Patents

Literature

312 results about "Surface projection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface projection enables you to extract curves from vertical surfaces. You can use these curves to create 2.5D features from surface or solid models. This method is a wizard that creates geometry by projecting straight-walled surfaces, for example:

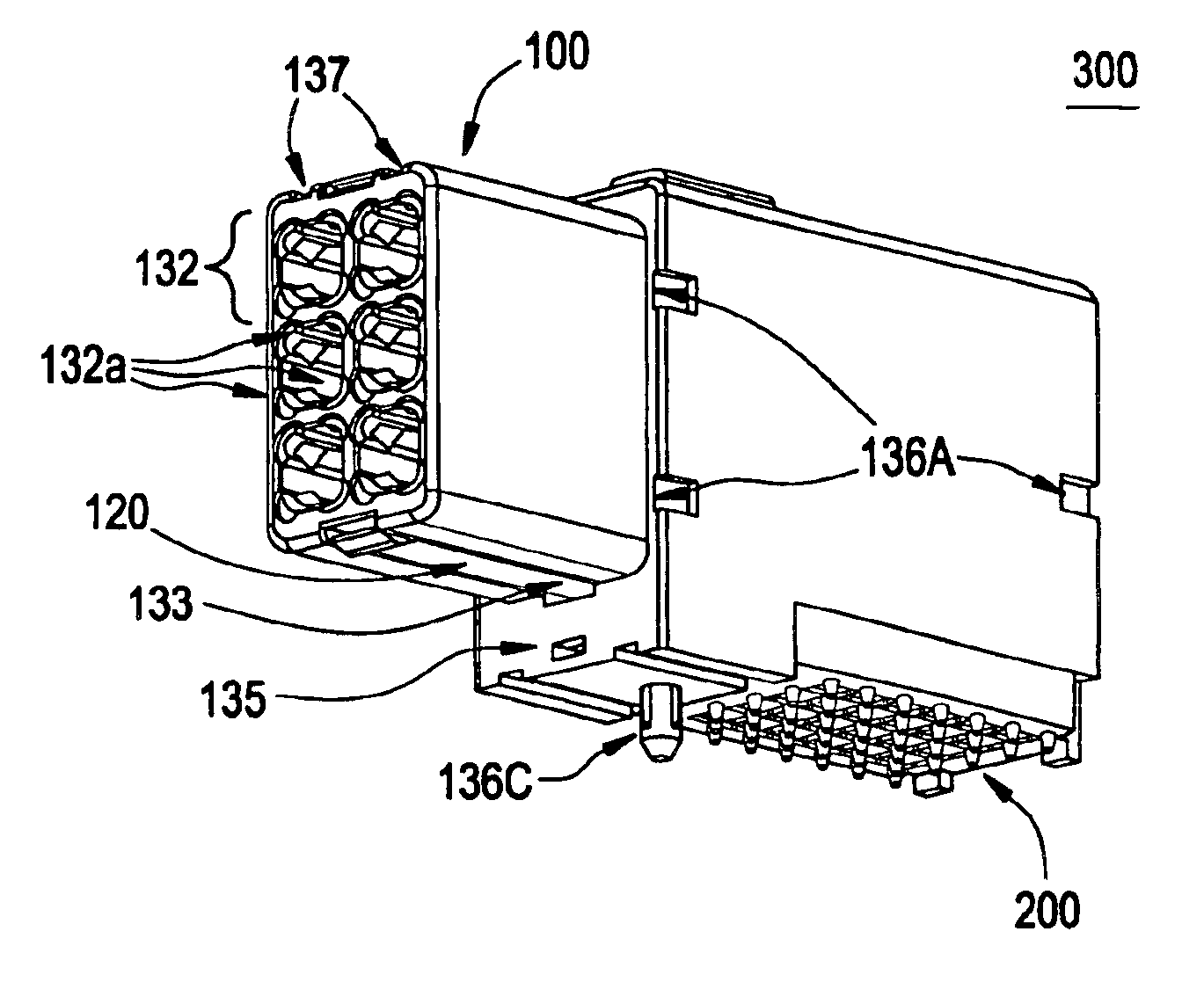

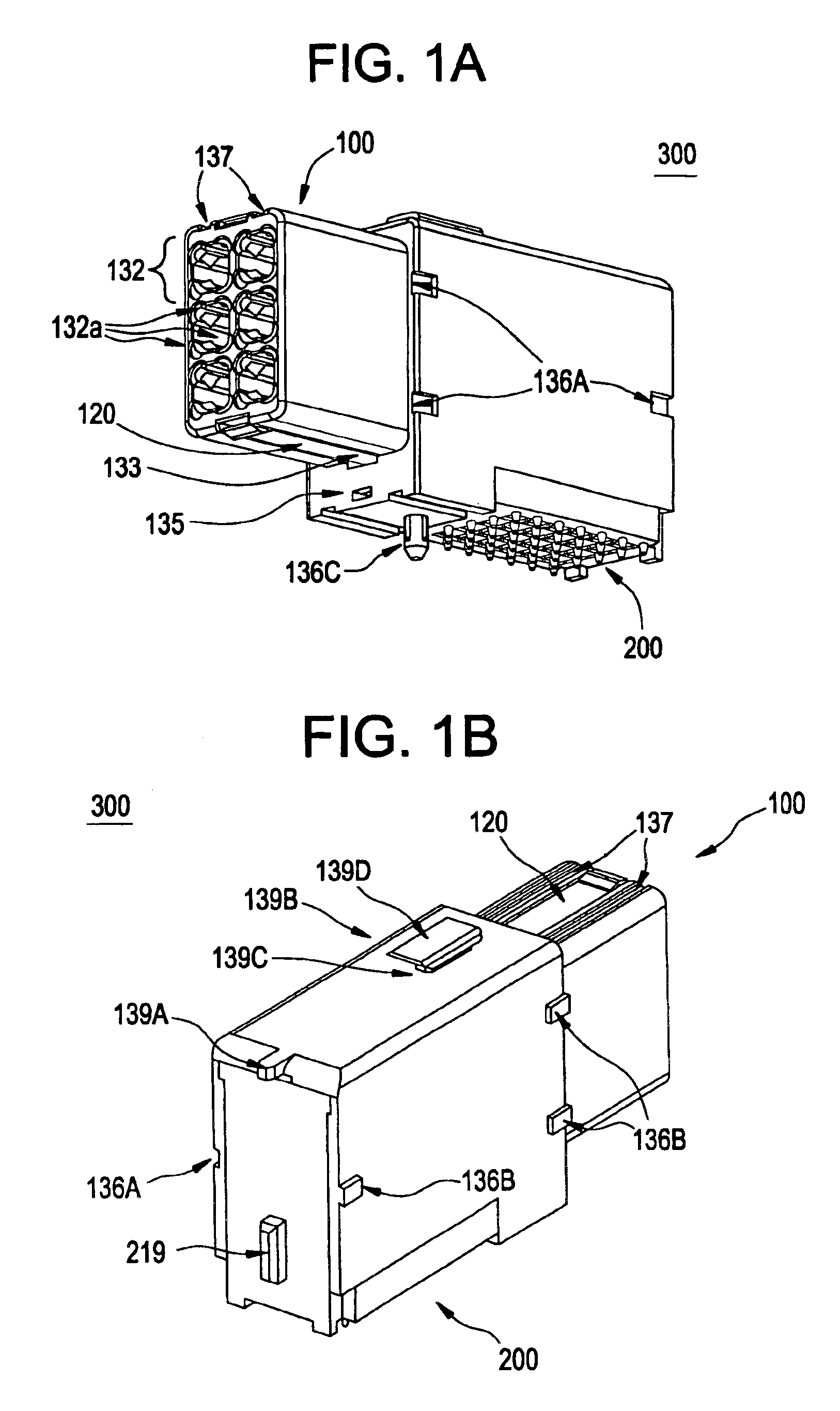

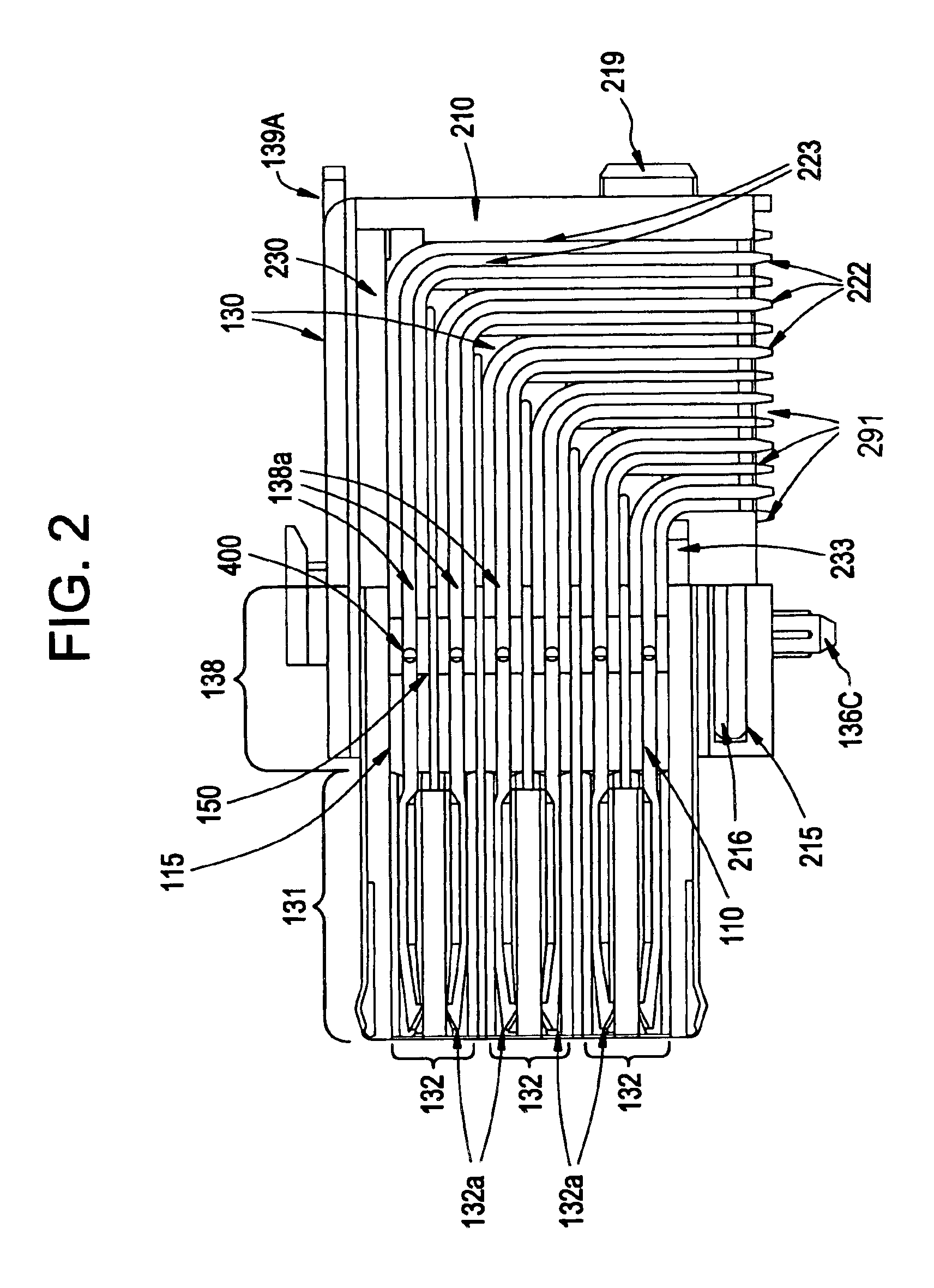

Modular coaxial electrical interconnect system having a modular frame and electrically shielded signal paths and a method of making the same

InactiveUS6905367B2Increasing signal speedEfficient space utilizationCoupling protective earth/shielding arrangementsModular connectorSurface projection

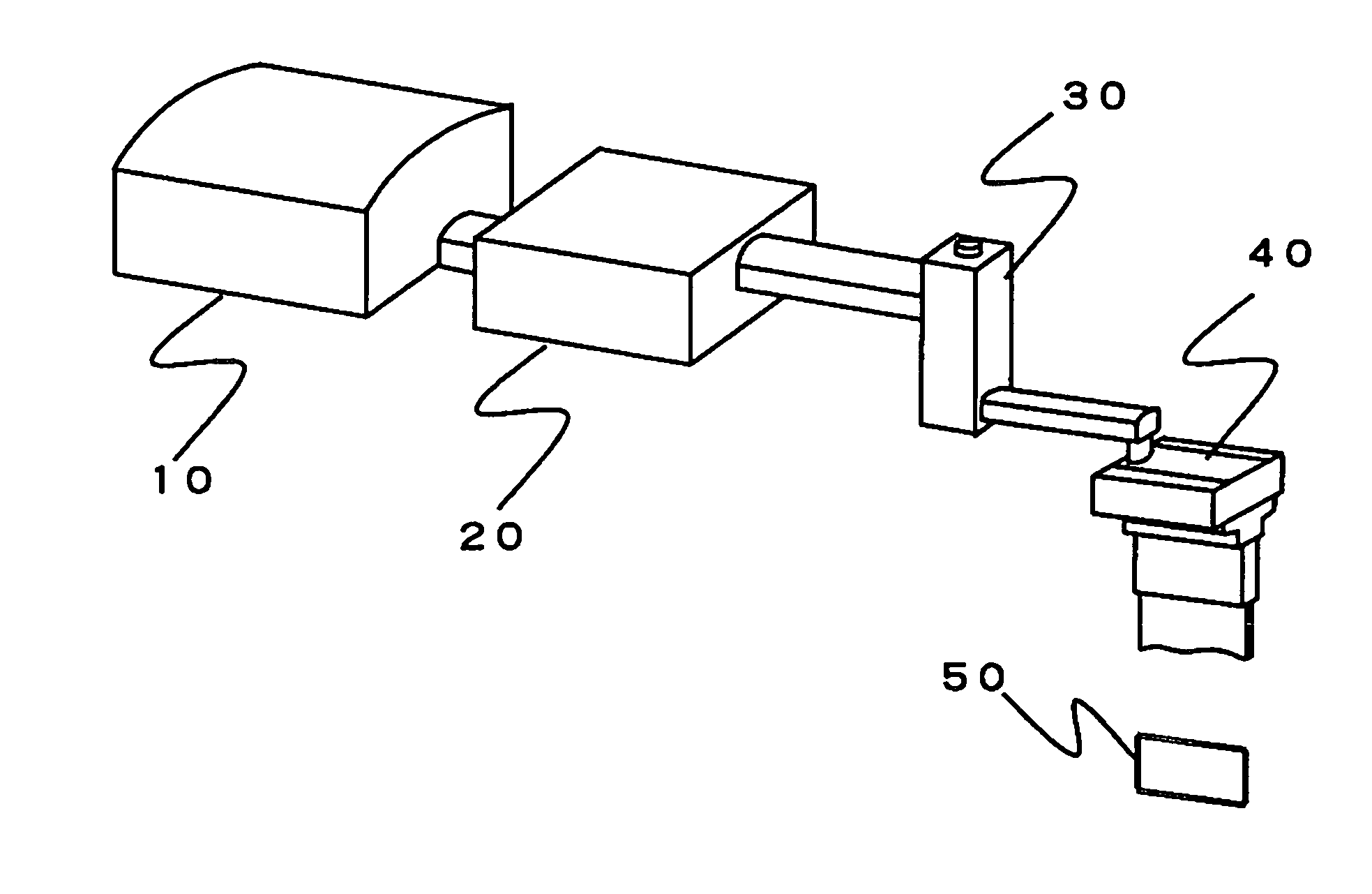

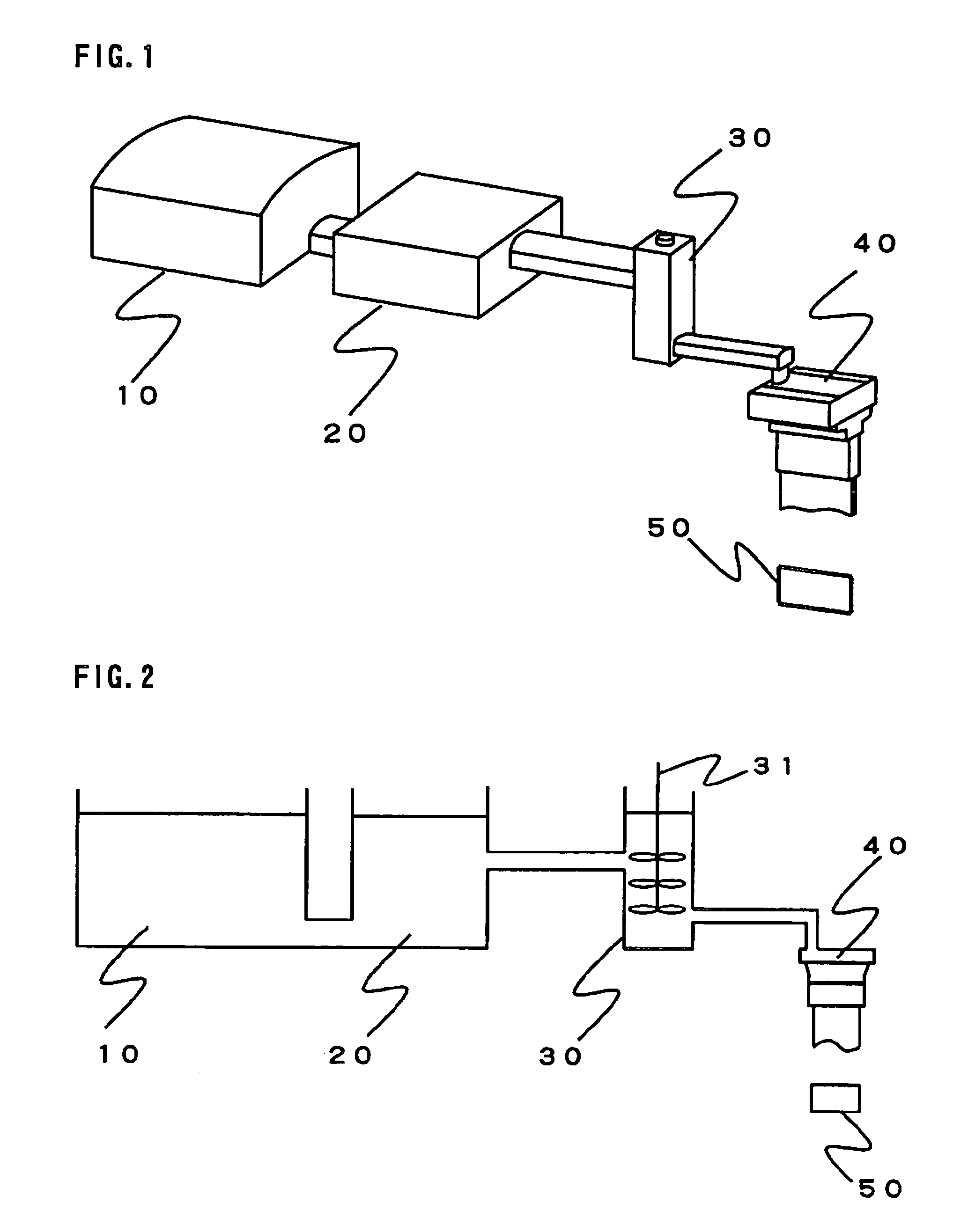

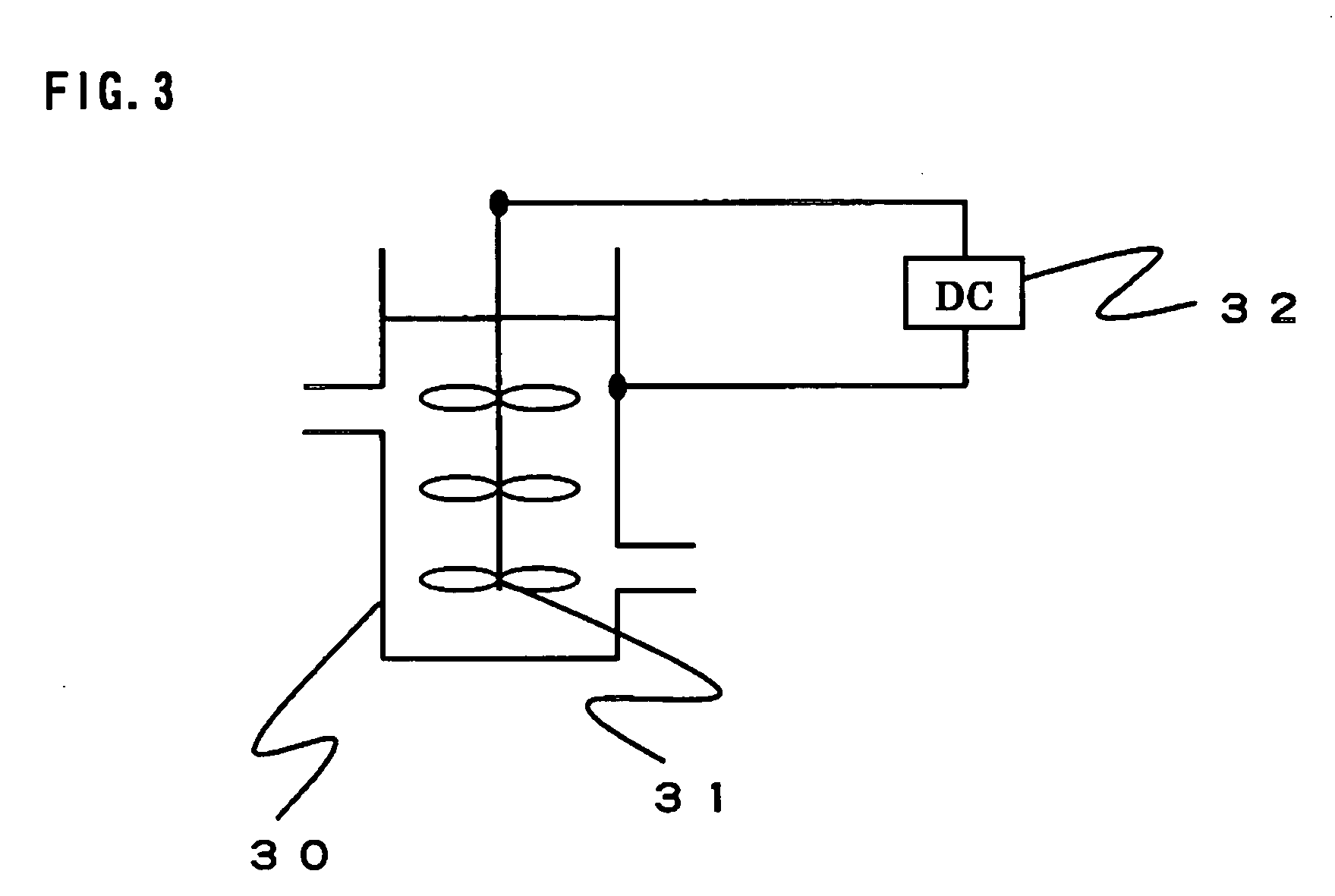

A modular connector assembly includes a modular frame having a first holes, second holes, and third holes formed at evenly spaced intervals. A plurality of modular interconnect components, fixable within the modular frame, have a back surface projection formed thereon. Each modular interconnect includes a contact housing made of electrically insulating material, an exterior of the contact housing comprising first and second side surfaces, a back surface, and a top surface. Contact signal pins are fixed within and electrically insulated from the contact housing.

Owner:SILICON BANDWIDTH

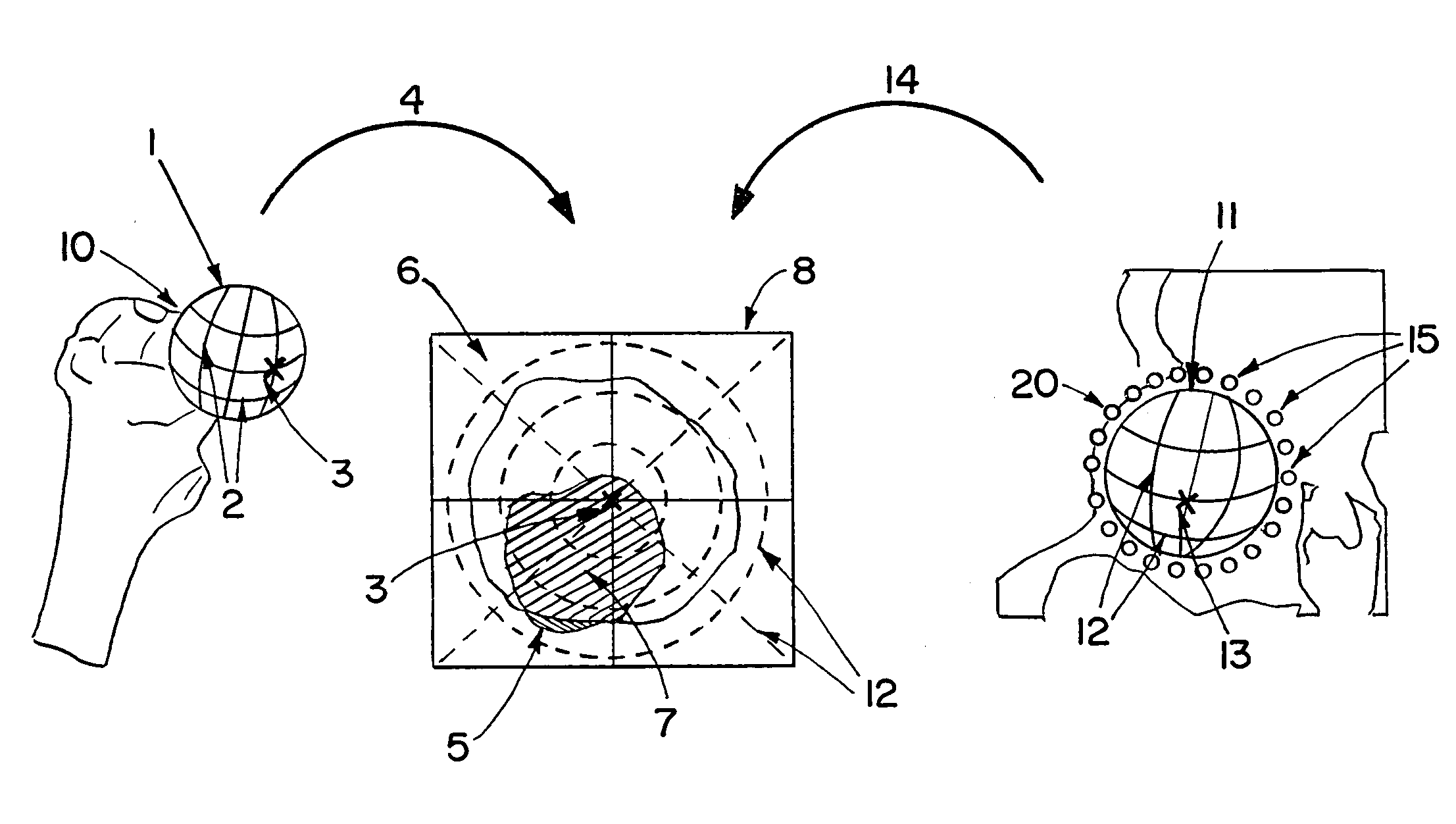

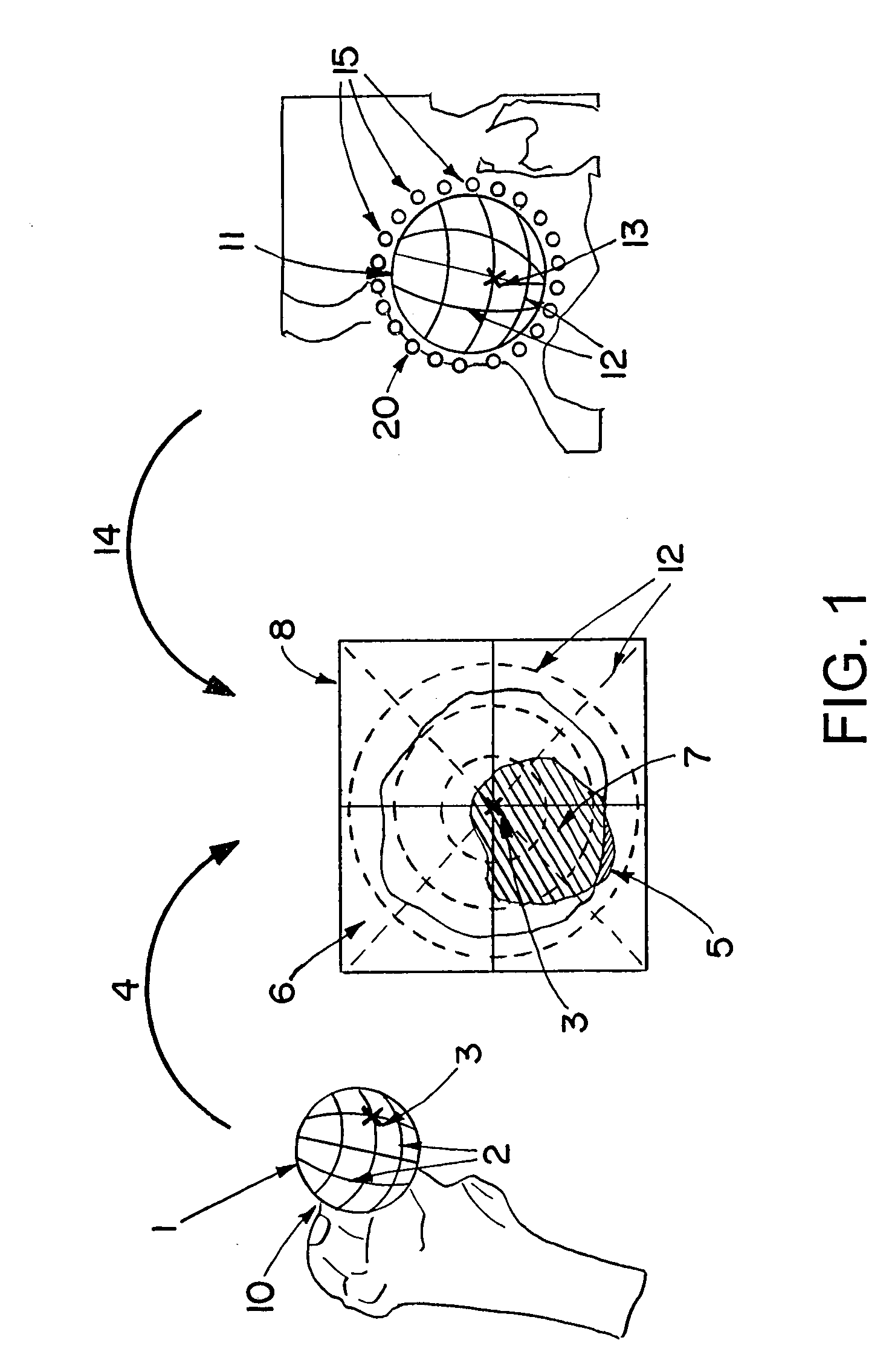

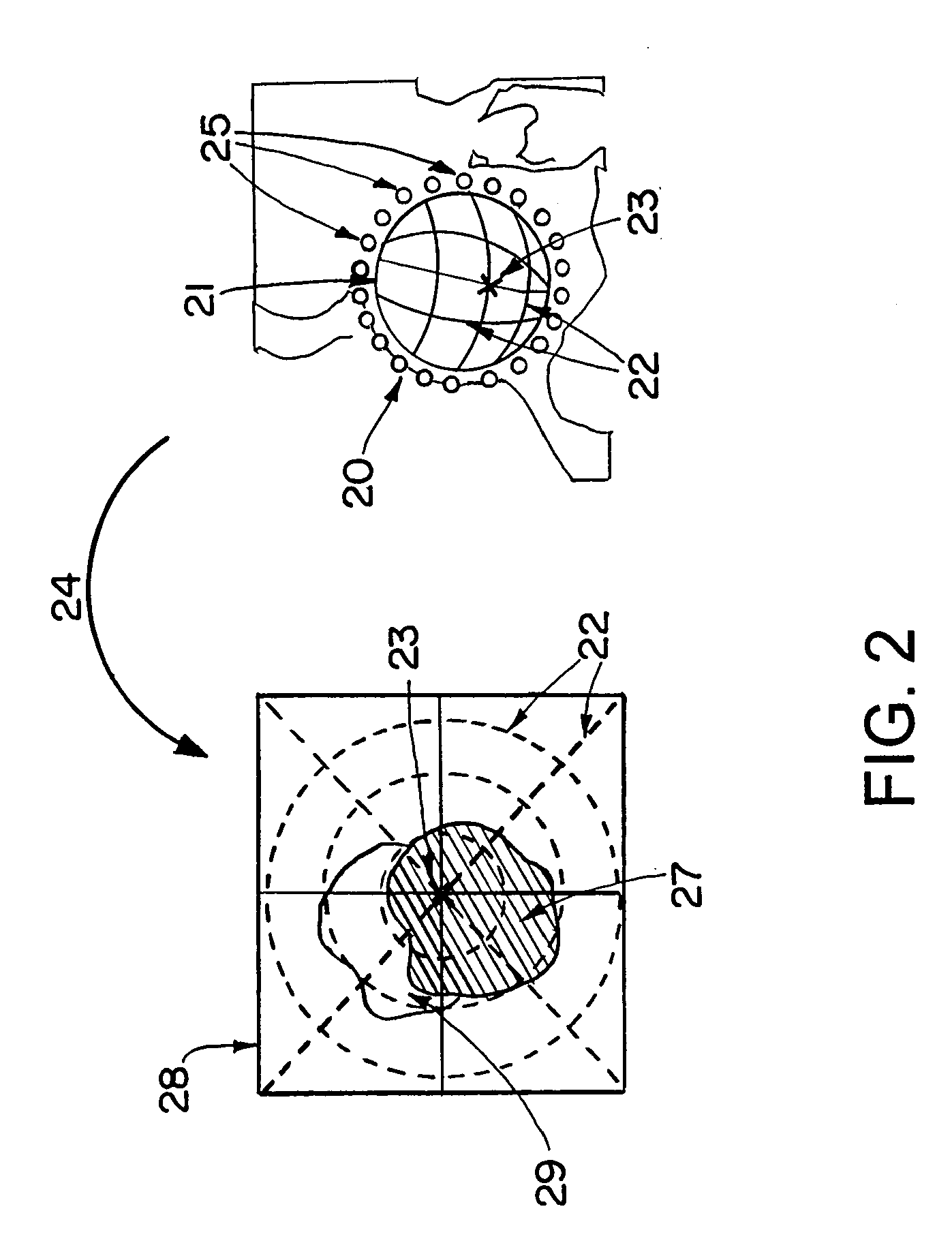

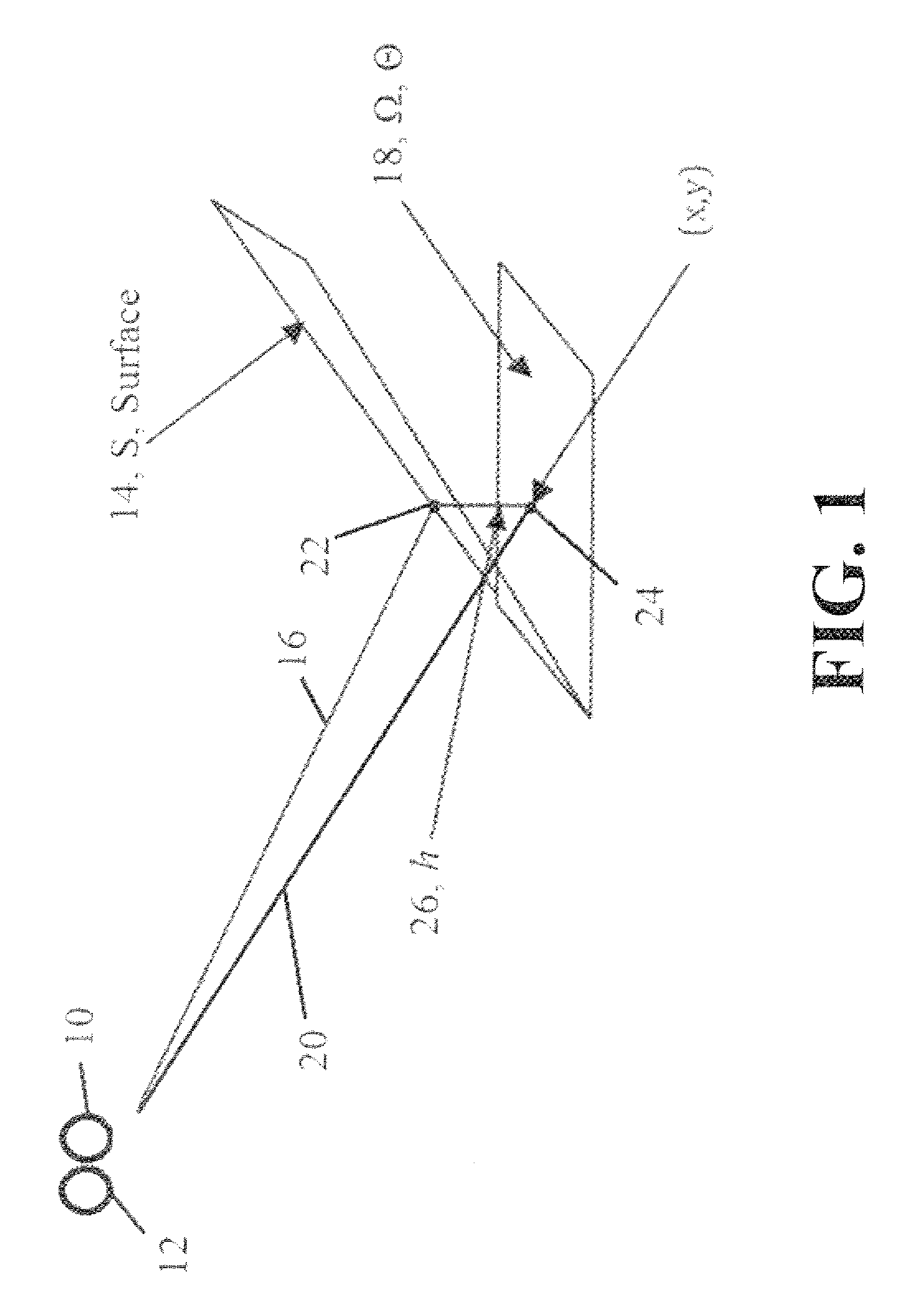

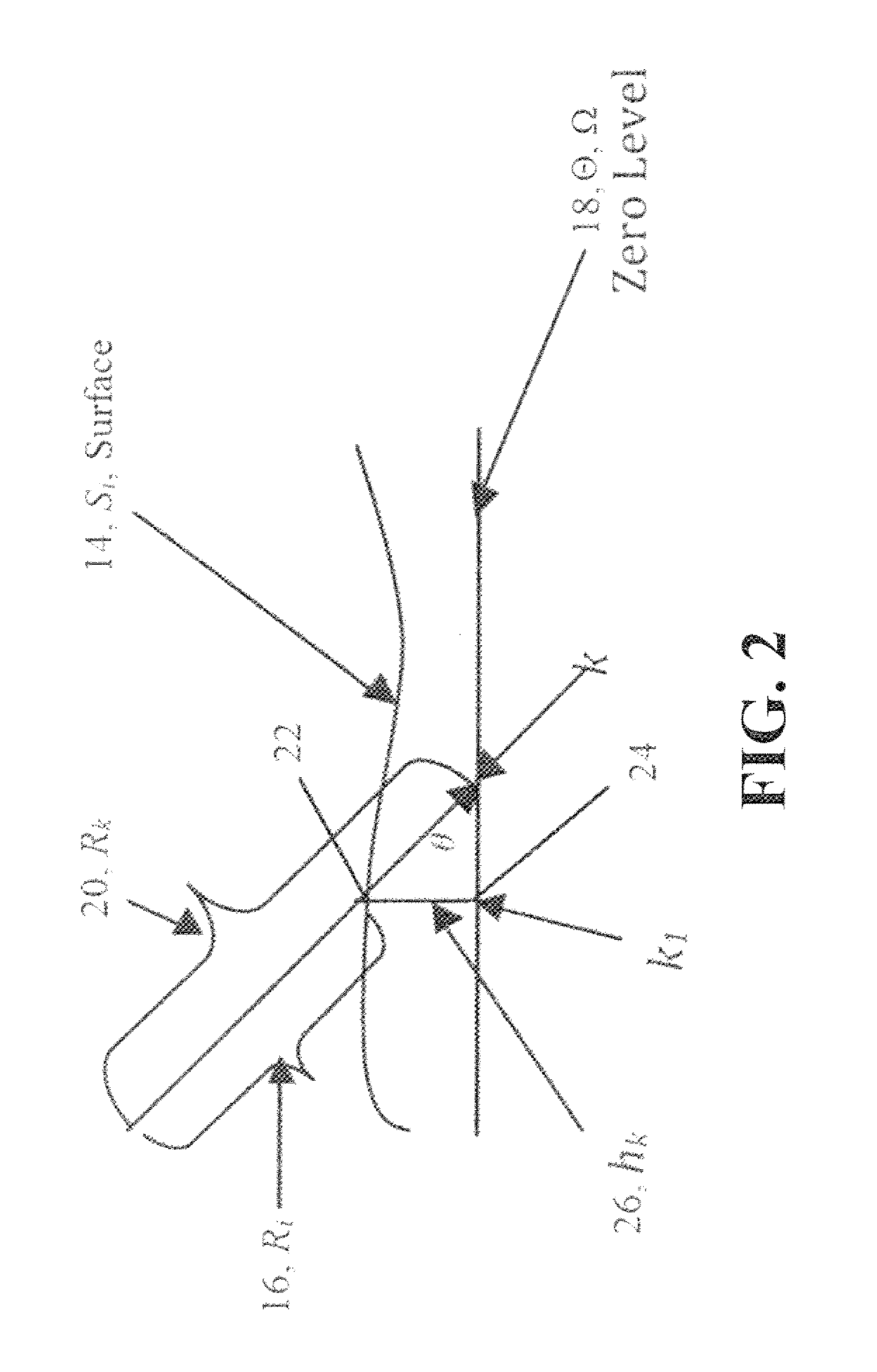

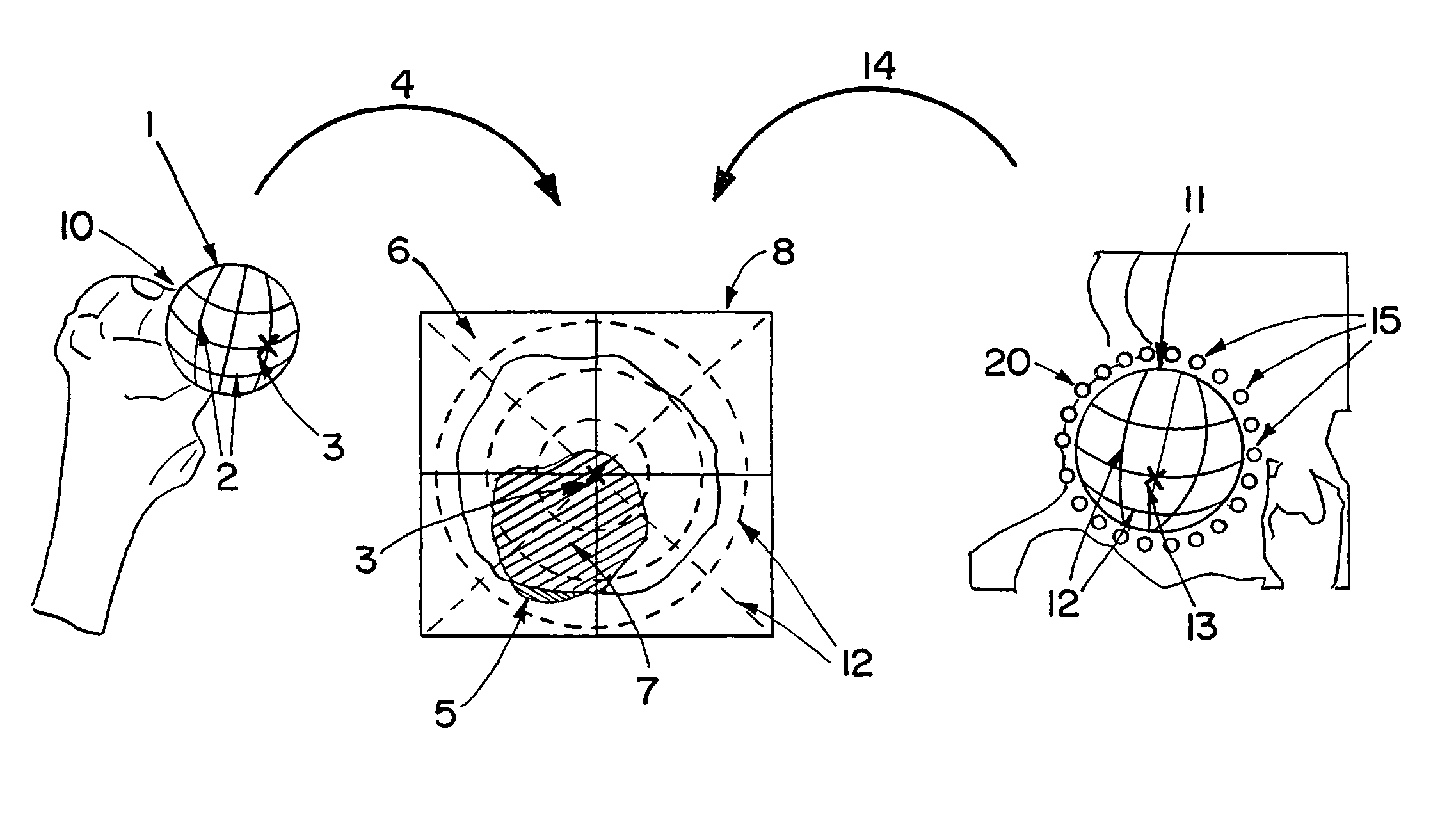

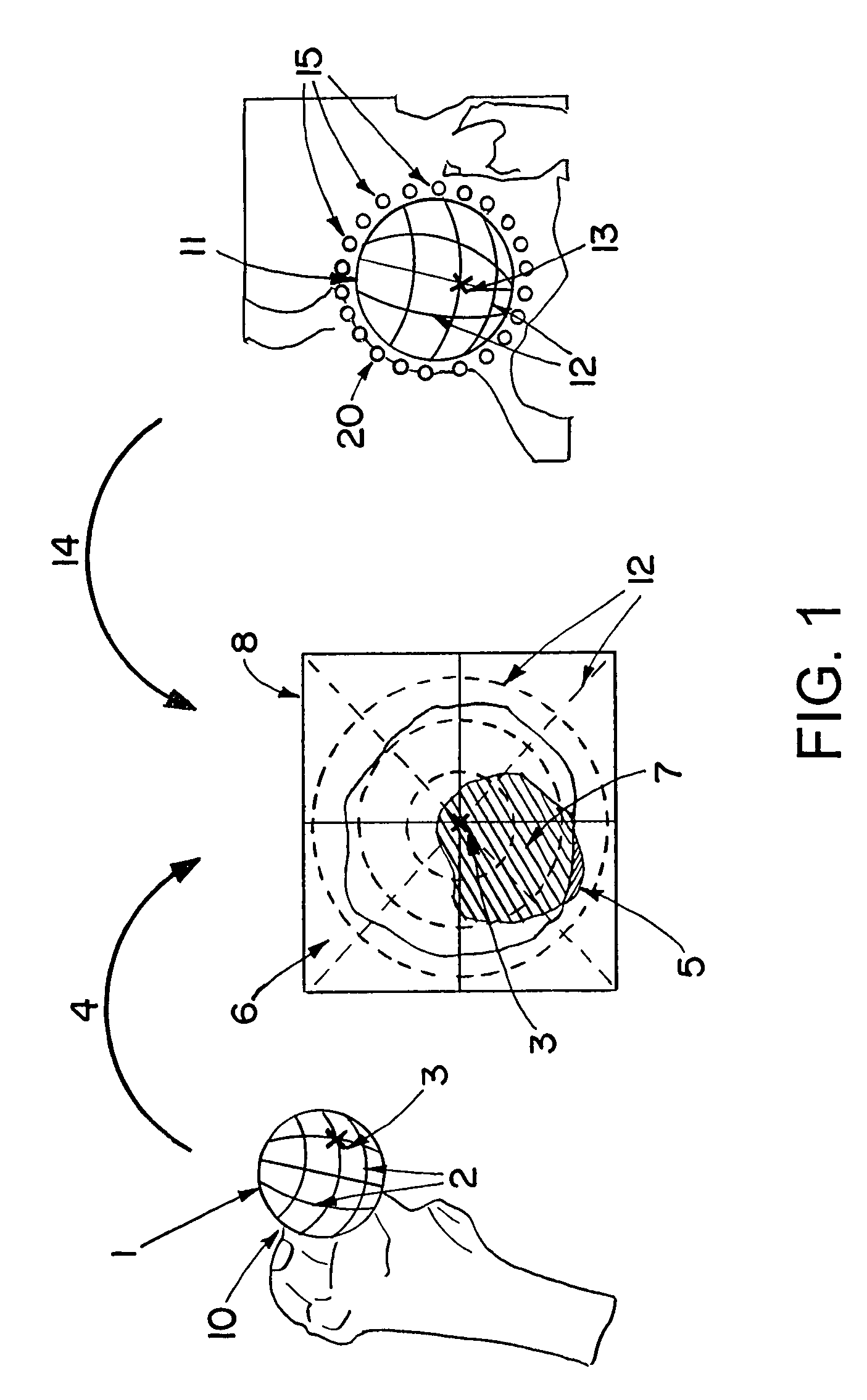

Computer-assisted joint analysis using surface projection

InactiveUS20080312663A1Improve visualizationReduce decreaseImage enhancementImage analysisData setJoint analysis

A system and method for computer-assisted joint analysis, wherein the joint elements in a three-dimensional imaging data set are segmented and then projected onto a two-dimensional or three-dimensional reference area for interference analysis and surgical planning.

Owner:BRAINLAB

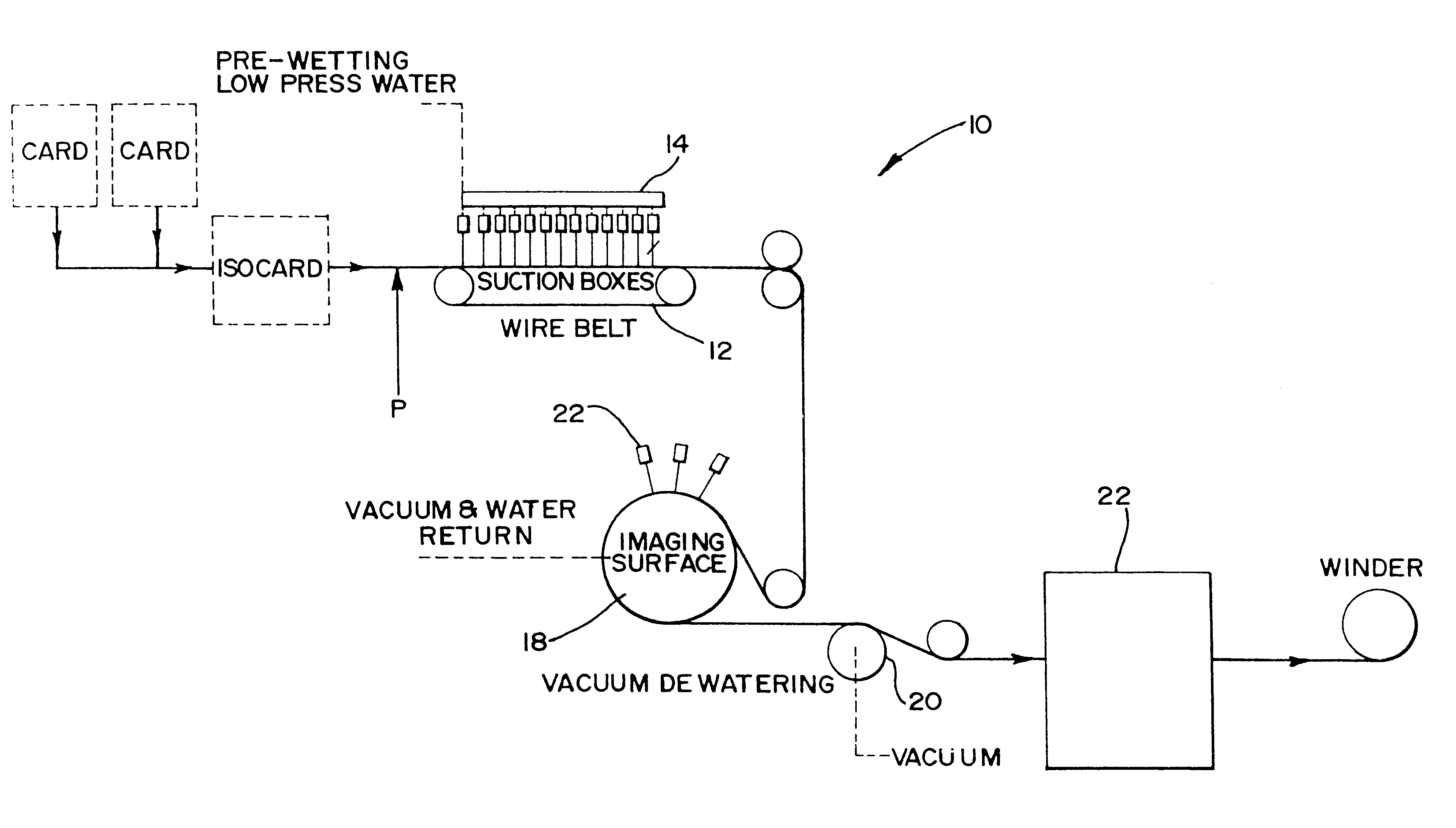

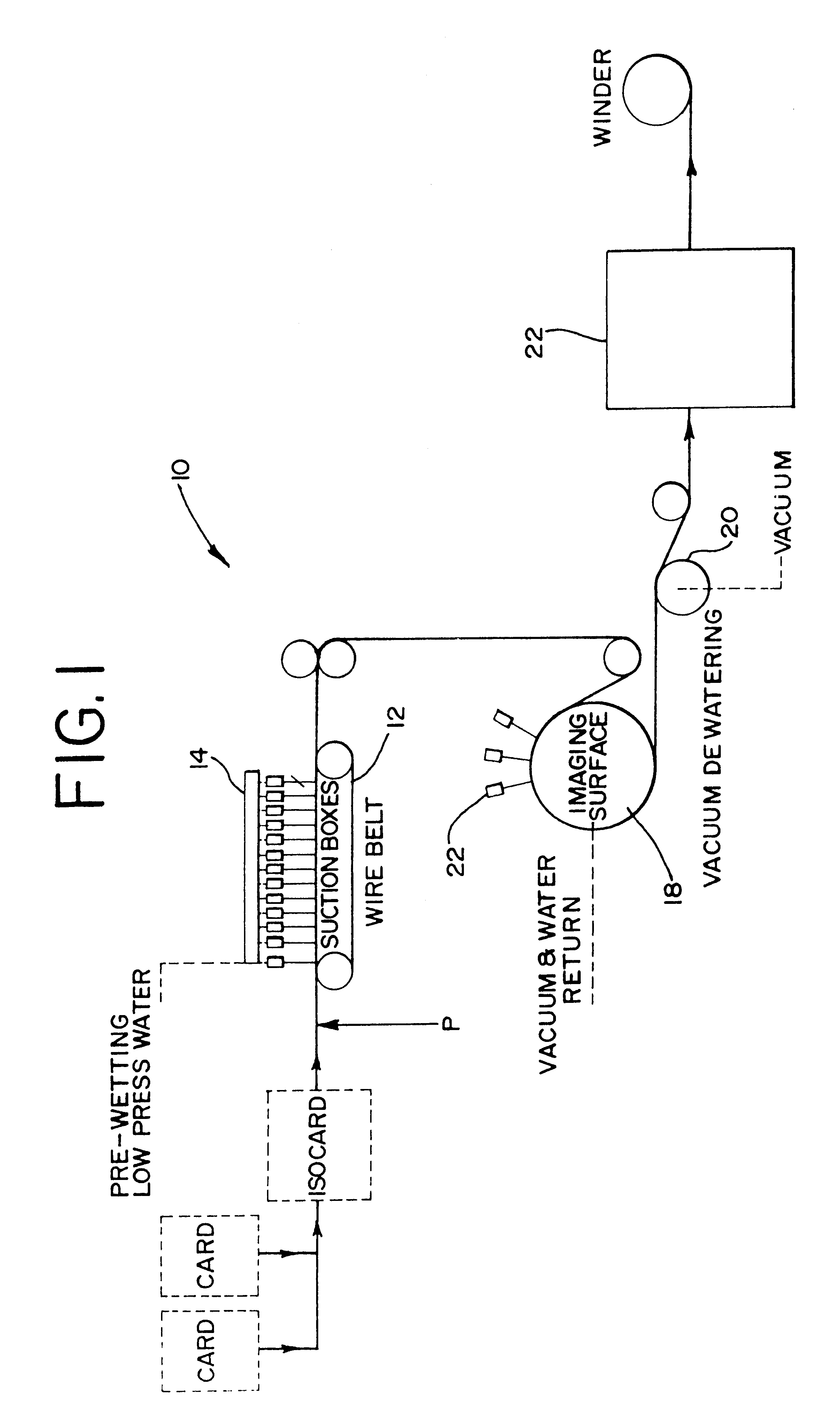

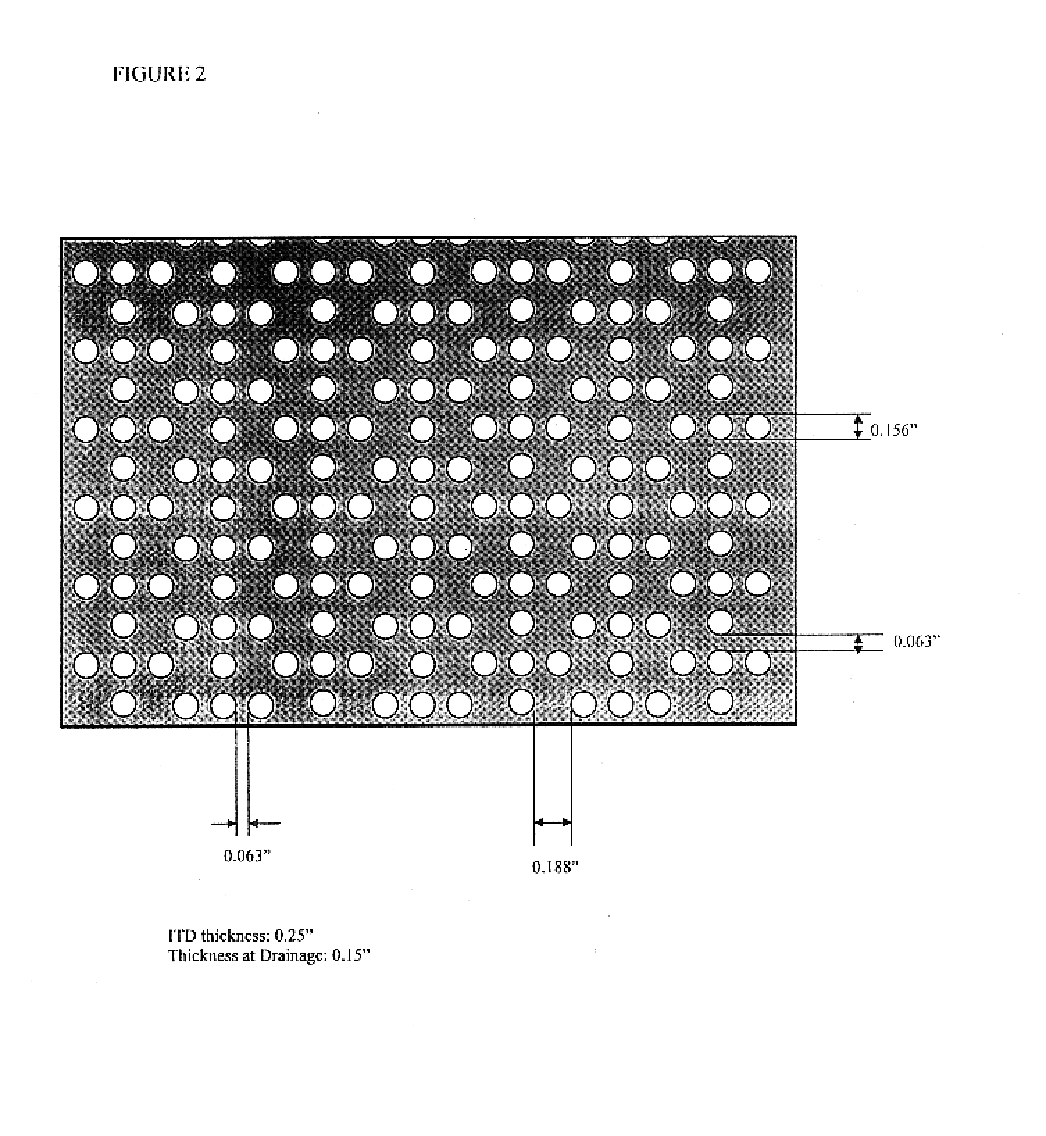

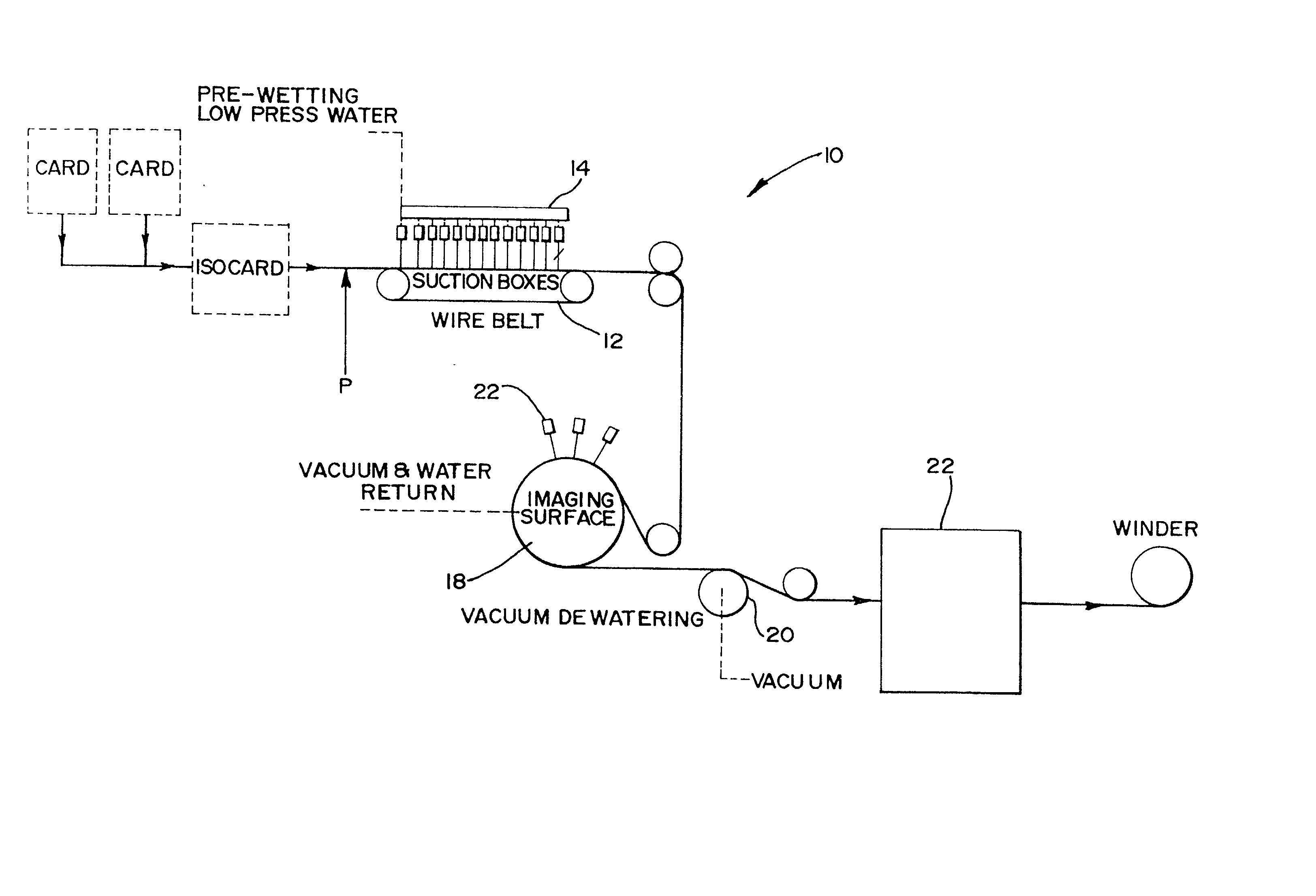

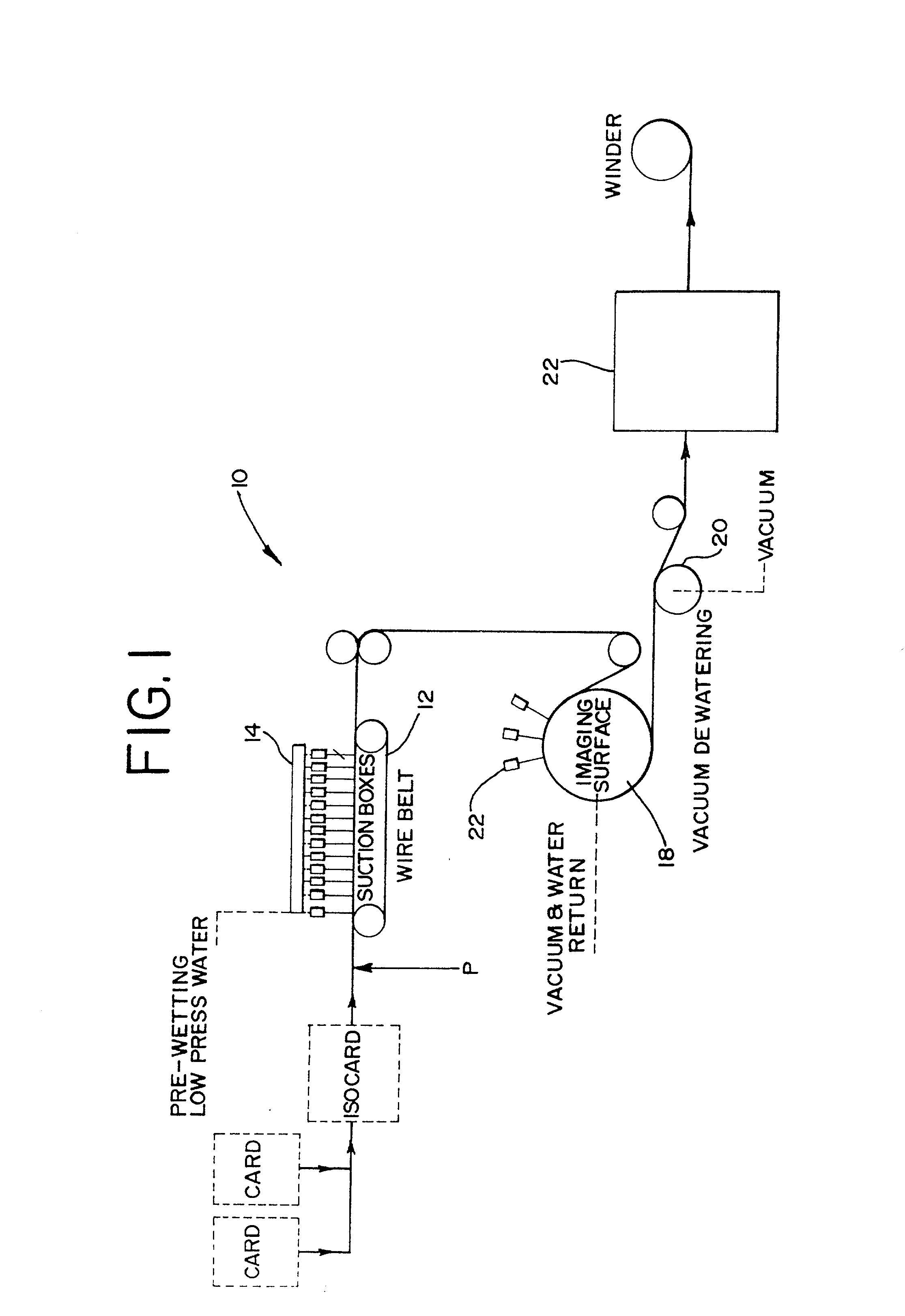

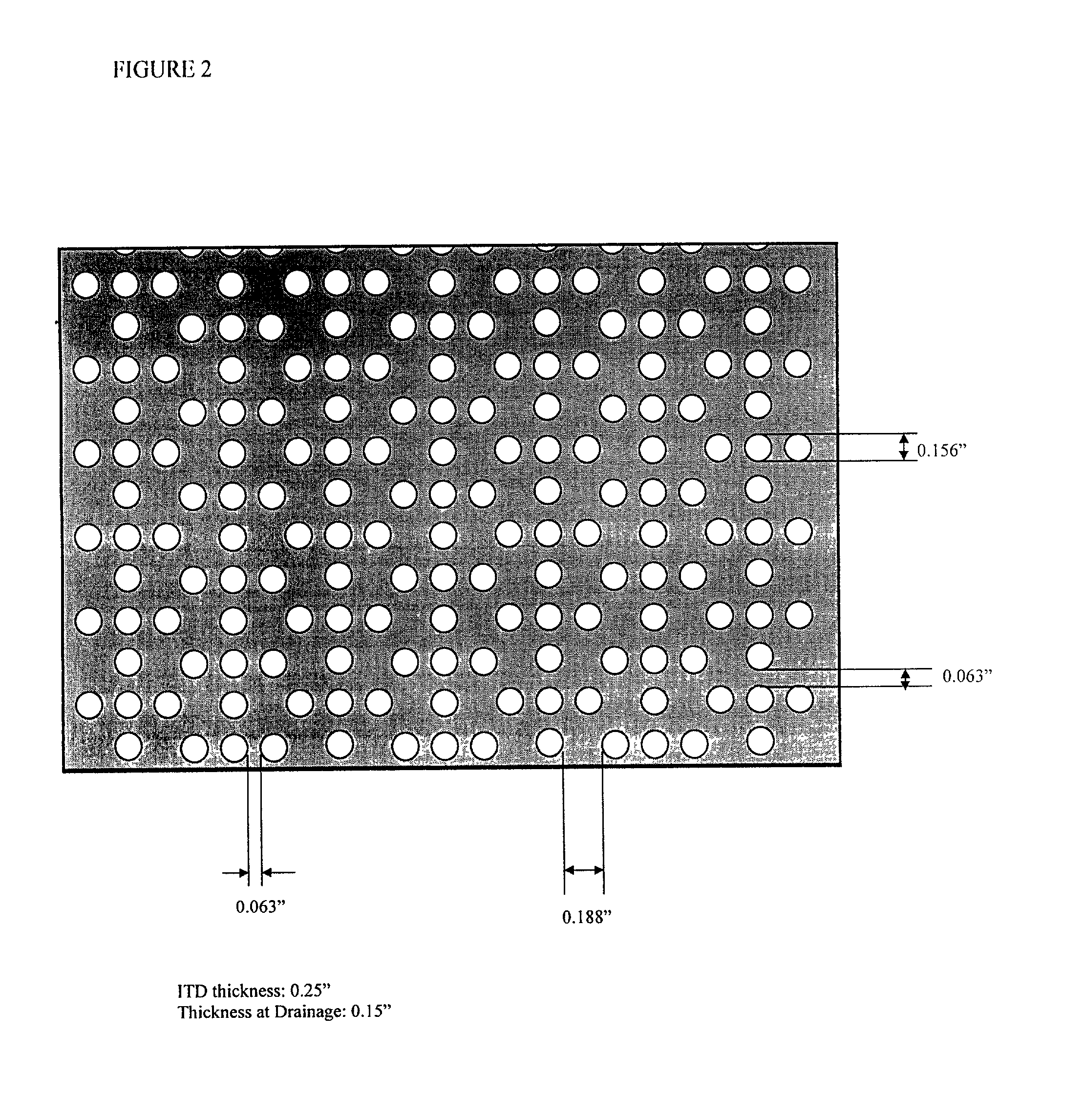

Imaged nonwoven fabric for cleaning applications

The present invention is directed to enhancing the cleaning of surfaces by the contact application of a non-apertured nonwoven fabric having a three-dimensional image imparted therein. The three-dimensional image of the non-apertured nonwoven fabric induces the formation of lather due to pronounced surface projections that come in contact with the cleaning surface and provide air passageways that are parallel to the plane of the substrate. The imaged nonwoven fabric disclosed herein exhibits low linting qualities thereby reducing the potential of fiber contamination of the cleaned surface and is sufficiently durable that the sample can be used in a brisk manner.

Owner:POLYMER GROUP INC

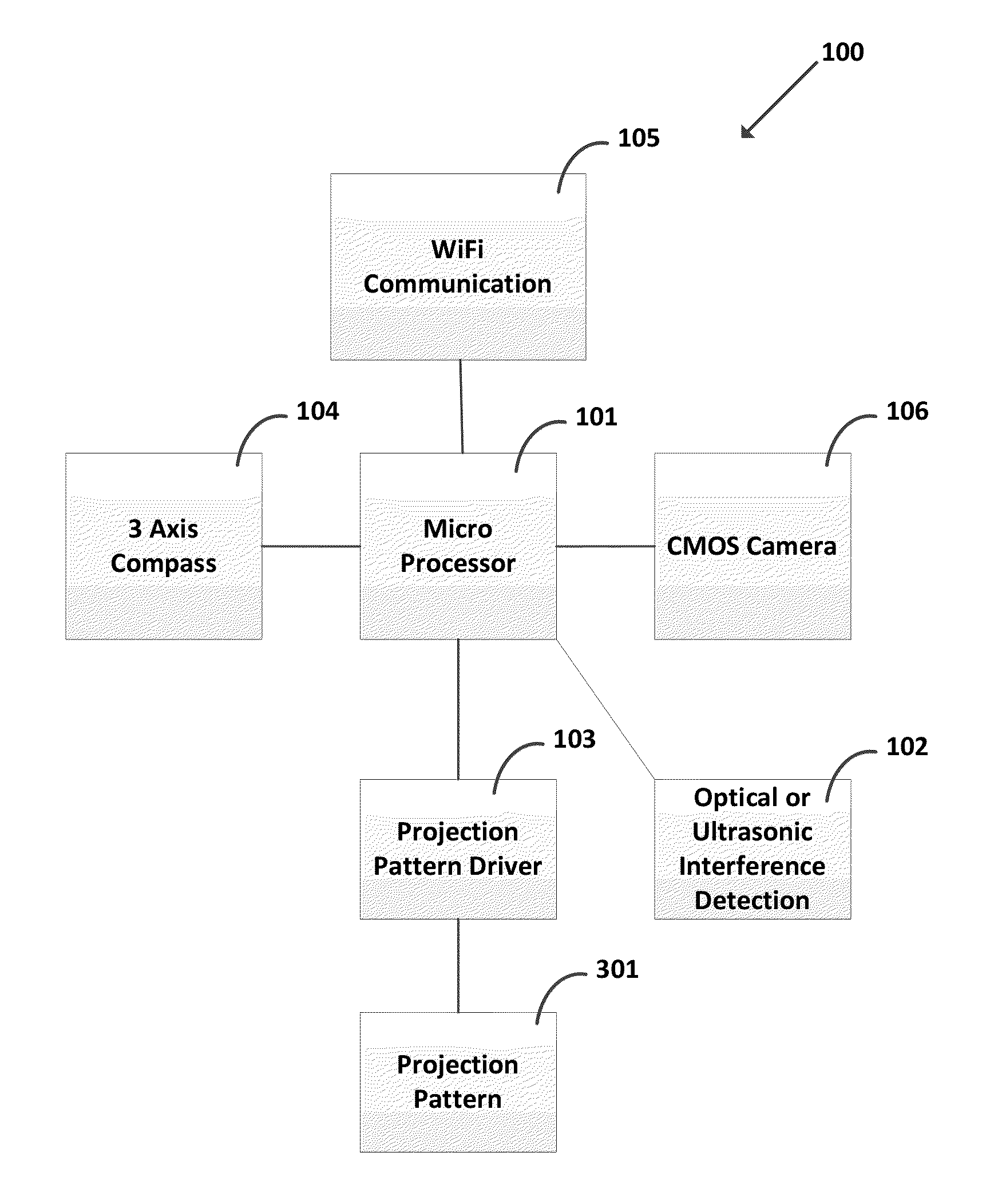

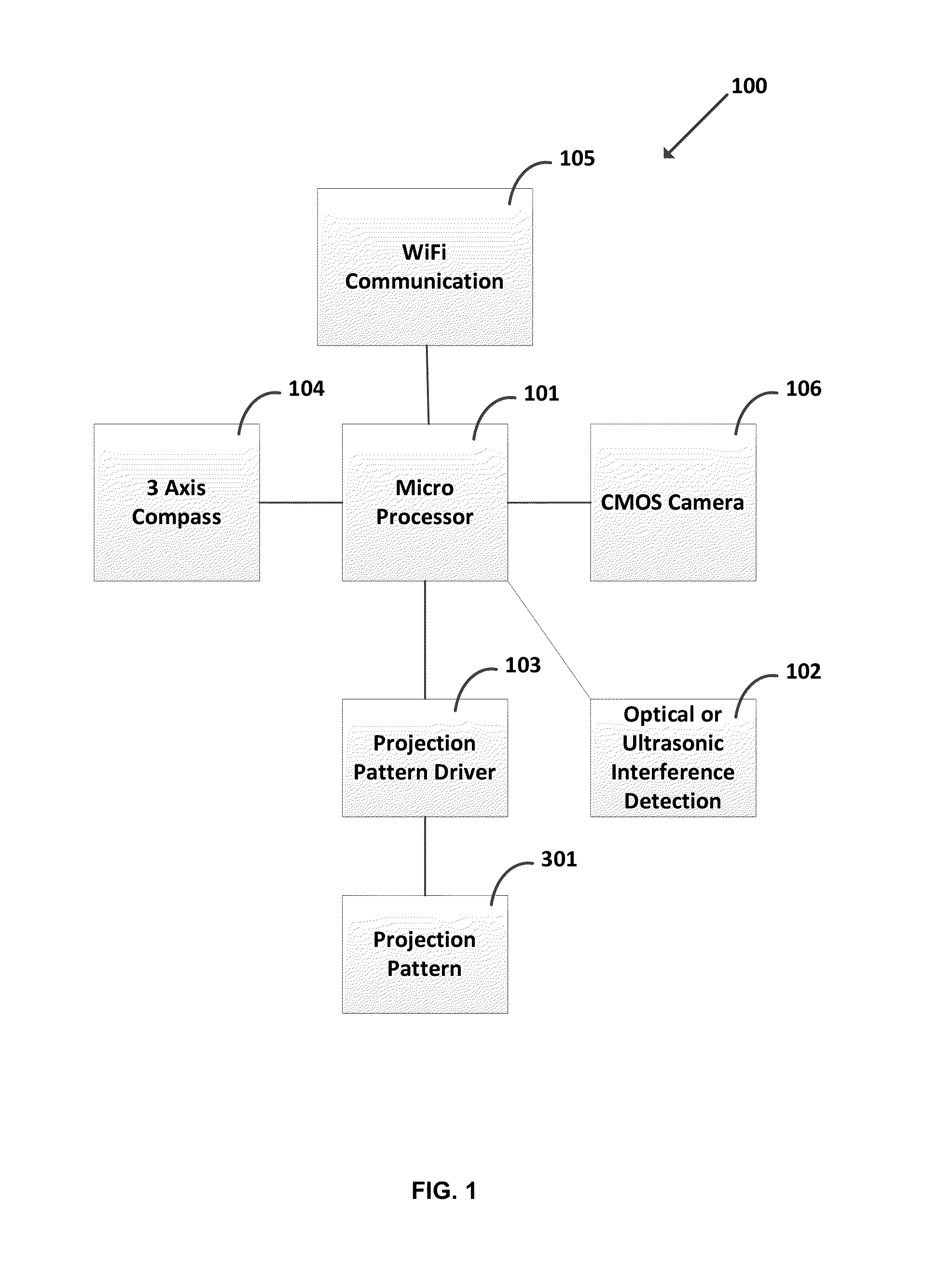

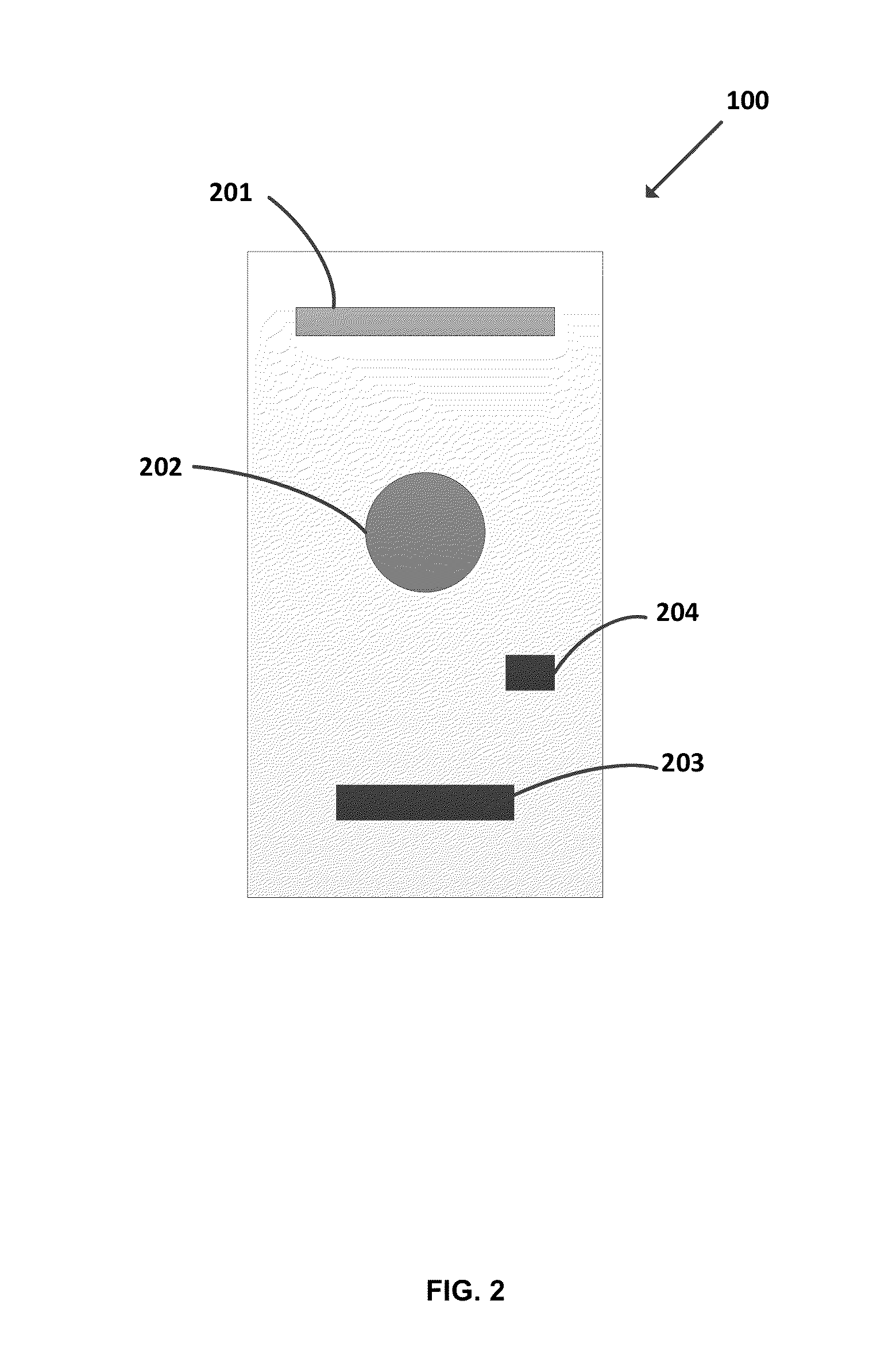

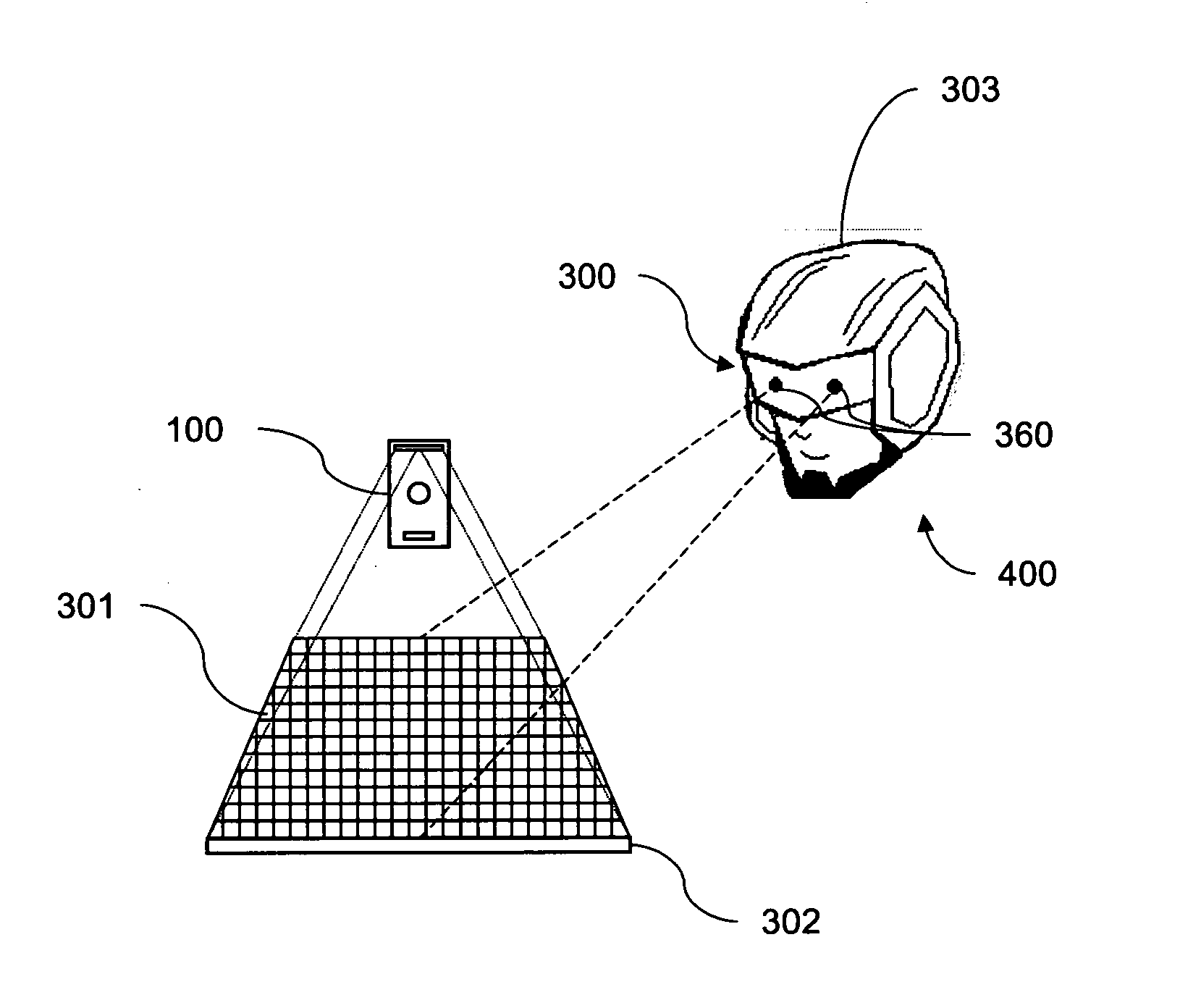

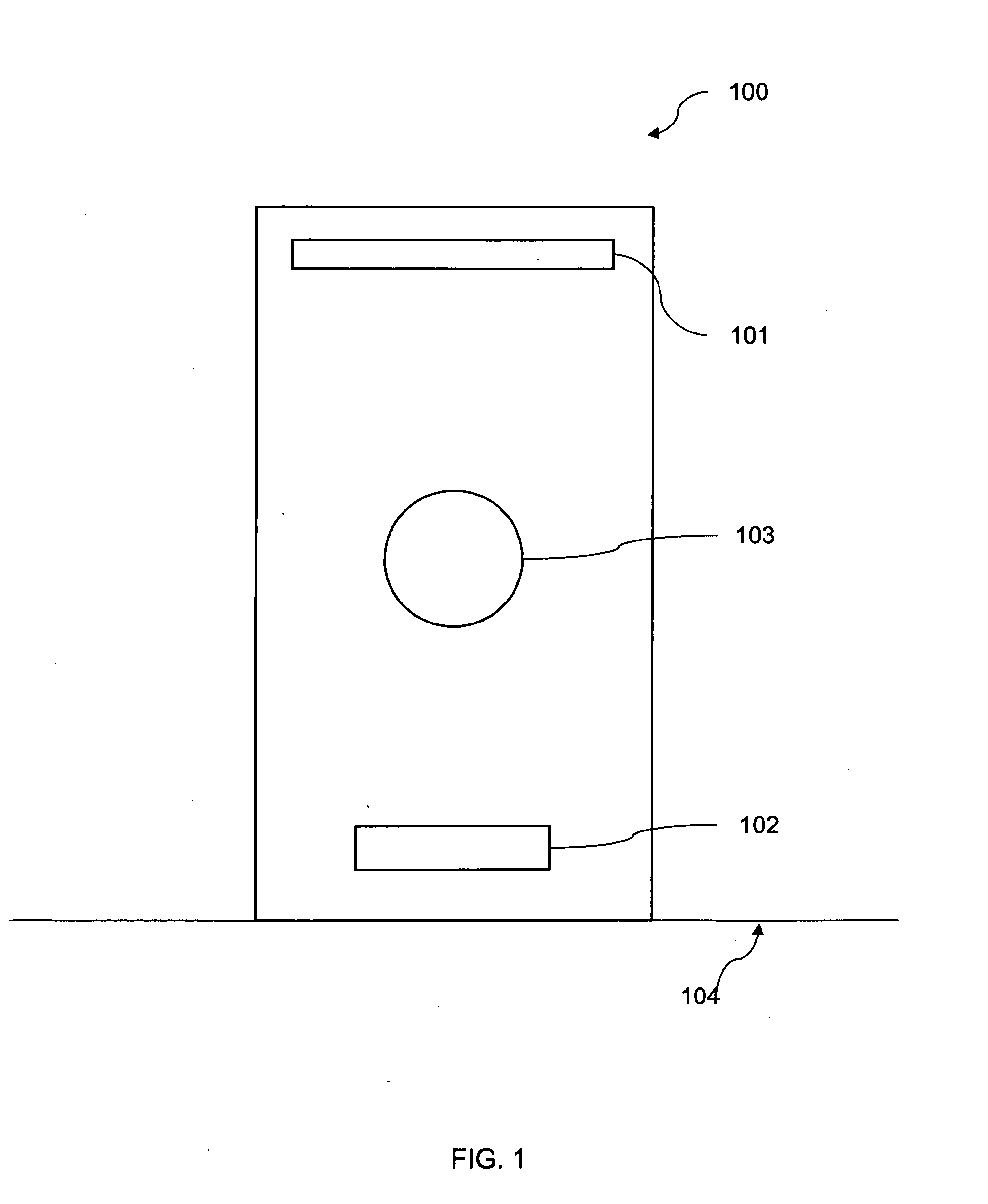

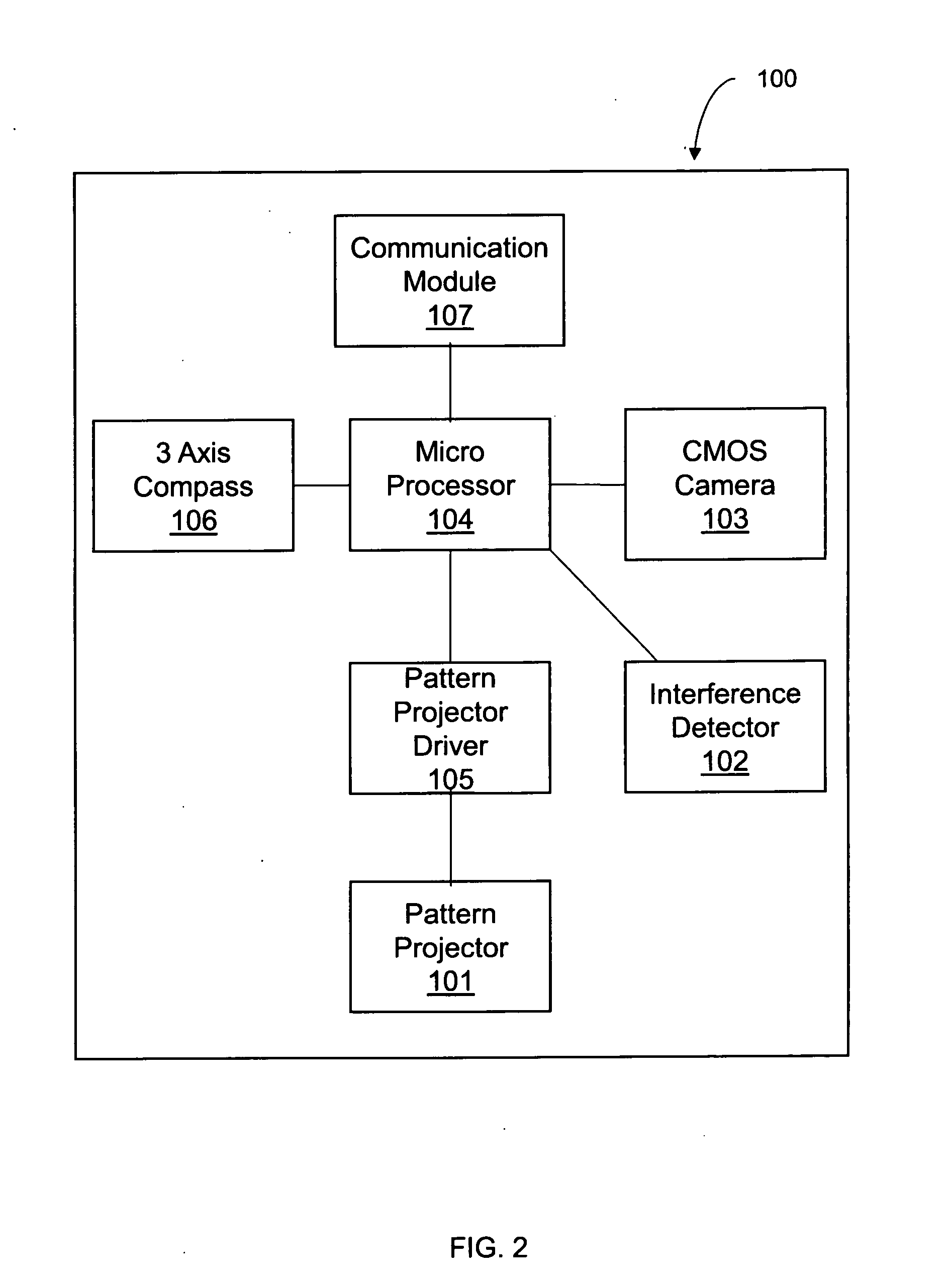

Surface projection device for augmented reality

Augmented reality (AR) is the process of overlaying or projecting computer generated images over a user's real world view of the physical world. The present invention allows for gameplay and / or training to contain augmented special effects. It is used to create surface patterns which are incorporated into augmented reality systems. It also allows for gesture control of AR elements during use.

Owner:SULON TECH

Surface projection system and method for augmented reality

InactiveUS20160140766A1Input/output for user-computer interactionPosition fixationReference patternsSurface projection

A surface projection system for augmented reality is provided. The surface projection system includes a surface projection device that is positionable adjacent a surface and having a light element and a sensor. The light element is configured to project a reference pattern on the surface. The sensor is positioned adjacent the surface and configured to gaze along the surface.

Owner:SULON TECH

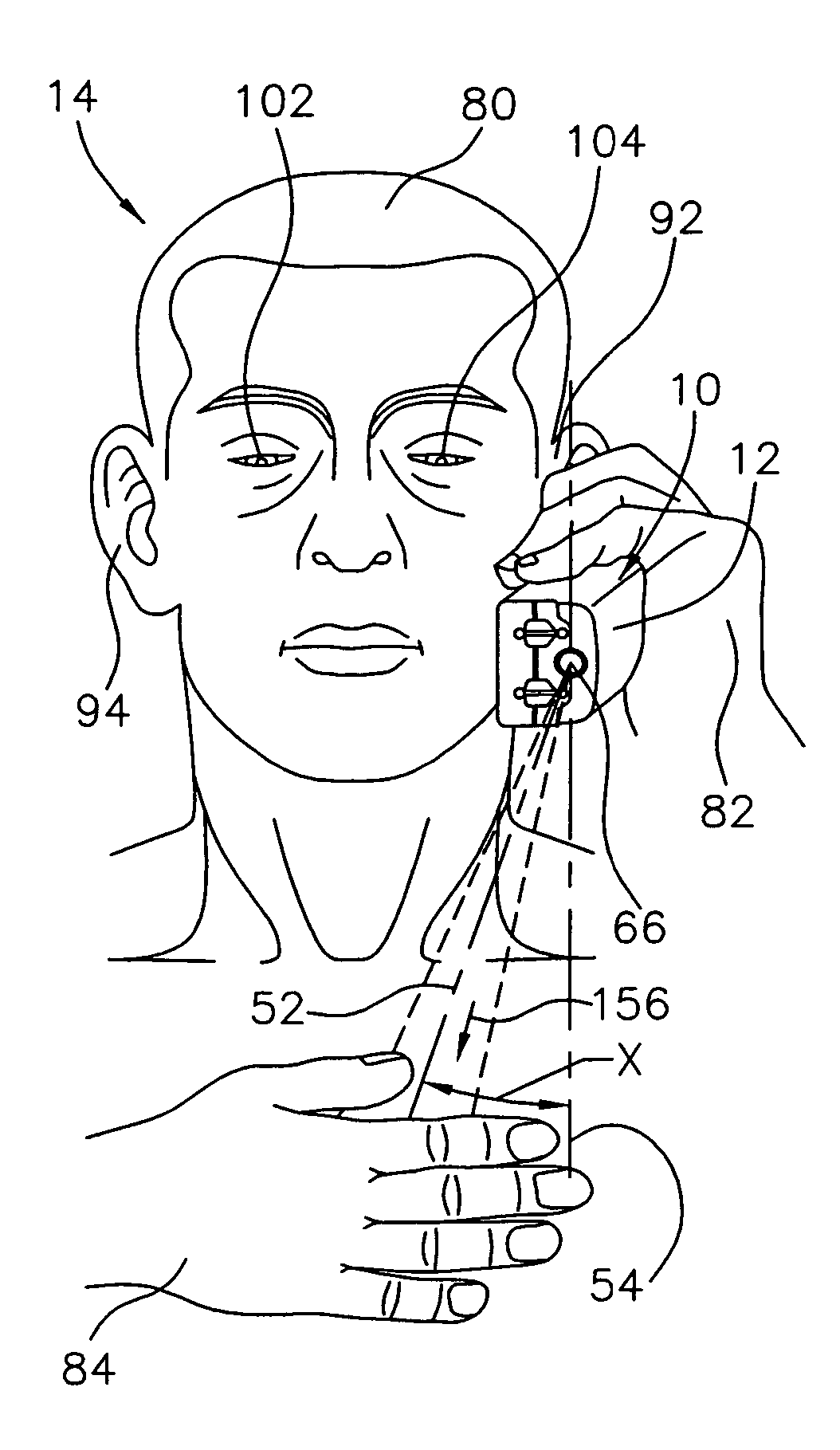

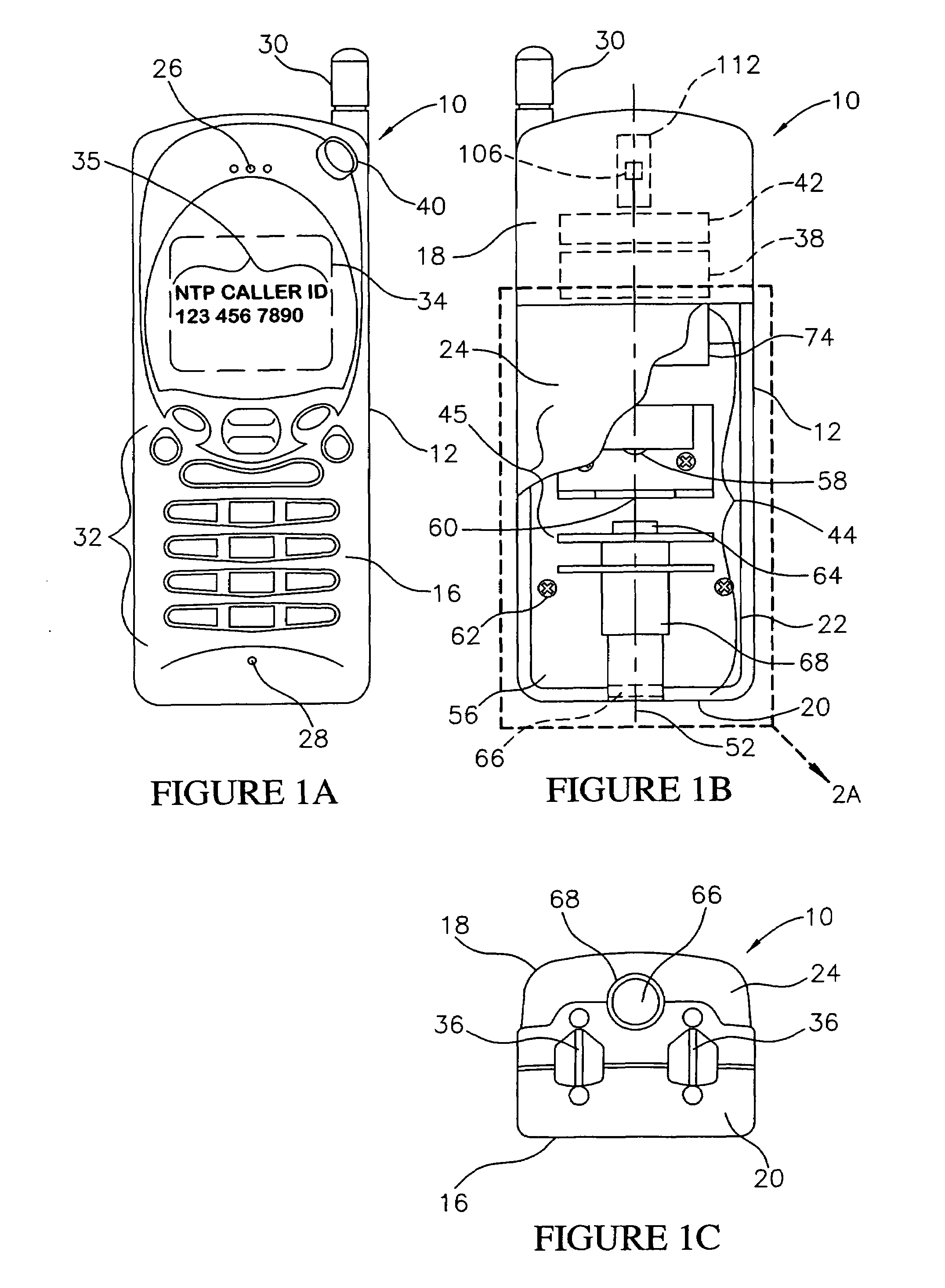

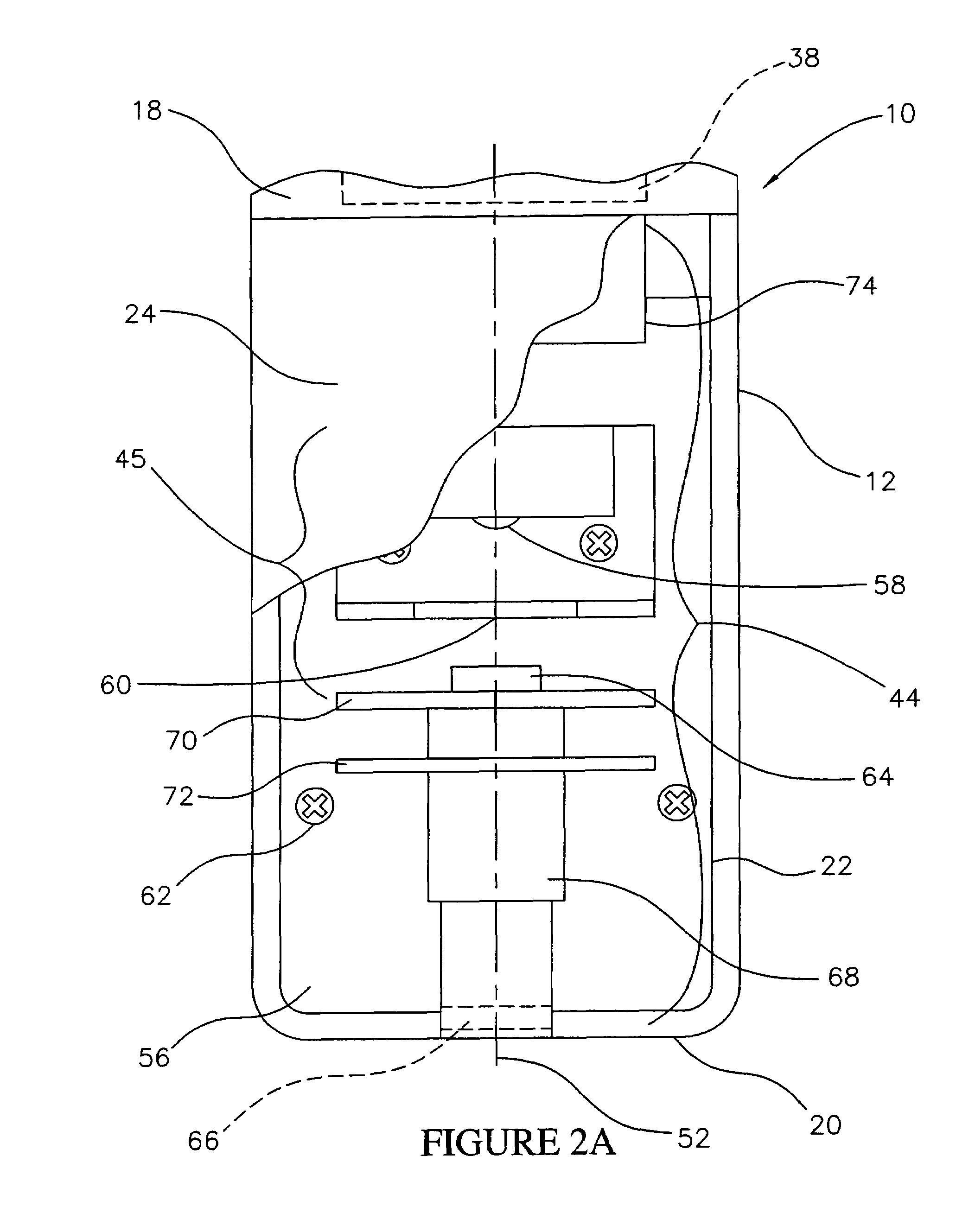

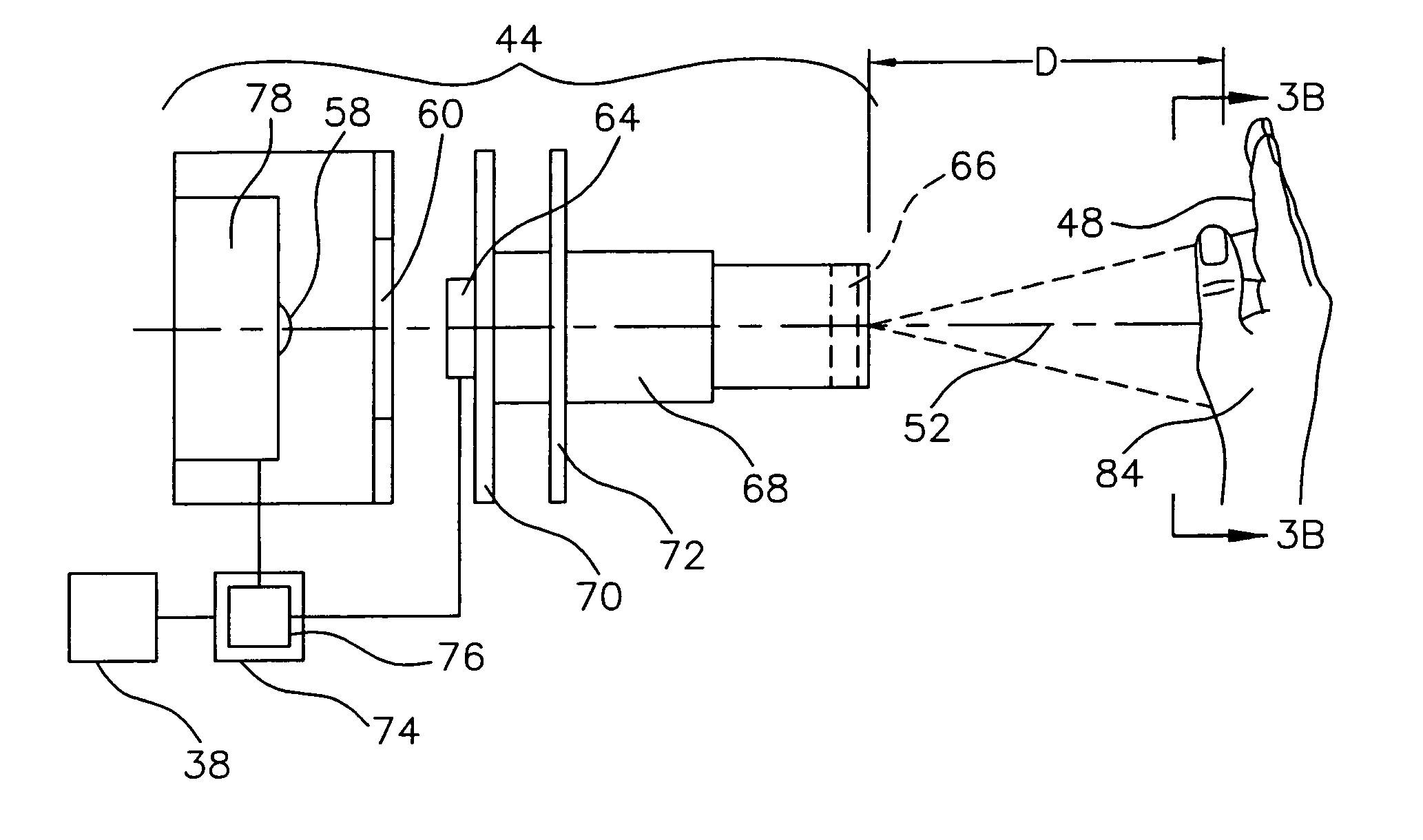

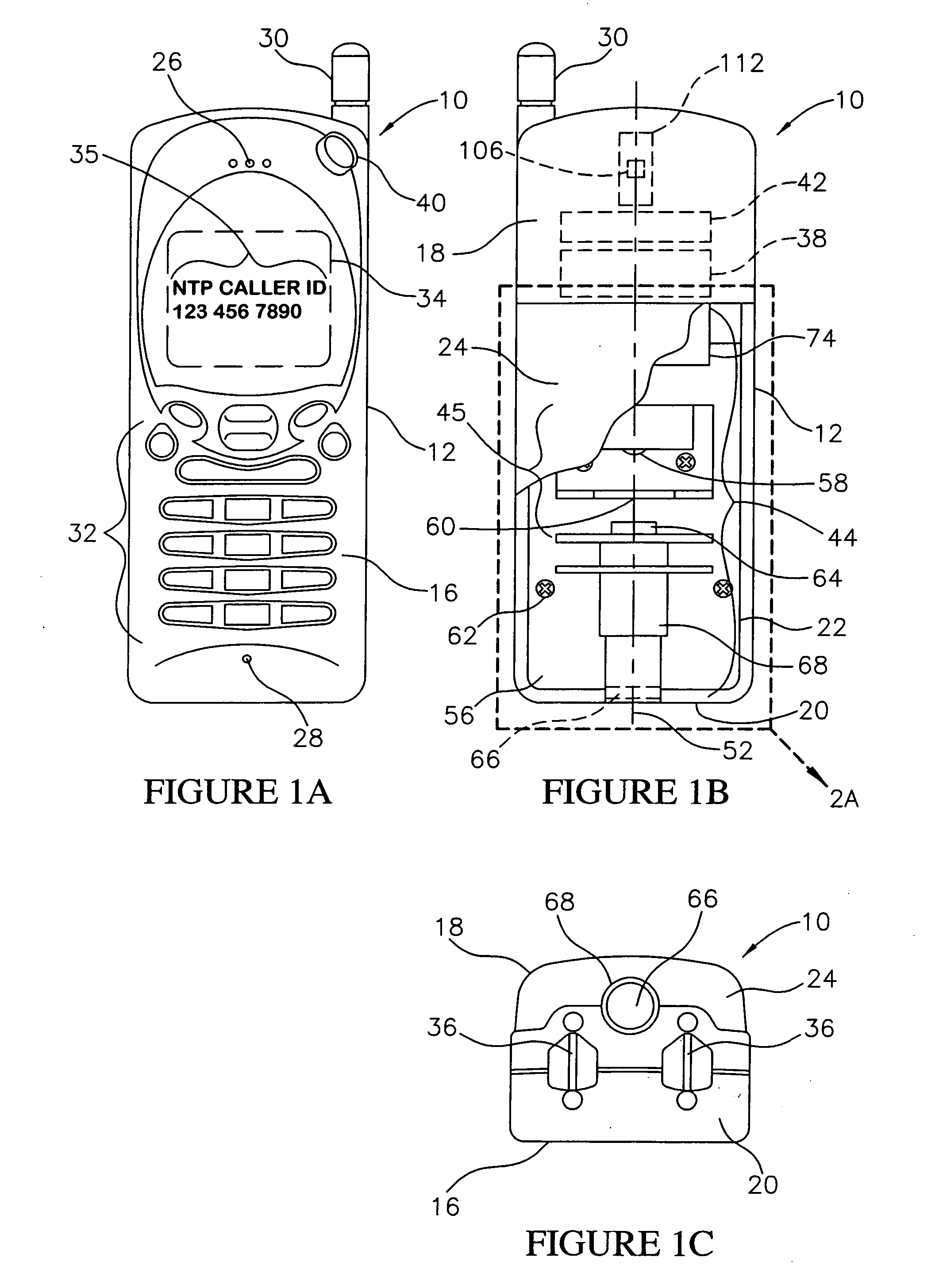

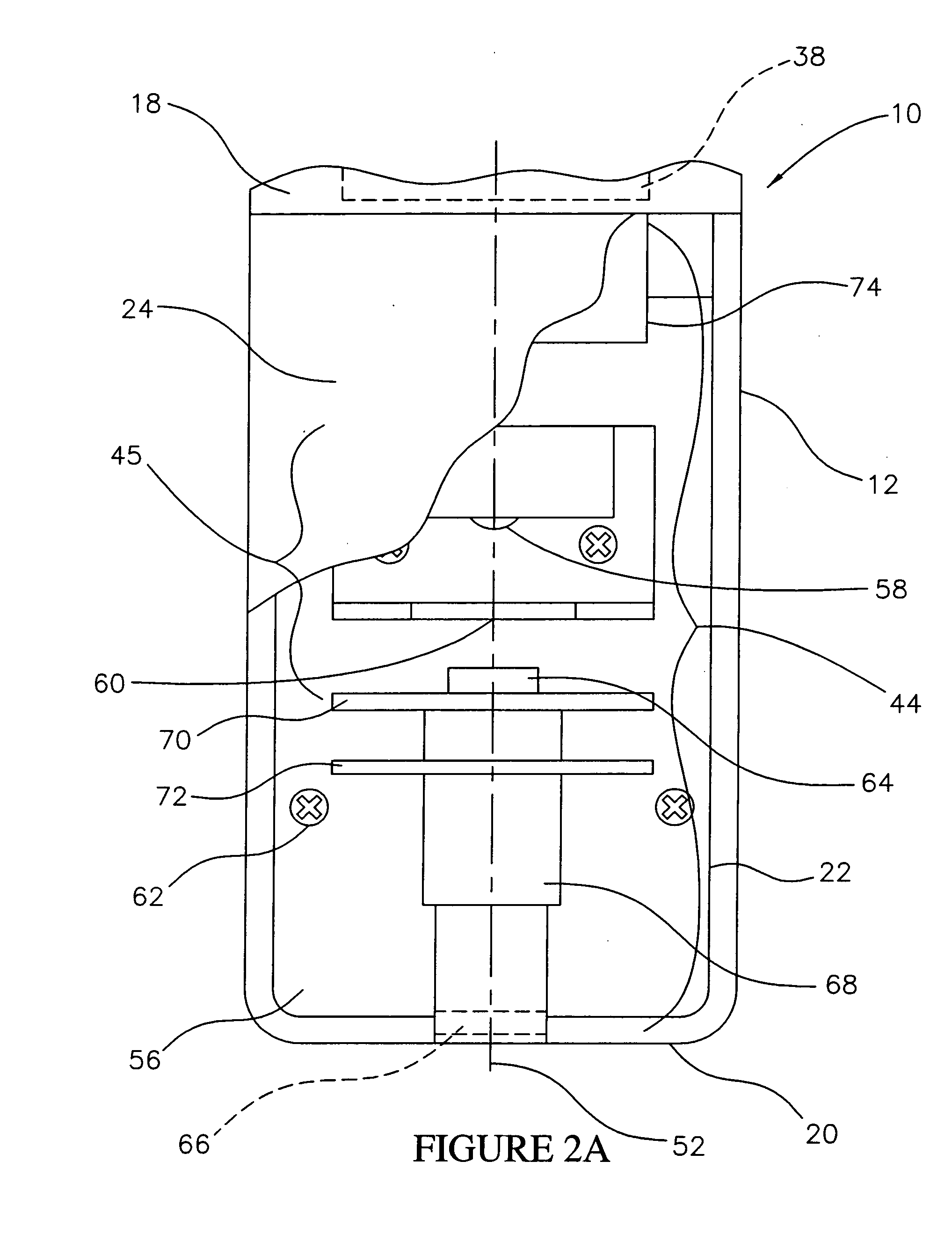

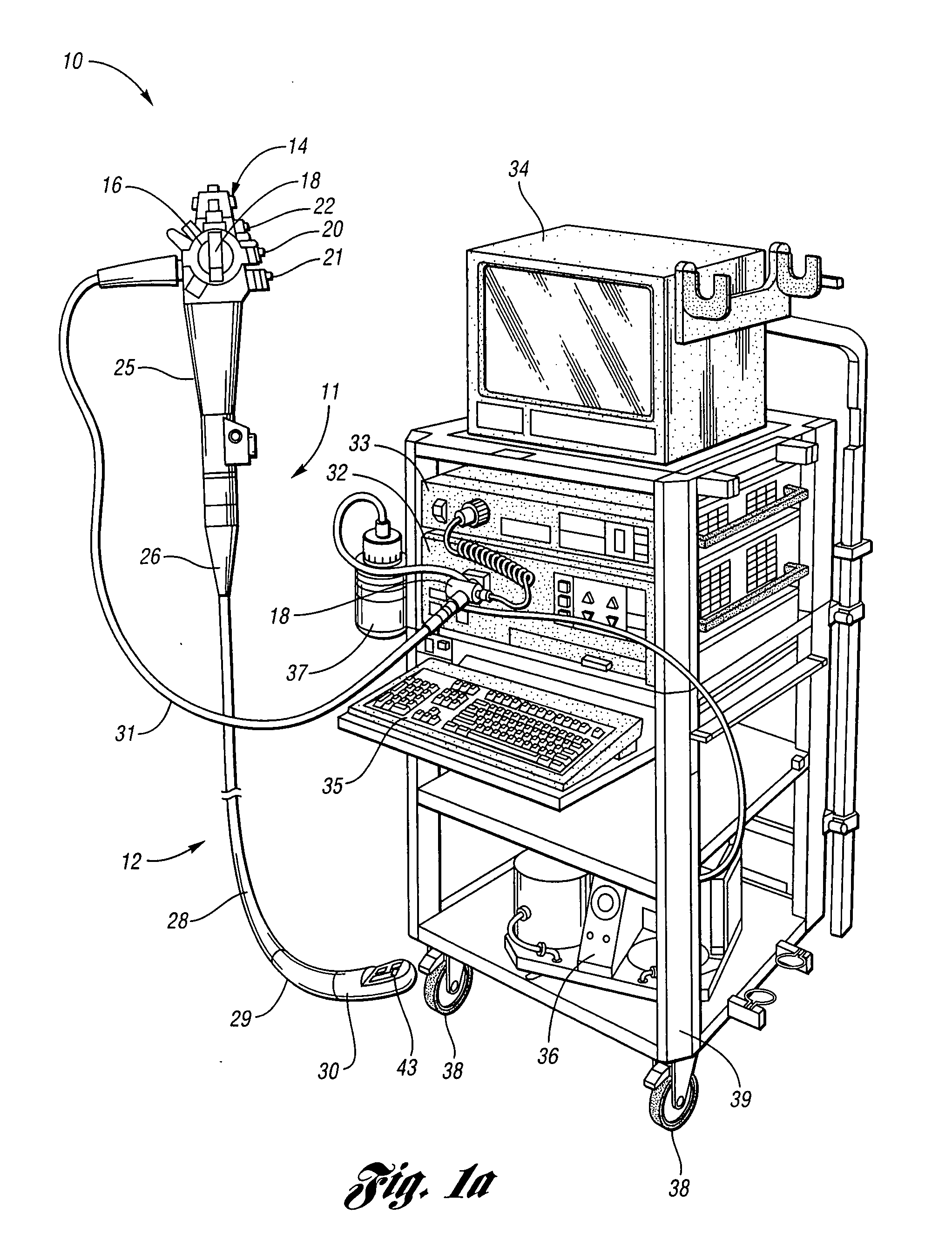

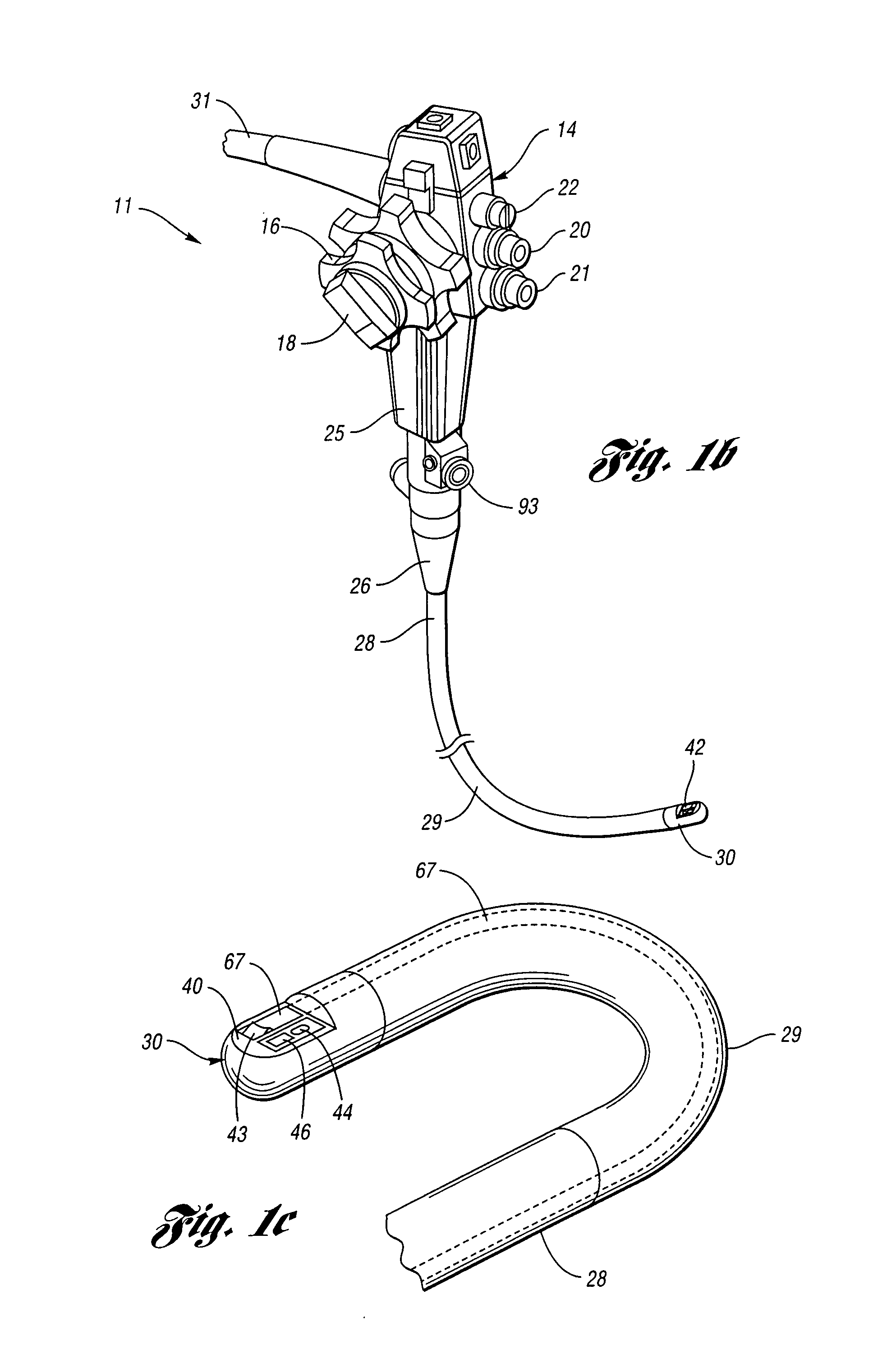

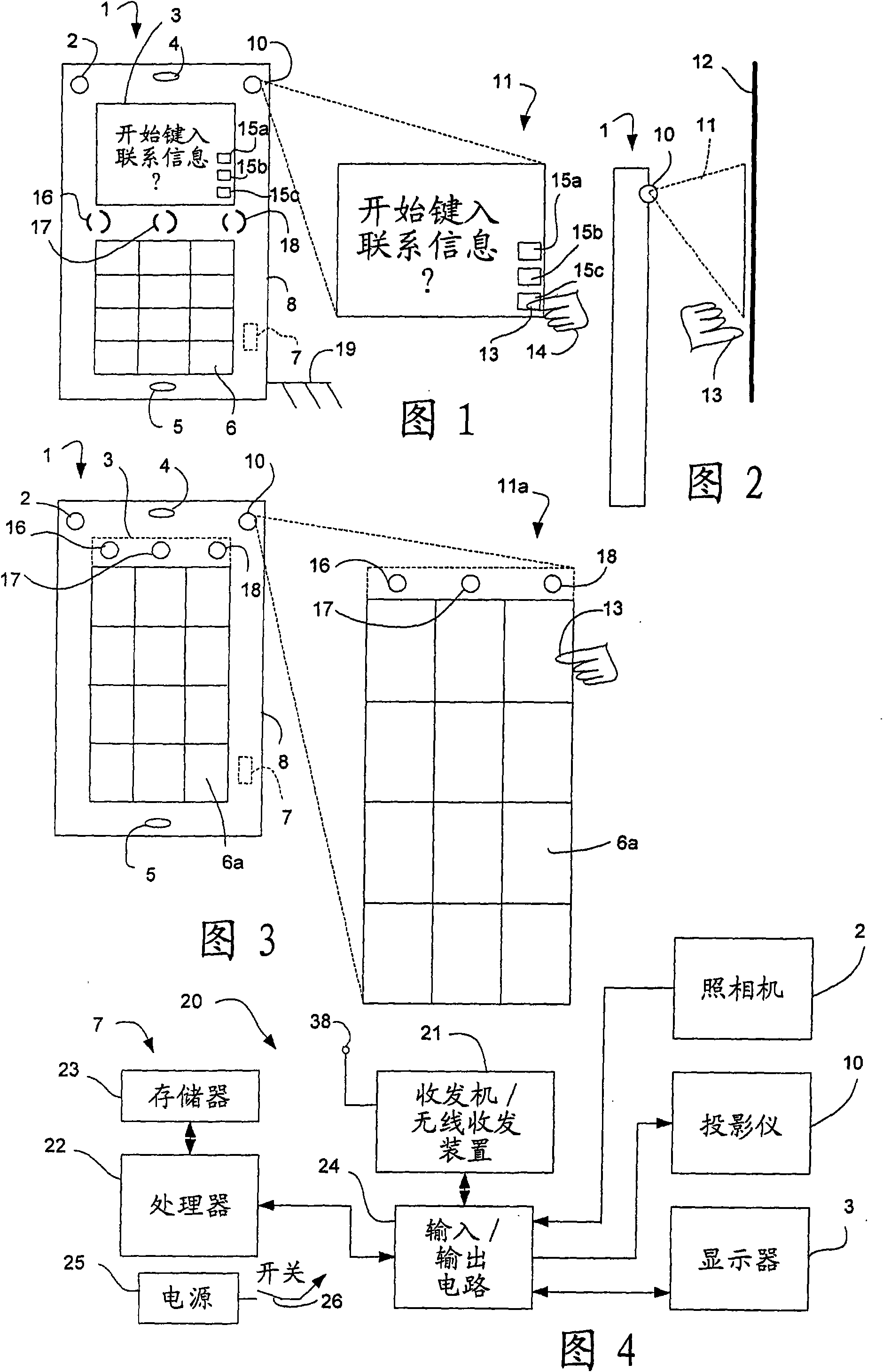

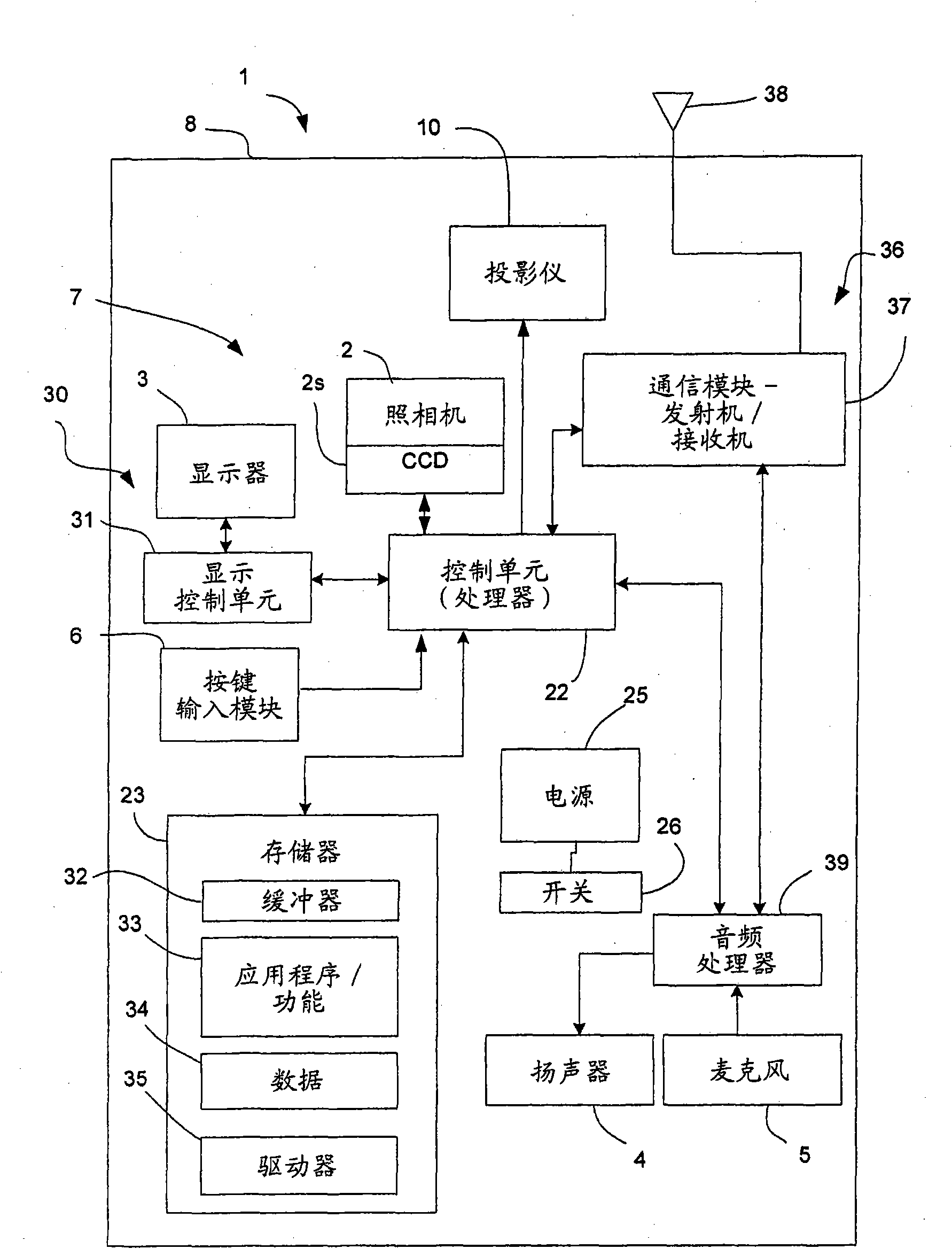

Portable phone with ergonomic image projection system

ActiveUS7539513B2Easy to viewPrecise positioningTelevision system detailsInterconnection arrangementsProjection systemMirror image

A portable phone includes a handset and a data projection system configured to form a visual image of data, such as caller waiting ID data, on a viewing surface viewable by a user during a two way conversation. The handset also includes a speaker, a microphone, conventional phone circuitry and a keyboard. The data projection system is configured to receive signals from the phone circuitry, to generate a pattern representative of the data, to process the pattern into a mirror image of the visual image, and to project the mirror image from a bottom end surface of the handset. The projection system includes an electro optic system for generating the pattern, and an optics system for projecting the mirror image onto the viewing surface.A method for projecting data in a portable phone includes the steps of: providing the handset with the data projection system, conducting a two way conversation with the handset held against the head of the user, and forming the visual image on the viewing surface during the two way conversation with the handset held against the head. The method can also include the steps of manipulating the handset and a body part to locate and focus the visual image, sensing an orientation of the handset during the two way conversation, and orienting the visual image as a function of the sensing step.

Owner:LAGOON POINT ENTERPRISES

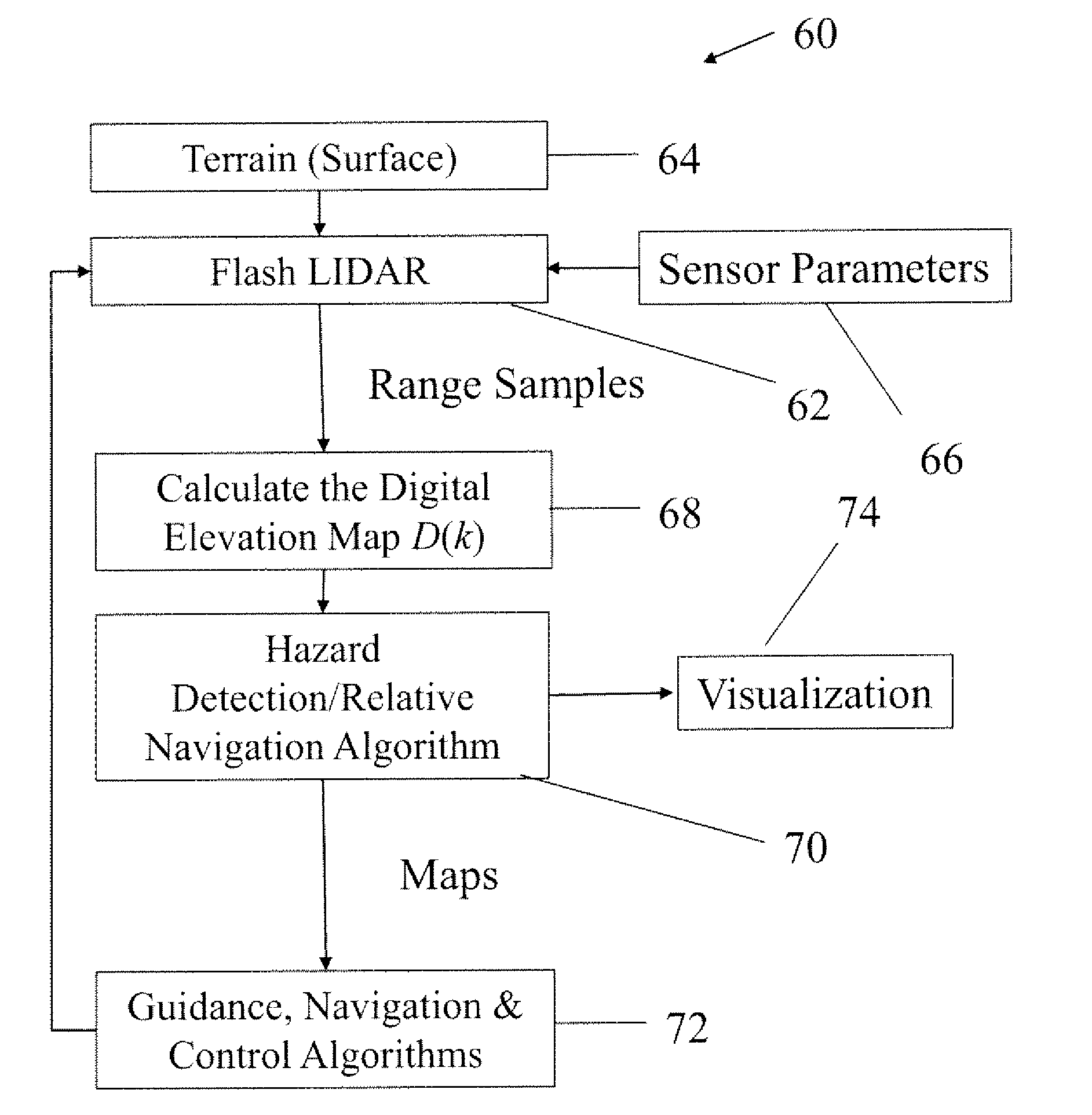

Method for Enhancing a Three Dimensional Image from a Plurality of Frames of Flash Lidar Data

ActiveUS20120033196A1Increase heightSafe preciseOptical rangefindersElectromagnetic wave reradiationConsecutive frameDigital elevation map

Owner:NASA

Portable phone with ergonomic image projection system

ActiveUS20060172767A1Easy to viewPrecise positioningTelevision system detailsInterconnection arrangementsBody areaProjection system

A portable phone includes a handset and a data projection system configured to form a visual image of data, such as caller waiting ID data, on a viewing surface viewable by a user during a two way conversation. The handset also includes a speaker, a microphone, conventional phone circuitry and a keyboard. The data projection system is configured to receive signals from the phone circuitry, to generate a pattern representative of the data, to process the pattern into a mirror image of the visual image, and to project the mirror image from a bottom end surface of the handset. The projection system includes an electro optic system for generating the pattern, and an optics system for projecting the mirror image onto the viewing surface. A method for projecting data in a portable phone includes the steps of: providing the handset with the data projection system, conducting a two way conversation with the handset held against the head of the user, and forming the visual image on the viewing surface during the two way conversation with the handset held against the head. The method can also include the steps of manipulating the handset and a body part to locate and focus the visual image, sensing an orientation of the handset during the two way conversation, and orienting the visual image as a function of the sensing step.

Owner:LAGOON POINT ENTERPRISES

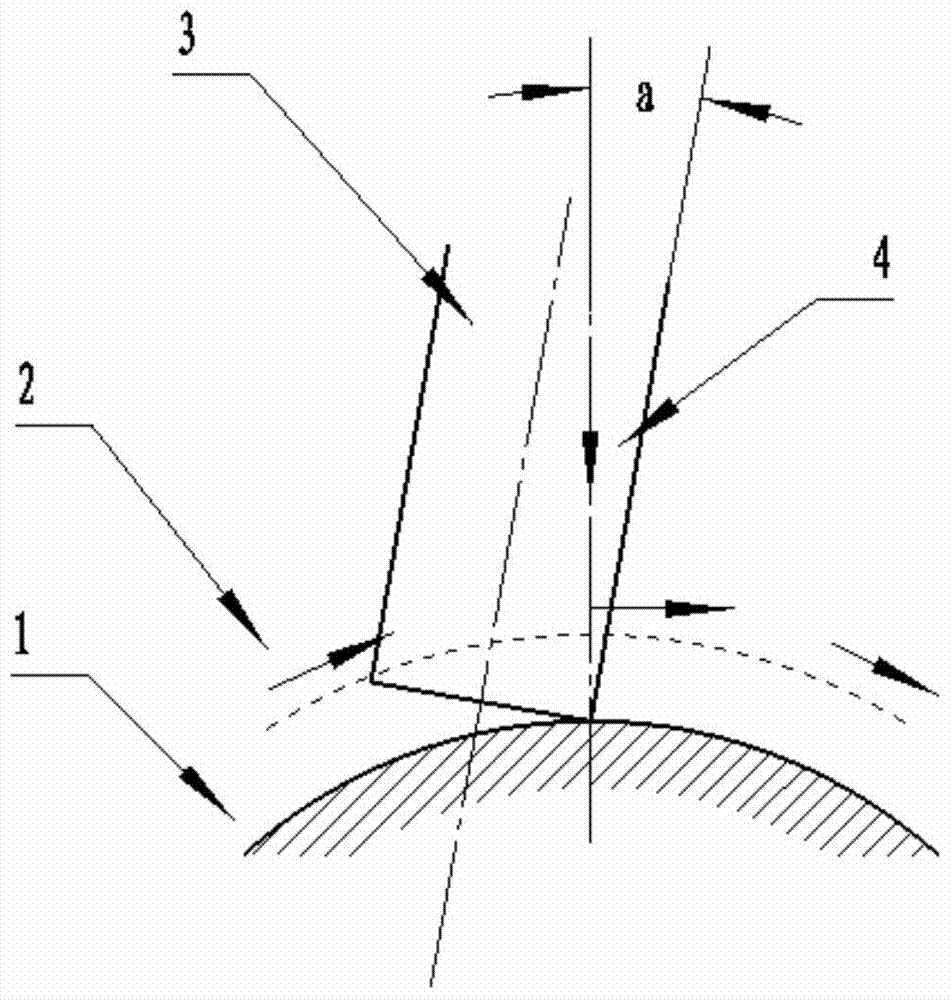

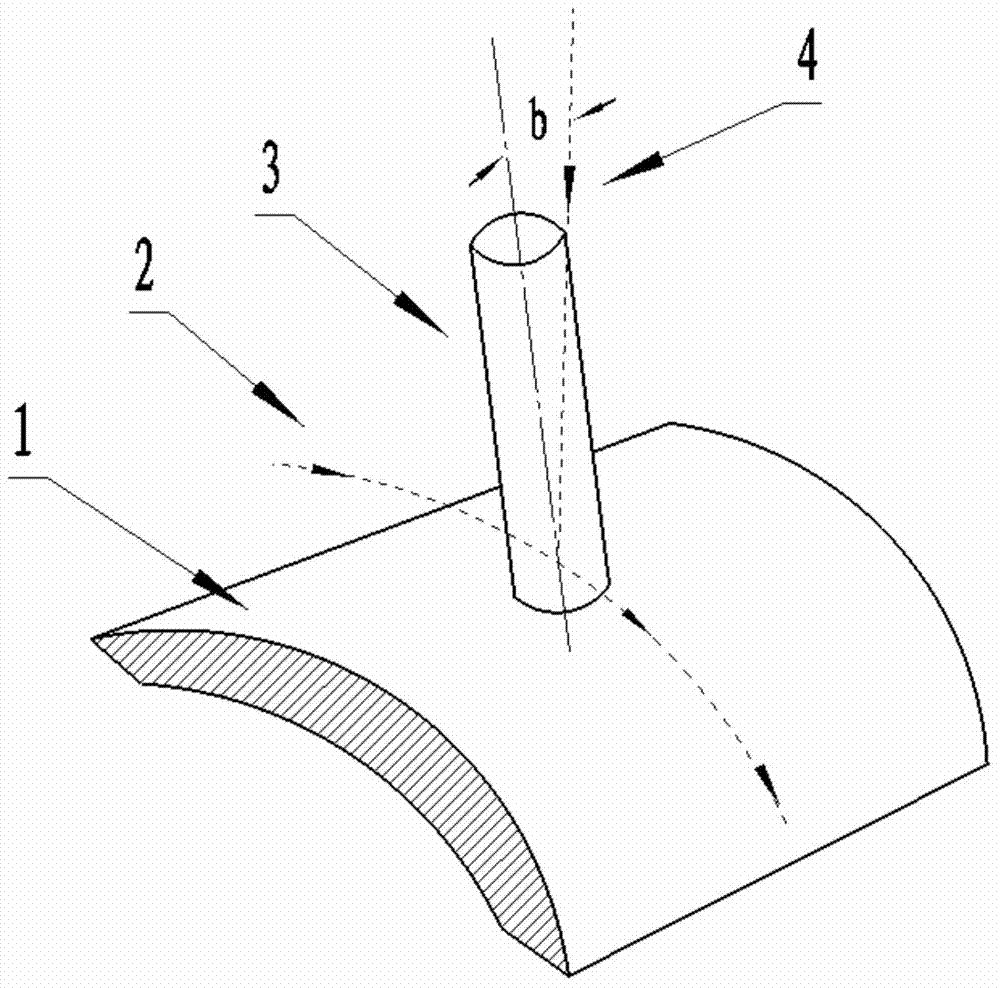

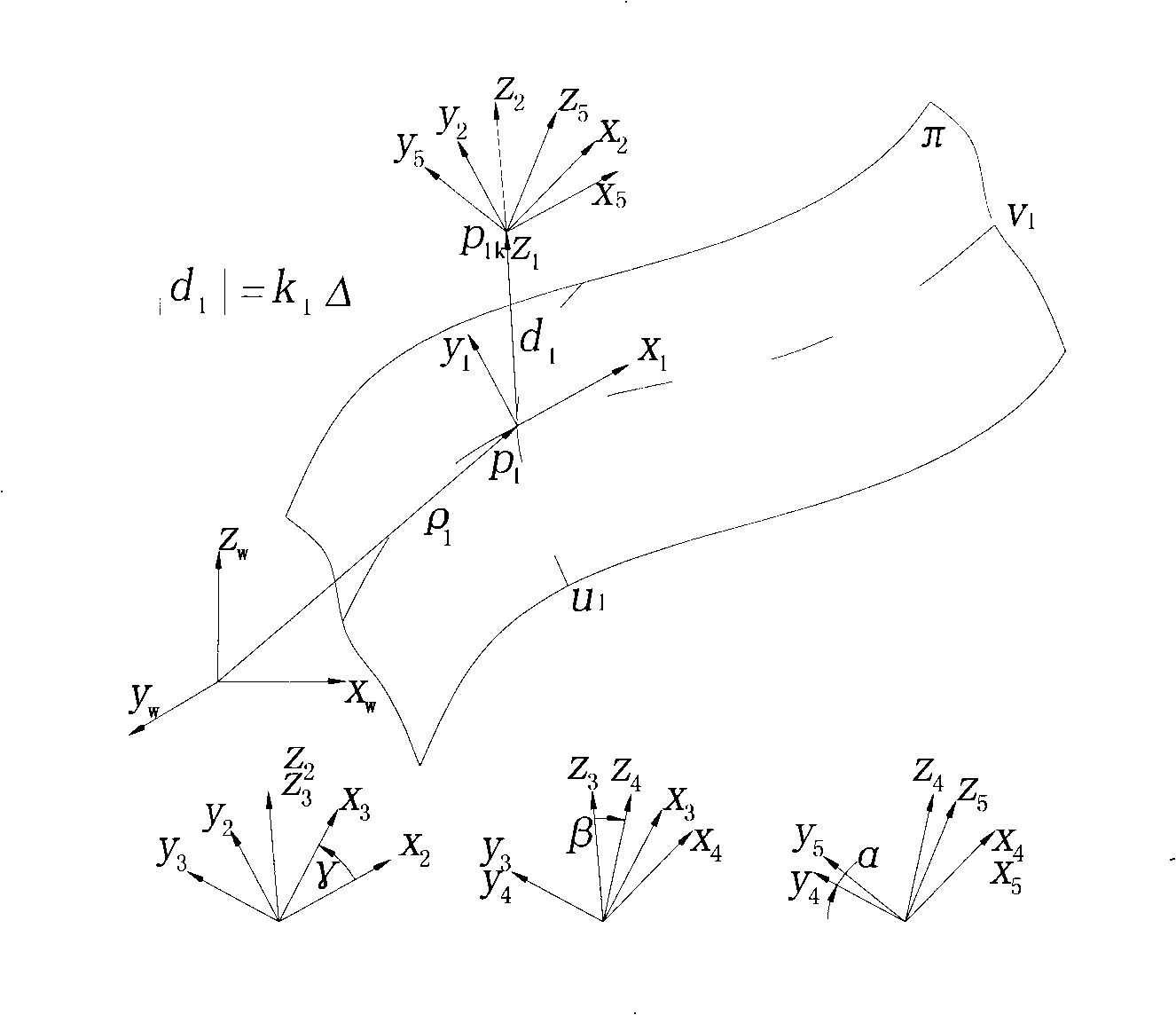

Multi-axis curved surface type numerically-controlled method for machining complicated curved surface part

ActiveCN103537743AImprove cutting efficiencySmall residualAutomatic control devicesFeeding apparatusNumerical controlMilling cutter

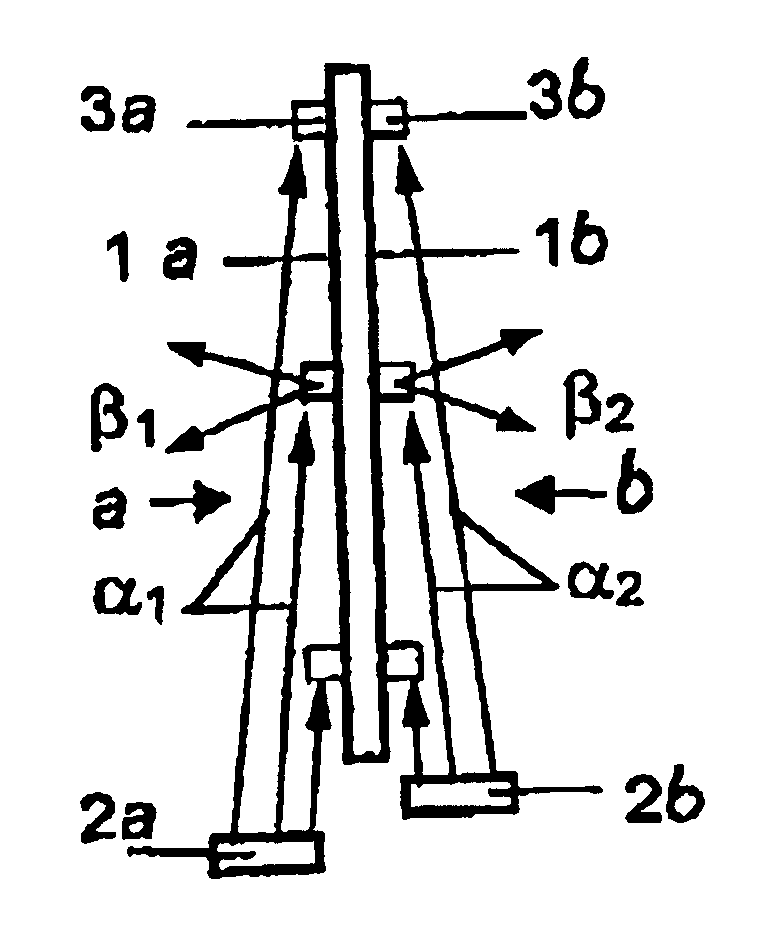

The invention discloses a multi-axis curved surface type numerically-controlled method for machining a complicated curved surface part. According to the method disclosed by the invention, the axis of a cutter can be arranged according to the directions of longitude and latitude normal lines for forming a curved surface, an inclined angle is adjusted to generate a cutter path, and the machining efficiency and the part surface smoothness can be improved. The numerically-controlled method can be realized by the following technical scheme: a part is fixed in a rotary center of a five-shaft machine tool; a curved surface is reconstructed according to the curvature change, the normal line direction of the curved surface and a machining path; a space change of an axis vector of the cutter is controlled by adjusting the front inclined angle and the side inclined angle of a cutter shaft of a flat-bottom end mill so that the cutter always keeps that a cutter tip participates in curved surface cutting in the five-axis continuous cutting process; a curved surface projection machining manner is adopted in the programming process so that the mill can carry out multi-axis linked milling machining according to the curvature change of the curved surface; the axis of the cutter is similar with a relatively small front inclined angle alpha overlapped to the normal line direction of the cutter path and a side inclined angle is set as 0; the axis of the cutter is kept vertical to the direction of the machining path to implement a five-axis linked machining numerical control procedure.

Owner:四川泛华航空仪表电器有限公司

Imaged nonwoven fabric for cleaning applications

The present invention is directed to enhancing the cleaning of surfaces by the contact application of a non-apertured nonwoven fabric having a three-dimensional image imparted therein. The three-dimensional image of the non-apertured nonwoven fabric induces the formation of lather due to pronounced surface projections that come in contact with the cleaning surface and provide air passageways that are parallel to the plane of the substrate. The imaged nonwoven fabric disclosed herein exhibits low linting qualities thereby reducing the potential of fiber contamination of the cleaned surface and is sufficiently durable that the sample can be used in a brisk manner.

Owner:POLYMER GROUP INC

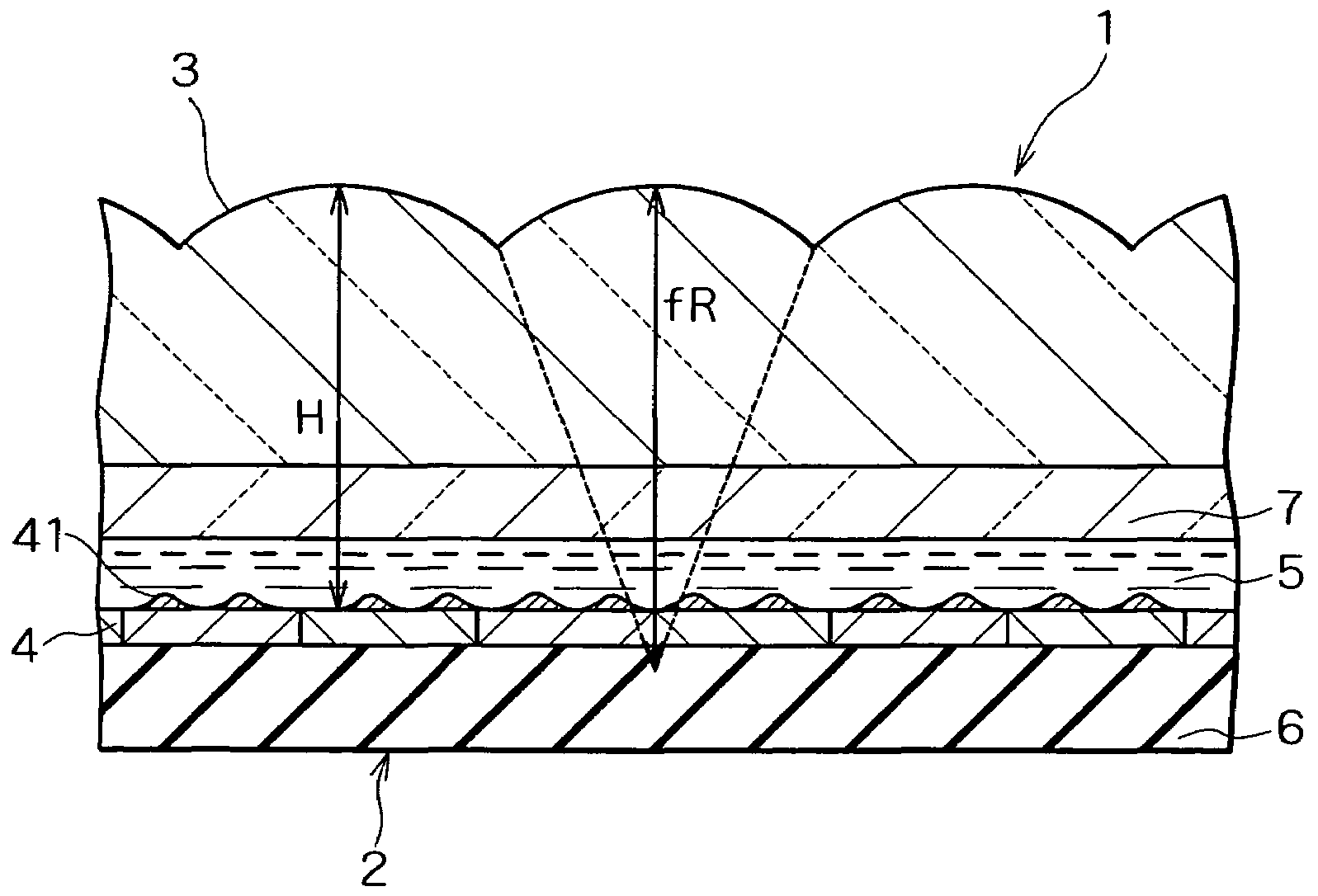

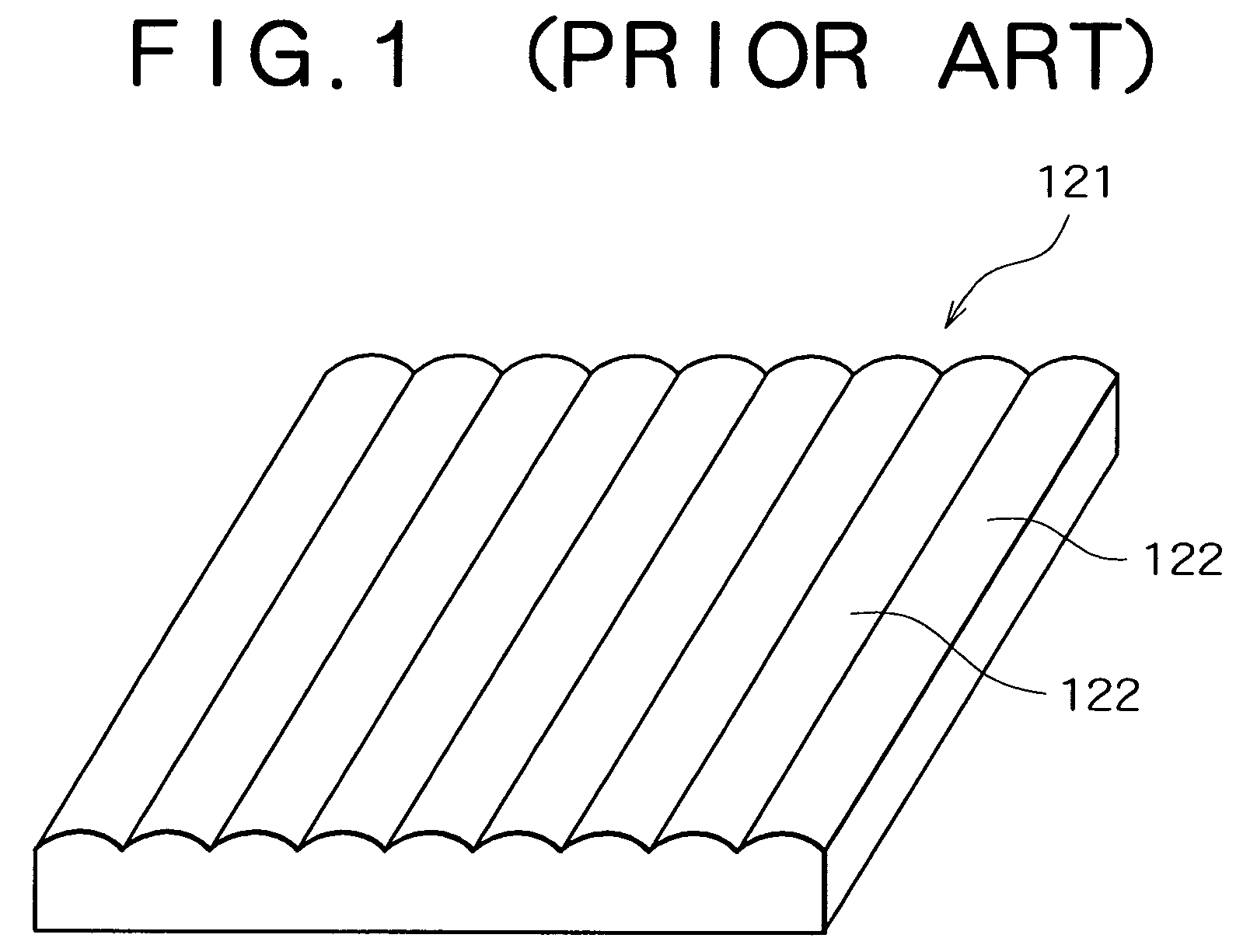

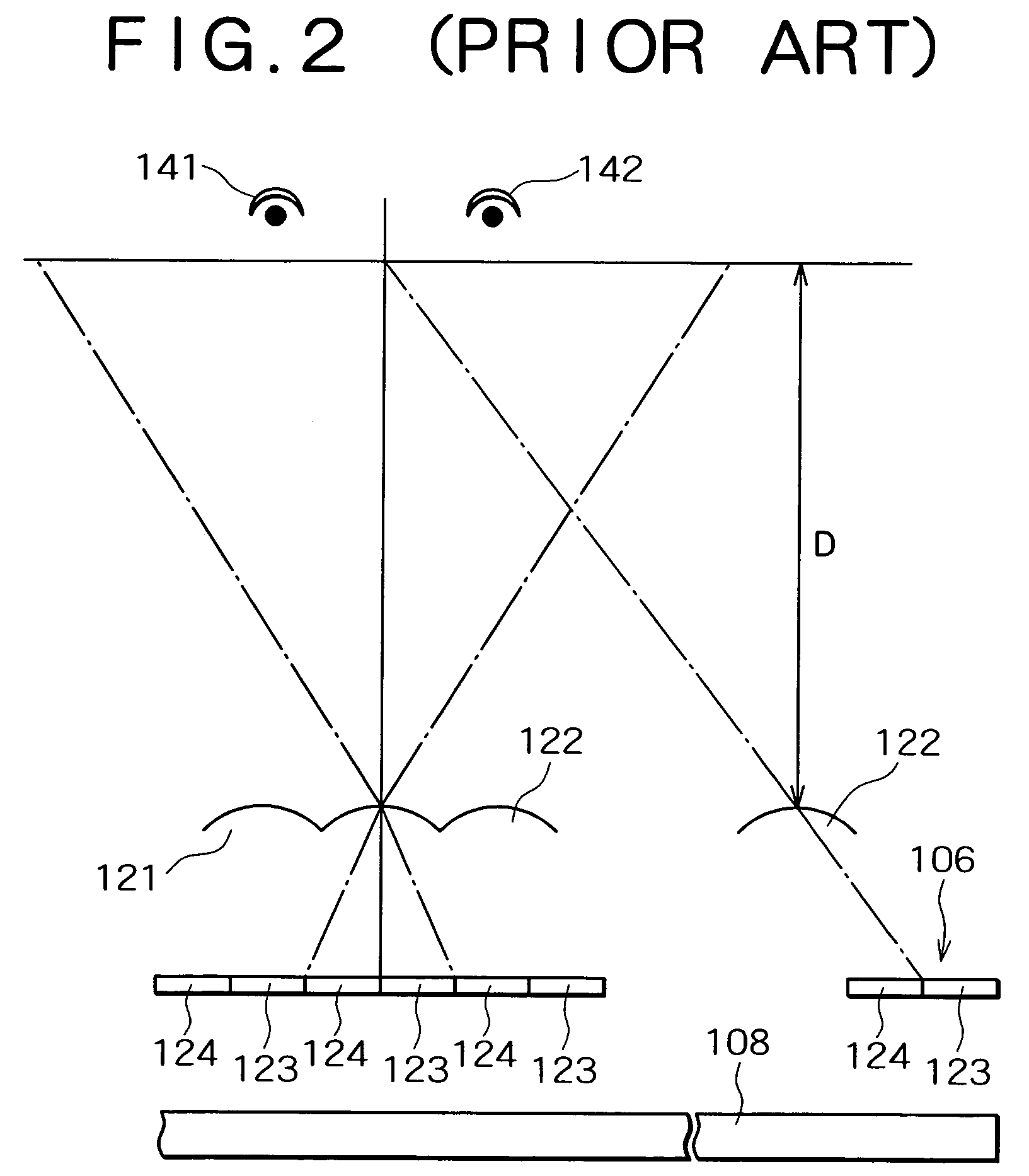

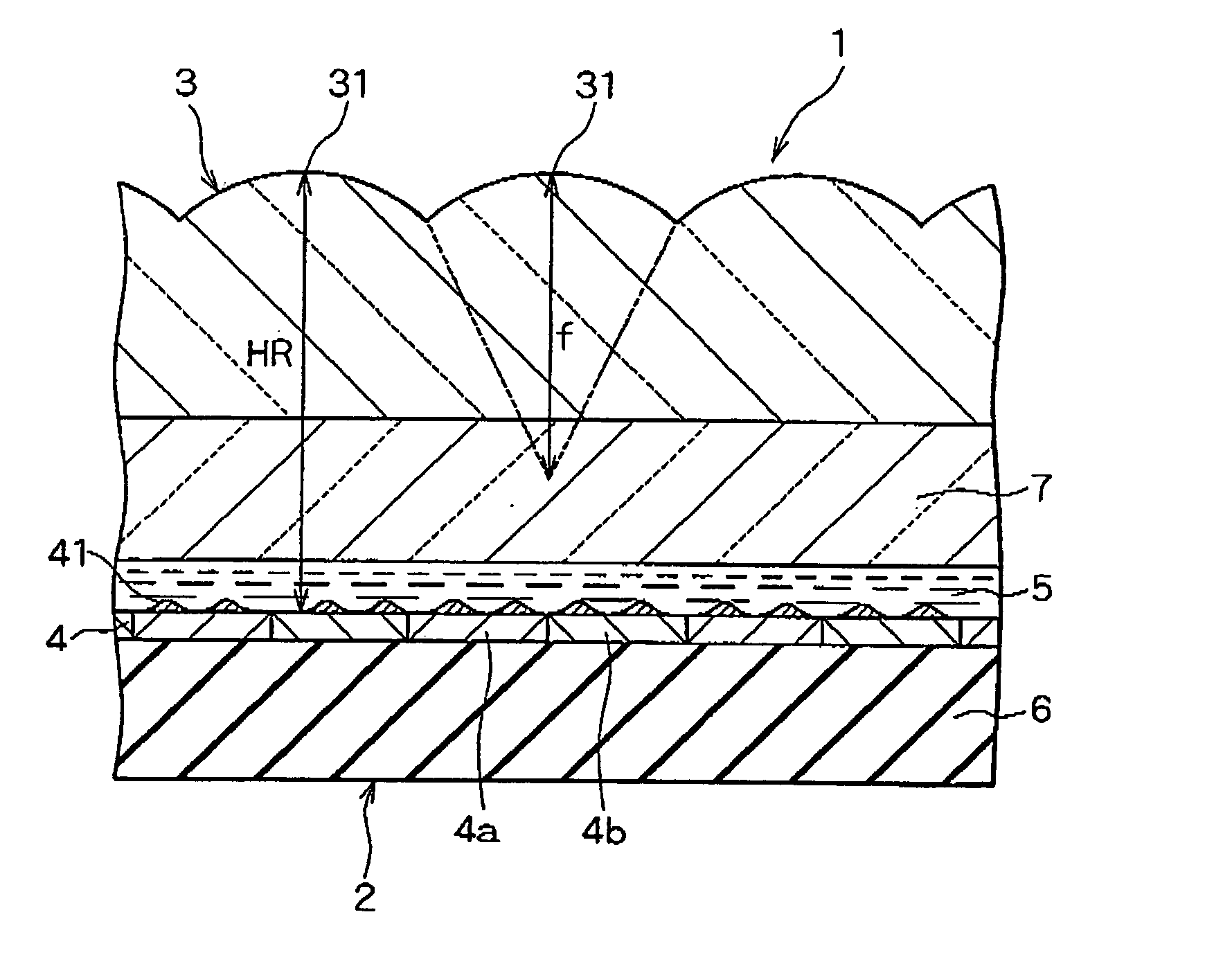

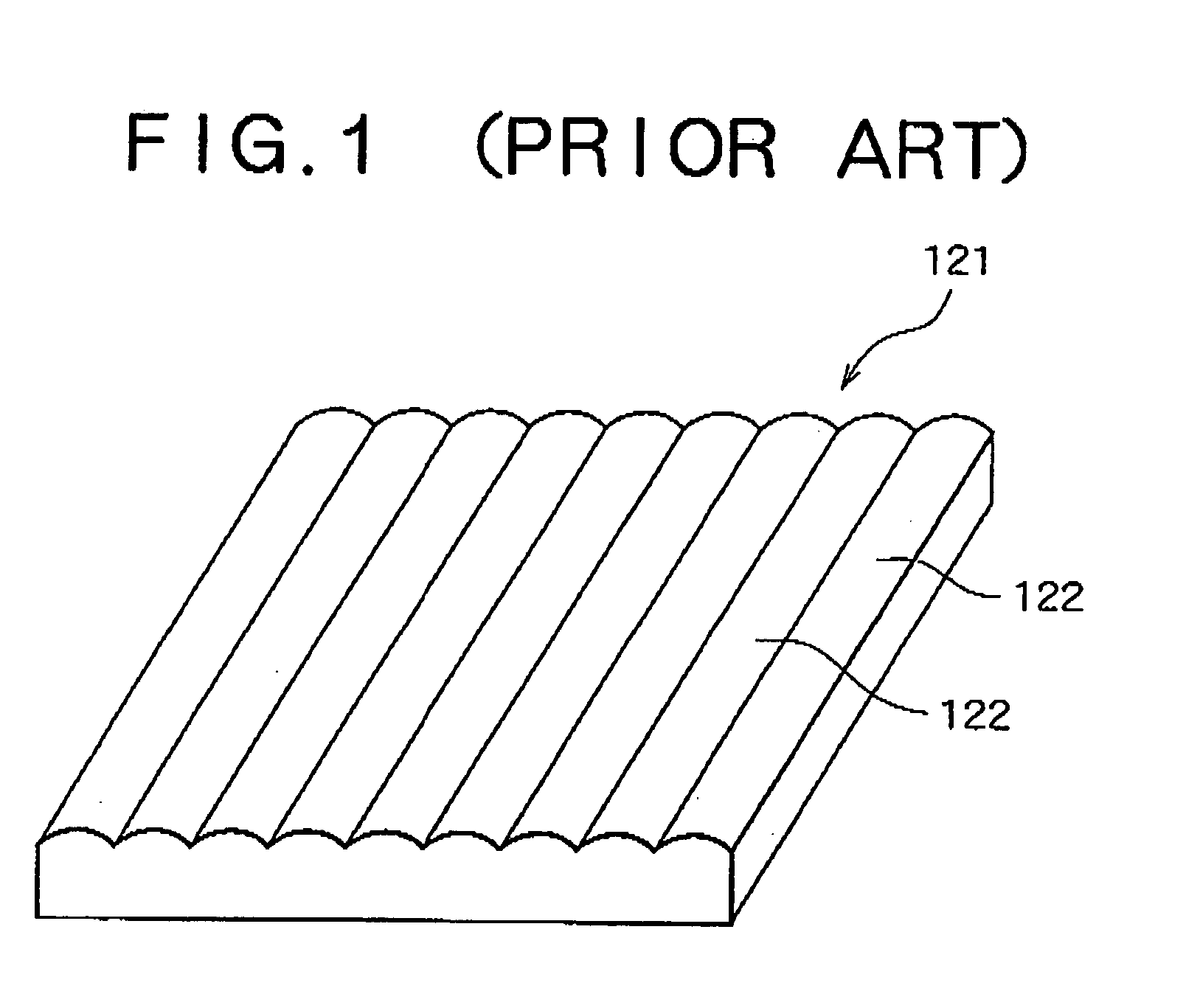

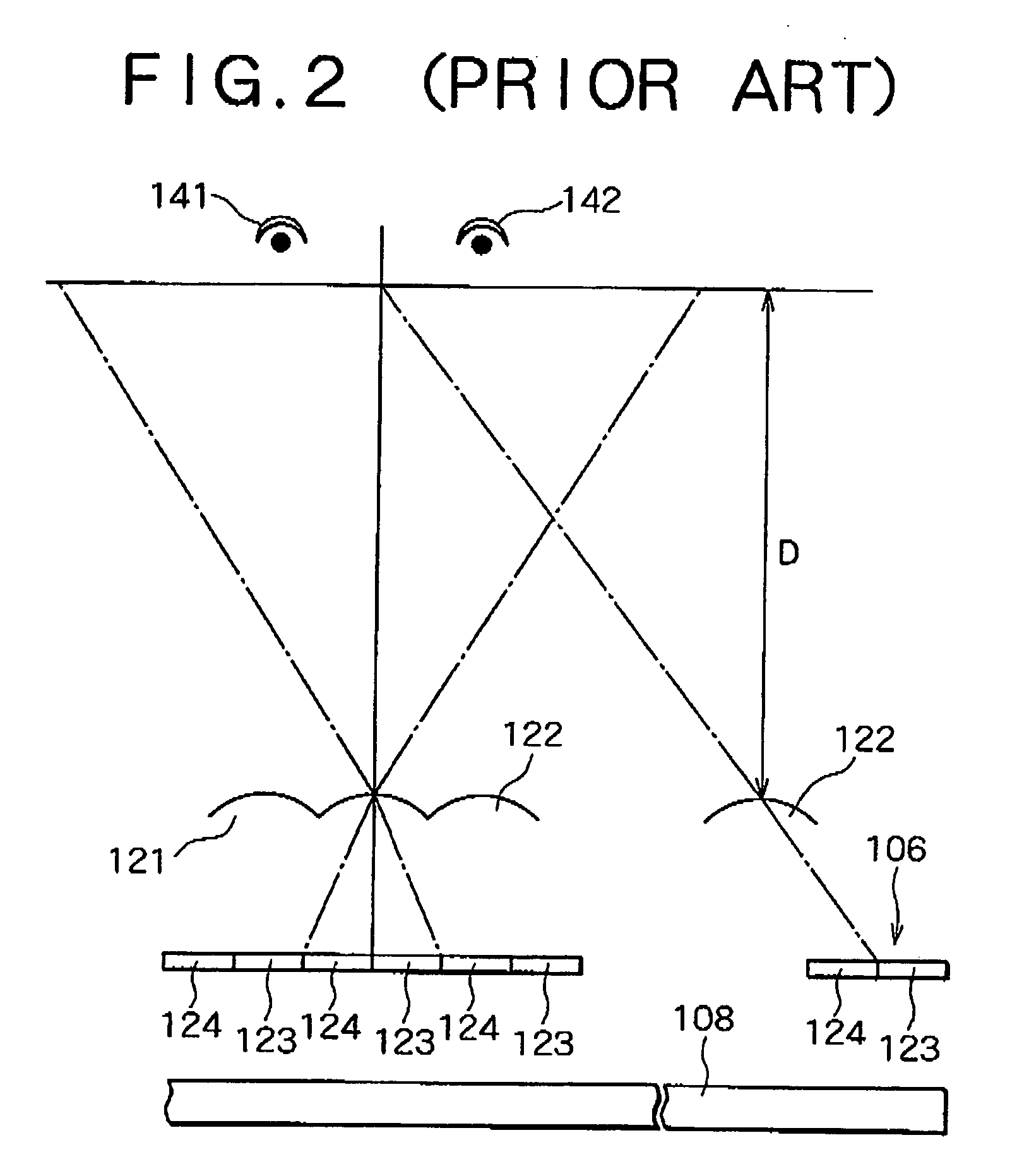

Image display device and portable terminal device using the same

ActiveUS7301587B2Improve display qualityQuality improvementProjectorsSteroscopic systemsComputer graphics (images)Terminal equipment

In a display panel, a plurality of pixel sections are arranged in the form of a matrix. Each of the pixel sections includes a pixel for displaying an image for the left eye and a pixel for displaying an image for the right eye. Lenticular lens having repeated convex surfaces is disposed in front of the display panel to deflect the light emitted from each pixel in the horizontal direction from the pixel for displaying the image for the left eye to the pixel for displaying the image for the right eye in each pixel section. Reflection plate reflects the exterior light toward the display panel and has surface projections on the surface. In this case, the focal distance f of the lens is different from the distance H between the surface of the reflection plate and the apex of the lens.

Owner:NEC LCD TECH CORP

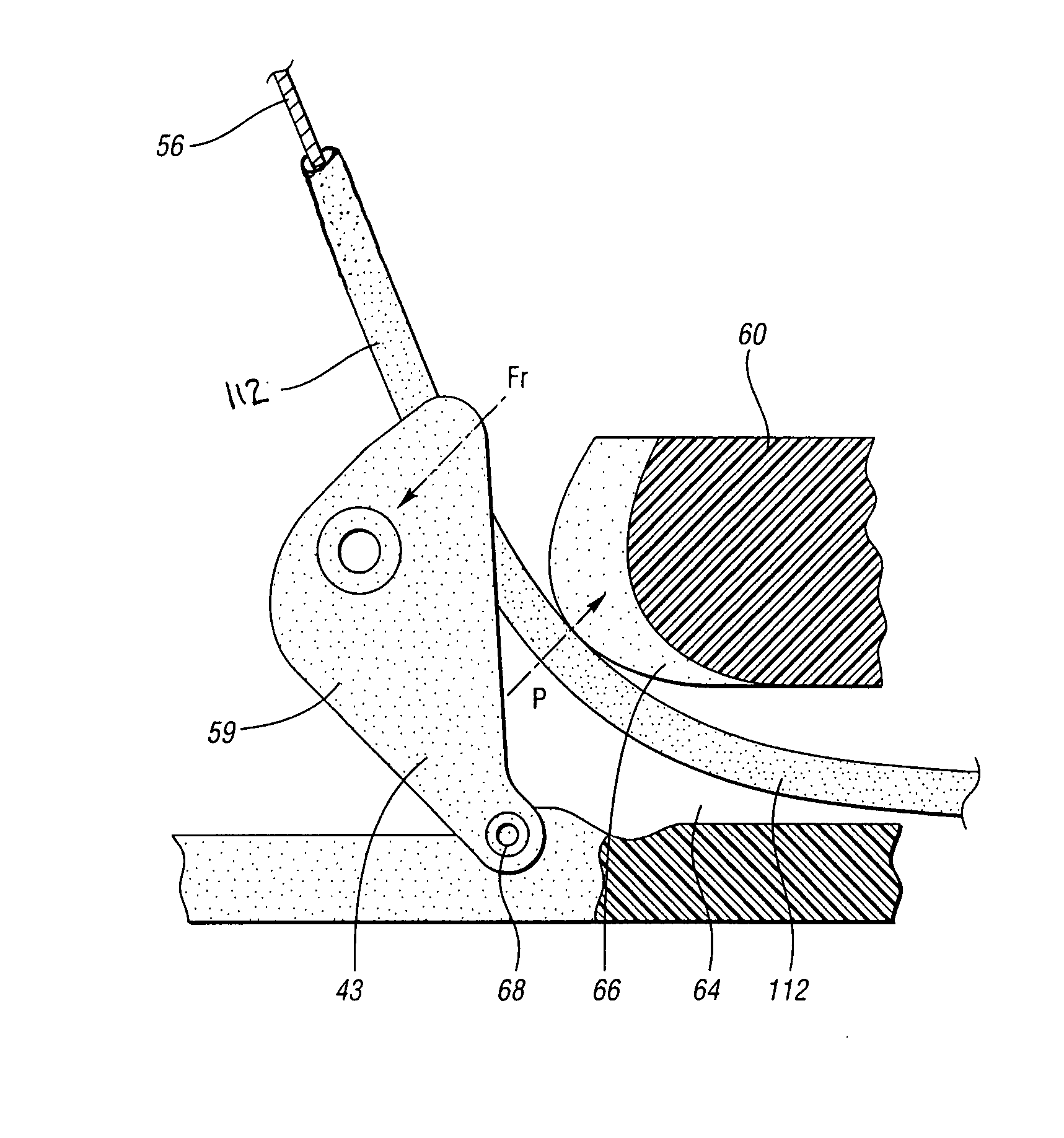

Endoscopic elevator apparatus

An endoscopic elevator apparatus cooperable with an insertion tube extending to a distal tip and having enhanced grasping and reduced scraping of an elongate medical device is disclosed. The apparatus comprises an elevator movably attached to the distal tip. The elevator has an inner side formed thereon defining a grasping slot for engagement with the endoscope. The elevator has a surface projection disposed thereon for inhibiting damage to the elongate medical device.

Owner:COOK MEDICAL TECH LLC

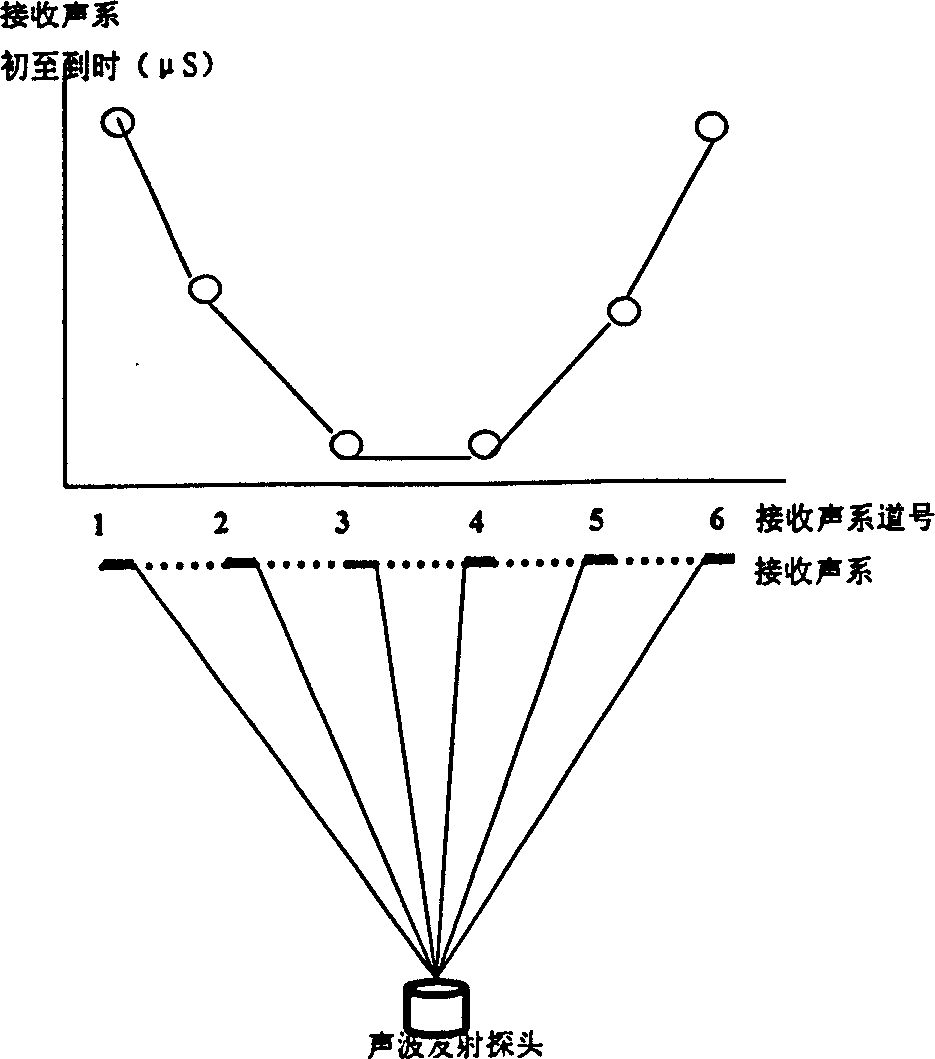

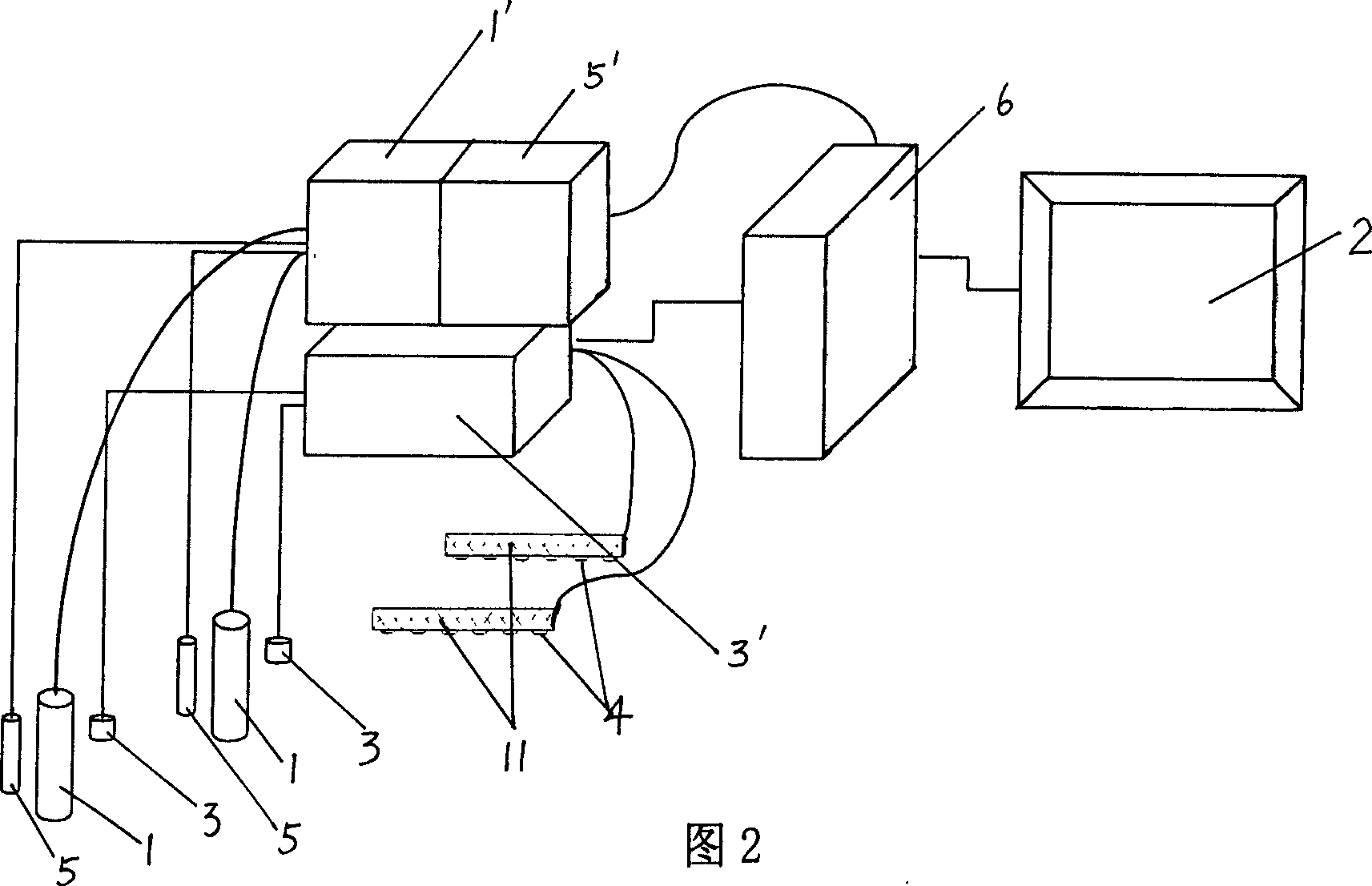

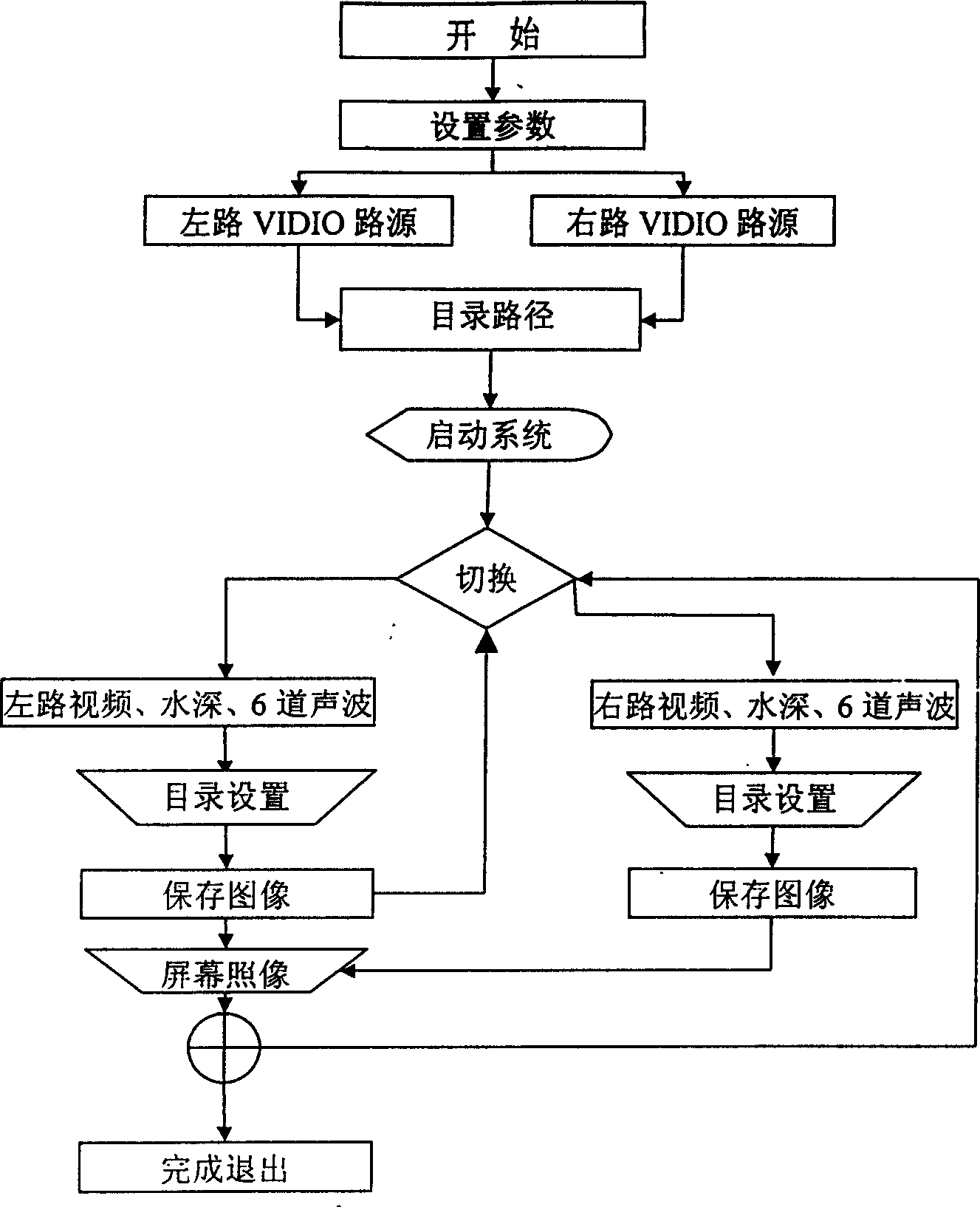

Automatic underwater object positioning method and system

InactiveCN1614441ALow costReduce the difficulty of settingTelevision system detailsPosition fixationAcoustic waveSurface projection

A method for positioning target under water automatically includes using wirerope on the ship to sink detection device down to water bottom at water area of target to be positioned and confirming its position through image; arranging sound wave receiversin linear array of intervals on water surface, launching sound wave to wards water surface by emitter; sending sound wave signal to computer for calculating out time difference, water depth and target water surface projection position value displayed in curve.

Owner:南京市长江河道管理处

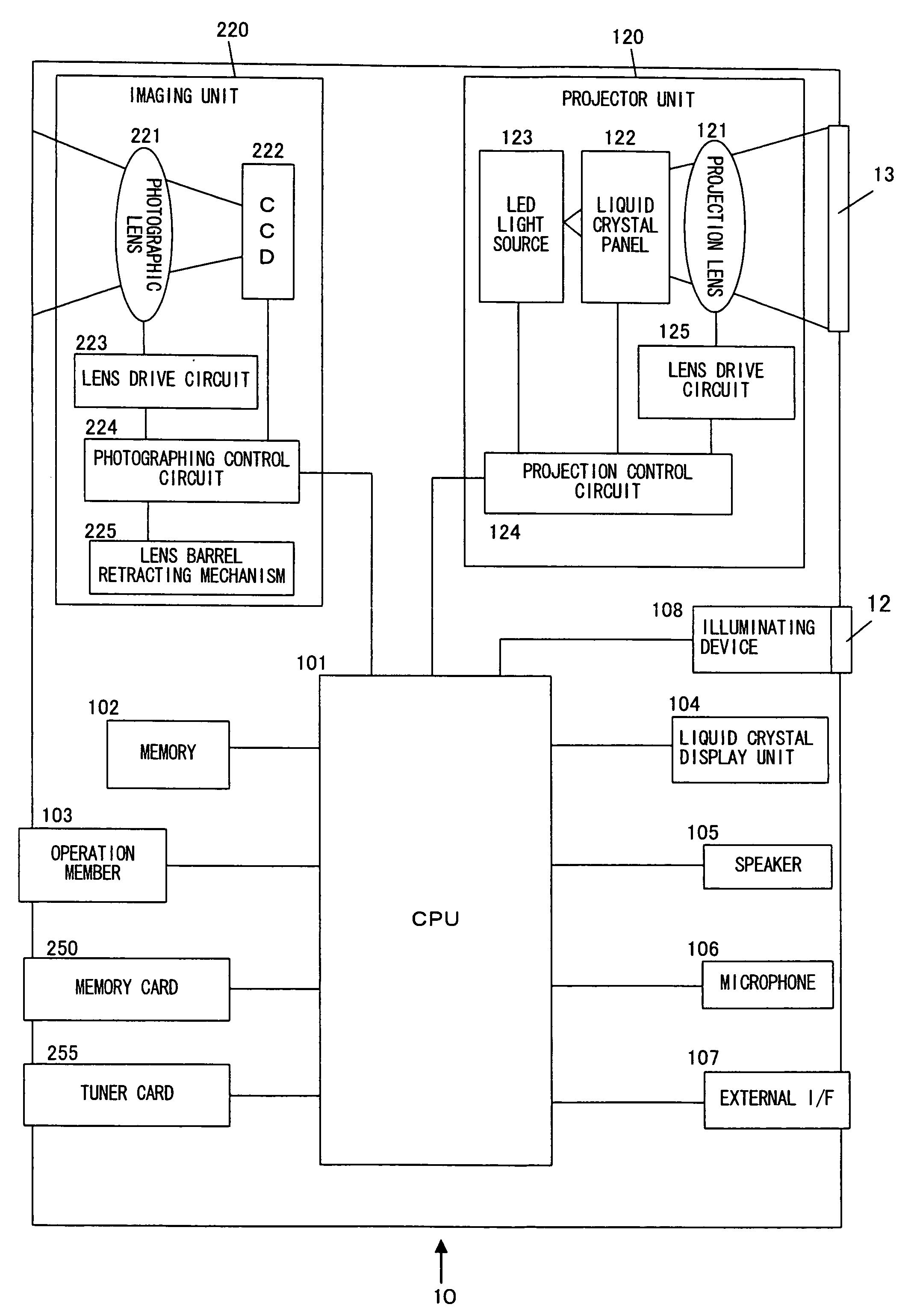

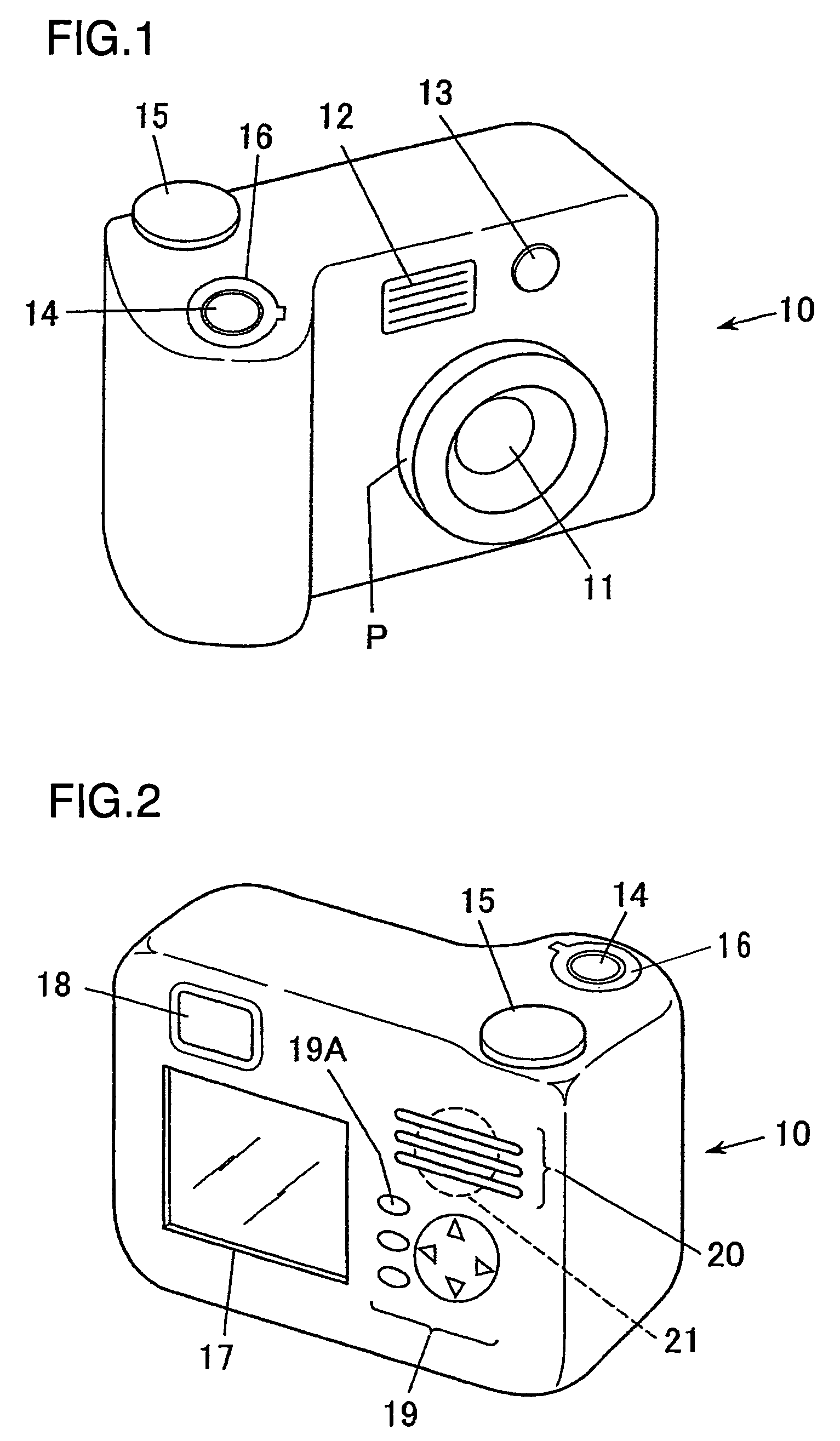

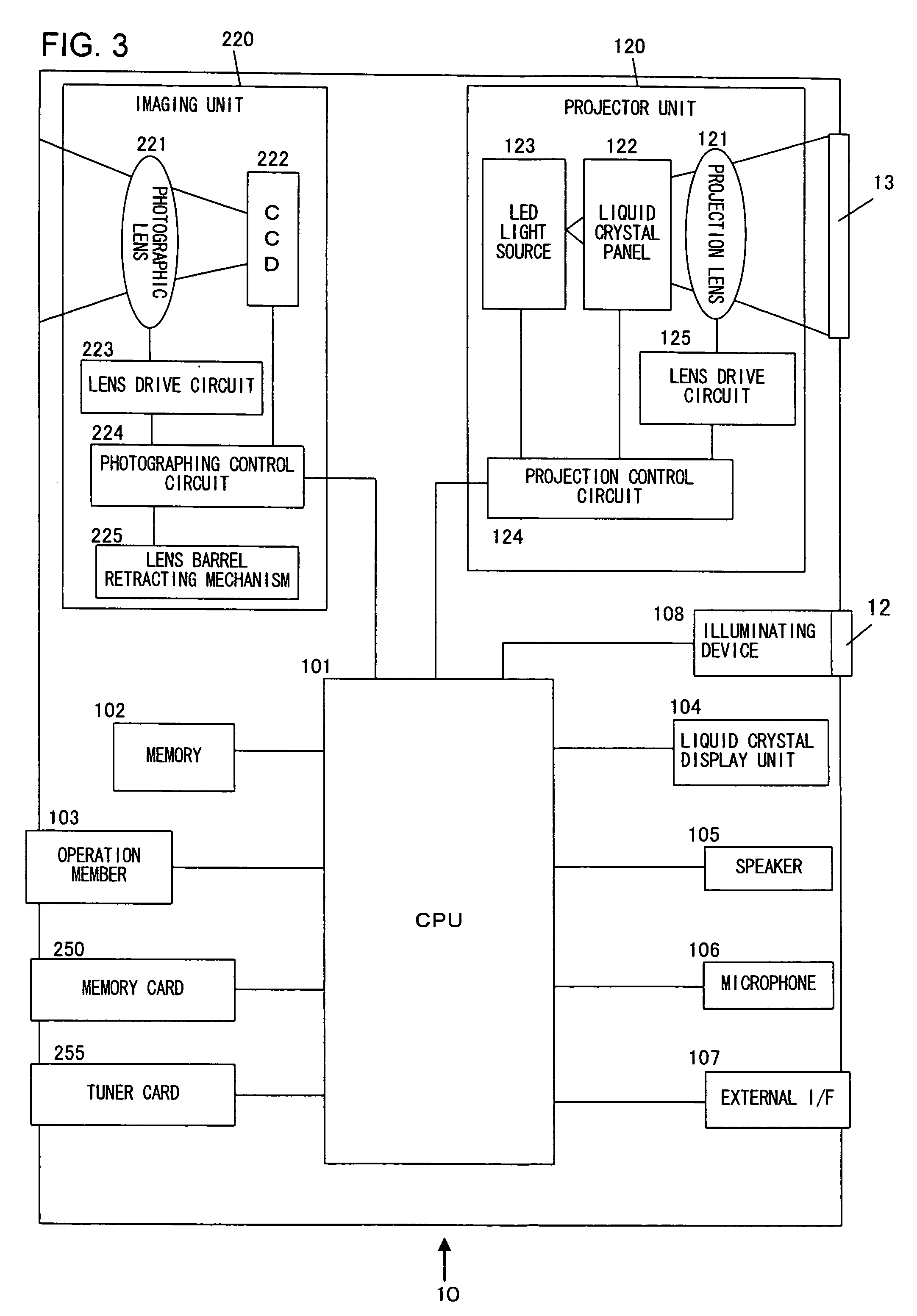

Digital camera with projector and digital camera system

InactiveUS20060291851A1Television system detailsProjector focusing arrangementOperation modeComputer science

A digital camera equipped with a projector, includes a photographing device; a projector device that projects an optical image; a mode switching operation member that outputs a switching operation signal indicating a changeover to one of a photographing operation mode in which image data photographed by the photographing device are saved as a photographic image file in a recording medium and a projection operation mode in which a reproduced image is projected by the projector device; a top surface operation member disposed at an upper surface of a casing; and a projection control device that controls the projector device based upon an operation signal provided by the top surface operation member upon receiving a switching operation signal indicating a changeover to the projection operation mode from the mode switching operation member.

Owner:NIKON CORP

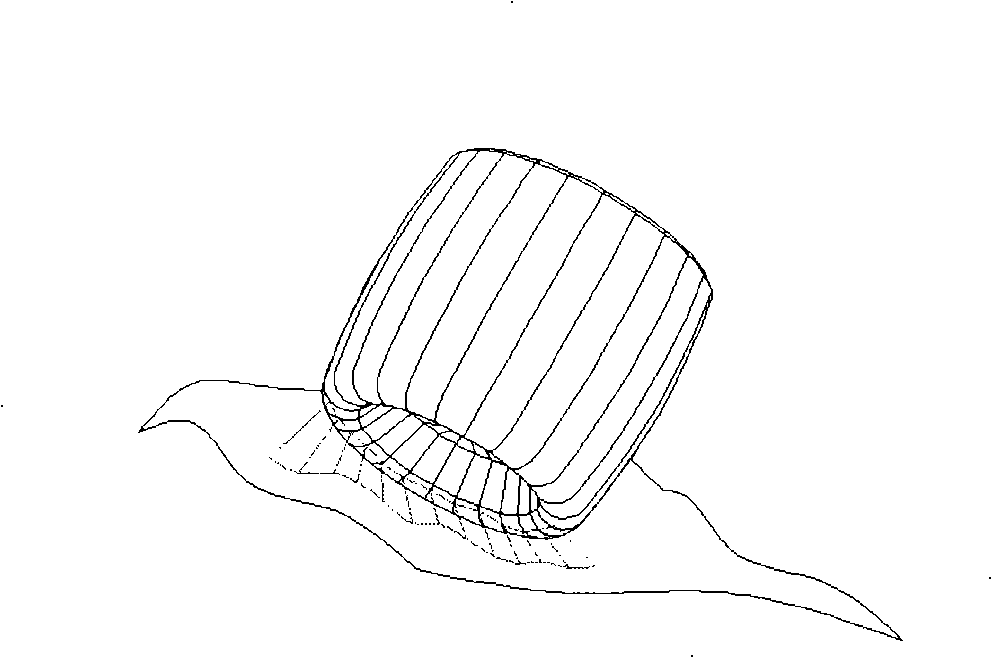

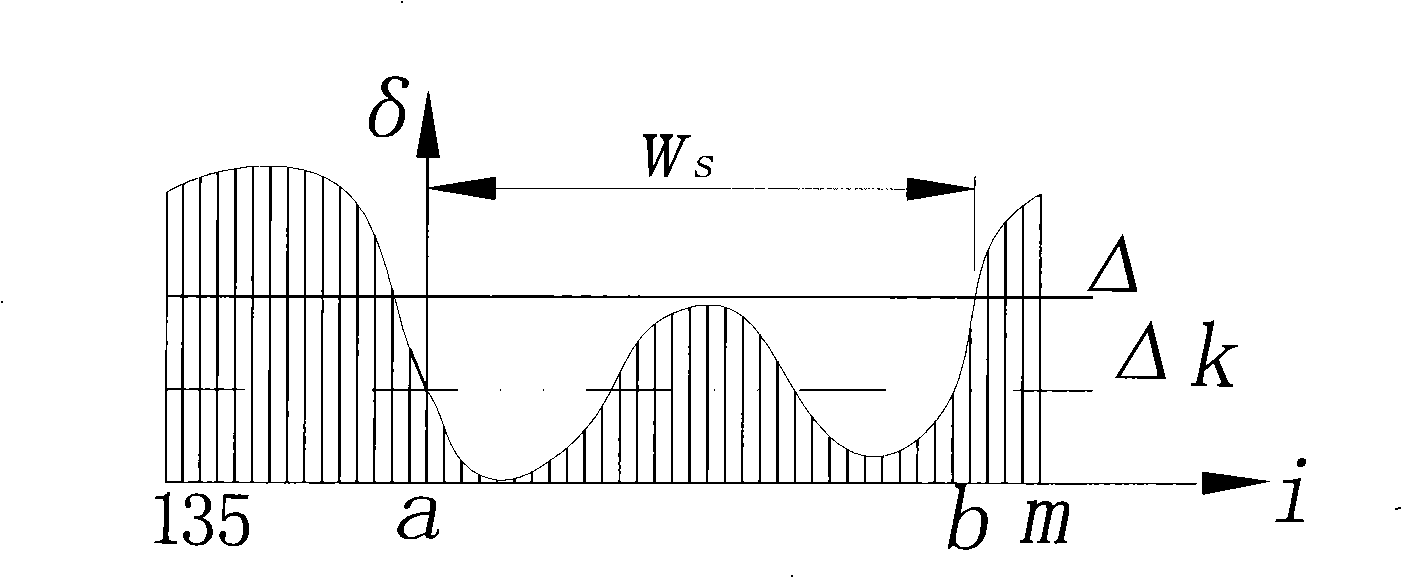

Multi-coordinate end milling process tool position optimization method using longitude line division tool bit

InactiveCN101269423AAvoid interferenceControl machining errorMilling cuttersMathematical modelLine width

The invention discloses an optimization method for a multi-coordinates end milling processing cutter spacing which adopts a meridian division cutter. Firstly, the working face of a cutter is dispersed into a set of enough dense meridians, and then the minimum distance among the meridians and a designed curved face so as to get a set of minimum-distance line segments; secondly, the points on the minimum-distance line segment at the cutter working face are connected together to form a curve in space, namely, a typical line; the typical line arranged in a programming tolerance range is regarded as an effective typical segment; with the distance between two endpoints of the effective typical segment, the surface projection vertical to the feed direction of the cutter is used as processing line width; the maximum of the processing line width is regarded as the object function of cutter spacing optimization; the non-negative distance between all meridians and the designed curved face is regarded as one of constraint conditions; a mathematic model of the cutter spacing optimization is constructed and is combined with a cutter rail for fair and smooth processing, getting the optimization cutter spacing through a solution procedure. The optimization method can be used for effectively avoiding interference and control the mismachining tolerance and improving the working efficiency.

Owner:BEIHANG UNIV

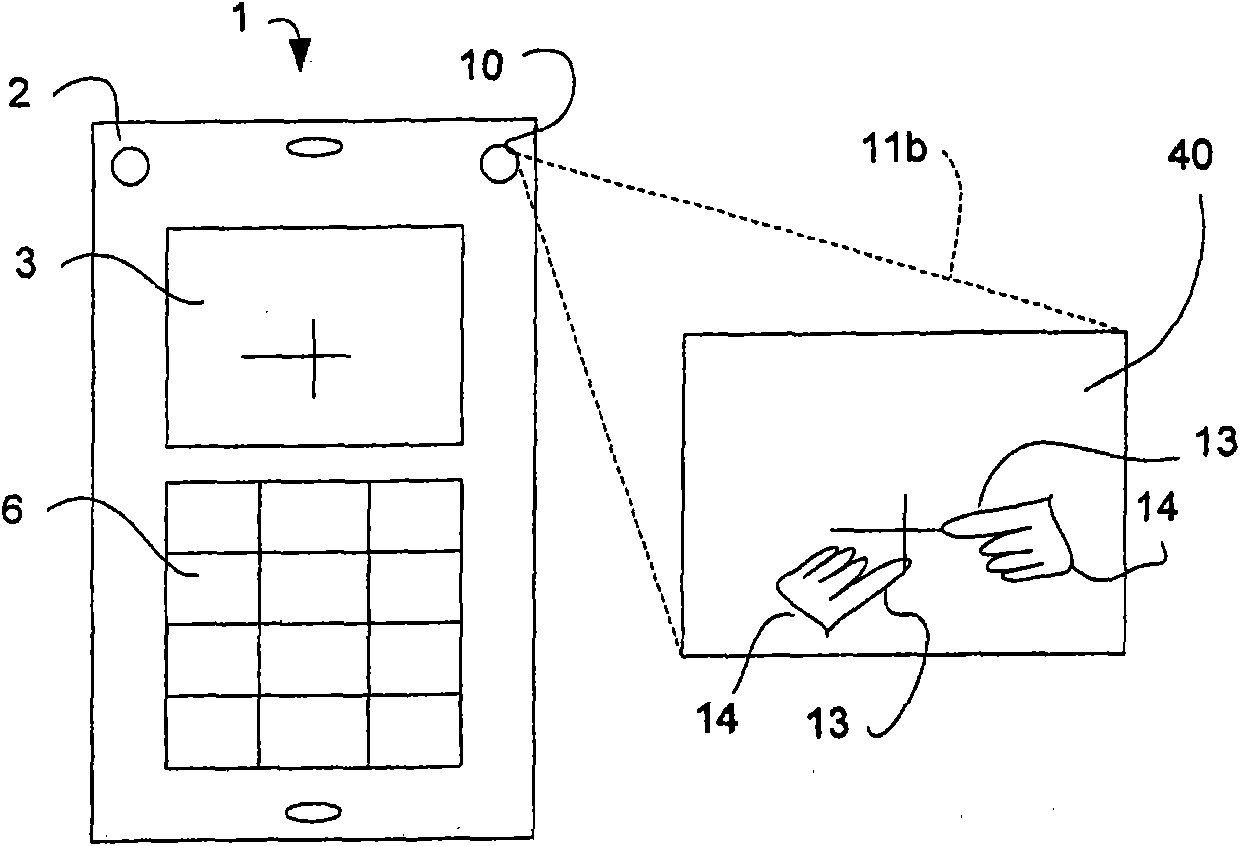

Visual laser touchpad of mobile telephone and method thereof

The invention discloses a visual laser touchpad of mobile telephones and a method thereof. A portable electronic communication device (such as a mobile phone) comprises a projector which is integratedinto the mobile phone for projecting images, and a camera detects views of projected images and views such as views which changes the projected images by inserting objects (for example, fingers, handwriting pens and the like) to the projected images. Change characteristics (for example changes of images) are taken as an input of the mobile phone. A method for using the portable communication device comprises the following steps: sending and receiving communication by a wireless transmitter receiver set, projecting images to a surface, detecting views including views of the projected images ofthe projector and detecting changes of the detected views of the projected images by a camera using the portable communication device to provide input for the portable communication device.

Owner:SONY ERICSSON MOBILE COMM AB

Glass substrate for display and manufacturing method thereof

InactiveUS20050026767A1Raise the gradeGlass furnace apparatusGlass drawing apparatusDisplay deviceMillimeter

Owner:NIPPON ELECTRIC GLASS CO LTD

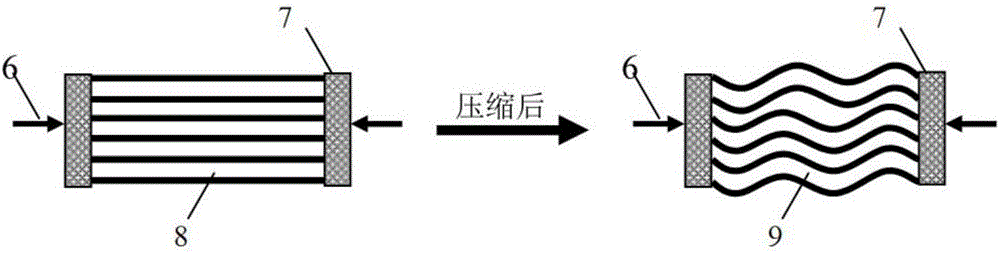

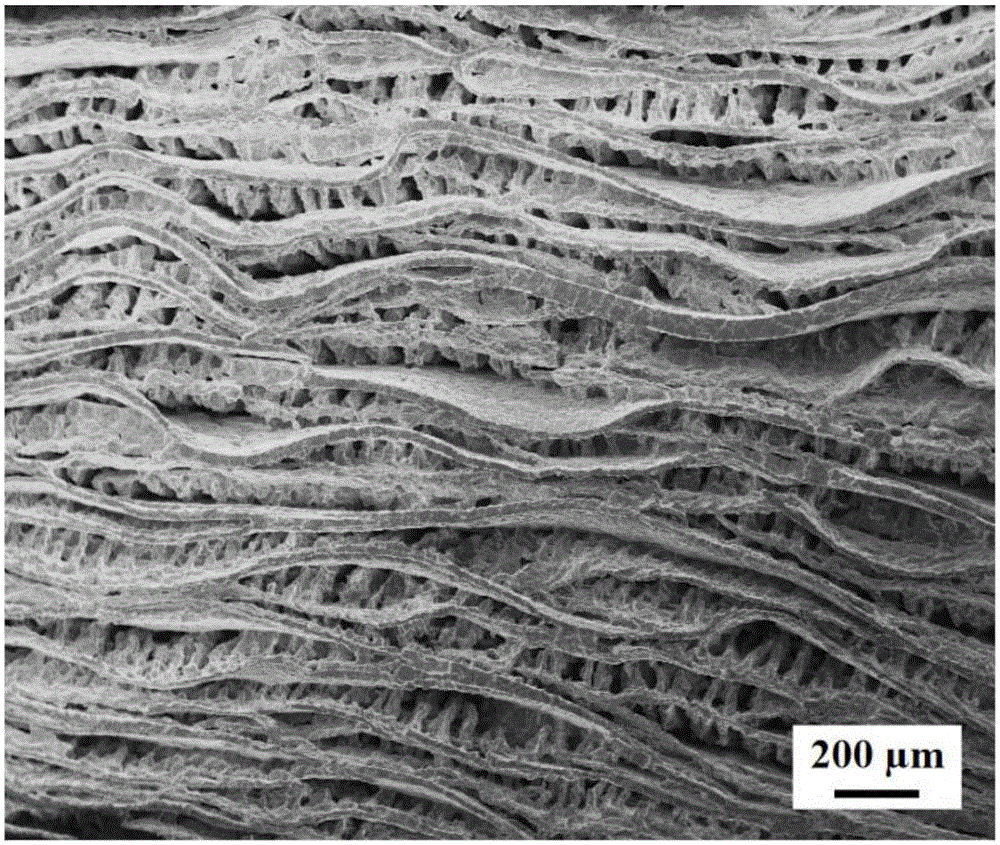

Shell-imitated ceramic-based composite material and preparation method thereof

ActiveCN107522475AHigh strengthImprove fracture toughnessUltimate tensile strengthSurface projection

The invention discloses a shell-imitated ceramic-based composite material. The shell-imitated ceramic-based composite material is prepared by an ice template method and a liquid-phase infiltration technology, and is characterized by comprising a layered structure, wherein ceramic layers and second phase layers are alternately overlapped to form a layered structure; each ceramic layer has surface projections and an interlayer bridging structure; and the ceramic layers and the second phase layers are bent in a wavy manner. Preparation of the wavy bent layered structure is realized by compression of a porous ceramic blank which has the straight layered structure, and meanwhile, the degree of bending of the ceramic layers can be controlled by adjustment of compression deformation of the blank. Along with increasing of amount of compression, the curvature of the bent ceramic layers in the blank is increased. Mechanical performance tests show that if the bending degree of the layered structure of the shell-imitated ceramic-based composite material is increased properly, the strength and fracture toughness of the composite material can be improved effectively.

Owner:DALIAN UNIV OF TECH

Image display device and portable terminal device using the same

ActiveUS20040169831A1Positive contributionImprove image qualityProjectorsSteroscopic systemsComputer graphics (images)Terminal equipment

In a display panel, a plurality of pixel sections are arranged in the form of a matrix. Each of the pixel sections includes a pixel for displaying an image for the left eye and a pixel for displaying an image for the right eye. Lenticular lens having repeated convex surfaces is disposed in front of the display panel to deflect the light emitted from each pixel in the horizontal direction from the pixel for displaying the image for the left eye to the pixel for displaying the image for the right eye in each pixel section. Reflection plate reflects the exterior light toward the display panel and has surface projections on the surface. In this case, the focal distance f of the lens is different from the distance H between the surface of the reflection plate and the apex of the lens.

Owner:NEC LCD TECH CORP

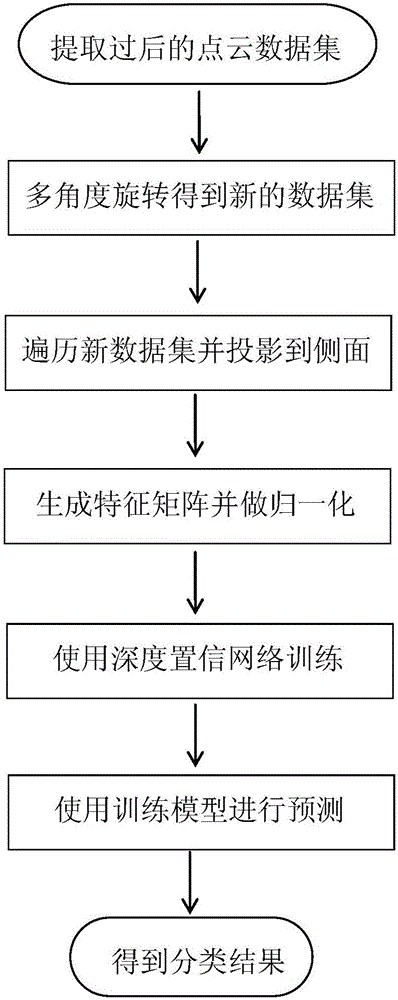

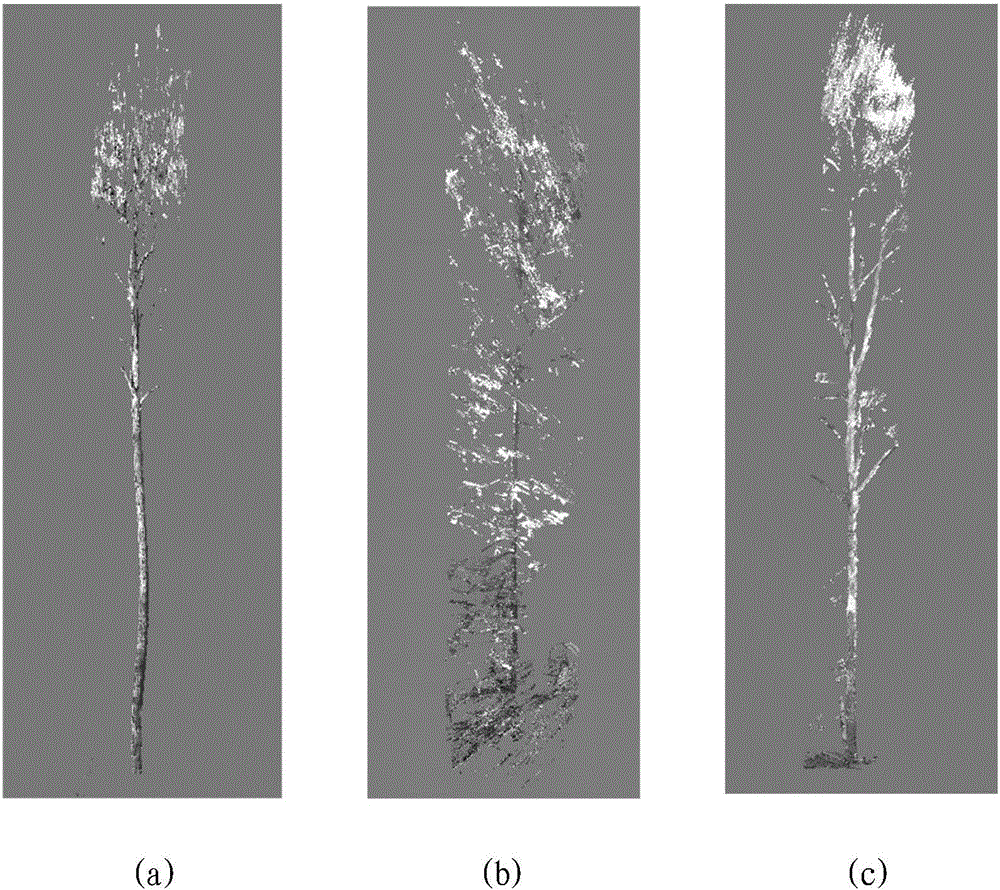

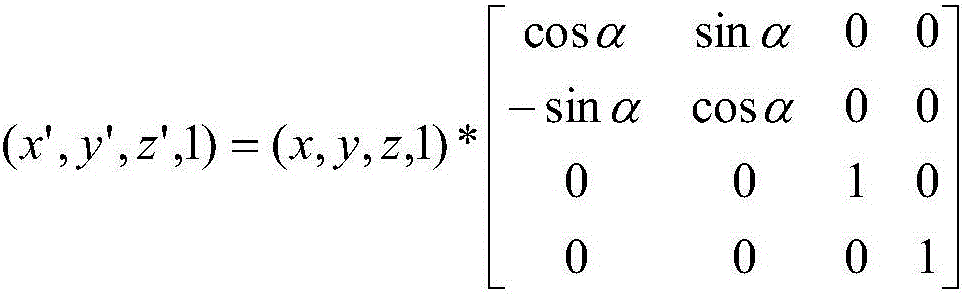

Laser scanning three-dimensional point cloud tree automatic classifying method based on deep learning

ActiveCN106408011AOvercome the problem of small sample sizeOvercome the problem of low quantityCharacter and pattern recognitionNeural learning methodsFeature vectorPretreatment method

The invention discloses a laser scanning three-dimensional point cloud tree automatic classifying method based on deep learning. The method can used to automatically classify an extracted single tree having a trunk and crown structure. A rotary side surface projection method is employed, and effective model training can be conducted even when tree data is less. Since a normalized pretreatment method is employed, the defect that the point cloud data densities of different distances (to a scanner) are non-uniform can be overcome. The influence of acquisition equipment on the result is minimal, and the result is more stable. Since deep learning is employed for model training, the accuracy for automatically classifying a plurality of trees is improved. A characteristic vector is used as a unit for calculation, and the calculation speed is fast. The method is more suitable for large-scale point cloud scene and has practical meanings and application values.

Owner:XIAMEN UNIV

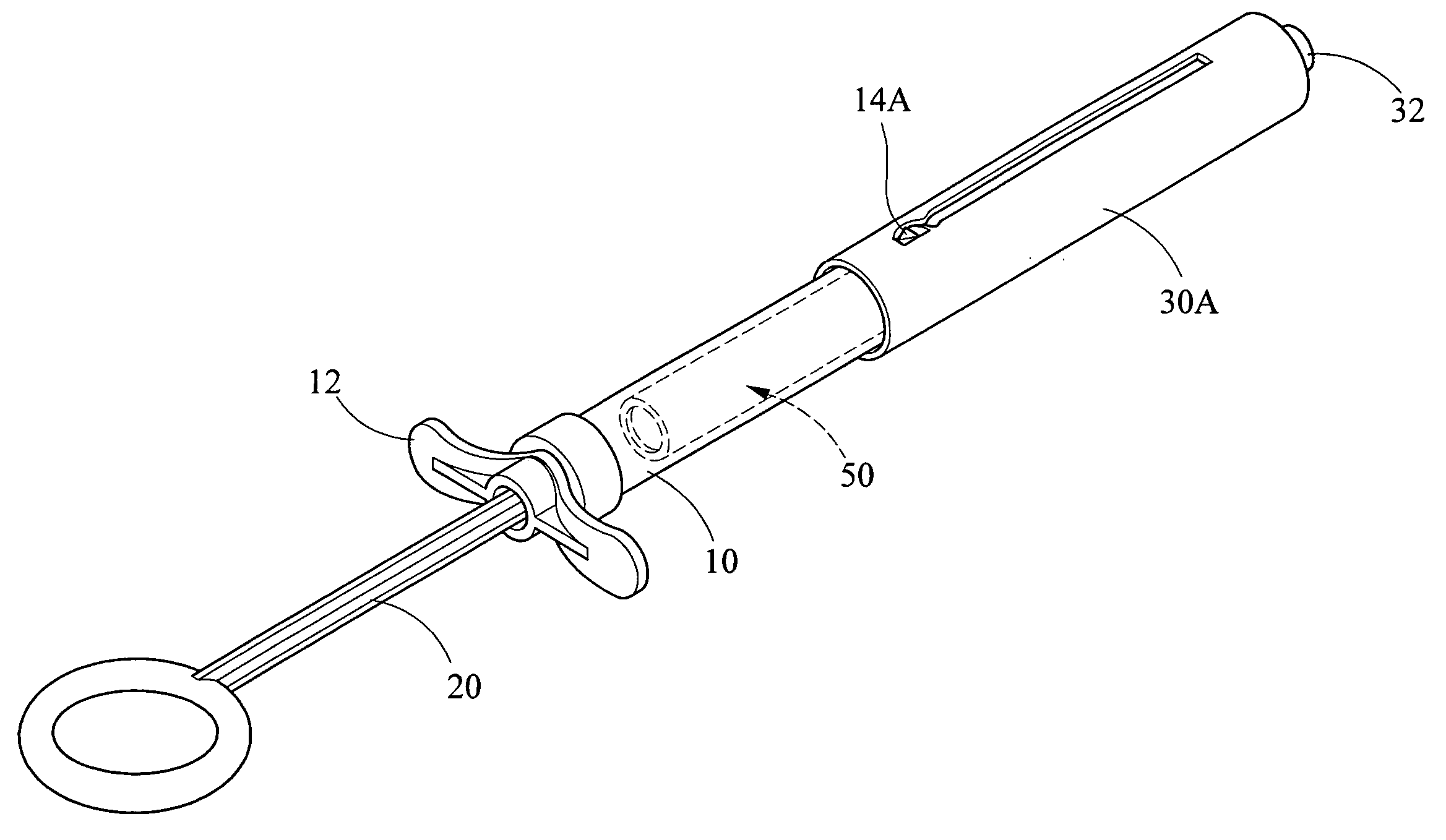

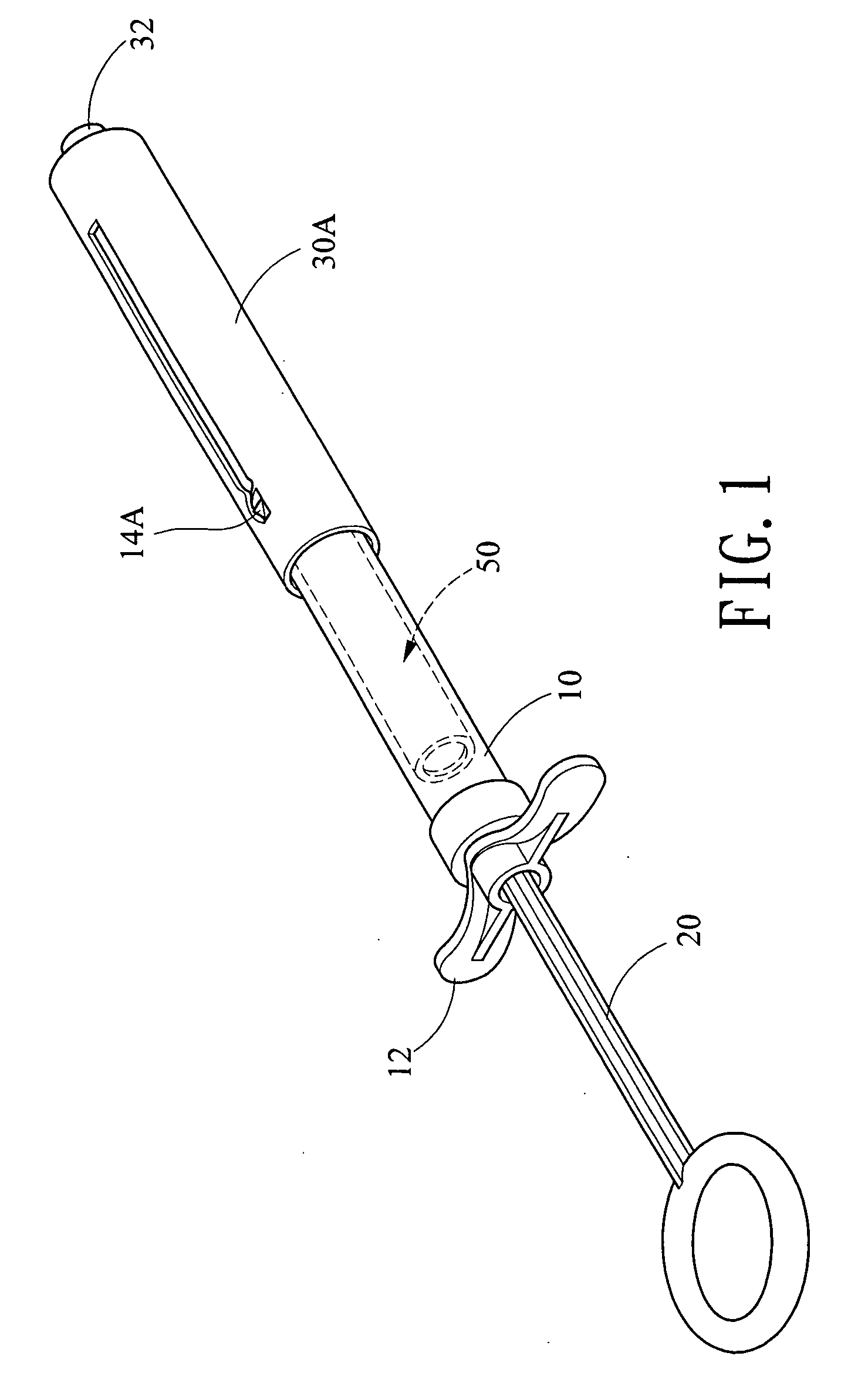

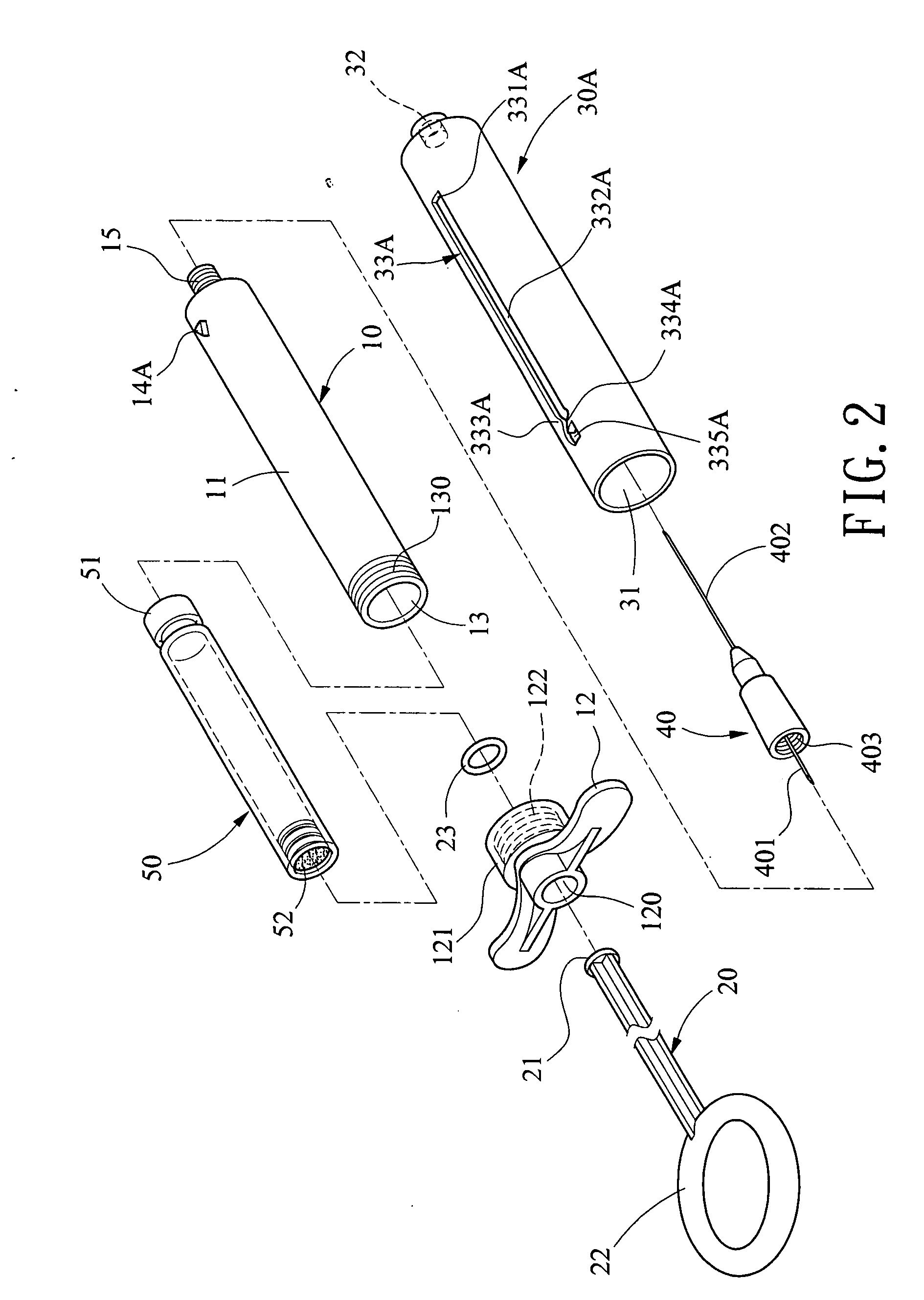

Disposable safety syringe for dispensing anesthetic

InactiveUS20070078408A1Rule out the possibilityPossibility of contaminationAmpoule syringesInfusion needlesNoseEngineering

A disposable syringe comprises an arm, a plunger for receiving a fluid cartridge and including a surface projection, a needle assembly secured to a forward nose of the plunger, and a syringe barrel including a lengthwise slot on its surface with the projection disposed therein, a locking trough proximate a curved rear end of the slot, and a flexible latch provided between the rear end of the slot and the locking trough. After dispensing anesthetic, pulling the plunger rearward will retract the needle assembly into the syringe barrel until the projection moves from a forward end of the slot to the locking trough by passing the latch for locking the projection in the locking trough.

Owner:WANG HSIEN TSUNG

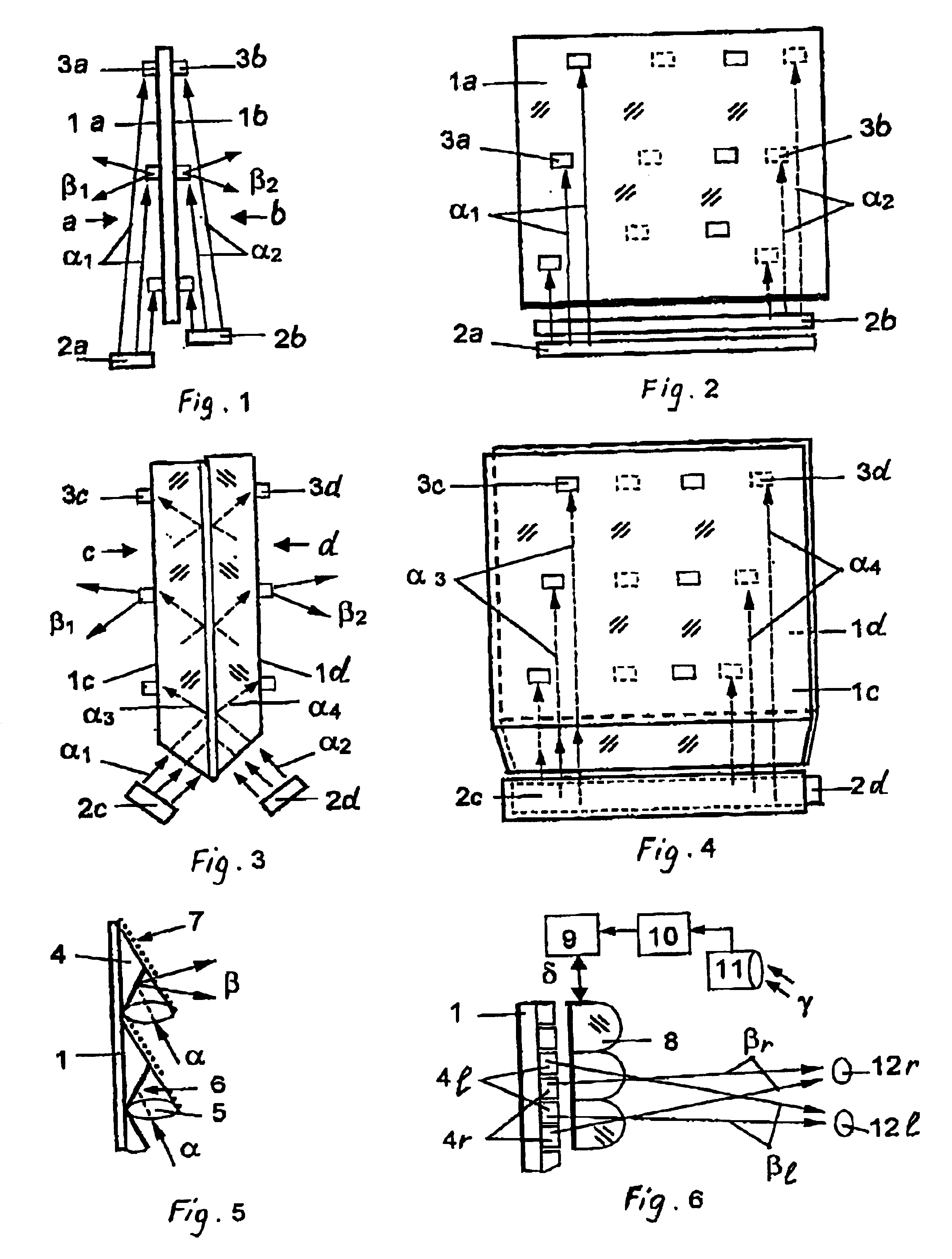

Projection system

InactiveUS6761459B1Reduce weightEasy to viewPrismsMechanical apparatusComputer graphics (images)Light beam

The present invention relates to projection systems for displaying visual information in a variety of applications in order to reduce the projection area, the weight and the dimensions thereof. In one embodiment, the projection system for producing an external surface projection on a visualization screen comprises a flat and thin visualization screen for carrying out projection on both sides. Images can be watched on the left side and on the right side of this screen. From the surface of the screen and on the left and right sides thereof, projectors are provided for projecting images simultaneously on both sides of the screen. Light diffusers are provided on both sides of the screen. The projections are converted through the optics of the projectors so as to form reduced-divergence projection beams which are entirely captured by the light diffusers and which are diverted and diffused at wide angles of image observation ranges.

Owner:ARSENICH SVYATOSLAV IVANOVICH

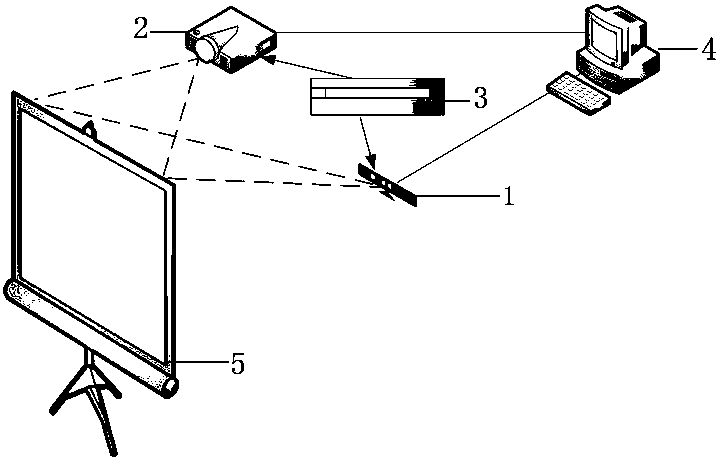

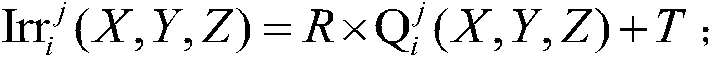

Irregular surface projection image geometric correction method based on ideal viewpoint

The invention relates to an irregular surface projection image geometric correction method based on an ideal viewpoint. The method is characterized in that a kinect v2.0 and a projector are fixed to asupport adjustment mechanism, and the direction, pitching direction and angle of the support adjustment mechanism can be adjusted manually, and thus shooting angle of the kinect v2.0 and the projecting angle of the projector can be adjusted to ensure that the kinect v2.0 can capture all pictures projected by the projector; and the kinect v2.0 and the projector are connected with a computer through cables. The method comprises the following steps: to begin with, carrying out 3D modeling on an irregular projection surface, and establishing the ideal viewpoint and a viewpoint coordinate system;converting the 3D information value of the projection surface into a 3D information value under the viewpoint coordinate system; and carrying out geometric correction on the projection image under theviewpoint coordinate system. The method does not need camera-projector joint calibration, and adopts the ideal viewpoint as a reference instead of the camera to carry out geometric correction; and most significant feature is that the geometric correction based on the ideal viewpoint meets visual demands of an observer.

Owner:CHANGCHUN UNIV OF SCI & TECH

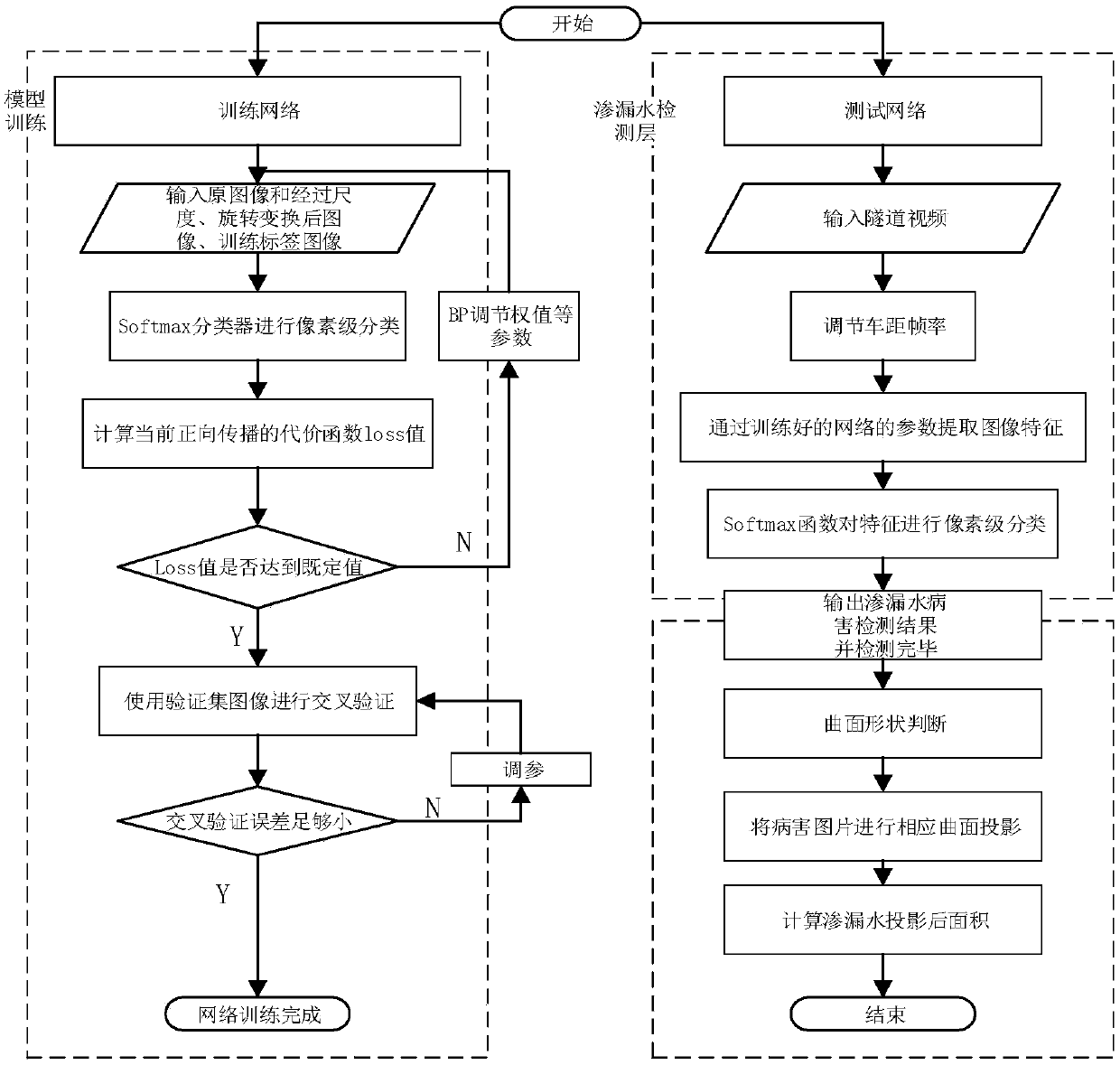

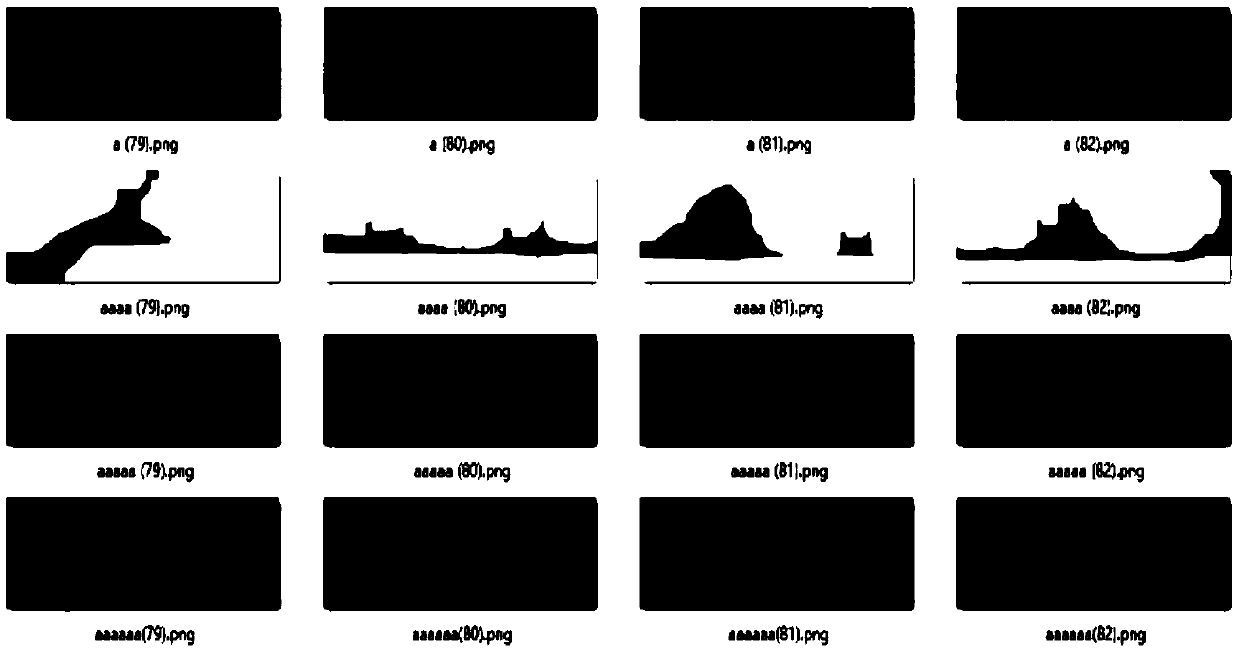

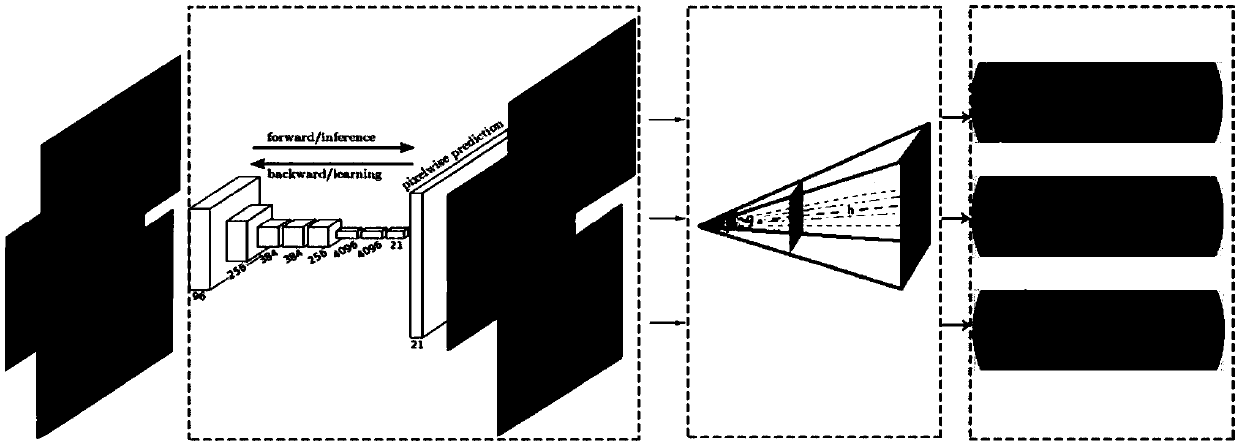

The invention discloses a wWater leakage area detection and identification methodrecognition method based on deep learning and a view field projection model

ActiveCN109615653AImprove work efficiencyThe leakage area is accurateImage enhancementImage analysisPoint cloudWater leakage

The invention discloses a water leakage area detection and identification method based on deep learning and a view field projection model. The method specifically comprises the following steps: 1) collecting video data and point cloud data of a to-be-detected area; 2) detecting the video data acquired in the step 1) through a water leakage image recognition neural network to obtain a water leakagearea picture; 3) identifying the point cloud data acquired in the step 1) to obtain a curved surface shape; A; and 4) performing corresponding curved surface shape projection on the water leakage area picture obtained in the step 2) according to the curved surface shape obtained in the step 3), and calculating the actual area of the water leakage area after projection. Manual participation is notneeded for subway tunnel leakage water area measurement, t, the working efficiency is improved, curved surface projection conversion can be carried out on the detected leakage water area, and the more accurate leakage water area is obtained. Therefore, t, the detection algorithm is high in efficiency and accurate in detection.

Owner:SHANGHAI UNIV

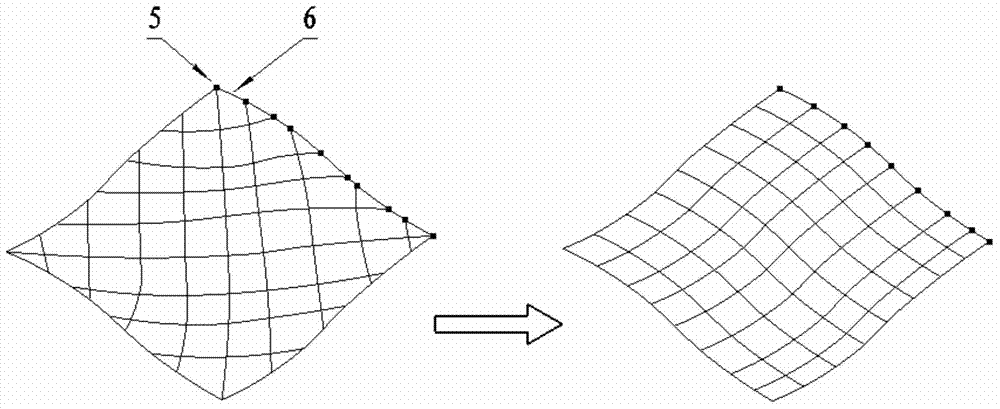

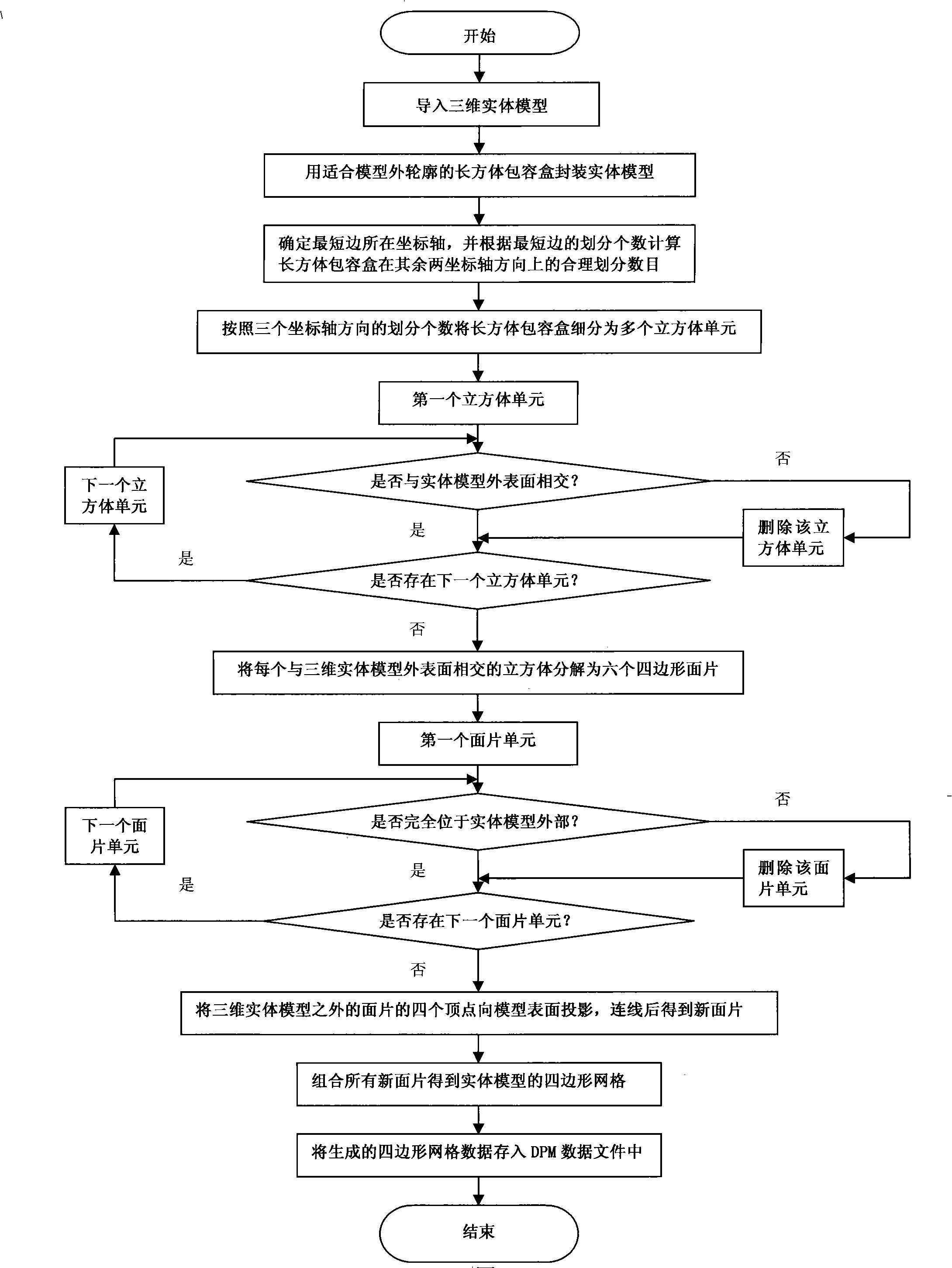

Method for generating quadrangle finite element grid based on three-dimensional solid model

InactiveCN101303774ASimplify complex issuesPromote generationSpecial data processing applications3D modellingElement analysisData file

The invention discloses a method for generating a quadrilateral finite element grid based on a three-dimension entity model, which is applicable to the preprocessing stage of the finite element analysis. The method comprises the steps of encapsulating a three-dimension entity model in a cuboid containing box adapting to the shape of the model, subdividing the cuboid containing box into a certain quantity of cubic units, deleting the cubic units disjointed with the surface of the three-dimension entity model, dividing each cubic unit intersected with the surface of the three-dimension entity model into six mutually independent quadrilateral facets, deleting quadrilateral facets intersected with and arranged in the three-dimension entity, projecting four nodes on each quadrilateral facet arranged outside the three-dimension entity model onto the surface of the model and combining four new nodes obtained after the projection into a new quadrilateral facet, combining all the quadrilateral facets to obtain the quadrilateral grid of the three-dimension entity model and storing the generated quadrilateral grid data into a user-defined data file in the DPM format.

Owner:DALIAN POLYTECHNIC UNIVERSITY

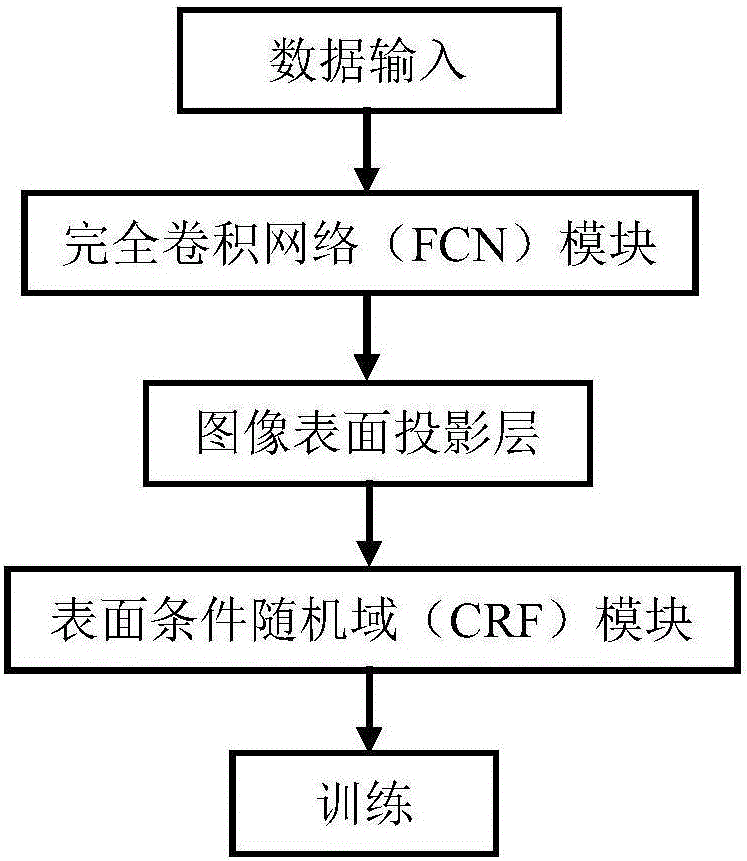

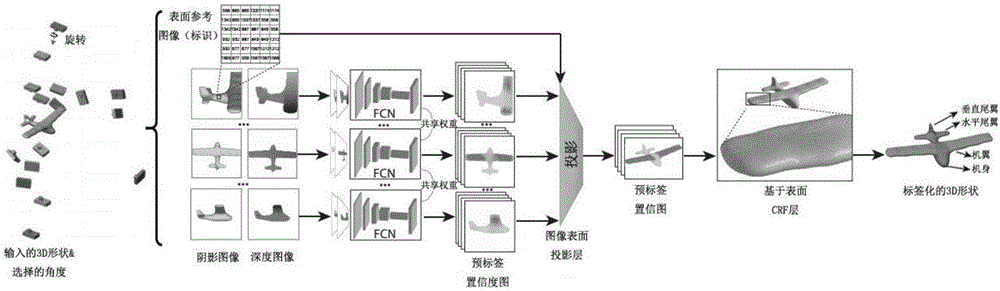

Three-dimensional shape segmentation and semantic marking method based on projection convolutional network

The invention proposes a three-dimensional shape segmentation and semantic marking method based on a projection convolutional network. An input is represented by adoption of a three-dimensional shape of a polygonal grid, information points cover a shape surface to a large extent, a rendering shape is a shadow image and a depth image, a dual-channel image is generated, through a fully-connected network (FCN) module of a same image, a confidence map is output for each function module of each input image, an image surface projection layer aggregates confidence maps of a plurality of views, combined with a boundary clue, surface condition random field (CRF) spreading is performed, modules of a task are trained, and finally a segmentation semantic marking result is obtained. The three-dimensional shape segmentation and semantic marking method based on a projection convolutional network does not need to use any manpower to adjust a geometric descriptor, reduces occlusion and covers the shape surface, does not lose a significant part label, effectively associates information, an occlusive part is also marked, integrity and coherence of segmentation are ensured, and the method is remarkably superior to previous methods.

Owner:SHENZHEN WEITESHI TECH

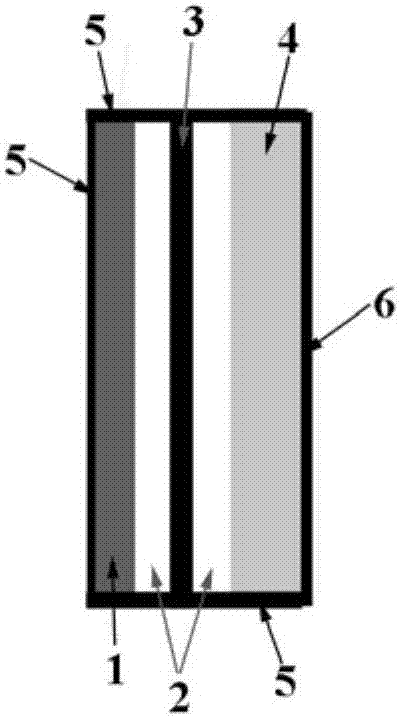

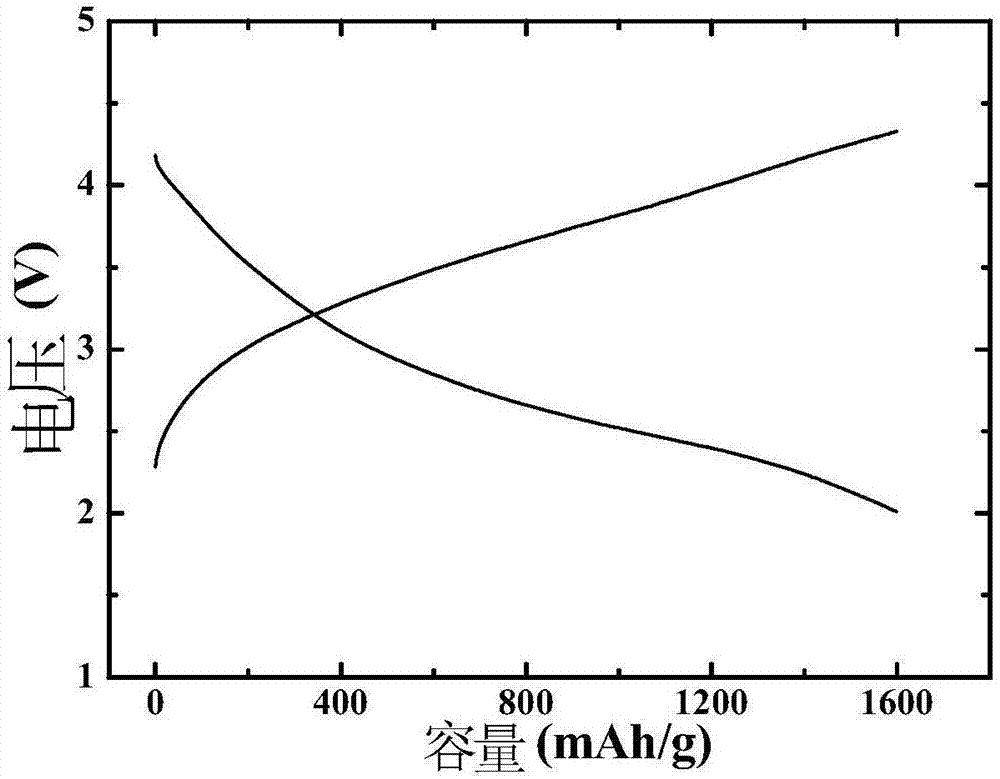

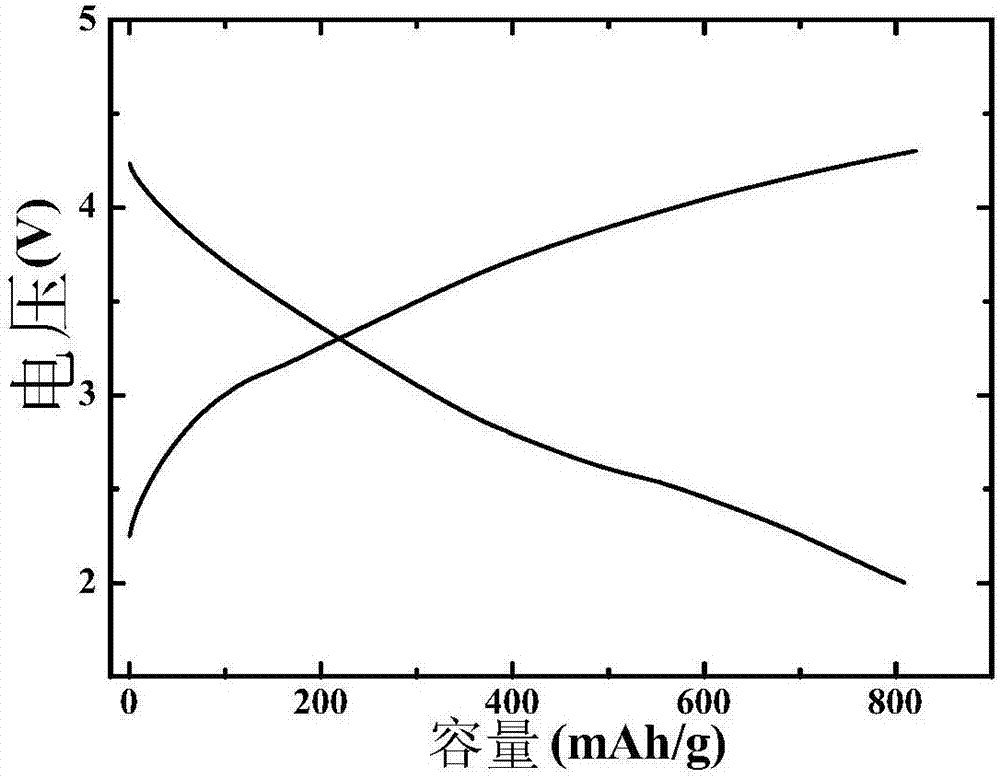

Metal-CO2 battery

ActiveCN107359386AIncrease capacityReduce overpotentialFuel and secondary cellsCell electrodesComposite electrodeSurface projection

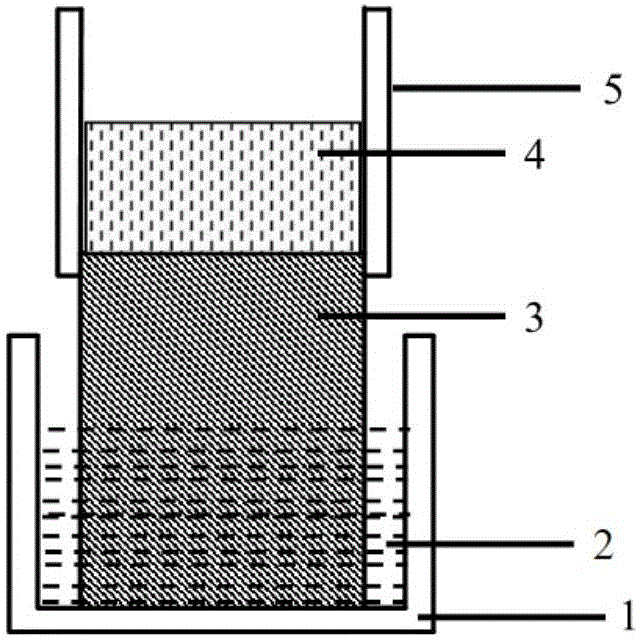

The invention discloses a metal-CO2 battery. The metal-CO2 battery comprises a positive electrode, a negative electrode, an organic electrolyte and a separator, wherein the positive electrode is an IrO2 / MnO2 composite electrode with a hierarchical structure, comprises sheet-shaped MnO2 and also comprises nanometer IrO2 particles, the sheet-shaped MnO2 is directly grown on a substrate, strip-shaped MnO2 also covers a surface of the sheet-shaped MnO2, the nanometer IrO2 particles are uniformly loaded on the surfaces of the sheet-shaped MnO2 and the strip-shaped MnO2, and the negative electrode is selected from an alkali metal electrode subjected to surface protection processing. The invention discloses the metal-CO2 battery, the IrO2 / MnO2 composite electrode with the hierarchical structure is used as the positive electrode, the alkali metal electrode subjected to surface projection processing is used as the negative electrode, electric energy is generated by greenhouse gas CO2, and the metal-CO2 battery obtained by assembly shows low polarization, high capacity and long cycle lifetime.

Owner:ZHEJIANG UNIV

Computer-assisted joint analysis using surface projection

InactiveUS8052623B2Improve visualizationRobust and quick and reliable data processingImage enhancementImage analysisData setJoint analysis

A system and method for computer-assisted joint analysis, wherein the joint elements in a three-dimensional imaging data set are segmented and then projected onto a two-dimensional or three-dimensional reference area for interference analysis and surgical planning.

Owner:BRAINLAB

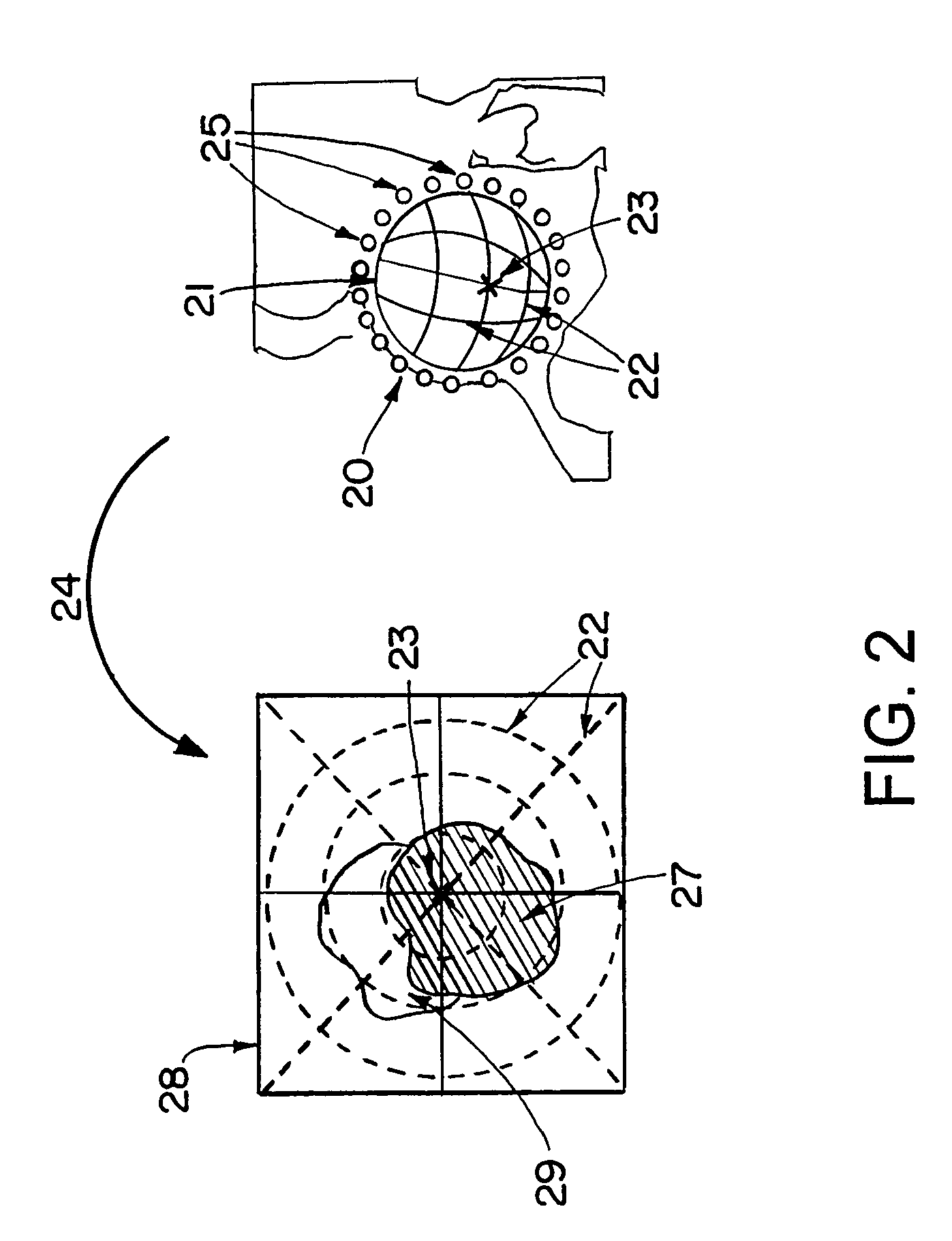

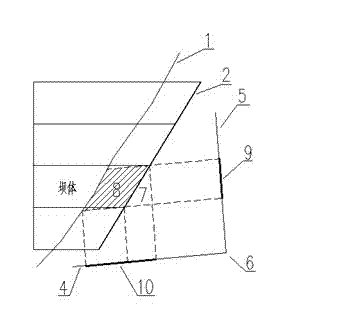

Method for determining inferior limit of safety coefficient of abutment stability of arch dam

ActiveCN102966078AReflect the real situation of stabilityReflect the real situationArch damsVertical projectionEngineering

The invention discloses a method for determining inferior limit of safety coefficient of abutment stability of an arch dam. The method comprises the following steps: drawing a three-dimensional figure by using a computer, wherein the three-dimensional figure comprises a sliding block body (8), a sliding surface (7), a bottom sliding surface (4) and a side sliding surface (5); and calculating the inferior limit value of the safety coefficient of the abutment stability of the arch dam by a sliding block body three-dimensional limit balance algorithm through the volume of the sliding block body (8), the area of side sliding surface projection (9) and the area of bottom sliding surface projection (10), wherein the volume of the sliding block body (8) is obtained through the three-dimensional figure, the area of side sliding surface projection (9) is obtained through the area of vertical projection of the sliding surface (7) on the side sliding surface (5) along the vertical direction of the bottom sliding surface (4) and a ridge (6), and area of bottom sliding surface projection (10) is obtained through the area of vertical projection of the sliding surface (7) on the bottom sliding surface (4) along the vertical direction of the siding sliding surface (5) and the ridge (6). The method can reflect the true situation of the abutment stability of the arch dam accurately and is favorable for the safety of engineering design.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

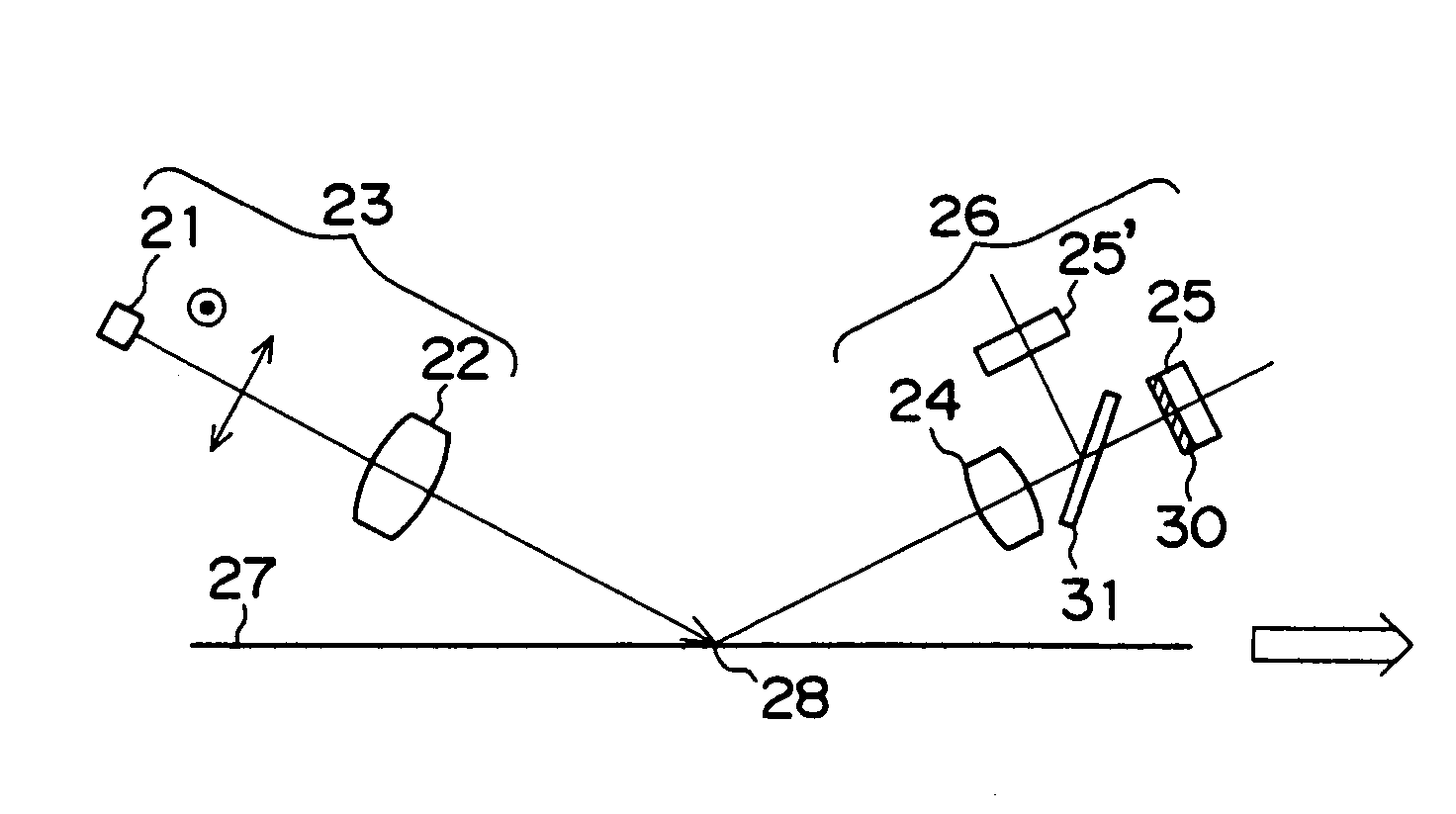

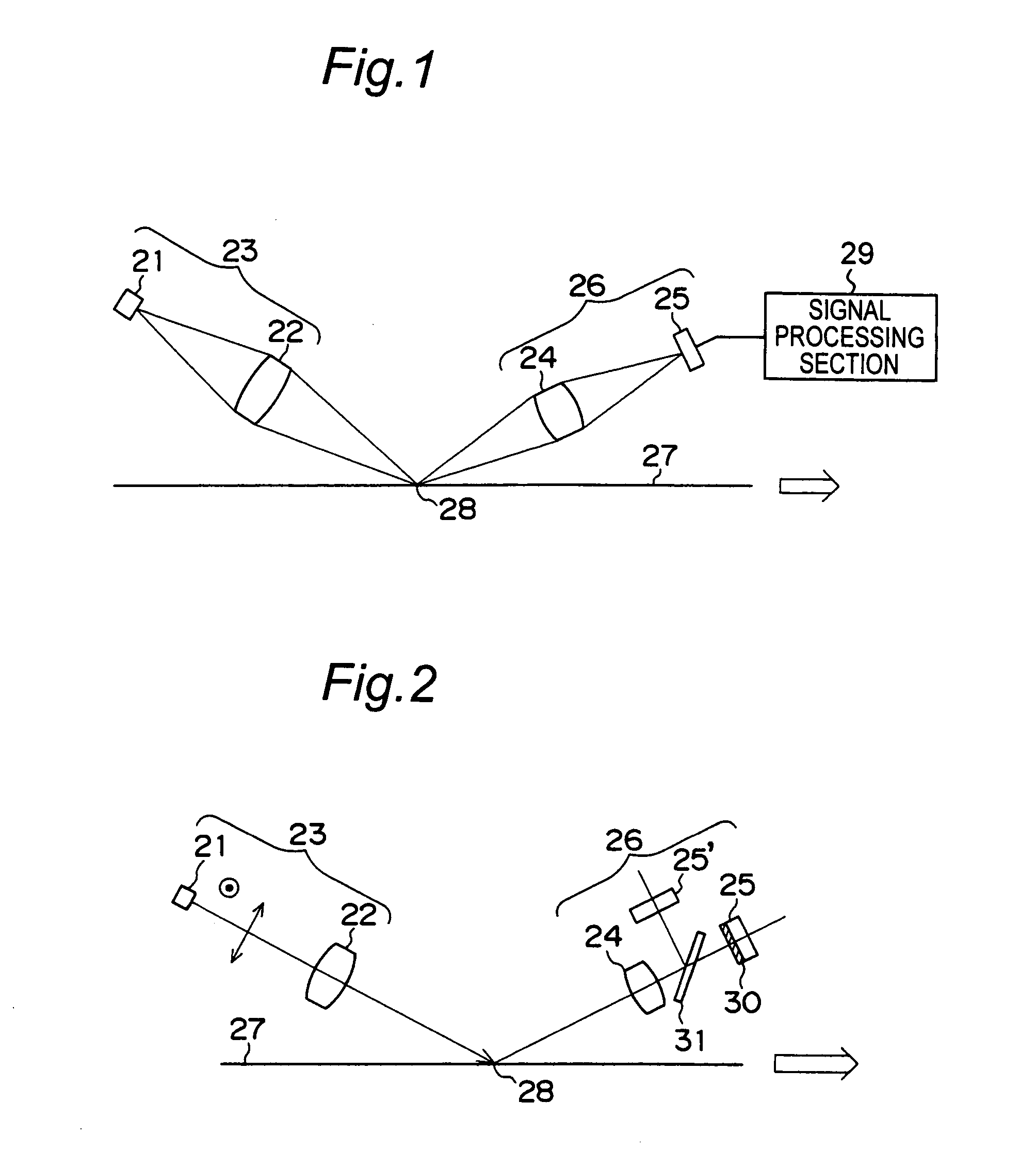

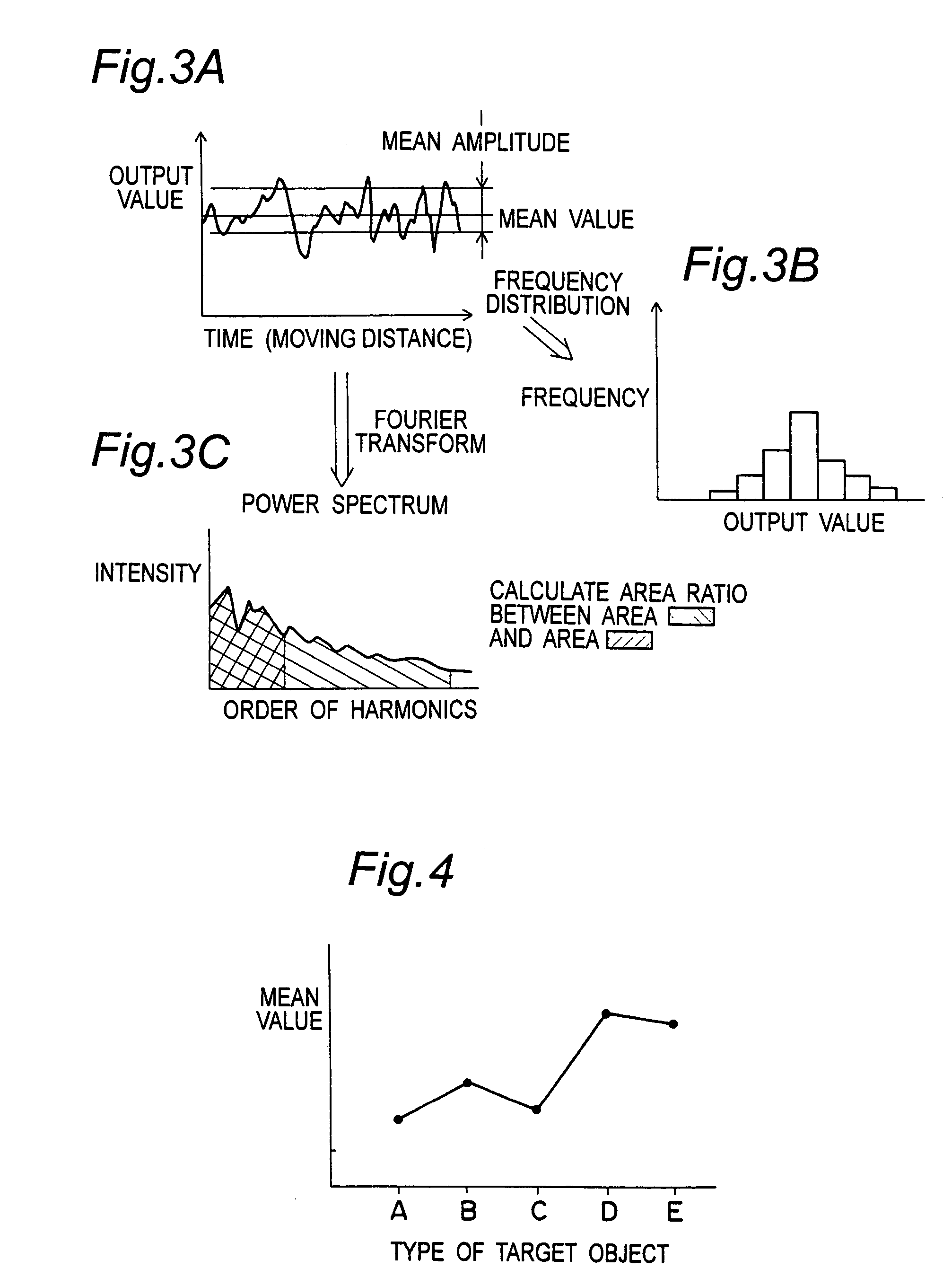

Optical object identification apparatus, and printing apparatus and object classification apparatus using same

InactiveUS7005661B2Easy to identifyPolarisation-affecting propertiesScattering properties measurementsIdentification deviceSurface projection

An optical object identification apparatus has a light emitting-side optical system (23), a light receiving-side optical system (26), and a signal processing section (29). The light emitting-side optical system (23) irradiates light from a light emitting device (21) via an objective lens (22) to a moving target object (27) such as printing paper sheets. The light receiving-side optical system (26) receives reflected light from the target object by means of the light receiving device (25) via an objective lens (24), and outputs an output signal with a waveform corresponding to the surface projections and depressions of the target object (27). The signal processing section (29) executes signal processing on the output signal by at least one signal processing method to identify the target object.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com