Patents

Literature

52results about How to "Little has been produced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic components

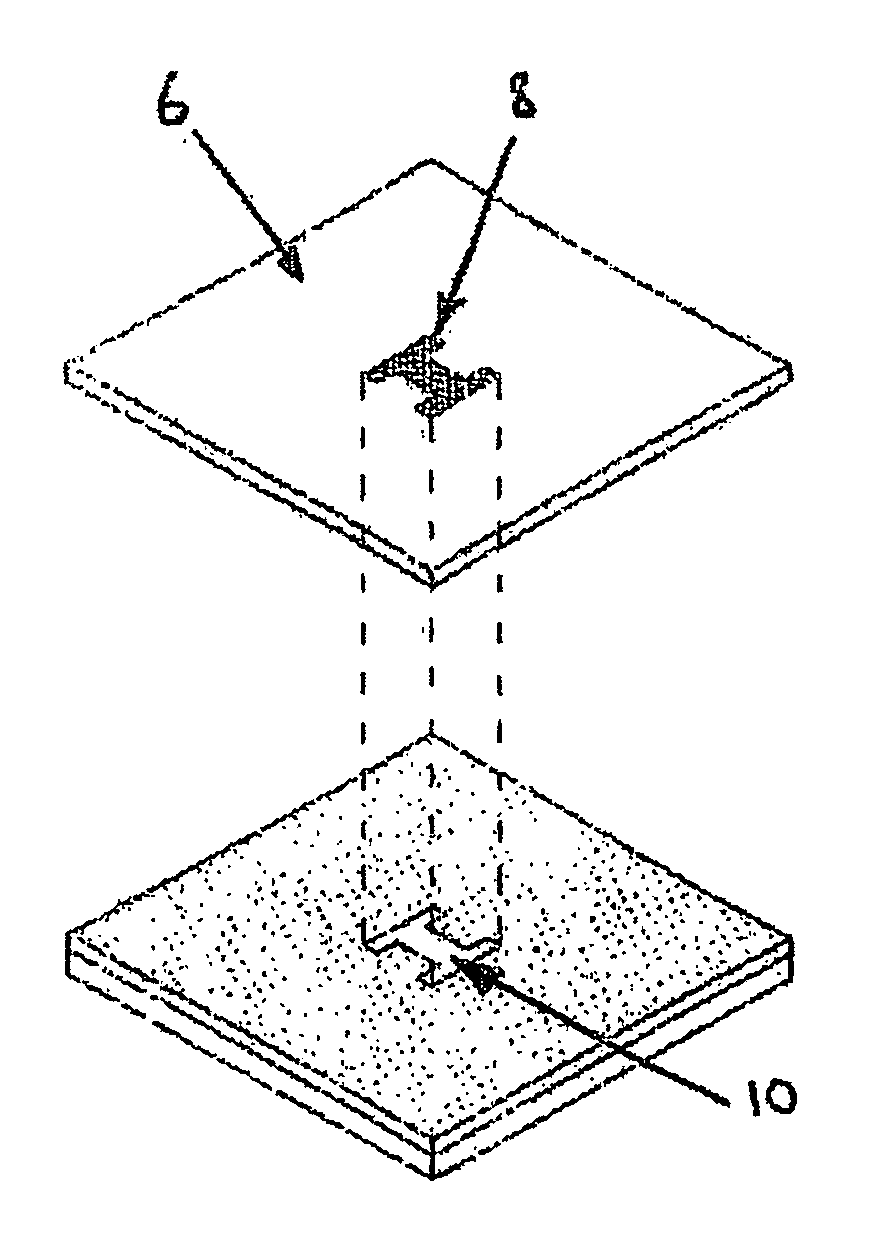

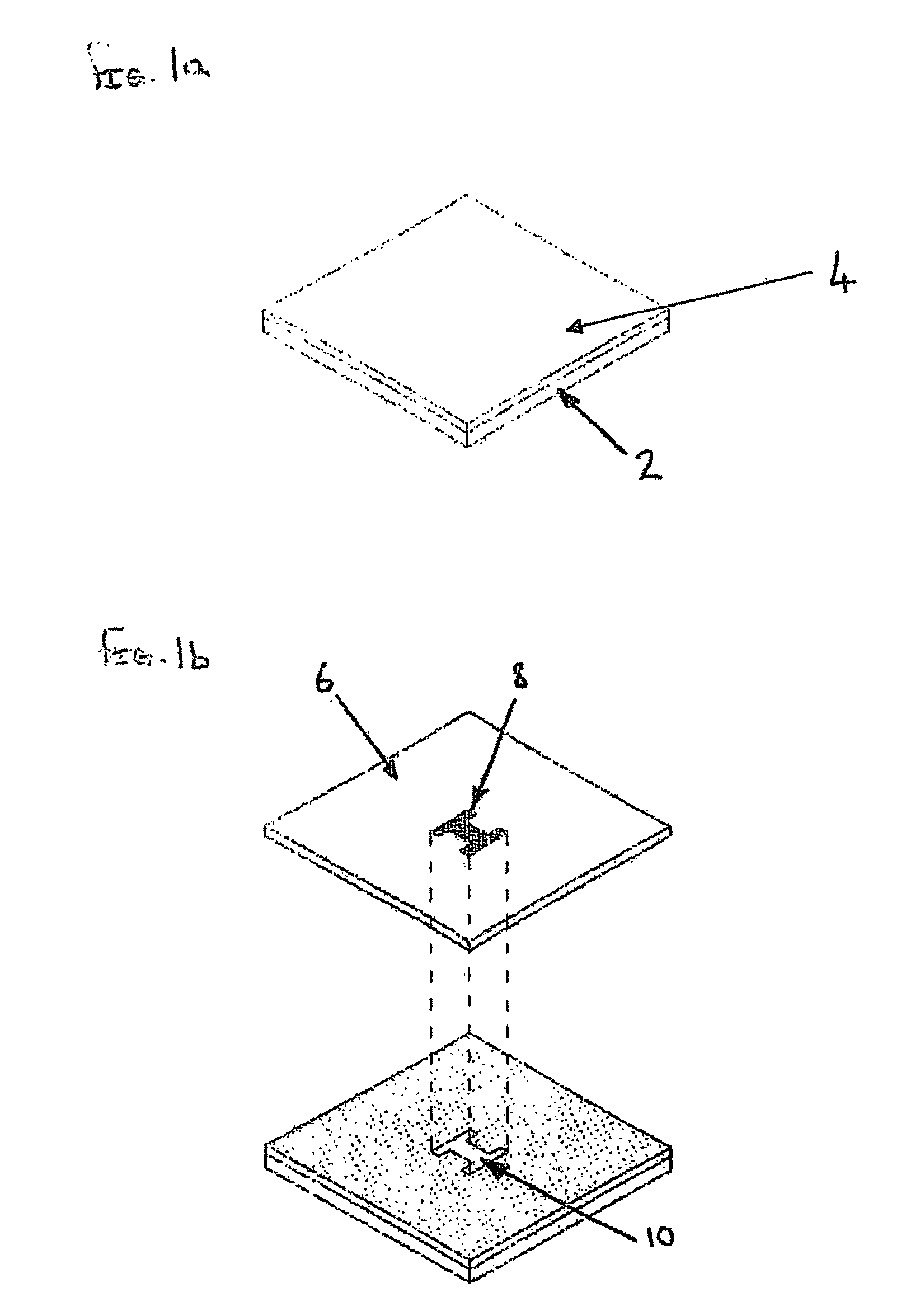

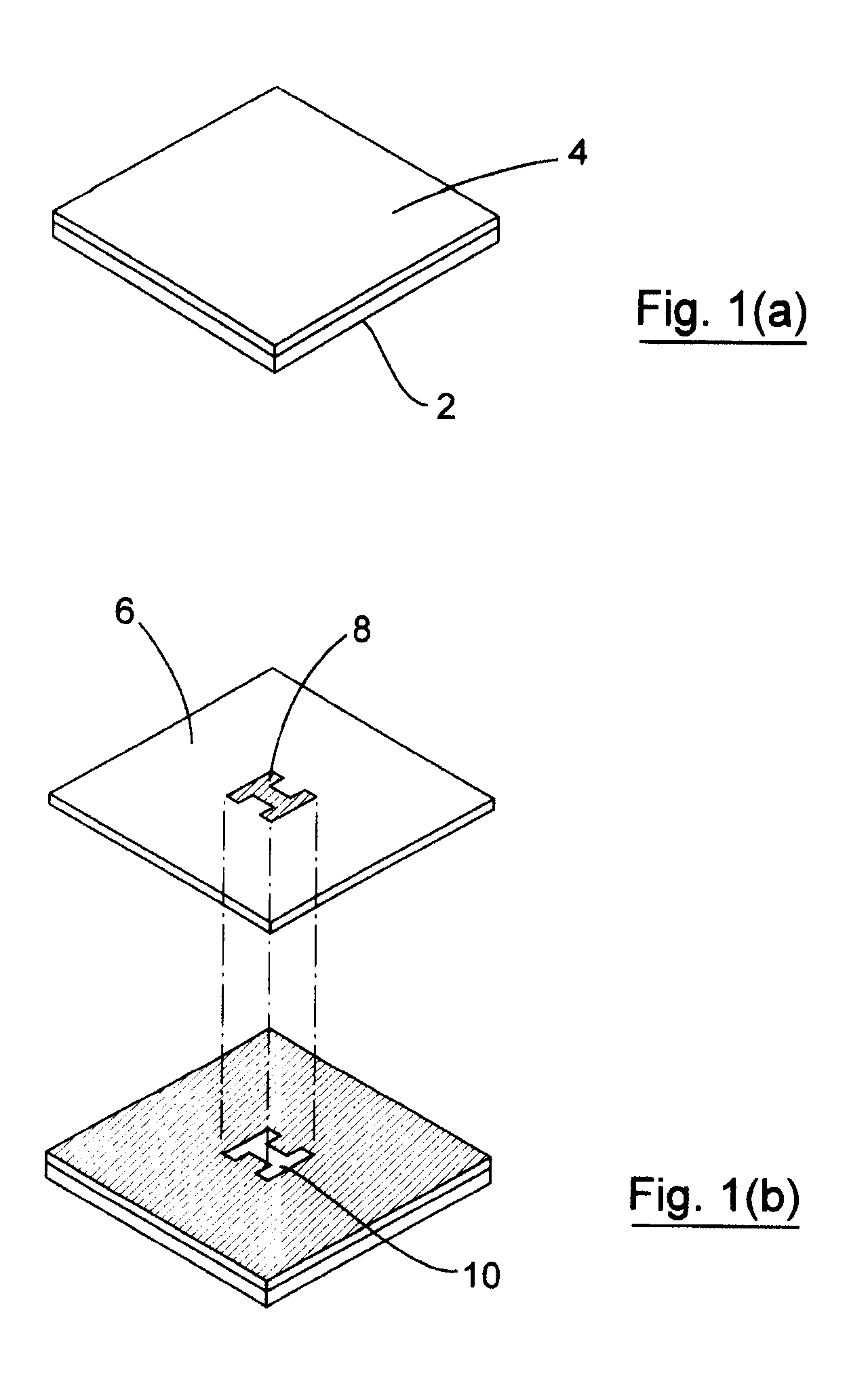

InactiveUS20060237719A1Improve electrical performanceImprove performanceTransistorSolid-state devicesDopantNanoparticle

A method of manufacturing an electronic component comprising at least one n- or p-doped portion, comprising the steps of: co-depositing inorganic semi-conducting nanoparticles and dopant on a substrate, the nanoparticles being a group four element such as silicon or germanium; fusing the nanoparticles by heating to form a continuous layer; and subsequently; and, recrystallising the layer.

Owner:HEWLETT PACKARD DEV CO LP

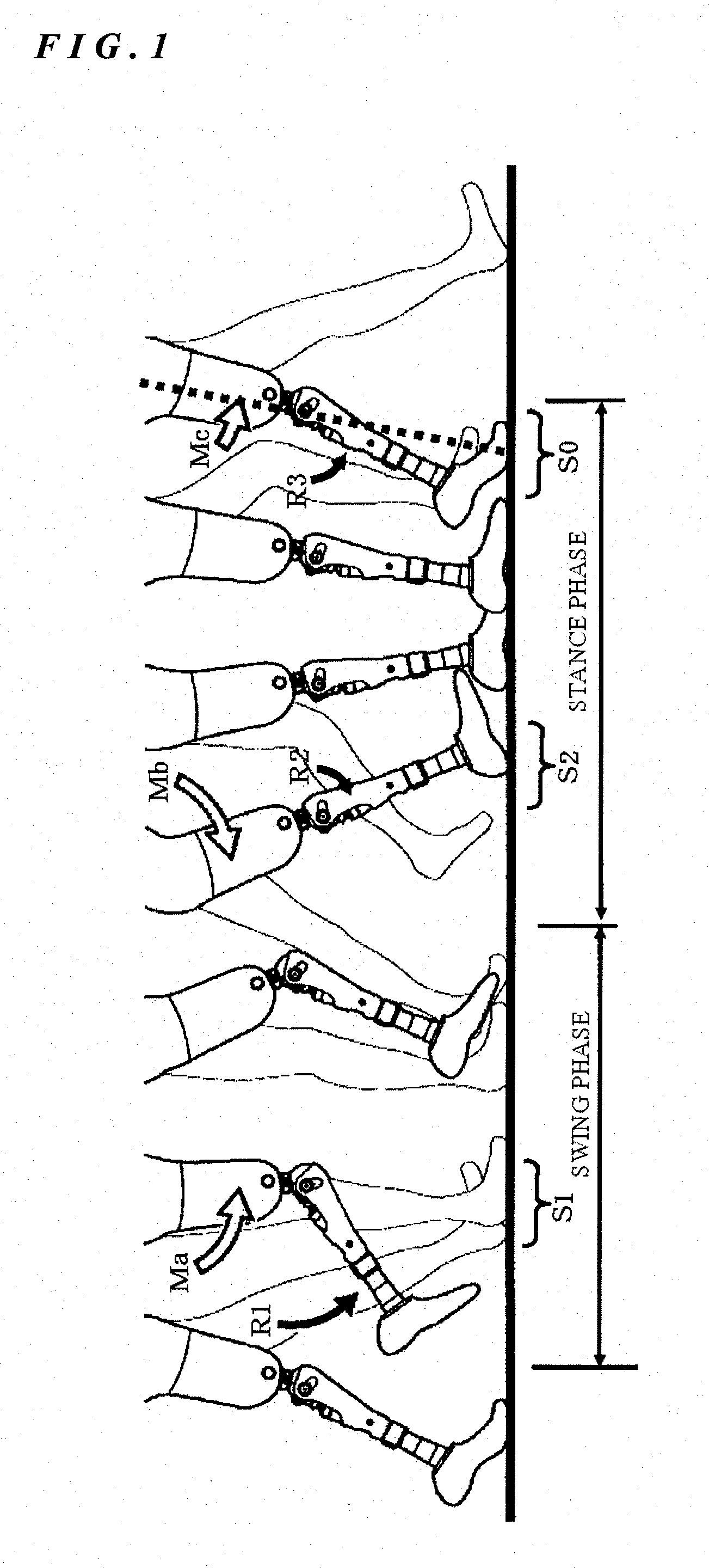

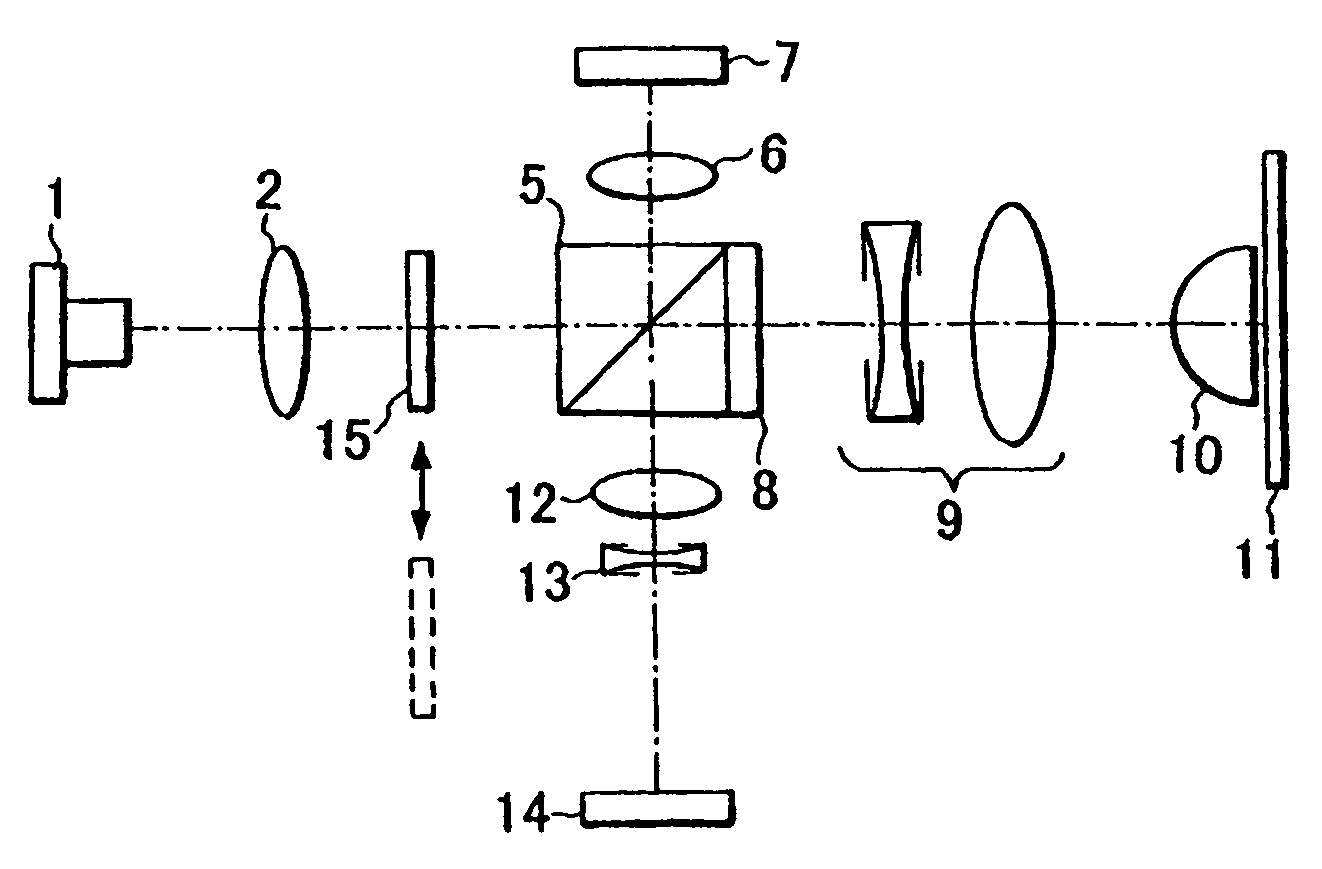

Optical detection system, device, and method utilizing optical matching

InactiveUS6927758B1Reduce total powerMinimize impactInput/output for user-computer interactionCathode-ray tube indicatorsData signalLight beam

An optical detection system and method detects movement of an optical pointing device in a data processing environment. The system works with any surface than can diffusely scatter a collimated beam from a coherent light source. Specifically, the system comprises a coherent light source and an optical sensing assembly. The optical sensing assembly comprises a plurality of photosensor arrays and a plurality of optical elements. Each photosensor array includes pixels of a particular size and shape. Each optical element has an artificially limited aperture and is associated, through optical matching, with a respective photosensor array. The coherent light source generates a collimated beam that is diffusely reflected off of the surface. The optical sensing assembly receives the diffusely reflected, or scattered, collimated beam and passes it through the artificially limited apertures of the optical elements to the associated corresponding photosensor array. Passing the scattered light through the optical elements generates speckle images that appear on the pixels, of the photosensor arrays. Based on the pixel shape, a pixel value associated with the speckle image provides a speckle image data signal. When there is translation of the pointing device, a new set of speckle images, each reassembling to a translated version of the previous speckle image, are generated and another speckle image data signal is generated. The new and the previous speckle image data signals are then used in a motion detection analysis to determine the points of the two data signals that give a displacement value.

Owner:LOGITECH EURO SA

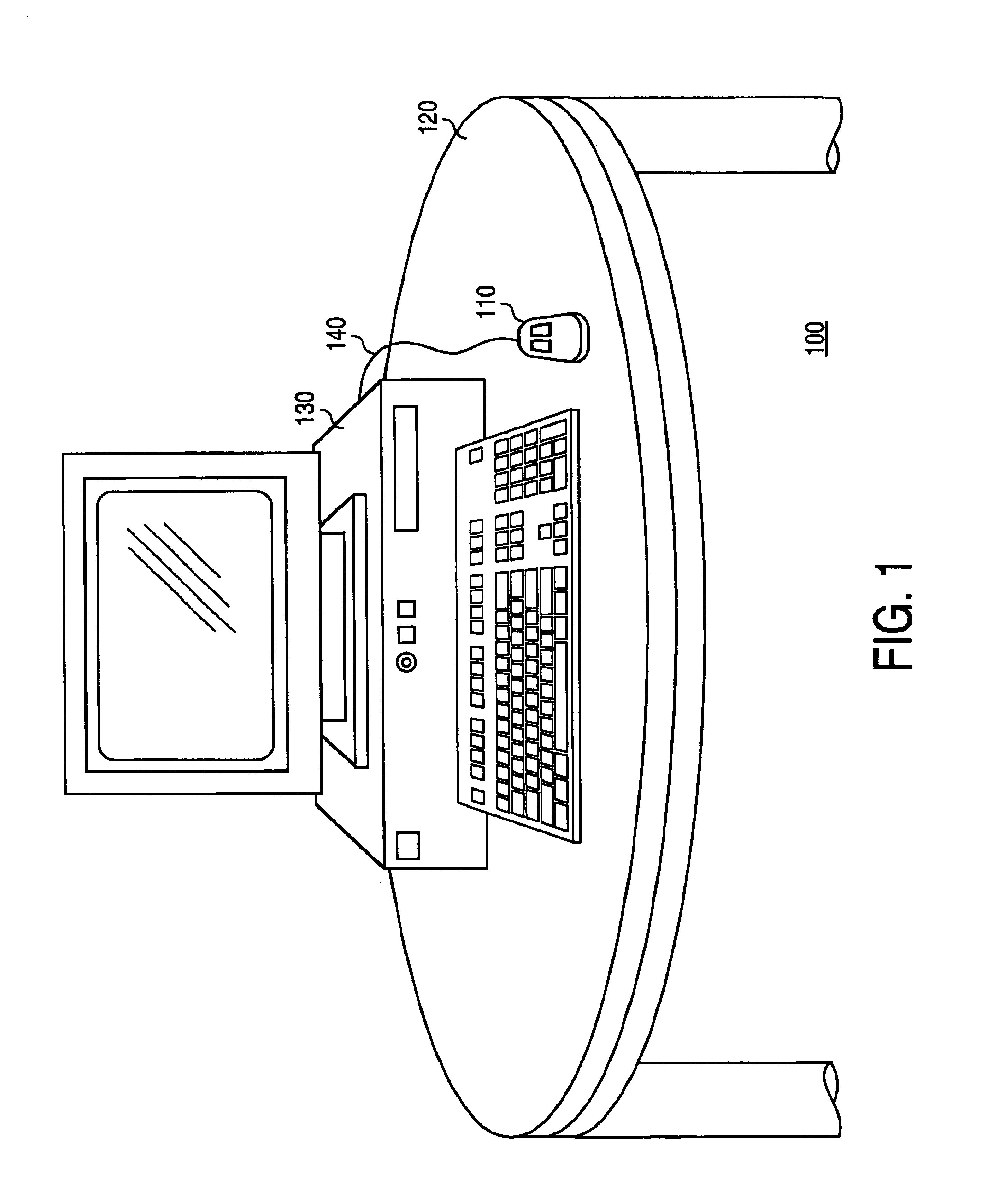

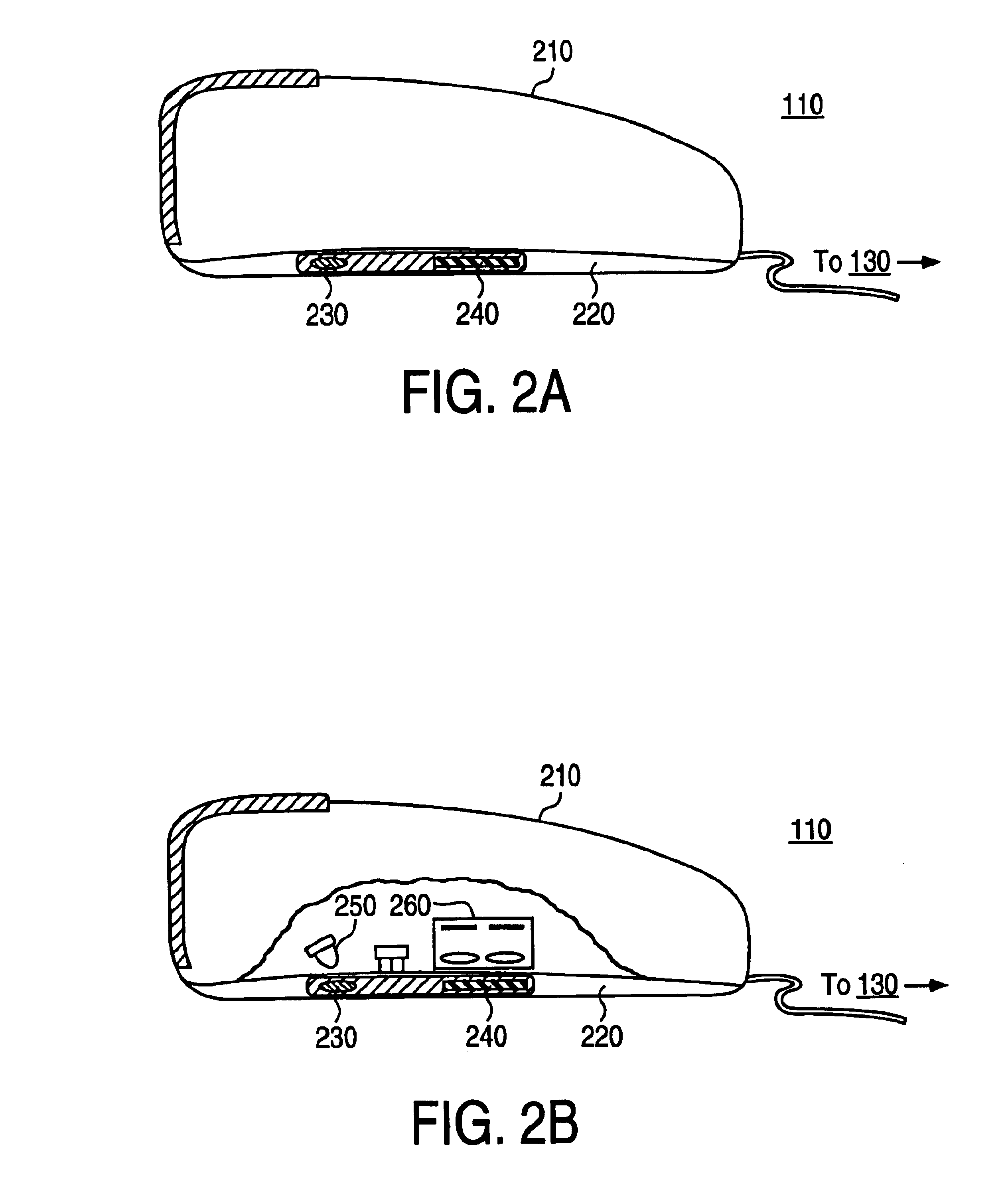

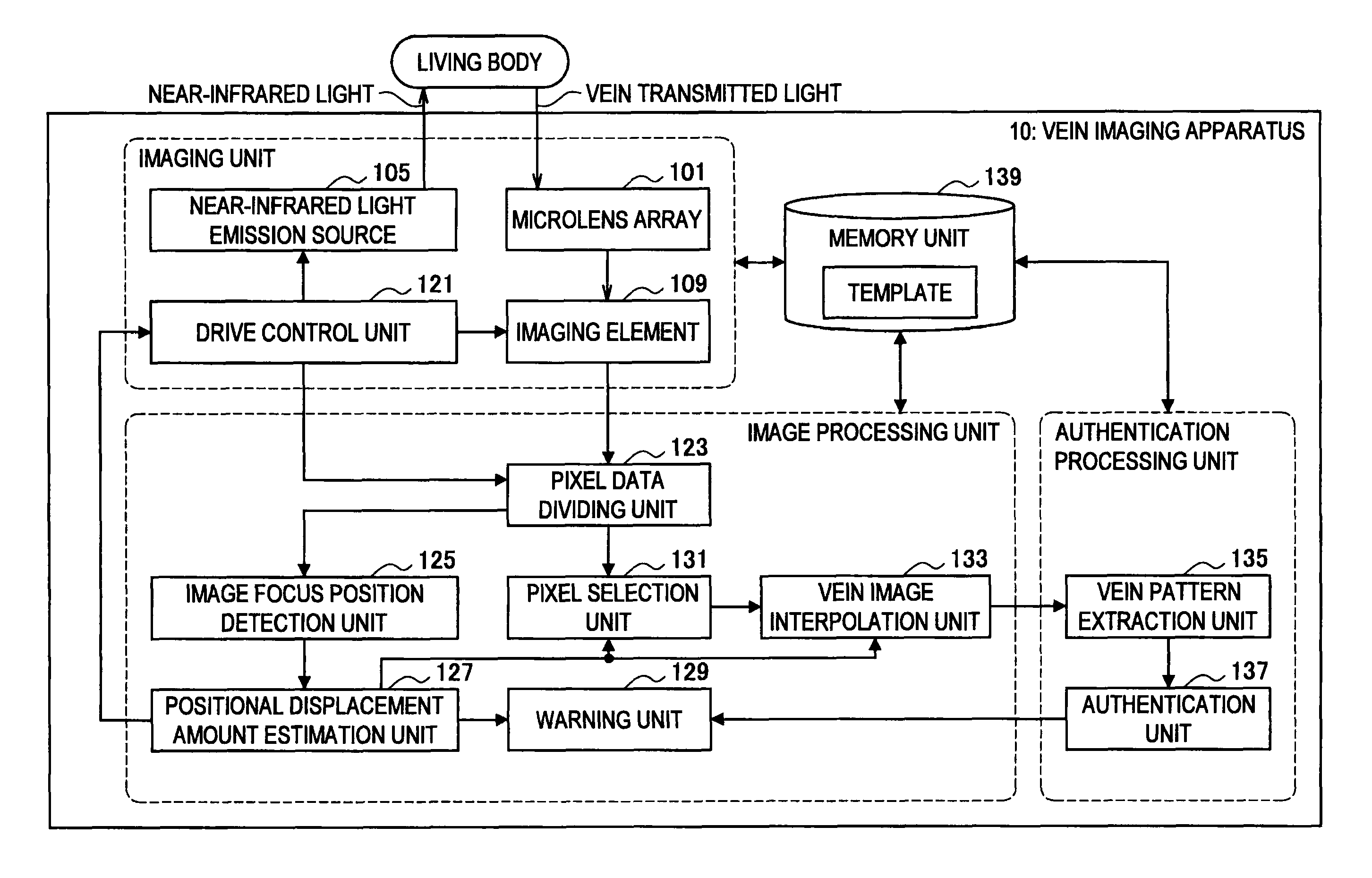

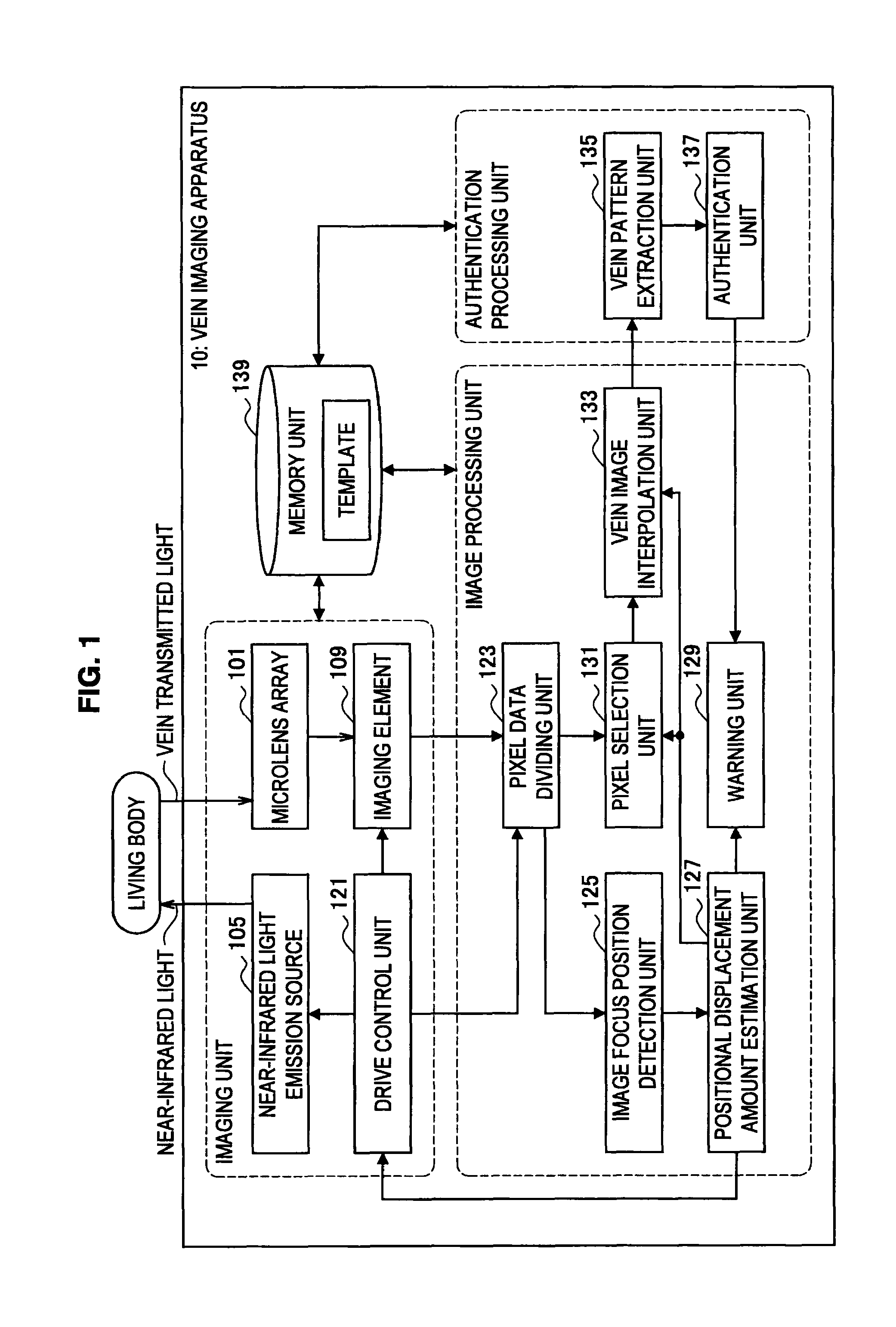

Vein imaging apparatus, positional displacement interpolation method, and program

ActiveUS8320998B2Little has been producedTelevision system detailsDiagnostics using lightVenographyComputer vision

An imaging element of a vein imaging apparatus includes a vein image data generation region generating image data of a vein based a near-infrared light that was condensed by a lens array and that was scattered in a living body and transmitted through the vein and a positional displacement detection data generation region that includes a shielded section in which pixels are shielded from the light and an opening section in which pixels are not shielded from the light, and generates data for detecting positional displacement that is used to detect, based on the light received via the opening section, variation in an image focus position according to an imaging temperature. The vein imaging apparatus detects the image focus position of the light and estimates the amount of positional displacement occurred in the apparatus. The vein imaging apparatus selects a pixel based on the obtained amount of positional displacement.

Owner:MOFIRIA

Polymer material, foam obtained from same, and polishing pad using those

ActiveUS20090298392A1Stable polishing rateHigh-precision polishingOther chemical processesSemiconductor/solid-state device manufacturingPolymer sciencePolymer

The subject is to provide a polymer material which enables to improve planarity and planarization efficiency of a polished surface and is useful as a polishing pad which generates only a few scratches. The said subject is solved by a polymer material having a tensile modulus at 50° C. after saturation swelling with 50° C. water of 130 to 800 MPa, a loss tangent at 50° C. of not more than 0.2, and a contact angle with water of not more than 80°.

Owner:KURARAY CO LTD

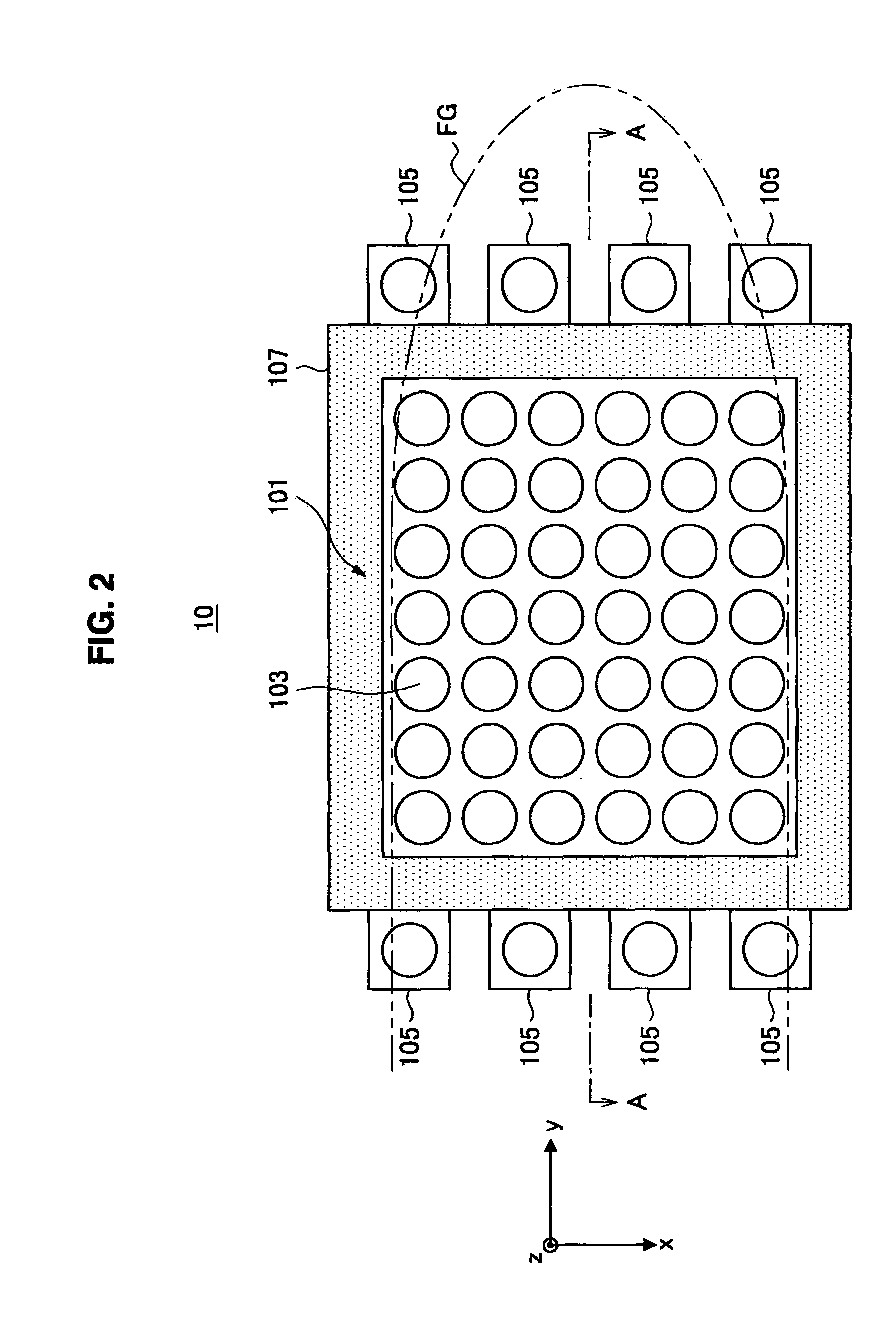

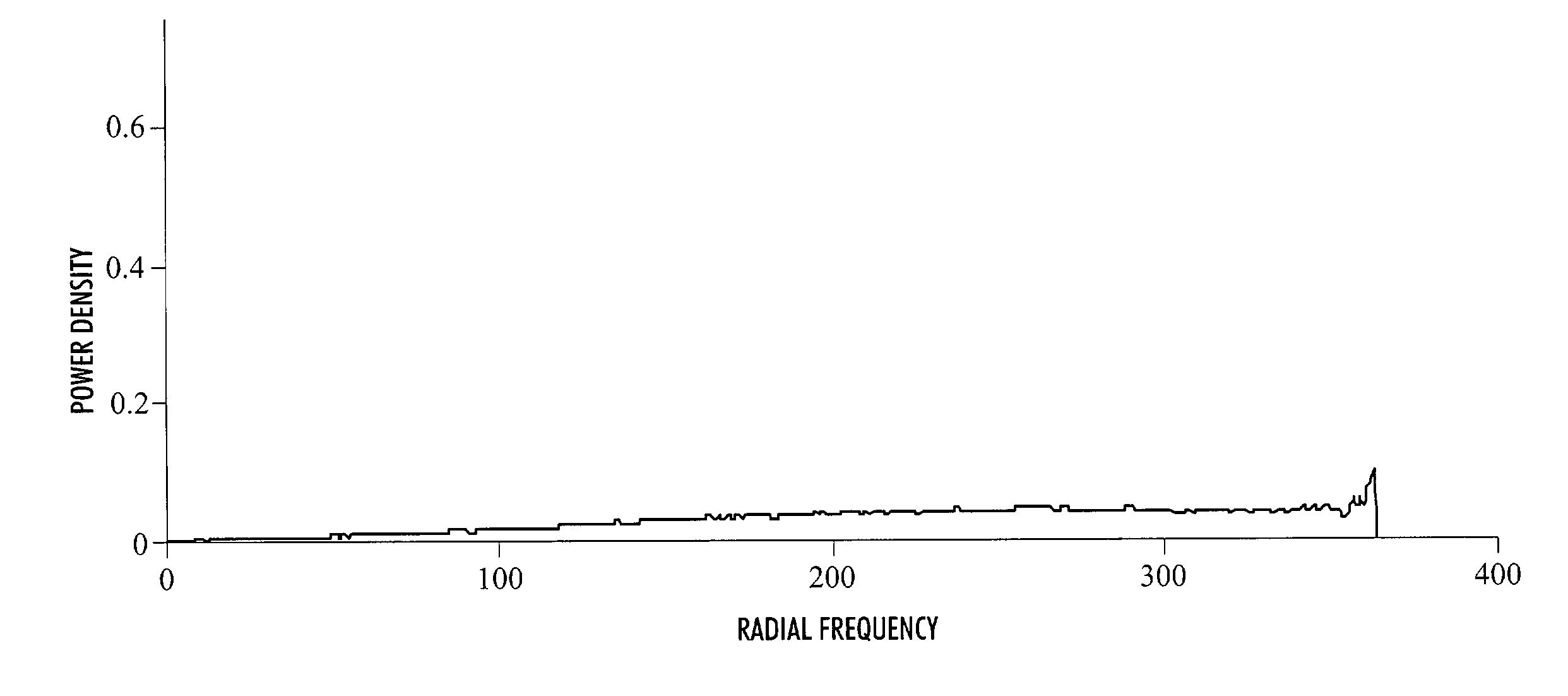

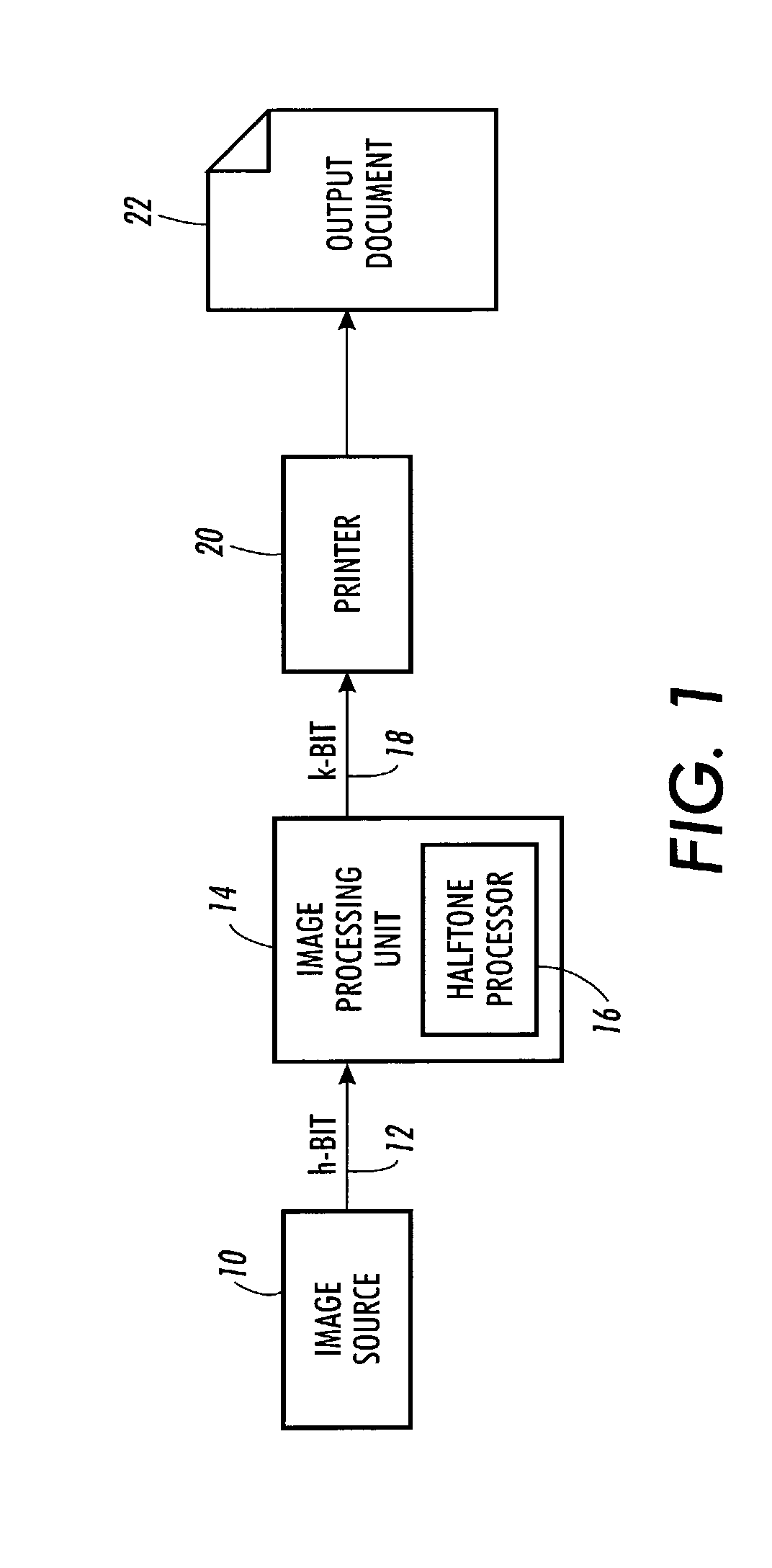

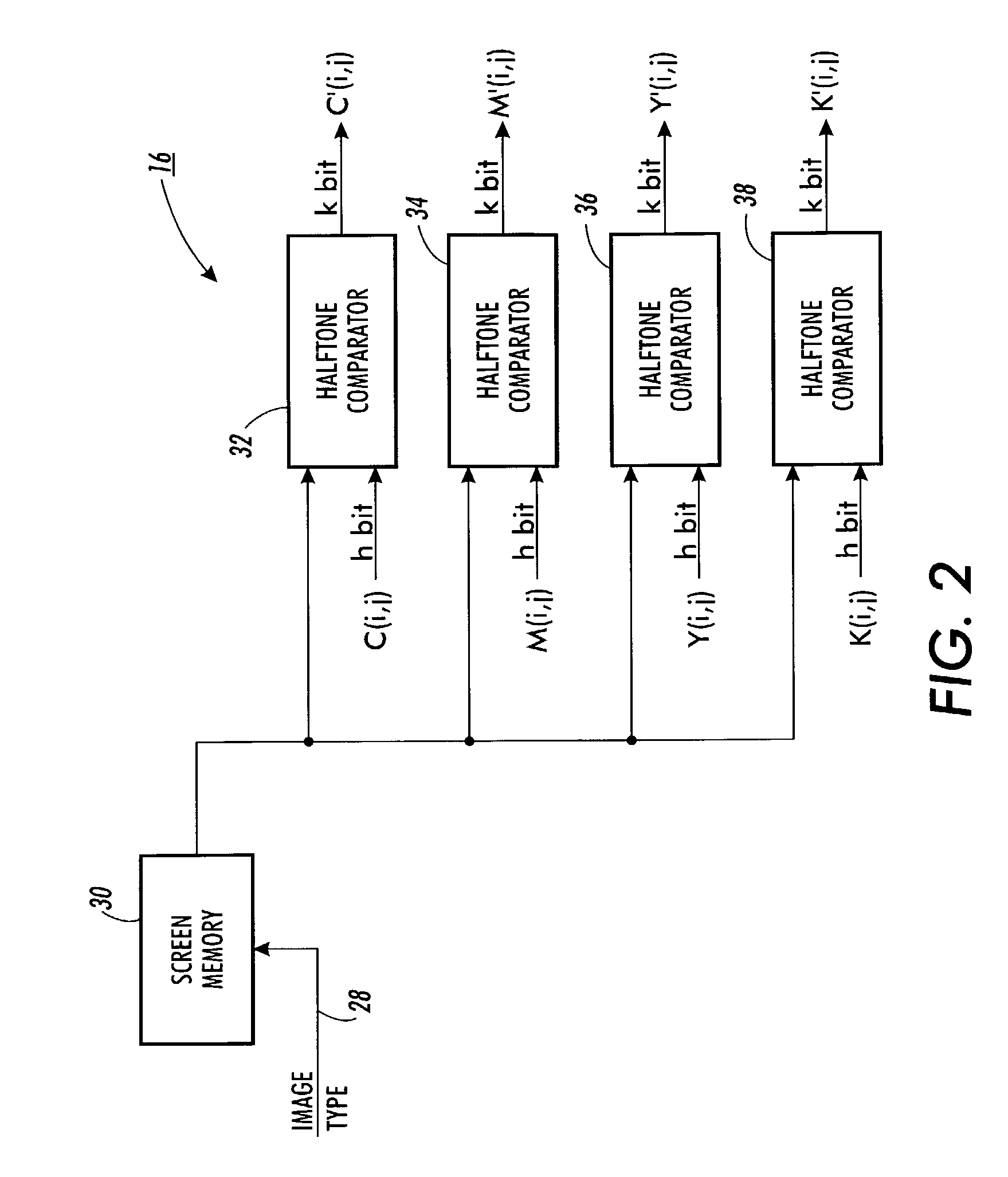

Anisotropic stochastic screen

InactiveUS7139101B2Improve image qualityReduced stabilityImage enhancementVisual presentationComputer graphics (images)Thresholding

A system and method for the halftoning of gray scale images by utilizing a pixel-by-pixel comparison of the image against an anisotropic stochastic screen is disclosed. The anisotropic stochastic screen comprises a non-deterministic, non-white noise function which, when thresholded, is designed to produce anisotropic dot patterns having a power spectrum characterized as having negligible low frequency components and a high-frequency region which has an absence of stronger dominant spikes.

Owner:XEROX CORP

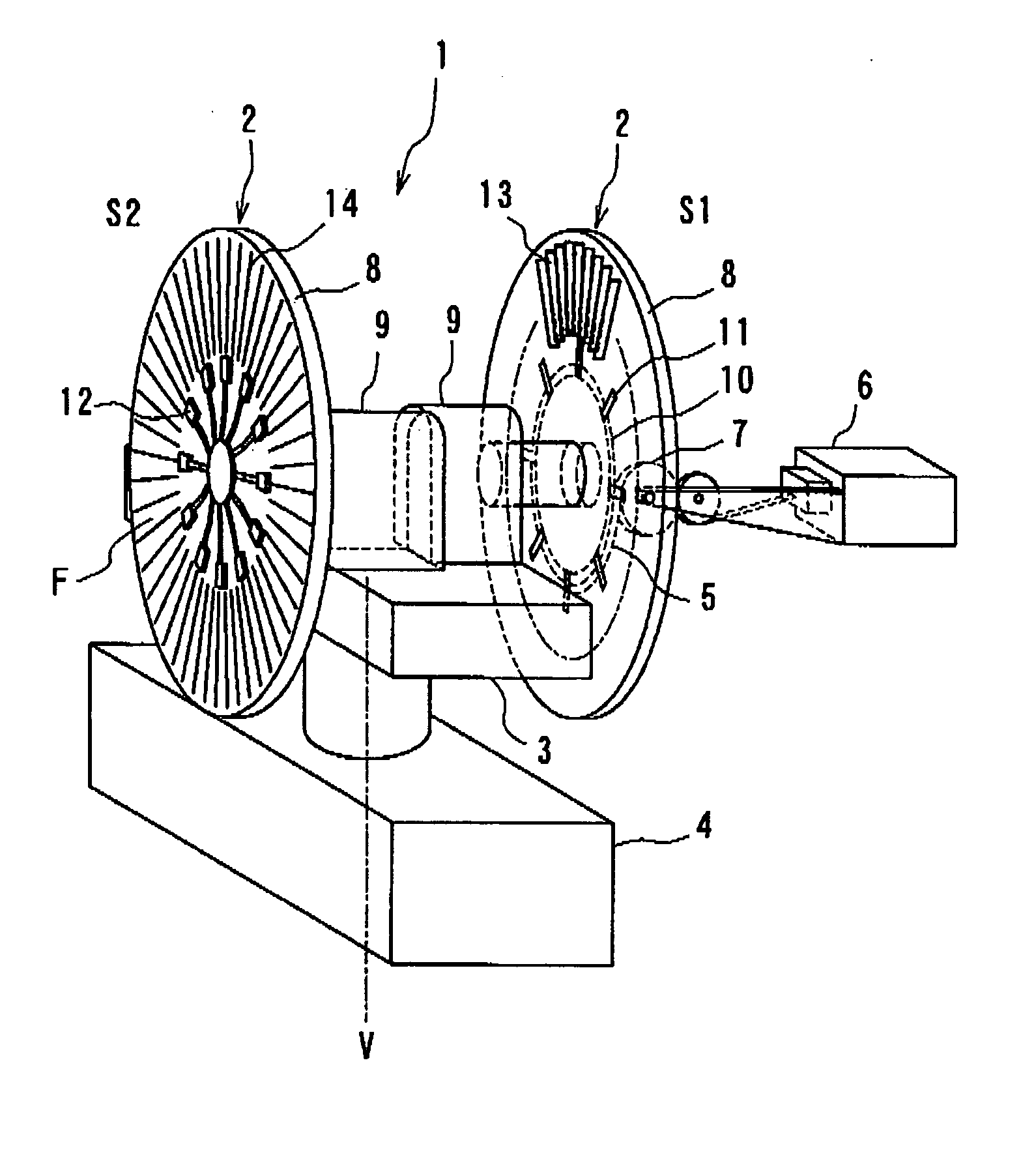

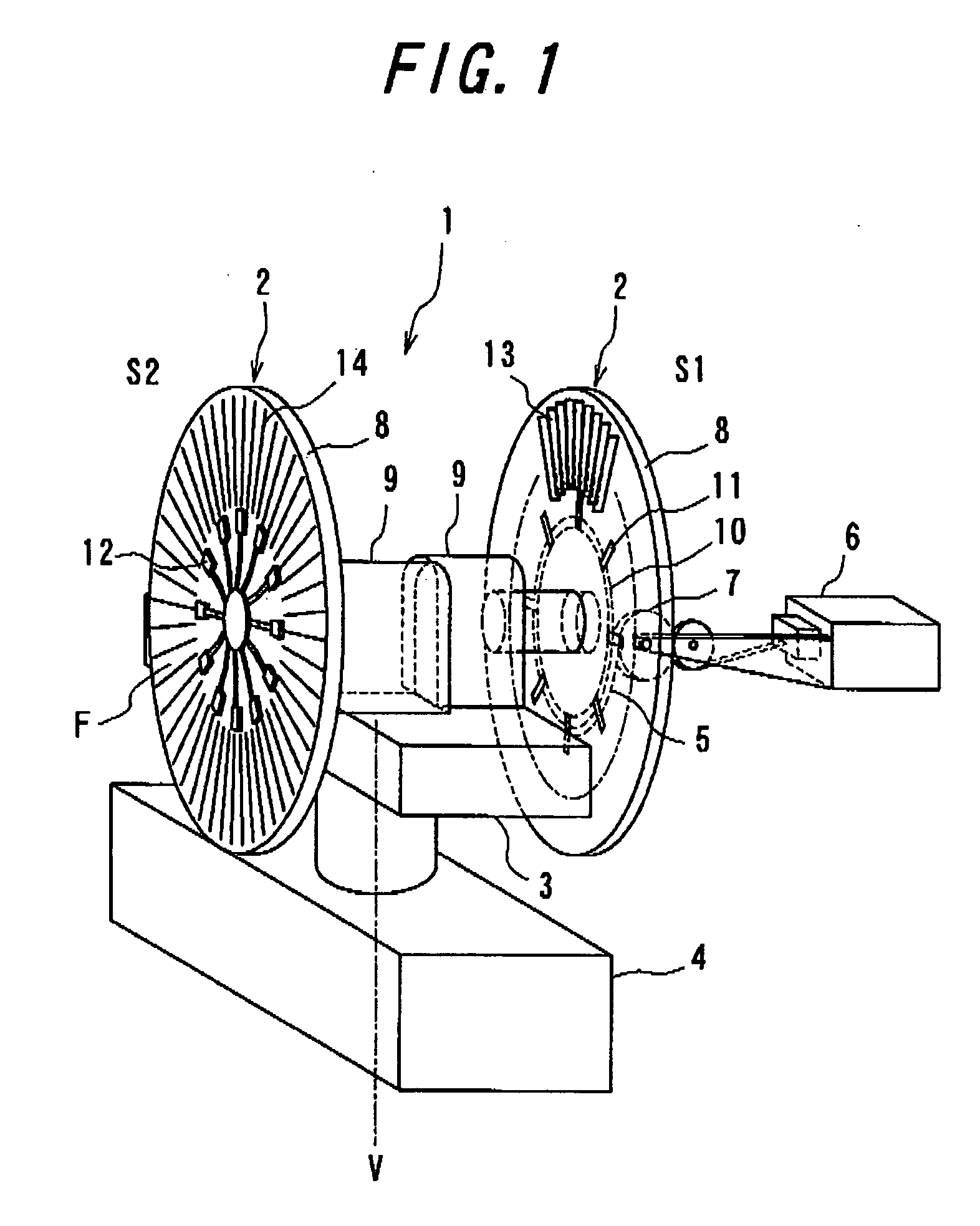

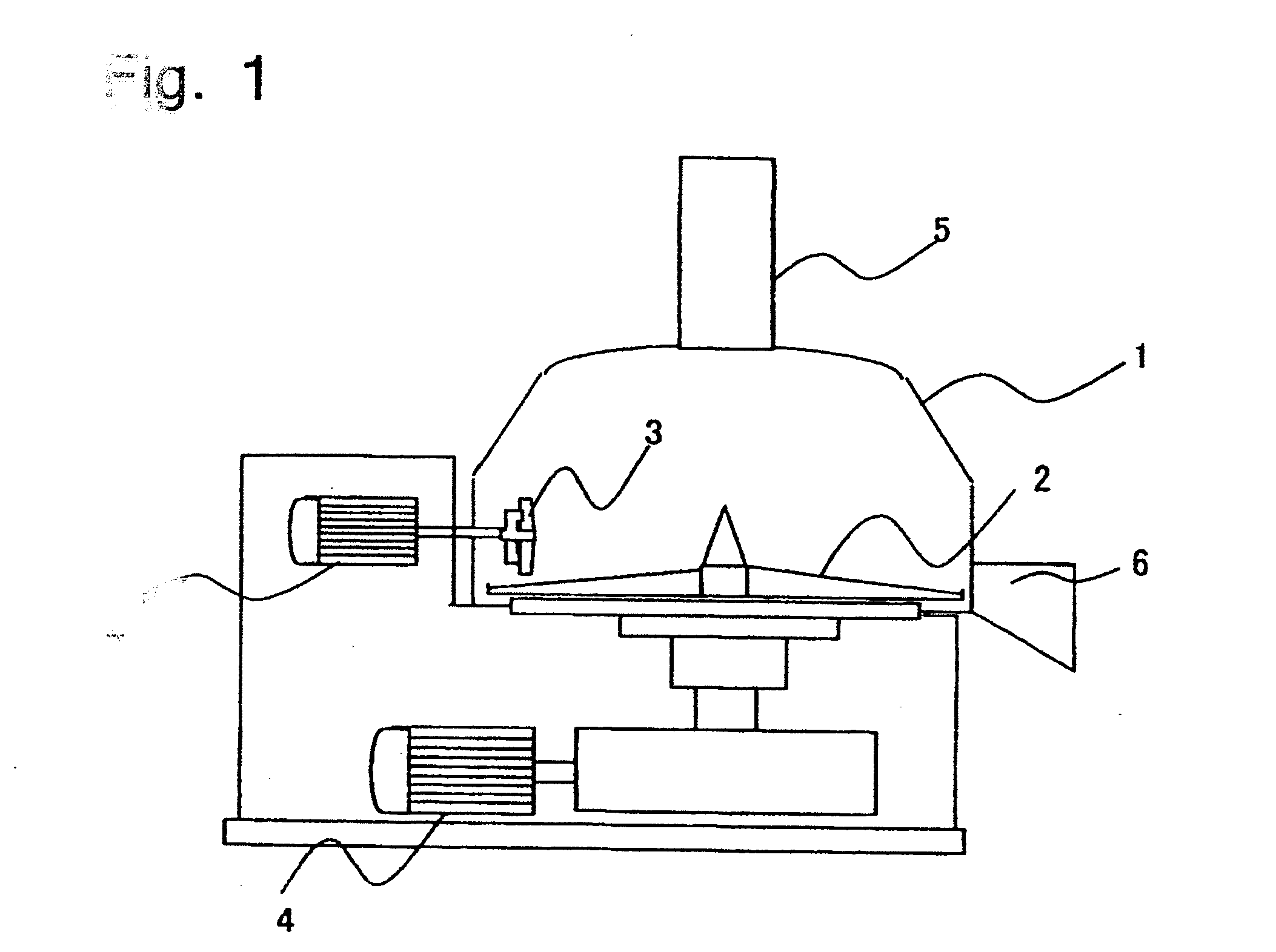

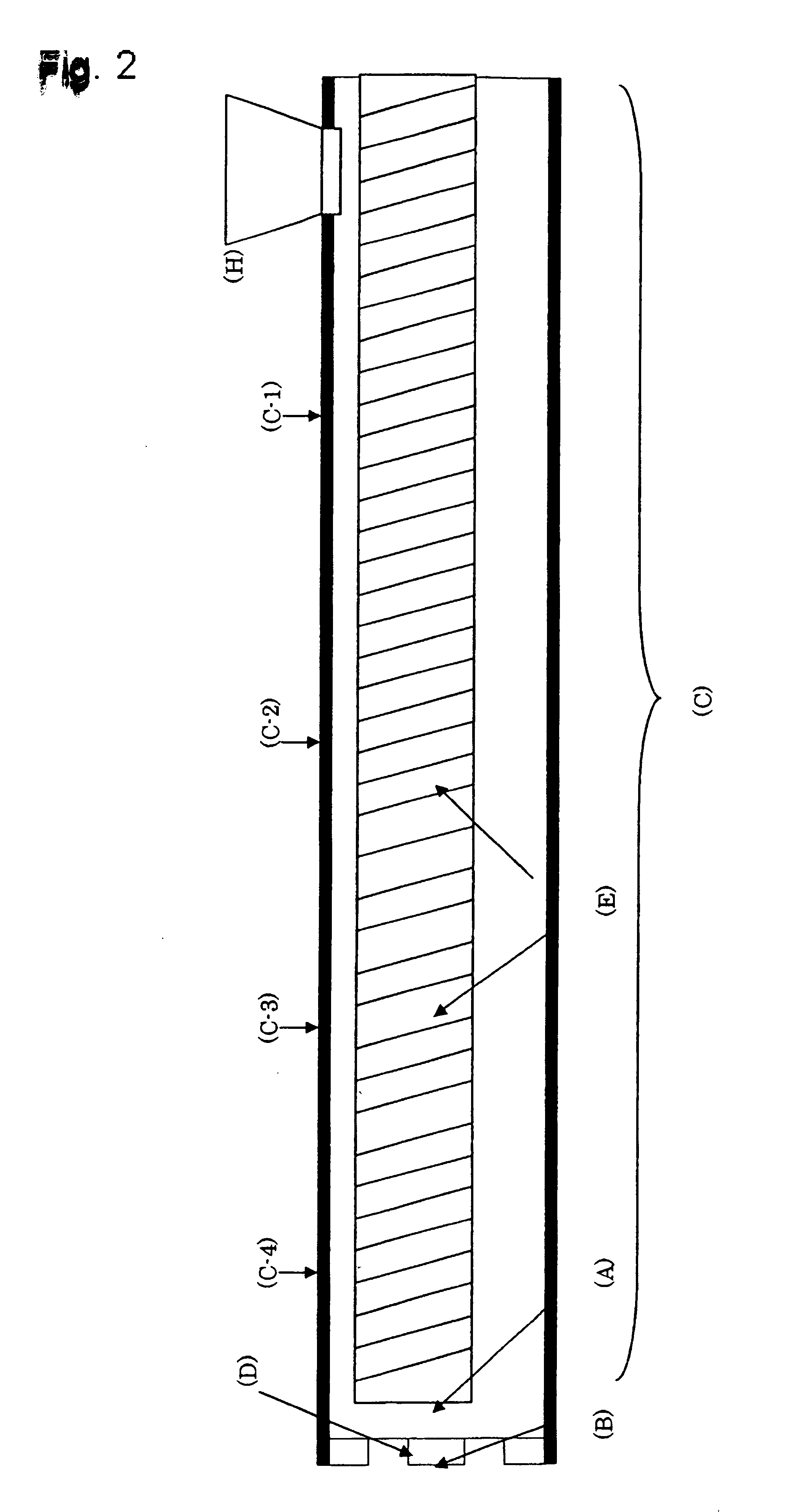

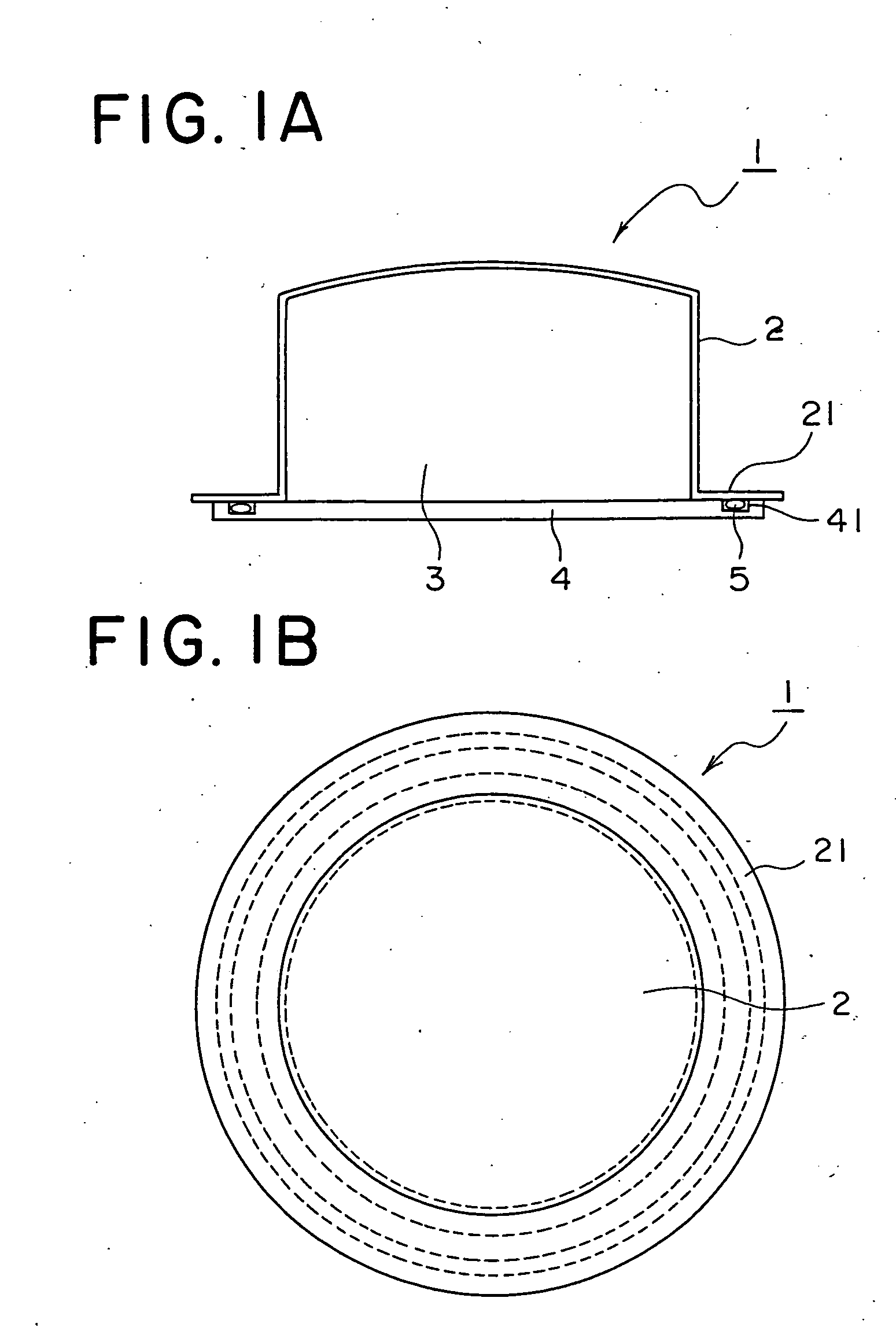

Tire Manufacturing Method, Preset Bead Molding Apparatus, and Preset Bead Molding

There is provided a method of tire manufacturing a tire in which preset-beads each preformed by mounting a bead filler on a bead core are disposed radially outward of a carcass band and both side portions of the carcass band are turned around the preset beads to build the tire. The method eliminates a need to bold the considerable intermediate stocks and does not deteriorate the tire uniformity due to the unevenness of the preset bead in the circumference direction. There are also provided an apparatus of forming a preset bead used therefore and a system of forming a preset bead. In the method of manufacturing a tire in which preset-beads each preformed by mounting a bead filler on a bead core are disposed radially outward of a carcass band and both side portions of the carcass band are turned around the preset beads to build the tire, the preset bead is formed by winding and laminating a ribbon-shaped filler rubber 5 radially outward of the bead core 10 over several laps.

Owner:BRIDGESTONE CORP

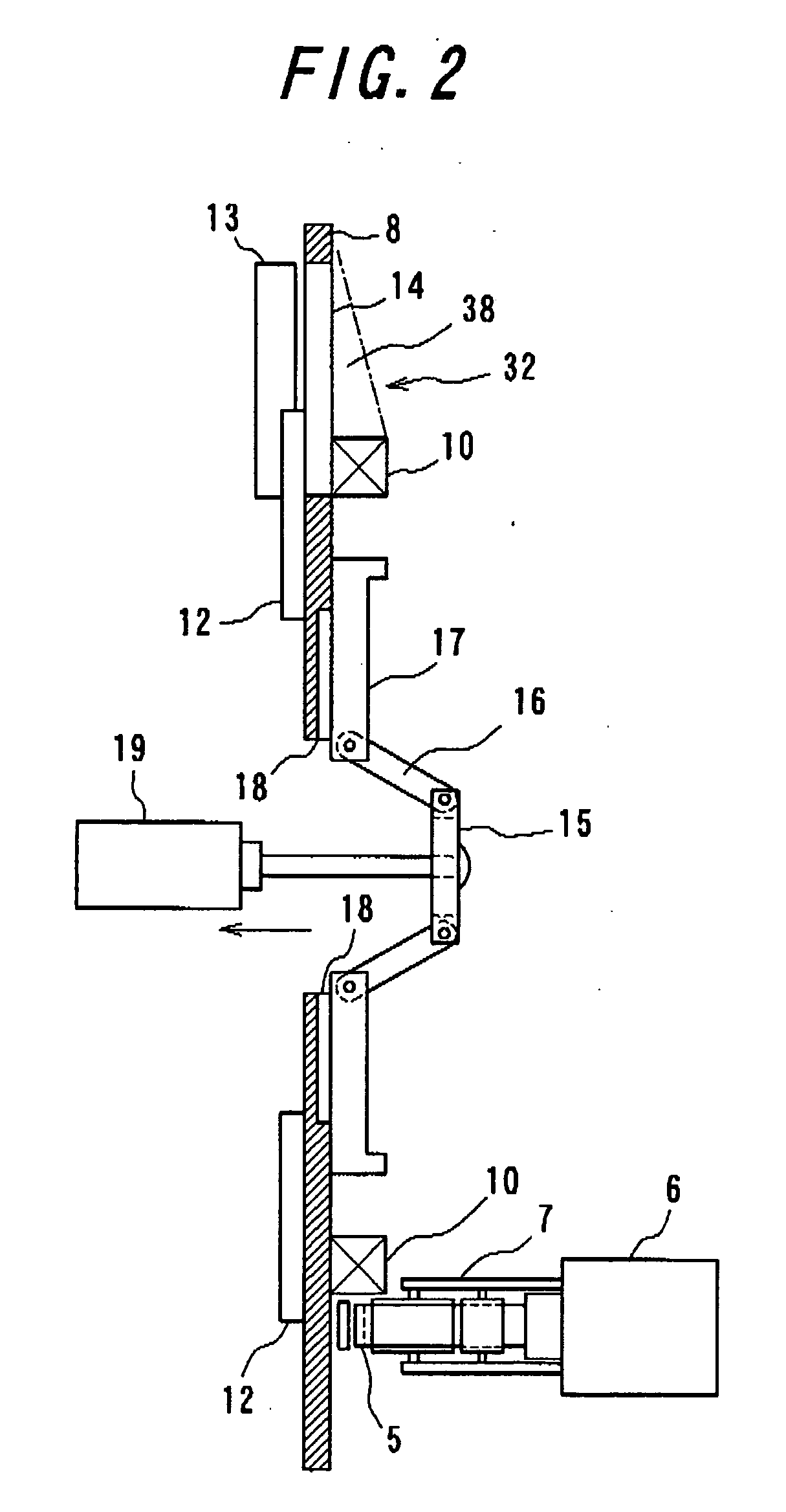

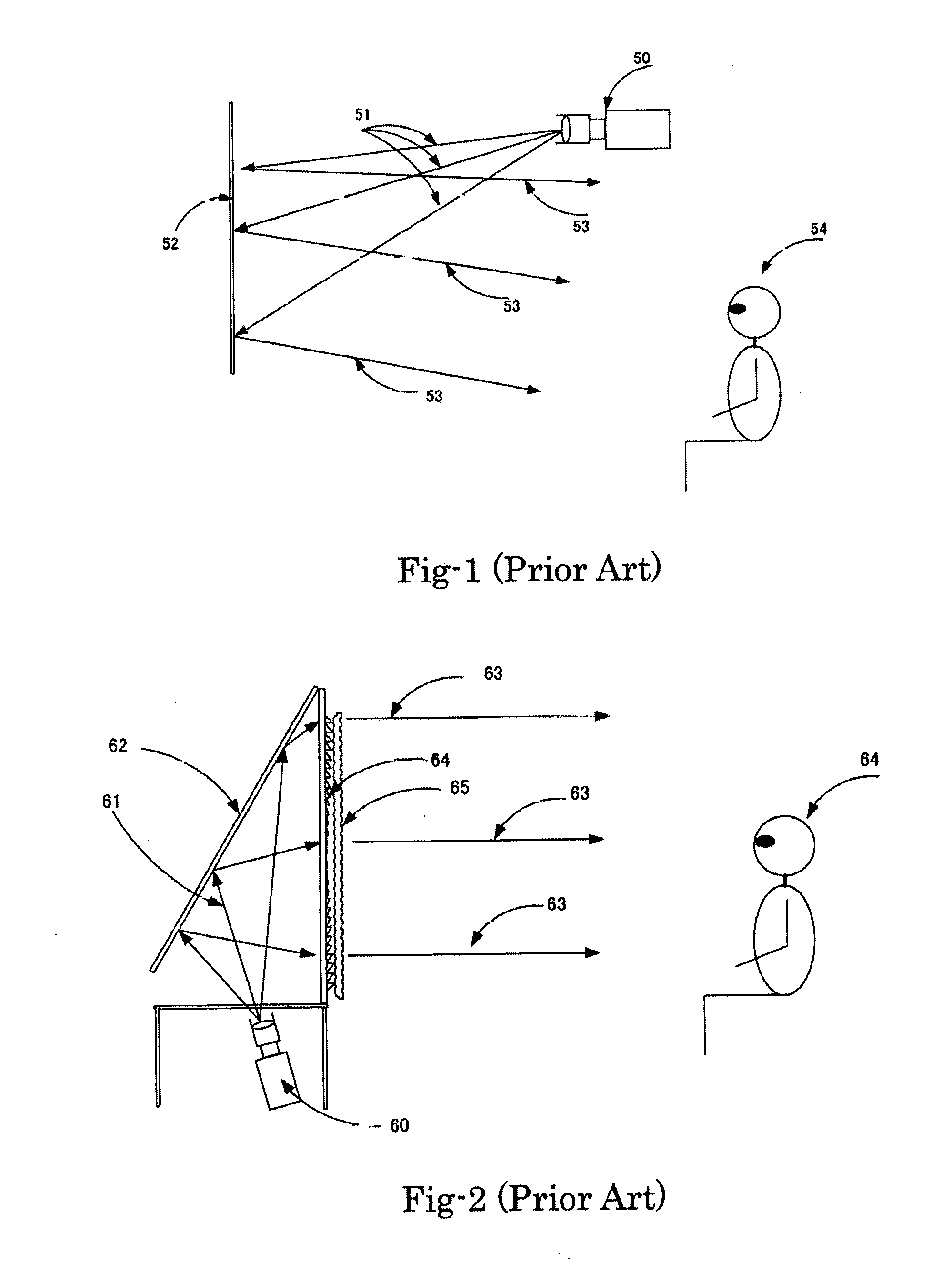

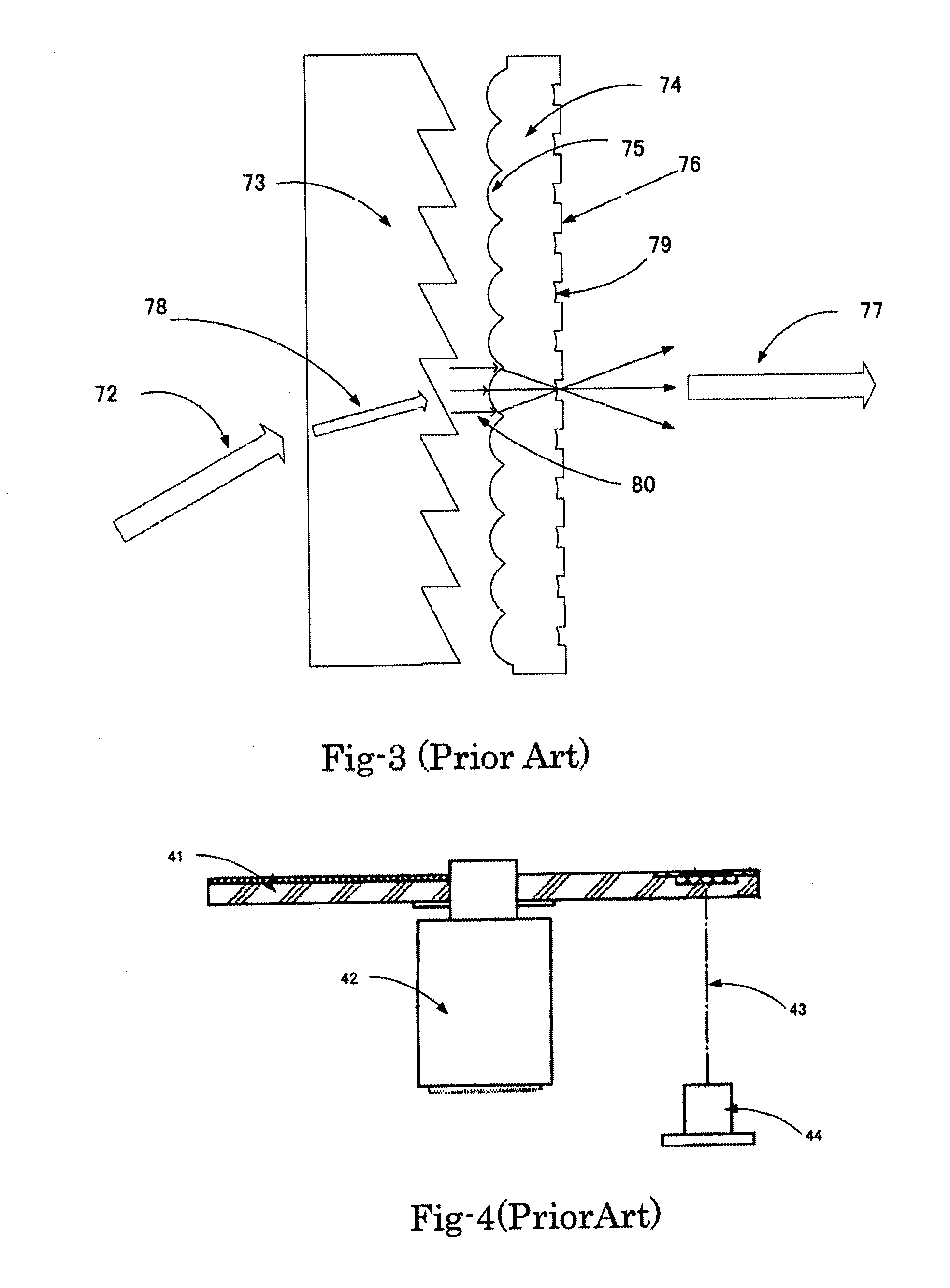

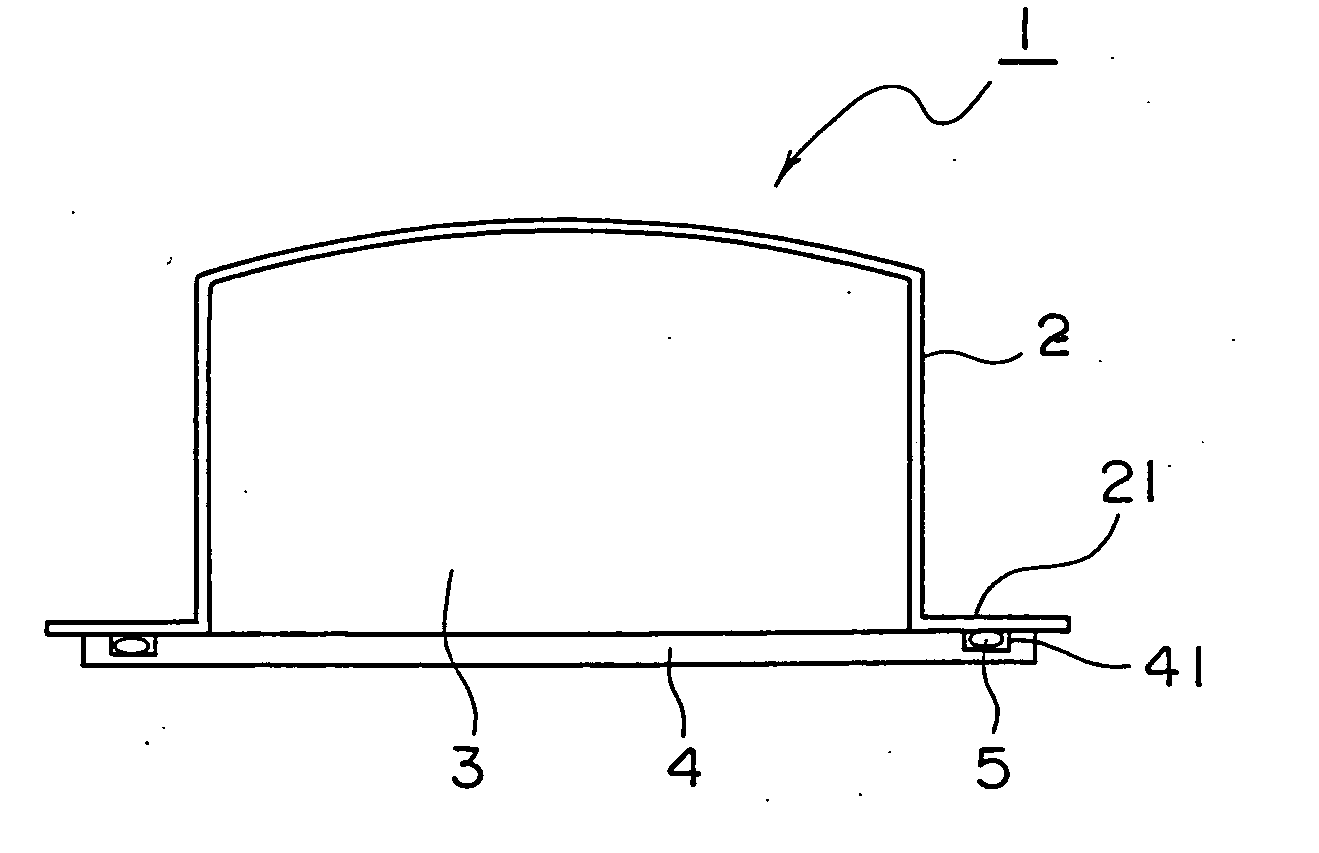

Optics of projecor

InactiveUS20160357094A1Speckle reductionReduce speckle of imageDiffusing elementsBuilt-on/built-in screen projectorsDisplay deviceLaser light

A projection display system is disclosed including a laser light source, projection lens or mirror, and screen. This invention enables a decorative screen which hides a display and matches near-by furniture. This invention also discloses a tiny cost-effective laser light source for projection displays.

Owner:ISHII FUSAO

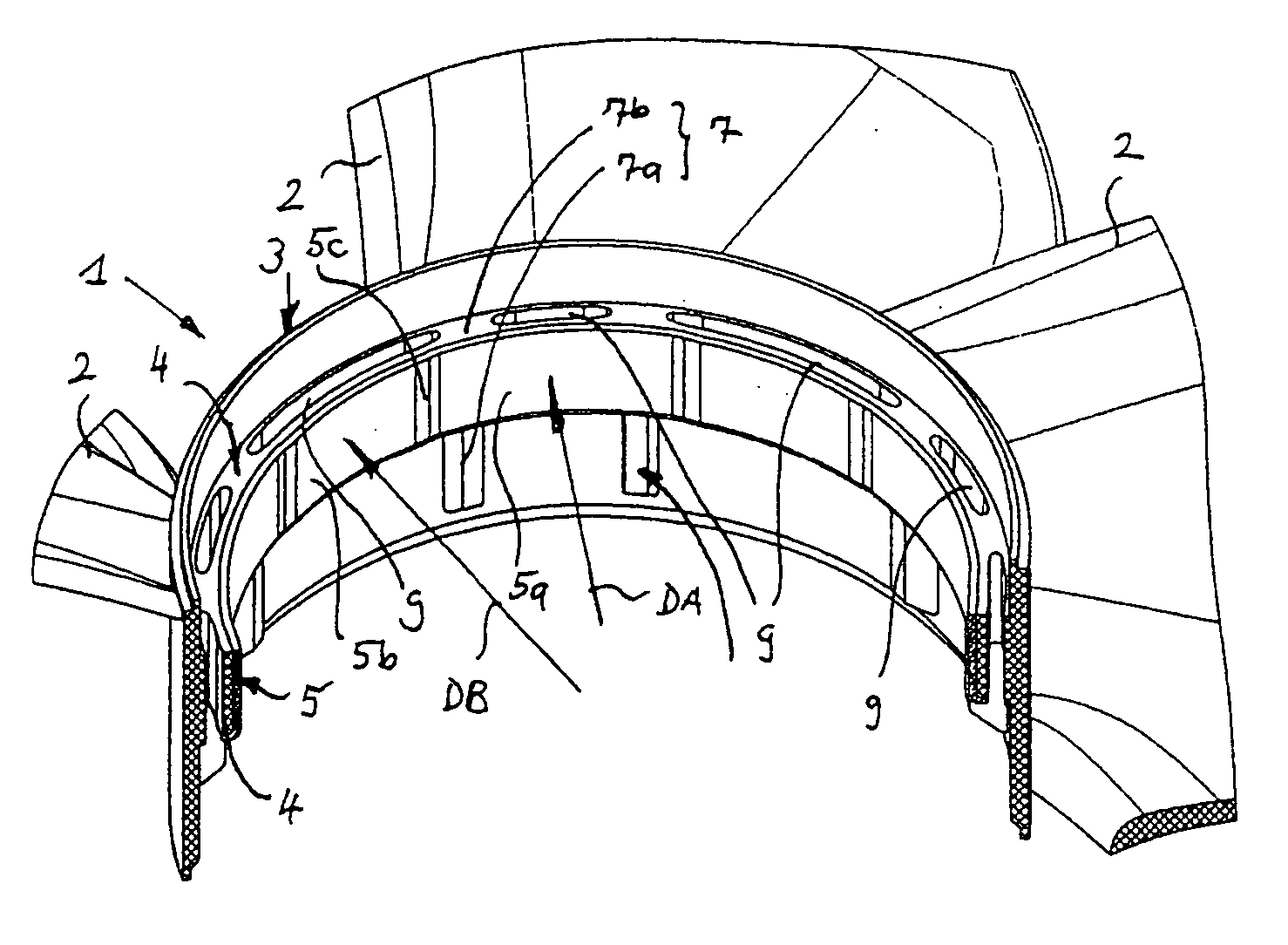

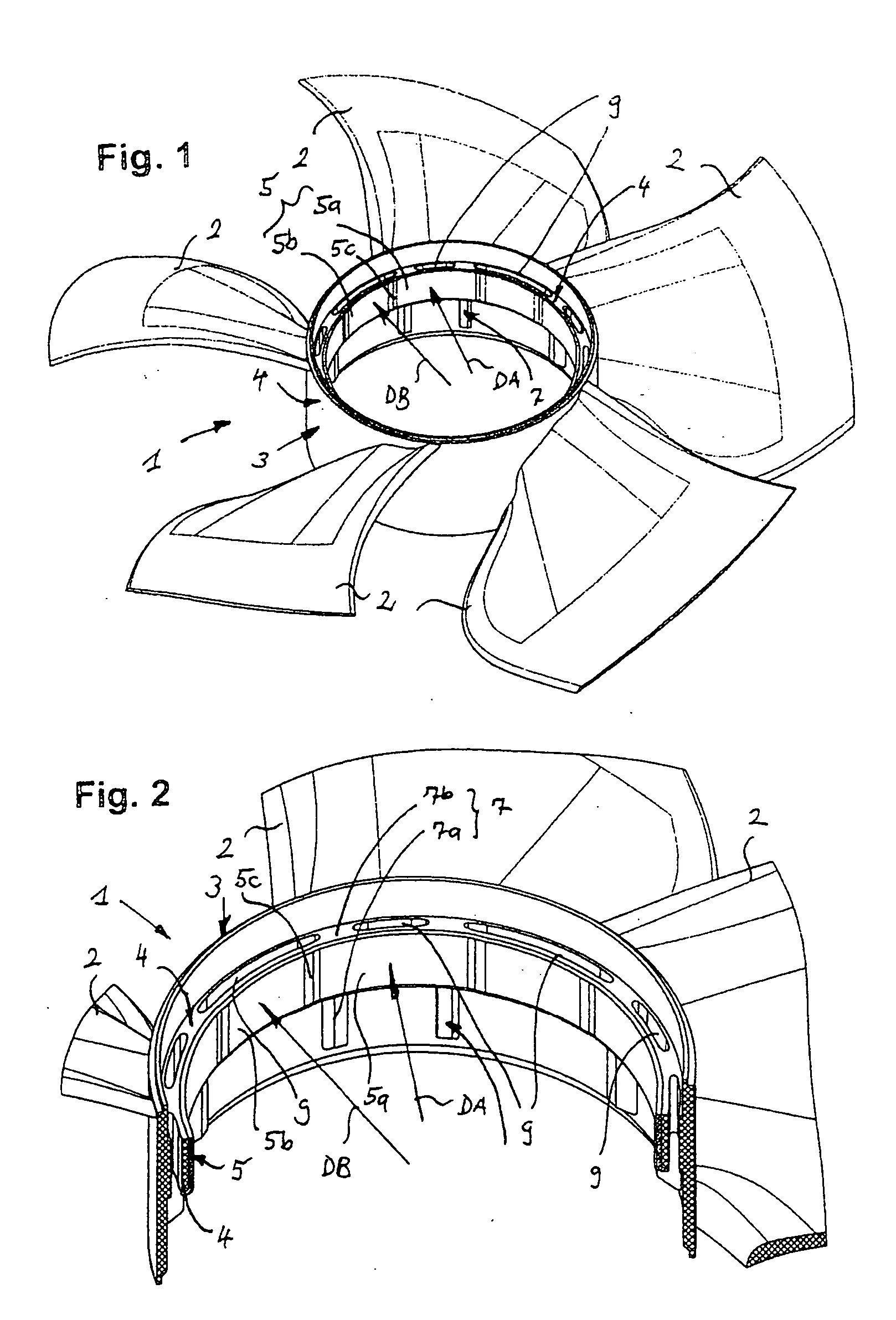

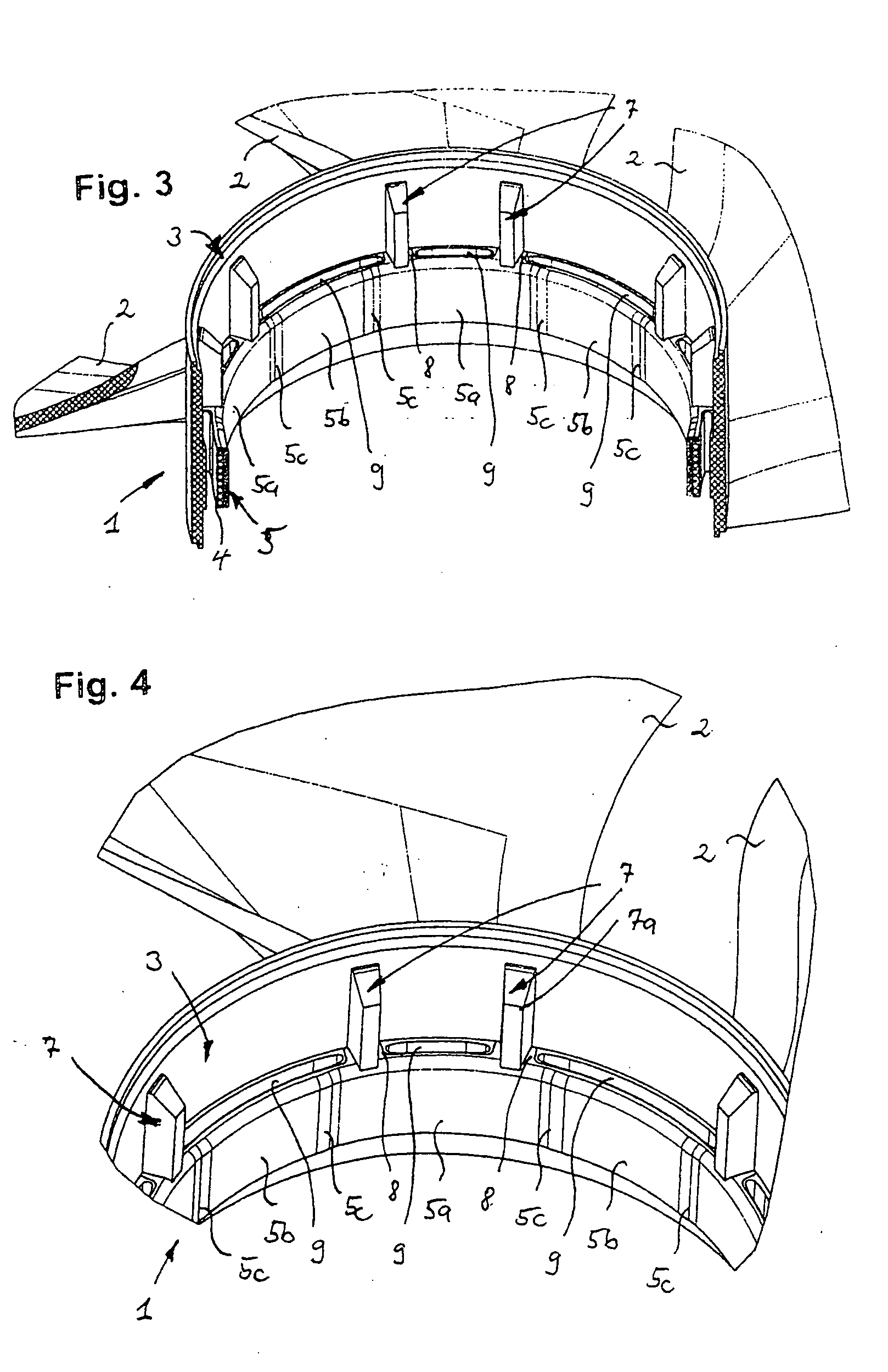

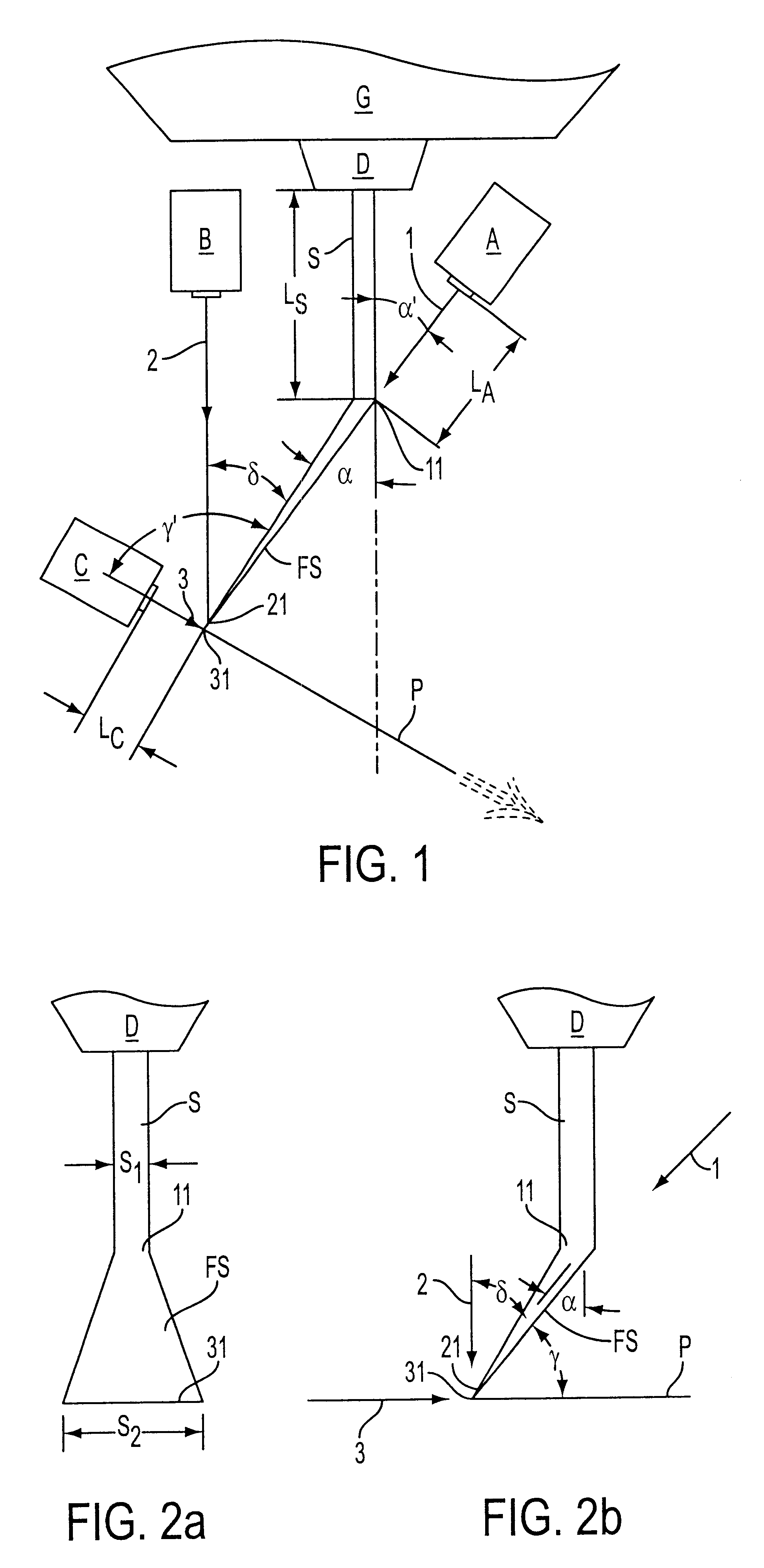

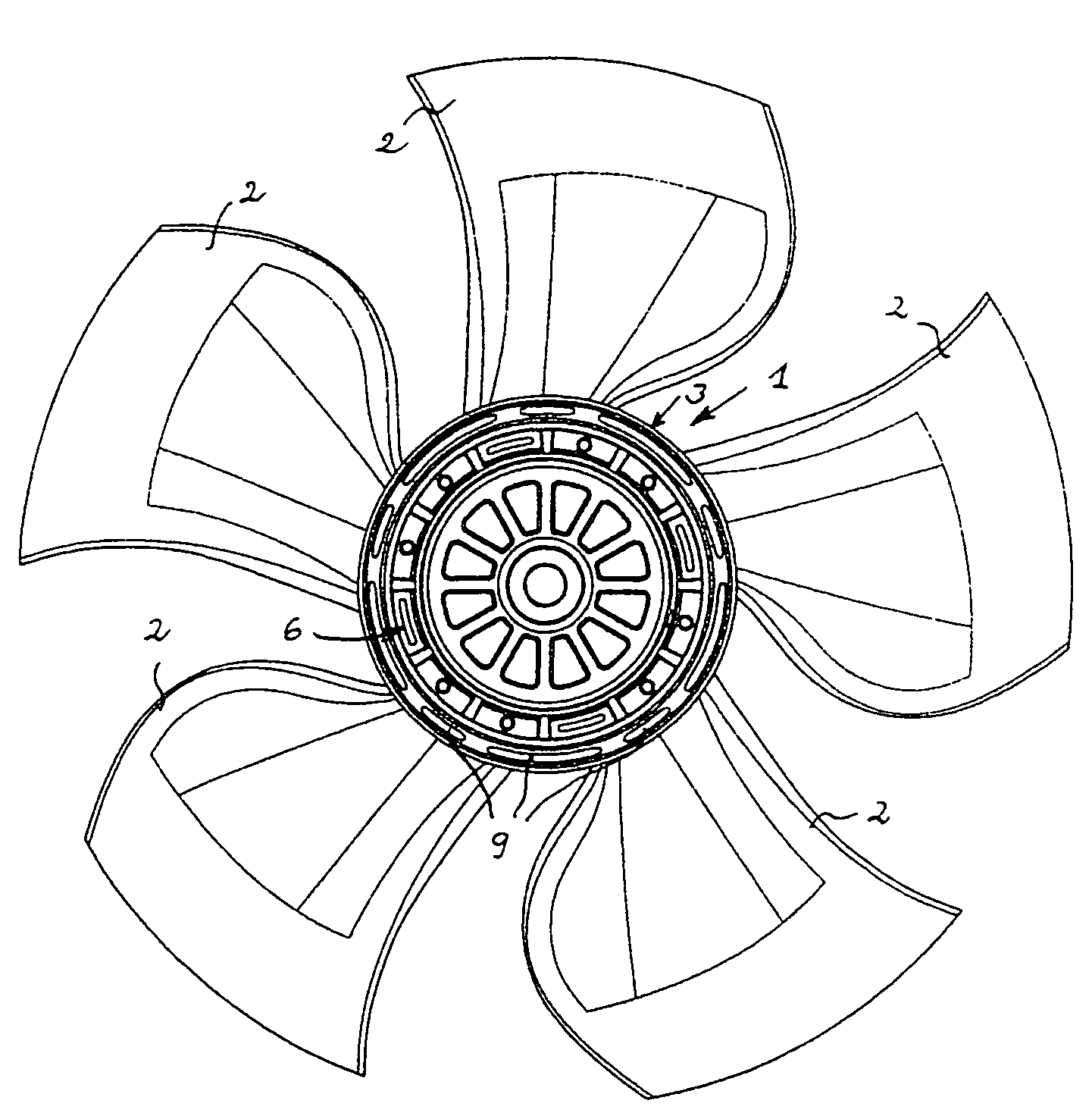

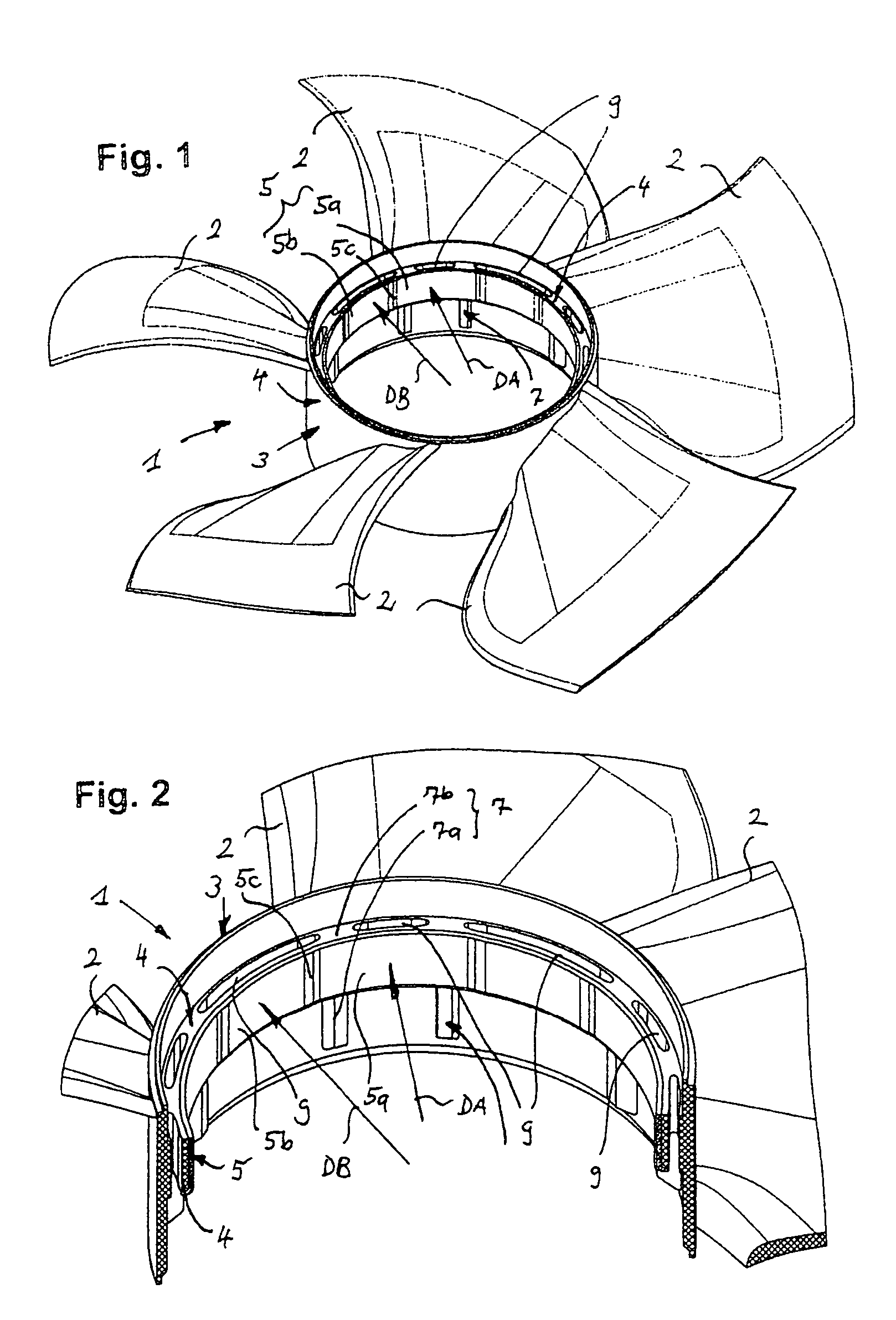

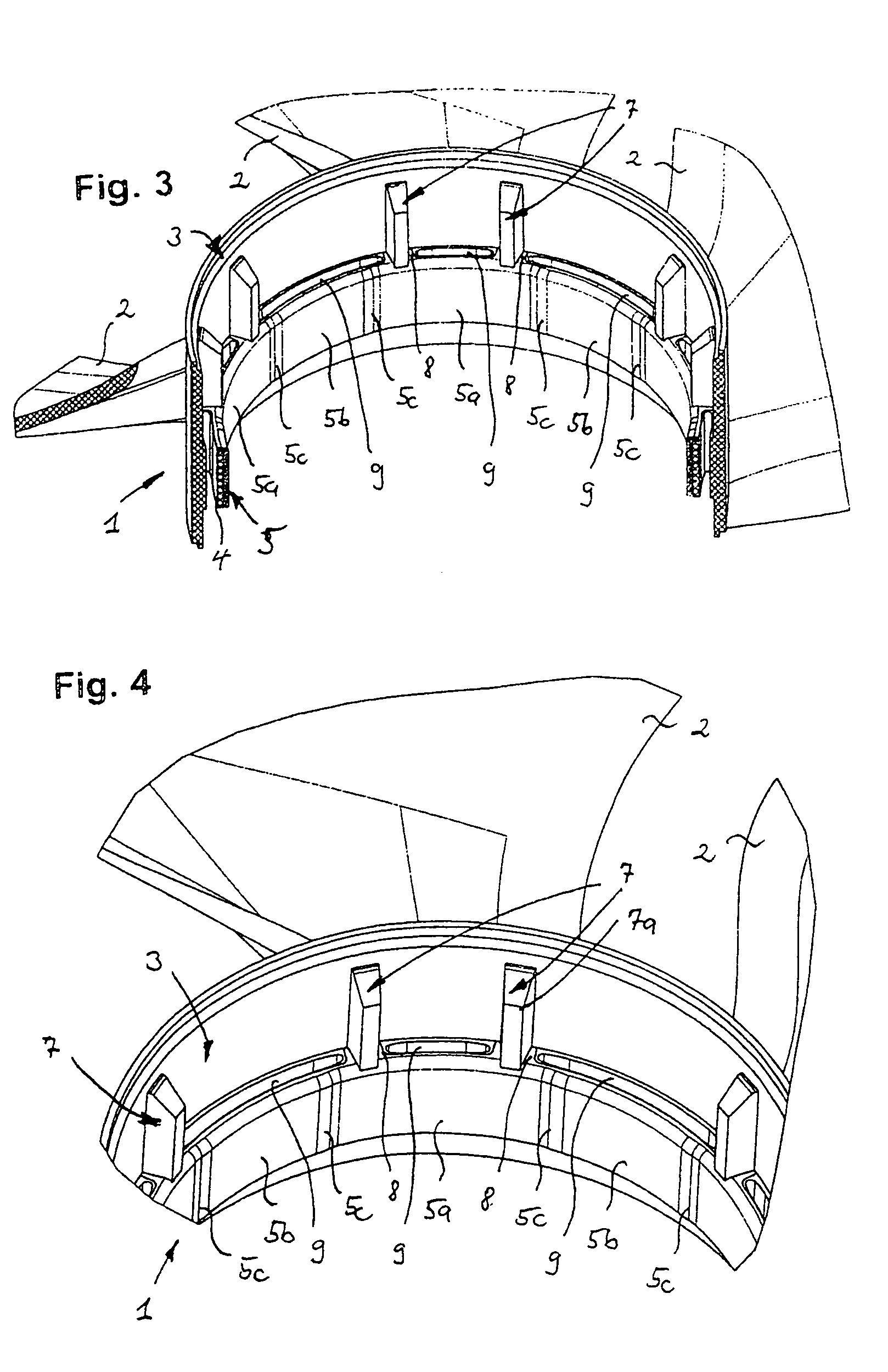

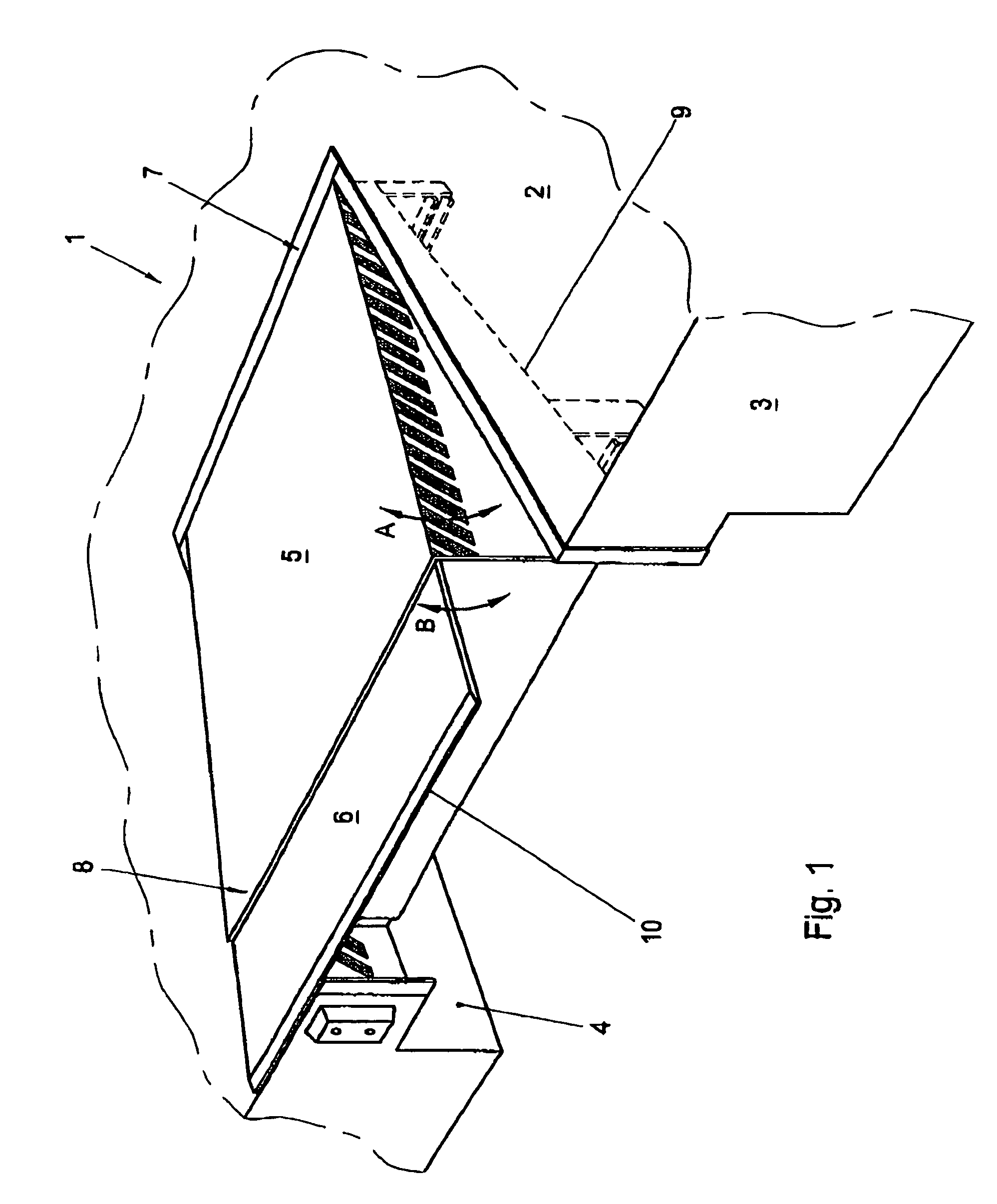

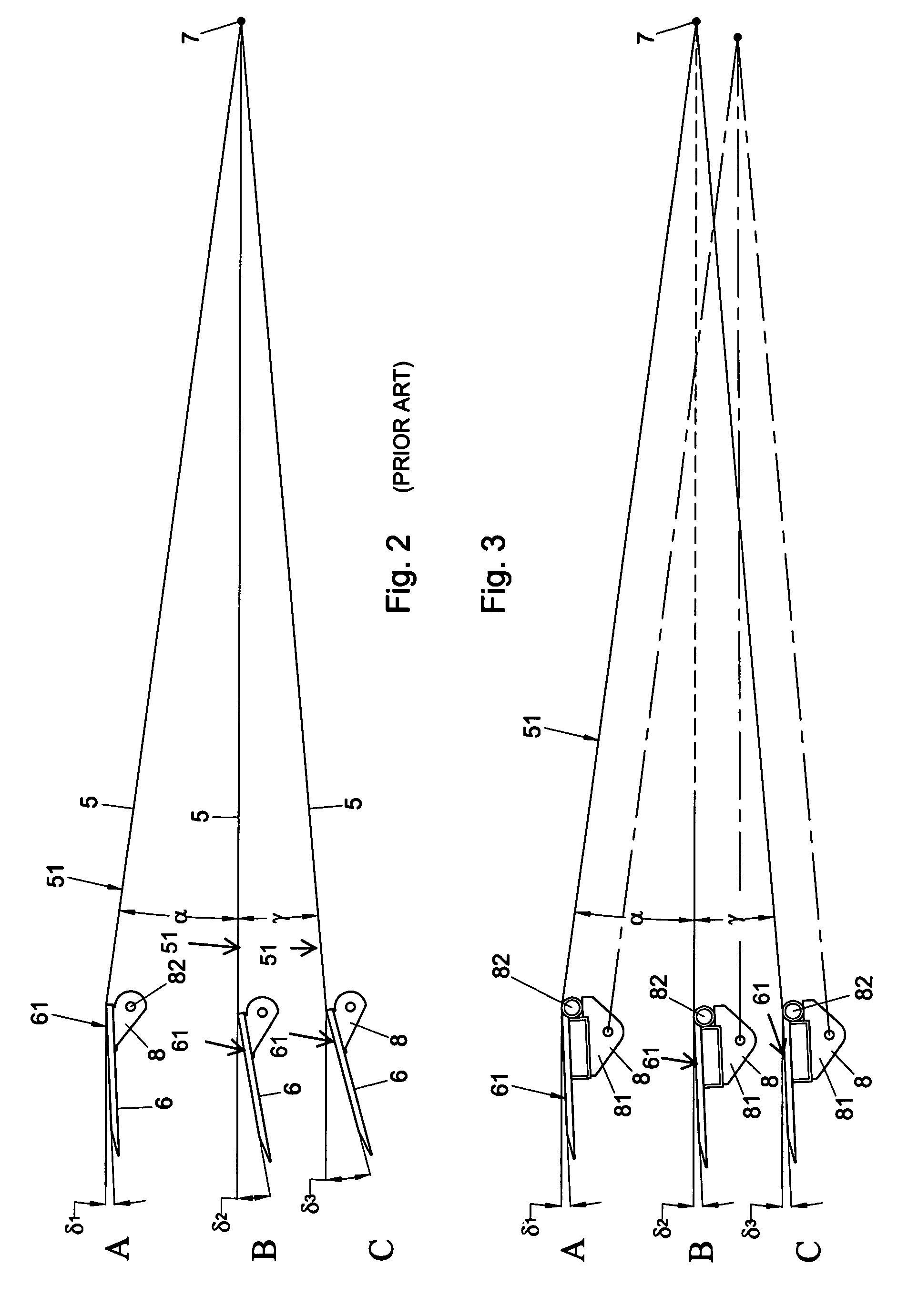

Impeller, in particular for an axial fan

ActiveUS20050287005A1Improve mechanical stabilityLittle has been producedPropellersRotary propellersImpellerEngineering

An impeller for an axial fan of the type adapted to be pressed onto a rotating rotor comprising a number of blades. The blades protrude radially outward from a substantially tubular hub, which carries the blades and is adapted to be pressed onto the rotating rotor. A substantially cylindrical blank is arranged inside the hub where the blank forms alternately arranged first and second portions. The first portions have a greater inside diameter than the inside diameter of the second portions.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

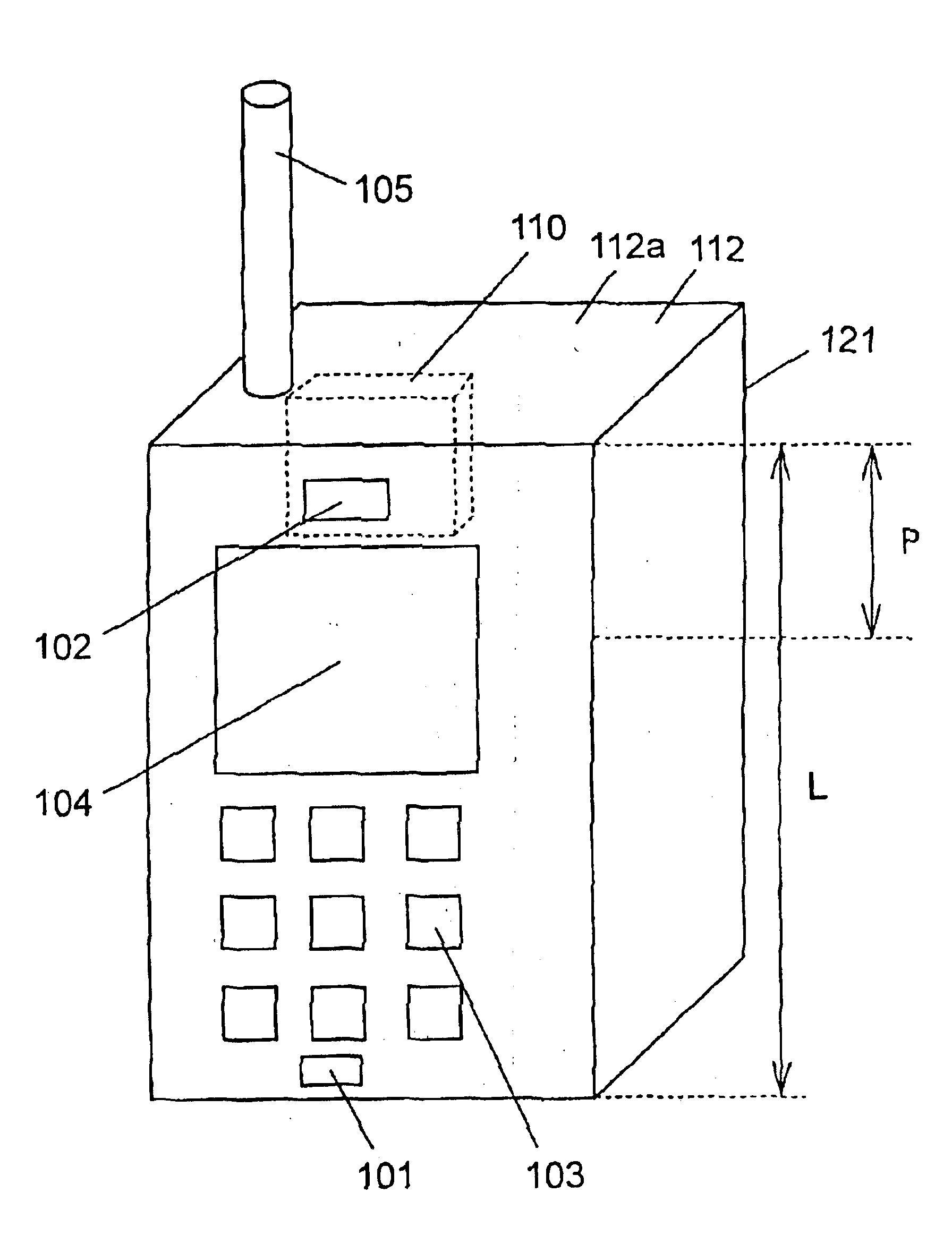

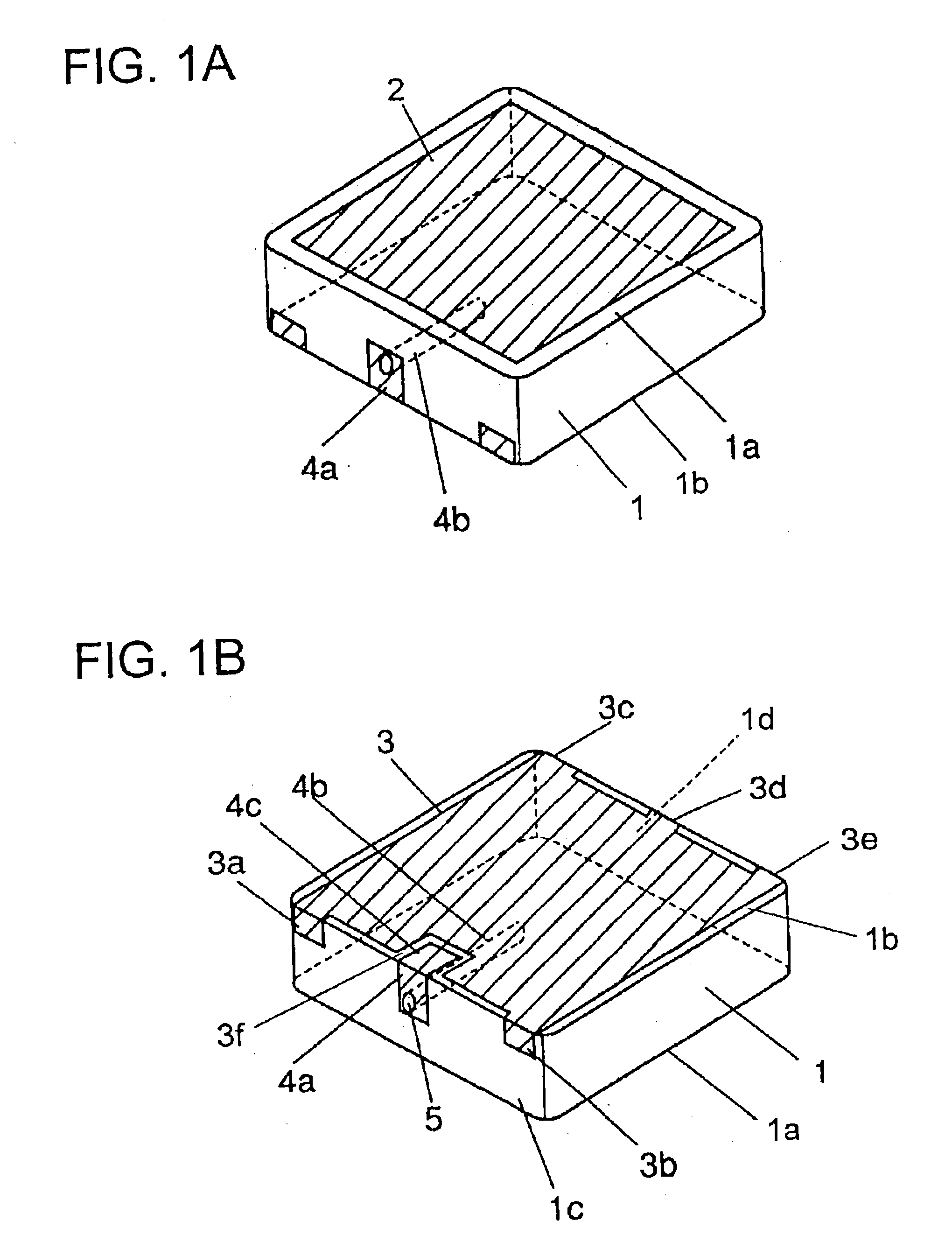

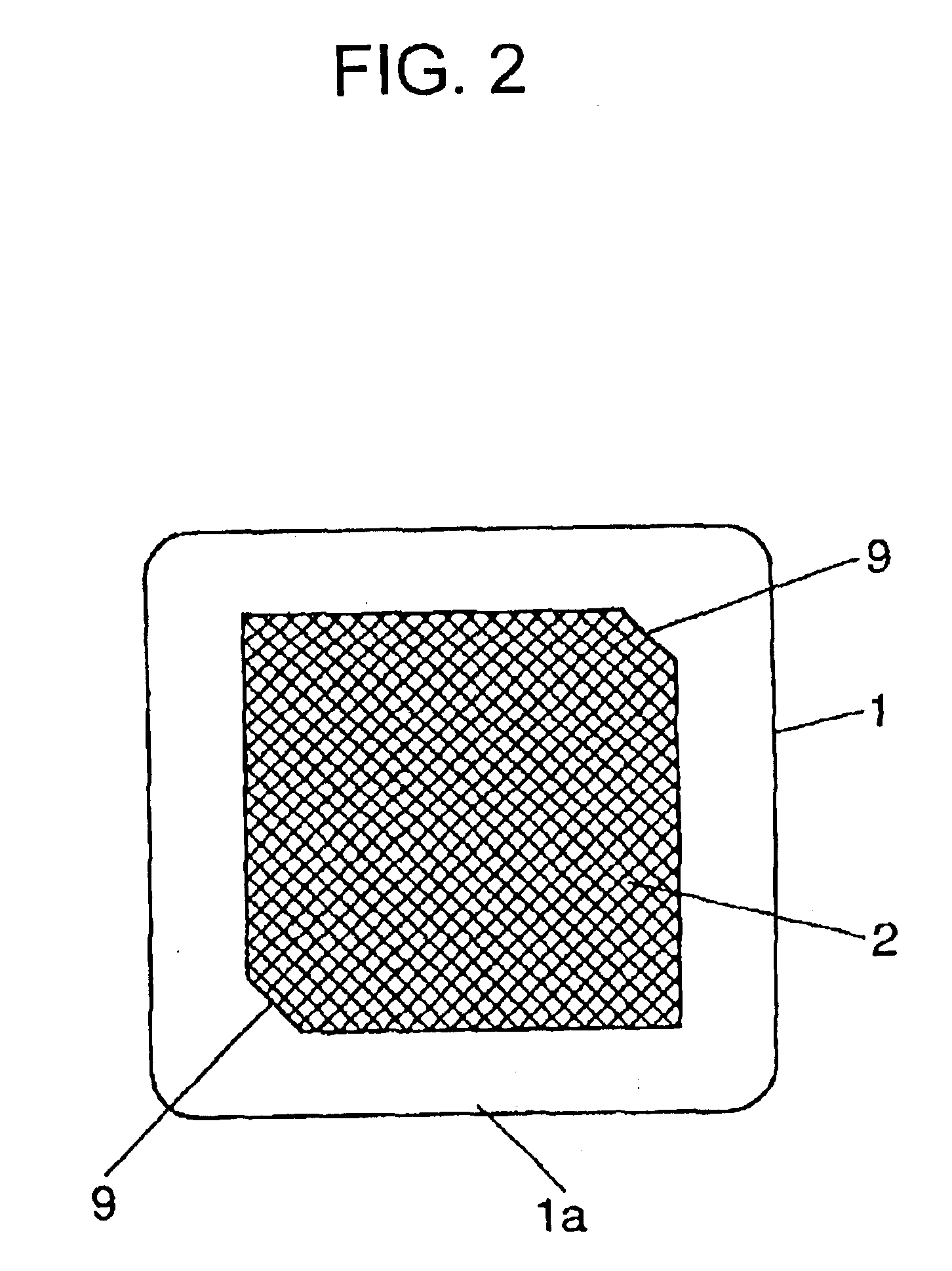

Surface-mount type antennas and mobile communication terminals using the same

InactiveUS6897815B2Easy to manufactureReduce variationAntenna supports/mountingsTelephonic communicationProduction rateSurface mounting

A surface-mount type antenna and a communication terminal using the same. A radiator electrode is provided on a first principal face of a substrate. A ground electrode is provided on the second principal face of the substrate. A first feeder electrode has at least a portion thereof provided on a side face and on the second principal face of the substrate. A second feeder electrode is provided on an inner wall face of a hole formed parallel to the first and second principal faces. The first feeder electrode and the ground electrode are kept in a non-contact state. The first feeder electrode and the second feeder electrode are in electrical contact. A mobile communication terminal using the surface-mount type antenna is small in size, exhibits small variations in characteristics, and provides high productivity and reliability.

Owner:PANASONIC CORP

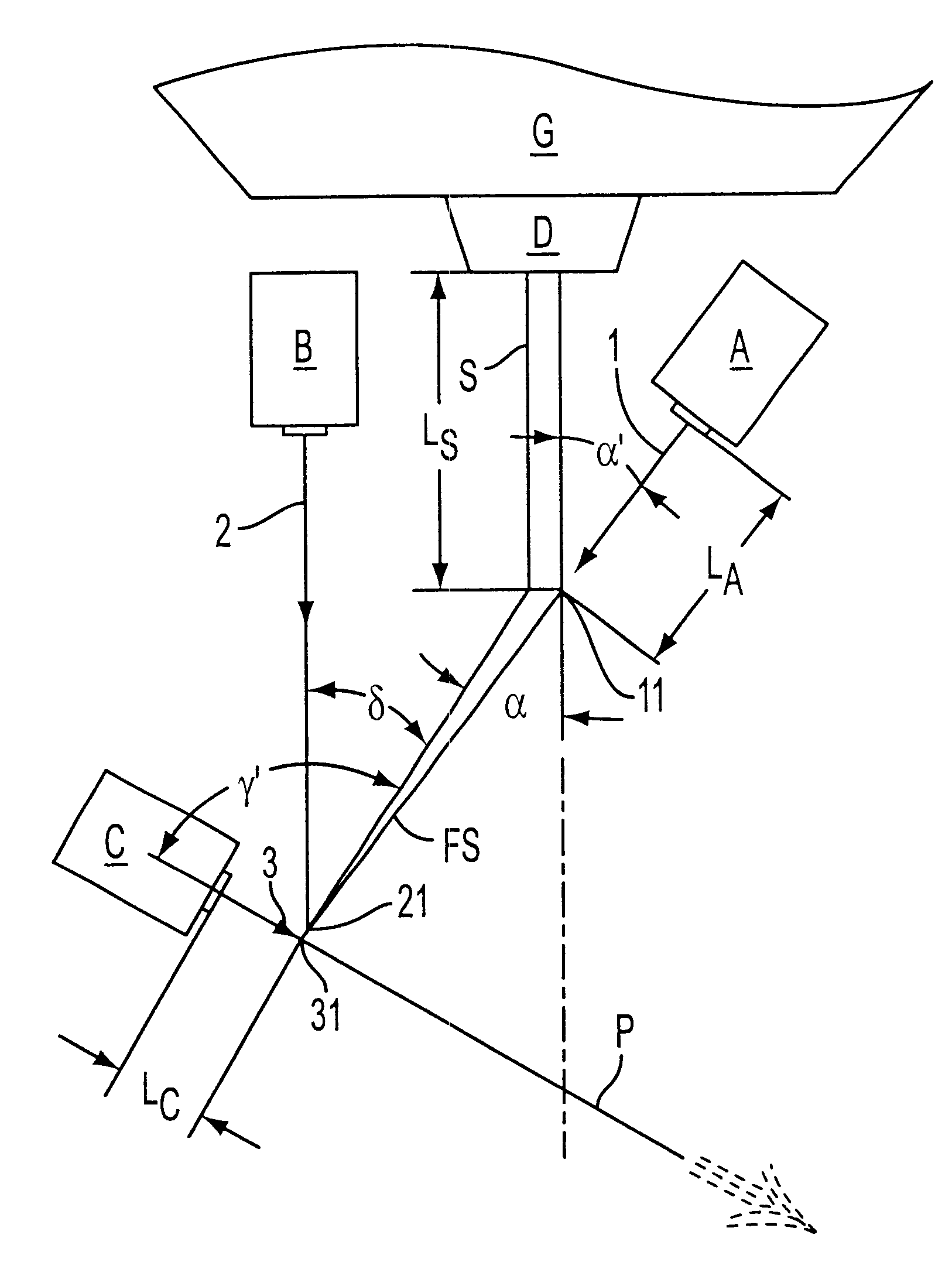

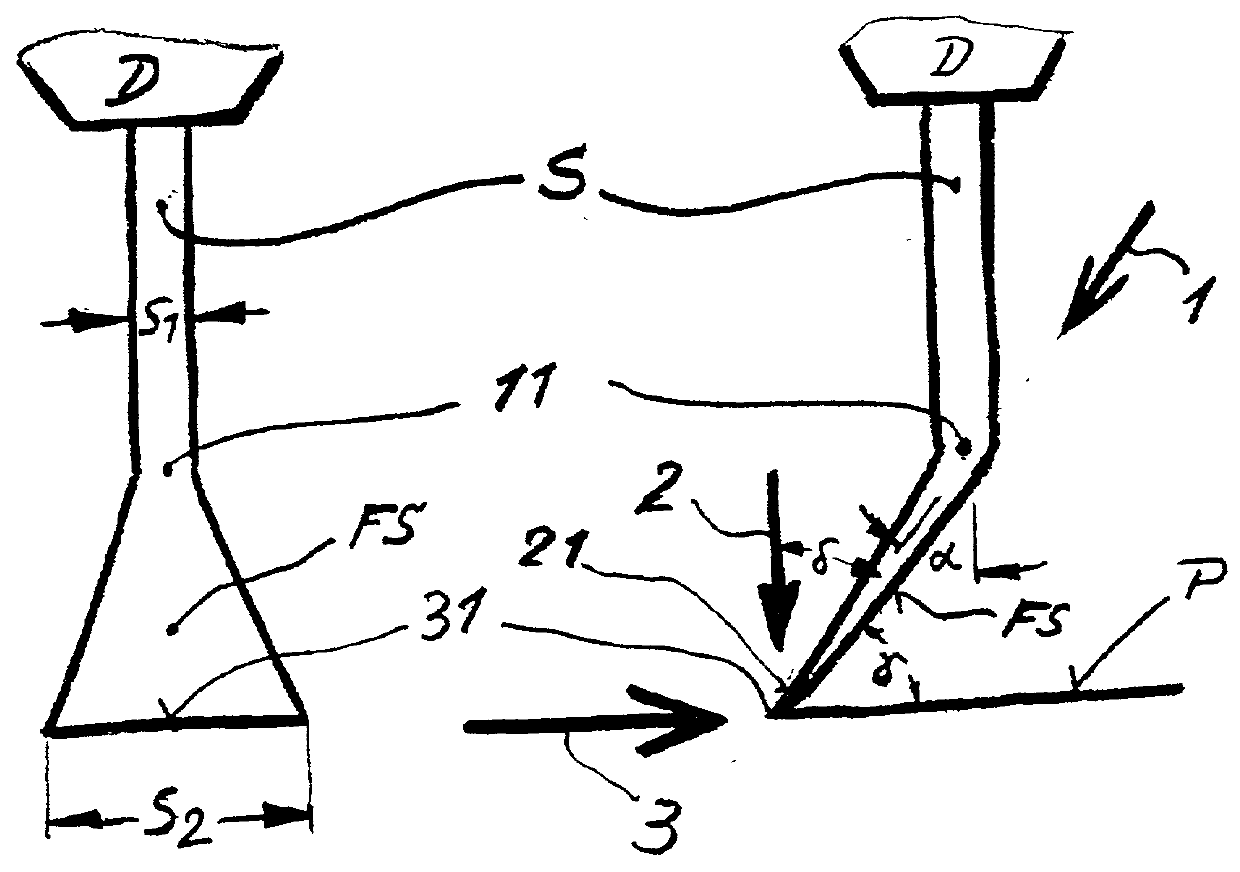

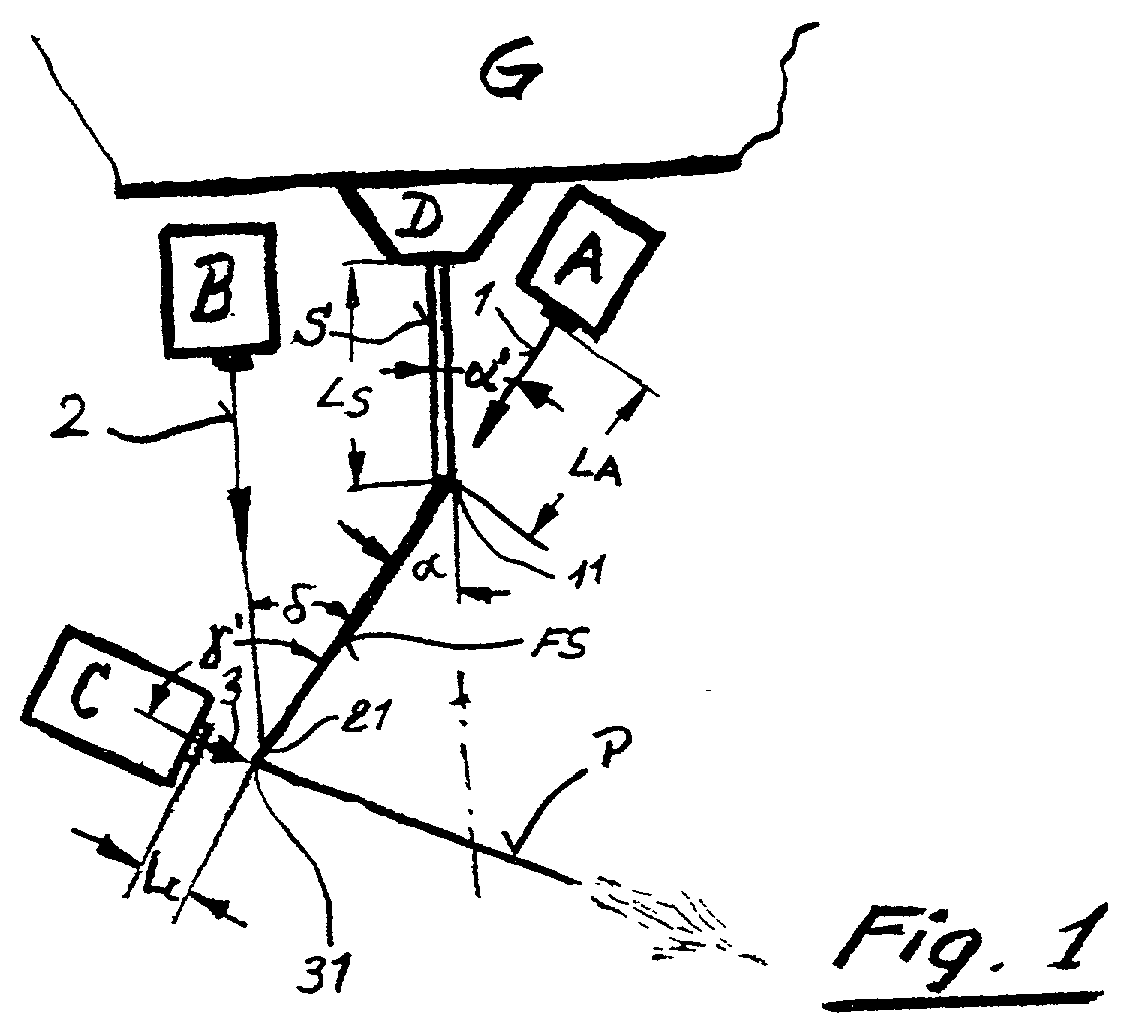

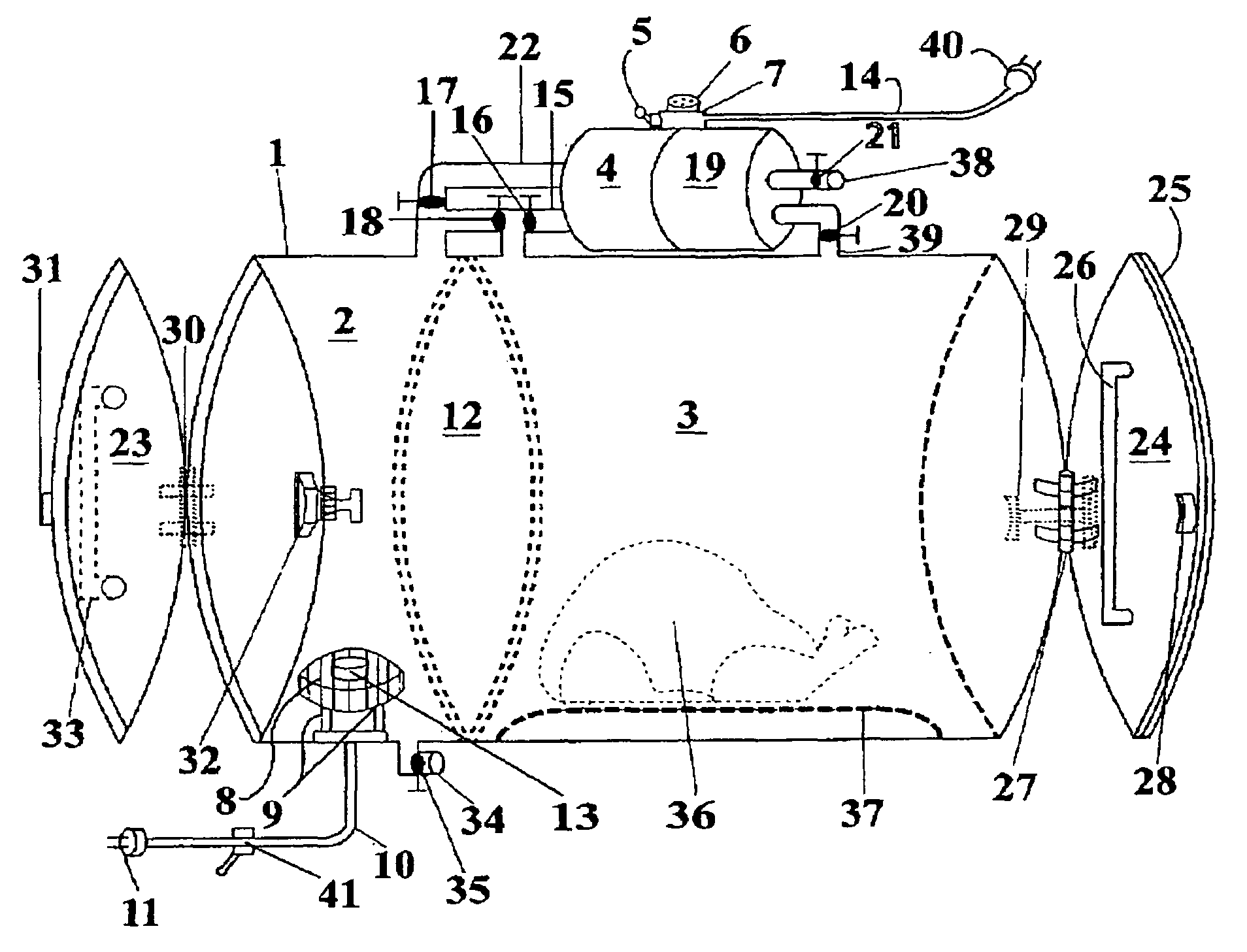

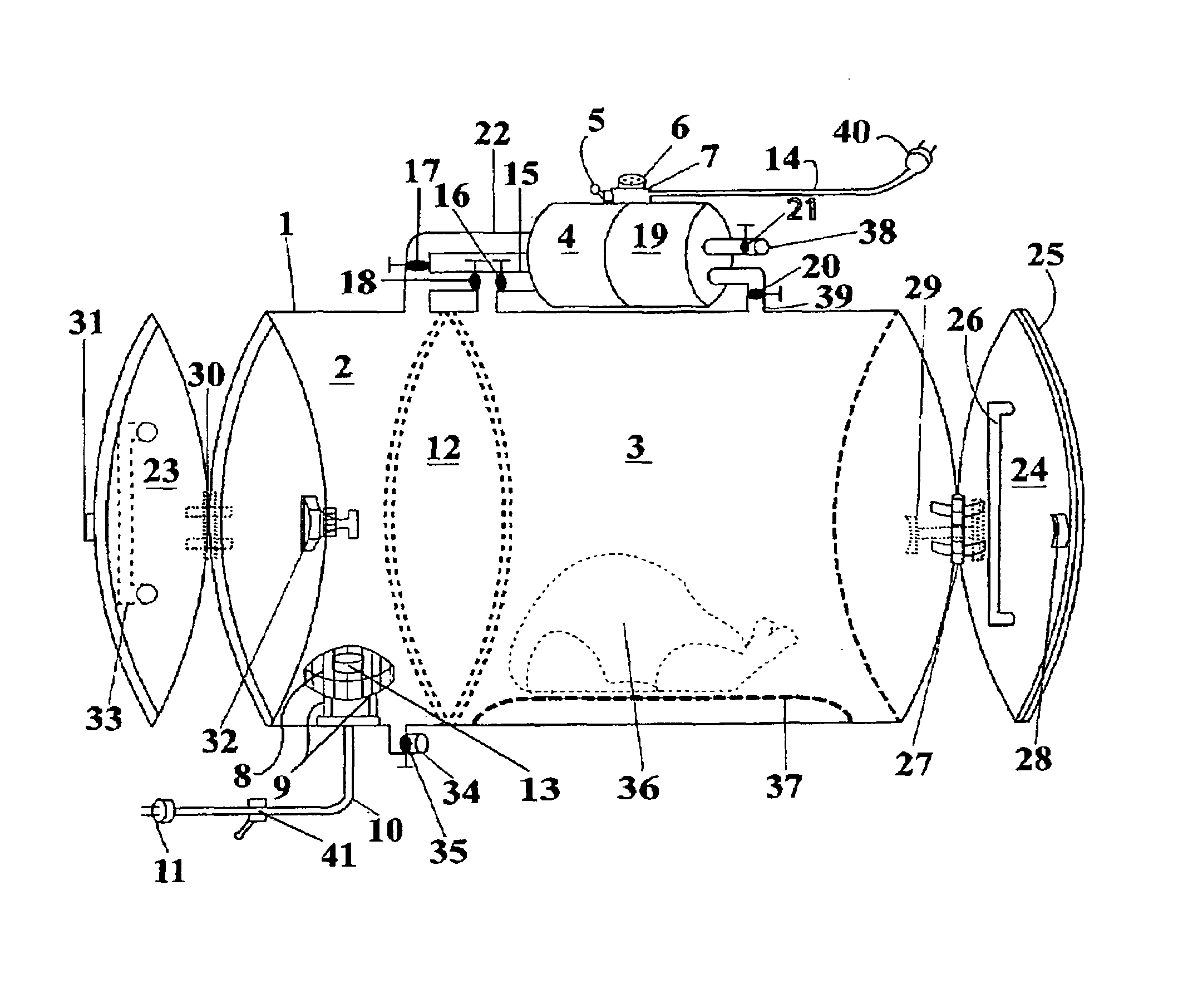

Process and device for producing metal powder

Process and a device for producing metal powders from molten metal. The process includes the provision of molten metal in a metallurgical vessel having a nozzle element, the nozzle element being directed into an atomization chamber associated with the metallurgical vessel. The molten metal is allowed to flow through the nozzle element of the metallurgical vessel into the atomization chamber whereby a molten metal stream is fed into the atomization chamber. At least three successive gas beams are directed at the molten metal stream inside the atomization chamber, the at least three gas beams being oriented in different directions. Thereby the molten metal stream is broken down into droplets which subsequently freeze into grains that are collected. The device includes a metallurgical vessel for holding molten metal provided with a nozzle element for discharging molten metal from the metallurgical vessel in the form of a molten metal stream and an atomization chamber in association with the metallurgical vessel for receiving the molten metal stream discharged from the nozzle element. It also includes at least three gas nozzle elements for providing at least three gas beams of different orientation and directed at different points of the molten metal stream inside the atomization chamber, at least one of the at least three gas nozzle elements being capable of providing a gas beam which deflects and widens and / or divides the molten metal stream entering the atomization chamber; and at least one other gas nozzle element being capable of providing a gas beam which breaks down a widened and thinned and / or divided molten metal stream into droplets.

Owner:BOHLER EDELSTAHL GMBH & CO KG

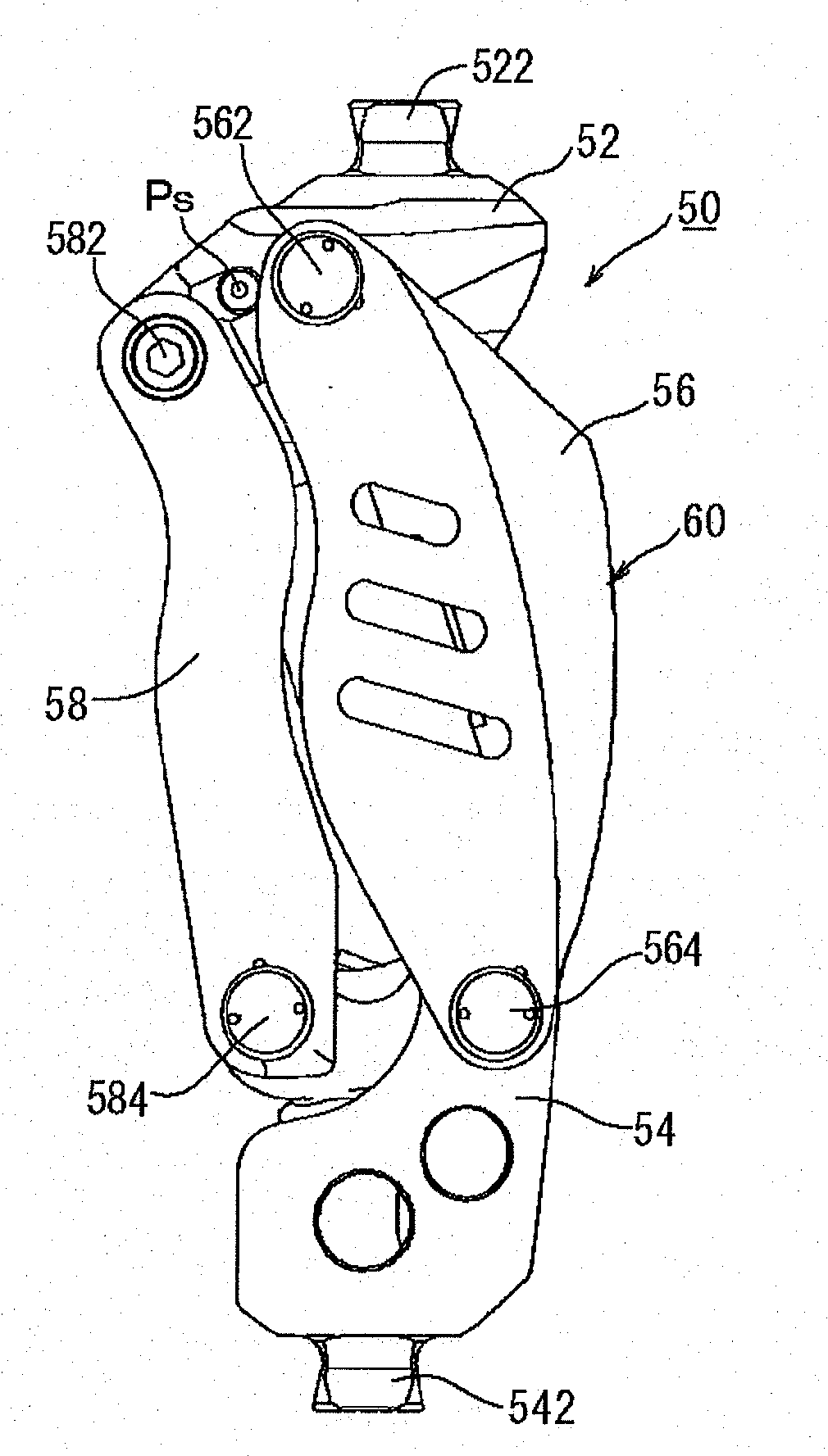

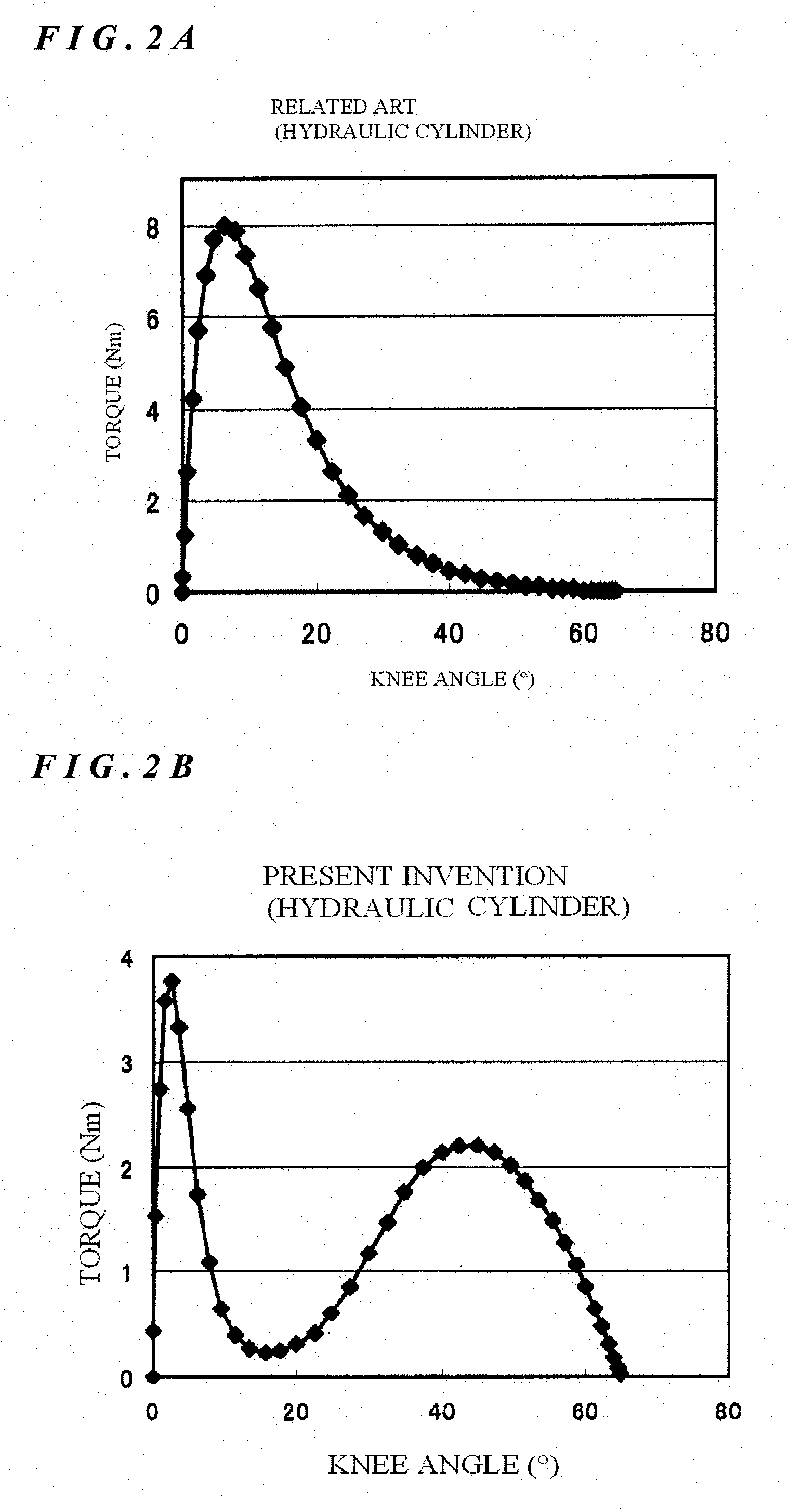

Prosthetic limbs with means capable of reducing torque in the initial period of bend of knee joint

ActiveUS20100049334A1Reduce the burden onSimple constitutionArtificial legsHydraulic cylinderPhysical medicine and rehabilitation

A technology for making the sensation at use of prosthetic limbs utilizing a hydraulic cylinder and a spring cylinder as comfortable as at use of those utilizing a pneumatic cylinder and further for improving walk following properties. In particular, the arrangement of drag generating means, such as a hydraulic cylinder and a spring cylinder, per se is specified. Accordingly, the resistance produced by the drag generating means in accordance with an increase of knee angle is increased. The first torque T1 at the first stage of initial period of bend of knee joint is made small, while the second torque T2 at the second stage of final period of the further advanced bend of knee joint is made large, thereby satisfying a relation of T1≦T2, as different from conventional ones.

Owner:NABLESCO CORP

Impeller, in particular for an axial fan

ActiveUS7442010B2Improve mechanical stabilityLittle has been producedPropellersRotary propellersImpellerEngineering

An impeller for an axial fan of the type adapted to be pressed onto a rotating rotor comprising a number of blades. The blades protrude radially outward from a substantially tubular hub, which carries the blades and is adapted to be pressed onto the rotating rotor. A substantially cylindrical blank is arranged inside the hub where the blank forms alternately arranged first and second portions. The first portions have a greater inside diameter than the inside diameter of the second portions.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

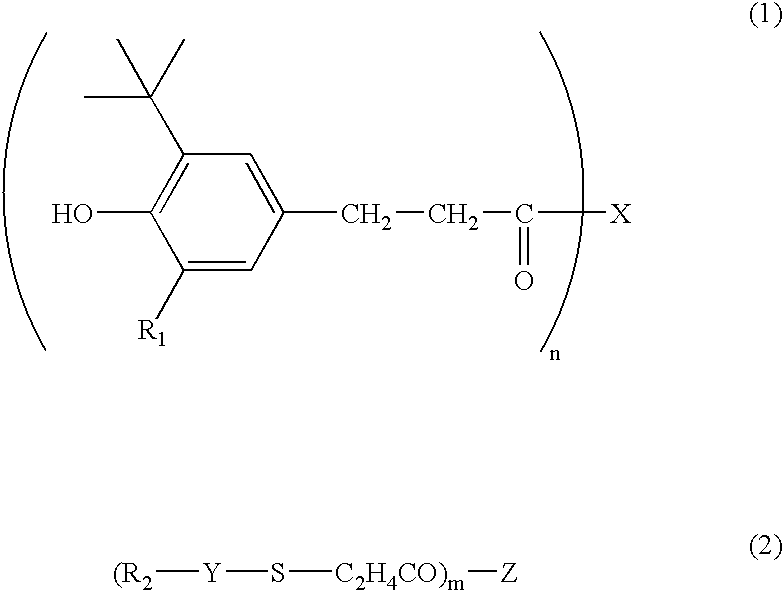

Granule mass

InactiveUS20070100045A1Improve liquidityLittle has been producedChemical inhibitorsPHENOL LIQUIDPolyolefin

An object of the present invention is to provide a granule mass containing an antioxidant as a main component, which is excellent in flowability, produces little dust from an additive, and can be prepared by a simple facility when an additive such as an antioxidant is added to a plastic such as polyolefin, and affords a plastic having thermal stability which is hardly ununiformized, and a process for producing the same. There is provided a granule mass comprising a granule containing a phenol-based antioxidant represented by the following formula (1) and a sulfur-based antioxidant represented by the following formula (2), wherein a content of the sulfur-based antioxidant (2) relative to a total of 100 parts by weight of phenol-based antioxidant (1) and the sulfur-based antioxidant (2) is 3 to 70 parts by weight.

Owner:SUMITOMO CHEM CO LTD

Container for precision substrate

InactiveUS20040224110A1Reduce pressureLittle has been producedEnvelopes/bags making machineryClosuresUltra high purityContamination

A container for precision substrate having one or more component formed by molding a thermoplastic resin, characterized in that the component satisfies characteristics [1] and [2] below. [1] When being brought to contact ultra high purity argon gas (impurity concentration: 1 ppb or less) at 25° C. having a flow rate of 1.2 L / min., a water amount in said argon gas after 300 minutes is 30 ppb or less per a surface area 1 cm<2 >of the component. [2] When being placed in the air at 100° C., an increase amount of organics in the air in 300 minutes is 150 ng or less per weight 1 g of the component. According to the container, demands for low contamination can be satisfied.

Owner:ZEON CORP +1

Process and device for producing metal powder

InactiveUS20010054784A1High fine grain fractionPromote resultsMelt-holding vesselsLiquid transferring devicesMetal powderMolten metal

Process and a device for producing metal powders from molten metal. The process includes directing at least three successive gas beams at a molten metal stream inside an atomization chamber, the at least three gas beams being oriented in different directions. The device includes a metallurgical vessel for holding molten metal provided with a nozzle element for discharging a molten metal stream into an atomization chamber as well as at least three gas nozzle elements for providing at least three gas beams of different orientation and directed at different points of the molten metal stream inside the atomization chamber.

Owner:BOHLER EDELSTAHL GMBH & CO KG

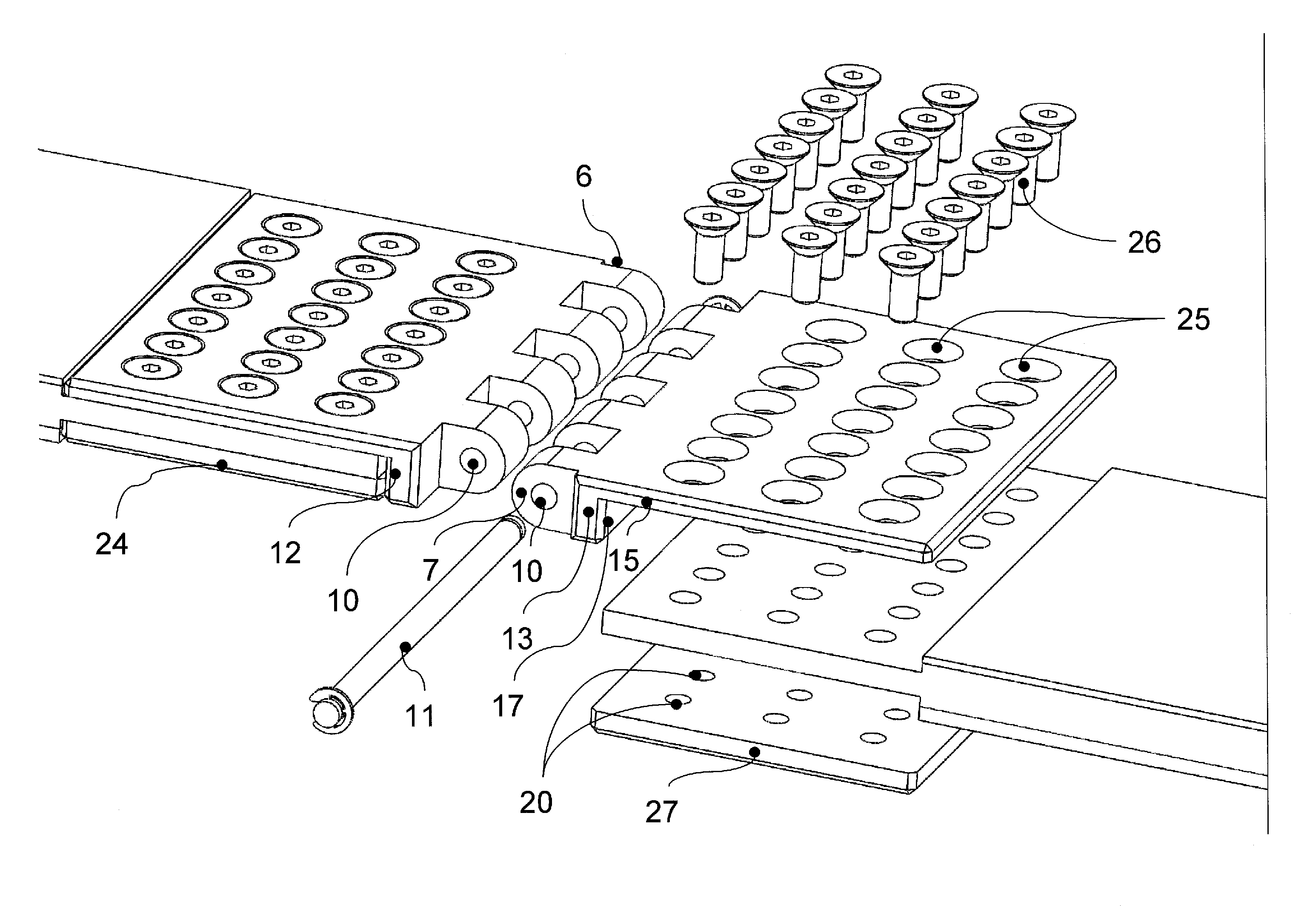

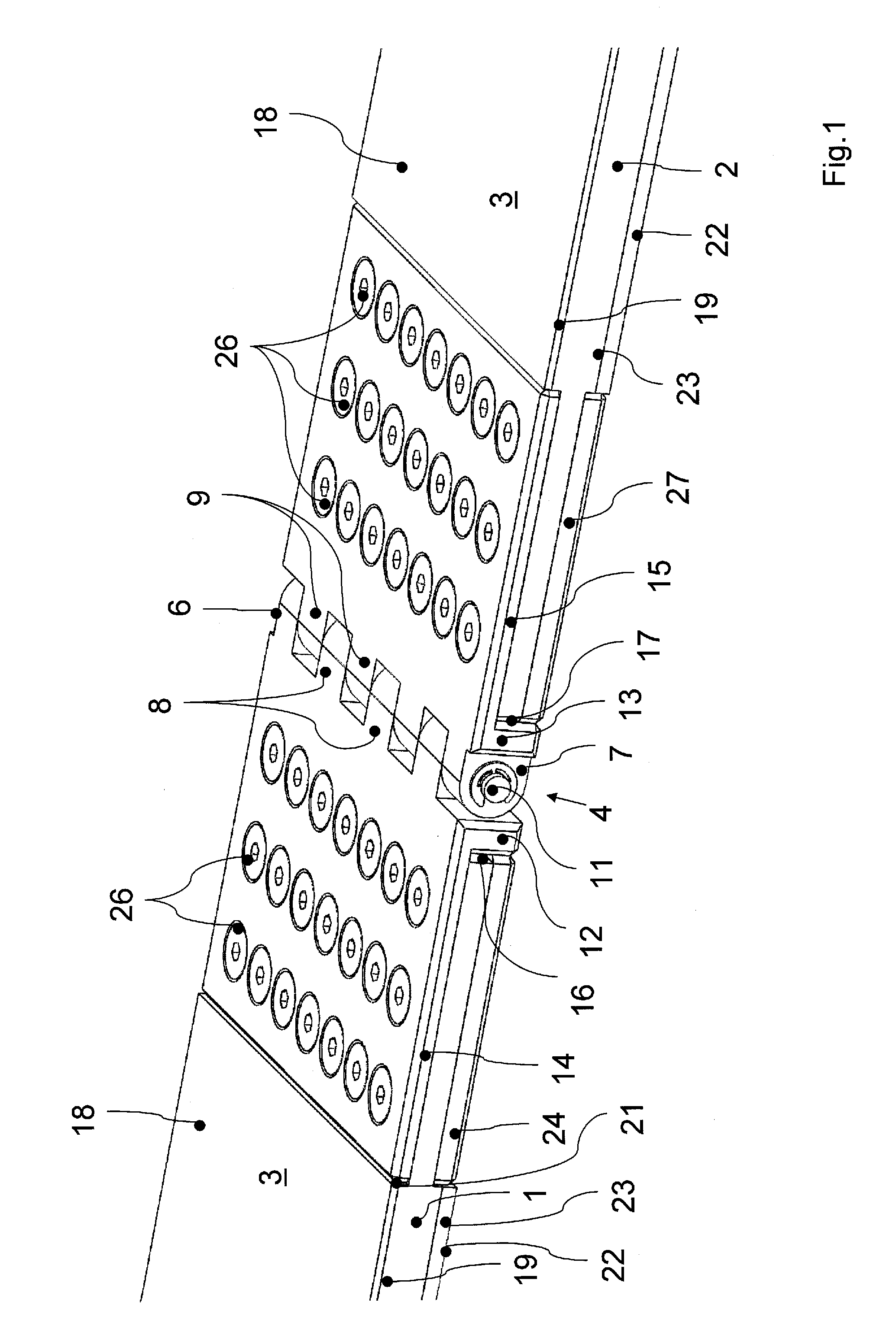

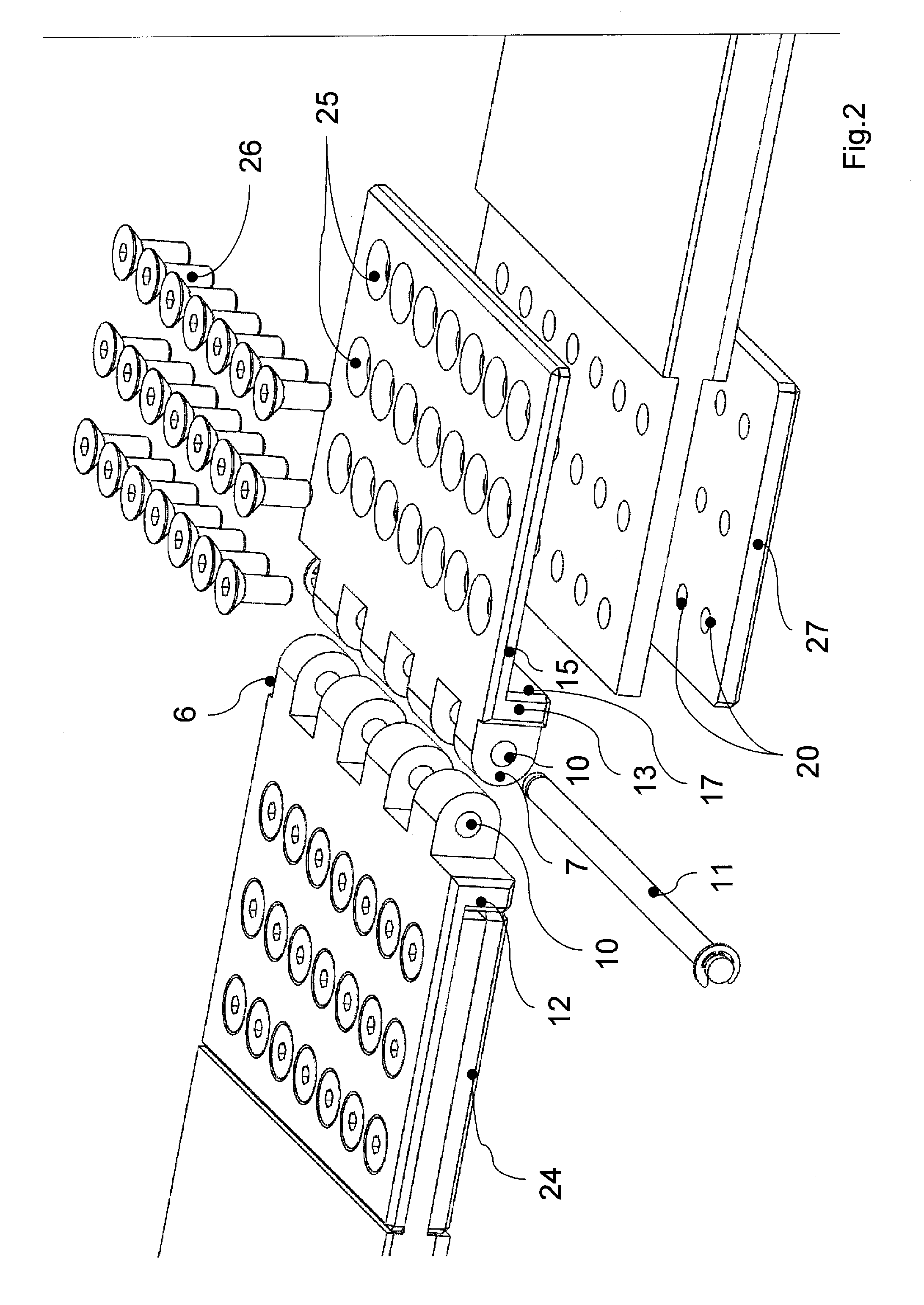

Steel cord conveyer belt with a connecting hinge for coupling two belt ends

A conveyor belt with a reinforcement support layer consisting of steel cords running in parallel has, at each end, the hinge-like configuration for coupling to another belt end. In order also to provide a hinge connection for steel cord conveyor belts having relatively large cord diameters, each belt end (1, 2) has a part hinge (6, 7). Each part hinge (6 and 7) has a hinge bar (12 and 13) on which an integrated clamping plate (14 and 15) is integrally formed. The integrated clamping plate (14 and 15) is seated in the one belt outer surface (18) of the conveyor belt. On the opposite belt outer surface (22), a corresponding, separate clamping plate (24 and 27) is seated in each case in the rubber cover layer there. The clamping plate of each part hinge securely clamps the corresponding thickness-reduced belt end therebetween.

Owner:CONTITECH TRANSPORTBANDSYSTEME GMBH

Methods and apparatus to form electronic components with at least one N- or P-doped portion

InactiveUS7737006B2Improve electrical performanceImprove performanceTransistorSolid-state devicesDopantNanoparticle

A method of manufacturing an electronic component comprising at least one n- or p-doped portion, comprising the steps of: co-depositing inorganic semi-conducting nanoparticles and dopant on a substrate, the nanoparticles being a group four element such as silicon or germanium; fusing the nanoparticles by heating to form a continuous layer; and subsequently; and, recrystallising the layer.

Owner:HEWLETT PACKARD DEV CO LP

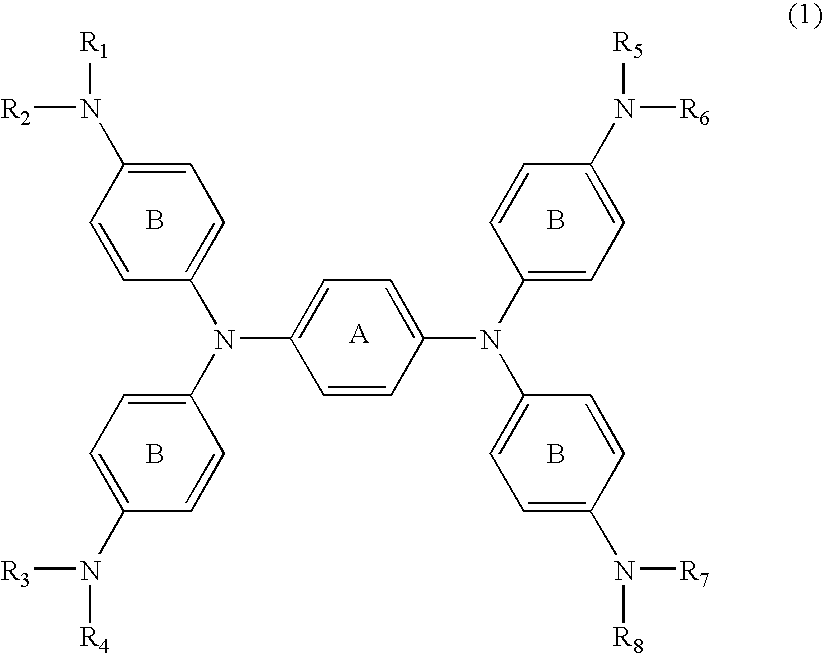

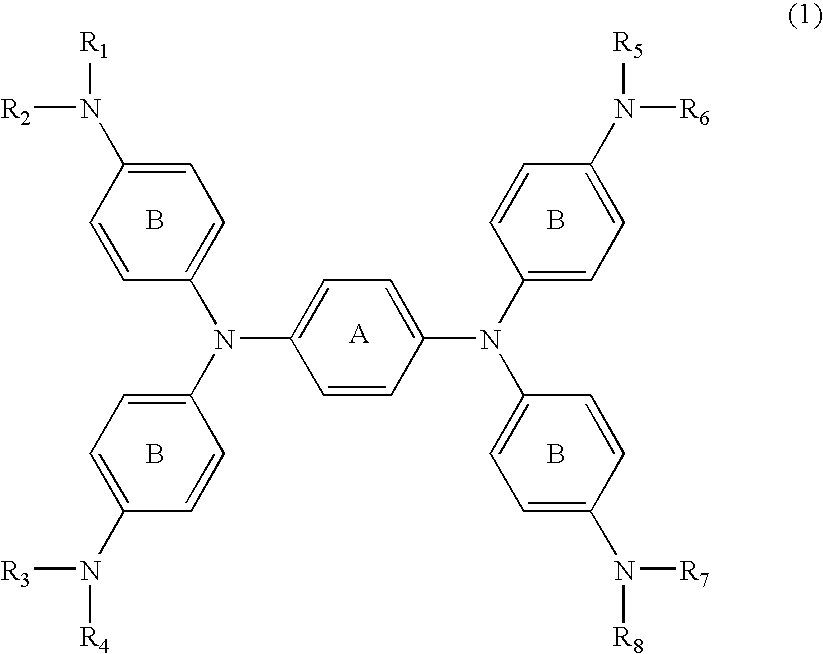

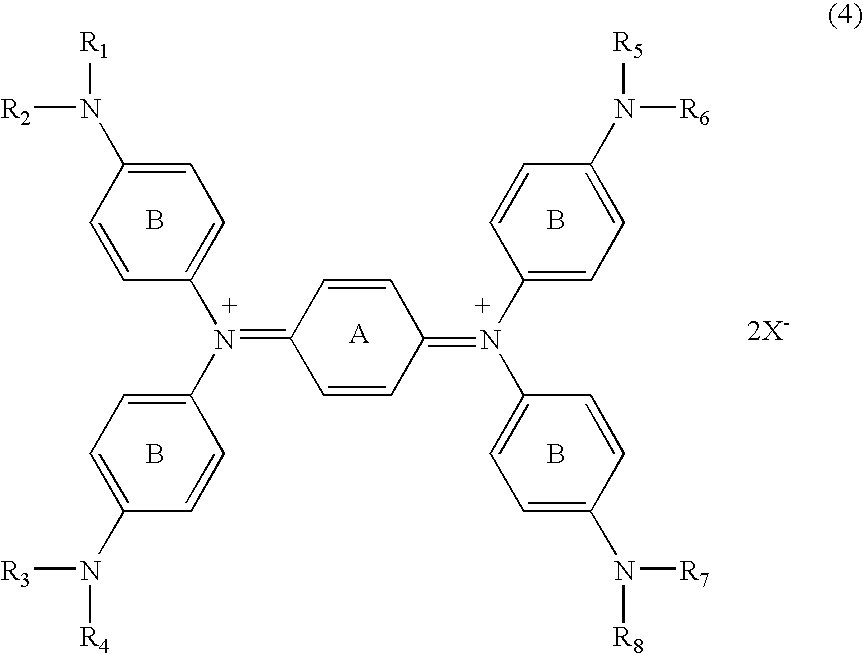

Near-infrared absorbing compound and near-infrared absorbing filter using same

InactiveUS20060091365A1High light transmittanceBroad absorptionOrganic chemistryOther chemical processesIonInfrared

A near-infrared absorbing filter which does not contain antimony, arsenic or the like and is excellent in heat resistance is disclosed. The near-infrared absorbing filter is characterized by containing a compound composed of a salt of cations obtained by oxidizing a substance represented by the formula (1) below and anions (X), which are alkylsulfonate ions having 1-8 carbon atoms that are necessary for neutralizing the cations and not substituted or may be substituted with a halogen atom, a lower alkyl group, a cyano group, or a hydroxy group. (1) (in the formula (1), rings A and B may have a substituent, and R1-R8 independently represent a substituted or non-substituted (C1 to C8) alkyl group, cycloalkyl group, alkenyl group or aryl group.)

Owner:NIPPON KAYAKU CO LTD

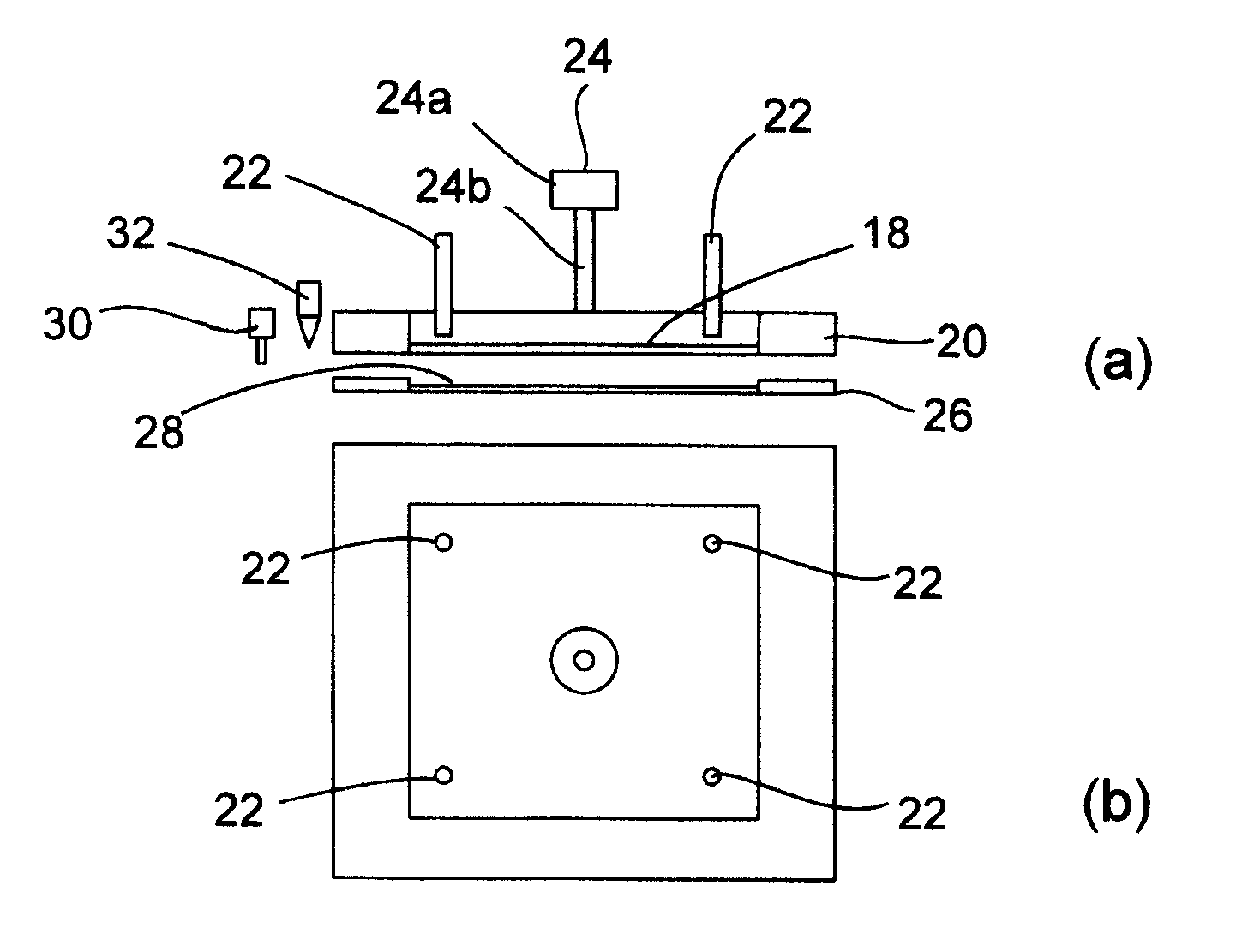

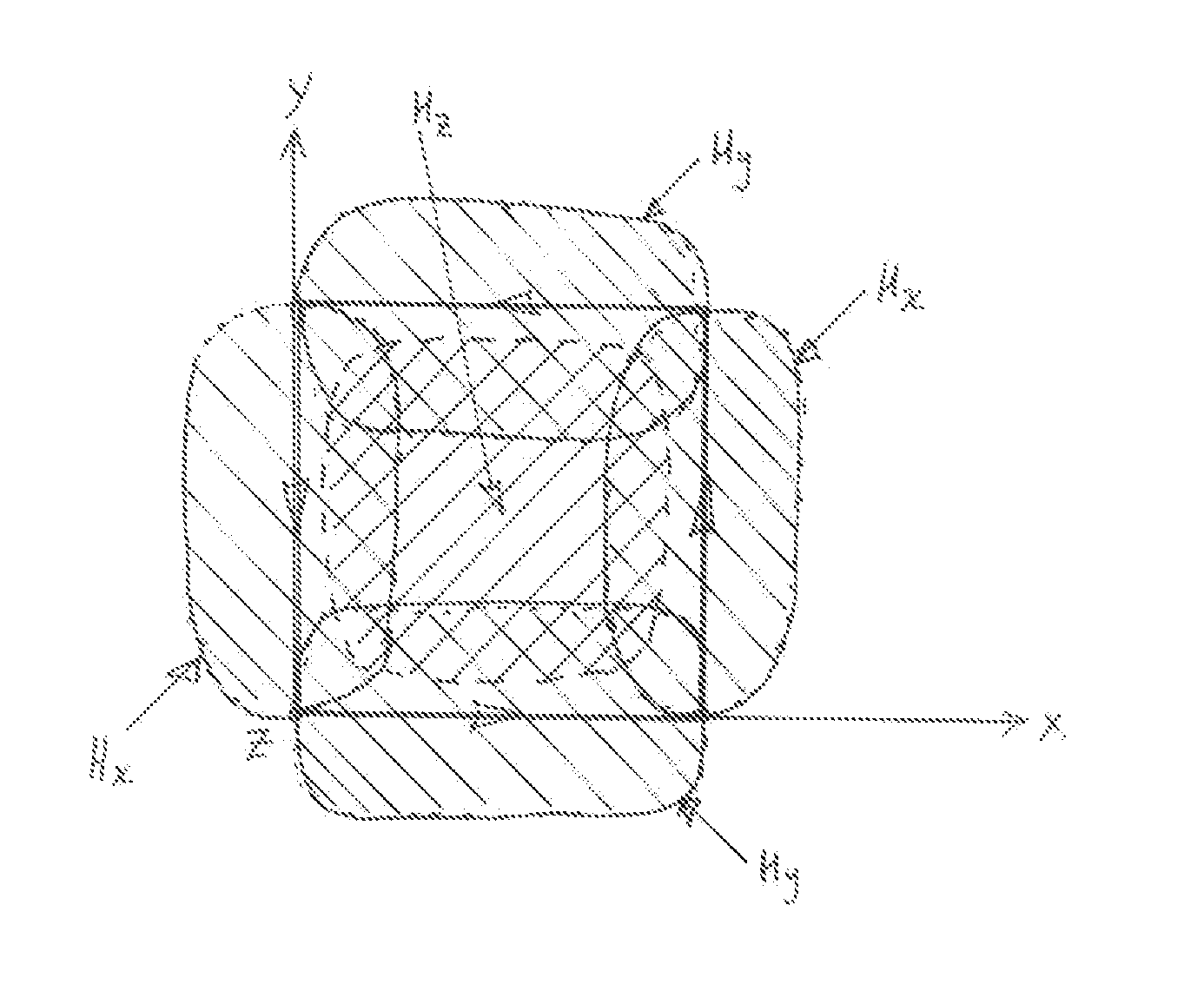

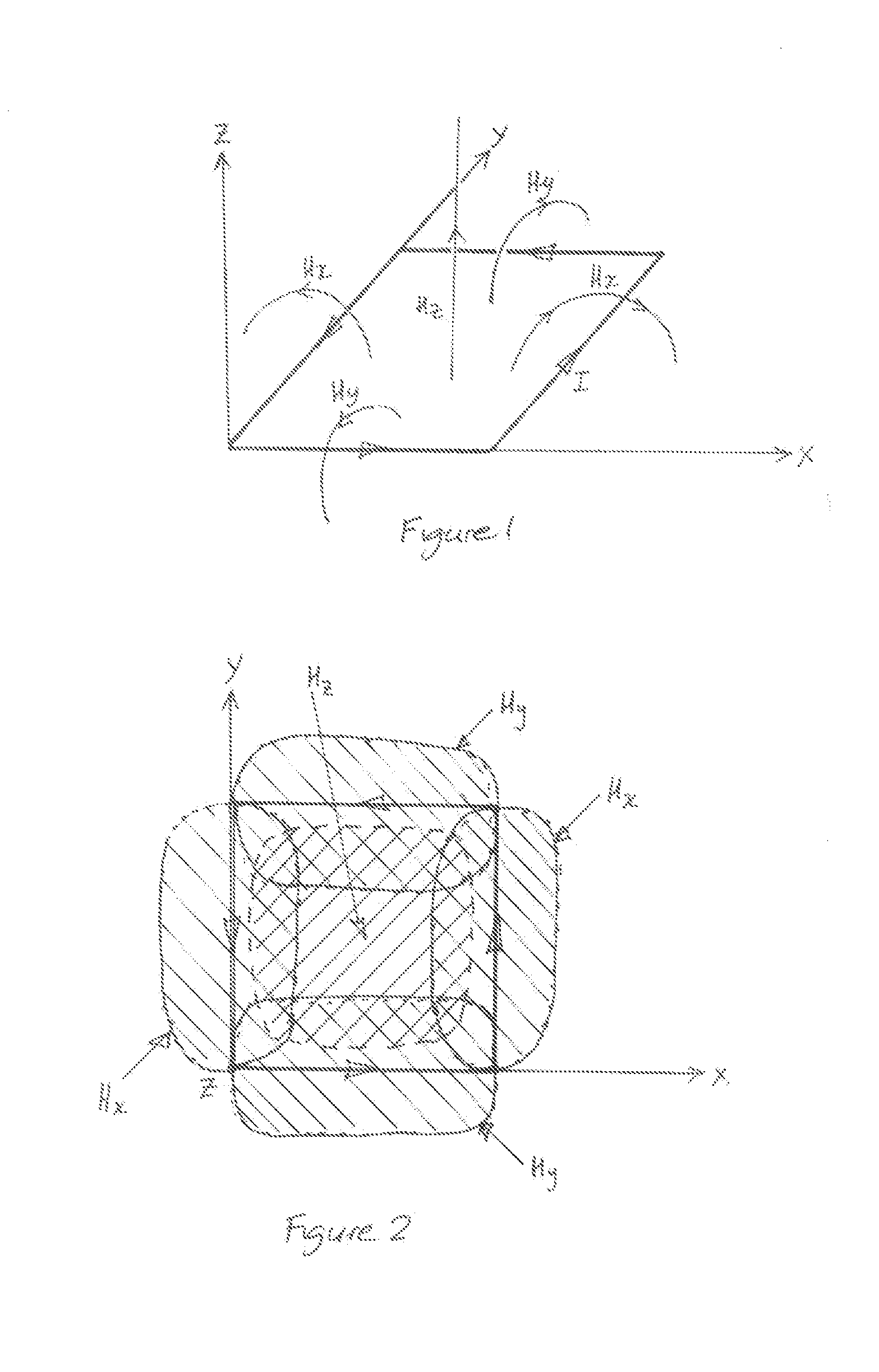

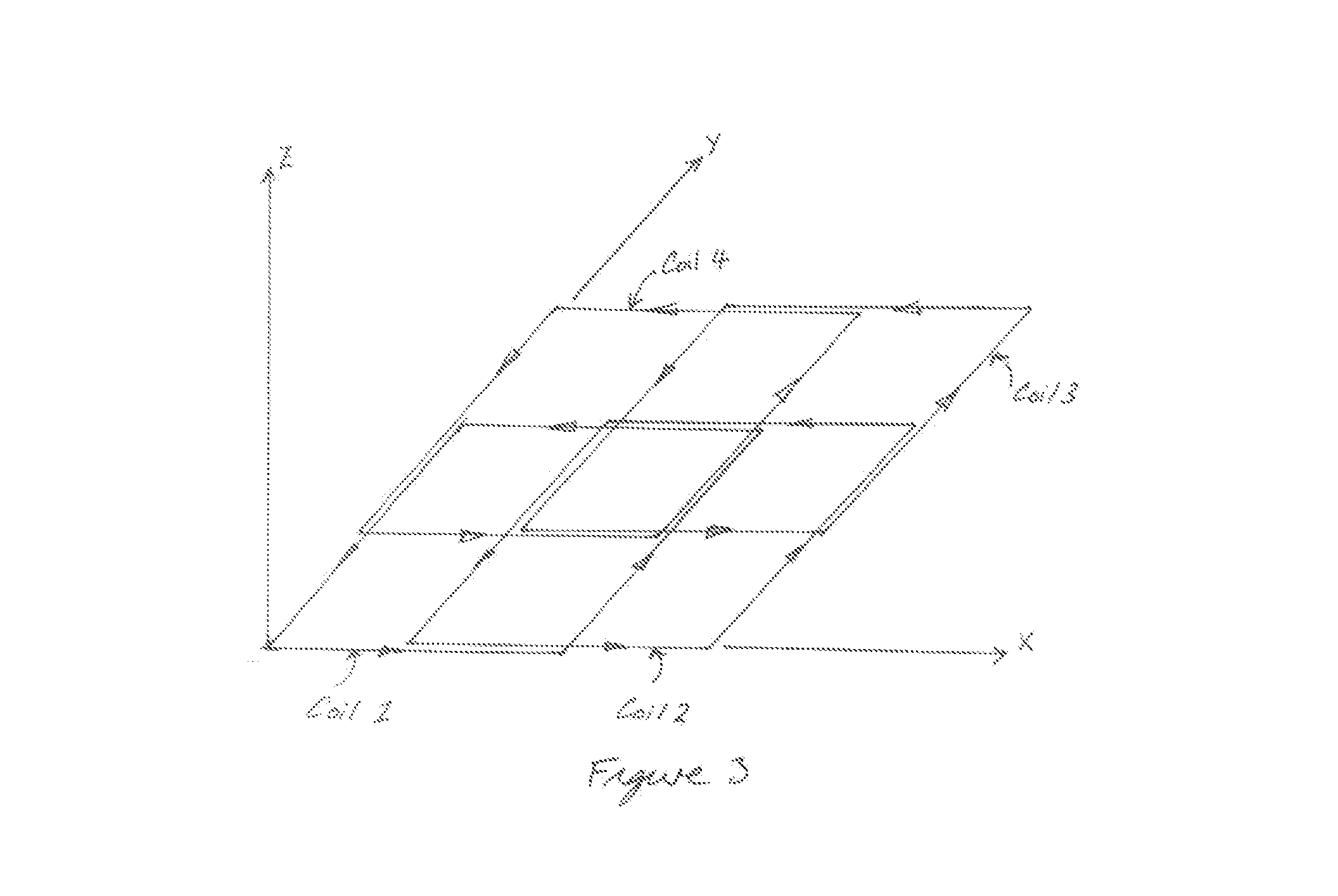

Antenna design and interrogator system

ActiveUS20140015648A1Low costArray sizeAntenna supports/mountingsSensing record carriersMobile antennasAntenna design

The present invention relates to the identification of RFID devices that are arranged closely together and placed on shelving for logistical and storage purposes. Furthermore, the aspects of the present invention relate to an arrangement and / or layout of antenna coils for example in an interrogator. There is disclosed a RFID interrogator and / or method of interrogating comprising an antenna, when activated, being adapted to radiate an interrogation signal in a first area, means adapted to shift the antenna within a second area, the second area being larger than the first area. The antenna may be mechanically moveable.

Owner:SATO HLDG CORP

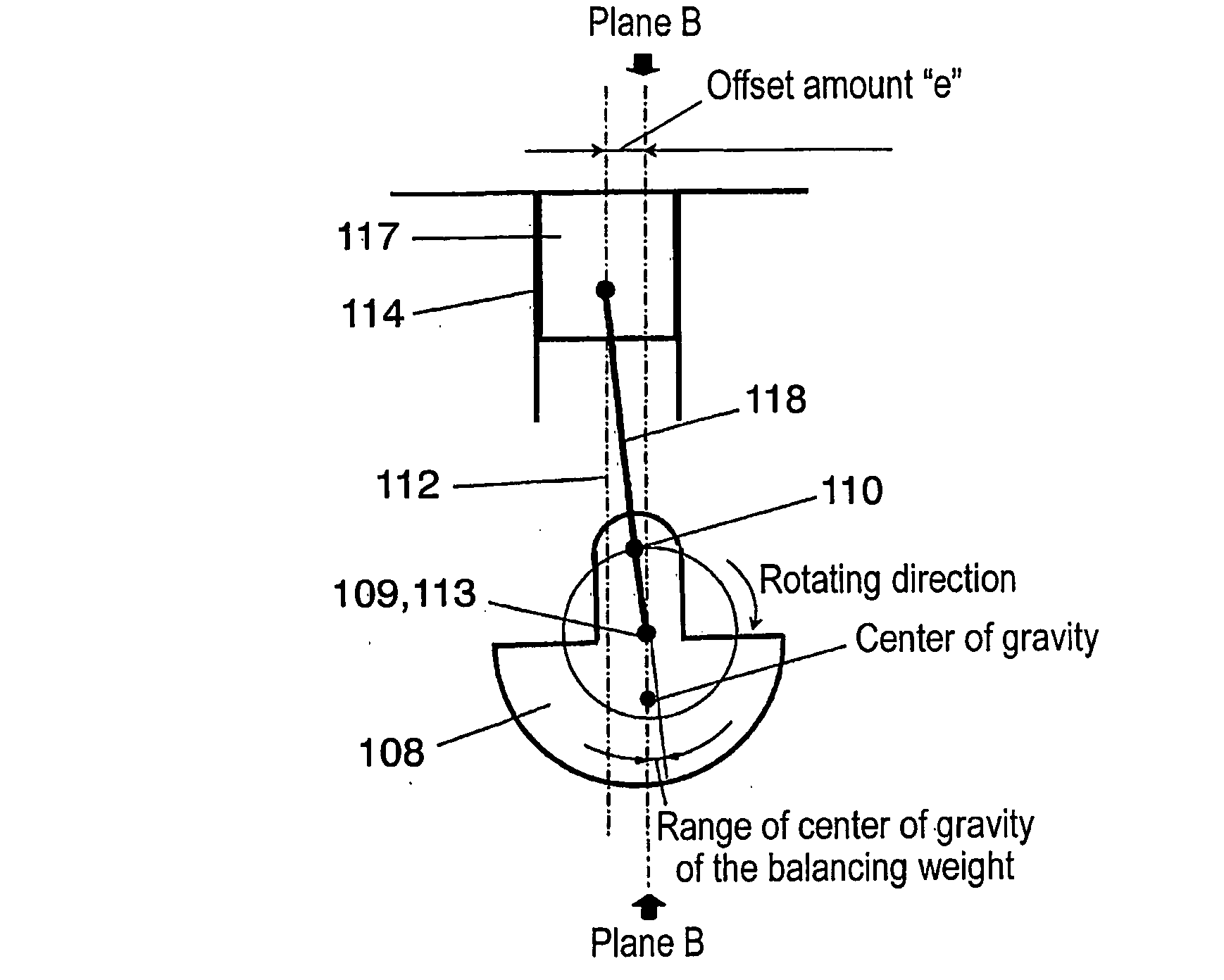

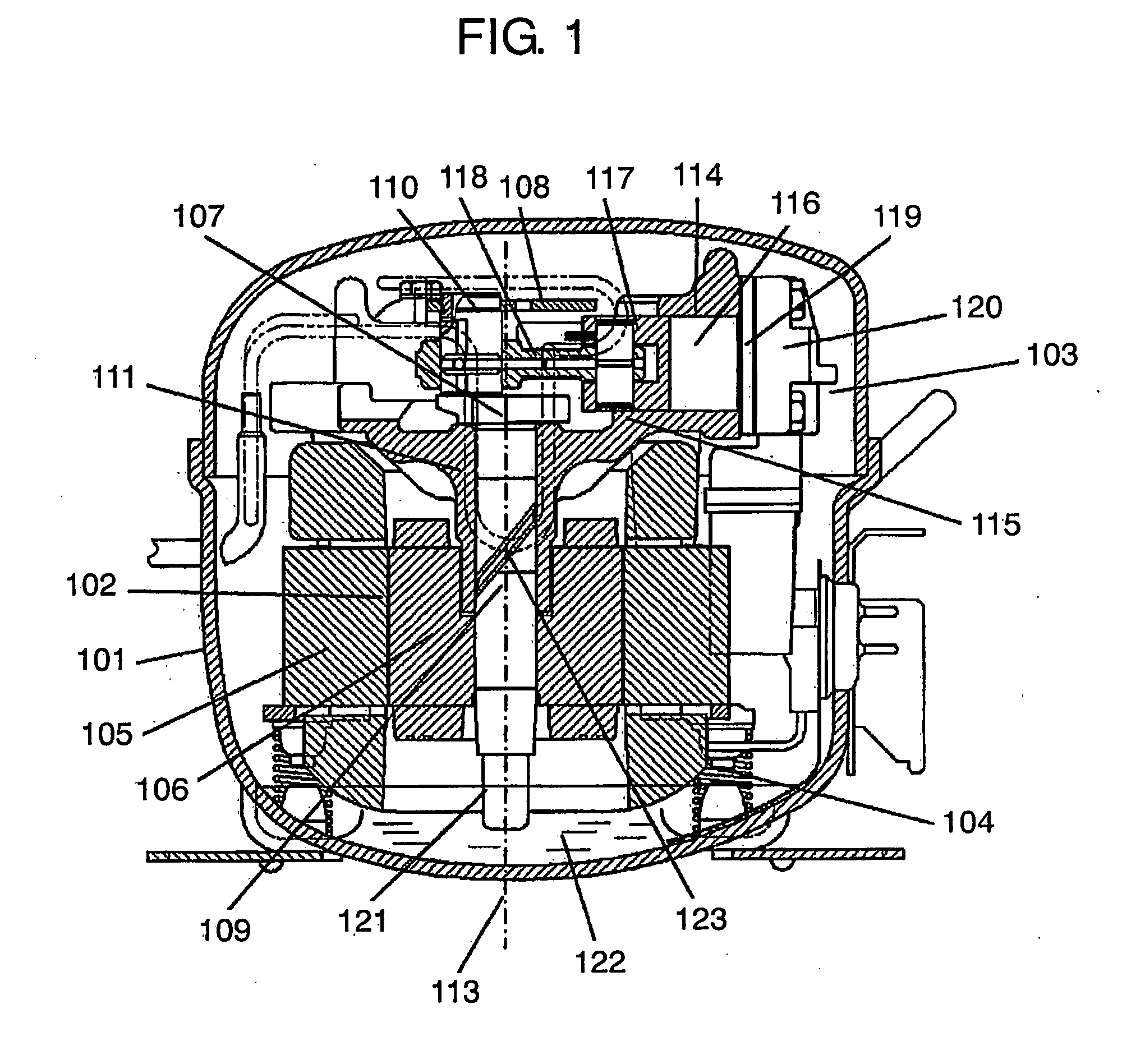

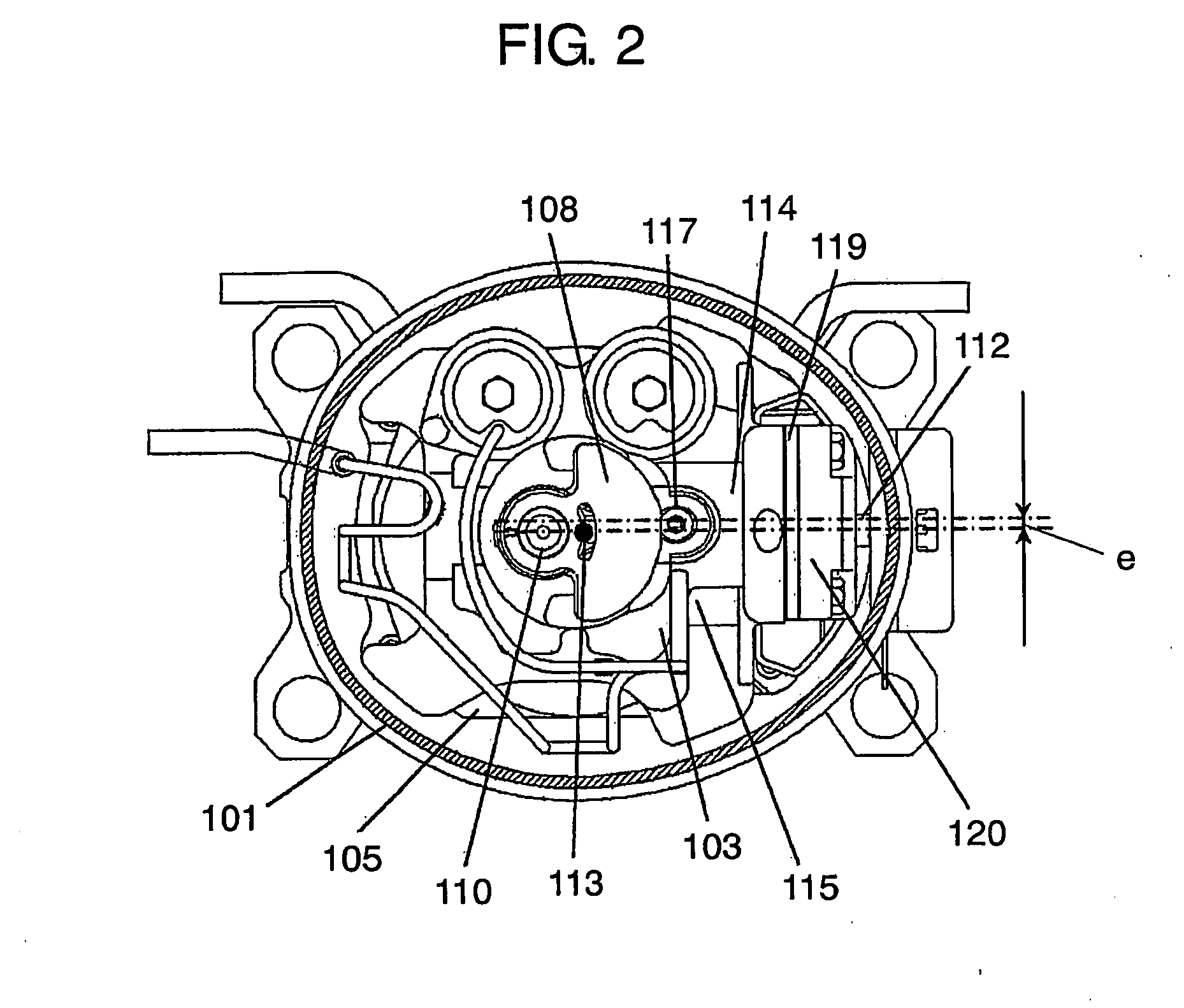

Recriprocating Compressor

InactiveUS20080247890A1Guaranteed to workLittle has been producedCompressorInertia force compensationEngineeringMechanical engineering

A highly reliable reciprocating compressor works efficiently with less energy, and produces smaller vibrations. This reciprocating compressor includes a crankshaft, a block, a piston, a connecting rod, and a balancing weight. The cylinder is placed offset such that an axis line thereof and an axis line of the main shaft do not cross each other. The center of gravity of the balancing weight is placed substantially opposite to the center of the eccentric section with respect to the axis line of the main shaft and deviated along a rotating direction of the main shaft from the place just opposite to the center of the eccentric section. The foregoing construction allows reducing lateral pressure of the piston, thereby increasing the reliability and efficiency of the reciprocating compressor, and allows to cancel unbalancing force produced by motions of the piston, the connecting rod and the eccentric section with motion of the balancing weight.

Owner:PANASONIC CORP

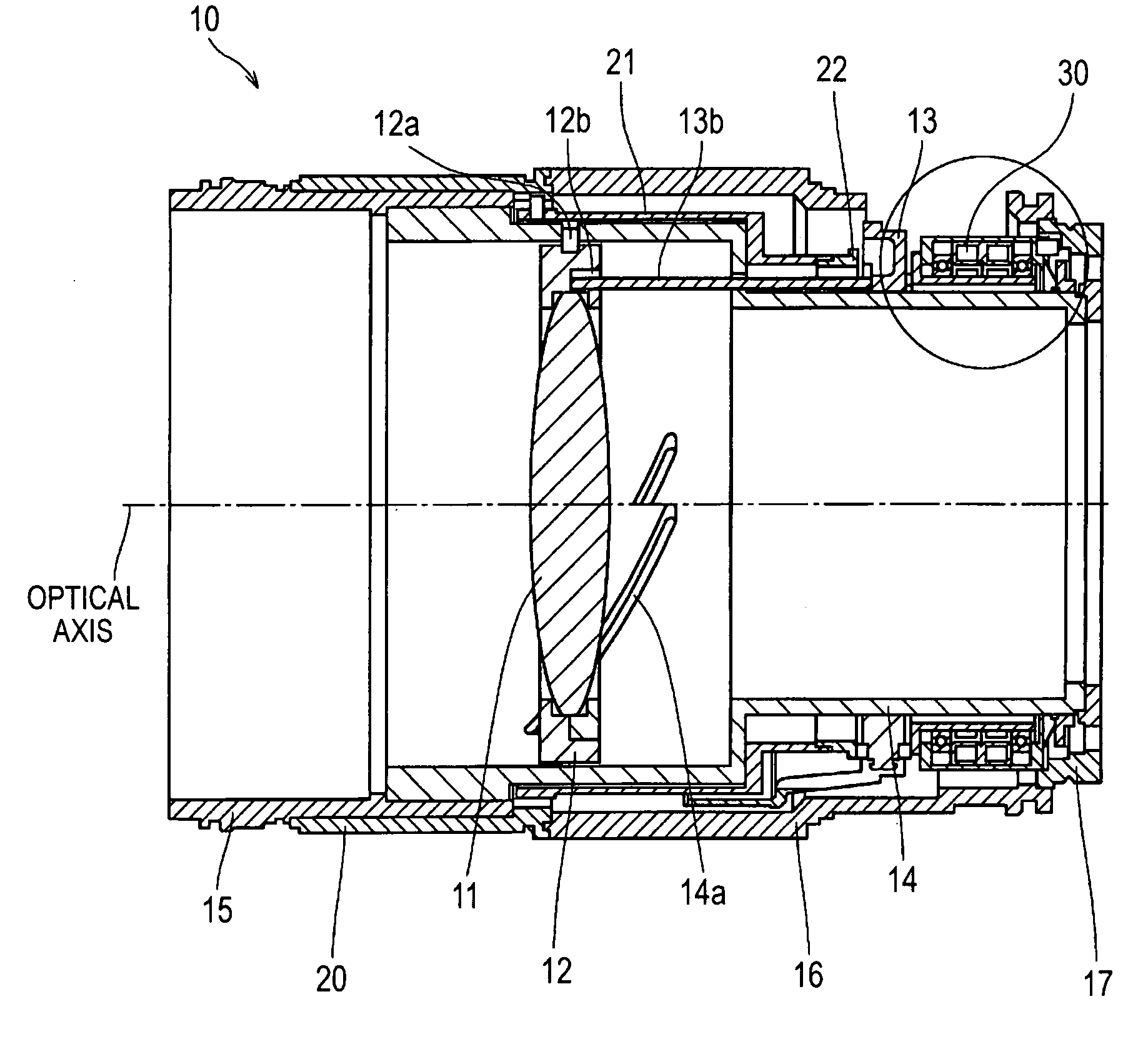

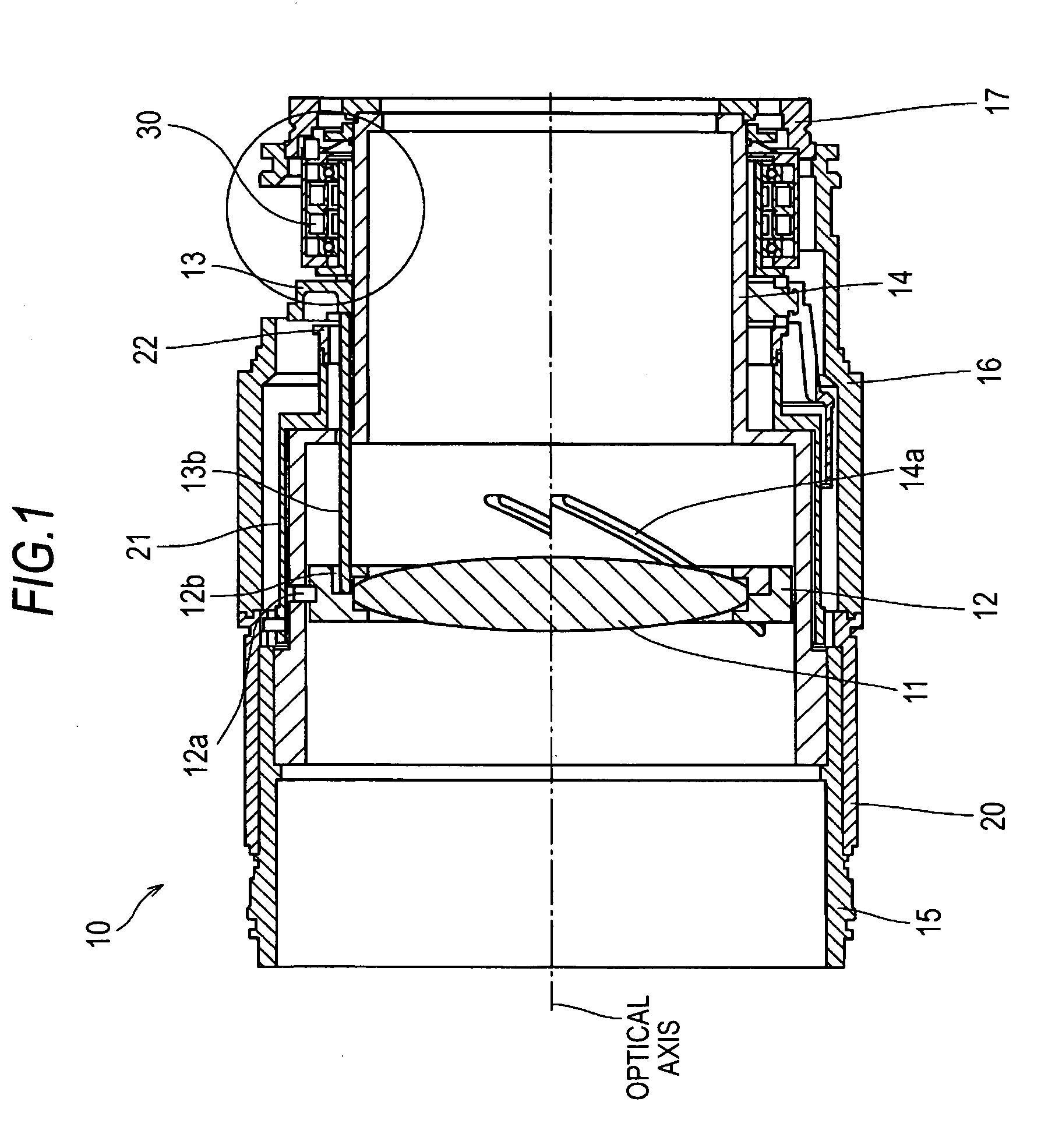

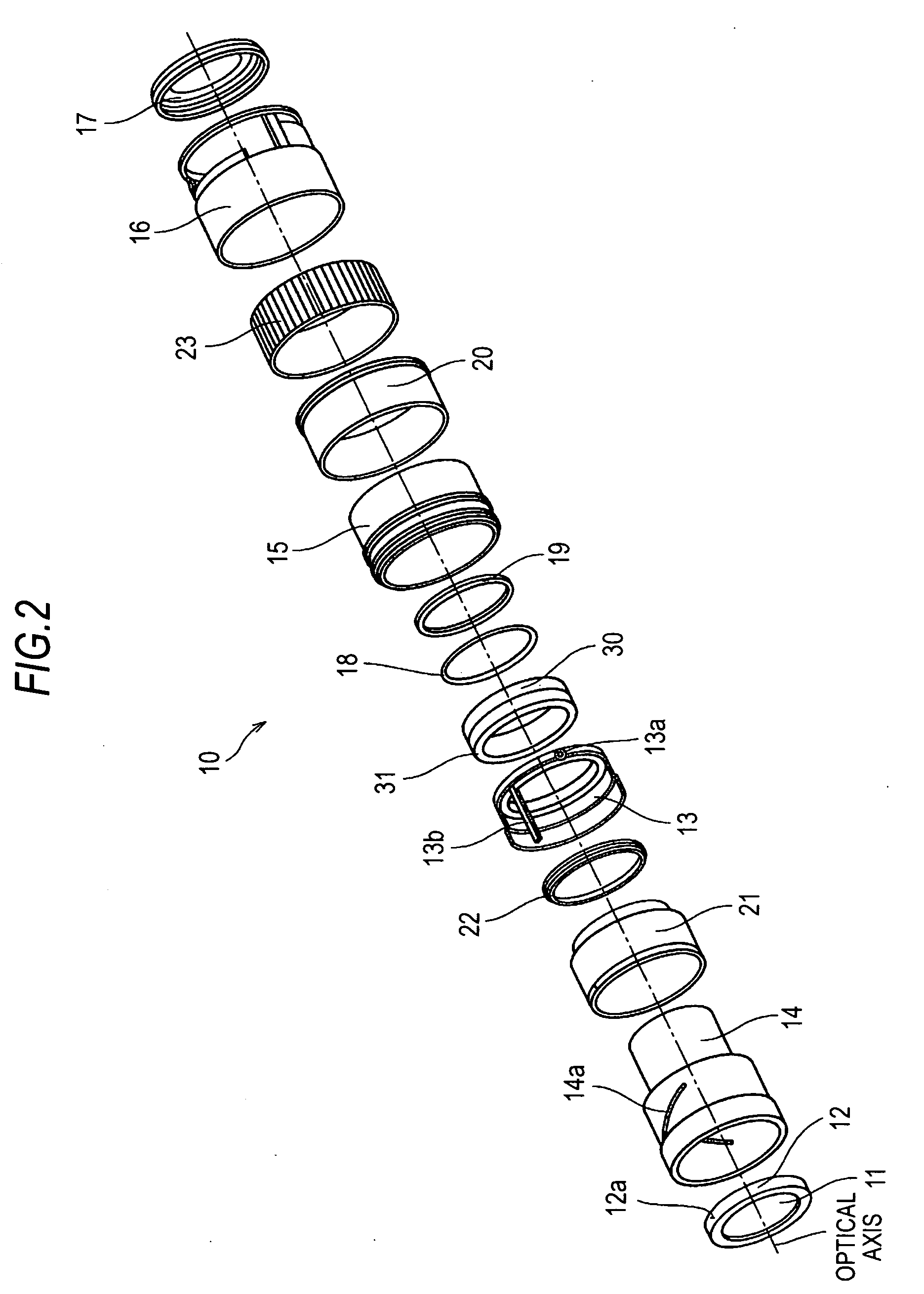

Lens barrel and imaging apparatus

InactiveUS20100134902A1Realize functionLittle has been producedMountingsCamera lensReciprocating motion

A lens barrel includes: a lens holding frame holding a lens; a barrel body housing the lens holding frame; motion conversion means for converting rotary motion of the lens holding frame into reciprocating motion along the optical axis of the lens; a manual ring provided on the outer side of the barrel body and rotating around the optical axis; a coreless stepper motor provided on the outer side of the barrel body and rotating around the optical axis; rollers provided between the manual ring and the stepper motor, and rotating in synchronization with the rotation of the manual ring and the stepper motor; motor rotation preventing means for preventing the stepper motor from rotating when the rollers transfer the rotation of the manual ring; an intermediate ring rotating around the optical axis; and a transfer unit transferring the rotary motion of the intermediate ring to the lens holding frame.

Owner:SONY CORP

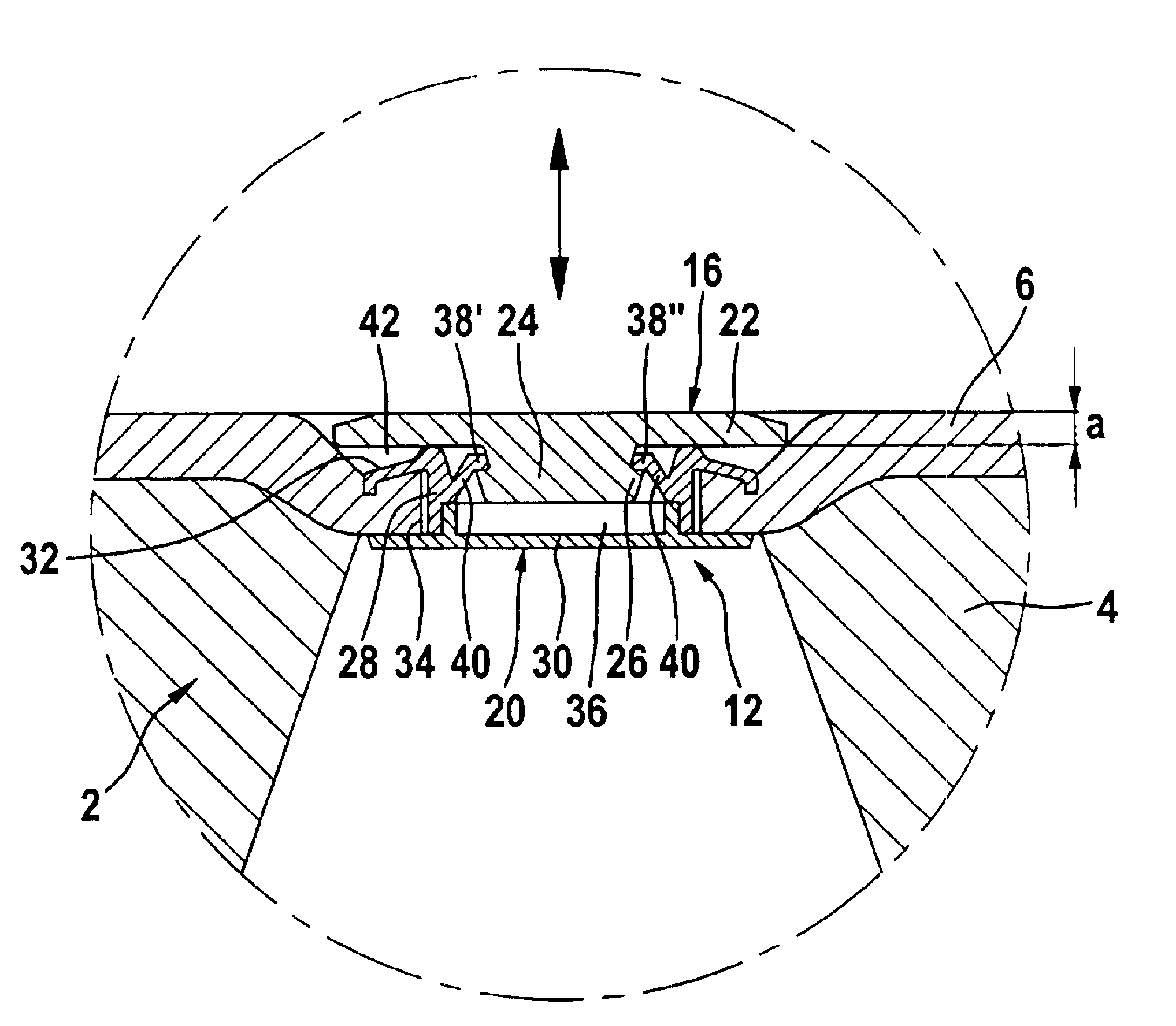

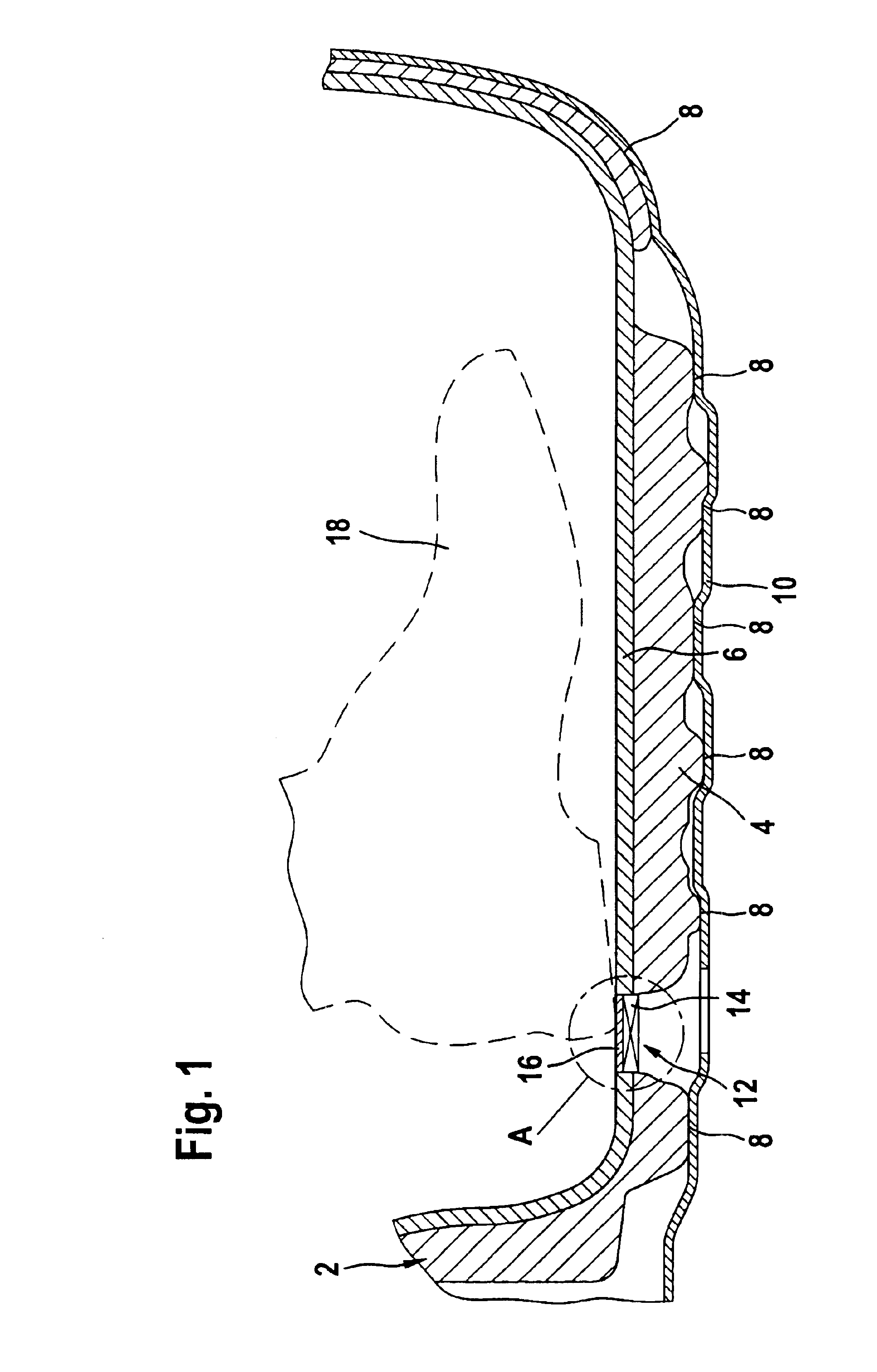

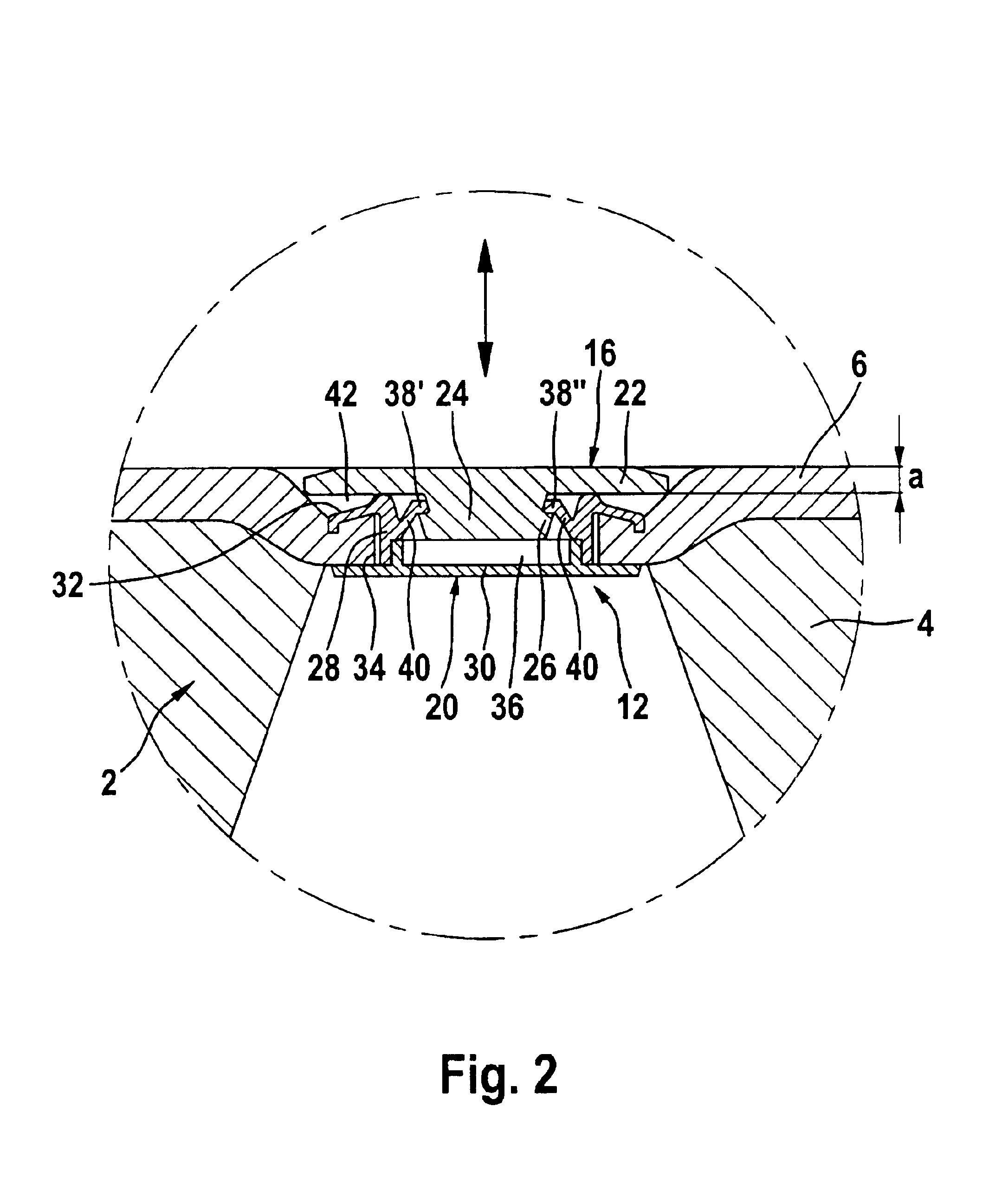

Floor covering for a powered vehicle

InactiveUS6821598B2Easy to separateEasy to cleanVehicle arrangementsLayered productsMechanical engineeringFloor covering

The present invention is directed to a floor covering for a powered vehicle having a base covering 44 and a least one affixing arrangement 56'' for the affixing of the supplemental mat 42 to the base covering wherein the affixing arrangement 56'' comprises a first affixing element 20 which may be connected releaseably with a complementary second affixing element 60 provided to the supplemental mat 42. In accordance with the present invention the first affixing element 20 is embedded in the base covering 44 wherein the upwardly extending distal end of the first affixing element 20 is provided no higher than the level of the nap side of the base covering 44. A further embodiment of the floor covering of the present invention comprises the supplemental mat 42 wherein a second affixing element 60 is invisibly provided to its underside. The driving comfort is also increased thereby, that the affixing arrangement 46 does not intrude into the foot space and a secure attachment of the supplemental mat 12 is obtained by the covering of the attaching arrangement 56.

Owner:DURA TUFTING

Polyvinyl butyral resin pellet, and method for producing the same

ActiveUS20100104866A1Small smellHigh apparent densityNatural mineral layered productsThin material handlingApparent densityMelt extrusion

According to the present invention, a polyvinyl butyral resin pellet is provided that gives off little odor when produced and handled, as well as has a high apparent density and favorable handleability. The present invention includes a method for producing a polyvinyl butyral resin pellet including the steps of: melting polyvinyl butyral resin powder with a water content of 0.01 to 6 wt % by means of a melt extruder that has at least one vent portion for devolatilization equipped with vacuum means, and cutting the melt of the polyvinyl butyral resin after extrusion of it from the melt extruder. The present invention further includes a polyvinyl butyral resin pellet having a total content of butyl aldehyde and 2-ethyl-2-hexenal of 100 ppm or less.

Owner:KURARAY EURO GMBH

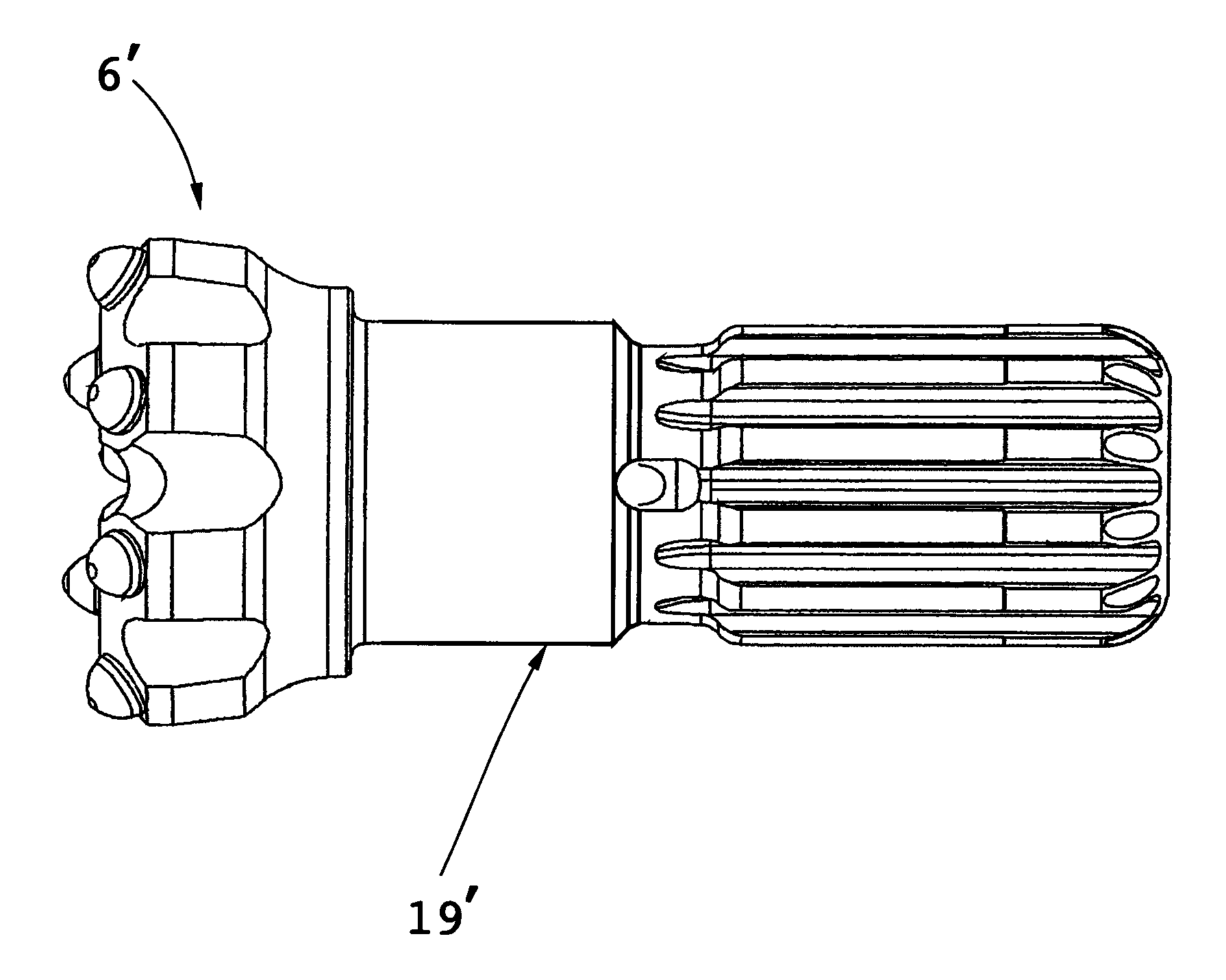

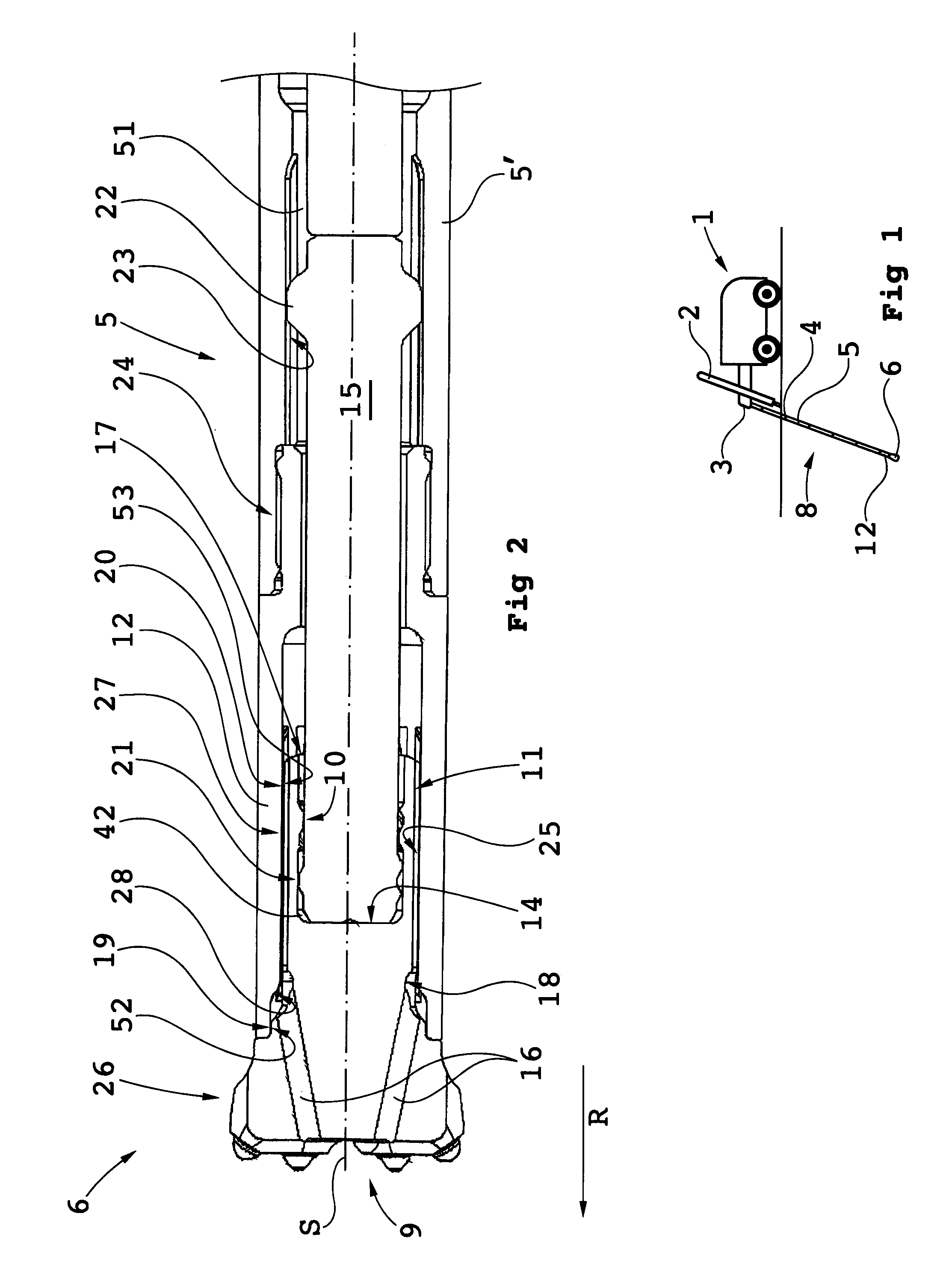

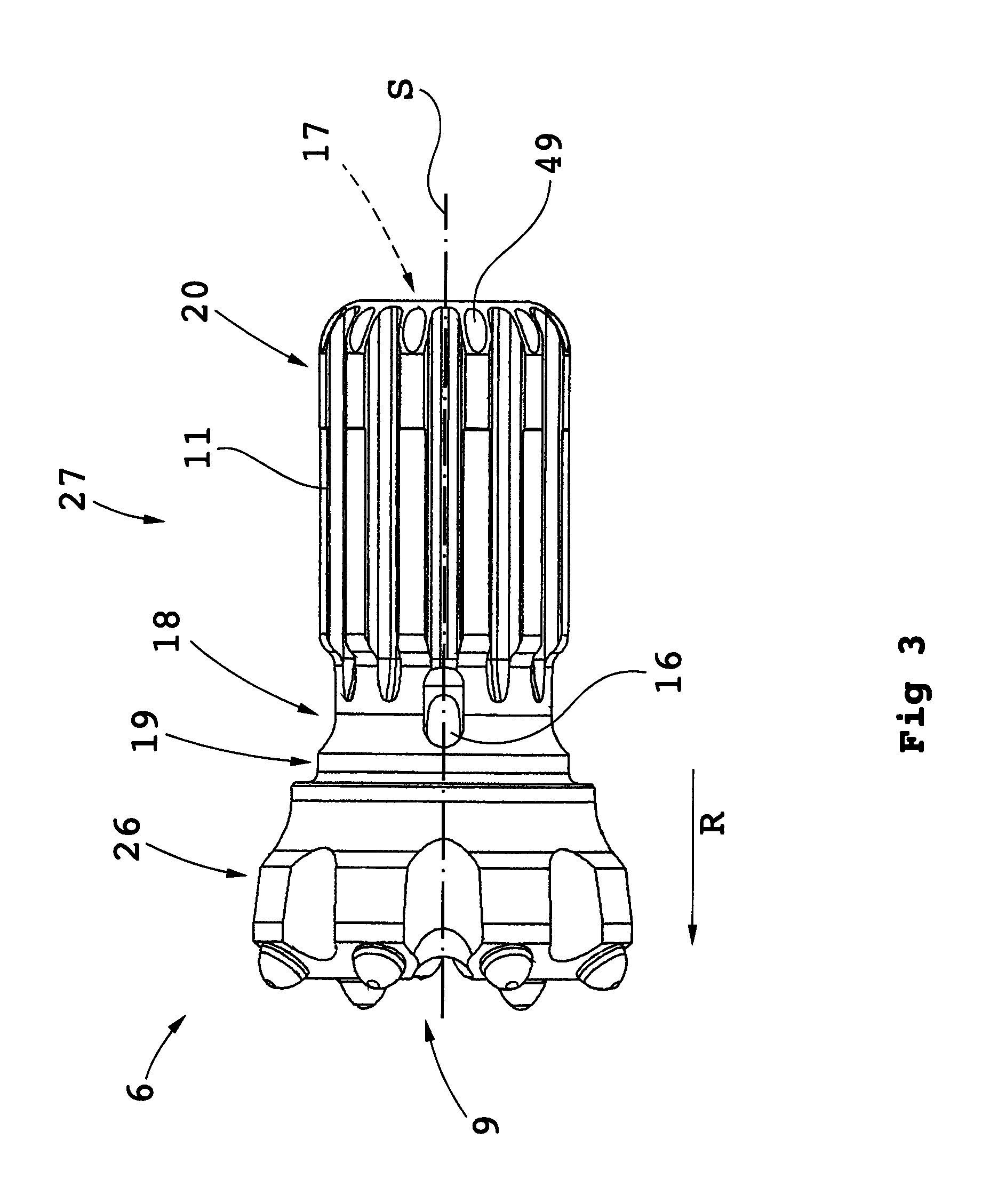

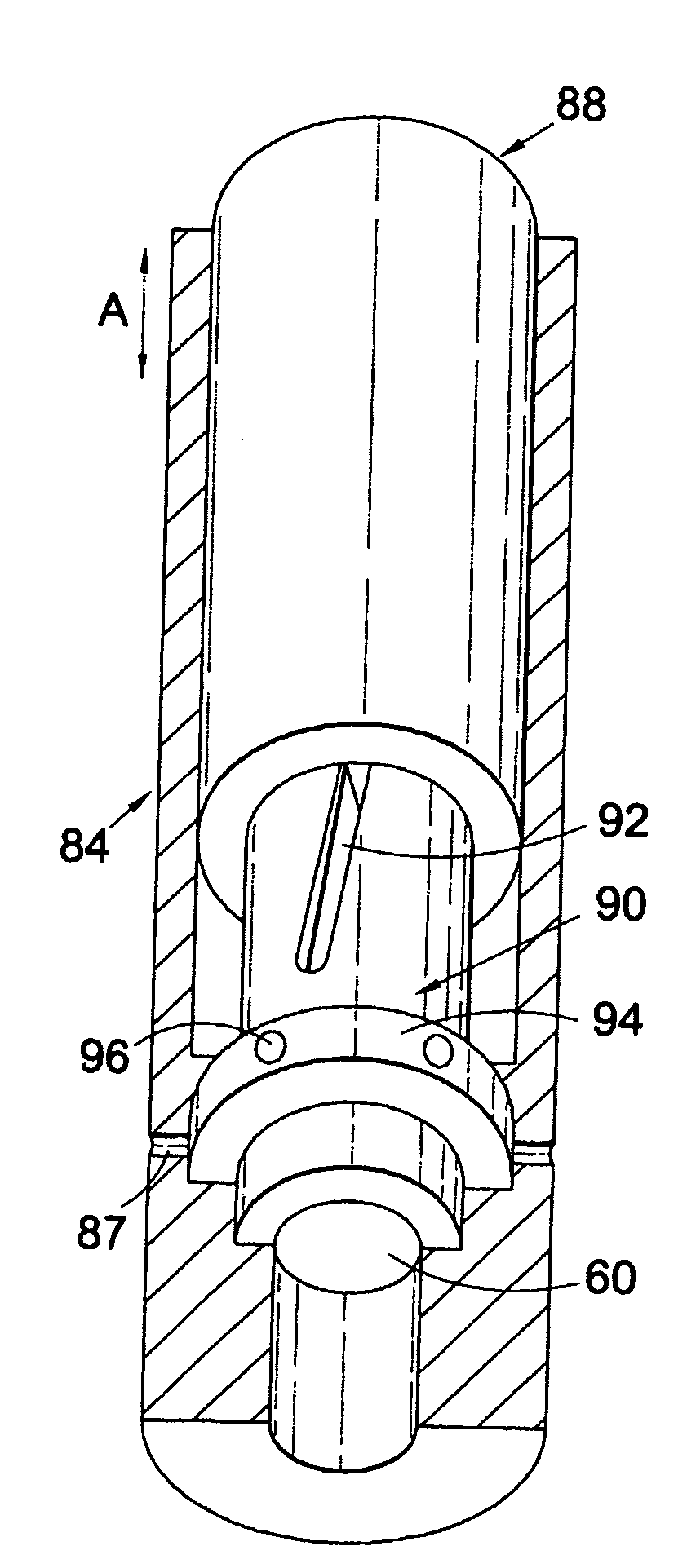

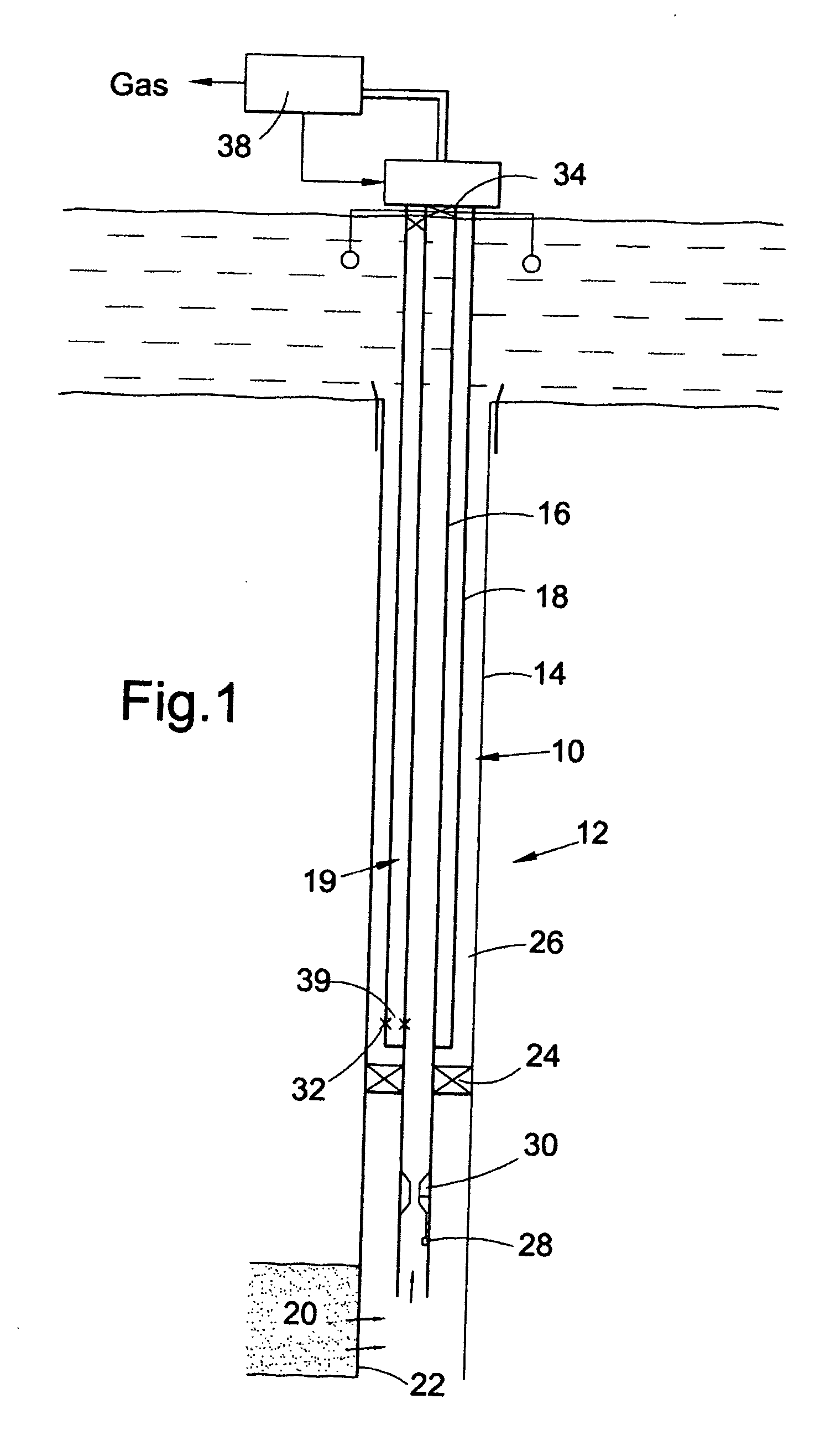

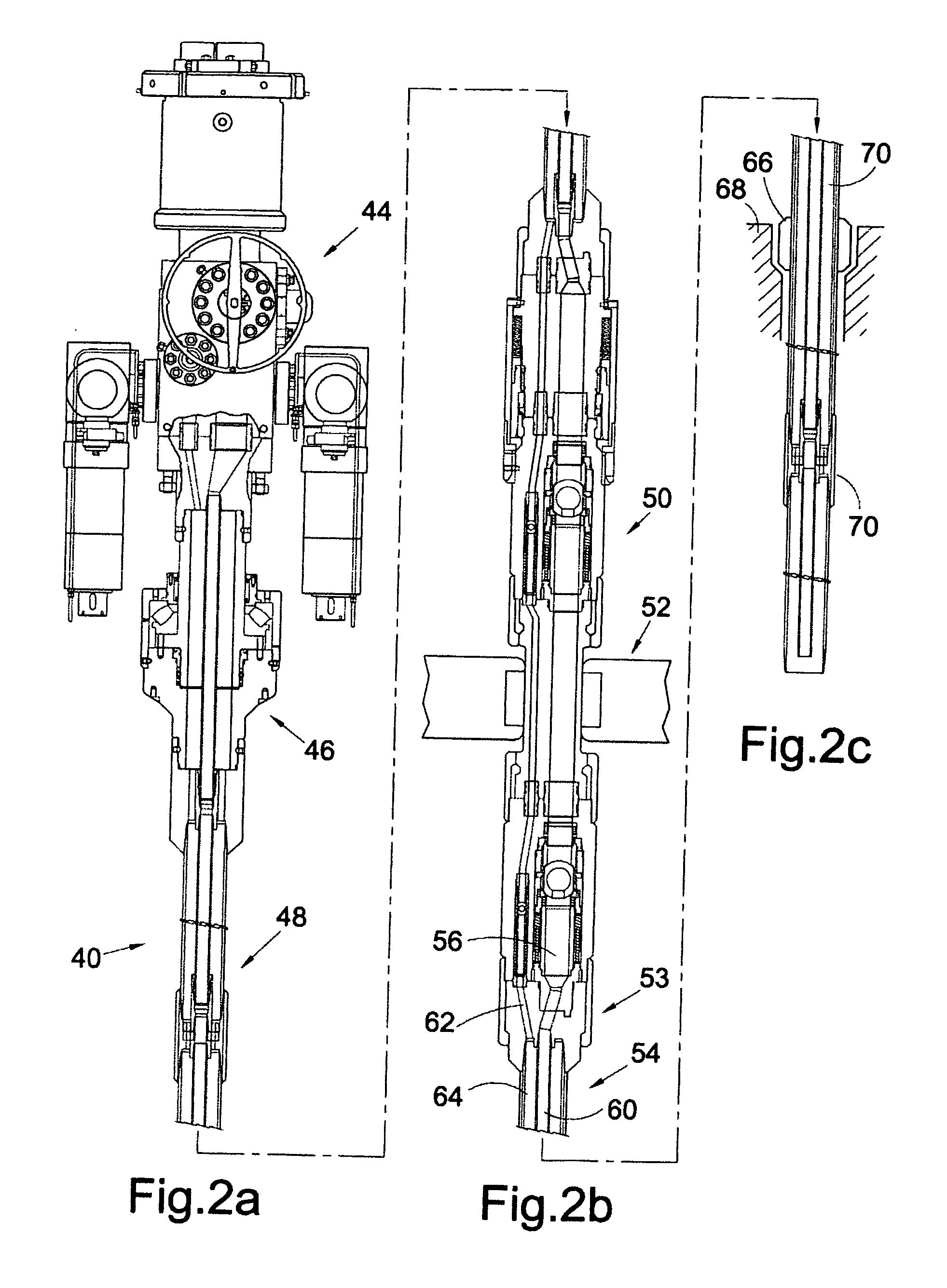

Device and system for percussion rock drilling

ActiveUS20160069134A1Little has been producedLess expensiveDrill bitsDrilling rodsShock wavePetroleum engineering

A drill bit for percussion rock drilling. An impact portion includes an impact surface for striking against rock in an impact direction. An engagement portion includes a holder configured to hold the drill bit axially in a drill head of a drill string, and a rotation engagement member configured to connect the drill bit with the drill head for rotating the drill bit. An anvil surface is directed opposite to the impact direction for receiving shock waves from a striker rod of the drill string. A flushing channel is configured to transfer flushing fluid to the impact surface. The holder and the anvil surface are inside a holder recess having an opening that is directed opposite to the impact direction. Also a drill string component, a system and a method.

Owner:EPIROC DRILLING TOOLS AB

Well testing system

InactiveUS20060196670A1Maximise radiusLittle has been producedOperating means/releasing devices for valvesDrilling rodsStream flowNo production

A well testing system and well testing method is described which can be operated as a closed system with no production of hydrocarbons outside the well or gas can be separated and flared at surface giving minimal environmental impact with the liquid hydrocarbon being re-injected. This is achieved by providing a string with at least two well conduits which may be arranged in a concentric or non-concentric parallel configuration. One conduit is used to produce formation fluids to surface or to produce / store unrepresentative initial flow products and the other conduit is used to store formation fluid. The storage conduit can be filled from the top (surface) or the bottom of the well. In a preferred arrangement a valve is provided between the storage conduit and the well annulus for well pressure control, and a shut-in or test valve, which is controllable from surface, is disposed in the non-storage production conduit. A flow control valve is provided at the lower end of the string or at surface and the size of the valve opening is controllable to allow formation fluid to enter the storage string at a controlled rate, so that the formation fluid flowing time is increased to maximise the radius of investigation into the formation to a similar order of magnitude of existing production tests and extended well tests, which are typically two to three times the order of magnitude of the radius of investigation of a wireline formation test. Other aspects and embodiments of the invention are described.

Owner:RICHARDS ANDREW +1

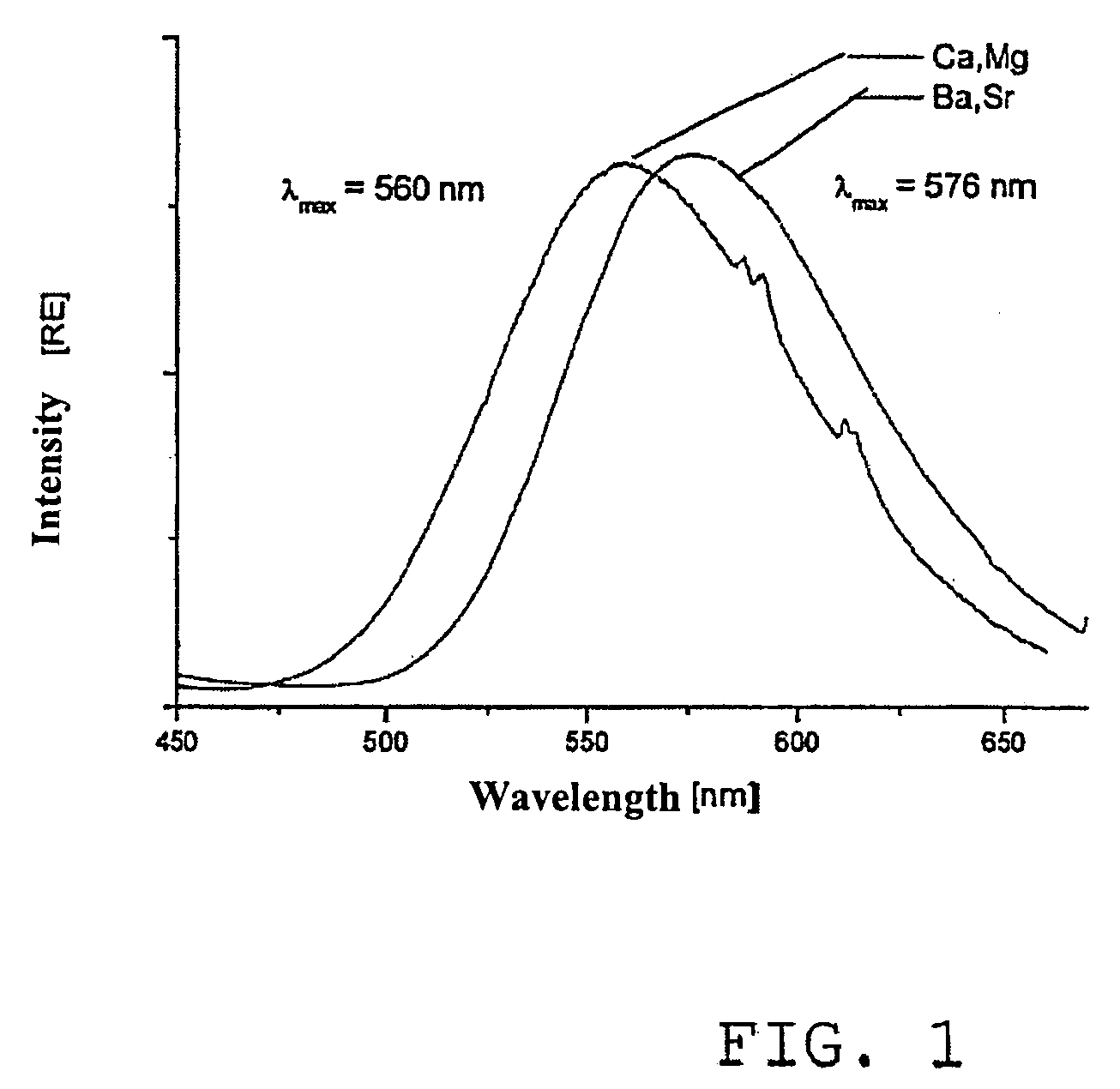

Method for producing alkaline earth sulphate nanoparticles

InactiveUS7288239B2Little has been producedSmall sizePowder deliveryPigmenting treatmentPolyethylene glycolSolvent

The invention relates to synthesis of nanoparticles, in particular to methods for producing nanoparticles with networks consisting of Z sulphate (Z=magnesium (Mg), calcium (Ca), strontium (Sr), barium (Ba) or the binary mixtures thereof). The inventive method consists in synthesising the nanoparticles by crystal growth from an ion Z source and a sulphate ion source in a liquid phase mixture. The invention produces Z sulphate nanoparticles having a small diameter and uniformly dispersible in water or other solvents in a simple way. Co-ordinating solvents like glycerine, glycol ethylene and other polyethylene glycols, polyalcohols or dimethylsulphoxide (DMSO) are used for the synthesis mixture.

Owner:CENT FUR ANGEWANDTE NANOTECH

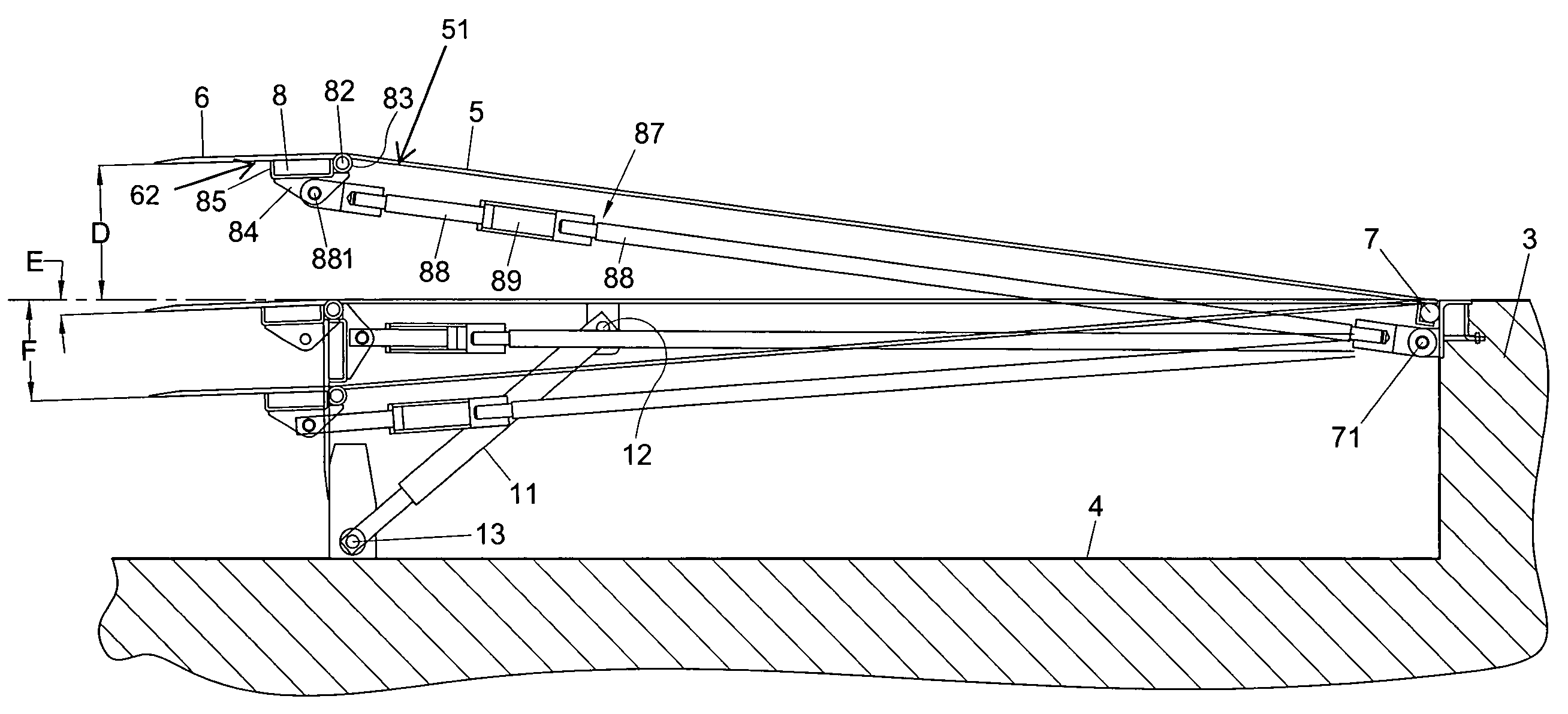

Dock leveller, lip for dock leveller and lip hinge construction

A dock leveller, comprising a deck plate having a deck upper surface, which deck plate is pivotably connectable with a platform; a lip having a lip upper surface, which lip upper surface, with the deck upper surface, forms at least a part of a transport surface; and a lip hinge construction with a pivot element which pivotably connects an end of the lip and an end of the deck plate of the dock leveller, characterized in that the upper surface of the lip, through the pivot element, is placeable at a positive angle or a negative angle relative to a position in line with the upper surface of the deck, being pivotable to both one side and the other side.

Owner:STERTIL

Food smoker apparatus

ActiveUS9198443B2Little has been producedAdd flavorDough treatmentMeat/fish preservationCompression PumpEngineering

This invention is a food preparation device used for imparting the flavor of smoke to foods by saturating the food with smoke in minutes, using very small amounts of wood or other smoke producing material, and upon completion of the process the food can be refrigerated, re-refrigerated, or cooked in any manner desired by the user. Efficiency of time and material is achieved by a unique design that allows a minute amount of smoke producing material to be ignited in a small ignition chamber before being transferred to a chamber containing the food in a partial vacuum created by a vacuum / compression pump, and through the unique design of valves and connector pipes the smoke filled chamber containing the food is subsequently subjected to compression by the vacuum / compression pump, thus leaving the food in the chamber smoke saturated within a few minutes of operation with little or no change in temperature.

Owner:DAVIS GEORGE MICHAEL

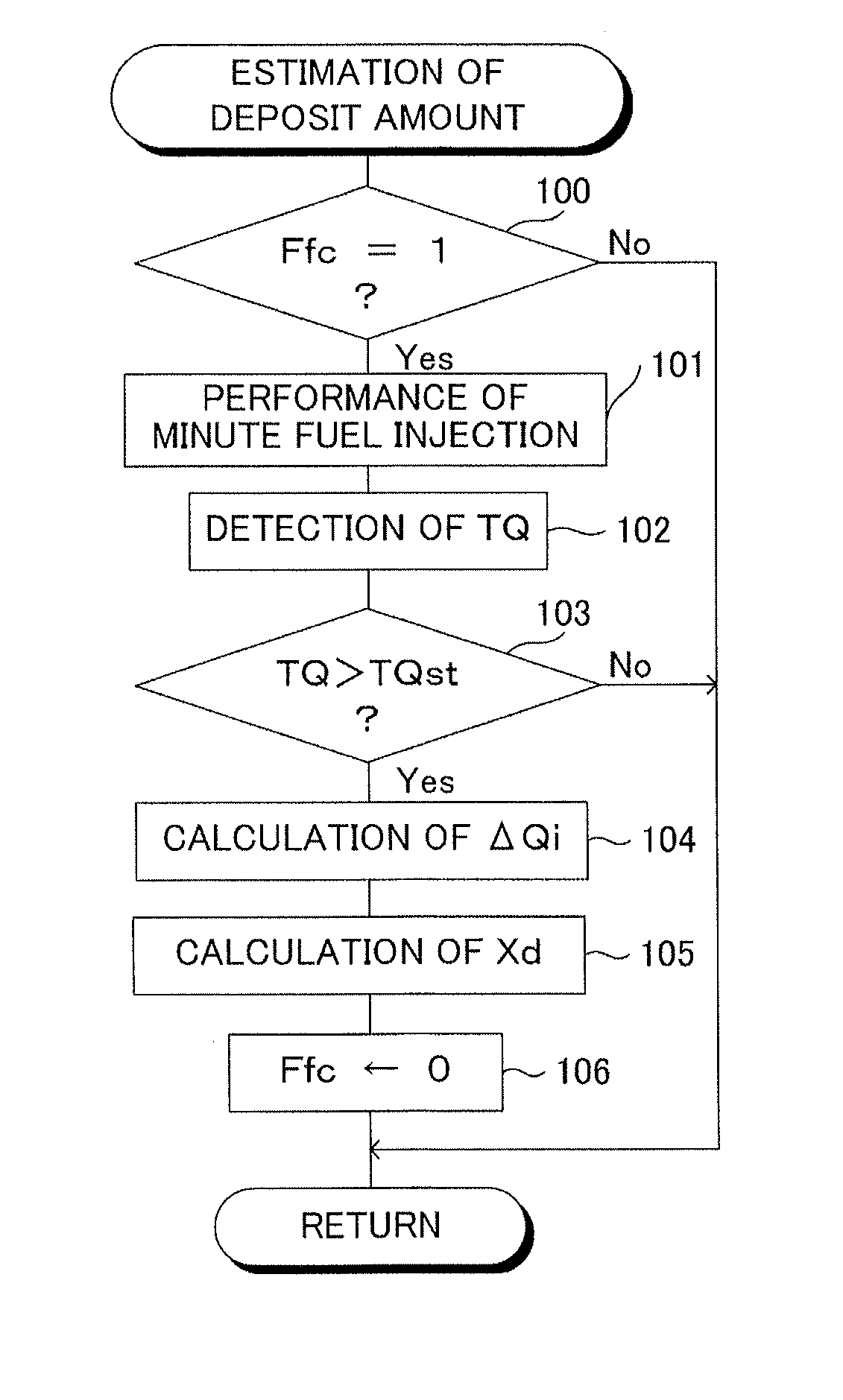

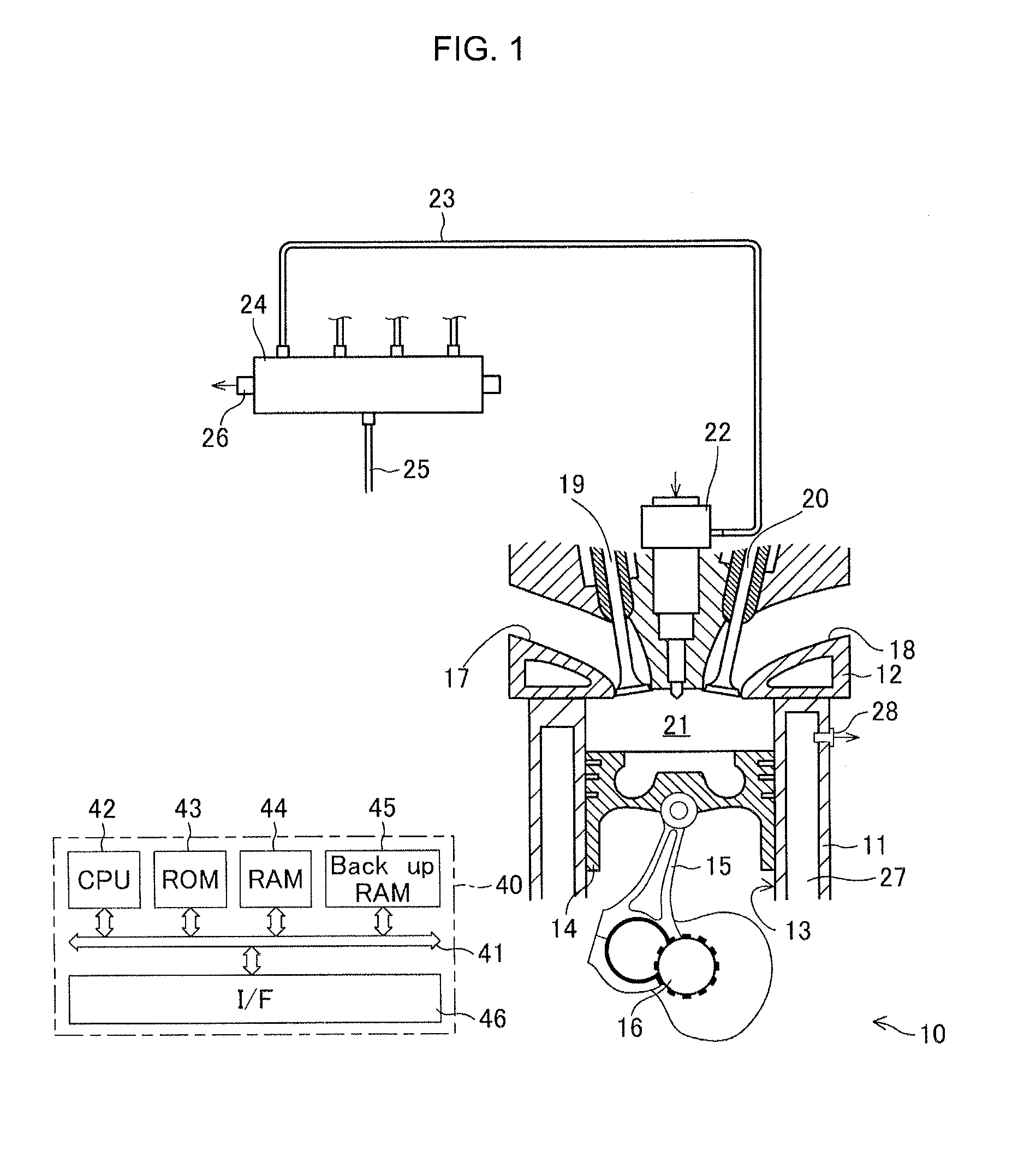

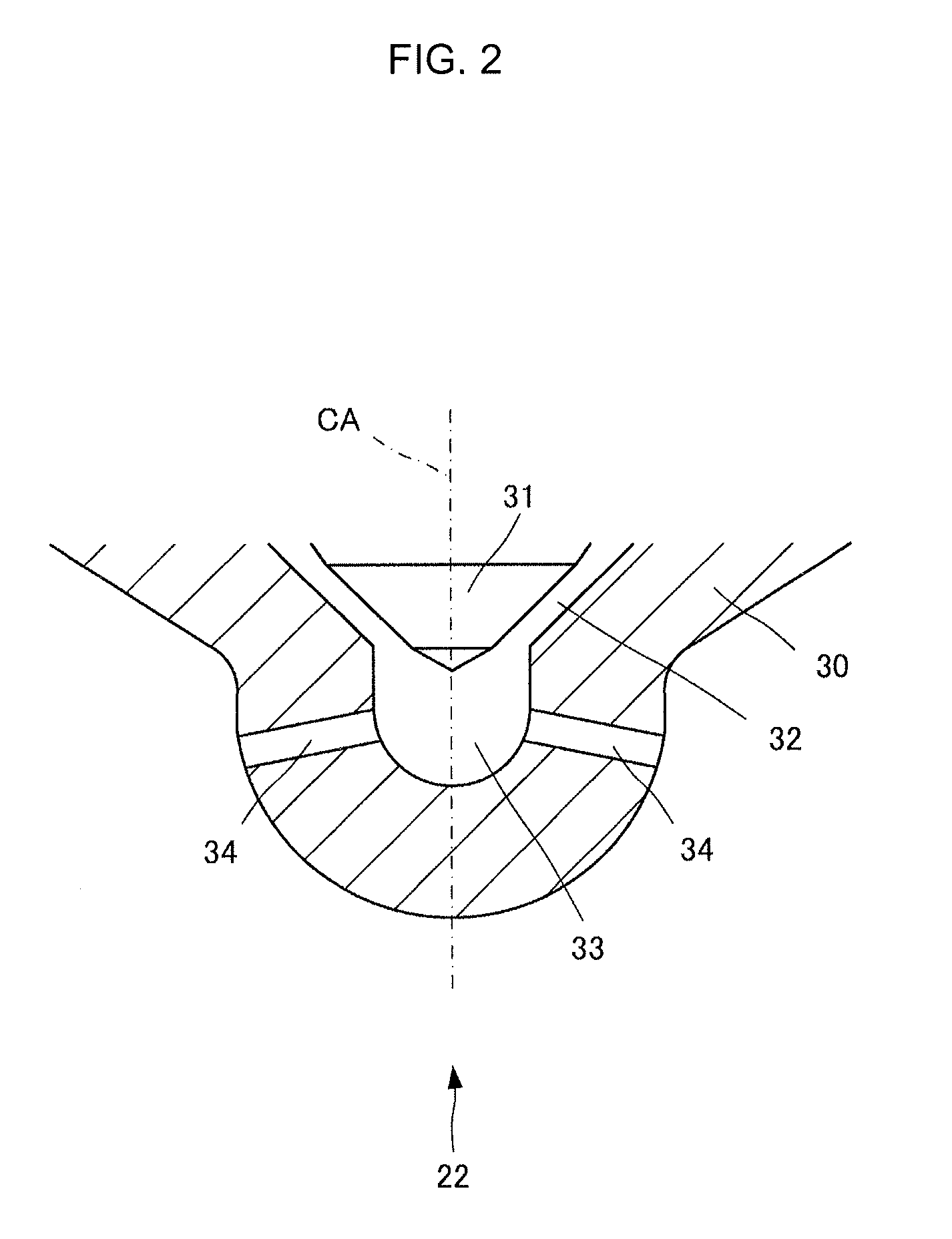

Deposit amount estimation device of engine

ActiveUS8869605B2Easy to understandLittle has been producedInternal-combustion engine testingElectrical controlFuel injectionInjector

The invention relates to a deposit amount estimation device for estimating a deposit amount by calculating an amount of a deposit on an injection hole wall face of a fuel injector (22). An increment judgment of whether an actual fuel injection amount is larger than the required fuel injection amount corresponding thereto when a fuel injection command value corresponding to a required fuel injection amount smaller than a predetermined amount is given to the fuel injector, is performed, and when it is judged that the actual fuel injection amount is larger than the required fuel injection amount corresponding thereto by the increment judgment, the deposit amount is estimated on the basis of the difference between the actual fuel injection amount and the required fuel injection amount corresponding thereto.

Owner:TOYOTA JIDOSHA KK

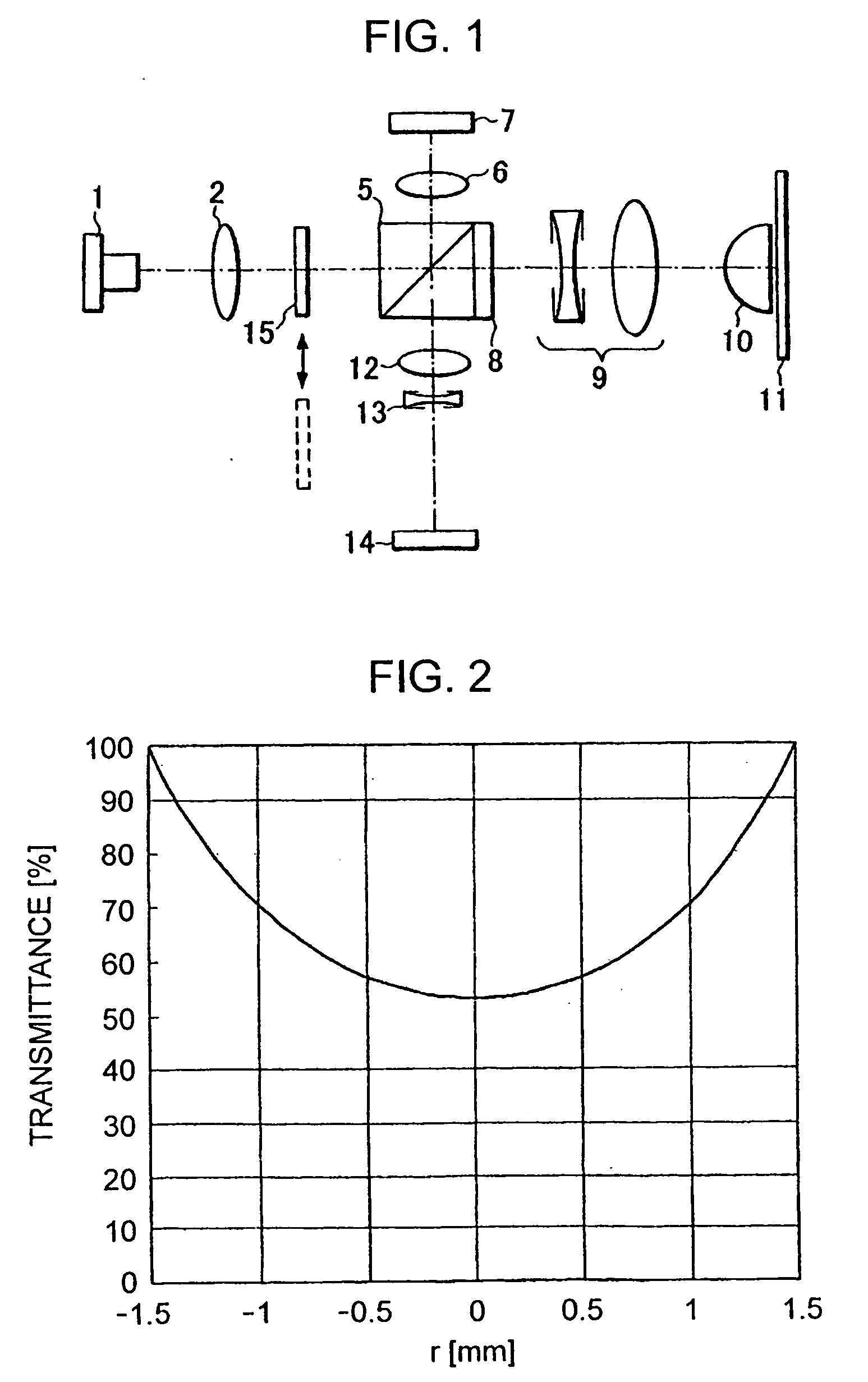

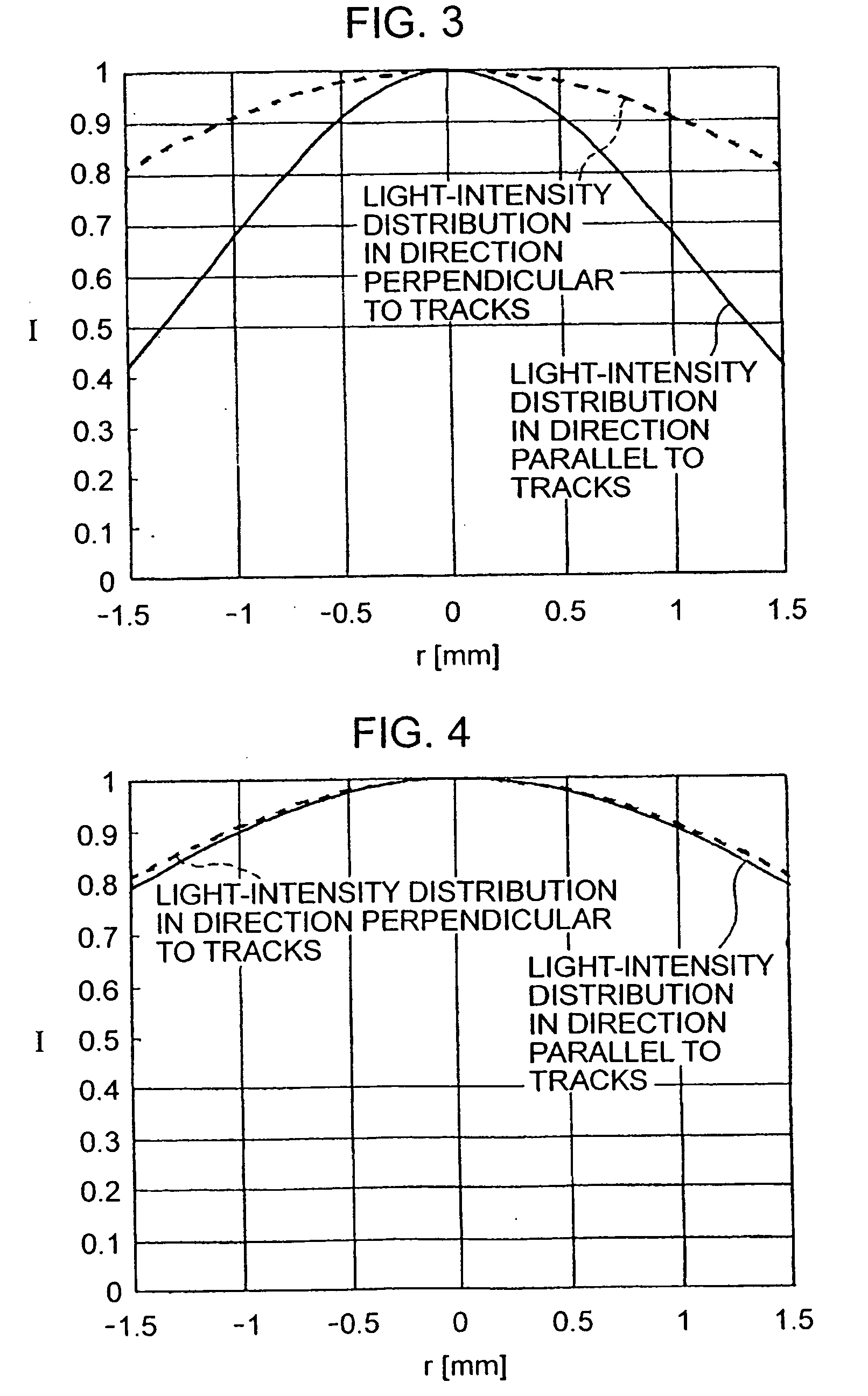

Apparatus using light-attenuating element for optically reproducing and recording information

InactiveUS20060280097A1Simple structureStable reading-writing operationRecord information storageOptical beam guiding meansTransmittanceLight beam

An apparatus for optically recording information in a recording medium and for optically reproducing the recorded information includes a semiconductor laser, an objective lens that focuses light beams from the laser on the recording medium, and a light-attenuating element for attenuating an amount of light of the light beams. The light-attenuating element has a transmittance distribution for shaping the section of the light beams into an approximate circle.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com