Patents

Literature

292results about How to "No protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

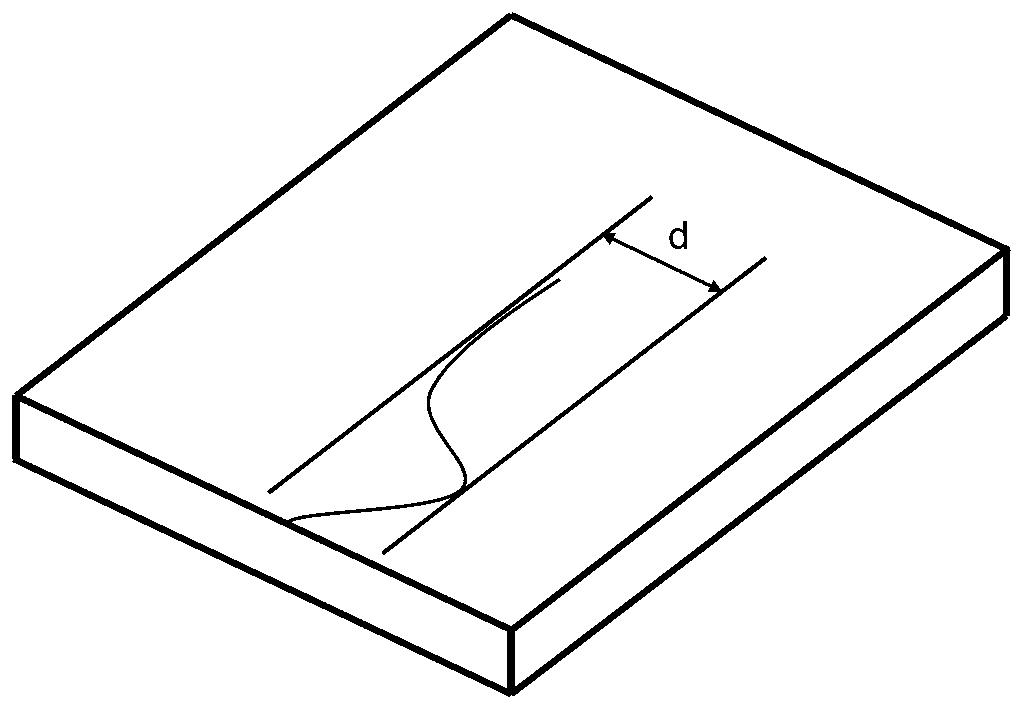

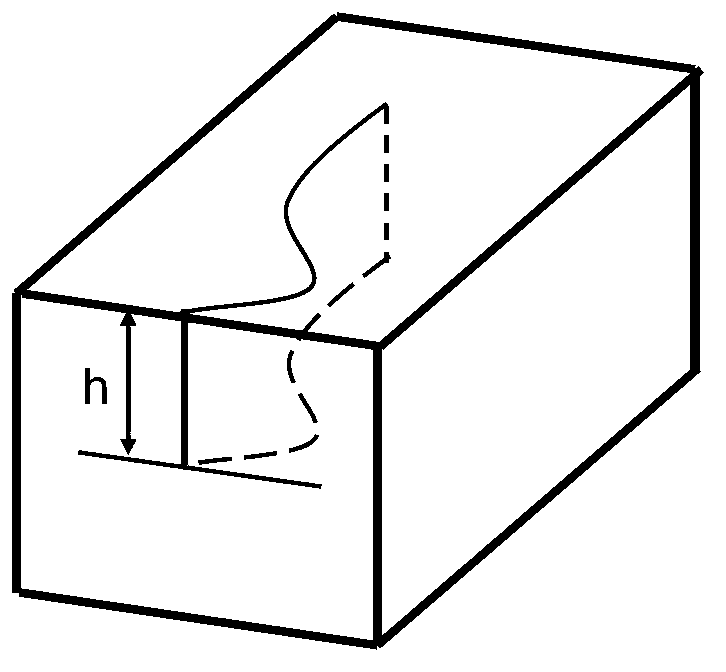

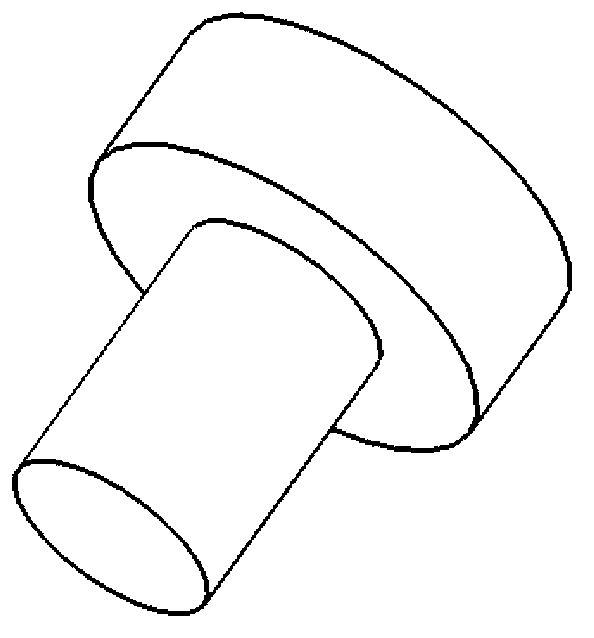

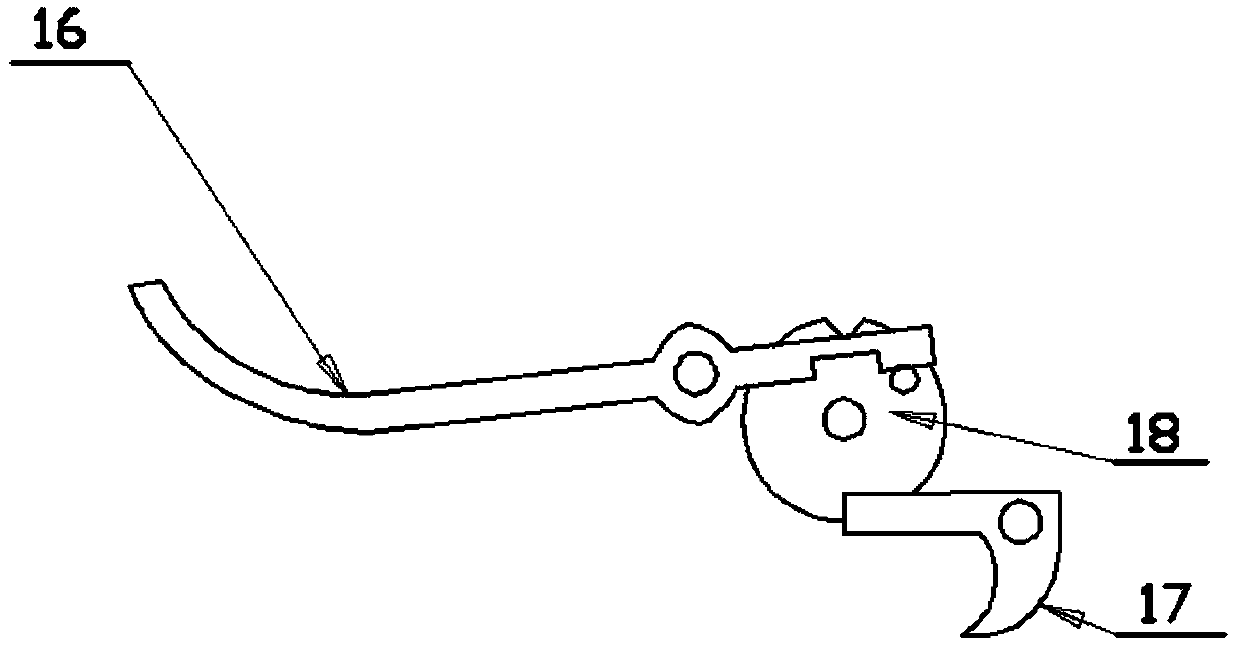

Stirring-friction-based crack repair method

InactiveCN103212778AReduce distortionReduce stressNon-electric welding apparatusUltimate tensile strengthAstronautics

The invention relates to a stirring-friction-based crack repair method which mainly is used for solving the problems in the prior art that the repair cost is high, the repair quality is poor and cracks appear repeatedly. The method is applied to the repair of surface cracks and through cracks of plate-shell metal structures, so as to enable cracked workpieces to meet reuse requirements. The method comprises the following specific steps of designing and manufacturing a friction repair tool according to the position and size of a crack, a material to be repaired, structural characteristics and the like; and realizing the friction between a shaft shoulder and the surface of the material to be repaired through the rotation of the repair tool so as to enable metal of a repair area to reach a thermoplastic state under the action of frictional heat, and realizing the flowing transfer and dynamic recrystallization of thermoplastic metal around the crack by using the rotating and upsetting action of the shaft shoulder of the repair tool, thereby realizing the filling repair of the crack. The method has the advantages that the method is simple, the damage to base metal is little, the quick, equal-strength and in-situ repair of engineering cracks can be realized, and the repair process is economical and environment-friendly. The method can be applied to the crack repair in fields, such as aeronautics and astronautics, shipbuilding, automobiles and rail transportation and has broad application prospects.

Owner:SHENYANG AEROSPACE UNIVERSITY

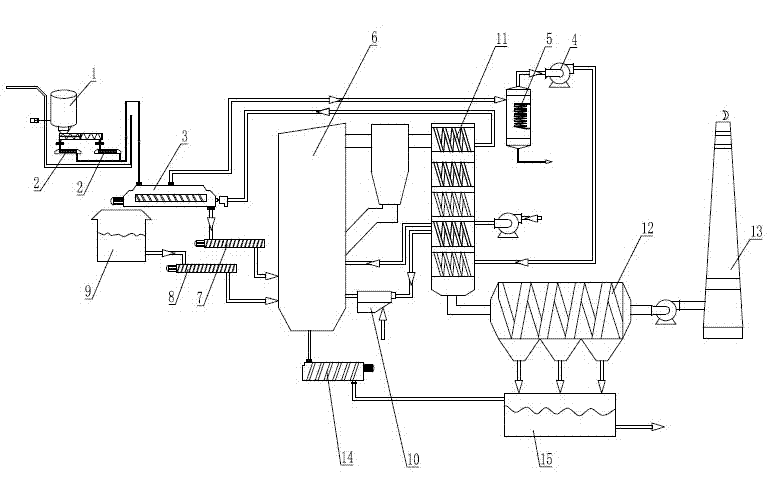

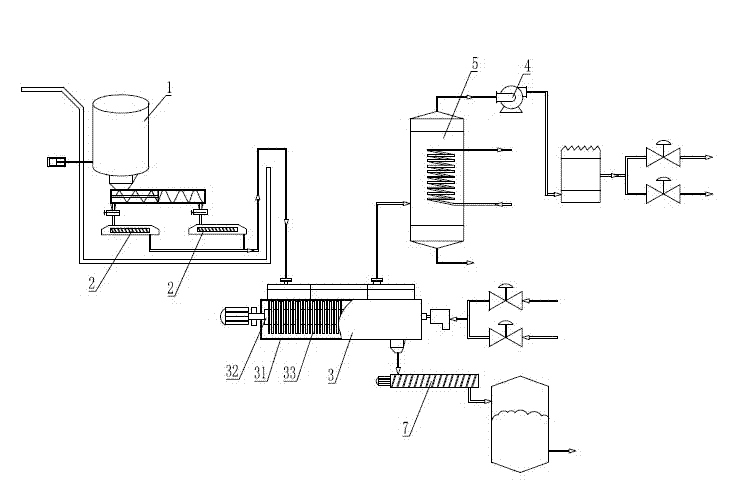

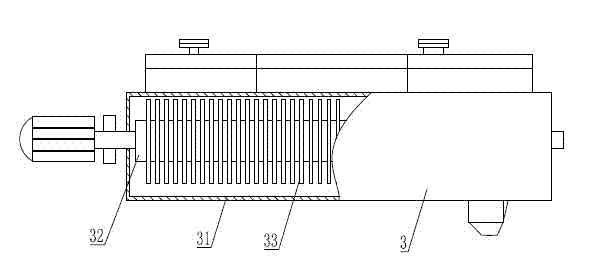

Water-containing sludge treatment method

InactiveCN102887619ANo protectionImprove operational reliabilitySludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeIncineration

The invention discloses a water-containing sludge treatment method which comprises the following steps of: conveying sludge into a sludge drying machine, heating and drying; conveying semi-dry sludge into a sludge incinerator; introducing air into the sludge incinerator after passing through an ignition device; enabling high-temperature smoke generated by incinerating sludge to pass through a waste heat recycling device, and then discharging the high-temperature smoke to the air through a smoke purifying and dust-removing system; and conveying residues generated by incinerating the sludge to an ash storage bunker. The semi-dry incineration of the sludge adopts the mode that the sludge directly passes through the sludge drying machine to reach a low-dryness and semi-dry degree and then enters the incinerator for being incinerated; and in the drying process, no full-dry sludge is generated, and the back-mixing operation is not needed. The water-containing sludge treatment method has the advantages that developed and reliable sludge drying and incineration devices are adopted, thus a system has high operation reliability; the dry sludge back-mixing operation is not needed for a semi-drying system, thus the dust quantity is low and the oxygen content and temperature are low during operation, the system is high in safety, and inert gas protection is not needed; and the whole system does not generate dust and odor during operation, and is environmental-friendly.

Owner:张开晓

Method for preparing heavy metal ion adsorption materials of crop straws

InactiveCN103992446ANo pollution in the processNo protectionOther chemical processesWater/sewage treatment by sorptionAdsorption equilibriumPhytic acid

The invention relates to a method for preparing heavy metal ion adsorption materials of crop straws. The method is characterized by comprising the following processing steps: adding straw powder into N, N-dimethyl formamide; putting the straw powder and the N, N-dimethyl formamide into an ultrasonic rinsing tank for ultrasonic cleaning at a certain temperature for a certain time; then adding phytic acid and urea into the above system, heating to 50-90 DEG C, cooling products to a room temperature after reaction for a certain time, and then precipitating, washing, drying and grinding the products to obtain phytic acid modified straws; neutralizing itaconic acid with NaOH, then adding the phytic acid modified straws, acrylamide, vinyl pyrrolidone and cross-linking agents, after the mixture is fully stirred, gradually heating to 40-60 DEG C, and finally slowly and dropwise adding redox initiators into the polymerization system to initiate a polymerization reaction that lasts for 3-5 hours; after the polymerization is completed, performing precipitation, washing and drying to obtain the heavy metal ion adsorption materials of crop straws. The adsorption capacity reaches 50-800mg / g for heavy metal ion water solutions of which the initial concentration is 100-1000mg / l, and adsorption equilibrium is reached after adsorption at the room temperature for 50-150 min.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

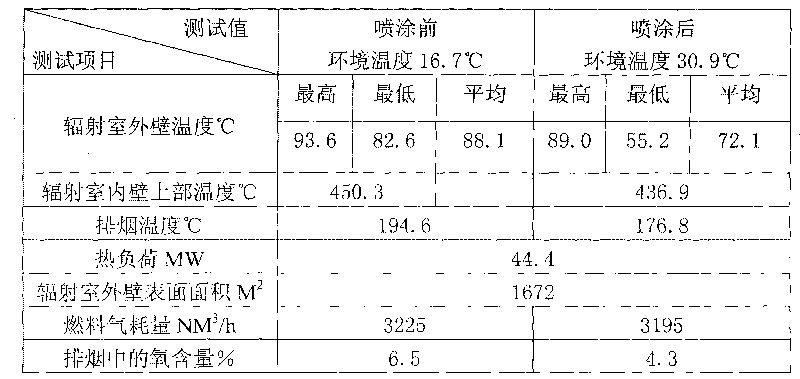

High-temperature counter radiation resistant inorganic coating and preparation method thereof

InactiveCN101760058AImprove thermal shock resistanceImprove thermal efficiencyFireproof paintsAlkali metal silicate coatingsPhosphateOxidation resistant

The invention relates to an energy-saving high-temperature counter radiation resistant inorganic coating for coating the liner of a kiln and a preparation method thereof. The coating mainly comprises oxides, such as cobalt oxide, zirconium oxide powder, aluminum oxide and chromic oxide, and silicon powder, silicon carbide, sodium silicate, aluminium dihydrogen phosphate, silica flour, graphite powder, boron oxide and other components and is prepared by grinding, soaking, heating reaction, stirring and mixing. The coating has high thermal shock resistance, high radiation utilization rate, high corrosion resistance, high cracking resistance, high oxidization resistance and high thermal stability. The inorganic coating of the invention has the advantages of allowing for normal construction without making special modification of the basal body of the kiln, along with small investment, quick response, no toxicity, no corrosion and desirable social and economic benefits.

Owner:上海乐恒石油化工集团有限公司

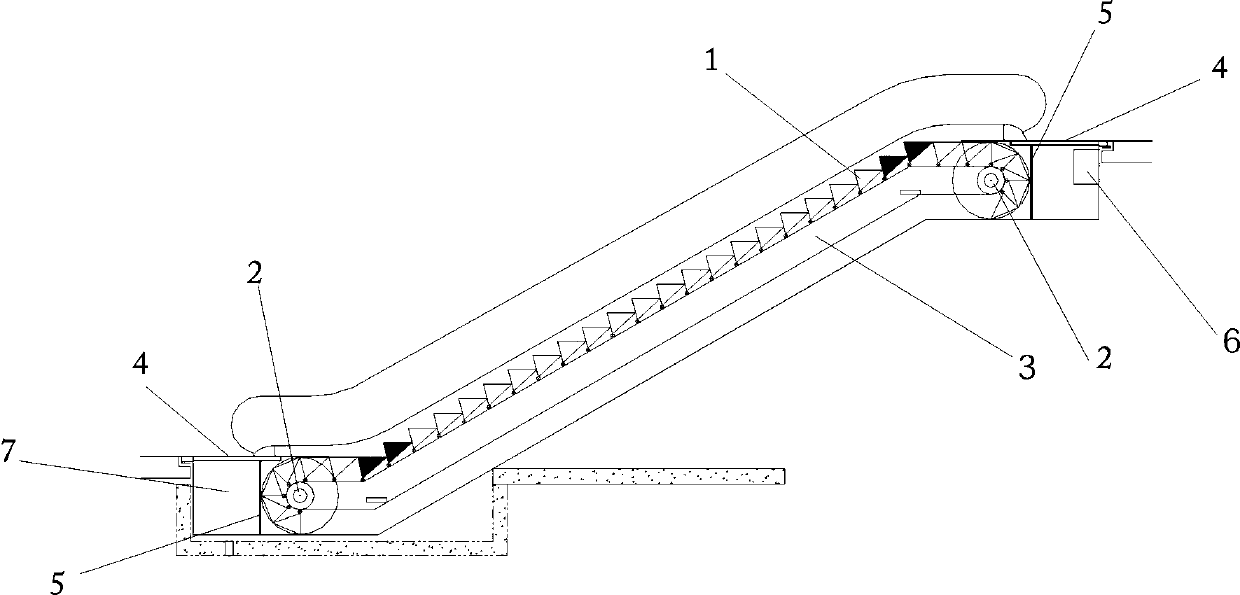

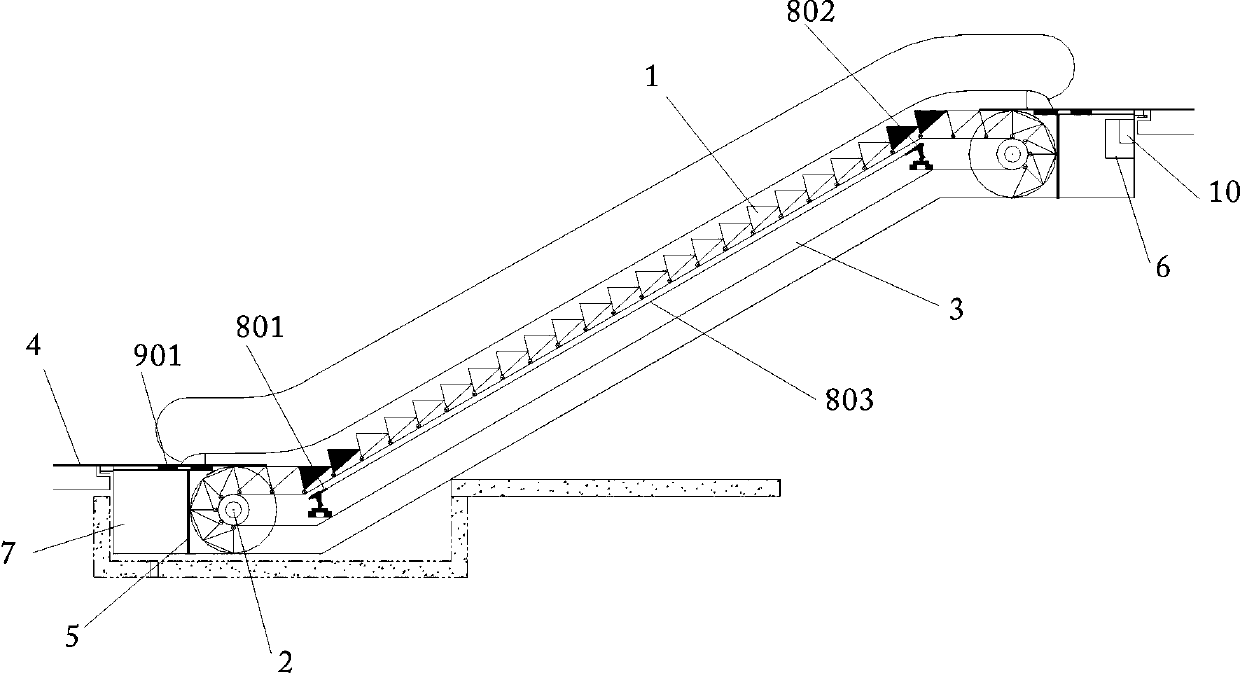

Escalator safety system

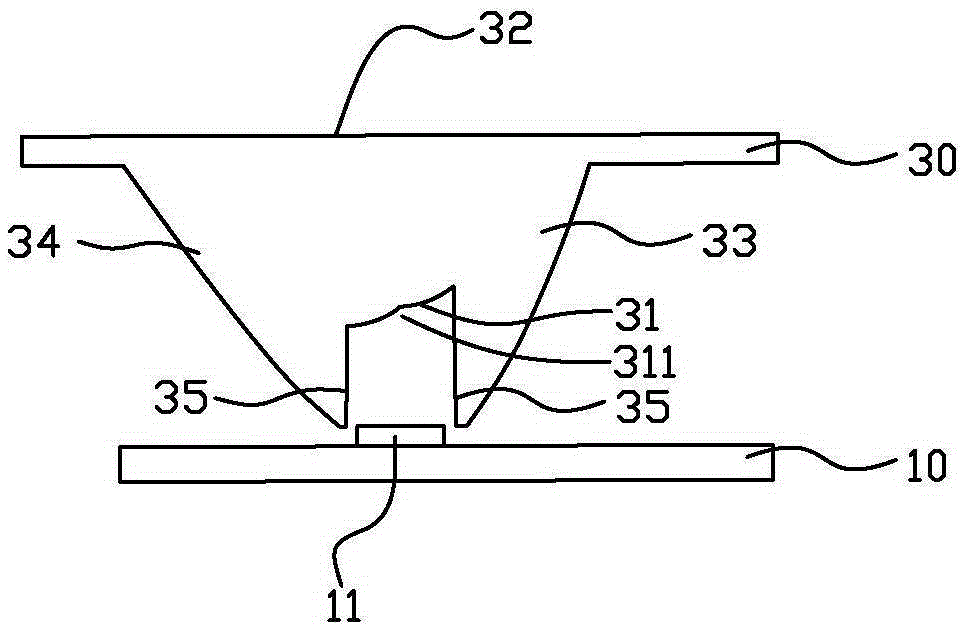

ActiveCN105502141ASolve the layout intensive energy consumptionFix layout sparse response notEscalatorsLaser transmitterComputer module

The invention discloses an escalator safety system which comprises a monitoring relay, a processing module, a laser emitter and a laser receiver. The output end of the monitoring relay is connected into an escalator operation loop. The processing module controls the monitoring relay to be closed and opened. The laser emitter is provided with a laser emitting opening and arranged at the high end of an escalator and the emitting opening faces the low end of the escalator or the laser emitter is arranged at the low end of the escalator and the emitting opening faces the high end of the escalator. The laser receiver receives laser from the laser emitter and is in signal connection with the processing module. The laser receiver and the laser emitter which are matched are arranged at the high end and the low end of the escalator respectively. The laser emitter and the laser receiver are arranged in a well of the escalator. According to the escalator safety system, the problem that power is consumed due to the fact that infrared detectors are arranged densely or response is not in time due to the fact that infrared detectors are arranged sparsely is solved, one induction line can monitor multiple stairs at the same time, the detectors can achieve feedback immediately once the stairs fall down, the number of required detectors is small, and power consumption is low.

Owner:JILIN BAIQIANG TECH CO LTD

Method for preparing polyatomic alcohol from crop straw

InactiveCN101186560AEasy to buySimple reaction conditionsPreparation by hydrolysisAgricultural residueChemistry

The invention relates to a method of preparing polyhydric alcohol by using crops straws, comprising the steps: counting by mass portion, 100 portions of organic solvent and 1 to 6 portions of catalyst are evenly mixed, then 15 to 40 portions of crops straws are added under 80 to 210 DEG C, and the polyhydric alcohol can be obtained by reacting for 60 to 240min. The method fully utilizes rich and reproducible agricultural residue; the hydroxyl value of the obtained polyhydric alcohol is 180 to 850mg KOH / g; crops straw catabolites of different contents and polyhydric alcohol of different hydroxyl values can be obtained by adjusting the production process and the portions according to requirements. The production process of the invention is simple and the invention can be directly used for synthesizing polyurethane foam plastics without the need of post-processing procedures of vacuum dehydration, product separation, etc.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

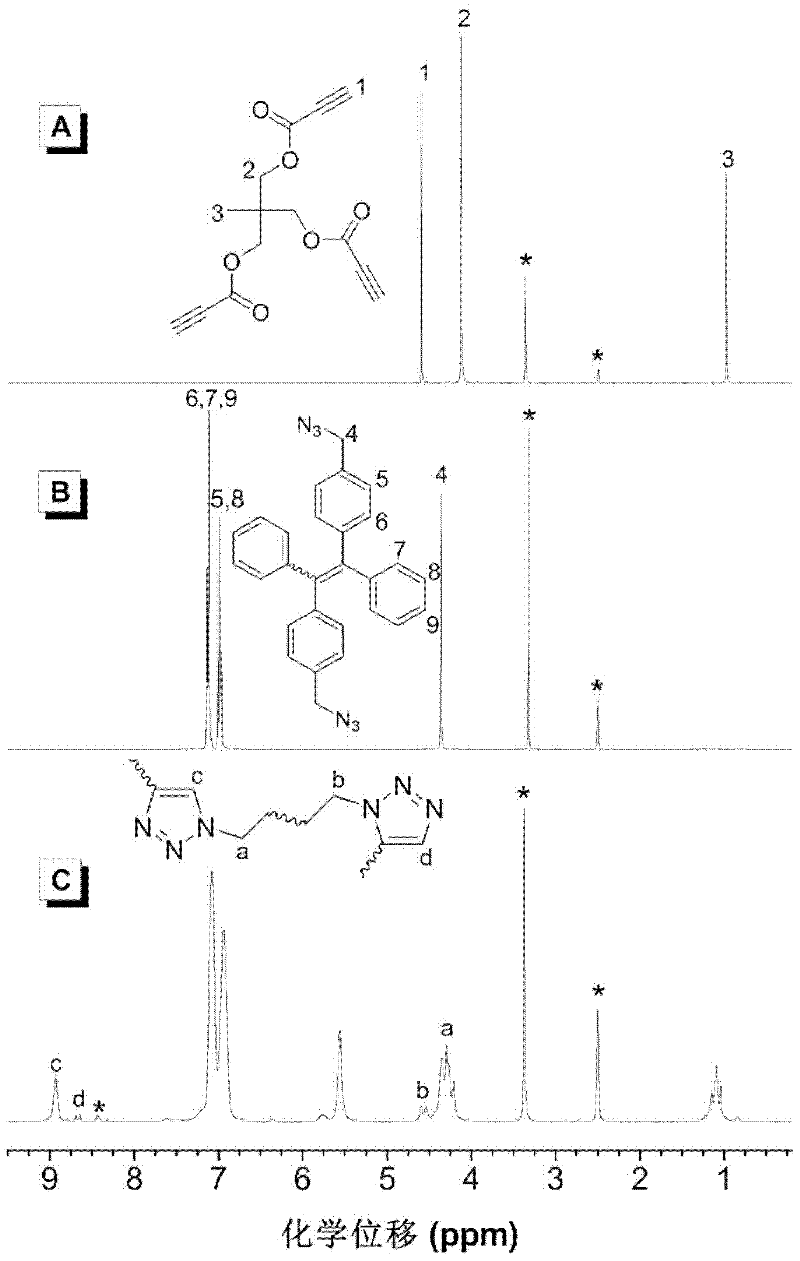

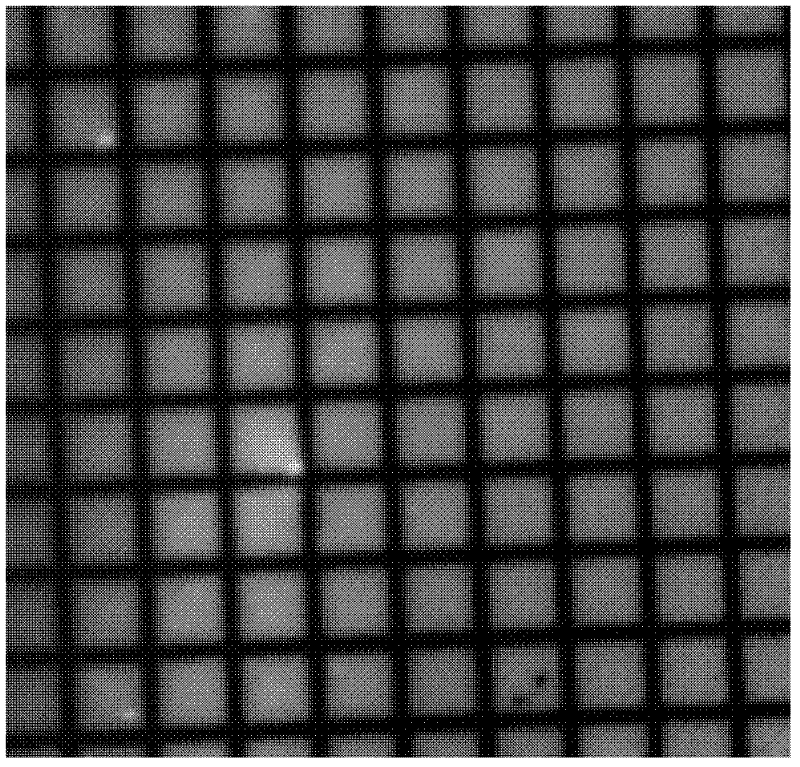

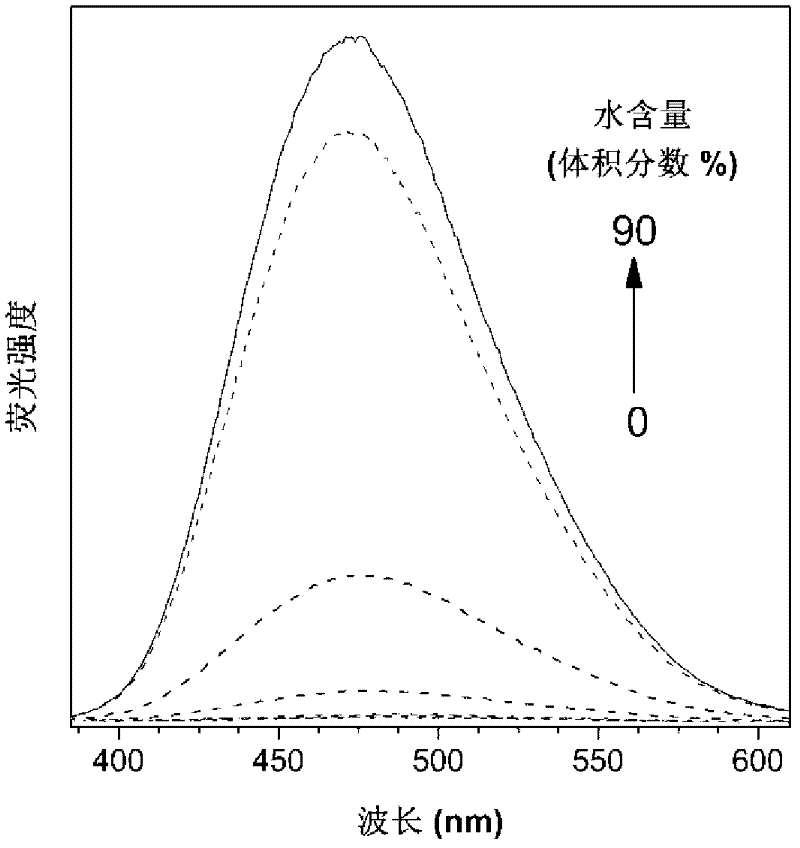

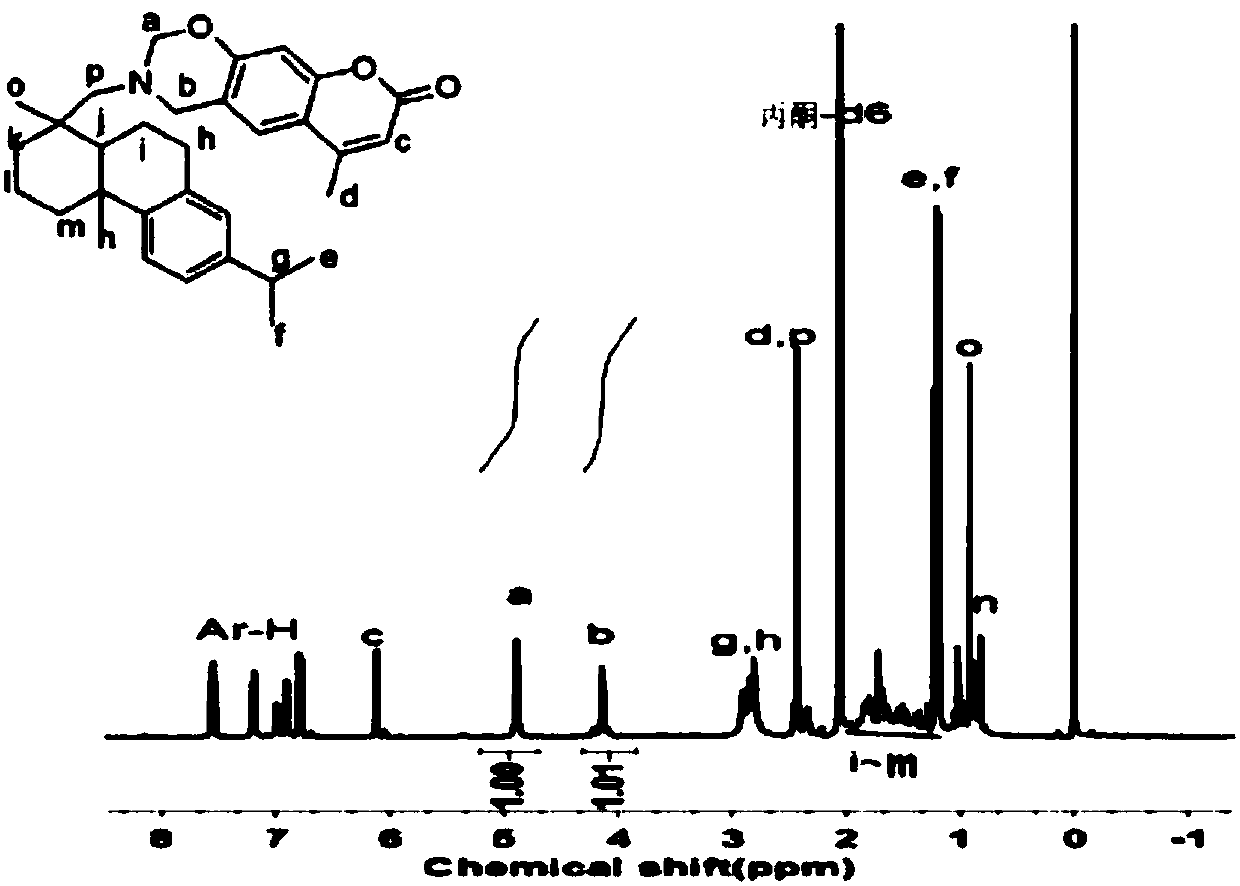

Hyperbranched polytriazole formate as well as preparation method and application thereof

ActiveCN102585220AHigh StereoselectiveNo protectionFluorescence/phosphorescenceLuminescent compositionsFormateSolvent

The invention discloses hyperbranched polytriazole formate as well as a preparation method and application thereof. The preparation method of hyperbranched polytriazole formate comprises the following steps: firstly, synthesizing binary azide containing a tetraphenyl ethylene unit; then synthesizing a ternary ester compound containing alkynyl based on ternary alcohol and propiolic acid as raw materials; and finally, carrying out non-metal-catalytic 'click' polymerization reaction under the heating condition in a polar solvent by utilizing the azide and the alkynyl-containing ester compound soas to obtain a target polymer in high yield. The hyperbranched polytriazole formate prepared by using the method is high in 1,4-stereoregularity, good in workability and high in thermal stability, degradability, illumination patterning and aggregation-induced emission property. The invention also discloses application of hyperbranched polytriazole formate in detection of a polynitroarene explosive.

Owner:ZHEJIANG UNIV

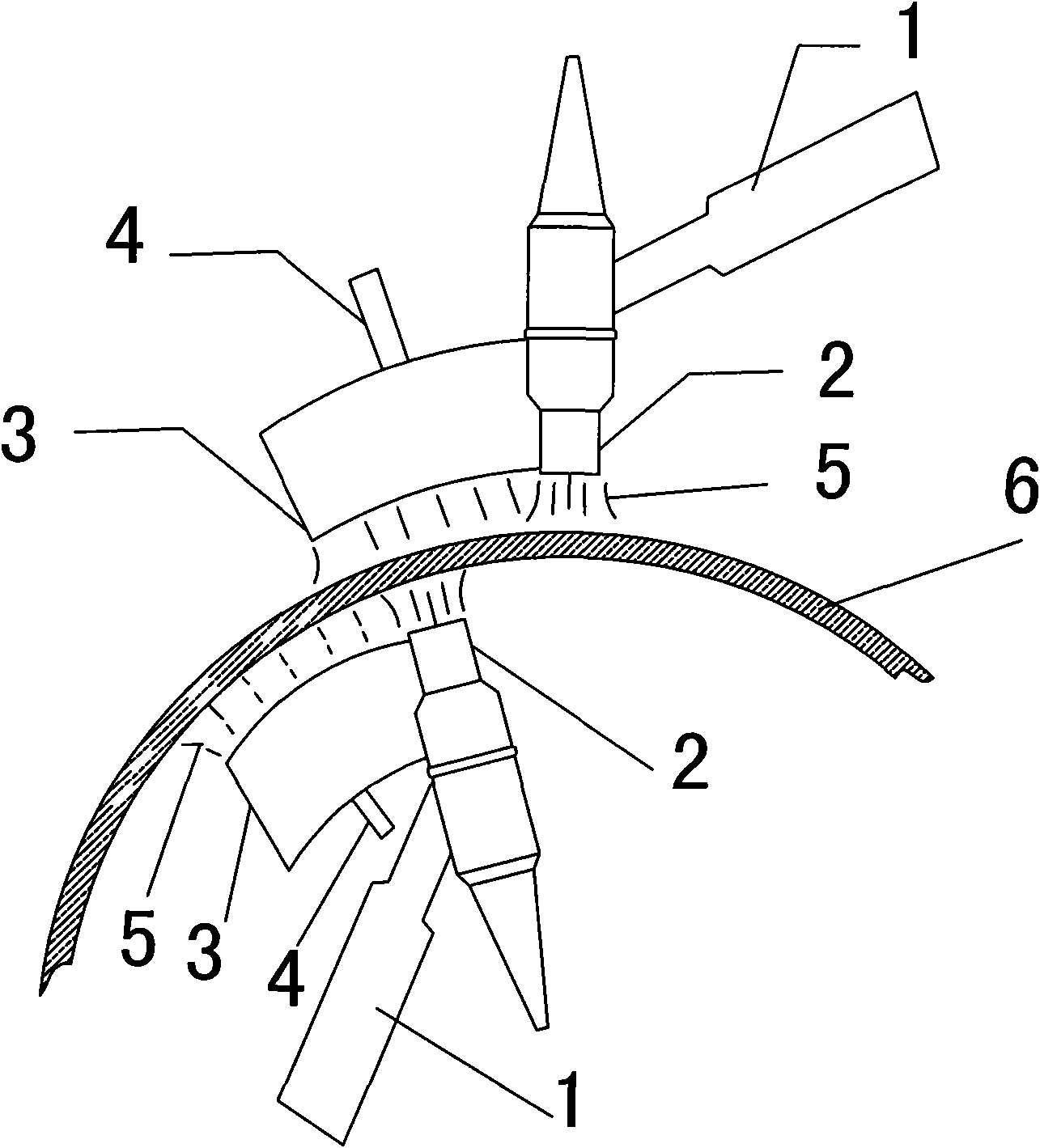

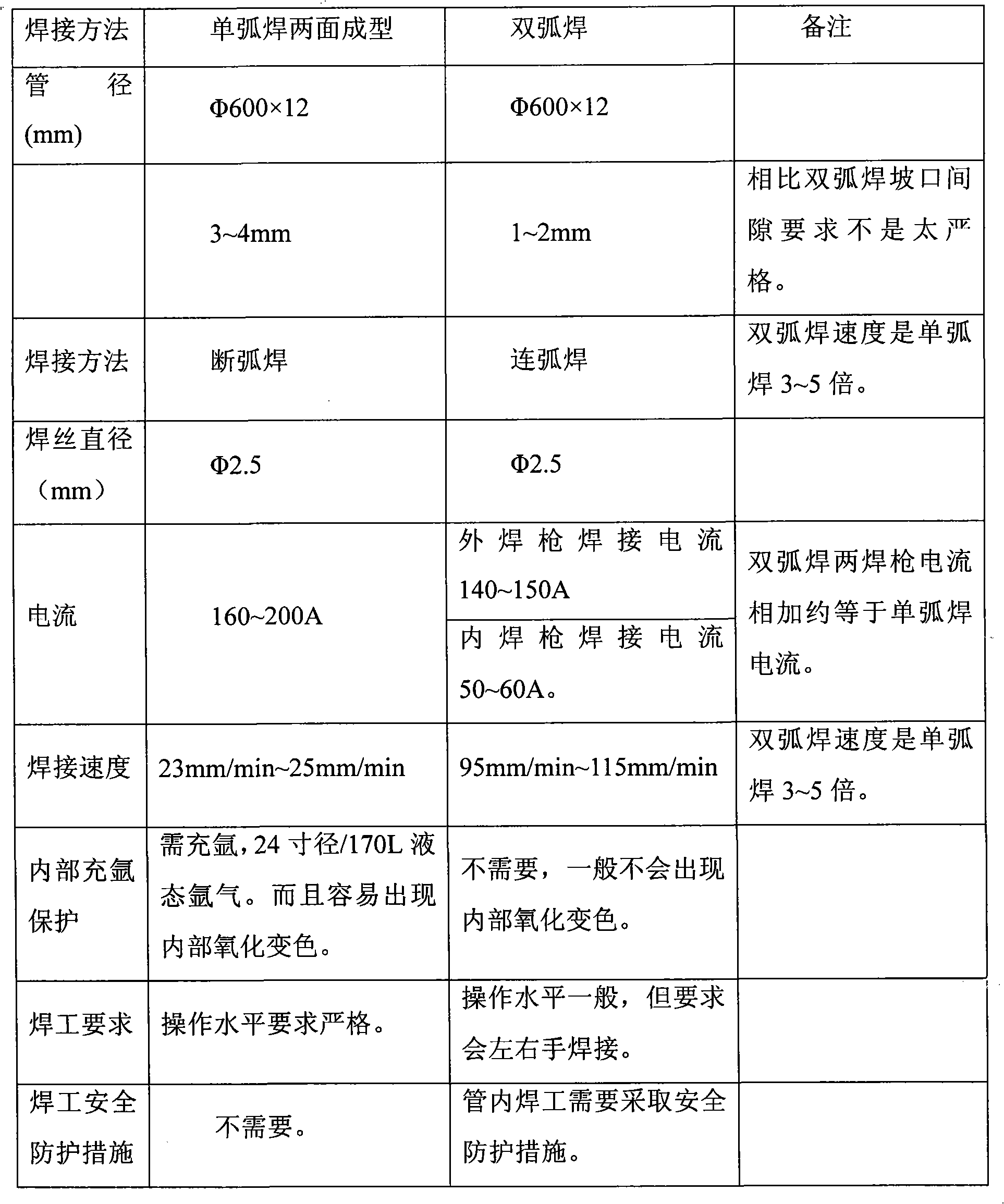

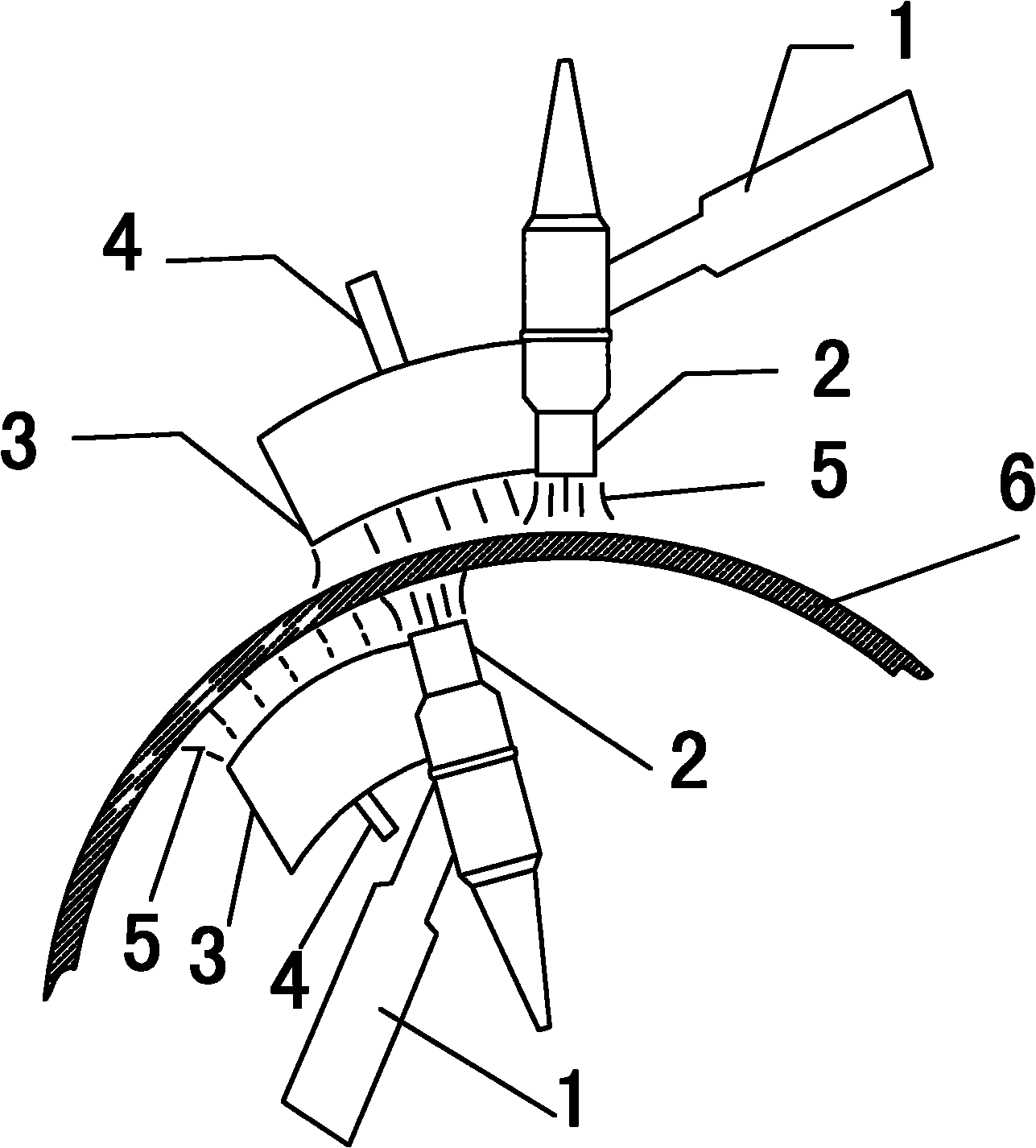

Bottom sealing twin arc welding method of large-caliber industrial pure titanium pipelines

ActiveCN102069274ANo protectionPlay a protective effectArc welding apparatusTubular articlesPower flowNonferrous metal

The invention relates to a bottom sealing twin arc welding method of large-caliber industrial pure titanium pipelines, which belongs to the technical field of pipeline welding and is suitable for root welding of large-caliber (phi is larger than or equal to 600mm) titanium pipelines, equipment and other non-ferrous metals. The method comprises the following steps of: cleaning greasy dirt and oxides on the surfaces of solder wires and weldments; chamfering pipelines; fitting up the pipelines, wherein the fitting-up gap is 1-2mm; and welding the titanium pipelines by simultaneously using two welding guns inside and the outside the titanium pipelines, wherein argon tungsten arc welding guns with protection dragging covers are adopted, during welding, the welding gun nozzles are in the front, and the protective dragging covers are on the back; and the argon flow of the outer welding gun nozzle is 25-30L / min, the argon flow of the inner welding gun nozzle is 15-20L / min, the argon flow of the dragging cover of the outer welding gun is 25-35L / min, the argon flow of the dragging cover of the inner welding gun is 25-30L / min, and the current of the outer welding gun is 140-160A. The method has the advantages of easy control of welding line molding quality, high welding speed, energy and raw material saving, and the like, wherein the welding speed is 3-5 times as fast as single arc welding.

Owner:SINOPEC TENTH CONSTR

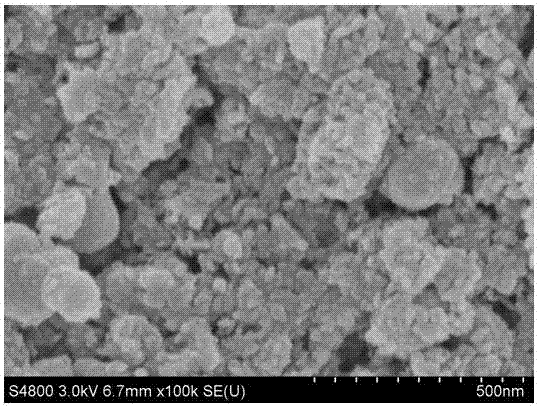

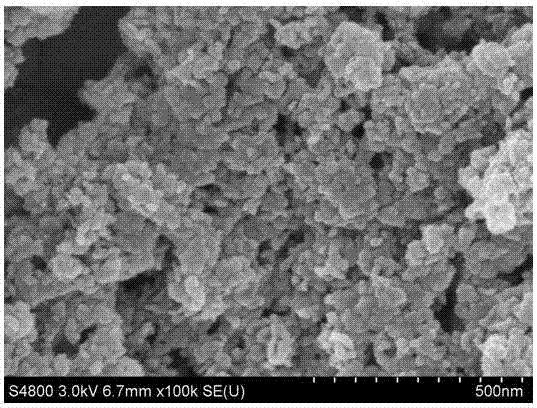

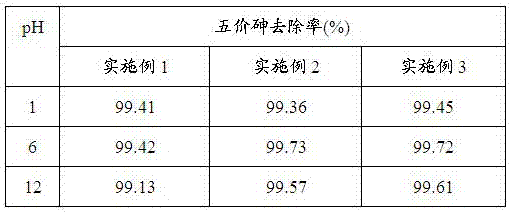

Arsenic removal adsorbent and preparation method thereof

InactiveCN106943984ALarge specific surface areaLarge pore volumeOther chemical processesWater contaminantsFenton reactionSorbent

The invention relates to a preparation method of an arsenic removal adsorbent and a preparation method thereof. The preparation method sequentially comprises the following steps: preparation of magnesium aluminum hydrotalcite; introduction of hydrogen peroxide to a laminated plate interlayer; a non-homogeneous Fenton reaction; and pickling. The adsorbent is applied to adsorb and remove arsenic from water. The preparation method has the advantages of simplicity and low cost, and the prepared adsorbent has the characteristics of ordered mesoporous pores, uniform particle size, high specific surface area and high pore volume, can be massively applied to high efficiency removal of arsenic from wastewater, and can be easily regenerated.

Owner:XIAN TECH UNIV

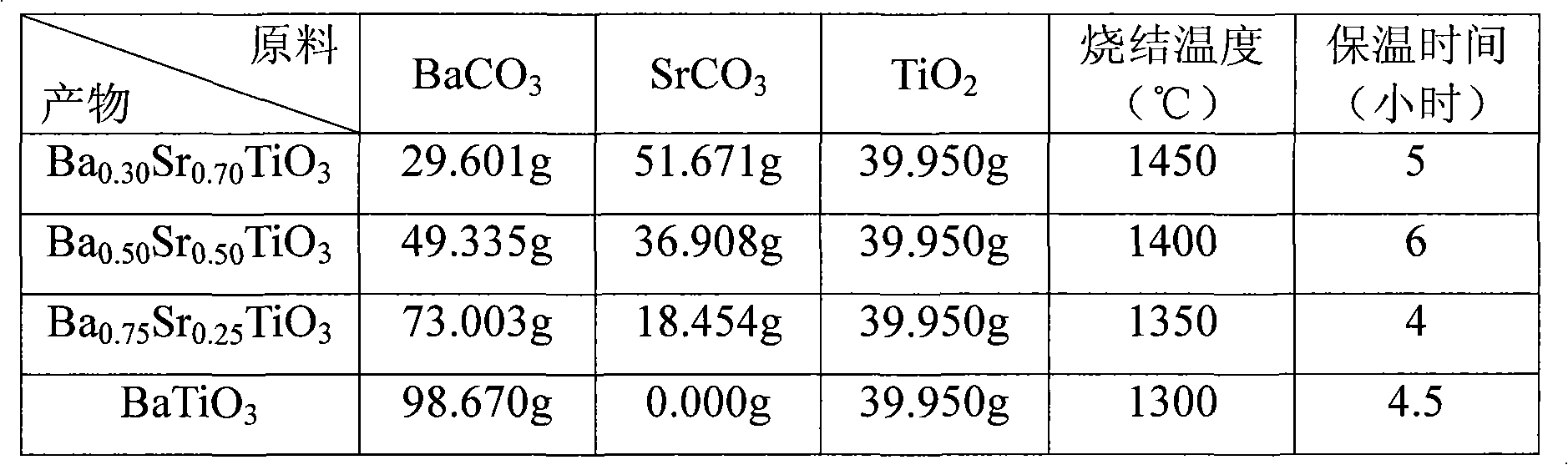

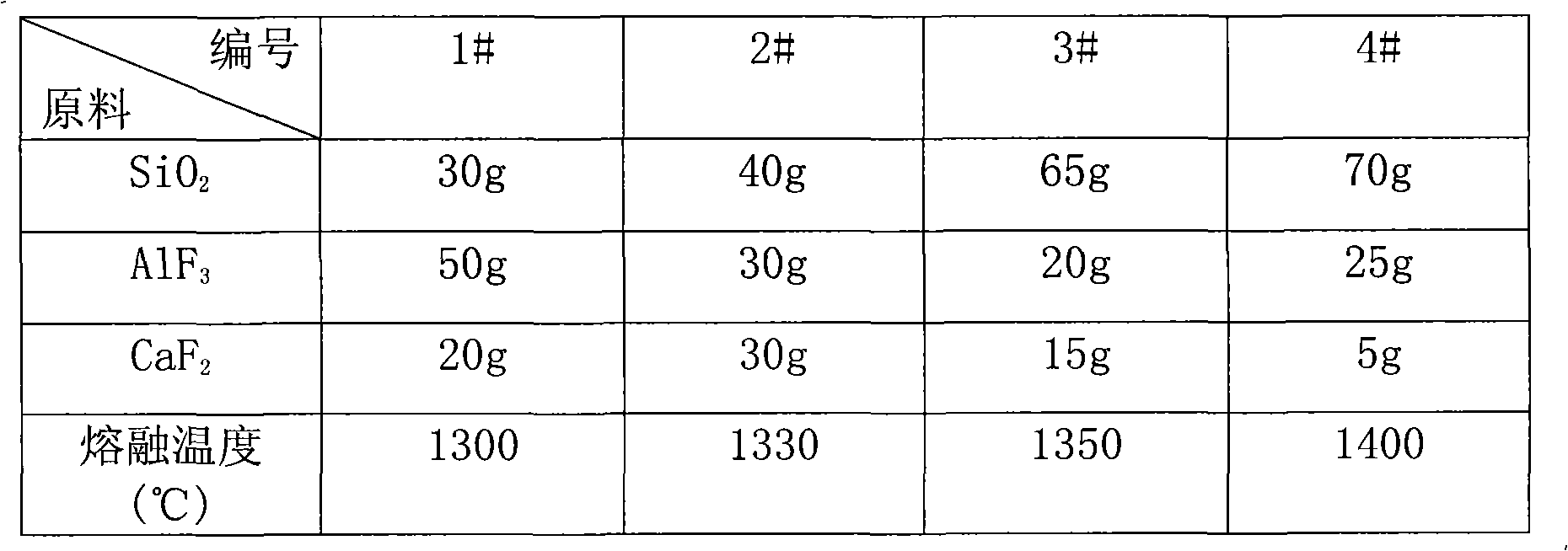

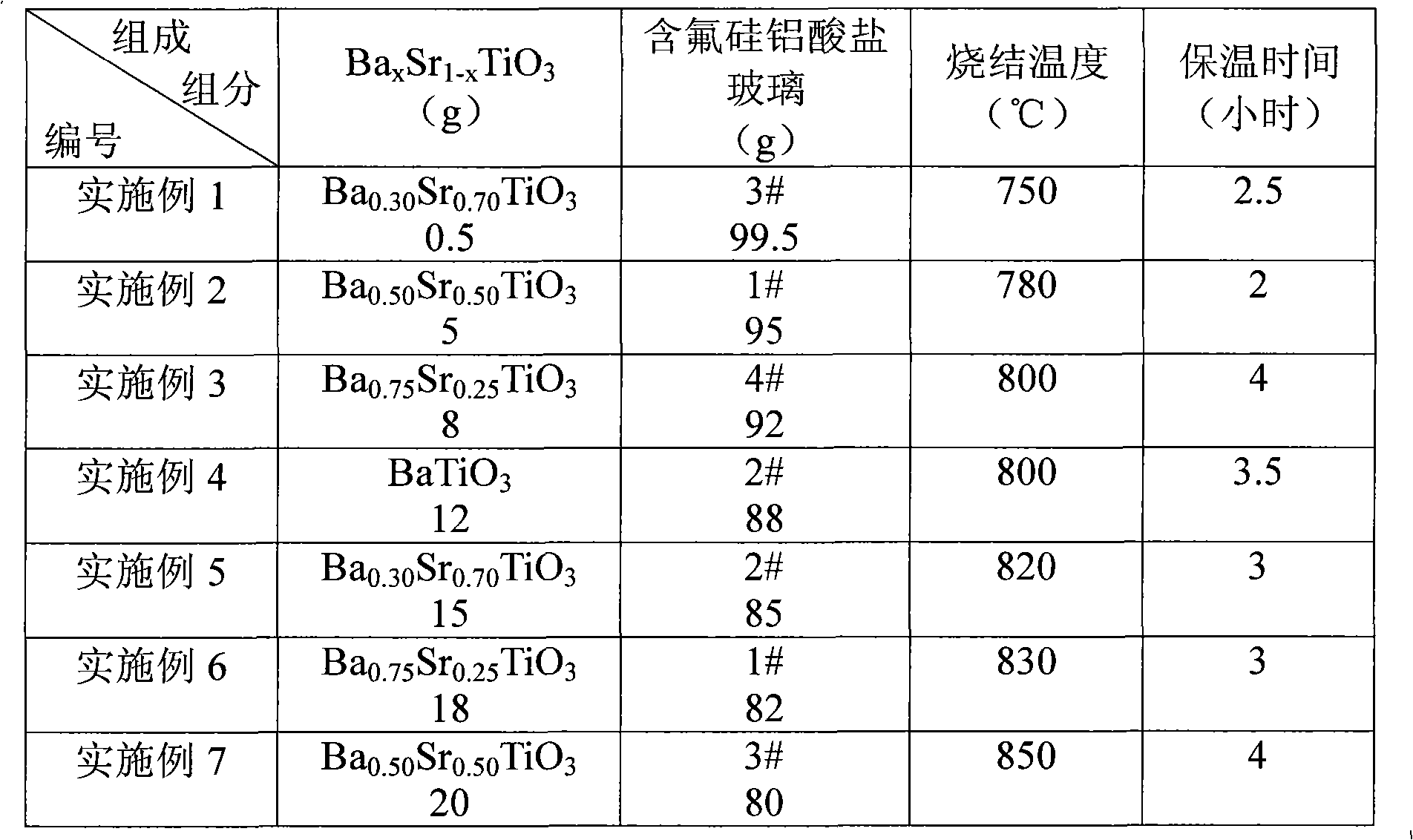

Low-temperature co-fired glass ceramic composite material with adjustable dielectric constant and preparation method thereof

The invention discloses a low-temperature co-fired glass ceramic composite material with adjustable dielectric constant and a preparation method thereof. The composite material is prepared from the following raw materials in percentage by mass: 0.5 to 20 percent of BaxSrl-xTiO3(x=0.3-1) and 80 to 99.5 percent of fluorinated aluminosilicate glass; wherein, the fluorinated aluminosilicate glass is prepared from the following raw materials in percentage by mass: 30 to 70 percent of SiO2, 20 to 50 percent of AlF3, and 5 to 30 percent of CaF2. After being mixed by the ratio, the components are added with ethanol or water, ball milled for 24h and dried to obtain low-temperature co-fired glass ceramic powder. The low-temperature co-fired glass ceramic composite material has the advantages that: (1) the sintering temperature is low (750 to 850DEG C) and the sintering shrinkage rate is 8 to 15 percent; and (2) the dielectric constant is adjustable from 8 to 50 (1GHz), and the dielectric loss is below 0.002 and the mechanical strength is higher. Consequently, the invention is applicable to low-temperature co-fired ceramic materials and electronic packaging materials.

Owner:TSINGHUA UNIV

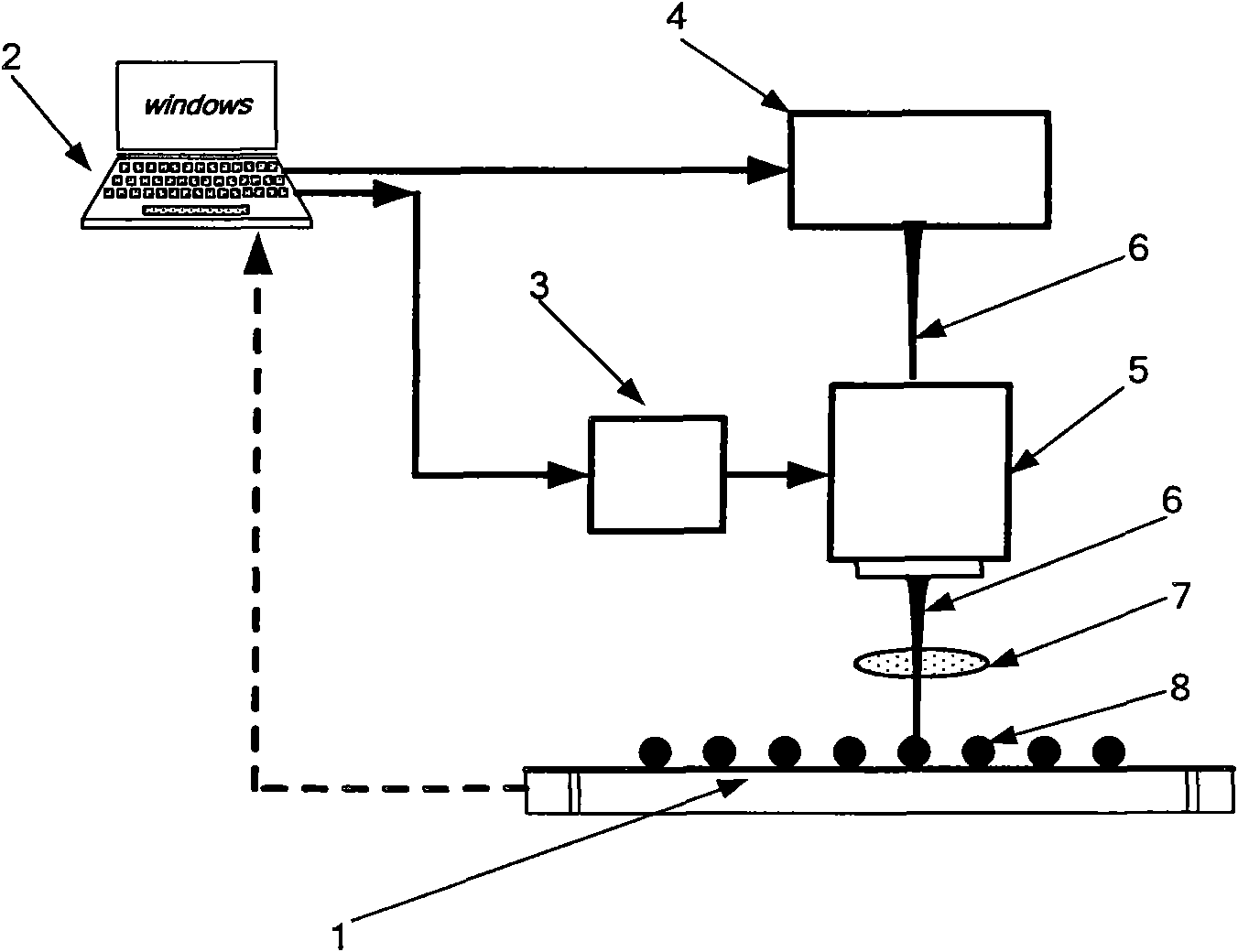

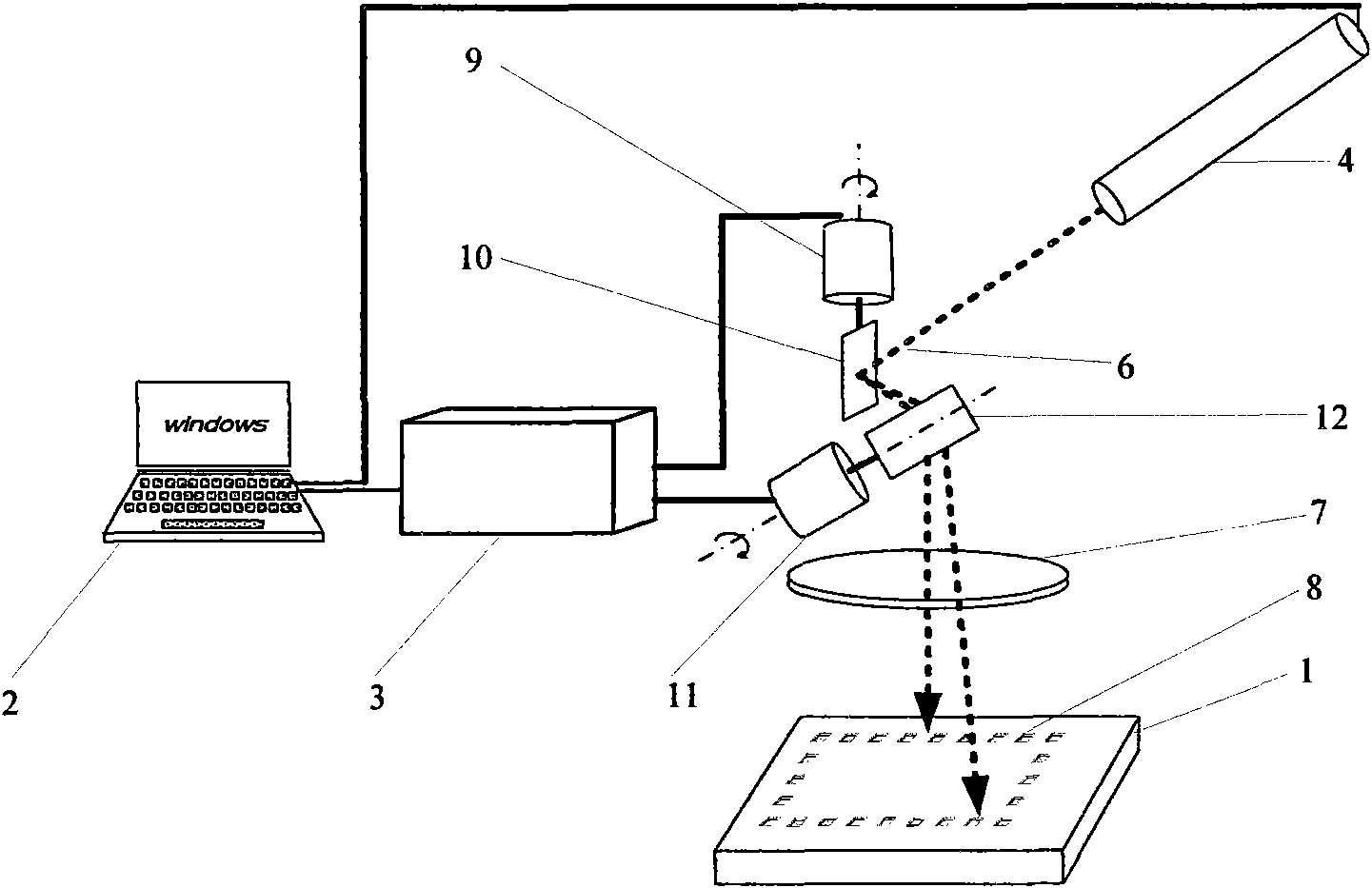

Method for producing leadless brazing alloy salient point by laser

InactiveCN101556925AAvoid harmImprove machining accuracySemiconductor/solid-state device manufacturingLaser beam welding apparatusGalvanometerBraze alloy

The invention provides a method for producing a leadless brazing alloy salient point by laser, comprising: coating leadless brazing alloy on the position for planting a ball on a substrate and placing the substrate on a process plane; then inputting the position data of the substrate ball planting position into a computer followed by computer programming for ball planting route planning; forming control signals of the planned ball planting route and sending the formed control signals into a control member and a laser by the computer; sequentially setting the various processing parameters; controlling a scanning galvanometer to work in cooperation with the laser by the control member, scanning the substrate coated with the leadless brazing alloy according to the ball planting route by the laser beam followed by the melting of the leadless brazing alloy; then moving the laser beam away, solidifying the leadless brazing alloy, forming metallurgical bonding with the substrate, and so far forming the leadless brazing alloy salient point. The leadless brazing alloy salient point produced by the invention is environment-friendly, harmless to human body, and the invention has fast processing and high processing accuracy, the processing requires no protection gas, so that the processing is simple and the automation degree is high.

Owner:SOUTH CHINA UNIV OF TECH

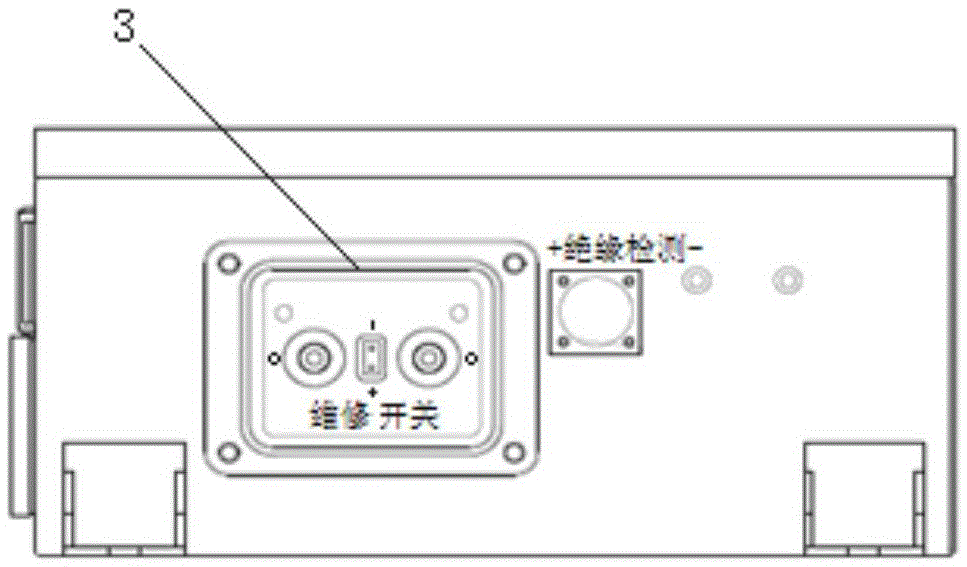

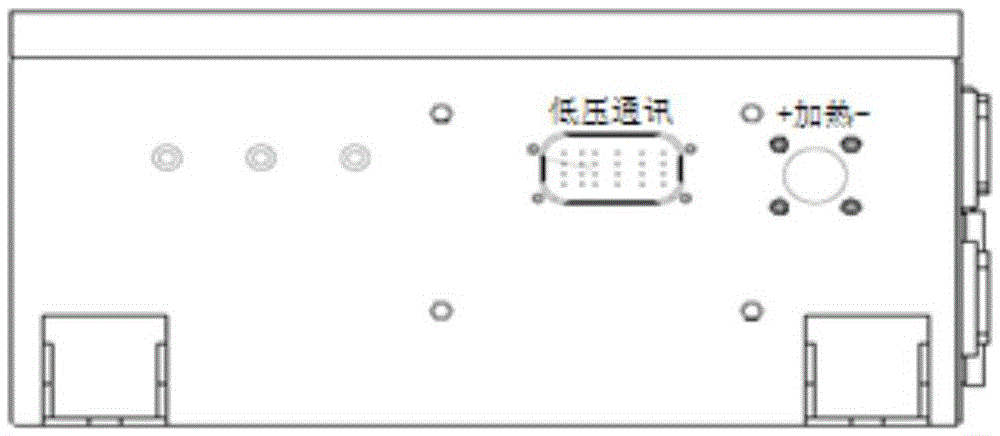

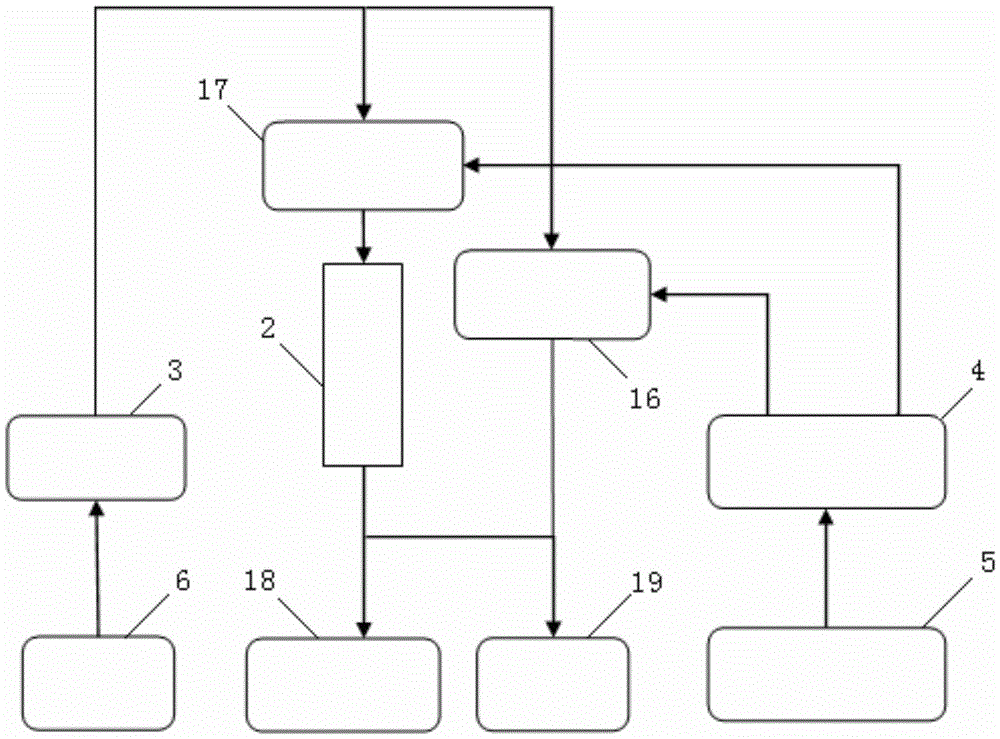

High-voltage distribution box based on vehicle-mounted CAN bus network

InactiveCN105539157AIncrease transfer rateImprove anti-interference abilityElectric devicesElectric vehicle charging technologyLow voltagePre-charge

The invention relates to a high-voltage distribution box based on a vehicle-mounted CAN bus network. The high-voltage distribution box comprises a high-voltage distribution box body, a high-voltage power supply part and a low-voltage control part, wherein the high-voltage distribution box body comprises a high-voltage distribution box housing and an insulating terminal; the high-voltage power supply part comprises a high-voltage connector socket, a copper bar, contactors, a pre-charge resistor, fuses, a maintenance switch and a high-voltage interface; the low-voltage control part comprises a low-voltage wire harness, a high-voltage distribution box control panel and a low-voltage interface. The high-voltage distribution box has the following superior effects: communication with a vehicle control unit is realized by a CAN bus, so that opening / closing of the contactors can be directly controlled; the CAN bus is excellent in anti-interference performance and stability and high in transmission rate; the high-voltage distribution box has the functions of low-voltage protection, overcurrent protection, starting current limitation, insulating detection, switch maintenance, fault code diagnosis, CAN communication and the like, effectively guarantees the vehicle and personal security and ensures normal running of the vehicles.

Owner:NANJING YUEBOO POWER SYST CO LTD

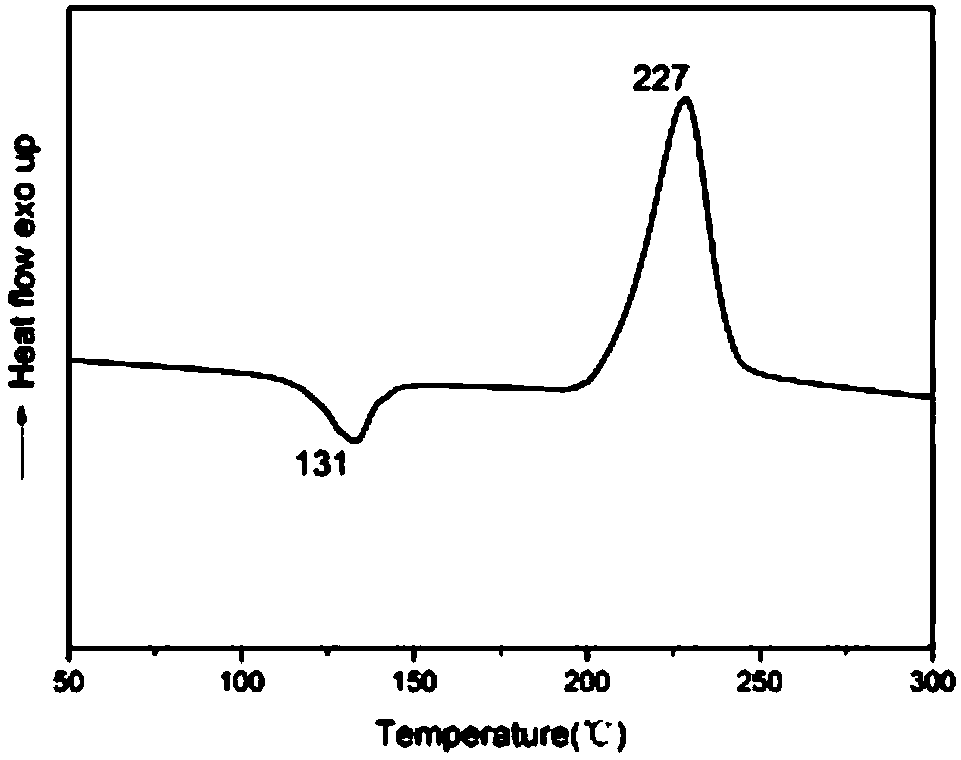

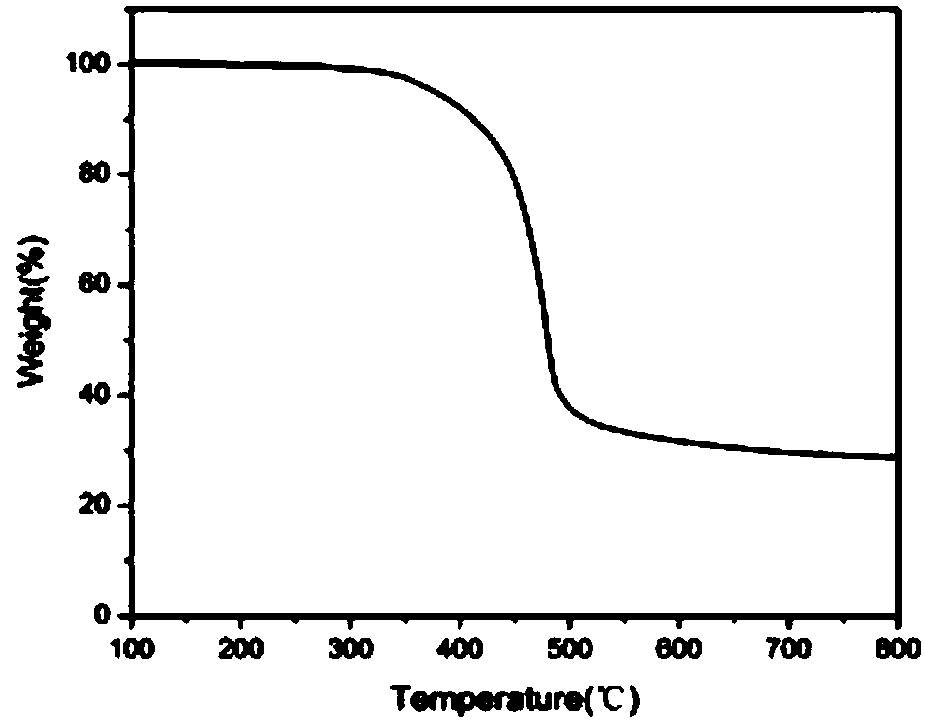

Total-biology-base benzoxazine resin and preparation method thereof

InactiveCN107759615AThe synthesis process is simpleThe synthesis process is reasonableOrganic chemistryAnti-corrosive paintsRosinPetroleum

The invention provides total-biology-base benzoxazine resin and a preparation method thereof. A monomer of the resin is prepared by reacting dehydroabietylamine as a rosin derivative, biological phenol and paraformaldehyde at the temperature of 85 DEG C with a solution method for 20 hours. The preparation method comprises the following steps: cooling reactants to room temperature, washing with a sodium bicarbonate solution, washing with deionized water, and crystallizing with ethanol to obtain a purified monomer; performing ring-opening crosslinking on the monomer in a heating state or in thepresence of an added catalyst to generate the total-biology-base benzoxazine resin. The total-biology-base benzoxazine resin has the advantages of reasonable synthesis process, no need of inertial gasprotection, high product purity and environmental friendliness; compared with other biology-base benzoxazine and a part of petroleum-base benzoxazine, the obtained novel total-biology-base benzoxazine resin has great competitiveness on the aspects of ring-opening temperature and thermal stability, and shows high corrosion resistance.

Owner:EAST CHINA UNIV OF SCI & TECH

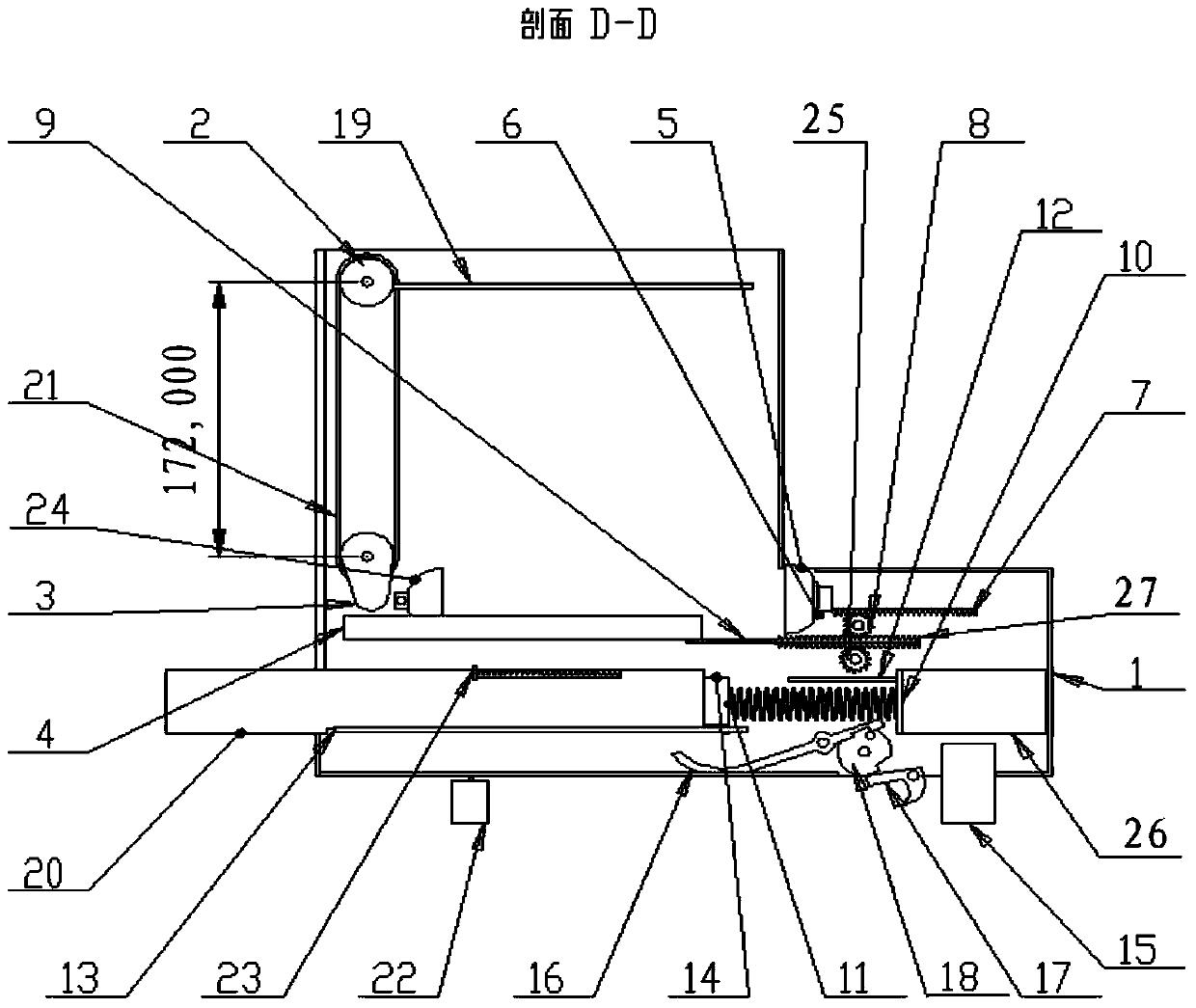

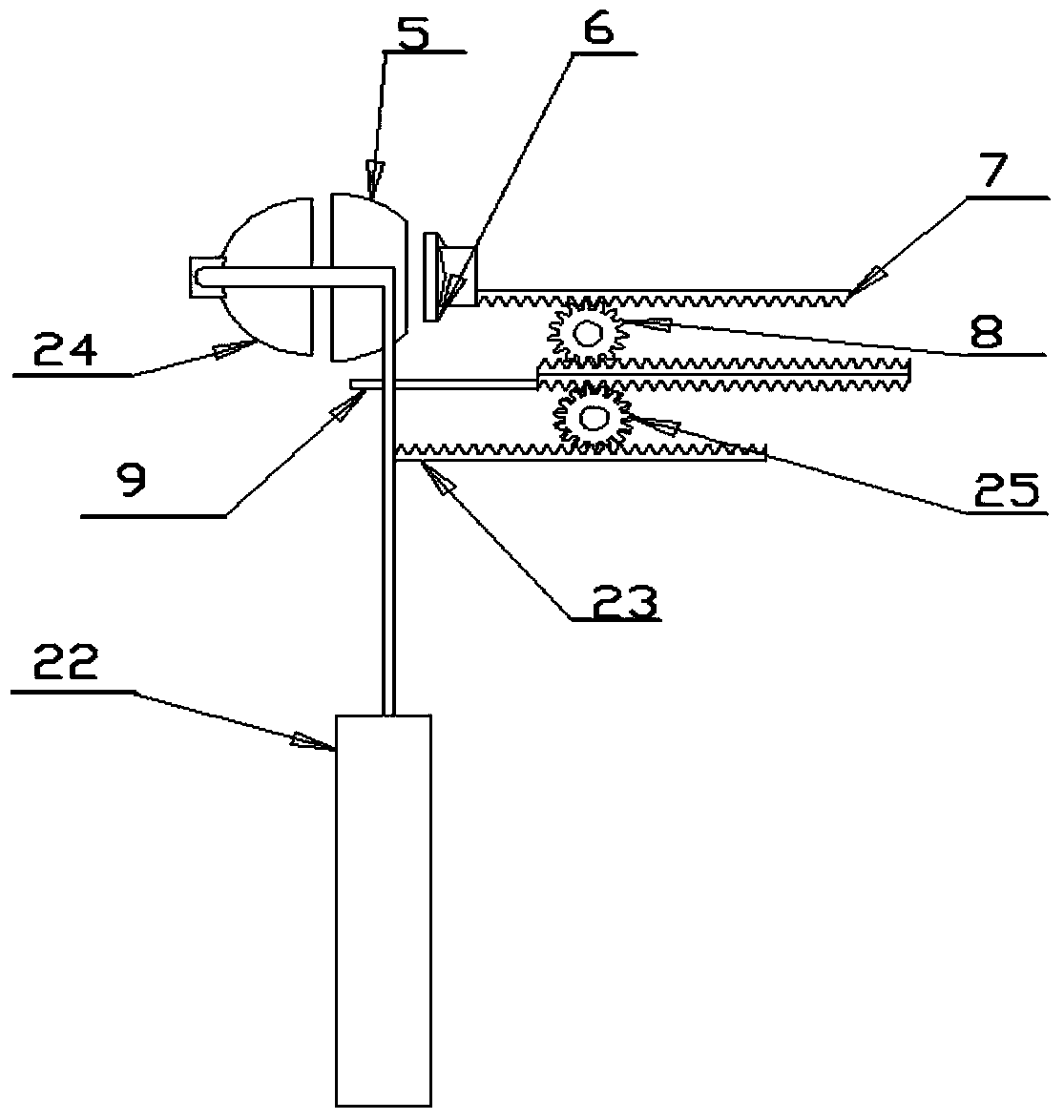

Snowball making machine gun

The invention discloses a snowball making machine gun. The machine gun comprises a snow storage device, a snowball making device and a snowball ejecting device, wherein the snow storage device comprises a snow storage bin, a fixed pulley is mounted above one side of the snow storage bin, a cam is mounted on the lower side of the same side where the fixed pulley is mounted, the fixed pulley and the cam are connected through a belt, a press plate is fixed on the belt, and the cam is contacted with a first casing of the snowball making device. By the aid of the snowball making machine gun, ejection of snowballs can be realized, all that is required is to slightly pull a trigger, and the snowballs can be ejected far. Thus, the strength is saved, and the farther snowball range can be realized.

Owner:QINGDAO UNIV

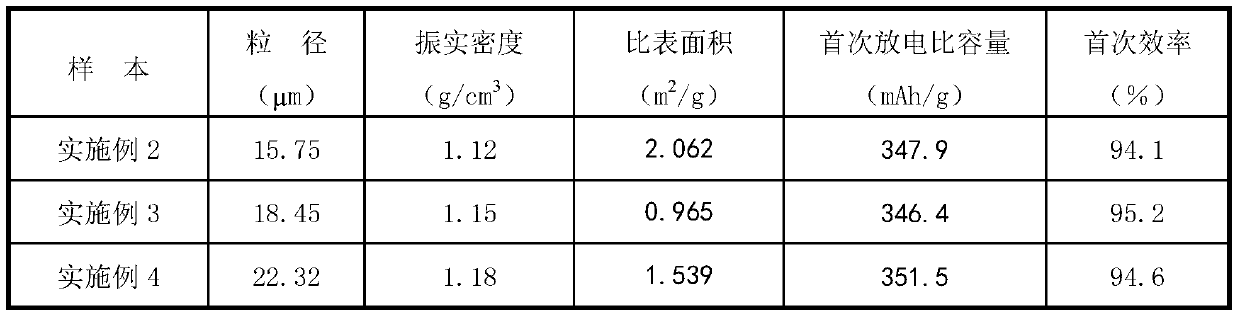

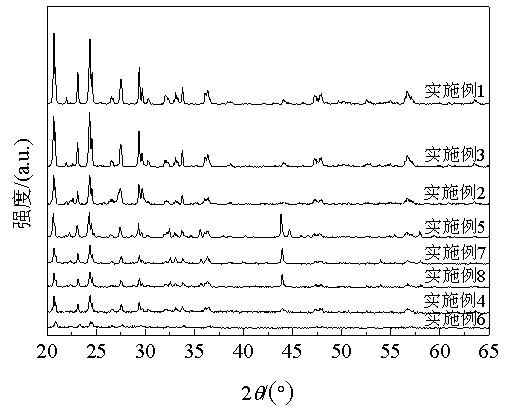

Preparation method of artificial graphite cathode material

The invention discloses a preparation method of an artificial graphite cathode material, and particularly relates to a preparation method of a clad lithium ion battery artificial graphite cathode material. The preparation method comprises the following steps: after reforming the artificial graphite by pulverization, cladding an ultramicropowder cladding material on the artificial graphite in a mechanical fusion machine, roasting, and graphitizing to obtain the artificial graphite cathode material with superior performance. The method is environment-friendly and can easily implement large-scale production; and the specific capacity per gram of the prepared lithium ion battery graphite cathode material exceeds 350 mAh / g, the initial Coulomb efficiency exceeds 94%, the tap density is greater than 1.1 g / cm<3>, and the specific area is less than 2 m<2> / g.

Owner:FANGDA CARBON NEW MATERIAL CO LTD

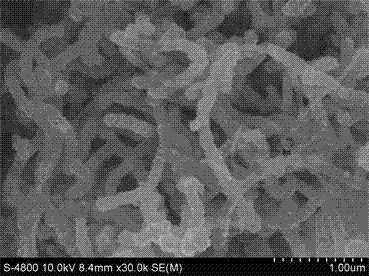

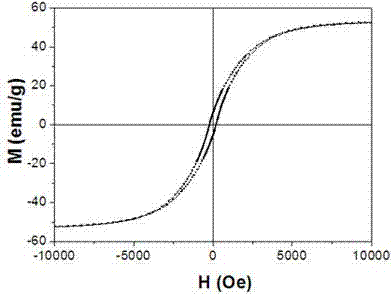

Carbon-nanometer-tube-based magnetic nanometer composite material and manufacturing method thereof

ActiveCN104124022ANo pre-functionalization requiredLow costInorganic material magnetismInductances/transformers/magnets manufactureManufacturing technologyChemical vapor deposition

The invention belongs to the technical field of nanometer materials, in particular to a carbon-nanometer-tube-based magnetic nanometer composite material and a manufacturing method thereof. In the method, a nitrogen-doped carbon nanometer tube is manufactured by the adoption of a chemical vapor deposition method, then, ferromagnetic metal nanometer particles are loaded on the nitrogen-doped carbon nanometer tube through a solvothermal method, and therefore the carbon-nanometer-tube-based magnetic nanometer composite material is obtained. The carbon-nanometer-tube-based magnetic nanometer composite material and the manufacturing method have the advantages that raw materials needed in the manufacturing method are low in cost, the manufacturing technology is simple, and carbon-nanometer-tube-based magnetic nanometer composite materials can be manufactured on a large scale and are suitable for large-scale production and application. The obtained composite material is good in dispersity, and the magnetic metal nanometer particles are evenly distributed on the surface of the nitrogen-doped carbon nanometer tube (CNx) in a granular mode and are uniform in size.

Owner:鉴翎环保科技(上海)有限公司

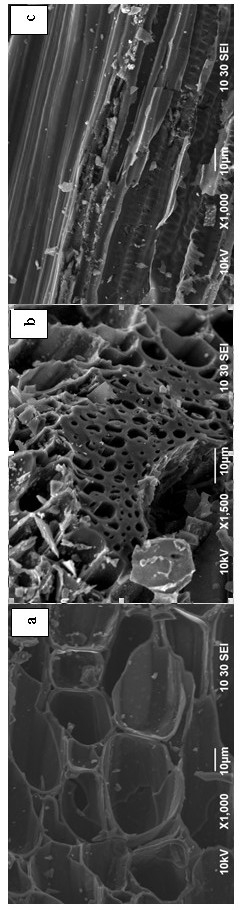

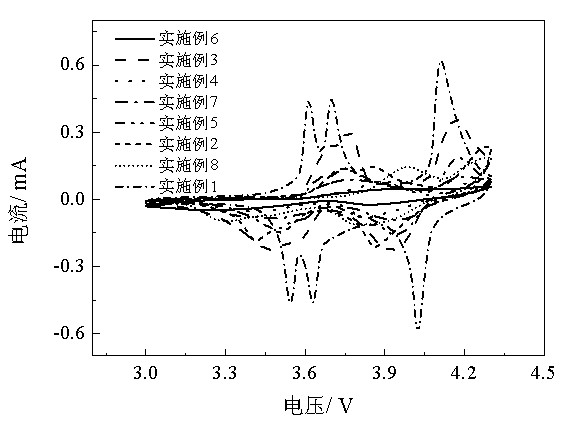

Preparation method for novel lithium vanadium phosphate/bamboo charcoal composite cathode material

The invention discloses a preparation method for a novel lithium vanadium phosphate / bamboo charcoal composite cathode material. The preparation method comprises the following steps of: uniformly mixing vanadium pentoxide, lithium hydroxide or lithium fluoride or lithium carbonate or lithium acetate, ammonium dihydrogen phosphate or phosphoric acid, salicylic acid or citric acid or ascorbic acid or tartaric acid or sucrose, and bamboo charcoal in proportion; evaporating water in a 50-80 DEG C water bath to form a sol; drying the sol in a vacuum drying oven for 8 hours at 120 DEG C to obtain a lithium vanadium phosphate precursor; cooling the lithium vanadium phosphate precursor to room temperature, grinding the precursor and putting the ground precursor into a die to prepare a cake under a certain pressure; putting the cake into a porcelain boat, and covering conductive carbon black (SP) powder on the cake; heating the cake in a microwave oven for a certain period of time; cooling the cake to room temperature; and taking the cake out, and grinding the cake to obtain a bamboo charcoal coated lithium vanadium phosphate / bamboo charcoal composite material sample, thus forming a bamboo charcoal connected conductive network. When used as a cathode material of a lithium ion power battery, the novel lithium vanadium phosphate / bamboo charcoal composite cathode material has the advantages of high capacity and magnification, long service life, low price and environmental friendliness.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

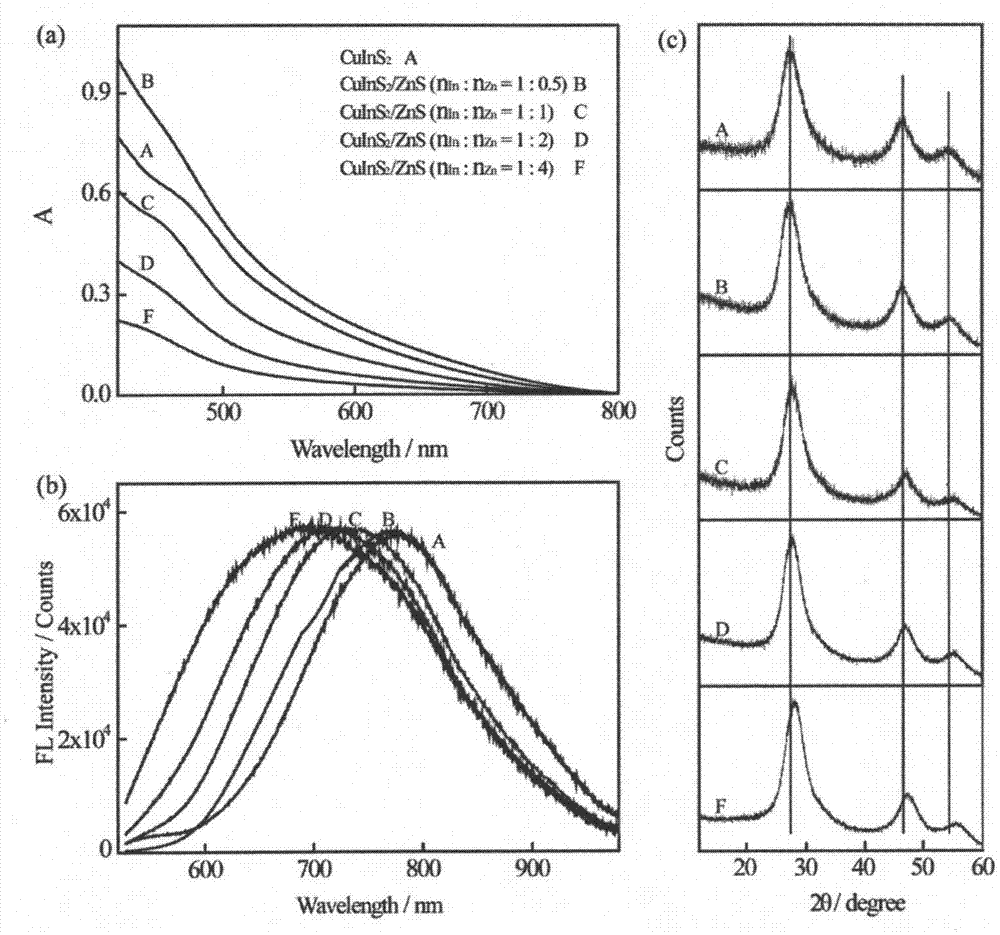

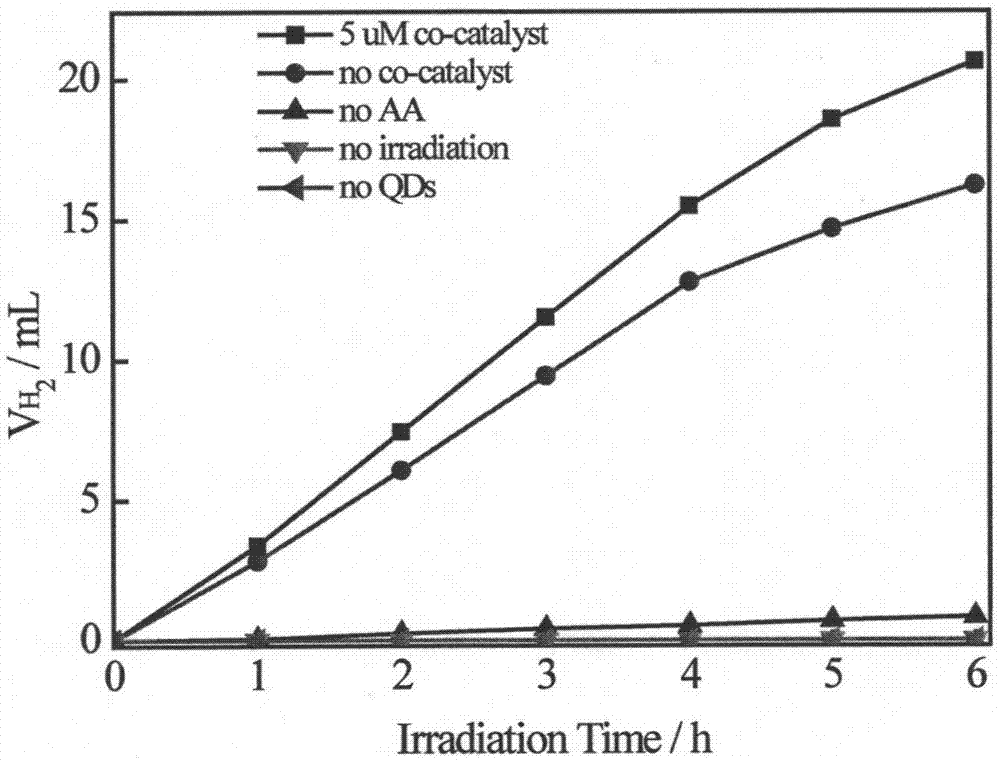

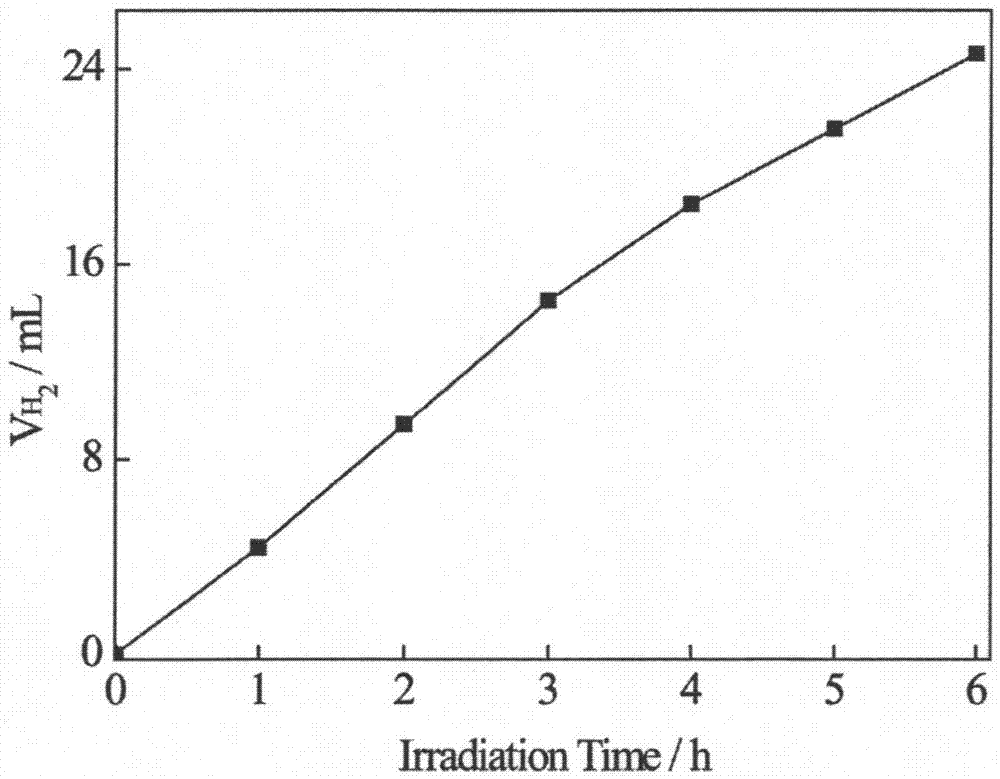

CuInS2 quantum dots, CuInS2/ZnS quantum dots and their preparation and application

InactiveCN107201226ALow toxicityEfficient Photolysis of Water for Hydrogen ProductionPhysical/chemical process catalystsNanoopticsQuantum efficiencyPtru catalyst

The invention provides CuInS2 quantum dots, CuInS2 / ZnS quantum dots and their preparation and application. A preparation method of the CuInS2 quantum dots is characterized by comprising the steps of 1, adding a copper-source compound, an indium-source compound and glutathione into water, adjusting pH to 7-10 to obtain mixed liquid A, and adding an aqueous solution containing a sulfur-source compound to obtain mixture B; 2, heating the mixture B to 70-100 DEG C, stirring at this temperature for 2-4 h, cooling, adding ethanol, centrifugally separating, and purifying to obtain the CuInS2 quantum dots. A quantum dot photocatalyst obtained herein has low toxicity, is able to produce hydrogen by water photocatalysis under zero co-catalysts, has good visible light absorption, and reaches about 10% of quantum efficiency in hydrogen production by photocatalysis at visible light band.

Owner:SHANGHAI TECH UNIV

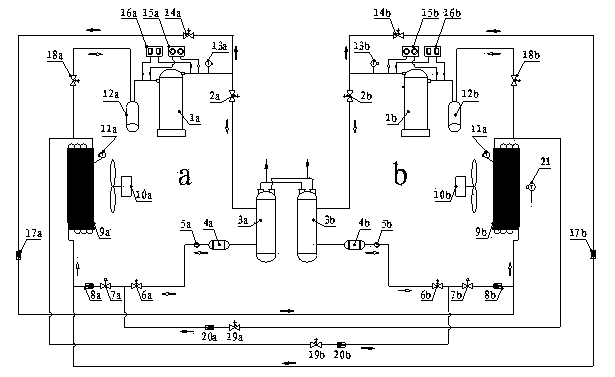

Double-system heat pump defrosting method and device

InactiveCN104344619ALow costNo protectionCorrosion preventionRefrigeration componentsStopped workEngineering

The invention discloses a double-system heat pump defrosting method and a double-system heat pump defrosting device. Two sets of defrosting mechanisms are arranged, when the temperature of evaporator fins is continuously lower than 0 DEG C and the ambient temperature is higher than 5 DEG C and lower than 10 DEG C, a fin evaporator 9a or 9b stops working in a heating loop and enters into a natural defrosting mode; when the temperature of the evaporator fins is continuously lower than 0 DEG C and the ambient temperature is lower than 5 DEG C, the fin evaporator 9a or 9b enters into a hot air defrosting mode, defrosting heat is provided for the defrosted fin evaporator (9a / 9b) from high-temperature air discharged from a compressor (1b / 1a) in another loop, and the defrosted fin evaporator (9a / 9b) stops working in the heating loop. The phenomena of pause protection and liquid compression caused when an evaporator is defrosted are avoided, and the purposes that the energy is saved, the consumption is reduced, the cost is reduced, the defrosting time is shortened, and the operation is safe, stable and reliable when the ambient environment is lower than 0 DEG C are achieved. The defrosting time is only 1 / 4 of that of a conventional defrosting mode.

Owner:LUOYANG ZHONGMAO ENVIRONMENTAL PROTECTION EQUIP

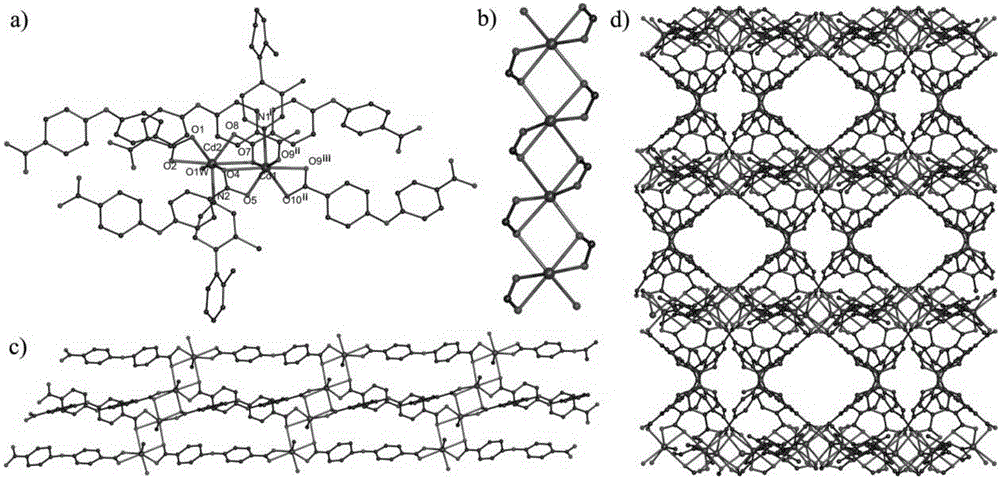

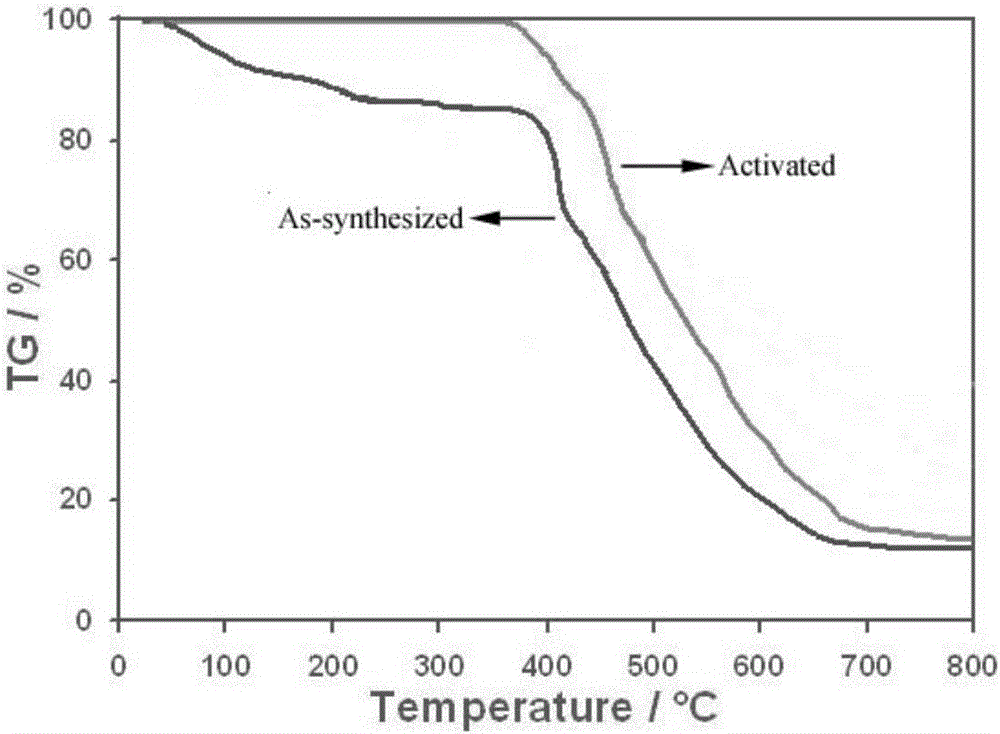

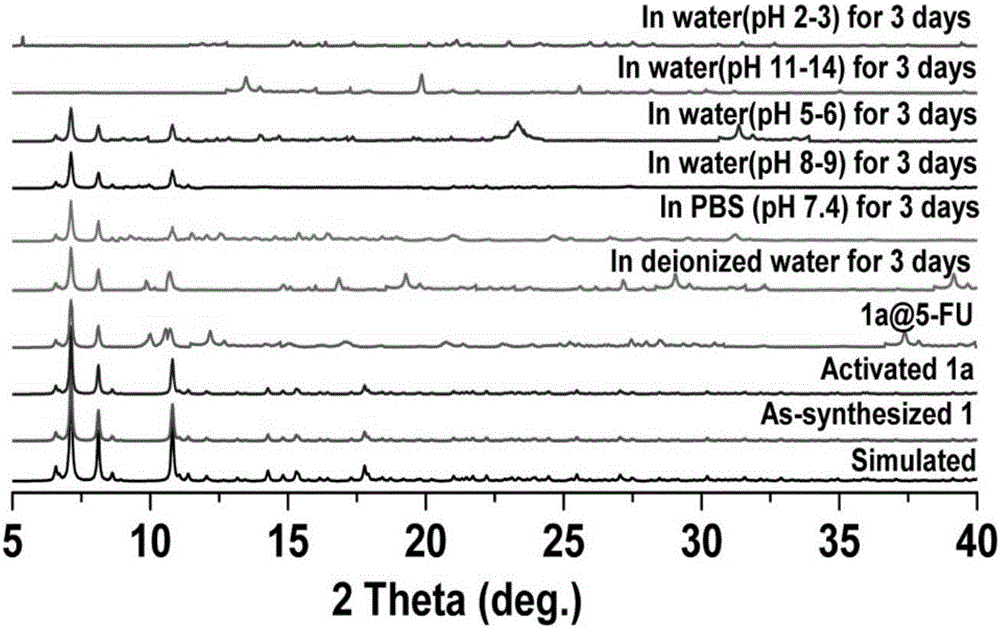

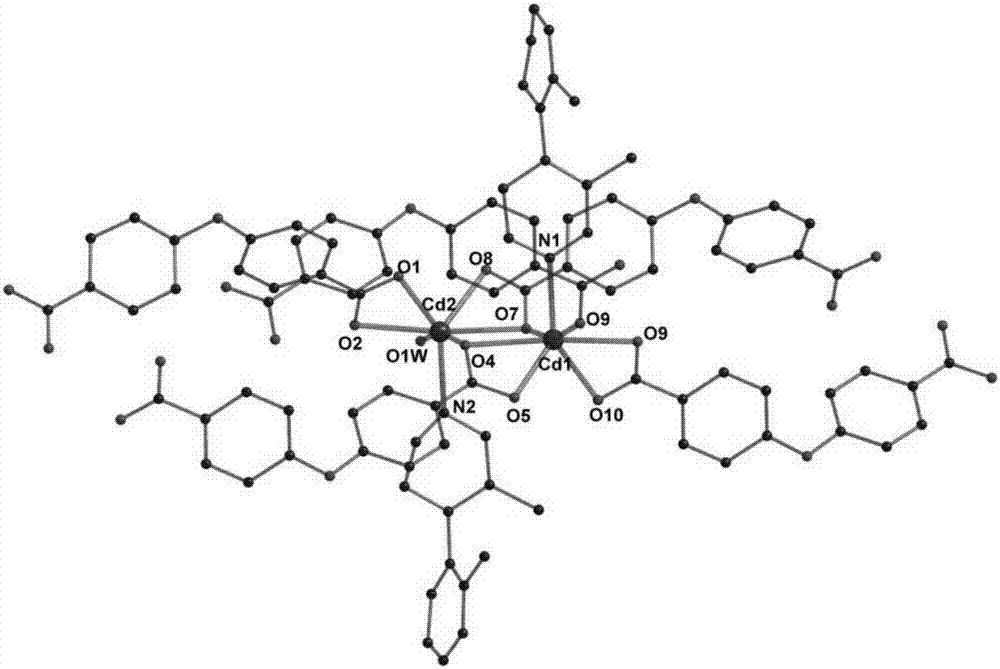

Cd-MOF based on 4,4'-dicarboxydiphenyl ether and preparation method thereof

ActiveCN106478959AMild reaction conditionsHigh purityOrganic active ingredientsPharmaceutical delivery mechanismEtherFluorouracil

The invention relates to Cd-MOF based on 4,4'-dicarboxydiphenyl ether, wherein MOF is a cadmium metallic coordination polymer of which a repeating unit is [Cd2(oba)2(dmbpy)(H2O)].2(EtOH).4(H2O); oba in the chemical formula [Cd2(oba)2(dmbpy)(H2O)].2(EtOH).4(H2O) is 4,4'-dicarboxydiphenyl ether ligand; dmbpy is 3,3'-dimehtyl-4,4'-bipyridine; EtOH is an ethanol molecule. The Cd-MOF provided by the invention can be used as a drug carrier for effectively loading 5-fluorouracil, and can be also used as a gas adsorbing material for selectively adsorbing the molecule of a CO2 gas.

Owner:广东优农品科技有限公司

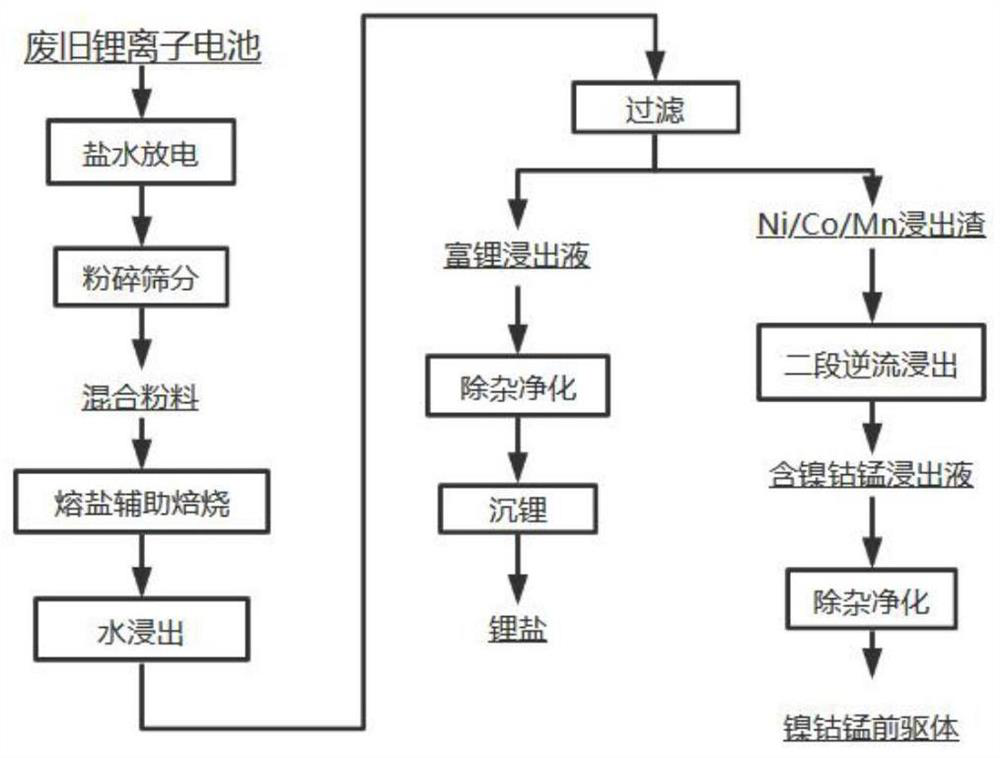

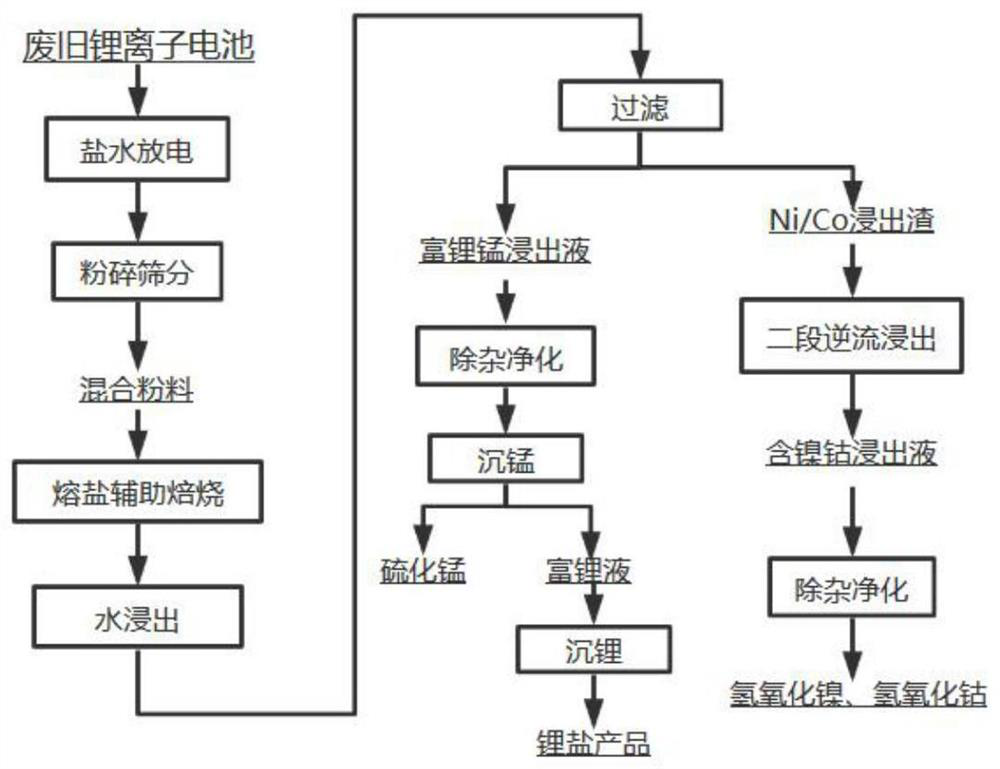

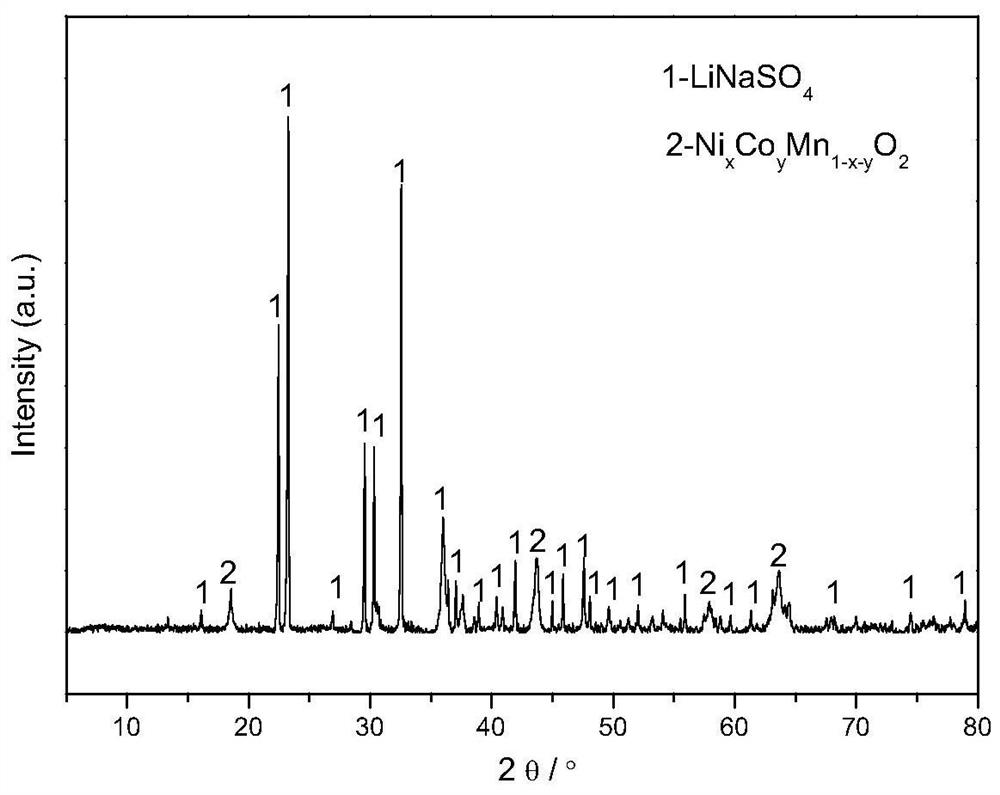

Waste lithium ion battery recovery method

ActiveCN112375913AAvoid concomitant leachingGood choiceProcess efficiency improvementChemistryProcess engineering

The invention belongs to the technical field of waste battery treatment, and particularly discloses a waste lithium ion battery recovery method. A to-be-recovered raw material containing a waste positive electrode active material and an auxiliary agent are roasted at 500-800 DEG C, and then water extraction treatment is performed; and the auxiliary agent is at least one of NaHSO4, KHSO4, CoSO4, NiSO4, MnSO4, NH4HSO4 and (NH4)2SO4. The method overcomes the disadvantages of a traditional recovery method, is simple, practical and economically feasible, realizes comprehensive utilization of wastelithium ion batteries, and is suitable for industrial production.

Owner:CENT SOUTH UNIV

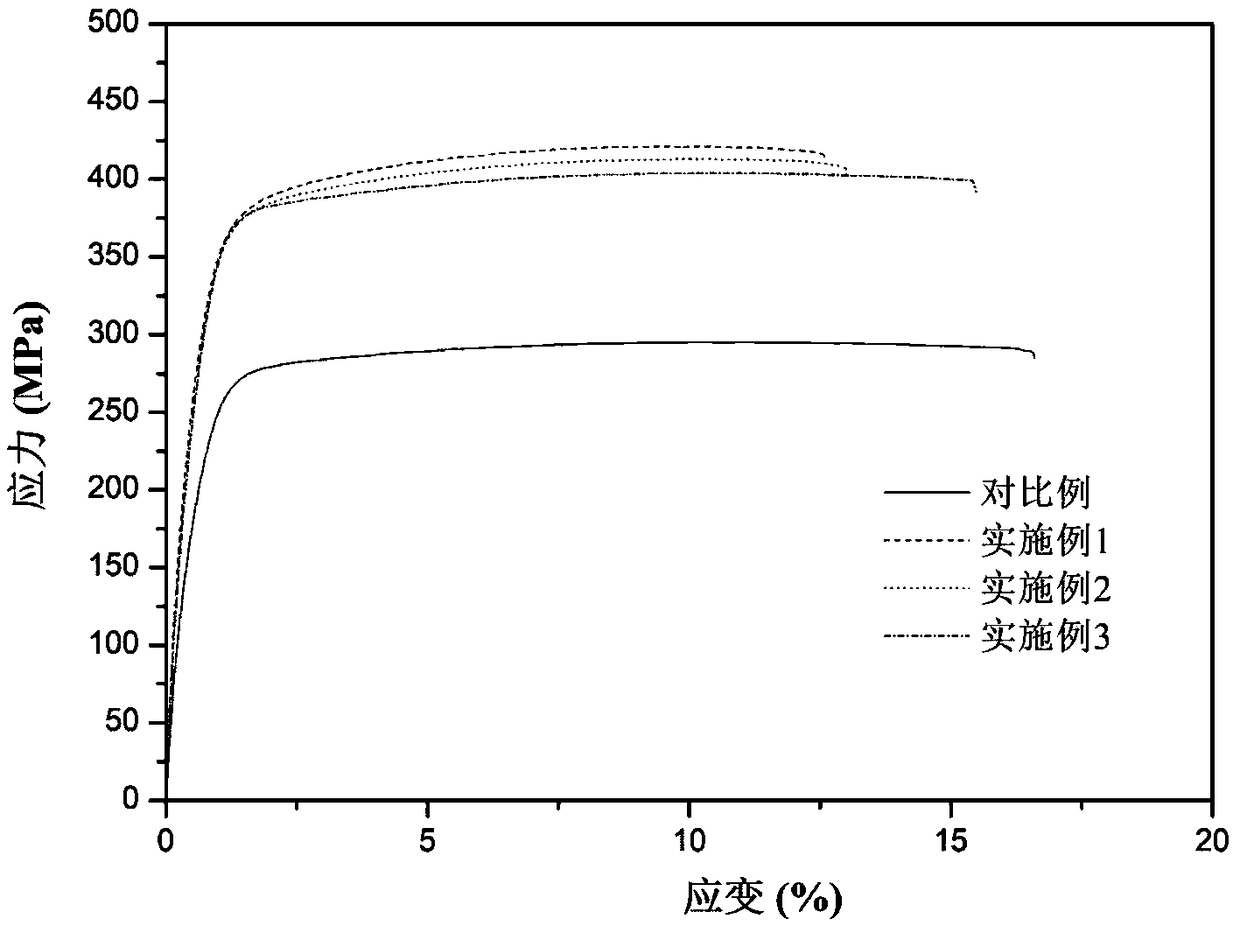

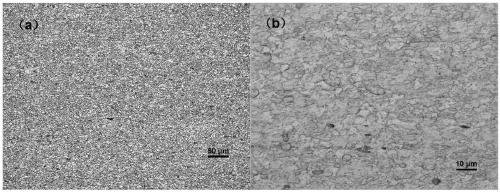

High strength and high-toughness wrought magnesium alloy and preparation methodthereof

ActiveCN109266930APromote dynamic precipitationHigh strengthChemical compositionUltimate tensile strength

The invention relates to a high-strength and high-toughness wrought magnesium alloy and a preparation method thereof. The alloy refers to Mg-Bi-Sn-Zn-Ca-Y magnesium alloy. The alloy includes the following components: by mass, 2.0-4.5 wt% of Bi, 2.0-4.5 wt% of Sn, 0.8-1.2 wt% of Zn, 0.1-0.3 wt% of Ca, 0.1-0.3 wt% of Y and the balance Mg and inevitable impurities; and the mass ratio of Bi to Sn is (0.7-1.5):1. The yield strength of the obtained alloy is 360 MPa or above, the tensile strength is more than 400 MPa, and the elongation rate is 12% or above. Moreover, the alloy has a good flame retardant effect and low cost and the mass production is easily achieved.

Owner:HEBEI UNIV OF TECH

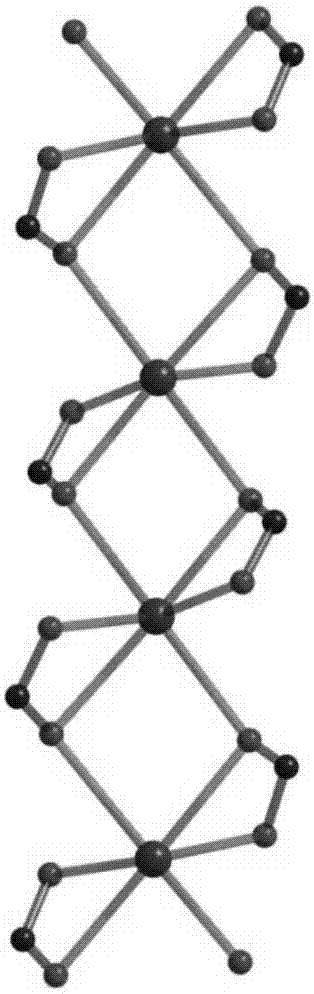

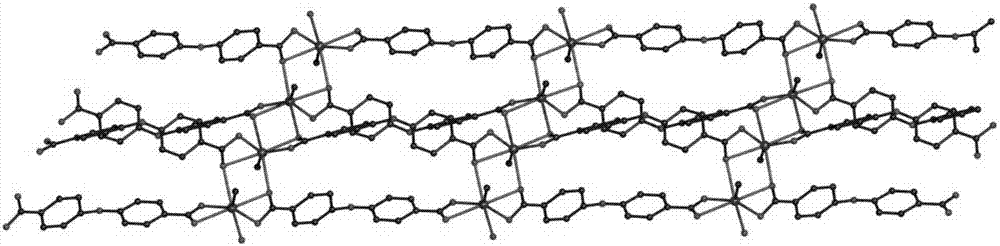

Cd MOF (metal-organic framework) material and preparation method thereof

InactiveCN107286185AWide variety of sourcesEasy to getProductsGas treatmentChemical industryCarbon dioxide

The invention relates to a Cd MOF (metal-organic framework) material capable of selectively adsorbing carbon dioxide gas and stable in water resistance. A chemical formula of the material is as follows: [Cd2(oba)2(dmbpy)(H2O)].2(EtOH).4(H2O), wherein oba represents 4,4'-oxy-biphenyldicarboxy, dmbpy represents 3,3'-dimethyl-4,4'-dipyridyl, and EtOH represents ethyl alcohol. 4,4'-oxy-biphenyldicarboxy and 3,3'-dimethyl-4,4'-dipyridyl are selected to synthesize a 3D MOF material with one-dimensional pores together with Cd under the hydrothermal condition. The Cd MOF material is stable in structure, and has strong water resistance, broad application prospect in the field of adsorptive separation of chemistry and chemical industry as well as the characteristics of being high in selectivity, high in adsorption capacity and resistant to water.

Owner:ZHAOQING UNIV

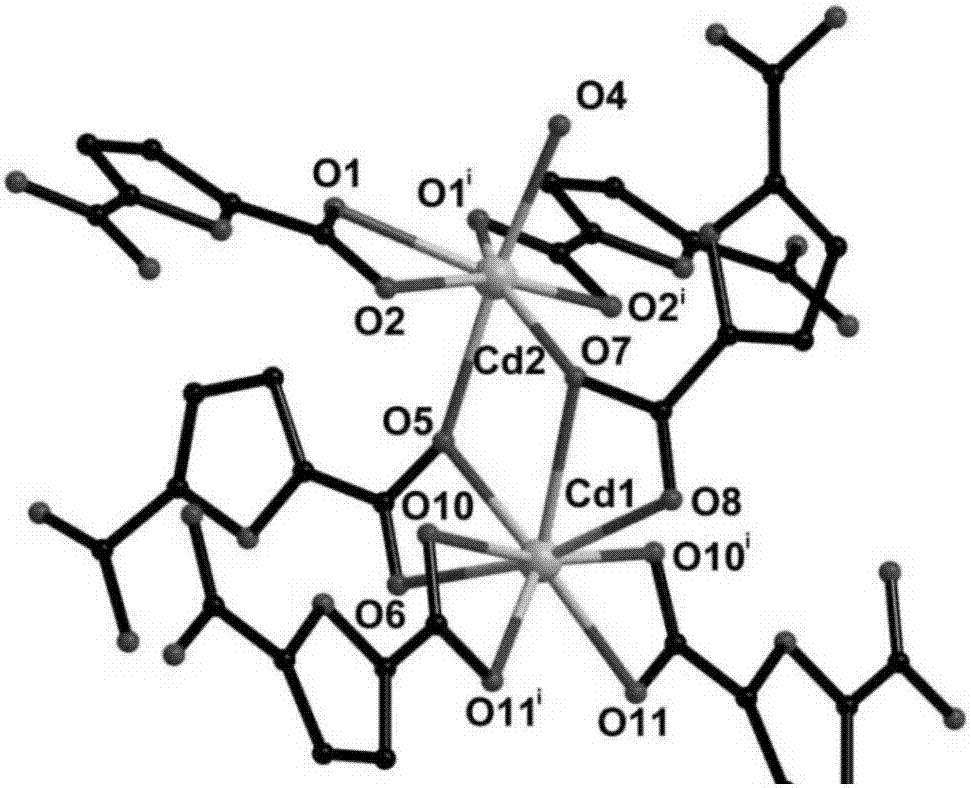

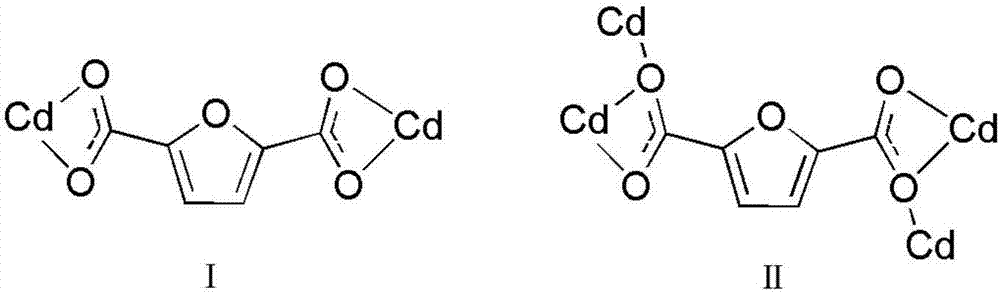

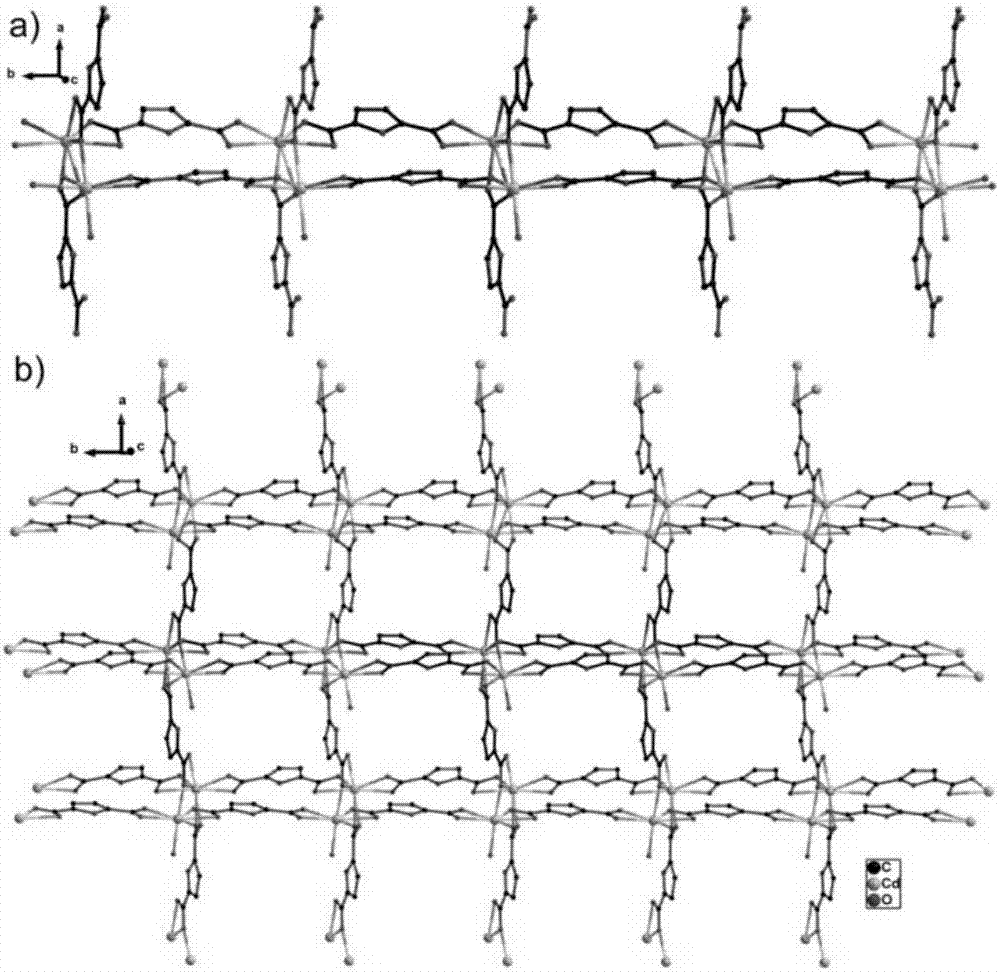

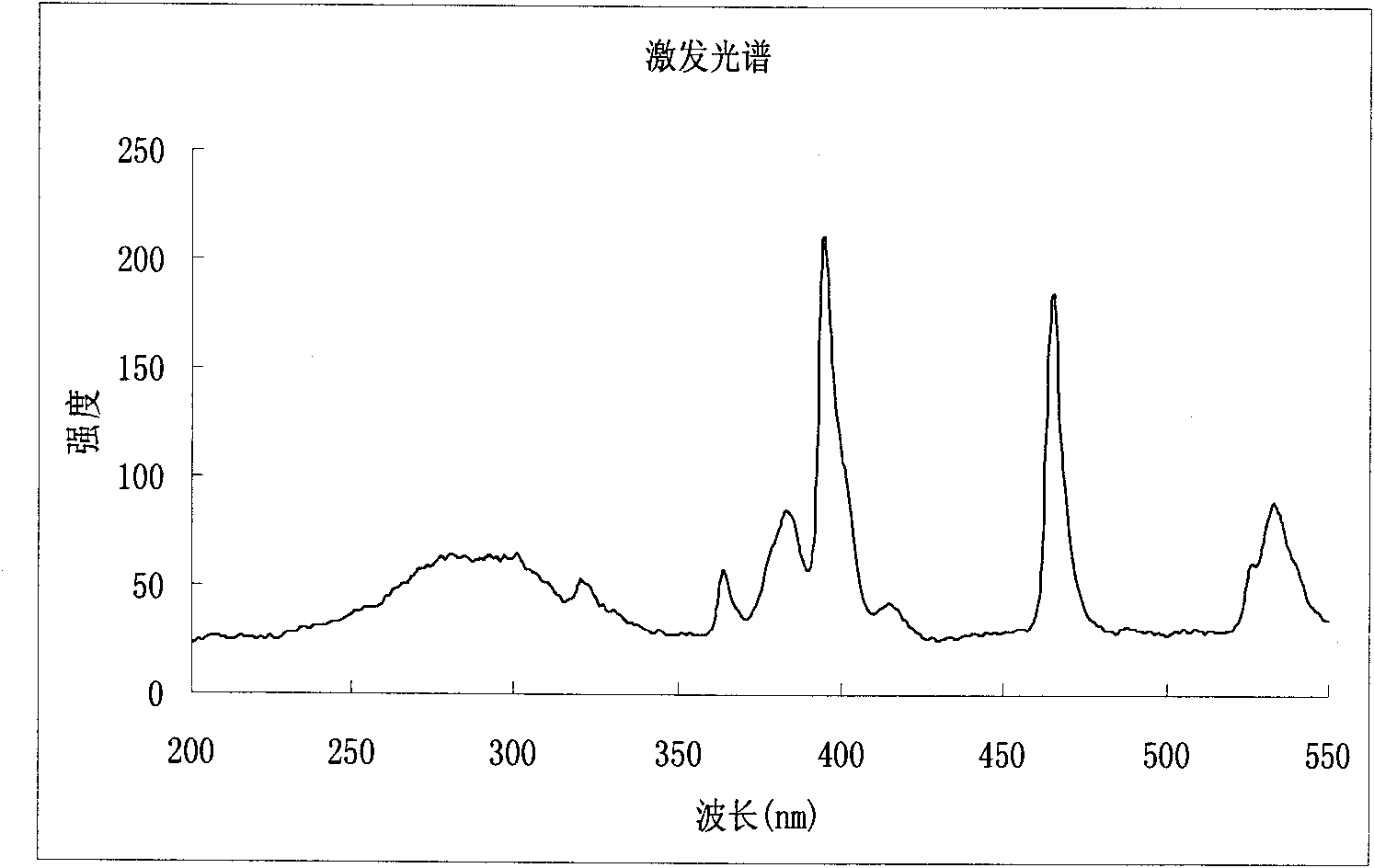

Cd (II) metallic organic complex and preparation method thereof

InactiveCN107383075AWide variety of sourcesEasy to getOrganic chemistry methodsGroup 2/12 organic compounds without C-metal linkagesFuranFluorescence

The invention relates to a Cd (II) metallic organic complex based on 2,5-furan dicarboxylic acid. The metallic organic complex is a cadmium metallic organic complex with a repetitive unit such as [(Me2NH2)2Cd2(FDC)3(H2O)2.(H20)4], wherein the FDC in the chemical formula [(Me2NH2)2Cd2(FDC)3(H2O)2.(H20)4] is a 2,5-furan dicarboxylic acid ligand with two H being deleted. The Cd (II) metallic organic complex provided by the invention is capable of emitting blue fluorescence; the fluorescent lifetime is 138.1ns; the Cd (II) metallic organic complex can be used for preparing a fluorescent material.

Owner:ZHAOQING UNIV

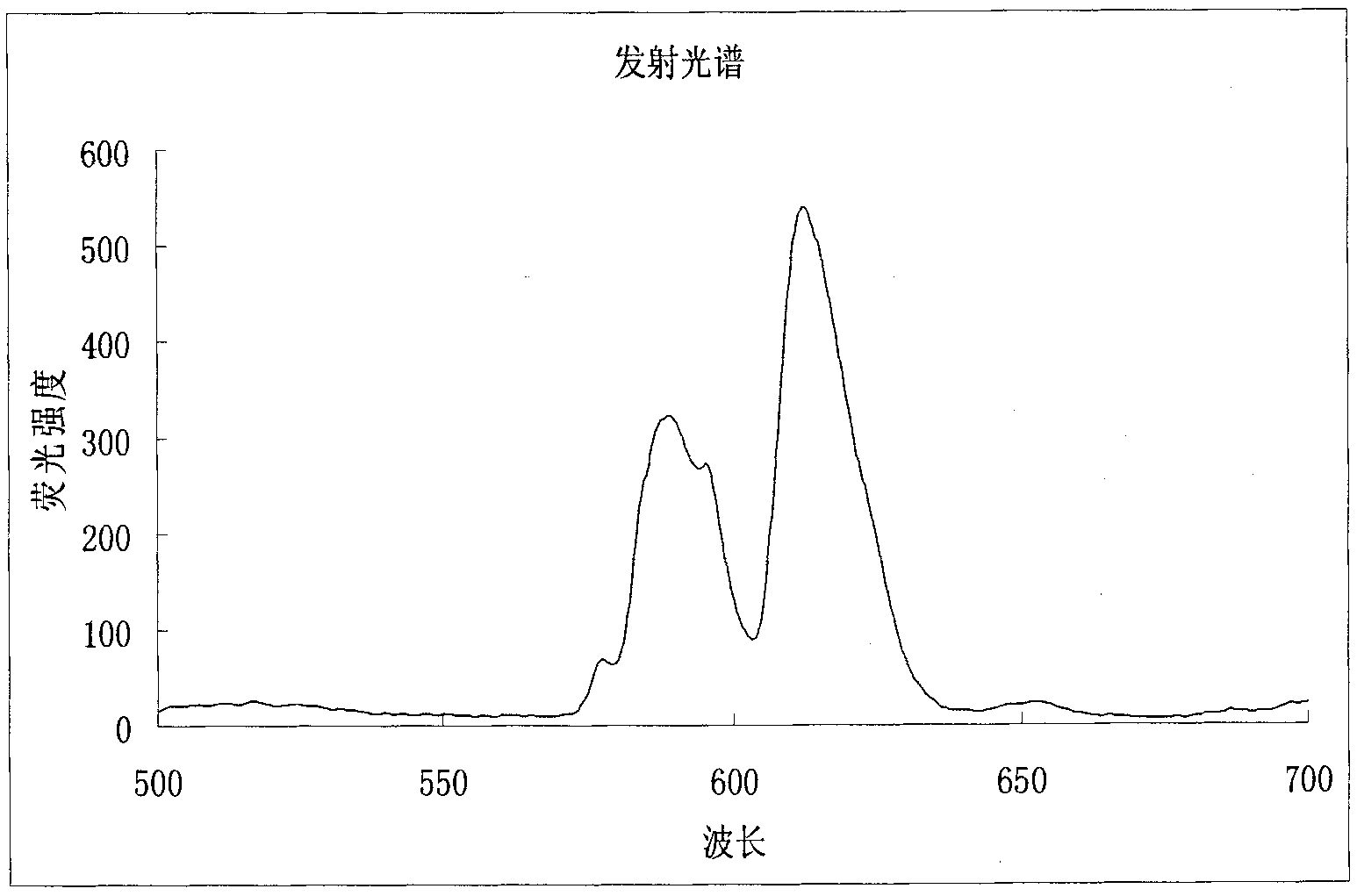

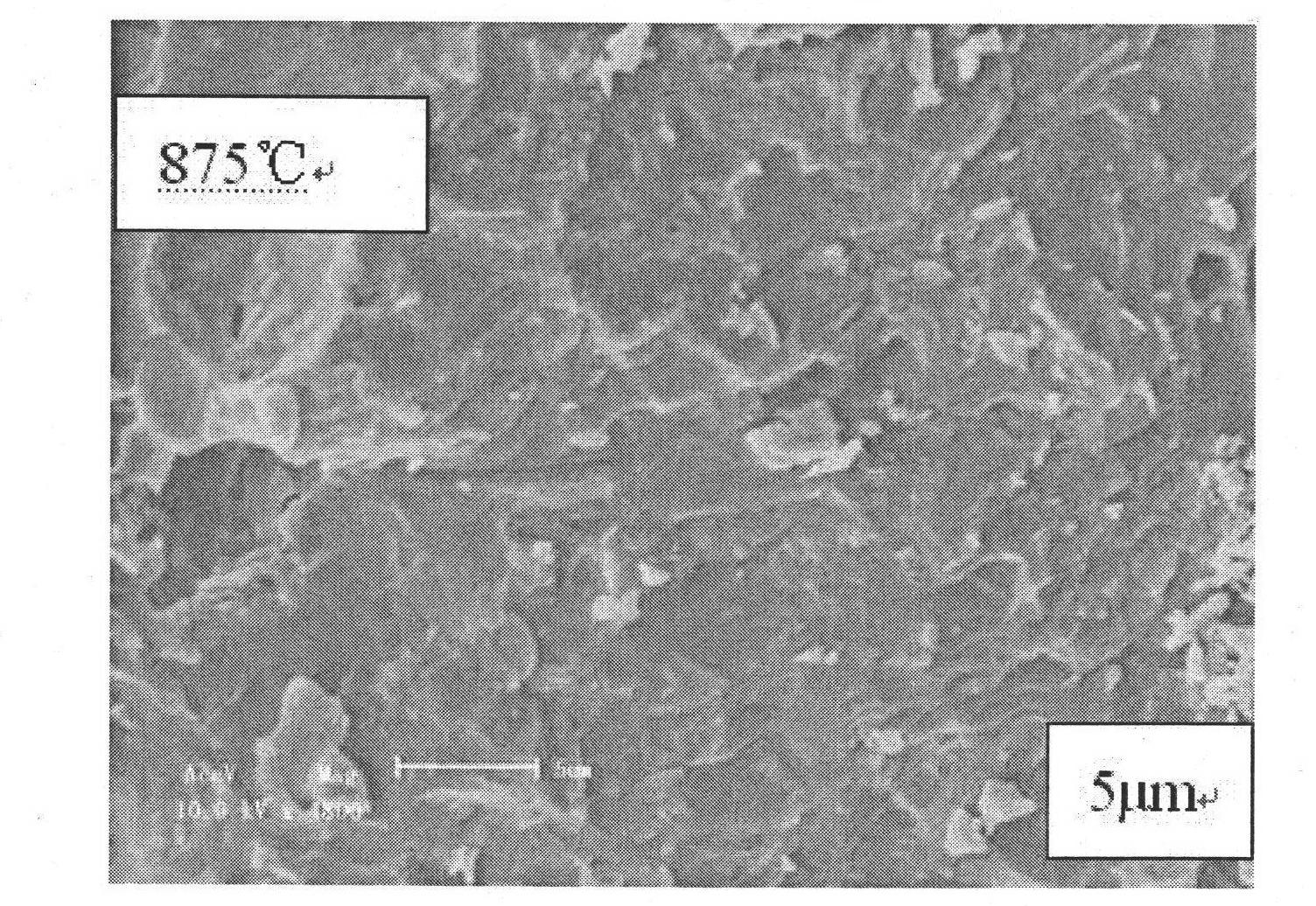

Light-emitting low-temperature co-fired ceramic powder, preparation method thereof and light-emitting low-temperature co-fired ceramic

The invention provides a light-emitting low-temperature co-fired ceramic powder, a preparation method thereof and a light-emitting low-temperature co-fired ceramic prepared from the light-emitting low-temperature co-fired ceramic powder. The light-emitting low-temperature co-fired ceramic powder is prepared from 15-20mol% of CaCO3, 60-70mol% of Si(OC2H5)4, 10-25mol% of B2O3, 3-11mol% of photoactivating agent, 0.9-3.2mol% of sensitizing agent and charge compensation agent gel equivalent to the total content of the photoactivating agent and the sensitizing agent by calcination. The low-temperature co-fired ceramic powder has the advantages of low sintering temperature, small dielectric loss, high mechanical strength and high light intensity, and can be used in the fields of ceramic base plates, electronic devices such as resonators and the like, other micro electronic potting materials and white light LED potting materials.

Owner:TSINGHUA UNIV

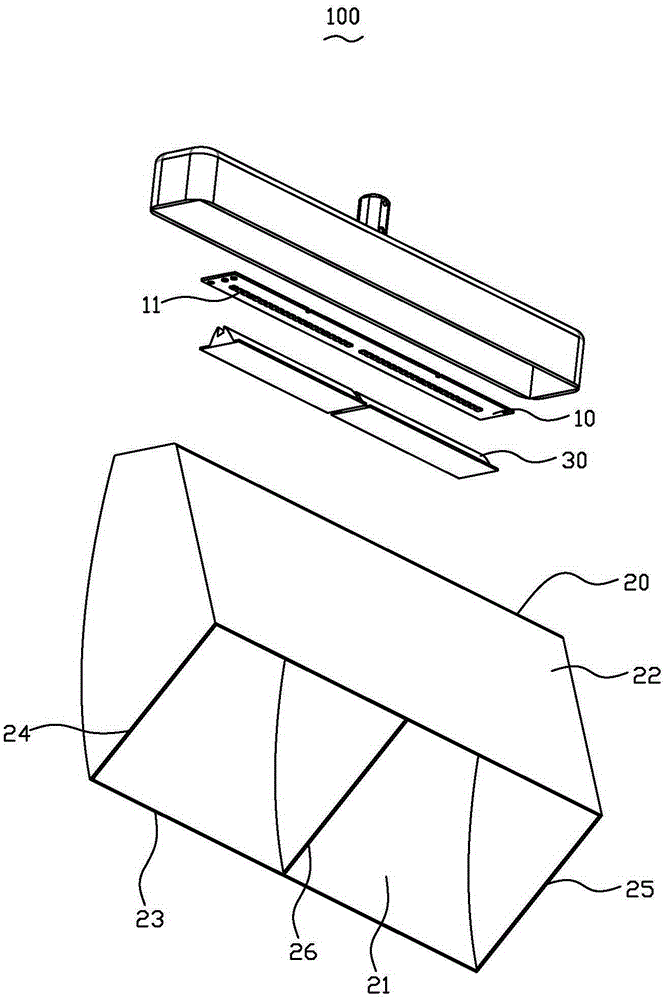

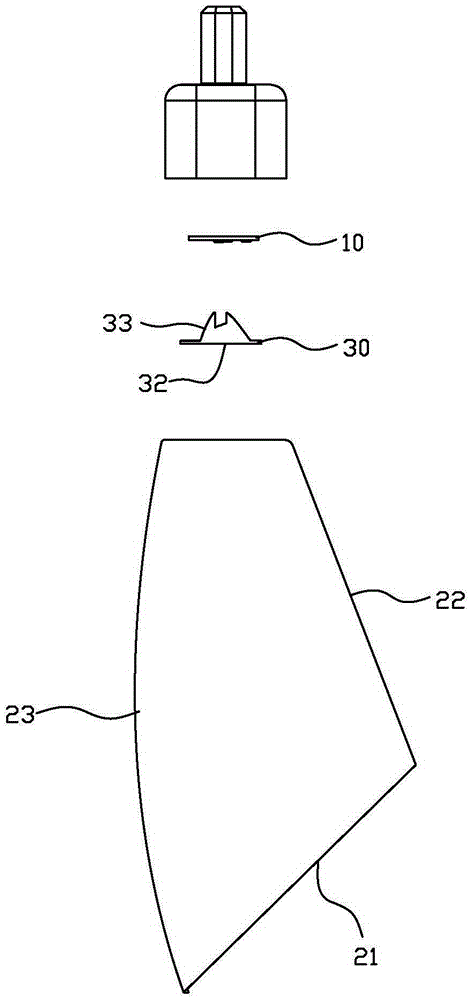

LED blackboard lamp

ActiveCN105351822ANo protectionImprove utilization efficiencyNon-electric lightingPoint-like light sourceEngineeringLight source

An LED blackboard is used for lighting a blackboard or a wall body and comprises an LED light source panel provided with an LED light source and a light shielding cover. The light shielding cover is of a shell structure, and the height of the light shielding cover is higher than that of the blackboard or the wall body to be lighted; one end of the light shielding cover is arranged at the periphery of the LED light source panel, a light outlet is formed in the other end of the light shielding cover, and the light outlet faces the blackboard or the wall body; the light shielding cover comprises an internal lateral plate close to one side of the blackboard or the wall body and an external lateral plate far from one side of the blackboard or the wall body; and the inner wall of the external lateral plate is used for reflecting light which emitted by the LED light source and under the blackboard or the wall body to the blackboard or the wall body. The LED blackboard lamp is high in light utilizing rate and can effectively avoid glare.

Owner:LEELEDS LIGHTING XIAMEN

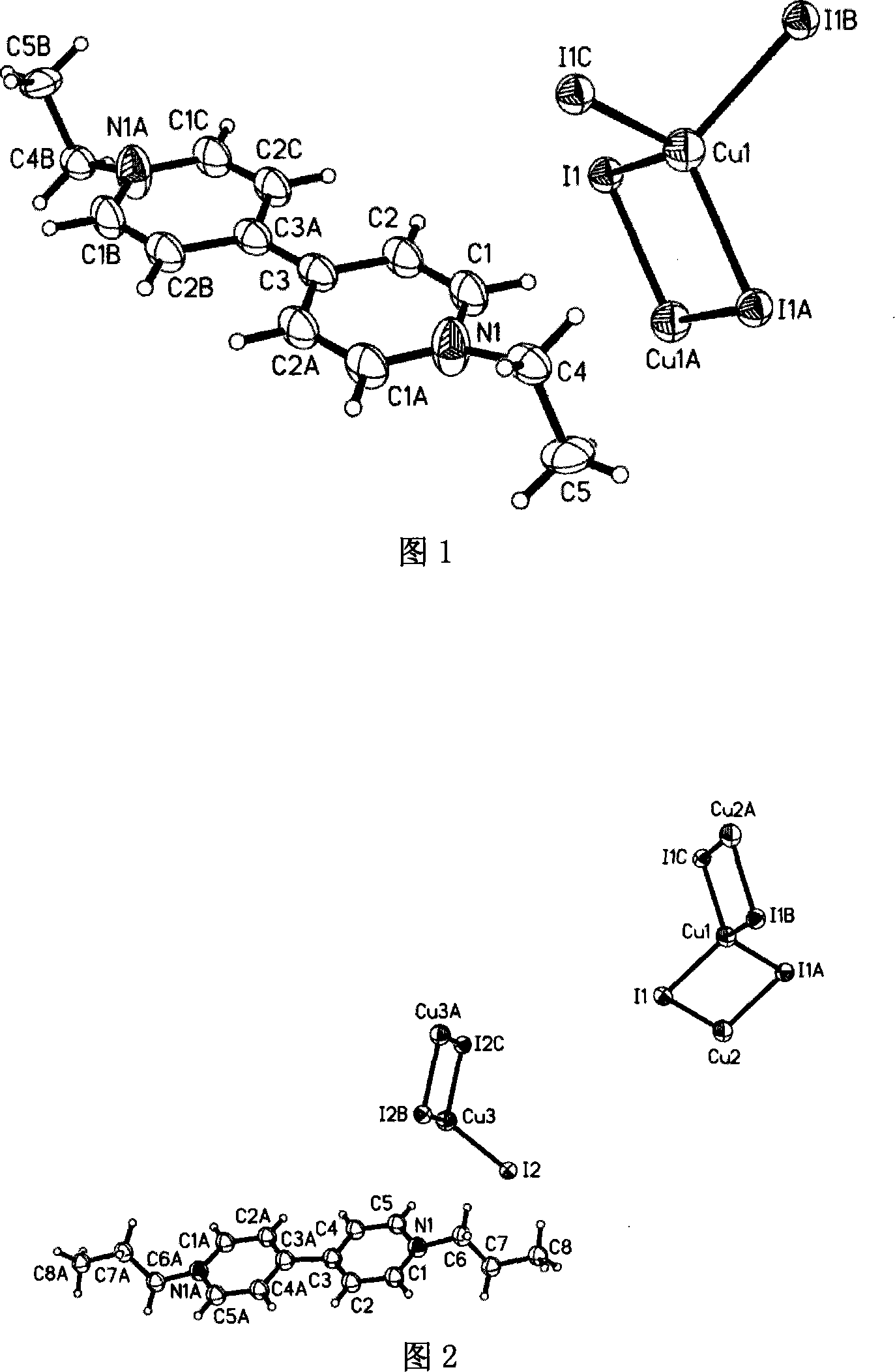

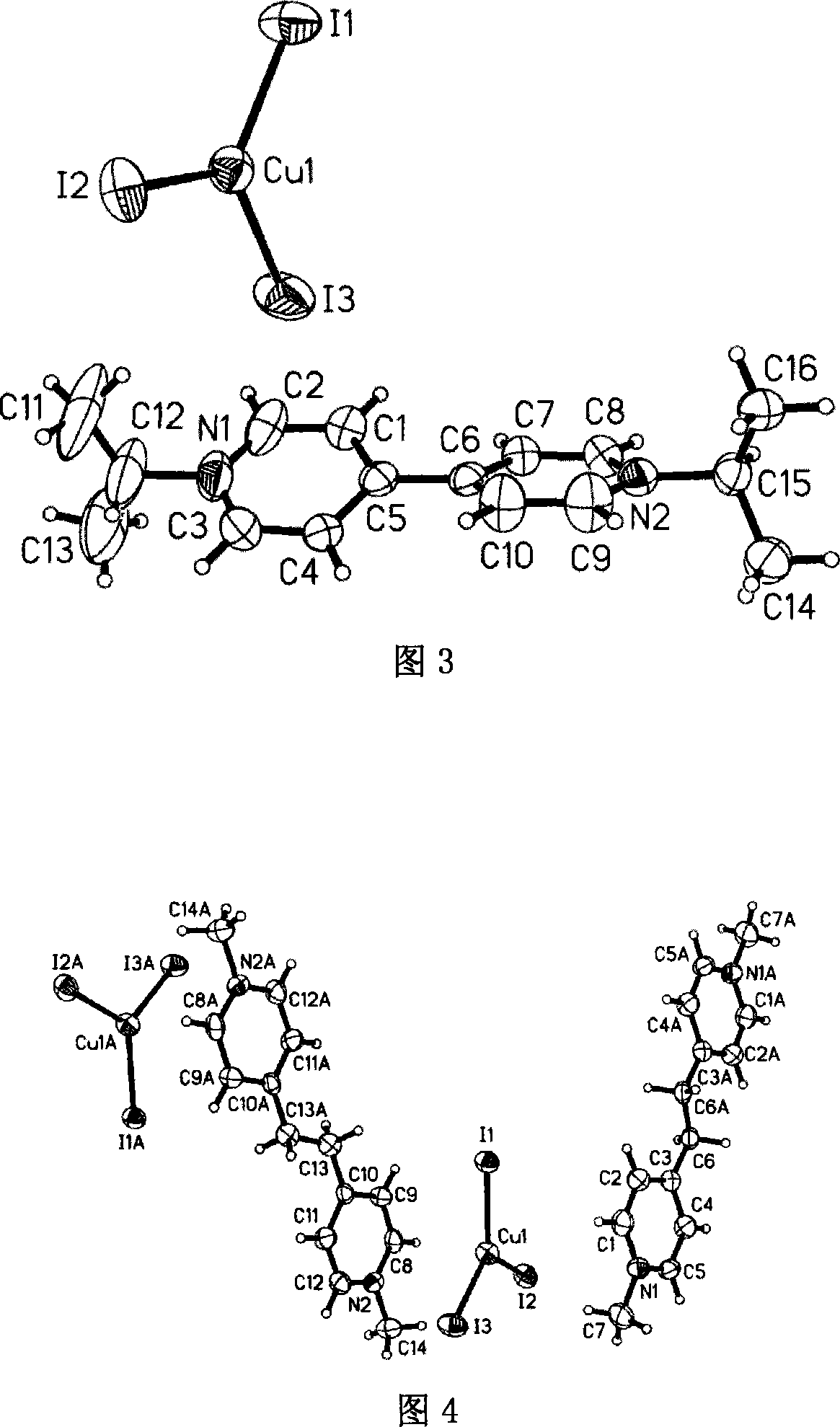

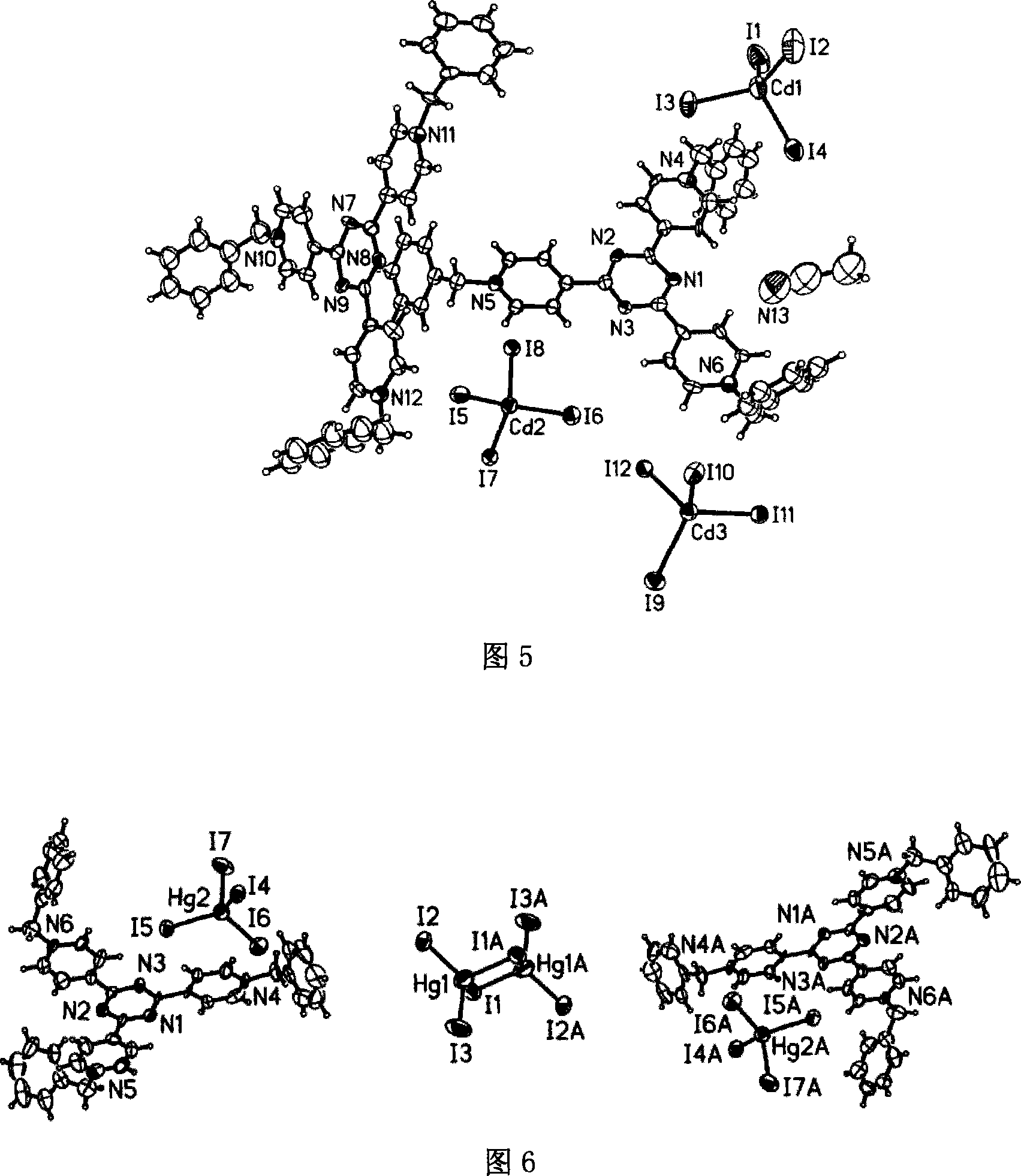

Method for preparing nitrogen-containing onium salt compounds

The invention discloses a method for preparing an onium salt compound: taking iodine simple substance, metal iodide, alcohol and a nitrogen-containing compound, mixing them in acetonitrile, and reacting for several hours under solvothermal conditions to generate a single crystal of the onium salt compound in situ. The method has strong applicability, wide source of raw materials, cheap and easy to obtain, high product purity and yield, simple reaction device, simple method, and no inert gas protection is needed in the reaction process.

Owner:SUZHOU UNIV

Method for preparing semi-conductor luminescent material manganese-doped zinc sulfide nano powder

InactiveCN101391802ANo protectionSave raw materialsZinc sulfidesLuminescent compositionsMANGANESE ACETATEFluorescence

The invention relates to a method for preparing semiconductor fluorescent material which is mixed with manganese, zinc sulphide and nanometer power. The method comprises the following steps: manganese acetate and zinc acetate are respectively weighted according to the mol ration of 1:99 or 3:97 or 5:95 to ensure that the amount of general matter of Zn<2+> and Mn<2+> is 0.01 mol; the two solid powder is mixed and dissolved with water to prepare 200 ml solution; 0.02 mol of sodium diethyldithiocarbamate powder is weighted and dissolved with water to prepare 200 mL solution; the two solutions are stirred and blended; the obtained precipitation is pumped and filtrated to obtain precursor Zn<1-x>Mn(DDTC)2, wherein, X is 0.01 or 0.03 or 0.05; 1.0 g of precursor Zn <1-x>Mn(DDTC)2 is put in a pot and placed in a muffle to be heated for 3 hours at the temperature of 300 DEG C, and then naturally cooled to the room temperature; finally Zn<1-x> MnxS of hexahedron phase is obtained. The invention solves defects such as complex operation, higher energy consumption, large kernels, many defects in crystals, plenty of water or organic solvent being polluted and wasted, long period, low productive rate, high cost and the like. The invention has the advantages of inexpensive and easy available raw materials, simple technique, low energy conservation, excellent semiconductor property and fluorescence property.

Owner:YANGZHOU UNIV

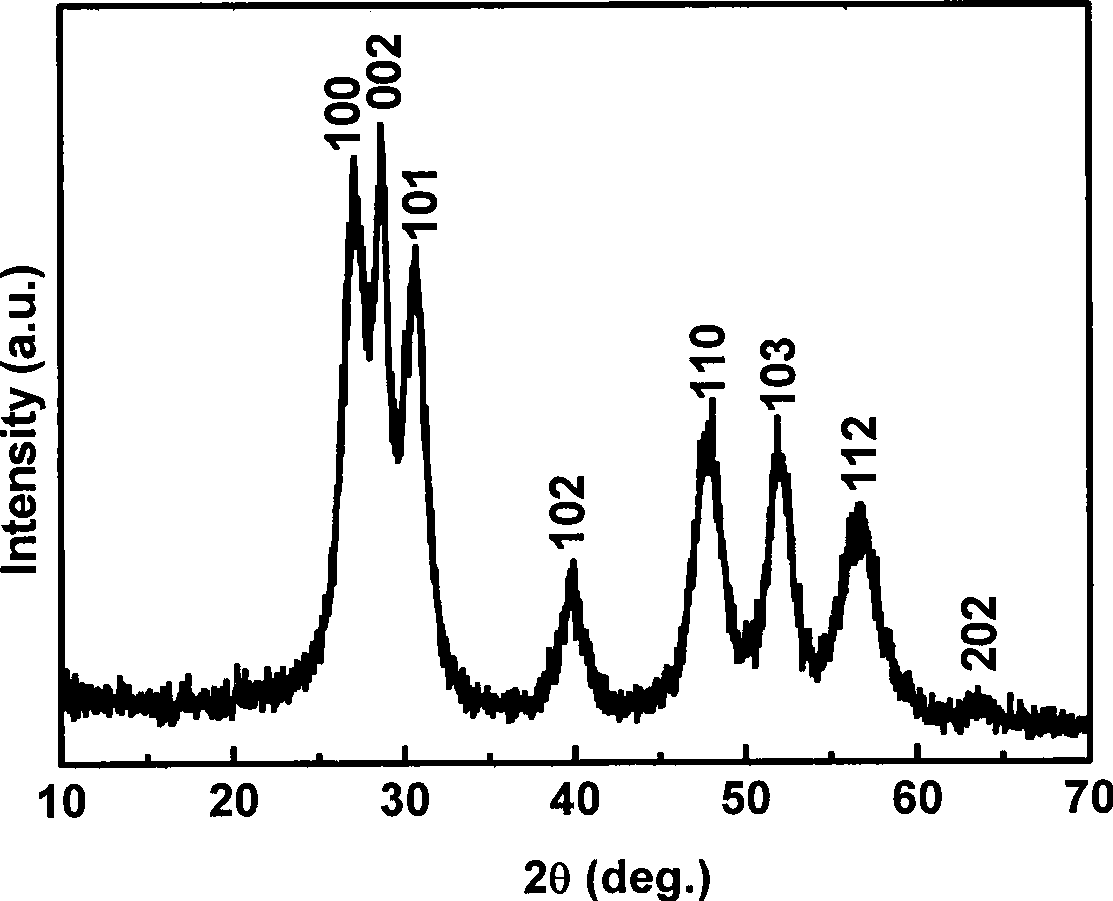

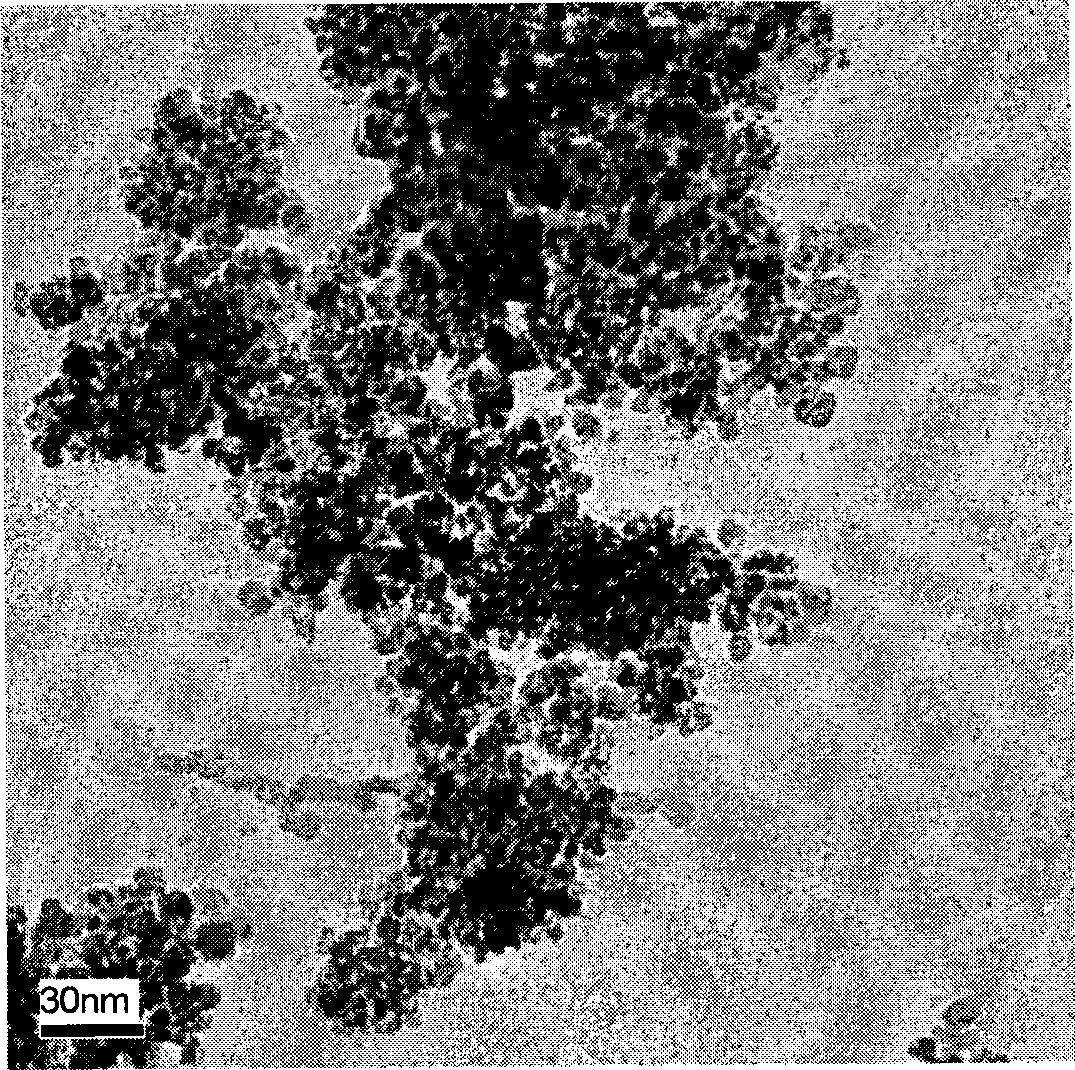

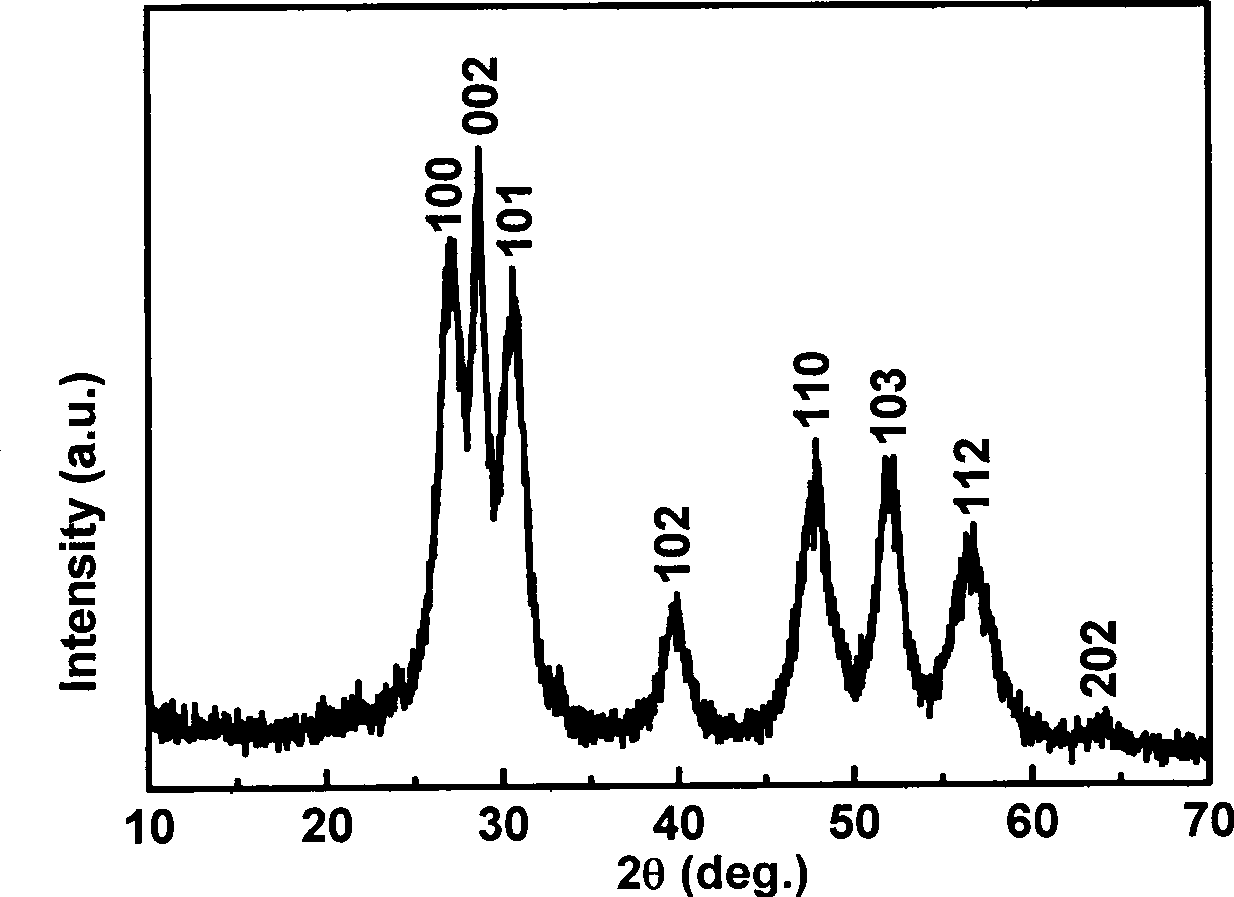

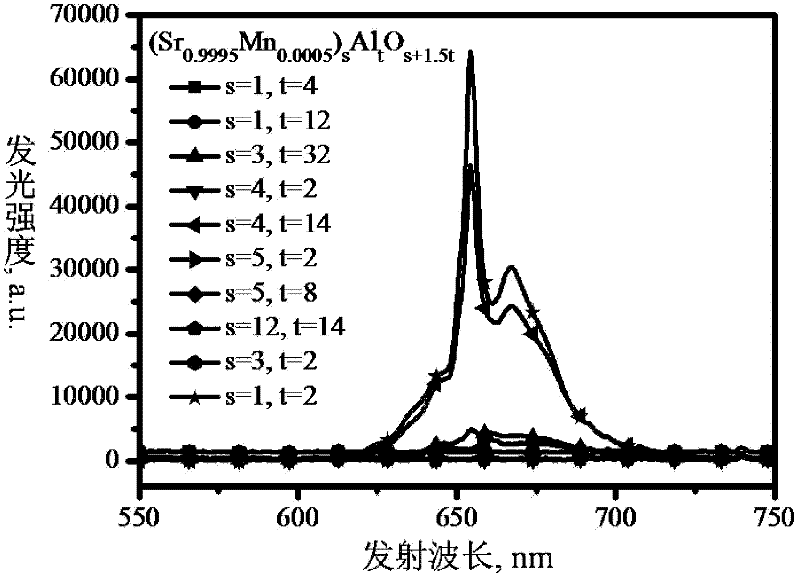

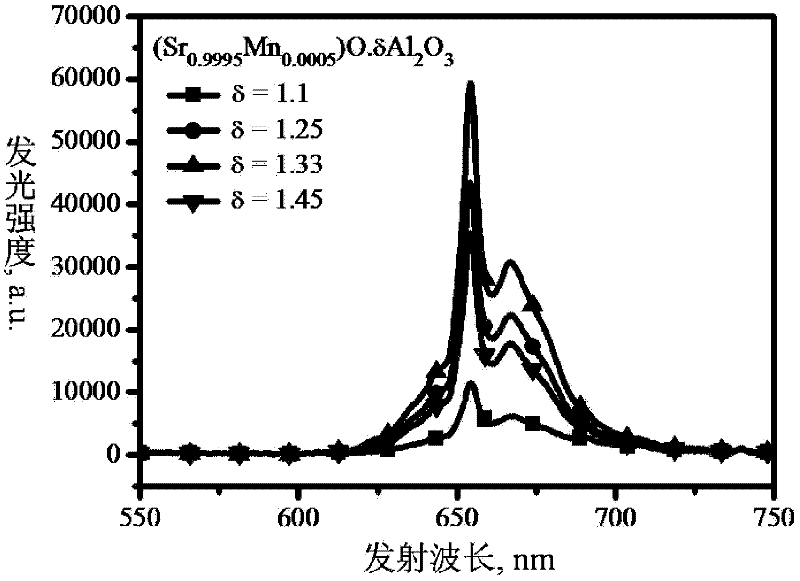

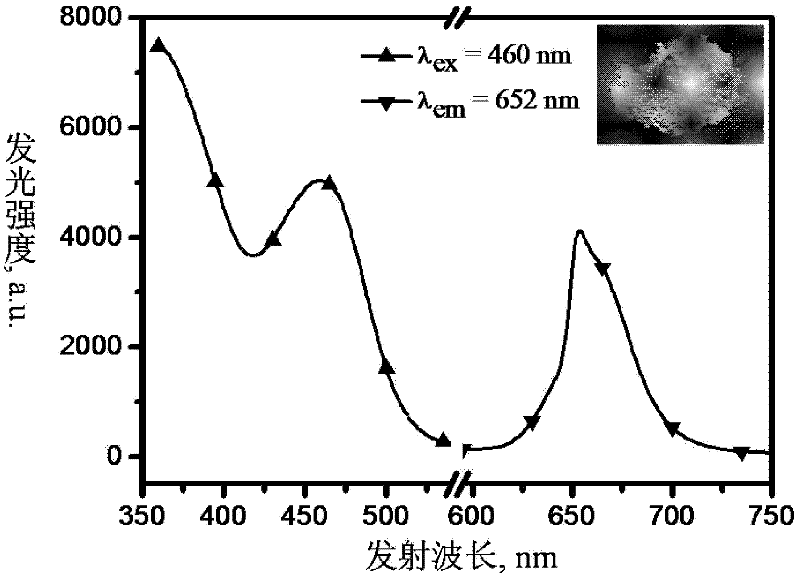

LED red fluorescent material and its preparation method

ActiveCN102352244AWide range of raw materialsLow costLuminescent compositionsRoom temperatureLight excitation

The invention discloses a LED red fluorescent material and its preparation method, wherein the composition of the LED red fluorescent material is expressed in a general formula (M1-rMnr)sAltOs+1.5t, wherein 0<r<=1.0; 1<=s<=12; 2<=t<=32, M is one or more from Sr, Ba, Ca, Mg and Zn; The preparation method comprises the following steps: mixing the raw materials according to the proportion and grinding to obtain a mixture, calcining the mixture under the temperature of 1100-1600 DEG C for 1-20 hours and cooling to the room temperature to obtain the sintered products, fragmenting the sintered products and grinding to obtain the fluorescent material. The LED red fluorescent material is capable of radiating with high efficiency by adopting 420-480nm blue light excitation or 380-420nm near ultraviolet light excitation. No harmful exhaust gas with a great amount is discharged to environment during the preparation process.

Owner:HEFEI UNIV OF TECH

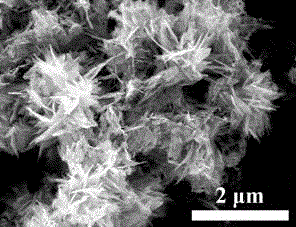

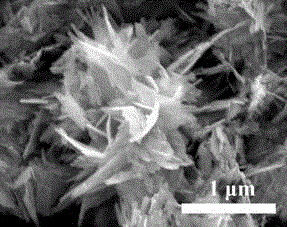

Preparation method for CdS flower-shaped self-assembly structure and obtained product

The invention discloses a preparation method for a CdS flower-shaped self-assembly structure and the obtained product. The preparation method comprises adding a cadmium salt, PVP, glycol, ethylenediamine and thiourea into water, and stirring to obtain a solution; adding the solution into a reaction kettle and performing solvothermal reaction; and performing centrifugation separation and washing after reaction, so as to obtain the CdS flower-shaped self-assembly structure. The basic unit of the self-assembly structure is a CdS sheet structure, and the thickness is 4-50 nm. The raw material cost is low, the preparation technology is simple, product yield is high, the microscopic morphology repeatability is good, the dimension distribution scope is narrow, and the product possesses relatively high physical chemical stability and photoelectric response properties, and possesses significant meaning on performance research and batch production of the CdS micro-nano material.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com