Nano columnar crystal thermal barrier coating layer and preparation method thereof

A technology of thermal barrier coatings and columnar crystals, applied in coatings, chemical instruments and methods, metal material coating processes, etc., can solve the problems of complex preparation processes and high raw material costs of precursor particles, and achieve simple preparation processes and low cost. The effect of low cost and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

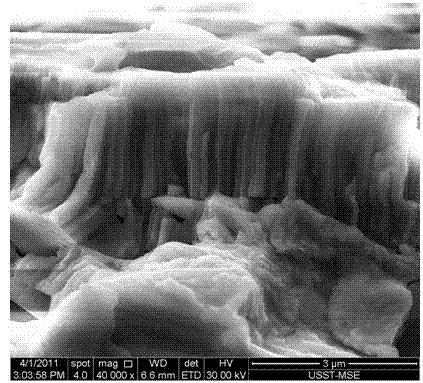

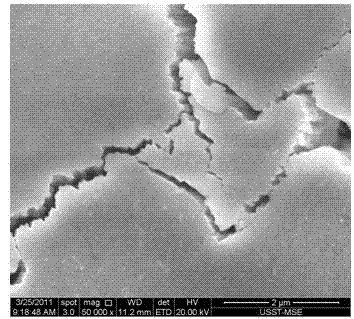

[0034] A nano-columnar crystal thermal barrier coating, which is a double-layer structure, including a bonding layer with an average thickness of 140 microns and a ceramic layer with an average thickness of 220 microns;

[0035] The bonding layer is obtained by spraying NiCrCoAlY powder by means of atmospheric plasma spraying;

[0036] In the NiCrCoAlY powder, calculated by mass percentage, Cr+Al:Ni+Co:Y is 22.81:75.88:1.31;

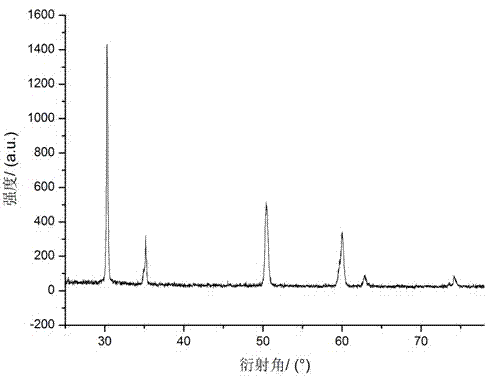

[0037] The ceramic layer is obtained by mixing zirconia powder and alumina powder stabilized with yttrium oxide at a mass ratio of 15.7:1, and then rolling and vibrating milling under the protection of argon to obtain a composite powder with atmospheric plasma. The method of spraying is obtained after spraying on the bonding layer;

[0038] The particle size of the yttrium oxide partially stabilized zirconia powder is 45-75 microns, and the particle size of the alumina powder is 2-10 microns.

[0039] The above-mentioned preparation method of a nano co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com