Physical similar simulation test device and physical similar simulation test method for tilted stratums

A technology of physical similarity simulation and test device, which is applied in the field of physical similarity simulation test device for inclined rock strata, can solve problems such as limited inclination angle, unstable center of gravity, collapse of filling model, etc., to achieve the effect of ensuring balance stability and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

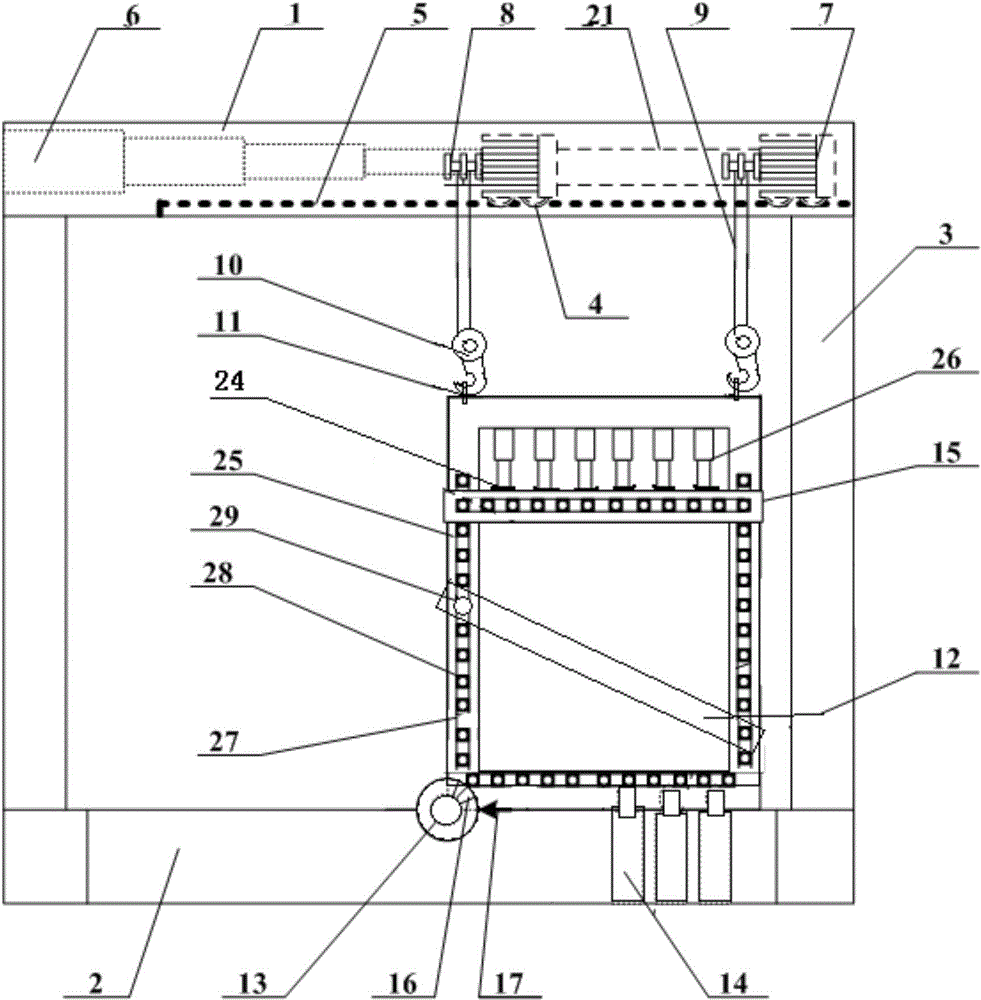

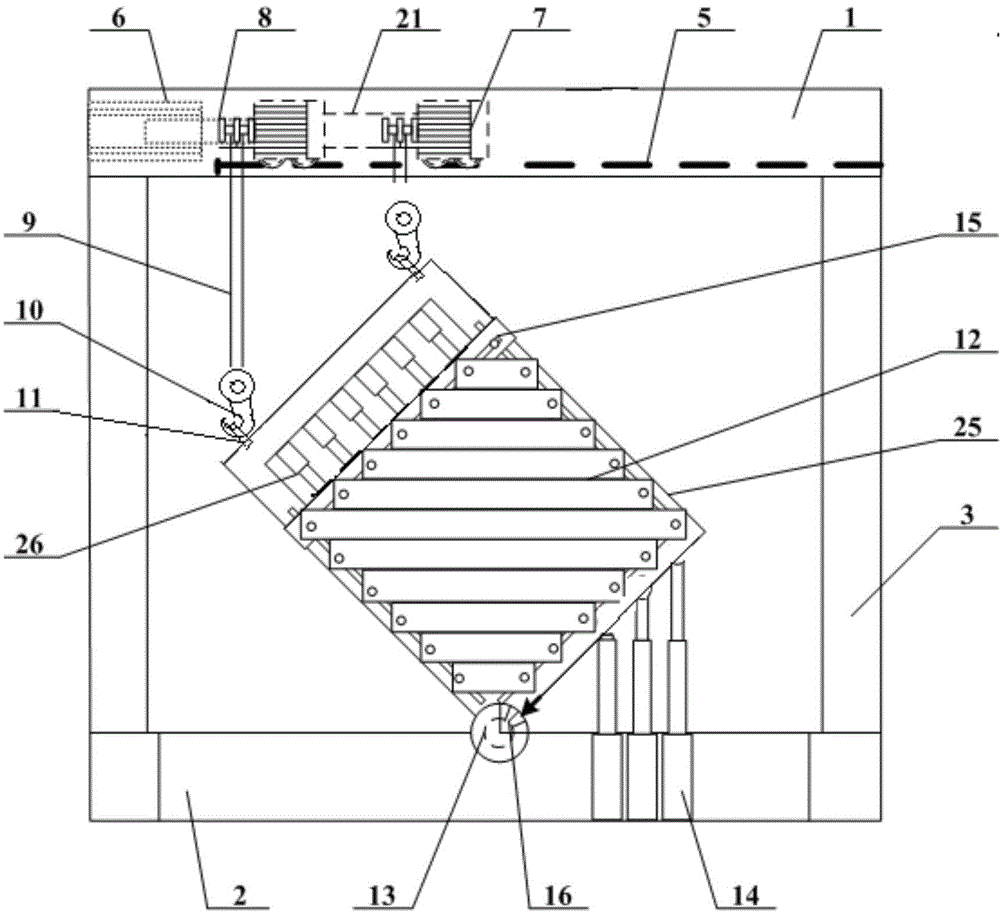

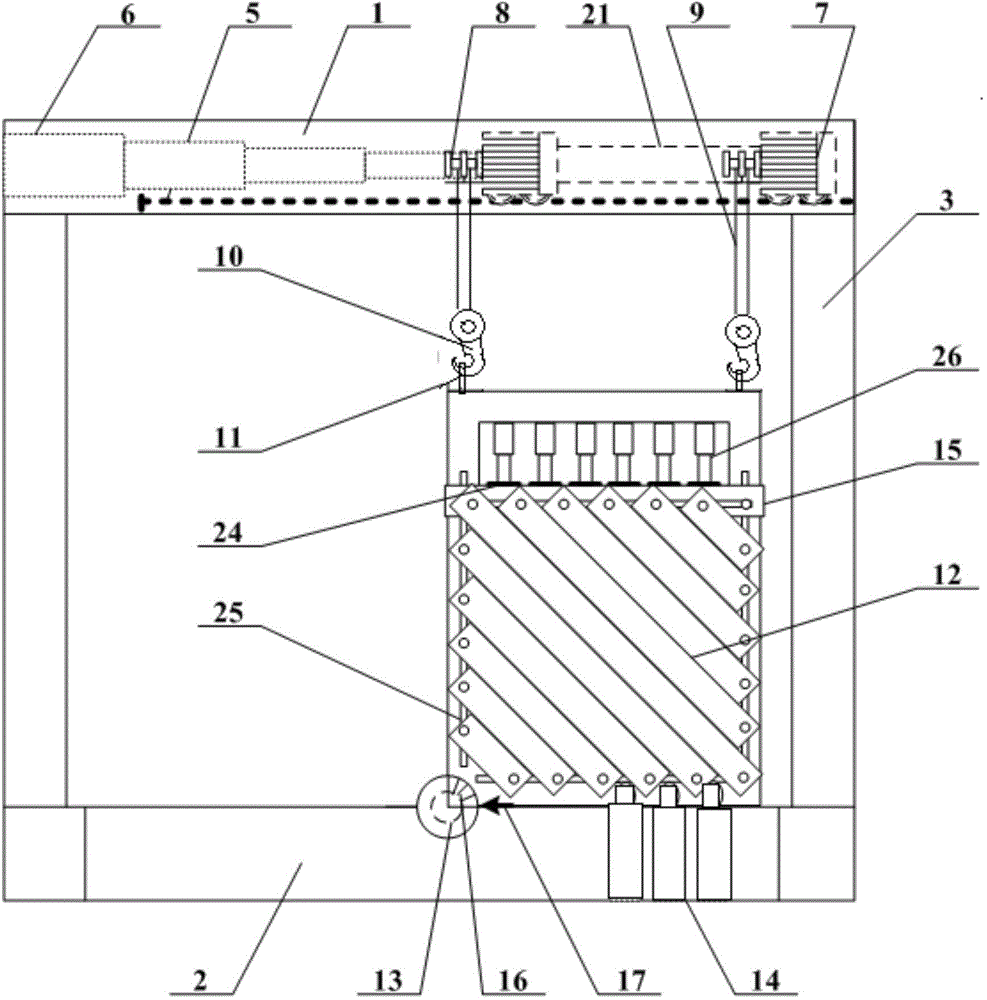

[0042] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] Such as figure 1 --As shown in 7, a physical similarity simulation test device for inclined rock formations is composed of an external frame, a tiltable frame, front and rear baffles, a hydraulic support device, and a suspension lifting device; wherein:

[0044] The external frame includes two vertical columns 3 , a transverse base 2 , an upper beam 1 and double pulley tracks 5 . The transverse base 2 is fixed on the ground by bolts, and the inner lower end surface of the upper beam 1 is equipped with parallel double pulley tracks 5 . The left and right vertical columns 3 are fixed on the base 2 and the upper beam 1 as a whole by bolts.

[0045] The aforementioned external frame has a length of 5 m, a height of 3.8 m, and a width of 0.4 m. Among them, the left and right columns are tetrahedral steel plates whose length×width×height are 0.2m×0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com