Patents

Literature

96 results about "Dried apricot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dried apricots are a type of traditional dried fruit. When treated with sulfur dioxide (E220), the color is vivid orange. Organic fruit not treated with sulfur vapor is darker in color and has a coarser texture. Generally, the lighter the color, the higher the SO₂ content. Light-colored varieties (with the sulfur content of more than 2000 ppm) are banned in the European Union.

Tea and drink with balanced nutrients

InactiveCN101147510AIncrease vitalityRegulate Yin and Yang balancePre-extraction tea treatmentFood preparationAdditive ingredientDried apricot

The present invention discloses a balanced nutrient tea and beverage. Its raw material composition includes (by weight portion) 0.5-3 portions of American ginseng, 1-3 portions of sterculia, 2-5 portions of dried longan flesh, 2-5 portions of dried jujube, 2-5 portions of dried apricot flesh, 1-3 portions of spiny jujube kernel, 1-4 portions of lyceum berry, 2-5 portions of raisins, 1-3 portions of tea, 0.5-3 portions of lonicera flower, 0.5-2 portions of notoginseng flower and 1-15 portions of honey. Said invention contains several nutrient components of vitamins, amino acids, saponin, mineral and organic acid, etc. and has several health-care functions of raising immunity of human body, etc.

Owner:李国林

Method for preparing low sugar preserved apricots

ActiveCN102204618AIncrease production capacityHigh technology contentConfectionerySweetmeatsLow glucoseDried apricot

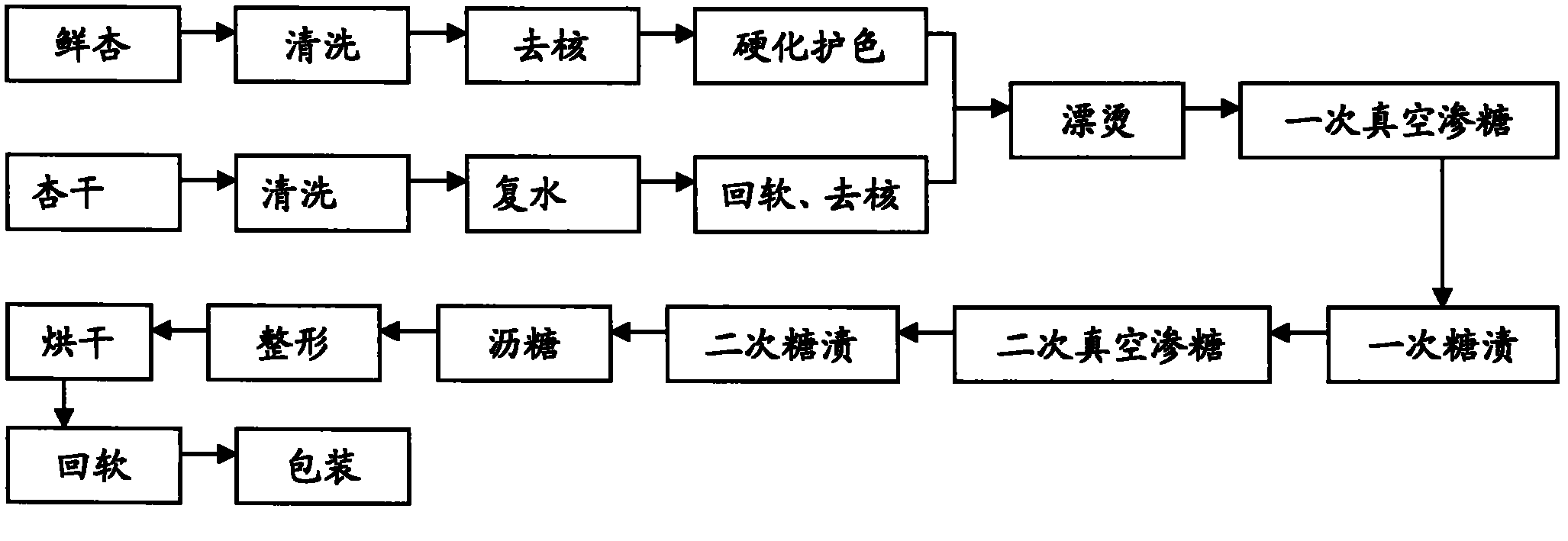

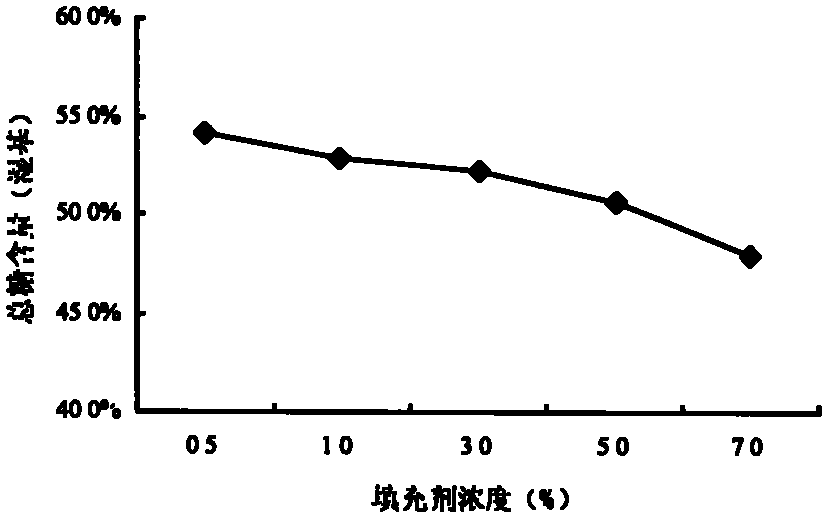

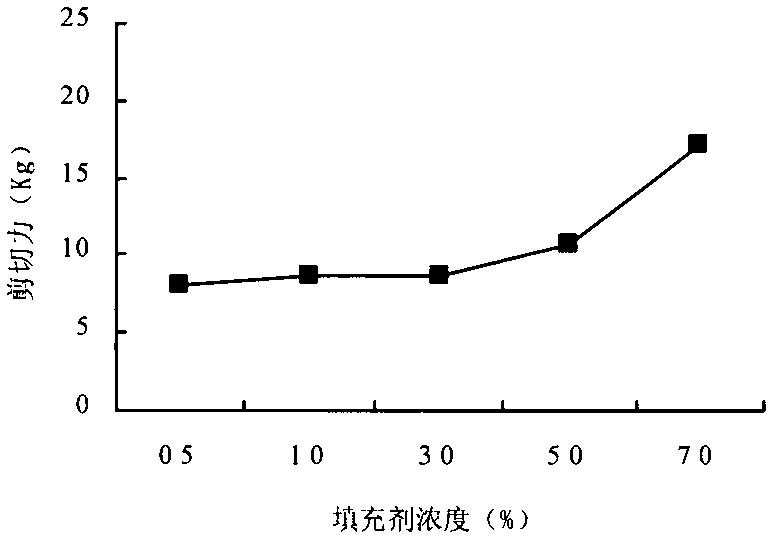

The invention discloses a method for preparing low sugar preserved apricots. Key technical parameters which can influence the quality of the low glucose preserved apricots are determined by using dried apricots or fresh apricots as raw materials and adopting novel nutritive sweeteners with specific physiological functions, i.e., maltooligosaccharides as a filler and using fructose syrups as a sweetener, wherein in the primary vacuum sugar permeability process, the concentration of sugar solution is in the range of 30-35 percent, the time is 20min, the sugar solution has a temperature of 60 DEG C, the vacuum degree is 0.07Mpa, and the sugaring time under normal pressure is in the range of 10-15 hours; in the secondary vacuum sugar permeability process, the concentration of the sugar solution is in the range of 40-45 percent, the time is 20min, the sugar solution has a temperature of 60 DEG C, the vacuum degree is 0.07MPa, and the sugaring time under normal pressure is in the range of 10-15hours; and color, plumpness, sugar content and shearing force of a product are used as integrated quality evaluation indexes, so that the method for preparing the low sugar preserved apricots is determined. The preserved apricots prepared by adopting the method provided by the invention not only has low total sugar content, but also has specific nutritional value and has wide applicable consumer range.

Owner:XINJIANG AGRI UNIV

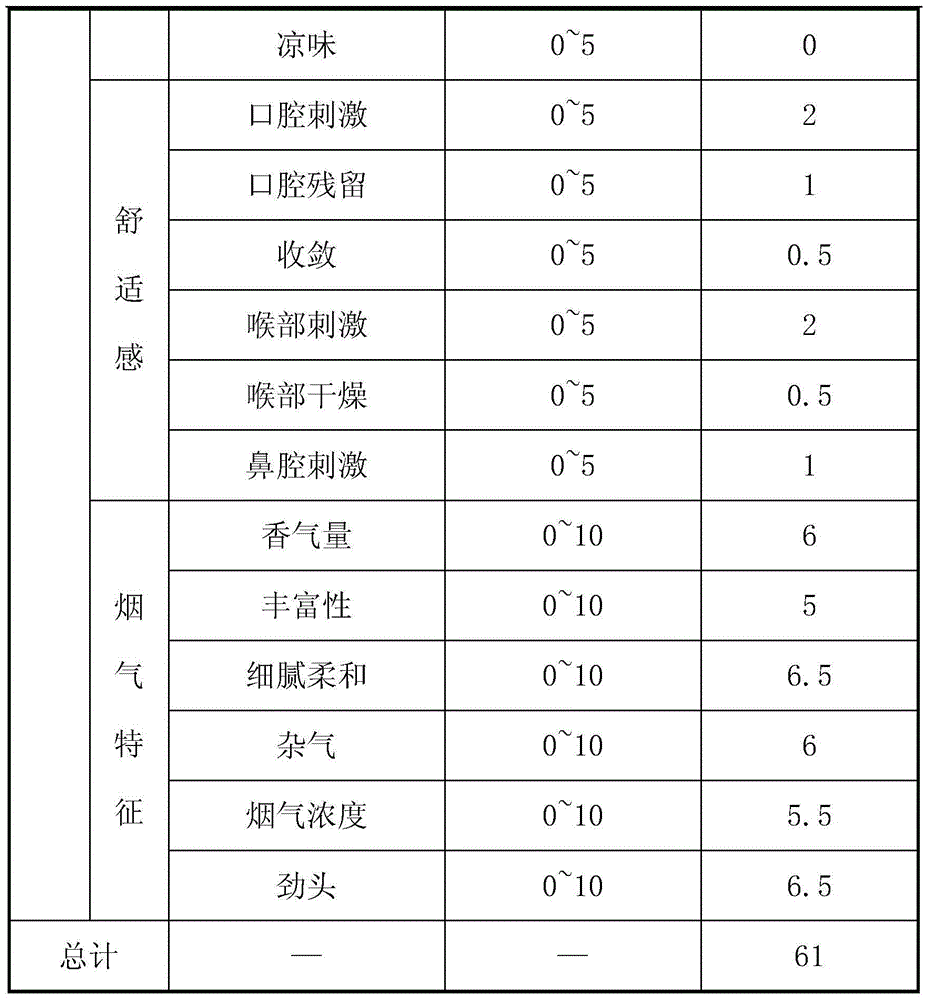

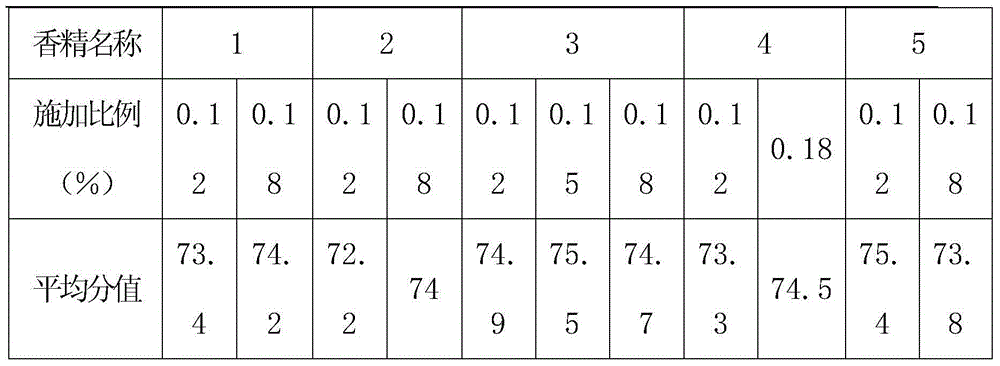

Flavored essence for increasing cigarette sour and sweet note

ActiveCN104886761AIncrease sweetnessEasy extractionTobacco treatmentDihydroactinidiolideFlavoring essences

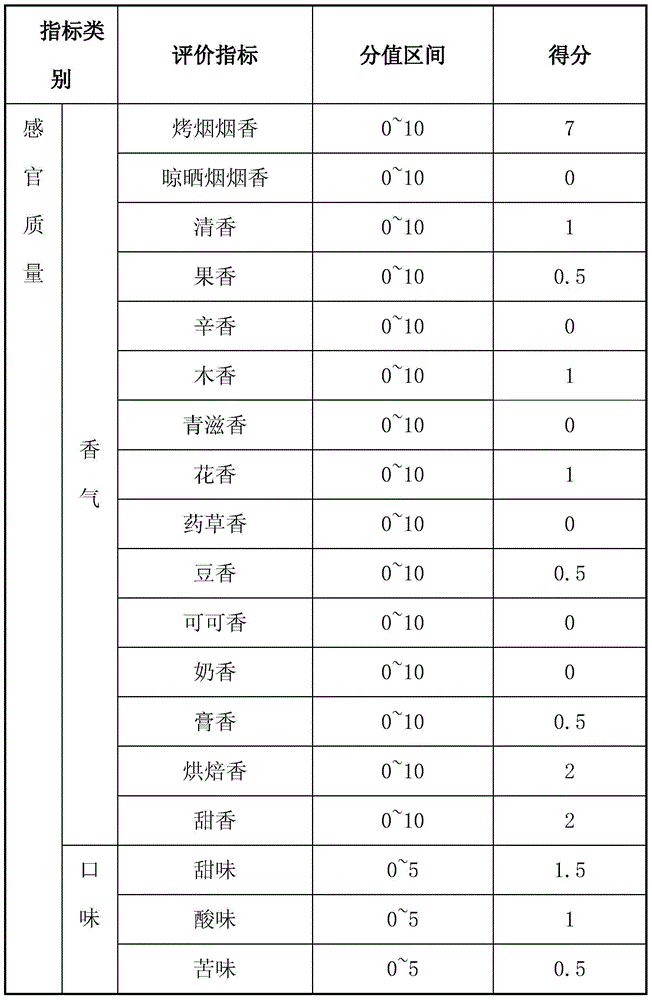

The invention relates to an essence, in particular to a flavored essence for increasing cigarette sour and sweet note. The flavored essence is made of raw materials including, in weight percent, 0.5-0.8% of 1% hydroxycitronellal, 1-2% of ethyl acetate, 5-8% of isoamyl acetate, 0.01-0.5% of beta-damascenone, 0.01-0.8% of dihydroactinidiolide, 0.01-0.8% of alpha-ionone, 1-2.5% of vanillin, 0.5-4% of butyric acid butylester, 0.5-5% of acetic acid, 0.5-5% of lactic acid, 4-10% of dried apricot slices extract, 4-10% of plum extract, 1-5% of tomato extract, 0.5-2% of iris extract, 3-8% of Zimbabwe tobacco extract, 20-30% of propanediol and 4.1-61.67% of 70% ethyl alcohol. The flavored essence solves the problems that an existing cigarette is single in fragrance and obvious in offensive odor and stimulation, smoking satisfaction and enjoyment of the cigarette is improved, the aroma amount of the cigarette is increased, obvious sour and sweet note is given for the cigarette, the flavored essence is rich in fragrance, and stimulation is reduced.

Owner:HUBEI CHINA TOBACCO IND +1

A kind of health fruit tea

The invention discloses health-care fruit tea. The health-care fruit tea is prepared from the following raw materials in part by weight: 40 to 60 parts of orange, 30 to 50 parts of apple, 30 to 50 parts of carrot, 15 to 25 parts of lemon, 15 to 25 parts of green tea, 15 to 30 parts of hawthorn, 15 to 30 parts of red date, 15 to 30 parts of dried apricot slices, 15 to 25 parts of grape, 5 to 15 parts of mint leaf, 15 to 25 parts of water chestnut and 5 to 15 parts of American ginseng. The health-care fruit tea is prepared from various natural fruits which are taken as the raw materials and hasrich nutrition; and the synergist effect of various active ingredients achieves good effects of whitening, nourishing appearances, clearing heat, cooling blood, promoting the secretion of saliva, quenching thirst and coordinating stomach and intestines. Moreover, the health-care fruit tea does not contain any additive, does not have a side effect, has good mouthfeel, is safe and low in cost, and is a natural environment-friendly health-care drink.

Owner:李丹榕

Solar drying technique for apricot

InactiveCN101171975AGolden colorSave energyFood processingFood preservationThermal energySolar drying

The invention provides a novel technology for drying apricot by combining the solar energy heating and the vapor heat energy heating, and combining the solar radiation drying and the hot blast convection drying. The drying processing of the apricot is divided into three steps, and the parameter such as dying temperature, humidness, etc. of each step is provided. The drying process cycle of the drying process is short, the energy is saved, and the dried apricot has the advantages that the color is golden, the taste is pure, and the quality product rate is high.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

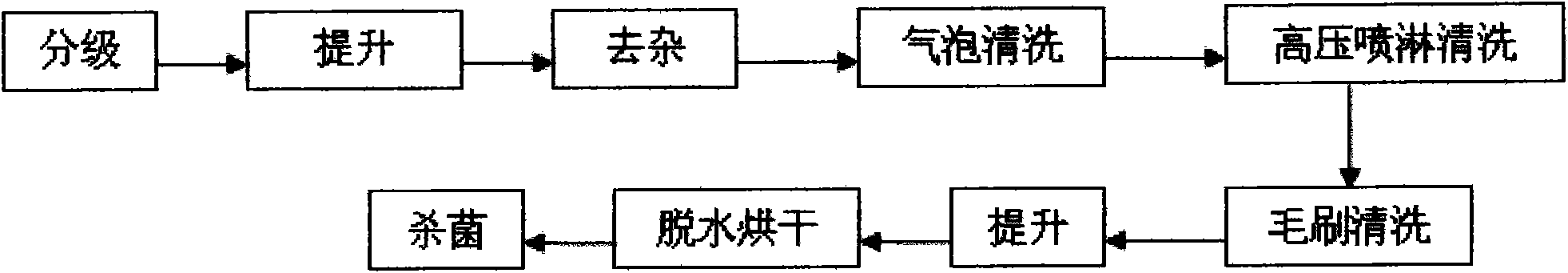

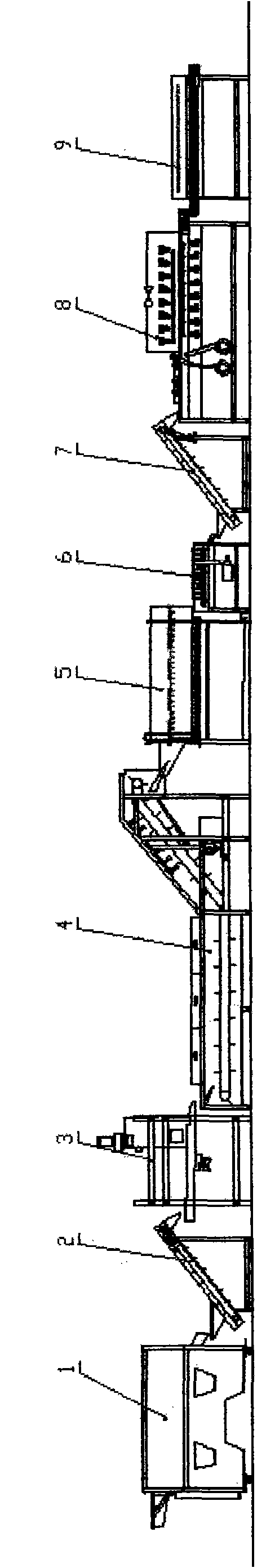

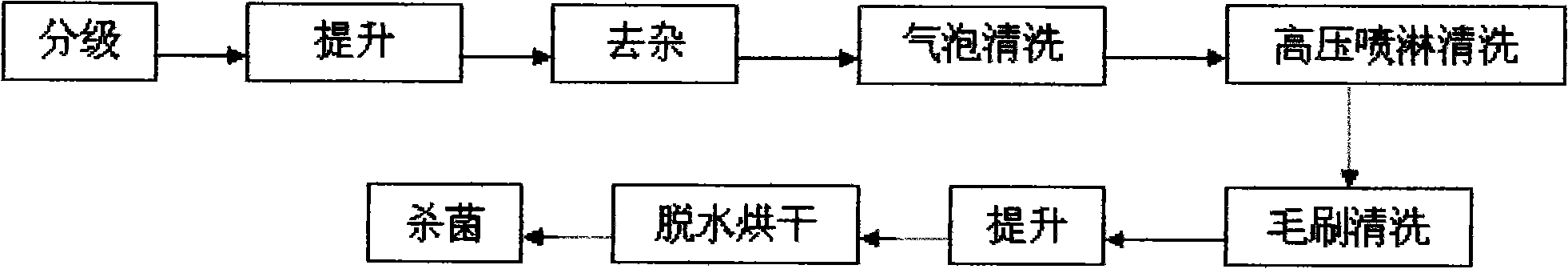

Process for processing dried fruits and mechanical production line

InactiveCN101878883AImprove productivityReduce productivityFood preparationProduction lineHigh pressure

The invention belongs to a process for processing dried fruits (red jujubes, dried apricots, raisins, barbary wolfberry fruit, fig and the like) and a mechanical production line. The invention aims to provide a process for processing dried fruits and a mechanical production line. The process for processing dried fruits comprises the working procedures of grading, impurity removal, air-bubble cleaning, high-pressure sprayed cleaning, hairbrush cleaning, dehydration, drying, sterilization and the like. The mechanical production line adopted in the invention comprises a grading machine, a scraping plate elevator, an impurity removal, an air-bubble cleaner, a high-pressure spraying cleaner, a multifunctional high-efficiency cleaner, a bucket type elevator, a continuous dehydrator, an ultraviolet sterilizer and the like. The process and the production line are mainly used for carrying out the working procedures of grading, impurity removal, cleaning, dehydration, drying, sterilization and the like to the dried fruits to finally obtain high-quality dried fruit products. The invention also fundamentally solves the problems of low artificial processing productivity, large labor intensity,turbid dried fruit grade and inexhaustive cleaning.

Owner:XINJIANG XINNONG FOOD

A dried apricot processing method

InactiveCN1994120AReduce oxygen contentPrevents enzymatic browningFruit stoningFood preparationDried apricotInjection air

The invention relates to a method for processing dried apricot, wherein it comprises that: washing, removing corn, heating, drying and vacuum packing; the apricot washed and removed corn enters into the air injection heater, impacted by 4. 0-20m / s, 100-200Deg. C and 10-100% humidity air flow for 2-15min, to disinfect enzyme; then enters into the drying box at 50-90Deg. C and 8. 0-15m / s airflow to be dried for 2-15h; then vacuum packing. The inventive dried apricot has high quality, without chemical agent and additive.

Owner:CHINA AGRI UNIV

Apricot peel water and preparation process thereof

The invention provides apricot peel water and a preparation process thereof. The apricot peel water comprises the following components in percentage by weight: 10 to 25 percent of hawthorn, 17 to 30 percent of liquorice, 25 to 28 percent of water, and 20 to 35 percent of dried Liguang apricot. The preparation process comprises the following steps: cleaning fresh Liguang apricot, hawthorn and liquorice, and baking or drying with air; cleaning and sterilizing the dried apricot, hawthorn and liquorice, and sterilizing, mixing 20 to 35 percent of dried Liguang apricot, 10 to 25 percent of hawthorn, 17 to 30 percent of liquorice and 25 to 28 percent of water, cooking in a digester with slow fire to prepare mixed juice, wherein the temperature is controlled to be between 90 and 100 DEG C, and the cooking time is between 50 and 100 minutes; and pouring the mixed juice, making a filter screen by absorbent cotton with thickness of between 3 and 6cm, filtering, cooling in a specific container, uniformly stirring, filling, and sealing the opening. The apricot peel water has the characteristics of high nutrient components and good taste.

Owner:张永宏

Health-care nutrient solution and method for preparing same

InactiveCN102228233AGood hypolipidemic effectImprove disease resistanceFood preparationCelluloseBiotechnology

The invention discloses health-care nutrient solution and a method for preparing the same. The health-care nutrient solution is prepared by the following raw materials in the same part by weight: prunus amygdalus butsch kernel, walnut kernel, apricot kernel, red date, wheat, corn, black rice, yellow bean, green bean, black bean, red bean, apple, pear, pomegranate, raisin, dried ebony, non-kernel dried apricot, dried fig, potato, brassica campestris, tomato, pepper, cabbage, onion, garlic, pumpkin, musk melon, eggplant, spinach, cucumber and celery. The health-care nutrient solution richly contains proteins, crude fat, vitamins, minerals and nutritive celluloses and can effectively control and help to treat cardiovascular and heart cerebrovascular diseases, diabetes, various inflammations, andrology diseases and gynecological diseases, enhance the functions of the immune system and provide sufficient nutrients for all tissues and organs of human bodies.

Owner:亚森·克力木

Raw candy preserved apricot and producing process and technology thereof

The invention discloses a process for producing raw-sugar preserved apricots and raw-sugar preserved apricots obtained by the process. The process is that: ripe apricots are parted off, core-removed and dried firstly, and then the dried apricot flesh is soaked, cleaned and softened; the water content of the apricot flesh is kept between 20-25 percent; the apricot flesh is heated with a tunnel-type microwave drying and sterilizing device to 70-75 DEG C; the cleaned apricot flesh is dried and sterilized by adjusting the speed of a tunnel conveyor belt to 0.1-0.3m / s; appearance-shaping and vacuum packaging are carried out in sequence so as to get the finished product. The invention is characterized in that the process of the invention does not adopt sulfuring or sulfurizing to keep color when processing preserved apricots, which is completely different from the prior process, and is not added with additives either. The product of the invention is safe, healthy, and special in flavor and has long-stem storage and no pollution, thus the invention can be widely applied in the preserved apricot processing field.

Owner:张大海

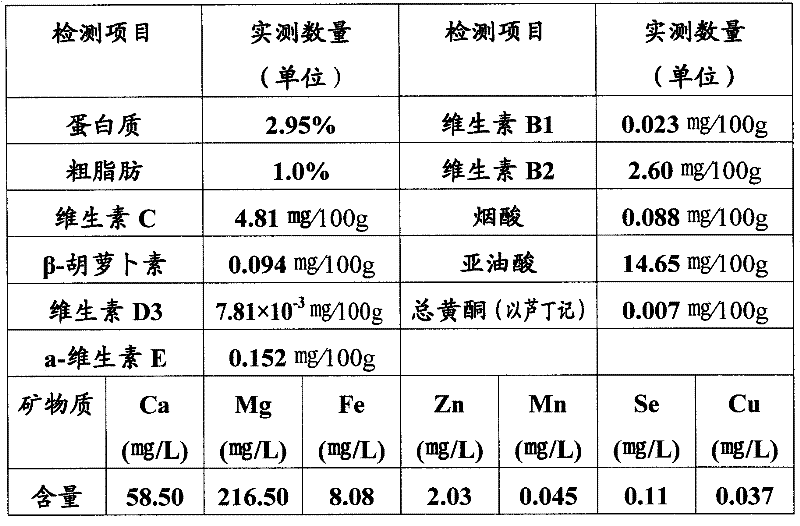

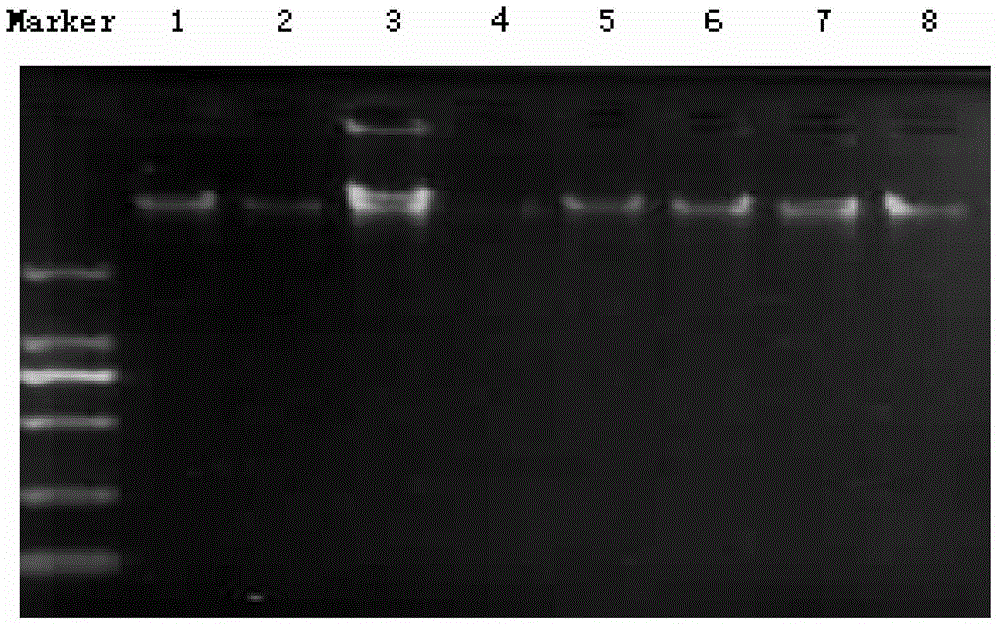

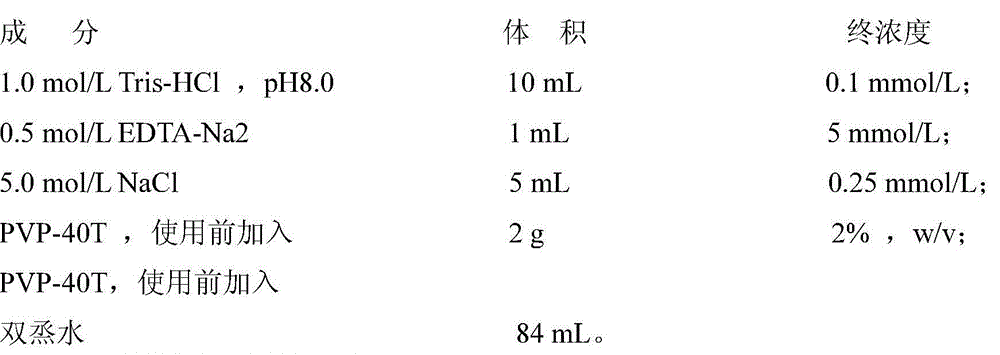

Method for extracting DNA from dry apricot leaf

InactiveCN104531679ASave operating timeHigh extraction purityDNA preparationSecondary metabolitePhenol

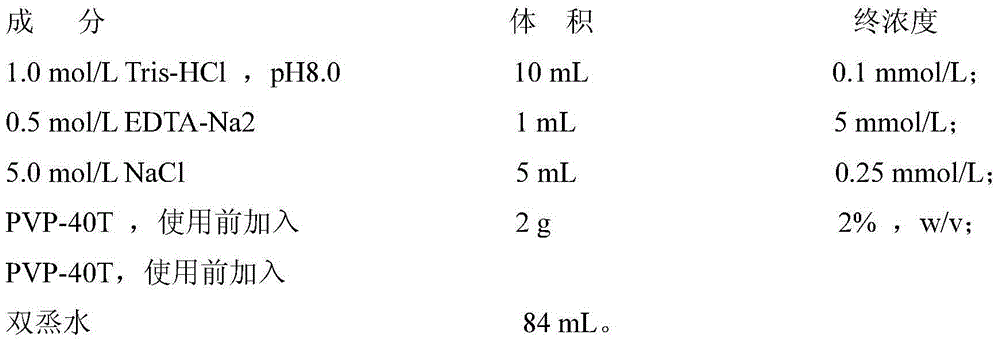

The invention belongs to the technical field of preparation of plant DNA and relates to a method for extracting DNA from a dry apricot leaf. The method comprises the following steps: firstly extracting secondary metabolite substances from the leaf; putting the grinded dry apricot leaf in an ice bath by using a precooling buffer extract solution, centrifuging, removing the supernatant liquid, and repeatedly extracting for a plurality of times to remove the secondary metabolite substances such as polysaccharide, polyphenol and ester from the apricot leaf before the DNA is released so as to prevent the secondary metabolite substances from forming a compound with the DNA; during liquid nitrogen grinding and treatment of the buffer extraction solution, adding a proper amount of PVP-40T to protect the DNA from oxidation and promote cell disruption so that more DNA can be released; adding a proper amount of RNA enzyme after the cell disruption so that RNA is removed and the introduced protease is removed as well; and extracting by using a proper amount of a mixed solution of phenol, chloroform and isoamylol by adopting an improved CTAB method to remove a great amount of protein so that the purity and quality of the DNA in the apricot leaf are improved. Compared with a generally-used method, the method disclosed by the invention is low in cost.

Owner:TARIM UNIV

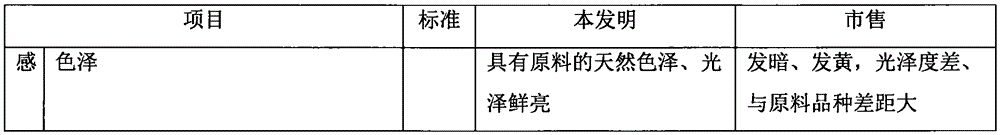

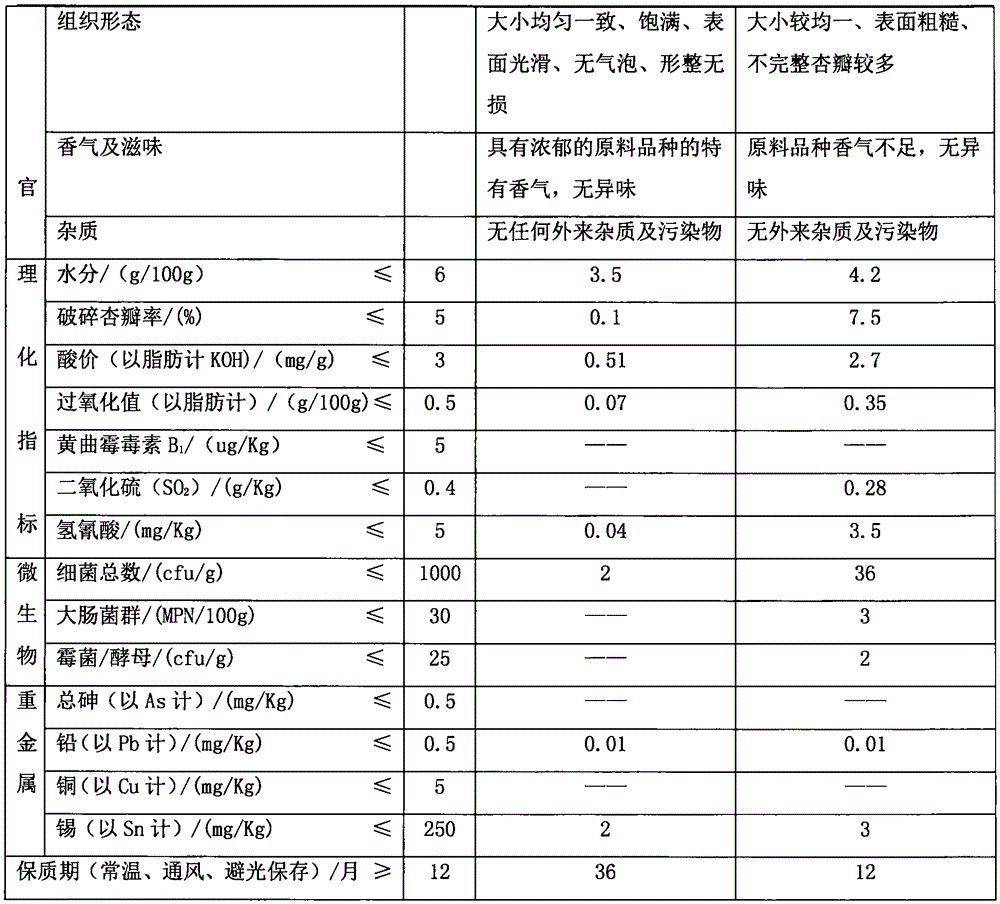

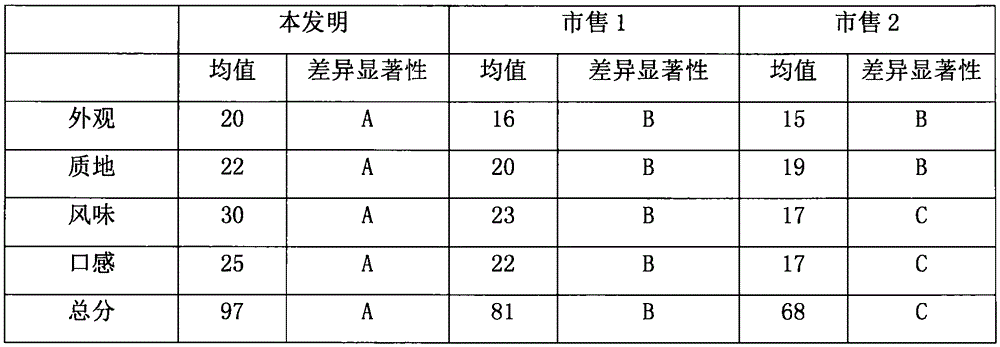

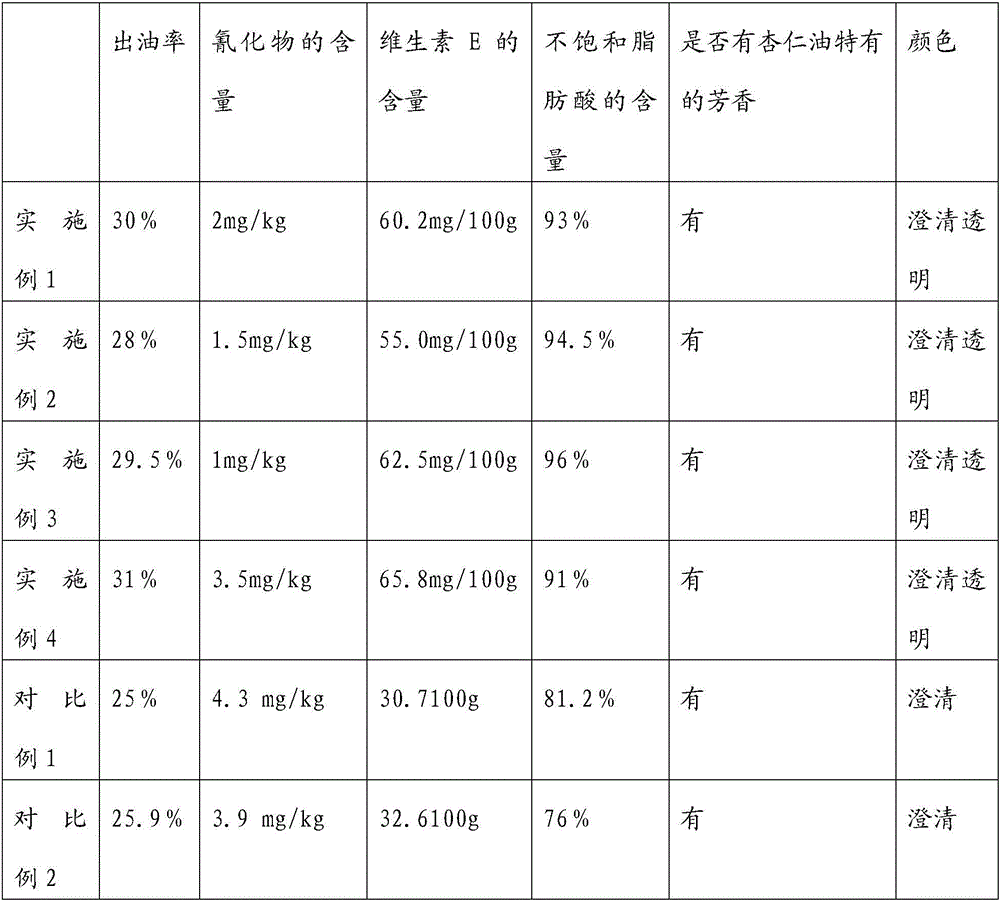

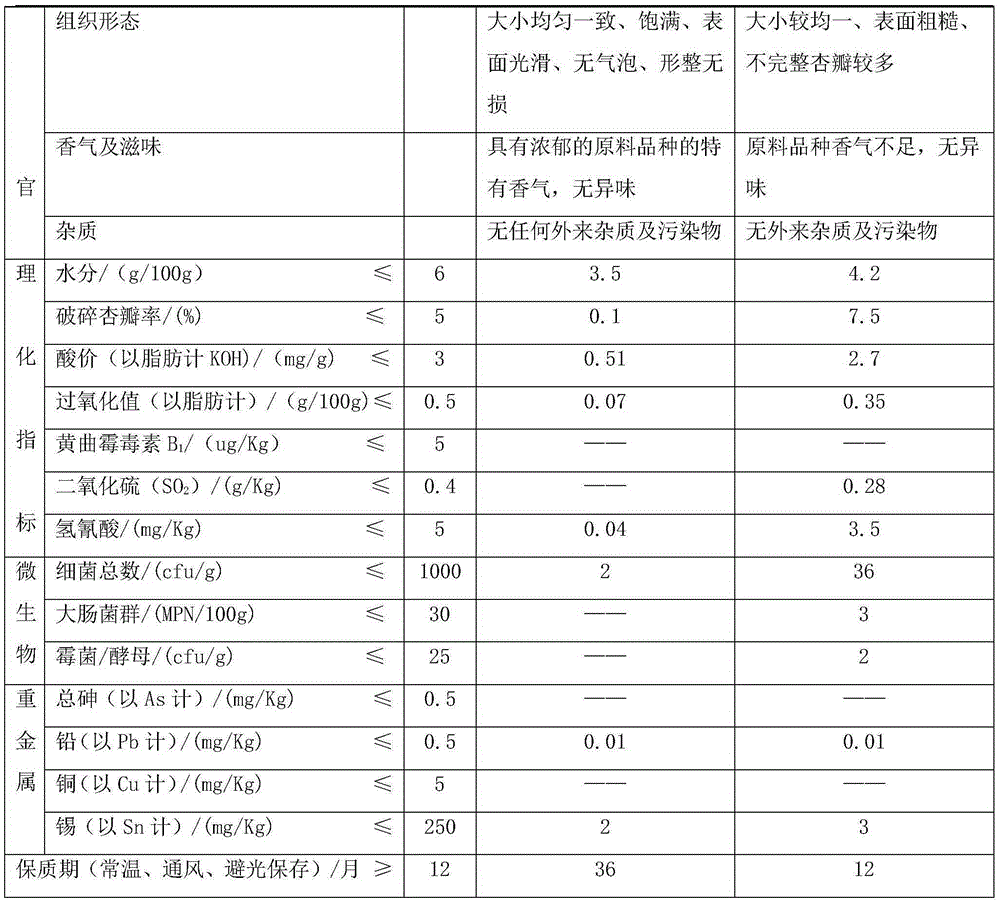

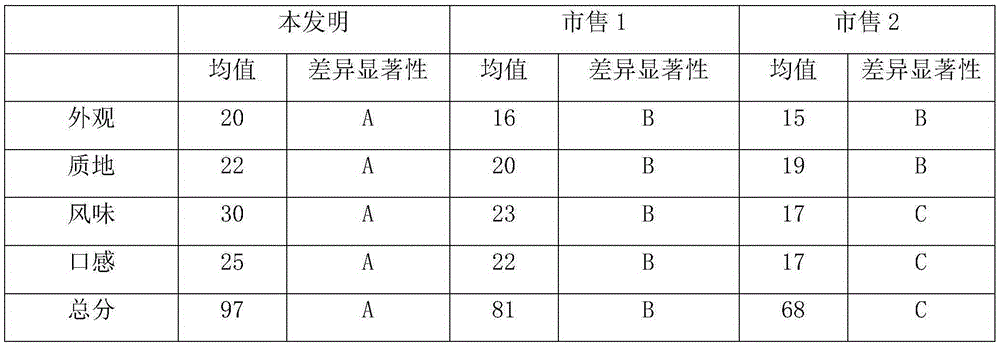

Debitterized and detoxified bitter apricot kernel and production method thereof

ActiveCN105595283AReduce processing breakage rateImprove food safetyFood processingFood preservationFlavorMicrowave

The invention discloses a debitterized and detoxified bitter apricot kernel and a production method thereof, and belongs to the technical field of primary processing of bitter apricot kernels. The method comprises the following steps: peeling bitter apricot kernels used as a raw materials, debitterizing the peeled bitter apricot kernels, detoxifying the debitterized bitter apricot kernels to obtain apricot kernel sections, carrying out microwave drying to obtain dry apricot kernel sections, collecting bitter apricot kernel skins, refrigerating the skins, crushing the refrigerated skins, uniformly mixing the crushed skins with a debitterizing liquid, carrying out enzymatic hydrolysis, distilling the obtained material twice to obtain an apricot kernel skin extract, decolorizing the extract, mixing the decolorized extract with the dry apricot kernel sections according to a certain ratio, and stir-frying the obtained mixture to obtain the bitter apricot kernel with the characteristics of bitter apricot kernel natural flavor, brightness, cleanness and regularity, high debitterizing rate (98.5-99.8%), substantial debitterizing effect (the cyanide residual quantity is 0.04-0.06mg / kg), long shelf life (24-36 months) and low cost. The preparation method has the advantages of simple process, short period, high efficiency, energy saving, large scale production, realization of zero discharge of toxic substances in the technical field of primary processing of the bitter apricot kernels, environmental protection, and exploration of a new way for depth processing of the bitter apricot kernels.

Owner:北京臻味坊食品有限公司

Flammulina velutipes culture medium

InactiveCN105503434AExpand sourceIncrease productionCalcareous fertilisersBioloigcal waste fertilisersBiotechnologyResource utilization

The invention relates to the technical field of flammulina velutipes cultivation, in particular to a flammulina velutipes culture medium. The flammulina velutipes culture medium is prepared from, by mass, 100-150 parts of sawdust, 40-80 parts of rice bran, 30-60 parts of cotton seed hulls, 30-60 parts of soybean cakes, 30-50 parts of beer grains, 20-40 parts of buckwheat kernels, 10-30 parts of dried apricots, 4-8 parts of gypsum powder, 8-16 parts of ammonium sulfate, 6-8 parts of slaked lime, 8-10 parts of agar, 8-10 parts of kudzurvine root powder, 10-20 parts of glucose, 2-4 parts of peptone, 0.4-0.8 part of polyglutamic acid, 0.6-1 part of lactic acid bacteria, 0.2-0.4 part of potassium sorbate and 9-10 parts of a nutrition additive. A method for culturing flammulina velutipes through the flammulina velutipes culture medium comprises the following steps of 1 material preparing; 2 sterilizing and inoculating; 3 culturing; 4 controlling after entities grow out; 5 harvesting. According to the flammulina velutipes culture medium, the raw material sources are widened, the resource utilization rate is increased, and the nutrition is comprehensive, so that hyphae are vigorous in growth, high in yield and good in quality.

Owner:ANQING DAYUANSHAN AGRI TECH CO LTD

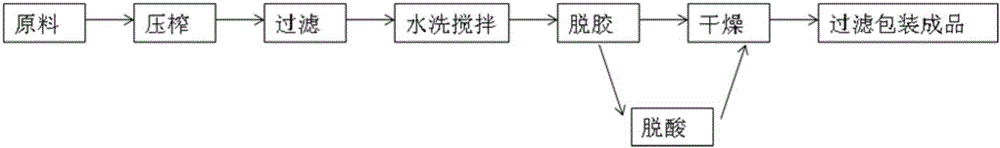

Processing technology of apricot kernel oil

InactiveCN106281656AStay nourishedImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionSaline waterCyanide

The invention relates to a processing technology of apricot kernel oil. The processing technology comprises the following steps: 1) debitterized dry apricot kernels or sweet apricot kernels are selected as raw materials and subjected to physical squeezing, and crude oil and oil cakes are obtained; 2) the crude oil is filtered, and a filtrate is collected; 3) water washing and stirring are performed: the filtrate is preheated, steam in sprayed into the filtrate, the mixture is stirred, and the oil temperature is increased; salt is added to the oil when the temperature is 85-90 DEG C, the mixture is evenly mixed and left to stand, three layers are obtained, cleaned oil on the middle layer is collected, and the temperature is reduced when reaching 125-145 DEG C; 4) degumming is performed: the cooled cleaned oil is heated to 90-110 DEG C, brine is added, the mixture is stirred and left to stand, floating oil on the upper layer is skimmed off, water at the bottom is discharged, and the degummed cleaned oil is obtained; 5) the degummed cleaned oil is subjected to vacuum drying, cooling is performed, and grease is obtained; 6) the grease is filtered and packaged, and a finished product is prepared. The processing technology has the advantages that an oxidant is not needed to be added, the cyanide content is low or even no cyanide is contained, the oil yield is high, the operation is simple, the cost is low and the like.

Owner:张立军

Preparation method of hawthorn and smoked plum compound fruit flesh beverage concentrate

InactiveCN103622105AReduce consumptionReduce lossesFood ingredient functionsFood preparationFlavorFruit juice

The invention provides a preparation method of hawthorn and smoked plum compound fruit flesh beverage concentrate. The hawthorn and smoked plum compound fruit flesh beverage concentrate is prepared from main raw materials including hawthorns, smoked plum, roselle, dried apricot slices, Chinese dates and the like according to a certain ratio by using processes of cleaning, soaking, saccharifying, enzymolysis, pulping, centrifugal-separating, concentrating, blending, sterilizing and the like. The hawthorn and smoked plum compound fruit flesh beverage concentrate is diluted by adding water according to a ratio of 1:6 when people drink the hawthorn and smoked plum compound fruit flesh beverage concentrate. The hawthorn and smoked plum compound fruit flesh beverage concentrate maintains the aroma which is special for the hawthorn and the smoked plum, brownish red in color, properly sour and sweet in flavor, and capable of dissolving grease and removing the peppery paste, and has the effects of tonifying spleen, stimulating appetite and promoting digestion. According to the preparation method, a conventional process of decocting plum juice is imitated, and a modern technology of concentrated fruit juice is combined. The preparation method is simple in process, quantitative in processing conditions, and capable of realizing the continuous industrialized production. The hawthorn and smoked plum compound fruit flesh beverage concentrate is concentrated juice, is preservative and fresh-keeping by depending on self sugar degree and can be conveniently stored and transported. Compared with a conventional process of decocting plum juice, the preparation method is low in cost and high in efficiency, and capable of realizing the industrialized control of flavor blending and the standardized production.

Owner:BEIJING NEW SPICY WAY RESTAURANT MANAGEMENT

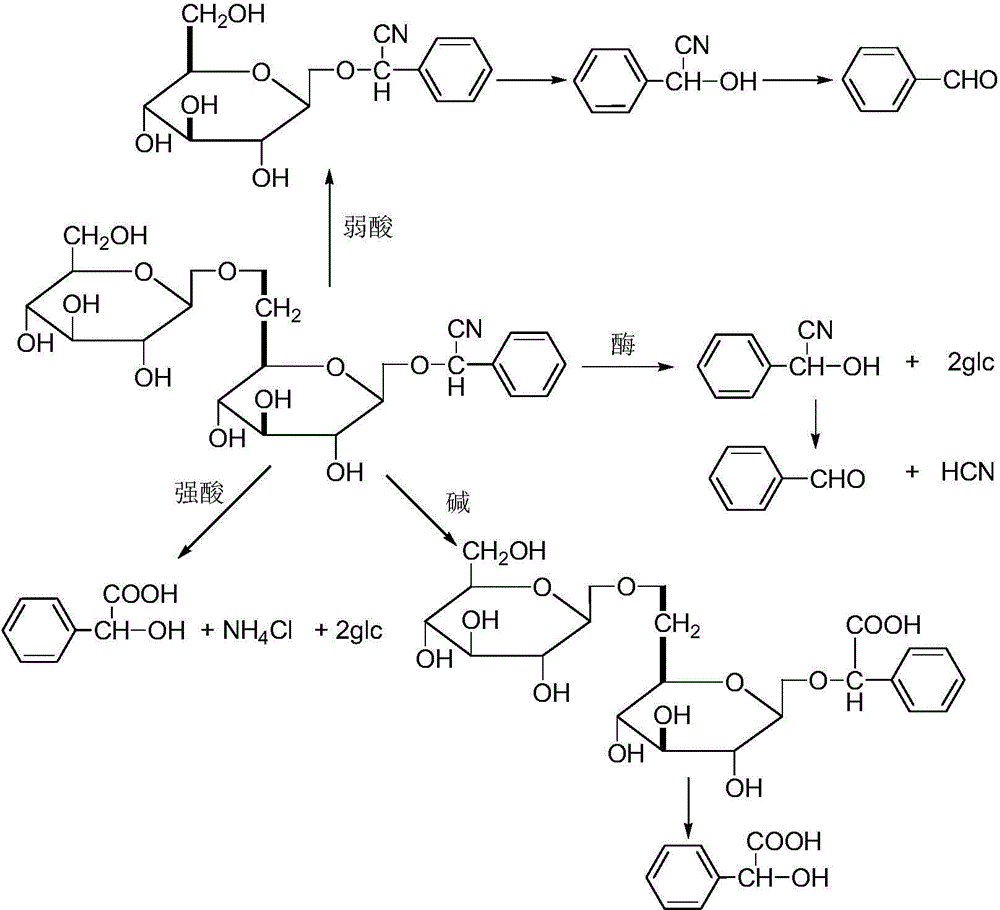

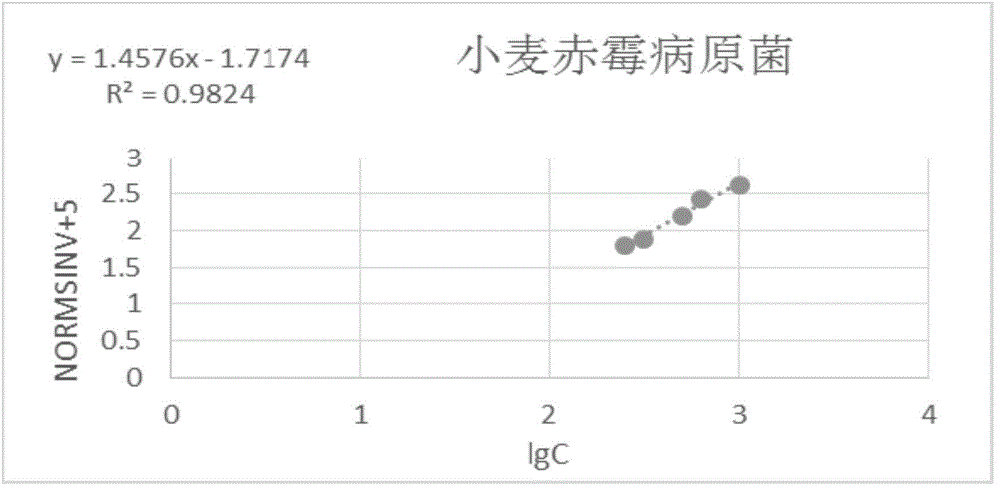

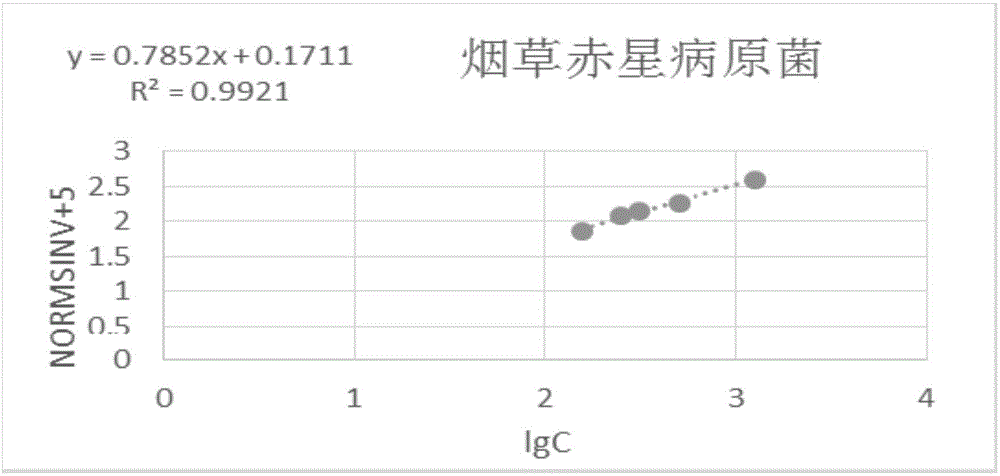

Bitter apricot kernel essential oil extraction method and application as plant pathogenic fungus inhibitor

The invention discloses a bitter apricot kernel essential oil extraction method. The extraction method comprises the following steps: removing grease oil from dry apricot kernels by a hot squeezing method, soaking the obtained powdery residual dregs into water with a pH value of 5 and a temperature of 40 DEG C for one hour to hydrolyze the amygdalin, and then extracting essential oil from the water solution by a water steam distillation method; wherein the distillation lasts for one hour. The invention further discloses an application of the bitter apricot kernel essential oil as a plant pathogenic fungus inhibitor. The extraction technology is simple, and the essential oil yield is high. The bitter apricot kernel has the advantages of low residue, safety, and easy degradation, and thus is a harmless plant-origin bacteriostatic agent.

Owner:NORTHWEST A & F UNIV

Airing method of Xinjiang Semaiti dried apricots

InactiveCN110521766AGood colorImprove qualityFruits/vegetable preservation by dehydrationGreenhouseDrying time

The invention provides an airing method of Xinjiang Semaiti dried apricots, which relates to the technical field of preparation of preserved fruits. According to the airing method, the idle sunlight greenhouse is used for airing the dried apricots, local materials are convenient to use, and the production and utilization efficiency of the dried apricots can be brought into full play; compared withtraditional natural open-field airing, the dried apricots aired in the sunlight greenhouse can be prevented from being influenced by adverse weather conditions such as strong wind, sand and dust andrain in an airing period, manpower input for carrying back and forth and the like can be reduced, meanwhile, sanitation and quality of products are guaranteed, and the drying time is shortened; the dried apricots aired in the sunlight greenhouse are good in color, good in quality and high in price, and the advantage that natural photo-thermal resources are sufficient from July to August in south Xinjiang can be fully utilized, so that the cost and the investment cost are saved to a certain extent compared with those of dried apricots aired in a coal-fired or electric heating drying room.

Owner:新疆林科院经济林研究所

Production method for quickly drying apricots in the sun

InactiveCN101653166AGood colorGreat tasteFruits/vegetable preservation by dehydrationEngineeringDried apricot

The invention discloses a production method for quickly drying apricots in the sun, which comprises the following steps of: screening mature apricots, washing the apricots, putting the apricots in a container, braising the apricots, and then taking out the apricots for standby application; selecting a flat ground serving as a drying place, uniformly layering a layer of support pad layer on the ground, and uniformly spreading the braised apricots for standby application on the support pad layer for continuously airing for 48h until the apricots are dry; batching the dry apricots, sequentially soaking the batched apricots in two boilers which are respectively filled with washing solution and sterile solution, wherein the soaking time of the apricots in the boiler filled with the sterile solution is less than that in the boiler filled with the washing solution; taking the sterilized apricots out of the pot and evenly spreading the apricots in the drying place for 2 hours; and then covering a layer of water absorbing cloth on the apricot layer for at least 10h, and packaging the apricots. The dried apricot slices prepared by the method are good in color and luster and mouthfeel, maintained in the original color of dried apricot slices, clean and bright, and short in production time.

Owner:苏力坦·马木提

Health-care fruit tea

Owner:李丹榕

Refreshing and anti-aging traditional Chinese medicine formula

InactiveCN112675240AEasy to makeLow costNervous disorderDigestive systemBiotechnologyMedicinal herbs

The invention provides a refreshing and anti-aging traditional Chinese medicine formula, and relates to the technical field of traditional Chinese medicine formulas. The refreshing and anti-aging traditional Chinese medicine formula consists of the following raw materials in parts by weight of 10-15 parts of lucid ganoderma, 10-15 parts of rhodiola rosea, 5-12 parts of radix astragali, 2-5 parts of Chinese dates, 3-6 parts of burdock, 1-3 parts of dried apricots, 1-3 parts of centella asiatica, 5-10 parts of cortex cinnamomi, 2-4 parts of lycopodium clavatum, 3-5 parts of herba taraxaci, 2-5 parts of echinacea purpurea, 1-2 parts of flax, 1-2 parts of gingko, 1-2 parts of fenugreek, 3-7 parts of green tea, 3-6 parts of radix glycyrrhizae, 2-4 parts of herba cirsii japonici and 4-6 parts of schisandra chinensis. The traditional Chinese medicine formula designed by the invention is simple to prepare, generally low in medicinal material cost, free of toxic and side effects, suitable for most middle-aged and elderly people, capable of effectively slowing down body aging of the middle-aged and elderly people, improving resistance, improving digestive ability, relieving fatigue, refreshing and recovering from fatigue, and extremely good in clinical effect.

Owner:宋义博

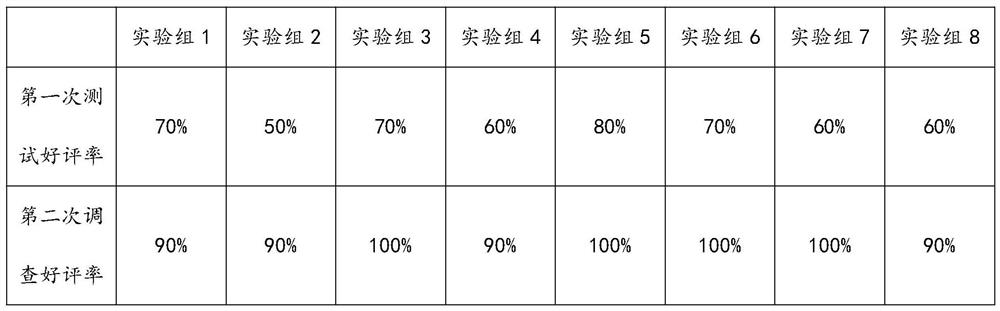

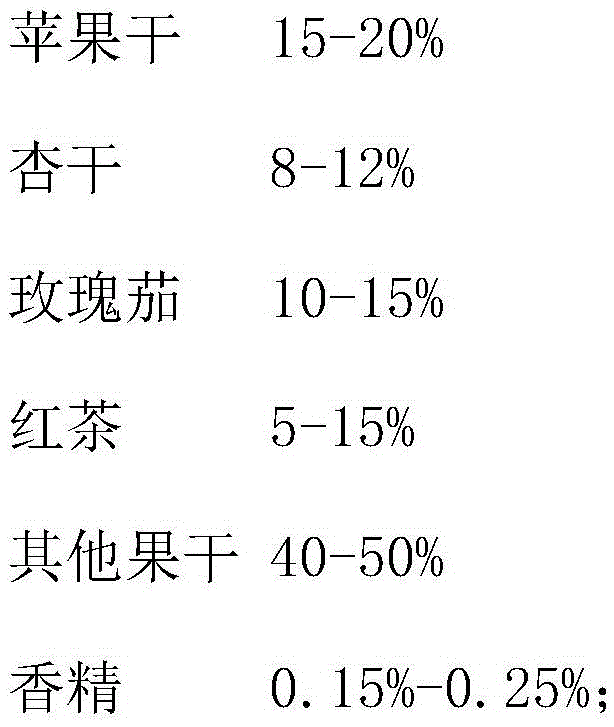

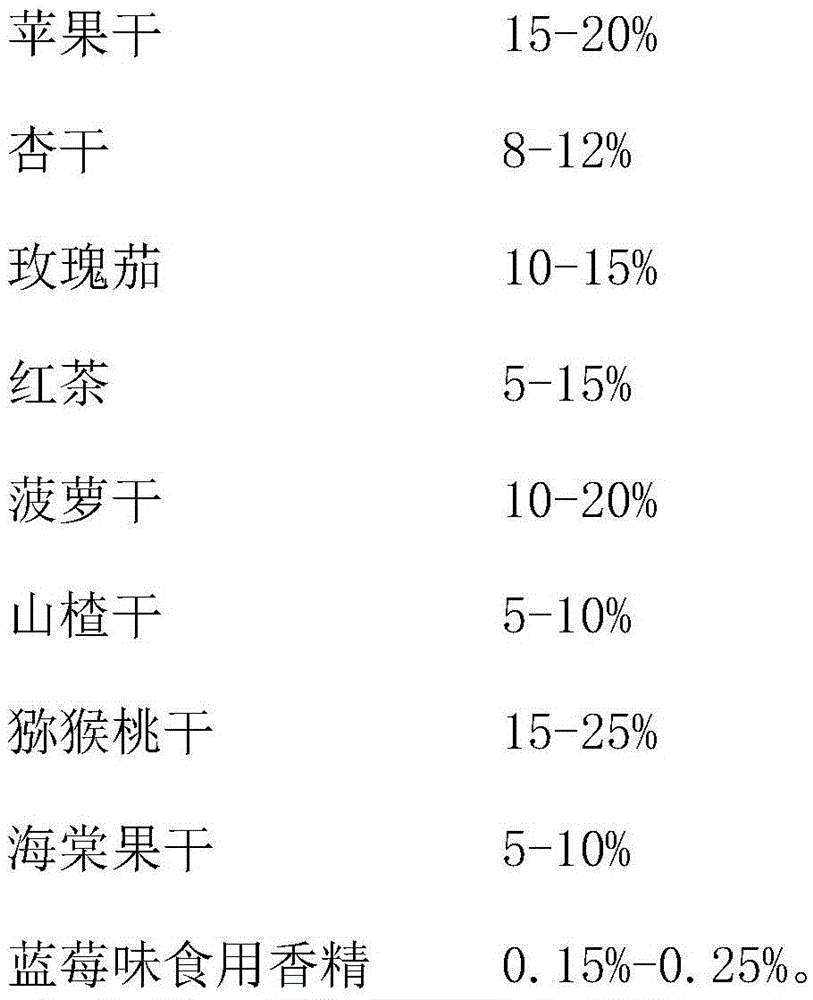

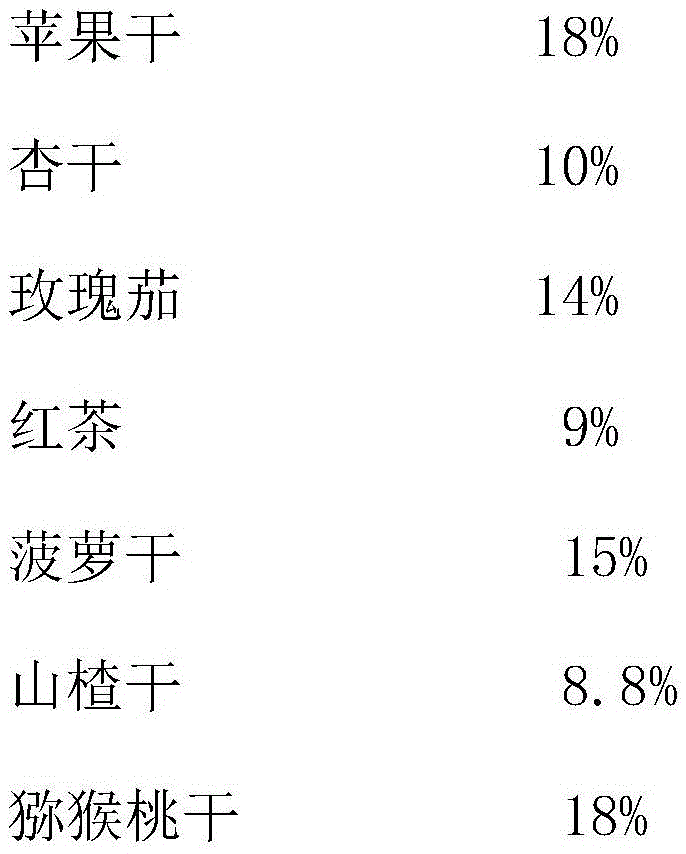

Blueberry-flavored fruit grain tea and preparation method thereof

The invention provides blueberry-flavored fruit grain tea and a preparation method thereof. The fruit grain tea comprises raw materials in percentage by weight as follows: 15%-20% of dried apple slices, 8%-12% of dried apricot slices, 10%-15% of hibiscus sabdariffa, 5%-15% of black tea, 40%-50% of other dried fruits and 0.15%-0.25% of essence. By comparison with the prior art, color matching of the blueberry-flavored fruit grain tea accords to aesthetic experience of people, the sizes of fruit grains are moderate, and the condition that dried fruit residues affect drinking and sale cannot be caused. Besides, the blueberry-flavored fruit grain tea has lasting and uniform blueberry flavor during drinking and has wide market prospect.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS

Bright bitter apricot seeds and preparation method thereof

InactiveCN105285867AReduce processing breakage rateImprove food safetyFood freezingNatural extract food ingredientsFlavorCyanide compound

The invention discloses bright bitter apricot seeds and a preparation method thereof, and belongs to the technical field of primary processing of bitter apricot seeds. The preparation method comprises the following steps of peeling, debitterizing and detoxifying the bitter apricot seeds serving as raw materials so as to obtain apricot seed cloves; then performing microwave drying so as to obtain dried apricot seed cloves; collecting bitter apricot seed peel, refrigerating the collected bitter apricot seed peel, crushing the refrigerated bitter apricot seed peel, uniformly mixing the crushed bitter apricot seed peel with debitterizing liquid, and performing enzymolysis and distillation twice so as to obtain an apricot seed peel extract; and then performing decoloration, mixing the apricot seed peel extract after the decoloration with the dried apricot seed cloves according to a certain proportion so as to obtain a mixture, and then stir-frying the mixture so as to obtain the bitter apricot seeds with natural flavor of the bitter apricot seeds, high smoothness and tidiness, high debitterizing rate (98.5-99.8%), significant detoxifying effects (the quantity of cyanide residues is 0.04-0.06mg / kg), long quality guarantee period (24-36 months) and low cost. The preparation method disclosed by the invention is simple in technology, short in cycle and high in efficiency, energy resources are saved, the large-scale production can be realized, zero discharge of toxic substances in the technical field of the primary processing of the bitter apricot seeds is realized, the preparation method is environment-friendly, and a new shortcut is explored for the deep processing of the bitter apricot seeds.

Owner:邵素英

Potato product or potato powder product and preparation method thereof

The invention belongs to the technical field of food processing, and particularly relates to a potato product or a potato powder product and a preparation method thereof. The potato product or the potato powder product comprises the following raw materials in parts by weight: 100 parts of the potato products or the potato powder products, 0-100 parts of ground meat or dried meat floss, 0-100 parts of dried fruits, 0-100 parts of nuts and 0-100 parts of chocolates, wherein the potato products or the potato powder products are in the shapes of pieces, balls, blocks or strips; meat selected for the ground meat or meat selected for the dried meat floss is beef, mutton, pork, chicken meat, duck meat or fish meat; the dried fruits are dried mangos, dried durians, raisins, dried strawberries, dried kiwi fruits, dried longans, dried waxberries, dried lemons or dried apricot pulp; the nuts are broad beans, pecans, pine nuts, macadamias, cashews, pistachios, peanuts, hazelnuts, shelled melon seeds or walnuts. The preparation method comprises the following steps: covering the ground meat or the dried meat floss, the dried fruits, the nuts or the chocolates on the potato products or the potato powder products; and packaging the potato products or the potato powder products and the ground meat or the dried meat floss, the dried fruits, the nuts or the chocolates. According to the potato product or the potato powder product and the preparation method thereof, people can enjoy multiple great tastes when having a bite of the potato products or the potato powder products.

Owner:孙明

Throat moistening and cough relieving tea and preparation method thereof

ActiveCN103636832AThe recipe is slow and moderateNo side effectsPre-extraction tea treatmentCooking & bakingCommon cold

The present invention discloses a throat moistening and cough relieving tea, wherein the raw materials comprise, by weight, 12-18 parts of dried orange peel, 5-10 parts of dried apricot, 5-12 parts of dried pear, 1-10 parts of green tea, and 2-5 parts of honey. The preparation method comprises: drying fresh orange peel, apricot flesh and white pear in a baking oven to obtain the dried orange peel, the dried apricot, the dried pear and the green tea, matching according to the weight part ratio, carrying out sterilization, uniform mixing, and crushing, adding a certain part of honey, uniformly stirring, and carrying out drying, crushing and bagging to prepare the teabag, wherein the obtained tea can be eaten after the teabag is infused for 3-5 min by using boiling water during use. The throat moistening and cough relieving tea has characteristics of slow and moderate formula, provides good treatment effects for dry and itching throat and cough caused by allergy, drying, smoking and the like, provides good prevention effects for cough caused by common cold, and can achieve effects of throat moistening, phlegm dissipating, body fluid regeneration and cough relieving.

Owner:江苏汉典生物科技股份有限公司

Plum syrup and preparation method thereof

InactiveCN107019134AWith activating blood and invigorating QiDigestive and greasySugar food ingredientsNatural extract food ingredientsNutritive valuesLicorice roots

The invention discloses plum syrup. The plum syrup is prepared from the following raw materials in parts by weight: 5 to 10 parts of dried apricot, 2 to 4 parts of pyracantha fortuneana fruit, 1 to 2 parts of licorice root, 0.4 to 0.8 part of tangerine peel and 1 to 2 parts of edible sugar. Liquid beverage or solid can be prepared by mixing the raw materials. The solid is plum syrup powder, an effervescing agent or plum syrup slices. The dried apricot and the pyracantha fortuneana fruit are taken as main materials of the plum syrup, and the licorice root, the tangerine peel and the edible sugar are taken as accessories. The defect that plum syrup is traditionally prepared from smoked plum, hawthorn and licorice root is overcome, and the plum syrup prepared from the dried apricot and the pyracantha fortuneana fruit is better than the traditional plum syrup in terms of soup color, taste and nutritive value, and is a good beverage product for relieving summer-heat, keeping healthy and preventing disease in summer.

Owner:ZUNYI MEDICAL UNIVERSITY

Fruit tea and preparation method thereof

InactiveCN108740227AIncrease resistanceWith health functionTea substituesZiziphus jujubaDried apricot

The invention relates to fruit tea and a preparation method thereof and relates to the technical field of substitute tea. The fruit tea comprises raw material in parts of by weight as follows: strawberry, mango, tomato, grapefruit, kunlunxueju, blueberry, medlar, dried apricot, banana, mint leaf, sugar cane, pear, white peony, sesame seed, plantain seed, aloe, Aatractylodes macrocephala, rock sugar, red jujube, dried longan, licorice, American ginseng. After adopting the above technical scheme, the beneficial effects of the invention are as follows: a variety of nutrient-rich fruits are added,a variety of vitamins and minerals in the body can be supplemented, some traditional Chinese medicine ingredients are added while the taste is not affected, and the fruit tea has healthcare functions, can clear heat and detoxify, promote digestion and enhance resistance.

Owner:陈伟清

Mangosteen enzyme nutrition liquid and preparation method thereof

InactiveCN106605920ATreating High CholesterolShort course of treatmentMetabolism disorderFood ingredient functionsYeastNutrient solution

The invention discloses mangosteen enzyme nutrition liquid and a preparation method thereof, and relates to the technical filed of enzyme nutrition liquid. The mangosteen enzyme nutrition liquid is prepared from the following raw materials in parts by weight: mangosteen fruits, dried apricot kernels, honey, oligosaccharides, glucose powder, dry yeast, and water. The preparation method of the mangosteen enzyme nutrition liquid comprises the following steps: peeling the mangosteen fruits, removing kernels from the peeled mangosteen fruits, and carrying pulping so as to prepare mangosteen pulp; decocting the dried apricot kernels with water so as to obtain an apricot kernel solution, and cooling the apricot kernel solution to 20-35 DEG C; blending the mangosteen pulp, the apricot kernel solution, the honey, the oligosaccharides and the dry yeast with the water, and containing the mixture in a container; sealing the container, and carrying out fermentation for 15-25 days so as to prepare a fermented liquid; and then, carrying out standing so as to obtain layered liquid, and carrying out filtering, so that the mangosteen enzyme nutrition liquid is prepared. Compared with prior art, the mangosteen enzyme nutrition liquid is capable of solving the problem of high cholesterol content.

Owner:LIUZHOU JINCHEN TECH

Preparation method for apricot powder

The invention discloses a preparation method for apricot powder. The apricot powder is prepared by, by weight, 55%-60% of dried apricots, 10% of almonds and 30%-35% of white granulated sugar. The apricot powder has the advantages that the nutrition is rich, the storage is convenient, and lumps are not generated when the materials are dissolved.

Owner:哈力克・艾力

Dried apricot confectionery and production method thereof

The invention relates to a dried apricot confectionery and a production method thereof. The dried apricot confectionery comprises raw materials of dried apricot, white granulated sugar, sorbic acid, citric acid and water and is prepared by selecting the dried apricot, blanching with sugar water, soaking, removing kernel and drying. The dried apricot confectionery obtained by applying the invention has the characteristics of bright color and luster, sour and sweet state and abundant nutrition. In addition, the defect that the production method or process of the apricot products is simpler is made up.

Owner:LUNTAI COUNTY XINGBAO FRUITS INDAL TRADE

Preparation method of licorice and herba cynomorii fruit tea

The present invention discloses a preparation method of licorice and herba cynomorii fruit tea. Impurity-free, mildew-free and worm-eaten-free licorice, herba cynomorii, Chinese prickly ash, red dates, haws, Chinese wolfberry fruits, longans, dried apples, raisins, walnut kernels and dried apricot kernels are respectively selected, the selected materials are put in a drying oven at 100 DEG C to bebaked for 30 min, the baked materials are then crushed using a crushing machine, stem-leaf-free and mildew-free roses and dried tangerine peels are selected, the selected materials are rinsed clean with clean water, the rinsed materials are baked at 60 DEG C for 30 min, then the baked materials are crushed using the crushing machine, compressed tea is selected to be crushed into tea powder usingthe crushing machine, water at 40 times of mass of a mixture is added, the mixture is cooked and filtered, crystal sugar, honey, 1% sodium benzoate, potassium sorbate, a stabilizer and water are added, and filling, inspecting, packaging and storing are conducted. The licorice and herba cynomorii fruit tea is simple in production processes and free of any food additive, integrates naturalness, nutritional value and health-care functions, and has better color and luster, taste and flavor than those of drink in the same type.

Owner:武威霖沐科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com