Method for culturing microalgae

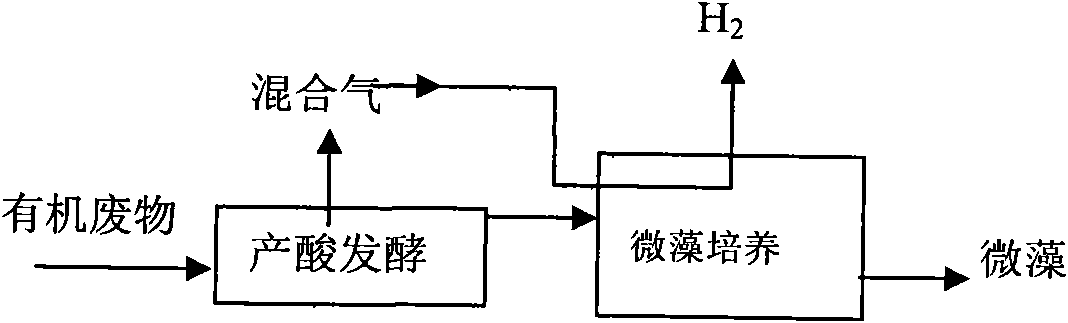

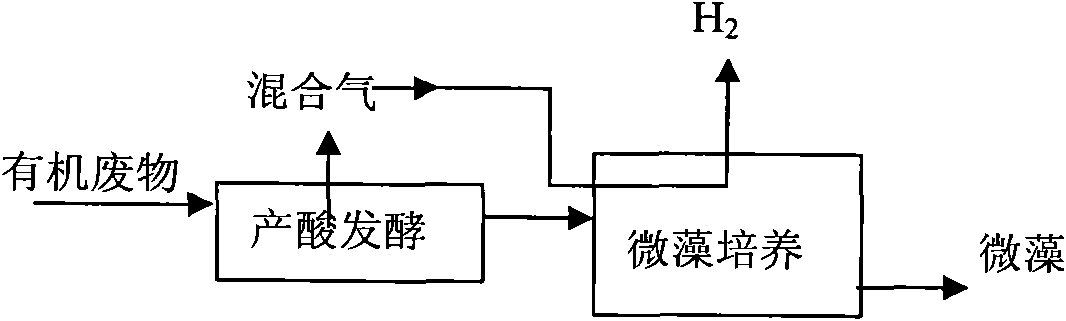

A microalgae culture and microalgae technology, applied in the field of microalgae culture, can solve the problems of low biomass and slow growth rate, and achieve the effects of high growth rate, short cycle and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Step 1: Acidogenic fermentation. With 500g cow dung as the fermentation substrate, add water to adjust the solid content to 6%, fill it in the reaction device, inoculate 25% activated sludge (taken from the sewage treatment plant) and start fermentation, the temperature is controlled at 25 ± 1 ° C, the produced The gas is collected in the gas storage tank, and after 48 hours of fermentation, the fermentation product is subjected to solid-liquid separation through a screw extruder.

[0020] Step 2: Cultivation of algae species: the algae species used is chlorella vulgaris (purchased from Texas Algae Collection, UTEX 2714). The medium component is NH 4 Cl 400mg / L, KH 2 PO 4 56mg / L, K 2 HPO 4 108mg / L, MgSO 4 ·7H 2 O 100mg / L, glacial acetic acid 1mg / L, trace elements 1ml / L, the total oil content in this medium can reach more than 40% of the dry weight of the cells, and it is oil-rich microalgae. The algae has been experimentally confirmed to survive in...

Embodiment 2

[0022] Embodiment 2: The similarities between this embodiment and Example 1 will not be described in detail. The difference is that the autotrophic process can be continued after the heterotrophic culture. On the basis of Example 1, the microalgae after the heterotrophic culture are placed in In the tank-type photobioreactor, the mixed gas in the gas cylinder is circulated for autotrophic culture. The culture conditions are 28°C and 6000Lux light intensity. After 7 days, the biomass of microalgae is 18g / L, and the oil content is 37 %, hydrogen purity over 90%.

Embodiment 3

[0023] Embodiment 3: Step 1: Acidogenic fermentation. Use 500g corn stalks as the fermentation substrate, mix it with 500g cow dung and fill it in the reaction device, add water to adjust the solid content to 8%, inoculate 25% activated sludge (taken from the biogas digester) and start fermentation, the temperature is controlled at 25 ± 1°C, the generated gas was collected in the gas storage tank, and after 72 hours of fermentation, the fermentation product was separated from solid and liquid by a screw extruder. The rest of the steps are the same as step 2 in the embodiment. After 5 days, the biomass is 18g / L and the oil content is 39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com