LED red fluorescent material and its preparation method

A technology of red fluorescence and mixing materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of complex process, high price, high price of synthesis equipment, etc., and achieve the effect of wide range of raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

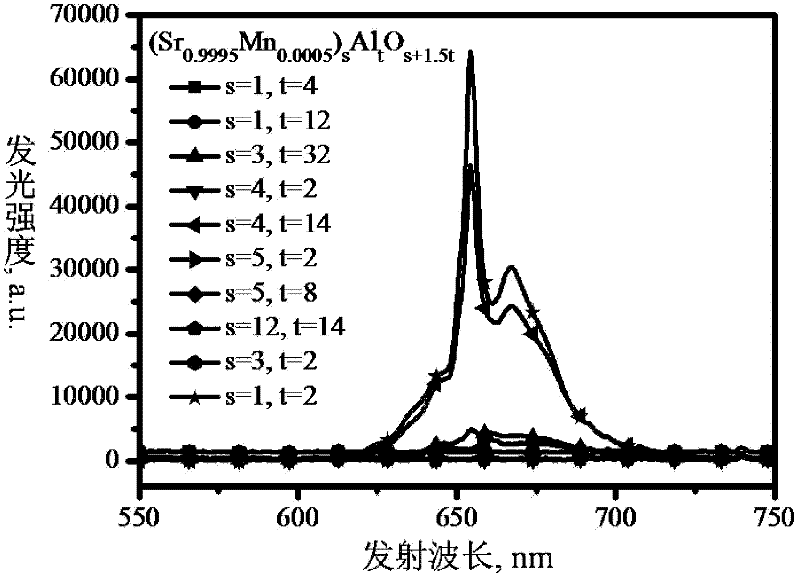

[0051] The chemical formula of the red fluorescent powder applied to the white light LED in this embodiment is (Sr 0.9995 mn 0.0005 ) Al 4 o 7 , (Sr 0.9995 mn 0.0005 ) Al 2 o 4 , (Sr 0.9995 mn 0.0005 )Al 12 o 19 , (Sr 0.9995 mn 0.0005 ) 3 al 32 o 51 , (Sr 0.9995 mn 0.0005 ) 4 al 2 o 7 , (Sr 0.9995 mn 0.0005 ) 4 al 14 o 25 , (Sr 0.9995 mn 0.0005 ) 5 al 2 o 8 , (Sr 0.9995 mn 0.0005 ) 5 al 8 o 17 , (Sr 0.9995 mn 0.0005 ) 12 al 14 o 33 and (Sr 0.9995 mn 0.0005 ) 3 al 2 o 6 , a total of 10 samples.

[0052] The red fluorescent powder applied to white light LED in this embodiment is prepared according to the following method:

[0053] SrCO 3 、Al 2 (CO 3 ) 3 and MnCO 3 Be raw material and take batching according to the atomic proportion shown in the chemical formula of this embodiment, take by weighing the AlF of raw material gross mass 2.5% 3 As a flux, SrCO 3 、Al 2 (CO 3 ) 3 , MnCO 3 and AlF 3 Put it into an agate mortar and ...

Embodiment 2

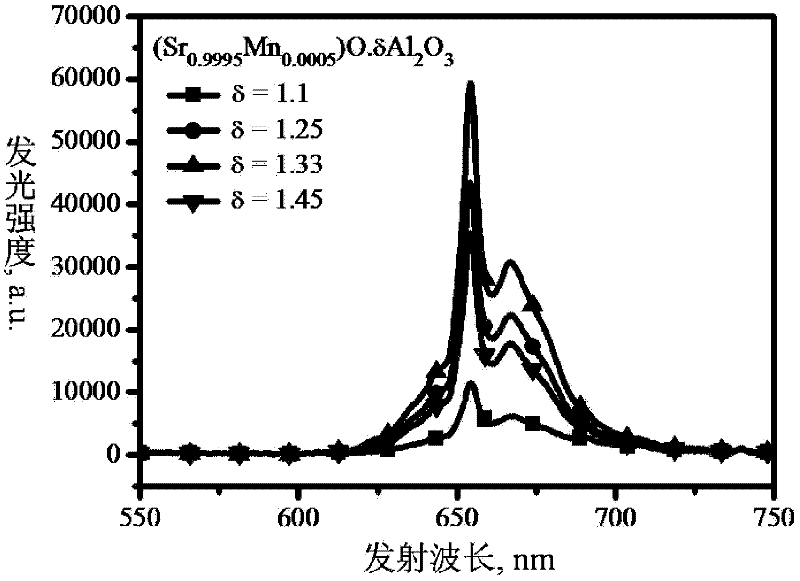

[0056] On the basis of the research conclusions of Example 1, this example further optimizes the Sr / Al ratio in order to obtain the best luminous efficiency, so the chemical formula of the synthesized fluorescent material designed in this example is (Sr 0.9995 mn 0.0005 )O·δAl 2 o 3 , where δ=1.1, 1.25, 1.33 and 1.45.

[0057] The preparation method is the same as in Example 1.

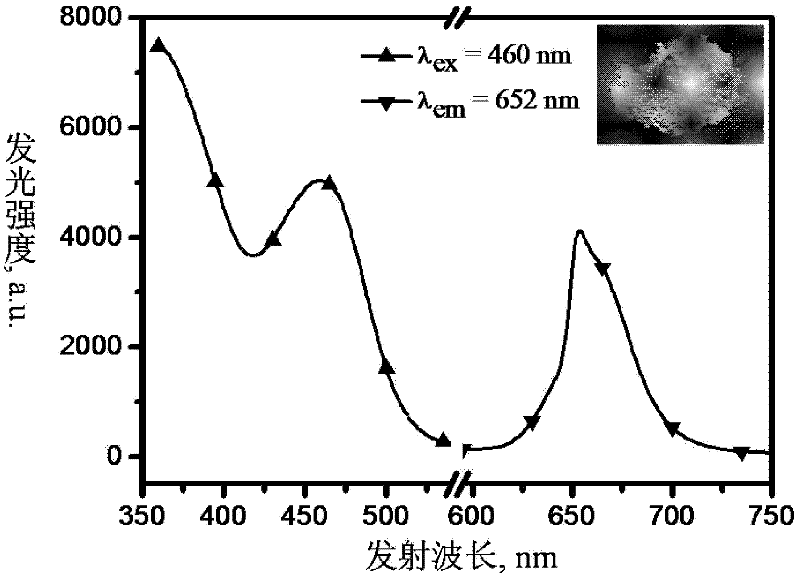

[0058] The emission spectrum of the fluorescent material prepared in this embodiment under 460nm excitation is as follows: figure 2As shown, the SrO:Al with the highest luminous intensity 2 o 3 The ratio is 1:1.33. Using a HITACHI F4500 spectrometer, the sample (Sr 0.9995 mn 0.0005 )O·1.33Al 2 o 3 The emission spectrum under excitation at 460nm and the excitation spectrum at 652nm are monitored as image 3 shown. From image 3 It can be seen that this fluorescent material has a broadband absorption in the range of 400-500nm, and this absorption band matches well with the emission wavelen...

Embodiment 3

[0060] On the basis of the above research conclusions, this embodiment further optimizes the concentration of the activator Mn in order to obtain the best luminous efficiency, so the chemical formula of the synthetic fluorescent material designed in this embodiment is (Sr 1-r mn r )Al 2.66 o 4.99 , where r=0.0001, 0.0005, 0.001 and 0.002.

[0061] The preparation method is the same as in Example 1.

[0062] The emission spectrum of the fluorescent material prepared in this embodiment under 460nm excitation is as follows: Figure 4 As shown, thus indicating that the optimum concentration of Mn is 0.05%M.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com