Packaging structure and method of MEMS optical chip based on silicon-glass bonding

A technology for optical chips and packaging methods, applied in microstructure devices, processing microstructure devices, optics, etc., can solve problems such as wafer-level packaging difficulties of MEMS optical chips, improve reliability and stability, reduce costs, The effect of reducing packaging requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

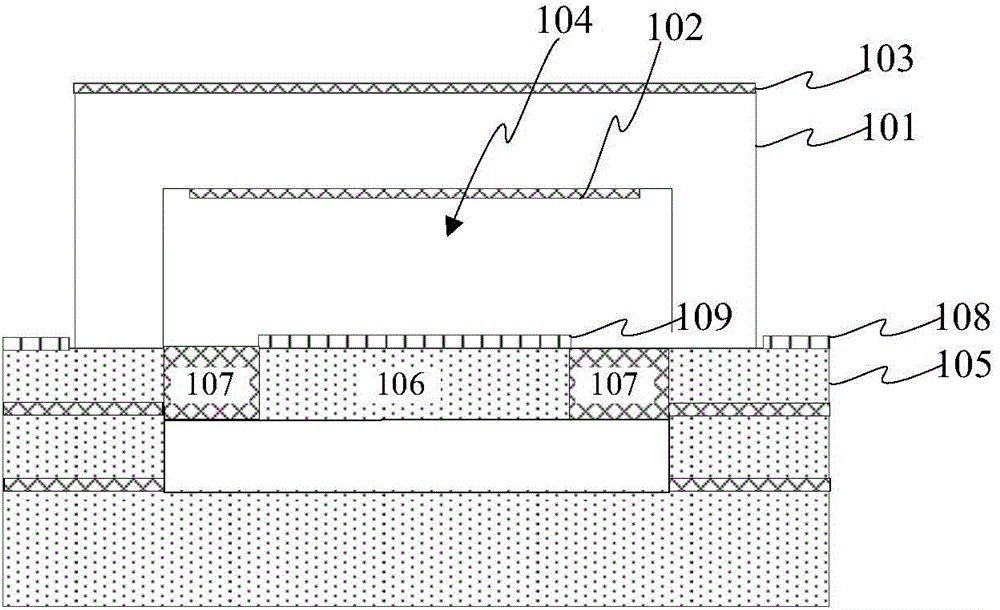

[0055] Such as figure 1 and Figure 3 ~ Figure 4 As shown, the present embodiment provides a packaging structure based on a silicon-glass bonding MEMS optical chip, including:

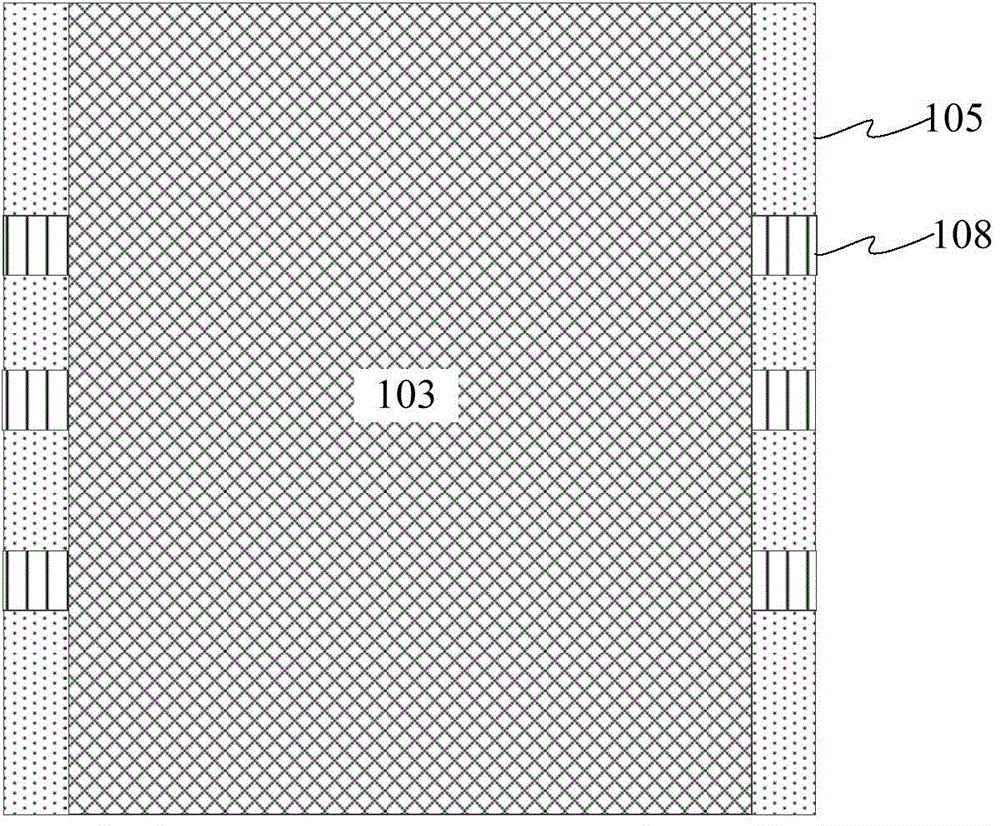

[0056] The first part comprises an optical glass 101, its upper surface is plated with an optical anti-reflection film 103, and a cavity 104 is formed on the lower surface to provide an airtight micromirror movement space for the MEMS optical chip. The upper surface of the cavity 104 Meet the requirements of optical surface finish, and coated with the lower optical anti-reflection film 102;

[0057] The second component includes a MEMS optical chip, and the MEMS optical chip can realize the manipulation of the optical signal under the action of the MEMS driver;

[0058] The first component and the second component realize wafer-level bonding through silicon-glass bonding, and form an independent sealed cavity for each MEMS optical chip. Specifically, the MEMS optical chip includes a bulk silicon su...

Embodiment 2

[0077] Such as figure 1 and Figure 3 ~ Figure 4 As shown, the present embodiment provides a packaging structure of MEMS optical chips based on silicon-glass bonding, and its basic structure is as described in Embodiment 1, wherein the optical glass 101 having a cavity 104 is composed of two optical Made of glass bonding, it includes a first optical glass 102 and a second optical glass 101 with through holes processed at positions corresponding to the MEMS optical chip, and then the optical glass with a cavity 104 is formed by bonding these two optical glasses.

[0078] Such as Figure 6a ~ Figure 6g As shown, this embodiment also provides a method for packaging MEMS optical chips based on silicon-glass bonding, the basic steps of which are as in Embodiment 1, wherein, as Figure 6a ~ Figure 6c As shown, step 1) includes steps:

[0079] Such as Figure 6b As shown, at first step 1-1) is carried out, the first optical glass 102 is provided, and a through hole is processed ...

Embodiment 3

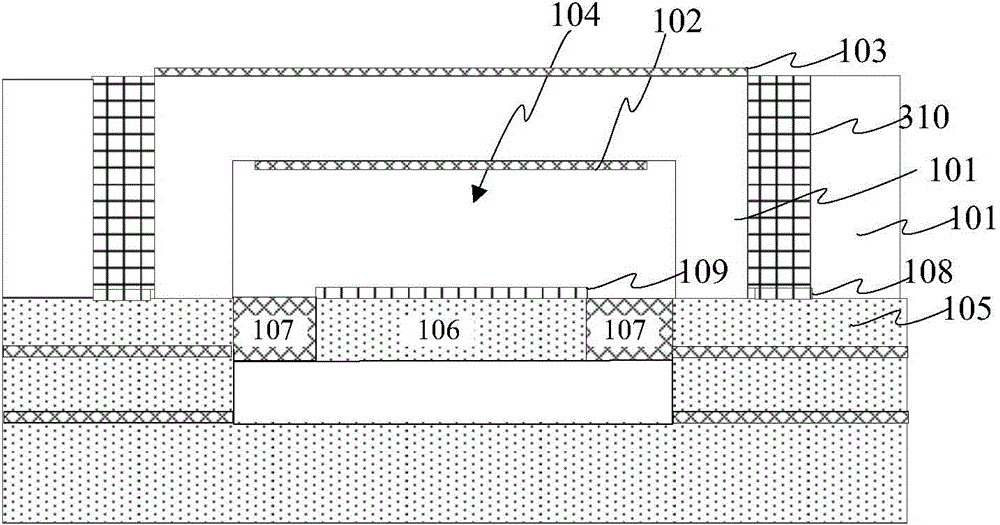

[0084] Such as Figure 2 ~ Figure 4 As shown, the present embodiment provides a packaging structure based on a silicon-glass bonding MEMS optical chip, and its basic structure is as in Embodiment 1, wherein, the TGV structure 310 is prefabricated in the optical glass, and its position is the same as that of the MEMS optical chip. The positions of the electrode pads 108 of the chips correspond one by one. After the silicon-glass bonding of the first component and the second component, the TGV structure 310 directly leads the electrode pads 108 of the MEMS optical chip to the upper surface of the optical glass.

[0085] Such as Figure 7a ~ Figure 7e As shown, this embodiment also provides a method for packaging MEMS optical chips based on silicon-glass bonding, the basic steps of which are as in Embodiment 1, wherein, as Figure 7b As shown, step 1) also includes: the step of prefabricating a TGV structure 310 on the optical glass, the position of the TGV structure 310 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com