Preparation method of gold nanoparticle modified boron-doped diamond electrode and application

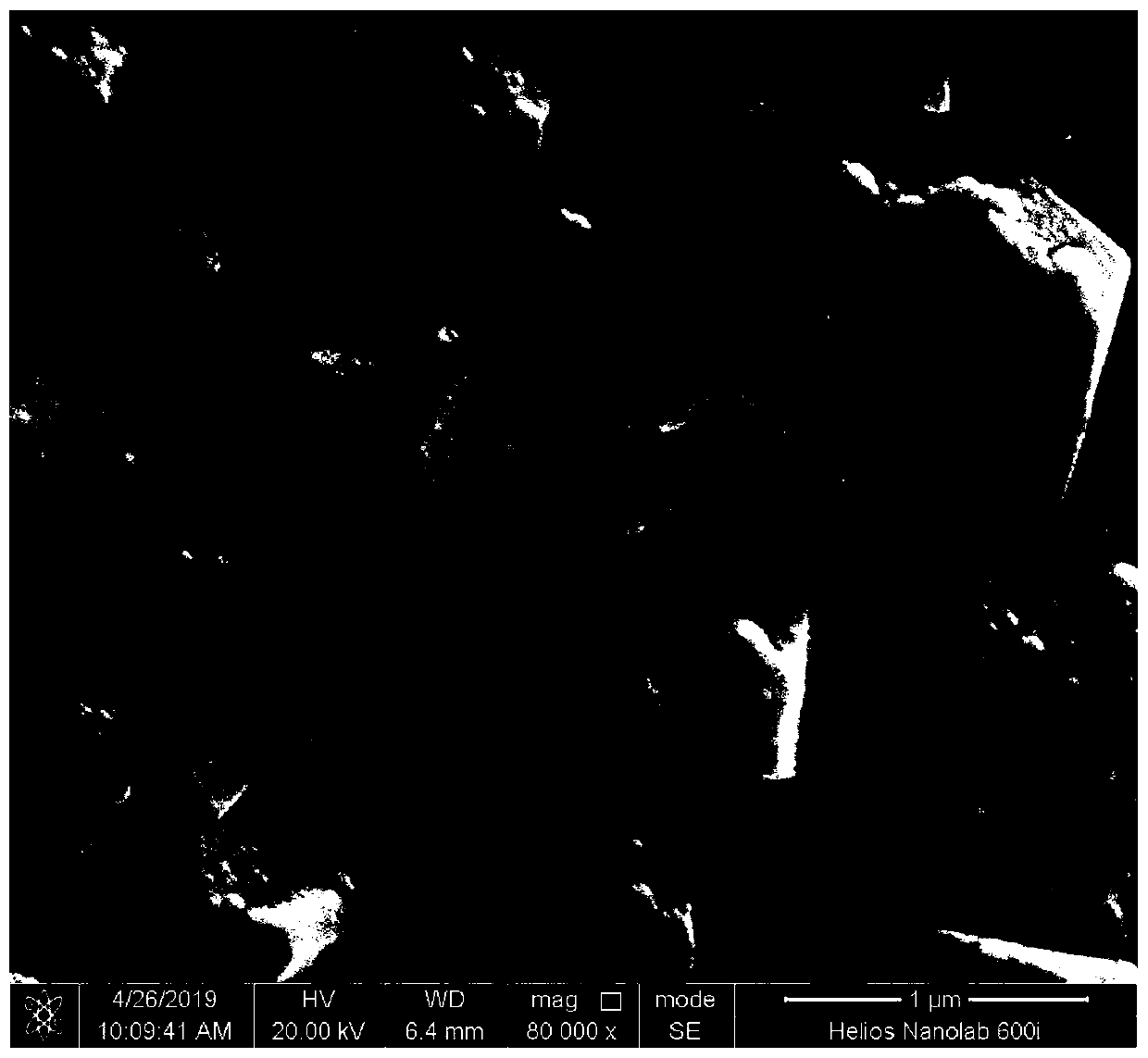

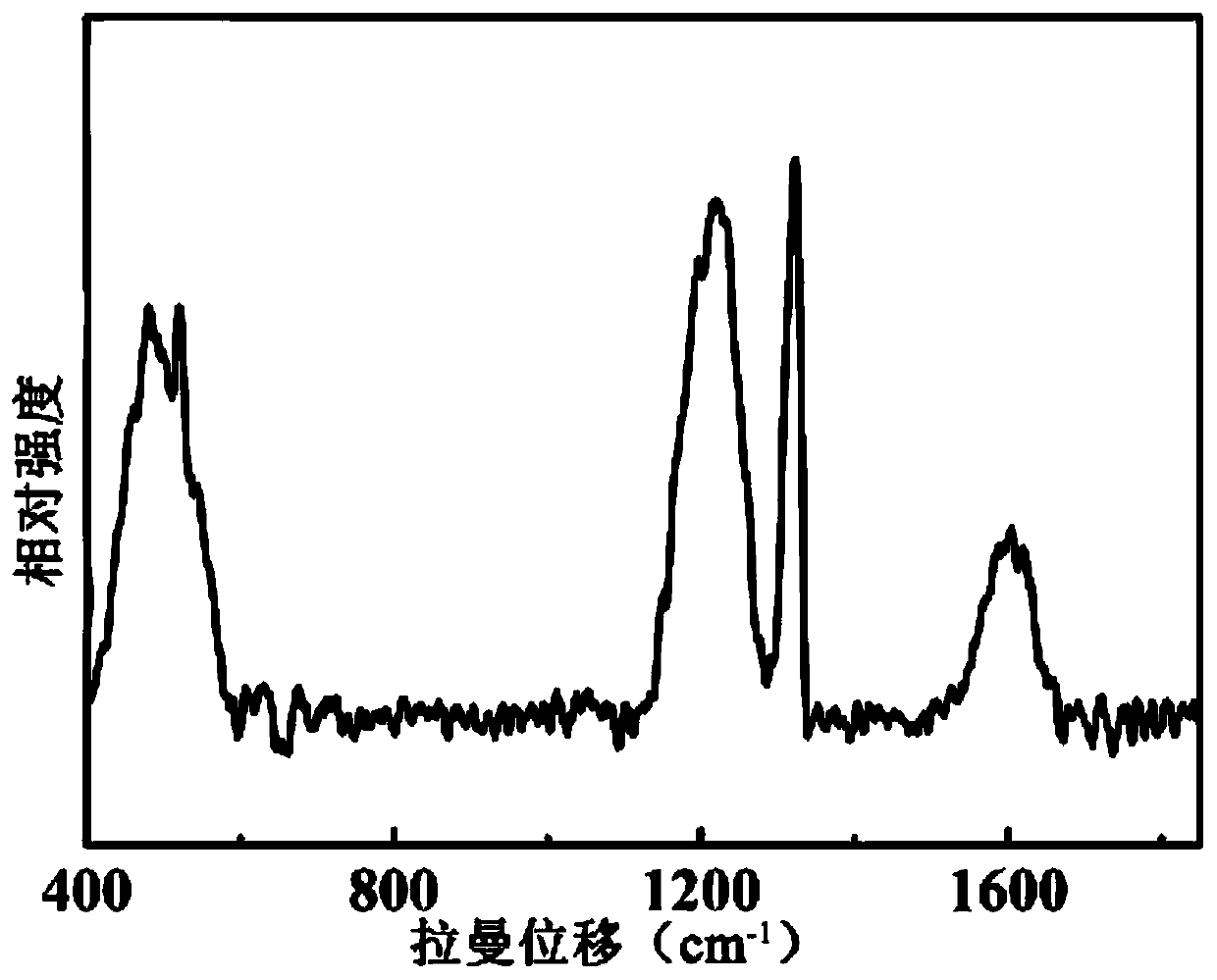

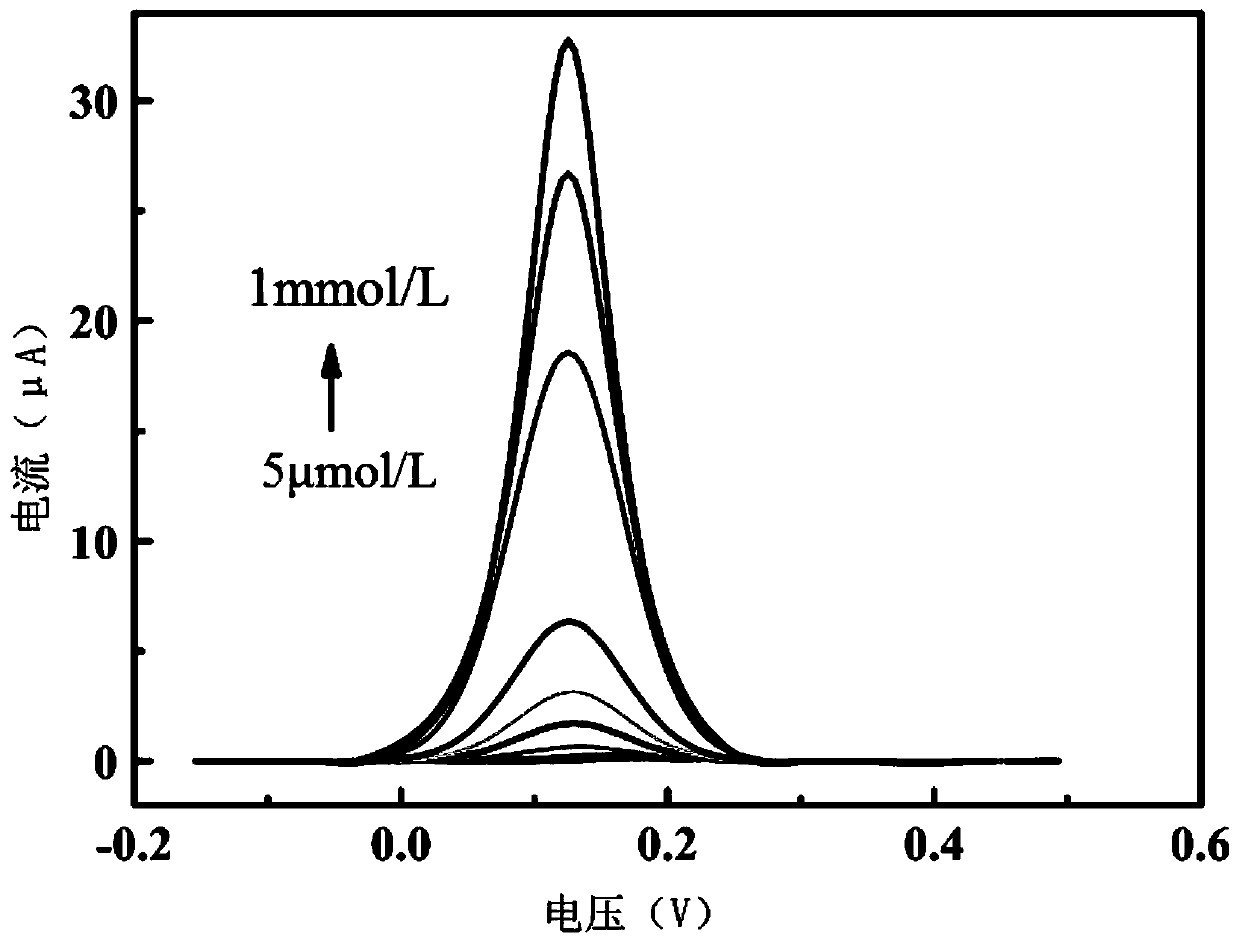

A technology of boron-doped diamond and gold nanoparticles, which is applied in the preparation and application fields of gold nanoparticles modified boron-doped diamond electrodes, can solve the problems of hindering the electrochemical performance of boron-doped diamond materials, poor bonding force, and the electrochemical performance of boron-doped diamond electrode materials. To solve problems such as low detection sensitivity, achieve high sensitivity, improve binding force, and improve surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: present embodiment a kind of preparation method of gold nanoparticle modification boron-doped diamond electrode, it is carried out according to the following steps:

[0027] One, the preparation of boron source:

[0028] Grind the boron oxide powder to a fine powder with a particle size of 5 μm to 100 μm, then add the fine powder with a particle size of 5 μm to 100 μm into the graphite powder, stir evenly, and then press it into a square sheet to obtain boron oxide with graphite as the carrier boron source;

[0029] The mass ratio of described boron oxide powder and graphite powder is 1:(1~200);

[0030] 2. Preparation of boron-doped diamond film:

[0031] Place the substrate and the boron oxide boron source with graphite as the carrier side by side on the sample stage of the microwave plasma chemical vapor deposition device, feed hydrogen and carbon source gas, and then flow the hydrogen at a flow rate of 20sccm to 400sccm and the flow rate o...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment differs from Embodiment 1 in that: the side length of the square sheet described in step 1 is 30 mm to 50 mm, and the thickness is 1 mm to 2.5 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the purity of graphite powder and boron oxide powder described in step 1 is both 99.99%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com