Patents

Literature

225results about How to "Guaranteed Optical Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

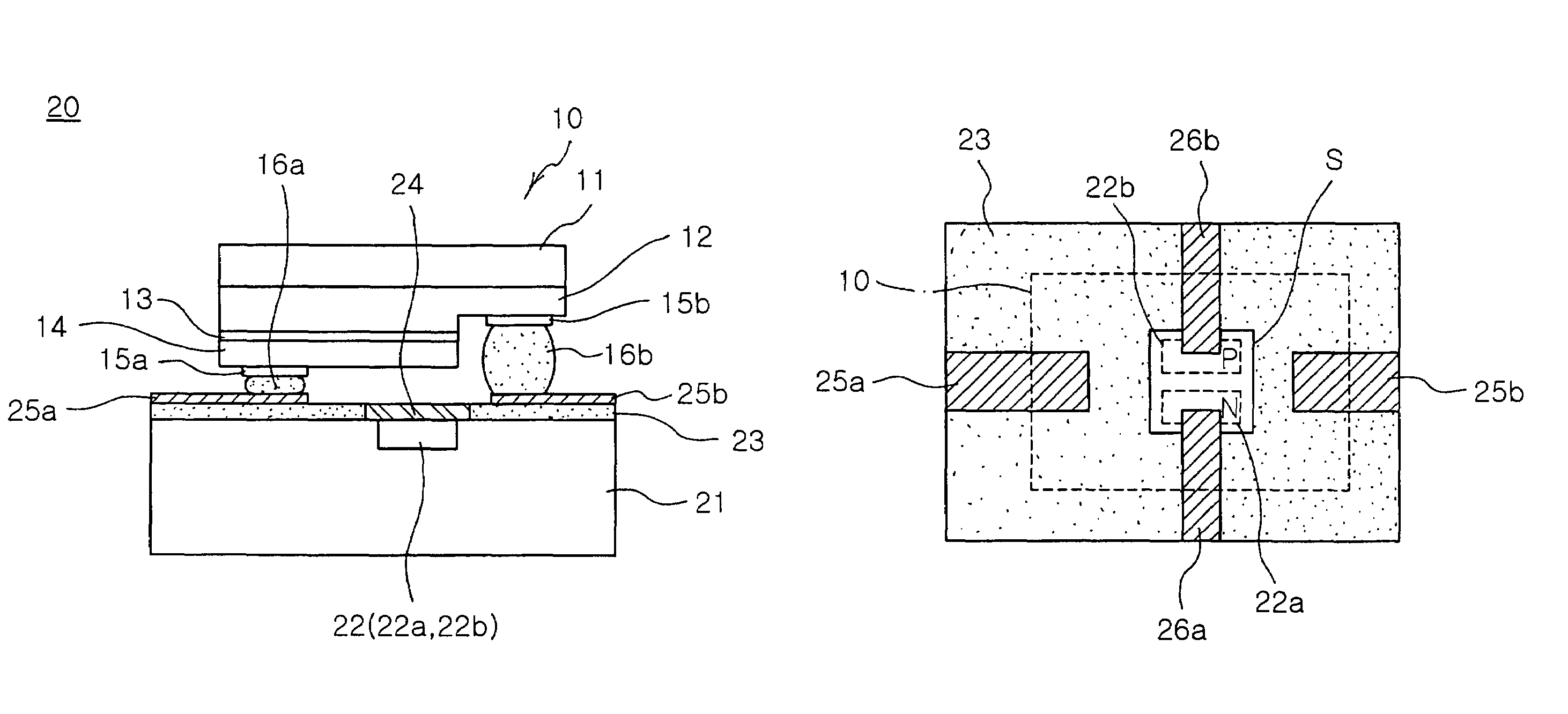

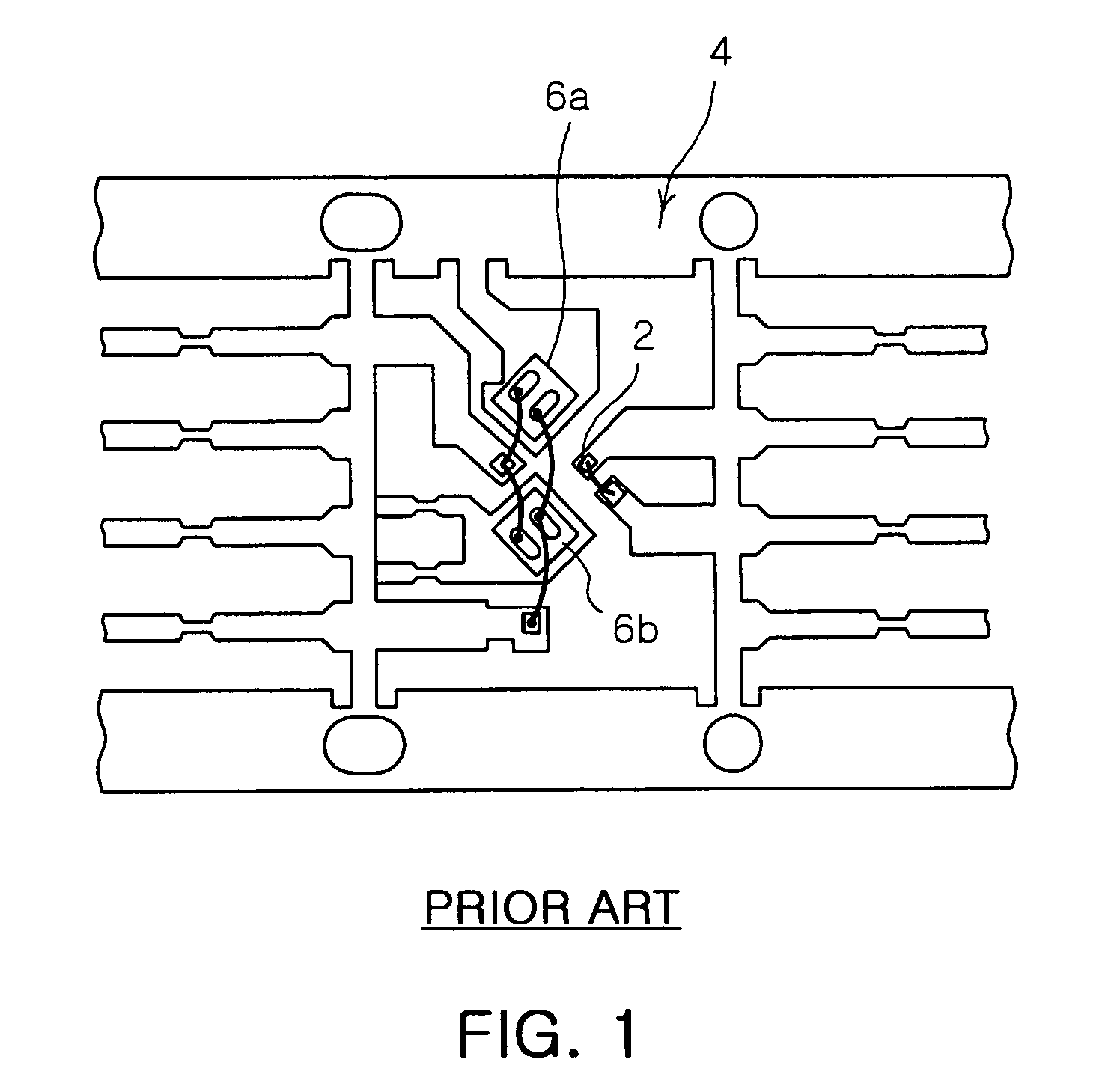

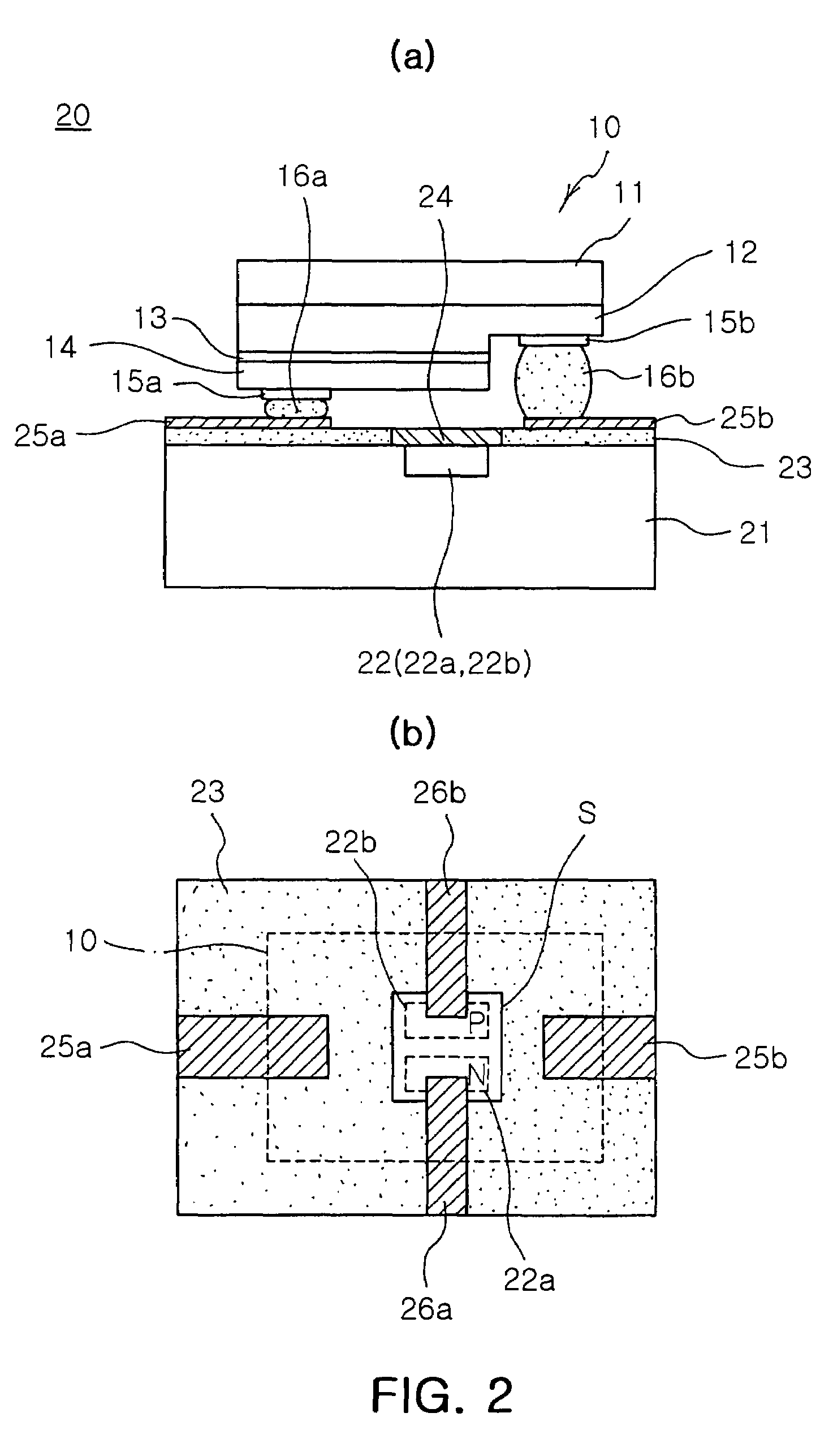

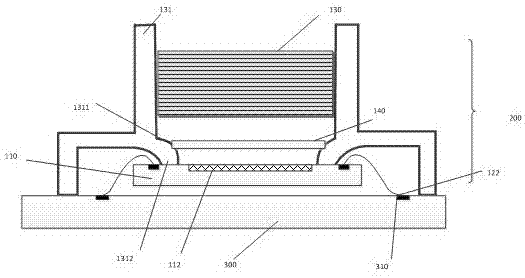

Light emitting diode package including monitoring photodiode

ActiveUS20060192084A1Improve reliabilityImprove optical connection efficiencySolid-state devicesMaterial analysis by optical meansInsulation layerEngineering

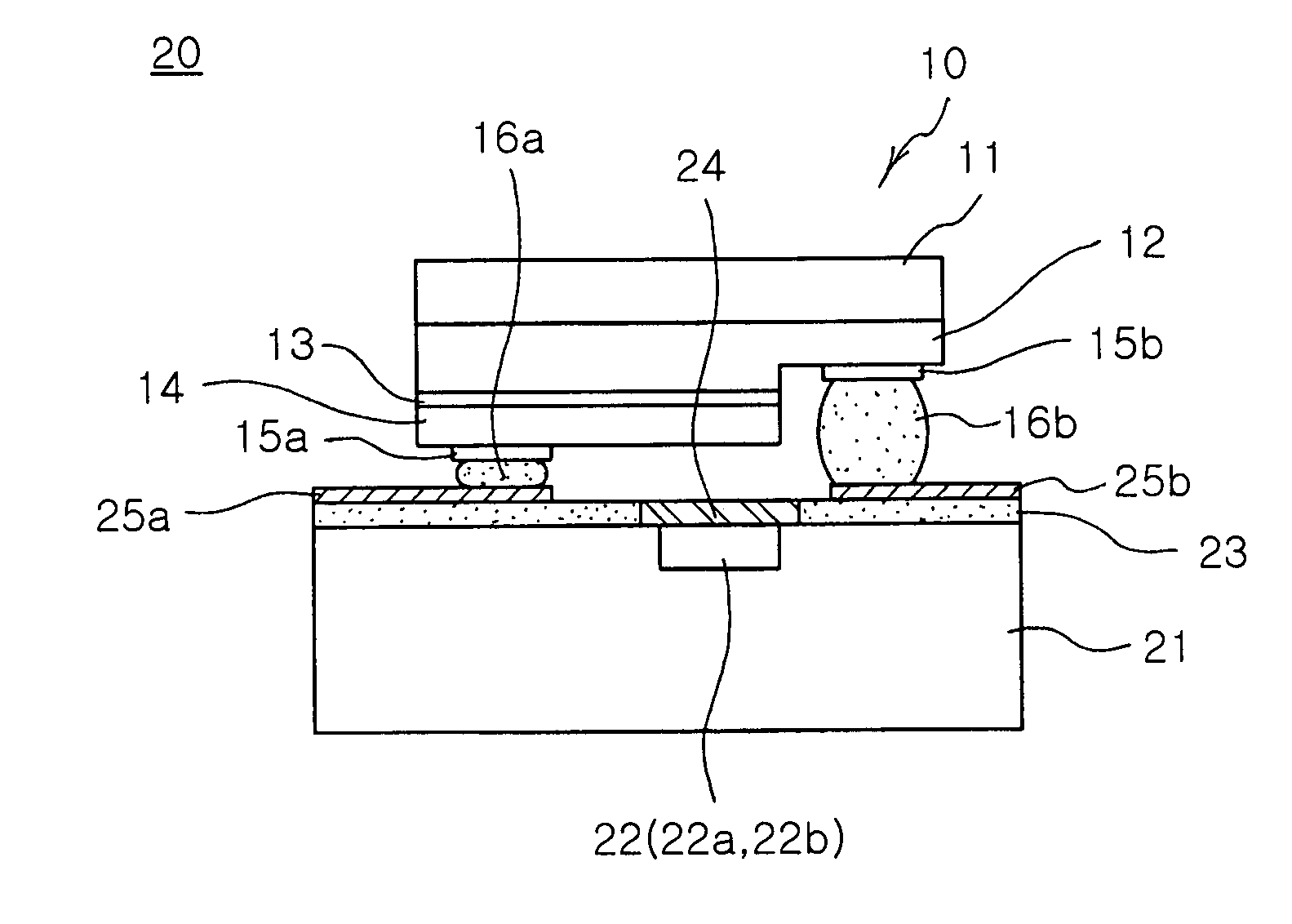

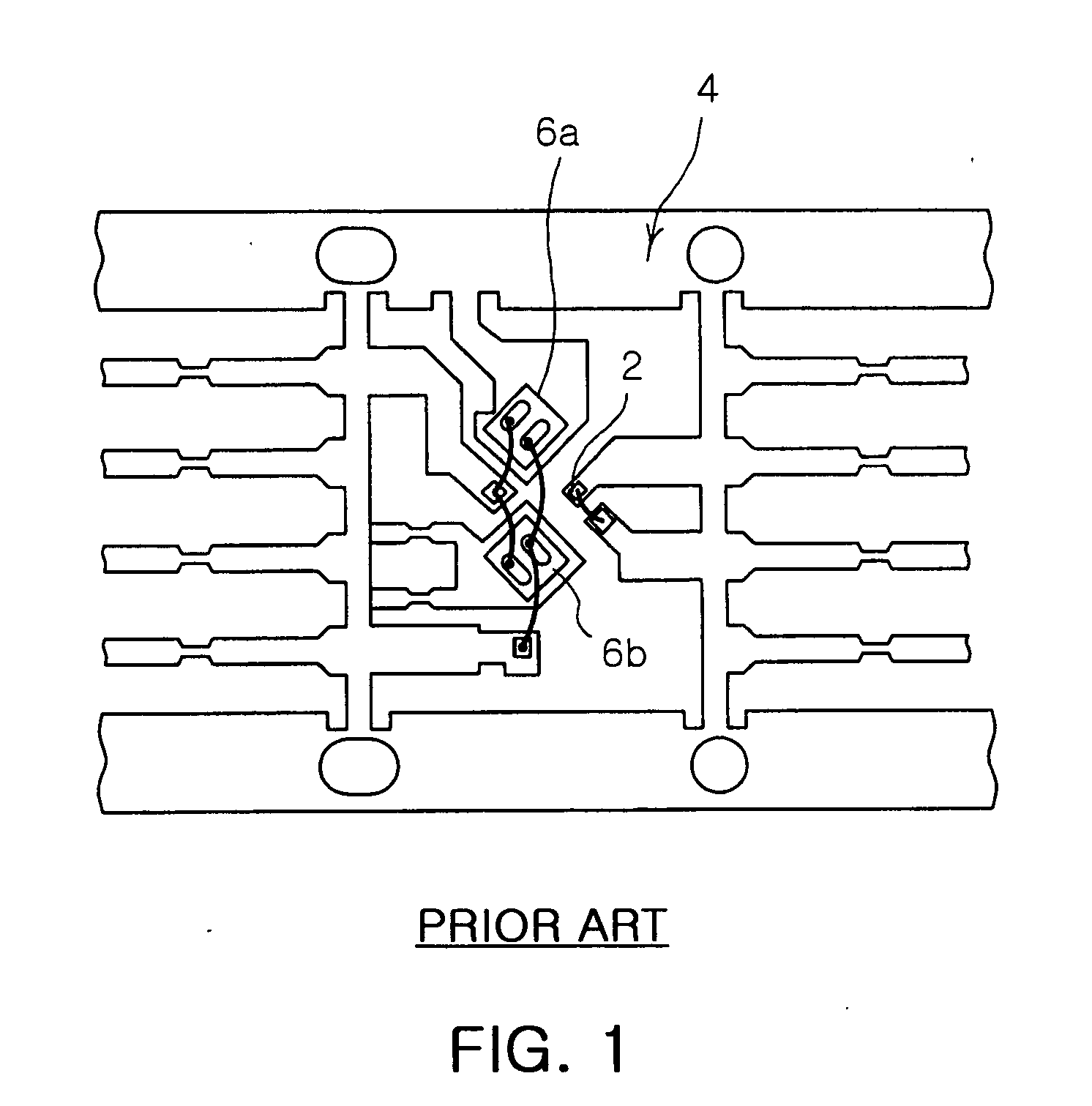

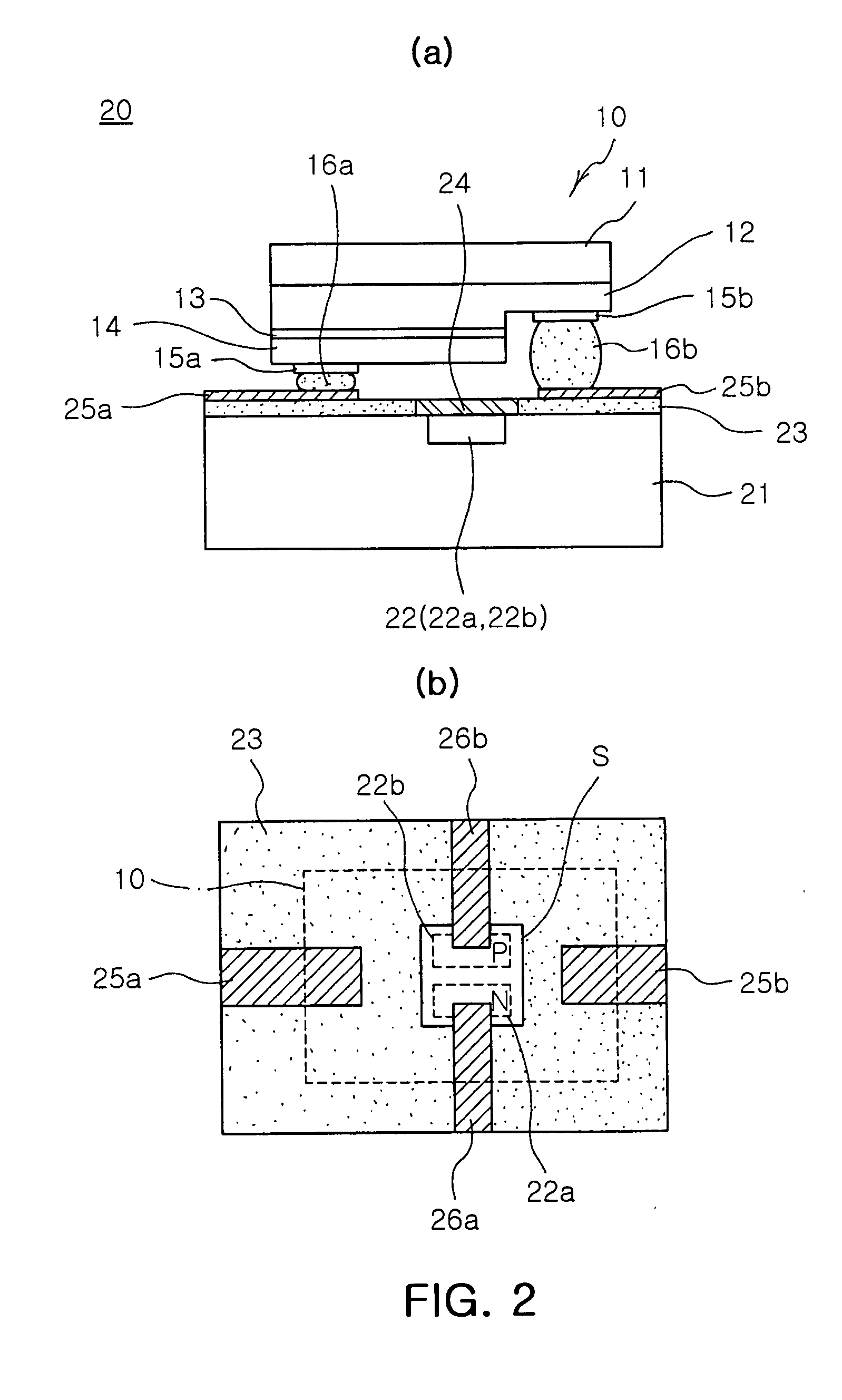

The present invention relates to an LED package including photo diode. The LED package includes a silicon substrate, and a photo diode is formed in an upper part thereof. Also, an insulation layer is formed on the silicon substrate excluding at least a light-receiving area of the photodiode. In the LED package, an LED terminal is formed on the insulation layer to be connected to the photo diode. First and second LED connecting pads are formed on the insulation layer, and arranged on both sides of the photo diode. In addition, an LED chip is mounted on the silicon substrate, and connected to the first and second LED connecting pads.

Owner:SAMSUNG ELECTRONICS CO LTD

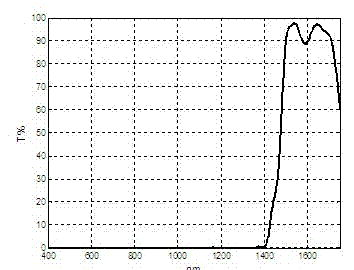

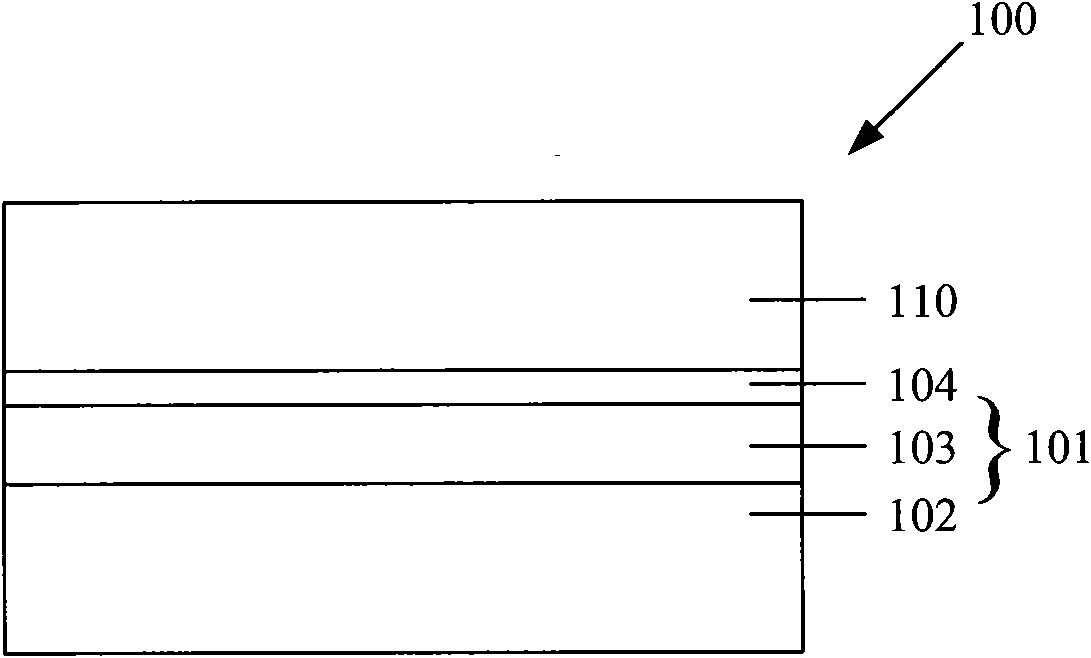

Antireflection glass and preparation method thereof

ActiveCN104553126AImprove anti-reflection effectGuaranteed Optical PerformanceGlass/slag layered productsReflectivityTransmittance

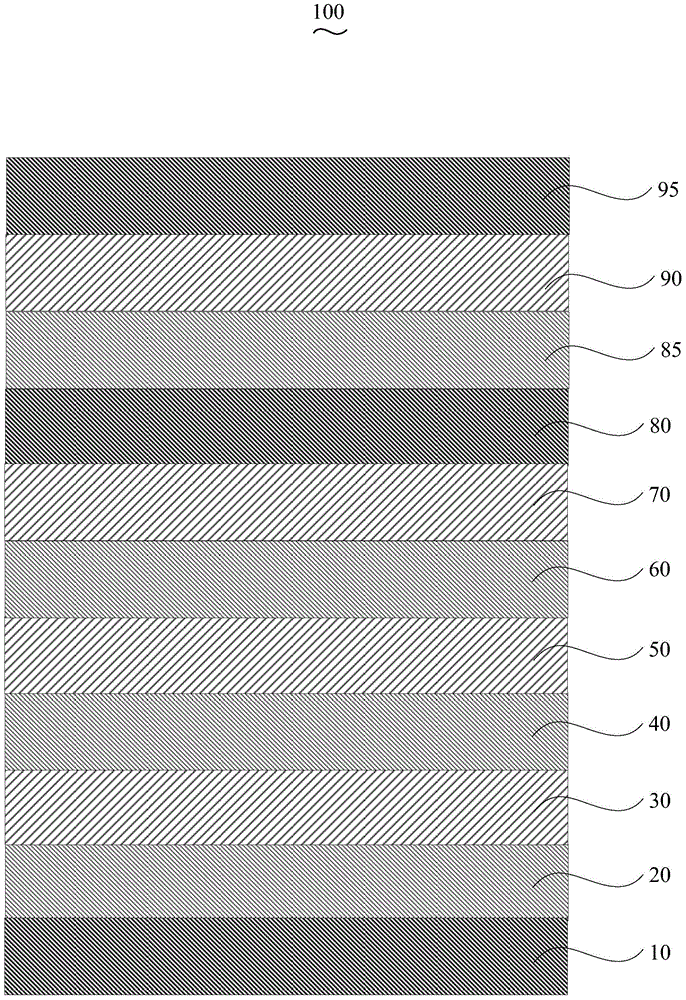

The invention discloses a piece of antireflection glass. The antireflection glass is prepared by using aluminosilicate glass as a substrate; the visible light full-wave band average transmittance is higher than or equal to 94.5%, and the film coated surface single-side full-wave band average reflectivity is smaller than or equal to 1%; the antireflection glass is high in hardness, scrape resistance, acid-base resistance and follow-up processability. The antireflection glass comprises the aluminosilicate glass substrate, a first low-refractive index layer, a first high-refractive index layer, a second low-refractive index layer, a second high-refractive index layer, a third low-refractive index layer, a third high-refractive index layer, a fourth low-refractive index layer, a fourth high-refractive index layer, a fifth low-refractive index layer, and a fifth high-refractive index layer, wherein the first low-refractive index layer is made of SiO2; the first high-refractive index layer is made of Nb2O5. The antireflection glass is lower in the film coated surface single-side full-wave band average reflectivity, higher in hardness, and very suitable for acid and alkali treatment in the follow-up manufacturing procedures, so as to be adapted to more working procedures and achieve wider application range. The invention further discloses a preparation method of the antireflection glass.

Owner:YICHANG NANBO DISPLAY

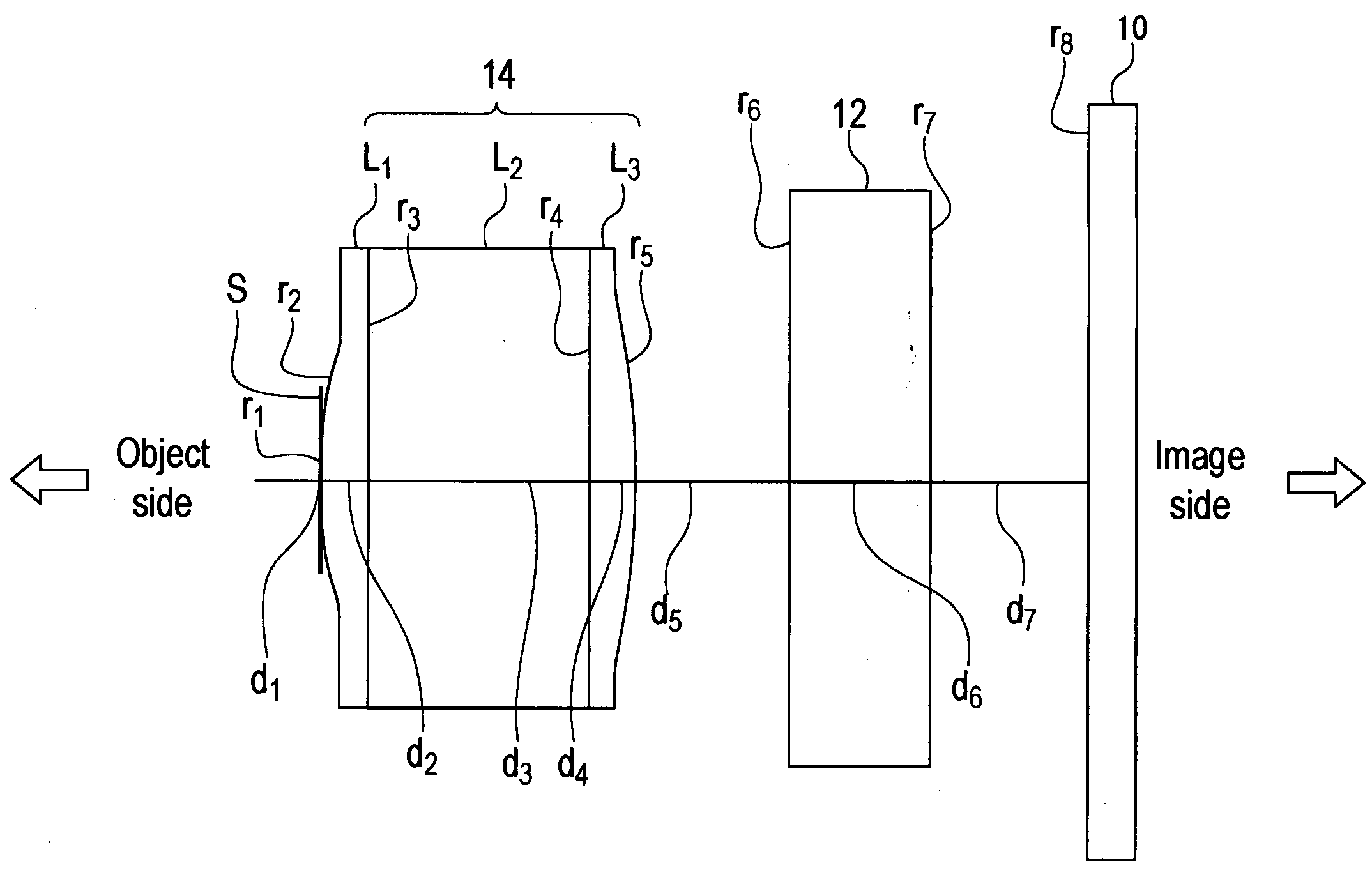

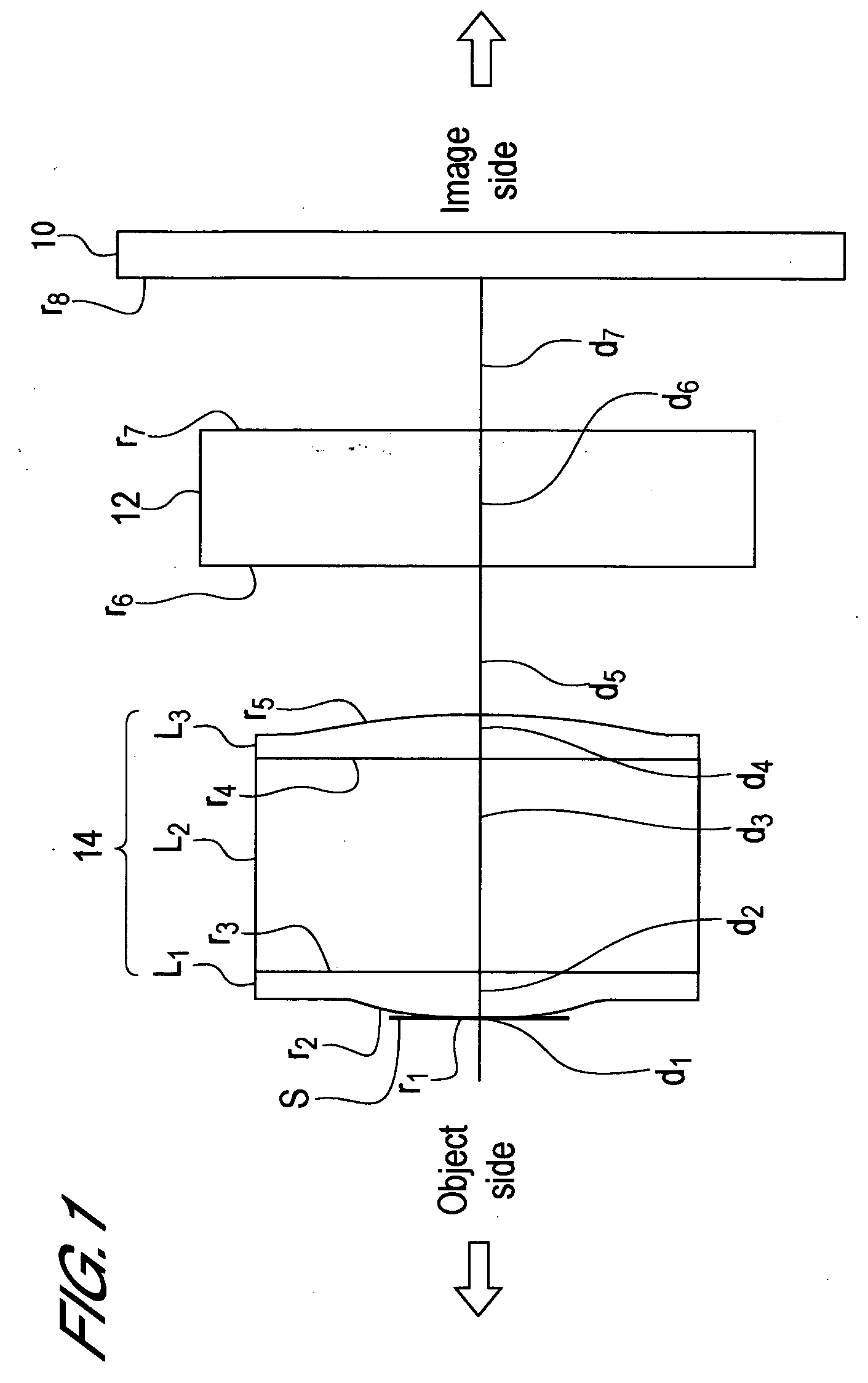

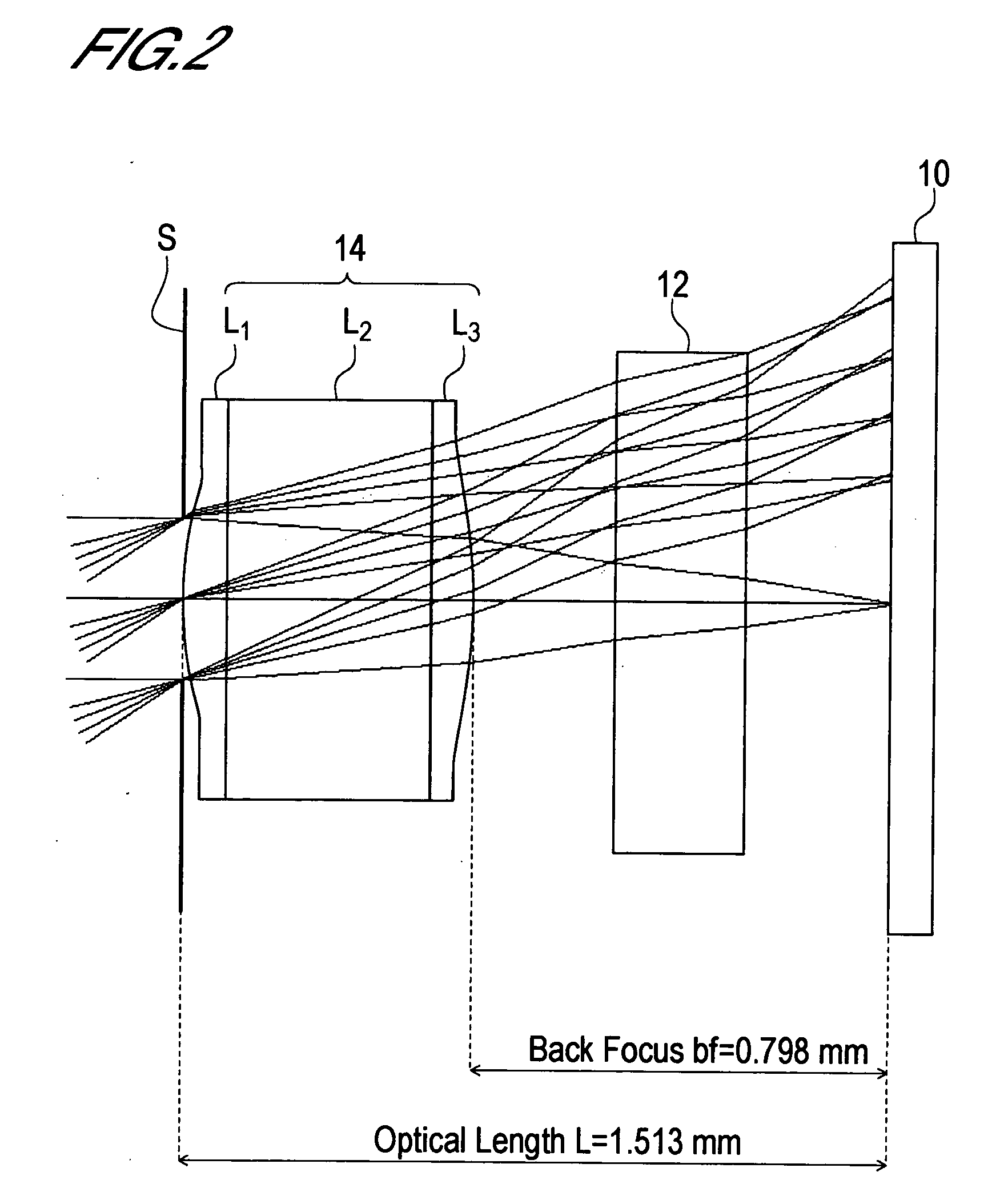

Imaging Lens

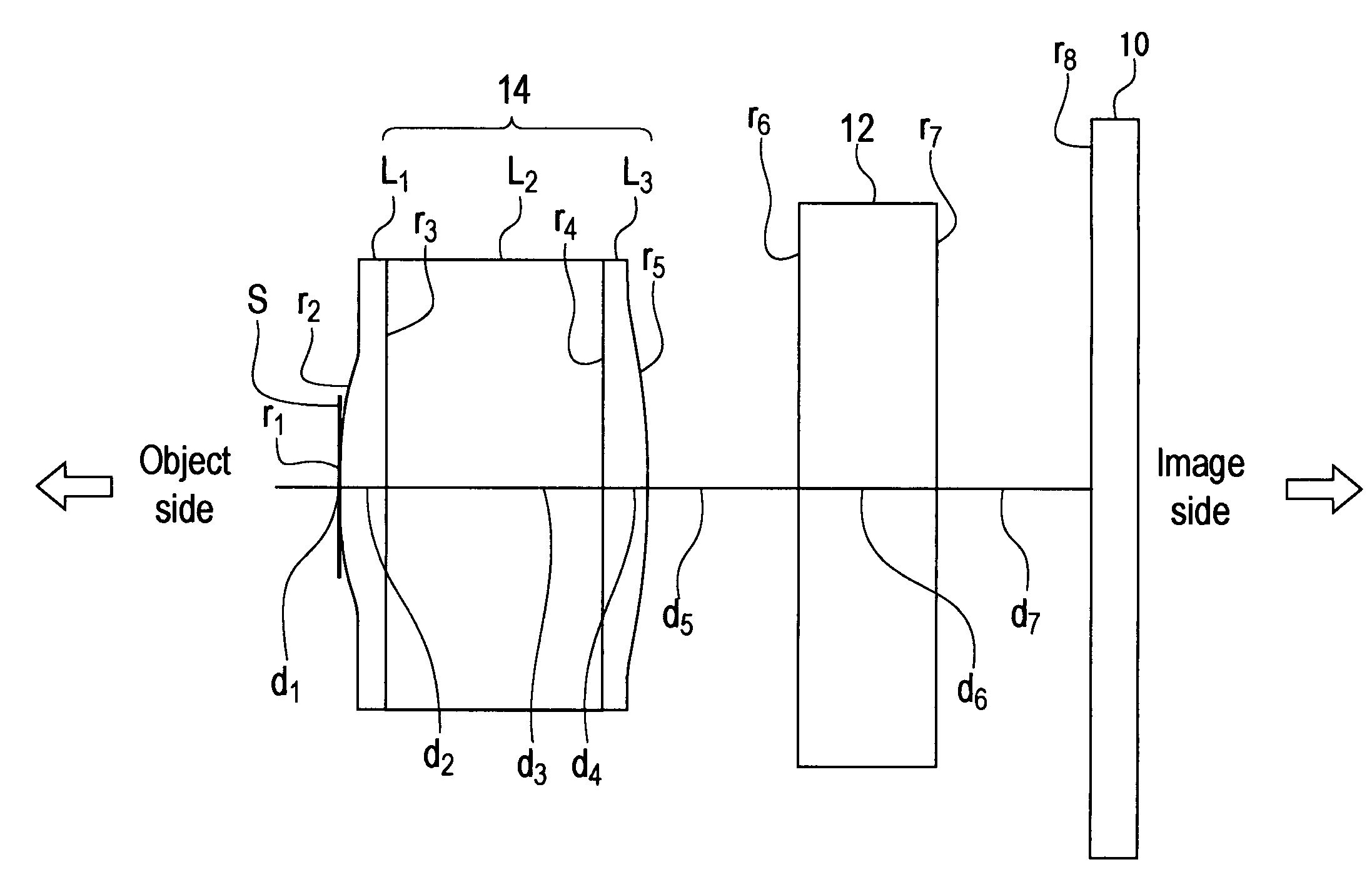

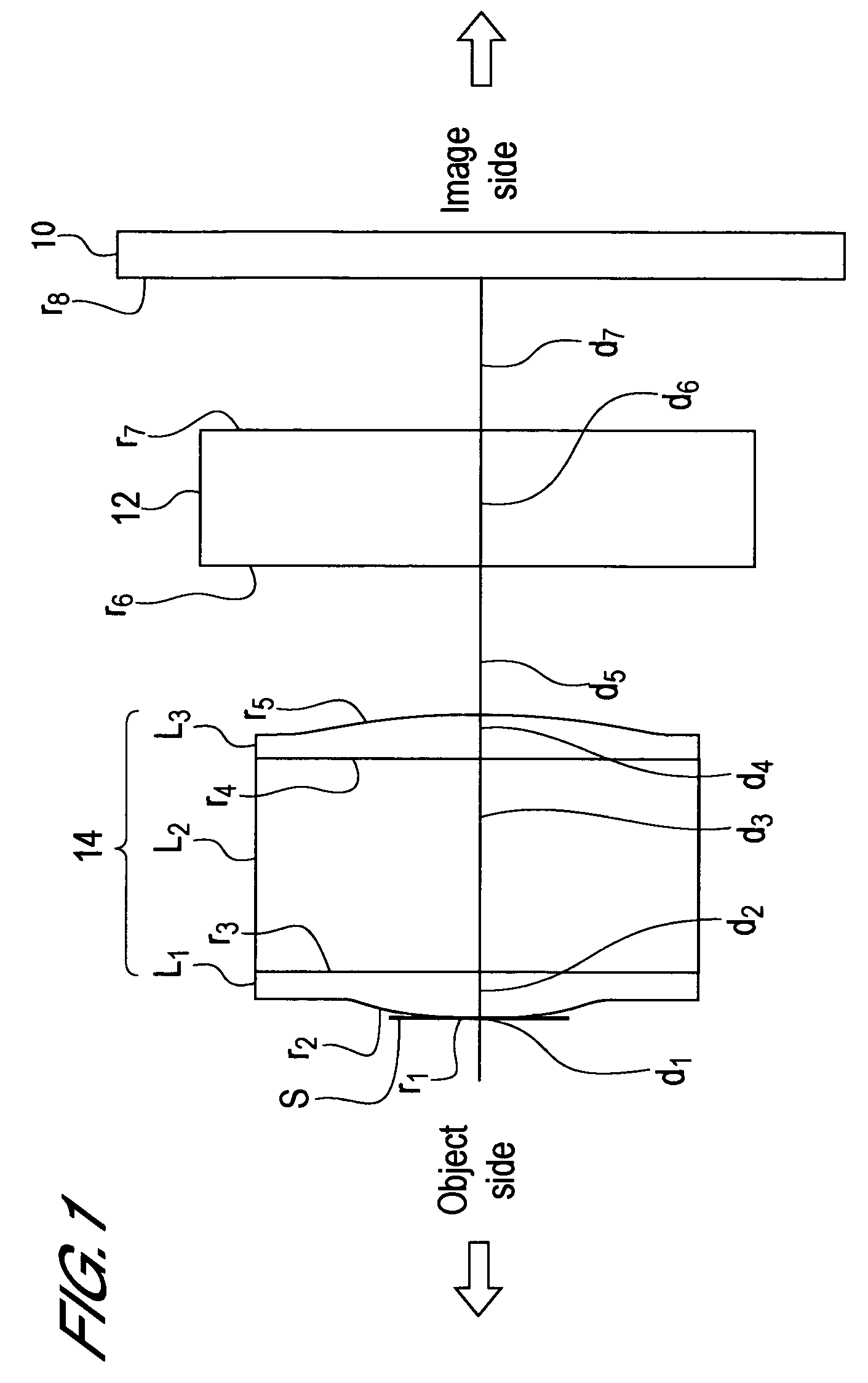

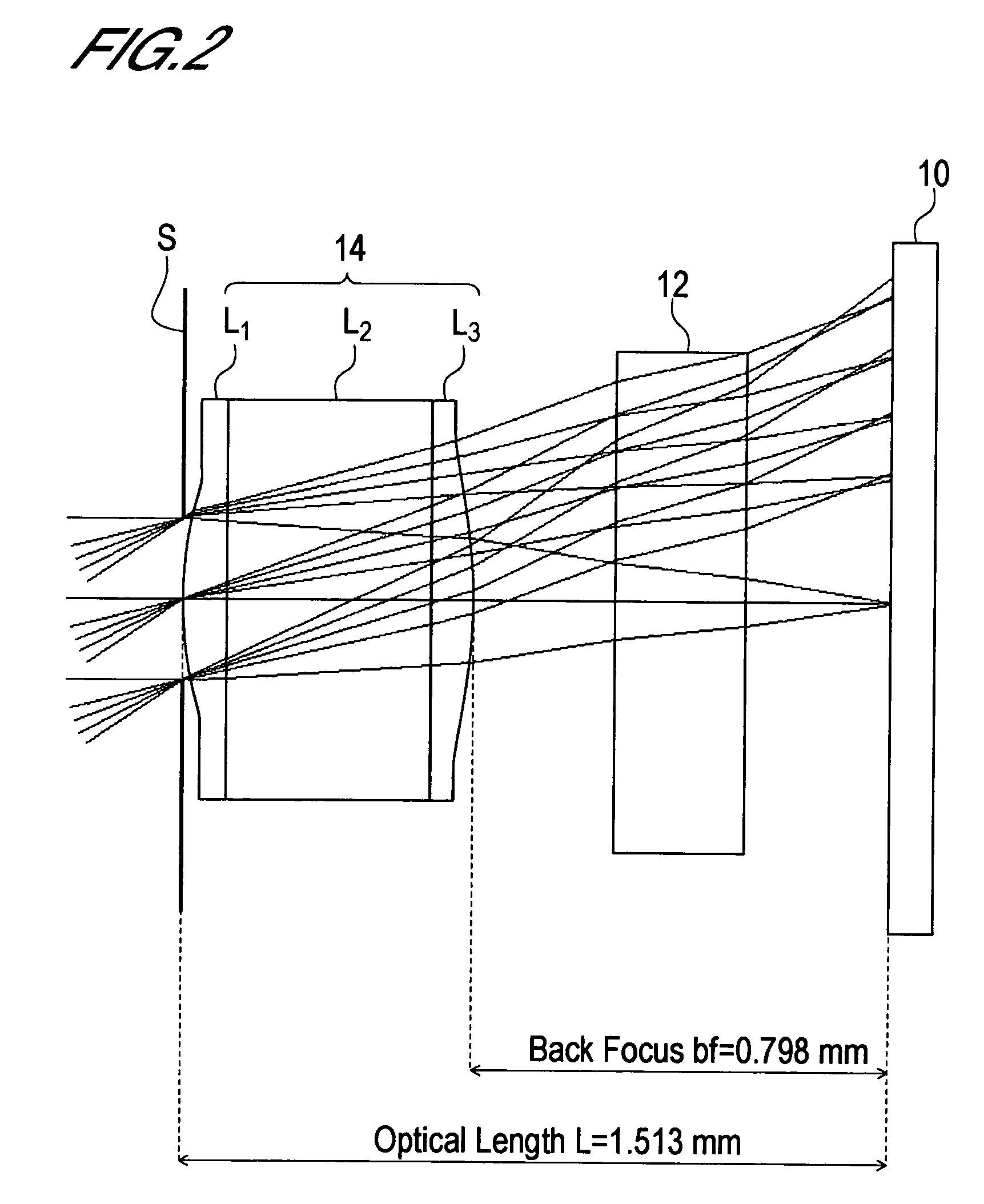

ActiveUS20090279188A1High melting pointGuaranteed Optical PerformanceOptical articlesLensCamera lensOptoelectronics

An imaging lens of which optical performance does not deteriorate even in a high temperature environment, various aberrations are well corrected, optical length is short, and back focus is sufficiently secured, comprising an aperture stop S and a junction type compound lens 14 having a positive refractive power, wherein the aperture stop and the junction type compound lens are arranged in this sequence from an object side to an image side. The junction type compound lens comprises a first lens L1, a second lens L2 and a third lens L3 arranged in this sequence from the object side to the image side. The first lens and the third lens are formed of a curable resin material, and the second lens is formed of an optical glass. The first lens and the second lens are directly bonded, and the second lens and the third lens are directly bonded. The object side face of the first lens and the image side face of the third lens are aspherical.

Owner:SEIKOH GIKEN +1

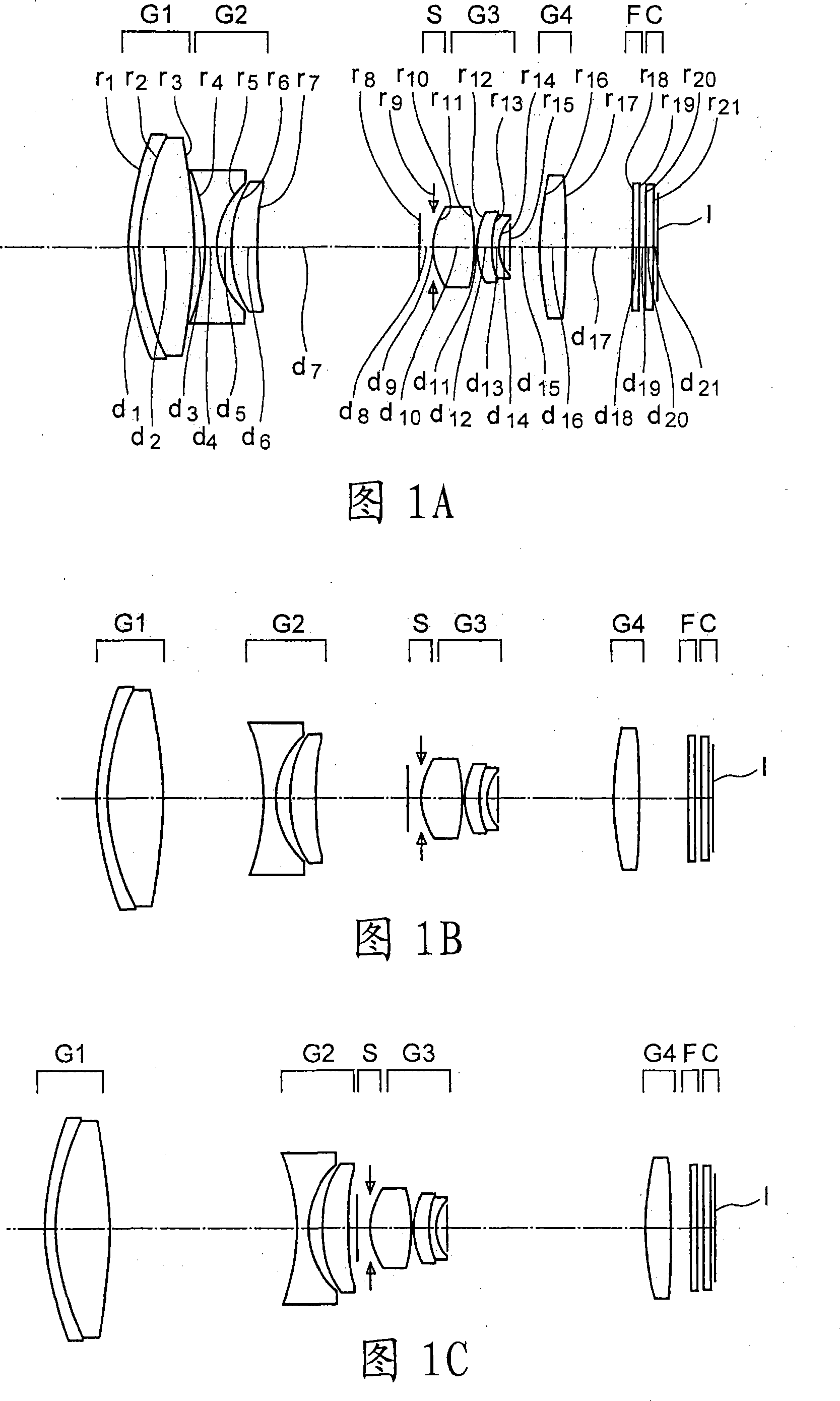

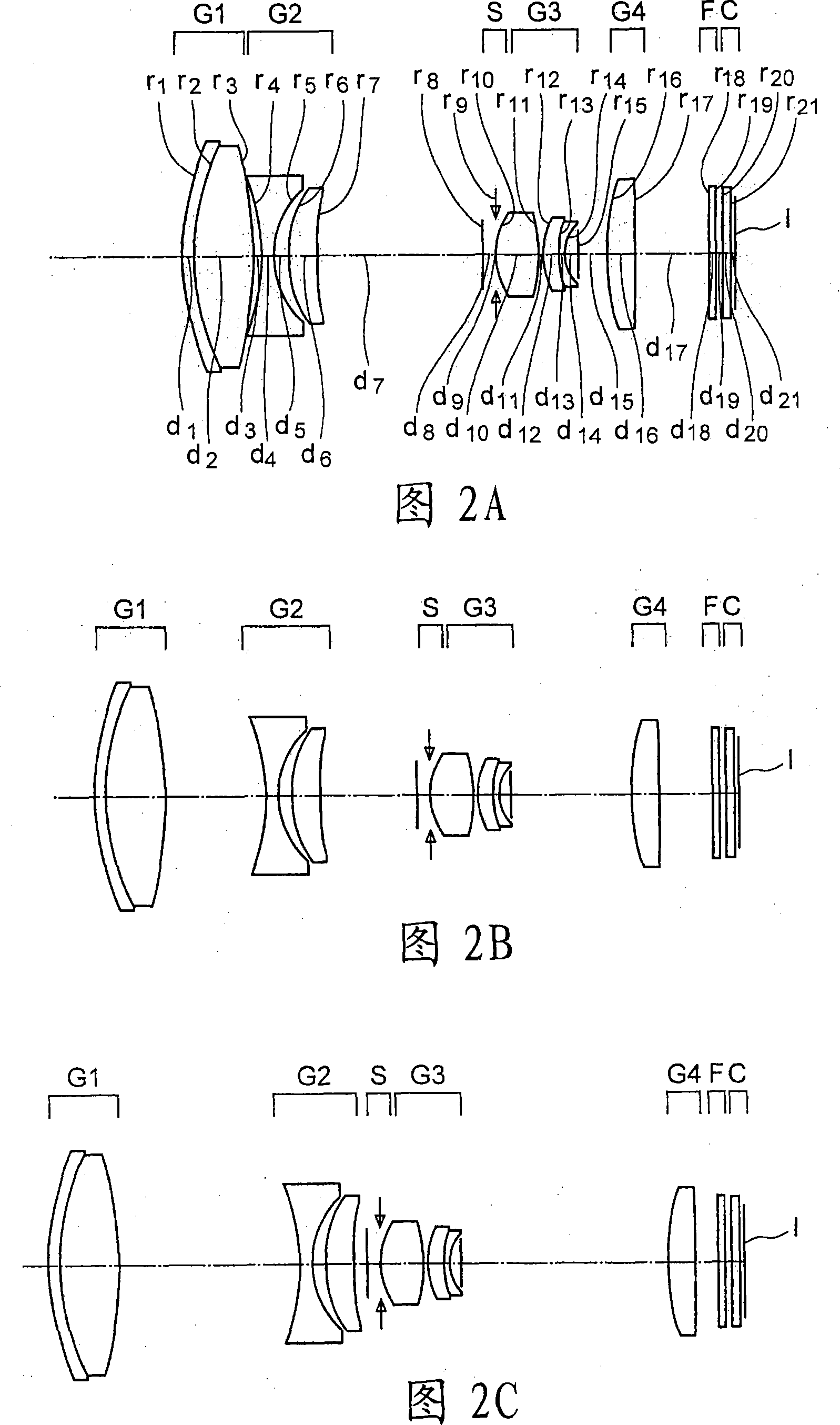

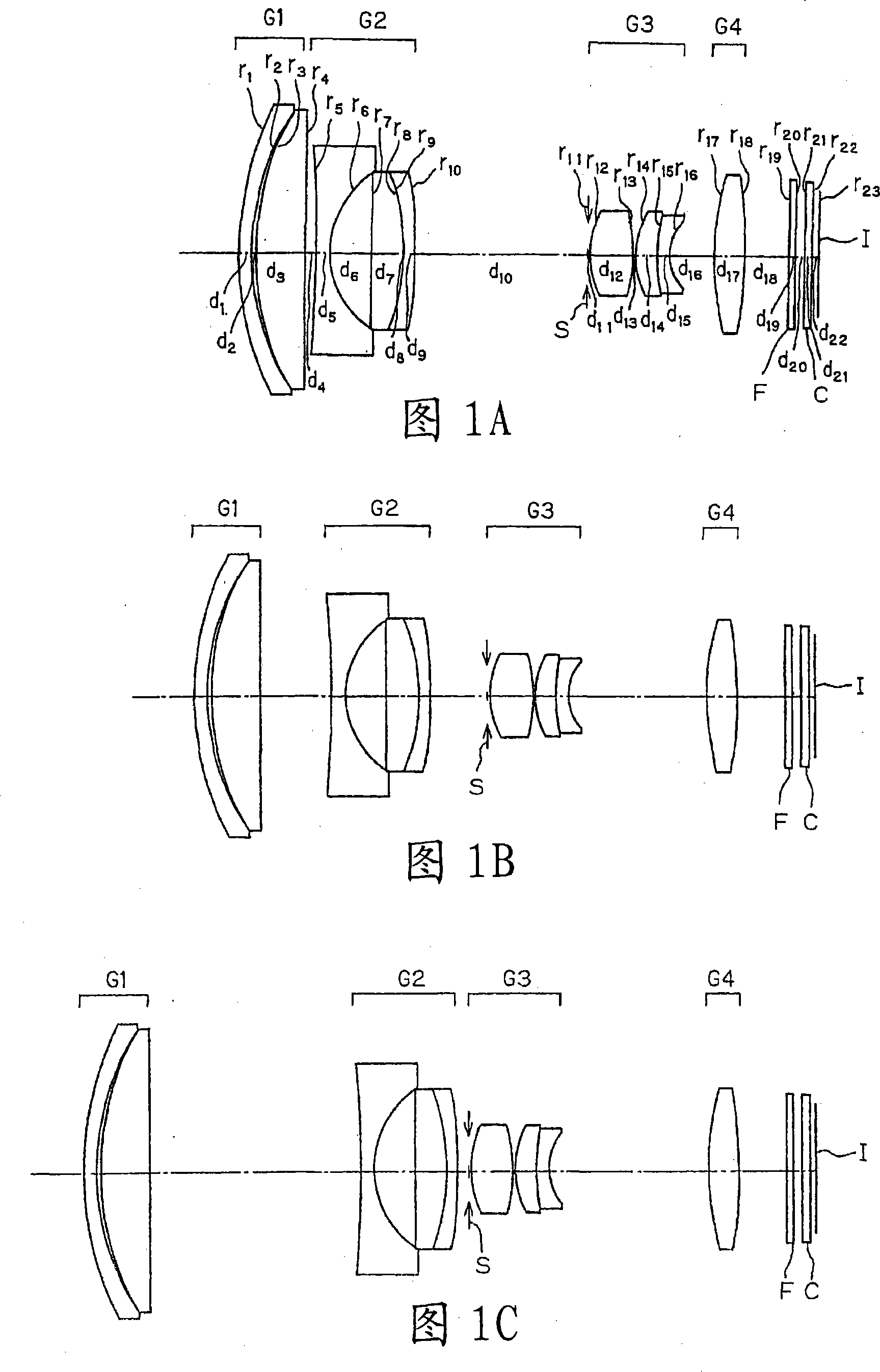

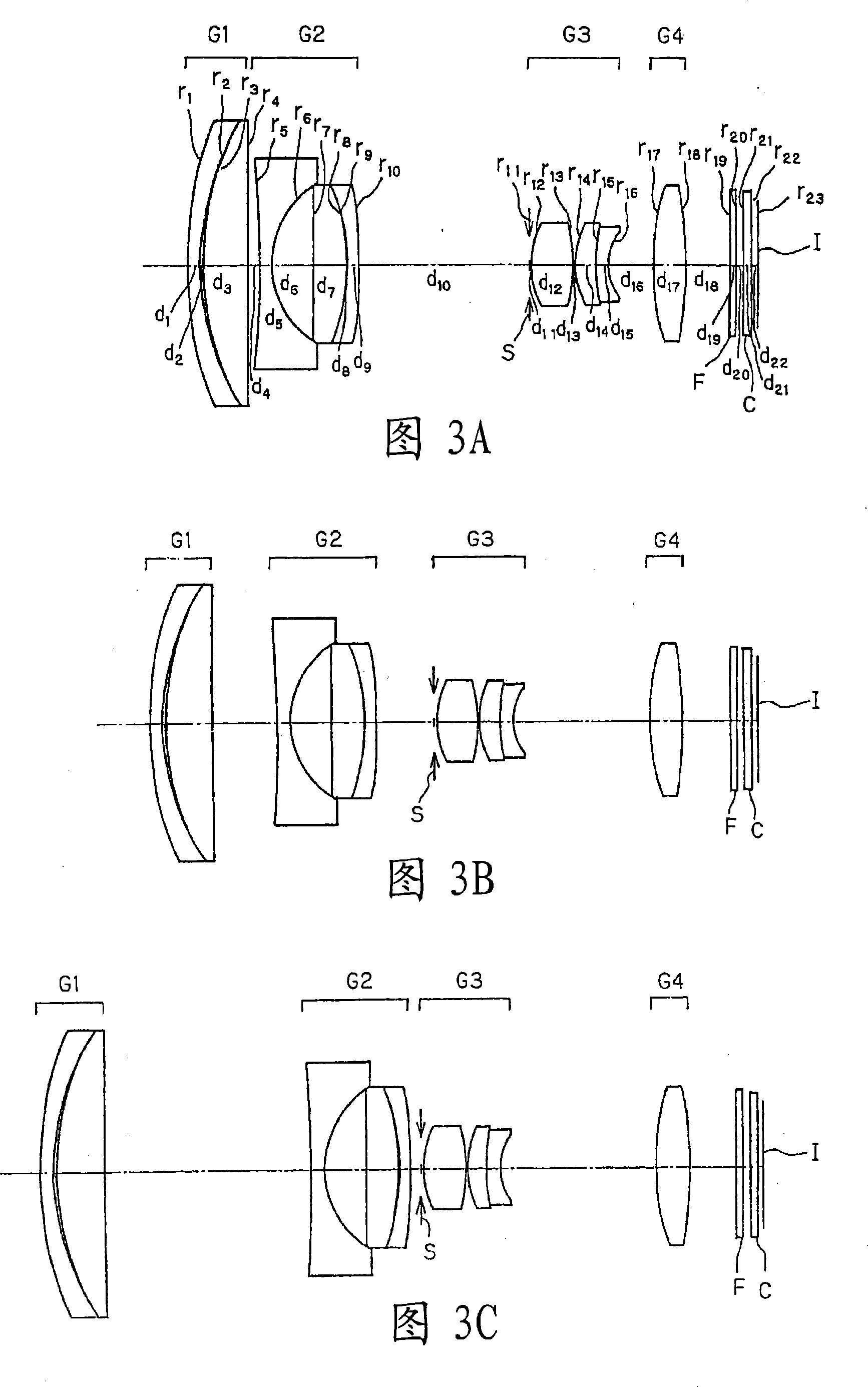

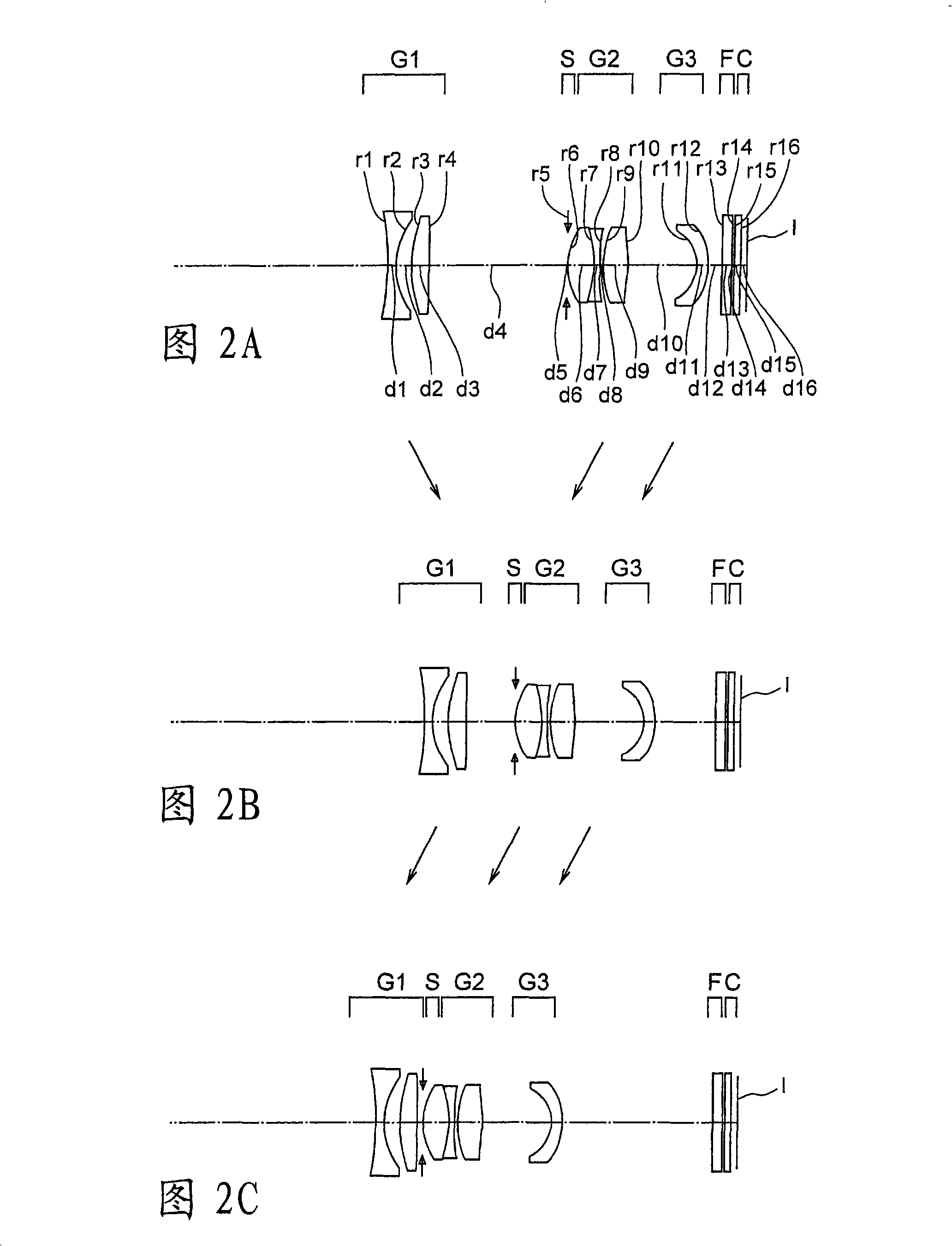

Zoom lens system and electronic image pickup apparatus using the same

ActiveCN101183172AHigh zoom ratioImprove compactnessTelevision system detailsColor television detailsPhysicsConditional expression

A four-unit zoom lens system includes in order from an object side, a first lens unit having a positive refracting power, a second lens unit having a negative refracting power, a third lens unit having a positive refracting power, and a fourth lens unit having a positive refracting power, in which at a time of zooming from a wide angle end to a telephoto end, at least the first lens unit, the second lens unit, and the third lens unit move, and a space between the lens units changes, and a total number of lenses in the second lens unit is not more than three, and the zoom lens system satisfies the following conditional expressions.1.2<(beta2t / beta2w) / (beta3t / beta3w)<6.0 and (1A)3.0 G02B 15 / 16 G02B 15 / 173 G02B 9 / 34 G02B 13 / 18 H04N 5 / 225 30 80 10 2007 / 11 / 15 101183172 2008 / 5 / 21 000000000 Olympus Image Corp. Japan Miyajima Toru lihui 11127 San You Patent Agency No.201 Entrance 1, Building 13, the East of Jinmenli, Haidian District, Beijing 100088 Japan 2006 / 11 / 15 2006-309666 Japan 2007 / 6 / 21 2007-163571

Owner:奥之心数字科技株式会社

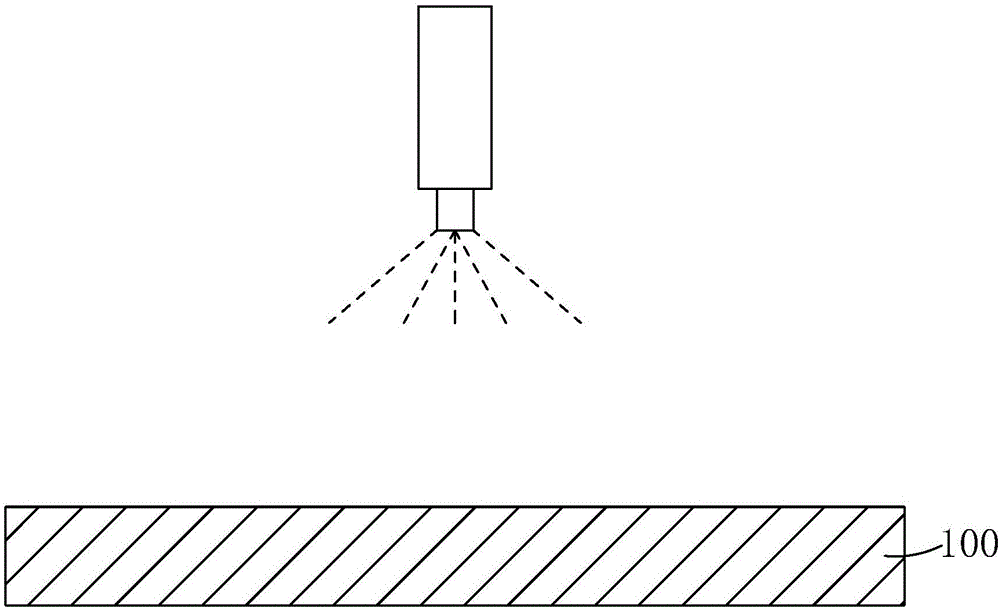

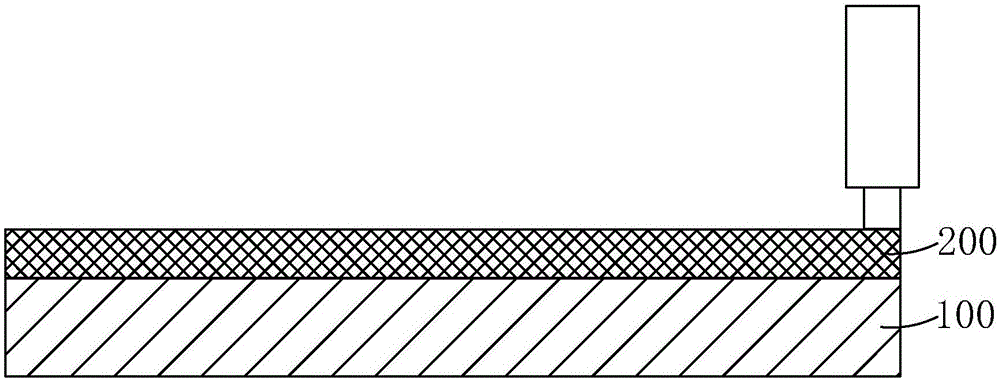

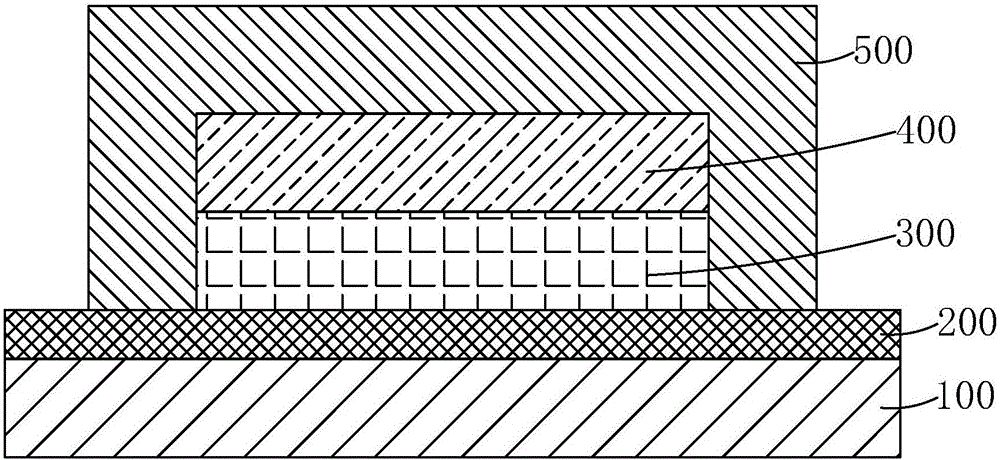

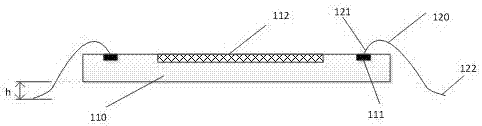

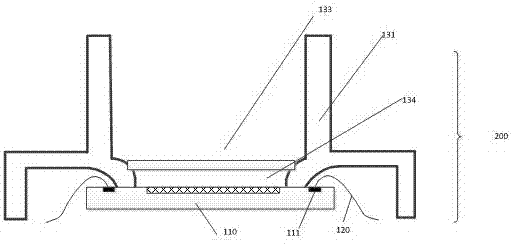

Flexible AMOLED display device preparation method

ActiveCN106449711AGuaranteed Optical PerformanceAvoid dentsSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsWater resistance

The invention provides a flexible AMOLED display device preparation method, before preparing a flexible substrate on a rigid substrate, firstly forming an inorganic substance film layer with flat surface, then coating a polymer material on the inorganic substance film layer, and forming the flexible substrate, the method not only can avoid the issue of bad pits and bulges on the flexible substrate caused by residual impurities from poor rinsing of the rigid substrate surface, but also can make the flexible substrate and the rigid substrate to easily be separated in the peeling process of the flexible substrate and the rigid substrate, protects the flexible substrate from being damaged, thereby enabling the prepared flexible substrate of the flexible AMOLED display device to have relatively high degree of evenness, the method increases the water resistance and oxygen resistance performance of the flexible substrate, and guarantees the optical performance of the flexible AMOLED display device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

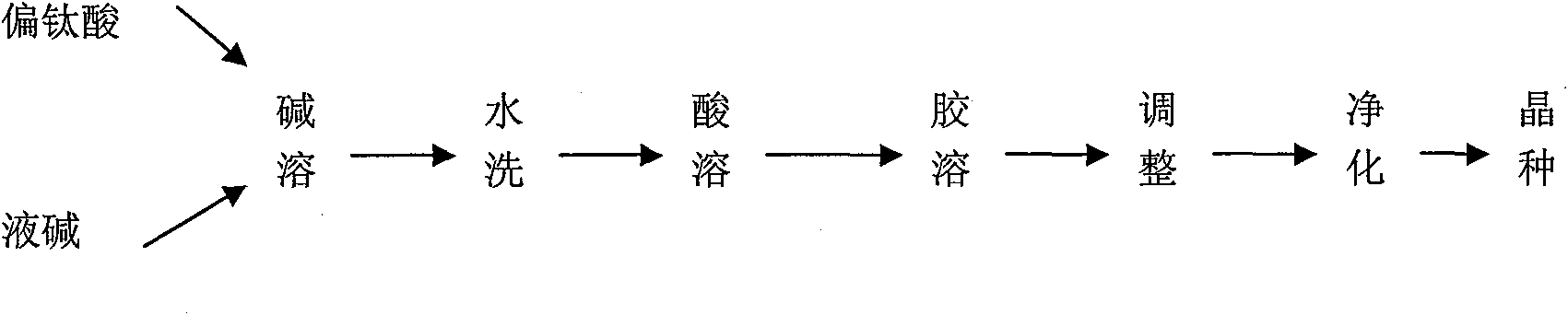

Preparation of white titanium pigment double action crystal seed from metatitanic acid

ActiveCN101565201AFast phase changeSimplify operating proceduresPigmenting treatmentTitanium dioxideX-raySodium sulfate

The invention relates to a preparation of white titanium pigment double action crystal seed from metatitanic acid, which is characterized in the process of (1) alkali dissolving, boiling the metatitanic acid purified by water washing with thermokalite; (2) water washing, removing residue sodium hydroxide and generated sodium sulfate thereby; (3) neutralizing and acid dissolving, neutralizing by hydrochloric acid and acid solution; (4) peptizing to generate a seed suspension, evaporating the suspension at a temperature from 105 to 300 DEG C., grinding, measuring the rutile microcrystalline with weight percentage over 90-98% by a X-ray diffractometer. The preparation uses metatitanic acid produced during sulphuric acid production process as raw material, adopts sol-gel process, with the produced rutile microcrystalline is safe and non-toxic, simple and easy to get raw material, low in cost, thus capable of evidently improving quality of product, enhancing stability of product quality and market competitiveness.

Owner:江西添光钛业有限公司

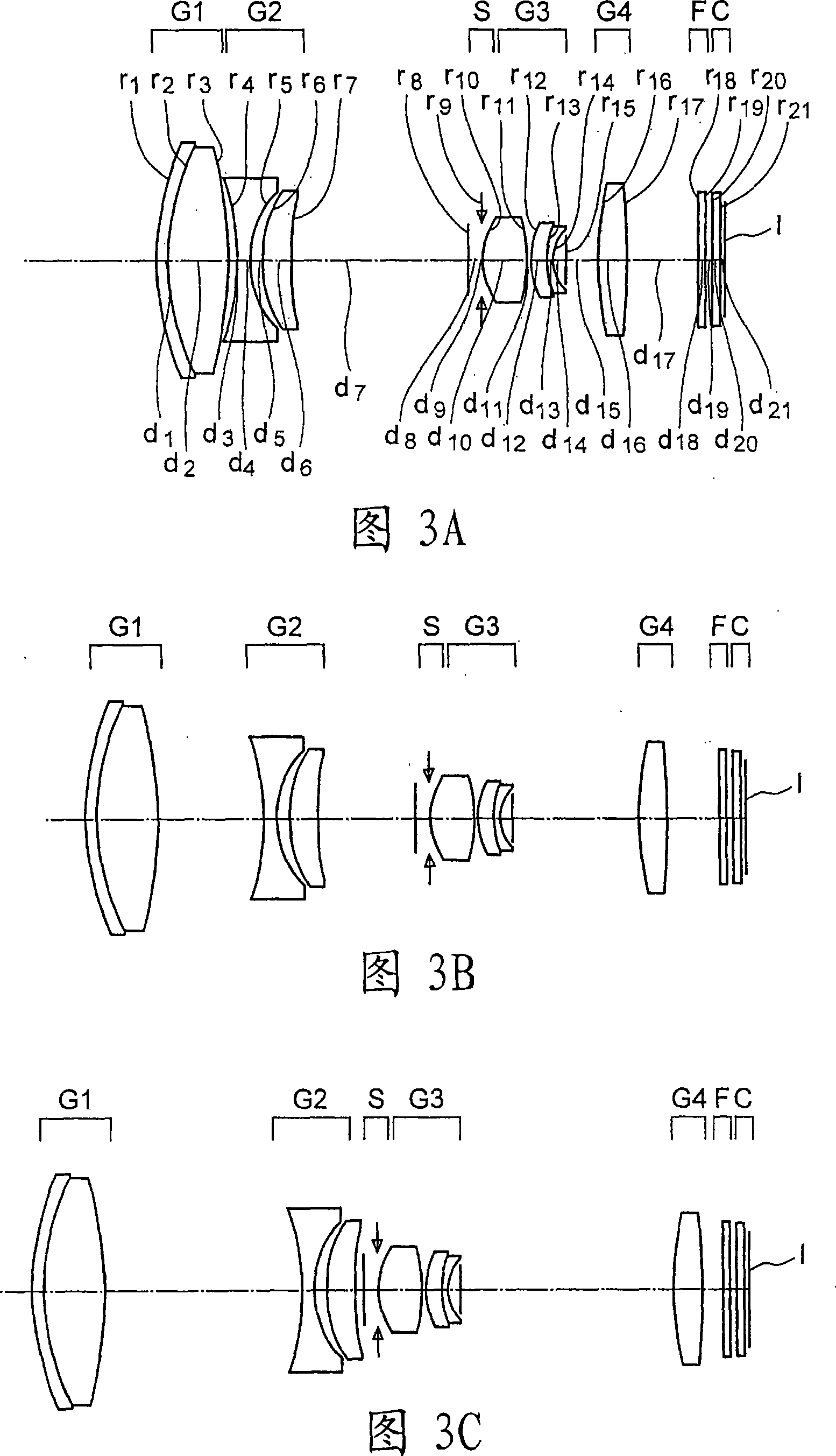

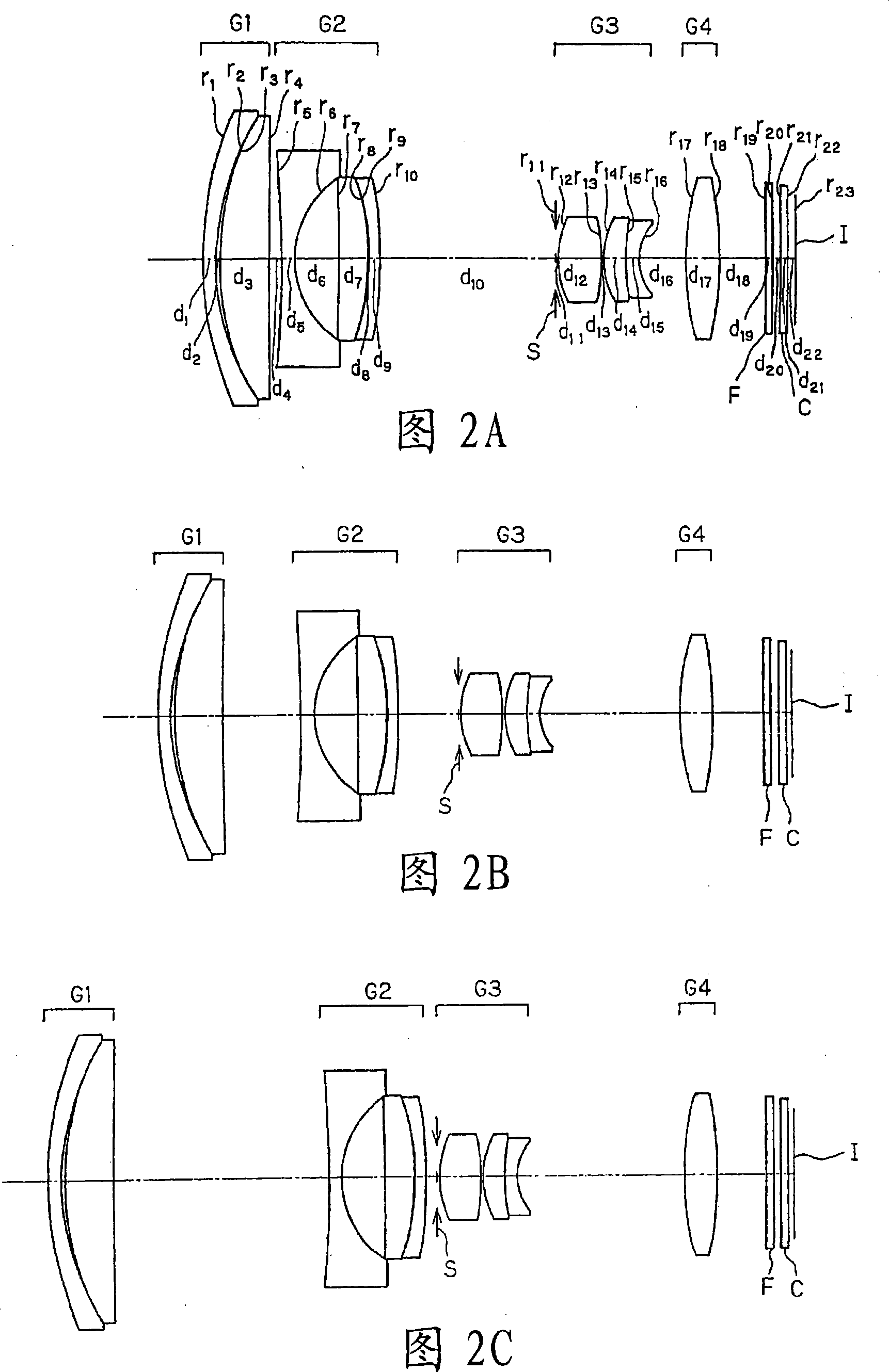

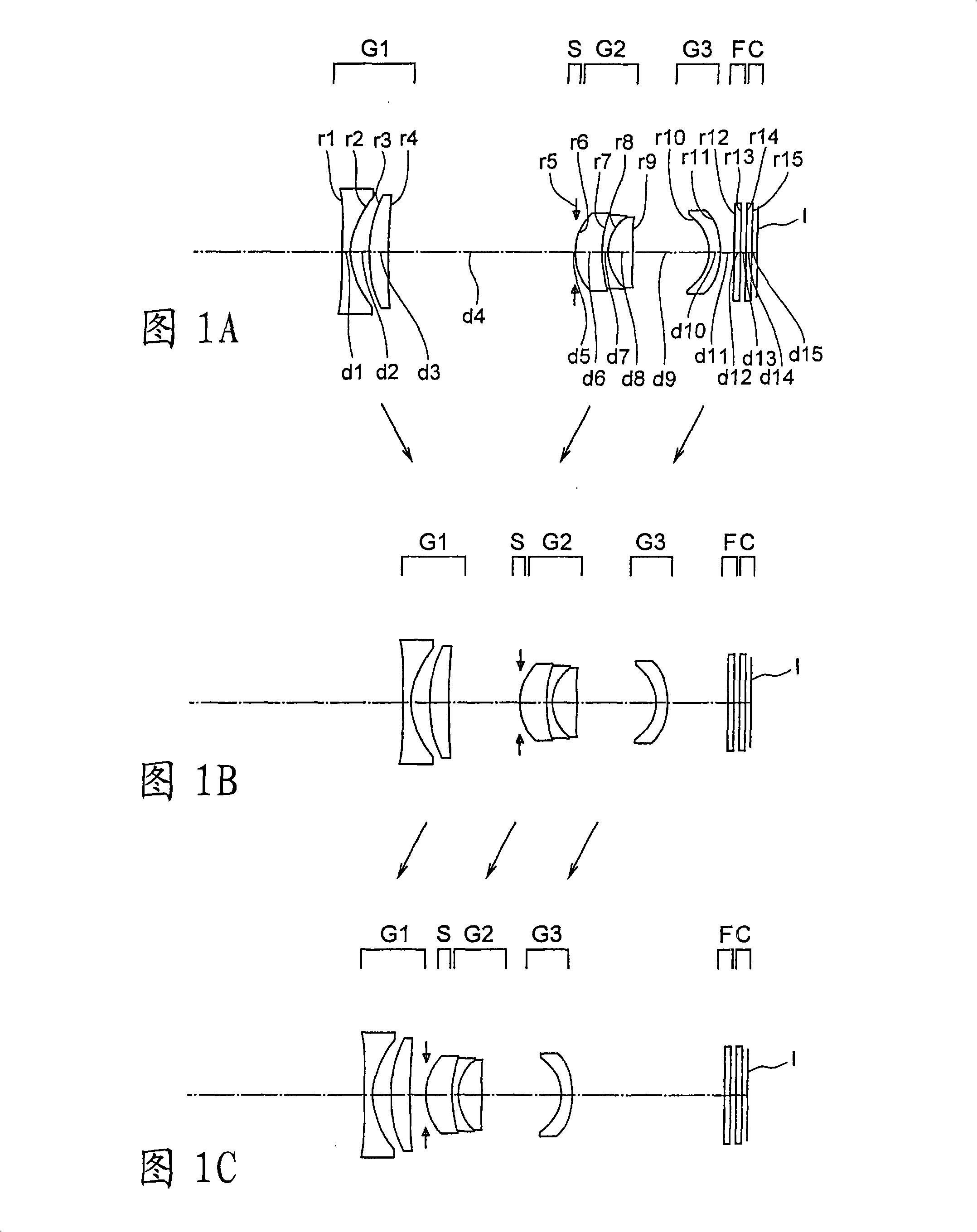

Zoom lens system and electronic image pickup apparatus using the same

InactiveCN101149466AMiniaturizationEnsure viewing angleTelevision system detailsColor television detailsCamera lensOptoelectronics

The present invention provides zoom lens system and electronic image pickup apparatus using the same. A zoom lens system comprises a first lens unit having a positive refractive power, a second lens unit having a negative refractive power and a third lens unit having a positive refractive power, and during zooming from a wide-angle end to a telephoto end, a space between a first lens (G1)unit and a second lens unit (G2) and a space between the second lens unit (G2) and a third lens unit (G3) are changed, the space between the first lens unit (G1)and the second lens unit (G2) is enlarged in the telephoto end as compared with the wide-angle end, and the space between the second lens unit (G2)and the third lens unit (G3)is narrowed in the telephoto end as compared with the wide-angle end.

Owner:OLYMPUS CORP

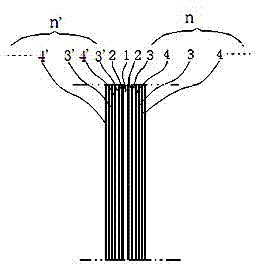

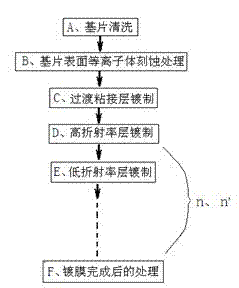

Super wide band cut-off long-wave-pass filter optical film and production method thereof

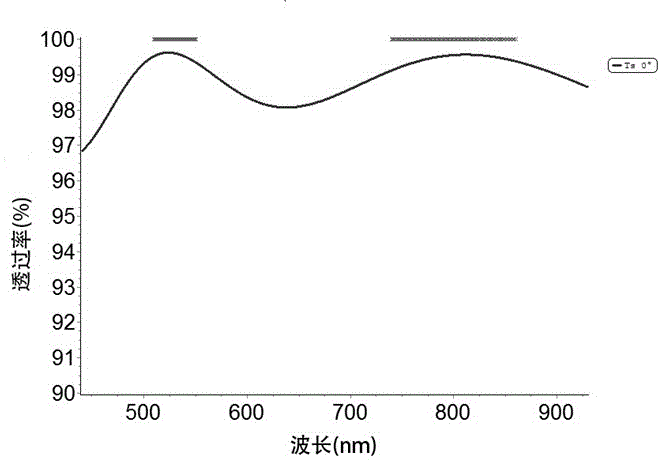

ActiveCN103207424AEliminate cumulative errorsImprove adhesionOptical filtersRefractive indexTransmittance

The invention relates to a super wide band cut-off long-wave-pass filter optical film and a production method thereof. A filter optical film comprises a substrate; transition bounding layers are respectively plated on a front surface and a rear surface of the substrate; a plurality of layers of long-wave-pass filter optical films with different central wavelengths are plated on the transition bounding layers in an alternating mode to form into two long-wave-pass filter optical film series which comprise a substrate front surface long-wave-pass filter optical film series and a substrate rear surface long-wave-pass filter optical film series; and the two long-wave-pass filter optical film series are formed by high refractive index layers and low refractive index layers. The production method of the super wide band cut-off long-wave-pass filter optical film comprises steps of substrate cleaning, substrate surface processing, transition bounding layer plating and high refractive index layer and low refractive index layer plating. The super wide band cut-off long-wave-pass filter optical film has the advantages of being high in transmittance, good in optical performance and good in adhesive force between film layers and the substrate. The production method of the super wide band cut-off long-wave-pass filter optical film has the advantages of being easy to refer and transplant, capable of adapting to mass coating film production of large size optical elements, capable of improving performance indexes of a detector and capable of being widely applied to the optical electric technical fields of an precision optical instrument, photoelectric detection and celestial navigation.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

Light emitting diode package including monitoring photodiode

ActiveUS7649208B2Improve reliabilityImprove optical connection efficiencySolid-state devicesRadiation controlled devicesInsulation layerEngineering

The present invention relates to an LED package including photo diode. The LED package includes a silicon substrate, and a photo diode is formed in an upper part thereof. Also, an insulation layer is formed on the silicon substrate excluding at least a light-receiving area of the photodiode. In the LED package, an LED terminal is formed on the insulation layer to be connected to the photo diode. First and second LED connecting pads are formed on the insulation layer, and arranged on both sides of the photo diode. In addition, an LED chip is mounted on the silicon substrate, and connected to the first and second LED connecting pads.

Owner:SAMSUNG ELECTRONICS CO LTD

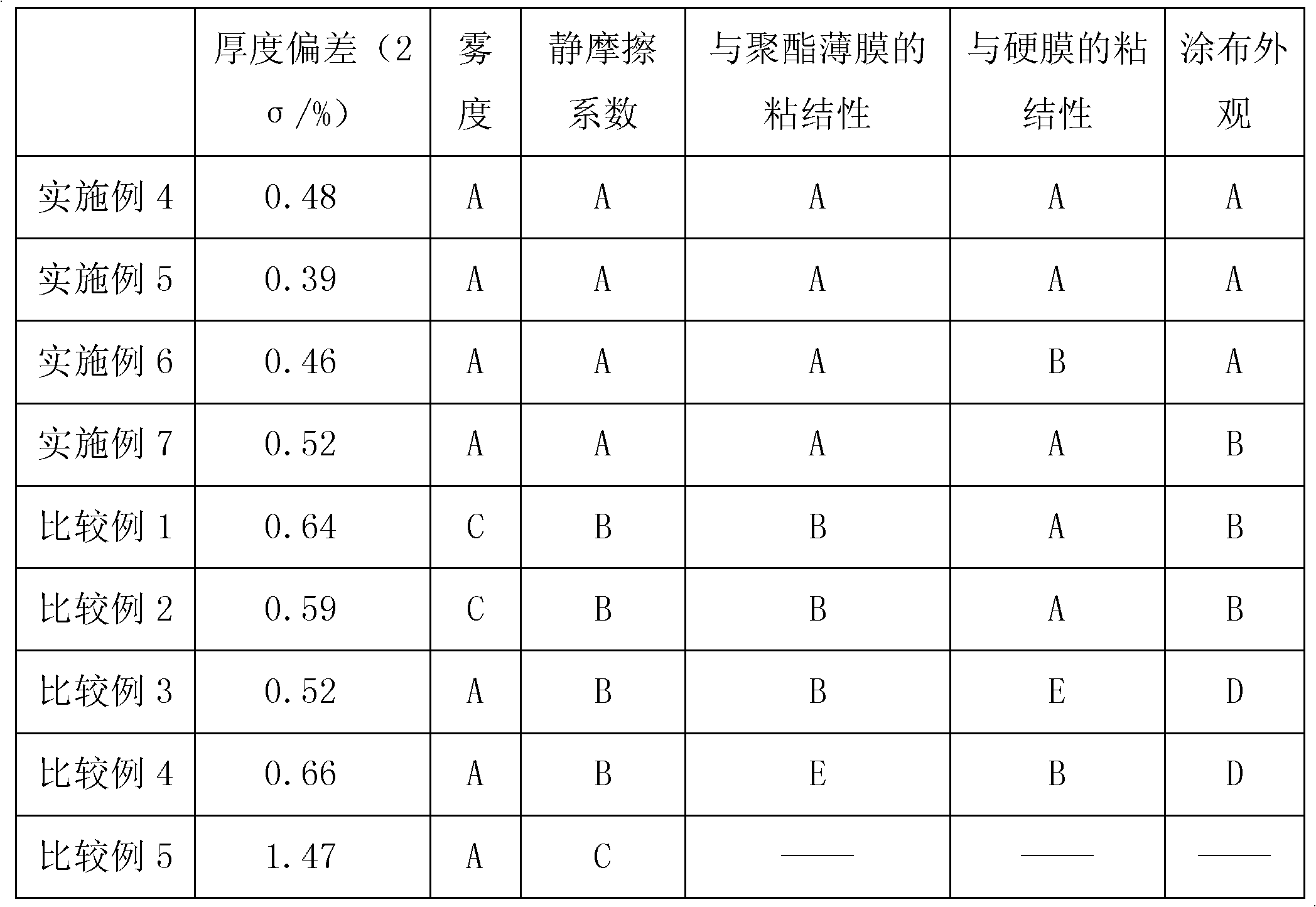

Aging-stable, high-gloss, low-haze and ultra-smooth BOPP film

ActiveCN103331974AReduce coefficient of frictionGuaranteed Optical PerformanceFlexible coversWrappersPolypropyleneAntistatic agent

The invention discloses an aging-stable, high-gloss, low-haze and ultra-smooth BOPP (Biaxially-oriented Polypropylene) film which is formed by coextru-lamination of a core layer, a surface layer and an inner layer, wherein the surface layer comprises the following ingredients in percentage by weight: 96%-99.8% of copolypropylene resin, 0.1%-3% of a smooth agent and 0.1%-1% of an antiblocking agent; the core layer comprises the following ingredients by weight percentage: 99.5%-99.7% of homopolypropylene resin and 0.3%-0.5% of an antistatic agent; and the inner layer comprises the following ingredients in percentage by weight: 97%-99.8% of copolypropylene resin, 0.1%-0.2% of the smooth agent and 0.1%-1% of the antiblocking agent. According to the film, the matching relationship between two assistants is optimized, the synergistic effect of the two assistants is made full use of, the contradiction between smoothness and anti-blocking due to the fact that excessive smooth agent is added to obtain an ultra-smooth effect in the existing product is overcome well, the friction coefficient of the film is reduced obviously, and the optical property of the film is ensured simultaneously.

Owner:中山北化高分子材料有限公司

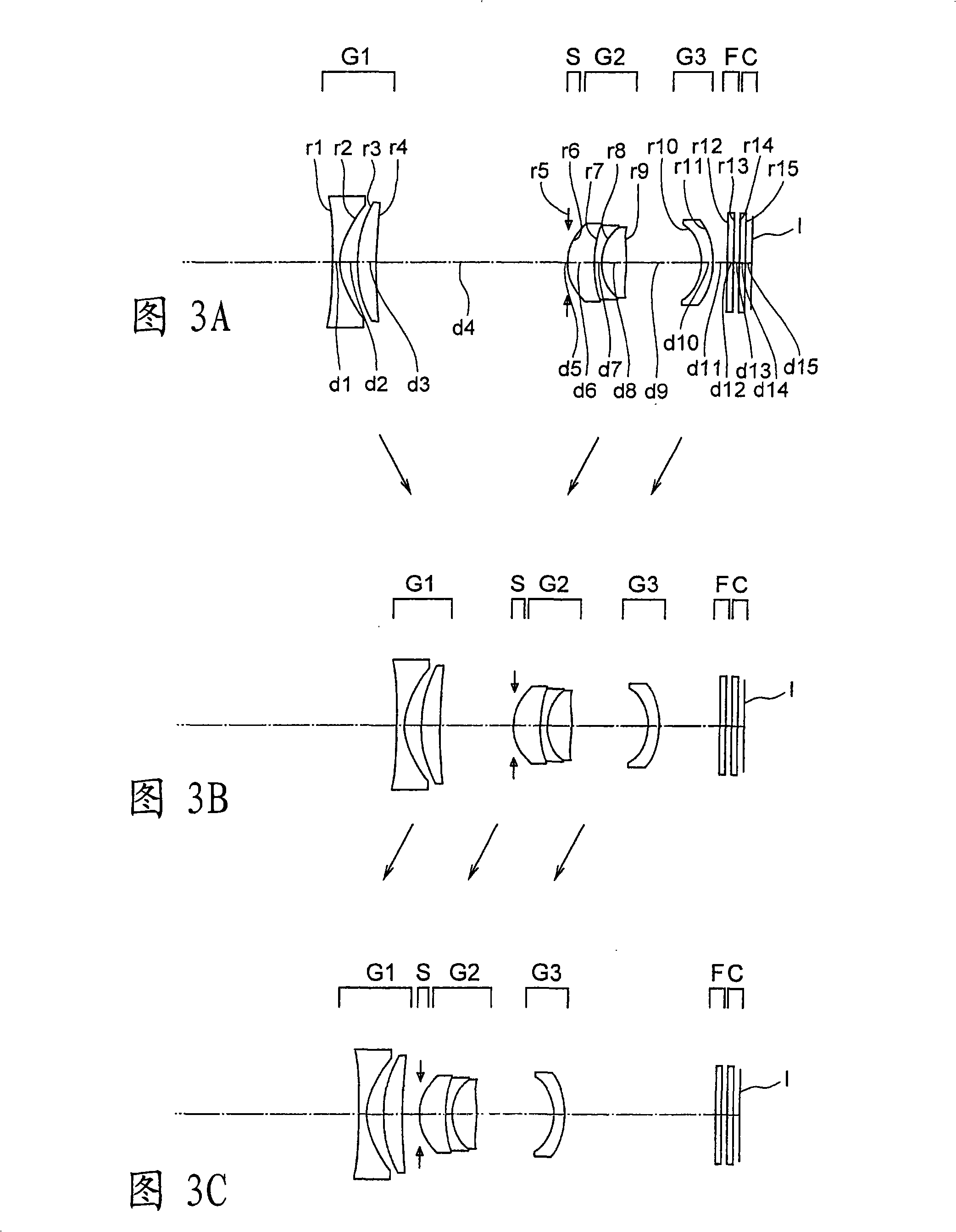

Three-unit zoom lens system and image pickup apparatus using the same

InactiveCN101344636AMake sure the zoom ratioGuaranteed miniaturizationTelevision system detailsColor television detailsConditional expressionOptoelectronics

The present invention relates to a three-unit zoom lens system and an image pick-up device using the same. A three-unit zoom lens system includes in order from an object side thereof a first lens unit G1 having a negative refracting power, a second lens unit G2 having a positive refracting power, a third lens unit G3 having a negative refracting power, and an aperture stop which is at an image side of the first lens unit G1, and at the object side of a lens surface nearest to the image side of the second lens unit G2, and which moves integrally with the second lens unit. At a time of zooming from a wide angle end to a telephoto end, a distance between the first lens unit G1 and the second lens unit G2 is narrowed, and a distance between the second lens unit G2 and the third lens unit G3 changes. The second lens unit G2 moves toward the object side at the time of zooming from the wide angle end to the telephoto end. The third lens unit G3 moves to be positioned at the object side at the telephoto end, with respect to the wide angle end. The three-unit zoom lens system satisfies predetermined conditional expressions.

Owner:OLYMPUS CORP

Camera module and assembly method thereof

ActiveCN107301988AGuaranteed Optical PerformanceQuality improvementTelevision system detailsSemiconductor/solid-state device detailsForeign matterEngineering

The invention provides an assembly method for a camera module. The assembly method comprises the following steps: providing an image sensor chip having suspended metal conducting wires, wherein first ends of the metal conducting wires are bonded on welding plates of the image sensor chip, and second ends of the metal conducting wires are suspended away from the image sensor chip; and assembling the image sensor chip, and a supporting frame provided with a light transmitting window into an encapsulation piece, wherein the image sensor chip, the light transmitting window and the supporting frame in the encapsulation piece are formed into a cavity, so that the pollution of external foreign matters to the image sensor chip is reduced; and then, through the second ends of the metal conducting wires, assembling the encapsulation piece with a circuit board and a lens module into the camera module.

Owner:GALAXYCORE SHANGHAI

Preparation method of antimony-doped tin dioxide nano-slurry

ActiveCN102491408AGuaranteed Optical PerformanceAvoid hard clumpingMaterial nanotechnologyTin oxidesSal ammoniacChemistry

The invention discloses a preparation method of antimony-doped tin dioxide nano-slurry, belonging to the field of preparation of chemical raw materials. The method comprises the following steps of: preparing a saline solution of tin and antimony consisting of nitrate of tin, ethanol and nitrate of antimony, and an alkaline liquor consisting of sodium hydroxide or ammonia water; dropwise adding the alkaline liquor into a saline solution till the pH value of a system is adjusted to 0.8-2, adding hydrogen peroxide, oxidizing a part of Sb<3+> in the system into Sb<5+> to obtain a precipitated tin-antimony hydroxide, washing the tin-antimony hydroxide with water, filtering, adding a dispersing agent, and stirring and dispersing into water to obtain a tin-antimony hydroxide dispersed solution; and performing hydro-thermal treatment on the hydroxide dispersed solution in a high-pressure reaction kettle to obtain antimony-doped tin dioxide nano-slurry. The method has the advantages of simple process, low energy consumption, high dispersity of prepared slurry and stable performance.

Owner:FIRST NEW MATERIAL TECH DEV

Addition type composite particle for polyester film, preparation method of addition type composite particle and optical polyester film added with composite particle

InactiveCN102627835AProblems Affecting Light TransmittanceEasy to slideSynthetic resin layered productsPolyester coatingsPolyesterSurface layer

The invention discloses an addition type composite particle for a polyester film, a preparation method and an optical polyester film added with the composite particle. The composite particle is a spherical microparticle formed by compounding at least two kinds of organic or inorganic microparticles; the difference between the refractive index of the compound particle and the refractive index of polyester is less than or equal to 0.02; the average particle size of the compound particle is 10-2000nm; the polyester film contains at least one polyester film layer; at least one kind of composite particle is added in a surface layer of the polyester film; and counted by 100 parts by weight, the polyester film comprises 1-20 parts by weight of composite particle. According to the invention, the composite particle of which the refractive index is approximate to that of the polyester is added during the preparation of the polyester film; on the premise of maintaining optical performances of the polyester film, mechanical performances of the polyester film are improved and the surface performance and processing performance of the polyester film are improved. The polyester film can be applied to the technical field having harsh requirement on the light transmittance in the optical field.

Owner:WEIFANG FUWEI PLASTIC

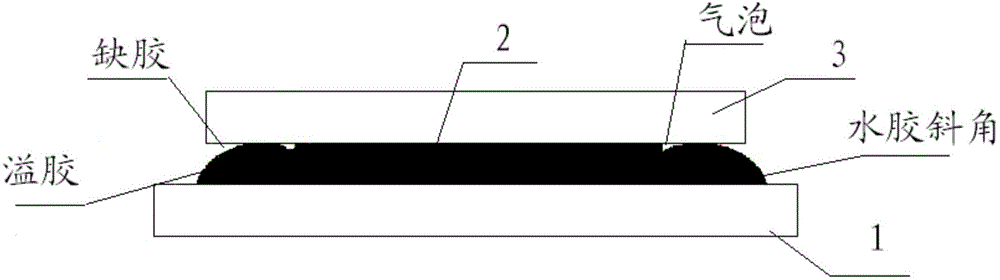

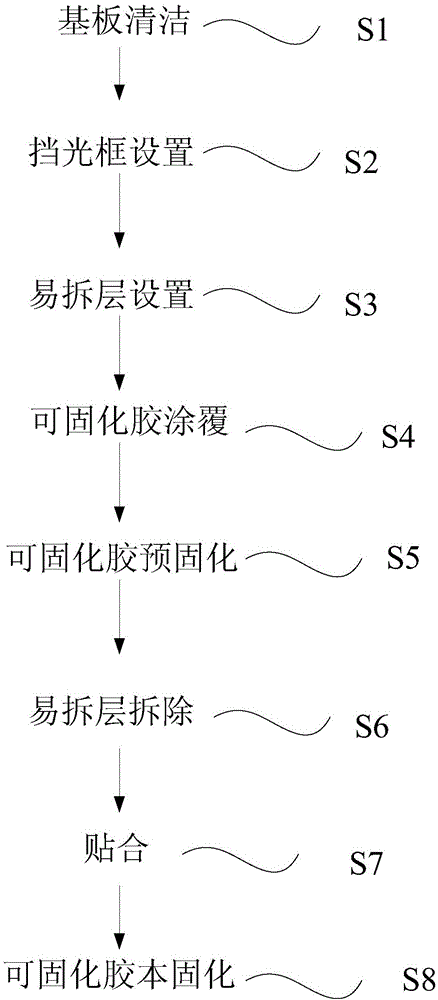

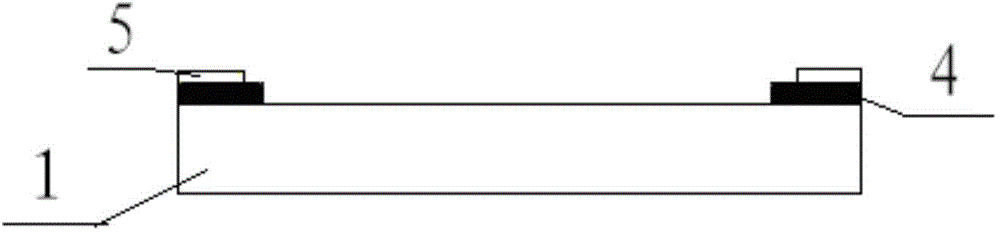

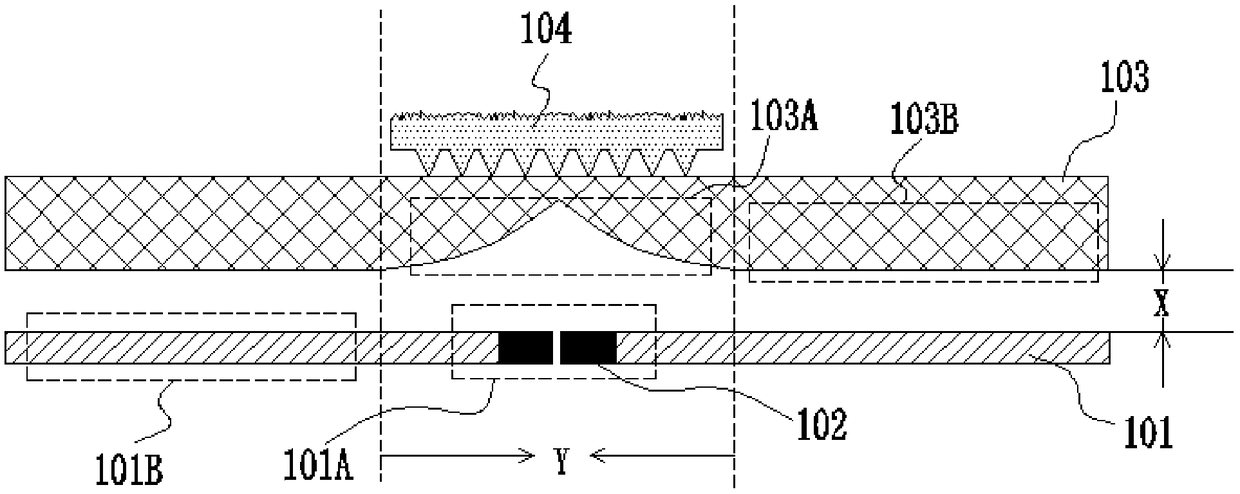

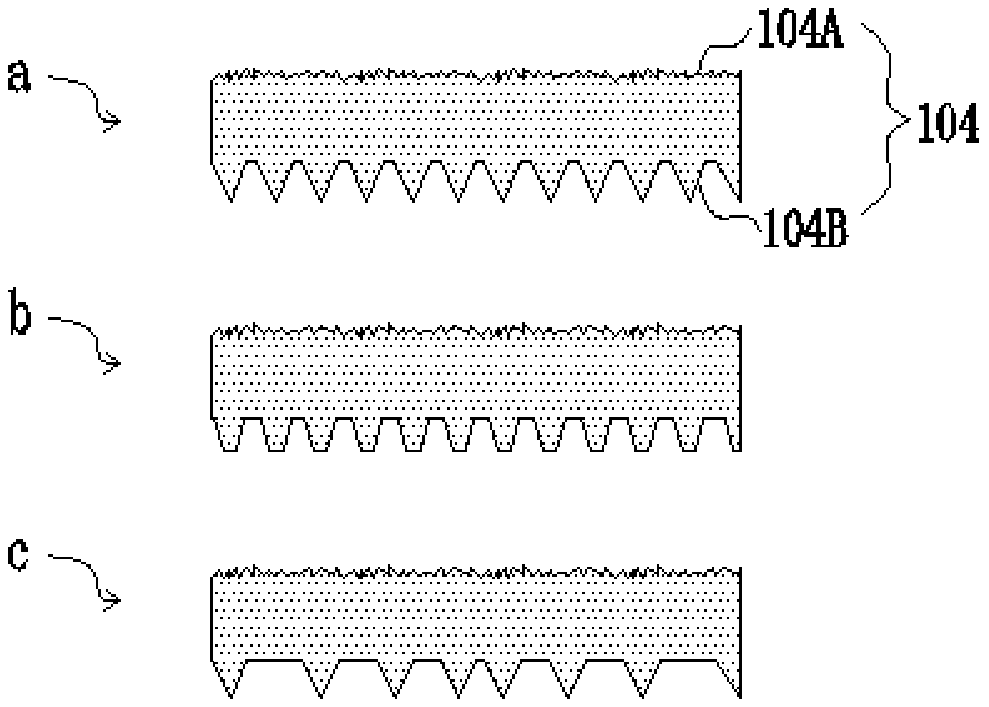

Substrate applying method, touch control display substrate and display apparatus

InactiveCN104309267AGuaranteed Optical PerformanceUniform thicknessLamination ancillary operationsLaminationAdhesiveSlope angle

The invention provides a substrate applying method, a touch control display substrate and a display apparatus. The substrate applying method comprises the following steps: arranging detachable layers in the circumference of a first substrate, coating a light curable adhesive, pre-curing the light curable adhesive, and dismounting the detachable layers to make the light curable adhesive form a special shape. The method makes the thickness of the layer of the light curable adhesive uniform, the surface of the adhesive layer flattened and the slope angle of edges close to 90DEG, and also has the advantages of effective reduction of applying bubbles, control of the adhesive leaking and the adhesive spilling phenomena in edge areas during applying, and guaranteeing of the optical performances of the display apparatus.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

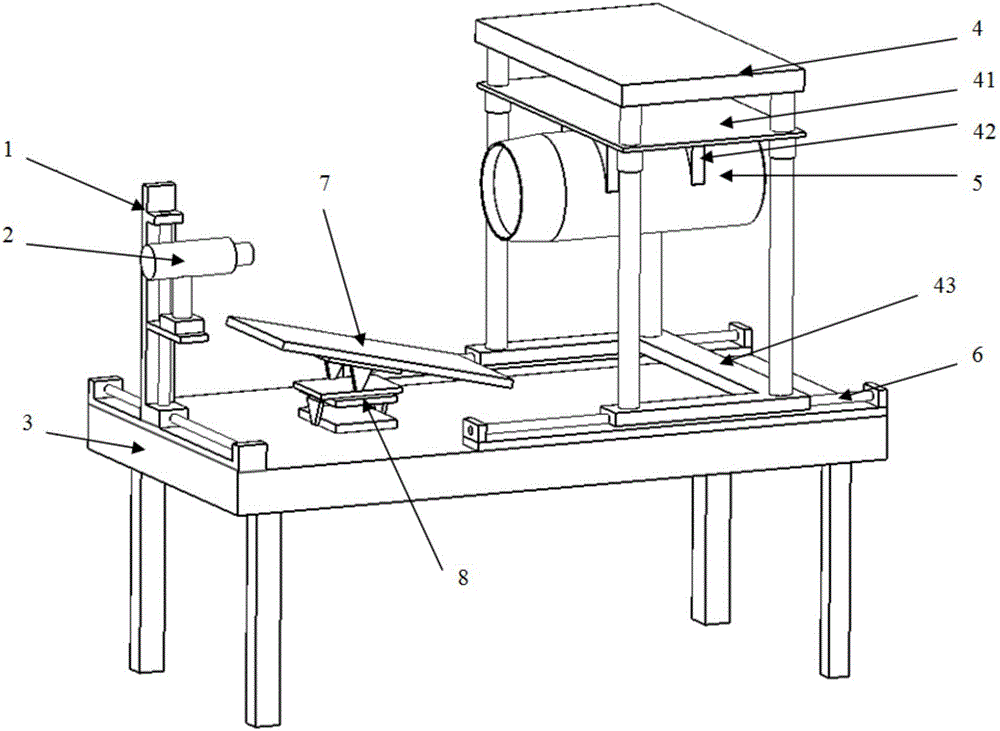

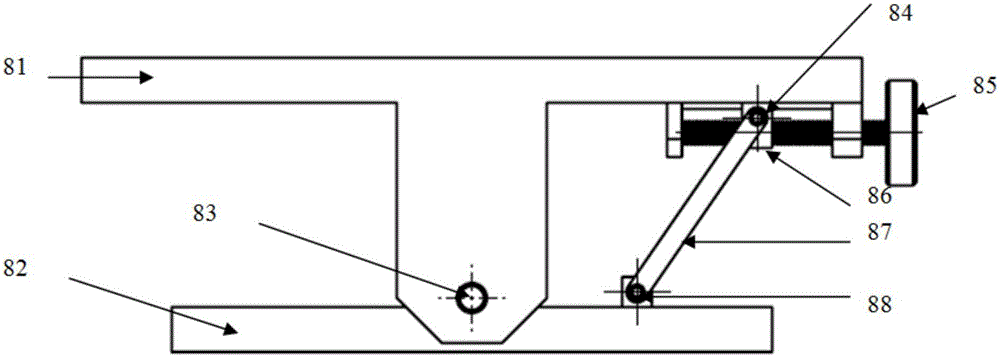

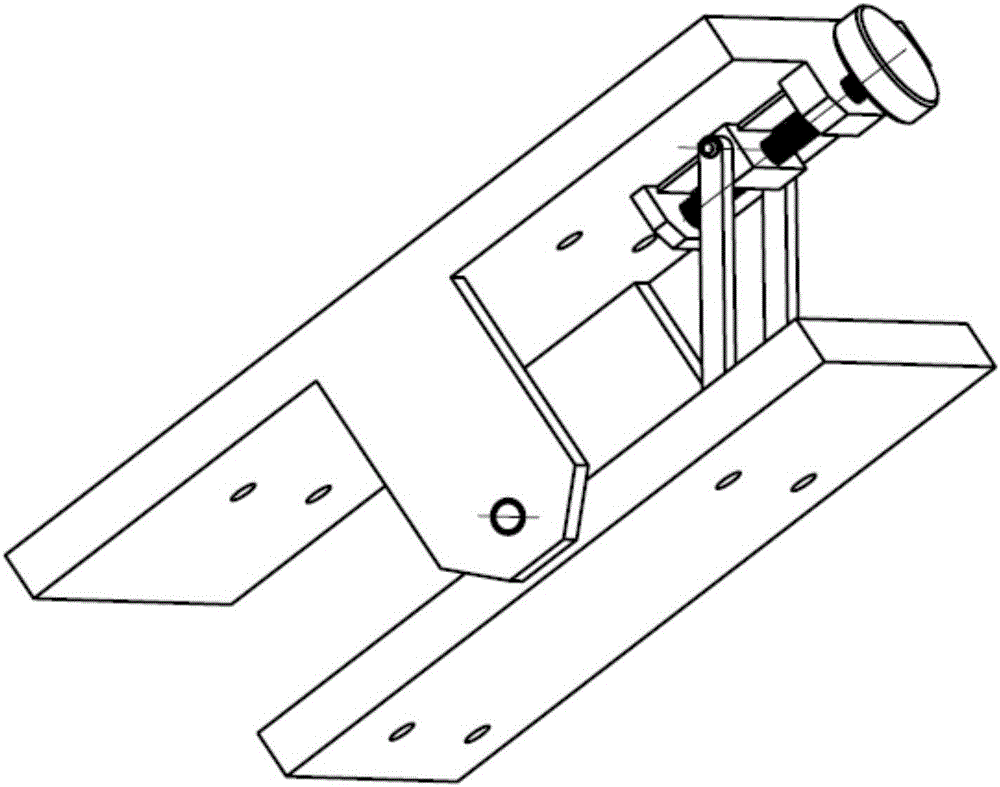

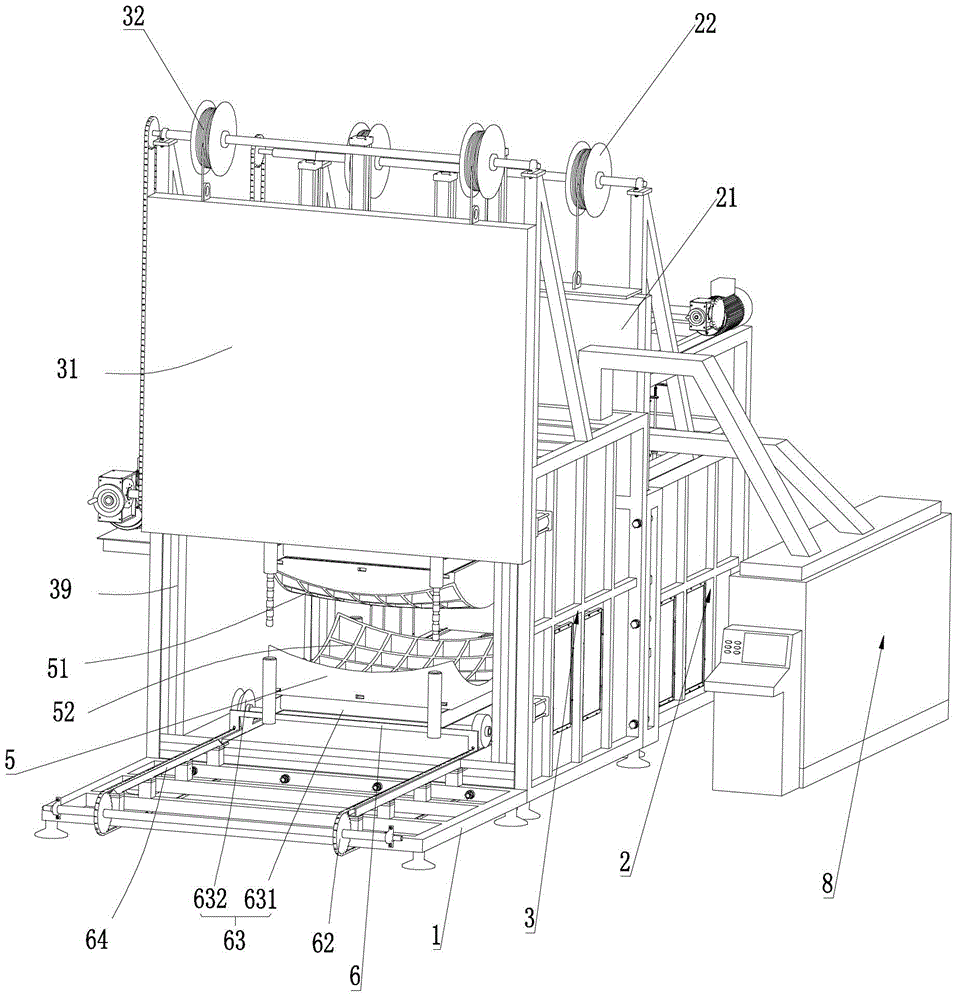

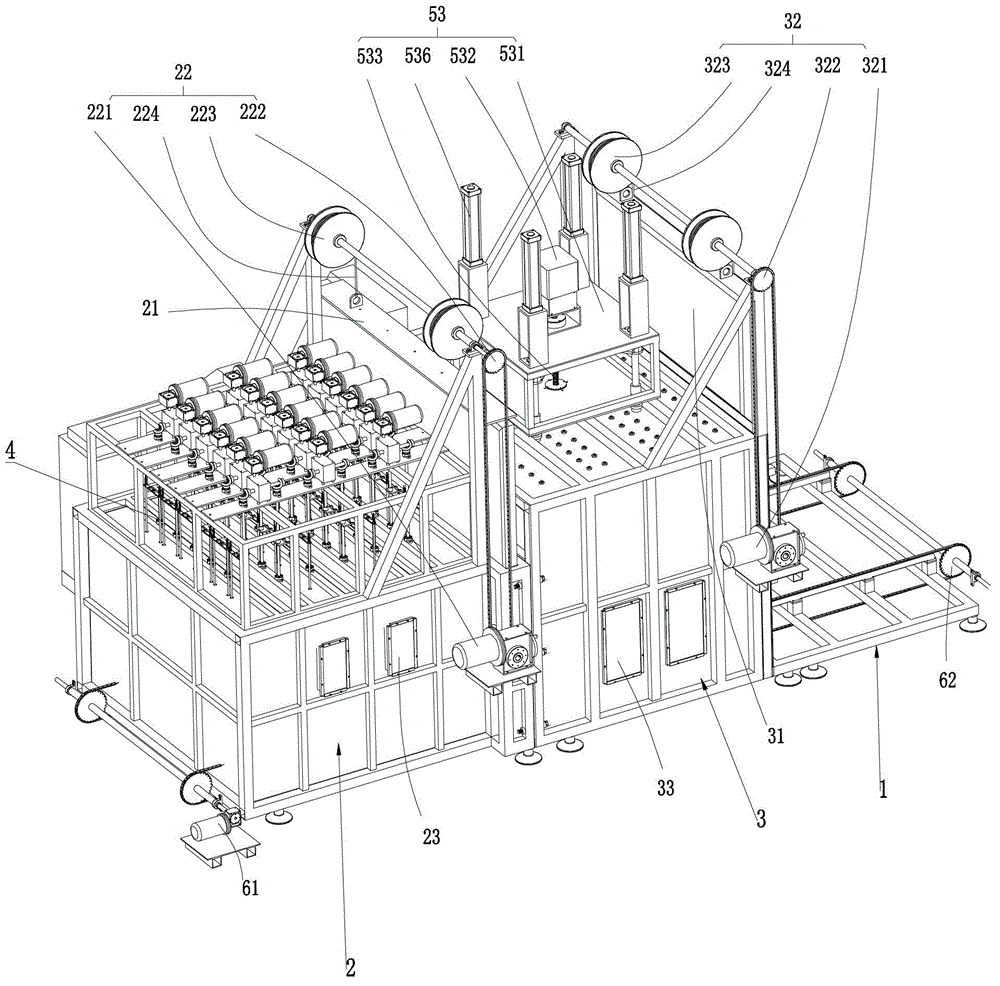

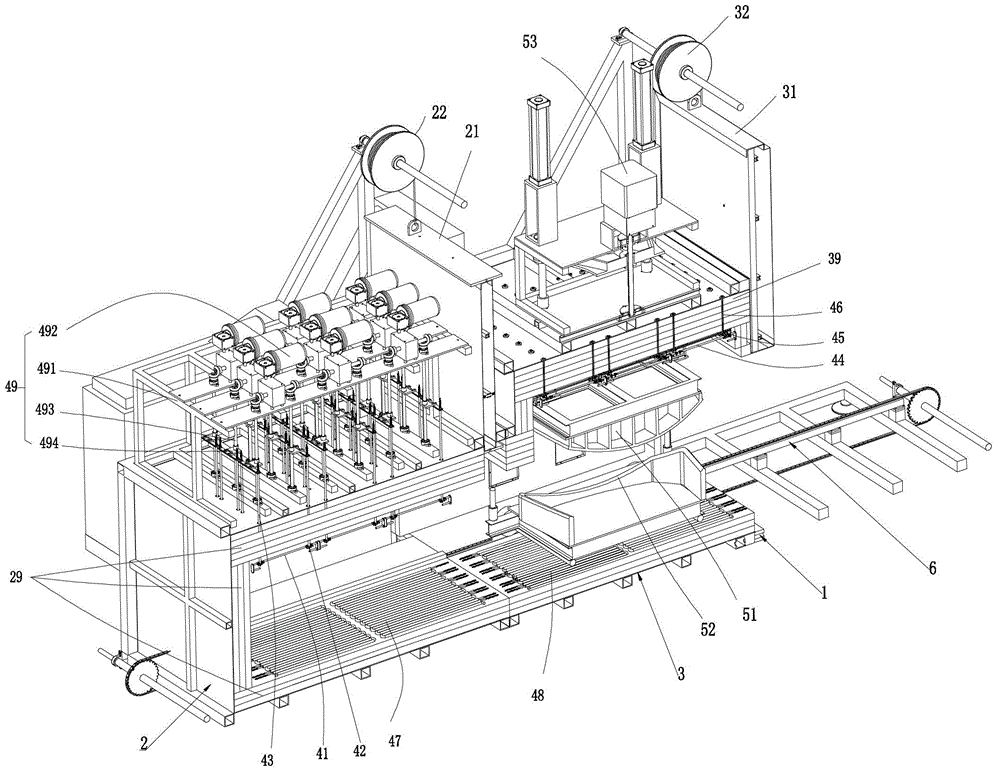

General test platform for optical performance of head-up display

InactiveCN106596061AGuaranteed Optical PerformanceEfficient use ofTesting optical propertiesHead-up displayTheodolite

The invention discloses a general test platform for the optical performance of a head-up display. The test platform composed of a 2D rotary table, an optical platform, a portal frame, a displacement platform, a theodolite, a 2D displacement platform and a parallel light pipe detects the optical performance of the head-up display. the parallel light pipe is hoisting over the optical platform via the portal frame, the parallel light pipe can move up and down on the portal fame and move left and right over the displacement platform with the portal frame, it is ensured the exit pupil caliber of the parallel light pipe can cover the observation range of the head-up display, the 2D rotary table is directly fixed in the middle position of the optical platform, a long flat plate is mounted on the rotary table to hold the head-up display, and installation test can be carried out on head-up displays of different installation states via angle adjustment; and the theodolite is fixed to the frontmost end of the optical platform via the 2D displacement platform, and thus, the head-up display erected in the position of the flat plate on the 2D rotary table can be tested. The test platform has the advantages that resources can be utilized effectively, the platform is simple and easy to operate, a measuring result is accurate and visual, and the detection efficiency is improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

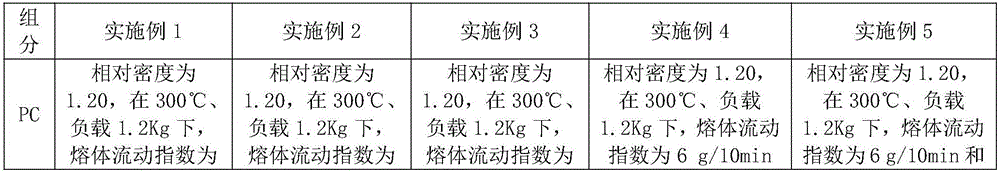

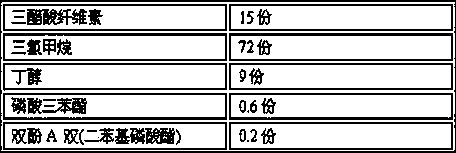

Weather-resistant and flame-resistant light-diffusion PC applicable to outdoor lampshades and preparation method of weather-resistant and flame-resistant light-diffusion PC

ActiveCN106810842AGuaranteed light transmittanceHigh flame retardant efficiencyWeather resistanceFire retardant

The invention discloses weather-resistant and flame-resistant light-diffusion PC applicable to outdoor lampshades and a preparation method of the weather-resistant and flame-resistant light-diffusion PC. The weather-resistant and flame-resistant light-diffusion PC is prepared by, by weight percentage, 81.25-90.17% of PC, 5-15% of toughening agent, 0.8% of light diffusion agent, 1.5-2.5% of flame retardant, 0.4-0.6% of synergic-effect flame retardant, 0.1-0.5% of hydrolysis-resistant agent, 0.1-0.5% of anti-UV agent, 0.03-0.05% of pigment, 0.3% of antioxidant and 0.3% of dispersing agent. The light-diffusion PC has the advantages that the light-diffusion PC is good in flame-retardant effect and weather resistance, indoor and outdoor use requirements can be satisfied, the light-diffusion PC is high in light permeability, good in toughness and ideal in appearance color, and consumers' requirements on lamps can be satisfied.

Owner:厦门天宇新材料科技有限公司

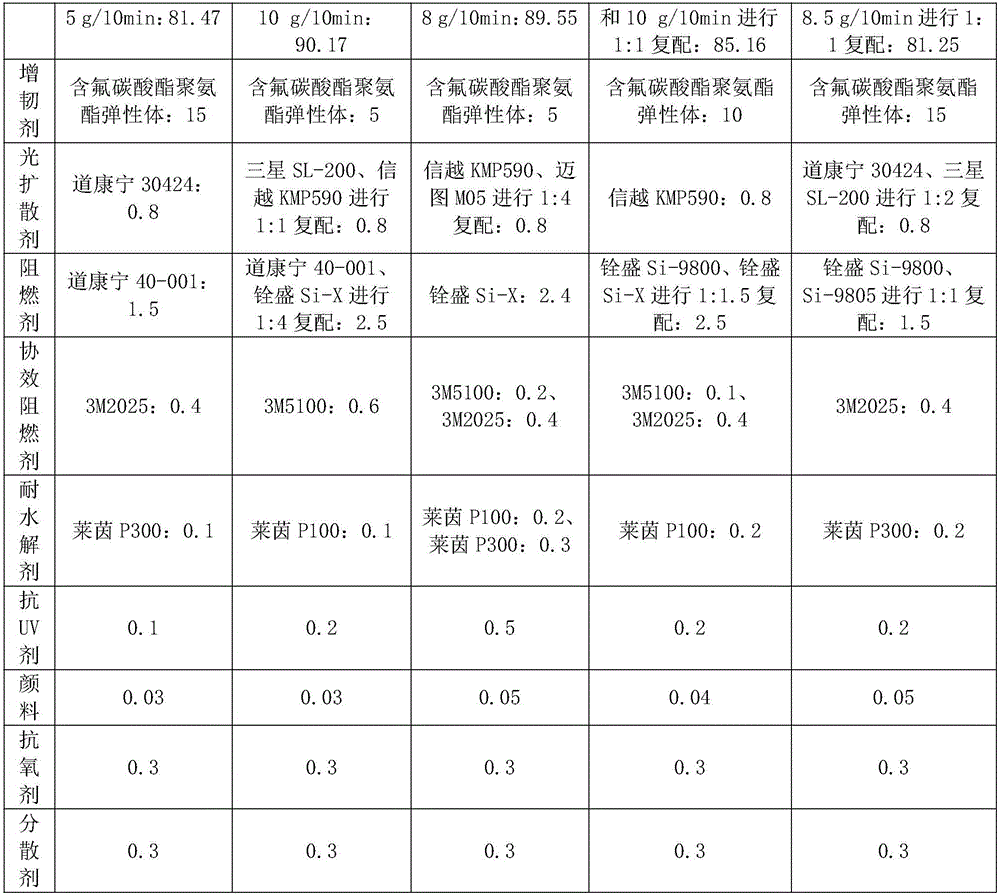

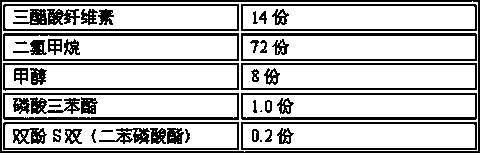

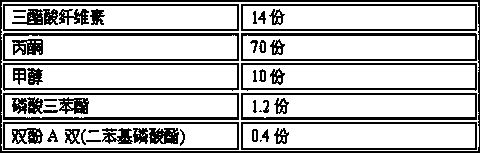

Cellulose triacetate membrane

InactiveCN103467779AAvoid apparent illsGuarantee the apparent qualityComposite materialPolymer chemistry

The invention discloses a cellulose triacetate membrane which is prepared from a solution containing cellulose triacetate, a solvent and a plasticizer by using a solution curtain-casting method. The cellulose triacetate membrane is characterized in that the dosage of the plasticizer is 3-15% of weight of the cellulose triacetate; the plasticizer is prepared from a triphenyl phosphate primary plasticizer and an aryl diphosphate coplasticizer; the weight ratio of aryl diphosphate to triphenyl phosphate is 1 / 6 to 4 / 5. By adopting the cellulose triacetate membrane, precipitation of the plasticizer caused by fluctuation of a production process condition in a membrane production process is solved; apparent defects of the membrane caused by precipitation of the plasticizer are avoided; the apparent mass, the optical property and the physical and mechanical properties of the membrane are ensured; meanwhile, the cellulose triacetate membrane accords with the environment-friendly emission requirements.

Owner:CHINA LUCKY FILM CORP

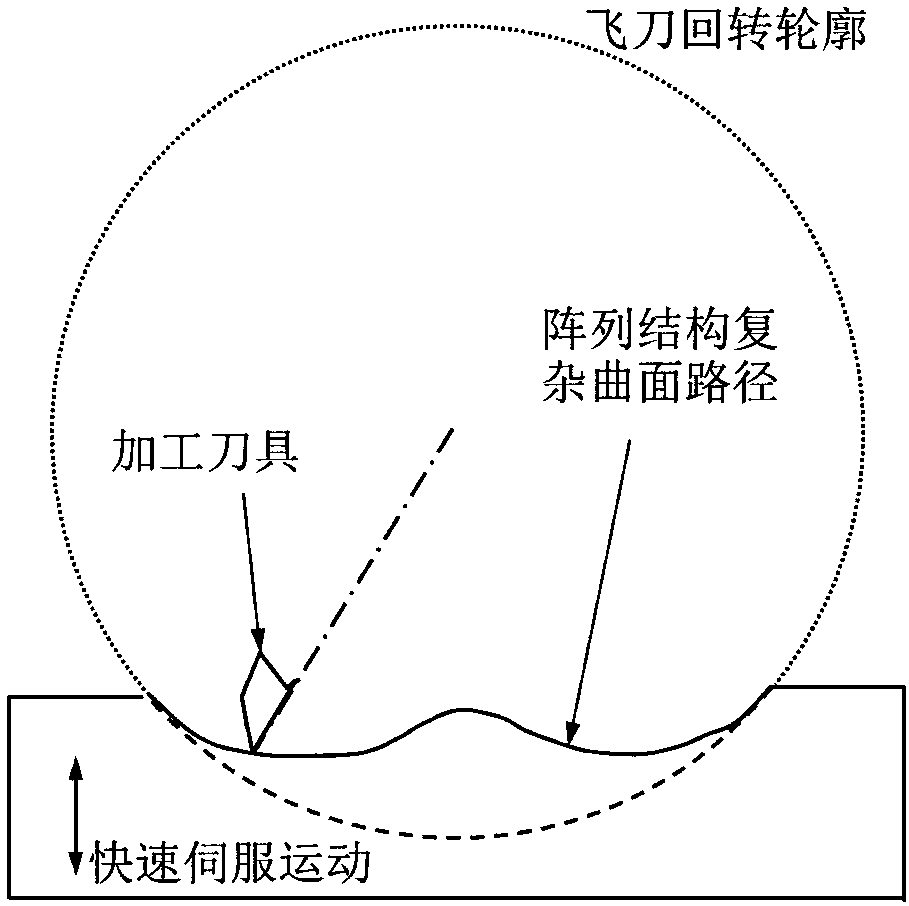

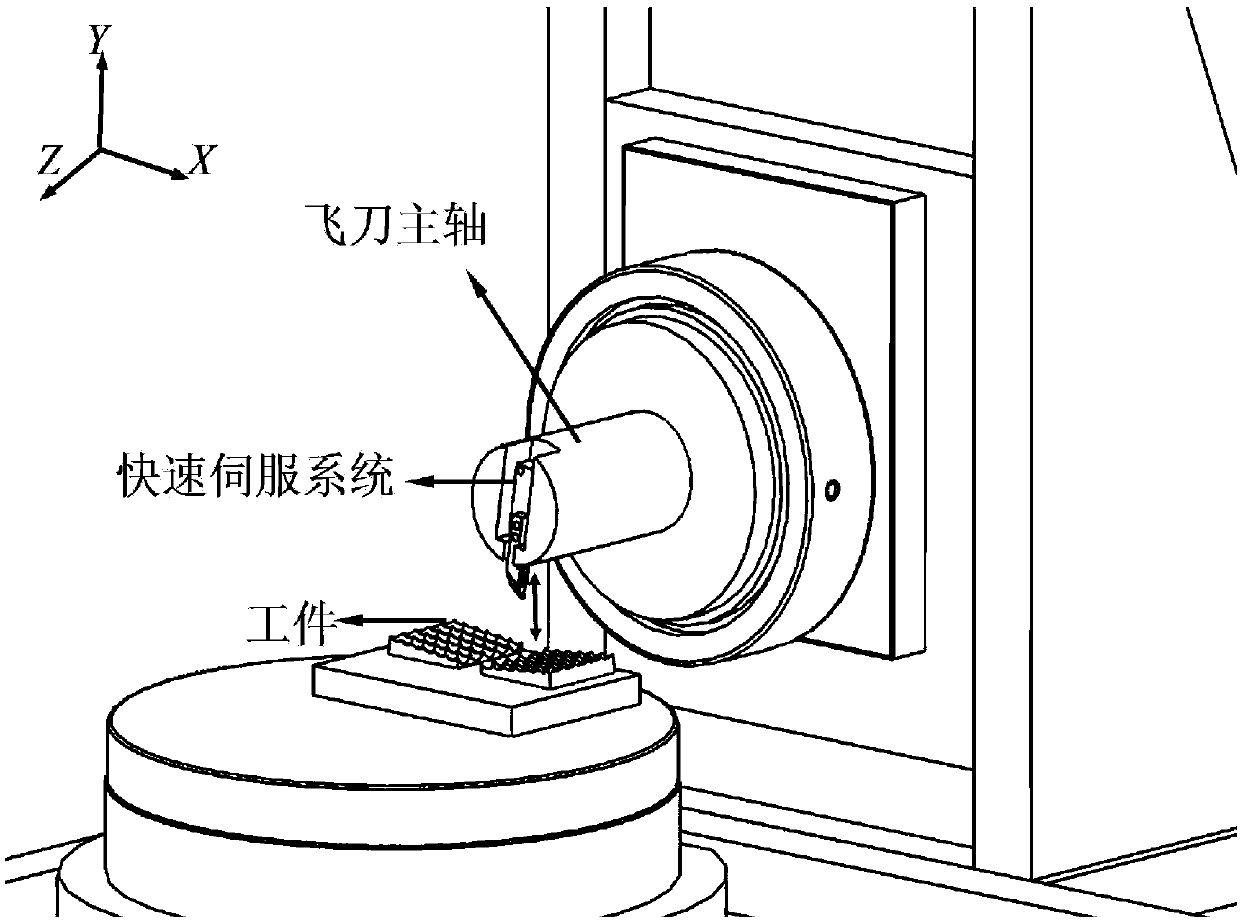

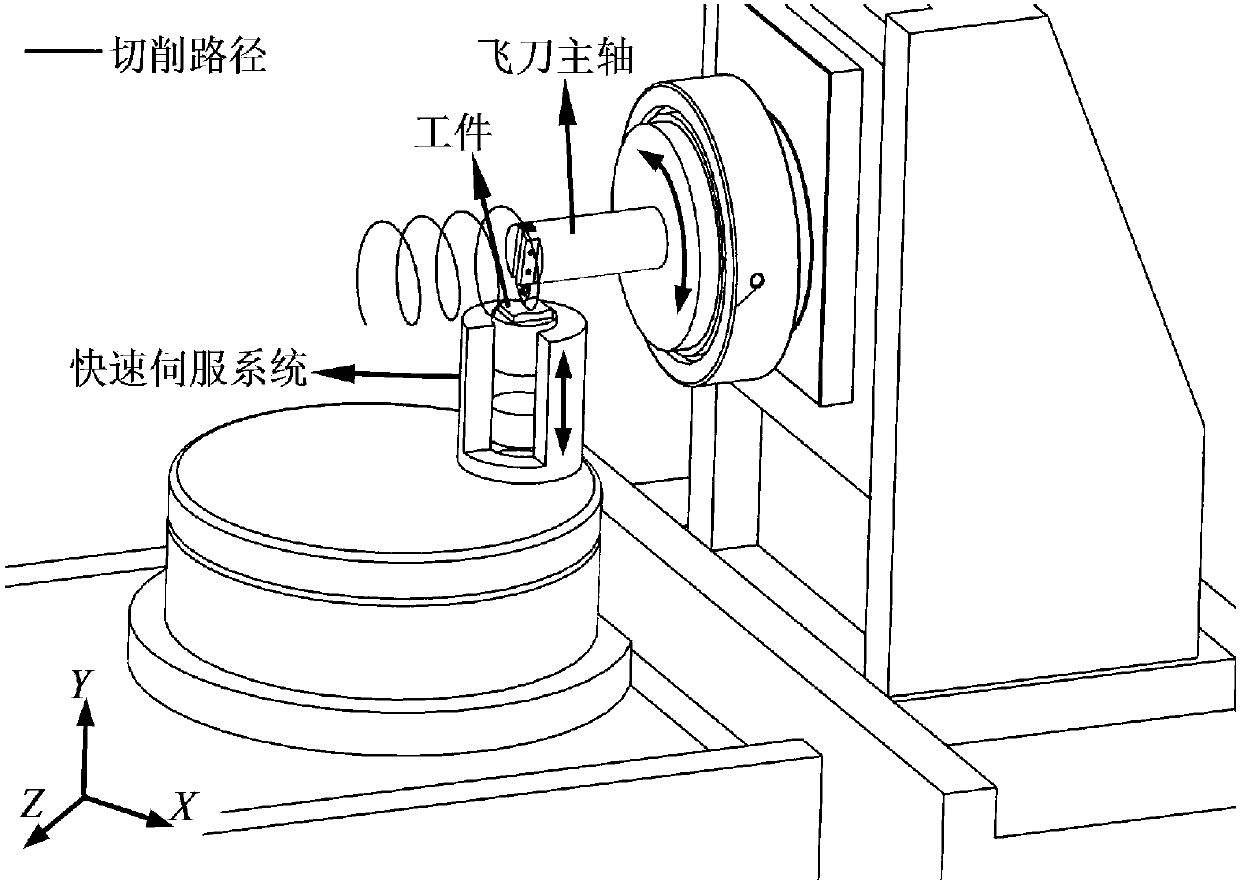

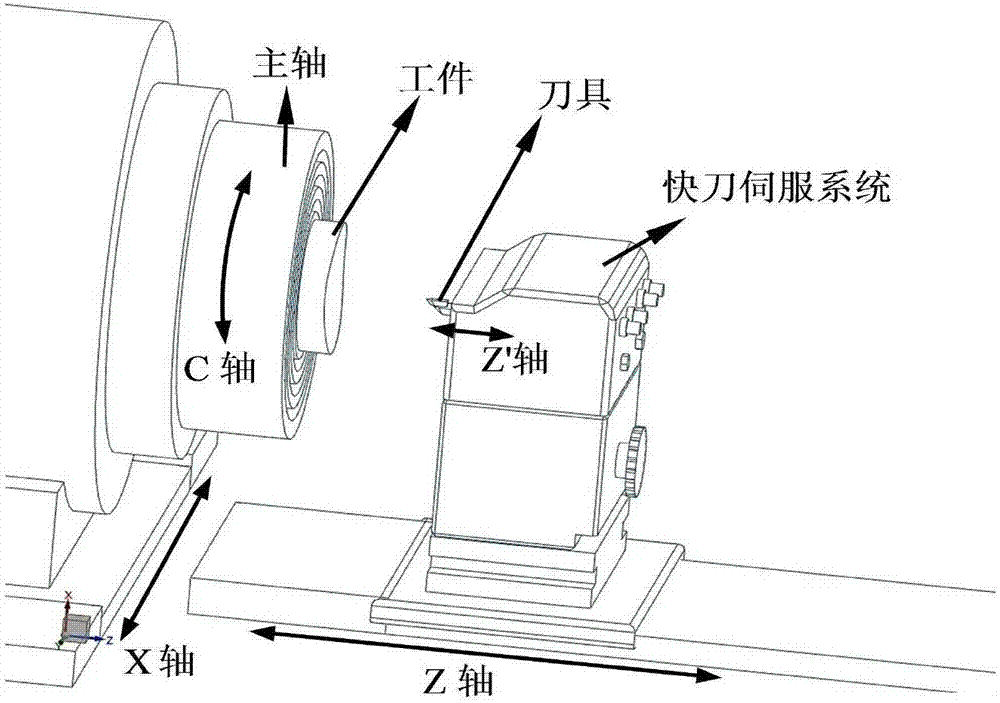

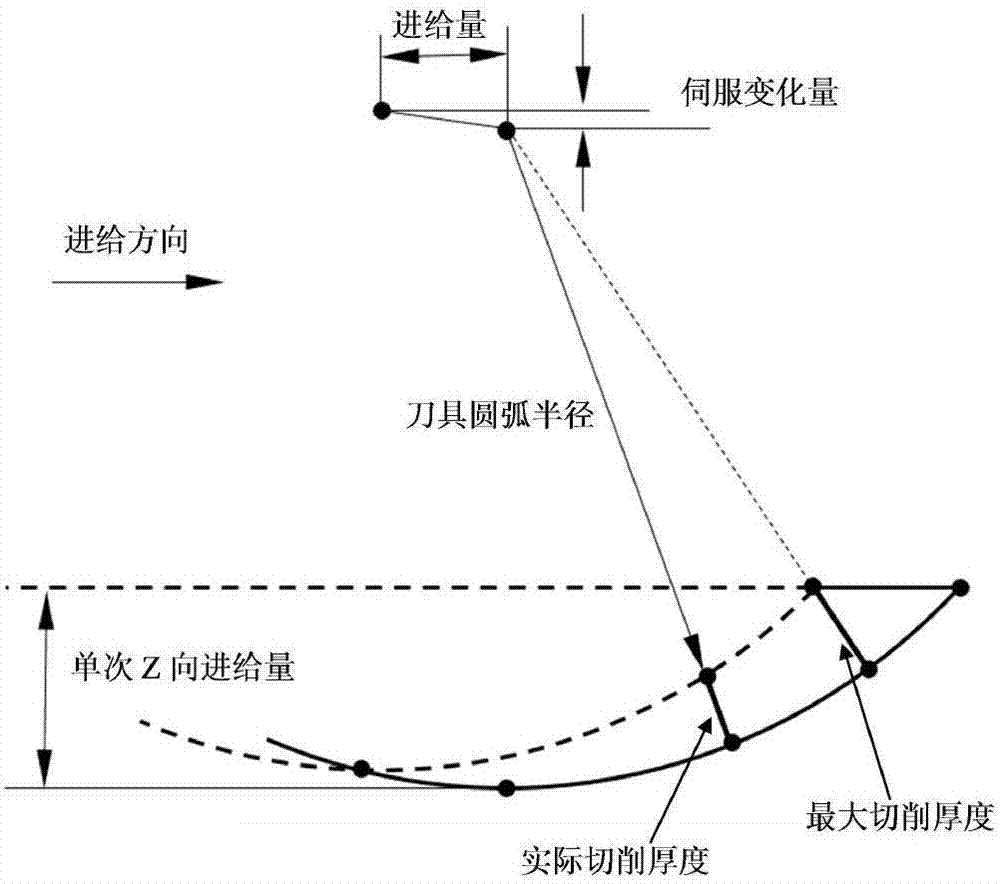

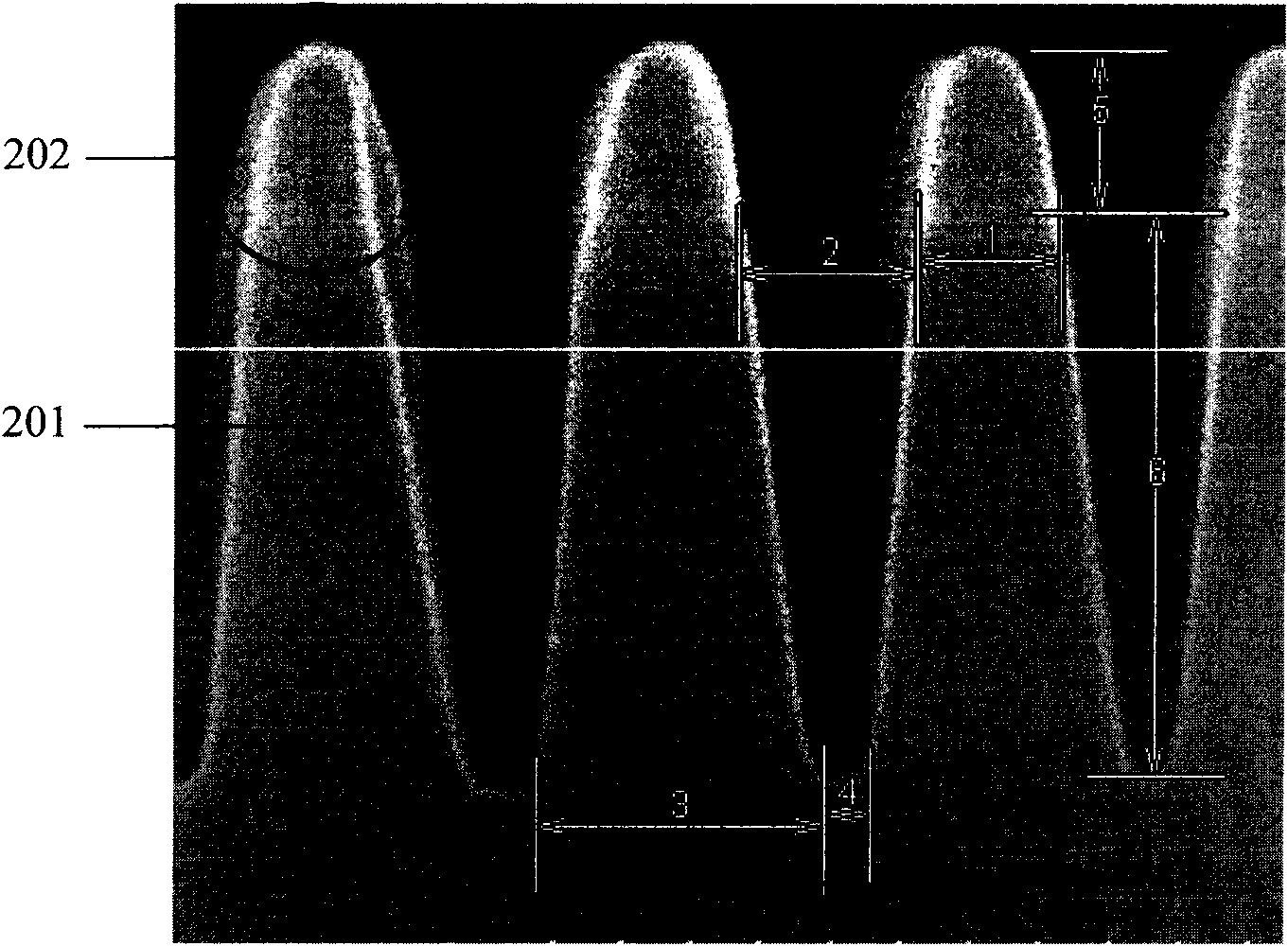

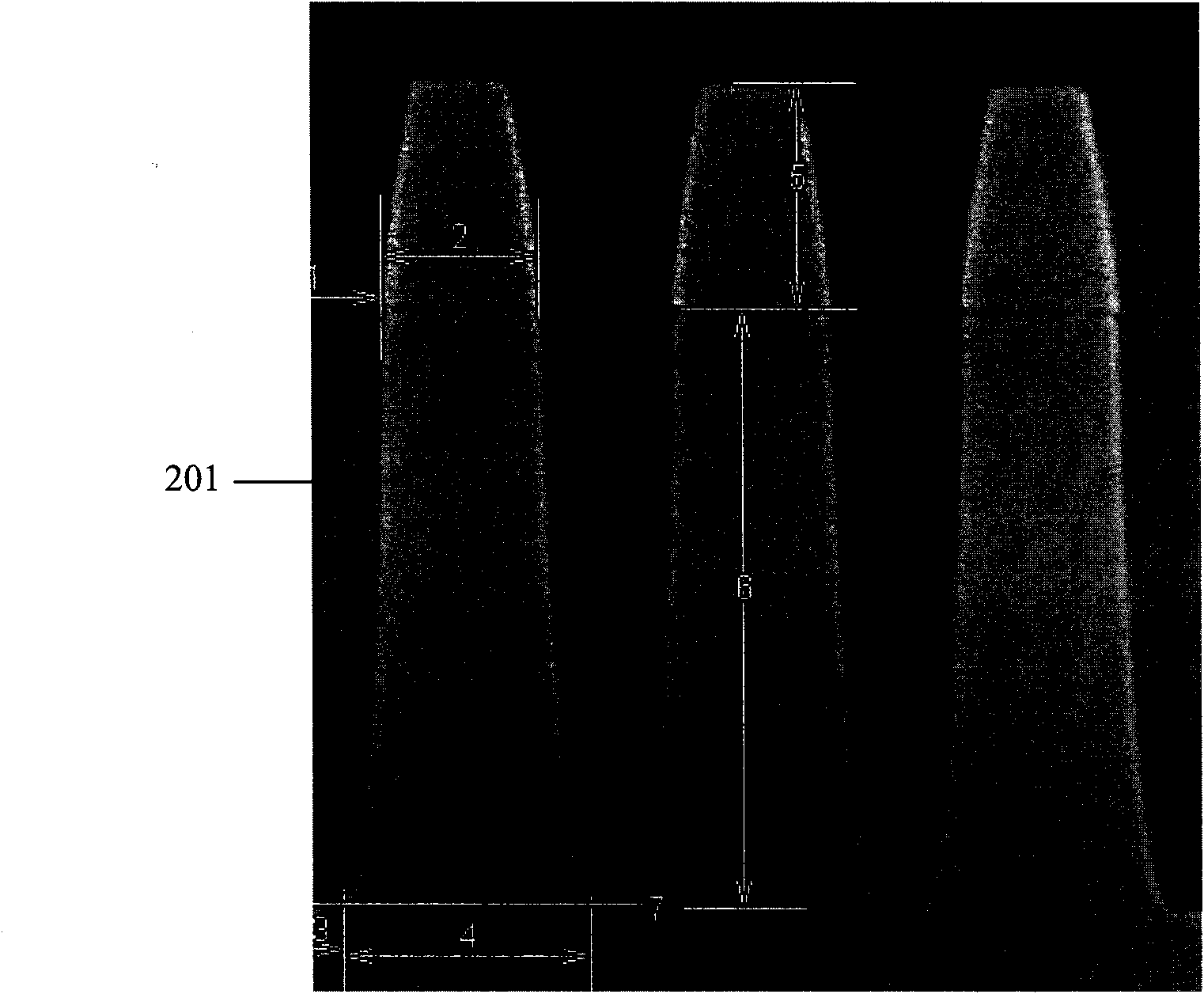

Fast servo ultraprecise fly cutting machining method for brittleness material complex curved surface

The invention relates to a fast servo ultraprecise fly cutting machining method for a brittleness material complex curved surface. The method includes the following steps that a machining system with a fast servo mechanism and fly cutting being combined is established; when a machined device is subjected to fly-cutter machining, a cutter is provided with an area nearest to the machined device every time a spindle is rotated once; at the area, due to the fact that the rotating speed of the fly-cutter spindle is unchanged, when the cutter makes contact with the surface of a workpiece, the fast servo mechanism can be used for driving the workpiece to make single-degree-of-freedom high-frequency motion in the cutting-in direction or make multi-degree-of-freedom high-frequency motion in the cutting-in direction and transverse feeding direction so as to be matched with fly-cutter rotation, and an array structure and complex surface can be machined; the proper cutting parameters and cutter geometrical parameters are designed; motion synchronization is achieved by controlling the servo motion and fly-cutter rotation angle, and thus the back cutting depth can be controlled when materials are cut; and finally cutter motion trajectories make fast and smooth traverse motion on the surface of the machined device.

Owner:TIANJIN UNIV

Imaging lens

ActiveUS8149525B2Guaranteed Optical PerformanceHeat stableOptical articlesLensCamera lensImaging lens

Owner:SEIKOH GIKEN +1

Method for making a lens and an apparatus for precise pressing both sides of the lens

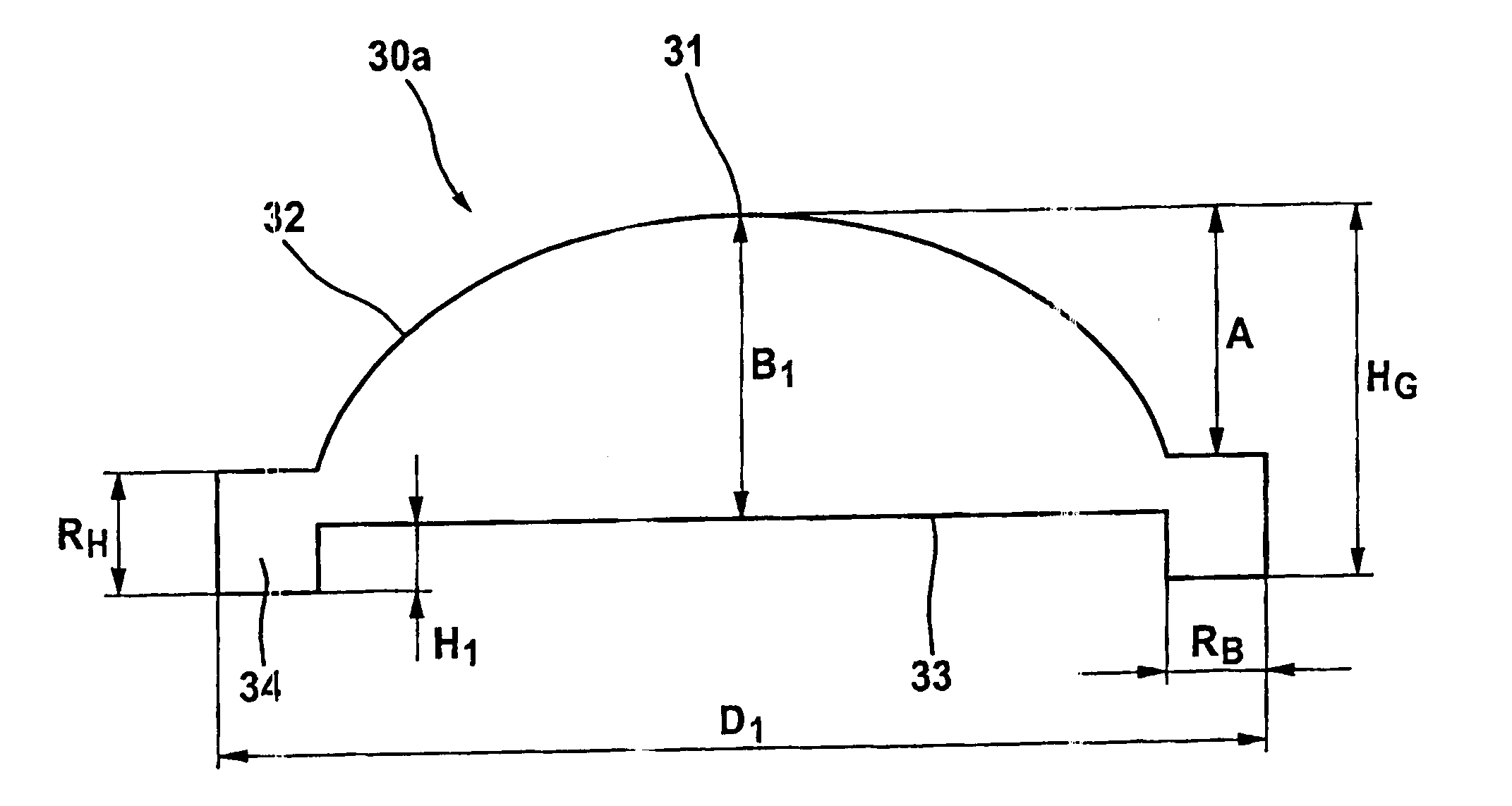

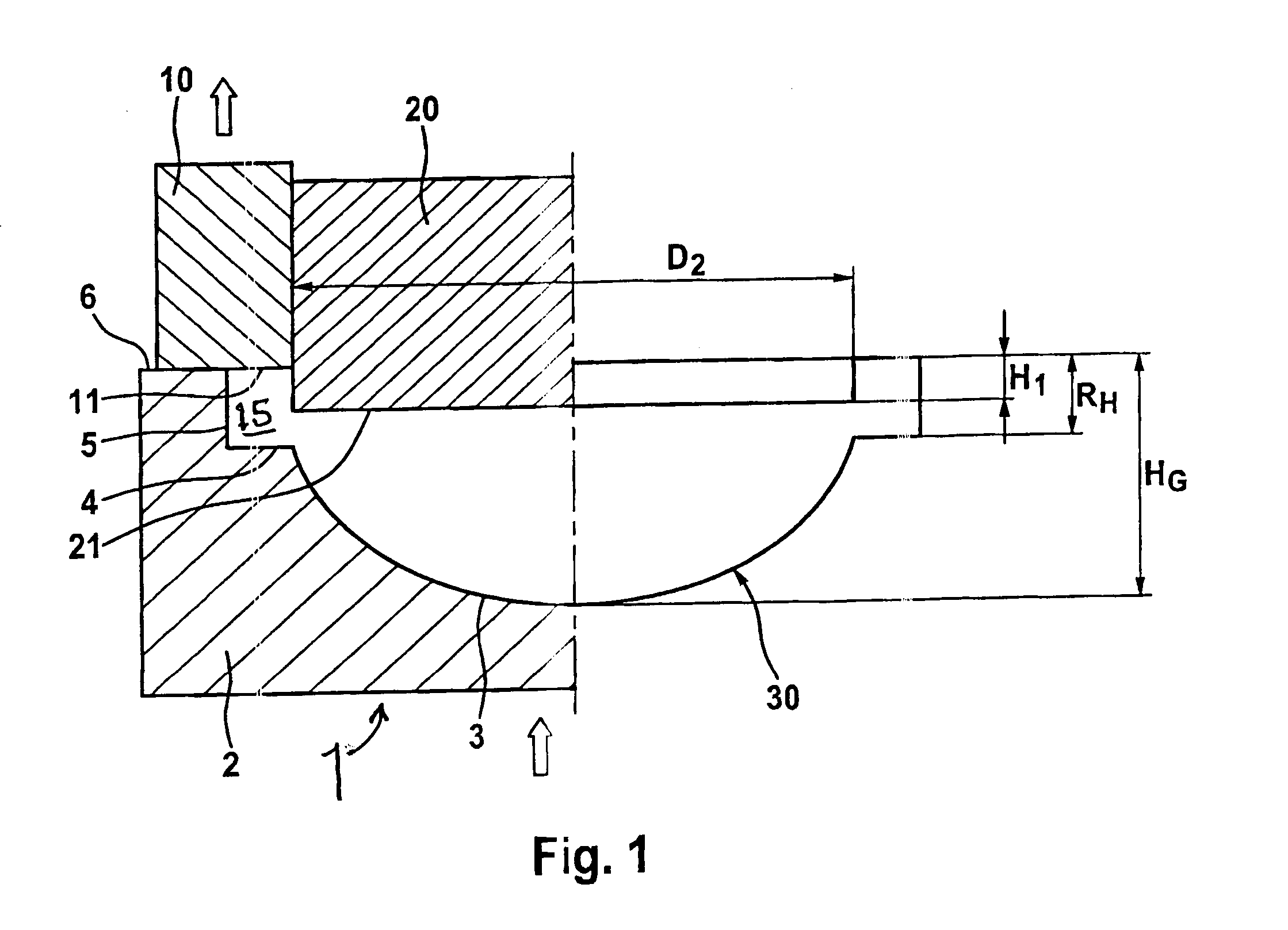

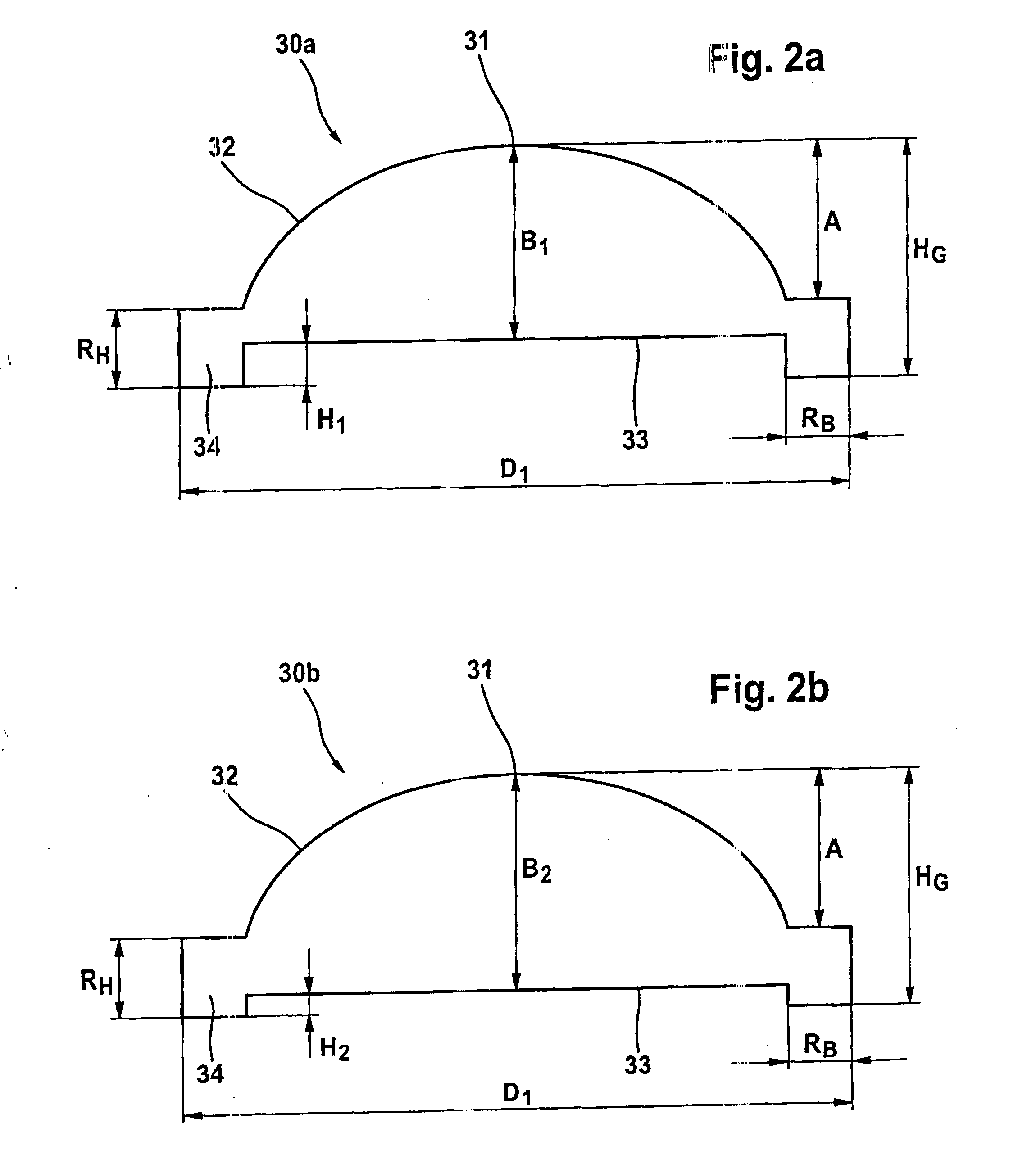

ActiveUS20060072208A1Reduce manufacturing costGuaranteed sizeLighting and heating apparatusGlass drawing apparatusEngineeringMechanical engineering

The method for making a lens with a first convex lens surface (32) and a second lens surface (33) includes feeding a glass melt drop into a concave mold (2, 10), precise pressing both sides of the glass melt drop in the concave mold (2, 10) together with a press die (20) and immersing the press die (20) in the glass melt drop so that a supporting rim (34) with predetermined dimensions, which protrudes beyond a highest point of the second lens surface (33), is formed on the lens by glass material displaced by the precise pressing. The apparatus for precise pressing includes an upper mold part (10) a lower mold part (2) and the press die (20).

Owner:DOCTER OPTICS SE

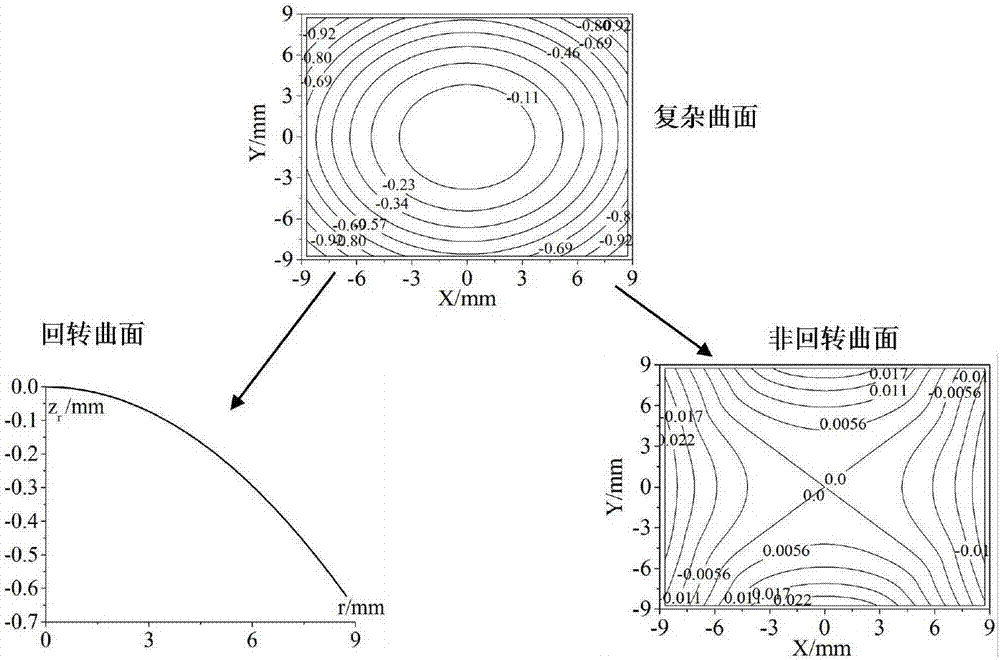

Ultraprecise turning forming method for complex curved face of fragile material

ActiveCN107139345ACutting stabilityQuality assuranceWorking accessoriesFine working devicesPath generationEngineering

The invention relates to an ultraprecise turning forming method for a complex curved face of a fragile material. The ultraprecise turning forming method comprises the steps that according to the optimal principle of the optical performance, the complex curved face approaching rotation of the fragile material is designed; face shape decomposing is carried out on the designed curved face according to a rotating part and a non-rotating part, and the non-rotating degree of a non-rotating face acquired from decomposing is calculated; a sharp knife servo turning system is erected, and a processing tool is arranged on a rapid servo mechanism to form a sharp knife servo mechanism; appropriate cutting parameters and tool geometrical parameters are designed according to the sharp knife servo turning process characteristics and the cutting performance of the material; based on the processing parameters and the tool geometrical parameters, rotating part and non-rotating part processing path generation is carried out, path compensation is carried out before processing, and after compensation is conducted, a processing surface is formed after a tool outline passes through the path; and a machined workpiece is arranged on a machine tool main shaft, and sharp knife servo turning is carried out.

Owner:TIANJIN UNIV

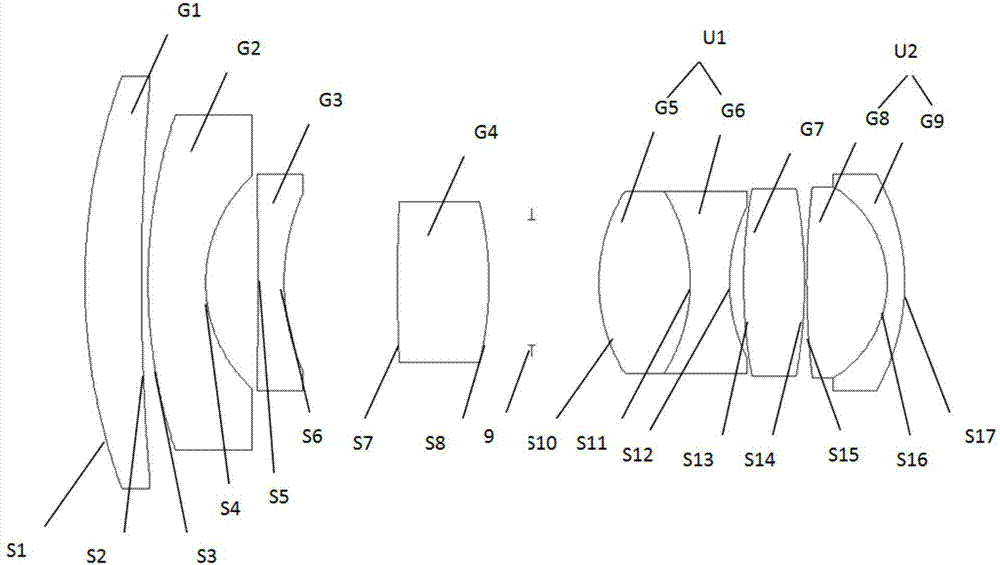

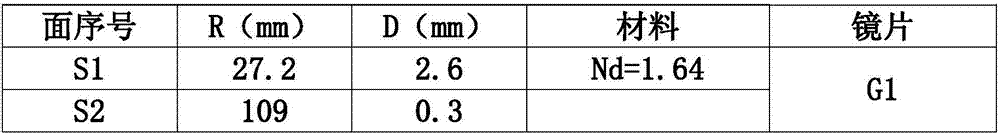

Wide-angle high-definition machine vision lens

The present invention provides a wide-angle high-definition machine vision lens. The lens comprises a focusing set and a fixing set; the focusing set comprises a first lens having positive focal power, a second lens having negative focal power and a third lens having negative focal power which are arrange in order from an object side to an image side along an optical axis; and the fixing set comprises a fourth lens having a positive focal power, a fifth lens having positive focal power, a sixth lens having negative focal power, a seventh lens having positive focal power, an eighth having positive focal power and a ninth lens having negative focal power which are arranged in order from the object side to the image side along the optical axis. Through adoption of the mode of grouping focusing, the lens ensures good imaging quality effect under object distance from 0.1mm to infinite distance, the distortion is less than 1%, and the relative illumination of the optical system marginal ray is more than 70%; the supporting field angle is larger than 70 degrees; and the wide-angle high-definition machine vision lens can ensure that resolution satisfies imaging requirements when usage in the environment of -40-70 DEG C.

Owner:DONGGUAN YUTONG OPTICAL TECH

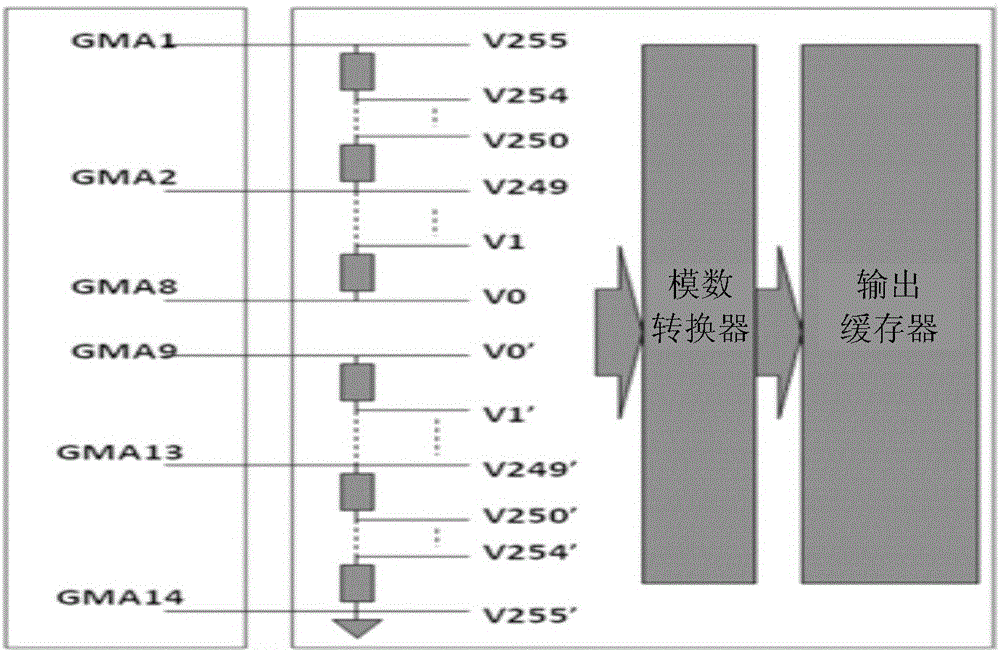

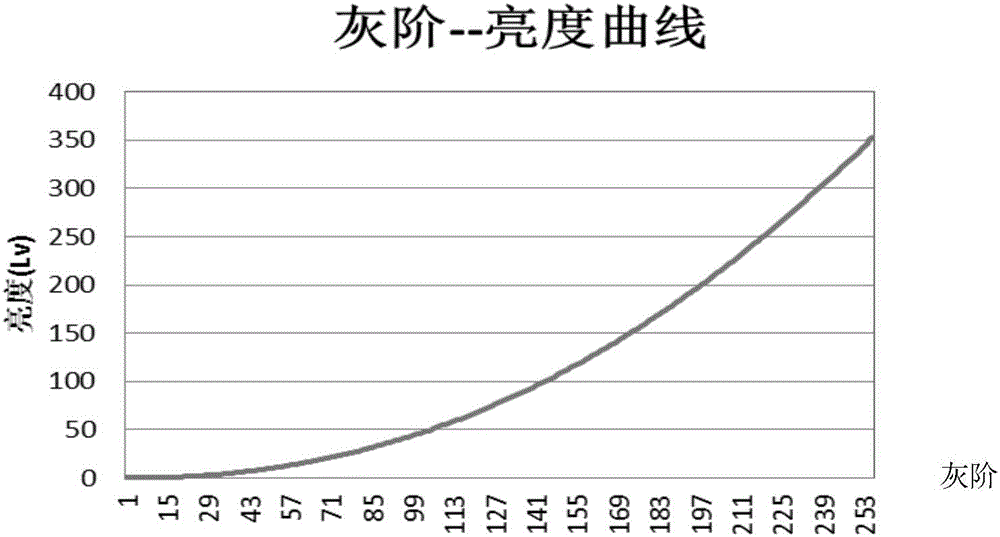

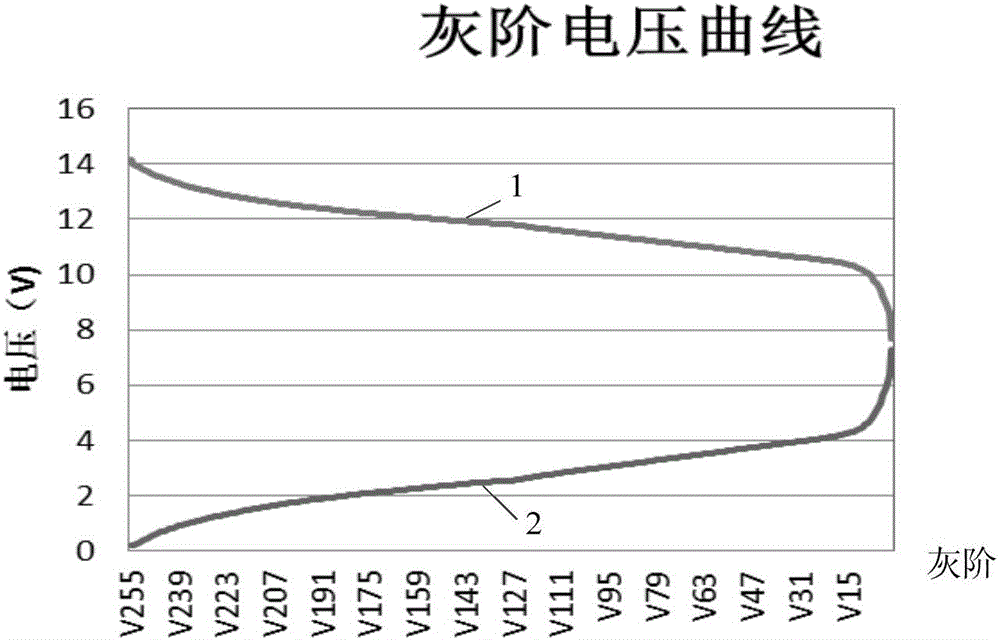

Gray scale display compensation method, gray scale display compensation system and display device

ActiveCN106548756AReduced precision requirementsGuaranteed Optical PerformanceStatic indicating devicesDisplay deviceEngineering

The invention provides a gray scale display compensation method, a gray scale display compensation system and a display device. The method comprises steps that an offset value of an actual driving voltage of each gray scale and a corresponding expected driving voltage of the gray scale searched from a white balance look-up table is calculated, and an offset value table is established; an expected driving voltage in the white balance look-up table corresponding to a to-be-displayed gray scale is taken as an actual driving voltage of a target gray scale, an offset value corresponding to the actual driving voltage of the target gray scale is searched from the offset value table; the actual driving voltage is corrected according to the offset value of the actual driving voltage of the target gray scale, and a gray scale corresponding to the actual driving voltage after correction is searched from the white balance look-up table and is taken as a target gray scale to replace the to-be-displayed gray scale for display. The method is advantaged in that LCD optical effects can be still guaranteed under the condition of a low precision driving chip, and precision requirements of the driving chip can be reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Laminated bottom antireflex structure and etching method

InactiveCN101770940ASo as not to damageGuaranteed accuracySemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusSilicon dioxideSilicon

The invention relates to a laminated bottom antireflex structure and an etching method, wherein the laminated bottom antireflex structure comprises an organic bottom antireflex layer and a first layer silicon-containing bottom antireflex layer thereof; and the first layer silicon-contained bottom antireflex layer is also provided with a silicon dioxide layer. Compared with the prior art, the silicon dioxide layer is also arranged on the silicon-contained bottom antireflex layer, and the silicon-contained bottom antireflex layer can be prevented from being damaged when etching the organic bottom antireflex layer, thereby the pattern transfer accuracy can be kept.

Owner:SEMICON MFG INT (SHANGHAI) CORP

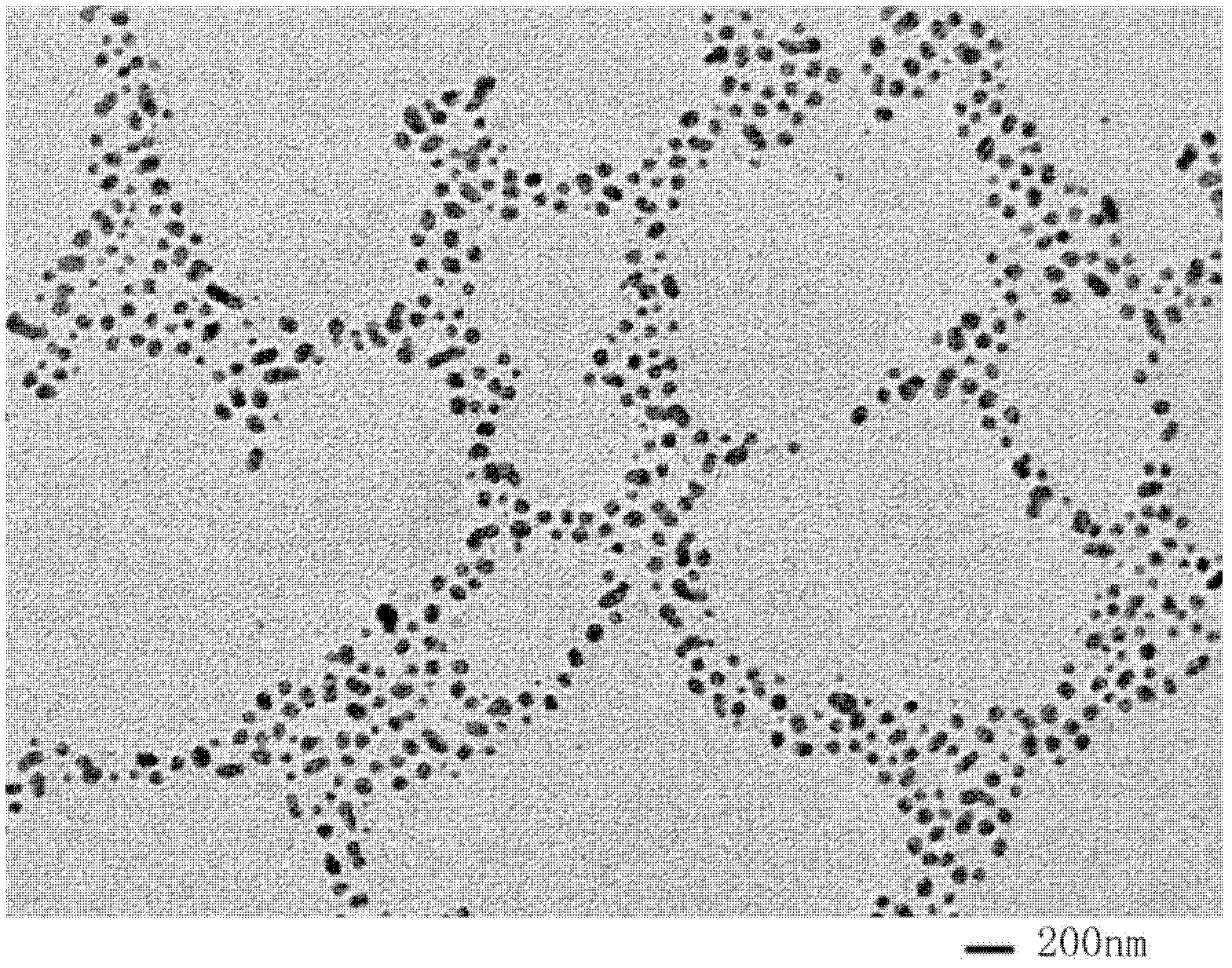

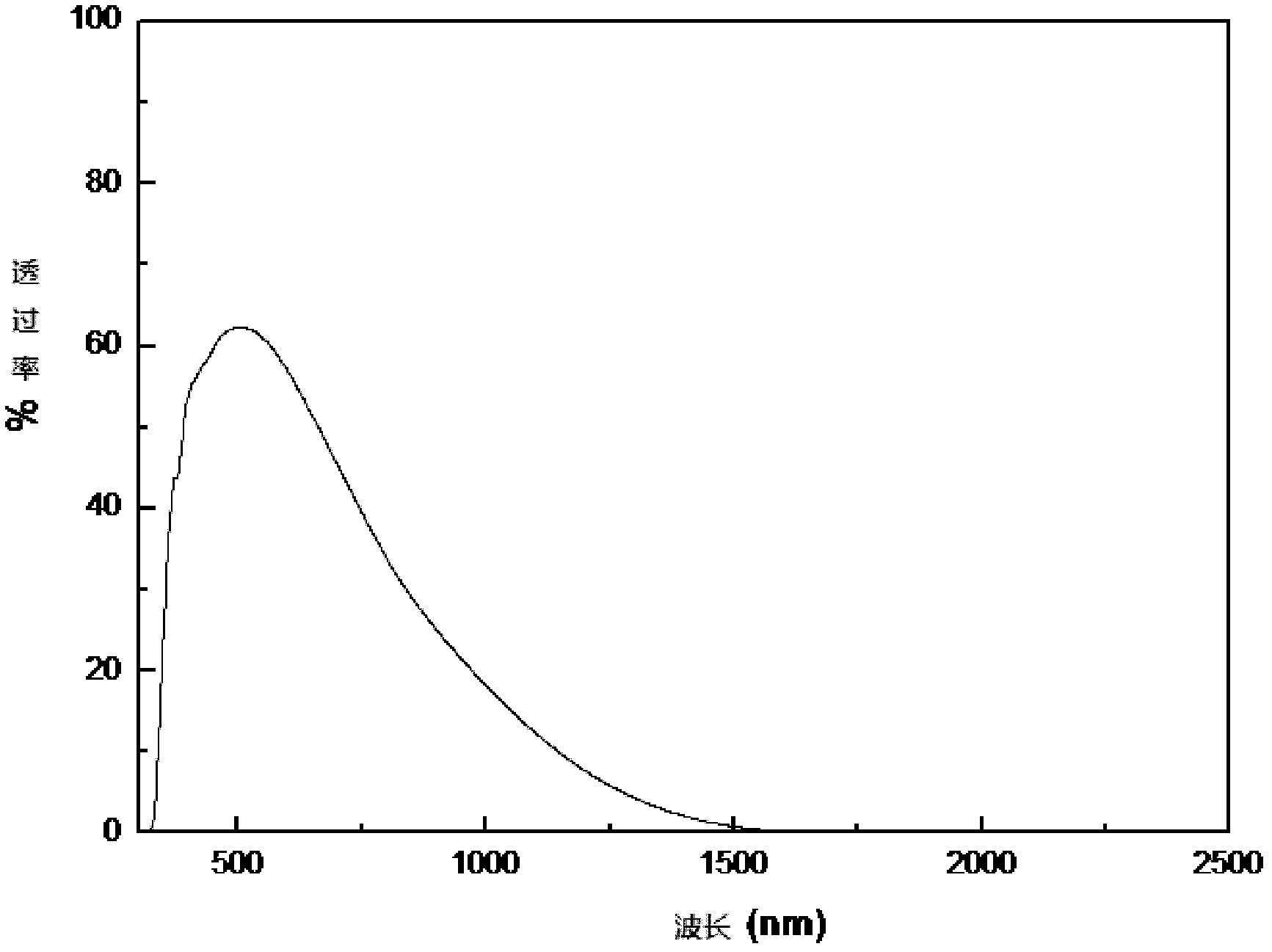

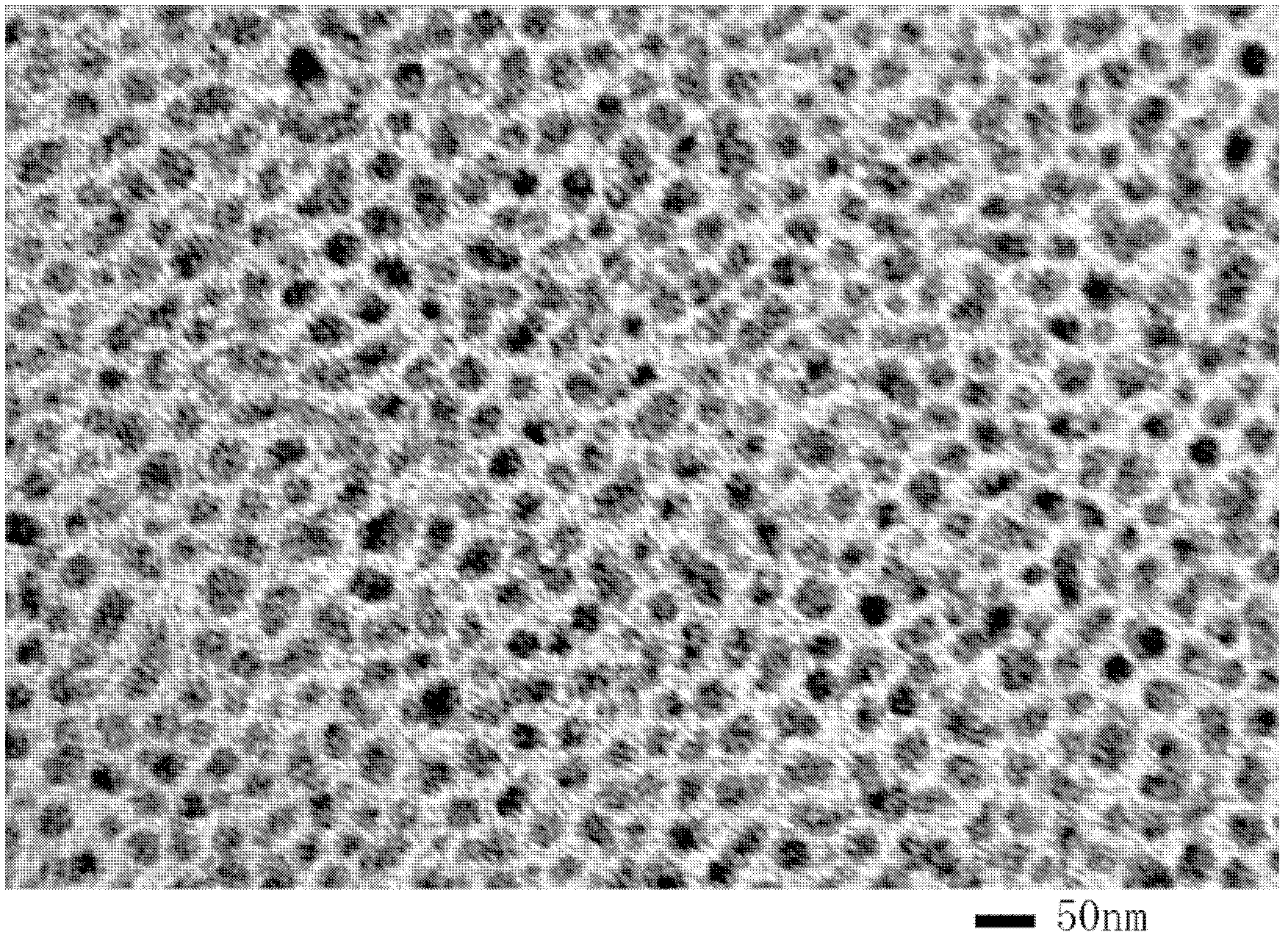

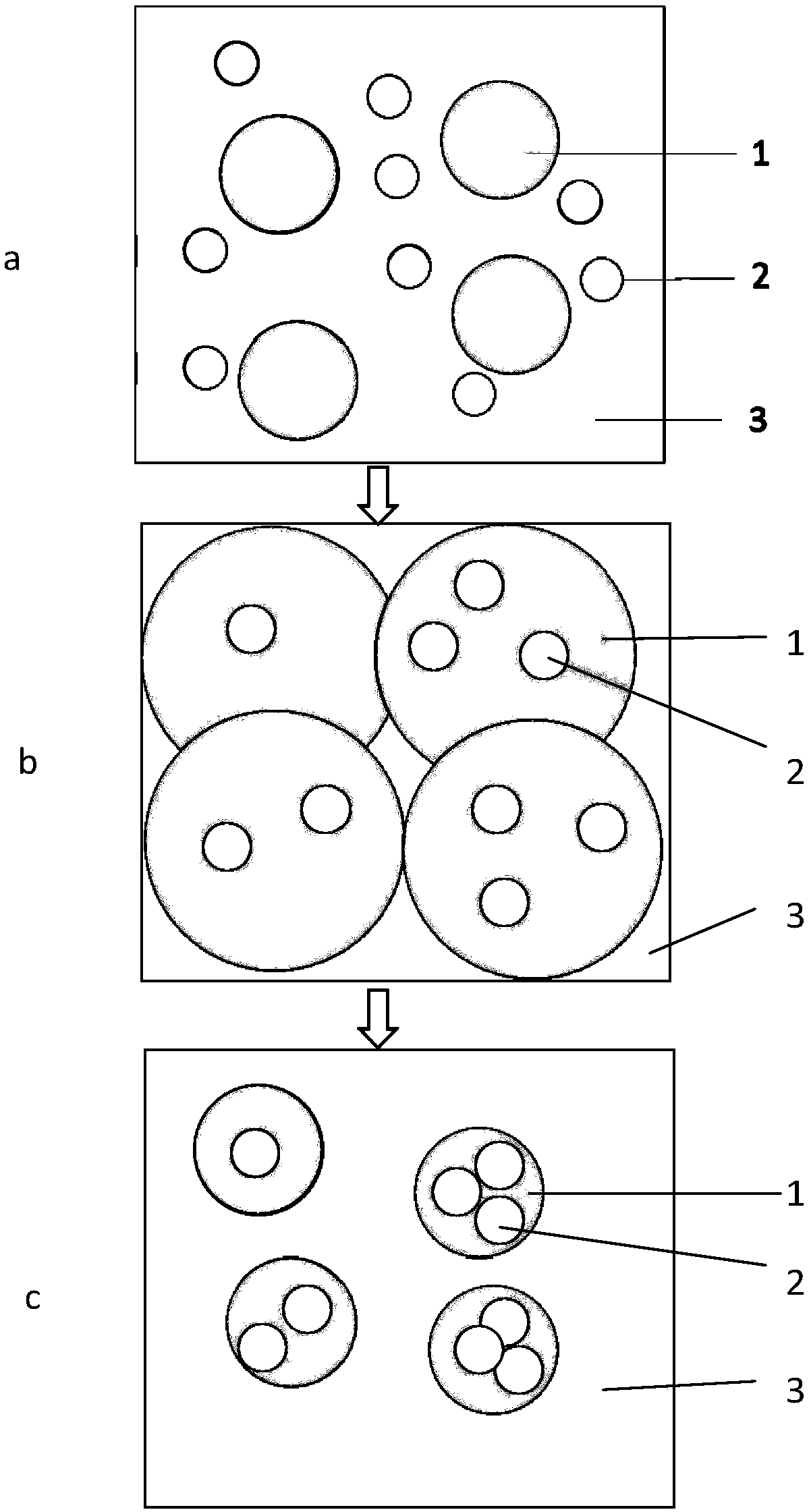

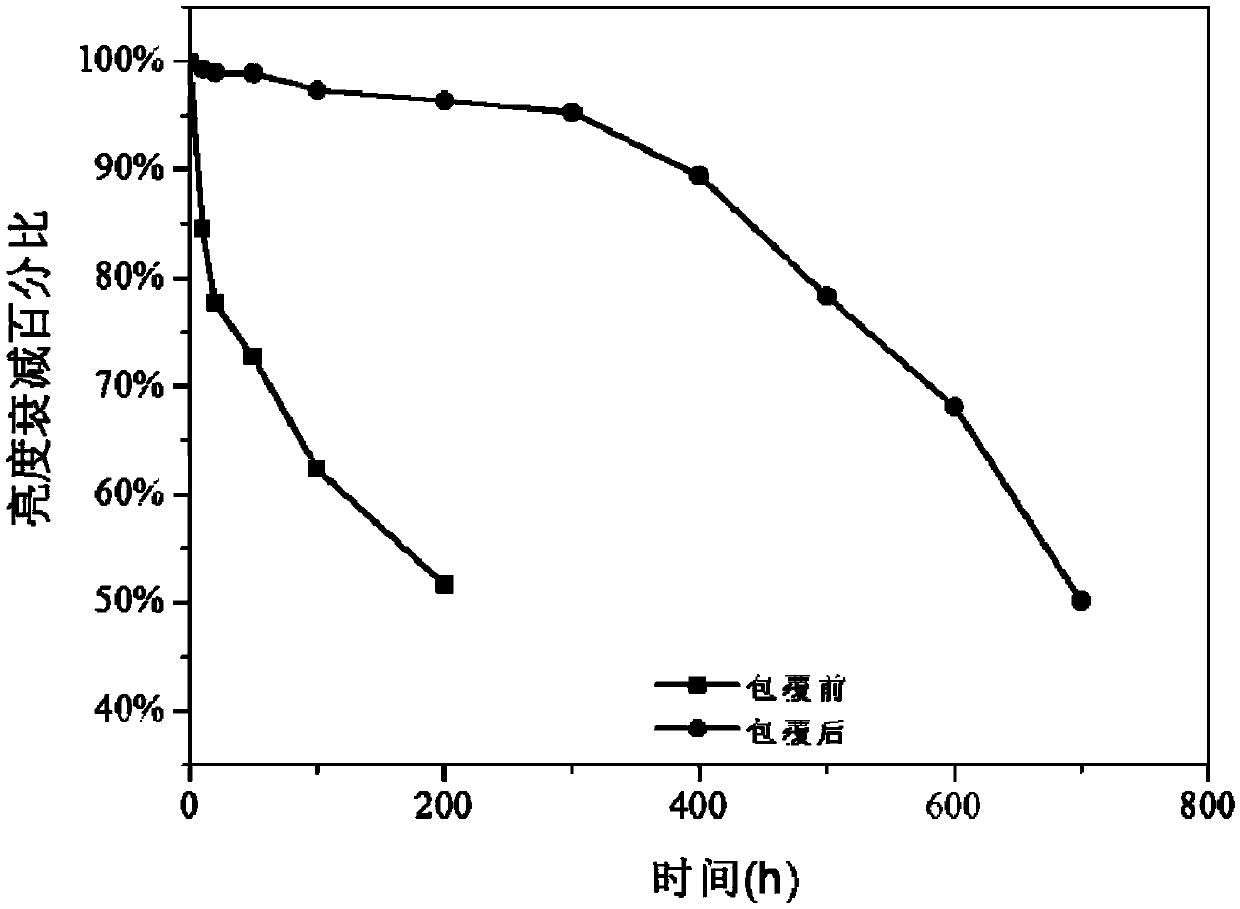

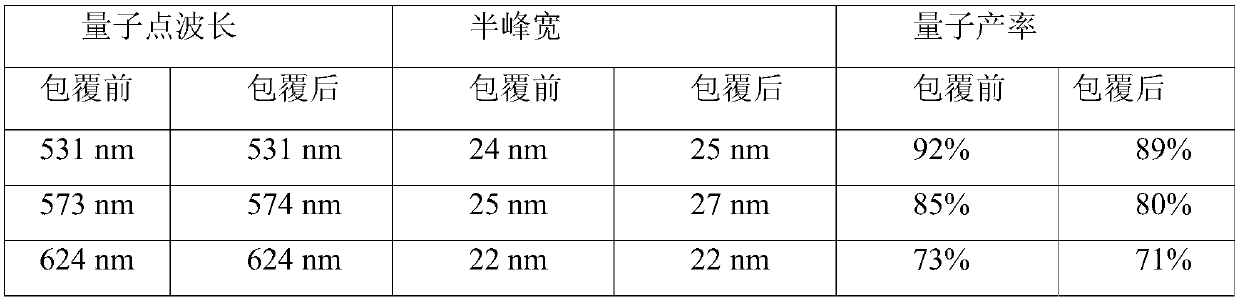

Quantum dot/polymer microsphere composite material, preparation method and application

ActiveCN109652061ARealize the physical packageUnique structureLuminescent compositionsSemiconductor devicesMicrosphereFluorescence

The invention relates to a quantum dot / polymer microsphere composite material. The material is characterized by comprising quantum dots and polymer microspheres, the polymer microspheres physically encapsulate the quantum dots, and the quantum dots are dispersed inside balls of the polymer microspheres. The invention also provides a preparation method and application of the quantum dot / polymer microsphere composite material. The material achieves the physical encapsulation protection of the quantum dots by the polymer microspheres, ensures the stability of the long-term use of the quantum dotsand the stability of the optical performance of a quantum dot backlight diaphragm as a whole, avoids the reduction or structural damage of the performance of the quantum dots caused by chemical changes, and ensures that the quantum dot luminescence efficiency and fluorescence efficiency of the quantum dot / polymer microsphere composite material are not affected.

Owner:GUANGDONG POLY OPTOELECTRONICS

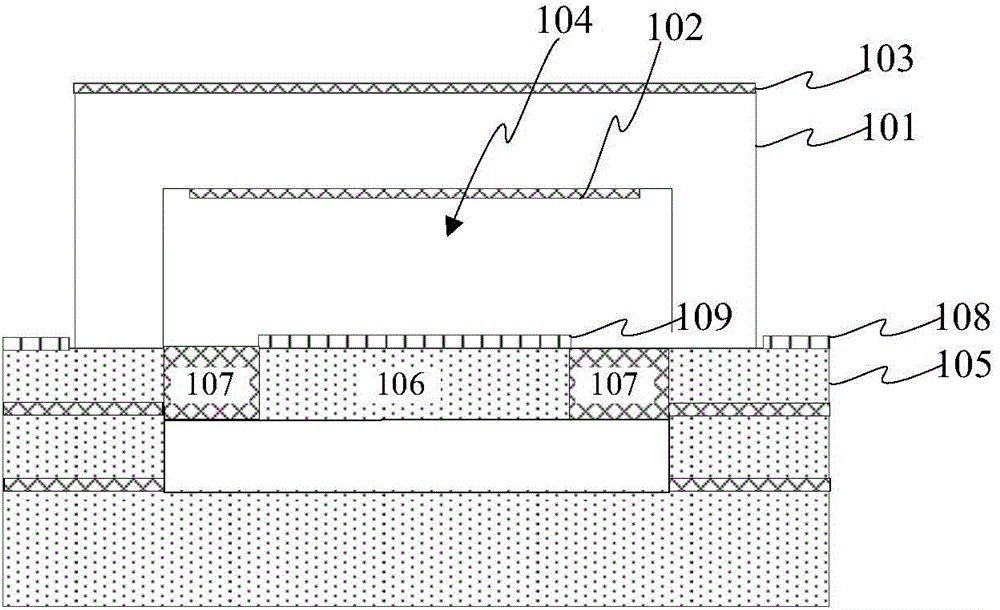

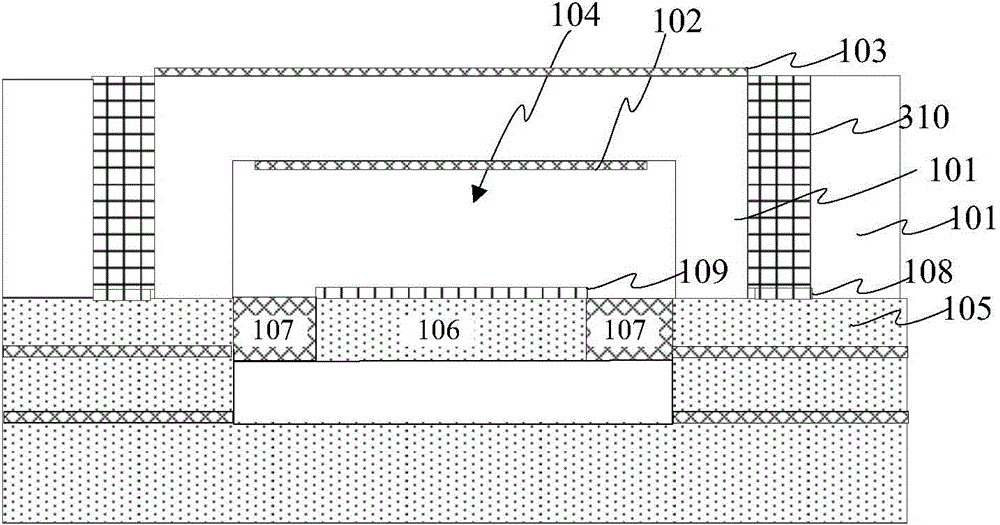

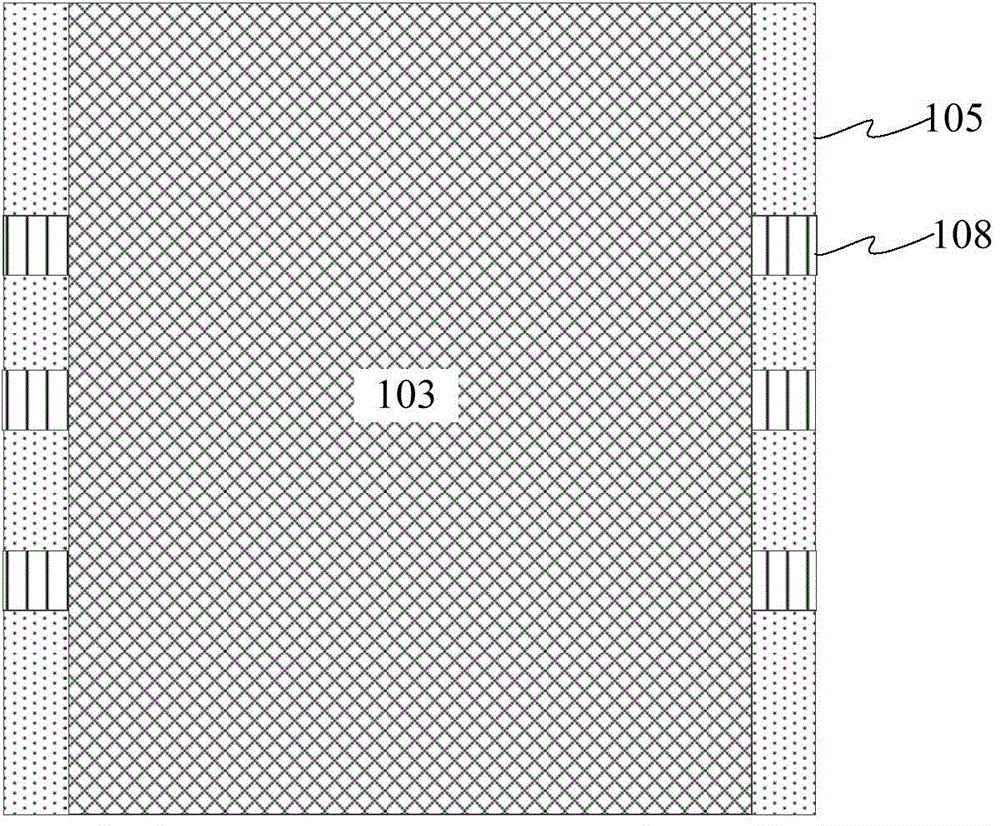

Packaging structure and method of MEMS optical chip based on silicon-glass bonding

ActiveCN104803340AImprove reliabilityImprove stabilityTelevision system detailsPrecision positioning equipmentElectricityGlass frit bonding

The invention provides a packaging structure and method of an MEMS optical chip based on silicon-glass bonding. The packaging structure comprises a first part and a second part, wherein the first part comprises optical glass of which the upper surface is coated with an upper optical antireflection film and while the lower surface is provided with a cavity; the upper surface of the cavity meets the requirement on smoothness of an optical surface, and a lower optical antireflection film is plated; the second part comprises the MEMS optical chips; the first part and the second part are subjected to silicon-glass bonding to achieve chip-stage bonding, and an independent sealing cavity is formed for each MEMS optical chip. With the adoption of the structure and the method, the chip-stage packaging requirement can be achieved; the reliability and stability of the chip can be improved; the electric performance, mechanical performance and optical performance for application of the optical chip can be ensured; in addition, the comprehensive level superior to that of other packaging technologies is brought; the packaging cost can be reduced; the packaging efficiency can be increased; the light loss can be decreased; the structure and the method have a wide application prospect in the packaging of optical communication devices and optical sensors.

Owner:ANHUI CHINA SCI MW ELECTRONIC TECH CO LTD

Preparation method of lithium triborate crystal high-laser-damaged-threshold antireflection film

InactiveCN106435487AHas a waterproof effectReduce deliquescenceVacuum evaporation coatingSputtering coatingHigh power lasersOptical property

The invention discloses a preparation method of a nonlinear crystal lithium triborate crystal surface high-laser-damaged-threshold antireflection film. Aiming at high LBO crystal anisotropy and the damage mechanism of the antireflection film, the method includes the steps that the surface of an LBO crystal is plated with a SiO2 film through an IAD process, and the film with which the surface of the LBO crystal is plated through the IAD process carries out plating through a sol-gel method. The LBO antireflection film prepared through the method has excellent optical properties, the high damage threshold and good environmental stability, and can be compatible with existing substrate machining, cleaning and film preparation processes. The preparation method has the beneficial effects of being high in process repeatability, high in controllability, easy to popularize and the like, and has wide application prospects in the field of high-power laser films in future.

Owner:TONGJI UNIV

Compression molding device and process of multi-curved-surface inorganic glass

ActiveCN102745885AGuaranteed curvature accuracyGuaranteed bending temperatureGlass reforming apparatusInternal temperatureTemperature control

The invention relates to a compression molding device and process of multi curved surface inorganic glass. The compression molding device comprises a heating box, a molding box and a heating device, wherein the heating box and the molding box are arranged adjacently and are isolated by an inner door; the molding box is internally provided with a molding mold and a mold carrier; the mold carrier can move forwards and backwards between the molding box and the heating box; the molding mold comprises a female mold arranged on the mold carrier, a male mold movably arranged on the molding box, and a male mold driving device which is used for driving the male mode to stamp relative to the female mold; the compression molding device further comprises a control box; the control box is internally provided with a molding control module which is used for controlling the molding mold to do molding action, a mold moving control mold which is used for controlling the movement and the positioning of the mold carrier, and a temperature control module which is used for controlling the internal temperature of the molding box and the heating box. The compression molding device is applicable for multi curved surface molding of inorganic glass; the curvature precision of the multi curved surface inorganic glass after being molded can be improved; and moreover a proper bending temperature of the inorganic glass and the optical property and the quality of the surface of the glass after being bent and transformed can be ensured.

Owner:SHENZHEN SANXIN JMT GLASS

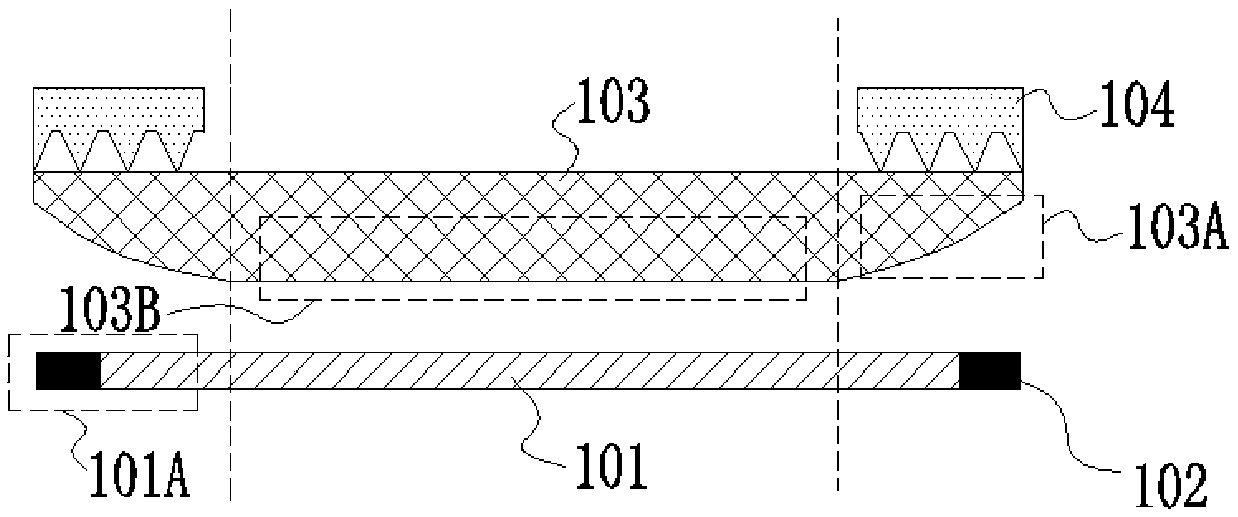

Spliced screen

InactiveCN109410773AGuaranteed Optical PerformanceEffective light gathering effectDiffusing elementsIdentification meansEngineeringOptical thin film

The invention provides a spliced screen. The spliced screen comprises at least two display panels, cover boards and optical thin films, wherein a non-display area on the peripheral edge of each display panel comprises a frame, and a gap is formed at the spliced position of each two adjacent display panels; the cover boards are arranged on the surfaces of the display panels, the surfaces of the sides, far away from the display panels, of the cover boards are planes, and the surfaces of the sides, close to the display panels, of the cover boards comprise bent areas and plane areas; the bent areas correspond to the frame areas of the display panels, and the plane areas correspond to display areas of the display panels; the optical thin films are arranged on the surfaces of the cover boards, and comprise upper surfaces far away from one sides of the cover boards and lower surfaces close to one sides of the cover boards; and the lower surfaces of the optical thin films comprise microstructural areas corresponding to the frame areas, and the upper surfaces of the optical thin films comprise scattering areas corresponding to the frame areas.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com