Patents

Literature

5512results about "Liquid cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

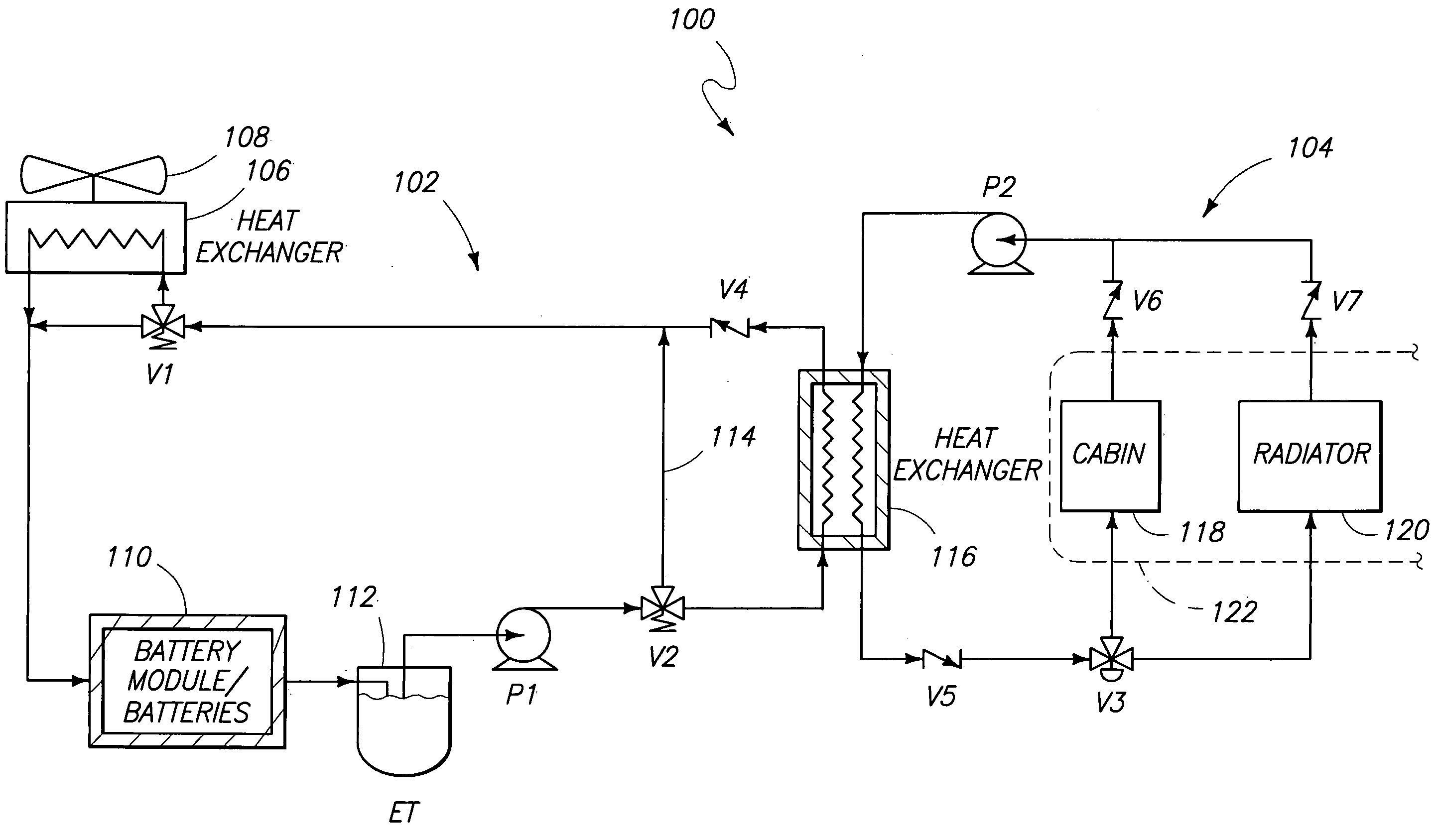

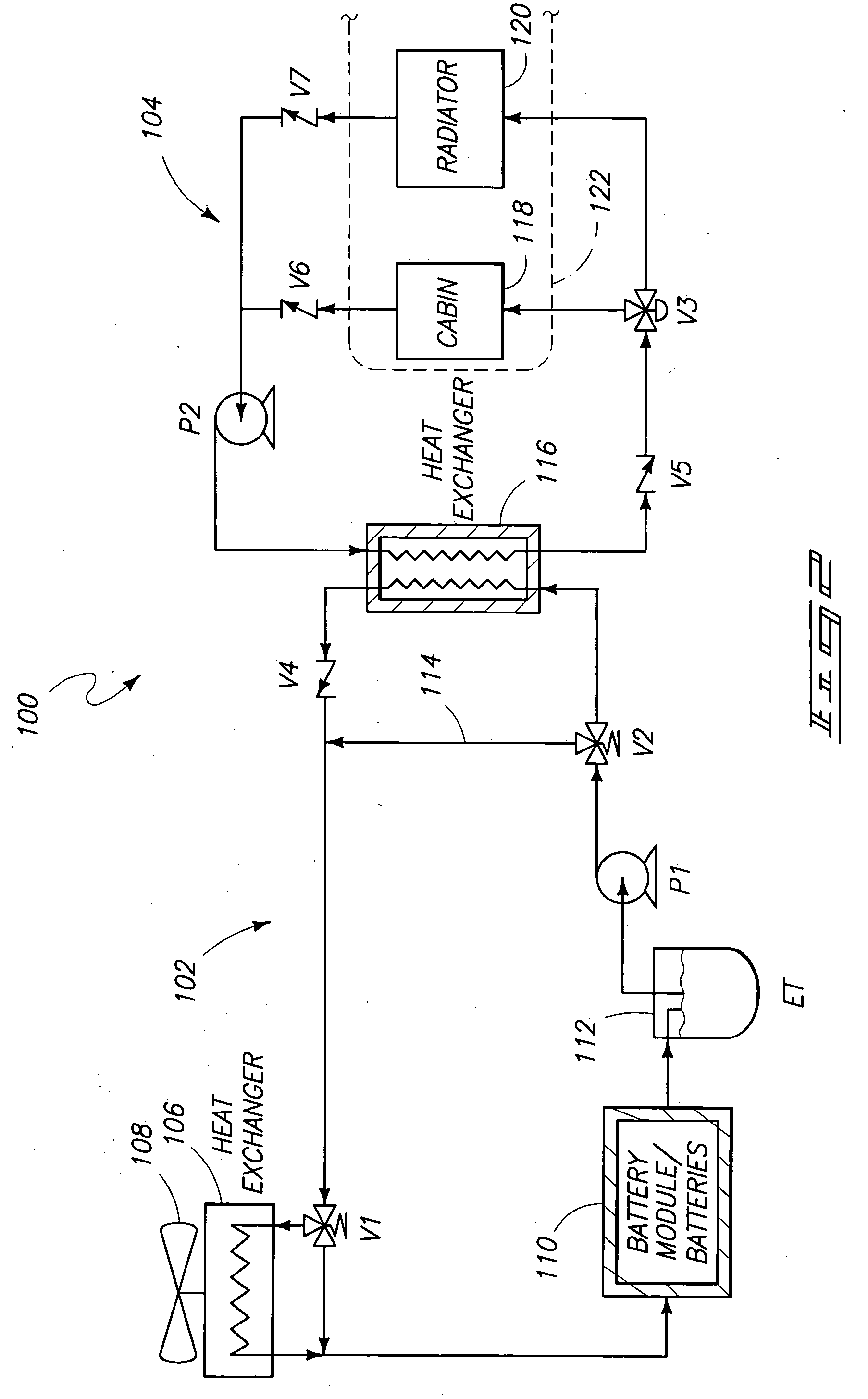

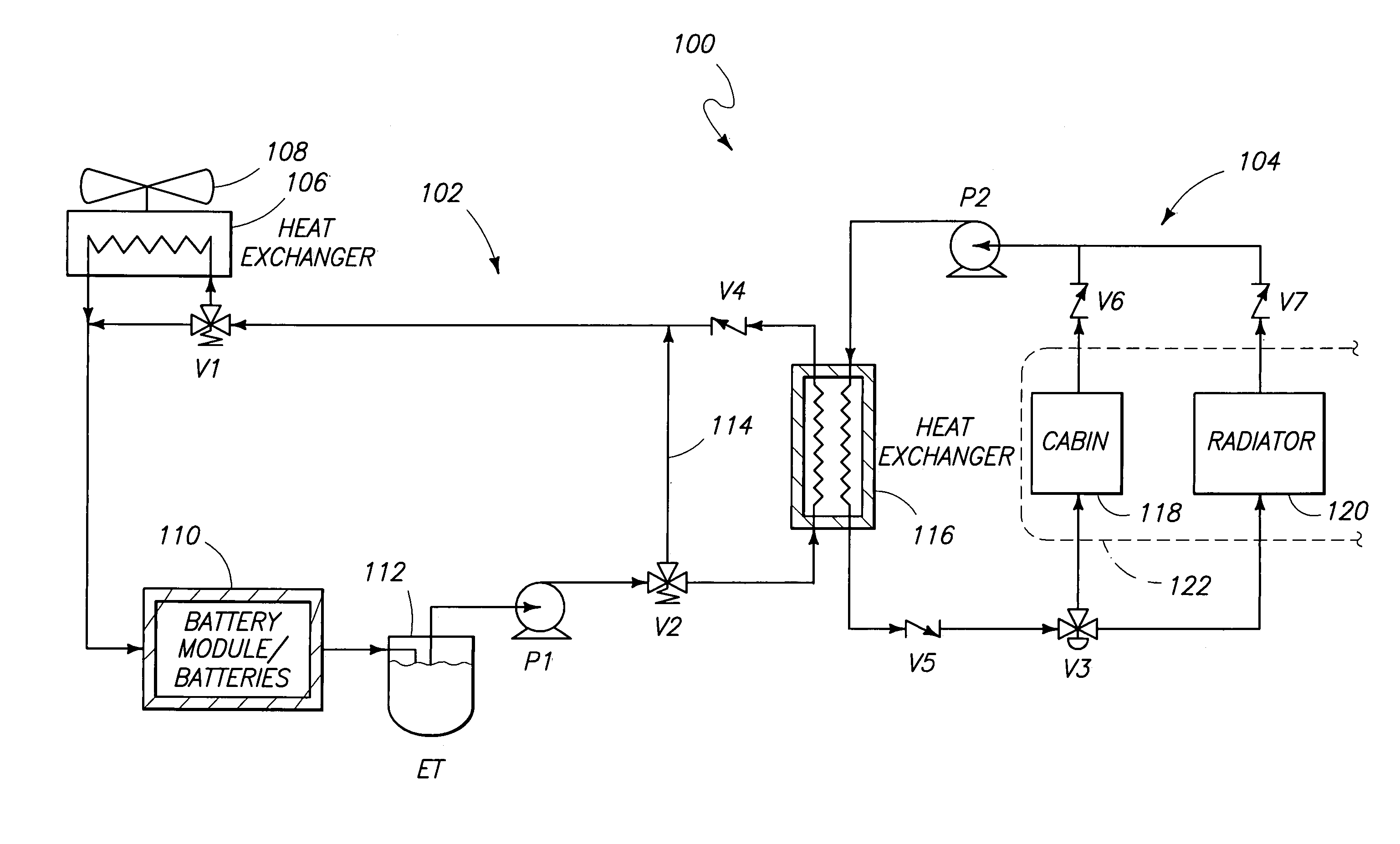

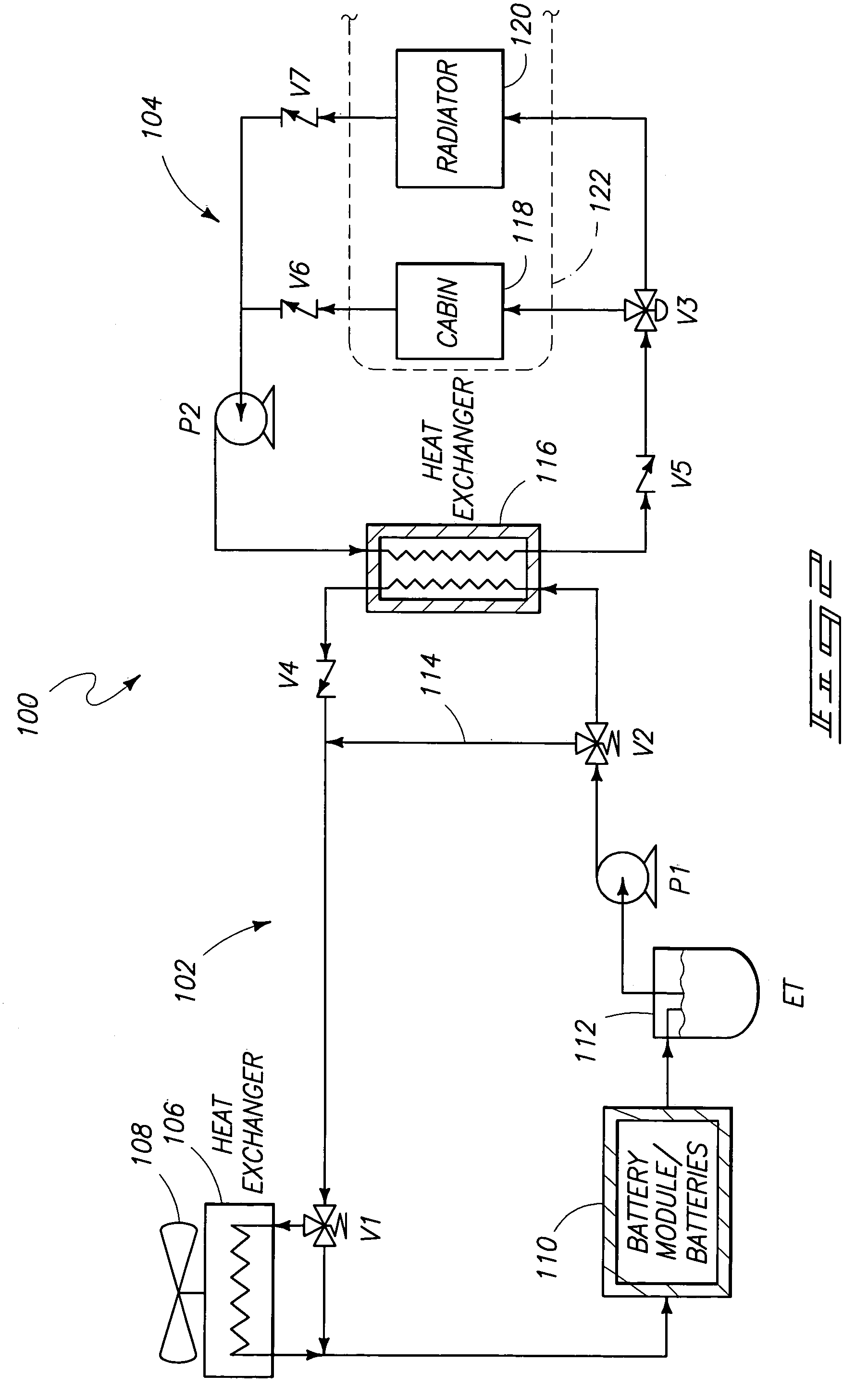

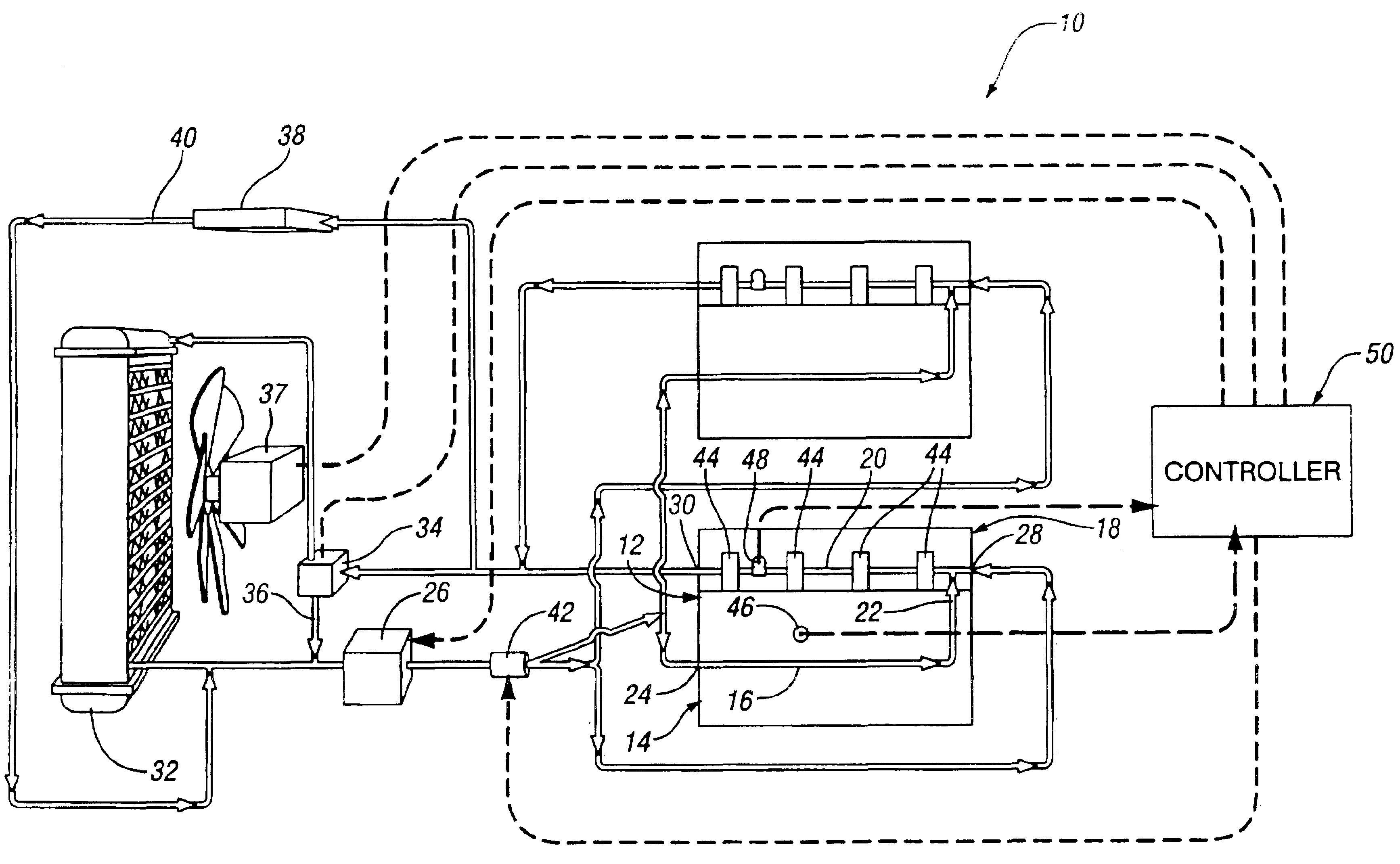

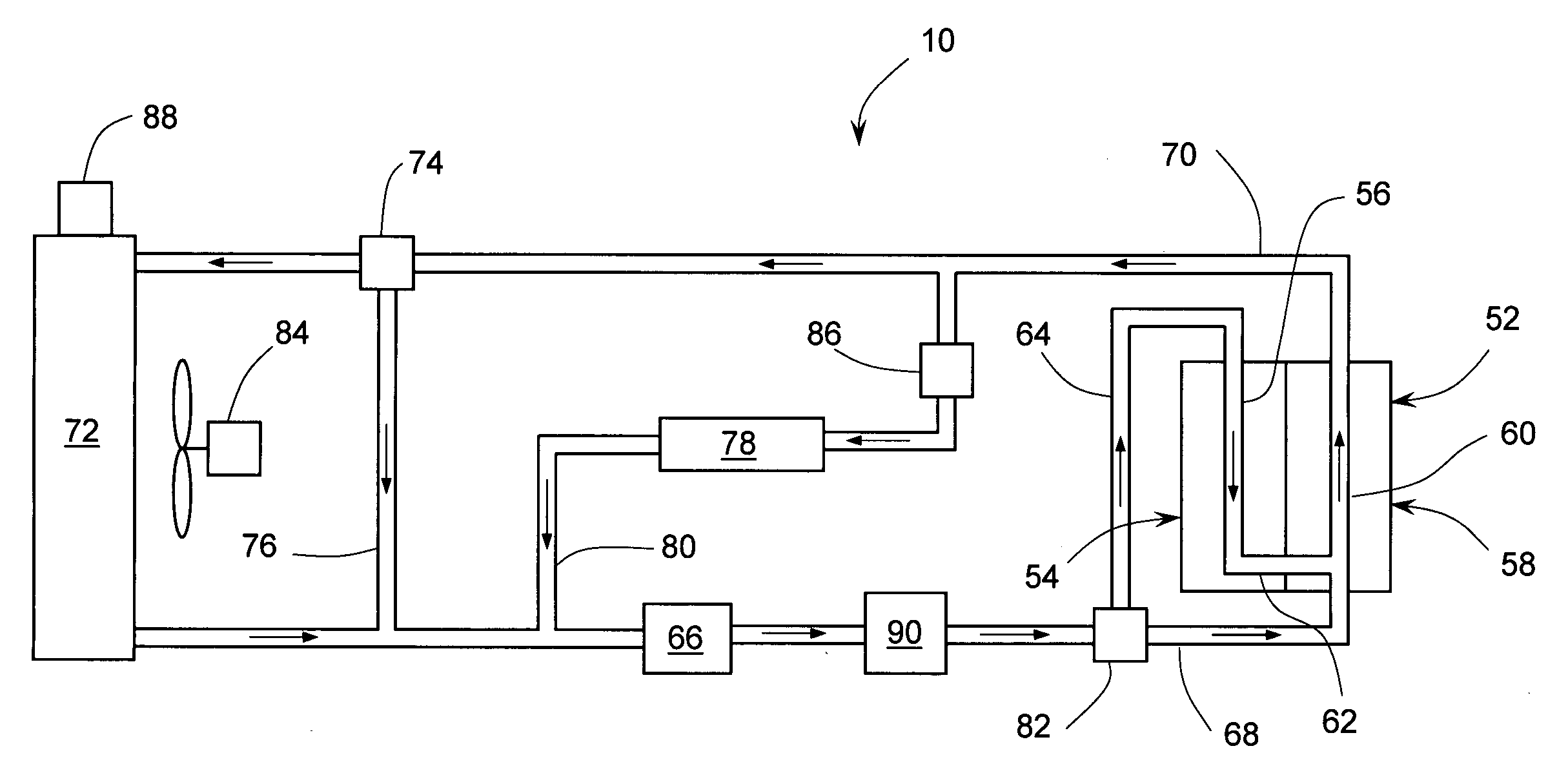

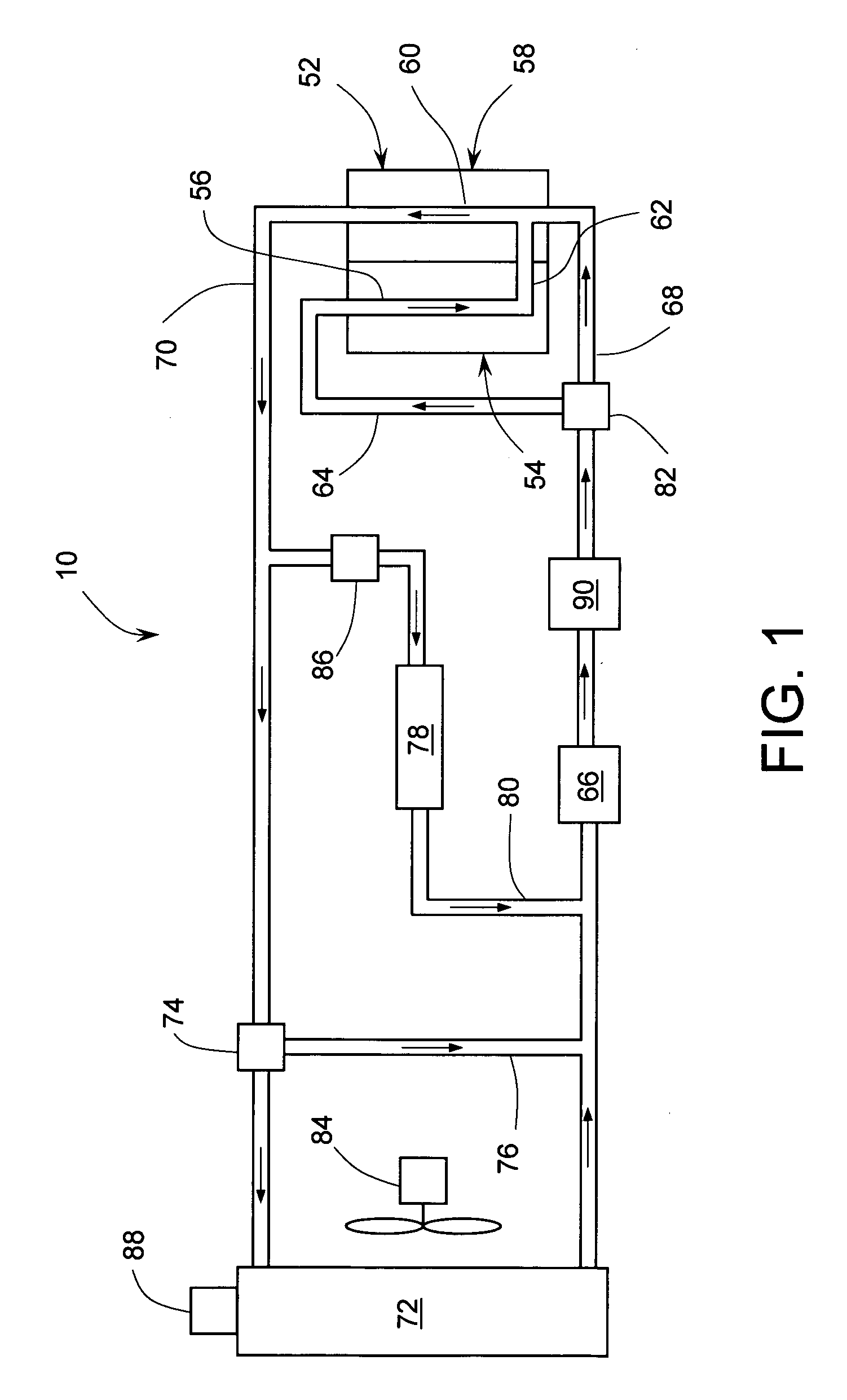

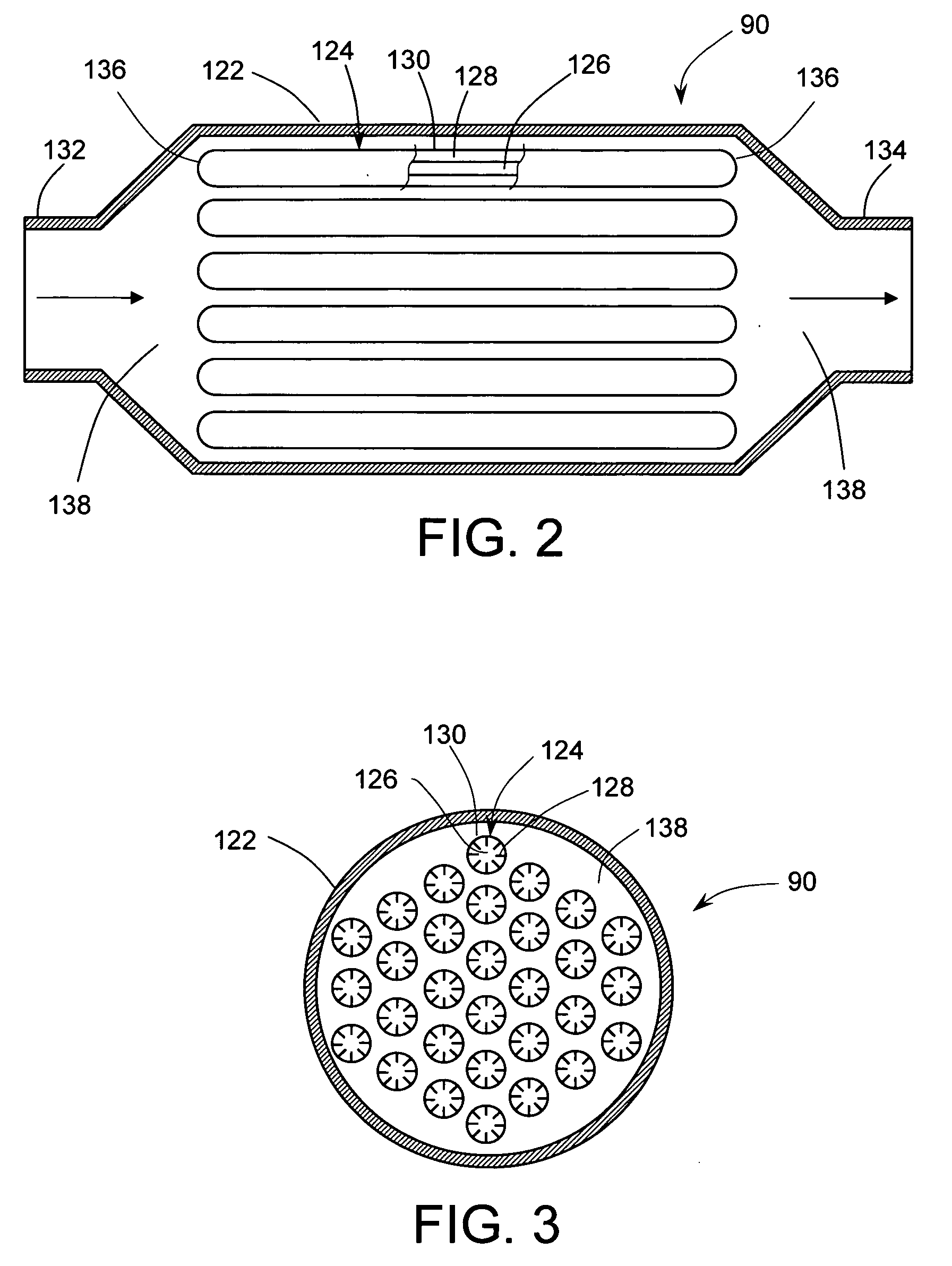

Thermal management systems and methods

InactiveUS20050167169A1Increase heatCell temperature controlMachines/enginesThermal energyThermal energy storage

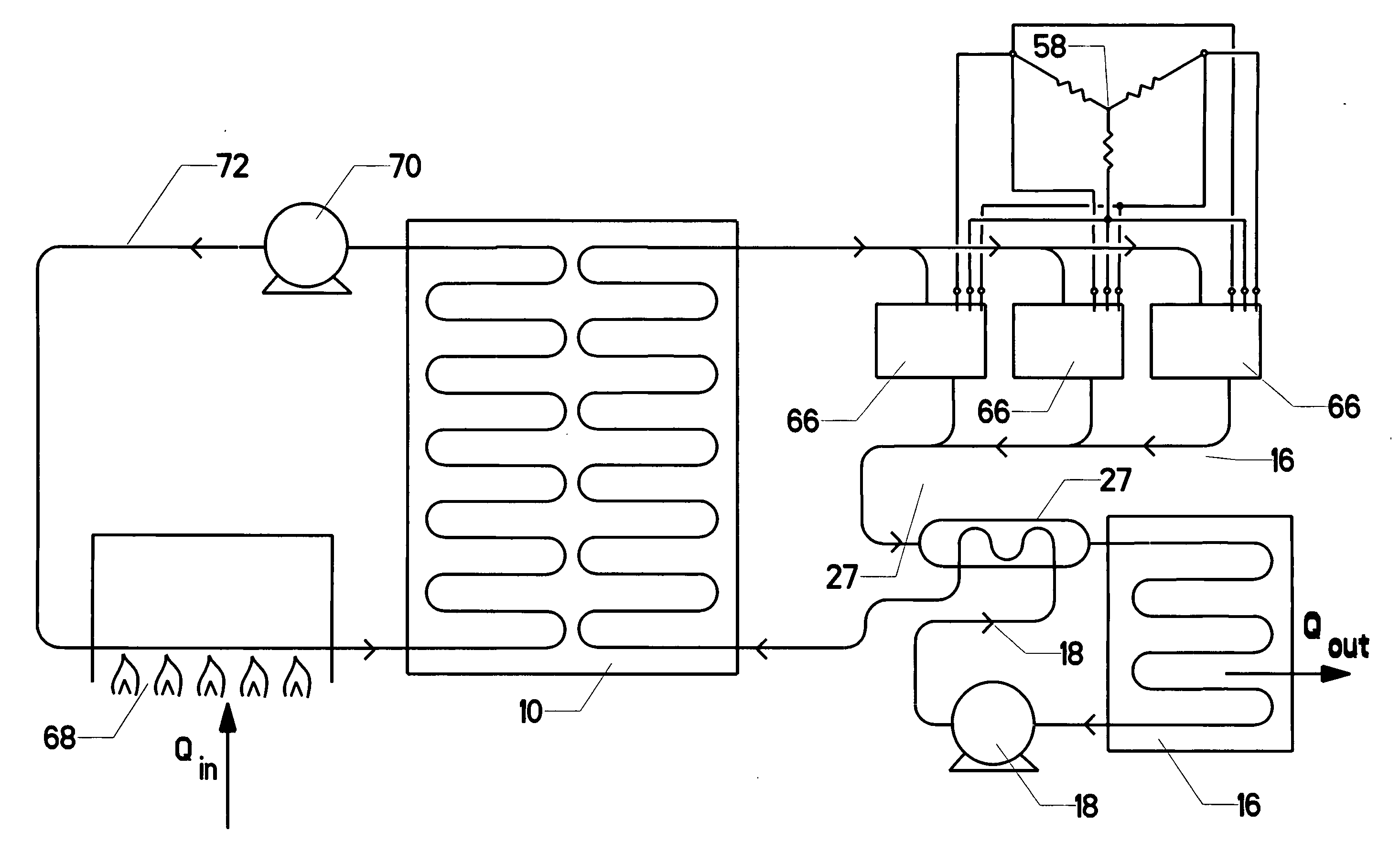

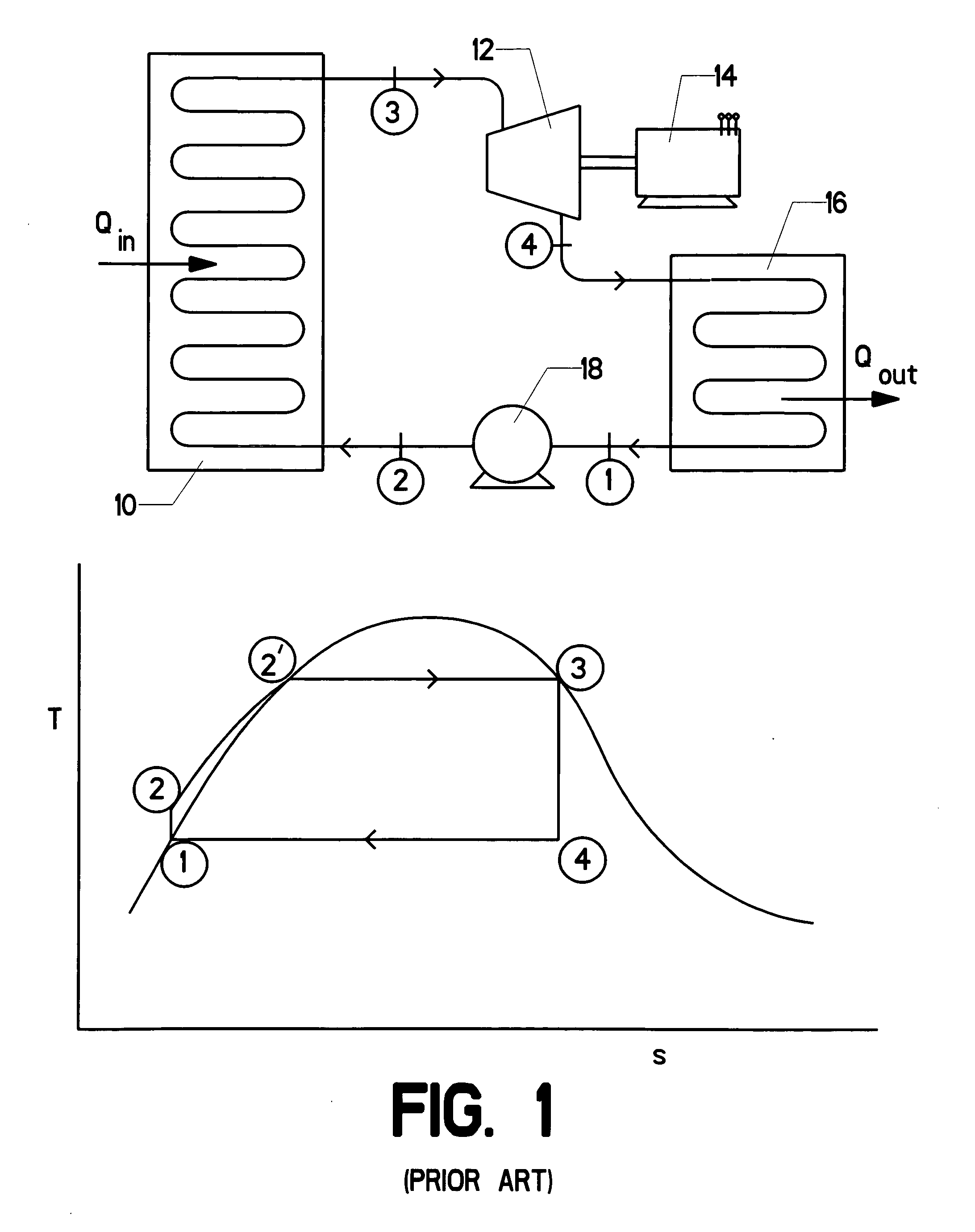

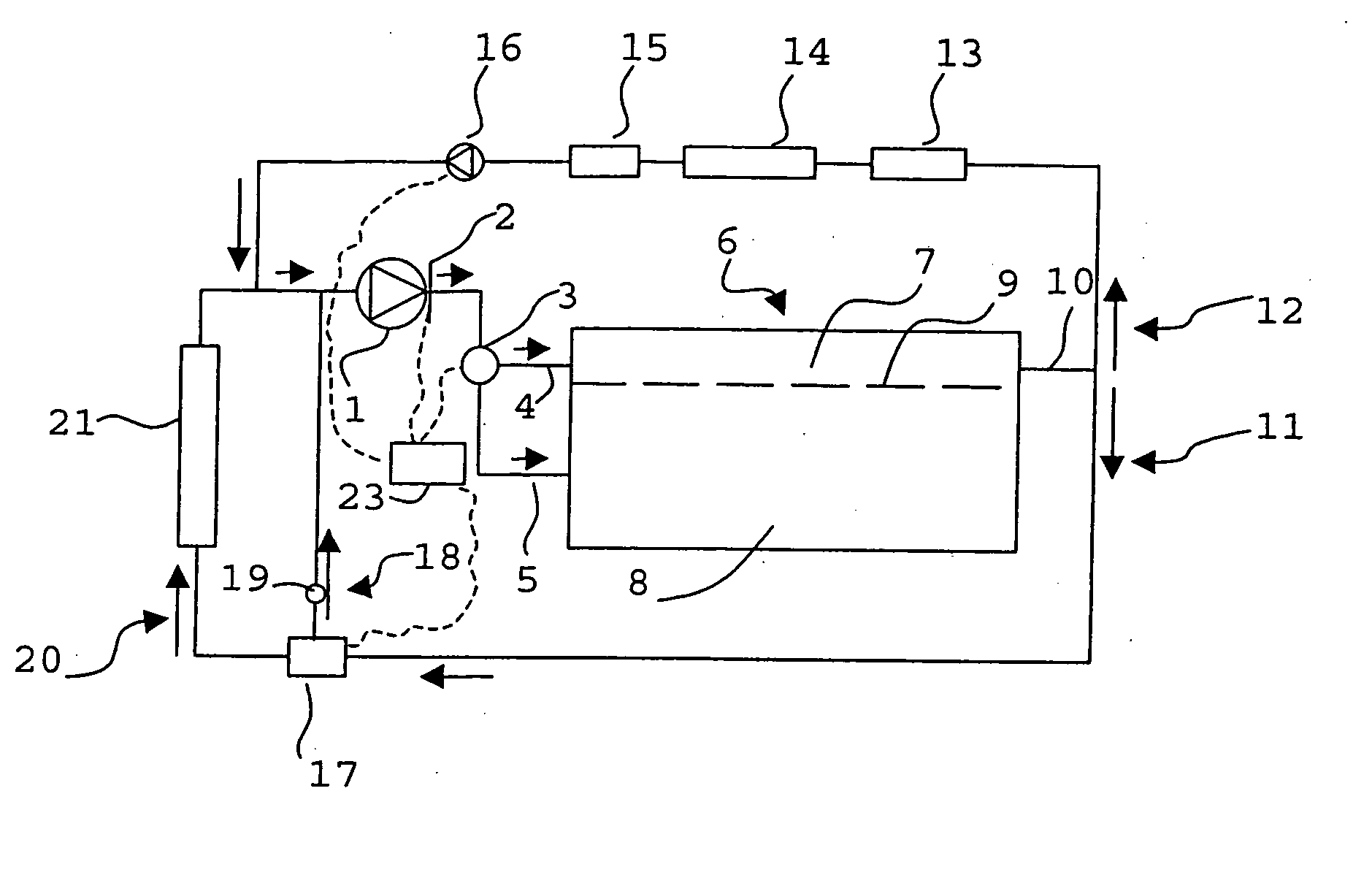

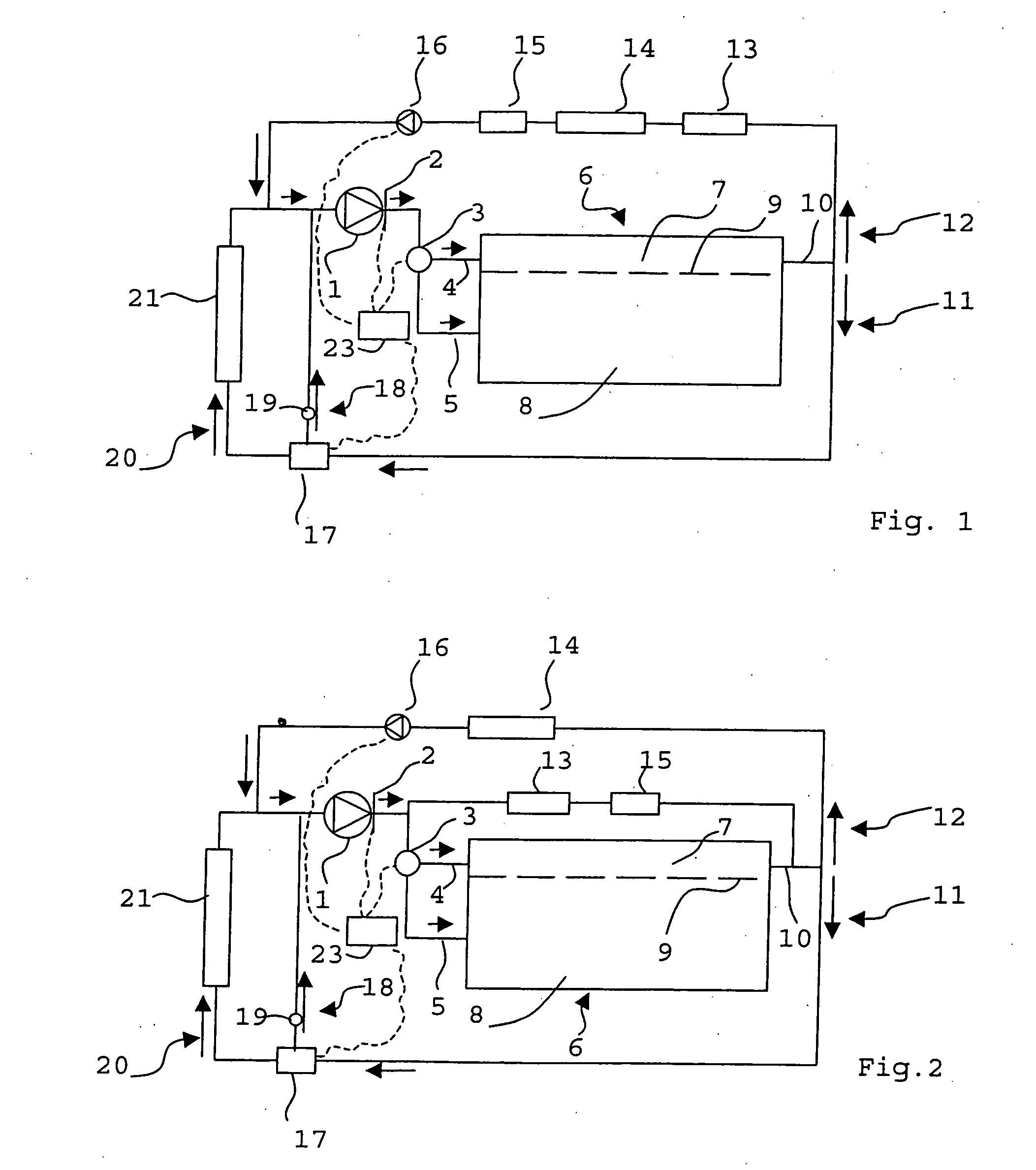

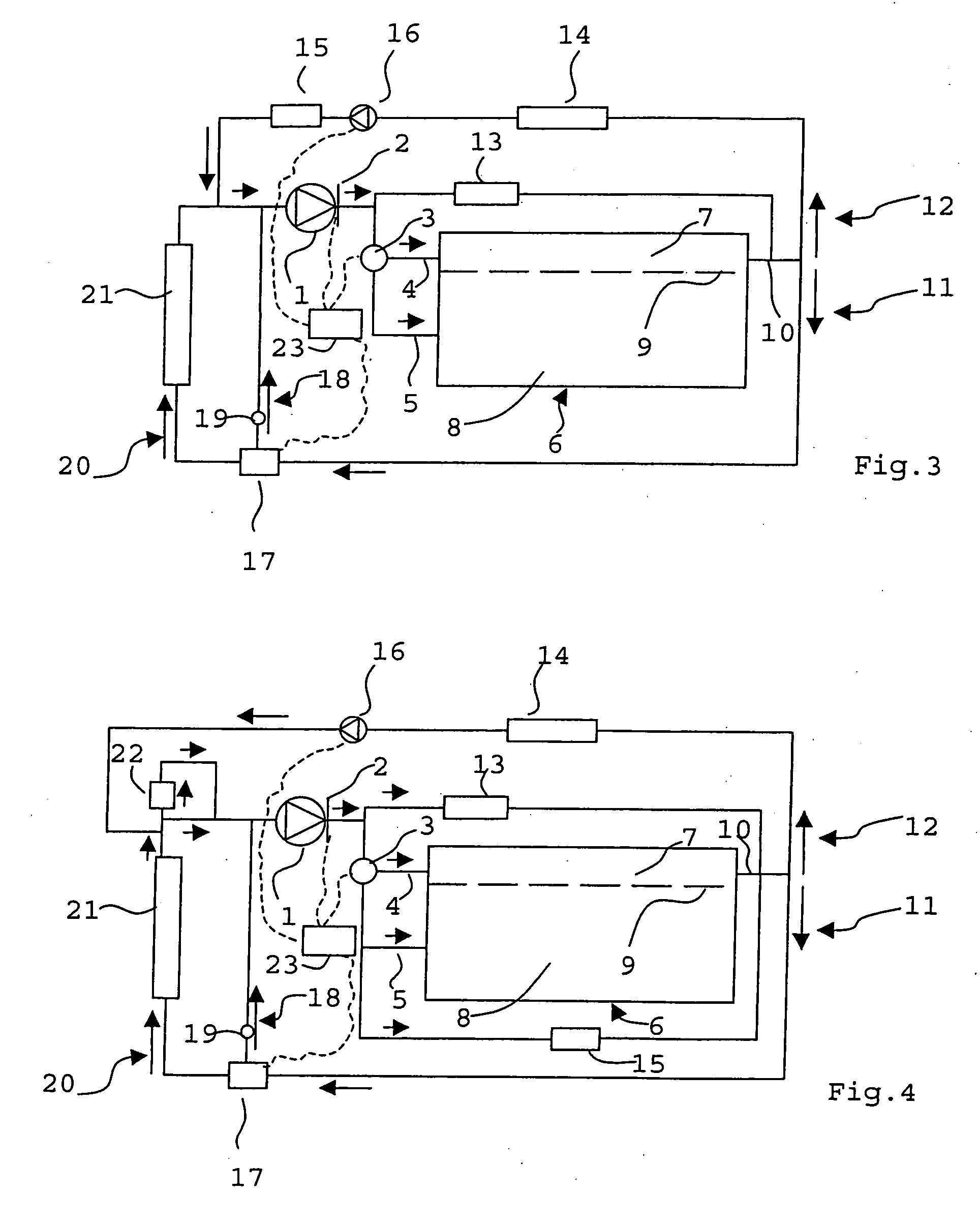

A thermal management system for a vehicle includes a heat exchanger having a thermal energy storage material provided therein, a first coolant loop thermally coupled to an electrochemical storage device located within the first coolant loop and to the heat exchanger, and a second coolant loop thermally coupled to the heat exchanger. The first and second coolant loops are configured to carry distinct thermal energy transfer media. The thermal management system also includes an interface configured to facilitate transfer of heat generated by an internal combustion engine to the heat exchanger via the second coolant loop in order to selectively deliver the heat to the electrochemical storage device. Thermal management methods are also provided.

Owner:BATTELLE ENERGY ALLIANCE LLC

Thermal management systems and methods

InactiveUS7147071B2Increase heatCell temperature controlMachines/enginesThermal energyThermal energy storage

A thermal management system for a vehicle includes a heat exchanger having a thermal energy storage material provided therein, a first coolant loop thermally coupled to an electrochemical storage device located within the first coolant loop and to the heat exchanger, and a second coolant loop thermally coupled to the heat exchanger. The first and second coolant loops are configured to carry distinct thermal energy transfer media. The thermal management system also includes an interface configured to facilitate transfer of heat generated by an internal combustion engine to the heat exchanger via the second coolant loop in order to selectively deliver the heat to the electrochemical storage device. Thermal management methods are also provided.

Owner:BATTELLE ENERGY ALLIANCE LLC

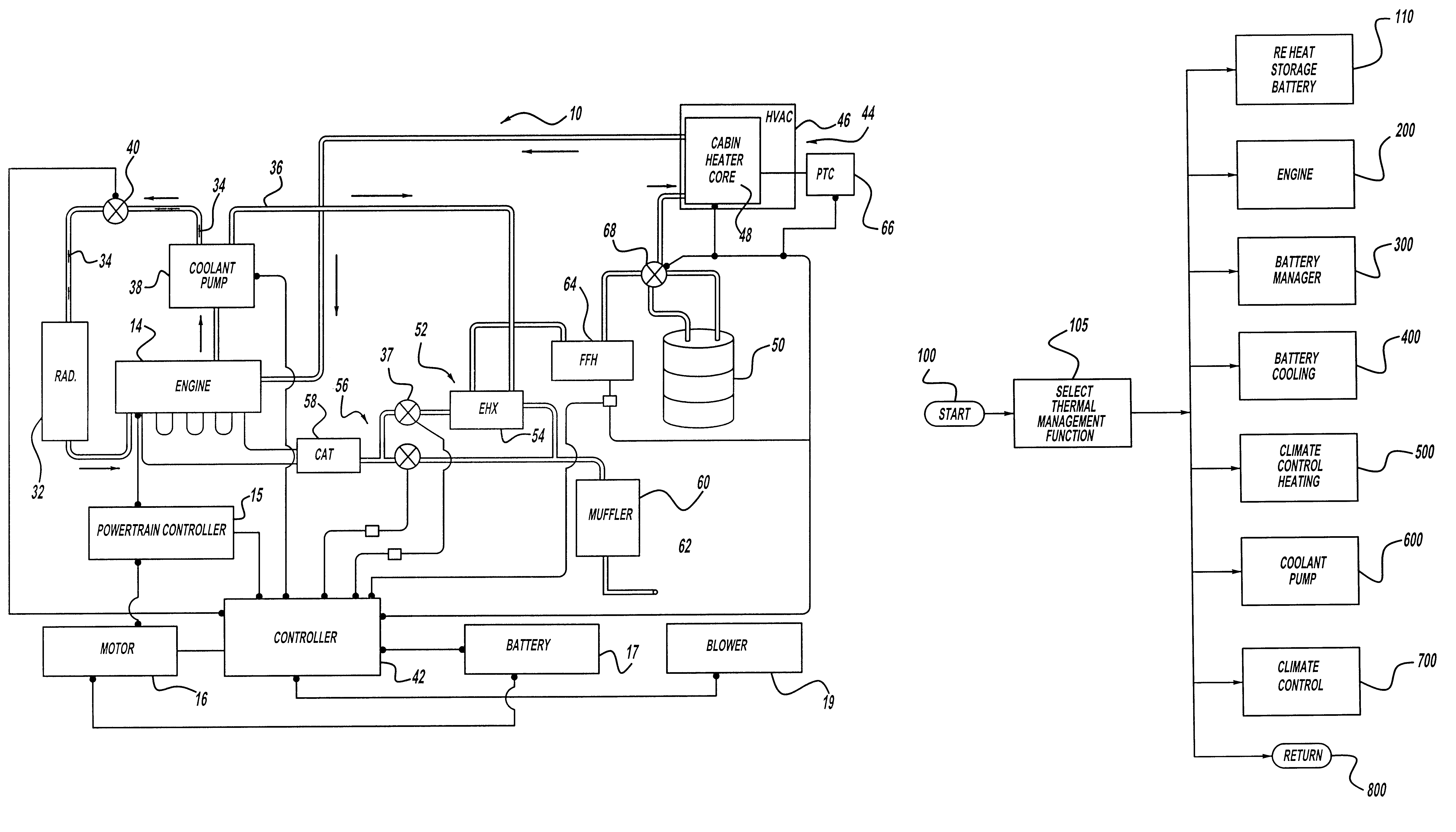

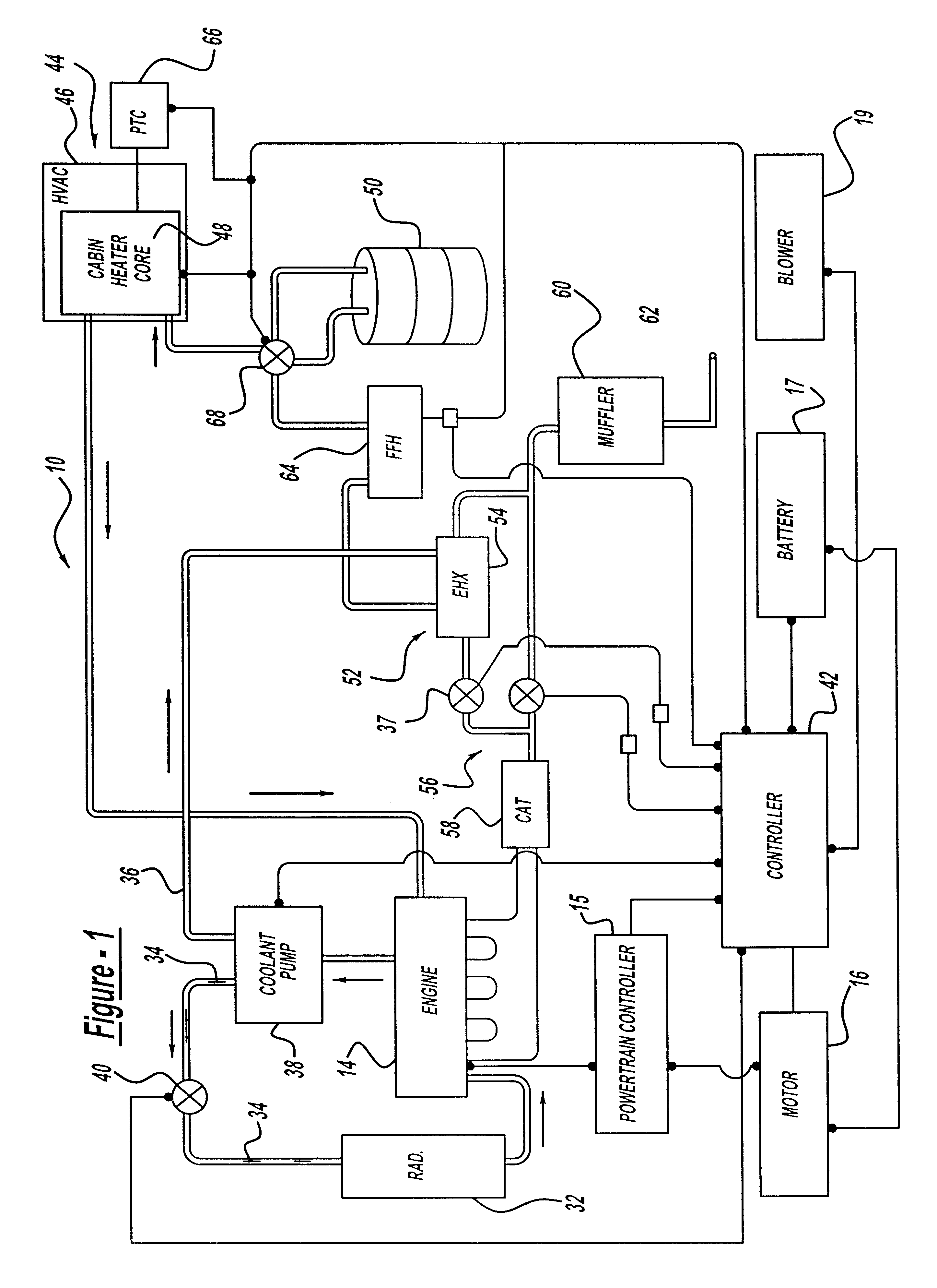

Method of thermal management for a hybrid vehicle

A method of thermal management for a thermal management system in a vehicle includes the steps of selecting a thermal management function. The method also includes the steps of adjusting a temperature within the thermal management system using the thermal management function and using the adjusted temperature within the thermal management system to control a temperature within an occupant compartment of the vehicle.

Owner:VISTEON GLOBAL TECH INC

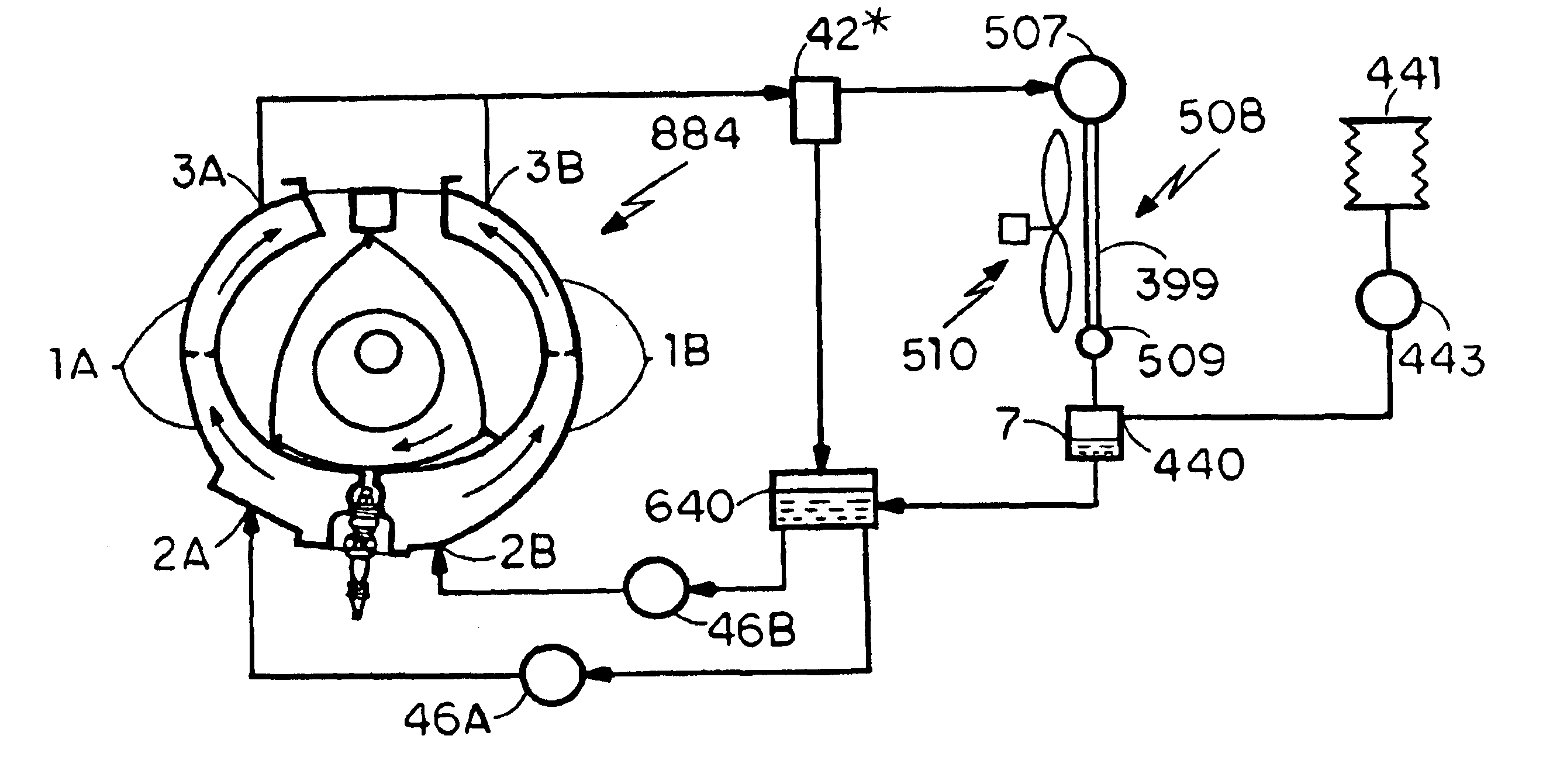

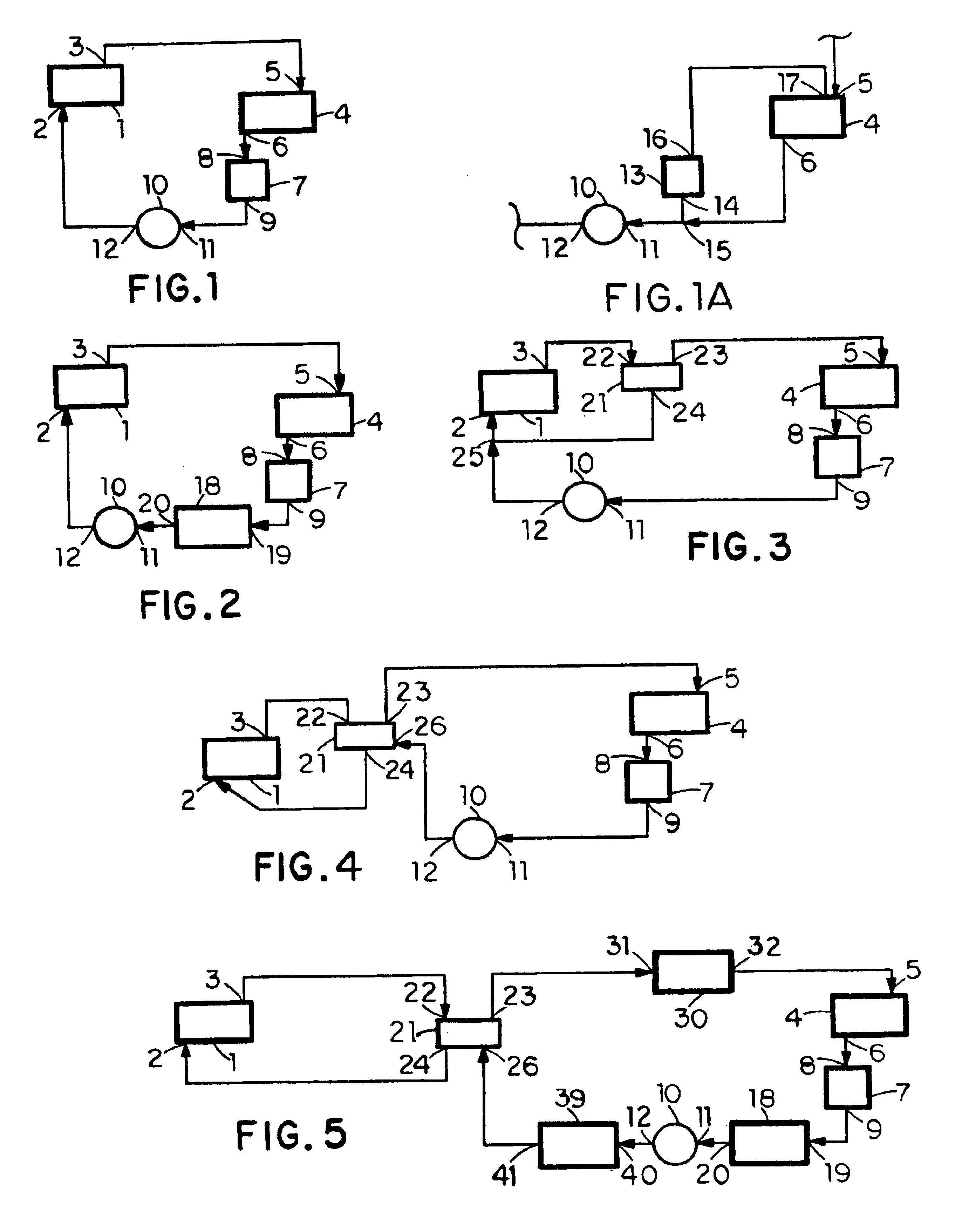

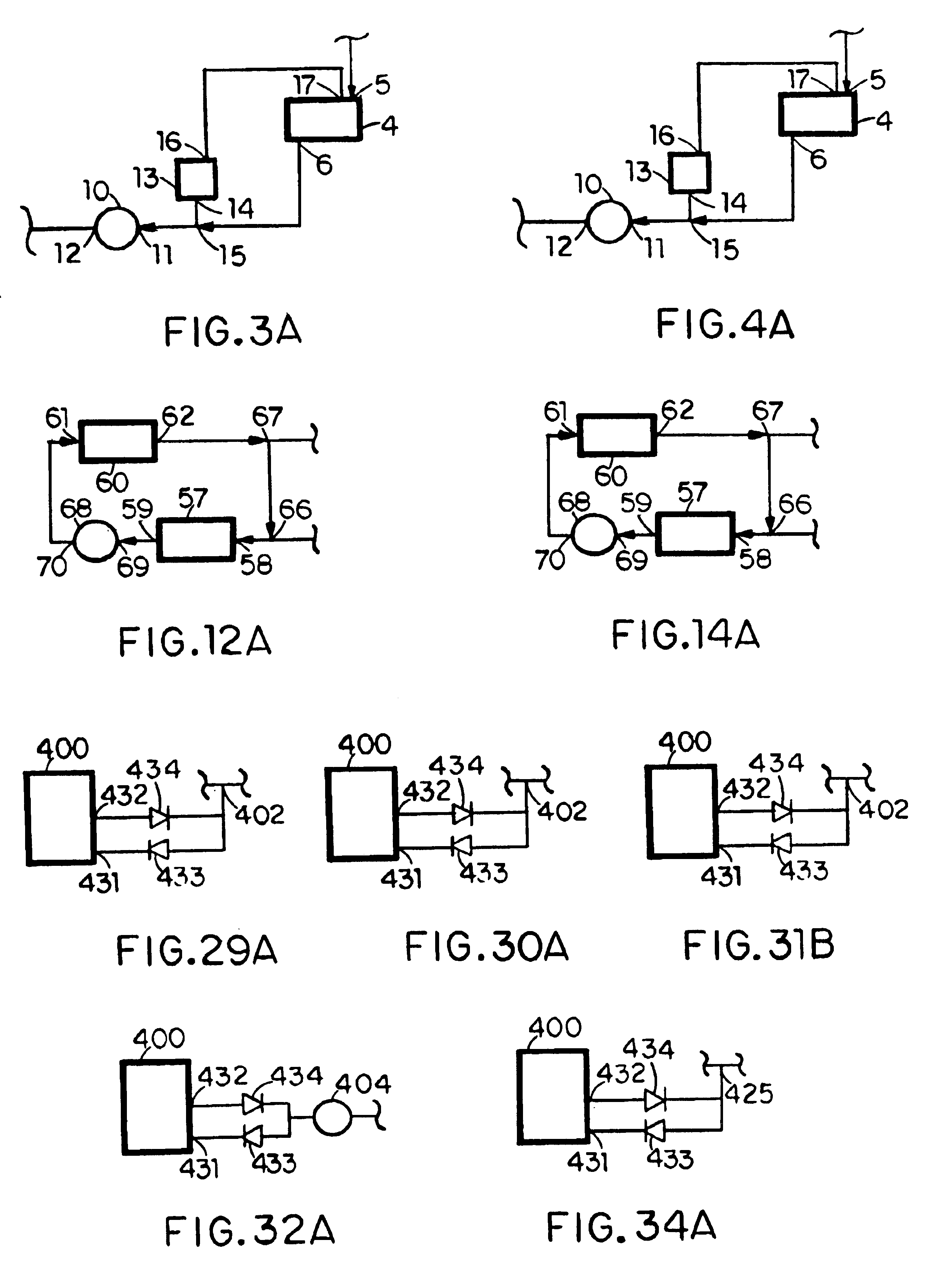

Two-phase heat-transfer systems

InactiveUS6866092B1Prevent freezingImprove the overall coefficientLiquid coolingCasingsLiquid jetInternal pressure

Various techniques are disclosed for improving airtight two-phase heat-transfer systems employing a fluid to transfer heat from a heat source to a heat sink while circulating around a fluid circuit, the maximum temperature of the heat sink not exceeding the maximum temperature of the heat source. The properties of those improved systems include (a) maintaining, while the systems are inactive, their internal pressure at a pressure above the saturated-vapor pressure of their heat-transfer fluid; and (b) cooling their internal evaporator surfaces with liquid jets. FIG. 43 illustrates the particular case where a heat-transfer system of the invention is used to cool a piston engine (500) by rejecting, with a condenser (508), heat to the ambient air; and where the system includes a heat-transfer fluid pump (10) and means (401-407) for achieving the former property.

Owner:MOLIVADAS STEPHEN

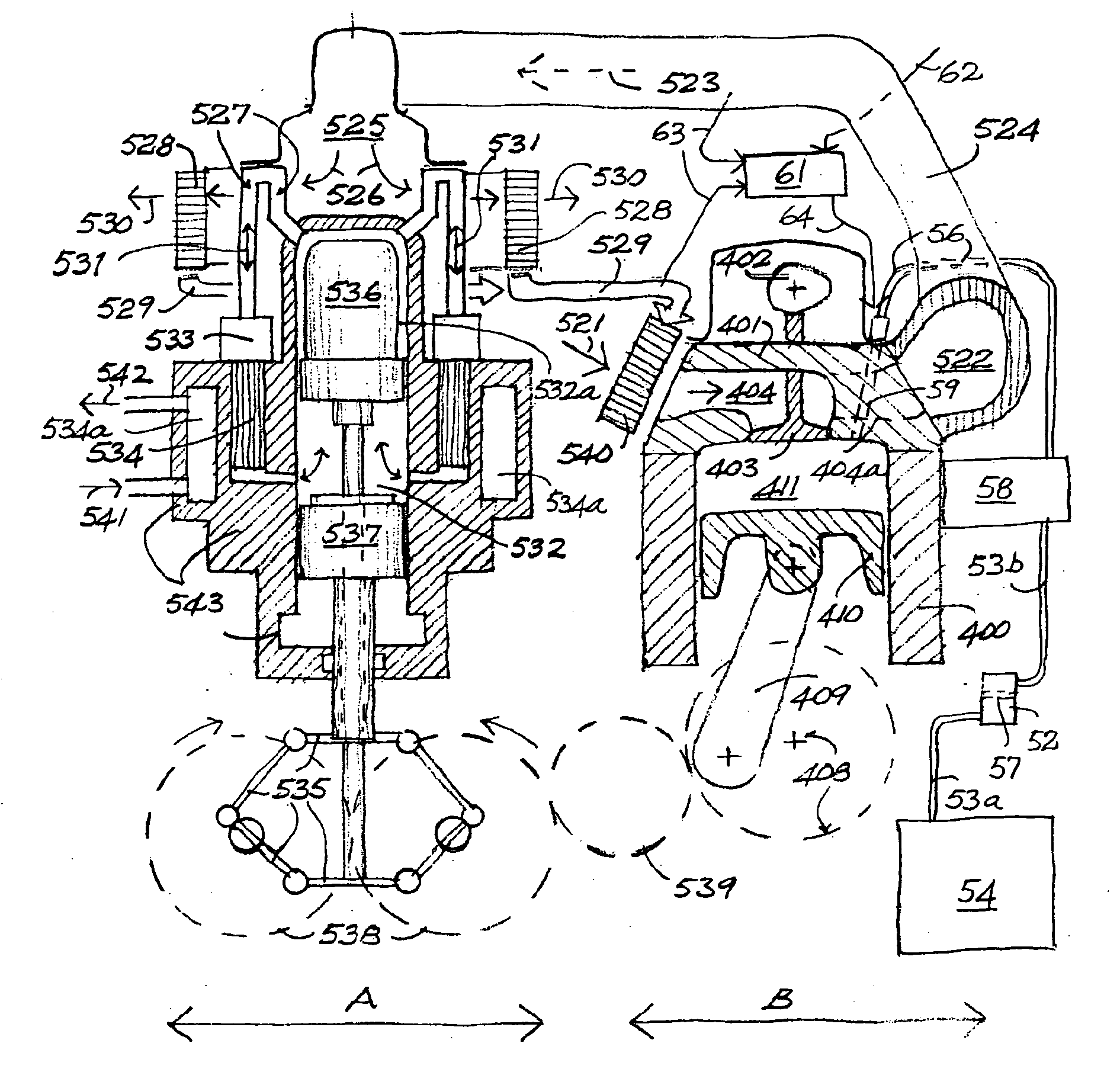

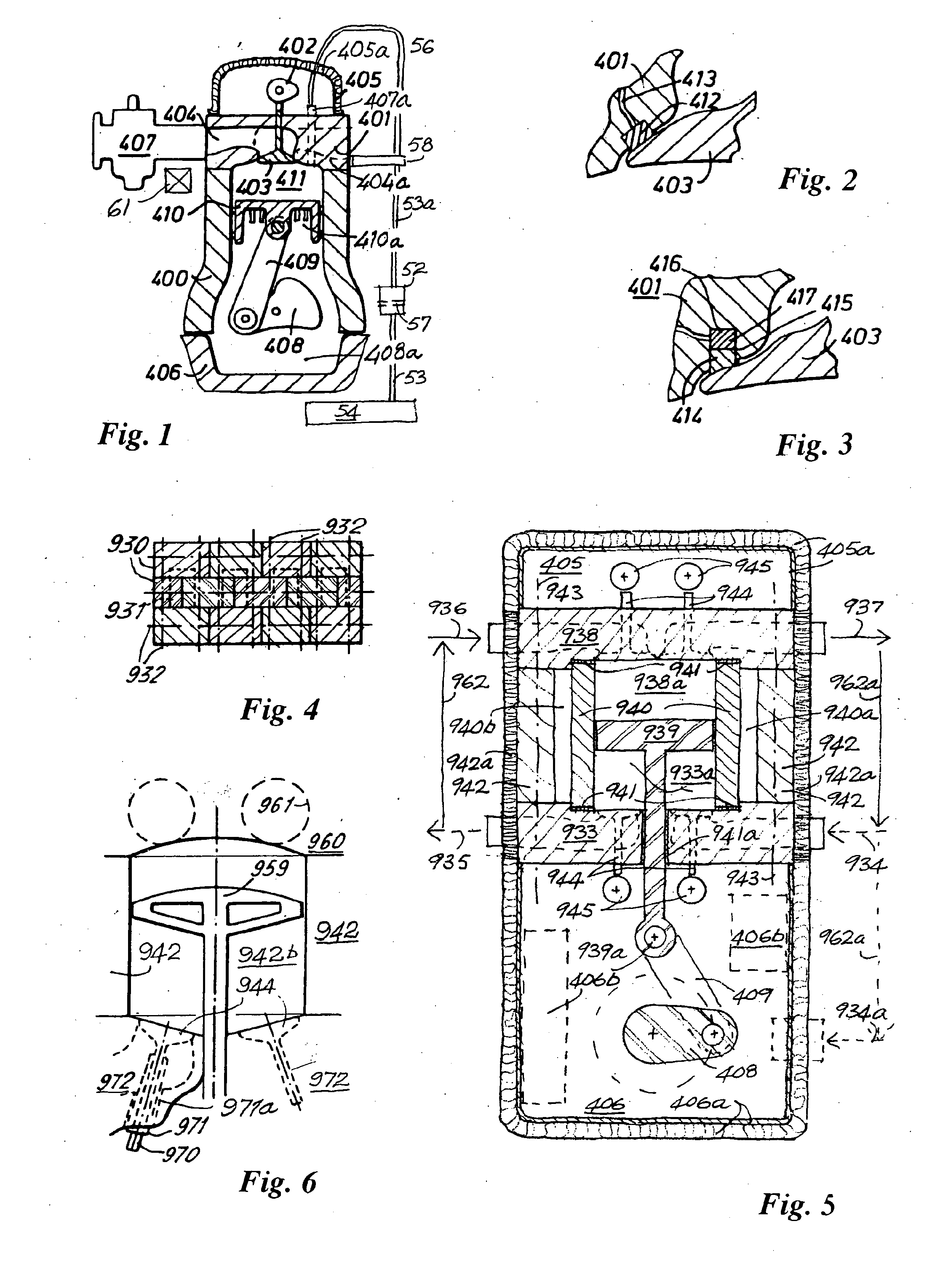

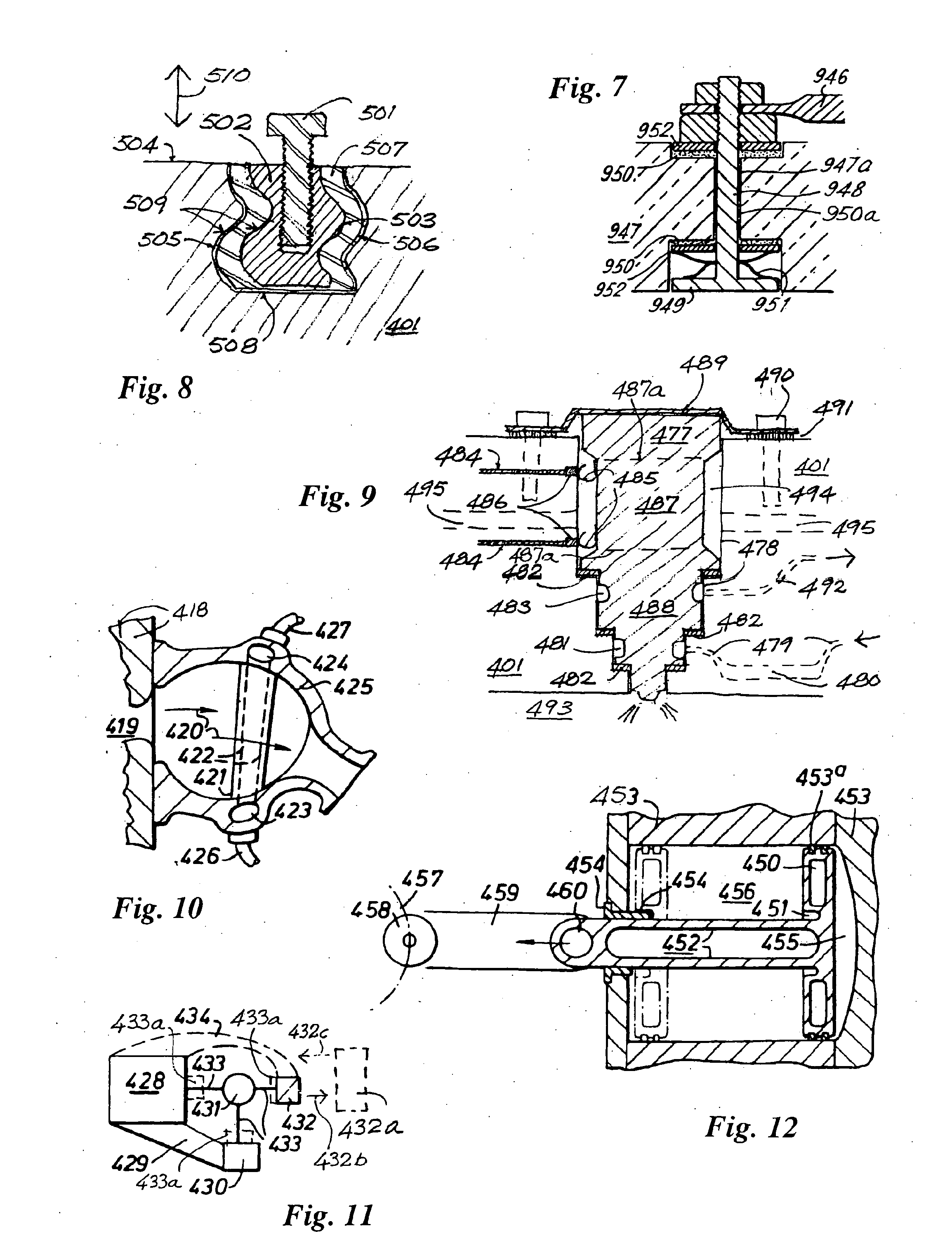

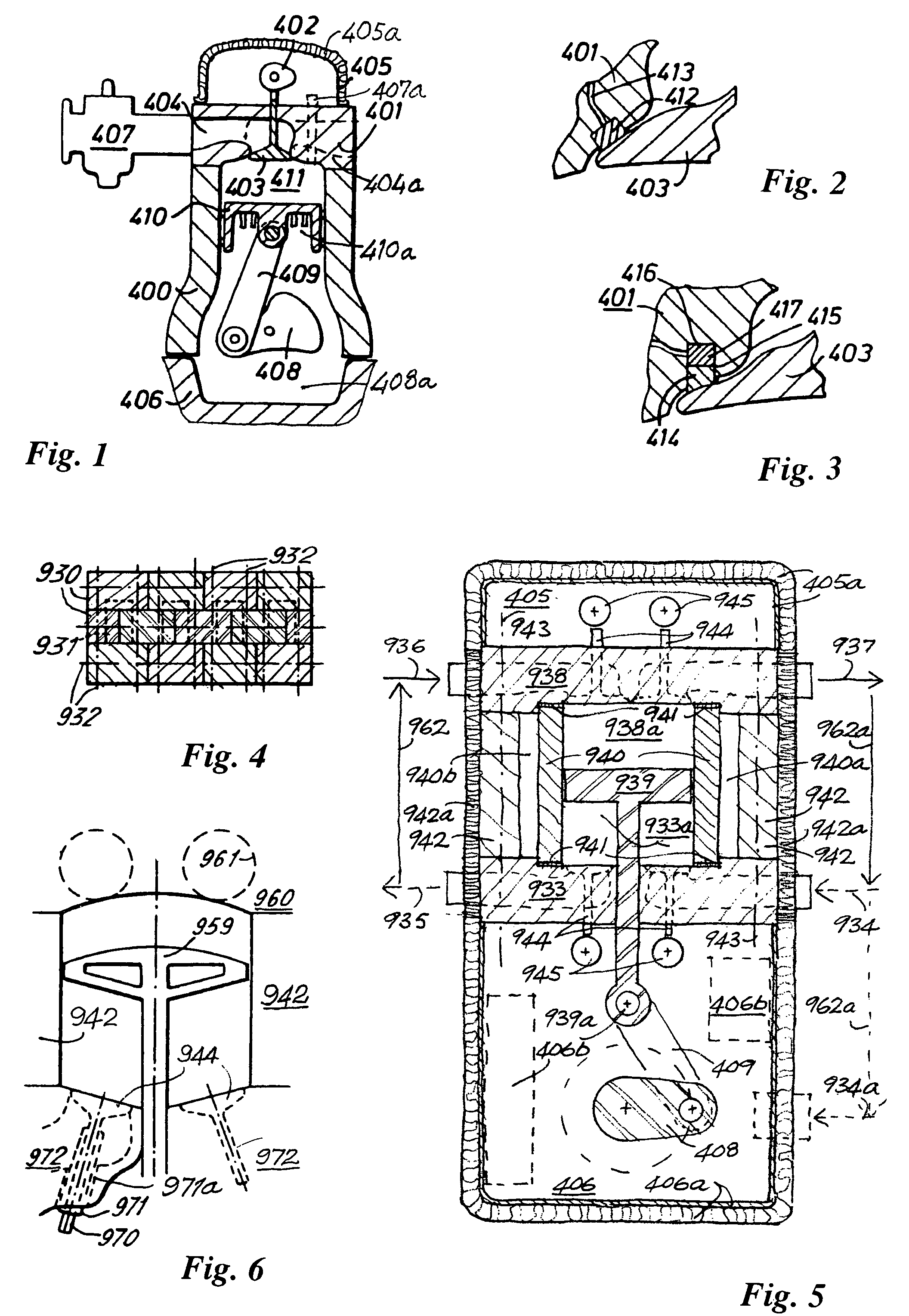

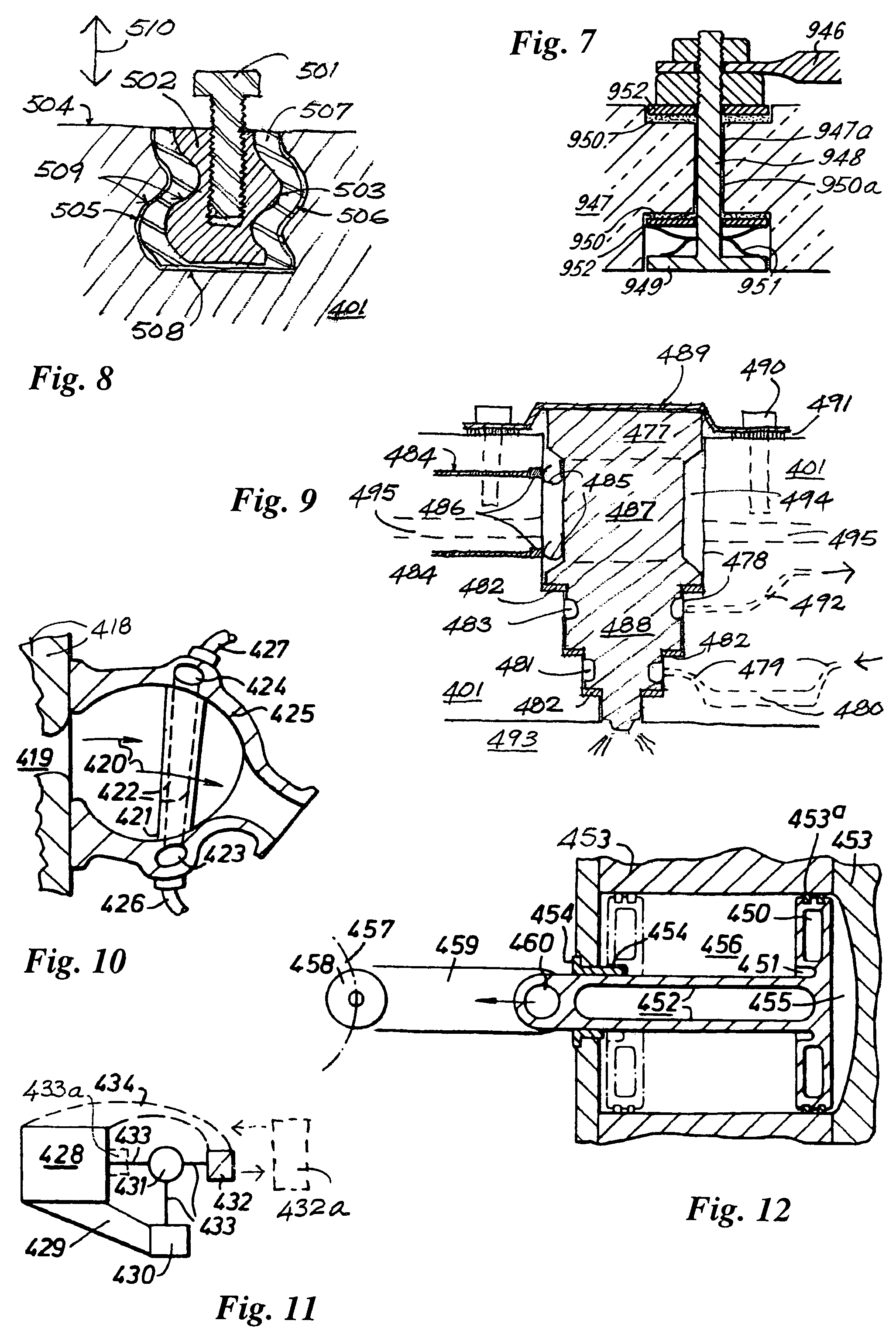

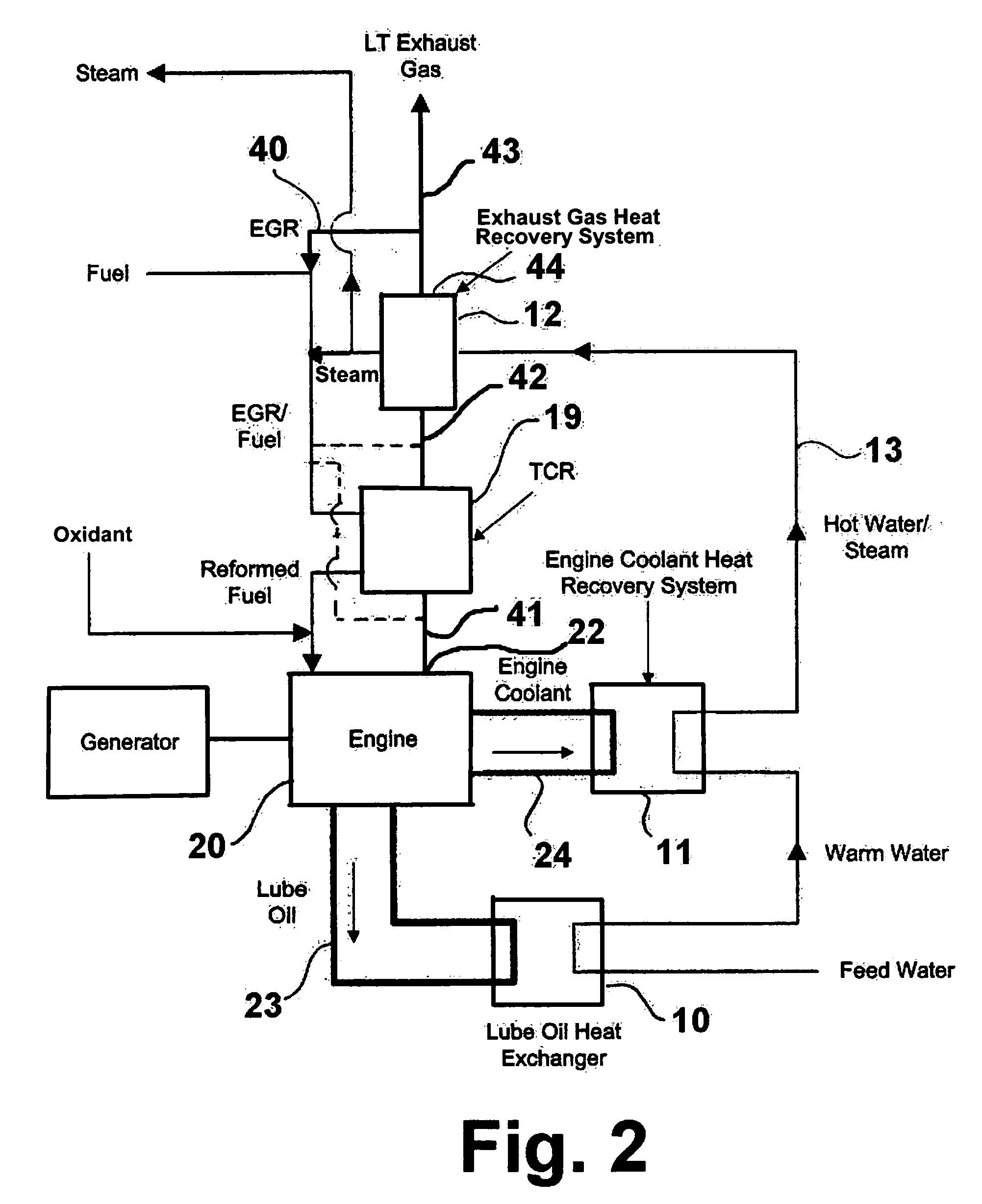

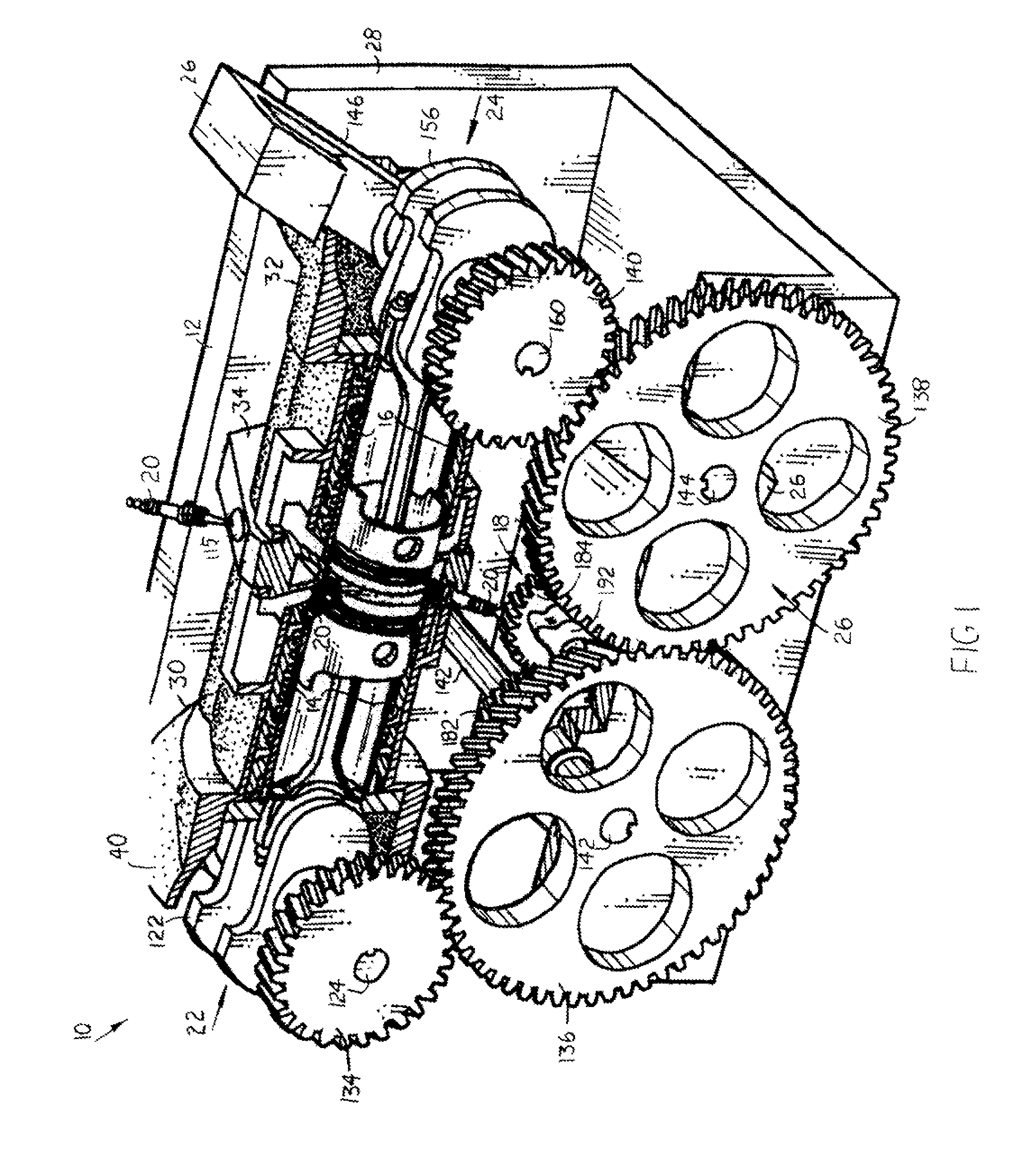

Reciprocating machine & other devices

InactiveUS20120227389A1Improve power densityImprove efficiencyLiquid coolingCasingsCombustionReciprocating motion

The disclosure relates to reciprocating fluid working devices including internal combustion engines, compressors and pumps. A number of arrangements for pistons and cylinders of unconventional configuration are described, mostly intended for use in IC engines operating without cooling. Included are toroidal combustion or working chambers, some with fluid flow through the core of the toroid, a single piston reciprocating between a pair of working chambers, tensile valve actuation, tensile links between piston and crankshaft, energy absorbing piston-crank links, crankshafts supported on gas bearings, cylinders rotating in housings, injectors having components which reciprocate or rotate during fuel delivery. In some embodiments pistons mare rotate while reciprocating. High temperature exhaust emissions systems are described, including those containing filamentary material, as are procedures for reducing emissions during cold start by means of valves at reaction volume exit. Also disclosed are improved vehicles, aircraft, marine craft, transmissions and exhaust emission systems suited to the engines of the invention.

Owner:HINDERKS MITJA VICTOR

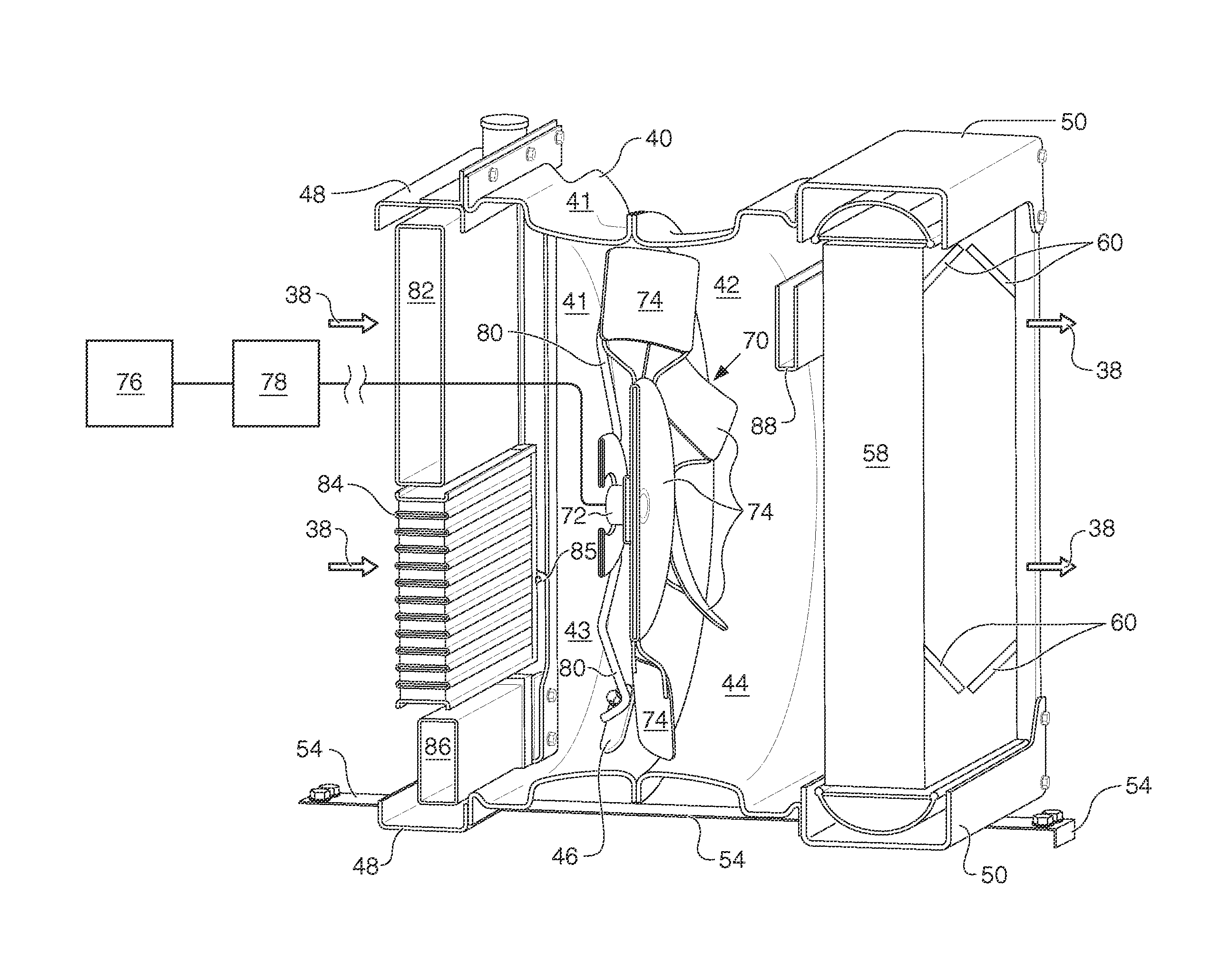

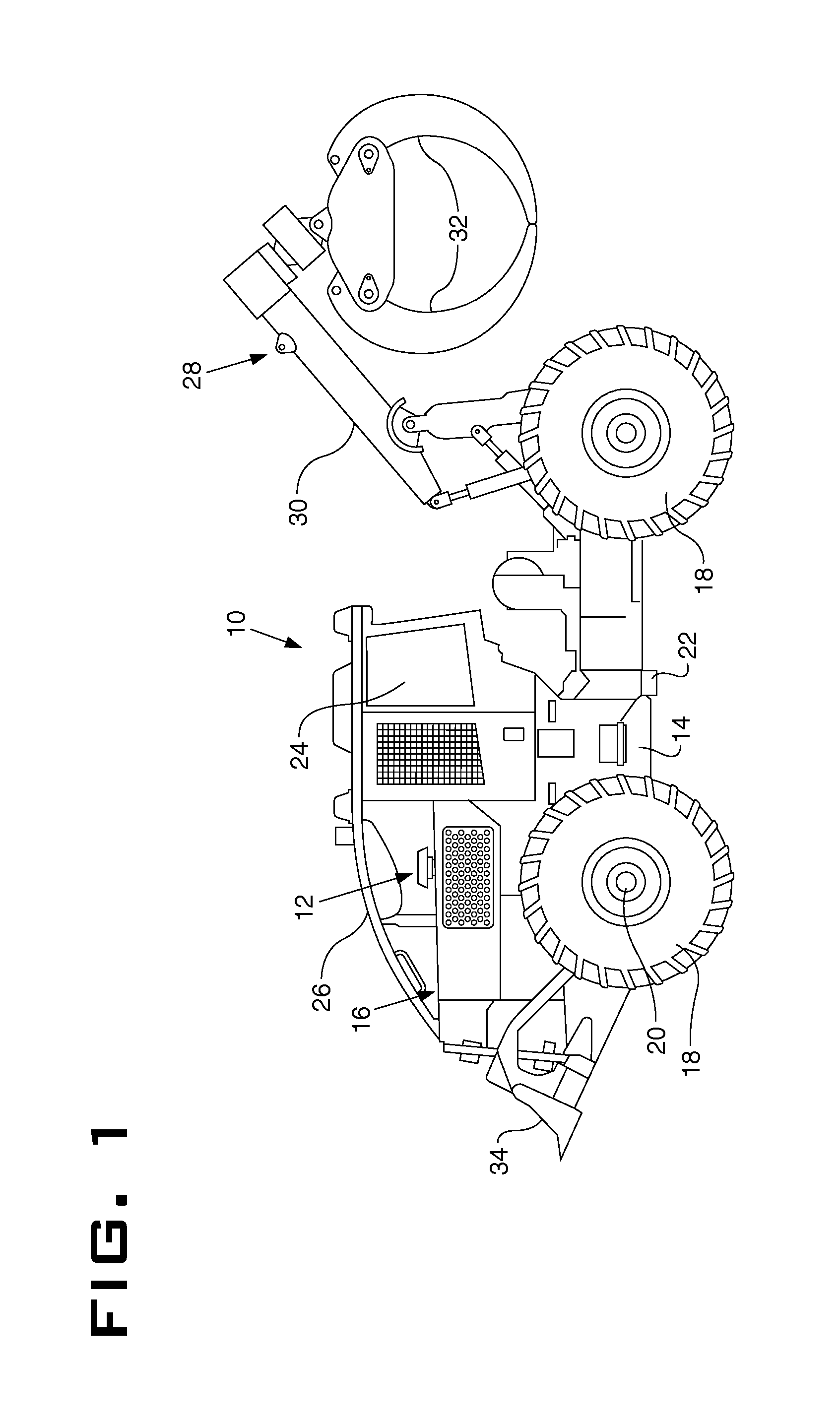

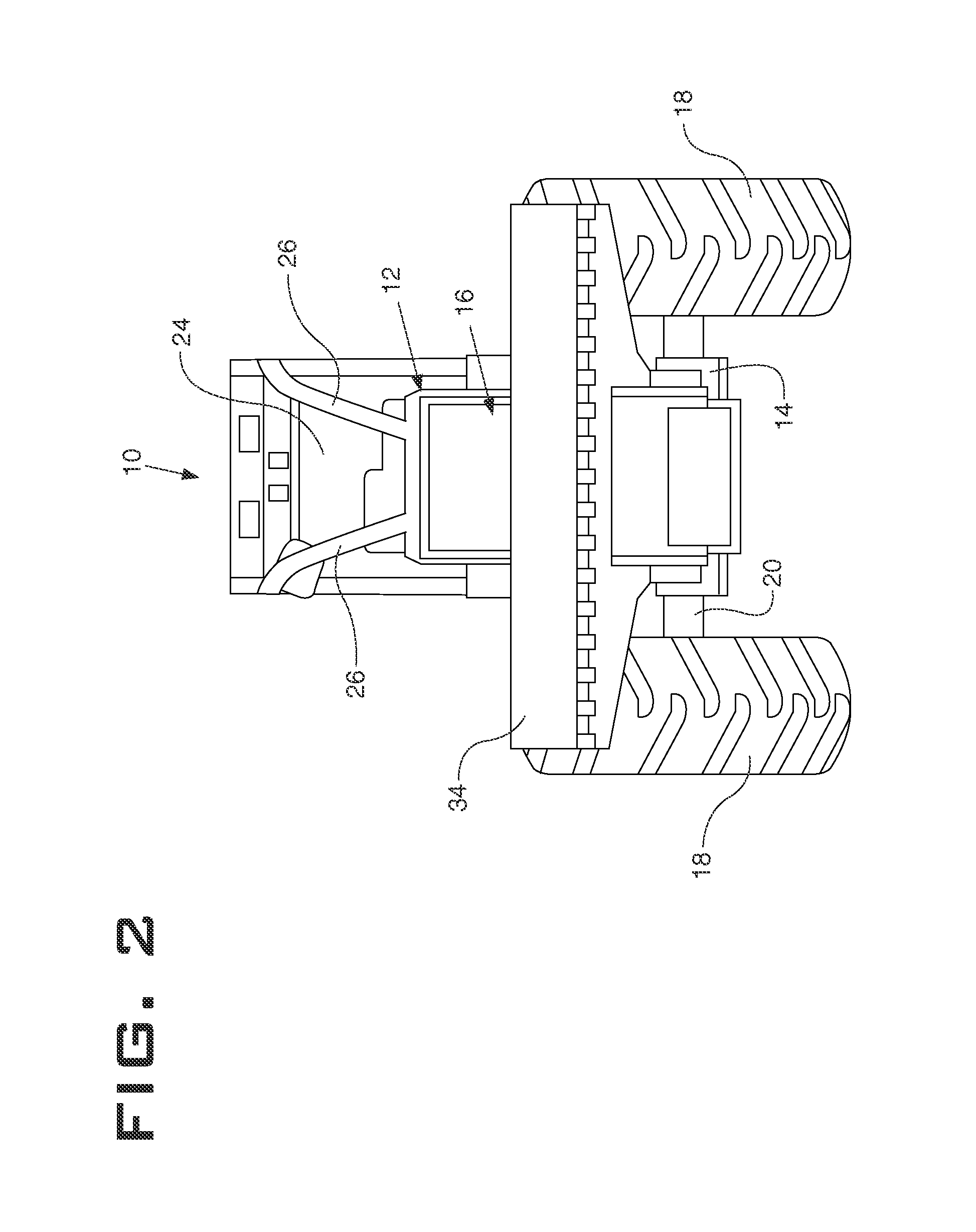

Engine cooling system

An engine cooling system includes a first heat exchanger receiving a first fluid and a second heat exchanger receiving a second fluid. The second heat exchanger is located adjacent the first heat exchanger, thereby creating a stacked heat exchanger. The engine cooling system also includes a third heat exchanger receiving a third fluid. The third heat exchanger is located apart from the stacked heat exchanger. A venturi is located between the stacked heat exchanger and the third heat exchanger. An air mover is mounted to the venturi and located within the venturi. The air mover is configured to move air through the stacked heat exchanger and through the third heat exchanger. In a specific embodiment, the engine cooling system is incorporated into a vehicle, such as a skidder vehicle.

Owner:CATERPILLAR FOREST PRODS

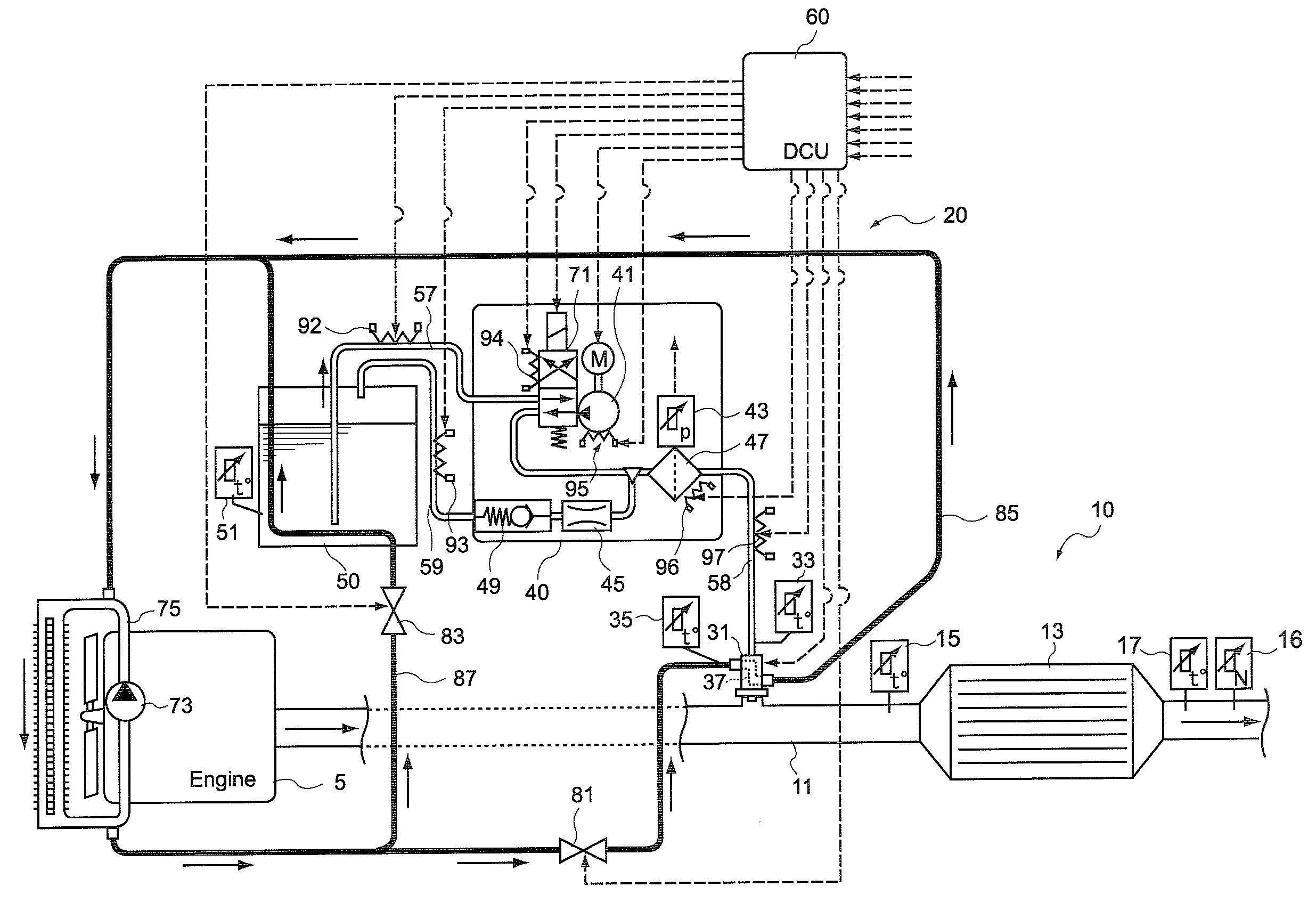

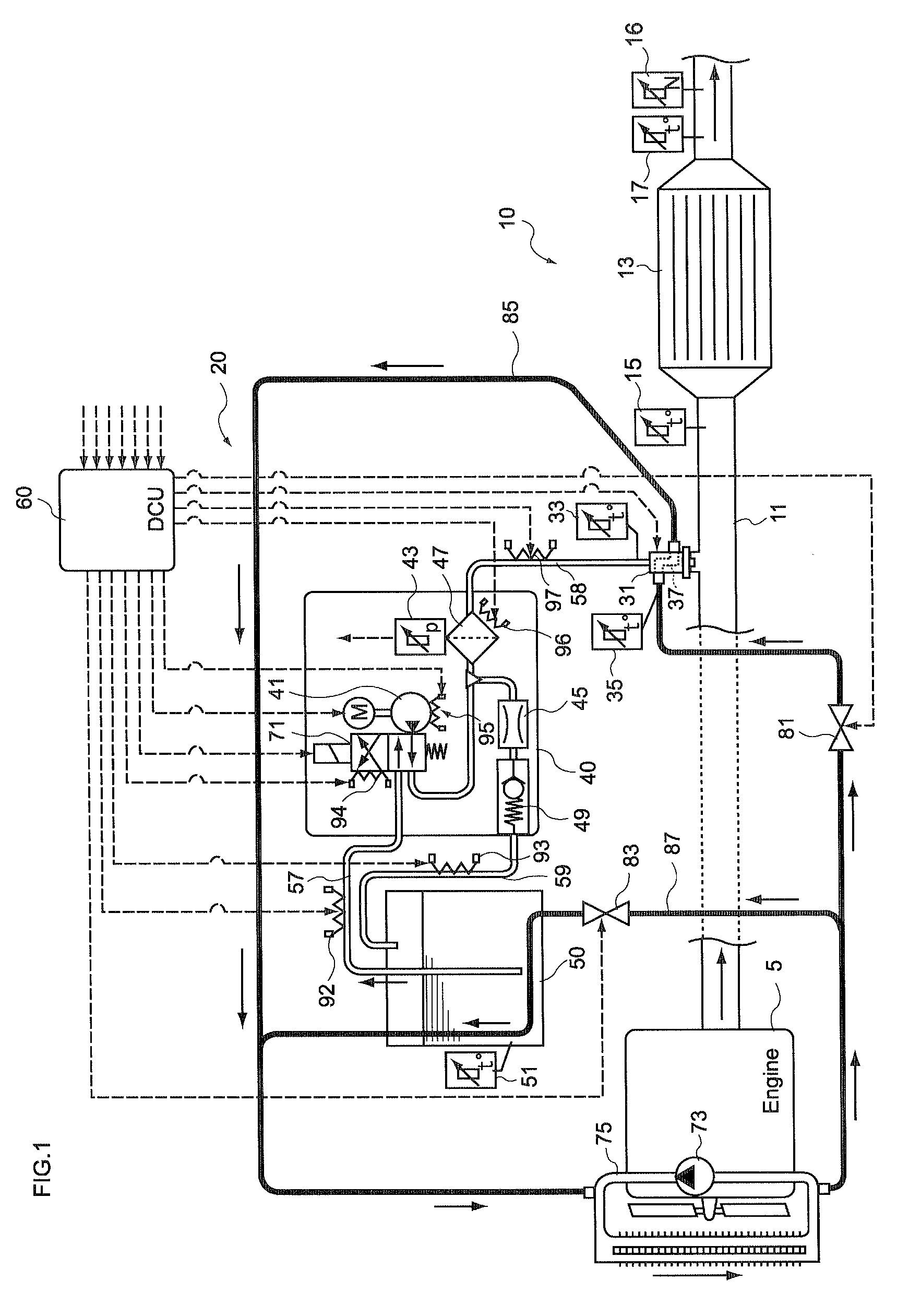

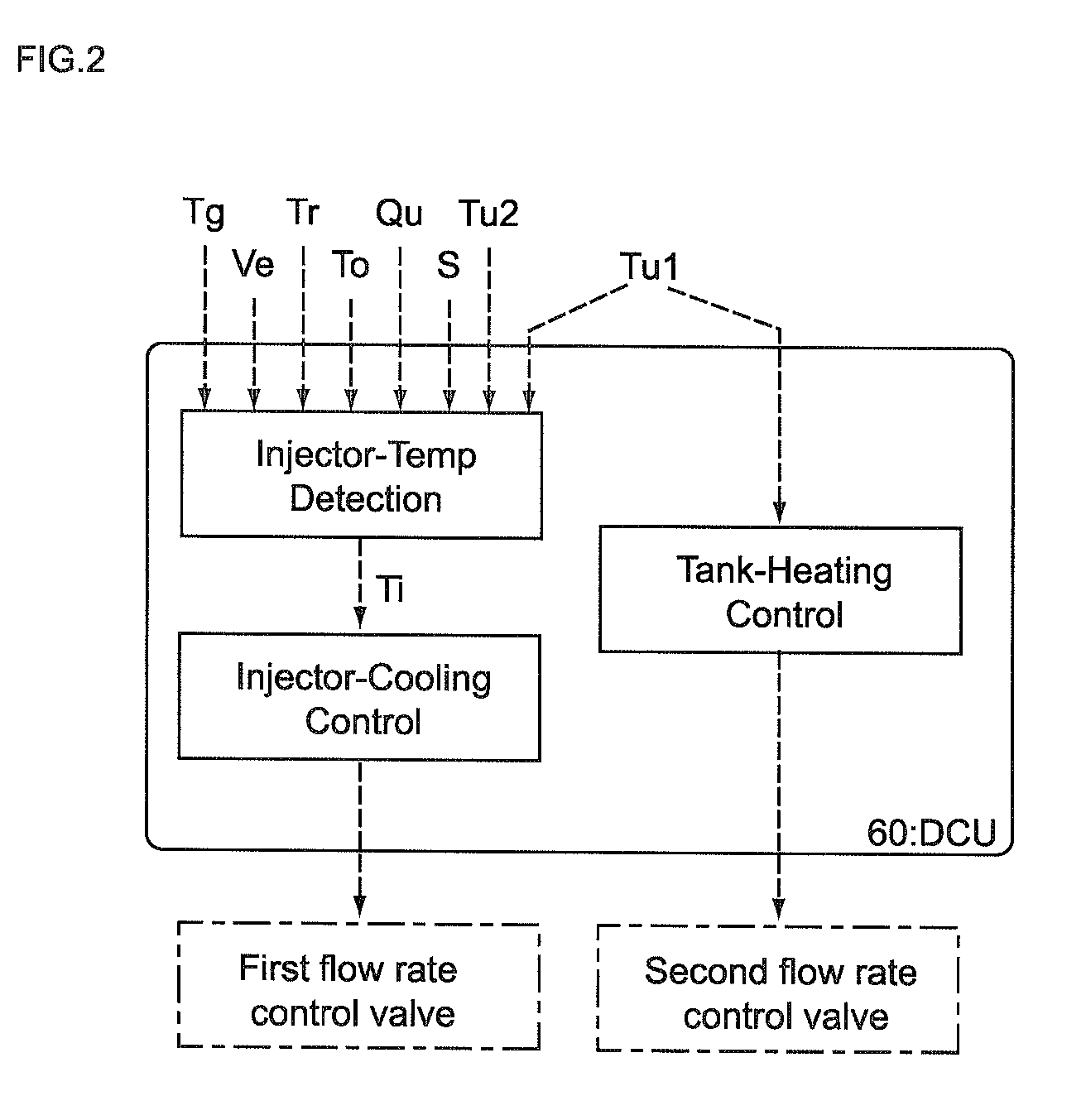

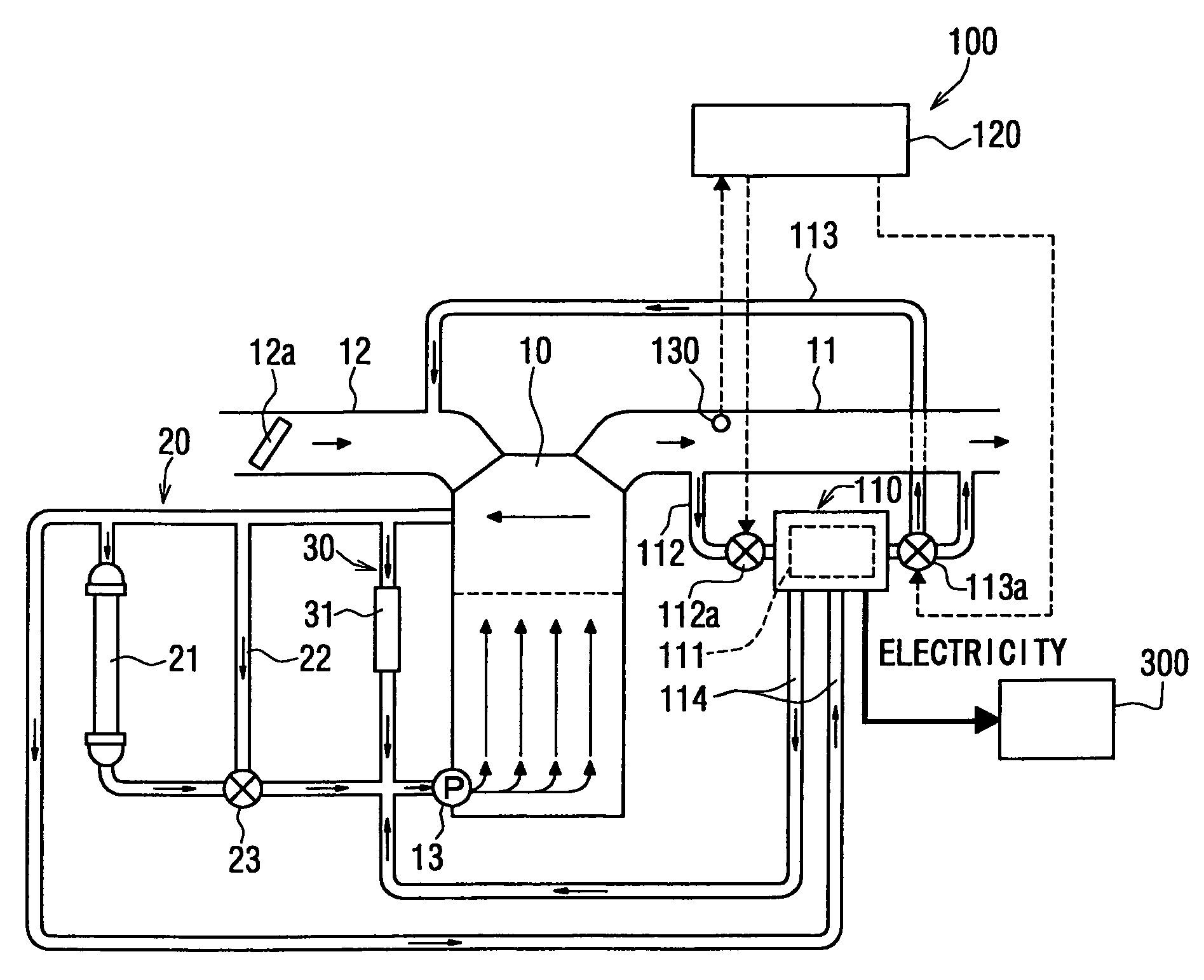

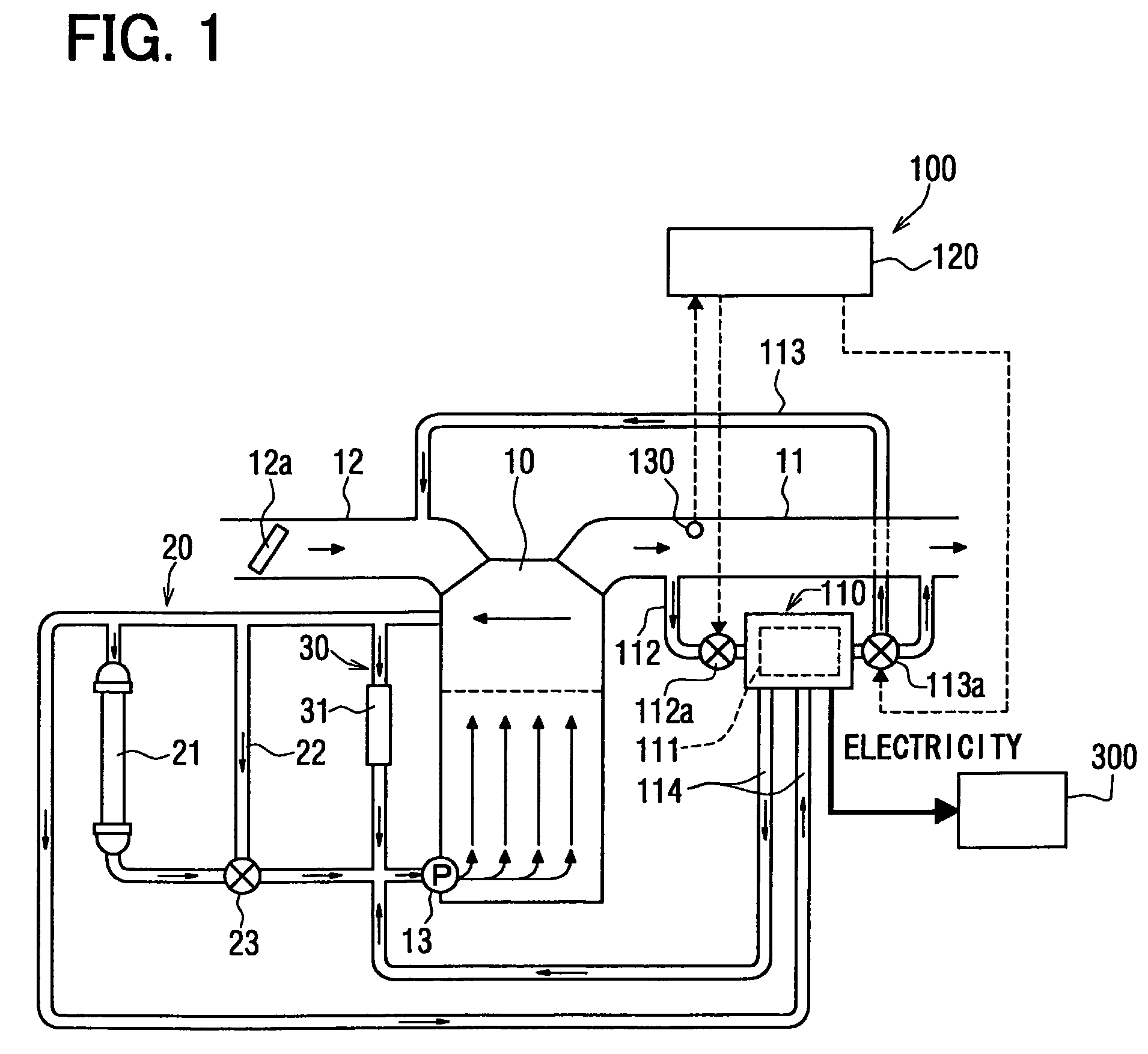

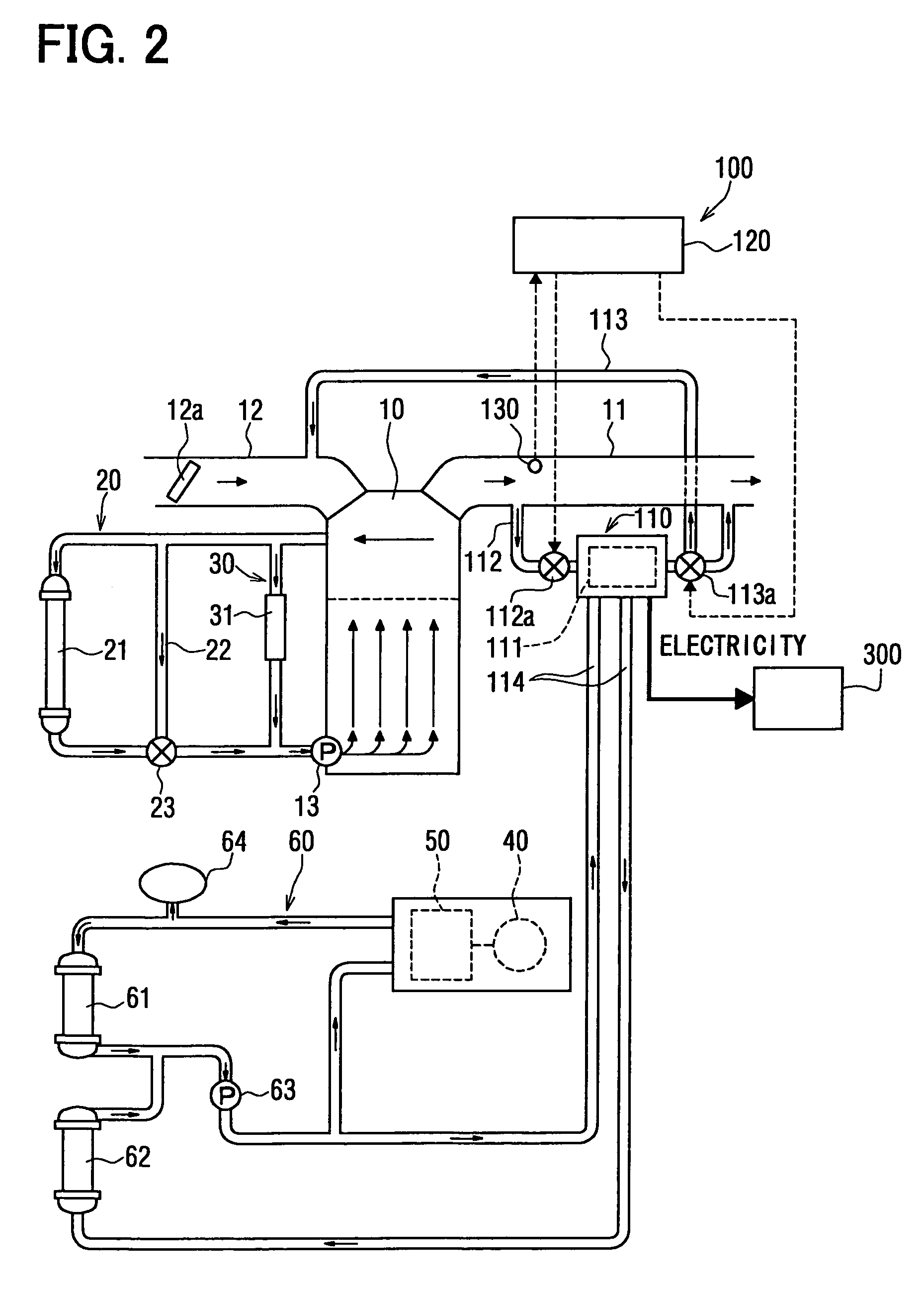

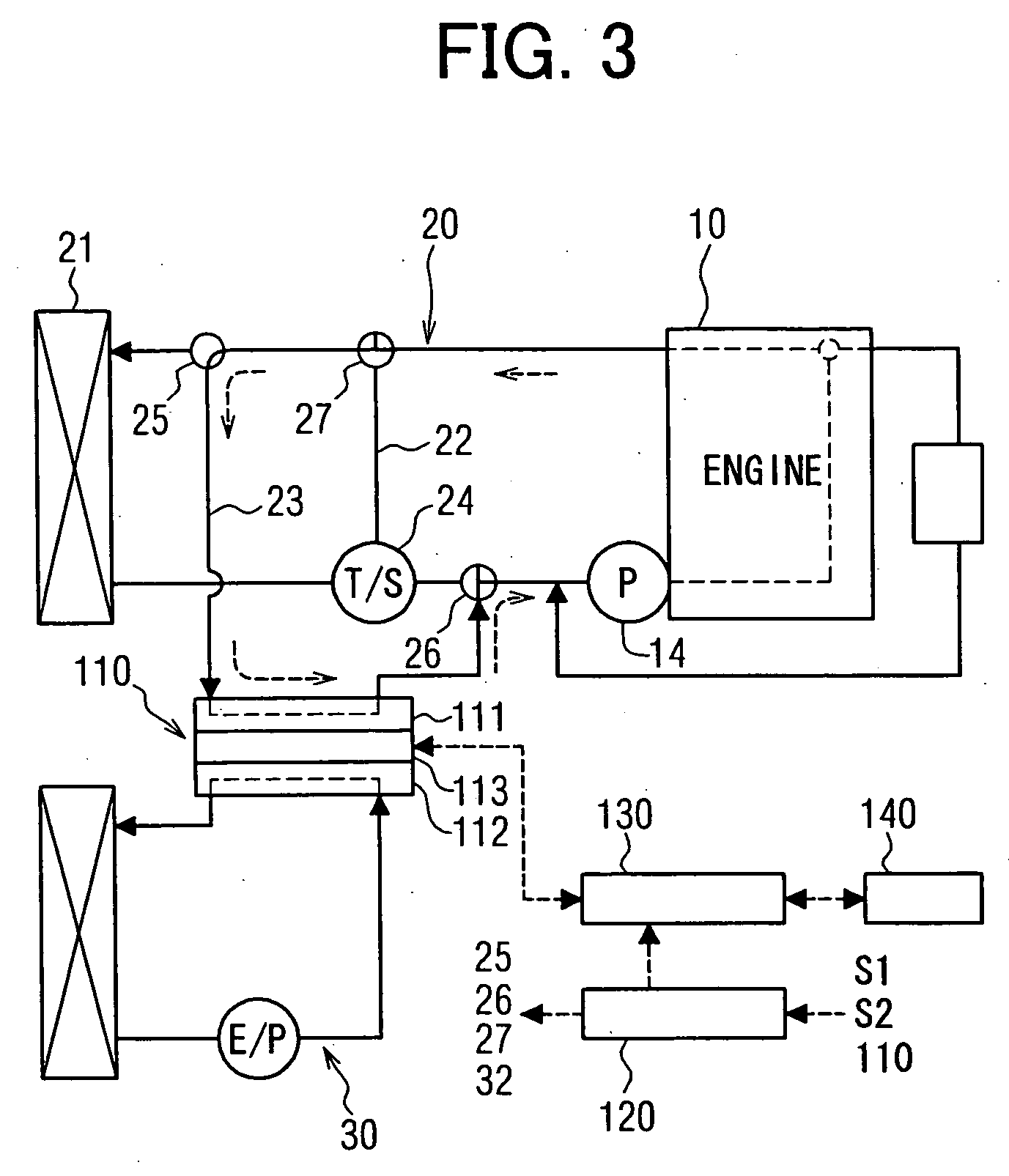

Control unit and control method for reductant supply device

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

Thermoelectric generating device

InactiveUS7100369B2Maximum electricityLiquid coolingCoolant flow controlElectricityThermoelectric element

A thermoelectric generating device has a thermoelectric element which utilizes an exhaust gas from an engine as a high temperature heat source and an engine coolant as a low temperature heat source in order to generate electricity. An introducing passage introduces a part of the exhaust gas passed through the thermoelectric element into an intake of the engine. An introducing valve opens and closes the introducing passage. A controller controls an opening degree of the introducing valve according to a load of the engine.

Owner:DENSO CORP

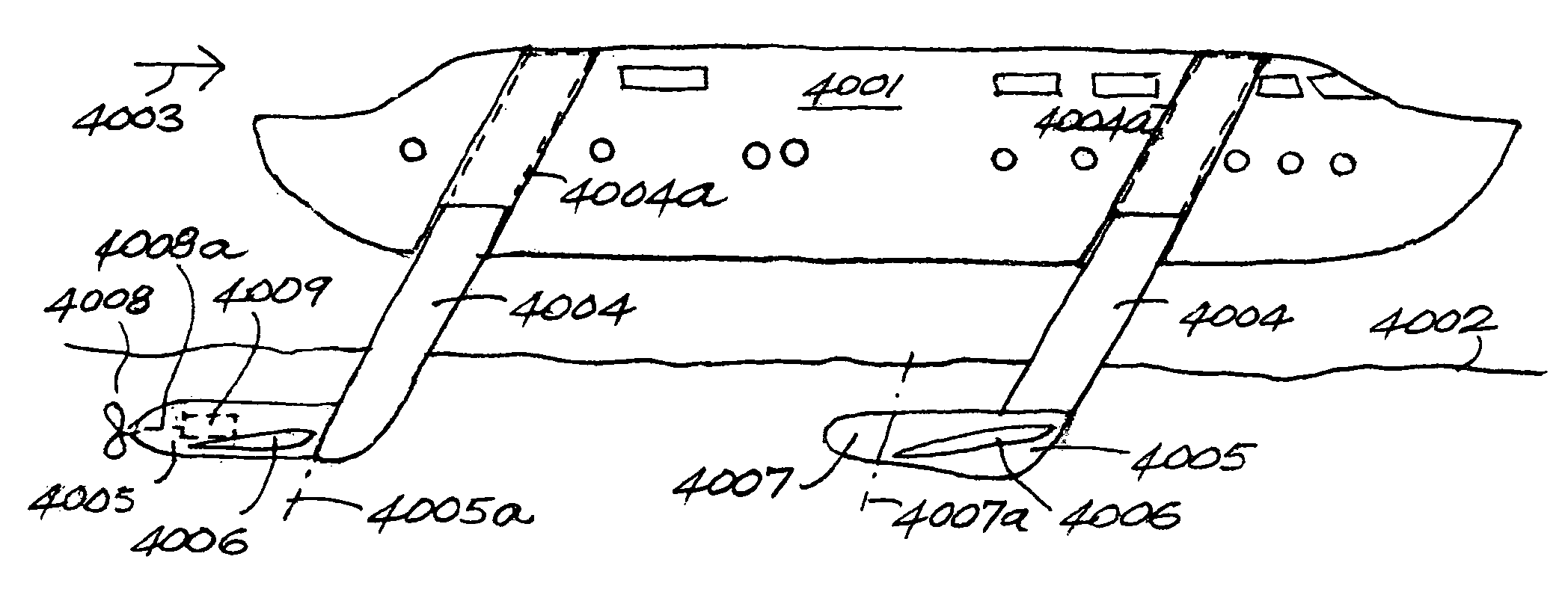

Marine hulls and drives

InactiveUS7984684B2Improve power densityNo coolingHybrid vehiclesInternal combustion piston enginesTravel modeCombustion

Owner:HINDERKS MITJA VICTOR

Engine cooling system

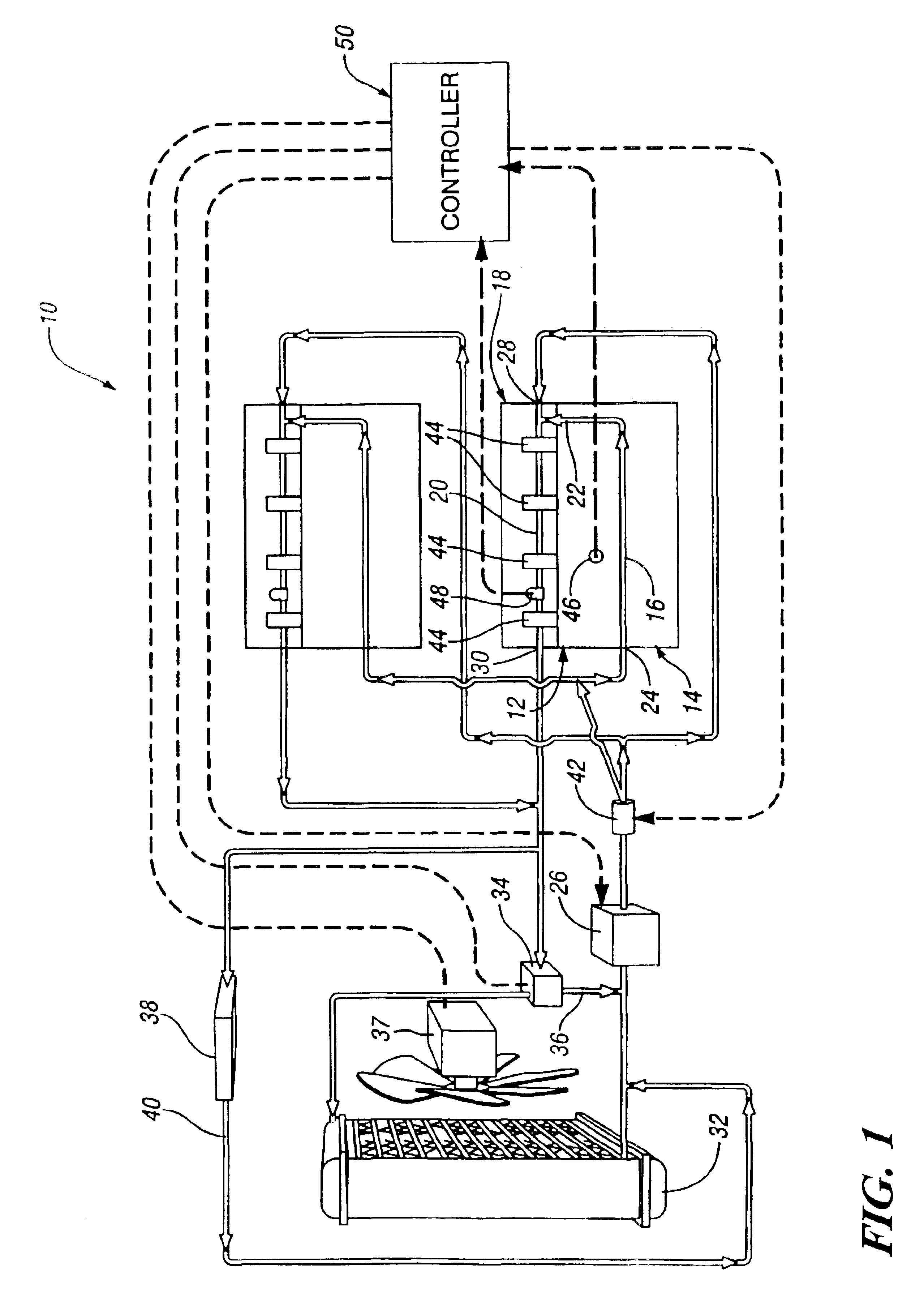

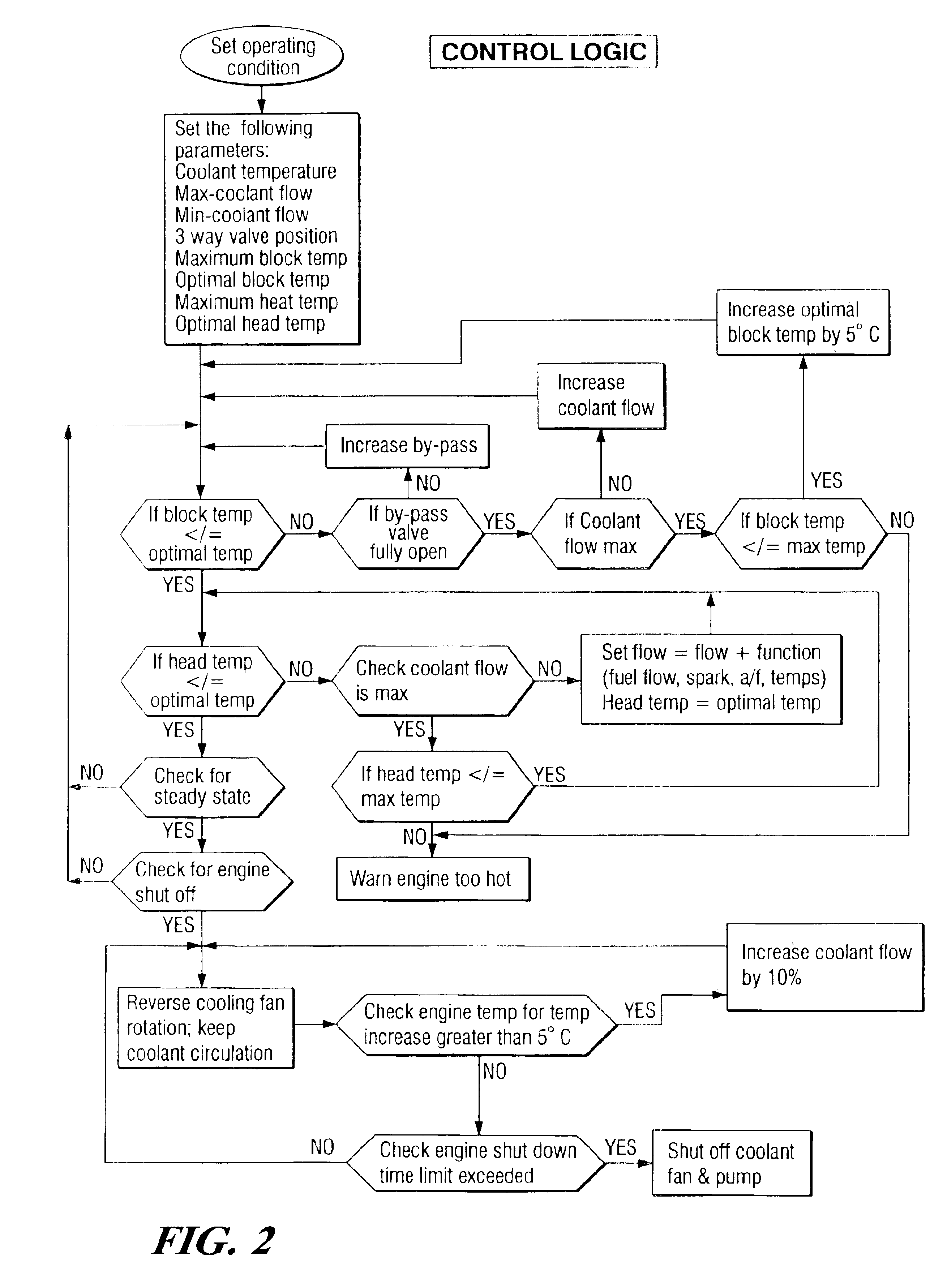

InactiveUS6955141B2Minimizes parasitic lossIncrease and decrease flow of coolantLiquid coolingCoolant flow controlCoolant flowCylinder head

A cooling system has a diverter valve to selectively control the flow of coolant through an internal combustion engine having a cylinder block with a cooling jacket and a cylinder head mounted on the block with a cooling jacket. A controller, responsive to the temperature of the block and the head, controls the diverter valve and a water pump to provide adequate coolant flow through the head and the block as needed to maintain optimal operating temperatures. After the engine is shut off, the controller continues to operate the water pump and a cooling fan to continue to cool the engine for a period of time.

Owner:GM GLOBAL TECH OPERATIONS LLC

Rankine cycle heat recovery methods and devices

InactiveUS20090277400A1Minimize frictional lossIncrease speedLiquid coolingCoolant flow controlRecovery methodMagnetic bearing

An integrated expansion turbine / electrical generator assembly (collectively referred to as a “turbo-generator”) suitable for use in waste heat recovery and similar applications. The turbo-generator uses a common shaft mounting a one or more stage expansion turbine and a homopolar electrical generator. Magnetic levitating axial and thrust bearings are used to hold the common shaft in its proper position with a fixed housing. The magnetic bearings minimize frictional losses, allowing the common shaft to spin at a very high rotational velocity. Sensor rings continually monitor the common shaft's position. This information is used by control electronics to regulate the magnetic bearings in order to hold the rotating shaft's position. Electrical energy is extracted from the rotating shaft in the form of a direct current. Preferably integrated power-switching electronics are used to generate single or three-phase AC power, which can be phase-matched to an existing power grid or other application.

Owner:DANFOSS AS

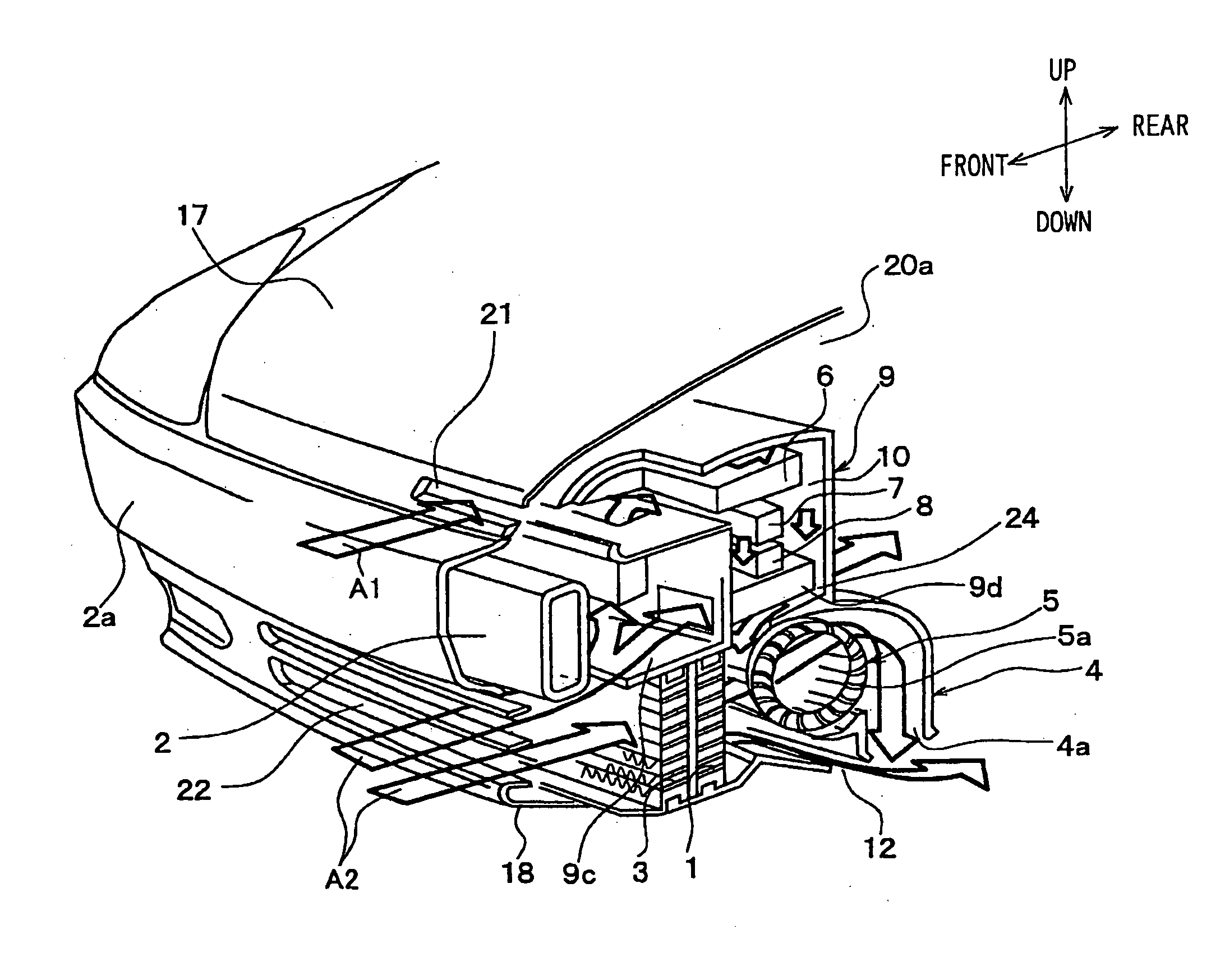

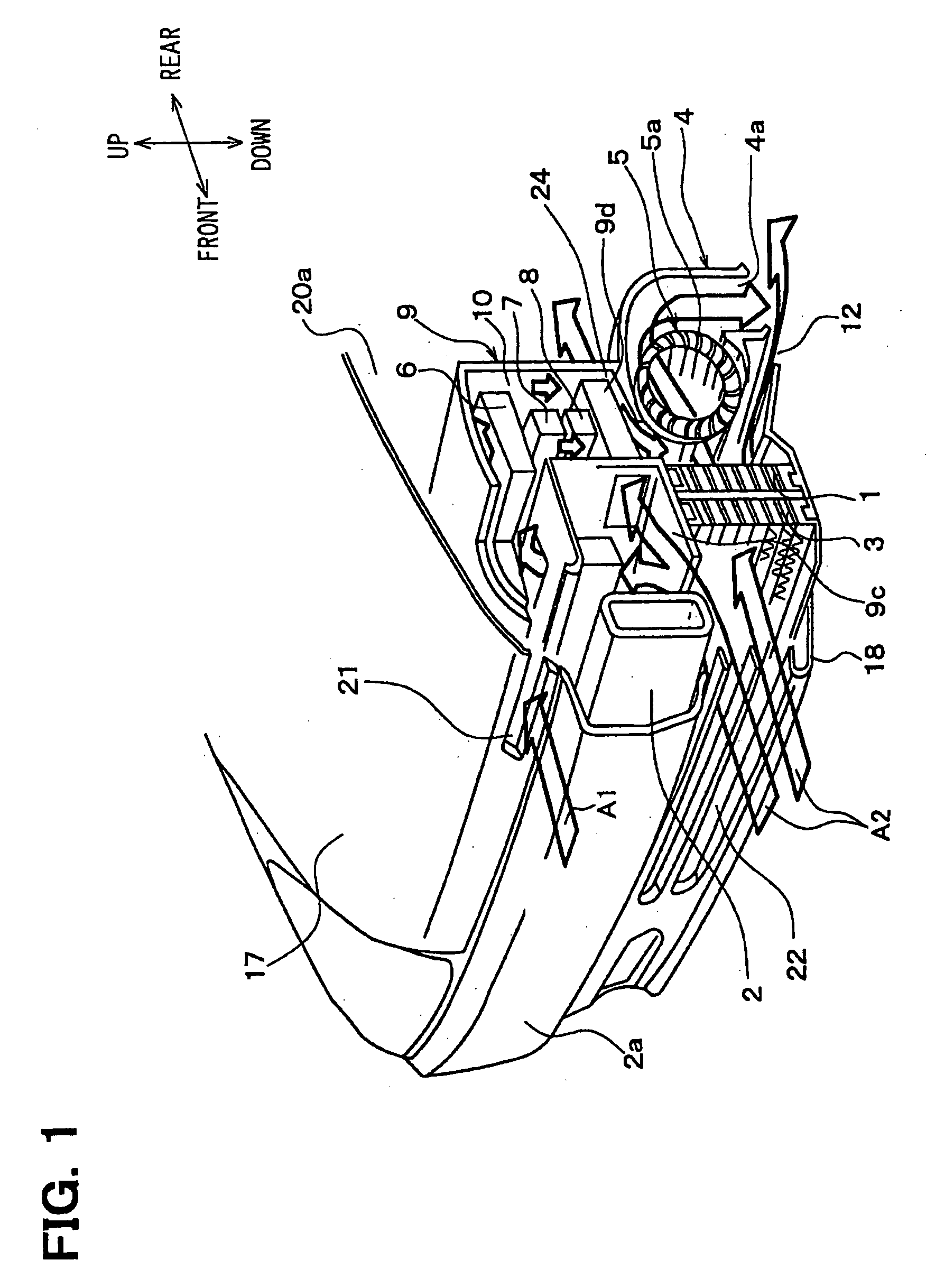

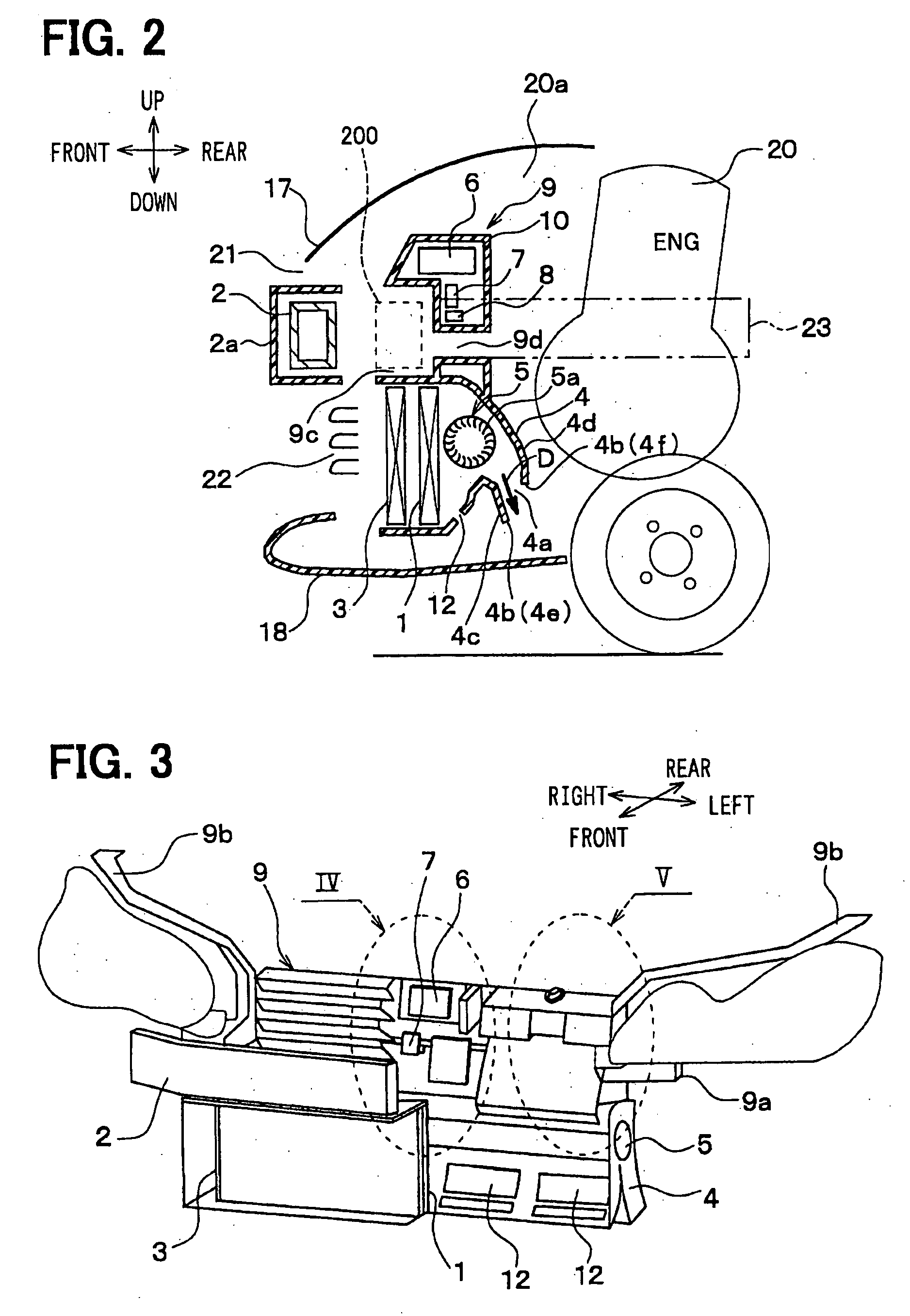

Vehicle front end structure

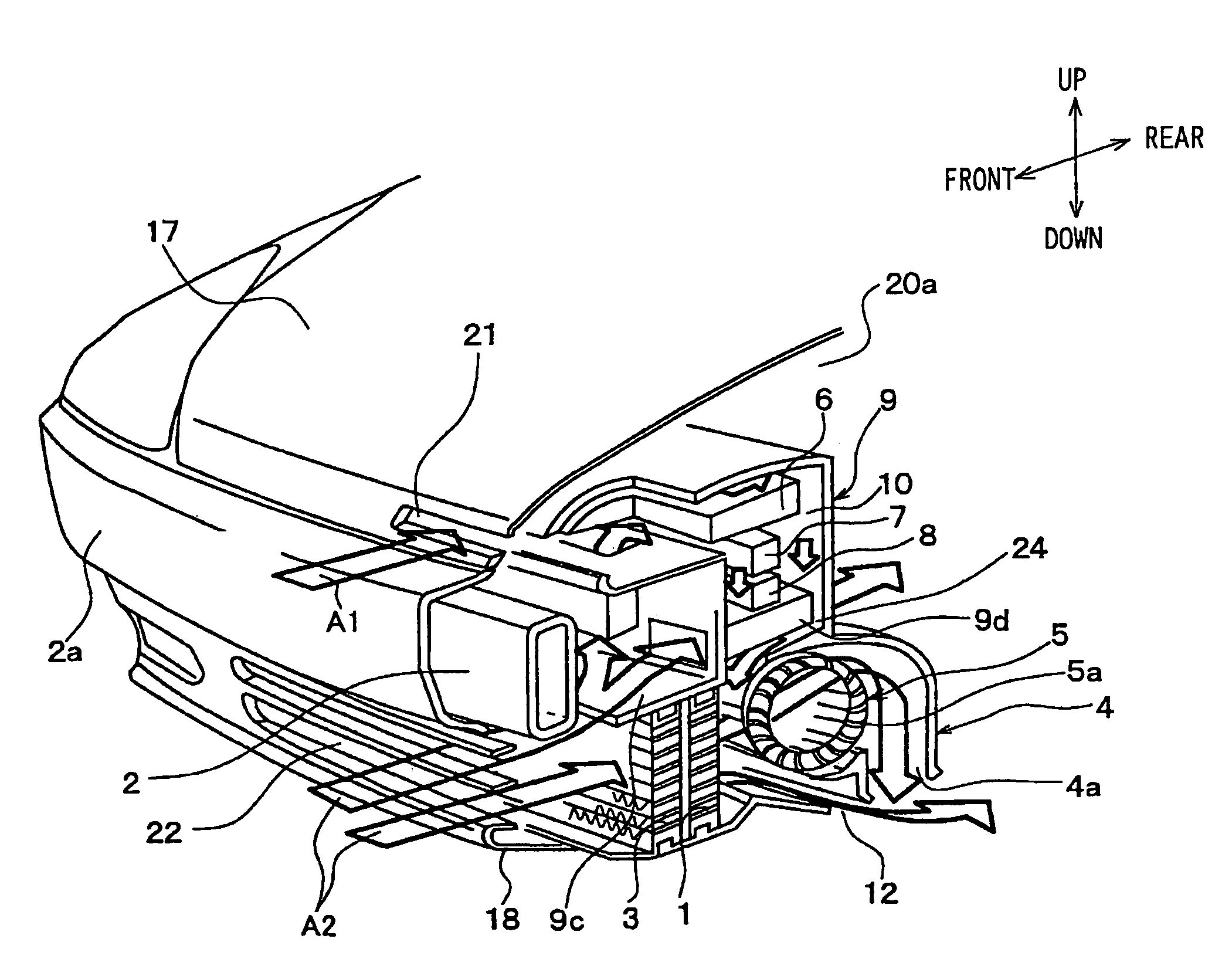

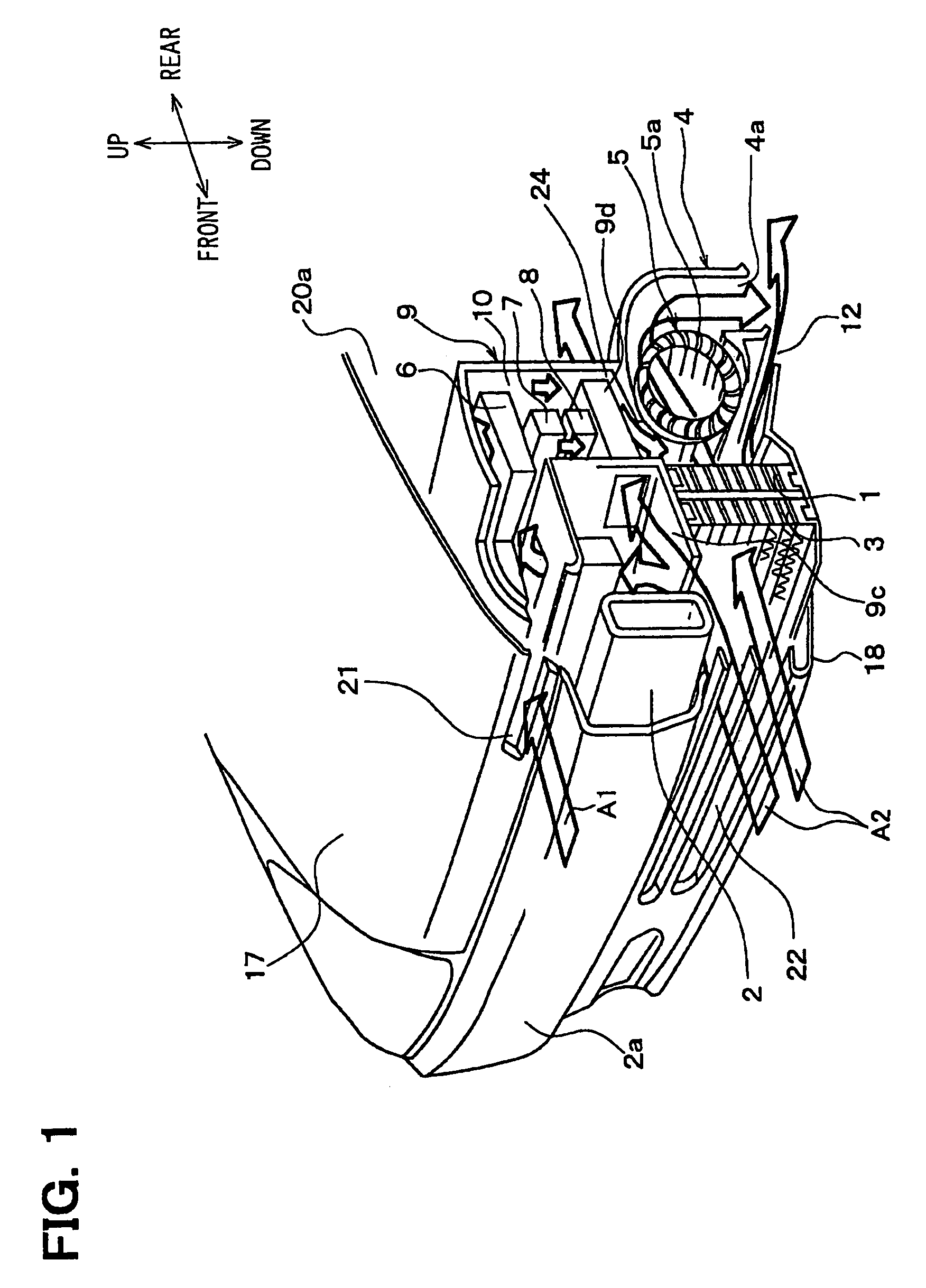

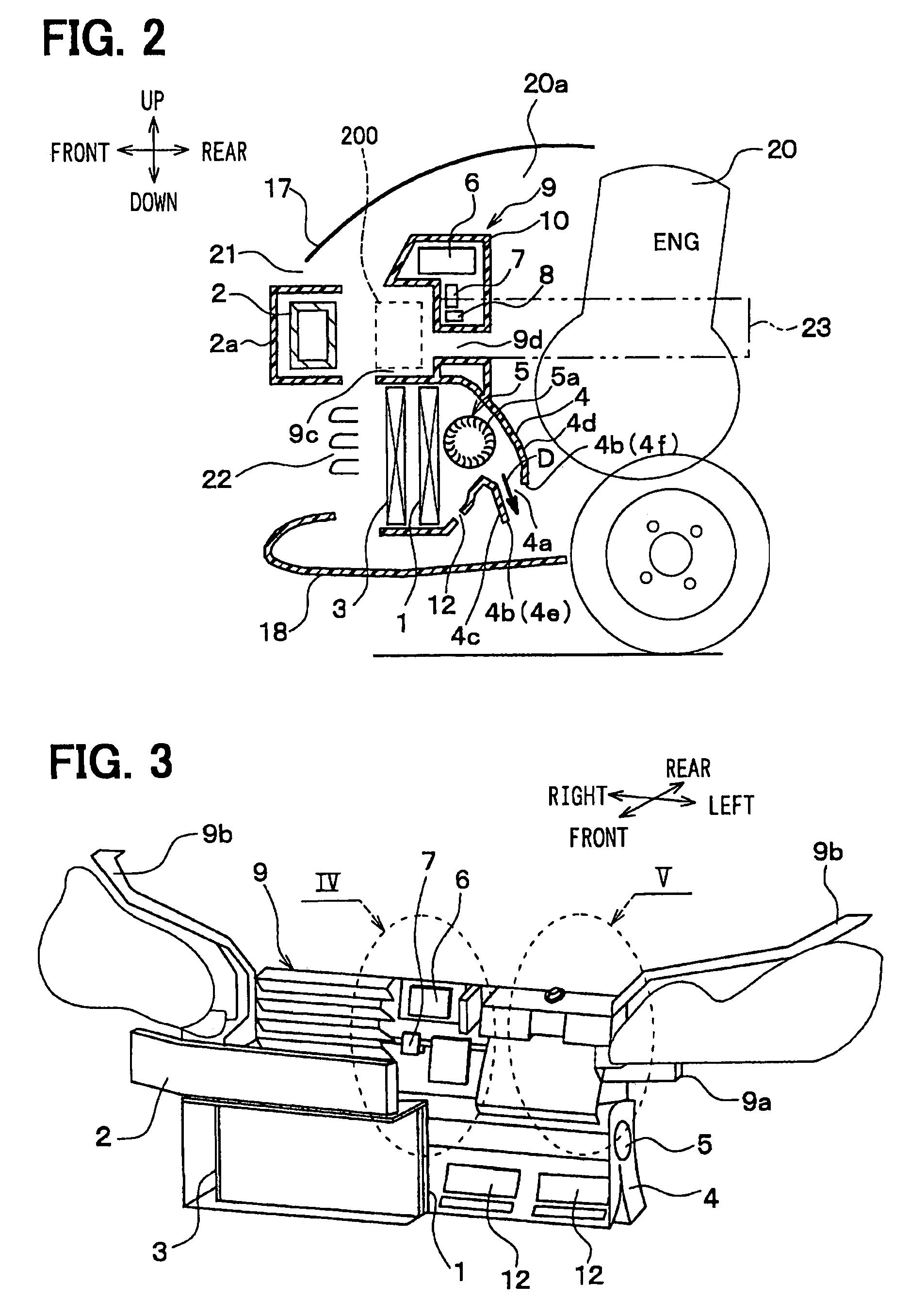

InactiveUS20050023057A1Lower center of gravityReduce harmLiquid coolingMachines/enginesRadarHeat exchanger

In a front end structure of a vehicle, a heat exchanger is arranged at a position lower than a bumper reinforcement member, so a position of an engine hood is lowered. Electric auxiliary devices such as a radar, electronic control units for lights, and an air cleaner are arranged at a position higher than the bumper reinforcement member or at the rear of the bumper reinforcement member. By this arrangement, the electric auxiliary devices are arranged at a position which is less likely to be affected by the bumper reinforcement member in a case of light frontal crush.

Owner:DENSO CORP

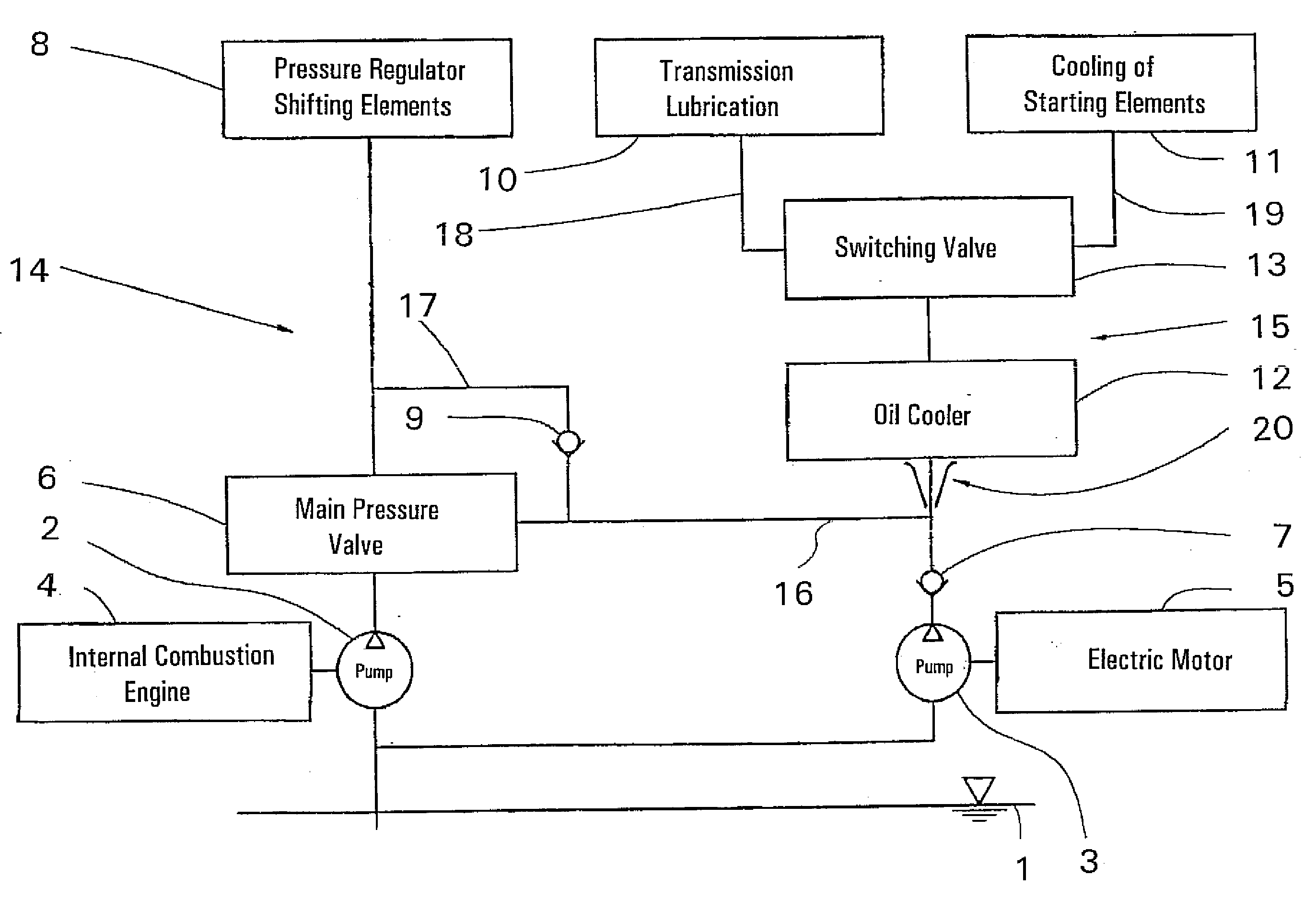

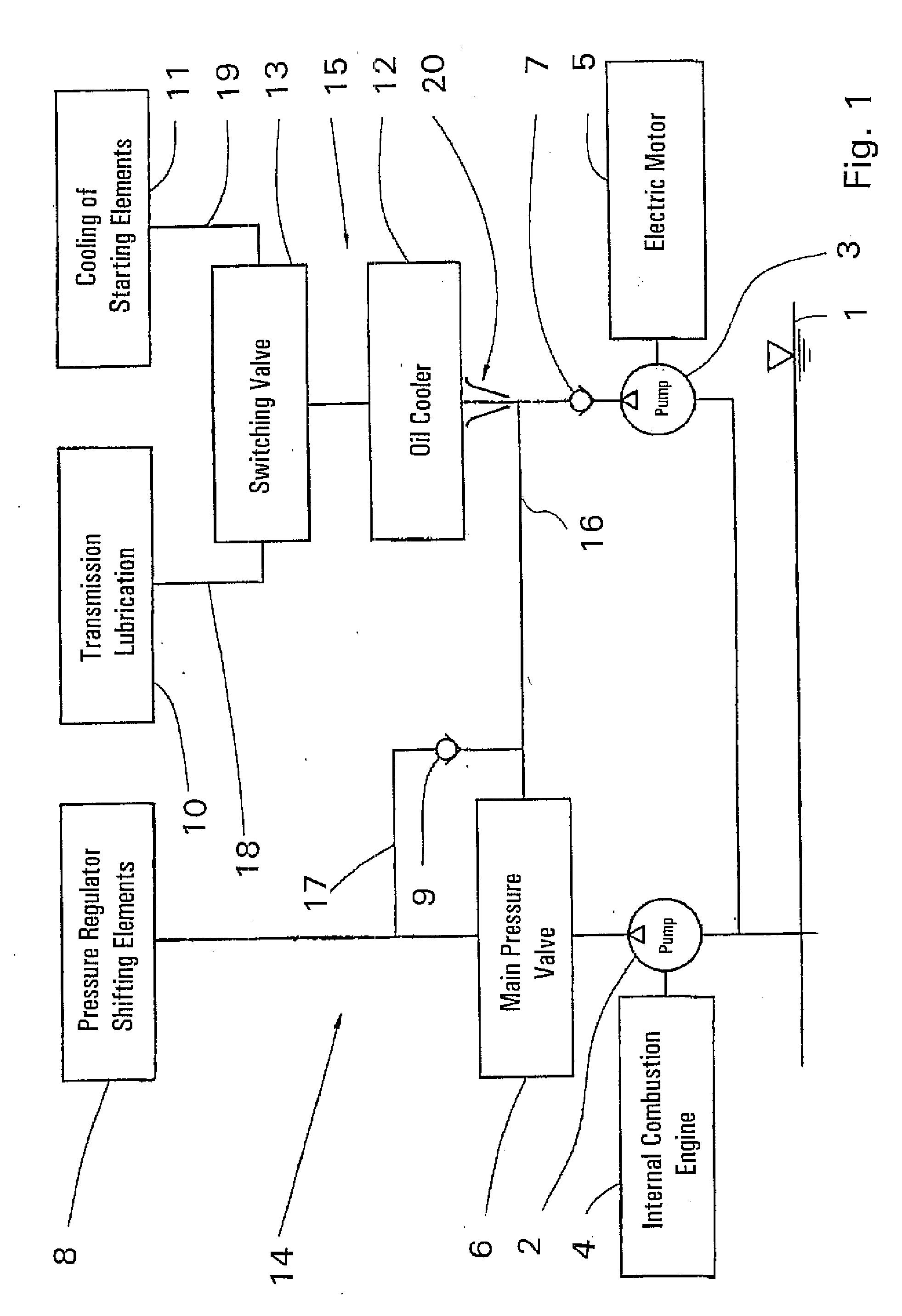

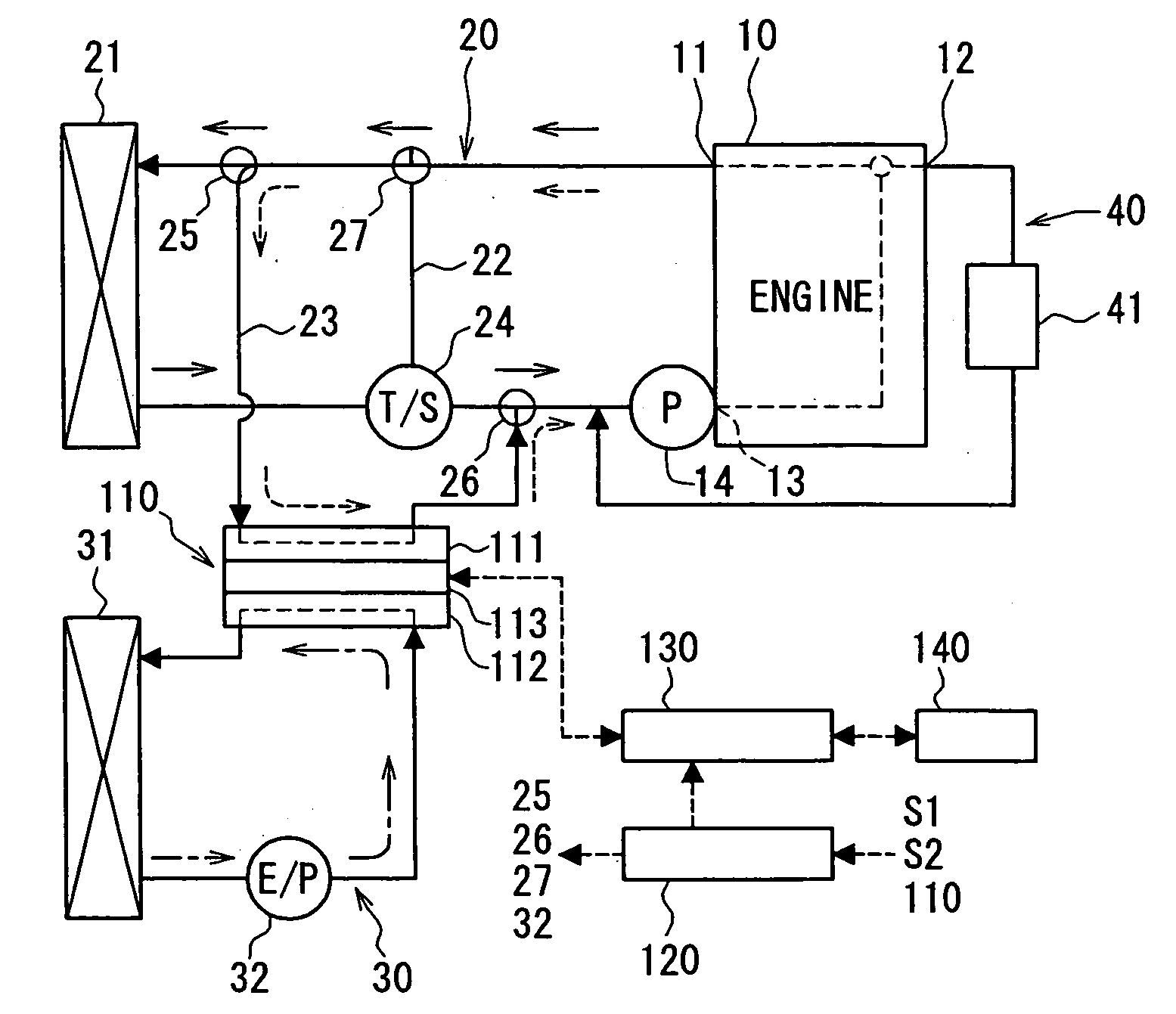

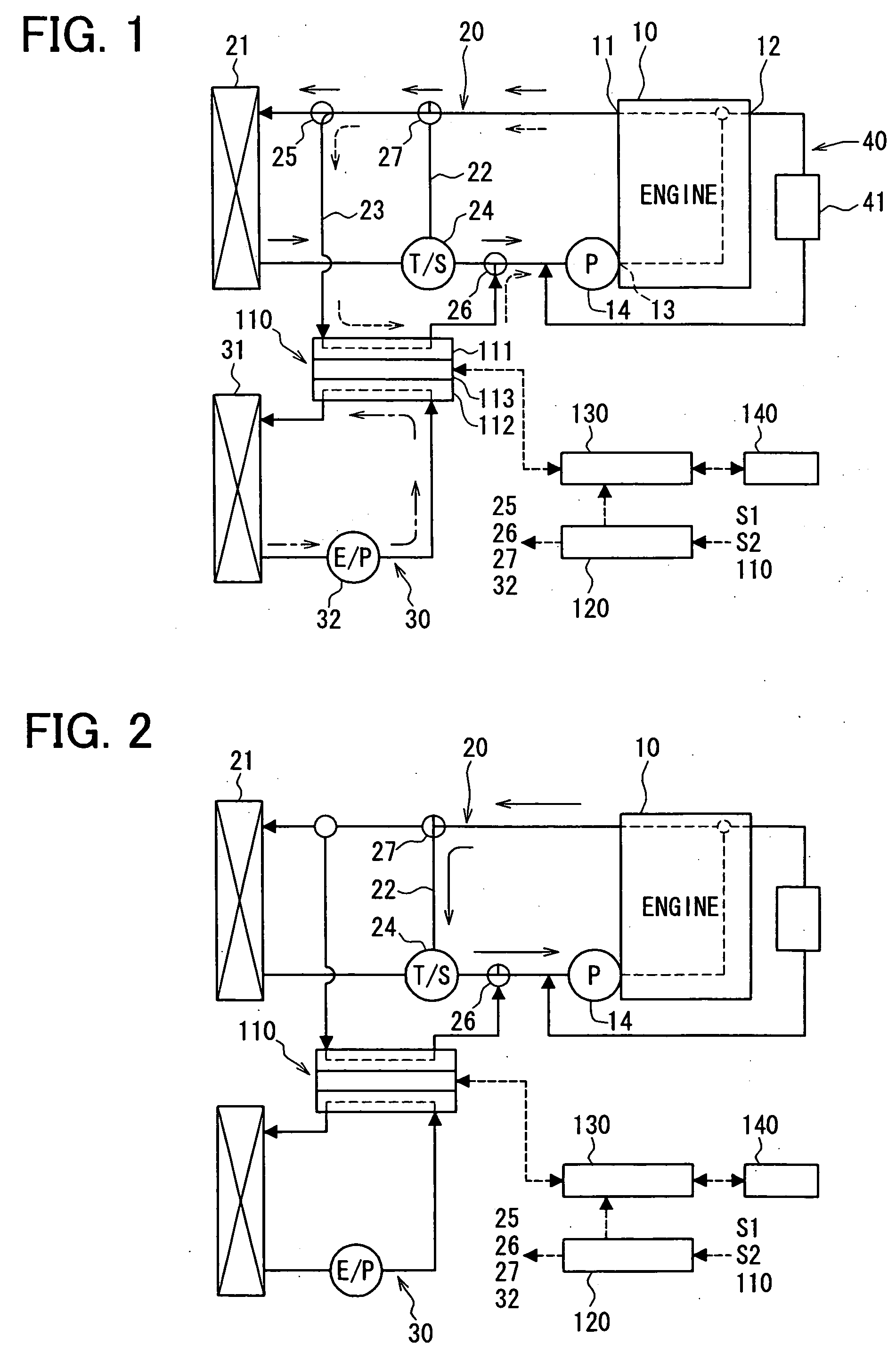

Method and device for controlling the oil supply of an automatic gearbox and a starting element

InactiveUS20090232673A1Avoiding substantial energy lossIncrease productionLiquid coolingGear lubrication/coolingHydraulic control unitElectricity

A method and a device for controlling the oil supply of an automatic transmission (gearbox) and to a starting element. The method can guarantee a sufficient supply of oil to a hydraulic control unit of the automatic transmission and / or the starting element, in particular an oil-cooled friction clutch, both during the operation of the internal combustion engine (4) and when the latter is at a standstill with the aid of an oil pump (2) that can be mechanically driven by the internal combustion engine (4) and a second oil pump (3) that can be electrically driven. In addition, the cooling oil supply of the starting element is guaranteed by the provision of a low-pressure oil by way of the electrically driven oil pump (3), at least during the starting operation, the stream cooling the starting element (11).

Owner:ZF FRIEDRICHSHAFEN AG

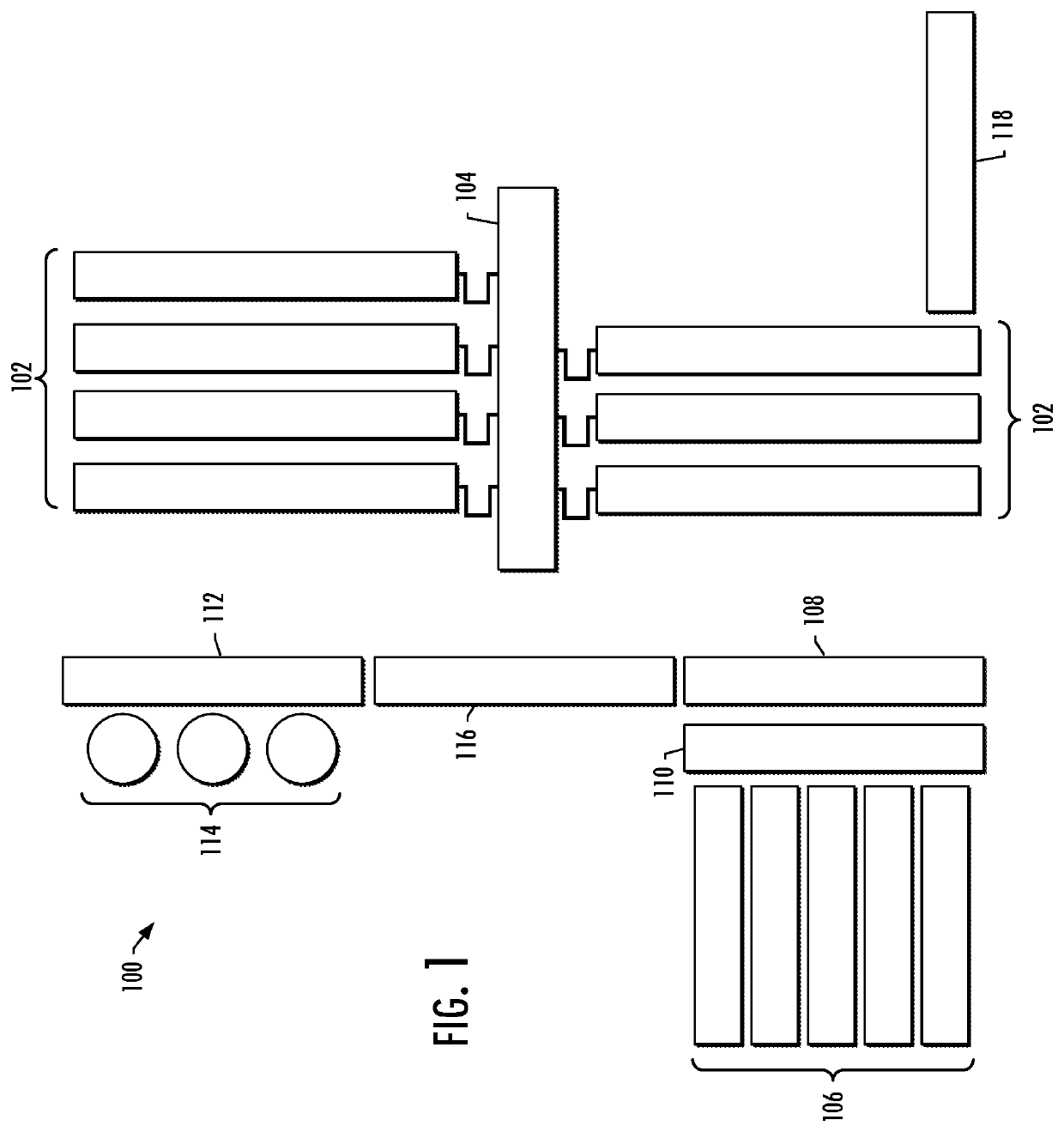

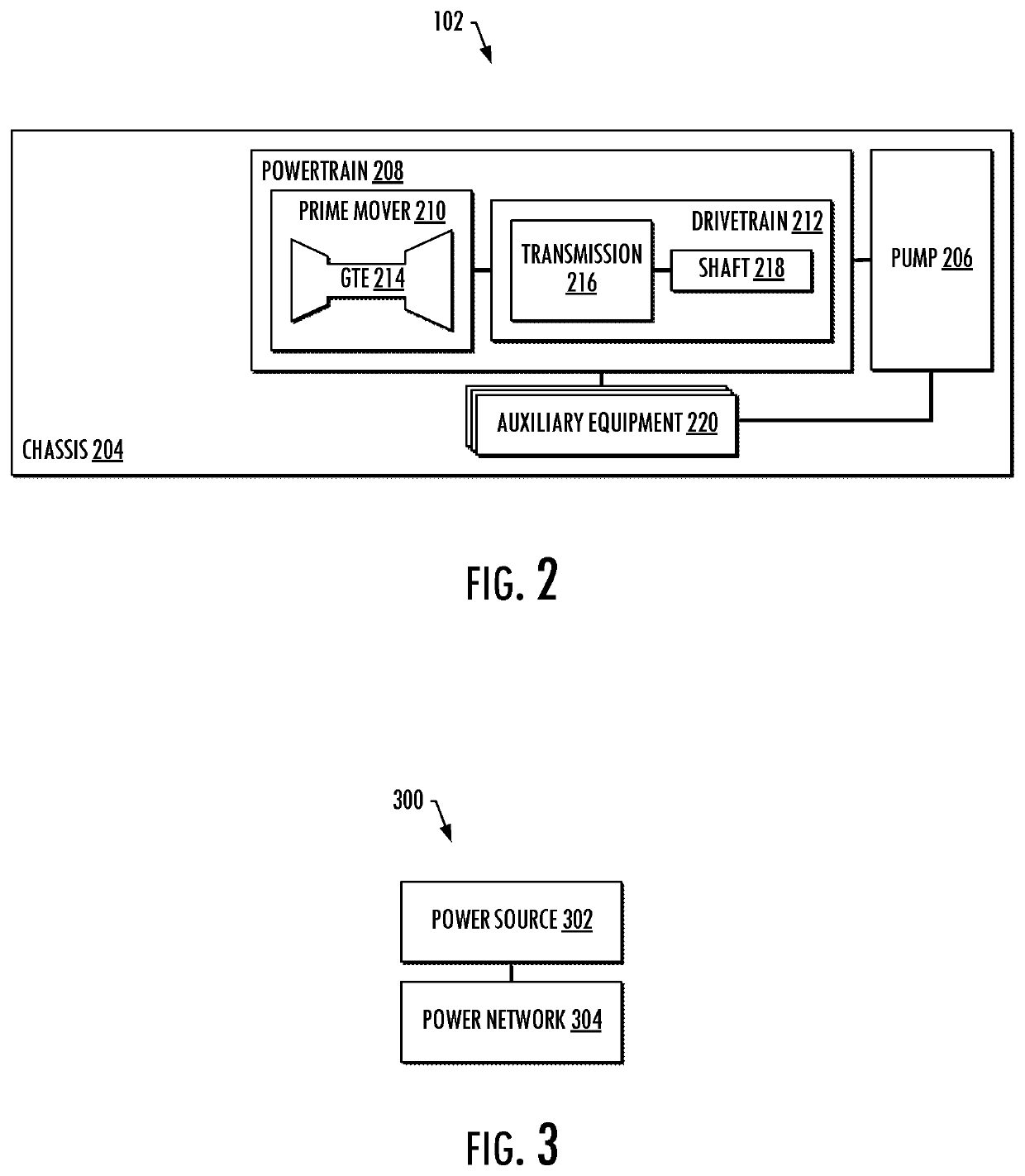

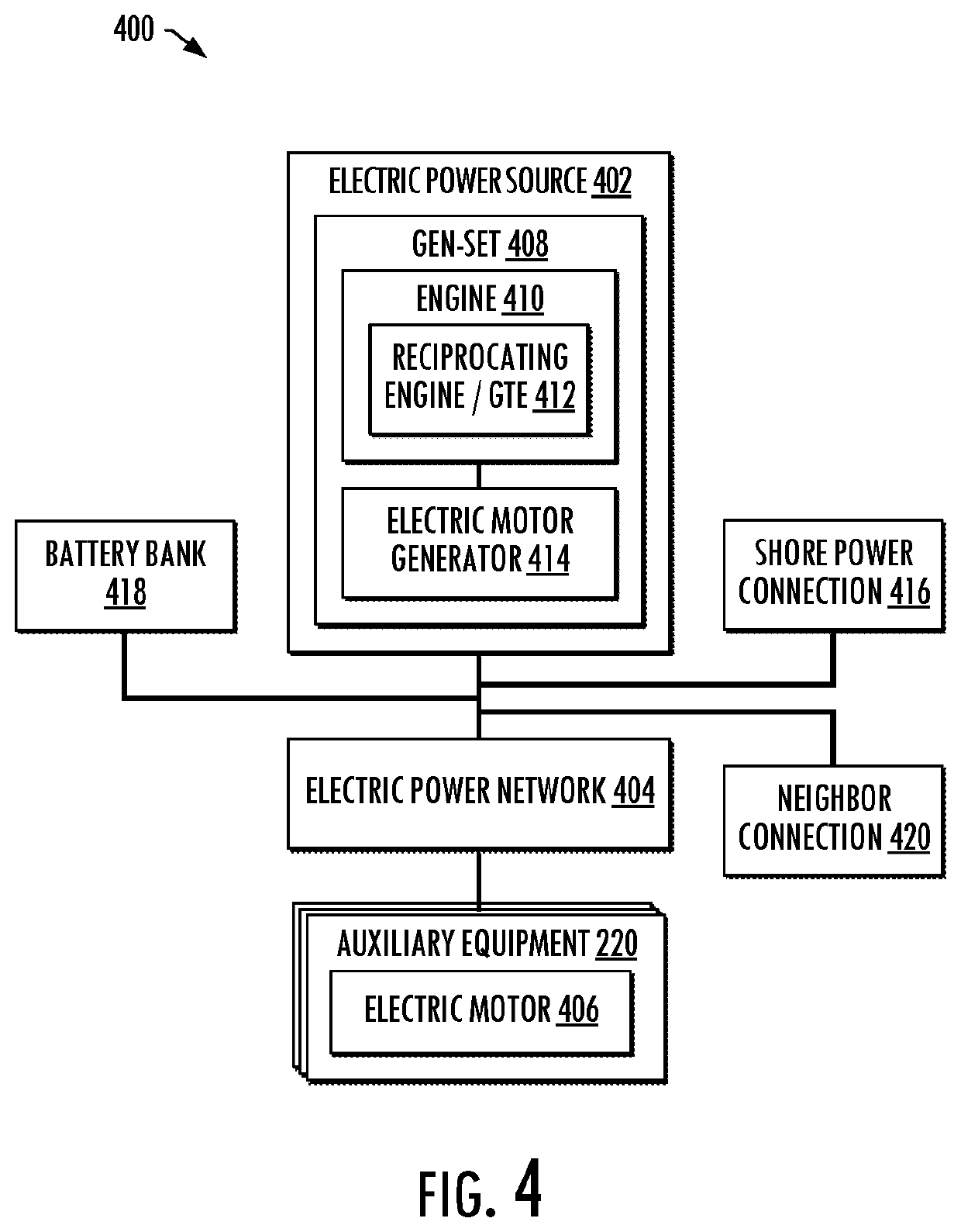

Power sources and transmission networks for auxiliary equipment onboard hydraulic fracturing units and associated methods

Embodiments of systems and methods disclosed provide a hydraulic fracturing unit that includes a reciprocating plunger pump configured to pump a fracturing fluid and a powertrain configured to power the reciprocating plunger pump. The powertrain includes a prime mover and a drivetrain, the prime mover including a gas turbine engine. The hydraulic fracturing unit also includes auxiliary equipment configured to support operation of the hydraulic fracturing unit including the reciprocating plunger pump and the powertrain. A power system is configured to power the auxiliary equipment. The power system includes a power source and a power network. The power source is configured to generate power for the auxiliary equipment. The power network is coupled to the power source and the auxiliary equipment, and configured to deliver the power generated by the power source to the auxiliary equipment. Associated systems including a plurality of hydraulic fracturing units are also provided.

Owner:BJ ENERGY SOLUTIONS LLC

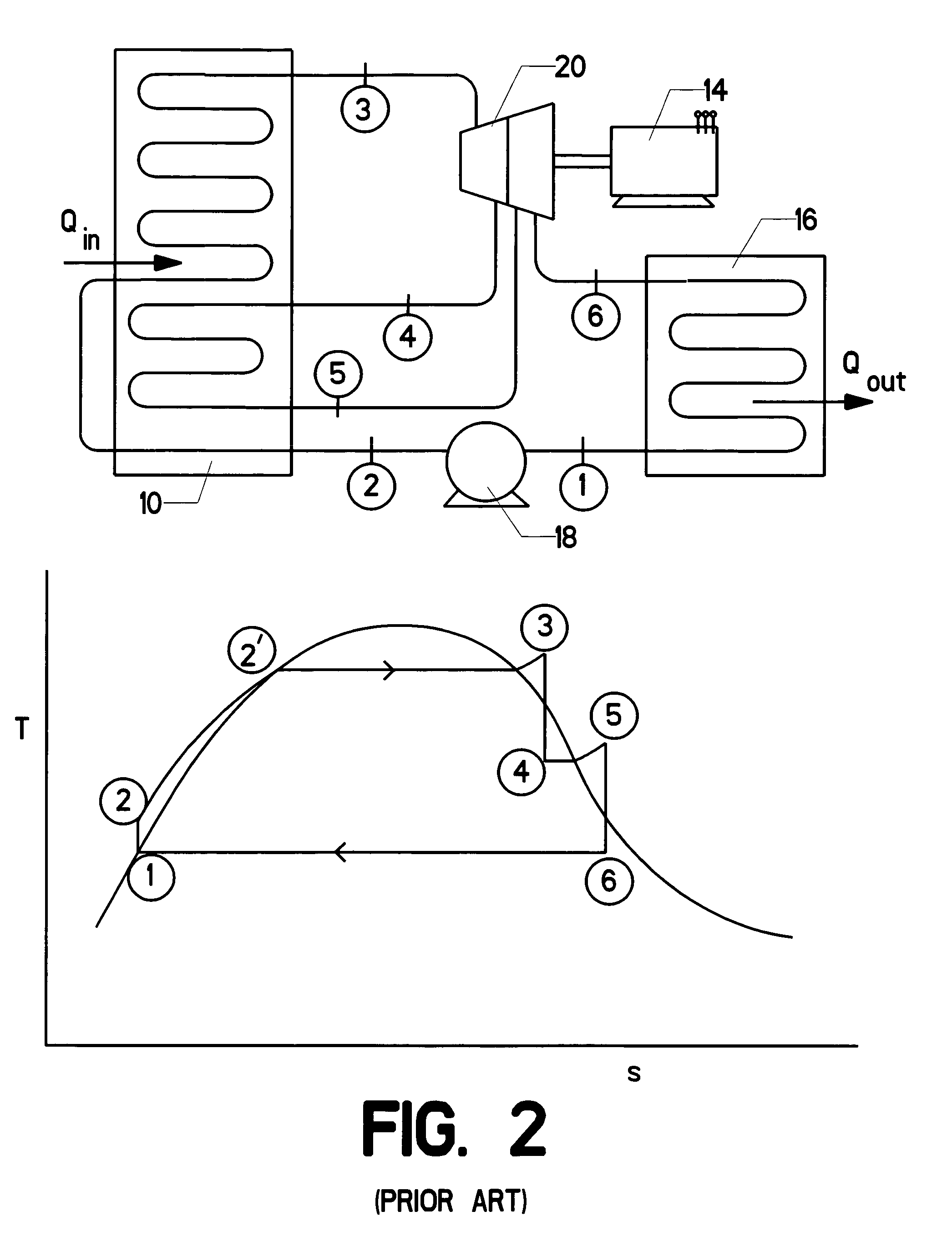

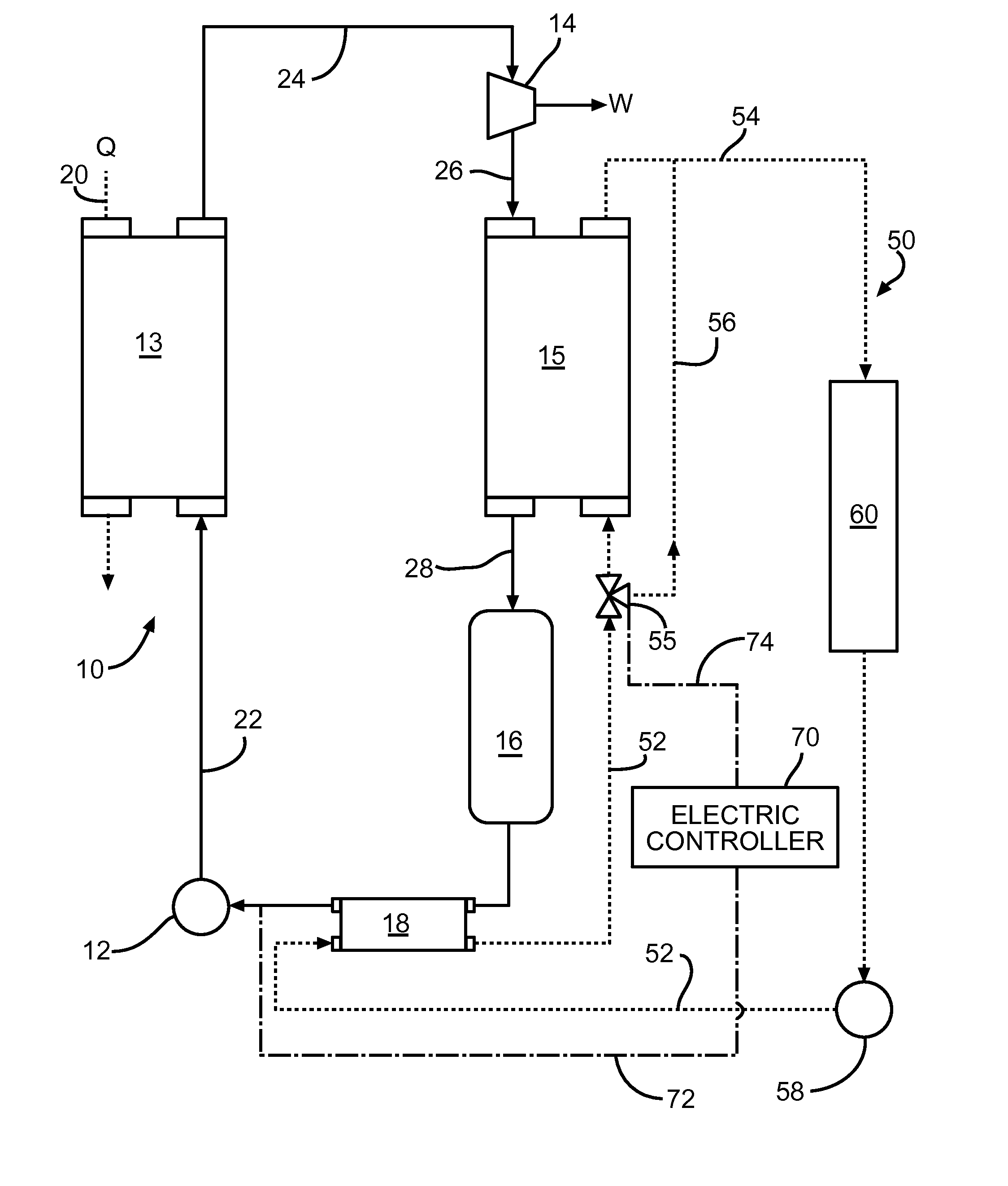

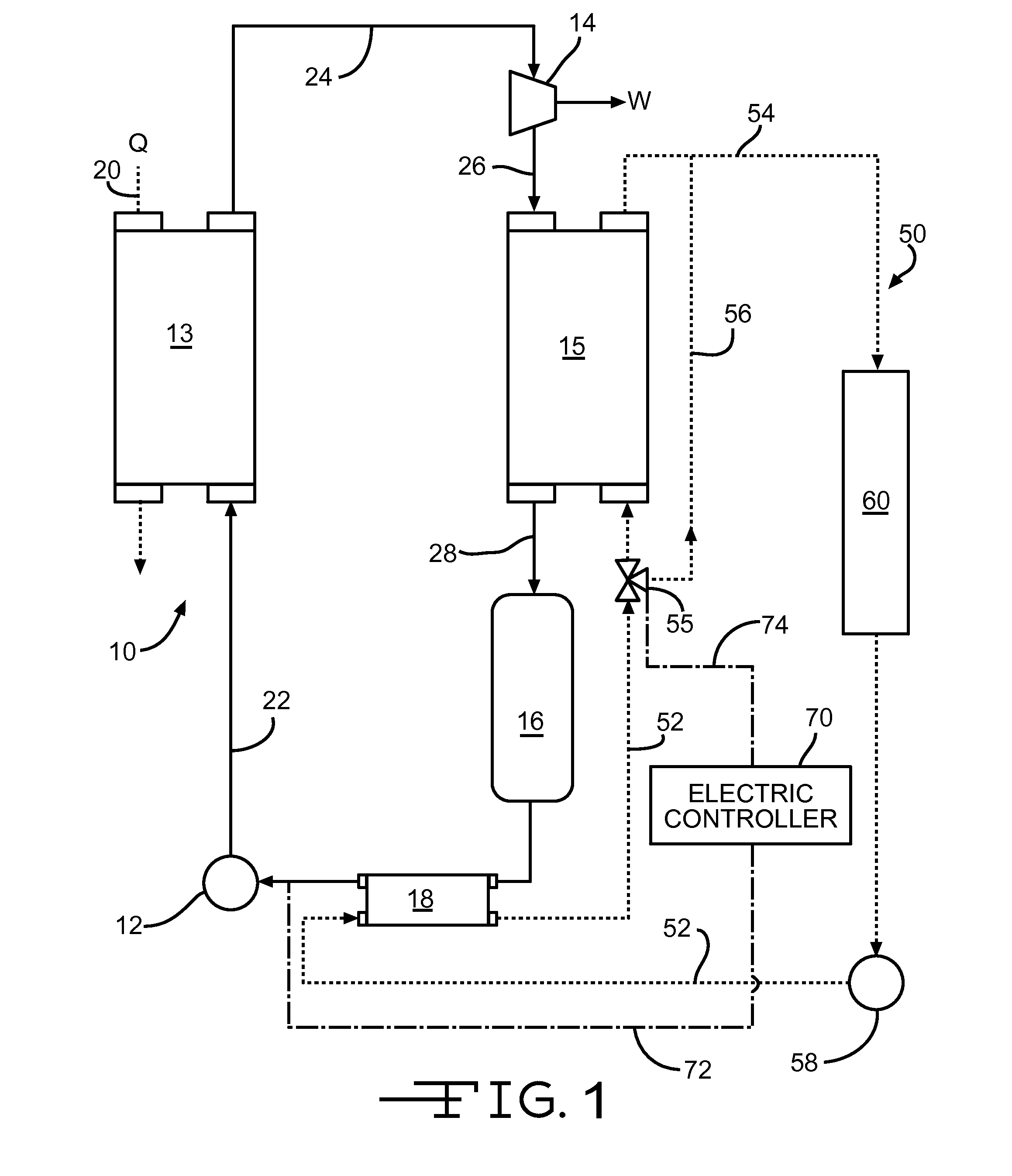

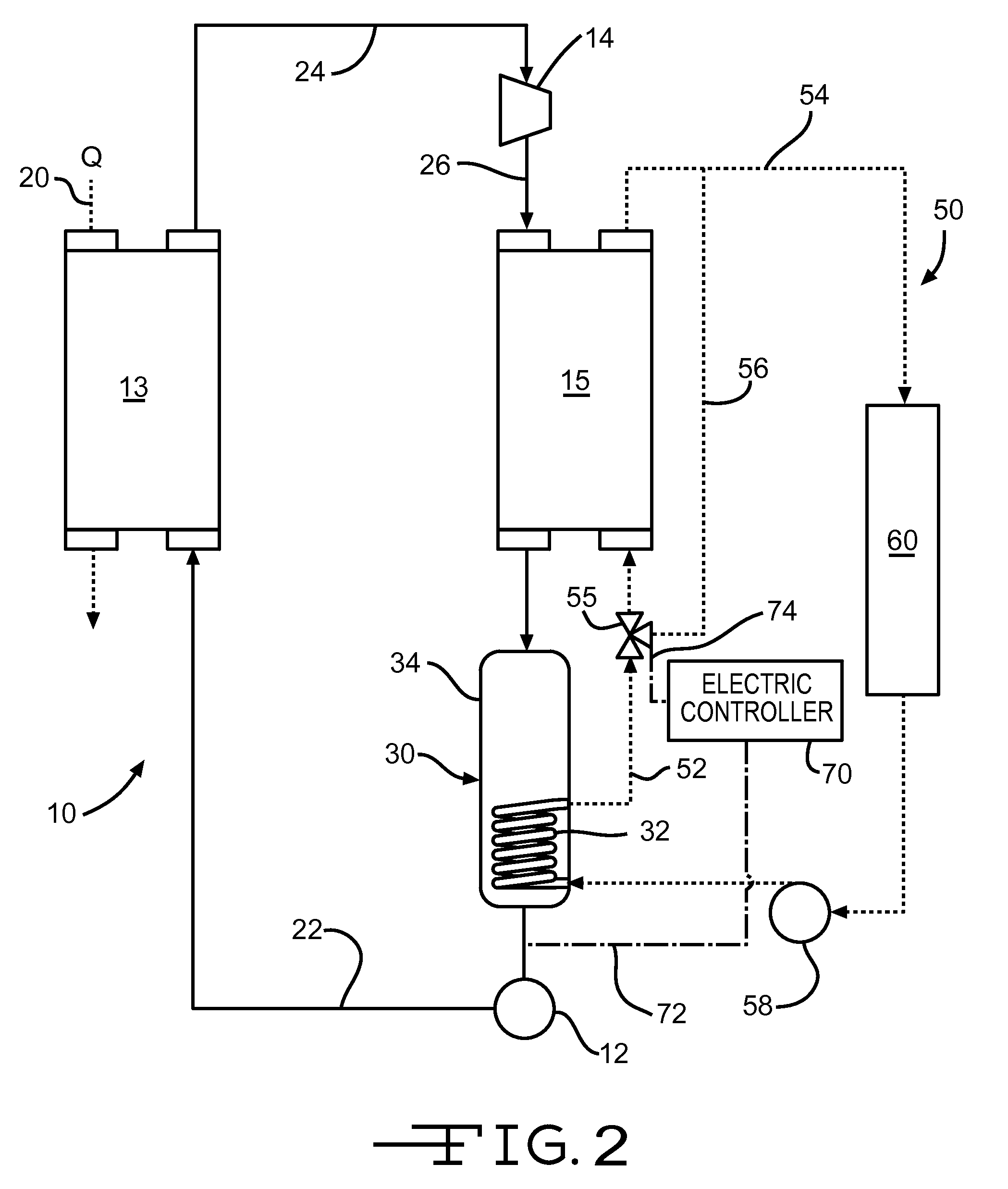

Energy recovery system and method using an organic rankine cycle with condenser pressure regulation

An energy recovery system and method using an organic rankine cycle is provided for recovering waste heat from an internal combustion engine, which effectively controls condenser pressure to prevent unwanted cavitation within the fluid circulation pump. A coolant system may be provided with a bypass conduit around the condenser and a bypass valve selectively and variably controlling the flow of coolant to the condenser and the bypass. A subcooler may be provided integral with the receiver for immersion in the accumulated fluid or downstream of the receiver to effectively subcool the fluid near the inlet to the fluid pump.

Owner:CUMMINS INTPROP INC

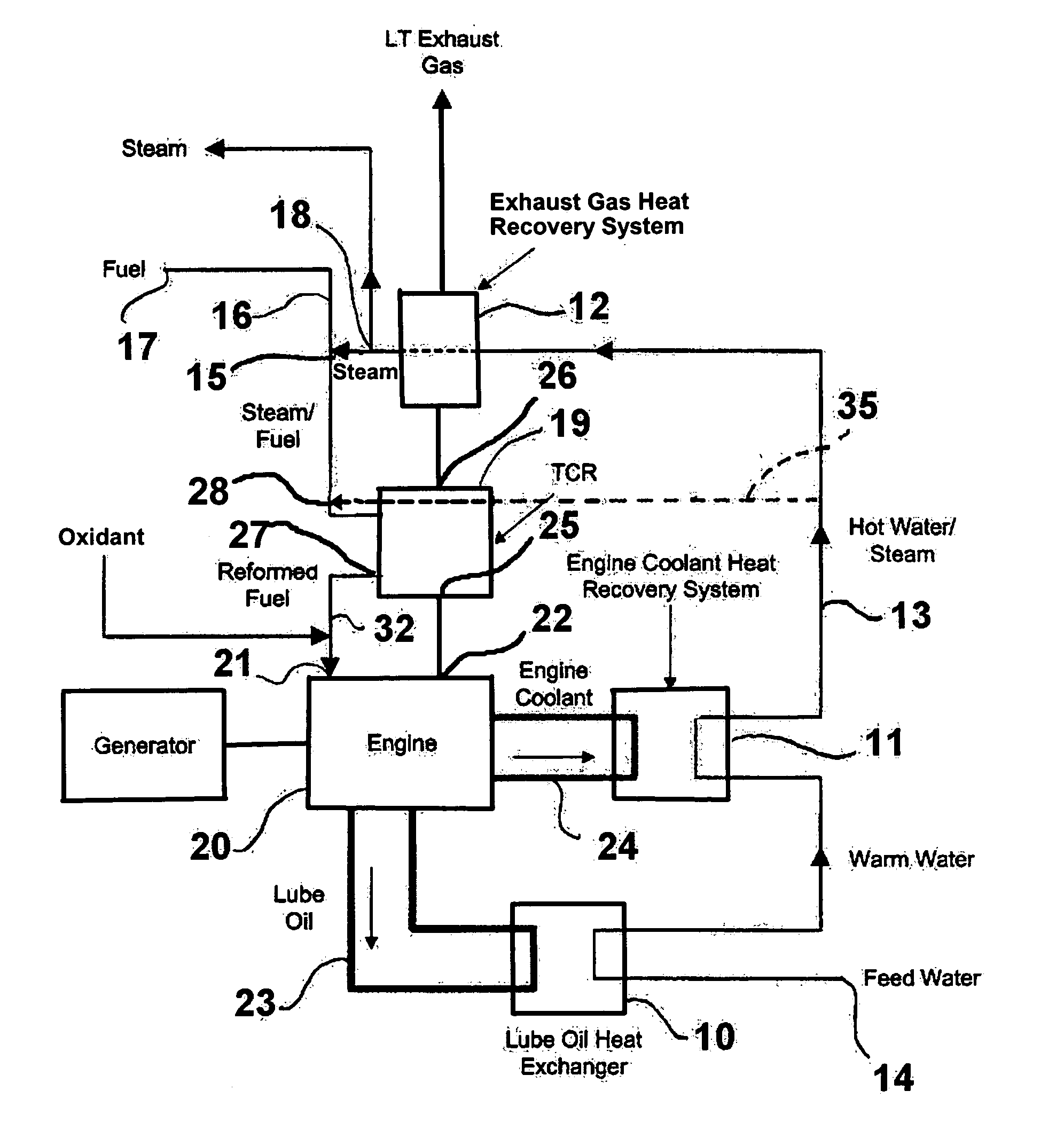

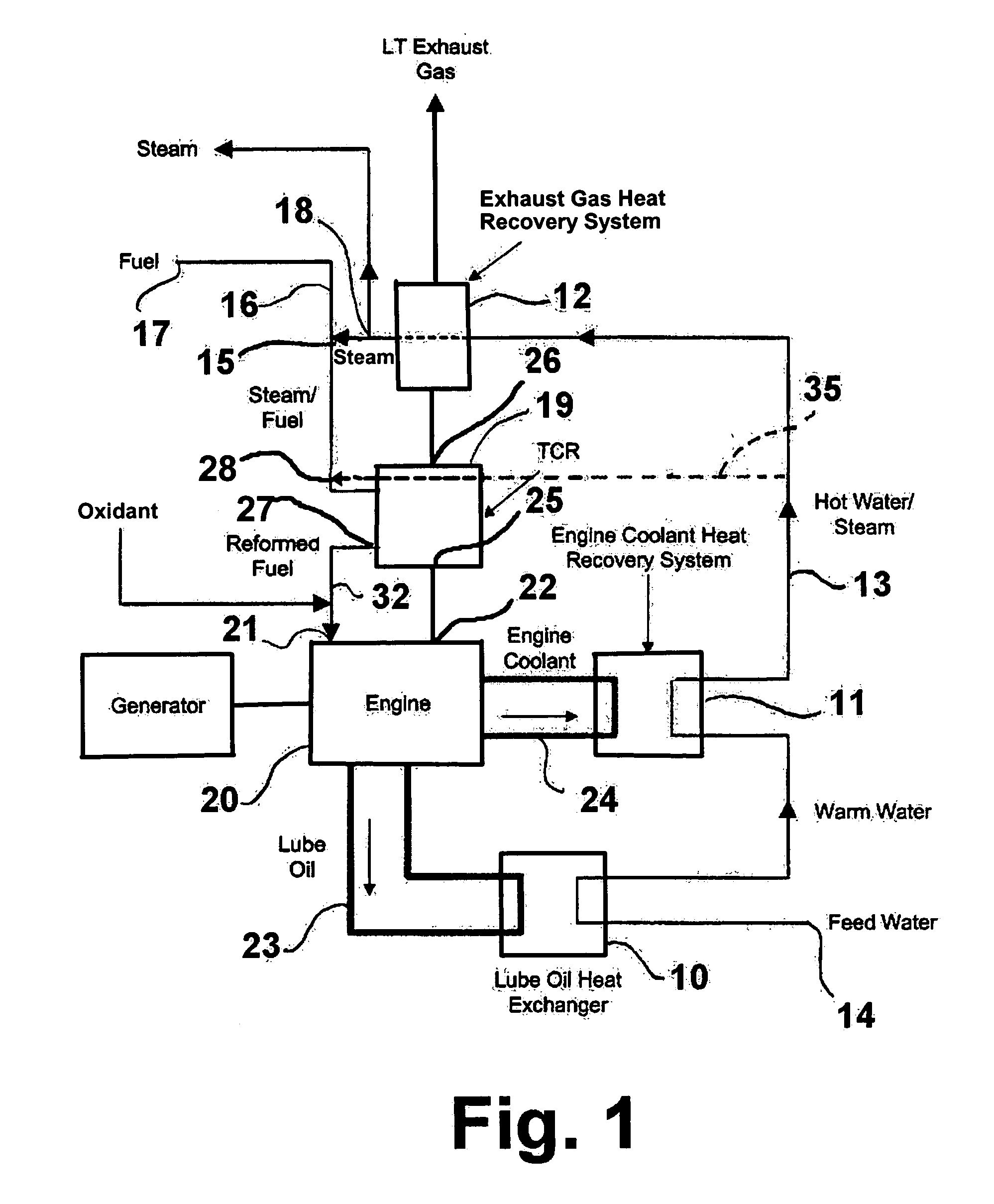

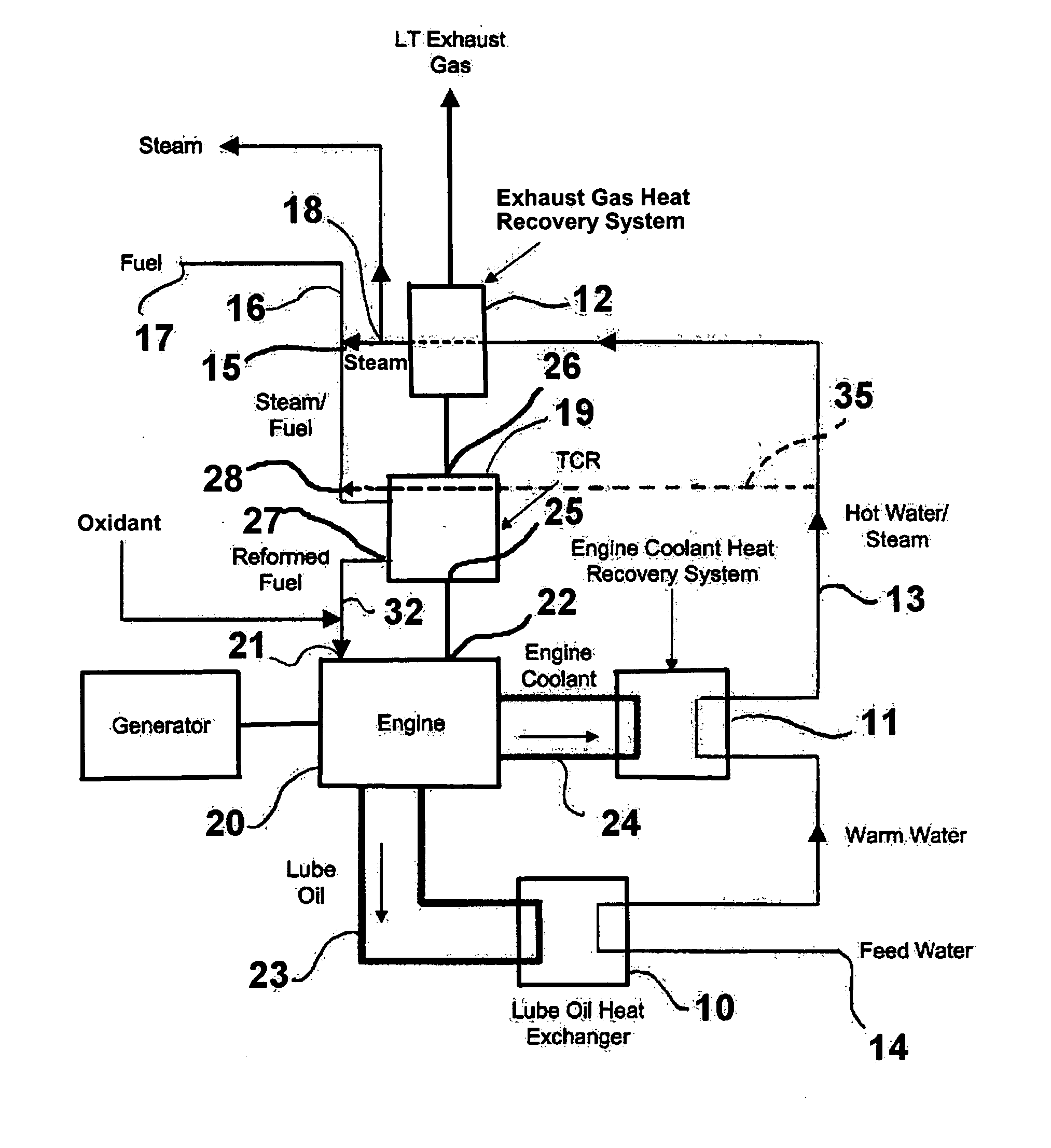

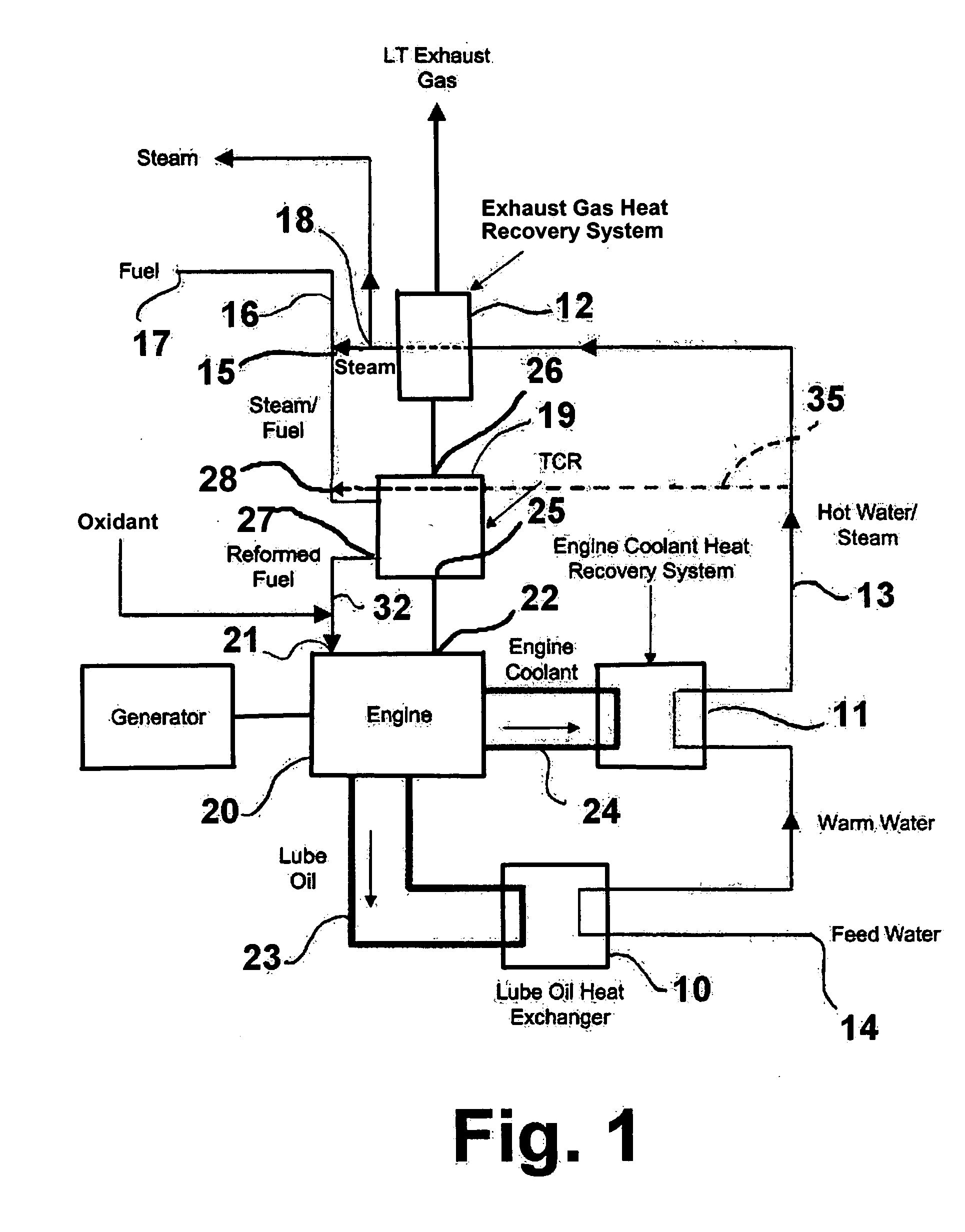

Advanced high efficiency, ultra-low emission, thermochemically recuperated reciprocating internal combustion engine

ActiveUS7210467B2Emission reductionImprove efficiencyInternal combustion piston enginesExhaust apparatusExternal combustion engineEngineering

An apparatus including a reciprocating internal combustion engine and a thermochemical recuperator in which a fuel is reformed. The thermochemical recuperator is heated by exhaust gases from the reciprocating internal combustion engine and steam for the reforming process is produced by passing feed water through an engine lubricating oil heat exchanger, an engine cooling system heat recovery system and an exhaust gas heat recovery system arranged in series.

Owner:GAS TECH INST

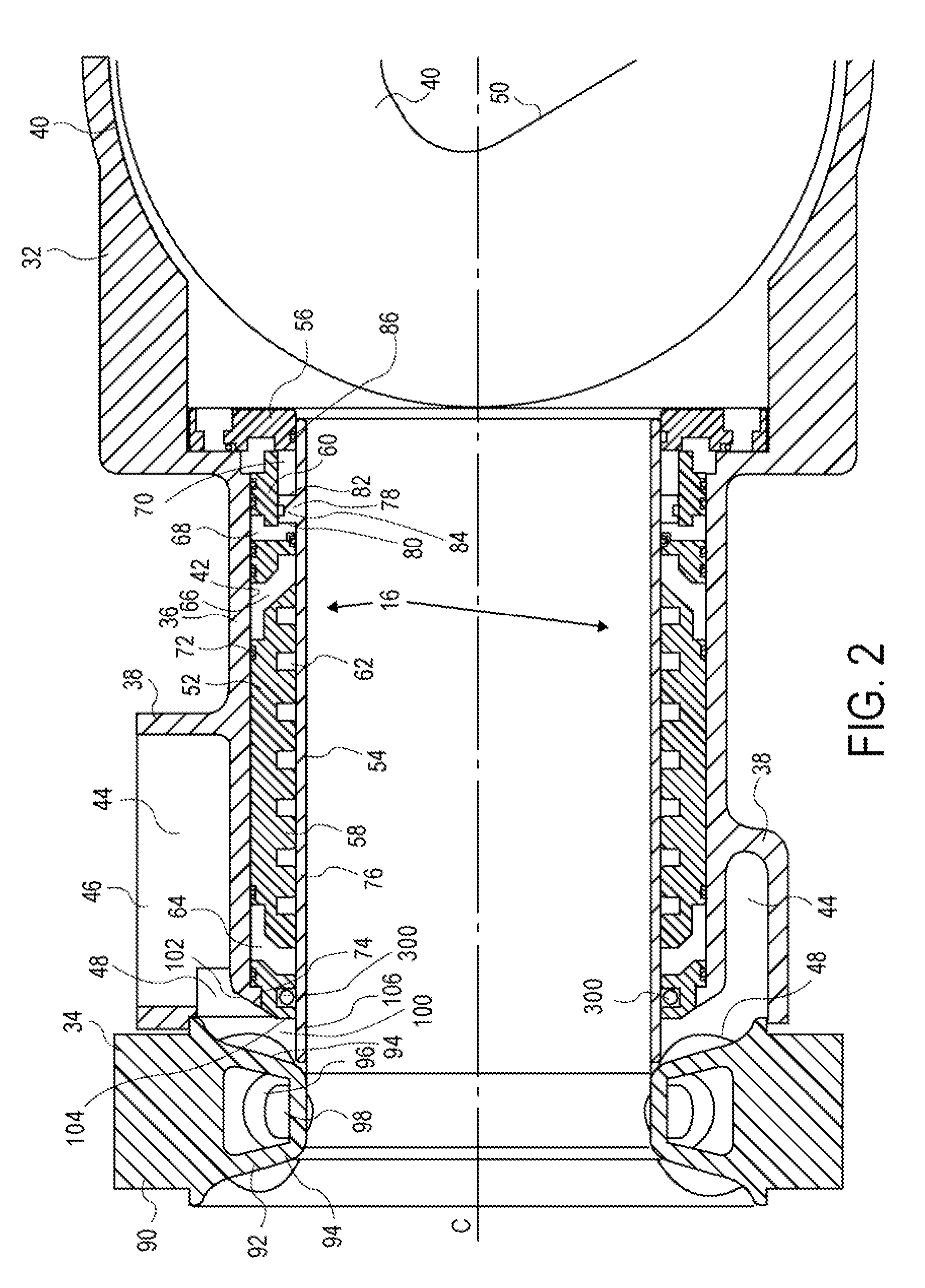

Internal combustion engine

InactiveUS7559298B2Assist in containment of heat energyReduce energy lossLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided. Facing pistons eliminate a cylinder head, thereby reducing heat losses through a cylinder head. Facing pistons also halve the stroke that would be required for one piston to provide the same compression ratio, and the engine can thus be run at higher revolutions per minute and produce more power. An internal sleeve valve is provided for space and other considerations. A combustion chamber size-varying mechanism allows for adjustment of the minimum size of an internal volume to increase efficiency at partial-power operation. Variable intake valve operation is used to control engine power.

Owner:CLEEVES ENGINES

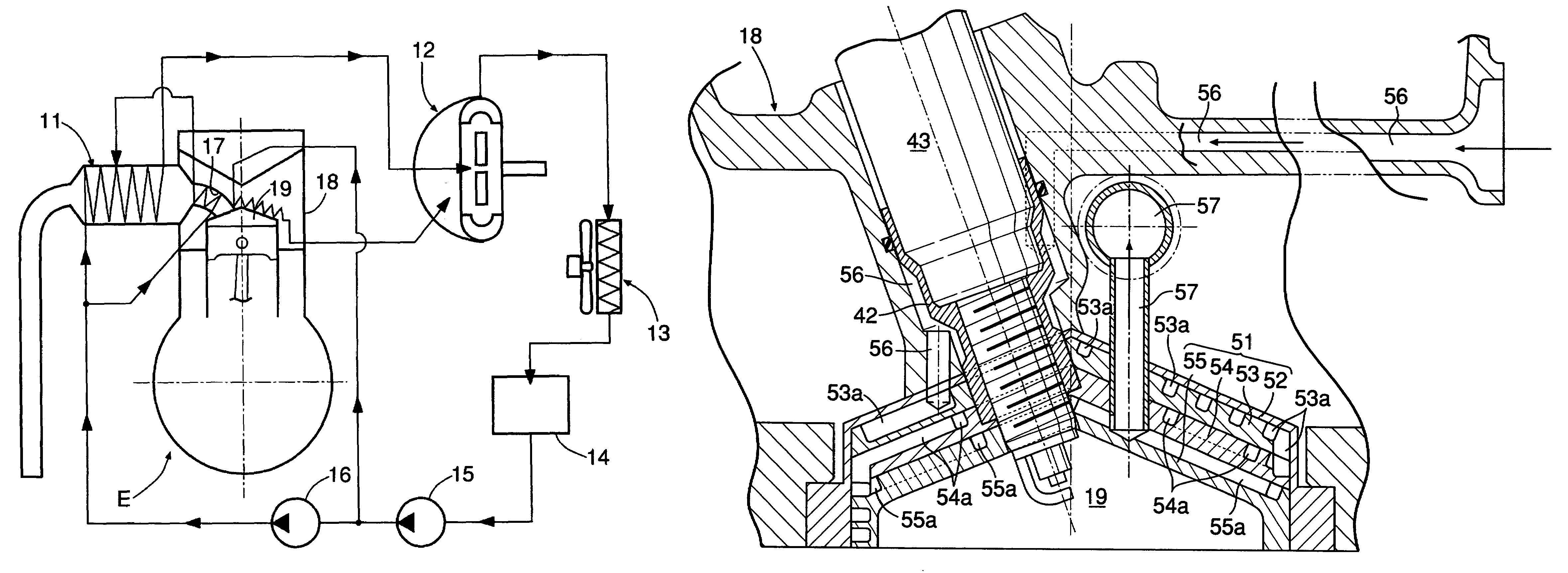

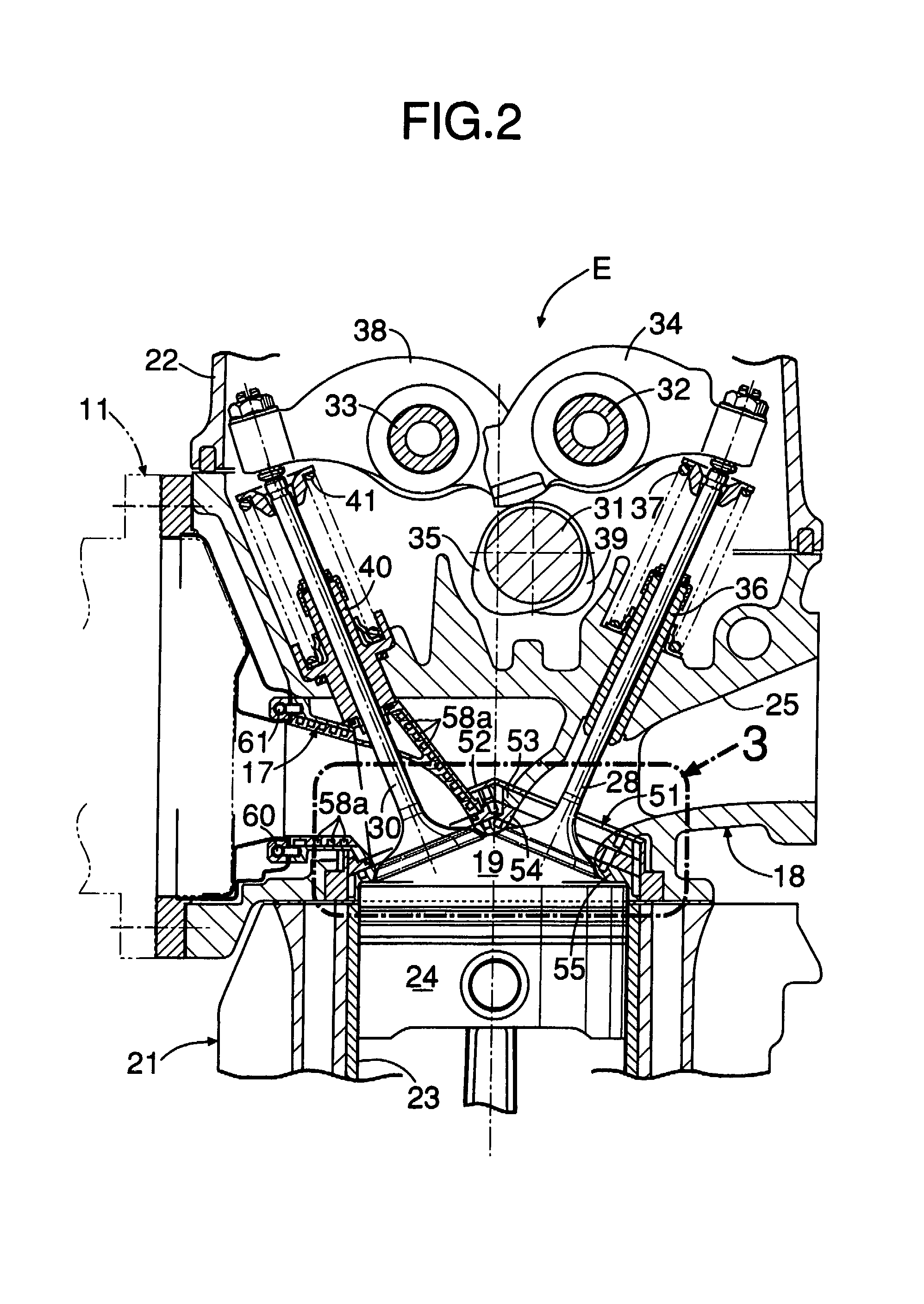

Internal combustion engine

InactiveUS7191740B2Good effectIncrease temperatureLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

A cooling block forming a top wall of a combustion chamber of an internal combustion engine is formed by layering, from the outside to the inside, a casing, an upper layer block, a middle layer block, and a lower layer block. Labyrinth-shaped cooling water passages are formed on upper side faces of the three layers of blocks, and cooling water supplied from a cooling water supply passage flows from the cooling water passage on the side far from the combustion chamber to the cooling water passage on the side close to the combustion chamber, and is discharged from a cooling water discharge passage. Since the cooling water flows in a direction opposite to the direction of emission of heat of combustion from the combustion chamber, it is possible to ensure that there is sufficient difference in temperature between a cylinder head and the cooling water throughout the cooling water passages.

Owner:HONDA MOTOR CO LTD

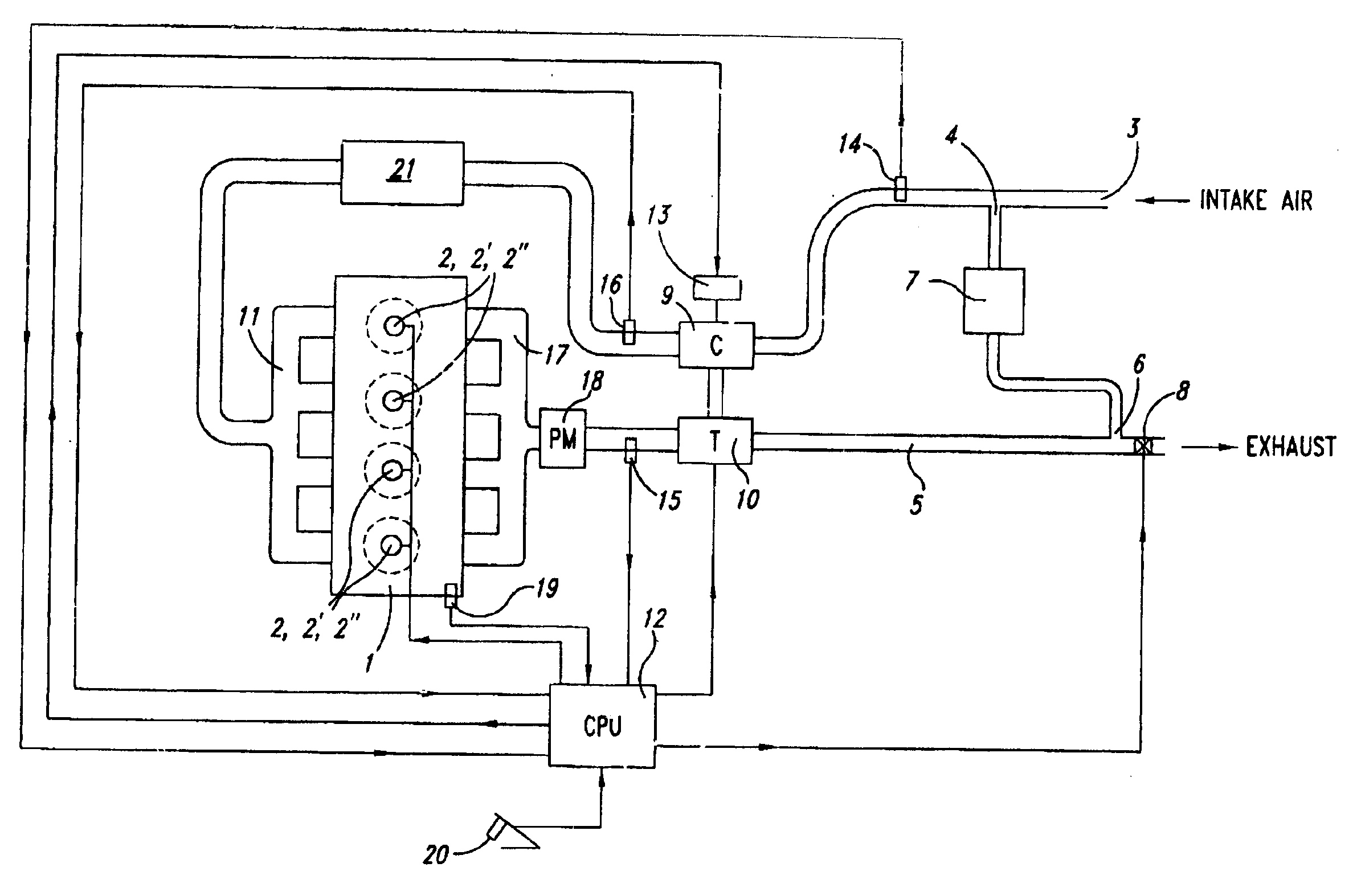

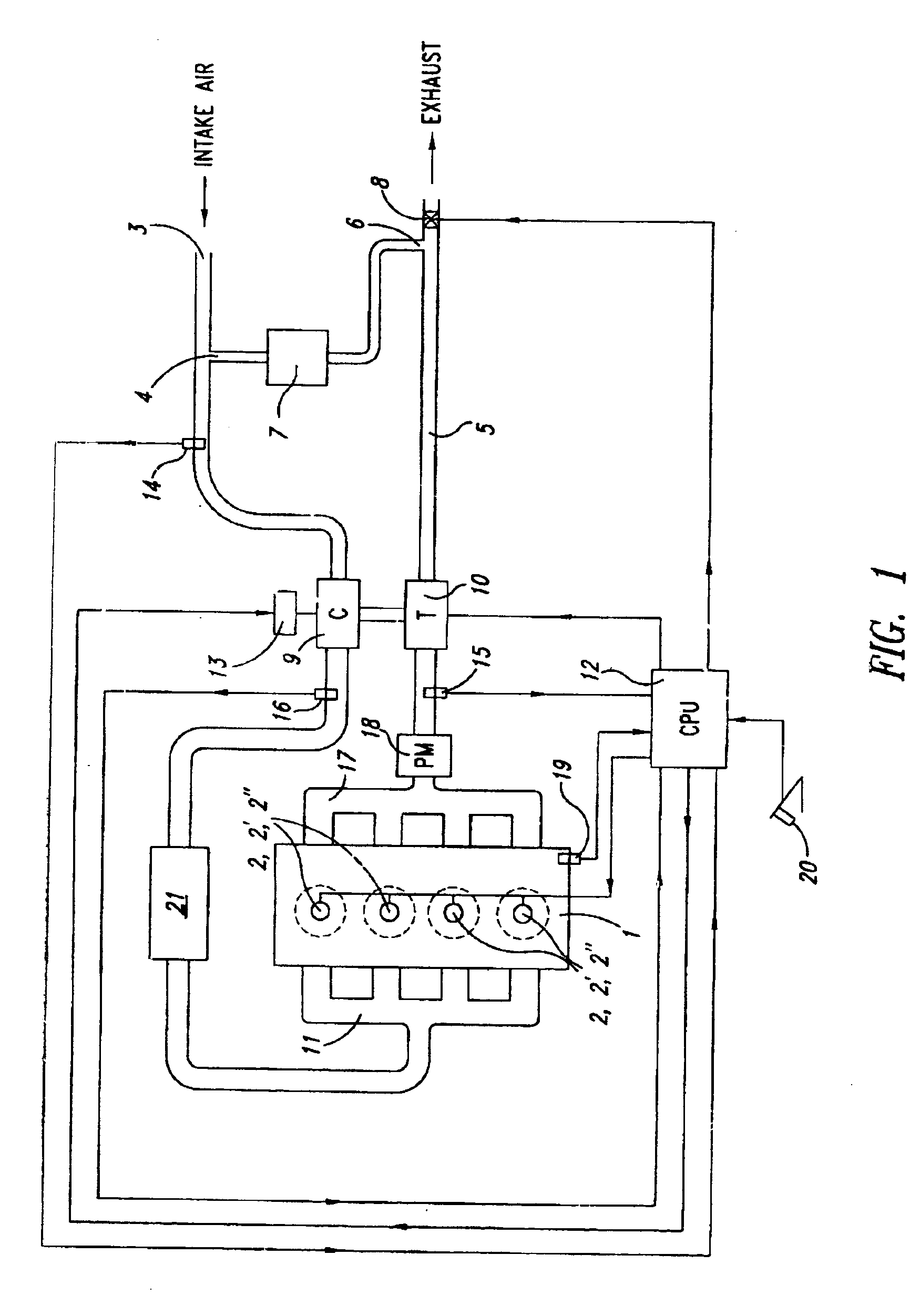

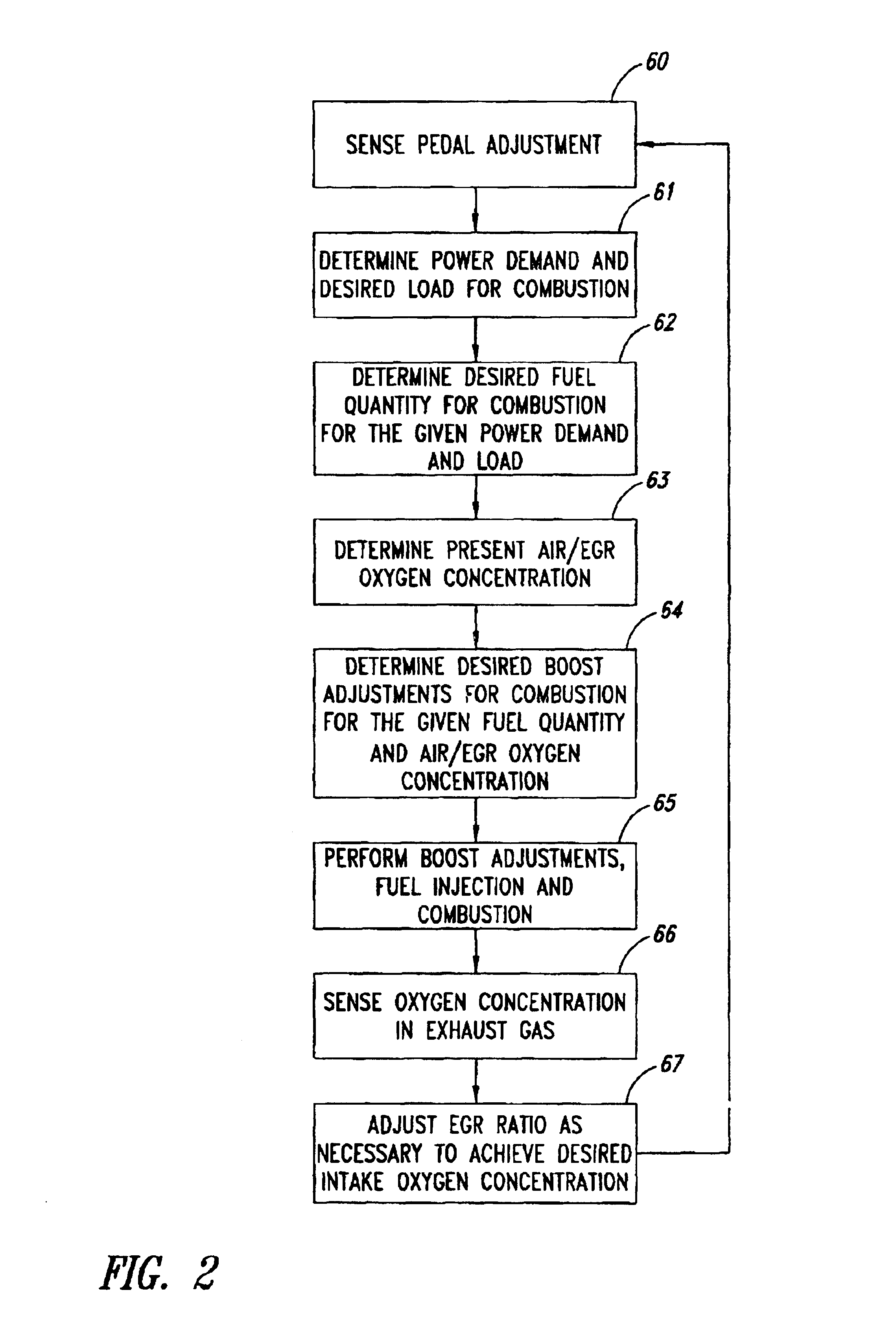

Low emission diesel combustion system with low charge-air oxygen concentration levels and high fuel injection pressures

InactiveUS6857263B2Cost effectiveLower Level RequirementsLiquid coolingEngine sealsLow loadMass ratio

This invention sets forth a commercially viable diesel combustion system that meets environmentally acceptable levels of NOx emissions (i.e. 0.2 g / bhp-hr or lower across a full map of engine speeds and loads) without the need for use of NOx aftertreatments, and simultaneously maintains engine-out PM emissions relatively close (e.g. with smoke levels at or below 3 BSN) to environmentally acceptable PM post-aftertreatment levels. The invention achieves these results by operating within a unique combination of parameters. These parameters comprise: (1) charge-air oxygen concentration below 16%, preferably between 10% and 15%, more preferably between 11% and 14%, and most preferably between 12% and 13.5% for virtually all engine operating conditions (but not necessarily at no-load or low load conditions), (2) fuel injection pressures at or exceeding 1800 bar, preferably exceeding 2100 bar, more preferably exceeding 2300 bar, and most preferably exceeding 2500 bar, at most engine speeds and loads, and (3) charge-air mass / fuel mass ratio between 25:1 and 45:1 for medium and high loads. Furthermore, the system is preferably run continuously slightly lean of stoichiometry, providing just enough excess oxygen to facilitate completeness of combustion and to maintain an exhaust oxygen level sufficient for continuous trap regeneration at a balance point in operation.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

Internal combustion engine for a motor vehicle

InactiveUS20060157002A1Reduce the ratioHeating fastLiquid coolingCoolant flow controlCylinder headEngineering

In an internal combustion engine for a motor vehicle, having a cylinder head and an engine block, each with a coolant inlet port and a coolant outlet port which is common to the cylinder head the engine block, a main coolant pump having an intake side connected to the coolant outlet port and a pressure side connected to a first control valve via which coolant reaches the inlet port of the cylinder head and the inlet port of the engine block depending on the temperature of the coolant, and to a method for operating such an internal combustion engine, wherein the main coolant pump is selectively actuated to pump the coolant through at least one of the cylinder head and the engine block or is shut down depending on the engine operating state.

Owner:DAIMLER AG

Heat transfer fluids and corrosion inhibitor formulations for use thereof

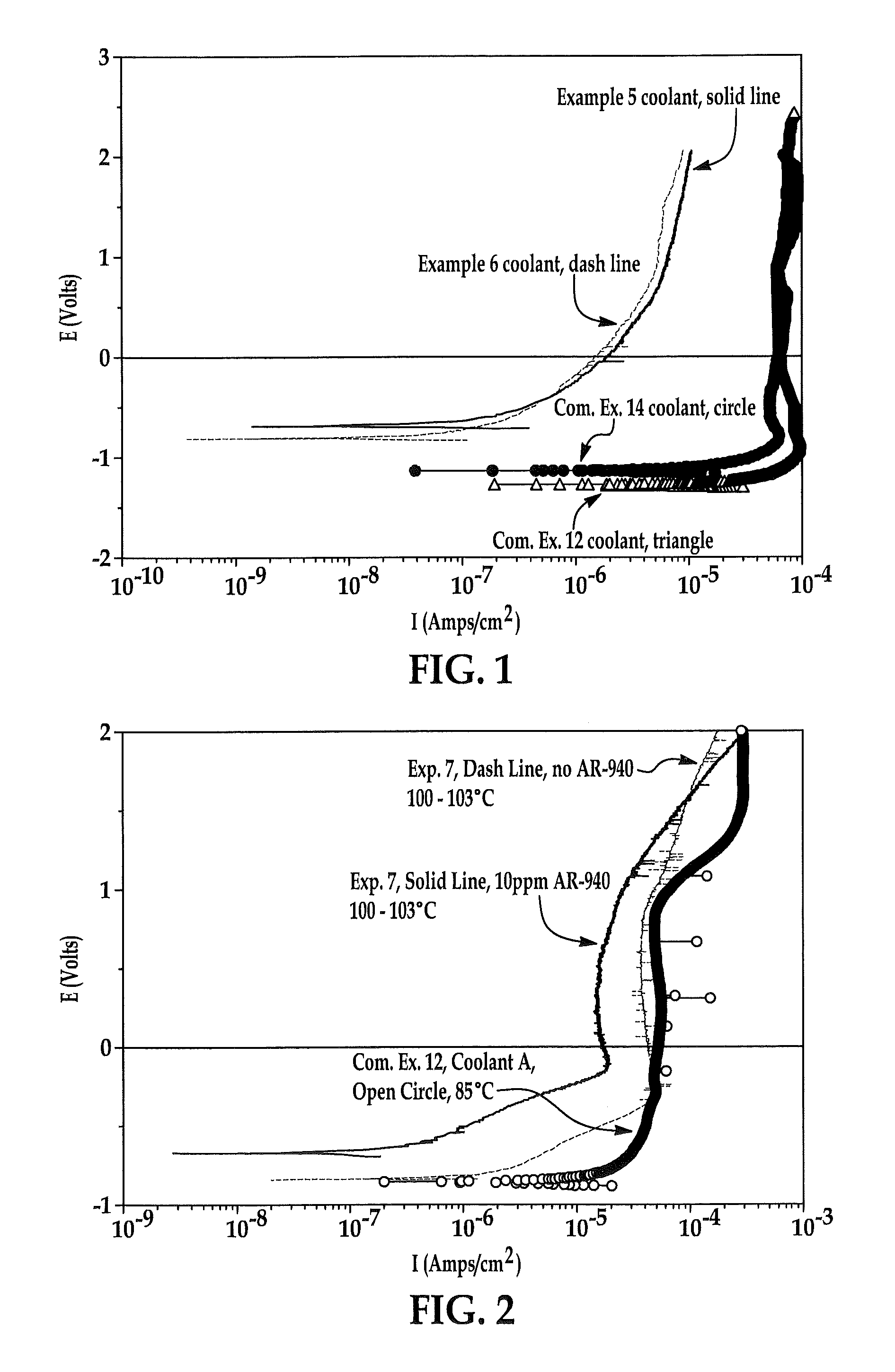

ActiveUS20100116473A1Corrosion protection is enhancedImprove anti-corrosion performanceLiquid coolingCorrosion preventionIonMagnesium

Disclosed herein is a heat transfer fluid comprises: a freezing point-depressant; an aliphatic carboxylic acid, a salt thereof, or a combination of the foregoing; an inorganic phosphate; a magnesium compound; deionized water; and a component selected from the group consisting of azole compounds, copper alloy corrosion inhibitors, phosphonocarboxylates, phosphinocarboxylates, and combinations of two or more of the foregoing components. Also described is a heat transfer system comprising the heat transfer fluid.

Owner:PRESTONE PROD CORP

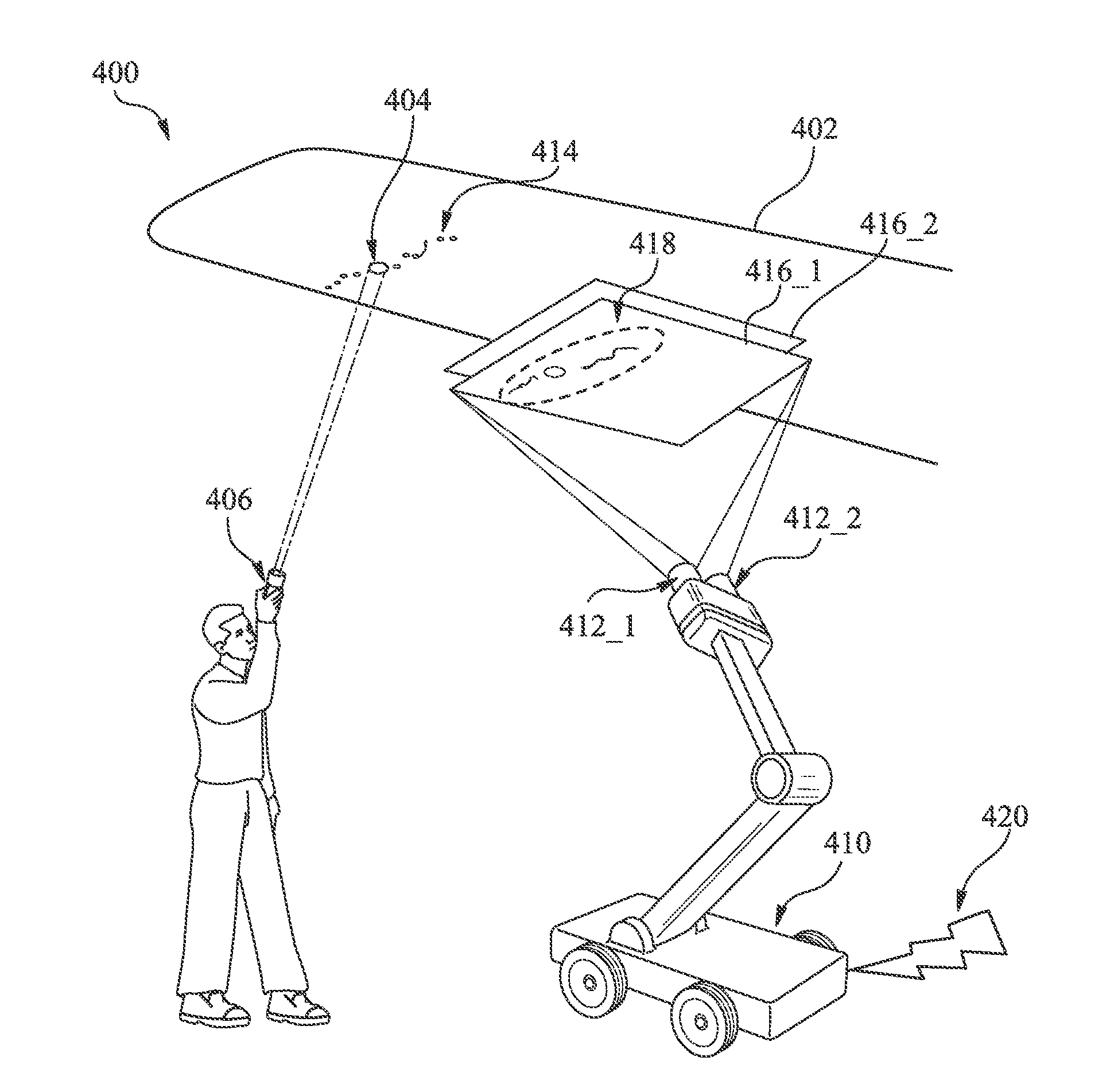

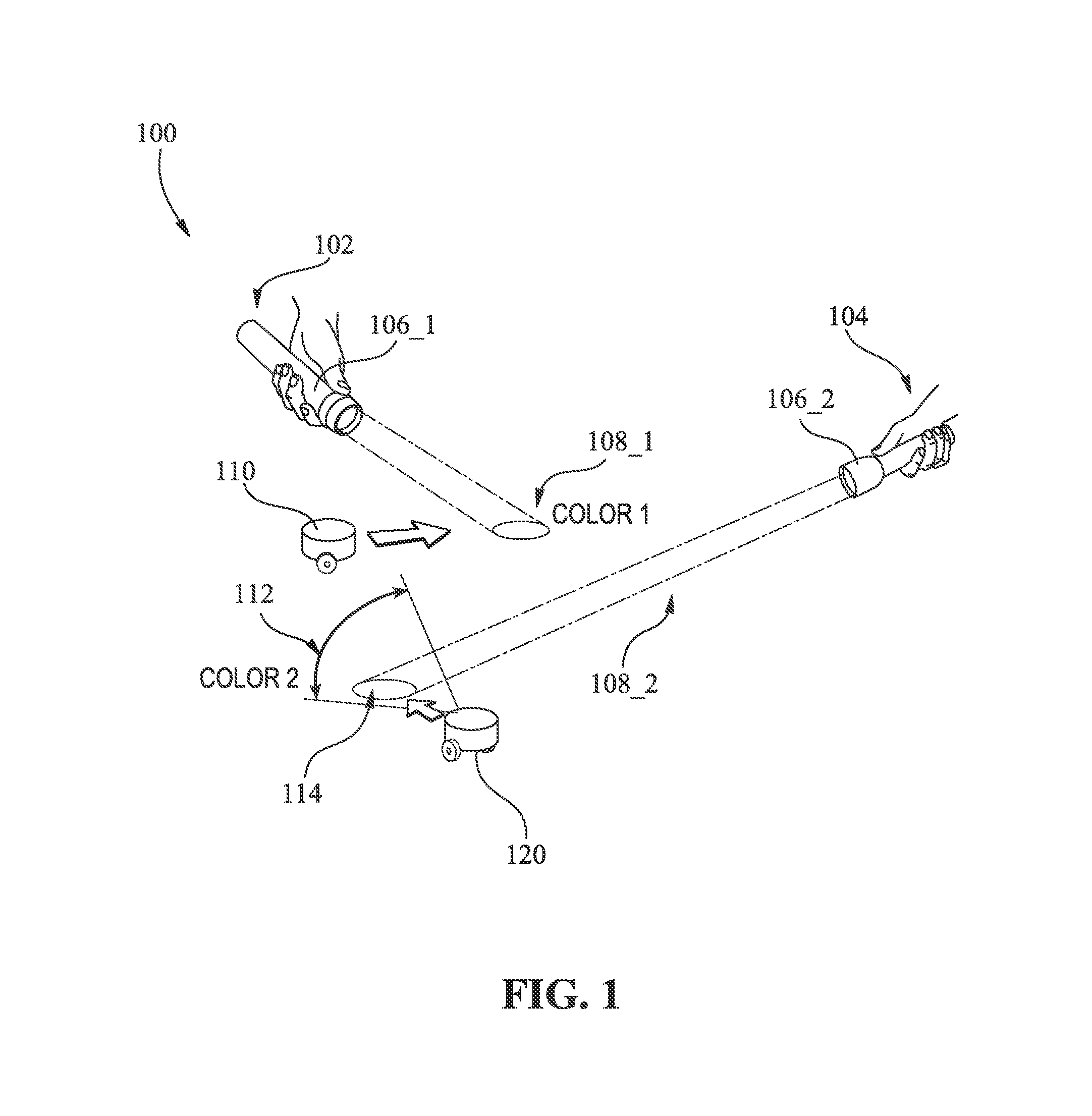

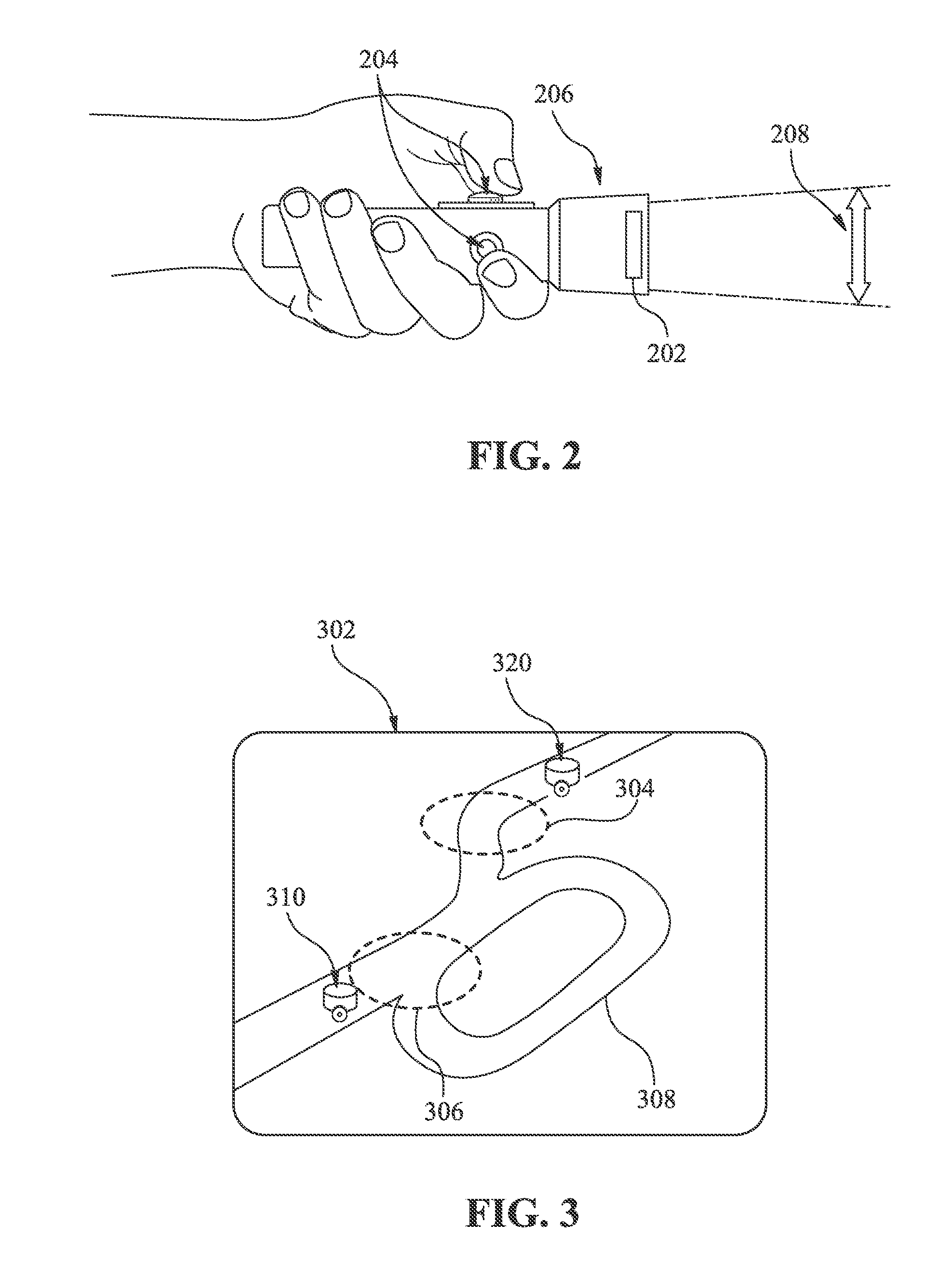

Apparatus and methods for controlling attention of a robot

Apparatus and methods for controlling attention and training of autonomous robotic devices. In one approach, attention of the robot may be manipulated by use of a spot-light device illuminating a portion of the aircraft undergoing inspection in order to indicate to inspection robot target areas requiring more detailed inspection. The robot guidance may be aided by way of an additional signal transmitted by the agent to the robot indicating that the object has been illuminated and attention switch may be required. Responsive to receiving the additional signal, the robot may initiate a search for the signal reflected by the illuminated area requiring its attention. Responsive to detecting the illuminated object and receipt of the additional signal, the robot may develop an association between the two events and the inspection task. The light guided attention system may influence the robot learning for subsequent actions.

Owner:GOPRO

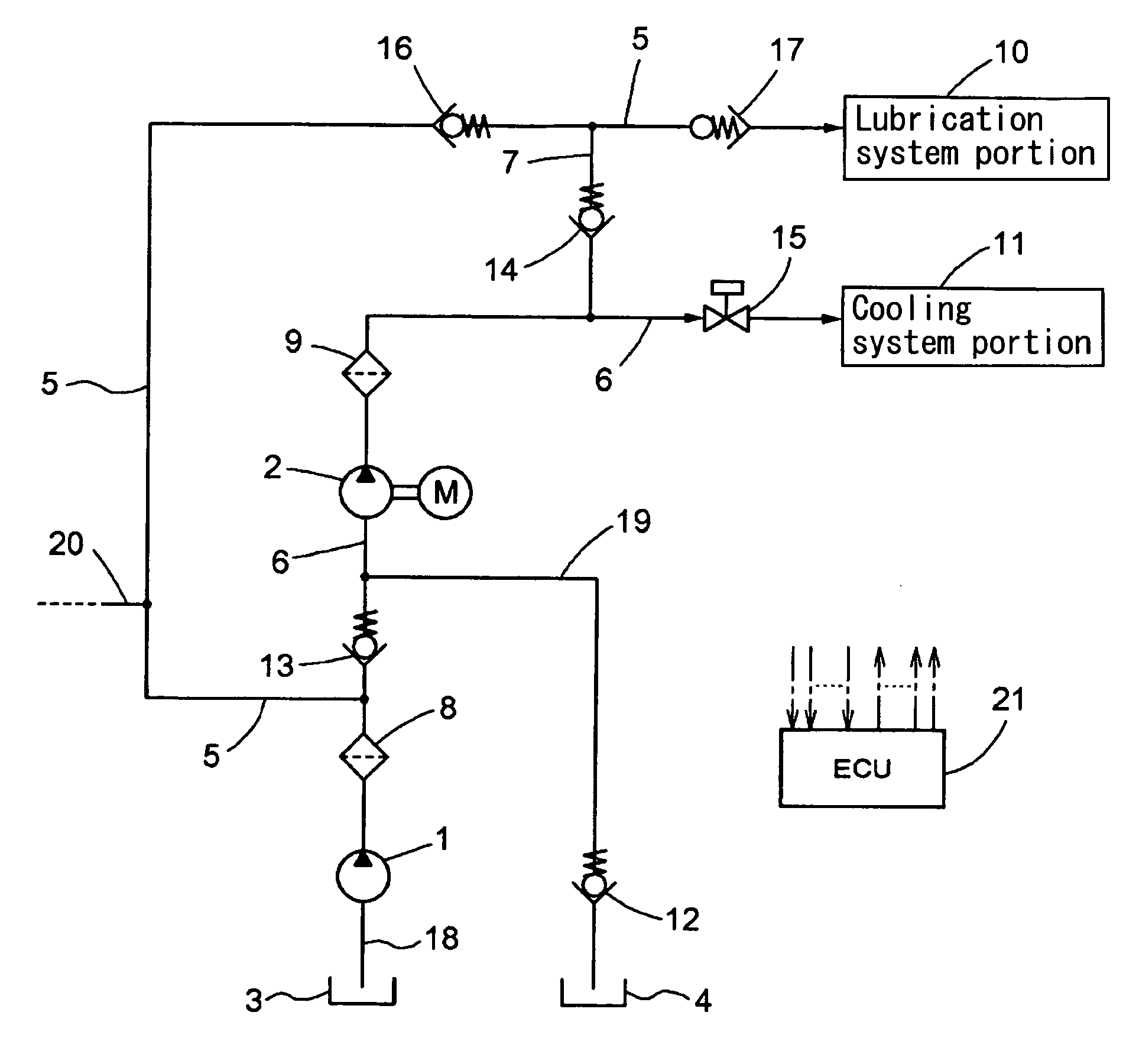

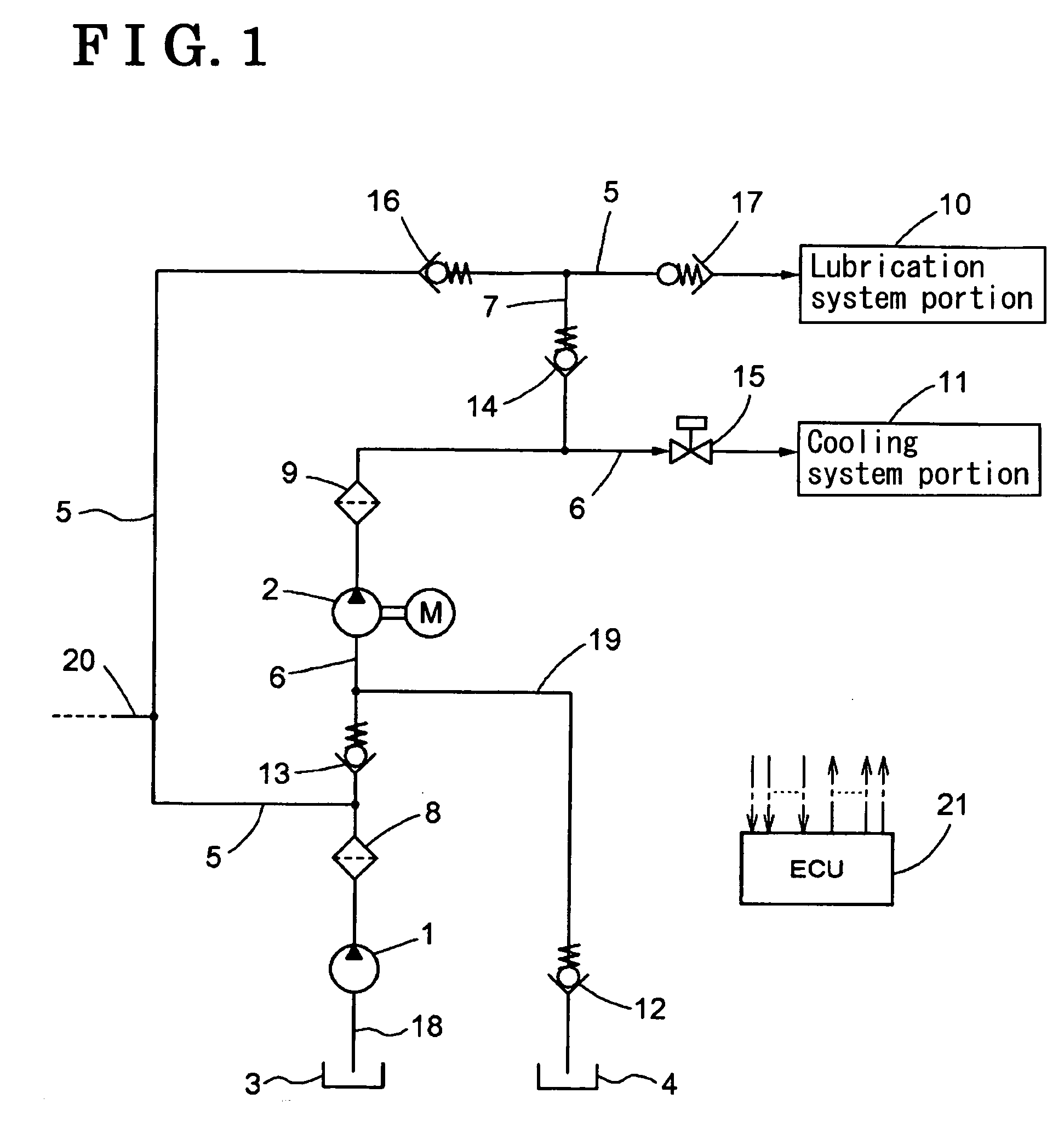

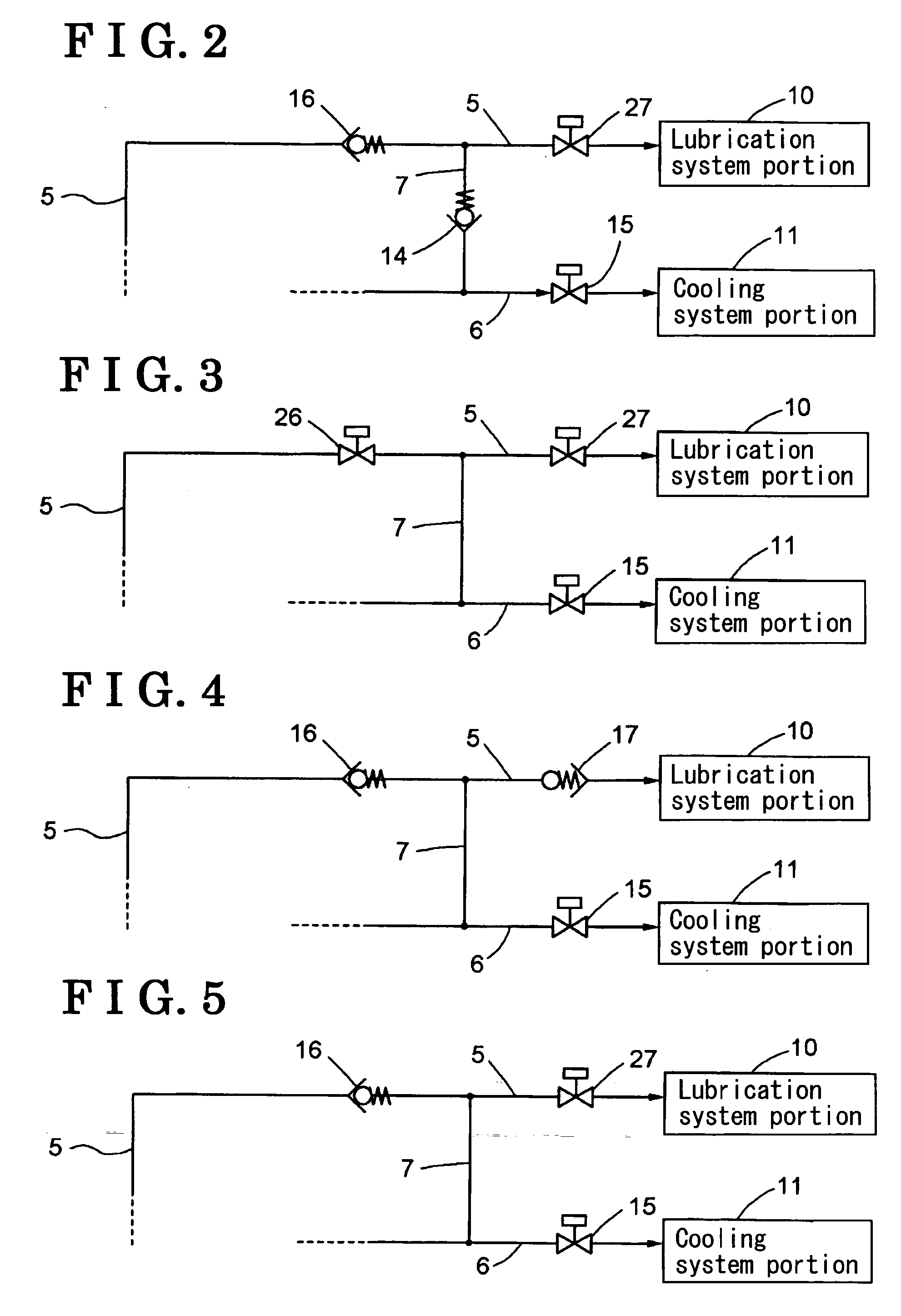

Oil supply device for engine

An oil supply device for an engine includes a first oil suction passage, a second oil suction passage, a first pump for sucking and discharging oil from the first oil suction passage, a second pump arranged in series with the first pump, the second pump for sucking and discharging oil from at least one of the first pump and the second oil suction passage, a check valve for blocking oil circulation, a first oil passage, a second oil passage, a third oil passage for establishing communication between the first oil passage and the second oil passage, and a supply volume control device for varying oil supply volume to a lubrication system portion, to a cooling system portion, or to the lubrication system portion and the cooling system portion in accordance with a change in at least one of an engine oil temperature, an engine rotation speed, and an engine load.

Owner:AISIN SEIKI KK

Thermoelectric generator

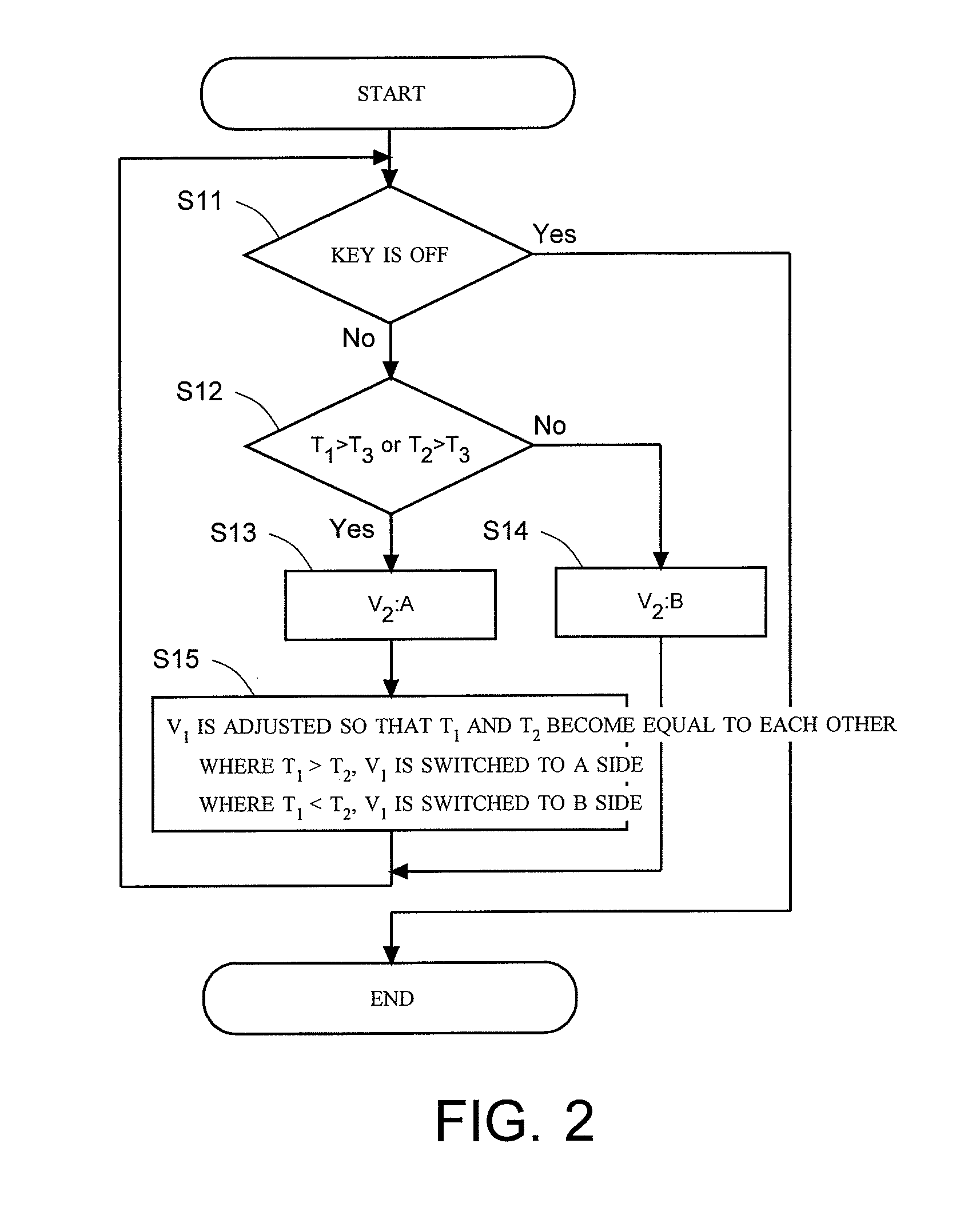

InactiveUS20060130888A1Suppressing decreaseSolve insufficient capacityLiquid coolingCoolant flow controlEngineeringTemperature difference

A thermoelectric generator has a high temperature heat source part provided on a first passage through which a first fluid for cooling an engine flows, a low temperature heat source part provided on a second passage through which a second fluid having a temperature lower than that of the first fluid flows, and a thermoelectric element for producing electric power by a temperature difference produced between the high temperature heat source part and the low temperature heat source part. The first passage is included in a first circuit in which the engine and a first radiator for cooling the first fluid are connected in loop through a main passage. Further, the first passage is in parallel to the first radiator in the first circuit. The second passage is included in a second circuit that is separate from the first circuit and includes a second radiator for cooling the second fluid.

Owner:DENSO CORP +1

Engine cooling system with overload handling capability

InactiveUS20090205590A1Suitable for mass productionSimple and compactLiquid coolingReinforcing meansMobile vehicleInternal combustion engine

A cooling system for an internal combustion engine incorporating a heat accumulator to temporarily store heat during peak heat loads. In automotive vehicles, the heat accumulator may store excess heat generated during vehicle acceleration or hill climbing and it may dissipate stored heat during vehicle cruise, deceleration, or engine idle. The heat accumulator contains phase change material with a solid-to-liquid transition temperature higher than the normal operating temperature of the cooling system. The invention enables reducing the size and weight of engine cooling system without compromising its performance. This is particularly important for improving fuel economy and reduction of emission in automotive vehicles. In addition, the invention enables reducing the coolant inventory in the system thereby allowing for faster engine warm-up and reduced emissions of harmful pollutants during a cold engine start. The invention may be also used for thermal management of engine oil, transmission fluid, or hydraulic fluid.

Owner:AGWEST

Advanced high efficiency, ultra-low emission, thermochemically recuperated reciprocating internal combustion engine

ActiveUS20050279333A1Improve engine efficiencyIncreases engine combustion efficiencyInternal combustion piston enginesExhaust apparatusEngineeringRecuperator

An apparatus including a reciprocating internal combustion engine and a thermochemical recuperator in which a fuel is reformed. The thermochemical recuperator is heated by exhaust gases from the reciprocating internal combustion engine and steam for the reforming process is produced by passing feed water through an engine lubricating oil heat exchanger, an engine cooling system heat recovery system and an exhaust gas heat recovery system arranged in series.

Owner:GAS TECH INST

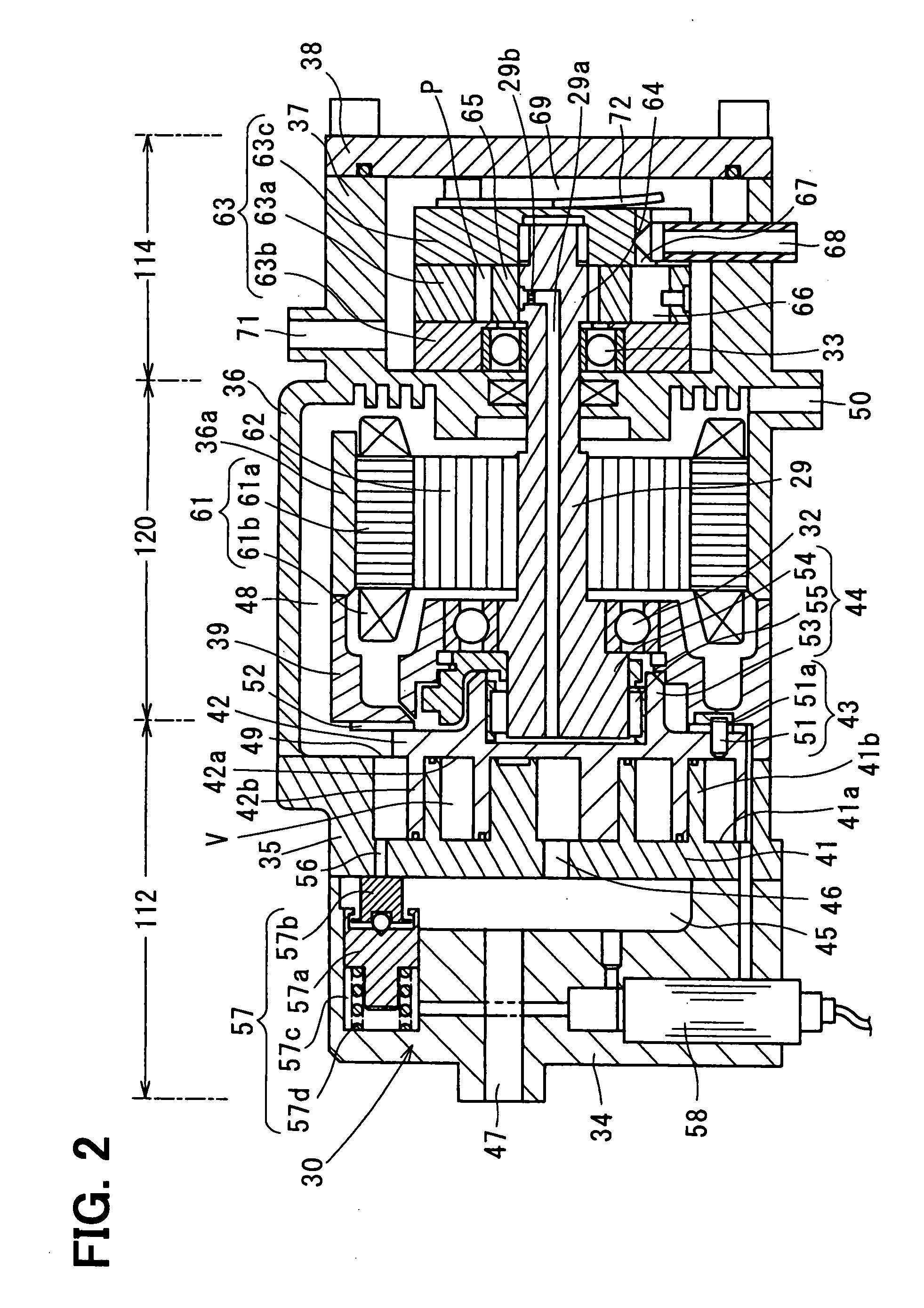

Waste heat collecting system having expansion device

InactiveUS20070227472A1Enlarges and complicates structureIncrease costLiquid coolingInternal combustion piston enginesEngineeringHigh pressure

An object of the invention is to provide a waste heat collecting system having an expansion device, in which an over expansion of refrigerant is prevented so that a loss to be caused by the over expansion is eliminated. A volume ratio of expansion for the expansion device is selected at a value, at which proper expansion of the refrigerant is achieved when the pressure difference between the high pressure and the low pressure is minimum.

Owner:DENSO CORP +1

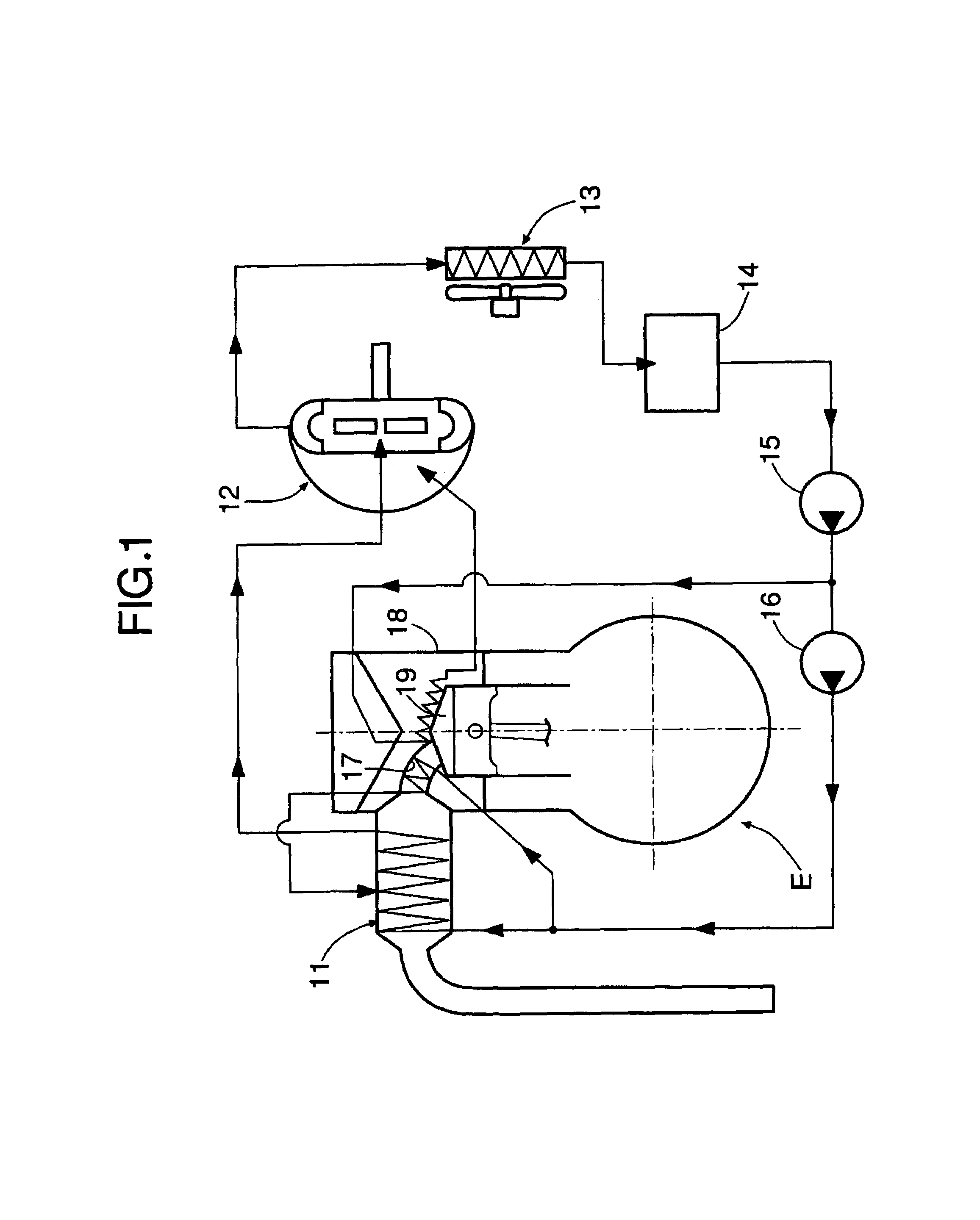

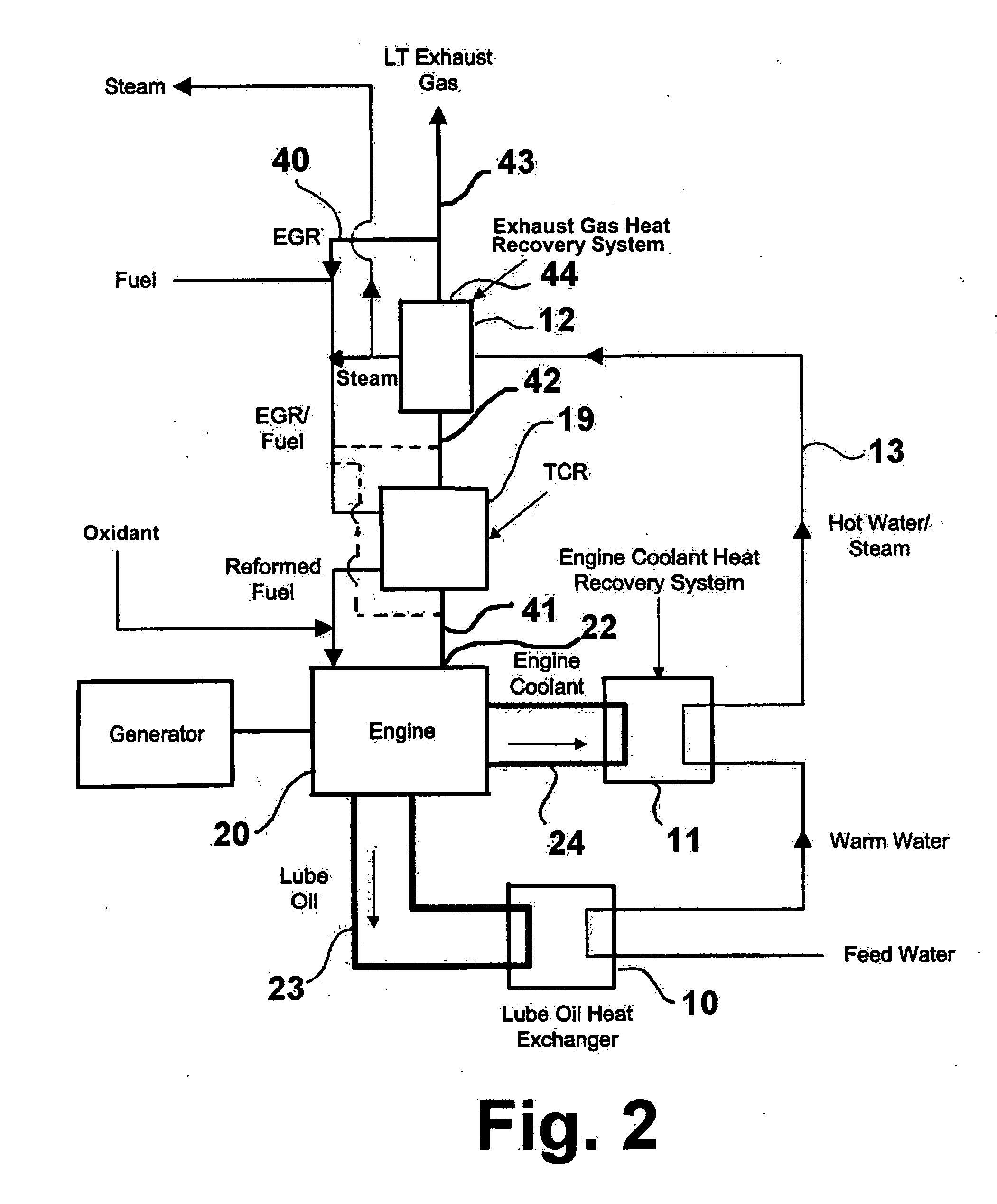

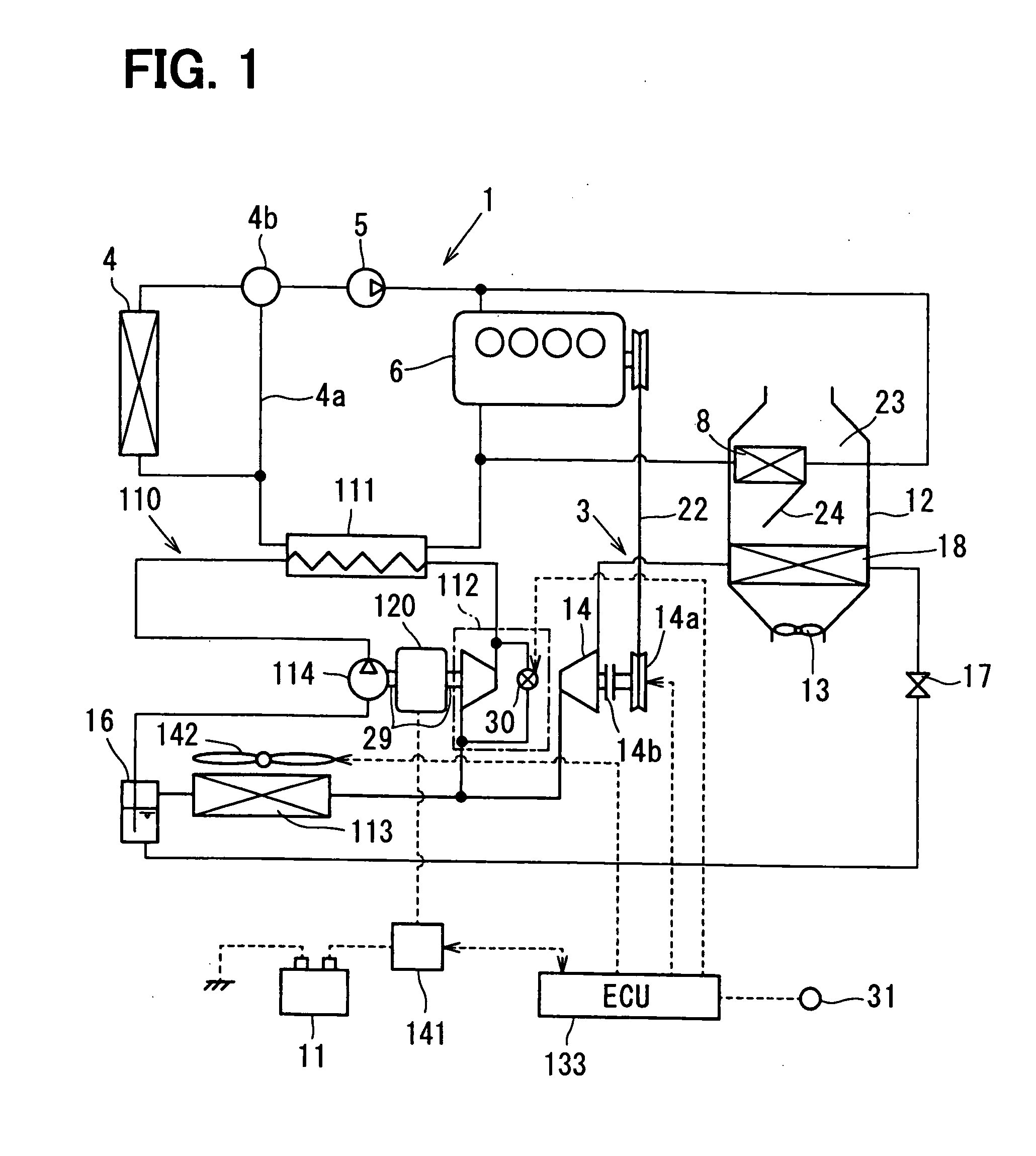

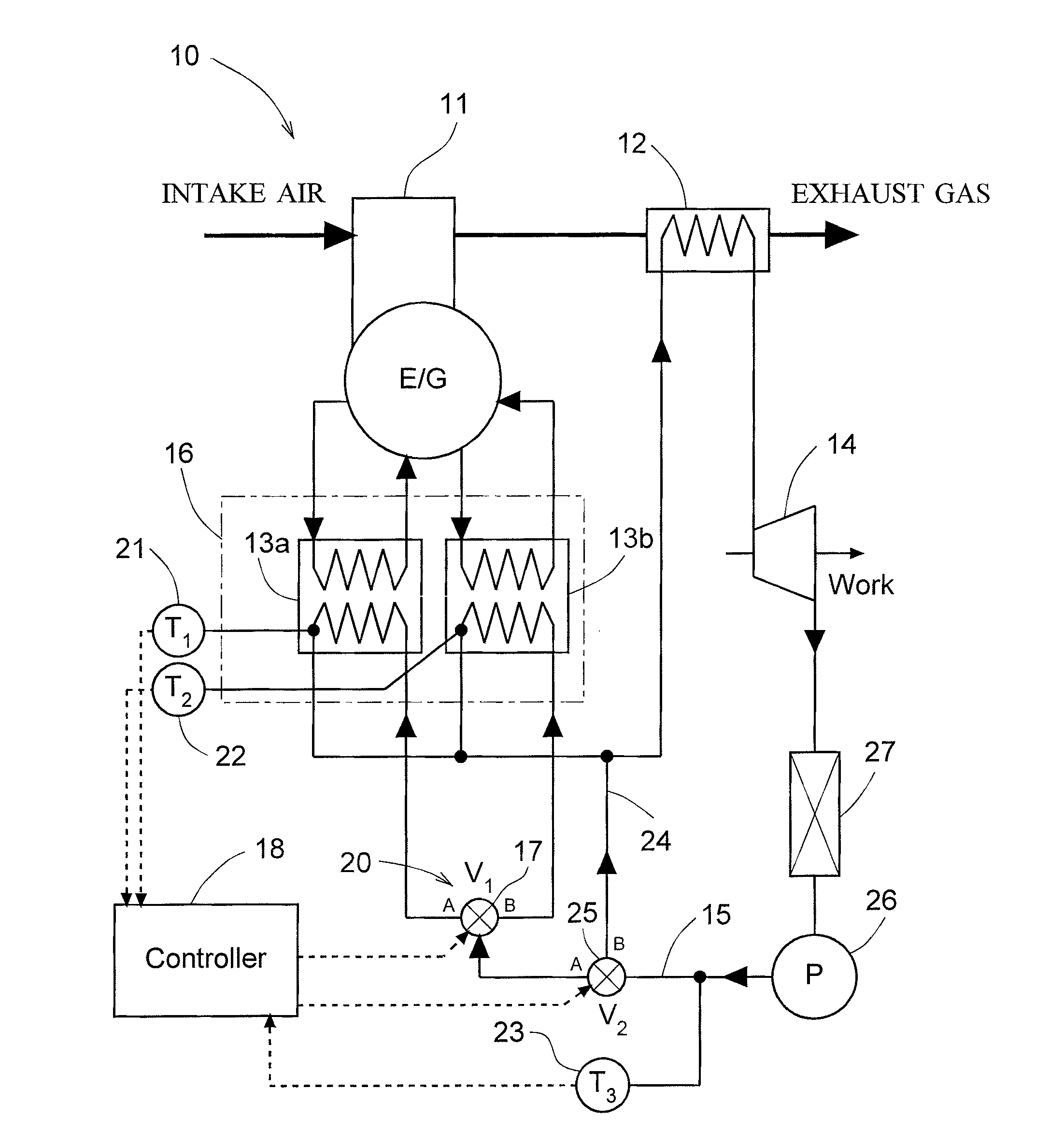

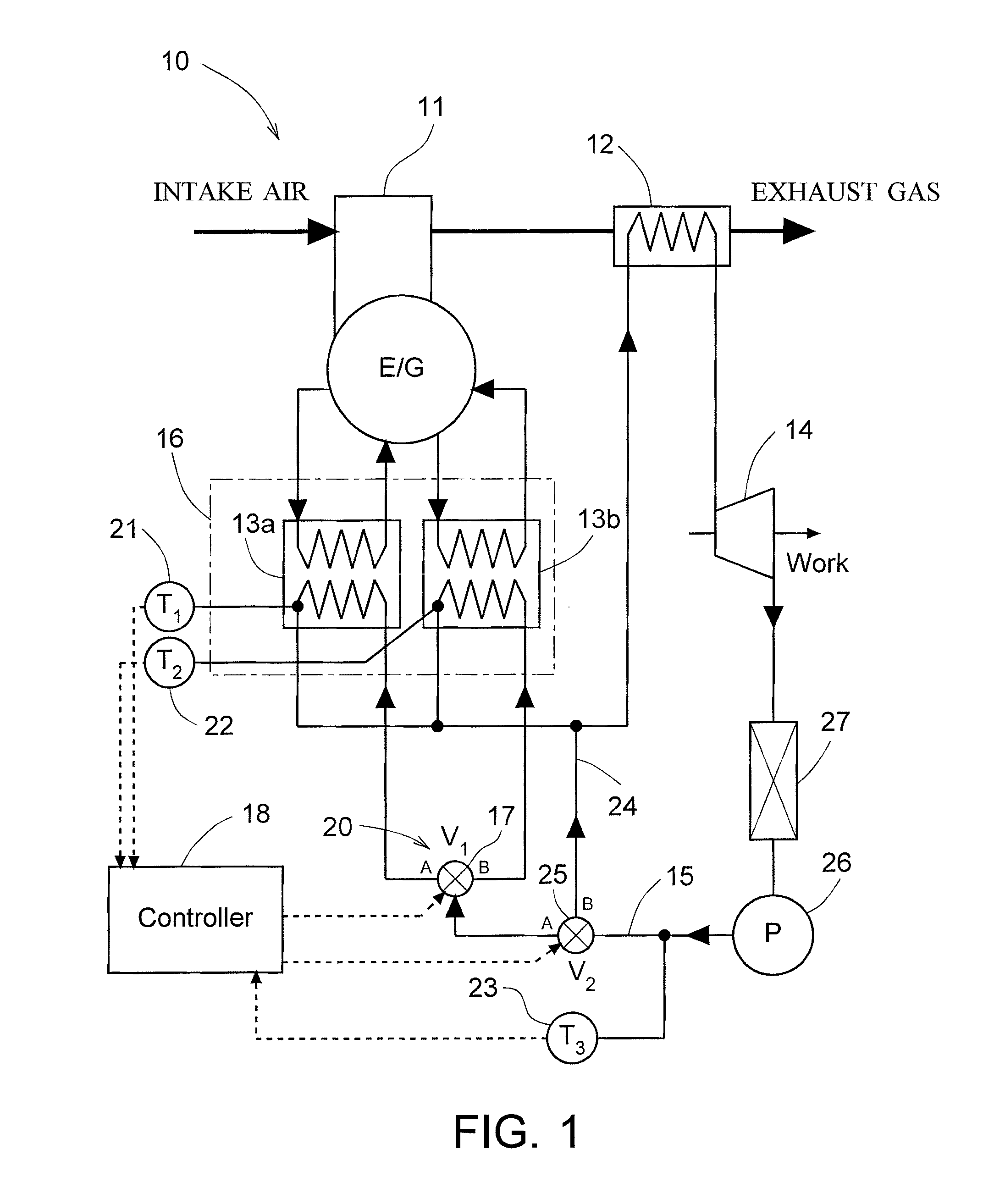

Waste heat recovering device

InactiveUS20110005477A1Efficient waste heat recoveryGood effectLiquid coolingInternal combustion piston enginesWorking fluidEngineering

The present invention provides a waste heat recovering device capable of recovering waste heat with good efficiency from various heat sources in an internal combustion engine. The waste heat recovering device for driving an expander 14 by evaporating a working fluid by waste heat of an internal combustion engine 11 includes: a working fluid circulation flow path 15 in which the working fluid of the expander 14 is caused to circulate; a high-temperature heat exchanger 12 for heating the working fluid flowing in the working fluid circulation flow path 15 by a high-temperature fluid such as exhaust gas of the internal combustion engine 11; a low-temperature heat exchanger group 16 having, for each of low-temperature fluids such as cooling water and oil of the internal combustion engine 11, a low-temperature heat exchanger 13a, 13b for heating the working fluid flowing in the working fluid circulation flow path 15 by any one of the low-temperature fluids, the low-temperature heat exchangers 13a, 13b being disposed in parallel with each other; a flow rate control valve 17 that controls a flow rate of the working fluid flowing into each low-temperature heat exchanger 13a, 13b of the low-temperature heat exchanger group 16; and control means 18 for controlling the flow rate control valve 17.

Owner:ISUZU MOTORS LTD

Vehicle front end structure

InactiveUS7290630B2Improve cooling efficiencyReduce harmLiquid coolingMachines/enginesRadarEngineering

Owner:DENSO CORP

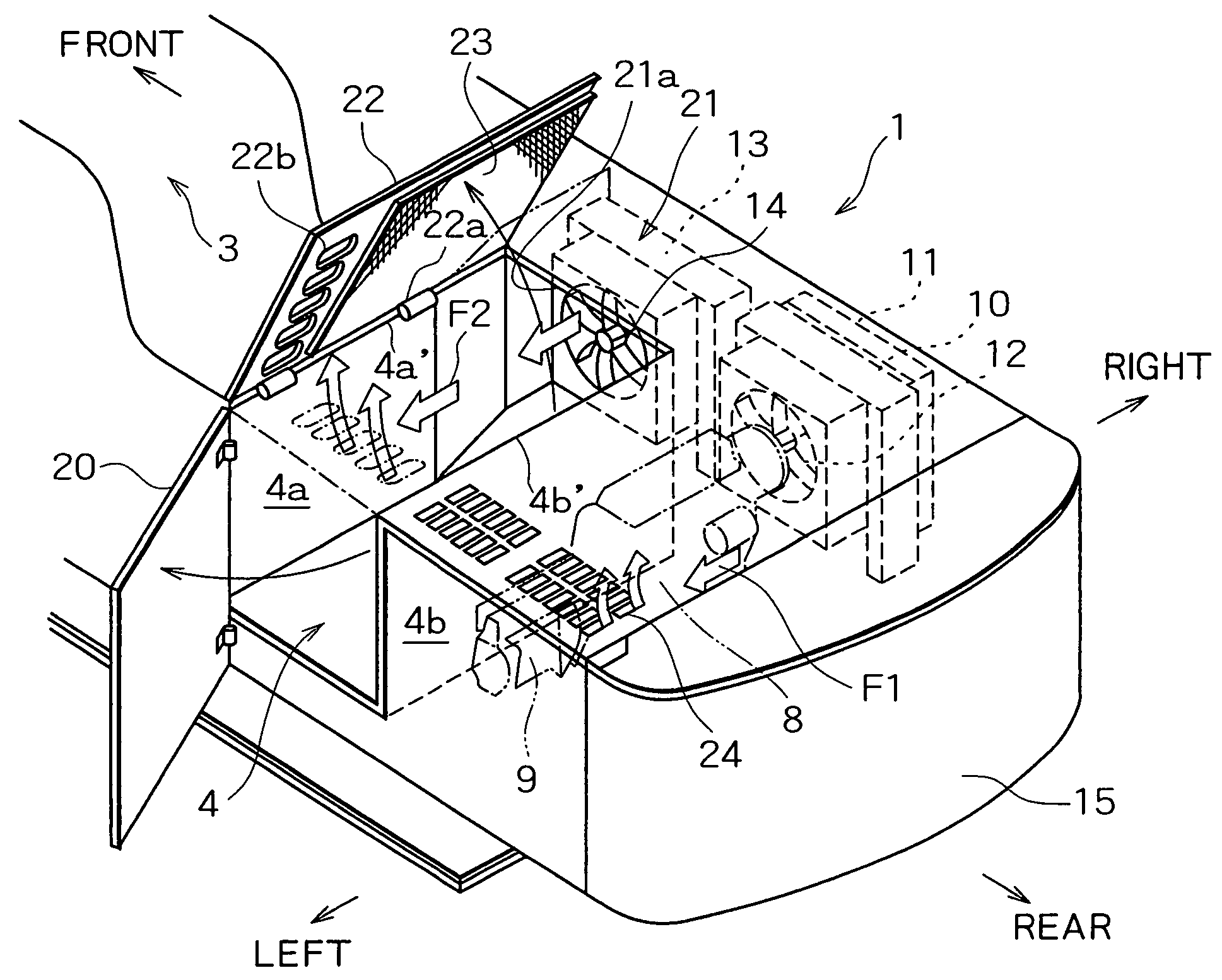

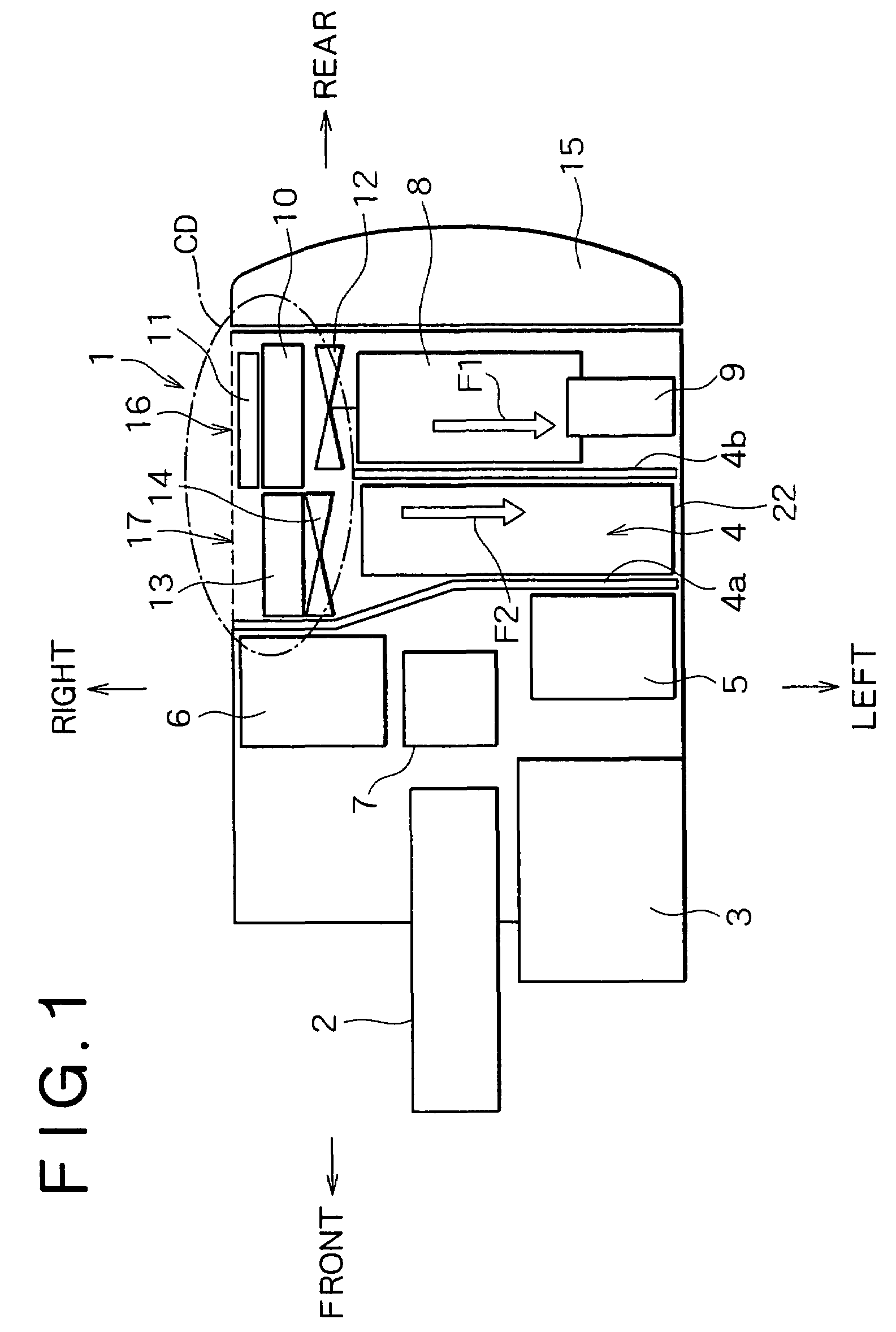

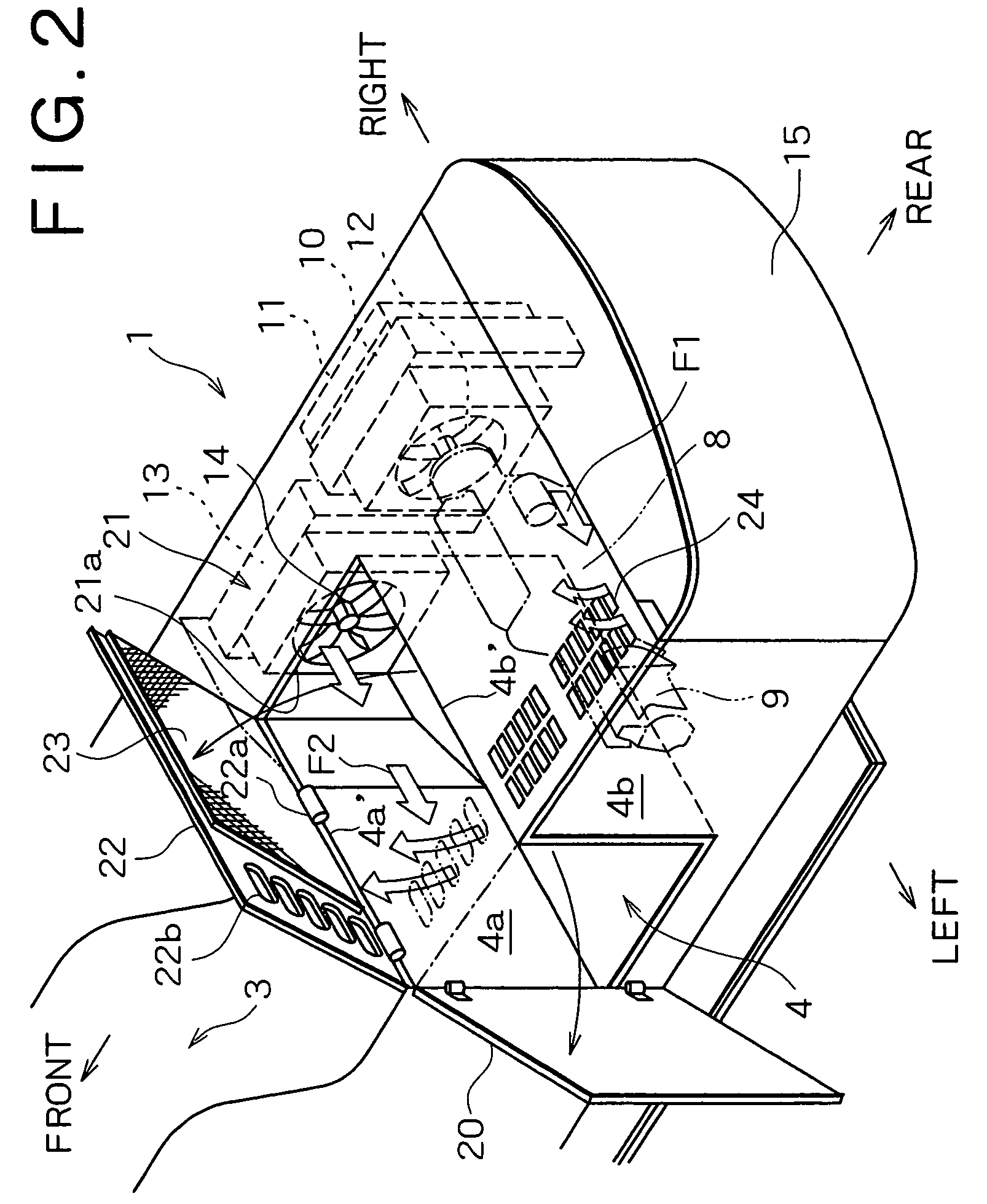

Construction machine

ActiveUS7134518B2Improve cooling efficiencySpeed up the flowLiquid coolingSoil-shifting machines/dredgersExhaust gasEngineering

In a construction machine comprising an engine, hydraulic device, and heat exchanger for cooling the engine and the hydraulic device, which are all disposed in an upper rotating body of the construction machine, there is formed a maintenance passage along which maintenance portions of the engine and the hydraulic device are disposed so as to cross the upper rotating body. Exhaust air from cooling fans for sending air to the heat exchanger is discharged to the exterior of the machine body through the passage. Thus, the passage is utilized as an exhaust air passage for the heat exchanger, whereby it is possible to provide a construction machine improved in cooling efficiency for the heat exchanger.

Owner:KOBELCO CONSTR MASCH CO LTD

Popular searches

Plural diverse prime-mover propulsion mounting Stationary tubular conduit assemblies Vehicular energy storage Propulsion cooling Electric propulsion mounting Gas pressure propulsion mounting Propulsion using engine-driven generators Vehicle heating/cooling devices Battery/fuel cell control arrangement Power to electric heating circuits

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com