Patents

Literature

466results about How to "High sensitivity detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

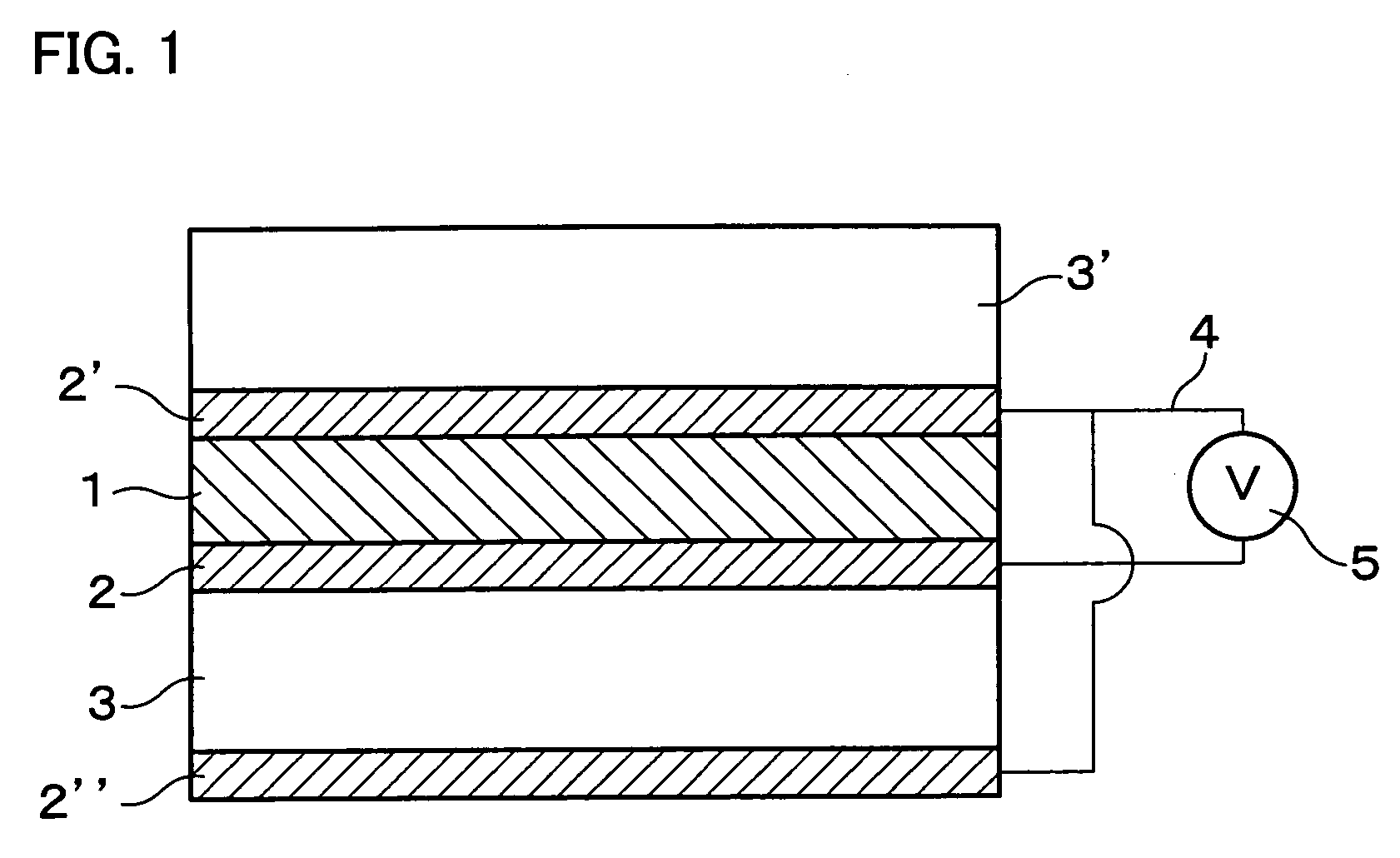

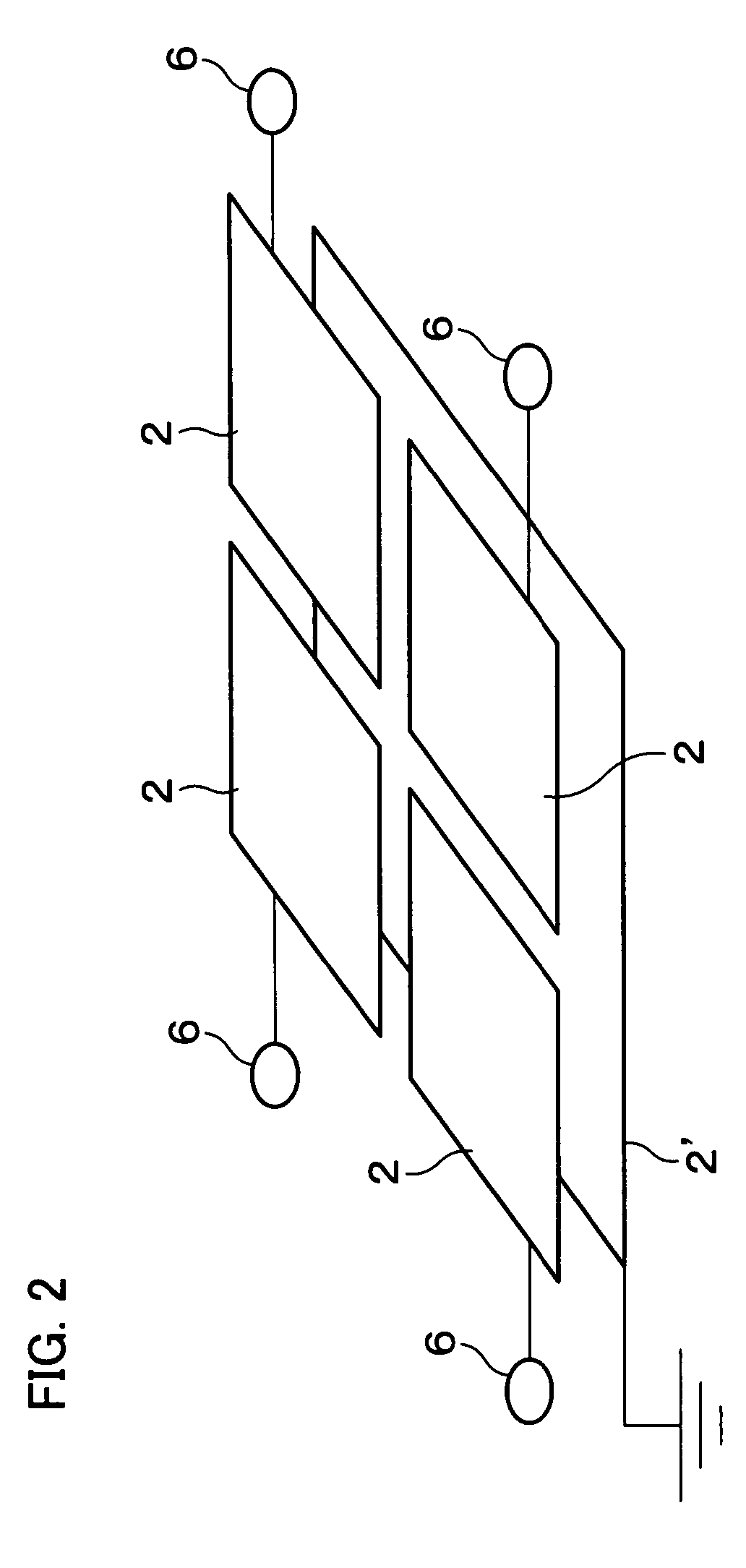

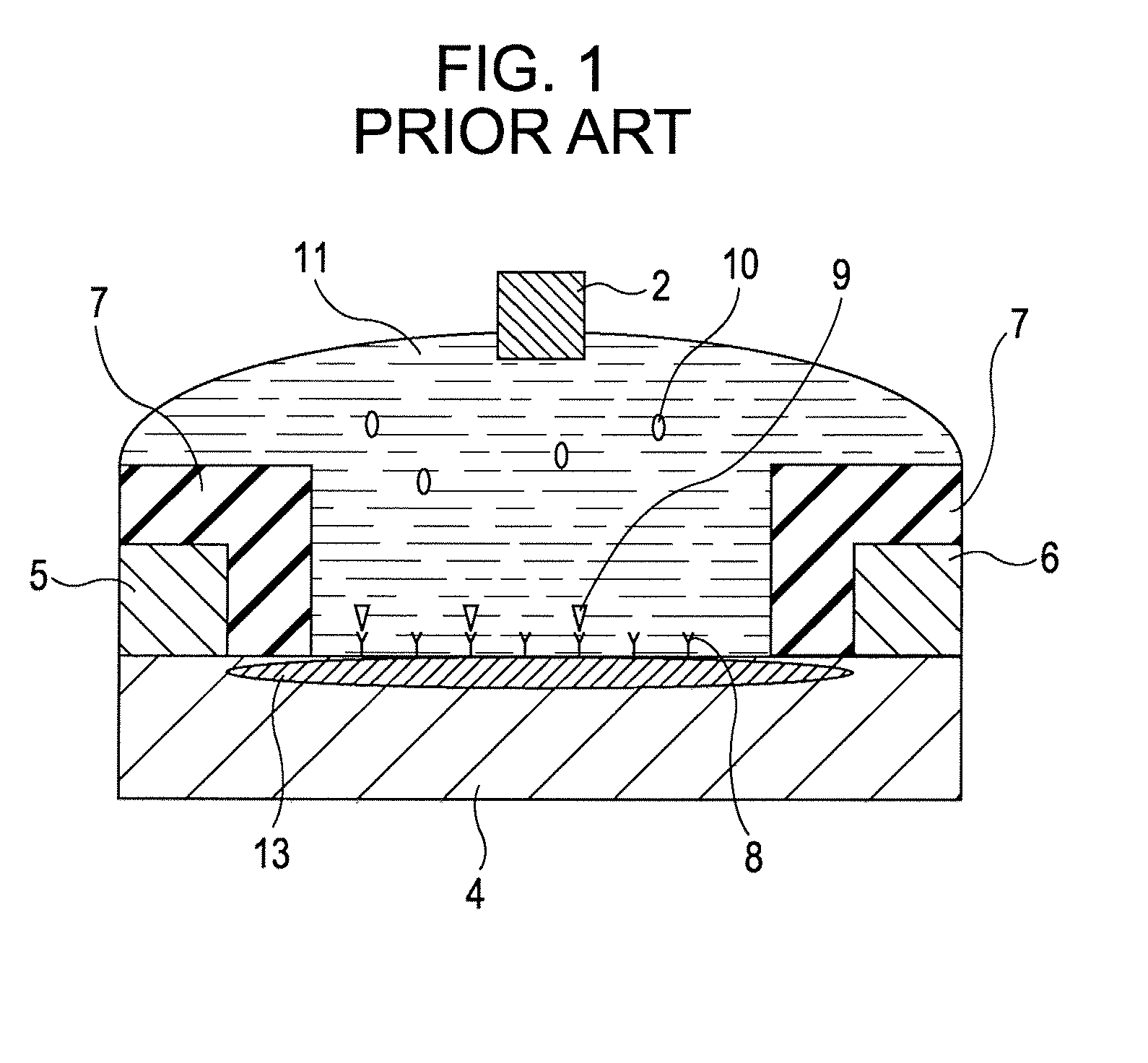

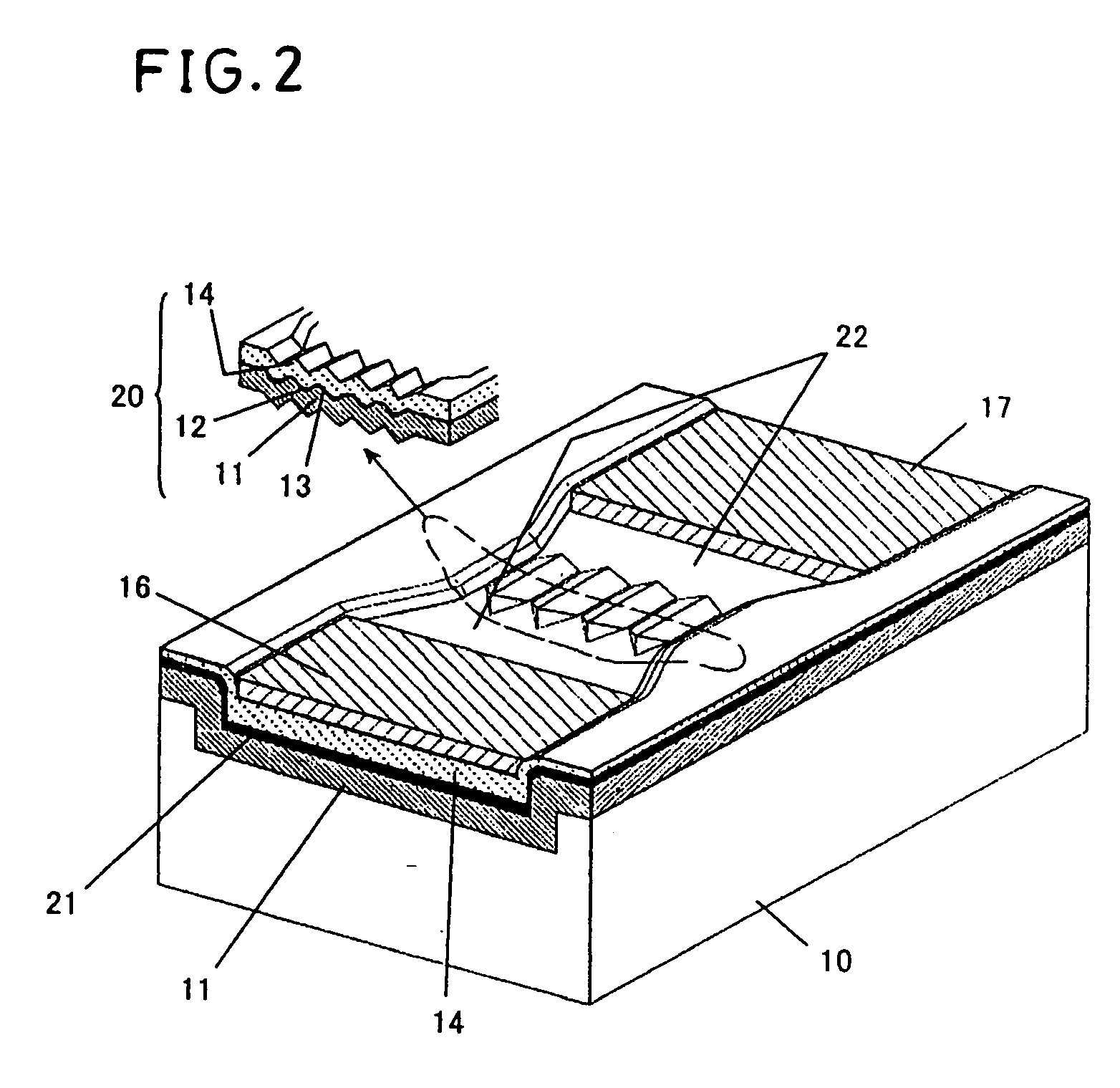

Piezoelectric sensor and input device comprising same

InactiveUS20060144154A1Increased durabilityFlaw can be preventedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorPressure transmission

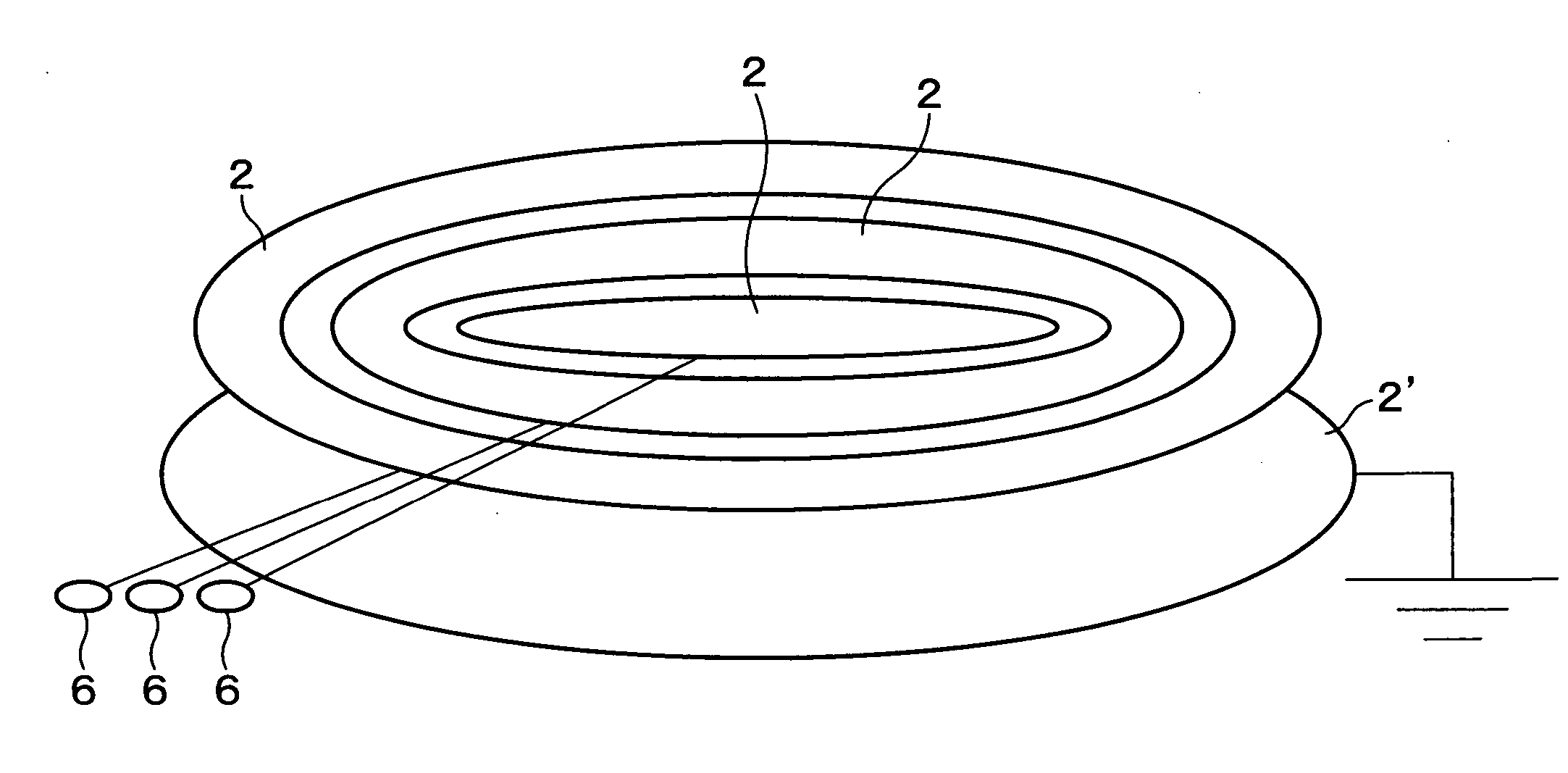

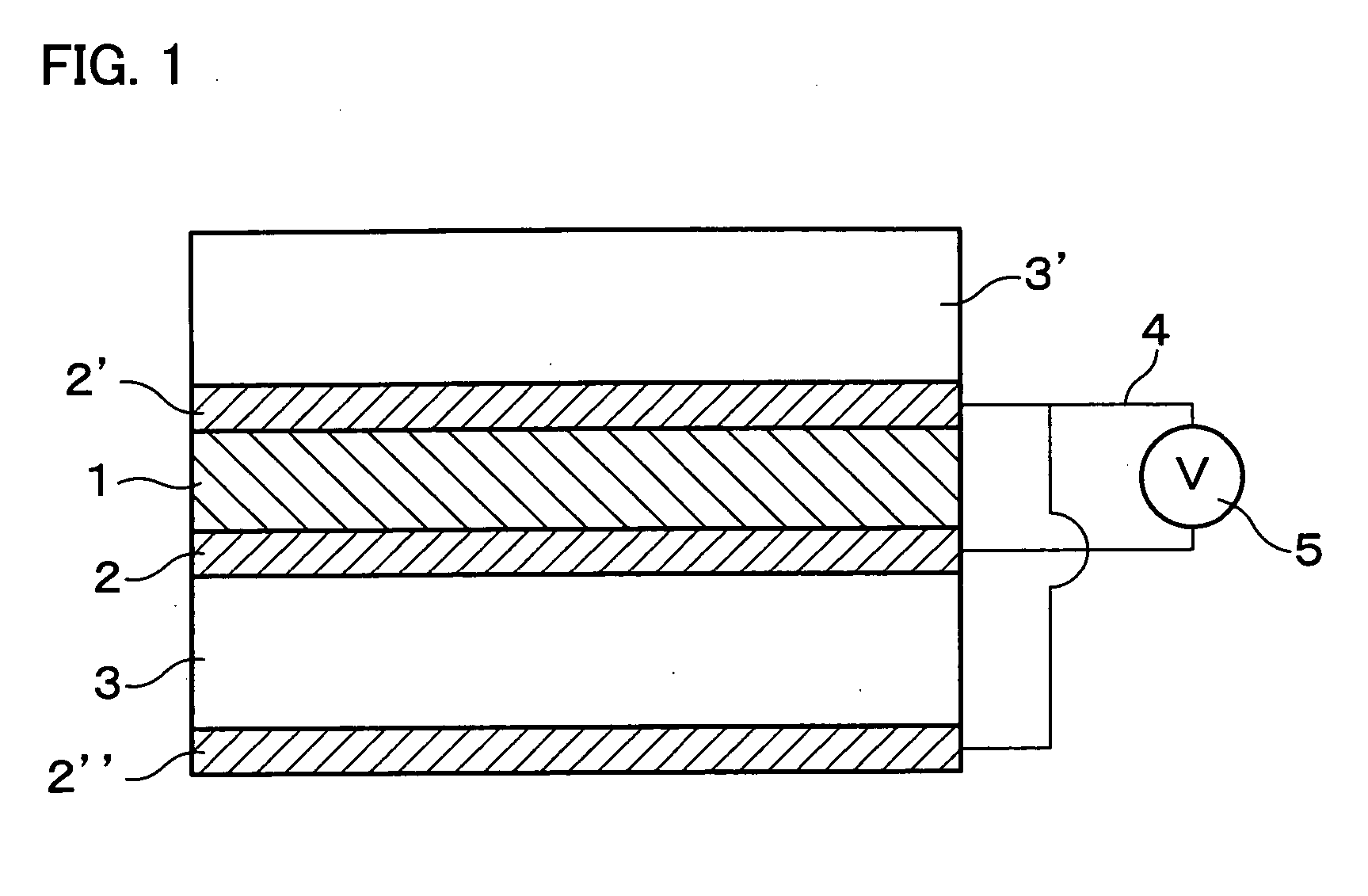

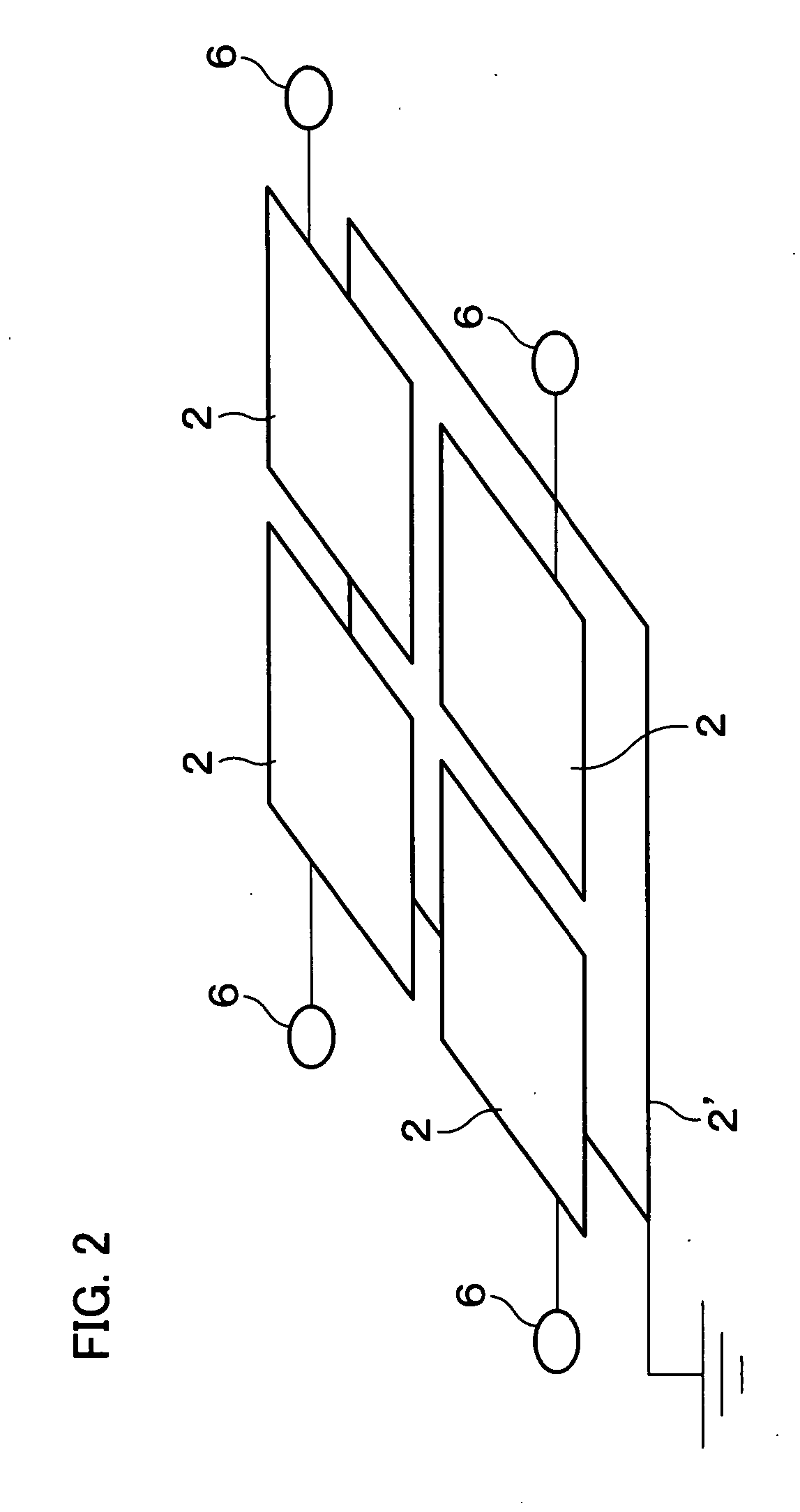

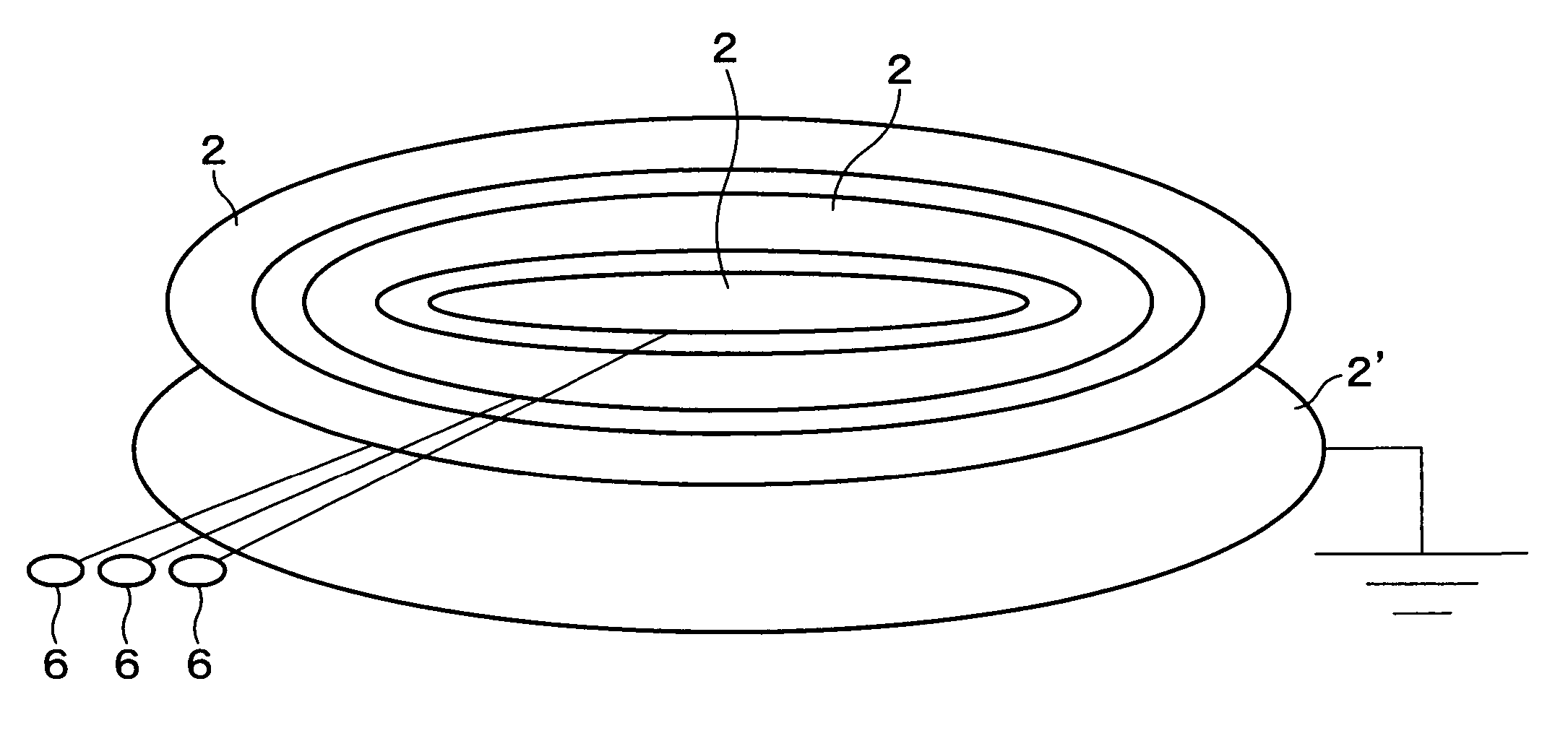

A piezoelectric sensor arranged so as to includes: a transparent piezoelectric element having a piezoelectric property; and a pair of transparent conductor film layers opposed to each other with the piezoelectric element therebetween, the transparent piezoelectric element and the transparent conductor film layers are formed between a pair of transparent substrates, opposed to each other, which serve as pressure transmission means. Consequently, the transparent piezoelectric sensor has an excellent durability. A piezoelectric sensor comprises a piezoelectric element with a piezoelectric property which is made of a piezoelectric material having no Curie point and has a dipole orientation degree of not less than 75%. Consequently, the piezoelectric sensor having an excellent durability and a simple structure is provided at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Piezoelectric sensor and input device including same

InactiveUS7152482B2Increased durabilityFlaw can be preventedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorPressure transmission

A piezoelectric sensor arranged so as to includes: a transparent piezoelectric element having a piezoelectric property; and a pair of transparent conductor film layers opposed to each other with the piezoelectric element therebetween, the transparent piezoelectric element and the transparent conductor film layers are formed between a pair of transparent substrates, opposed to each other, which serve as pressure transmission means. Consequently, the transparent piezoelectric sensor has an excellent durability. A piezoelectric sensor comprises a piezoelectric element with a piezoelectric property which is made of a piezoelectric material having no Curie point and has a dipole orientation degree of not less than 75%. Consequently, the piezoelectric sensor having an excellent durability and a simple structure is provided at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

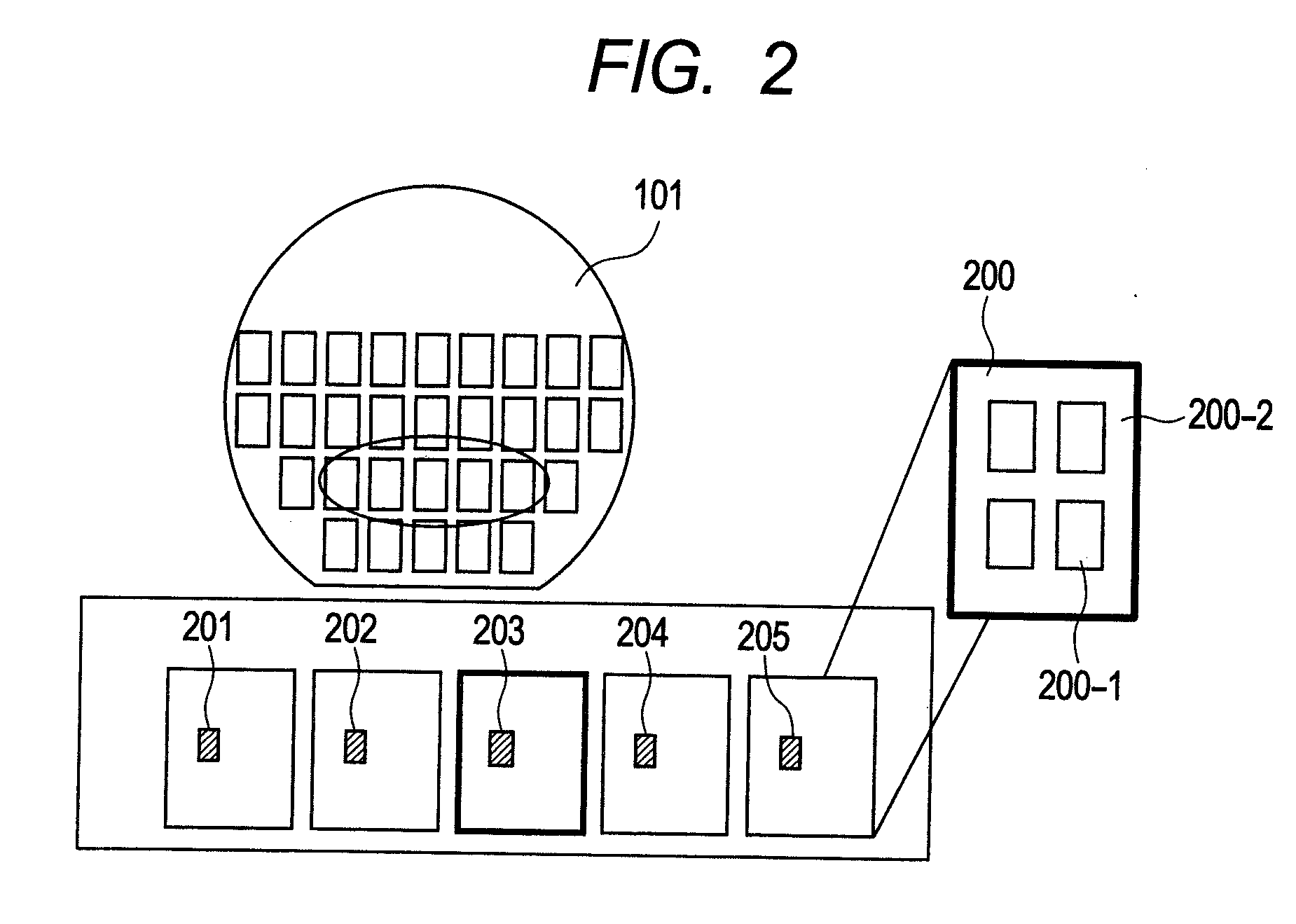

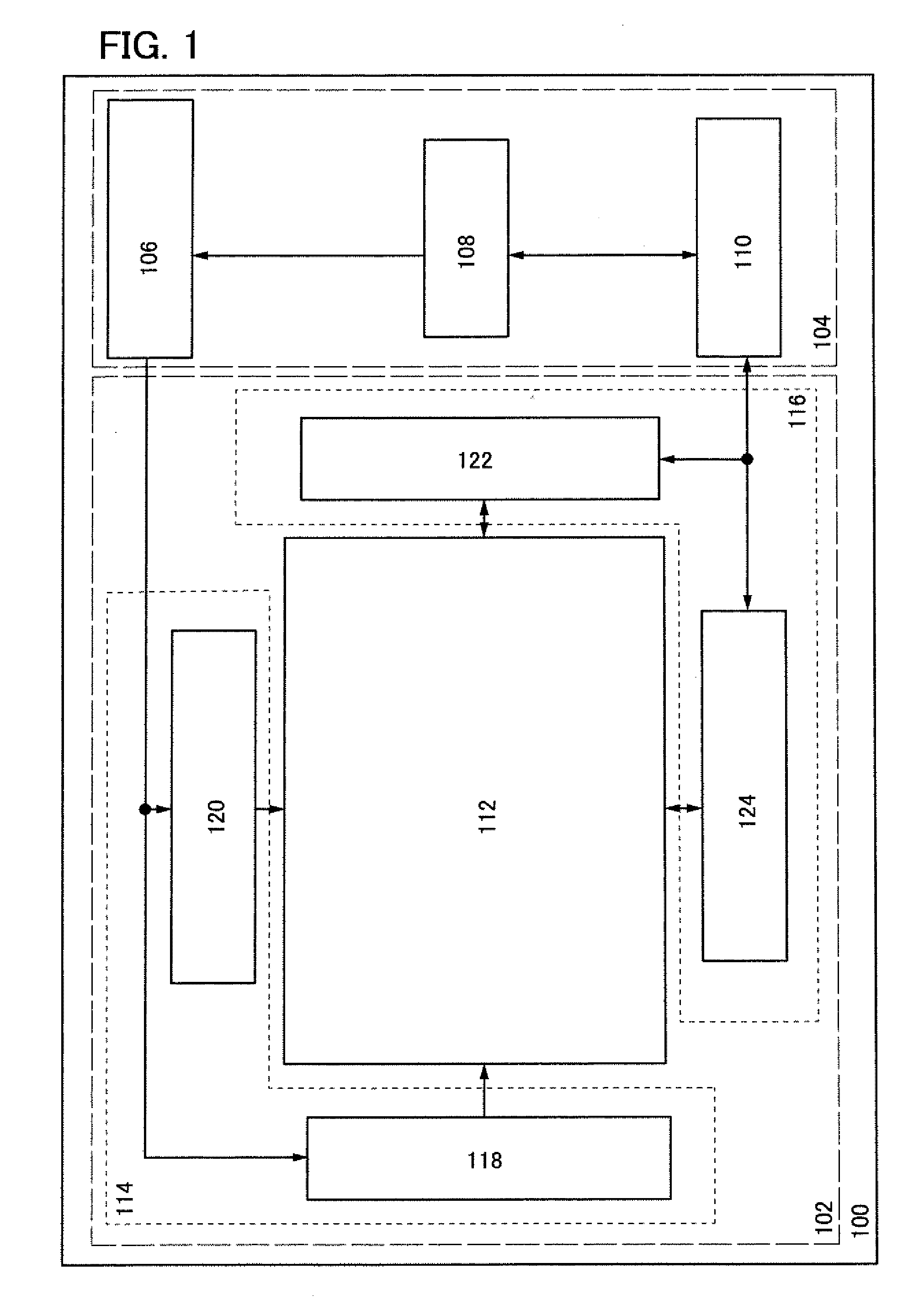

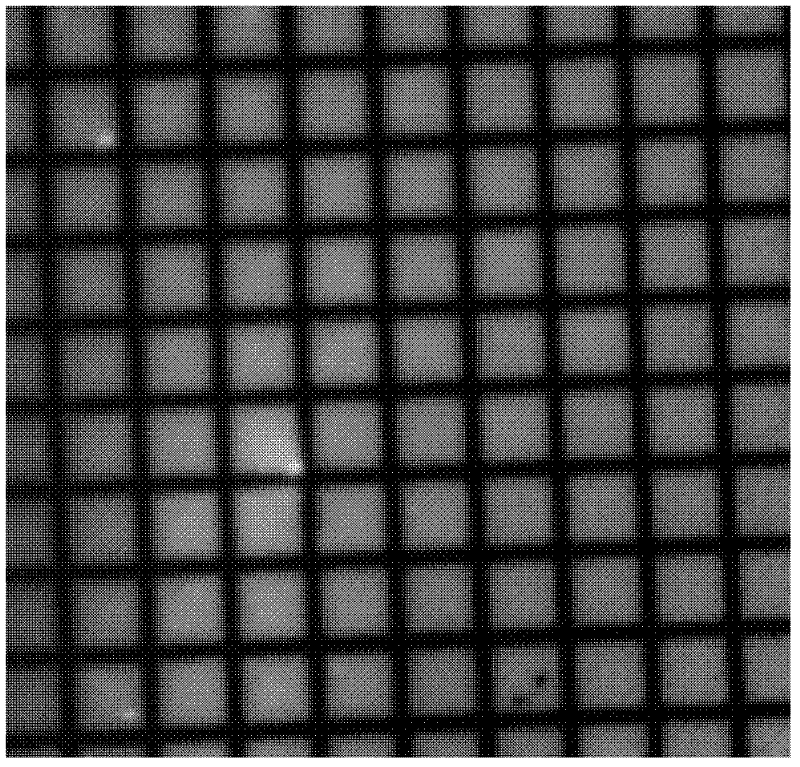

Defect inspection device and defect inspection method

ActiveUS20120229618A1High sensitivity detectionImage enhancementImage analysisFeature basedInspection method

Disclosed is a defect inspection device that has an illumination optical system; a detection optical system; and a processing unit which includes a defect feature quantity calculation unit that calculates the feature quantities of each defect candidate, a defect candidate grouping unit that groups the aforementioned defect candidates on the basis of the feature quantities, a defect classification evaluation value calculation unit that calculates defect classification evaluation values for the aforementioned defect candidates, a defect classification evaluation value updating unit that, on the basis of instructions, updates the evaluation values, a defect classification threshold determination unit that, on the basis of evaluation valued updated by the aforementioned defect classification evaluation value updating unit, determines a classification boundary that is a threshold for classifying defect types of the aforementioned defect candidates, and a defect detection unit that detects defects using the thresholds.

Owner:HITACHI HIGH-TECH CORP

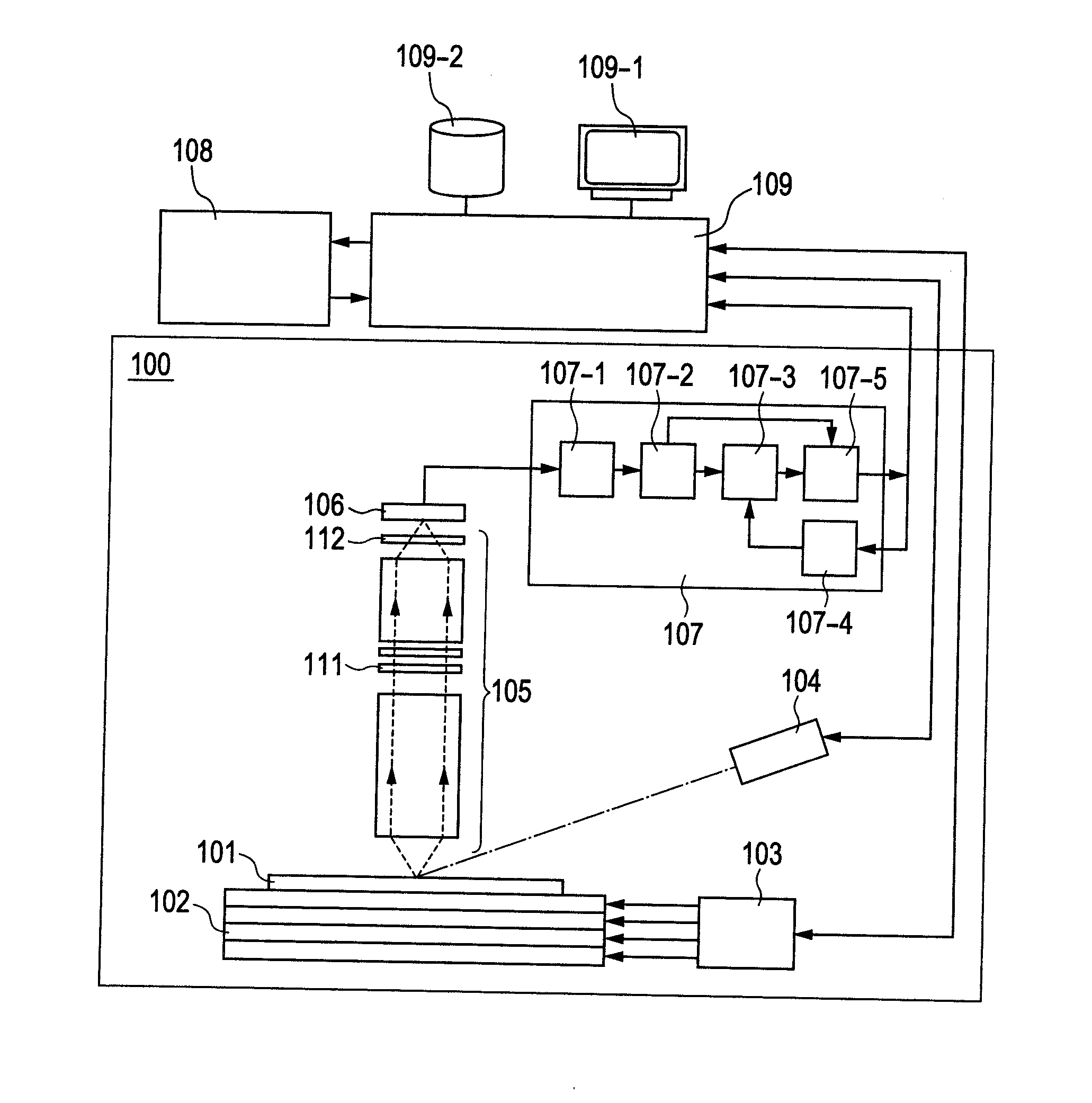

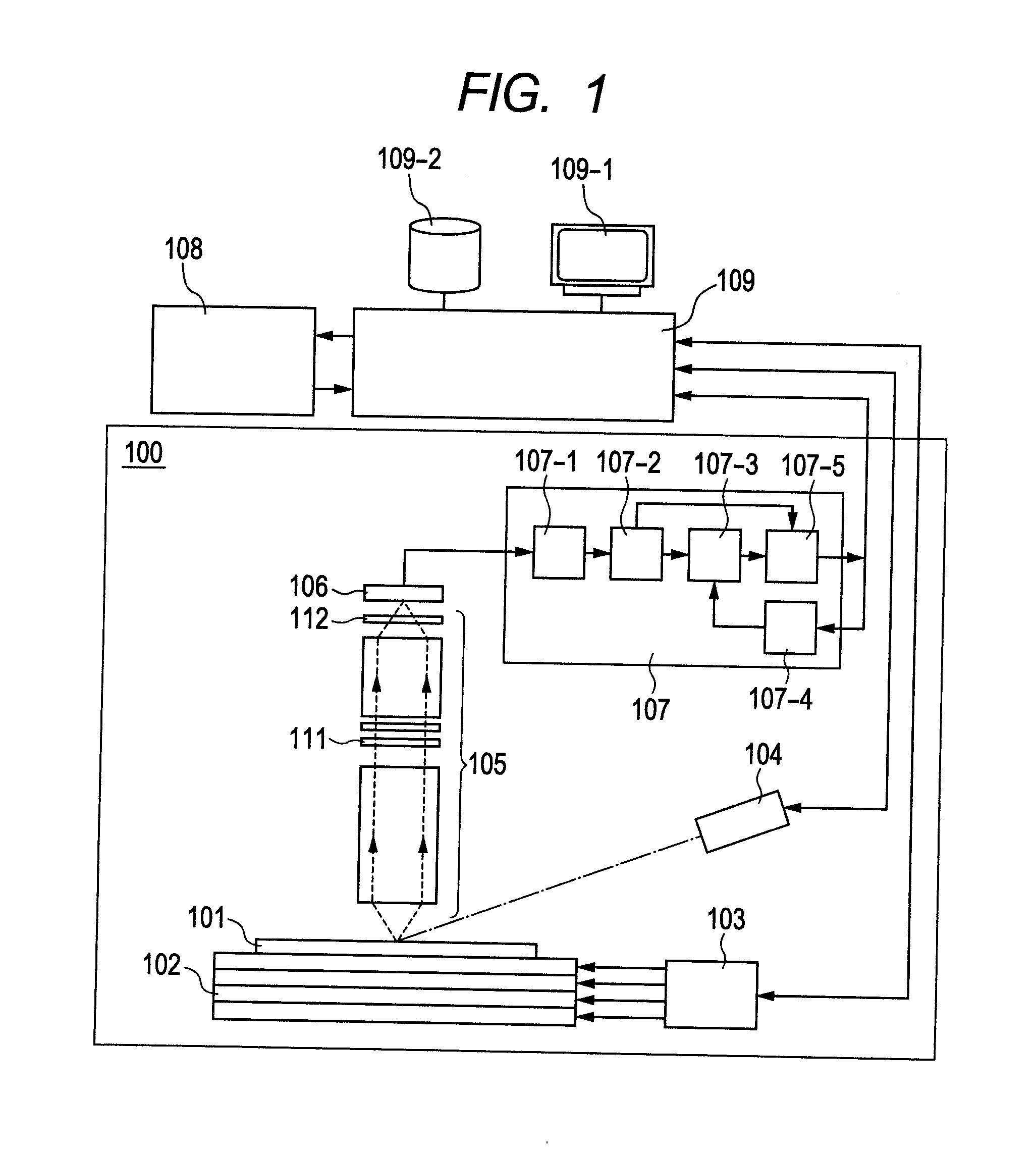

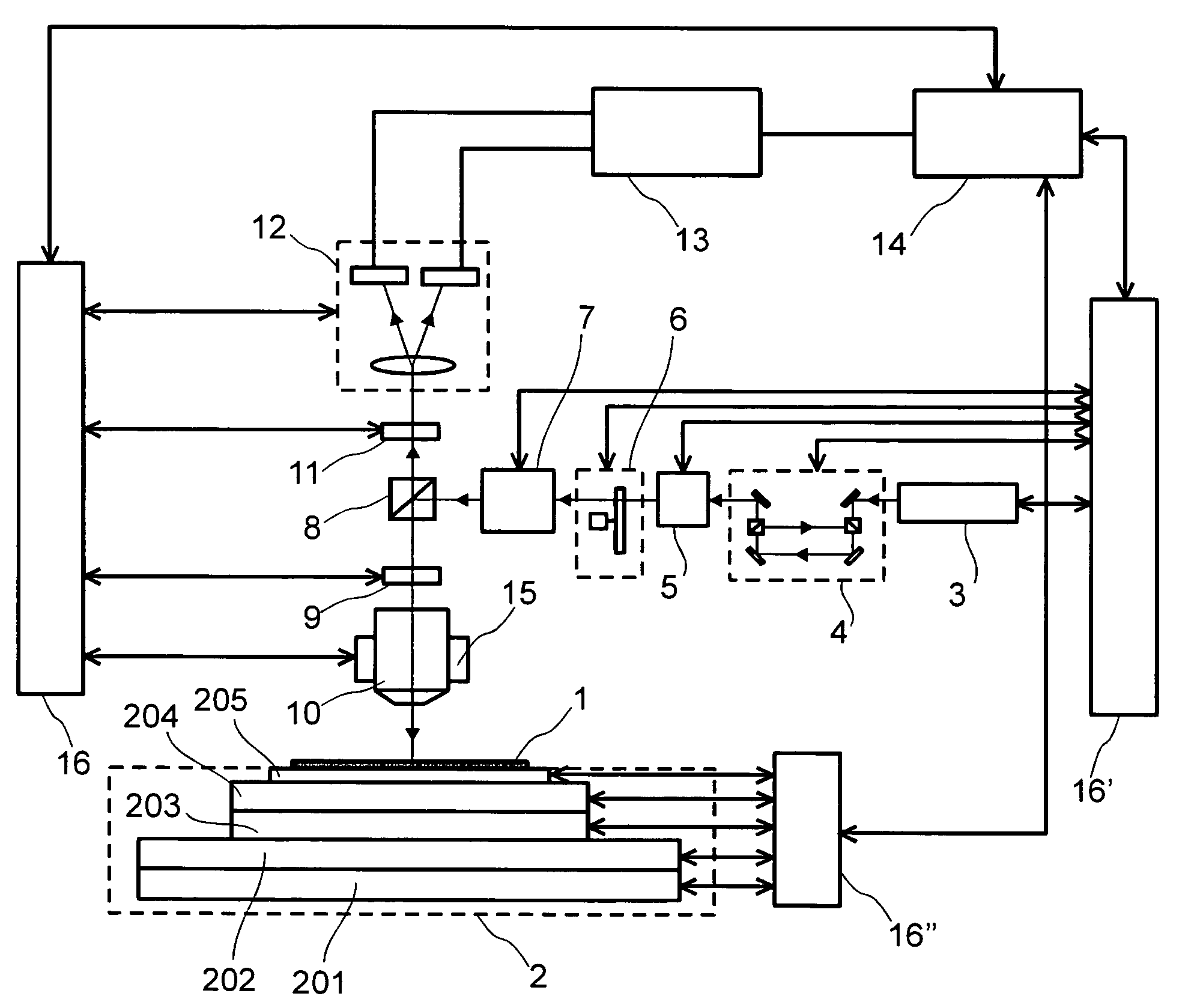

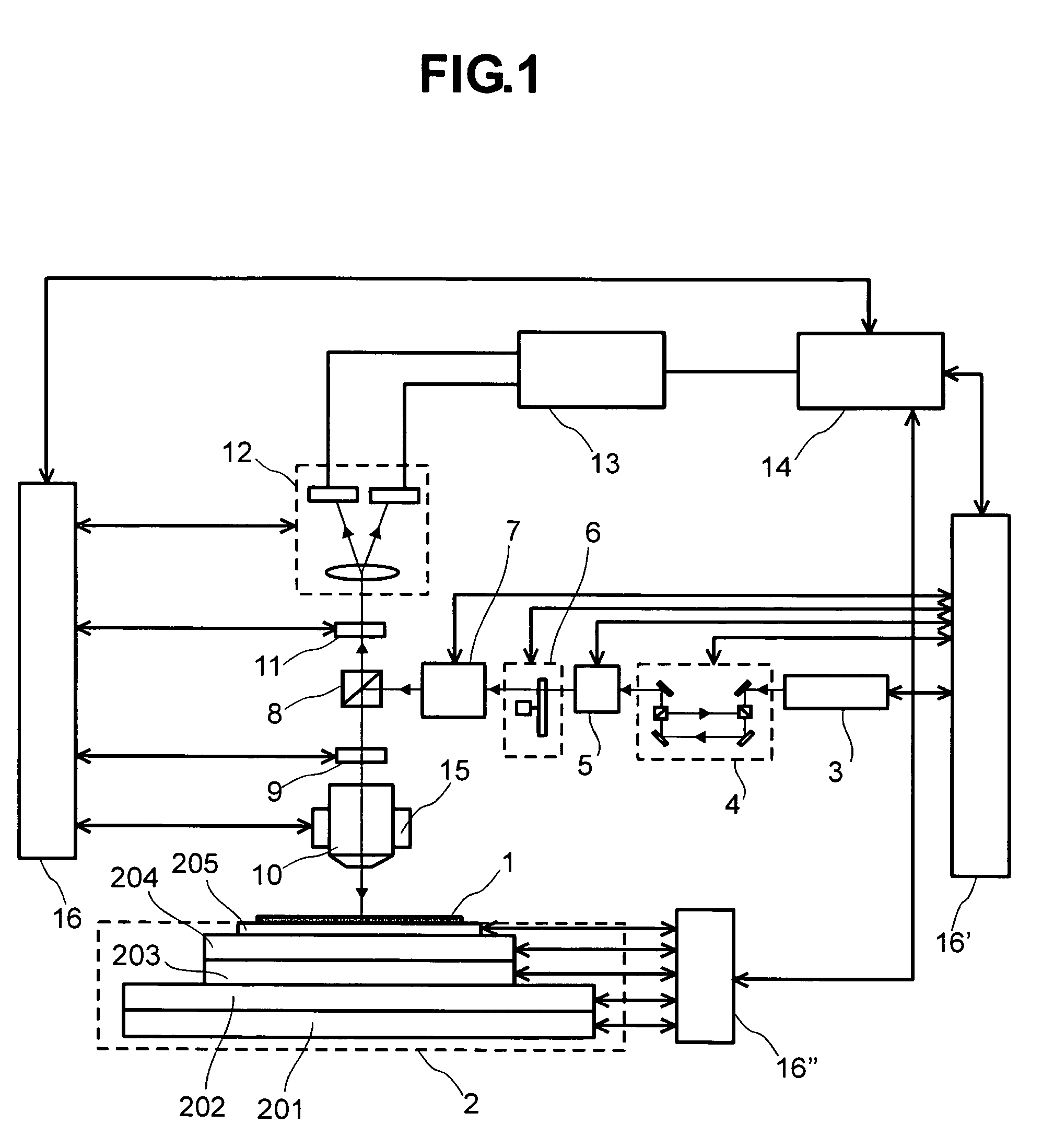

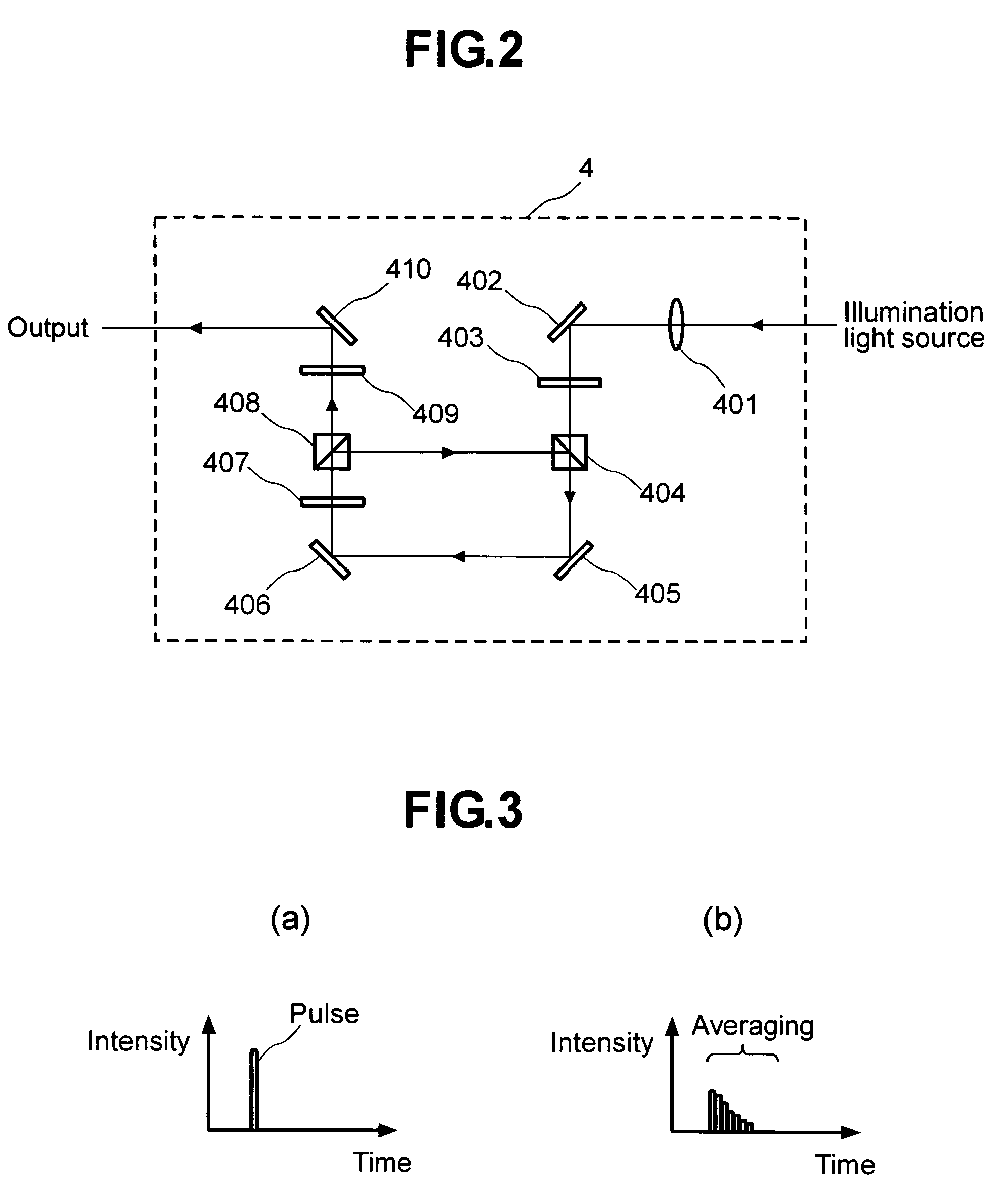

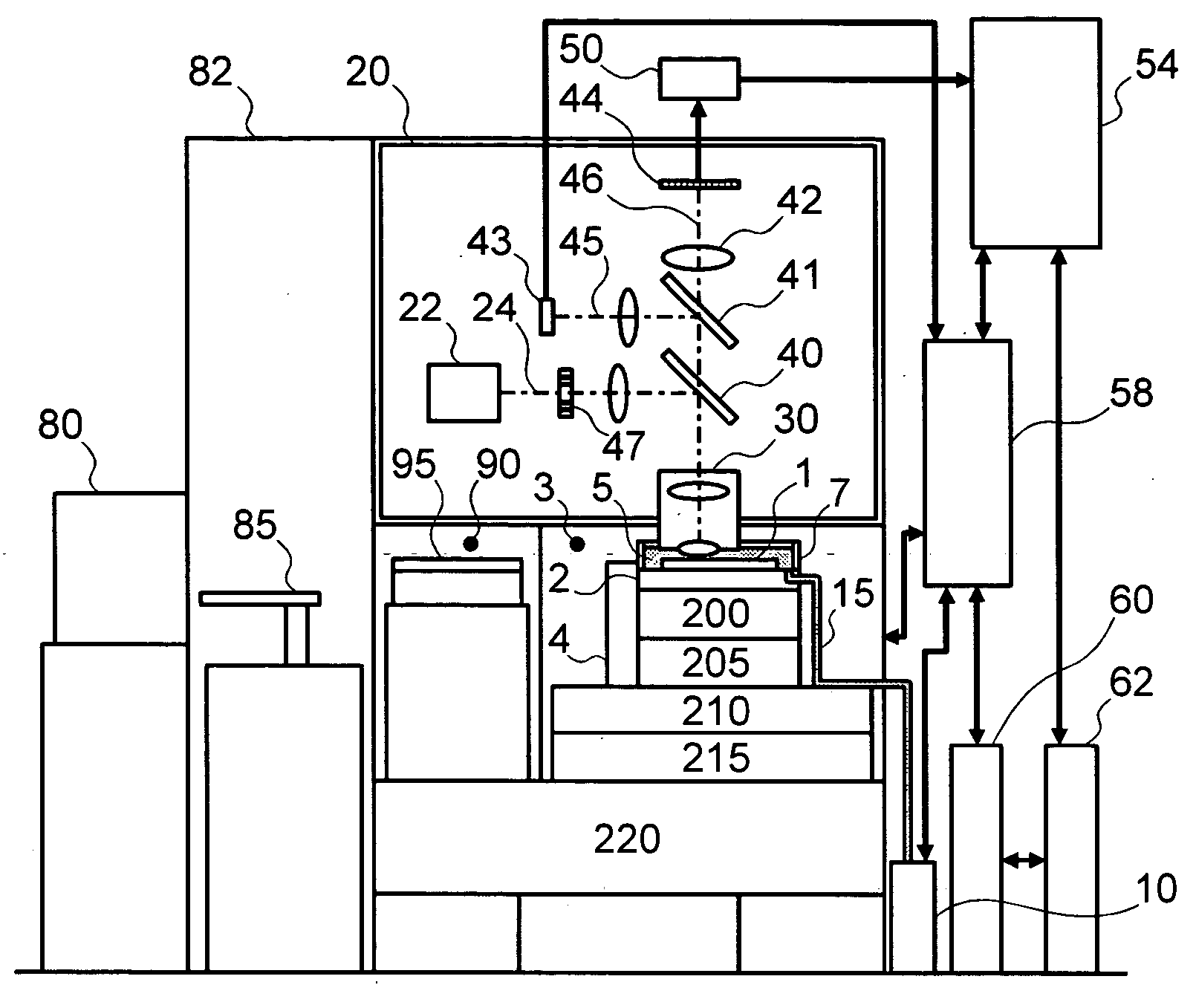

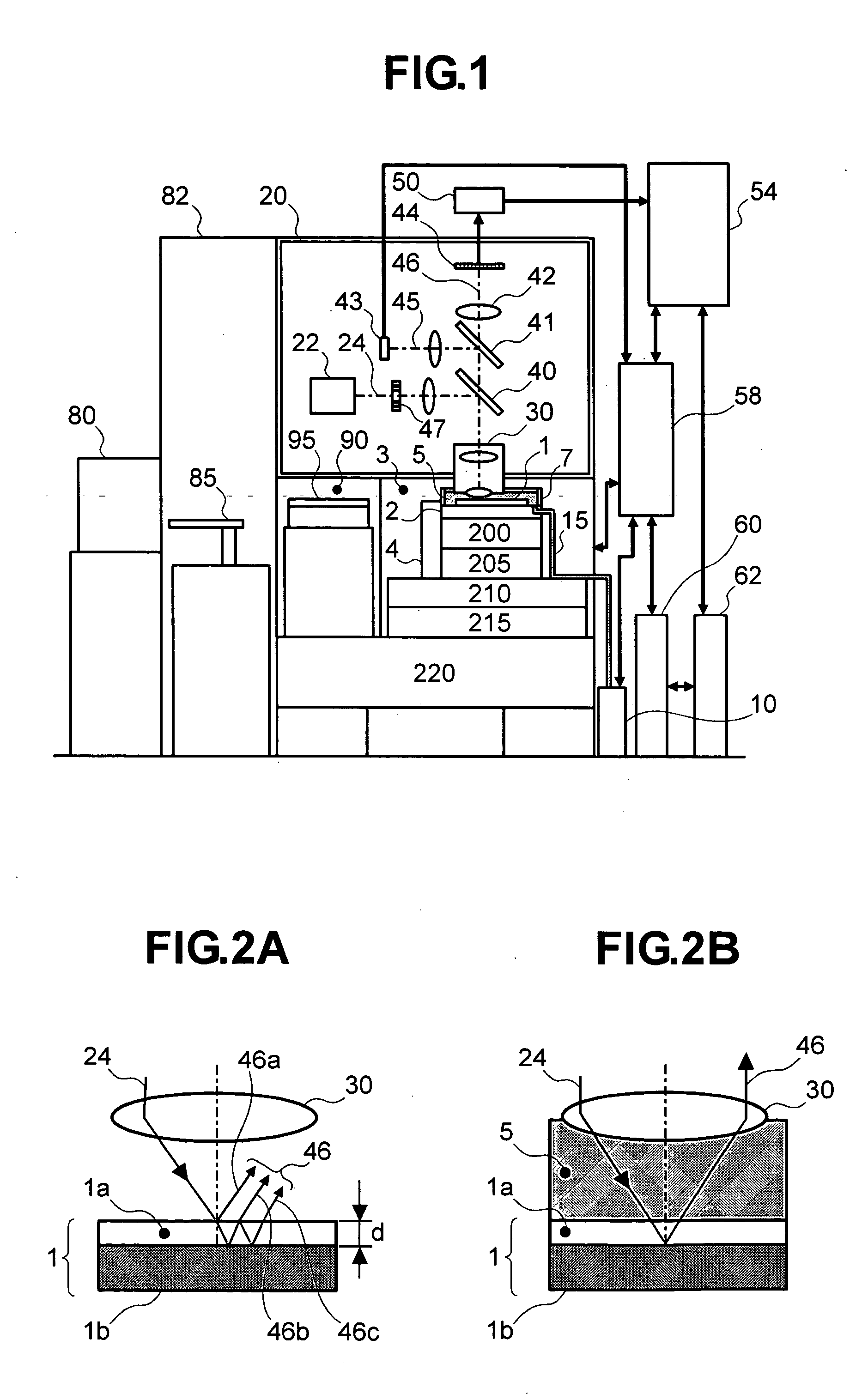

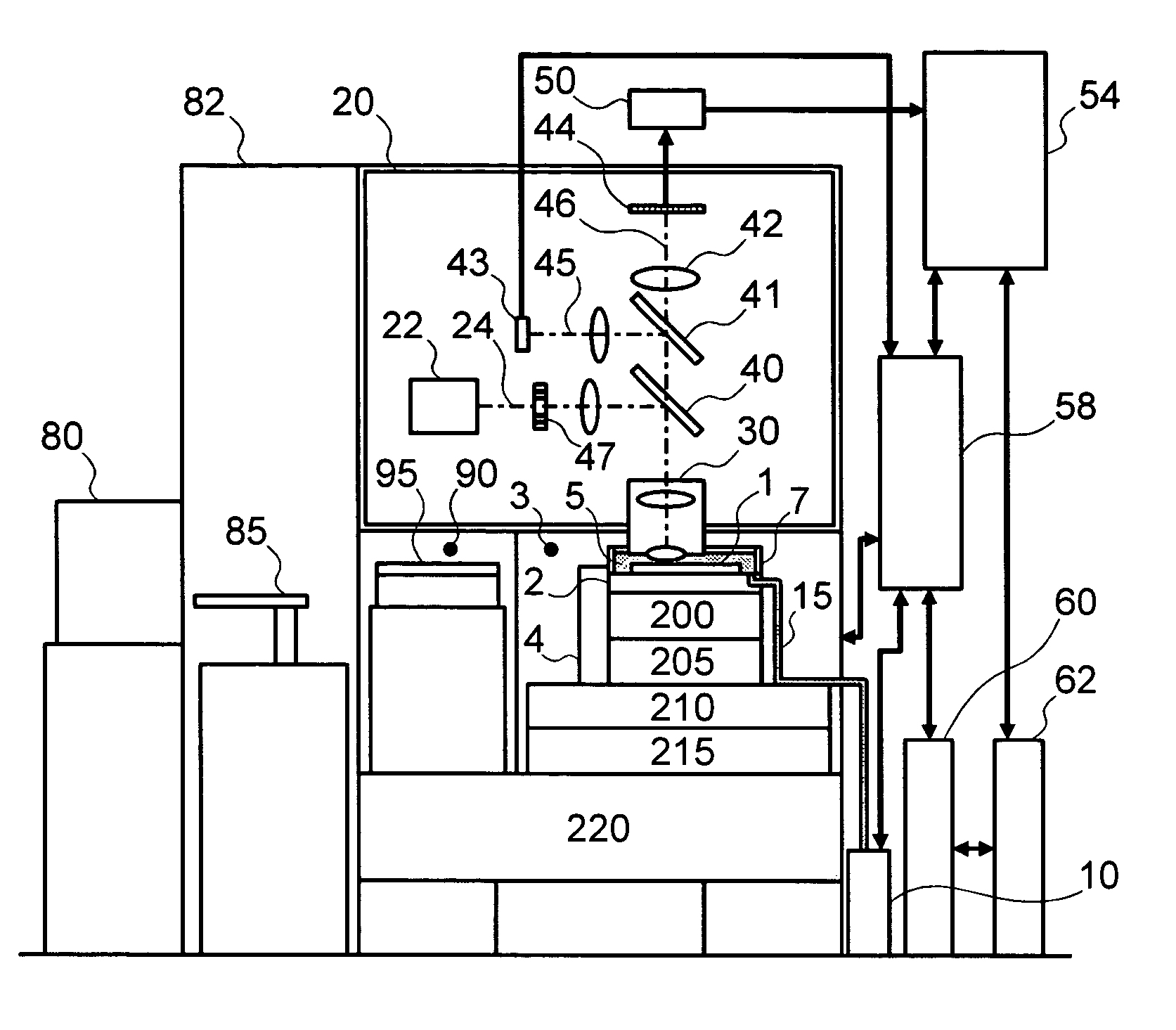

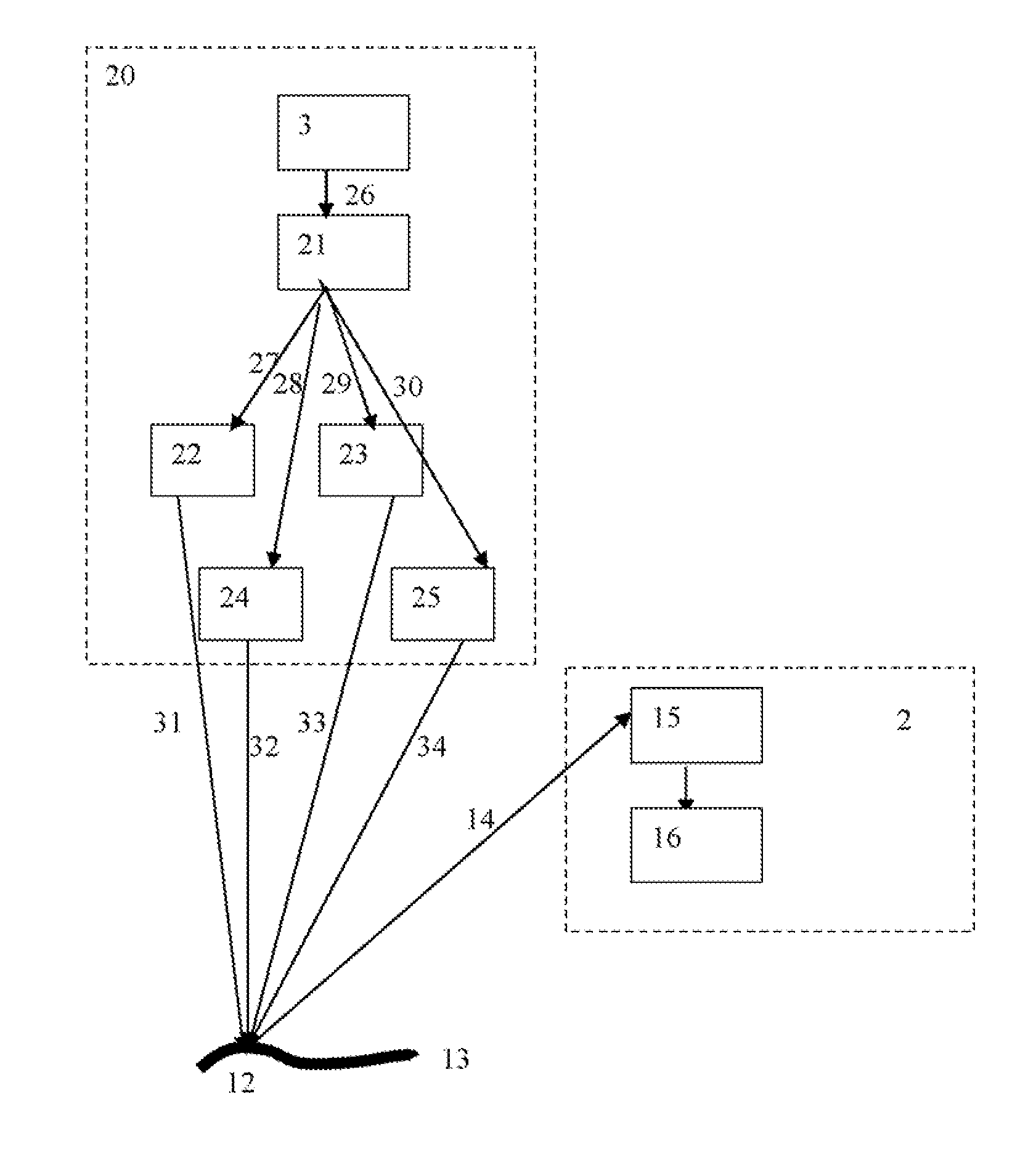

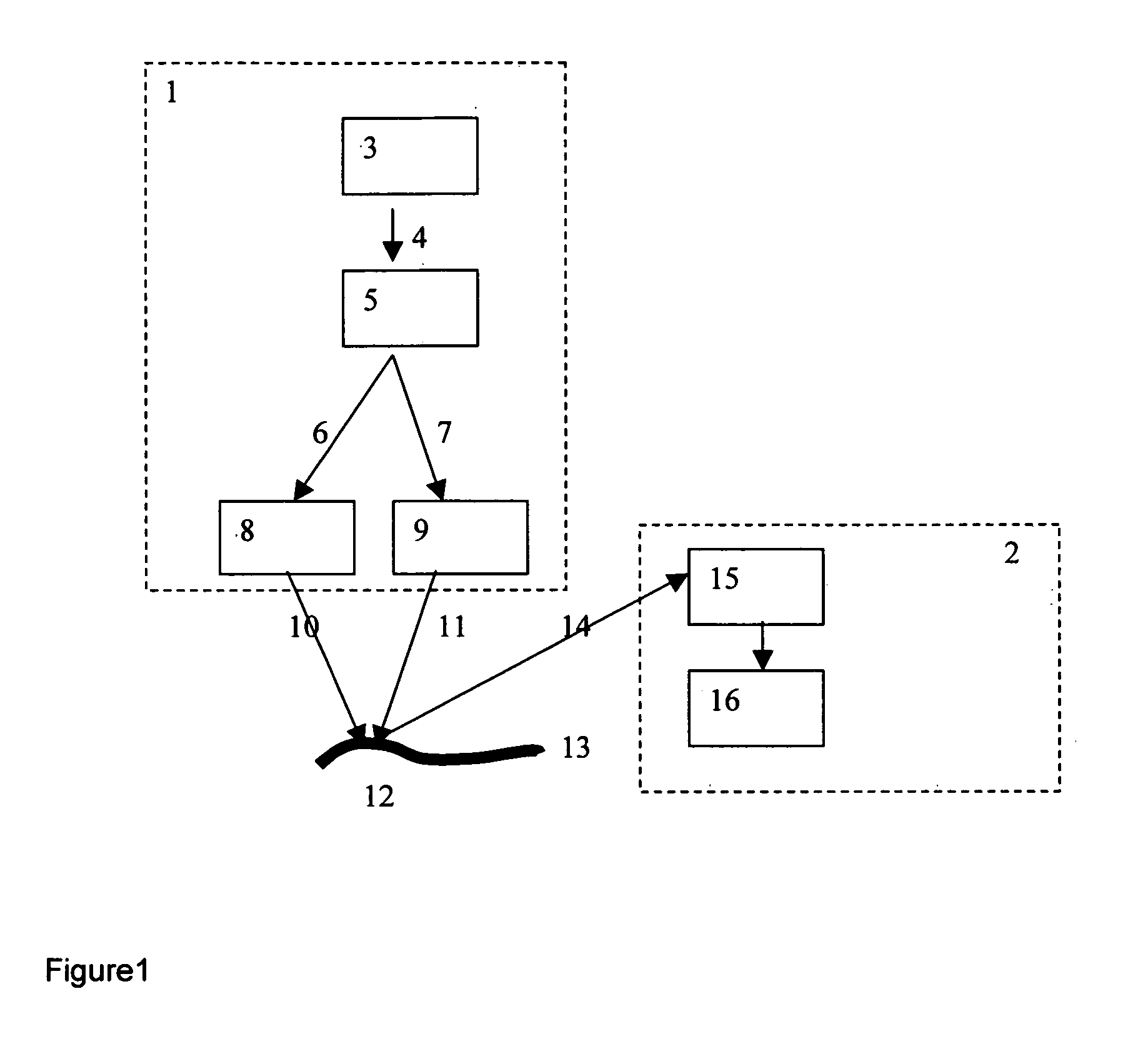

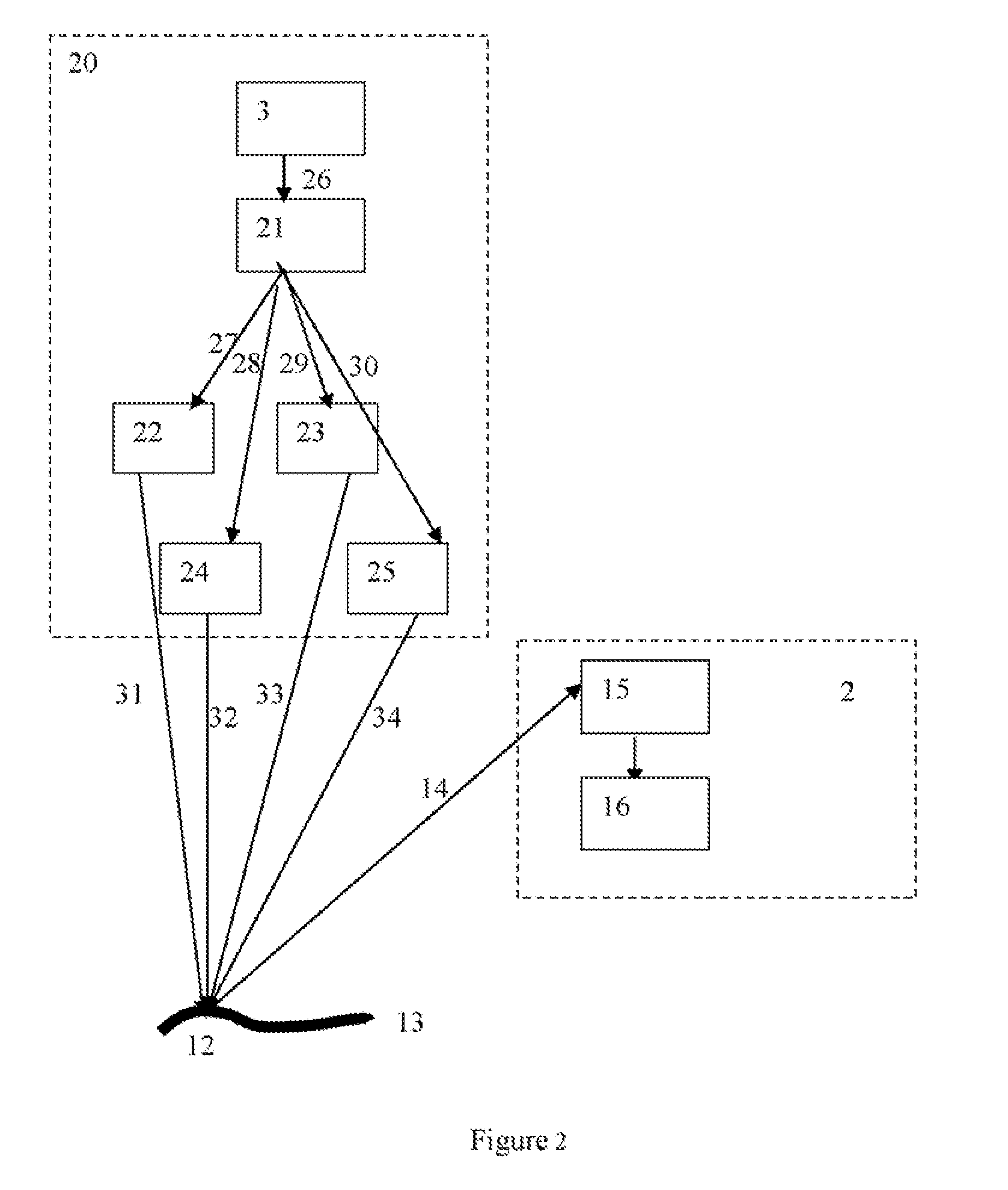

Method and apparatus for inspecting defects of patterns

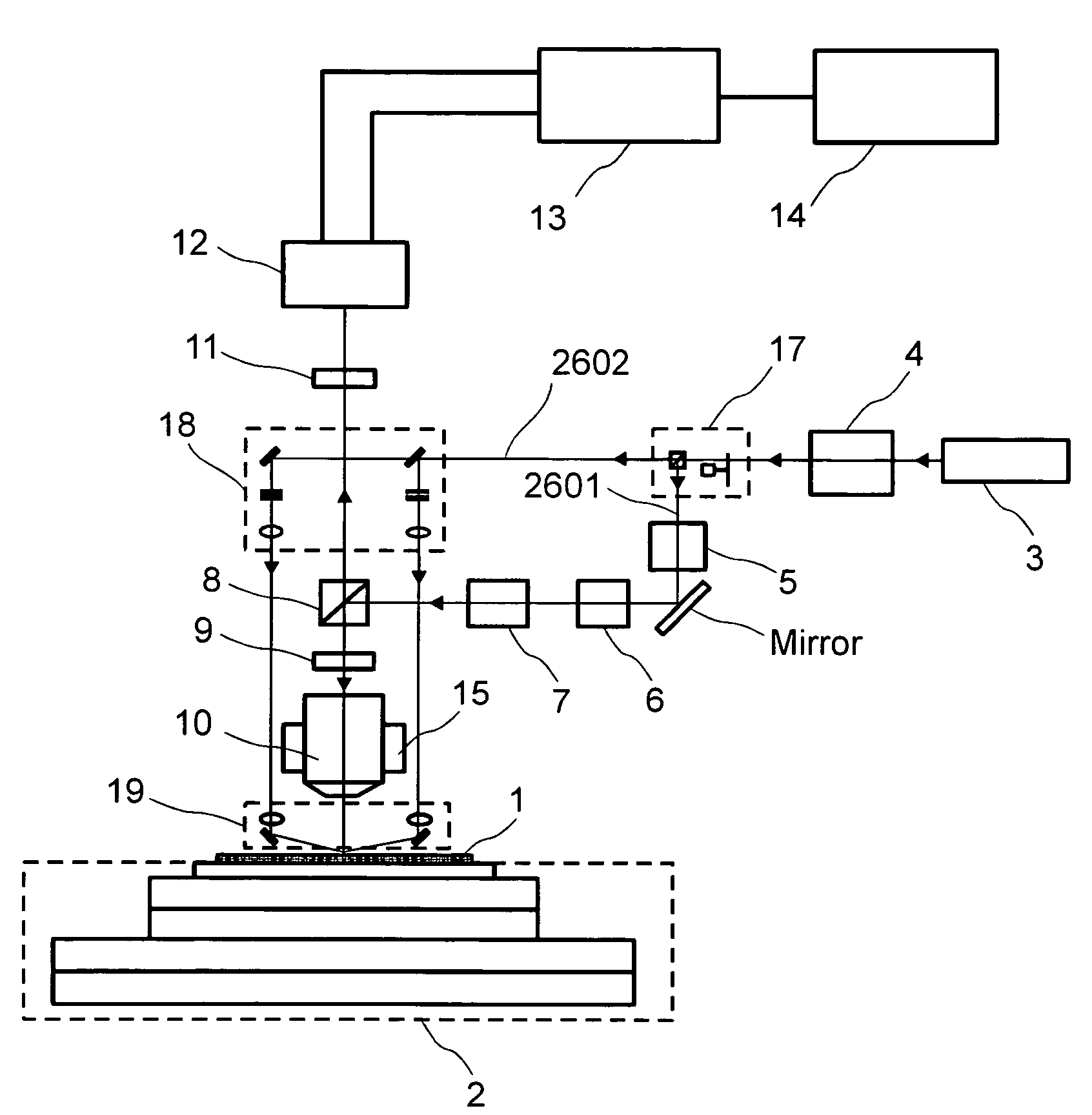

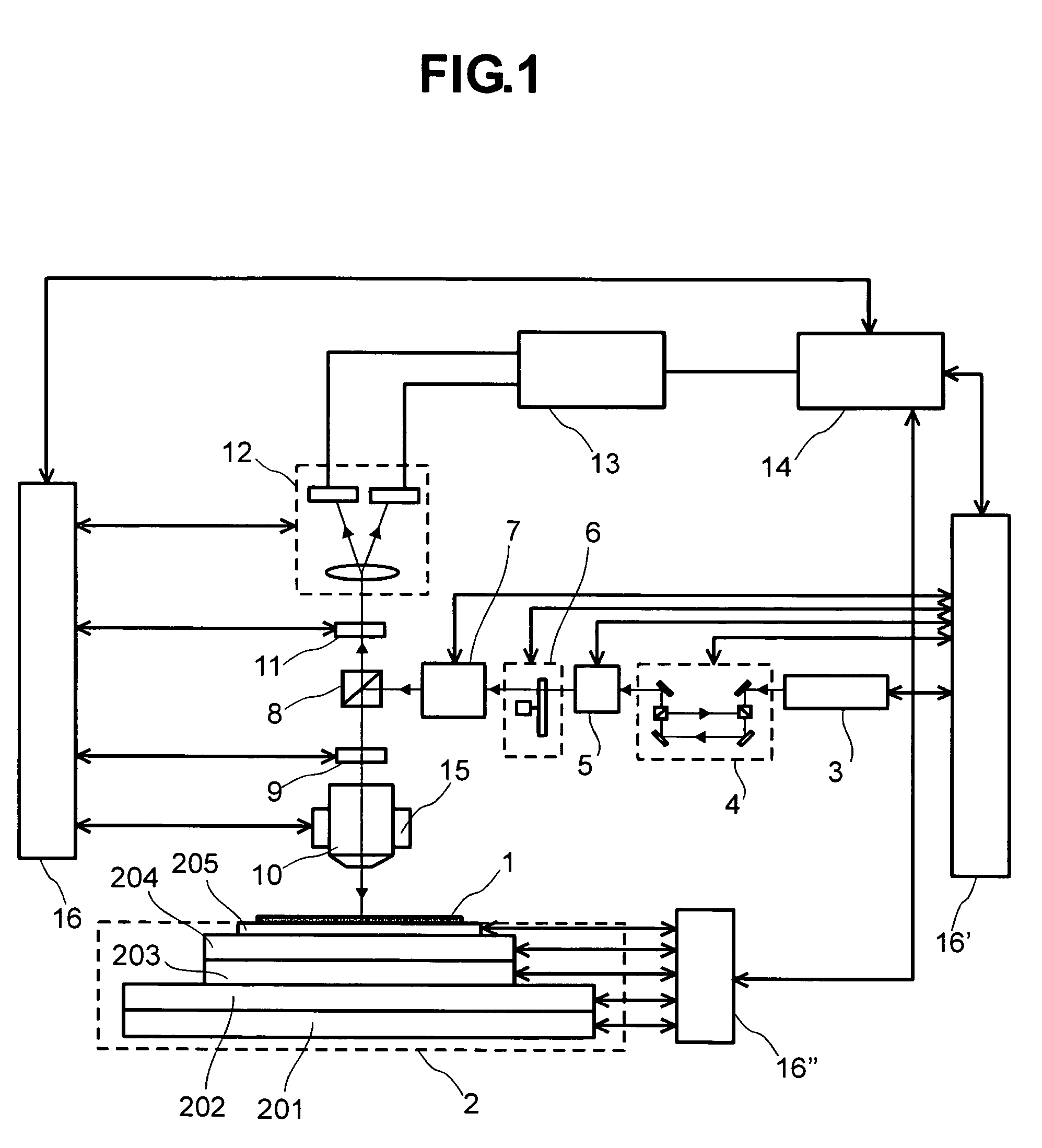

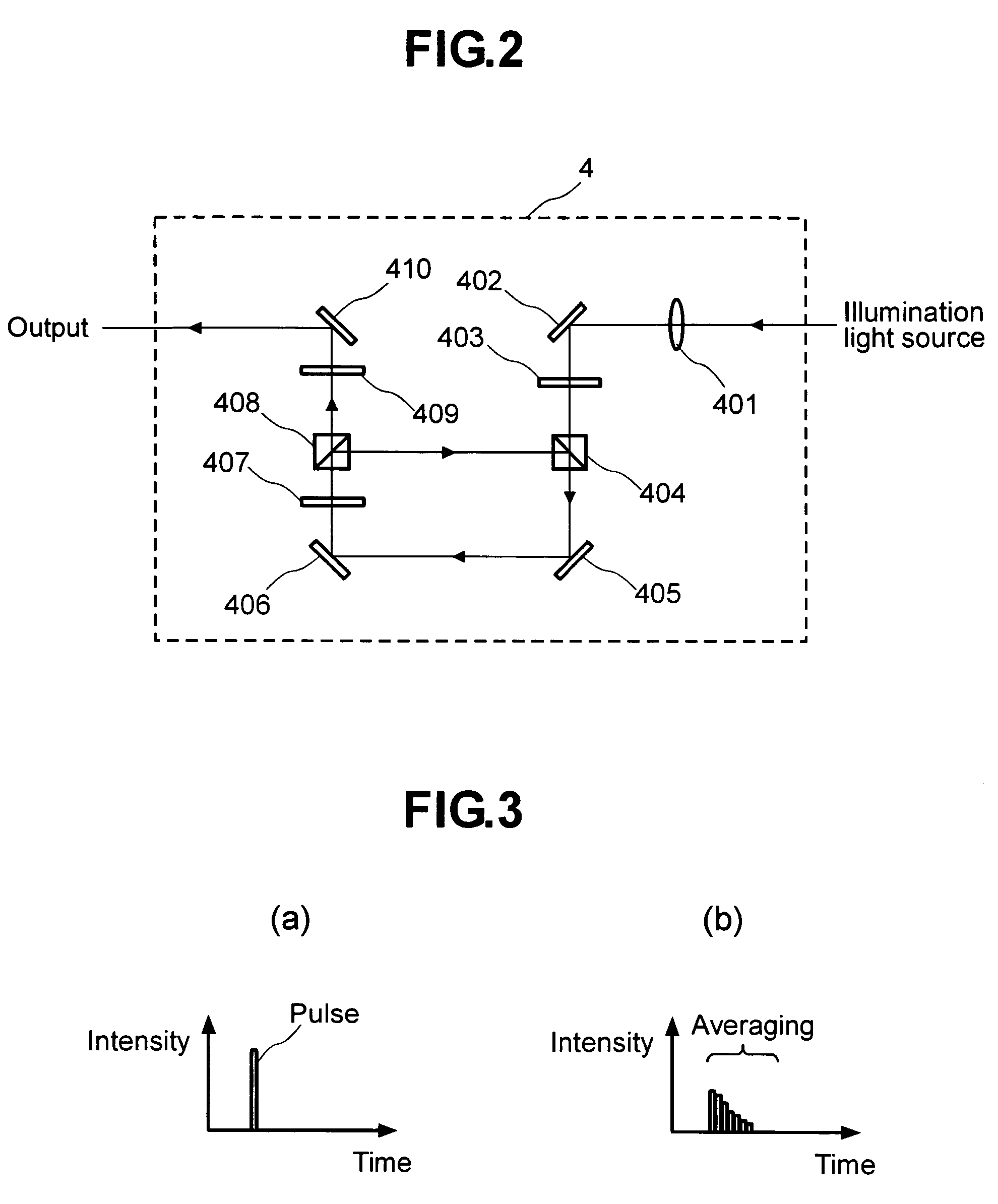

InactiveUS20050110988A1Reducing amount-of-light unevennessDamage on the wafer caused by the illumination light can be reducedOptically investigating flaws/contaminationVisual field lossLight beam

Disclosed is a method and apparatus for inspecting defects of patterns of a sample at high speed and with high sensitivity while damage of the sample arising from high-power pulsed light is reduced. Light emitted from a pulsed laser light source is transmitted through a pseudo continuous-wave forming optical system having an optical system capable of reducing energy per pulse and yet maintaining the entire amount of light of the pulsed light, a beam formation optical system, and a coherence reduction optical system, and a beam deflected by a deformation illumination optical system is made to reflect on a PBS to be irradiated on a wafer. The apparatus is configured so that the diffracted light from the wafer is focused by an objective lens, transmitted through light modulation units, focused to form a plurality of images on a plurality of image sensors in a visual-field divided parallel detection unit 12, and then defects are detected by a signal processing unit.

Owner:HITACHI HIGH-TECH CORP

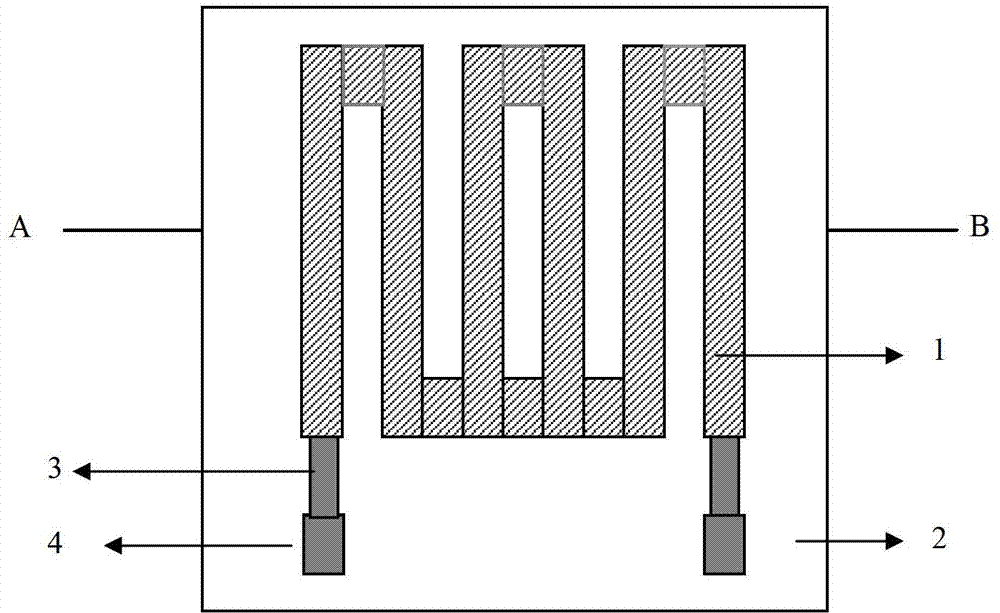

High-sensitivity terahertz microfluidic channel sensor and preparation method thereof

ActiveCN103499534AHigh sensitivity detectionDecorative surface effectsVacuum evaporation coatingResonanceMicrofluidic channel

The invention provides a high-sensitivity terahertz microfluidic channel sensor and a preparation method thereof. The sensor comprises a substrate and a cover layer; the substrate and the cover layer are respectively provided with a metal planar mirror and a metal microstructure layer; microfluidic channels are formed between the metal planar mirror and the metal microstructure layer; when liquid to be tested exists in the microfluidic channels, the composite structure formed by the metal microstructure layer, the liquid to be tested, and the metal planar mirror has strong absorption property caused by resonance in the terahertz wave band. The method comprises: respectively processing and forming the metal planar mirror and the metal microstructure layer on the substrate and the cover layer; fixedly connecting the substrate with the cover layer, forming the enclosed microfluidic channels between the substrate and the cover layer, arranging through holes communicated with the microfluidic channels on the substrate and / or the cover layer so as to form liquid channels for inputting or outputting liquid to be tested into or out of the sensor. The sensor of the invention is simple in structure, and easy to process and use, and has greatly improved detecting sensitivity when compared with existing sensors.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

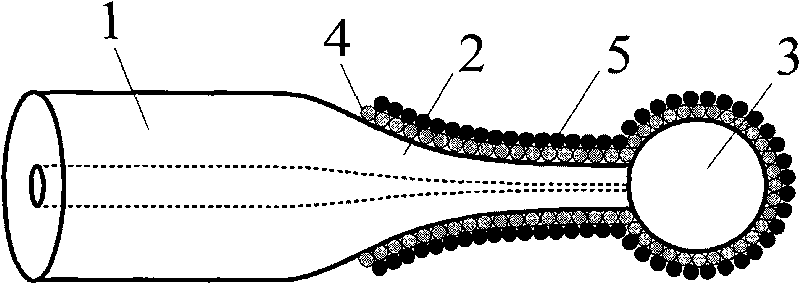

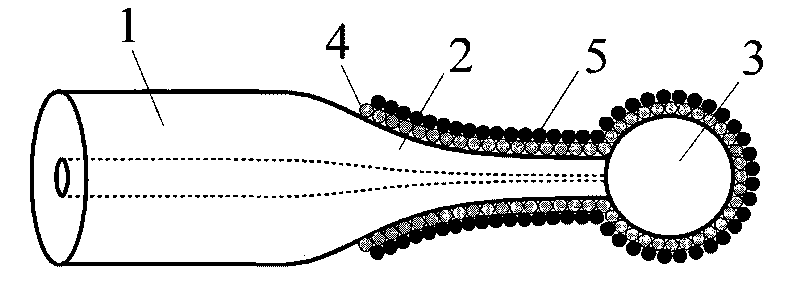

Surface-enhanced Raman scattering optical fiber probe

InactiveCN101713738AEnhanced Penetration DepthImprove detection sensitivityRaman scatteringCoupling light guidesAmount of substanceLiving sample

The invention relates to a surface-enhanced Raman scattering optical fiber probe, comprising an optical fiber which can be simultaneously used for transmitting exciting light and receiving Raman scattering spectrum, a tapered optical fiber and one quartz microballoon, wherein the tapered optical fiber is formed on one end of the optical fiber, and then one quartz microballoon is thermally welded on the tip of the tapered optical fiber; when the exciting light passes through the tapered optical fiber and the quartz microballoon, evanescent waves transmitted by the tapered optical fiber and the quartz microballoon can excite the Raman spectrum of a solution or a gas molecule to be tested; meanwhile, metal nano particles are coated on the optical fiber and the surface of the quartz microballoon, so that the Raman scattering strength can be enhanced. In addition, a sensing structure of the combination of the tapered optical fiber and the quartz microballoon also has the functions of reflecting, focusing and collecting the surface-enhanced Raman scattering spectrum. The optical fiber probe is combined with a monochromatic source and a high-sensitivity Raman spectrometer so that a Raman detection sensing device can be formed. The invention has simple structure, strong capacity of resisting disturbance and high sensitivity, thereby being suitable for information acquisition and transmission of on-line analysis occasions, real-time detection occasions, live sample analysis occasions, trace hazardous and noxious substance measurement occasions and the like.

Owner:SHANGHAI UNIV

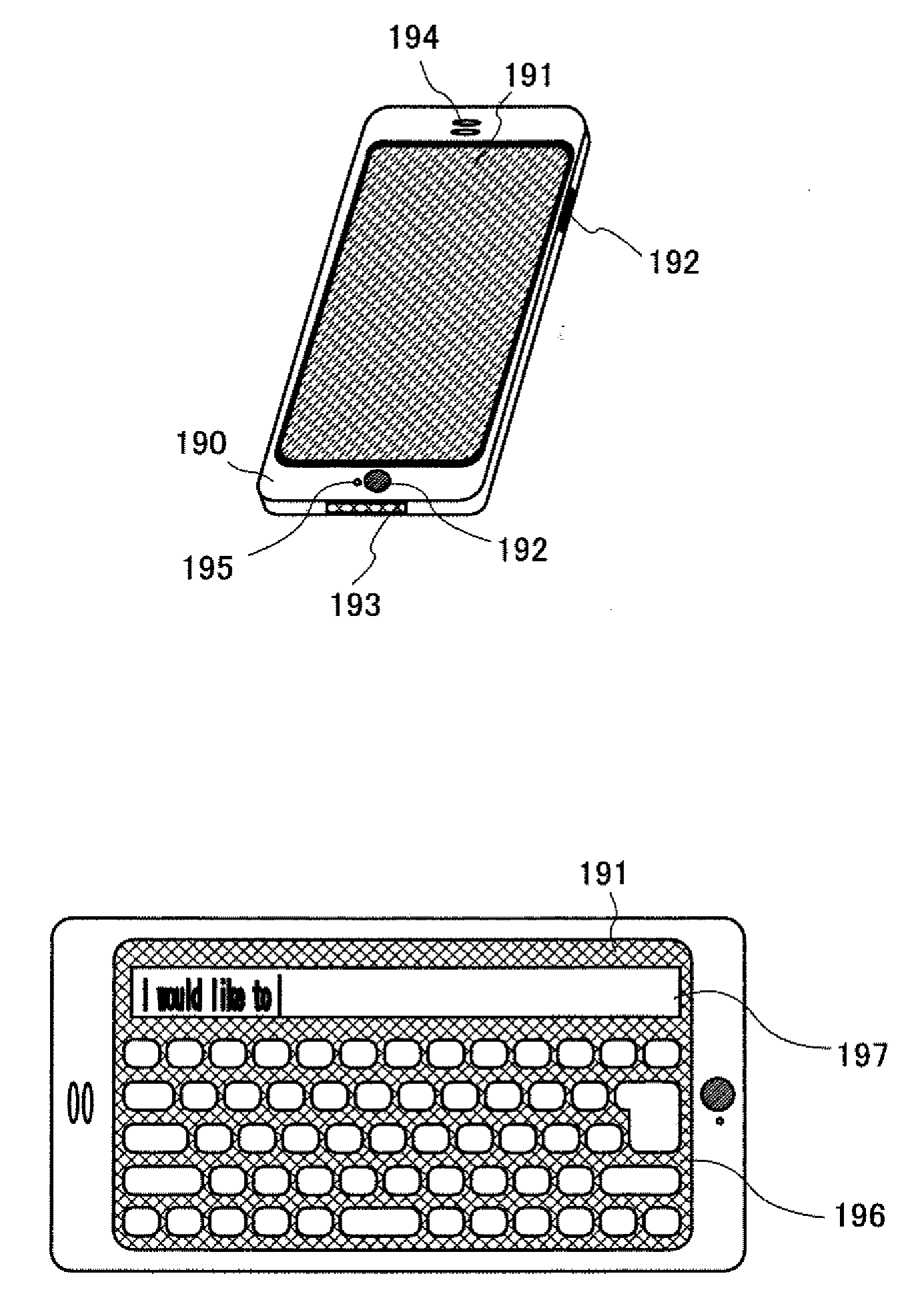

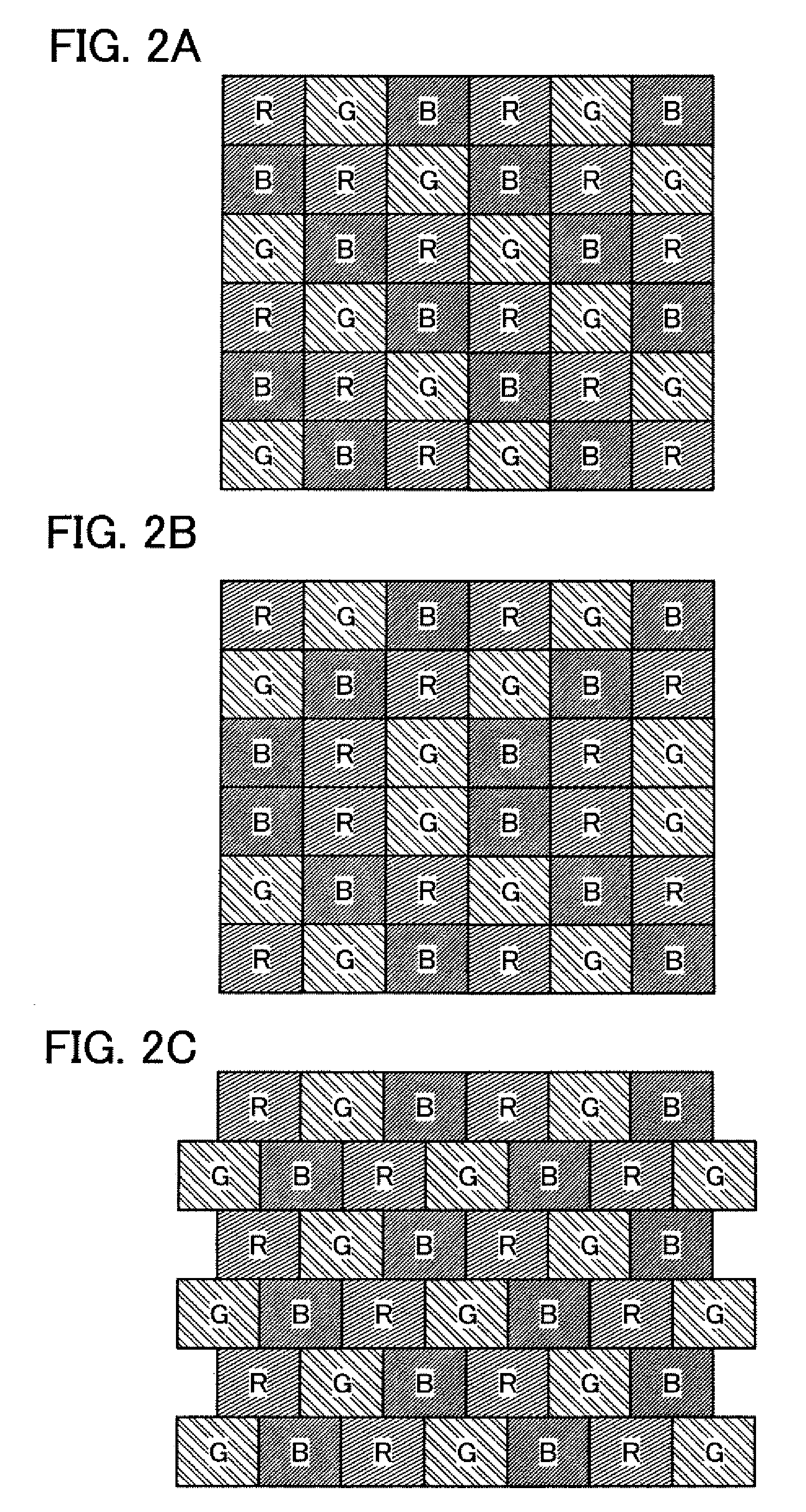

Touch panel and method for driving the same

ActiveUS20100085331A1High sensitivity detectionImprove reading accuracyCathode-ray tube indicatorsDetails for portable computersHigh ReadingsTouchpad

A touch panel having high reading accuracy of an object to be detected is provided. In a method for driving a touch panel which is provided with a photo sensor in a pixel, an image is displayed in a display portion of a touch panel, a detection region is determined by detecting approach or contact of an object to be detected in a state in which the image is displayed, and the object to be detected is read while substantially equalizing the intensity of light of pixels in the detection region per unit time and unit area. The intensity of light of the pixels per unit time and unit area, which is to be substantially equal, is preferably the maximum intensity of light in the detection region before adjustment, more preferably, the intensity of light for white display.

Owner:SEMICON ENERGY LAB CO LTD

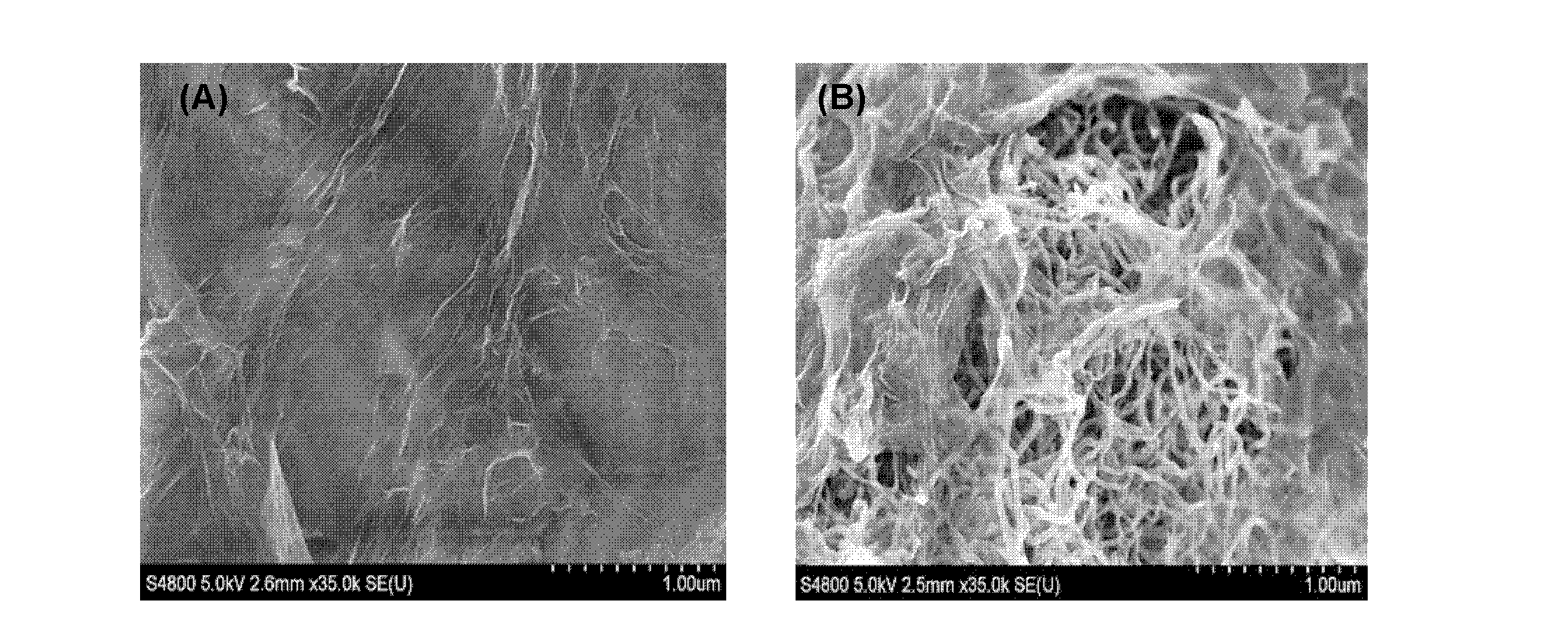

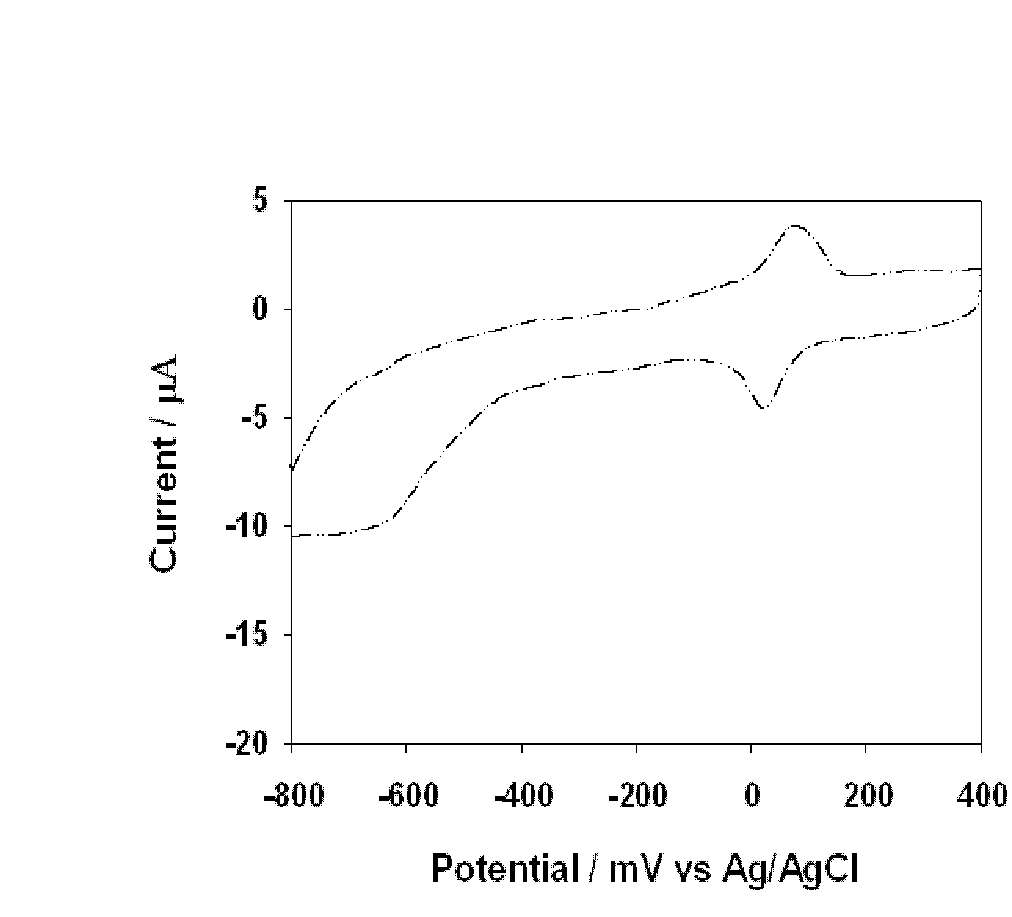

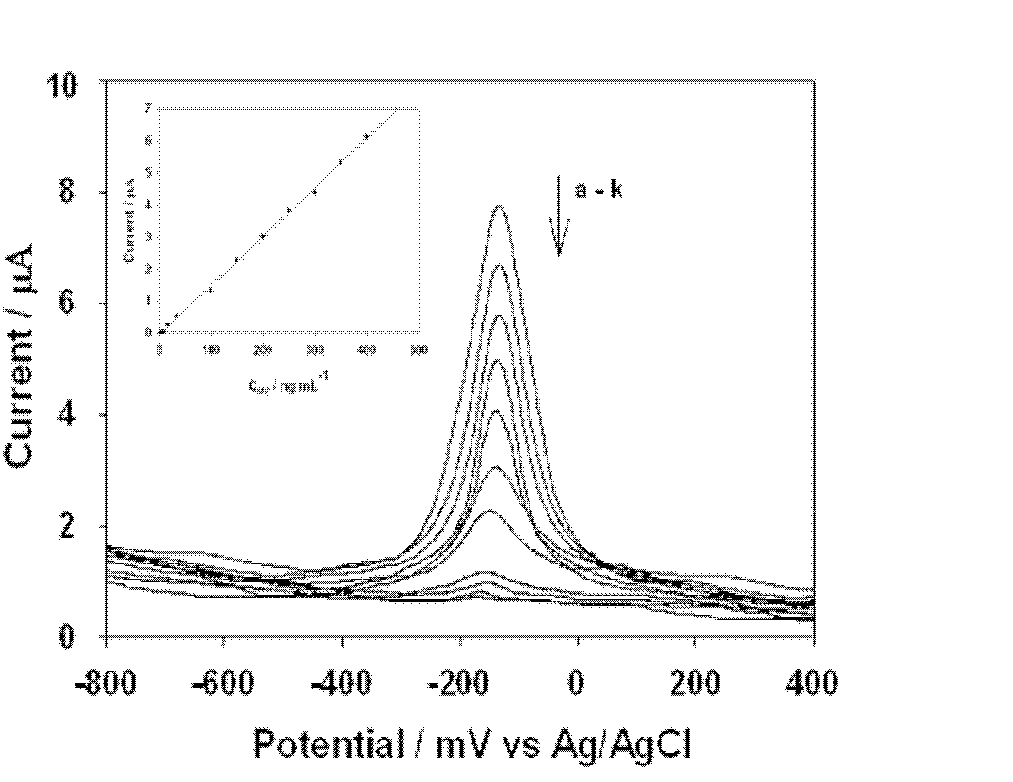

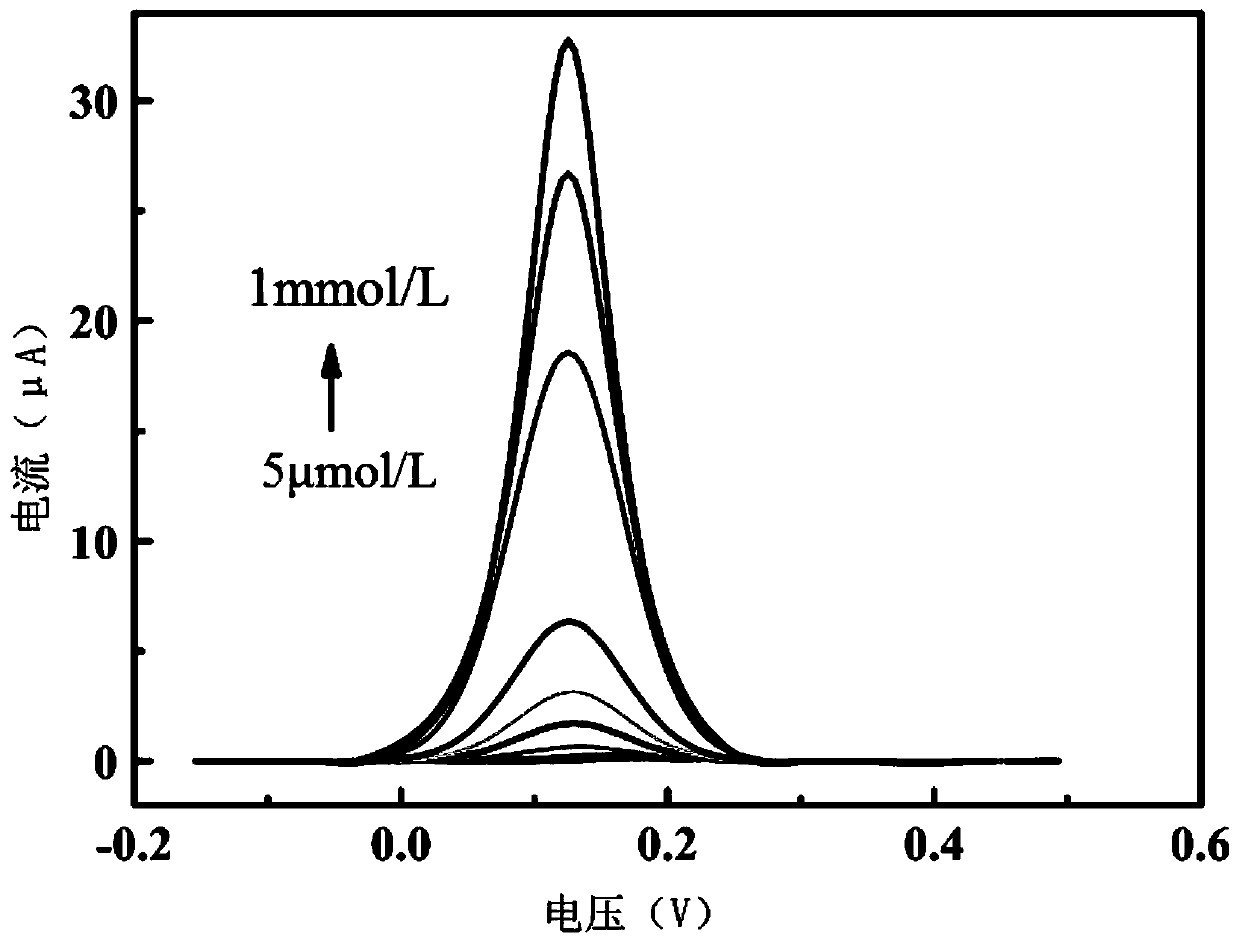

Enzyme-free methyl parathion detection sensor, and preparation and application methods thereof

InactiveCN102636537AHigh Sensitivity DetectionShort preparation timeMaterial electrochemical variablesEnvironmental resistanceCarbon nanotube

The invention discloses an enzyme-free methyl parathion detection sensor, and preparation and application methods thereof. The sensor comprises a three-electrode system, wherein a graphene / carbon nanotube / chitosan deposition modified glassy carbon electrode is used as a working electrode, a platinum sheet is used as a counter electrode, and a calomel electrode is used as a reference electrode. In the detection process, by using the graphene / carbon nanotube / chitosan deposition modified glassy carbon electrode as the working electrode, the platinum sheet as the counter electrode and the calomel electrode as the reference electrode, an electrochemical work station is utilized to determine the content of methyl parathion. The enzyme-free methyl parathion detection sensor disclosed by the invention has the advantages of short preparation time and environment friendliness, is simple to operate, and can be recycled; and the low detection limit is 0.8ng / L. The invention also has the advantages of short sample detection time and simple treatment.

Owner:HUNAN UNIV

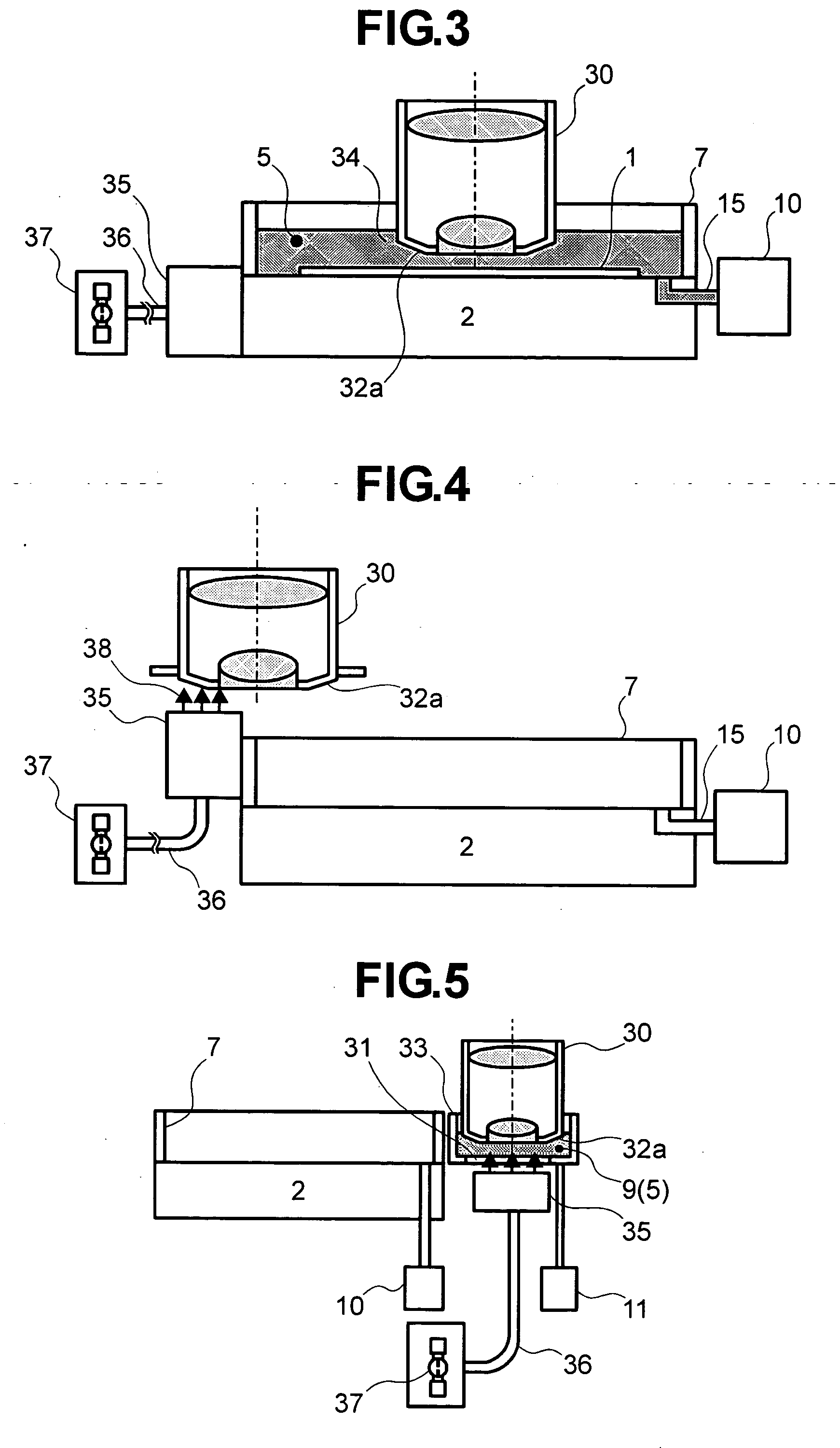

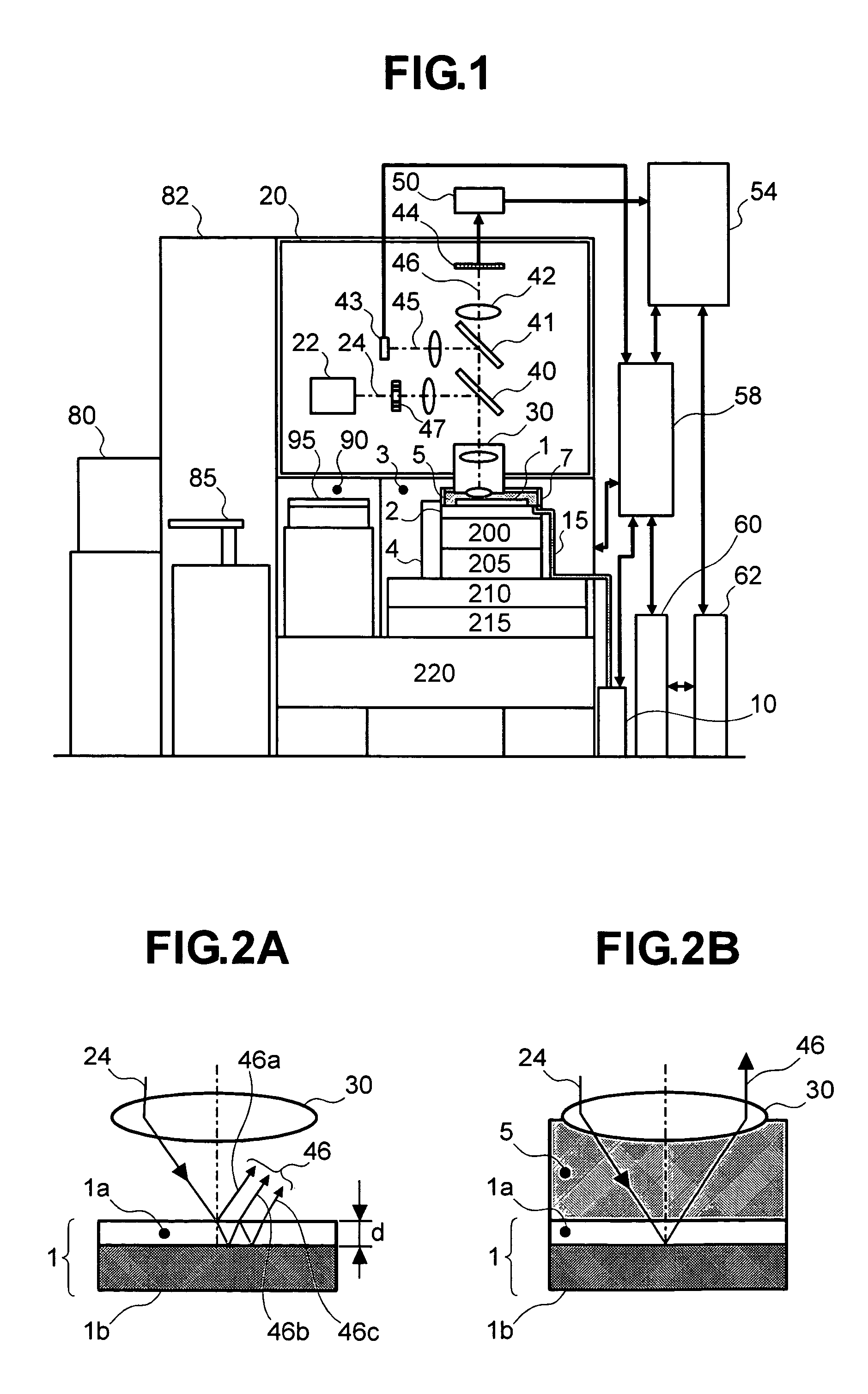

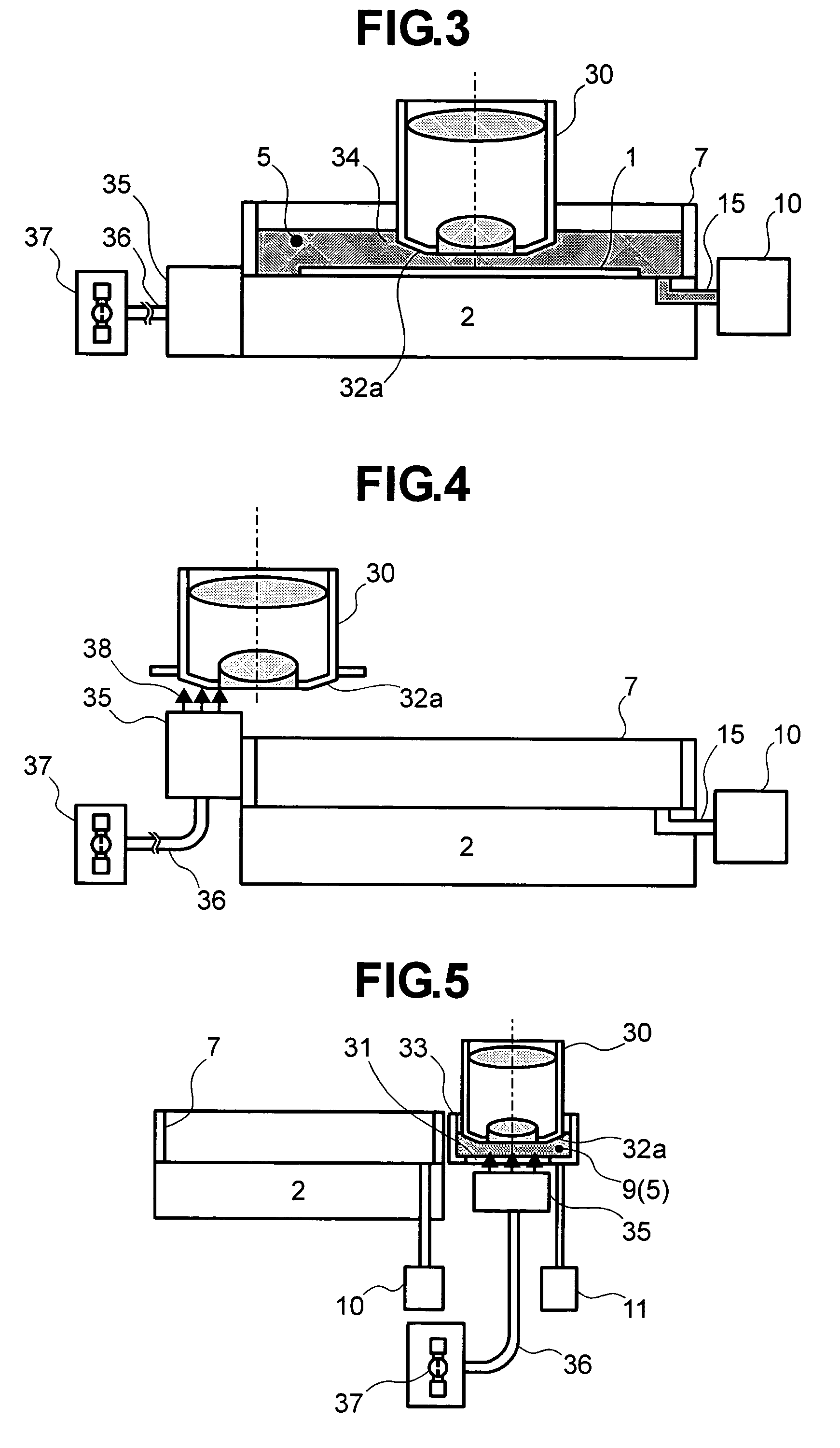

Method and its apparatus for inspecting defects

InactiveUS20050052642A1Increasing effective NAHigh resolutionSemiconductor/solid-state device testing/measurementCharacter and pattern recognitionImage resolutionNumerical aperture

The present invention relates to a high-sensitivity inspection method and apparatus adapted for the fine-structuring of patterns, wherein defect inspection sensitivity is improved using the following technologies: detection optical system is improved in resolution by filling the clearance between an objective lens 30 and a sample 1, with a liquid, and increasing effective NA (Numerical Aperture); and when a transparent interlayer-insulating film is formed on the surface of the sample, amplitude splitting at the interface between the liquid and the insulating film is suppressed for reduction in the unevenness of optical images in brightness due to interference of thin-film, by immersing the clearance between the objective lens and the sample, with a liquid of a refractive index close to that of the transparent film.

Owner:HITACHI HIGH-TECH CORP

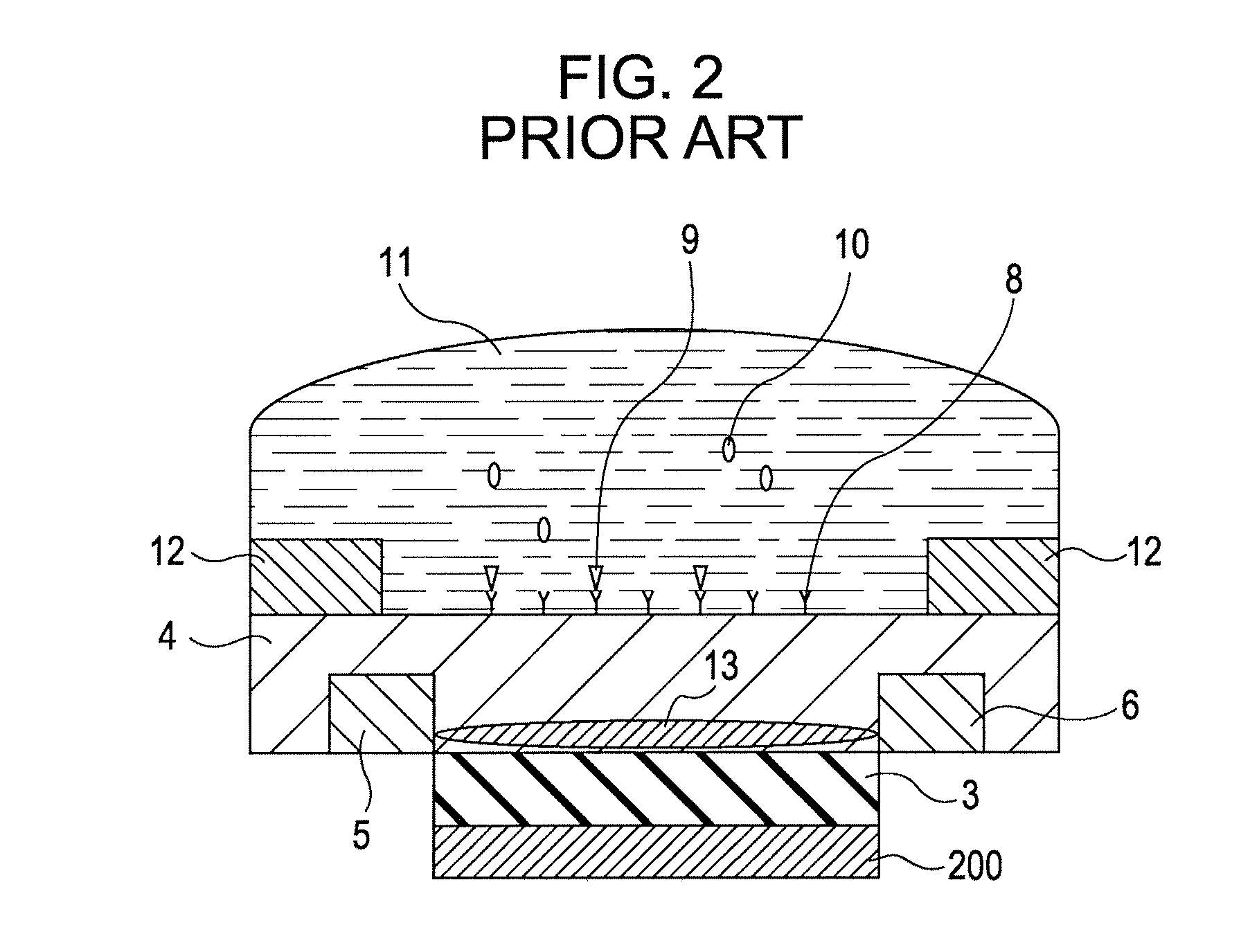

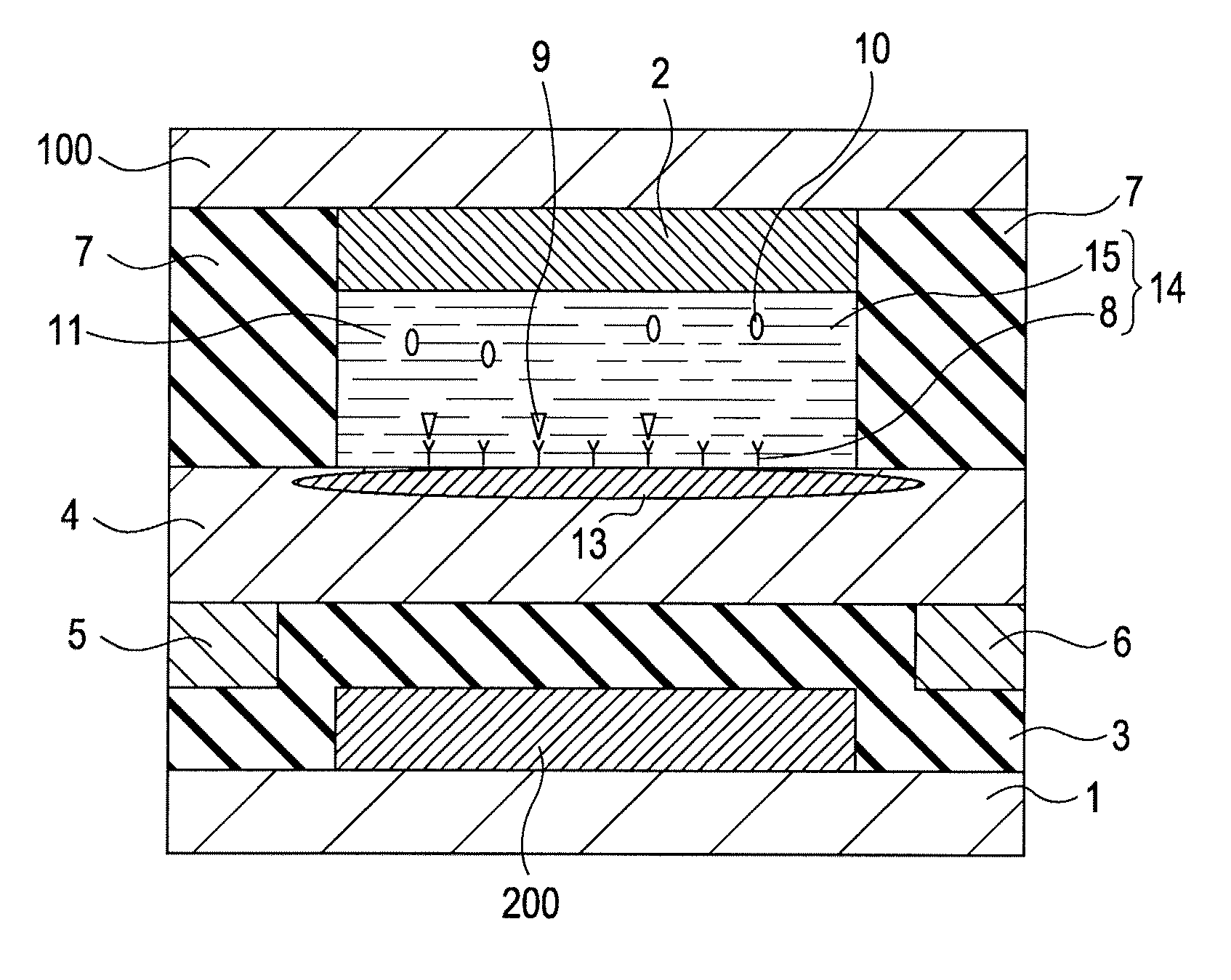

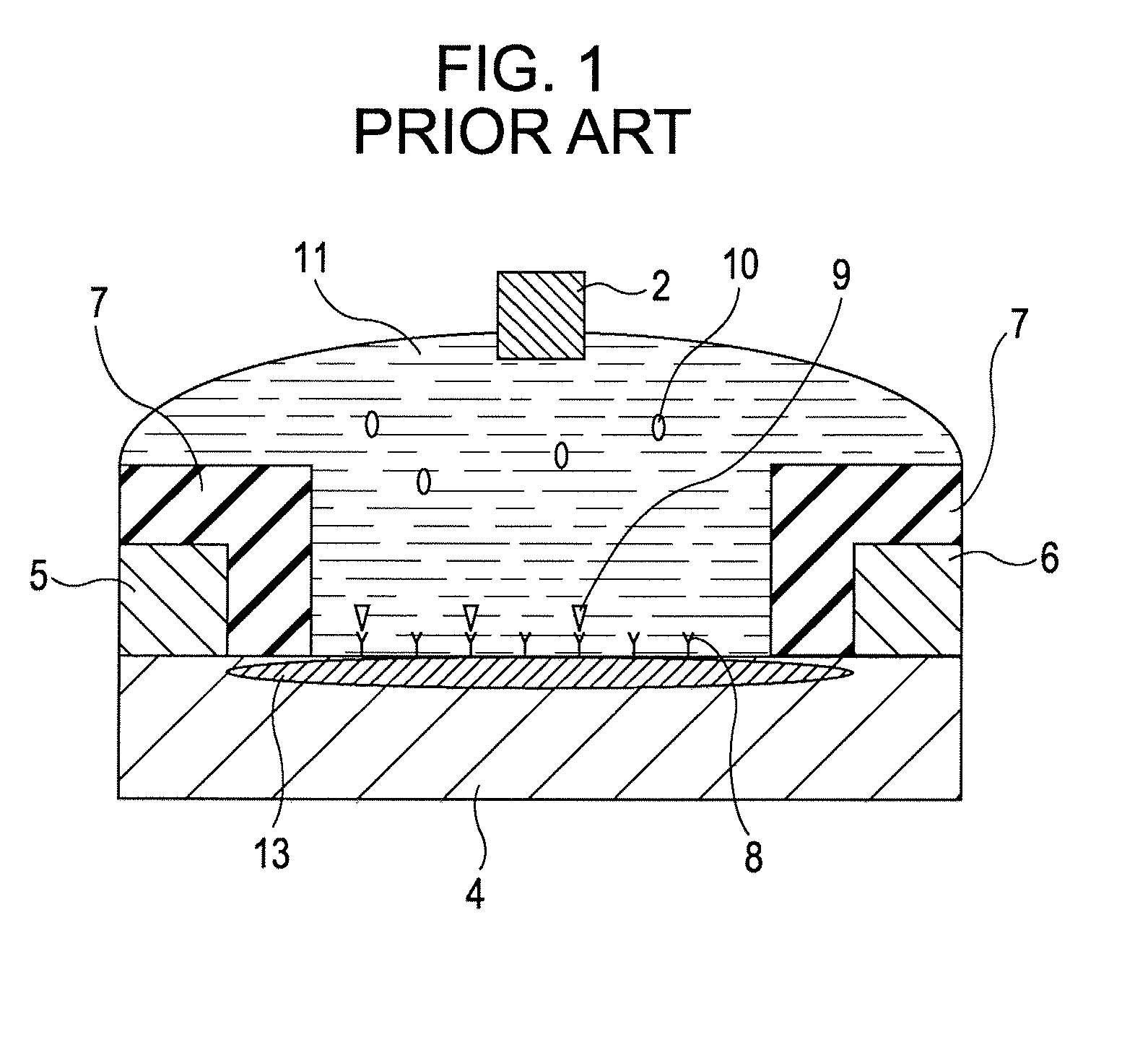

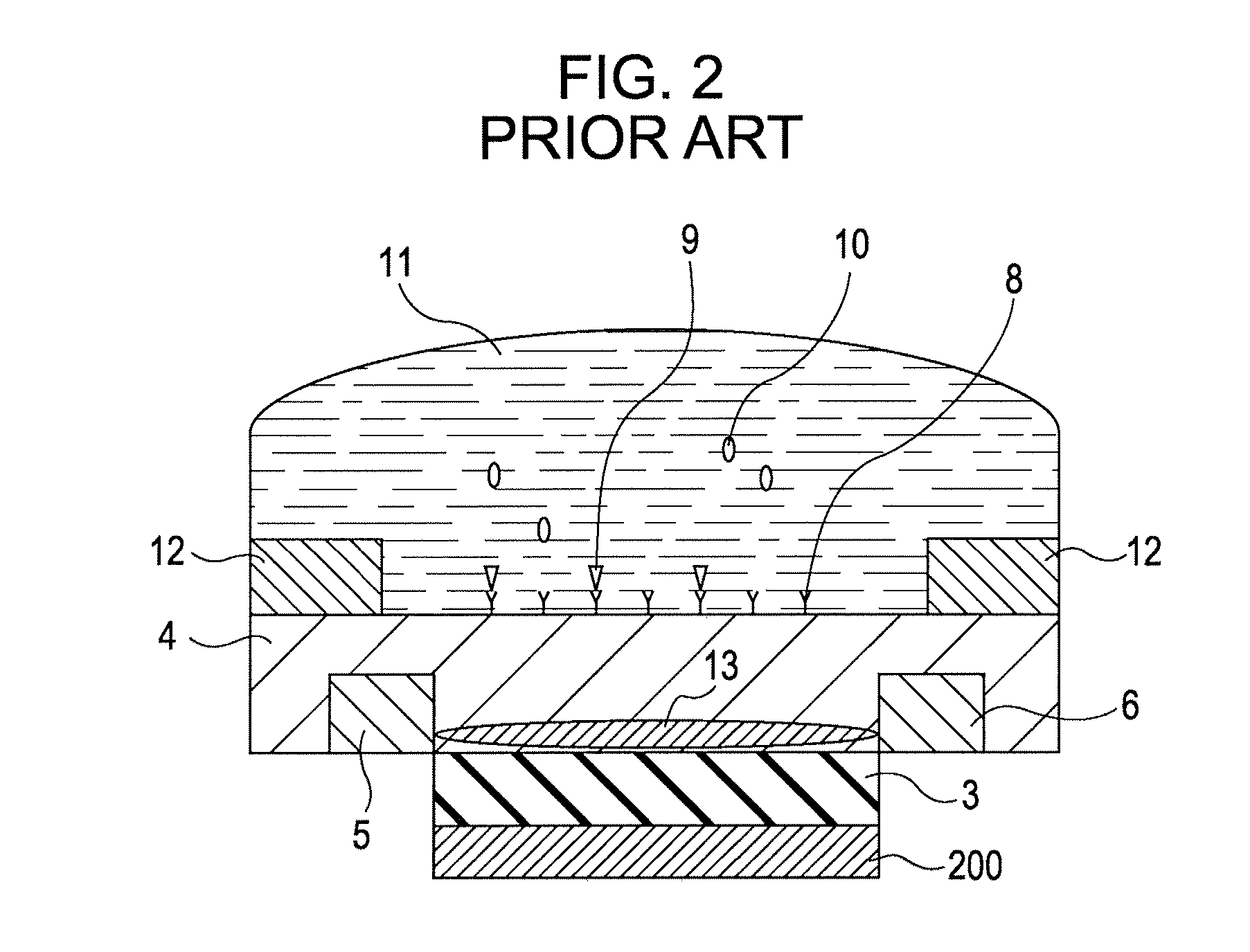

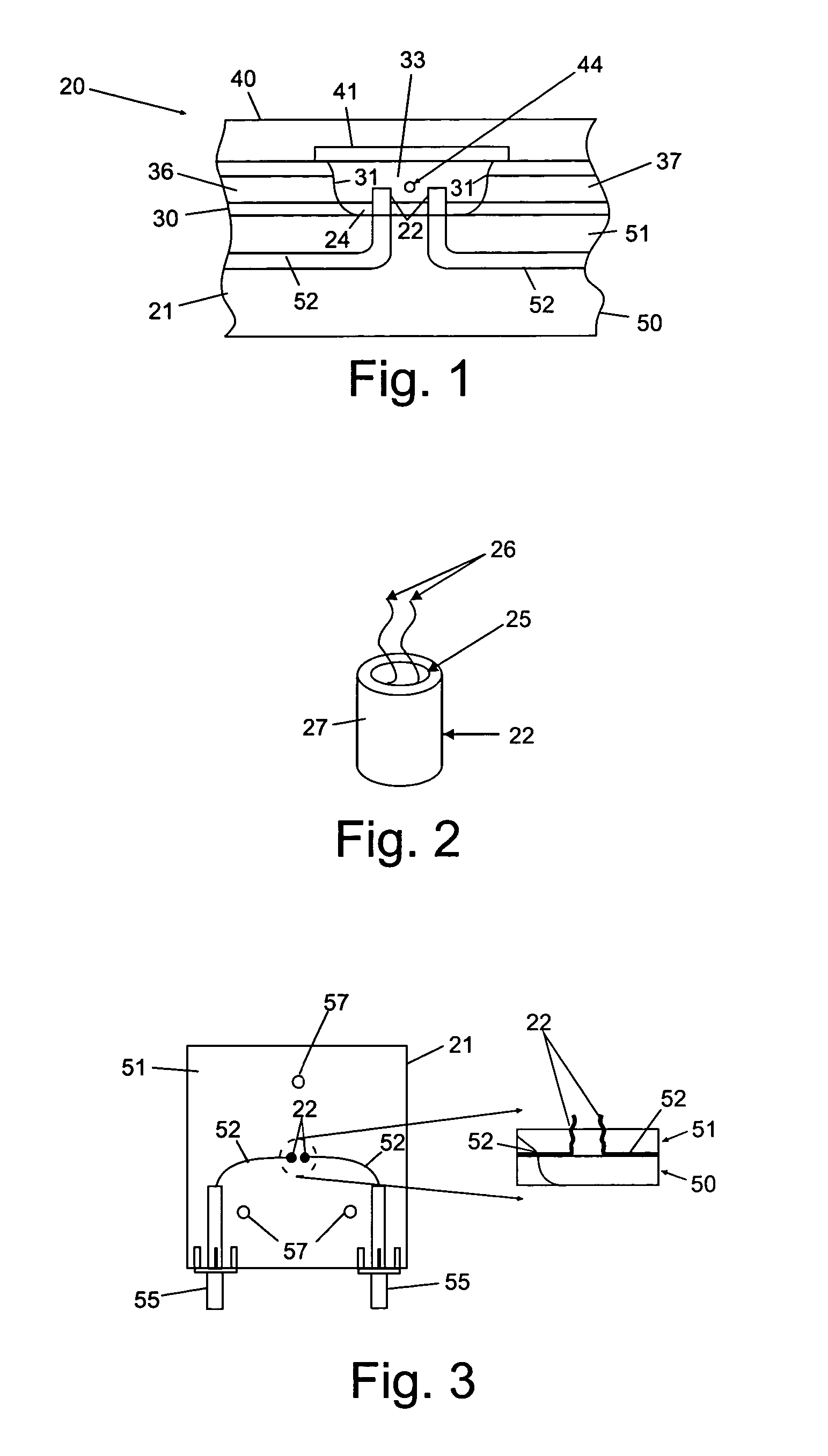

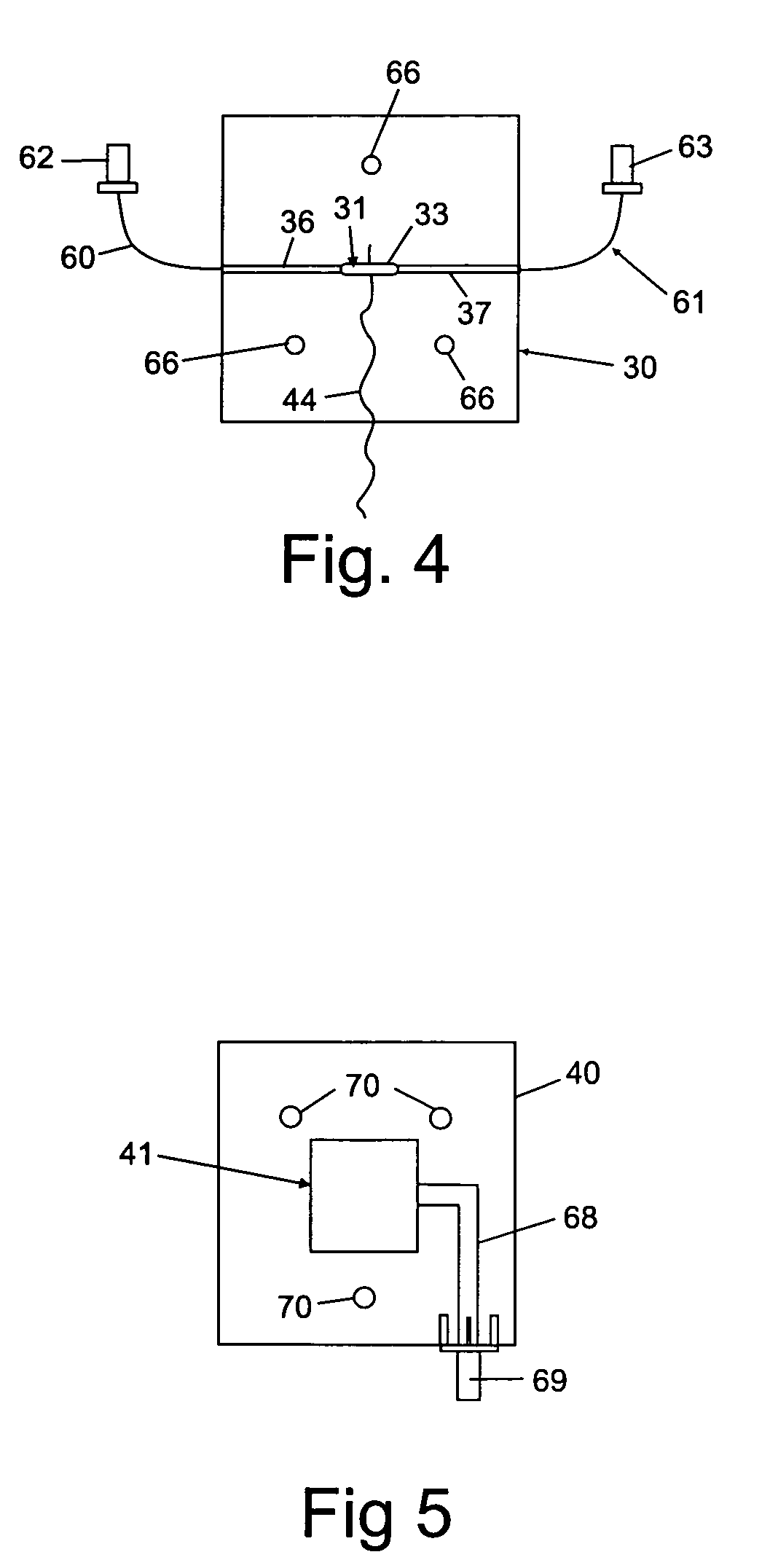

Dual-gate sensor

InactiveUS20070295988A1High sensitivity detectionMeasurement stabilityThyristorMaterial analysis by electric/magnetic meansElectrode ContactSemiconductor

A sensor includes a first gate electrode, a second gate electrode, a semiconductor layer, a gate-insulating layer, a source electrode, a drain electrode, and a sensing portion including an accommodating part and a receiving layer. The first and second gate electrodes are opposed to each other with the sensing portion, the semiconductor layer, and the gate-insulating layer therebetween. One surface of the semiconductor layer is in contact with a surface of the sensing portion, and another surface of the semiconductor layer is in contact with the gate-insulating layer. A surface of the gate-insulating layer is in contact with the second gate electrode. The first gate electrode and the receiving layer are opposed to each other with the accommodating part therebetween. The source and drain electrodes are in contact with the semiconductor layer.

Owner:CANON KK

Dual-gate sensor

InactiveUS7696530B2High sensitivity detectionMeasurement stabilityMaterial analysis by electric/magnetic meansSemiconductor devicesElectrode ContactSemiconductor

A sensor includes a first gate electrode, a second gate electrode, a semiconductor layer, a gate-insulating layer, a source electrode, a drain electrode, and a sensing portion including an accommodating part and a receiving layer. The first and second gate electrodes are opposed to each other with the sensing portion, the semiconductor layer, and the gate-insulating layer therebetween. One surface of the semiconductor layer is in contact with a surface of the sensing portion, and another surface of the semiconductor layer is in contact with the gate-insulating layer. A surface of the gate-insulating layer is in contact with the second gate electrode. The first gate electrode and the receiving layer are opposed to each other with the accommodating part therebetween. The source and drain electrodes are in contact with the semiconductor layer.

Owner:CANON KK

Method and its apparatus for inspecting defects

InactiveUS7599545B2Increasing effective NAHigh resolutionSemiconductor/solid-state device testing/measurementCharacter and pattern recognitionImage resolutionThin-film interference

The present invention relates to a high-sensitivity inspection method and apparatus adapted for the fine-structuring of patterns, wherein defect inspection sensitivity is improved using the following technologies: detection optical system is improved in resolution by filling the clearance between an objective lens 30 and a sample 1, with a liquid, and increasing effective NA (Numerical Aperture); and when a transparent interlayer-insulating film is formed on the surface of the sample, amplitude splitting at the interface between the liquid and the insulating film is suppressed for reduction in the unevenness of optical images in brightness due to interference of thin-film, by immersing the clearance between the objective lens and the sample, with a liquid of a refractive index close to that of the transparent film.

Owner:HITACHI HIGH-TECH CORP

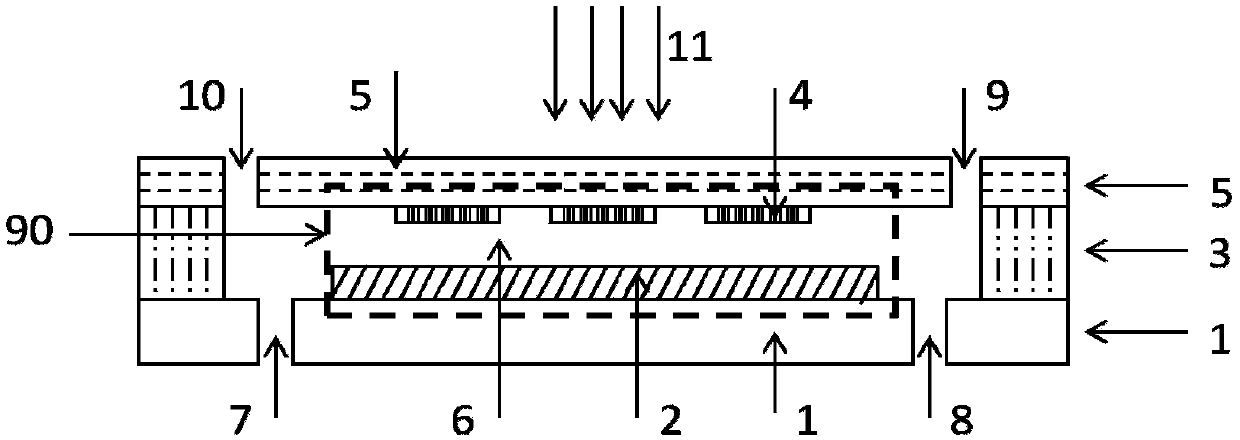

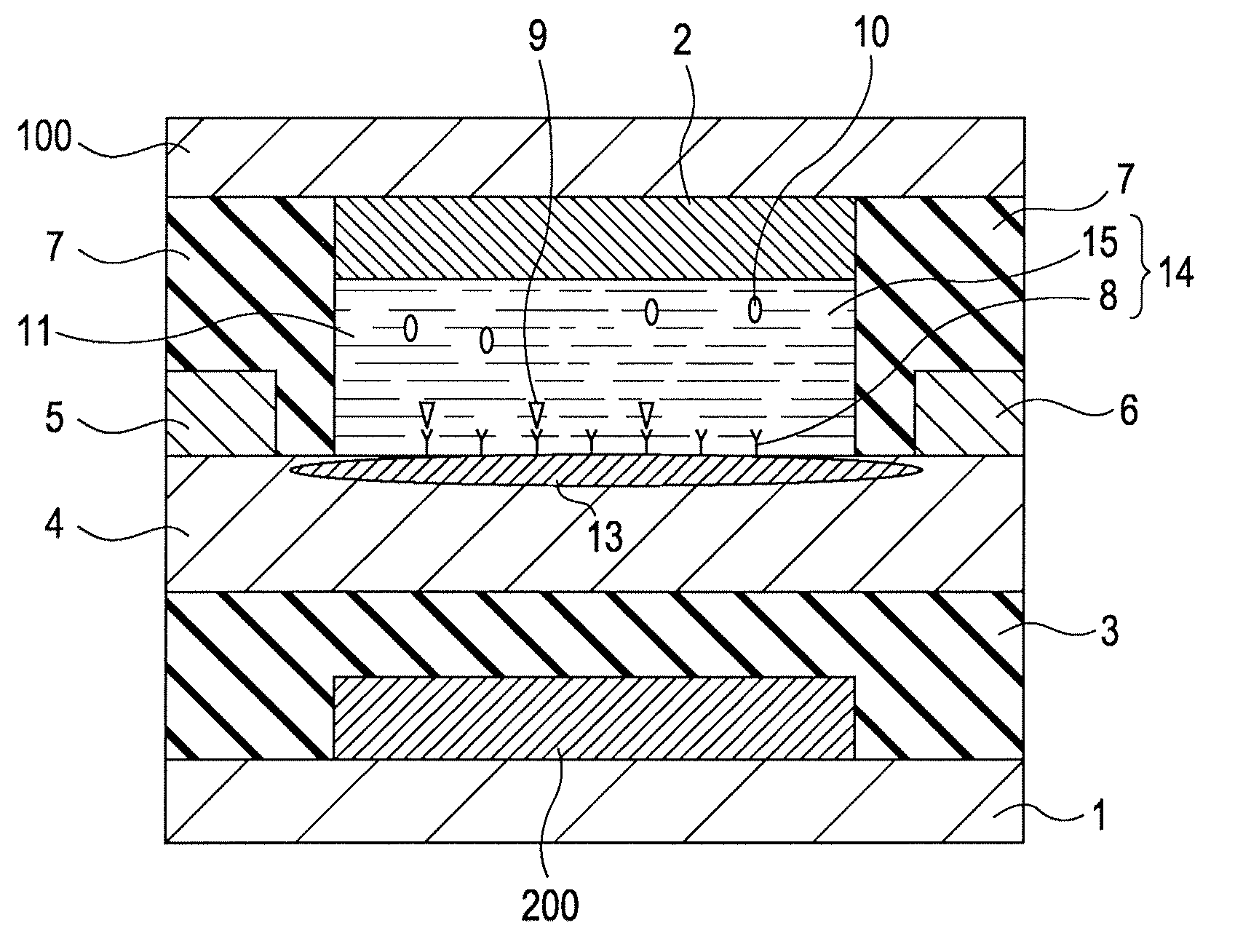

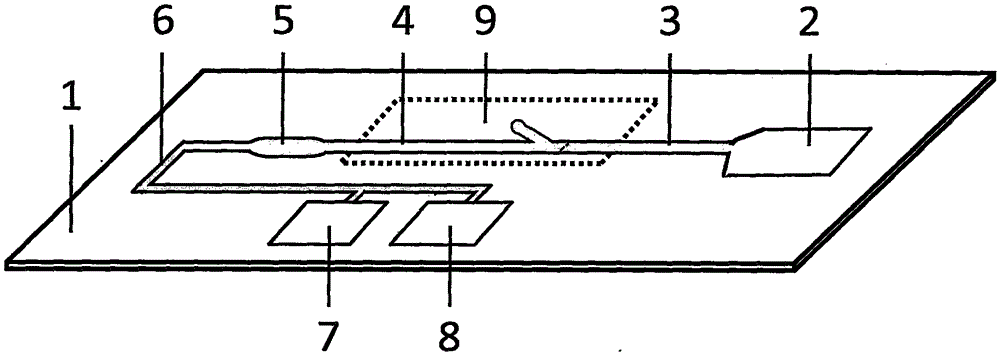

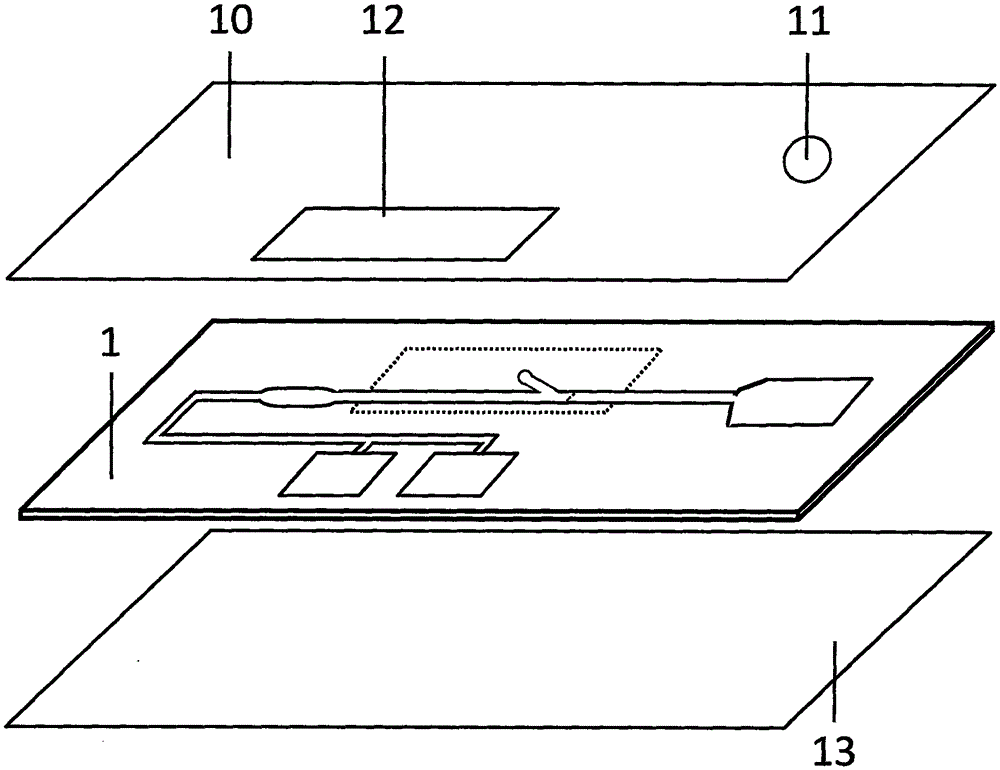

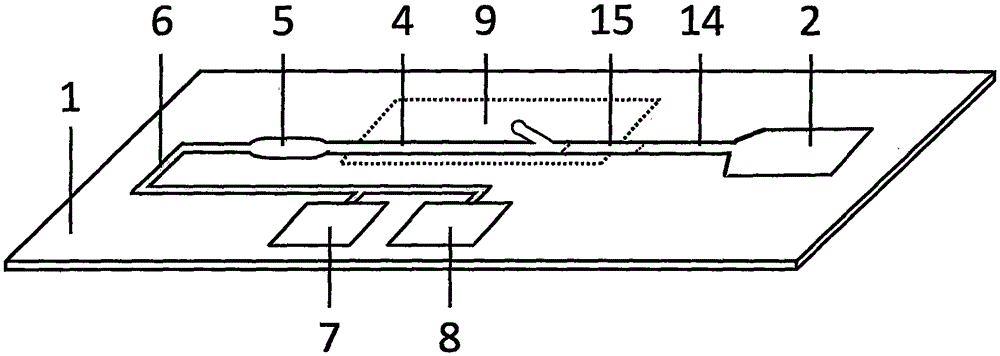

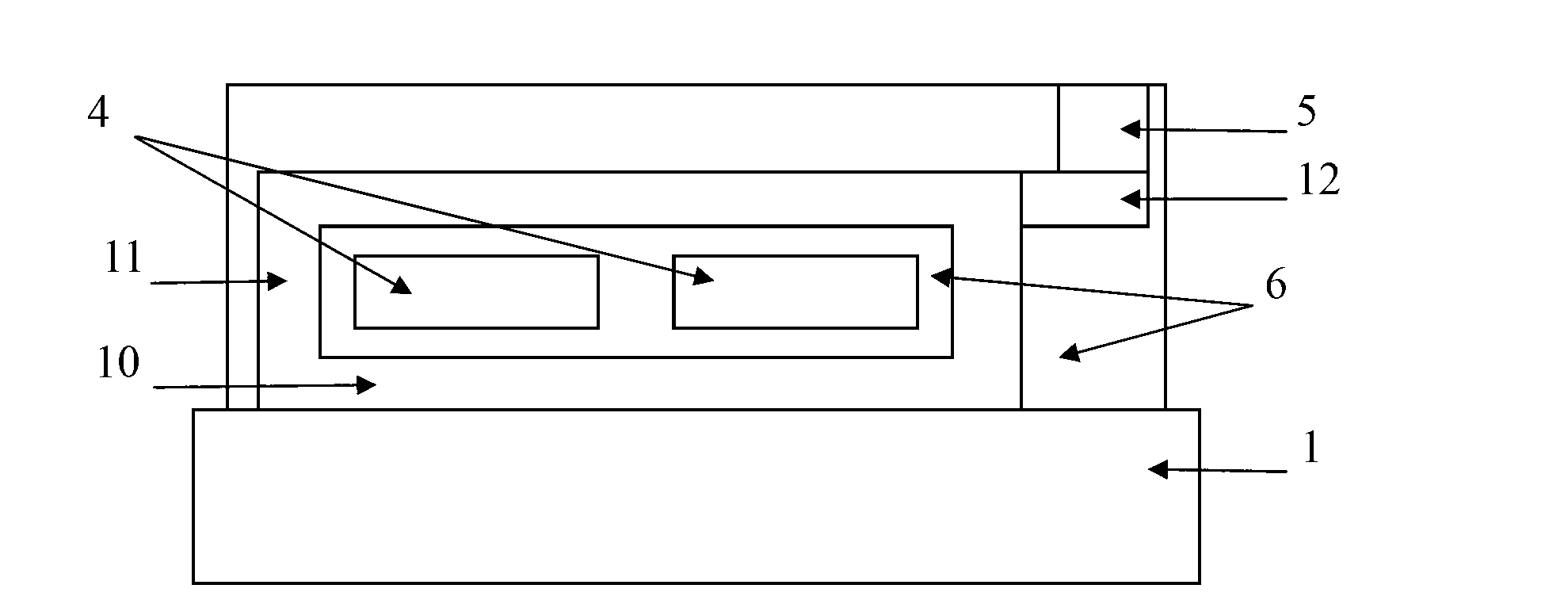

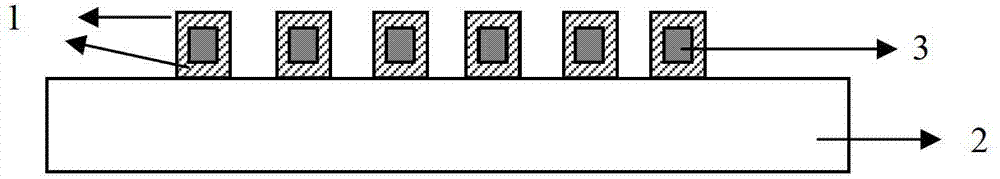

Magnetic particle direct chemiluminiscence microfluidic chip for whole blood sample testing

ActiveCN105259163AAnalyte fastAnalyte AccurateChemiluminescene/bioluminescenceLaboratory glasswaresLuminescenceWhole blood sample

The invention relates to a magnetic particle direct chemiluminiscence microfluidic chip for whole blood sample testing. The chip is composed of a top adhesive tape (10), a chip substrate (1) and a bottom adhesive tape (13); the chip substrate comprises a filtering area (2), a coating area (3), a cleaning area (4), a testing area (5), a cleaning liquid storing pool (7), a luminescence substrate liquid storing pool (8) and a waste liquid pool (11), wherein the testing area is connected with the cleaning liquid storing pool and the luminescence substrate liquid storing pool through liquid releasing channels (9) respectively; the top adhesive tape comprises a sample feeding opening (11) and a cleaning liquid storing pool demising hole (12).

Owner:SHENZHEN HUAMAIXINGWEI MEDICAL TECH CO LTD

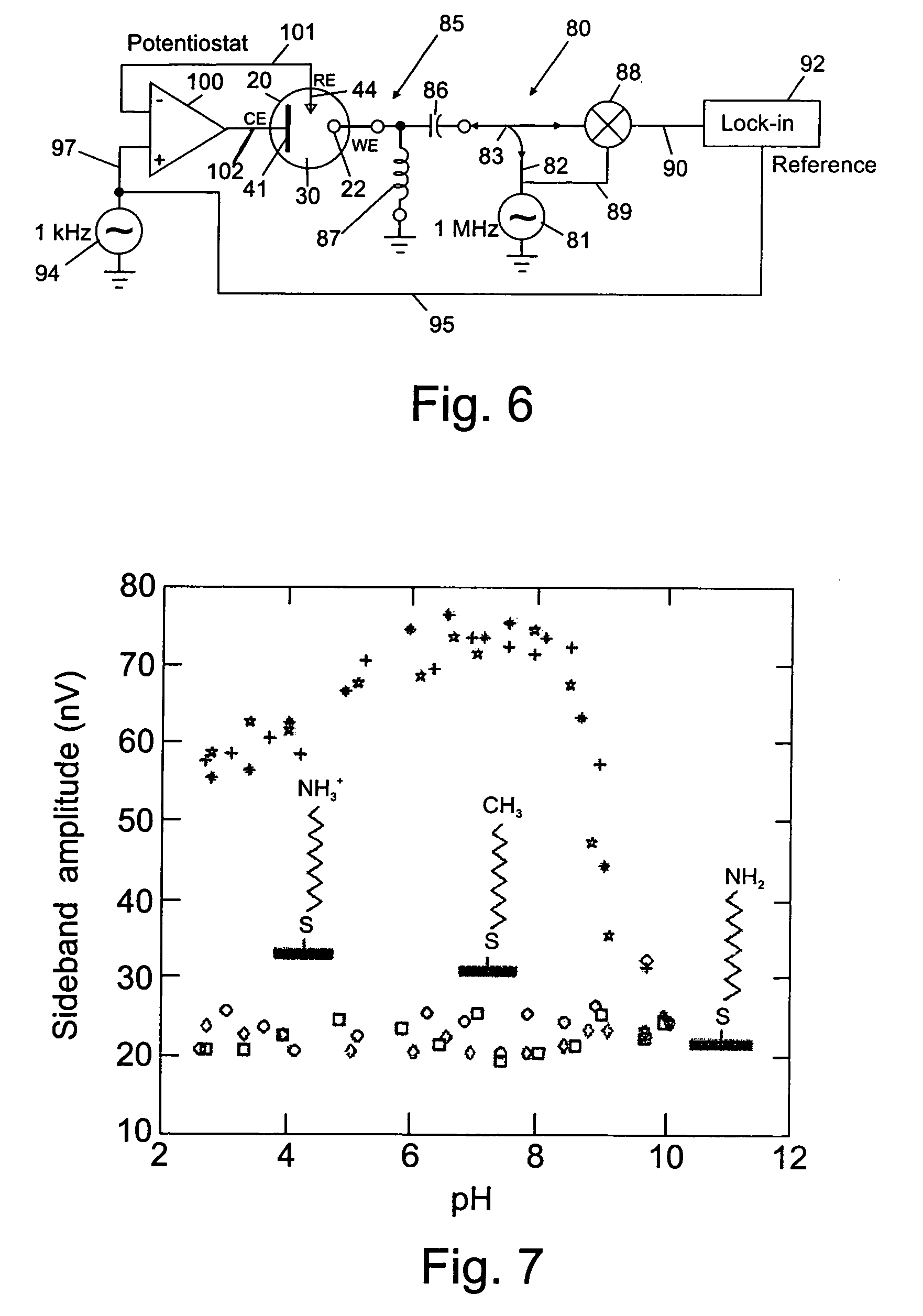

Direct radio-frequency detection of nucleotide hybridization at microelectrodes

ActiveUS7183055B2High sensitivity detectionWell mixedBioreactor/fermenter combinationsMaterial nanotechnologyCapacitanceNucleotide

Radio-frequency (RF) excitation is used for direct detection of hybridization events at microelectrodes with surface-attached DNA oligomers. A homodyne reflectometer operates on a high frequency carrier to detect the presence of a low-frequency modulation signal. Without non-linearities in an interface, the modulation signal is not impressed upon the carrier signal. As such, the reflectometer can sensitively measure changes in dielectric properties without interference from other sources of capacitance / resistance unrelated to the reaction at the surface.

Owner:WISCONSIN ALUMNI RES FOUND

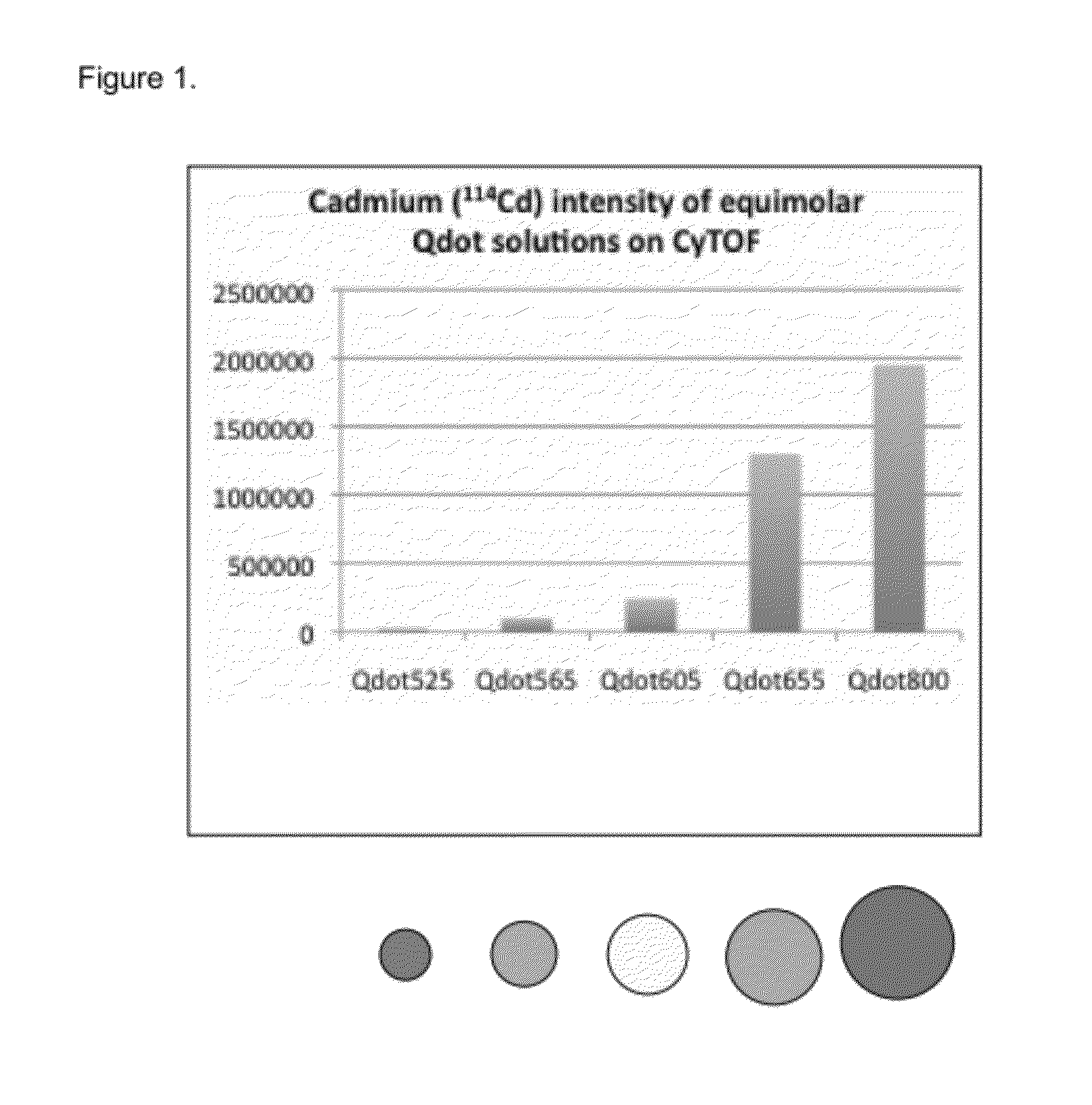

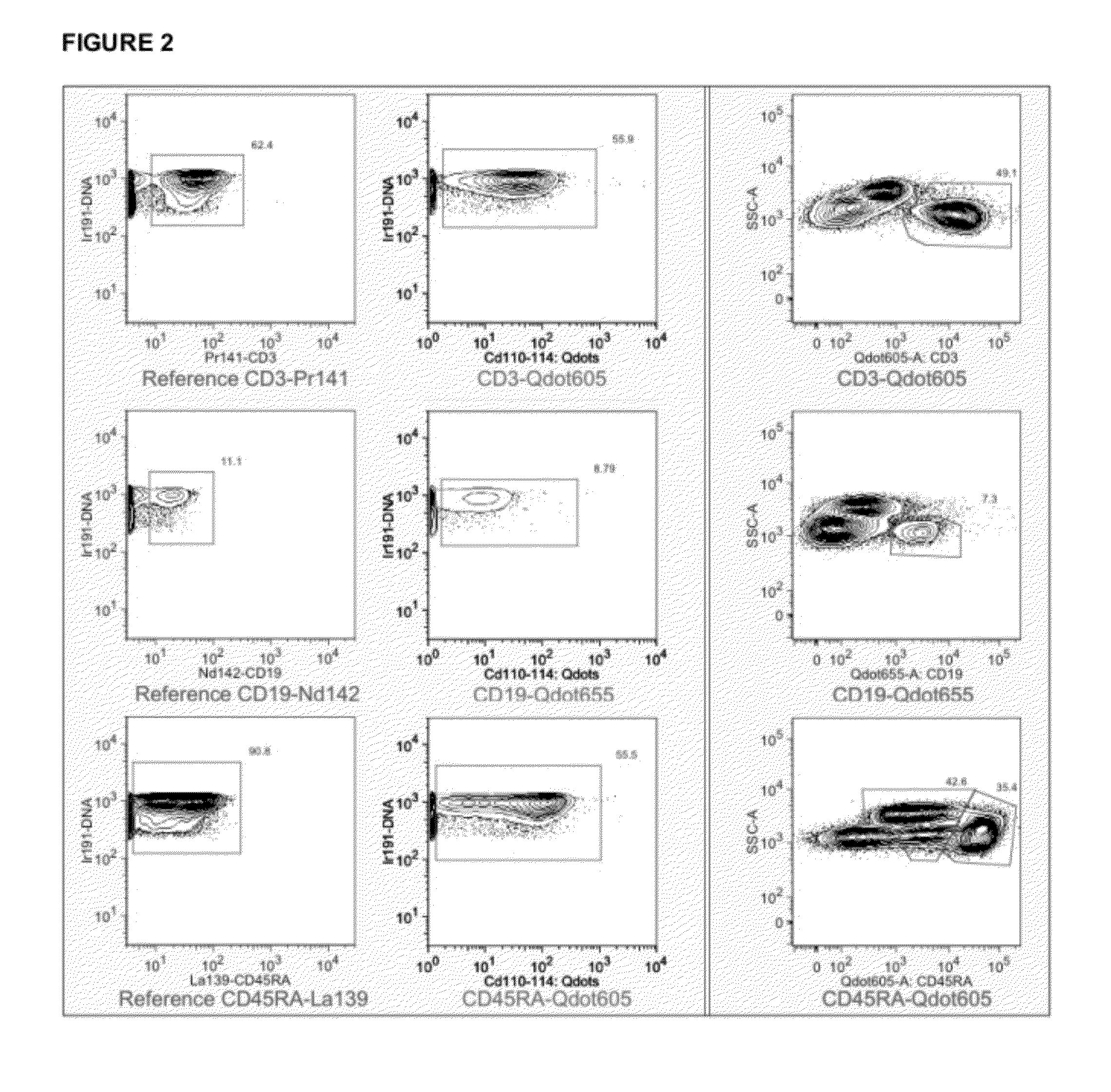

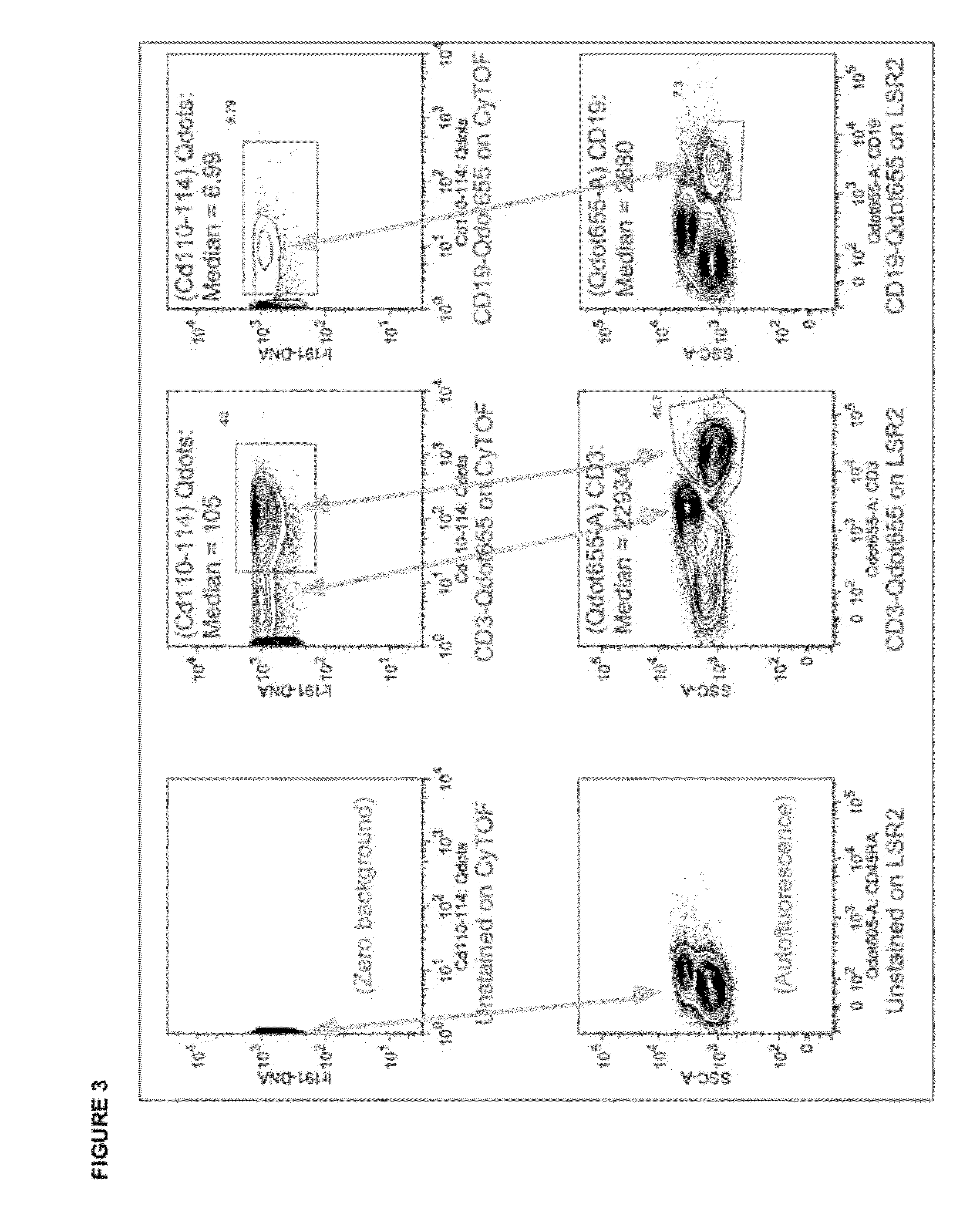

Mass Dots: Nanoparticle Isotope Tags

InactiveUS20120178183A1Improve bindingMinimizing detrimental effectSugar derivativesMaterial analysis by electric/magnetic meansAptamerNanoparticle

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

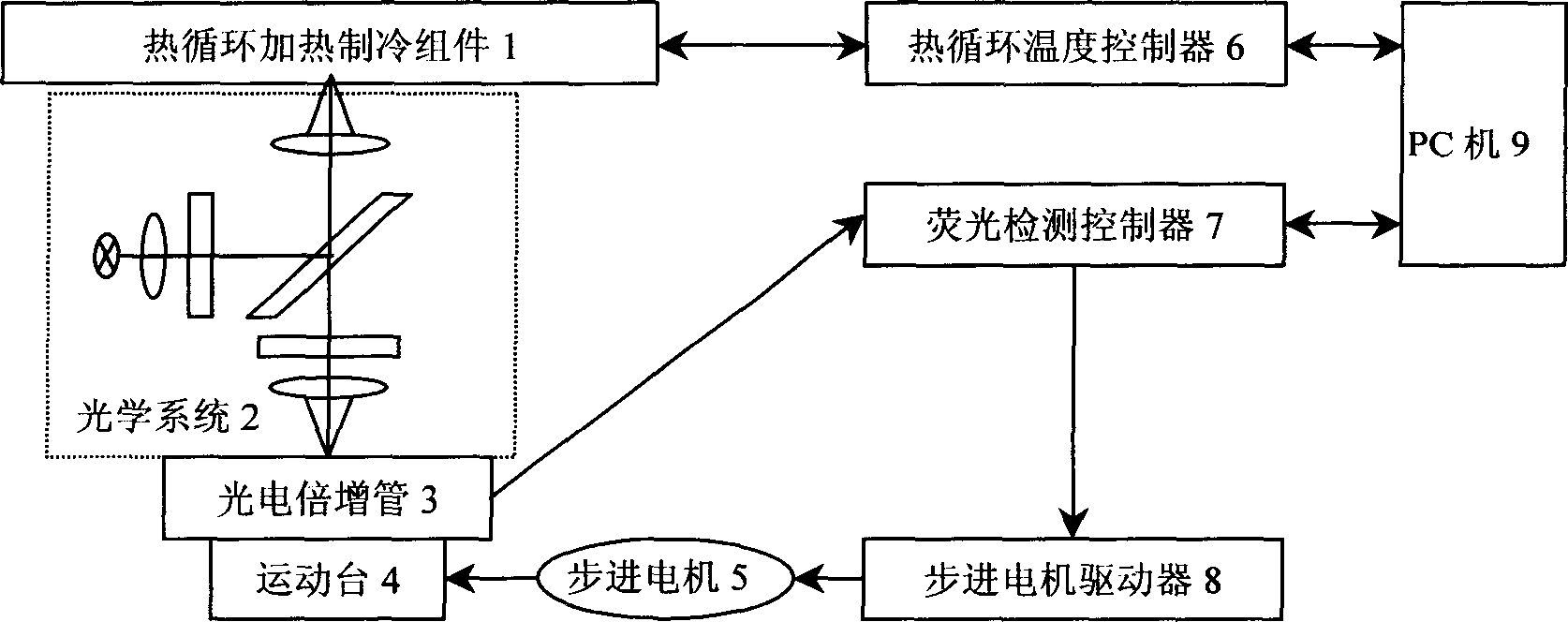

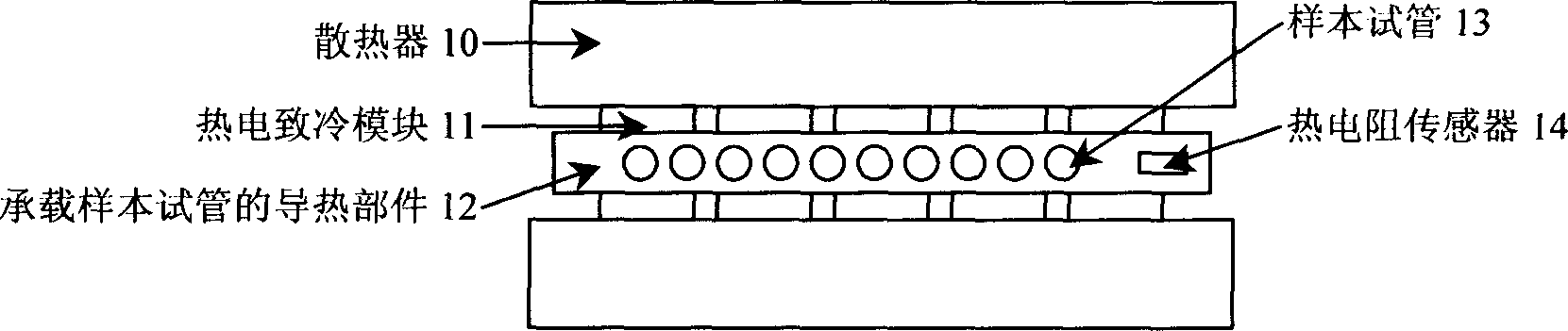

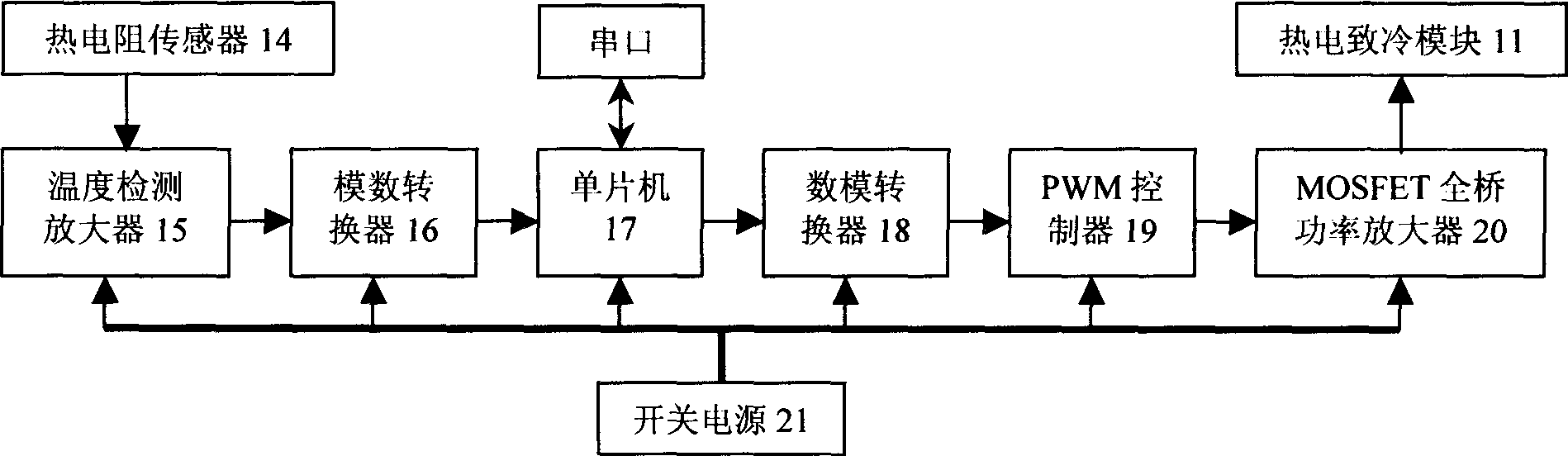

Heating cycle controlled polymerase chain reaction biological detection system

InactiveCN1800411ARich requirementsFlexible useMicrobiological testing/measurementFluorescence/phosphorescenceCycle controlFluorescence

The invention relates to a heat cycle control polyase chain reaction biological detection system which is formed by a heat cycle heating freezing component (1), an optical system (2), an electron-multiplier phototube (3), a moving table (4), a step motor (5), a heat cycle temperature controller (6), a fluorescence detecting controller (7), a step motor driver (8) and a PC machine (9). It adopts fluorescence real-time detecting mode to analyze the augmentation of PCR form; it adopts thermoelectric semiconductor cryogenic technique to achieve PCR course and uses high-fidelity photoelectric system to detect the fluorescence signal; it adopts micro machine as upper machine to do heat cycle craft controlling and adopts light intensity to real-time detect the PCR biology detecting system.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

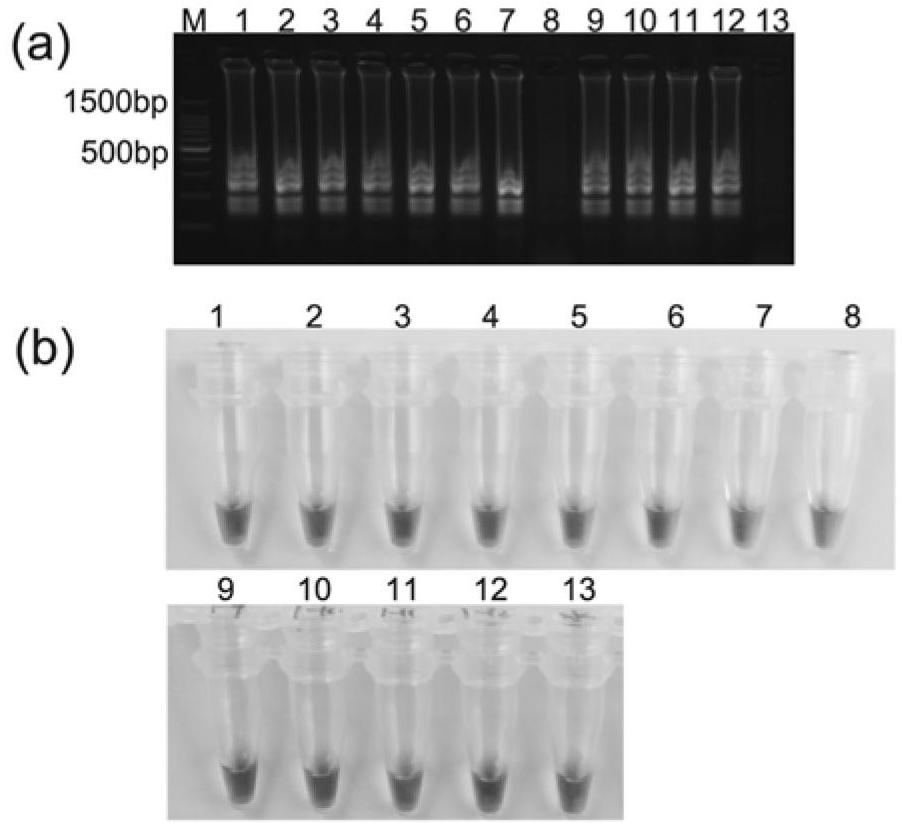

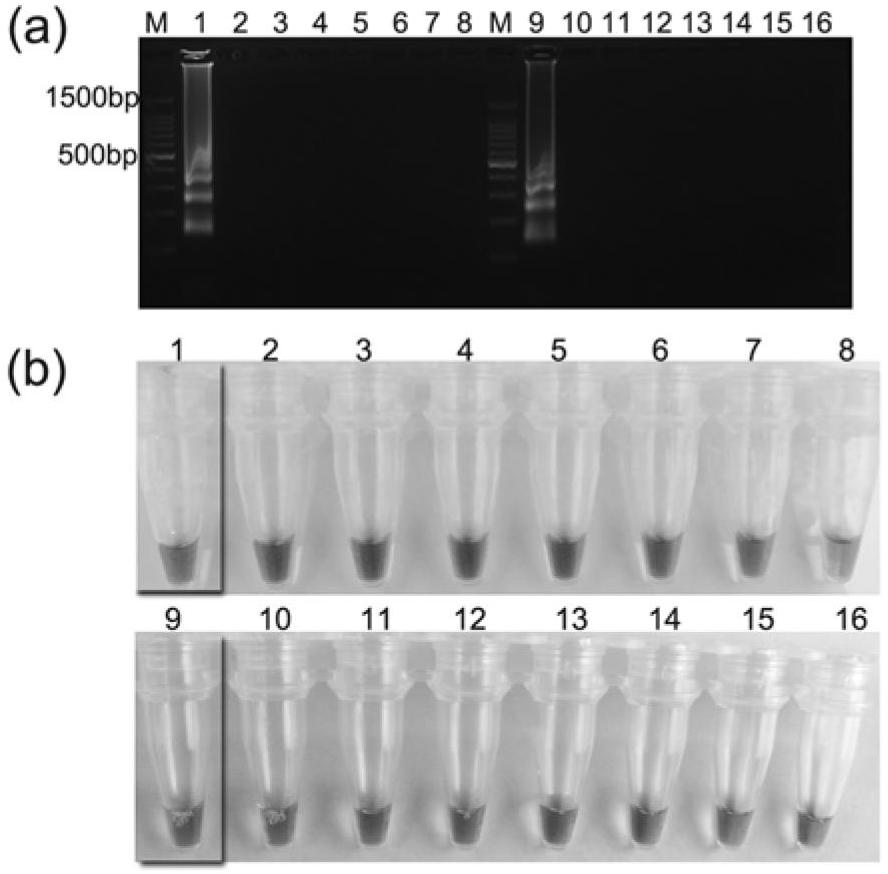

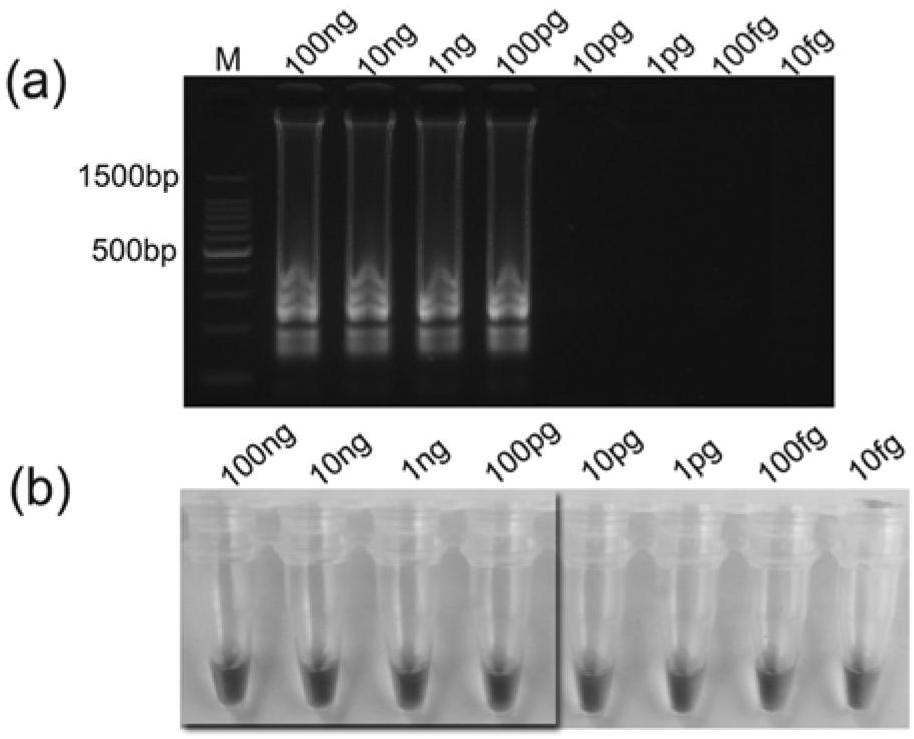

Loop-mediated isothermal amplification (LAMP) primer composition for detecting phytophthora rot and application thereof

ActiveCN102643925AGood practicalityHigh application valueMicrobiological testing/measurementMicroorganism based processesGenetic engineeringLoop-mediated isothermal amplification

The invention belongs to the field of a genetic engineering, and relates to a loop-mediated isothermal amplification (LAMP) primer composition for detecting phytophthora rot and an application thereof. The primer composition comprises a forward inner primer FIP showed in SEQ ID NO.1, a backward inner primer BIP showed in SEQ ID NO.2, a forward outer primer F3 showed in SEQ ID NO.3, a backward outer primer B3 showed in SEQ ID NO.4, and a reverse annular primer LB showed in SEQ ID NO.5. The LAMP primer composition can be applied to detection or identification of phytophthora rot. The LAMP primer composition has the advantages of good sensibility for specificity, rapid amplification, high efficiency and simple identification in the application of detecting phytophthora rot.

Owner:NANJING AGRICULTURAL UNIVERSITY

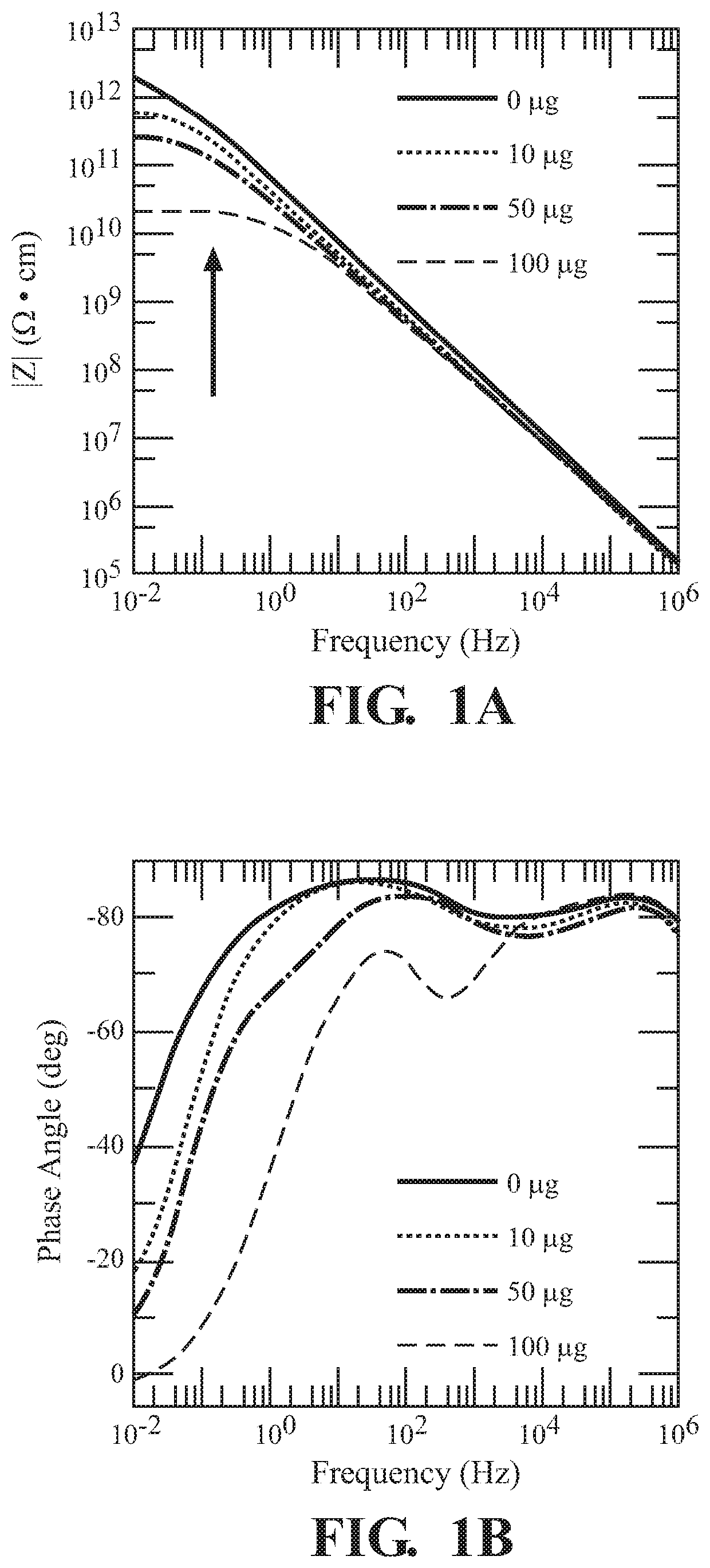

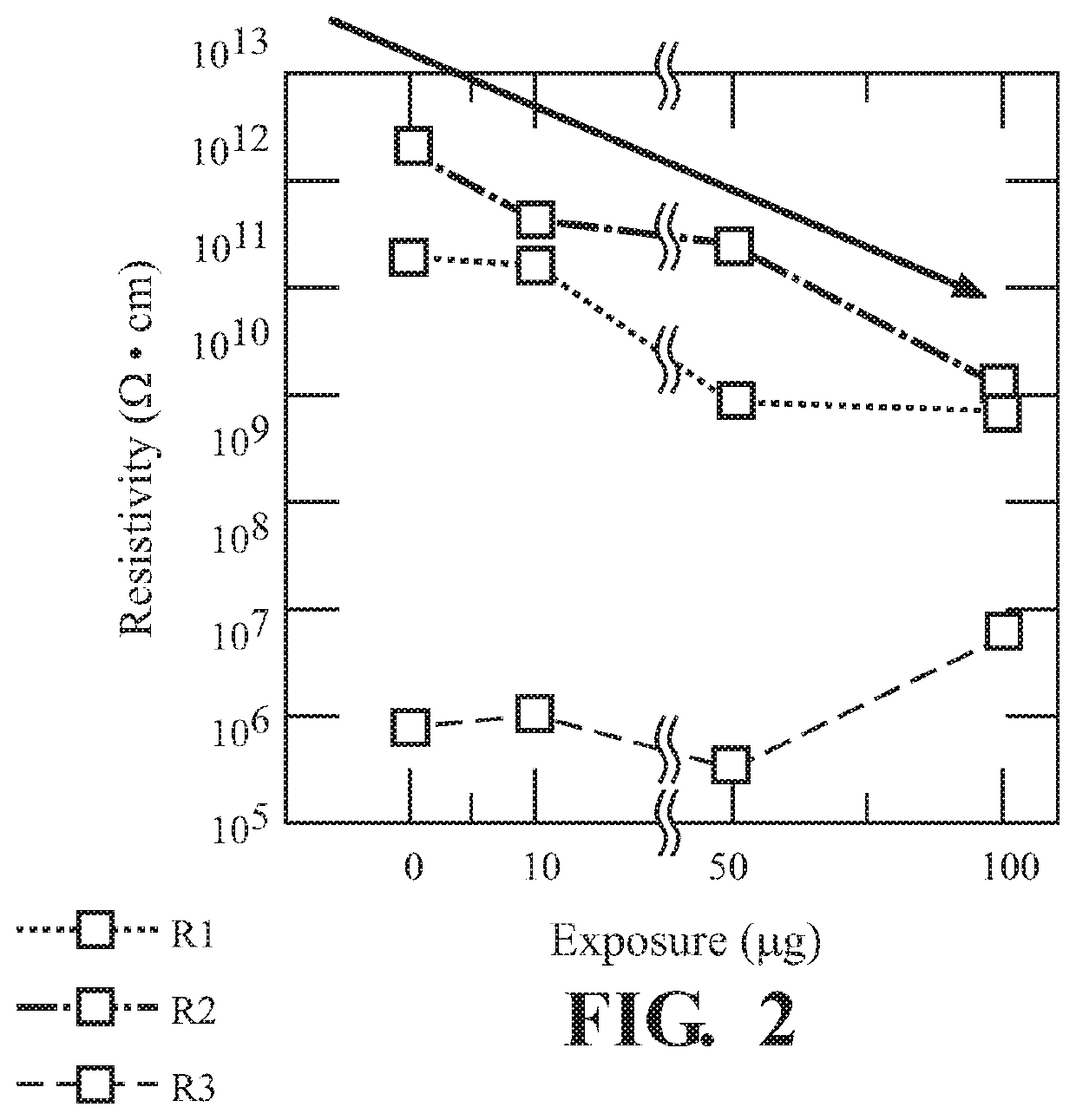

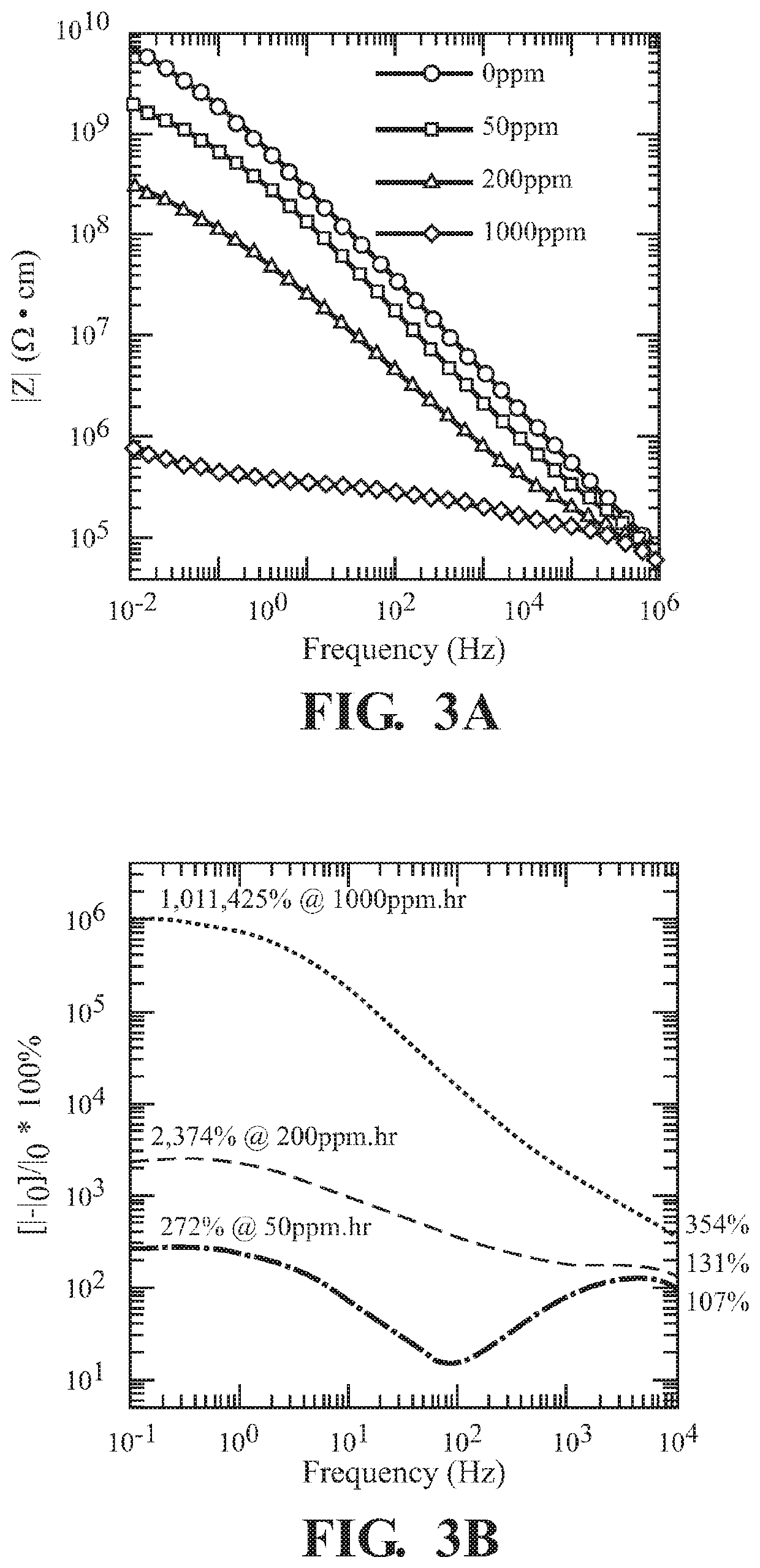

Use of metal-organic frameworks and metal oxides for sensing chemicals using electrical impedance spectroscopy

ActiveUS10495592B1The implementation process is simpleHigh sensitivity detectionFuel testingTesting metalsMetal-organic frameworkChemical agent

Provided are processes for the sensitive detection of the presence of, absence of, and optionally the identity of, one or more chemical agents. The processes use the binding of chemical agents to a metal organic framework or metal oxide / hydroxide electrically connected to a pair of electrodes to detect low levels of chemical in a sample. By exposing the surface of the metal organic framework or the surface of the metal oxide / hydroxide to the chemicals and then measuring changes in impedance magnitude and / or phase shift through electrical impedance spectroscopy, the presence of a chemical agent is readily detected.

Owner:UNITED STATES OF AMERICA

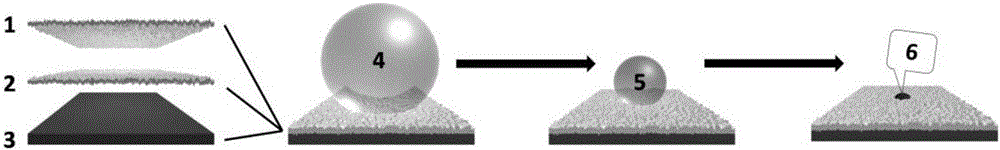

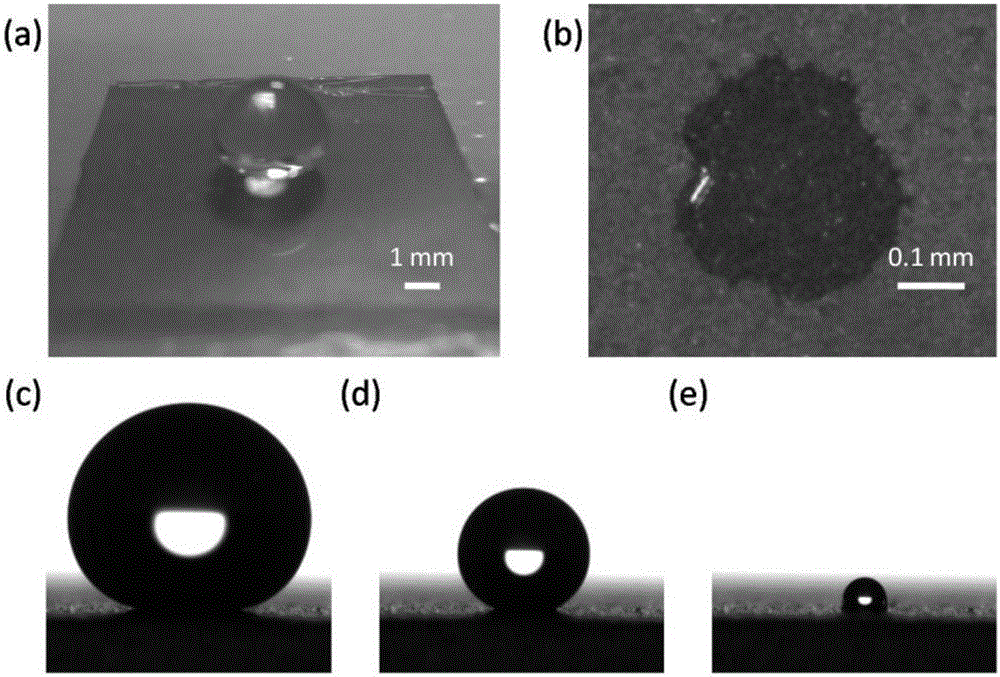

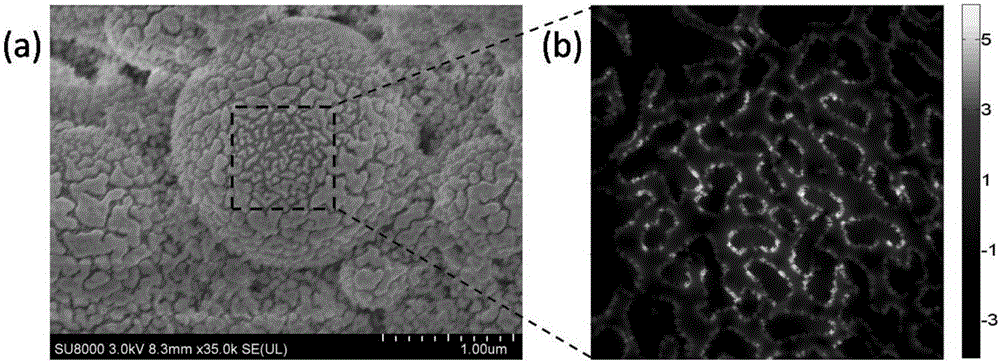

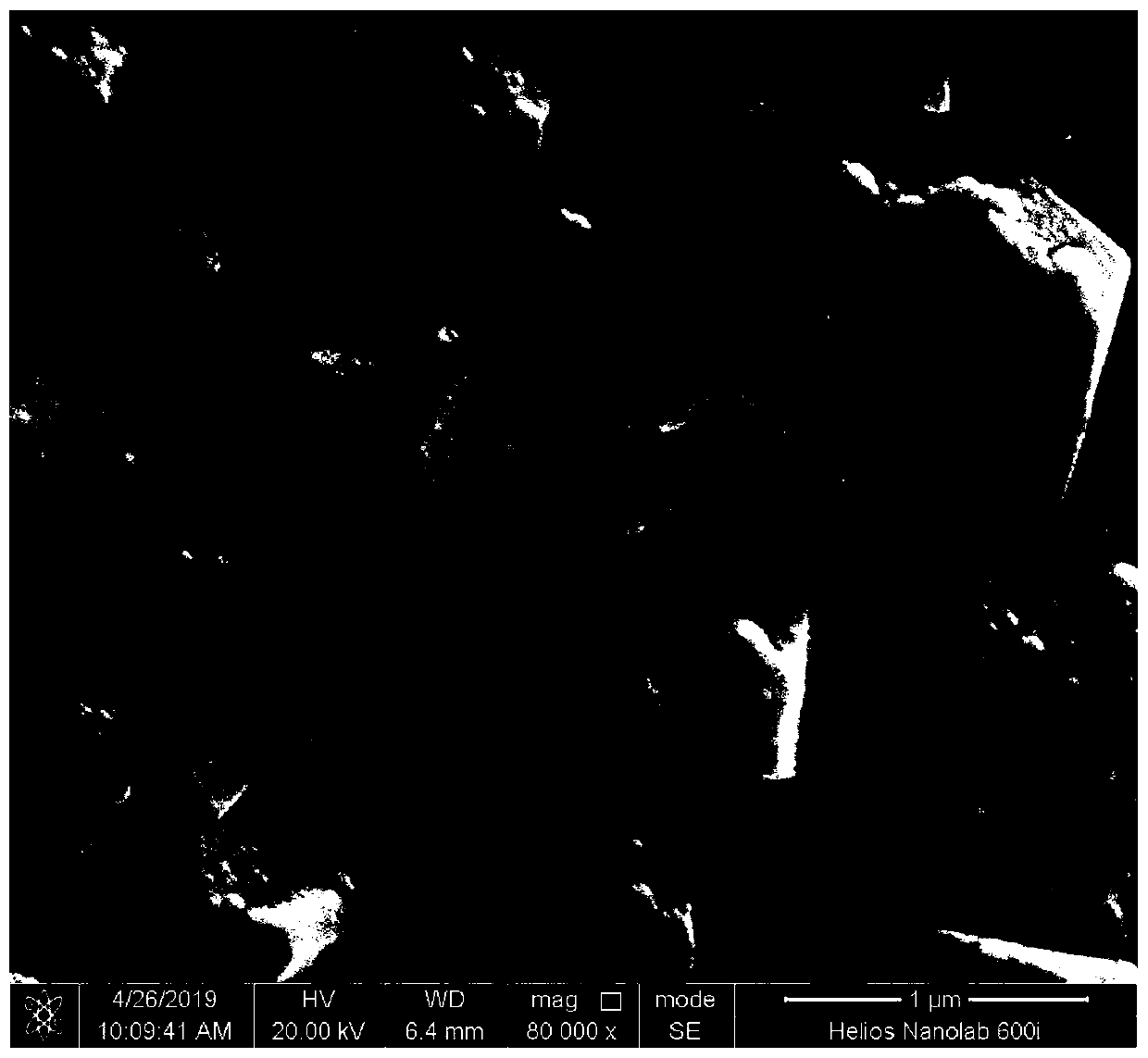

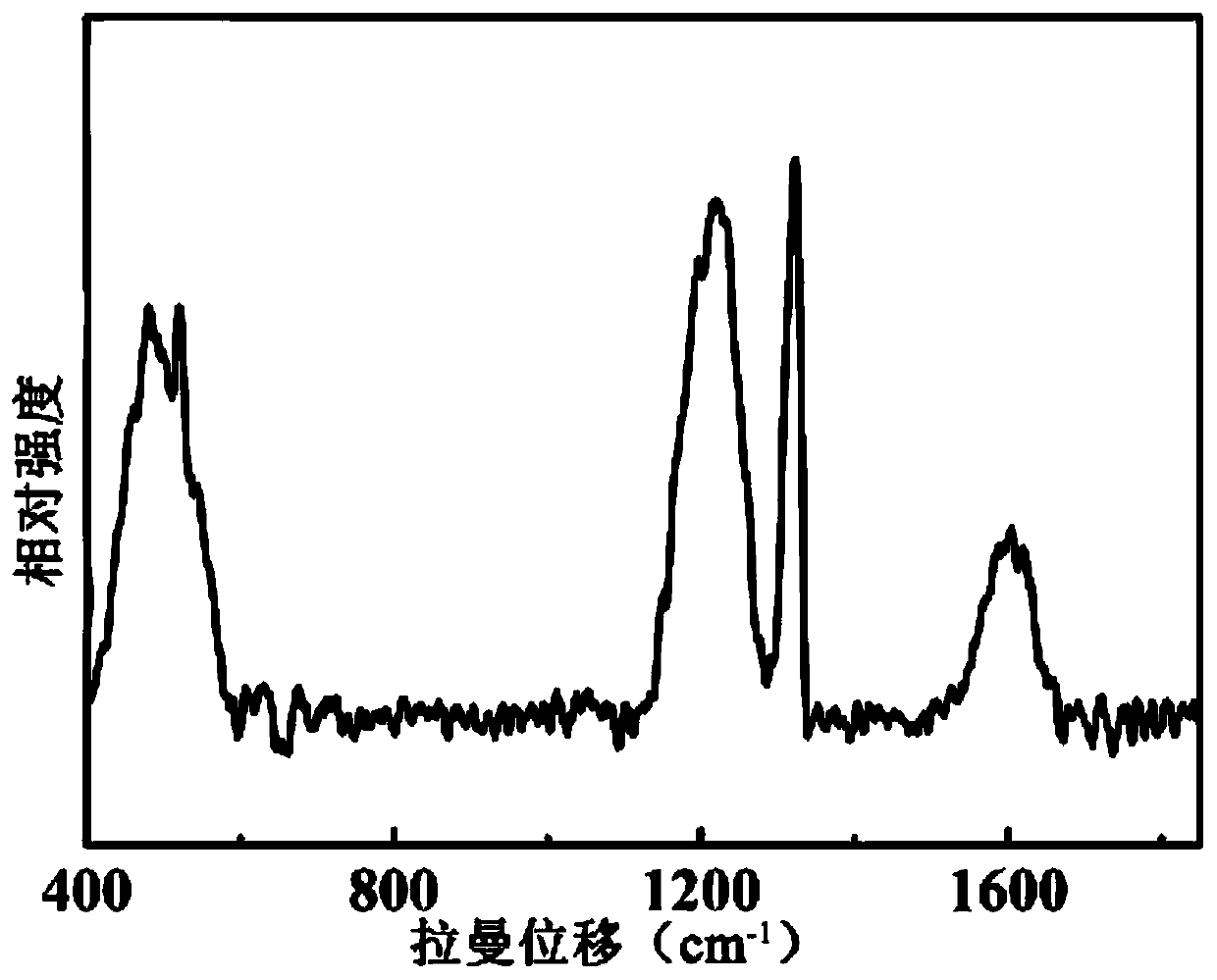

Method for producing low-friction super hydrophobic surface enhanced Raman substrate by using micro-nano particle coating layer

InactiveCN105973866AGood chemical hydrophobicityGood SHD performanceRaman scatteringCoated surfaceAnalyte

The invention relates to a method for producing a low-friction super hydrophobic surface enhanced Raman (SERS) substrate by using a micro-nano particle coating layer, and belongs to the field of analysis and detection. The method concretely comprises the following steps: dispersing micro-nano spheres in ethanol, and carrying out hydrophobization surface modification to prepare a hydrophobic coating; coating a substrate with the coating to form a super hydrophobic coating layer; and slowly and uniformly depositing silver on the surface of the coating layer to complete substrate production. A silver film has enough chemical hydrophobicity and roughness, and has low-friction Kaixi-state super hydrophobous properties; and the surface of the coarse silver film has abundant SERS hot spots. A solute can be enriched in a zone with a small area in a condensed manner in the surface evaporation process of an analyte solution in order to realize Raman detection of a trace quantity of a substance. The low-friction super hydrophobic surface enhanced Raman substrate has the advantages of extremely high SERS sensitivity, extremely low detection limit, and good repeated and quantitative detection ability.

Owner:JILIN UNIV

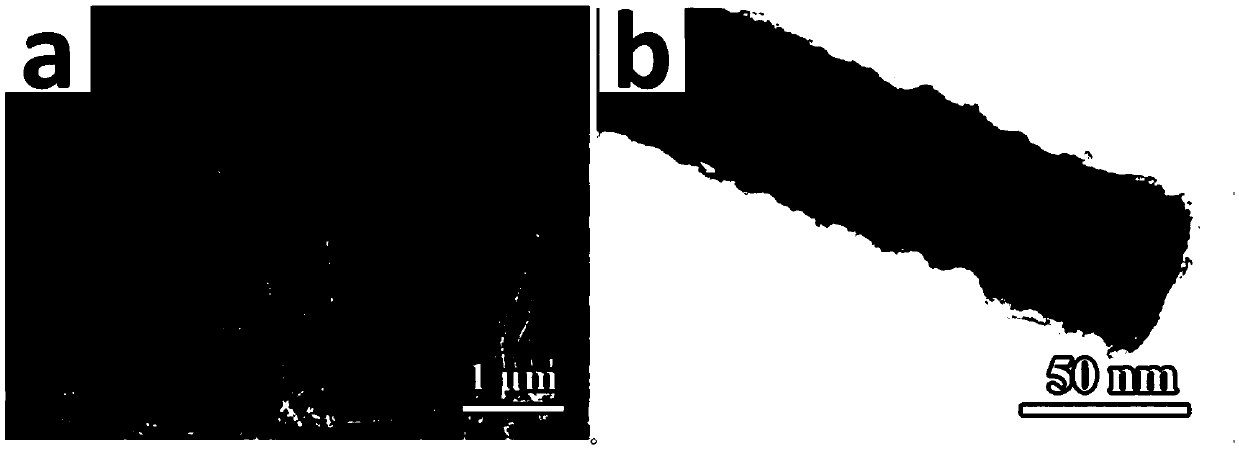

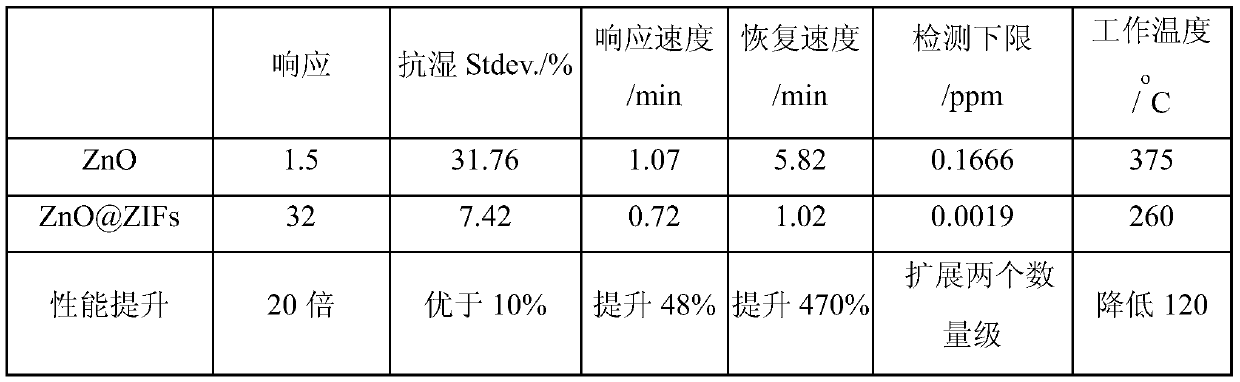

Metal oxide-metal-organic frameworks (MOX@MOFs) nanometer core-shell structure one-dimensional array as well as preparation method and application thereof

ActiveCN105510395AHigh Sensitivity DetectionEasy to promoteMaterial resistanceOperating temperatureMicrometer

The invention provides an MOX@MOFs (metal oxide-metal-organic frameworks) nanometer core-shell structure one-dimensional array film which is characterized in that the film thickness is 2 to 4 micrometers, and the film is formed by a one-dimensional MOX@MOFs core-shell structure, wherein the diameter of a core MOX nanowire is 50 to 100nm, the thickness of a shell MOFs can be adjusted between 1nm to 200nm, metal nodes and organic chains of the MOFs can be adjusted. A typical preparation method comprises the steps of setting an MOX face of a ZnO one-dimensional array film downwards, adding into a mixed solution of water in which zinc salt, cobalt salt and organic ligands are dissolved and DMF, sealing a reaction still, then heating for reacting, after reacting, washing the surface of a compound array film, and drying the film in the air. The MOX@MOFs core-shell structure one-dimensional array film provided by the invention has excellent gas-sensitive property, not only can humidity interference be selectively eliminated, but also the working temperature can be reduced and the sensitivity can be improved through a Co catalysis. Meanwhile, the film also has the advantages that the method is simple, and the cost is low.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

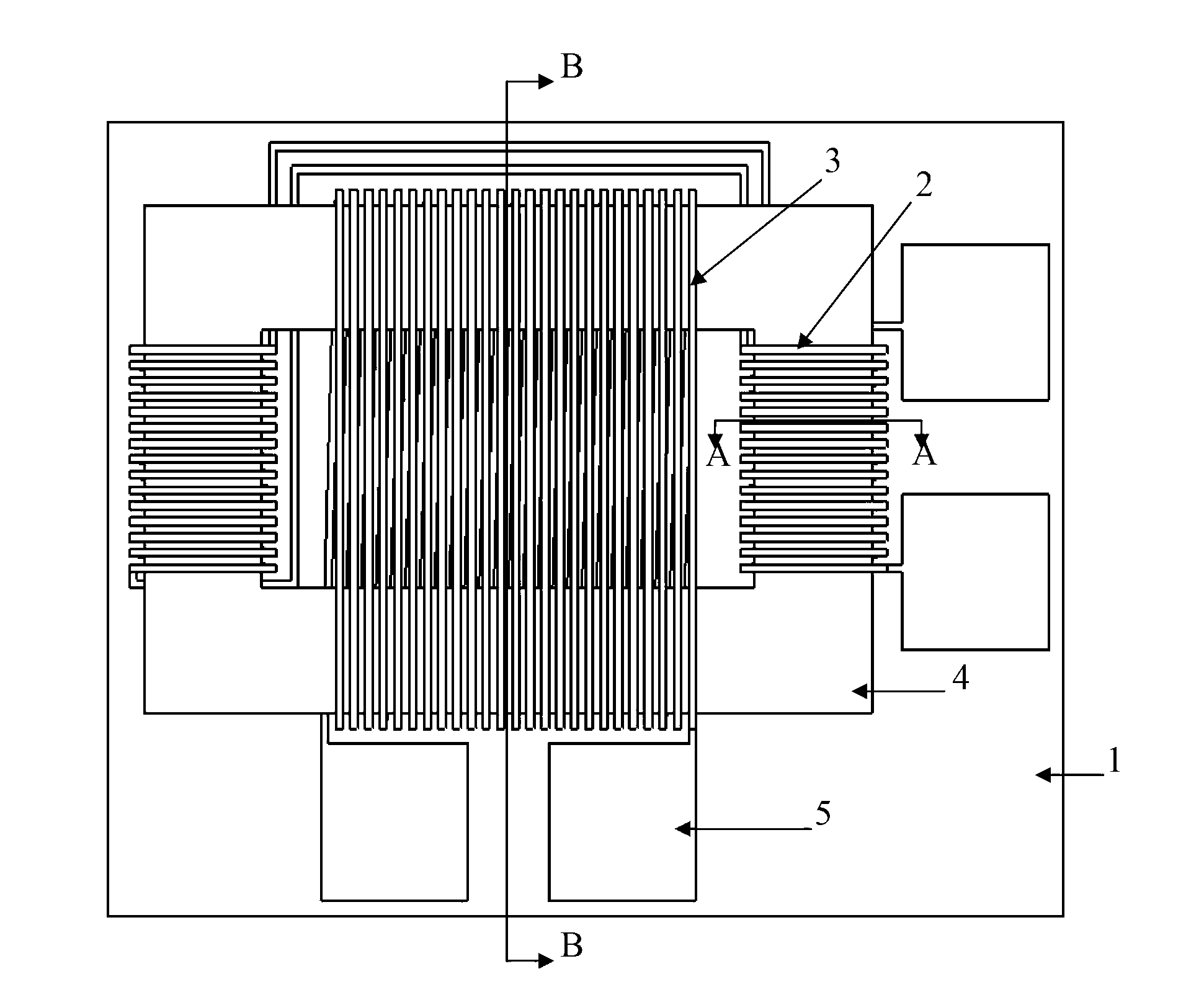

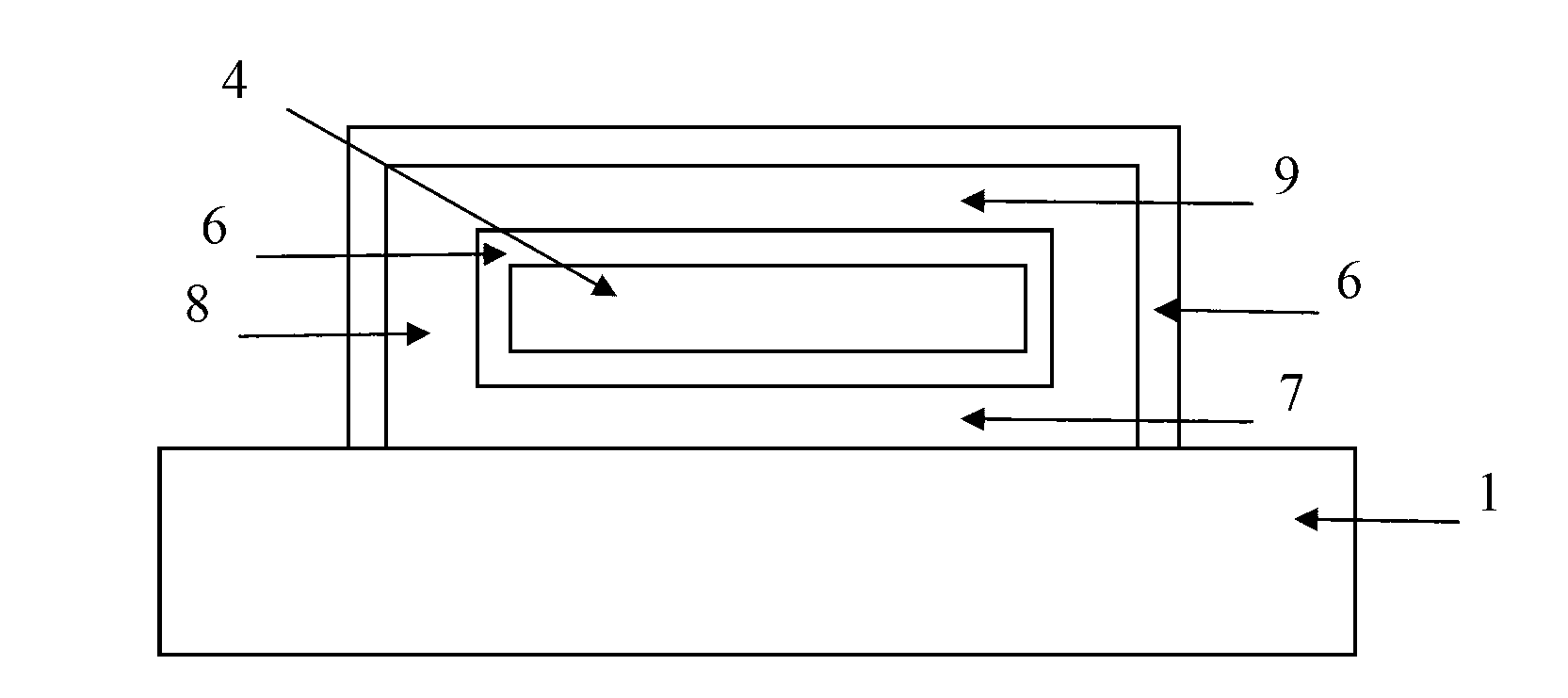

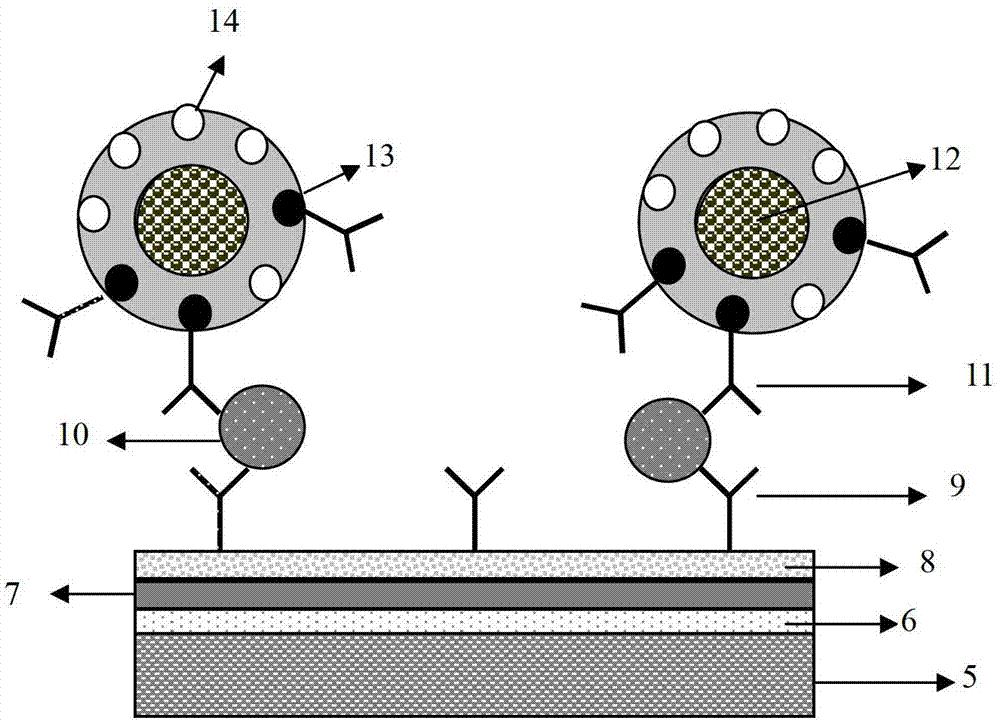

Miniaturized magnetic fluxgate biosensor for serum tumor marker detection

The present invention provides a miniaturized magnetic fluxgate biosensor for serum tumor marker detection. The biosensor comprises a miniaturized magnetic fluxgate sensor positioned on a glass substrate, a biochip and a signal acquisition system, wherein the biochip comprises a Au film on the glass substrate, a bio-sensitive film and a magnetic tag, the Au film is a sputtered Cr / Au film, the bio-sensitive film is a self-assembled film having a nano-scale thickness, and can be linked with various monoclonal antibodies, and the magnetic tag comprises streptavidin-modified magnetic nanoparticles or magnetic beads formed by magnetic nanoparticles, and can be combined with biotin modified monoclonal antibodies or polyclonal antibodies. According to the biosensor, the detection principle adopts a double antibody sandwich method, and the detection sensitivity is that serum tumor marker antigen having a concentration up to 1 ng / ml can be detected.

Owner:SHANGHAI JIAO TONG UNIV

Laser vibrometry with coherent detection

InactiveUS7242481B2High sensitivity detectionSubsonic/sonic/ultrasonic wave measurementUsing optical meansLight beamLaser vibrometry

An optical system provides information about tangential vibration components of a surface at remote location. The optical system includes a light source assembly that emits first and second beams, each having one or more wavelengths and one or two polarizations. The first and second beams are directed to the interrogated surface. A detector system is positioned to detect a third beam formed by at least a portion of the first and second beams being reflected from the interrogated surface. The first, second and third beams having incident and reflection angles relative to the interrogated surface that do not lay in a same plane. The detector system positioned remotely from the interrogated surface, and providing information on a phase change in the third beam relative to the first and second beam. The phase change is indicative of at least one surface vibration vector component of the interrogated surface. The detector system is a 90 degree optical hybrid balanced detector with four photodiodes.

Owner:CELIGHT

Method and apparatus for detecting defects of a sample using a dark field signal and a bright field signal

InactiveUS7463350B2Damage on the wafer caused by the illumination light can be reducedReduce coherenceMaterial analysis by optical meansVisual field lossLight beam

Disclosed is a method and apparatus for inspecting defects of patterns of a sample at high speed and with high sensitivity while damage of the sample arising from high-power pulsed light is reduced. Light emitted from a pulsed laser light source is transmitted through a pseudo continuous-wave forming optical system having an optical system capable of reducing energy per pulse and yet maintaining the entire amount of light of the pulsed light, a beam formation optical system, and a coherence reduction optical system, and a beam deflected by a deformation illumination optical system is made to reflect on a PBS to be irradiated on a wafer. The apparatus is configured so that the diffracted light from the wafer is focused by an objective lens, transmitted through light modulation units, focused to form a plurality of images on a plurality of image sensors in a visual-field divided parallel detection unit 12, and then defects are detected by a signal processing unit.

Owner:HITACHI HIGH-TECH CORP

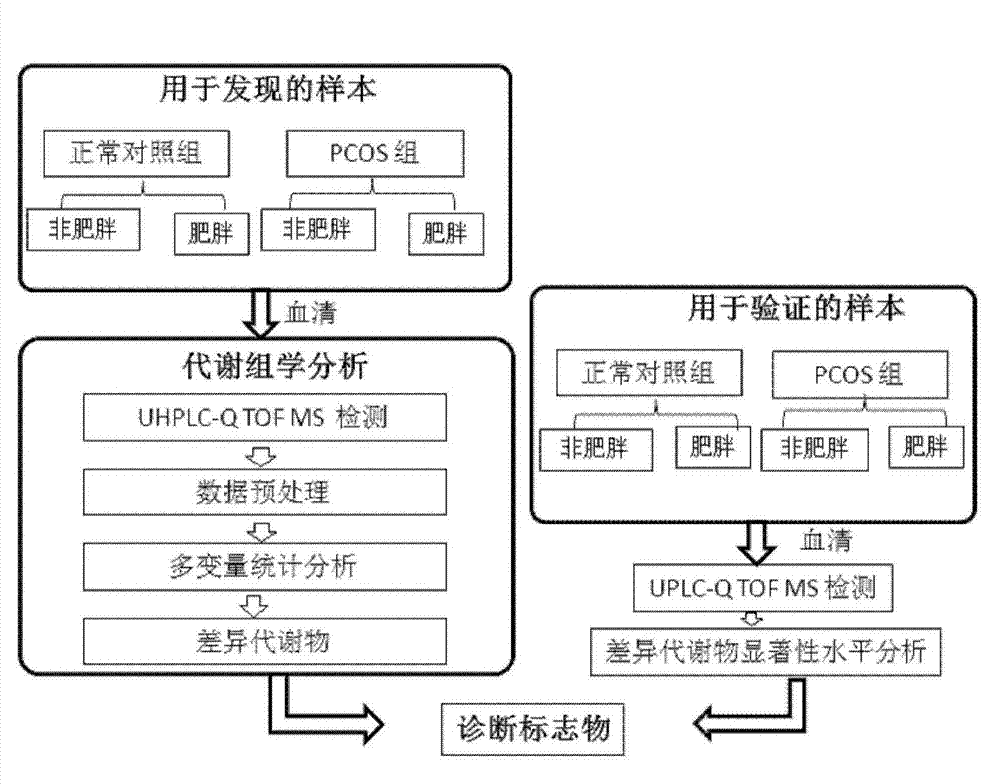

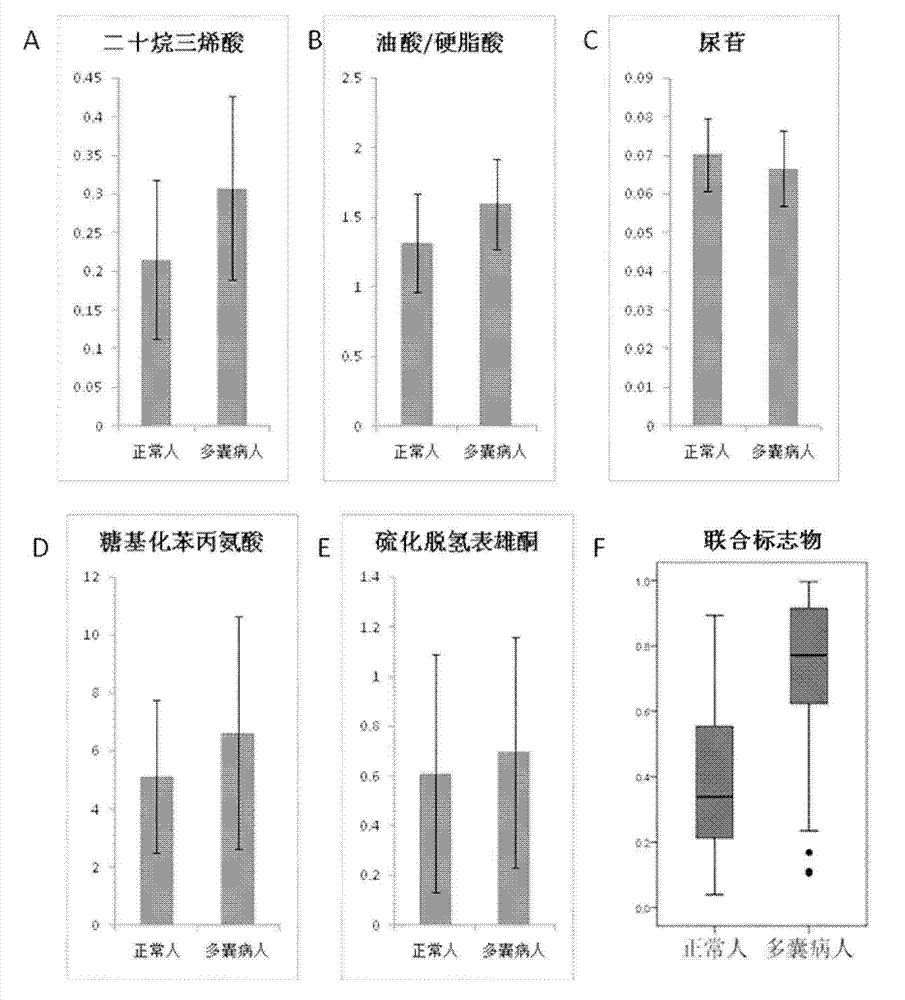

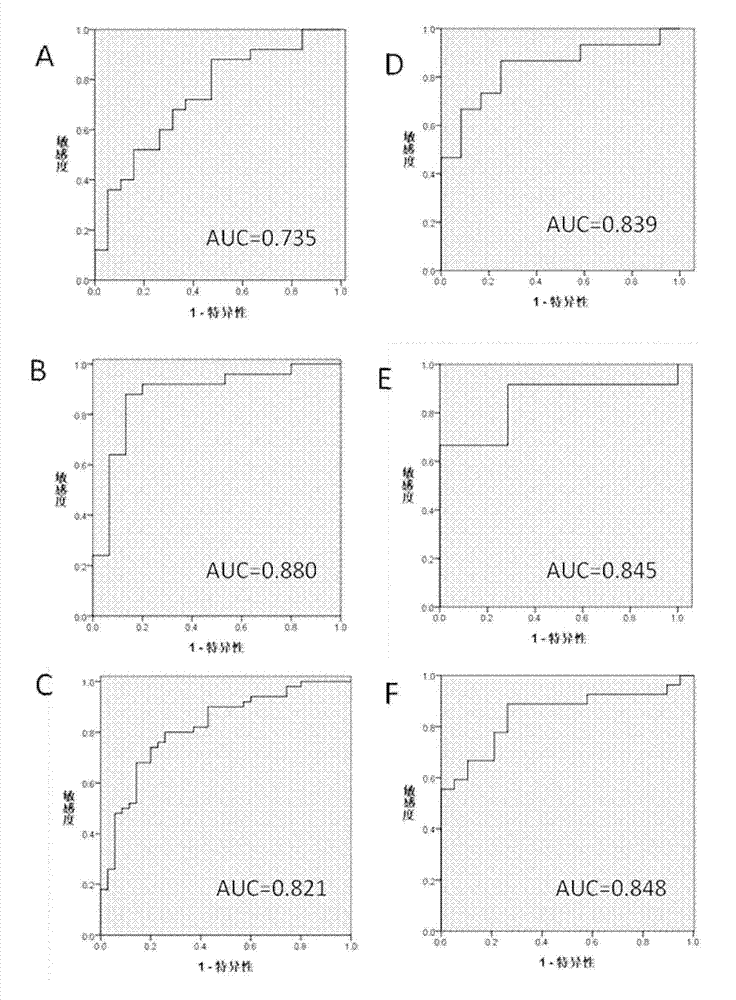

Combined markers, kit and system for diagnosis of polycystic ovarian syndrome

InactiveCN104777242AGlobal metabolic abnormalitiesEasy to identifyComponent separationMetabolitePhysiology

The invention relates to a novel use of serum sample micromolecule metabolites such as oleic acid, stearic acid, eicosatrienoic acid, dehydroepiandrosterone sulfate, glycosylated phenylalanine and uridine as combined markers in preparation of a kit for diagnosis of polycystic ovarian syndrome of subjects. The invention also relates to a kit of diagnosis of polycystic ovarian syndrome of subjects. The kit is used for detecting respective concentrations of the combined markers in a serum sample of a female subject, calculating combined marker variable based on a binary logistic regression equation, and determining if the subject suffers from polycystic ovarian syndrome based on the determined intercept point value. The kit can realizes high sensitivity and high efficiency detection of the micromolecular metabolites and has the characteristics of low detection cost and good repeatability. Through combined use of the micromolecular metabolites, the kit can be used in auxiliary diagnosis of different symptoms of polycystic ovarian syndrome.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

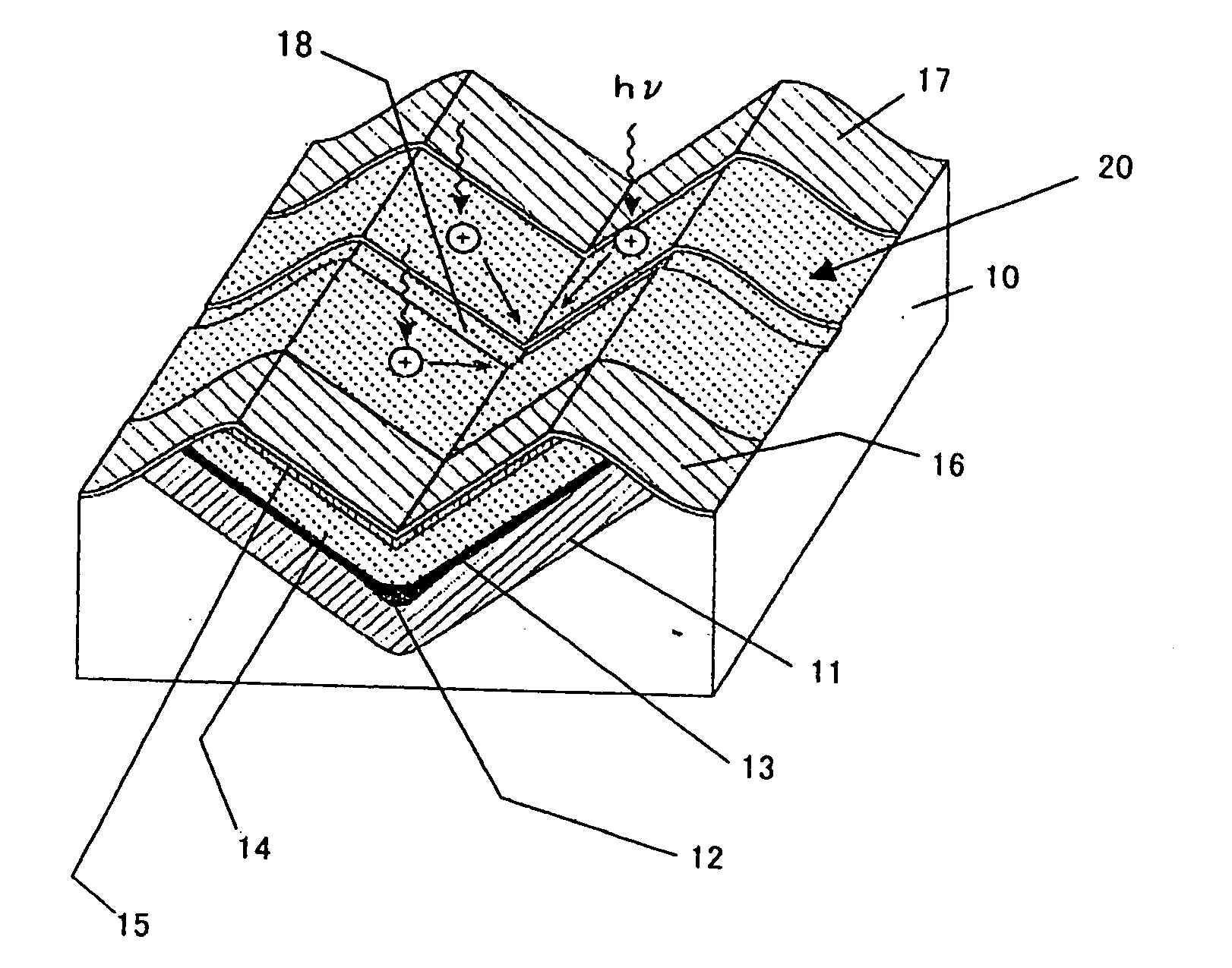

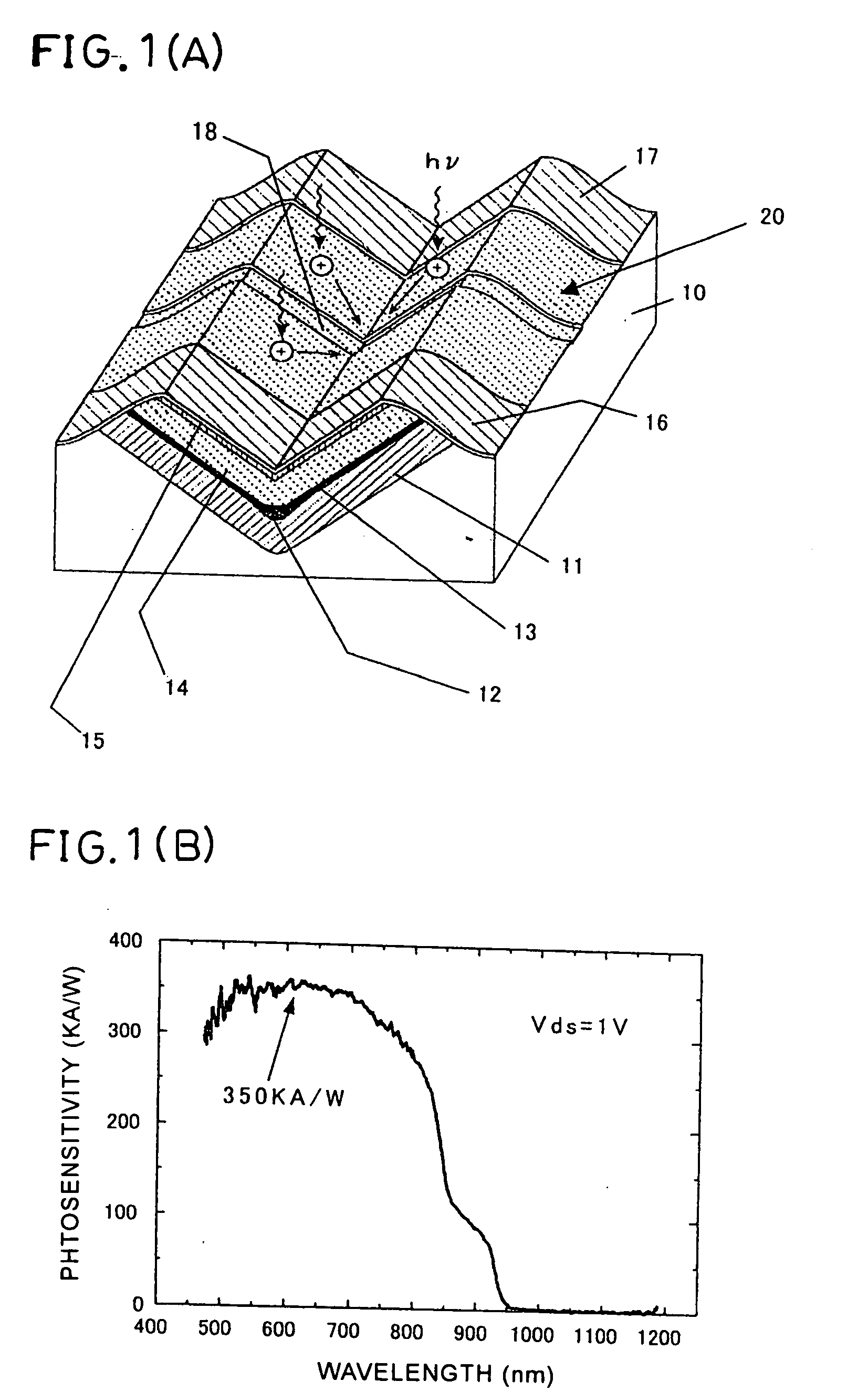

Photodetector

InactiveUS20050151061A1Increase speedHigh sensitivity detectionNanoinformaticsMaterial analysis by optical meansPhotovoltaic detectorsPhotodetector

Quantum wire is formed on the bottom of a V-shaped groove in a V-grooved substrate as a channel between source and drain electrodes or as at least part of the channel. A photocarrier accumulation region is provided within the quantum wire or at a position connected to or adjacent to the quantum wire for accumulating charges generated when light shines onto a photosensitive region that comprises at least a clad layer that covers the quantum wire. A recess is provided in the upper clad layer to localize the photocarrier accumulation region. As a result, it is possible to provide a photodetector that exhibits high sensitivity, high speed and low power consumption in an expanded wavelength region. It is also possible to provide a photodetector capable of constructing core portions thereof by one-time selective growth.

Owner:NAT INST OF ADVANCED IND SCI & TECH

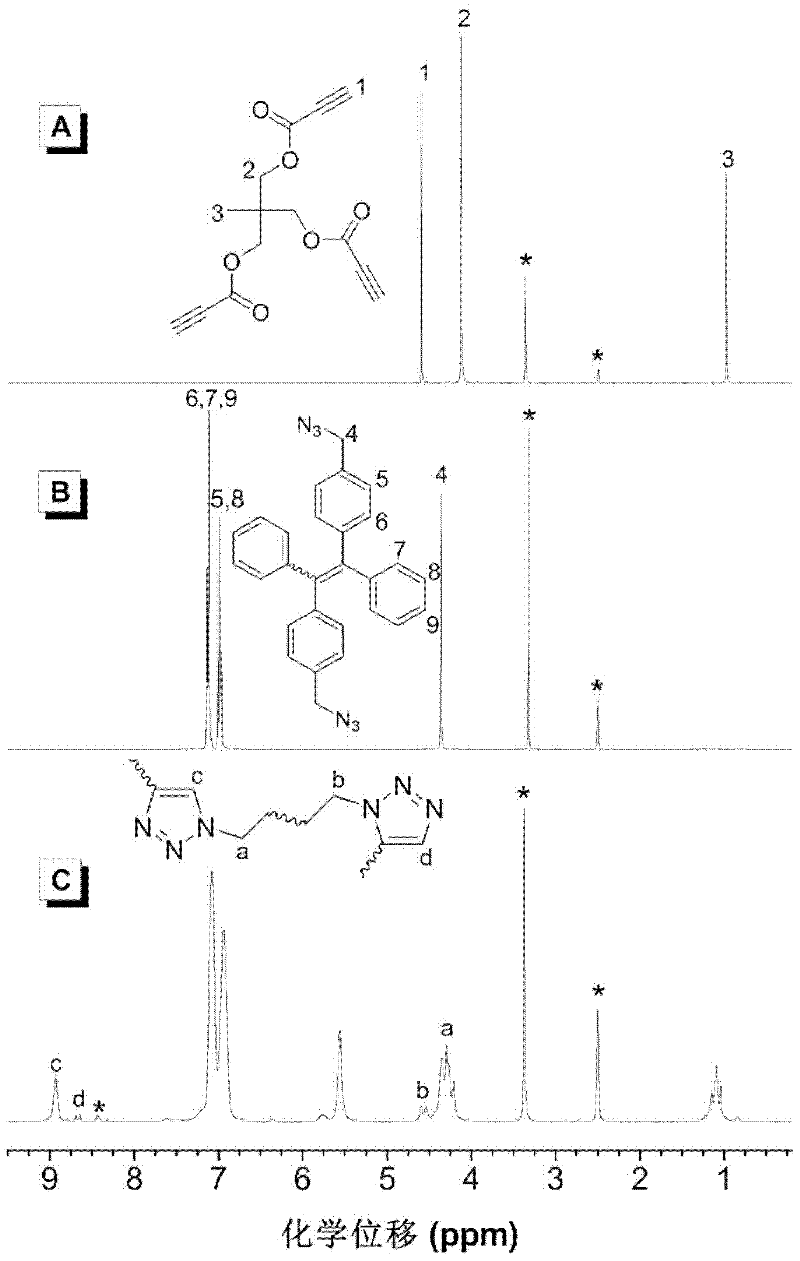

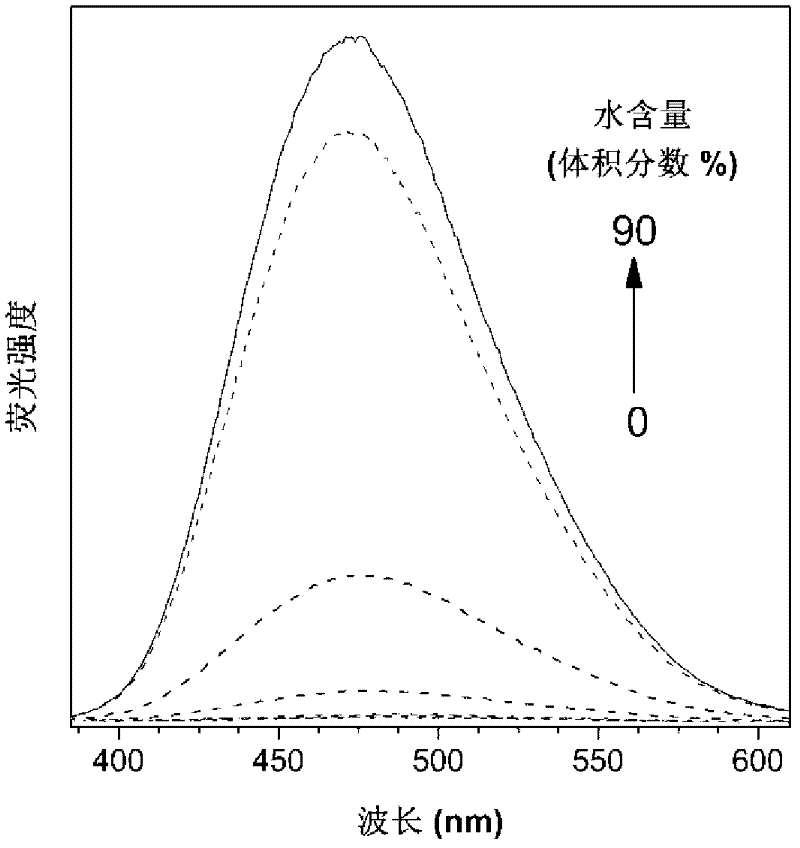

Hyperbranched polytriazole formate as well as preparation method and application thereof

ActiveCN102585220AHigh StereoselectiveNo protectionFluorescence/phosphorescenceLuminescent compositionsFormateSolvent

The invention discloses hyperbranched polytriazole formate as well as a preparation method and application thereof. The preparation method of hyperbranched polytriazole formate comprises the following steps: firstly, synthesizing binary azide containing a tetraphenyl ethylene unit; then synthesizing a ternary ester compound containing alkynyl based on ternary alcohol and propiolic acid as raw materials; and finally, carrying out non-metal-catalytic 'click' polymerization reaction under the heating condition in a polar solvent by utilizing the azide and the alkynyl-containing ester compound soas to obtain a target polymer in high yield. The hyperbranched polytriazole formate prepared by using the method is high in 1,4-stereoregularity, good in workability and high in thermal stability, degradability, illumination patterning and aggregation-induced emission property. The invention also discloses application of hyperbranched polytriazole formate in detection of a polynitroarene explosive.

Owner:ZHEJIANG UNIV

Preparation method of electrochemical luminescence immunosensor for detecting beta-amyloid protein by isoluminol functionalization MOFs

InactiveCN109668874AIncrease loadLarge specific surface areaChemiluminescene/bioluminescenceMaterial electrochemical variablesElectrochemiluminescenceElectrochemistry

The invention relates to a preparation method of an electrochemical luminescence immunosensor for detecting beta-amyloid protein by isoluminol functionalization MOFs, and belongs to the field of an electrochemical luminescence sensor. A luminescence reagent functionalized MOFs is synthesized to be used as a signal marker; isoluminol is used as a luminescence reagent; hydrogen peroxide is used as aco-reaction agent; cobalt-based MOFs is used as a co-reaction accelerator; good catalyst performance of the cobalt-based MOFs on hydrogen peroxide is used; the luminescence reagent ECL signal amplification is realized; meanwhile, the loading capacity of the isoluminol is increased through the big specific surface area of the MOFs; the luminescence efficiency and the stability of the luminescencereagent are improved. The linear range on the beta-amyloid protein is 10 fg*mL<-1> to 100 fg*mL<-1>; the detection limit is 3 fg*mL<-1>.

Owner:UNIV OF JINAN

Giant magneto-impedance effect biosensor for detecting serum tumor markers

ActiveCN102928596ALow costLow priceDecorative surface effectsChemical vapor deposition coatingAbnormal tissue growthBiotin-streptavidin complex

The invention provides a giant magneto-impedance effect biosensor for detecting serum tumor markers. The biosensor consists of a giant magneto-impedance effect sensor positioned on a glass substrate, an insulated layer, an Au film, a biologically sensitive film, a magnetic tag and a signal acquisition system, wherein the giant magneto-impedance effect sensor consists of the NiFe / Cu / NiFe multi-layer film on the glass substrate and is made by the microelectromechanical system (MEMS) technology; the insulated layer is the aluminum oxide layer, the Au film is the splashed Cr / Au film, and the biologically sensitive film is the self-assembled film with nano-level thickness and can be connected with various monoclonal antibodies; and the magnetic tag is streptavidin-modified magnetic nano particles or magnetic beads consisting of magnetic nano particles and can be combined with biotin-modified monoclonal antibodies or polyclonal antibodies. Based on the detection principle of a double-antibody sandwich method, the sensor has a high detection sensitivity and can detect the antigens of which the content of serum tumor markers is as high as 1ng / ml.

Owner:SHANGHAI JIAO TONG UNIV

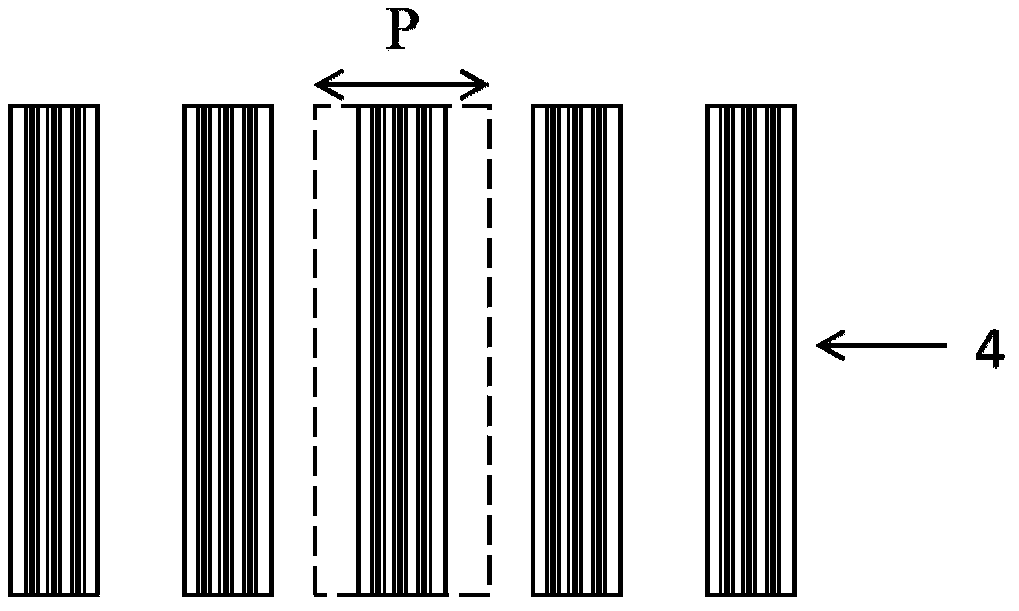

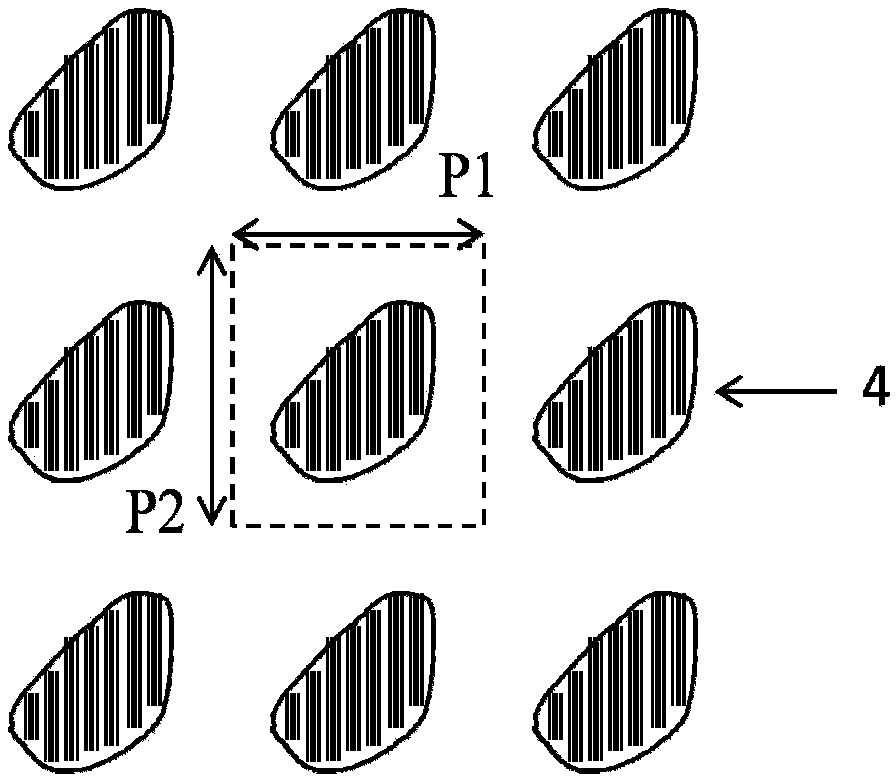

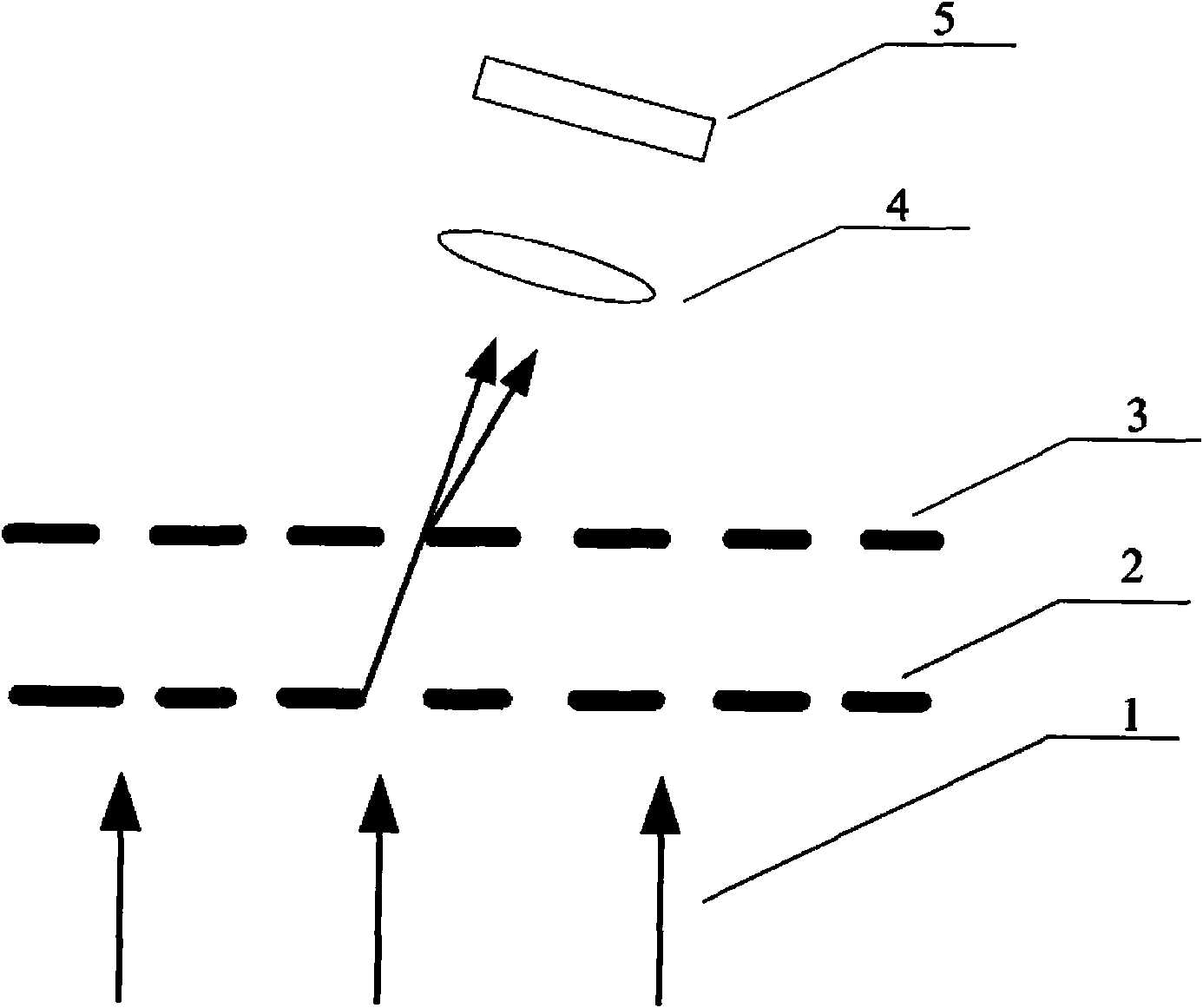

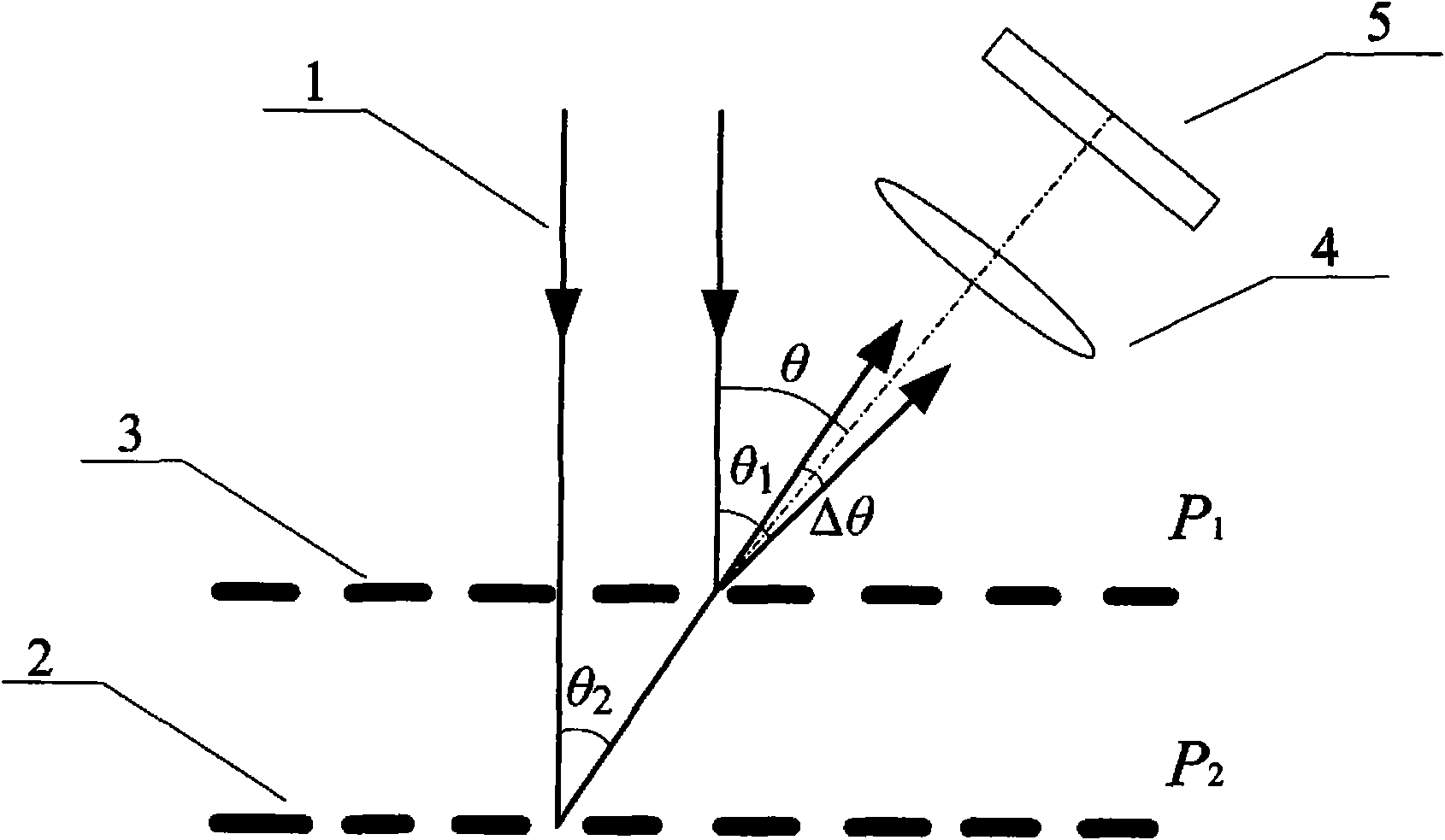

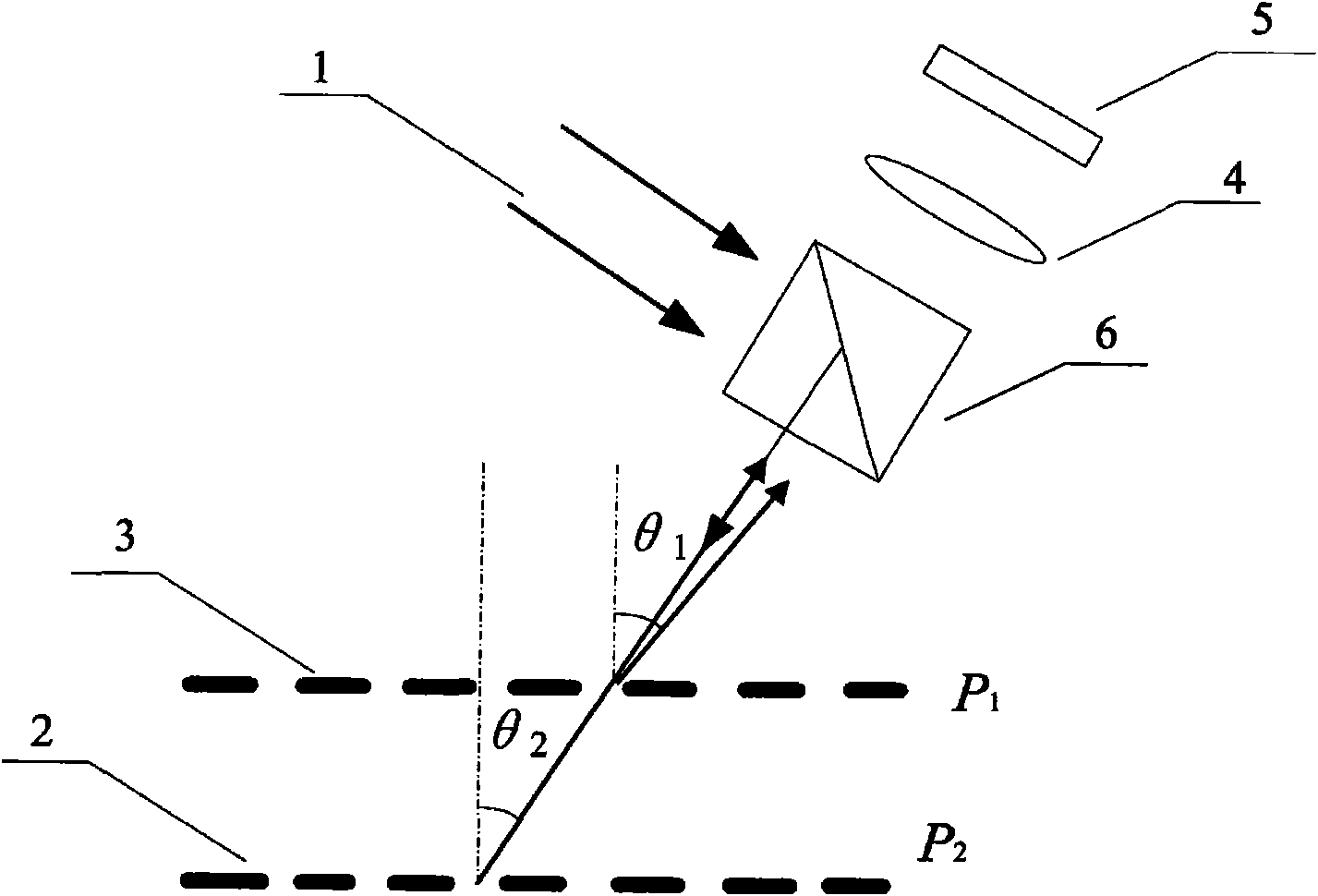

Method for measuring clearance in proximity nanometer lithography

InactiveCN101876538AHigh Sensitivity DetectionHigh measurement accuracyUsing optical meansNanolithographyGrating

The invention discloses a method for measuring clearance in proximity nanometer lithography and mainly aims at the controlling of the clearance of a masking silicon wafer in nanometer manufacturing technology, such as nano-imprint, wave zone plate array imaging and the like. The basic process of the method can be simply explained in the picture 1 that: incident plane waves pass through a silicon wafer gratings and a mask grating and diffract for multiple times, wherein the two periods of the gratings are approximate and the two gratings are overlapped with a certain gap; two beams of lateral diffracted light from the two gratings interfere with each other and are superposed, and form Moire interference fringes of which the period is amplified relative to the conventional gratings on the surfaces of the silicon wafer grating; and the fringes are imaged on a CCD image detector through an objective lens with certain multiplying power. The change of the gap between the two gratings causes the change of optical path difference of the two beams and then causes the change of the movement or phases of the interference fringes so that the aim of measuring the gap is fulfilled; the more approximate the period is, the higher the sensitivity of the measurement is; and, at the same time, because the periods of the two gratings are approximate, the included angle between the lateral diffracted light is very small, the frequency of the interference fringes is very low (namely, the period is long), and the requirement on the numerical aperture of the objective lens is low. With the development of microfabrication technology, the machining accuracy of the grafting is higher and the method has great significance for gap measurement in proximity nanometer lithography and the related field.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Preparation method of gold nanoparticle modified boron-doped diamond electrode and application

ActiveCN110643972AIncrease growth rateImprove surface roughnessVacuum evaporation coatingSputtering coatingDiamond electrodesElectrochemical detection

The invention discloses a preparation method of a gold nanoparticle modified boron-doped diamond electrode and application, and relates to a preparation method of the gold nanoparticle modified boron-doped diamond electrode and the application. The invention aims to solve one of the problems that when a boron-doped diamond prepared by a method modifies other substances on the surface of the boron-doped diamond, the bonding force of the boron-doped diamond and the substances is poor, and solve the other problem that the electrochemical detection sensitivity of an boron-doped diamond electrode material is low, and the existing modification method can hinder the electrochemical performance of the boron-doped diamond material. The preparation method comprises the following steps that 1, a boron source is prepared; 2, a boron-doped diamond film is prepared; and 3, coating film and annealing are conducted. The preparation method and the application are used for preparing a gold nanoparticlemodified boron-doped diamond electrode and the application.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com