Ultra-high purity/superfine carbon nano tube conductive paste and preparation method and application thereof

A carbon nanotube, ultra-high-purity technology, used in circuits, electrical components, battery electrodes, etc., can solve problems such as high viscosity and less sedimentation, and achieve the effect of reducing viscosity, ensuring safety, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A kind of preparation method of ultrahigh purity / ultrafine carbon nanotube conductive paste, the raw material that it adopts is:

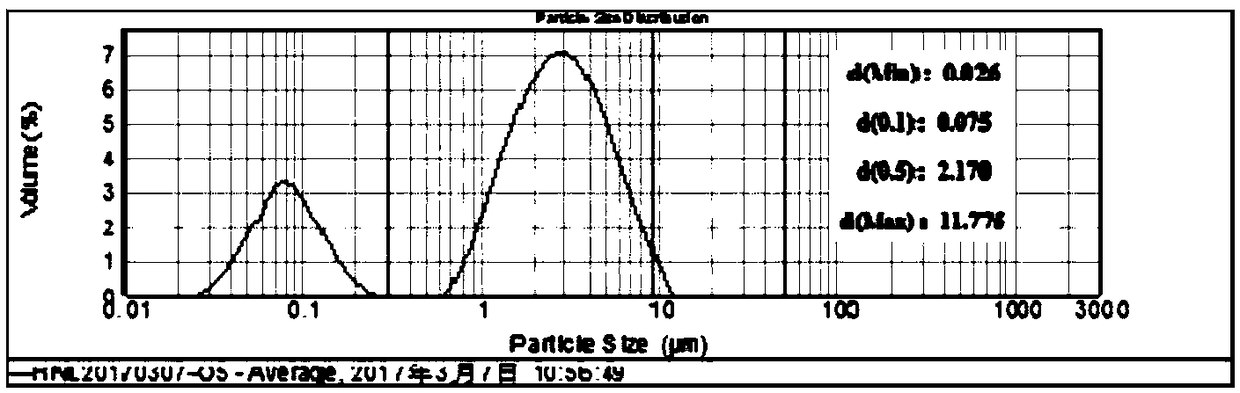

[0069]The tube diameter is 8-15nm, the tube length is 10-30μm, and the specific surface area is 280m 2 / g, the purity is 99.5% ultra-high purity / ultrafine carbon nanotubes, its ICP metal impurity composition analysis is shown in the "raw material sample" data in Table 1, and the SEM figure of this carbon nanotube powder raw material is as 1 (comprising Figure 1A with Figure 1B ) shown; the dispersant is selected polyvinylpyrrolidone (PVP); the solvent is selected N-methylpyrrolidone (NMP).

[0070] Concrete preparation method comprises the following steps:

[0071] (1') Pre-mixing and dispersing: Weigh 1 kg of polyvinylpyrrolidone and 5 kg of the above-mentioned carbon nanotubes, first add the dispersant to 94 kg of N-methylpyrrolidone, and use 1# grinding and dispersing equipment to carry out the pre-mixing process of the dispersant to m...

Embodiment 2

[0079] A kind of preparation method of ultrahigh purity / ultrafine carbon nanotube conductive paste, the raw material that it adopts is:

[0080] The tube diameter is 8-15nm, the tube length is 10-50μm, and the specific surface area is 293m 2 / g, the purity is 99.59% ultra-high purity / ultrafine carbon nanotubes, and its ICP metal impurity composition analysis is shown in the "raw material sample" data in Table 2; Dispersant selects polyvinylpyrrolidone (PVP) for use; Solvent selects N-formazol for use Nylpyrrolidone (NMP).

[0081] Concrete preparation method comprises the following steps:

[0082] (1') Premixing and dispersion: Weigh 1.25kg of polyvinylpyrrolidone and 5.75kg of carbon nanotubes, first add the dispersant to 93.0kg of N-methylpyrrolidone, and use 1# grinding and dispersing equipment to carry out the dispersant premixing process, Make the dispersant and solvent fully mixed, disperse until the solution is homogeneous, and control the temperature of the material ...

Embodiment 3

[0090] A kind of preparation method of ultrahigh purity / ultrafine carbon nanotube conductive paste, the raw material that it adopts is:

[0091] The tube diameter is 8-15nm, the tube length is 10-50μm, and the specific surface area is 284m 2 / g, the purity is 99.76% ultra-high purity / ultrafine carbon nanotubes, its ICP metal impurity composition analysis is shown in the "raw material sample" data of Table 3, the dispersant is selected polyvinylpyrrolidone (PVP), and the solvent is selected N-methyl Pyrrolidone (NMP).

[0092] Concrete preparation method comprises the following steps:

[0093] (1') Premixing and dispersion: Weigh 1.25kg of polyvinylpyrrolidone and 5kg of ultra-high-purity ultrafine carbon nanotubes, first add the dispersant to 93.75kg of N-methylpyrrolidone, and use 1# grinding and dispersing equipment for dispersant premixing process, so that the dispersant and solvent are fully mixed, dispersed until the solution is uniform, and the temperature of the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com