Four axis deep hole drilling machine

A deep hole drilling machine and bed technology, applied in the field of machine tools, can solve the problems of unrealistic multi-hole drilling, complex overall structure, high production cost, etc., and achieve obvious energy saving effect, accurate and stable transmission, and equipment simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

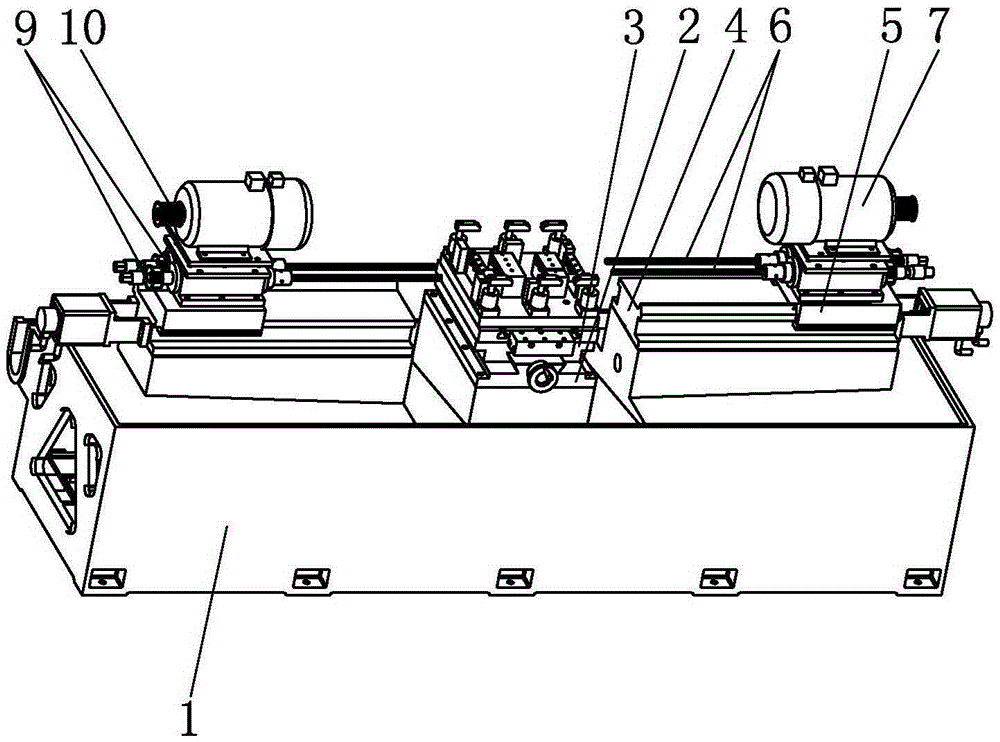

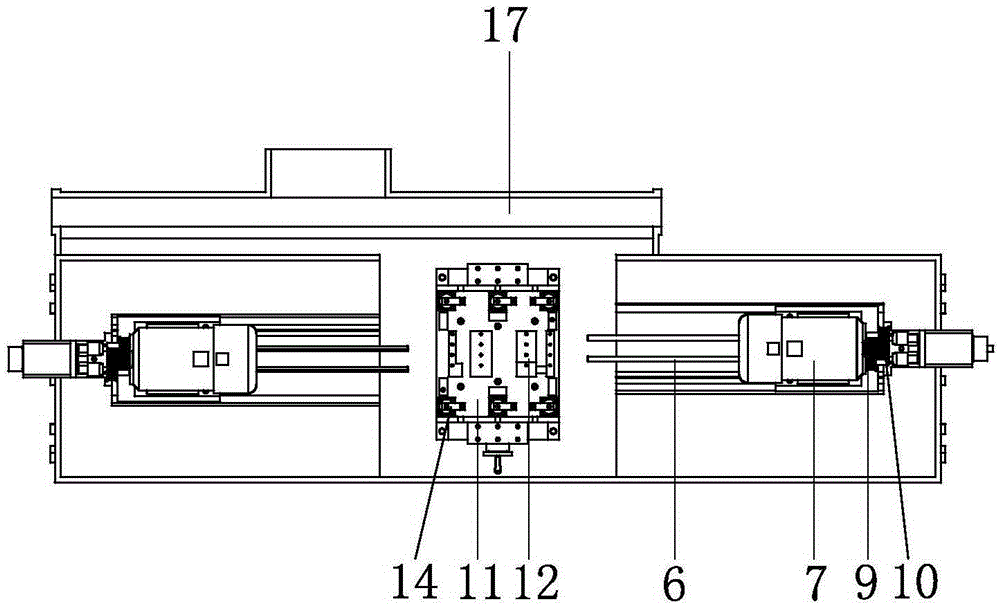

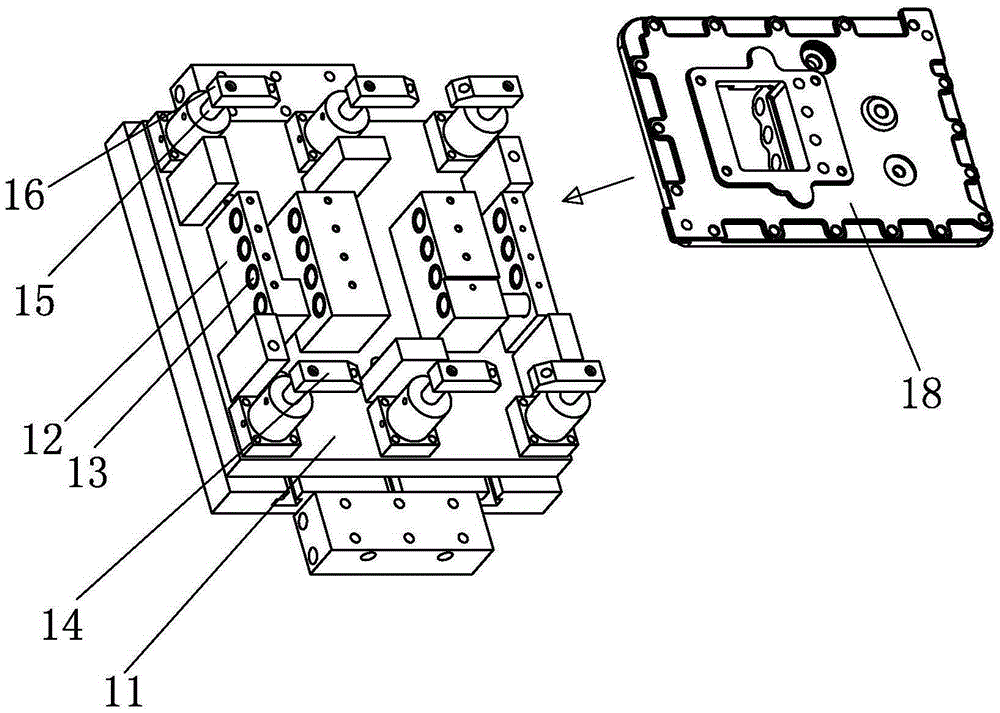

[0020] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4:

[0021] The four-axis deep hole drilling machine includes a bed 1, a tooling fixture is provided in the middle of the bed, and transverse guide rails 4 are respectively provided on both sides of the tooling fixture. Horizontal sliding table 5, workpiece drilling mechanism is all provided on two horizontal sliding tables, described workpiece drilling mechanism is: each horizontal sliding table is provided with some straight long drills 6, and several straight long drills all pass through each The motor 7 on the transverse slide table is driven synchronously.

[0022] In the automobile gearbox in the present invention, multiple rows of holes need to be drilled at one time, and four holes need to be drilled in each row. The common drilling machine needs to be clamped and positioned four times, and the drilling also needs to be process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com