Anti-scratching diffusion film and method for preparing the same

A technology of diffusion film and diffusion particles, which is applied in optics, instruments, nonlinear optics, etc., can solve the problem that the particles in the anti-adhesion layer are easy to fall off, etc., achieve good anti-scratch effect, reduce adverse phenomena, and improve optical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

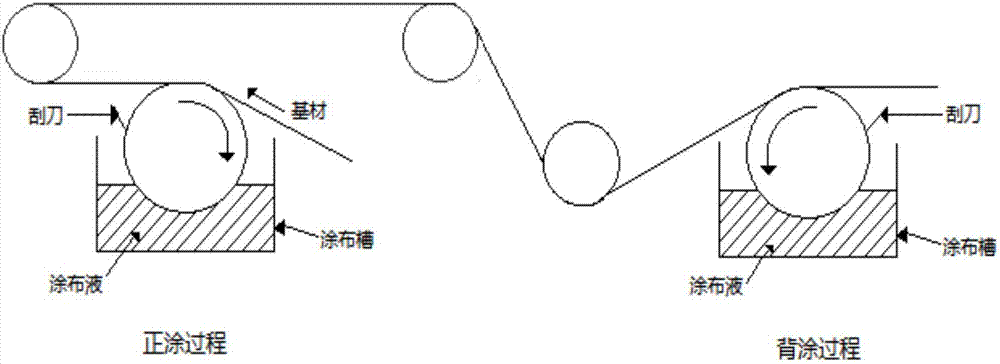

[0051] The present invention provides the preparation method of described anti-scratch diffusion film, and this method comprises the following steps:

[0052] (1) The substrate is firstly coated by wet coating. The particle size of the scattering particles is 3-15 μm, the particle size range of the front-coated particles is 5-15 μm, and the particle size range of the back-coated particles is 3 μm. ~5μm;

[0053] (2) The coating solution is mainly composed of scattering particles and UV glue, wherein the scattering particles are preferably polymethyl methacrylate, and the UV glue is preferably an acrylic resin composition;

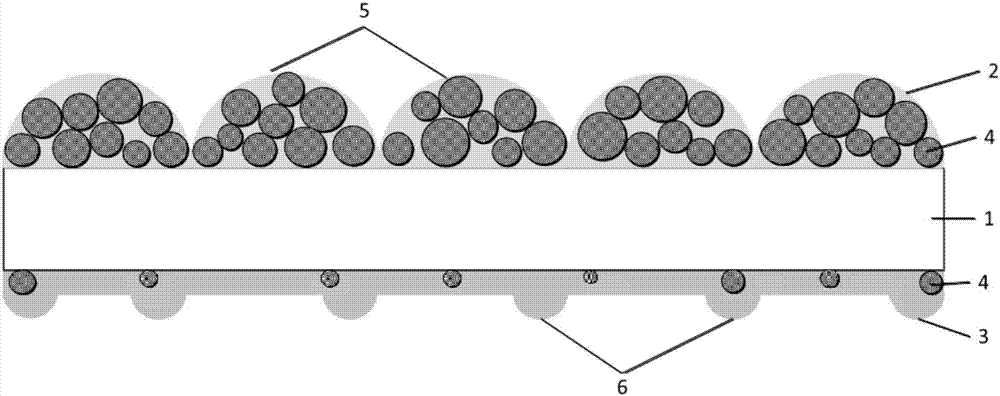

[0054] (3) The coated substrate enters the structure area, passes through the structured concave roller with microstructure on the surface, forms the front coating microstructure by transfer printing on the front coating, forms the back coating microstructure on the back coating, and the front coating microstructure The diameter range of the structure is p...

Embodiment 1

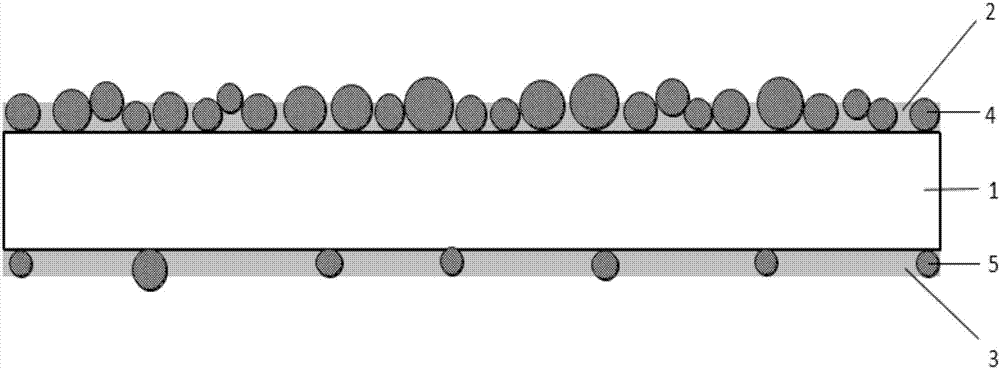

[0068] The anti-scratch diffusion film provided by the present invention, the diffusion film comprises a substrate PET with a thickness of 250 μm, one side of the substrate is provided with a positive coating, and the other side is provided with a back coating; the positive coating contains Scattering particles, the particle size of the scattering particles ranges from 5 to 15 μm; the surface of the positive coating has a positive coating microstructure, the positive coating microstructure is hemispherical and has a diameter of 30 μm, and the positive coating microstructure is The spacing is 0 (closely arranged); the back coating contains scattering particles, the diameter of the scattering particles is D, and 0<D≤5 μm, the surface of the back coating has a back coating microstructure, the The back-coated microstructure is hemispherical with a diameter of 10 μm, and the pitch of the back-coated microstructure is 60 μm.

[0069] The material of the positive coating comprises ul...

Embodiment 2

[0072] The anti-scratch diffusion film provided in Example 1, wherein, the microstructure of the positive coating is hemispherical, with a diameter of 50 μm, and the spacing of the microstructures of the positive coating is 0 (closely arranged); the surface of the back coating has Back-coated microstructures, the back-coated microstructures are hemispherical, with a diameter of 10 μm, and the pitch of the back-coated microstructures is 60 μm. The diameter range of the scattering particles in the back coating is 3-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com