Patents

Literature

3869 results about "Diffraction grating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

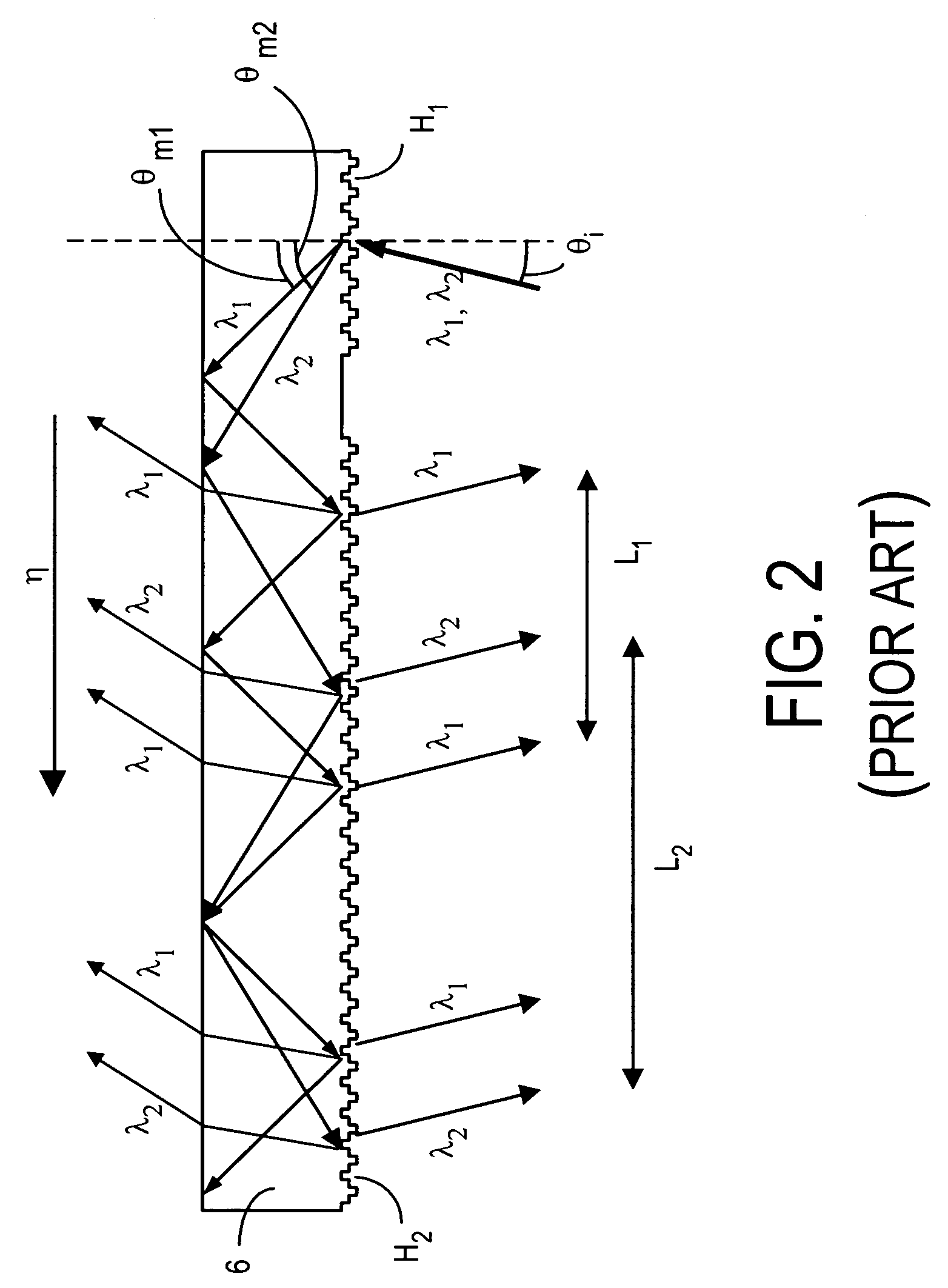

In optics, a diffraction grating is an optical component with a periodic structure that splits and diffracts light into several beams travelling in different directions. The emerging coloration is a form of structural coloration. The directions of these beams depend on the spacing of the grating and the wavelength of the light so that the grating acts as the dispersive element. Because of this, gratings are commonly used in monochromators and spectrometers.

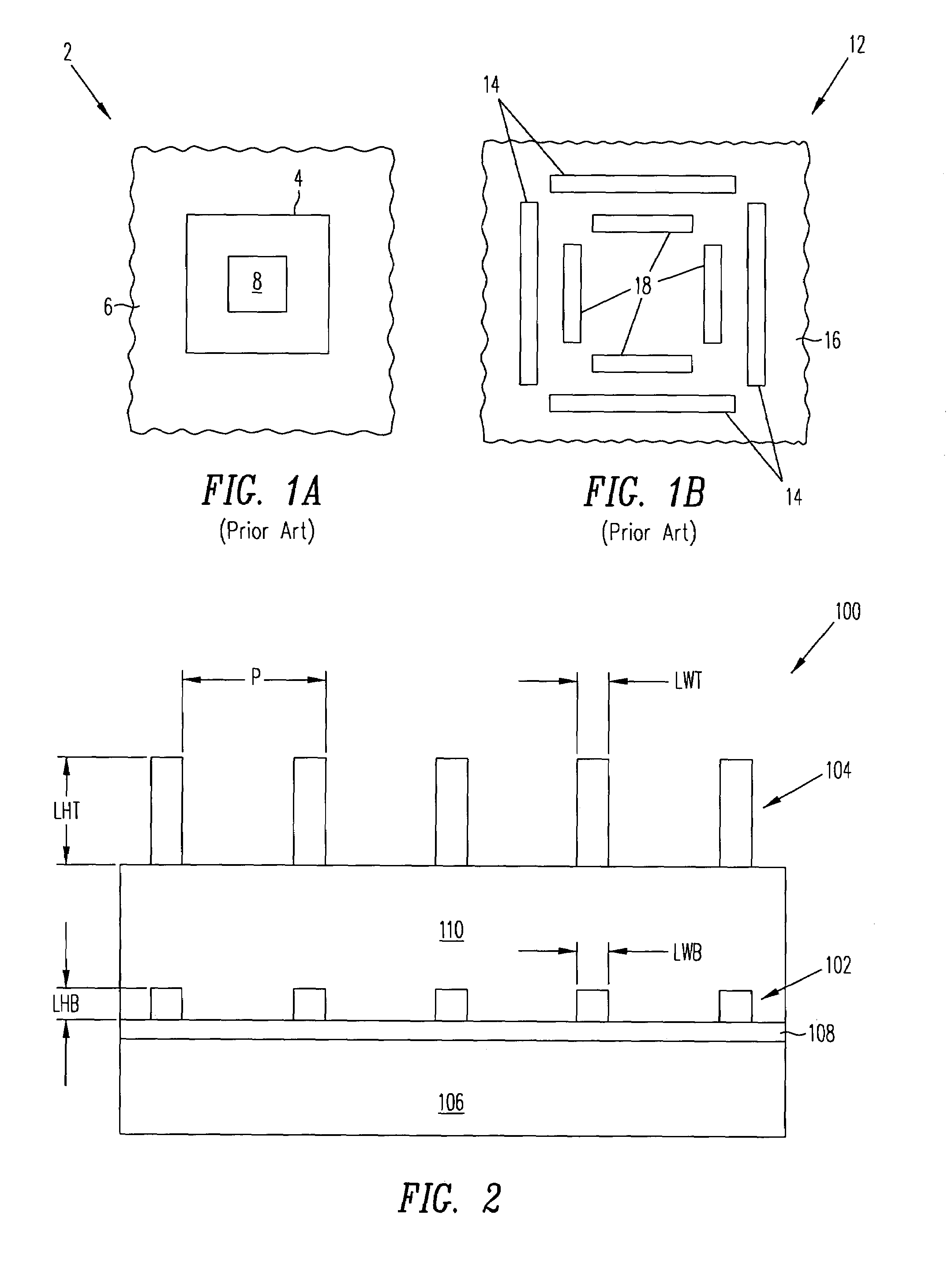

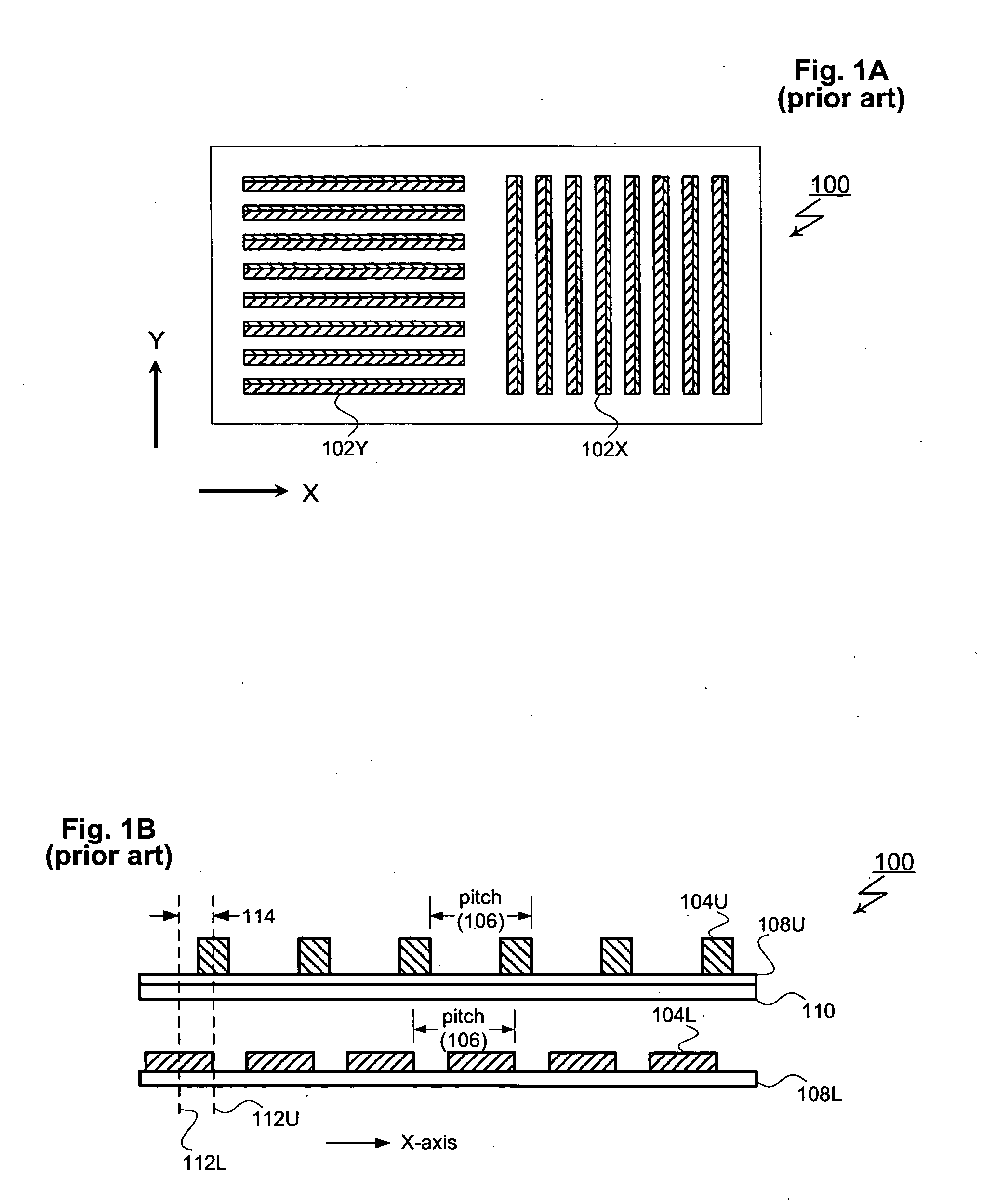

Overlay alignment metrology using diffraction gratings

InactiveUS6819426B2Accurate measurementLimited space availableSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMetrologyAngle of incidence

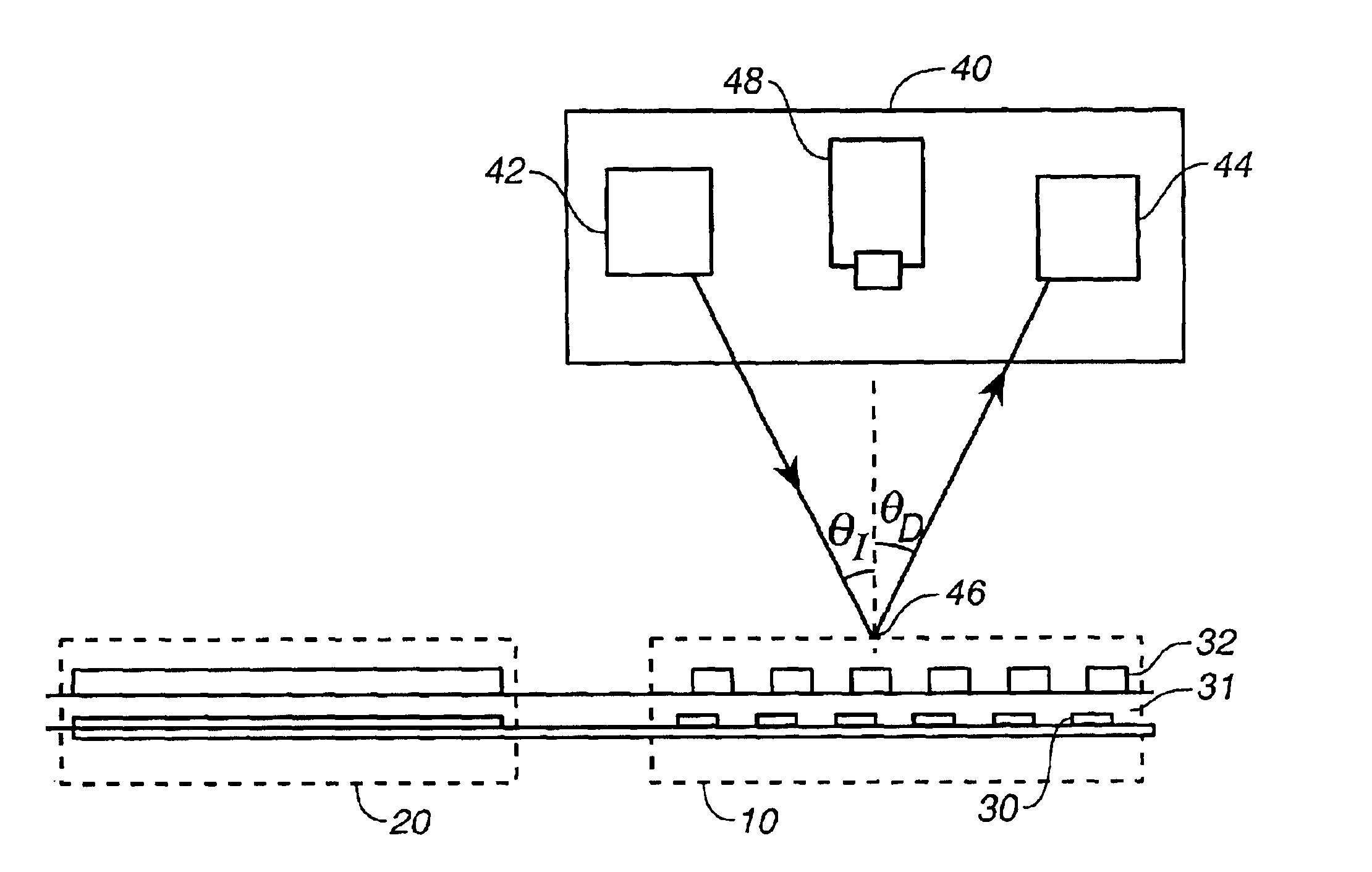

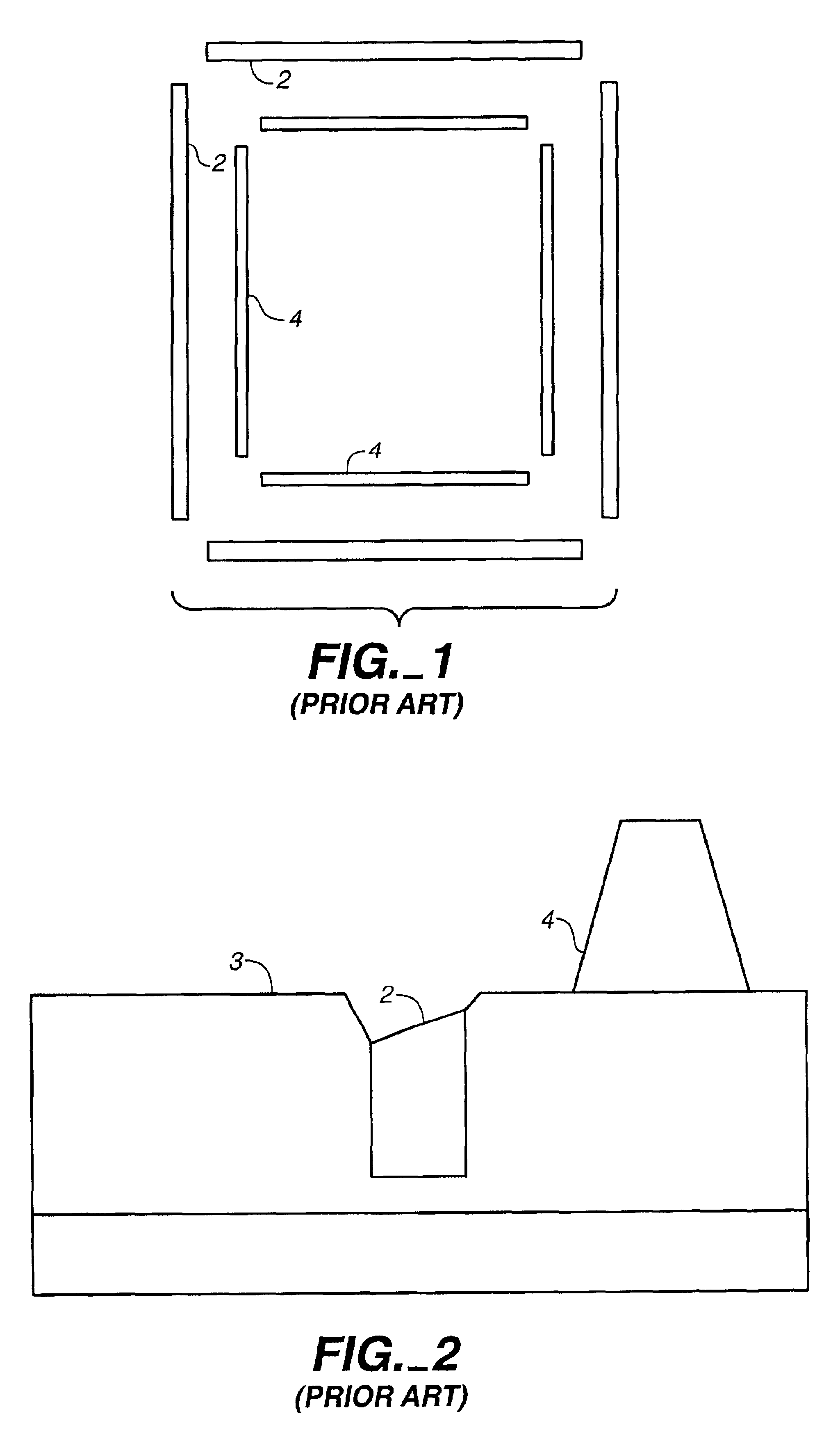

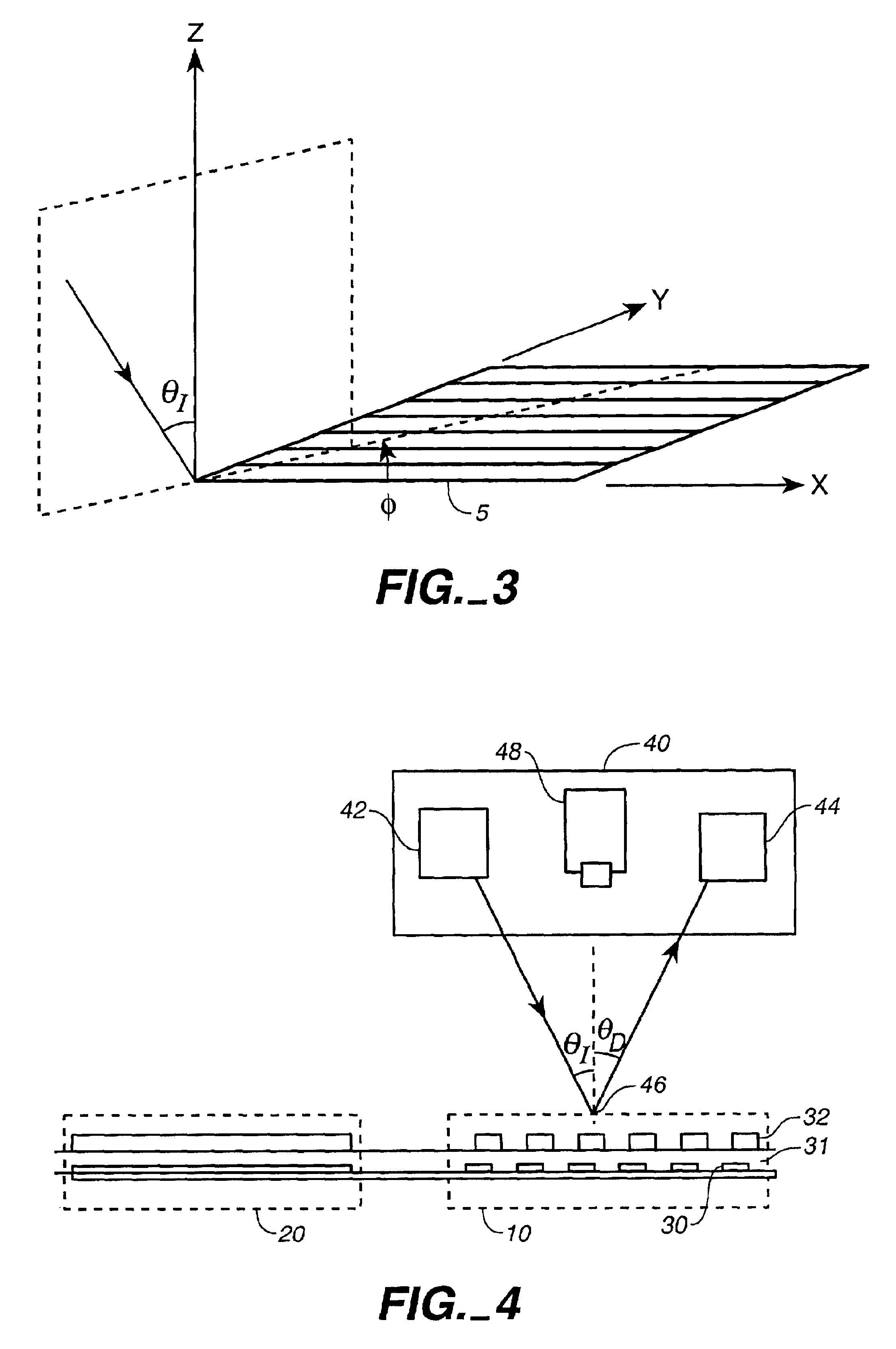

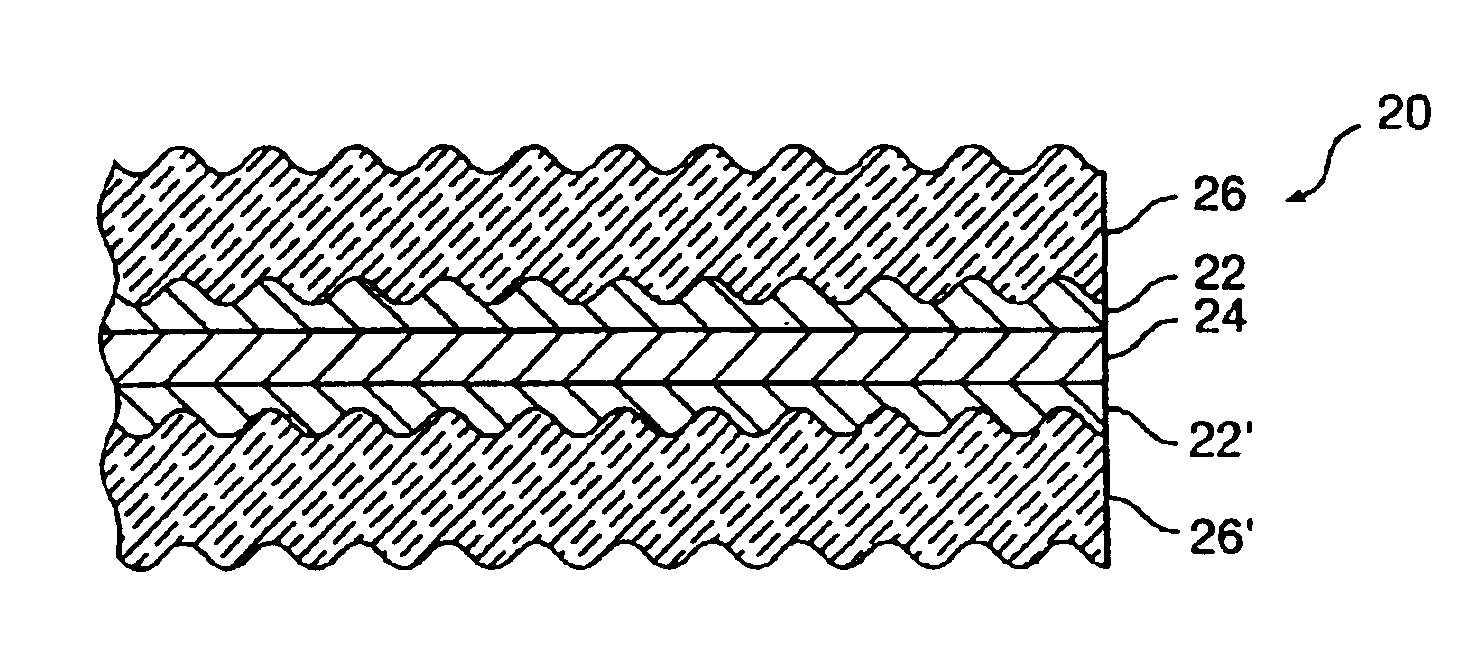

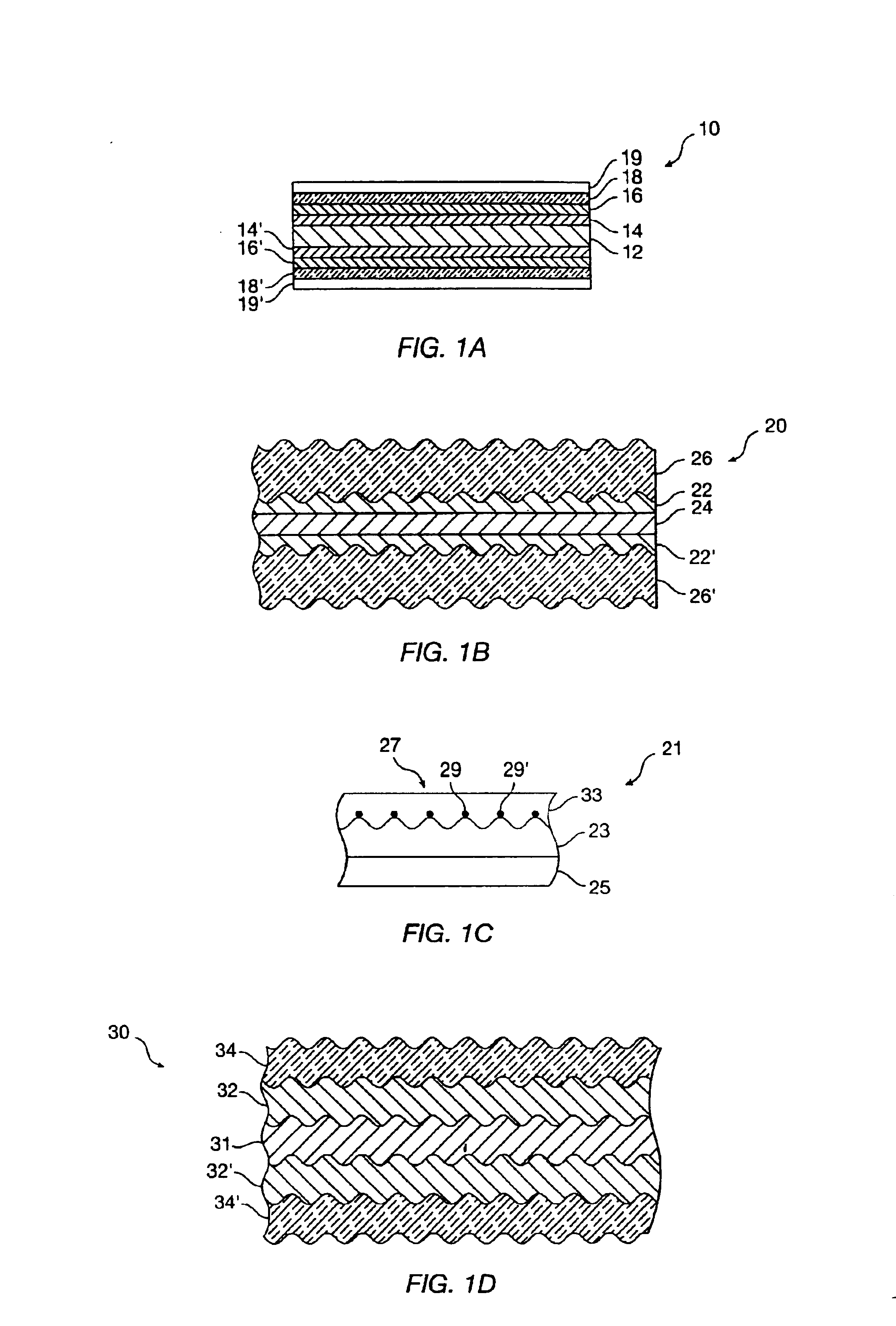

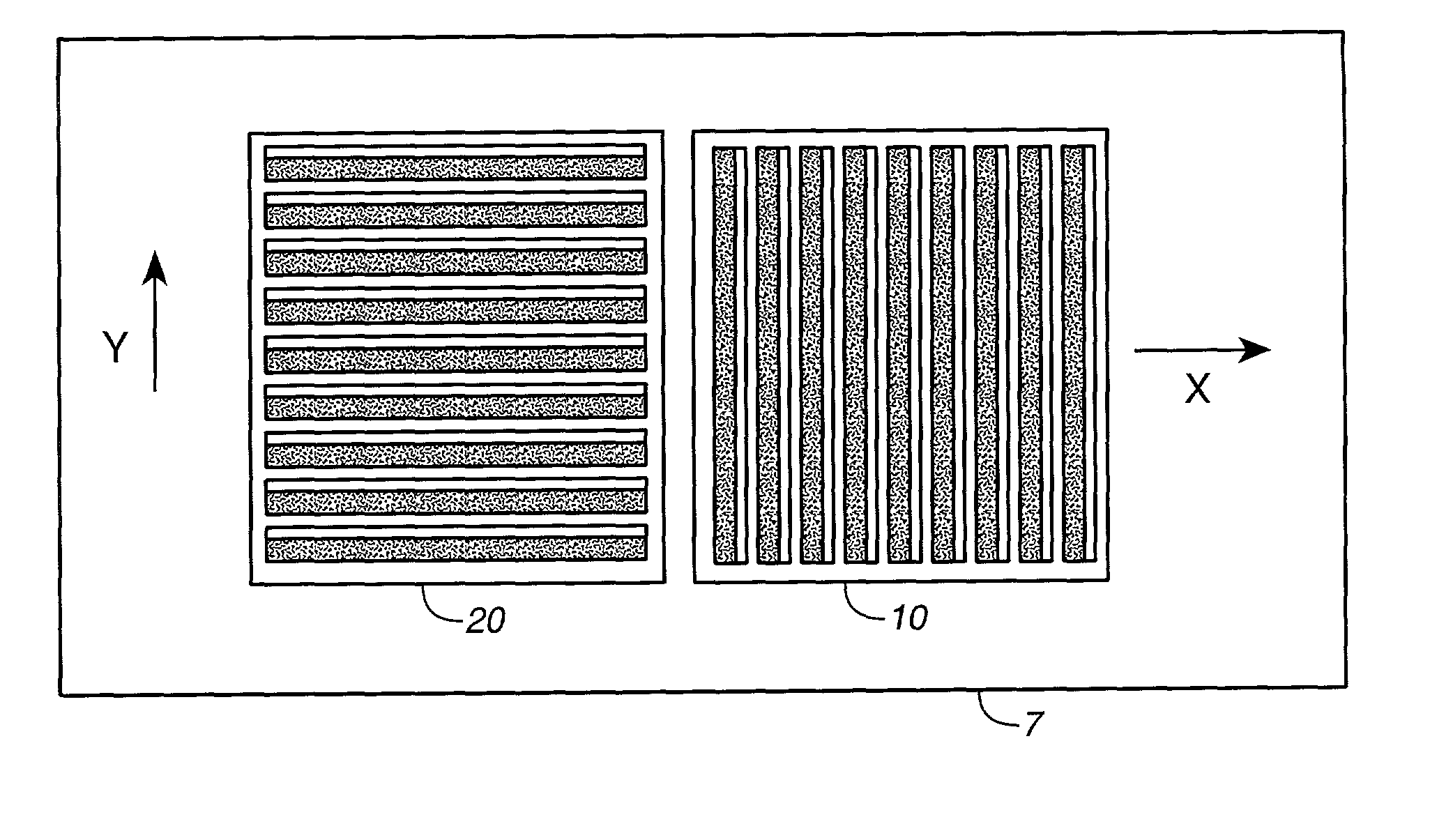

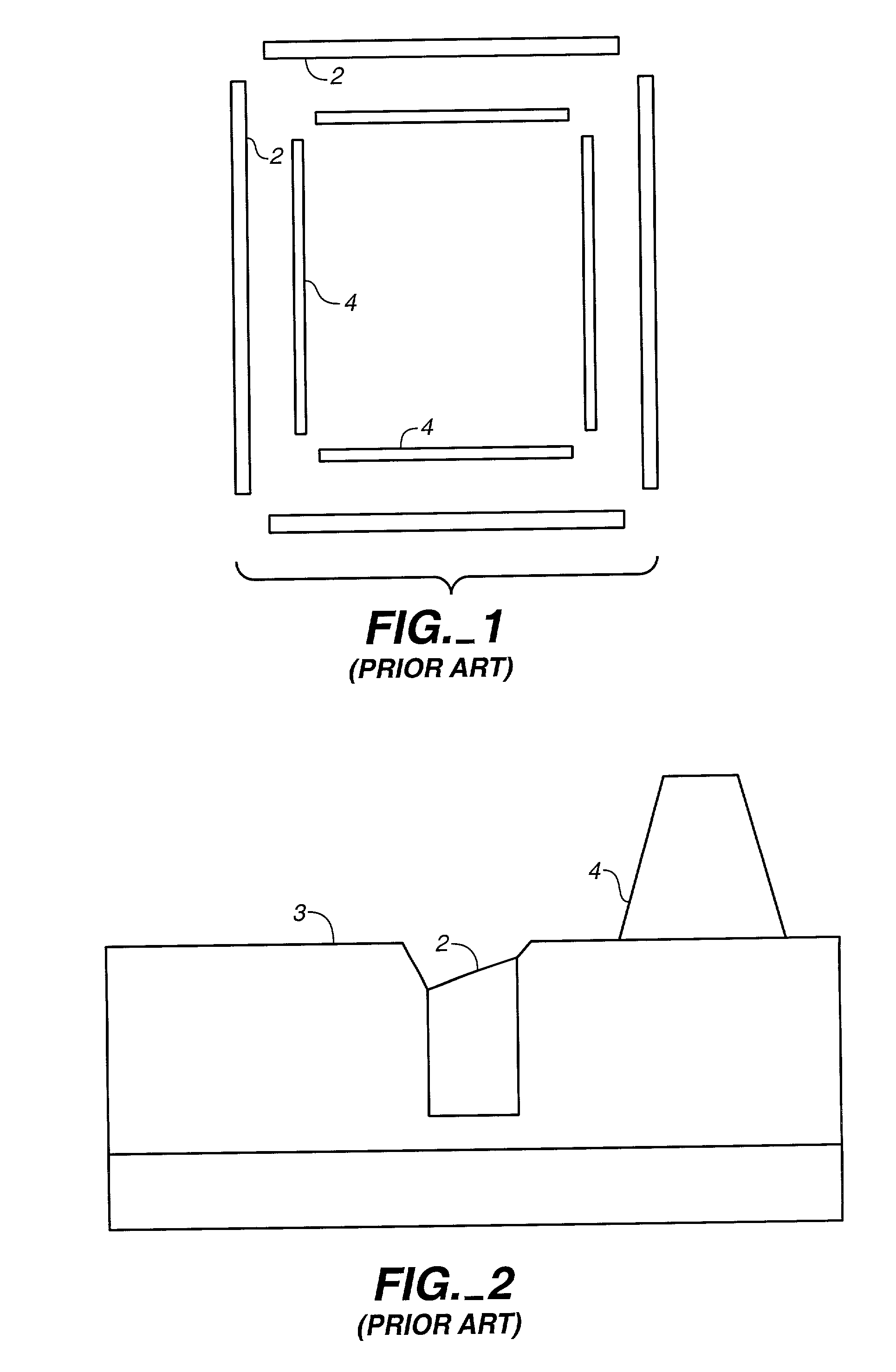

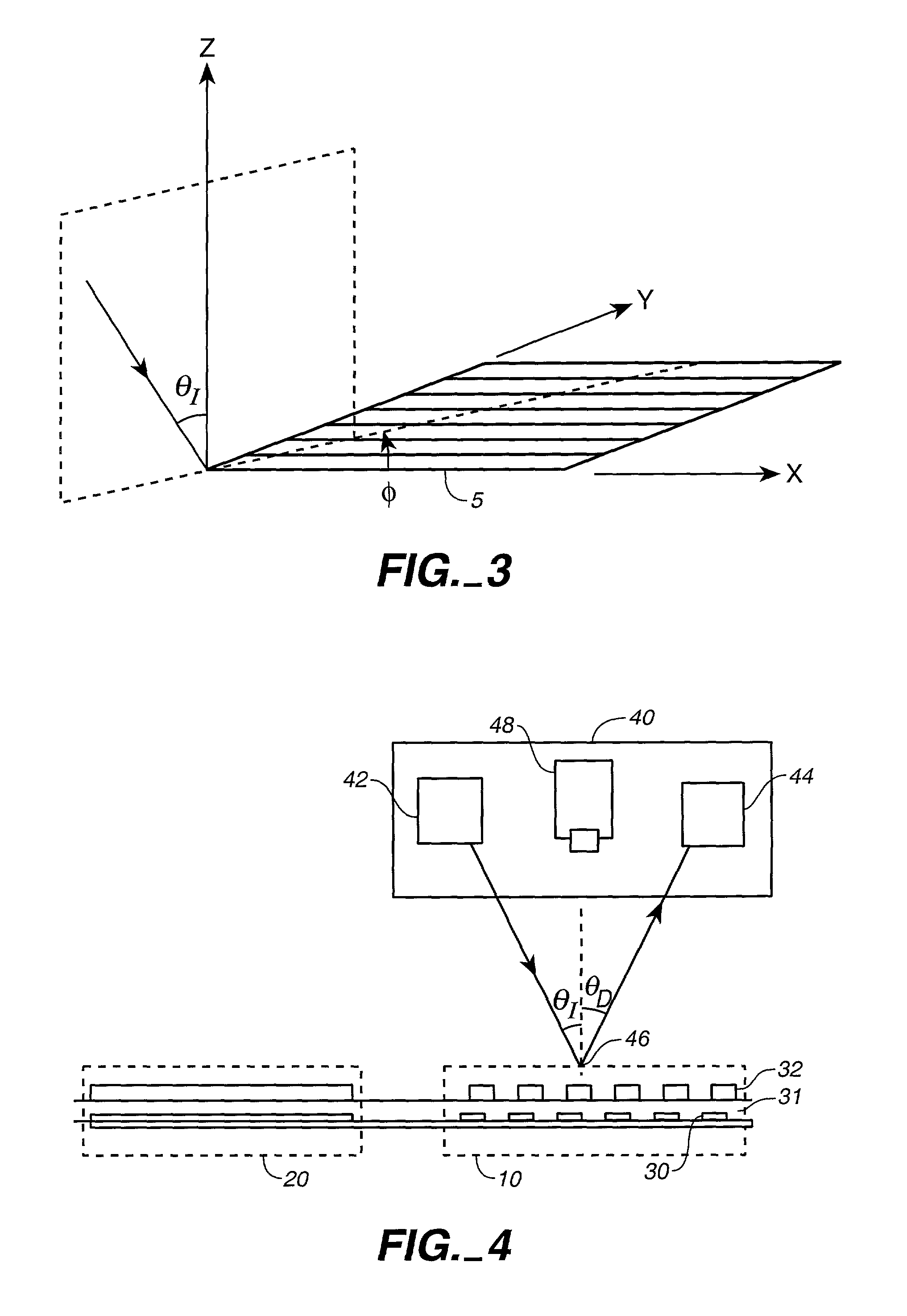

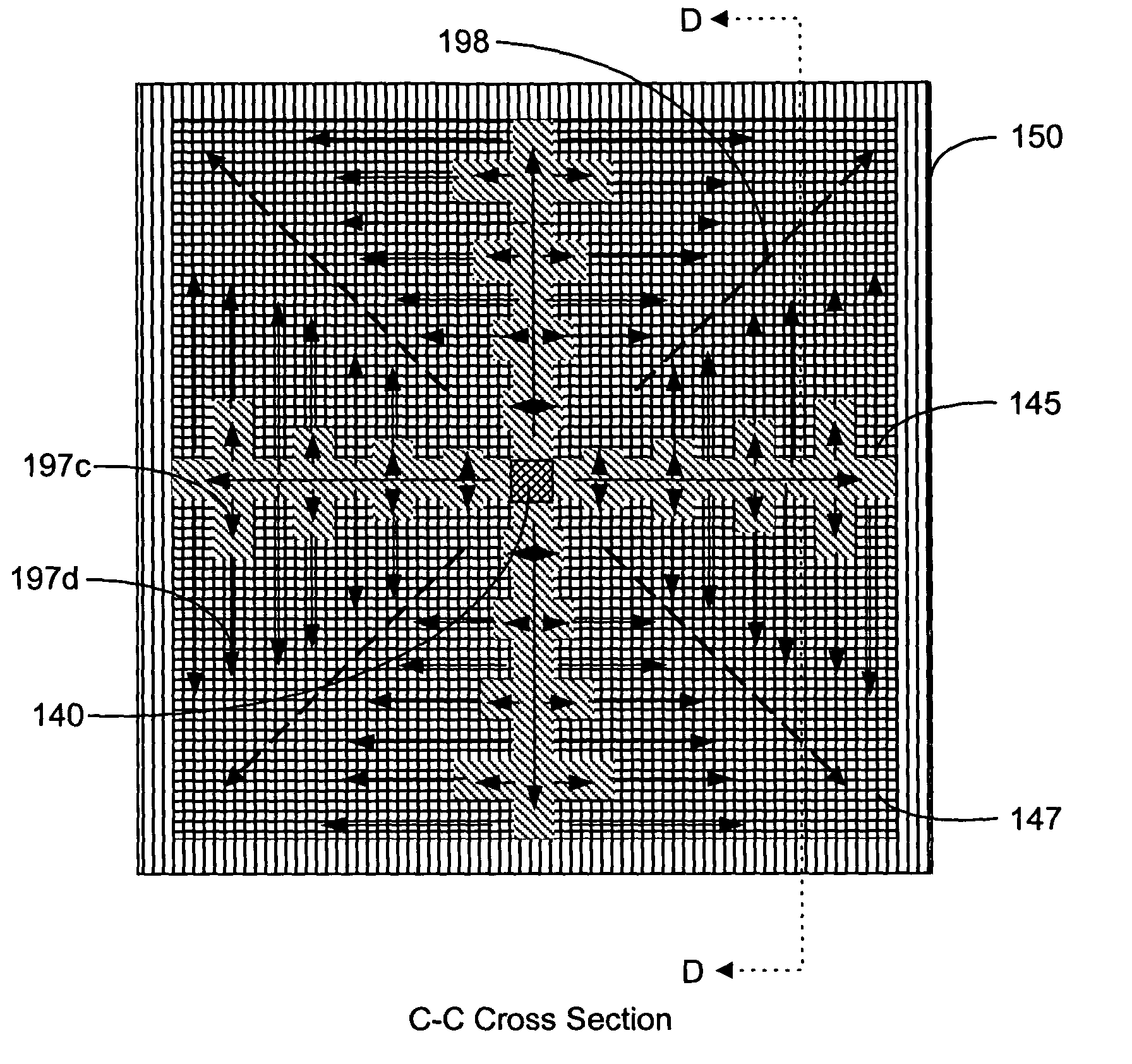

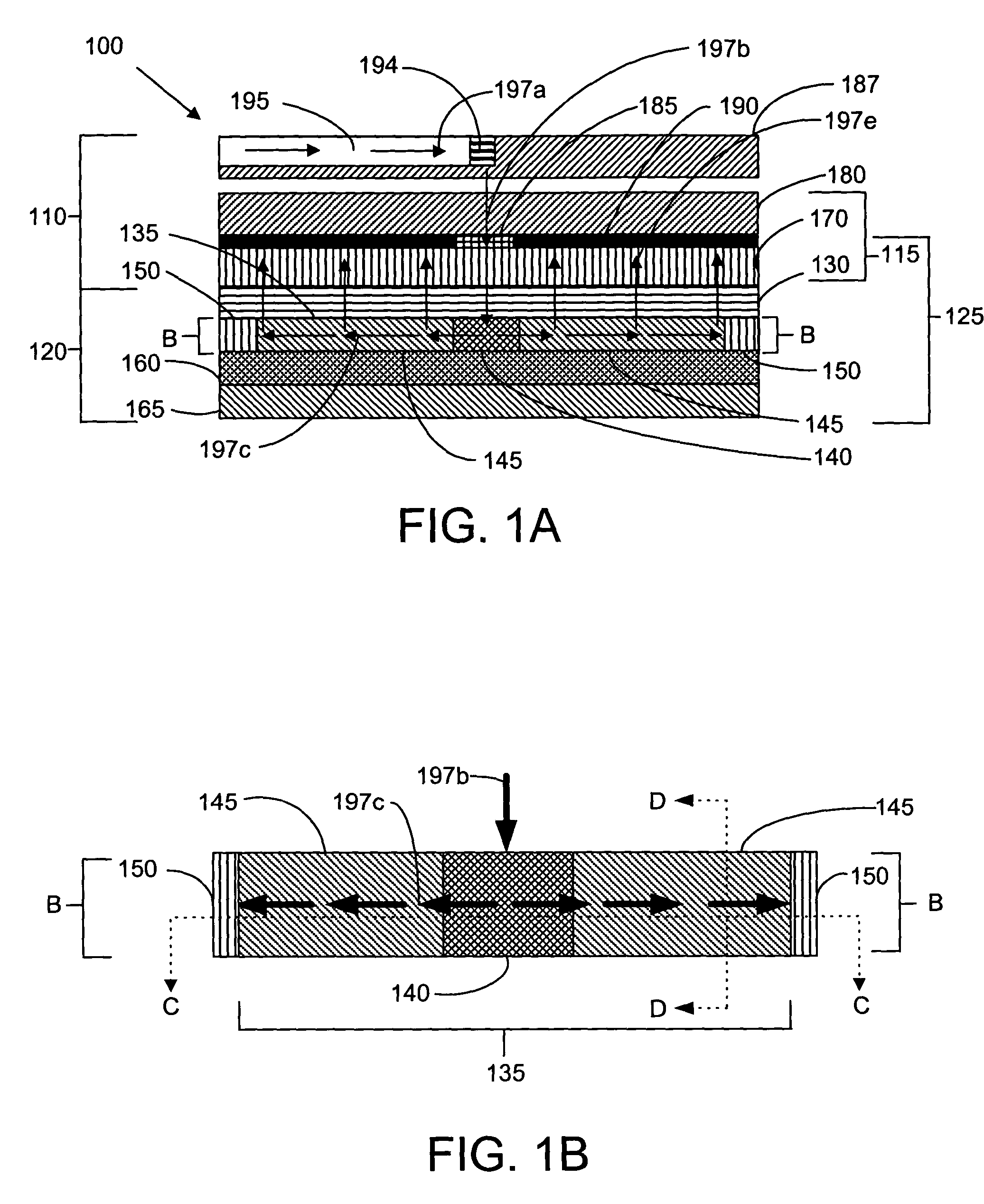

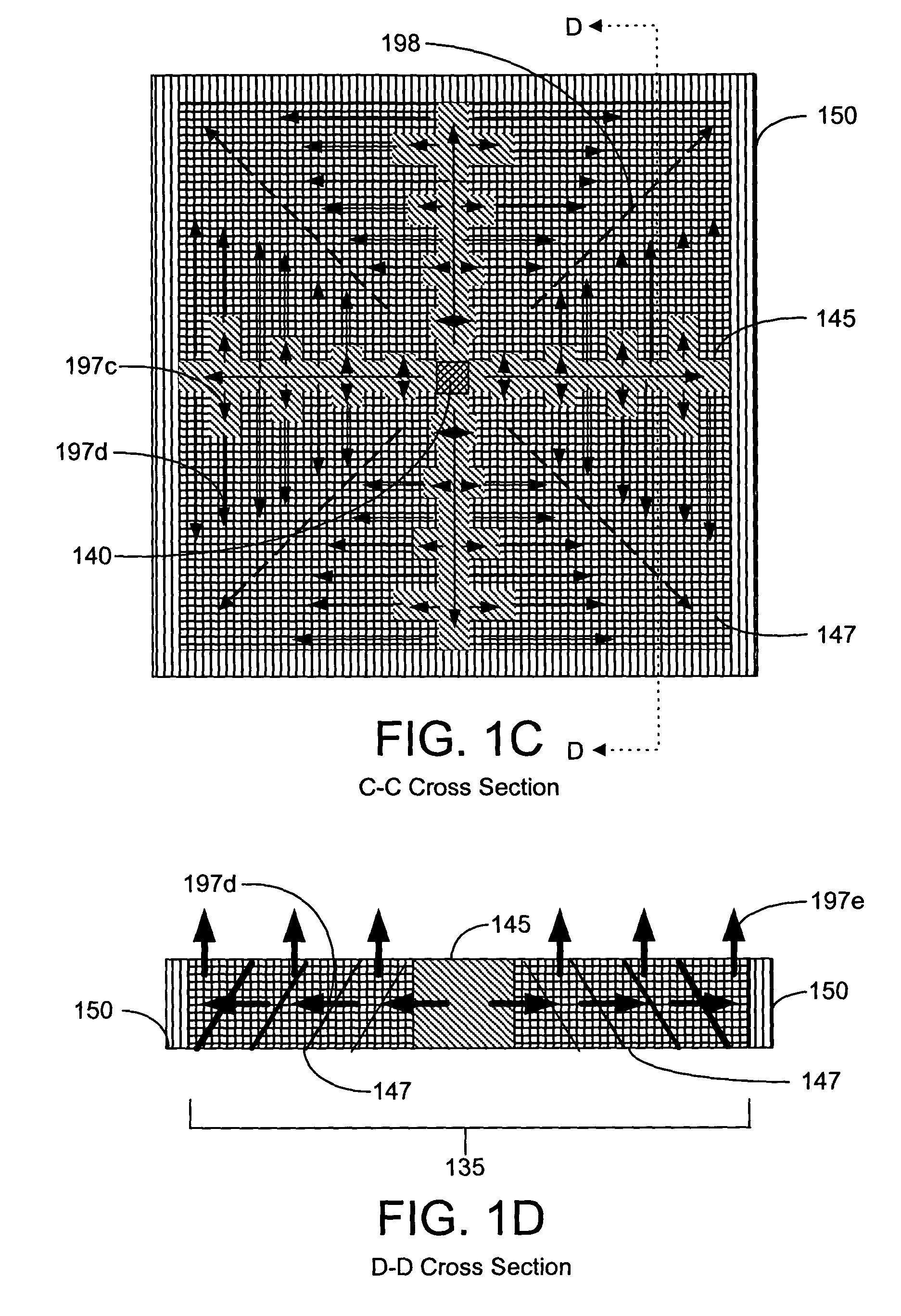

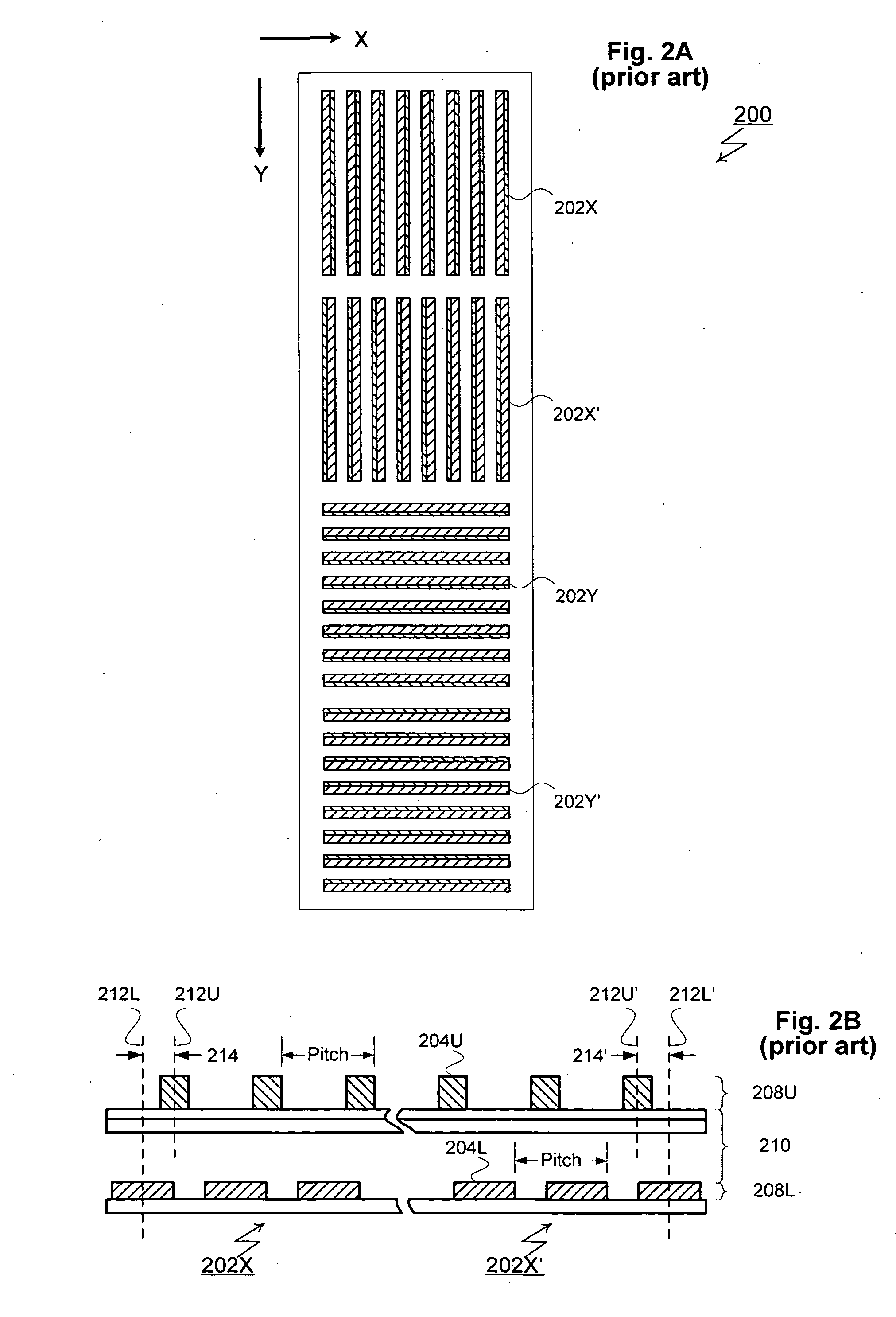

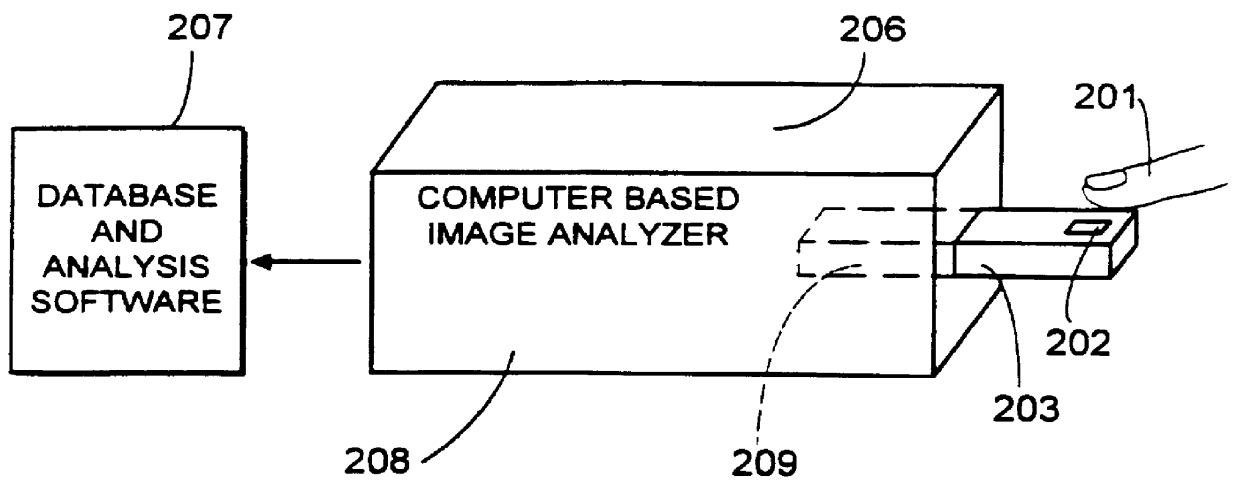

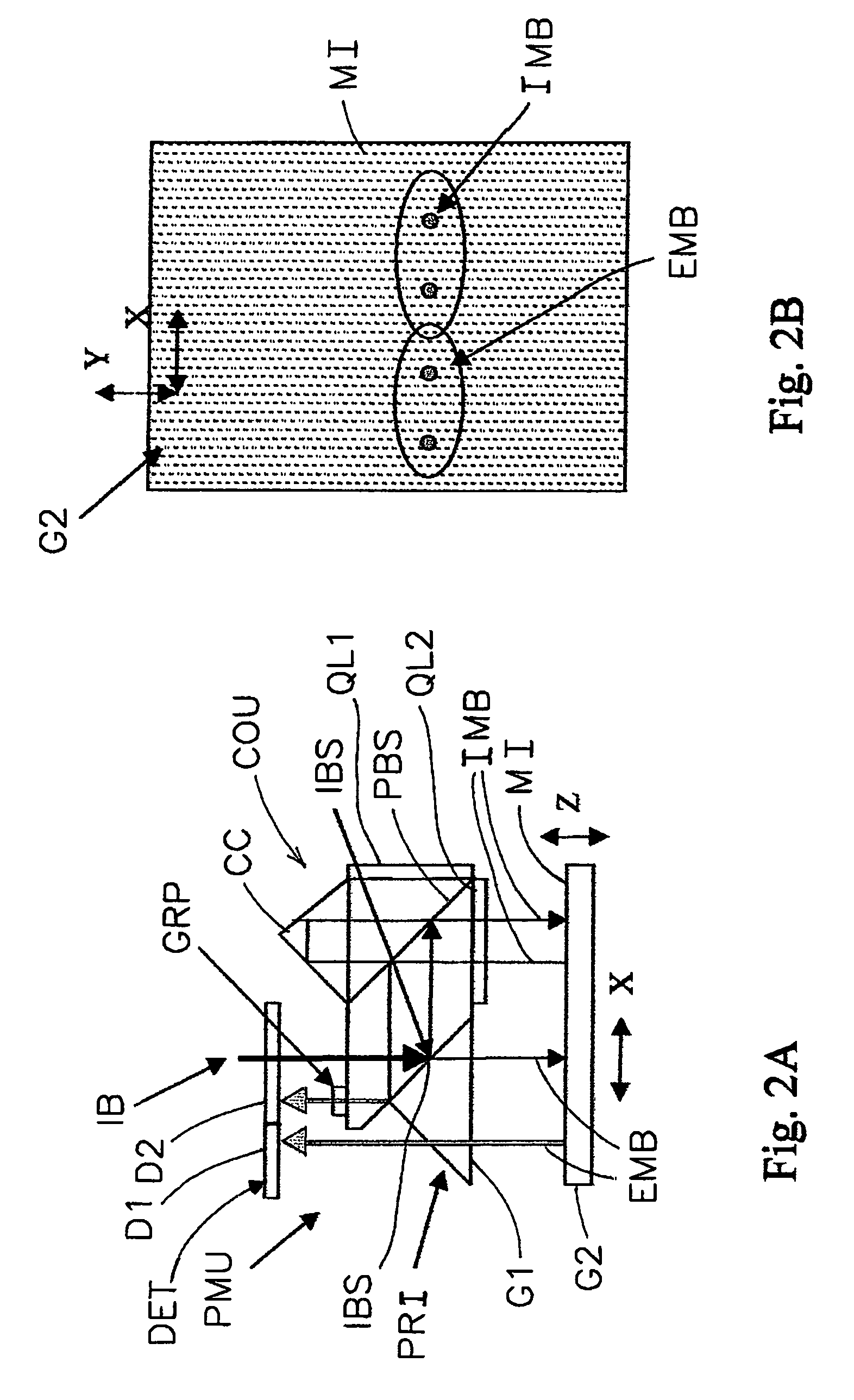

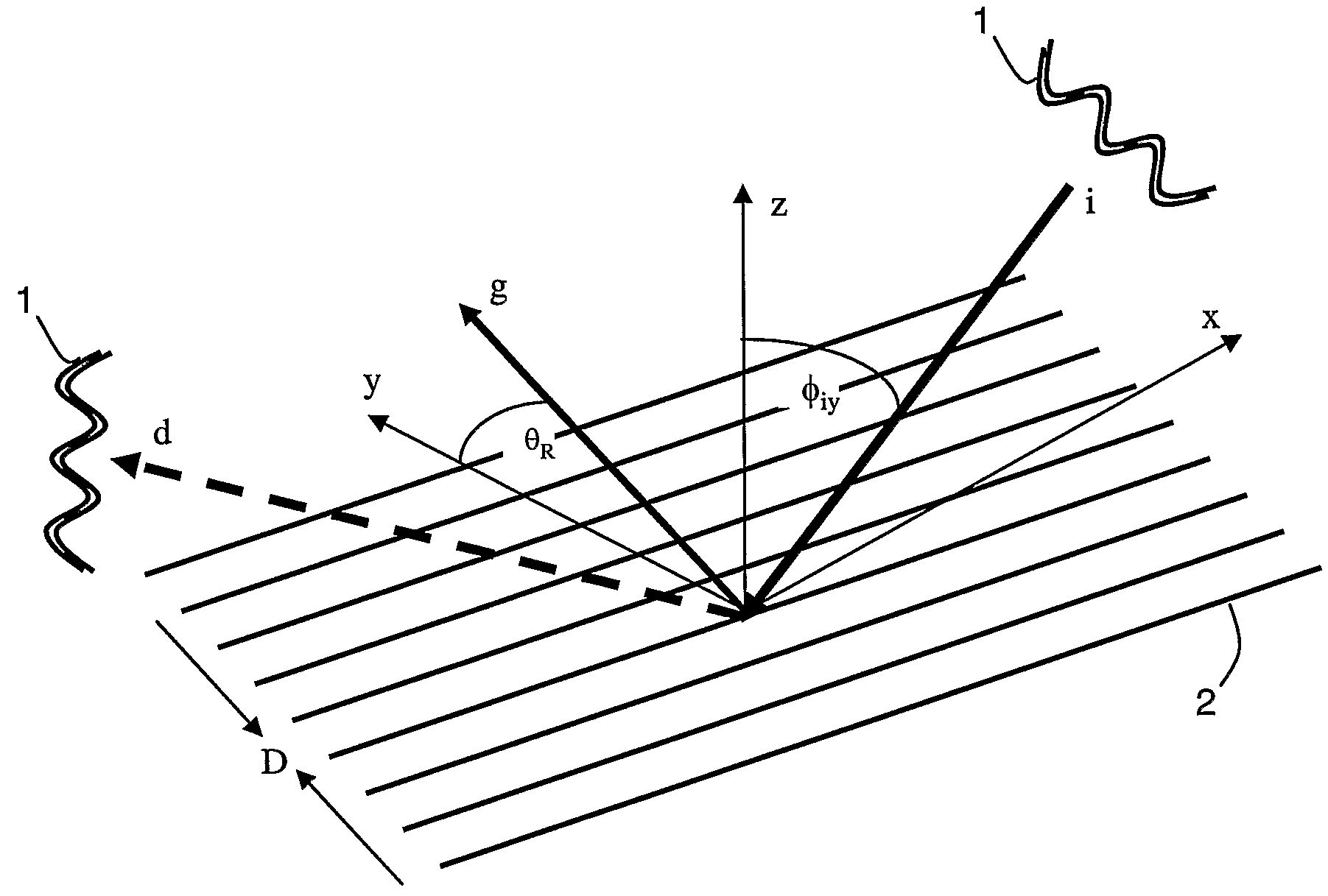

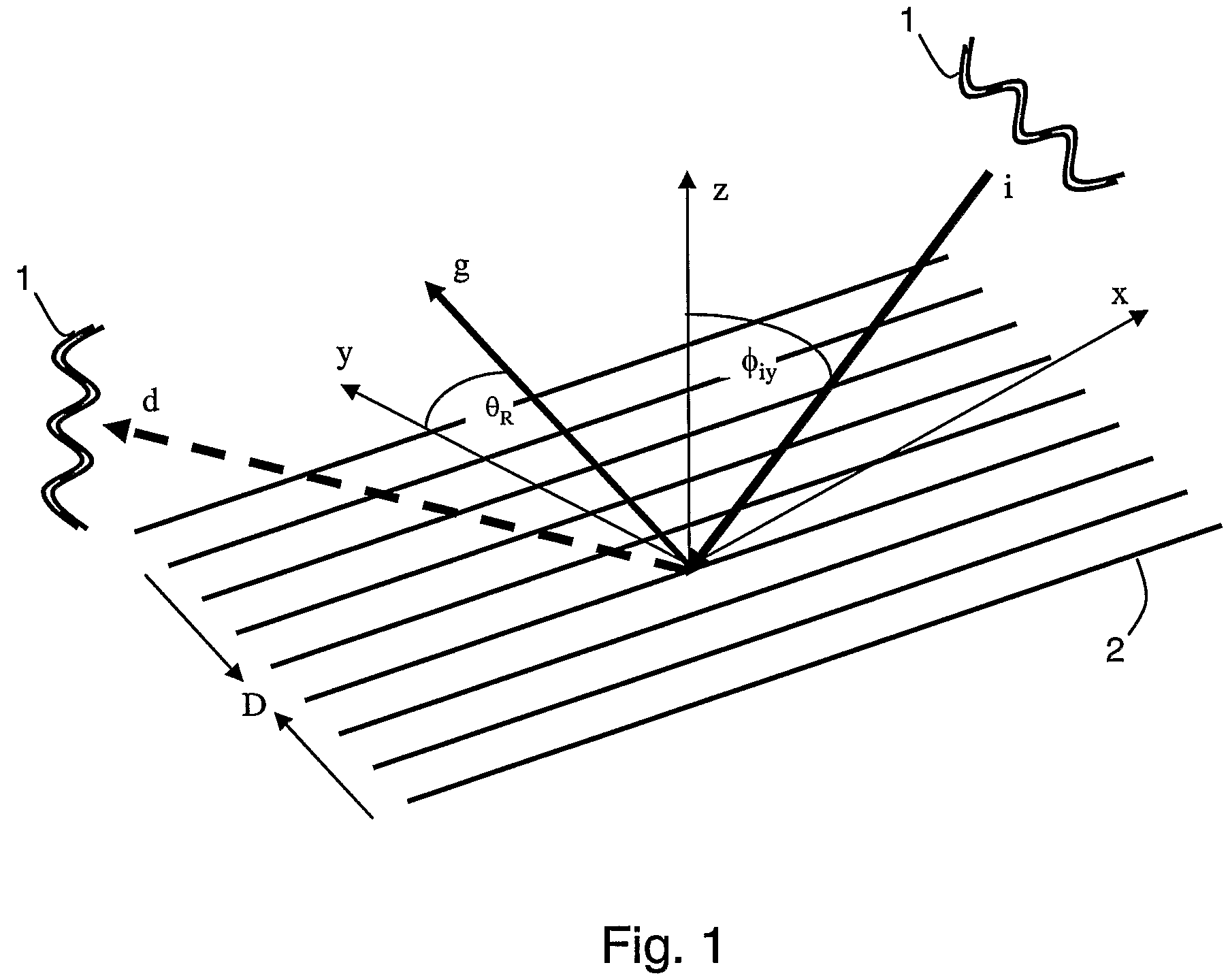

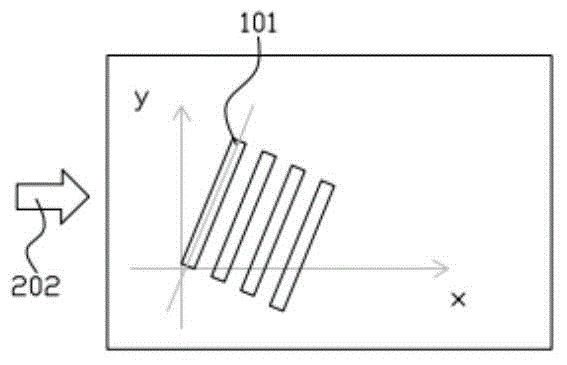

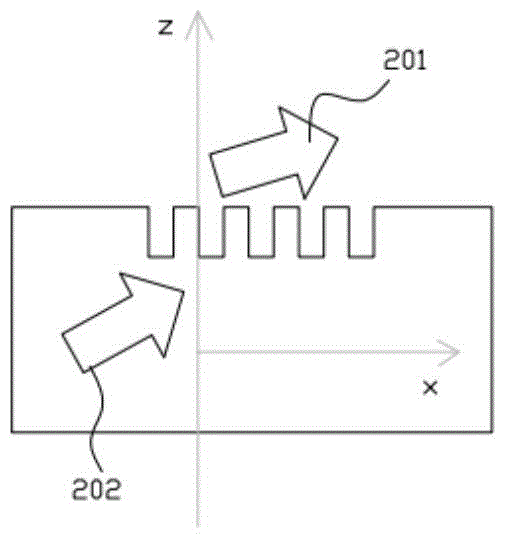

Alignment accuracy between two or more patterned layers is measured using a metrology target comprising substantially overlapping diffraction gratings formed in a test area of the layers being tested. An optical instrument illuminates all or part of the target area and measures the optical response. The instrument can measure transmission, reflectance, and / or ellipsometric parameters as a function of wavelength, polar angle of incidence, azimuthal angle of incidence, and / or polarization of the illumination and detected light. Overlay error or offset between those layers containing the test gratings is determined by a processor programmed to calculate an optical response for a set of parameters that include overlay error, using a model that accounts for diffraction by the gratings and interaction of the gratings with each others' diffracted field. The model parameters might also take account of manufactured asymmetries. The calculation may involve interpolation of pre-computed entries from a database accessible to the processor. The calculated and measured responses are iteratively compared and the model parameters changed to minimize the difference.

Owner:TOKYO ELECTRON LTD

Alignable diffractive pigment flakes

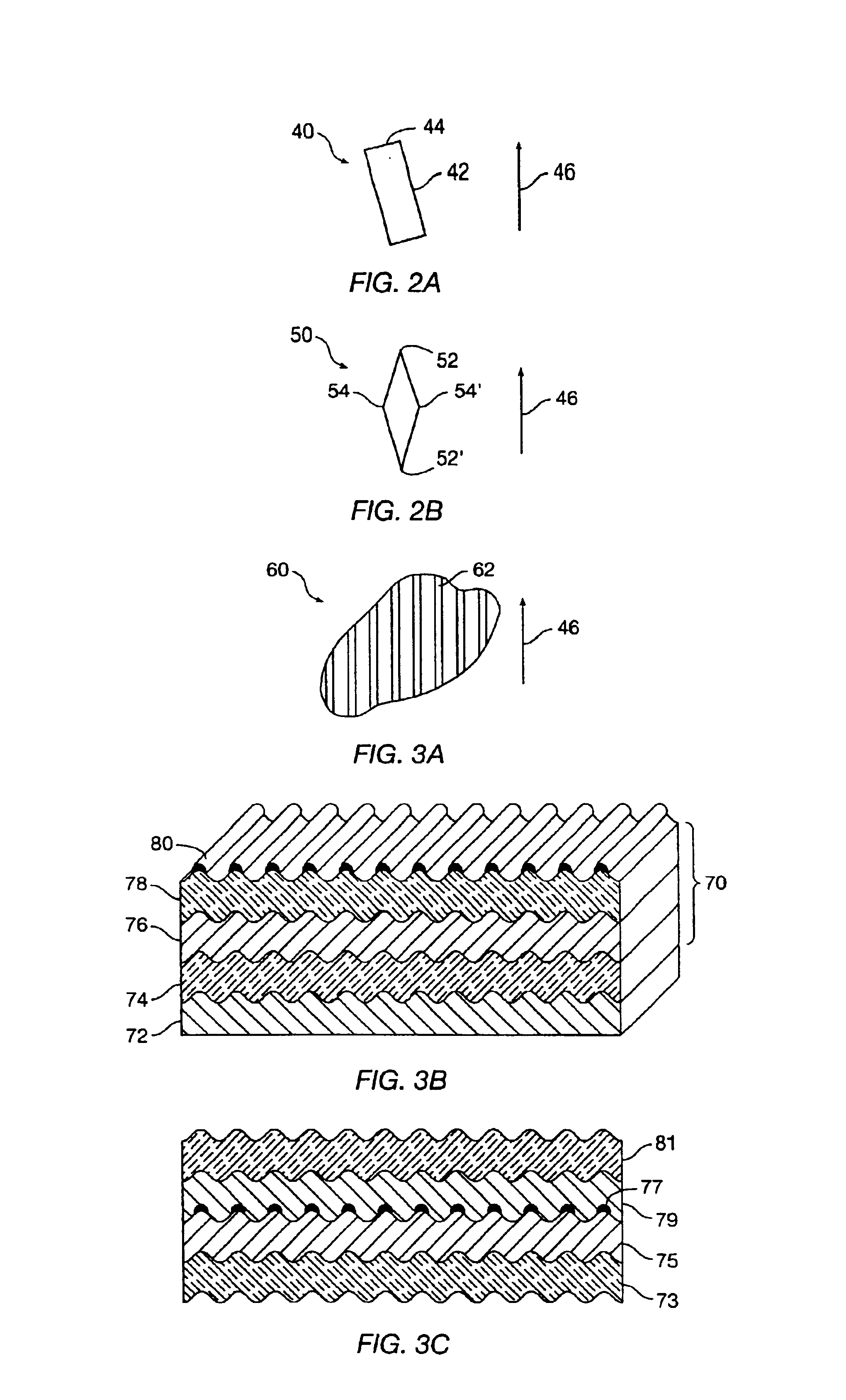

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

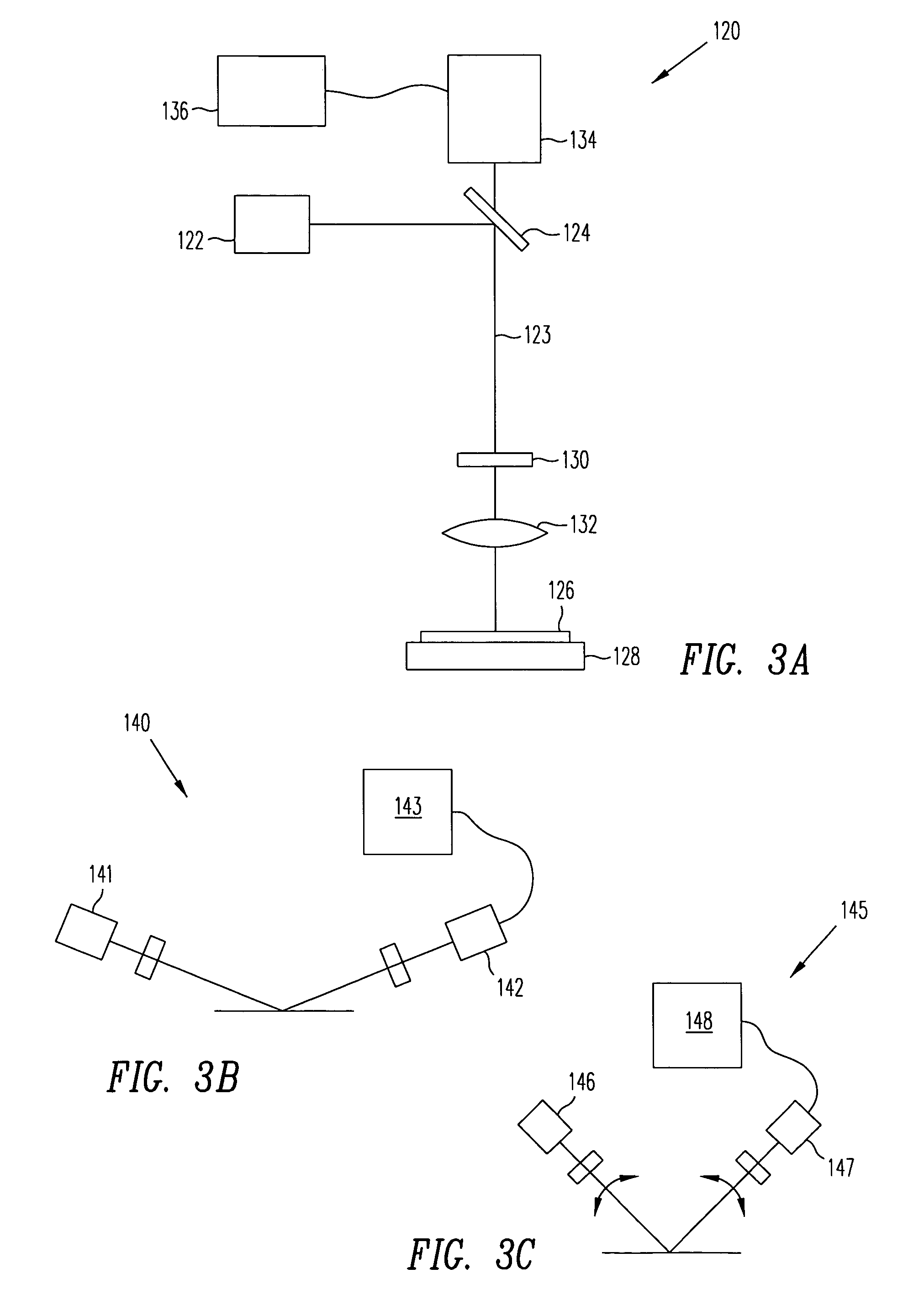

Diffraction grating based interferometric systems and methods

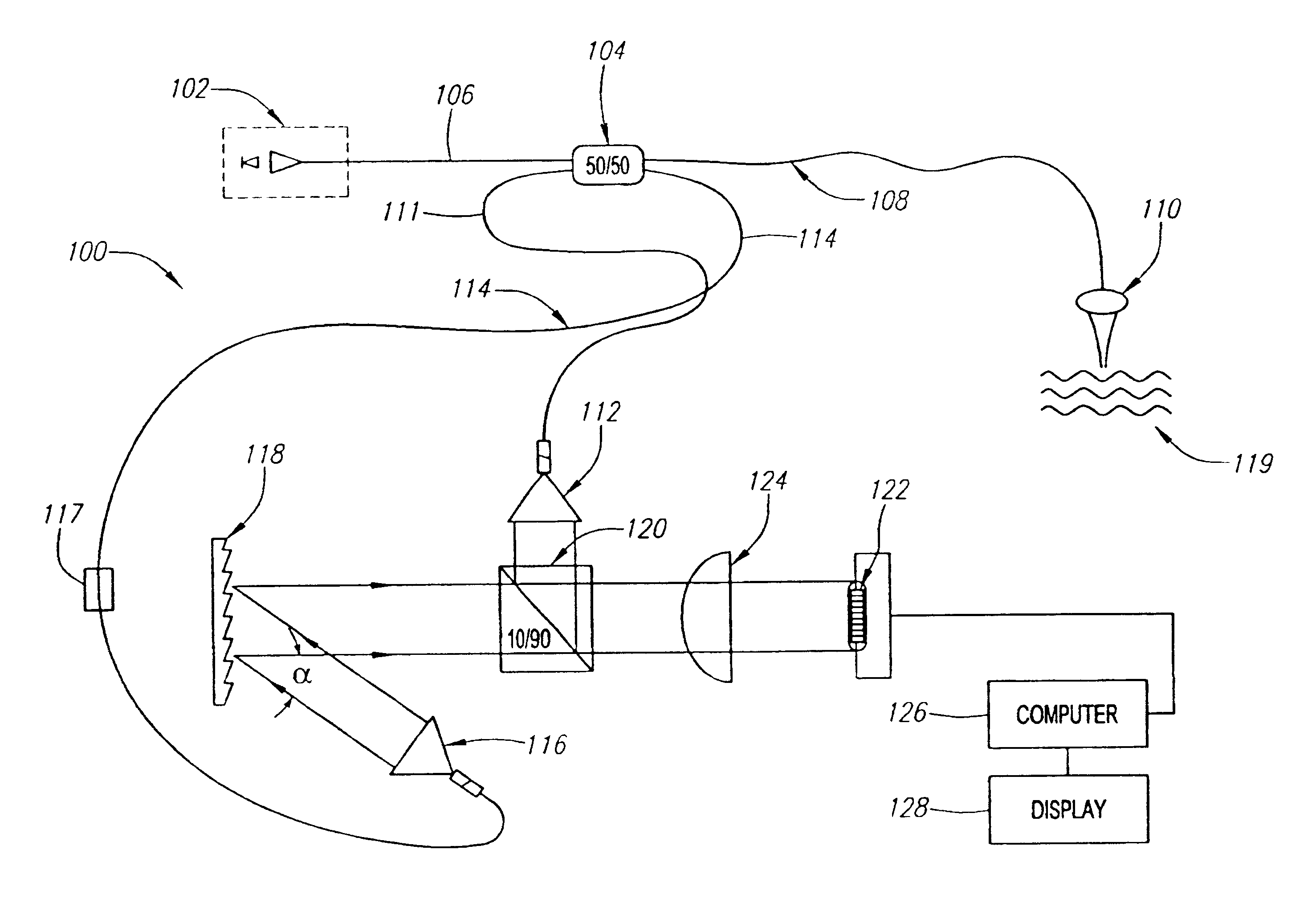

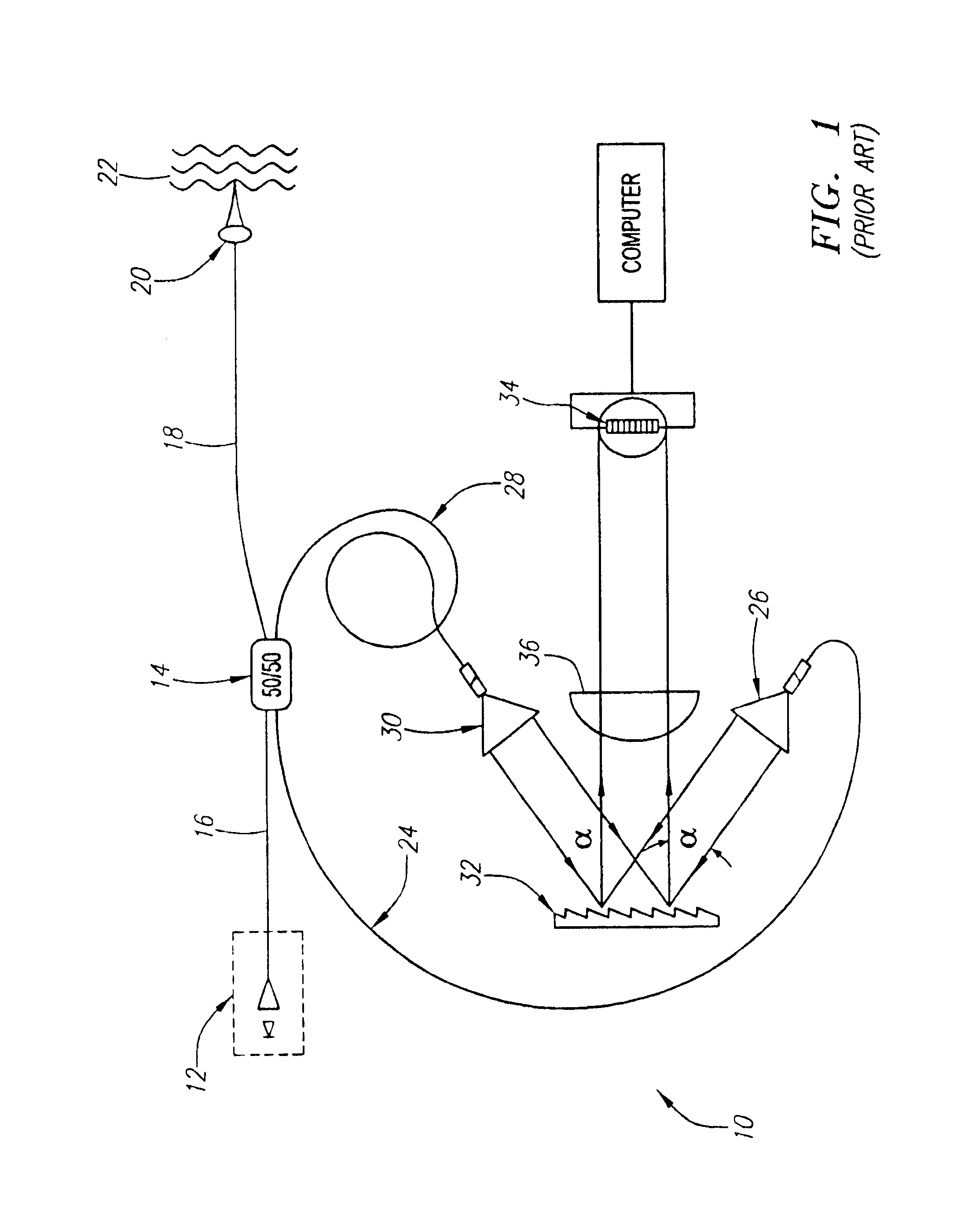

Diffraction grating based fiber optic interferometric systems for use in optical coherence tomography, wherein sample and reference light beams are formed by a first beam splitter and the sample light beam received from a sample and a reference light beam are combined on a second beam splitter. In one embodiment, the first beam splitter is an approximately 50 / 50 beam splitter, and the second beam splitter is a non 50 / 50 beam splitter. More than half of the energy of the sample light beam is directed into the combined beam and less than half of the energy of the reference light beam are directed into the combined beam by the second beam splitter. In another embodiment, the first beam splitter is a non 50 / 50 beam splitter and the second beam splitter is an approximately 50 / 50 beam splitter. An optical circulator is provided to enable the sample light beam to bypass the first beam splitter after interaction with a sample. Two combined beams are formed by the second beam splitter for detection by two respective detectors. More than half of the energy of the light source provided to the first beam splitter is directed into the sample light beam and less than half of the energy is directed into the reference light beam. The energy distribution between the sample and reference light beams can be controlled by selection of the characteristics of the beam splitters.

Owner:BOSTON SCI SCIMED INC

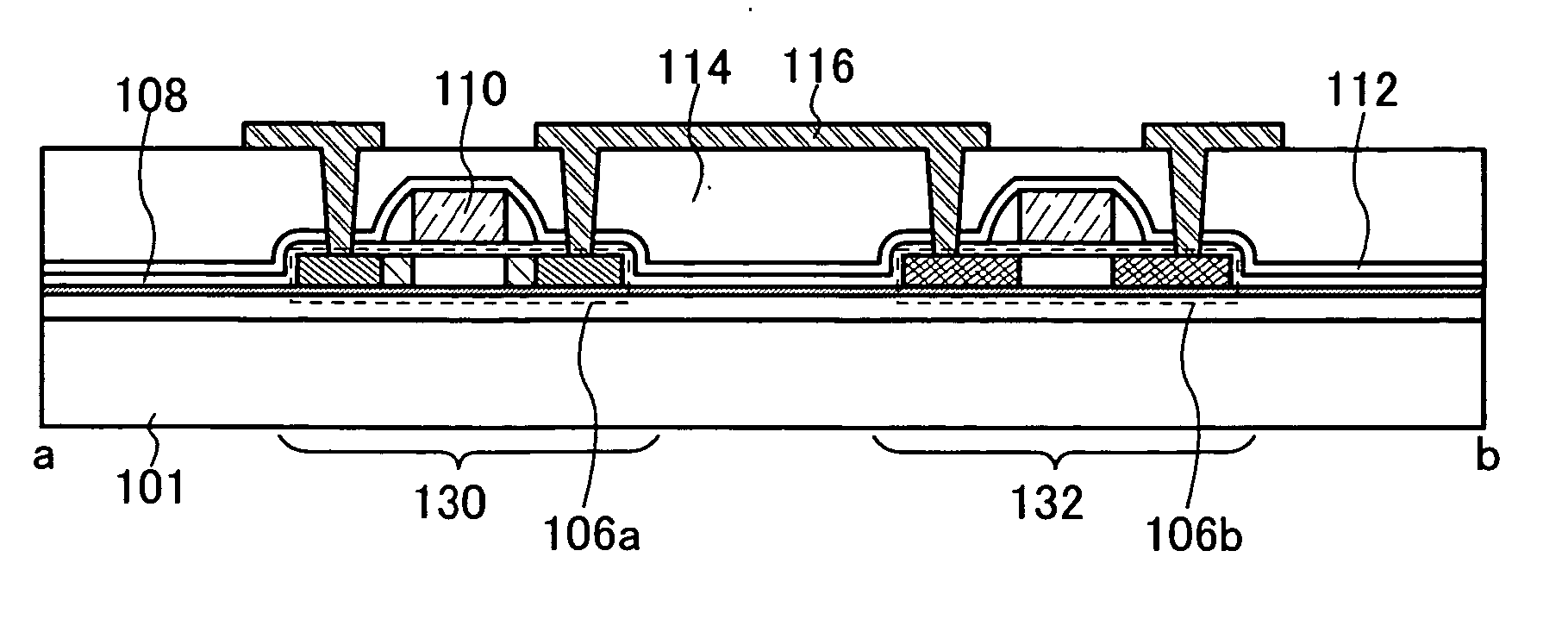

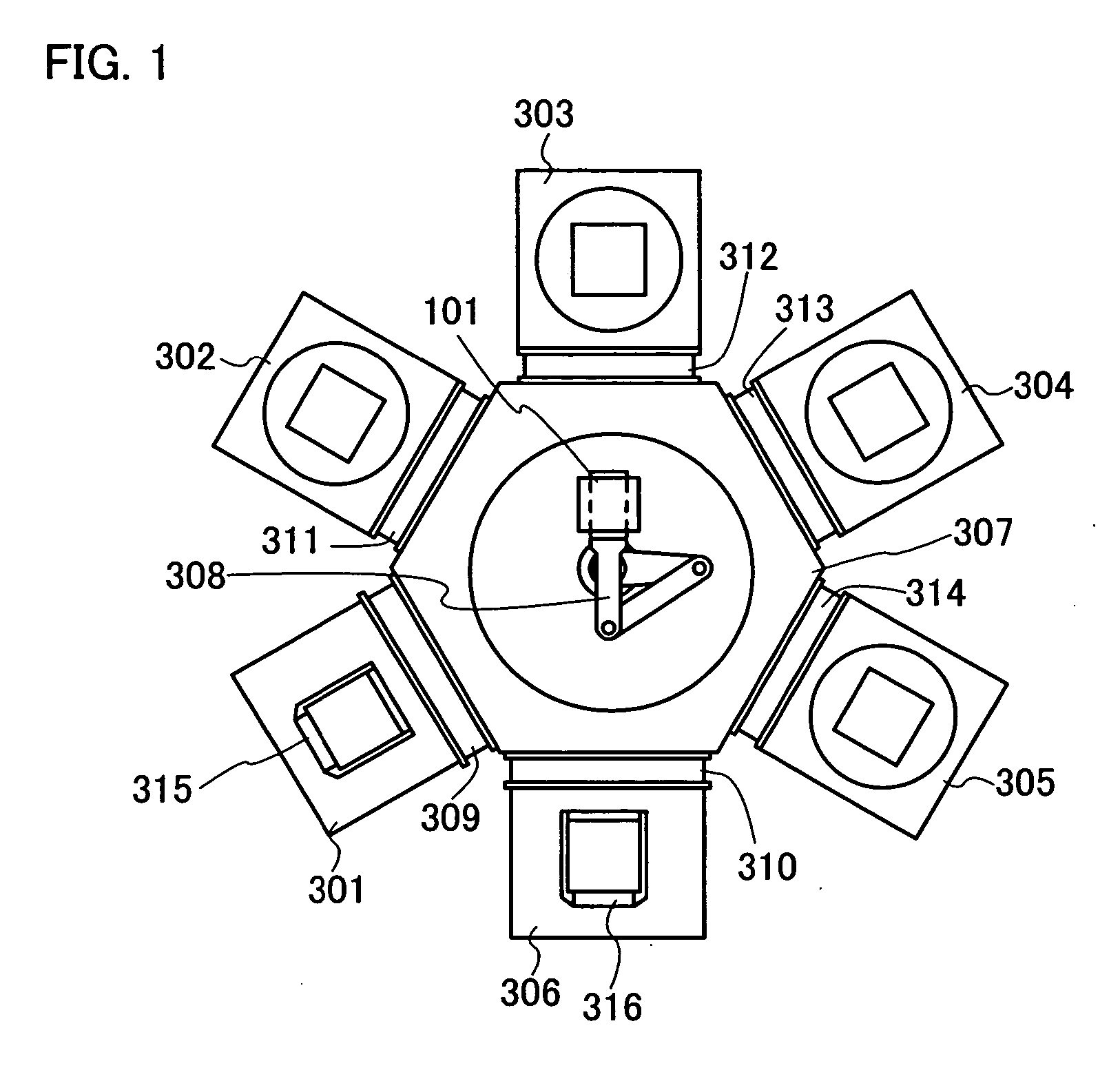

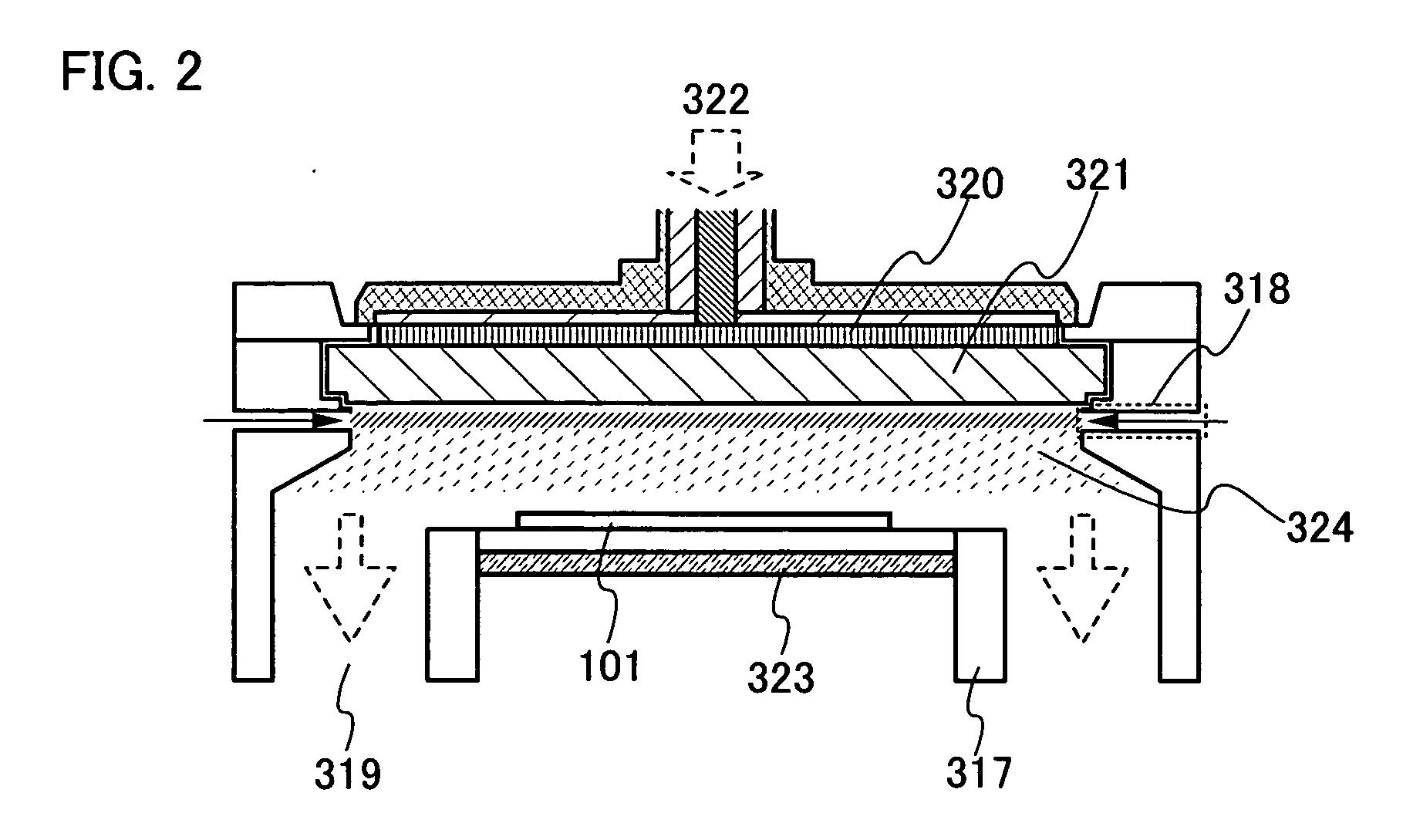

Semiconductor device and manufacturing method thereof

InactiveUS20060275710A1Reduce light intensityImprove routing densitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialContinuous wave laser beam

To provide a semiconductor device having a circuit with high operating performance and high reliability, and improve the reliability of the semiconductor device, thereby improving the reliability of an electronic device having the same. The aforementioned object is achieved by combining a step of crystallizing a semiconductor layer by irradiation with continuous wave laser beams or pulsed laser beams with a repetition rate of 10 MHz or more, while scanning in one direction; a step of photolithography with the use of a photomask or a leticle including an auxiliary pattern which is formed of a diffraction grating pattern or a semi-transmissive film having a function of reducing the light intensity; and a step of performing oxidation, nitridation, or surface-modification to the surface of the semiconductor film, an insulating film, or a conductive film, with high-density plasma with a low electron temperature.

Owner:SEMICON ENERGY LAB CO LTD

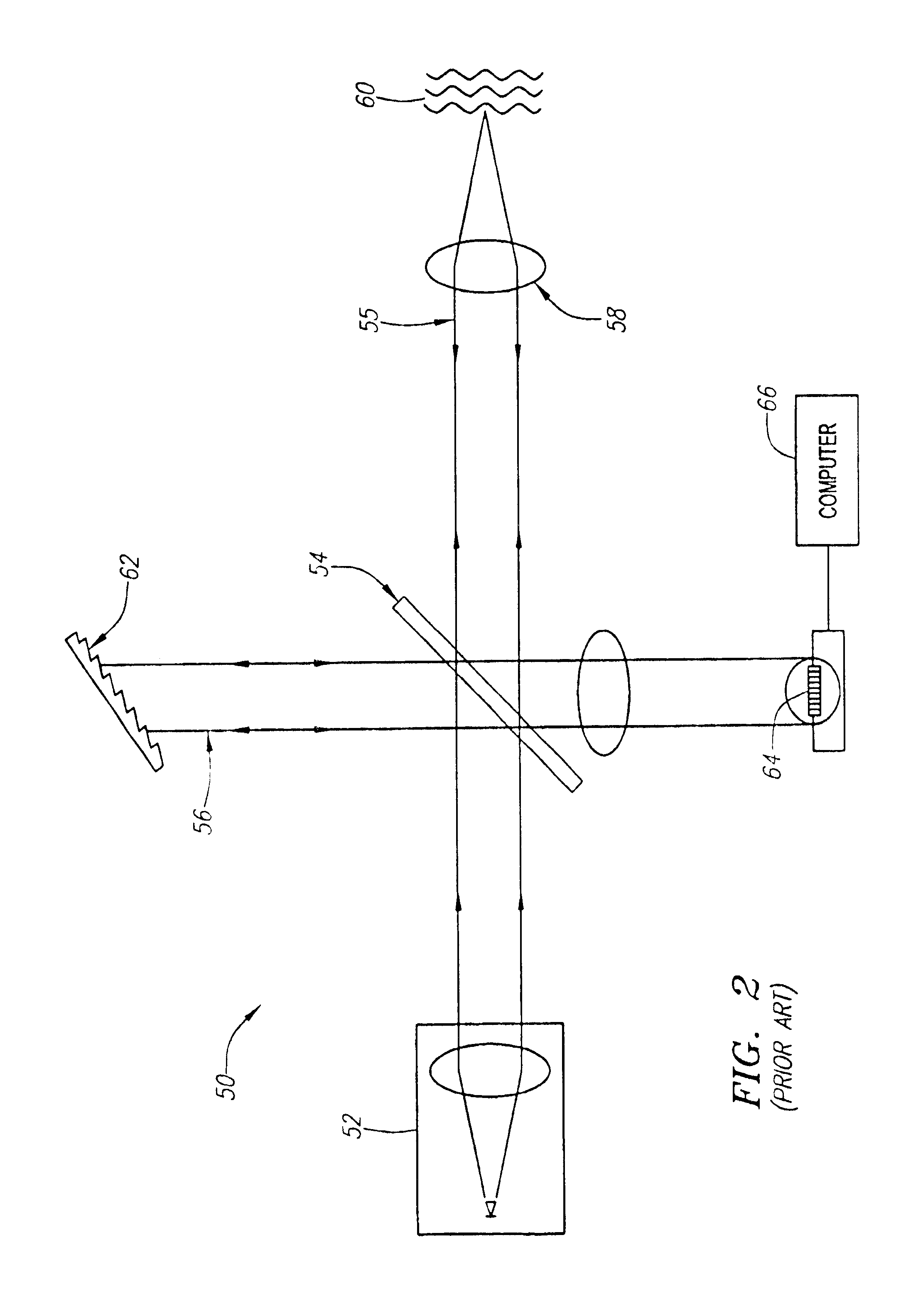

Overlay alignment metrology using diffraction gratings

InactiveUS20020158193A1Limited space availableOvercome difficultiesBeam/ray focussing/reflecting arrangementsSemiconductor/solid-state device testing/measurementMetrologyAngle of incidence

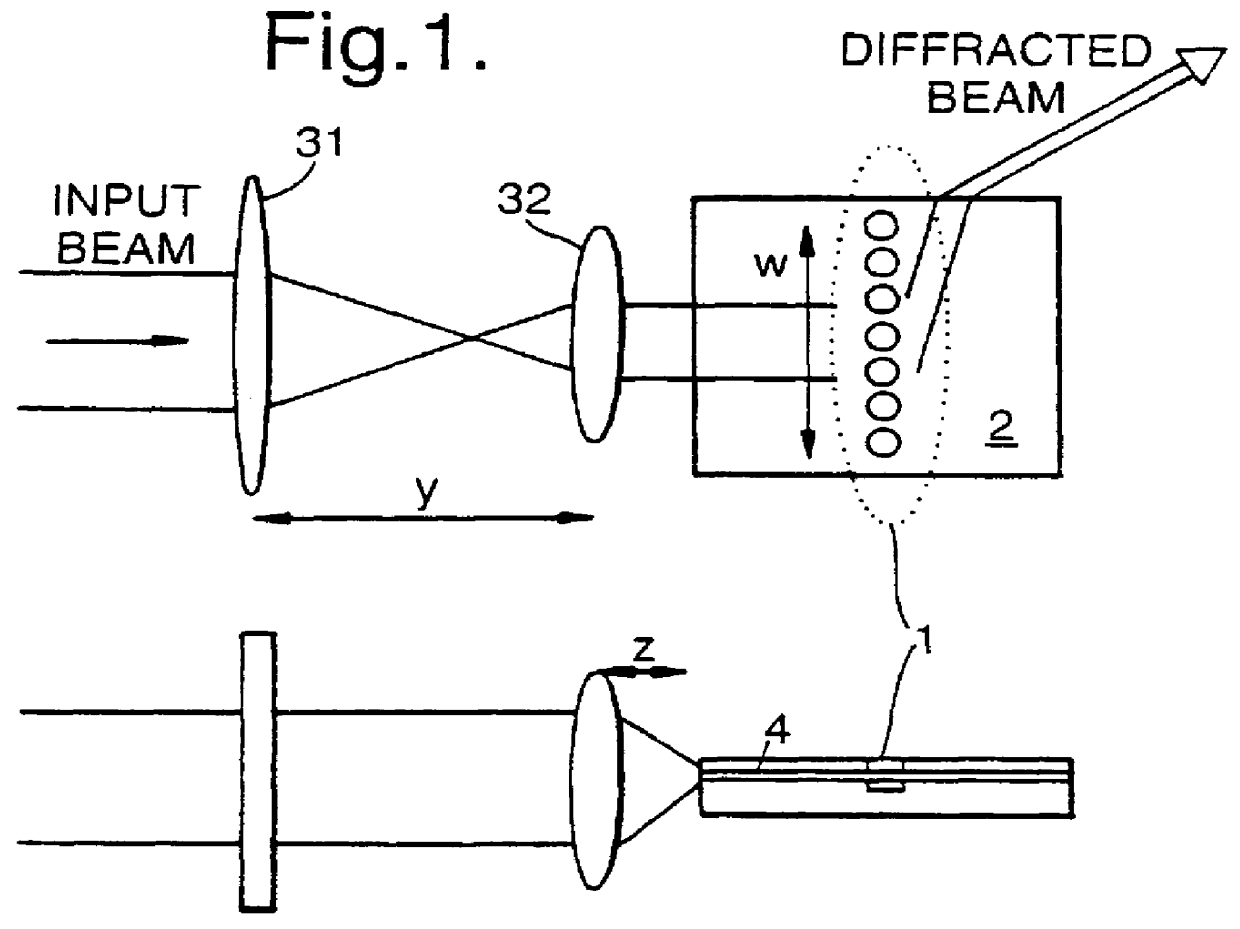

Alignment accuracy between two or more patterned layers is measured using a metrology target comprising substantially overlapping diffraction gratings formed in a test area of the layers being tested. An optical instrument illuminates all or part of the target area and measures the optical response. The instrument can measure transmission, reflectance, and / or ellipsometric parameters as a function of wavelength, polar angle of incidence, azimuthal angle of incidence, and / or polarization of the illumination and detected light. Overlay error or offset between those layers containing the test gratings is determined by a processor programmed to calculate an optical response for a set of parameters that include overlay error, using a model that accounts for diffraction by the gratings and interaction of the gratings with each others' diffracted field. The model parameters might also take account of manufactured asymmetries. The calculation may involve interpolation of pre-computed entries from a database accessible to the processor. The calculated and measured responses are iteratively compared and the model parameters changed to minimize the difference.

Owner:TOKYO ELECTRON LTD

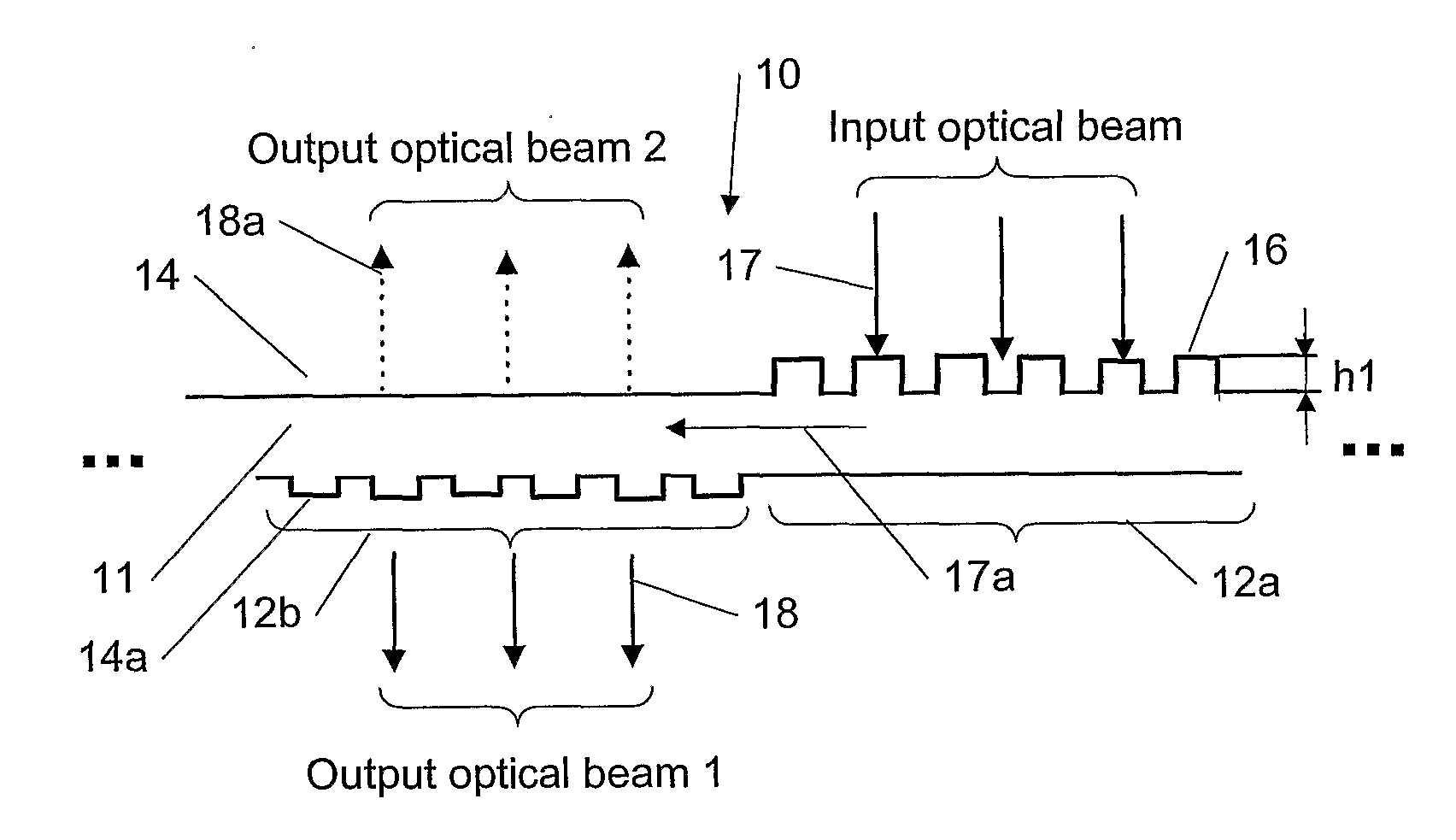

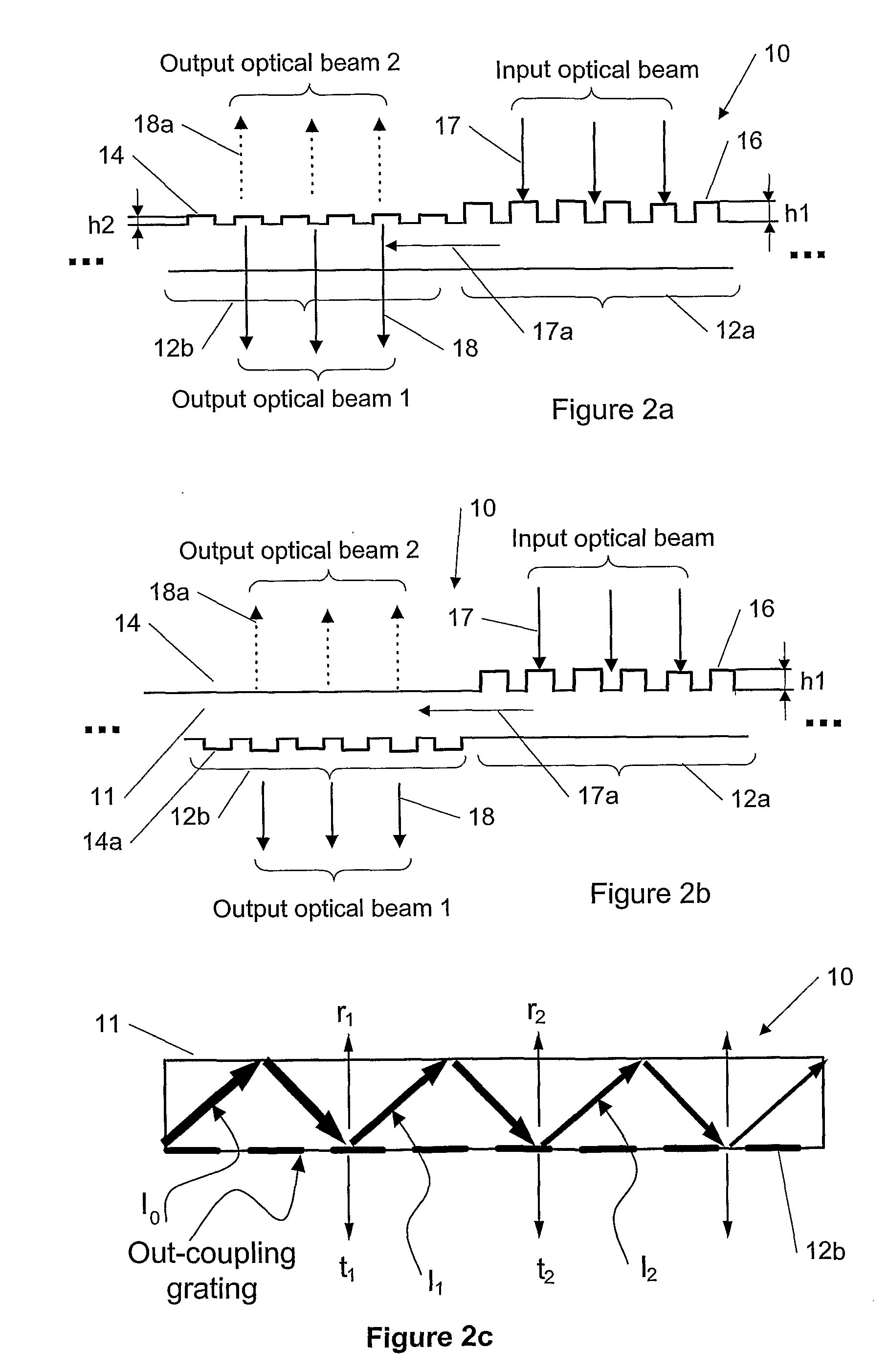

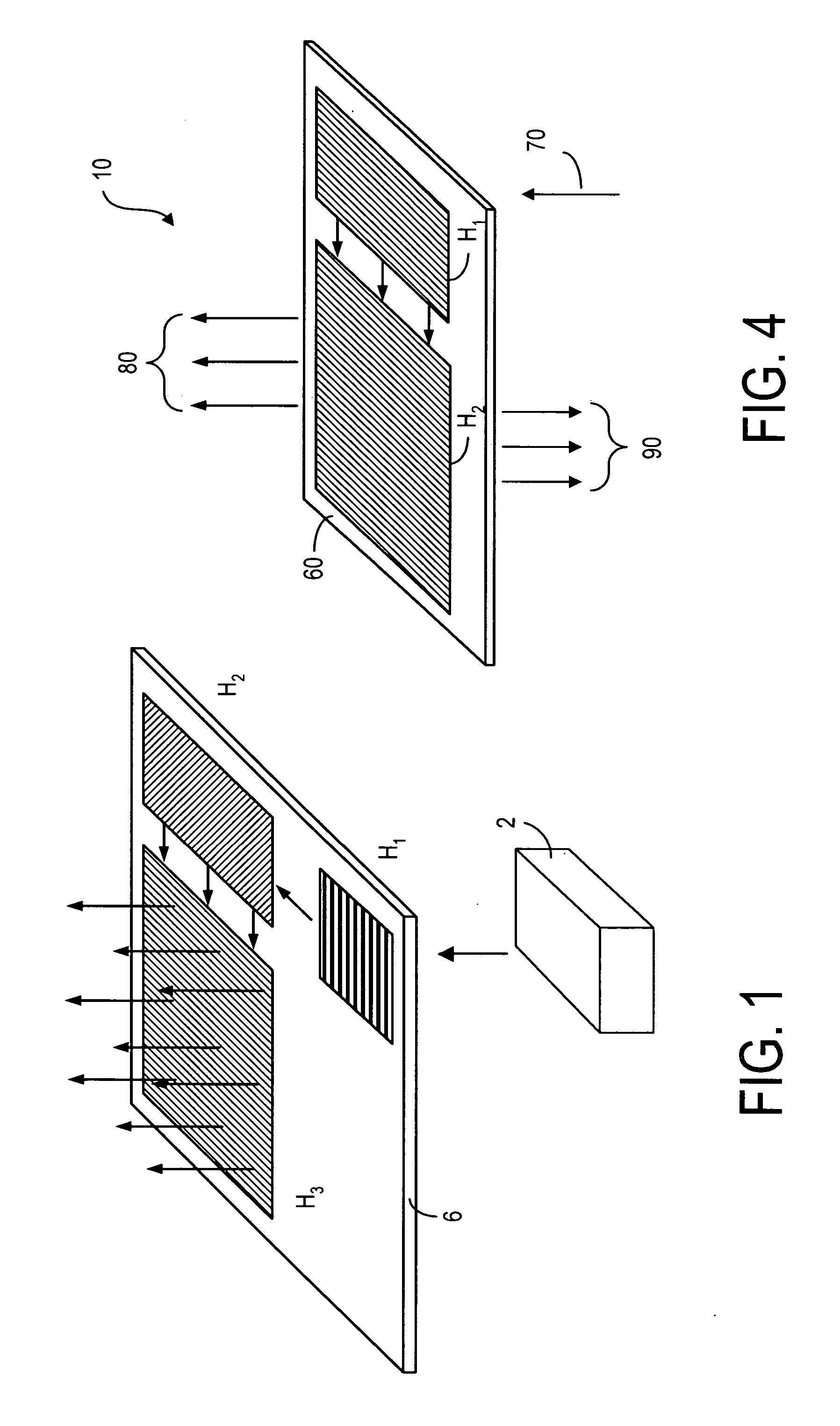

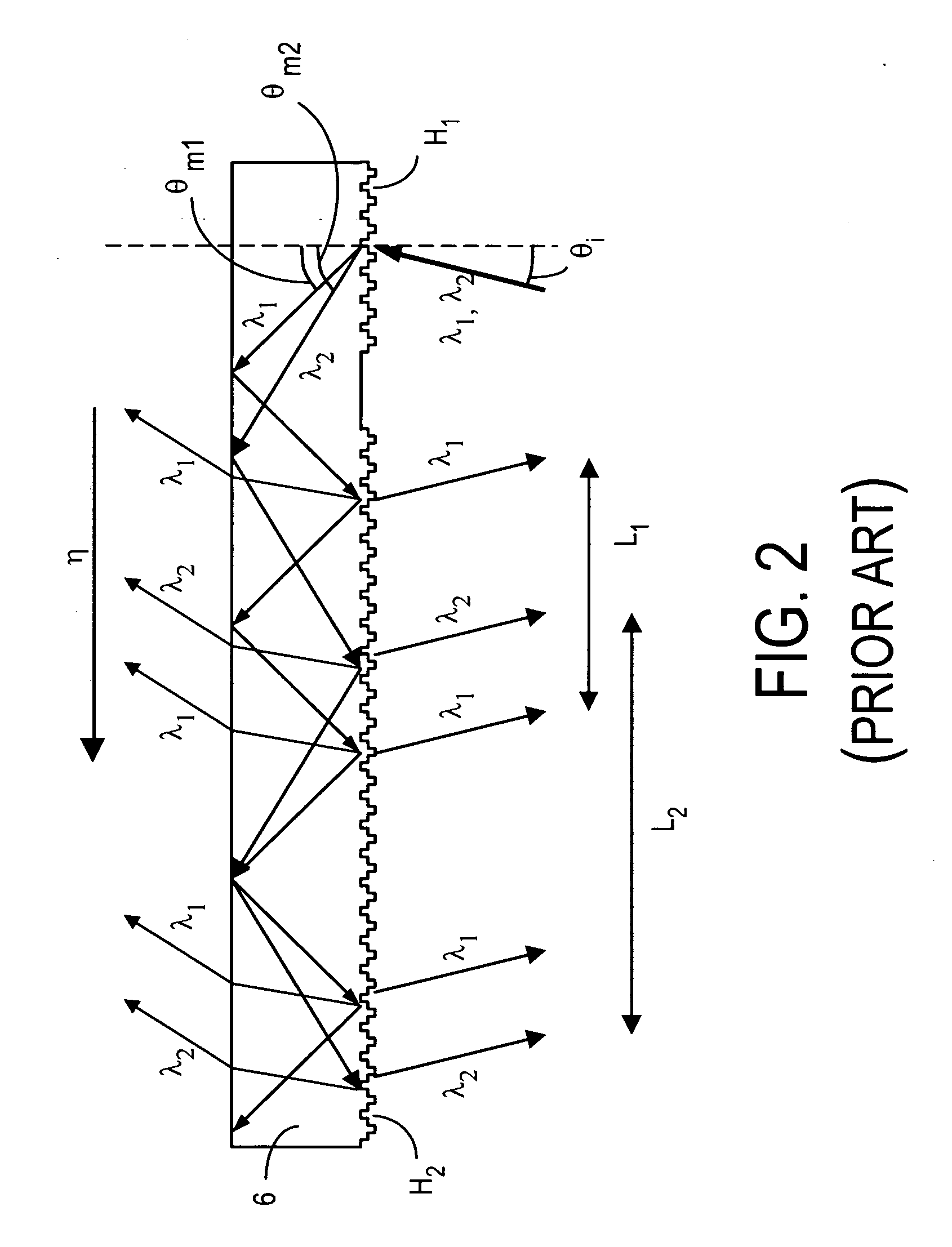

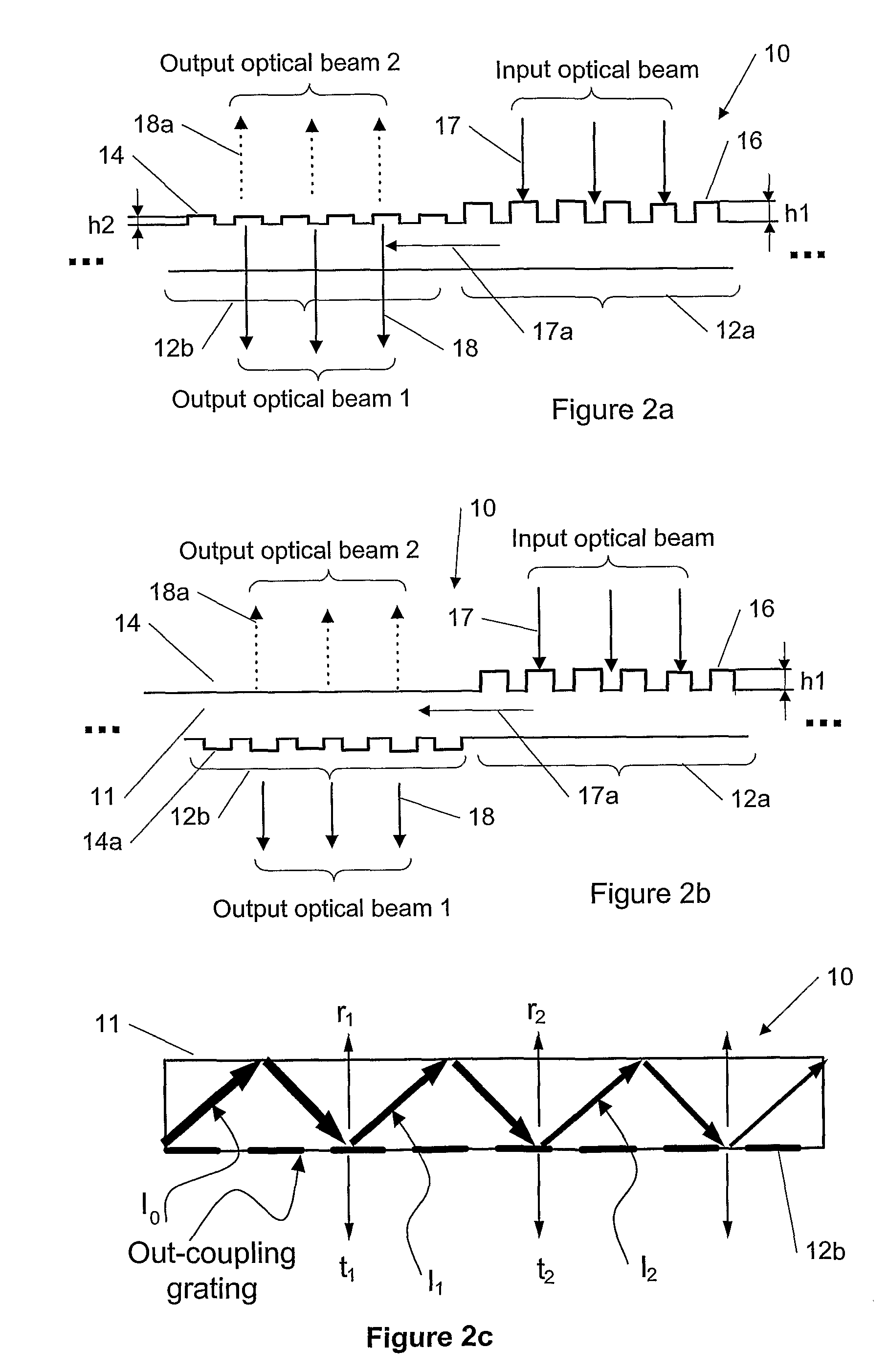

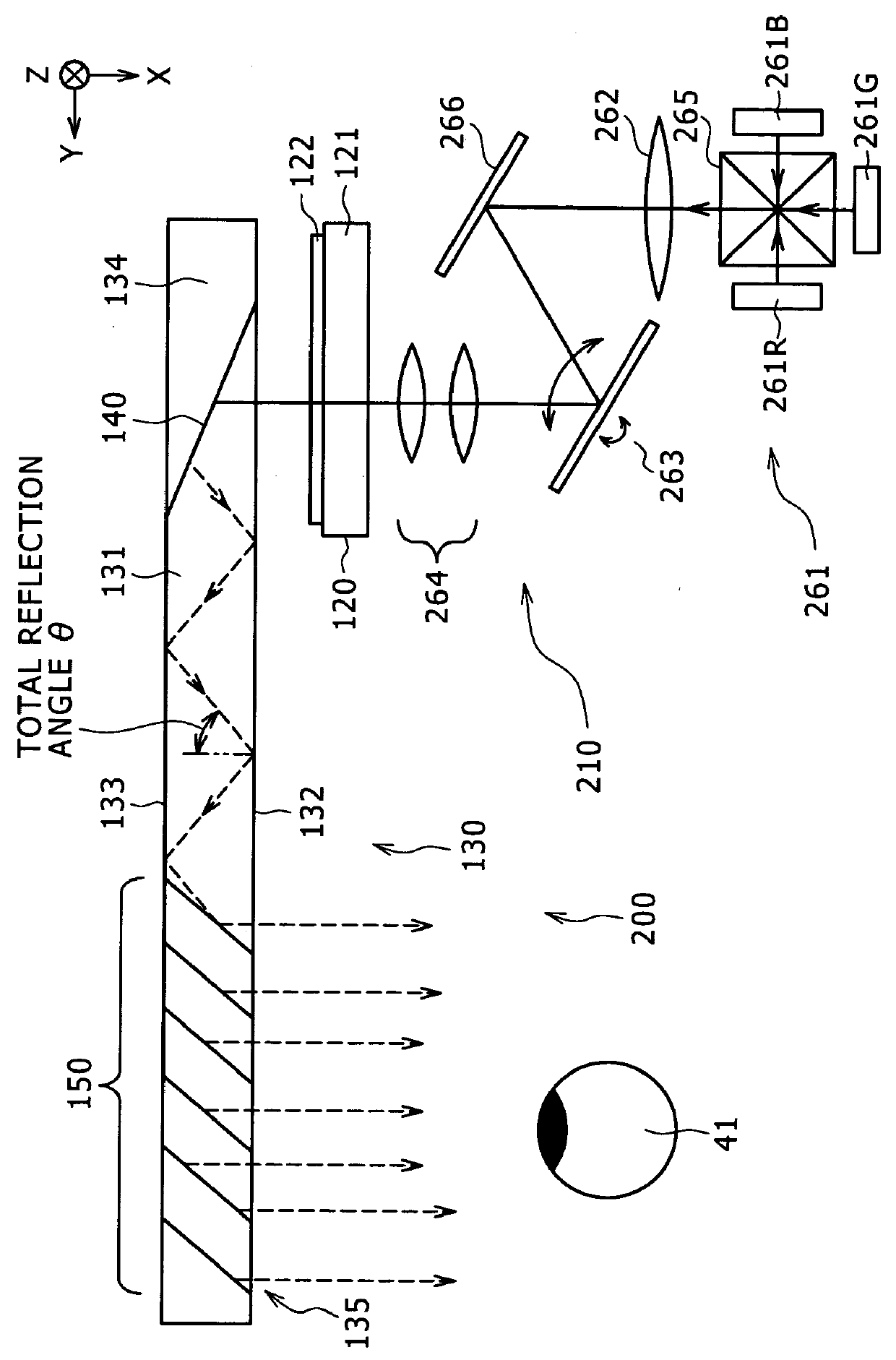

Method and system for beam expansion in a display device

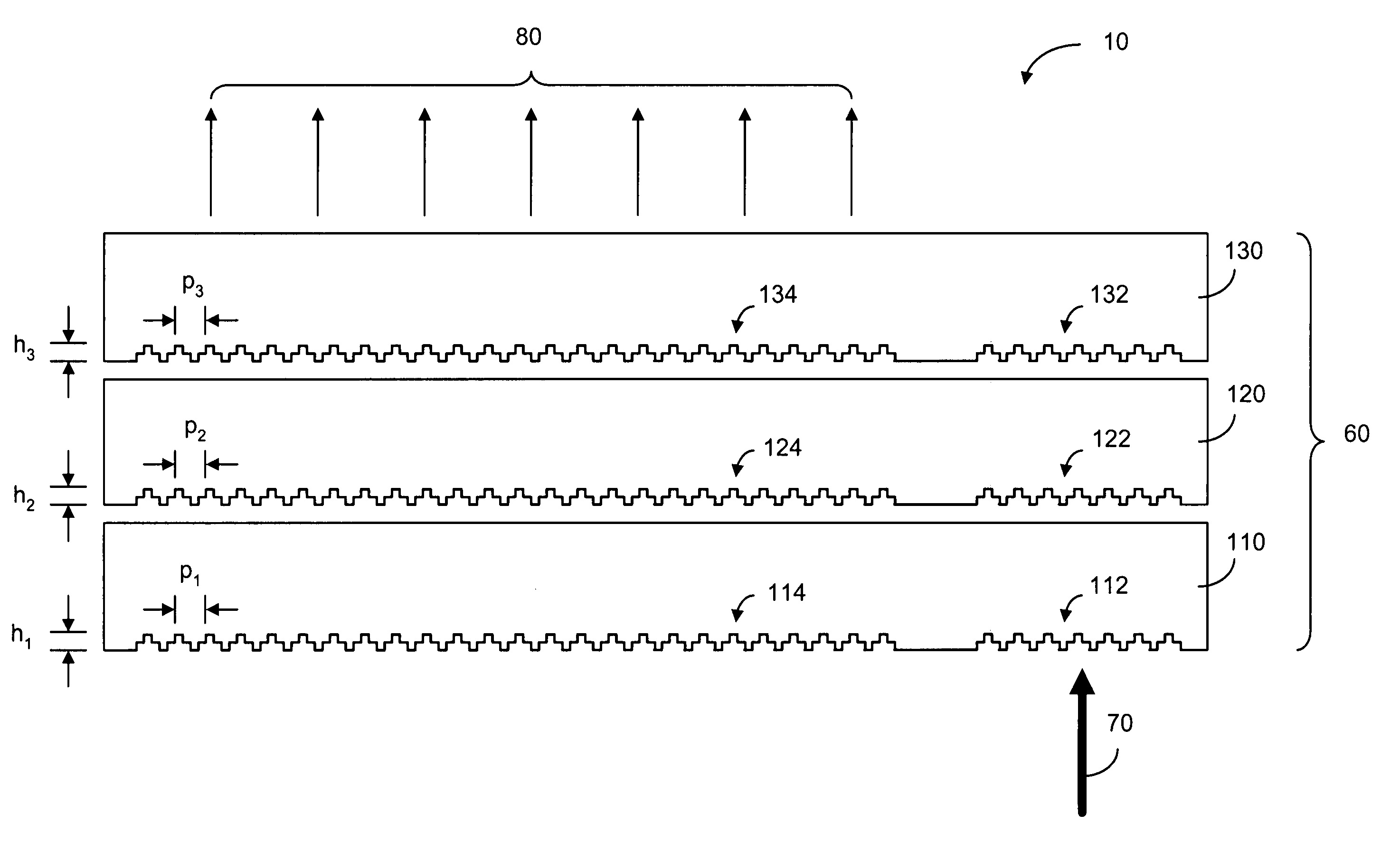

ActiveUS7206107B2Increase volumeReduce the amount requiredDiffraction gratingsPlanar/plate-like light guidesExit pupilDisplay device

An exit pupil extender wherein the relative amount of different color components in the exit beam is more consistent with that of the input beam. In order to compensate for the uneven amount in the diffracted color components in the exit beam, the exit pupil extender, comprises a plurality of layers having additional diffraction gratings so as to increase the amount of diffracted light for those color components with a lower amount. Additionally, color filters disposed between layers to reduce the diffracted light components with a higher amount.

Owner:MAGIC LEAP INC

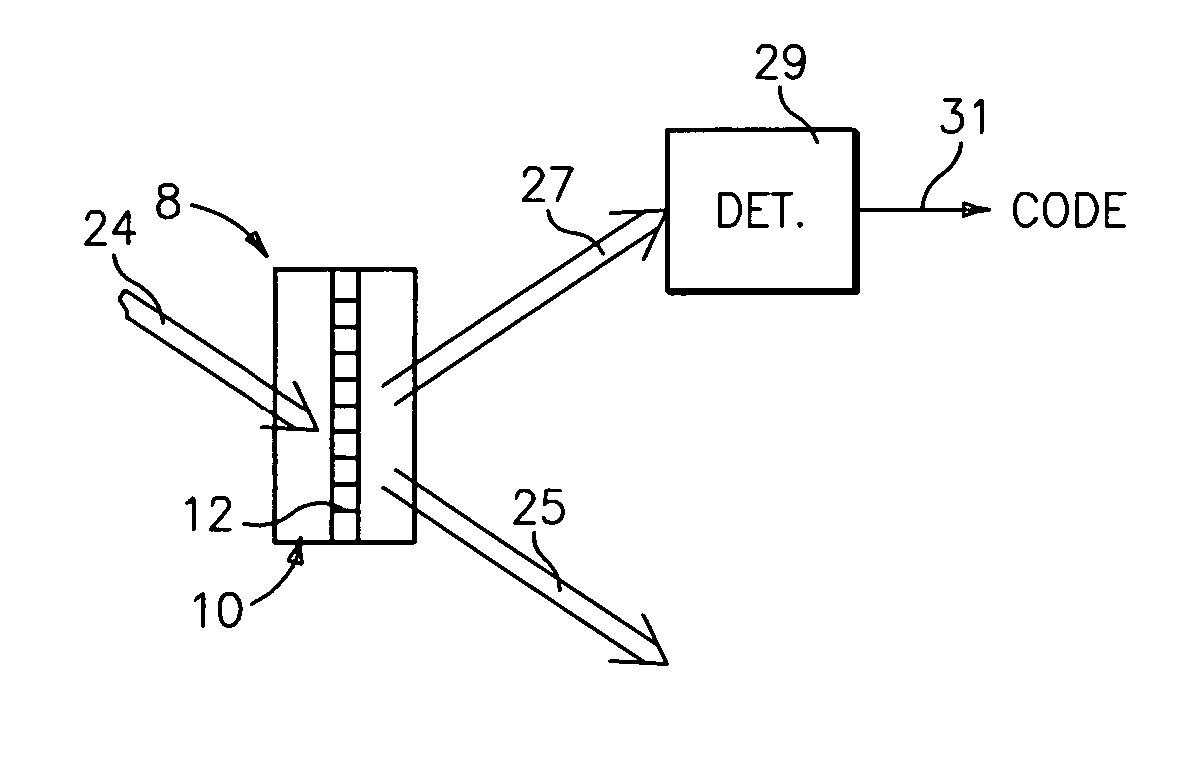

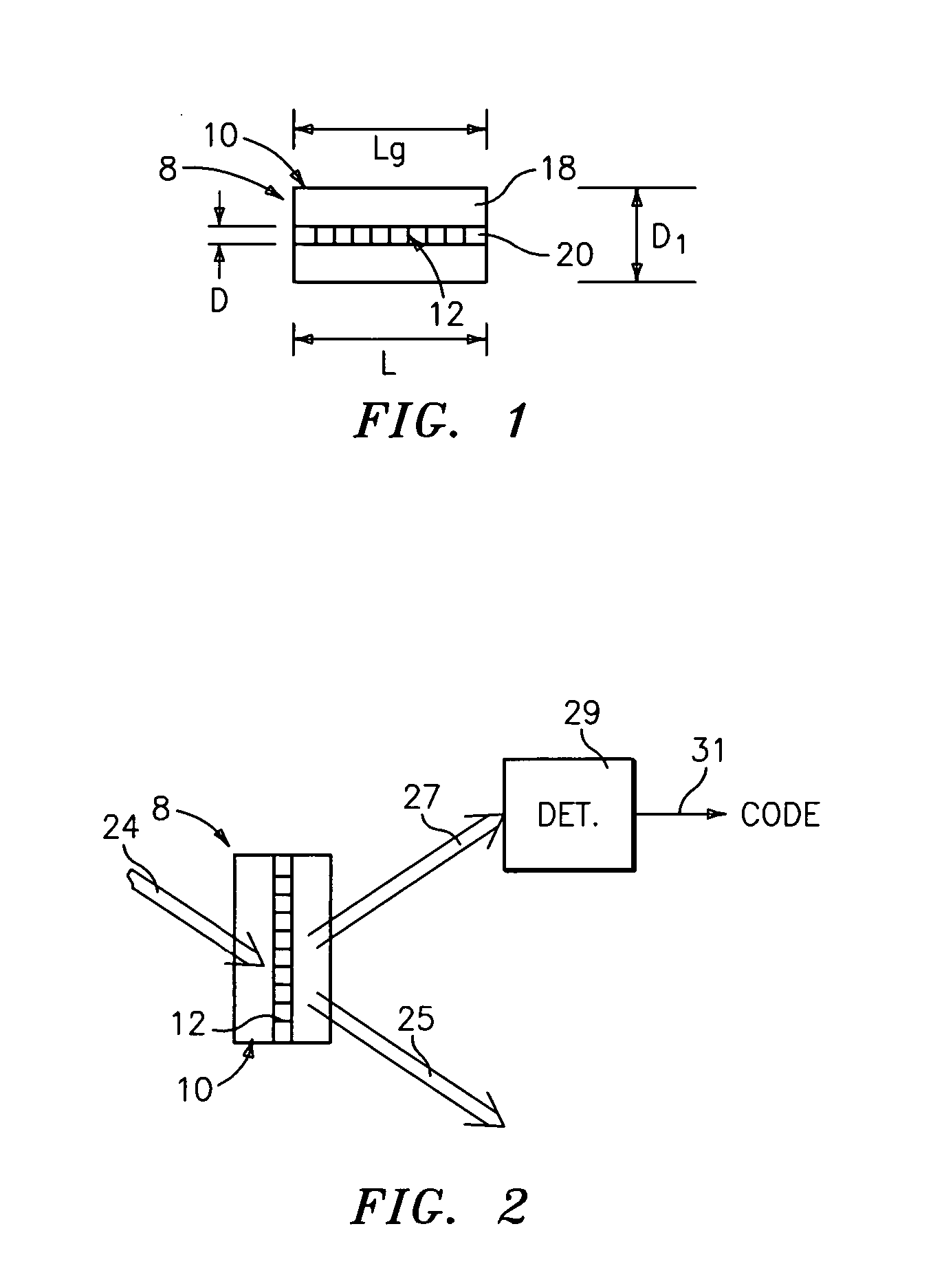

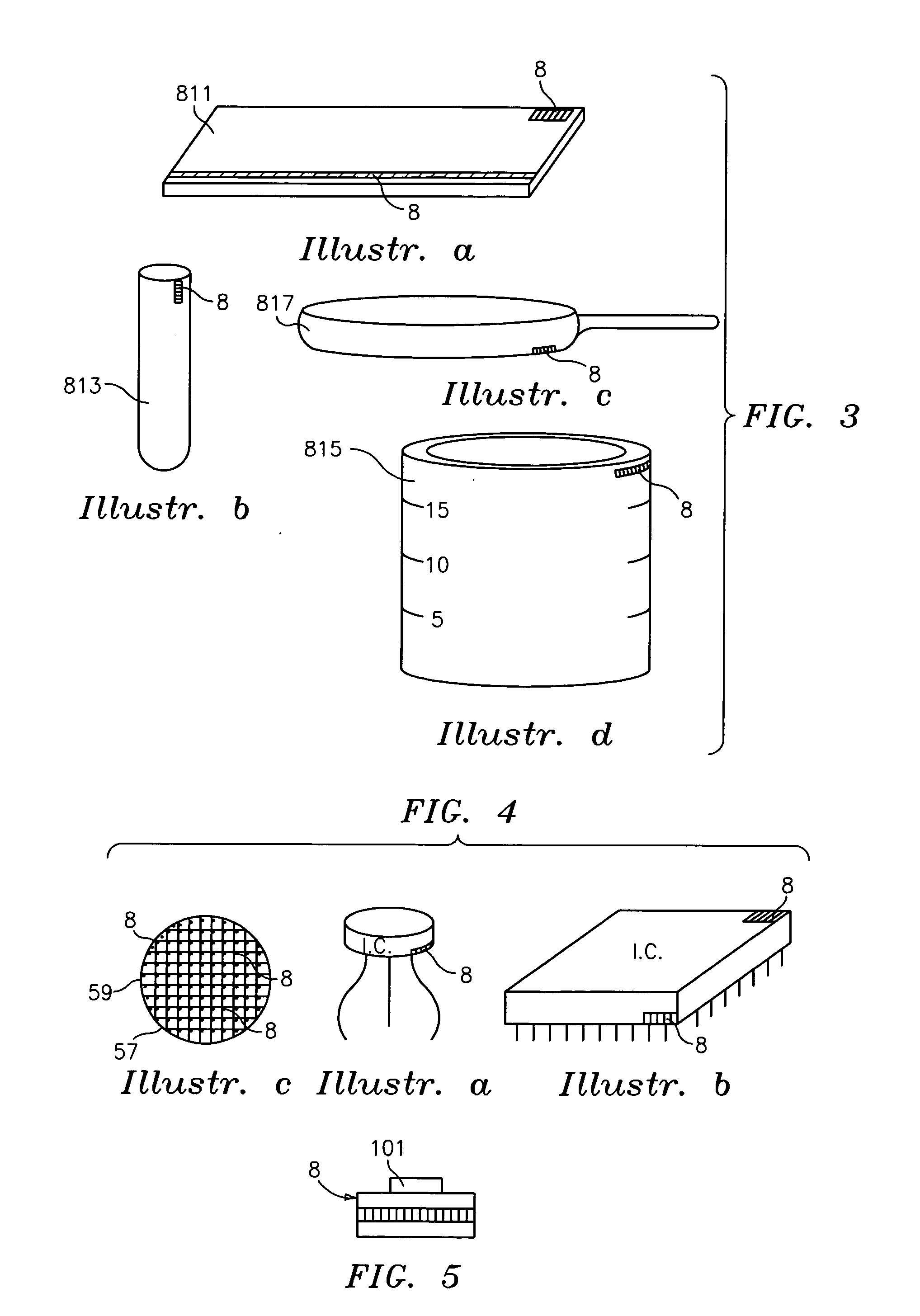

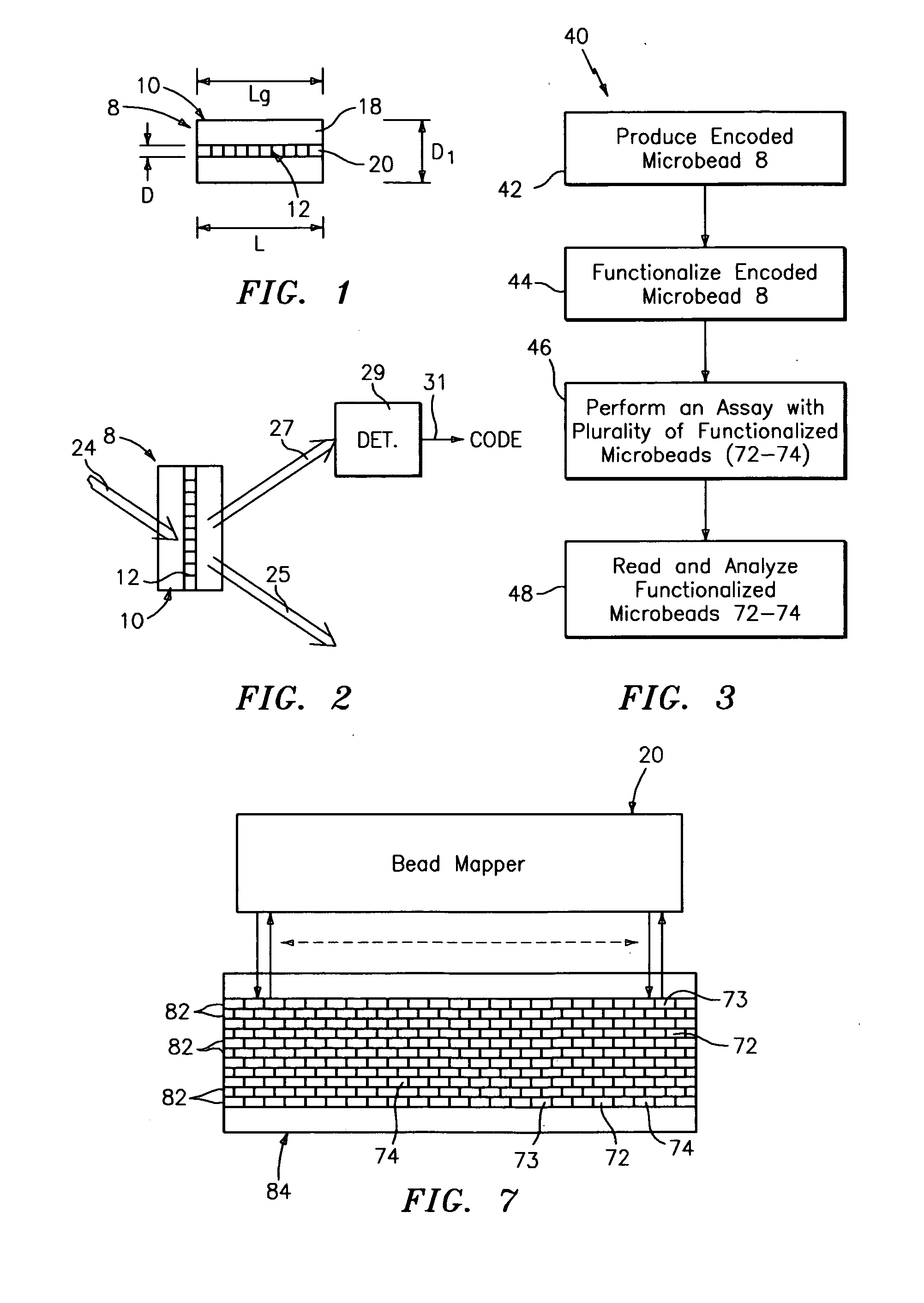

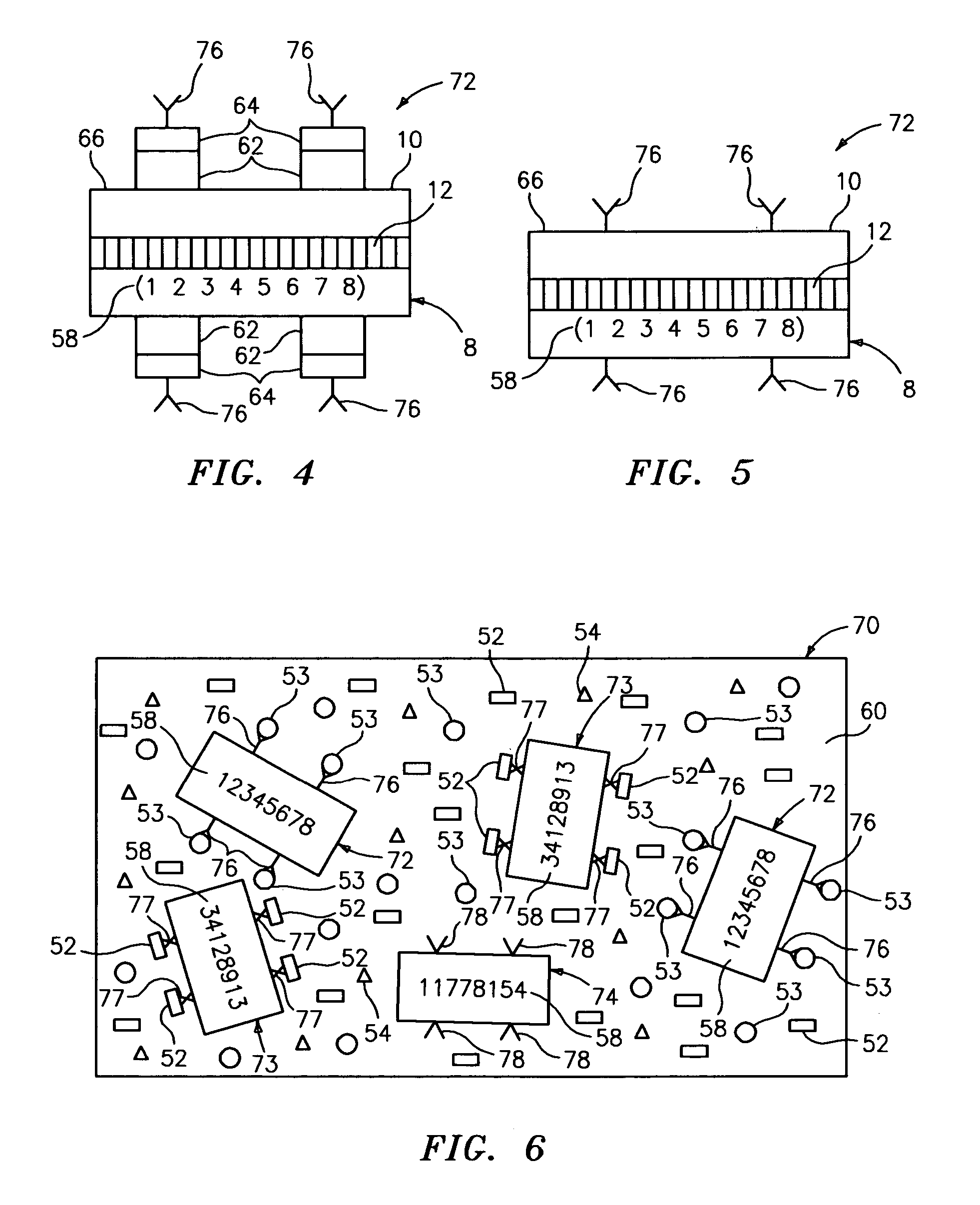

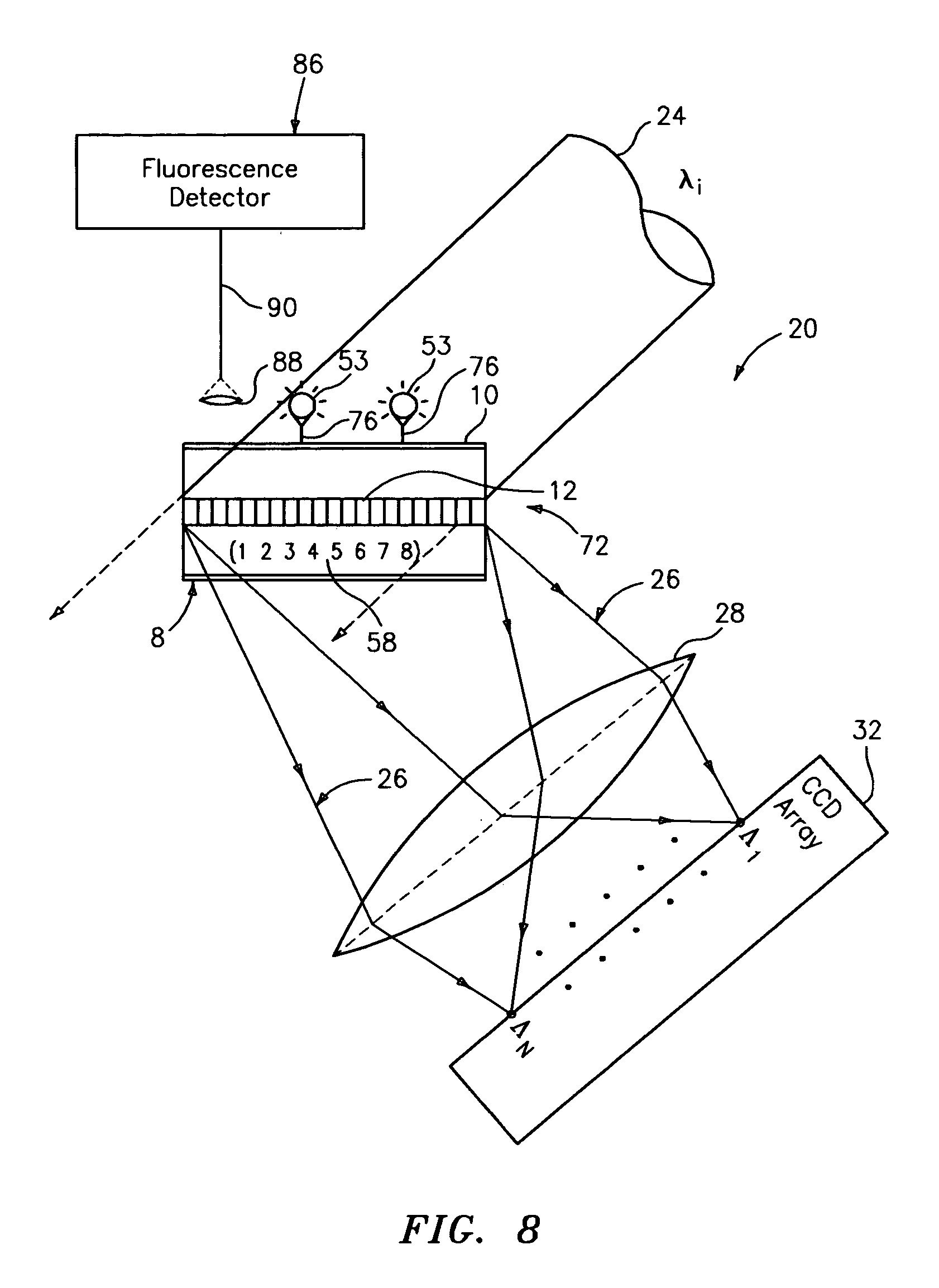

Method and apparatus for drug product tracking using encoded optical identification elements

ActiveUS20060028727A1Made smallMade flexiblePaper-money testing devicesPharmaceutical delivery mechanismAuthenticationPhysics

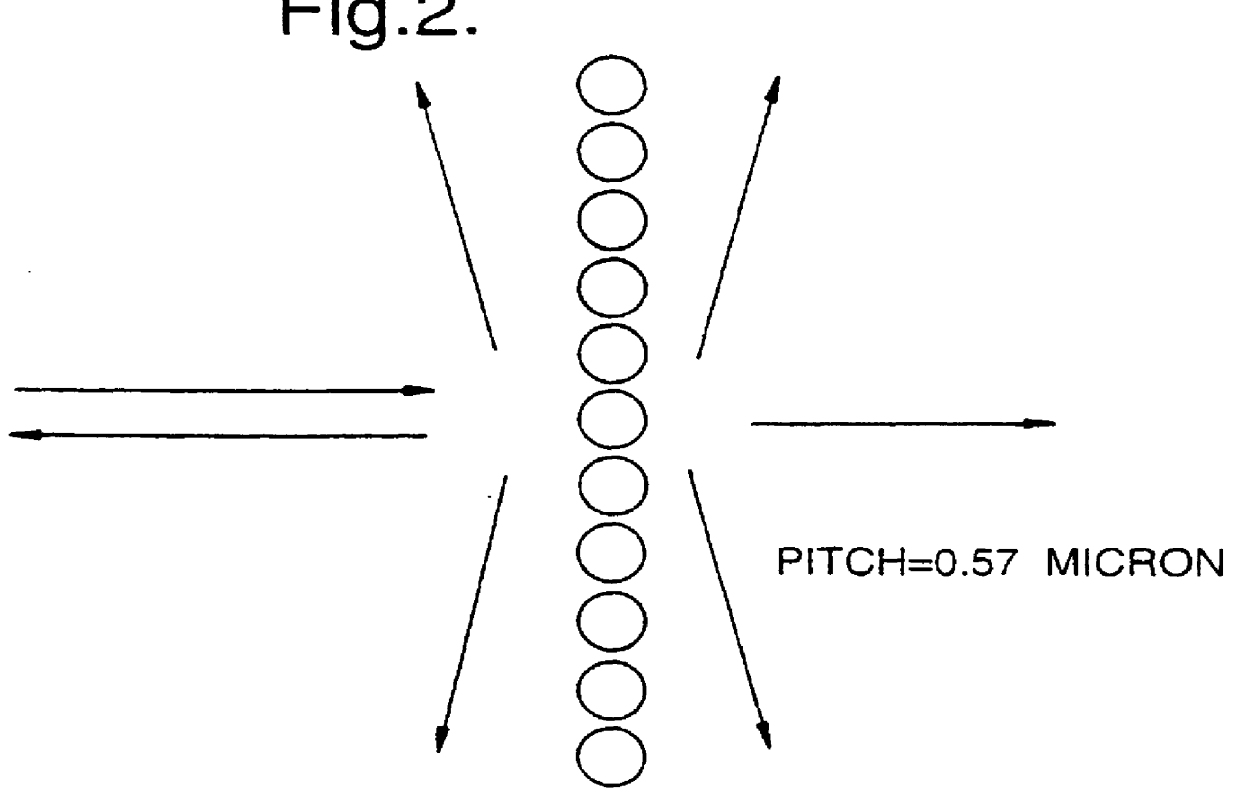

A method and apparatus for drug product tracking (or other pharmaceutical, health care or cosmetics products, and / or the packages or containers they are supplied with) using diffraction grating-based encoded optical identification elements 8 includes an optical substrate 10 having at least one diffraction grating 12 disposed therein. The grating 12 has one or more colocated pitches Λ which represent a unique identification digital code that is detected when illuminated by incident light 24. The incident light 24 may be directed transversely from the side of the substrate 10 (or from an end) with a narrow band (single wavelength) or multiple wavelength source, and the code is represented by a spatial distribution of light or a wavelength spectrum, respectively, or a combination thereof. The encoded element 8 may be used to label any desired item, such as drugs or medicines, or other pharmaceutical or health care products or cosmetics. The label may be used for many different purposes, such as for sorting, tracking, identification, verification, authentication, anti-theft / anti-counterfeit, security / anti-terrorism, or for other purposes. In a manufacturing environment, the elements 8 may be used to track inventory for production information or sales of goods / products. Such labeling provides product identification at the pill or liquid medicine level, which provides traceability of these products to their manufacturer, thereby reducing counterfeit products in the marketplace. Also, the elements 8 may be incorporated into a film, liquid, coating or adhesive tape at attached to the product package.

Owner:ILLUMINA INC

Back-side-of-die, through-wafer guided-wave optical clock distribution networks, method of fabrication thereof, and uses thereof

InactiveUS7016569B2Coupling light guidesOptical waveguide light guideDistribution systemOptical clock

Systems and methods for back-of-die, through-wafer guided-wave optical clock distribution systems (networks) are disclosed. A representative back-of-die, through-wafer guided-wave optical clock distribution system includes an integrated circuit device with a first cladding layer disposed on the back-side of the integrated circuit device, and an core layer disposed on the first cladding layer. The core layer, the first cladding layer, or the second cladding layer can include, but is not limited to, vertical-to-horizontal input diffraction gratings, a horizontal-to-horizontal diffraction gratings, and horizontal-to-vertical output diffraction gratings.

Owner:GEORGIA TECH RES CORP

Spectroscopically measured overlay target

InactiveUS7061615B1Adequate fitEasy to measureSemiconductor/solid-state device detailsSolid-state devicesImage resolutionLine width

An overlay target for spectroscopic measurement includes at least two diffraction gratings, one grating overlying the other. The diffraction gratings may include an asymmetry relative to each other in order to improve resolution of the presence as well as the direction of any mis-registration. For example, the asymmetry between the two diffraction gratings may be a phase offset, a difference in pitch, line width, etc. The overlay target may be spectroscopically measuring, for example, using an optical model and a best fit analysis. Moreover, the overlay target may be optimized by modeling the overlay target and adjusting the variable parameters and calculating the sensitivity of the overlay target to changes in variable parameters.

Owner:ONTO INNOVATION INC

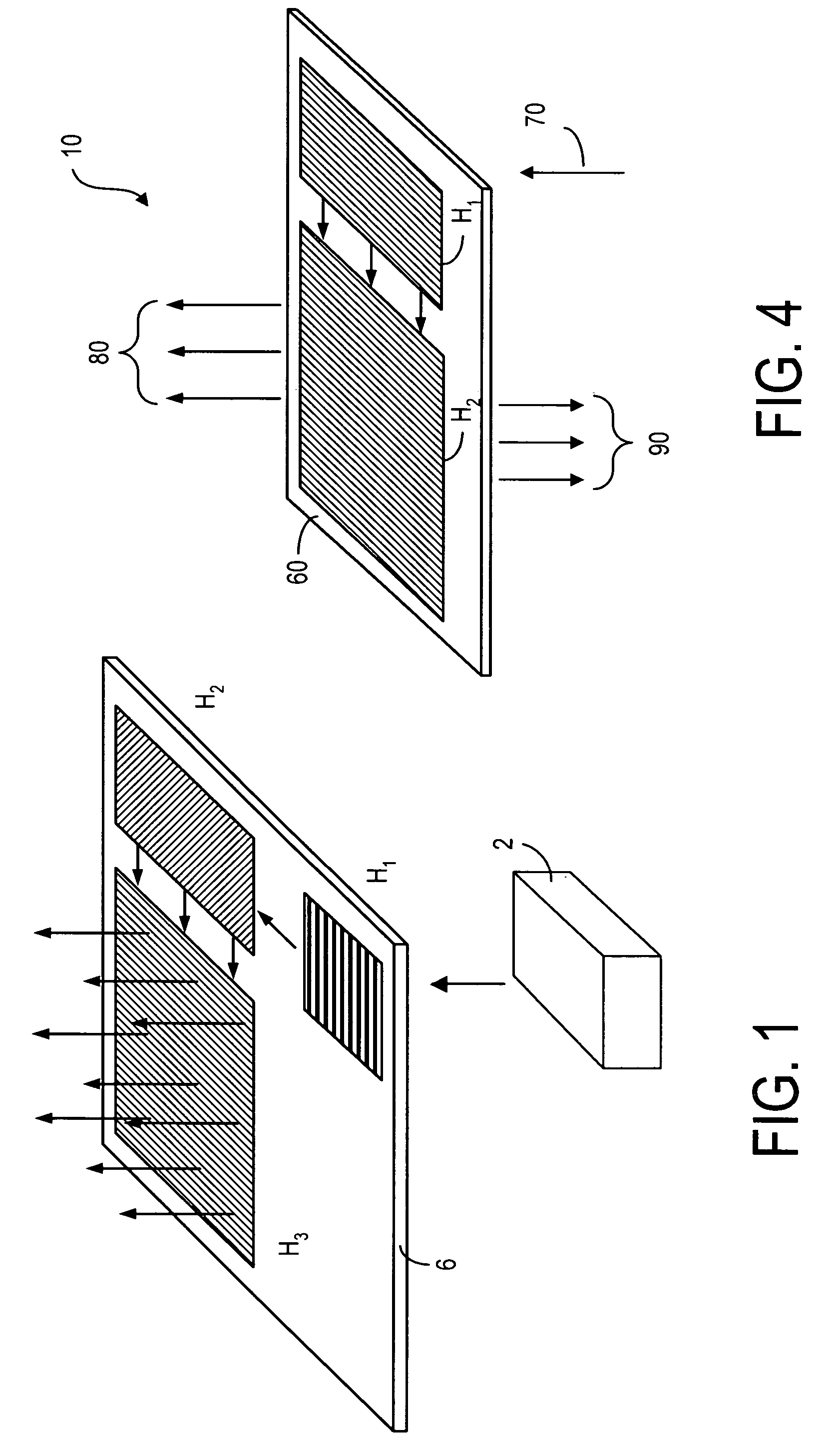

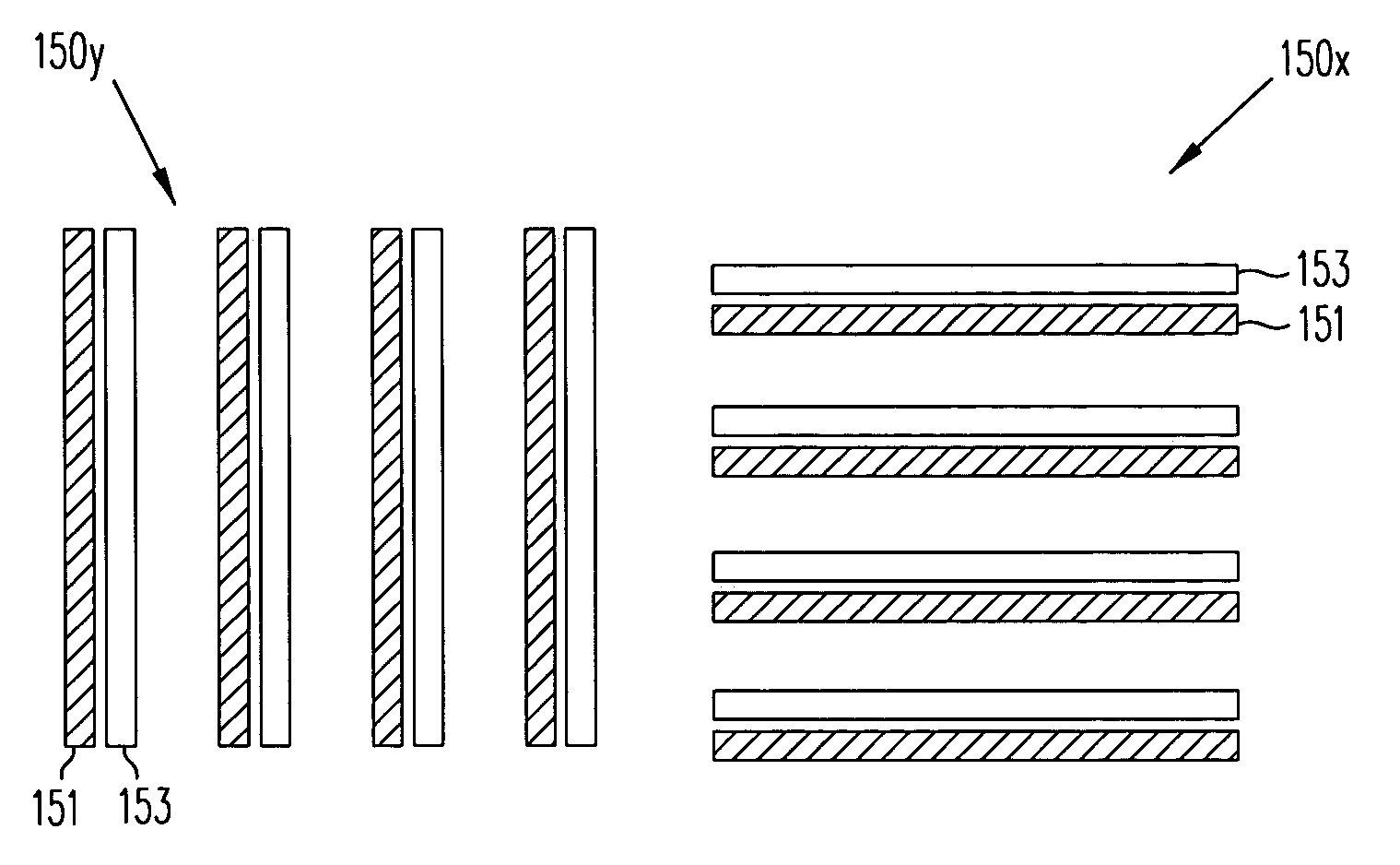

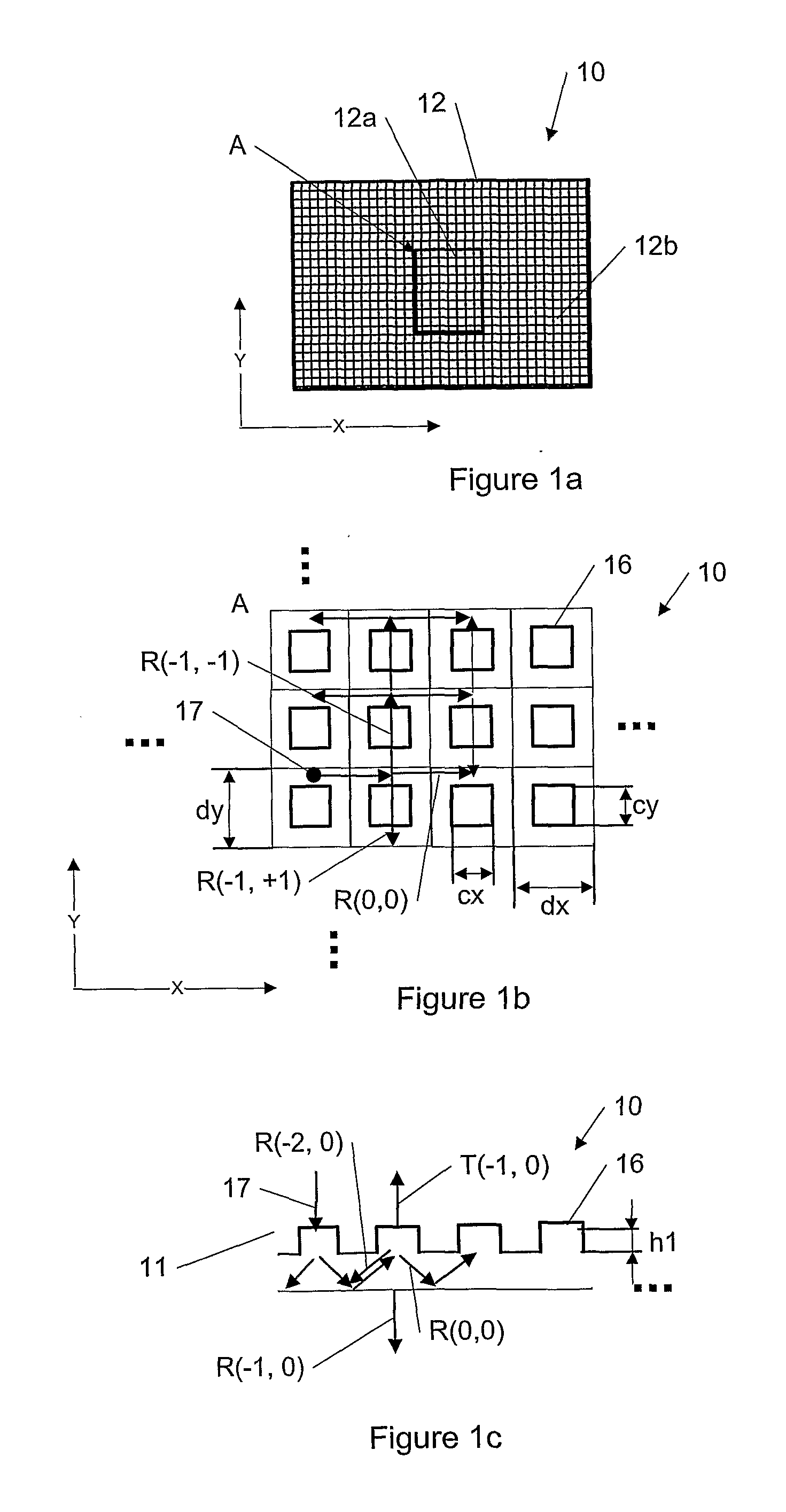

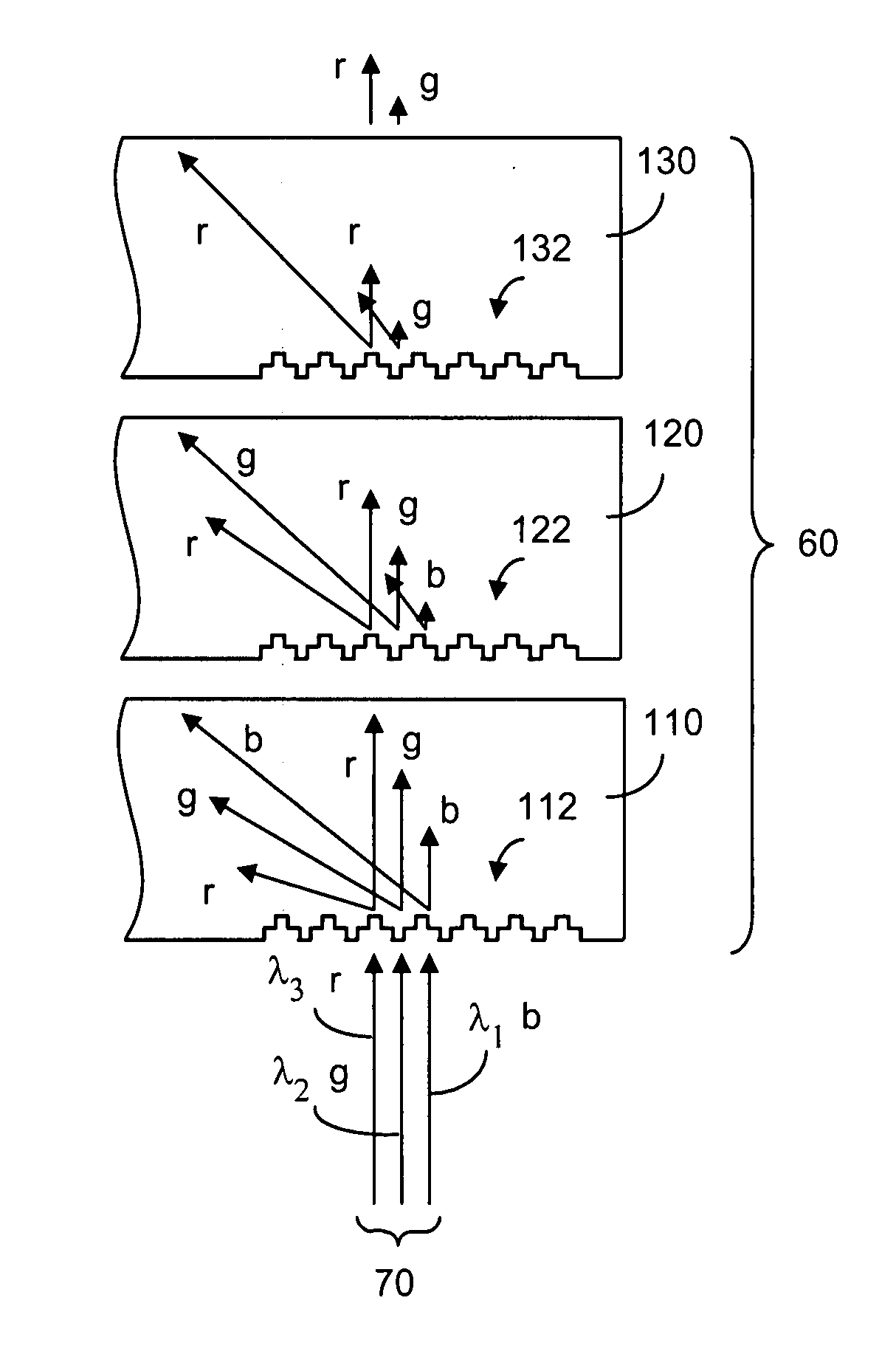

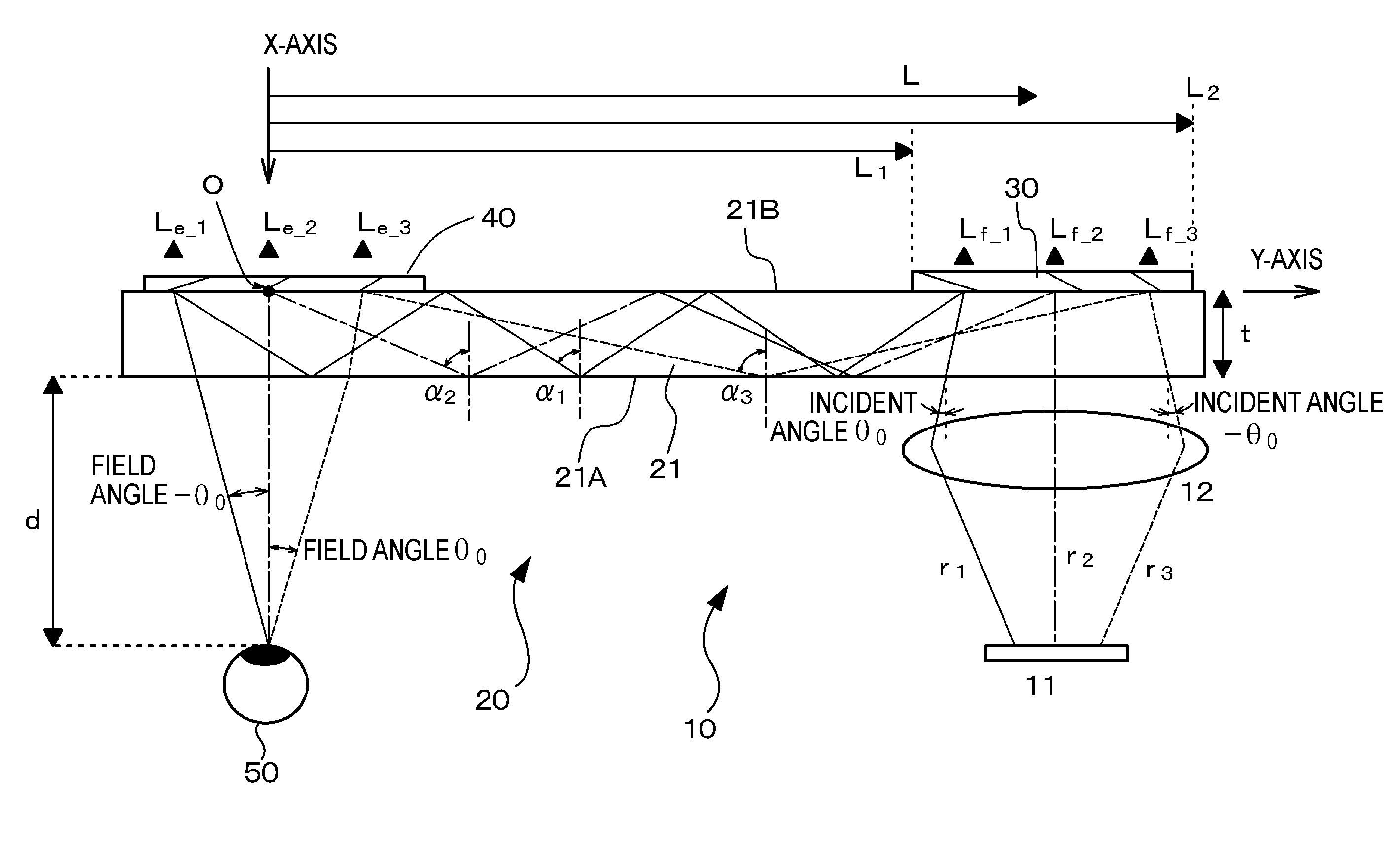

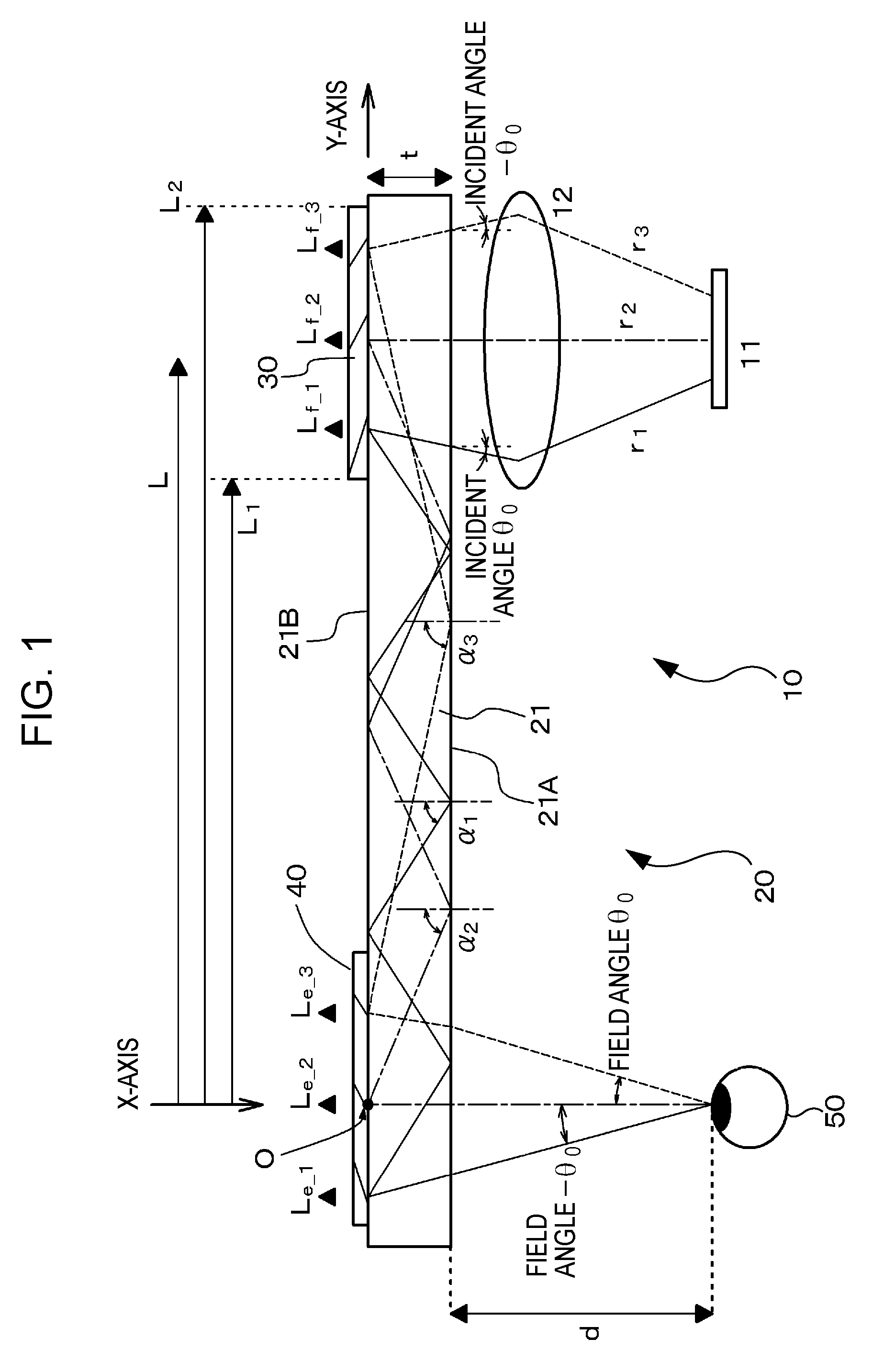

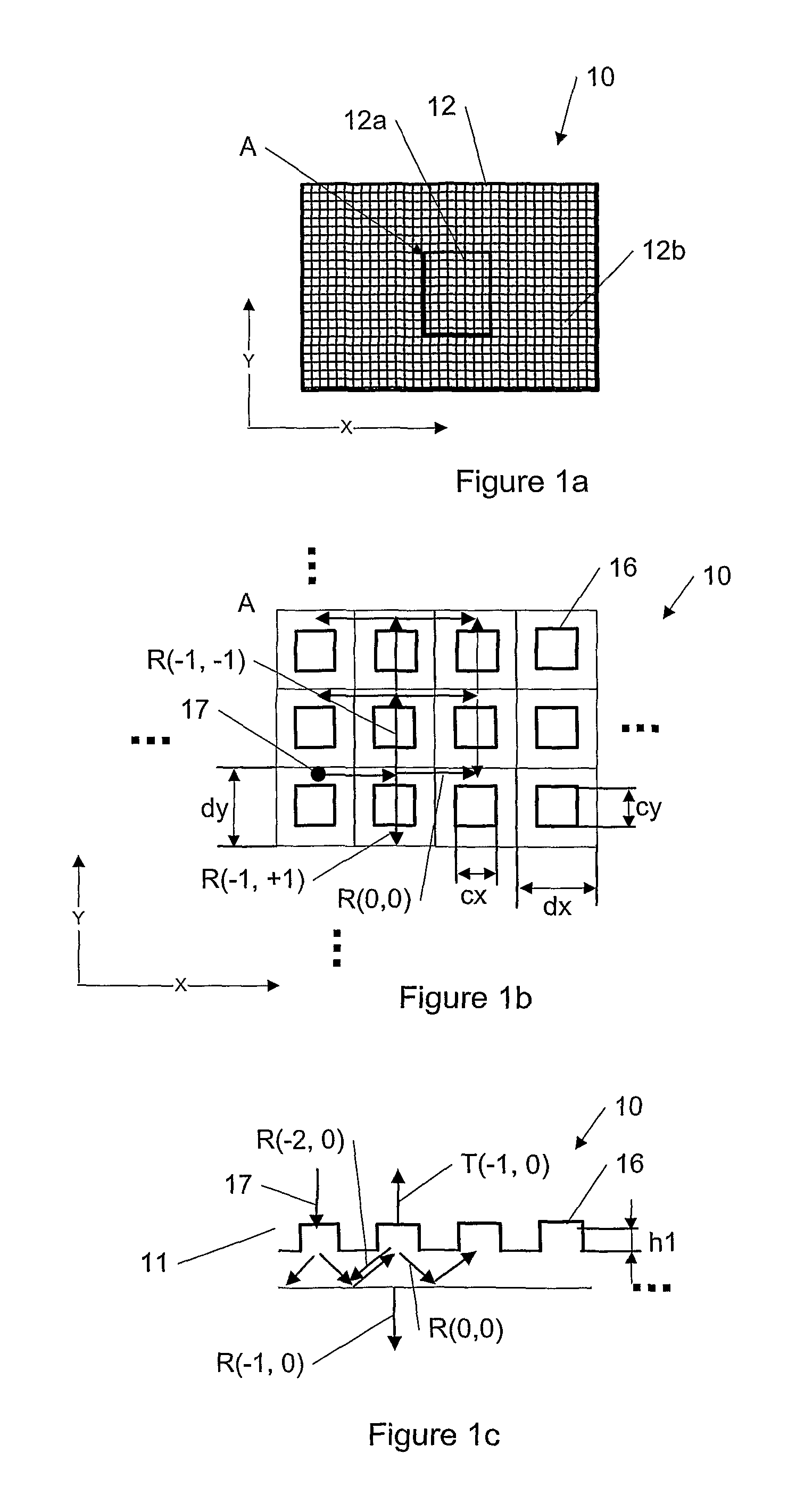

Beam expansion with three-dimensional diffractive elements

The specification and drawings present a new apparatus and method for using a three-dimensional (3D) diffractive element (e.g., a 3D diffractive grating) for expanding in one or two dimensions the exit pupil of an optical beam in electronic devices. Various embodiments of the present invention can be applied, but are not limited, to forming images in virtual reality displays, to illuminating of displays (e.g., backlight illumination in liquid crystal displays) or keyboards, etc.

Owner:MAGIC LEAP

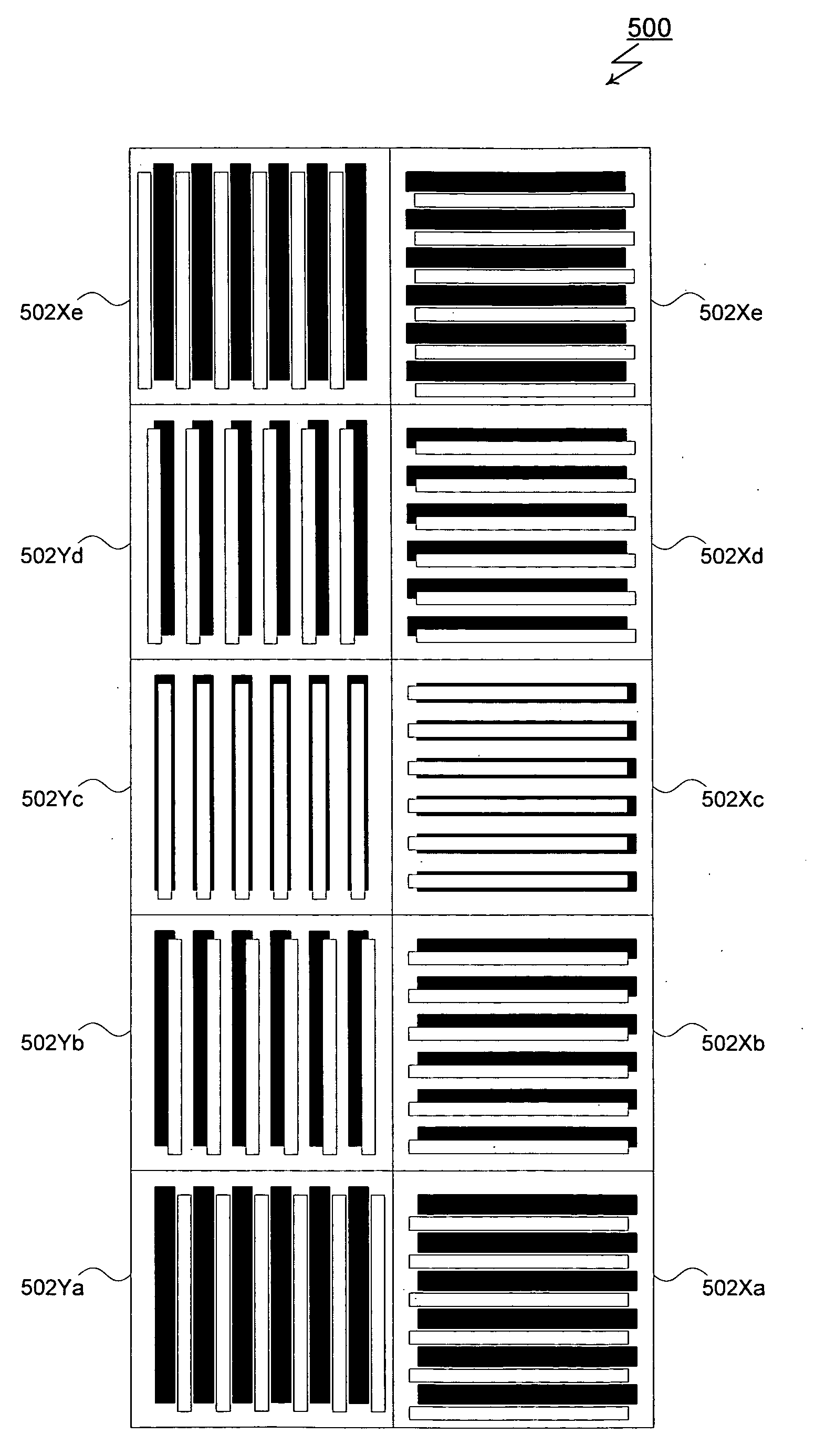

Apparatus and method for measuring overlay by diffraction gratings

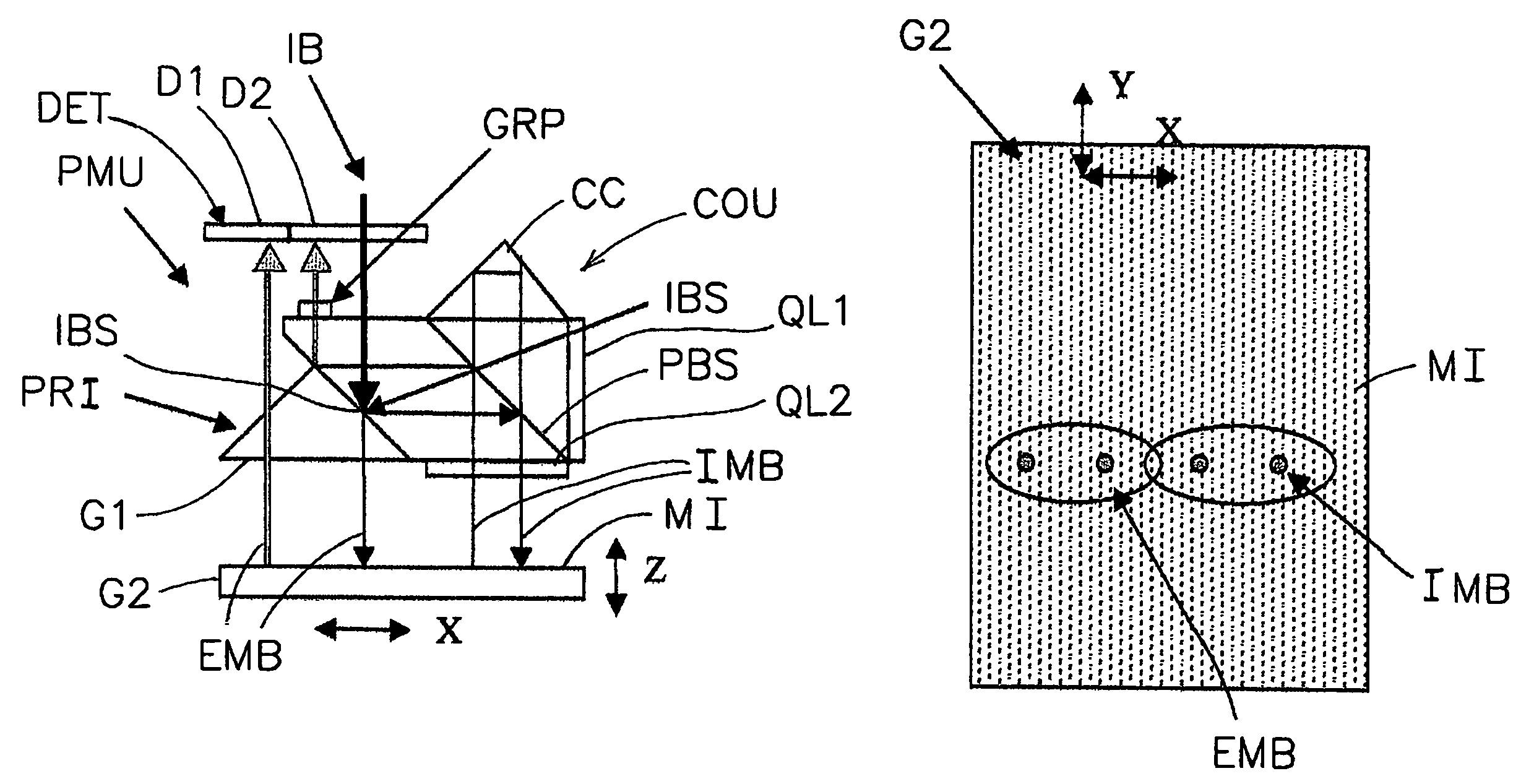

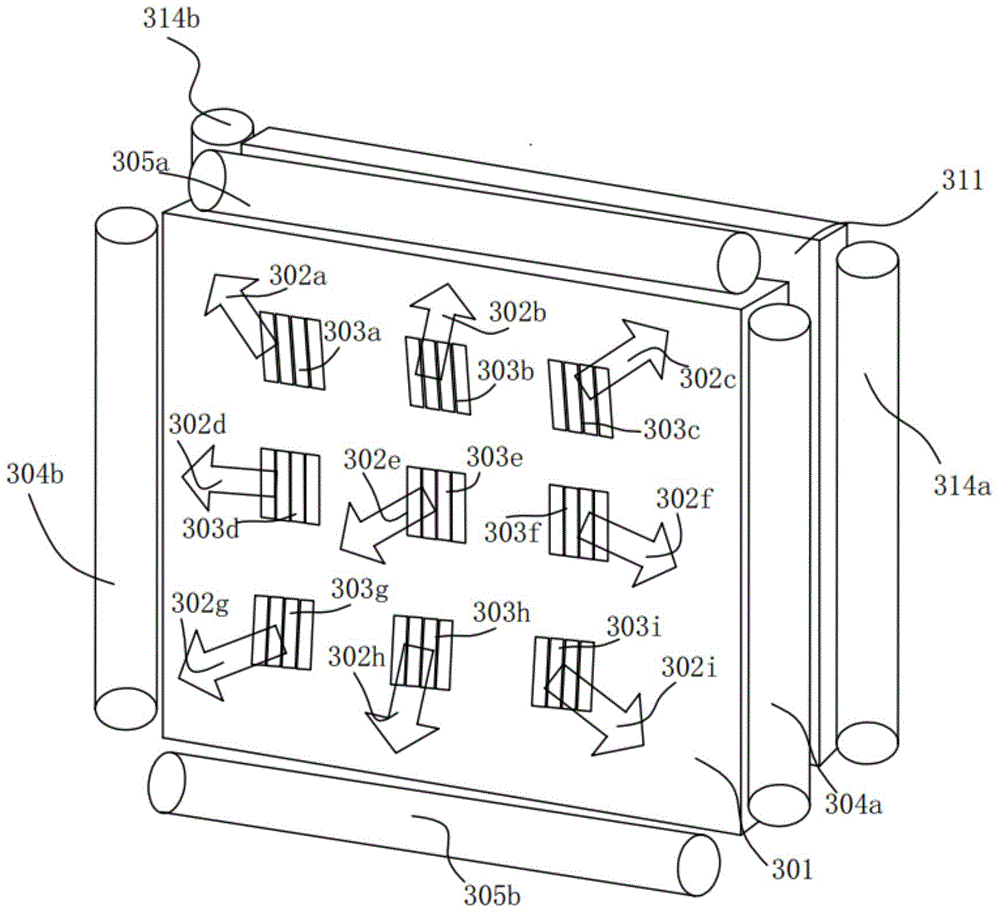

InactiveUS20050012928A1Immune to lens aberrationImmune to vibrationSpectrum investigationUsing optical meansNumerical apertureDiffraction grating

A method for measuring overlay in a sample includes obtaining an image of an overlay target that includes a series of grating stacks each having an upper and lower grating, each grating stack having a unique offset between its upper and lower grating. The image is obtained with a set of illumination and collection optics where the numerical aperture of the collection optics is larger than the numerical aperture of the illumination optics and with the numerical apertures of the illumination and collection optics are selected so that the unit cells of gratings are not resolved, the grating stacks are resolved and they appear to have a uniform color within the image of the overlay target.

Owner:TOKYO ELECTRON LTD

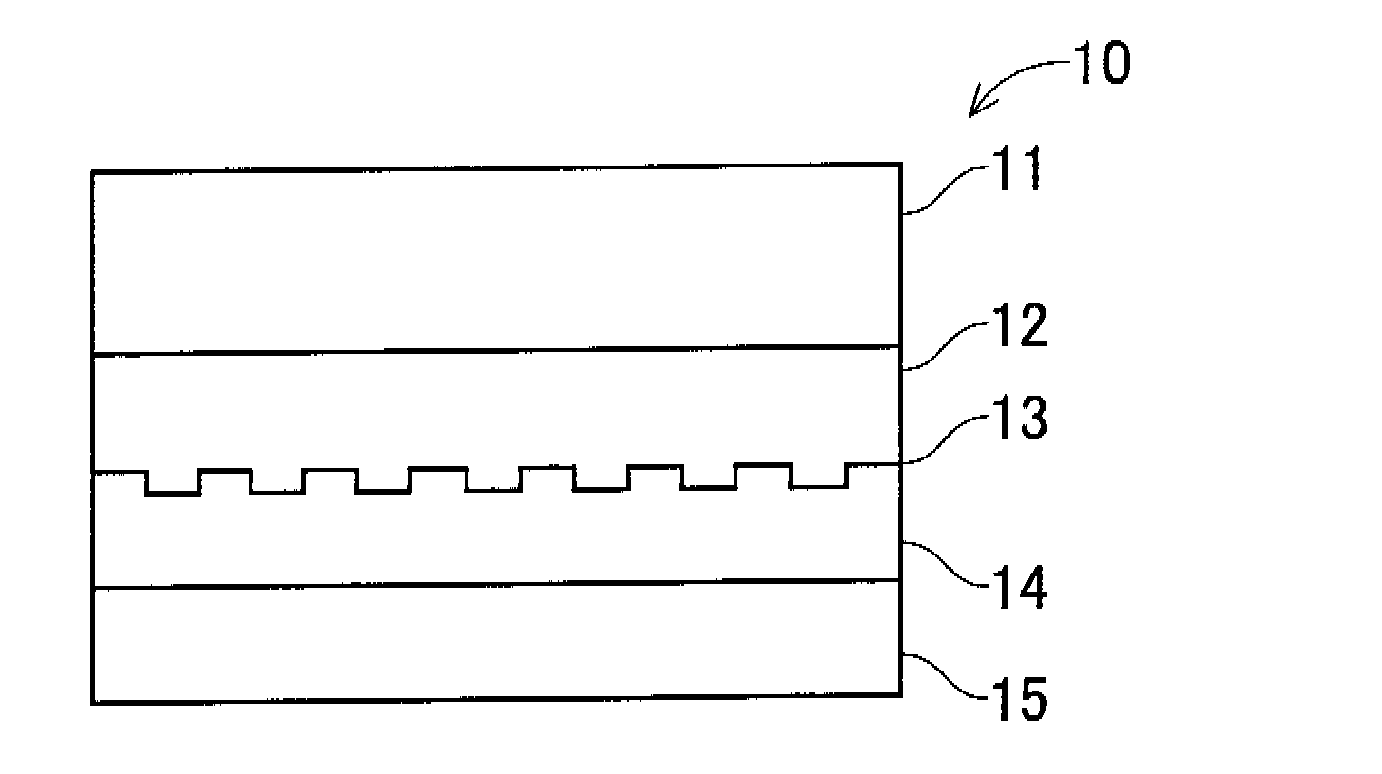

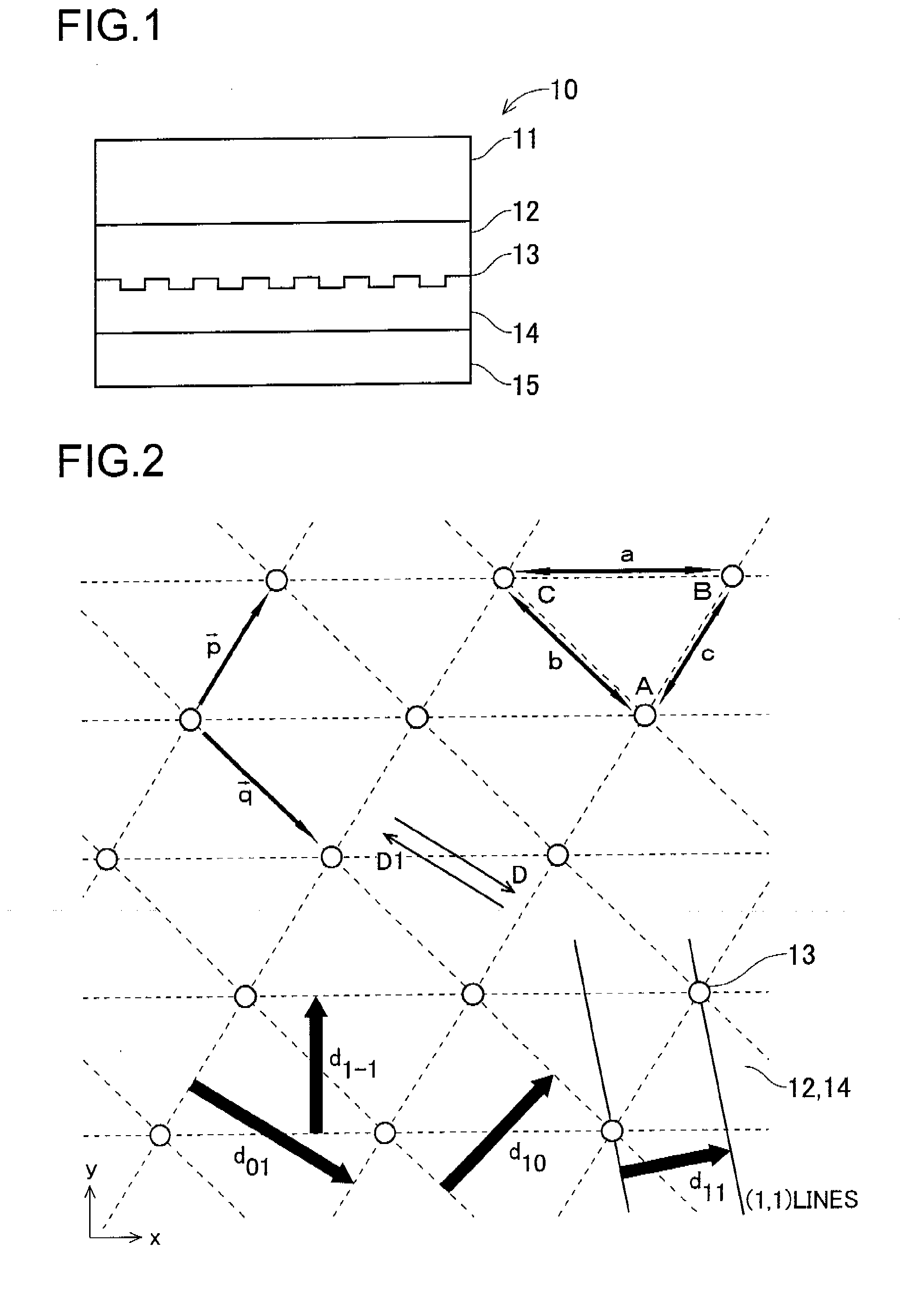

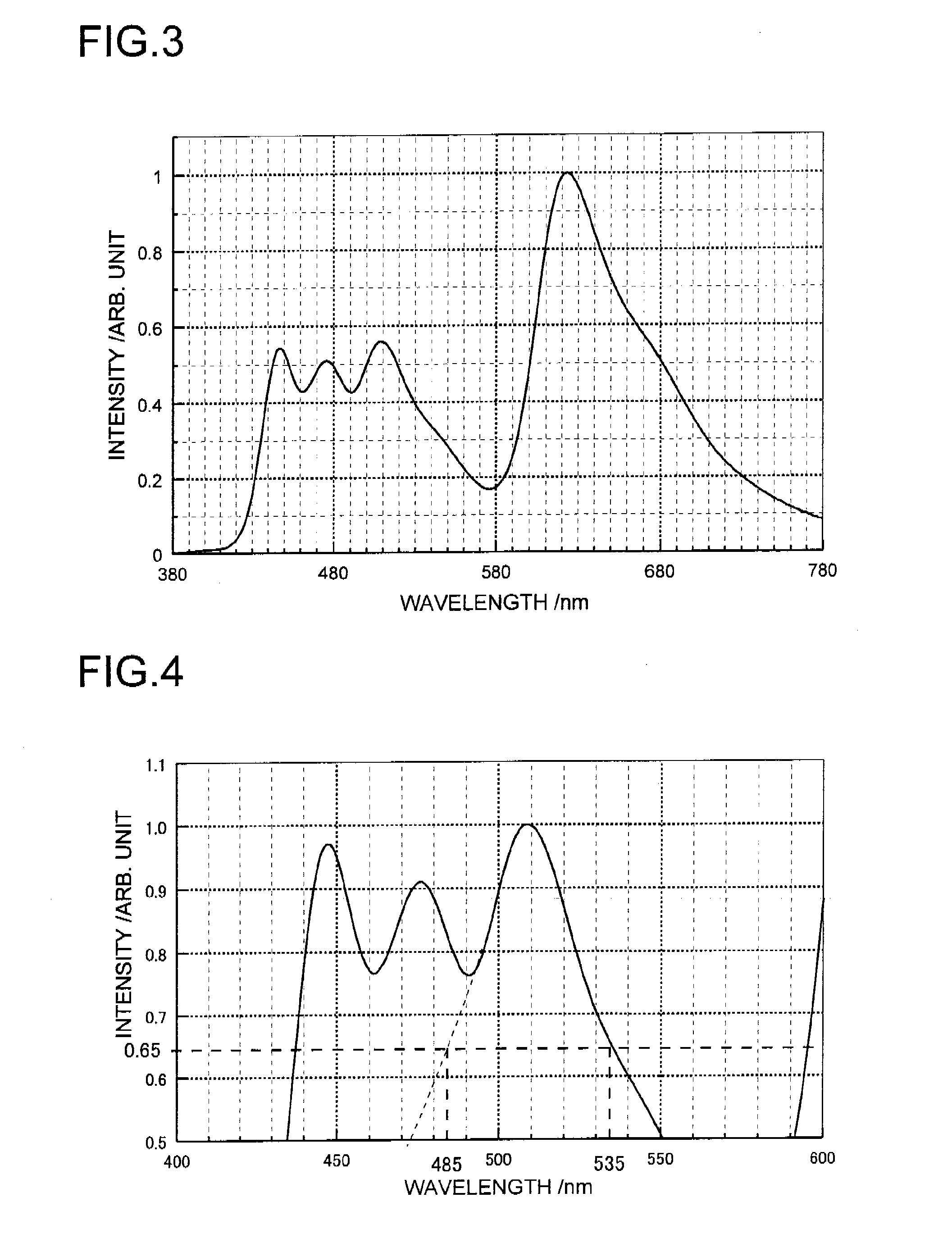

Organic electroluminescence element, and illuminating device and display device therewith

ActiveUS20090066241A1Avoid breakingImage displayed display sharpDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOrganic electroluminescence

In an organic EL element, at the interface between a first electrode and a light-emitting layer, a diffraction grating with grating constants a, b, and c is provided in the form of surface irregularities on the first electrode. The grating constants are determined such that, when the effective refractive index as light experiences in the organic EL element is n, with respect to the periods d01, d10, and d1−1 defining the periodicity of the diffraction grating, n×d01 corresponds to a red region and n×d10 and n×d1−1 correspond to a blue to green region.

Owner:MERCK PATENT GMBH

Method and system for beam expansion in a display device

ActiveUS20060126179A1Increase volumeReduce the amount requiredDiffraction gratingsPlanar/plate-like light guidesExit pupilDiffraction grating

An exit pupil extender wherein the relative amount of different color components in the exit beam is more consistent with that of the input beam. In order to compensate for the uneven amount in the diffracted color components in the exit beam, the exit pupil extender, comprises a plurality of layers having additional diffraction gratings so as to increase the amount of diffracted light for those color components with a lower amount. Additionally, color filters disposed between layers to reduce the diffracted light components with a higher amount.

Owner:MAGIC LEAP

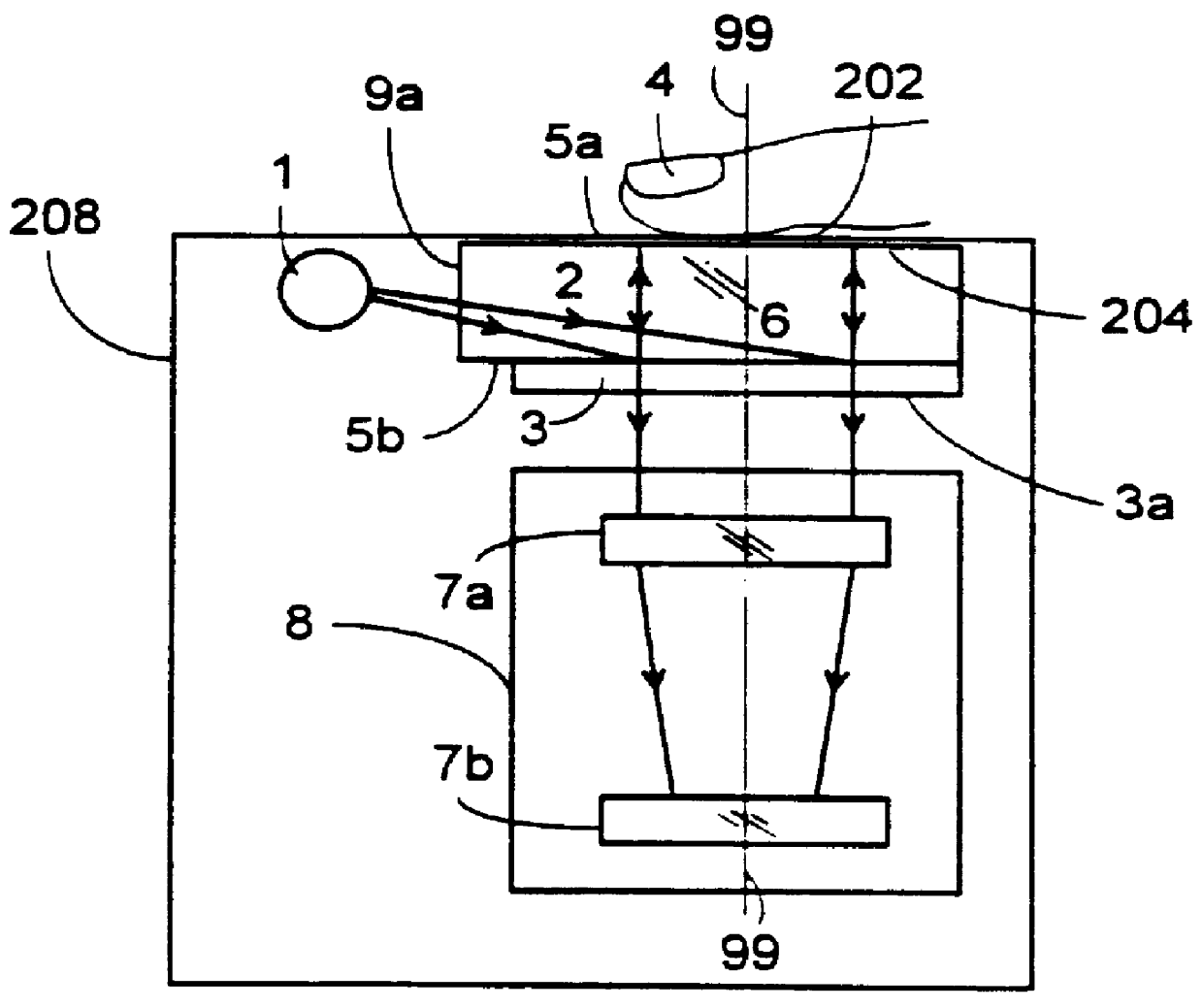

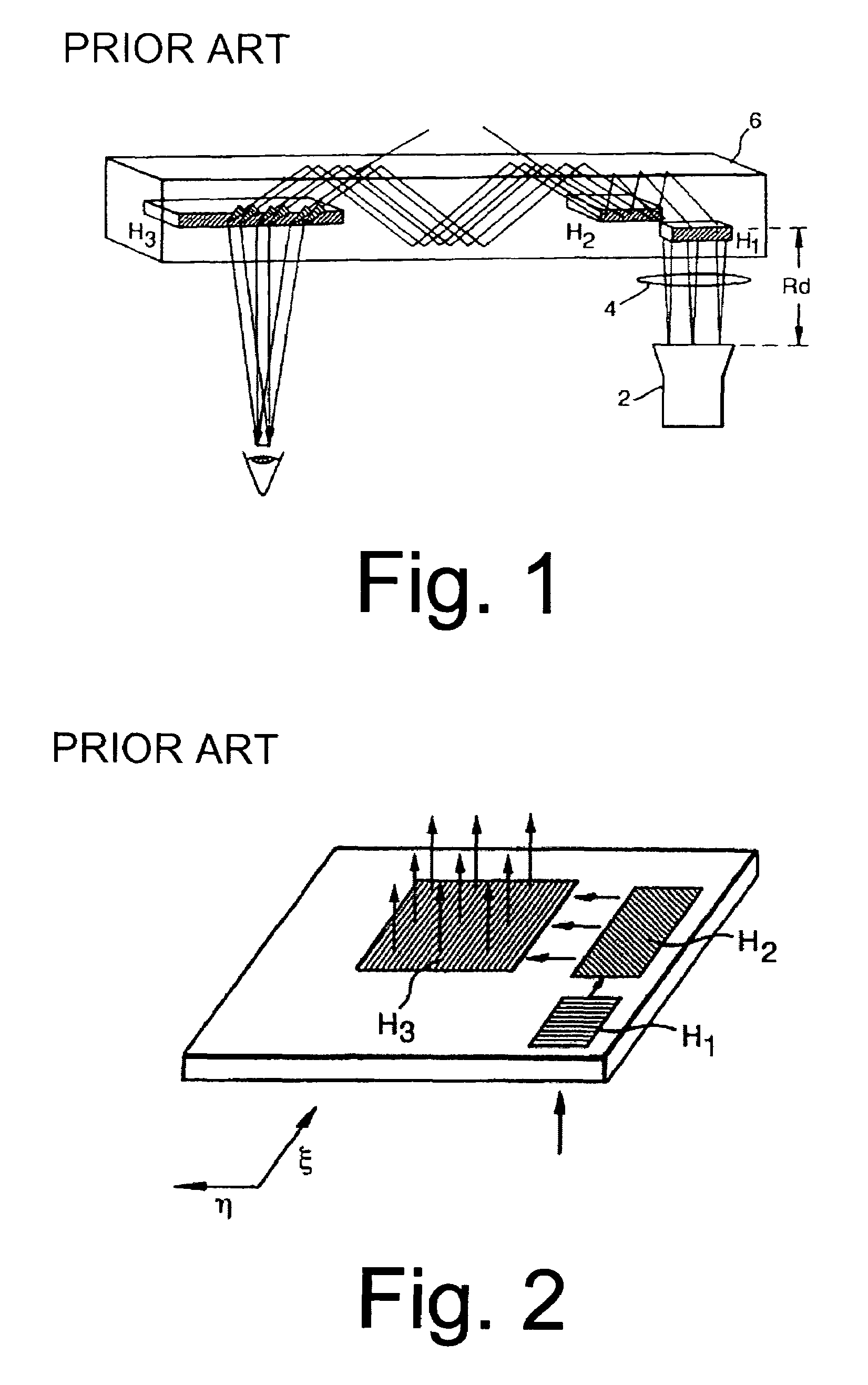

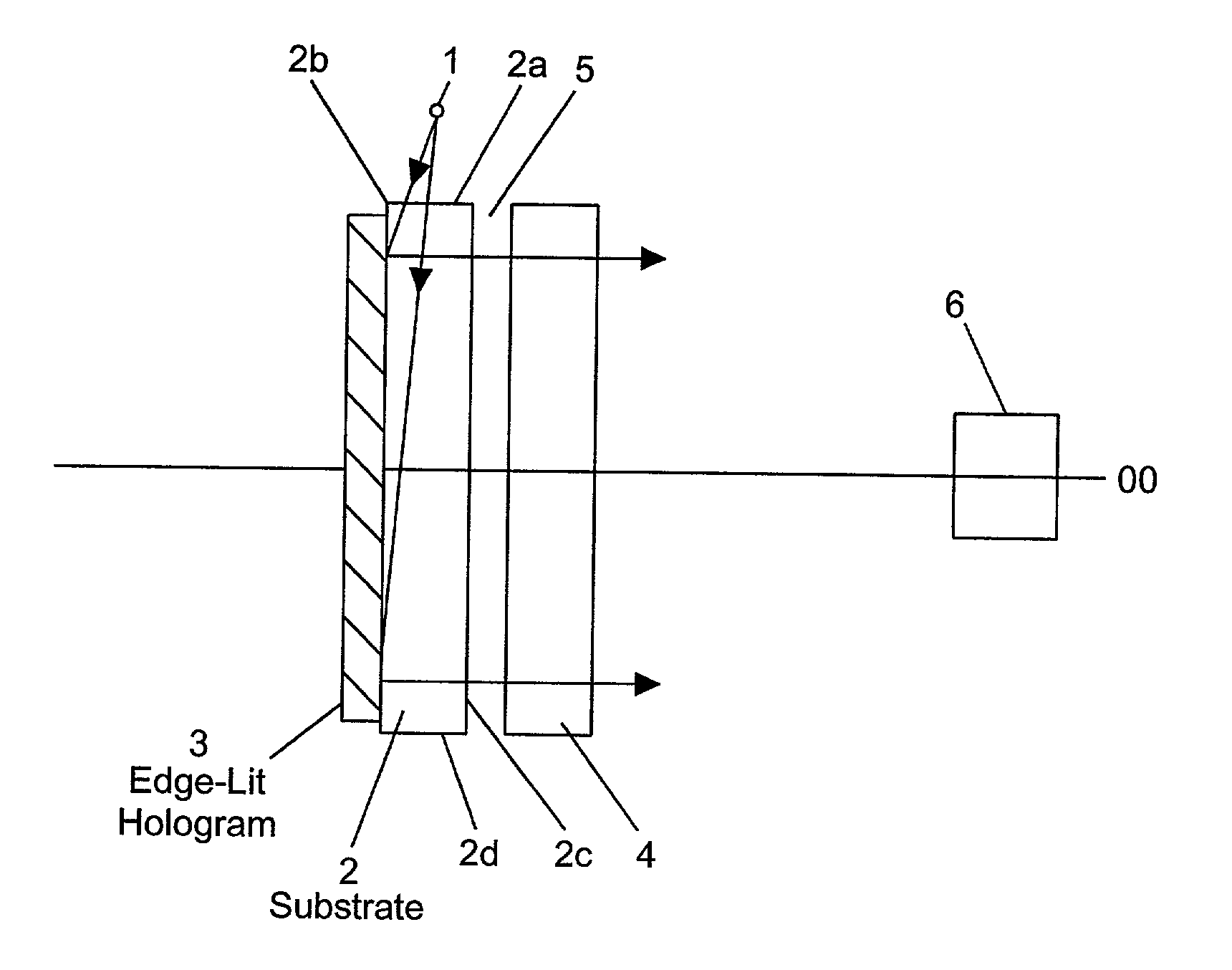

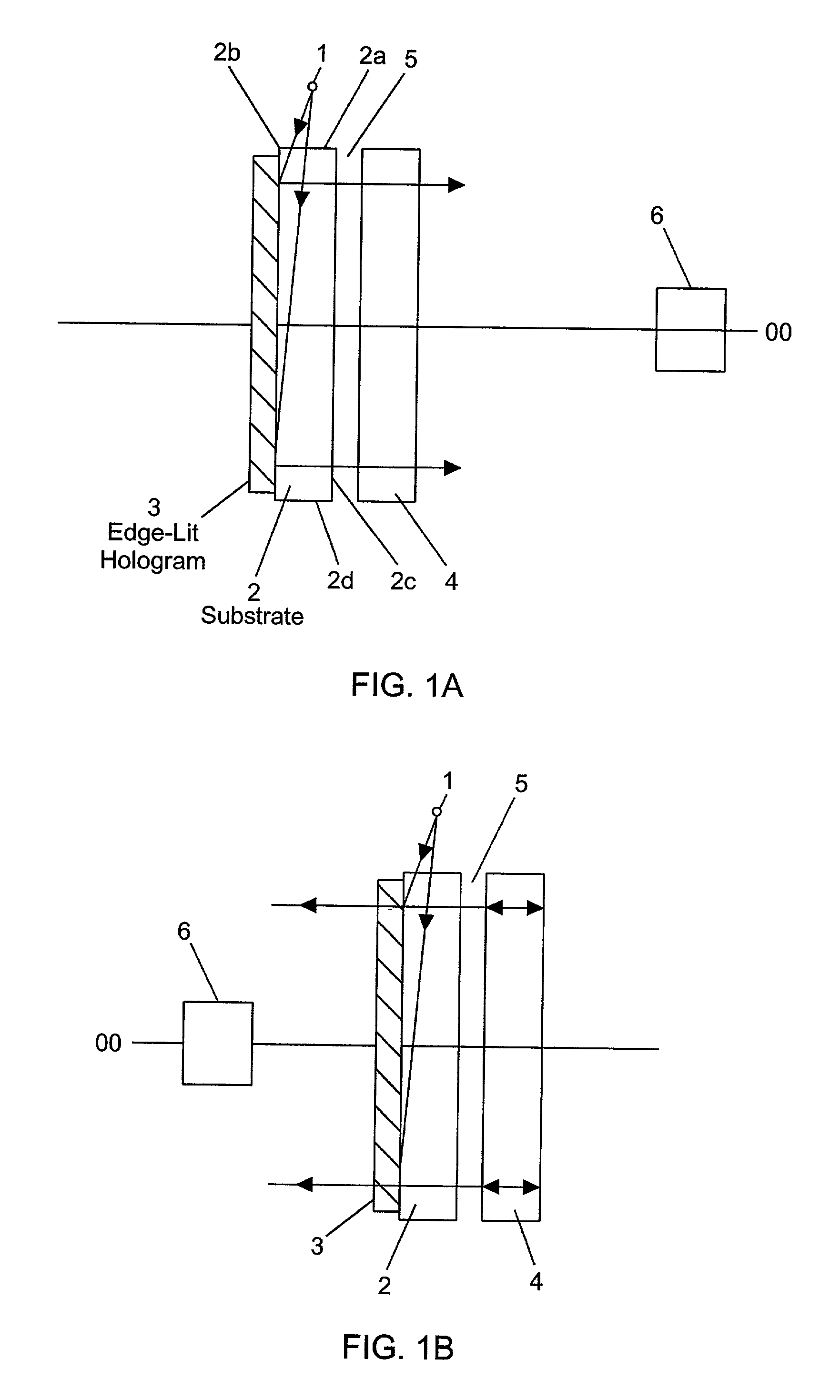

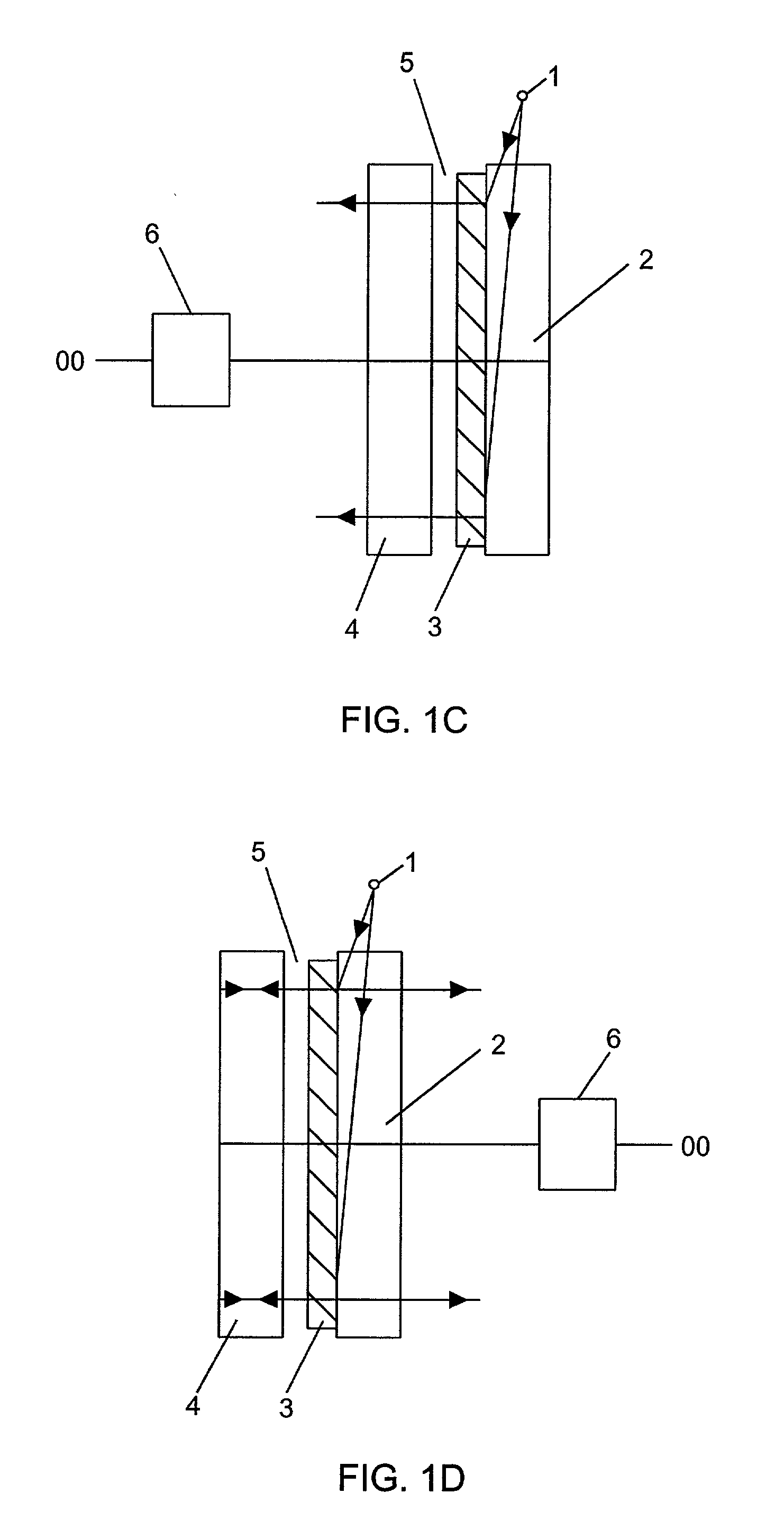

Holographic fingerprint device

InactiveUS6061463AIncrease contrastLittle and no aberration and distortionCharacter and pattern recognitionImage detectionIntensity modulation

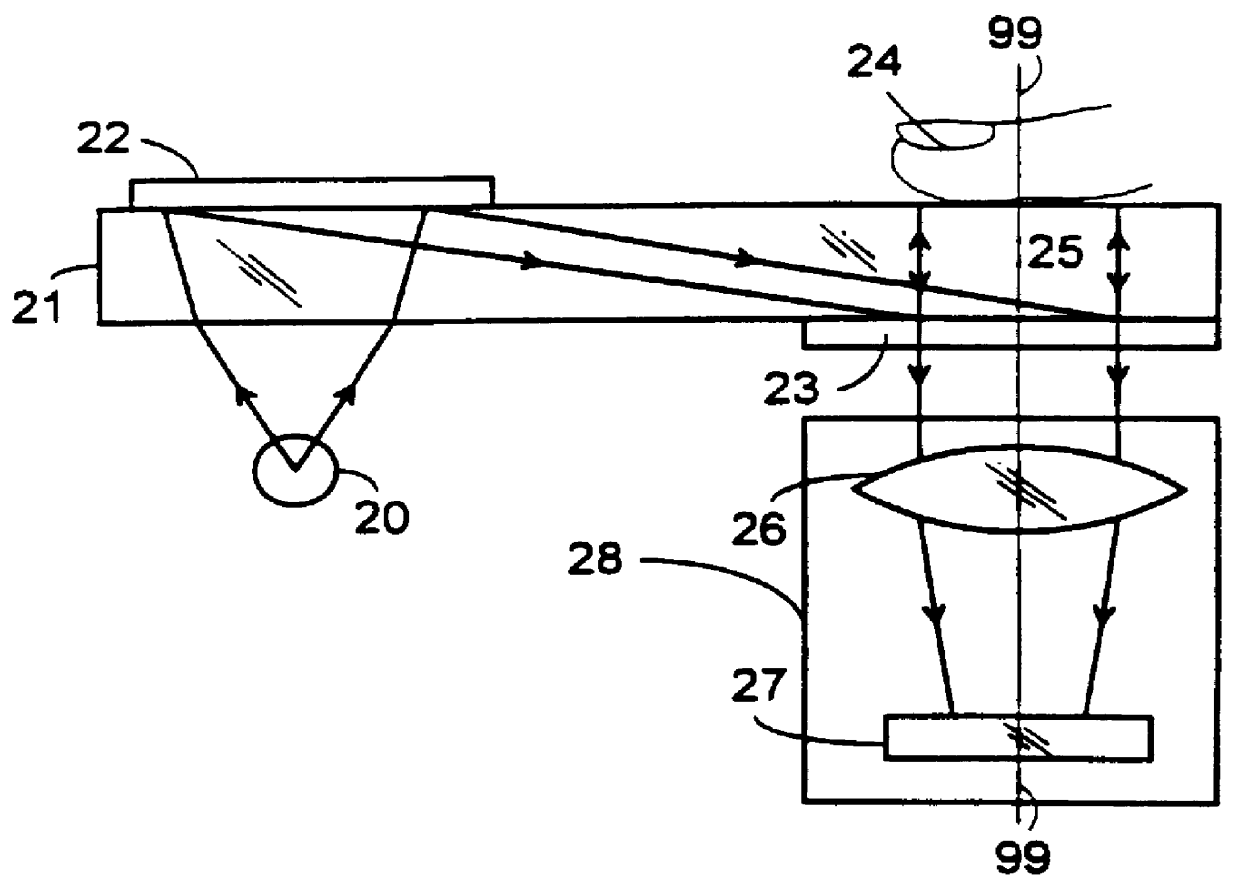

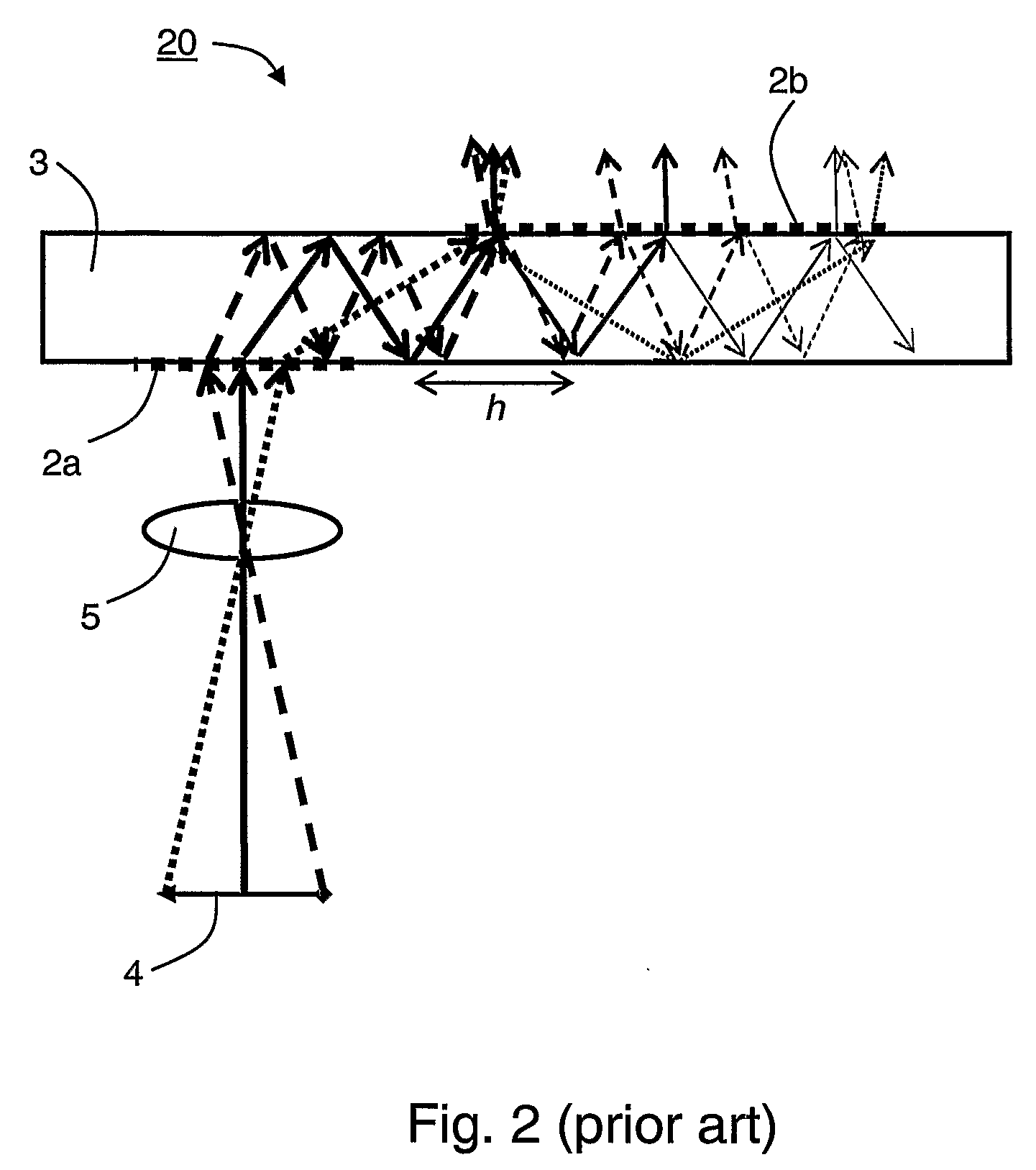

PCT No. PCT / US95 / 02155 Sec. 371 Date Dec. 22, 1997 Sec. 102(e) Date Dec. 22, 1997 PCT Filed Feb. 21, 1995 PCT Pub. No. WO95 / 22804 PCT Pub. Date Aug. 24, 1995A method and ultra-compact system has been developed for illuminating and detecting the surface topography of an object such as the finger (4) of an individual. The system (8) is capable of producing high-contrast images which can be electronically transmitted in real-time, or stored using electronic or photographic recording devices. Light traveling within a light transmitting substrate (2) is redirected by a slanted-fringed light diffractive grating preferably embodied within a volume hologram (3). The volume hologram (3), either of the reflection or transmission type, is attached to the light transmitting substrate (2). and functions to diffract light striking thereupon and illuminate an object having topographical surface structure. After being spatially and intensity modulated in accordance with topographical details of the illuminated object, the insulated light passes back through the light transmitting substrate (2) and the volume hologram (3), onto an image detection array. for subsequent analysis. Each of the disclosed embodiments has a compact geometry suitable for use in diverse object identification applications.

Owner:KREMEN MR STANLEY H

Position measurement unit, measurement system and lithographic apparatus comprising such position measurement unit

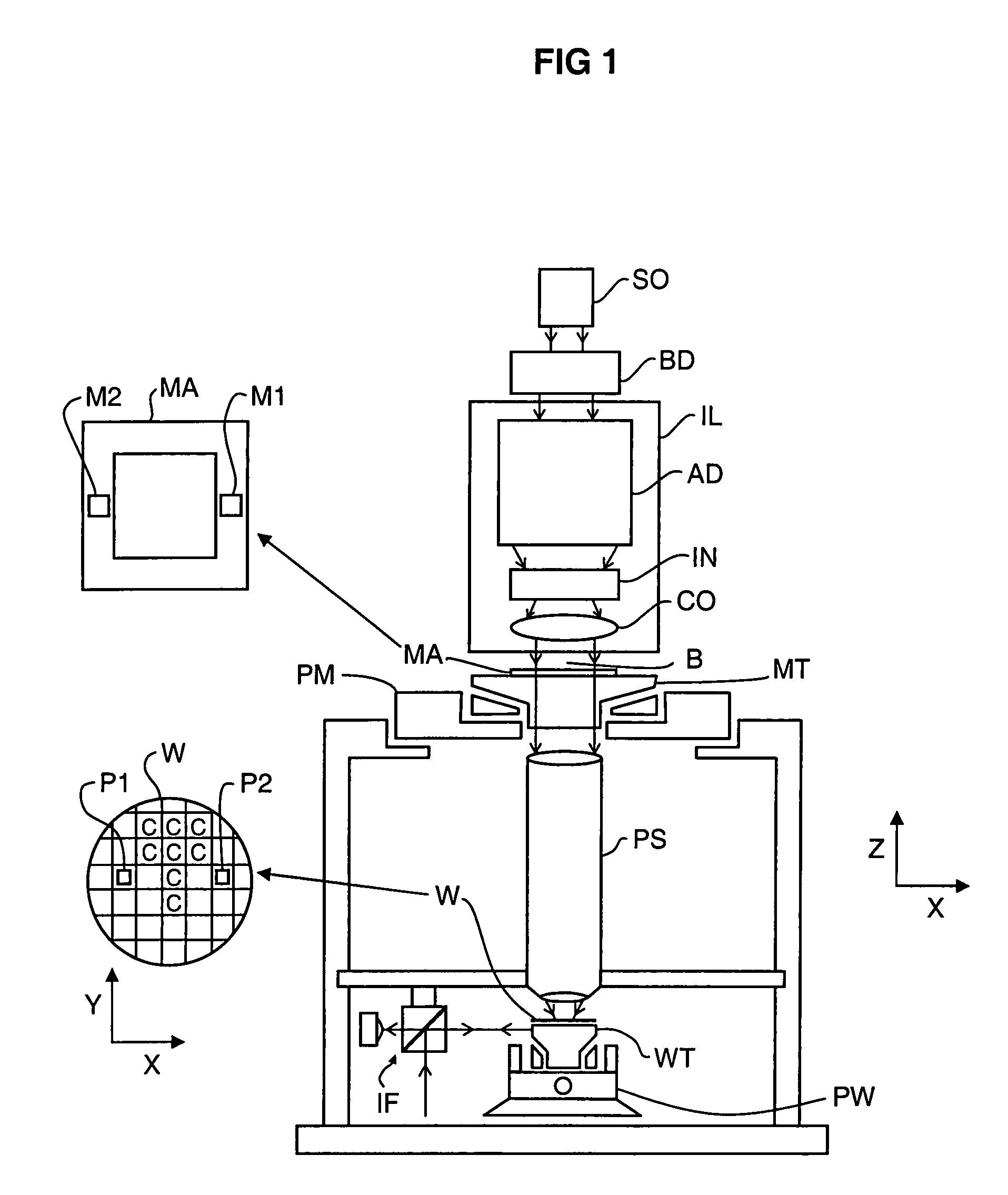

A measurement unit to determine a position in a first and second dimension includes a diffraction type encoder and an interferometer. The diffraction type encoder determines by means of a diffraction on a first and a second diffraction grating the position in the first dimension of the second grating with respect to the first grating, The interferometer determines the position in the second dimension of a mirror. The measurement unit includes a combined optical unit to transfer an encoder measurement beam as well as an interferometer measurement beam. Further, the measurement unit may include a combined light source for the encoder as well as the interferometer. One of the first and second diffraction gratings may further show some degree of zero order reflection to provide the mirror of the interferometer.

Owner:ASML NETHERLANDS BV

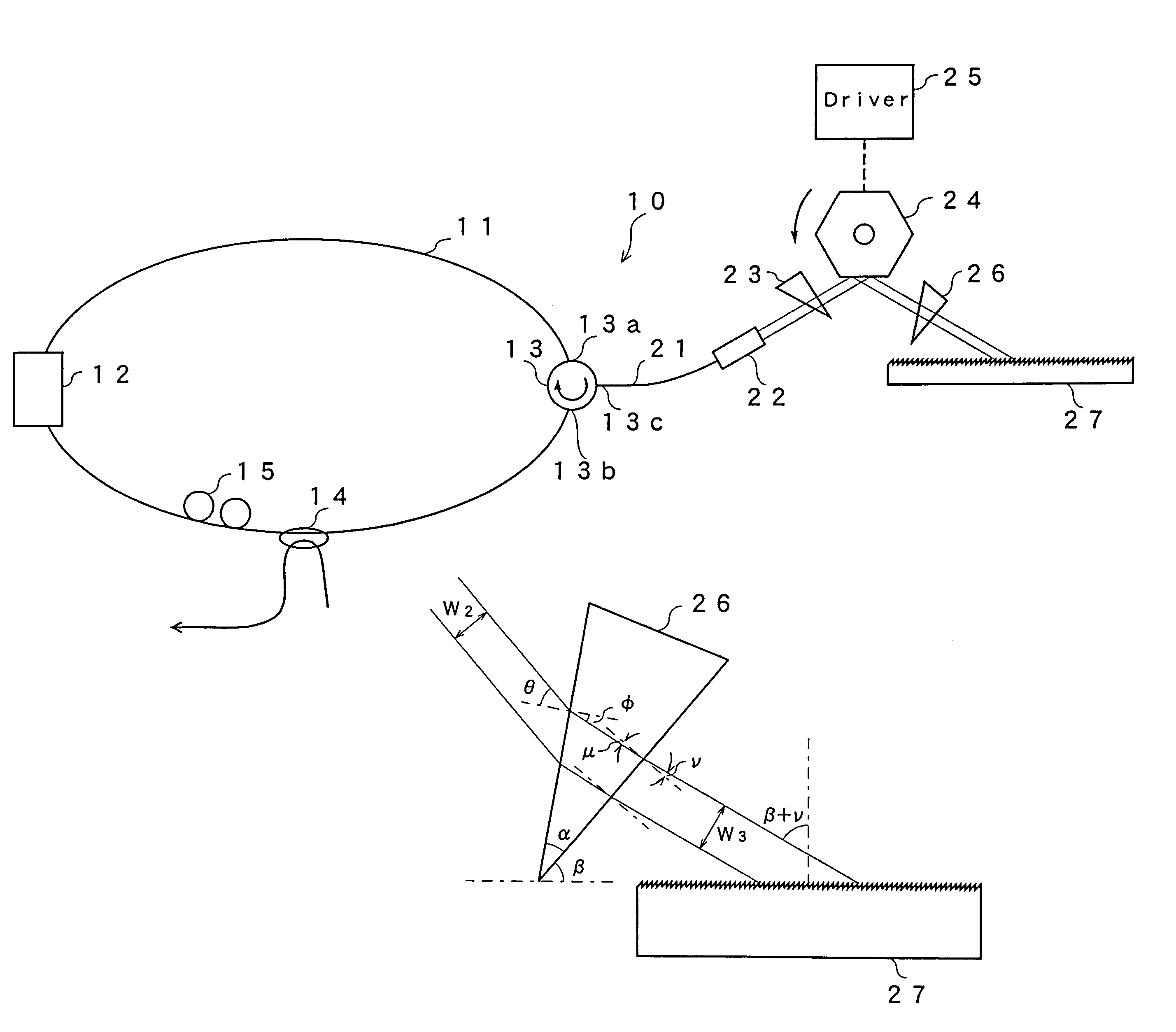

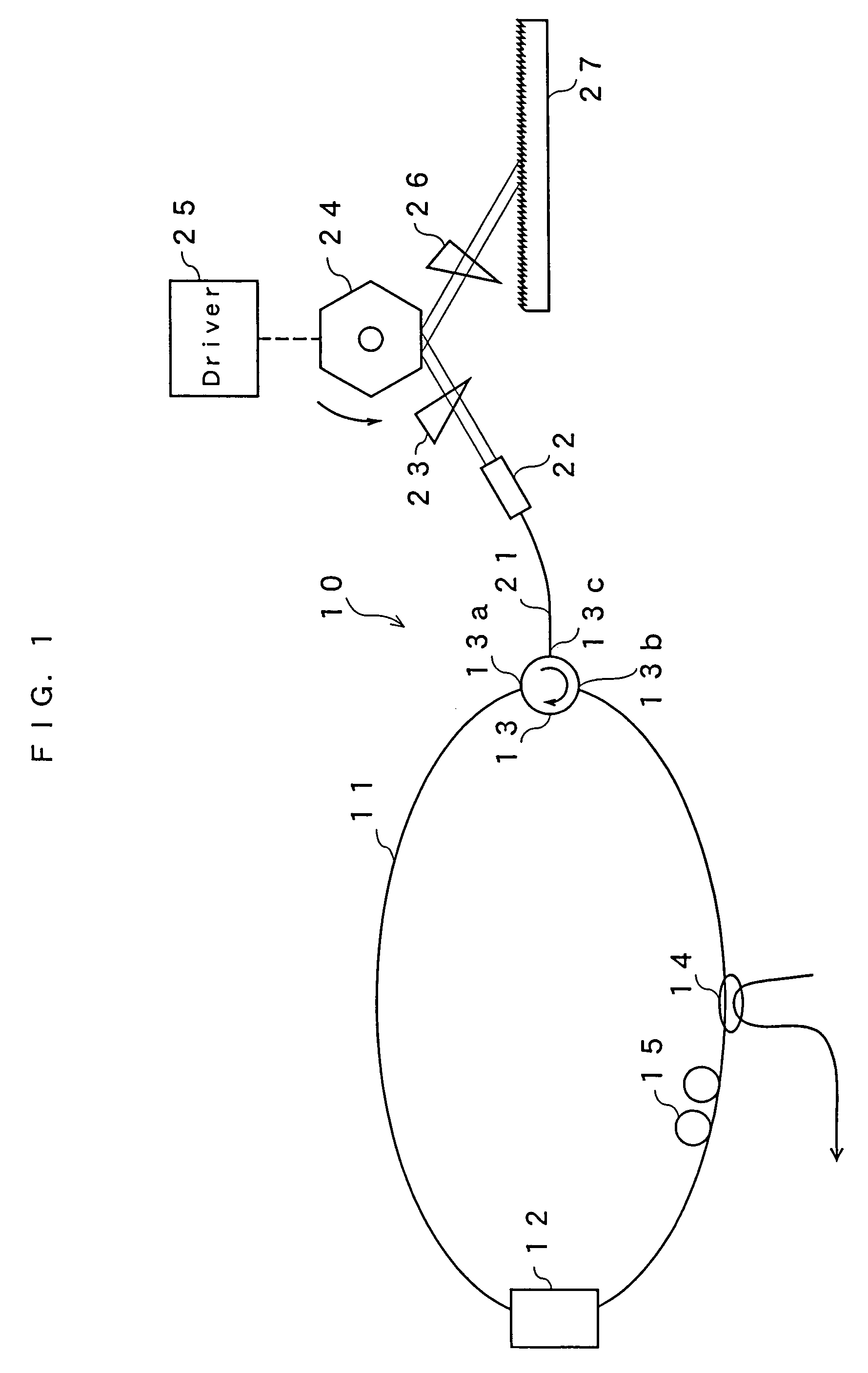

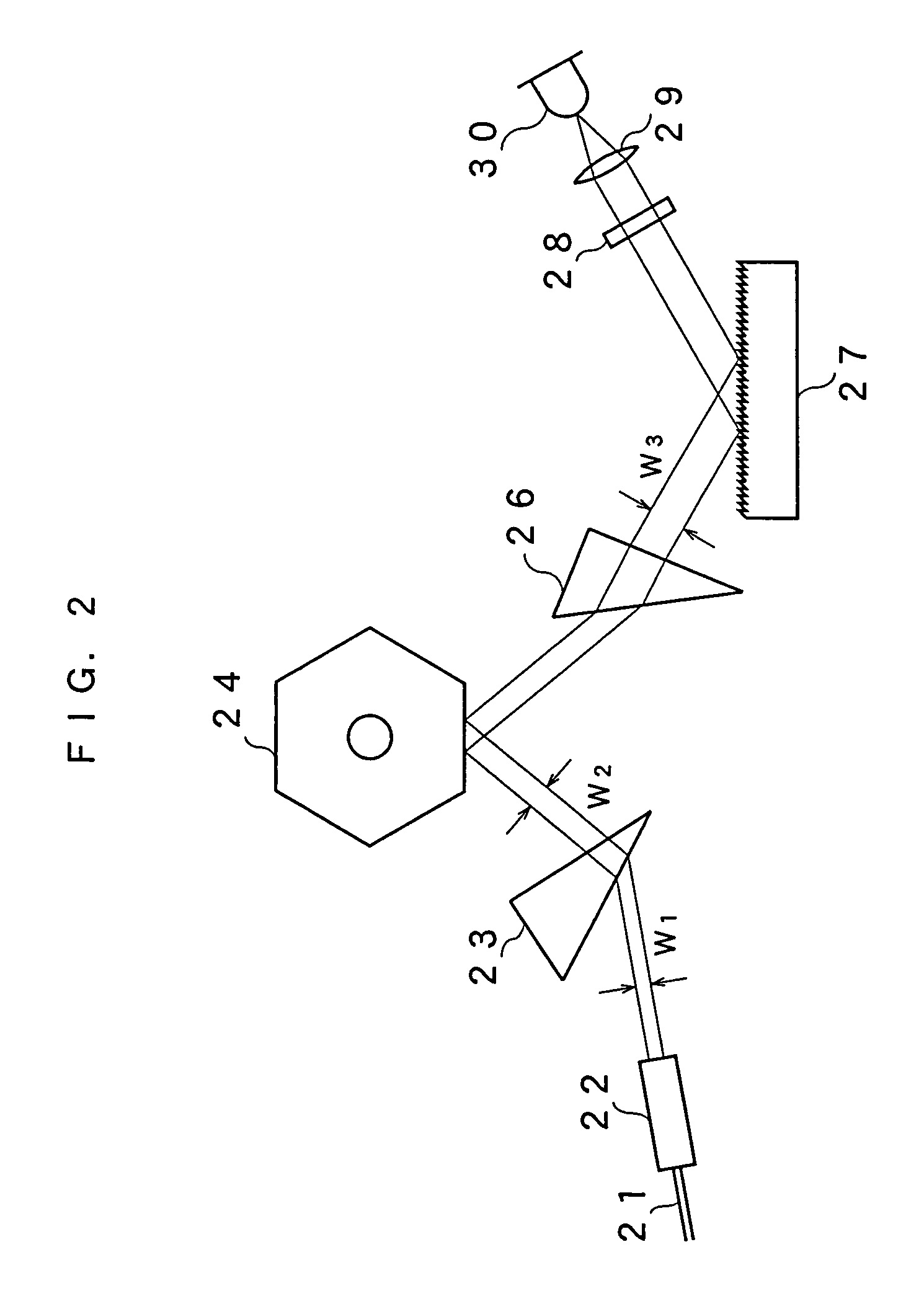

Tunable laser light source

ActiveUS7099358B1Small distortionLittle noiseOptical resonator shape and constructionSemiconductor lasersLight beamPrism

A gain medium 12 and a tunable filter are provided in an optical path of laser oscillation. The tunable filter has an optical beam deflector for periodically changing an optical beam at a constant angular speed, a prism 26 on which deflected light is made incident, and a diffraction grating 27. Appropriate selection of the apex angle α of the prism 26 and an angle β formed by the prism 26 and the diffraction grating 27 can provide a tunable laser light source for changing the oscillation frequency at high speed and a constant variation rate.

Owner:SANTEC

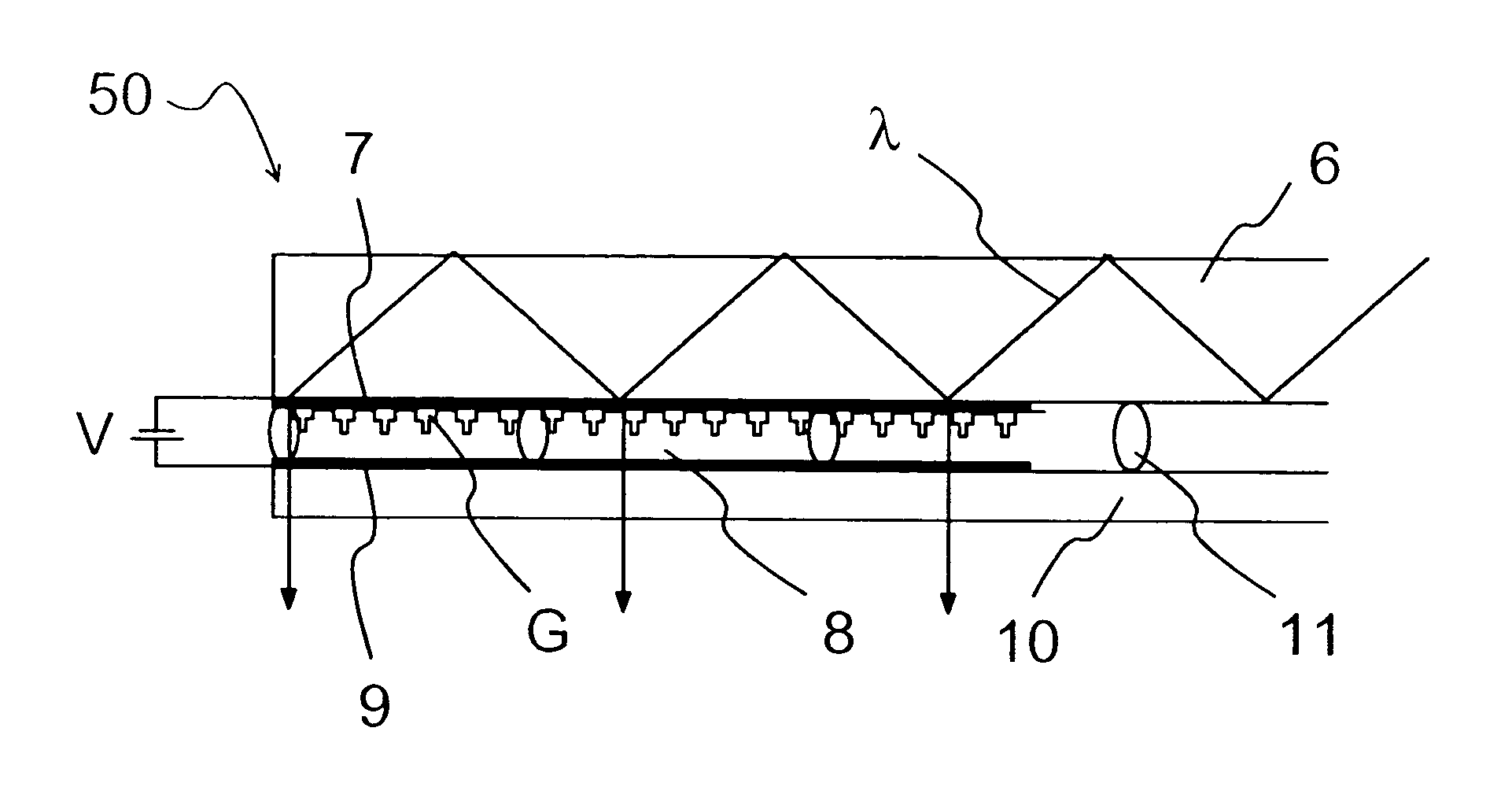

Electrically tunable diffractive grating element

ActiveUS7184615B2Improve color uniformityImprove image qualityDiffraction gratingsCoupling light guidesElectricityExit pupil

The invention relates to an optical device (50) for manipulating a light wave (λ) using a diffractive grating structure (G). According to the basic idea behind the invention a prior art type diffractive grating structure having a permanently shaped surface relief is substituted with an electrically deformable diffractive grating structure (G), where a preformed, basic surface relief of the grating is composed of dielectric and deformable viscoelastic material, which can be electrically and sequentially fine tuned in shape to adjust the diffraction properties of said grating individually for different wavelengths. The invention permits manufacture of virtual display devices with a significantly larger exit pupil diameter than prior art solutions without degrading the color uniformity of the display device.

Owner:MAGIC LEAP

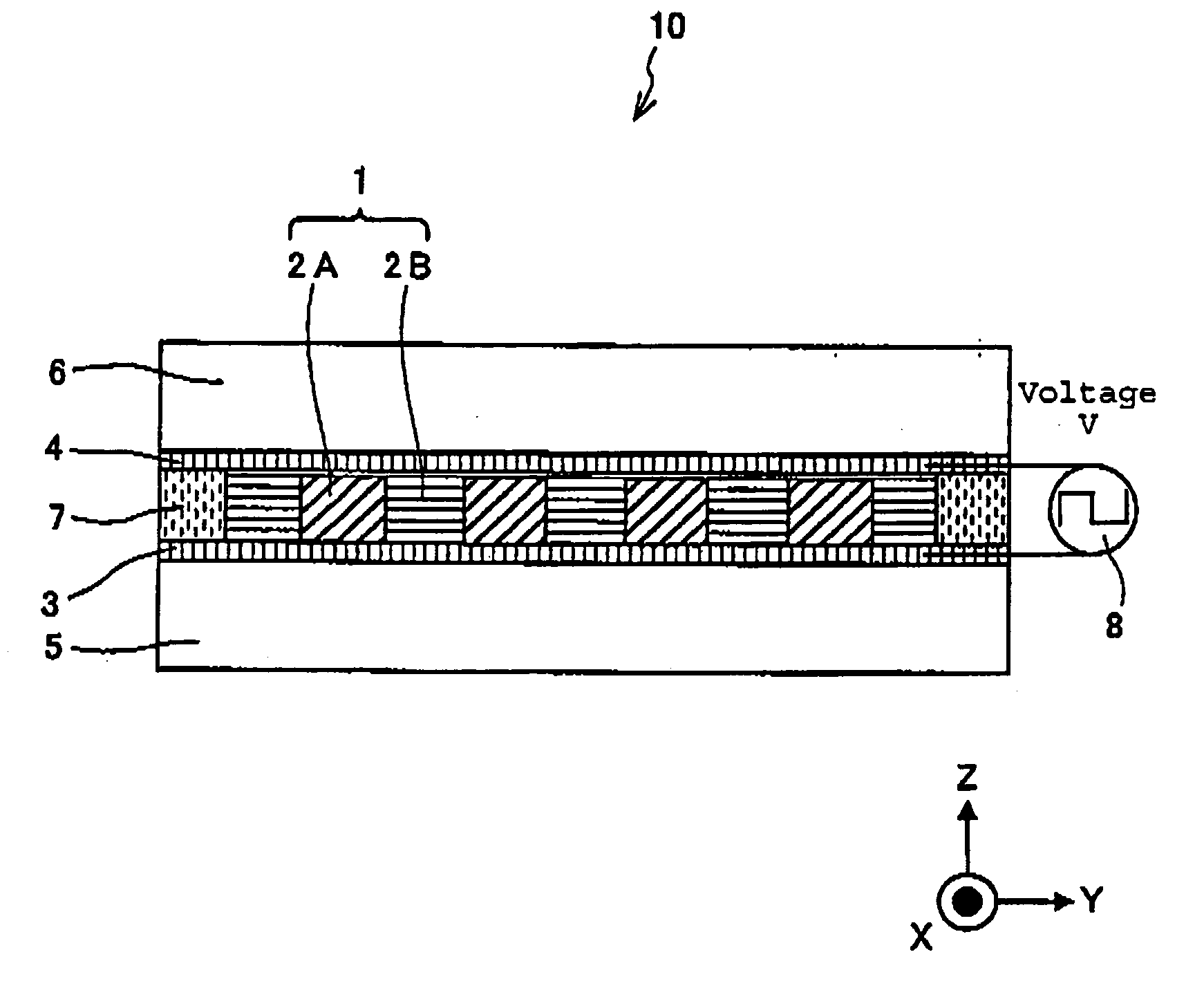

Optical element employing liquid crystal having optical isotropy

InactiveUS20060227283A1High speed responseHigh-speed opticalStatic indicating devicesNon-linear opticsRefractive indexIsotropy

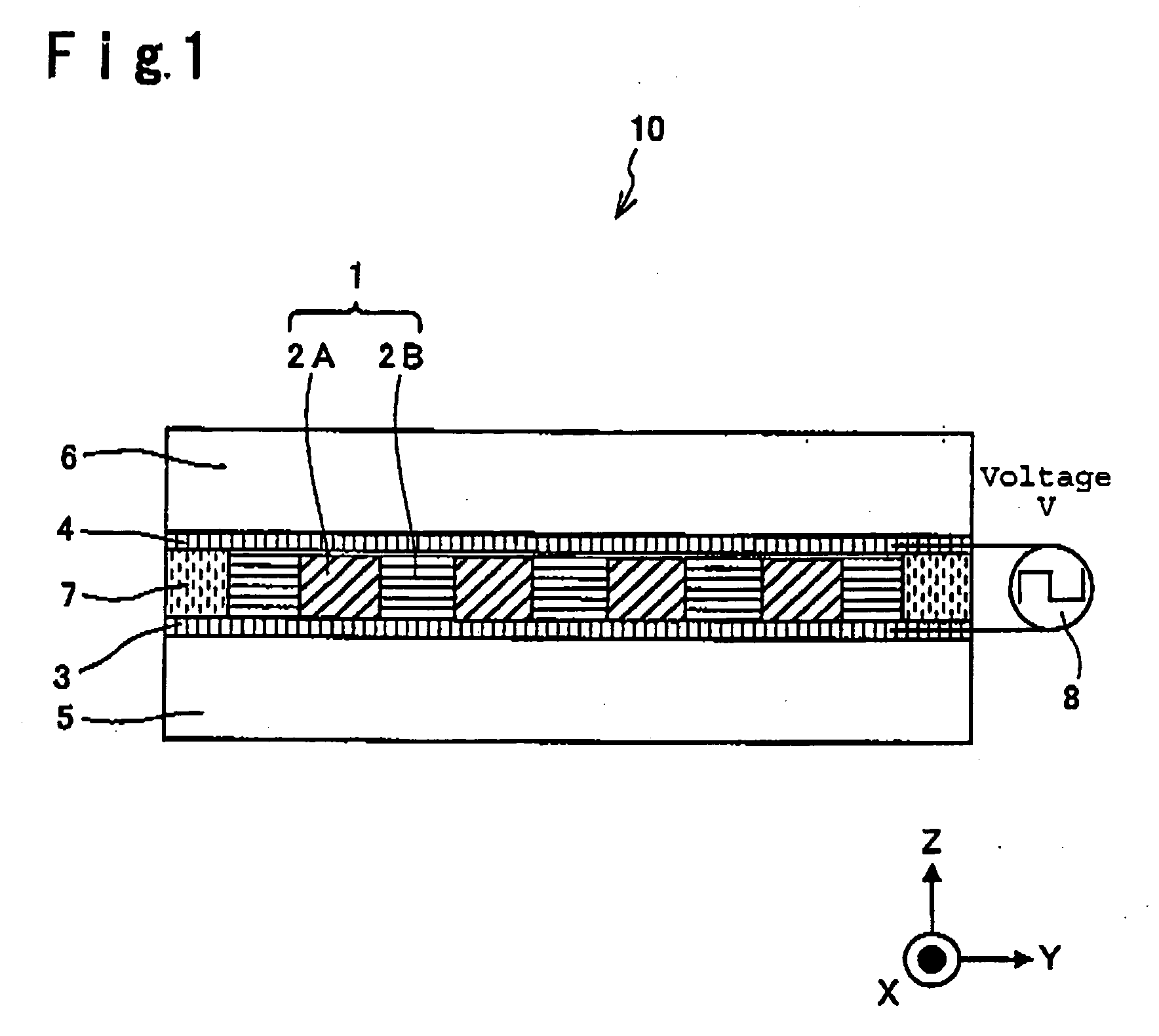

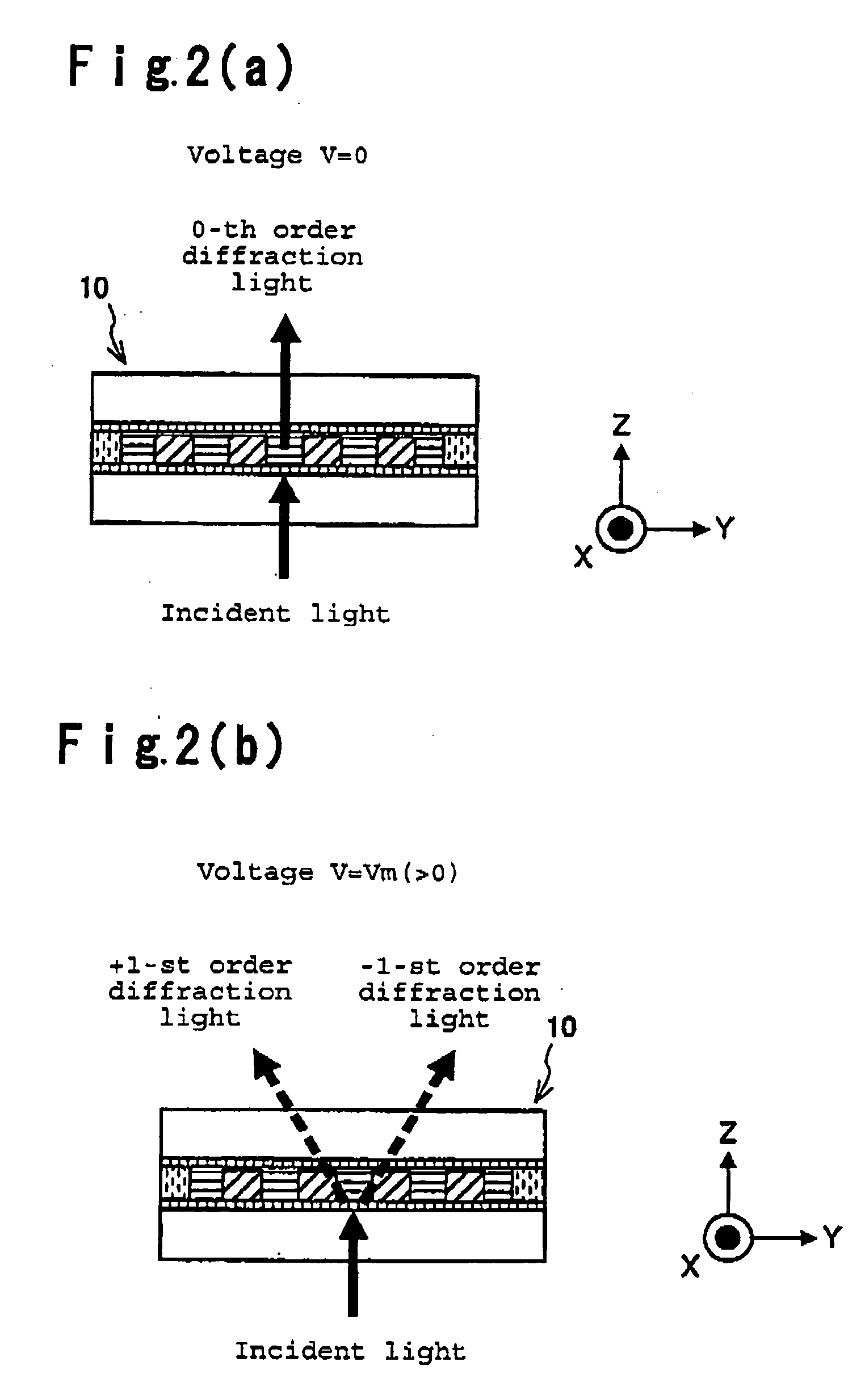

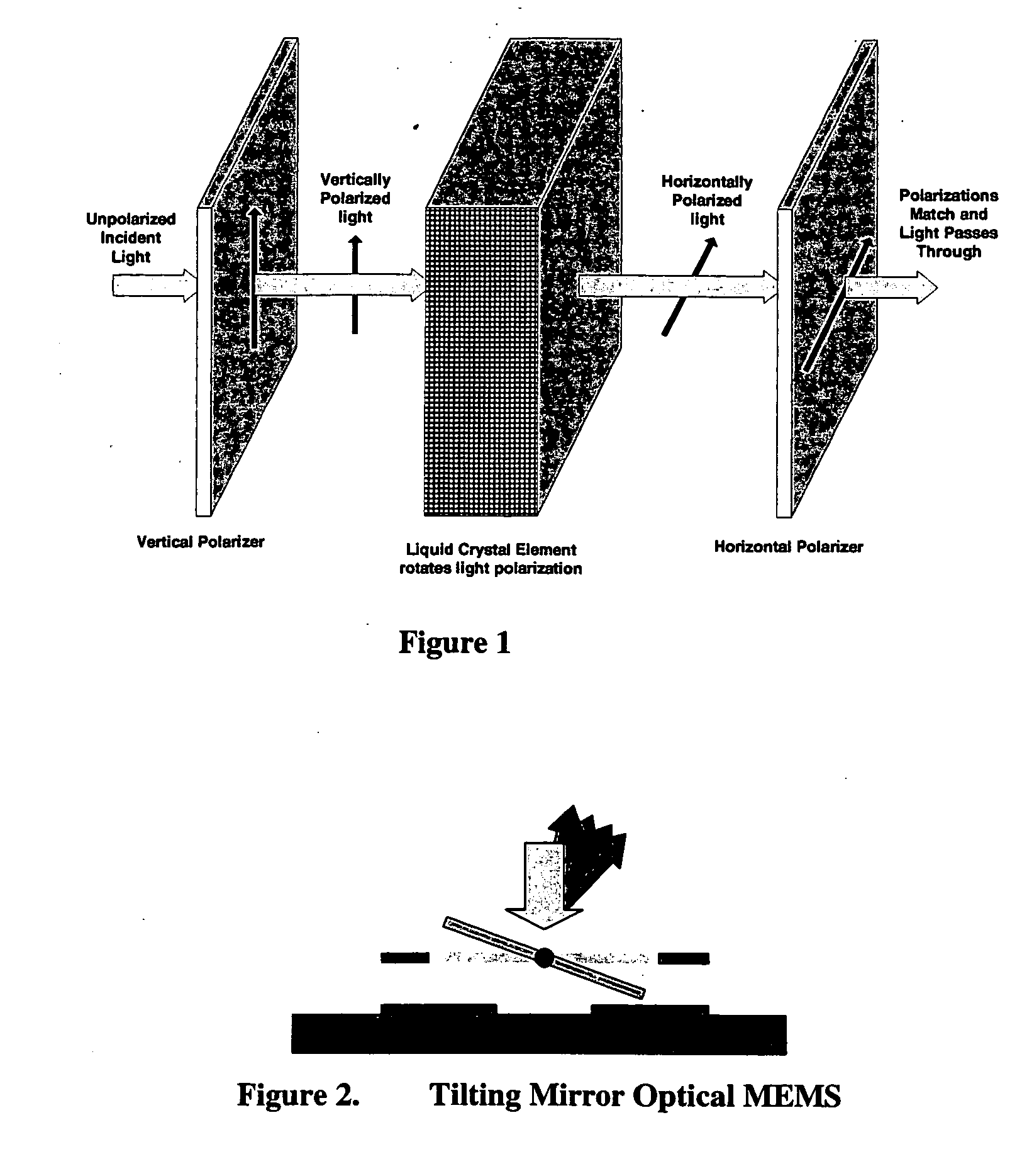

An optical element is provided, which can realize high speed response equivalent or more than that of conventional elements without depending on incident polarization. A diffraction element 10 comprises transparent substrates 5 and 6, a grating 2A made of an isotropic refractive index solid material formed on the transparent substrate 5 and having a cross-sectional structure having a periodical concavo-convex shape, a blue phase liquid crystal 2B which fills the concave portions of grating 2A including a periodical concave-convex shape having a refractive index which changes isotropically, and transparent electrodes 3 and 4 for applying voltage to the blue phase liquid crystal 2B, wherein the grating 2A and the blue phase liquid crystal 2B constitutes a diffraction grating 1, and the diffraction element 10 has a construction that the refractive index of the blue phase liquid crystal 2B is changed by the voltage applied via the transparent electrodes 3 and 4.

Owner:ASAHI GLASS CO LTD

Diffraction Grating With a Spatially Varying Duty-Cycle

InactiveUS20090128911A1Diffraction gratingsPlanar/plate-like light guidesSpatial changeDiffraction optics

A diffractive optical element is disclosed. The optical element comprises a grating having a periodic linear structure in at least one direction. The linear structure is characterized by non-uniform duty cycle selected to ensure non-uniform diffraction efficiency.

Owner:MIRAGE INNOVATIONS LTD

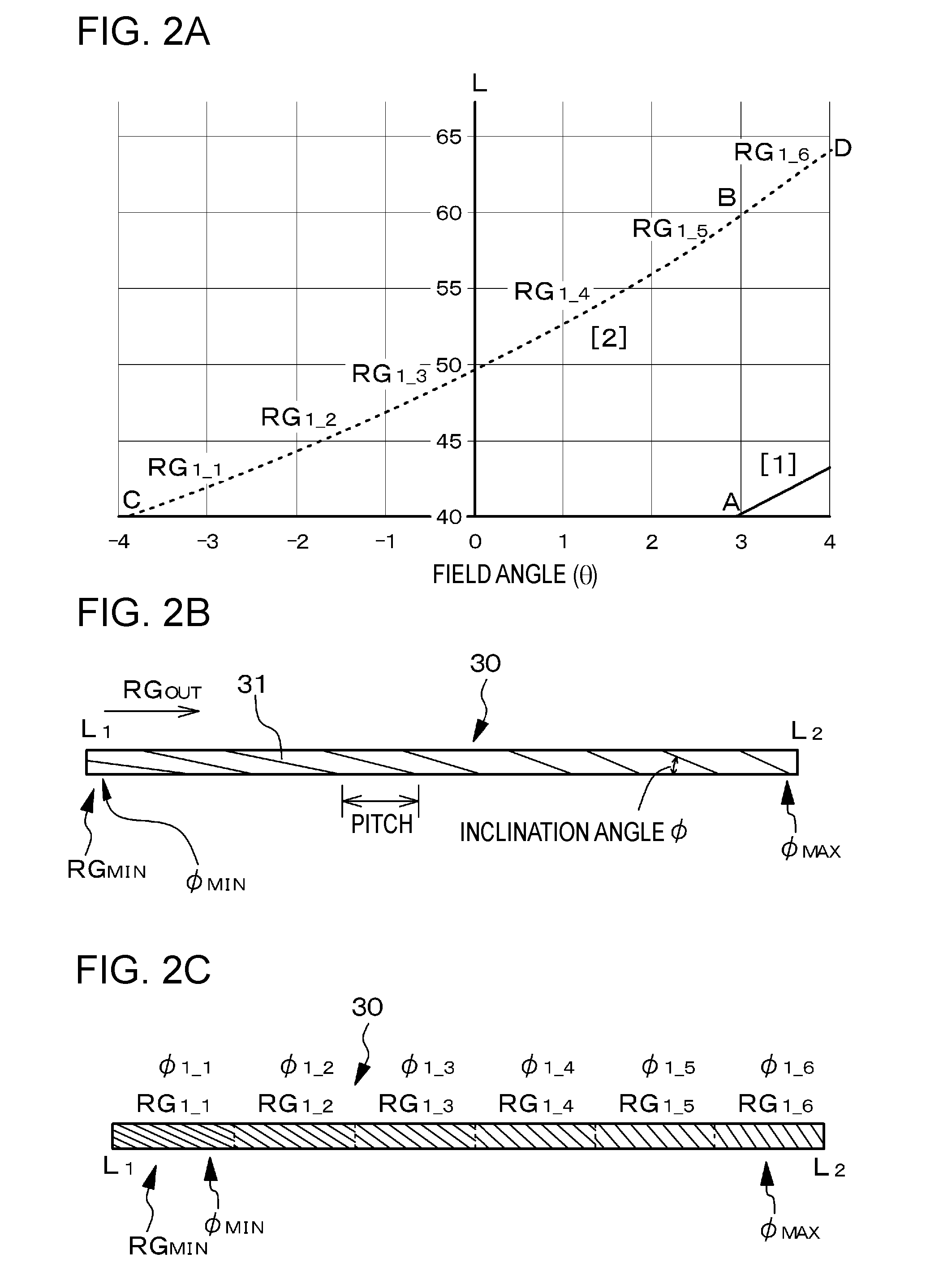

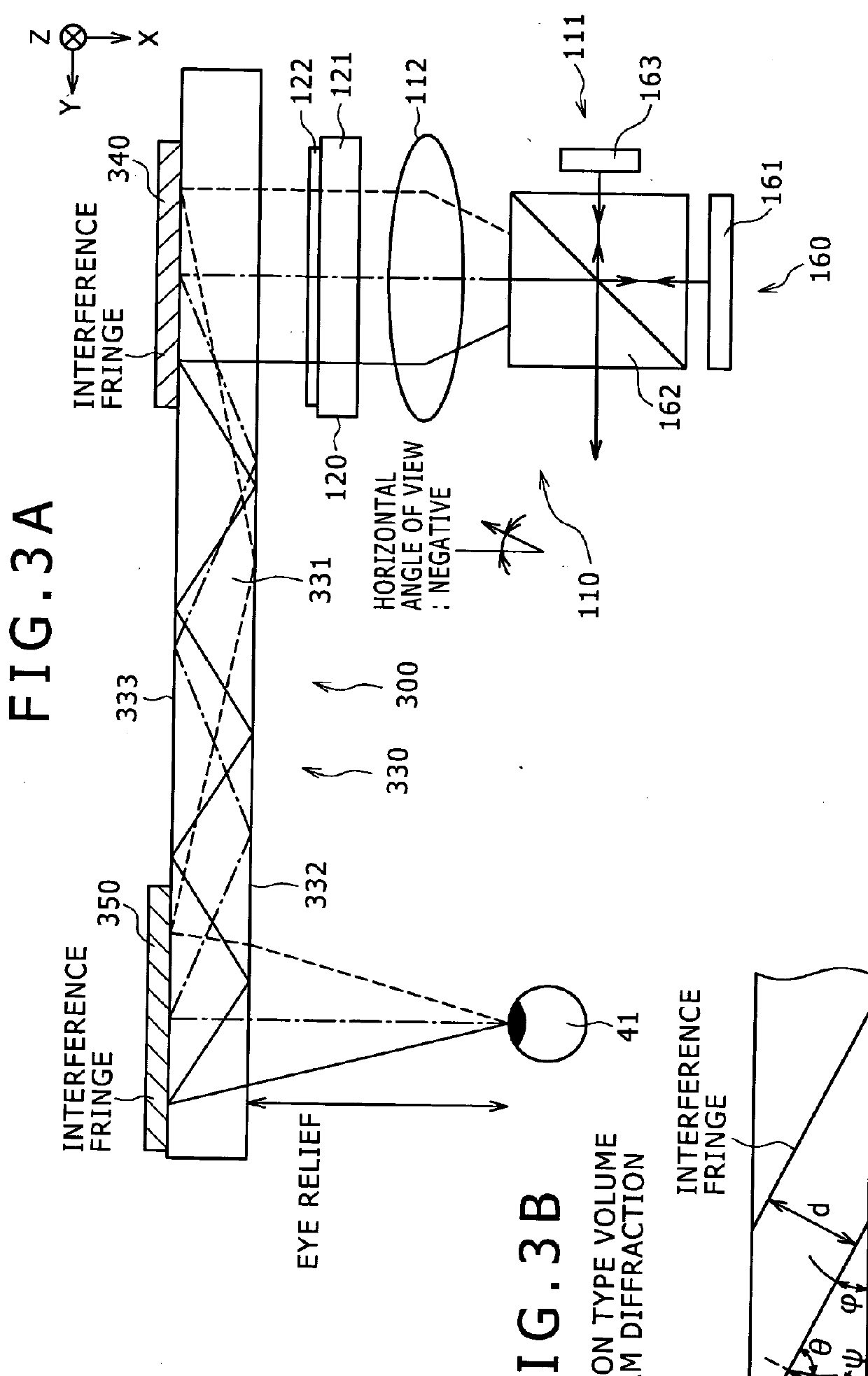

Optical device and image display apparatus

InactiveUS20070070504A1Increase rangeReduce thicknessDiffraction gratingsOptical light guidesLight guideSlant angle

An optical device includes a light guide plate, and first and second reflective volume hologram diffraction grating members. The first member has interference fringes extending from therewithin towards surfaces thereof and arranged at an equal pitch. Each interference fringe and each surface of the first member form an inclination angle therebetween. The first member has the following conditions. (a) In an outer region positioned farther away from the second member than a minimum inclination angle region having a minimum inclination angle, the inclination angles of the interference fringes increase with increasing distance from the minimum inclination angle region. (b) In an inner region positioned closer to the second member than the minimum inclination angle region, the inclination angles of the interference fringes include a maximum inclination angle in an inner area disposed adjacent to the minimum inclination angle region and decrease with increasing distance from the minimum inclination angle region.

Owner:SONY CORP

Multi-view pixel directional backlight module and naked-eye 3D display device

ActiveCN104460115AEasy to integratePlanar/plate-like light guidesSteroscopic systemsLight guideDisplay device

The invention discloses a multi-view pixel directional backlight module and a naked-eye 3D display device. The multi-view pixel directional backlight module comprises at least two rectangular light guide plates, wherein all the rectangular light guide plates are tightly stacked together, multiple pixels which are formed through nanometer diffraction gratings and point to different directions are formed on the light emergence surface of each rectangular light guide plate, at least one side edge of each rectangular light guide plate is provided with a light source set, and emergent light is formed by light emitted by the light source sets on pixels of multiple pixel arrays on the light emergency surfaces of the light guide plates after the light emitted by the light source sets enters the corresponding light guide plates. According to the multi-view pixel directional backlight module and the naked-eye 3D display device, due to the fact that the multiple light guide plates are stacked, the problem that mutual interference of three light sources can not be avoided on one light guide plate is solved, the pixel directional rectangular light guide plates are obtained, a feasible scheme is provided for industrial application of the multi-view pixel directional light guide plates in the naked-eye 3D display technique, and the problems which can not be solved in the prior art are solved.

Owner:SUZHOU UNIV +1

Optical diffraction grating

InactiveUS6052213ADiffraction gratingsOptical waveguide light guideOptical diffractionPhotonic crystal

PCT No. PCT / GB97 / 00817 Sec. 371 Date Apr. 13, 1998 Sec. 102(e) Date Apr. 13, 1998 PCT Filed Mar. 24, 1997 PCT Pub. No. WO97 / 36198 PCT Pub. Date Oct. 2, 1997An optical diffraction grating is formed from a region of photonic crystalline material Light is coupled into the photonic crystalline material, and the grazingly emergent output beam is collected. The photonic crystalline material may include an array of holes formed in a substrate of dielectric material, e.g., InP, and integrated with planar waveguide structures.

Owner:IPG PHOTONICS CORP

Electronically controlled volume phase grating devices, systems and fabrication methods

InactiveUS20050232530A1Efficient and small device form factorLow costOptical light guidesNon-linear opticsSemiconductor materialsPhase grating

Electrically controlled volume phase gratings and electrically controlled Bragg Gratings can provide variable diffraction gratings that can be operated in a transmissive and / or reflective mode. They can be made from electro-optic materials placed directly on glass or semiconductor materials, utilizing conventional Liquid Crystal on Silicon (LCOS) processes and equipment. Highly efficient and / or small device form factors may be provided.

Owner:META PLATFORMS TECH LLC

Beam expansion with three-dimensional diffractive elements

Owner:MAGIC LEAP INC

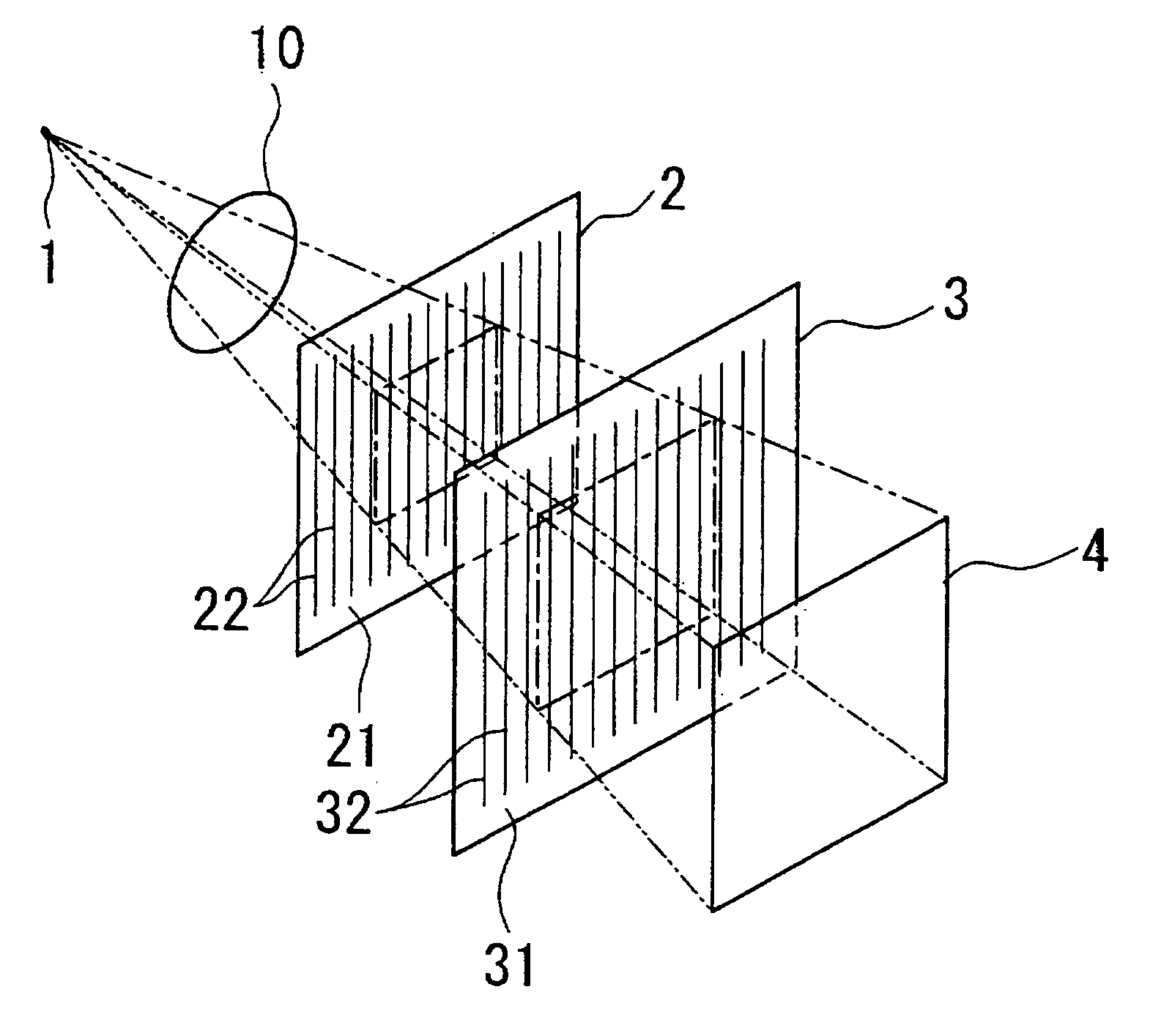

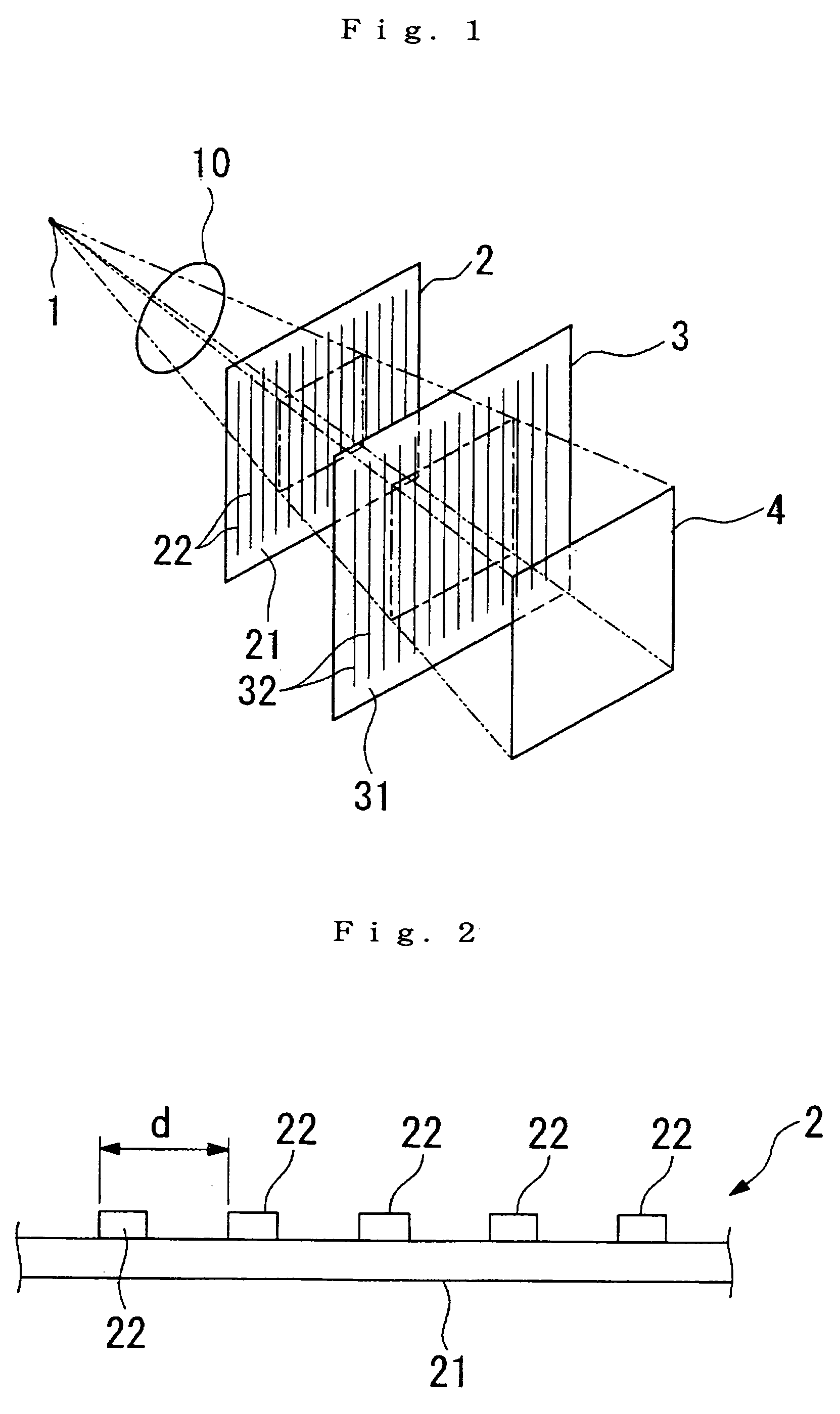

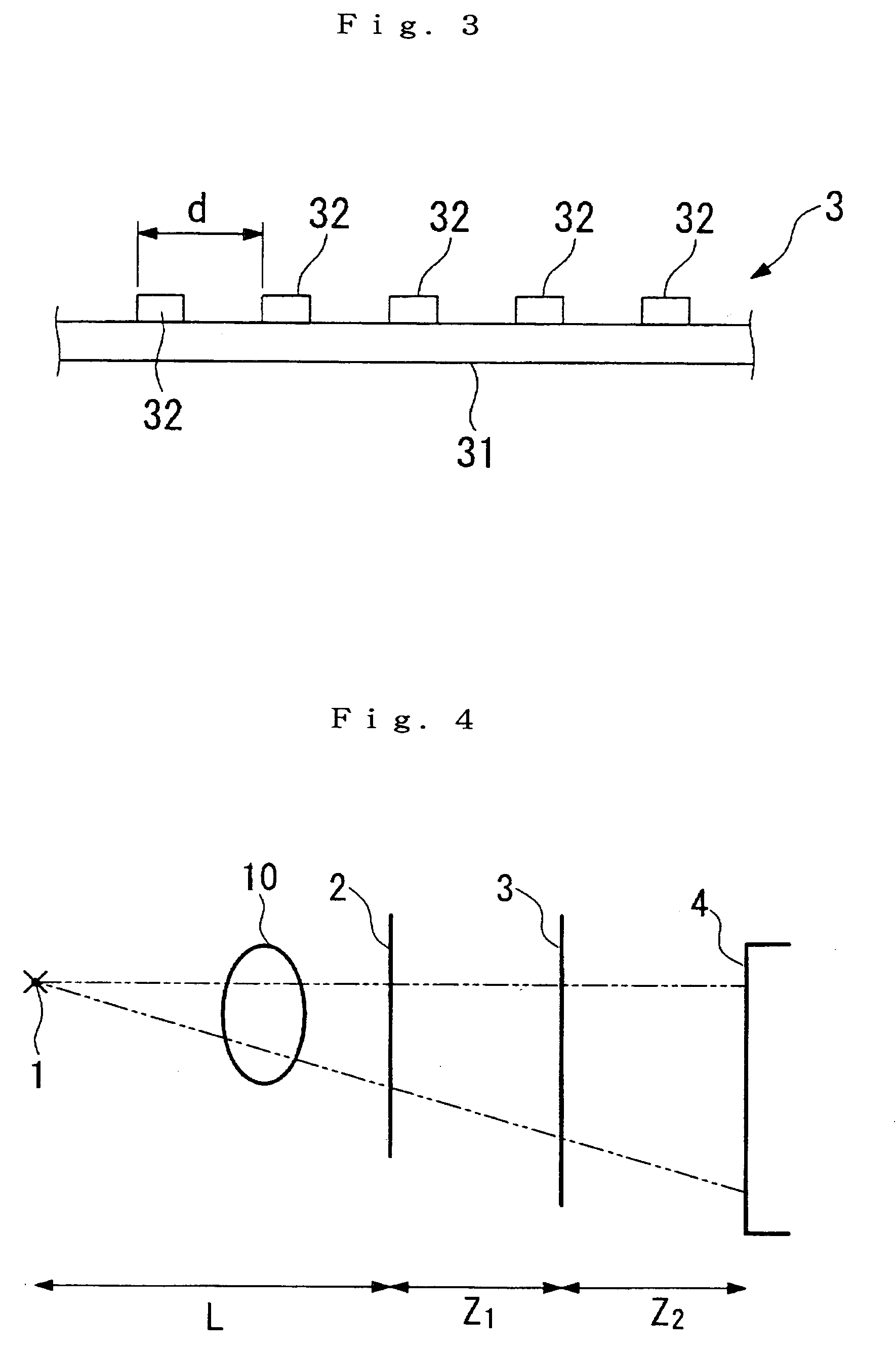

X-ray imaging system and imaging method

ActiveUS7180979B2Easy constructionImaging devicesHandling using diffraction/refraction/reflectionImage contrastImage detection

The present invention provides an apparatus capable of X-ray imaging utilizing phase of X-rays. An X-ray imaging apparatus equipped with first and second diffraction gratings and an X-ray image detector are described. The first diffraction grating generates a Talbot effect and a second diffraction grating diffracts X-rays diffracted by the first diffraction grating. An image detector is provided to detect the X-rays diffracted by the second diffraction grating. In this manner, image contrasts caused by changes in phase of X-rays due to a subject arranged in front of the first diffraction grating or between the first diffraction grating and the second diffraction grating can be achieved.

Owner:MOMOSE ATSUSHI

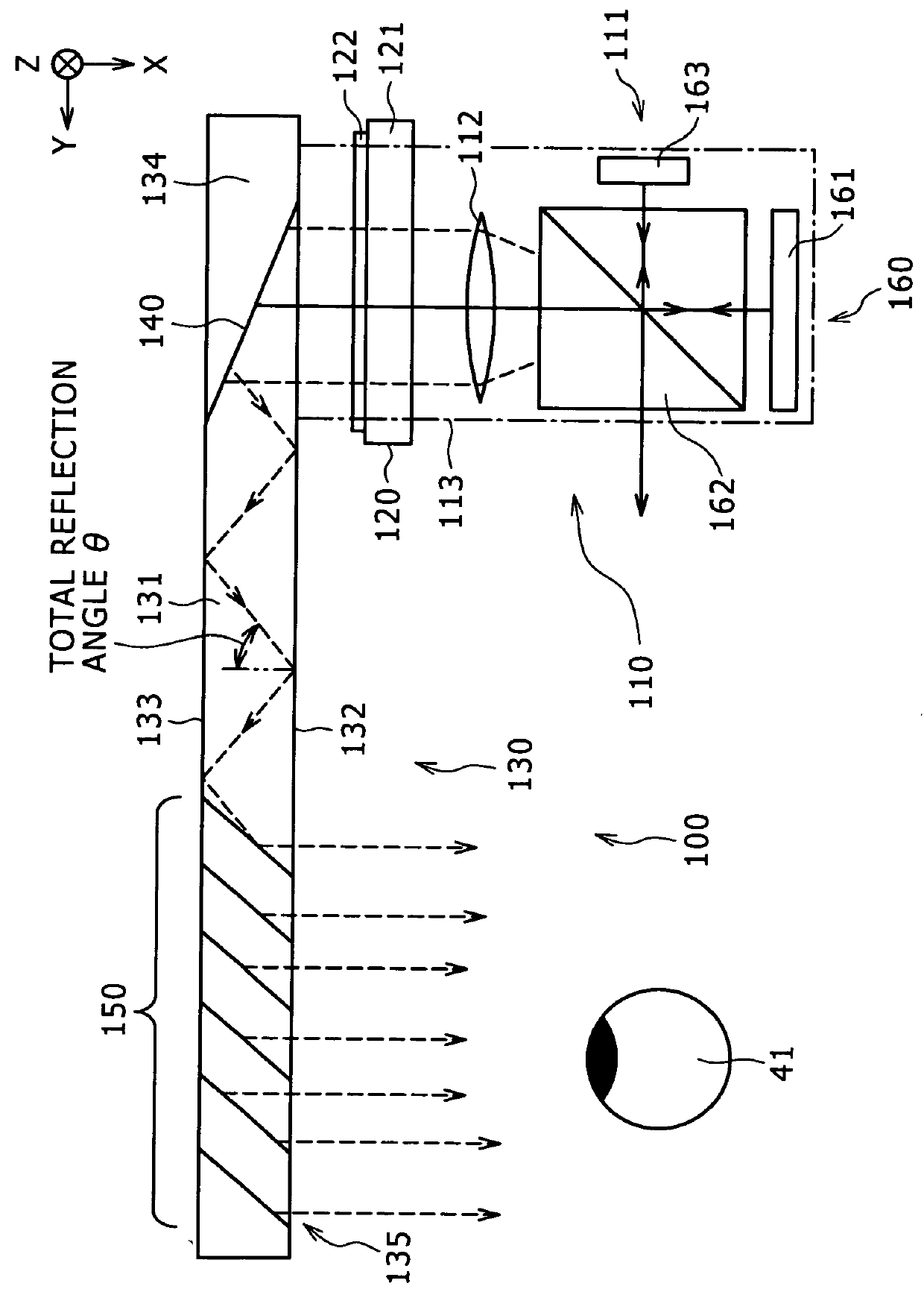

Image displaying apparatus and optical Apparatus

InactiveUS20110019250A1Small sizeReduce weightMirrorsOptical light guidesOptoelectronicsDiffraction grating

The image displaying apparatus includes an image production apparatus, a first light conduction section and a second light conduction section. The first light conduction section includes a first light conduction plate which propagates part of incident light thereto by total reflection in the inside thereof and emits the propagated light, and a reflection type volume hologram diffraction grating disposed on the first light conduction plate. The second light conduction section includes a second light conduction plate, a first deflection section and a second deflection section.

Owner:SONY CORP

Diffraction grating-based encoded articles for multiplexed experiments

InactiveUS20050227252A1Easy to useBioreactor/fermenter combinationsBiological substance pretreatmentsMultiplexingAnalyte

The present invention provides methods and compositions directed toward assays of a broad range of analytes using specific targeting chemicals that bind to the analytes. The assays are founded on the use of coded assay articles to which the targeting chemicals are attached. Additionally the codes are such that they are interrogated and determined in real time. The target is analyzed as to identity, presence and quantity in real time. The methods and compositions of the invention are highly suitable for use in high-complexity multiplexed assay systems. All the methods and compositions are based on assay article that includes an optical substrate to which the chemical is bound, and in which is disposed at least one diffraction grating. The grating provides an output optical signal when illuminated by an incident light signal which is indicative of the code in the substrate. In general, coded assay article or sets thereof are employed in assay methods, including multiplexed assay methods, according to which a sample is contacted with an article or a set, and any analytes that bind to the attached chemical are identified according to the code, detected and / or quantitated.

Owner:ILLUMINA INC

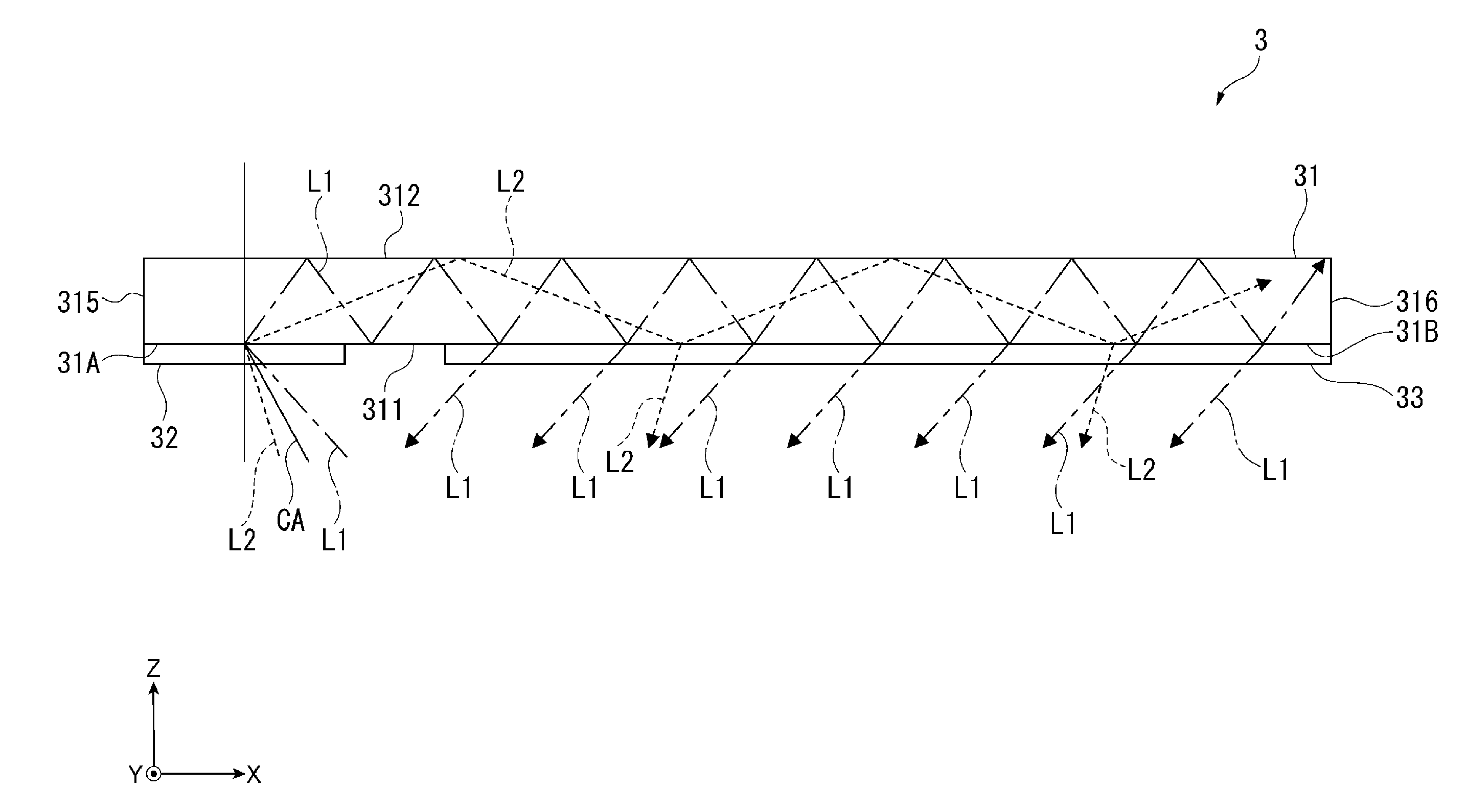

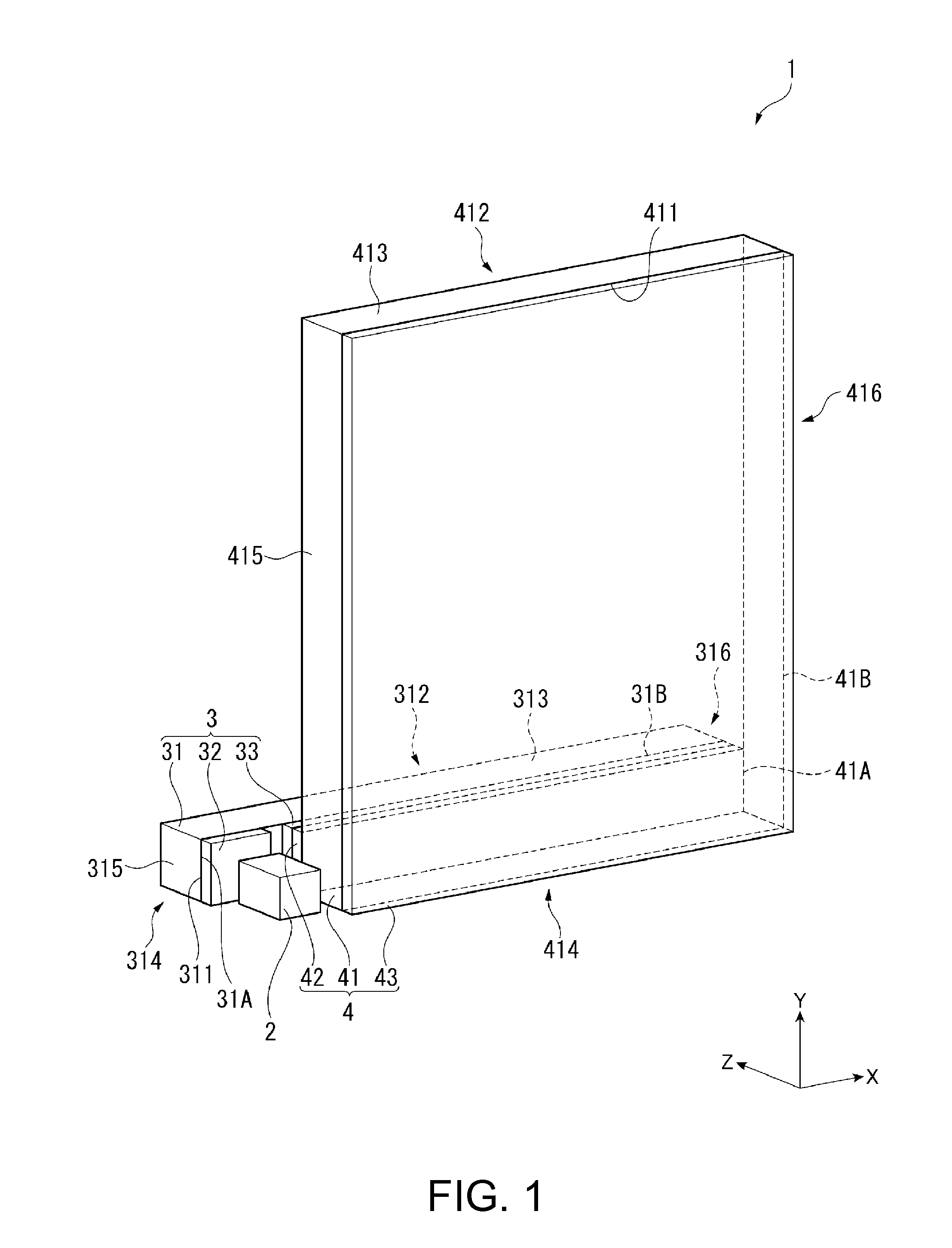

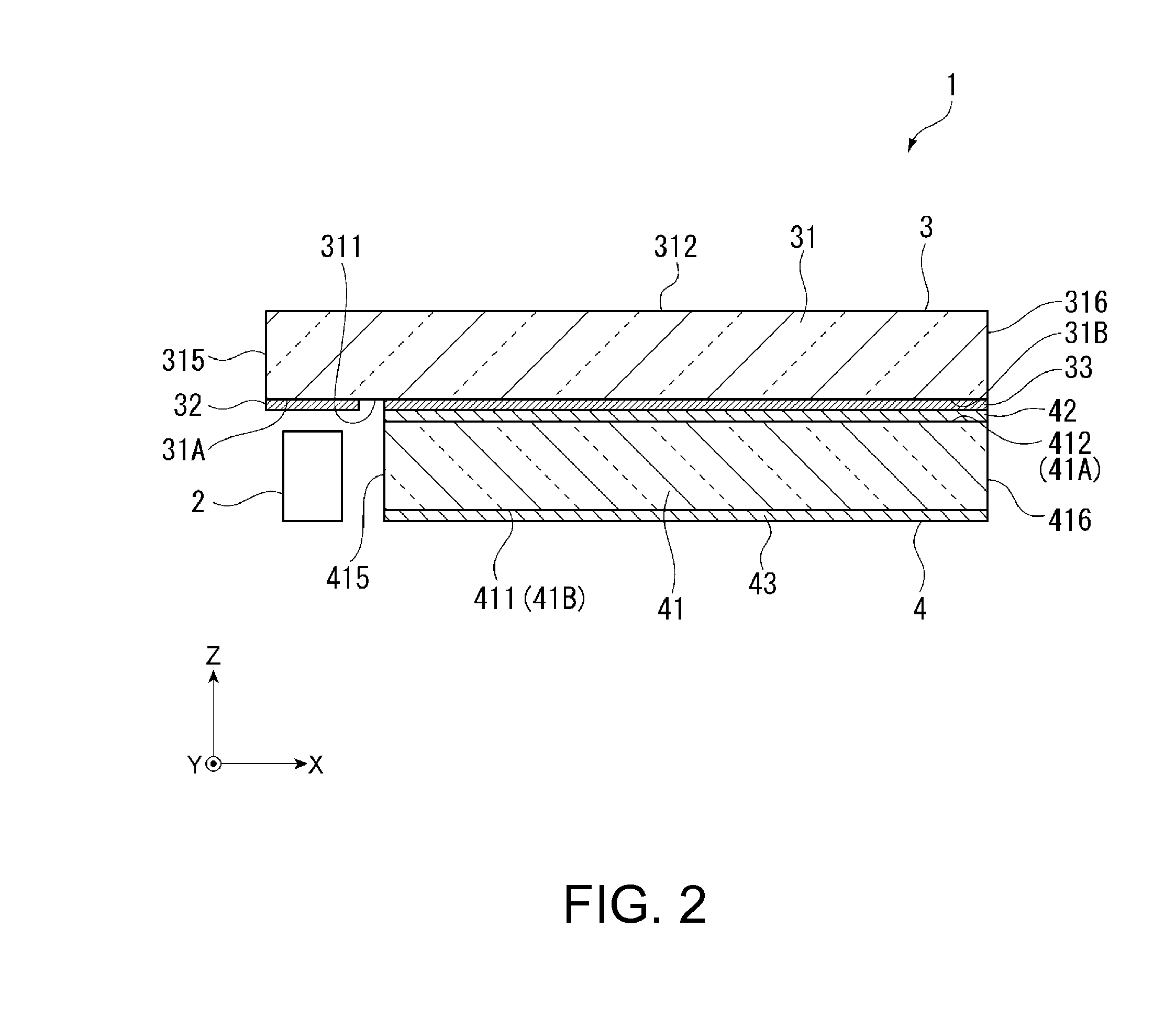

Virtual image display apparatus

InactiveUS20160124223A1Change in luminanceSuppressing image degradationMechanical apparatusPlanar/plate-like light guidesLight beamDisplay device

A virtual image display apparatus includes a first light guide that not only causes a display light flux incident through a first light incident surface to repeatedly undergo internal reflection to travel in a first direction away from the first light incident surface but also causes part of the display light flux to exit to the outside through areas of a first light exiting surface that is at least one of interfaces with the outside and extends in the first direction, a first light-incident-side diffraction grating that diffracts light incident thereon to cause the diffracted light to enter the first light guide, and a first light-exiting-side diffraction grating that diffracts light incident from the first light guide.

Owner:SEIKO EPSON CORP

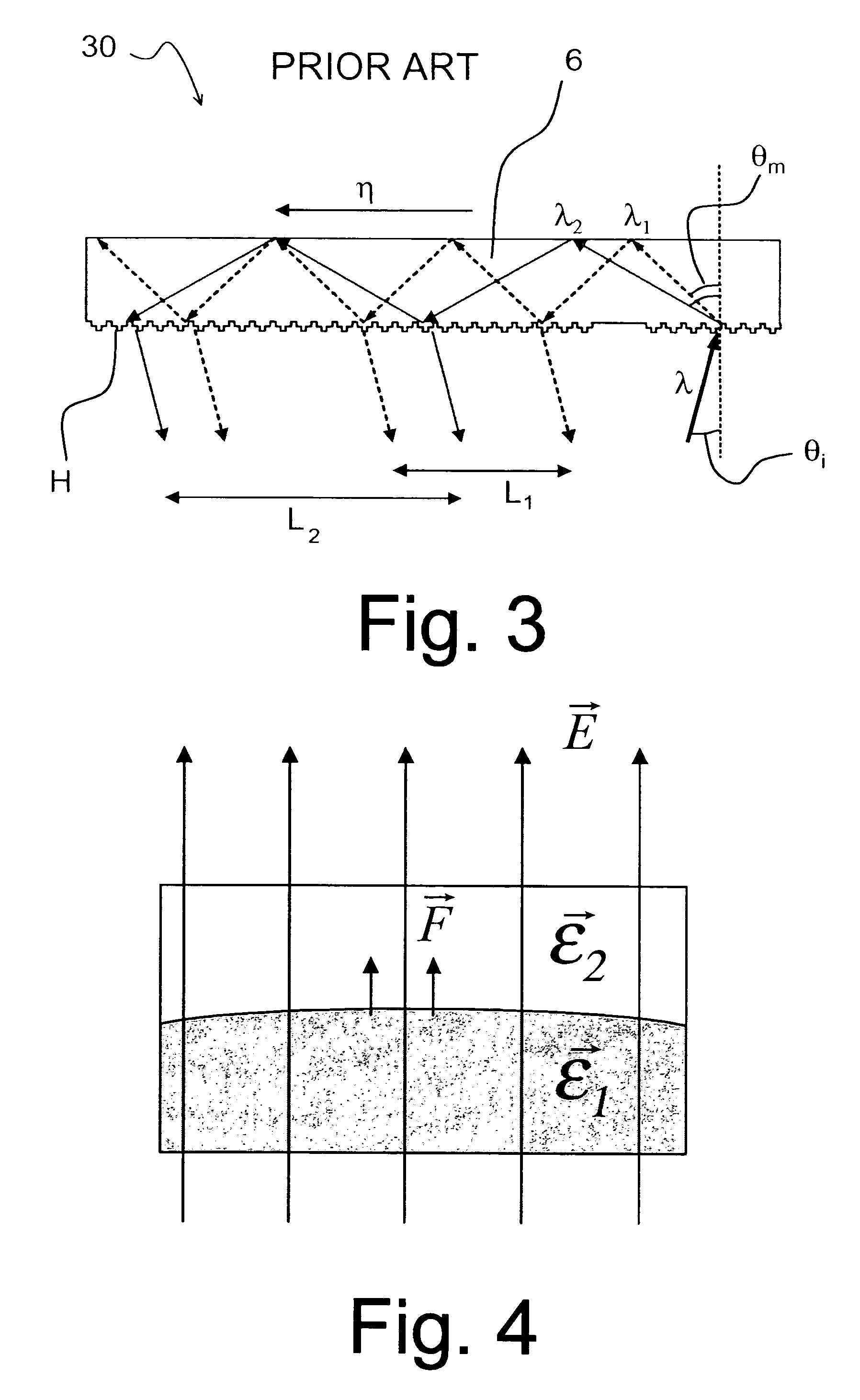

Holographic light panels and flat panel display systems and method and apparatus for making same

InactiveUS20050259302A9Reduce physical sizeMechanical apparatusChromate compound compositionsColor imageDisplay device

An illumination panel for illuminating an object, comprising a substrate, a light diffractive grating and a light source. The substrate is made from an optically transparent material having first and second area surfaces disposed substantially parallel to each other and a light input surface for conducting a light beam into the substrate. The light diffractive grating is mounted to the first areal surface and has a slanted fringe structure embodied therein for diffracting the light beam falling incident thereto, along a first diffractive order of the slanted fringe structure. The light source produces a light beam for transmission through the input surface and direct passage through the substrate to the slanted fringe structure so as to produce an output light beam of areal extent that emerges from either the first or second areal surface along the first diffractive order, for use in illuminating an object. A spatial-intensity modulation panel can be mounted to the illumination panel to form a color image display device. In the illustrative embodiments, the light diffractive grating is a volume hologram that is pixelated and spectrally-tuned in order to carry out spectral filtering functions within the color image display device.

Owner:KREMEN STANLEY H

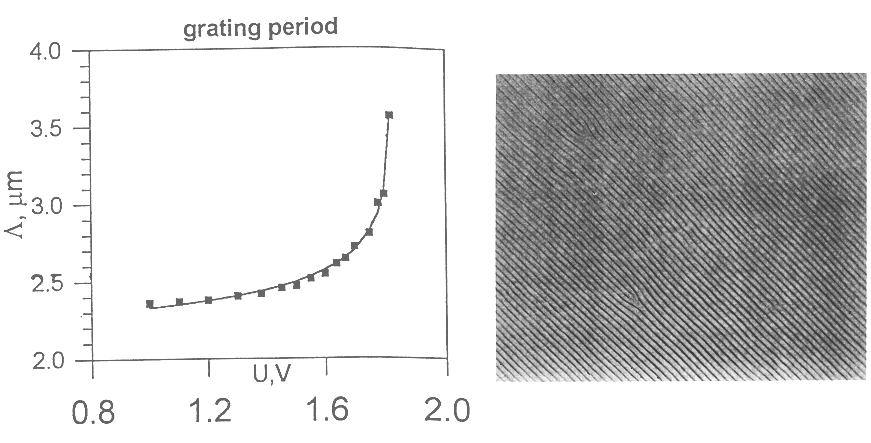

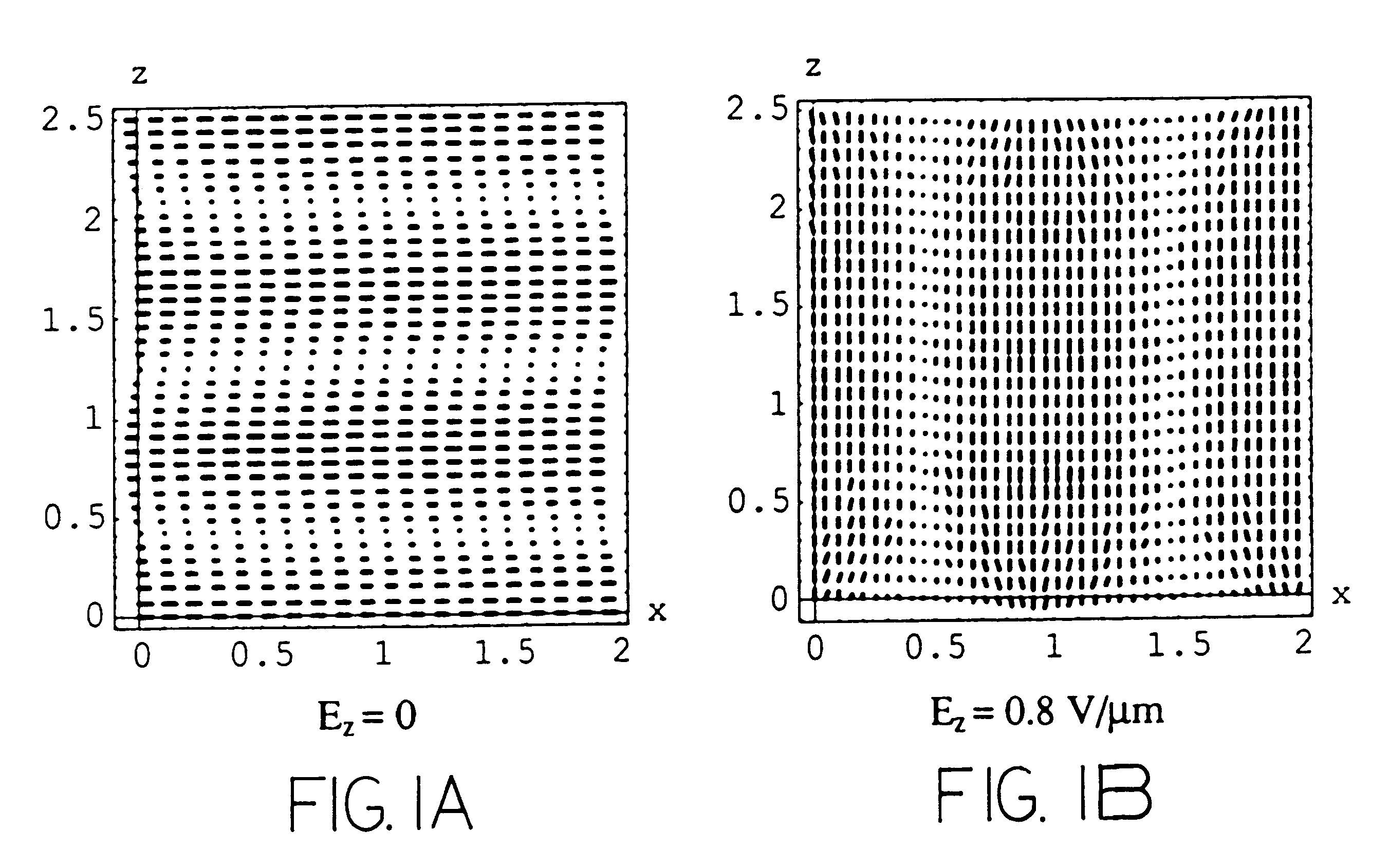

Diffraction grating with electrically controlled periodicity

The present invention is directed to liquid crystal diffraction gratings with electrically controlled periodicity. An electrical field is applied to liquid crystal device wherein the liquid crystals align to form a diffraction grating. The period of the diffraction grating is varied by changing the applied electrical field. The diffraction grating therefore has a period that can be varied by an electrical field.

Owner:KENT STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com