Patents

Literature

54 results about "Coating microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

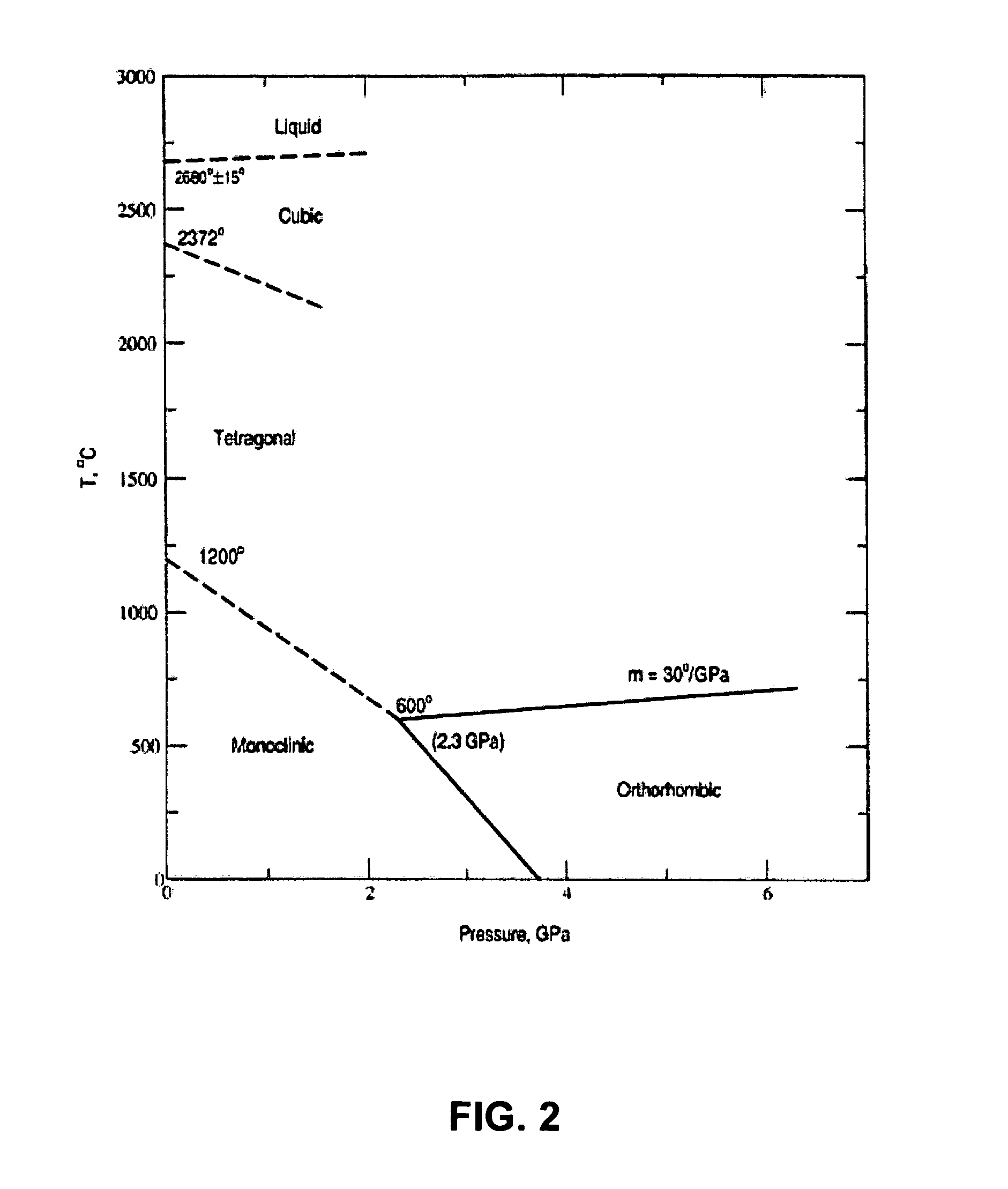

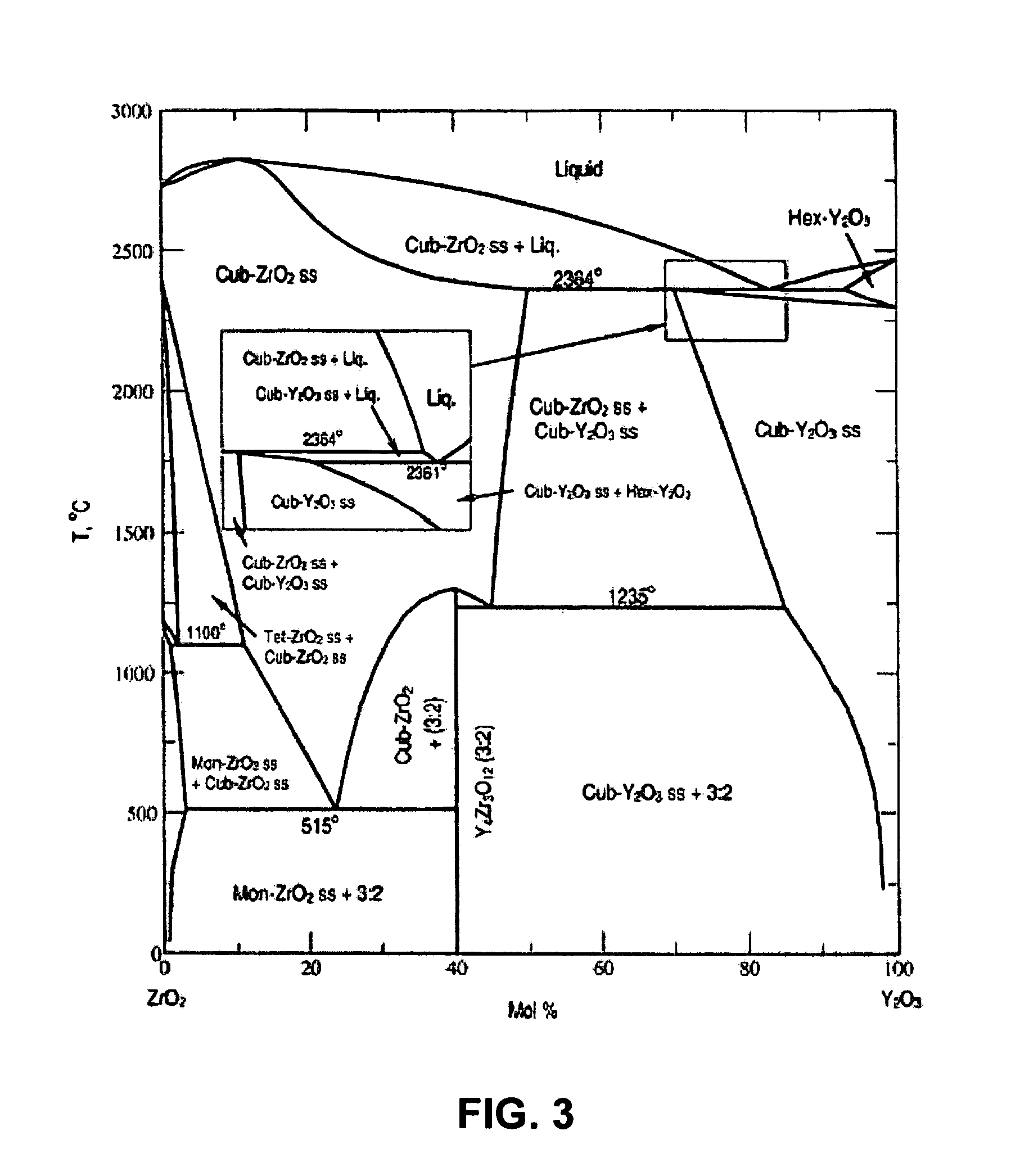

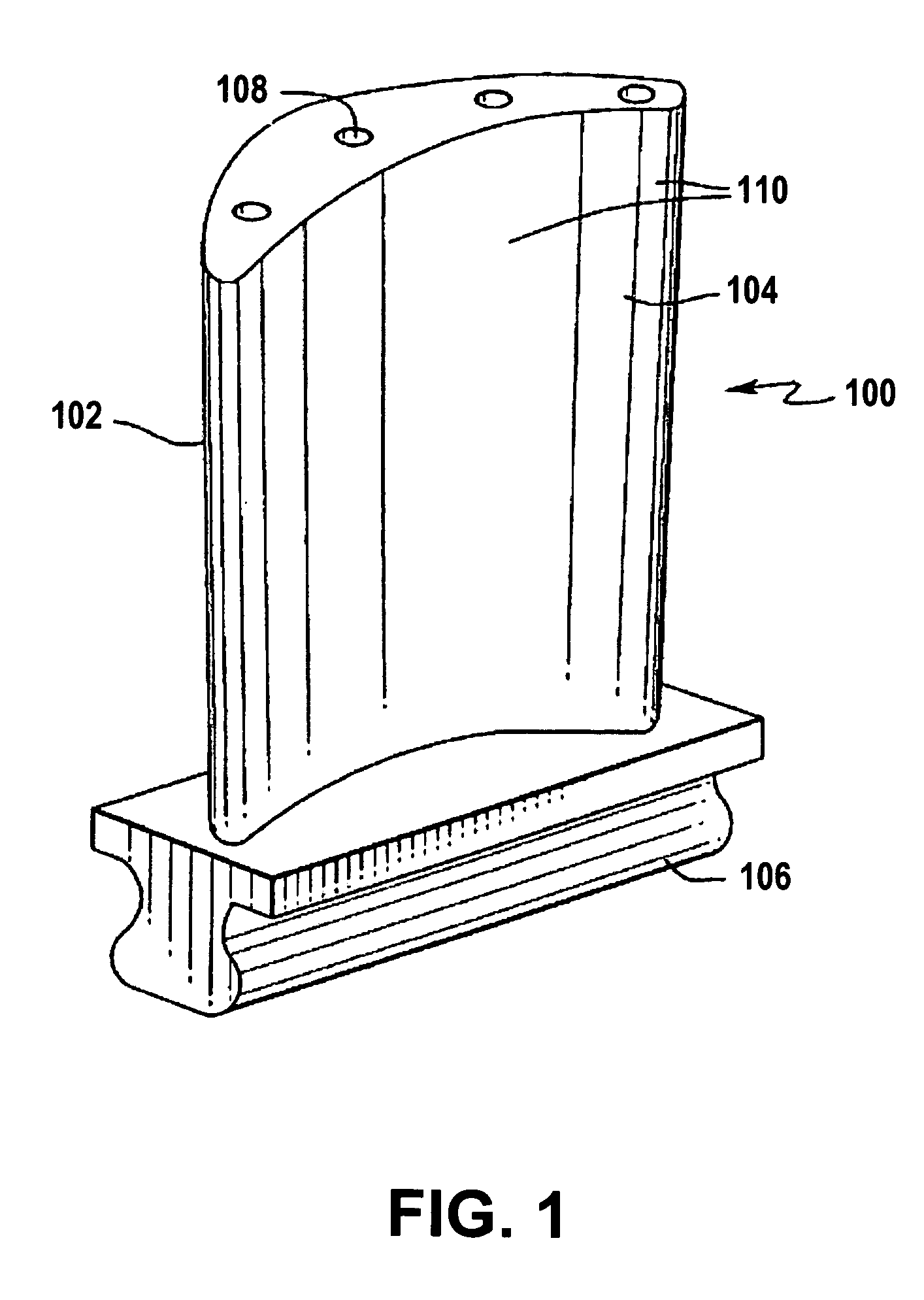

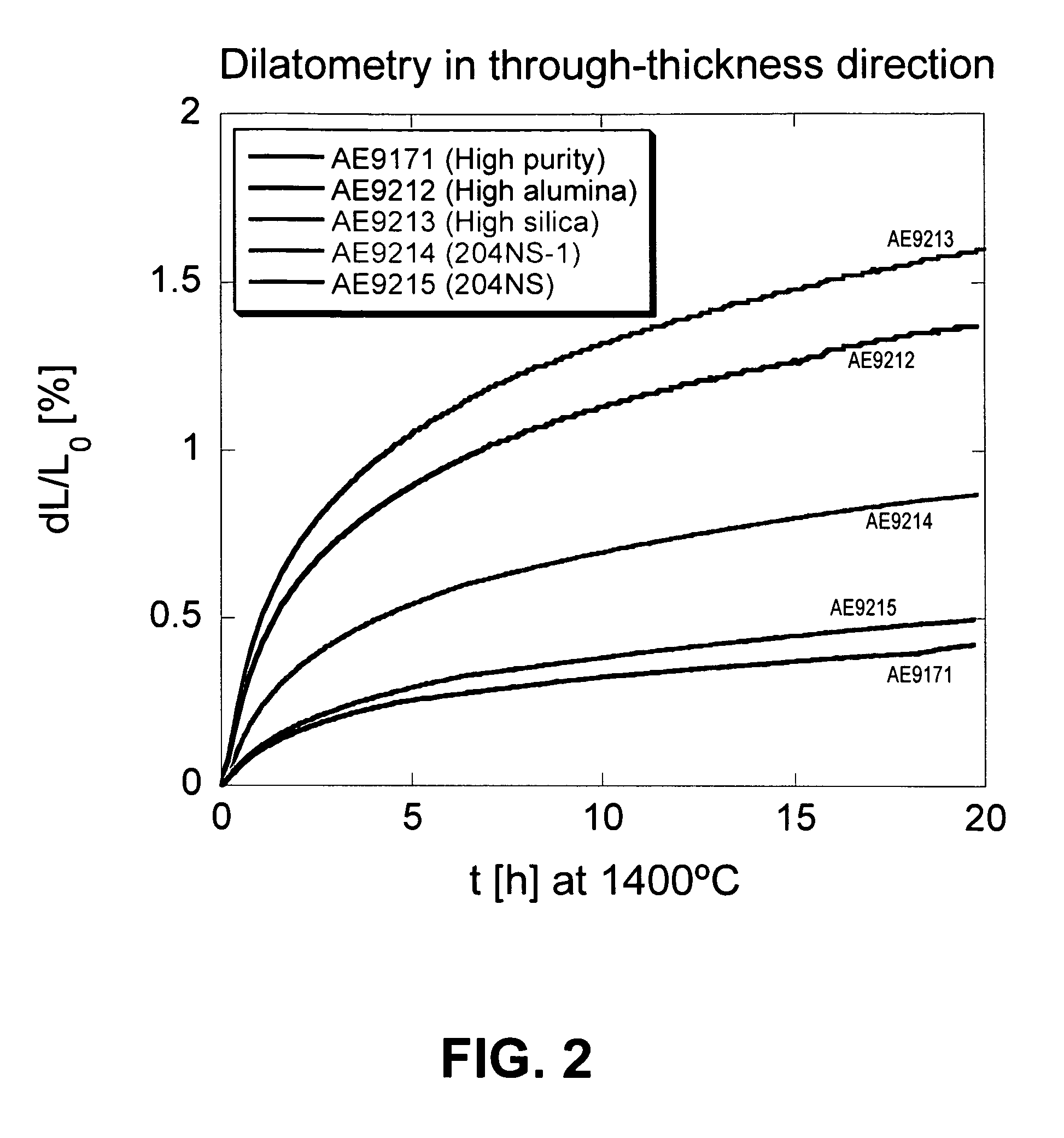

Optimized high purity coating for high temperature thermal cycling applications

InactiveUS20070082131A1Reduced sintering rateSuitable for applicationLiquid surface applicatorsMolten spray coatingCoating microstructureOperating temperature

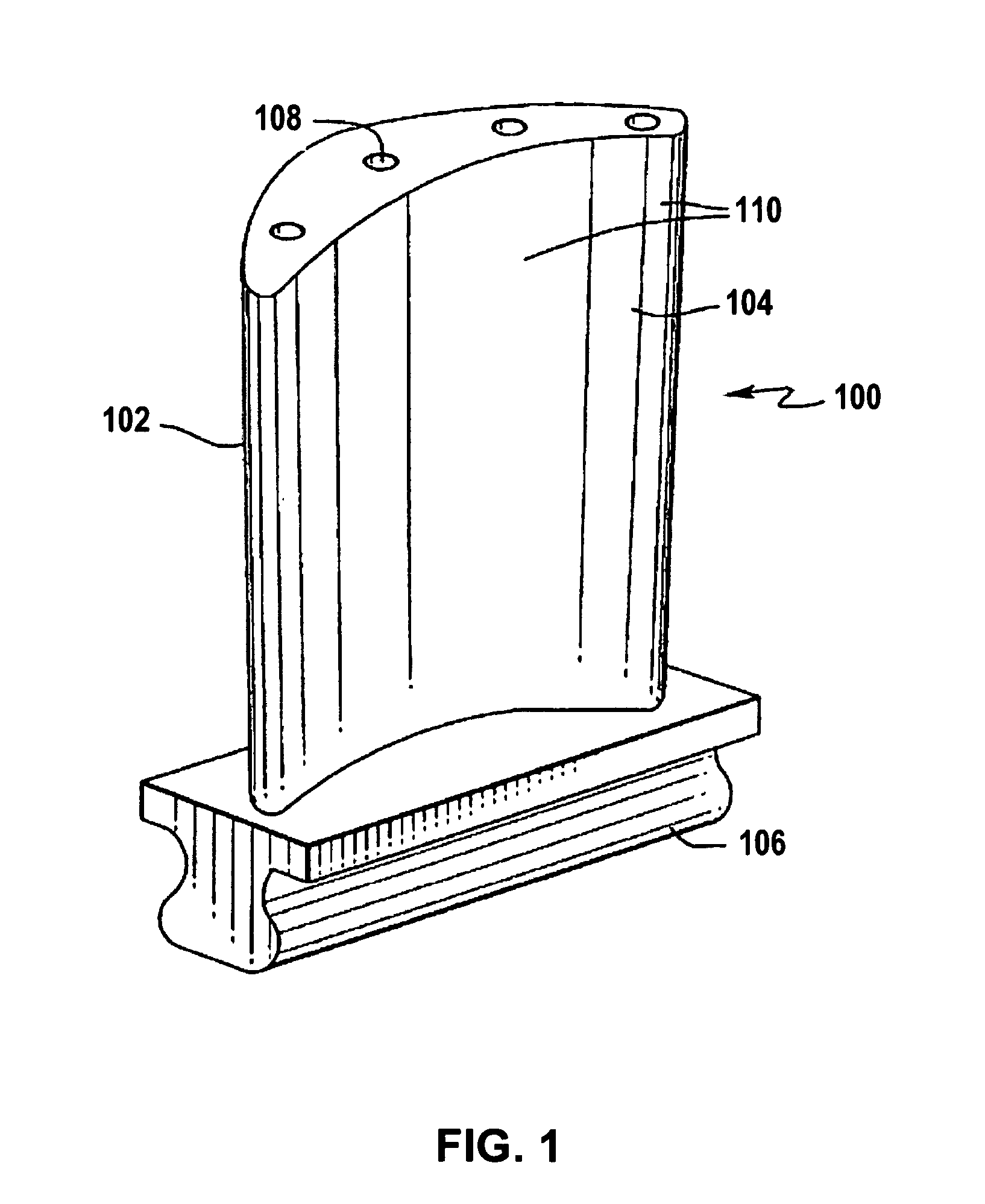

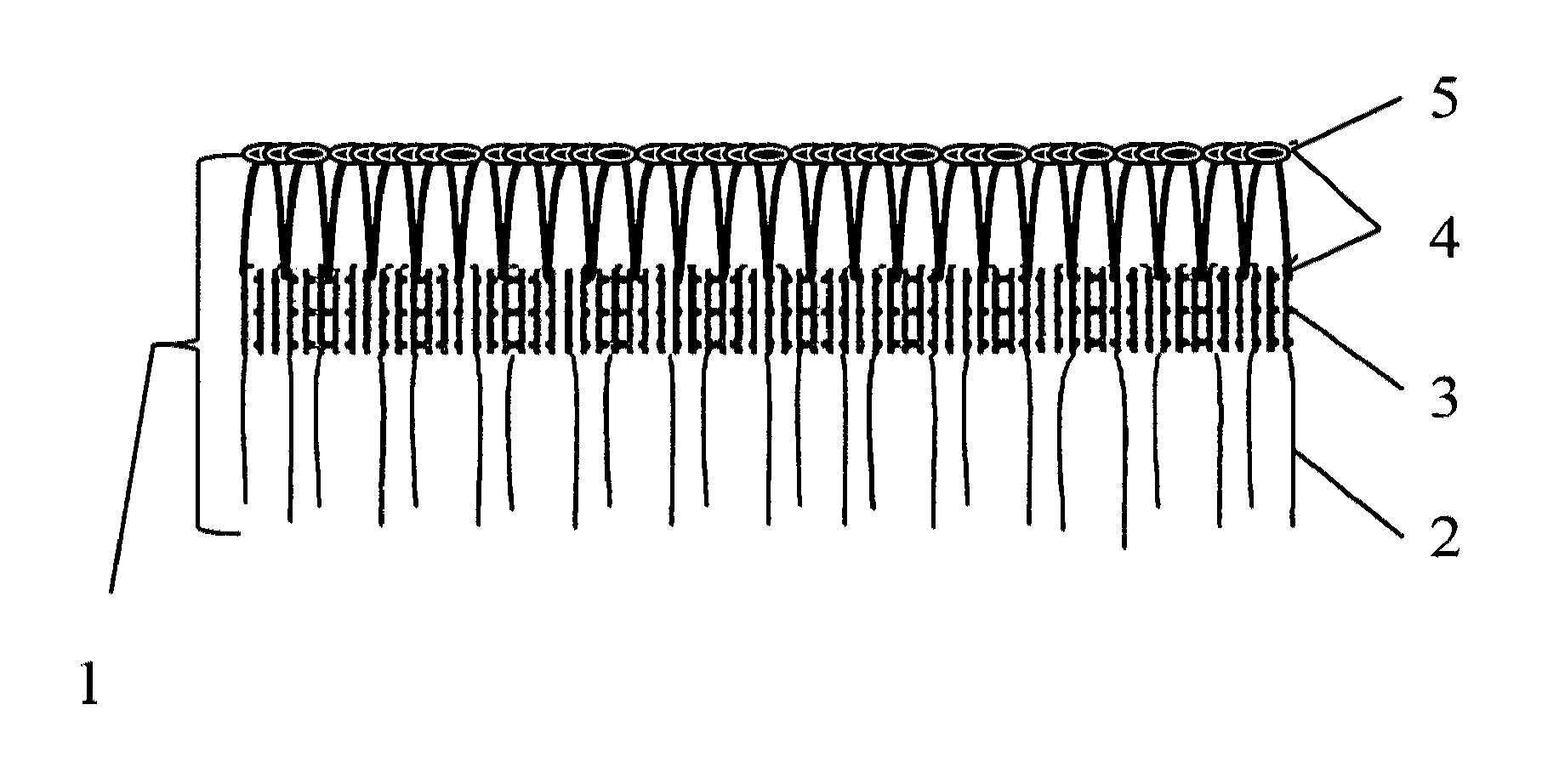

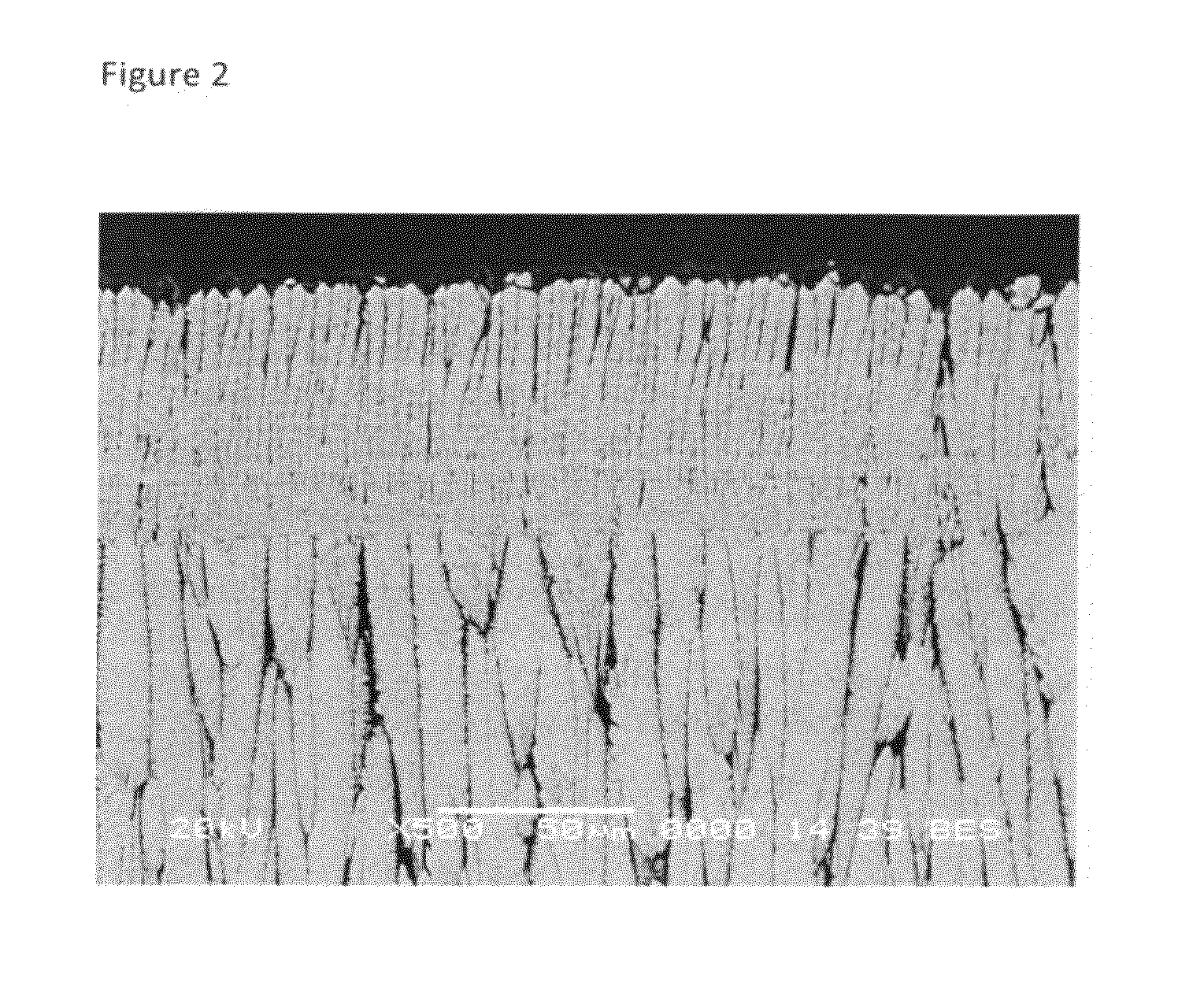

The invention is directed to a blended material and method for obtaining thermal barriers for high temperature cycling applications that have both high sintering resistance to achieve a high service lifetime and low thermal conductivity to achieve high operating temperatures. These materials are additionally suited for use in high temperature abradable (rub seal) coatings. The invention provides desired coating structures so that the changes in the coating microstructure over the in-service lifetime are either limited or beneficial.

Owner:SULZER METCO (US) INC

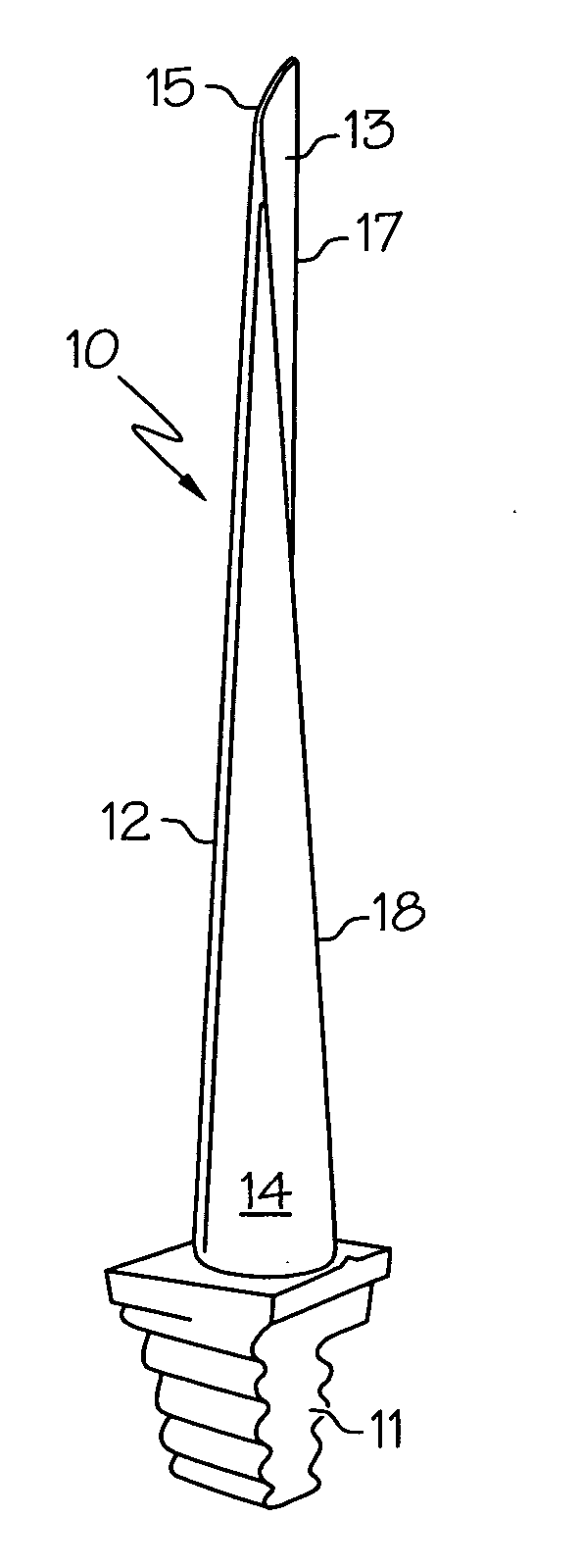

Low cost inovative diffused MCrAIY coatings

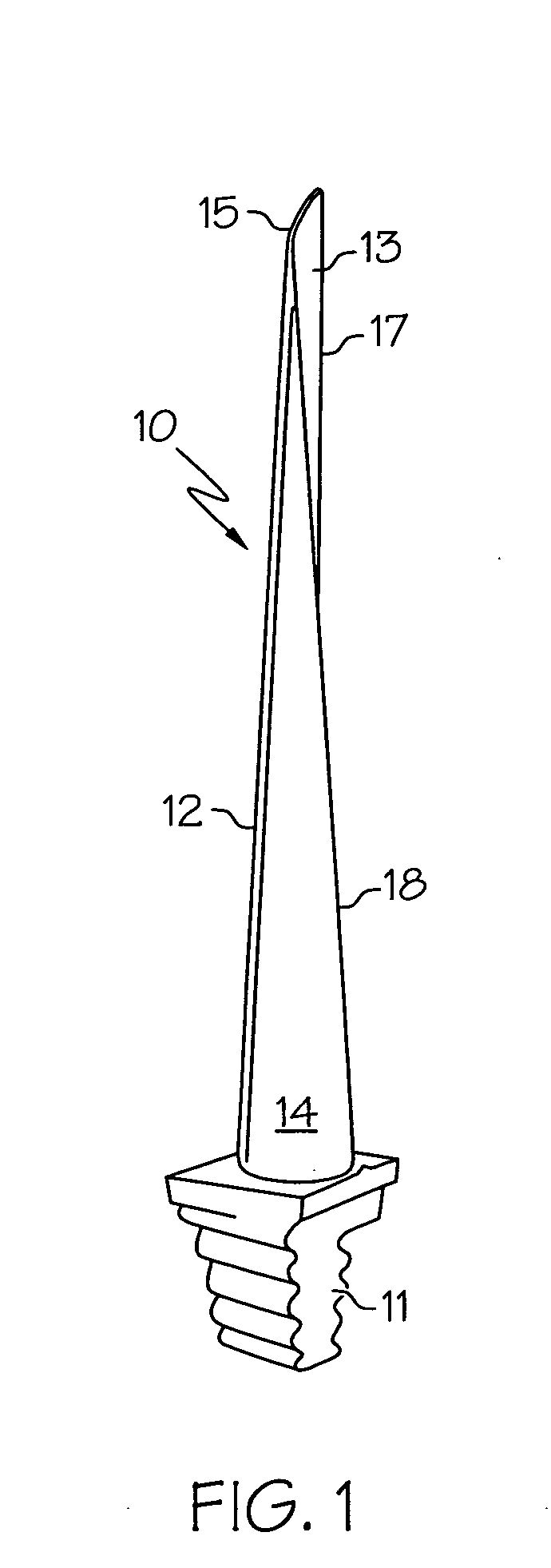

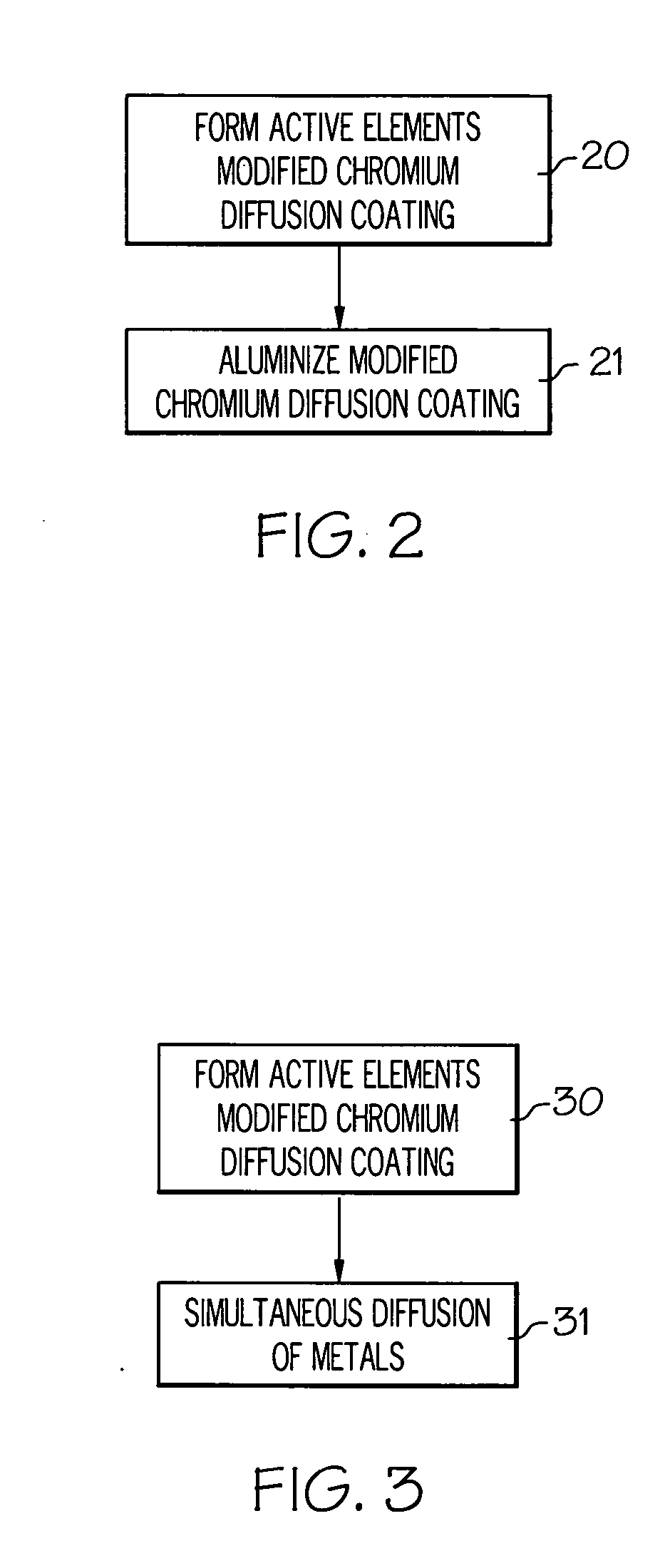

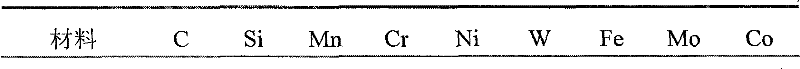

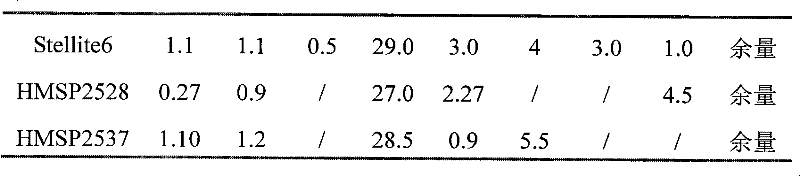

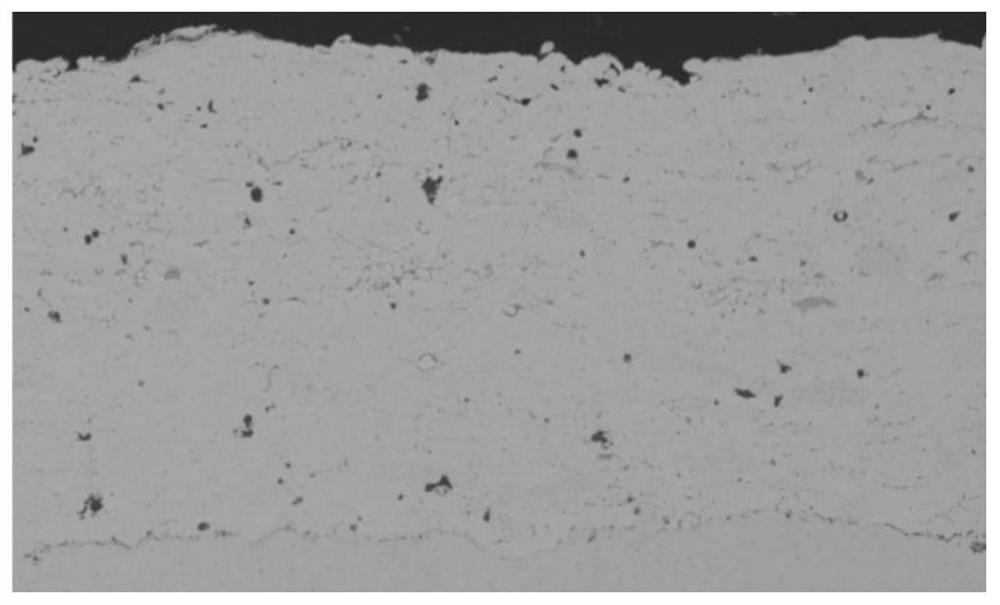

The present invention provides a low cost diffused MCrAlYX type coating that may be used on a surface of gas turbine engine component such as a turbine blade. The coating may be used as a protective coating that impedes the progress of corrosion, oxidation, and sulfidation in superalloy materials that comprise the substrate of the turbine blade. The method of depositing the coating includes steps such as: (1) forming an active elements modified chromium diffusion coating; (2) depositing noble metals such as platinum to a thickness in the range of 3 to 6 microns through known procedures such as electroplating or PVD techniques; (3) performing a diffusion cycle in the temperature range of approximately 1800° F. to 2000° F.; (4) performing an aluminizing step to generate coating microstructures; and (5) optionally performing a post coat diffusion treatment in the 1900° F. to 2025° F. temperature range.

Owner:HONEYWELL INT INC

A kind of metal surface modification method

InactiveCN102268626AWide range of applicationsSave resourcesMolten spray coatingCoated surfaceState of art

The invention relates to a metal surface modification method. The invention first obtains a textured surface with a certain surface roughness value on the surface of a material by an electron beam texturing method, forms uniform tiny pits, and increases the bonding strength of the interface; then uses plasma The spraying process uses Co-based alloy or Ni-based alloy powder as the material to form a coating; finally, laser remelting technology is used to remelt the coating surface to improve the surface structure of the coating and improve the surface performance. Compared with the existing technology, this process can realize high temperature resistance, corrosion resistance, oxidation resistance, and fatigue resistance, and has high bonding strength, and the coating structure is uniform and compact, thereby greatly broadening the application range.

Owner:SHANGHAI UNIV OF ENG SCI

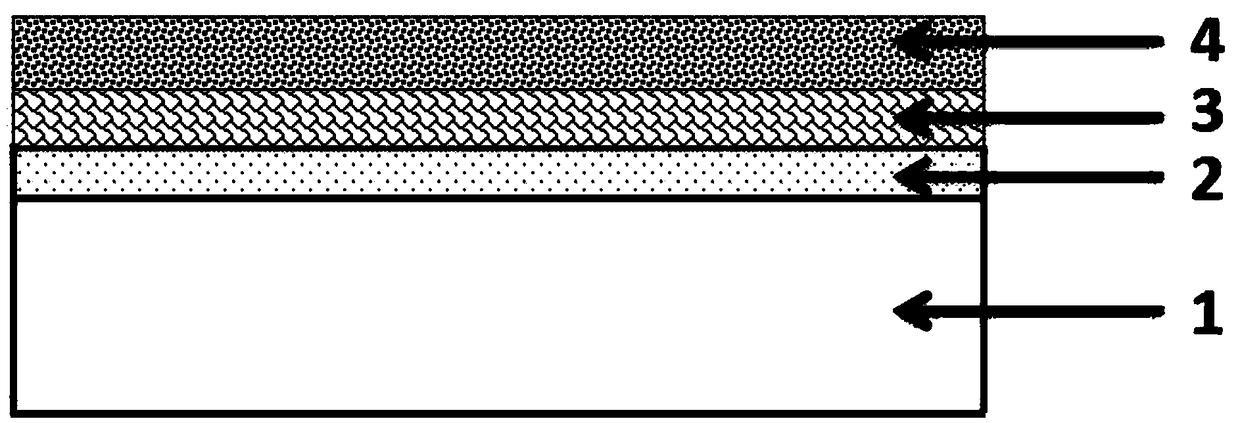

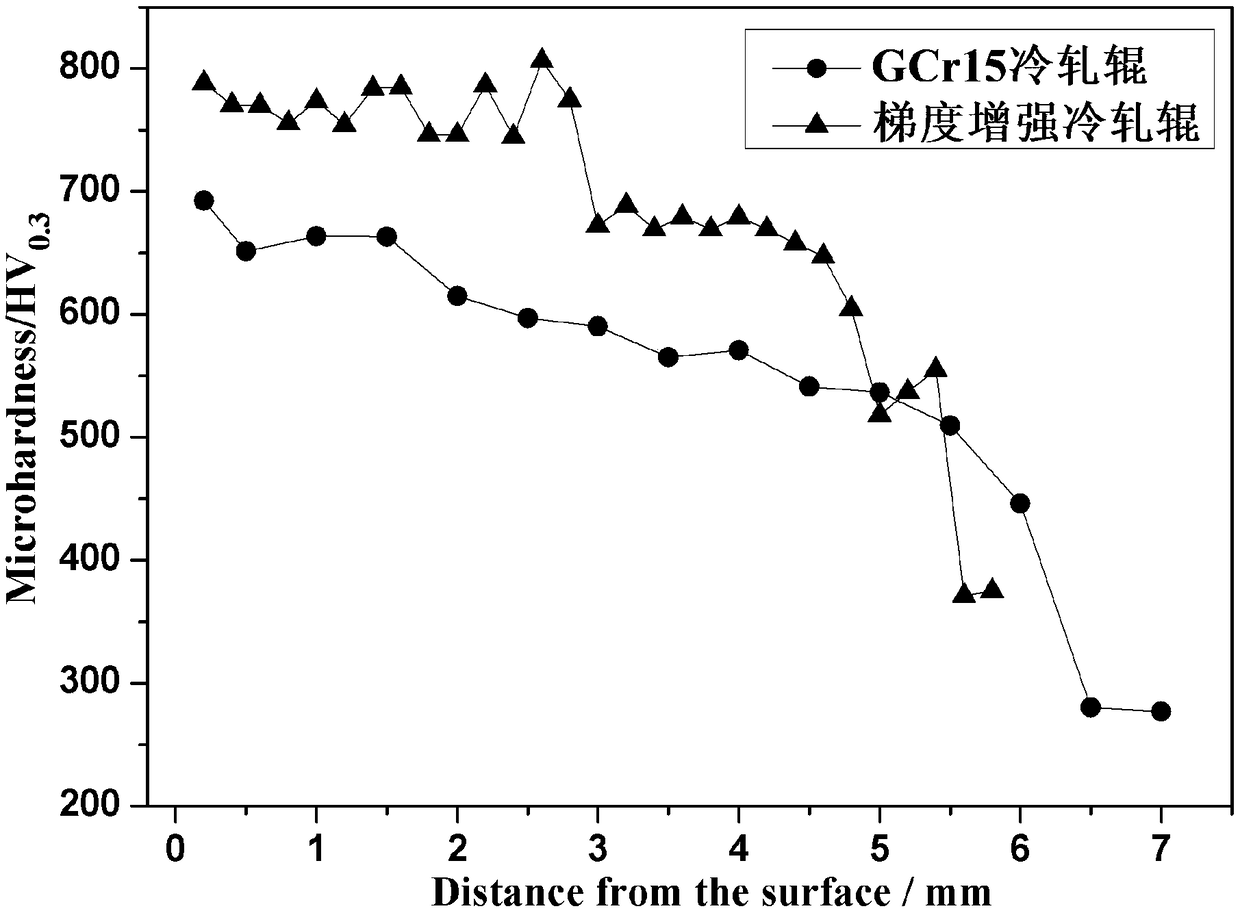

High hardness gradient enhanced cold roll and preparation method for surface laser cladding coating thereof

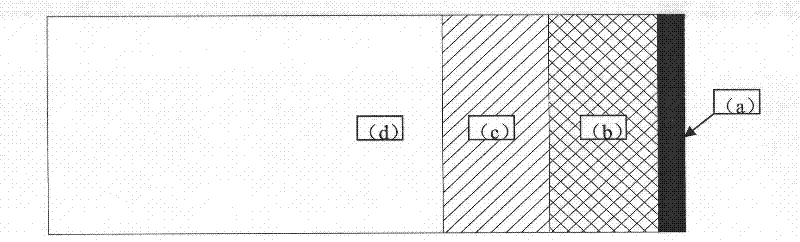

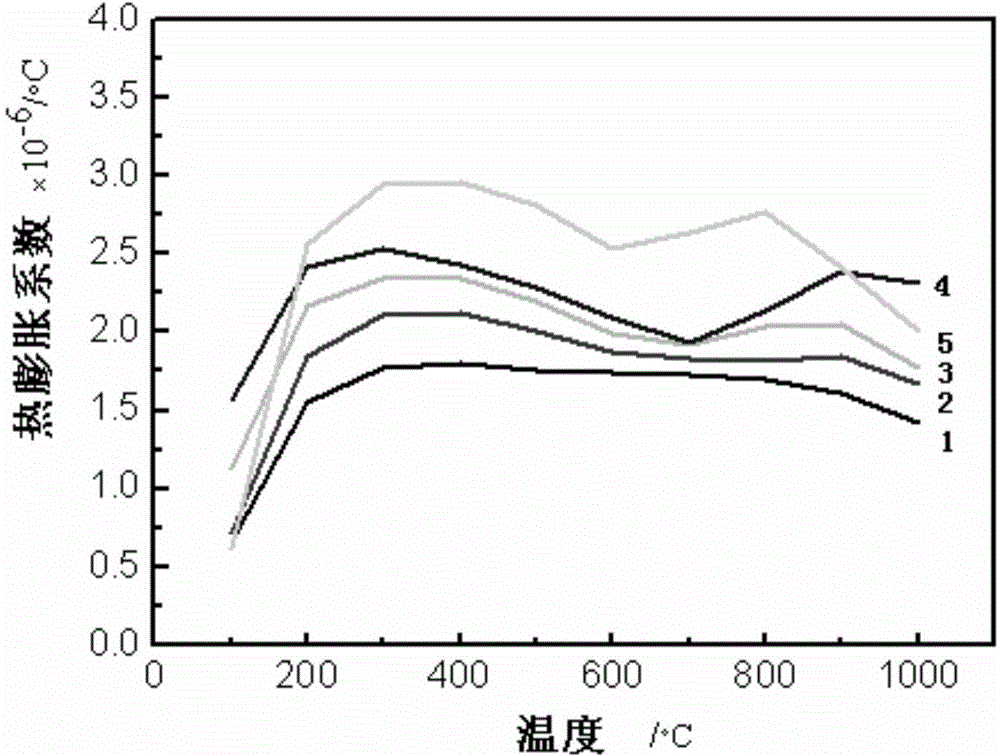

ActiveCN109402631ASmall coefficient of thermal expansionHigh bonding strengthRollsSuperimposed coating processHigh carbonThermal expansion

The invention discloses a high hardness gradient enhanced cold roll and a preparation method for a surface laser cladding coating thereof. The cold roll comprises a cold roll base and the surface laser cladding coating. The surface laser cladding coating is arranged into a gradient structure including a laser cladding priming coating, a laser cladding transition layer and a laser cladding workinglayer. The laser cladding priming layer can reduce a thermal expansion coefficient between the laser cladding coating and the cold roll base with high carbon content, reduce the carbon content, and improve the toughness of the laser cladding coating. By adding the CeO2 strengthening phase, the laser cladding coating microstructure obtains refined grains, and the friction coefficient of the laser cladding coating can be reduced favorably at the same time. By designing the compositional gradient change of the laser cladding coating, the crack sensitivity of the laser cladding coating can be reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

InactiveCN102676981AAvoid crackingSolve large surface roughnessSolid state diffusion coatingSurface cleaningTitanium nitride

The invention provides a method for a laser preparation of a titanium nitride gradient coating on a surface of titanium and titanium alloy. The method comprises the steps of performing surface cleaning treatment, surface blackening treatment and preheating treatment for a workpiece subatrate; and then carrying out laser nitriding treatment. The method is characterized in that the laser nitriding treatment is performed in a condition of filling reaction gas, and simultaneously laser scanning treatment and ultrasonic oscillating treatment for the surface of the workpiece subatrate are carried out. The titanium nitride gradient coating with a thickness of 50-200 [mu]m is obtained on the surface of the titanium and titanium alloy. The titanium nitride gradient coating is mainly composed of a nitride layer and a nitrogen diffusion layer, and has uniform transition of the coating microstructure. The surface hardness, wear resistance and corrosion resistance of the titanium nitride gradient coating are improved significantly than those of the matrix. Also, problems that crack are easy to produce, surface roughness is large, and the crystal grains of dendrite crystals of a nitride layer are coarse, in ordinary laser gas nitriding processes, are solved.

Owner:山东万丰煤化工设备制造有限公司 +1

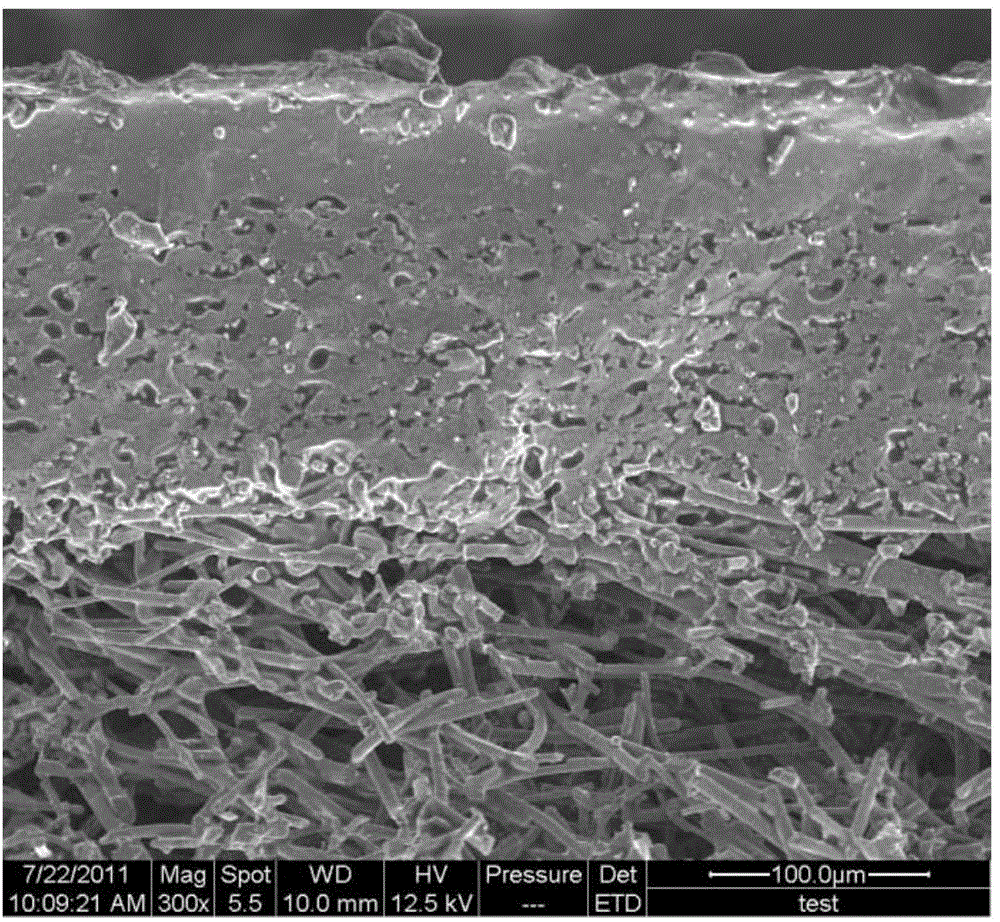

Rigid ceramic thermal-insulation tile surface coating preparation method

ActiveCN104860717AMeet the harsh working conditionsSatisfy working conditionsPorous substrateMaterials preparation

The invention relates to a rigid ceramic thermal-insulation tile surface coating preparation method, and relates to a ceramic thermal-insulation tile surface coating preparation method. The invention aims at solving technical problems of high water absorption, low oxidation resistance and low thermal radiation coefficient of rigid porous ceramic thermal-insulation tiles. The method comprises the steps of 1, raw material powder preparation; 2, mixed material preparation; 3, spray coating; and 4, sintering. With the method provided by the invention, the microstructure of the coating has a gradual gradient feature. The coating at a porous substrate side is porous, and the surface coating is smooth and compact. With the existence of the porous transition layer, a coating and substrate expansion mismatch characteristic can be coordinated. The method provided by the invention is used for preparing the rigid ceramic thermal-insulation tile surface coating.

Owner:芜湖市德明新材料科技发展有限公司

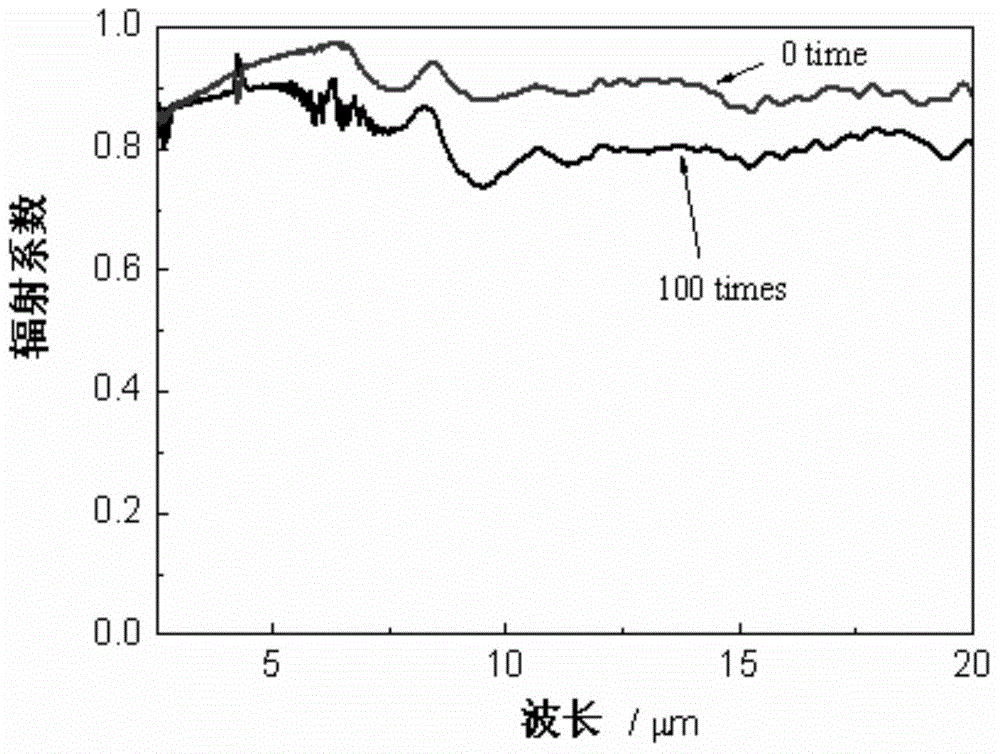

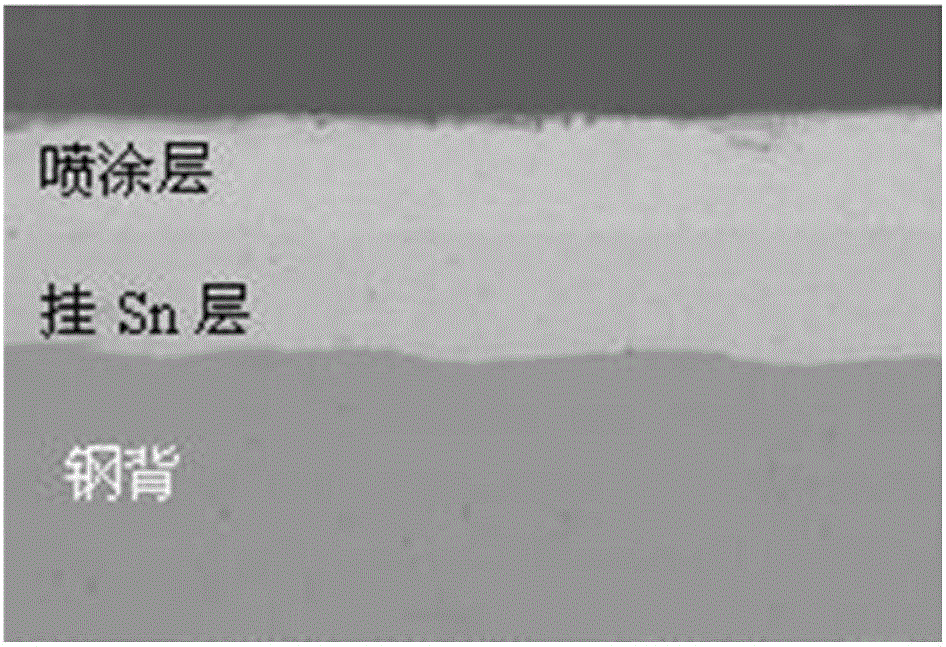

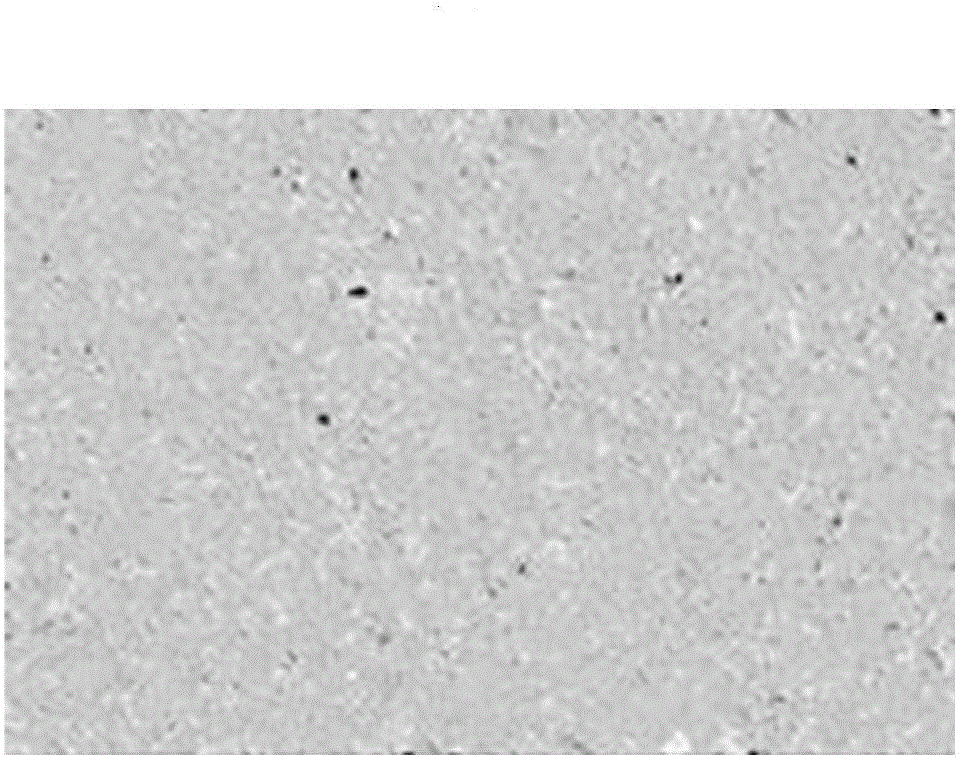

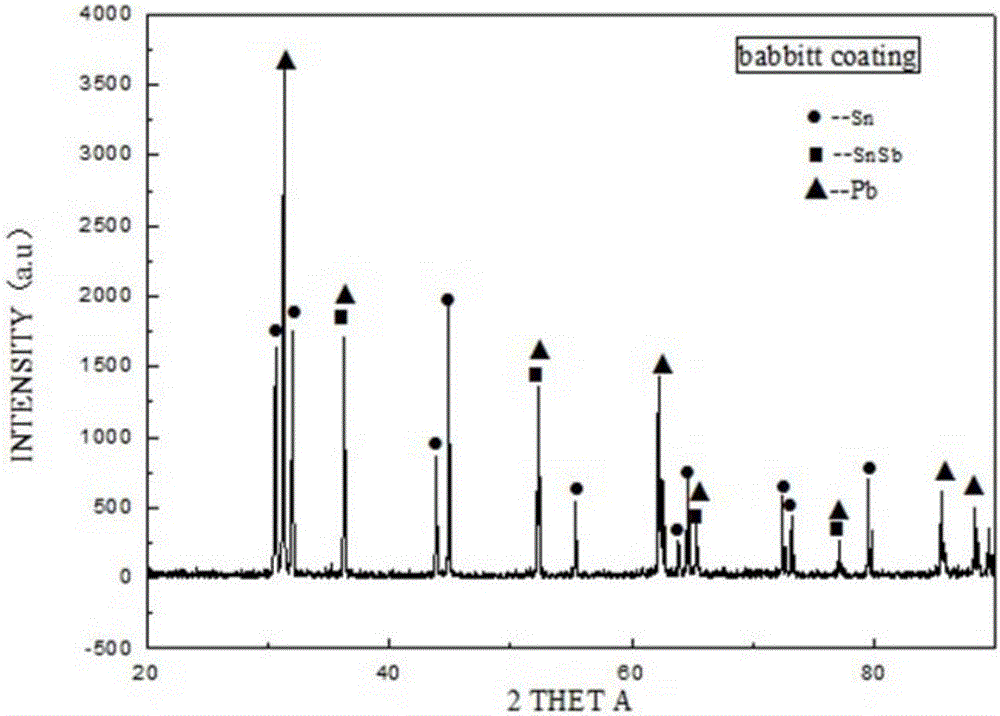

Method for coating bearing bush steel backing with Babbitt metal coating

ActiveCN106435563AImprove product qualityImprove the level ofHeat inorganic powder coatingSocial benefitsThermal spraying

The invention relates to the technical field of preparation and repair of sliding bearing Babbitt metal anti-friction layers. The novel cold spraying technology is introduced into manufacturing and repair remanufacturing of a Babbitt metal sliding bearing bush lining anti-friction layer, atomization powder feeding is adopted to obtain coating microstructures with uniform components and fine dispersely-distributed and uniformly-dense crystal grains and second phases through cold spraying, and the good interface bonding characteristic is obtained through tinning layer setting and sprayed thermal treatment; the defects of poor structure uniformity, thermal impact, stress, cracking and oxidizing burning losses existing in the technologies such as a traditional casting method, an overlaying method and a thermal spraying method are overcome, the bearing bush component preparation quality and level are improved, the bush burning frequency is decreased, stopping supercritical vibration is lowered, the stability, accuracy and reliability of a bearing transmission unit are improved, and the service life of the bearing transmission unit is prolonged; the method is rapid, efficient and environmentally friendly, is used for bearing bush manufacturing and repair remanufacturing, and has good economic benefits and social benefits.

Owner:UNIV OF SCI & TECH BEIJING

Tri-barrier ceramic coating

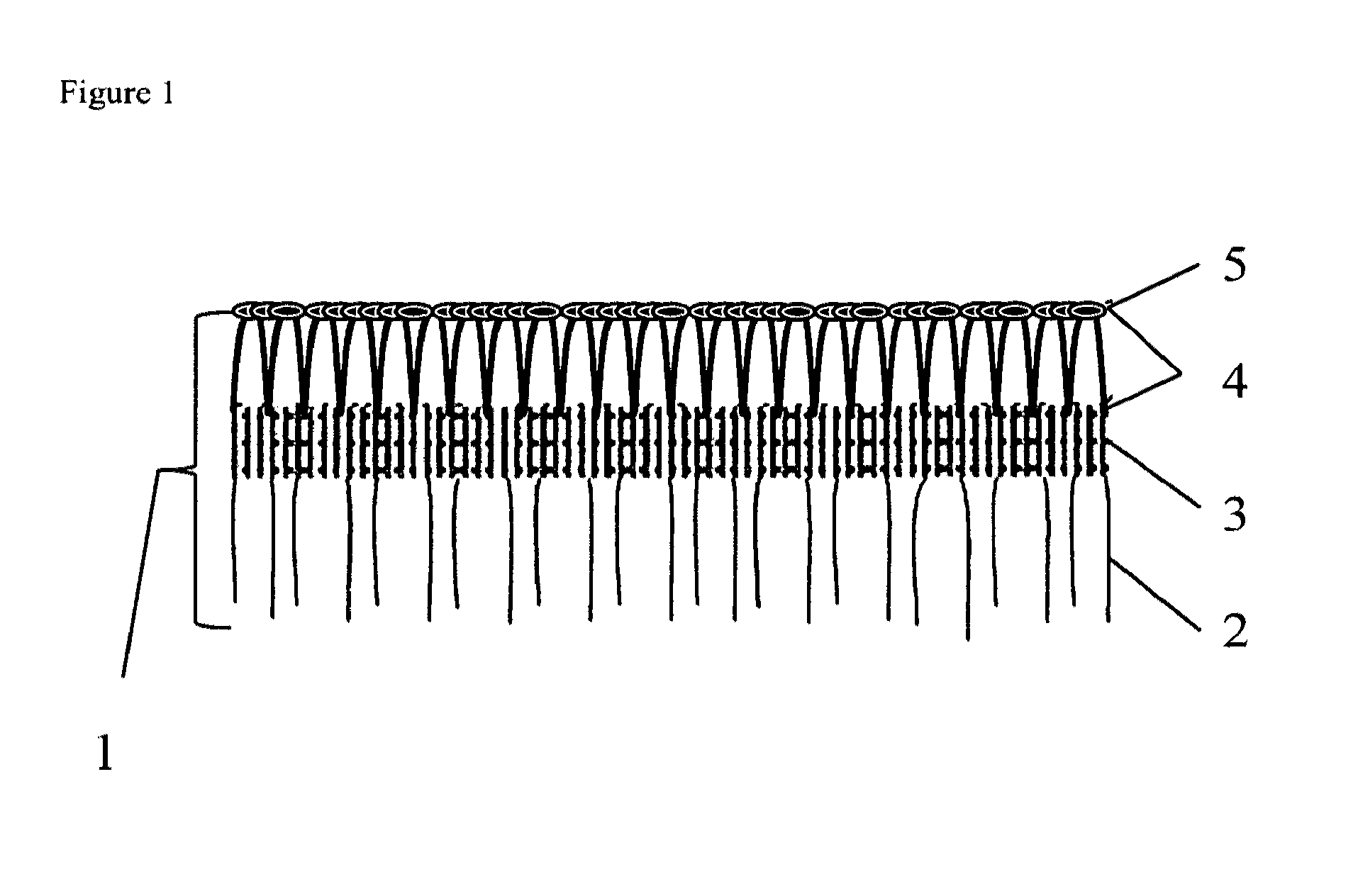

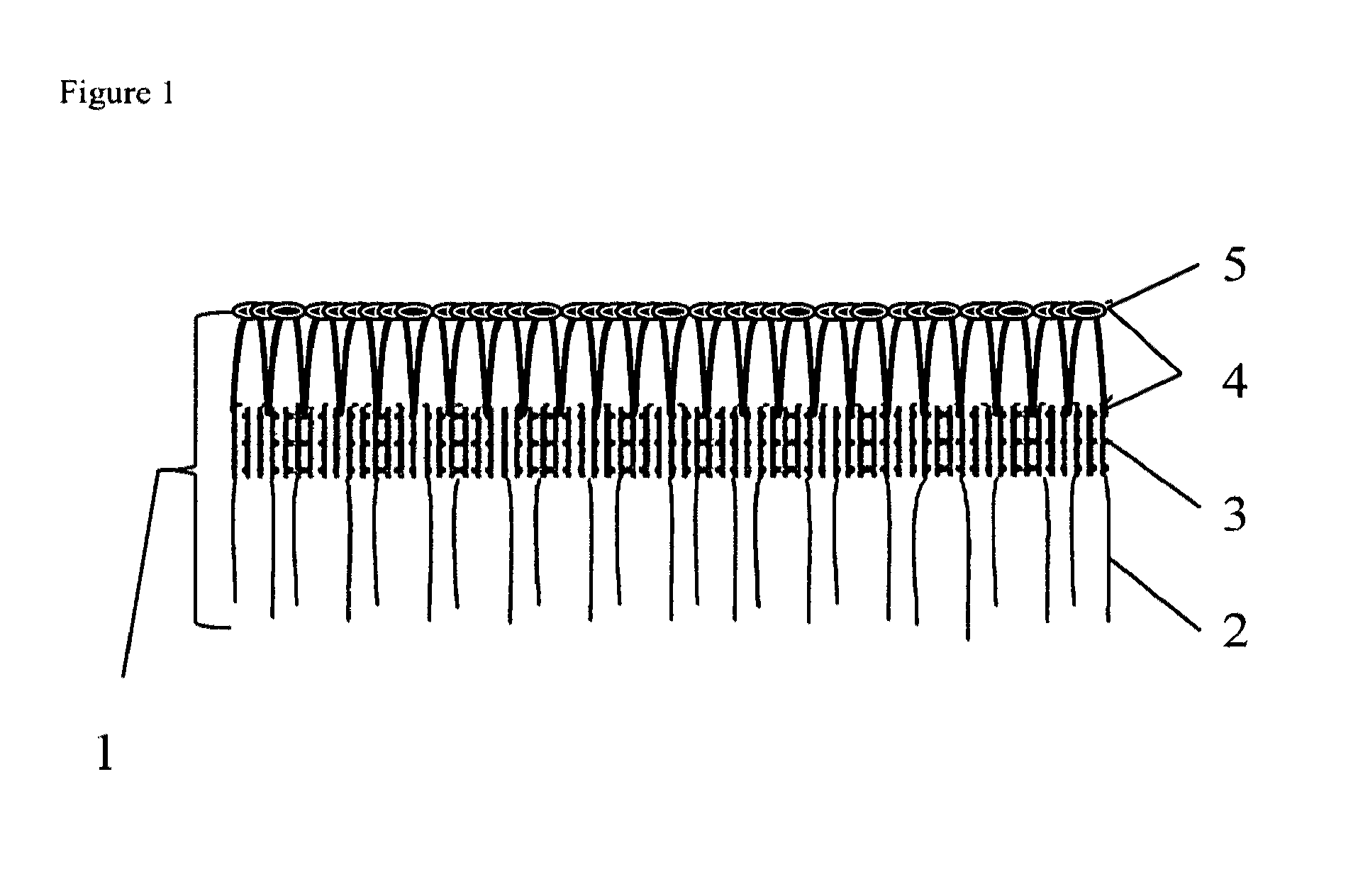

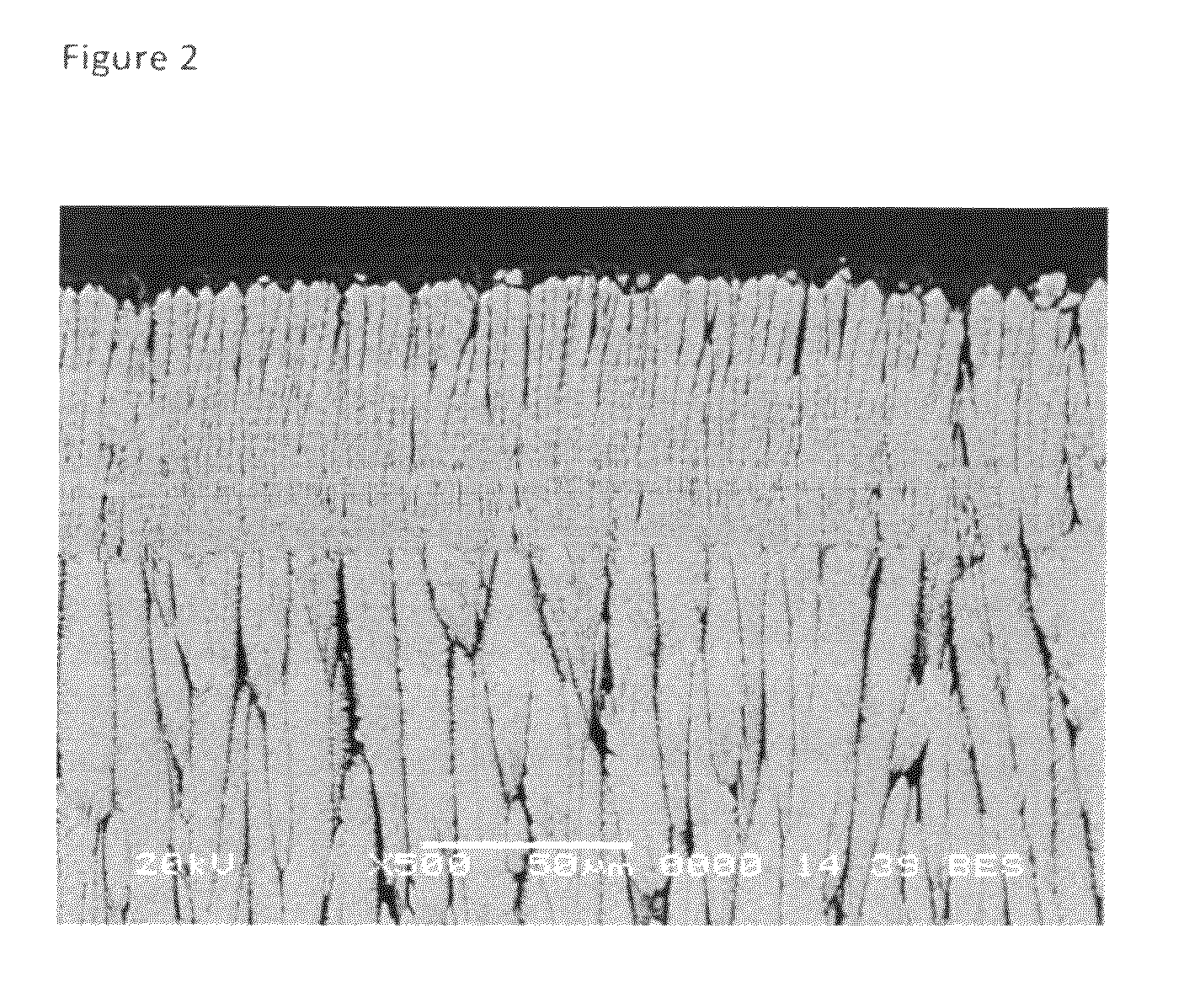

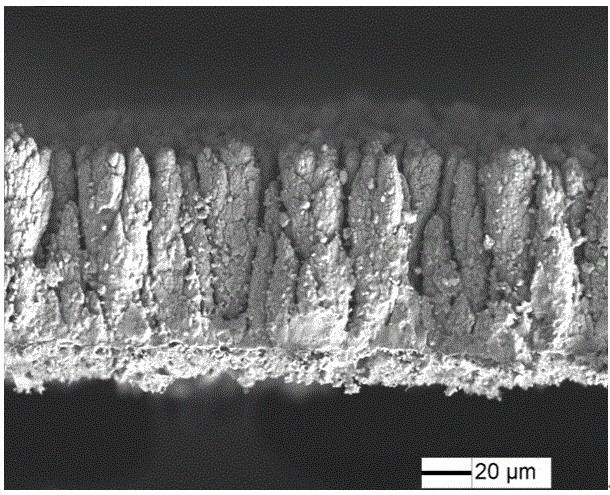

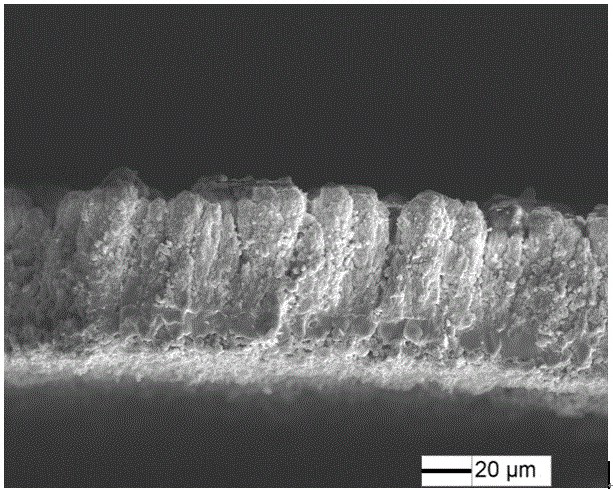

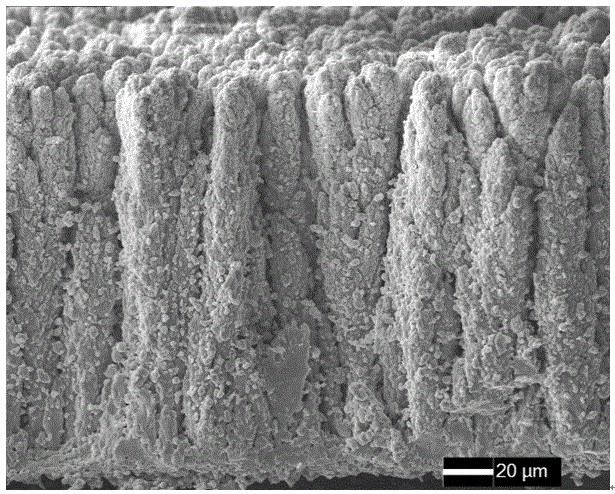

A tri-barrier ceramic coating system is provided having a base thermal barrier layer, an intermediate CMAS barrier layer, and a top erosion barrier layer, and the method of applying such a coating system to a substrate. The base layer has a typical columnar structure with inter-columnar gaps and intra-columnar micro-pores that provides the stress tolerance during thermal cycles. The intermediate CMAS barrier layer has the fiber-like columns with inter-columnar nano-pores and a grid structure on the bottom of the layer. The fine structured intermediate layer covers the gaps between the columns of the base layer and will block CMAS infiltration effectively. The top erosion resistant layer contains wider TBC columns with narrow inter-columnar gaps and a modified cauliflower-like TBC head that provides erosion resistance for the underlying layers. The tri-barrier coating microstructure will further reduce the thermal conductivity as comparing to the conventional single layer system.

Owner:CHROMALLOY GAS TURBINE

Ceramic material for high temperature service

ActiveUS20100075147A1Improve stabilizerEffect on its overall performanceMolten spray coatingVacuum evaporation coatingAlloyProviding material

Owner:SULZER METCO (US) INC

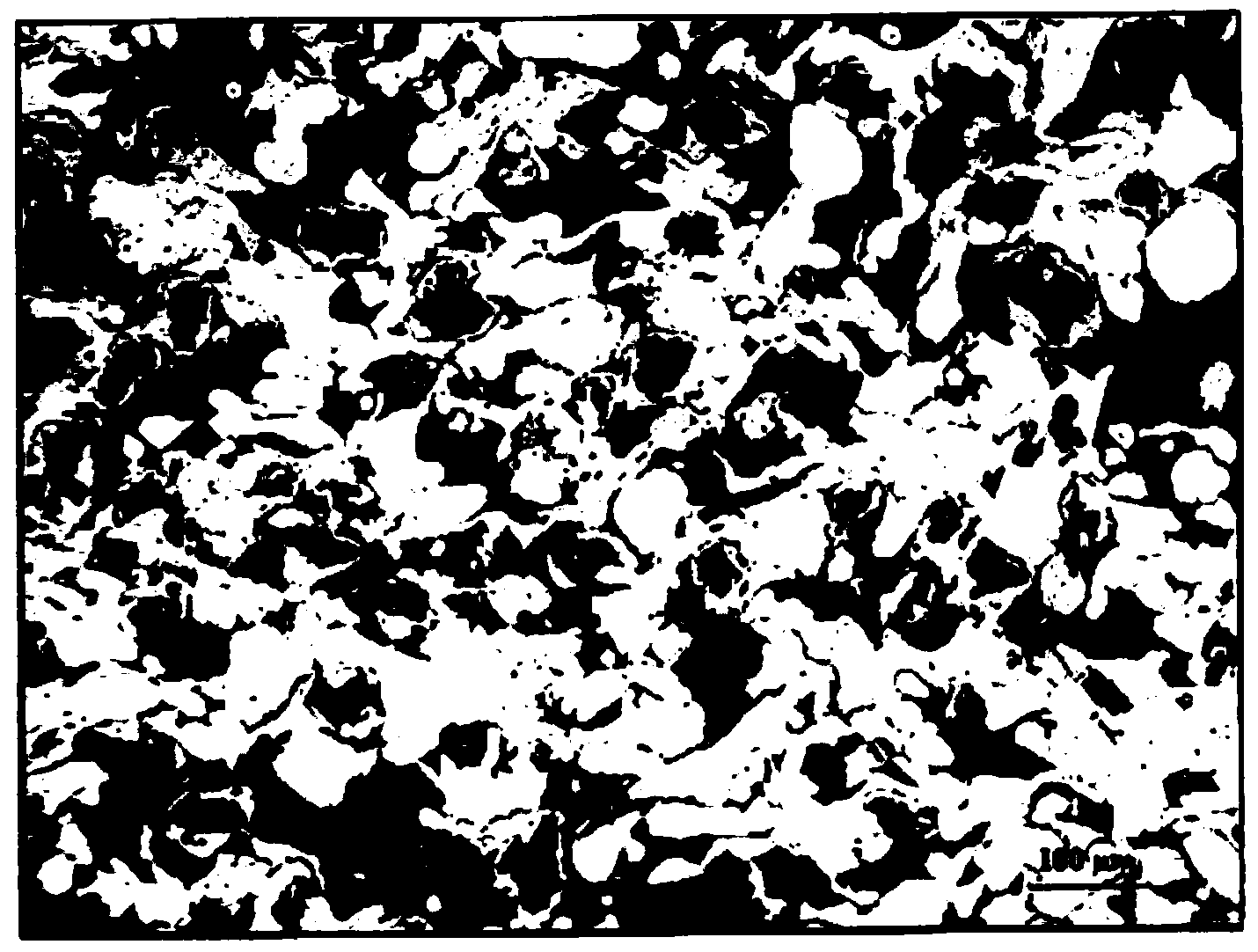

High wear-resisting iron-base thermal spraying coating material and preparation method thereof

InactiveCN104831208AGood high temperature oxidation resistanceImprove densification performanceMolten spray coatingCrazingSpray coating

The present invention discloses a high wear-resisting iron-base thermal spraying coating material, the high wear-resisting iron-base thermal spraying coating powder is made of a metal material, the metal material comprises the following the chemical components by weight: 10-18% of Cr, 0.20-0.50% of C, 0.8-2.0% of Si, 1.5-3.0% of Mn, 0.62-0.88% of Al, 0.55-0.87% of Ti, 0.5-2.0% of Ni, Mn and Ni with the total content of 3.2-3.6%, at least one of Mo and W with the total content of 1-8%, 0.41-0.63% of lanthanum rare earth, and balance of Fe and unavoidable impurities; the coating microstructure is Cr7C3 strengthening phase dispersed austenite, the lanthanum rare earth comprises the following the components by mass: 4-11% of cerium, 10-13% of terbium, 15-22% of gadolinium, 12-15% of praseodymium and balance of lanthanum, the total content of the cerium, terbium, gadolinium, praseodymium and lanthanum is 100%, and the iron-base composite coating powder has good high temperature oxidation resistance, can avoid excessive oxidation in the process of spraying so as to improve the compactness of internal combination of the sprayed coating, the sprayed coating is moderate in pore size and smooth and round in shape, the production of cracks can be effectively reduced, and the tank body oil storage function can be well played.

Owner:SUZHOU TONGMING MACHINERY

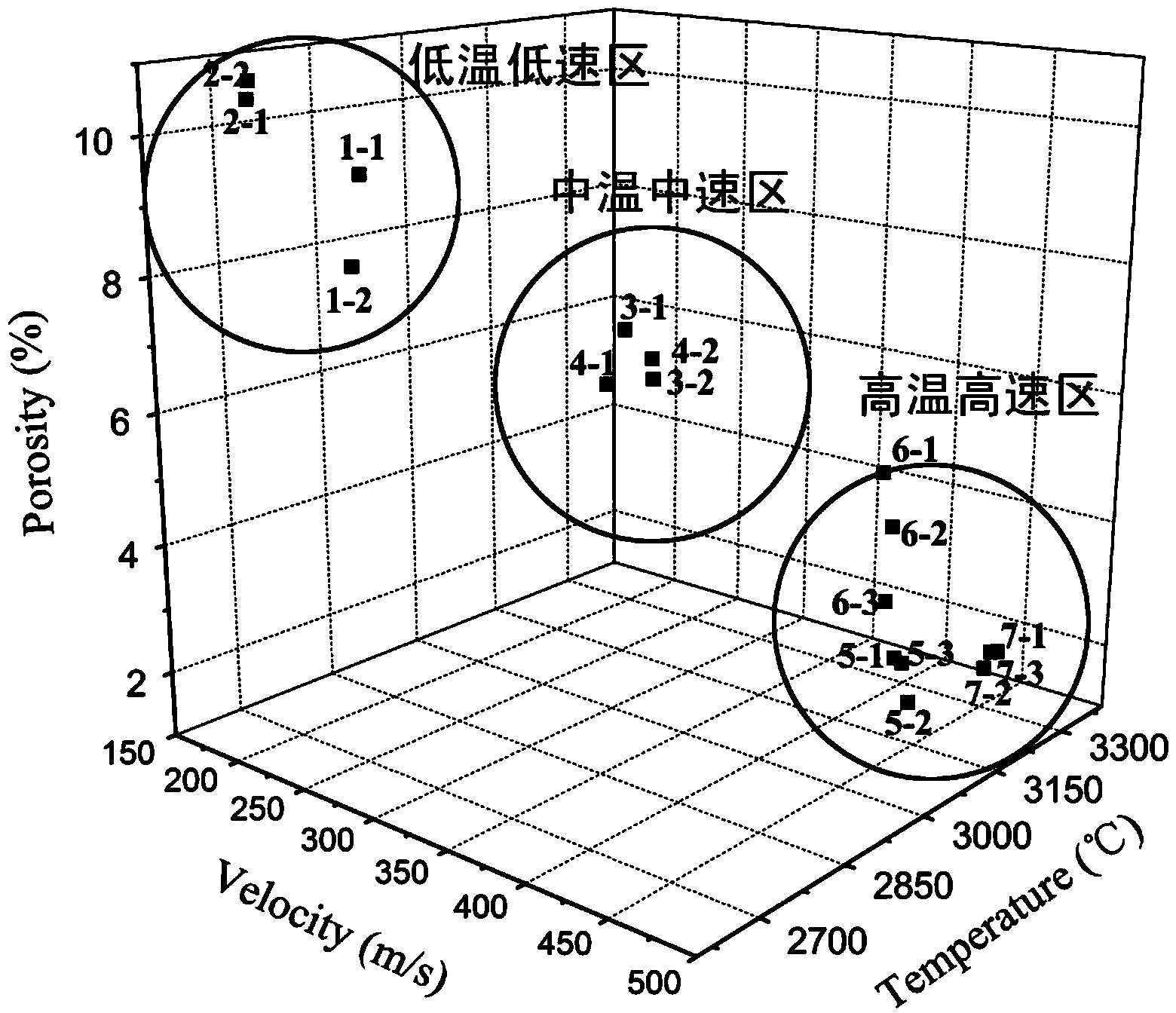

Control method for thermal barrier coating porosity

ActiveCN104032255AAchieving Consistency in QualityMeet different conditions of useMolten spray coatingEfficient propulsion technologiesPorosityLow speed

The invention discloses a control method for thermal barrier coating porosity. Through adjusting plasma spraying process parameters, online measurement is performed for spraying particles of different embodiments by using Spray Watch2i to obtain particle flying speeds and particle surface temperatures under different process parameters; the particle flying speeds and surface temperatures are grouped to three areas of high-temperature and high-speed, medium-temperature and medium-speed and low-temperature and low-speed; the three areas are sprayed to obtain coating layers; and the coating porosity is obtained by performing scanning electron microscope measurement; the quantitative relation between the particle flying speeds and surface temperatures and the coating porosity is determined; and the spraying process parameters are adjusted to realize effective control of coating microstructures.

Owner:洛阳铭天再制造科技有限公司

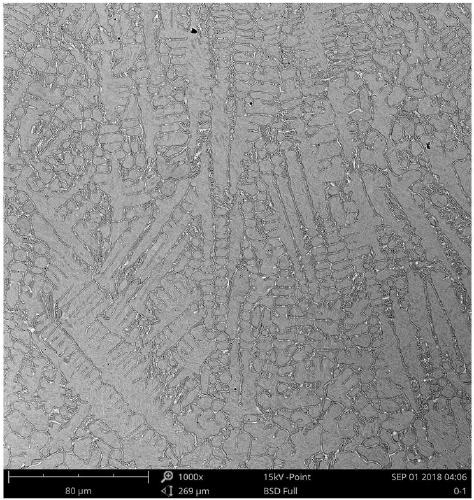

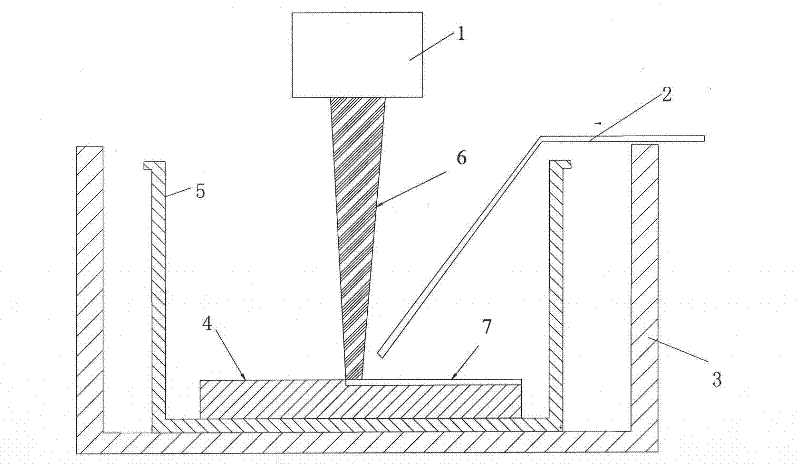

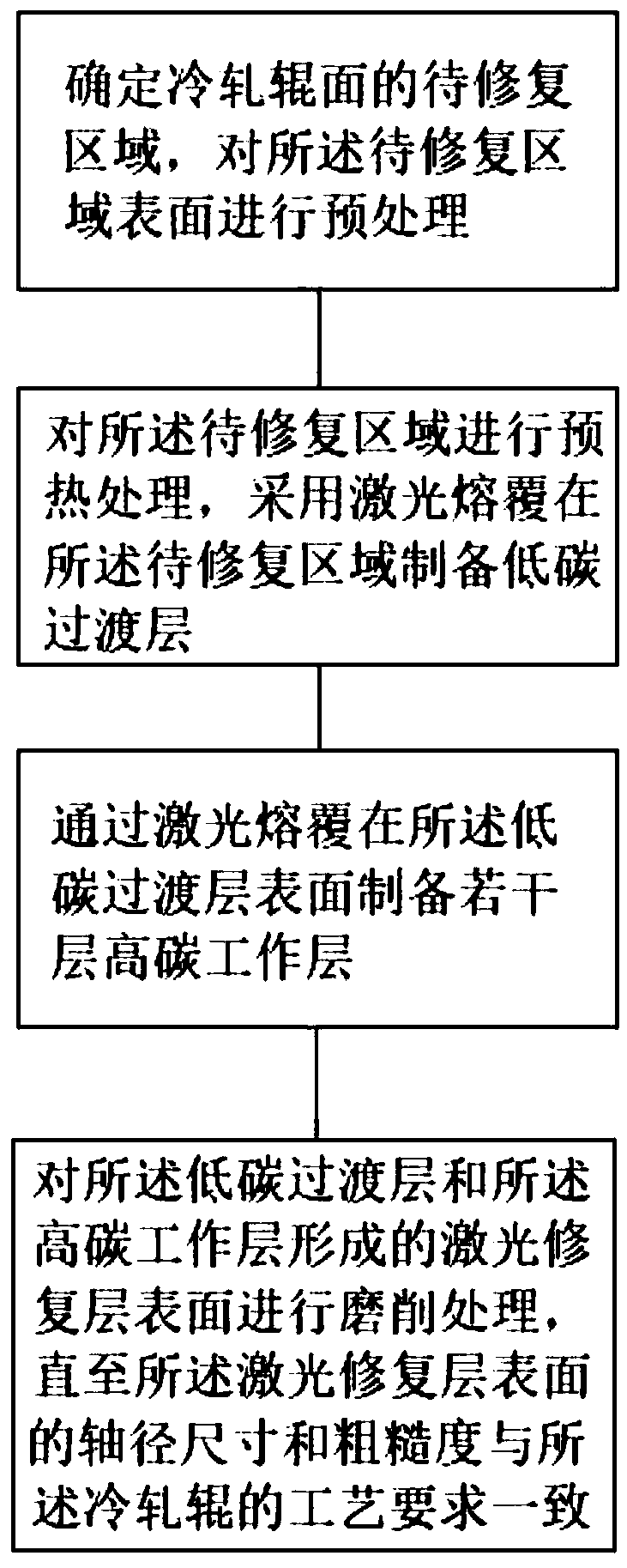

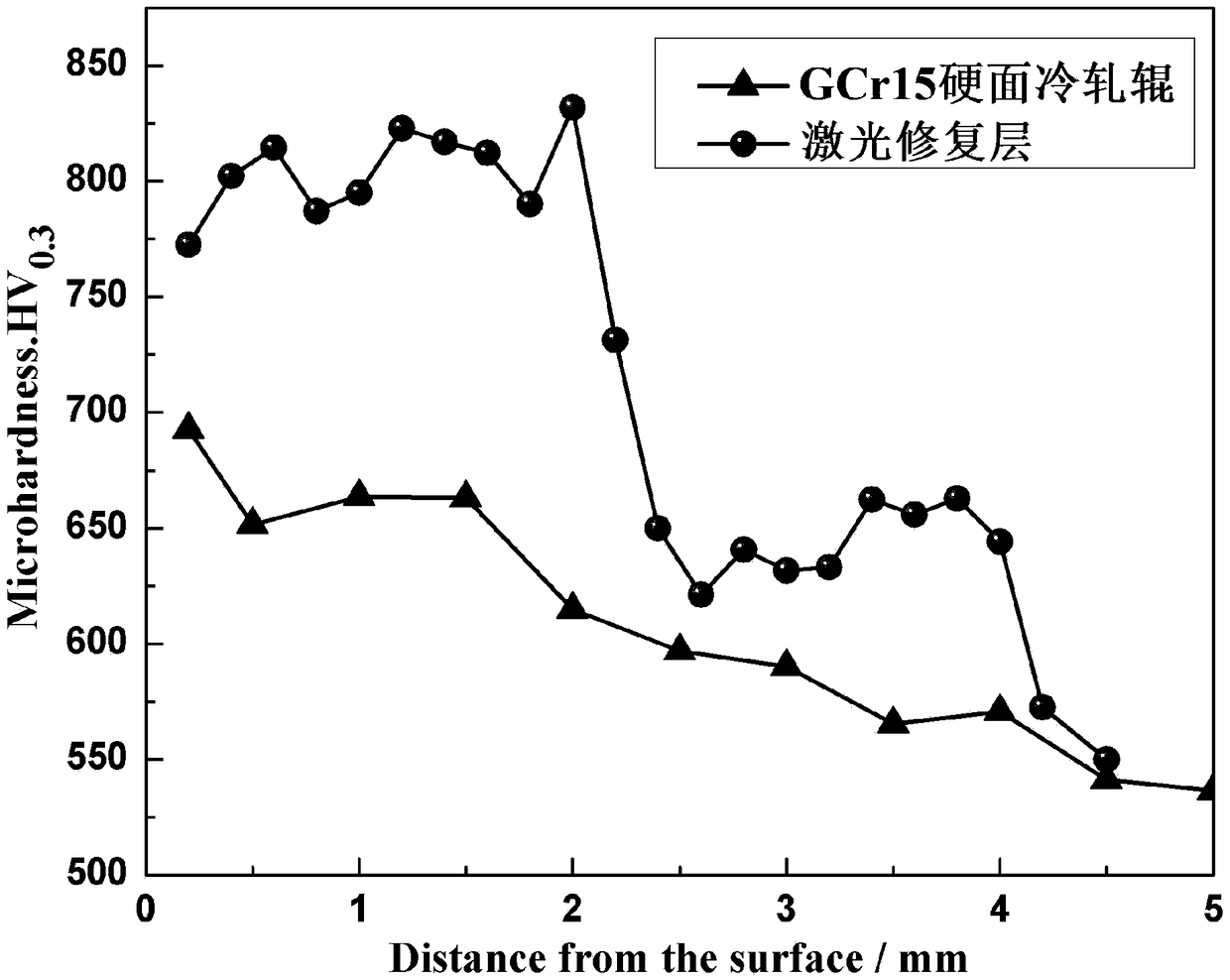

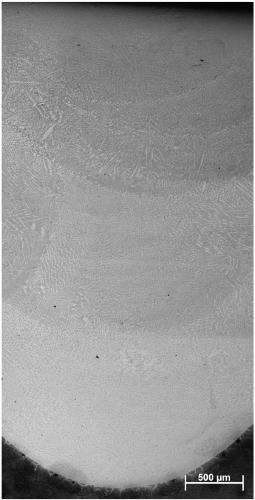

Laser repair method of high-carbon hard-face crack-free large-thickness cold roll

ActiveCN109371396AImprove repair efficiencyCooperate effectivelyMetallic material coating processesCrack freeHigh carbon

The invention discloses a laser repair method of a high-carbon hard-face crack-free large-thickness cold roll. The laser repair method comprises the steps that a to-be-repaired area of the cold roll face is determined, and the surface of the to-be-repaired area is pretreated; the to-be-repaired area is subjected to preheating treatment, and a low-carbon transition layer is prepared on the to-be-repaired area through laser cladding; multiple high-carbon work layers are prepared on the surface of the low-carbon transition layer through laser cladding; and the surface of a laser repair layer formed by the low-carbon transition layer and the high-carbon work layers is subjected to grinding treatment till the axle diameter dimension and roughness of the surface of the laser repair layer are consistent to the process requirements of the cold roll. According to the laser repair method, through reasonable design to alloy powder components and optimization selection of process parameters, the crack-free laser repair layer is prepared, and the coating microstructure is uniform and compact; and through reasonable control over the structures and thickness of the laser repair layer, the structure and performance of multiple cladding layers effectively cooperate, the laser repair layer large in thickness and high in performance can be prepared, and the repair efficiency of the roll is greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Method of covering devices with ceramic layers, ceramic surface layers and coated devices

Surface coating method for applying a chemically bonded ceramic coating on a sub-strate, comprising the steps of preparing a powder mixture based on a hydraulic ceramic binder phase, preparing a substrate surface, applying at least one layer of the powder mixture on the substrate, and finally hydrating the powder layer / layers by addition of a water-based solution. The present invention method can be applied without using elevated temperatures, complicated and complex equipment, while maintaining control over the microstructure of the coating. The inventive procedure can suitably be used for producing general orthopaedic and dental implants. The inventive coatings can also be used in microstructure technology applications or in wear and friction applications.

Owner:CERBIO TECH AB

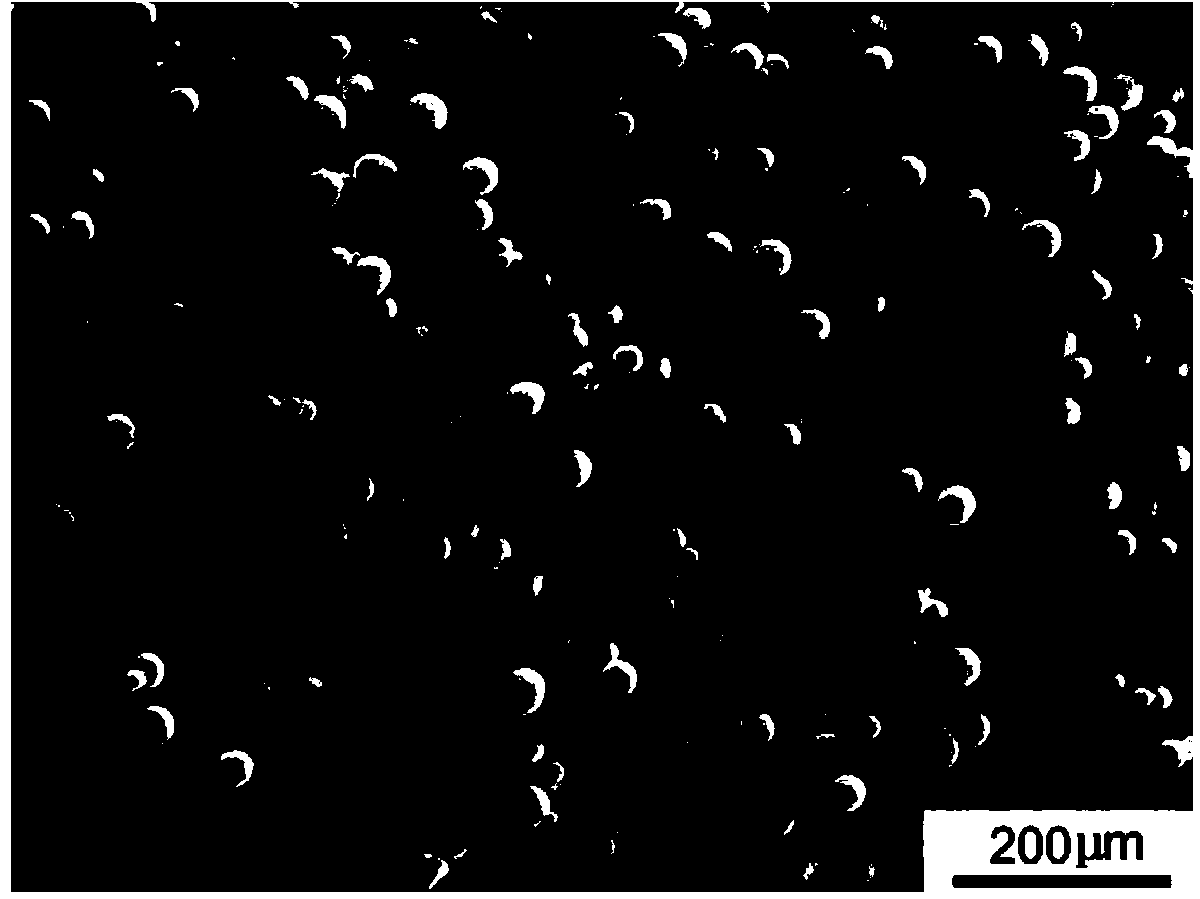

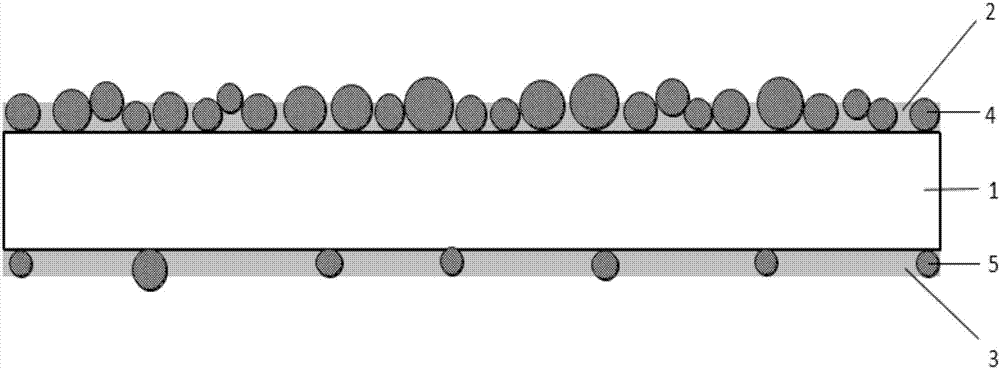

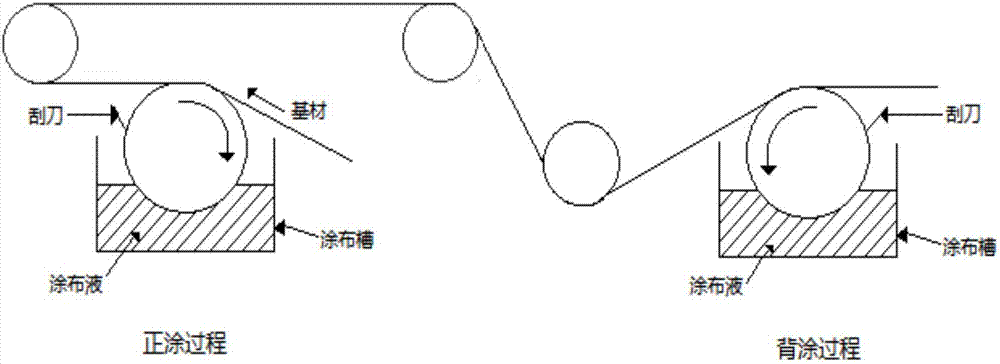

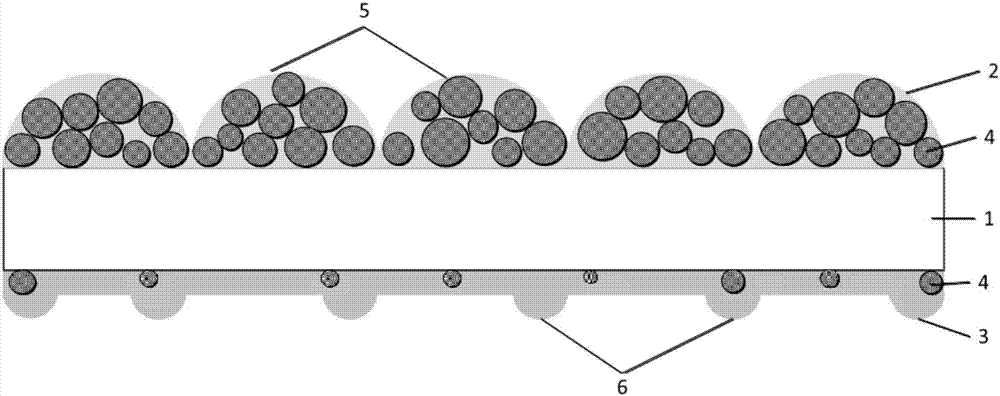

Anti-scratching diffusion film and method for preparing the same

ActiveCN106908872AGuaranteed Optical PerformanceImprove scratch resistanceDiffusing elementsNon-linear opticsDiffusionLiquid-crystal display

The invention, which belongs to the technical field of the backlight source device in a liquid crystal display module group, relates to a diffusion film, particularly to an anti-scratching diffusion film and a method for preparing the same. In order to solve a problem that particles in an anti-adhesion layer are easy to shed during a diffusion film assembling process, the invention provides an anti-scratching diffusion film and a method for preparing the same. The diffusion film comprise a base material; and a positive coating layer is arranged at one side of the base material and a back coating layer is arranged at the other side. The positive coating layer contains scattering particles; a positive coating microstructure being in a hemispherical shape is formed at the surface of the positive coating layer and the diameter range is 30 to 70 microns. The back coating layer contains scattering particles; a back coating microstructure being in a hemispherical shape is formed at the surface of the back coating layer and the diameter range is 5 to 30 microns. The diffusion film has an excellent optical performance and good anti-scratching property. Besides, the preparation method employs a way of simultaneous transferring of the front side and the back side; and thus one-step moulding is realized, the process is simple, and the method is easy to implement.

Owner:NINGBO CHANGYANG TECH

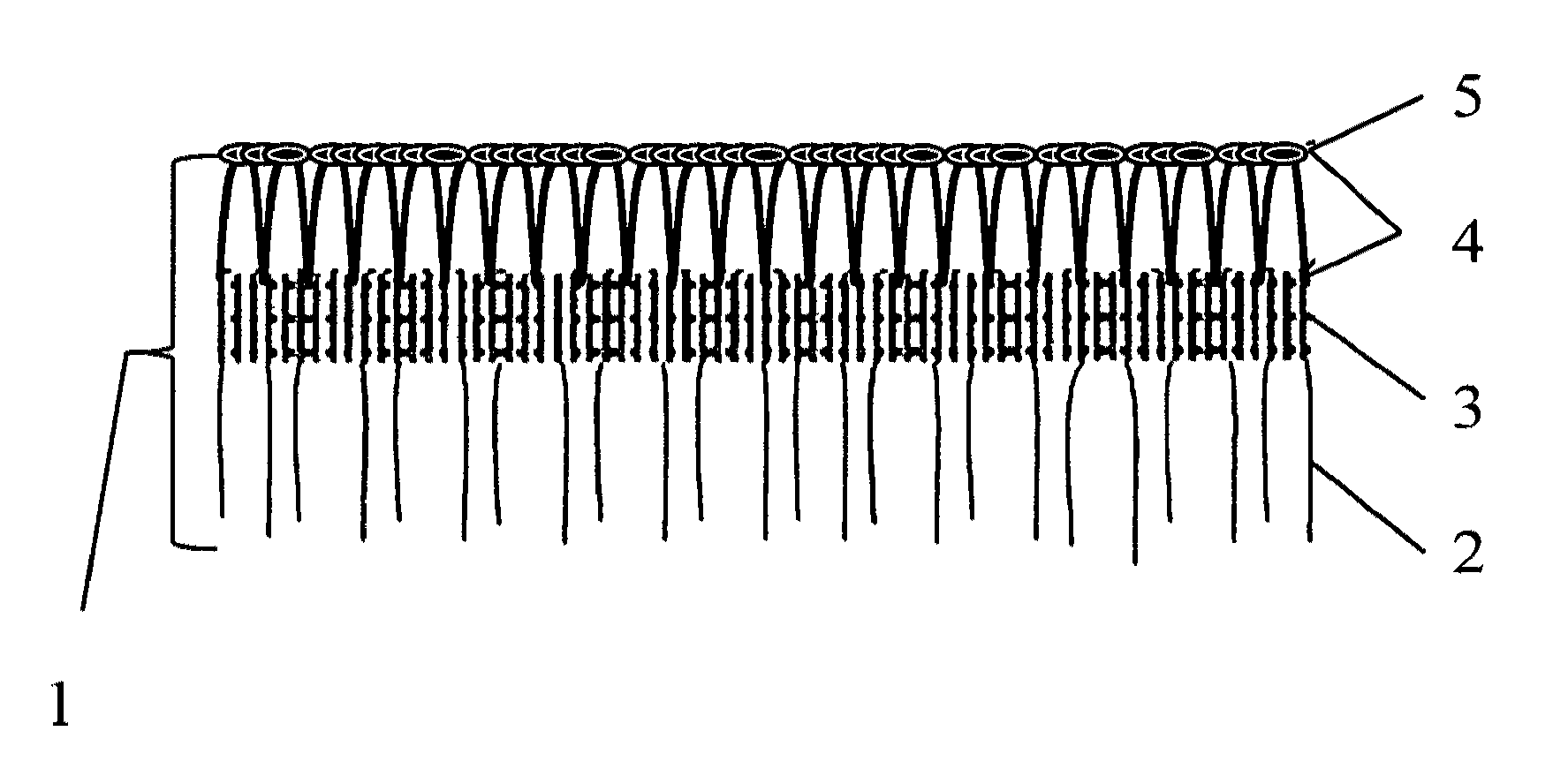

Method for preparing large-size micro-groove bionic antifouling coating by template imprinting method

PendingCN112756233ANo crackNo sheddingPretreated surfacesSpecial surfacesCoated surfaceCoating microstructure

The invention relates to a method for preparing a large-size micro-groove bionic antifouling coating by a template imprinting method. The method comprises the following steps that a specific bionic microstructure morphology is etched on a plane template or a roller template through laser, the microstructure template is coated with a release agent, then the bionic microstructure template is directly imprinted on the surface of a surface-dried antifouling coating to be subjected to overturning and forming, the bionic antifouling coating with the microstructure morphology is obtained, and then the bionic antifouling coating with the large-area microstructure is prepared through multiple times of imprinting of the microstructure plane template or continuous rolling imprinting of the microstructure roller template. The method can be carried out under the room temperature condition, the requirement for preparation conditions is low, operation is easy, and preparation of the large-area coating microstructure surface can be achieved; and the prepared bionic antifouling coating has the advantages of uniform surface microstructure morphology, no crack, no shedding, and good antifouling effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

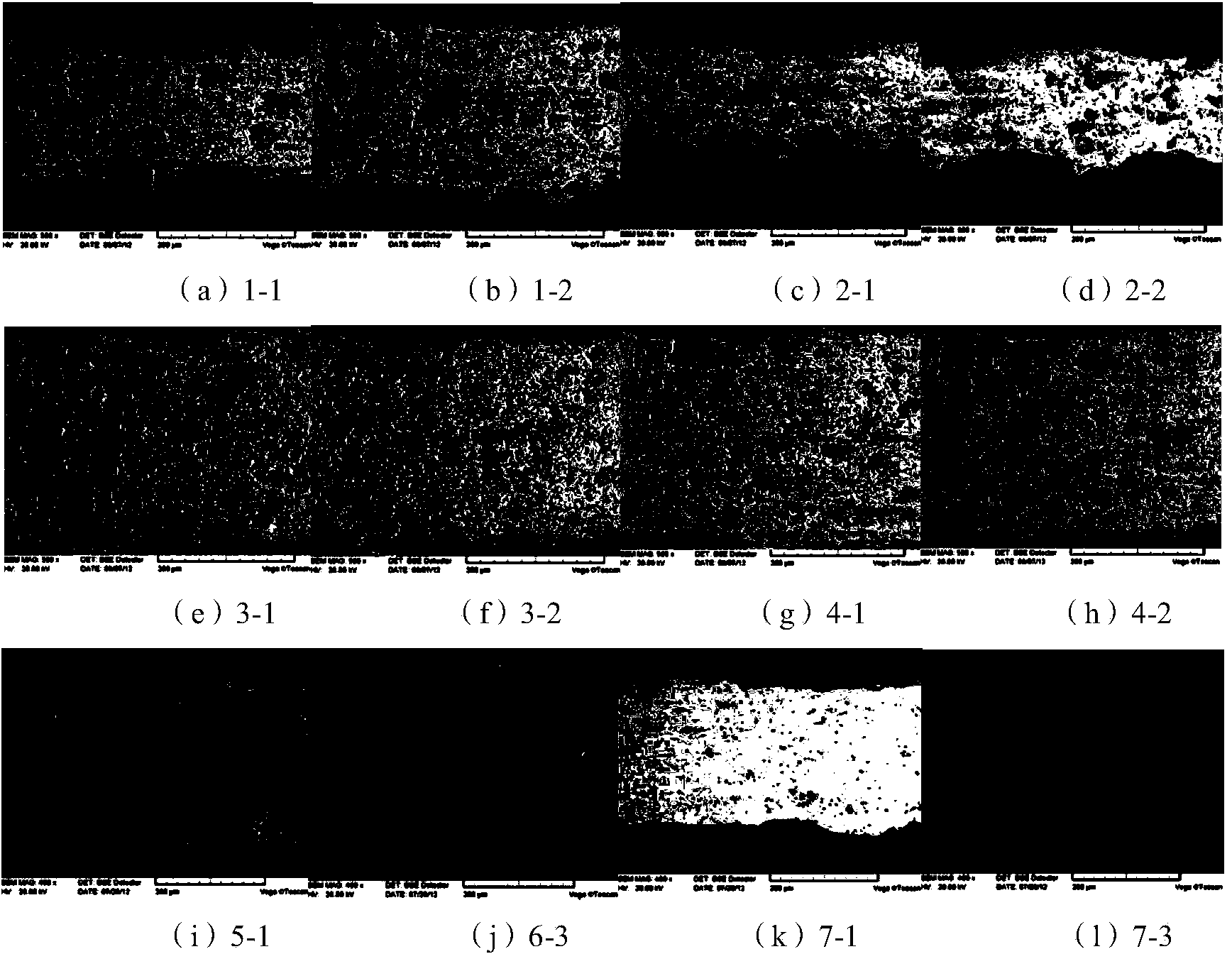

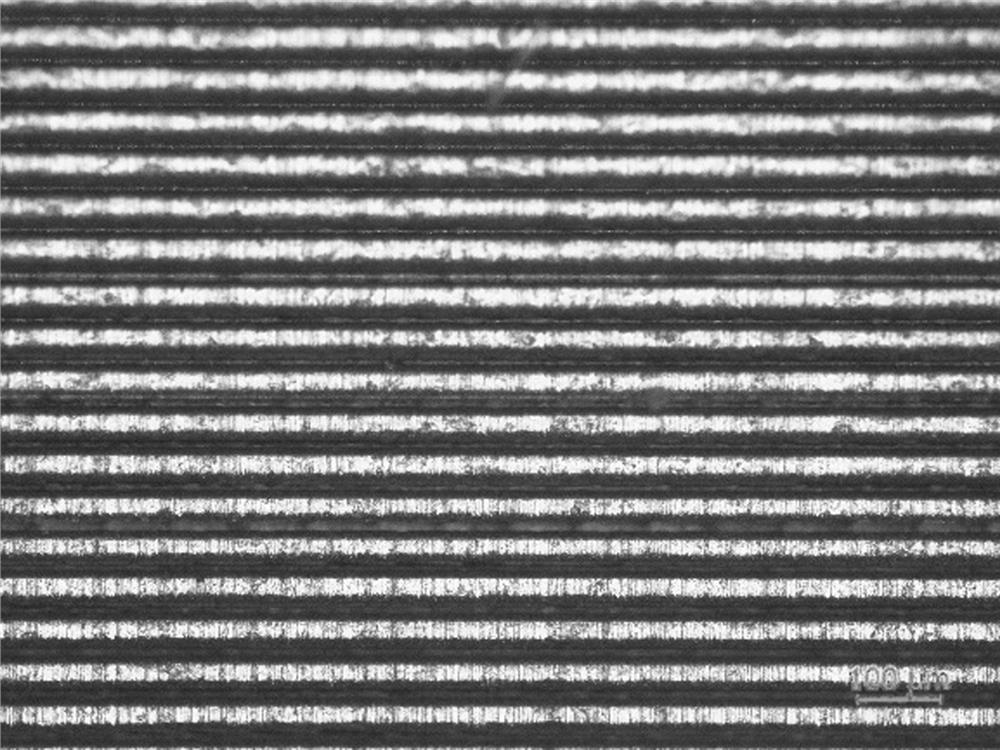

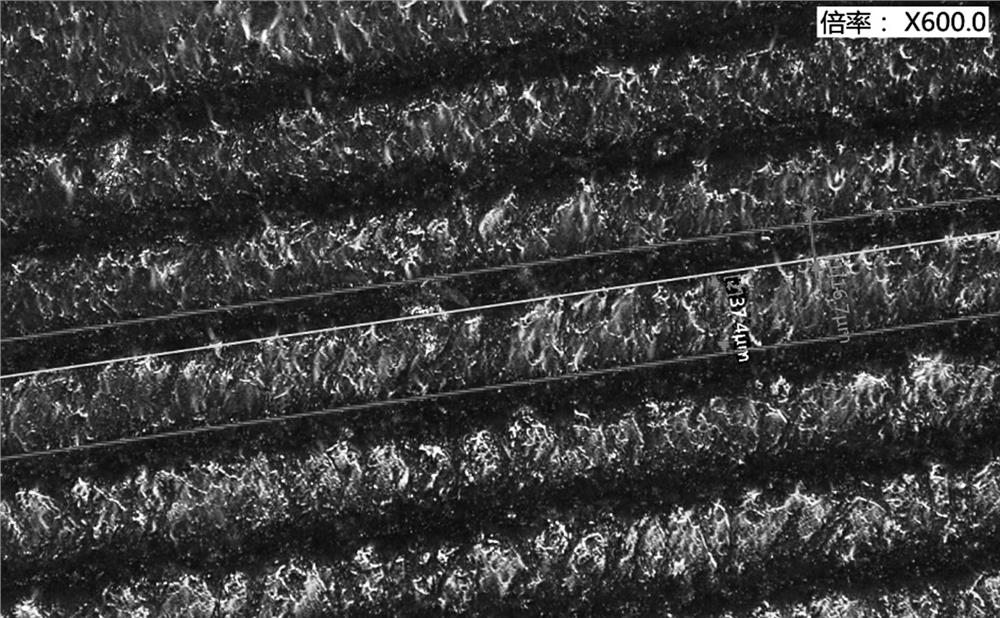

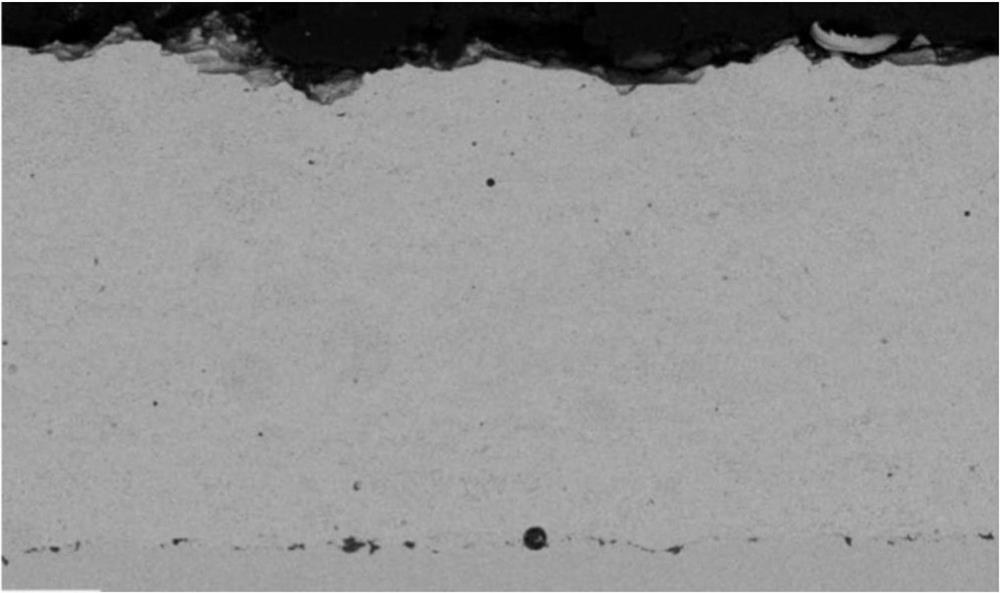

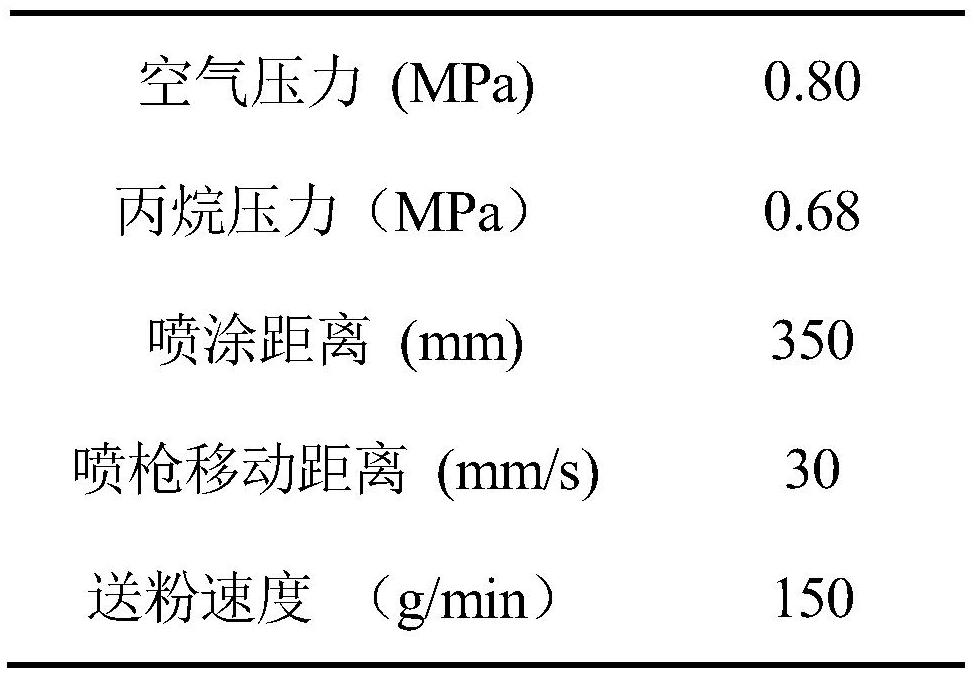

Detection method of flame spraying type CuAl/NiC coating microstructure

InactiveCN103558151AAvoid changeAvoid formingPreparing sample for investigationMaterial analysis by optical meansQuality controlCoating microstructure

The invention relates to a detection method of a flame spraying type CuAl / NiC coating microstructure. The detection method comprises the following steps: (1) preparing metallographic specimens; (2) detecting the coating microstructure; (3) determining a qualified index of the coating microstructure; (4) judging whether the coating microstructure is qualified or not. Through using the detection method, the metallographic specimens can be prepared systematically according to the requirement; the judging method and the qualified index of the coating microstructure can be proposed; the quality control level of the flame spraying type CuAl / NiC abrasive sealed coating is increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Tri-barrier ceramic coating

Owner:CHROMALLOY GAS TURBINE

Composite photocatalytic coating and preparation method thereof

InactiveCN105664900AEnhanced photocatalytic functionImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectronic structureAlloy

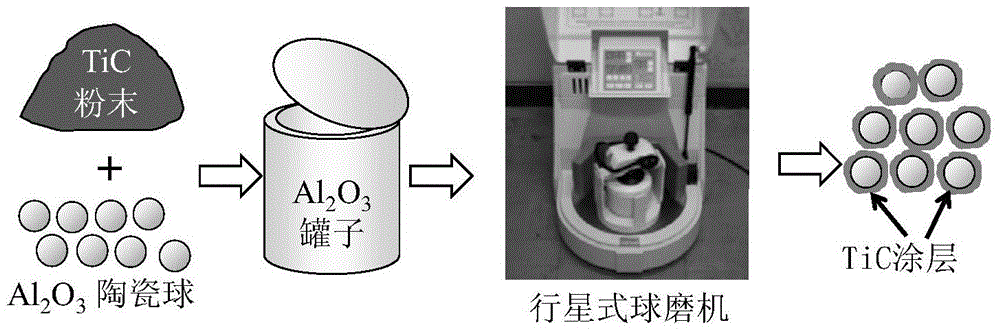

The invention belongs to the field of composite photocatalytic coatings and relates to a composite photocatalytic coating and a preparation method thereof. The preparation method of the composite photocatalytic coating comprises coating a base with a coating material through a ball milling method to obtain a coated body and keeping the coated body at a temperature of 973-1273 K for 2-15h, wherein the base comprises one or more of an Al2O3 ceramic body, a metal body and an alloy body and the coating material comprises one or more of TiC powder, titanium dioxide powder, metal powder and alloy powder. The coating microcosmic structure and even atomic and electronic structures of the composite photocatalytic coating produce substantial change in a mechanical coating process. In thermal oxidation, a series of physical and chemical changes are produced so that a functional coating with a unique microstructure is formed and has substantially higher photocatalysis functions.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for characterizing microstructure of nano-structure thermal barrier coating by adopting terahertz nondestructive testing technology

ActiveCN113109294AAvoid discretenessHigh precisionPhase-affecting property measurementsEfficient propulsion technologiesCeramic coatingTerahertz nondestructive evaluation

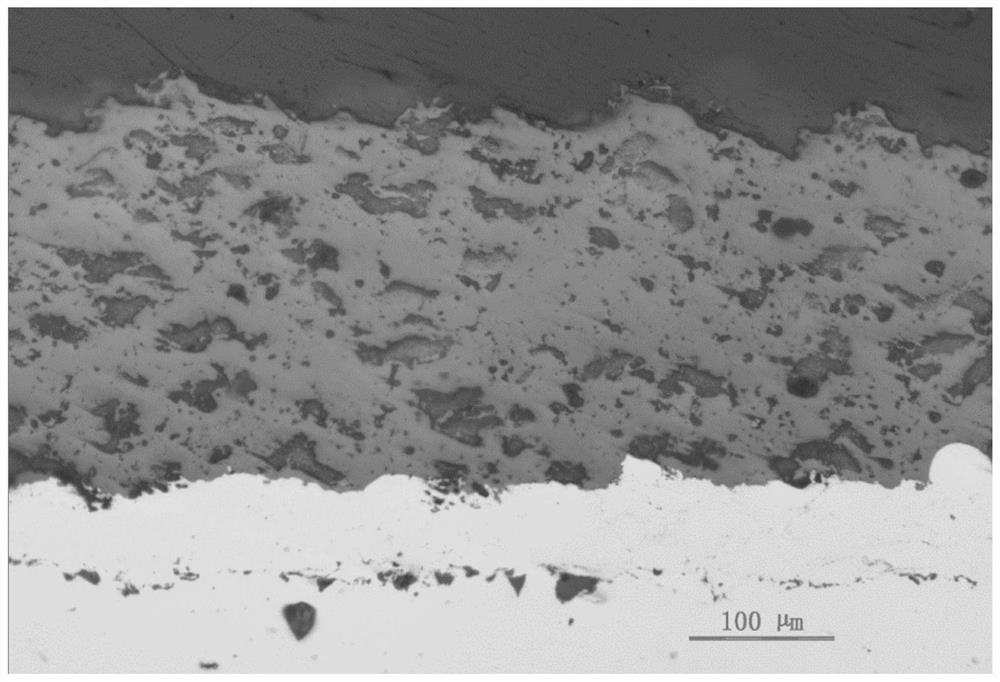

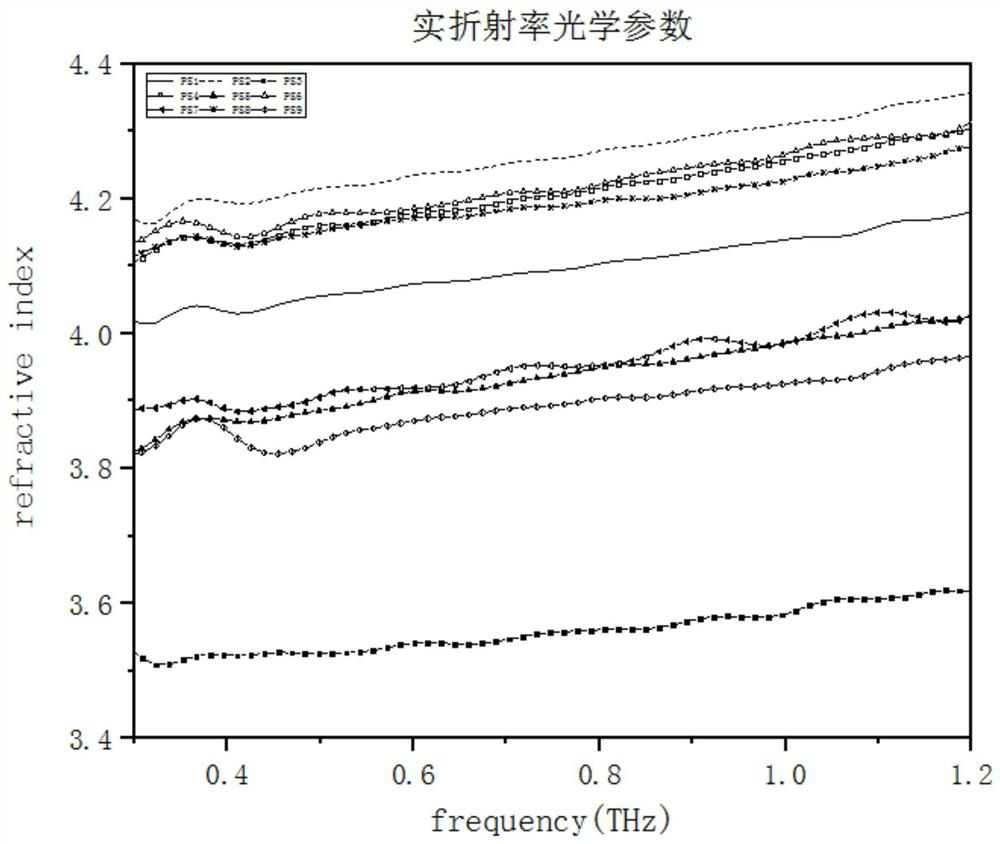

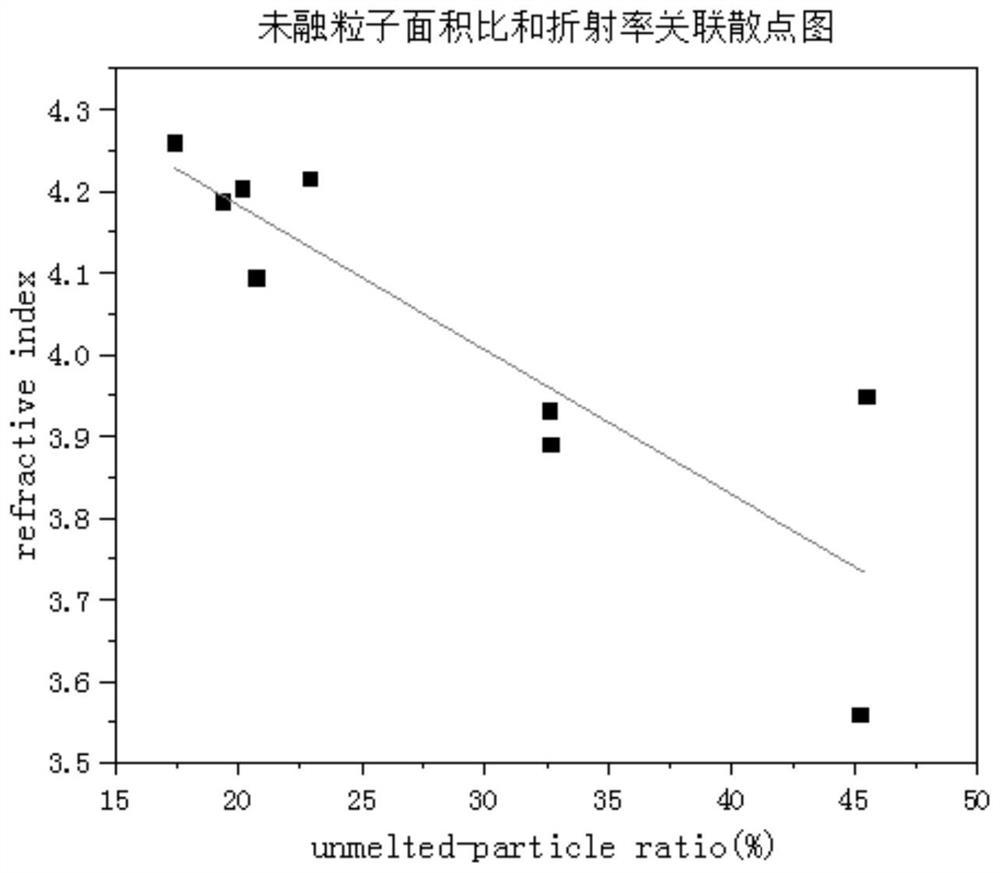

The invention provides a method for characterizing the microstructure of a nano-structure thermal barrier coating by adopting a terahertz nondestructive testing technology, which comprises the following steps: preparing different microstructure coatings by adopting an adjusting process, and determining the microstructure characteristics of the coatings by adopting metallographic analysis; carrying out terahertz nondestructive testing to obtain the real refractive index of the ceramic coating; constructing a linear relation between the real refractive index and the coating microstructure characteristics; and based on the linear relation, constructing the range comparison relation between the real refractive index and the coating microstructure characteristics, wherein the coating microstructure characteristics of coatings prepared by different processes can be qualitatively or semi-quantitatively analyzed through terahertz nondestructive testing by utilizing the range comparison relation. The method has the characteristics of no damage, high efficiency, convenience in operation and high detection precision. Meanwhile, the data result of the method shows the characteristics that the data parameter rule guidance is clear, the data characterization method is simple, convenient, efficient and scientific, and powerful support can be provided for controlling the coating quality or providing rapid and effective nondestructive testing for process optimization.

Owner:BEIJING GOLDEN WHEEL SPECIAL MACHINE +1

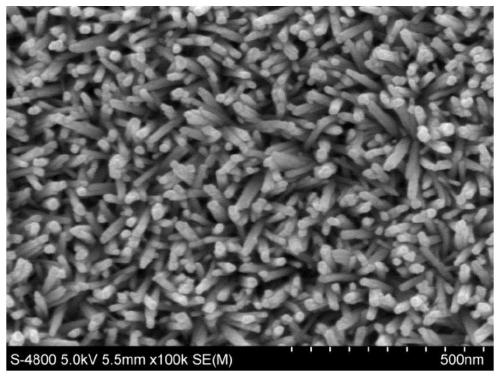

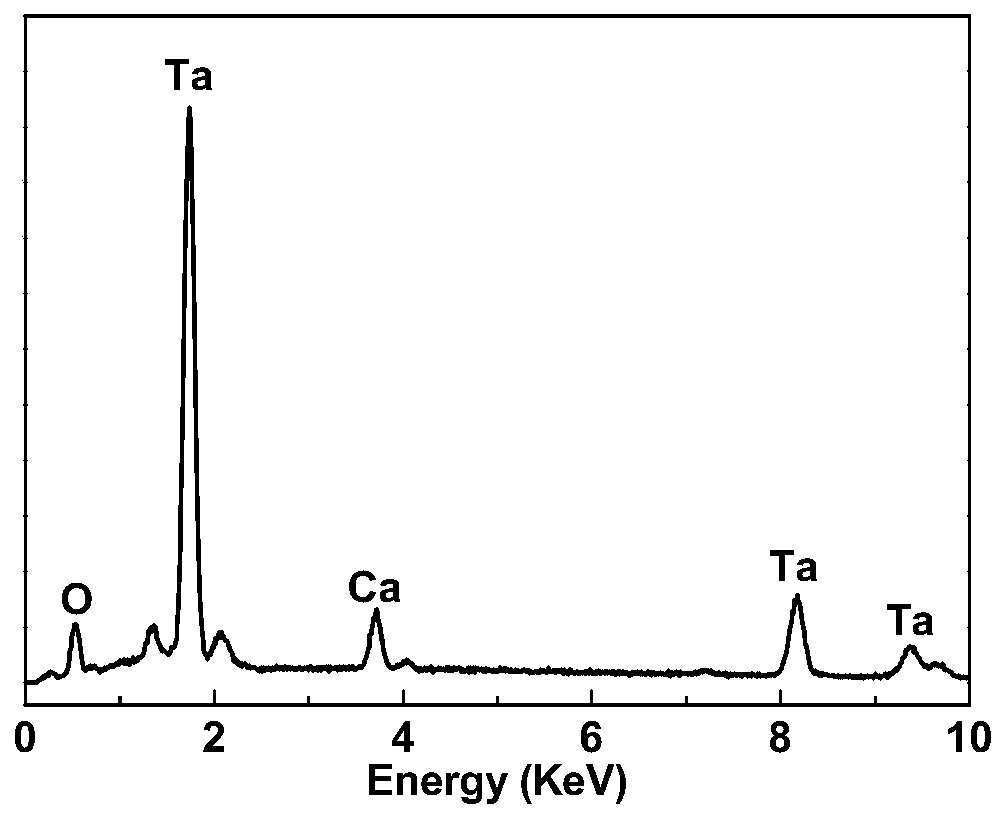

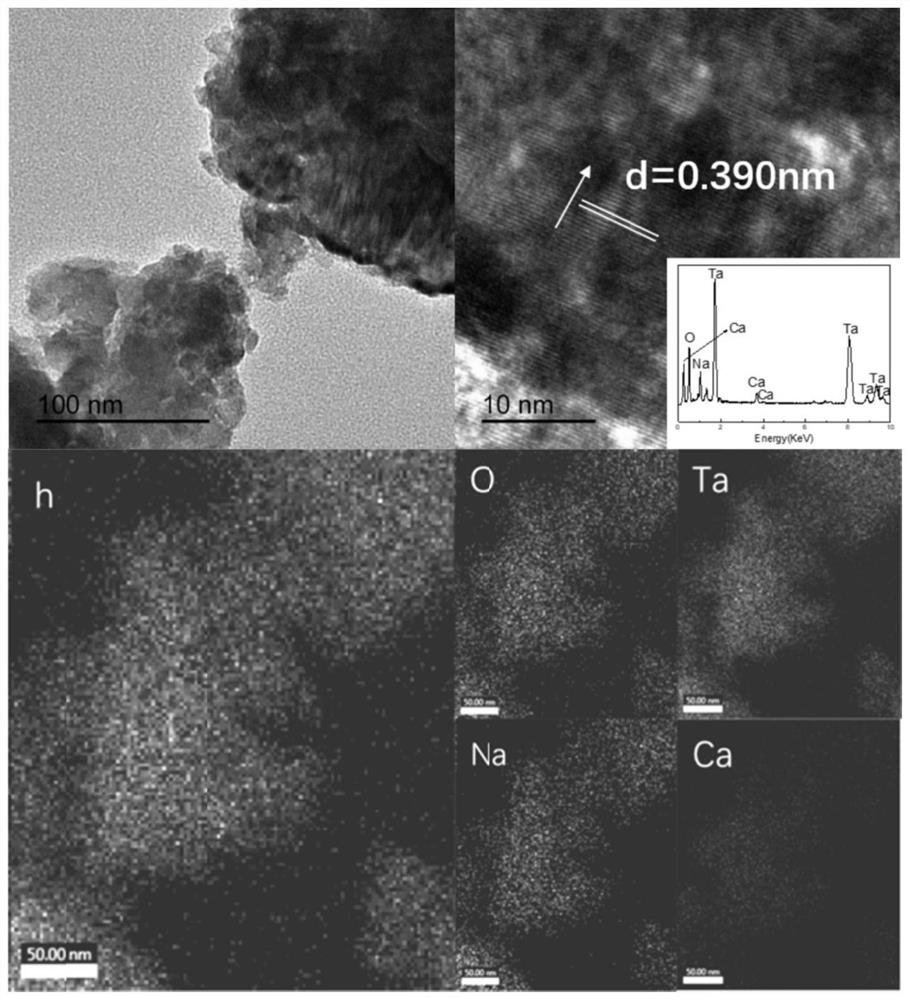

Calcium-mingled tantalum oxide nanometer bar structure biological activity coating and preparation method thereof

InactiveCN109722660ASimple ingredientsEasy to controlMetallic material coating processesProsthesisApatiteDrug biological activity

The invention discloses a calcium-mingled tantalum oxide nanometer bar structure biological activity coating and a preparation method thereof. According to the method, at first, a water solution containing hydrofluoric acid and hydrogen peroxide serves as a water heat solution, different water heat conditions are adopted for carrying out water heat treatment on a tantalum base body, then a tantalum oxide nanometer bar structure coating obtained again is subjected to water heat treatment under the calcium-contained water heat environment condition, the obtained coating microstructure is of a nanometer bar shape, the phase is tantalum pentoxide, and the nanometer bar structure coating is mingled with a calcium element. The high combination strength between the calcium-mingled nanometer bar structure coating and the base body is achieved, the calcium element separated out from the coating is increased gradually along with prolonging of soaking time, bone apatite can be induced and formedrapidly in the liquid-like environment, and the coating has good biological activity.

Owner:SHAANXI UNIV OF SCI & TECH

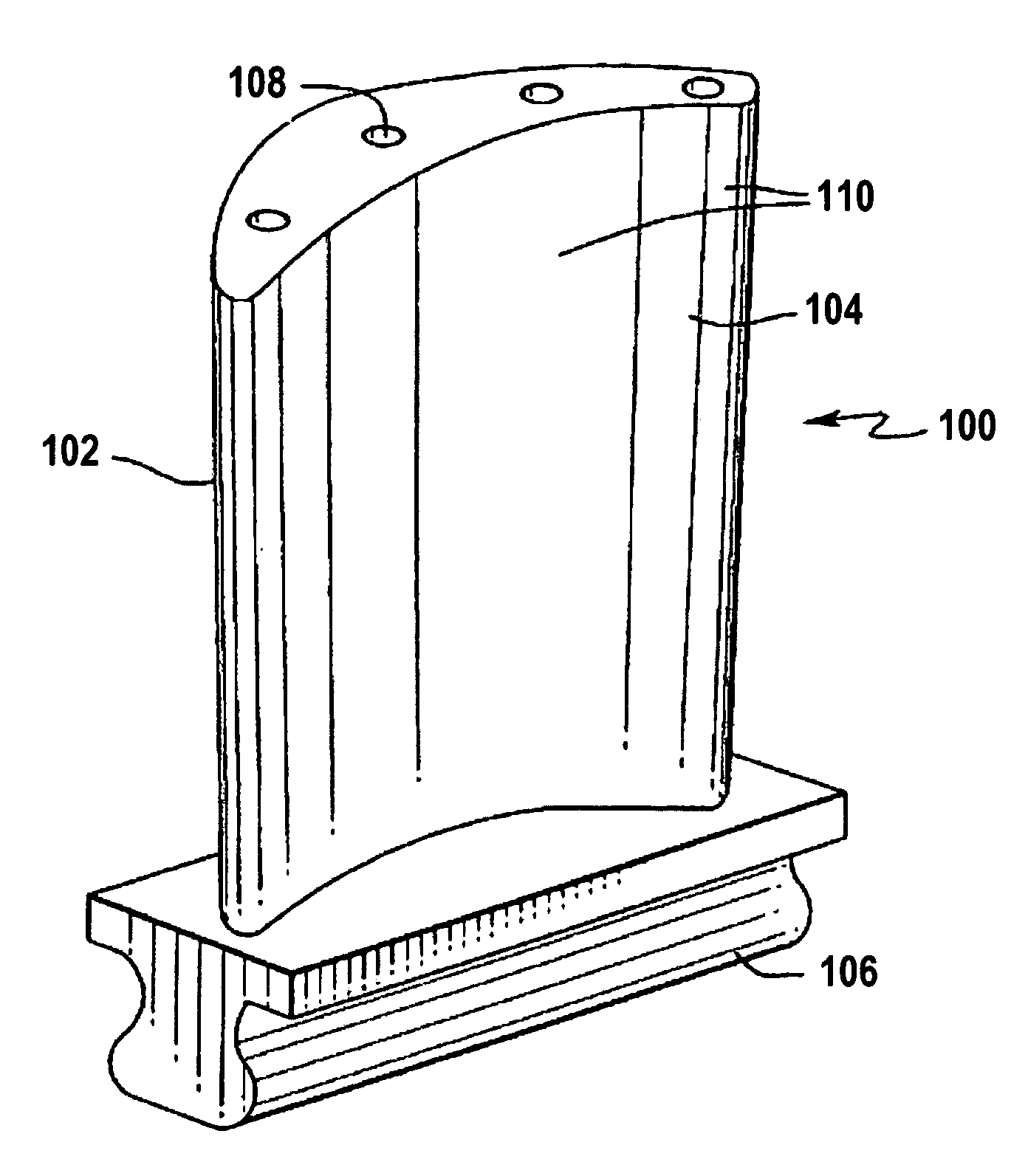

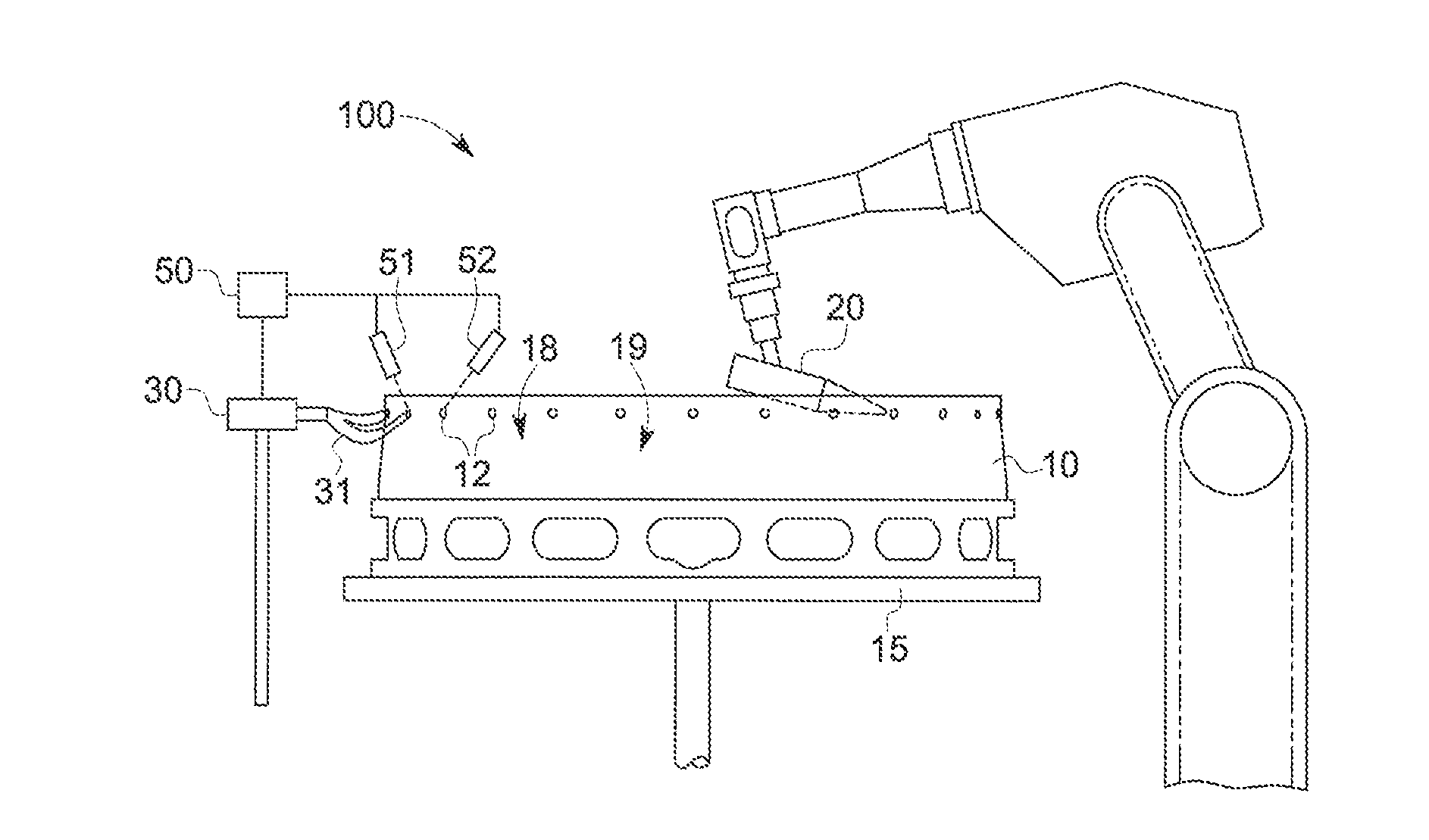

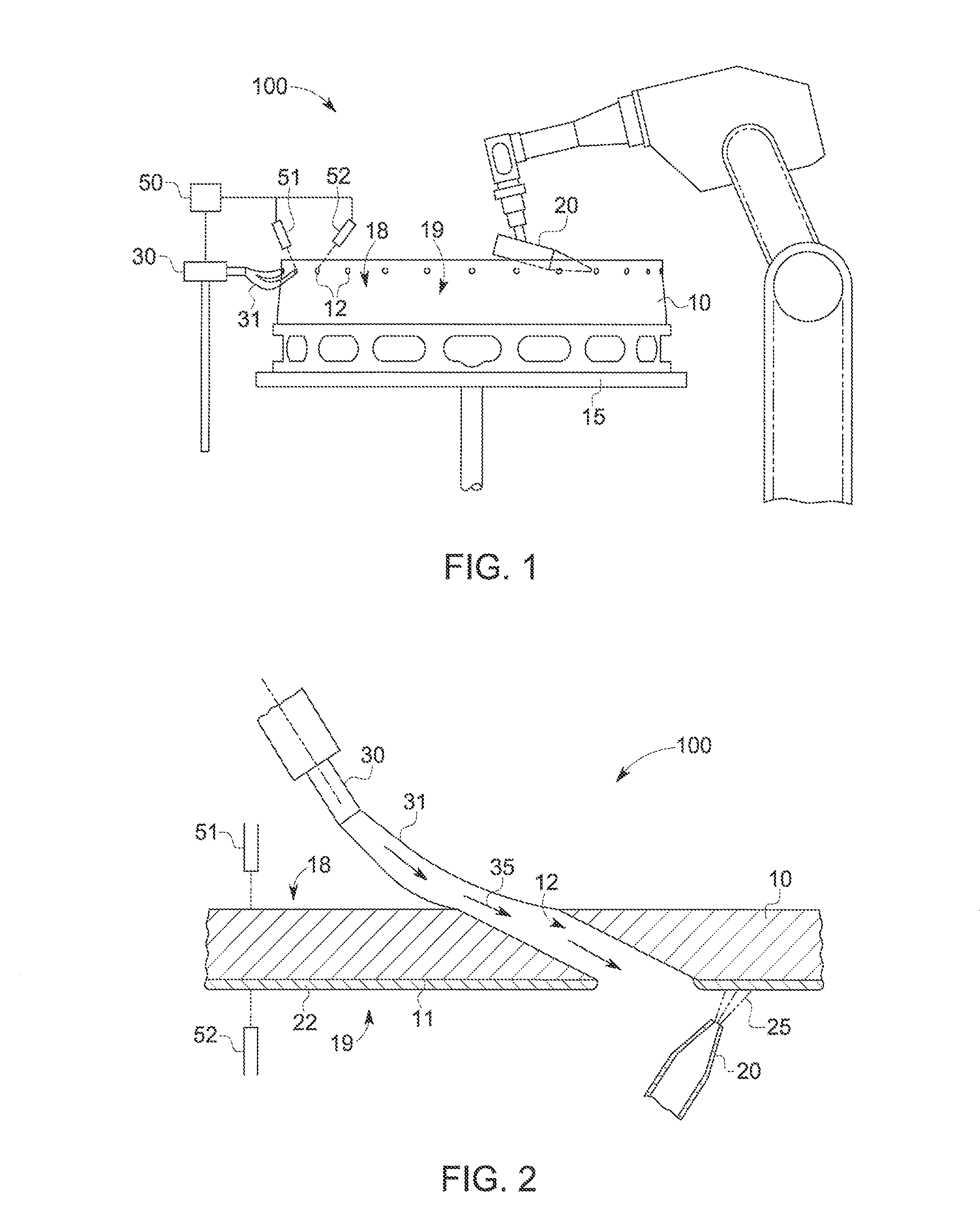

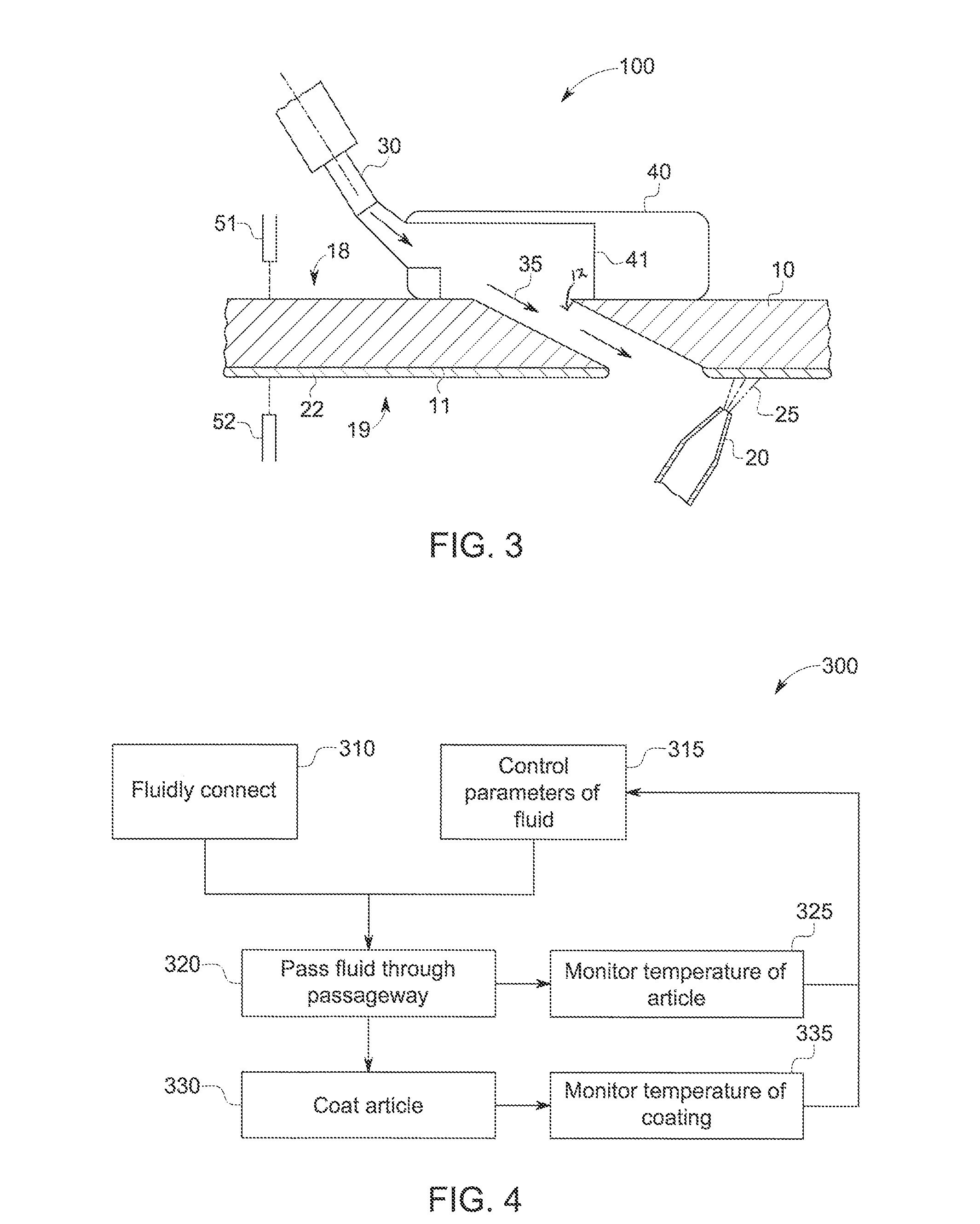

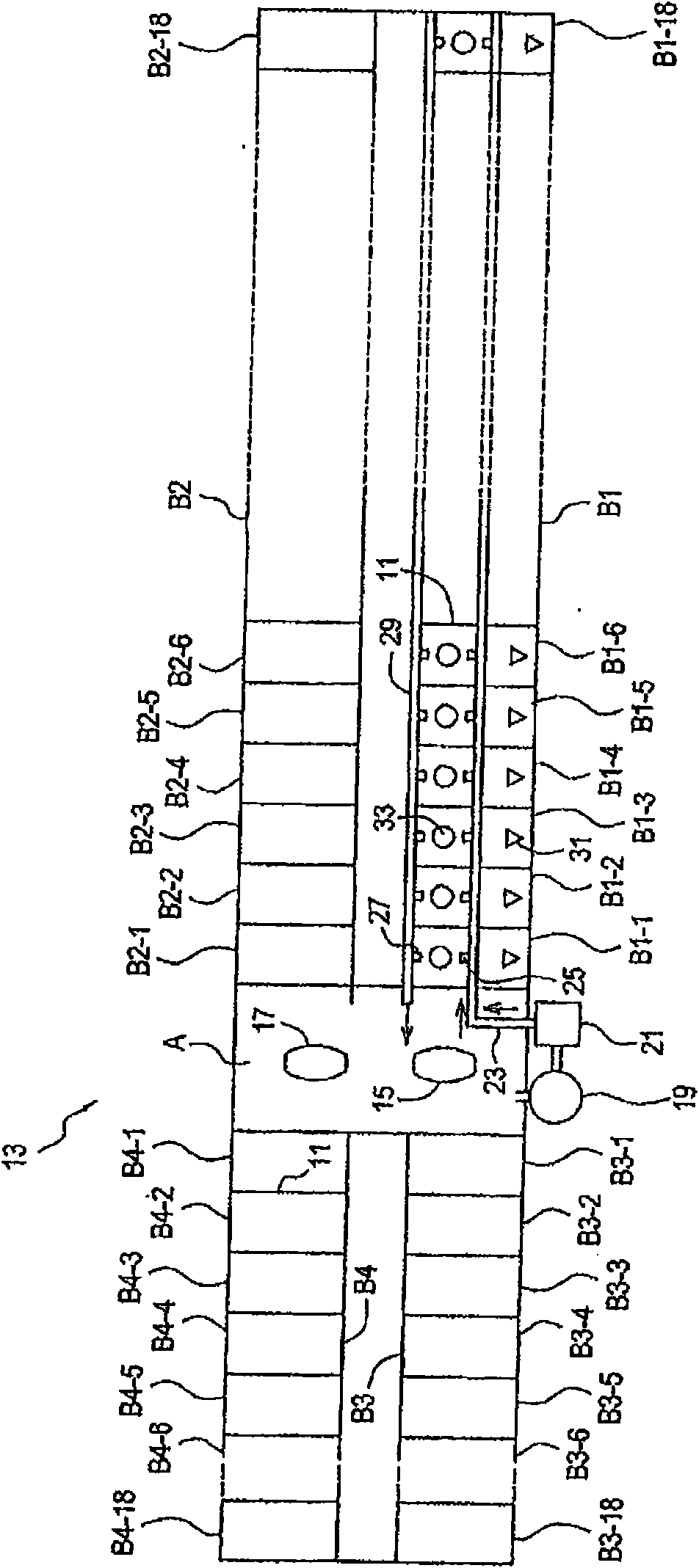

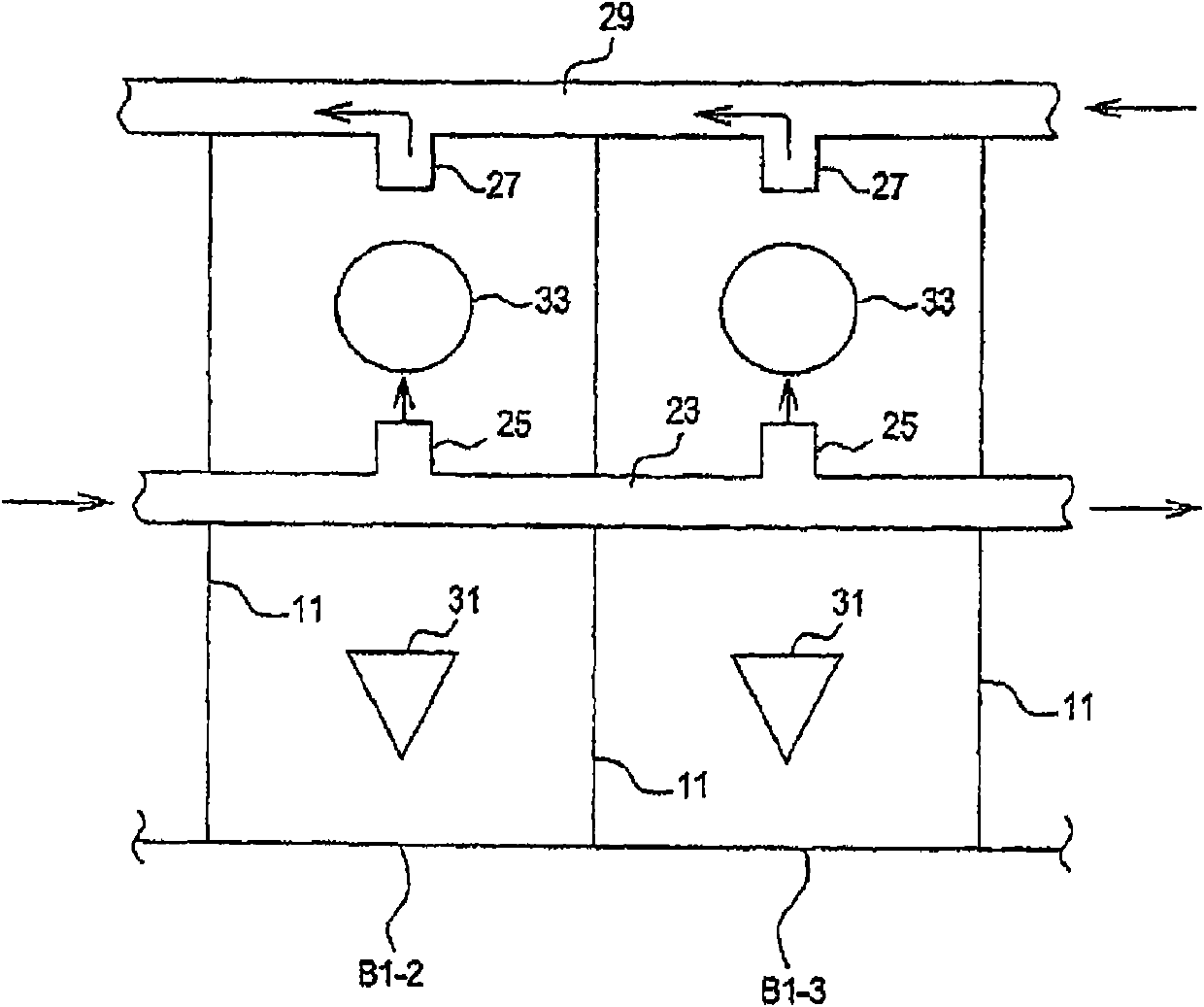

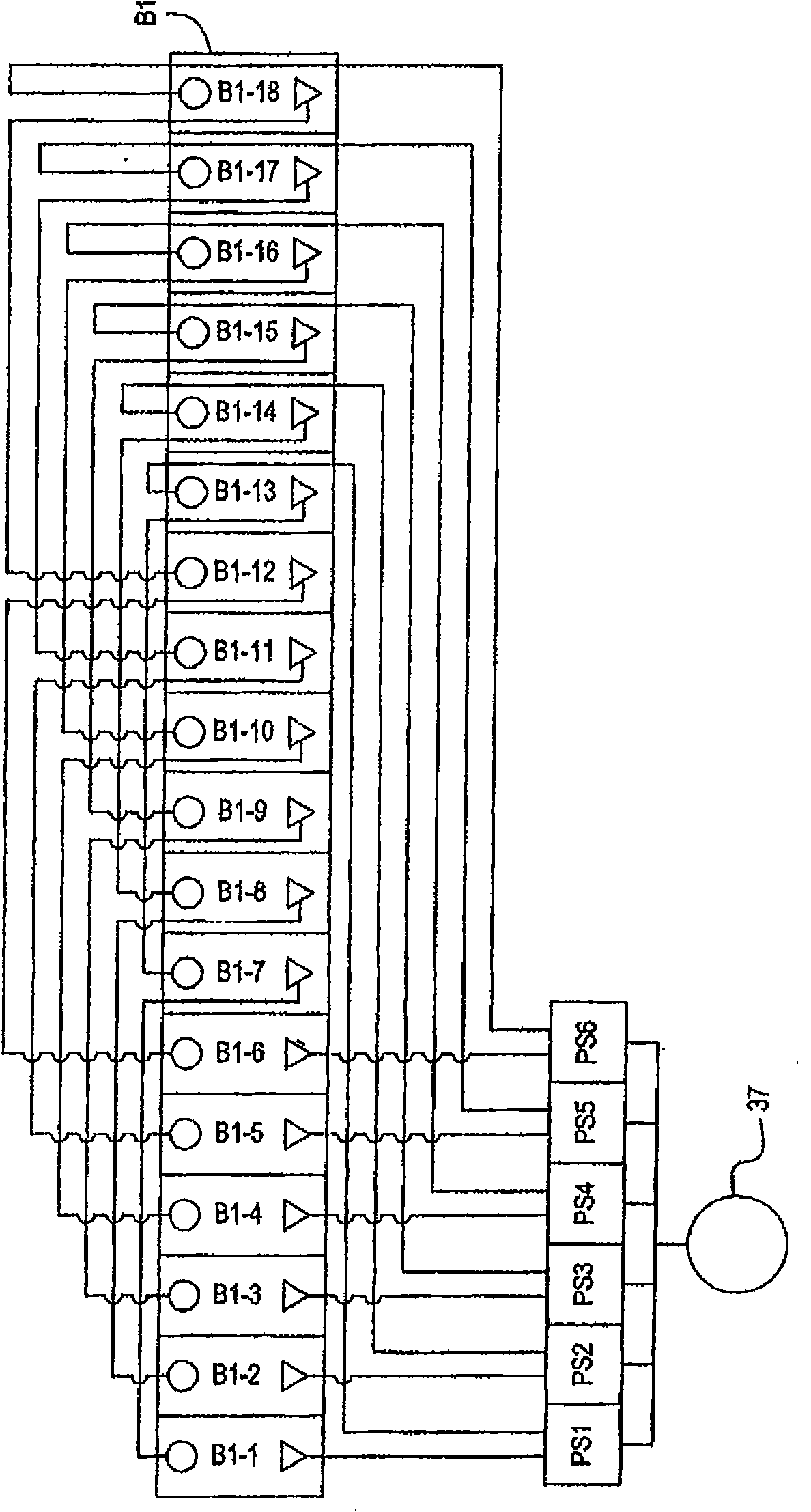

Coating methods and pressurized masking systems for controlling coating microstructures

InactiveUS20140272104A1Liquid surface applicatorsMolten spray coatingTemperature controlTarget surface

Methods for coating a target surface of an article having one or more passageways include fluidly connecting a temperature controlled fluid to at least one passageway, passing the temperature controlled fluid through the at least one passageway, wherein the temperature controlled fluid at least partially controls a temperature profile of the article, and coating the target surface, wherein the temperature profile of the article at least partially controls a microstructure of the coating.

Owner:GENERAL ELECTRIC CO

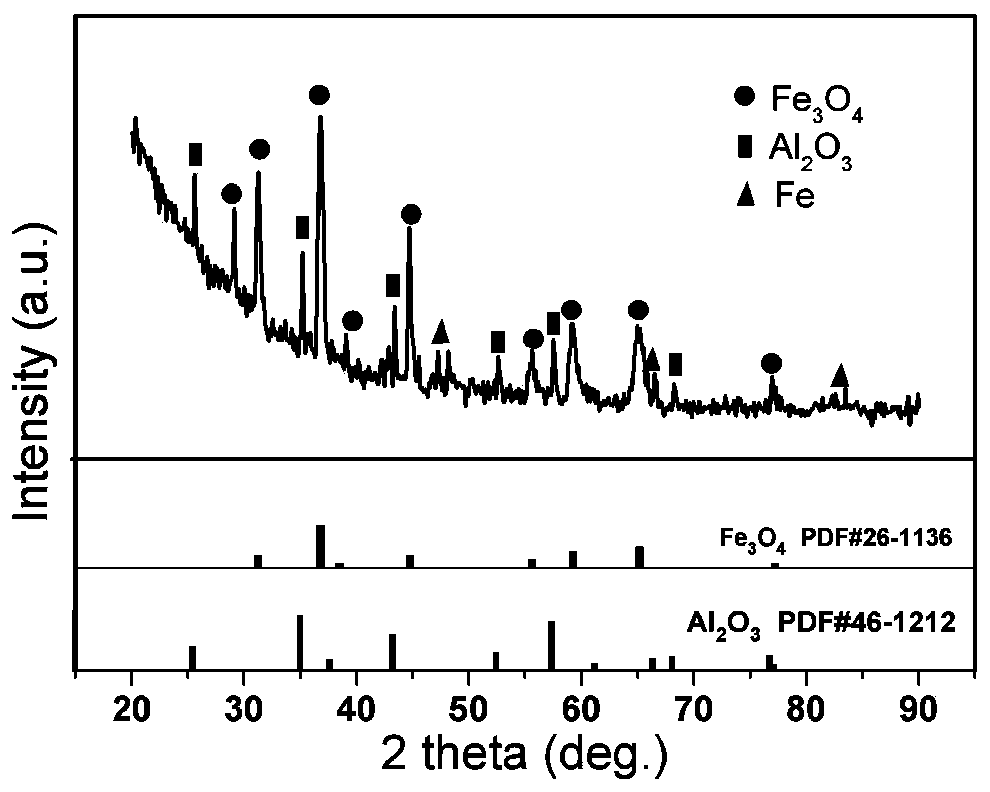

Preparation method for ferrite/reductive metal composite particles and method for preparing high-temperature invisible coating layers based on laser 3D printing

ActiveCN110405196ASimple processMeet the requirements of high temperature stealthAdditive manufacturing apparatusTransportation and packagingFerrite powderTemperature wave

The invention discloses a preparation method for ferrite / reductive metal composite particles and a method for preparing high-temperature invisible coating layers based on laser 3D printing, belongs tothe technical field of wave absorption coating layer preparation, and solves the problems of insufficient coating layer / basal body bonding force of traditional high-temperature wave absorption coating layers, difficult control of microscopic structures of the coating layers and incapability of guaranteeing electromagnetic performances. Nanoscale ferrite powder and nanoscale reductive metal powderare prepared as composite particles through a mixed granulation process; in a closed preparation cavity of 3D printing equipment, the composite particles are prepared as the high-temperature invisible coating layers on the surfaces of substrates through laser induced in-situ reaction. The preparation method is applied to high-temperature invisibility and electromagnetic pollution prevention of components.

Owner:HARBIN INST OF TECH

Electroplating method and apparatus

InactiveCN102007232AConsistent mechanical propertiesCellsCurrent conducting devicesElectricityEngineering

An apparatus and method is disclosed for simultaneously electroplating at least two parts in a series electrical configuration in an electroplating system using a shared electrolyte with excellent consistency in thickness profiles, coating weights and coating microstructure. Parts in high volume and at low capital and operating cost are produced as coatings or in free-standing form.

Owner:INTEGRAN TECH

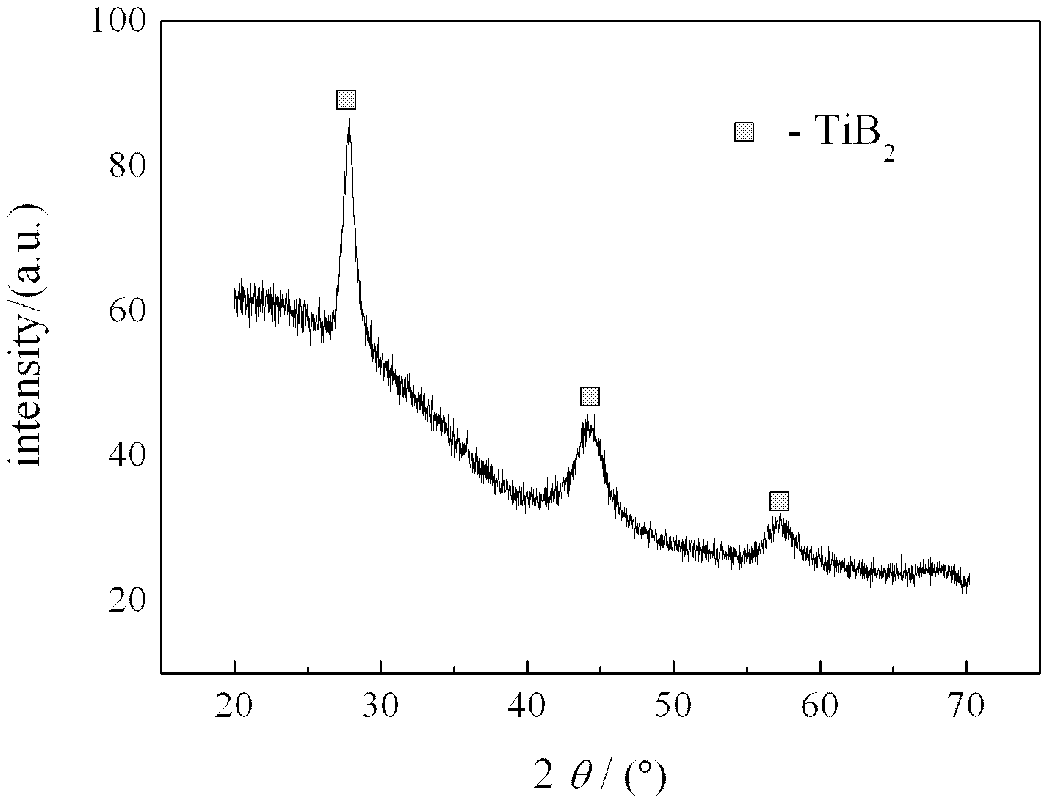

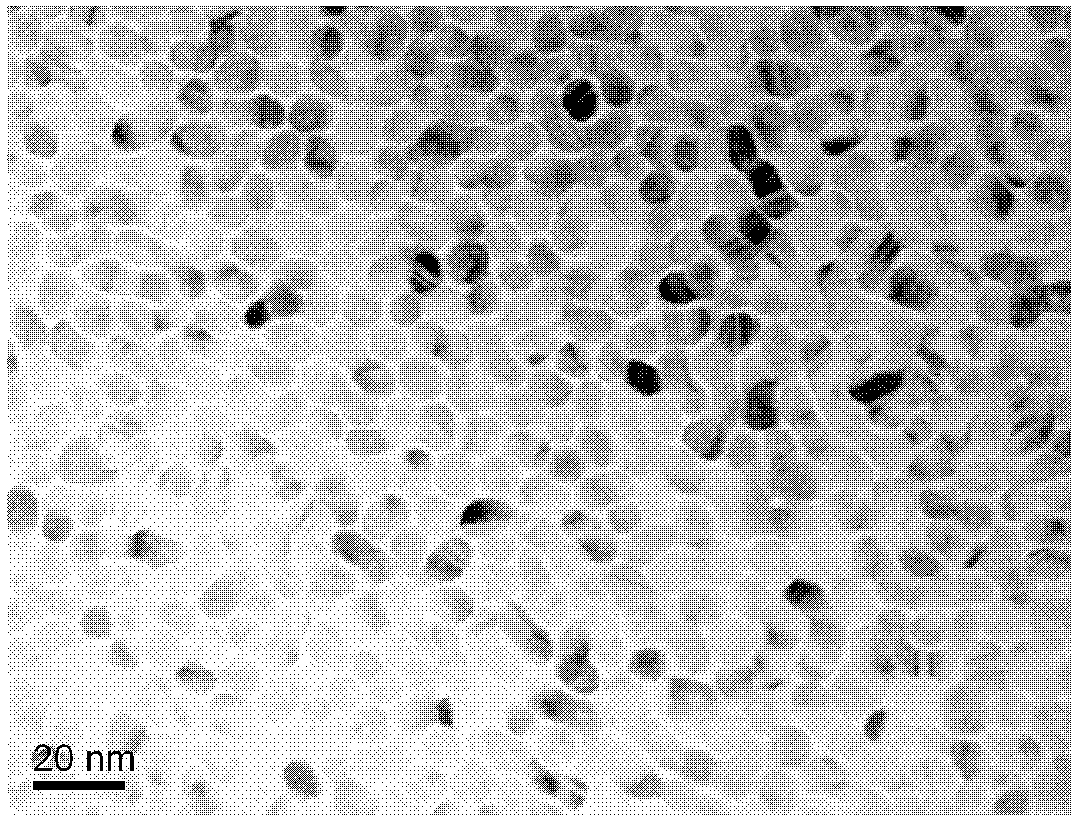

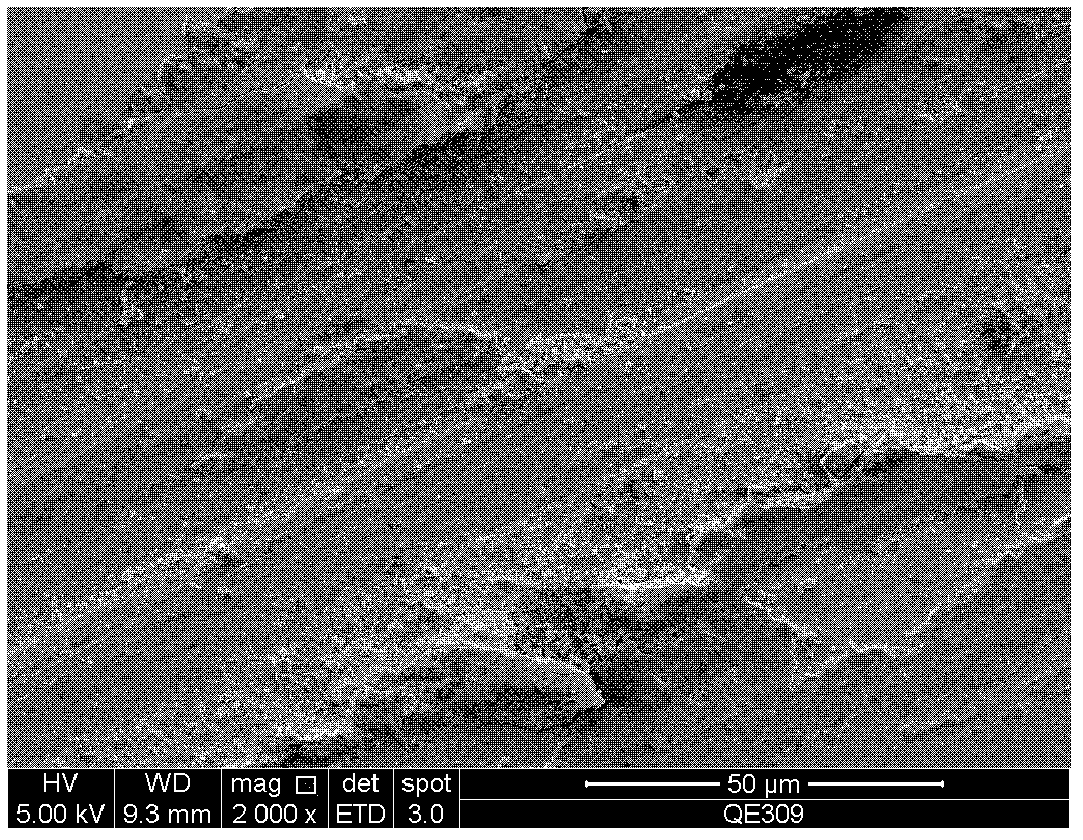

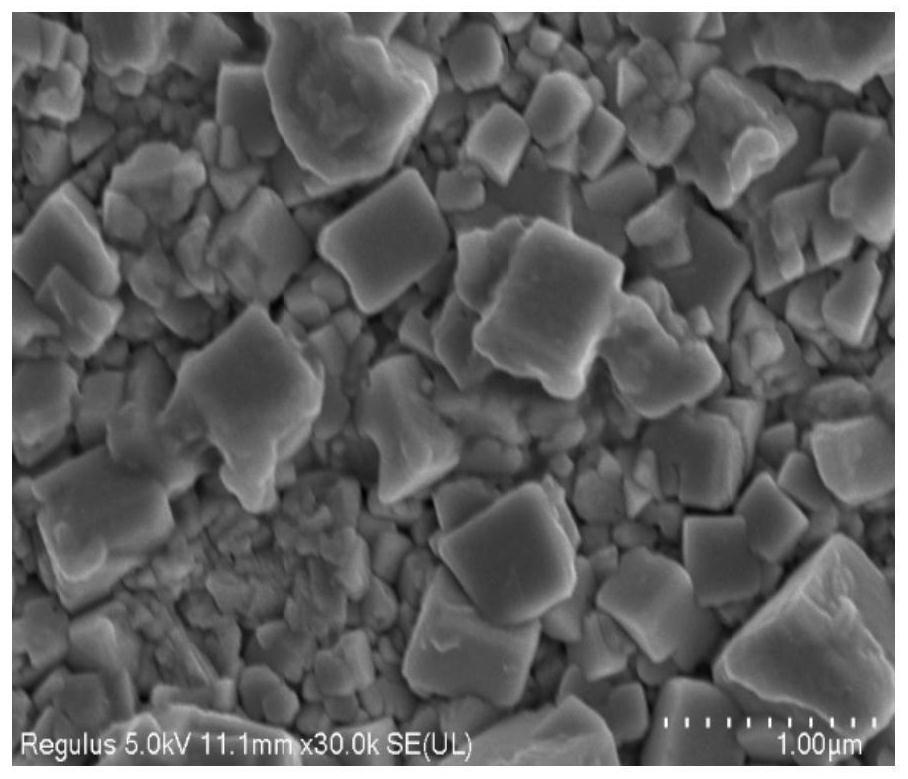

Titanium diboride-nickel thin film with coating structure and preparation method thereof

ActiveCN103160777AImprove toughnessHigh hardnessVacuum evaporation coatingSputtering coatingDiborideHardness

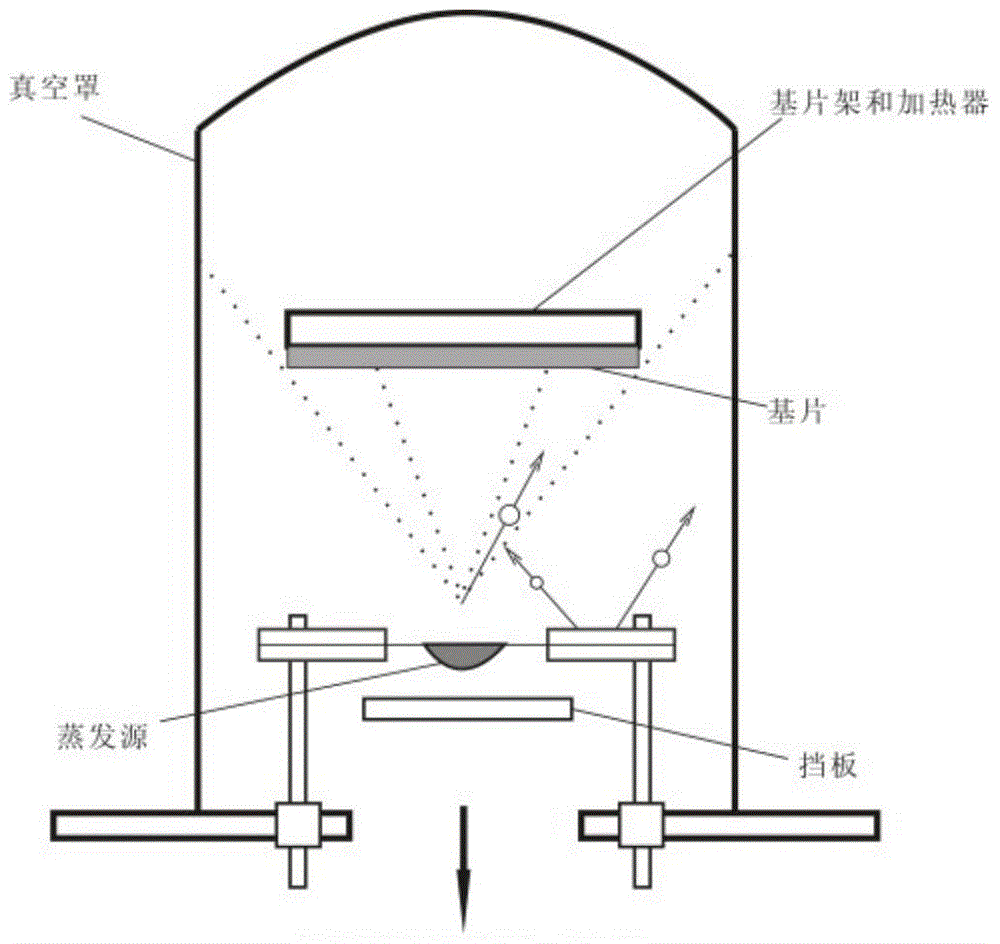

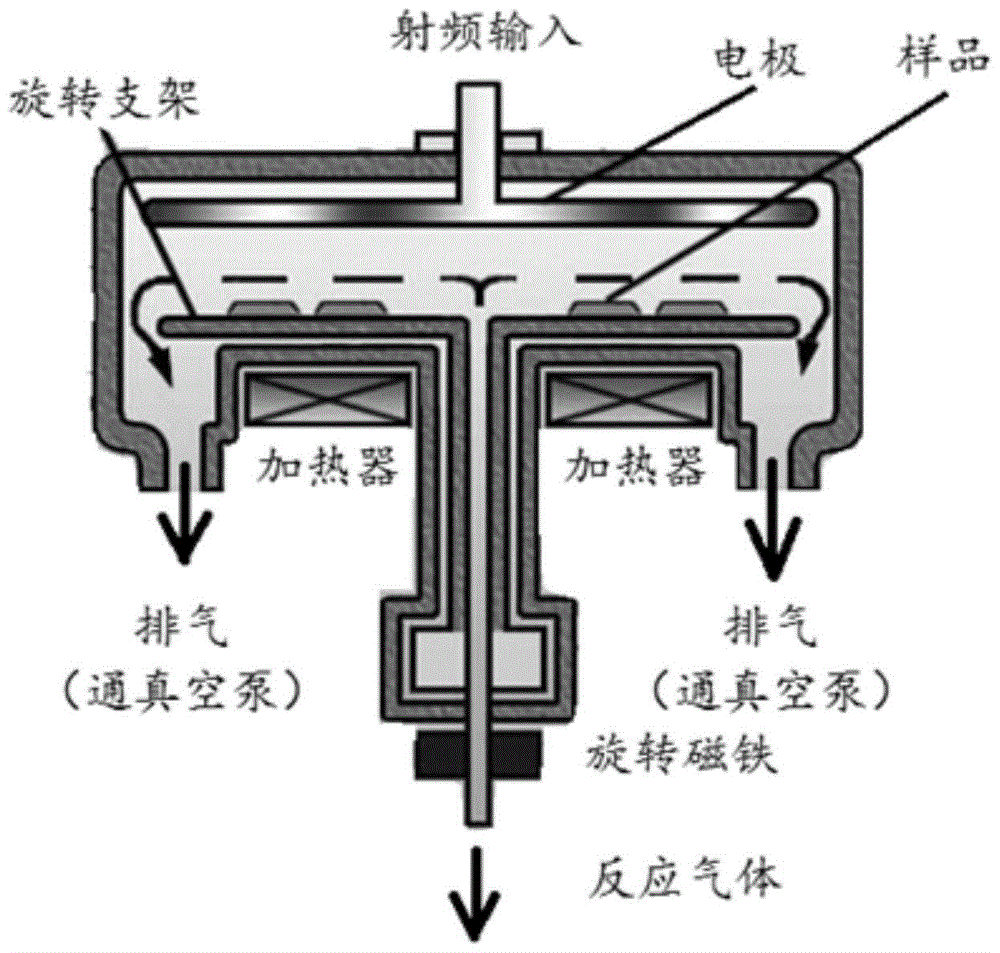

The invention relates to a titanium diboride-nickel thin film with coating structure. The TiB2-Ni thin film is characterized by being prepared from a continuous phase metal Ni and a dispersed phase TiB2 grains through in-situ synthesis. In the TiB2-Ni thin film, metal Ni in a three-dimensional continuous cellular structure uniformly form a basic framework of the thin film, and the TiB2 grains in granular shape uniformly fill in the cellular structure, so as to form a coating microstructure with metal Ni evenly coated with TiB2 grains; and the TiB2 accounts for 60- 95at.%, and Ni accounts for 5-40at.%. The TiB2-Ni thin film with coating structure provided by the invention shows good toughness and high hardness, so as to greatly expand the scope of application of the thin film. A double-target co-sputtering magnetron sputtering technology is easy to operate; composition, structure and performance of the TiB2-Ni thin film material can be well controlled through control of process conditions; and the method does not require a post-treatment process, has short preparation period, low cost and good reproducibility, and is easy to realize industrialized production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

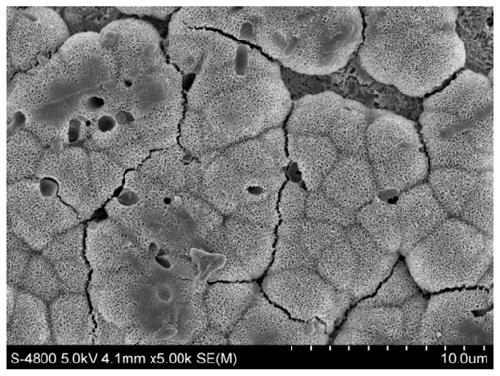

Tantalum surface calcium-doped sodium tantalate bioactive layer and preparation method thereof

PendingCN114150303AIncreased proliferationInduced fastSolid state diffusion coatingOsteoblastMolten salt

The invention discloses a preparation process of a calcium-doped sodium tantalate bioactive film layer on a tantalum surface, which comprises the following steps of: firstly, carrying out hydrothermal treatment on a tantalum substrate by using a NaOH-containing aqueous solution as a hydrothermal solution and adopting an optimal hydrothermal condition, and then carrying out molten salt treatment in calcium-containing powder to obtain a calcium-doped sodium tantalate coating on the tantalum surface. The microstructure of the obtained coating is cubic, the phase is sodium tantalate, calcium is doped in the coating of the cubic structure, the calcium-doped sodium tantalate coating is tightly combined with a base body and good in hydrophilicity, the surface roughness of the obtained film layer is moderate, bone apatite can be rapidly induced to be formed in a similar body fluid environment, osteoblast proliferation can be well promoted, and the bone repairing effect is good. The excellent biological activity is realized.

Owner:SHAANXI UNIV OF SCI & TECH

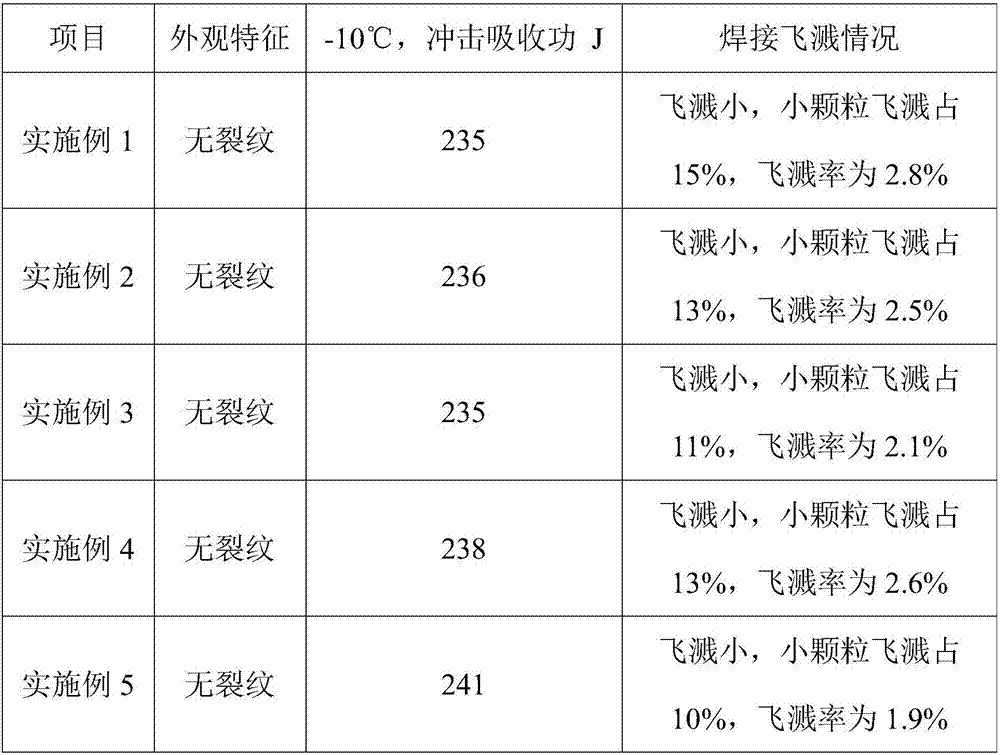

Flux-cored welding wire with good toughness and low porosity

InactiveCN107297583AWell mixedReduce surface tensionWelding/cutting media/materialsSoldering mediaPorositySilicon dioxide

The invention discloses a flux-cored welding wire with good toughness and low porosity. The welding wire includes a mild-carbon steel strip sheath and a flux core, wherein the flux core is prepared from, by weight, 0.4-0.6% of graphite, 10-14% of chromium powder, 2-4% of manganese dioxide, 3.5-5.5% of nickel powder, 3-5% of columbium powder, 2-4% of zirconium powder, 0.4-0.6% of silicon dioxide, 9-10% of rhenium oxide, 12-14% of magnalium, 6-8% of fluoride, 1.5-4.5% of lithium carbonate and the balance iron powder. The welding coating of the flux-cored welding wire has the advantages of being low in porosity, compact in coating microstructure and good in toughness.

Owner:安徽飞弧焊业股份有限公司

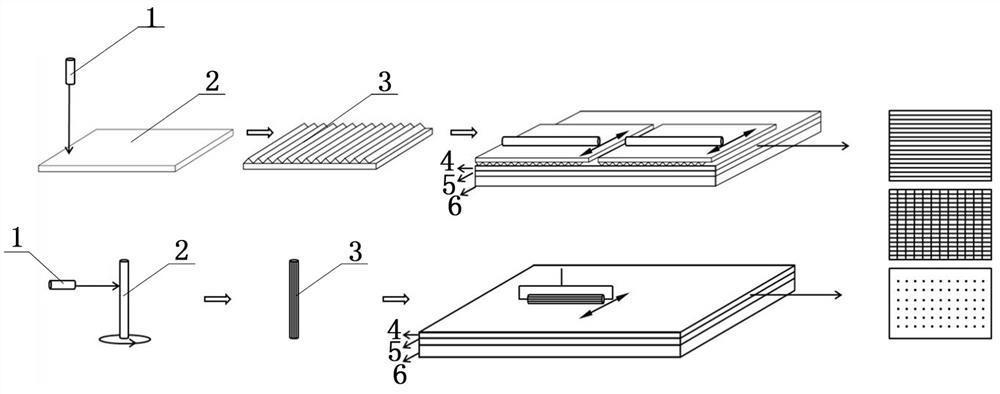

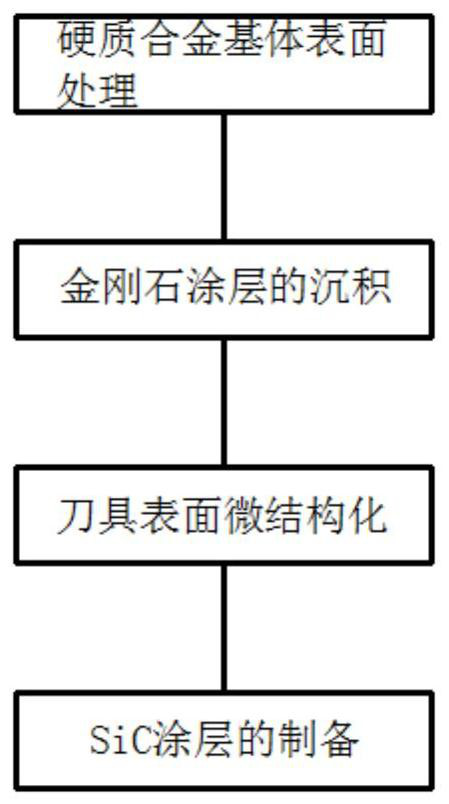

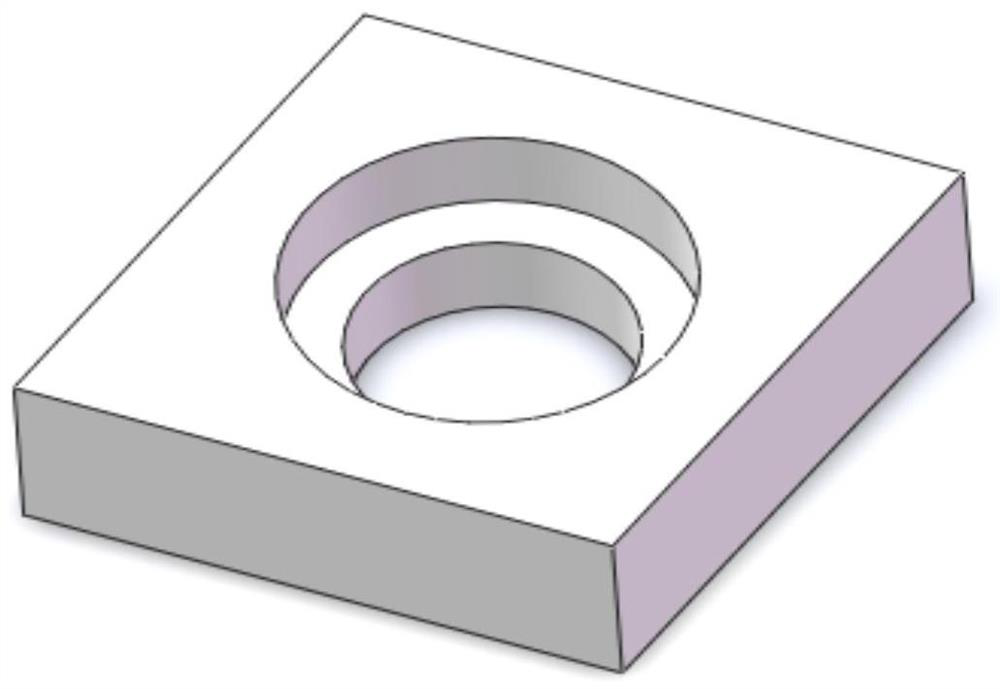

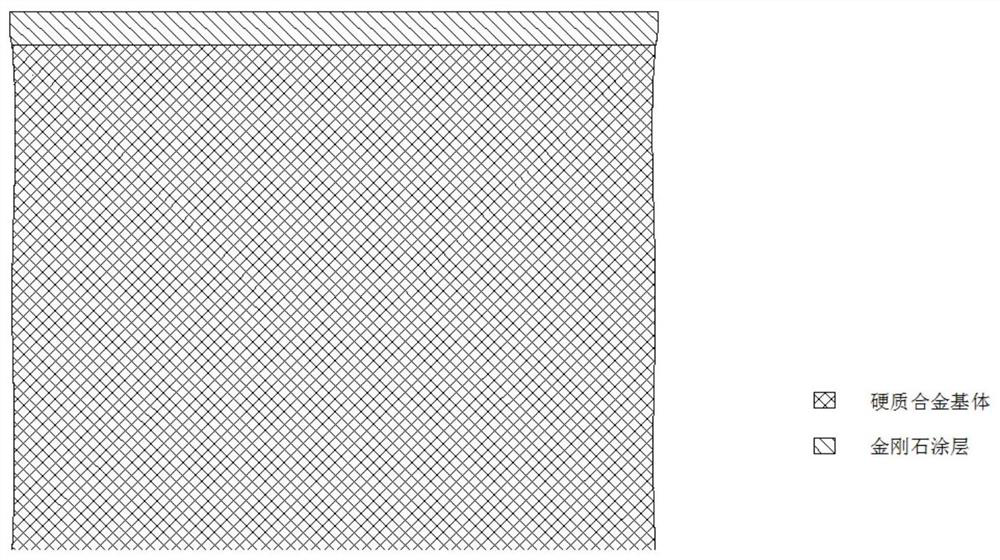

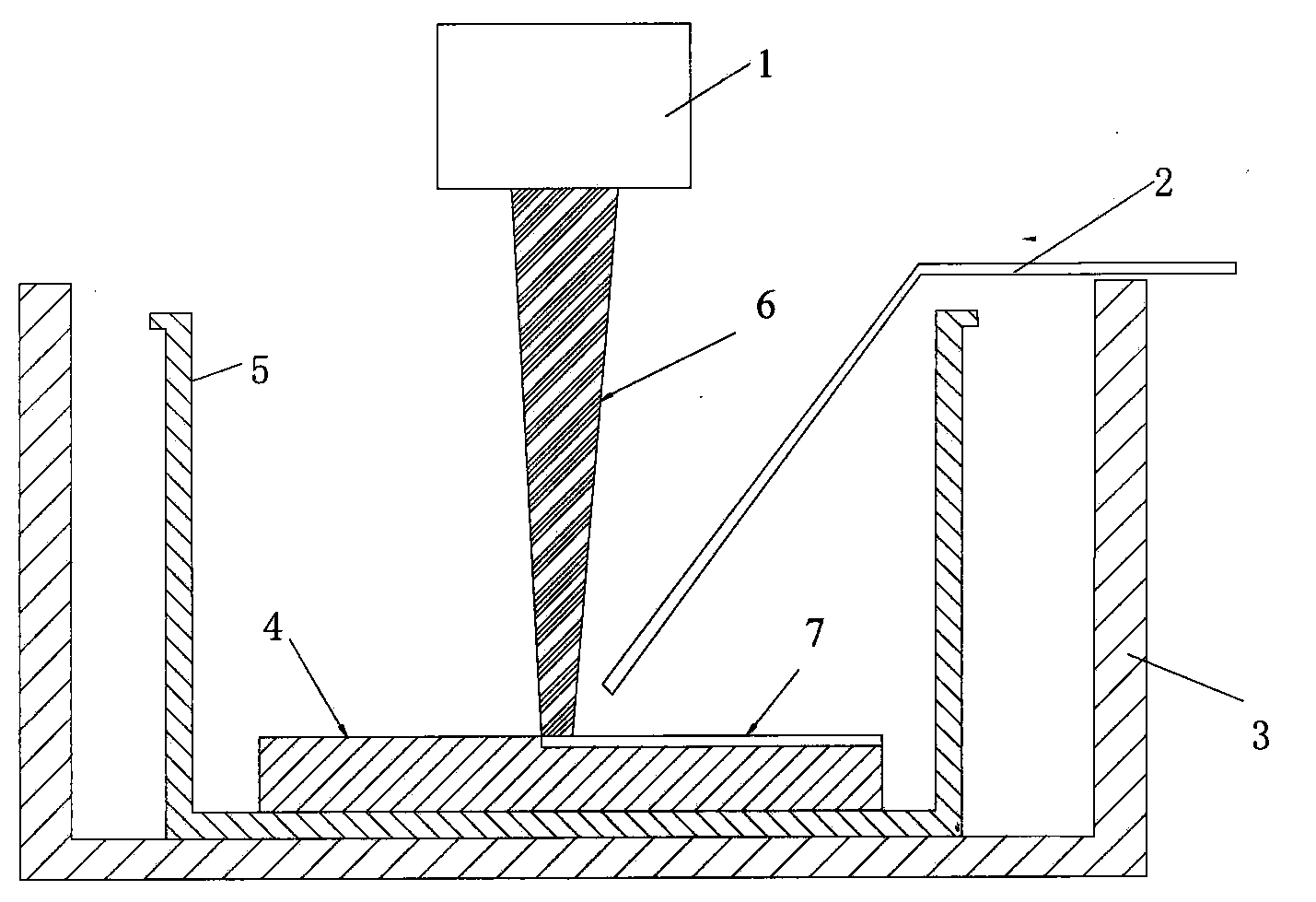

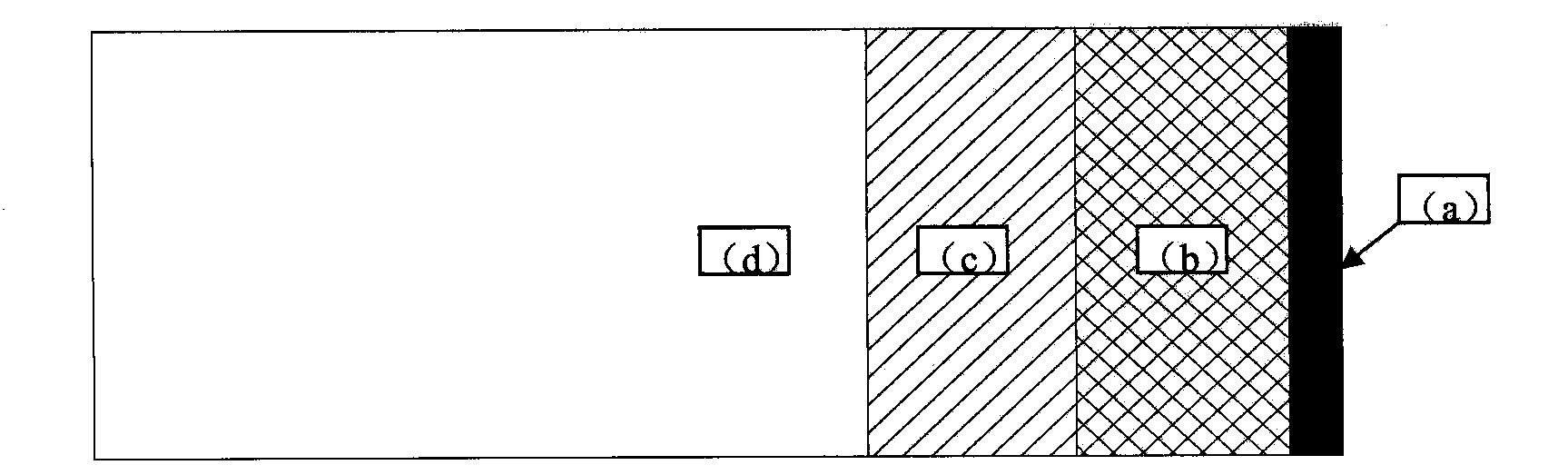

Processing method of coating microstructured bionic surface type diamond cutter

PendingCN112538612AImprove the lubrication effectReduce wearChemical vapor deposition coatingLaser beam welding apparatusCarbide siliconOxidation resistant

The invention discloses a machining method of a coating microstructured bionic surface type diamond cutter. The method comprises the following steps of 1, surface treatment of a hard alloy base body;2, deposition of a diamond coating; 3, microstructural treatment of the surface of a cutter; and 4, preparation of a silicon carbide coating. By the adoption of the technical scheme, the lubricating capacity of the cutter can be improved through cutter surface microstructuring, friction among the cutter, scraps and the surface of a workpiece in the machining process of the cutter is reduced, and therefore the cutting force, the cutting temperature, friction factors, cutter abrasion and other aspects in the cutting process are reduced, the cutting mechanism is achieved; the microstructure shapeis a vein stem shape; researches show that vein stems have a heat transfer effect, so that the heat transfer of the cutter surface is more uniform, and the heat dissipation effect of the cutter is better; and the silicon carbide coating has excellent properties such as high hardness, high strength, high thermal conductivity, corrosion resistance and low expansion coefficient, and after coating, the cutter has higher hardness, strength, wear resistance, oxidation resistance and the like in performance.

Owner:GUIZHOU UNIV

Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

InactiveCN102676981BHigh hardnessImprove wear and corrosion resistanceSolid state diffusion coatingSurface cleaningTitanium nitride

The invention provides a method for a laser preparation of a titanium nitride gradient coating on a surface of titanium and titanium alloy. The method comprises the steps of performing surface cleaning treatment, surface blackening treatment and preheating treatment for a workpiece subatrate; and then carrying out laser nitriding treatment. The method is characterized in that the laser nitriding treatment is performed in a condition of filling reaction gas, and simultaneously laser scanning treatment and ultrasonic oscillating treatment for the surface of the workpiece subatrate are carried out. The titanium nitride gradient coating with a thickness of 50-200 [mu]m is obtained on the surface of the titanium and titanium alloy. The titanium nitride gradient coating is mainly composed of a nitride layer and a nitrogen diffusion layer, and has uniform transition of the coating microstructure. The surface hardness, wear resistance and corrosion resistance of the titanium nitride gradient coating are improved significantly than those of the matrix. Also, problems that crack are easy to produce, surface roughness is large, and the crystal grains of dendrite crystals of a nitride layer are coarse, in ordinary laser gas nitriding processes, are solved.

Owner:山东万丰煤化工设备制造有限公司 +1

Coating preparation method for realizing high-efficiency operation of PS-PVD equipment

ActiveCN114086128AJet diameter shrinksImprove the heating effectMolten spray coatingVacuum evaporation coatingPlasma jetFluid phase

The invention discloses a coating preparation method for realizing high-efficiency operation of PS-PVD equipment, and aims to solve the technical problems that in the existing process of preparing a thermal barrier coating through plasma physical vapor deposition, the plasma jet utilization rate is low, the preparation cost is increased, and the microstructure consistency and the thickness uniformity of a surface coating are difficult to guarantee when a workpiece is sprayed. In the process of preparing the thermal barrier coating through plasma physical vapor deposition, the vacuum degree of a vacuum chamber, the spraying power of PS-PVD equipment and the spraying current are regulated and controlled, the diameter of plasma jet is made to be 50-100 mm, and an optimized design scheme is provided for the regulation and control range of three parameters and the coordinated regulation and control range of the three parameters. The heating capacity of the plasma jet is correspondingly improved, spraying powder is gasified more sufficiently, liquid phases and unmelted particles in the jet are correspondingly reduced, the utilization rate of the plasma jet is greatly increased, energy is effectively saved, the production cost is reduced, and the consistency of the microstructure of the prepared coating is better.

Owner:BEIHANG UNIV

A method for improving microstructure of coating

ActiveCN112275593AImprove microstructureEasy to operatePretreated surfacesSpecial surfacesCoated surfaceCoating microstructure

The invention discloses a method for improving a microstructure of a coating. Before spraying, heating the back surface of a base material to a certain temperature (the heating temperature of the backsurface of a ceramic powder spraying base material is 600 DEG C to 700 DEG C, and the heating temperature of the back surface of a metal powder spraying base material is 350 DEG C to 450 DEG C). In the spraying process, heating of the back face of the base material is kept all the time, and meanwhile the surface of the deposited coating is subjected to strengthening treatment (shot blasting strengthening can be adopted for ceramic powder spraying, and laser shock strengthening can be adopted for metal powder spraying). The steps are repeated until the coating reaches a certain thickness, andthen spraying is stopped. The microstructure of the coating is improved by heating the back surface of the base material to a constant temperature and carrying out impact strengthening on the surfaceof the deposited coating in the spraying process, and the method is simple and high in operability. Compared with a coating microstructure prepared by a traditional method, the improved coating microstructure is compact, the porosity is reduced, the layered structure partially disappears, and the performance of the coating is greatly improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com