Multi-axis curved surface type numerically-controlled method for machining complicated curved surface part

A technology for complex curved surfaces and curved surfaces, which is applied in the field of multi-axis curved surface CNC machining of complex curved surface parts, can solve the problems of large tool marks on the machined surface, unsatisfactory processing quality, and large distance between cutting tools, so as to improve the surface finish of parts and reduce impact , High cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

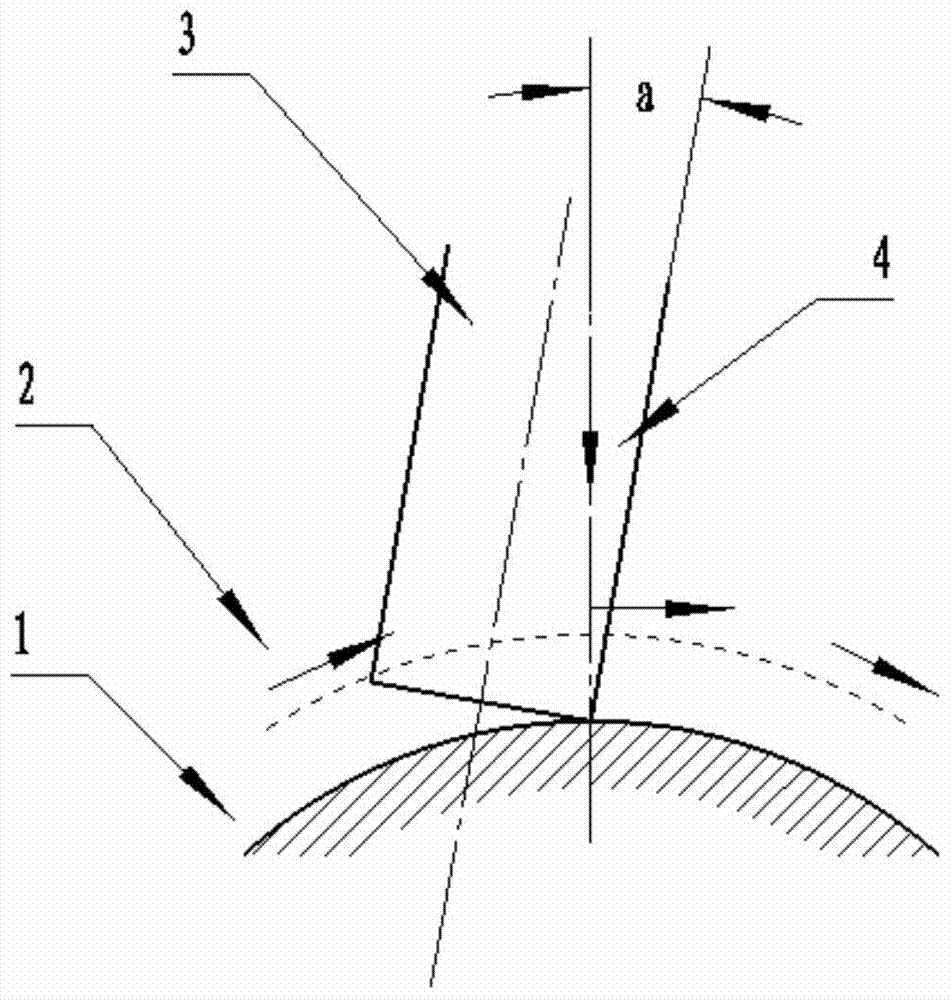

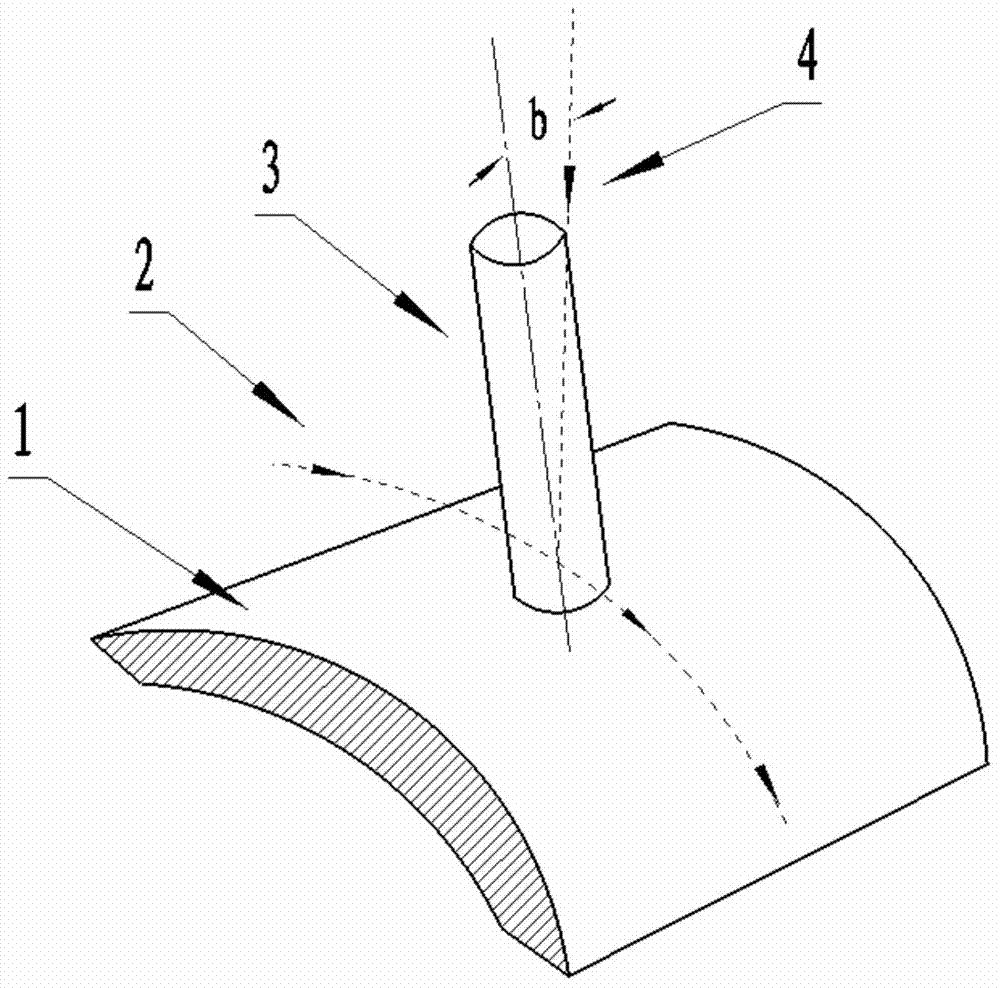

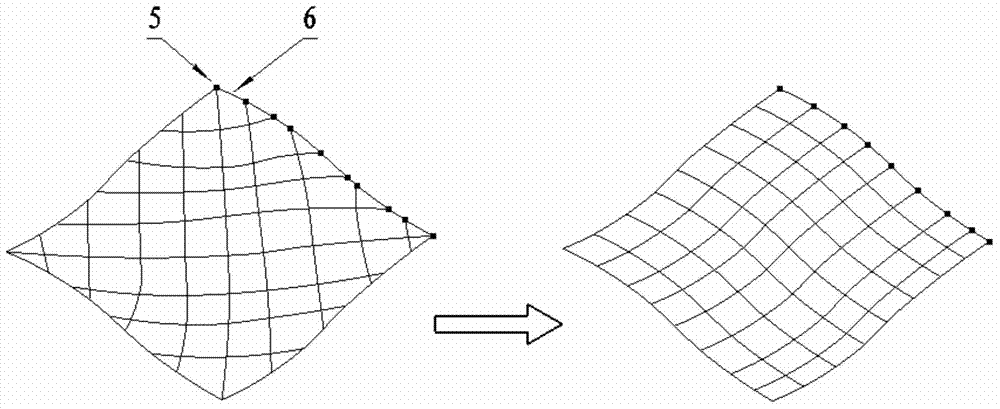

[0021] refer to figure 1 . According to the characteristics of the typical five-axis machine tool DMU70eV, its structure is a double-swing table, in order to keep the tool axis vector change evenly during the cutting process, the curved surface parts are fixed on the rotation center of the five-axis machine tool. The flat-bottomed end mill 3 is based on the normal direction 4 of the tool path, and runs on the surface 1 of the complex curved surface part according to the arc track of the curved surface in the direction 2 of the tool path. Such as figure 1 The rake angle a shown is the given angle rake angle of the tool along the direction of the tool path. When it is set to a large value, the tool axis vector will change too much and cause a large change in the rotational angular velocity of the turntable, which will cause machining errors and reduce the machining quality. When the inclination angle a is set to be small, 0 figure 2 The side tilt angle shown is a given angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com