Apparatus and method for measuring overlay by diffraction gratings

a technology of diffraction gratings and apparatus, which is applied in the direction of optical radiation measurement, instruments, spectrometry/spectrophotometry/monochromators, etc., can solve the problems of not solving the unit cells of the gratings, and achieve the effects of reducing the number of diffraction gratings, and improving the accuracy of diffraction gratings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Metrology Target

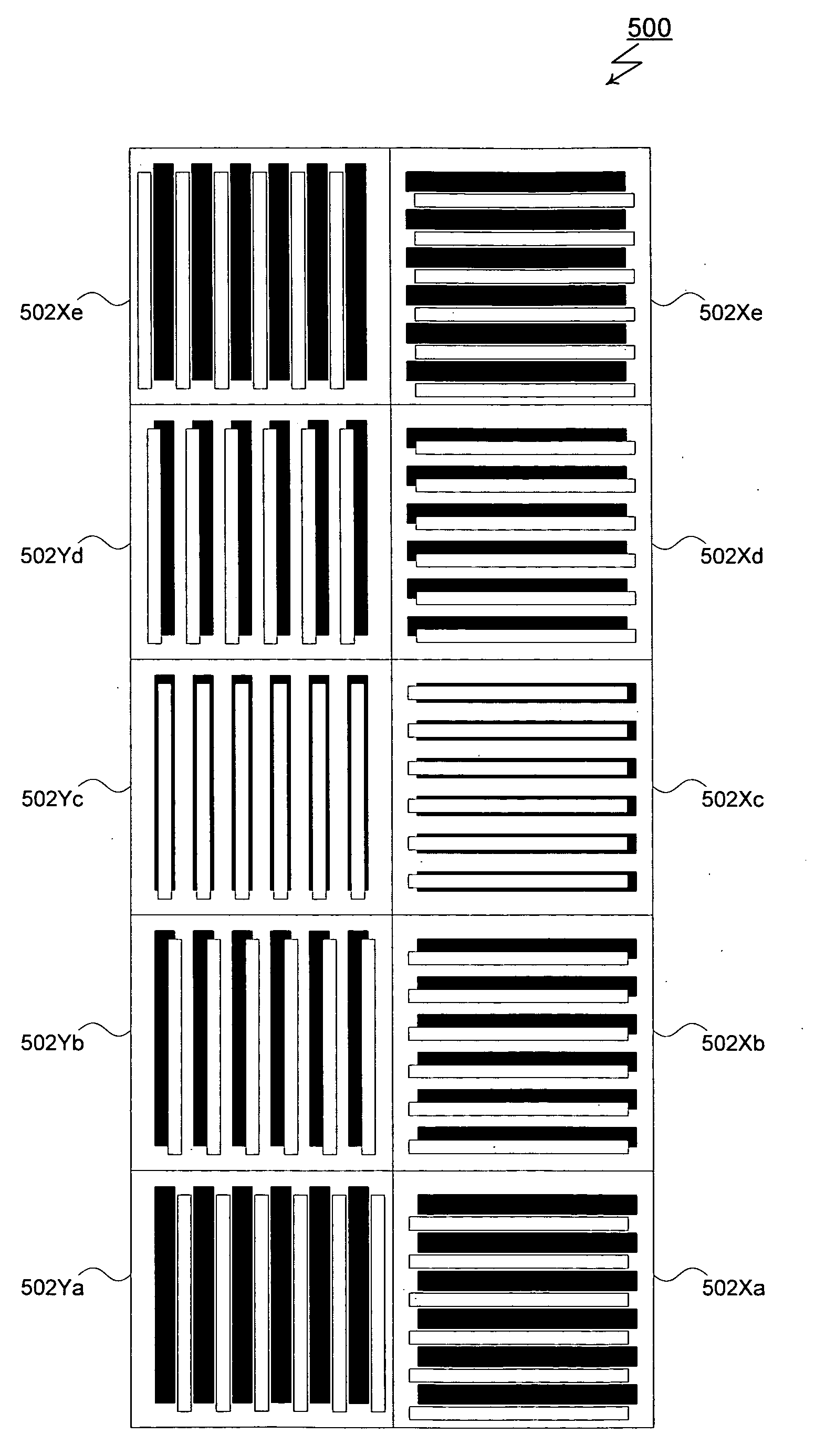

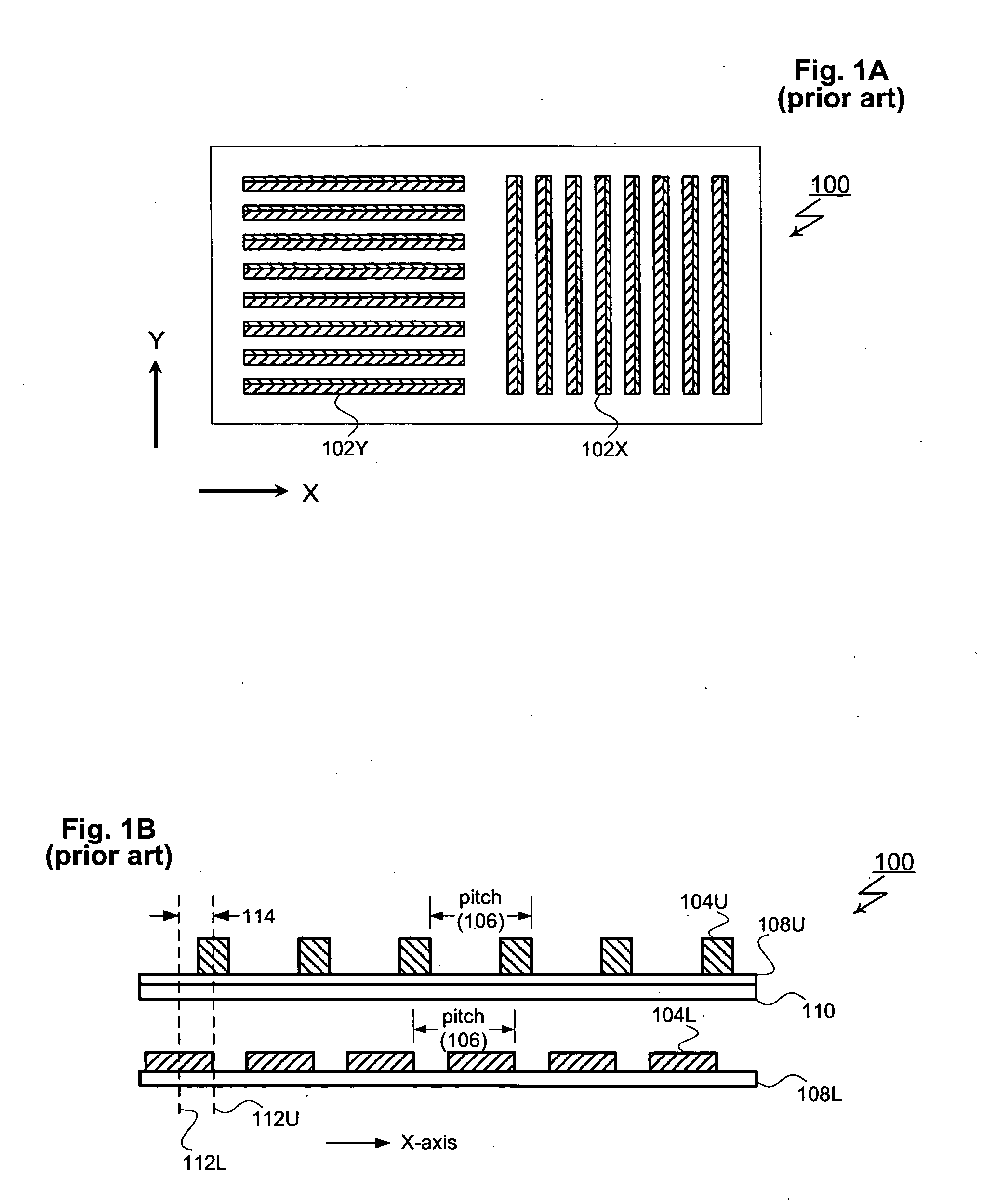

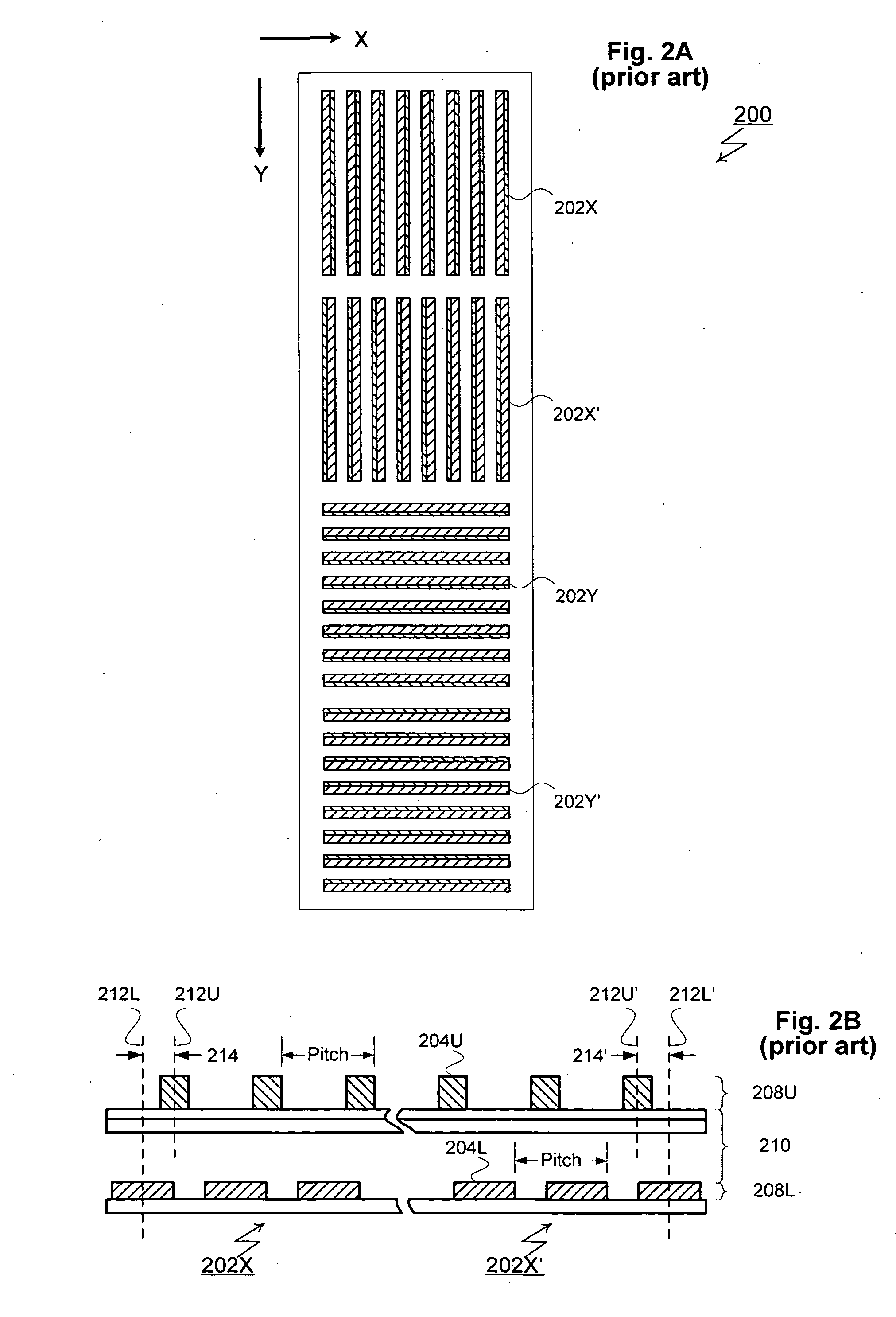

The symbol R(λ,θ,ξ) denotes the optical response of the grating stack as a function of wavelength λ, angle of incidence θ, and ξ, which denotes offset 114 in FIG. 1B. The optical response could be polarized or unpolarized reflectance or ellipsometric parameters ψ and Δ, or Fourier coefficients of intensity measured by a rotating polarizer or rotating compensator ellipsometer. Optical response R(λ,θ,ξ) has the following properties:

R(λ,θ,ξ)=R(λ,θ,ξ+Pitch) Eq. 5a

R(λ, θ,+ε)=R(λ, θ,−ε) Eq. 5b

R(λ, θ,(Pitch / 2)+ε)=R(λ, θ,(Pitch / 2)−ε) Eq. 5c

Eq. 5a follows from the periodicity of the gratings. Because of reciprocity theorem of Helmholtz and symmetry of the grating lines, Eq. 5b and 5c hold for arbitrary offset ε and arbitrary angle of incidence θ. Eq. 5b follows from the symmetry of the grating stack when the centerlines of the lower and upper grating lines are aligned. Eq. 5c follows from the symmetry of the grating stack when the centerlines of the lower grating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com