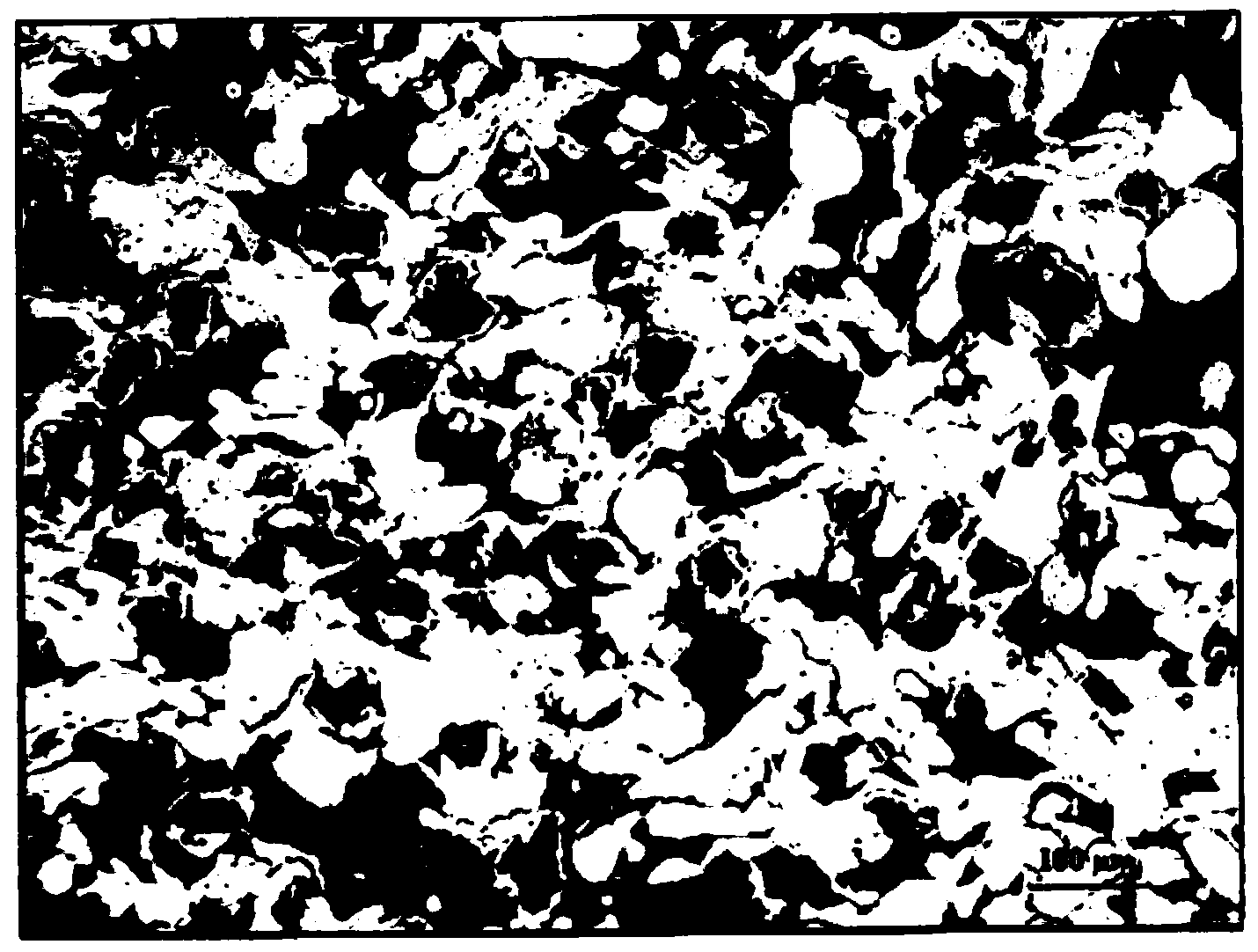

Detection method of flame spraying type CuAl/NiC coating microstructure

A technology of microstructure and detection method, applied in the field of detection, can solve the problems of difficult identification and differentiation, difficult calculation and analysis of solid lubricant and pore phase content, etc. Coating structure, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A detection method for flame sprayed CuAl / NiC coating microstructure, comprising the steps:

[0027] (1) Metallographic sample preparation steps

[0028] The parts with the coating are cut by a water-cooled grinding wheel cutting machine to obtain a metallographic sample, and the cutting machine adopts Al 2 o 3 A grinding wheel, the thickness of the grinding wheel is 1.5mm, and the cutting speed of the cutting machine is 0.3mm / s;

[0029] Use epoxy resin to carry out vacuum impregnation to the metallographic sample, and the vacuum degree is at 80mbar, so that the epoxy resin is completely filled into the coating hole of the metallographic sample; For metallographic sample preparation, the vacuum degree is 80mbar;

[0030] The metallographic sample preparation is ground and polished to obtain a metallographic sample, the grinding and polishing pressure is 18 Newtons, and a lint-free polishing cloth is used for polishing;

[0031] (2) Detection of the microstructure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com