Oil supply device for engine

a technology for oil supply devices and engines, which is applied in the direction of machines/engines, mechanical equipment, auxilaries, etc., can solve the problems of both pumps should be high output pumps, and not being able to supply oil to the destination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

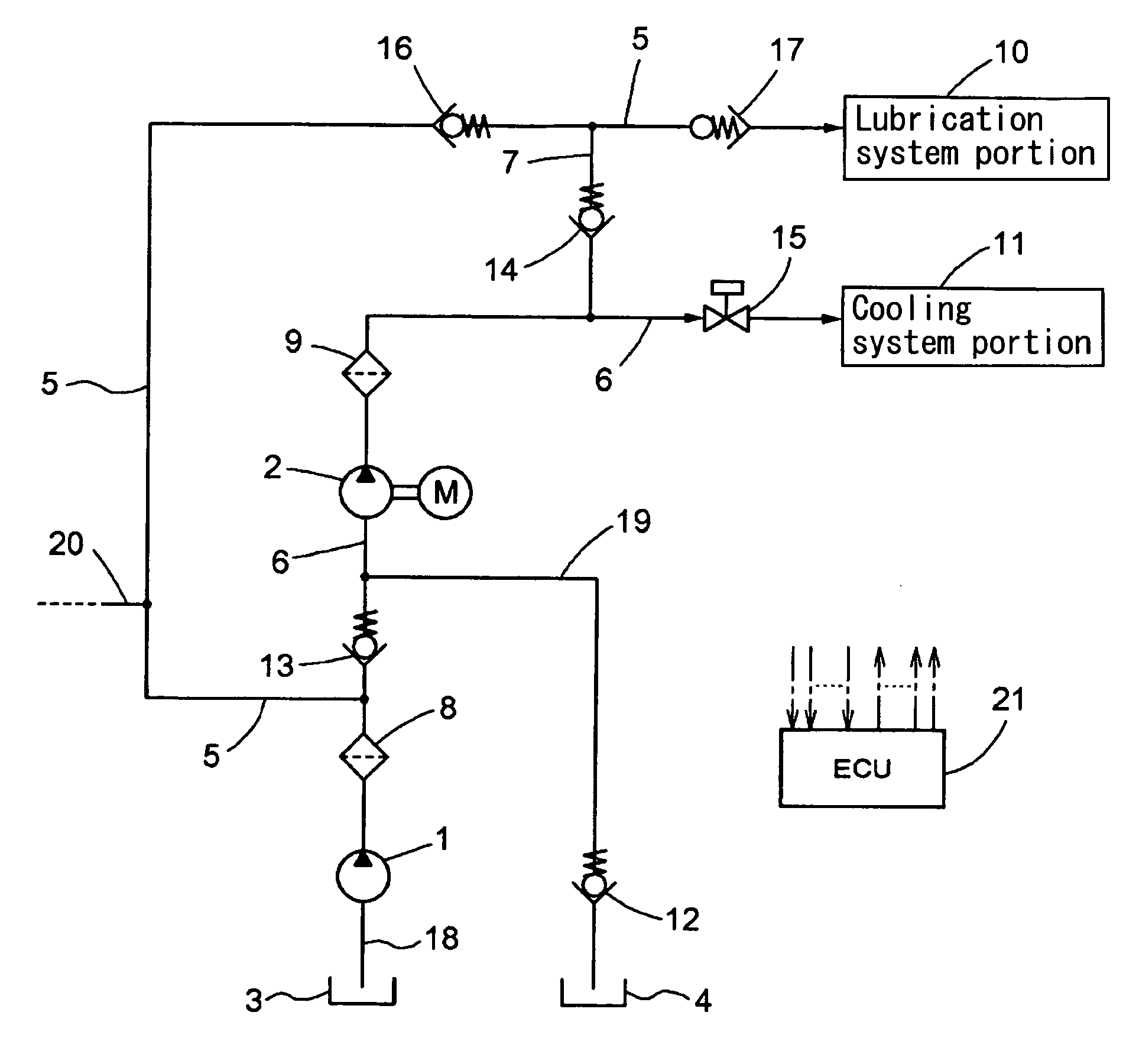

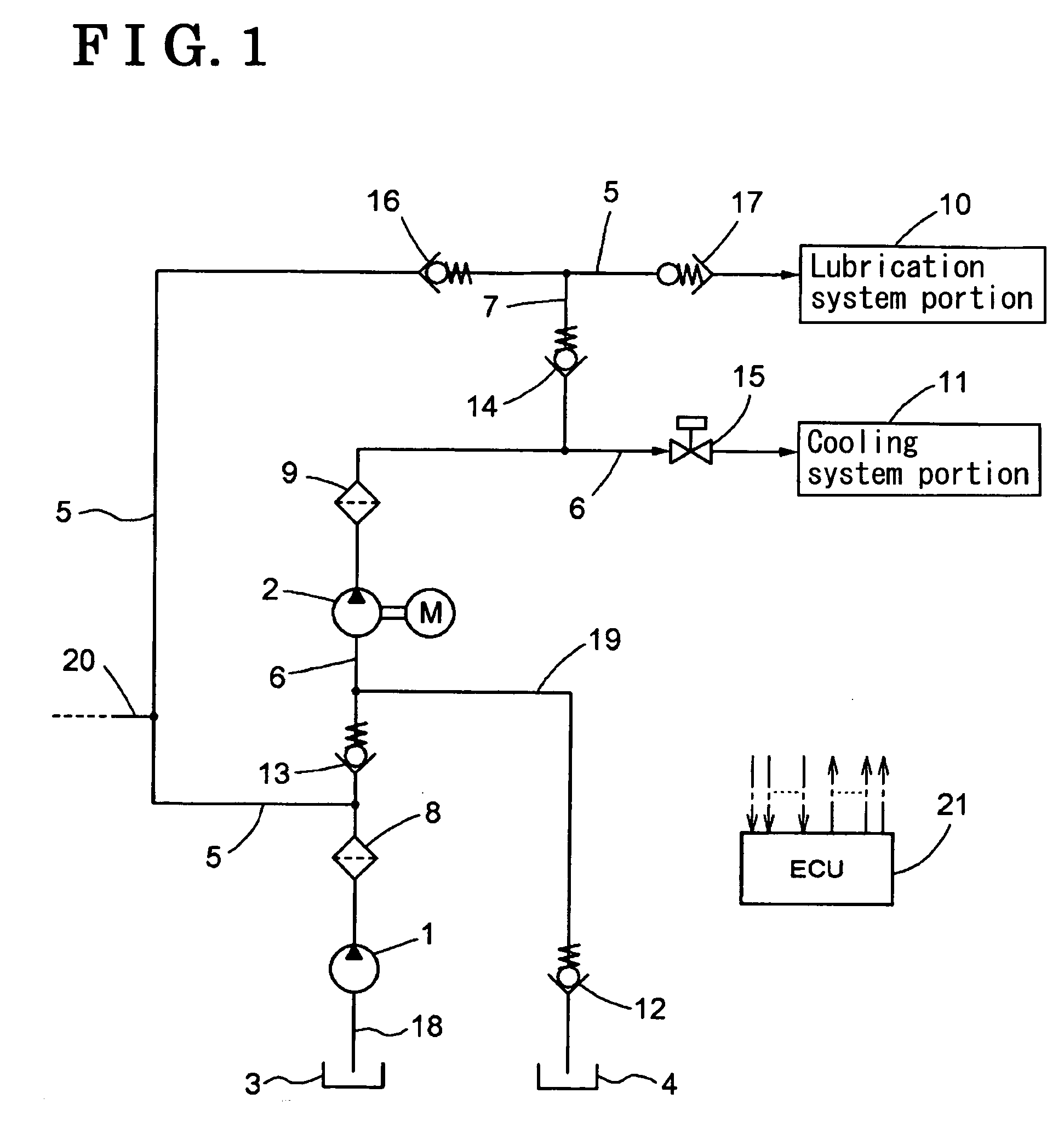

[0018] As shown in FIG. 1, an oil supply device for an engine according to the present invention includes an oil supply circuit which includes a lubrication system portion 10 where oil for lubrication is supplied in the engine and a cooling system portion 11 where the oil for cooling is supplied. For example, the lubrication system portion 10 includes a cam shower for showering oil for lubrication to a cam, and a chain jet for jetting oil for oil to a cam chain, or the like. The cooling system portion 11, for example, includes a piston jet for jetting cooling oil to a piston.

[0019] According to this oil supply circuit, oil is supplied to the lubrication system portion 10 and the cooling system portion 11 from either a first oil reservoir 3 or a second oil reservoir 4. More particularly, the oil supply circuit includes a first pump 1 and a second pump 2 for discharging oil to the lubrication system portion 10 and the cooling system portion 11 by sucking oil from the first oil reservo...

third embodiment

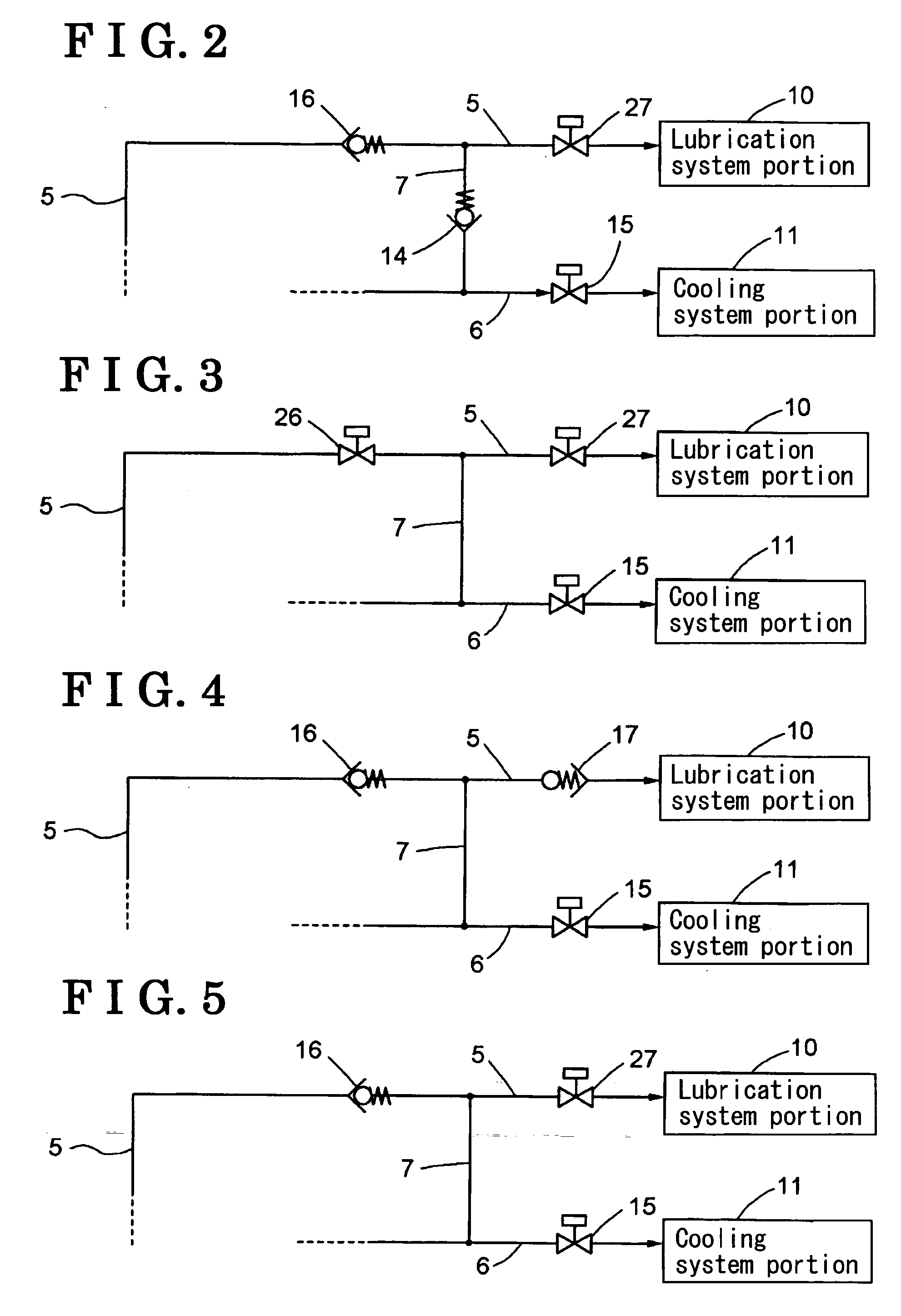

[0040] A third embodiment of the present invention will be explained with reference to FIG. 3. According to the present invention, as shown in FIG. 3, a third valve 27 (i.e., a opening and closing valve) is provided on the first oil passage 5 at the upstream side of the connection point between the first oil passage 5 and the third oil passage 7 instead of the check valve, a third valve 27 (i.e., opening and closing valve) is provided on the first oil passage 5 at the downstream side of the connection point between the first oil passage 5 and the third oil passage 7 instead of the stop valve, and the first valve 14 shown in FIG. 1 is not provided. The ECU 21 commands to open the second valve 26 and the third valve 27 and to close the fourth valve 15 for supplying oil for lubrication only to the lubrication system portion 10 by the first pump 1. The ECU 21 commands to open the third valve 27 and to close the fourth valve 15 and the second valve 26 for supplying oil only to the lubric...

seventh embodiment

[0044] A seventh embodiment of the present invention will be explained with reference to FIG. 7. According to the present invention, the oil pressure actuation portion 33 according to the sixth embodiment is replaced with a shape memory spring 43. An operation of the oil supply device according to the seventh embodiment of the present invention is as follows. First, when the ECU 21 stops the second pump 2, operational oil is supplied from the first pump 1 to the lubrication system portion 10. The ECU 21 operates the second pump 2 with low pressure for discharging oil when engine rotation speed is low and an engine oil temperature is high. As a result, the shape memory spring 43 is expanded by oil temperature of the operational oil, the spool valve biased by a spring 32 is moved to the left in FIG. 7, and operational oil from the second pump 2 is supplied to the lubrication system portion 10. The ECU 21 operates the second pump 2 with high pressure to discharge high-pressured oil whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com