Ultraprecise turning forming method for complex curved face of fragile material

A technology for complex curved surfaces and brittle materials, applied in the field of turning processing, can solve problems such as low processing efficiency, easy embedding of abrasives, and failure of optical functions, and achieve the effects of reducing difficulties, avoiding brittle cracks, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

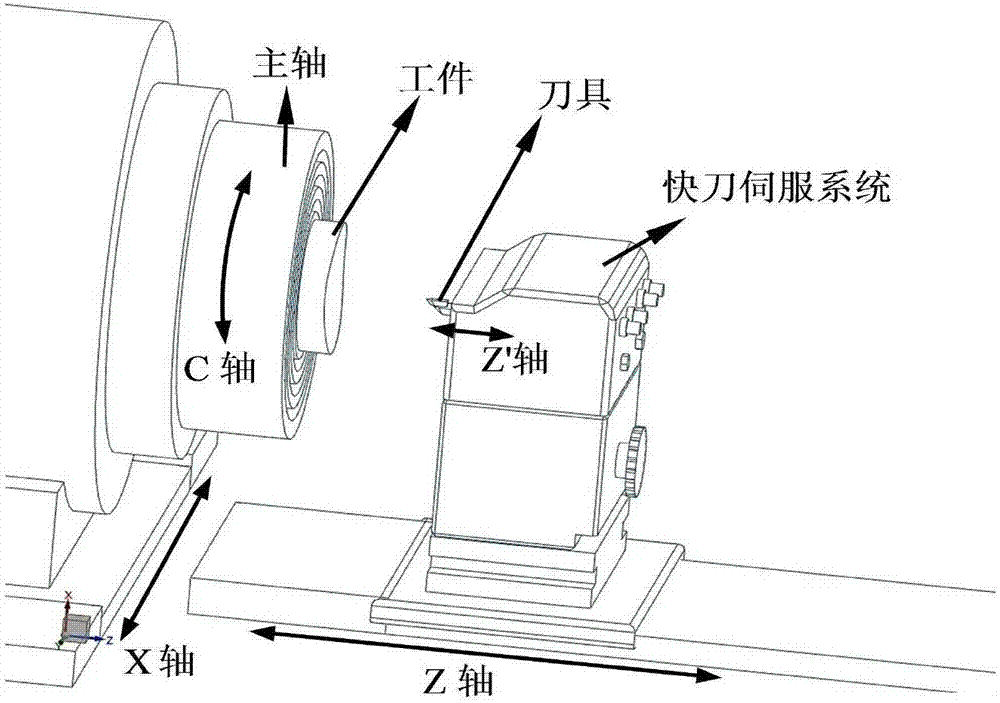

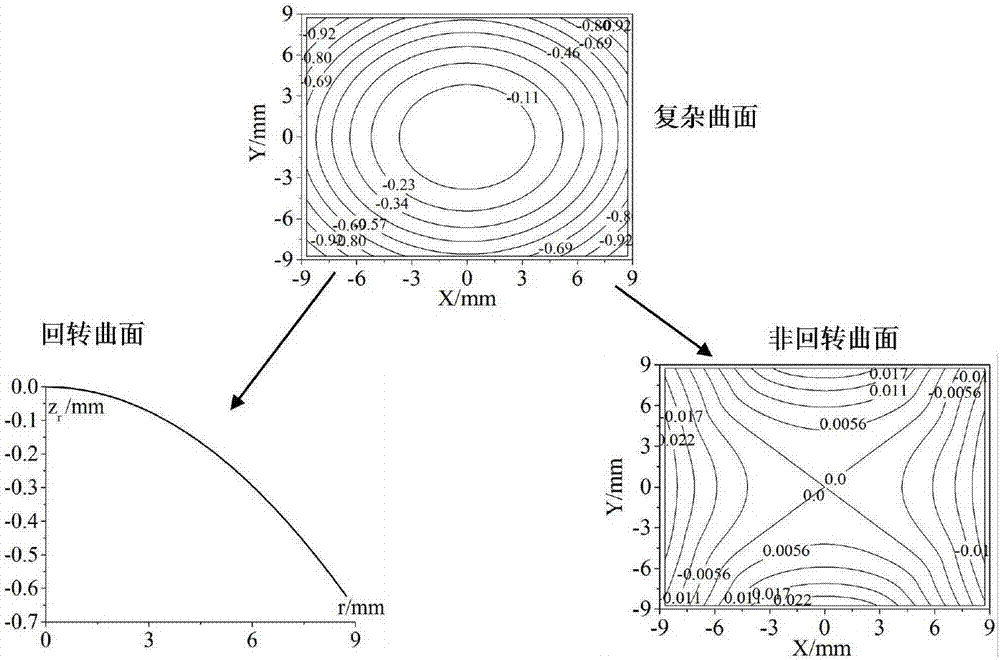

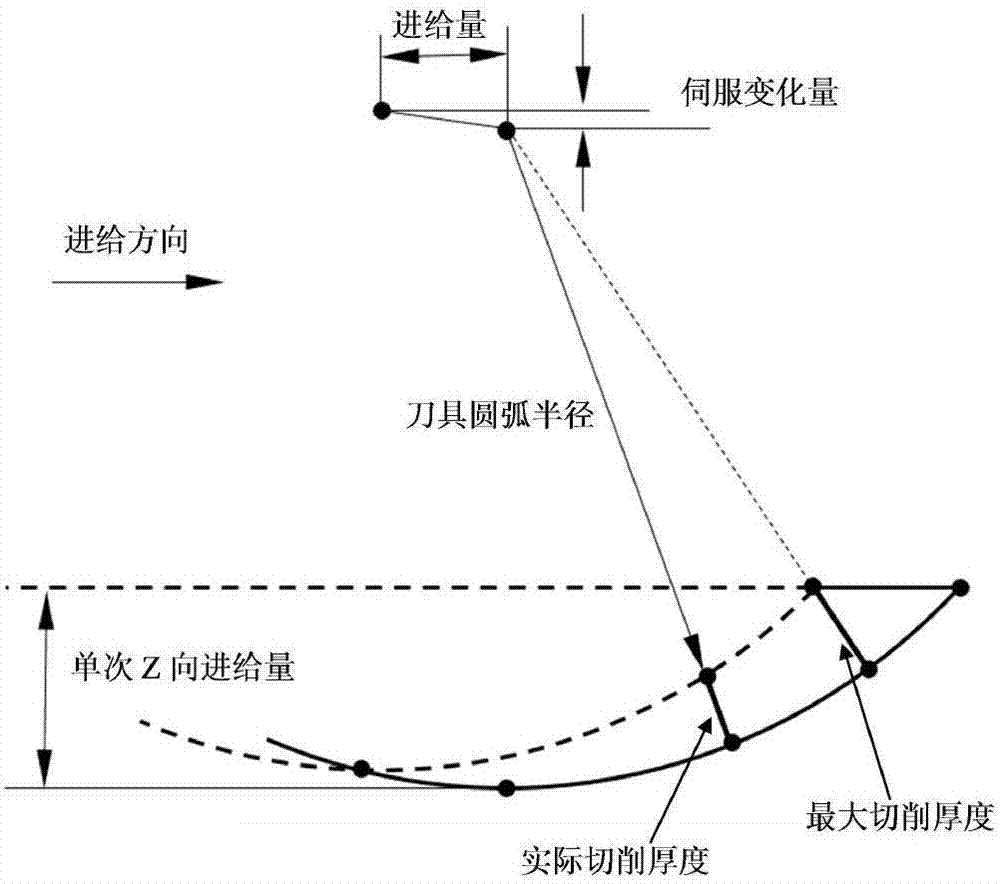

[0020] Aiming at the processing and forming of complex curved surfaces of brittle materials, the present invention proposes a fast tool servo turning method, which adds fast servo motion to the traditional turning, and adds one-dimensional fast motion to the tool motion, that is, the tool can make a small stroke along the sagittal height direction (Z direction) High-frequency reciprocating motion, this method is also called fast knife servo. Adding fast tool servo-assisted machining in the turning process can add the corresponding non-rotational amount on the basis of the surface of revolution, so as to generate complex surfaces with non-rotational symmetry. When the fast tool servo system has a high frequency response, it can adapt to the high-speed spindle speed, thereby ensuring the rapid cutting and forming of complex curved surfaces.

[0021] The specific implementation is as follows:

[0022] 1. Optimize the design of brittle materials near-revolving complex surfaces ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com