Conveying and slitting device for diaphragm bags

A diaphragm bag and conveying platform technology, applied in the direction of transportation and packaging, sending objects, electrolyte battery manufacturing, etc., can solve the problems of high cost, traction deviation, adjustment difficulties, etc., and achieve the effect of convenient control, accurate and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

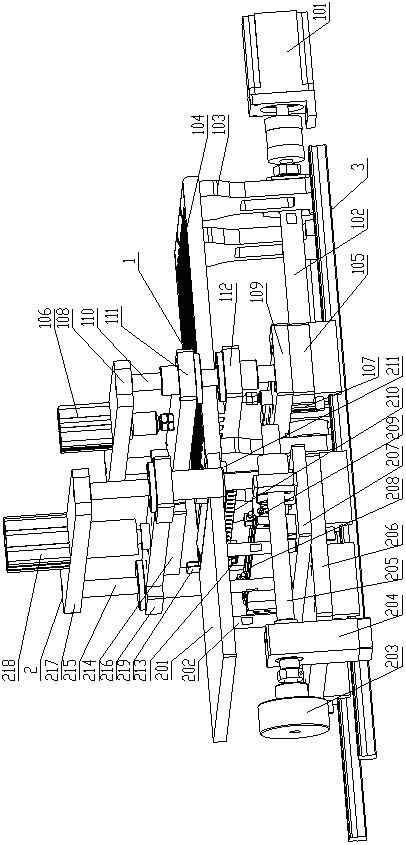

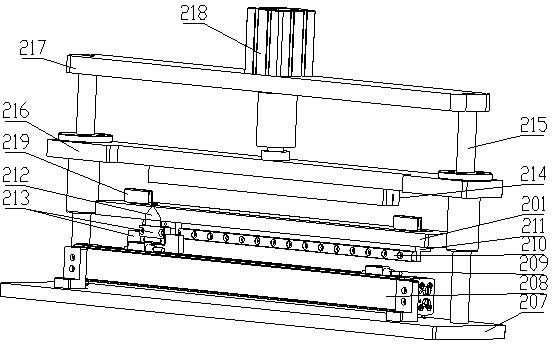

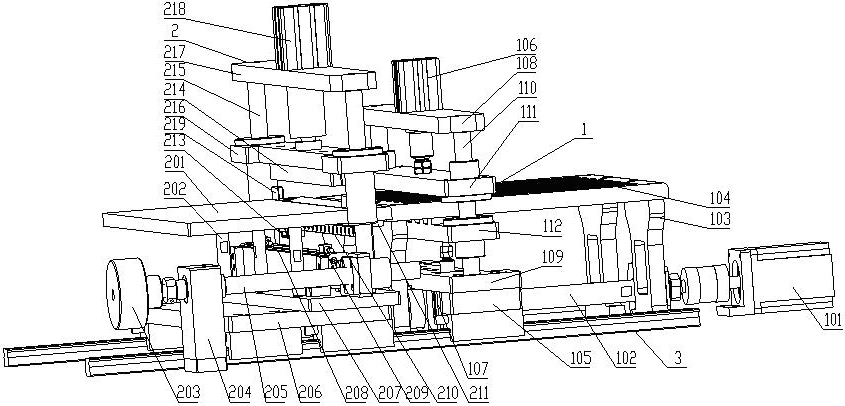

[0019] A conveying and cutting device for a diaphragm bag, comprising a cutting mechanism for cutting the diaphragm bag and a conveying mechanism for conveying the diaphragm bag to the cutting mechanism, the conveying mechanism includes a conveying platform, a clamping unit and A conveying drive unit that drives the clamping unit to move back and forth along the conveying platform; the clamping unit includes an upper clamping block, a lower clamping block and a clamping drive device, and the upper clamping block is located on the conveying platform Above, the lower clamping block is located below the conveying platform, the lower clamping block is provided with serrated protrusions arranged at intervals, and the conveying platform is provided with a through slot, and the clamping driving device is used to drive the upper clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com