Debitterized and detoxified bitter apricot kernel and production method thereof

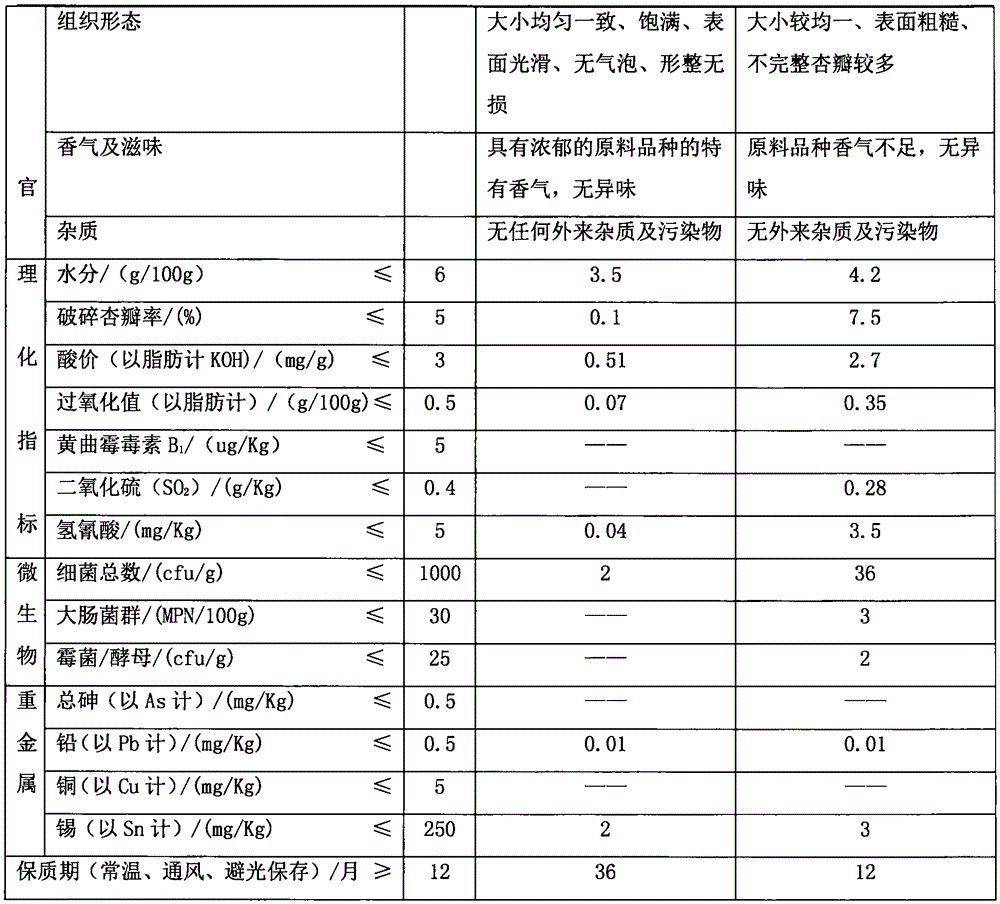

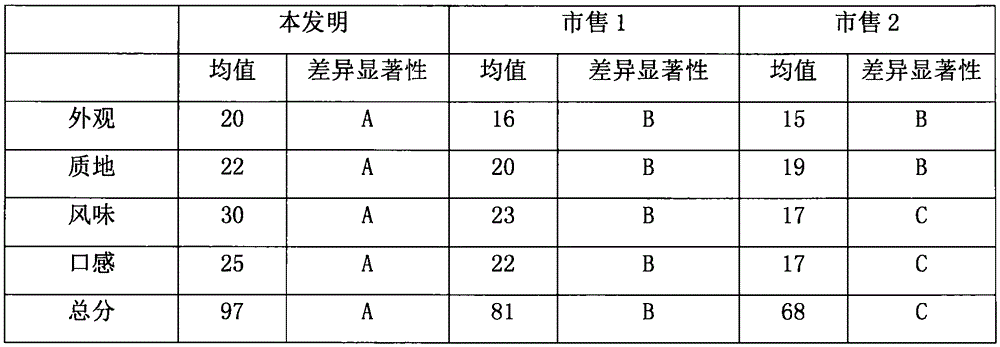

A technology for removing bitterness from bitter almonds, which is applied in food science, food preservation, and applications. It can solve the problems of affecting product appearance and natural flavor, losing the natural flavor of bitter almonds, and increasing the cost of separation processes. It achieves remarkable color fixation effects, Improvement of material exchange capacity and improvement of food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method for debittering and detoxifying bitter almonds, comprising the steps of:

[0039] 1) Preparation of dry almond petals: immerse bitter almonds in a sodium bicarbonate solution with a concentration of 0.08% by mass, rinse at room temperature, drain, put in a container to seal, let it stand for moistening for 3 hours, and peel off the peeled almond petals. Freeze at -23°C, material layer thickness 3cm for 2 hours, take it out, microwave pre-drying for 3 minutes to get pre-dried almond petals; add 3 times its mass of citric acid solution with a mass percentage concentration of 0.2%, soak at room temperature for 3 hours, take it out, and put it on a stainless steel screen Clean water circulation and spray for 15 minutes, then transfer to 2.2% calcium ascorbate solution with twice the weight of pre-dried almond petals, soak for 4 hours, drain, microwave dry for 6 minutes to obtain dry almond petals;

[0040] The microwave pre-drying conditions are: freque...

Embodiment 2

[0050] A preparation method for debittering and detoxifying bitter almonds, comprising the steps of:

[0051]1) Preparation of dry almond petals: immerse bitter almonds in a sodium bicarbonate solution with a concentration of 0.06% by mass, rinse at room temperature, drain, put in a container to seal, let it stand for moistening for 2 hours, and peel the peeled almond petals in -20°C, material layer thickness 2cm, freeze for 1.5h, take it out, microwave pre-drying for 2min to get pre-dried almond petals; add twice its mass of 0.1% citric acid solution, soak at room temperature for 2h, take it out, put it on a stainless steel sieve Circulate and spray clean water on the net for 10 minutes, then transfer to 1.5% calcium ascorbate solution of 1.5% by mass of pre-dried almond petals, soak for 3 hours, drain, and microwave dry for 4 minutes to obtain dried almond petals;

[0052] The microwave pre-drying conditions are: frequency 2450MHz, power 1000W, temperature 80°C, material lay...

Embodiment 3

[0062] A preparation method for debittering and detoxifying bitter almonds, comprising the steps of:

[0063] 1) Preparation of dry almond petals: immerse bitter almonds in 0.1% sodium bicarbonate solution by mass percentage, rinse at room temperature, drain, put in a container to seal, let it stand for moistening for 4 hours, and peel the peeled almond petals in -25°C, material layer thickness 4cm, freeze for 2.5h, take it out, microwave pre-drying for 4min to get pre-dried almond petals; add 4 times its mass of 0.3% citric acid solution, soak at room temperature for 4h, take it out, put it on a stainless steel sieve Spray and wash with clean water on the net for 20 minutes, then transfer to a calcium ascorbate solution with a mass percentage concentration of 3% of the pre-dried almond petals, soak for 5 hours, drain, and microwave dry for 8 minutes to obtain dried almond petals;

[0064] The microwave pre-drying conditions are: frequency 2450MHz, power 1500W, temperature 90°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com