Patents

Literature

172results about How to "Reduce side pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

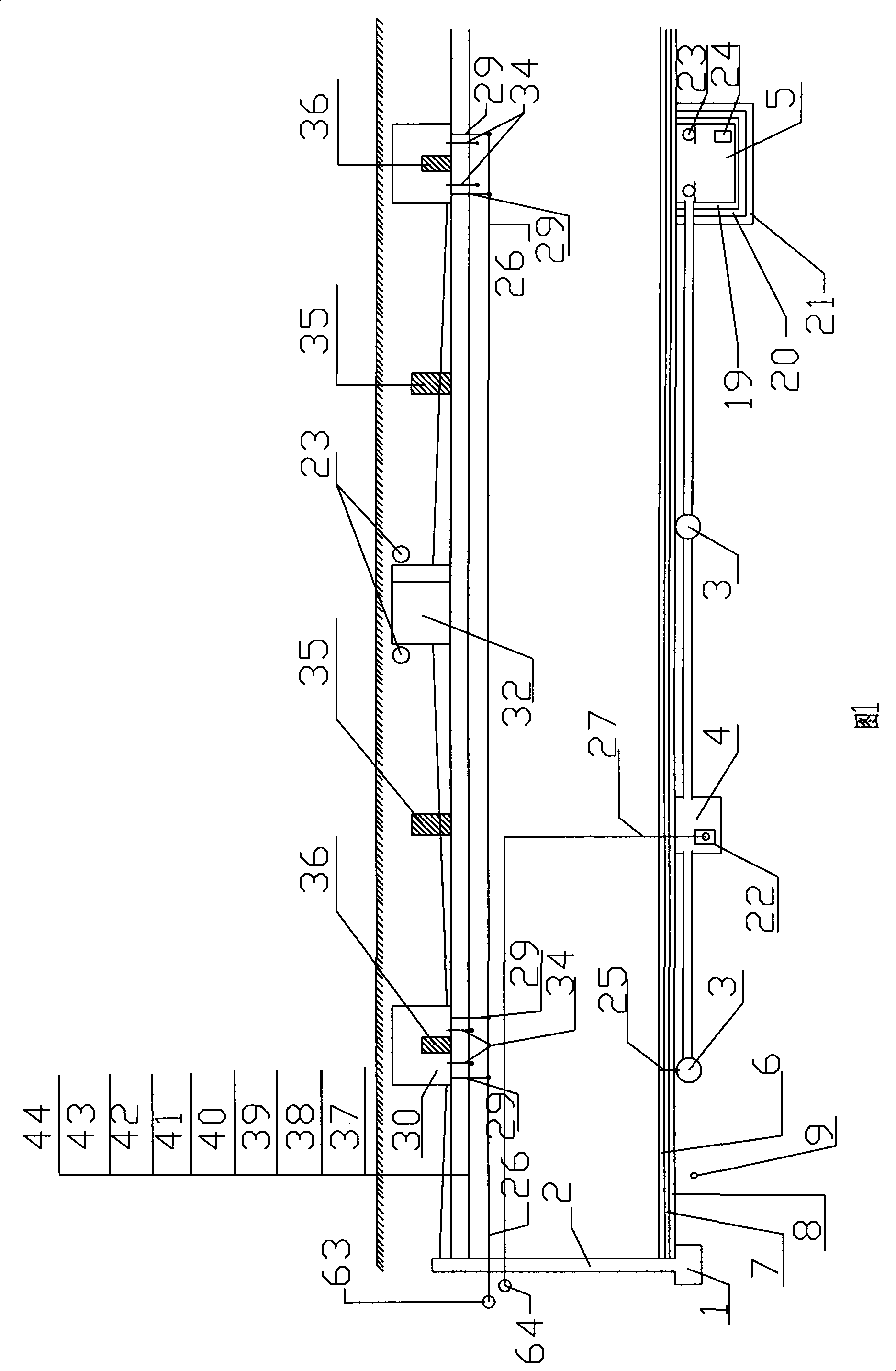

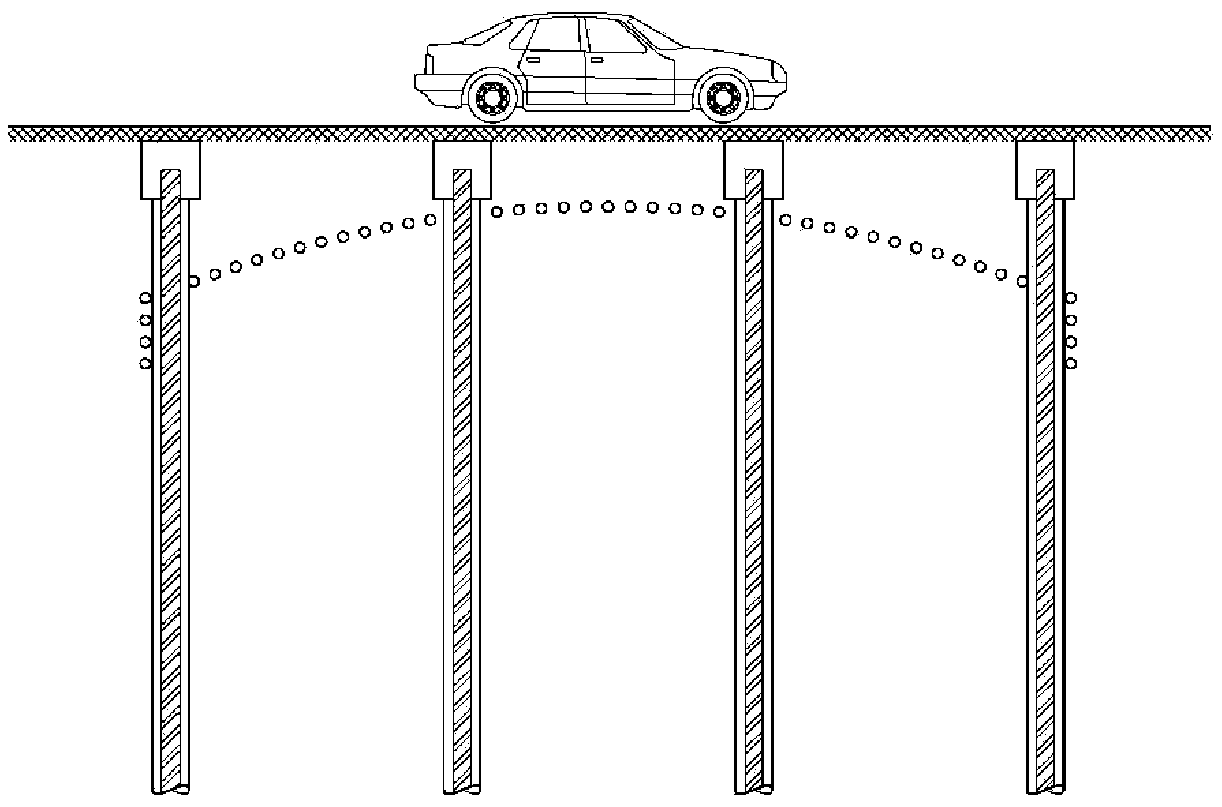

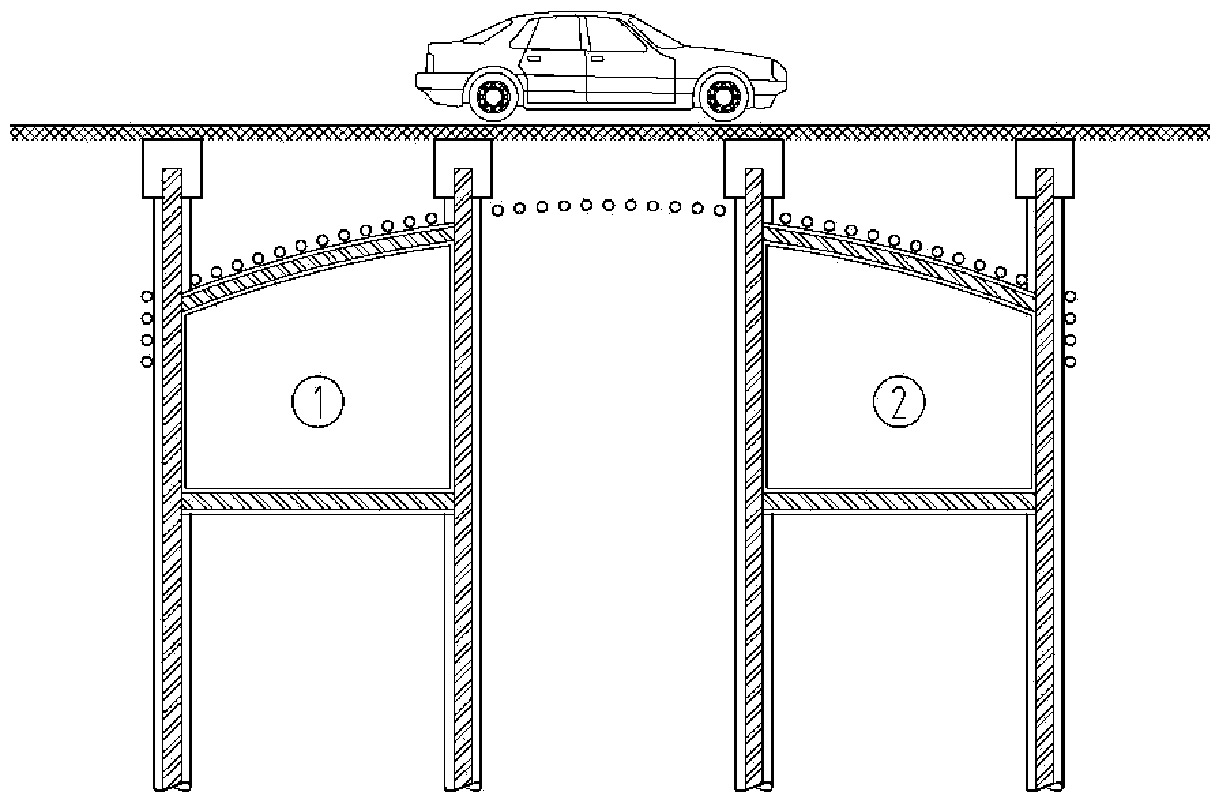

Method and system for basement engineering water proof and water drain

InactiveCN101298782AFree from buoyancyFrom erosionArtificial islandsProtective foundationBasementLine tubing

A basement engineering waterproof and drainage method is provided. The wall footing of the outside wall in basement engineering is embedded in watertight or micro-watertight soil rock layer or cement soil layer. The wall footing intercepts water by a thin-part structure. The cushion of the basement engineering soleplate and the falling layer of the top board are composed of combined water-proof layers. The late poured band, the movement joint and the horizontal construction joint at the lower part of the outside wall are treated by a water-proof structure combined with waterproofing measures. The basement engineering is provided with a drainage system. The groundwater and surface water at the soleplate are drained into city drainage pipelines via a soleplate part of the drainage system. The rainwater of overburden layer bottom of the top board is then drained into city drainage pipelines via the indoor part of the drainage system. The invention is designed by adopting a one-body method of arranging the basement engineering waterproofing, drainage and anti-floating as well as underground engineering space enclosing structure and pipelines, thereby shortening the construction period, reducing the engineering cost, increasing the durability and reliability of underground building space enclosing structure and waterproof layer as well as pipelines.

Owner:朱邃科 +2

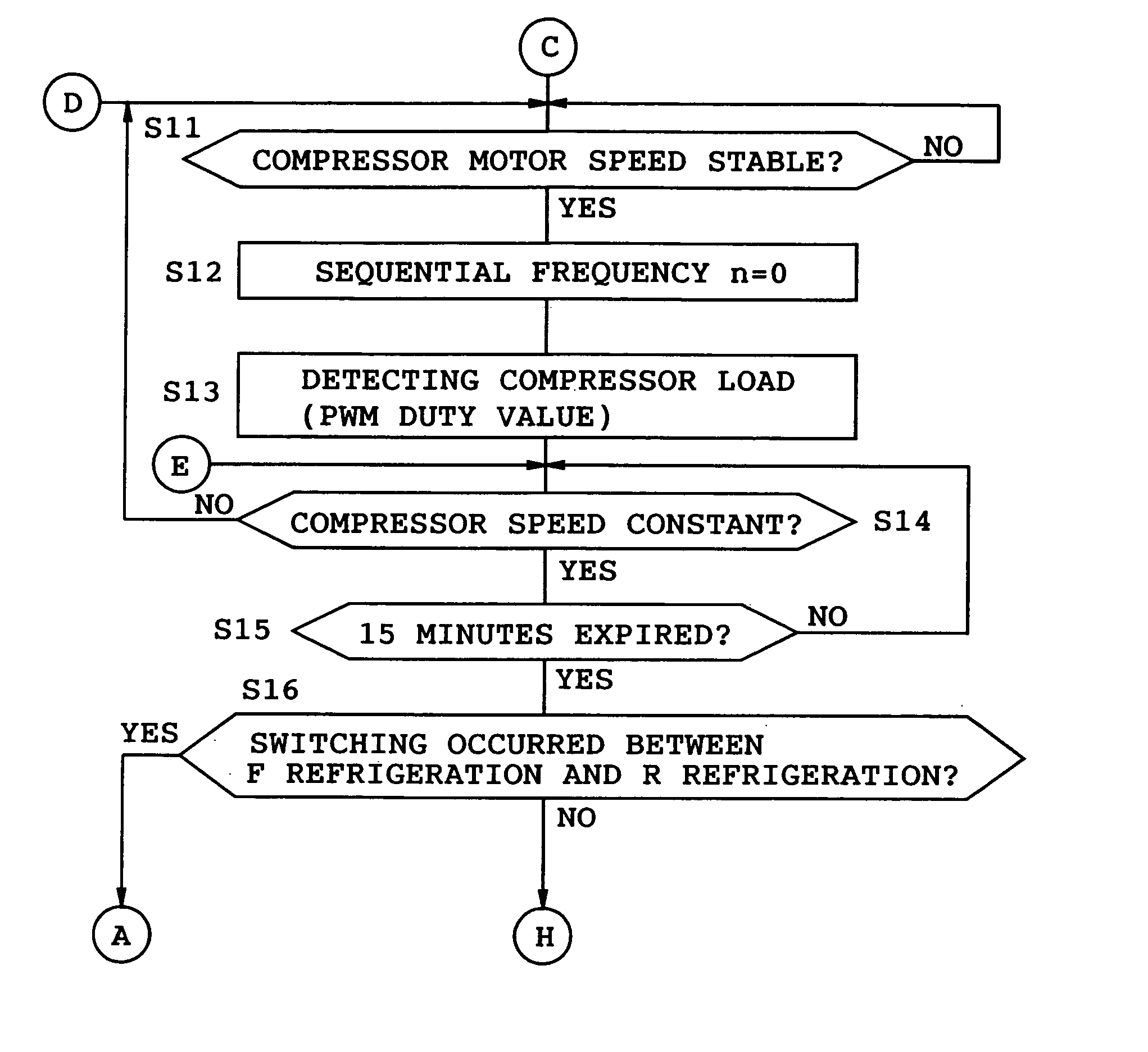

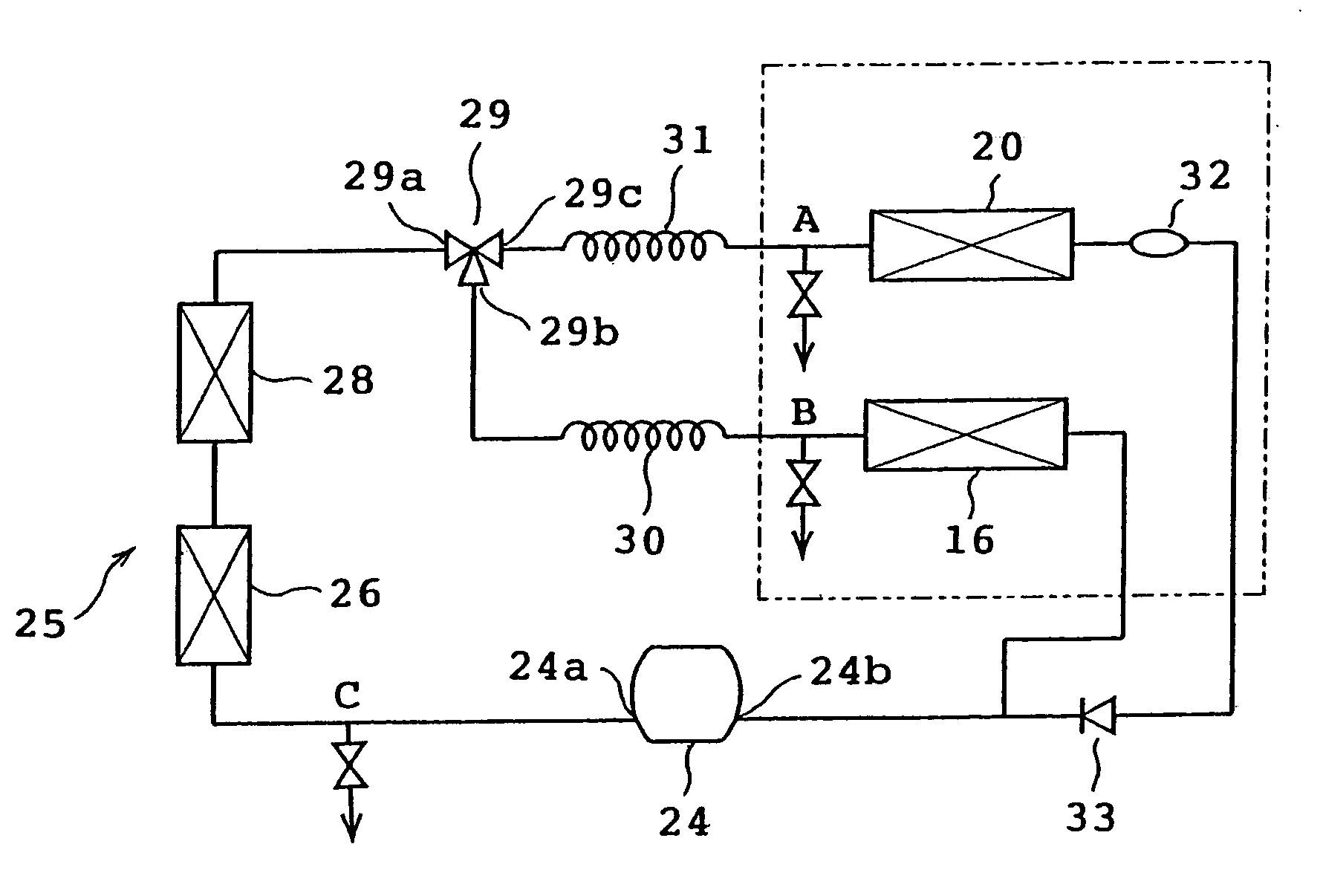

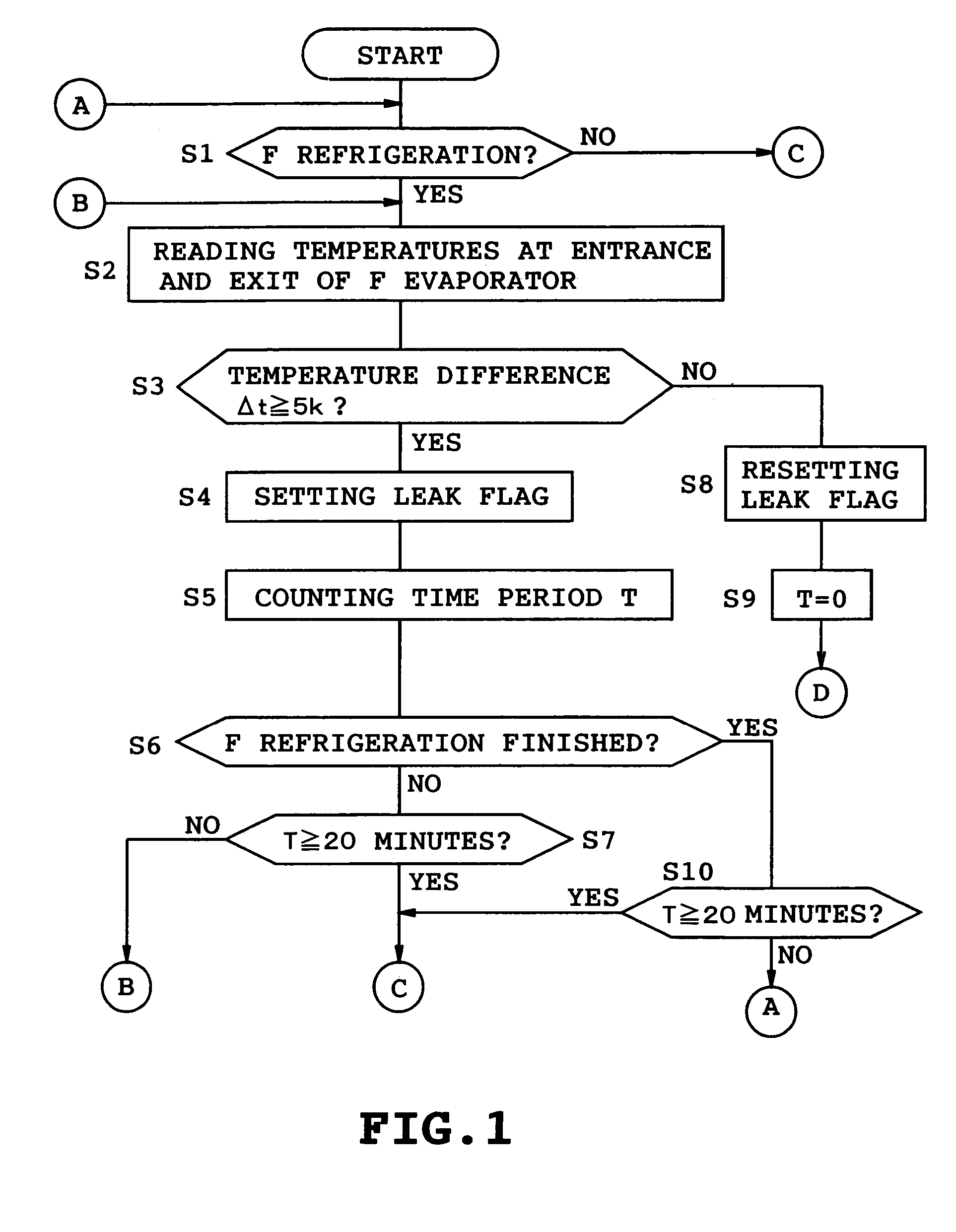

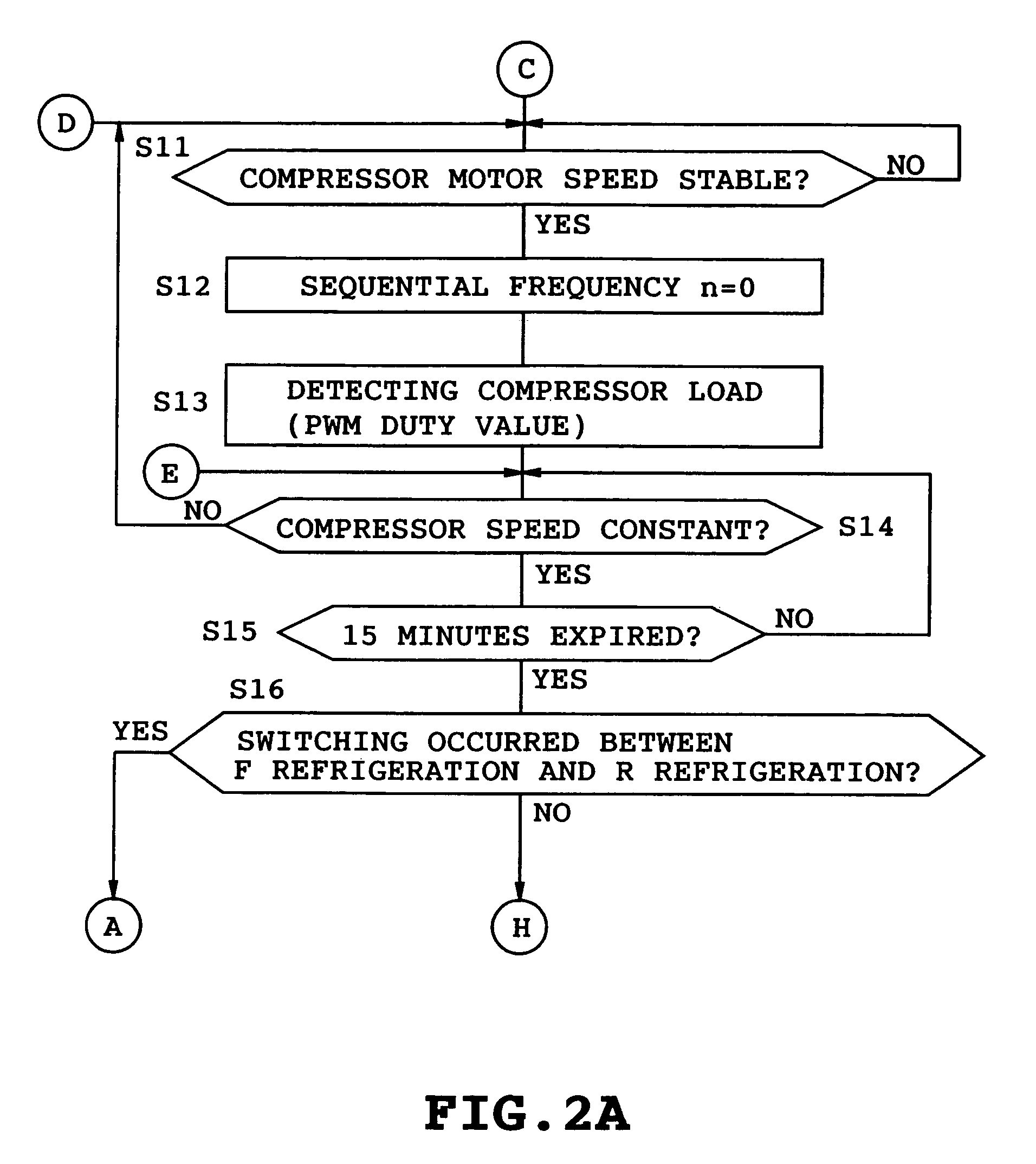

Refrigerator

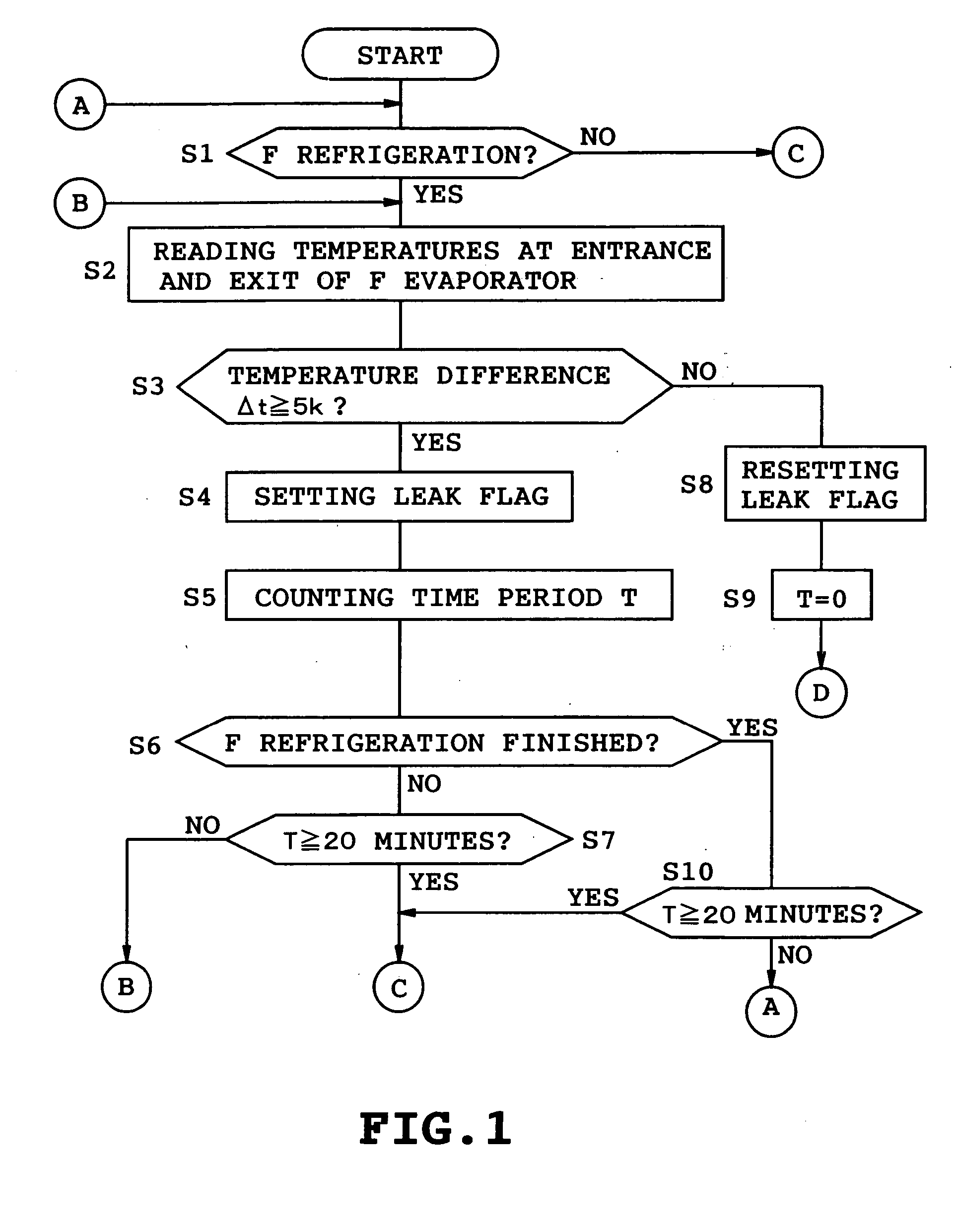

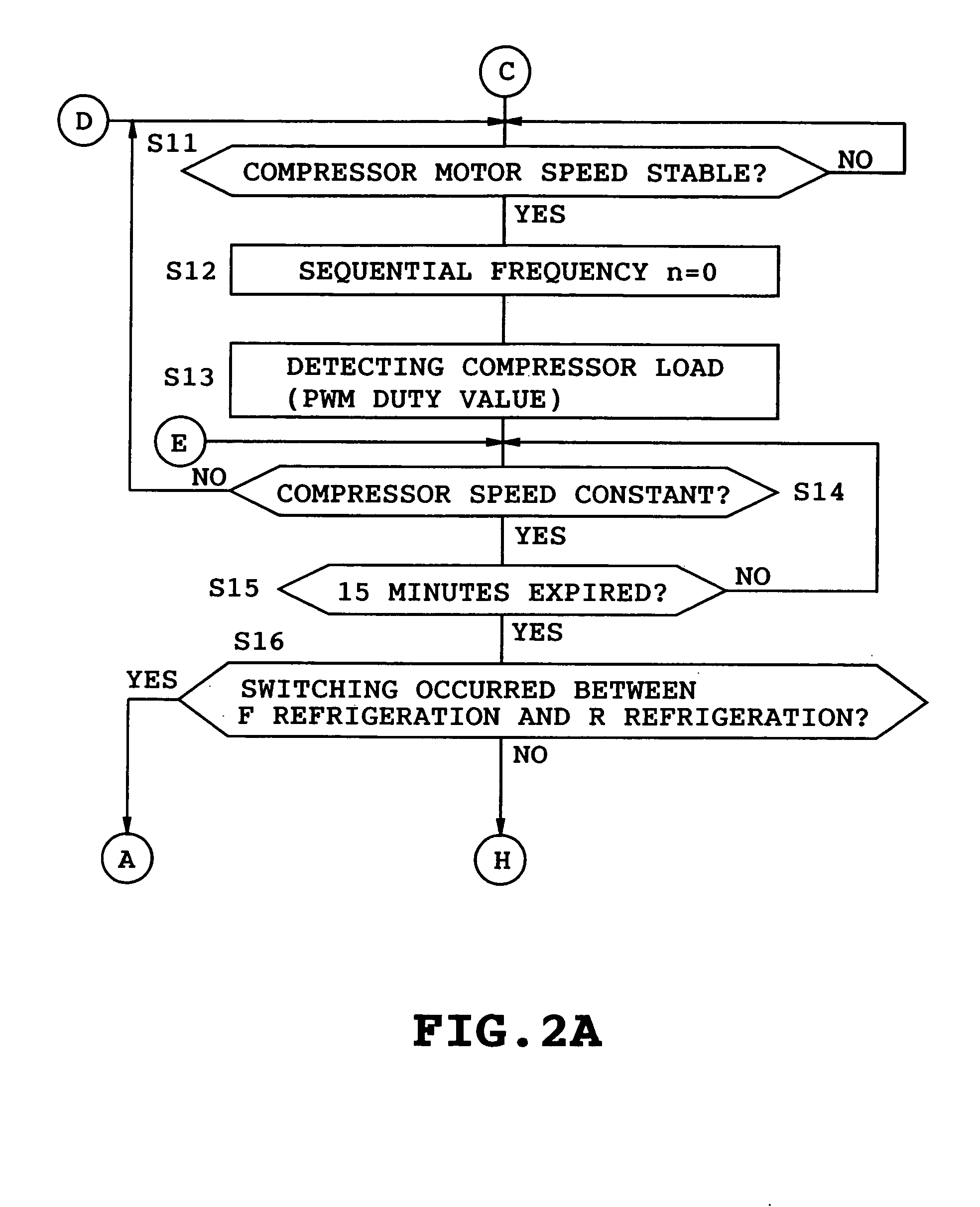

InactiveUS20050039469A1Easy loadingReduce loadCompression machines with non-reversible cycleDomestic refrigeratorsRefrigerantRefrigerated temperature

A refrigerator of the present invention includes a refrigerating cycle including a compressor (24), a condenser (25), an expander (30, 31) and an evaporator (16, 20) and filled with a flammable refrigerant, a load detector (41) detecting a change in load of the compressor (25), and a control device (43) detecting a damage which is a cause for leak of the refrigerant from the refrigerating cycle, based on a detection output of the load detector (41).

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

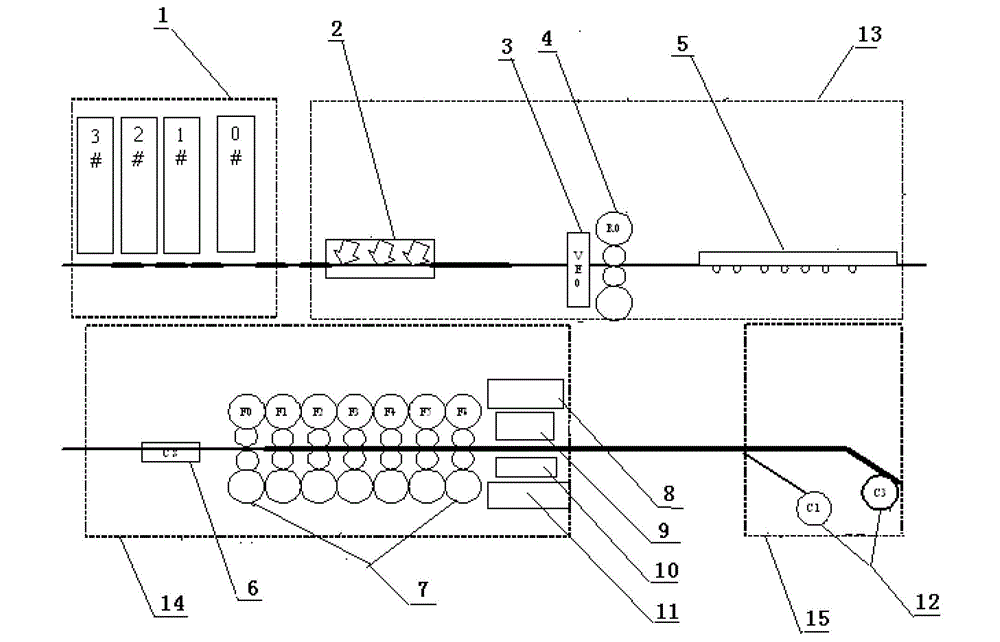

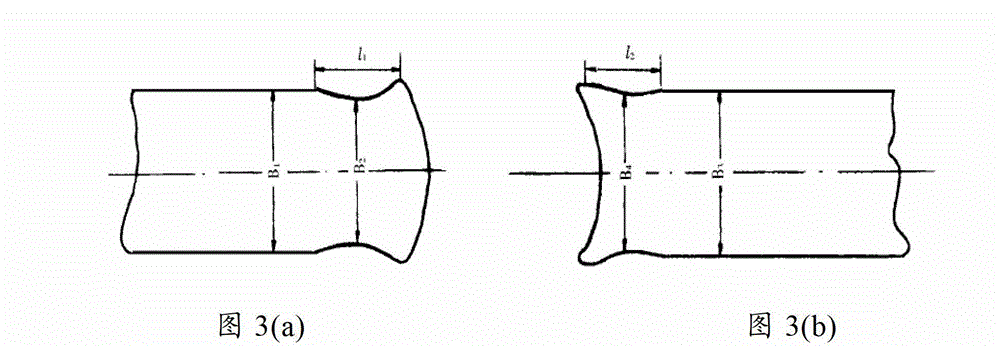

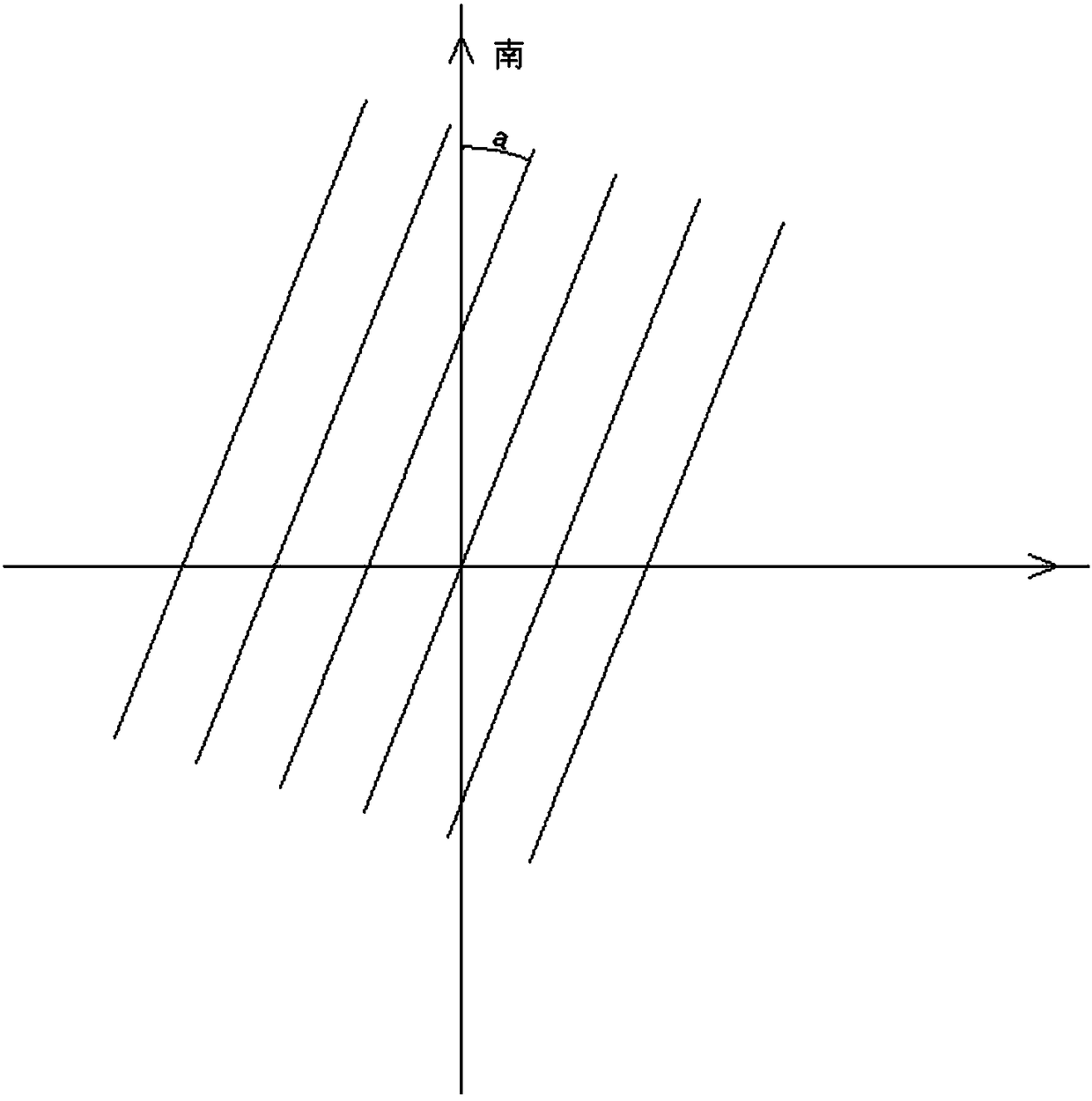

Parameter compensation method and control method for short stroke control of head-tail width of strip steel

ActiveCN102974622AControl head and tail shapeWidth extra wide lowMetal rolling stand detailsStrip steelControl theory

The invention relates to a parameter compensation method and a control method for short stroke control of the head-tail width of strip steel in a hot rolling process. The parameter compensation method comprises the steps as follows: correcting fb1, fb2 and fb3 in SSC (Short Stroke Control) parameters and calculating by the following formulae in the correcting process: fb1'=fb1+(swid-cwid)*w_coff1, fb2'=fb2+(swid-cwid)*w_coff2, and fb3'=fb3+(swid-cwid)*w_coff3, wherein swid represents the width of a plate blank, cwid represents the width of a finished product, and w_coff1, w_coff2 and w_coff3 represent lateral pressure quantity correcting coefficients and have different values according to different values of swid-cwid. The invention further relates to the control method for the shape of the head-tail width of the strip steel, and the SSC parameters in the control method are determined through the SSC parameter compensation method. The control method also comprises the step of classifying width values of blanks adopted in the hot rolling process according to the practical widths of the blanks. The exceeded part of the head-tail width of the strip steel after control is smaller and the reduced part is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

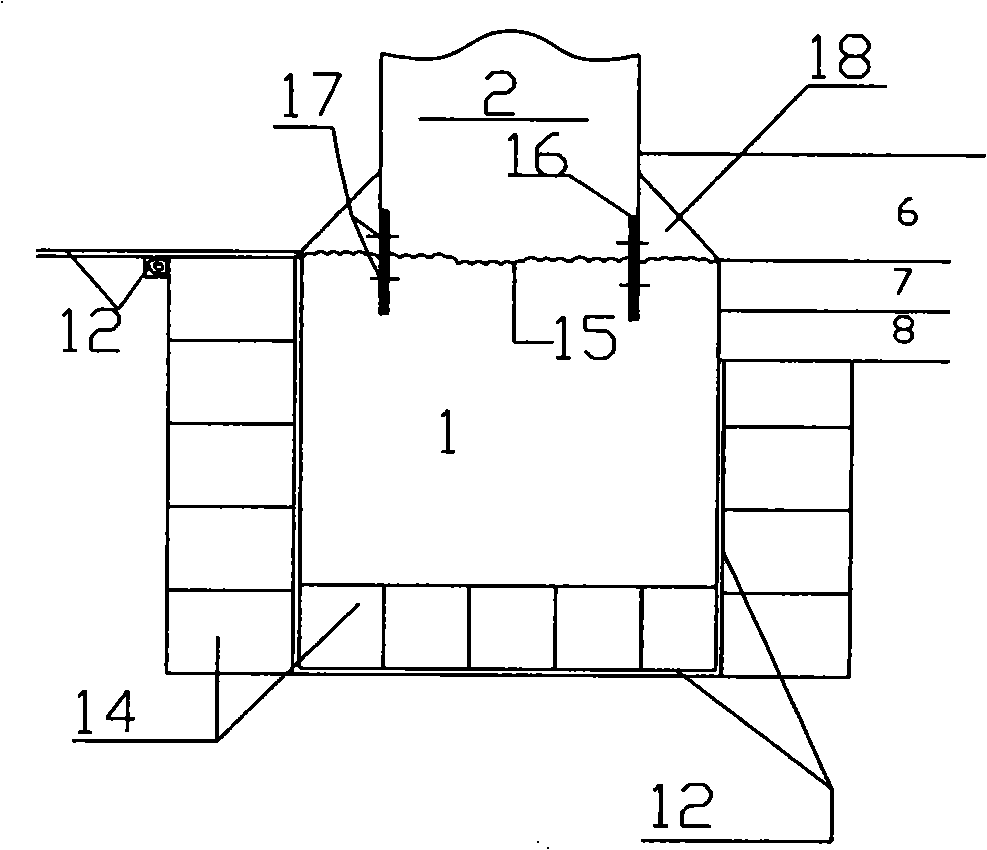

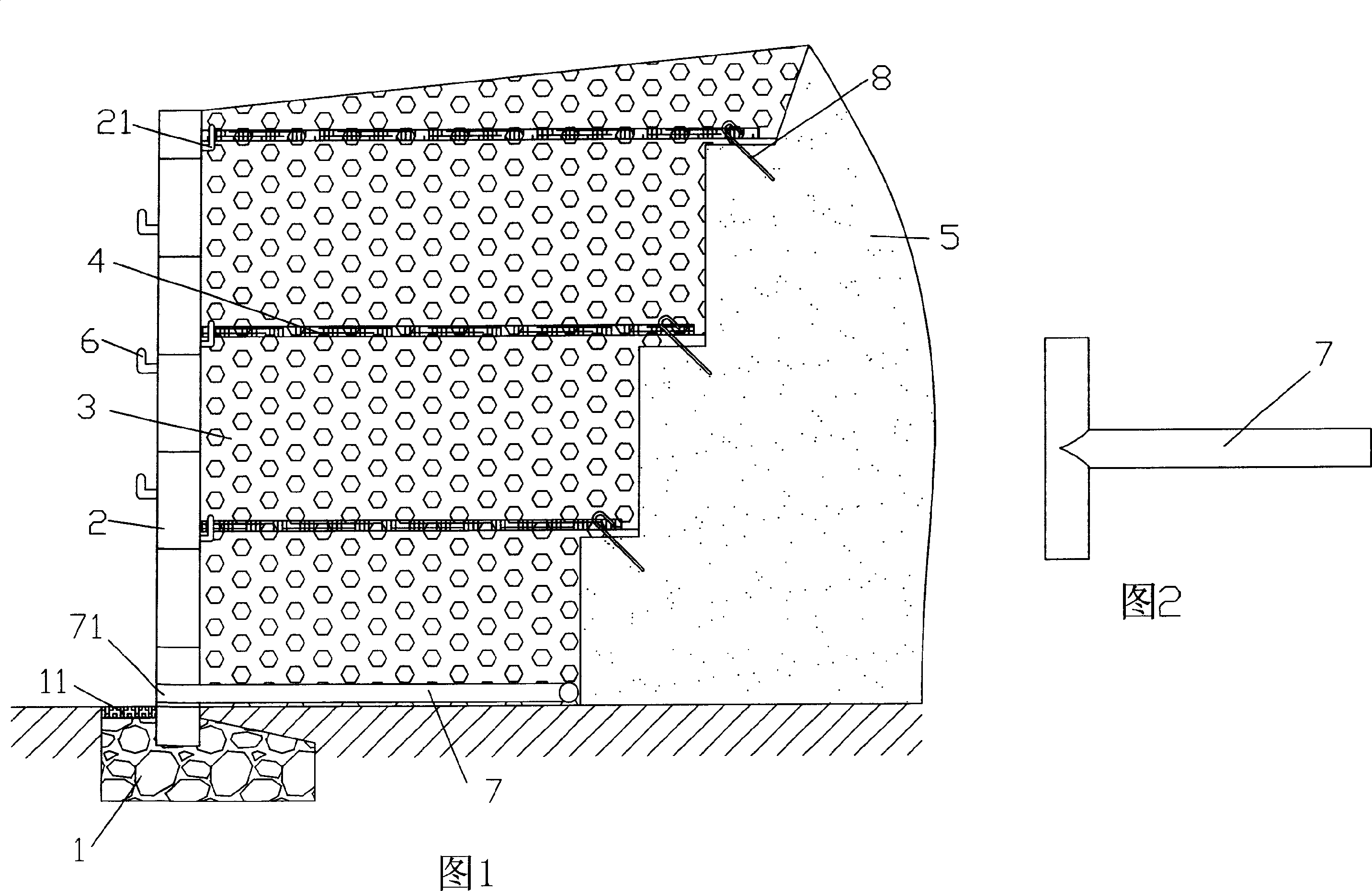

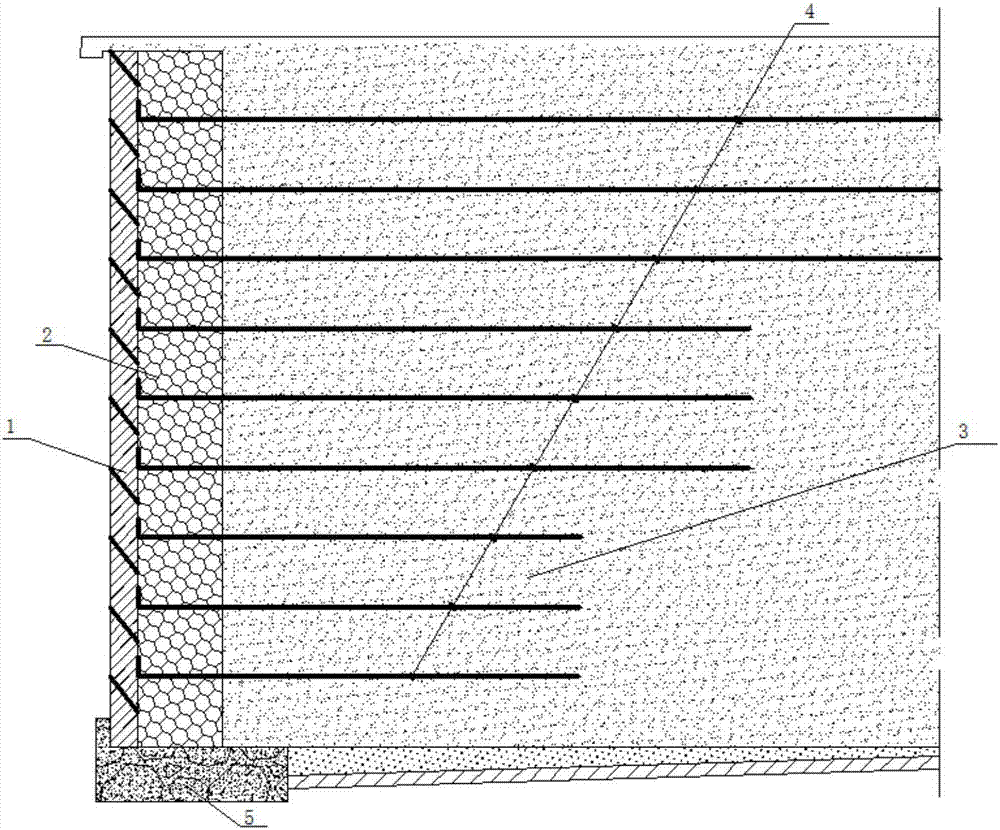

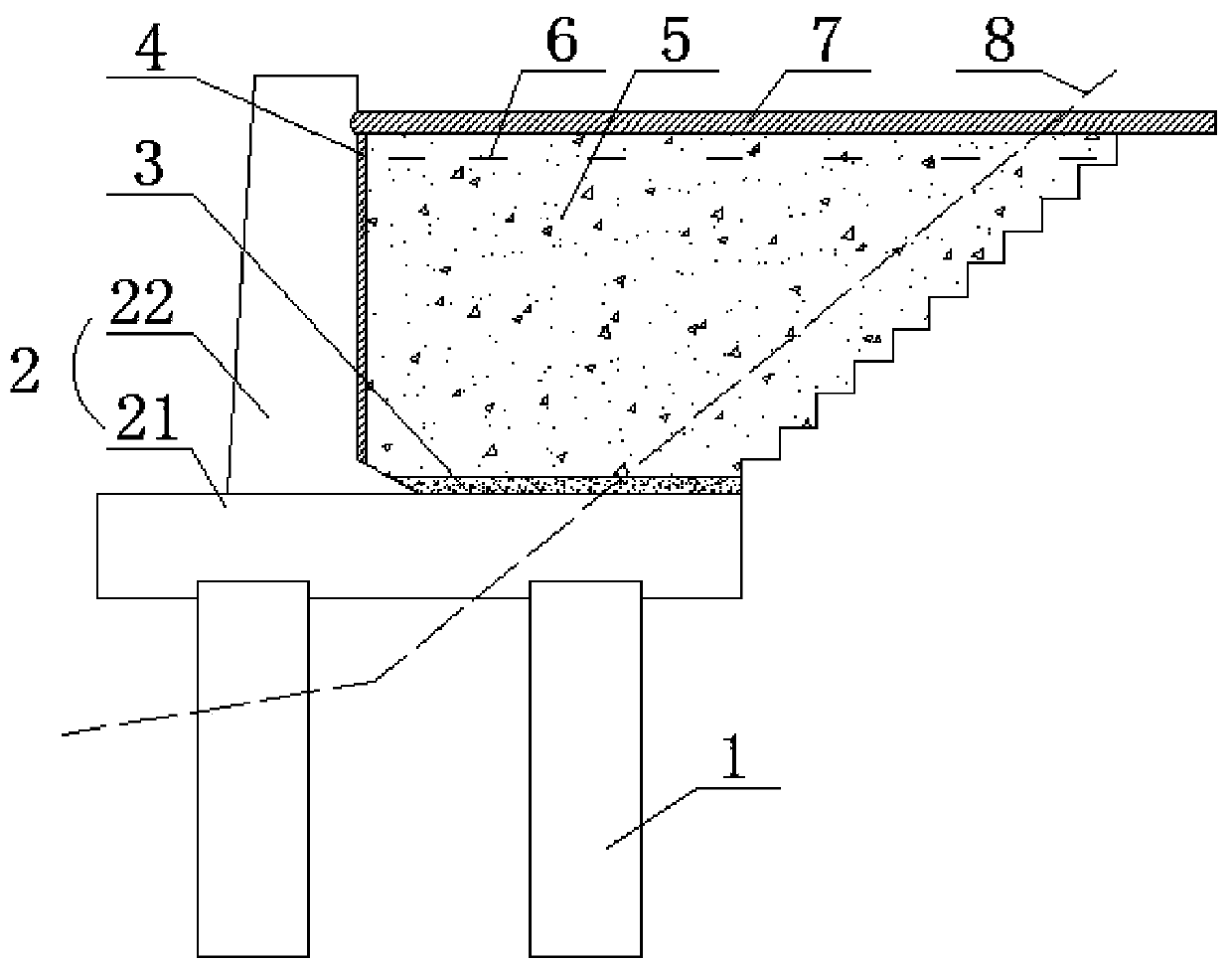

Retaining wall in lightweight, and construction method

InactiveCN101003975AMeet the needs of vertical greeningReduce side pressureArtificial islandsUnderwater structuresFilling materialsCement mortar

The present invention discloses a light retaining wall and its construction method. Said method includes the following steps: firstly, building foundation, laying cement mortar on the foundation and making cement mortar surface be parallel to the horizontal plane, inserting first layer of wall panel into the cement mortar and making the plane of wall panel be perpendicular to the cement mortar surface, after the cement mortar is solidified and the wall panel and foundation are connected into one body, after the wall panel laying first layer of light filling material, then laying reinforcing bar on the compacted light filling material, making one end of reinforcing bar be firmly connected with wall panel and making its another end be inserted into light filling material, then successively mounting second layer of wall panel, laying second layer of filling material and setting reinforcing bar according to the above-mentioned steps until the predefined height is reached so as to obtain the light retaining wall.

Owner:程卫国

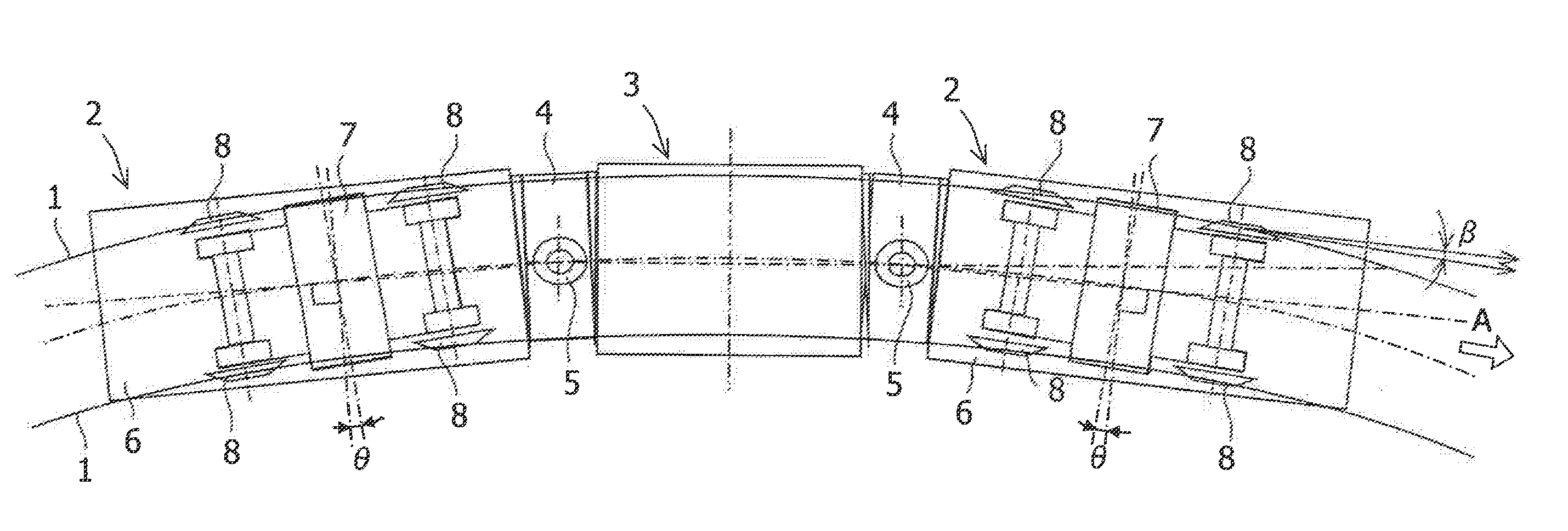

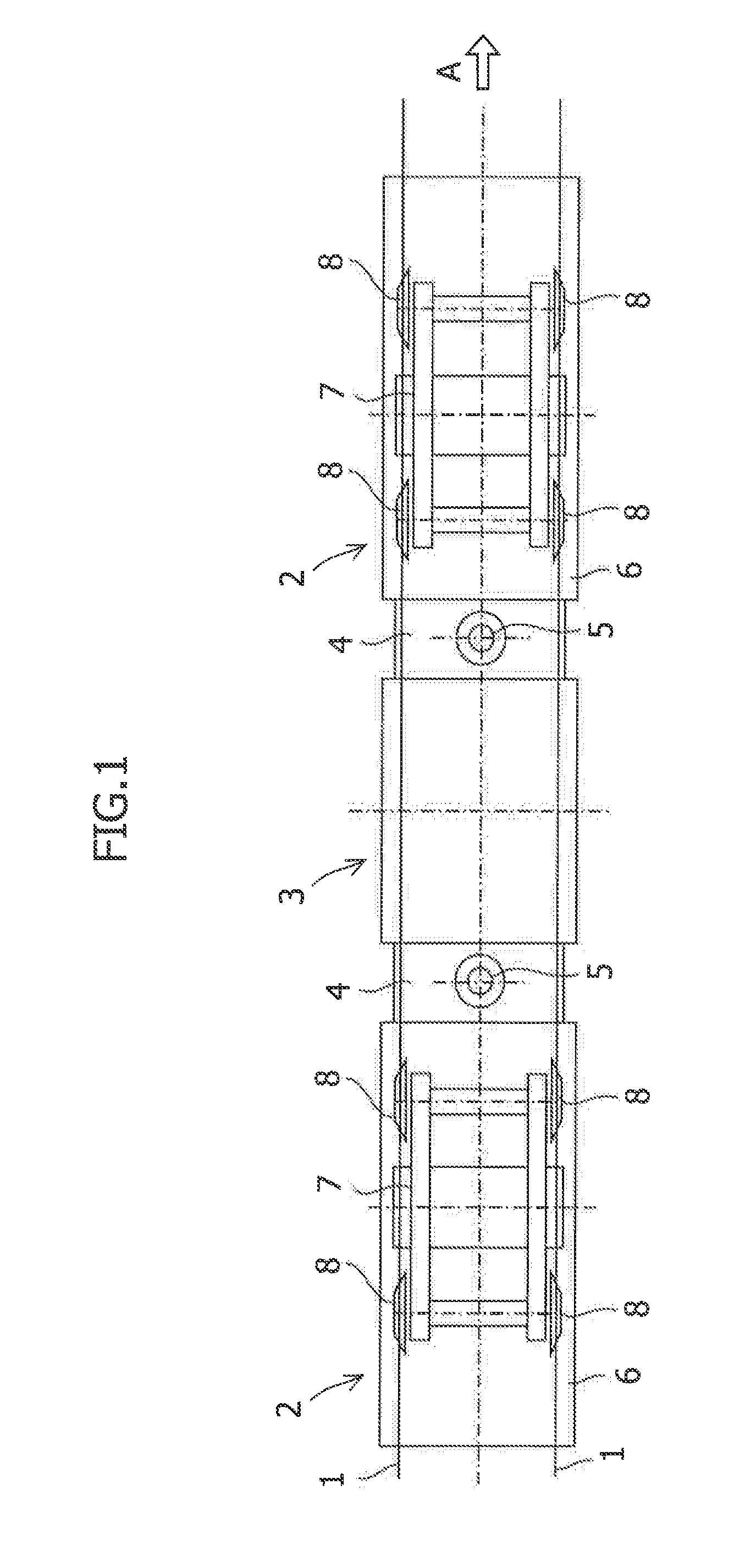

Low floor vehicle

InactiveUS20110239899A1Easily affectedReduce side pressureUnderframesPassenger carriagesBogieFront edge

A low floor vehicle reduces, when the vehicle enters a curved track, the lateral force of the vehicle, prevents occurrence of vibration and creaking sounds of the vehicle, improves riding quality of passengers, and reduces wear of wheel flanges. A low floor vehicle includes a bogie frame 9 of a bogie 7, a pair of bogie frame cross beams 9a arranged along a vehicle lateral direction in the middle of a vehicle longitudinal direction of the bogie frame 9 and arranged spaced apart from each other in the vehicle longitudinal direction, and a pair of wheels 8 provided in each of a vehicle front edge direction and a vehicle rear edge direction with respect to the pair of bogie frame cross beams 9a of the bogie frame 9 and configured to travel on a track 1. A pair of flexible traction rods 15 arranged along the vehicle longitudinal direction and configured to be capable of extending and retracting in the vehicle longitudinal direction are provided in the bogie 7, the pair of flexible traction rods 15 are arranged spaced apart from each other in a vehicle lateral direction, one ends 15b of the flexible traction rods 15 are attached to the bogie frame cross beams 9a, and the other ends 15c of the flexible traction rods 15 are attached to a receiving section 6c of in the vehicle body 6, and the bogie 7 is configured to be capable of turning with respect to the vehicle body 6.

Owner:MITSUBISHI HEAVY IND LTD

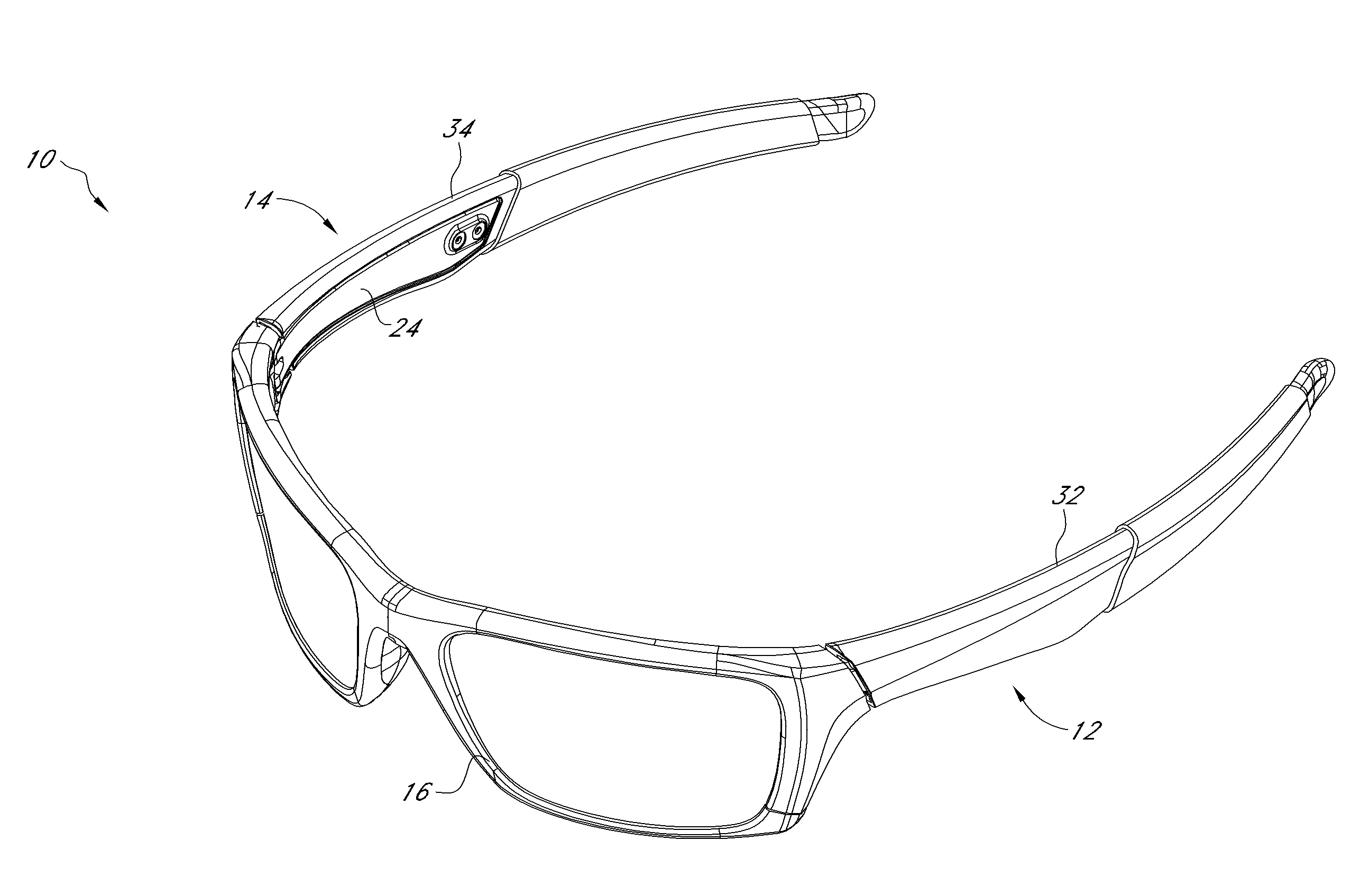

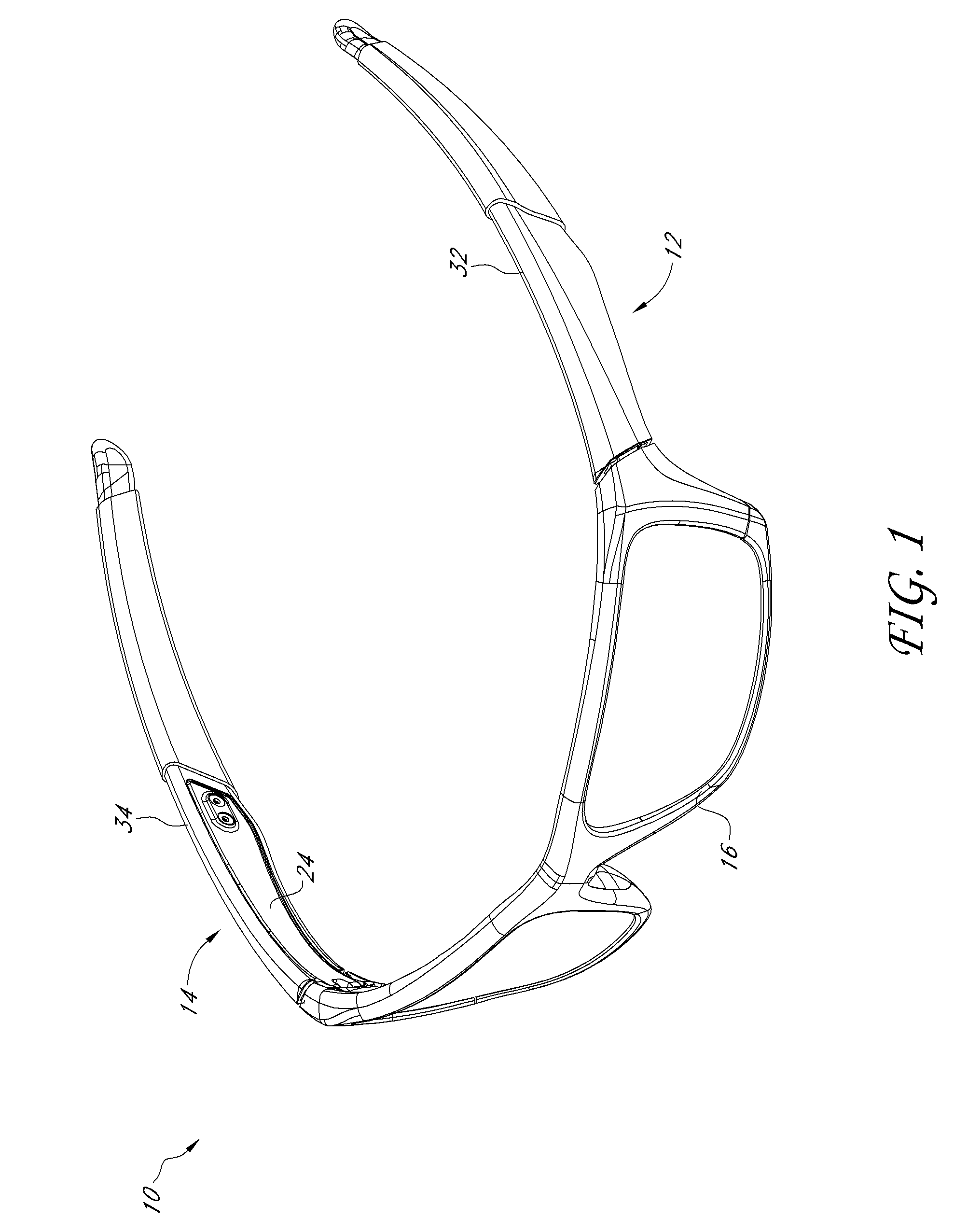

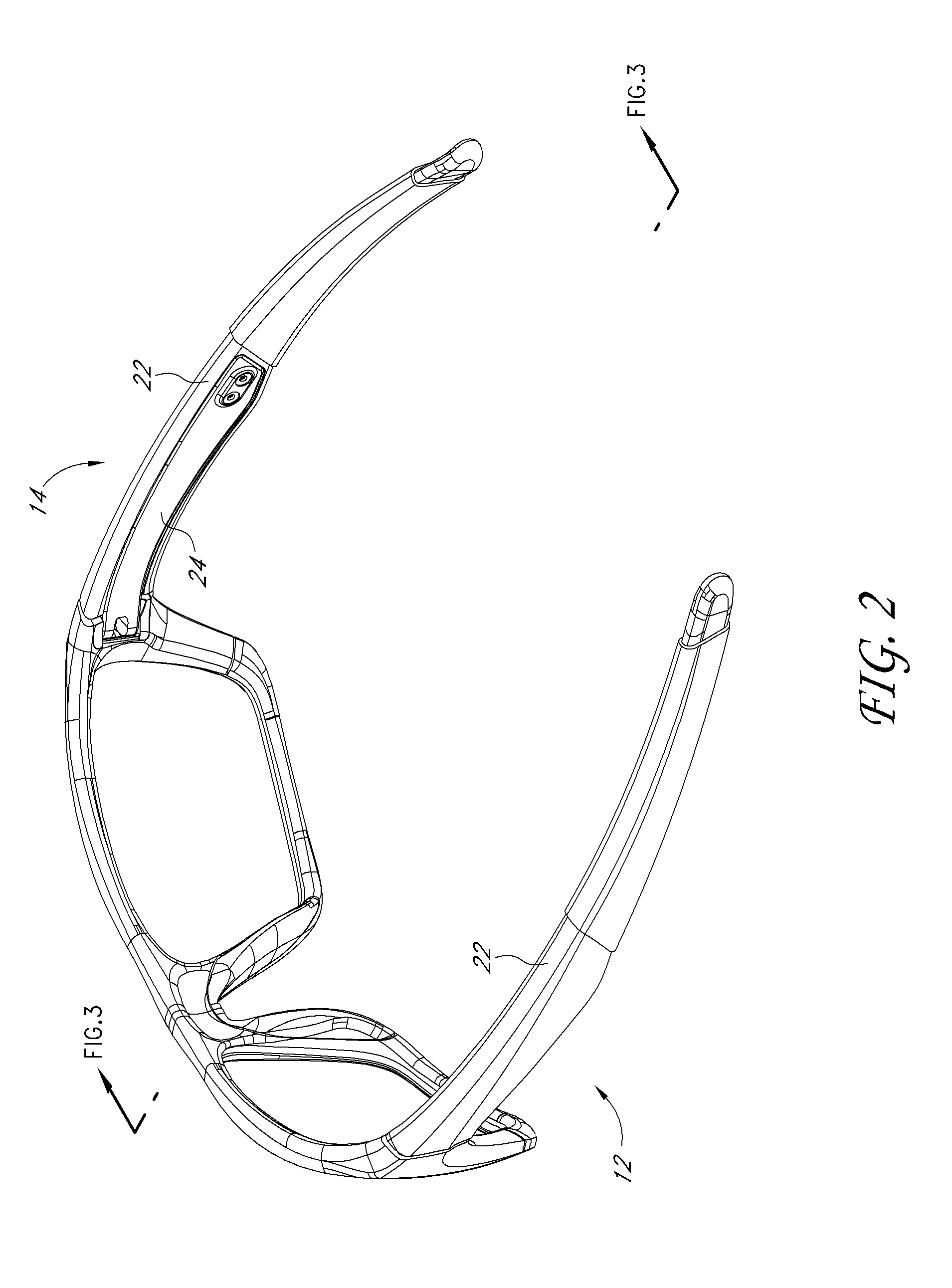

Eyeglass earstem with enhanced performance

ActiveUS20110109873A1Improve fitImprove comfortNon-optical partsMulti-purpose toolsClassical mechanicsEyewear

Owner:OAKLEY INC

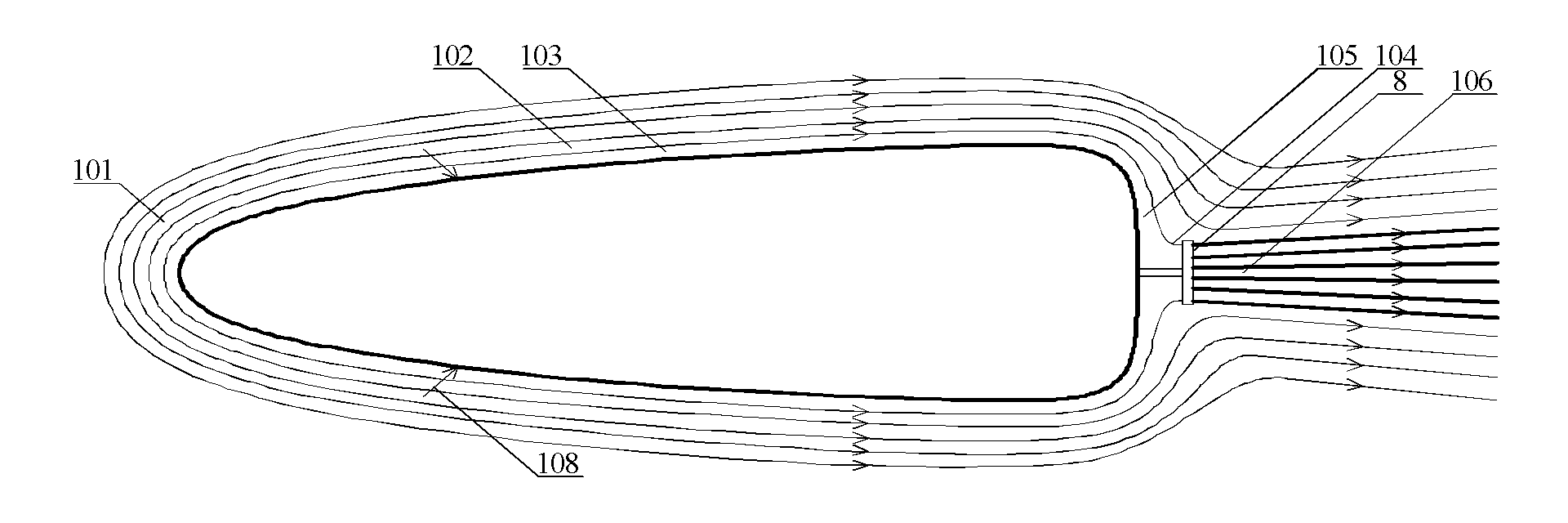

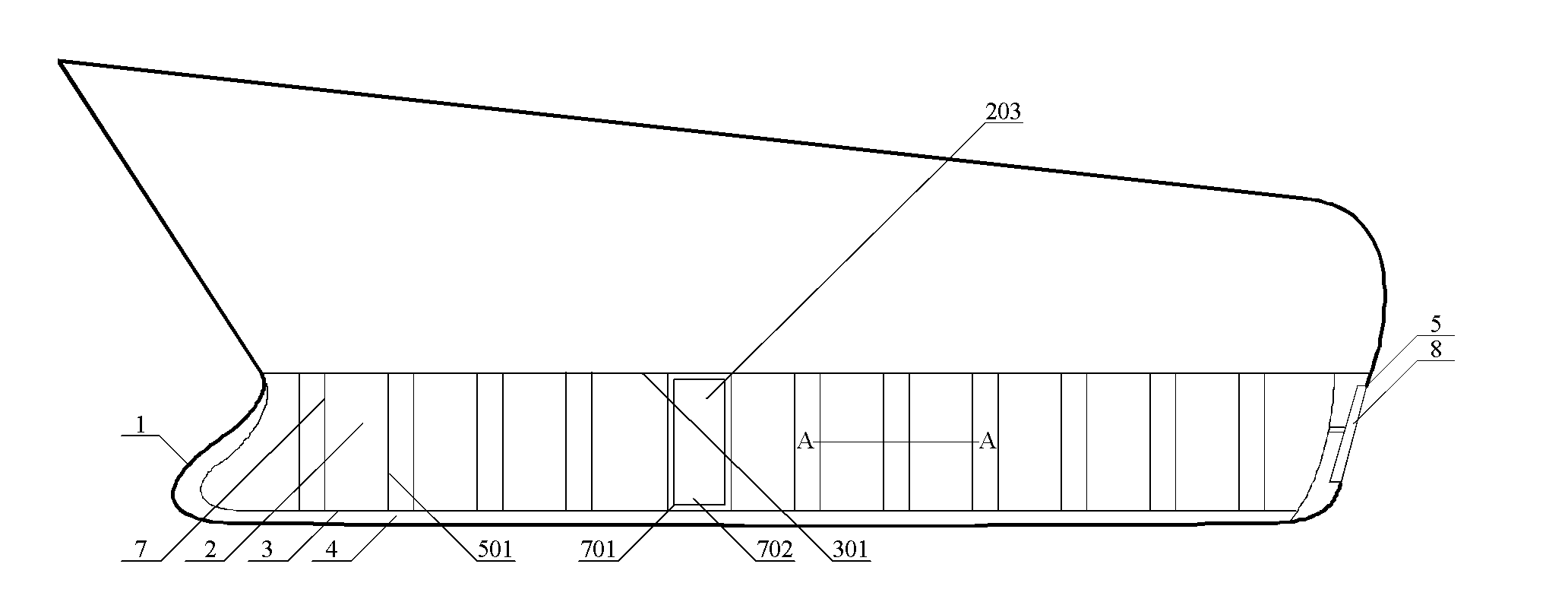

Car or train running system and housing body thereof

ActiveCN101973275AEfficient driveReduce or eliminate dragVehicle body stabilisationRailway tunnelsSolar cellEnergy storage

The invention discloses a car or train running system and a housing body thereof. The housing body is fixed above a railway or a road and comprises a top, two side edges connected with the top, solar cells and an energy storage device, wherein, the distance between the top of the housing body and the railway or the road is more than the height of a train or a car; the bottom edges of the two sideedges of the housing body are fixed at two sides of the railway or the road; the solar cells are arranged on the top and the two side edges of the housing body or the whole housing body and are connected with the energy storage device; and the energy storage device supplies electric energy to the traveling car or train in the housing body. By adopting the system and the housing body of the invention, the car or the train can run at a high speed with lower energy consumption.

Owner:朱晓义

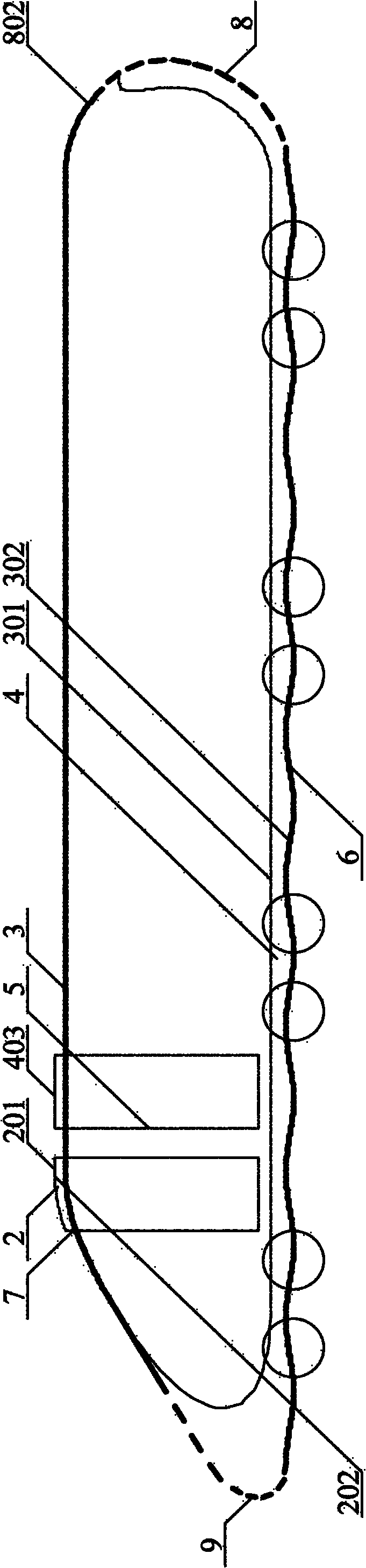

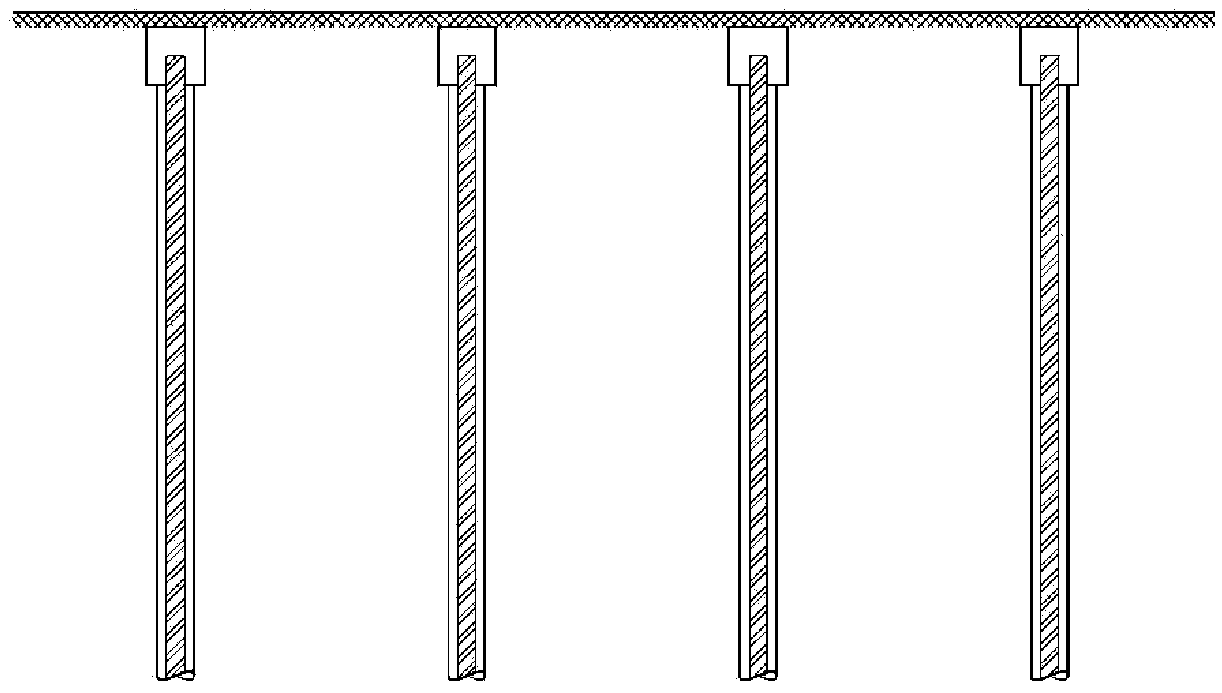

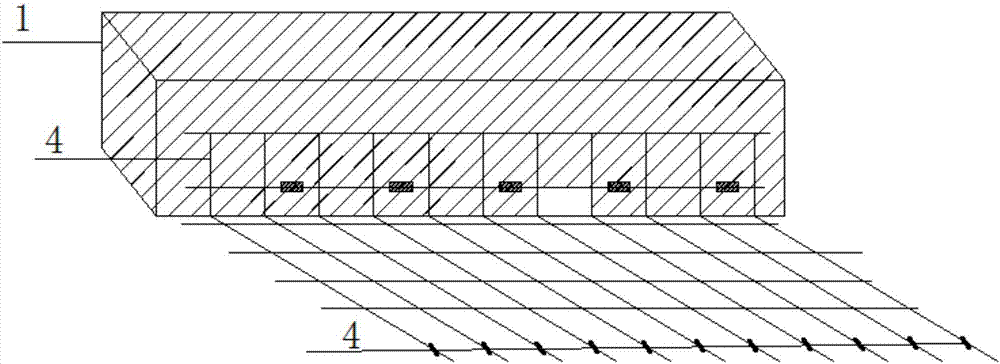

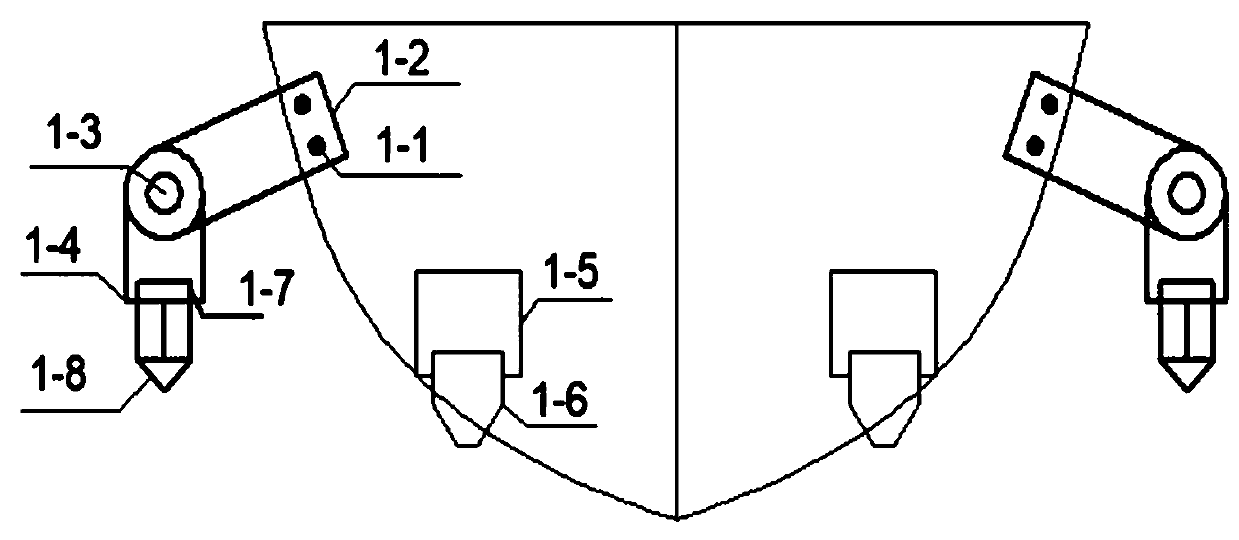

Bored pile construction process

InactiveCN103132509AReduce side pressureReduce risk of churnBulkheads/pilesArchitectural engineeringRebar

The invention discloses a bored pile construction process which includes the steps: 1) drilling a bored pile hole; 2) weaving a reinforcement cage; 3) hoisting the reinforcement cage; and 4) casting concrete. The reinforcement cage comprises main reinforcements and a hoop reinforcement, wherein the main reinforcements are vertically encircled into a cylinder, and the hoop reinforcement is strapped on the main reinforcements. The reinforcement cage is provided with a steel screen surrounding the main reinforcements, and the thickness of the steel screen is 2mm, the specification of a mesh of the steel screen is 10mm*10mm. In the bored pile construction process, by the aid of the steel screen, lateral pressure of a pile body on a hole wall in pile-forming concreting is decreased, accordingly, the bearing capacity of a protecting wall is relatively increased, and the risk of concrete loss due to squeezing breakage of the protecting wall caused by breakthrough of the critical point of the lateral bearing capacity of the protecting wall is decreased.

Owner:ZHONGTIAN CONSTR GROUP

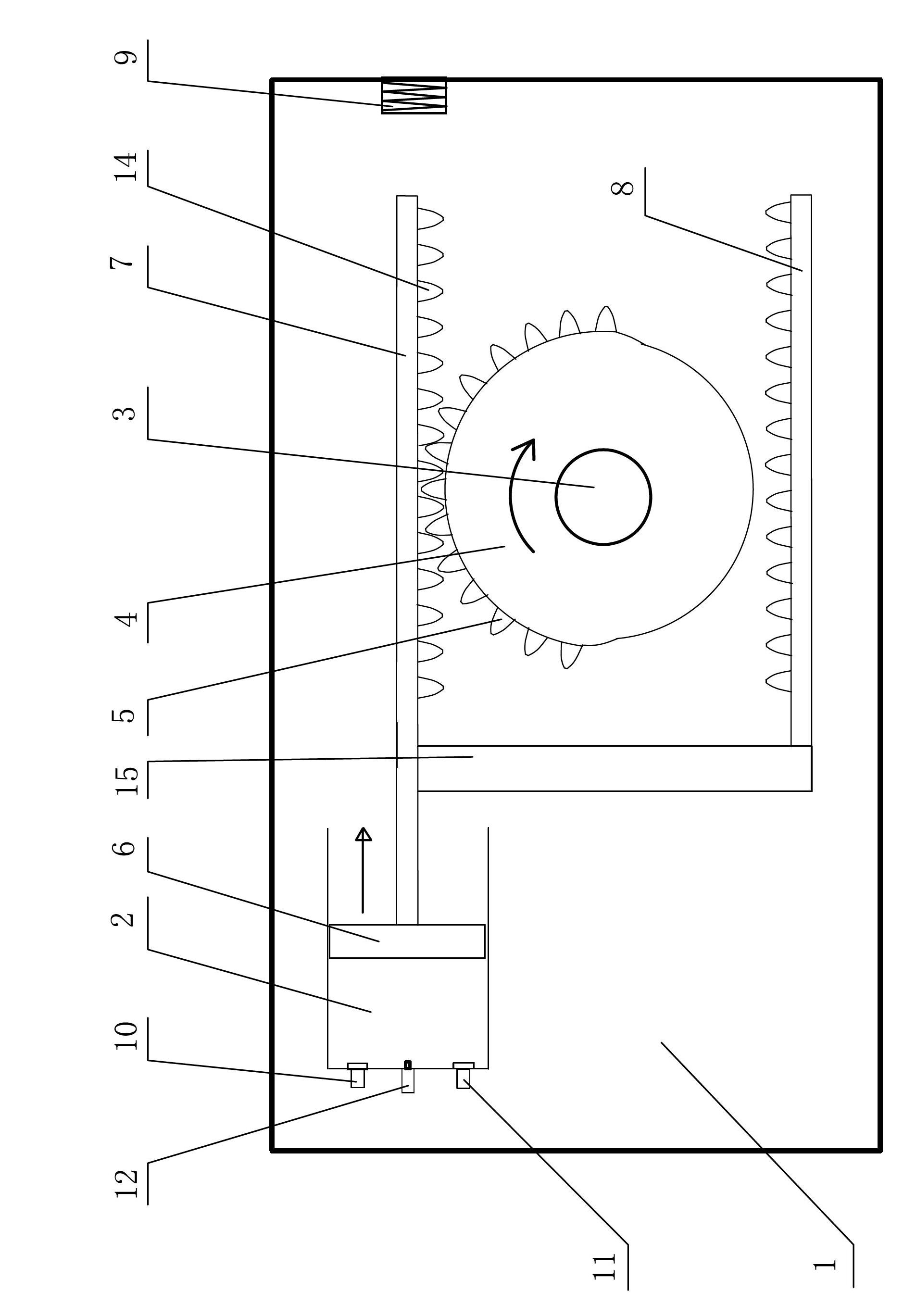

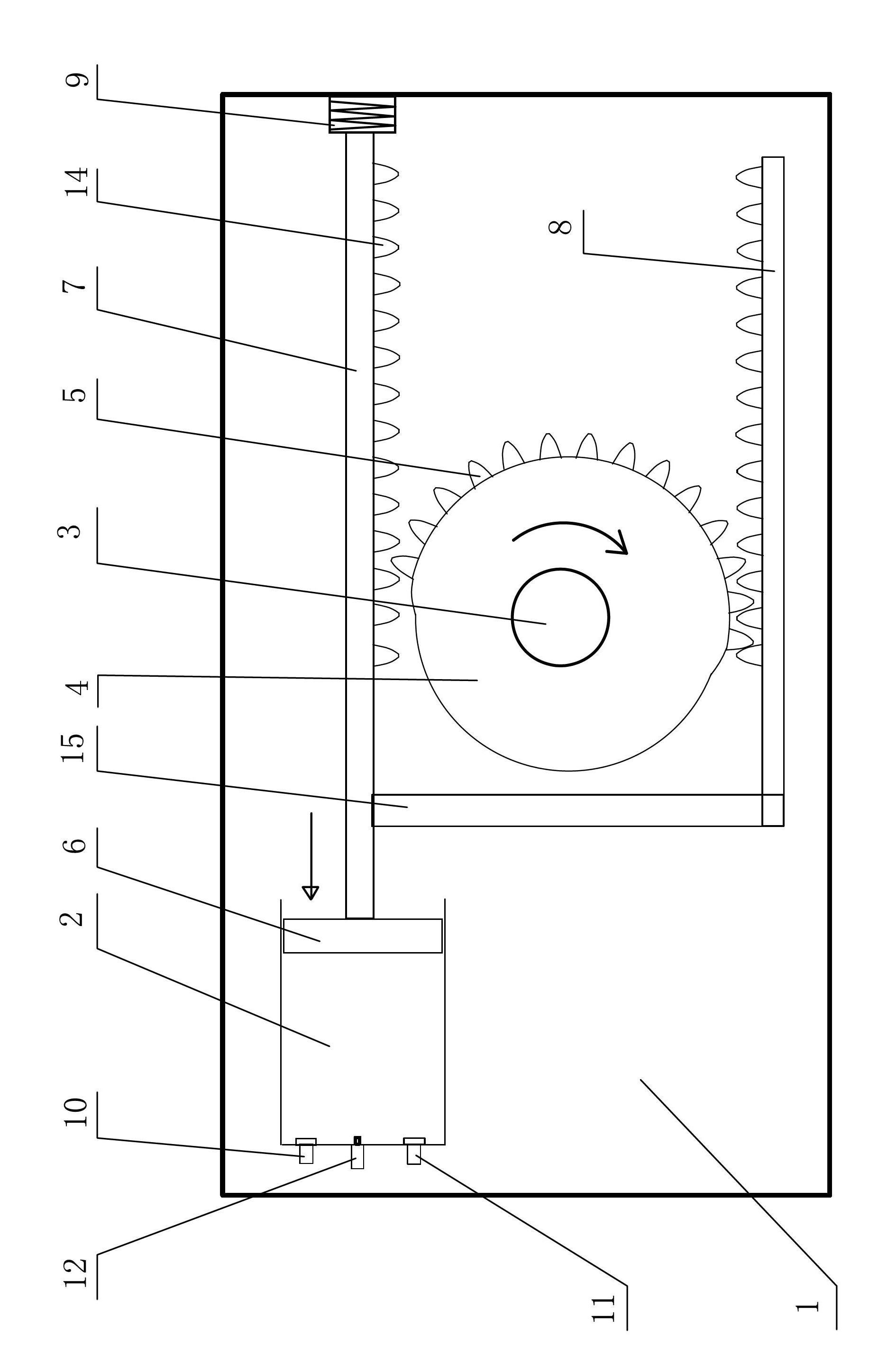

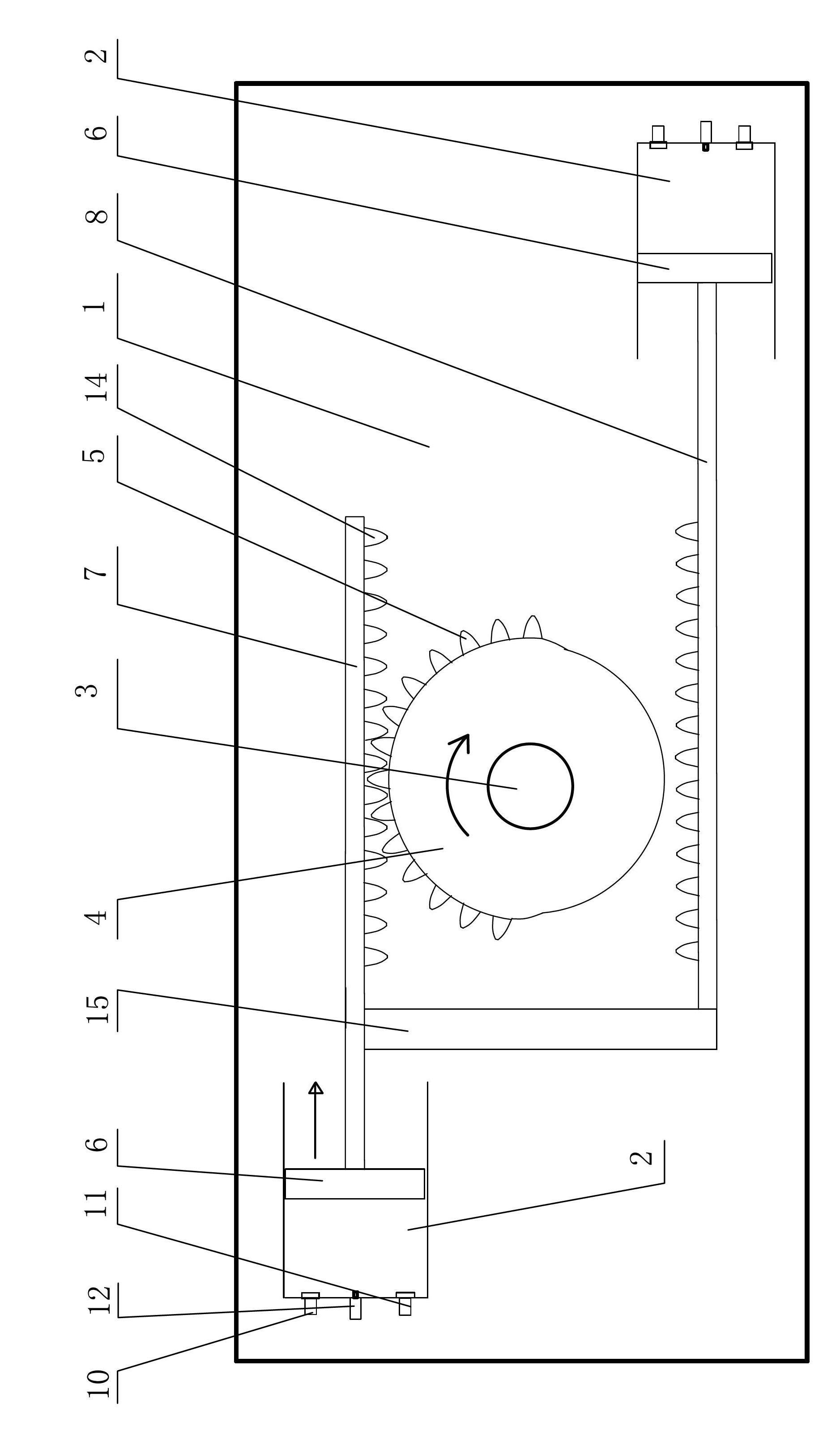

Method and device for driving internal combustion engine by straight shaft

InactiveCN102661199ARealize four-cylinder driveGuaranteed uptimeGearingMachines/enginesReciprocating motionEngineering

The invention discloses a method and a device for driving an internal combustion engine by a straight shaft. Operating cycle of air intake, compression, do work and air exhaust is completed by the piston motion of the air cylinder driven by a straight connecting rod; the configuration direction of the straight connecting rod is consistent with the motion direction of a piston; an auxiliary connecting rod which is linked with the straight connecting rod in parallel is also arranged; the straight shaft is arranged between the straight connecting rod and the auxiliary connecting rod; a transmission wheel and a flywheel are installed on the straight shaft; the transmission wheel is positioned in the same plane with the straight connecting rod and the auxiliary connecting rod; the transmission wheel is provided with a semi-cycle gear; during the rotation process of the transmission wheel, the semi-cycle gear is alternatively meshed with gear racks on the straight connecting rod and the auxiliary connecting rod so as to generate opposite pushing to the straight connecting rod and the auxiliary connecting rod, thus the straight connecting rod and the auxiliary connecting rod perform linear reciprocating motion at the same time, and the operating cycle of the piston is realized; and by applying the technique provided by the invention, the single-cylinder driving, the dual-cylinder driving, the four-cylinder driving, the eight-cylinder driving and the twelve-cylinder driving can be realized. According to the invention, the output efficiency of the internal combustion engine can be improved by 50%-70%.

Owner:曹德新

Refrigerator

InactiveUS7143591B2Easy loadingReduce loadCompression machines with non-reversible cycleDomestic refrigeratorsEngineeringRefrigerant

A refrigerator of the present invention includes a refrigerating cycle including a compressor, a condenser, an expander and an evaporator and filled with a flammable refrigerant, a load detector detecting a change in load of the compressor, and a control device detecting a damage which is a cause for leak of the refrigerant from the refrigerating cycle, based on a detection output of the load detector.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

Construction method of shallow-buried large-span tunnels

InactiveCN105370288AThe pile forming process is matureQuality improvementUnderground chambersTunnel liningRoad surfaceUltimate tensile strength

The invention discloses a construction method of shallow-buried large-span tunnels. The method comprises the following steps: (1) building vertical piles on the ground by using the shallow-buried characteristics of the tunnels, putting the pile bottoms in a stable force-keeping layer below the bottoms of the tunnel arches to be built, namely reserving vertical support piles in advance in the peripheries and the lands of the tunnels to be built before carrying out underground excavation construction of the tunnels; (2) carrying out partial excavation during underground excavation construction, and connecting transverse supports of initial bracing structures to the preset vertical support piles; and (3) completing a process of pouring secondary linings under the condition that the initial vertical temporary supports are not removed; and removing the vertical temporary supports in the structures after the secondary linings form the strength and completing structure construction. Through the construction method of the shallow-buried large-span tunnels, the technical problems of the construction safety risk during pouring the secondary linings and the sedimentation control of the poured road surface can be solved.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

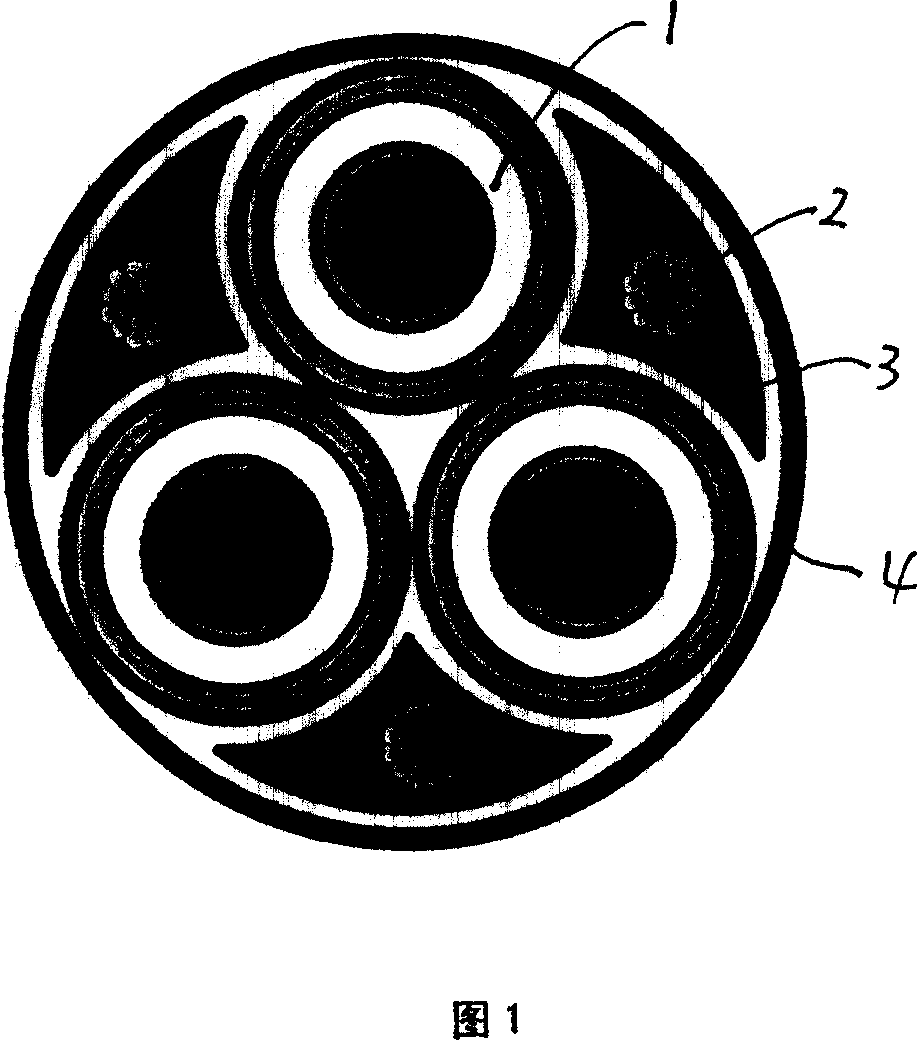

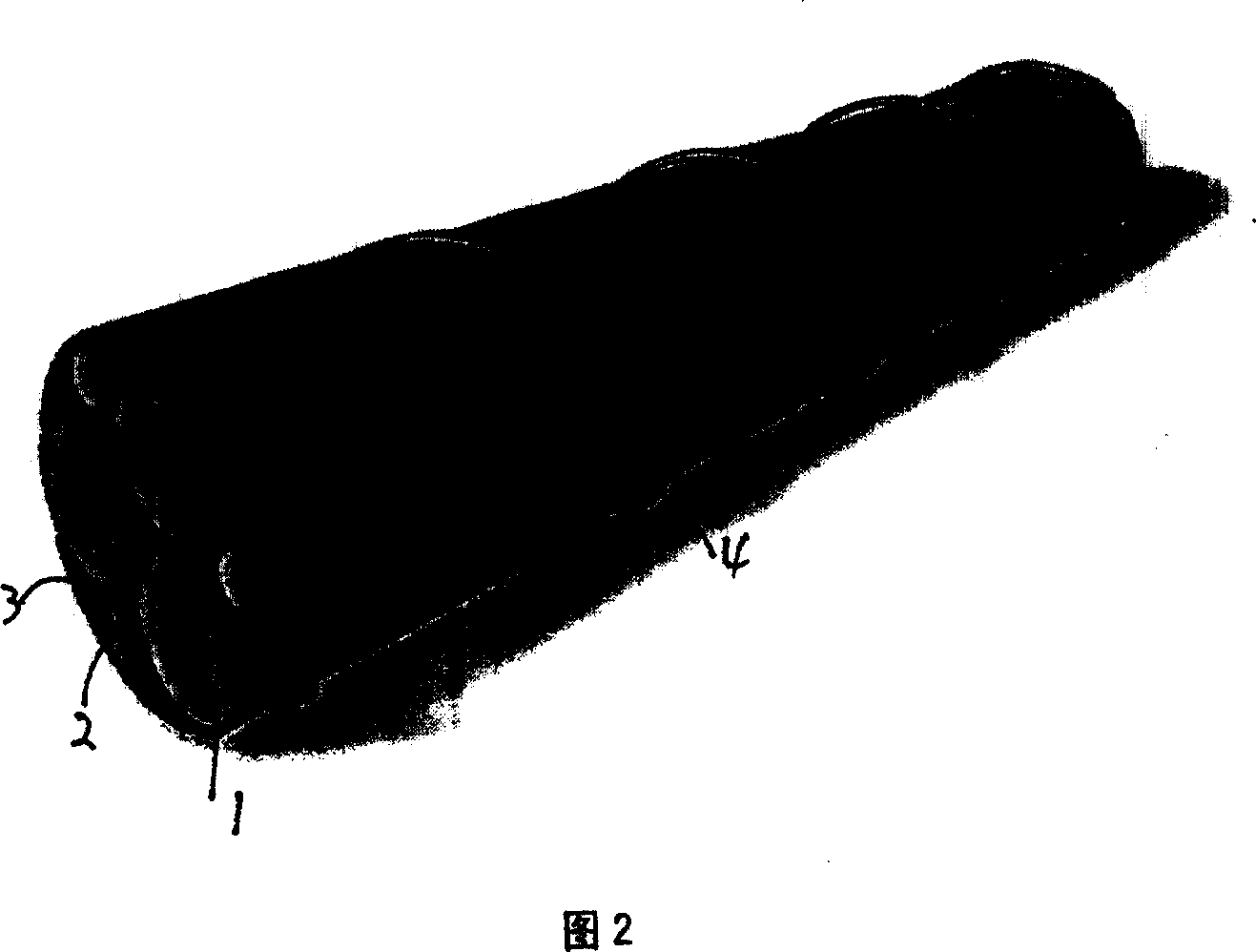

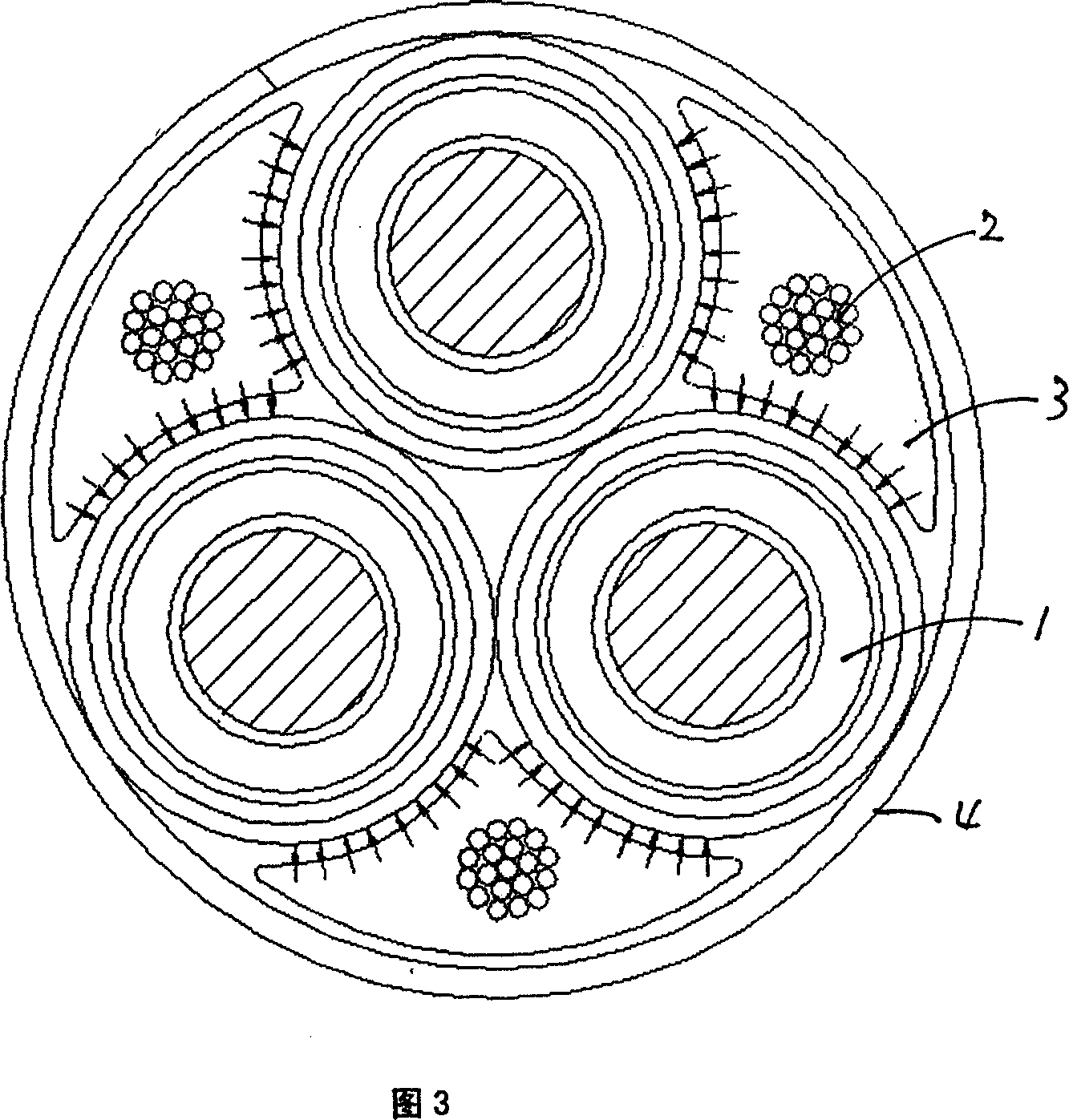

Crane cable for high-building

ActiveCN1941220ARaise the tensile strengthGood for hanging layingInsulated cablesInsulated conductorsAbsolute structureEngineering

An improvement of three cores high voltage lifting cable of high-rise building is adopting single core insulating cables and between them filled by three carrying steel cores with insulating coat of arc sector section. They cross into cable and outside is pricked by high-intensity strap. The arc sector bearing touches with closed cable core with large acreage and this enhances the friction of them greatly. For the crossing and strap, it increases the friction between them and greatly enhances the whole tensile strength of cable to endure more strength and is suit for lifting 150 meters or higher construction. It also increases current capacity of cable about 10-30% and reduces the weight of cable about 20-30% to cut down the cost. The arc sector bearing gives more little side pressure to cable and the cable is safe with good reliability. The absolute structure of three cores bearing reduces the difficulty of production.

Owner:FAR EAST CABLE

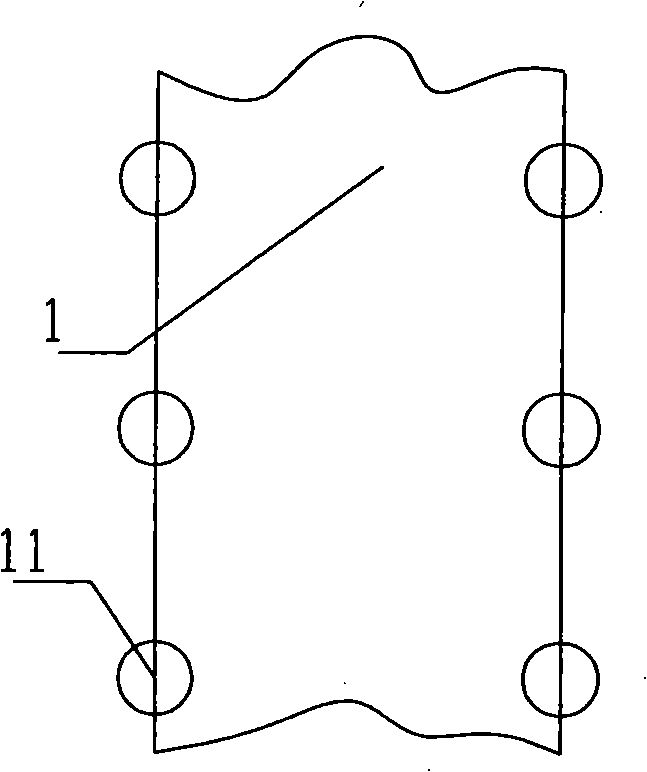

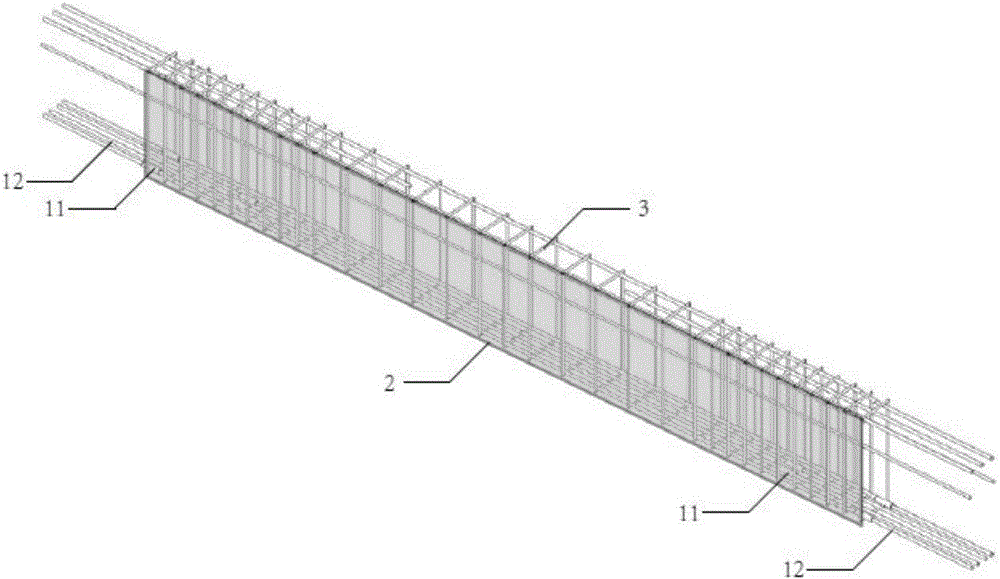

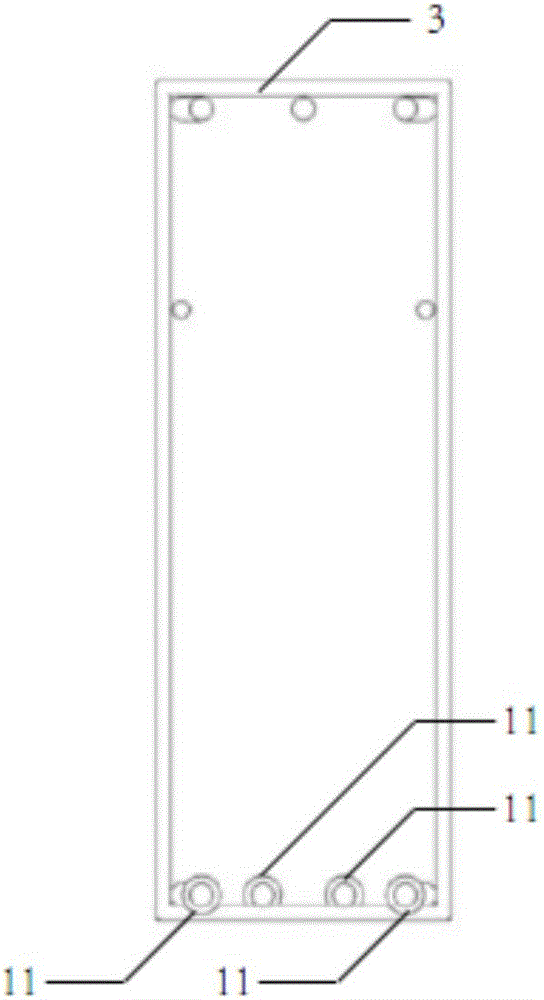

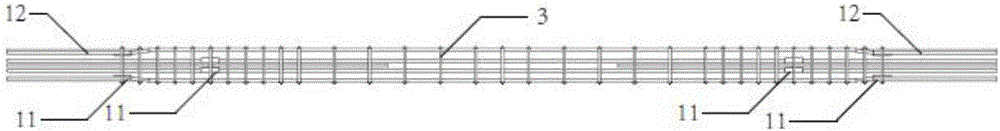

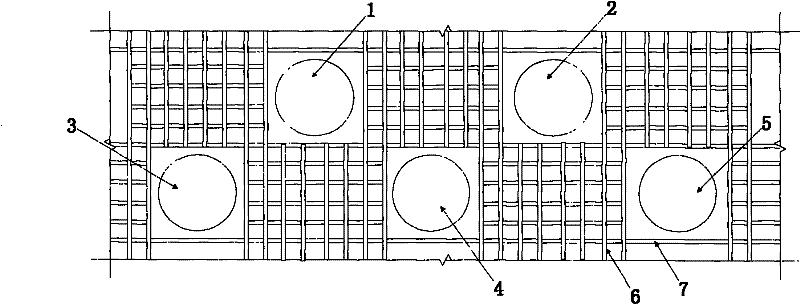

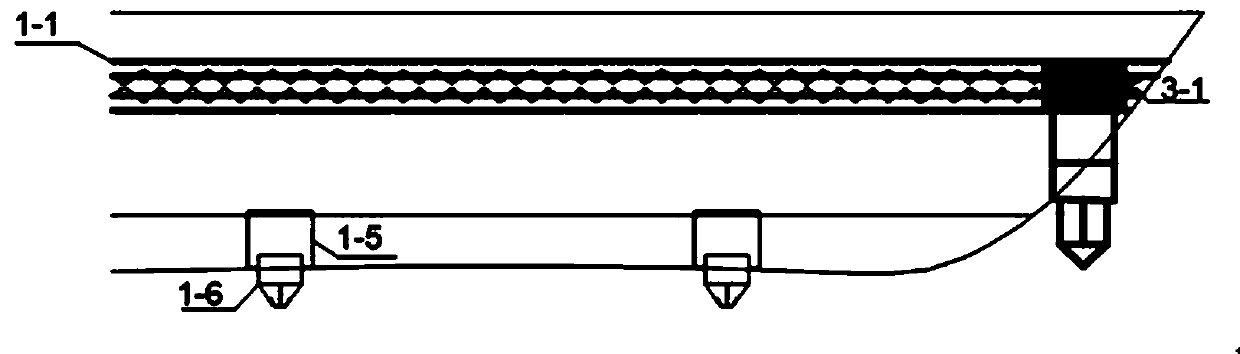

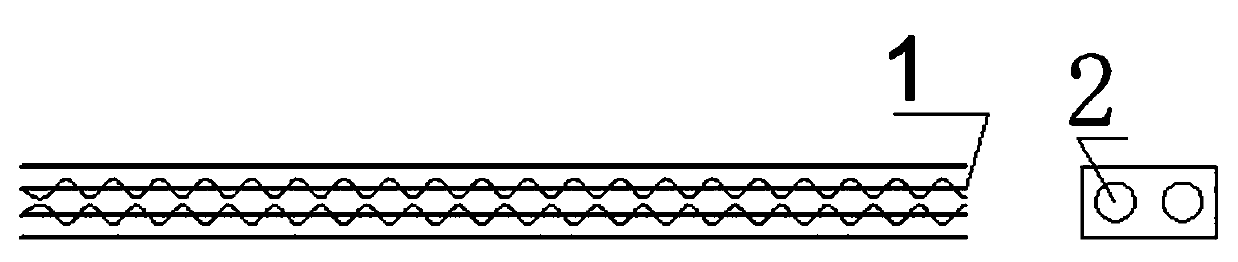

Precast beam reinforcement cage component and assembling method thereof

InactiveCN105952060AMeet construction requirementsEnables step-by-step installation combinationsBuilding reinforcementsBuilding material handlingReinforced concreteRebar

The invention discloses a precast beam reinforcement cage component and an assembling method thereof. The precast beam reinforcement cage component comprises a reinforcing steel bar assembly and a disassembly-free mould connected with the reinforcing steel bar assembly, wherein the reinforcing steel bar assembly is formed by connecting a horizontal reinforcing bar and a stirrup, and the disassembly-free mould is laid along the front side surface, the rear side surface and the bottom surface of a precast beam and is connected with the reinforcing steel bar assembly into a whole by virtue of a locating fixed part. The precast beam reinforcement cage component has the advantages that a large component and a reinforced concrete large-structure-space civil building can be realized, a working procedure is simplified, high-altitude operation is reduced, and current national reinforced concrete reinforcing bar specification can be met; meanwhile, cost is reduced, locating and supporting precision, assembling efficiency and quality of a structural component are improved, site construction is convenient, and a technology is controllable.

Owner:SOUTHEAST UNIV

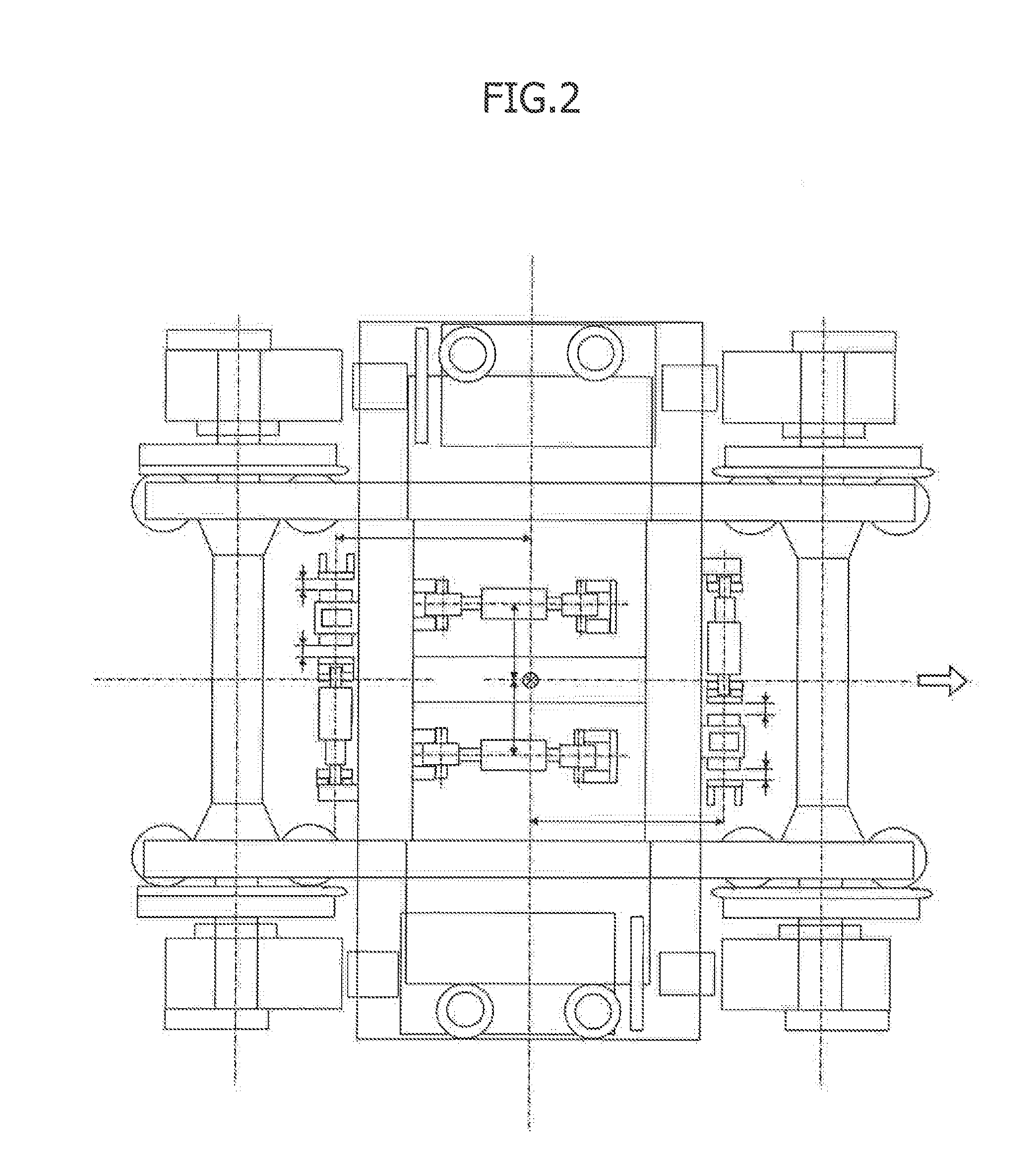

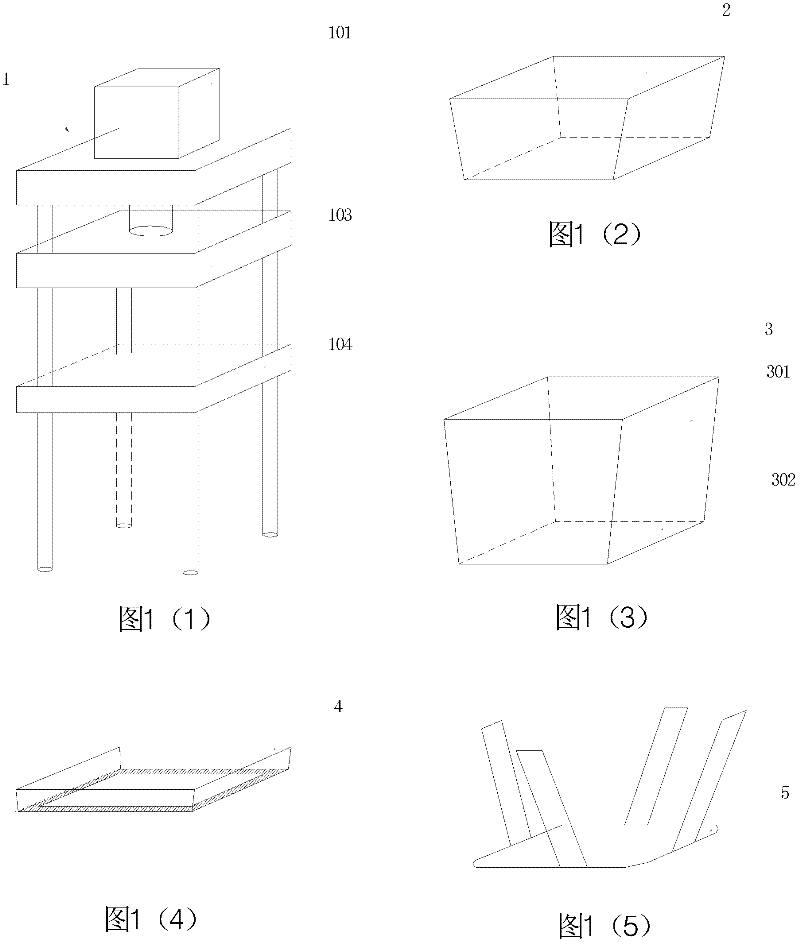

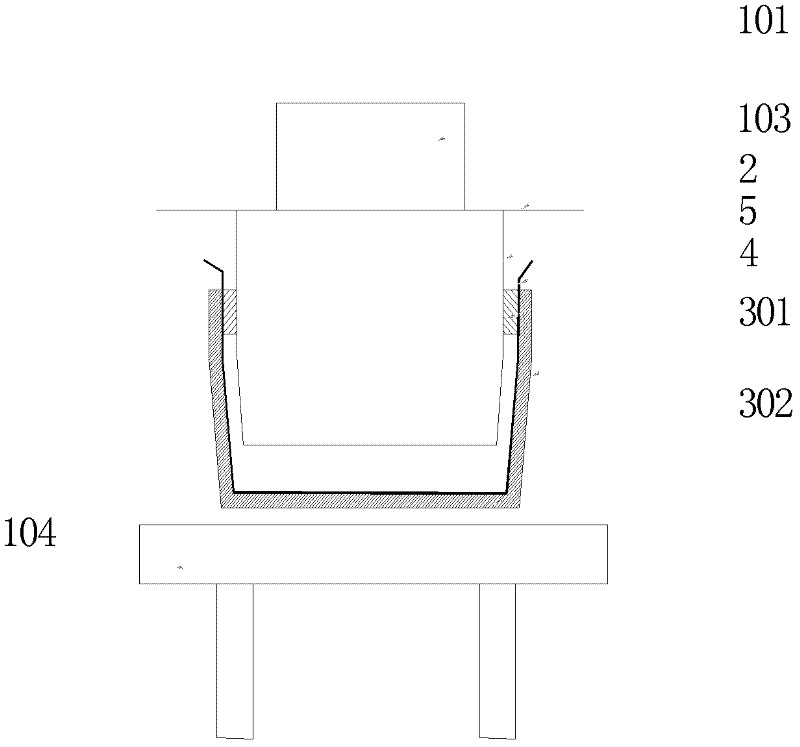

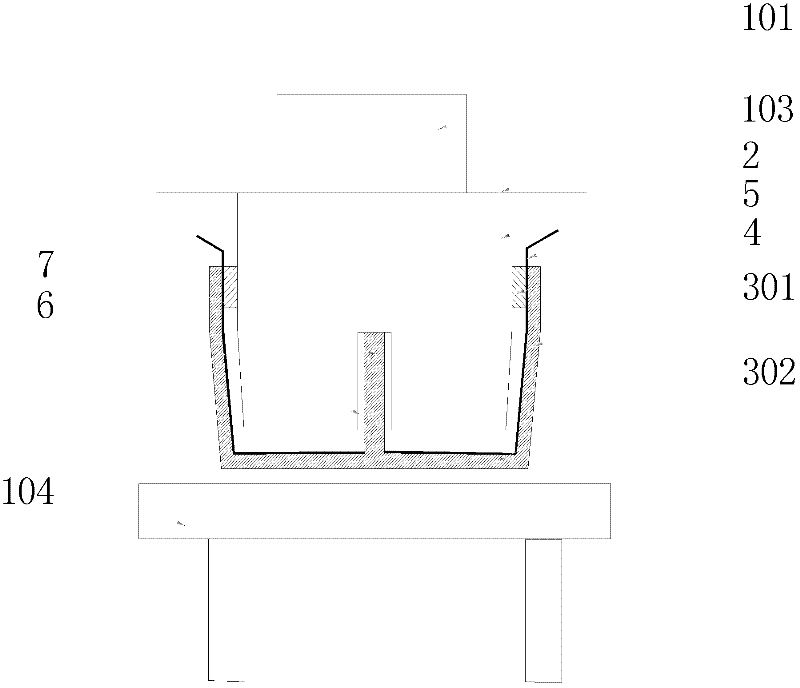

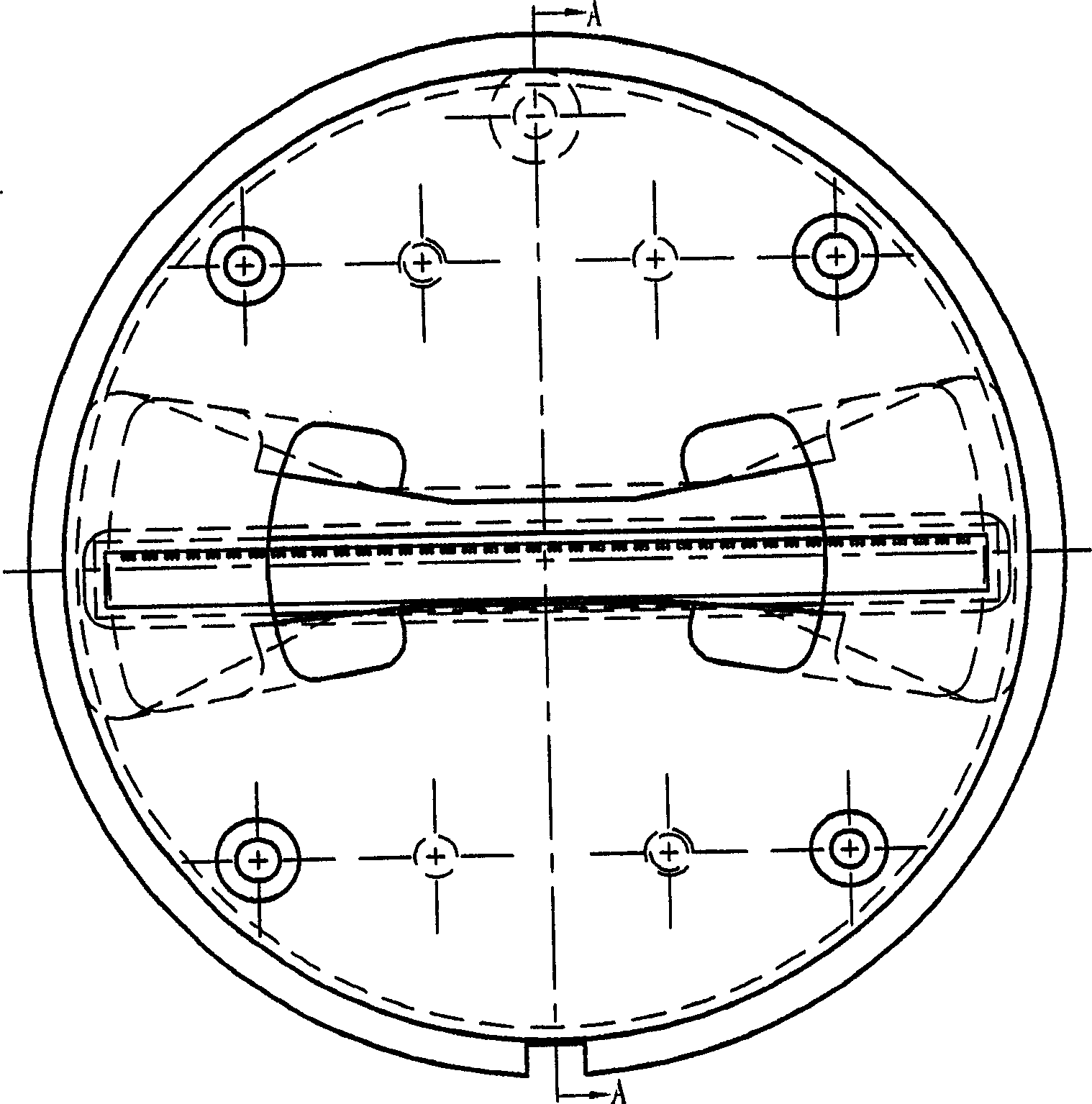

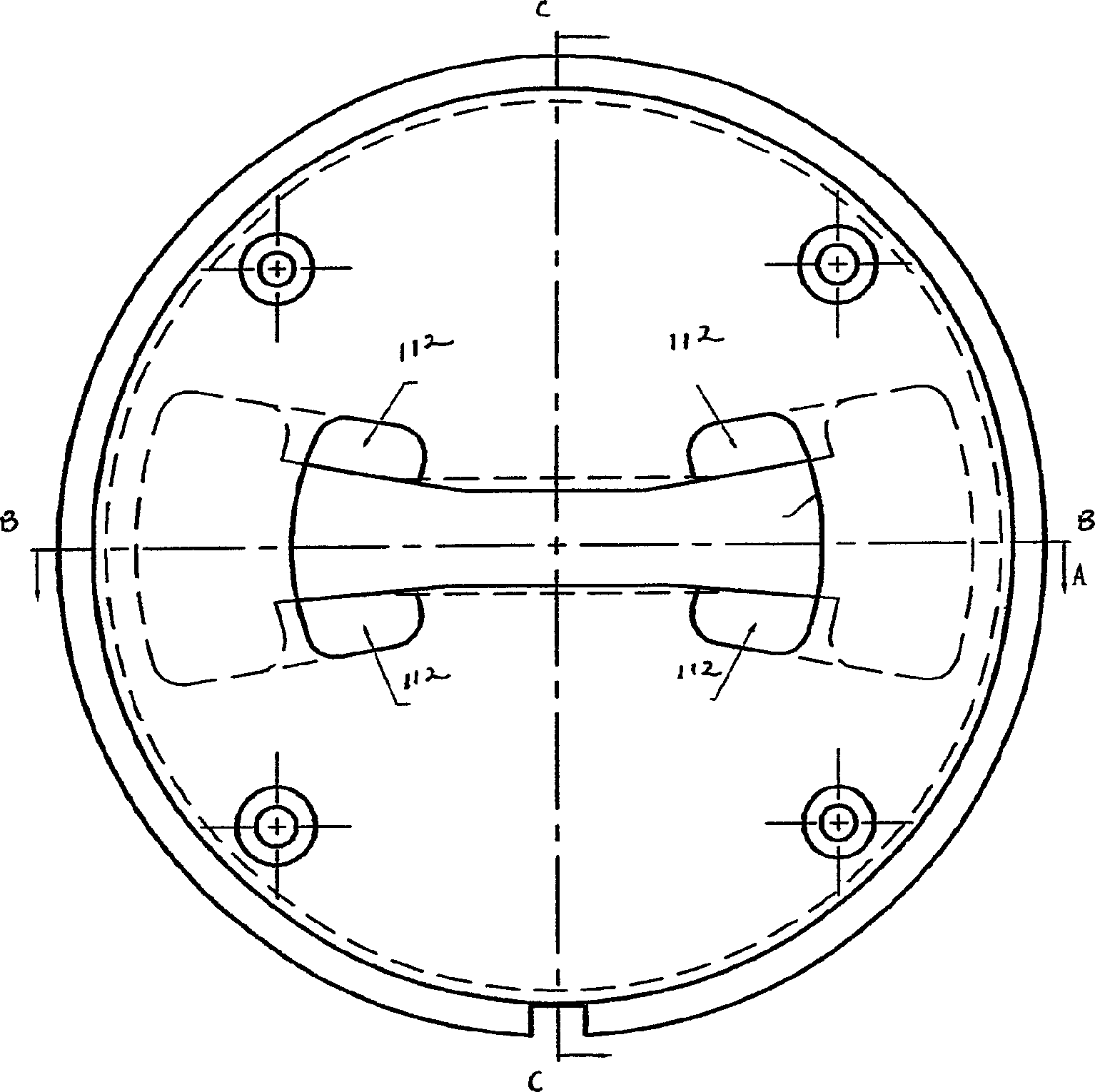

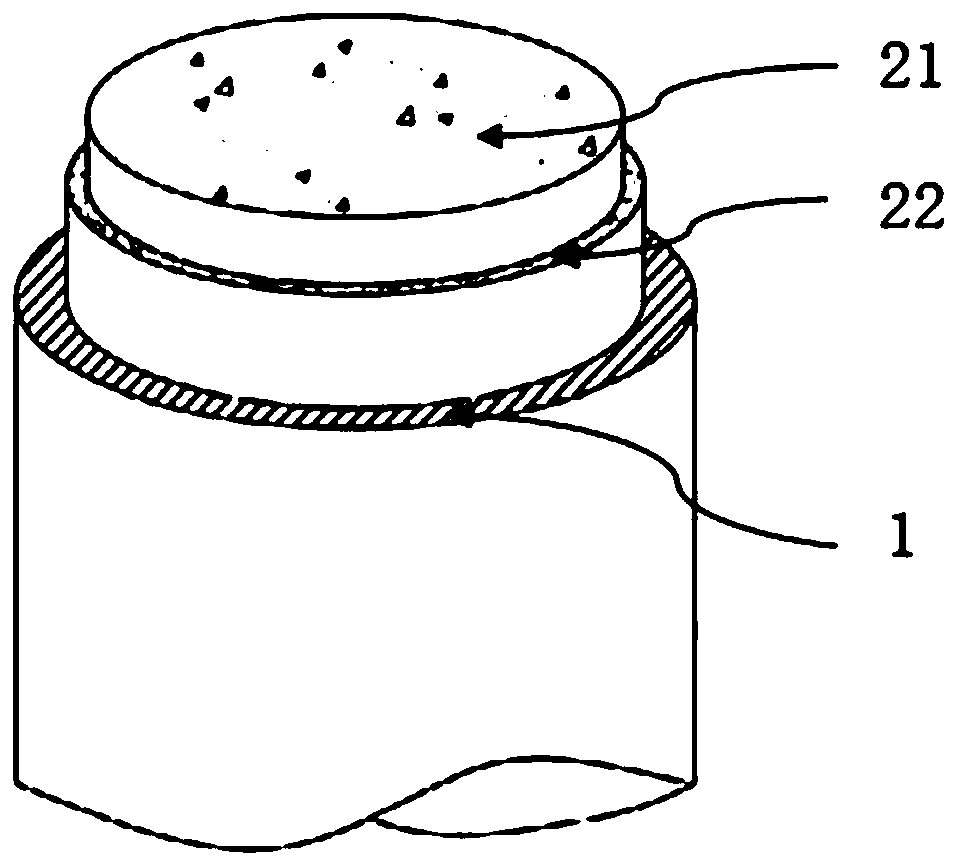

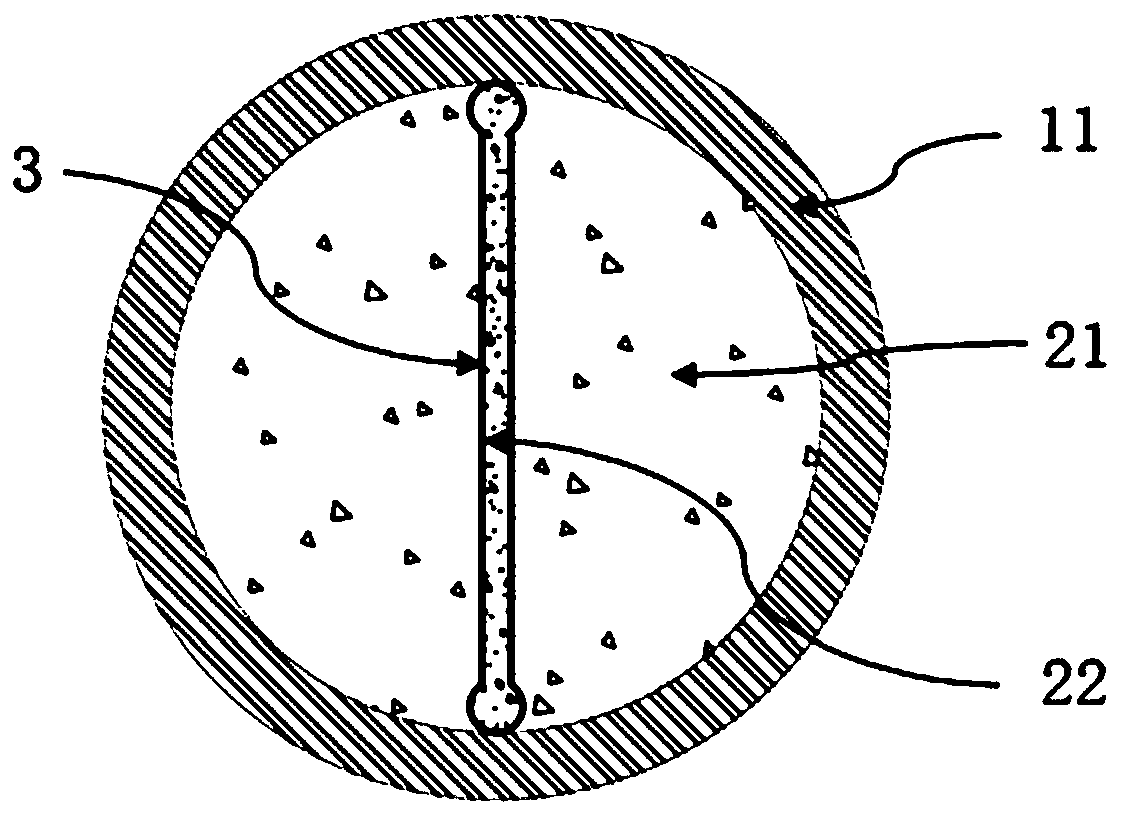

Machine manufactured mould system for manufacturing combined open-web member

The invention relates to a machine manufactured mould system for manufacturing a combined open-web member. The system comprises a pressure machine, an internal mould, an external mould, a seal plate and a demoulding device, wherein the seal plate is arranged on the upper part of the side of the internal mould and is a ring-shaped block to block off the gap between the internal mould and the external mould; the demoulding device is put at the internal side of the external mould; partial parts of the demoulding device extend from the external mould; and the partial parts or the whole part, which is arranged in the external mould, of the demoulding device is matched with the contact part on the inside surface of the external mould. The system has the following beneficial effects: the hydraulic machinery is utilized to press the dry cementing materials; after being formed, the open-web member is timely taken out of the mould system by utilizing the demoulding device; machining of the member can be completed in a shorter time; industrialized production of the open-web member is realized; and the manufactured open-web member has high density, uniform thickness and high production efficiency and is convenient to transport and simple to construct when being applied to the cast-in-situ open-web floor systems.

Owner:王本淼

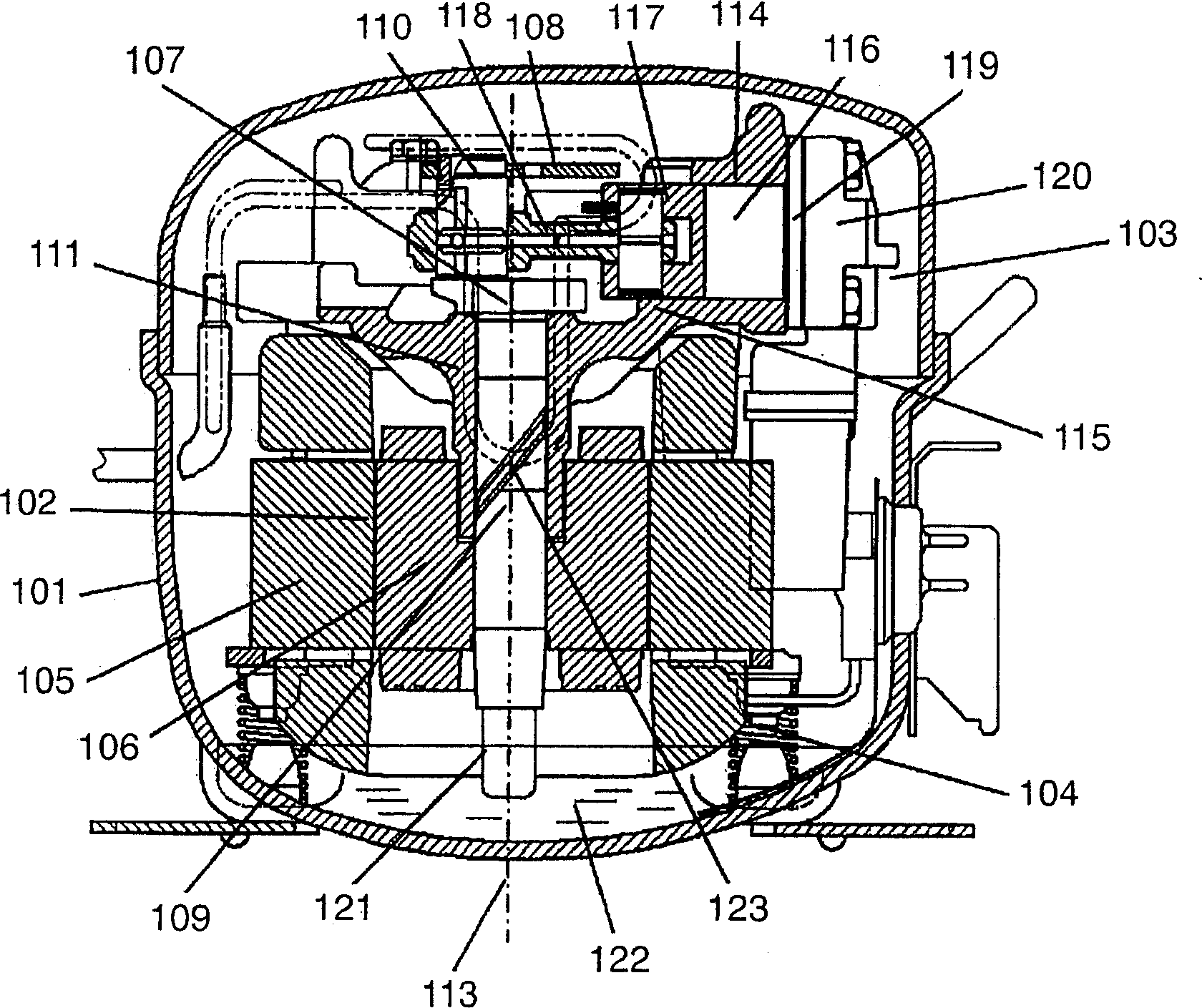

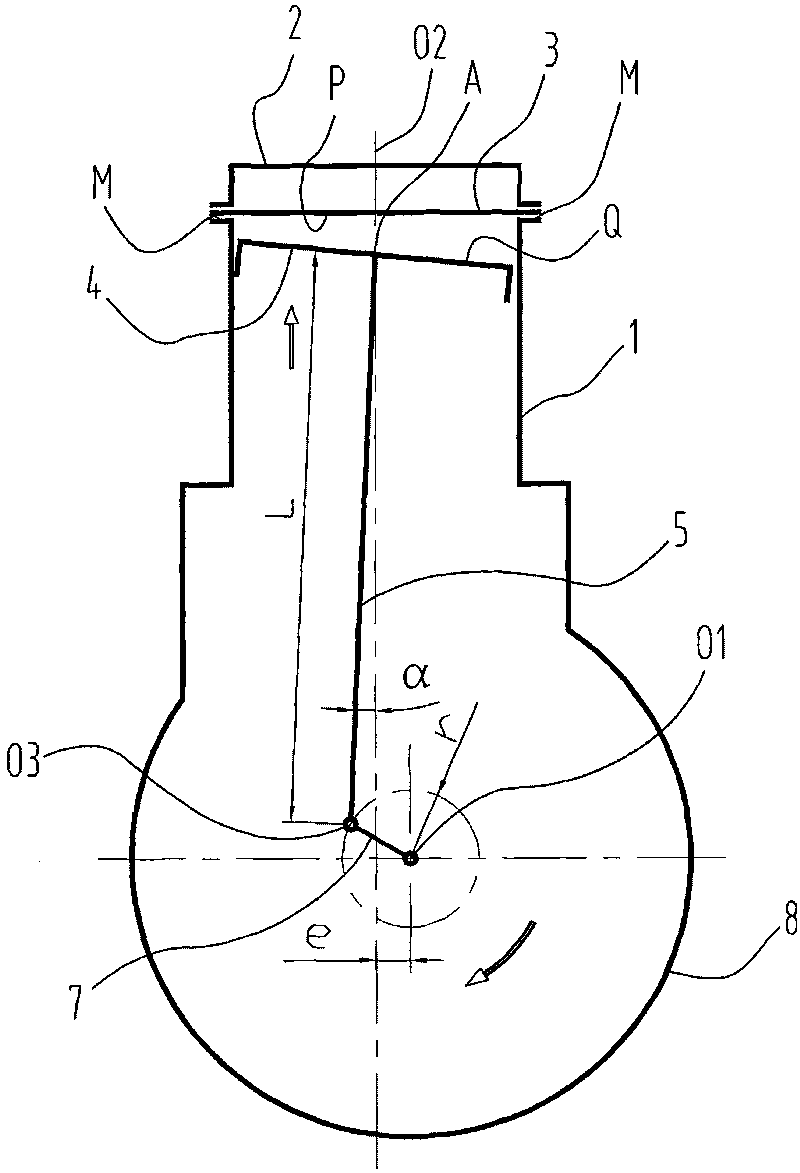

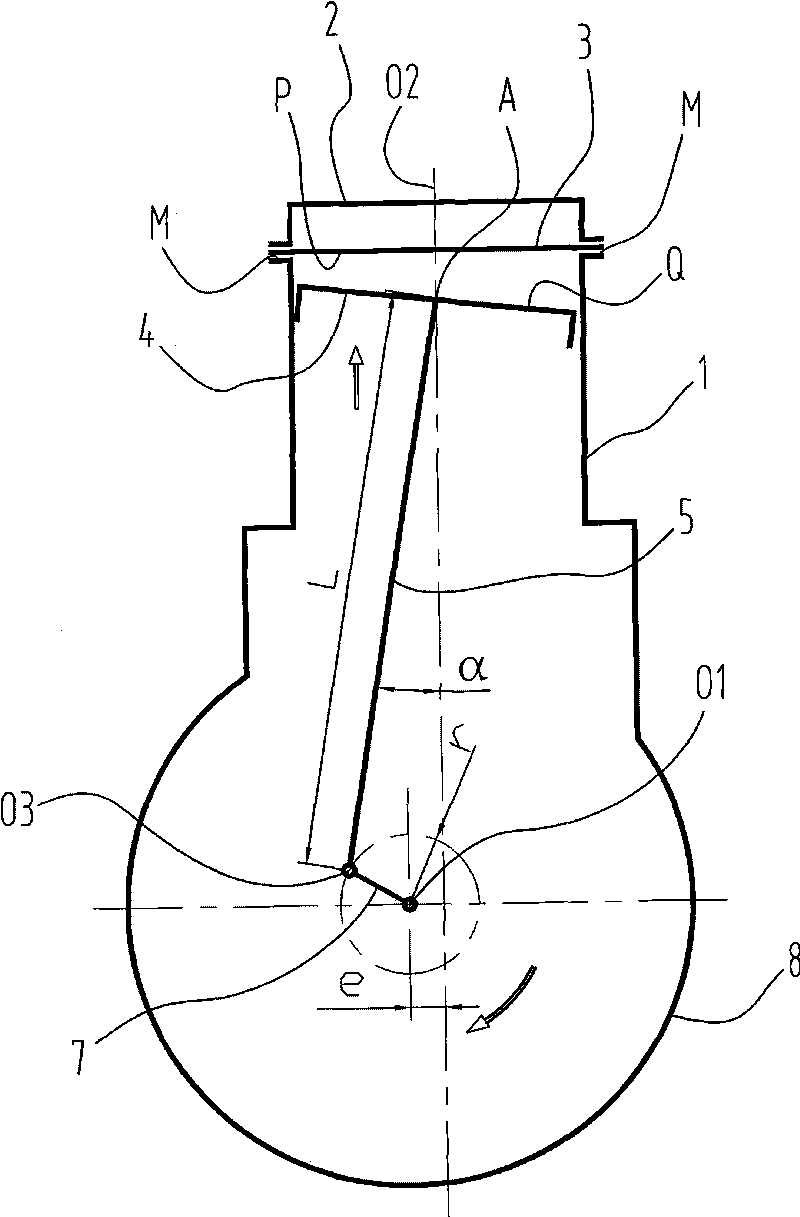

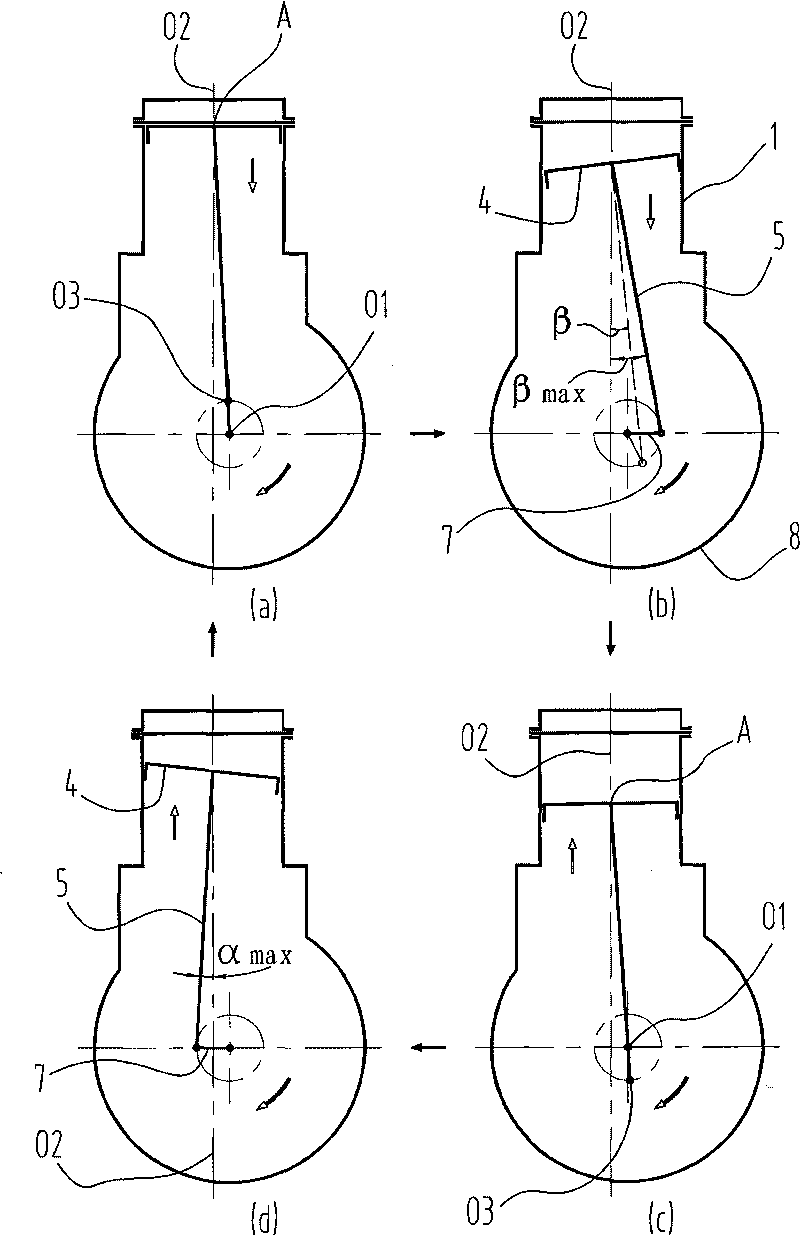

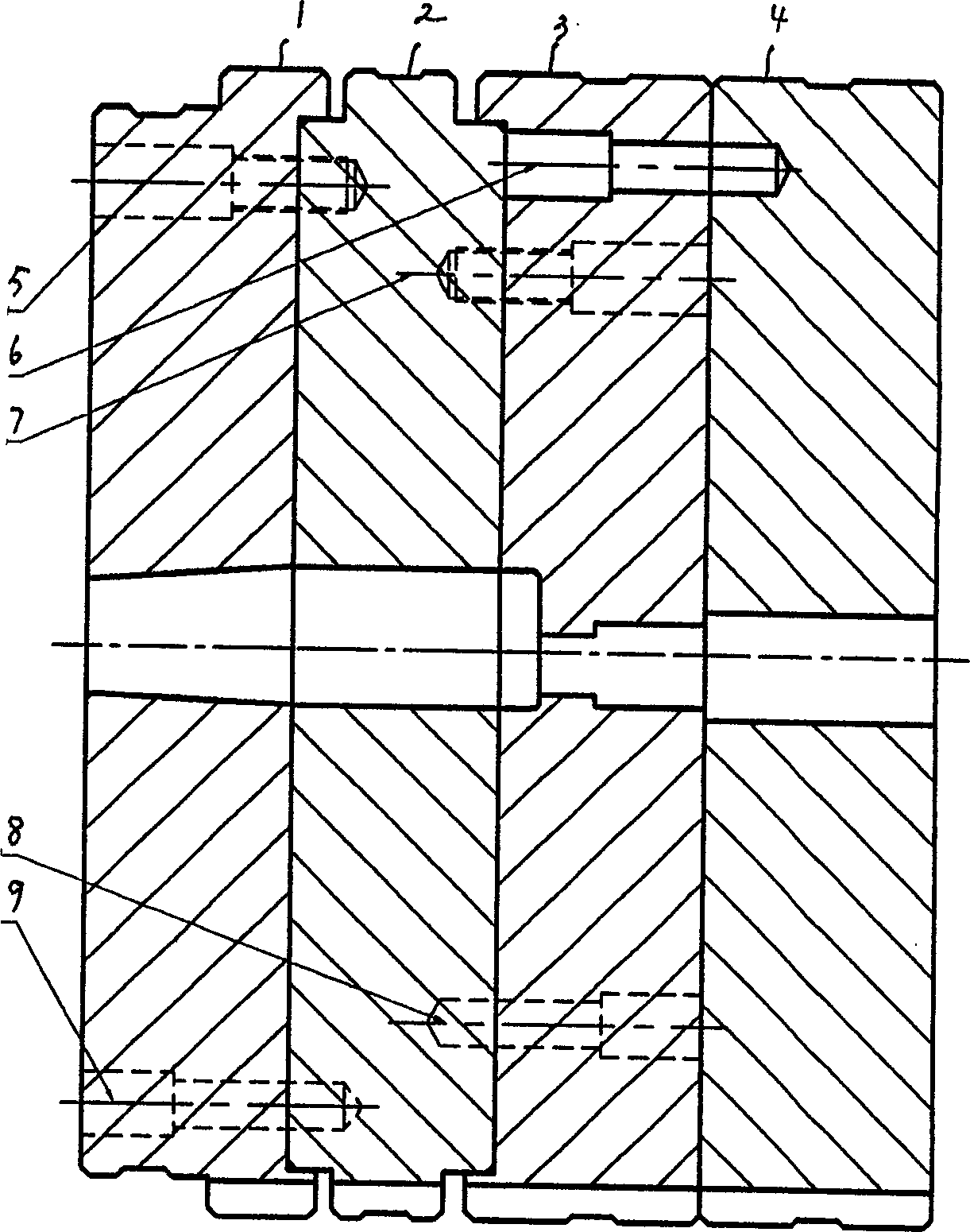

Reciprocating compressor

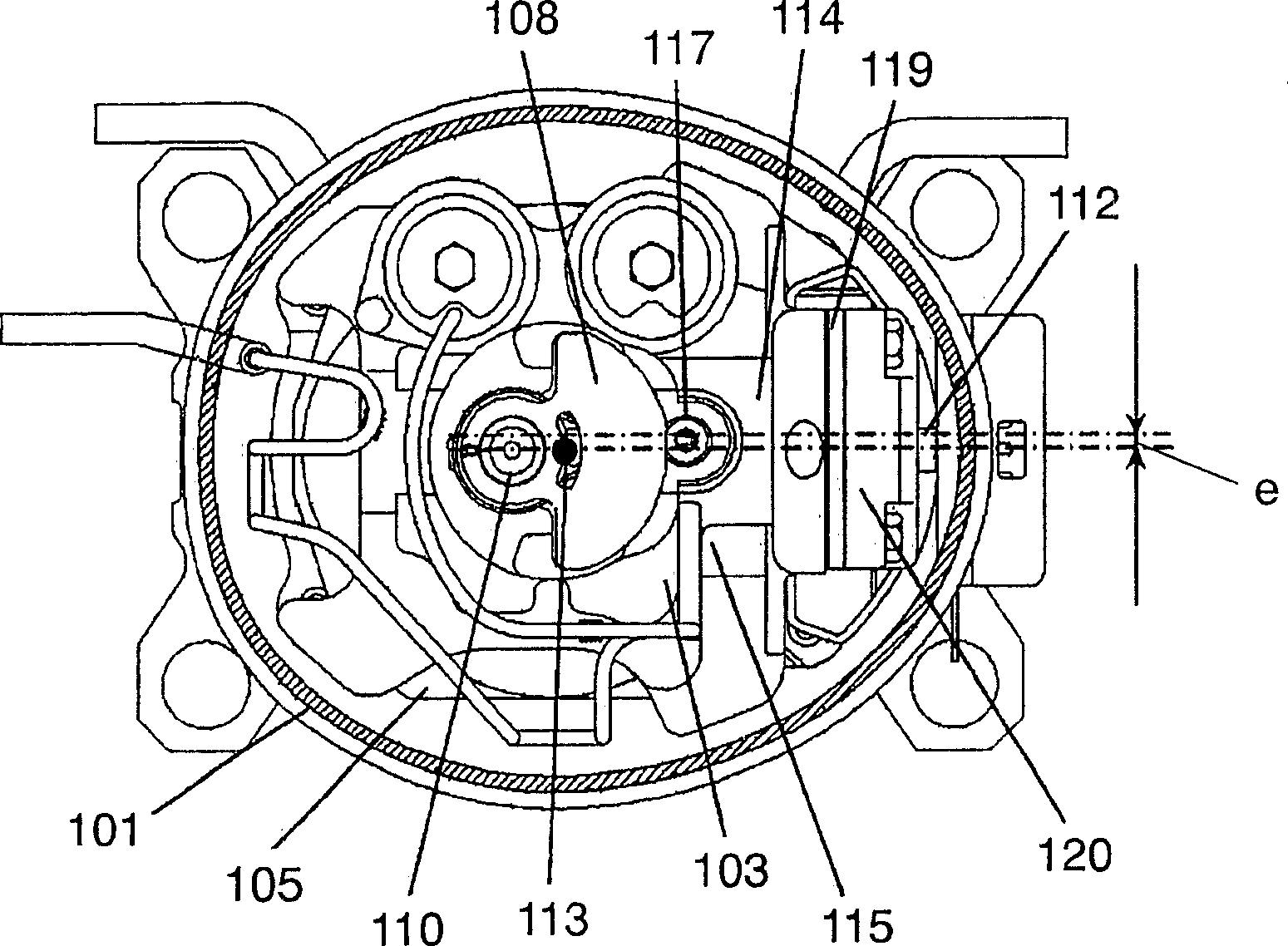

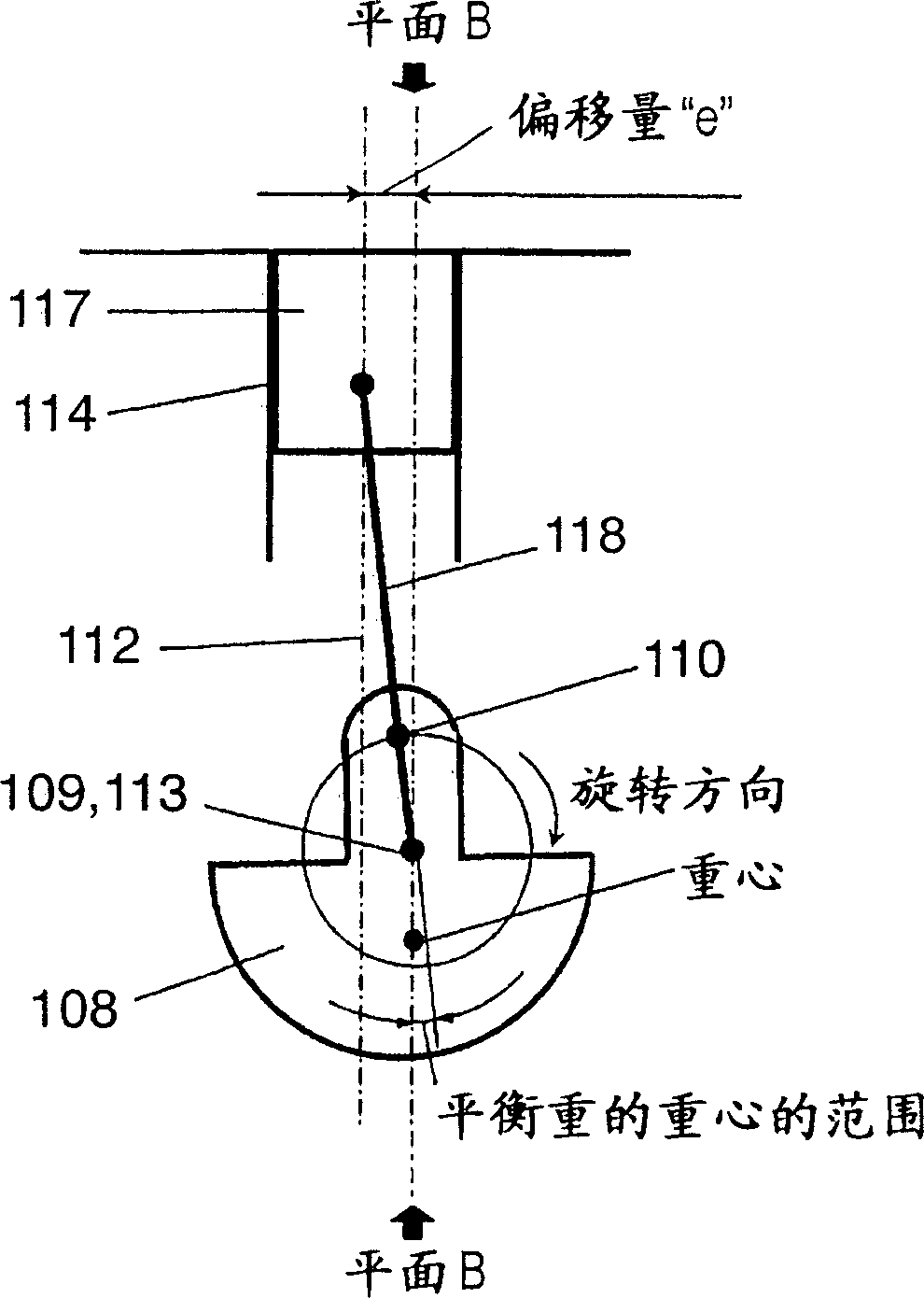

ActiveCN1906413AGuaranteed to workReduce vibrationCompressorInertia force compensationEngineeringMechanical engineering

The present invention relates to a highly reliable reciprocating compressor that operates efficiently using less energy and generates less vibration. The reciprocating compressor includes a crankshaft, a cylinder, a piston, a connecting rod and a balance weight. The cylinder is offset so that its axis does not intersect the axis of the main shaft portion. The center of gravity of the balance weight is disposed substantially opposite to the center of the eccentric portion with respect to the axis of the main shaft portion, and deviated in the rotational direction from a position just opposite to the center of the eccentric portion. The above structure allows reducing the side pressure of the piston, thereby improving the reliability and efficiency of the reciprocating compressor, and allowing the movement of the balance weight to eliminate unbalanced forces generated by the movement of the piston, the connecting rod, and the eccentric portion.

Owner:PANASONIC APPLIANCES REFRIGERATION DEVICES SINGAPORE

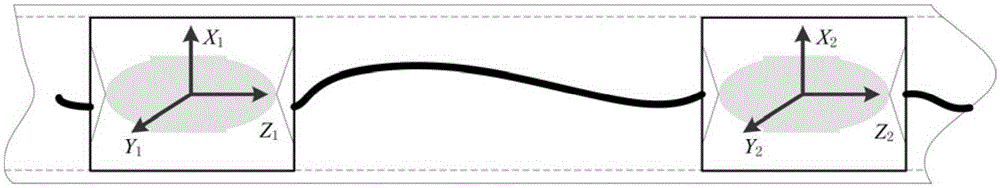

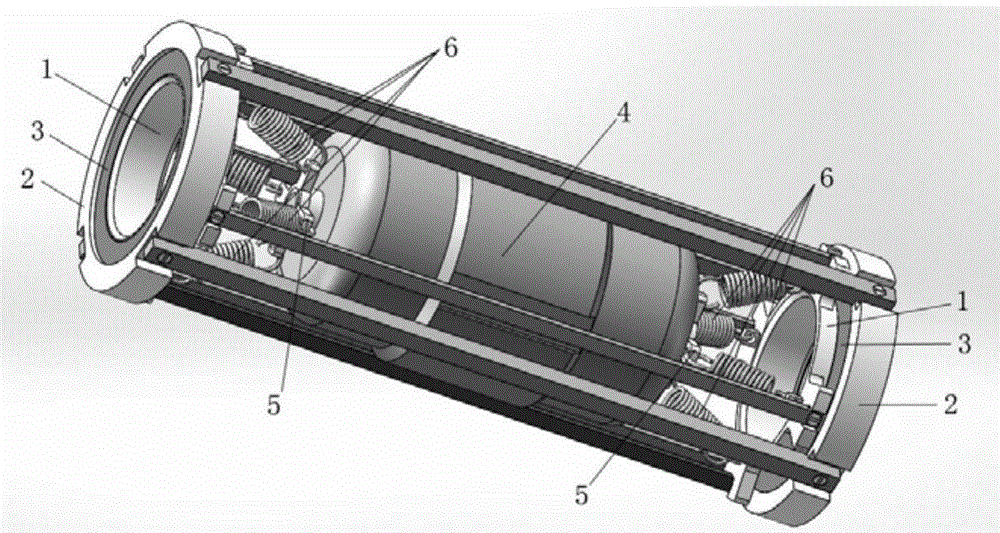

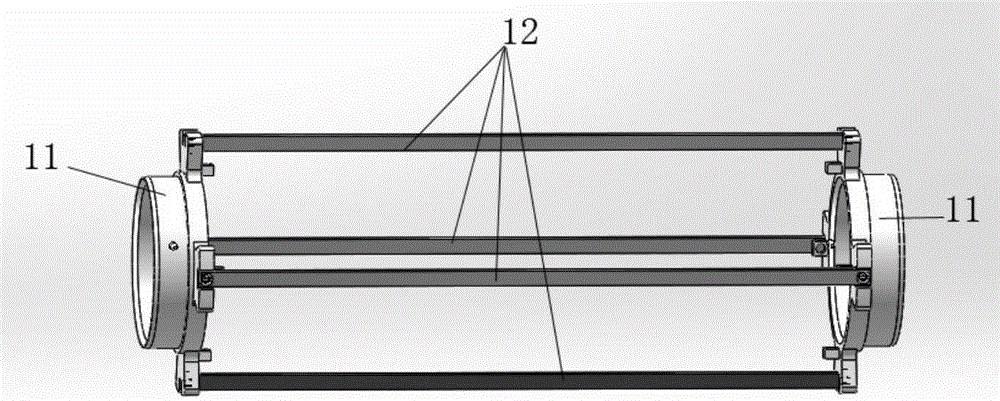

Fiber optic vector hydrophone with posture self-correcting function

ActiveCN105387924AEnsure consistencyReduce side pressureSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberHydrophone

The invention belongs to the technical field of optical fiber sensing, and in particular relates to a fiber optic vector hydrophone with a posture self-correcting function. The vector hydrophone is special for a towed sonar array, and can realize the posture self-correcting in a roll direction of the vector hydrophone, so as to reach the aim that all vector hydrophone element postures in the array are automatically kept consistent. The invention specifically designs a suspension support system with a bias center of gravity, the system is fixedly connected with the vector hydrophone and can freely rotate. According to a principle of dynamics, the vector hydrophone can automatically keep a state of lowest center of gravity, so as to ensure that all elements of the array are kept in the same posture. The fiber optic vector hydrophone provided by the invention is applicable to the control on the posture of a towed vector array vector hydrophone, and also applicable to the control on the posture of a towed array posture sensor, and can ensure that the posture sensor in the towed array is kept in a horizontal state all the time, so as to improve the measuring accuracy of the posture sensor.

Owner:NAT UNIV OF DEFENSE TECH

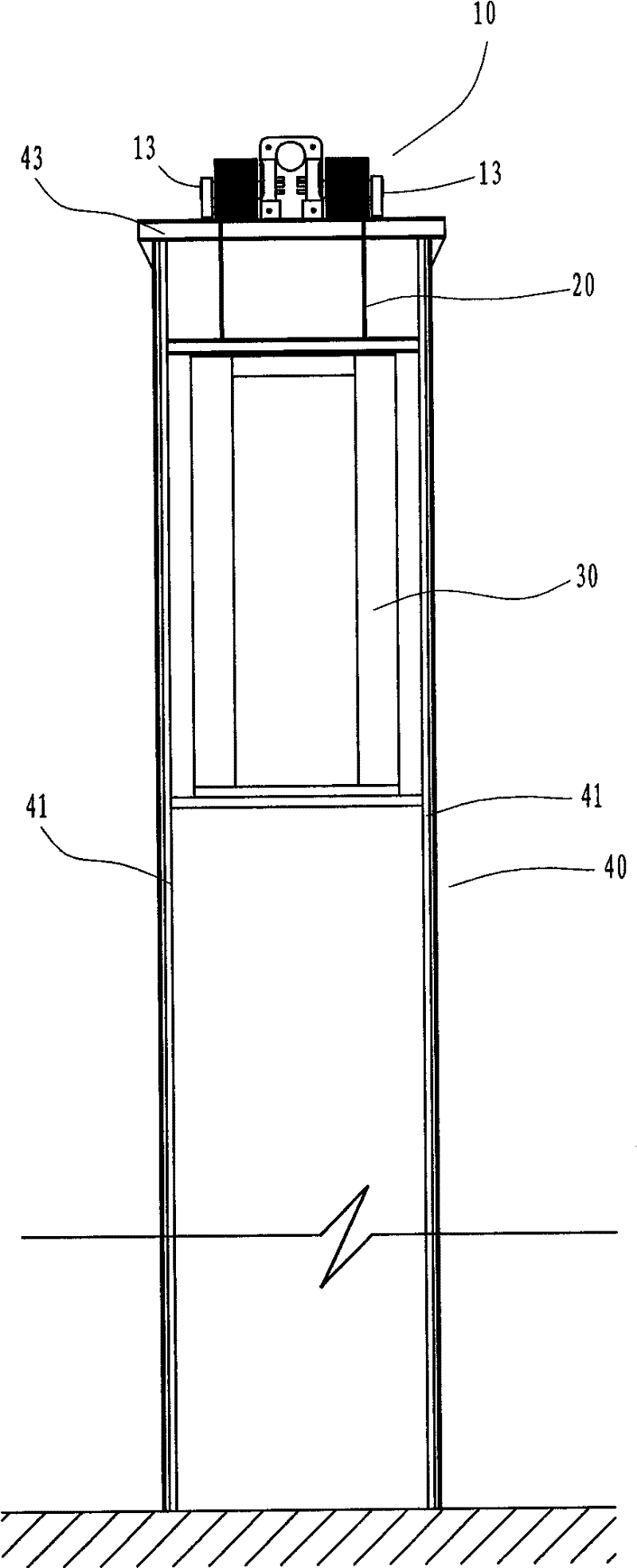

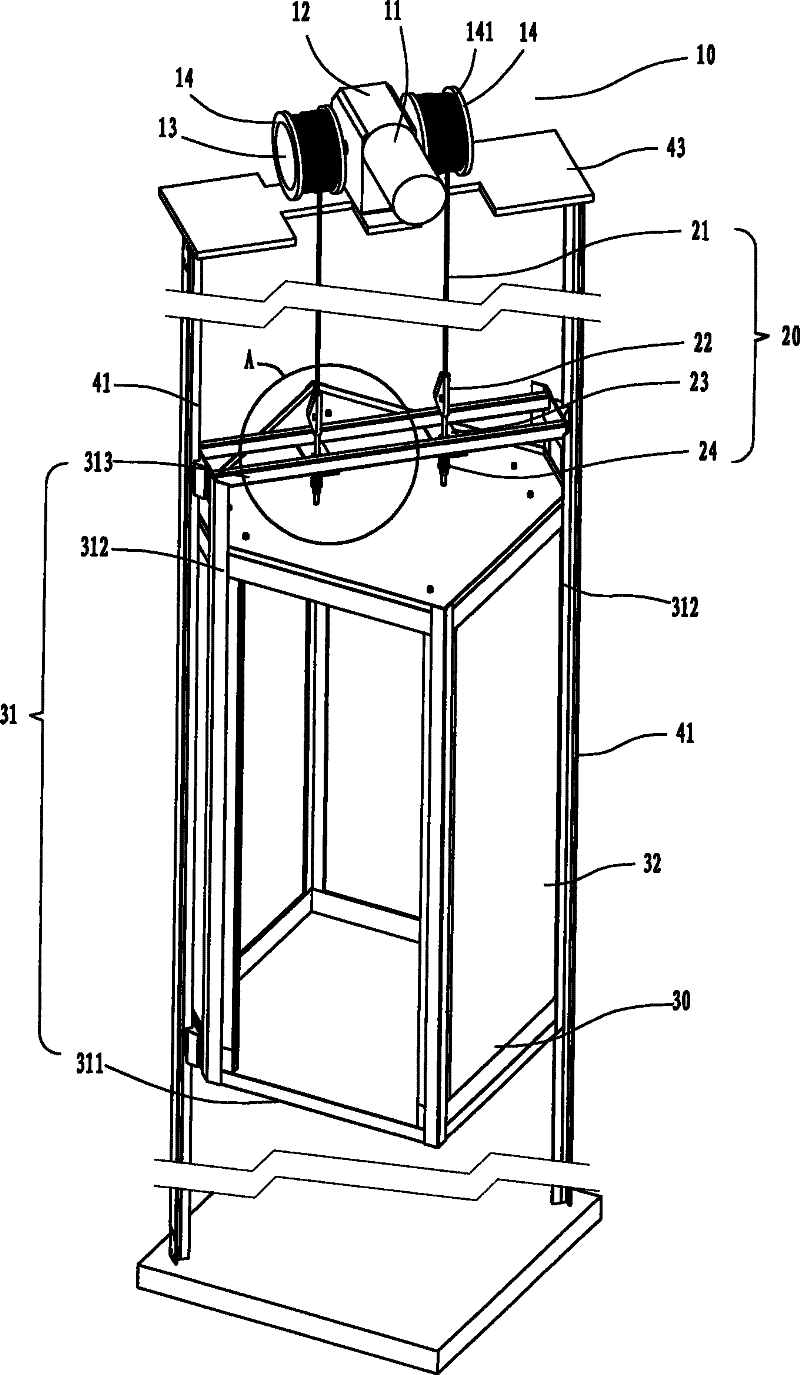

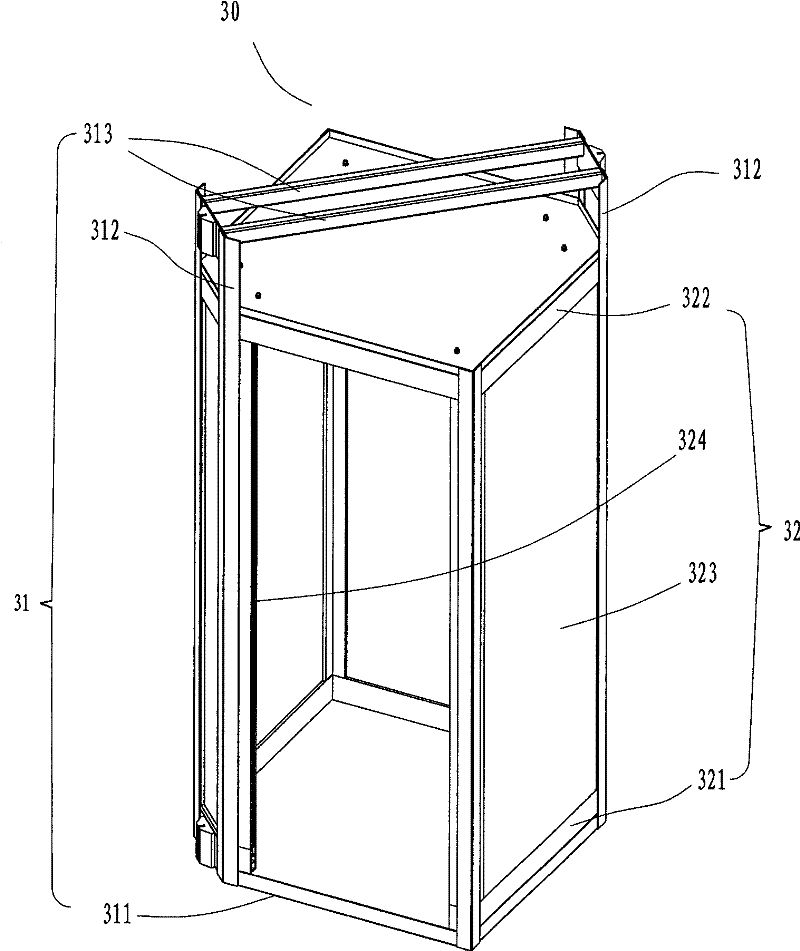

Home elevator

InactiveCN102241353ANo need to add load-bearing wallsTake advantage ofElevatorsBuilding liftsSmall footprintEngineering

The invention relates to a home elevator, which comprises a vertically arranged guide device, a car lifting frame which is arranged in the guide device in a way of being capable of sliding up and down, a positive drive device and a connecting device of which the two ends are connected with the top of the car lifting frame and the power output shaft of the winding driving device, wherein the guide device comprises two bearing guide rails which are positioned on the two sides of the car lifting frame respectively. The home elevator does not need any counter-weight device, is low in cost, has a simple structure and takes up small floor area.

Owner:BEIJING ANTAI HONGYUAN ELEVATOR DESIGN

Reinforced fly ash soil retaining wall and construction method

The invention discloses a reinforced fly ash soil retaining wall and a construction method. The reinforced fly ash soil retaining wall is composed of three parts including padding, reinforcing ribs arranged in the padding and a wall face plate. The method includes the steps that firstly, a retaining wall base groove is excavated on a to-be-constructed ground, foundation construction is conducted, the wall face plate is built on a foundation through building blocks, a settlement joint and an expansion joint are arranged when the wall face plate is built, and geogrids are built between the building blocks of the wall face plate at certain intervals; then, an EPS foam plastic plate is stuck to the wall face plate and is polished; and finally, the saponification residual slag-fly ash-soil light padding is used for backfilling, the performance of the padding should meet the design requirement in the compaction process during filling, manual spreading is adopted close to the EPS foam plastic plate, the rest of the parts are spread, ground and compacted through a machine till each layer of geogrid rib materials are spread and the padding is spread and compacted, and construction of the reinforced fly ash soil retaining wall is completed. The reinforced fly ash soil retaining wall has good performance that the structure is simple, construction is convenient, durability is good, and ageing resistance is achieved.

Owner:HUBEI UNIV OF TECH

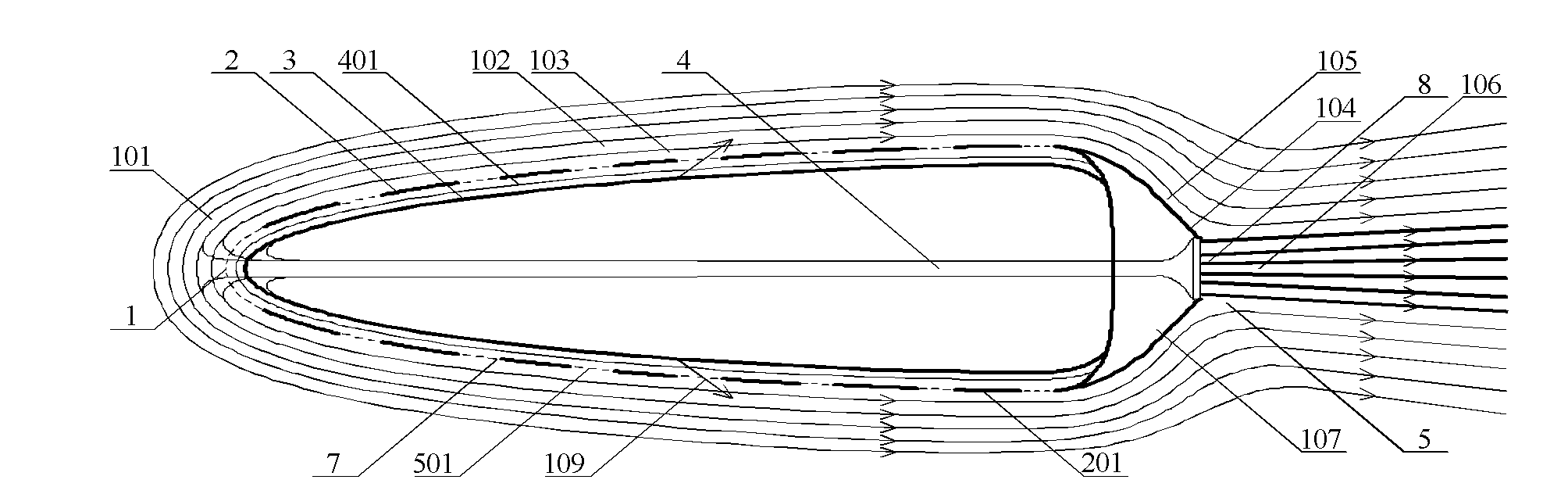

Navigation-hydraulic motor-driven device

The invention discloses a navigation-hydraulic motor-driven device comprising an outer shell and a sealed inner shell. A fluid channel in a navigation direction is arranged between the outer shell and the inner shell; the outer shell is provided with a pressure lead-in port and a pressure lead-out port which are internally and externally communicated with each other; the fluid channel is respectively communicated with the pressure lead-in port and the pressure lead-out port on the outer shell; and a surface path of the outer surface of the outer shell in the navigation direction is longer than that of a fluid path in the fluid channel so that the flowing velocity of the fluid flowing through the surface path of the outer surface is faster than that in the fluid channel. The invention can improve the speed of the navigation-hydraulic motor-driven device with energy source conservation.

Owner:朱晓义

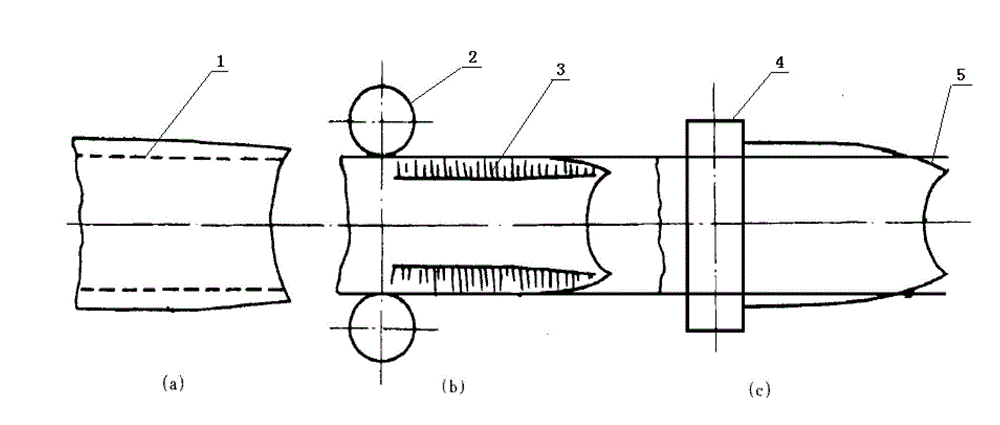

Reciprocating-piston type oil-less air compressor

InactiveCN101737297AReduce side pressureReduce slapping intensityPositive displacement pump componentsPiston pumpsInlet channelLinear compressor

The invention relates to a reciprocating-piston type oil-less air compressor. In the invention, a piston of a compressor is fastened with a connecting rod or integrally manufactured with the connecting rod; and the piston is arranged in an air cylinder and reciprocates and swings relative to the air cylinder. The reciprocating-piston type oil-less air compressor is characterized in that: the air cylinder adopts an offset structure, which means the axial line of the air cylinder is not intersected with the axial line of a crankshaft, so the offset angle of the piston relative to the air cylinder is reduced in the compression stroke, and the lateral pressure and panting strength of the piston on the air cylinder and the abrasion loss of a sealing ring or a sealing rubber cup are reduced; besides, the oval deformation of the sealing ring or the sealing rubber cup is reduced, so the fatigue state thereof is relieved and the screech which is generated by the leakage at an oval gap and the escape of gas is reduced; and moreover, structures such as a closed crankcase structure, a crankcase air inlet soundproofing chamber, an air inlet channel and the like are adopted for effectively reducing the induction noise and the induction jetting noise and an exhaust soundproofing housing is adopted for reducing the exhaust noise, so the reciprocating-piston type oil-less air compressor can be used for manufacturing the air compressor, an air pump, a vacuum pump or a fluid pump.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

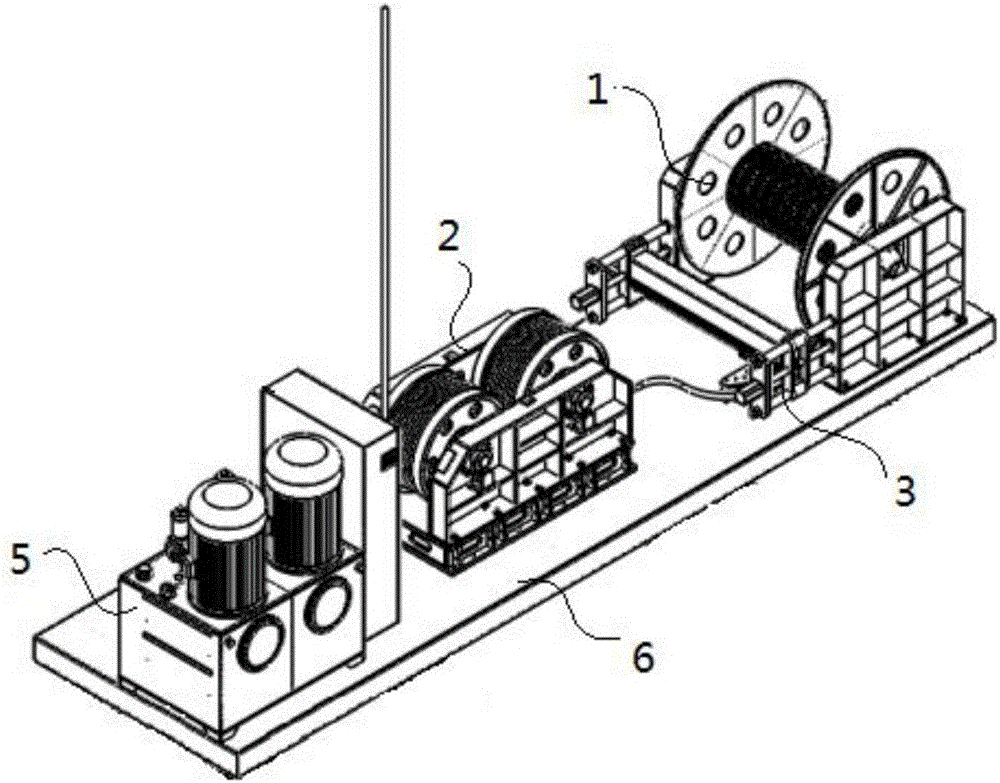

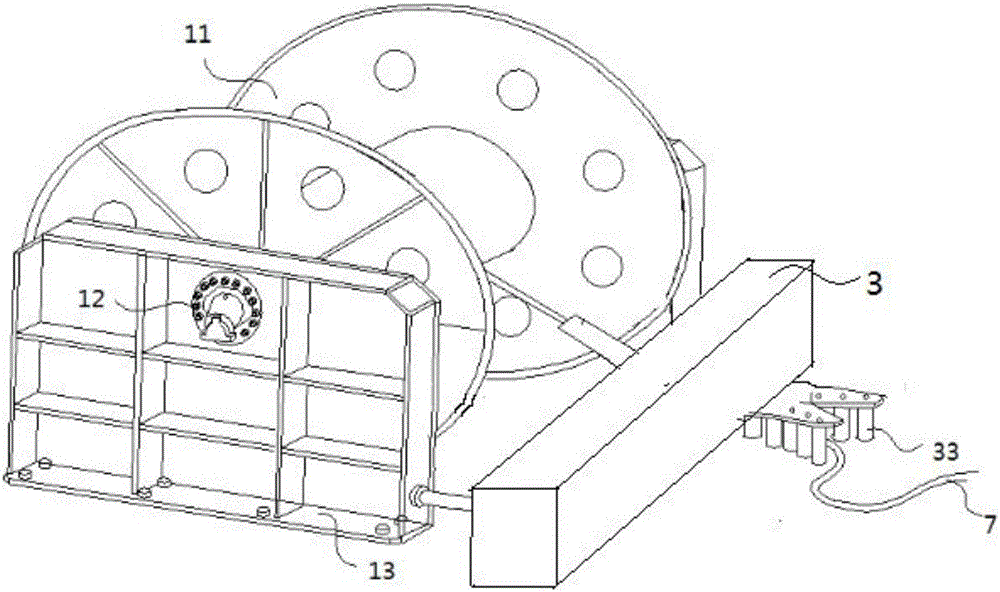

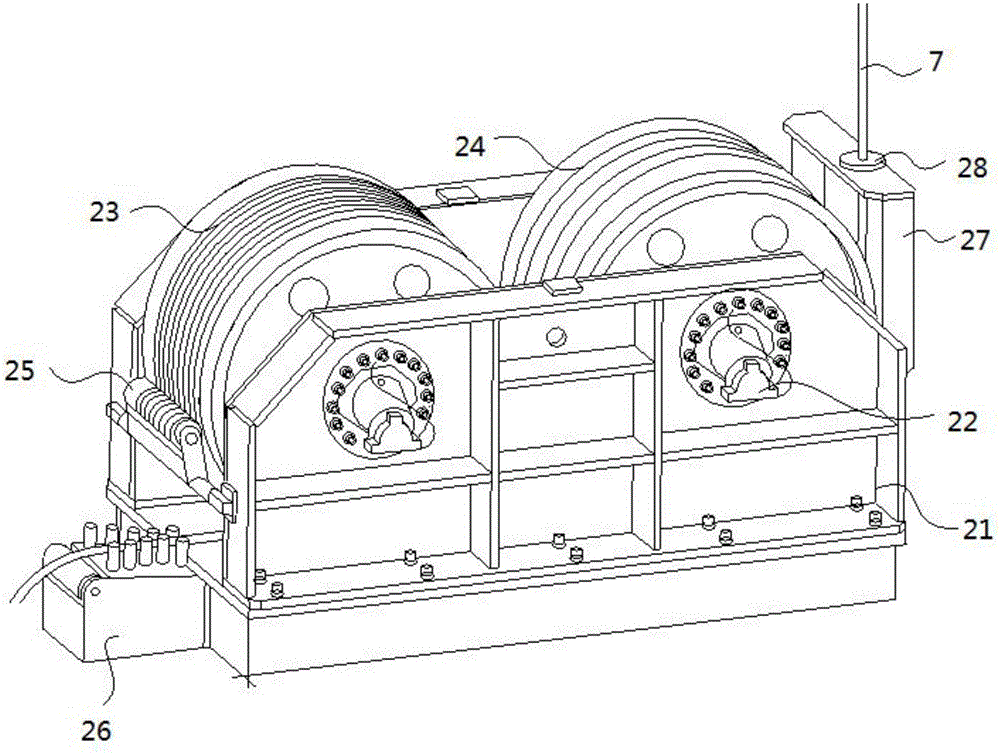

Tie-down rope winding and unwinding device

The invention discloses a tie-down rope winding and unwinding device, and belongs to the field of floating-observation platforms. The tie-down rope winding and unwinding device comprises a winding device, a traction device and an unwinding device, wherein the winding device comprises a winding drum connected with a hydraulic transmission device; the traction device comprises a first traction wheel and a second traction wheel which are connected with the hydraulic transmission device; skewed slots which correspond to each other are formed in the first traction wheel and the second traction wheel in an engraved manner; a mooring rope is wound on the first traction wheel and the second traction wheel in 8-shaped repeated, alternate, single-layer and multi-turn manner; the unwinding device is positioned between the winding device and the traction device; and the winding direction and force of the mooring rope are controlled by a plurality of servo motors of the unwinding device. By a hydraulic transmission mode, volume and weight are reduced, and energy consumption is lowered. Moreover, in a mooring rope winding and unwinding process of the device, stable control on winding and unwinding of the mooring rope and protection to the mooring rope are fully considered in the design, and use safety of a tie-down platform is ensured.

Owner:HUAINAN GUOLI HYDRAULIC MACHINERY MFG

Hot extruding mould for gear shaping sheet heat radiator aluminium profile

The present invention relates to hot extruding mold for aluminum profile of fin inserting heat radiator. The hot extruding mold consists of front guide plate, guide plate and mold face. The front guide plate has two inclined expanding guide ports, the guide plate has expanding guide port in the material feeding end and straight guide port in the discharge end, and the mold face has guide notch in the same shape as the straight guide port in the discharge end of the guide plate. The present invention can perform three pre-deformations of different properties to facilitate the production of aluminum profile of fin inserting heat radiator.

Owner:JIANGYIN GIANSUN MOLD

Special foam concrete for exterior wall external thermal insulation system engineering

InactiveCN108314378AImprove crack resistanceGood flexibilityCeramicwareThermal insulationSetting time

The invention provides a special foam concrete for exterior wall external thermal insulation system engineering. The special foam concrete comprises the following components in parts by weight: 100 parts of a cementing material, 0-50 parts of an admixture, 2-10 parts of a high polymer, 0.5-2 parts of fiber, 2-10 parts of a foaming agent and 2-15 parts of an additive. According to the special foamconcrete provided by the invention, other components are introduced into the common foam concrete, so that the special foam concrete has the characteristics of good fluidity, crack resistance, light weight, good affinity with a thermal insulation material, high bonding strength, adjustable setting time, function of repairing defects of a base wall, and the like, and the special foam concrete is filled between the insulation board and the base wall to play the role of bonding and repairing.

Owner:SHAANXI ACAD OF ARCHITECTONICS

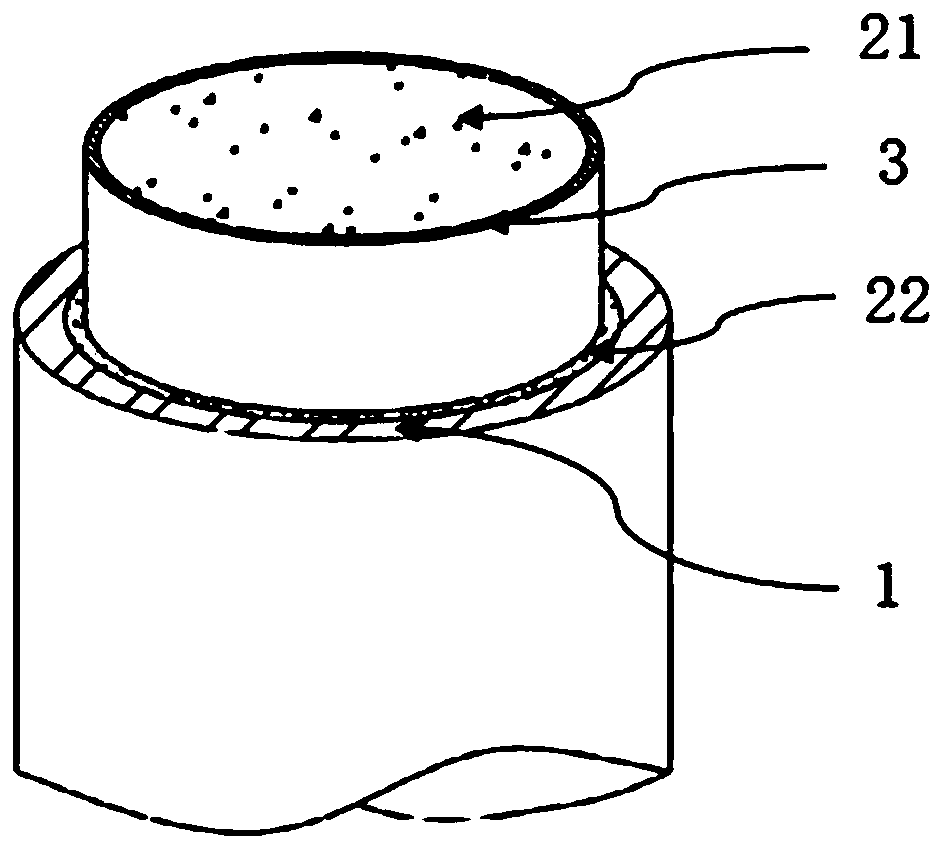

Composite structure and manufacturing method thereof

The invention relates to a composite structure with a high bearing capacity. The composite structure with the high bearing capacity comprises a part A and a part B. The part A is provided with a cavity, and the part B is a solidifiable material filled in the cavity and is under the pressure in the solidification process. The part B comprises a part B1 and a part B2, a material B1 is a cement-basedmaterial, a material B2 is a solidifiable material, and the material B2 has relatively high flowability compared with the material B1. A built-in or / and external volume compensation device is / are arranged. When the material(s) B1 and / or B2 are / is contracted and the material B2 has flowability, the built-in volume compensation device is expanded, or the external volume compensation device squeezesthe flowing and semi-flowing solidifiable material or solid material into a material B2 area in the cavity. The volume compensation device fills up the contracted volume, the pressure of the materialB2 in the cavity is maintained, and the pressure of the material B1 is further maintained. Optimally, the flowing time of the material B2 is larger than the time for the material B1 to arrive at a contraction turning point, and the pressure maintaining time at least exceeds the time for the contraction turning point of the material B1 to appear.

Owner:王哲

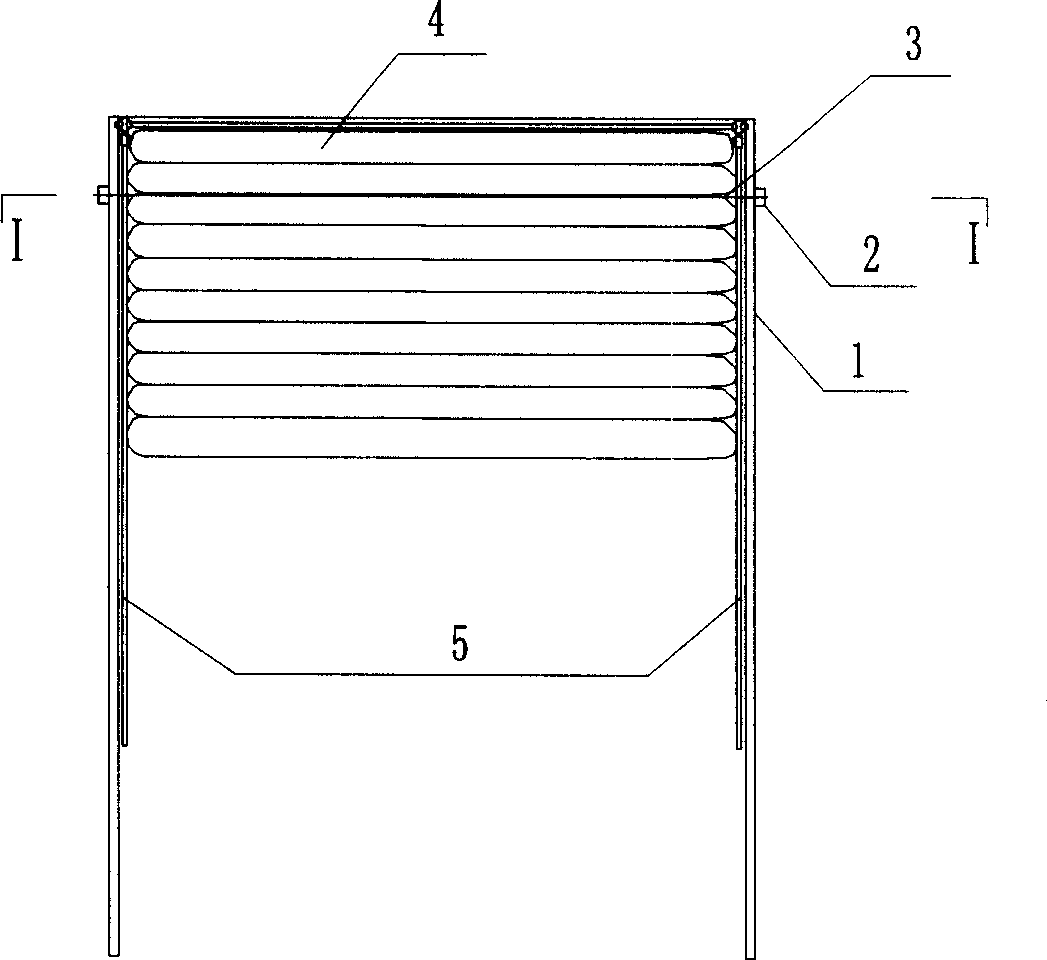

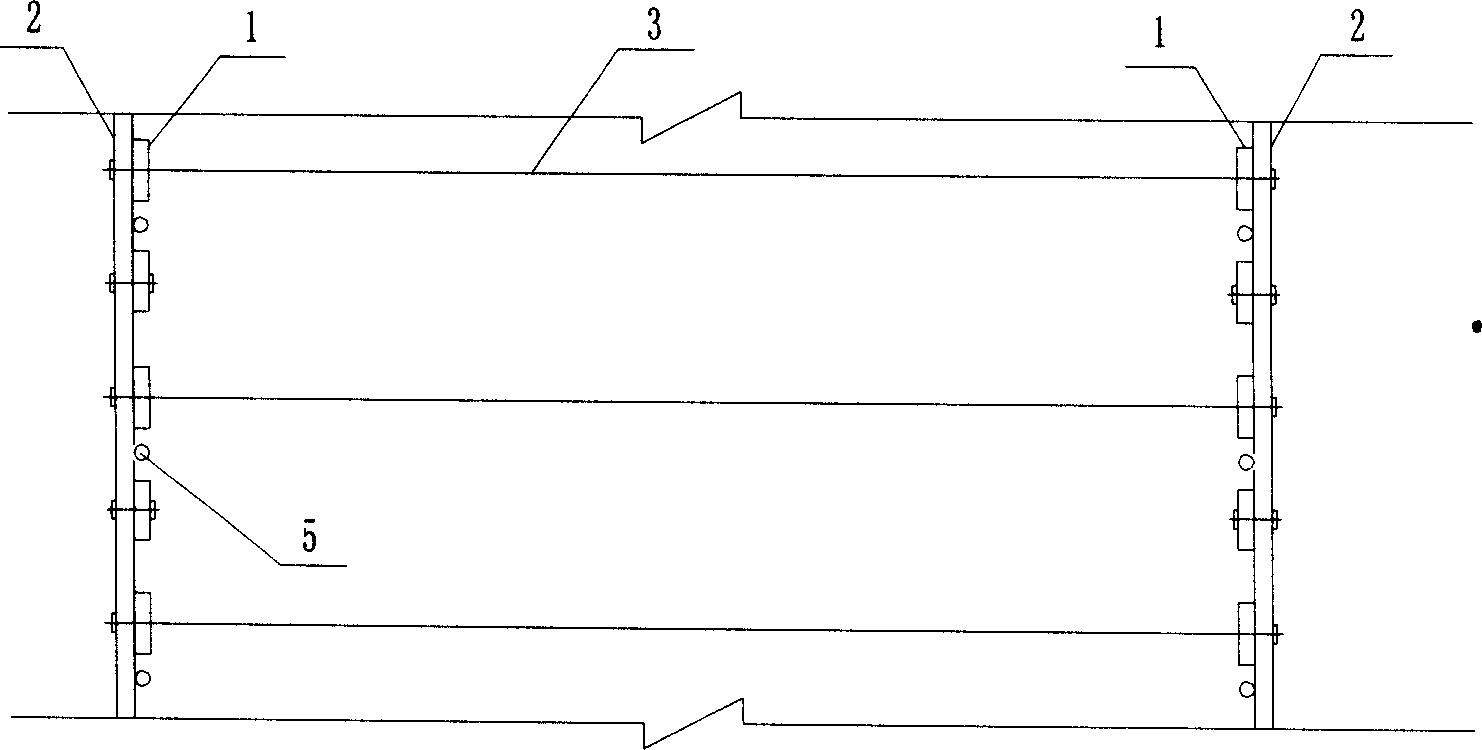

Water-retaining cofferdam structure and construction method thereof

ActiveCN1876968ASimple construction methodReduce difficultyFoundation engineeringCofferdamEngineering

The invention relates to a water retaining coffer structure, which comprises two rows of posts; at least two coffers connected to each transverse direction of one row of posts; at least one row of upper steel drawing rod connected between two rows of posts. Wherein, said posts, coffers, and upper steel drawing rods form the solid frame; and the long blow stuff is filled with soil to be fixed into the frame. The invention has easy application.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

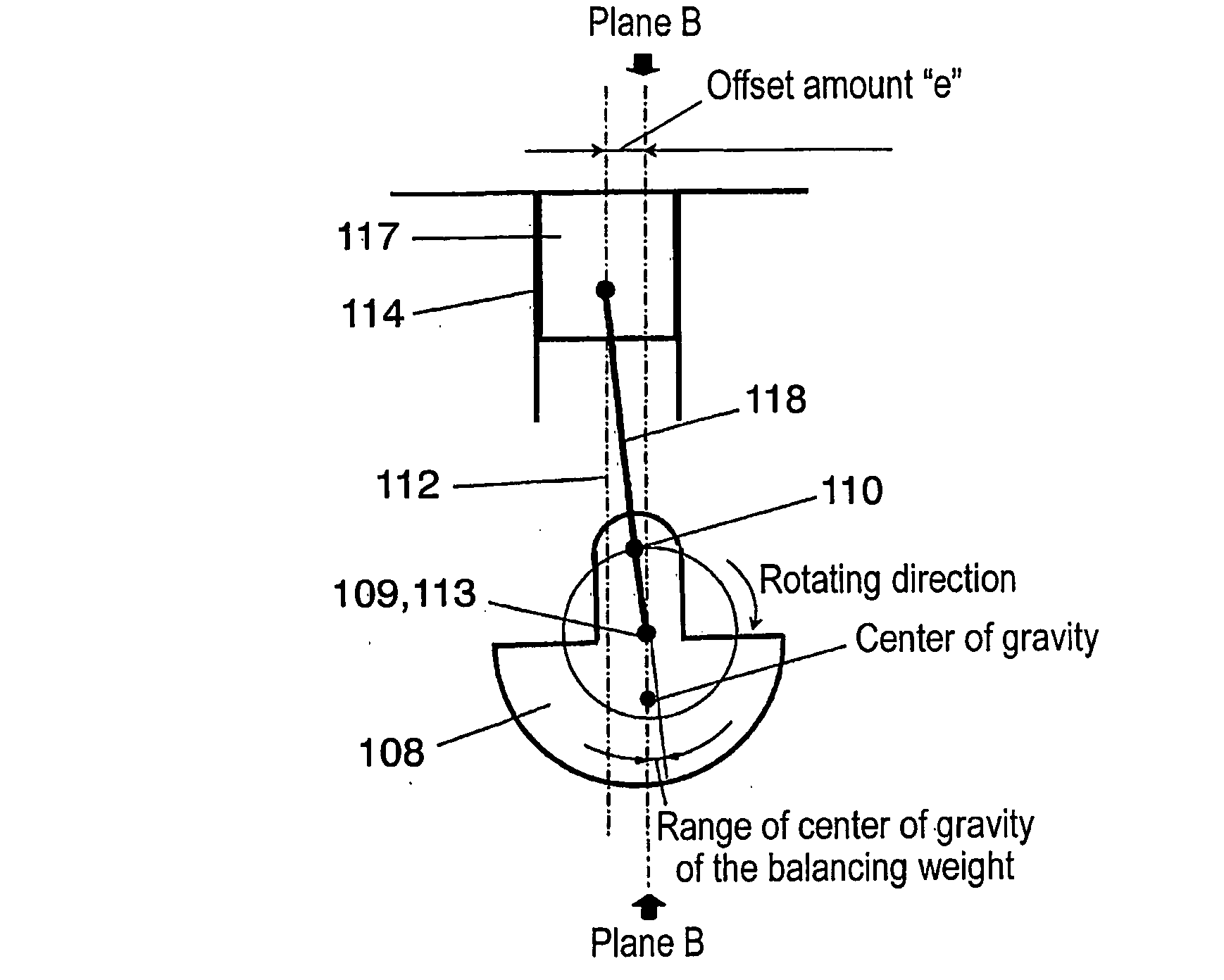

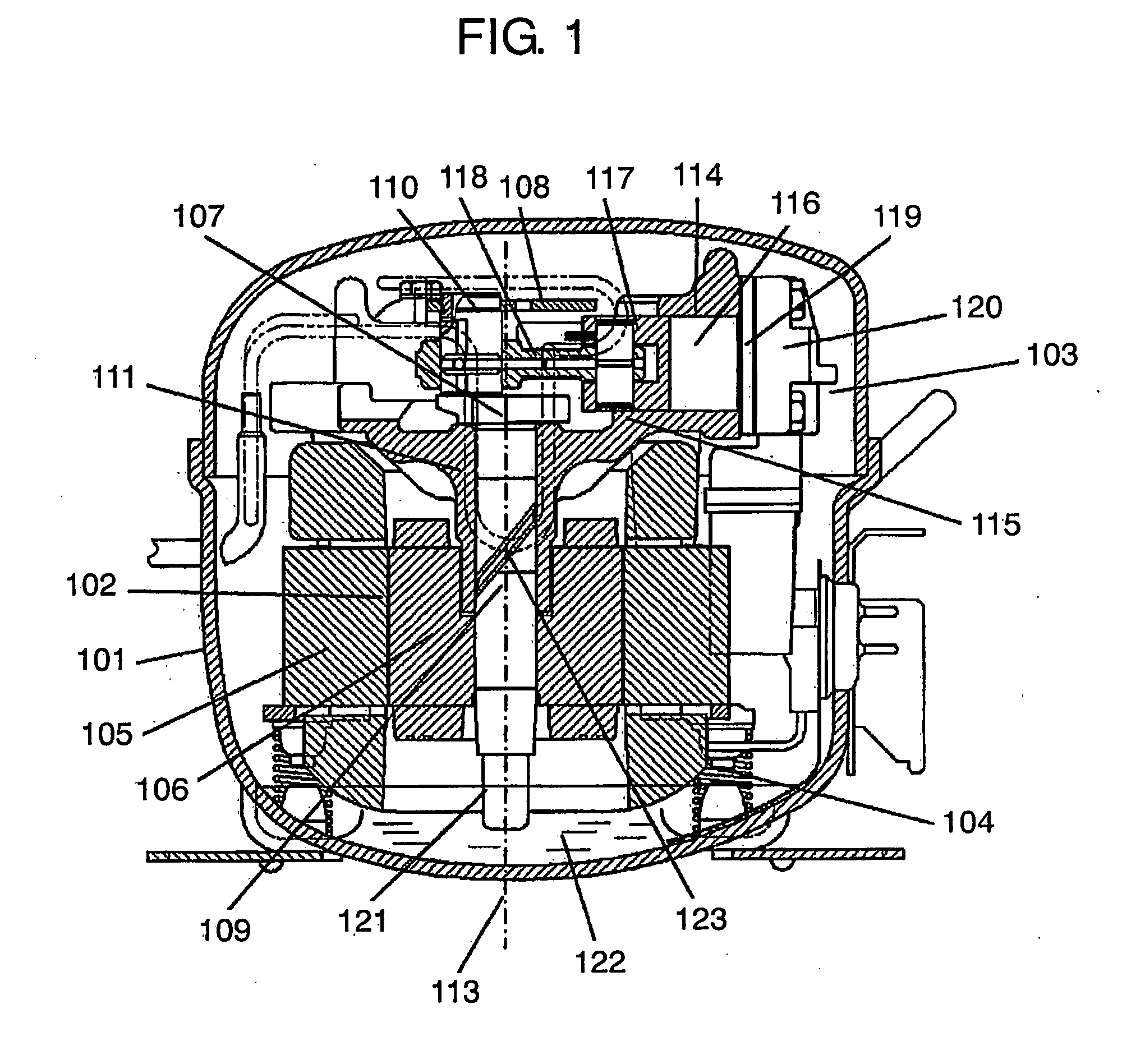

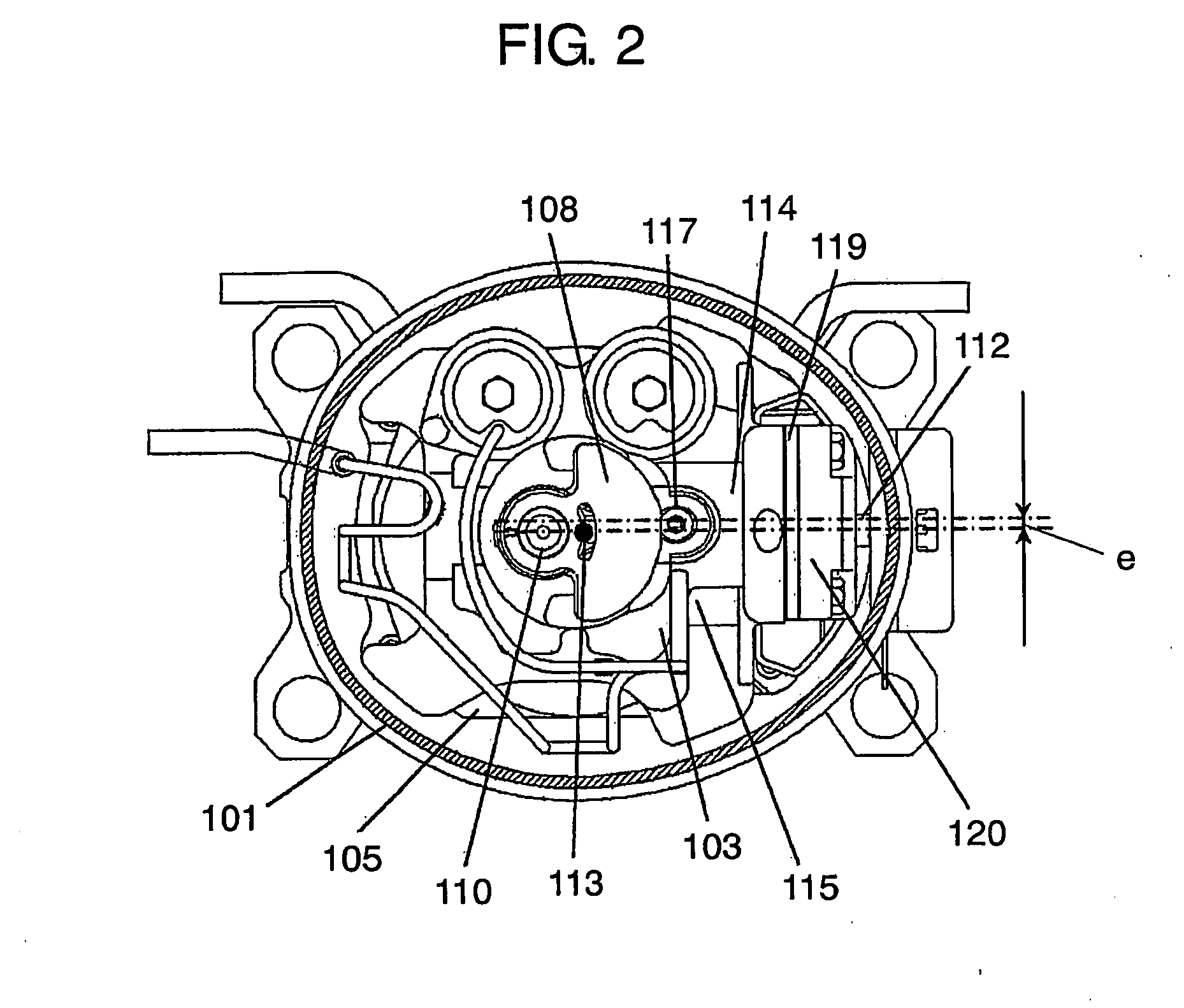

Recriprocating Compressor

InactiveUS20080247890A1Guaranteed to workLittle has been producedCompressorInertia force compensationEngineeringMechanical engineering

A highly reliable reciprocating compressor works efficiently with less energy, and produces smaller vibrations. This reciprocating compressor includes a crankshaft, a block, a piston, a connecting rod, and a balancing weight. The cylinder is placed offset such that an axis line thereof and an axis line of the main shaft do not cross each other. The center of gravity of the balancing weight is placed substantially opposite to the center of the eccentric section with respect to the axis line of the main shaft and deviated along a rotating direction of the main shaft from the place just opposite to the center of the eccentric section. The foregoing construction allows reducing lateral pressure of the piston, thereby increasing the reliability and efficiency of the reciprocating compressor, and allows to cancel unbalancing force produced by motions of the piston, the connecting rod and the eccentric section with motion of the balancing weight.

Owner:PANASONIC CORP

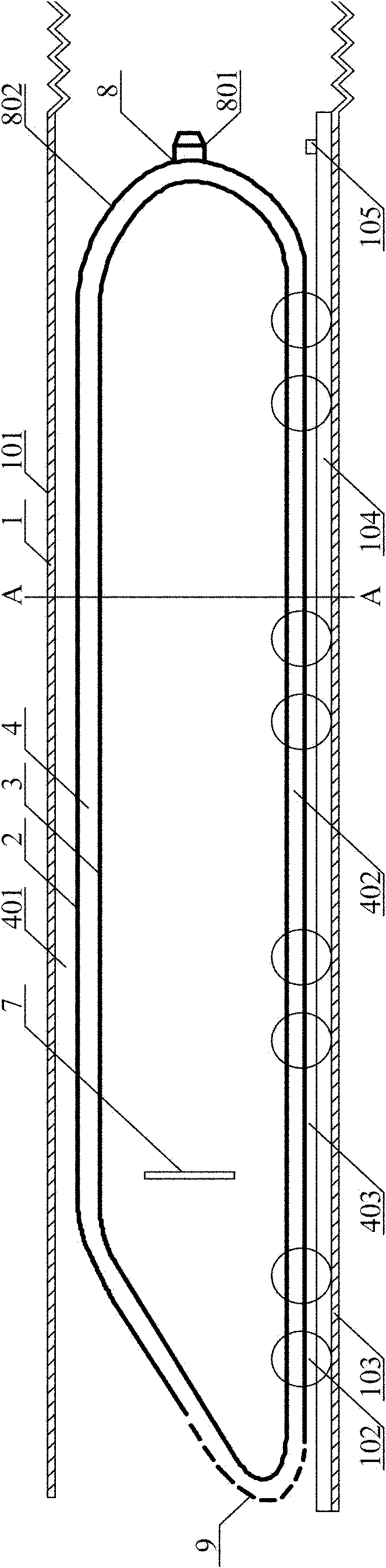

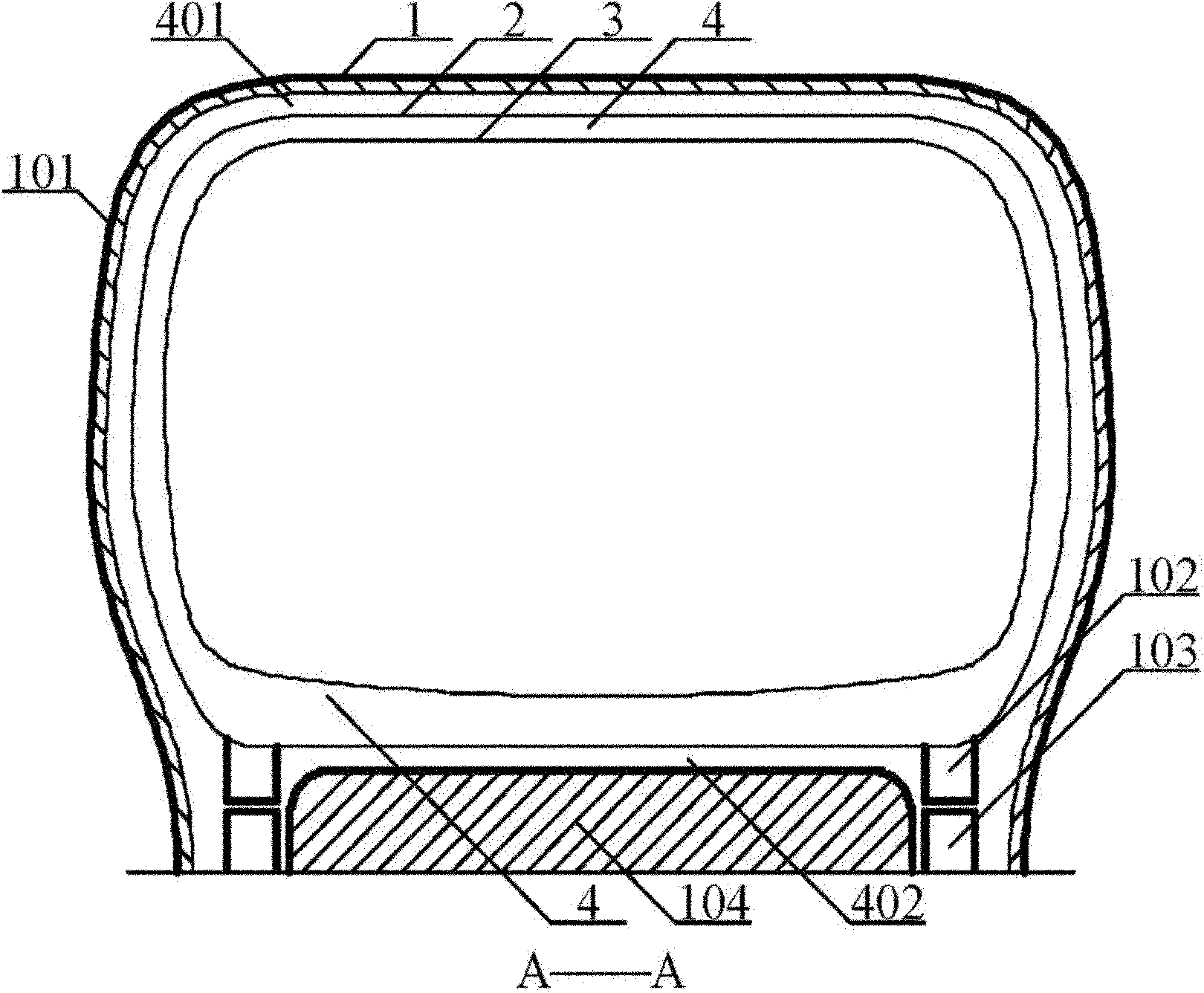

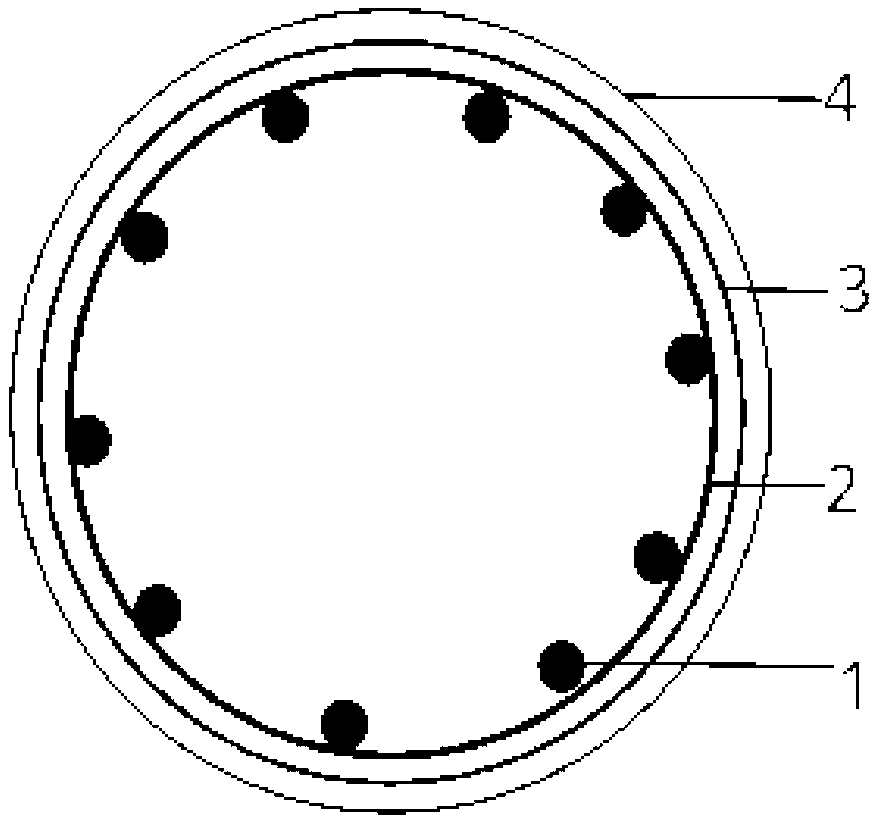

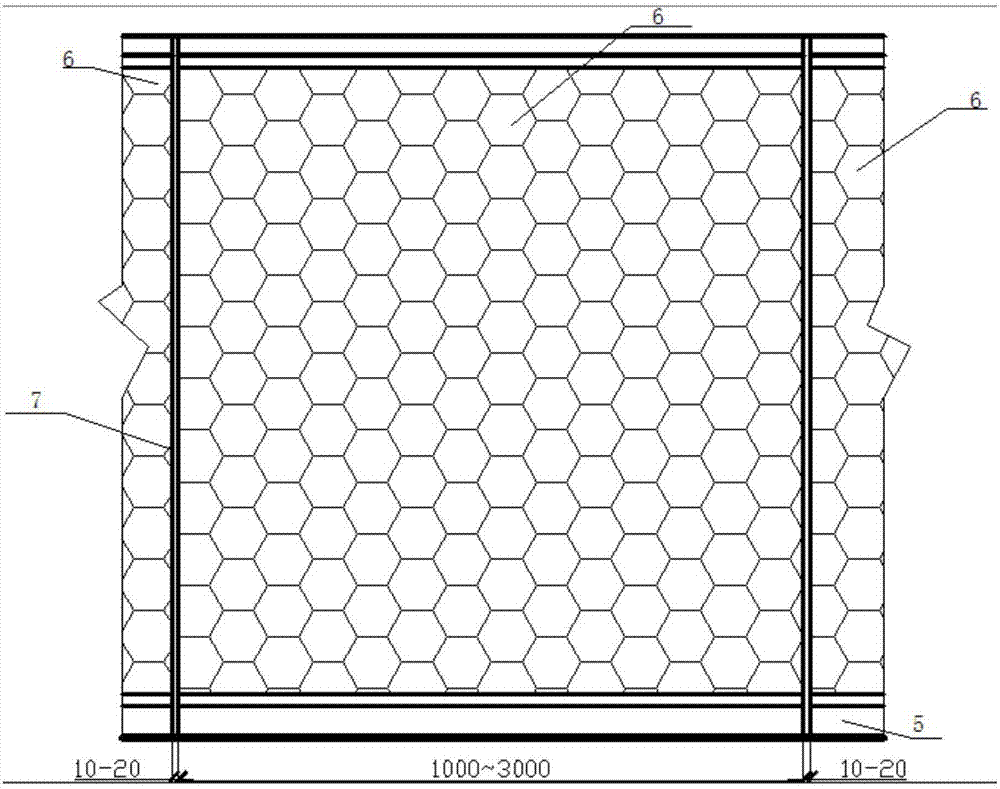

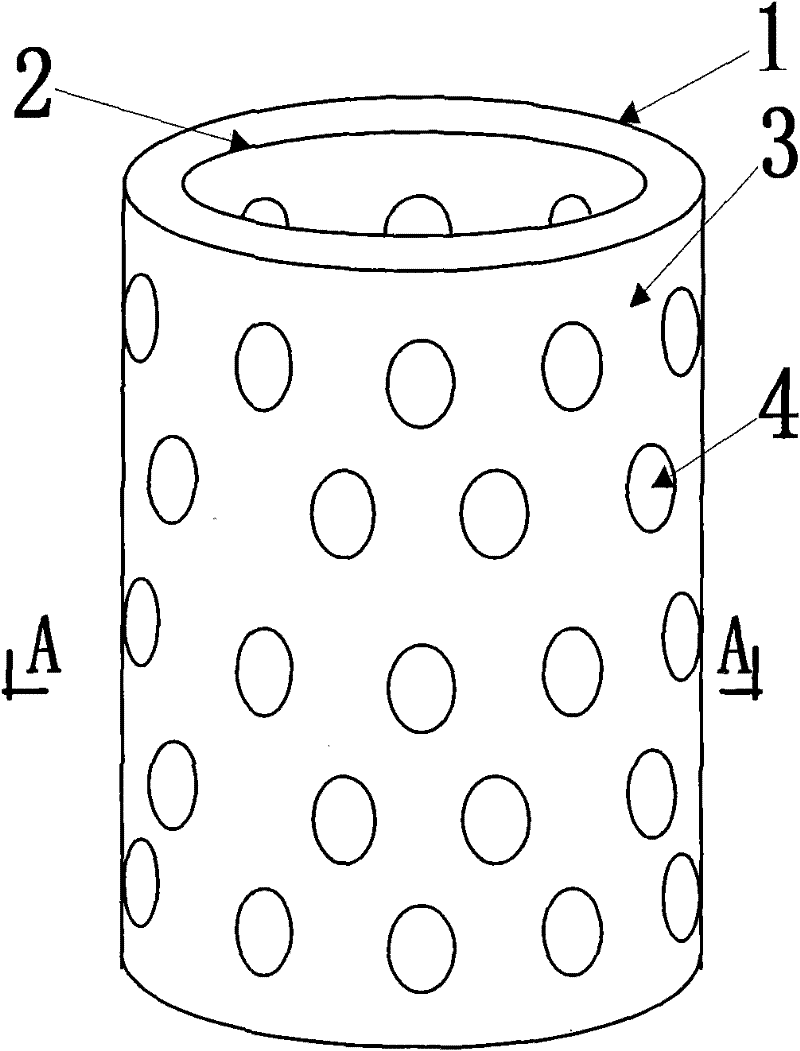

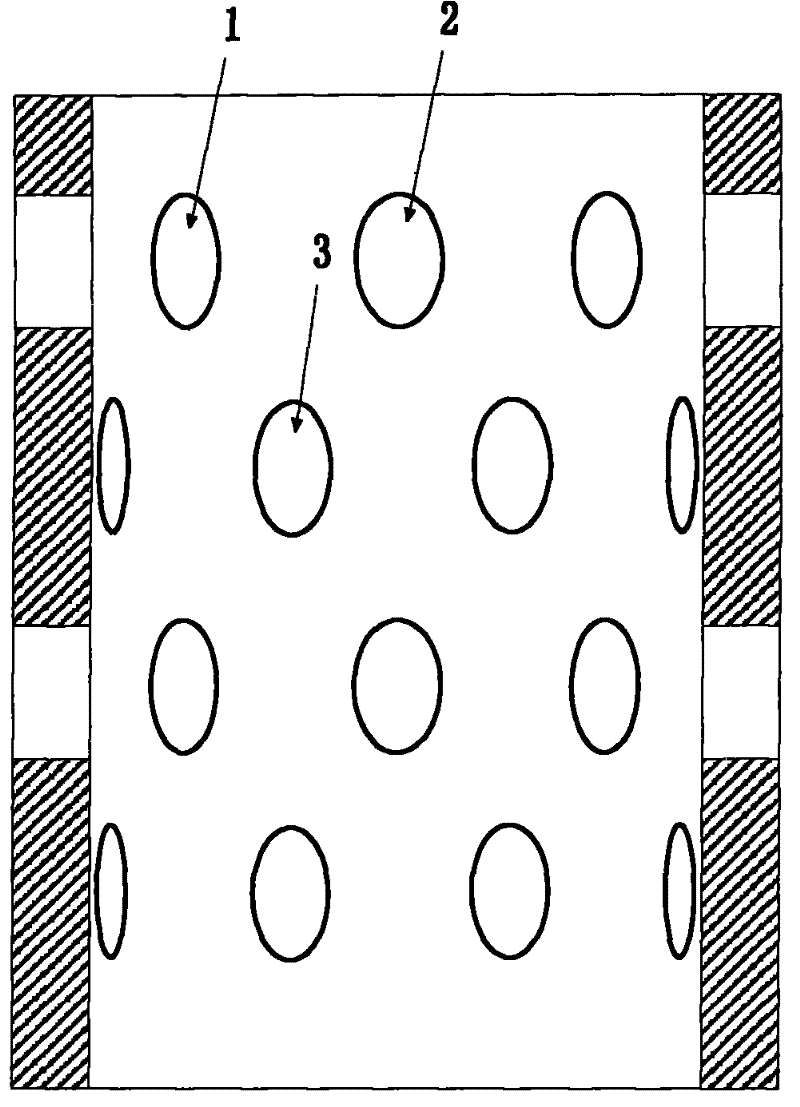

Hollow pile with multiple holes on lateral wall

InactiveCN102433873AAccelerated drainage consolidationImprove bearing capacityBulkheads/pilesSoil preservationPore water pressureHoneycomb Pattern

The invention provides a hollow pile with multiple holes on a lateral wall, belonging to a novel hollow pile for civil engineering. With the adoption of the hollow pile with multiple holes on the lateral wall, soil drainage and solidification can be accelerated, the bearing capacity of a pile body is improved, namely punched holes 4 are formed between an internal wall 2 and an external wall 1 of the pile body of the traditional hollow pile, and upper rows of holes and lower rows of holes are arranged in a staggered manner to form a honeycomb shape. Compared with the traditional hollow pile with the same section size, the holes are formed on the lateral wall and are arranged in a staggered manner and in a honeycomb shape, so that the pile body has a function of transverse water permeability, the dissipation rate of excess pore-water pressure in a foundation soil body can be accelerated, and the efficiency of foundation drainage and solidification is greatly improved; moreover, after pile sinking is completed, soil body extruded from the holes of the pile body is compacted and solidified with a surrounding soil body, the influence of a water film on a critical face between the pile and soil on the side friction resistance of the pile can be effectively reduced, the bearing capacity of the pile body is improved, building garbage is reduced, the environment is protected, and social resources are saved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

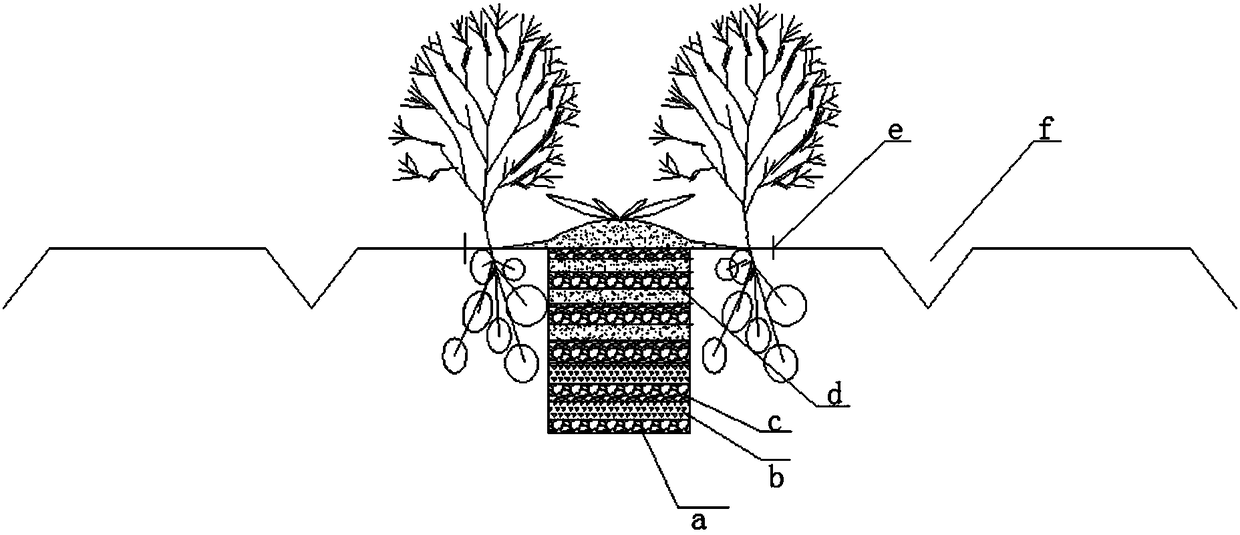

Intercropping method of potato and dandelion

InactiveCN108377872ASolve the problem of easy running entropyImprove moisture conservation effectClimate change adaptationExcrement fertilisersHectarePlastic mulch

An intercropping method of potato and dandelion is a potato planting method. The invention is intended to solve the problem that in the existing potato planting process, rainfall and crushing from agricultural machinery affect the quality and yield of potato. The intercropping method comprises: I, preparing a land; II, digging drain ditches; III, filling the drain ditches, sowing dandelion and applying film; IV, after emergence of dandelion seedlings, guiding the dandelion seedlings out of pores of the film, and earthing around the roots of the dandelion seedlings; V, planting potato; VI, managing a field; VII, harvesting potato; VIII, stagewise harvesting dandelion. The intercropping method has the advantages that potato yield can be increased by 5-10% based on the prior art, the yield per mu of dandelion stem and leaf reaches 1800-2000 kg, and 600-800 cubic meters of straws are consumed per hectare. The intercropping method is applicable to potato planting.

Owner:黑龙江省农业科学院植物脱毒苗木研究所

Novel anti-seismic retaining backfilling composite structure

PendingCN107905249AShorten the construction periodConvenient and efficient constructionArtificial islandsUnderwater structuresCrushed stoneRetaining wall

The invention belongs to the technical field of slope supporting, and discloses a novel anti-seismic retaining backfilling composite structure for solving the problems that an existing retaining structure is high in construction cost and prone to sedimentation, and potential safety hazards exist. The novel anti-seismic retaining backfilling composite structure comprises an L-shaped retaining wallarranged on a pile foundation. The retaining wall comprises a straight wall and a bottom plate arranged on the pile foundation. The straight wall and the bottom plate are connected together to form the L-shaped stop wall. The upper portion of the bottom plate is filled with a rubble layer. Cavities between the rubble layer and the slope body and between the straight wall and the slope body are filled with foam light concrete. The novel anti-seismic retaining backfilling composite structure has the beneficial effects that the stop wall settlement deformation is little, the wall lateral pressureis small, and the construction period is short.

Owner:GUYUAN CHENTONG TECH DEV CO LTD

Ice breaking ship

The invention provides an ice breaking ship. Continuous method ice breaking devices are correspondingly arranged on the broadsides on the two sides of a ship body, an impact method ice breaking deviceis arranged at the bottom of the ship body, according to the ice breaking ship, the continuous method ice breaking devices are provided, before the ice breaking ship is contacted with an ice layer, the action of a cone head structure on a hydraulic device is used for providing an instantaneous impact force for the vertical cross section of the ice layer, multiple times of impact can be achieved and used for breaking the inner part structure of the ice layer, crushability of the ice layer can be increased, and thus resistance is reduced in continuous ice breaking; and the action can also be used for breaking floating ice on the two sides of the ice breaking ship during sailing, thus lateral pressure on the ship body broadsides from the floating ice is reduced, and wear-out failure is reduced. According to the ice breaking ship, the impact method ice breaking device is provided, the ice breaking device extending out of the bottom of the ship and the potential energy effect are used, theice breaking efficiency is increased, the gravity of the ship bottom can be used for being gathered at one point or a part, thus stress of the ice layer is increased, the ice breaking efficiency is increased, and meanwhile the ship body structure is not damaged.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com