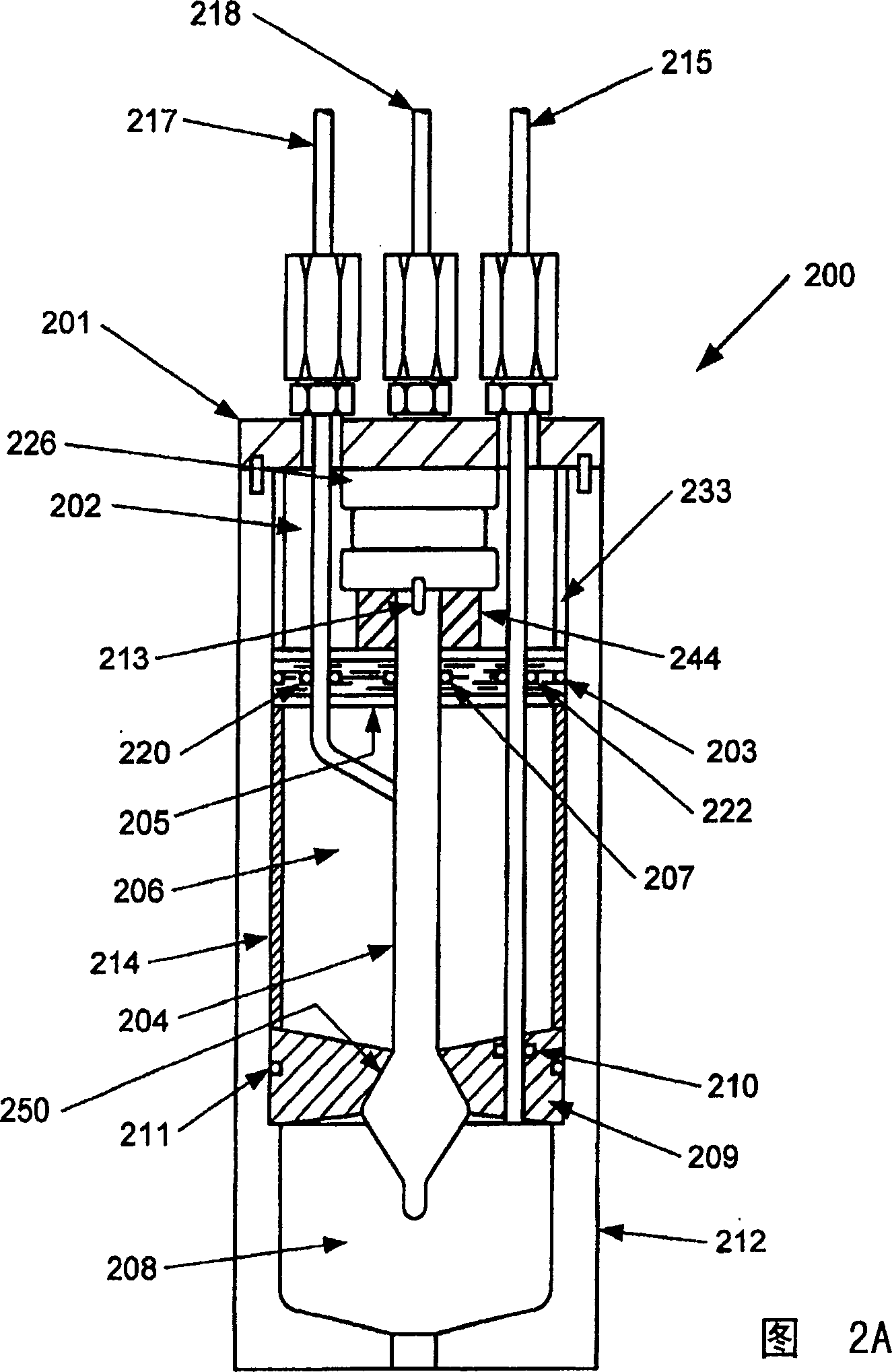

Chemical mix and delivery systems and methods thereof

InactiveUS7007822B2Accurate flowBlock deliveryLiquid flow controllersSemiconductor/solid-state device manufacturingChemical mixturesCompound (substance)

The present invention relates to chemical delivery systems and methods for delivery of liquid chemicals. In one embodiment, the present invention relates to systems having multi-reservoir load cell assemblies for delivering chemicals used in the semiconductor industry. In one embodiment, the present invention provides a multi-reservoir load cell assembly, including a controller, a buffer reservoir, a main reservoir, one or more load cells, coupled to the assembly and to the controller, operable to weigh the liquid in the reservoir(s), a plurality of supply lines, each supply line having a valve and connecting one of the supply containers to the main reservoir, and a gas and vacuum sources for withdrawing the liquid from the assembly when demanded by the controller and for refilling the assembly from the supply containers.

Owner:AIR LIQUIDE ELECTRONICS US LP

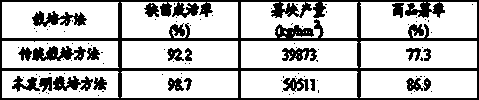

Method for cultivating fresh-eaten type sweet potatoes with high quality and high yield

Owner:QINGDAO AGRI UNIV

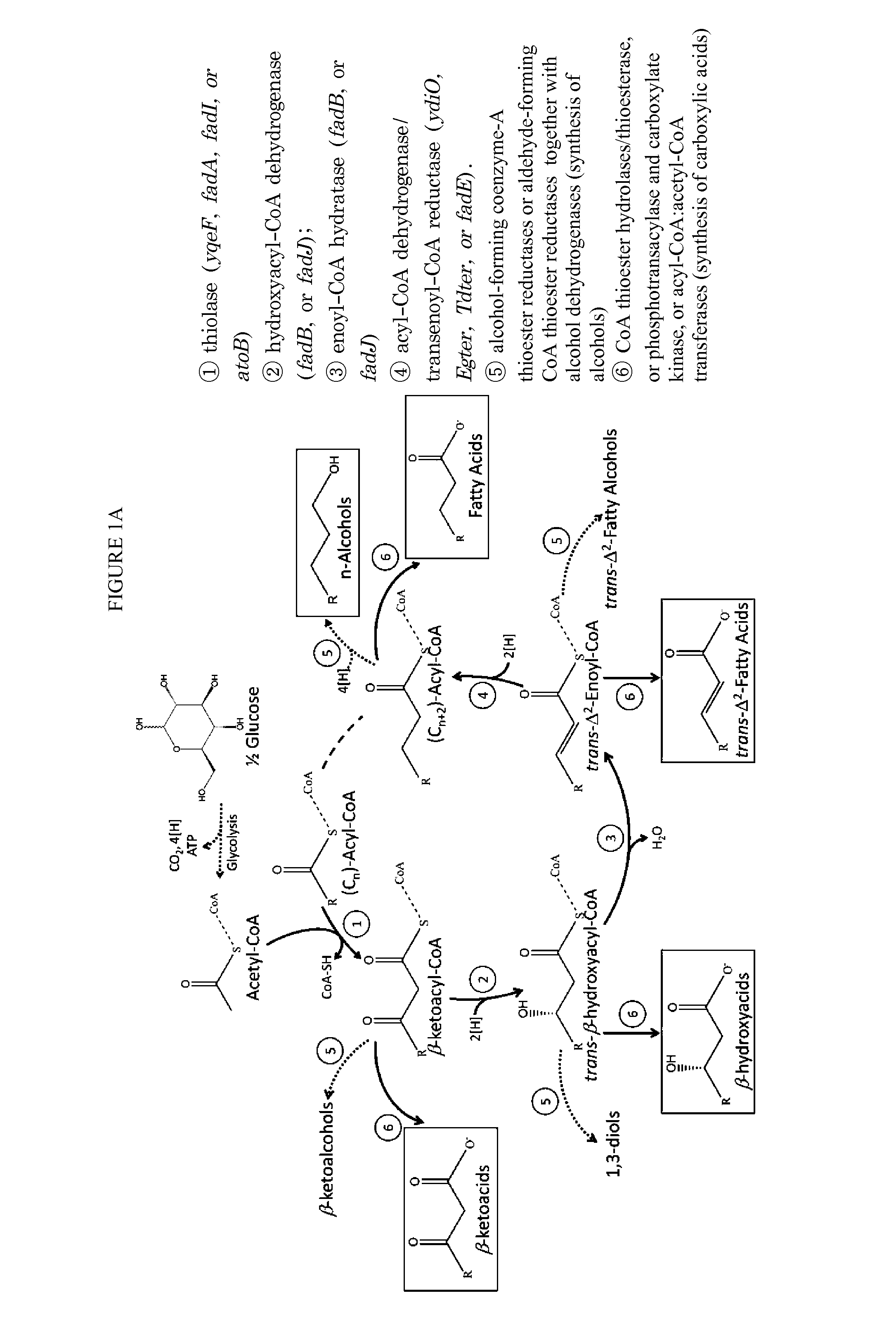

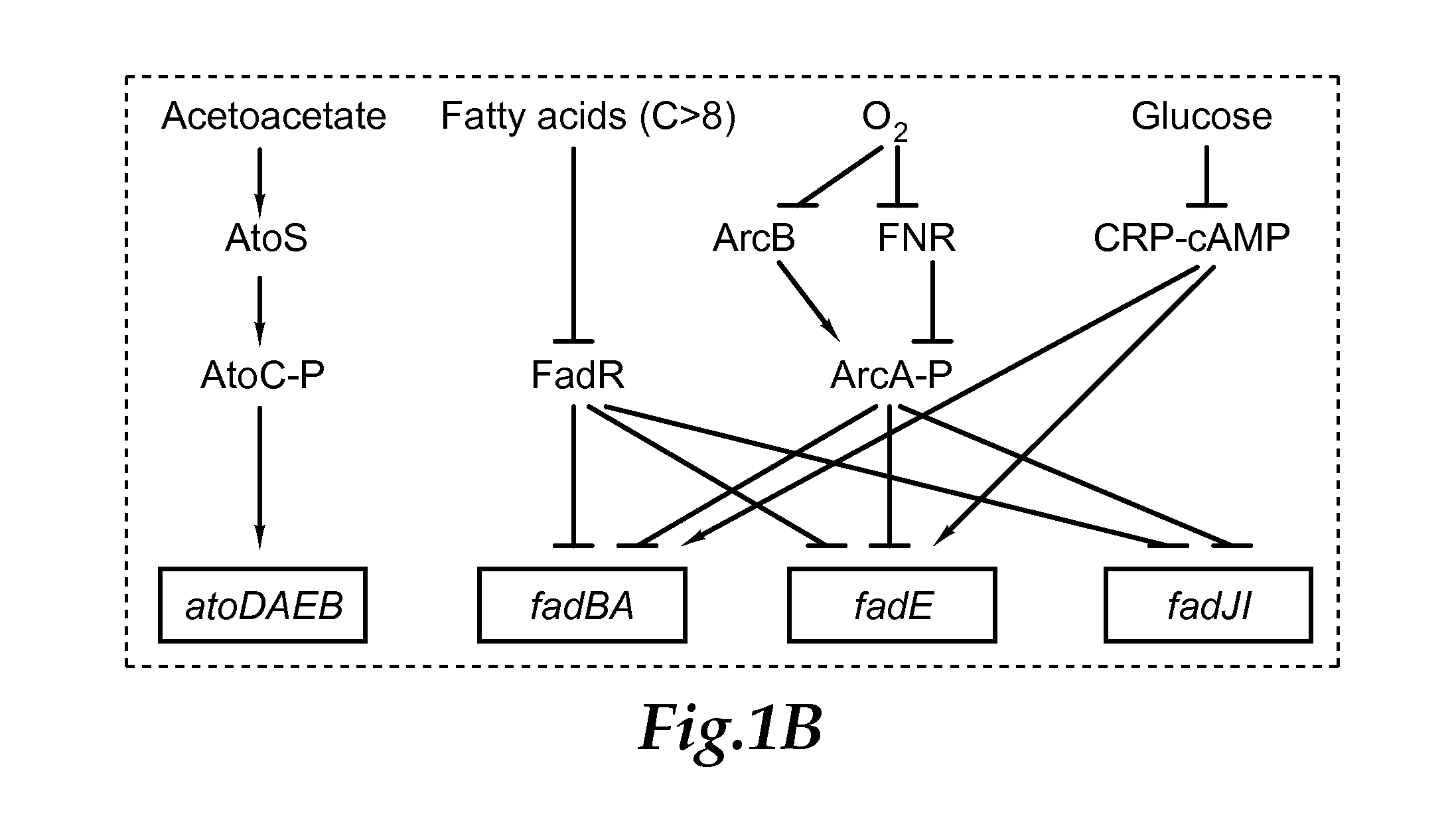

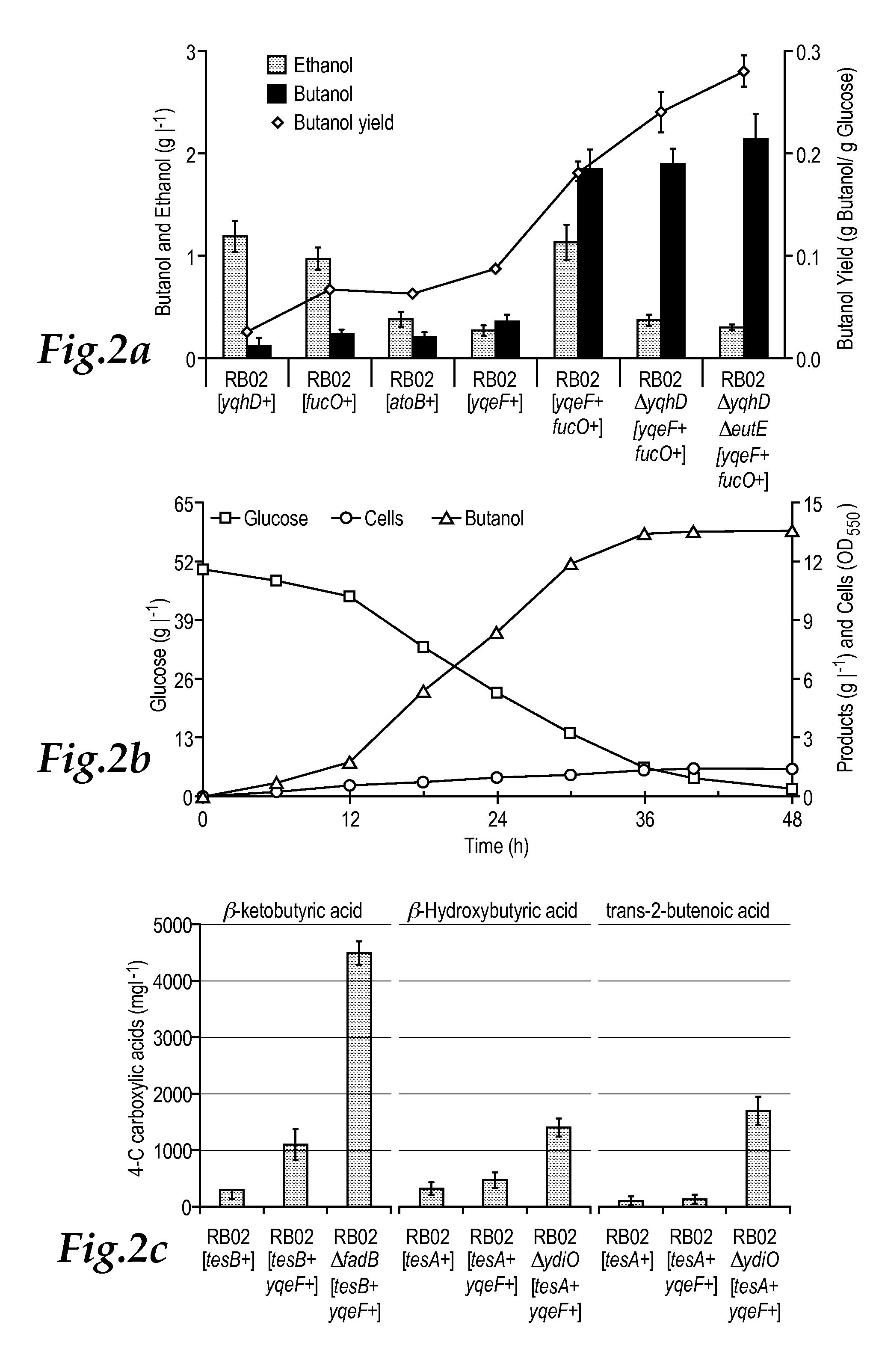

Reverse beta oxidation pathway

ActiveUS20130316413A1Prevents/minimizes the metabolism of acetyl-CoABacteriaBiofuelsMicroorganismBeta oxidation

The invention relates to recombinant microorganisms that have been engineered to produce various chemicals using genes that have been repurposed to create a reverse beta oxidation pathway. Generally speaking, the beta oxidation cycle is expressed and driven in reverse by modifying various regulation points for as many cycles as needed, and then the CoA thioester intermediates are converted to useful products by the action of termination enzymes.

Owner:RICE UNIV

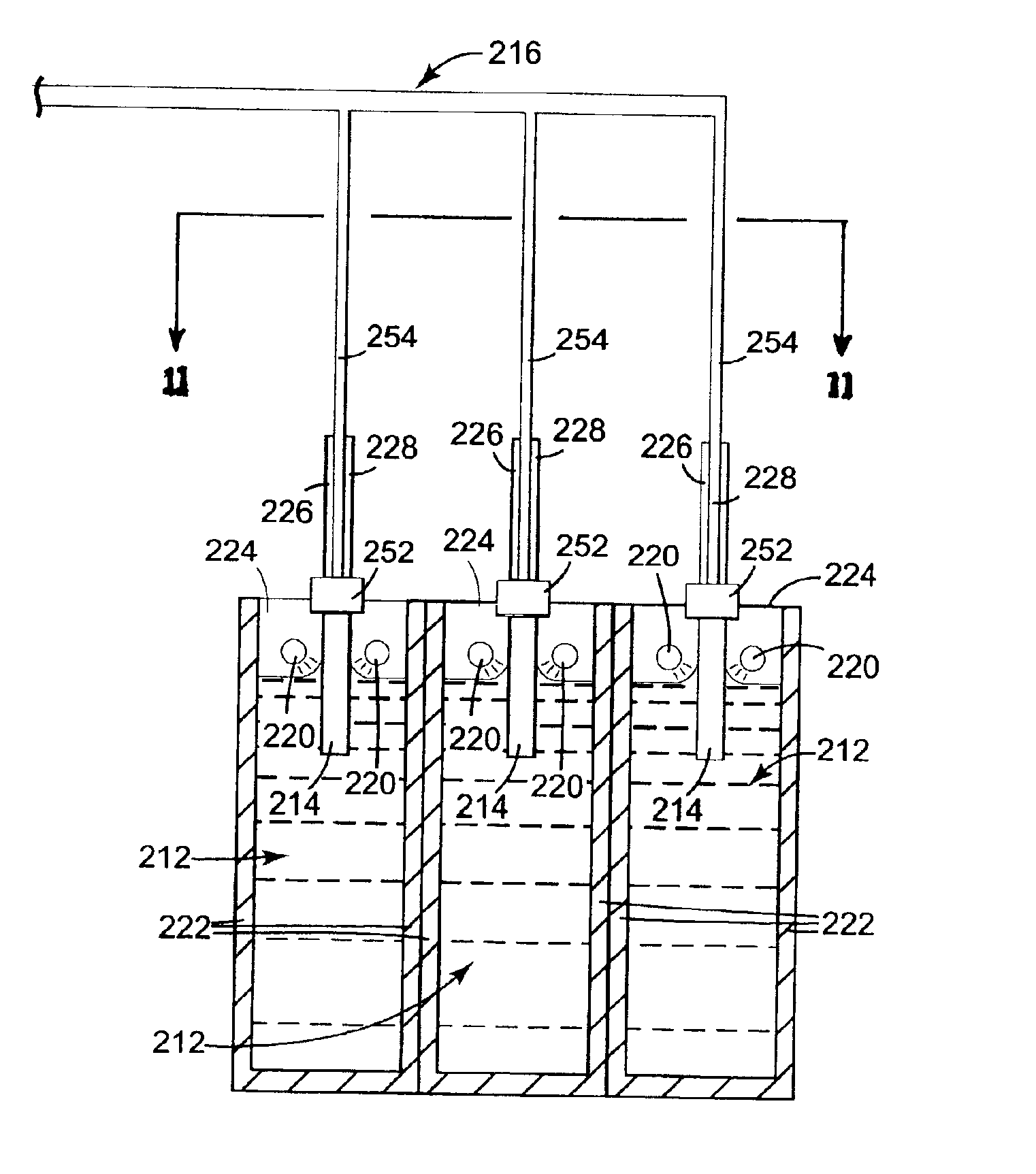

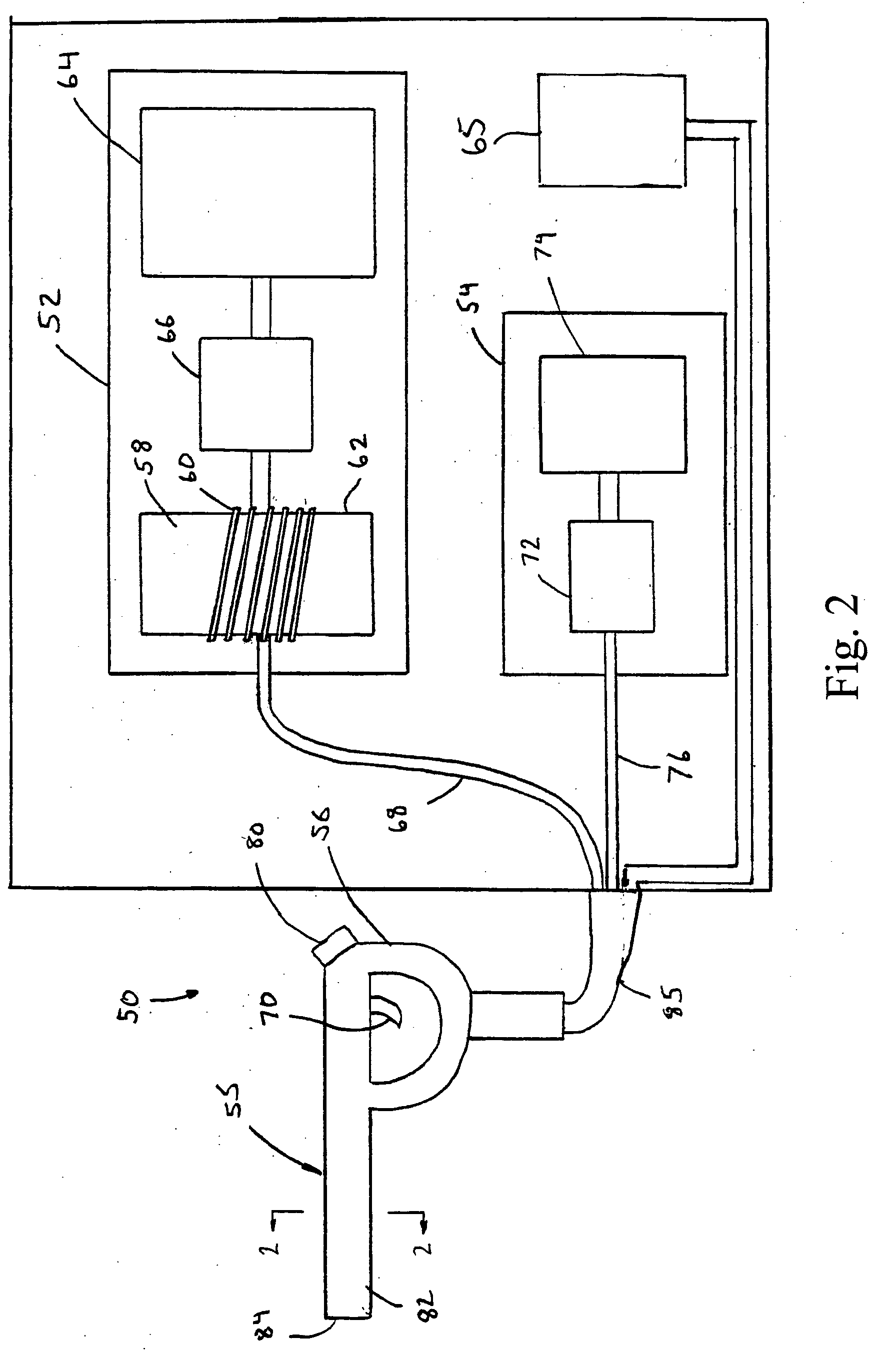

Chemical mix and delivery systems and methods thereof

InactiveCN1665718AReal-time display of residuesAvoid it happening againSemiconductor/solid-state device manufacturingMixer accessoriesEngineeringSemiconductor

Chemical delivery systems and methods for delivery of liquid chemicals are disclosed. In on embodiment, systems having multi-reservoir load cell assemblies (Figs. 2, 4, 5, 7, 9, 11) for delivering chemicals used in the semiconductor industry are disclosed. In another embodiment (Fig. 12), the present invention provides a multi reservoir load cell assembly (69, 92, 71), including a controller (PLC), a buffer reservoir (92, 71), a main reservoir (69), one or more load cells (12, 13, 67, 68, 91, 96) coupled to the assembly and to the controller, operable to weigh the liquid in the reservoirs, a plurality of supply lines (A-D), each supply reservoir, and a gas and vacuum sources for withdrawing the liquid from the assembly when demanded by the controller and for refilling the assembly from the supply containers. A proportional valve block including a buffer control Intel (80) and outlet (81) valves adjust the pressure to the buffer reservoirs.

Owner:液化空气电子美国有限公司

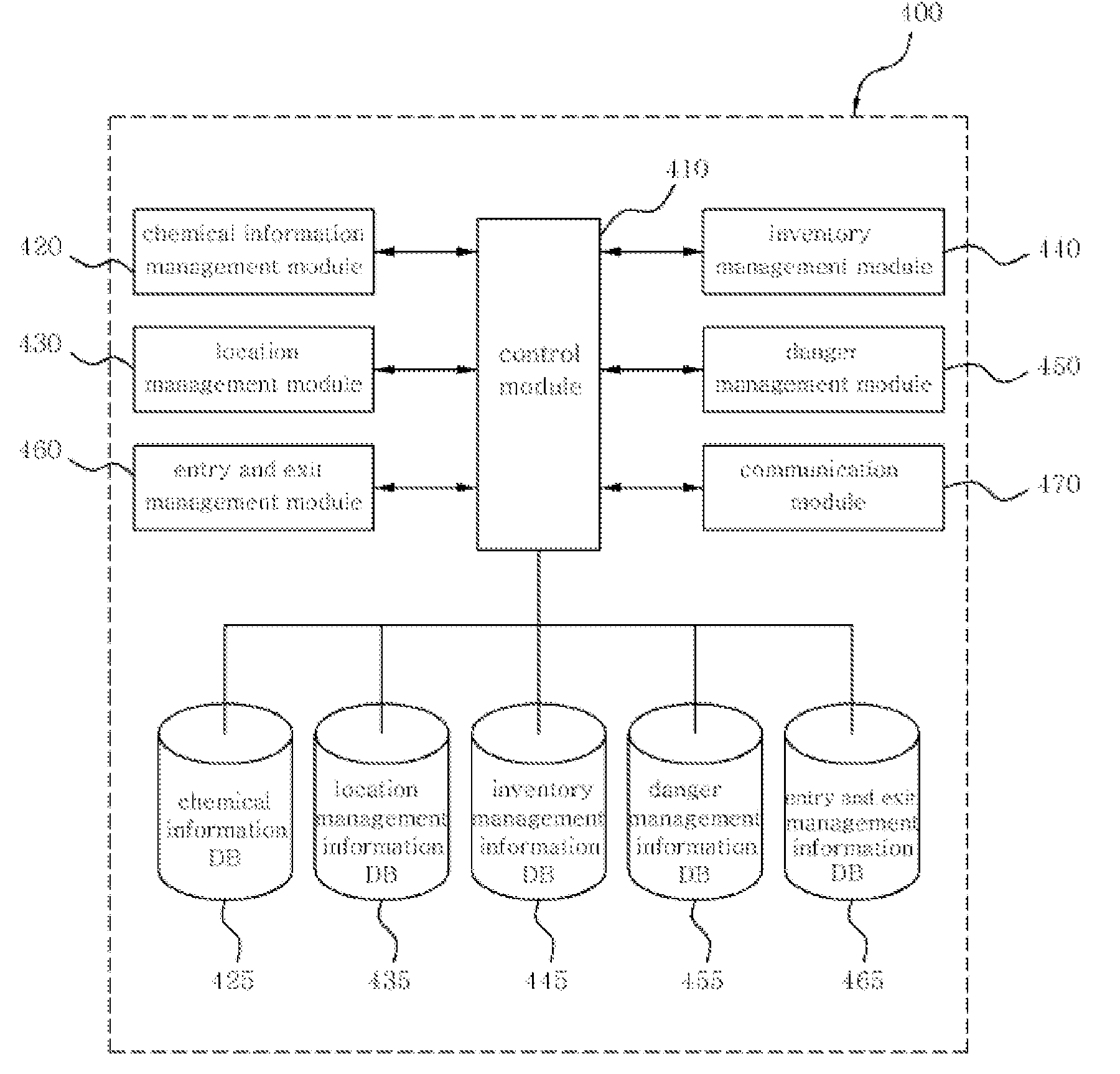

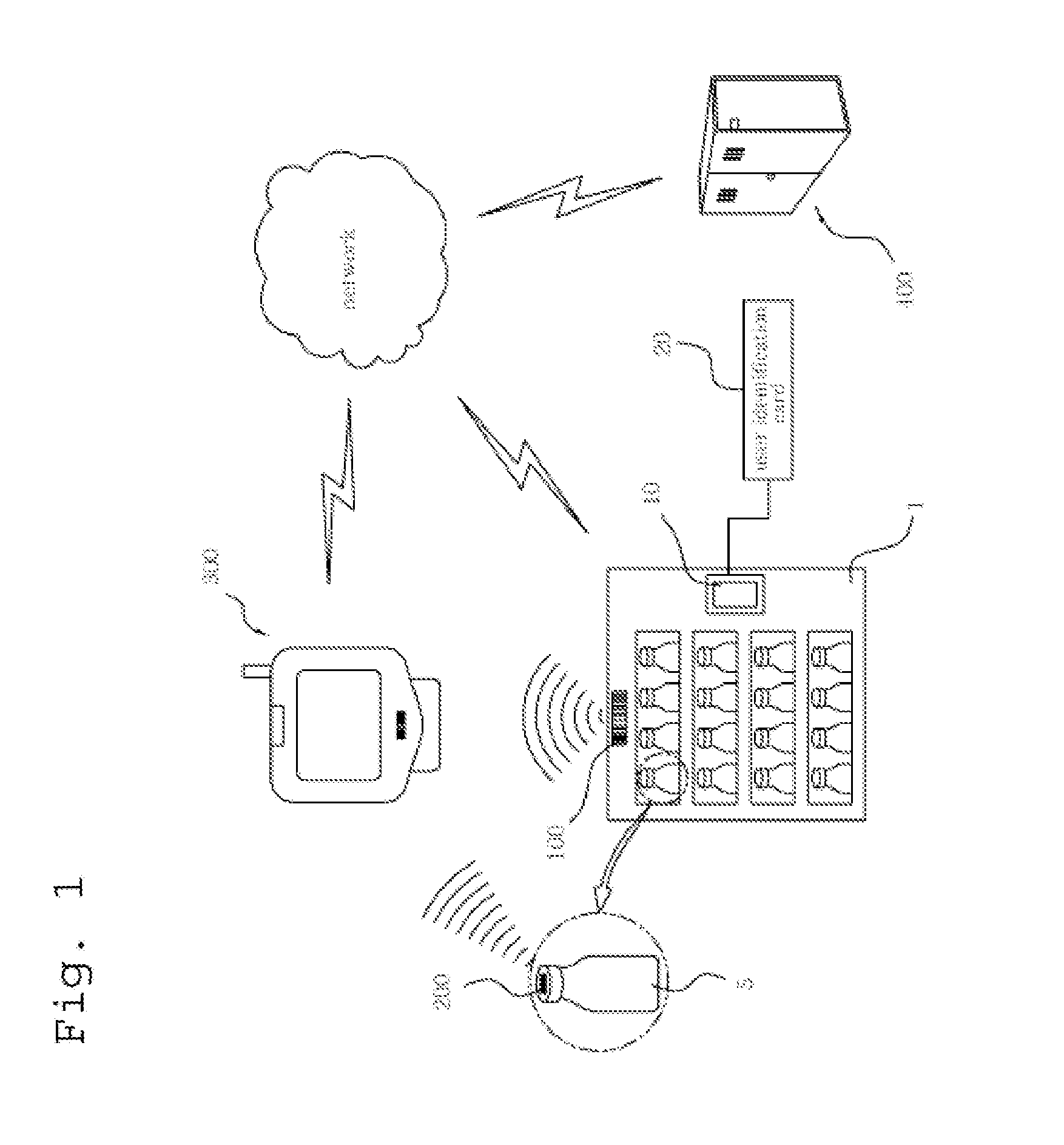

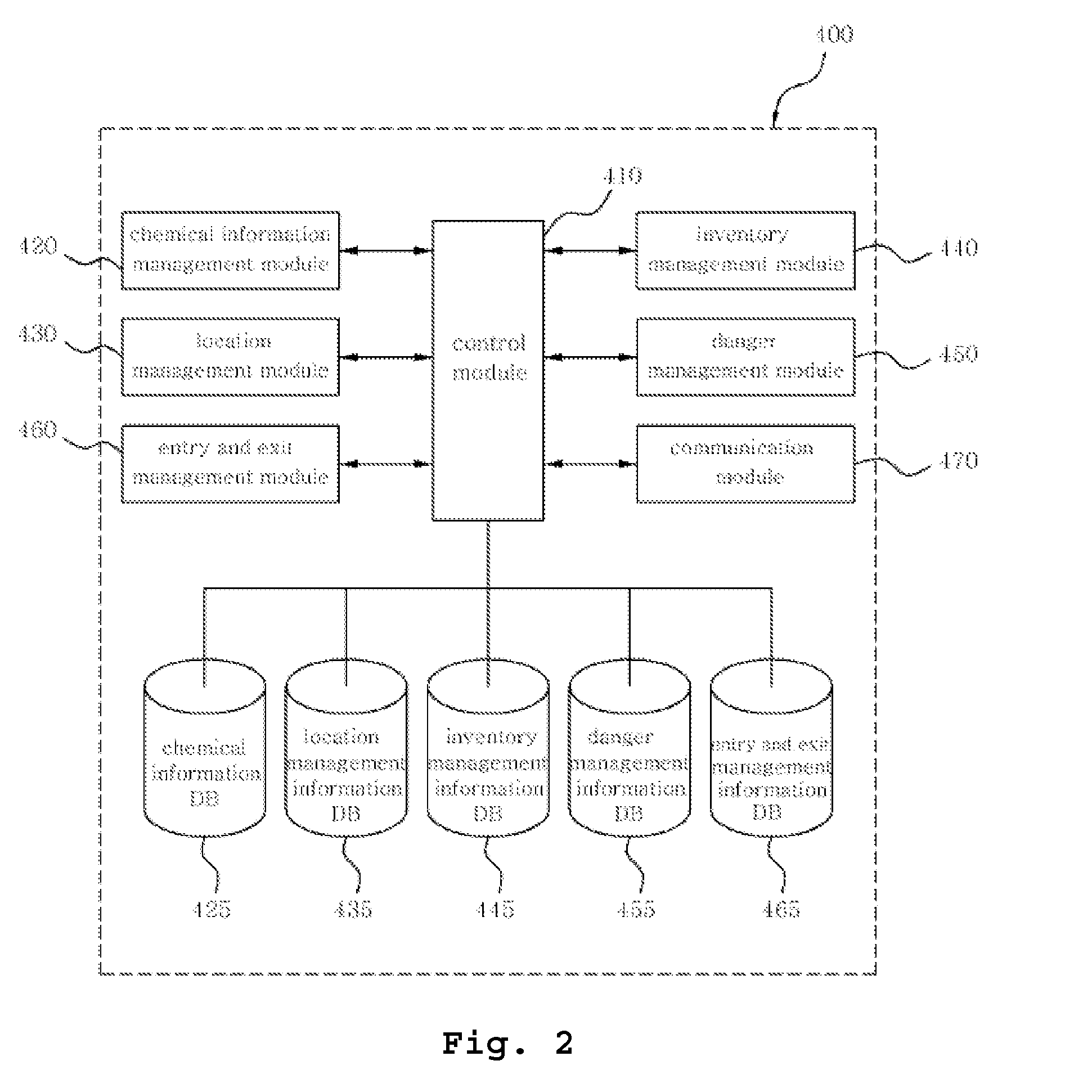

System for managing chemicals using RFID

InactiveUS20090243856A1Efficient managementSubscribers indirect connectionRecord carriers used with machinesChemical storageChemical management

Disclosed herein is a system for managing chemicals using Radio-Frequency Identification (RFID). A storage facility identification tag, attached to a chemical storage facility in a laboratory, stores the unique identification code of the chemical storage facility and a list of chemicals. A chemical identification tag, attached to the cover of a chemical container, stores the unique identification code of the chemical storage facility and chemical-related information. A mobile terminal, provided with an RFID reader, receives and outputs the unique identification code of the chemical storage facility, the list of the chemicals, and the chemical-related information. A chemical management server receives information, stores the chemical-related information, manages the use details and inventory quantity of the chemical, checks the storage location of the chemical container and provides warning when the storage location of the chemical container is wrong, and provides warning and information about countermeasures when a danger situation occurs.

Owner:REPUBLIC OF KOREA (MINIST OF FOOD & DRUG SAFETY)

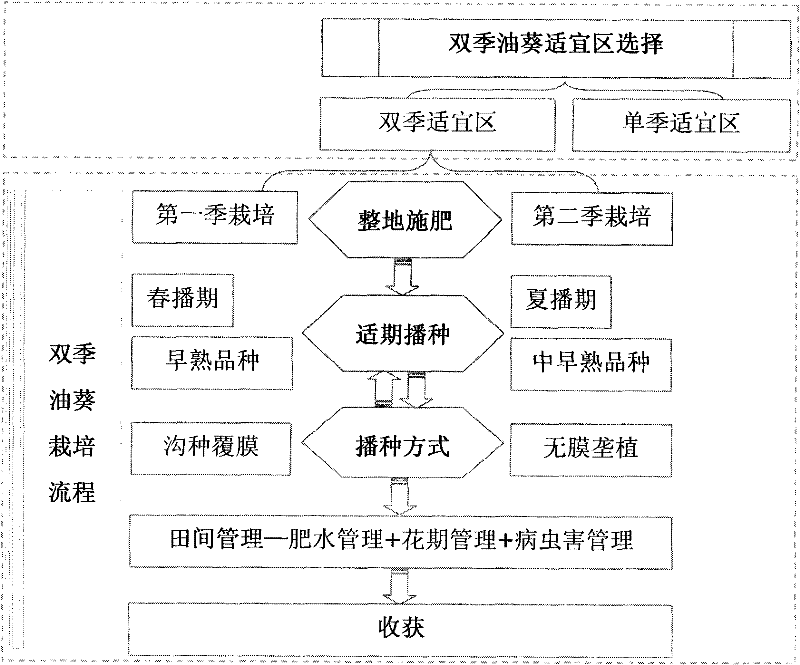

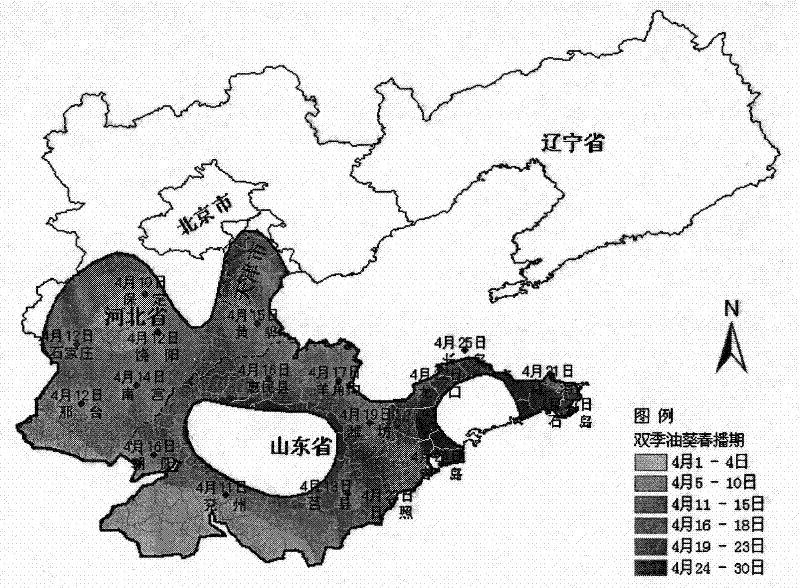

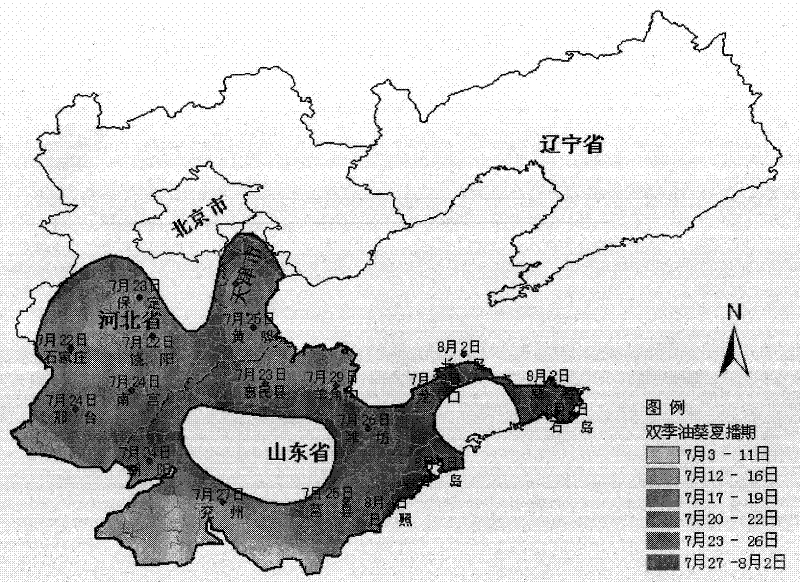

Double-season sunflower planting method

InactiveCN101743842AAchieve double croppingImprove seed setting rateHorticultureSoil-working methodsInsect pestLand preparation

The invention relates to a double-season sunflower planting method which comprises that two-season sunflowers are planted in a double-season sunflower planting area of a Bohai Sea coastal saline area worked out through years of meteorological data and a geographic information systems method in spring and in summer; and the method comprises a first season sunflower spring planting and a second season sunflower summer planting. The whole process is divided into five parts, i.e. land preparation and fertilization, timely sowing, sowing method, field management and harvest. By fully satisfying the heat need required by the two-season sunflower crops, the invention reduces insect pest and the chemical use times, improves the land utilization rate, constructs the double-season sunflower planting method by accumulating temperature in the area suitable for growth, and realizes the high yield, the high quality and the high-efficiency plantating of the sunflower crops.

Owner:BEIJING NORMAL UNIVERSITY

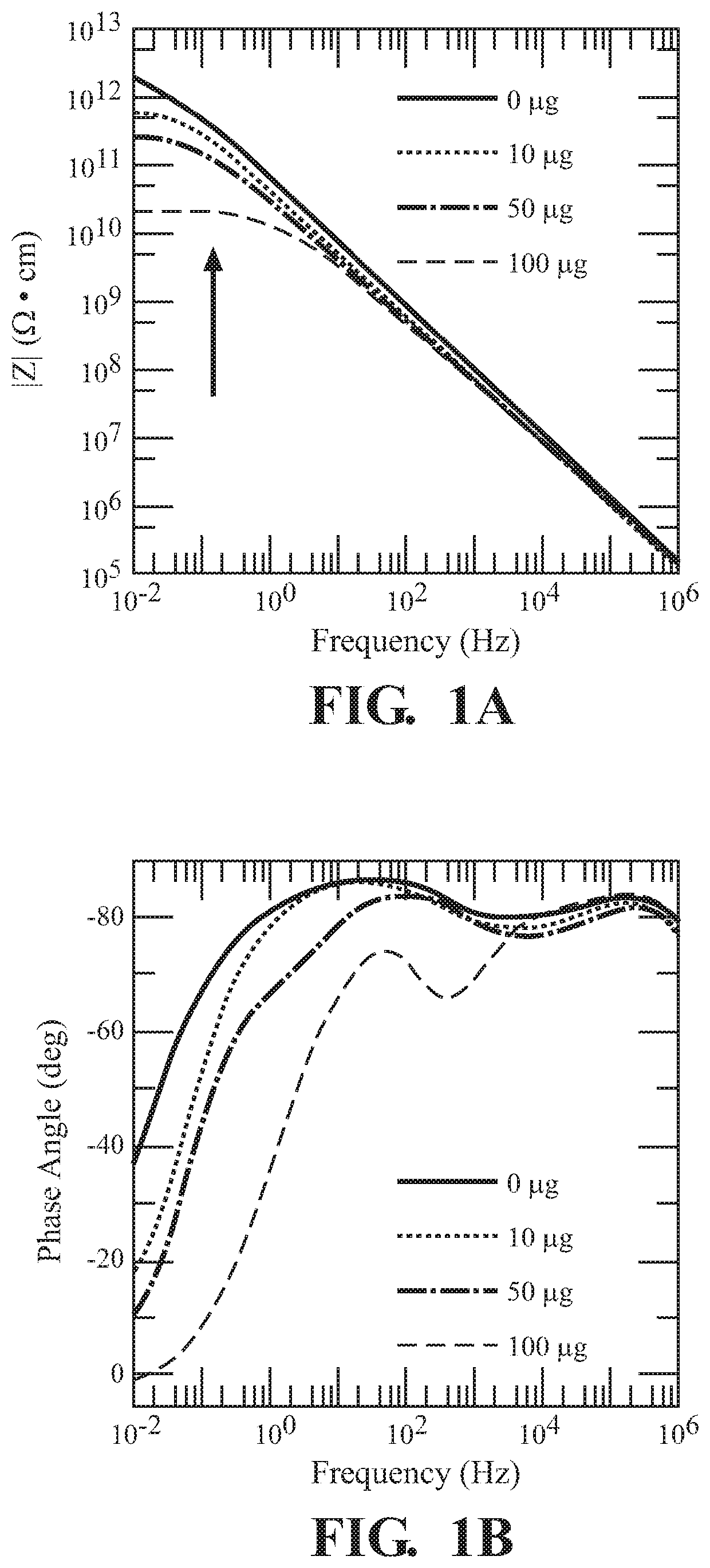

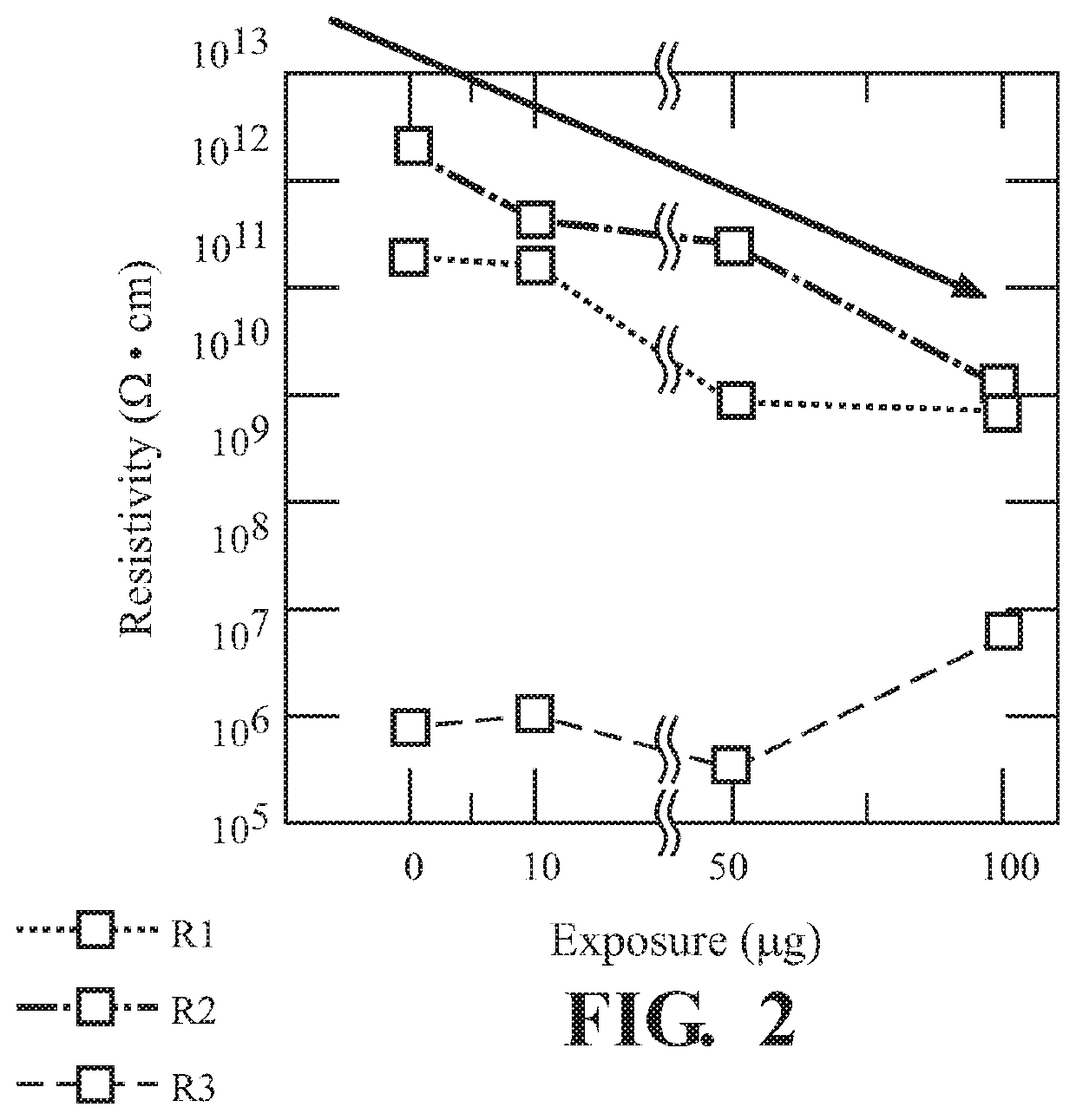

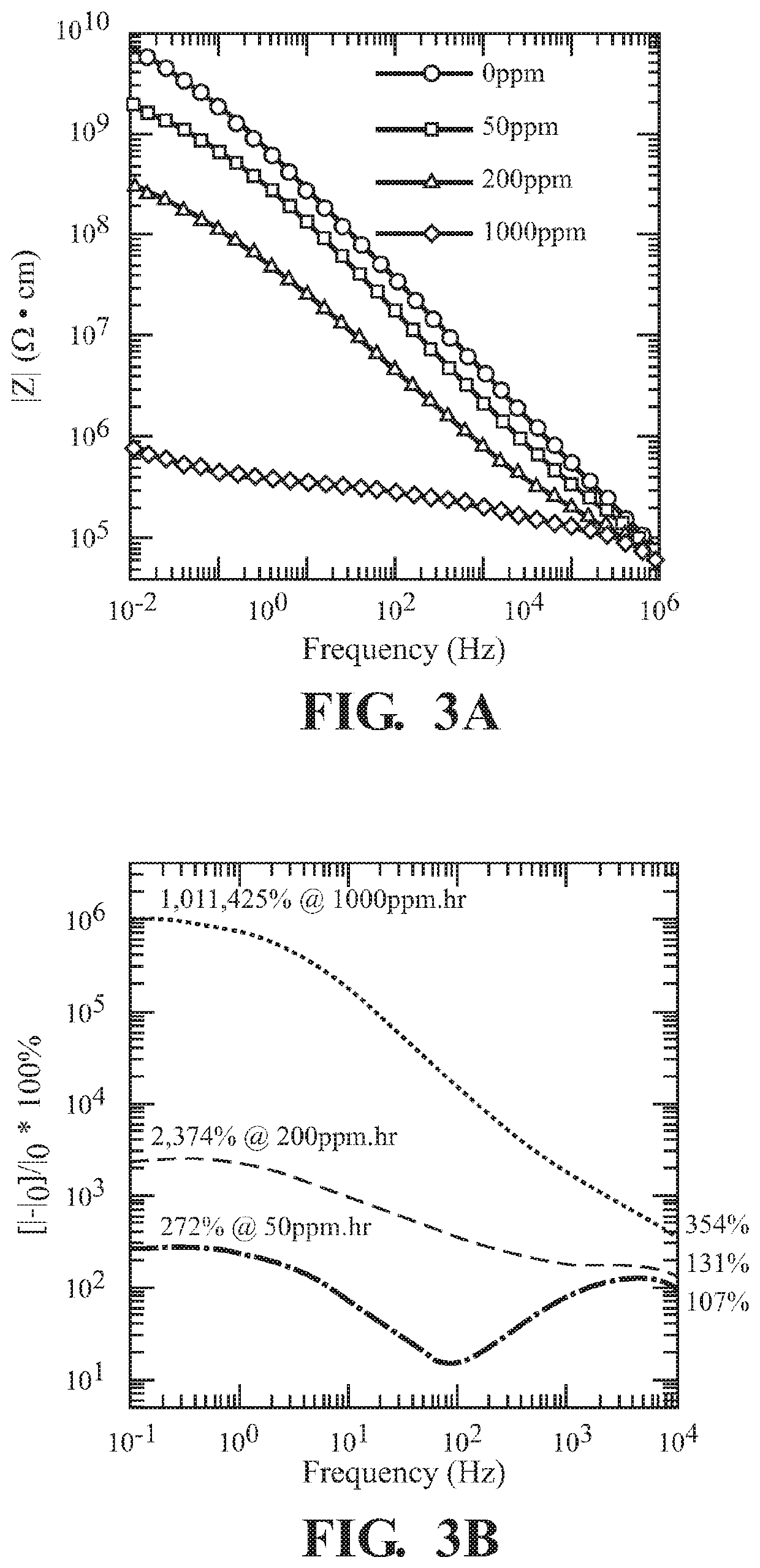

Use of metal-organic frameworks and metal oxides for sensing chemicals using electrical impedance spectroscopy

ActiveUS10495592B1The implementation process is simpleHigh sensitivity detectionFuel testingTesting metalsMetal-organic frameworkChemical agent

Provided are processes for the sensitive detection of the presence of, absence of, and optionally the identity of, one or more chemical agents. The processes use the binding of chemical agents to a metal organic framework or metal oxide / hydroxide electrically connected to a pair of electrodes to detect low levels of chemical in a sample. By exposing the surface of the metal organic framework or the surface of the metal oxide / hydroxide to the chemicals and then measuring changes in impedance magnitude and / or phase shift through electrical impedance spectroscopy, the presence of a chemical agent is readily detected.

Owner:UNITED STATES OF AMERICA

Method and apparatus for recycling wash chemicals used in powder coating

InactiveUS6932910B2Liquid separation auxillary apparatusHot-dipping/immersion processesEngineeringPowder coating

Owner:MELCHER JEFFREY S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com