Patents

Literature

299results about "Closed-circuit pressure lubricating systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

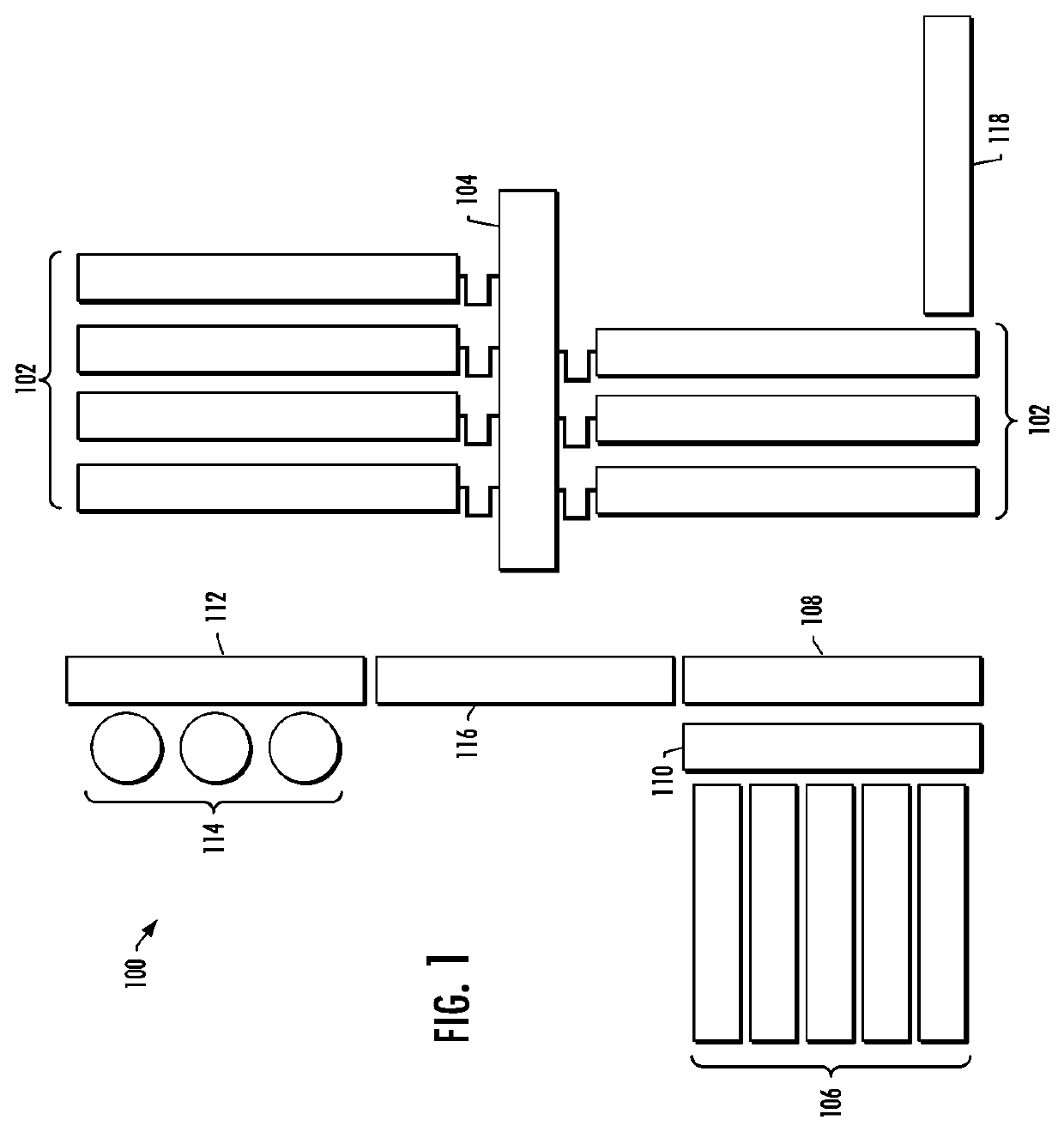

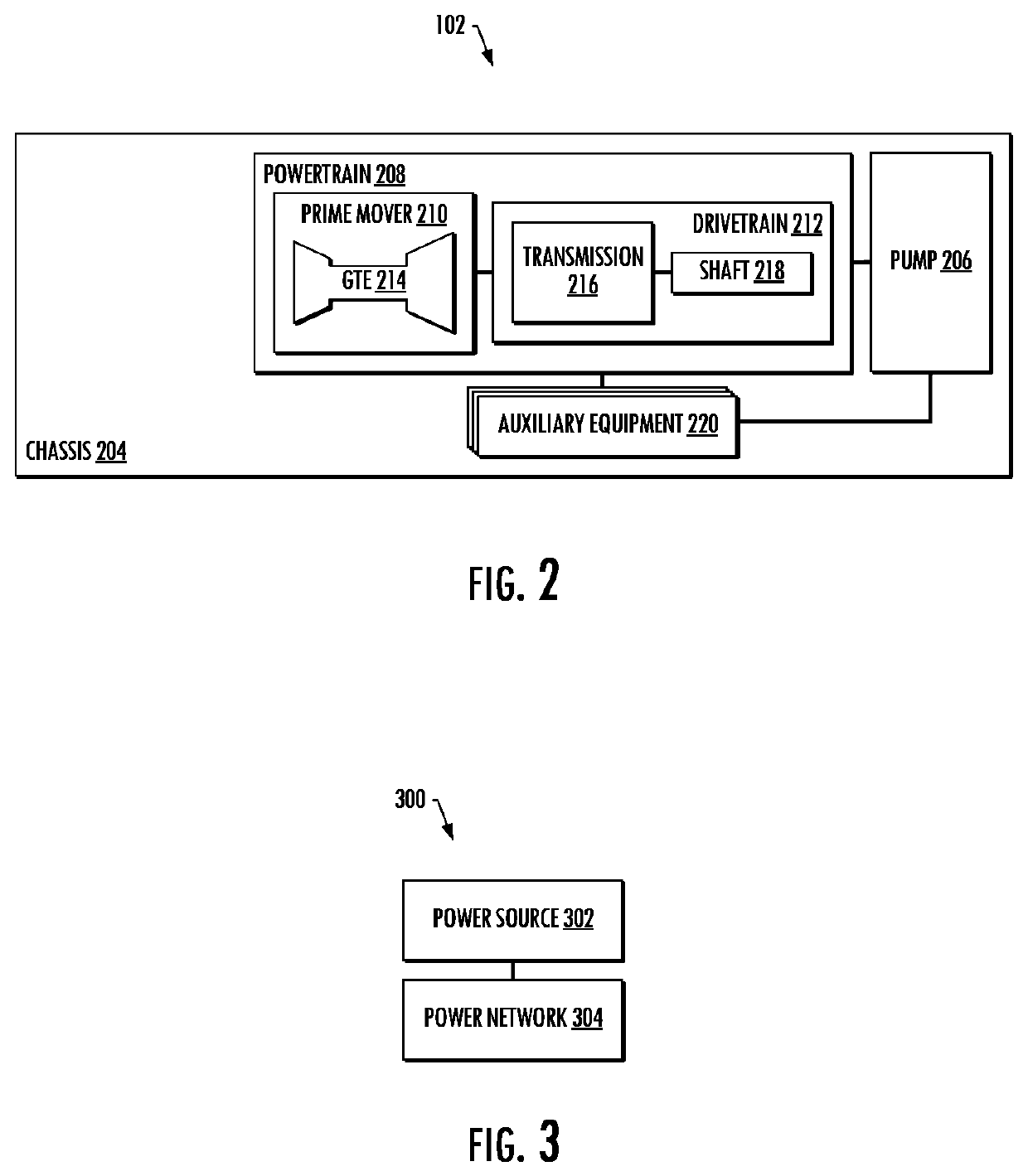

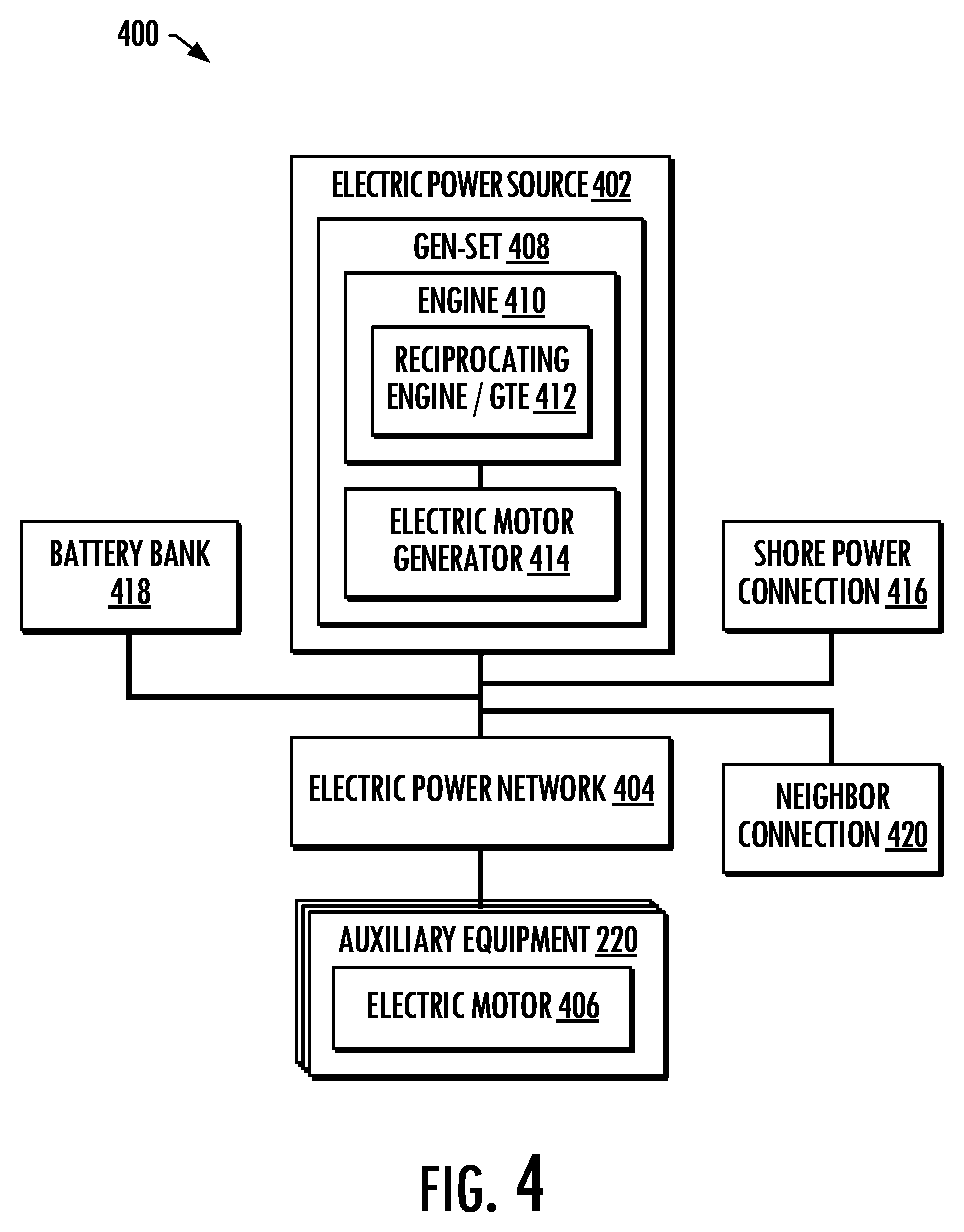

Power sources and transmission networks for auxiliary equipment onboard hydraulic fracturing units and associated methods

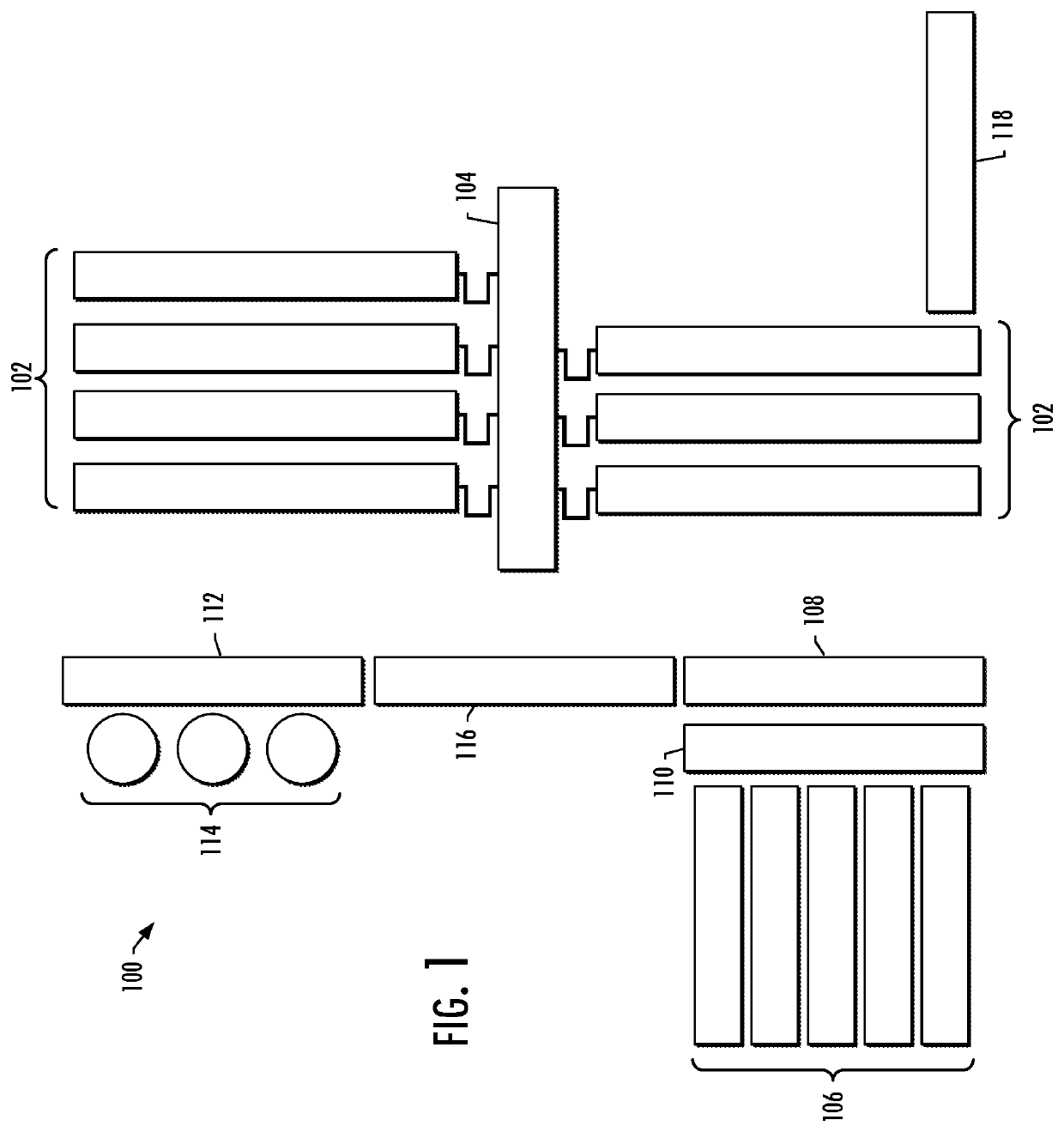

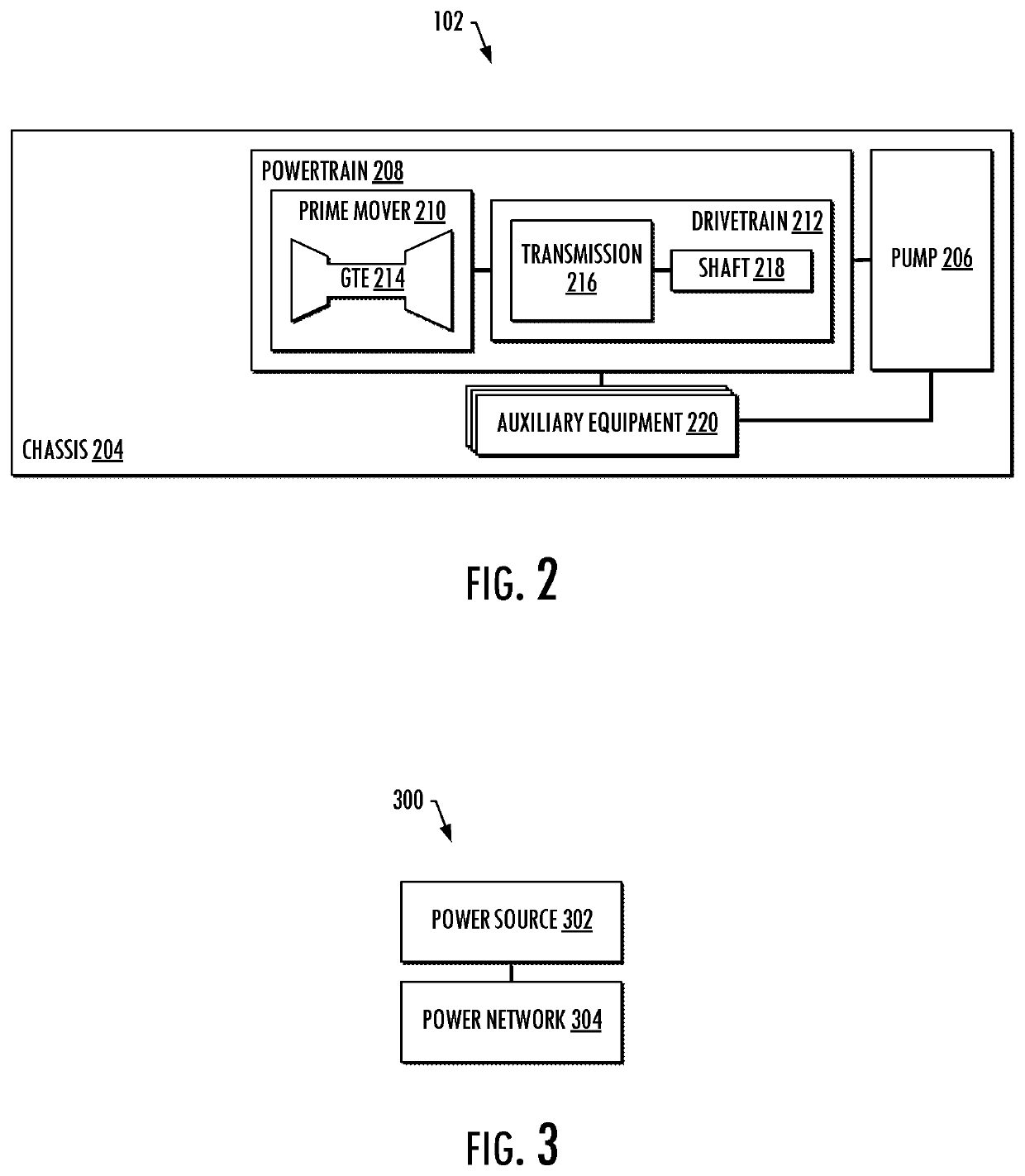

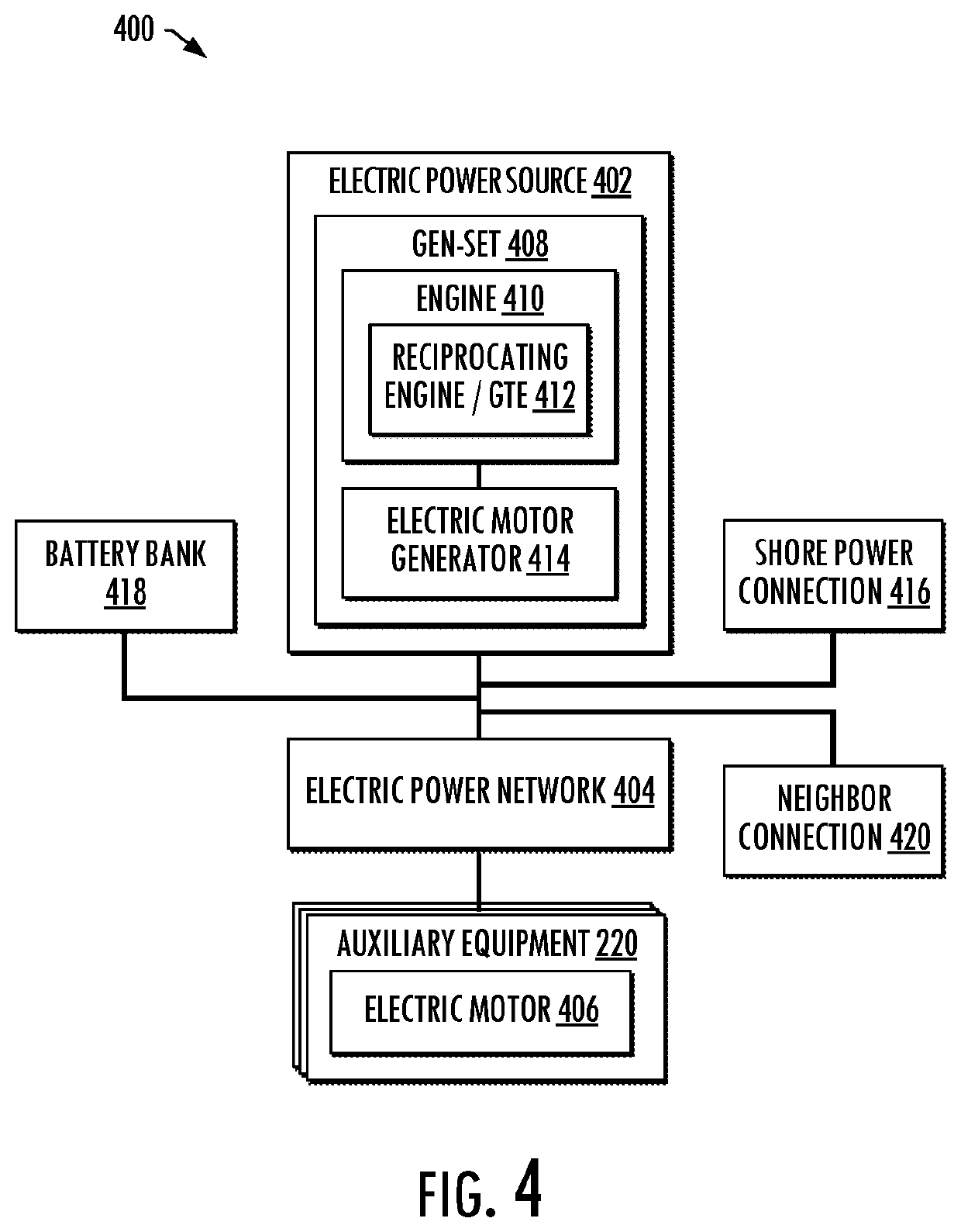

Embodiments of systems and methods disclosed provide a hydraulic fracturing unit that includes a reciprocating plunger pump configured to pump a fracturing fluid and a powertrain configured to power the reciprocating plunger pump. The powertrain includes a prime mover and a drivetrain, the prime mover including a gas turbine engine. The hydraulic fracturing unit also includes auxiliary equipment configured to support operation of the hydraulic fracturing unit including the reciprocating plunger pump and the powertrain. A power system is configured to power the auxiliary equipment. The power system includes a power source and a power network. The power source is configured to generate power for the auxiliary equipment. The power network is coupled to the power source and the auxiliary equipment, and configured to deliver the power generated by the power source to the auxiliary equipment. Associated systems including a plurality of hydraulic fracturing units are also provided.

Owner:BJ ENERGY SOLUTIONS LLC

Engine lubrication system

ActiveUS6941922B2Small sizeLubrication of auxillariesLubricant conduit arrangementsLine tubingEngineering

A lubrication system for an engine including a sump for lubricant, a main pump operable to pump lubricant to first lubrication positions within the engine, and an auxiliary lubricant pump also operable to pump lubricant to second lubrication positions within the engine and wherein the auxiliary pump is an electrically driven pump which is controlled by a system controller the output of the auxiliary pump being controlled according to engine operating conditions, the main pump in use, pumping lubricant to the first lubrication positions within the engine along a main lubricant feed line, and the auxiliary pump when operated pumping lubricant to the second lubrication positions within the engine along an auxiliary feed line, and wherein the main and auxiliary feed lines, are connected via a communication passage which includes a closeable communication valve, the communication valve when closed preventing the flow of lubricant from the auxiliary feed line to the first lubrication positions, and when open permitting the flow of lubricant from the auxiliary feed line to the first lubrication positions.

Owner:PIERBURG PUMP TECH UK

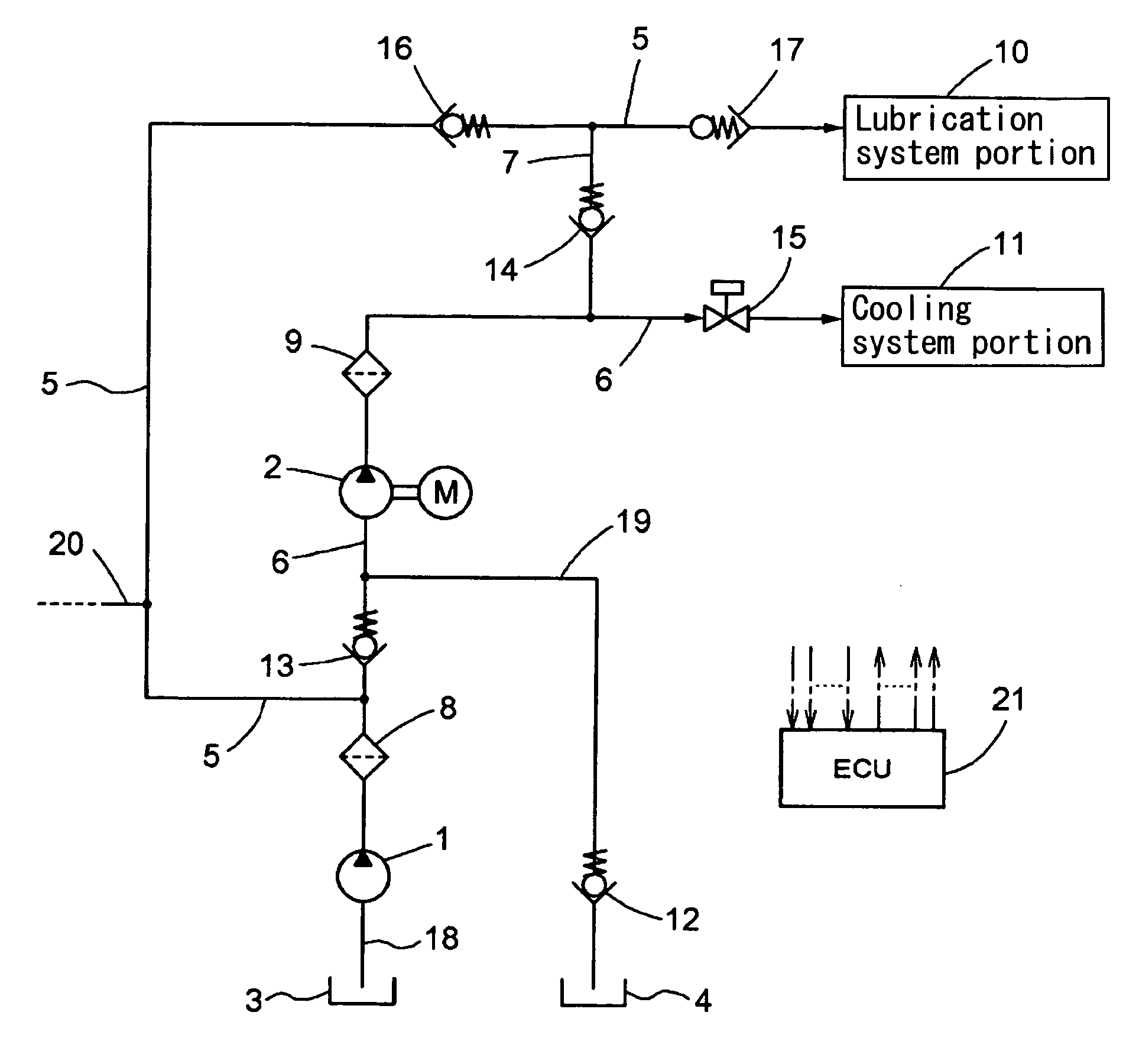

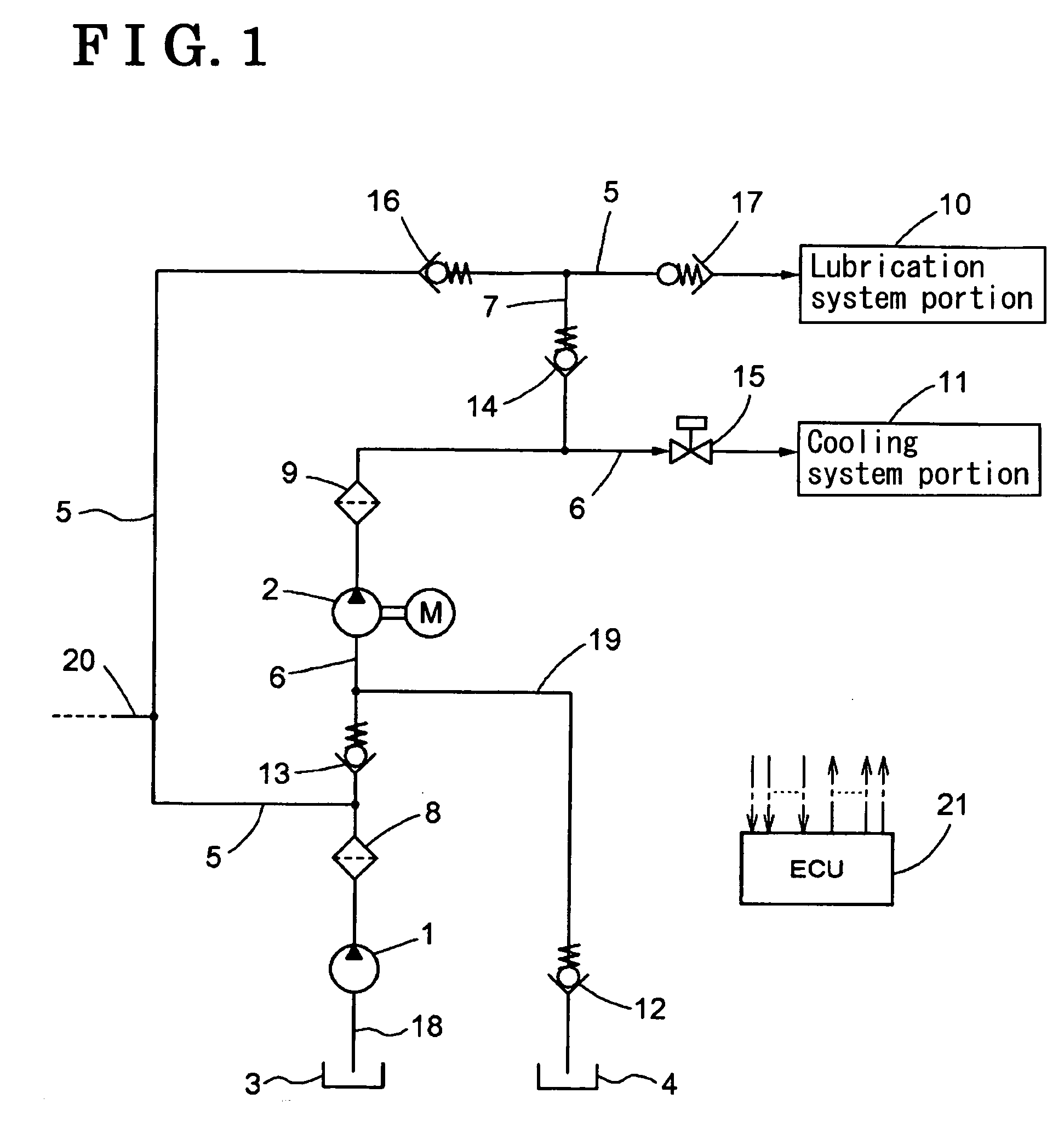

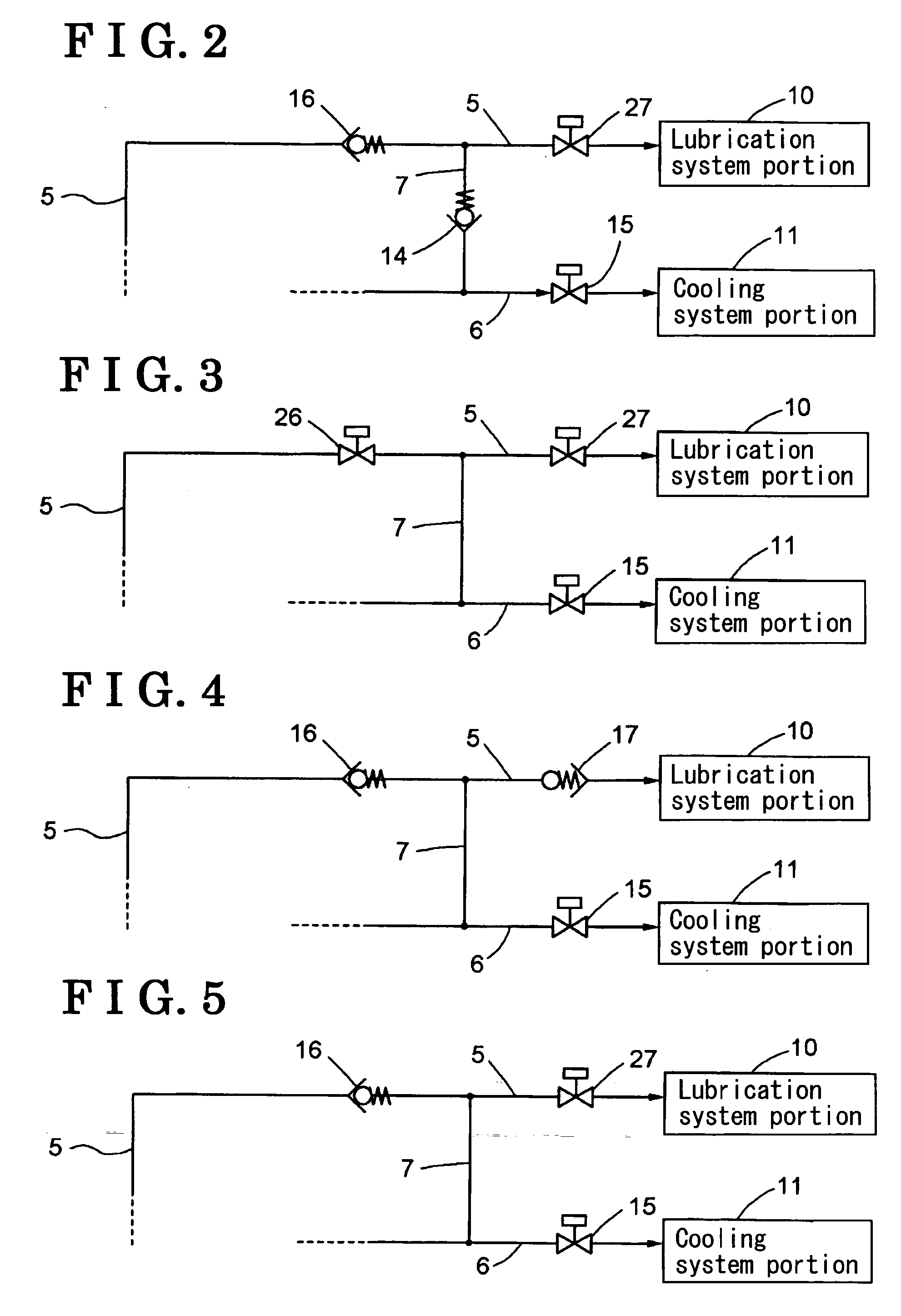

Oil supply device for engine

An oil supply device for an engine includes a first oil suction passage, a second oil suction passage, a first pump for sucking and discharging oil from the first oil suction passage, a second pump arranged in series with the first pump, the second pump for sucking and discharging oil from at least one of the first pump and the second oil suction passage, a check valve for blocking oil circulation, a first oil passage, a second oil passage, a third oil passage for establishing communication between the first oil passage and the second oil passage, and a supply volume control device for varying oil supply volume to a lubrication system portion, to a cooling system portion, or to the lubrication system portion and the cooling system portion in accordance with a change in at least one of an engine oil temperature, an engine rotation speed, and an engine load.

Owner:AISIN SEIKI KK

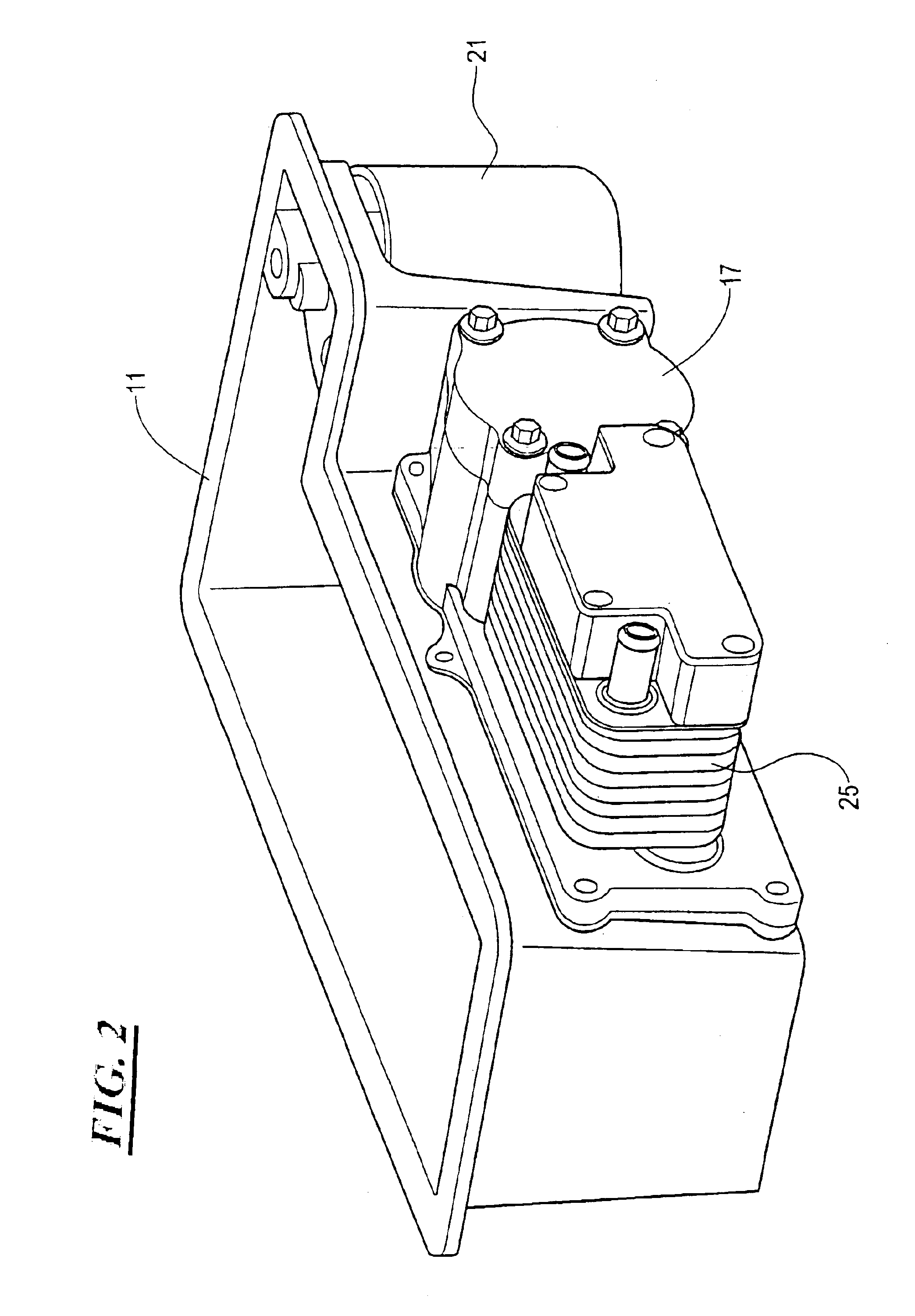

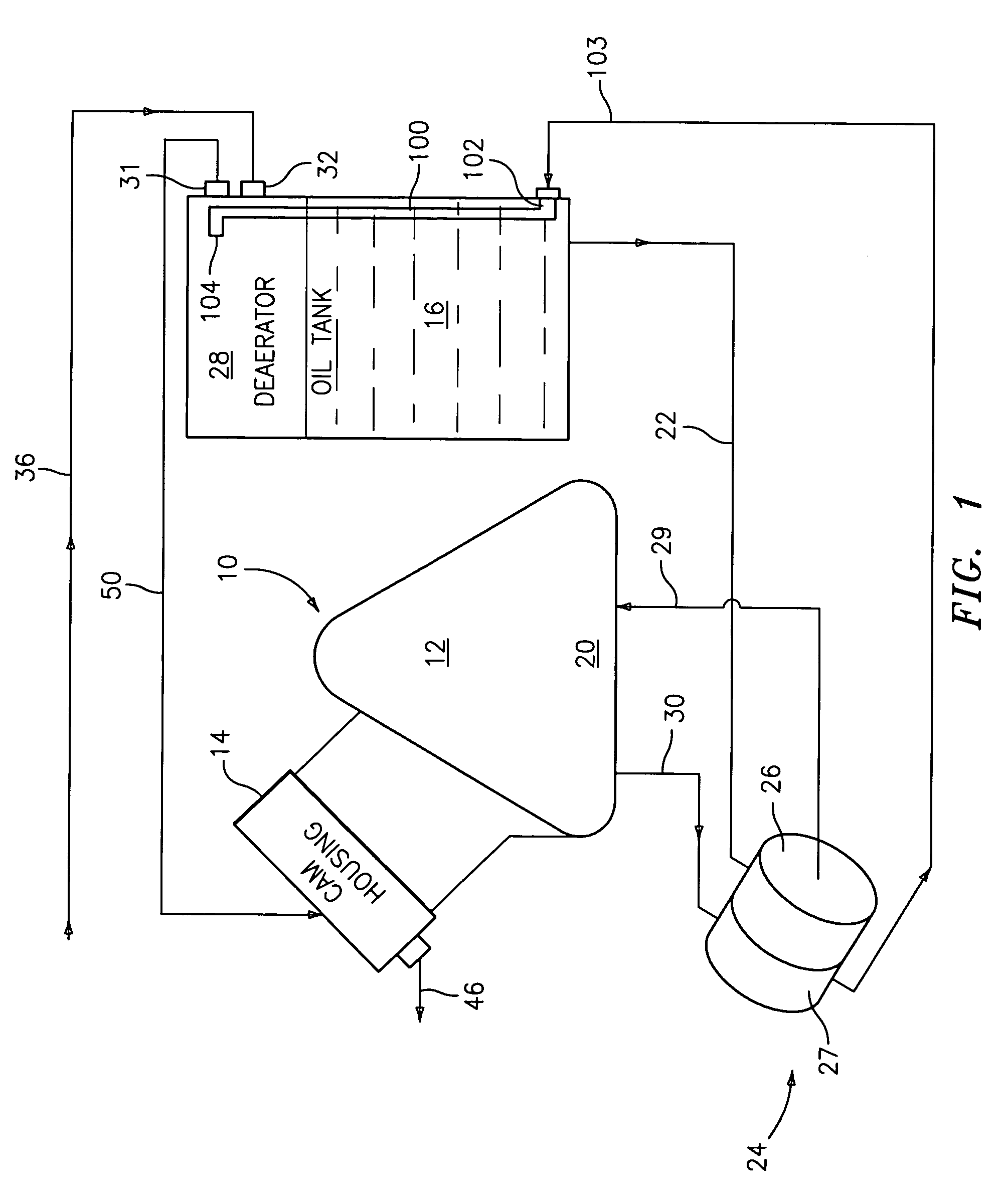

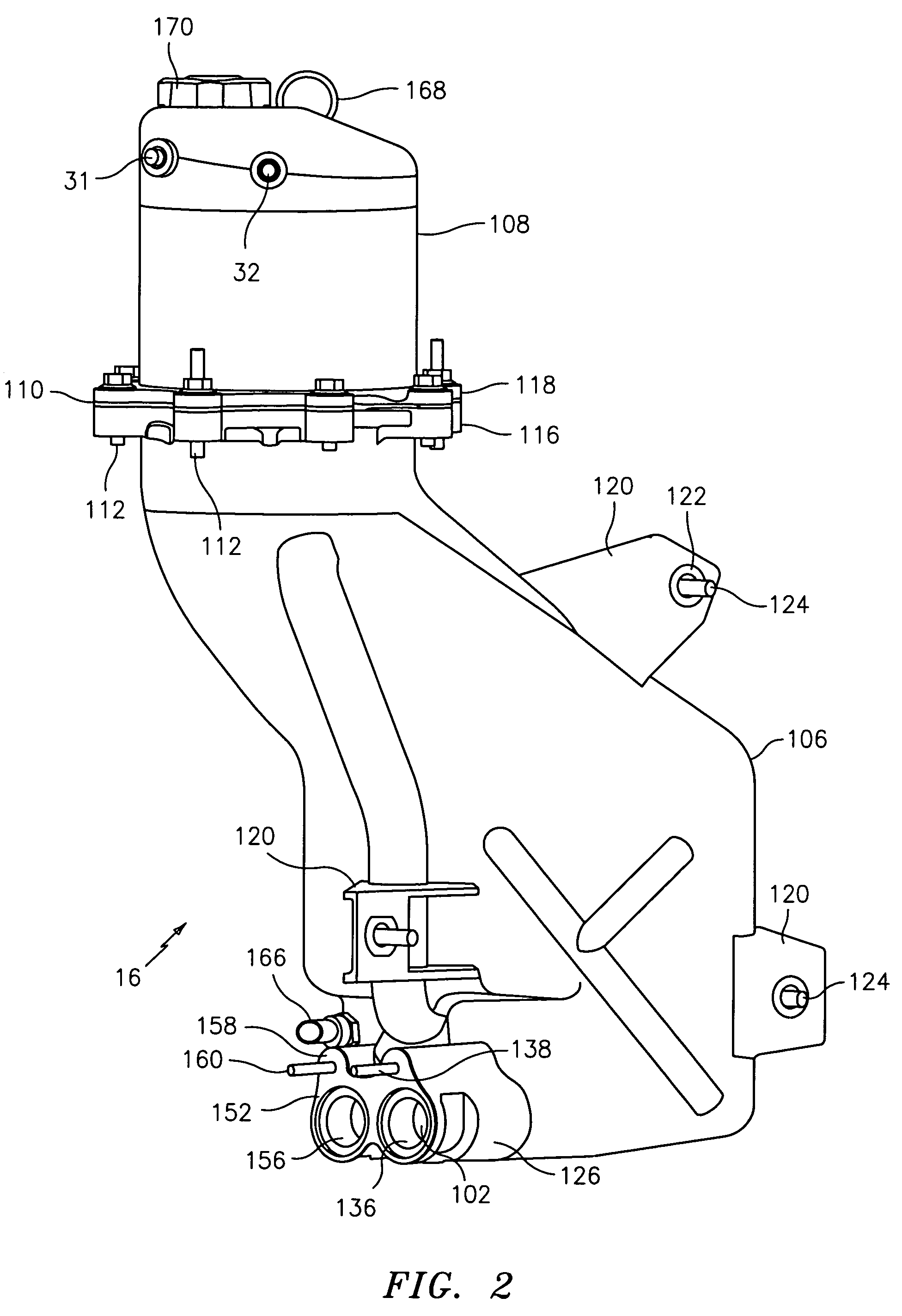

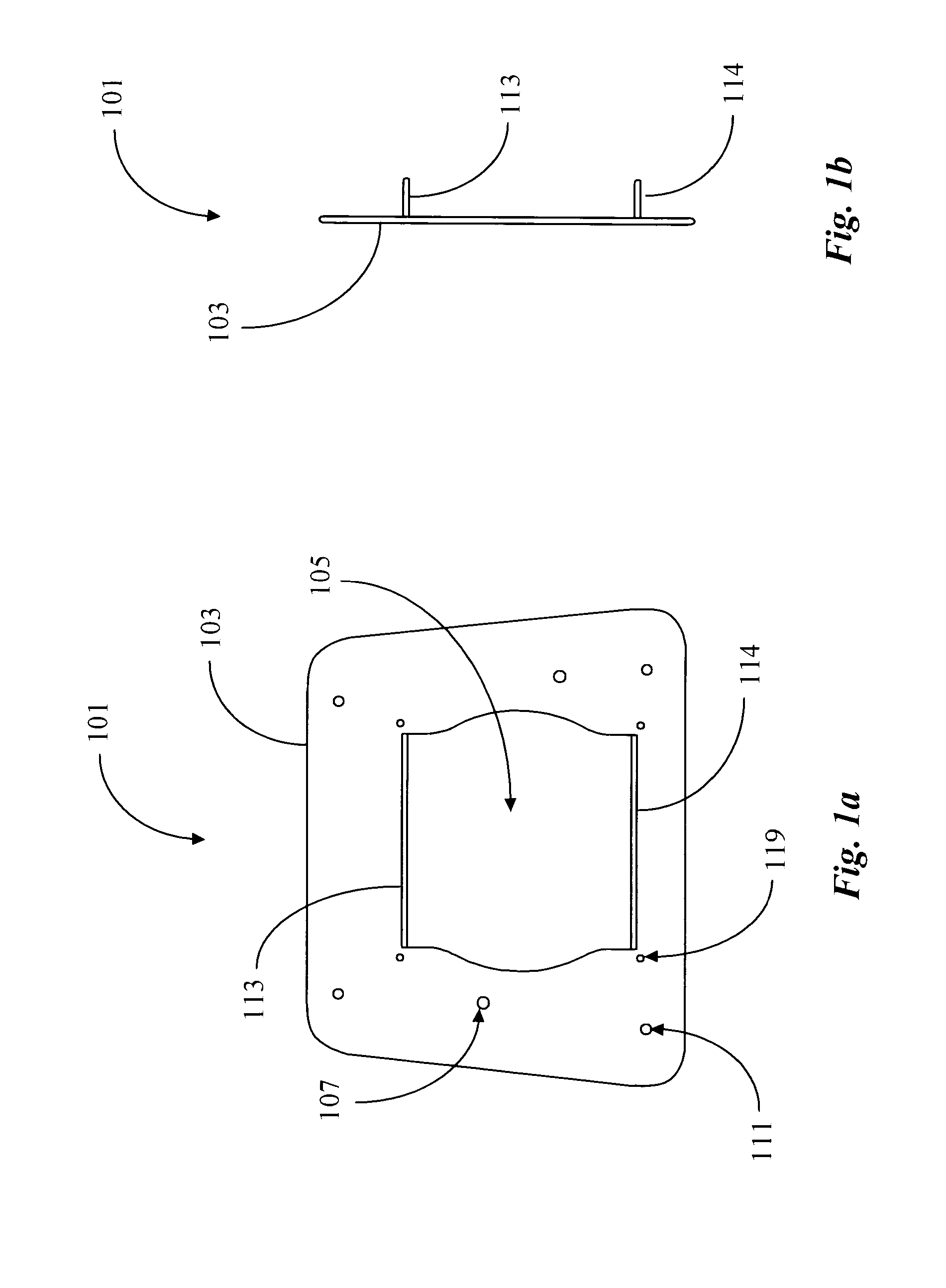

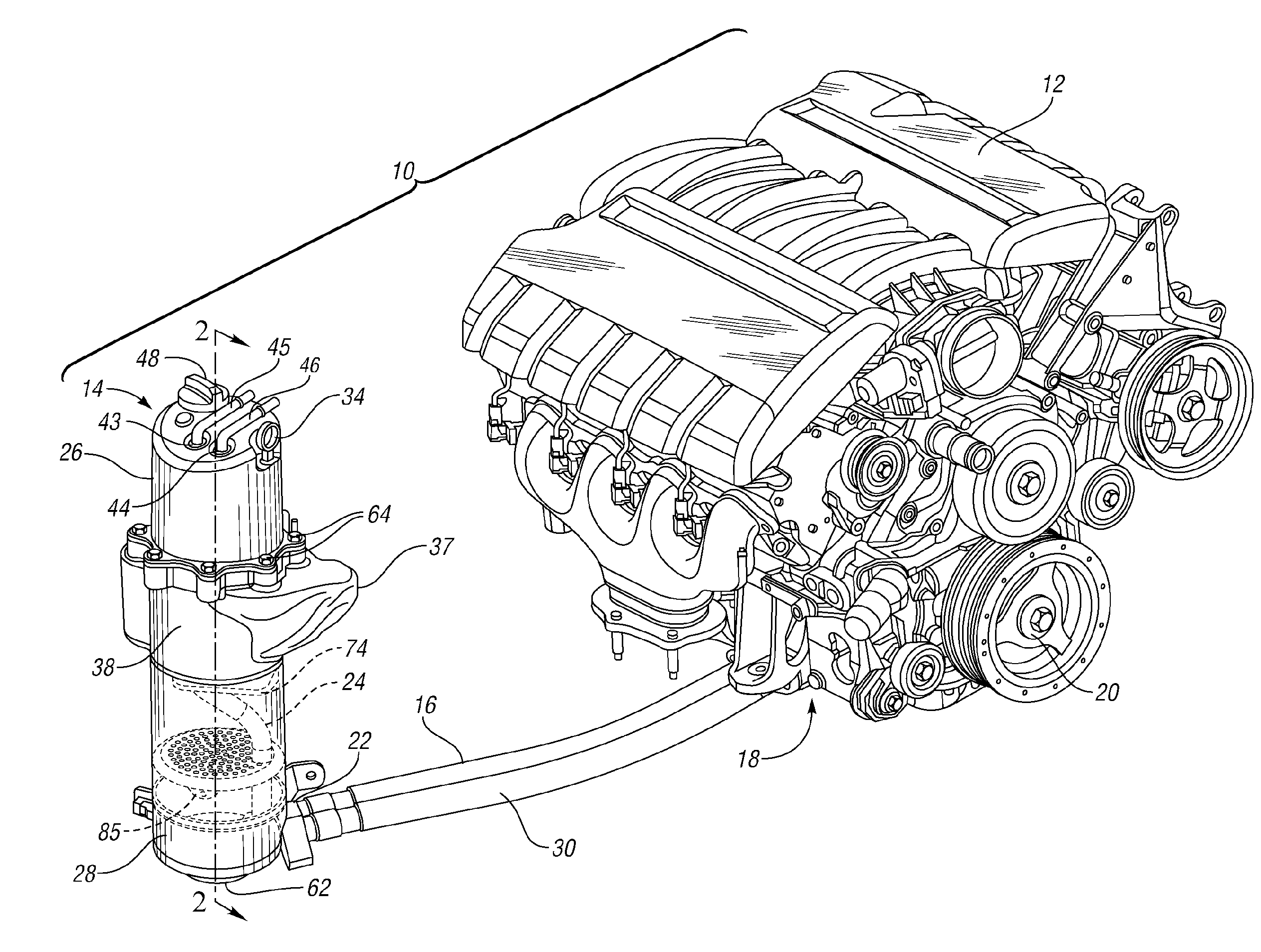

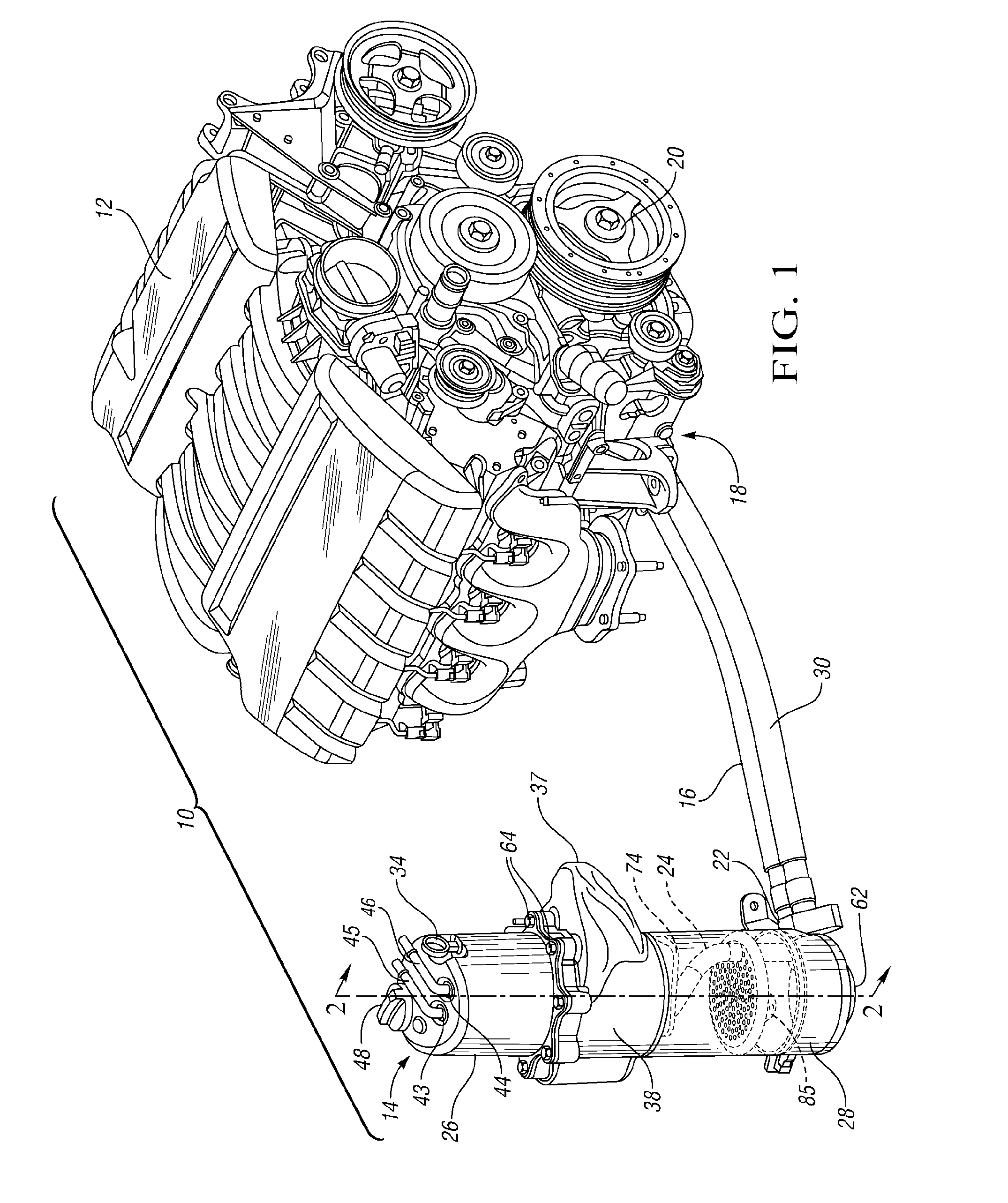

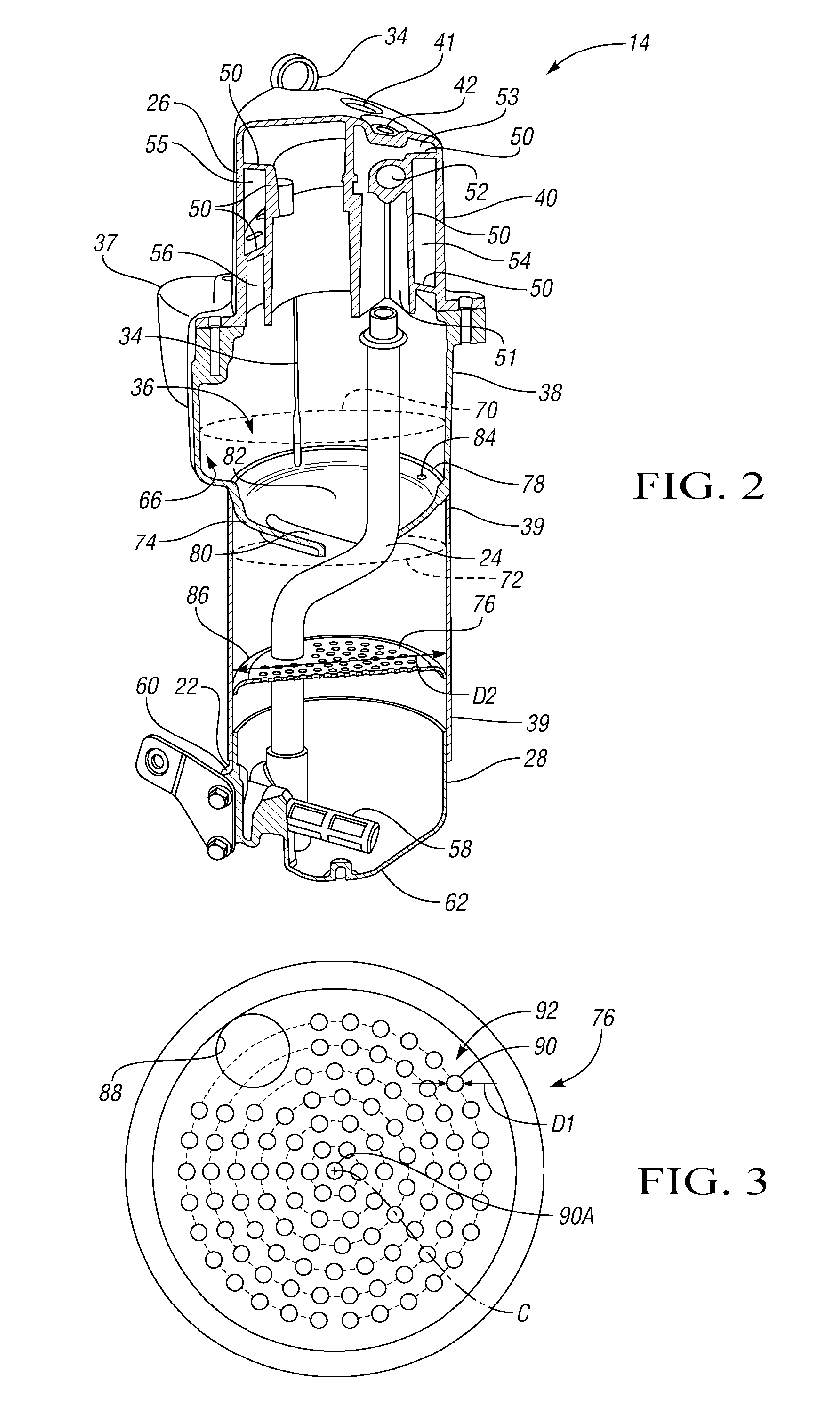

Dry sump oil tank assembly

A tank assembly for a dry sump lubrication system for an internal combustion engine is disclosed. The tank assembly includes a tank having an upper tank portion and a lower tank portion. An interface assembly is disposed at the lower tank portion and is configured to operably deliver and receive a lubricant to and from the engine. A first end of a return tube in fluid communication with a second end is configured to receive lubricant from the engine at the interface assembly. The second end opposite the first end is in fluid communication with the upper tank portion. In this manner, a return hose and a feed hose may be connected to a same portion of the tank assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC

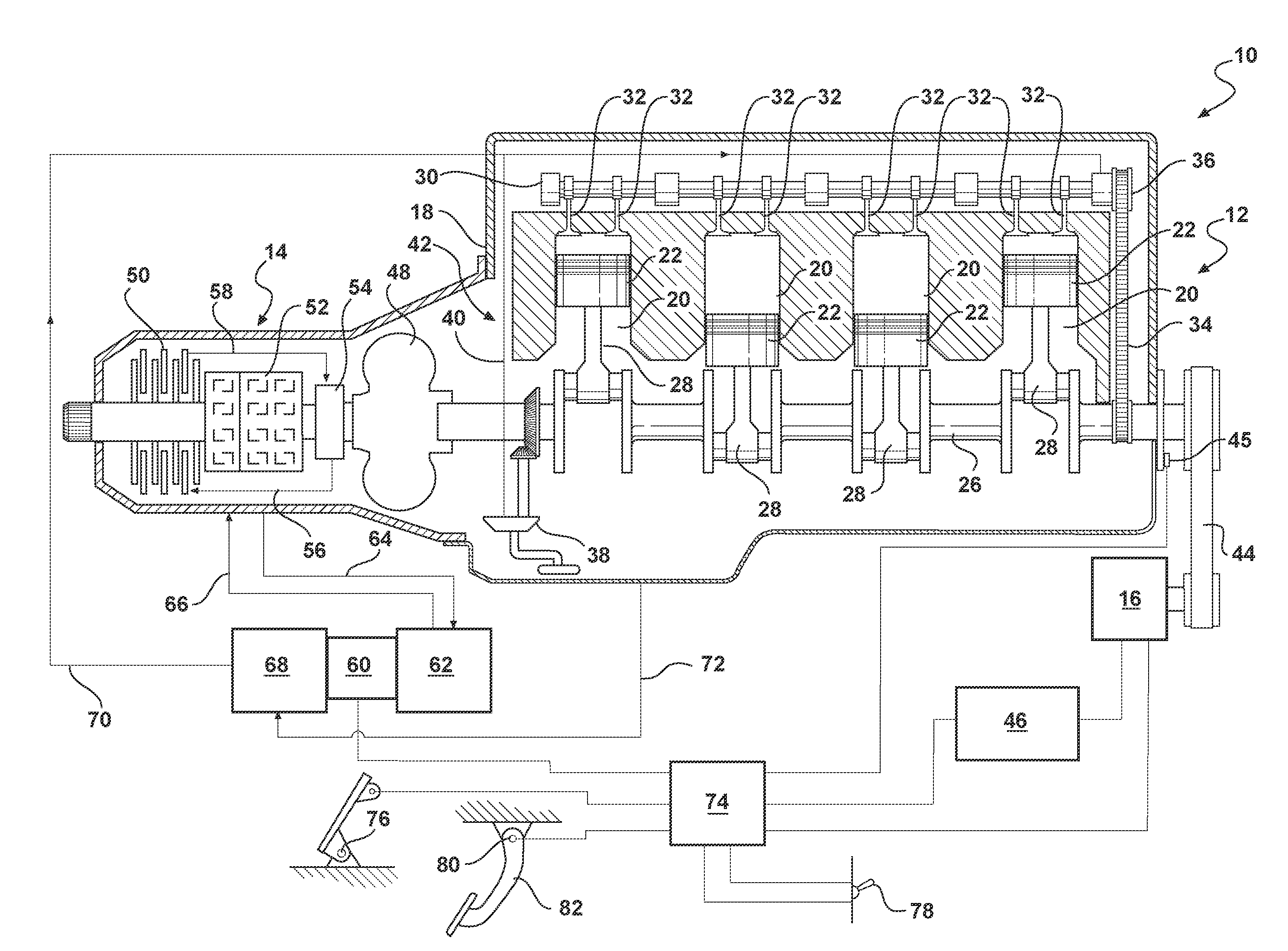

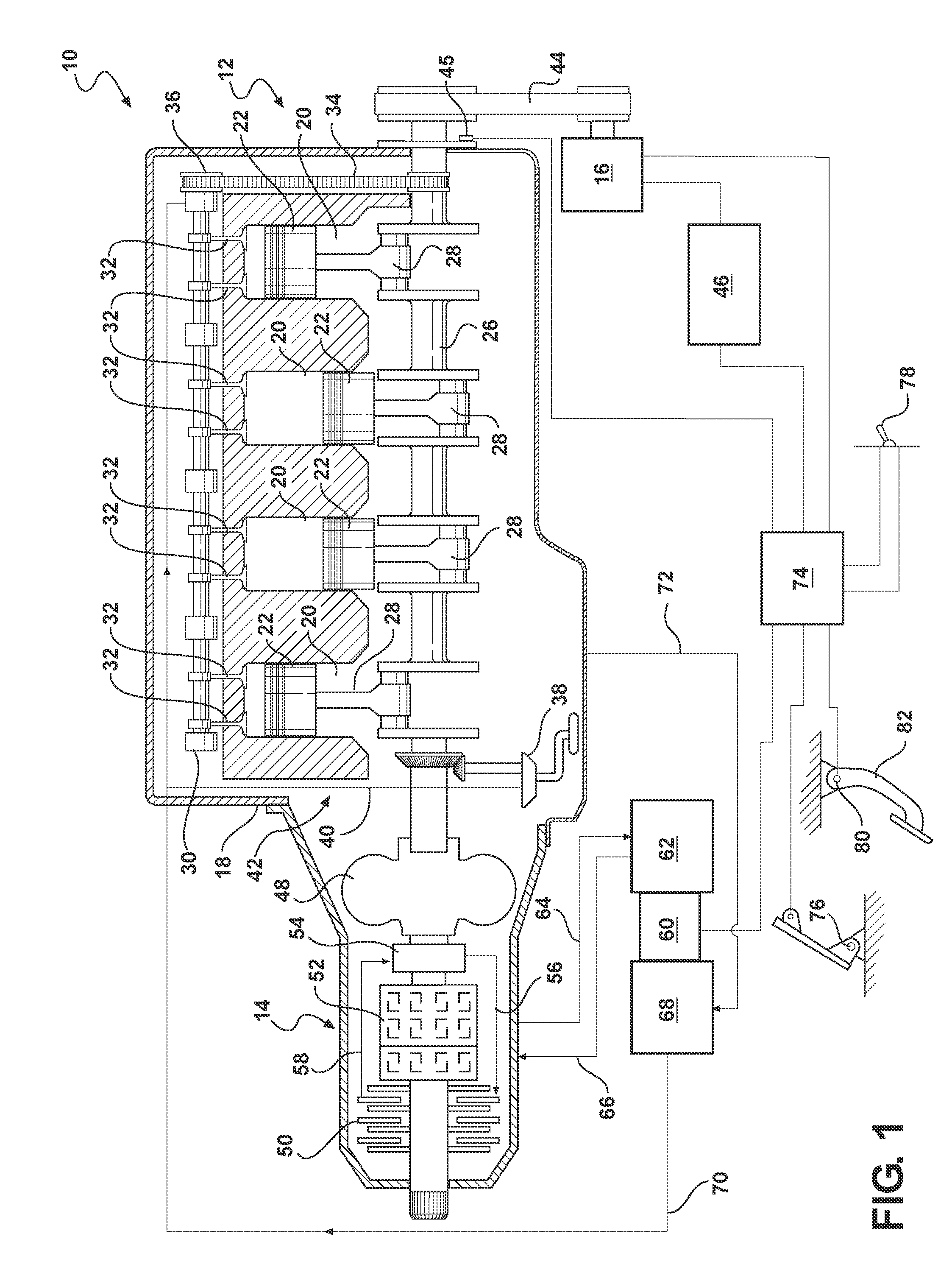

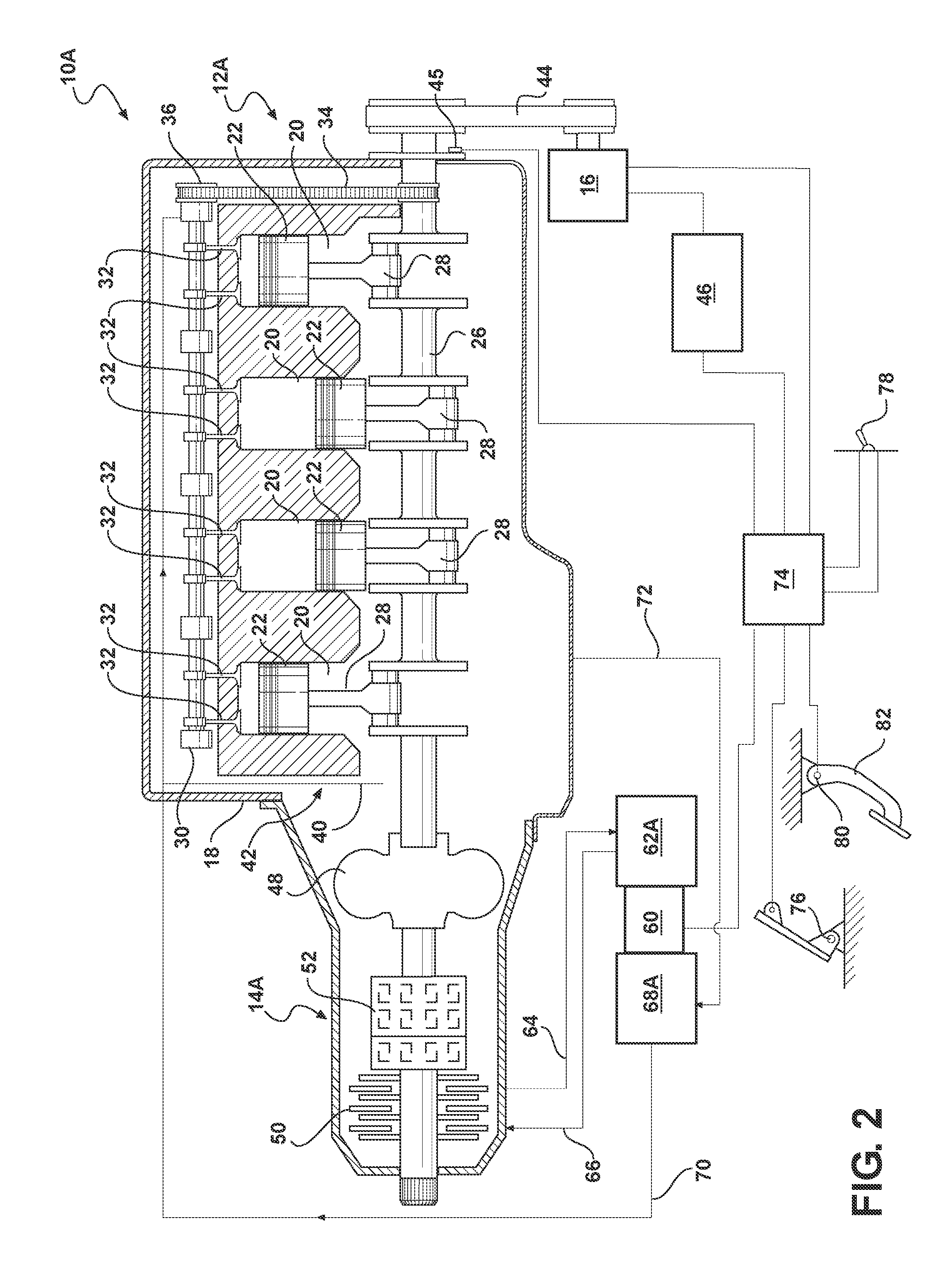

Power sources and transmission networks for auxiliary equipment onboard hydraulic fracturing units and associated methods

ActiveUS10989180B2Liquid coolingPositive displacement pump componentsDrivetrainElectric power system

Embodiments of systems and methods disclosed provide a hydraulic fracturing unit that includes a reciprocating plunger pump configured to pump a fracturing fluid and a powertrain configured to power the reciprocating plunger pump. The powertrain includes a prime mover and a drivetrain, the prime mover including a gas turbine engine. The hydraulic fracturing unit also includes auxiliary equipment configured to support operation of the hydraulic fracturing unit including the reciprocating plunger pump and the powertrain. A power system is configured to power the auxiliary equipment. The power system includes a power source and a power network. The power source is configured to generate power for the auxiliary equipment. The power network is coupled to the power source and the auxiliary equipment, and configured to deliver the power generated by the power source to the auxiliary equipment. Associated systems including a plurality of hydraulic fracturing units are also provided.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

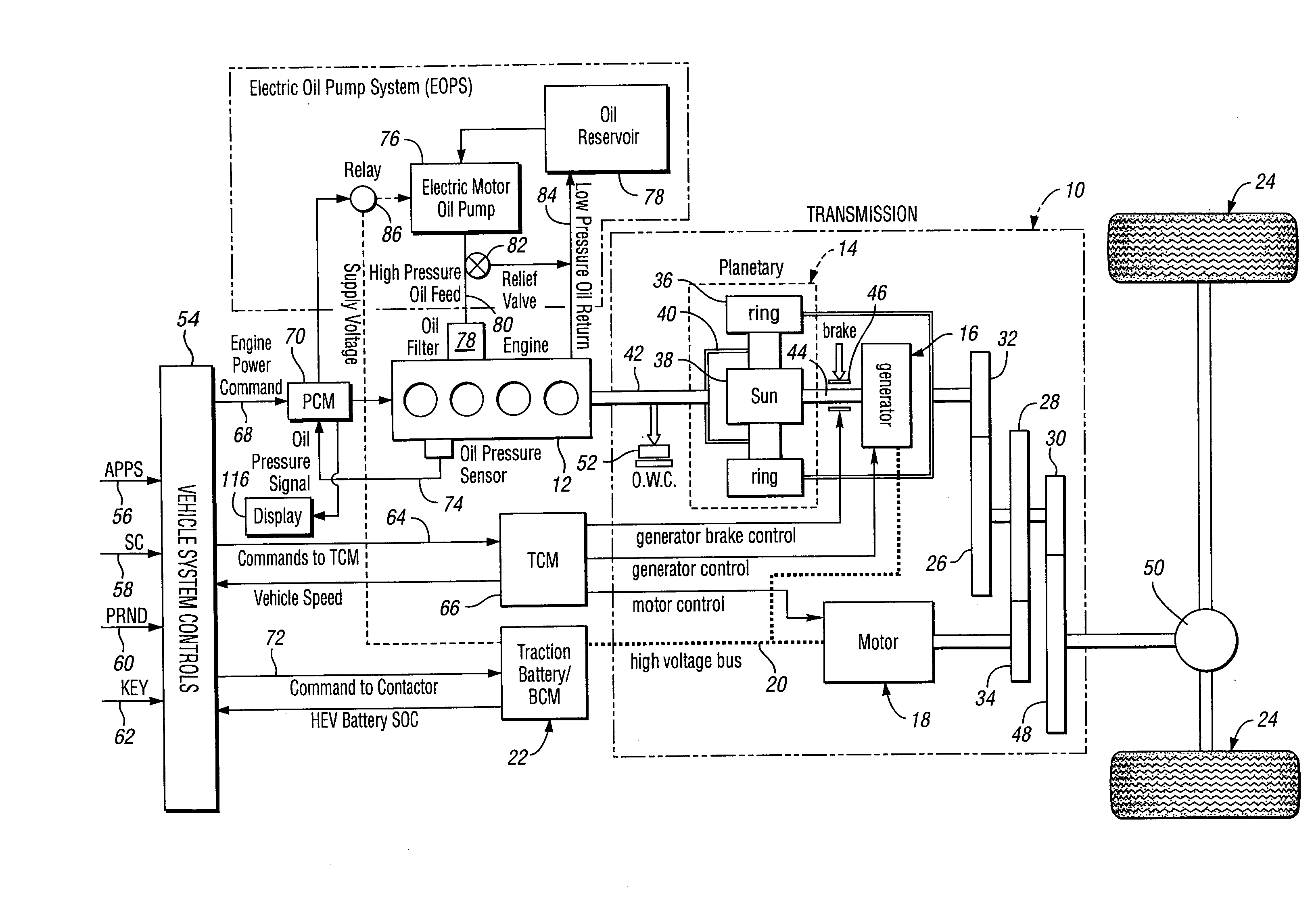

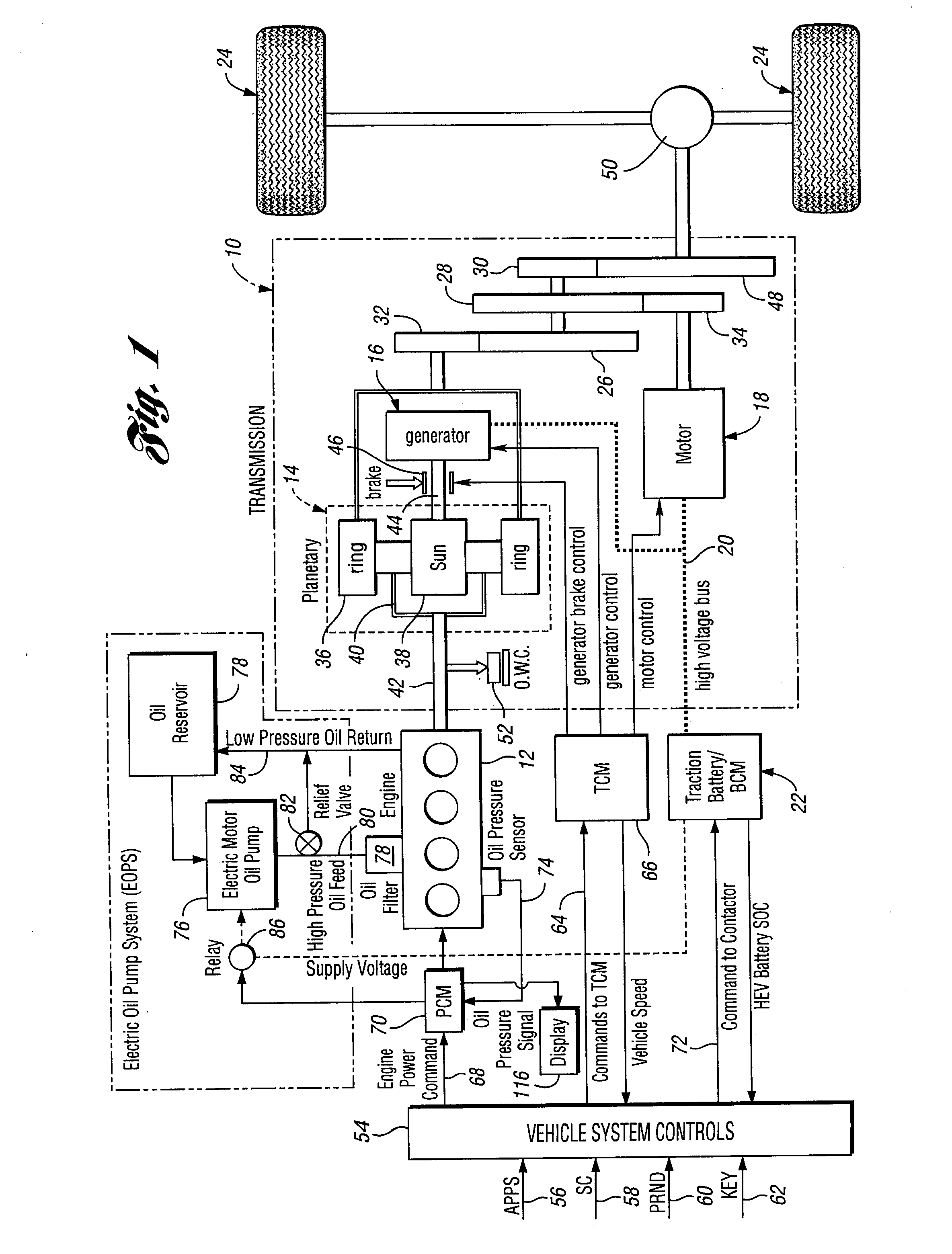

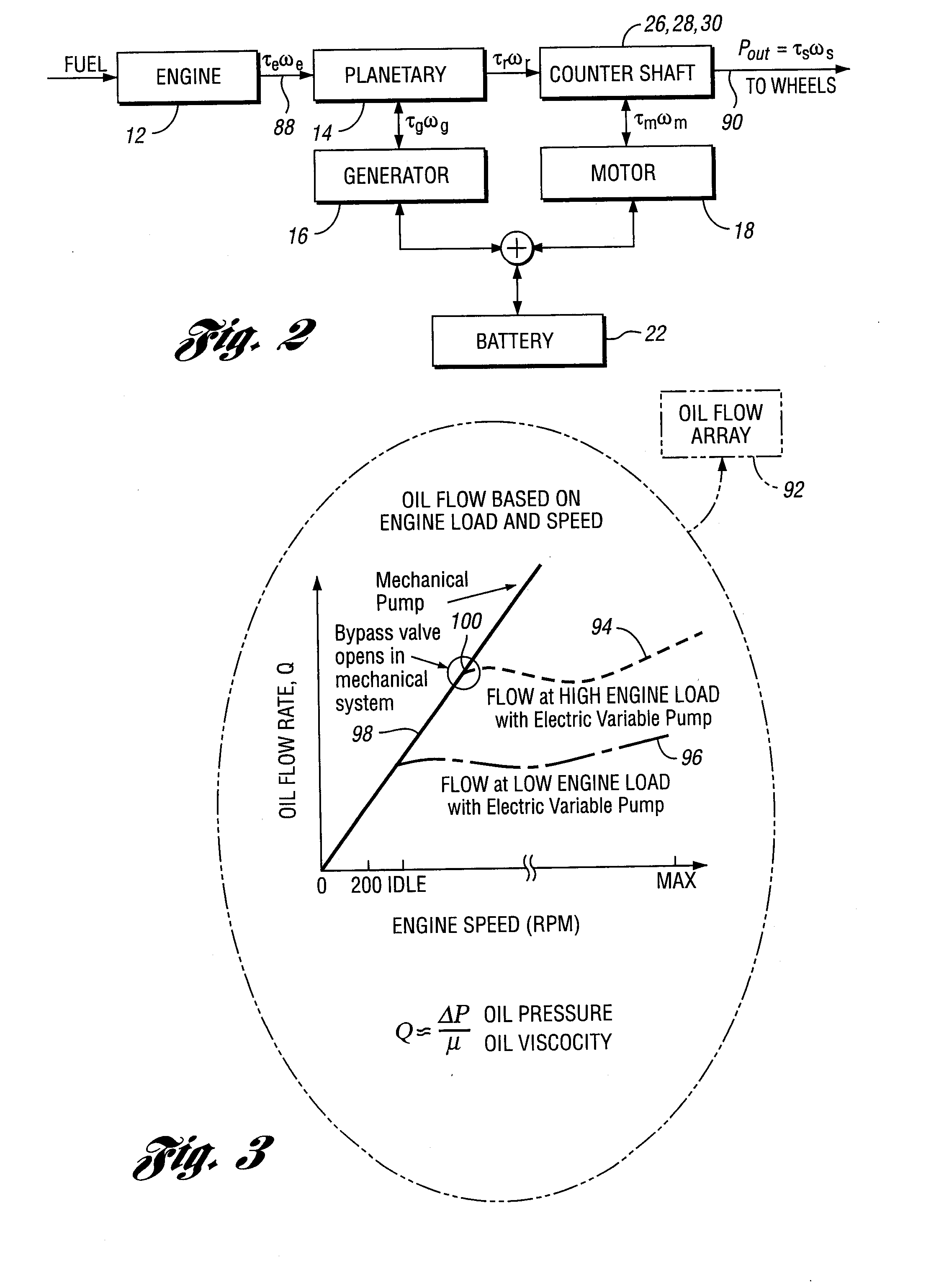

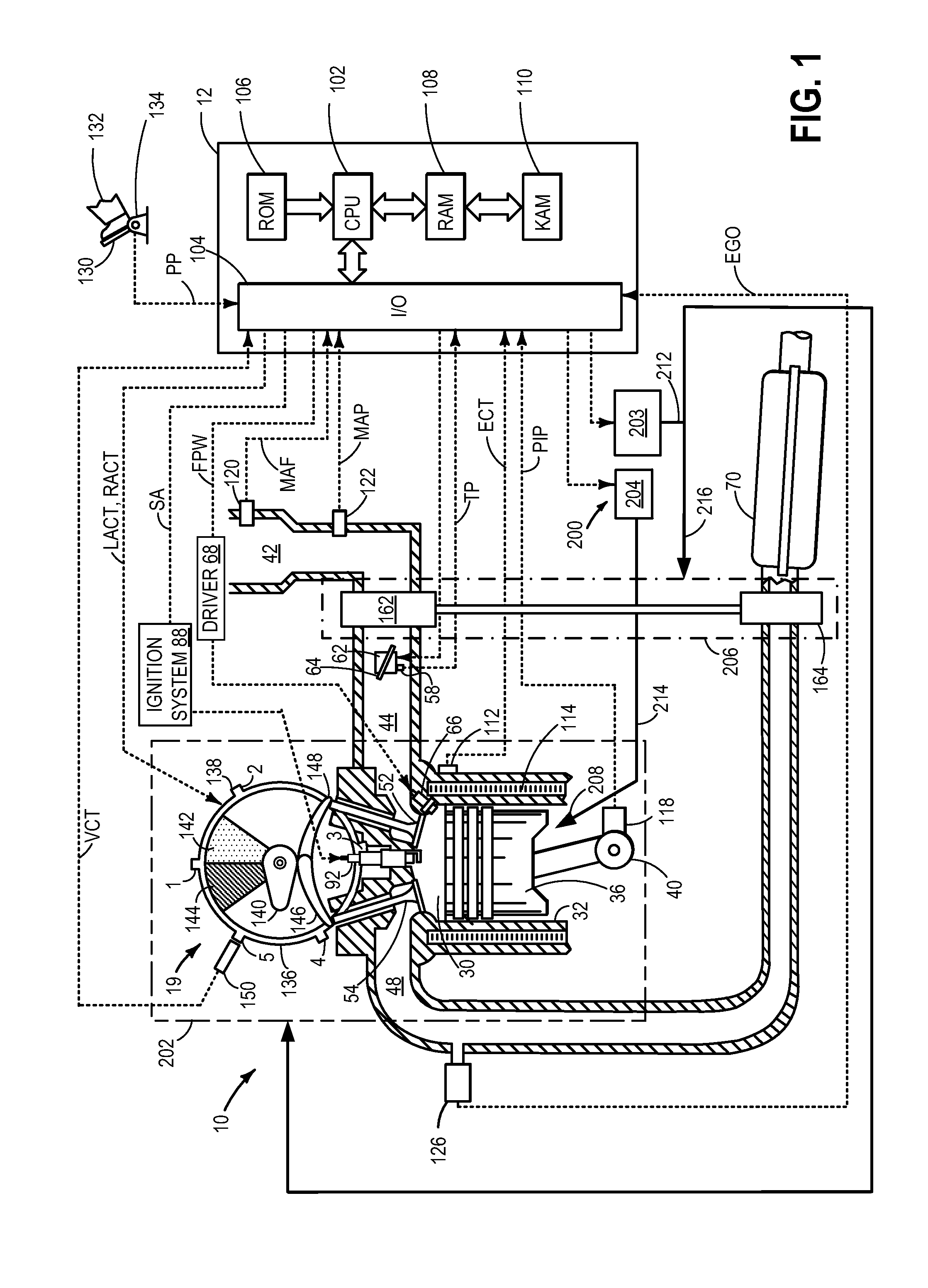

Electric Oil Pump System and Controls for Hybrid Electric Vehicles

ActiveUS20080121464A1Operation efficiency can be improvedAccurate measurementHybrid vehiclesDigital data processing detailsControl systemElectric vehicle

An engine lubrication oil flow control system and control method for an engine in a hybrid electric vehicle powertrain is disclosed. An engine lubrication oil pump is powered by a lubrication oil pump motor. Provision is made to start the lubrication pump motor at the initiation of engine cranking upon a transition from an engine-off driving mode to an engine-on driving mode. An engine oil pressure signal is used to indicate engine filter maintenance is needed. The oil pump motor may be powered by a vehicle powertrain traction battery.

Owner:FORD GLOBAL TECH LLC

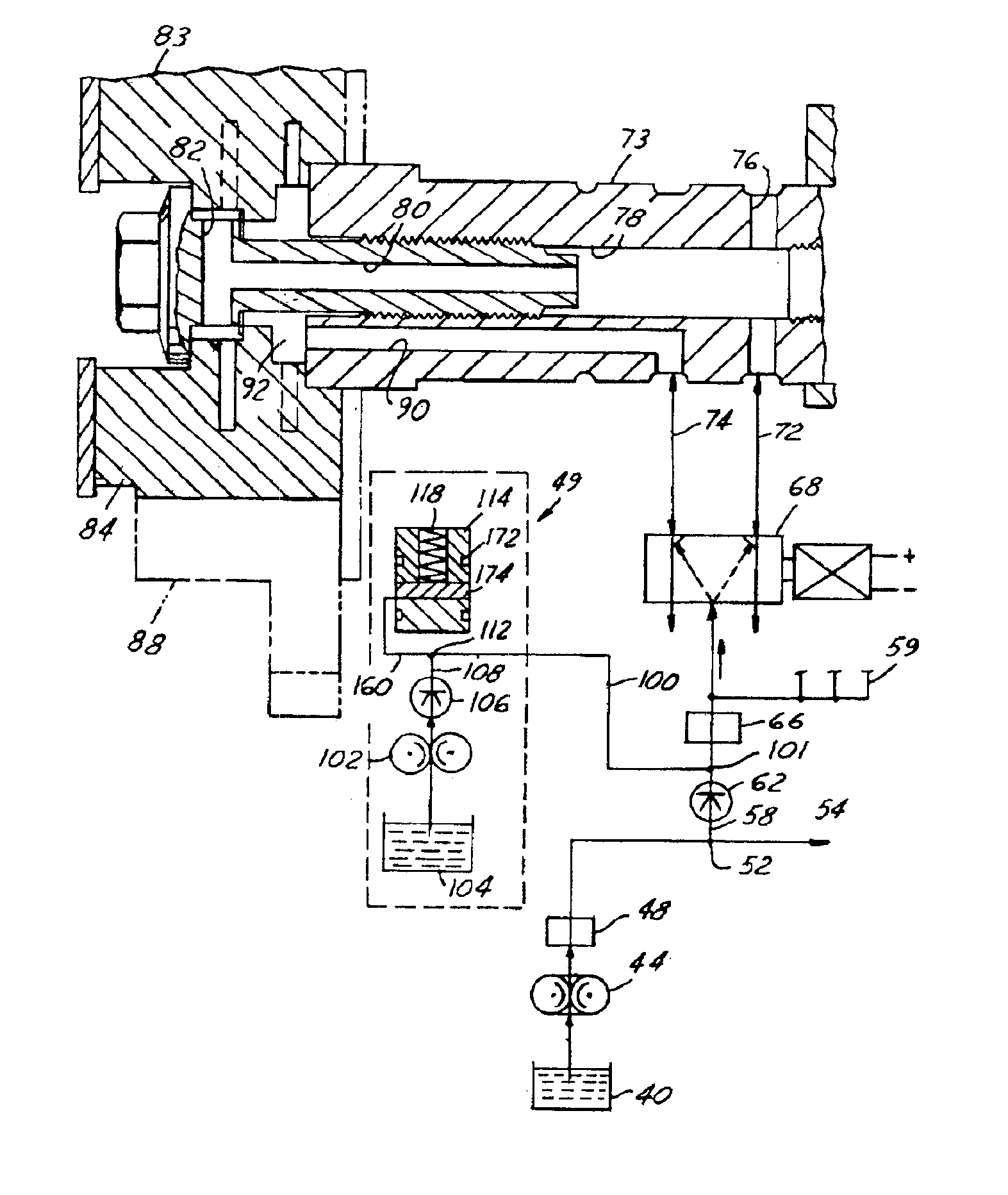

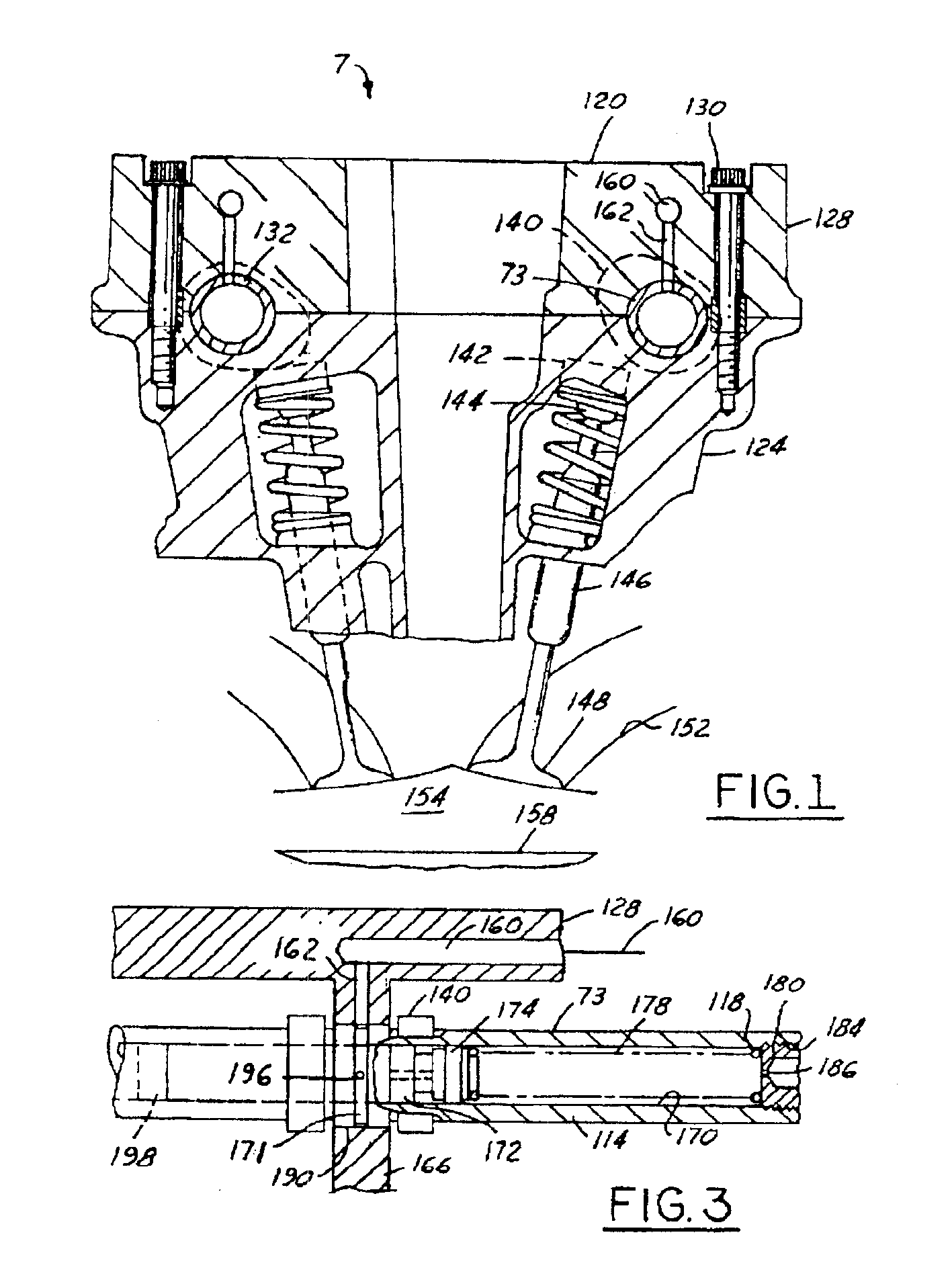

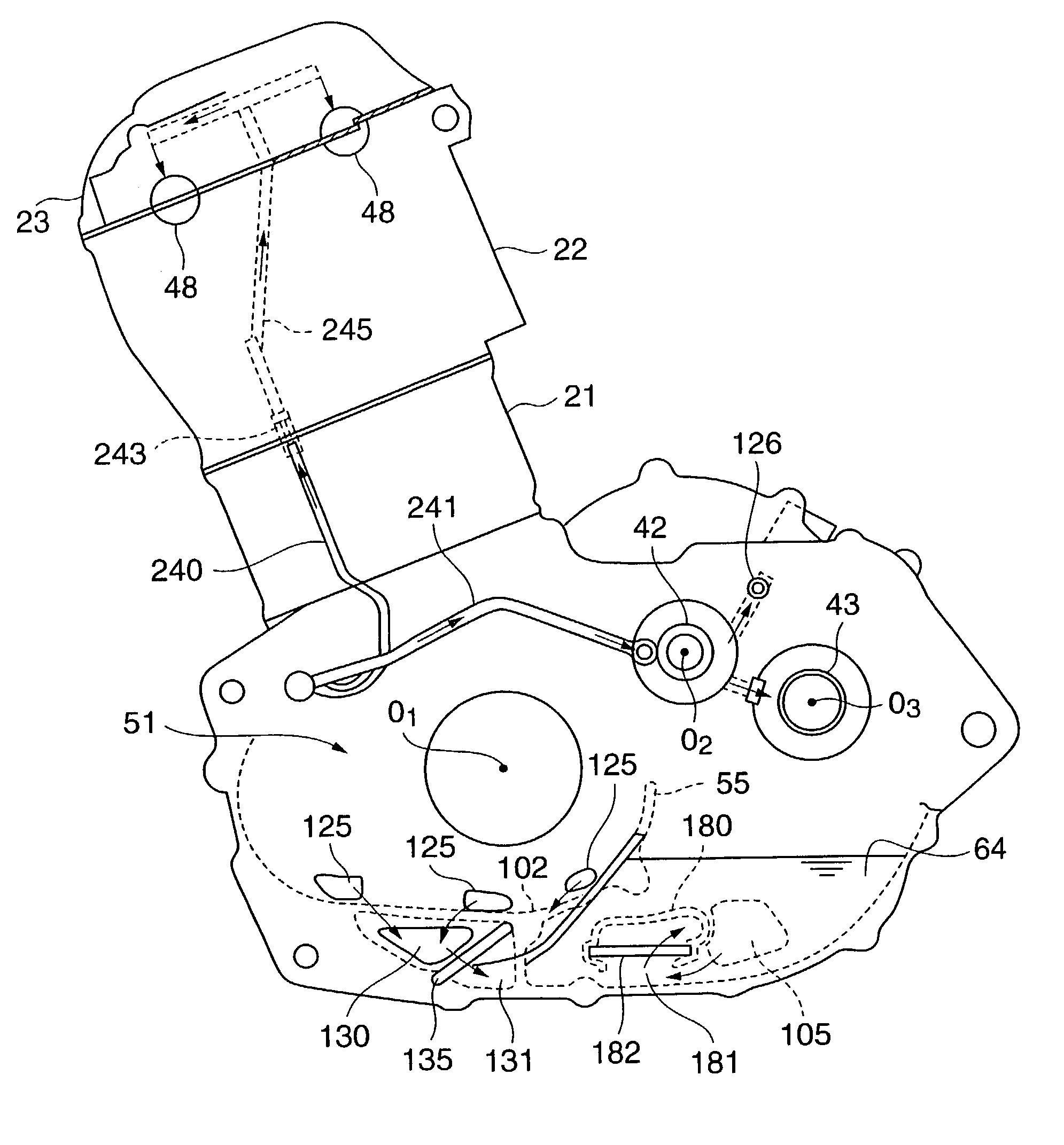

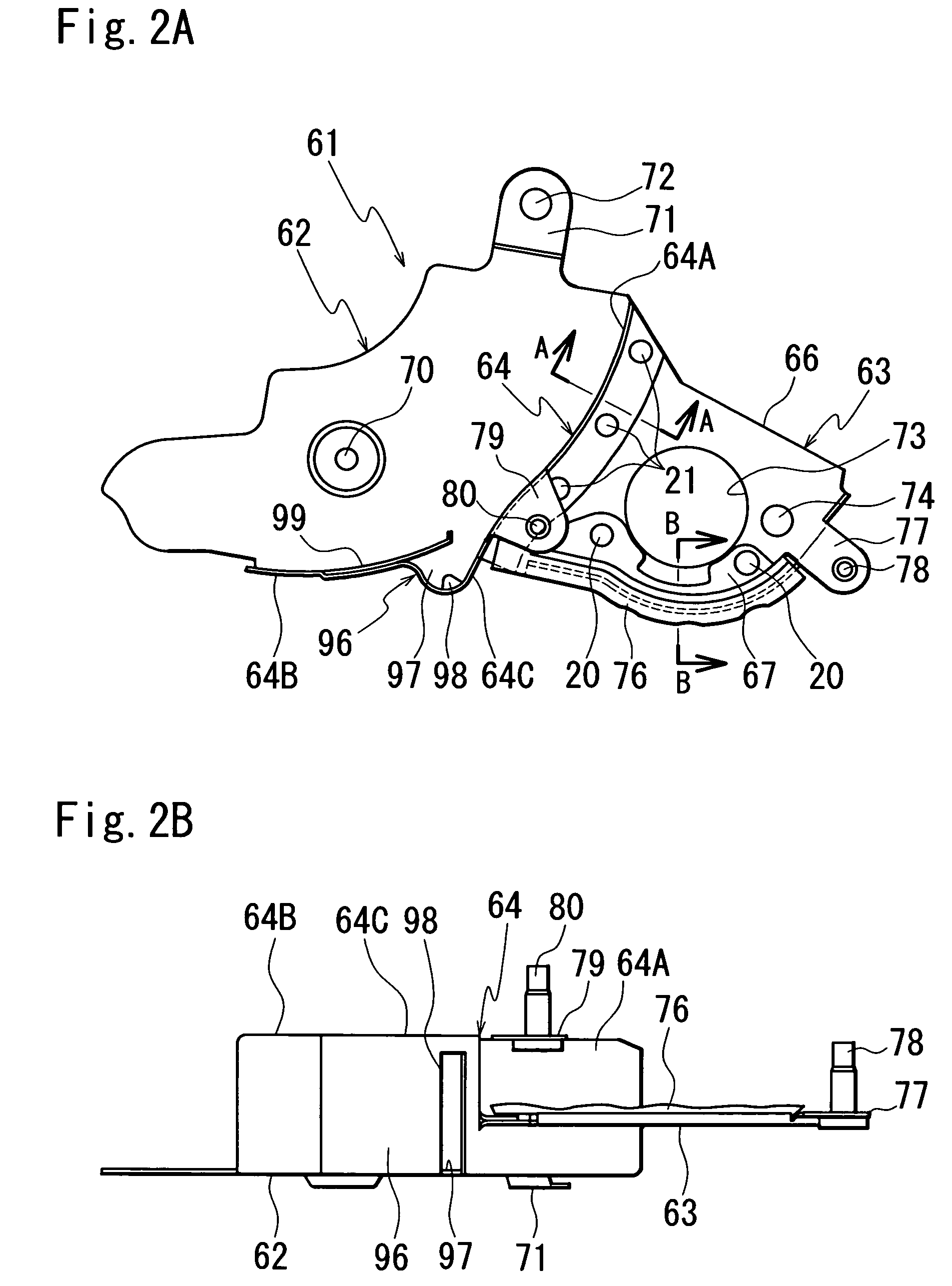

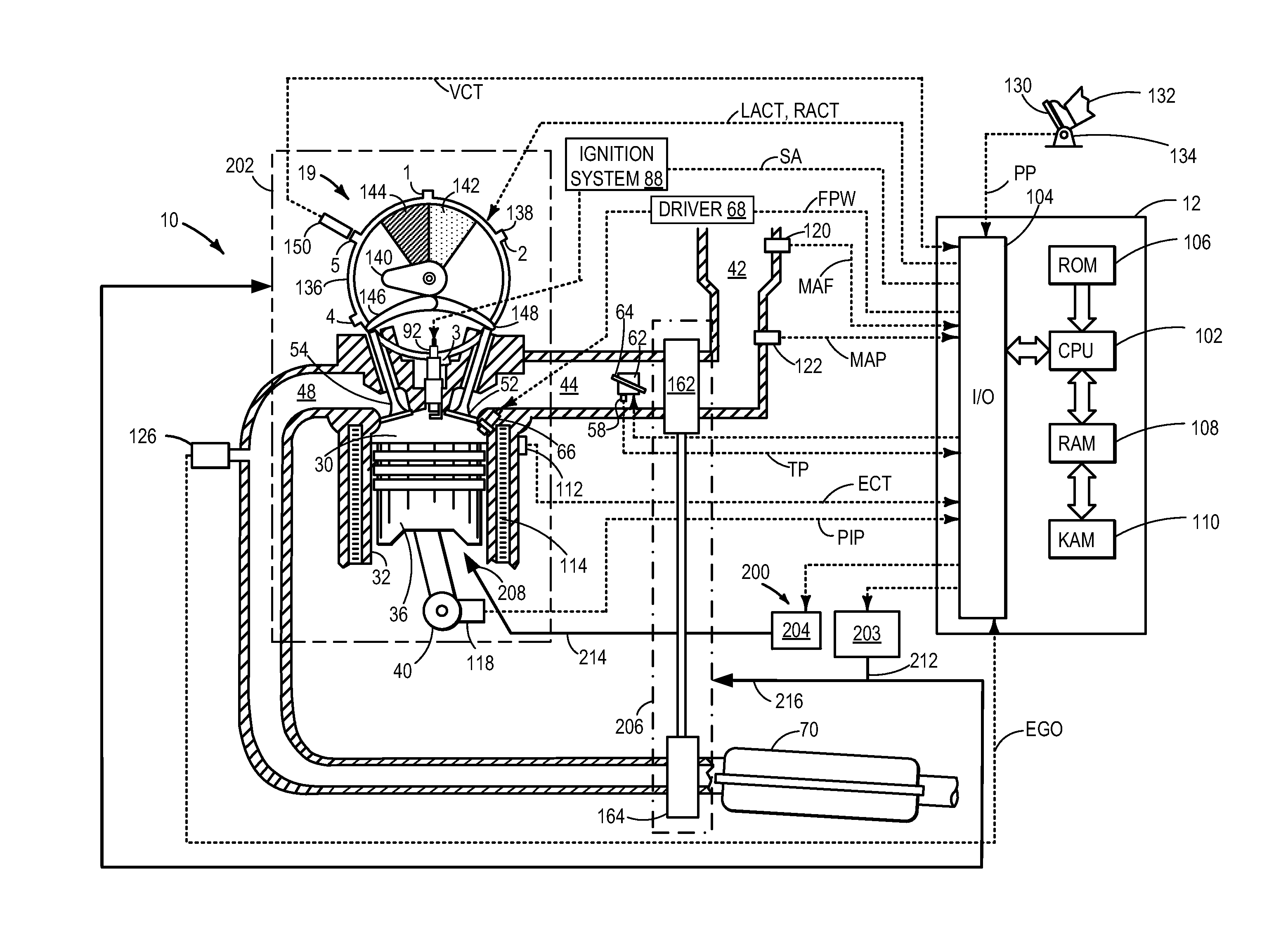

Variable cam timing unit oil supply arrangement

InactiveUS6871620B2High oil pressureIncrease flow rateValve arrangementsLubrication of auxillariesInternal combustion engineCheck valve

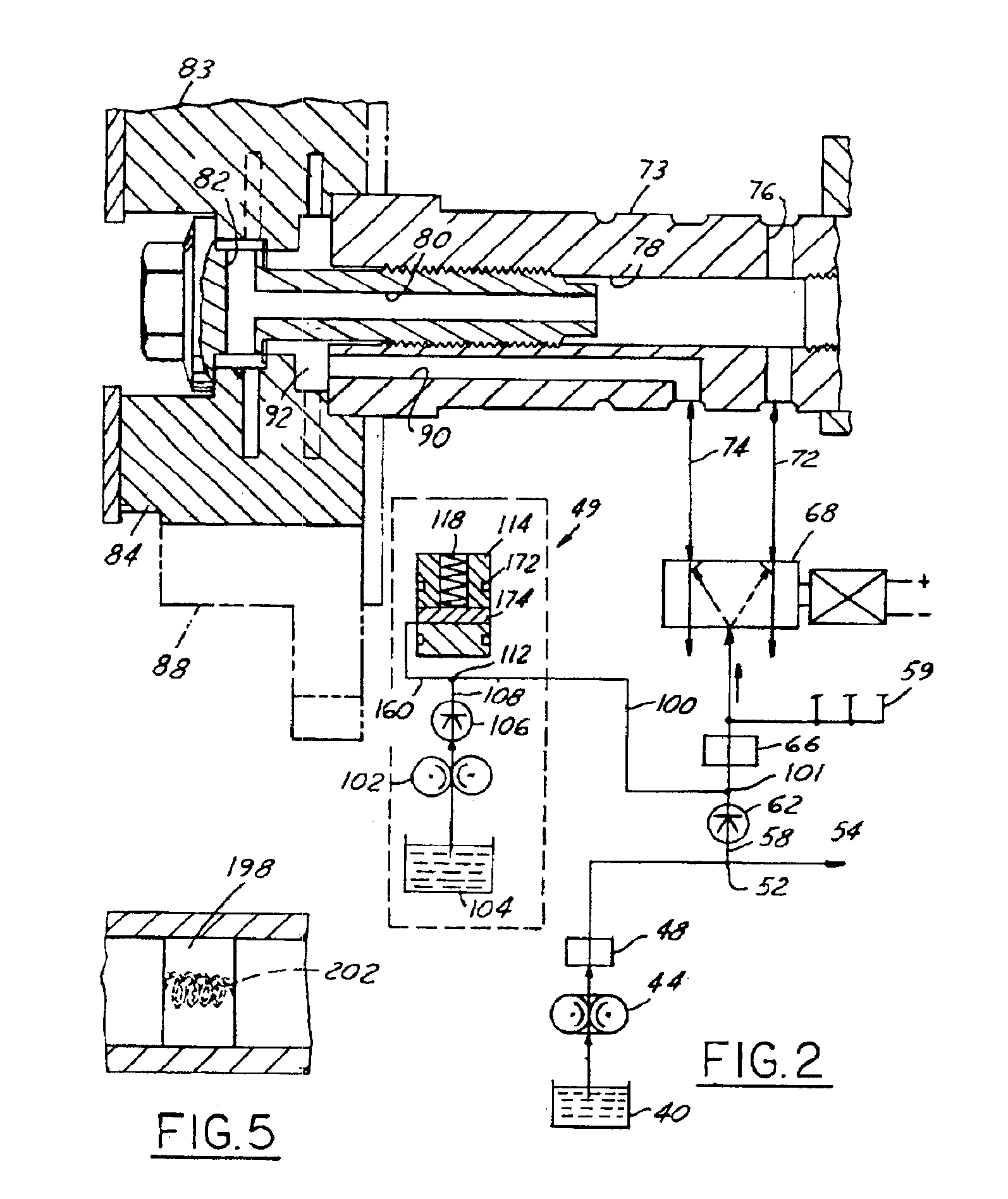

An internal combustion engine arrangement 7 with a variable cam timing unit pressurized oil supply arrangement 49 is provided. A first pump 44 delivers oil through a first check valve 62 to a VCT unit 83 and additionally provides oil to the engine lubrication system. A second oil pump 104 provides pressurized oil to the VCT unit 83 through a second check valve 106. An accumulator 114 is connected between the first 62 and second 106 check valves to pressurize oil delivered to the variable cam timing unit 83.

Owner:FORD GLOBAL TECH LLC

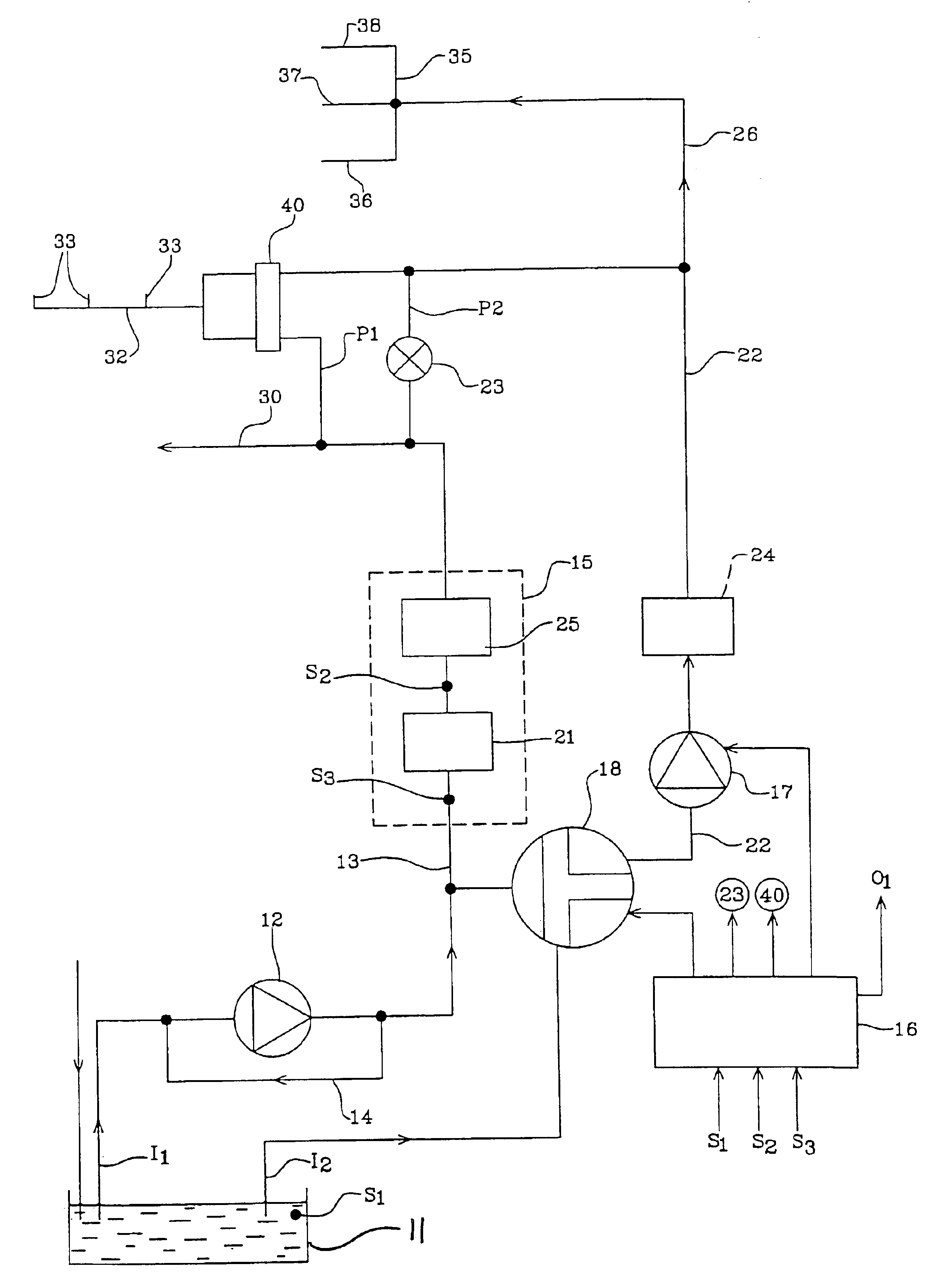

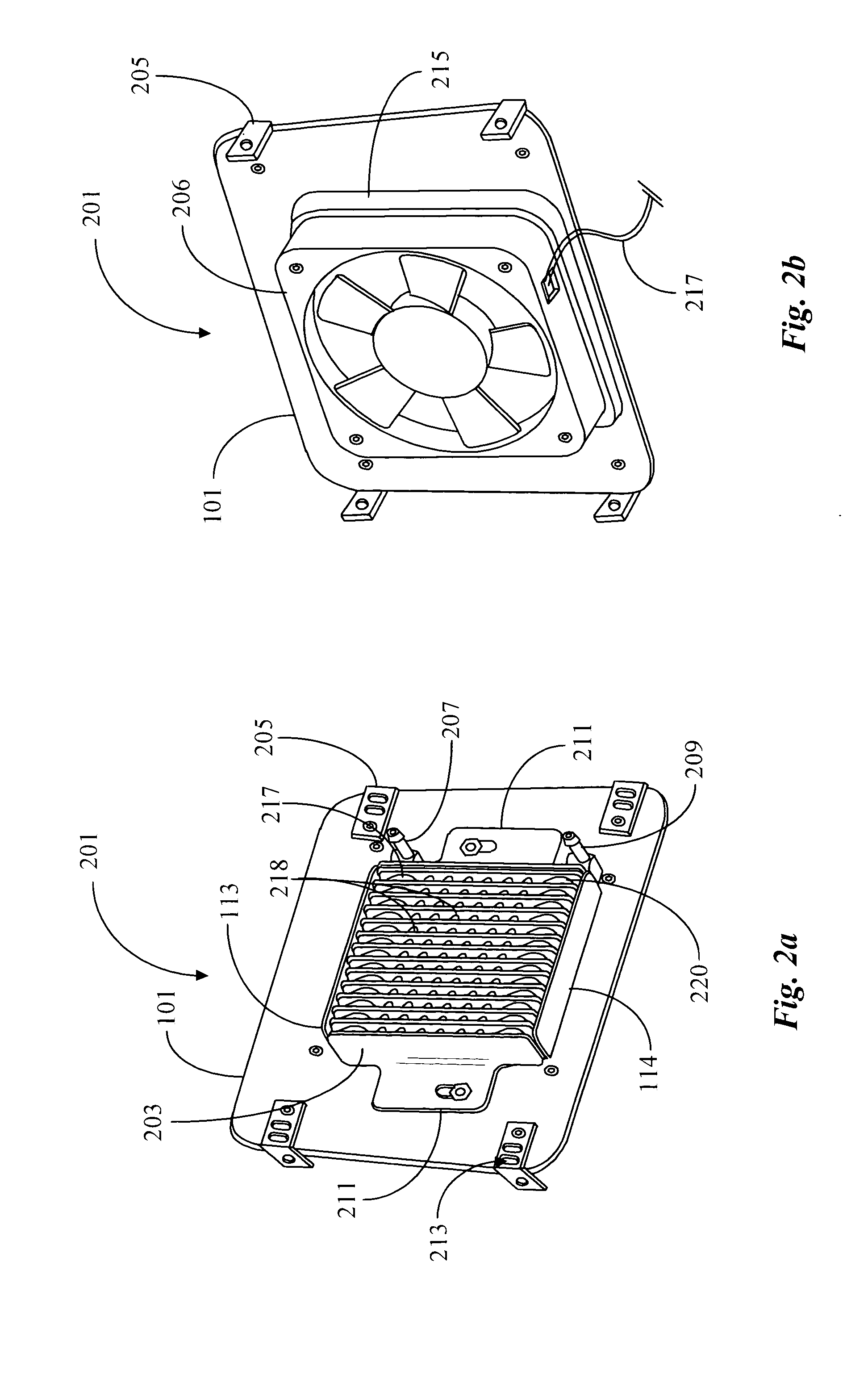

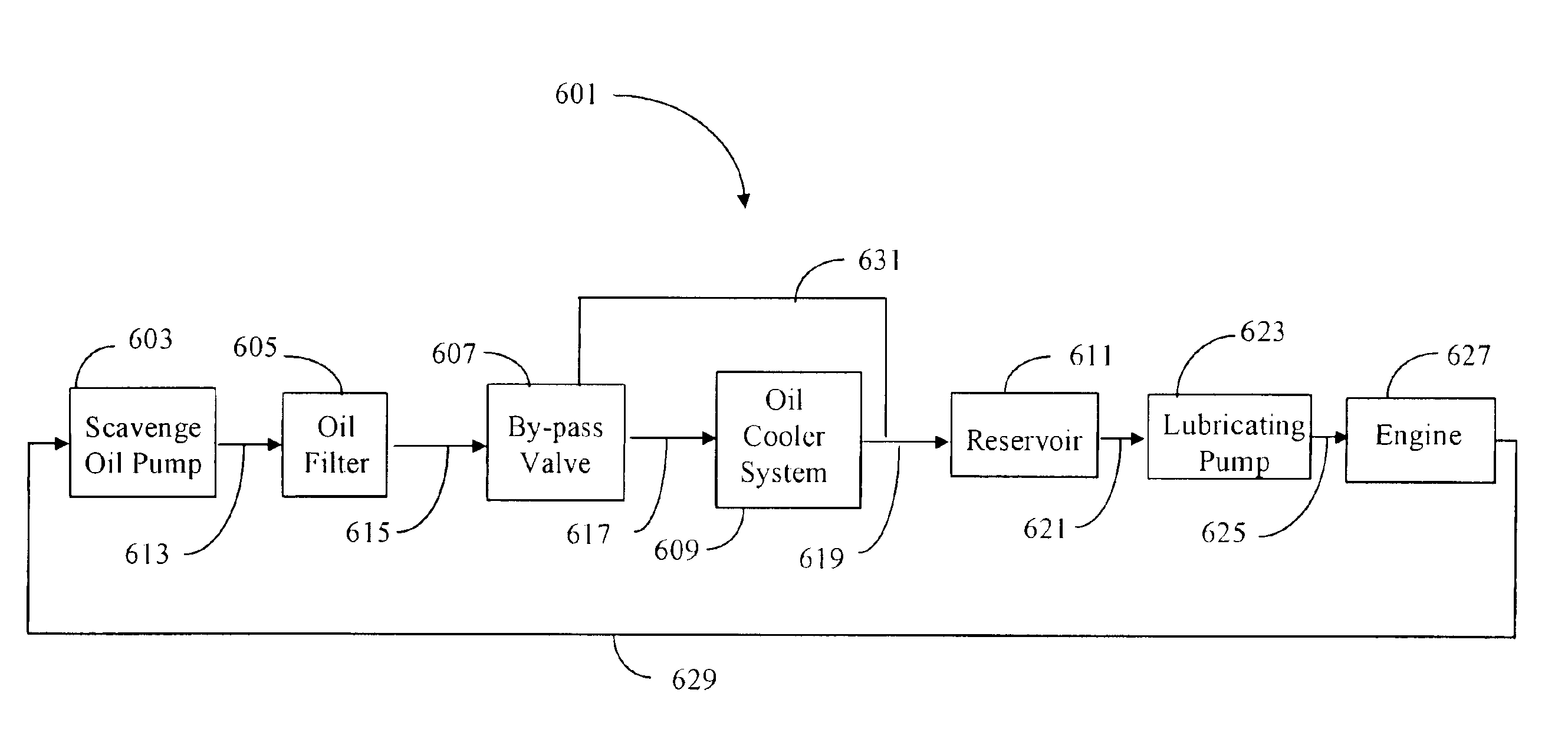

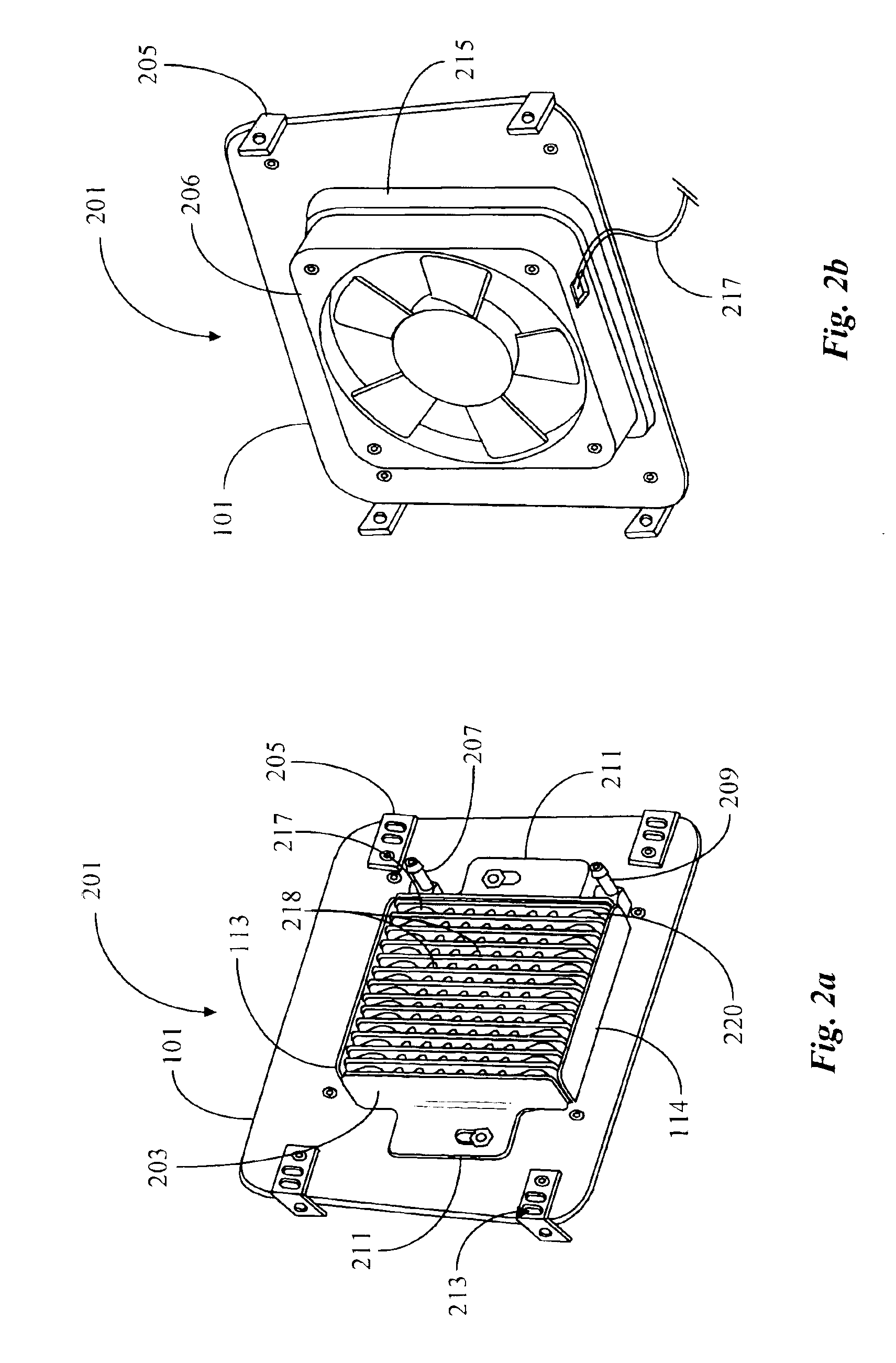

Method and apparatus for efficiently cooling motocycle engines

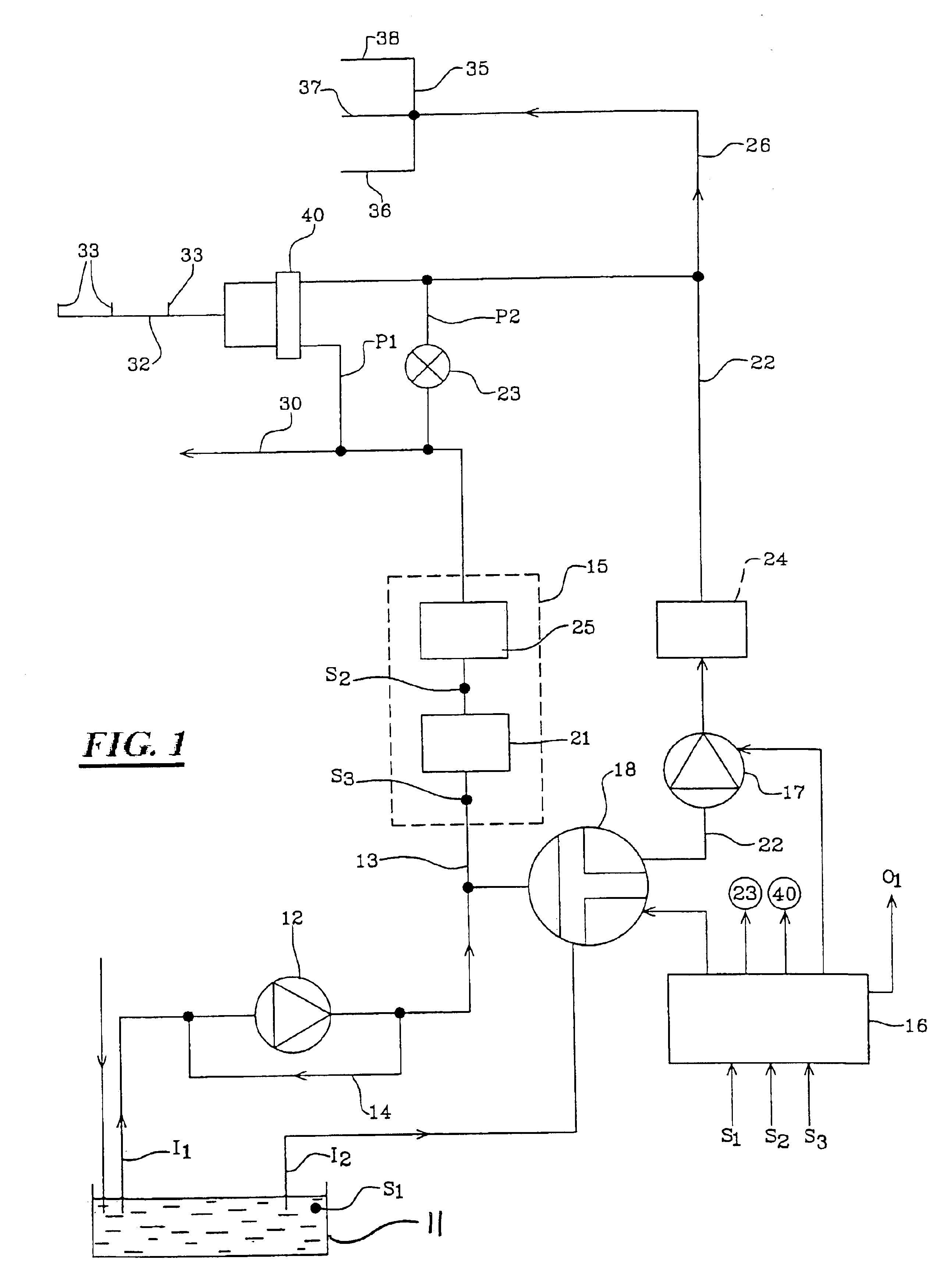

InactiveUS20050039719A1Improve abilitiesMachines/enginesClosed-circuit pressure lubricating systemsForced-airControl valves

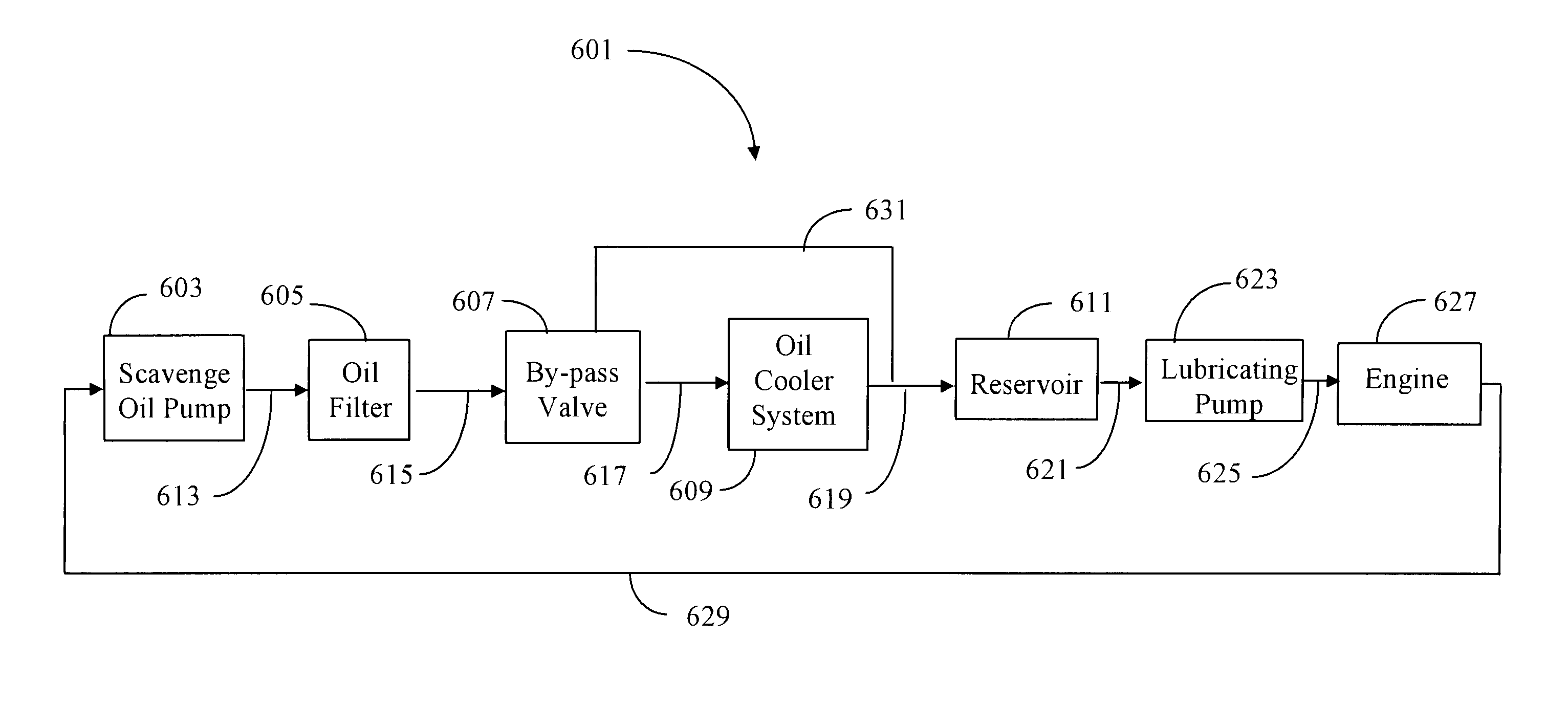

A method for managing oil temperature for a vehicle engine comprises the steps of (a) determining a preferred temperature window for oil in operation of the vehicle, comprising a first, lower temperature, and a second, higher temperature; (b) pumping oil from the vehicle engine to a control valve controlling oil passage into a radiator, and bypassing the radiator via a by-pass passage in the control valve more than seventy-percent of the oil to return to the vehicle engine without passing through the radiator upon cold start-up; (c) closing the bypass passage at the first oil temperature, forcing all oil entering the control valve to pass through he radiator before returning to the vehicle engine; (d) starting a forced-air fan at the second temperature to urge ambient air through air passages of the radiator, thereby enhancing ability of the radiator to cool the oil passing though; and (e) as oil temperature falls, opening the bypass passage again at the first temperature.

Owner:PETCHEL JOHN JOSEPH

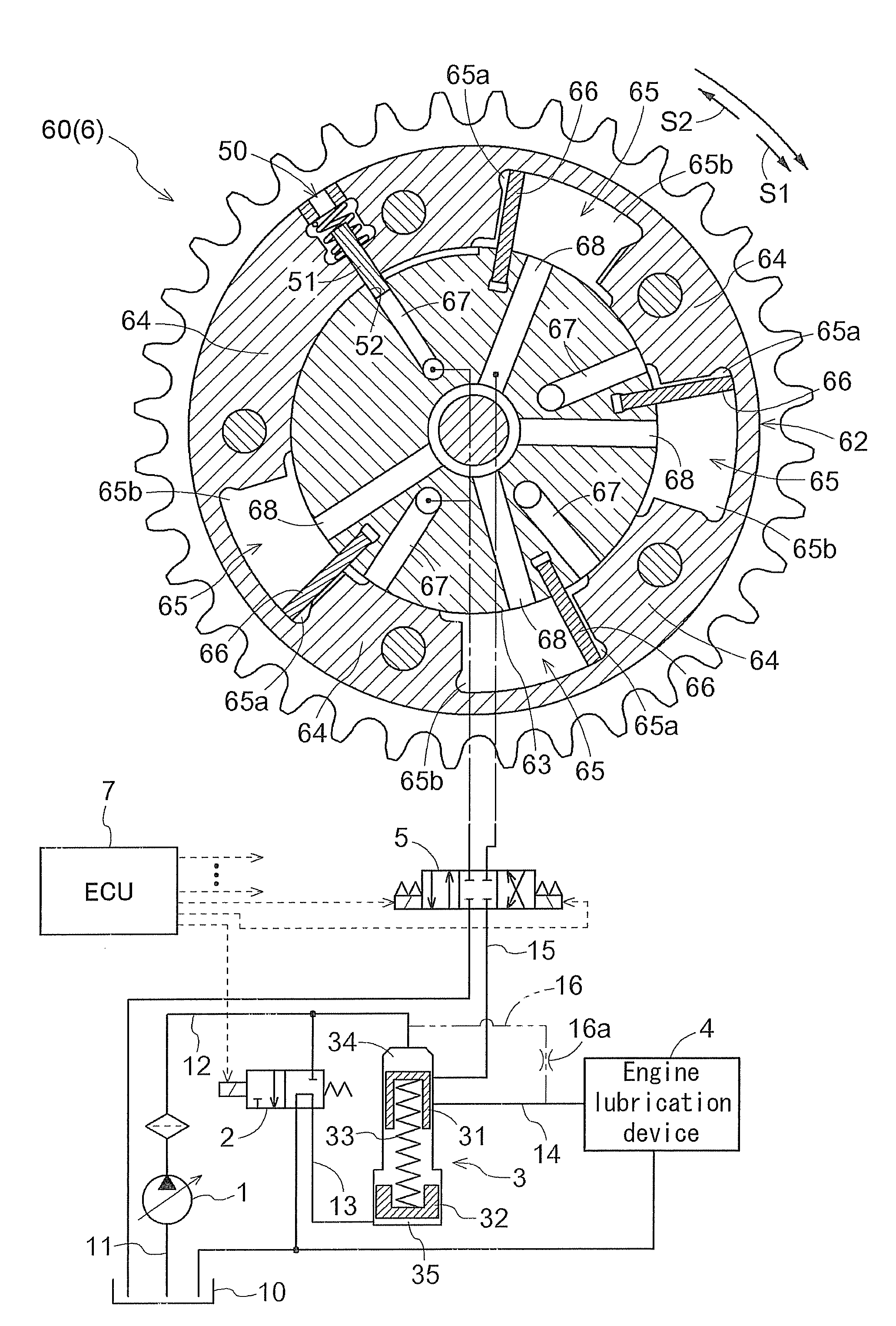

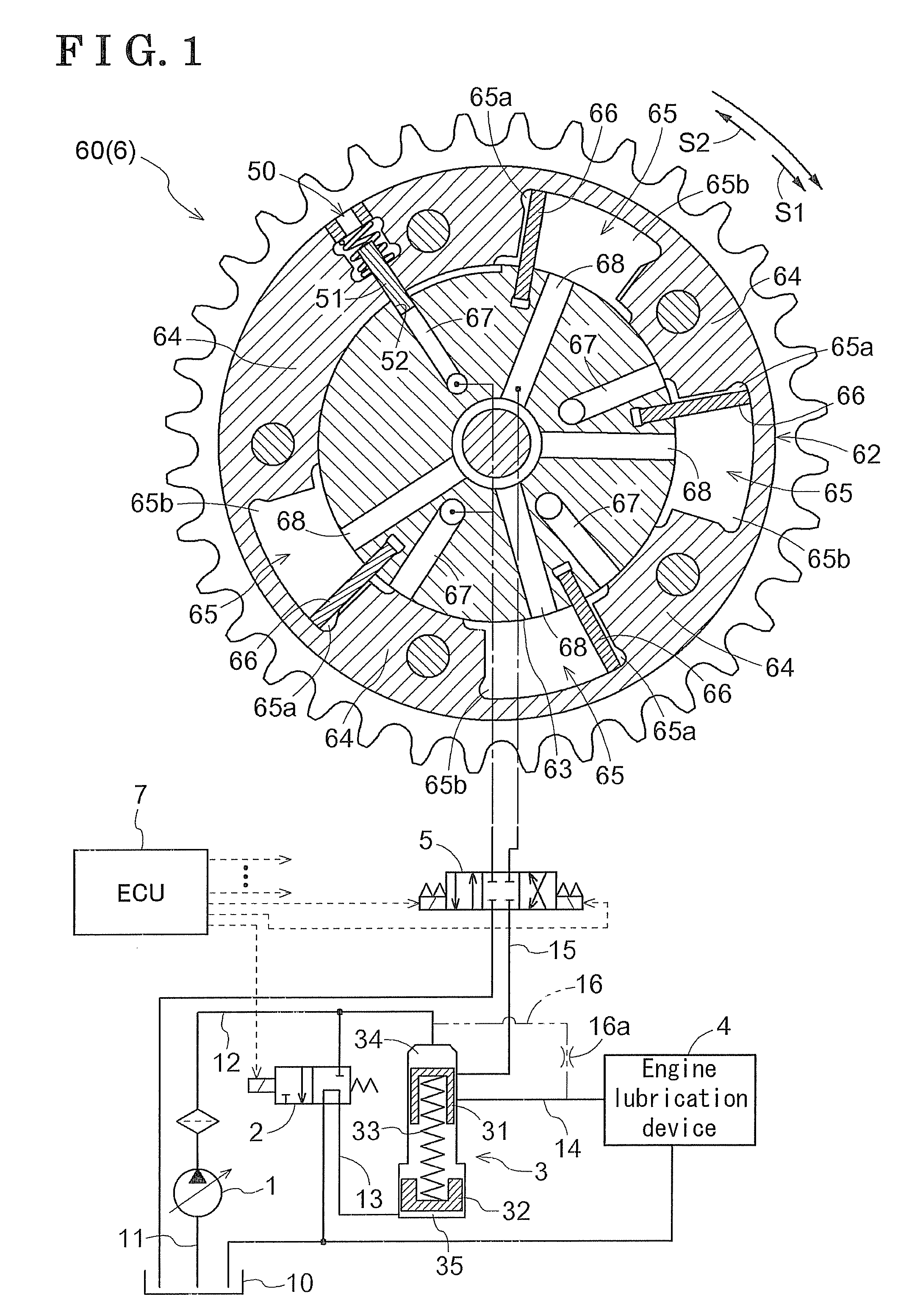

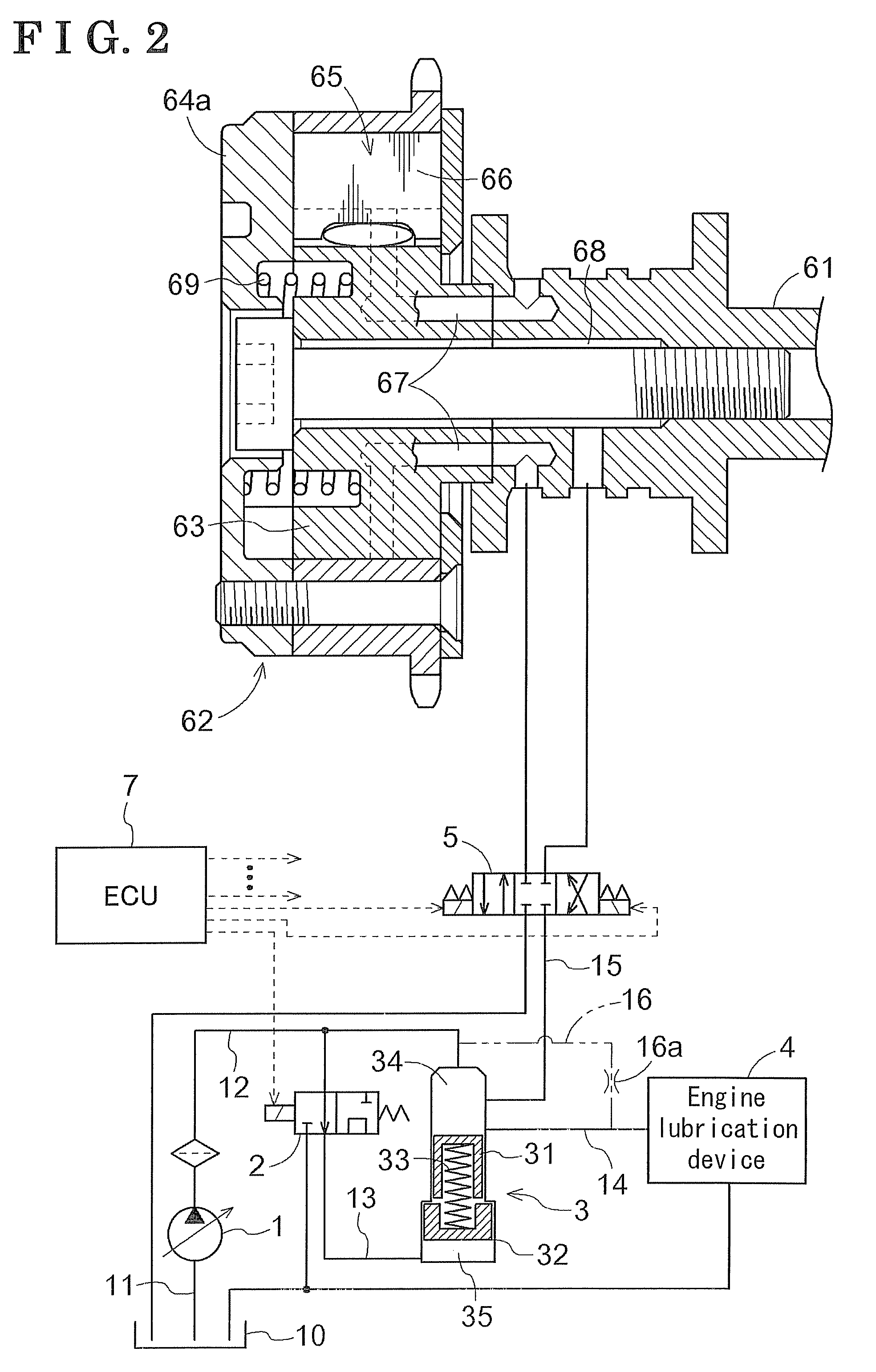

Oil supplying apparatus for vehicle

An oil supplying apparatus for a vehicle, includes an engine driven mechanical oil pump, a hydraulic actuator operated by pressure of oil supplied from the engine driven mechanical oil pump to the hydraulic actuator, an engine lubrication device lubricating each member of the engine with the oil supplied from the engine driven mechanical oil pump, and a priority flow valve selectively establishing priority flow and secondary flow conditions when a low oil pressure is working on the hydraulic actuator and when a high oil pressure is working on the hydraulic actuator, respectively, the priority flow condition allowing an oil supply from the engine driven mechanical oil pump to the hydraulic actuator with priority over an oil supply from the engine driven mechanical oil pump to the engine lubrication device, the secondary flow condition allowing the oil supply from the engine driven mechanical oil pump to the engine lubrication device.

Owner:AISIN SEIKI KK

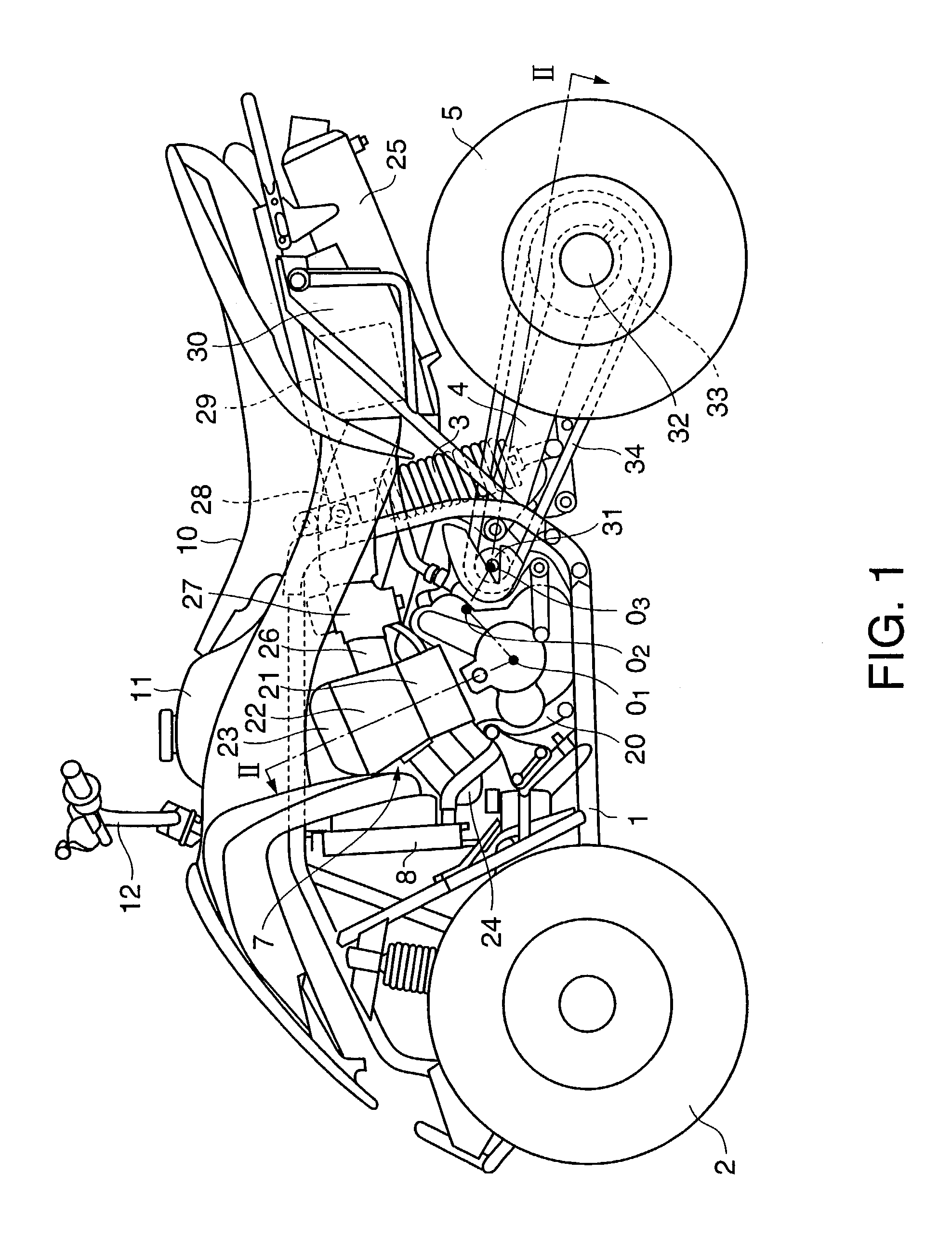

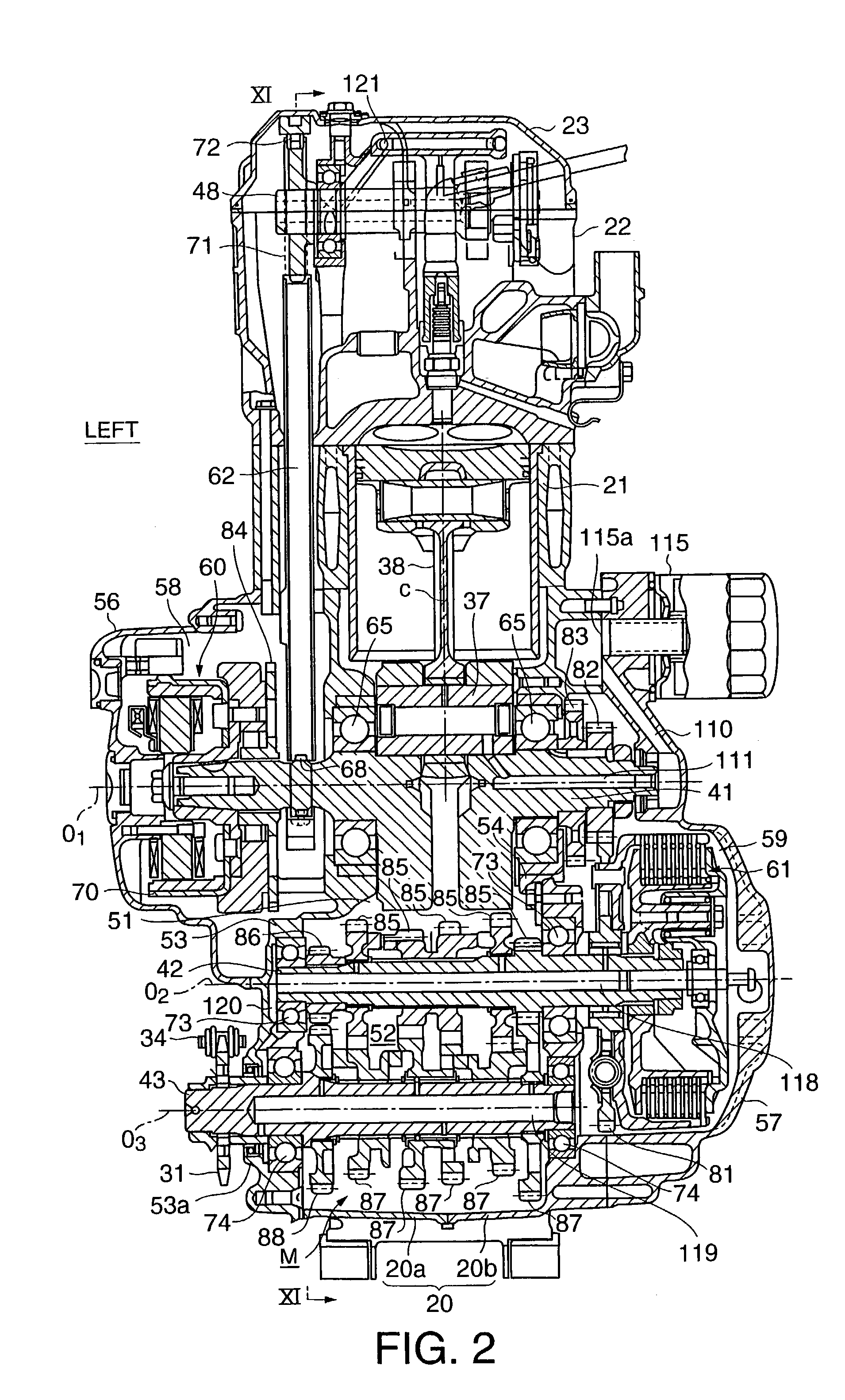

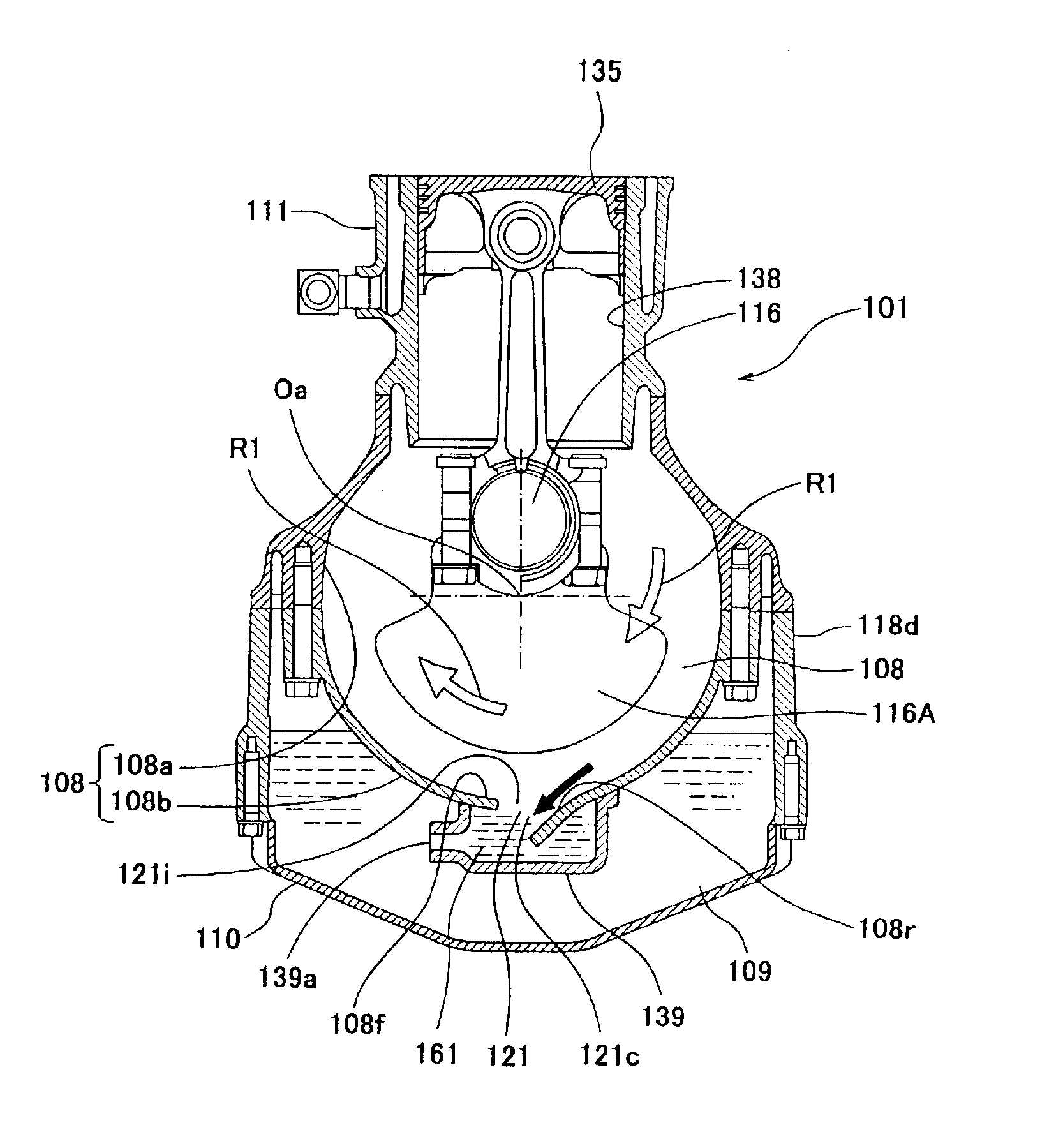

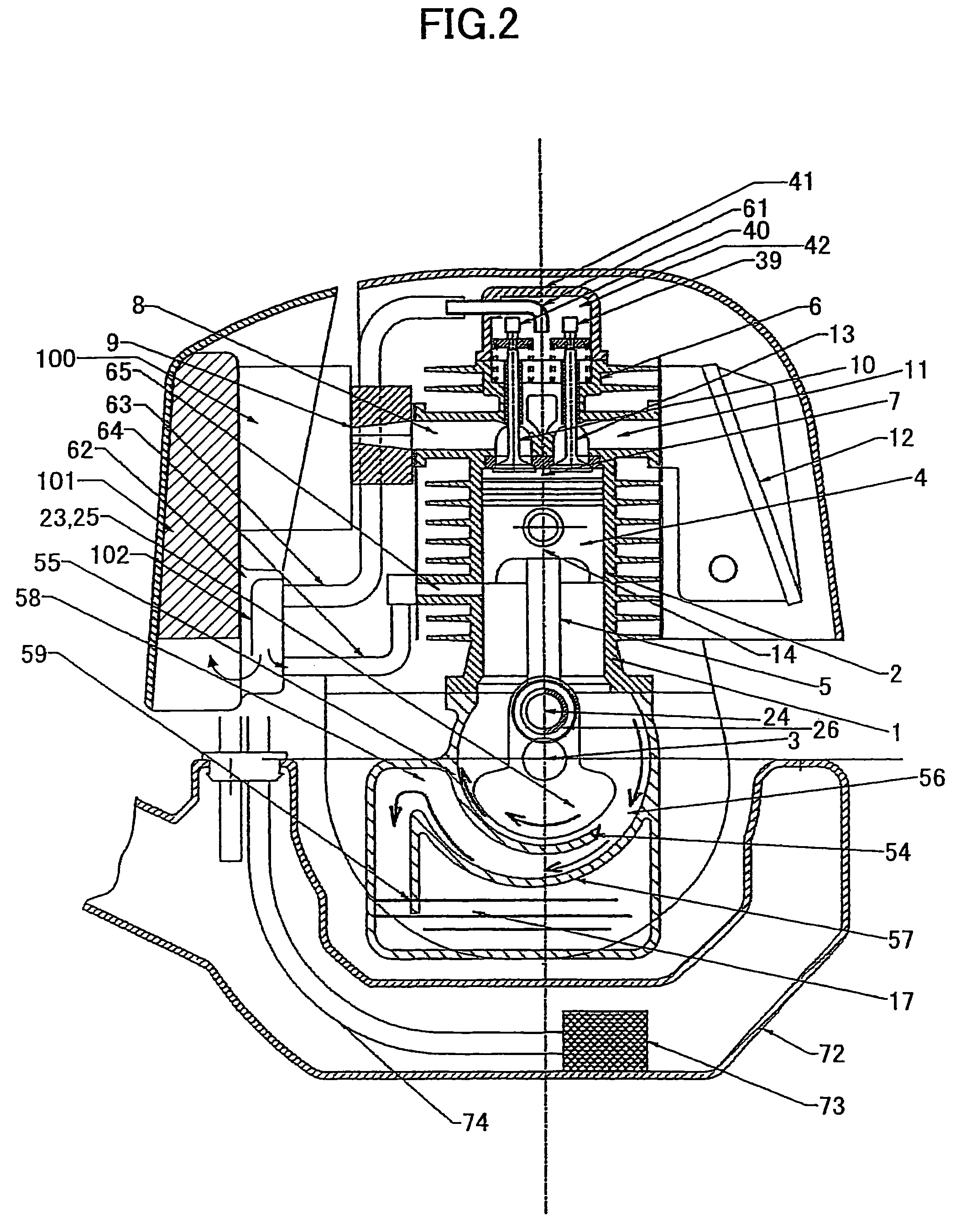

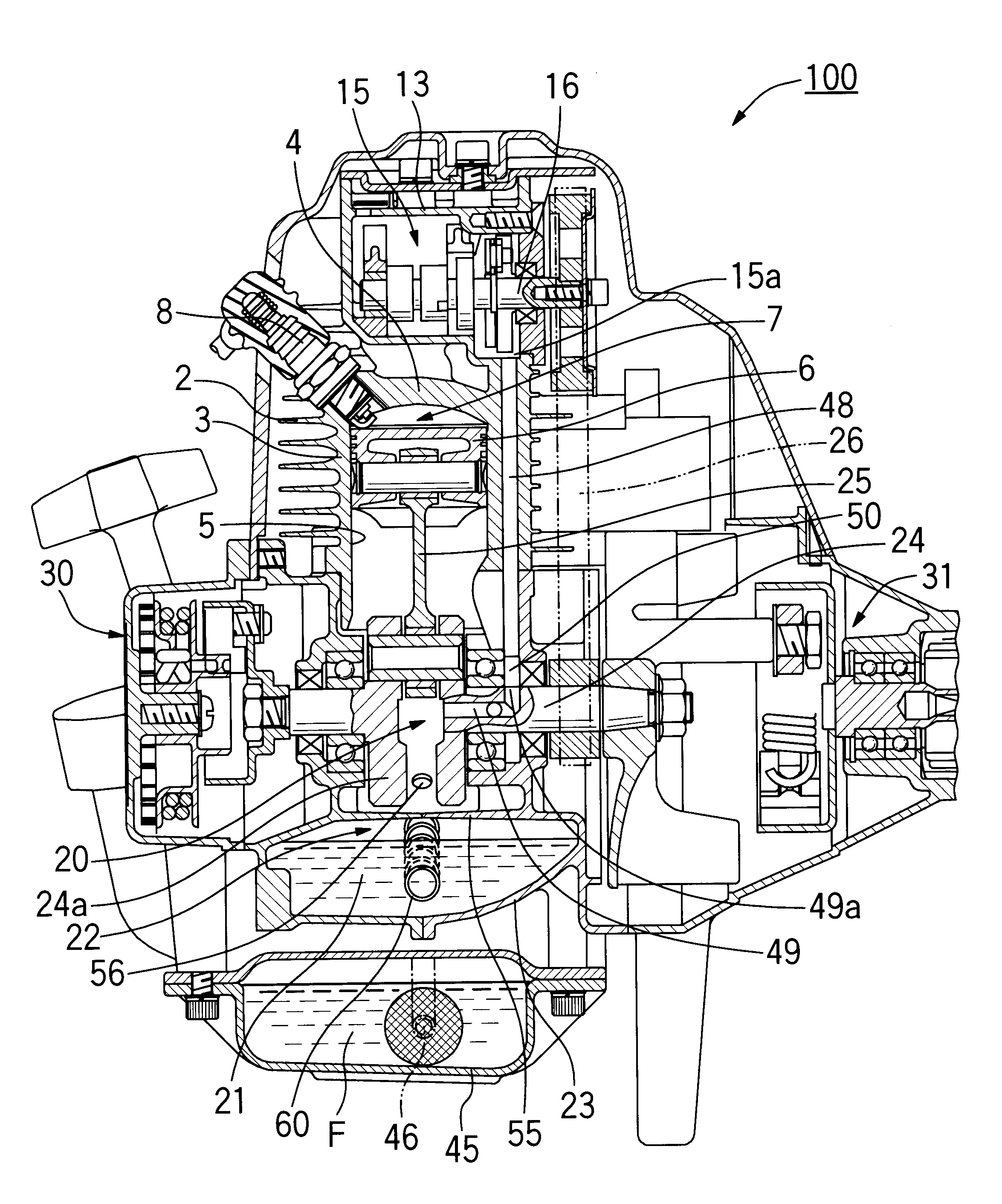

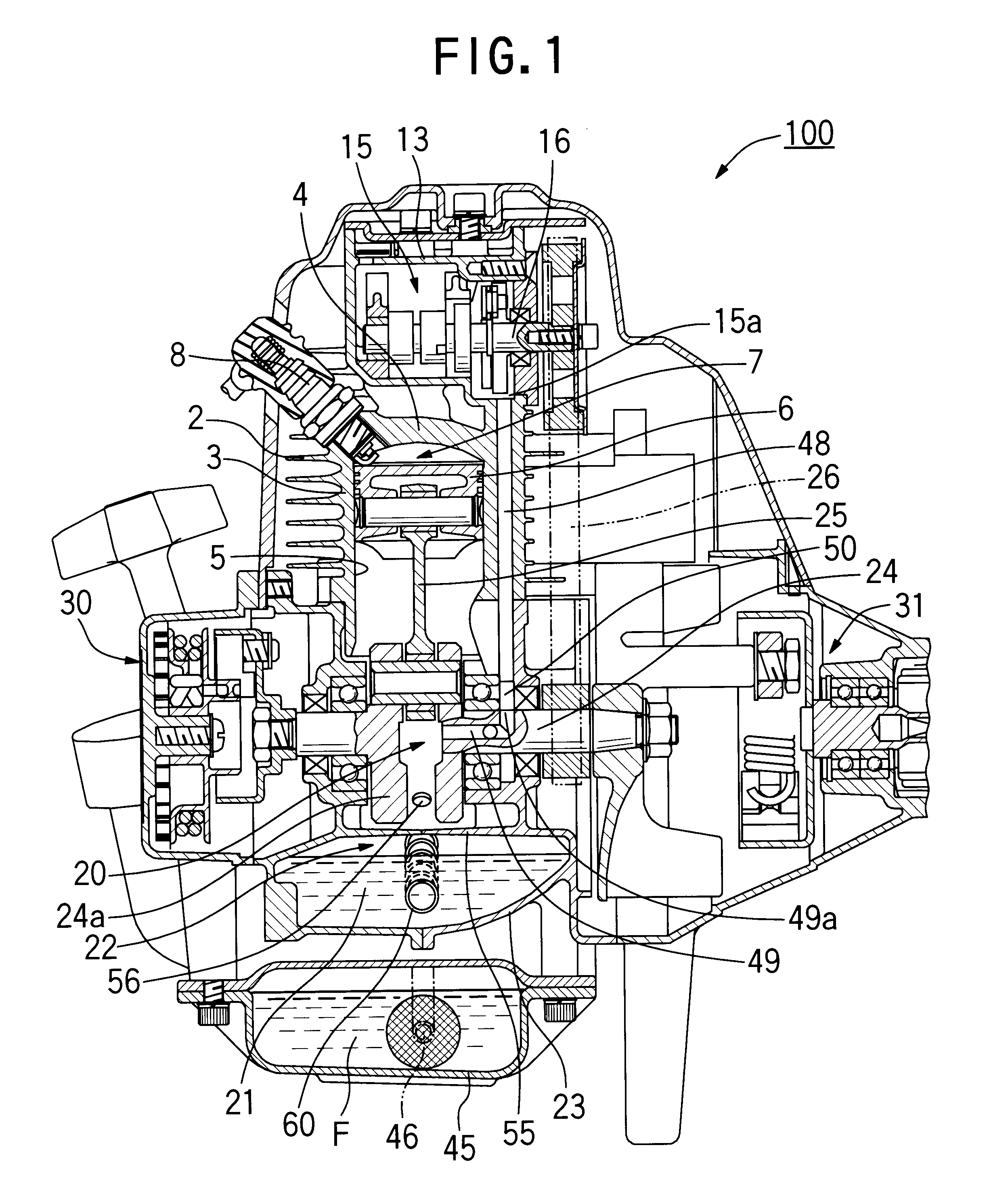

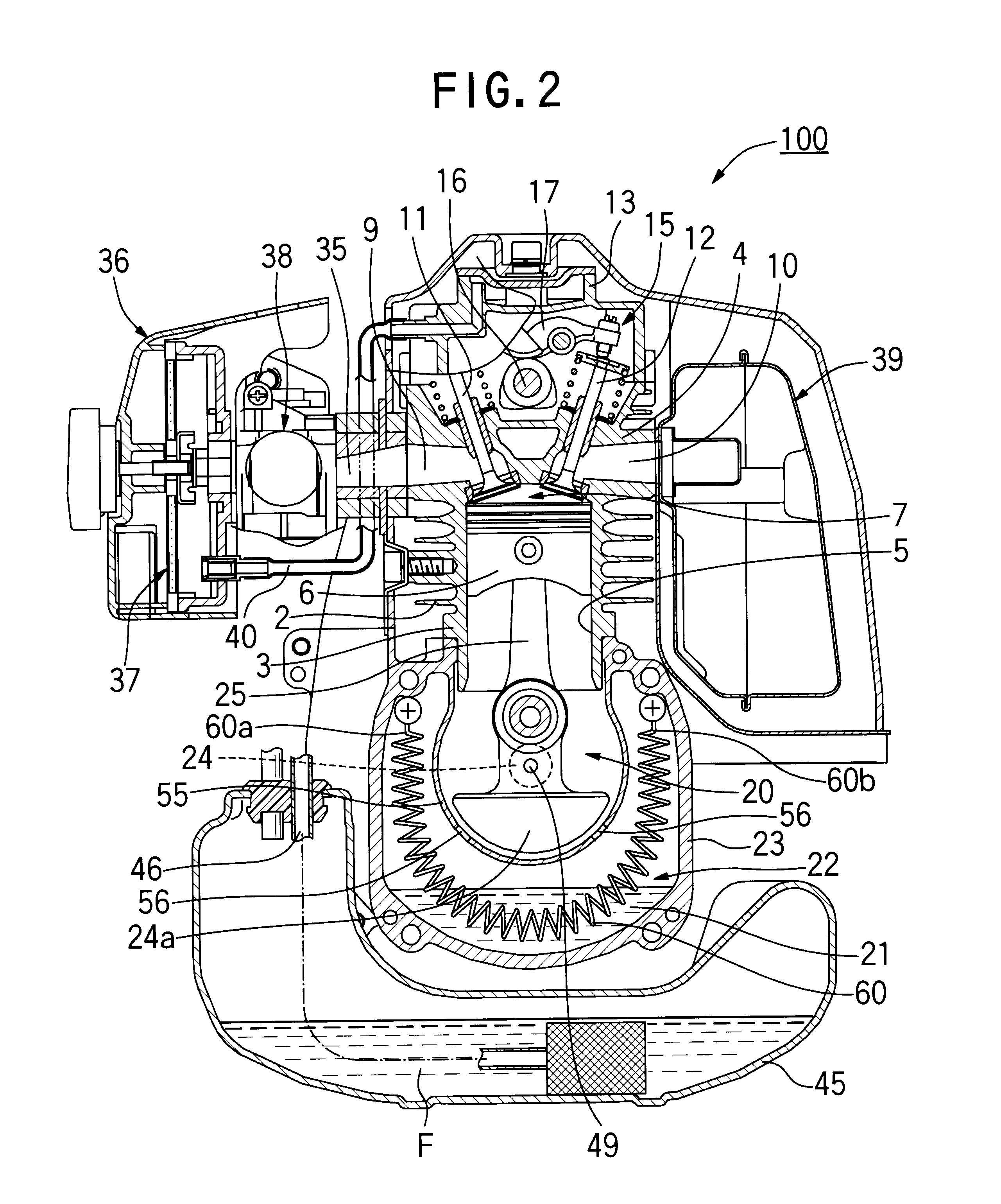

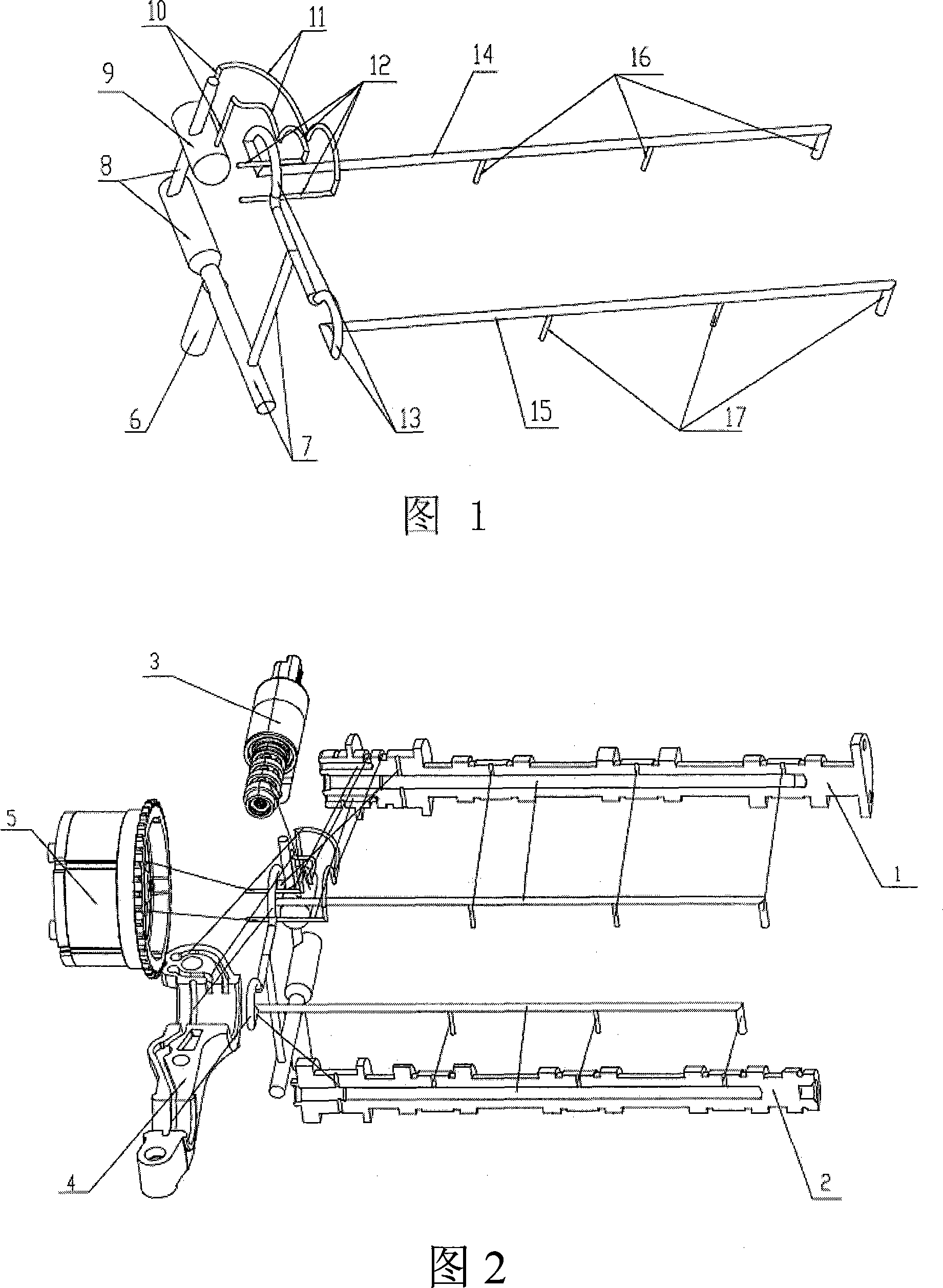

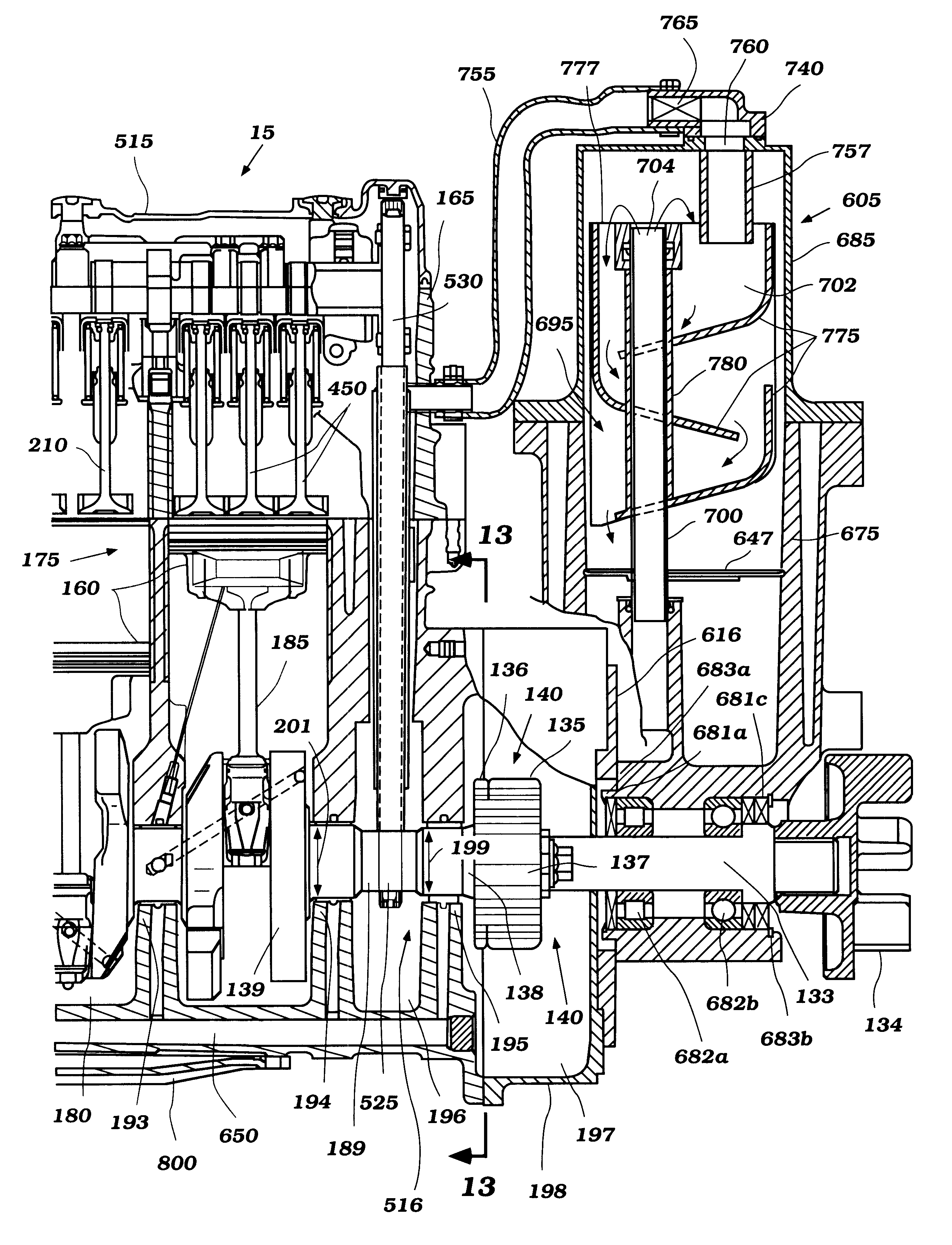

Dry-sump lubrication type four-stroke cycle engine

InactiveUS7040454B2Easy to usePrecision lubricationLubrication of auxillariesLubricant conduit arrangementsAir pumpFour-stroke engine

The interior of a crankcase is divided into a front crank chamber and a rear transmission chamber by a partition wall of a given height. A lower part of the transmission case is used as an oil reservoir chamber for reserving lubricating oil. Opposite ends of the crankcase are covered with covers to form a generator chamber and a clutch chamber. The crank chamber is connected to the generator chamber by a drain passage to drain oil collected in the crank chamber into the generator chamber. A scavenging pump placed in the clutch chamber sucks the oil collected in the generator chamber through an oil passage extending across the crankcase under the crank chamber and discharges the oil into an air space in the clutch chamber.

Owner:KAWASAKI HEAVY IND LTD

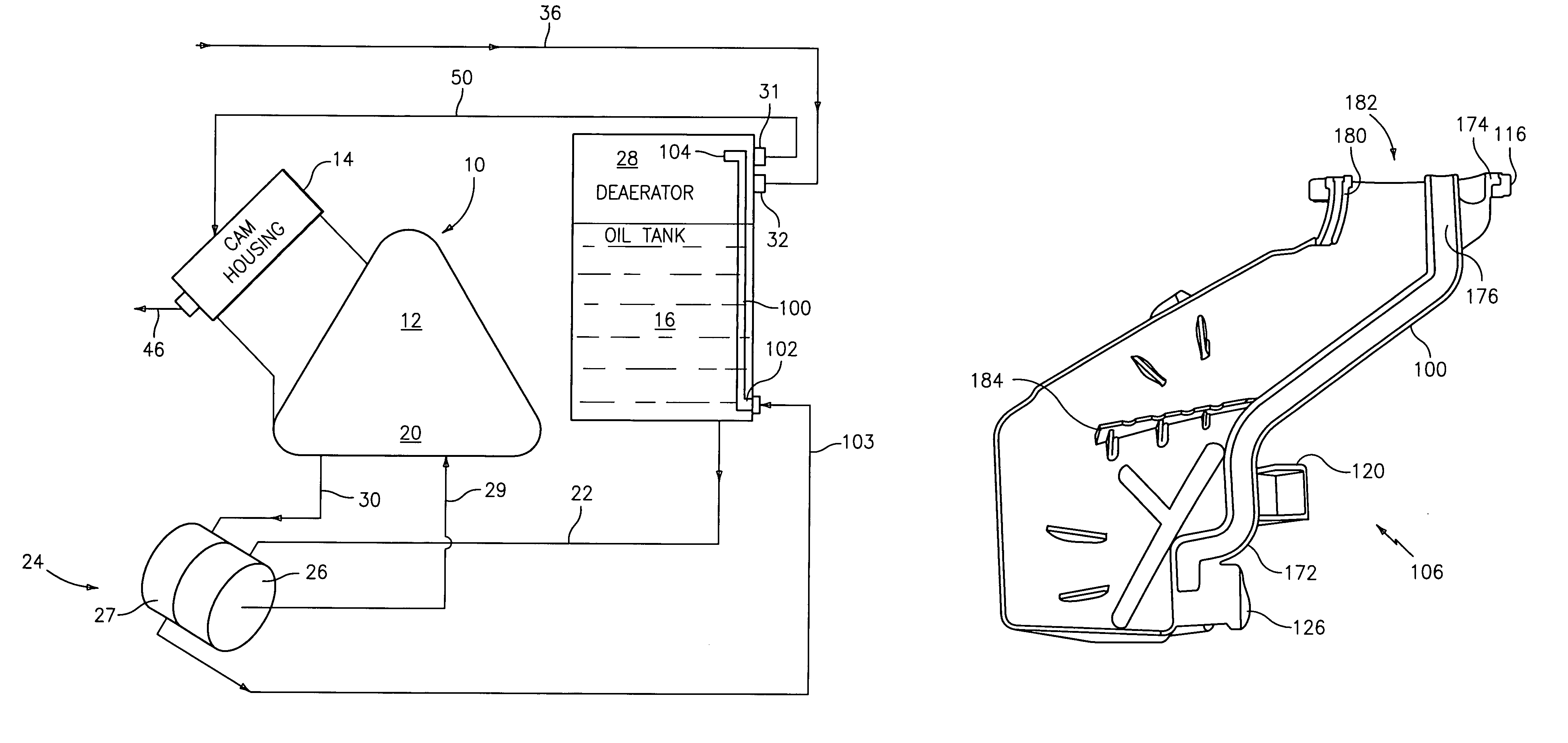

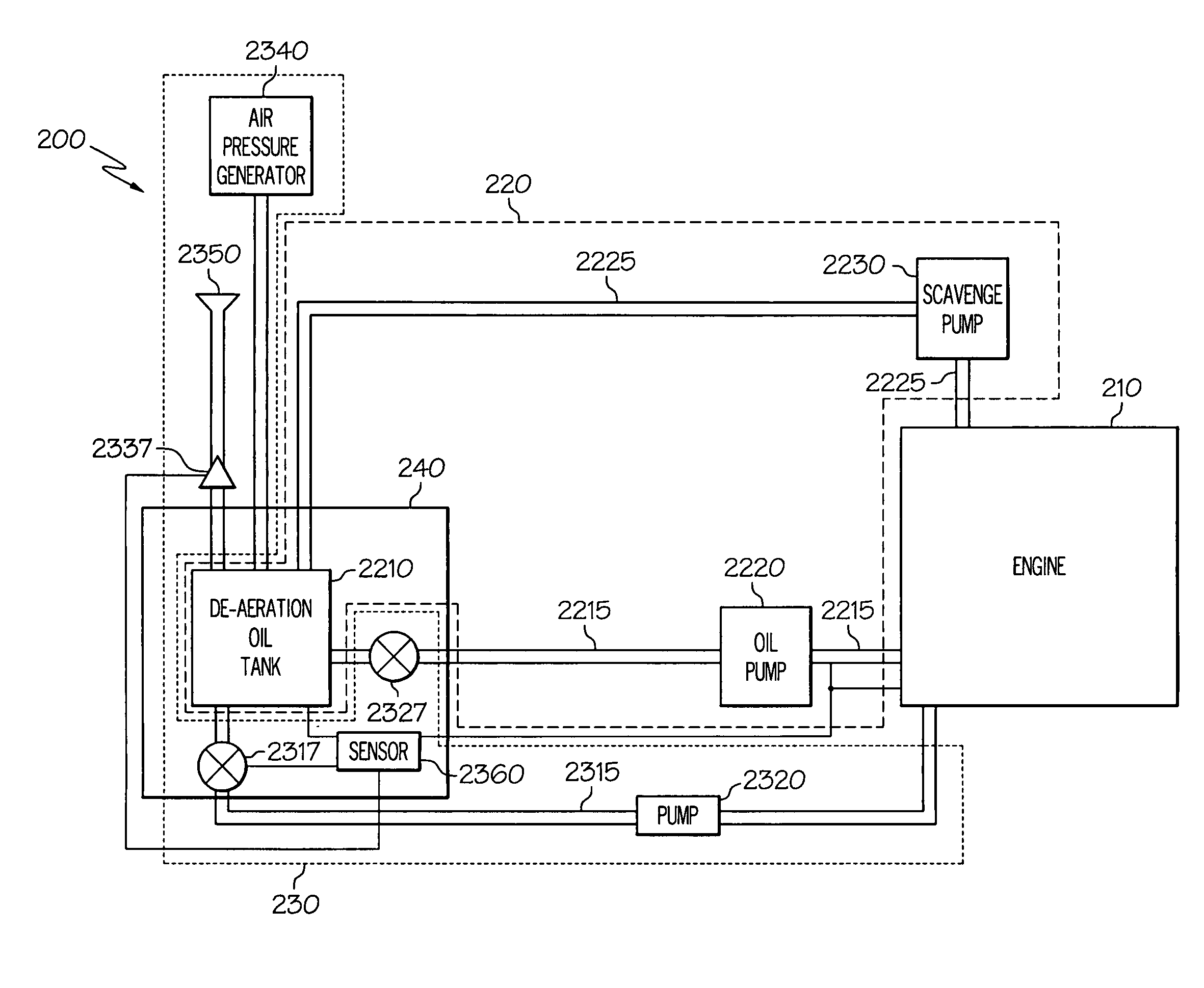

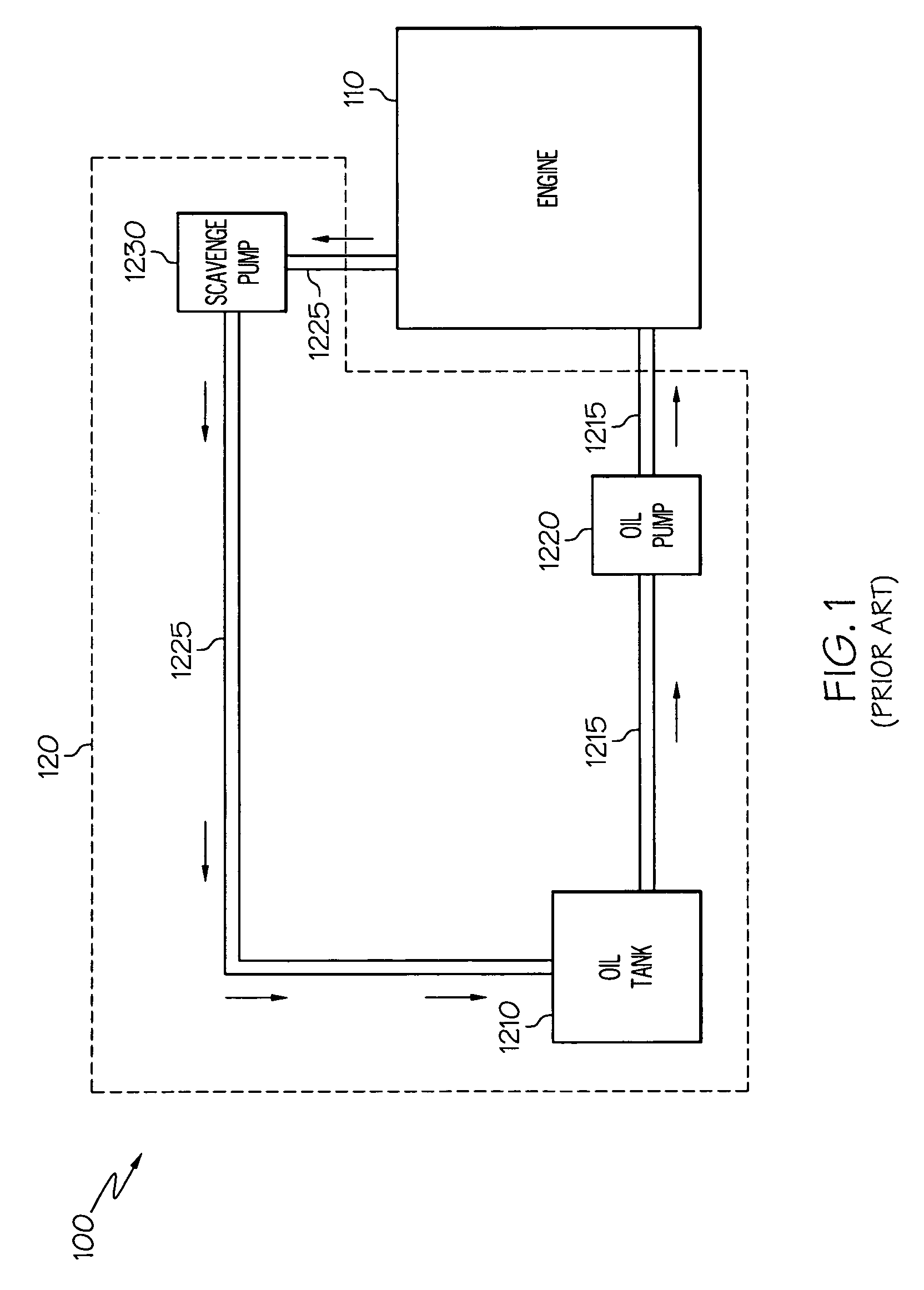

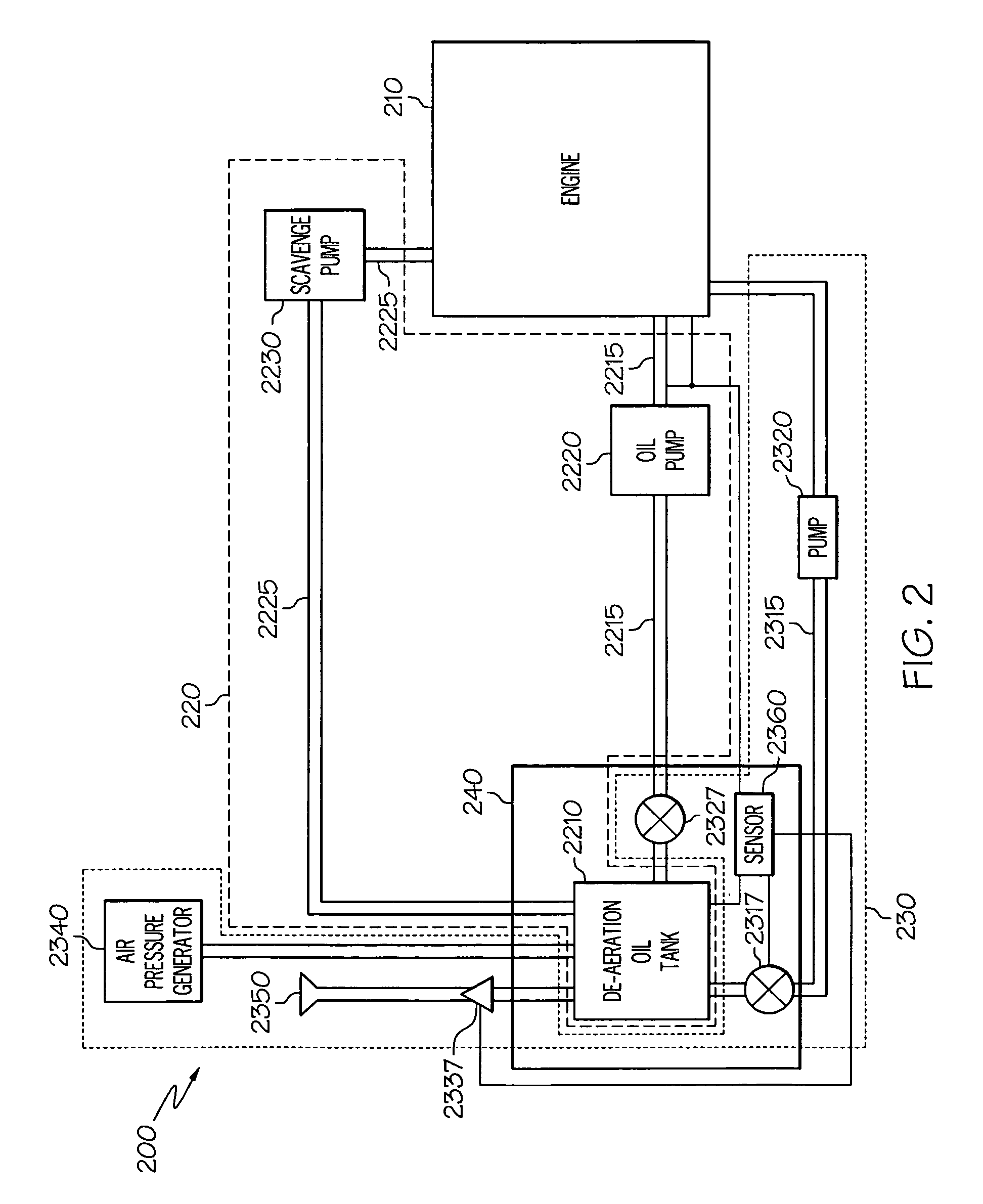

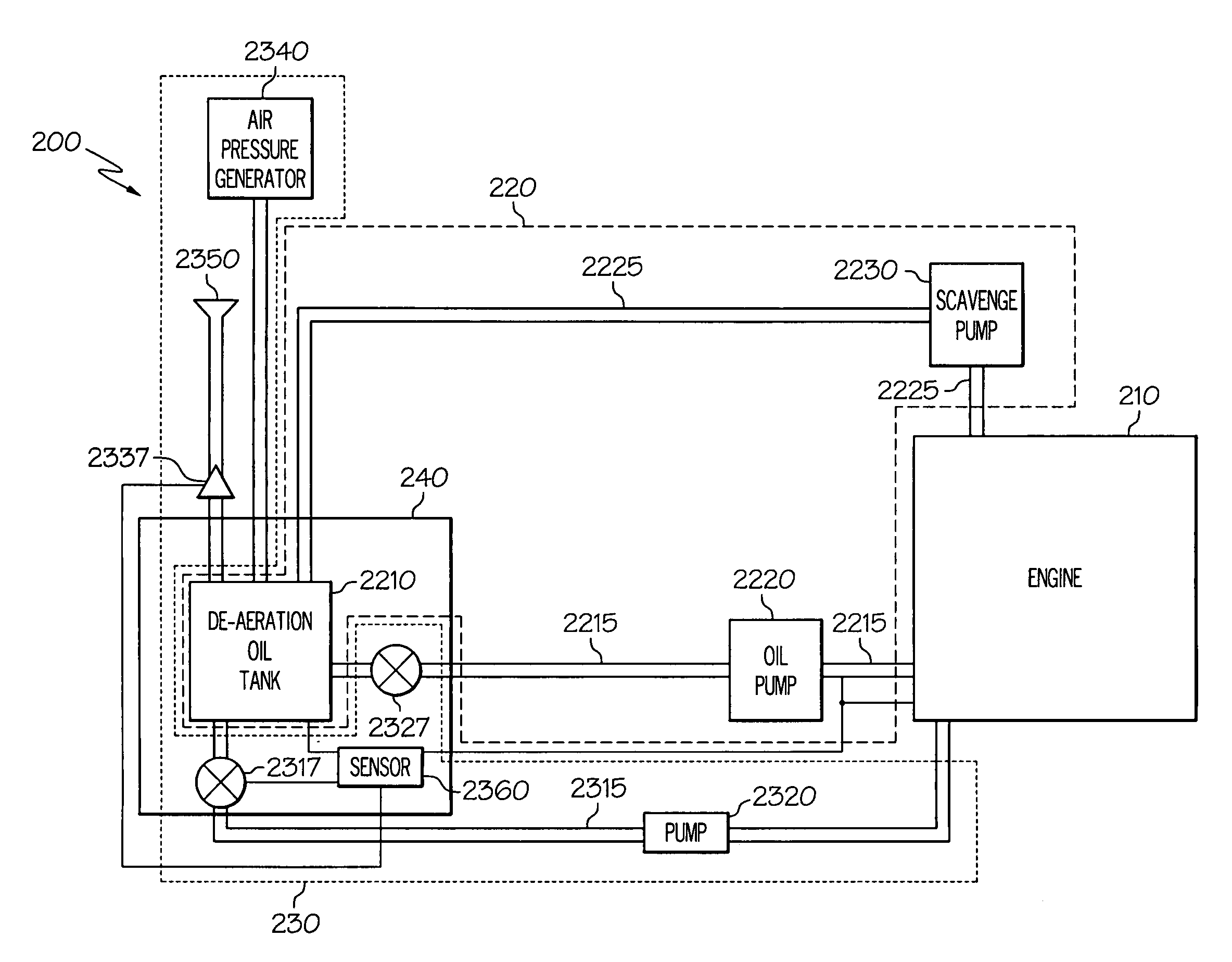

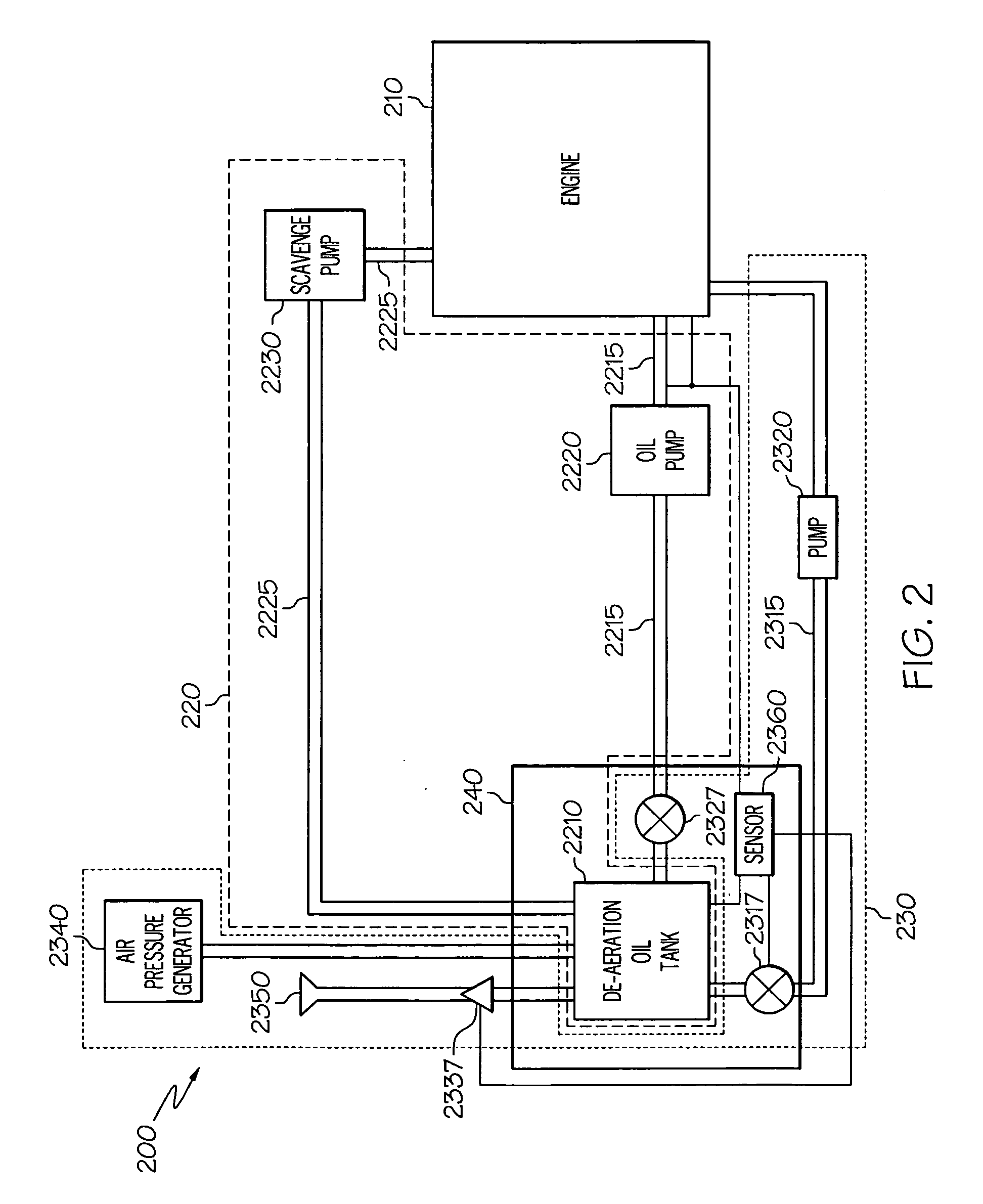

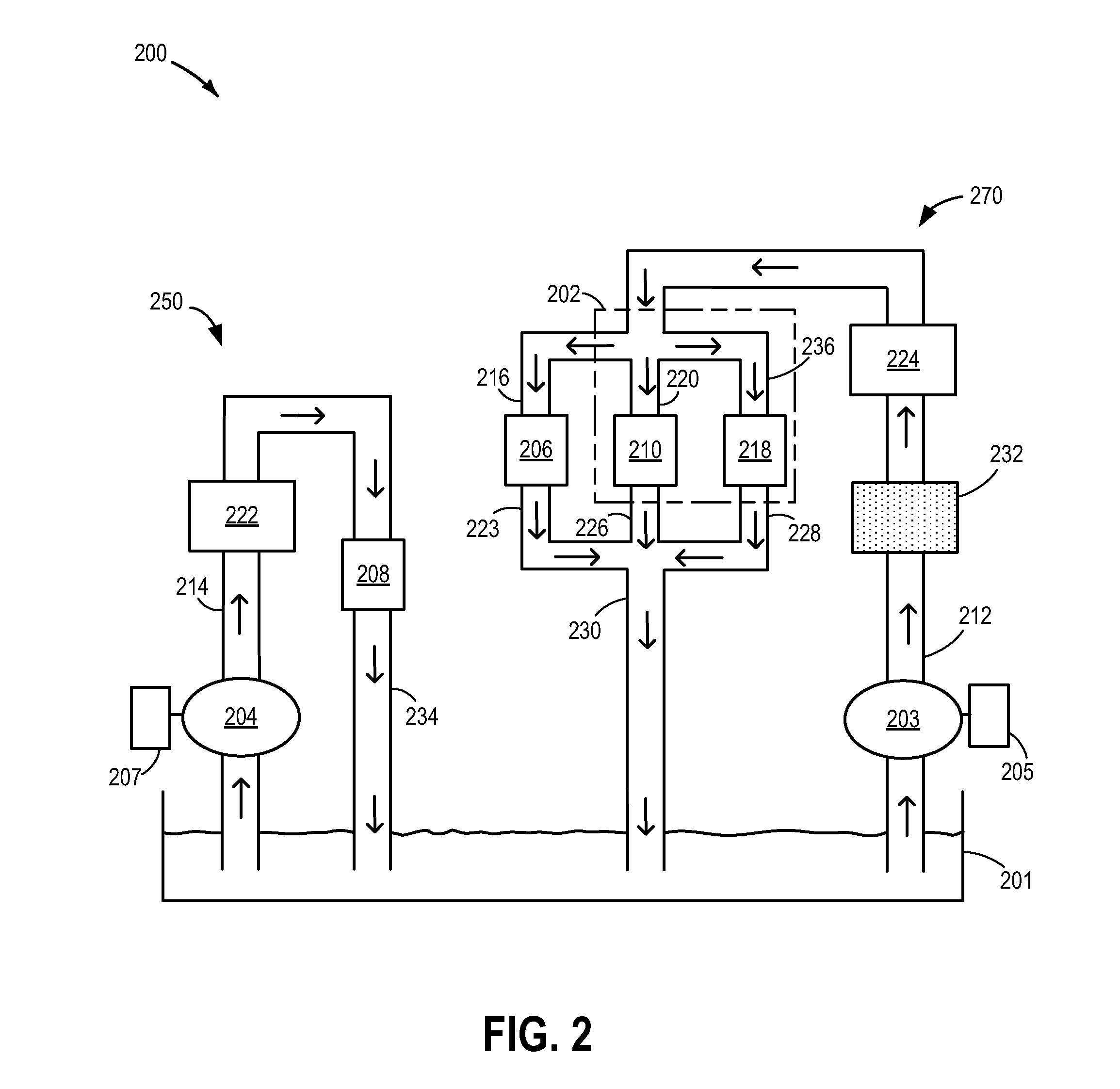

Emergency engine lubrication systems and methods

Emergency lubrication systems and methods for an engine are provided. One system includes a primary lubrication system including a de-aeration oil tank configured to store de-aerated oil until the oil is de-aerated, a first oil supply line configured to provide de-aerated oil to the engine, and a first valve configured to control the flow of oil through the primary lubrication system. The system further includes a secondary lubrication system including a second valve coupled to the de-aeration oil tank and configured to control the flow of oil through the secondary lubrication system, and a second oil supply line coupled to the engine and to the de-aeration oil tank via the second valve. One method includes the steps of detecting a predetermined event in the engine, preventing the aerated oil from entering the primary lubrication system, and using the aerated oil in the secondary lubrication system to lubricate the engine.

Owner:HONEYWELL INT INC

Lubrication scavenge system

A method and apparatus for scavenging lubricant is disclosed herein. In the invention, a rotating structure is encircled within a sump housing and subjected to lubrication. The sump housing collects high-momentum lubricant flow and low-momentum lubricant flow. The interior of the sump housing is separated into a plurality of chambers with at least one dynamic seal. The at least one dynamic seal extends between the sump housing and the rotating structure to isolate the high-momentum lubricant flow from the low-momentum lubricant flow.

Owner:ROLLS ROYCE CORP

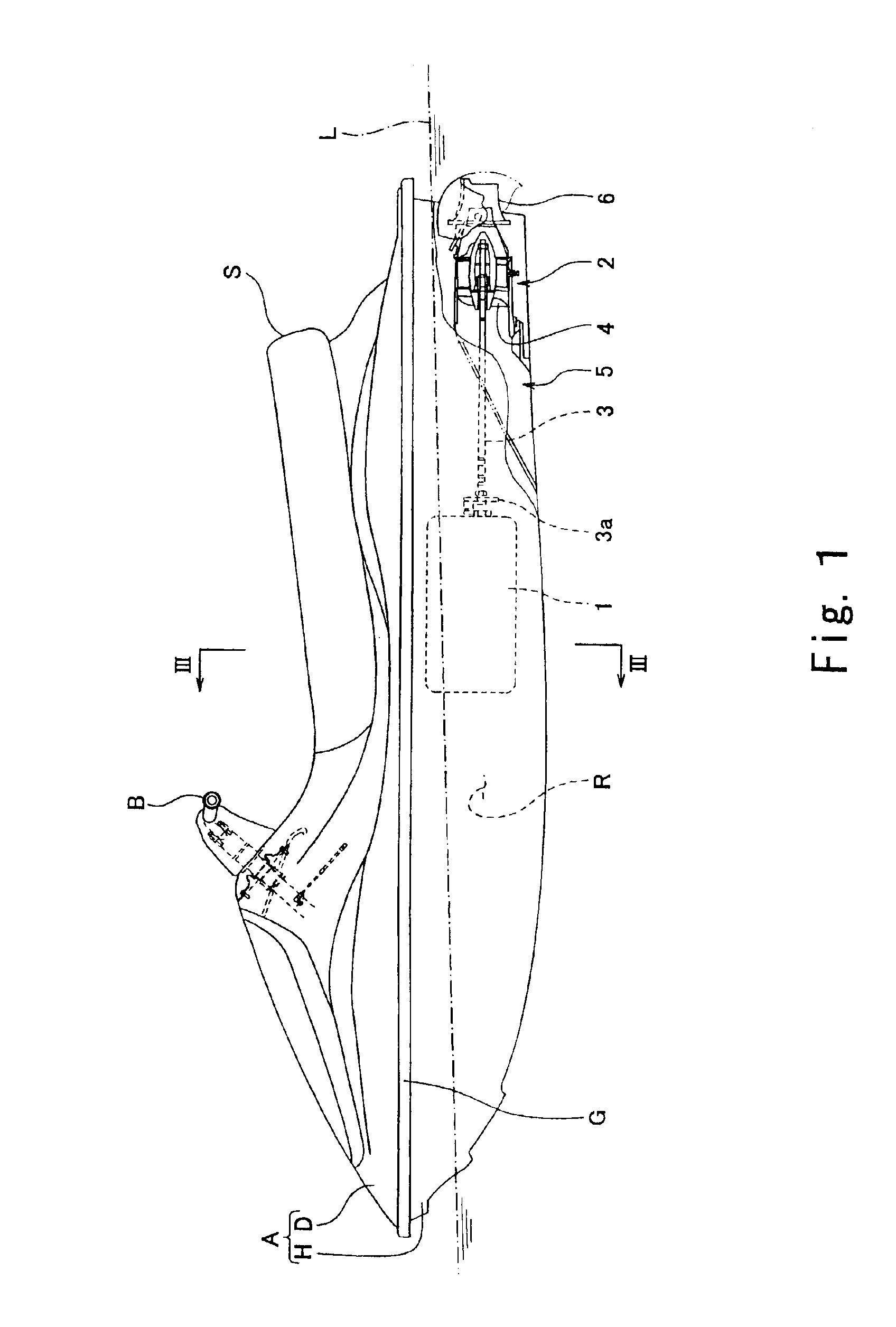

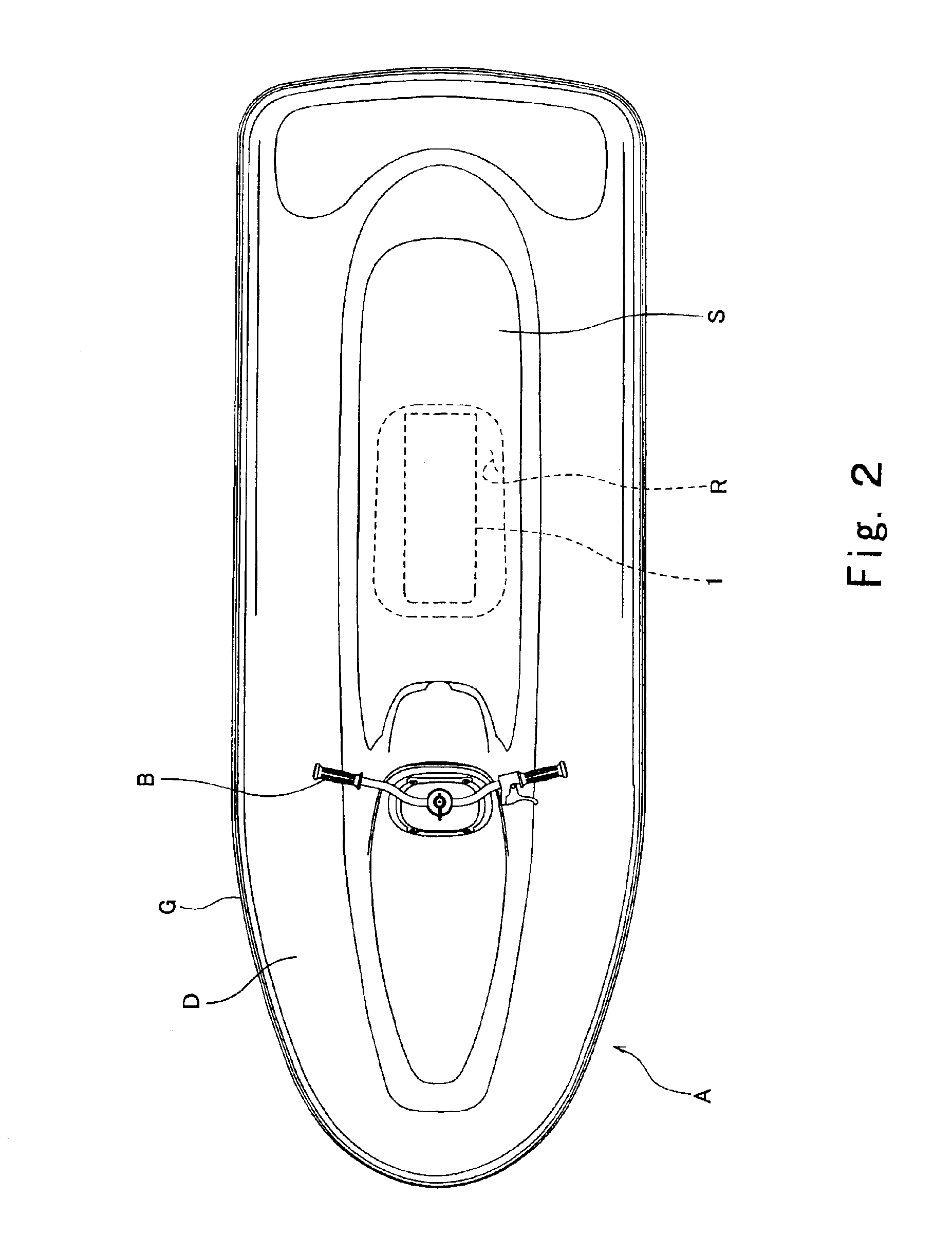

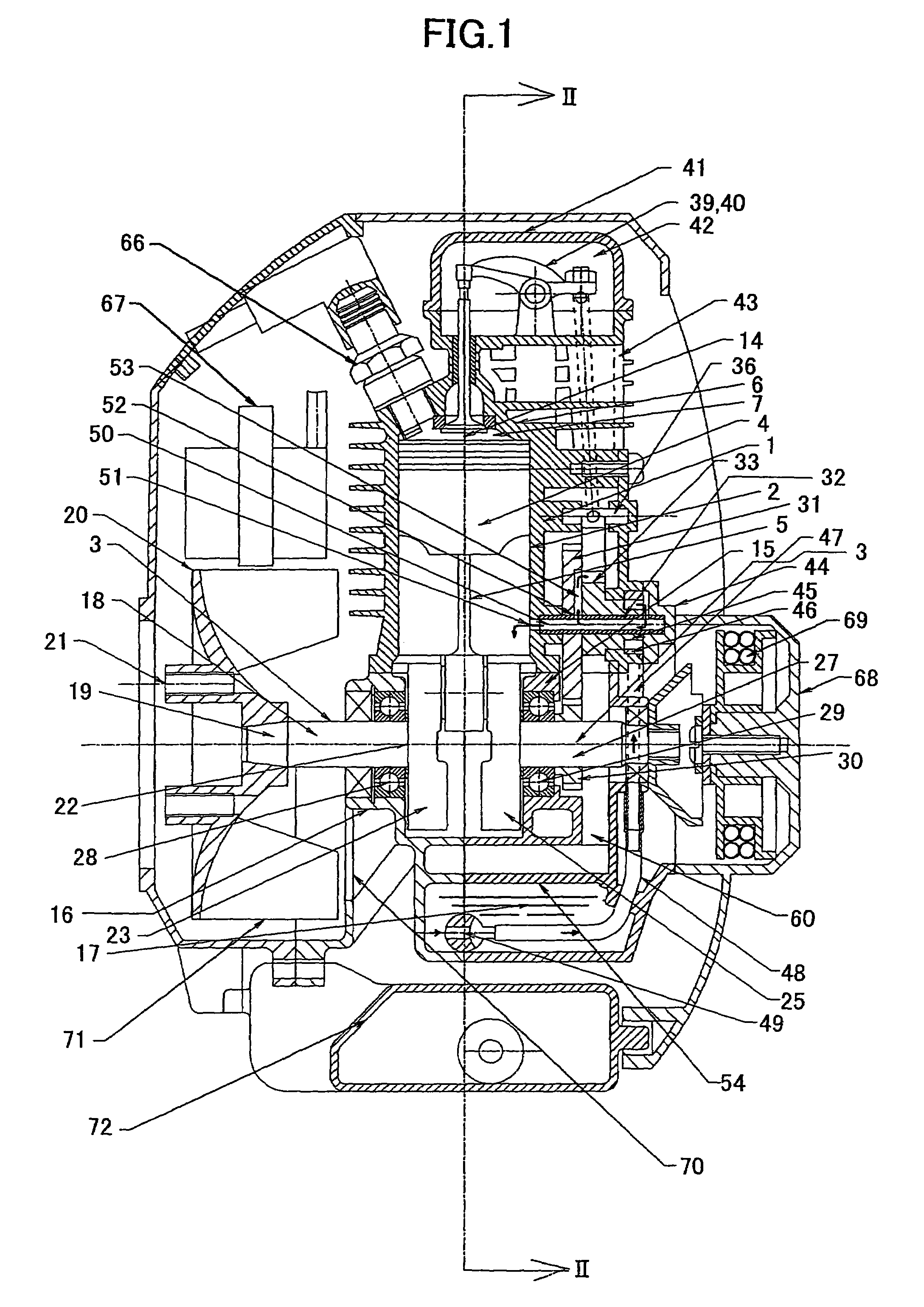

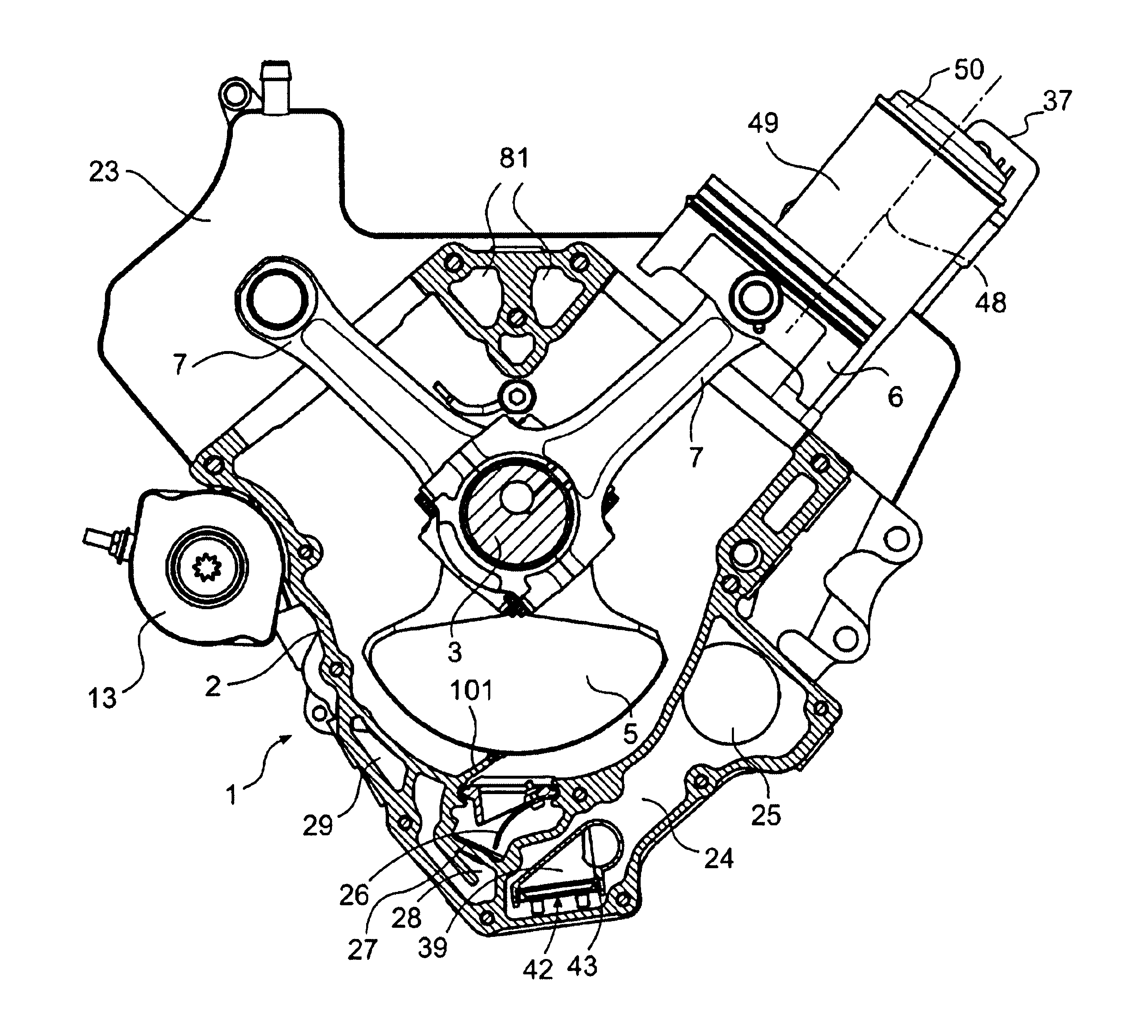

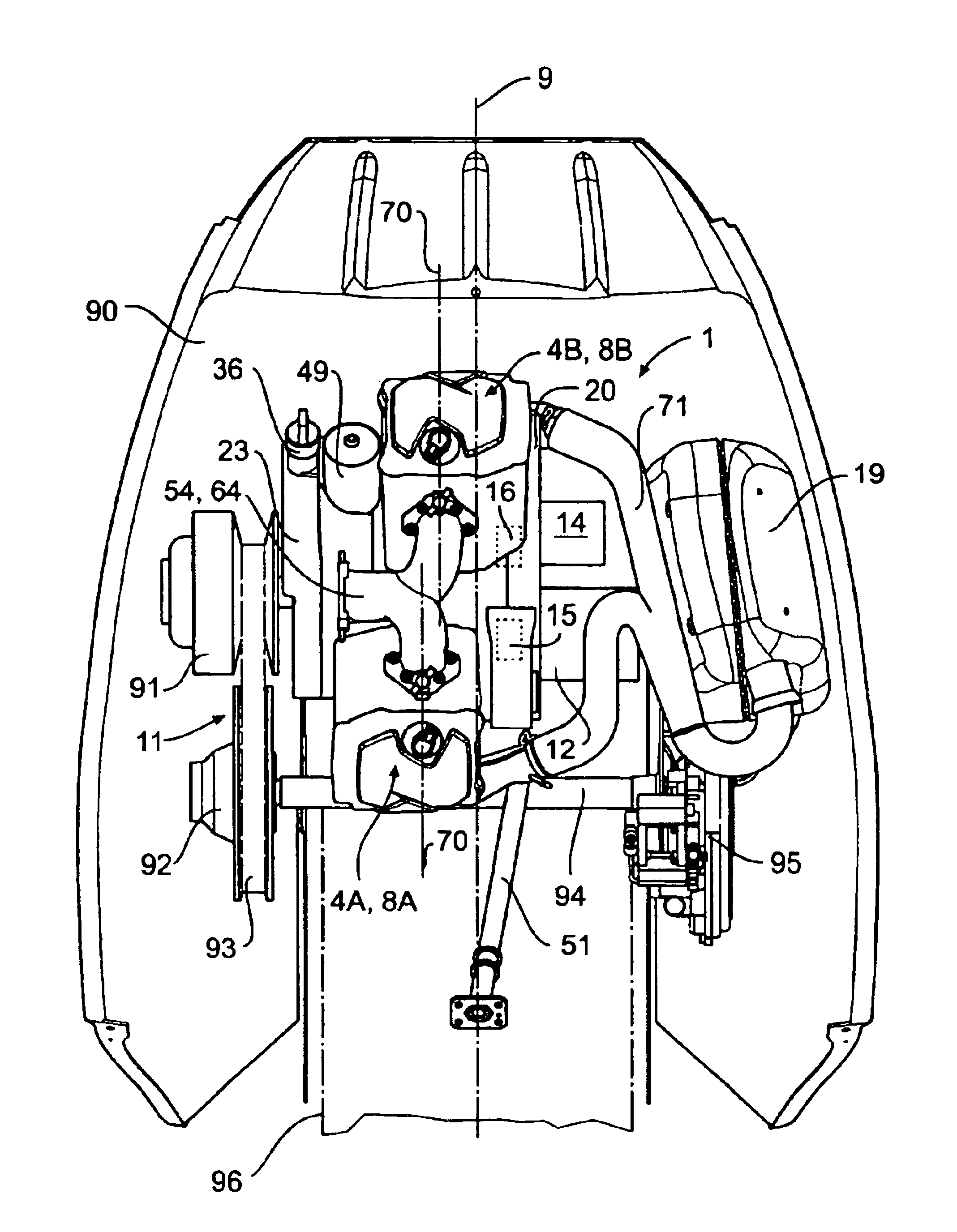

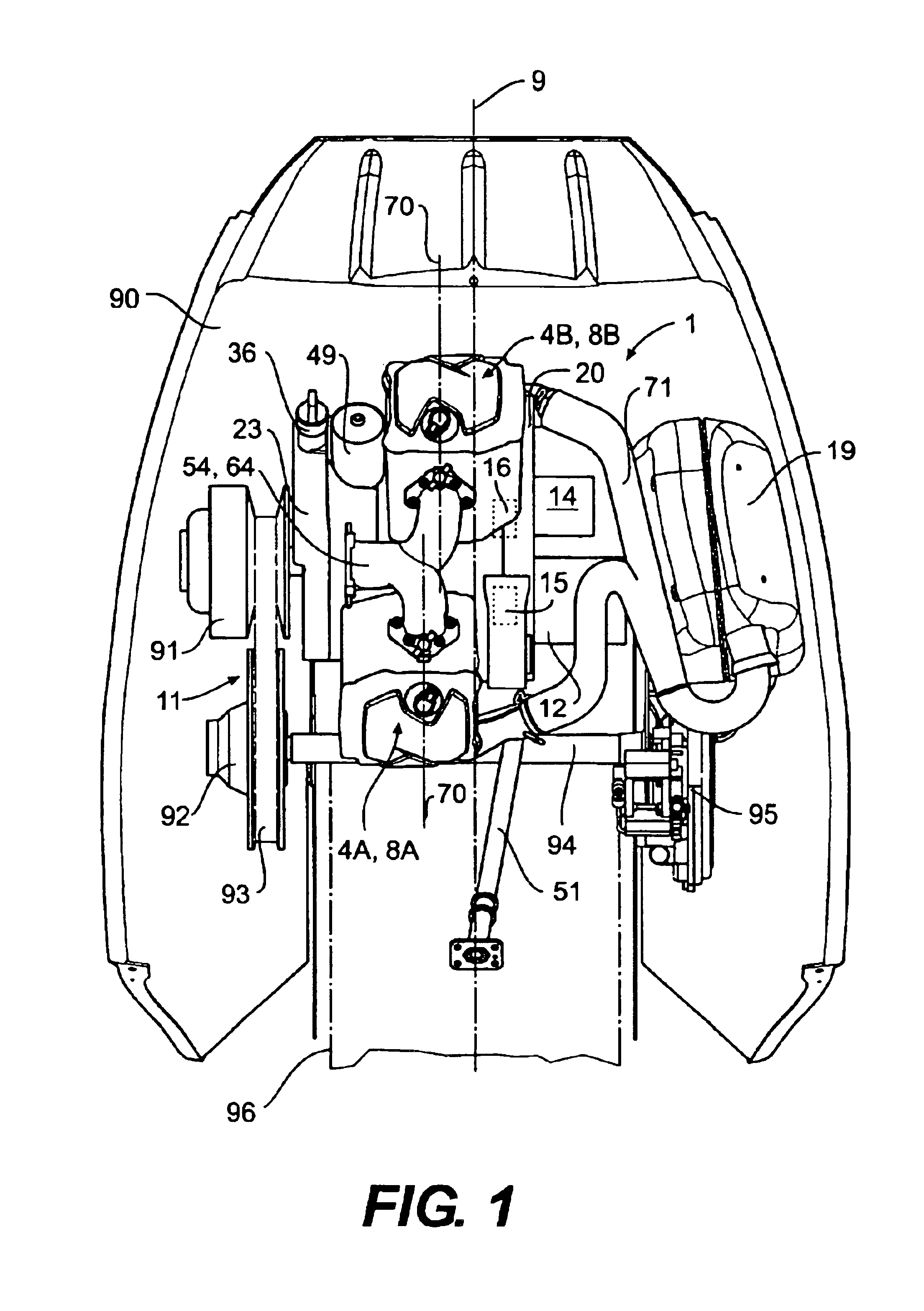

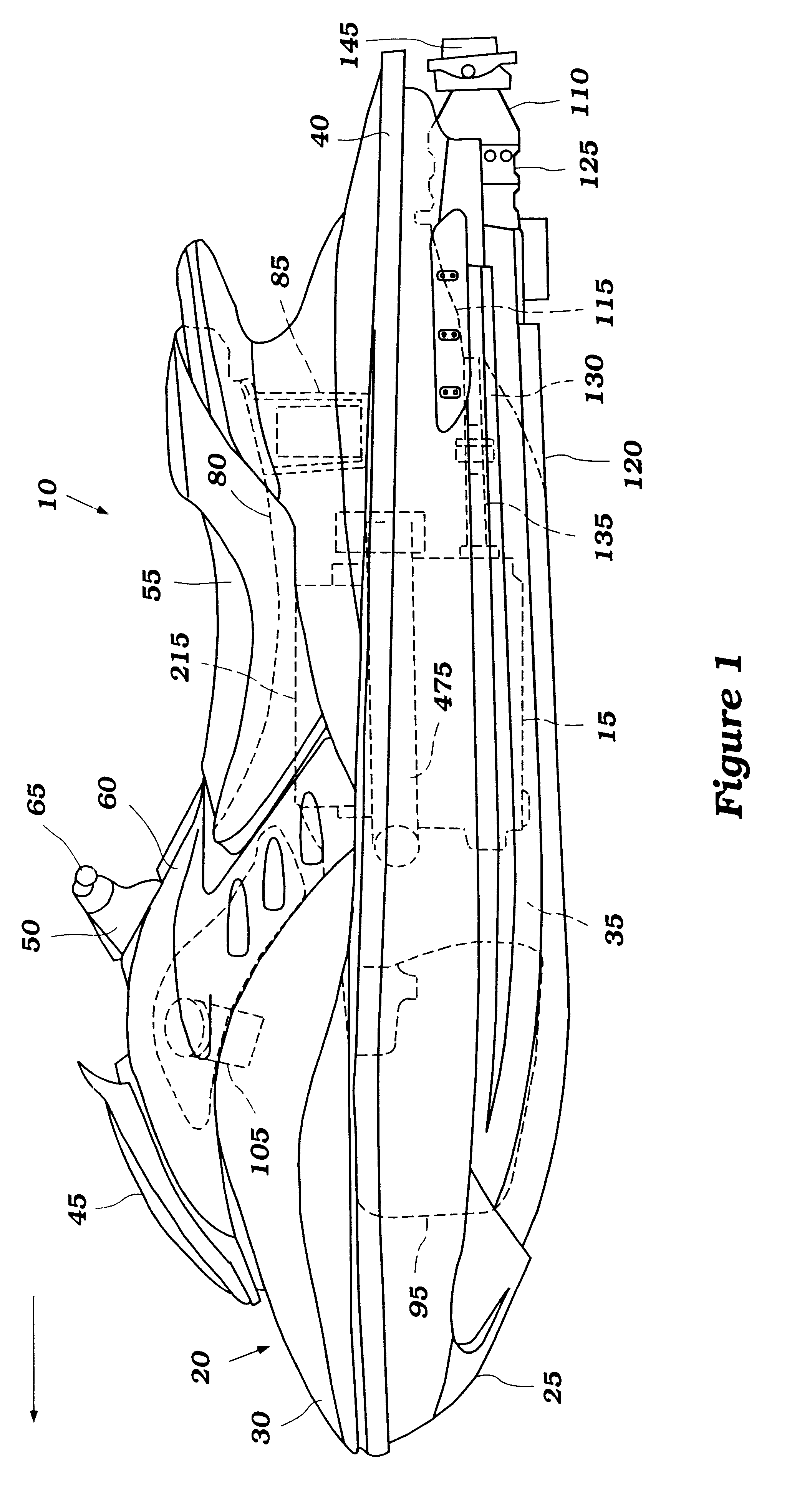

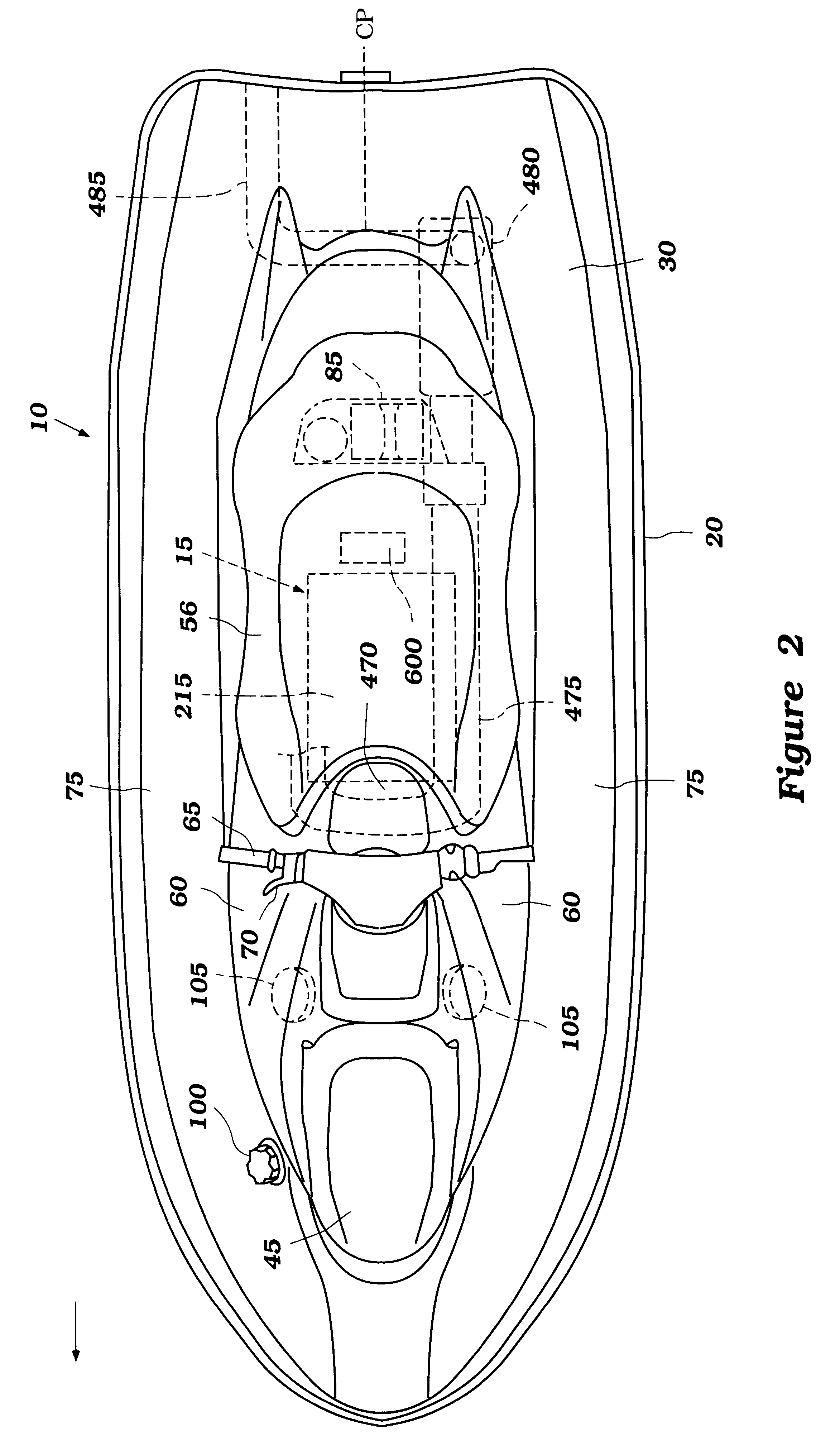

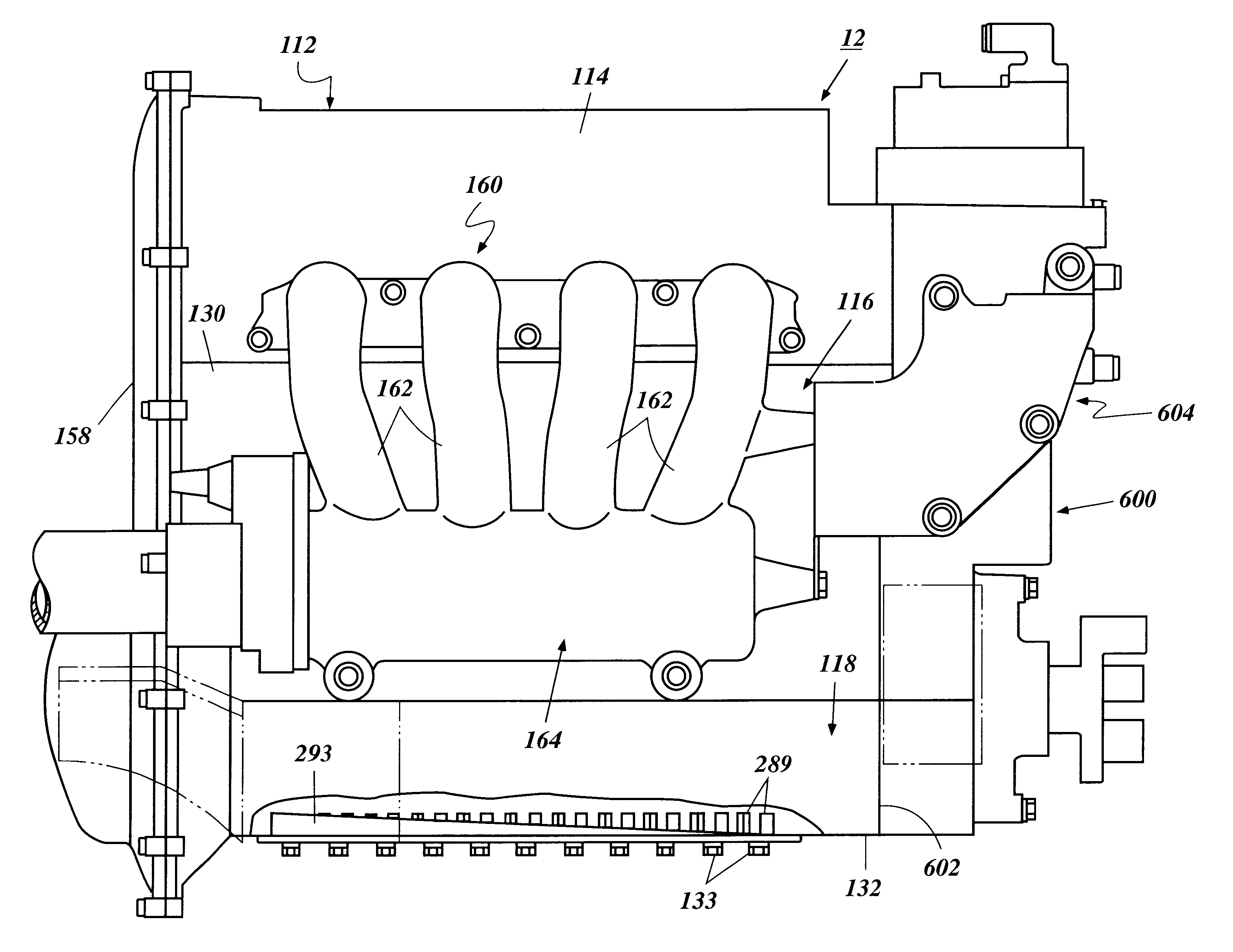

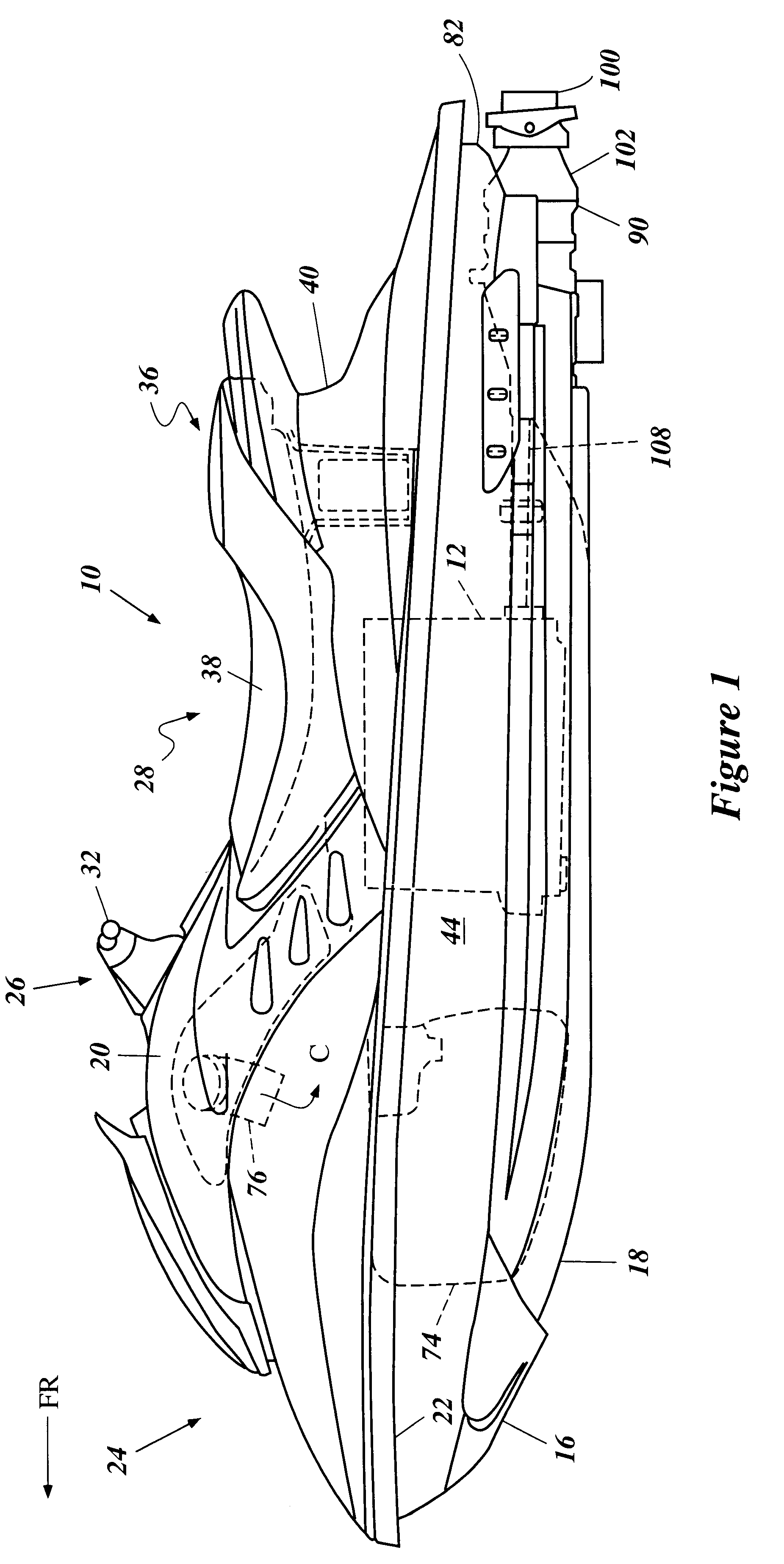

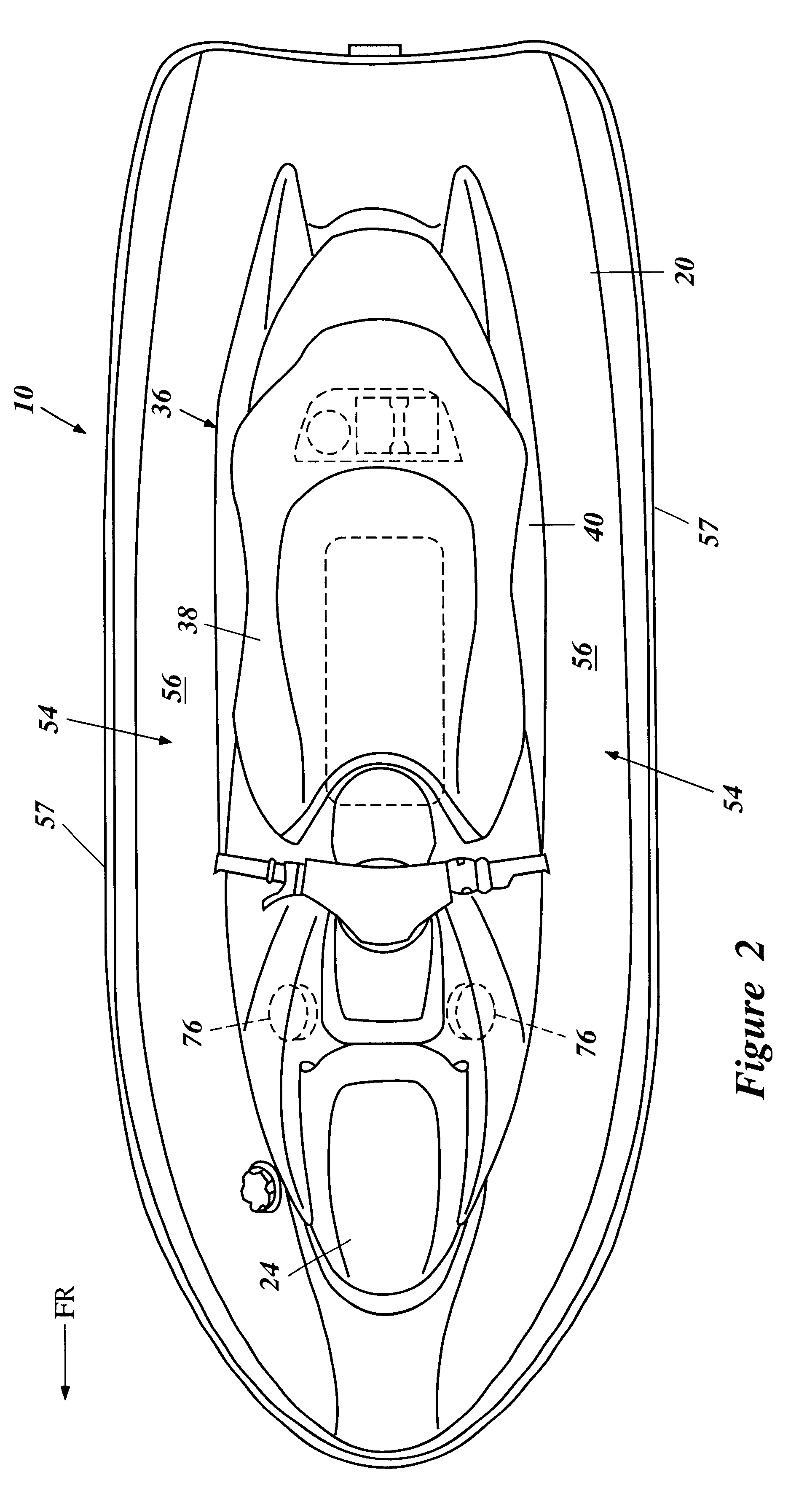

Engine and personal watercraft equipped with engine

InactiveUS6889651B2Efficient arrangementEfficiently dead spacePower plants using condensersLubrication of auxillariesCylinder headFuel tank

Owner:KAWASAKI MOTORS LTD

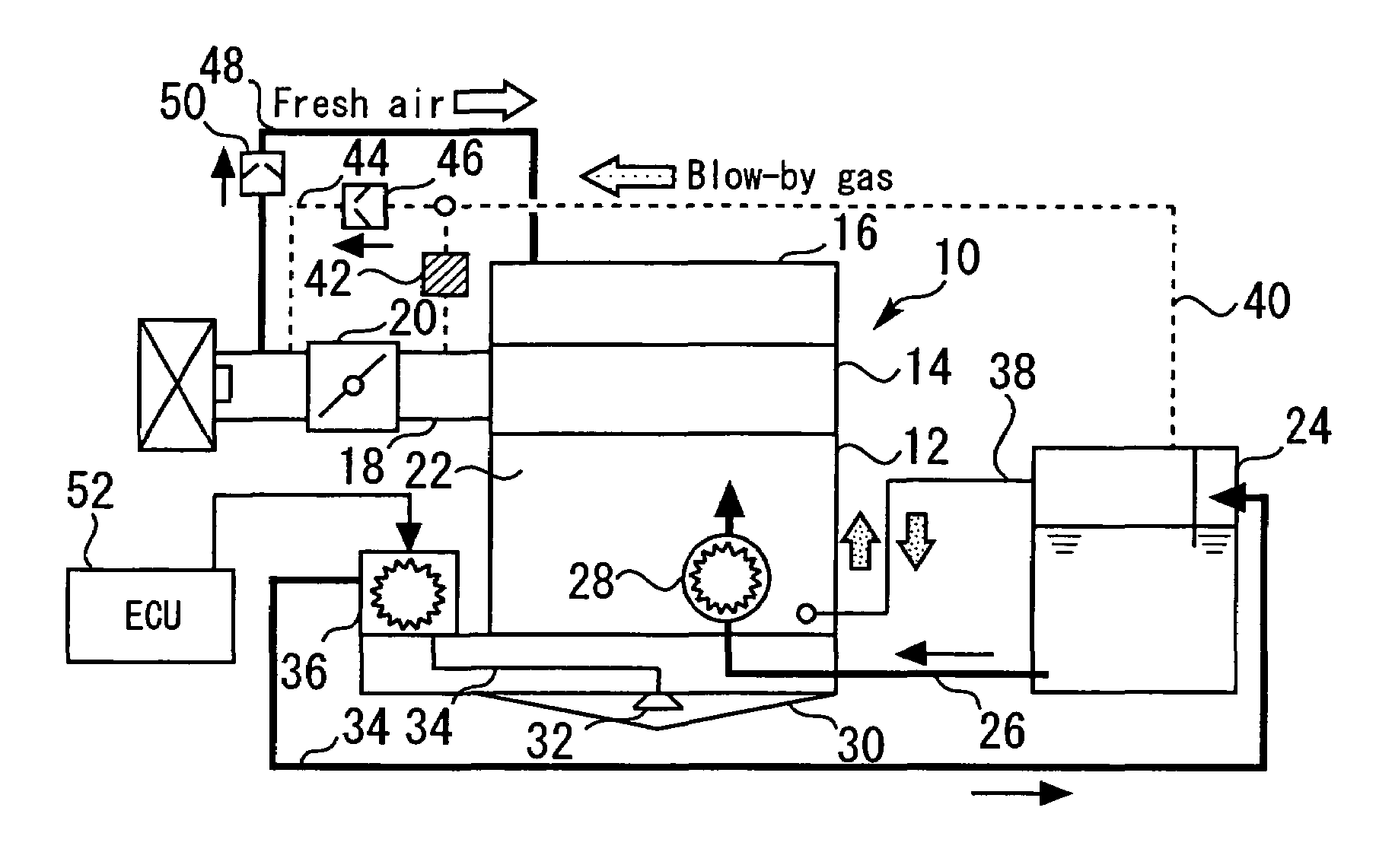

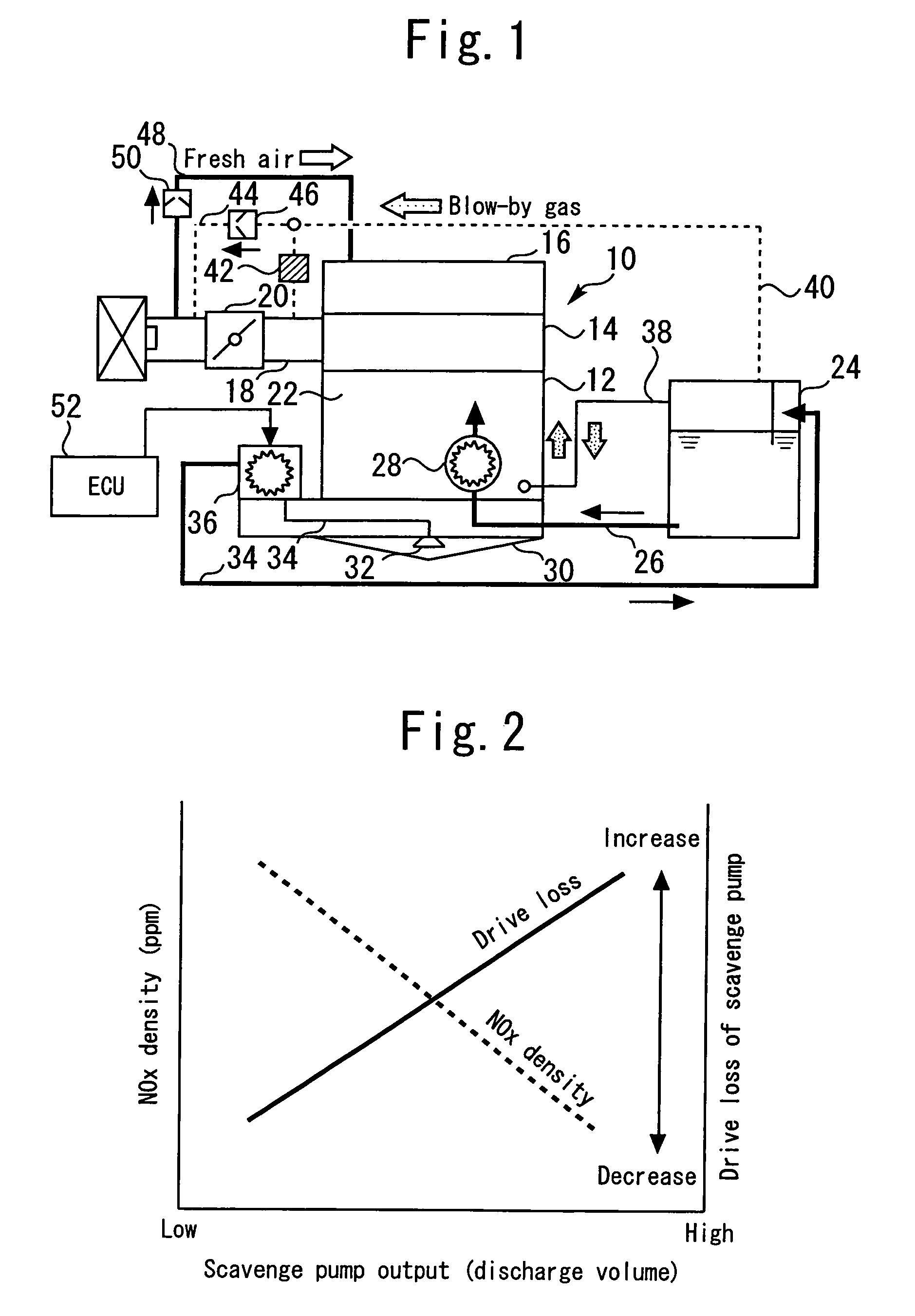

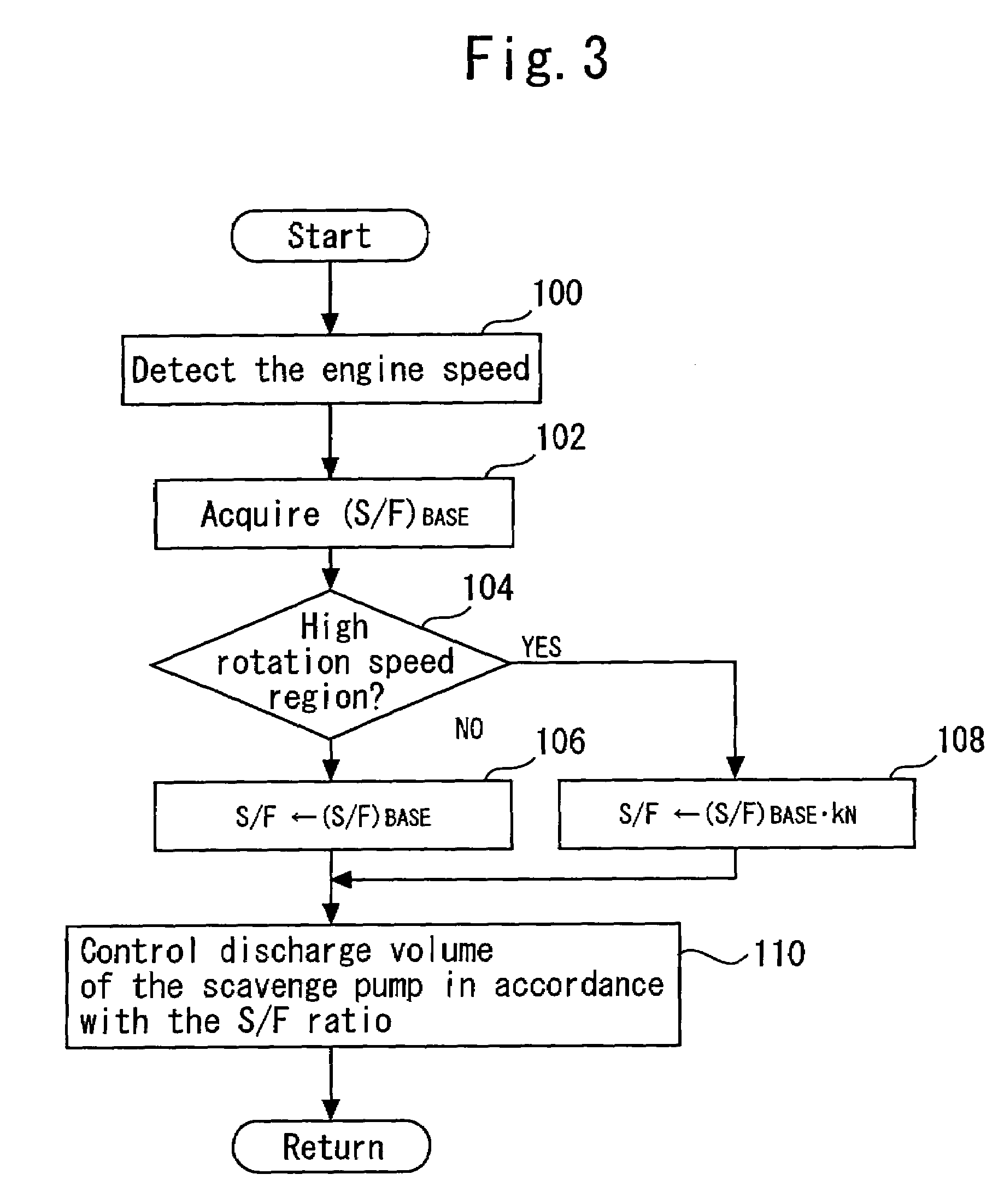

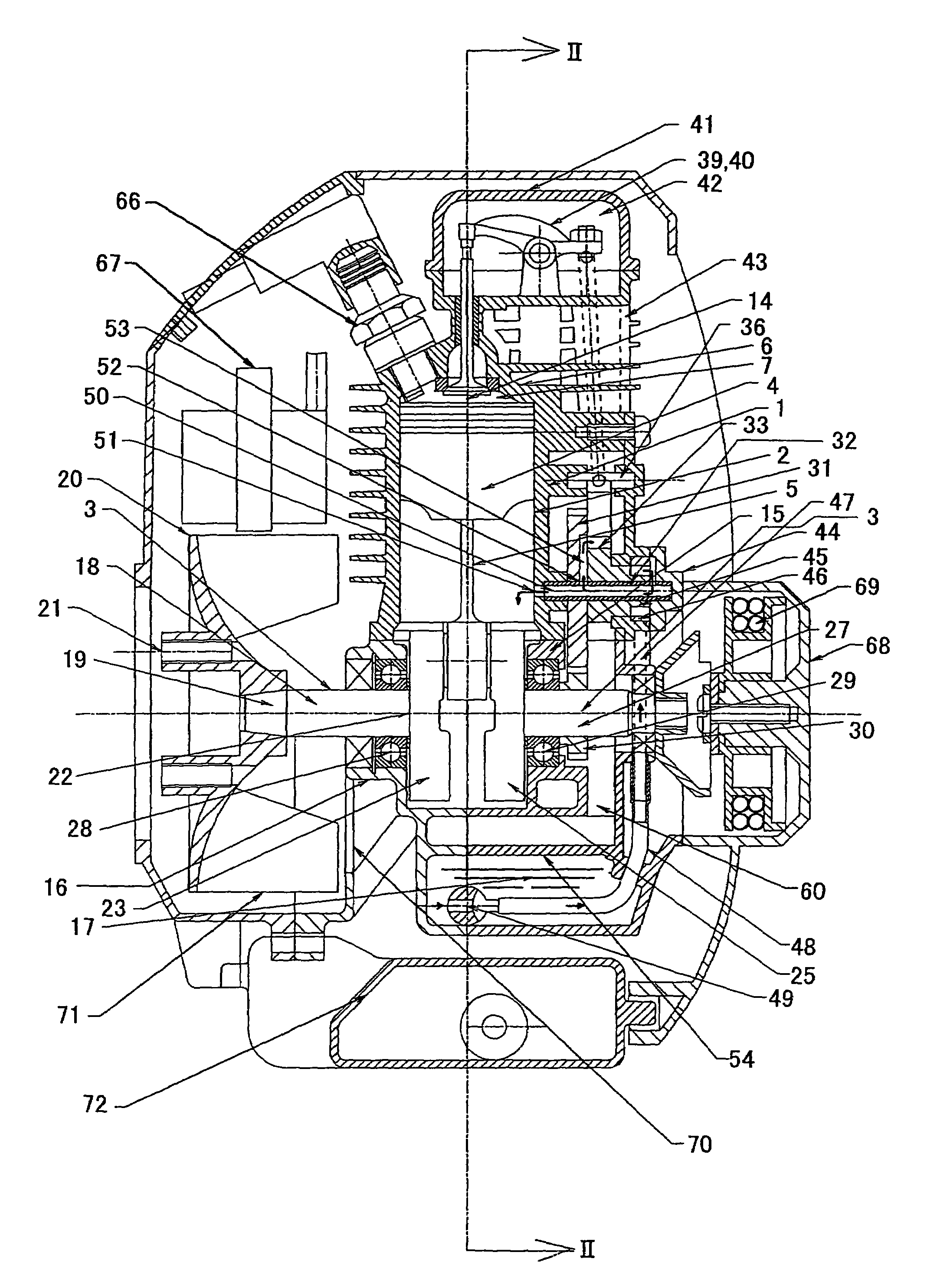

Control apparatus for dry sump type internal combustion engine

ActiveUS7174876B2Effectively deteriorationImprove energy consumptionElectrical controlLubrication of auxillariesExternal combustion engineEngineering

A feed pump 28 that is driven by the axial torque of an internal combustion engine 10 is installed. An electric scavenge pump 36 is installed. A base value for the ratio (S / F ratio) between the discharge volume of the scavenge pump 36 and feed pump 28 is calculated. The base value is corrected so that the S / F ratio is lower in a region where the engine speed is high than in a region where the engine speed is low. The discharge volume of the scavenge pump 36 is controlled in accordance with the S / F ratio that is corrected in the above manner.

Owner:TOYOTA JIDOSHA KK +1

Engine lubrication method

InactiveUS7287508B2Emission reductionSufficient lightingLubrication of auxillariesDrip or splash lubricationExhaust valveCombustion chamber

An engine lubrication method is provided. The four-cycle engine has a lightweight aluminum alloy engine block having a cylindrical bore and an enclosed oil reservoir formed therein. A crankshaft is rotatably mounted in the engine block for rotation about a crankshaft axis. A piston reciprocates within the bore and is connected to the crankshaft by a connecting rod. An oil pump driven by the cam gear, which mates with crank gear that is driven by crank shaft, inhales the oil from the oil reservoir to splash lubricate into the cylinder bore. The engine is provided with a cylinder head assembly defining a compact combustion chamber having a pair of overhead intake and exhaust ports and cooperating intake and exhaust valves. A lightweight, high-powered engine is thereby provided having relatively low HC and CO emissions. A circular arc wall surrounds around web of the crankshaft with a slight distance from the web. A scroll shaped wall has gradually increased distance from said wall to the direction of rotation of the web and has partial overlap with the circular arc wall. The crankshaft web splashes and flies the oil to lubricate engine parts and the oil after lubricating the parts is forced to return into the oil reservoir guided by scroll shaped wall.

Owner:ETG

Method and apparatus for efficiently cooling motorcycle engines

InactiveUS6955150B2Improve abilitiesMachines/enginesClosed-circuit pressure lubricating systemsEngineeringForced-air

A method for managing oil temperature for a vehicle engine comprises the steps of (a) determining a preferred temperature window for oil in operation of the vehicle, comprising a first, lower temperature, and a second, higher temperature; (b) pumping oil from the vehicle engine to a control valve controlling oil passage into a radiator, and bypassing the radiator via a by-pass passage in the control valve more than seventy-percent of the oil to return to the vehicle engine without passing through the radiator upon cold start-up; (c) closing the bypass passage at the first oil temperature, forcing all oil entering the control valve to pass through he radiator before returning to the vehicle engine; (d) starting a forced-air fan at the second temperature to urge ambient air through air passages of the radiator, thereby enhancing ability of the radiator to cool the oil passing through.

Owner:PETCHEL JOHN JOSEPH

Tandem dual pumps for a hybrid propulsion system

A hybrid propulsion system and a method of controlling same are provided. The hybrid propulsion system includes an internal combustion engine having a fluid lubrication and control system. The hybrid propulsion system also includes an engine oil pump arranged externally with respect to the engine and configured to maintain fluid pressure to the lubrication and control system when the internal combustion engine is shut off. Additionally, the hybrid propulsion system includes a motor / generator and a transmission in operable communication with the internal combustion engine. The transmission includes a transmission oil pump arranged externally with respect to the transmission and configured to maintain fluid pressure to the transmission when the engine is shut off. Furthermore, the hybrid propulsion system includes an auxiliary motor driving the externally arranged engine oil pump and the externally arranged transmission oil pump.

Owner:GM GLOBAL TECH OPERATIONS LLC

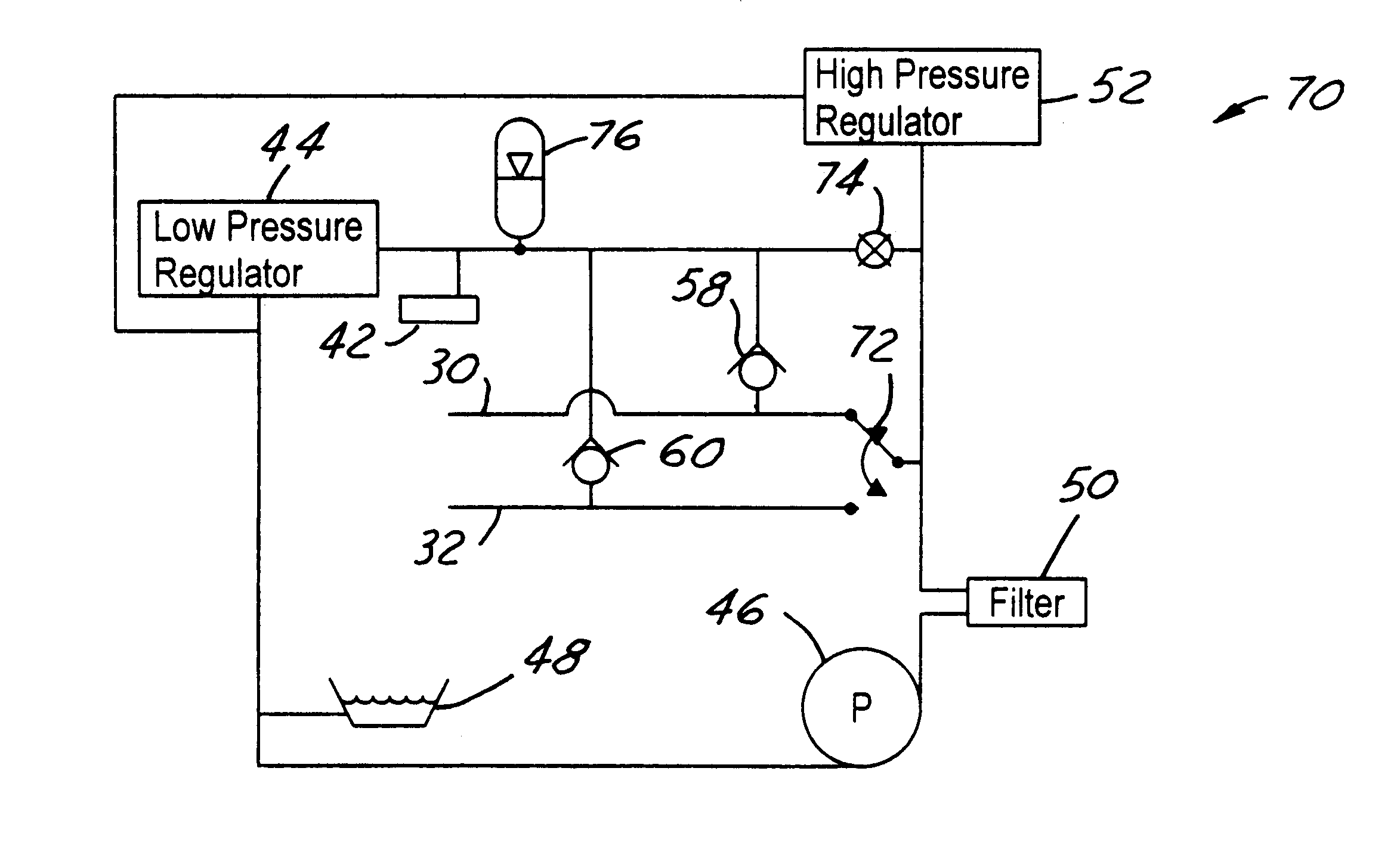

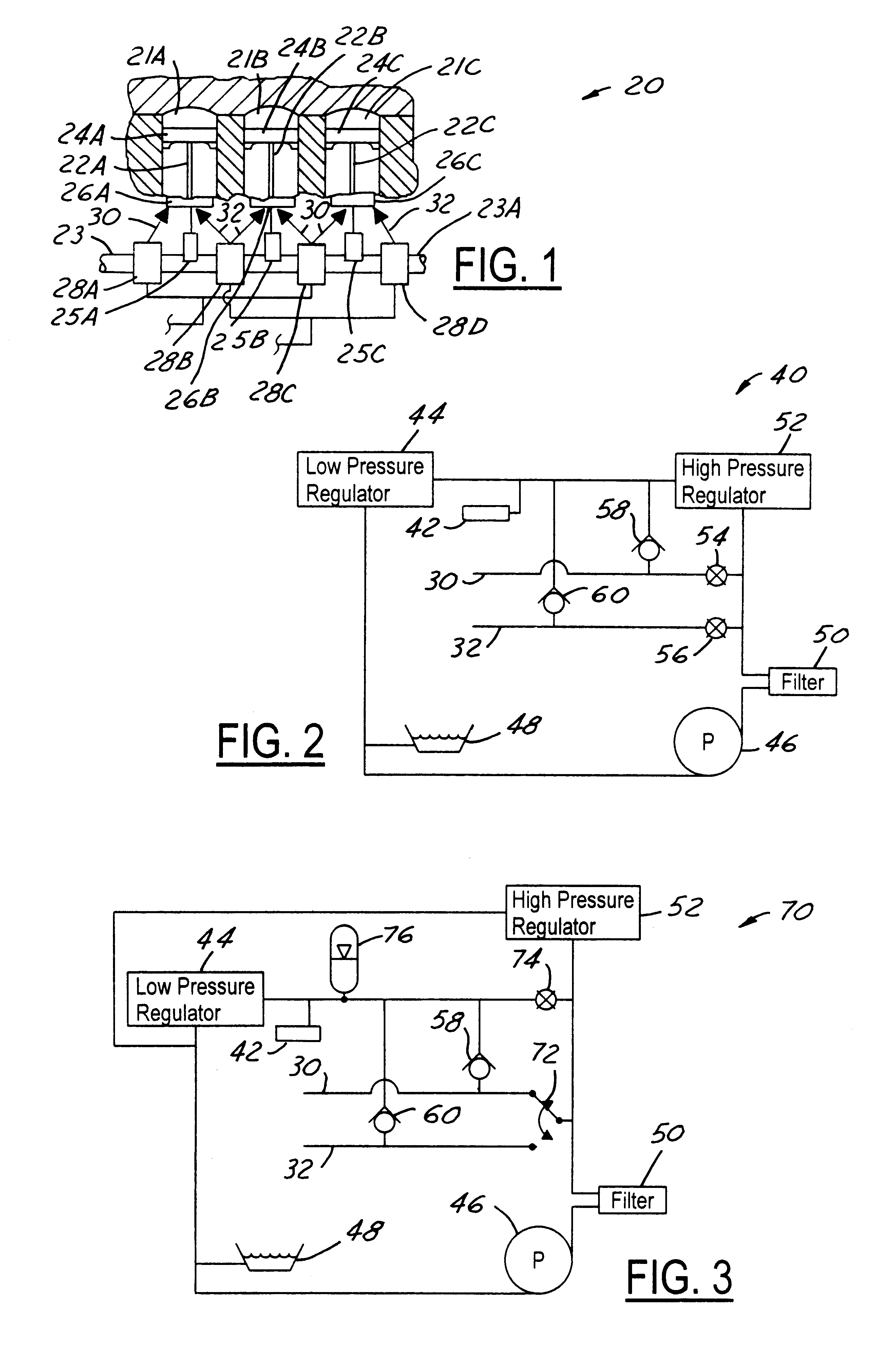

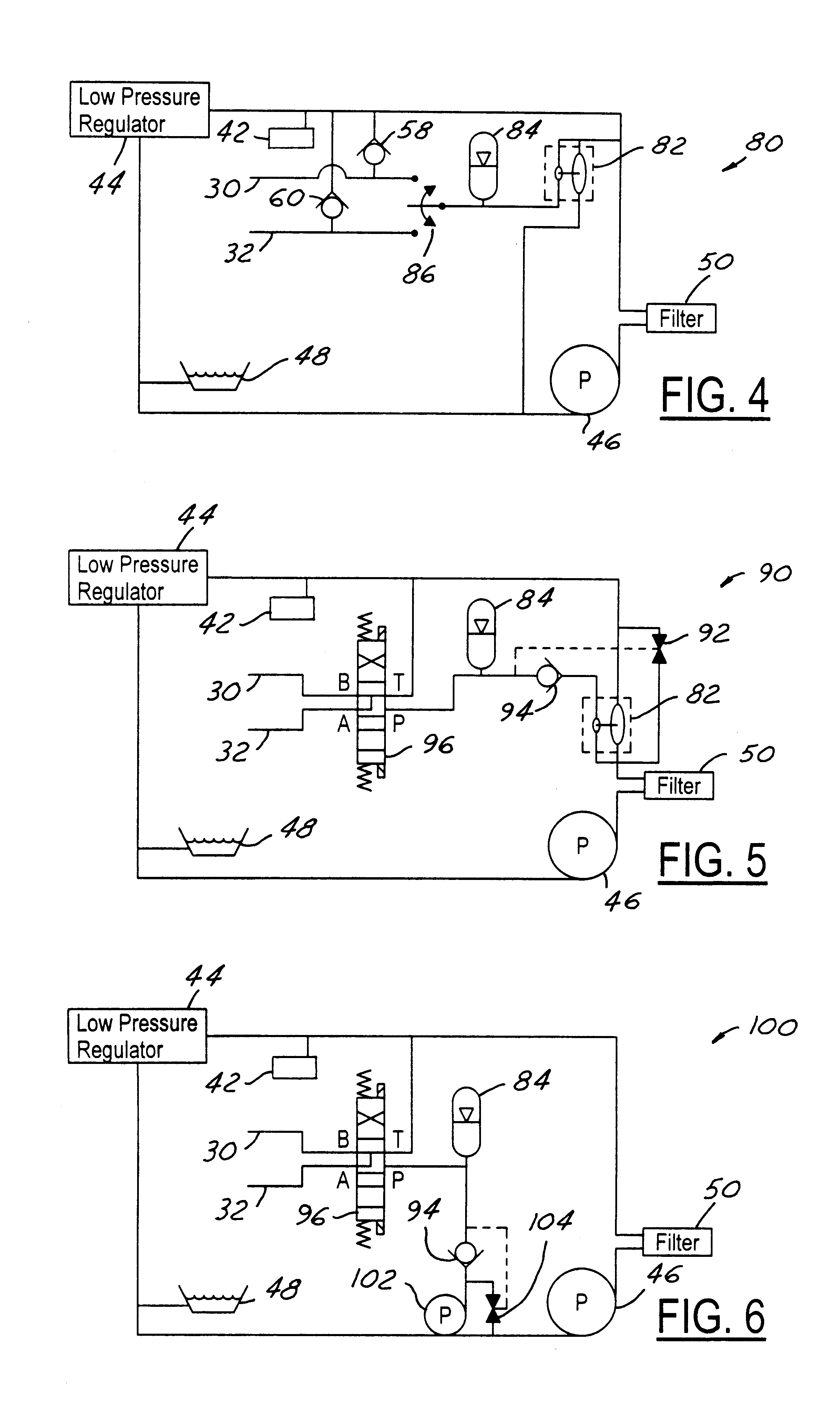

Oiling systems and methods for changing lengths of variable compression ratio connecting rods

An engine 20 has an oiling system including a pump (46) that delivers oil under nominal engine lubrication pressure to lubricate moving surfaces of the engine mechanism (42). The system also has first and second control passages (30, 32) to effect engine compression ratio change by operating connecting rod length change mechanisms (26A, 26B, 26C). Selectively operated hydraulic control devices cause pressure in the first passage to be greater than pressure in the second passage to effect an increase in engine compression ratio and pressure in the second passage to be greater than pressure in the first passage to effect a decrease in engine compression ratio. Multiple embodiments of the invention are disclosed.

Owner:FORD GLOBAL TECH LLC

Internal combustion engine

InactiveUS6786187B2Amount of oil in can optimizedSimple structureCrankshaftsLubrication of auxillariesFuel tankEngineering

An internal combustion engine capable of optimizing the amount of oil in the crank chamber with a simplified structure of lubrication system, in which a U-shaped oil reservoir is formed surrounding and adjacent to a crank chamber. At least one small hole is formed on a partition wall which separates the oil reservoir and the crank chamber from each other so that the crank chamber may always communicate with the oil reservoir through the small hole. Due to a flow resistance in the small hole, a pressure Po in the oil reservoir changes following a change of pressure Pc in the crank chamber with some delay, and where the pressure difference between the oil reservoir and the crank chamber caused by a delay in the change of the pressure Po in the oil reservoir, results in the introduction of the oil in the oil reservoir into the crank chamber. It further allows excessive oil in the crank chamber to be circulated back into the oil reservoir.

Owner:KIORITZ

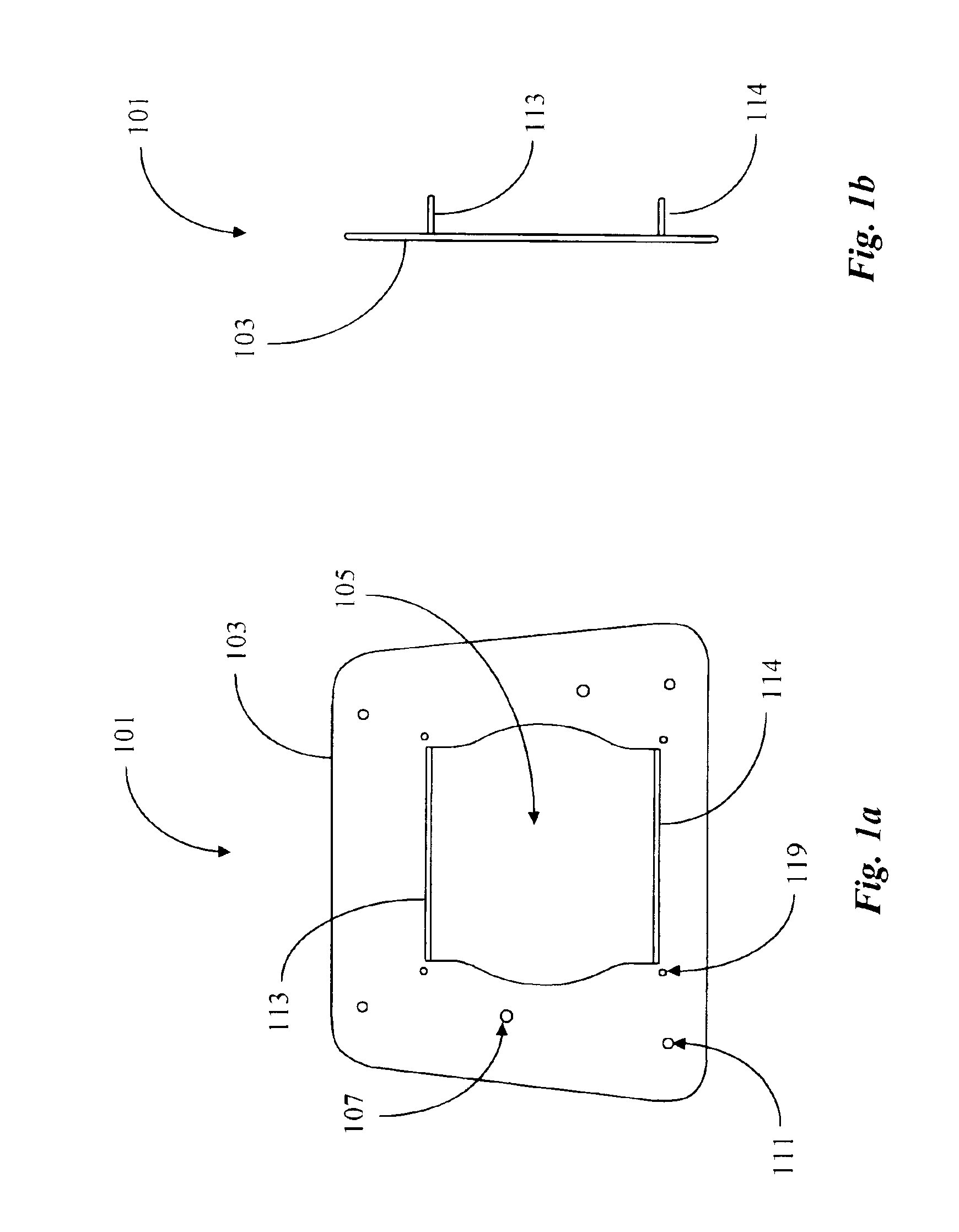

Dry sump oil tank assembly for a vehicle

ActiveUS20090211552A1Increase heightIncrease volumeLubrication of auxillariesCombustion enginesDry sumpWaste management

A dry sump oil tank assembly for a vehicle is provided with a housing defining an internal cavity. The housing is configured with a laterally-extending portion to add lateral volume to the internal cavity and has at least one internal baffle attached to the housing within the internal cavity below the laterally-extending portion and configured to reduce sloshing of oil within the cavity. The dry sump oil tank assembly is particularly useful for high performance applications, such as racing vehicles, and may utilize components from standard vehicle applications, thus maximizing the economies of scale of producing such components and being suited for a vehicle that may be typically used in standard driving conditions, but occasionally subjected to high performance use.

Owner:GM GLOBAL TECH OPERATIONS LLC

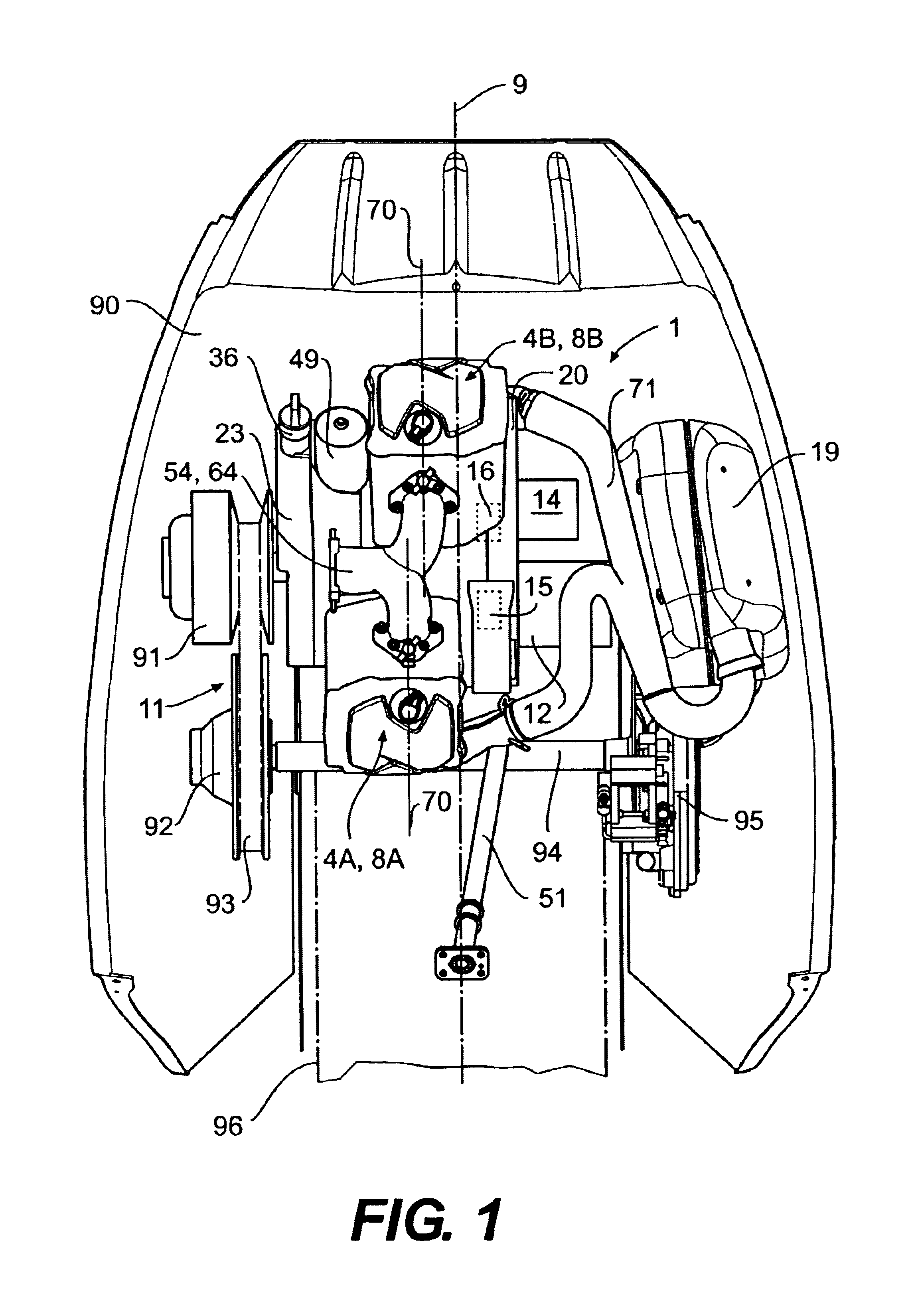

Vapor system arrangement for marine engine

A personal watercraft features a hull defining an engine compartment. An engine is mounted within the engine compartment. The engine comprises a cylinder head, a cylinder body and a crankcase. An induction system supplies air to the engine for combustion. The induction system comprising an intake box, an intake silencer, and a set of intake pipes that extend from the intake box to the engine. The intake pipes extend upward and inward toward the engine. A protective chamber is formed by an inside surface of the intake box, an outside surface of the engine and a lower surface of the pipes. A vapor separator is disposed within this protective chamber. The protective chamber can be augmented by an overhanging portion of the cylinder head, a protrusion from the cylinder body or other extensions from the intake box.

Owner:YAMAHA MOTOR CO LTD

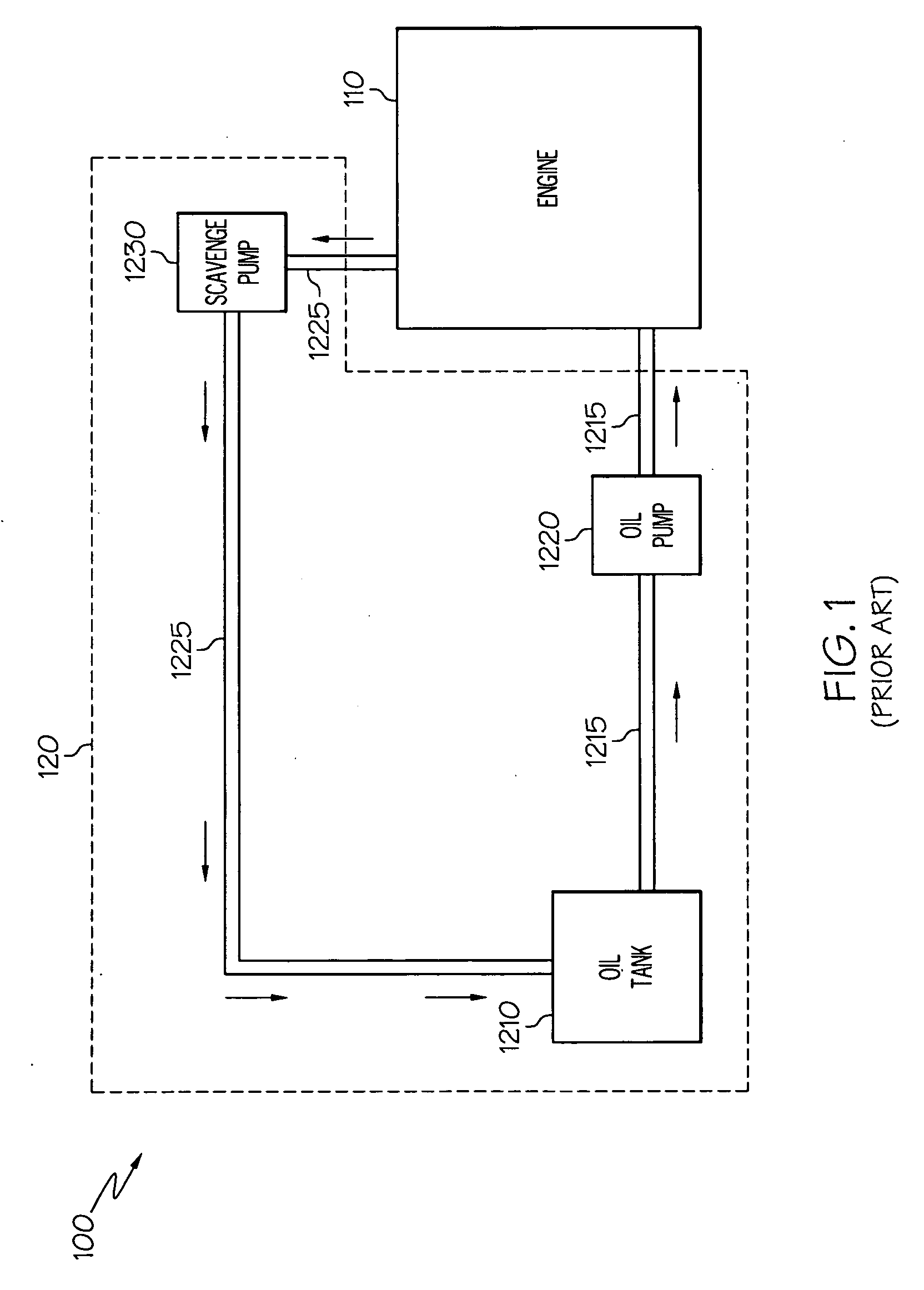

Emergency engine lubrication systems and methods

InactiveUS20100229823A1Lubrication of auxillariesLiquid degasificationLubricationEmergency situations

Emergency lubrication systems and methods for an engine are provided. One system includes a primary lubrication system including a de-aeration oil tank configured to store de-aerated oil until the oil is de-aerated, a first oil supply line configured to provide de-aerated oil to the engine, and a first valve configured to control the flow of oil through the primary lubrication system. The system further includes a secondary lubrication system including a second valve coupled to the de-aeration oil tank and configured to control the flow of oil through the secondary lubrication system, and a second oil supply line coupled to the engine and to the de-aeration oil tank via the second valve. One method includes the steps of detecting a predetermined event in the engine, preventing the aerated oil from entering the primary lubrication system, and using the aerated oil in the secondary lubrication system to lubricate the engine.

Owner:HONEYWELL INT INC

Oil separating structure of automatic transmission

There is provided an oil separating structure of an automatic transmission, which makes it difficult for an oil strainer of an oil pump to draw oil containing air bubbles. A baffle plate base separates a space around the oil strainer and a space around a driven sprocket as well as a final gear, and therefore, oil containing air bubbles formed as a result of agitation by the driven sprocket, chain, and final gear does not flow directly into the oil strainer. As a result, the oil strainer is unlikely to draw oil containing air bubbles.

Owner:JATCO LTD

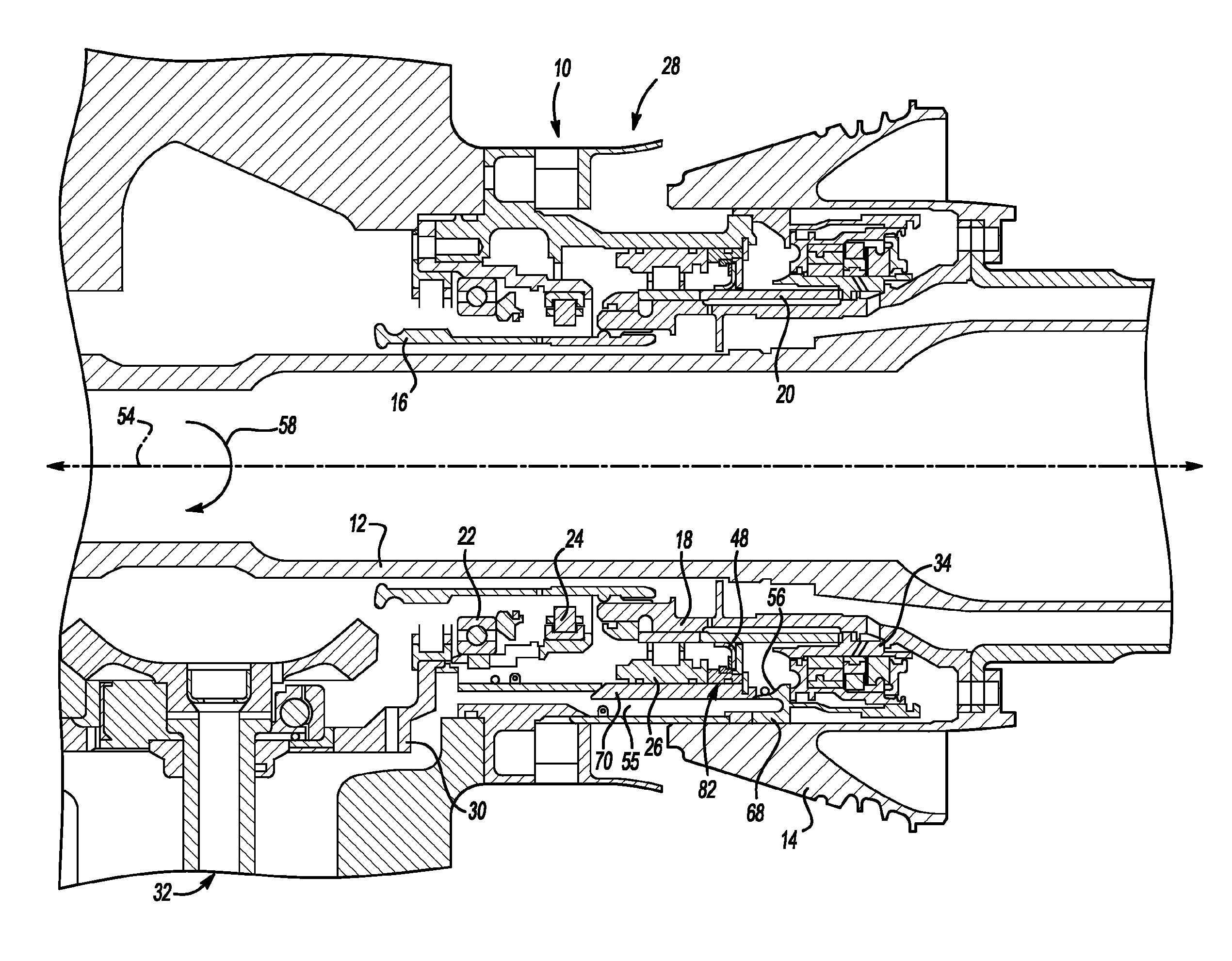

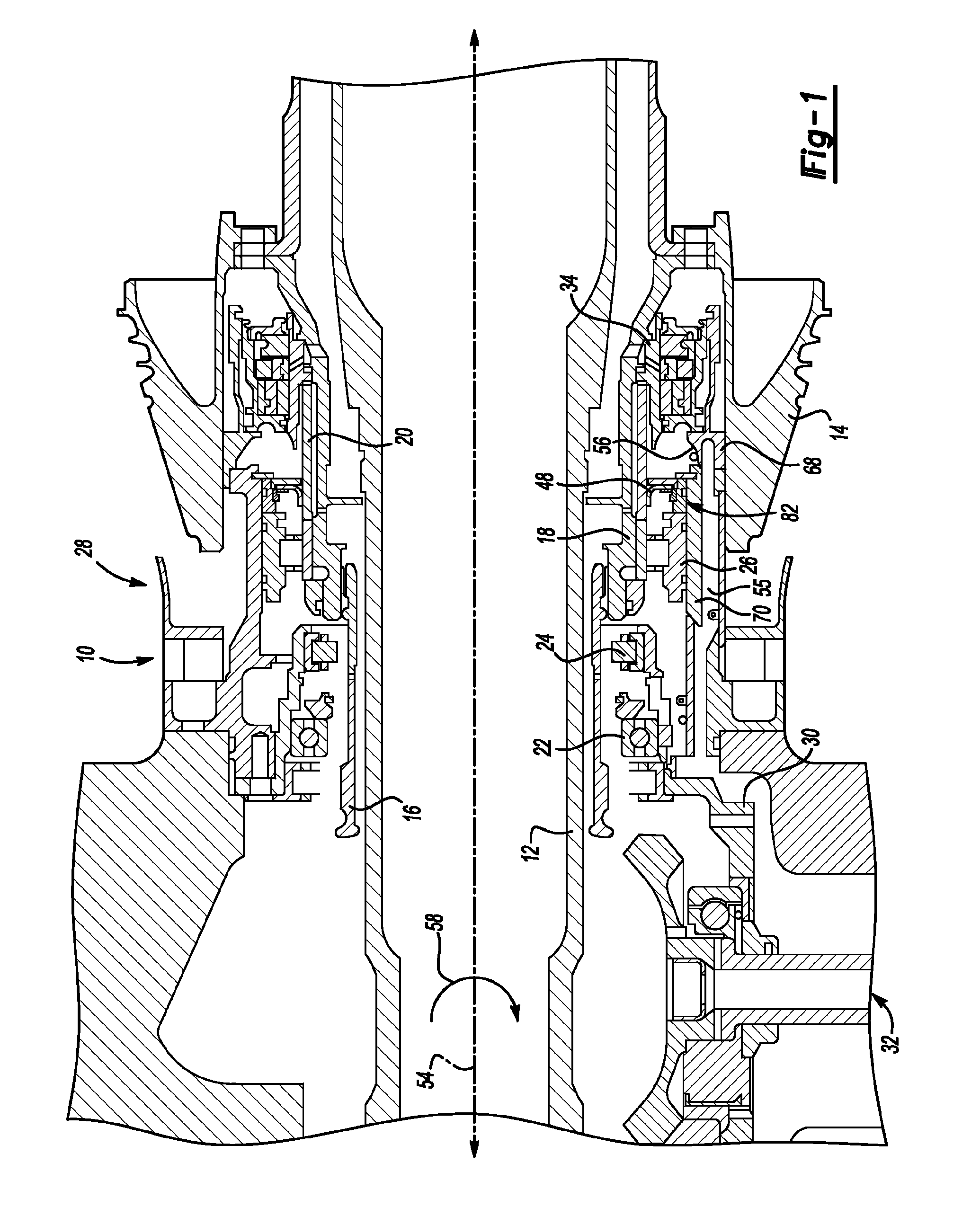

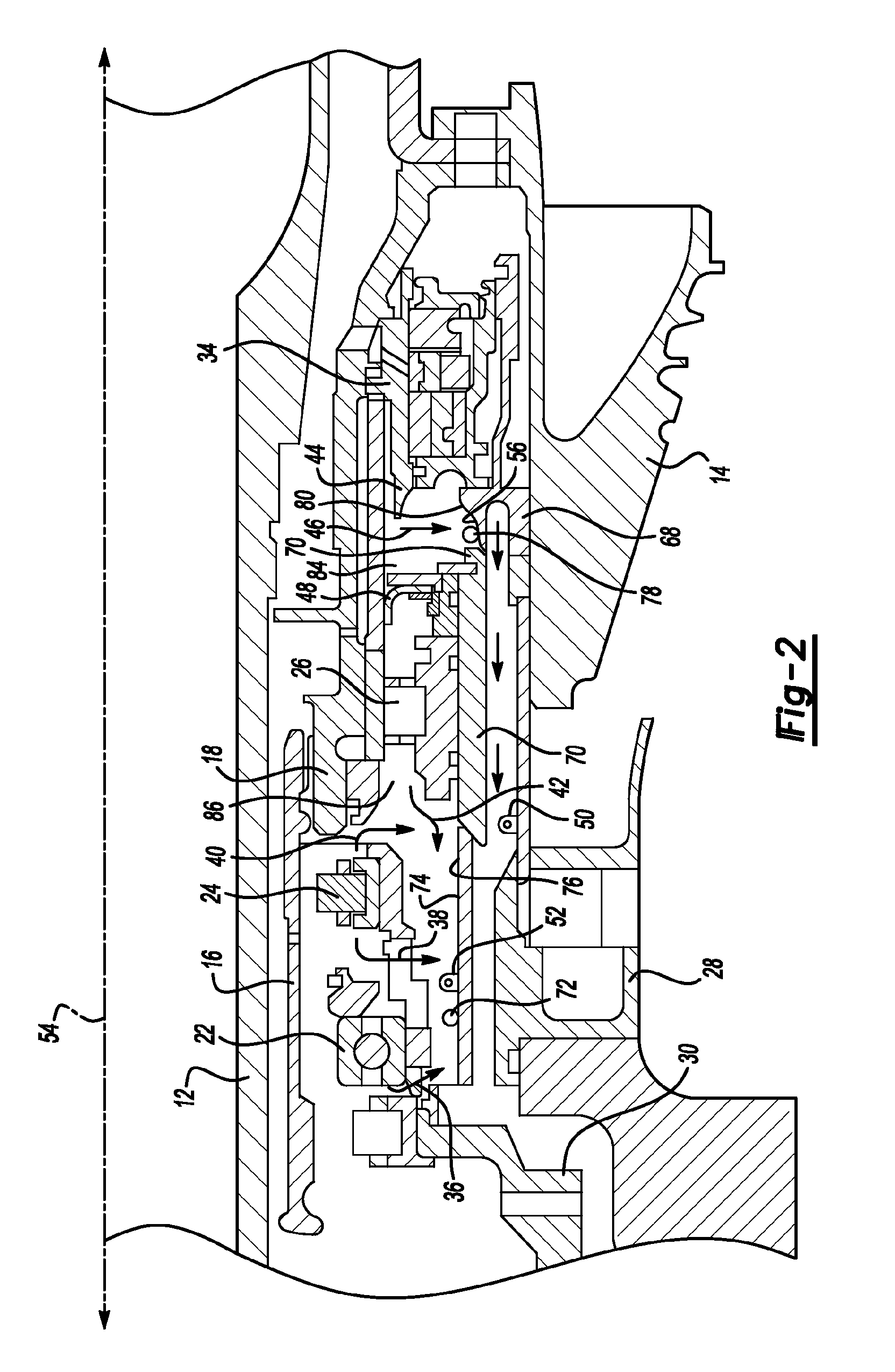

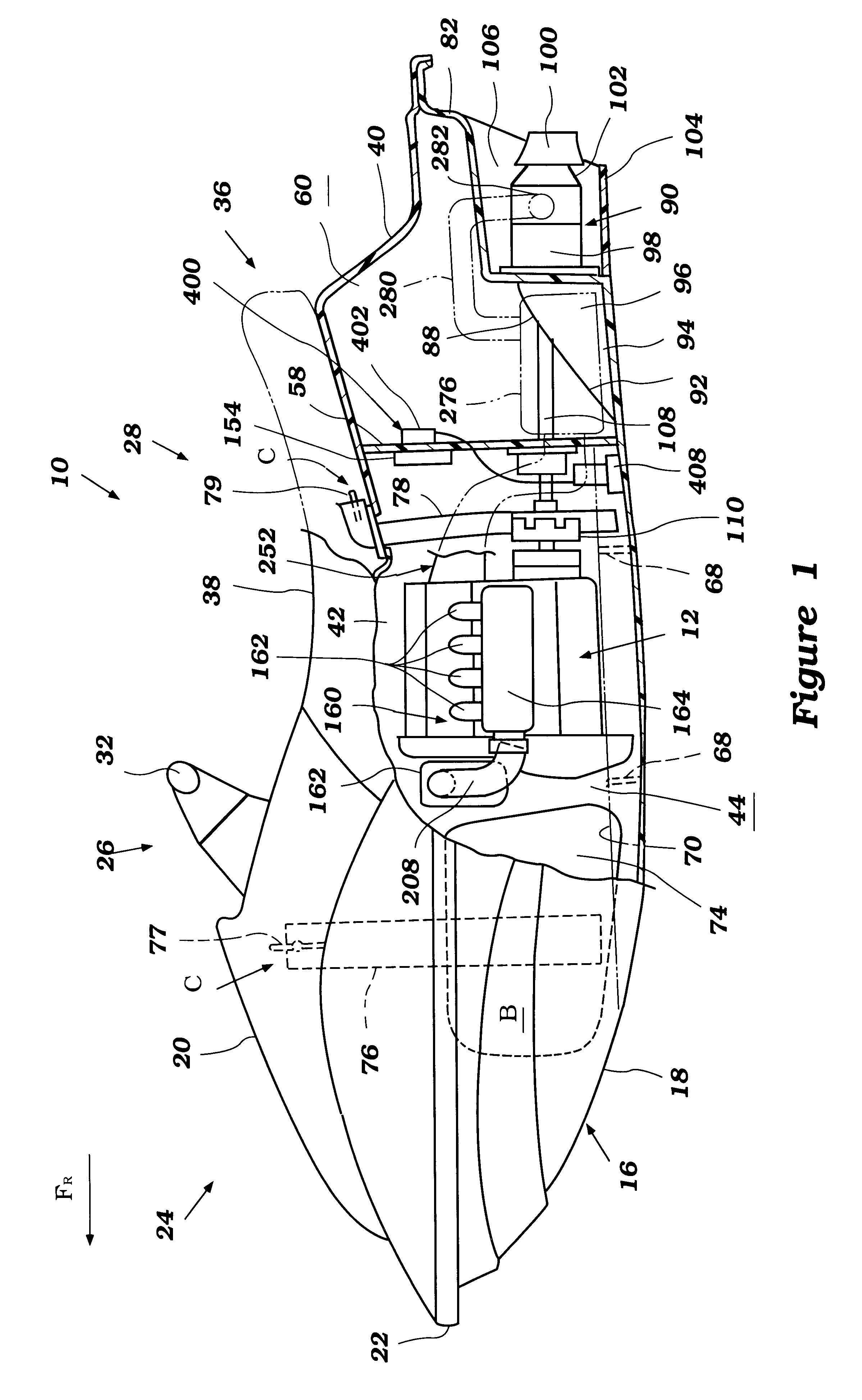

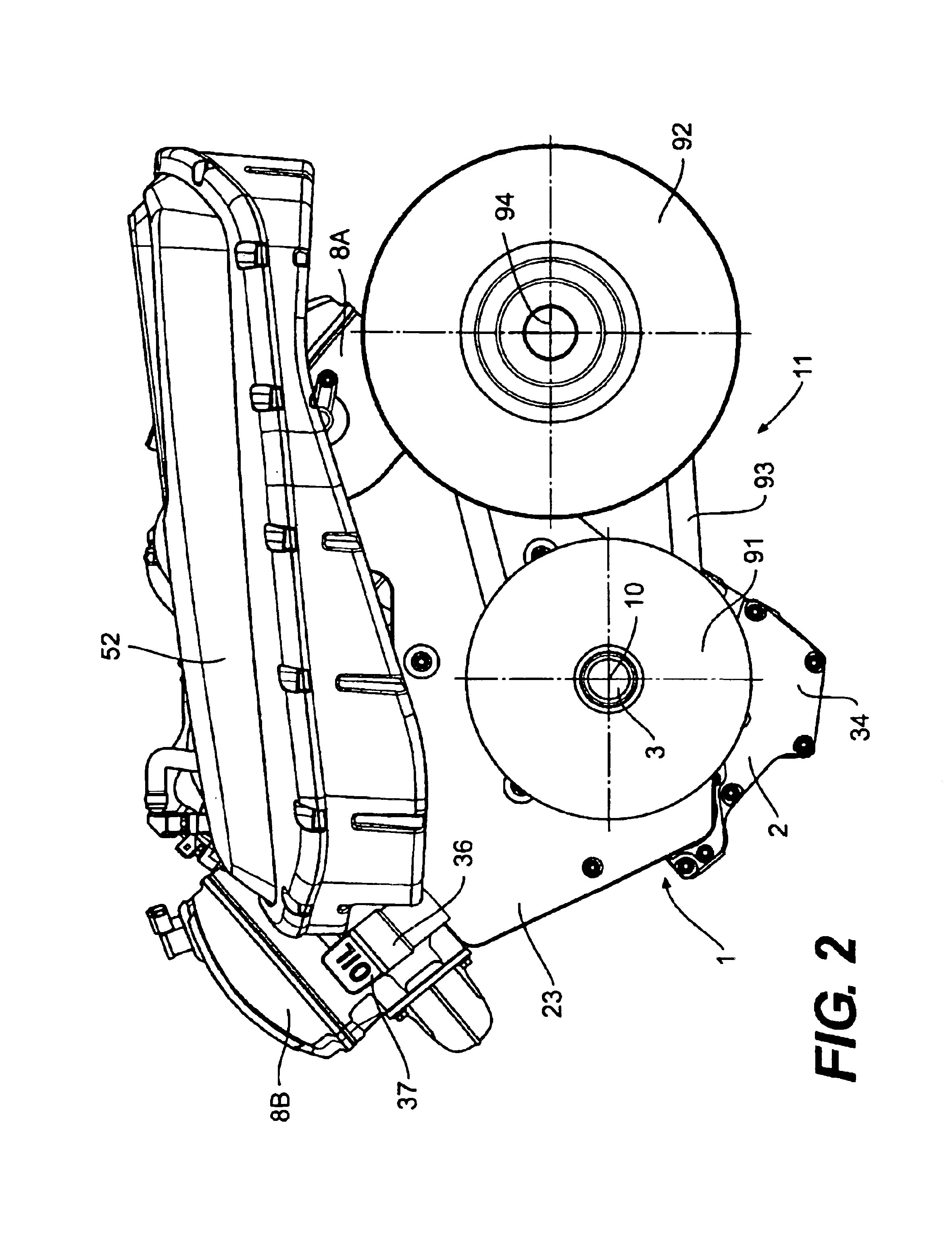

Lubrication system for a four cycle engine

InactiveUS6848528B2Improve cylinder chargingSimple wayInternal combustion piston enginesClosed-circuit pressure lubricating systemsEngineeringDry sump

A dry sump lubrication system for a four cycle engine is disclosed. The dry sump lubrication system has at least two lubricant storage chambers. A first lubricant storage chamber stores a first volume of lubricant. The first lubricant storage chamber may be located in a lower part of the crankcase. A second lubricant storage chamber is an oil tank and stores a second volume of lubricant. The oil tank may be secured to the output end of the crankcase. The first lubricant storage chamber is capable of storing at least 30% of a total volume of lubricant within the dry sump lubrication system.

Owner:BRP ROTAX

VVT engine oil gallery

ActiveCN101182793AReduce weightSave spaceLubrication of auxillariesClosed-circuit pressure lubricating systemsCylinder headEngineering

The present invention relates to a lubricant passage way of VVT engine with a simple and compact structure, which can effectively reduce the weight of the engine. The technical proposal is that the lubricant passage way of VVT engine consists of a cylinder head, a phase electromagnetic valve, a cam shaft phasing device, an air inlet cam shaft, an air outlet cam shaft, a cam shaft bearing cover, a cam, a tapper arm and a valve. The present invention is characterized in that the cylinder head is provided with a main oil passage communicated with the cylinder and the main oil passage is the screw hole of the cylinder head.

Owner:CHERY AUTOMOBILE CO LTD

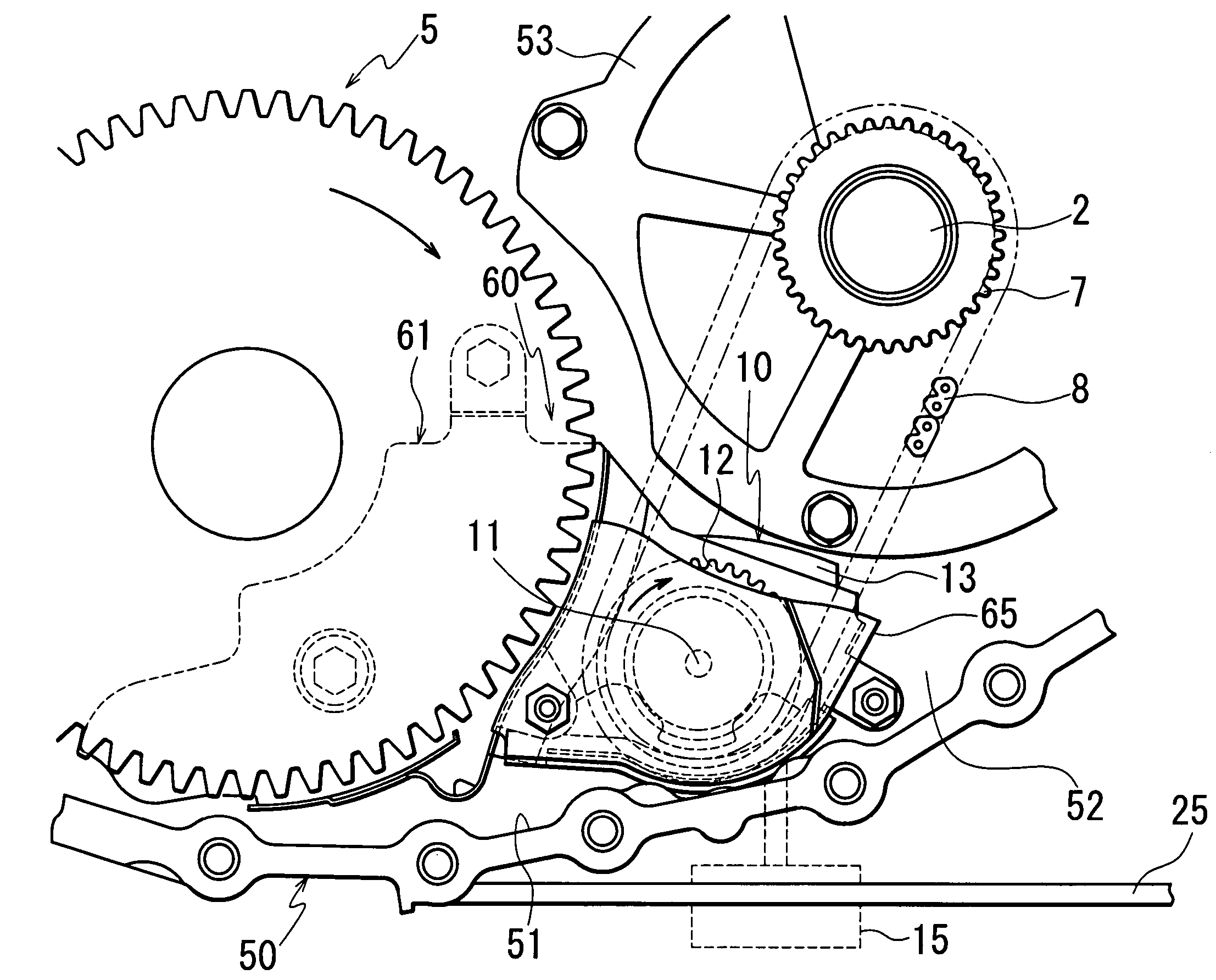

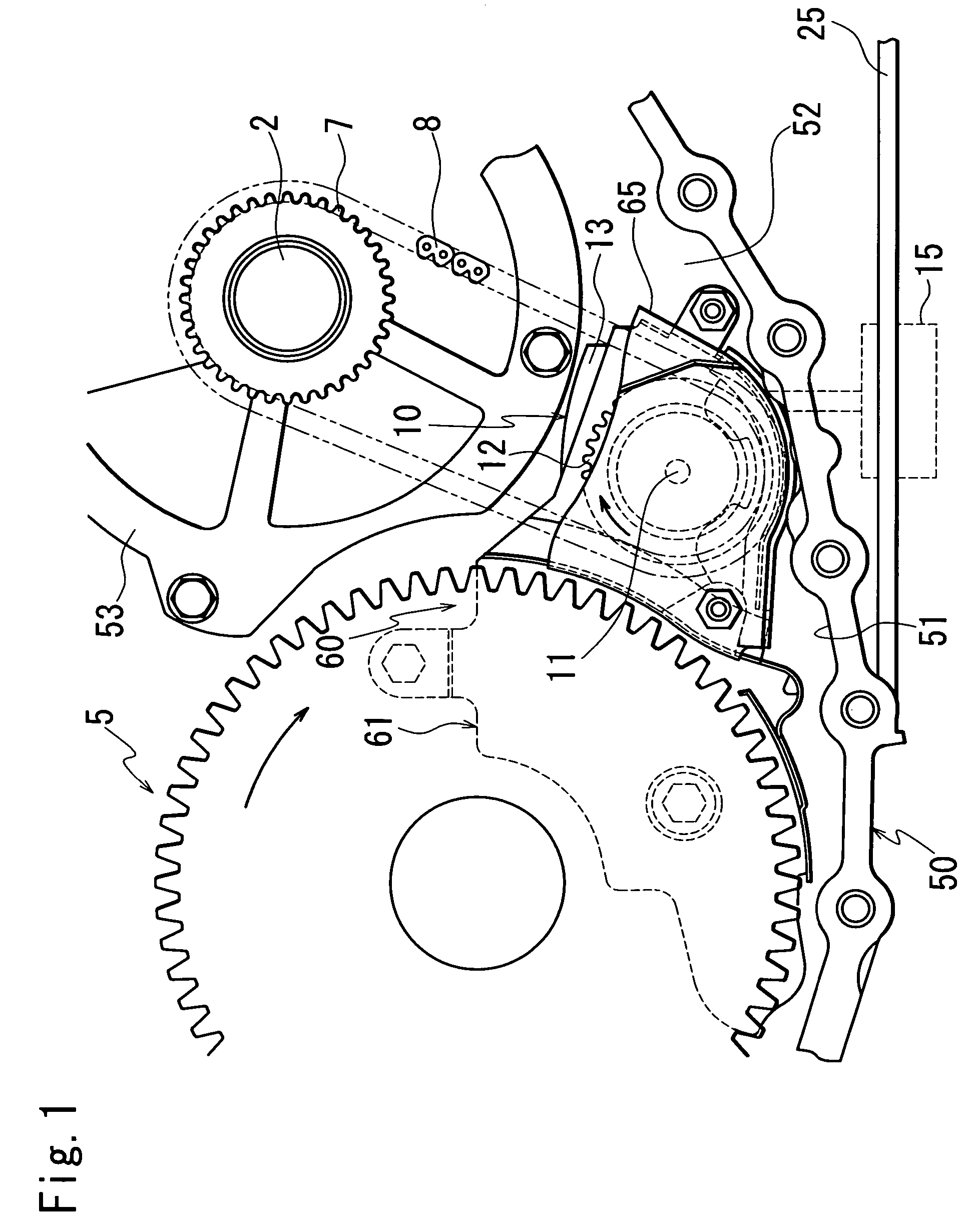

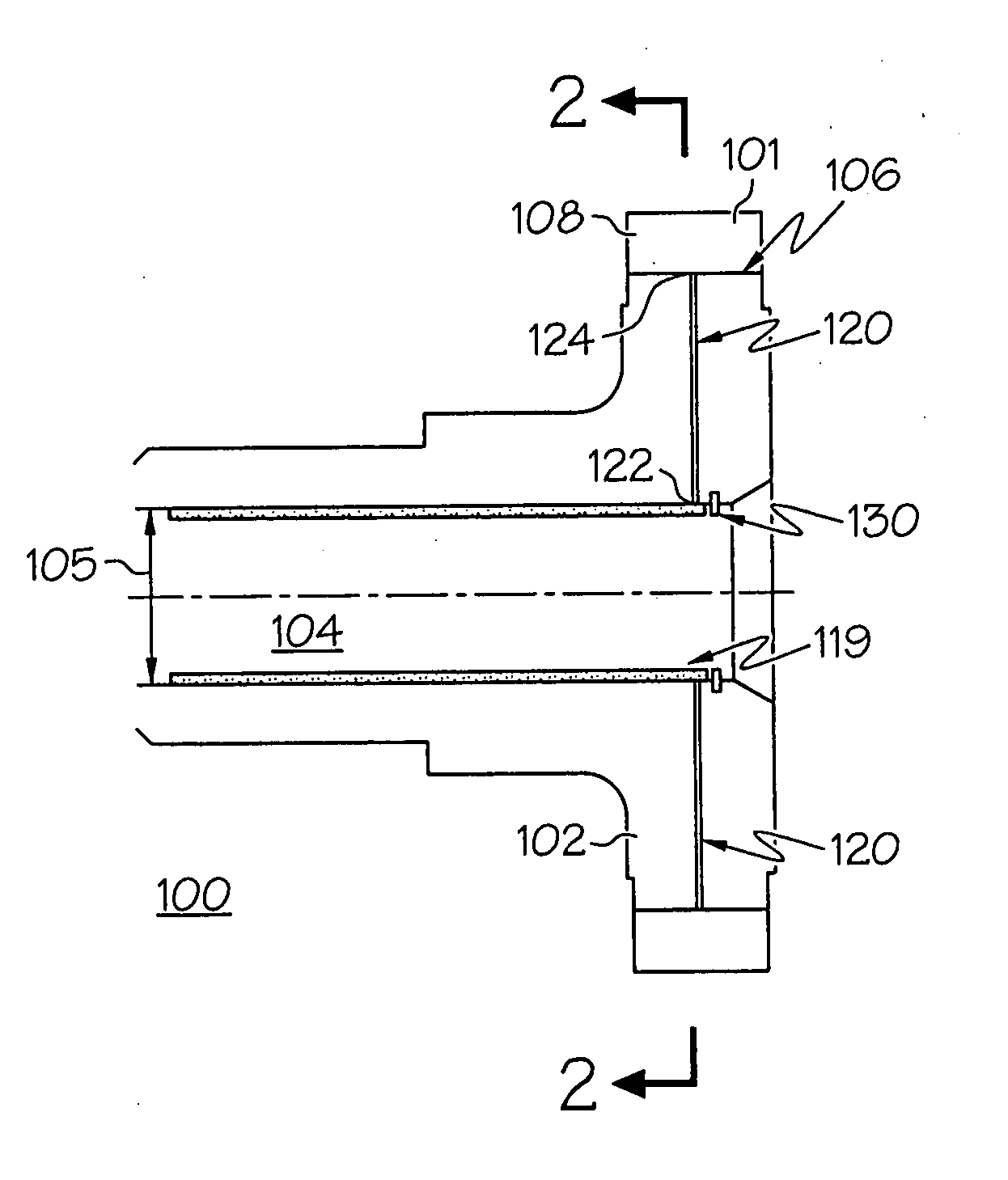

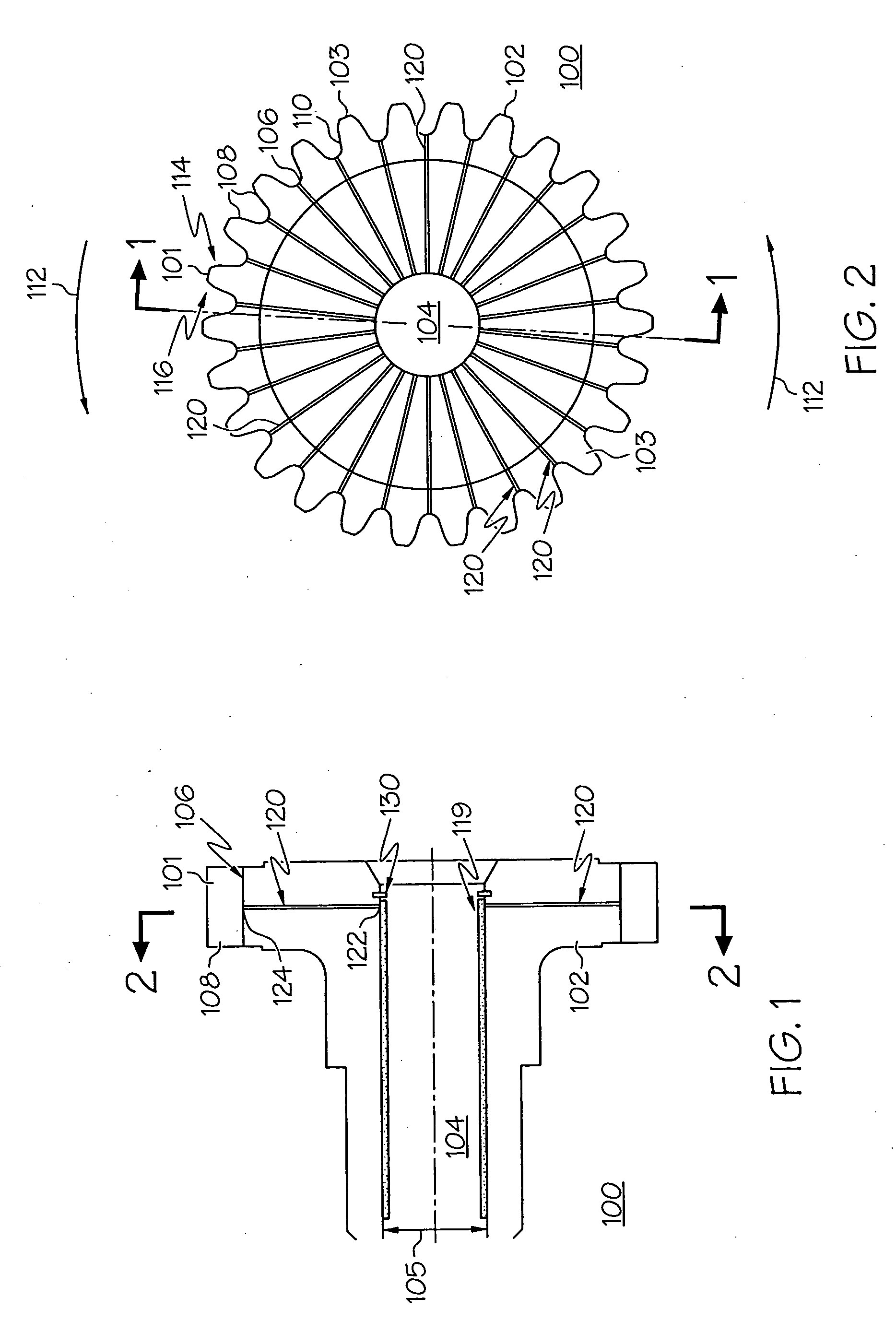

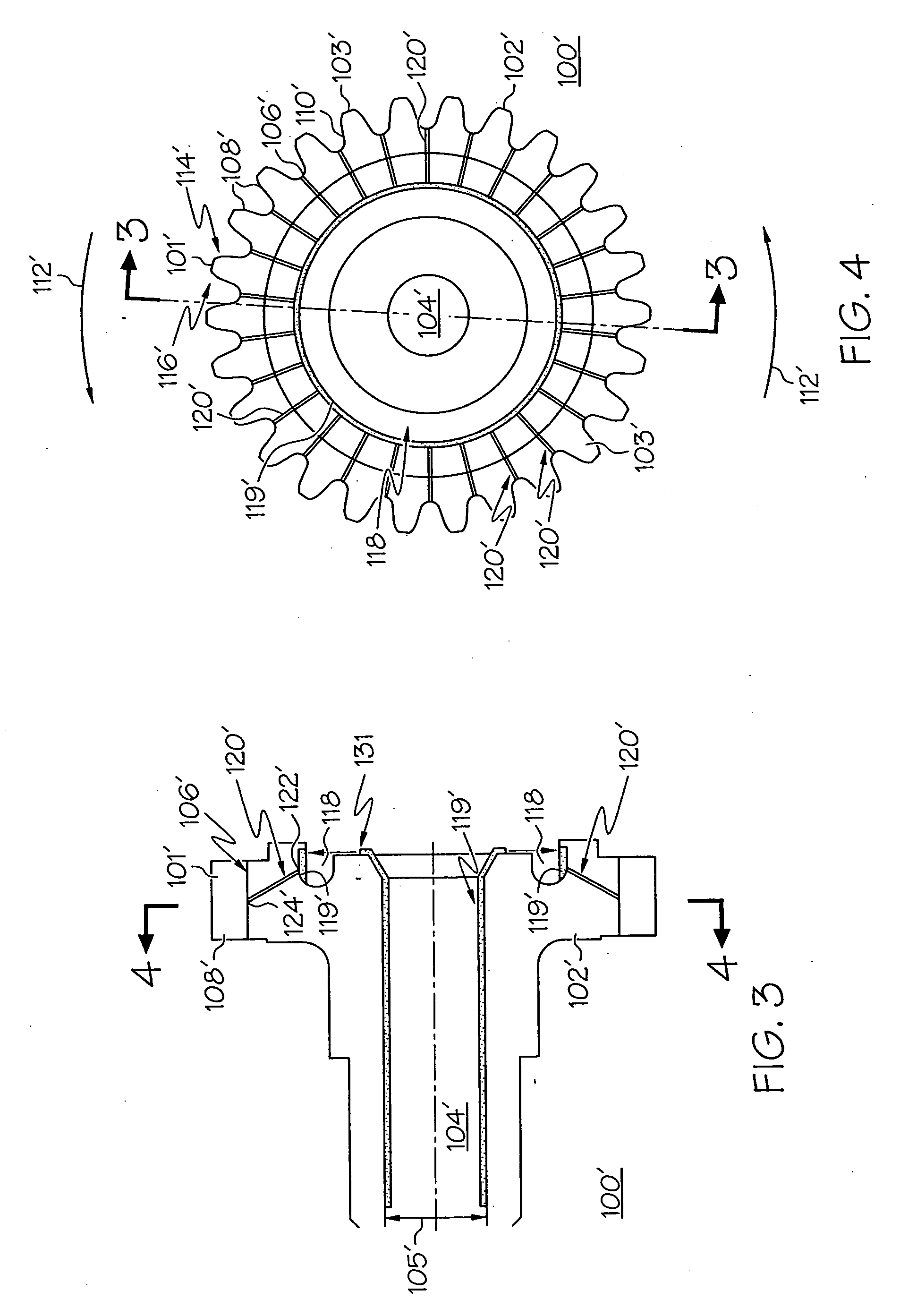

Positive lubrication of a meshing gear

A device and method for the lubrication of teeth in a meshing gear. A plurality of teeth are formed about a periphery of a toothed wheel. Each tooth is defined by a root portion, an involute profile portion, and a minimal stress portion. The device and method includes the formation of a plurality of fluidic passages, each including an inlet and an outlet, in fluidic communication with a lubricant and the minimal stress portion of at least one of the plurality of teeth. During operation, the lubricant contained flows via centrifugal force to the minimal stress portion of each of the plurality of teeth via the fluidic passages. The fabrication of the outlet of the fluidic passages at a minimal stress portion of at least one of the plurality of teeth eliminates any further stress fabrication on the portion of the tooth structure that is under stress during operation.

Owner:HONEYWELL INT INC

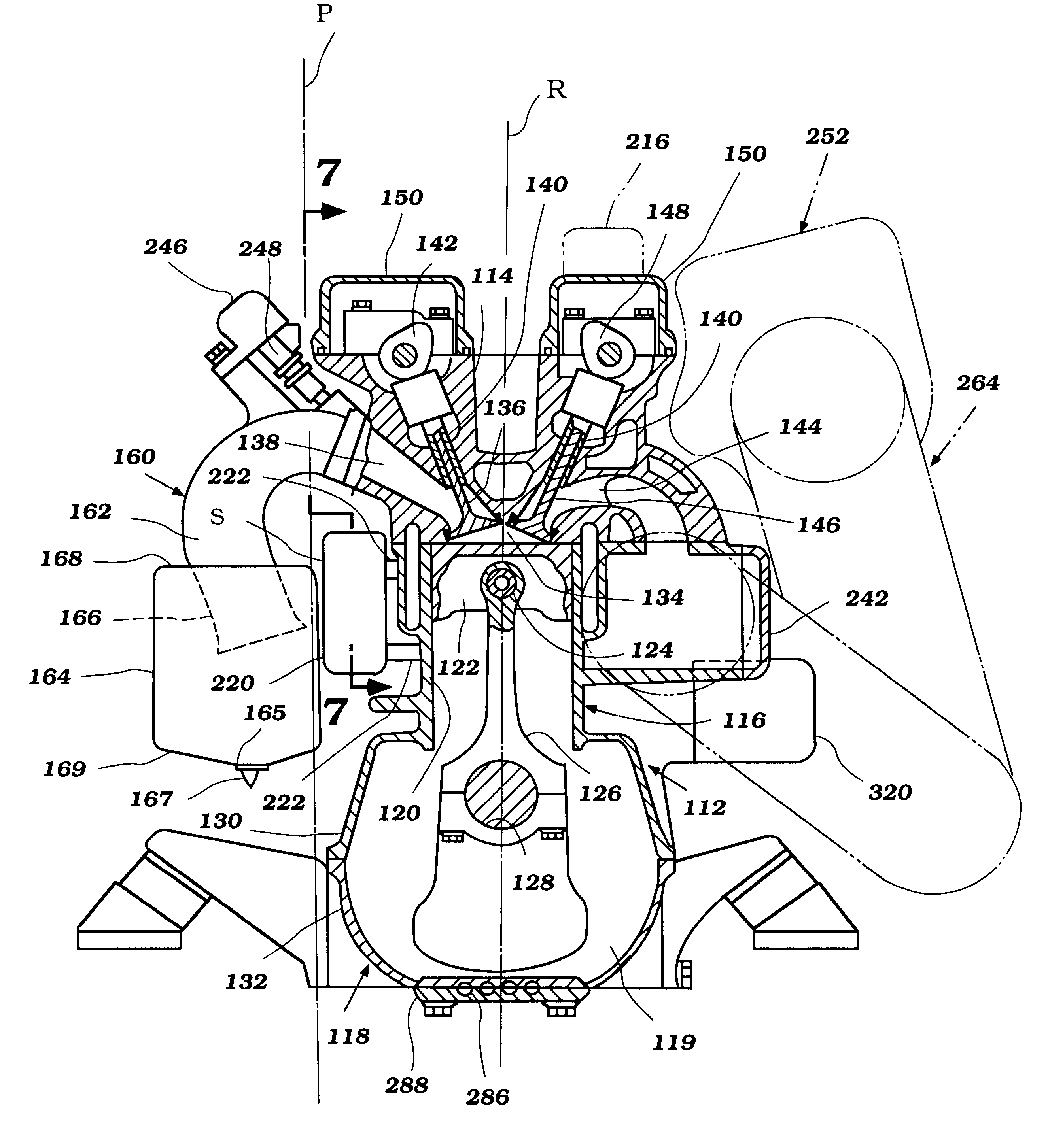

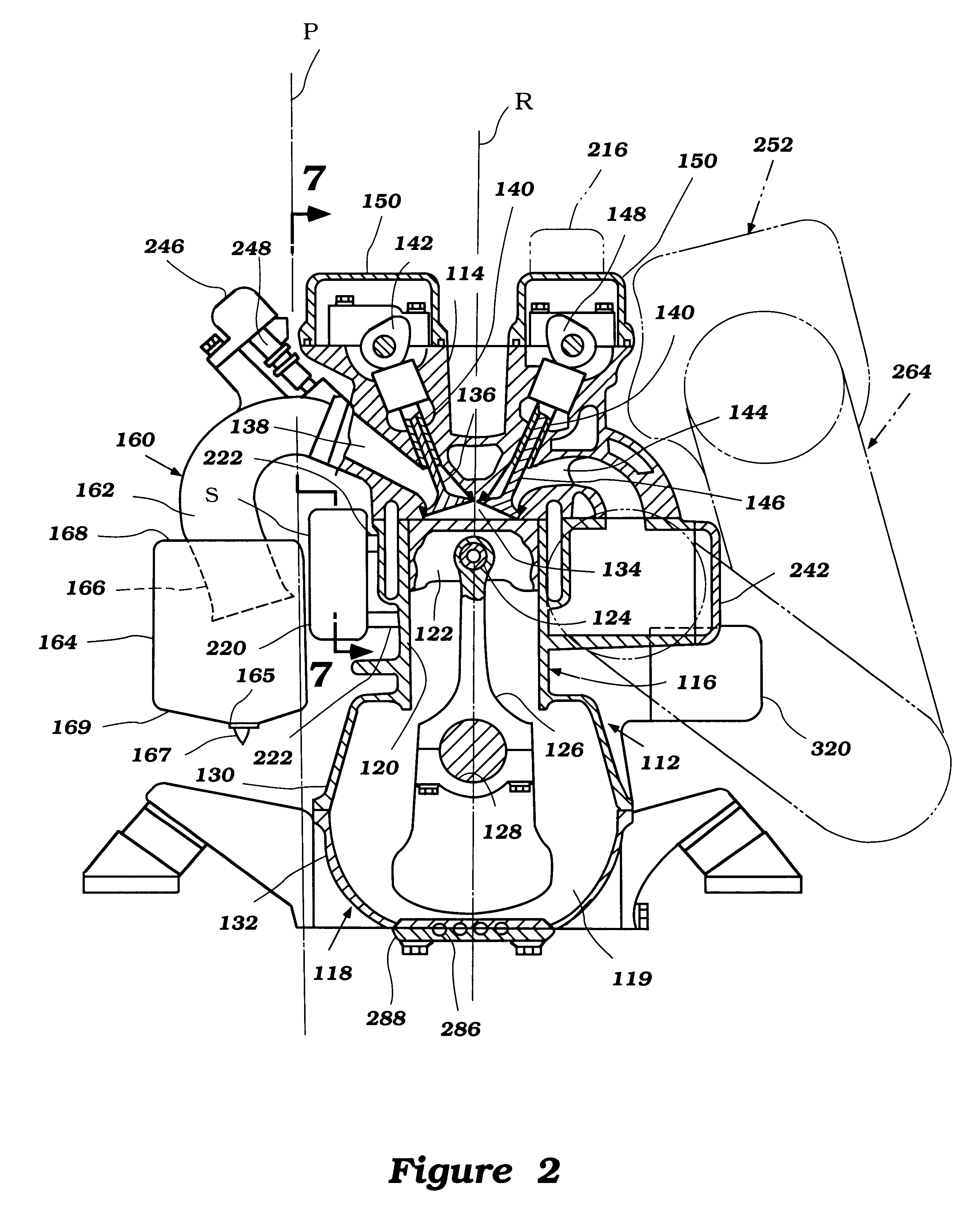

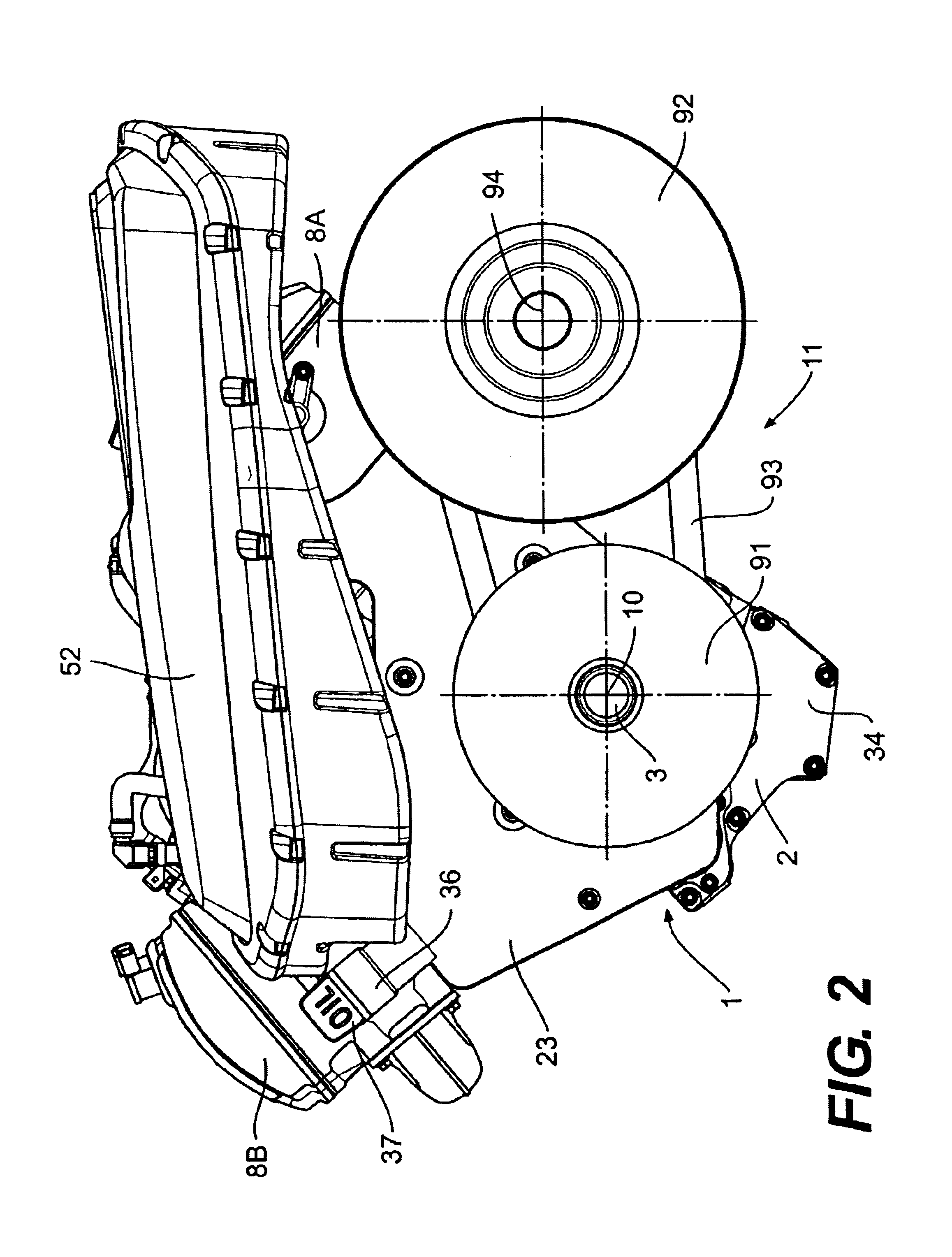

Engine arrangement for a four cycle engine

InactiveUS6929081B2Improve vehicle handlingLower center of gravityInternal combustion piston enginesClosed-circuit pressure lubricating systemsCrankshaftGravitation

An arrangement of a four cycle engine is disclosed for use in a vehicle providing a relatively low center of gravity for improved handling and maneuverability. The engine components are located on opposing sides of the longitudinal axis of the vehicle and behind the axis of the crankshaft to move the center of gravity to the middle of the vehicle.

Owner:BRP ROTAX

Oil pump construction for watercraft engine

A lubrication system for an internal combustion engine includes an oil pump assembly driven by the crankshaft. The oil pump can be mounted in various positions for maintaining a low center of gravity of the engine. Optionally, or in addition, the engine can include a bearing disposed between a valvetrain drive gear and an output drive gear.

Owner:SANSHIN KOGYO CO LTD

Lubrication system for 4-cycle engine of small watercraft

A watercraft includes a lubrication system having a lubricant pump assembly and a lubrication reservoir defined between a lower crankcase member and an oil cover. At least one oil passage connects a crankcase to the reservoir. The oil cover, or both the oil cover and the crankcase member may contain one or more baffles configured to impede a flow of oil away from the lubricant pump assembly. Additionally, the cover may include one or more projections securing one or more plugs within one or more countersink portions of the crankcase member.

Owner:SANSHIN KOGYO CO LTD

Method and system of oil delivery in a combustion engine

ActiveUS20150275713A1Reduce power consumptionImprove fuel economyLiquid coolingMachines/enginesCombustionCylinder head

Methods and systems are described for an oil delivery system of an engine. In one method, oil is pumped via a lower pressure oil pump to piston cooling jets while oil is separately pumped via a higher pressure oil pump to a cylinder head, bearings, a turbocharger, or a variable valve operation system. Herein, the higher and lower pressure oil pumps each draw oil from a common, shared sump, and return oil back to the common, shared sump.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com