Patents

Literature

1368results about How to "Cutting stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

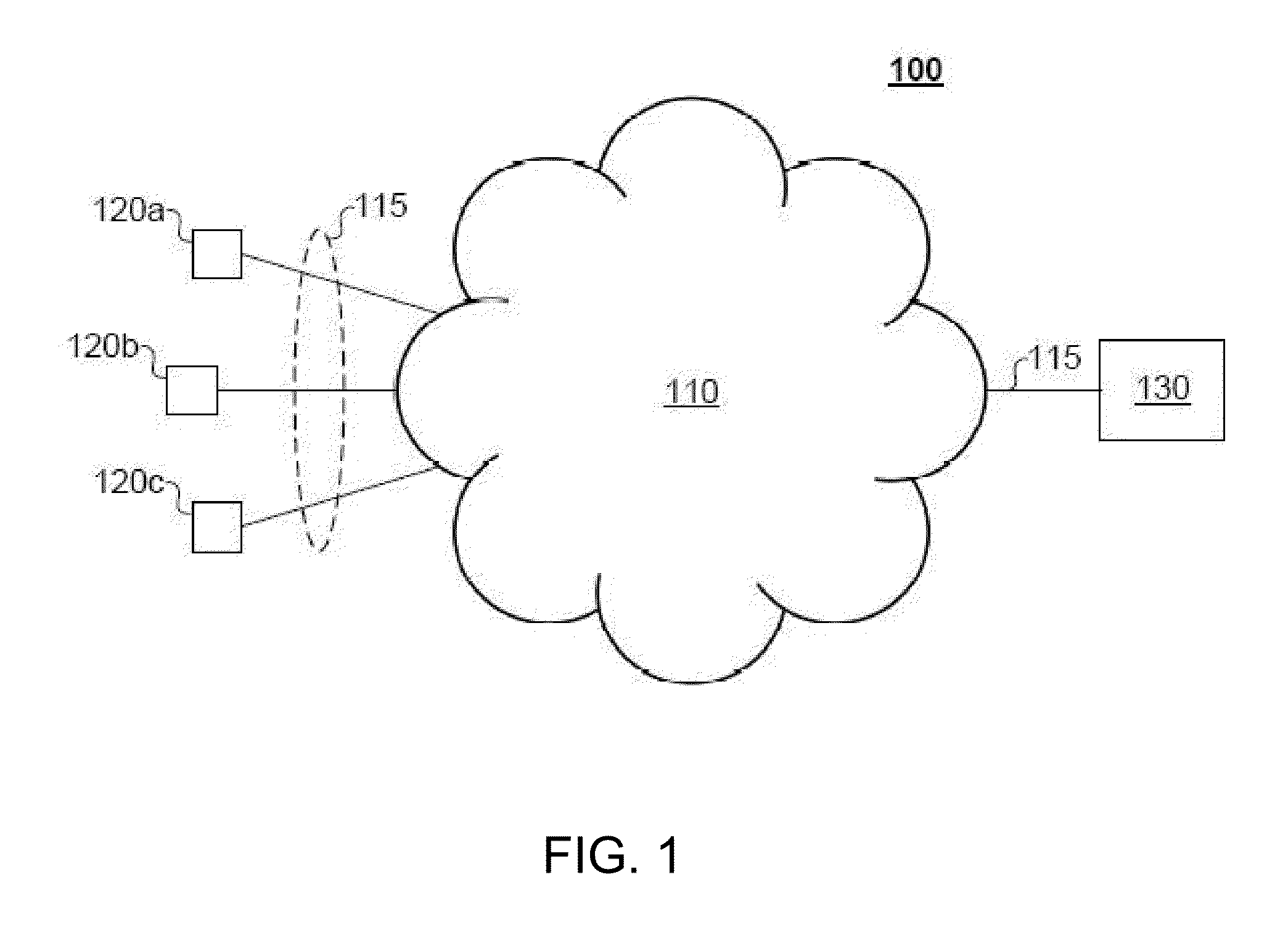

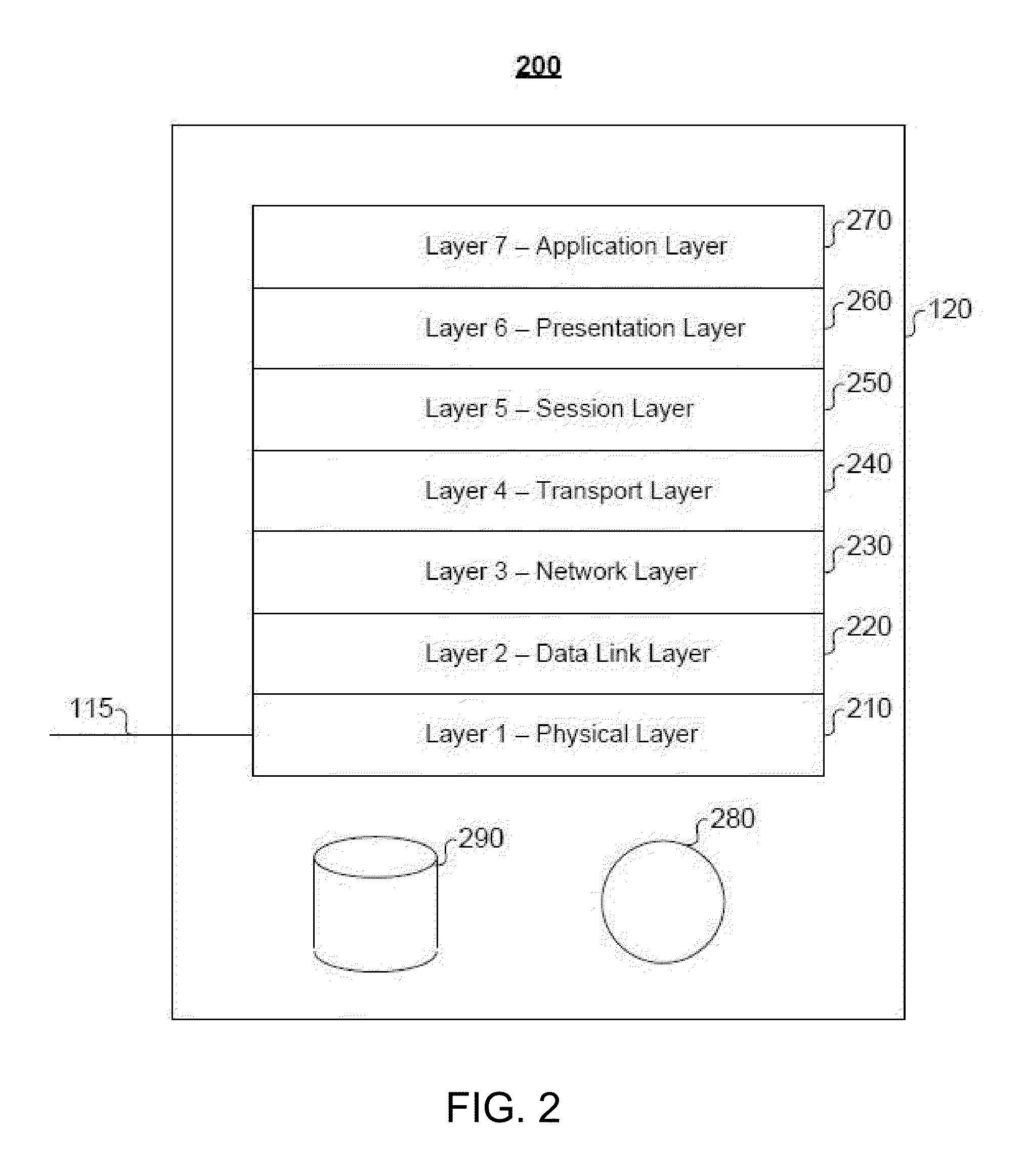

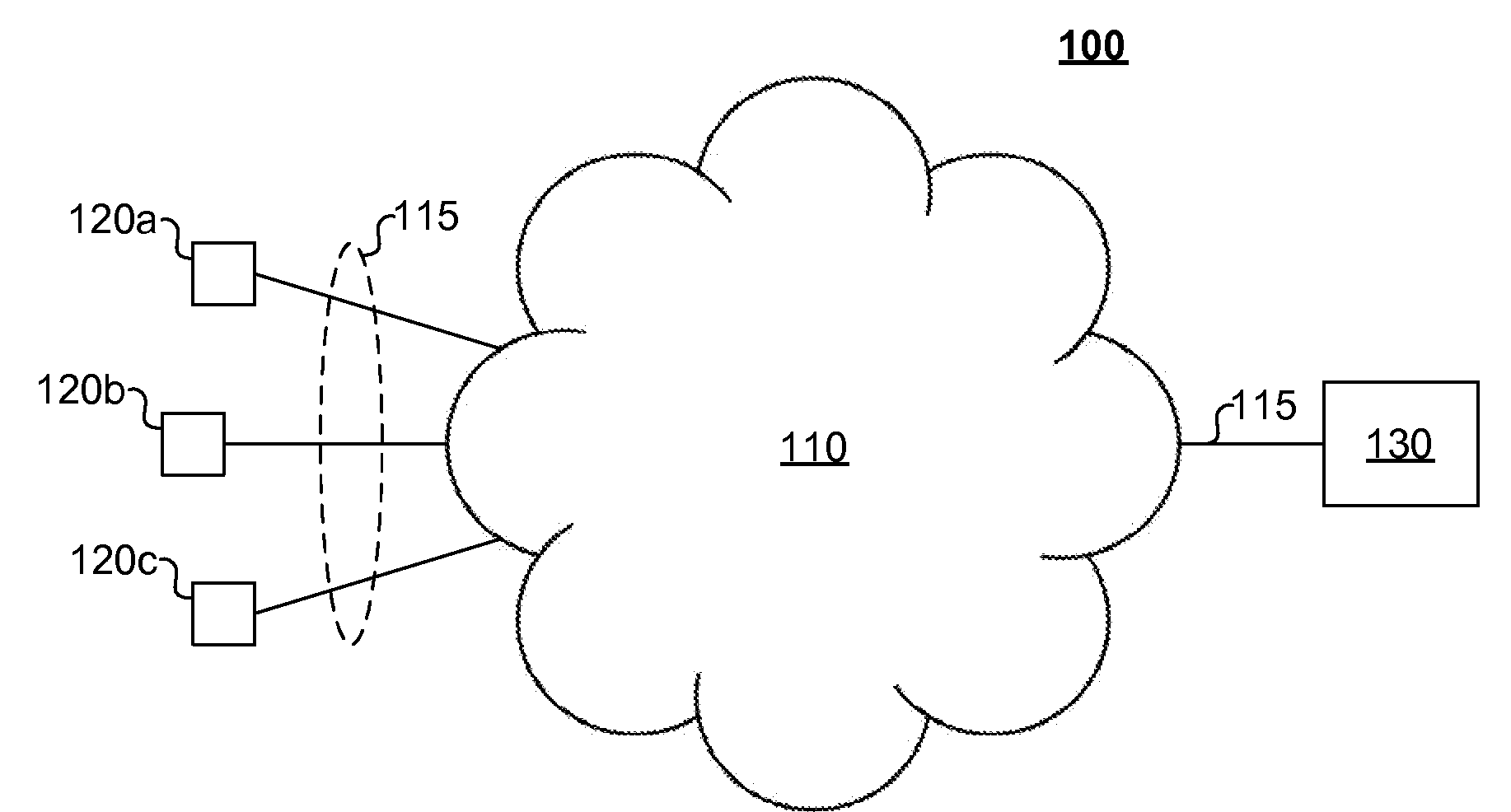

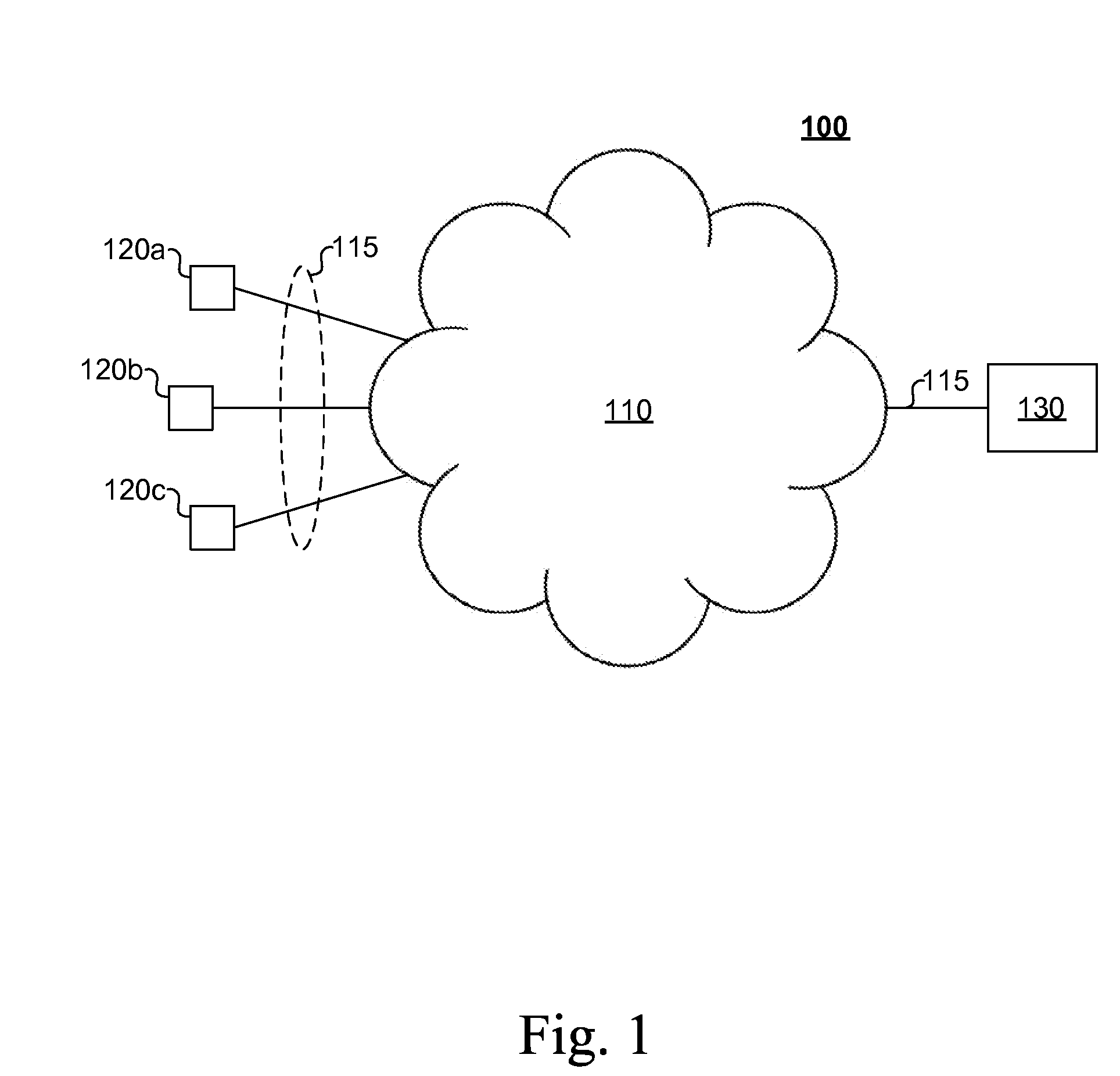

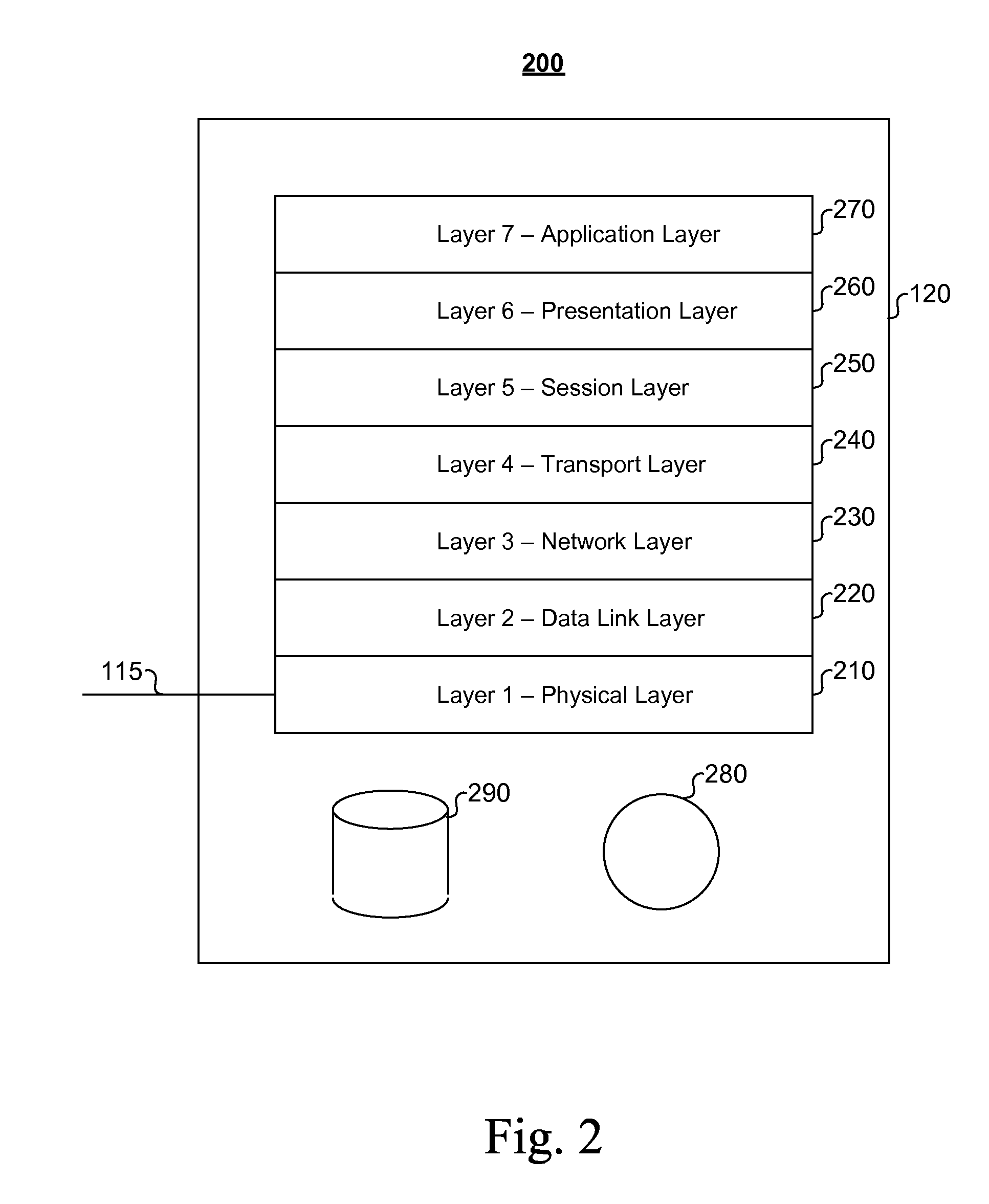

Methods and apparatus for detecting and limiting focused server overload in a network

InactiveUS20100274893A1Low transfer rateReduce in quantityEnergy efficient ICTDigital computer detailsHash functionComputer program

Computer-based methods and apparatuses, including computer program products, are described for detecting and limiting focused server overload in a network. A feedback message is received from a downstream server, wherein the feedback message includes a communication protocol statistic. The methods and apparatuses determine which of one or more counters that store a number of feedback messages received that include the statistic, from an array of counters, are associated with the downstream server using one or more hash functions based on information included in the feedback message. The one or more counters are incremented in response to the feedback message including the statistic. Using the one or more hash functions, a value of the number stored in the one or more counters is determined. The value is determined to be indicative of an overload episode in the network for the downstream server based on whether the value satisfies a predetermined criteria.

Owner:SONUS NETWORKS

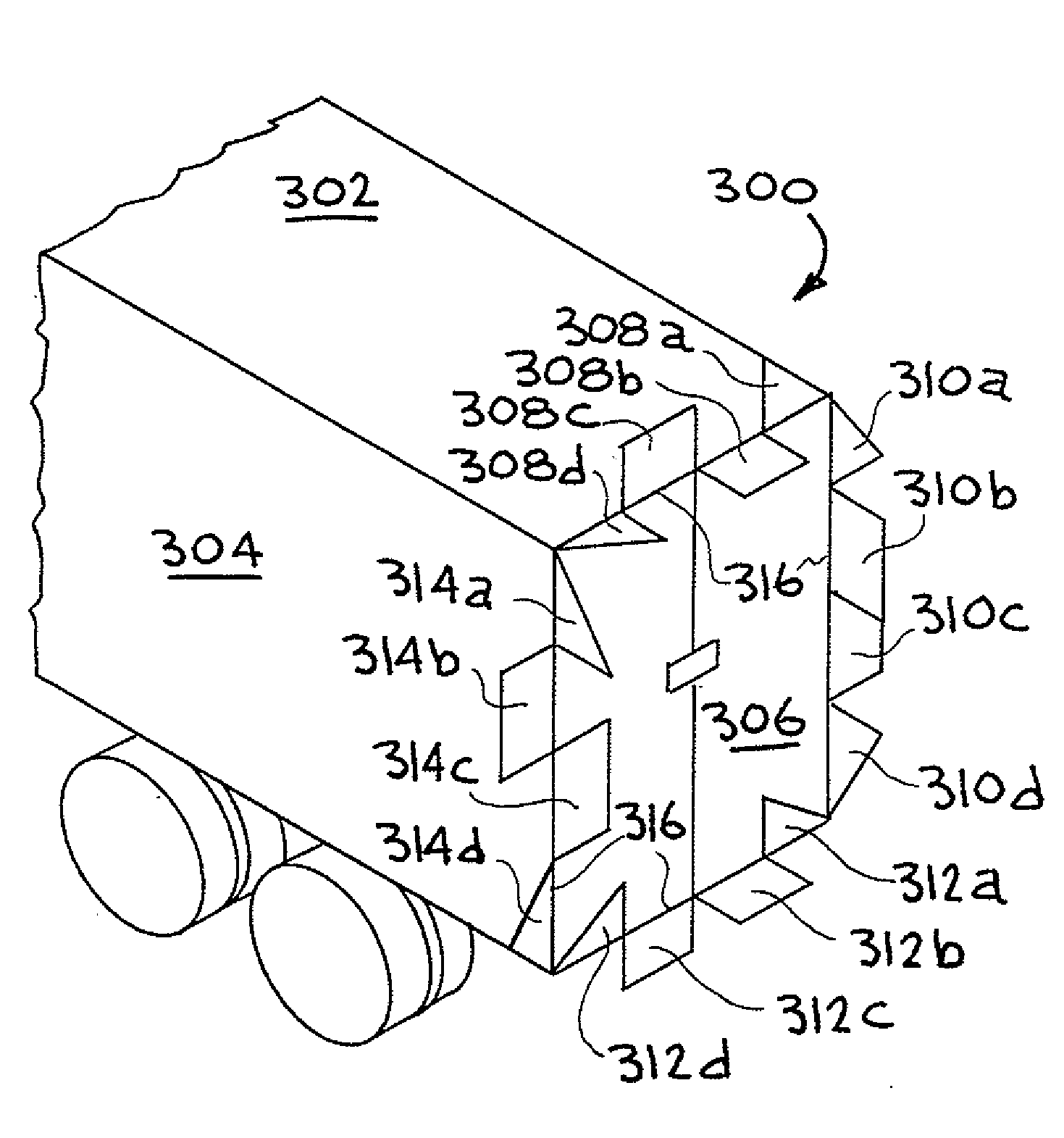

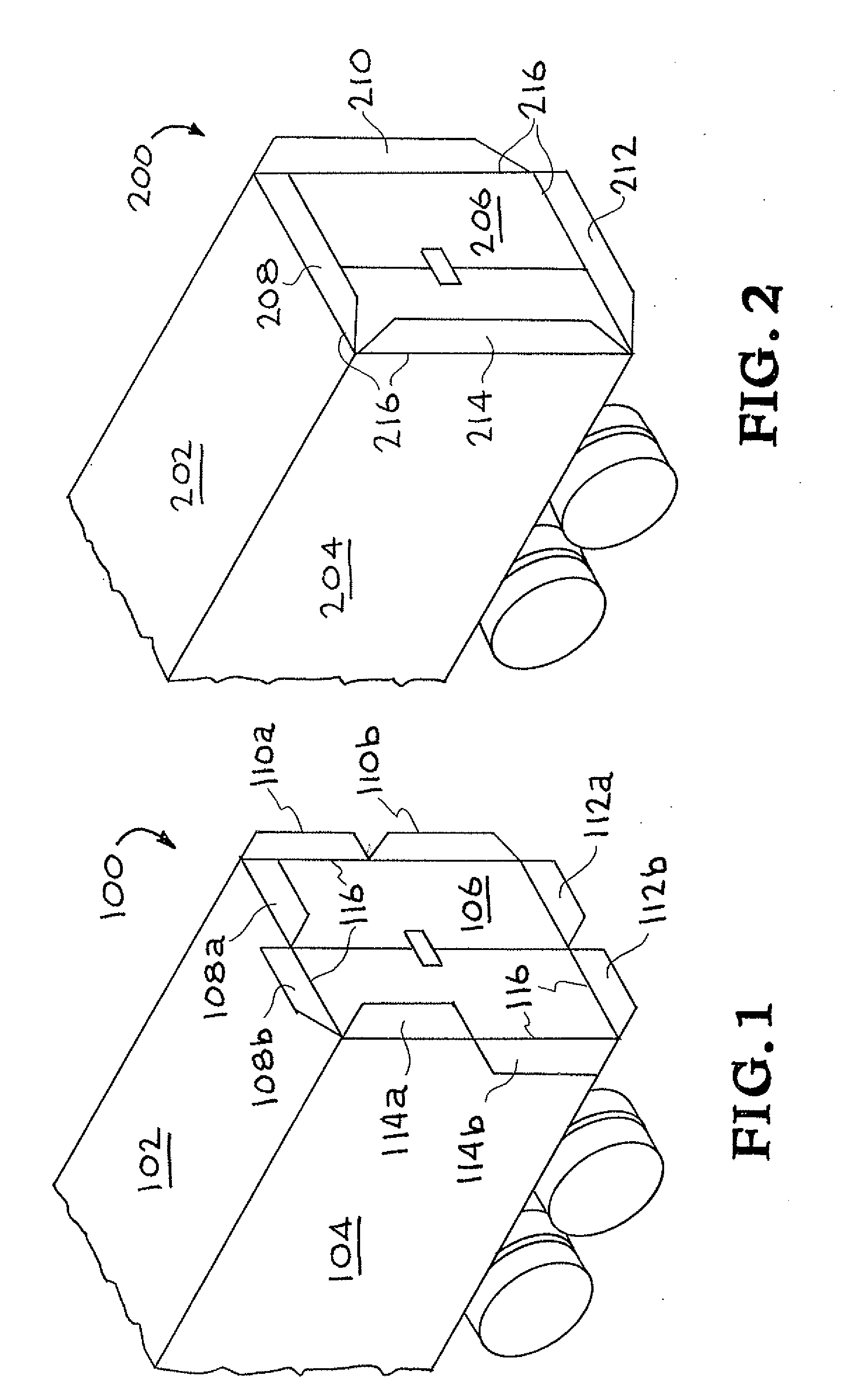

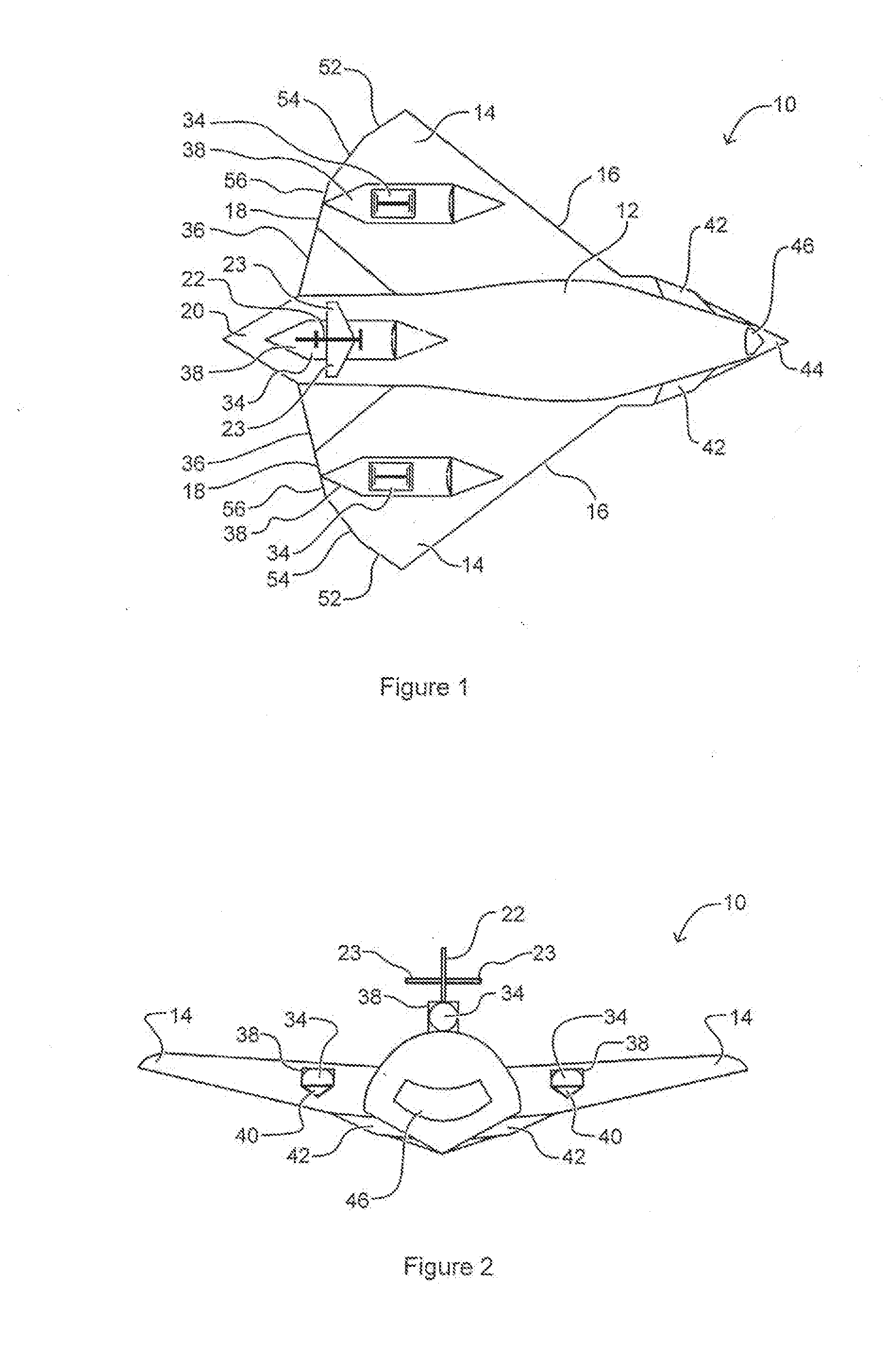

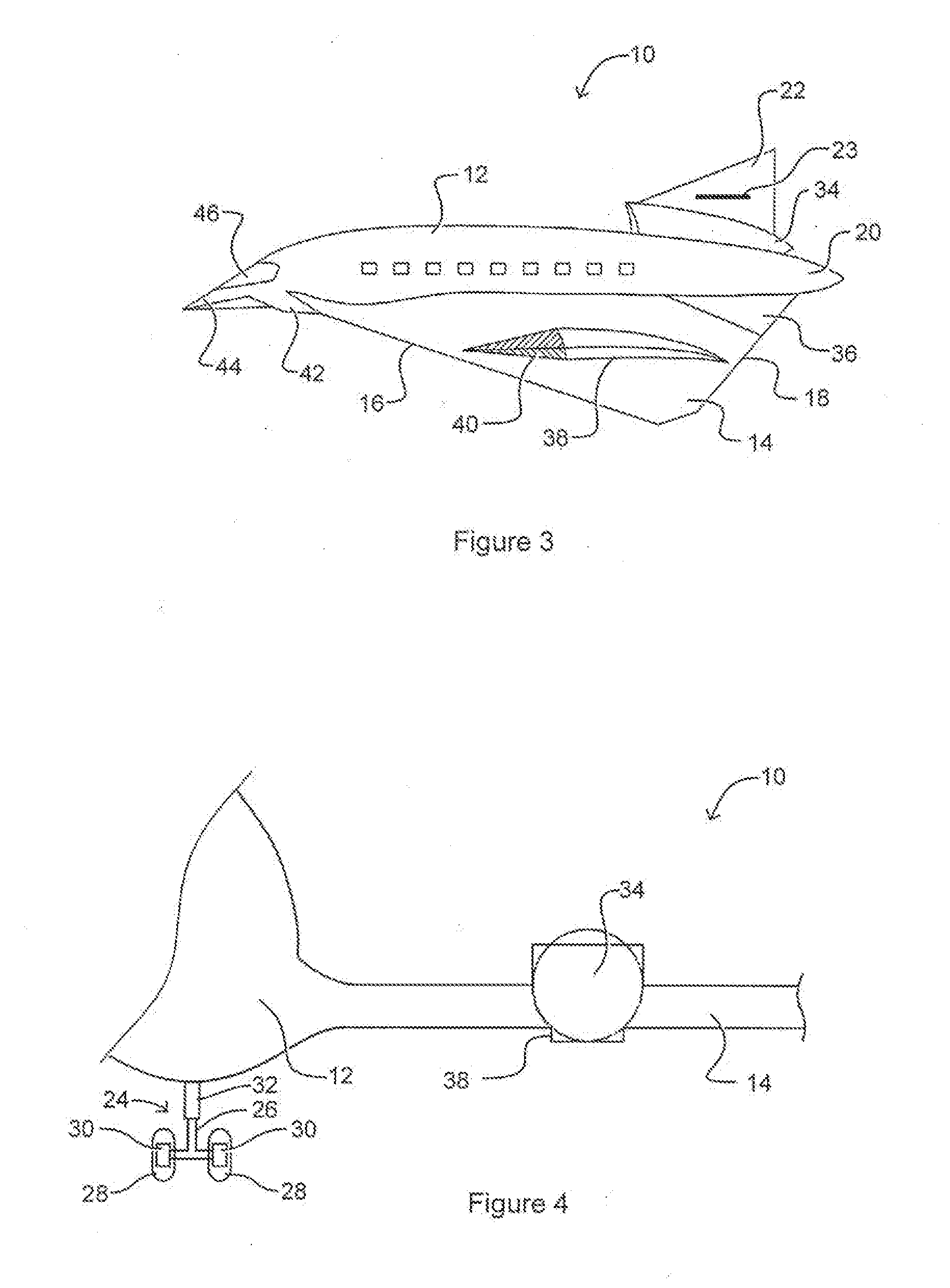

Articulating base flaps for aerodynamic base drag reduction and stability of a bluff body vehicle

InactiveUS20100106380A1Cutting stabilityVehicle seatsVehicle body stabilisationAerodynamic dragRange of motion

An aerodynamic base drag reduction and stability control apparatus and method uses a plurality of articulable base flaps each hingedly connected near one of a left side edge, a right side edge, a top side edge, and a bottom side edge of a rear end base of a vehicle so that each of the base flaps have a corresponding range of motion between a first position subject to direct impingement by a free stream adjacent the vehicle in motion and a second position not subject to direct impingement by the free stream. And a controller independently actuates the base flaps to corresponding desired positions relative to the free stream and within the corresponding ranges of motion to produce a desired combined aerodynamic drag reducing and / or stabilizing effect on the vehicle in motion.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

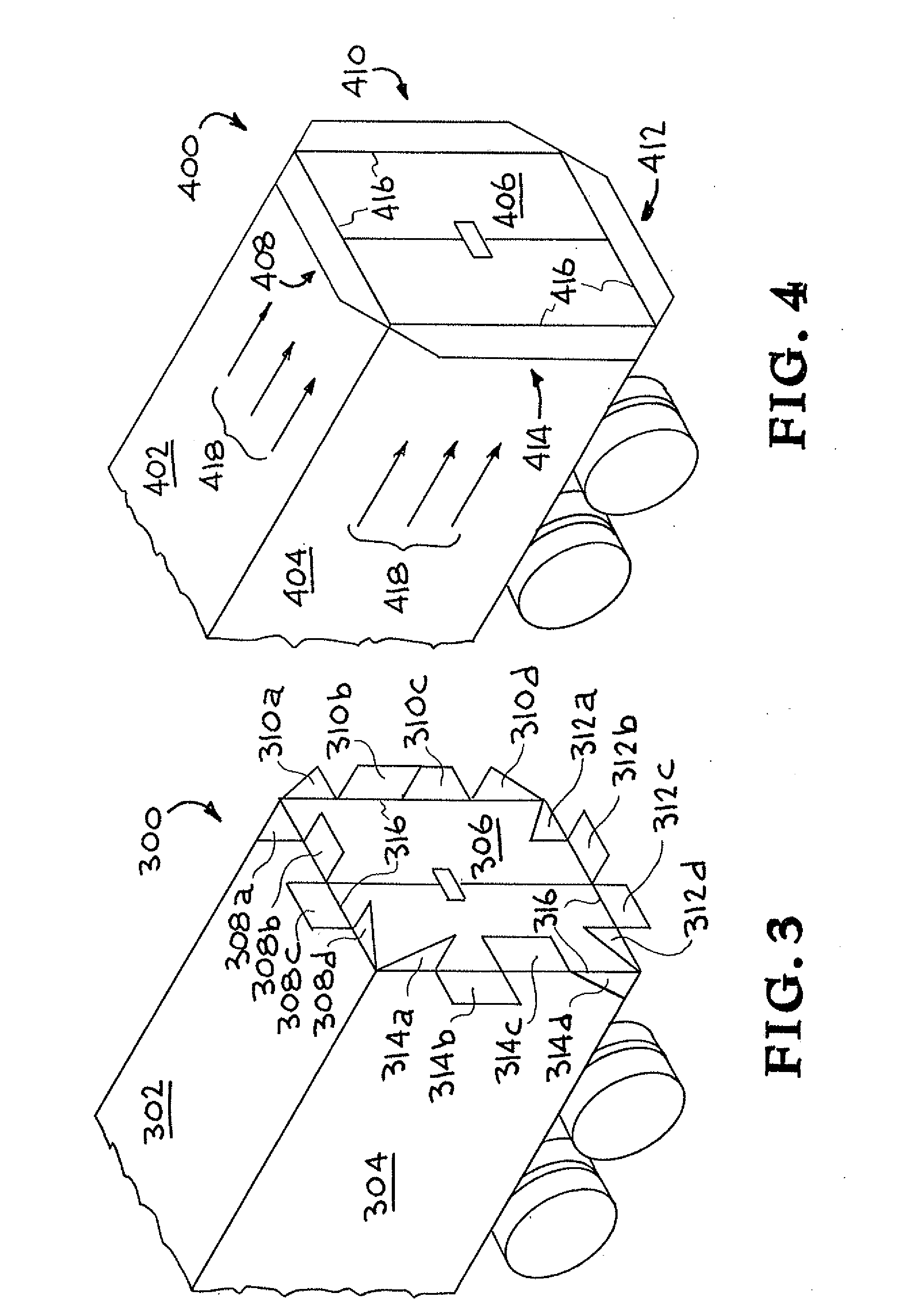

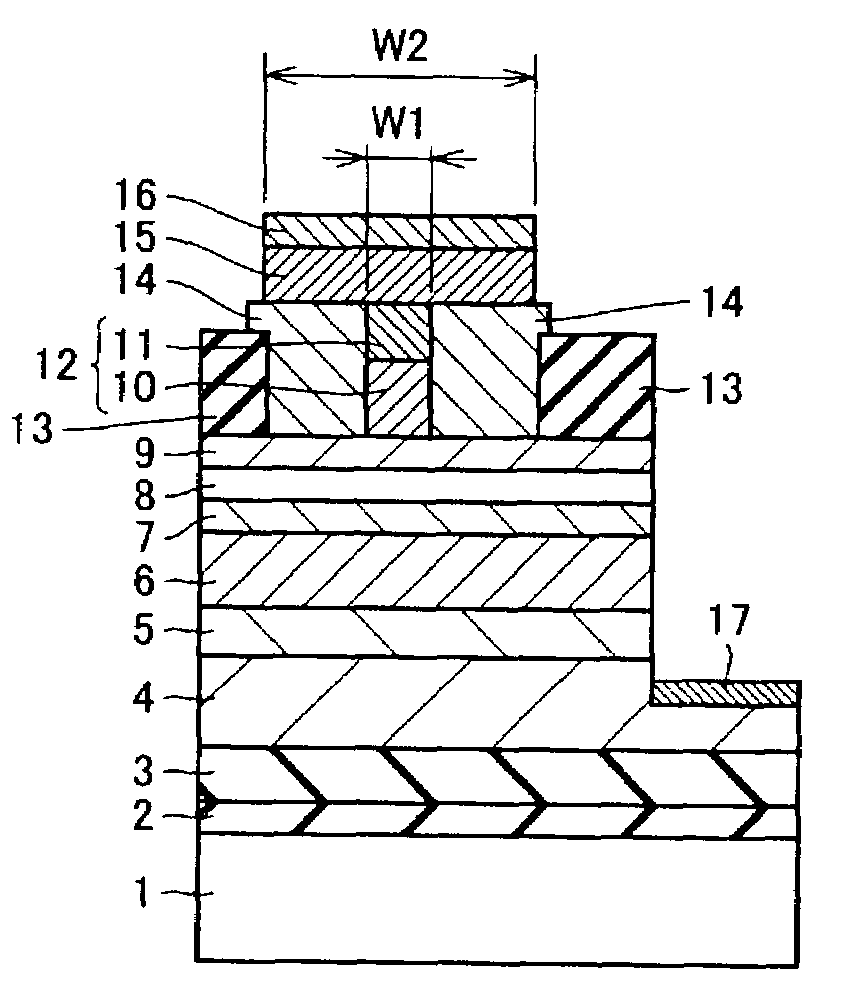

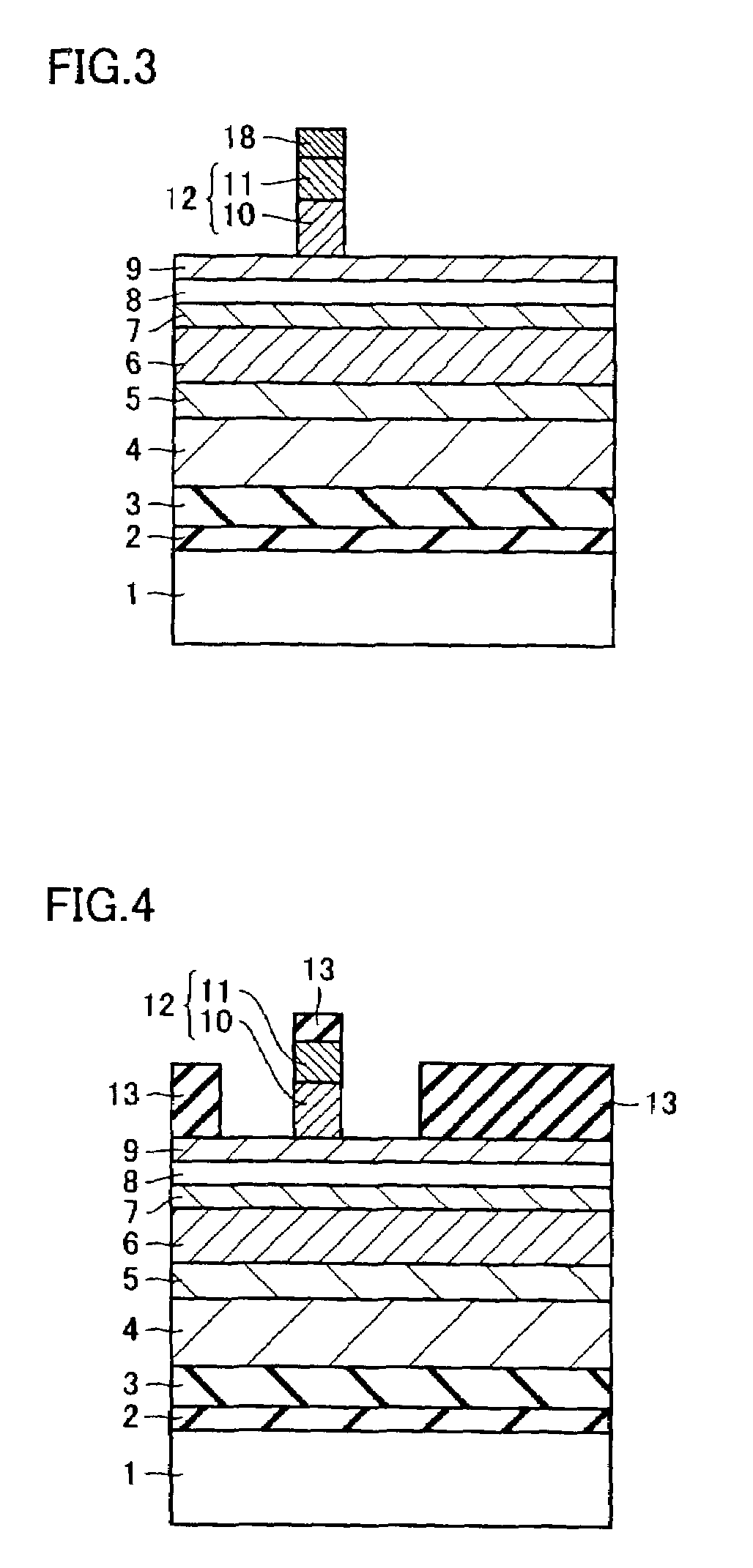

Nitride-based semiconductor light-emitting device and method of fabricating the same

InactiveUS6977953B2Cutting stabilityInhibition formationOptical wave guidanceSolid-state devicesNitrideLight emitting device

A nitride-based semiconductor light-emitting device capable of stabilizing transverse light confinement is obtained. This nitride-based semiconductor light-emitting device comprises an emission layer, a cladding layer, formed on the emission layer, including a first nitride-based semiconductor layer and having a current path portion and a current blocking layer, formed to cover the side surfaces of the current path portion, including a second nitride-based semiconductor layer, while the current blocking layer is formed in the vicinity of the current path portion and a region having no current blocking layer is included in a region not in the vicinity of the current path portion. Thus, the width of the current blocking layer is reduced, whereby strain applied to the current blocking layer is relaxed. Consequently, the thickness of the current blocking layer can be increased, thereby stabilizing transverse light confinement.

Owner:EPISTAR CORP

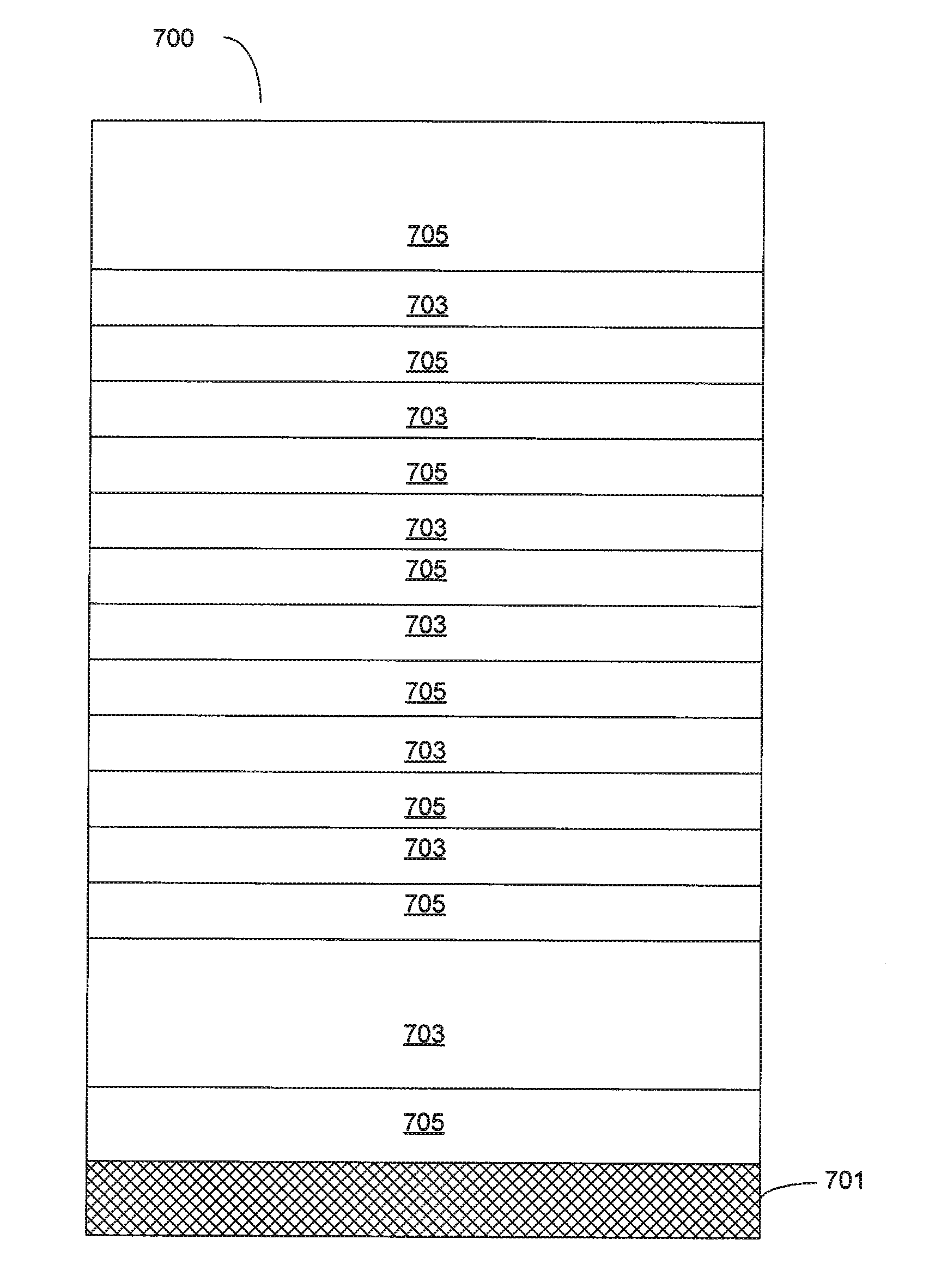

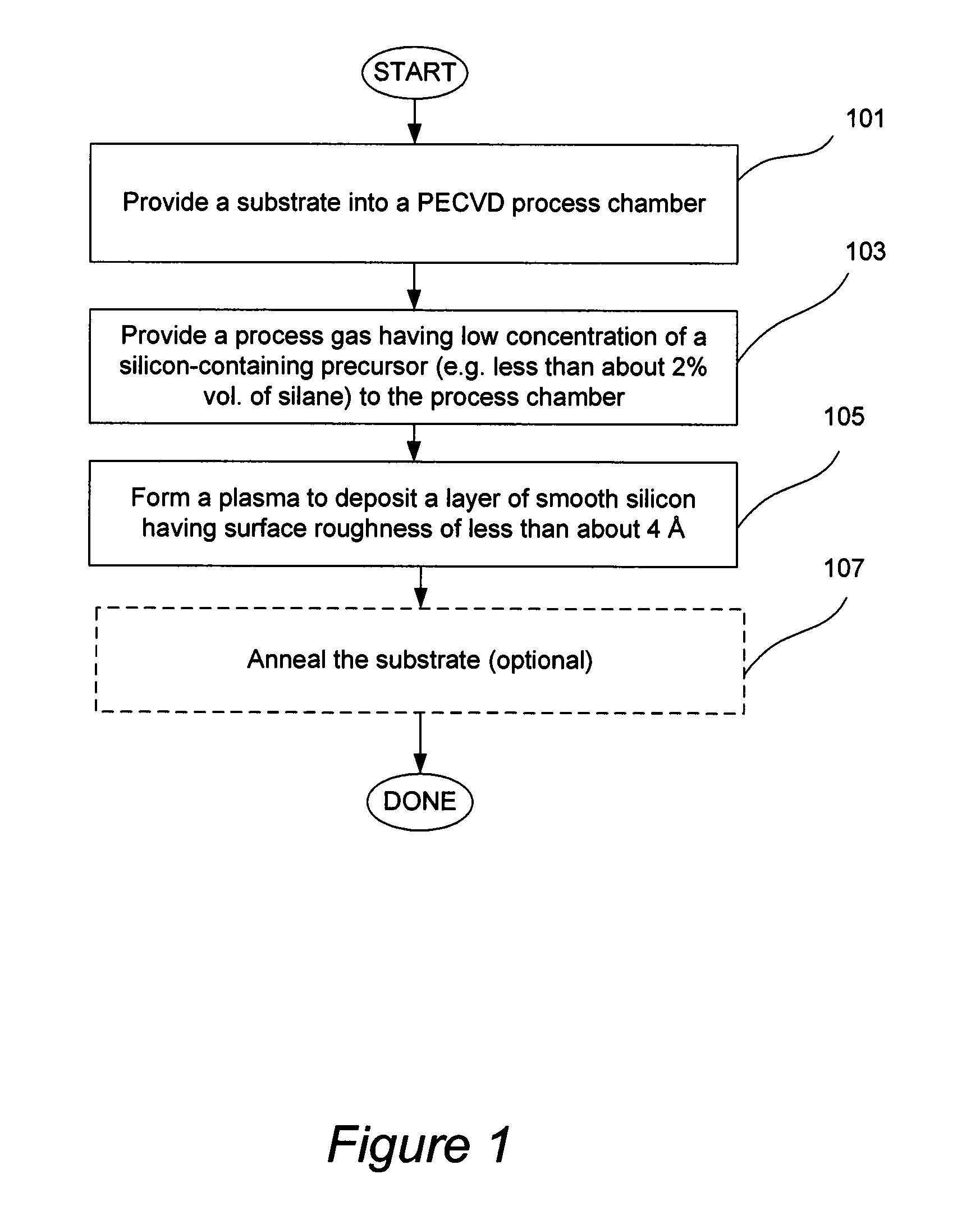

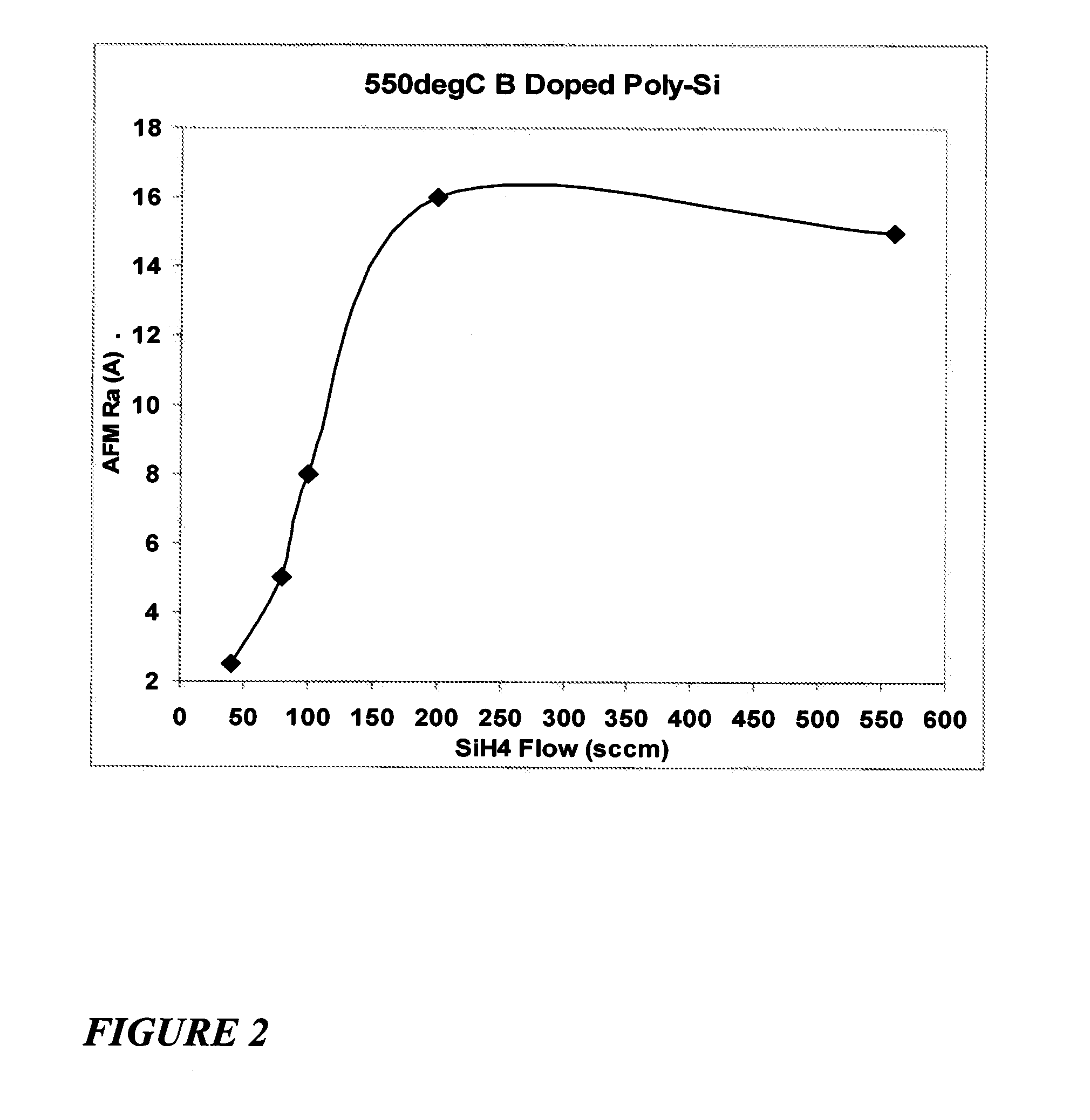

Pecvd deposition of smooth polysilicon films

InactiveUS20120142172A1Beneficial for thermal budgetReduced stabilityLiquid surface applicatorsSemiconductor/solid-state device manufacturingDopantSilicon oxide

Smooth silicon and silicon germanium films are deposited by plasma enhanced chemical vapor deposition (PECVD). The films are characterized by roughness (Ra) of less than about 4 Å. In some embodiments, smooth silicon films are undoped and doped polycrystalline silicon films. The dopants can include boron, phosphorus, and arsenic. In some embodiments the smooth polycrystalline silicon films are also highly conductive. For example, boron-doped polycrystalline silicon films having resistivity of less than about 0.015 Ohm cm and Ra of less than about 4 Å can be deposited by PECVD. In some embodiments smooth silicon films are incorporated into stacks of alternating layers of doped and undoped polysilicon, or into stacks of alternating layers of silicon oxide and doped polysilicon employed in memory devices. Smooth films can be deposited using a process gas having a low concentration of silicon-containing precursor and / or a process gas comprising a silicon-containing precursor and H2.

Owner:NOVELLUS SYSTEMS

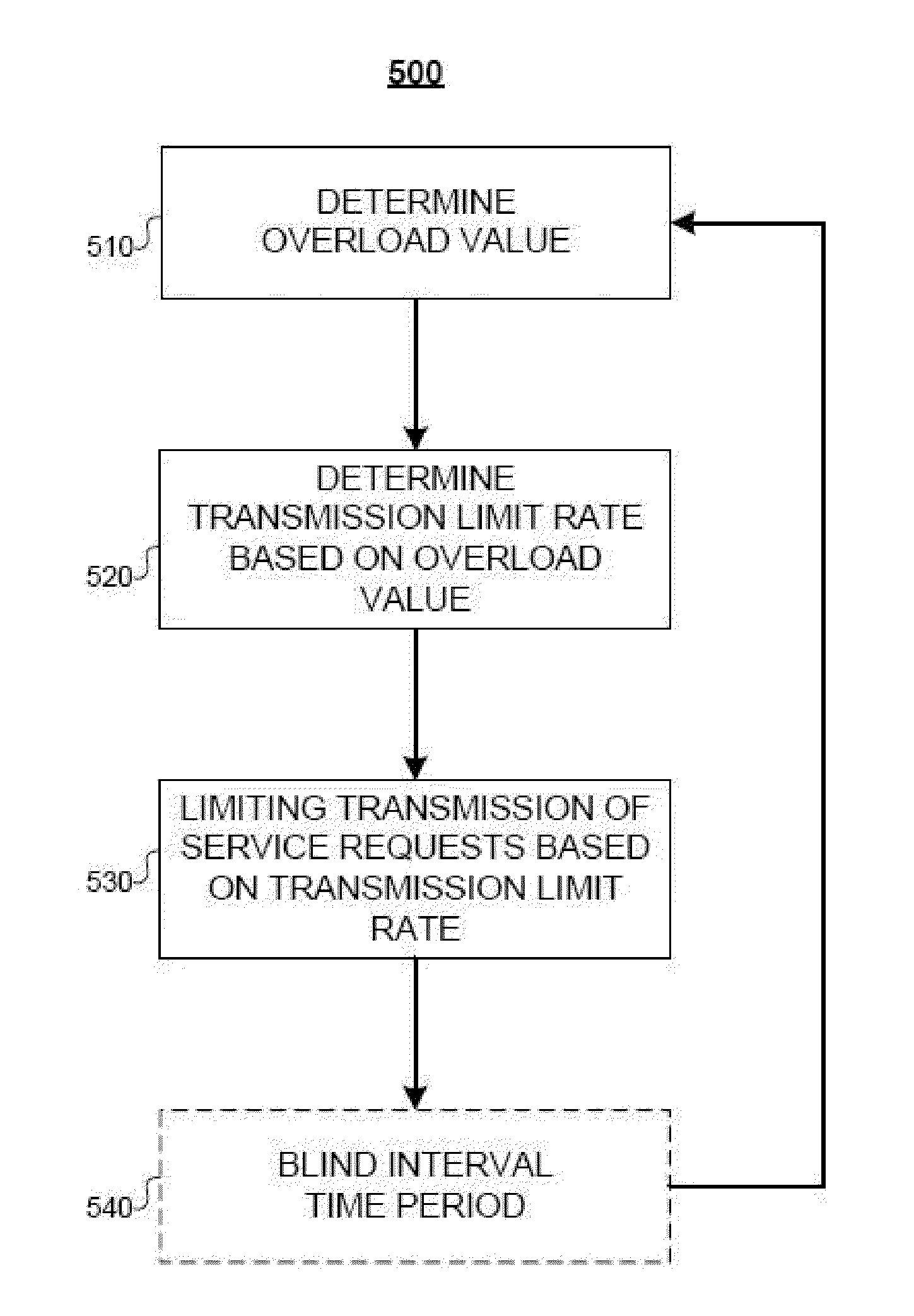

Adaptive rate control based on overload signals

ActiveUS20100271947A1Maximize server throughputReduce Feedback LatencyEnergy efficient ICTError preventionComputer programReal-time computing

Described are methods and apparatuses, including computer program products, for limiting server overload via client control. A first set of a plurality of requests are transmitted to a server at a first transmission rate during a first period of time. The first transmission rate is limited to be less than or equal to a first transmission limit rate. An overload value is determined based on whether at least two or more requests of the first set of requests for service satisfy an overload criterion. A second transmission limit rate is determined based on the overload value and the first transmission limit rate. A second set of a plurality of requests is transmitted to the server at a second transmission rate during a second period of time. The second transmission rate is limited to be less than or equal to the second transmission limit rate.

Owner:RIBBON COMM OPERATING CO INC

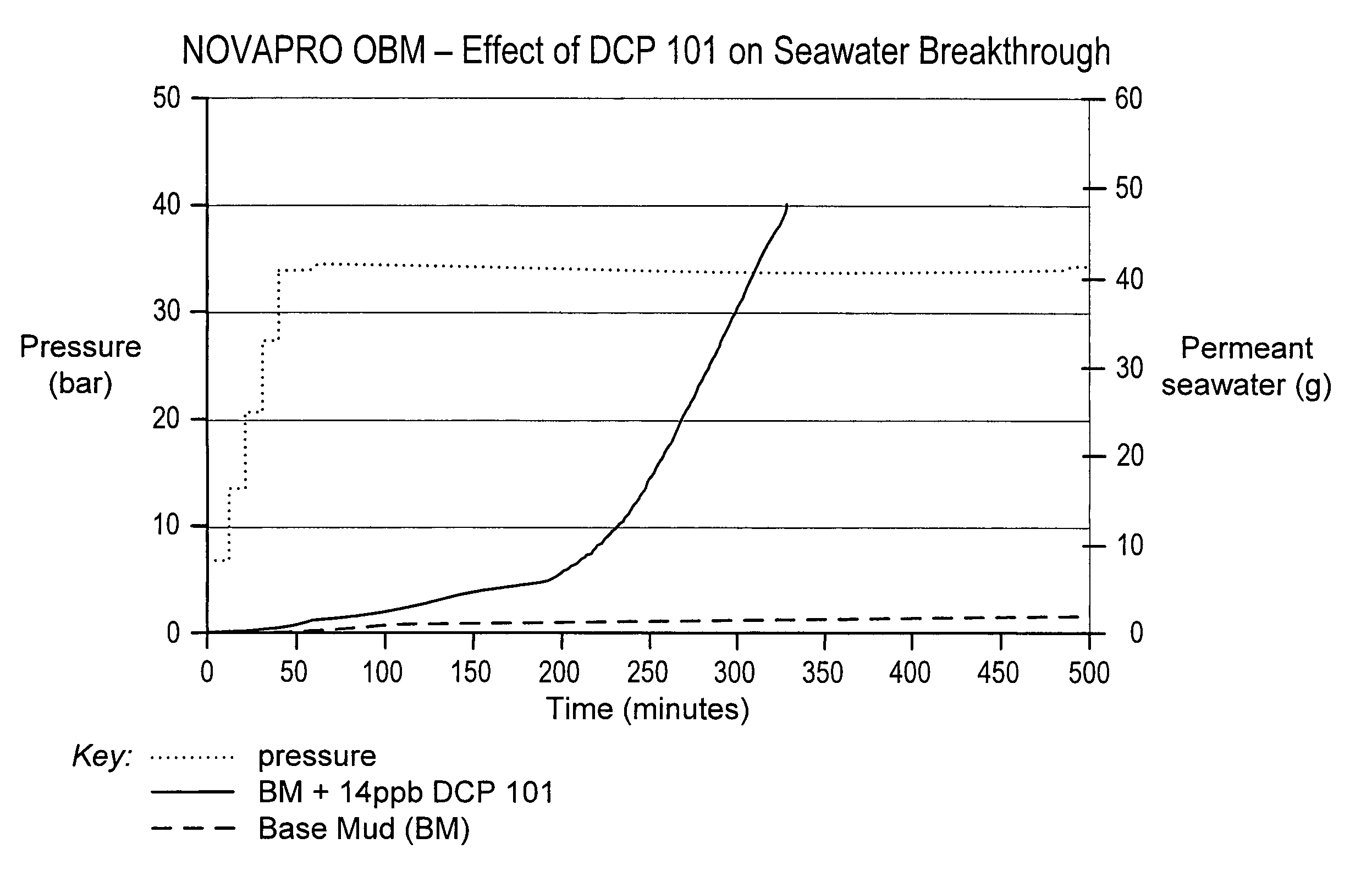

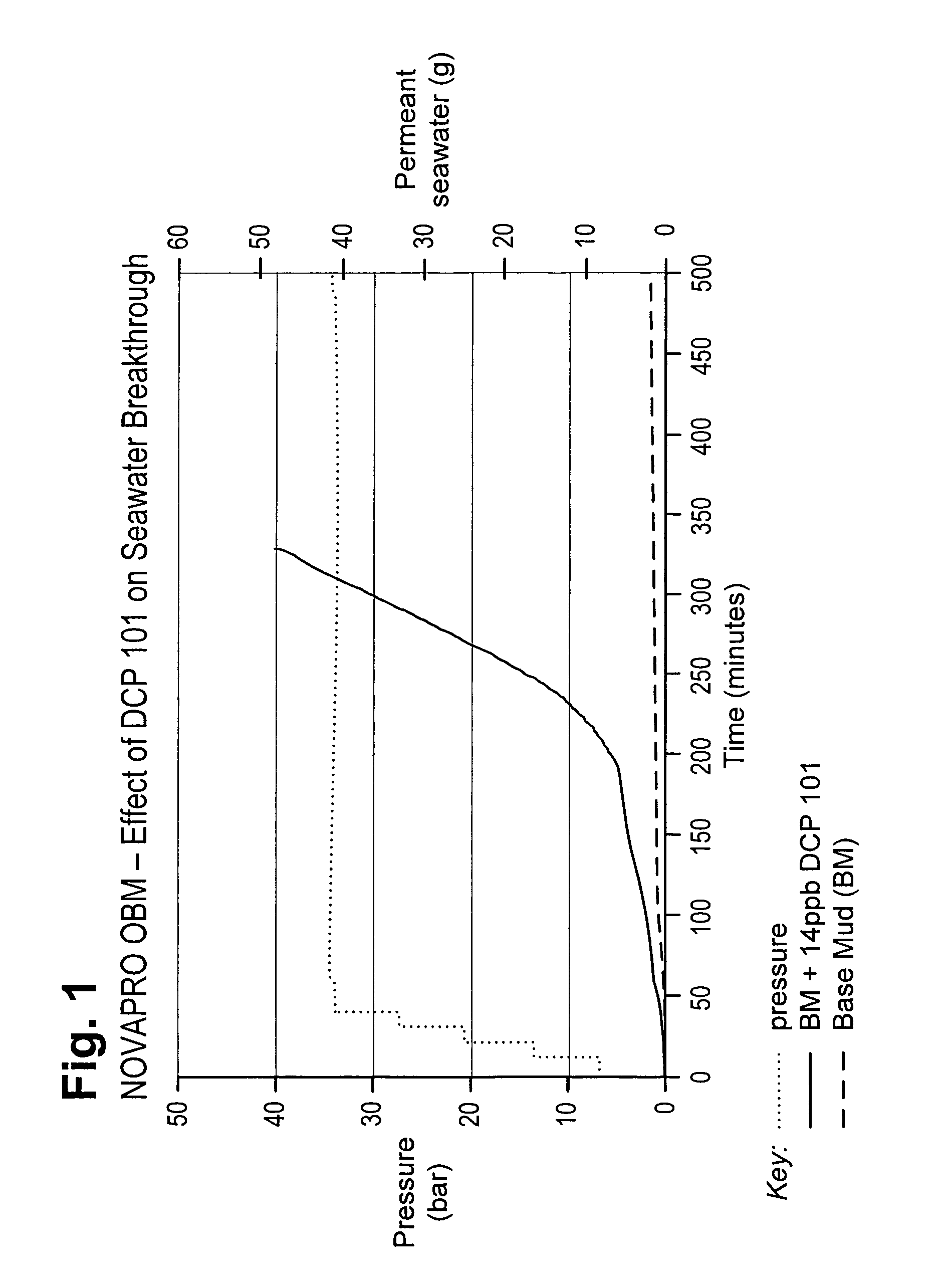

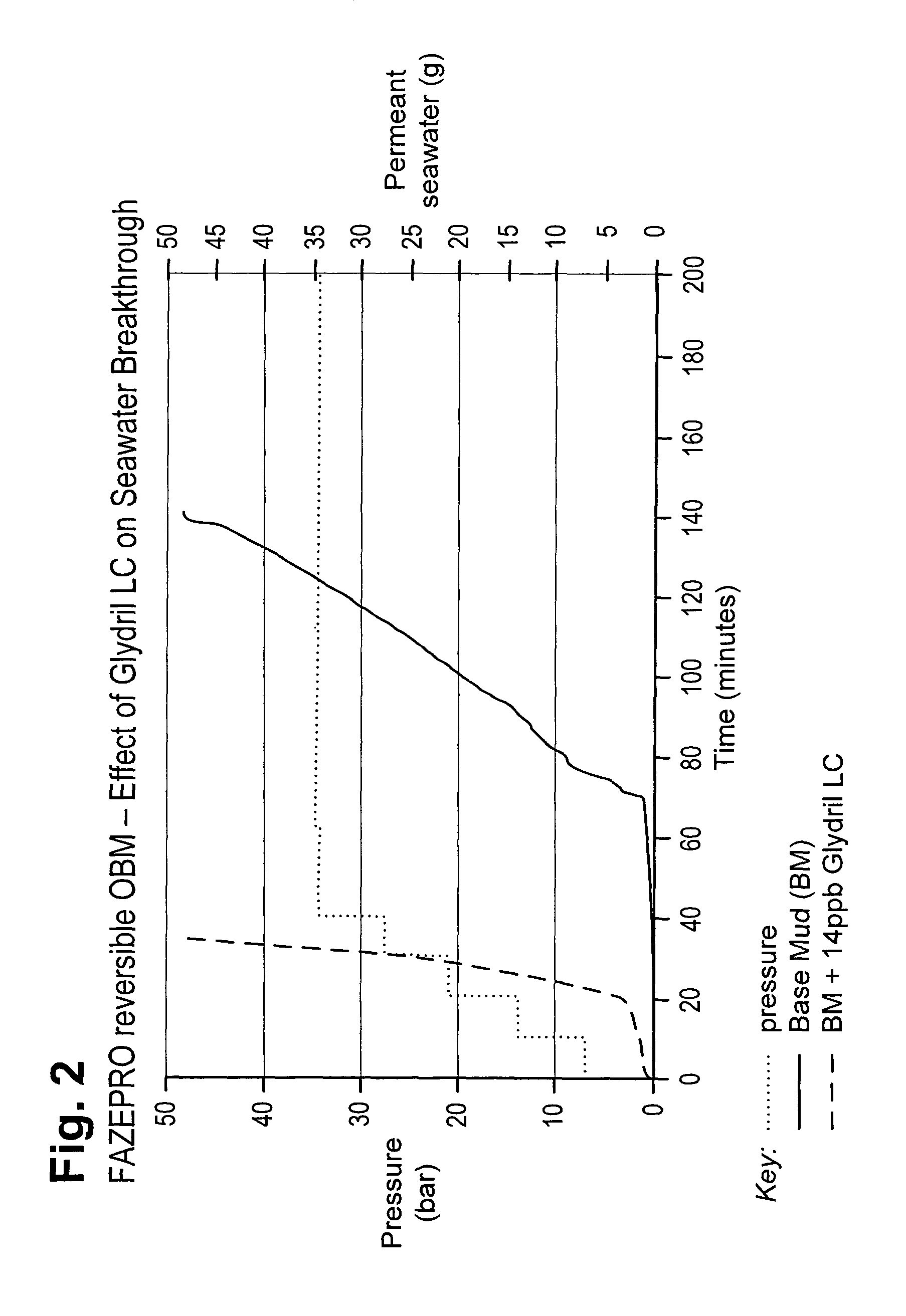

Wellbore fluid

Oil-based wellbore fluid in the form of an emulsion having a continuous phase containing an oil and, dispersed therein, a first dispersed liquid phase and a second separate dispersed liquid phase. The first dispersed liquid phase is a brine phase containing at least 5% by weight of a dissolved salt or a mixture of salts, and the second dispersed liquid phase is a polar organic liquid which is insoluble or sparingly soluble in the brine and contains the first dispersed liquid phase, but is soluble in pure water. The second dispersed liquid phase is in the form of droplets having an average diameter of not less than 5 microns.

Owner:BP EXPLORATION OPERATING CO LTD

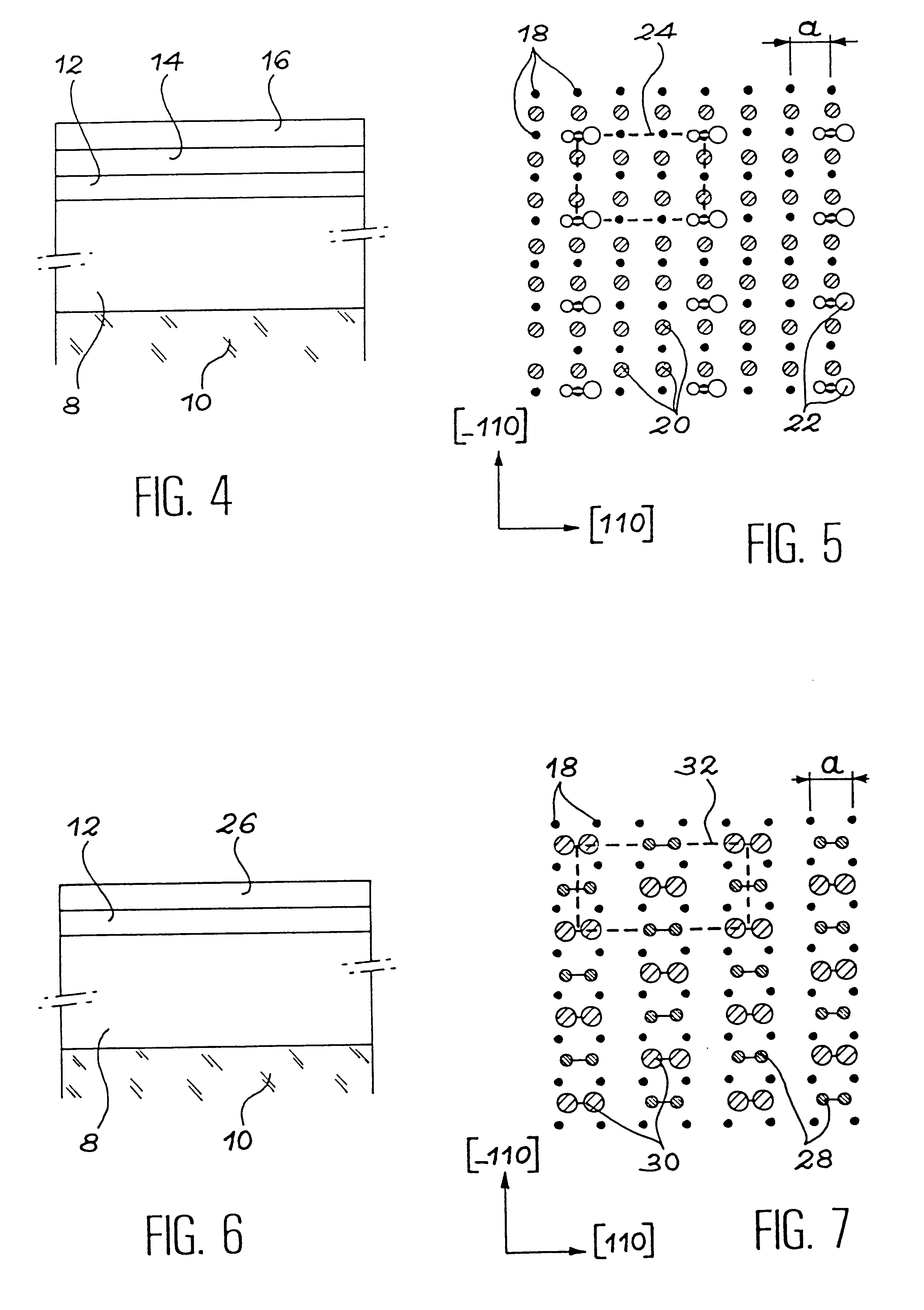

Very long and highly stable atomic wires, method for making these wires, application in nano-electronics

InactiveUS6274234B1Convenient lengthImprove stabilityNanoinformaticsSolid-state devicesEngineeringSic substrate

Atomic wires of great length and great stability are formed on the surface of a SiC substrate as straight chains of dimers of an element chosen from amongst SiC and C. In order to produce same, layers of the element are formed on the surface and the assembly is constructed by means of annealings of the surface provided with the layers. The resulting wires have application to nanoelectronics.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

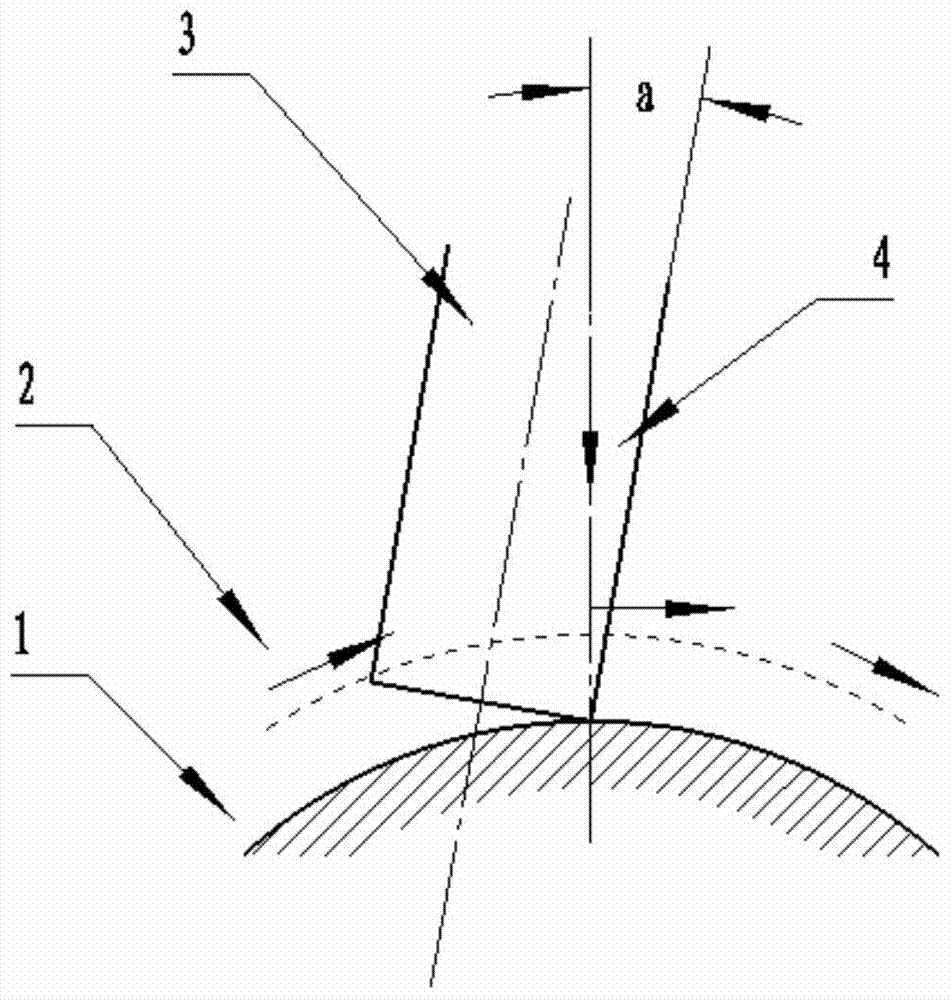

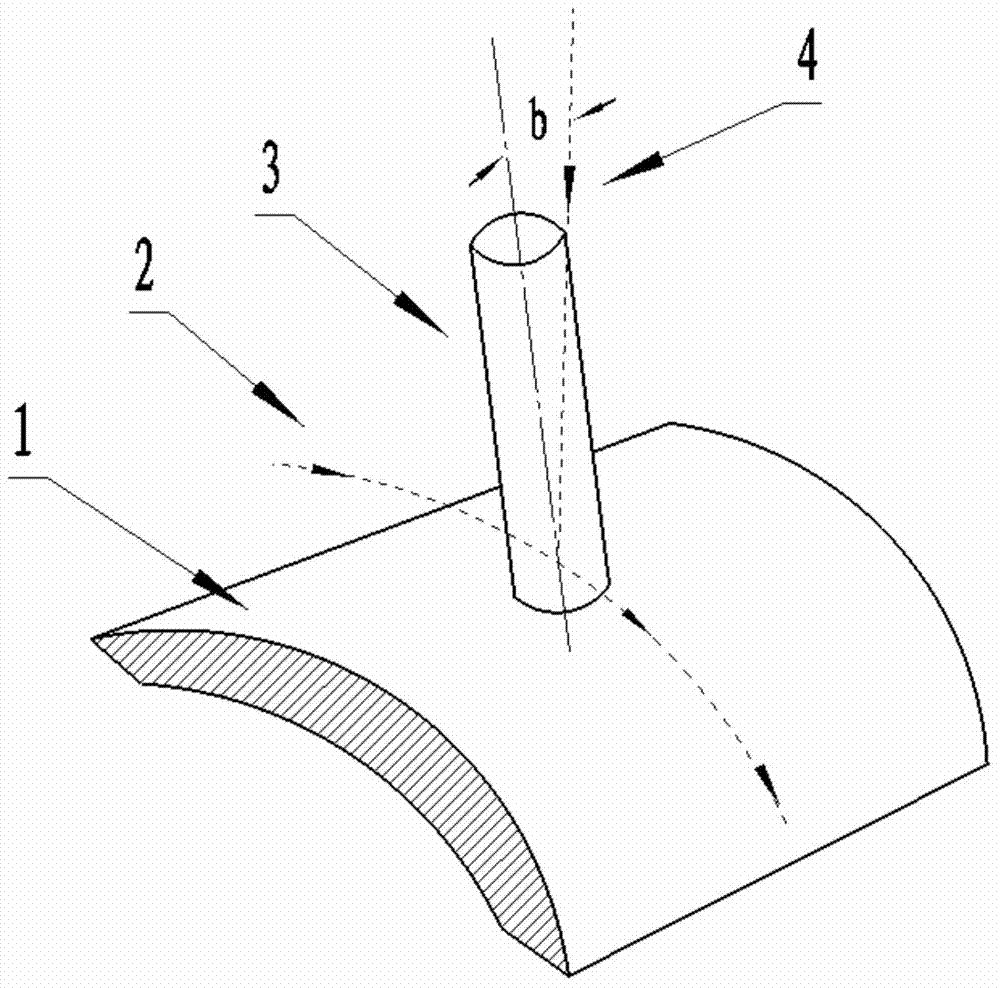

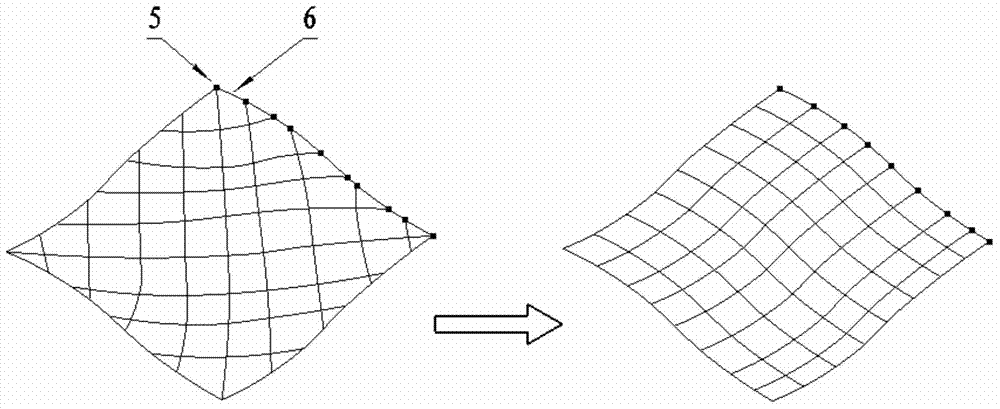

Multi-axis curved surface type numerically-controlled method for machining complicated curved surface part

ActiveCN103537743AImprove cutting efficiencySmall residualAutomatic control devicesFeeding apparatusNumerical controlMilling cutter

The invention discloses a multi-axis curved surface type numerically-controlled method for machining a complicated curved surface part. According to the method disclosed by the invention, the axis of a cutter can be arranged according to the directions of longitude and latitude normal lines for forming a curved surface, an inclined angle is adjusted to generate a cutter path, and the machining efficiency and the part surface smoothness can be improved. The numerically-controlled method can be realized by the following technical scheme: a part is fixed in a rotary center of a five-shaft machine tool; a curved surface is reconstructed according to the curvature change, the normal line direction of the curved surface and a machining path; a space change of an axis vector of the cutter is controlled by adjusting the front inclined angle and the side inclined angle of a cutter shaft of a flat-bottom end mill so that the cutter always keeps that a cutter tip participates in curved surface cutting in the five-axis continuous cutting process; a curved surface projection machining manner is adopted in the programming process so that the mill can carry out multi-axis linked milling machining according to the curvature change of the curved surface; the axis of the cutter is similar with a relatively small front inclined angle alpha overlapped to the normal line direction of the cutter path and a side inclined angle is set as 0; the axis of the cutter is kept vertical to the direction of the machining path to implement a five-axis linked machining numerical control procedure.

Owner:四川泛华航空仪表电器有限公司

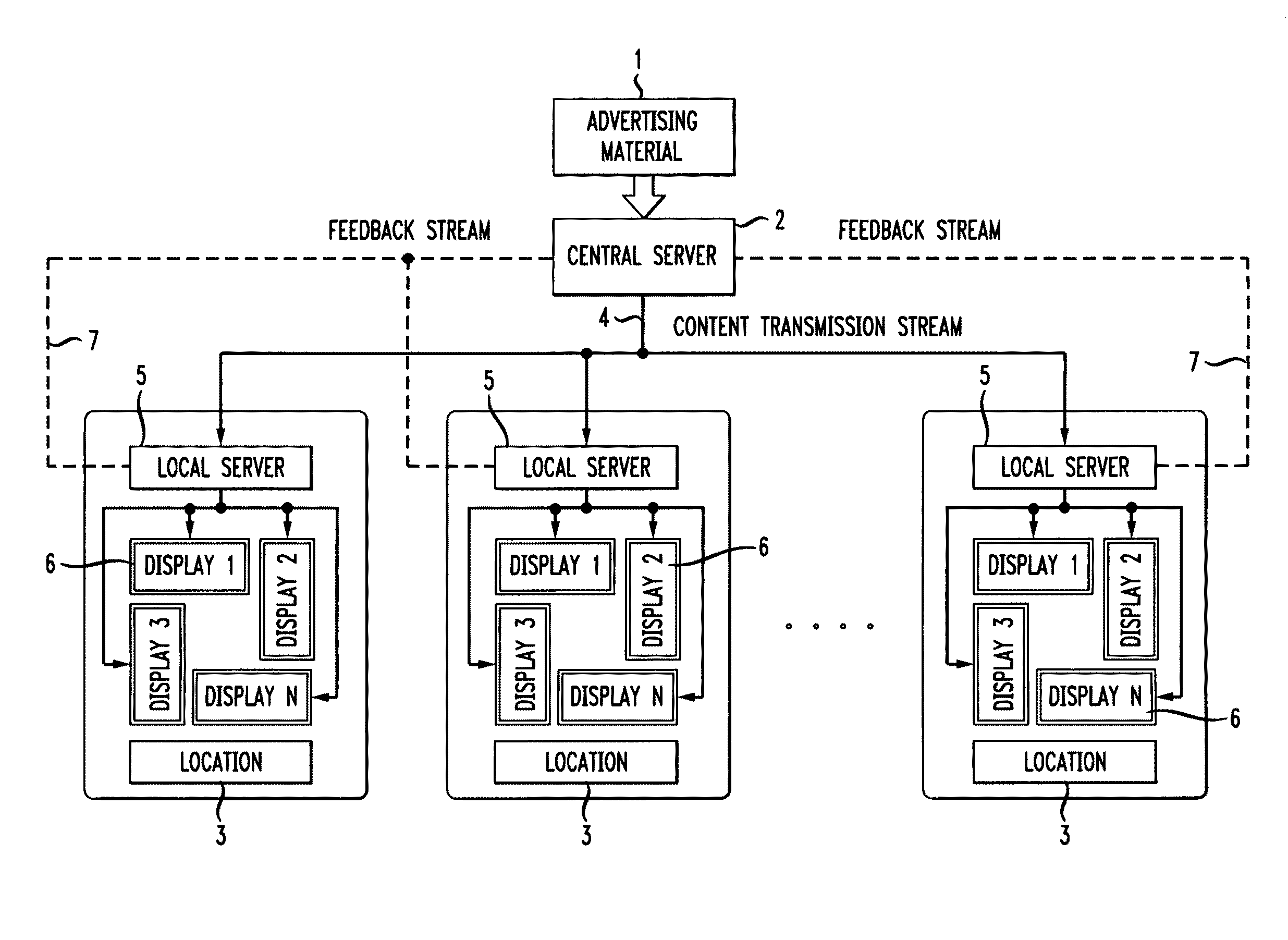

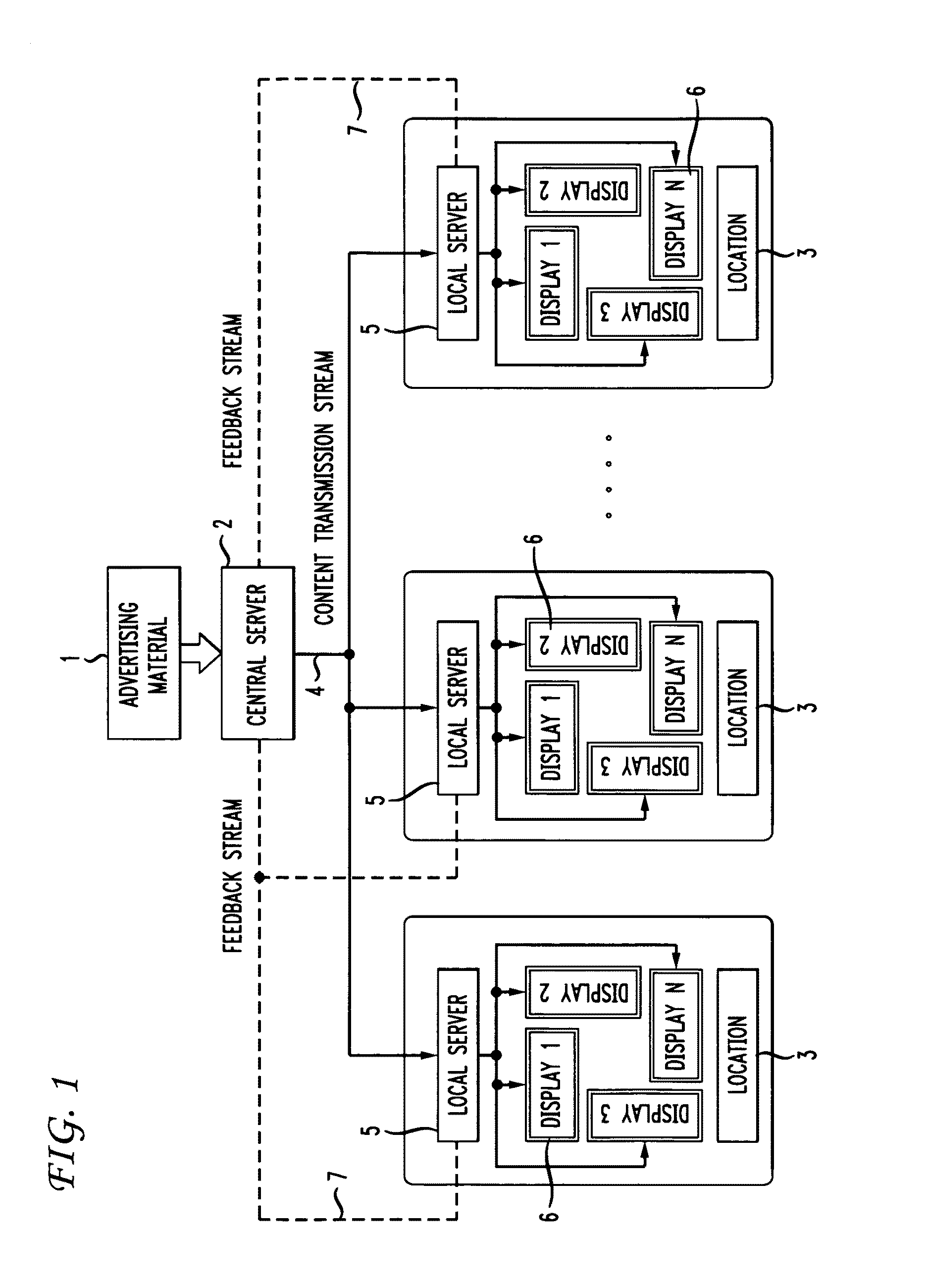

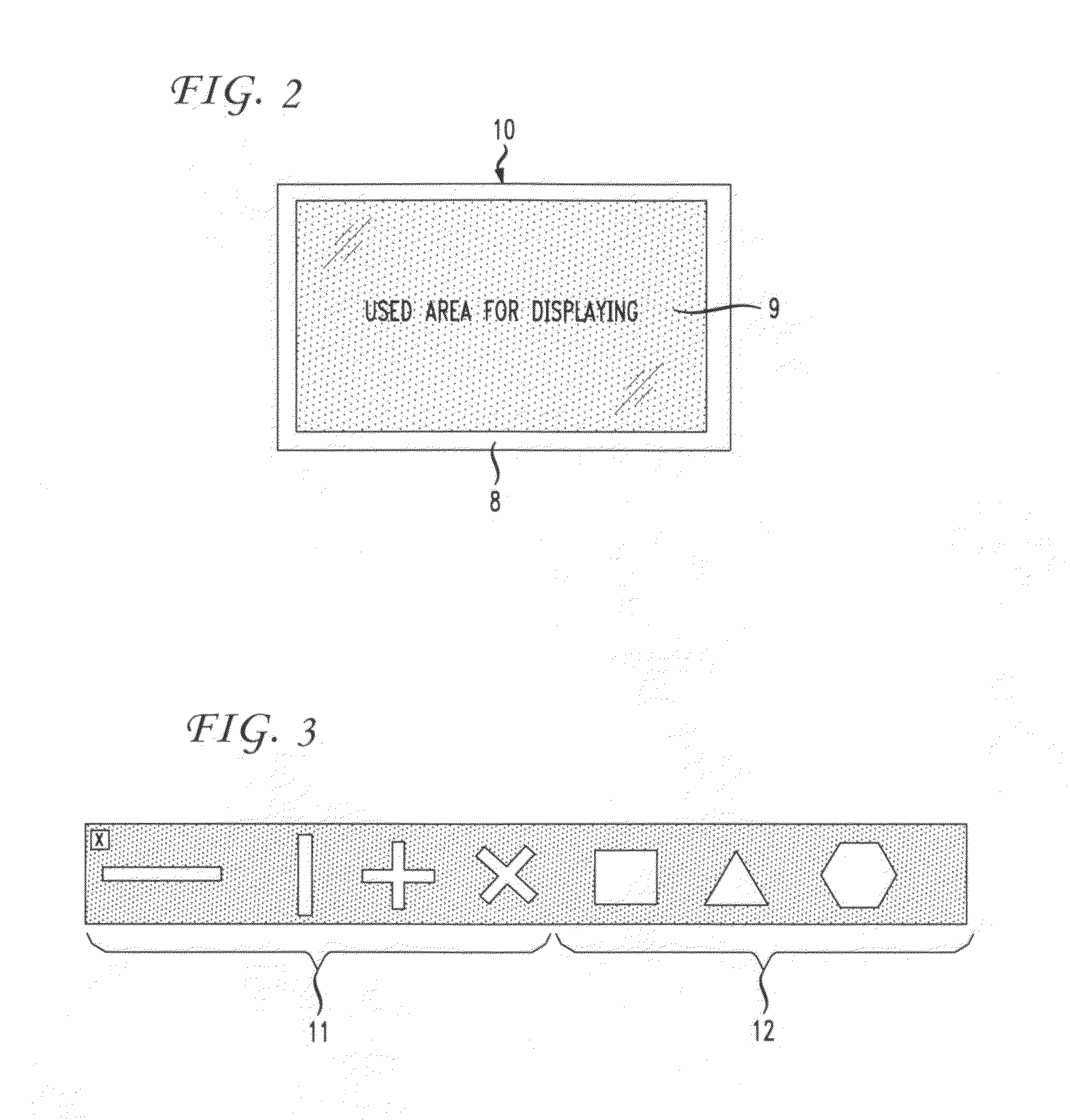

Display device with feedback elements and method for monitoring

InactiveUS20100157152A1Cost-effectiveAccurate monitoringPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningSignal onComputer graphics (images)

A display system including a plurality of display units shall be supervised as to its proper functioning as well as the right content to be displayed. Therefore, there is provided a display device and a corresponding method for monitoring the presentation of a video signal on a display screen having a plurality of screen drivers. A mark signal is added to the video signal and a mark (13) is displayed within a picture on the basis of the video signal including the mark signal. The mark is sensed by a specific sensor and a corresponding sensing signal is provided. In order to supervise the functioning of each screendriver a specific mark signal is added for each screendriver into the video signal. Each of the plurality of marks is sensed and specific sensing signals are provided for each of the plurality of marks.

Owner:THOMSON LICENSING SA

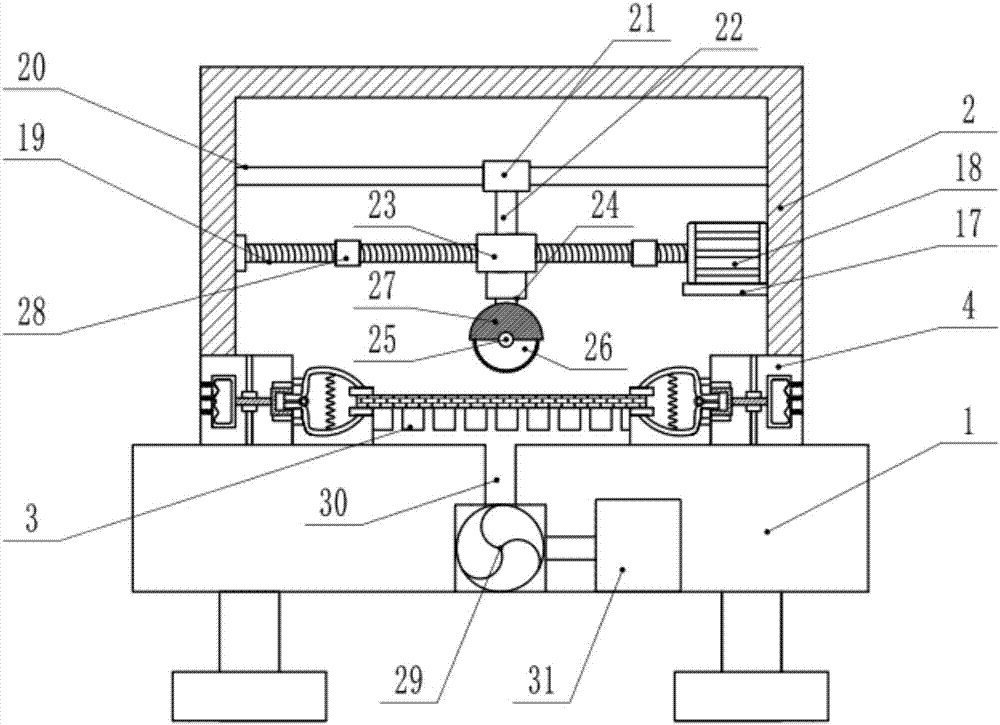

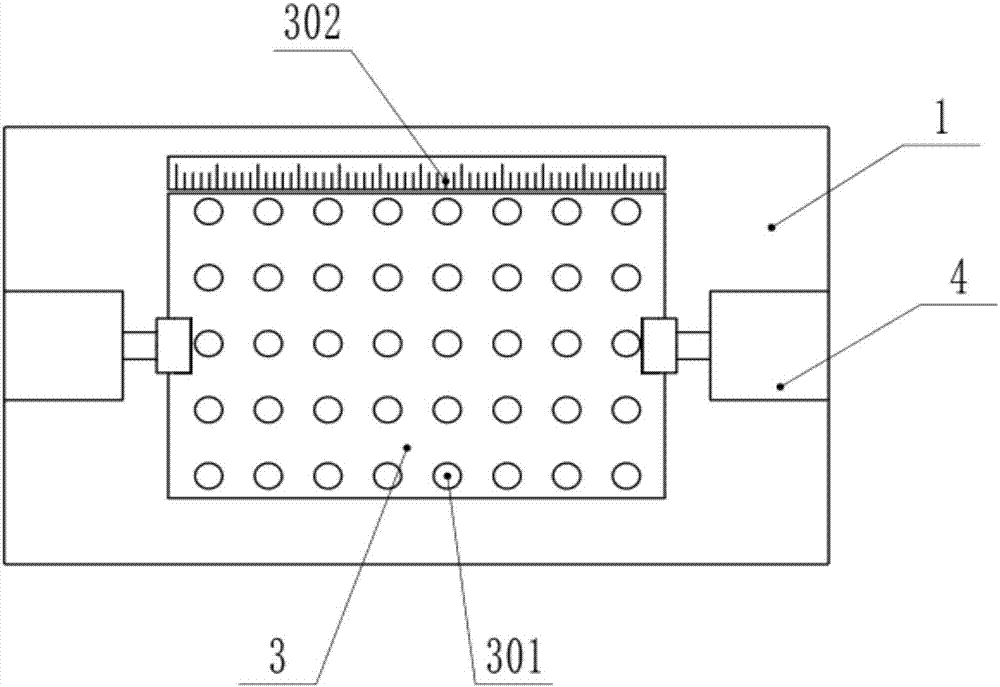

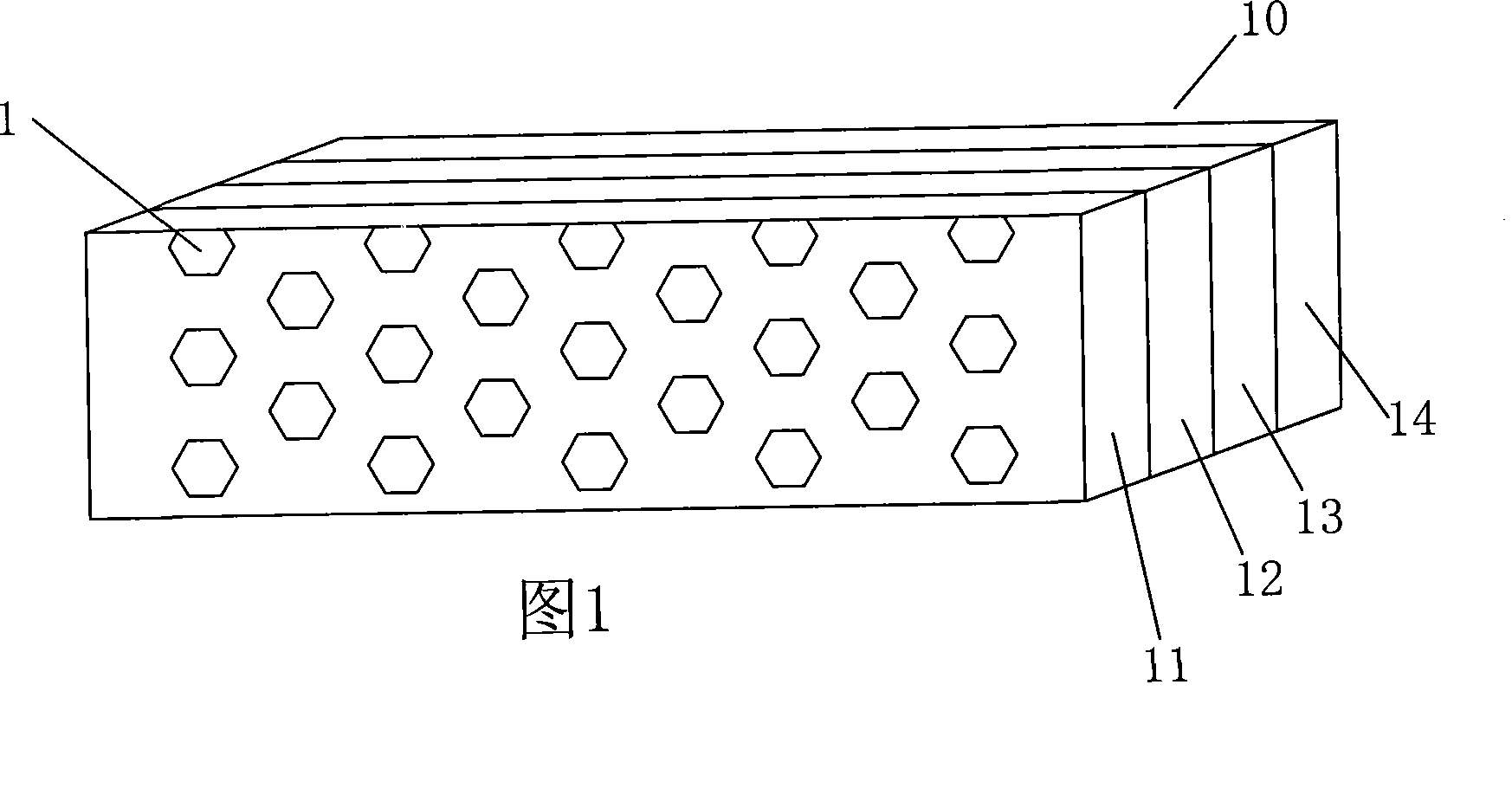

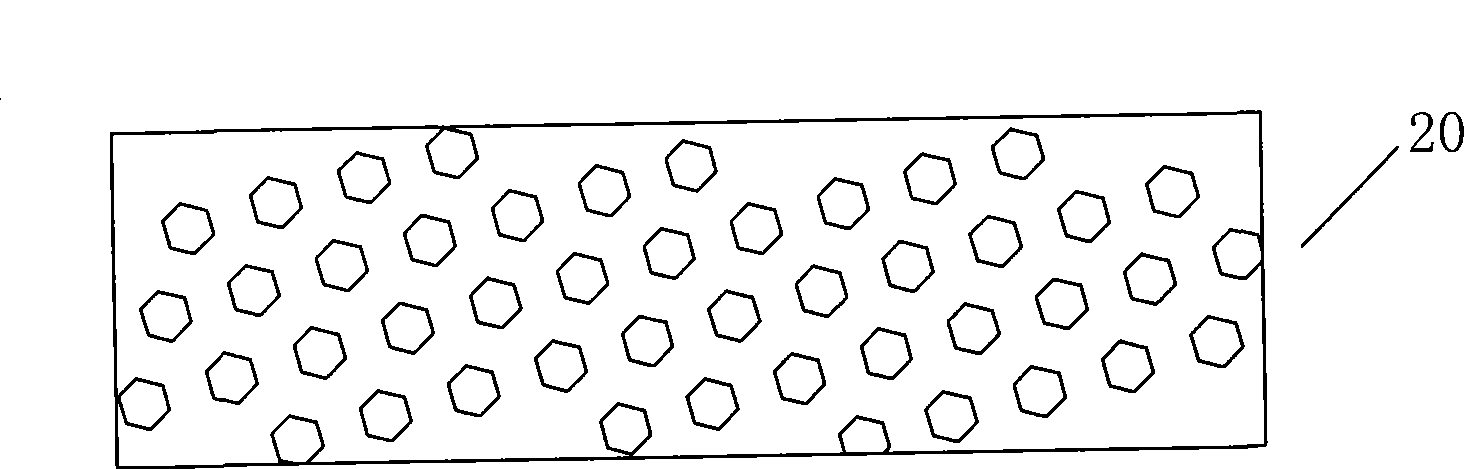

Deviation-prevention-type cutting device for building ceramic tiles

InactiveCN107322445ACutting stabilityAvoid offsetWorking accessoriesGrinding machinesMotor driveDrive motor

The invention discloses an anti-offset cutting device for architectural tiles, which comprises a base, a casing, a cutting table, a clamping device, a driving motor, a cylinder, a cutting motor, a cutting wheel and a fan. The upper surface of the cutting table is provided with several Through holes, a fan is fixedly installed inside the base, a foam collection box is connected to the air outlet of the fan, a clamping device is fixedly installed on the upper surface of the base, the output shaft of the driving motor is horizontal to the left and connected with a screw, the screw A sliding sleeve is installed on the upper thread, and a cutting motor is fixedly connected to the piston rod of the cylinder. Set the clamping device to clamp the tiles to prevent the tiles from shifting during the cutting process and improve the cutting accuracy; by using the drive motor to drive the screw to cooperate with the sliding sleeve, the cutting wheel can move left and right, so that the tiles can be cut stably, saving It saves time and effort, improves production efficiency, and at the same time, compared with manual cutting, it has higher precision and higher safety.

Owner:黄娜茹

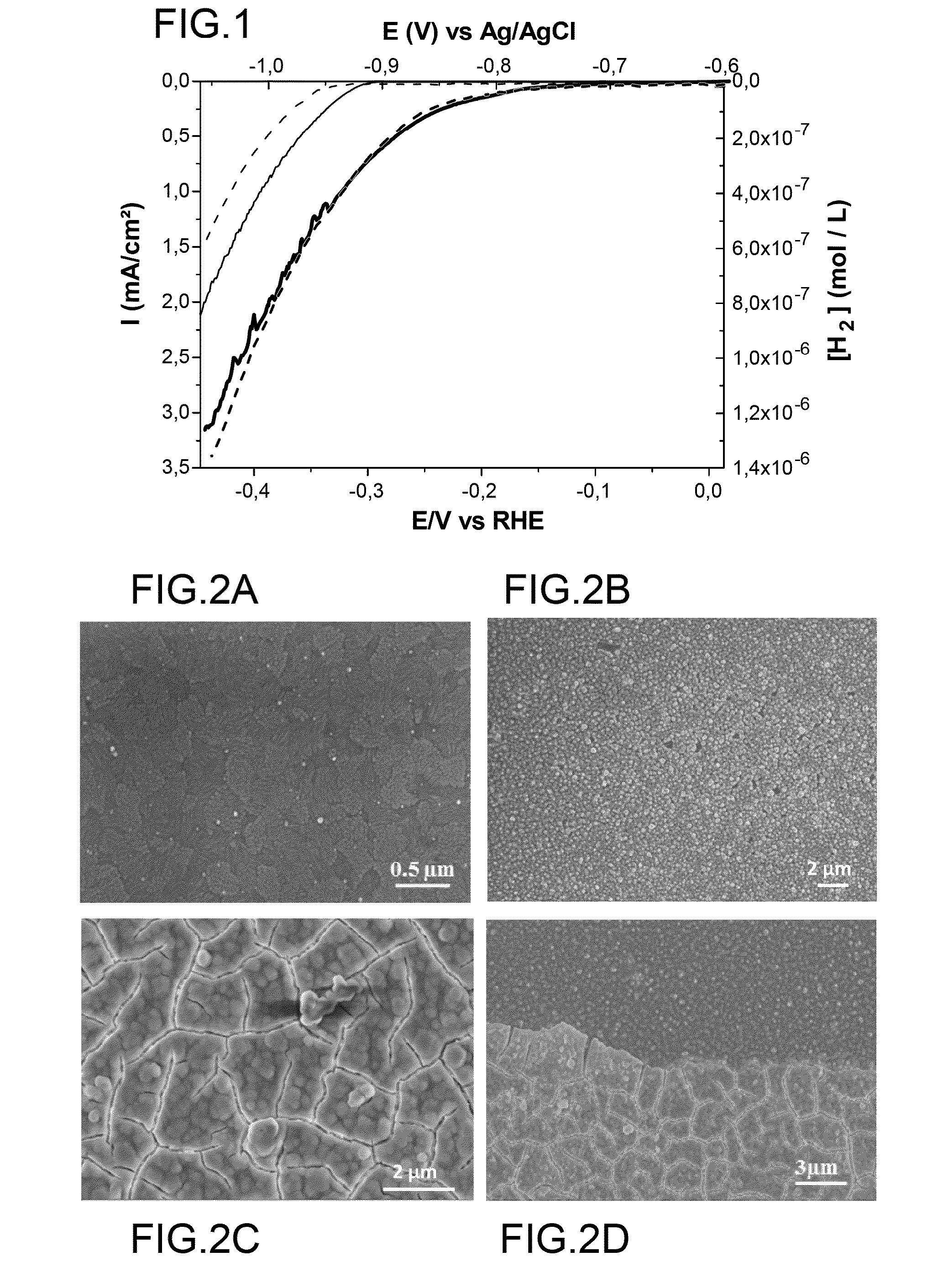

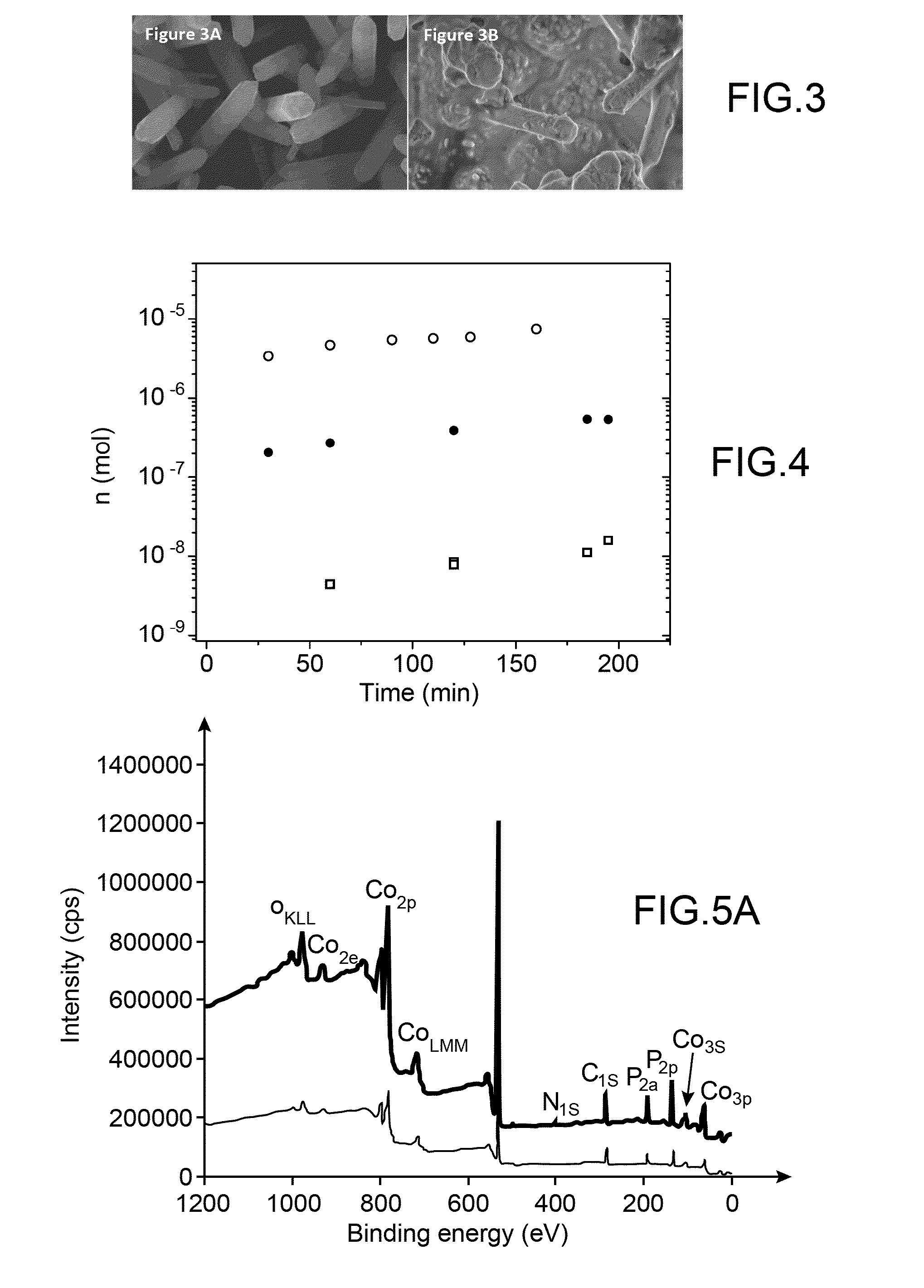

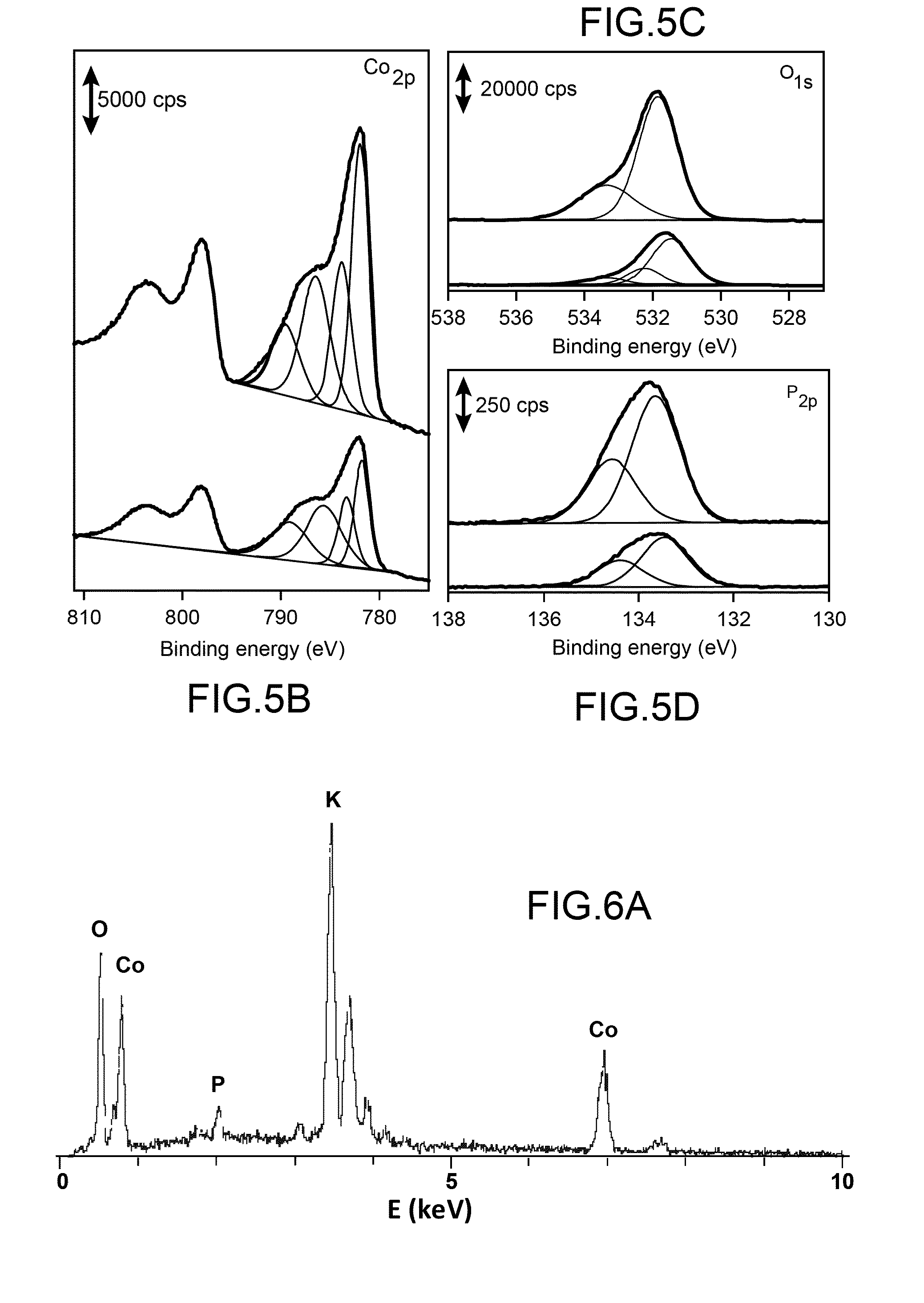

Method for preparing a catalyst mediating h2 evolution, said catalyst and uses thereof

The present invention concerns a method for the preparation of a catalyst onto a solid support of a (semi-)conductive material consisting in depositing said catalyst onto said support from a near-neutral aqueous solution containing at least one nickel or cobalt organic complex and at least one basic oxoanion, by a method selected in the group consisting of reductive electrodeposition, photochemical electrodeposition and photoelectrochemical deposition. The present invention also concerns said catalyst and uses thereof.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

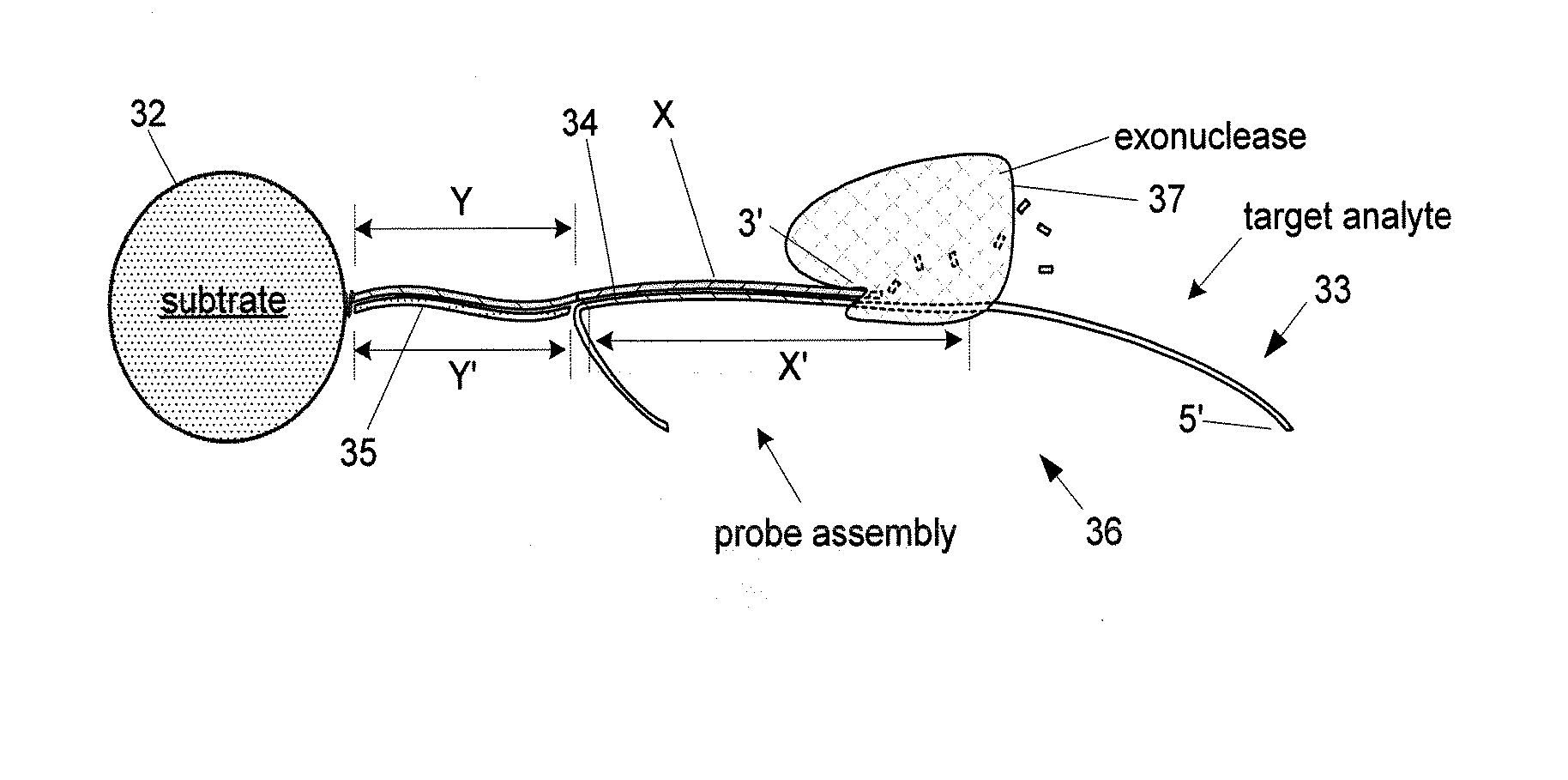

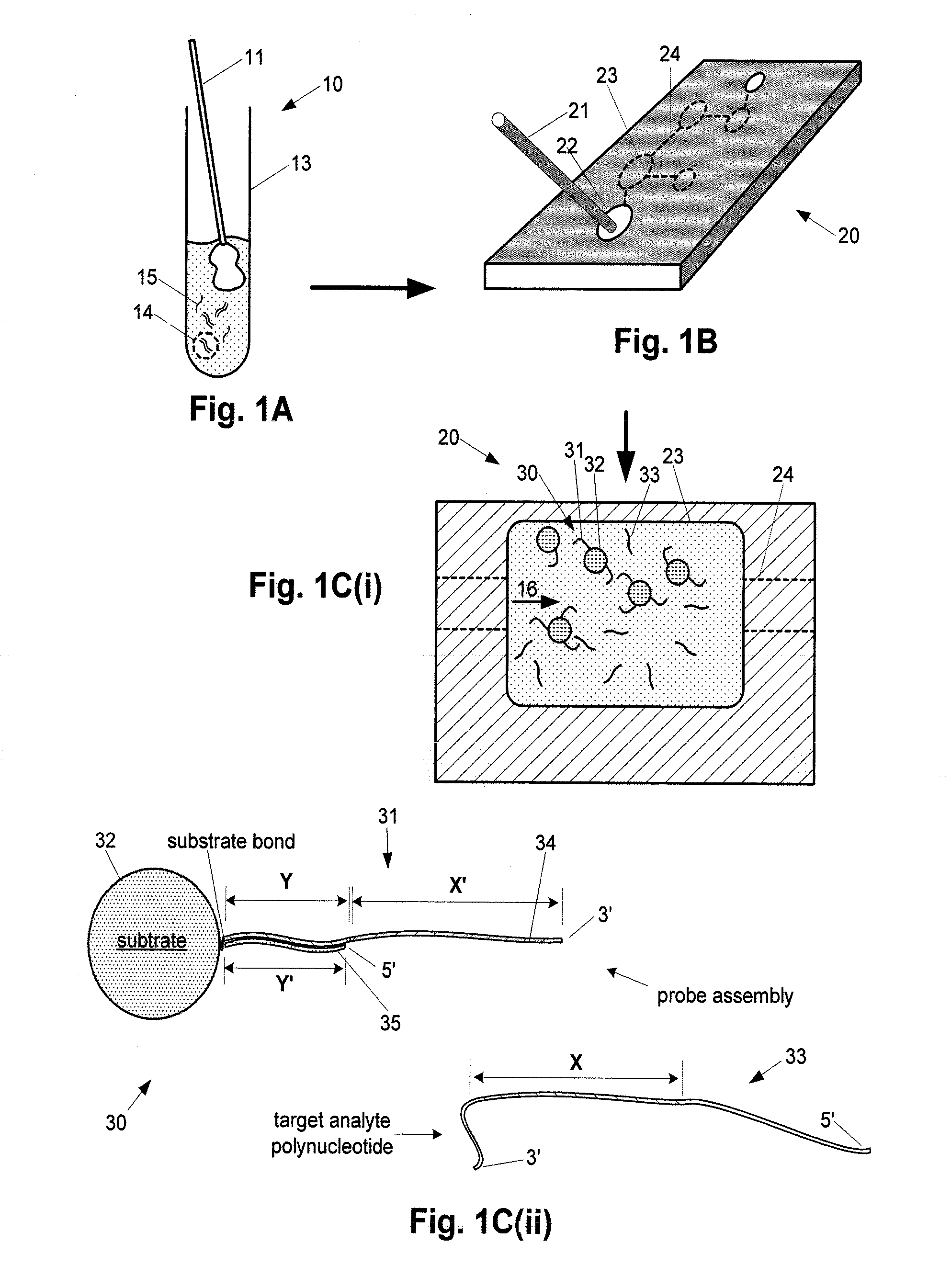

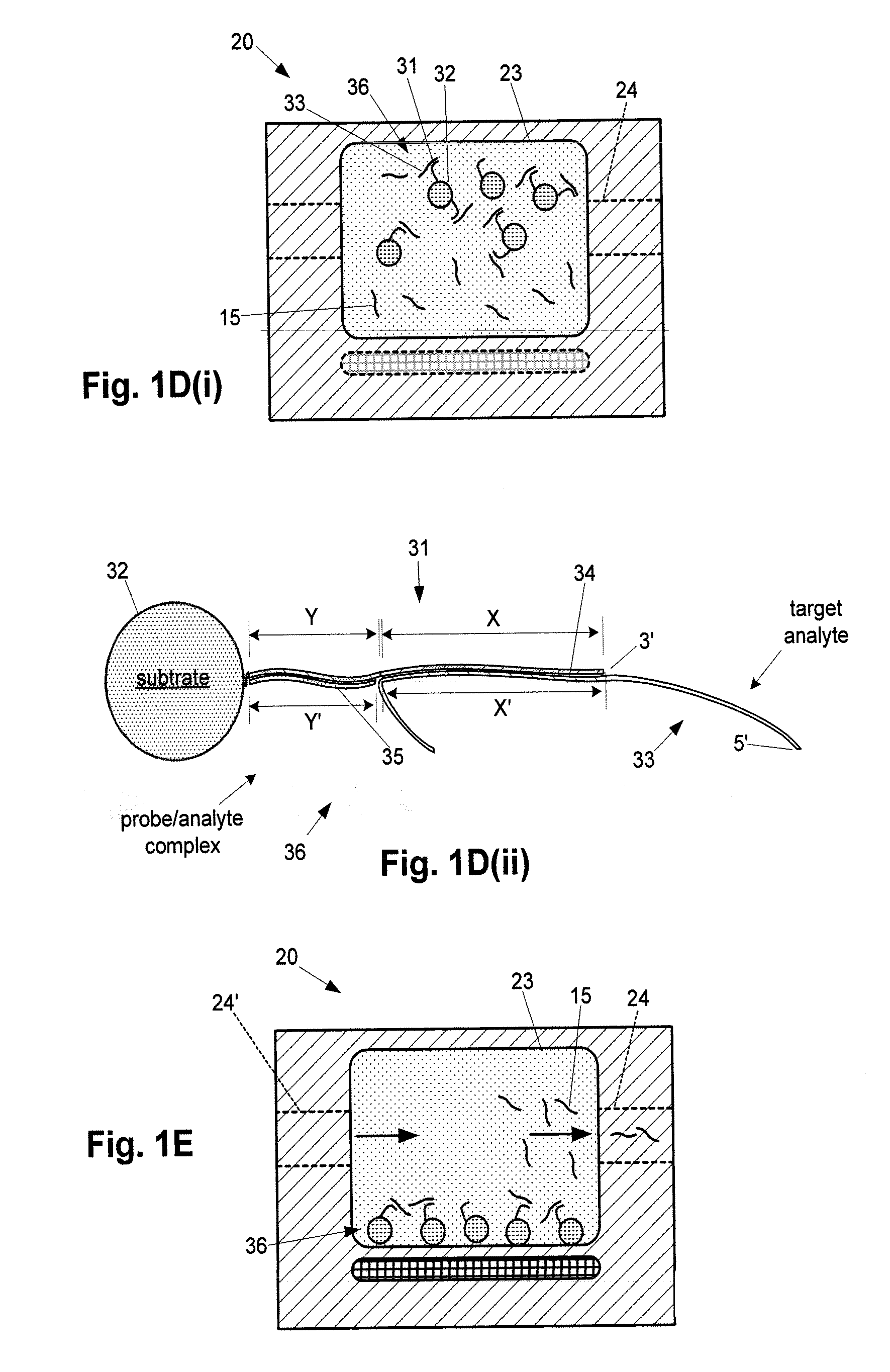

Nanoelectronic Detection of Biomolecules Employing Analyte Amplification and Reporters

InactiveUS20070259359A1Excellent characteristicsHigh selectivityMicrobiological testing/measurementBio moleculesAnalyte

Methods of detection of biomolecules are described, including methods of amplification of analyte target species and target reporters by analyte-triggered action of an enzyme such a nuclease, polymerase, and the like. Amplified target species (e.g., amplicons and reporters) are detectable by several embodiments of nanoelectronic sensors having aspects of the invention, and by alternative convention biomolecule detection methods.

Owner:NANOMIX

High-strength diamond saw blade

The present invention is a high-strength diamond saw blade, which includes a substrate and a diamond cutter head. The substrate of the diamond saw blade includes the following components by weight: 28-37 parts of copper powder, 0-5 parts of aluminum powder, and 2-6 parts of tin powder , 2-4 parts of zinc powder, 5-8 parts of rare earth, 15-18 parts of titanium powder, 11-15 parts of nickel powder, 8-12 parts of cobalt powder, 1-3 parts of manganese powder, 0-1 part of phosphorus powder, silicon 1-3 parts of vanadium powder, 0.2-0.9 parts of vanadium powder, 2-5 parts of silver powder, 2-6 parts of molybdenum powder, 0.1-2 parts of tungsten powder, 0.5-3 parts of chromium powder, and the rest are iron and unavoidable impurities; diamond The cutter head of the saw blade includes the following components by weight: copper powder 35‑40 parts, tin powder 8‑11 parts, zinc powder 1‑2 parts, titanium powder 6‑10 parts, diamond 13‑18 parts, iron powder 9‑ 14 parts, nickel powder 1-5 parts, rare earth 1-4 parts, tungsten powder 1-3 parts. The invention can effectively improve the cutting performance of the diamond saw blade, and has high strength, high wear resistance, firmness and durability, great pressure resistance and low cost.

Owner:JIANGSU SUPER PEAK TOOLS CO LTD

Design method and system for no air gap stable filling casting

InactiveCN1552542AReduce design sizePrevent splashFoundry mouldsFoundry coresSystems designNonferrous metal

A method for designing the non-air-gap smooth-filling casting features controlling the filling smoothness, lowering the filling speed, preventing air and oxidized film from coming in molten metal, reducing the size of pouring channel, and increasing the technological output rate. Its casting system has a pouring cup, a plug rod system connected with said pouring cup and opened when filled molten metal in the pouring cup reaches its 1 / 2-1 / 3 height, and the arc corner between vertical and horizontal pouring channels. Its pouring speed is 0.5-1.0 m / s.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

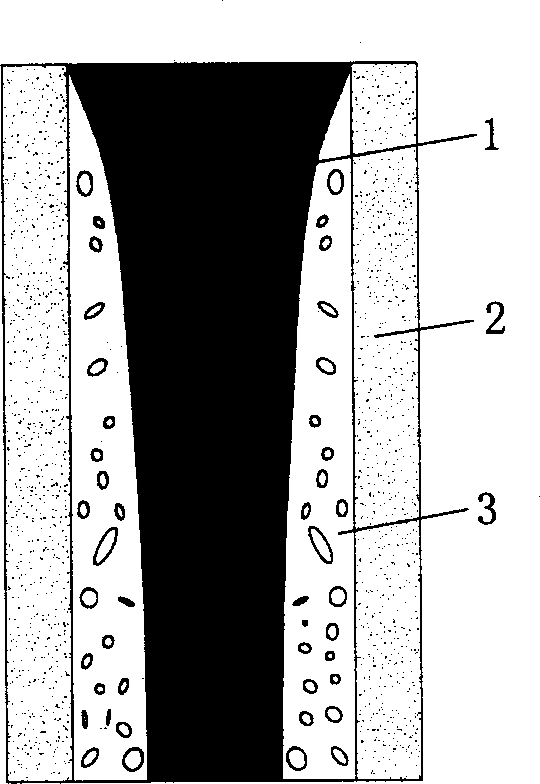

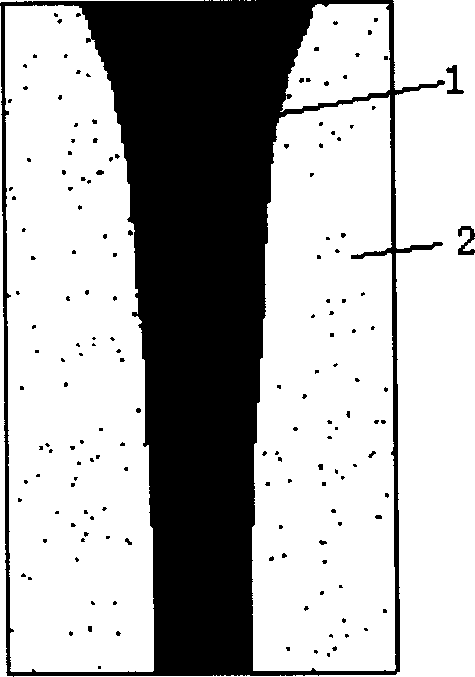

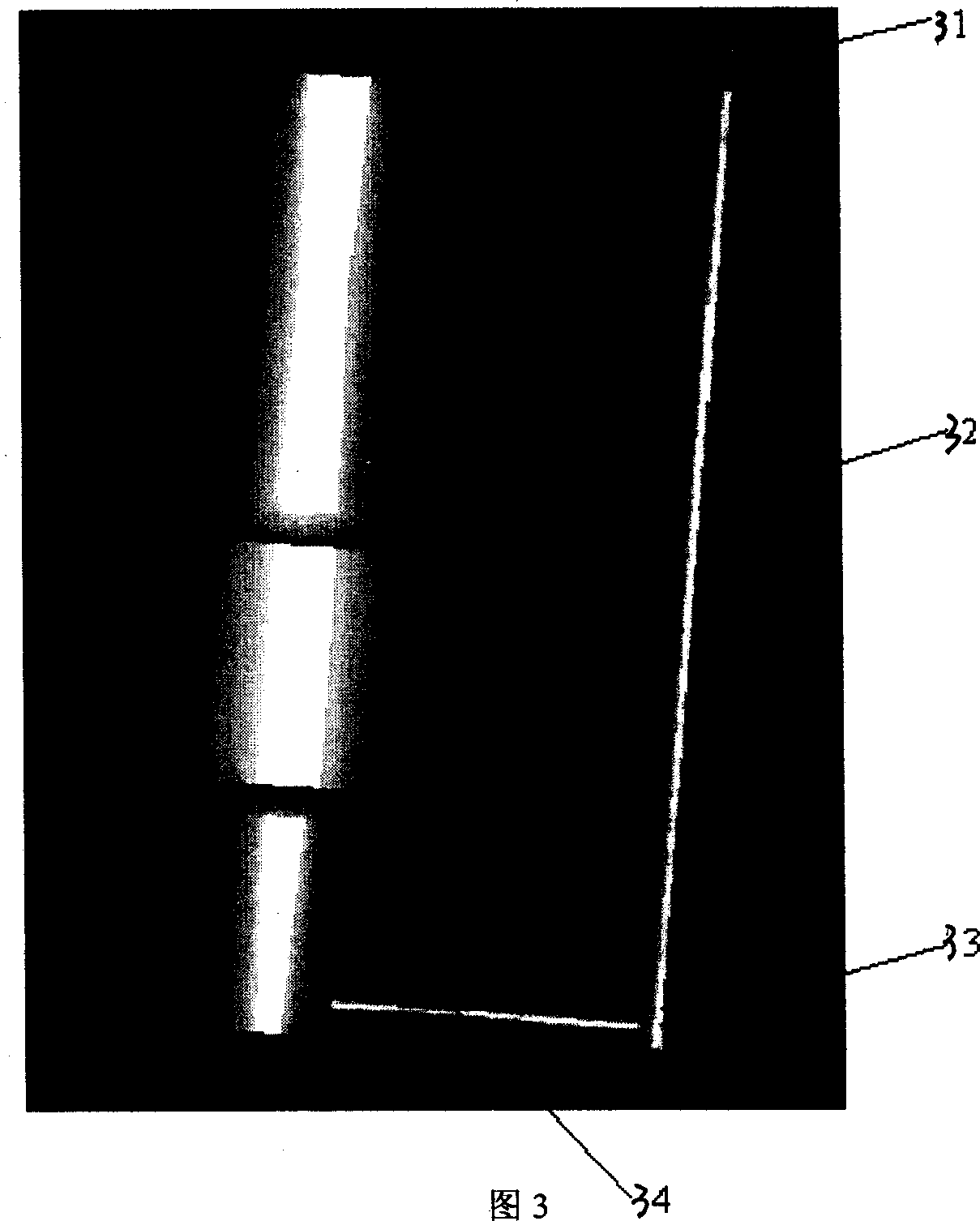

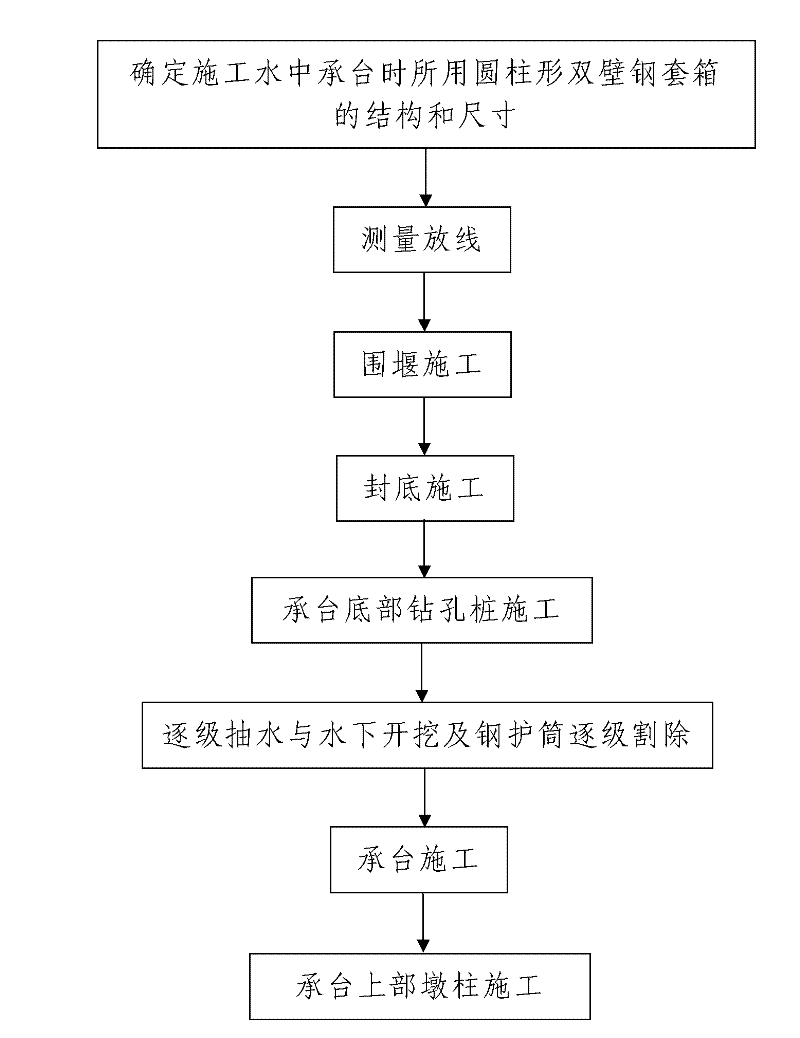

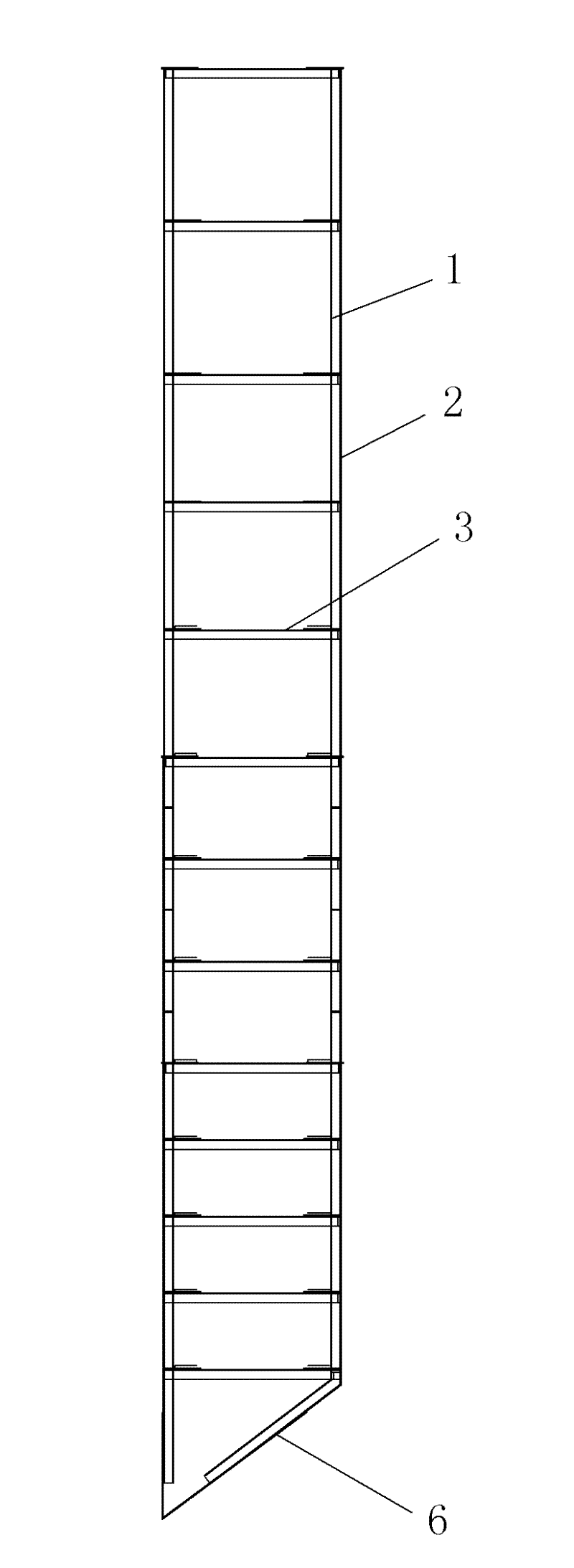

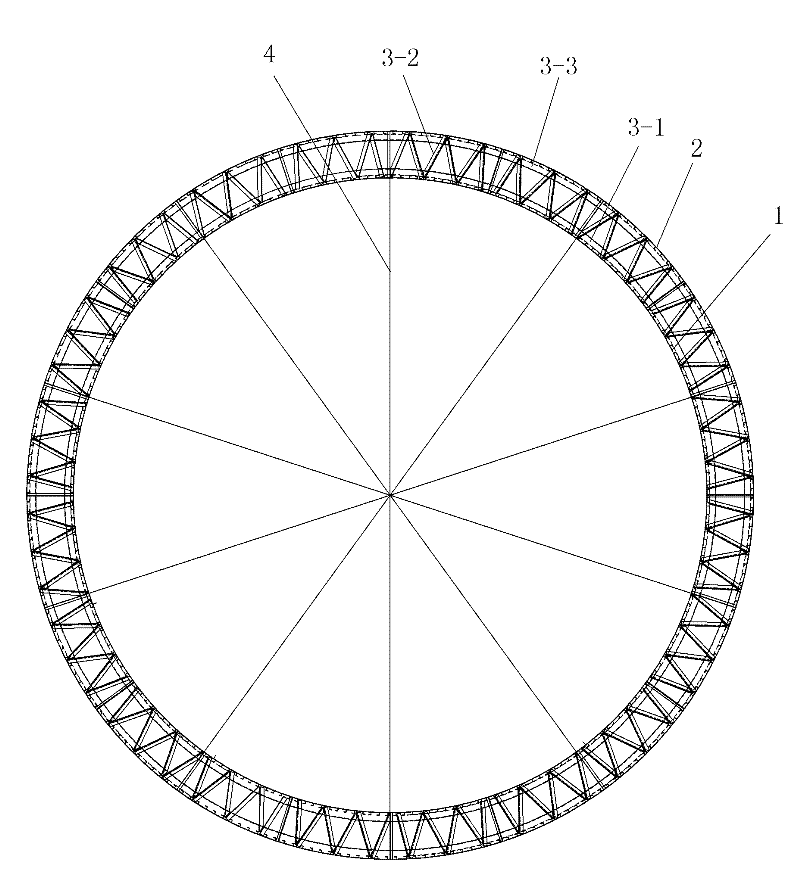

Construction process of double-wall steel cofferdam for construction of pier bearing platform in main river water of Yellow River

ActiveCN102251530ASolve the water stop problemReasonable designFoundation engineeringDouble wallCofferdam

The invention discloses a construction process of a double-wall steel cofferdam for construction of a pier bearing platform in main river water of the Yellow River. The construction process comprises the following steps of: 1, determining the structure and the size of a cylindrical double-wall steel sleeve box used in the construction of the bearing platform in the water; 2, measuring and paying off; 3, performing cofferdam construction: gradually lowering the cylindrical double-wall steel sleeve box to a preset position by adopting hoisting equipment, and fixing the bottom of the cylindrical double-wall steel sleeve box lowered in place by adopting a supporting fixer; 4, sealing the bottom; 5, constructing drilled piles at the bottom of the bearing platform; 6, gradually pumping water, performing underwater digging, and gradually cutting a steel protecting canister; 7, constructing the bearing platform; and 8, constructing pier columns on the upper part of the bearing platform. The process is reasonable in construction step design, convenient in construction, low in construction cost and short in construction period; and integrated construction of the bearing platform and the drilled piles is realized, meanwhile, the sinking operation of the double-wall steel sleeve box can be simply, conveniently and efficiently finished with high quality, and multiple defects in the construction of the conventional double-wall steel sleeve box cofferdam are overcome.

Owner:中铁二十局集团第二工程有限公司

Torch-flame cutting process for super-thick steel plates

InactiveCN102528210AQuality assuranceMeet quality requirementsGas flame welding apparatusNumerical controlSlag

The invention discloses a torch-flame cutting process for super-thick steel plates, which includes steps of utilizing a numerical-control torch-flame cutting machine for torch-flame cutting of the super-thick steel plates, placing a to-be-cut steel plate on the numerical-control torch-flame cutting machine while keeping the surface of the to-be-cut steel plate perpendicular to a cutting torch of the numerical-control torch-flame cutting machine and keeping the distance from the cutting torch to the surfaces of the to-be-cut steel plates ranging from 10mm to 30mm; setting cutting speed, preheating time, preheating oxygen pressure, cutting oxygen pressure and dimethylmethane pressure of the numerical-control torch-flame cutting machine; regulating flame strength of the cutting torch by utilizing the right-angle position formed between the surface of the to-be-cut steel plate and the lateral side thereof as an initial cutting point, enabling the secondary flame to be longer enough to reach the bottom of the to-be-cut steel plate, preheating the initial cutting point for a preset preheating time before initial cutting, and then turning on cutting oxygen, moving the cutting torch forwards when slag flows downwards along edges, and finally increasing moving speed of the cutting torch when the slag is discharged from the bottom until completing the normal cutting operation. The torch-flame cutting process for the super-thick steel plates is capable of guaranteeing quality of cut surfaces, is simple and stable, is safe in use and meets production requirements.

Owner:CITIC HEAVY INDUSTRIES CO LTD

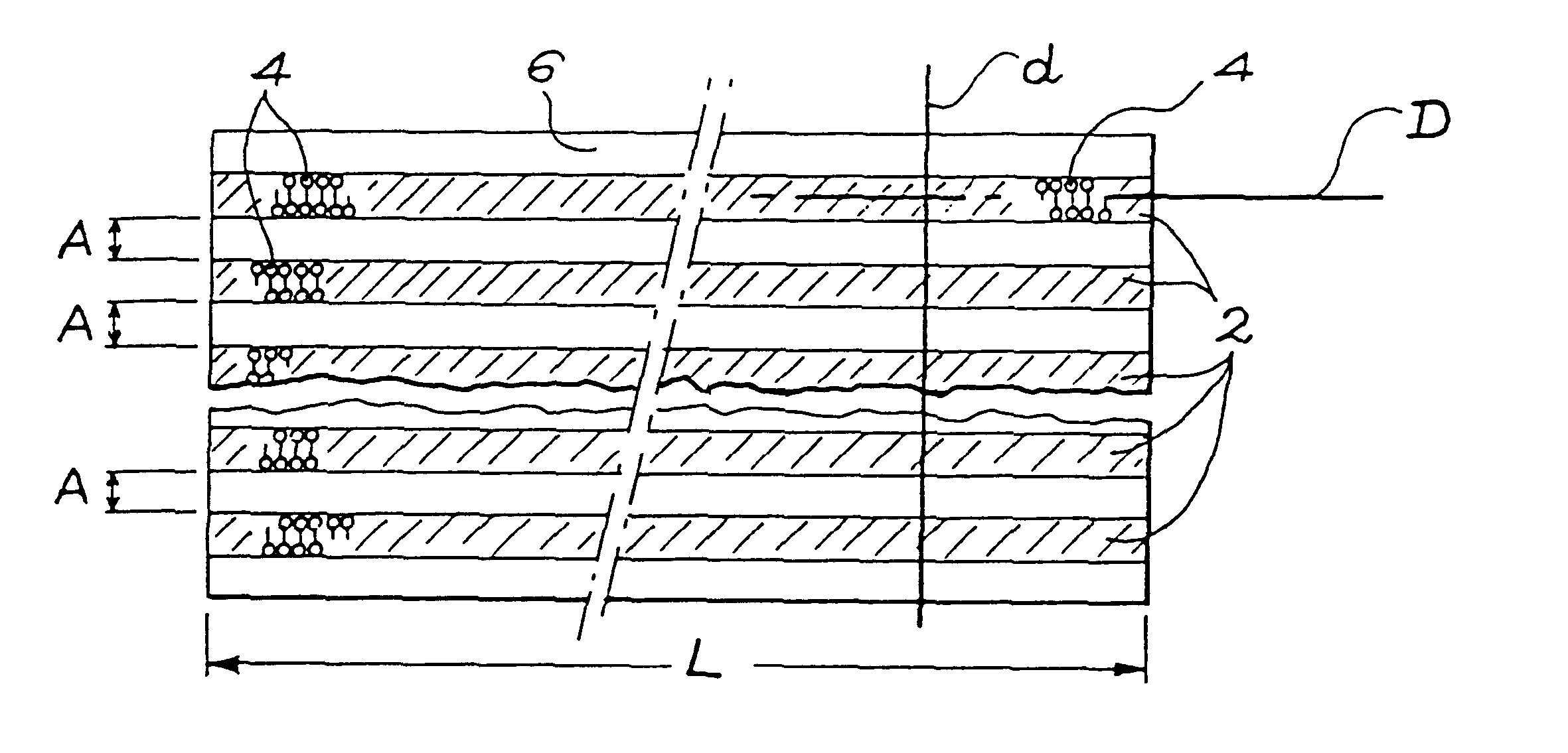

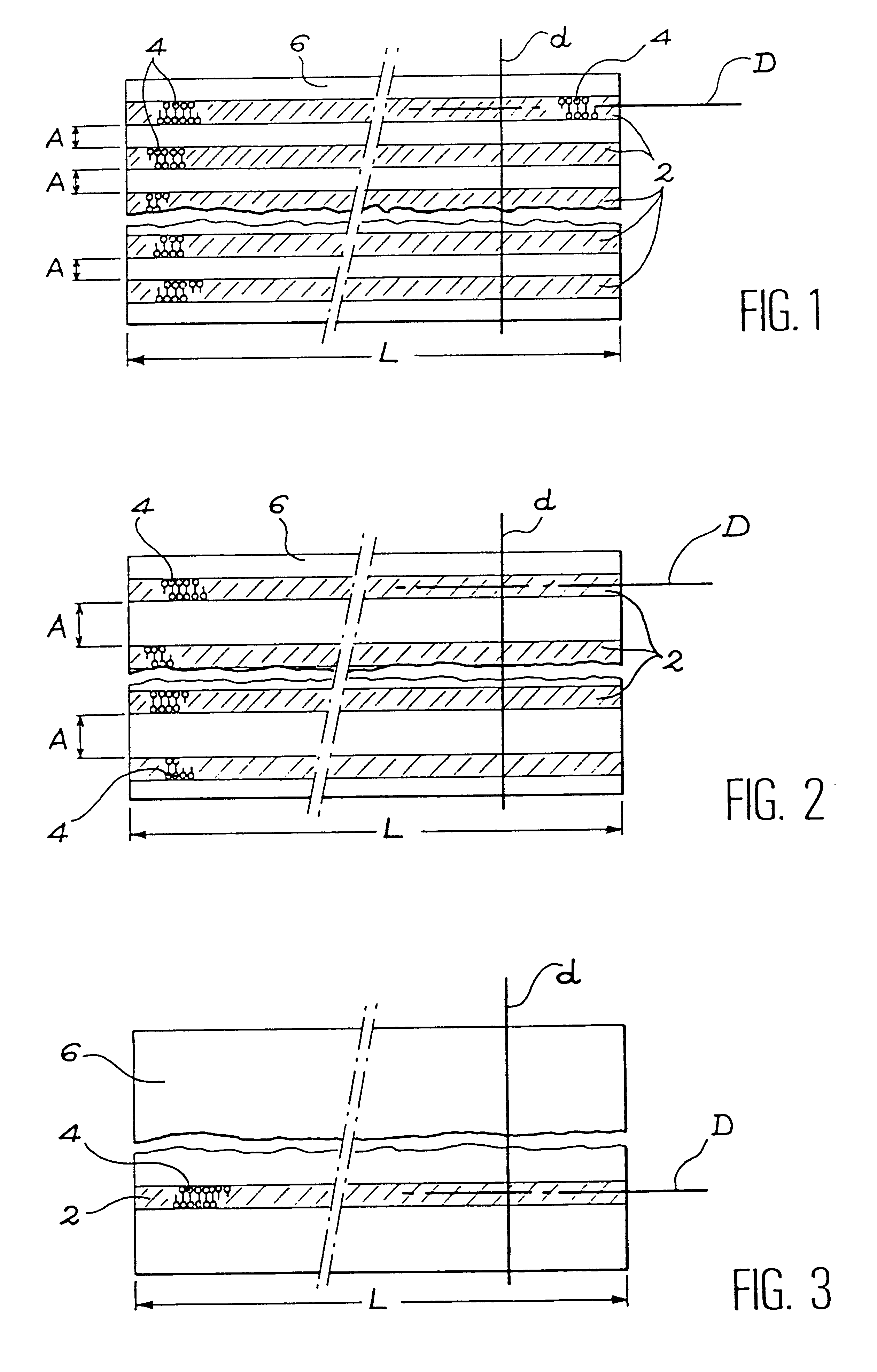

Ordered arrangement method for abrading agent granule on abrading tool and abrading tool

ActiveCN101376234AReduce concentrationReduce power consumptionBonded abrasive wheelsGrinding devicesMaterials scienceDiamond tool

Owner:侯家祥

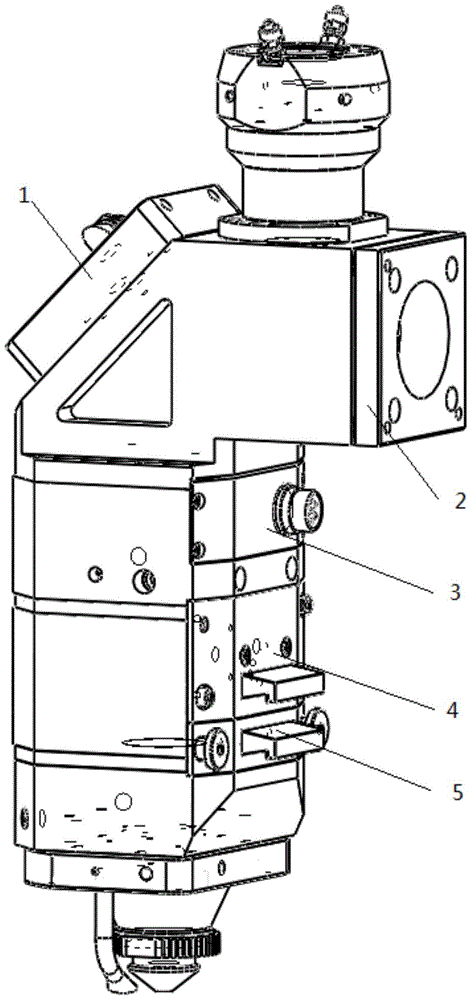

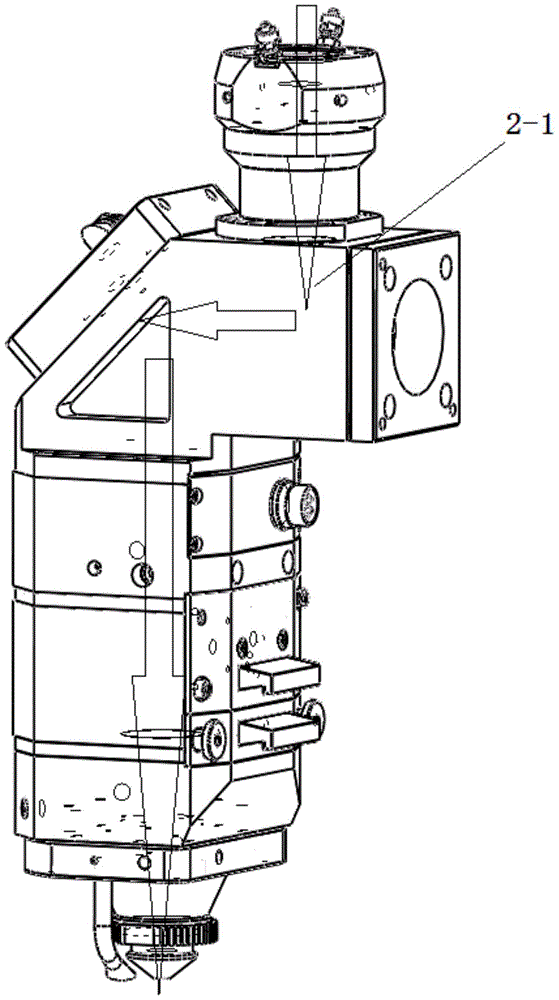

Automatic focusing cutting head for optical fiber laser cutting machine and control method

InactiveCN106670656AEliminate waiting timeReal-time temperature monitoringLaser beam welding apparatusAutomatic controlPunching

The invention relates to an automatic focusing cutting head for an optical fiber laser cutting machine and a control method. The automatic focusing cutting head comprises a cutting head body, a focusing lens drawer, a protection lens drawer, a reflection lens and a CNC; the focusing lens drawer is located above the protection lens drawer located above the cutting head body; the automatic focusing cutting head further comprises a punching detecting unit and an automatic focusing lens system, the reflection lens is located between the automatic focusing lens system and the punching detecting unit, and the punching detecting unit is located above the focusing lens drawer; and the CNC is electrically connected with the automatic focusing lens system and the punching detecting unit. According to the automatic focusing cutting head, automatic control over focus and punching time in the full cutting process from punching to cutting is achieved, manual intervene is not needed, the cutting efficiency and the automatic level are greatly improved, and the excellent good market prospect is achieved.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

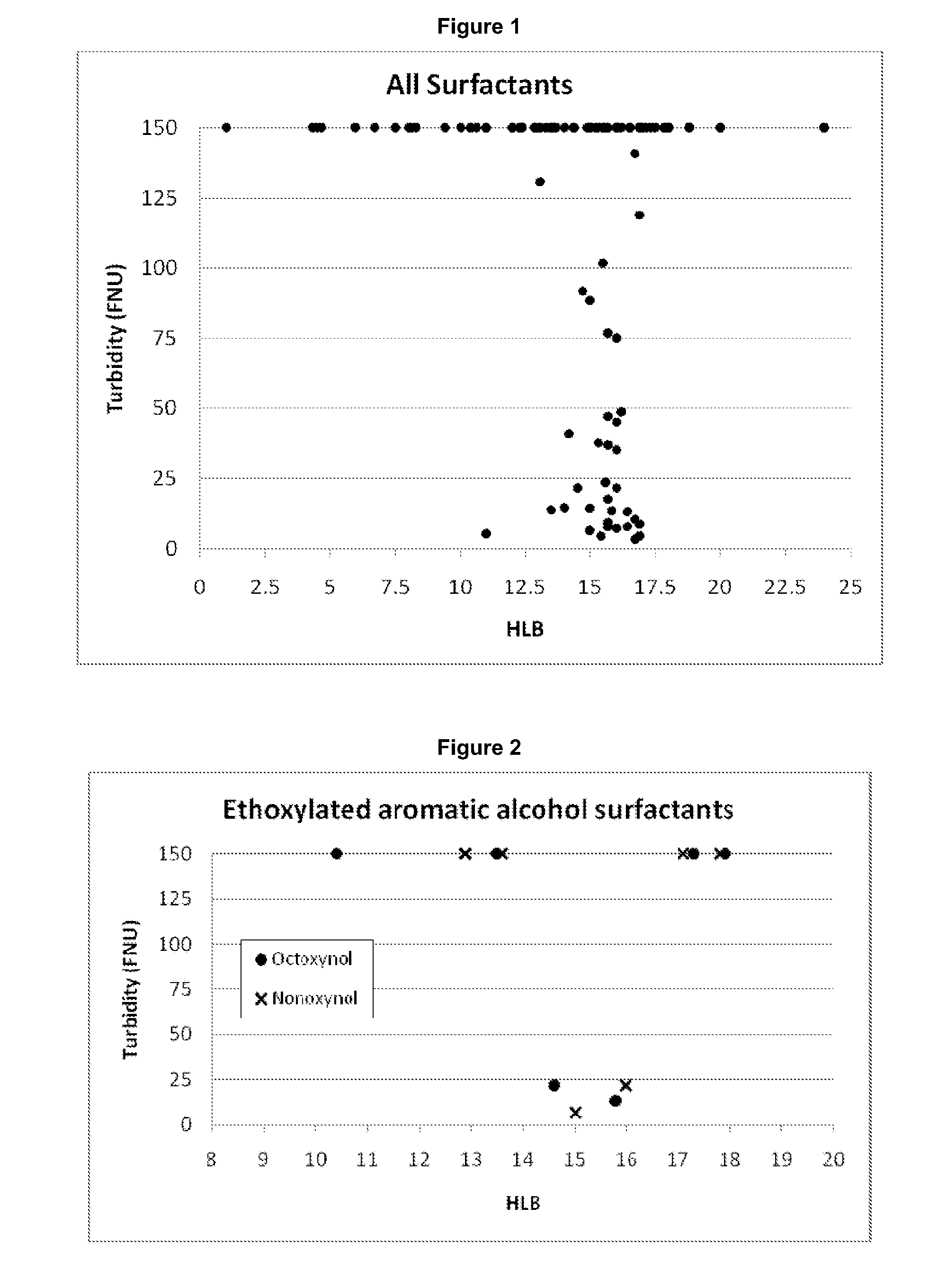

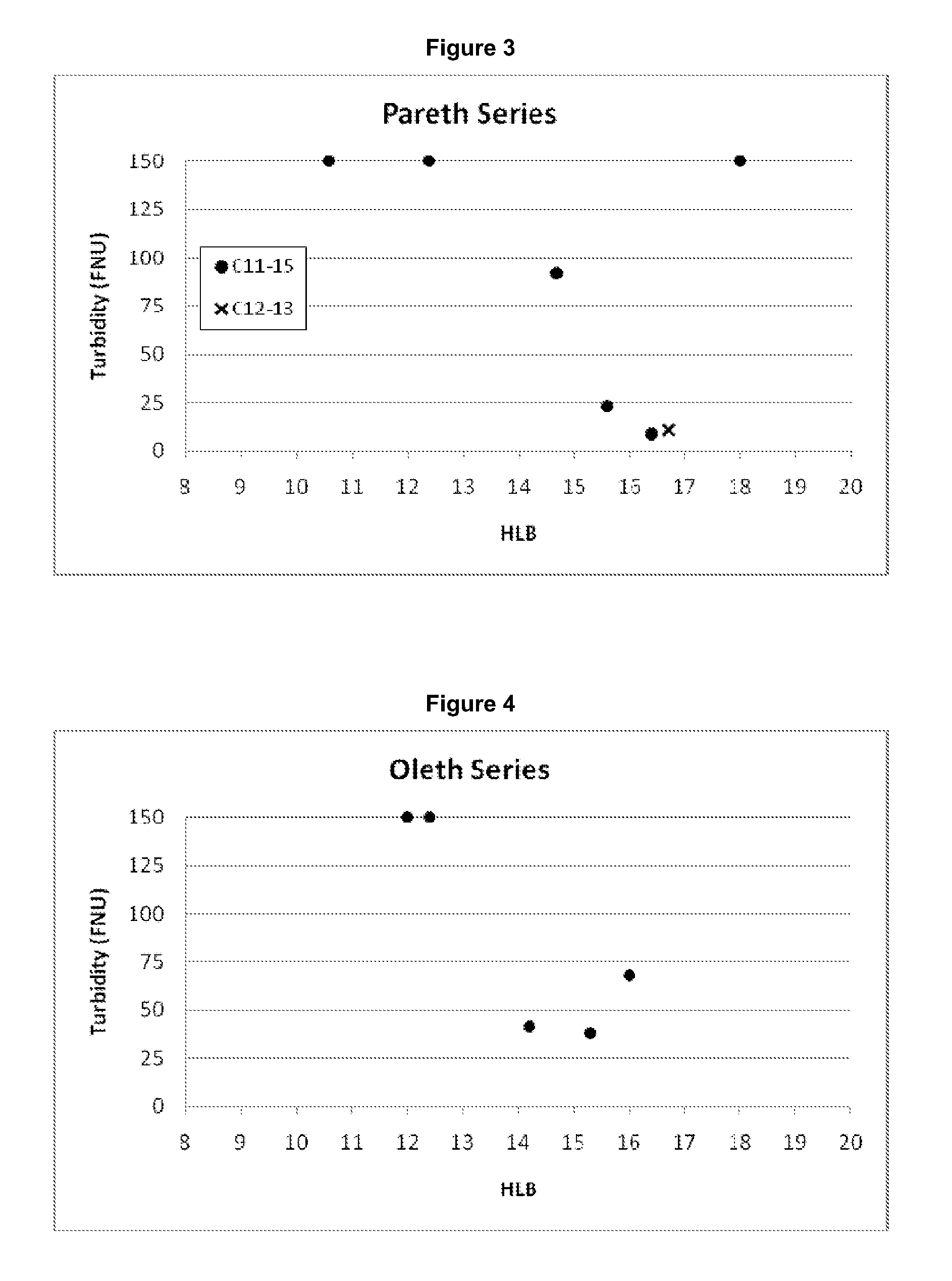

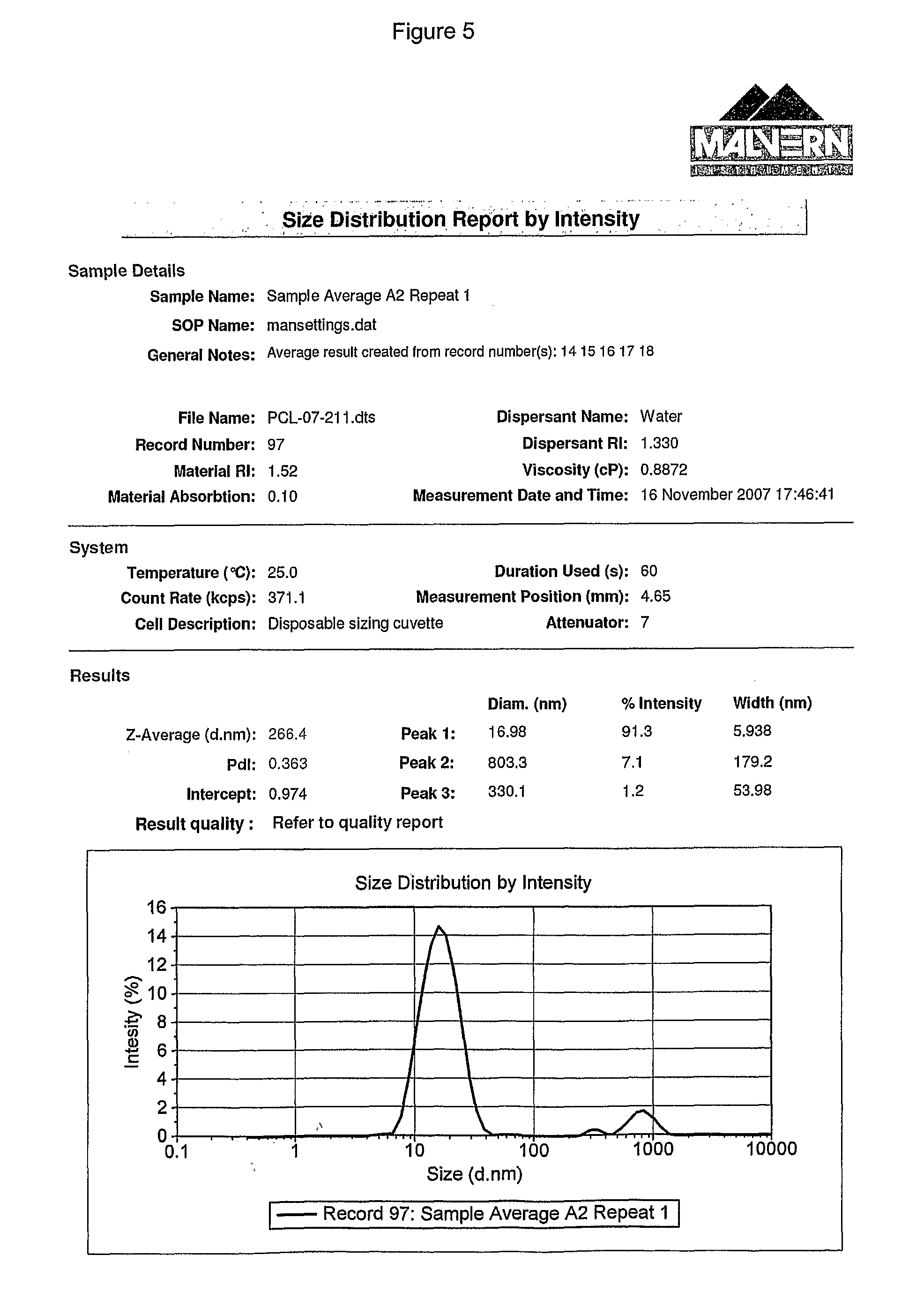

Compositions comprising macromolecular assemblies of lipid and surfactant

InactiveUS20100062067A1Improve abilitiesCutting stabilityBiocideCosmetic preparationsLipid formationEther

Owner:MALVERN COSMECEUTICS LTD

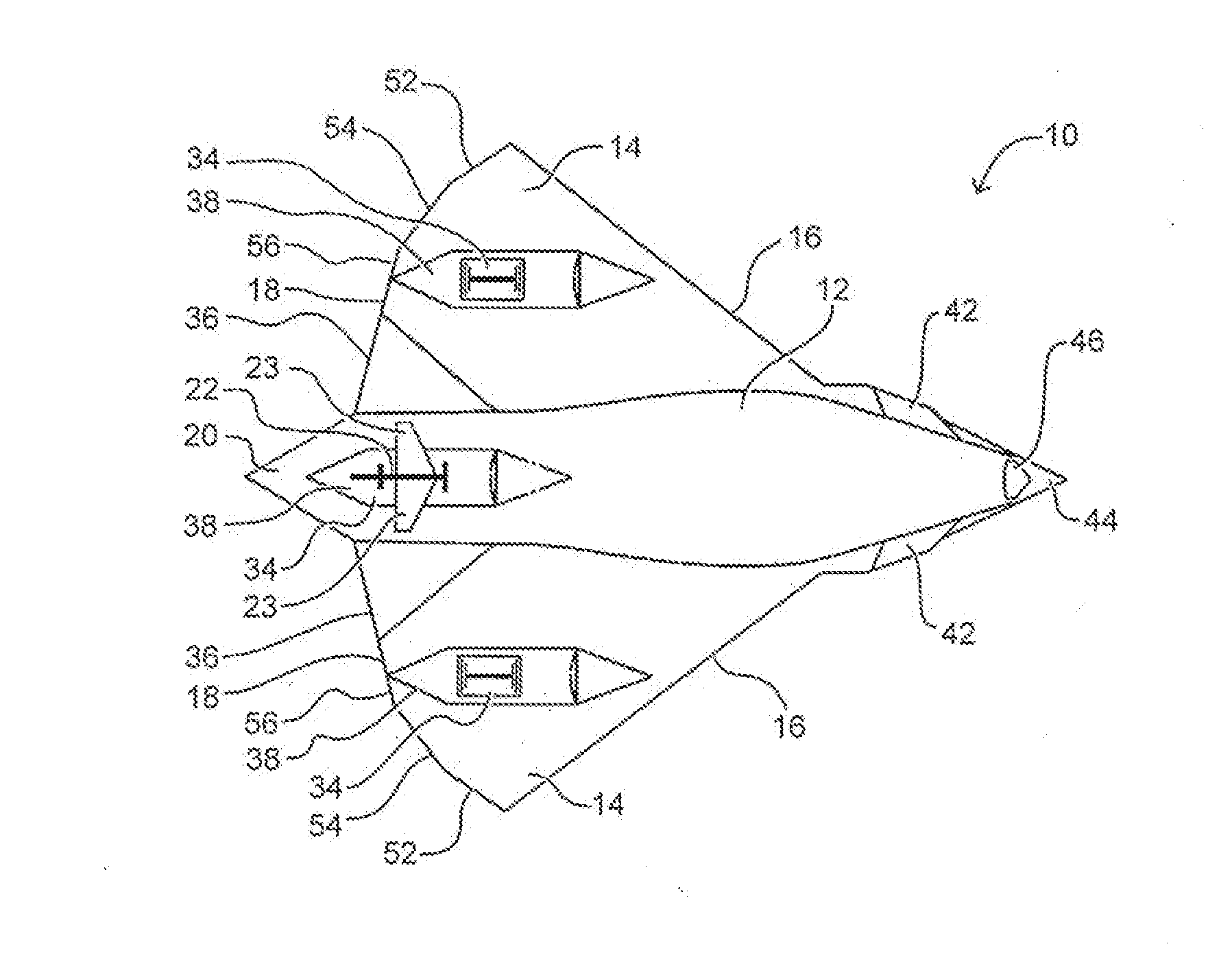

Aerospace plane system

ActiveUS20160152318A1Successful engine relightAvoid flowAircraft navigation controlAircraft stabilisationAviationTrailing edge

An aerospace plane having an elongate body supporting a pair of wings each having at least two angled, trailing edge portions. The pair of wings are adapted to extend away from the elongated body in opposing directions. A landing gear assembly is operatively associated with the elongated body to be moveable from a retracted position where the landing gear assembly is substantially locatable within the elongated body and an extended position where the landing gear assembly extends at least partially away from the elongated body. At least one engine adapted to generate thrust. At least one stabilizer adapted to assist with movement of the aerospace plane during flight. The at least one engine is located at least partially within an intake housing adapted to direct air into said at least one engine. The intake housing having at least one inlet door adapted to move from a fully open position, which allows air to pass into the engine, to a sealingly closed position which prevents air from flowing into the engine, when the engine is shut down during flight.

Owner:COMML AEROSPACE PLANE PTY

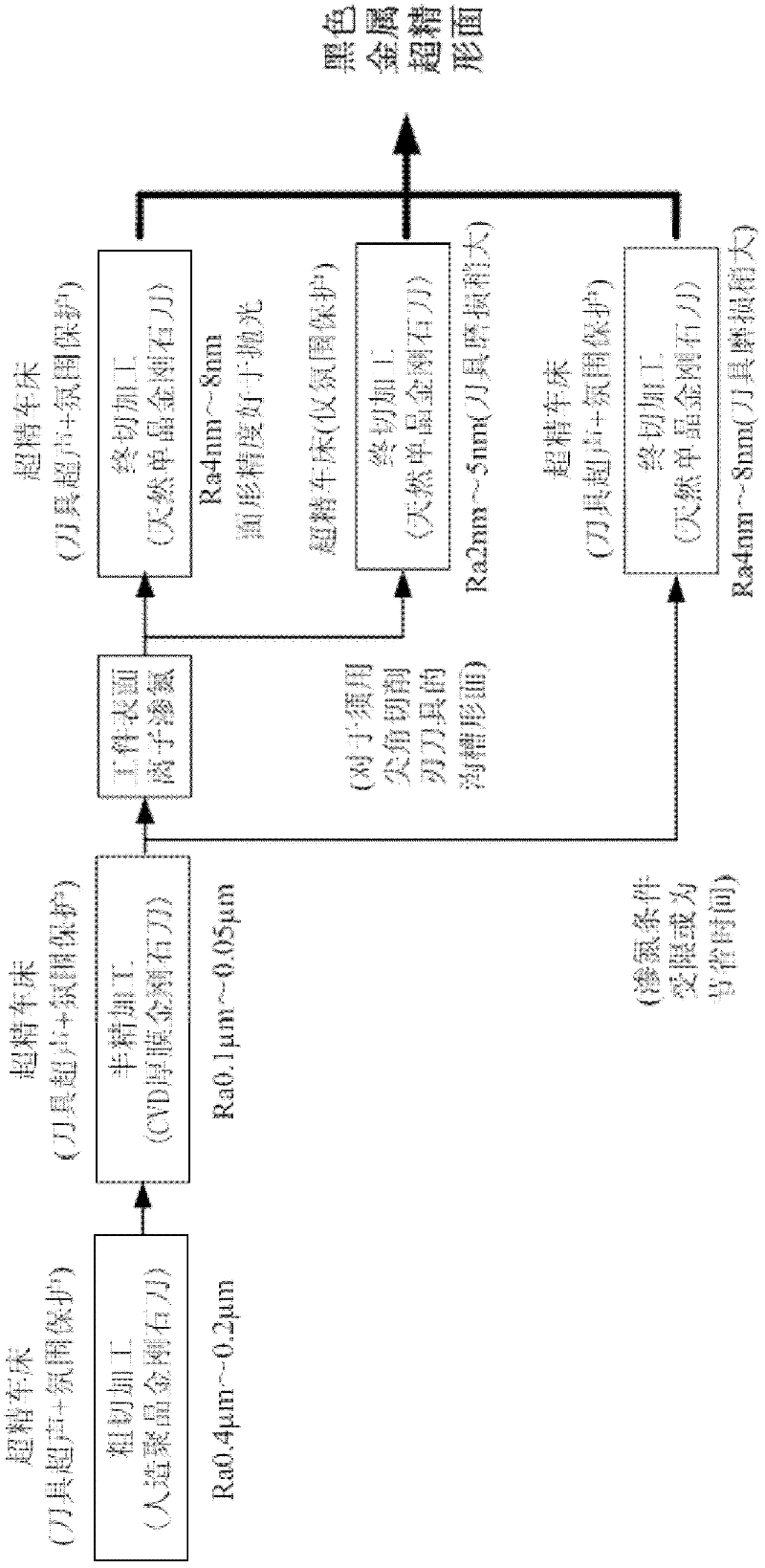

Processing method of ferrous metal super-finishing surface

InactiveCN102528077AInhibit wearEnhance chemical anti-friction effectSolid state diffusion coatingTurning toolsPolycrystalline diamondMachining process

Owner:TSINGHUA UNIV

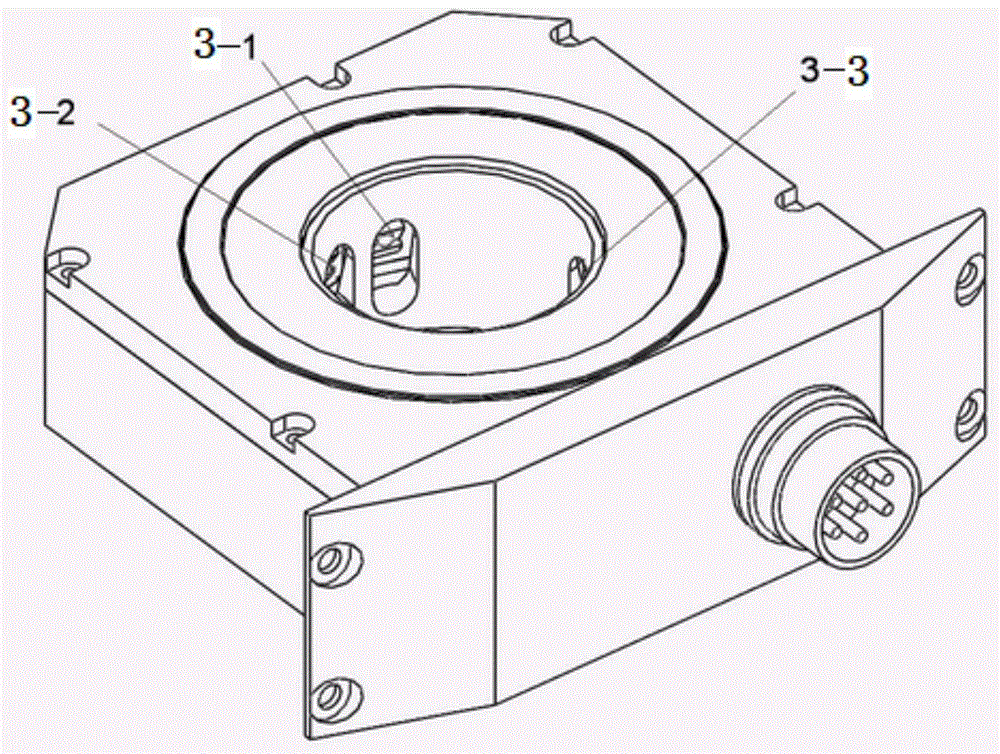

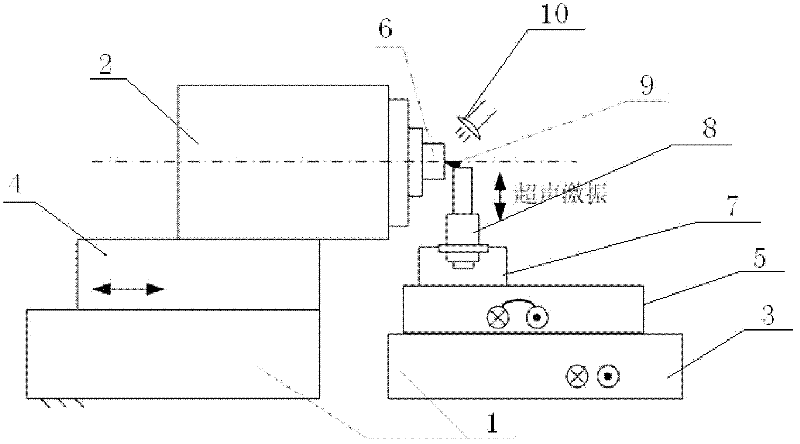

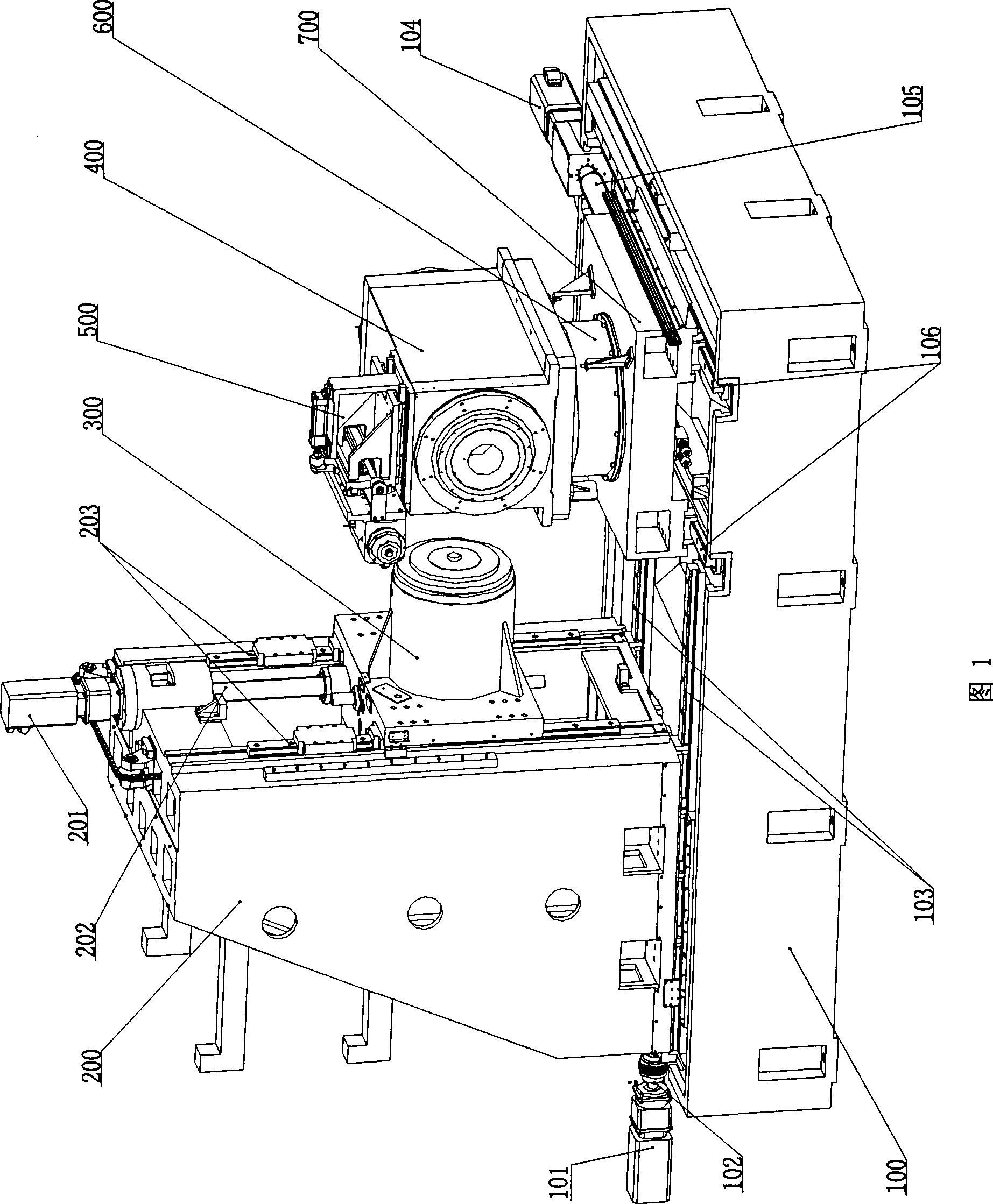

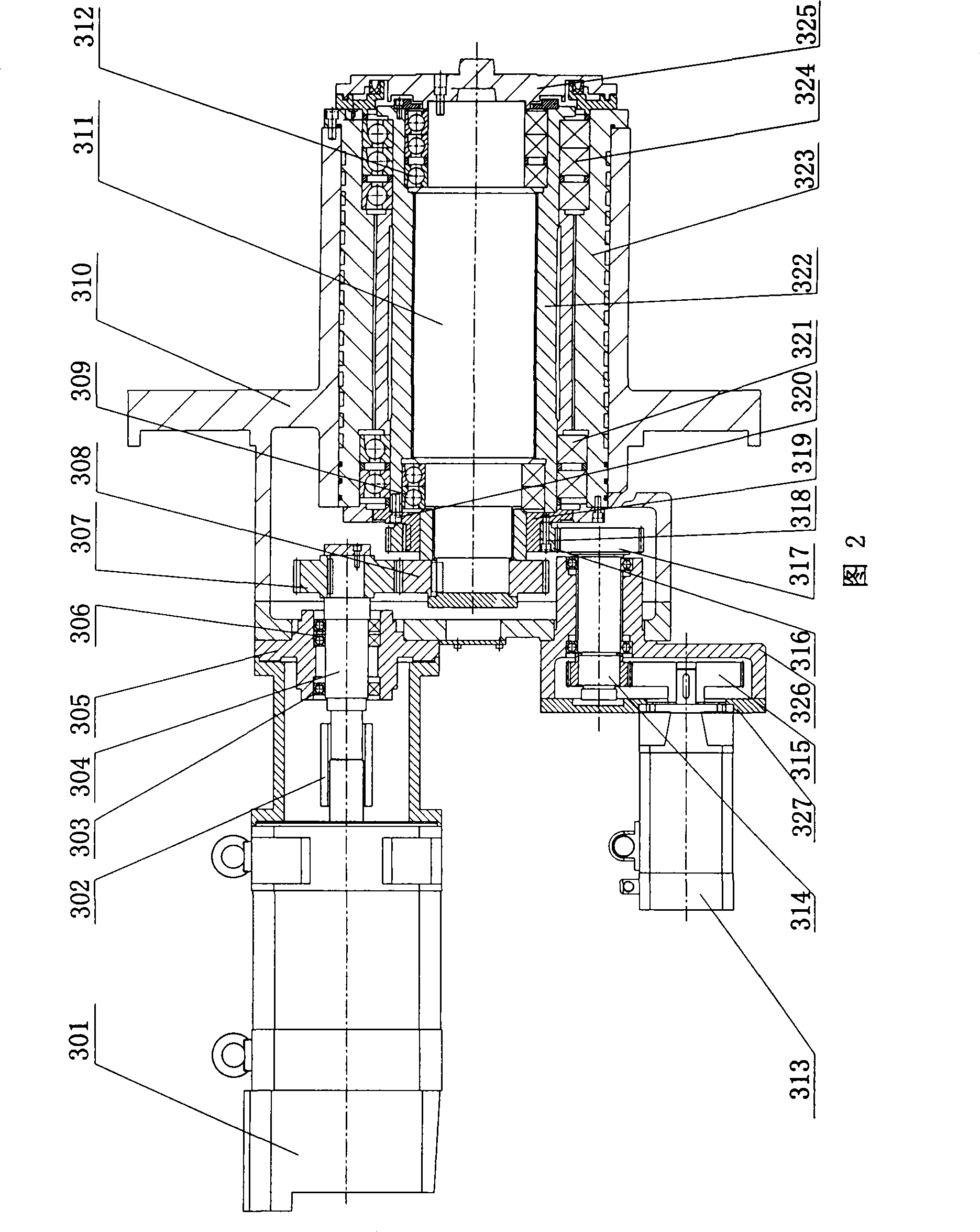

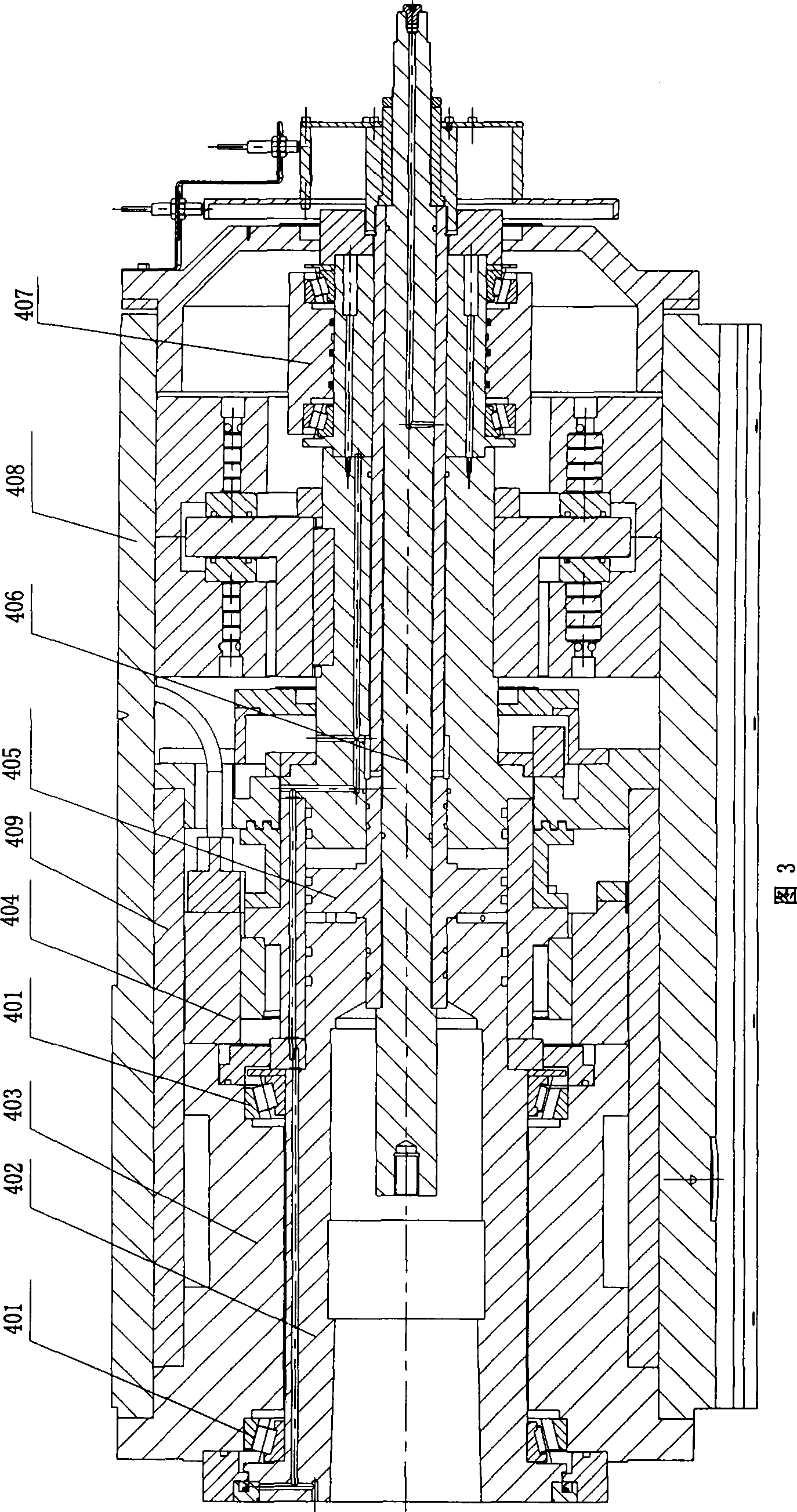

Numerical control tooth grinder for spiral bevel gear

InactiveCN101433983AGuaranteed stabilityCutting stabilityGear-cutting machinesGear teethGrinding wheelMachine tool

The invention relates to a numerical control curve-tooth bevel gear grinder, which comprises a lathe bed, and is characterized by also comprising an upright post, a grinding wheel main shaft box, a workpiece main shaft box, an electric turntable, a grinding wheel correcting mechanism and a numerical control system. The lathe bed in the horizontal direction is provided with linear guide rails vertical to each other, the upright post and a bed saddle are arranged on the linear guide rails respectively, and an upright post automatic moving mechanism is arranged between the bottom of the upright post and the lathe bed; one lateral surface of the upright post is provided with the linear guide rail and the grinding wheel main shaft box, and the same side of the upright posts close to the top is provided with a moving mechanism for driving the grinding wheel main shaft box to move; and the bed saddle is provided with the electric turntable which is provided with the workpiece main shaft box on which the grinding wheel correcting mechanism is arranged. The numerical control curve-tooth bevel gear grinder has the advantages that the grinder simplifies the prior mechanical transmission, shortens adjusting time of a machine tool, has compact and reasonable structure, accurate processing with high accuracy, high automation degree to remarkably improve processing efficiency, and has low manufacturing cost to relieve economic burden of enterprises.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

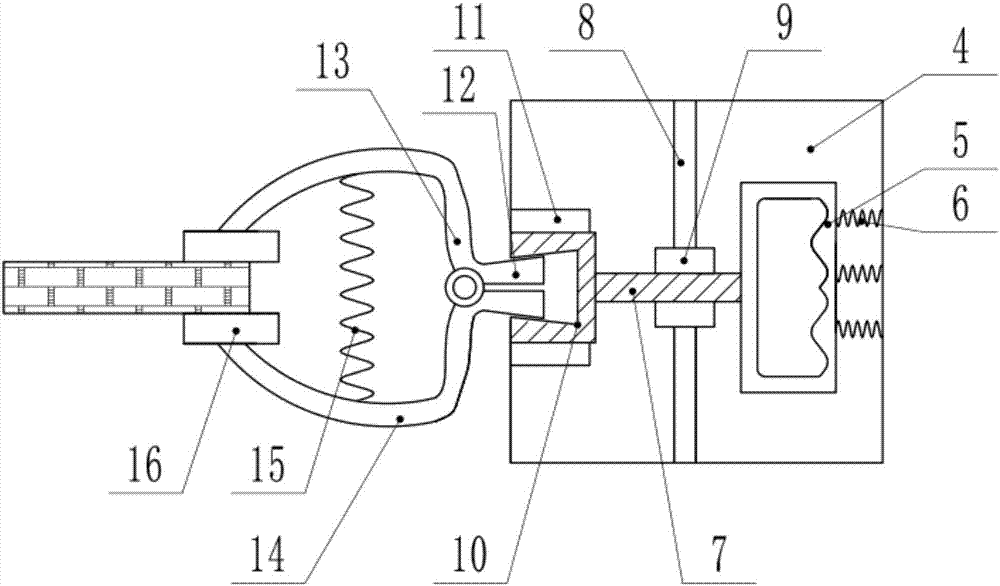

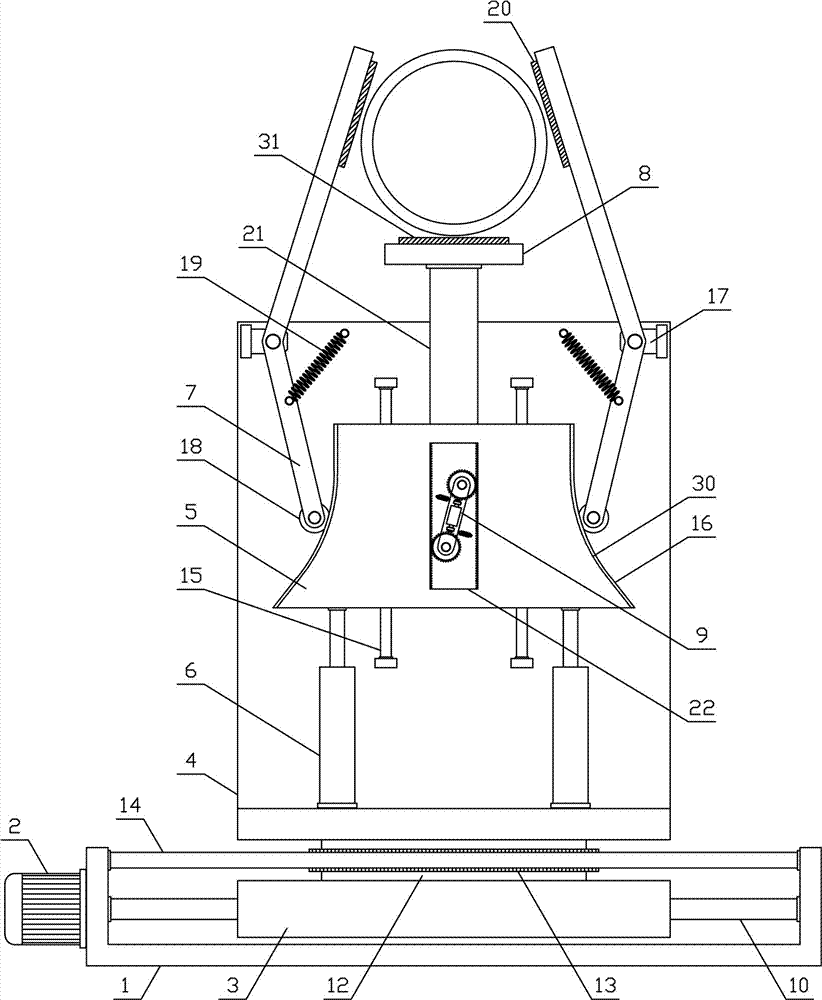

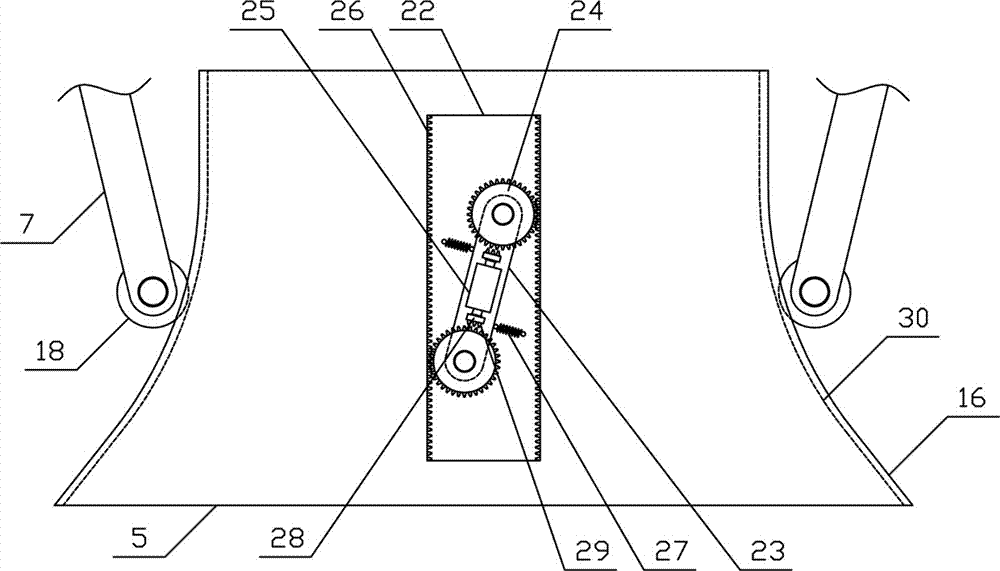

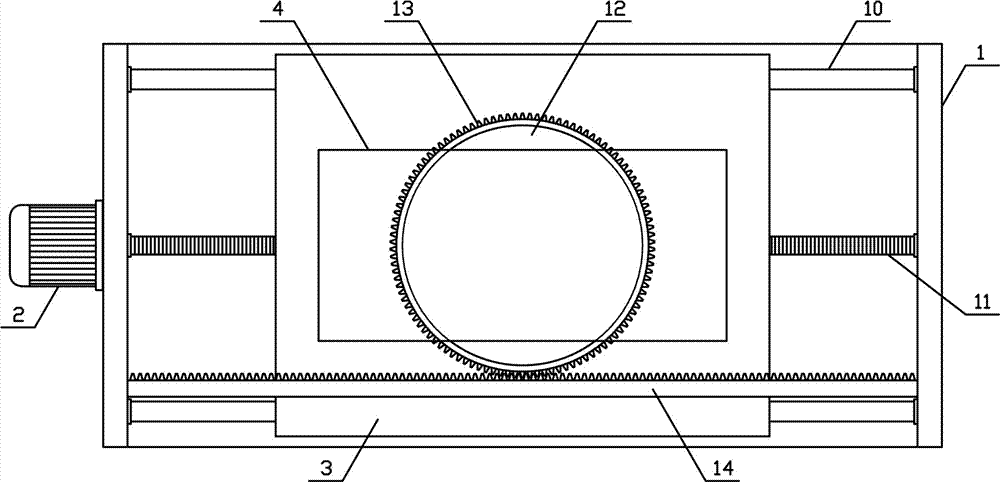

Pipe fitting pinching mechanism

InactiveCN107416518AReasonable structural designEasy clampingConveyorsConveyor partsPipe fittingElectric machinery

The invention discloses a pipe fitting pinching mechanism, and belongs to the field of pipe machining conveyance mechanical equipment. The pipe fitting pinching mechanism comprises a translation base, a translation motor, a translation support, a pipe clamping support, a lifting push plate, lifting air cylinders, pipe clamping plates, a pipe bearing plate and a plate clamping mechanism. The translation support is arranged on translation guide rods in a sliding mode in the horizontal direction. The pipe clamping support is vertically arranged at the upper side of a fixed rotating shaft. The lifting push plate is arranged on lifting guide rods in a sliding mode in the vertical direction. Arc-shaped plate push surfaces are symmetrically arranged at the two sides of the lifting push plate correspondingly. The pipe clamping plates are symmetrically arranged at the two sides of the pipe clamping support separately. The pipe bearing plate is horizontally arranged at the upper side of a pipe bearing supporting rod. The plate clamping mechanism is arranged on the pipe clamping support and located at one side of a lifting clamping groove. The pipe fitting pinching mechanism is reasonable in structural design, pipe fittings of various sizes and dimensions can be clamped and fixed firmly, the pipe fittings can be stably rotated and adjusted synchronously in the translation process of the pipe fittings, and the production and use needs are met.

Owner:浙江绿康农产品配送有限公司

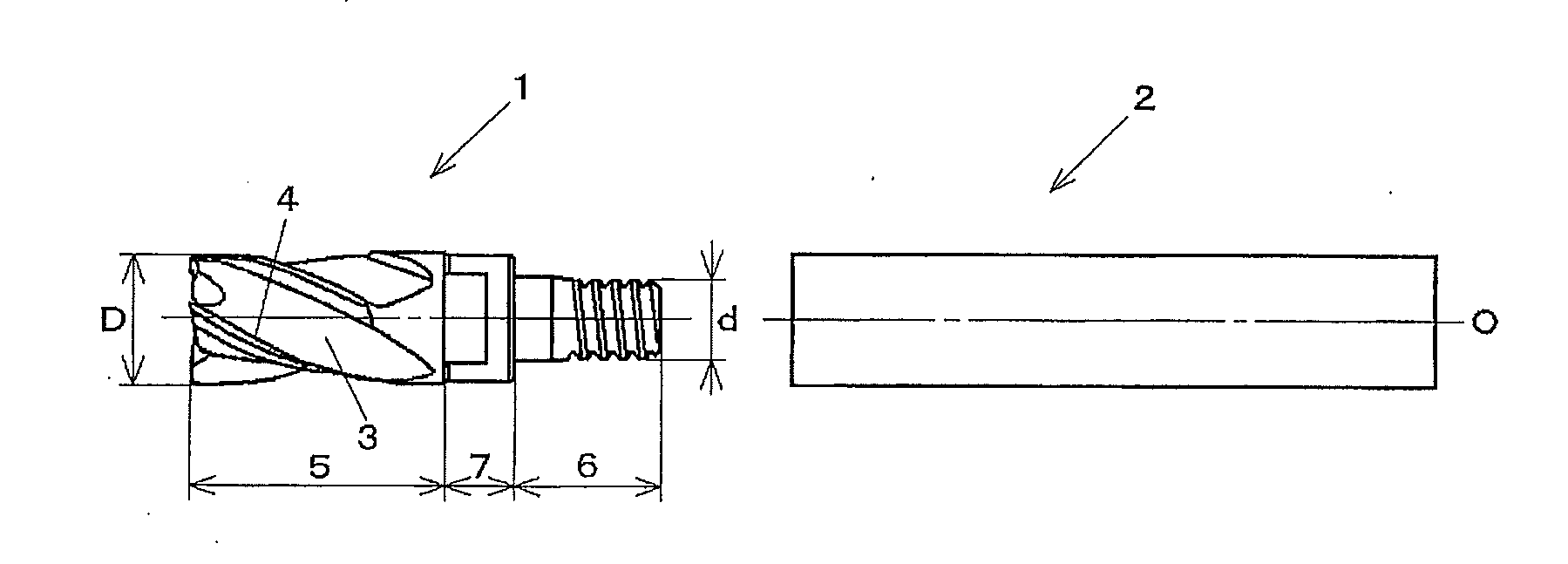

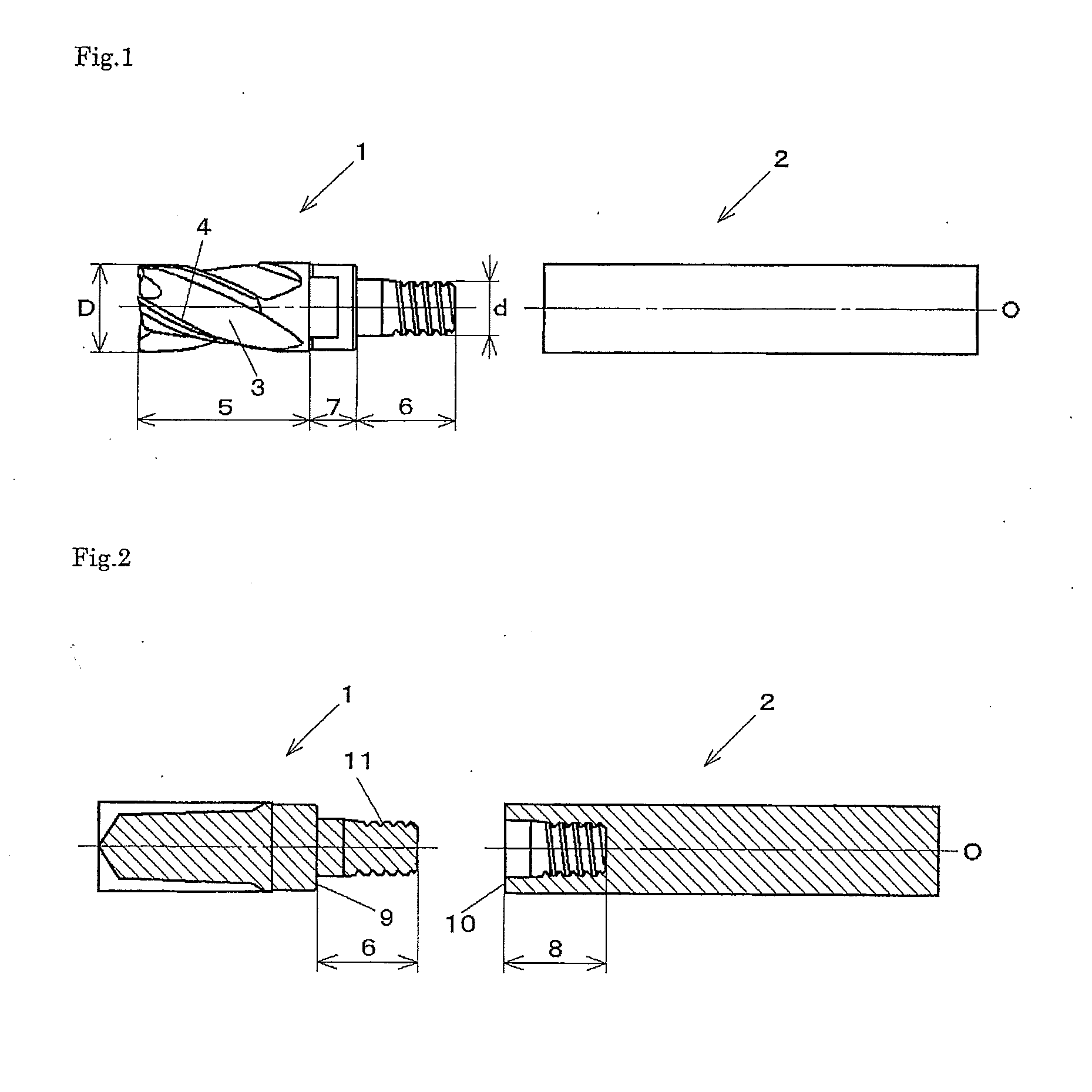

Machining head, holder and exchangeable tip cutting tool

InactiveUS20150063928A1Efficient cuttingDamage suppressionTool workpiece connectionMilling cuttersTool bitEngineering

Provided are: an exchangeable tip cutting tool in which breakage of the threaded section and breakage of the thread ridges during installation of the machining head and under increased cutting load during cutting are limited and which is capable of performing machining with high efficiency; and a machining head and a holder to be used in the exchangeable tip cutting tool. The flank angle (α) of the pressure flank (11) is set to be larger than the flank angle (β) of the clearance flank (12); and a holder (2, 2a) having a female threaded fastening section (8) wherein the angle of the screwing surface of the pressure flank is set to be larger than the angle of the screwing surface of the clearance flank.

Owner:HITACHI TOOL ENG LTD

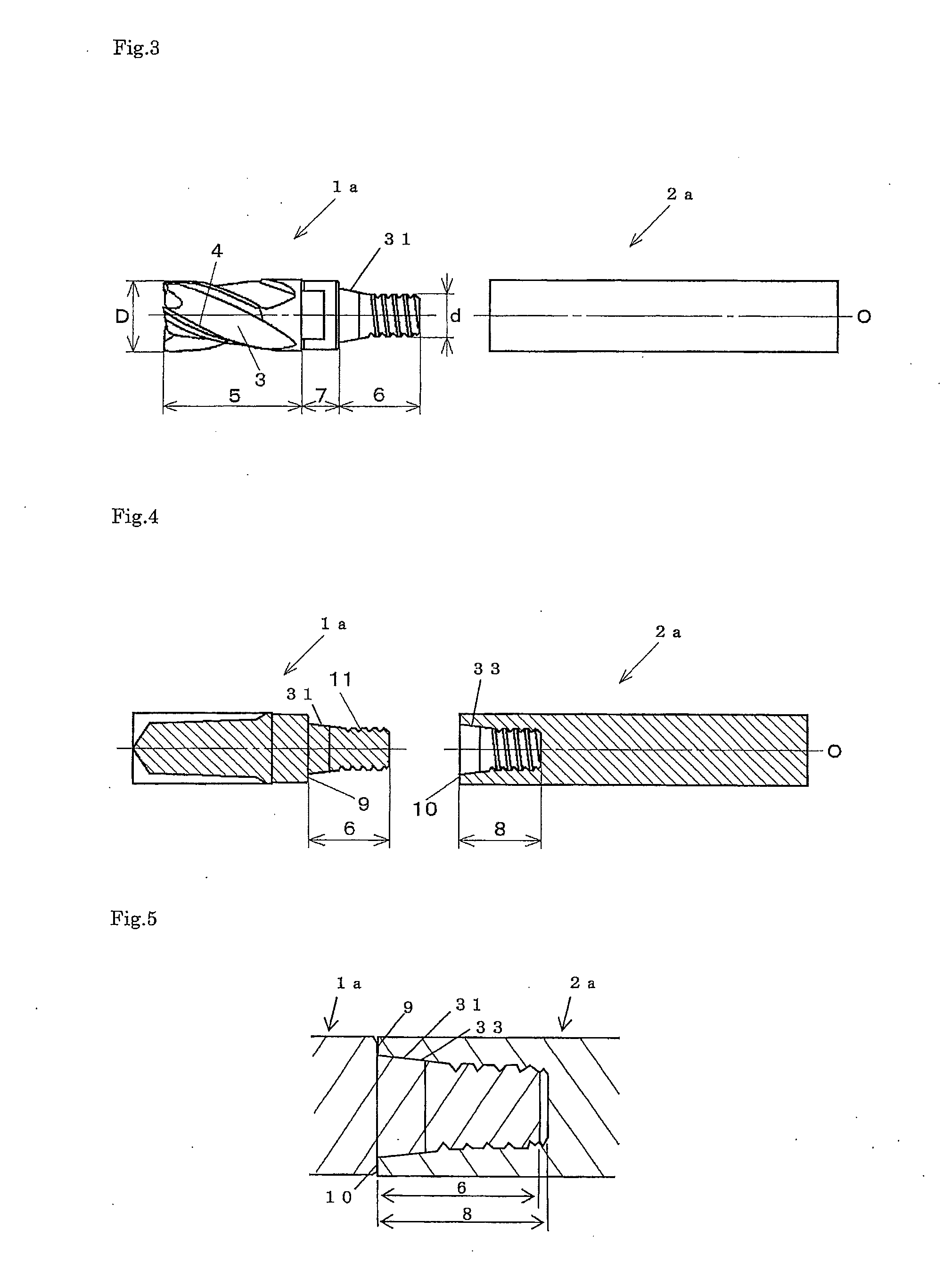

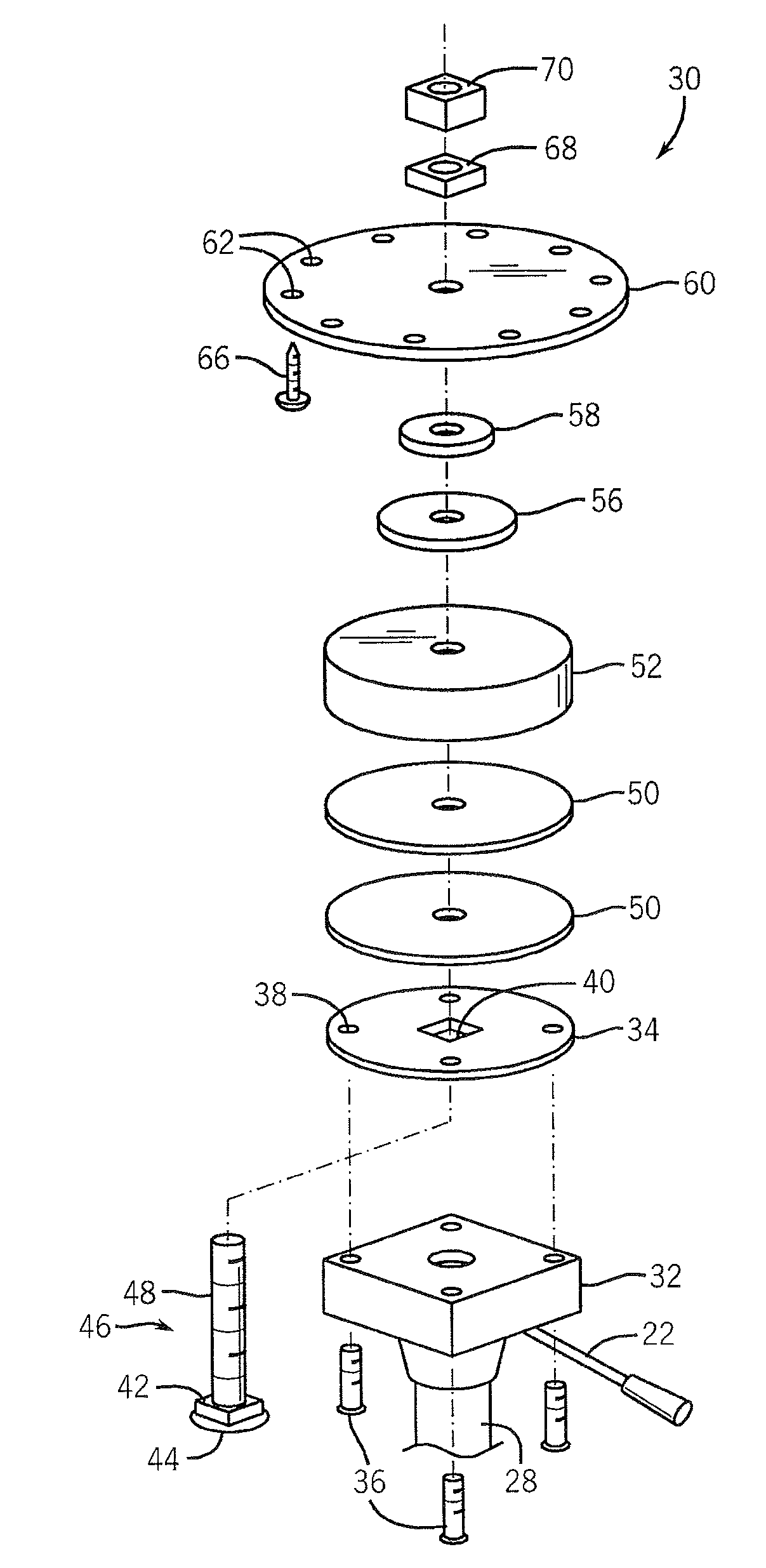

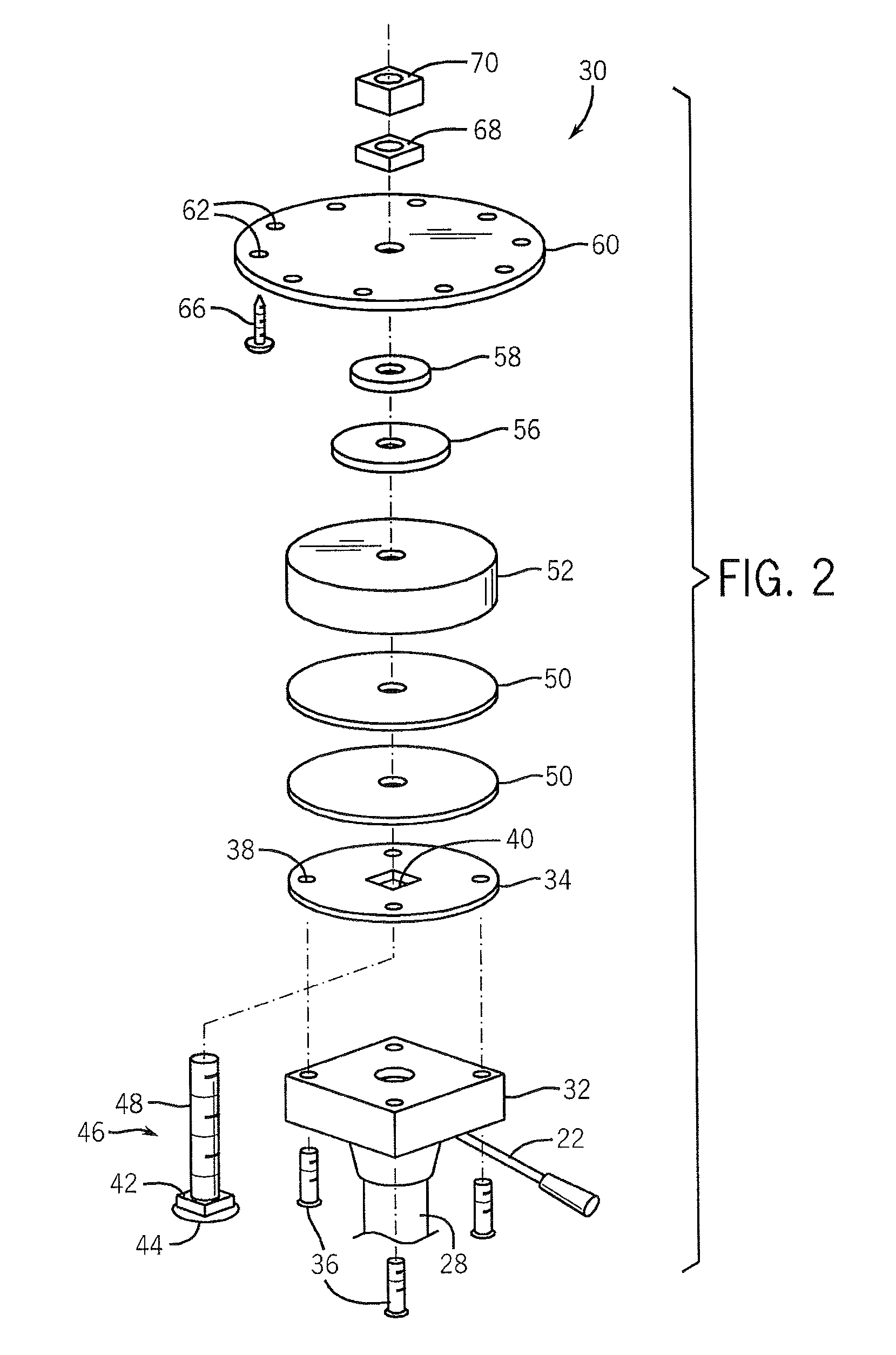

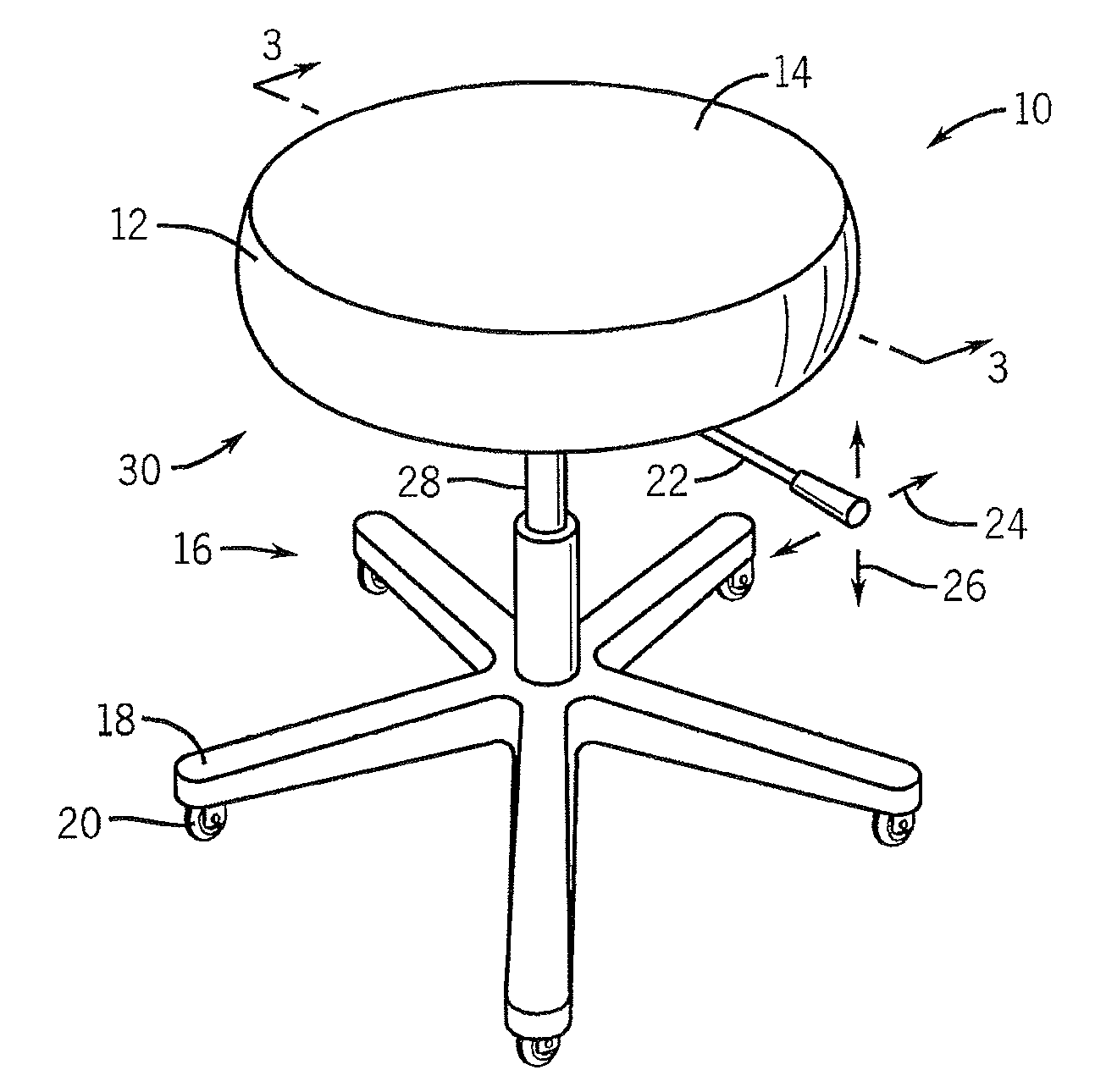

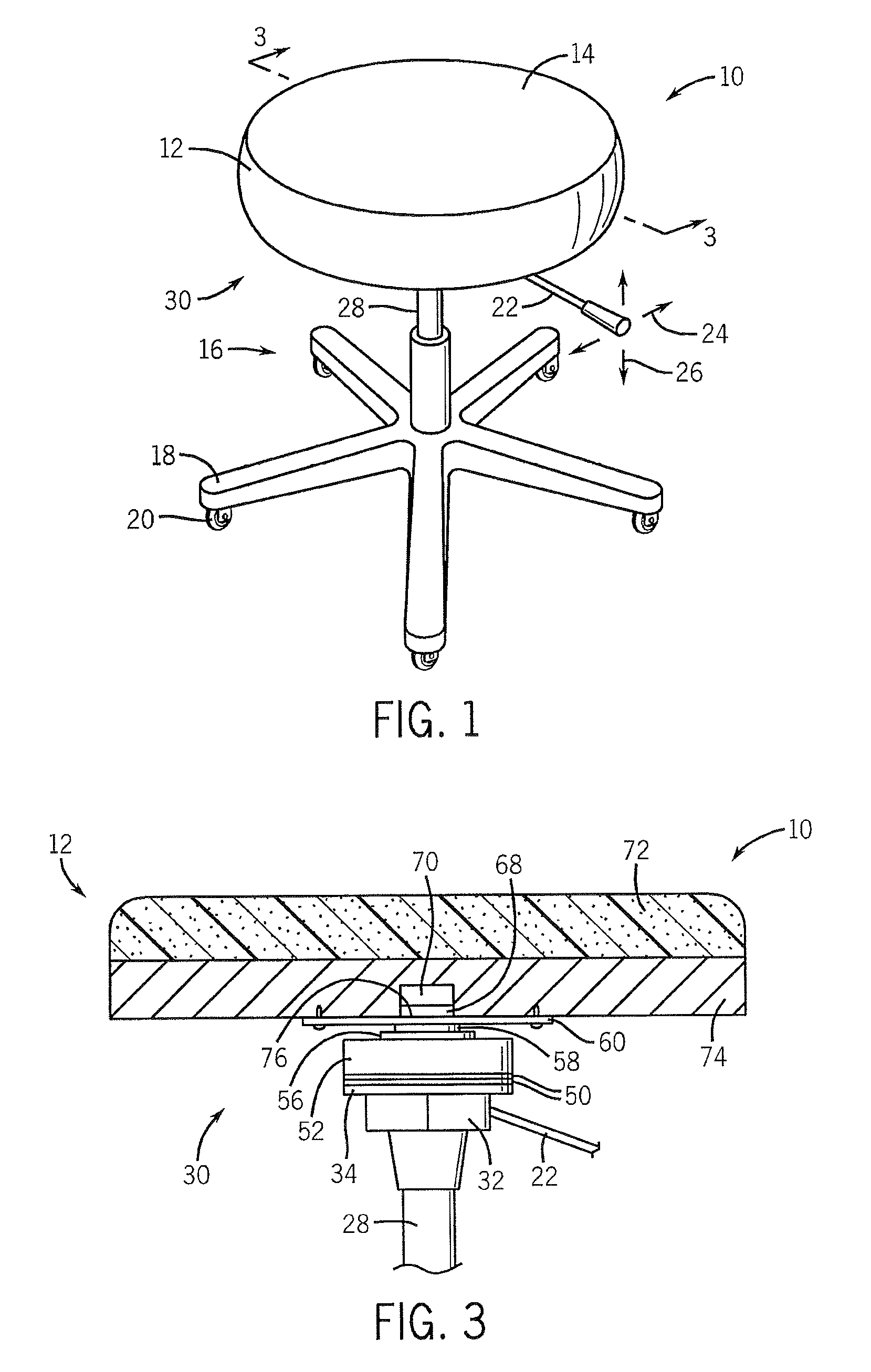

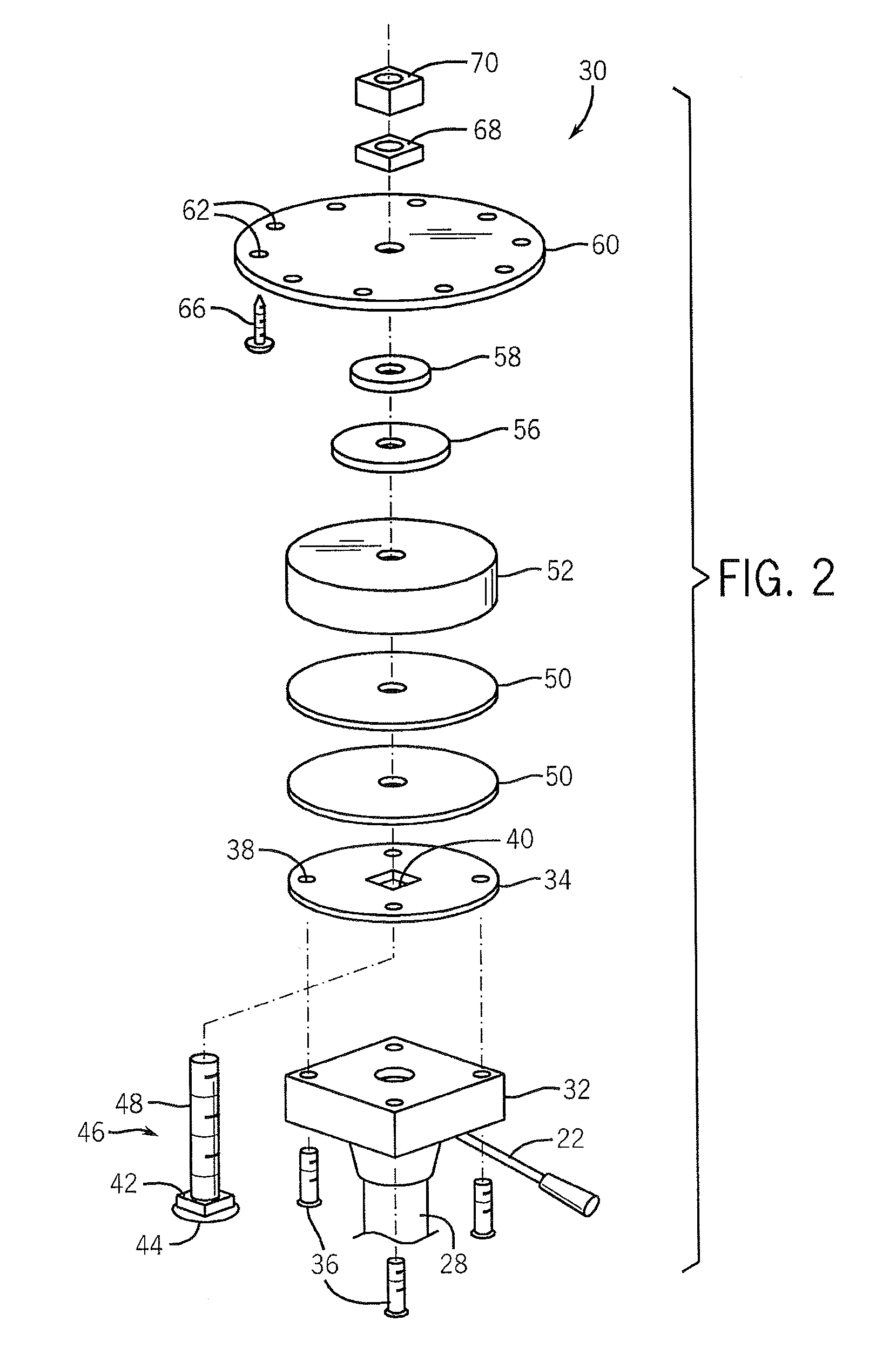

Seat with adjustable dynamic joint

InactiveUS7806479B2Promotes small movementCutting stabilityOperating chairsDental chairsCouplingEngineering

A pivoting joint for use in a task chair or the like provides an adjustable elastomeric coupling that permits multi-axis rocking of the seat pan with a restoring force that provides controlled stability.

Owner:WISYS TECH FOUND

Seat with adjustable dynamic joint

InactiveUS20080191525A1Promotes small movementLimit stabilityOffice stoolsOperating chairsCouplingEngineering

A pivoting joint for use in a task chair or the like provides an adjustable elastomeric coupling that permits multi-axis rocking of the seat pan with a restoring force that provides controlled stability.

Owner:WISYS TECH FOUND

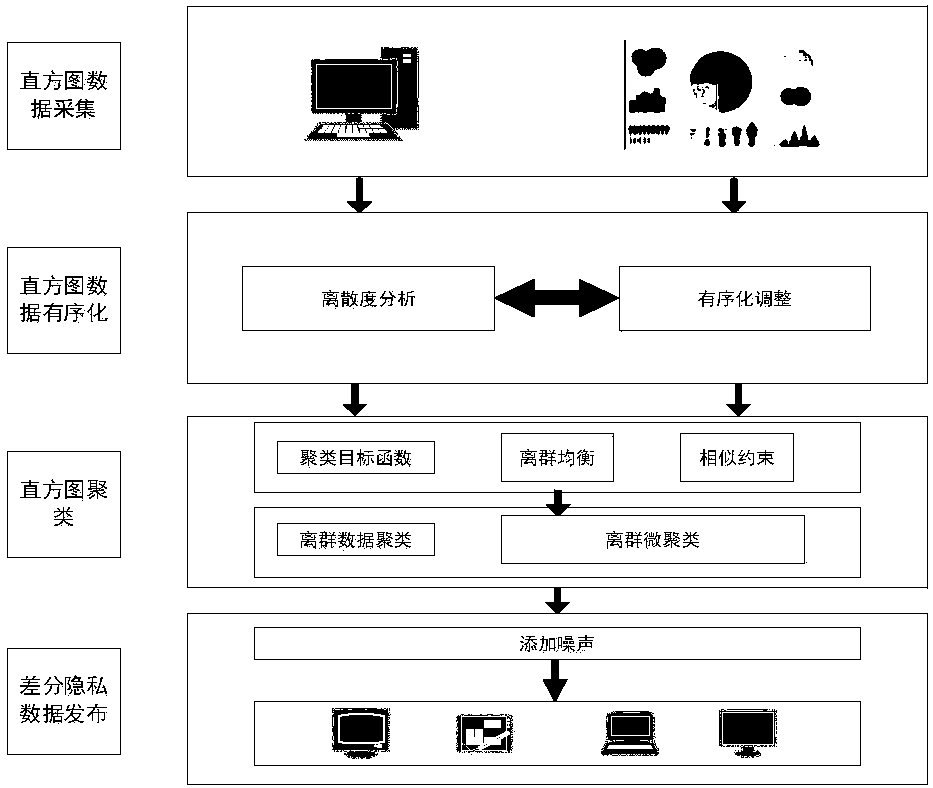

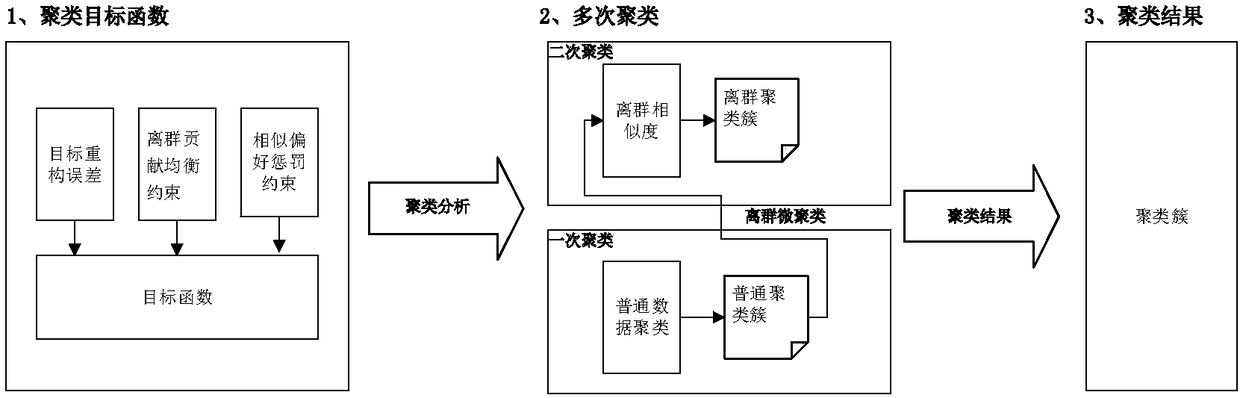

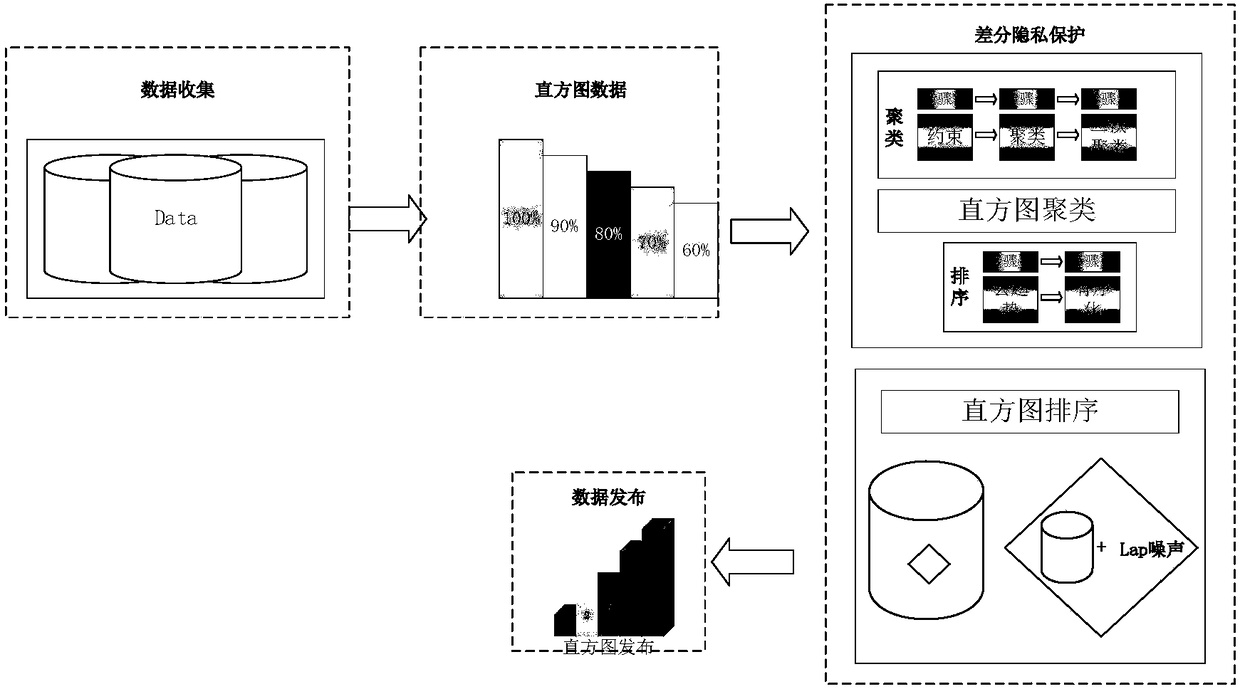

Detrended analysis differential privacy protection-based histogram data release method

ActiveCN108446568ACutting stabilityOutlier reductionCharacter and pattern recognitionDigital data protectionPrivacy protectionDifferential privacy

The invention discloses a detrended analysis differential privacy protection-based histogram data release method. A method for judging a signal sequence trend is introduced in judgment of histogram anomaly distribution; a large amount of outliers cause relatively great fluctuation of data distribution, so that the stability is reduced; and from the perspective, a histogram bucket count distribution condition is regarded as continuous digital signals to perform data outlier processing. Meanwhile, for a clustering objective function causing the large amount of the outliers in a conventional method, outlier balance constraints and similar penalty constraints are added for balancing the influence of similar bucket and outlier bucket data on clustering, so that the occurrence of the outliers isreduced; and outlier data micro-clustering is performed based on outlier similarity for outlier data.

Owner:NORTHWEST UNIV

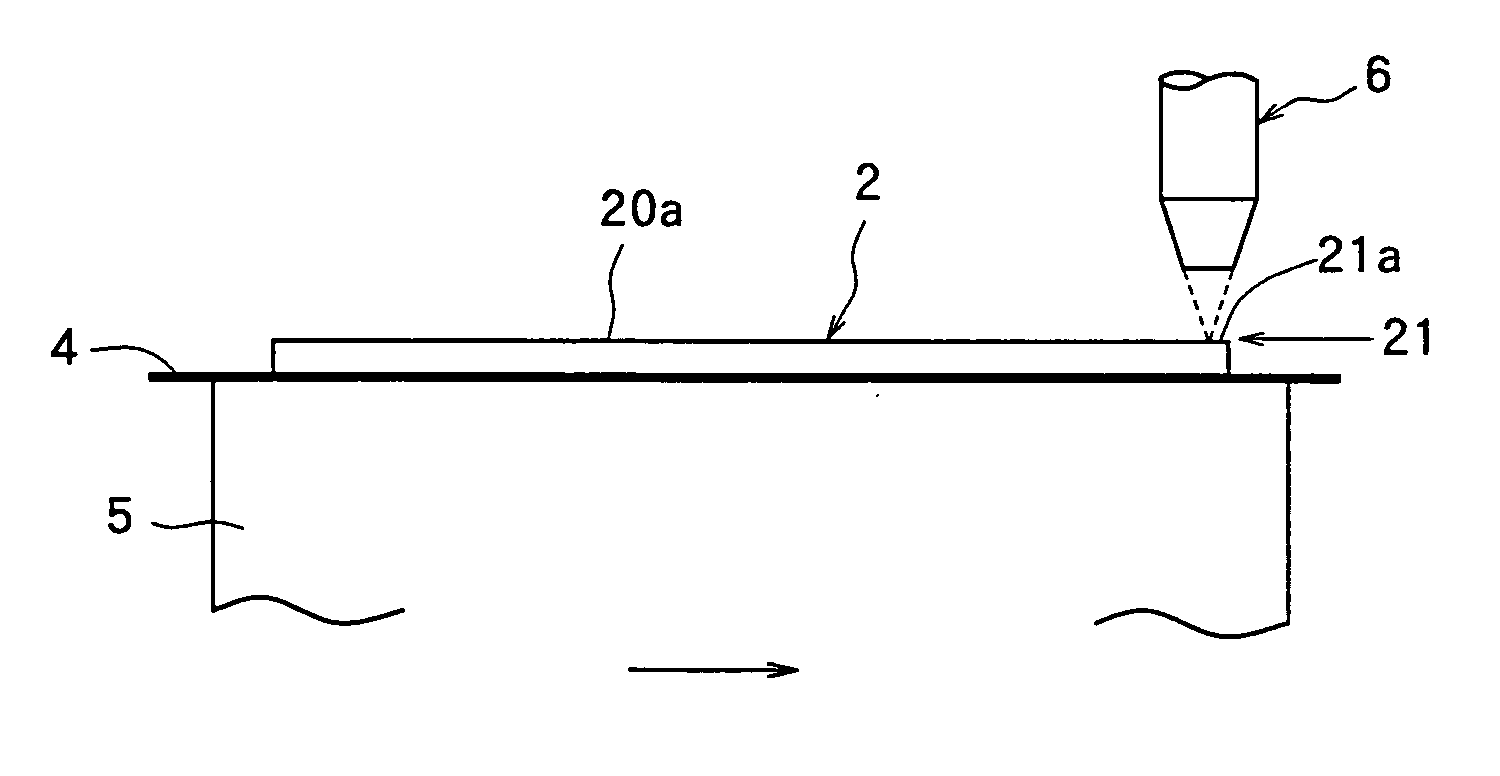

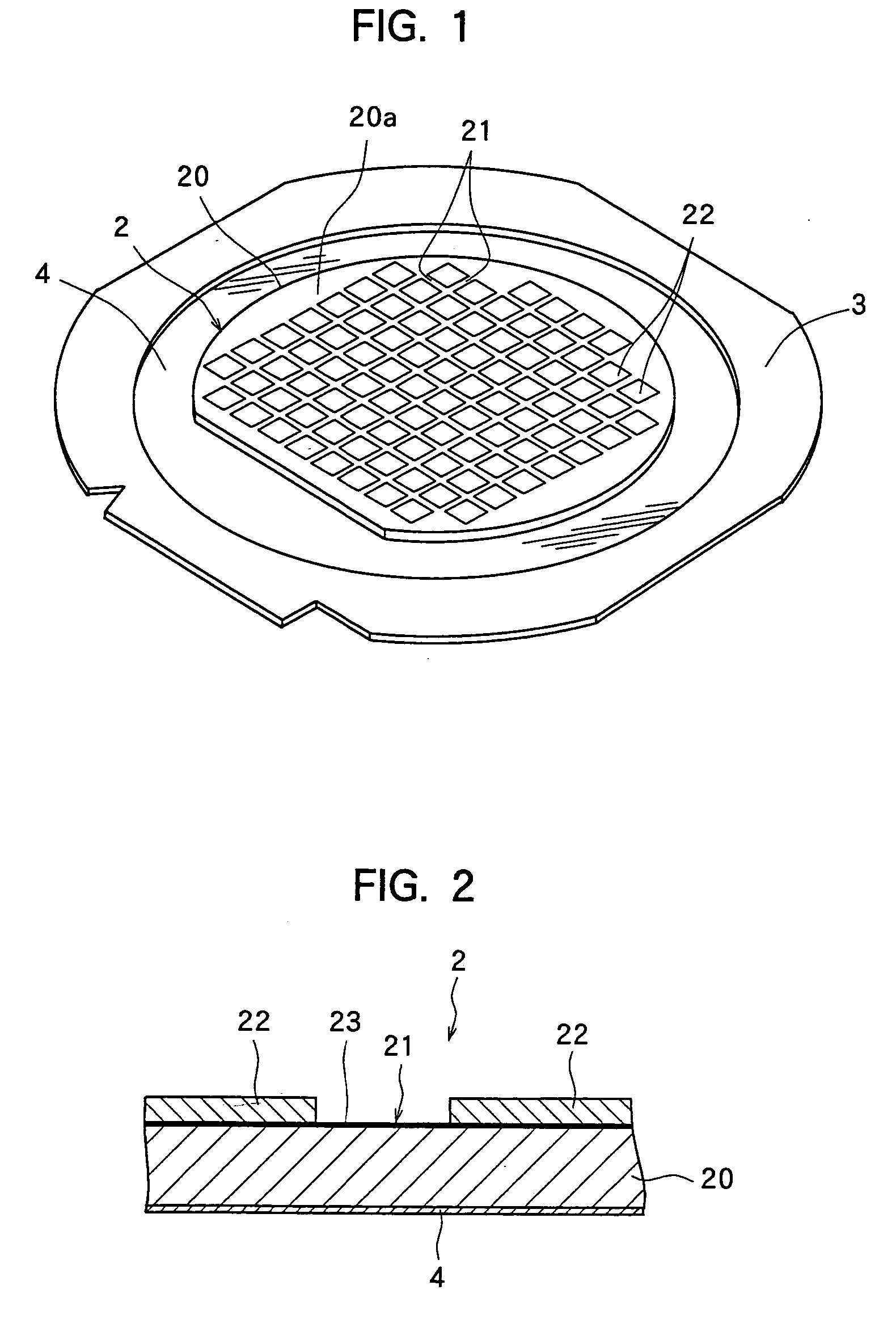

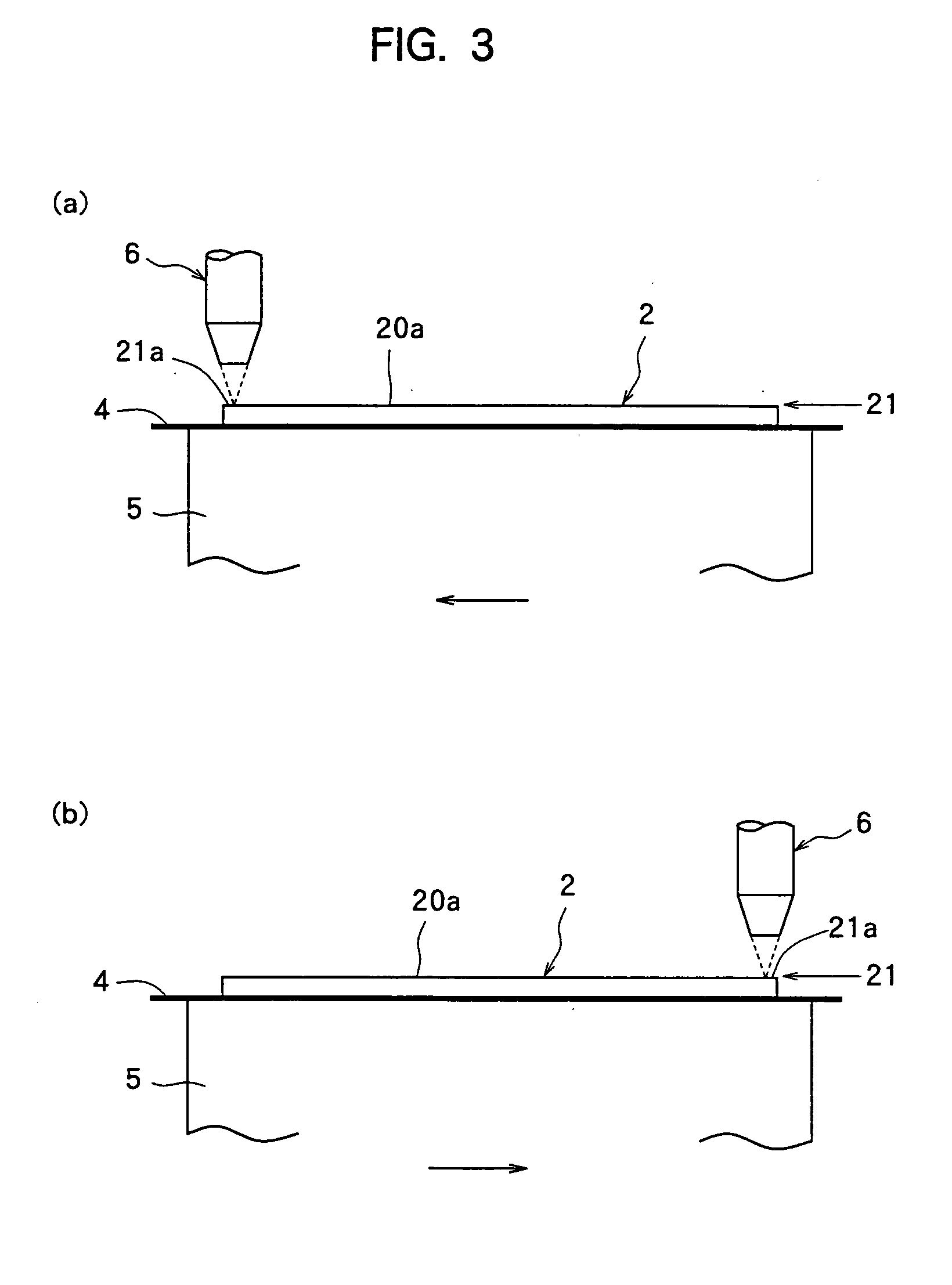

Method of dividing a plate-like workpiece

ActiveUS20050035099A1Cutting stabilityPrecise cuttingSemiconductor/solid-state device manufacturingFine working devicesPhysicsLaser beams

A method of dividing a plate-like workpiece having a layer that is made of a different material from that of a substrate and is formed on the front surface of the substrate along predetermined dividing lines, comprising a laser beam application step for applying a laser beam to each dividing line formed on the plate-like workpiece except for a non-processed area in at least one end portion thereof to form grooves deeper than the layer; and a cutting step for cutting the plate-like workpiece along each dividing line by positioning a cutting blade on the side of the non-processed area in the dividing line where the grooves have been formed in the laser beam application step and moving the plate-like workpiece relative to the cutting blade while rotating the cutting blade.

Owner:DISCO CORP

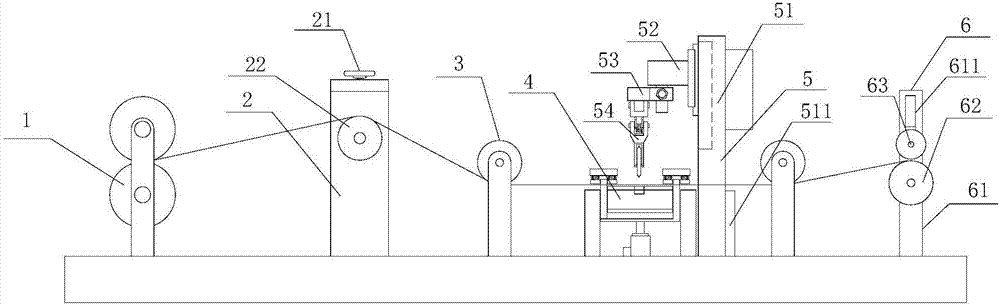

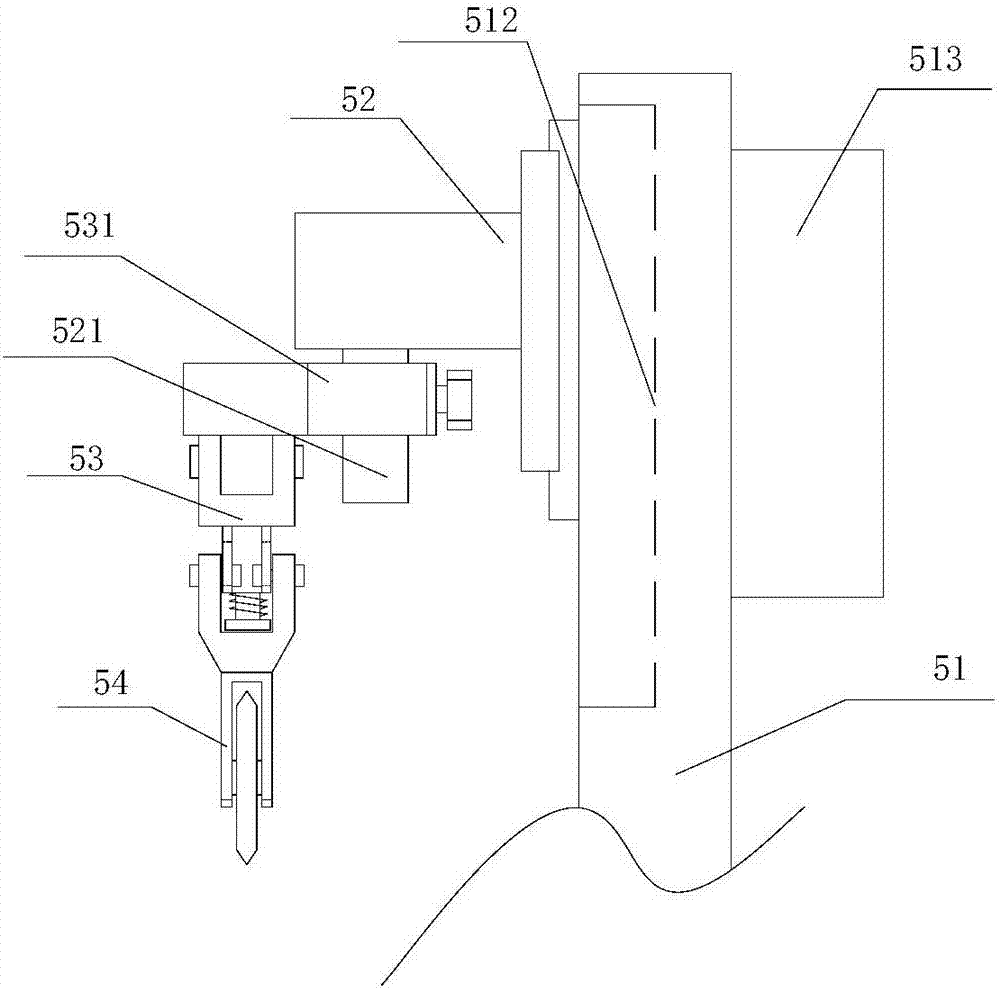

Cloth cutting device

ActiveCN107142704AReduce cloth deformationReduce impactSevering textilesEngineeringMechanical engineering

The invention provides a cloth cutting device comprising a transport roller device, an adjustable guide roller mechanism, an auxiliary roller assembly, a press unit, a cutter and a rolling device; the press unit is provided with a tool rest; two sides of the tool rest are provided with a press mechanism; the cutter is arranged above the press unit; two sides of the cutter are provided with the auxiliary roller assembly; the cutter is provided with a vertical slide seat; a transverse slide seat is arranged on the vertical slide seat; one side of the transverse slide seat is provided with a buffer mounting rack; a cutter assembly is arranged below the buffer mounting rack; the cloth on the transport roller device passes the guide roller assembly, the auxiliary roller assembly, the press unit and the rolling device in sequence along the transport direction; the press unit can press tight the cloth on two sides of the tool rest, thus maximumly reducing the cloth deformation level, and ensuring the cutting process to be stable; the cutter assembly is provided with the buffer mounting rack, thus reducing bumps between the cutter and the tool rest in a cutting process, and reducing the cutter wearing.

Owner:杭州世佳布艺有限公司

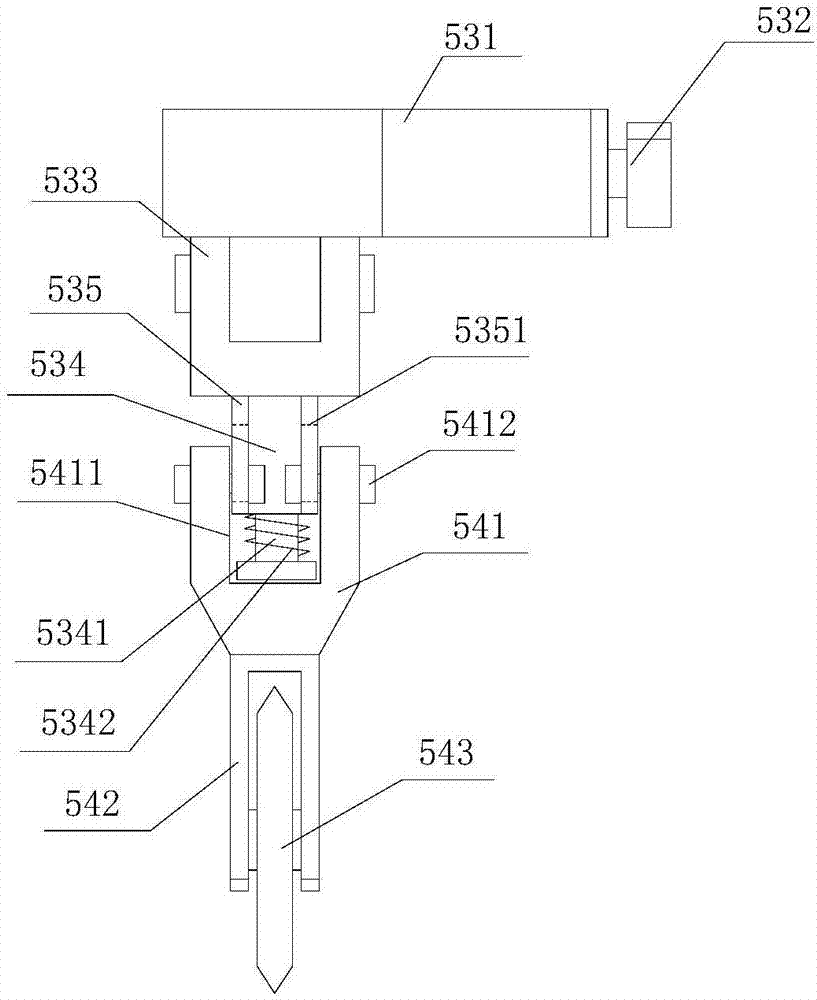

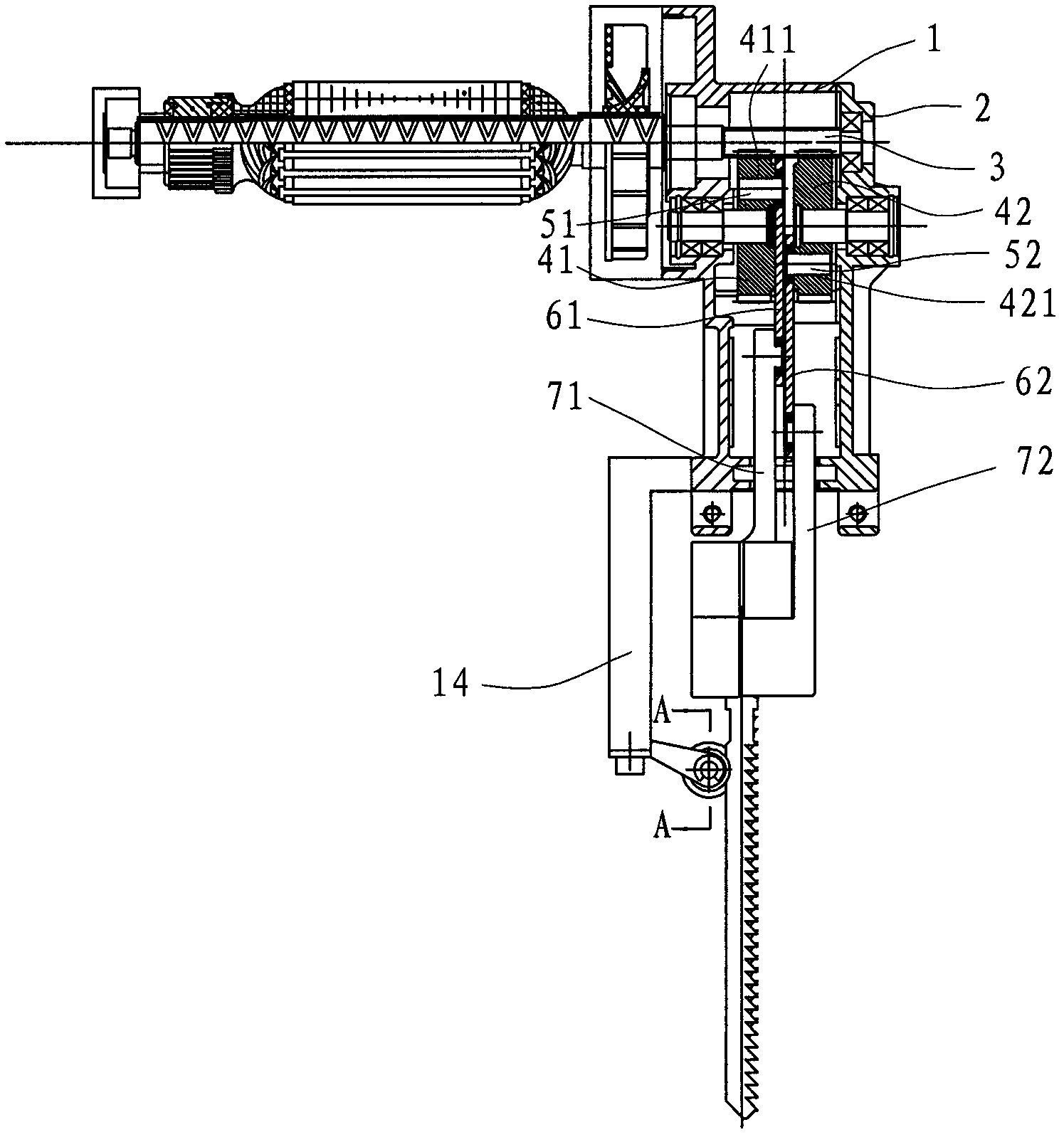

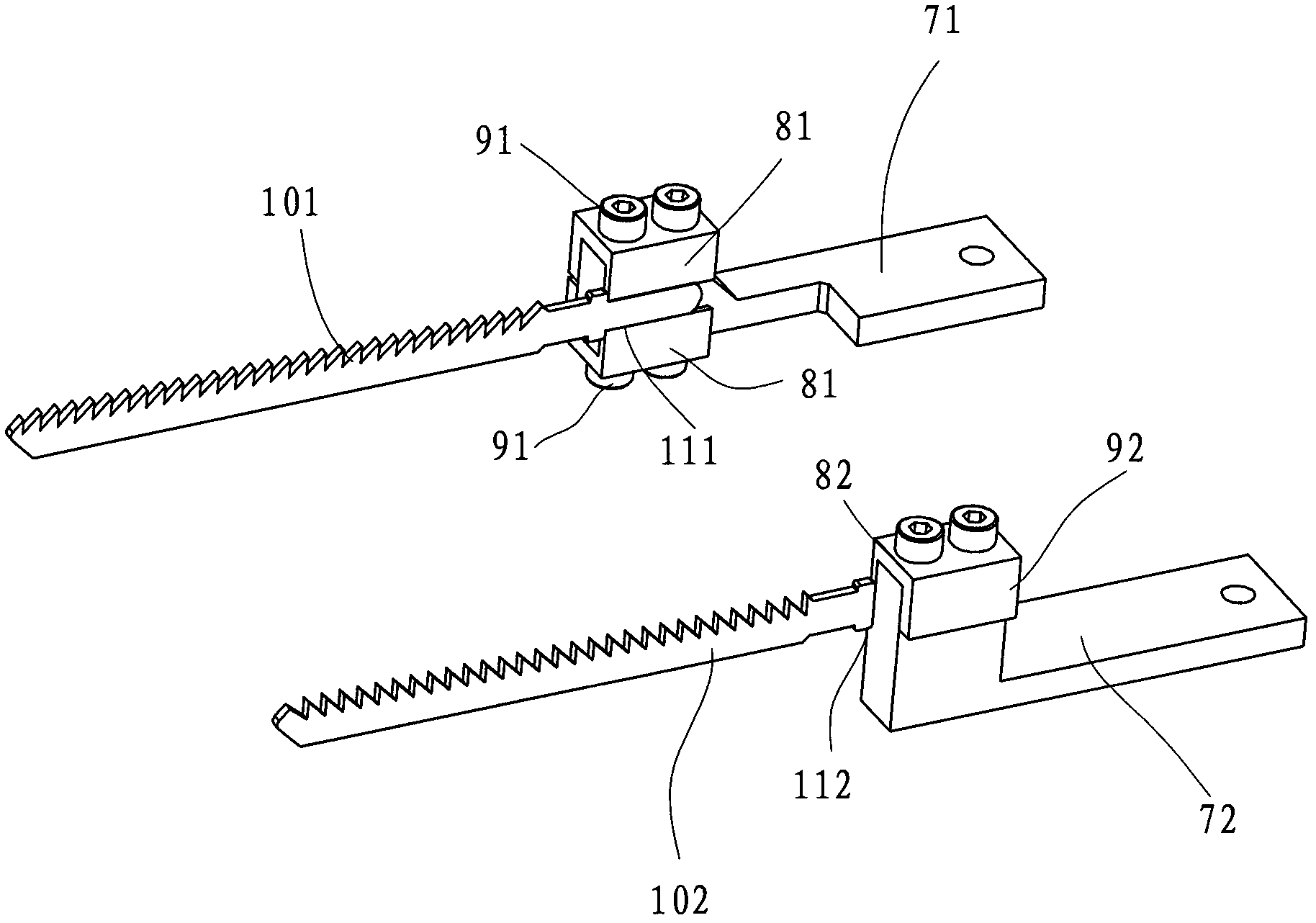

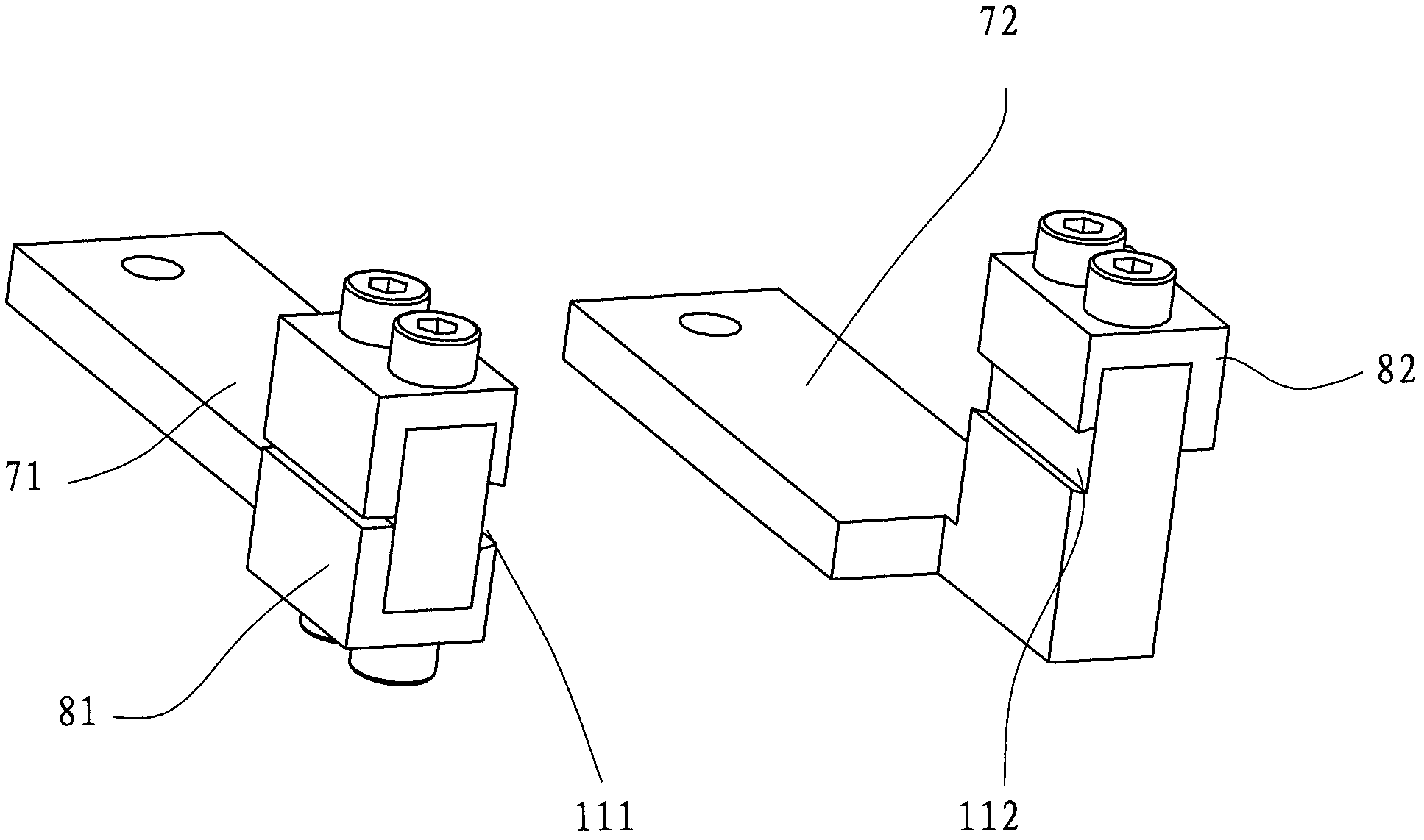

Novel jig saw

Owner:NINGBO LUTZ TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com