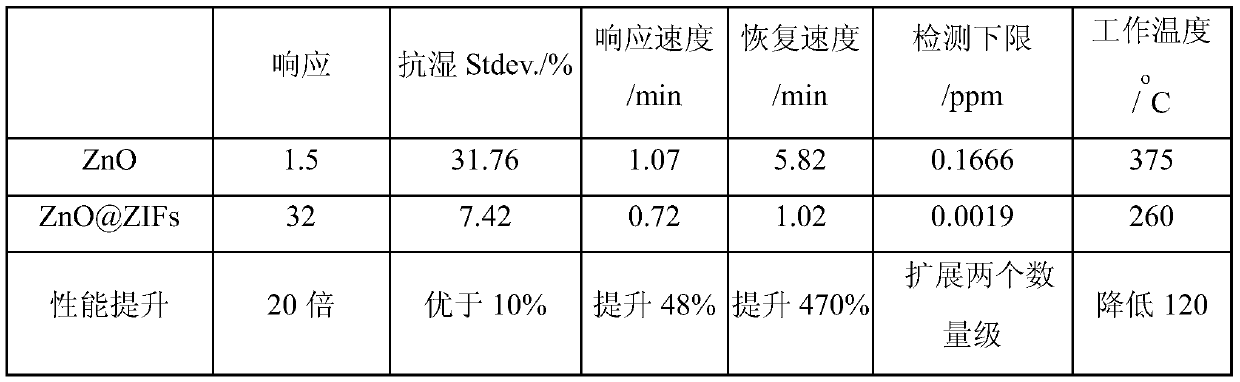

Metal oxide-metal-organic frameworks (MOX@MOFs) nanometer core-shell structure one-dimensional array as well as preparation method and application thereof

A nano-core-shell and array technology is applied in the field of gas sensors, which can solve problems such as poor selectivity, achieve high-sensitivity detection, and be easy to promote.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh zinc chloride and cobalt chloride (Zn:Co=1:1, total molar concentration 0.86mM), add 2.5mL water and 13.5mLDMF to dissolve in the reaction kettle, add 2-methylimidazole (30.4mM) and stir to form Transparent solution, put the ZnO one-dimensional array film grown by hydrothermal method on the sapphire wafer with the face down, put it into the solution, seal the reaction kettle and react at 60°C for 2h, rinse the surface of the composite array film after the reaction, and dry it in the air to dry.

Embodiment 2

[0028] Weigh zinc nitrate and cobalt nitrate (Zn:Co=0:1, total molar concentration 0.86mM), add 0mL water and 16mLDMF to dissolve in the reaction kettle, add 2-methylimidazole (76.0mM) and stir to form a transparent solution, and Solvothermal Growth of TiO on Sapphire Chips by Seed Layer Method 2 Put the one-dimensional array film face down into the solution, seal the reactor and react at 25°C for 12 hours. After the reaction, rinse the surface of the composite array film and dry it in the air.

Embodiment 3

[0030] Weigh zinc chloride and cobalt chloride (Zn:Co=3:1, total molar concentration 0.86mM), add 4mL water and 12mL DMF to dissolve in the reaction kettle, add imidazole (30.4mM) and stir to form a transparent solution, and the seed crystal Hydrothermal Growth of SnO on Polycrystalline Alumina Ceramic Sheets by Layer Method 2 Put the one-dimensional array film face down into the solution, seal the reactor and react at 120°C for 0.5h. After the reaction, rinse the surface of the composite array film and dry it in the air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com