Patents

Literature

279 results about "Ultra high purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

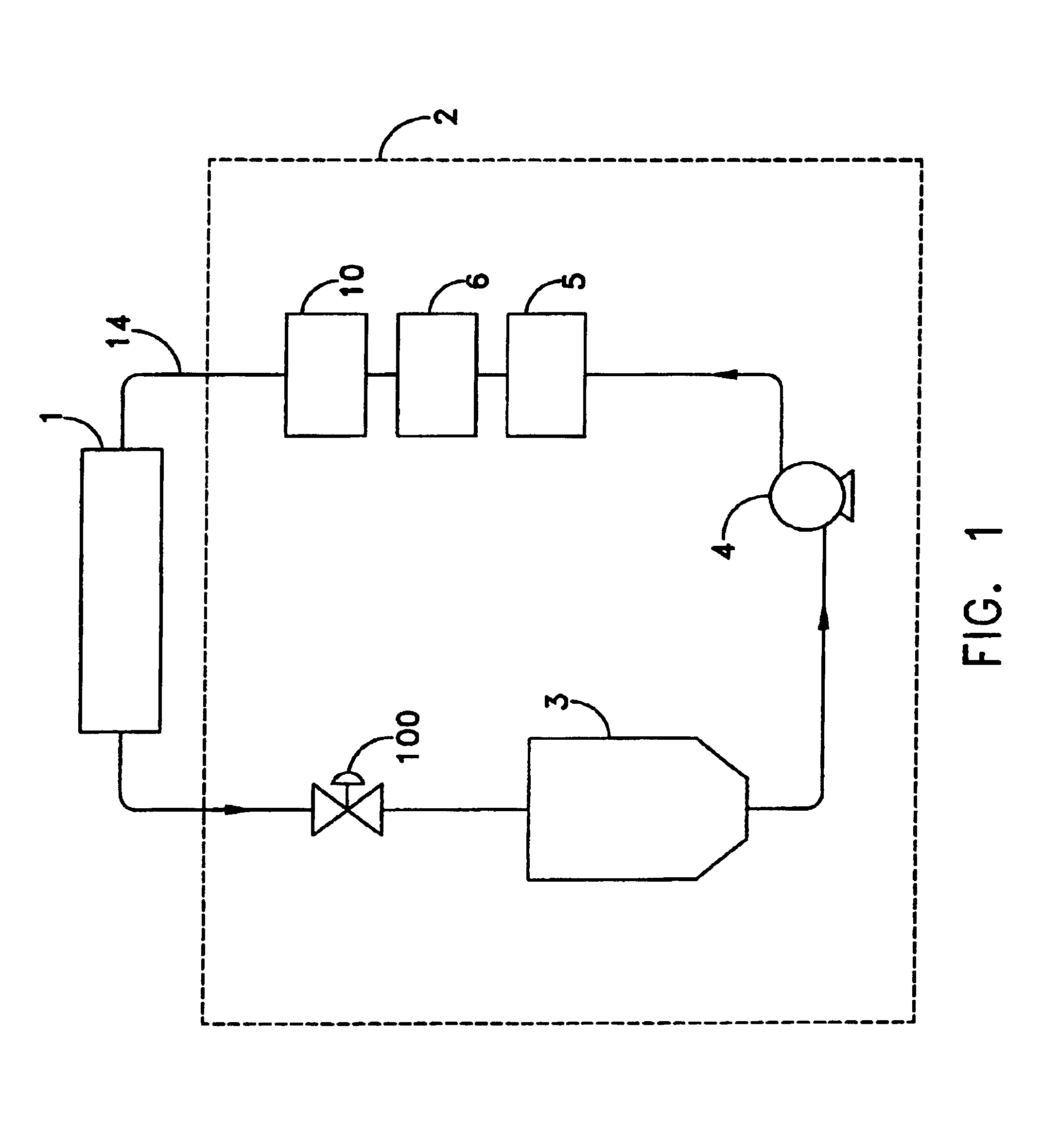

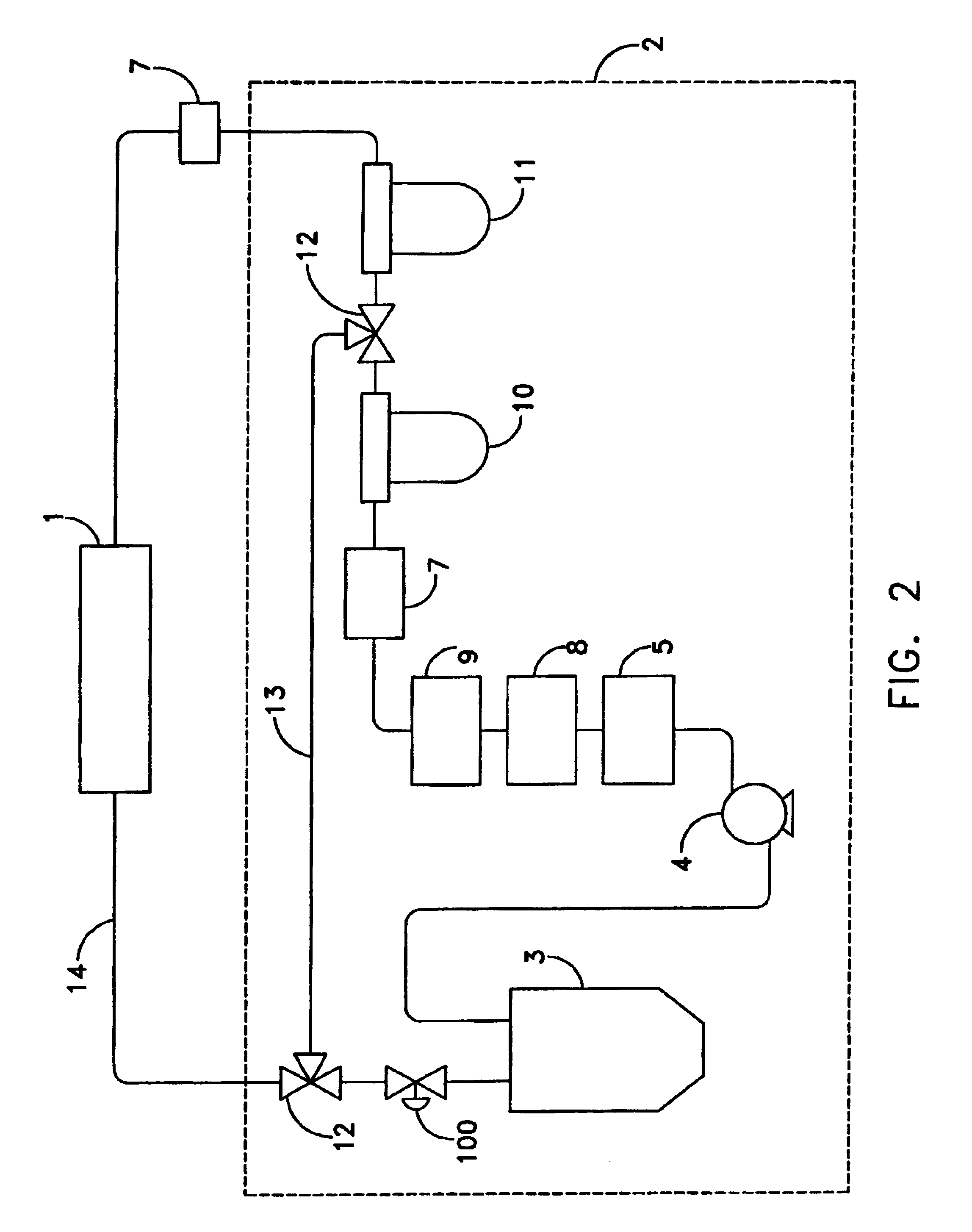

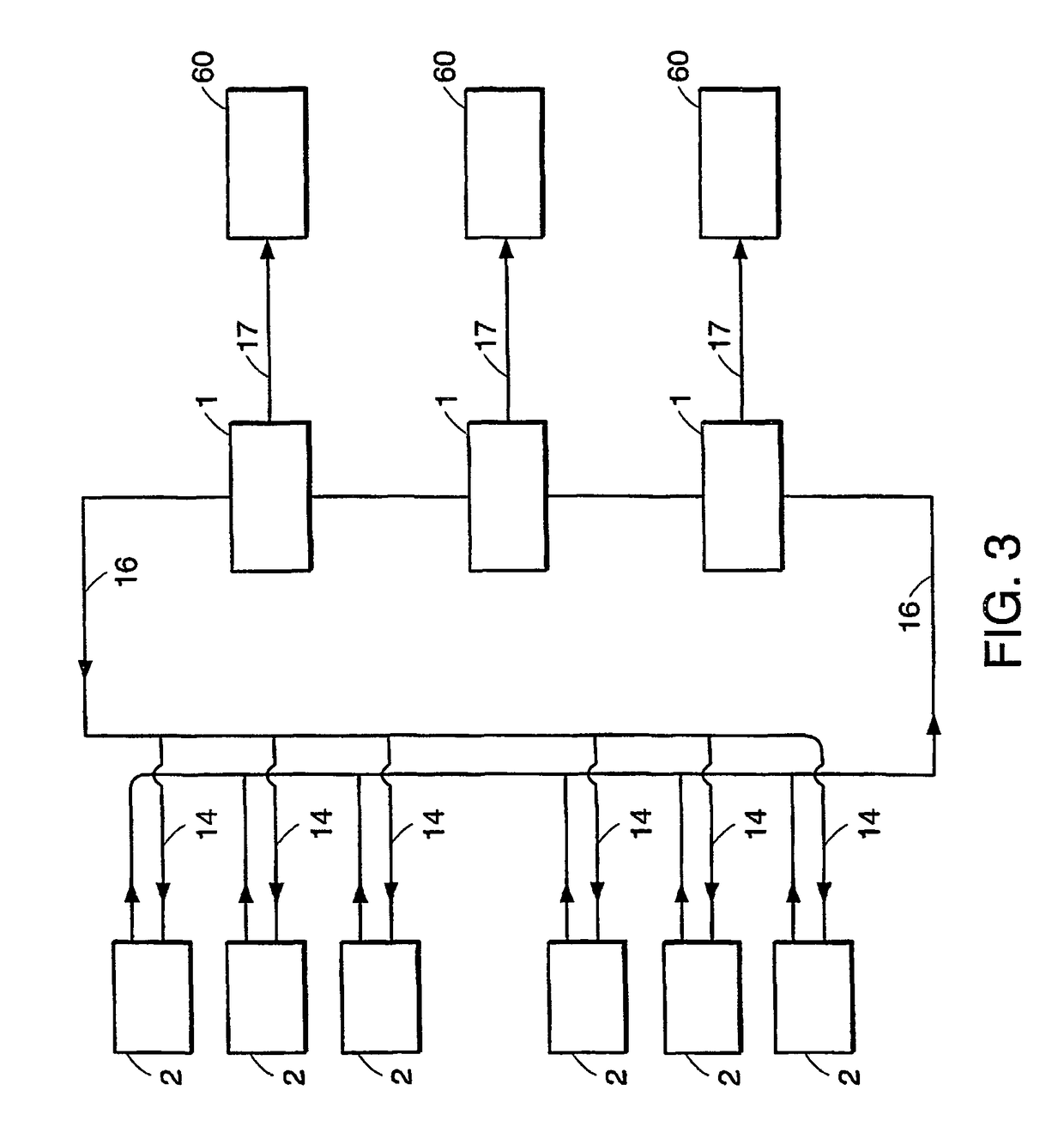

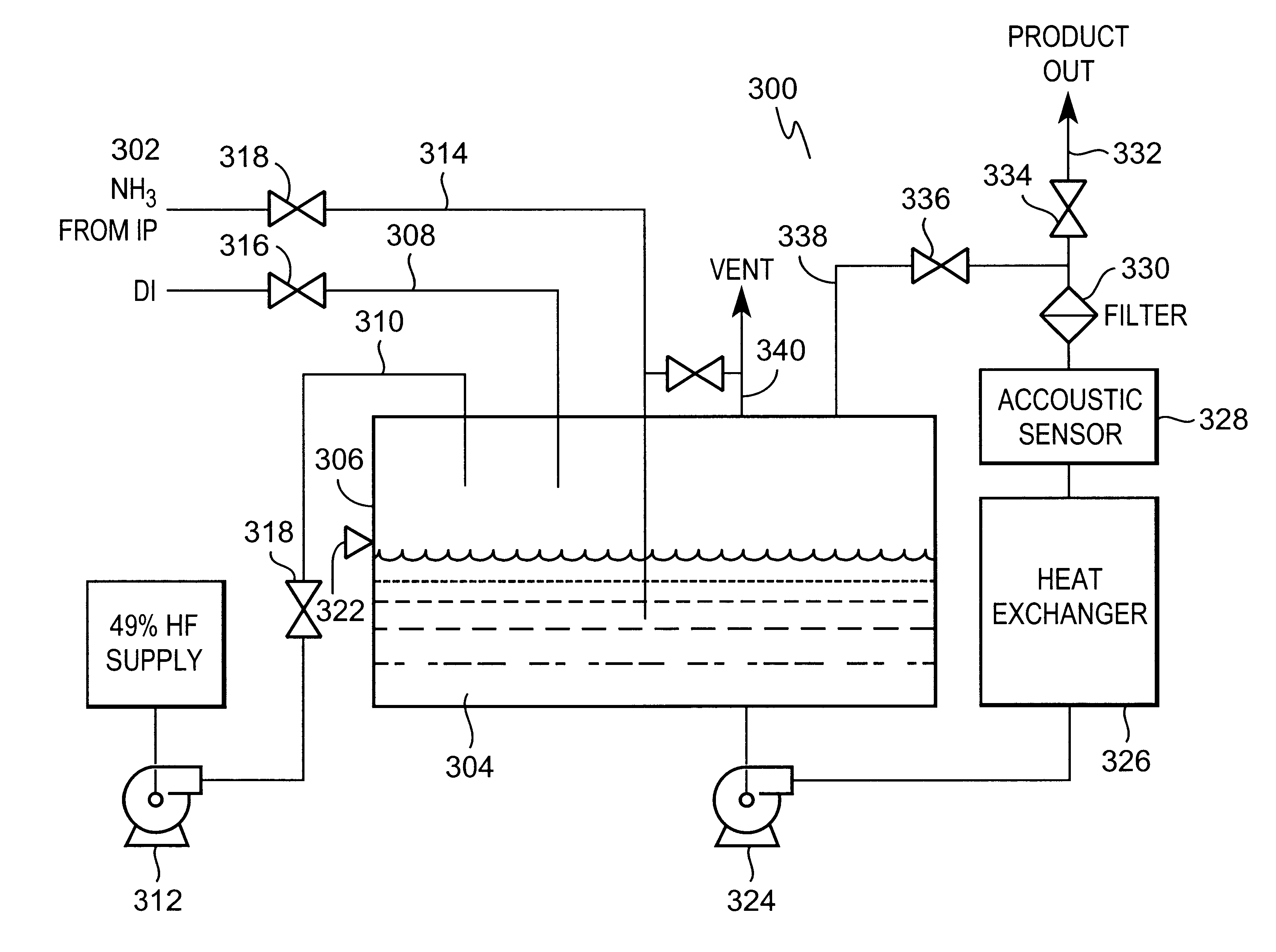

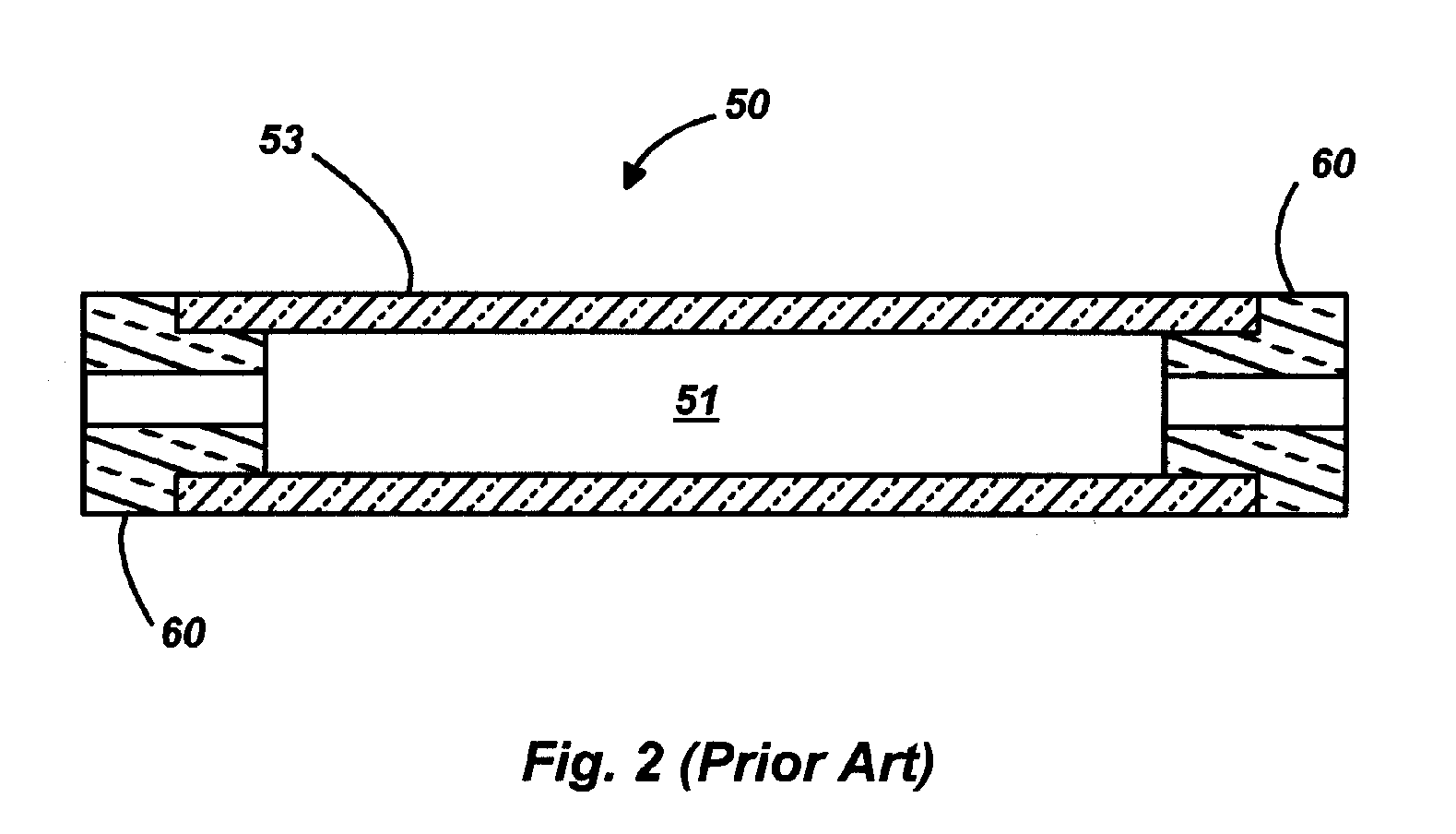

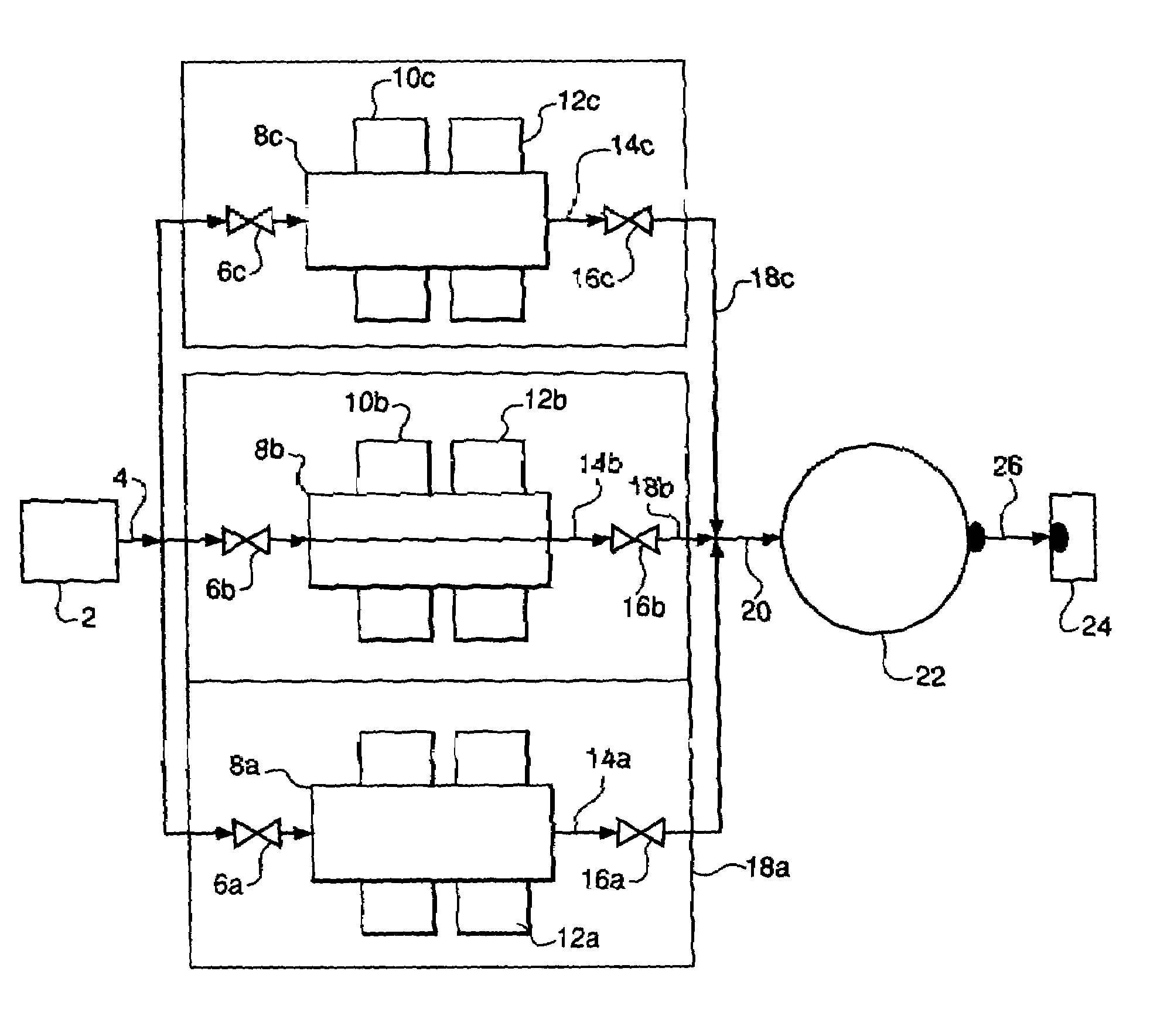

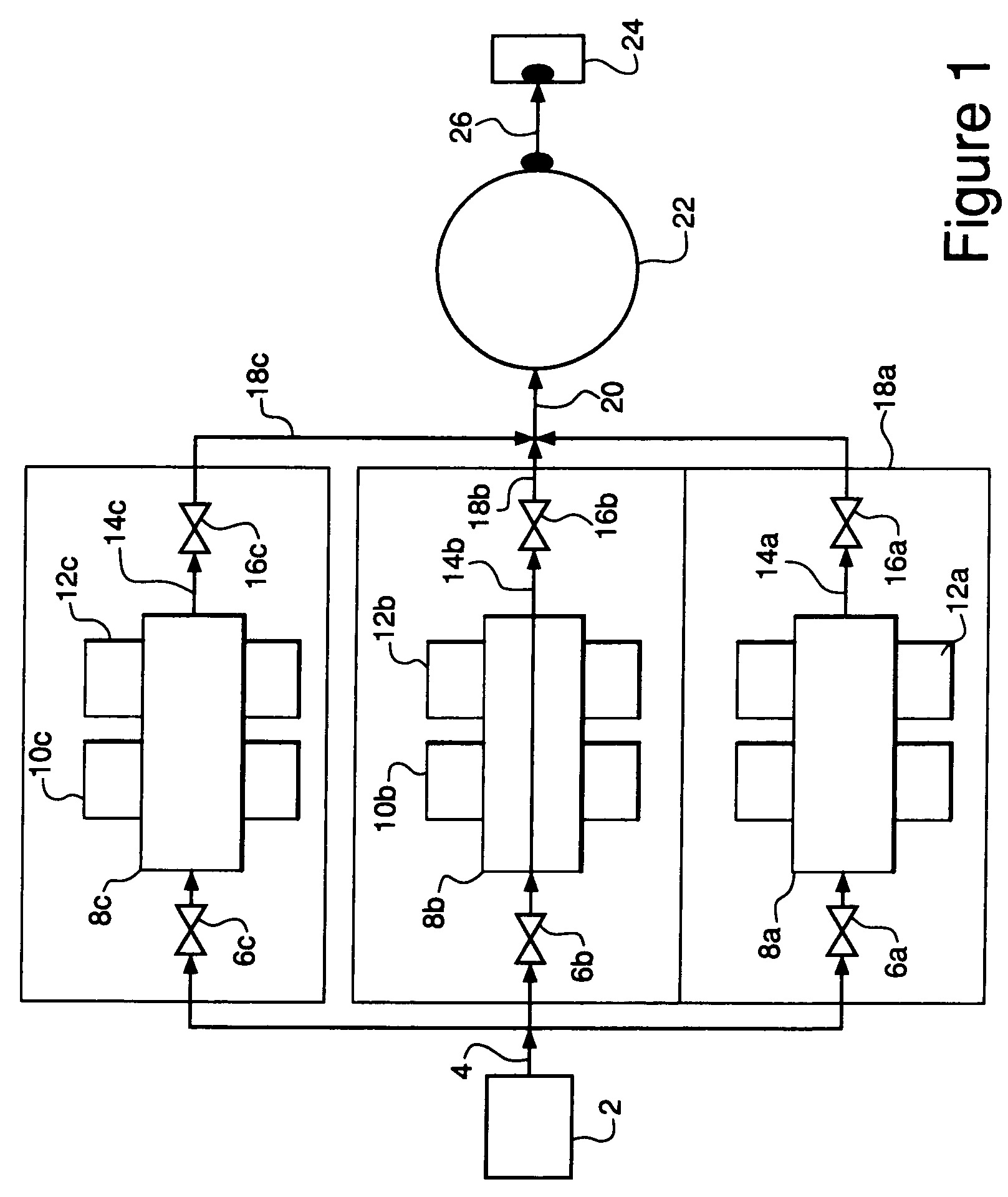

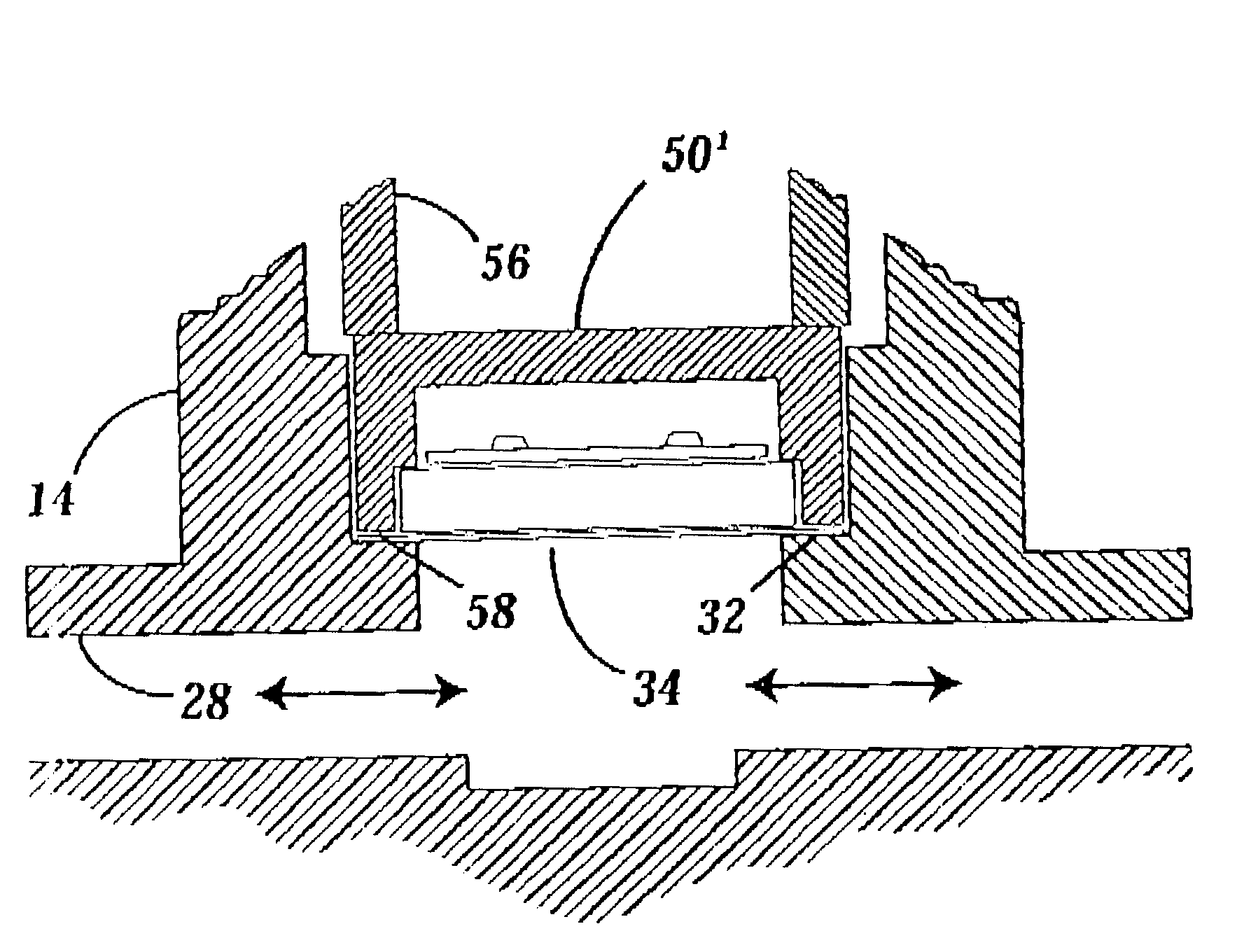

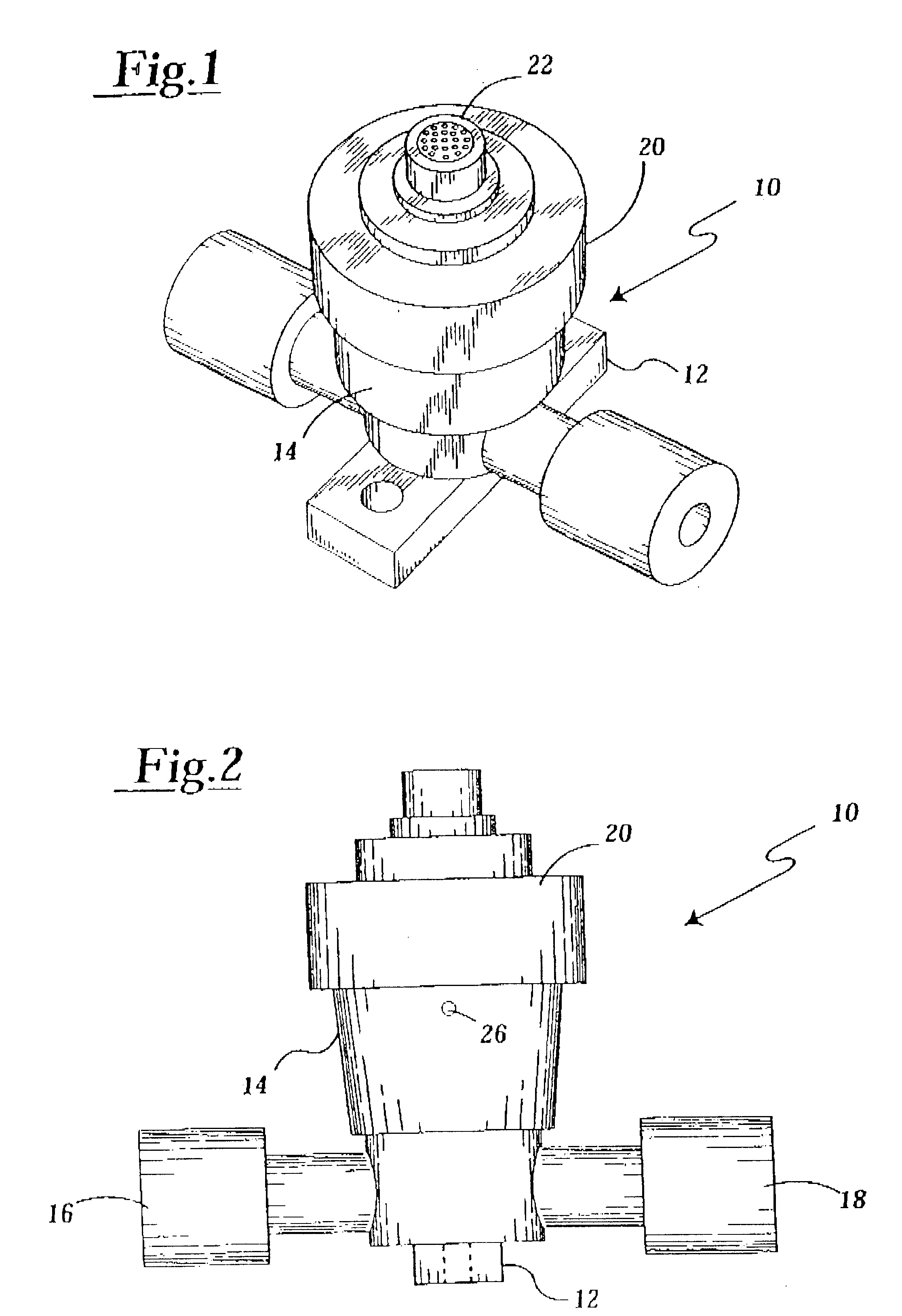

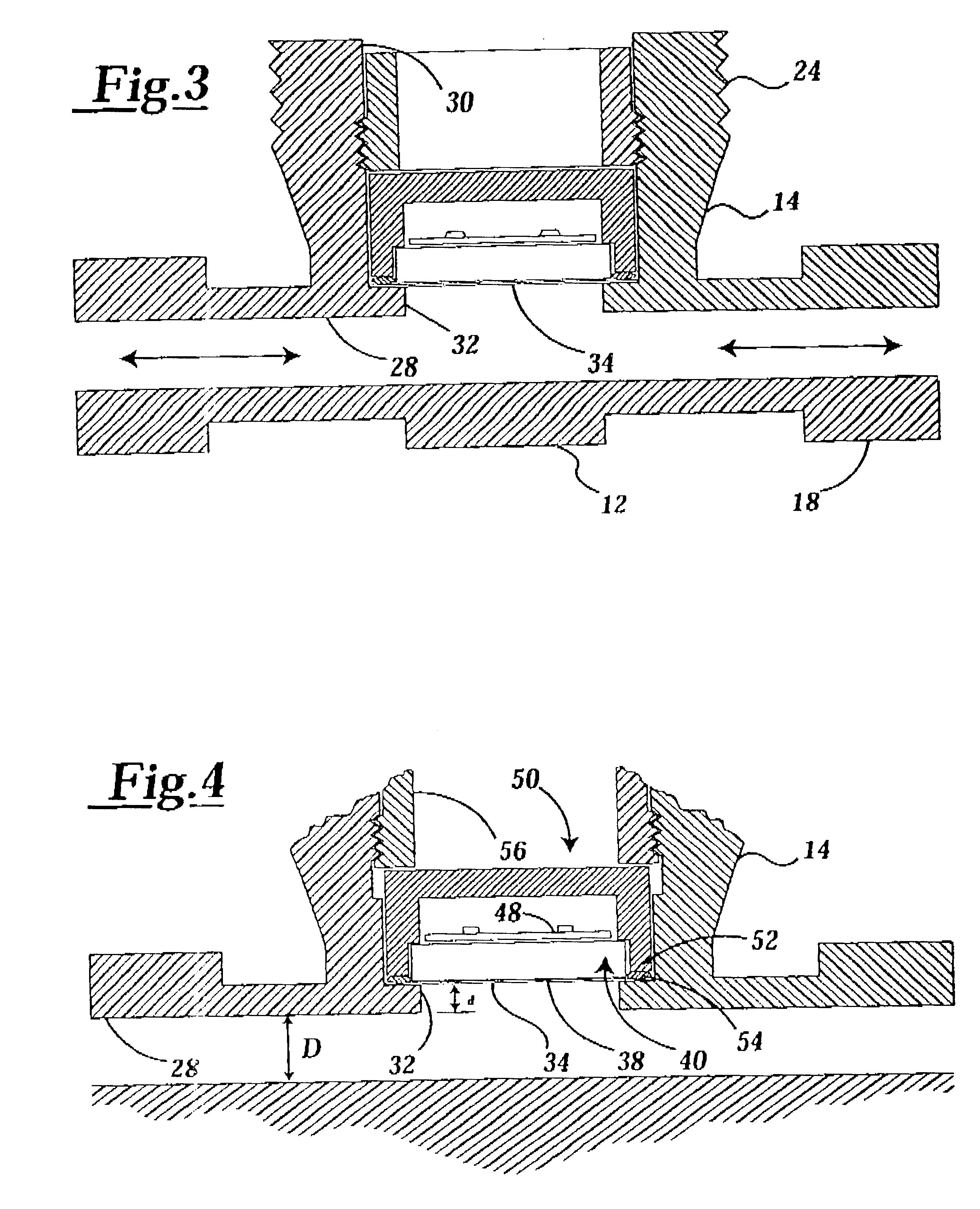

Method and apparatus for blending process materials

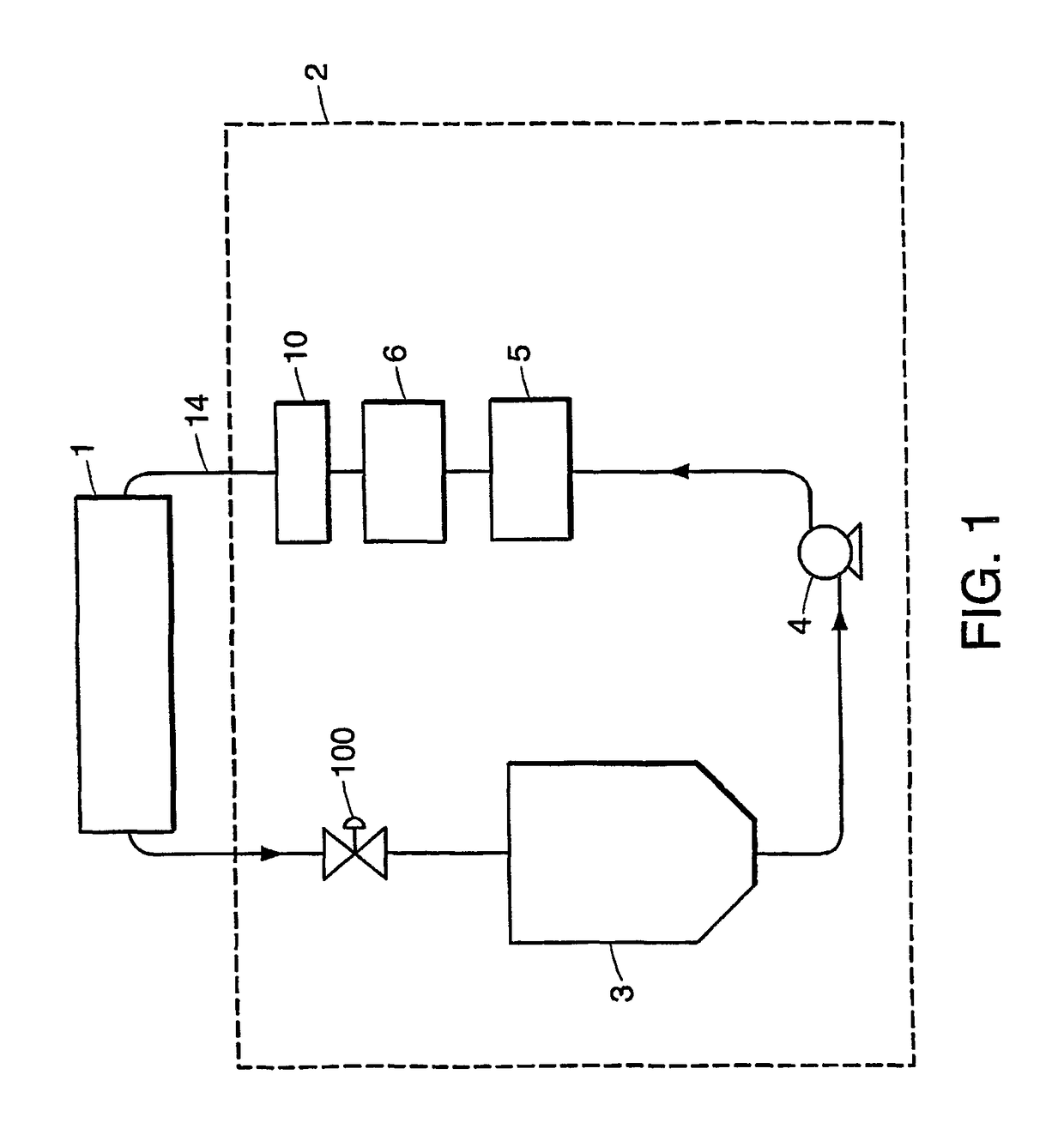

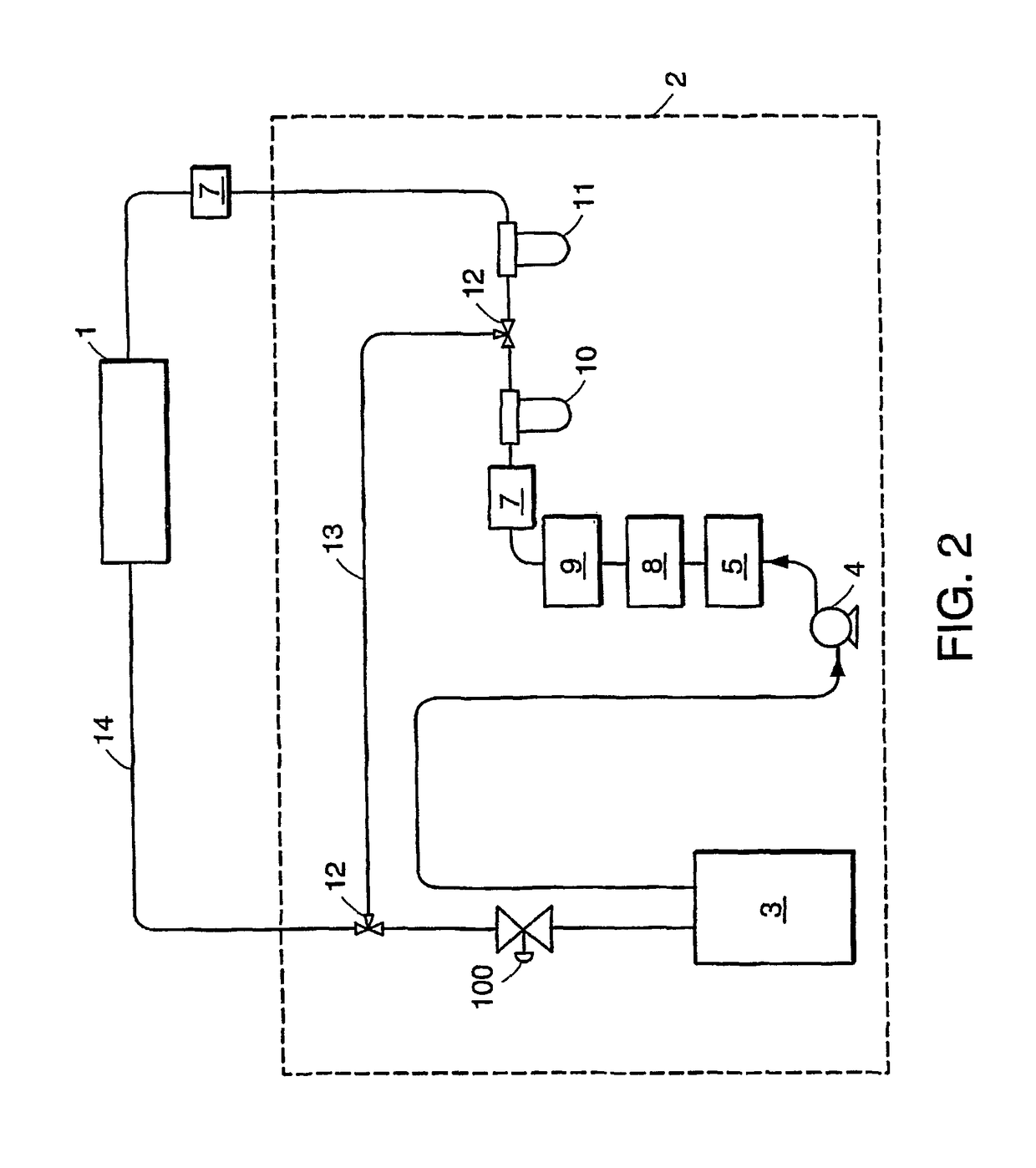

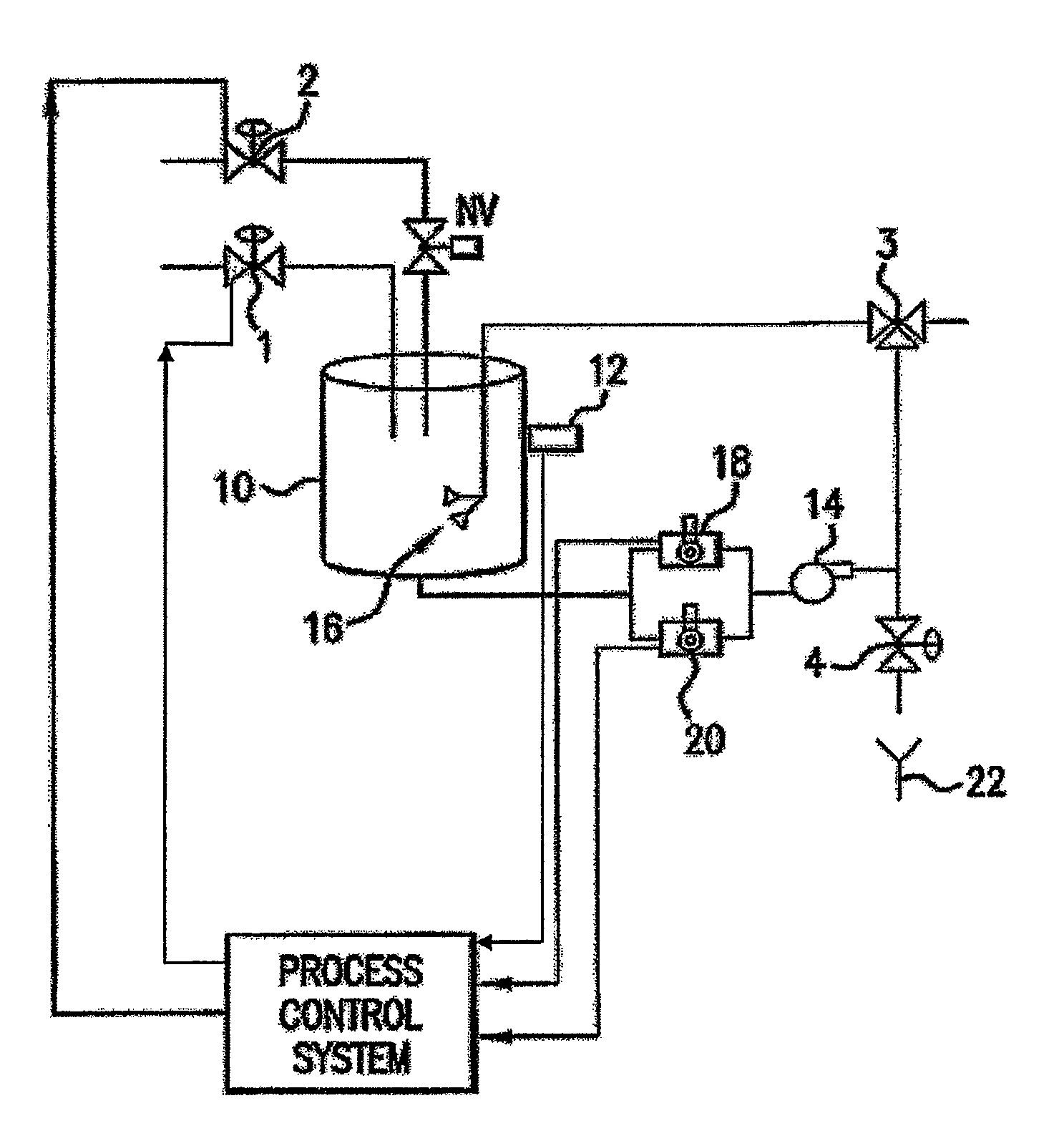

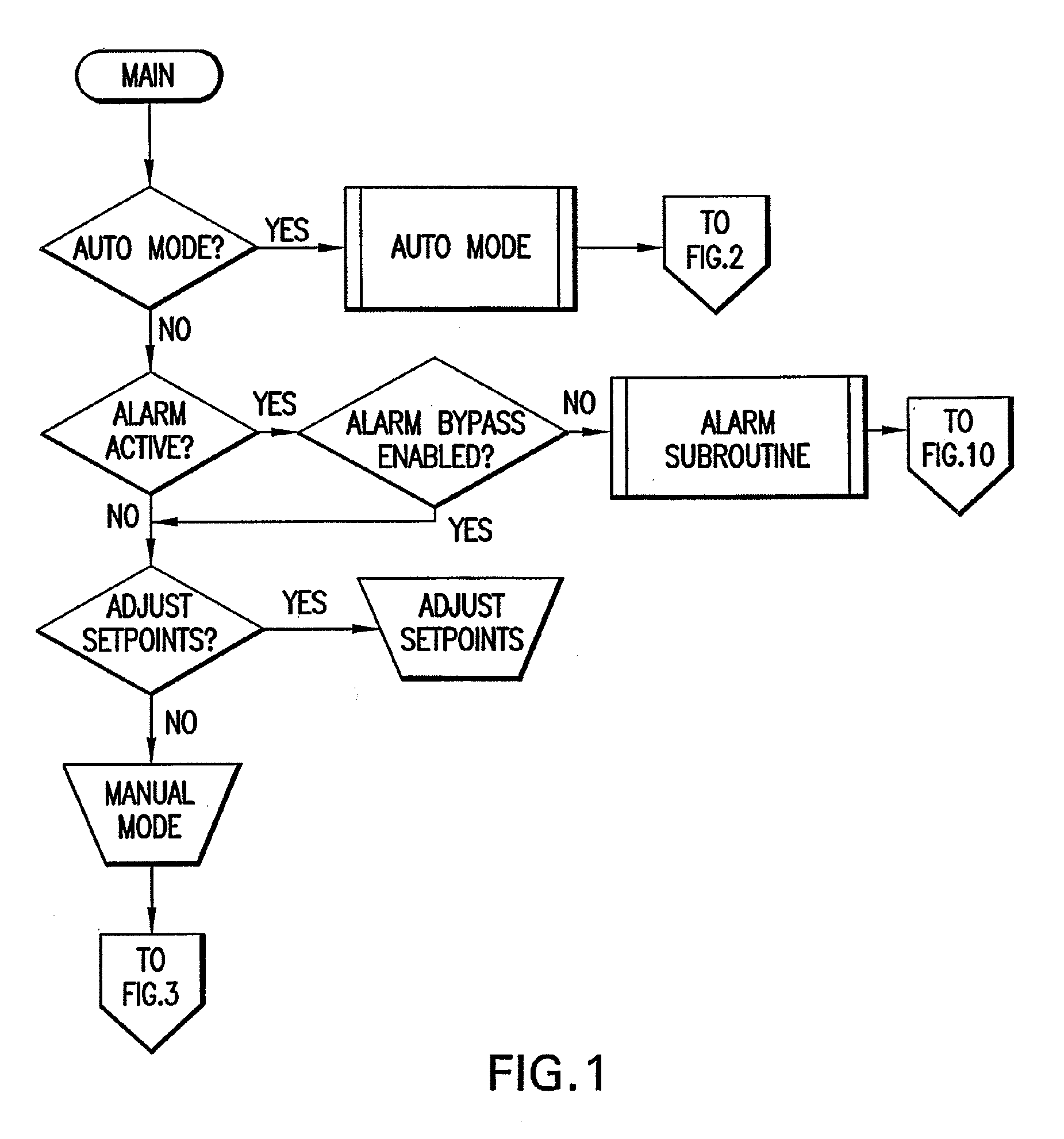

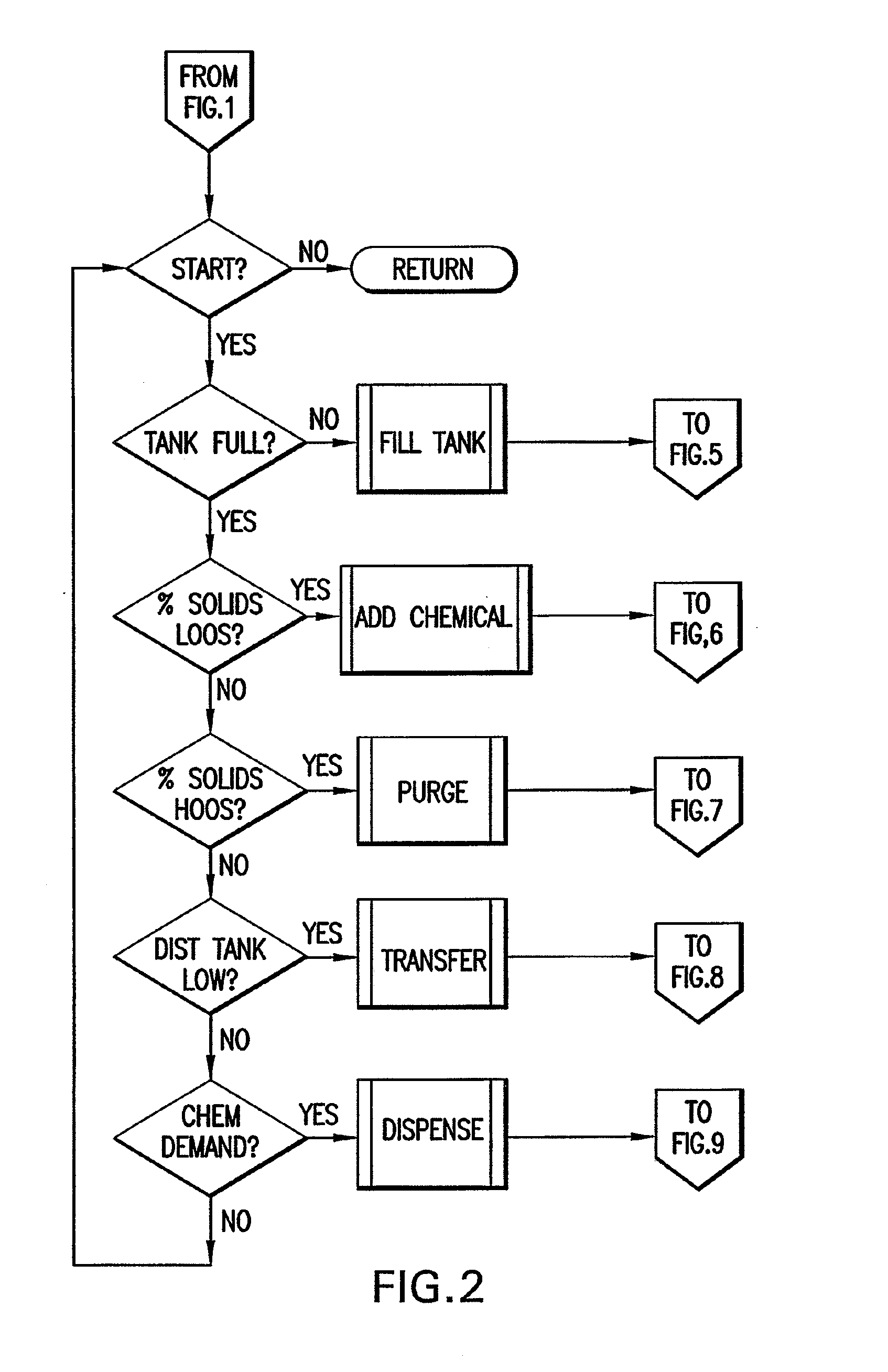

A method and apparatus for blending and supplying process materials. The method and apparatus are particularly applicable to the blending of ultra-high purity chemicals, the blending of abrasive slurries with other chemicals for the polishing of semiconductor wafers, and high-accuracy blending of chemicals. The apparatus may include a dispensing subsystem that supplies process materials to a mixing subsystem where they are blended with a static mixer. The method may include supplying process materials with a dispensing subsystem and blending the process materials in a static mixer.

Owner:MEGA FLUID SYST

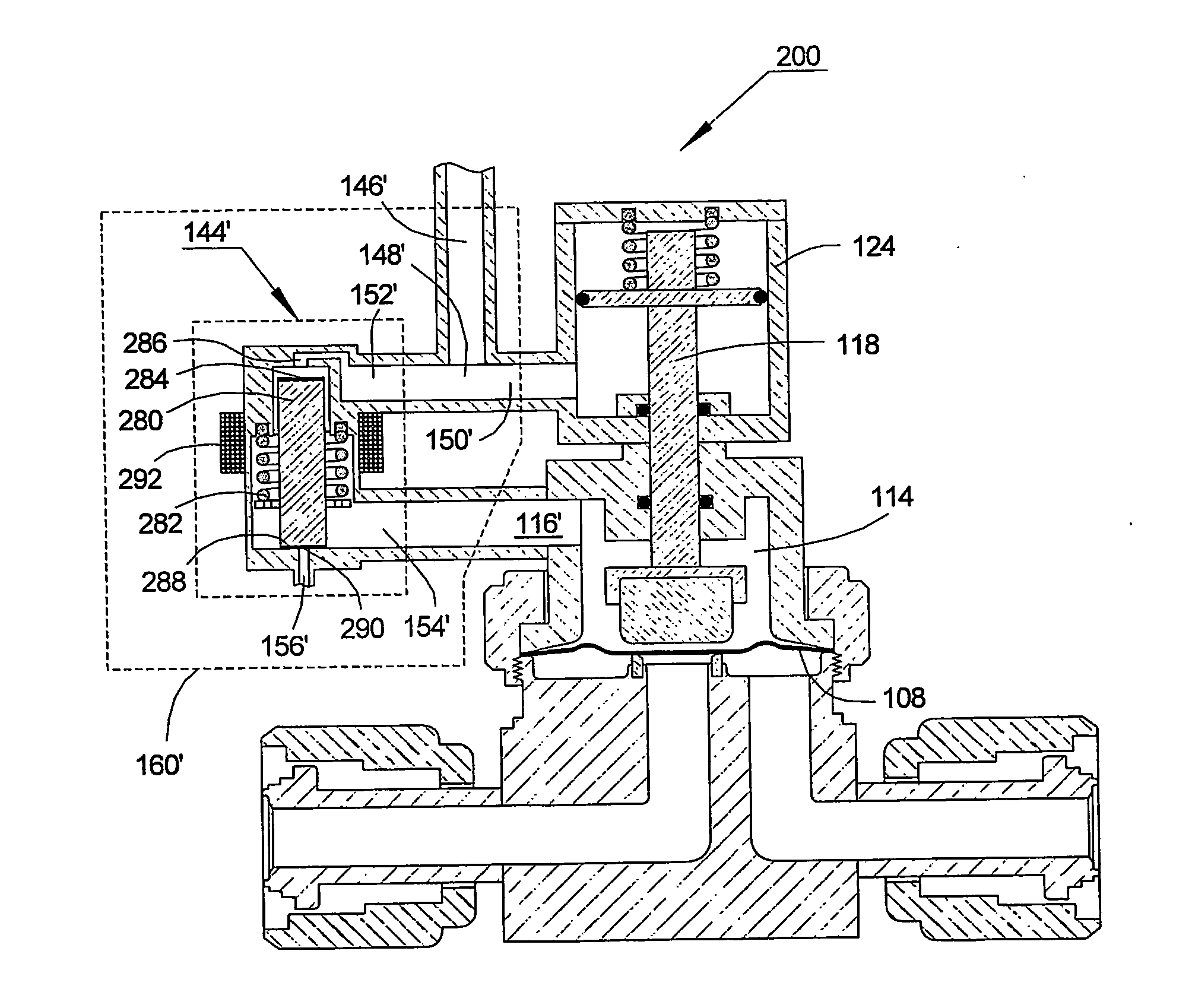

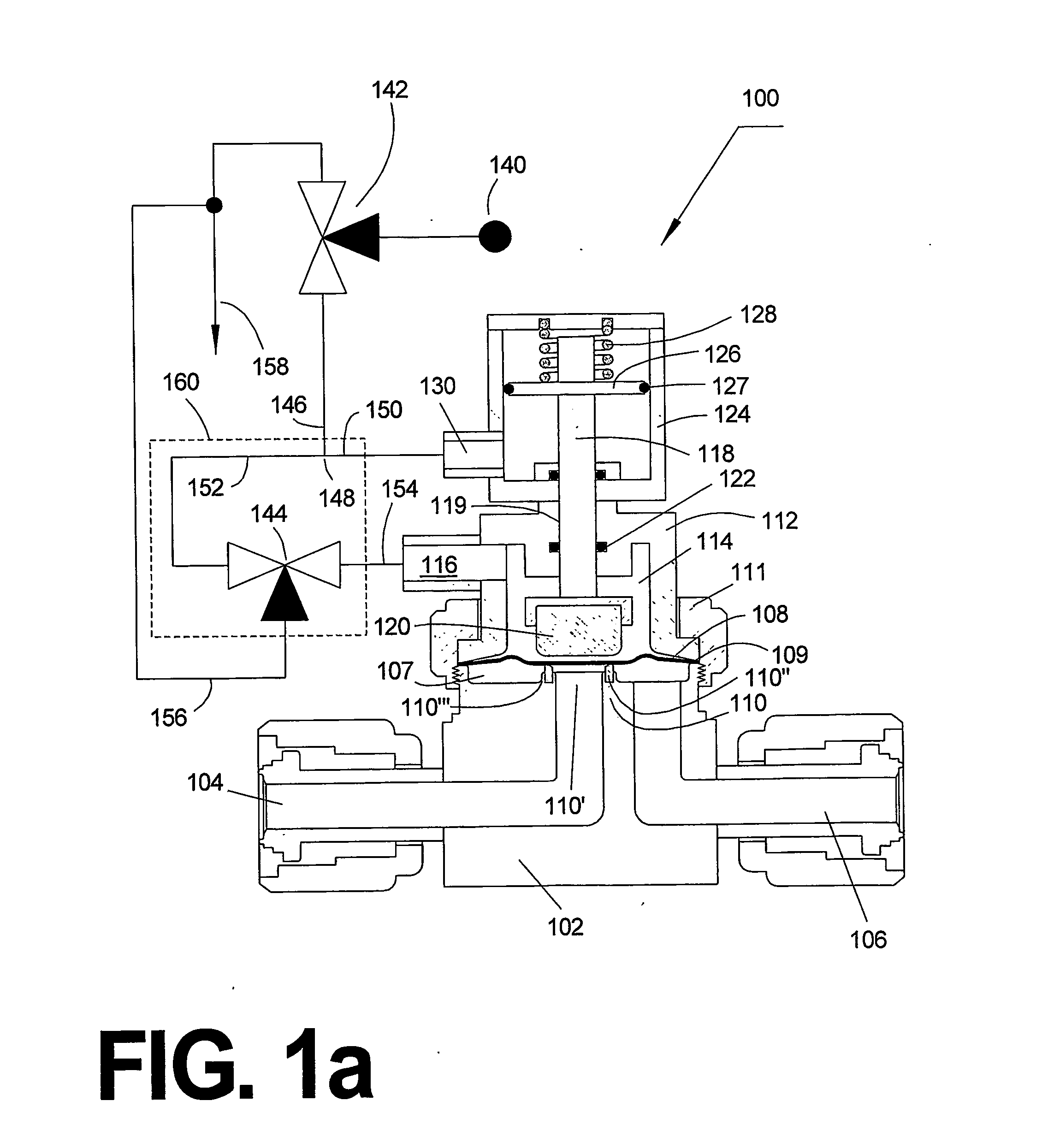

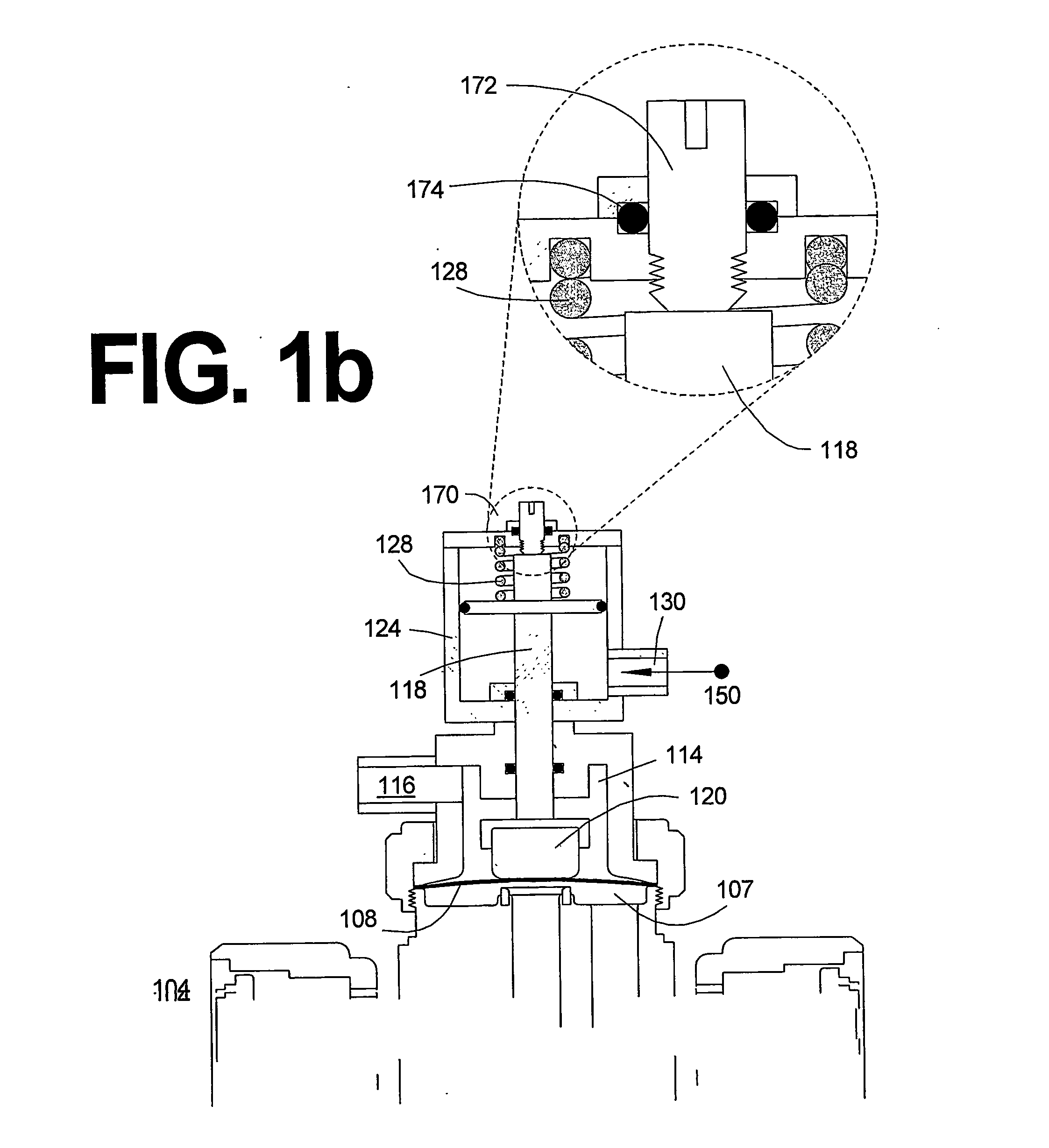

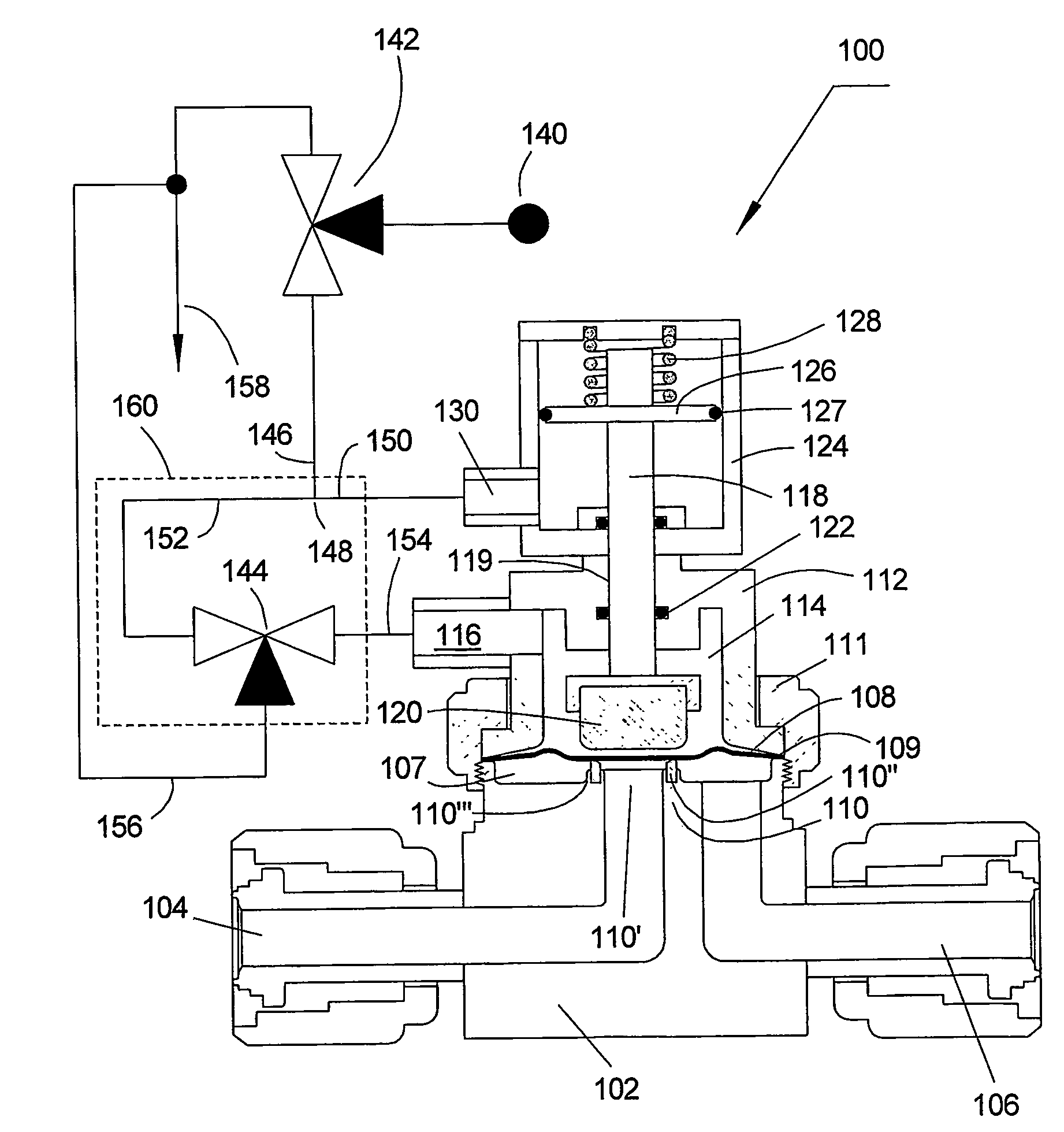

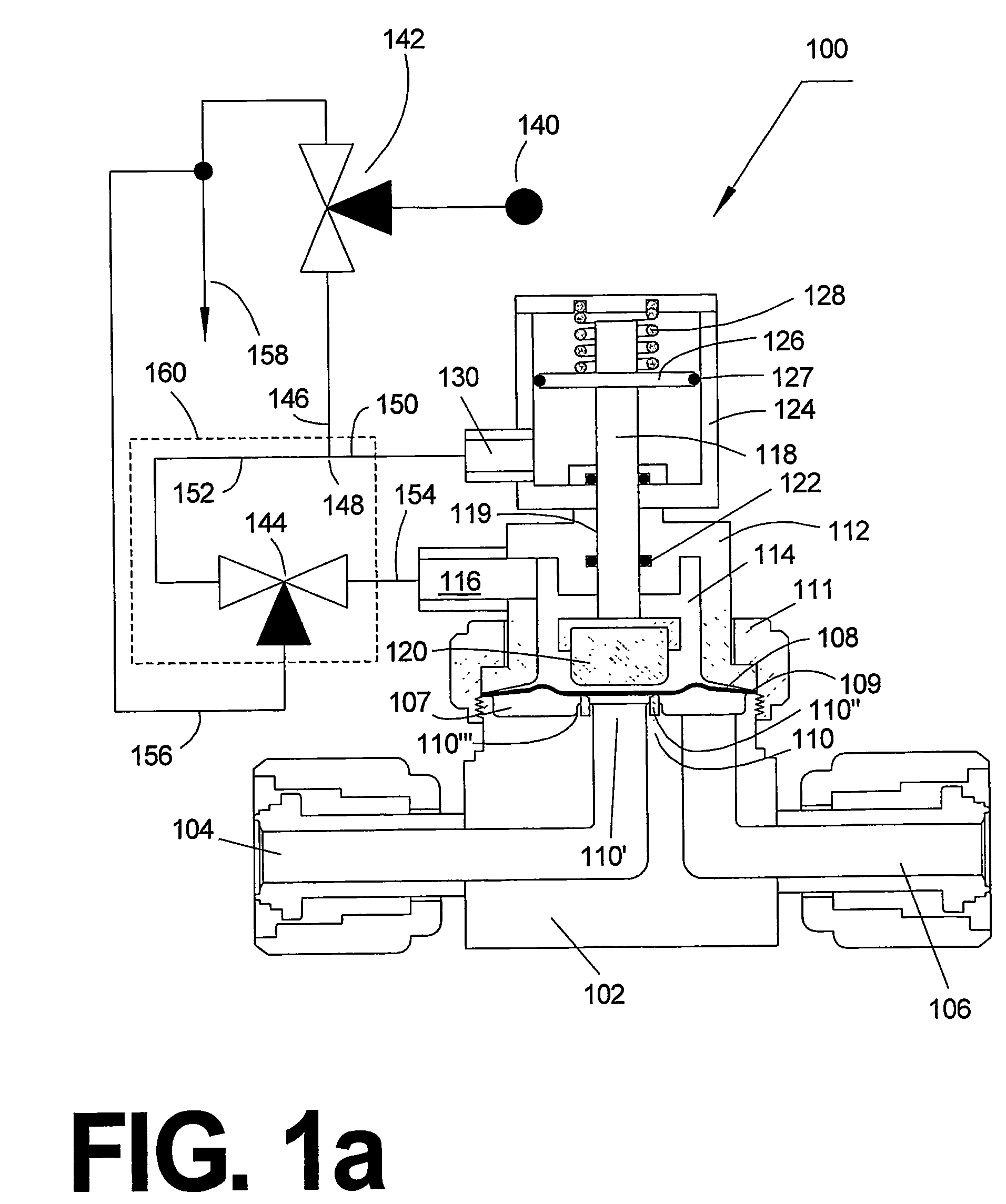

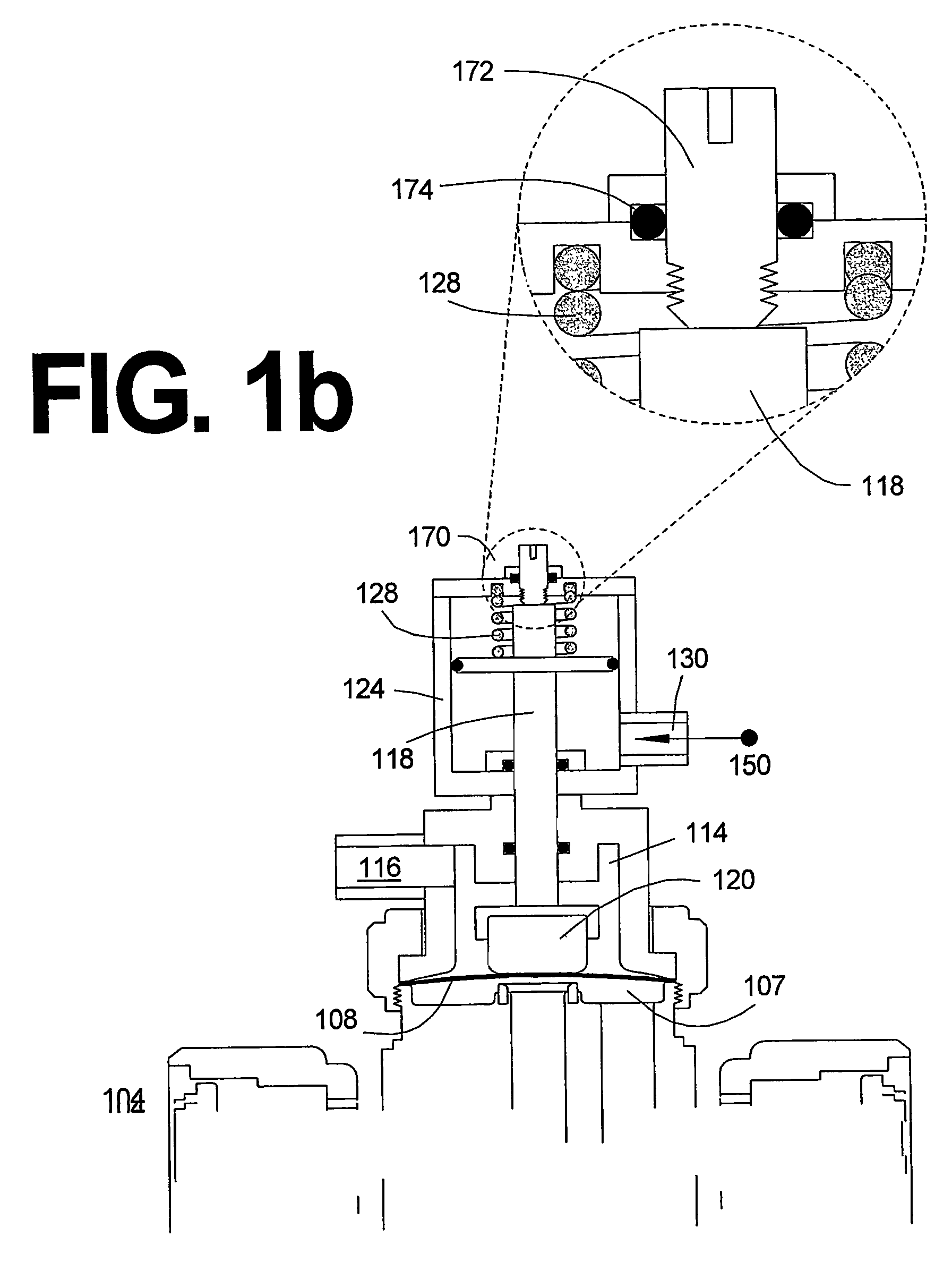

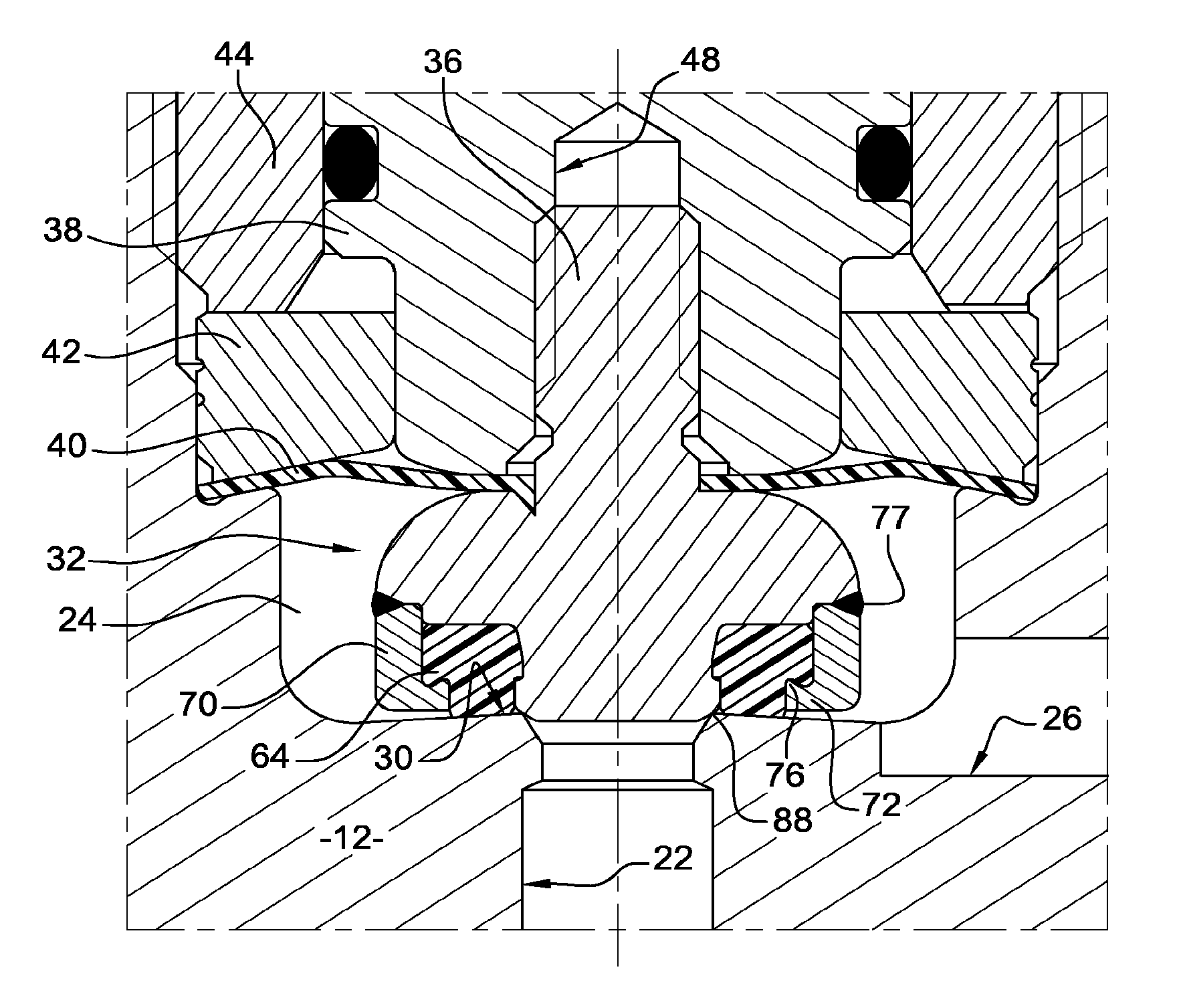

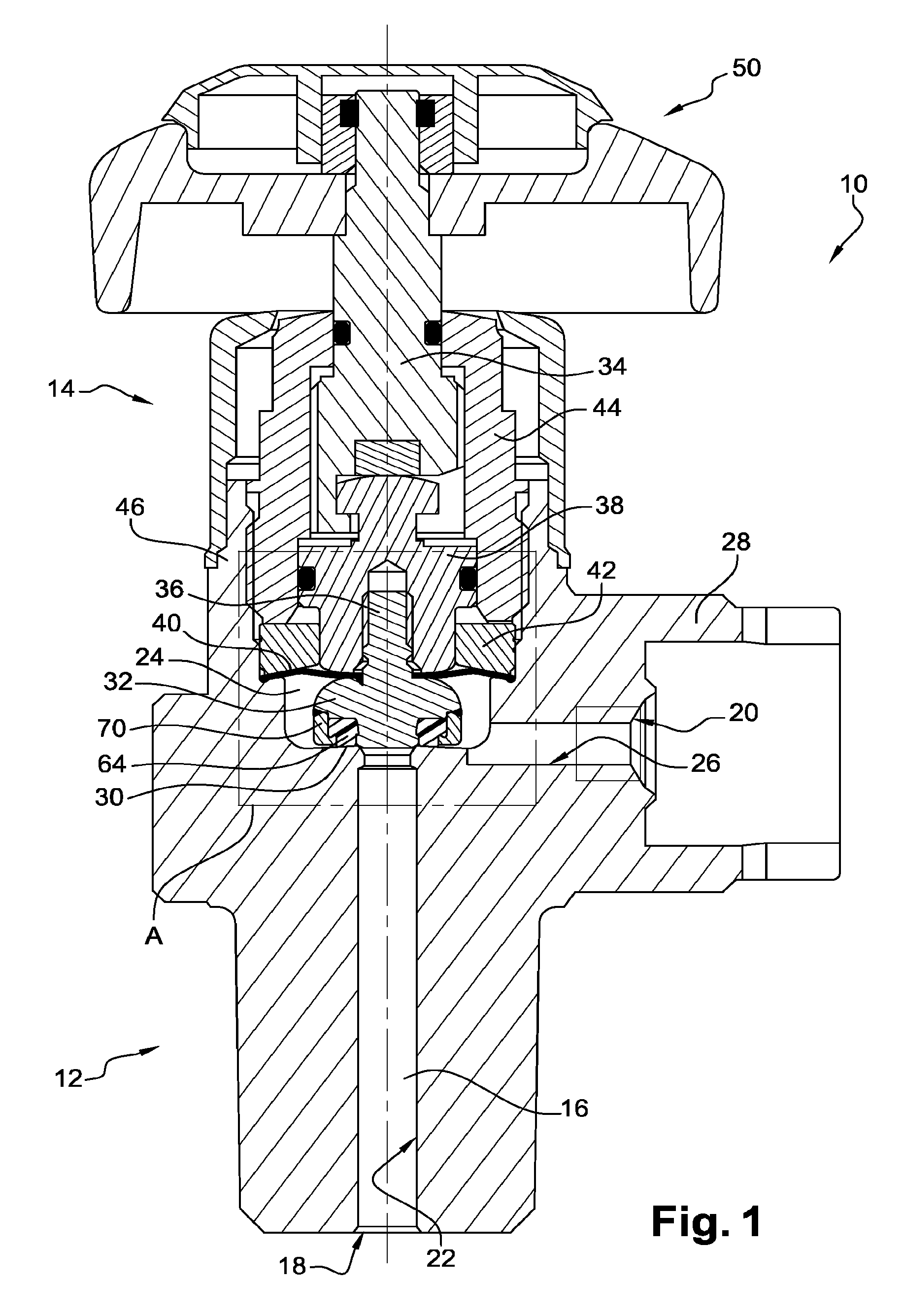

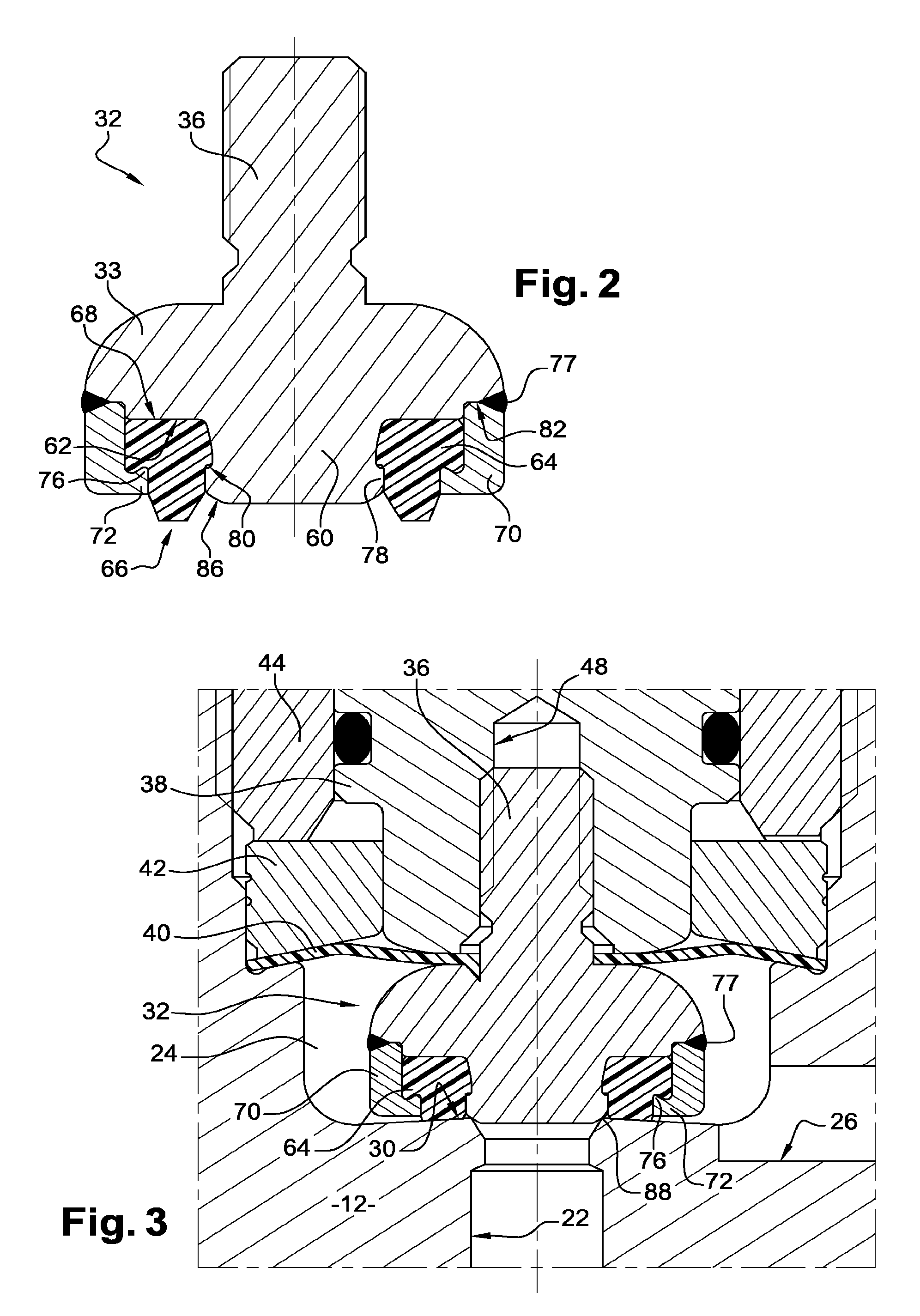

Fail-safe pneumatically actuated valve with fast time response and adjustable conductance

ActiveUS20070187634A1Improve cycle lifeImprove securityDiaphragm valvesOperating means/releasing devices for valvesEngineeringAtomic layer deposition

Apparatus and method for fail-safe high-speed-pneumatic valve is disclosed. Fail-safe dependability is provided by a spring-loaded normally-closed pneumatic actuator. When the spring-loaded actuator is pressurized, the normally closed mechanism is actuated to the valve active position. Concurrently, the pressure is directly applied to deflect a diaphragm or a bellow-assembly back to sealing position. Ultra high purity embodiments with standard dome shaped diaphragms are disclosed. Additional high conductance diaphragms and bellows embodiments are employed for higher conductance valves. Novel flow path layouts are disclosed. The valves are applicable for fast gas and fluid switching and are particularly suitable for high productivity Atomic Layer Deposition (ALD) applications. Additional embodiments cover improved diaphragm and seal reliability, externally adjustable valve conductance, improved valve safety and high temperature valve seals.

Owner:SUNDEW TECH

Growth of ultra-high purity silicon carbide crystals in an ambient containing hydrogen

ActiveUS20050022724A1Good colorEasy to disassemblePolycrystalline material growthFrom chemically reactive gasesSmall animalHydrogen

A garment for the transporting, observing, entertaining, training, and displaying of small animals, reptiles and insects (gerbils, mice, snakes, tarantulas, spiders, lizards, etc.) in the tunnels of the garment while on the shoulders of their owners. The garment consists of a see-through, mesh washable fabric panel on top and a brightly colored washable panel underneath, attached to each other using releasable fasteners. The fasteners also provide means to construct tunnel walls and nesting areas for the small animal. The fasteners further provide attachment to the garment tunnel's floor and walls for toys and other paraphernalia to entertain the pet and adorn the garment. This garment allows the owner to hold, observe, and transport his pet without damaging or soiling his clothes while his pet has a tunnel in which to play and rest safely. Also the owner can remove toys, food and nesting material in order to launder the garment.

Owner:CREE INC

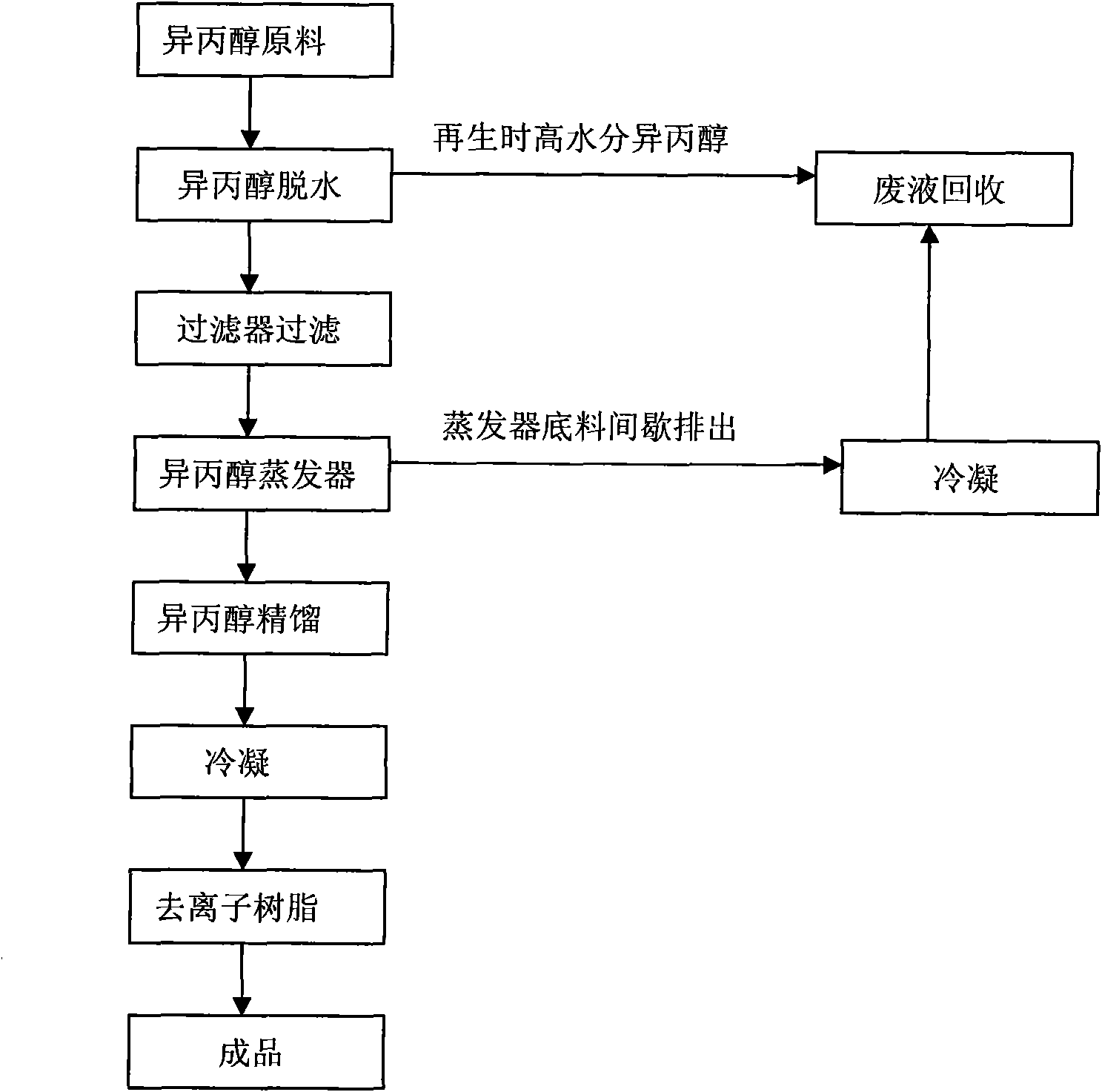

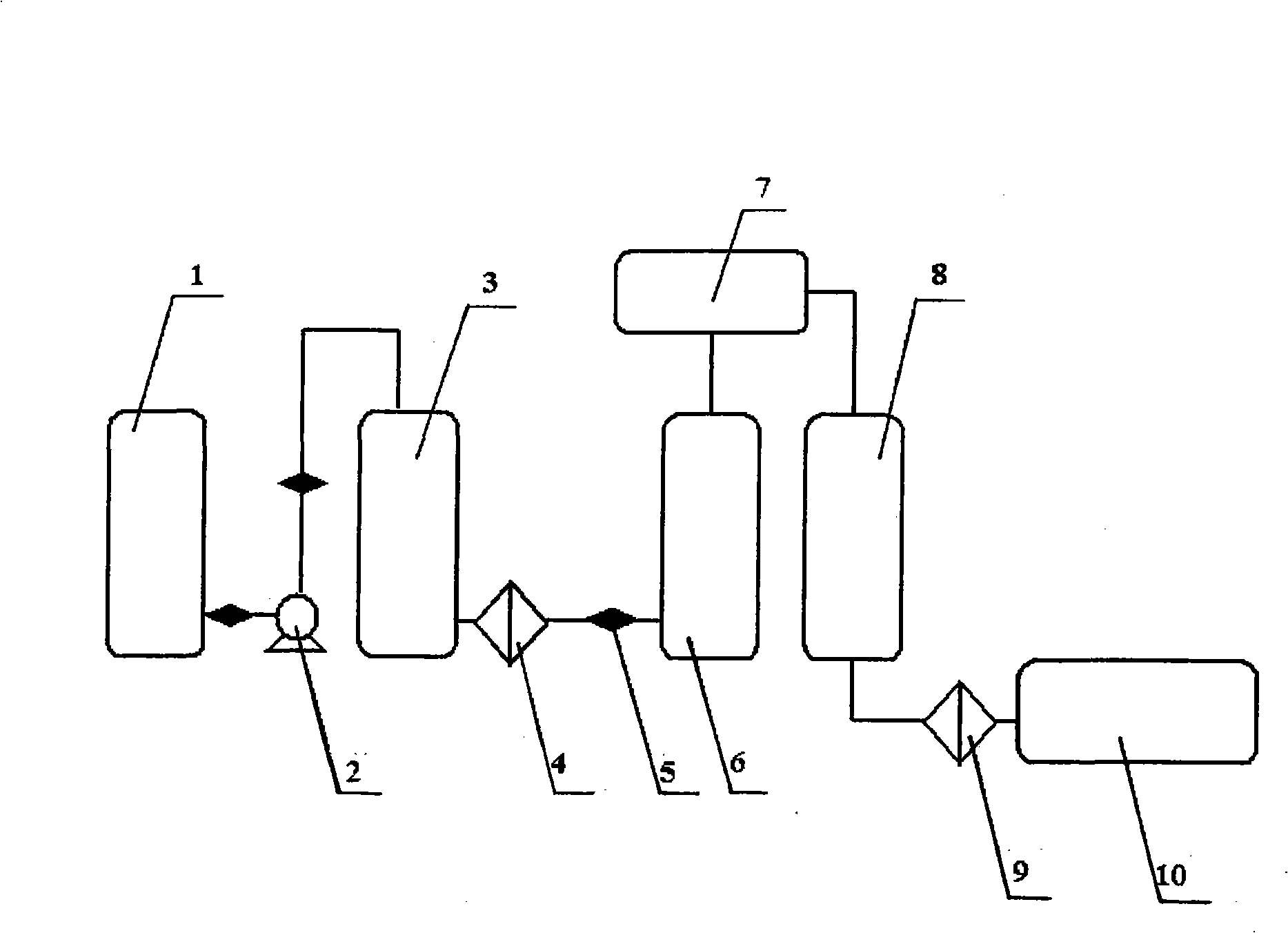

Production process of ultra-high-purity isopropanol

InactiveCN102452897AMild reaction conditionsSimple operation processOrganic compound preparationHydroxy compound separation/purificationMolecular sieveDistillation

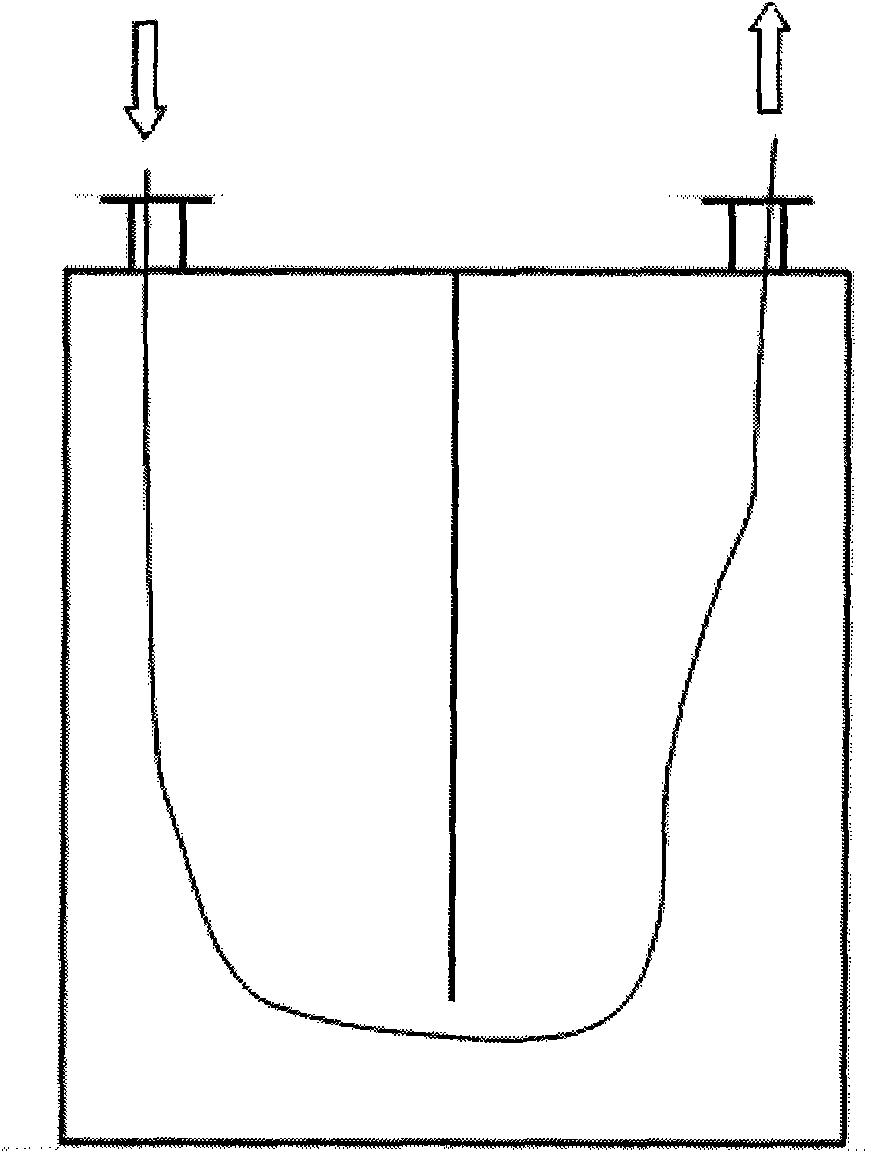

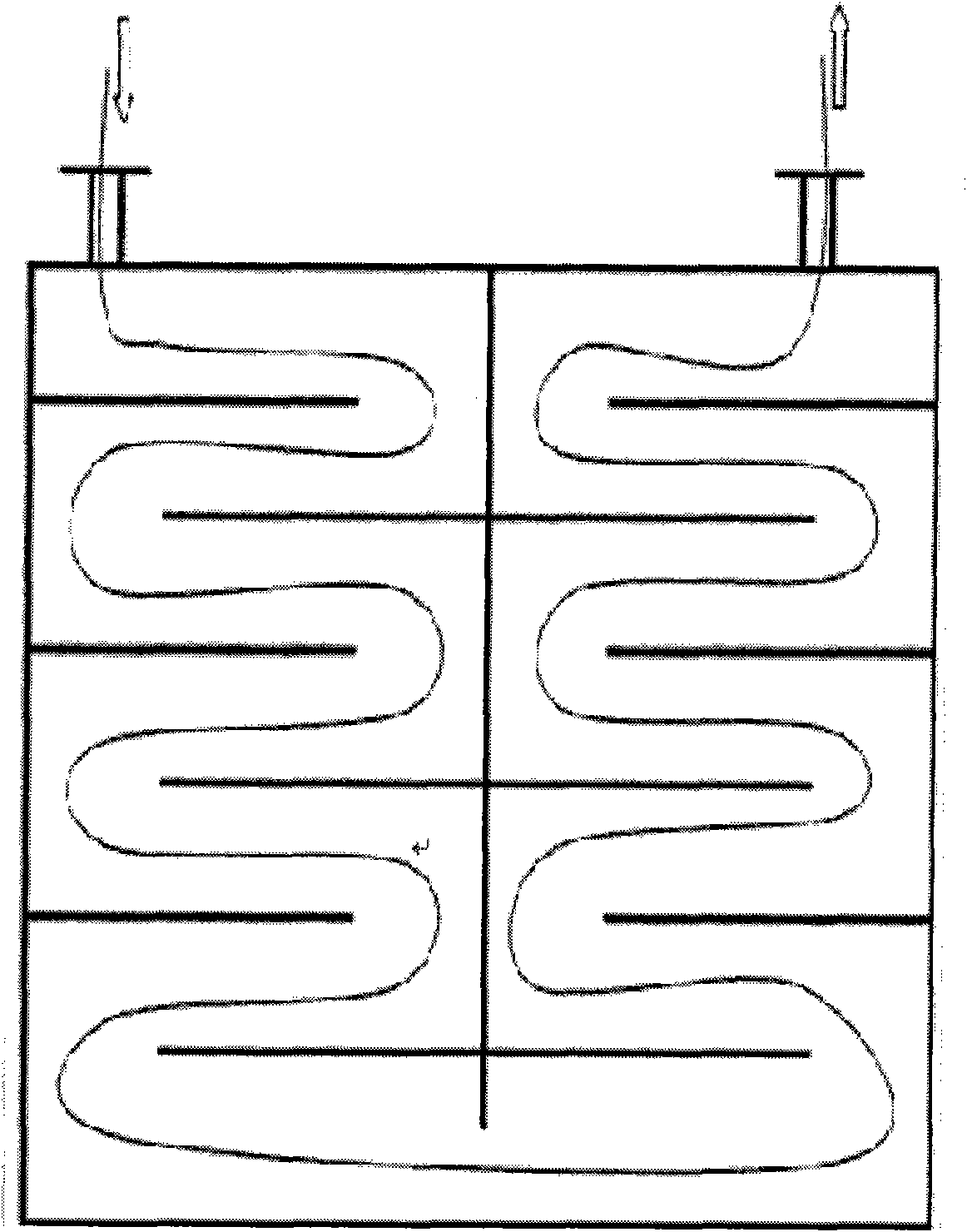

The invention discloses a production process of ultra-high-purity isopropanol, which comprises the following process steps of: (1) delivering a feed stream containing at least 98% of industrial grade isopropanol into a molecular sieve adsorption tower from the bottom of the molecular sieve adsorption tower, dehydrating through a molecular sieve, and then flowing out of the top of the tower to obtain high-purity isopropanol of which the moisture content is less than 100ppm; (2) filtering the high-purity isopropanol taken out of the molecular sieve adsorption tower by using a filter so as to remove particles of which the sizes are more than 1mum; and (3) transferring the high-purity isopropanol which is qualified by filtering into a distillation tower and a rectification column for rectifying, then transferring the rectified high-purity isopropanol into a condenser to be condensed into high-purity liquid isopropanol, enabling the condensed high-purity liquid isopropanol after rectifying to pass through a deionized resin tank, and deionizing through ionic resin so as to obtain ultra-high-purity isopropanol of which the metallic impurity is less than 0.1ppb. The production process disclosed by the invention is carried out under the normal pressure, and has the advantages of mild reaction conditions, simple operation processes and good safety performance.

Owner:JIANGSU DENOIR TECH CO LTD

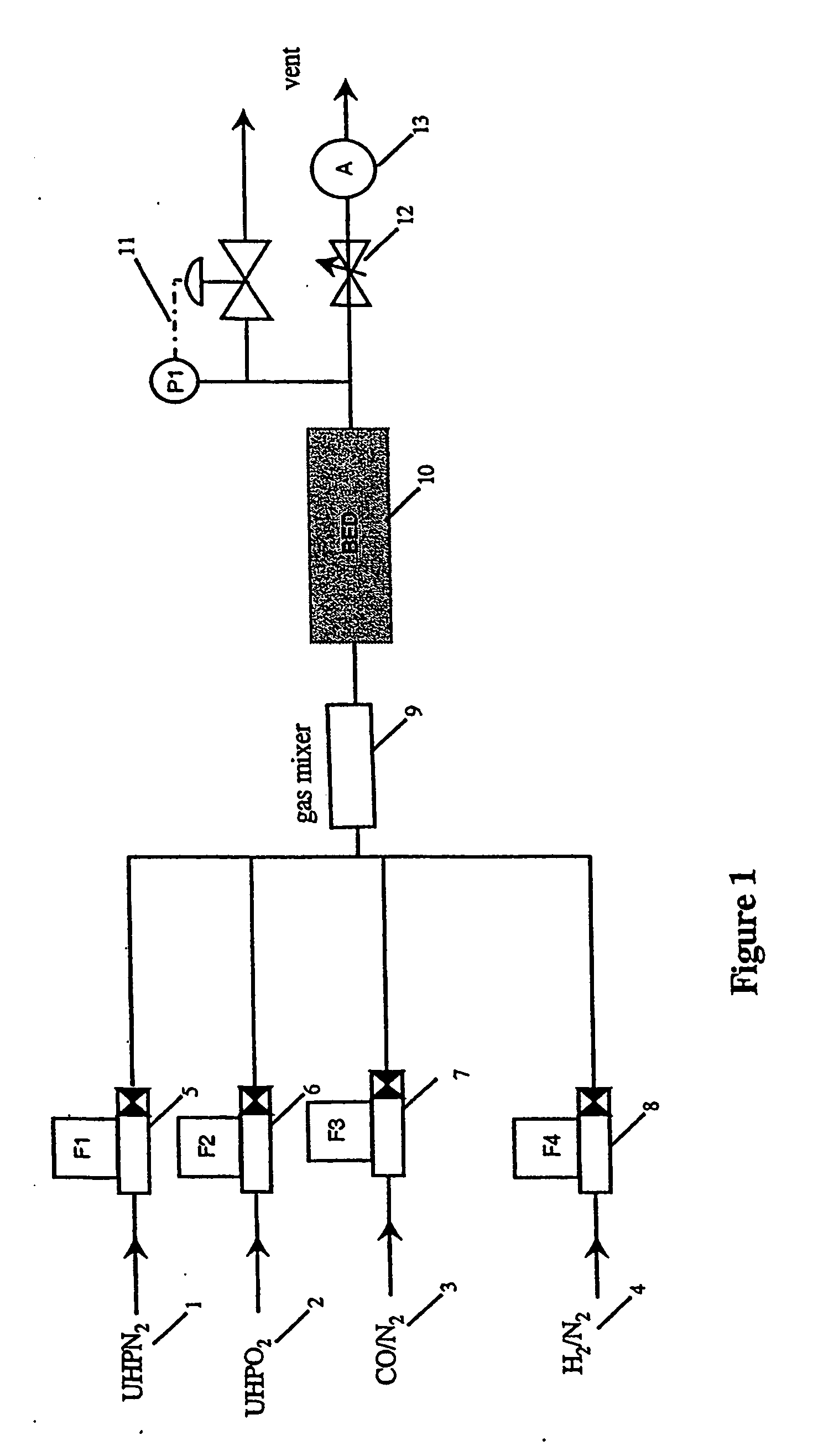

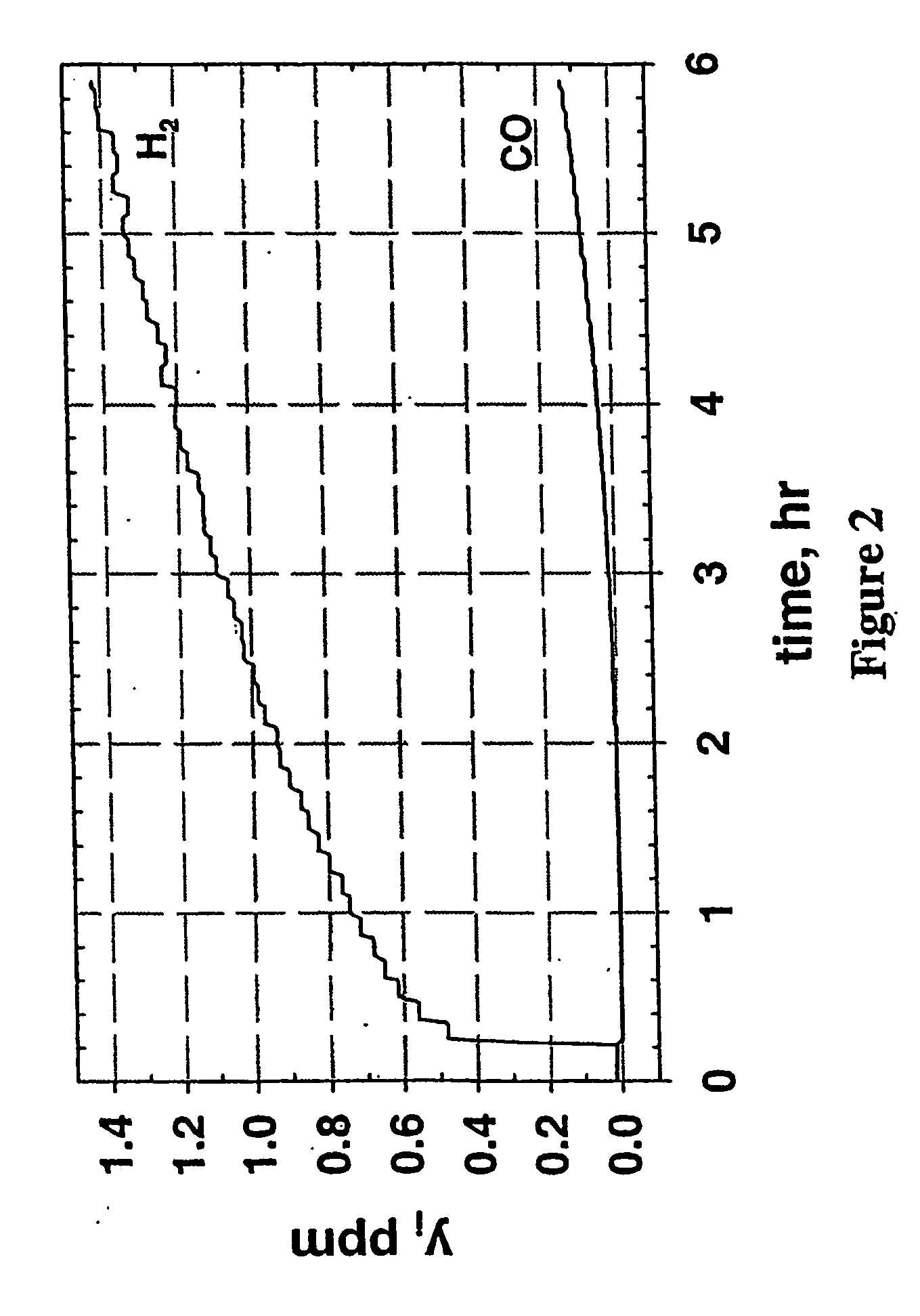

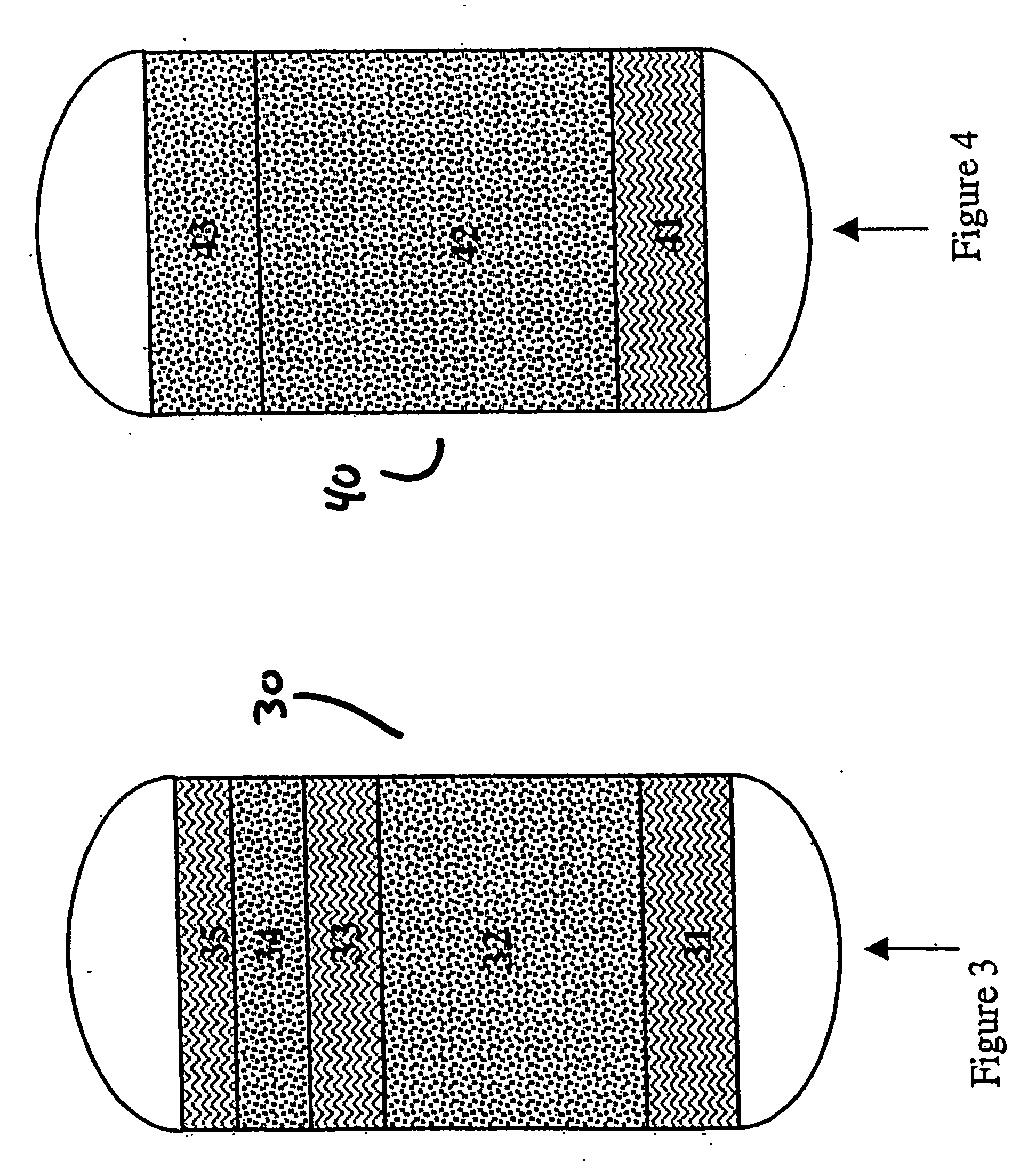

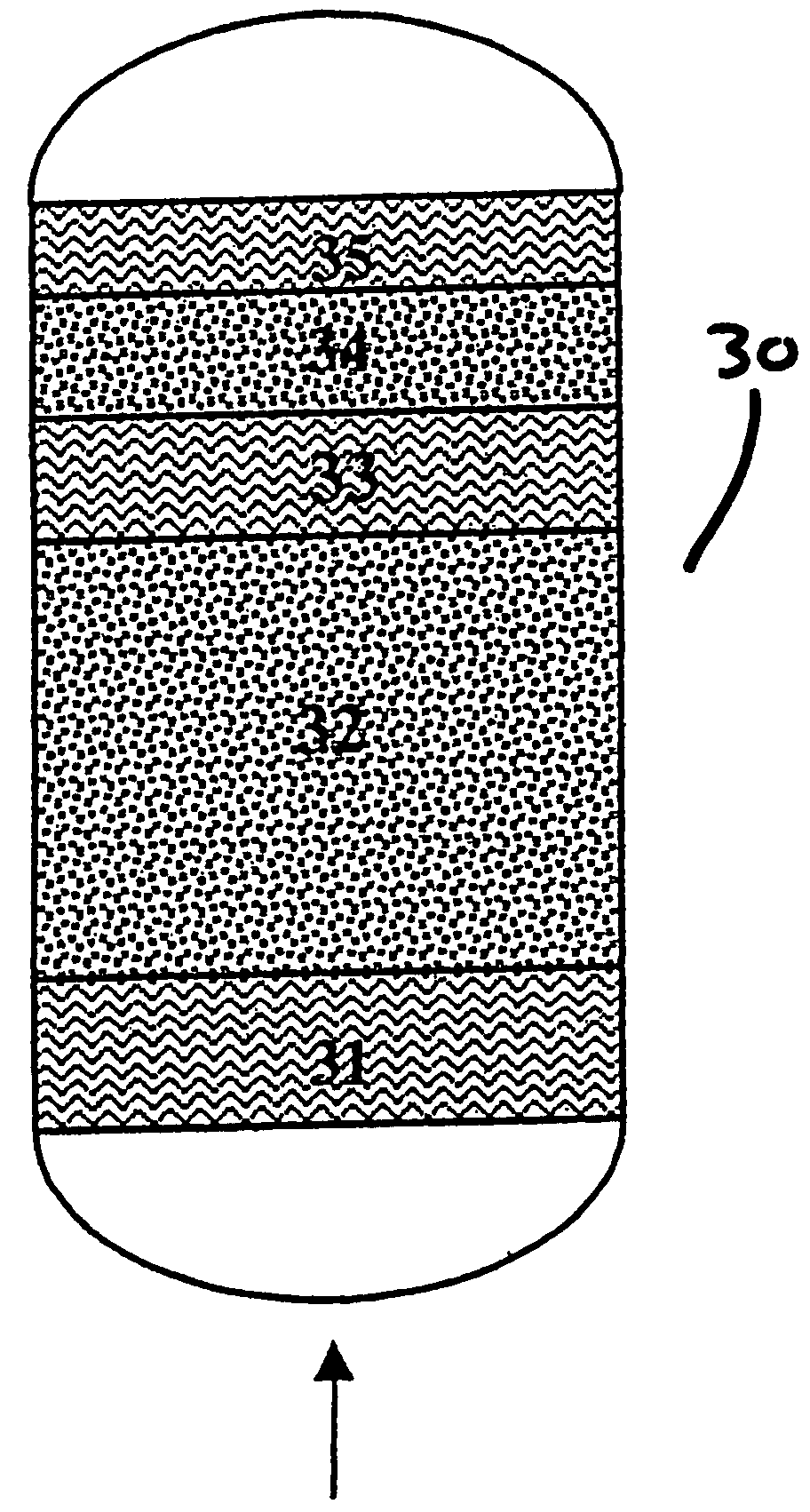

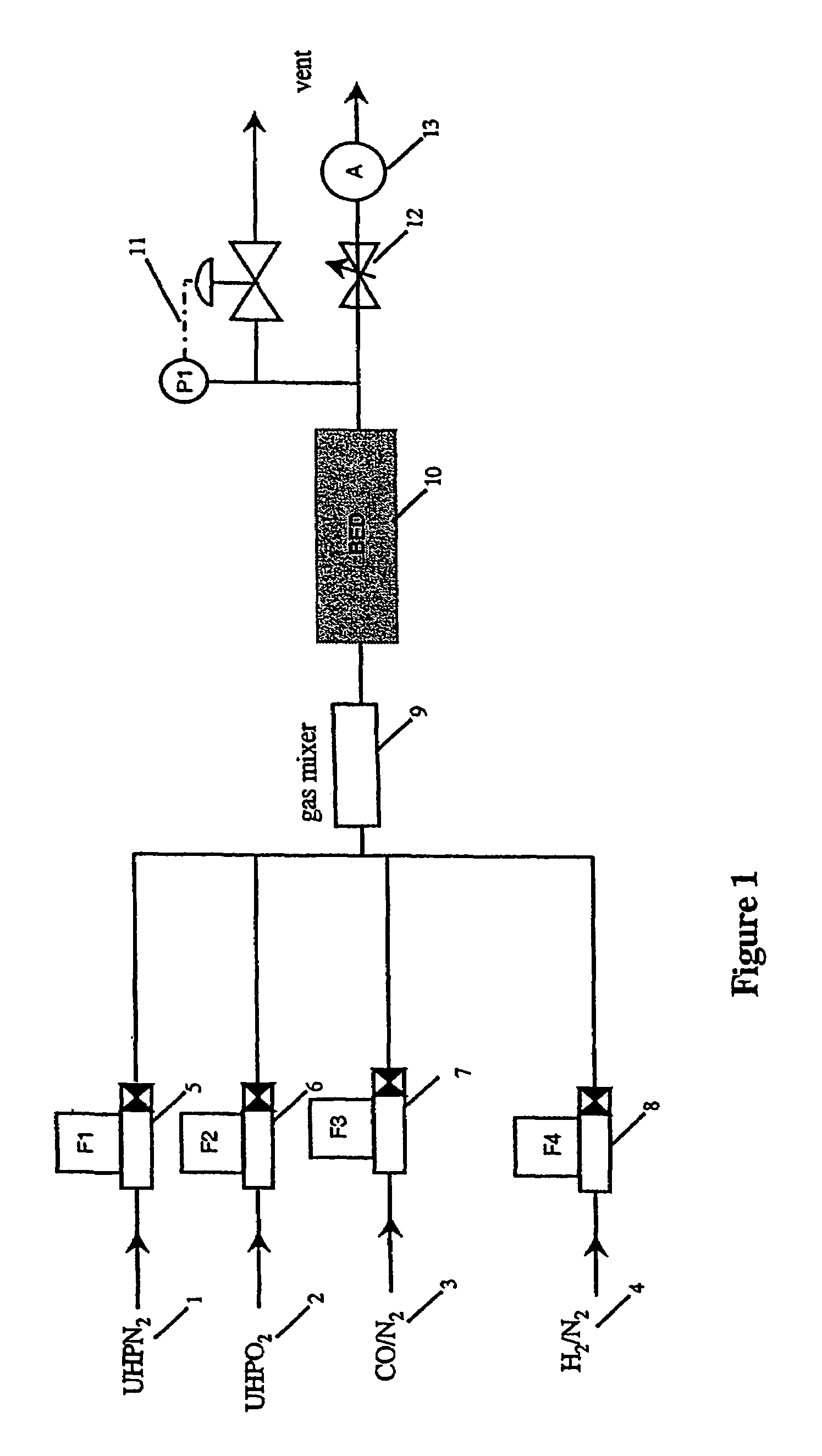

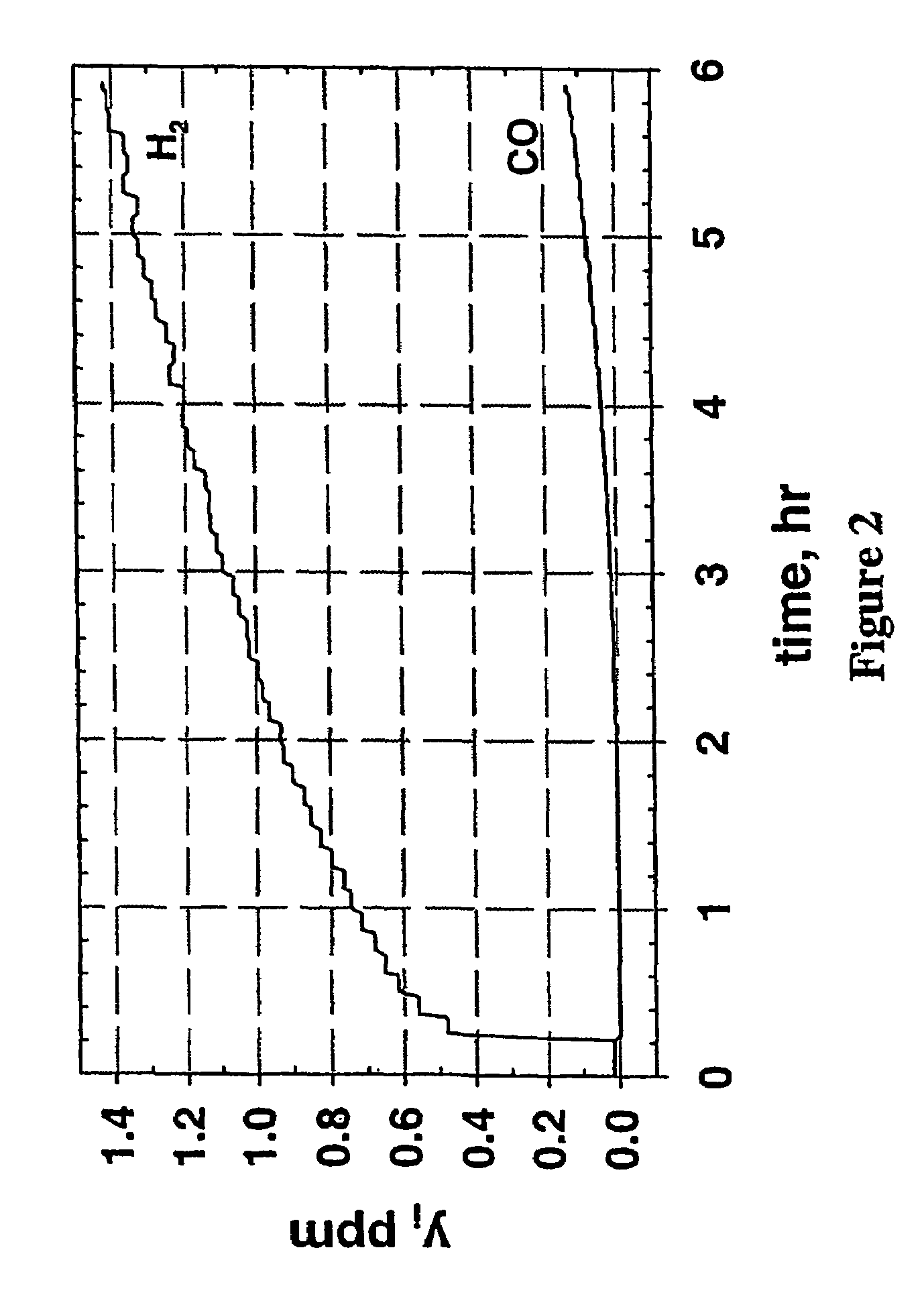

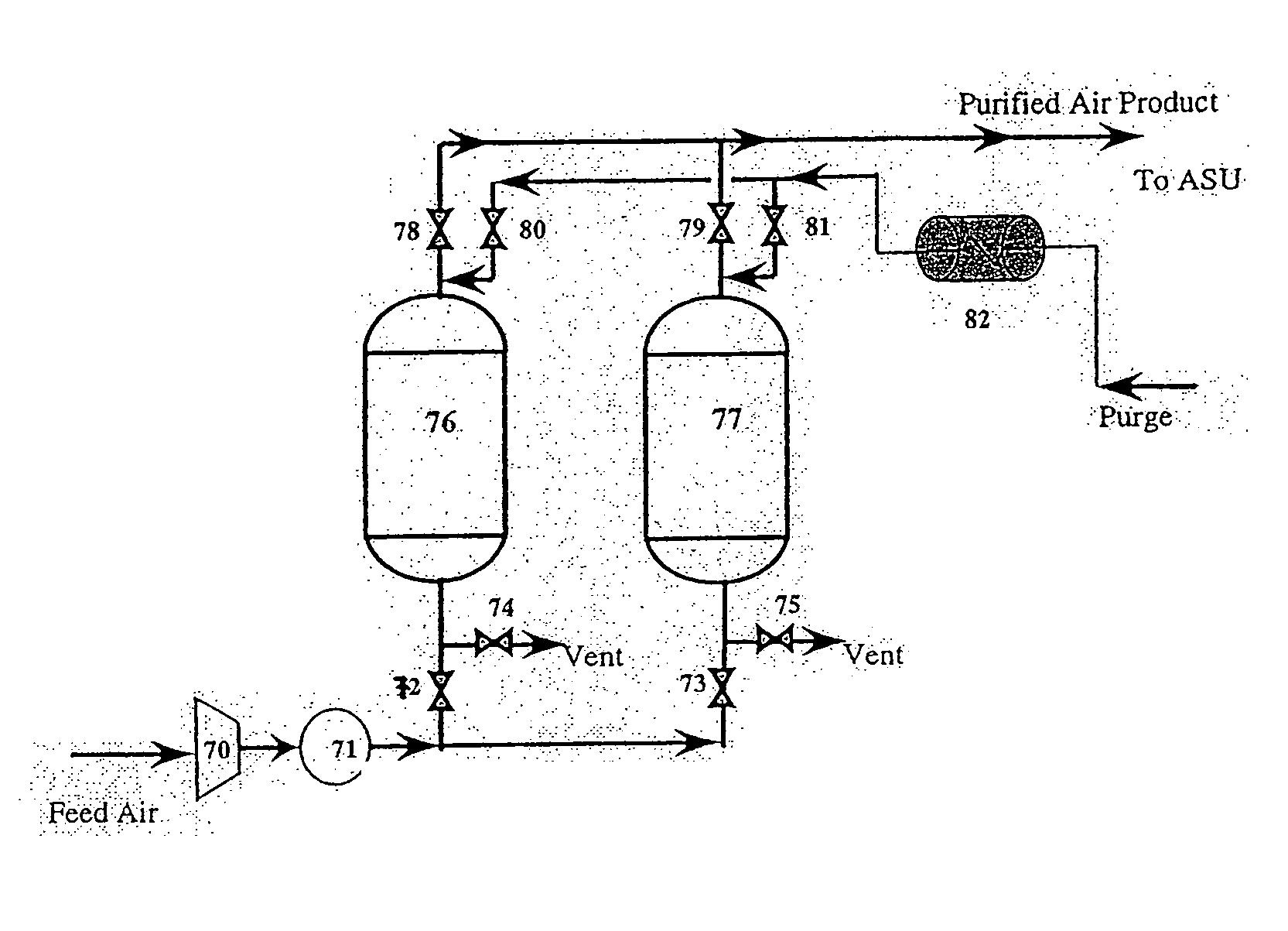

Production of high purity and ultra-high purity gas

InactiveUS20060210454A1Low costSuperior CO and H<subNitrous oxide captureCombination devicesHydrogenOperational costs

Trace amounts of carbon monoxide and optionally hydrogen are removed from gaseous feed streams by passing the feed stream through a carbon monoxide adsorbent (33) prior to passing it through a supported metal catalyst (34). The invention saves significant capital and operational costs over existing processes.

Owner:PRAXAIR TECH INC

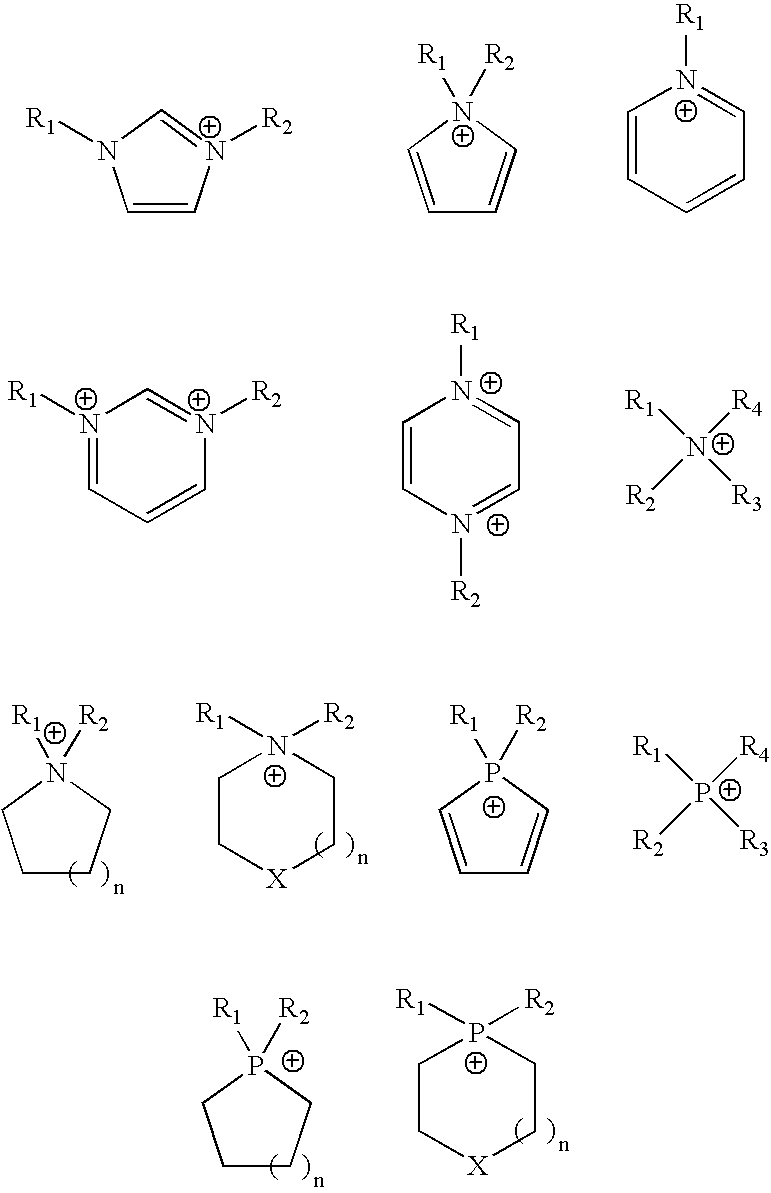

Superhigh purity ionic liquid

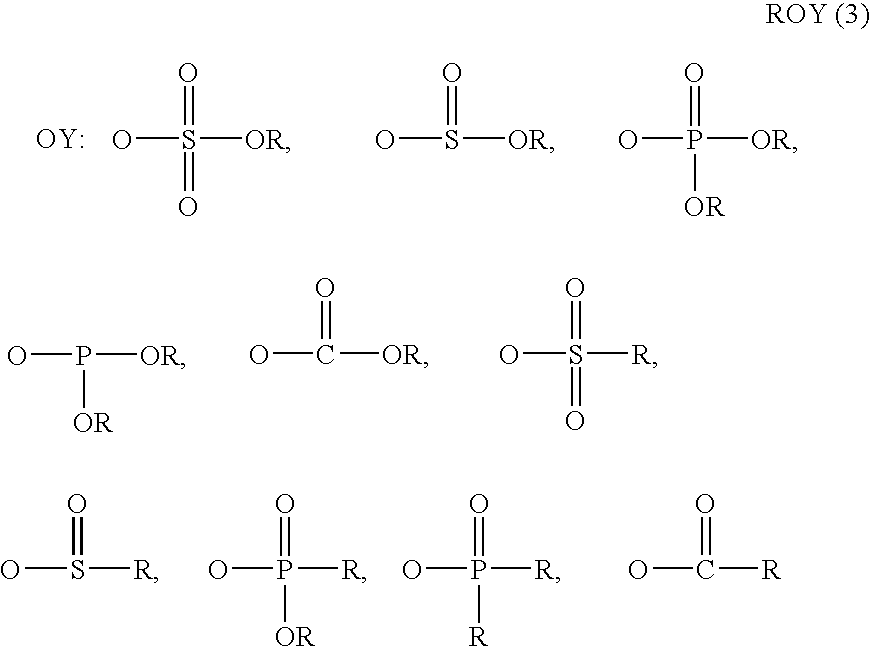

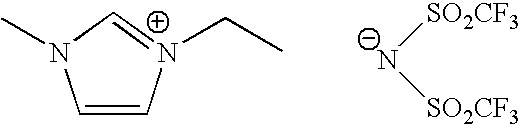

InactiveUS7605271B2Less content of impurityLow costNon-metal conductorsHybrid capacitor electrolytesHalogenPhosphate

Provided is an ionic liquid, represented by the formula K+A−, having a very low content of impurities, especially a low content of halogen ions and / or a low content of alkali metal, wherein K+is a quaternary ammonium ion, for example an imidazolium ion. Also provided is a quaternarization process for making the ionic liquid in reacted with an acid ester such as a sulfate or phosphate.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

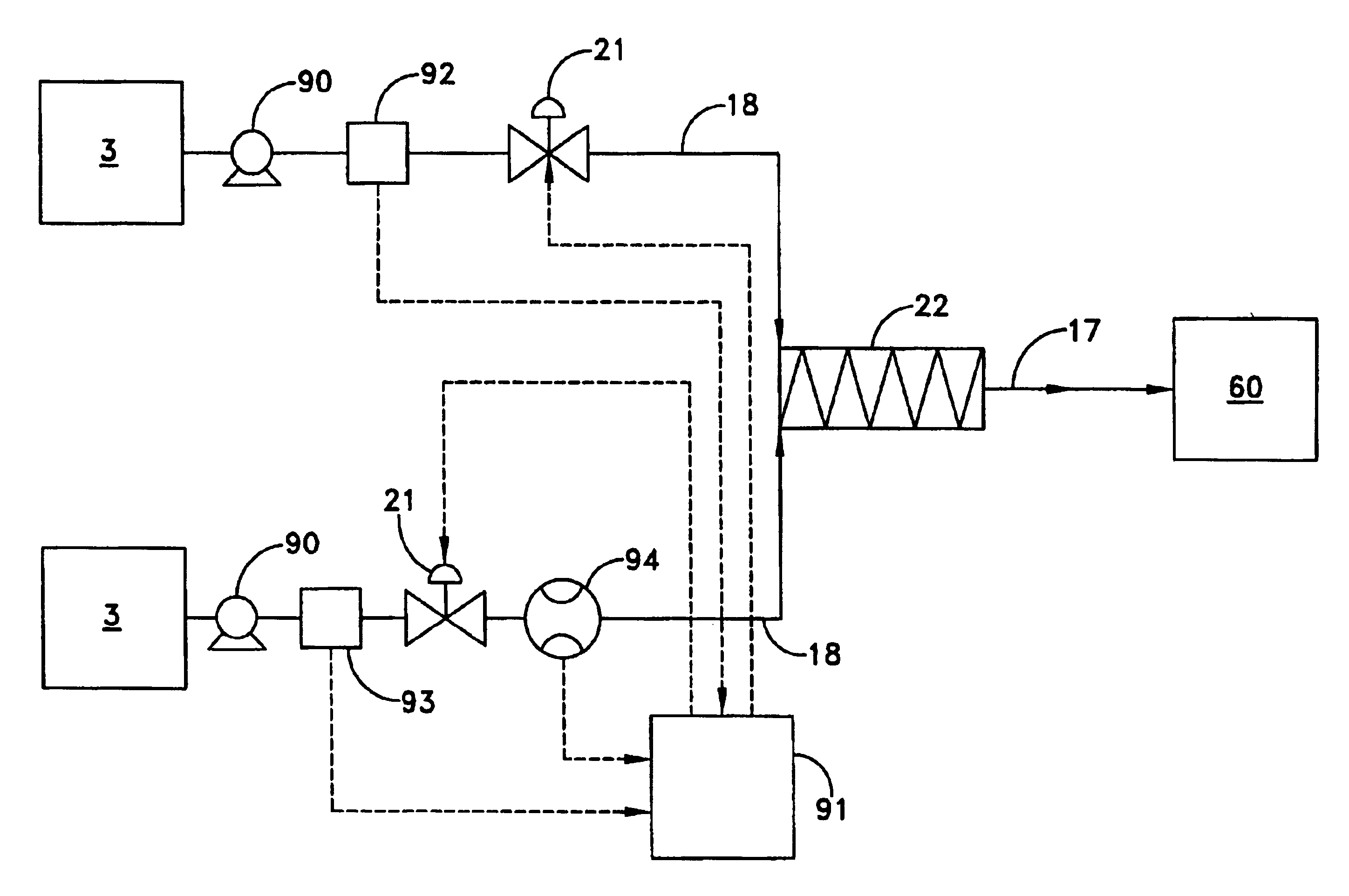

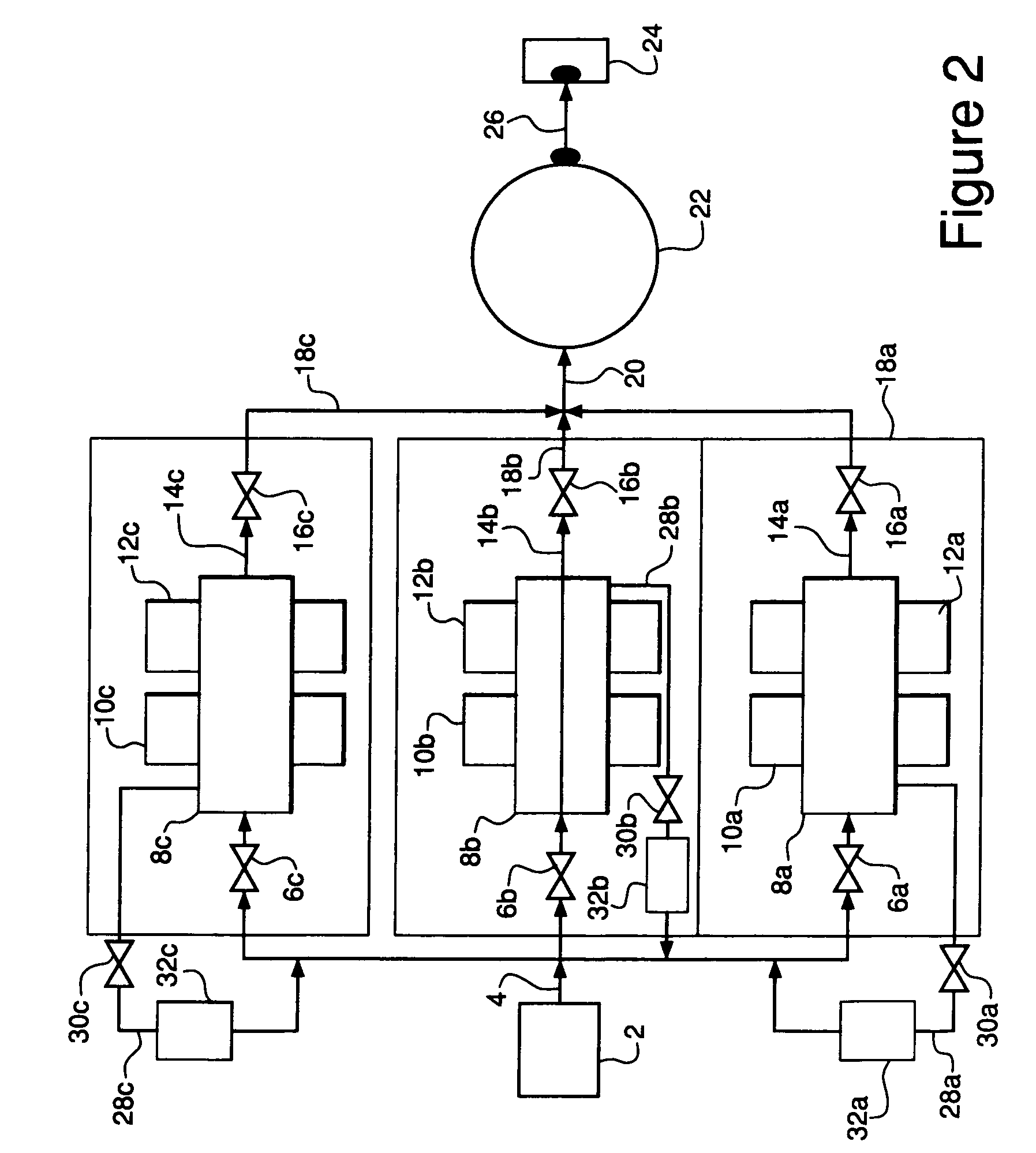

Method and apparatus for blending process materials

A method and apparatus for blending and supplying process materials. The method and apparatus are particularly applicable to the blending of ultra-high purity chemicals, the blending of abrasive slurries with other chemicals for the polishing of semiconductor wafers, and high-accuracy blending of chemicals. The apparatus may include a dispensing subsystem that supplies process materials to a mixing subsystem where they are blended with a static mixer. The method may include supplying process materials with a dispensing subsystem and blending the process materials in a static mixer.

Owner:MEGA FLUID SYST

Production of high purity and ultra-high purity gas

InactiveUS7524358B2Low costSuperior CO and H<subNitrous oxide captureCombination devicesOperational costsHydrogen

Trace amounts of carbon monoxide and optionally hydrogen are removed from gaseous feed streams by passing the feed stream through a carbon monoxide adsorbent (33) prior to passing it through a supported metal catalyst (34). The invention saves significant capital and operational costs over existing processes.

Owner:PRAXAIR TECH INC

Method and apparatus for blending process materials

ActiveUS7344298B2Controlling ratio of multiple fluid flowsTransportation and packagingProcess engineeringSlurry

A method and apparatus for blending and supplying process materials. The method and apparatus are particularly applicable to the blending of ultra-high purity chemicals, the blending of abrasive slurries with other chemicals for the polishing of semiconductor wafers, and high-accuracy blending of chemicals.

Owner:MEGA FLUID SYST

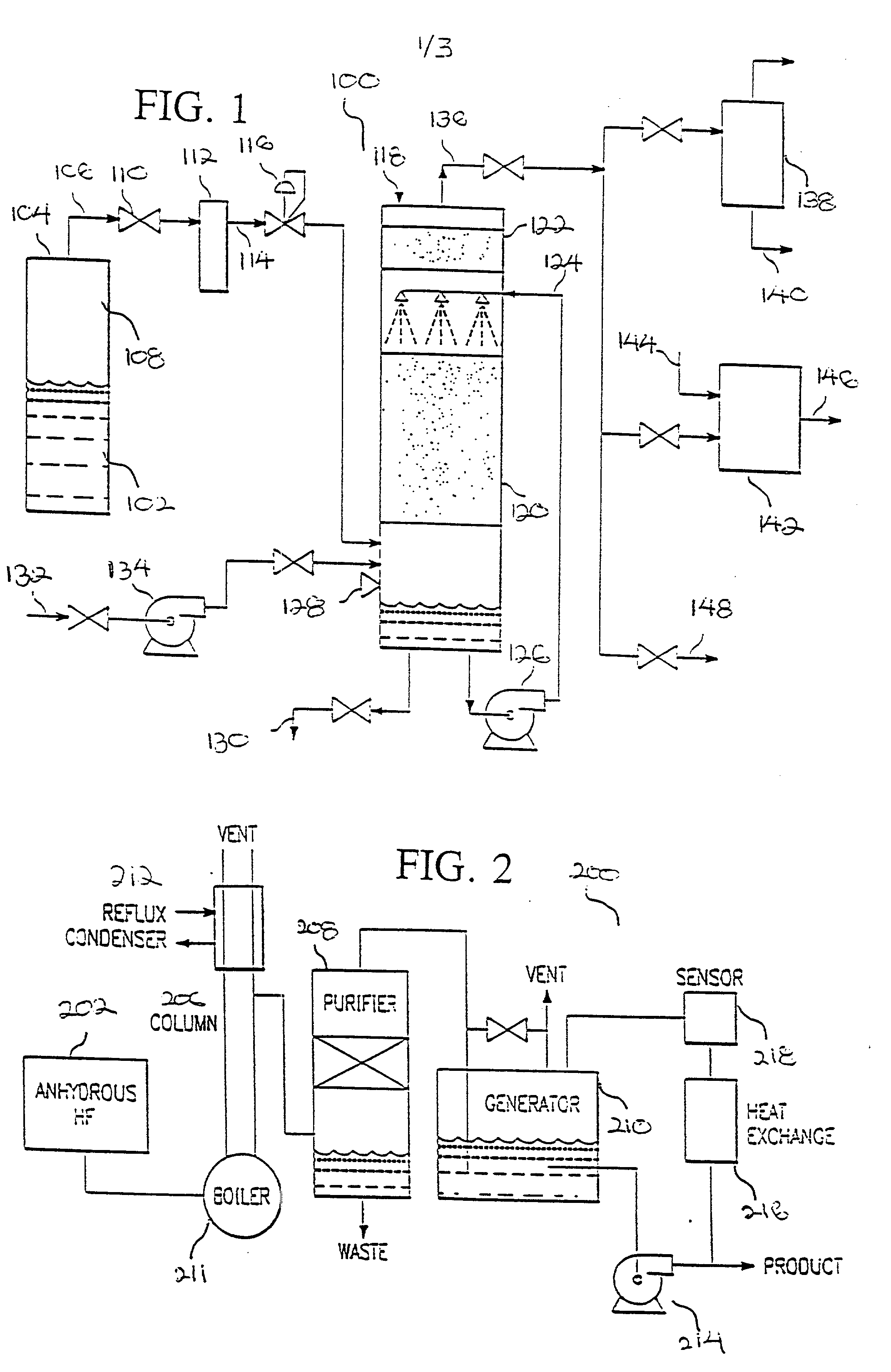

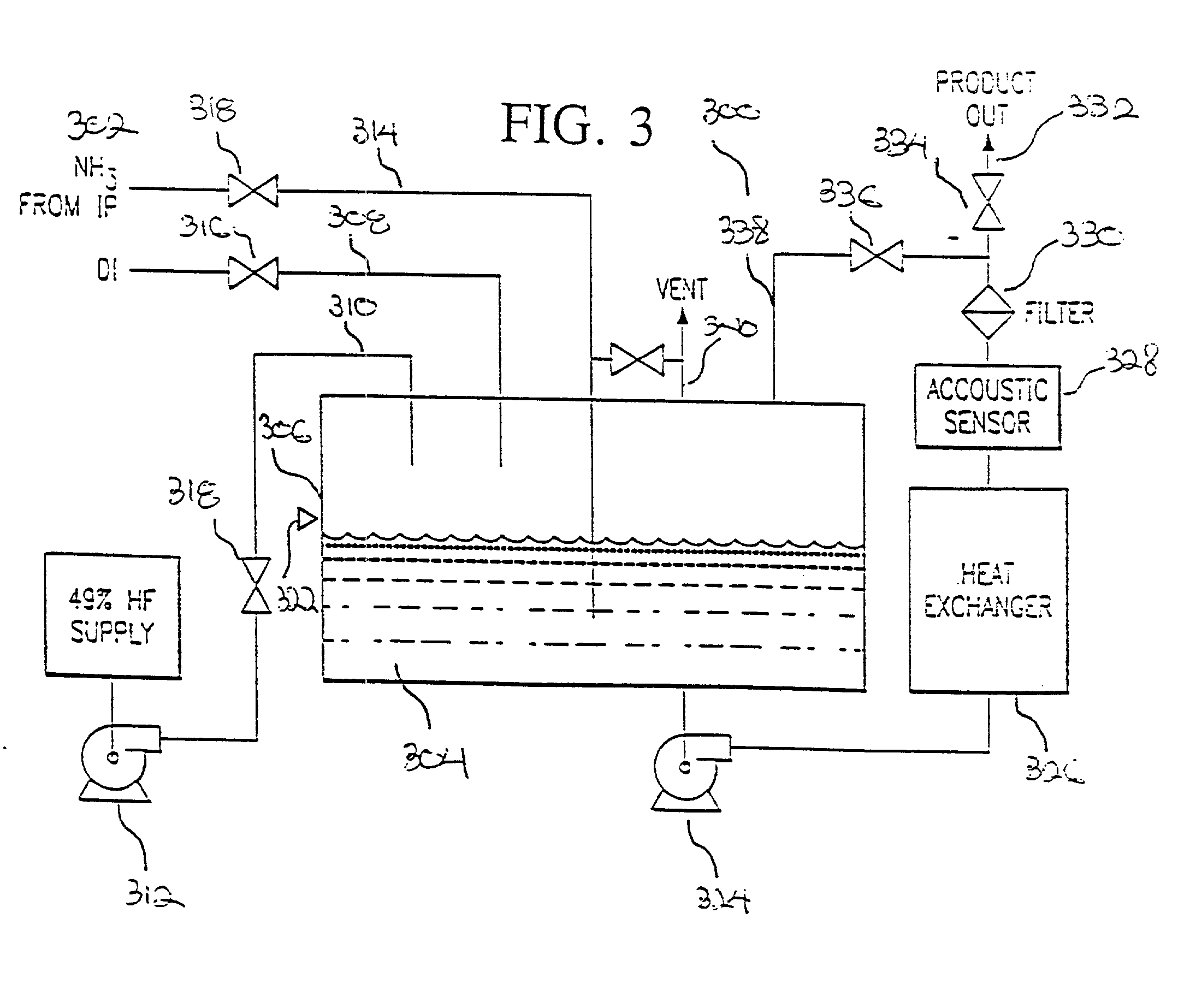

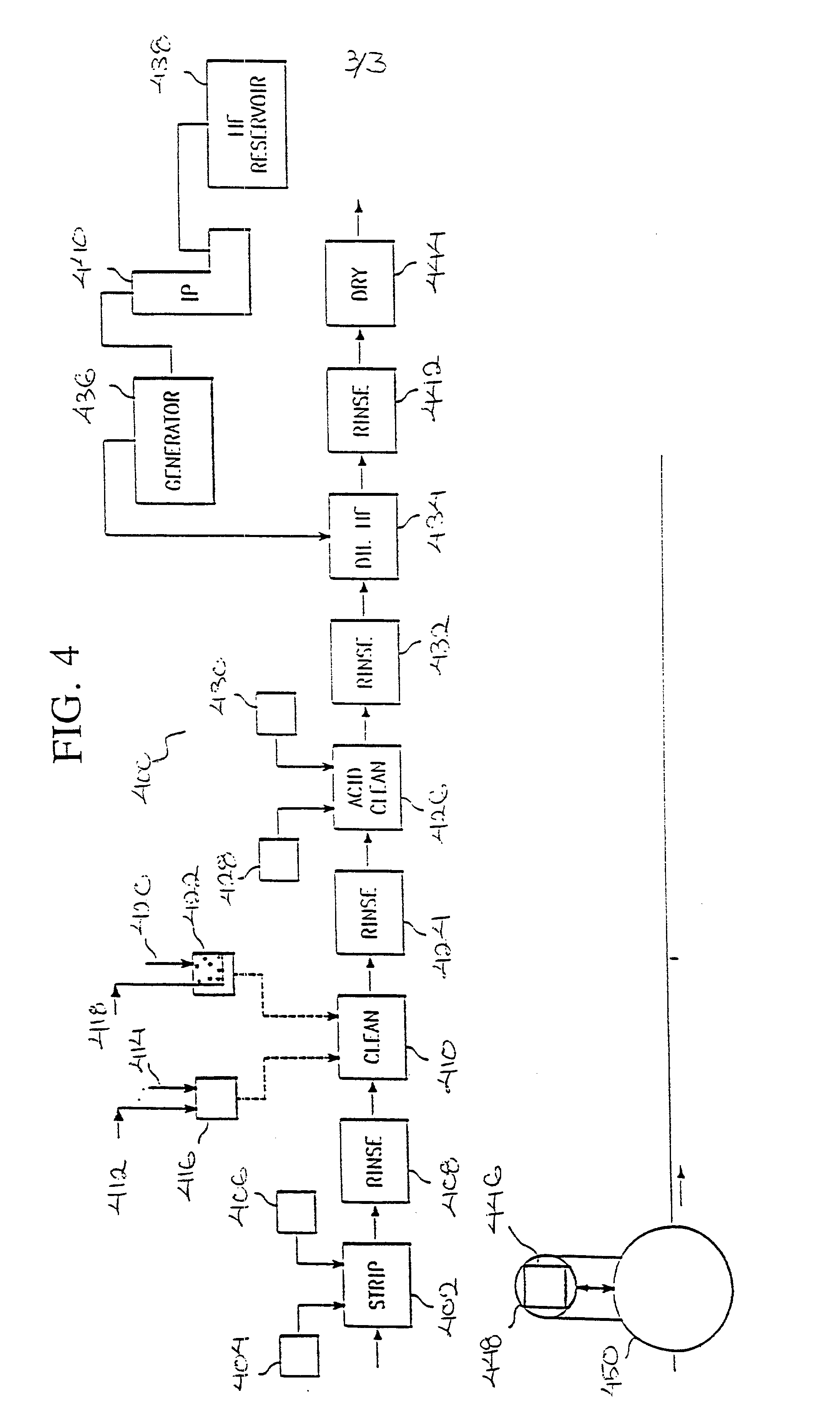

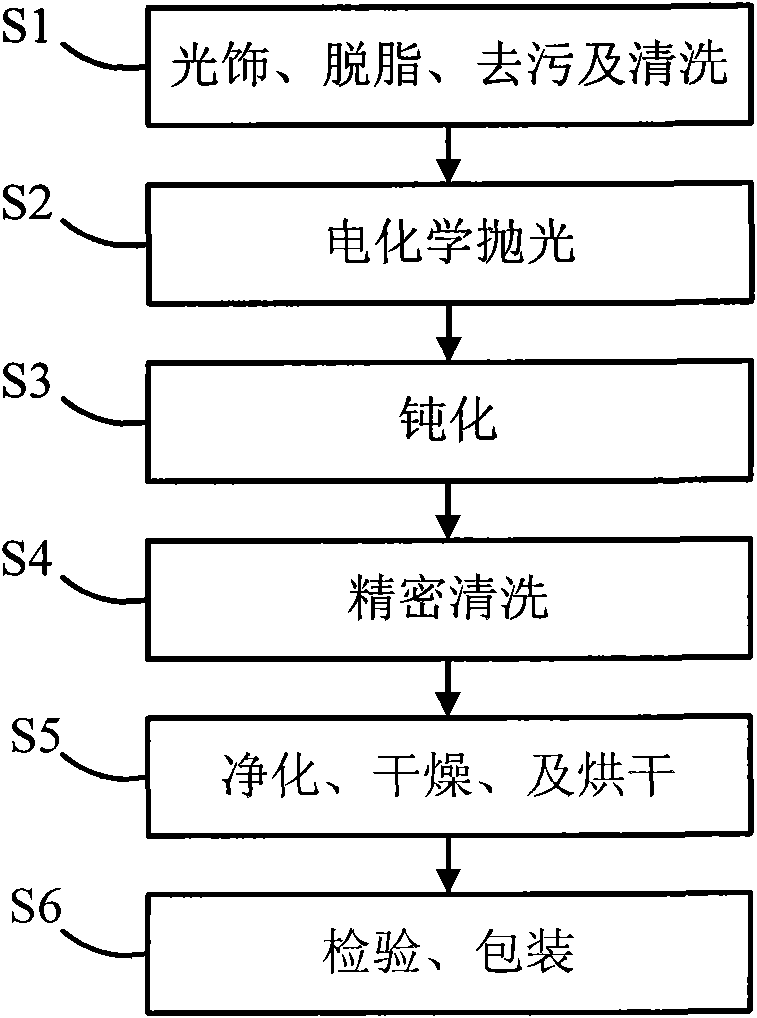

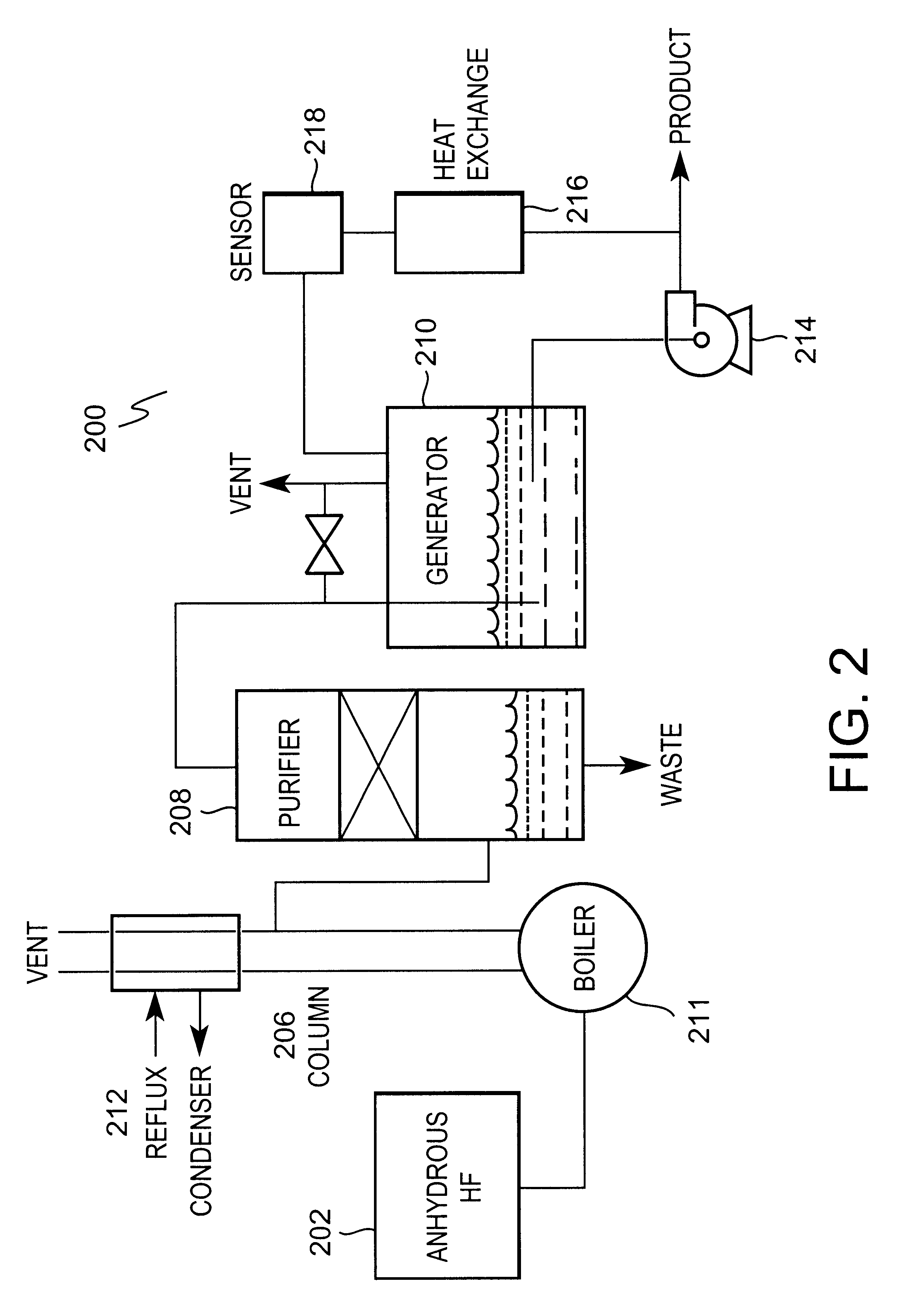

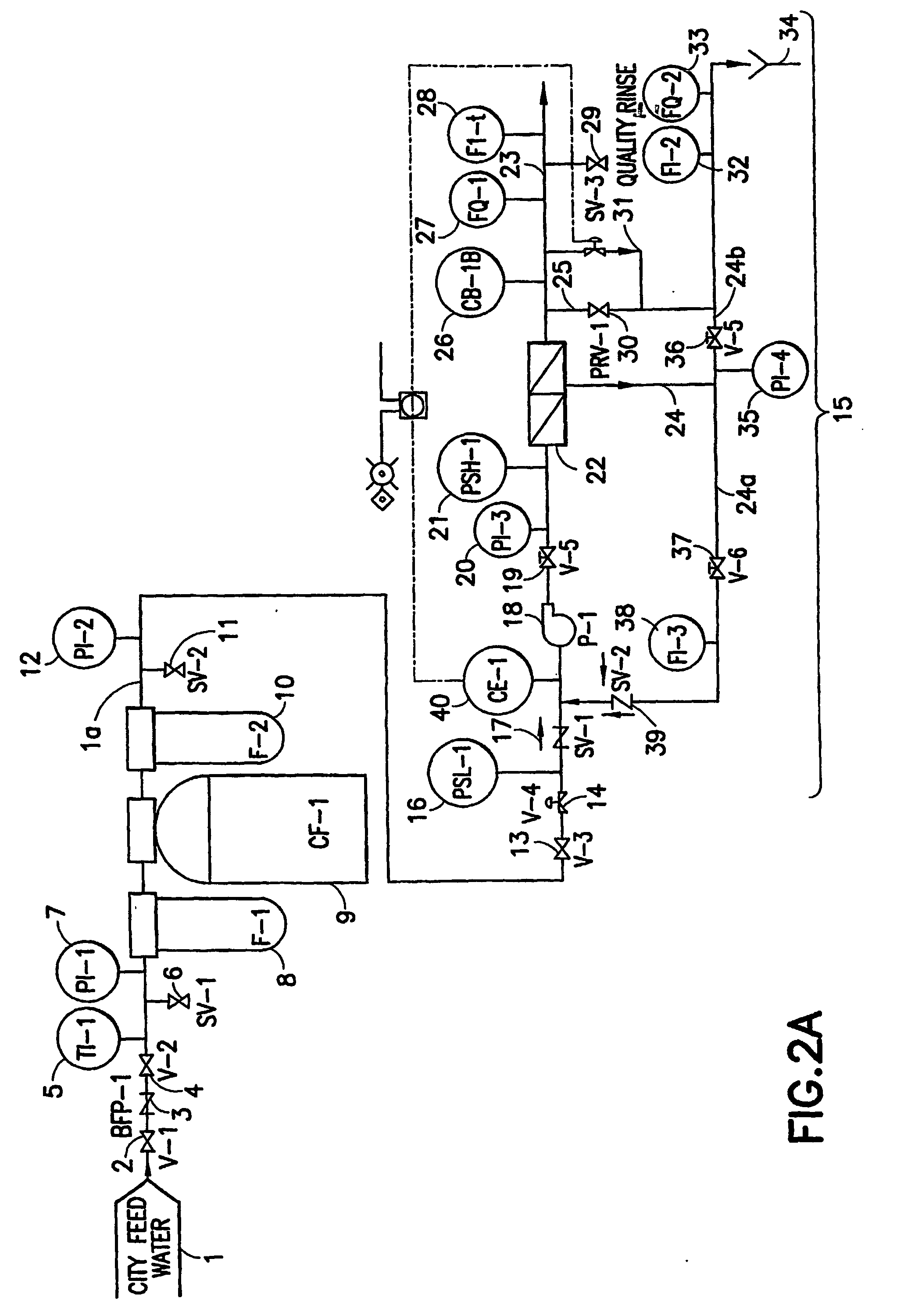

On-site generation of ultra-high-purity buffered-hf and ammonium fluoride

InactiveUS20010051128A1Low impurity contentImprove device characteristicsChlorine/hydrogen-chloride purificationControlling ratio of multiple fluid flowsHydrofluoric acidUltra high purity

Provided is a novel method and system for preparing ultra-high-purity buffered-hydrofluoric acid or ammonium fluoride controlled concentration. The method comprises bubbling purified ammonia vapor into ultra-pure hydrofluoric acid. The inventive method and system can be used as an on-site subsystem in a semiconductor device fabrication facility for supplying the buffered-hydrofluoric acid and ammonium fluoride to points of use in the semiconductor device fabrication facility.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method for preparing vacuum zone melting high resistant silicon single crystal

ActiveCN101525764AHigh resistivityEnhanced ultra-high purityPolycrystalline material growthBy zone-melting liquidsZone meltingSingle crystal

The invention discloses a method for preparing vacuum zone melting high resistant silicon single crystal, comprising the two sequential major processes: polysilicon purification and crystal forming of silicon single crystal, wherein, the process of polysilicon purification comprises the steps of cleaning fire, charging, evacuating, preheating, melting materials heat sealing, growing narrow necks, shouldering, shoulder circuiting, equating diameter, ending and repeating; the process of crystal forming of silicon single crystal comprises the steps of cleaning fire, charging, evacuating, preheating, processing of chemicals, crystal seeding, shouldering, shoulder circuiting, equating diameter, ending and blowing out. With the method of the invention adopted to prepare silicon single crystal, electric resistivity, ultra-high purity, resistivity profile, uniformity of cross-section electric resistivity and minority carrier lifetime are greatly improved; purity of the silicon single crystal is above 11N, electric resistivity reaches 8000 omega / cm-30000omega / cm, uniformity of cross-section electric resistivity is less than 15%, and minority carrier lifetime is more than 600-1000Mus, thus greatly improving performance, stability and safety of the devices while realizing mass production of vacuum zone melting high resistant silicon single crystal.

Owner:峨嵋半导体材料研究所

Fail-safe pneumatically actuated valve with fast time response and adjustable conductance

ActiveUS7744060B2Improve cycle lifeImprove safety and environmental protectionDiaphragm valvesOperating means/releasing devices for valvesTime responseProduction rate

Apparatus and method for fail-safe high-speed-pneumatic valve is disclosed. Fail-safe dependability is provided by a spring-loaded normally-closed pneumatic actuator. When the spring-loaded actuator is pressurized, the normally closed mechanism is actuated to the valve active position. Concurrently, the pressure is directly applied to deflect a diaphragm or a bellow-assembly back to sealing position. Ultra high purity embodiments with standard dome shaped diaphragms are disclosed. Additional high conductance diaphragms and bellows embodiments are employed for higher conductance valves. Novel flow path layouts are disclosed. The valves are applicable for fast gas and fluid switching and are particularly suitable for high productivity Atomic Layer Deposition (ALD) applications. Additional embodiments cover improved diaphragm and seal reliability, externally adjustable valve conductance, improved valve safety and high temperature valve seals.

Owner:SUNDEW TECH

Ultrahigh-Purity Copper and Process for Producing the Same, and Bonding Wire Comprising Ultrahigh-Purity Copper

InactiveUS20090272466A1Efficient preparationReduce hardnessCellsSolid-state devicesElectrolysisCopper nitrate

Provided is ultrahigh purity copper having a hardness of 40 Hv or less, and a purity of 8N or higher (provided that this excludes the gas components of O, C, N, H, S and P). With this ultrahigh purity copper, the respective elements of O, S and P as gas components are 1 wtppm or less. Also provided is a manufacturing method of ultrahigh purity copper based on two-step electrolysis using an electrolytic solution comprised of copper nitrate solution, including the procedures of adding hydrochloric acid in an electrolytic solution comprised of copper nitrate solution; circulating the electrolytic solution; and performing two-step electrolysis while eliminating impurities with a filter upon temporarily setting the circulating electrolytic solution to a temperature of 10° C. or less. The present invention provides a copper material that is compatible with the thinning (wire drawing) of the above, and is capable of efficiently manufacturing ultrahigh purity copper having a purity of 8N (99.999999 wt %) or higher, providing the obtained ultrahigh purity copper, and providing a bonding wire for use in a semiconductor element that can be thinned.

Owner:JX NIPPON MINING& METALS CORP

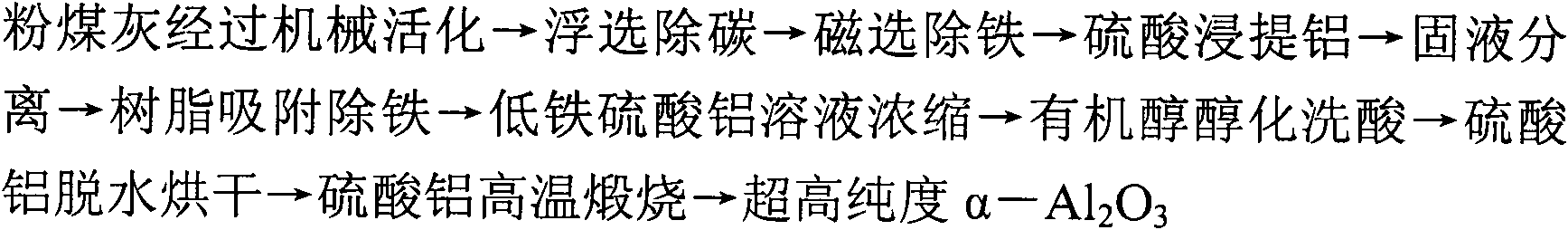

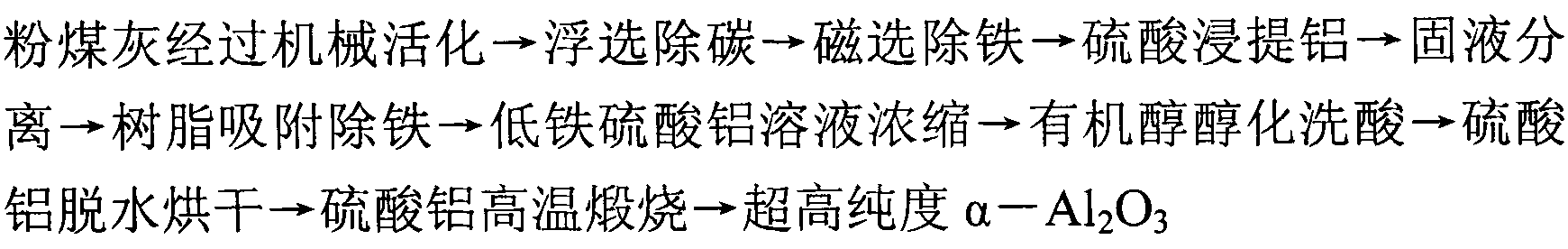

Process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina

InactiveCN102101686AReduce energy consumptionEasy to operatePigmenting treatmentSolid waste disposalAcid washingBiological activation

The invention discloses a process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina. In the process method, mechanical activation, flotation decarbonization, magnetic separation iron removal sulfuric acid aluminum lixiviation, solid-liquid separation, resin absorption iron removal, low-iron aluminum sulfate concentration, organic alcohol alcoholization acid washing, aluminum sulfate dehydration drying and aluminum sulfate high-temperature calcination are carried out on the coal ash so as to obtain ultra-high purity alpha-Al2O3, wherein the content of the Fe2O3 in the ultra-high purity alpha-Al2O3 is less than 2 ppm. By using the process method, the complicated purification problem that intermediate aluminum sulfate in the process of coal ash reclamation is necessarily subjected to a called Bayer circulation process is avoided, thereby simplifying the process flow, reducing the energy consumption, reducing the resource consumption and solving the technical problem of over-large secondary residue quantity accumulation. The process method has the advantages that the extraction efficiency is high, and the circulation recovery of organic alcohol and sulfuric acid and comprehensive utilization of byproducts such as resin and the like are achieved. In the invention, the process is simple, the process flow is short, the production process is easy to control, the content of the impurity in the product is low, and the quality of the product is stable.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

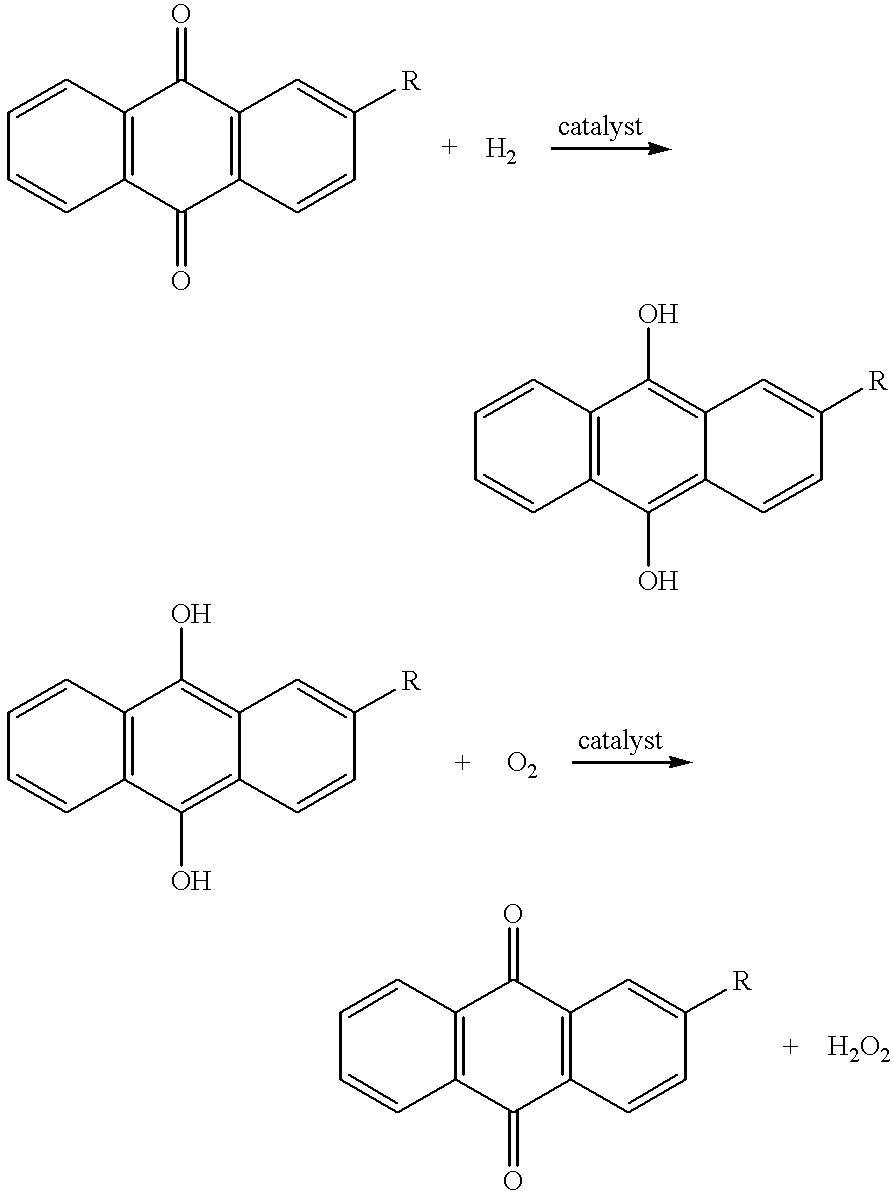

Process for on-site production of ultra-high-purity hydrogen peroxide for the electronics industry

InactiveUS6274114B1Electrolysis componentsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesUltra high purityElectronic industry

Process for preparing hydrogen peroxide, comprising the following steps:a) a step of reduction of dioxygen in acidic medium with a hydrophobic organometallic complex, andb) a step of separation of the oxidized organometallic complex resulting from step a) and of the hydrogen peroxide by liquid / liquid extraction.

Owner:CENT NAT DE LA RECHERCHE SCI

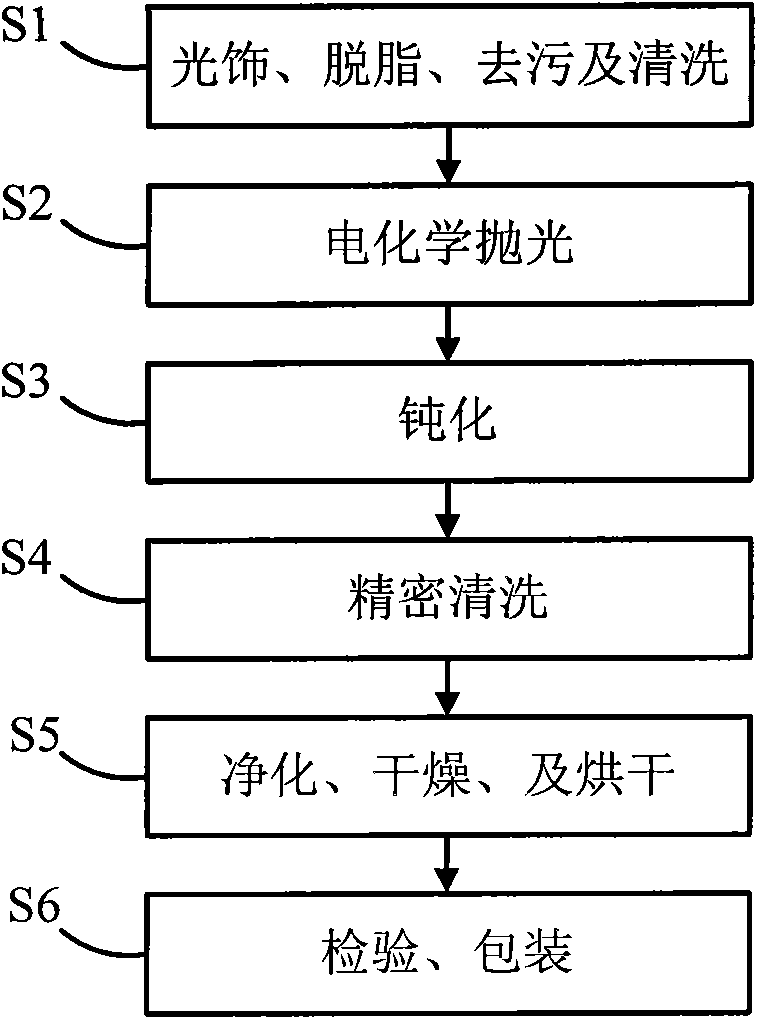

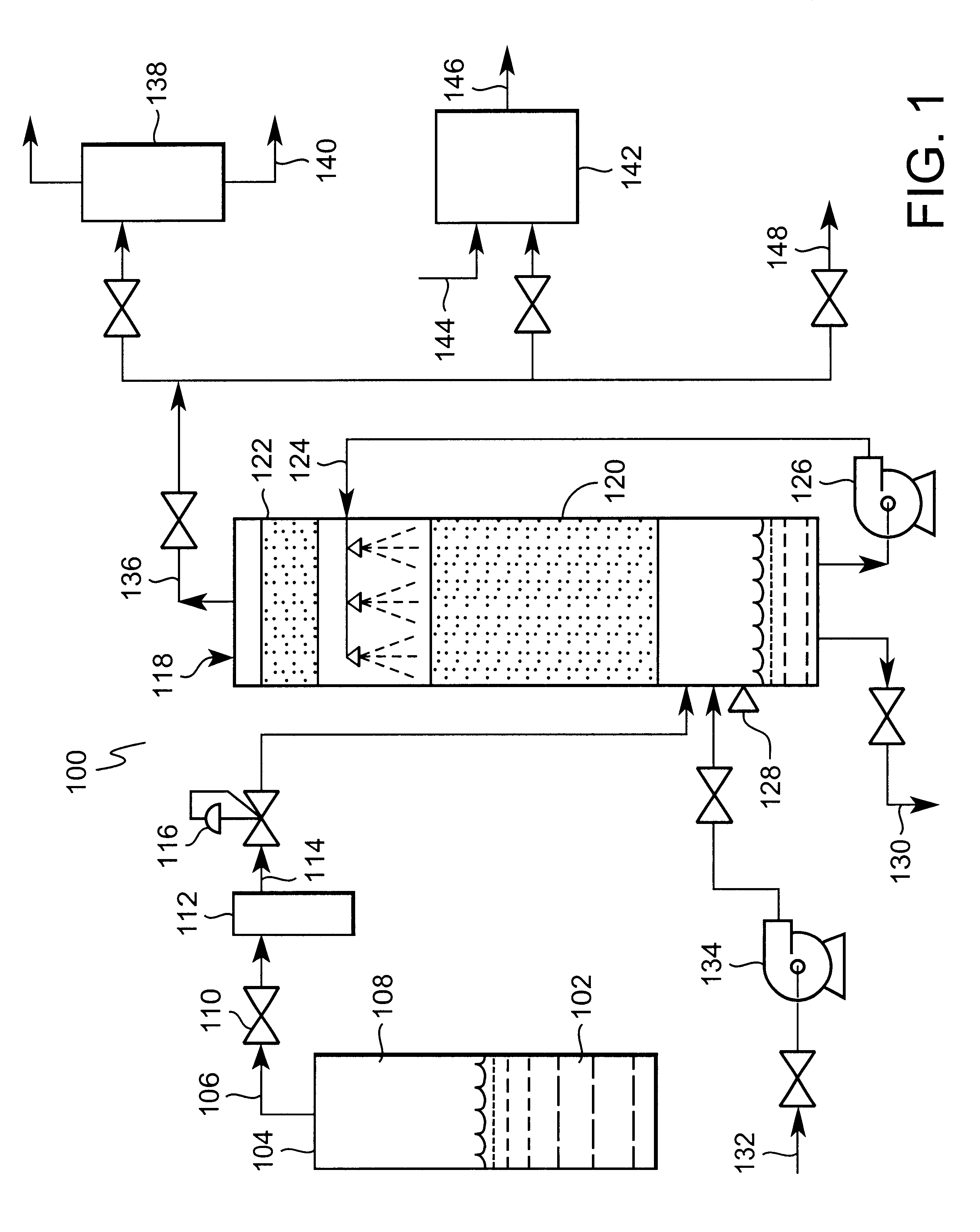

Method for treating stainless steel surfaces

ActiveCN101906655AThe method flow is detailed and clearSimple and fast operationMetallic material coating processesMetallurgyUltra high purity

The invention relates to a method for treating stainless steel surfaces, comprising the following steps of: burnishing, degreasing, decontaminating and cleaning the surfaces of stainless steel parts to be treated; carrying out electrochemical polishing to the burnished, degreased, decontaminated and cleaned stainless steel parts; passivating the electrochemically polished stainless steel parts; precisely cleaning the passivated stainless steel parts; purifying, drying and baking the precisely cleaned stainless steel parts; and inspecting the stainless steel parts in a dust-free room and carrying out double-layer anti-static packaging and vacuum sealing to the stainless steel parts. The stainless steel parts treated with the method meet the use requirements of high-end industries comprising semiconductor processing and equipment manufacturing, solar energy, micro-electronics, electric industry, restaurant and food, biological pharmaceutics, medicine and medical treatment, analytical instruments, petrifaction industries, aerospace and the like and completely accord with the regulations of the standards comprising SEMI (Semiconductor Equipment and Materials International), ASTM (American Society for Testing Material) and the like on the high cleanness and ultra-high purity (UHP) of the stainless steel surfaces.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

On-site generation of ultra-high-purity buffered-HF and ammonium fluoride

InactiveUS6350425B2Reduce processingLow impurity contentChlorine/hydrogen-chloride purificationControlling ratio of multiple fluid flowsHydrofluoric acidUltra high purity

Provided is a novel method and system for preparing ultra-high-purity buffered-hydrofluoric acid or ammonium fluoride controlled concentration The method comprises bubbling purified ammonia vapor into ultra-pure hydrofluoric acid. The inventive method and system can be used as an on-site subsystem in a semiconductor device fabrication facility for supplying the buffered-hydrofluoric acid and ammonium fluoride to points of use in the semiconductor device fabrication facility.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

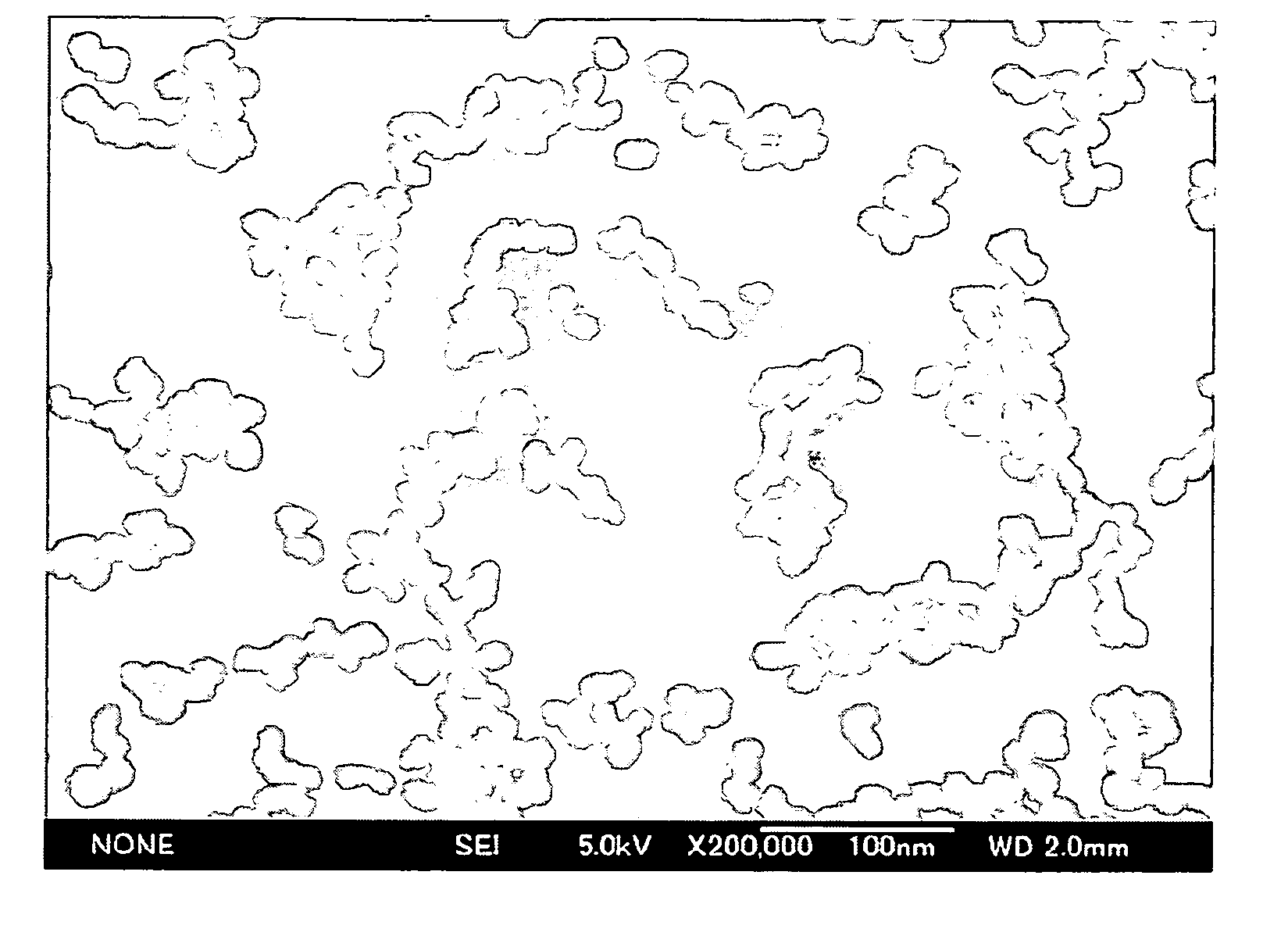

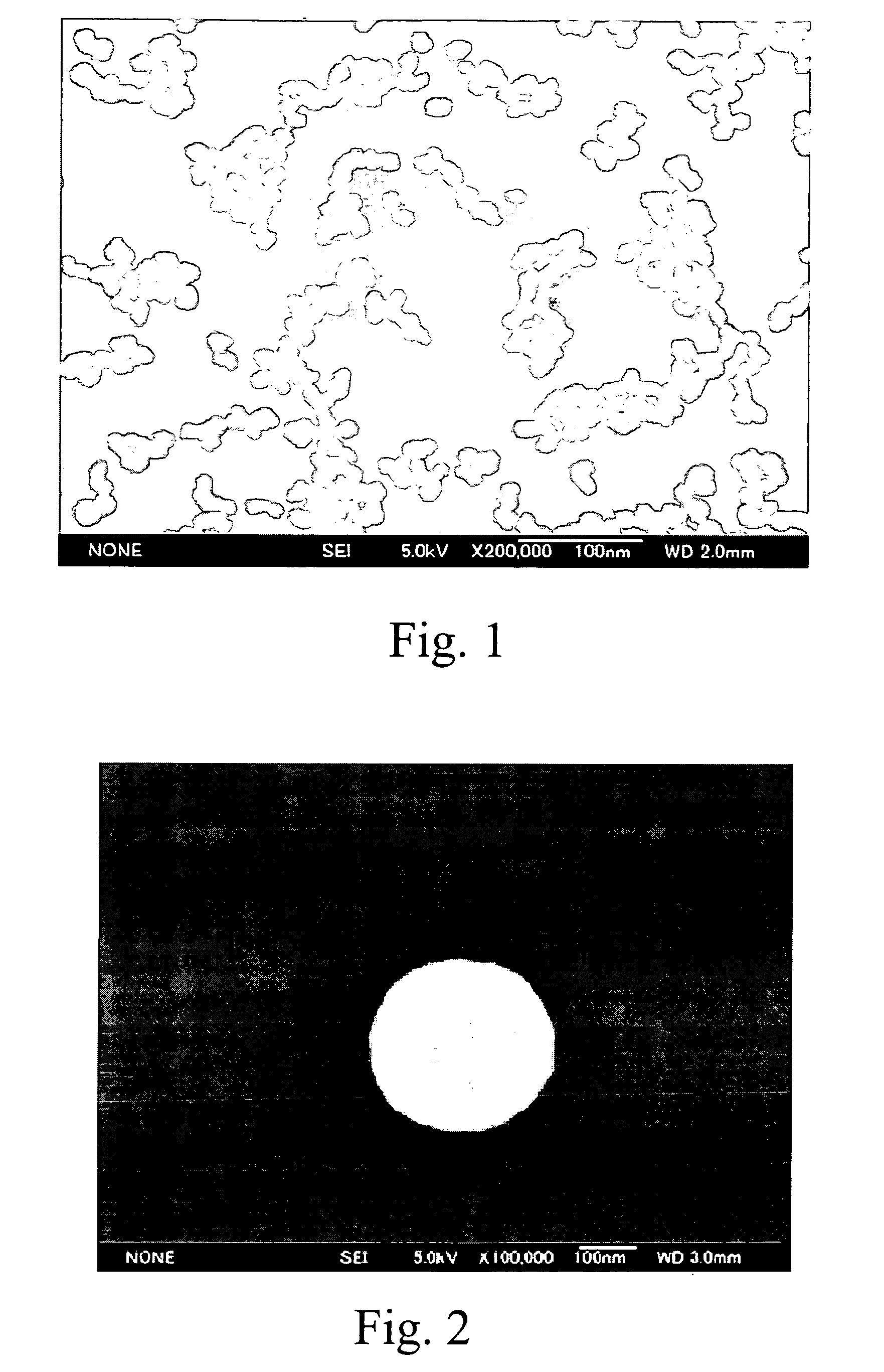

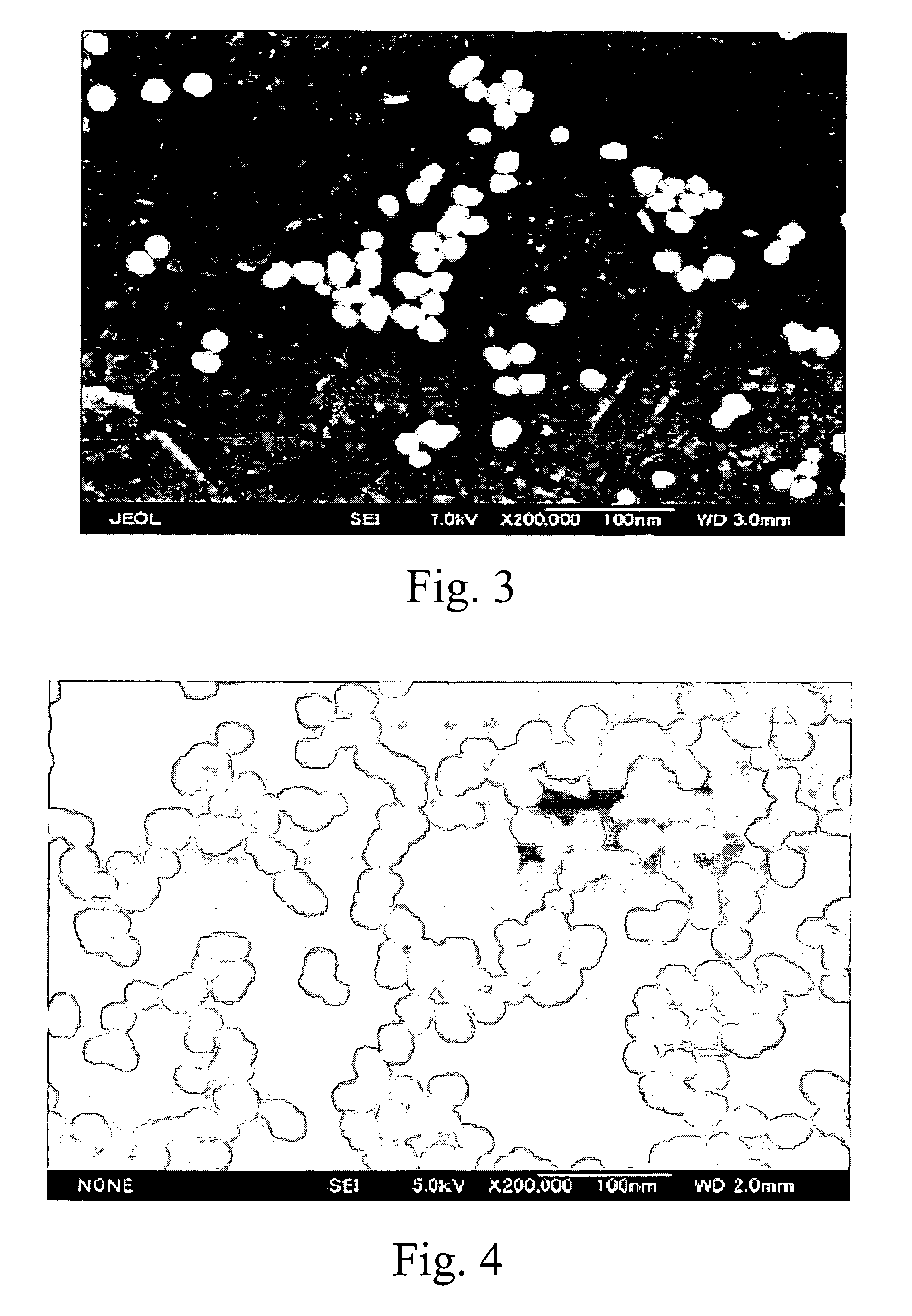

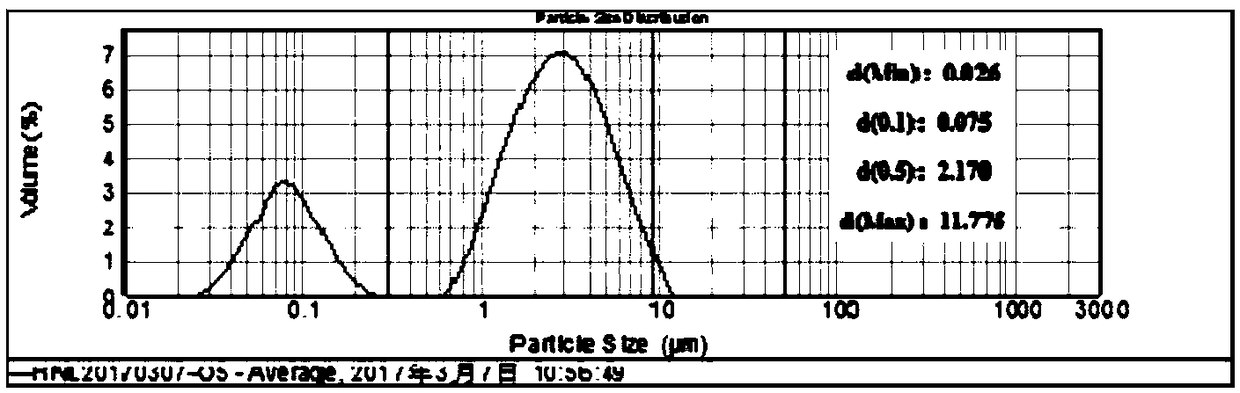

Colloidal silica based chemical mechanical polishing slurry

A composition for chemical mechanical polishing a surface of a substrate having a plurality of ultra high purity sol gel processed colloidal silica particles for chemical mechanical polishing having alkali metals Li, Na, K, Rb, Cs, Fr and a combination thereof, at a total alkali concentration of about 300 ppb or less, with the proviso that the concentration of Na, if present, is less than 200 ppb; and a medium for suspending the particles is provided. Also, provided are methods of chemical mechanical polishing which included a step of contacting a substrate and a composition according to the present invention. The contacting is carried out at a temperature and for a period of time sufficient to planarize the substrate.

Owner:PLANAR SOLUTIONS

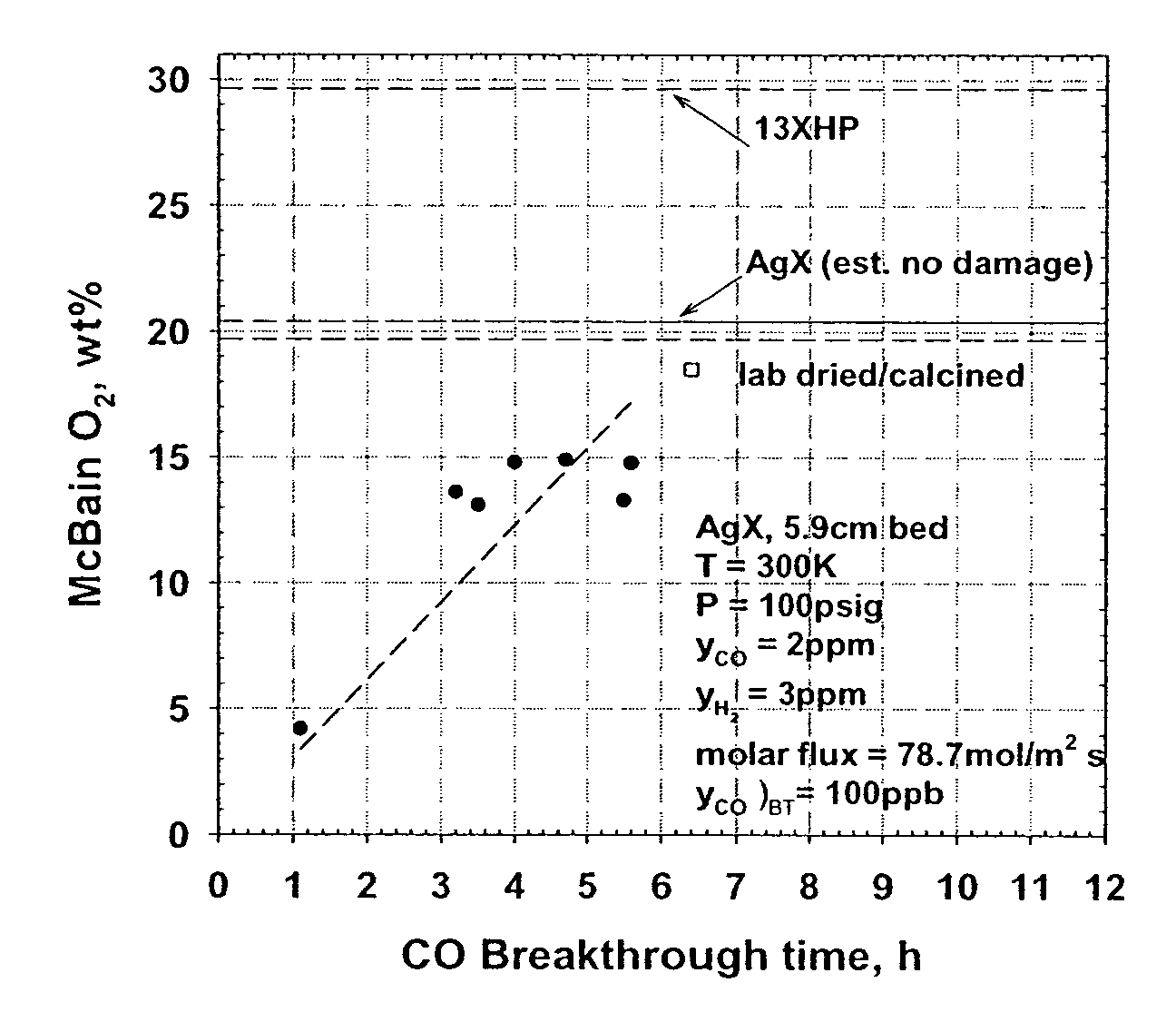

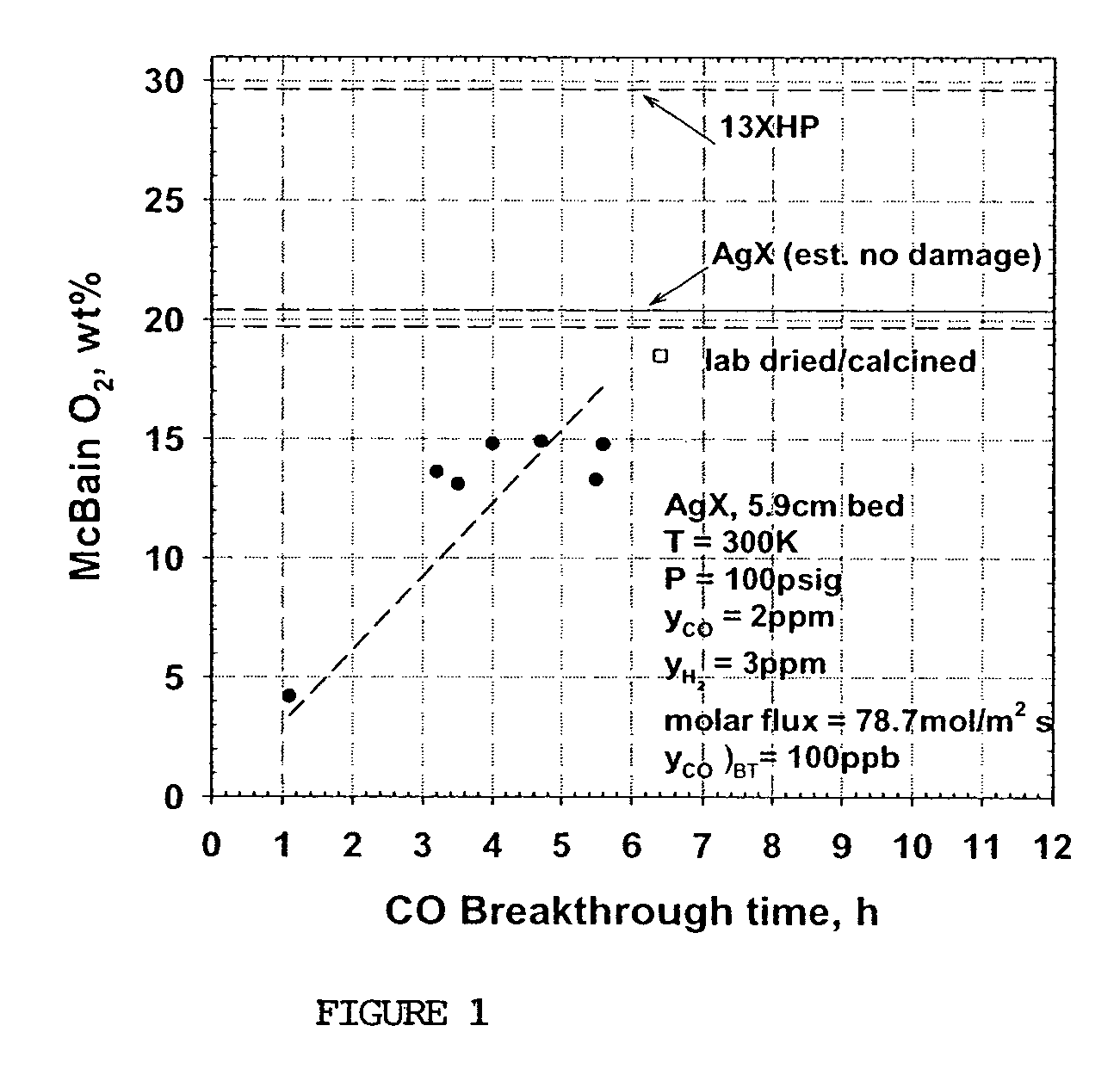

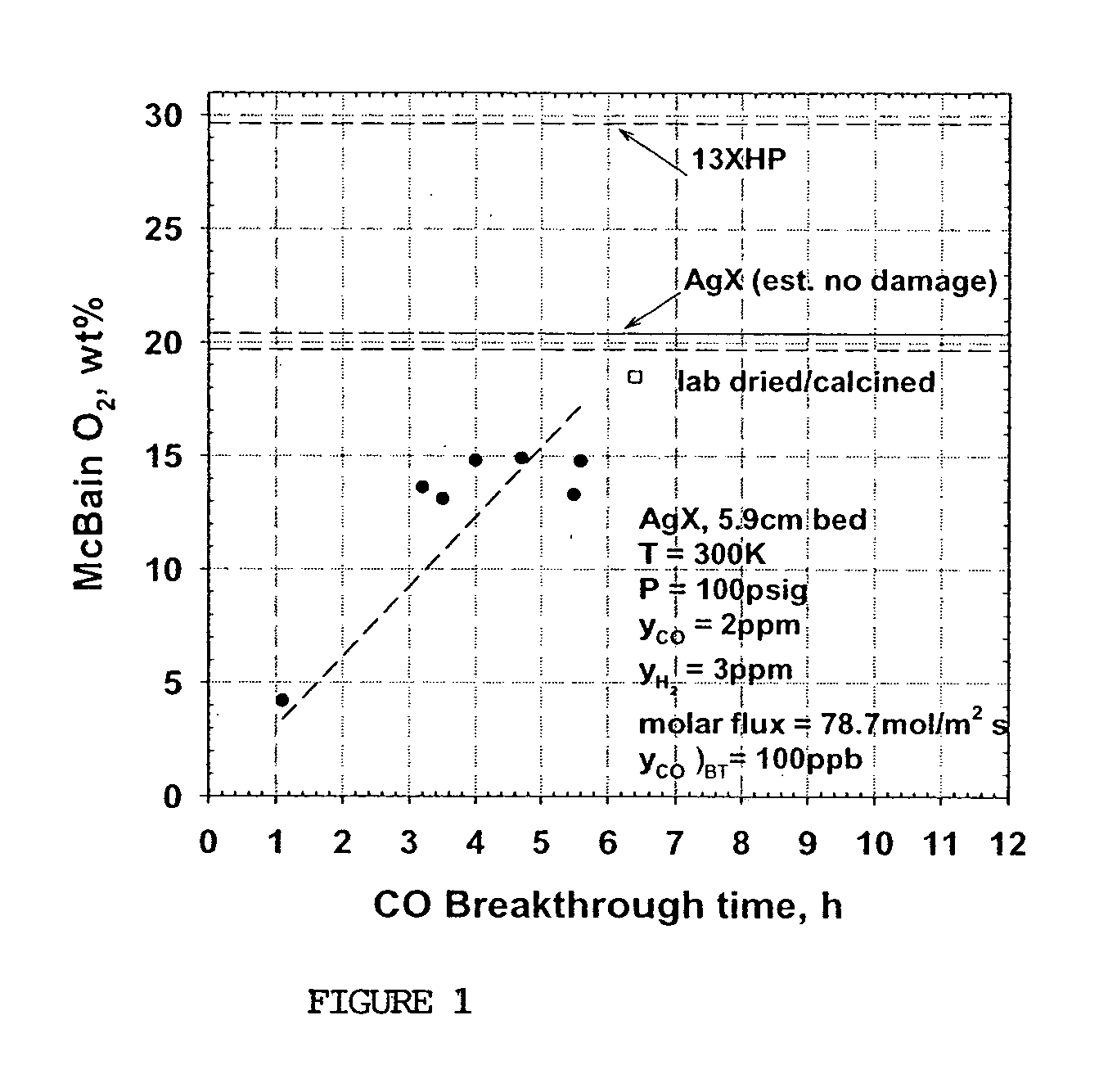

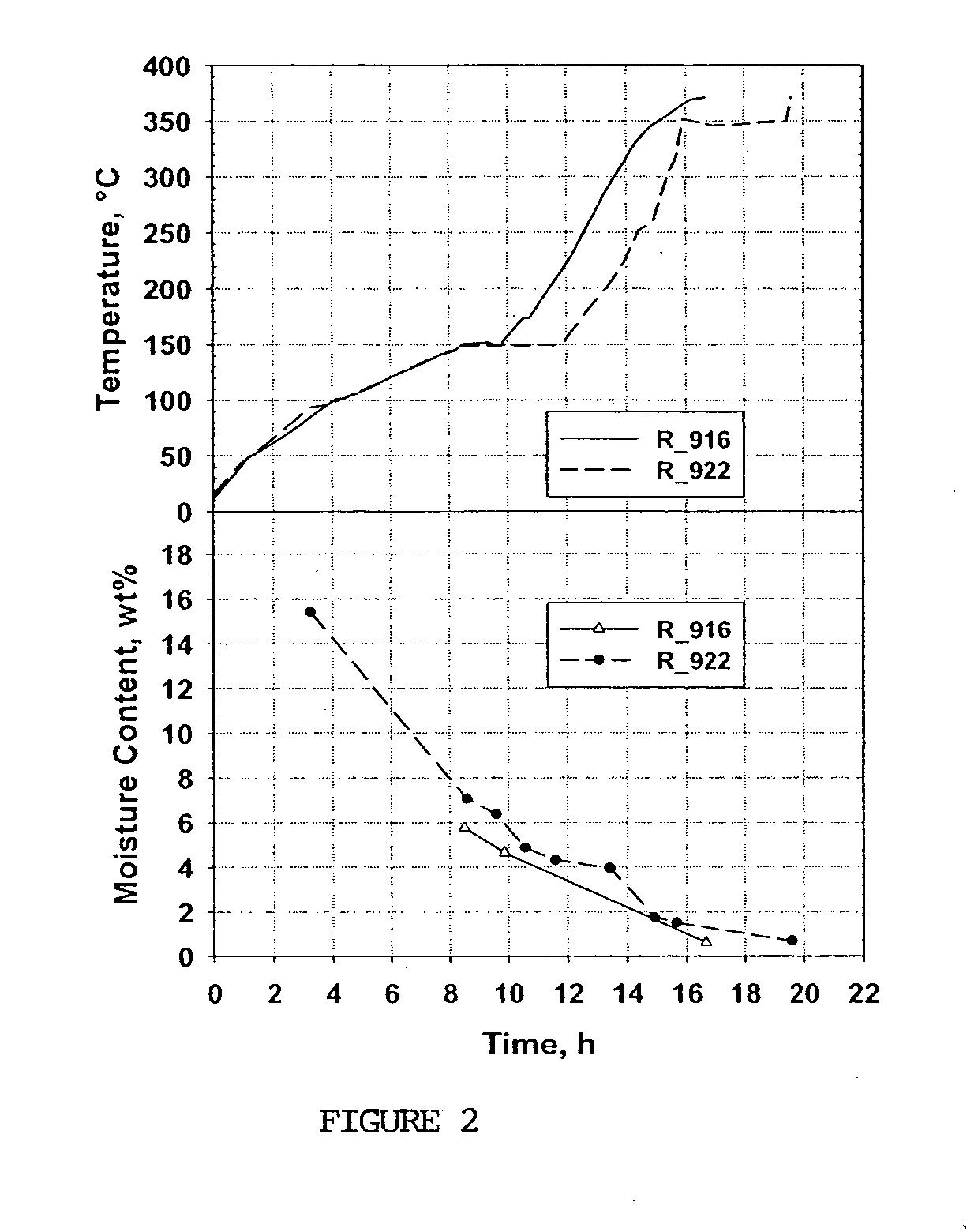

Silver-exchanged zeolites and methods of manufacture therefor

ActiveUS7455718B2Improved and consistent and reproducible working capacity characteristicImproved performance characteristicsCombination devicesGas treatmentChemical reactionSorbent

The present invention relates generally to zeolites having a silica / alumina ratio of less than or equal to 10 (Si / Al≦10) that are exchanged with Ag+ and thermally treated in such a way to favor adsorption over alternative catalytic and chemically reactive functionalities. The adsorbents of the present invention and the method of producing such adsorbents maximize the working adsorption capacity through π-complexation. Applications for such adsorbents include any process in which contaminants from gas streams can form π-complexes with the Ag in the zeolite, particularly the removal of CO, ethylene, propylene and the like from air and CO / H2 from air in prepurifier adsorbers in the production of ultra high purity (UHP) N2.

Owner:PRAXAIR TECH INC

Translucent PCA Ceramic, Ceramic Discharge Vessel, and Method of Making

InactiveUS20050184636A1Easy to transportMaterial nanotechnologyCathode ray tubes/electron beam tubesGas phaseMetal-halide lamp

A translucent polycrystalline material suitable for use in ceramic discharge vessels for metal halide lamps is produced by sintering an alumina powder doped with a MgO sintering aid in a nitrogen atmosphere containing a partial pressure of a vapor phase carbon-containing species. The sintered polycrystalline alumina has a grain boundary phase containing aluminum, oxygen and nitrogen. The formation of the AL—O—N grain boundary phase is believed to facilitate the transport of nitrogen from entrapped pores during sintering. Preferably, the PCA is sintered in a carbon-element furnace under flowing ultra-high-purity nitrogen.

Owner:OSRAM SYLVANIA INC

Generation and delivery system for high pressure ultra high purity product

The invention relates to a process and apparatus for delivering an ultra high purity fluid comprising at least one component to a point of use at a required pressure without mechanical pumping. In one embodiment, a high purity feed comprising at least one component in gaseous or liquid form is charged into a vessel and at least partially converted to a solid phase source. As the feed is converted to a solid phase source, additional feed may be added until the vessel is at least substantially filled with a solid phase source or slush. Once filled, the solid phase source or slush may be isochorically heated whereby the solid phase source is converted to a product at an elevated pressure.

Owner:AIR PROD & CHEM INC

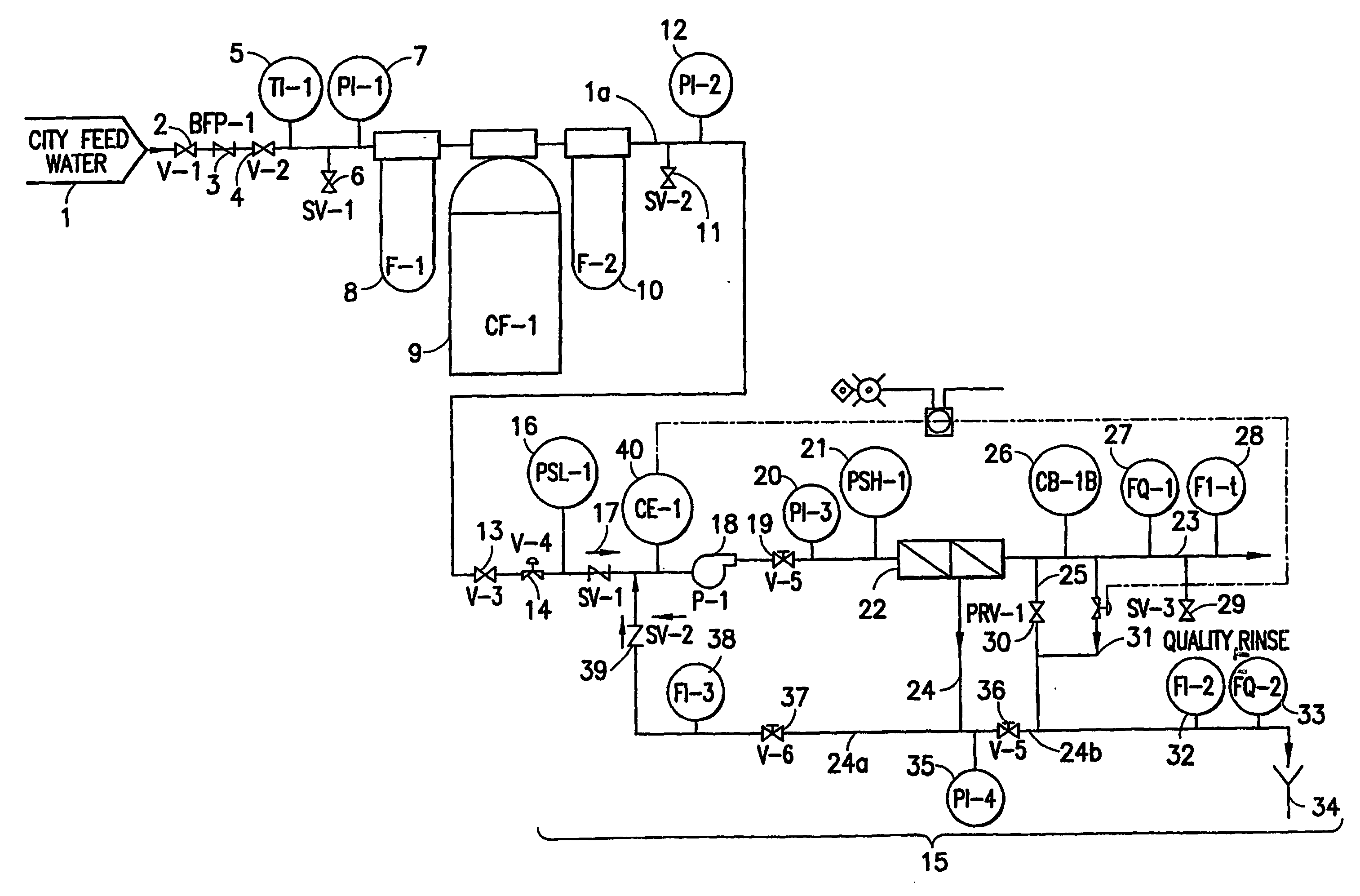

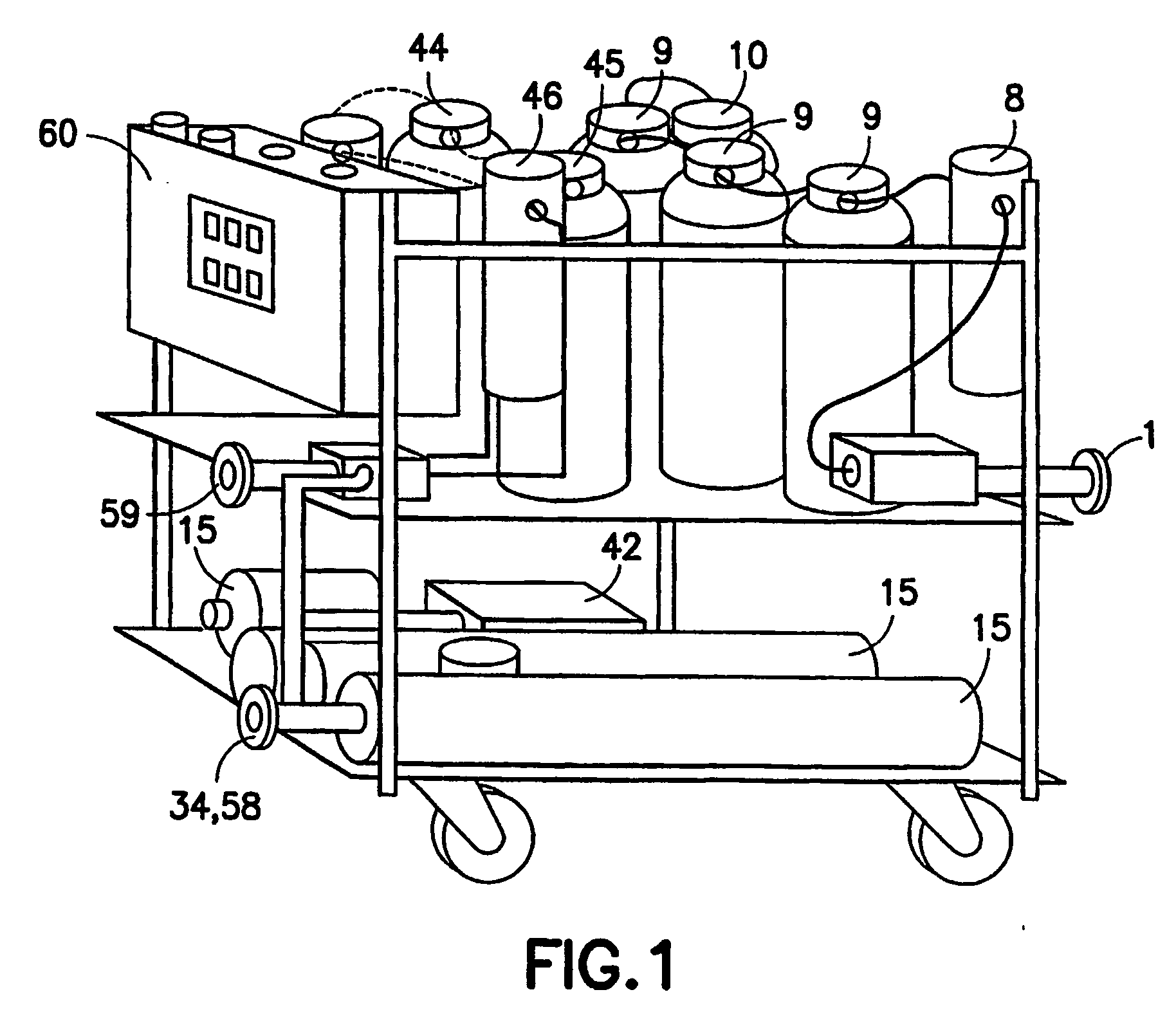

Portable compact ultra high purity water system via direct processing from city feed water

InactiveUS20060011546A1Preventing pressurizationMembranesWater treatment parameter controlEnvironmental engineeringUltra high purity

The present invention relates to a water purification system. This system is portable, compact and produces ultra higher purity water. The system is suitable for use with direct processing from city feed water.

Owner:LIVINGSTON ROBERTC

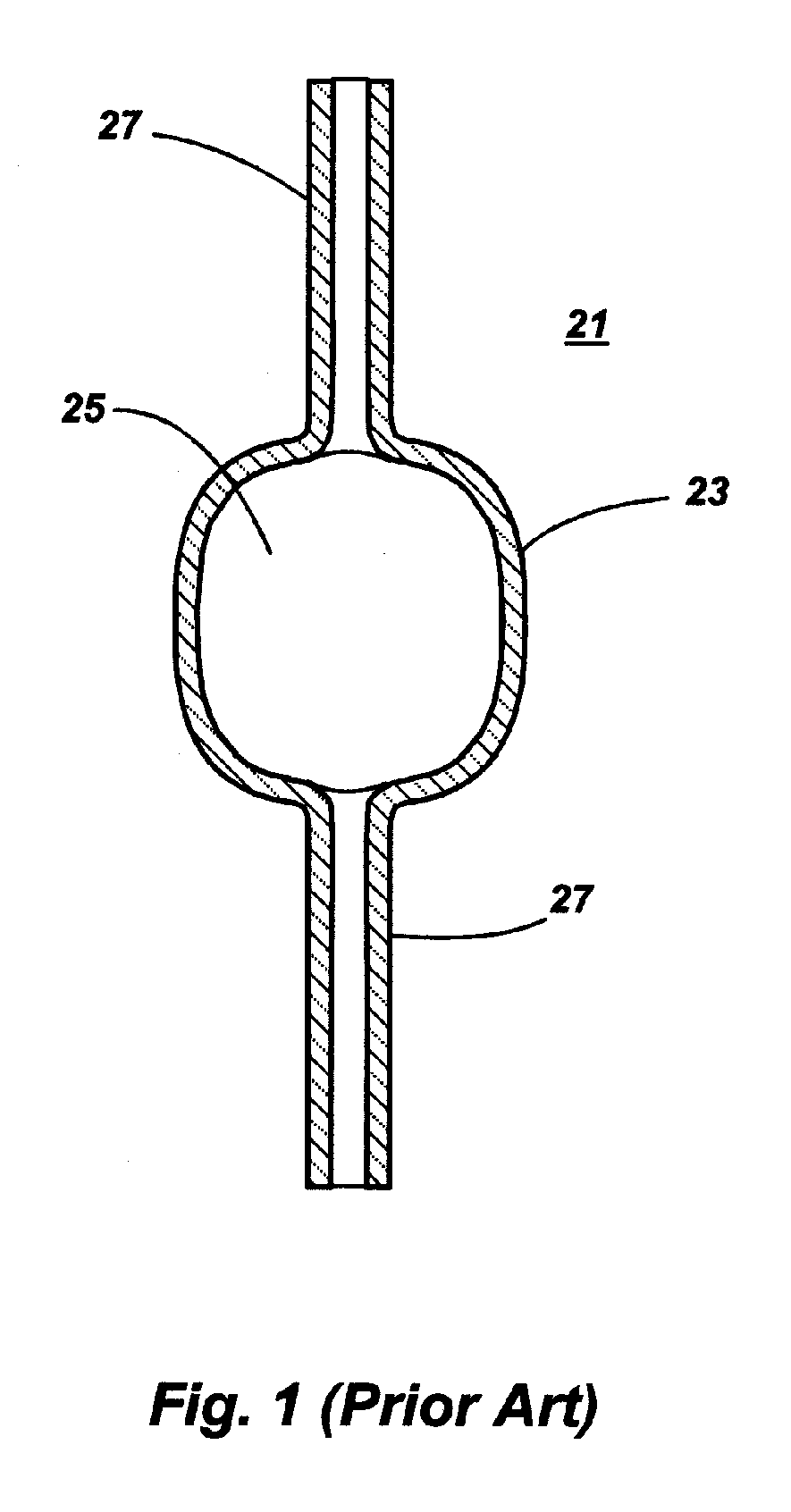

Valve, namely for bottles for ultra-high purity gas

ActiveUS8297593B2Avoiding damage assemblySmall sizeOperating means/releasing devices for valvesContainer filling methodsBottleUltra high purity

Owner:ROTAREX SA

Continuous producing technique for ultra-high pure nitric acid

The invention relates to a process for continuously producing extra high purity nitric acid, which comprises the following steps: first, industrial grade 80-90% nitric acid raw material and double allyl 18-crown-6 ether organosilicon macromolecular complexing agent accounting for 0.2-2% of the weight of nitric acid raw material are mixed in a pretreater, then, the mixture is filtered by a micro-filtration membrane under a working pressure of 0.1-0.2 Mpa, the filtrate enters a rectification tower, and the semi-finished product going through the rectification tower is diluted by ultra pure water in a dilution device; after the dilution is finished, the dissociative NO2 is expelled by high pure nitrogen in a whitening device, and the obtained finished product is filtered by a nanometer filter membrane and enters a finished product receiver under the working pressure of 0.5-0.8 Mpa; wherein, the aperture of the micro filtration membrane is 0.2 to 0.8 Mu m, and the aperture of the nanometer filter membrane is 0.5 to 1.5 nm. In the prepared ultra high purity nitric acid, the content of single cation is lower than 1 ppb, the content of single anion is lower than 100 ppb, and the content of the dust particle larger than 0.5 Mu m is lower than 5 per milliliter. The production process for extra high purity nitric acid has the advantages of simple technique, low production costs, high purity of products, low content of impurity ions, and applicability for large-scale mass production.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

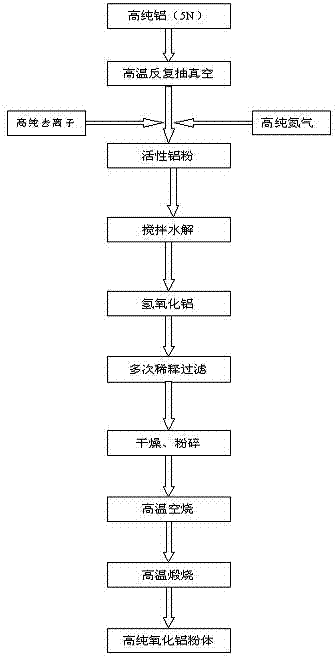

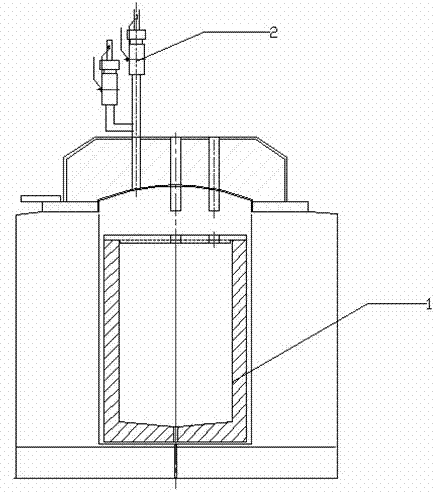

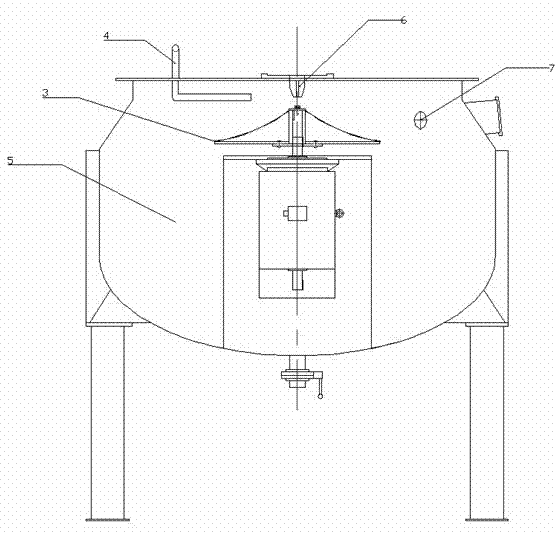

Method for preparing micron-sized ultra-high-purity aluminum oxide powder by virtue of full-process regulation control

The invention relates to high-purity aluminum oxide powder and in particular relates to a method for preparing micron-sized ultra-high-purity aluminum oxide powder by virtue of full-process regulation control. The method comprises the following steps: melting a high-purity aluminum ingot, repeatedly vacuumizing at a high temperature, filling nitrogen gas for protection, performing ultrasonic pneumatic nebulization, centrifuging, quenching and dispersing of a high-speed pure aluminum turntable and quick cooling of high-purity de-ionized water on molten aluminum by virtue of a ceramic liquid guide pipe to obtain high-activity aluminum slurry, producing an active hydrolysis reaction to generate aluminum hydroxide, repeatedly diluting and filtering through the high-purity de-ionized water to further remove impurities, drying and grinding products, and calcining at 1000-1300 DEG C to obtain the micron-sized (less than 2 microns) aluminum oxide powder with the purity of 99.999%. According to the method, the processes in different stages are optimized, so that the purity of active aluminum powder, the aluminum hydroxide and the final aluminum oxide are well controlled and the cost is reduced; the pollution is avoided, the operation is convenient, and the industrial production is facilitated.

Owner:NANJING CHANGJIANG IND FURNACE TECH GRP CO LTD

Non-contaminating pressure transducer module

InactiveUSRE38557E1Minimal accuracyMinimal resolutionFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsParticulatesControl signal

A non-contaminating pressure transducer module having an isolation member is disclosed. The isolation member isolates a pressure sensor within the transducer module from exposure to ultra high purity fluids flowing through a conduit in the module without significantly affecting the accuracy of the pressure measurement. The transducer module may be positioned within a fluid flow circuit carrying corrosive materials, wherein the pressure transducer module produces a control signal proportional to either a gauge pressure or an absolute pressure of the fluid flow circuit. The pressure transducer module of the present invention also avoids the introduction of particulate, unwanted ions, or vapors into the flow circuit.

Owner:NT INT

Ultra-high purity/superfine carbon nano tube conductive paste and preparation method and application thereof

The invention relates to an ultra-high purity / superfine carbon nano tube conductive paste and a preparation method and application thereof. The preparation method of the ultra-high purity / superfine carbon nano tube conductive paste comprises the following steps: (1) adding an ultra-high purity / superfine carbon nano tube as raw material into a mixed solution of a dispersing agent and a solvent, andperforming dispersion twice, so as to obtain initial carbon nano tube conductive paste; (2) and treating the initial carbon nano tube conductive paste obtained in step (1) by adopting a high pressuredispersing device twice, wherein the pressure range of the high pressure dispersing device is 7000-30000psi, and the flow range is 0.5-3L / min, so as to obtain the carbon nano tube conductive paste product with a small particle size and a low viscosity. The initial carbon nano tube conductive paste prepared according to the invention can come into good contact with an active substance, improve transfer of electrons between the active substance and the carbon nano tube, and full fills up gaps of anode and cathode materials of a lithium ion battery, thus being favorable for tight contact betweenmaterials and absorption of electrode.

Owner:哈尔滨万鑫石墨谷科技有限公司

Silver-exchanged zeolites and methods of manufacture therefor

ActiveUS20070000382A1Maximize working adsorption capacityEnhanced π-complexationCombination devicesGas treatmentSorbentSilicon dioxide

The present invention relates generally to zeolites having a silica / alumina ratio of less than or equal to 10 (Si / Al≦10) that are exchanged with Ag+ and thermally treated in such a way to favor adsorption over alternative catalytic and chemically reactive functionalities. The adsorbents of the present invention and the method of producing such adsorbents maximize the working adsorption capacity through π-complexation. Applications for such adsorbents include any process in which contaminants from gas streams can form π-complexes with the Ag in the zeolite, particularly the removal of CO, ethylene, propylene and the like from air and CO / H2 from air in prepurifier adsorbers in the production of ultra high purity (UHP) N2.

Owner:PRAXAIR TECH INC

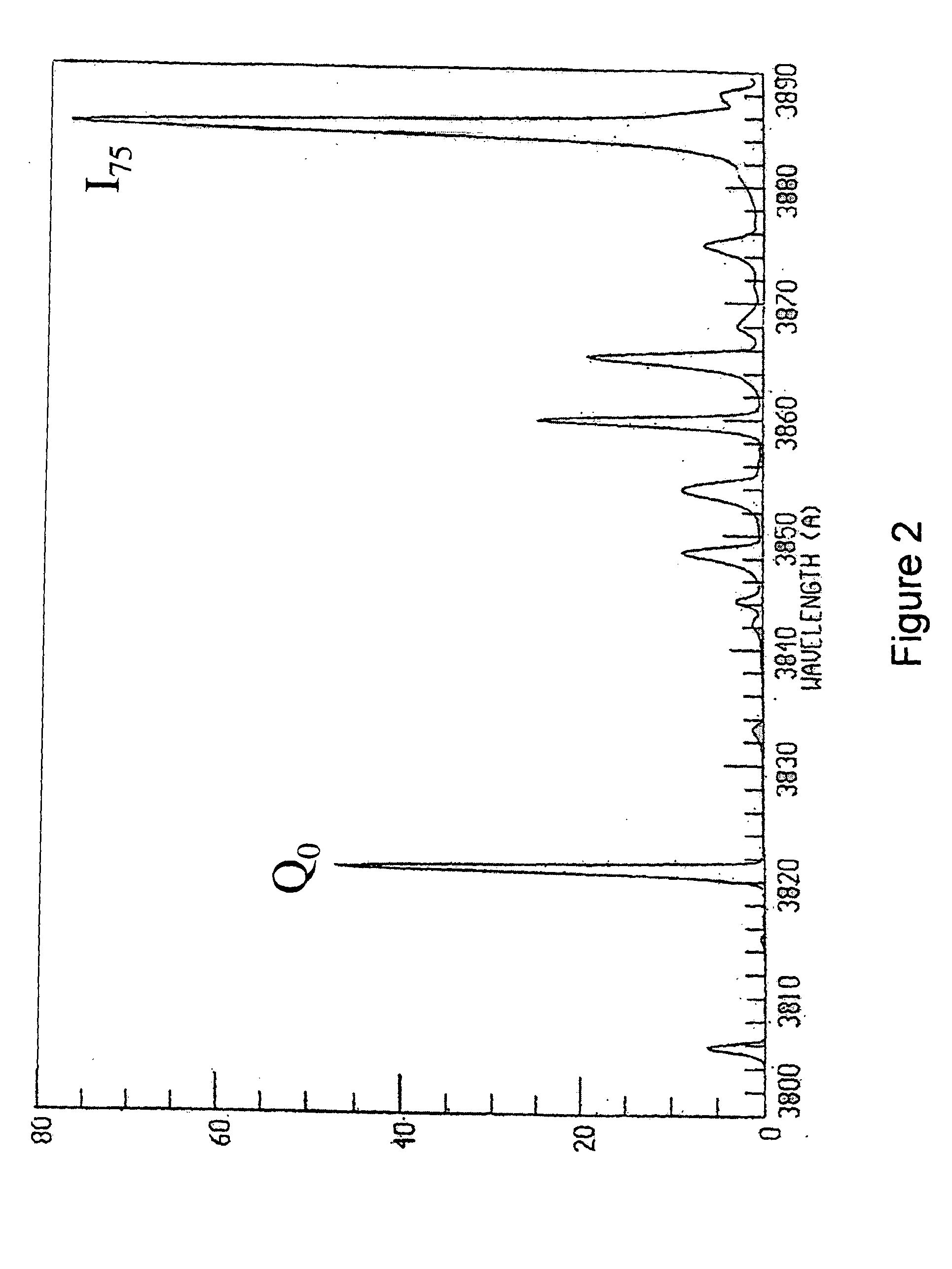

Growth of ultra-high purity silicon carbide crystals in an ambient containing hydrogen

ActiveUS7147715B2High purityReduce total nitrogen concentrationPolycrystalline material growthFrom chemically reactive gasesHydrogenNitrogen

A method is disclosed for producing semi-insulating silicon carbide crystal with a controlled nitrogen content. The method includes the steps of introducing an ambient gas containing hydrogen into a sublimation growth chamber, heating a silicon carbide source powder to sublimation in the hydrogen ambient growth chamber while, heating and then maintaining a silicon carbide seed crystal in the hydrogen ambient growth chamber to a second temperature below the temperature of the source powder, at which second temperature sublimed species from the source powder will condense upon the seed crystal, continuing to heat the silicon carbide source powder until a desired amount of silicon carbide crystal growth has occurred upon the seed crystal, while maintaining an ambient concentration of hydrogen in the growth chamber sufficient to minimize the amount of nitrogen incorporated into the growing silicon carbide crystal, and while maintaining the source powder and the seed crystal during sublimation growth at respective temperatures high enough to increase the number of point defects in the growing crystal to an amount that renders the resulting silicon carbide crystal semi-insulating.

Owner:CREE INC

Method for preparing ultra high-purity alcohol compound

ActiveCN1844070AOther chemical processesHydroxy compound separation/purificationAlcoholSurface oxidation

The invention discloses a method using adsorption to remove microscale metallic cation and non-metallic anion in alcohol compound, adopting surface oxidation active carbon that is disposed by oxidant as adsorbent, getting ultra-pure alcohol compound after contact adsorpting alcohol compound and surface oxidation active carbon, the mentioned alcohol compound is liquefied alcohol compound in common temperature and pressure. This method is easy to operate, convenience, safe and clean to prepare, compared with resinous exchange method, the treatment effect is homologous to resinous exchange method, the purity velocity and efficiency are higher than resinous exchange method, the dried surface oxidation active carbon would not bring new moisture for alcohol compound.

Owner:FOSHAN XILONG CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com