A kind of manufacturing method of special aluminum foil material for bottle caps

A manufacturing method and technology of aluminum foil, applied in metal rolling and other directions, can solve the problems of low production efficiency and yield, influence of painting and glazing effects, and easy oxidation of aluminum foil, so as to reduce oxidative corrosion, improve surface quality and Paint quality, excellent bake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

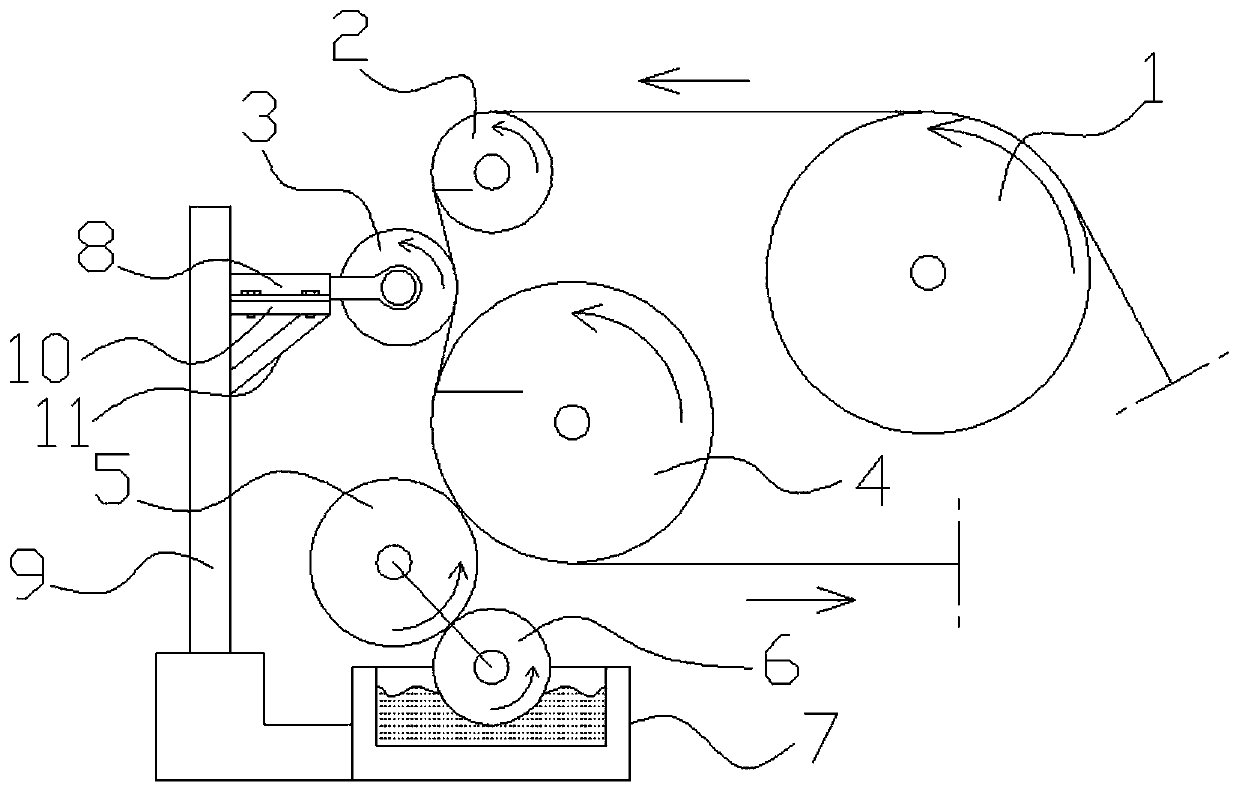

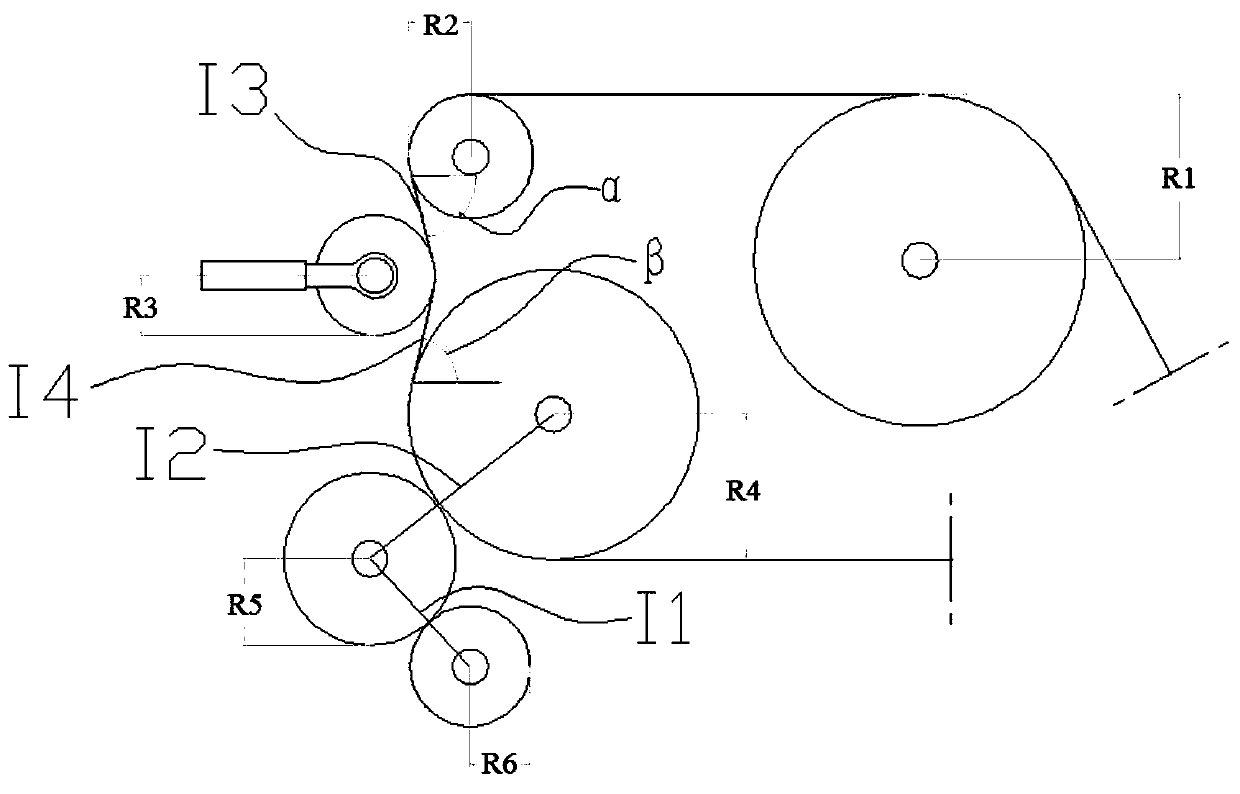

Method used

Image

Examples

Embodiment 1

[0024] A method for manufacturing a special aluminum foil material for bottle caps, characterized in that the alloy composition and weight percentage in the special aluminum foil material for bottle caps are: Fe, Si mixture 0.99%, Cu 0.04%, Mn 0.04%, Mg 0.03%, Zn 0.03%, Ti 0.055%, and the balance is Al.

[0025] Its manufacturing method comprises the following specific steps:

[0026] a: Melting, casting and rolling: Select a specific aluminum alloy ingot according to the composition and weight percentage of the alloy, and add the aluminum alloy ingot to a large-capacity regenerative melting furnace, and melt it at 735°C and 725°C respectively and refining. After the refining is completed, the aluminum melt is obtained. The aluminum melt enters the front box of the casting and rolling machine through the launder, and is cast and rolled by the casting and rolling machine. The thickness of the aluminum foil blank after casting and rolling is 6.0±0.4mm;

[0027] b: Intermediate ...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that it is a method for manufacturing a special aluminum foil material for bottle caps. It is characterized in that the alloy composition and weight percentage in the special aluminum foil material for bottle caps are: Fe, Si Mixture 1.22%, Cu 0.03%, Mn 0.02%, Mg 0.06%, Zn 0.04%, Ti 0.065%, and the balance is Al.

[0040] Its manufacturing method comprises the following specific steps:

[0041] a: Melting, casting and rolling: select a specific aluminum alloy ingot according to the alloy composition and weight percentage, and add the aluminum alloy ingot to a large-capacity regenerative melting furnace, and melt it at 745°C and 730°C respectively and refining. After the refining is completed, the aluminum melt is obtained. The aluminum melt enters the front box of the casting and rolling machine through the launder, and is cast and rolled by the casting and rolling machine. The thickness of the aluminum foil bla...

Embodiment 3

[0048] The difference between this embodiment and Embodiments 1 and 2 is that it is a method for manufacturing a special aluminum foil material for bottle caps, which is characterized in that the alloy composition and weight percentage in the special aluminum foil material for bottle caps are: Fe , Si mixture 1.45%, Cu 0.03%, Mn 0.01%, Mg 0.03%, Zn 0.03%, Ti 0.065%, and the balance is Al.

[0049] Its manufacturing method comprises the following specific steps:

[0050] a: Melting, casting and rolling: Select a specific aluminum alloy ingot according to the composition and weight percentage of the alloy, and add the aluminum alloy ingot to a large-capacity regenerative melting furnace, and melt it at 750°C and 730°C respectively and refining. After the refining is completed, the aluminum melt is obtained. The aluminum melt enters the front box of the casting and rolling machine through the launder, and is cast and rolled by the casting and rolling machine. The thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com