Patents

Literature

147results about "Power plants using condensers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

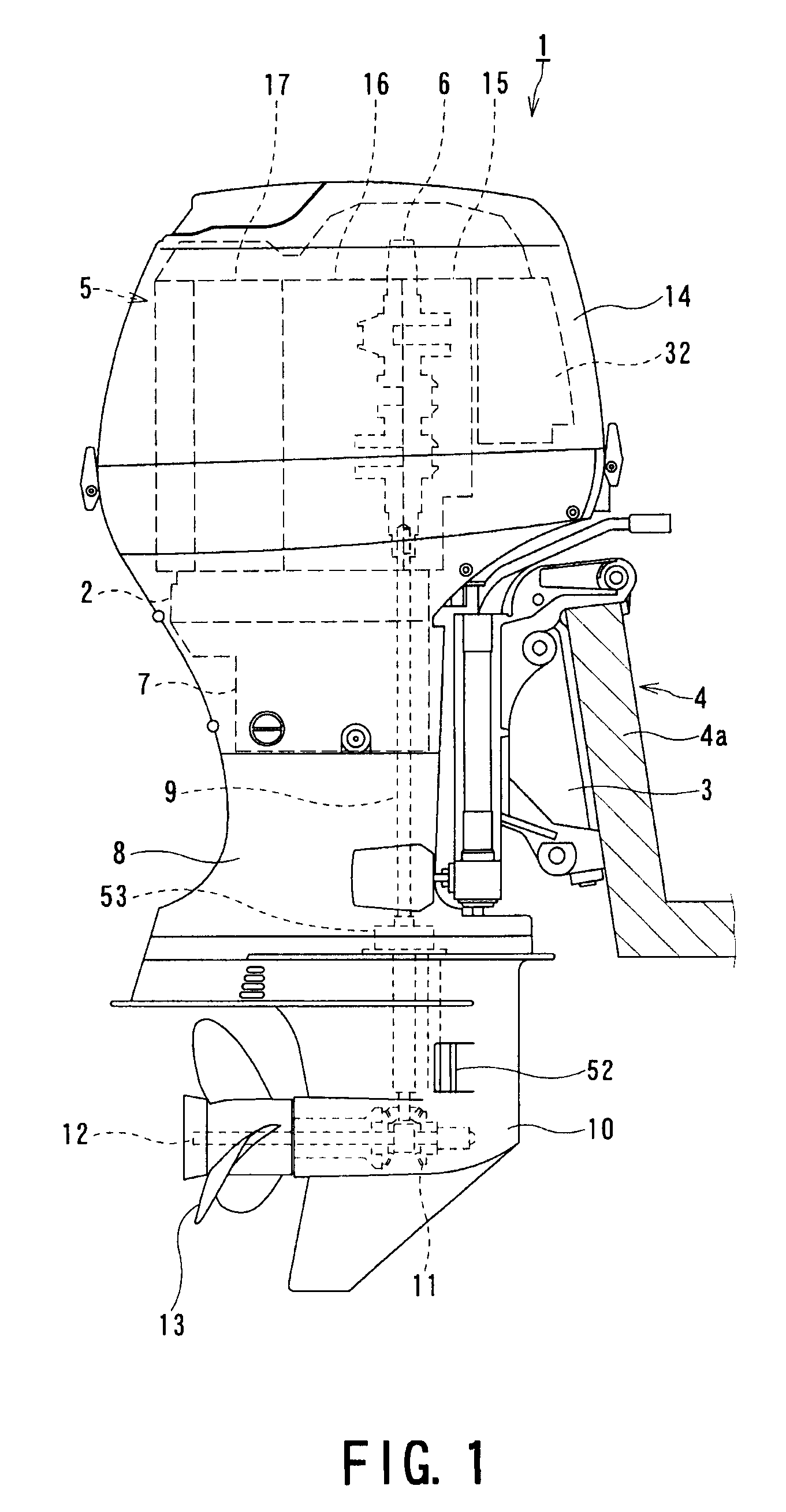

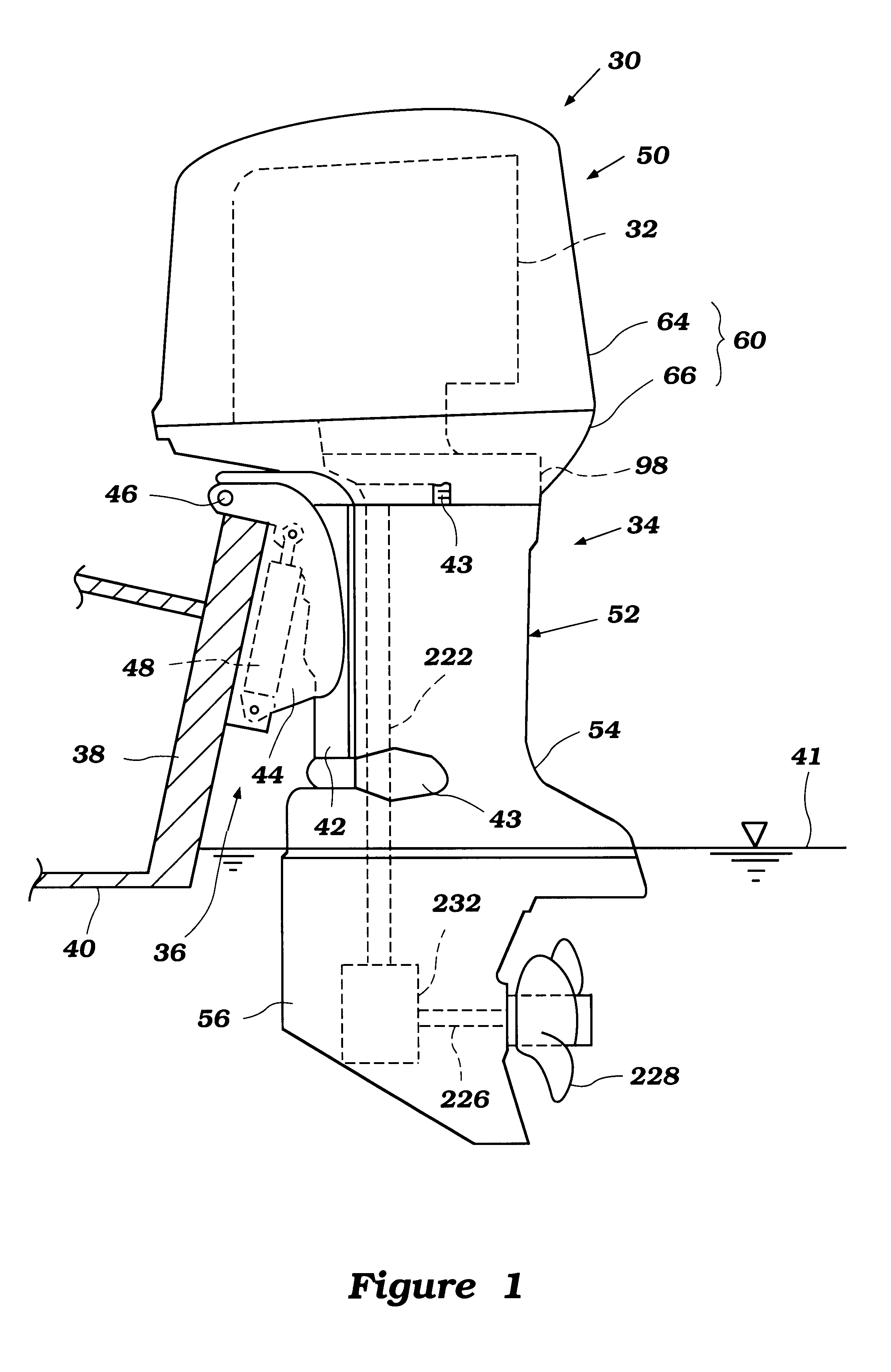

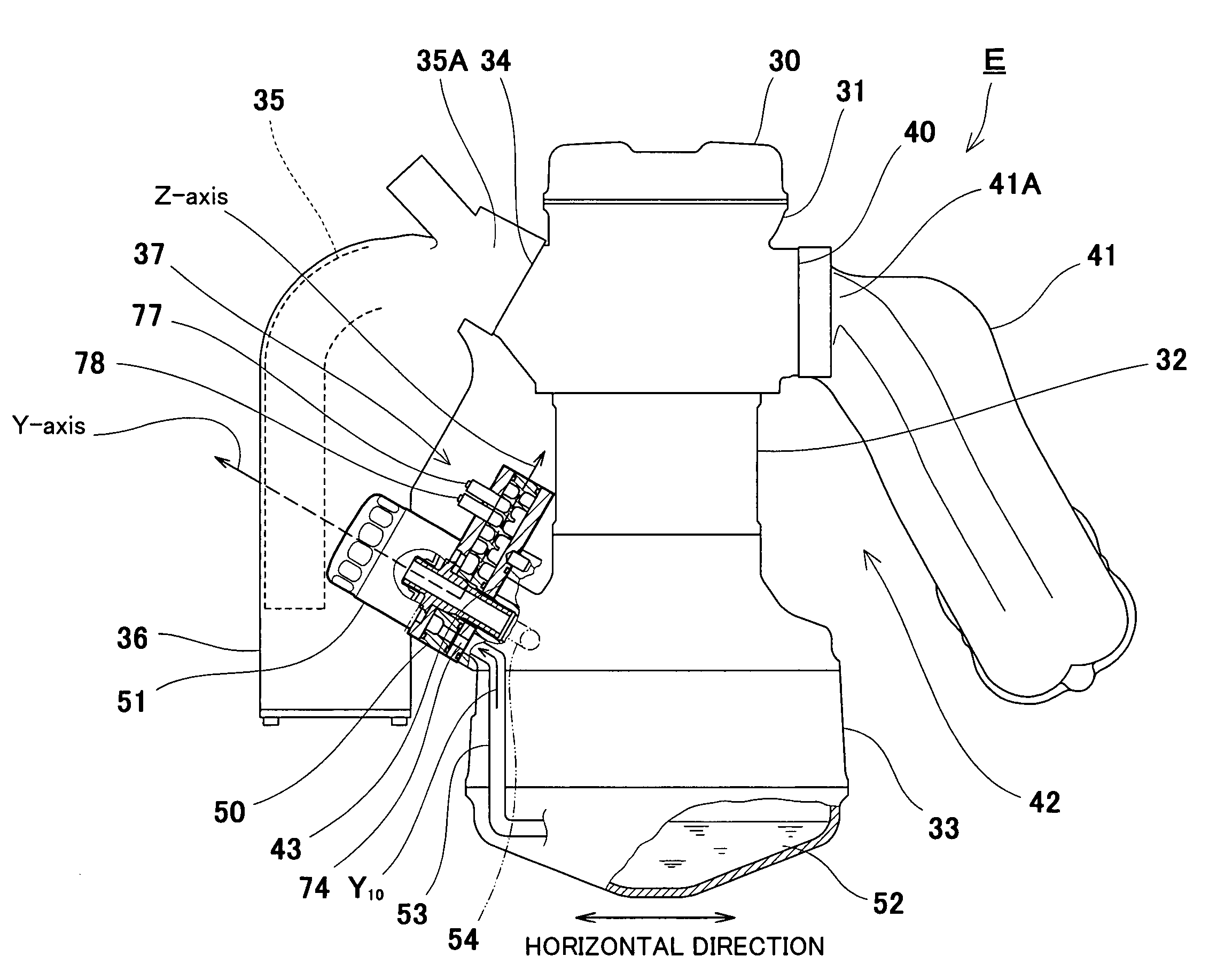

Cooling system for outboard motor

InactiveUS6513463B2Power plants using condensersLiquid coolingMetallic materialsMechanical engineering

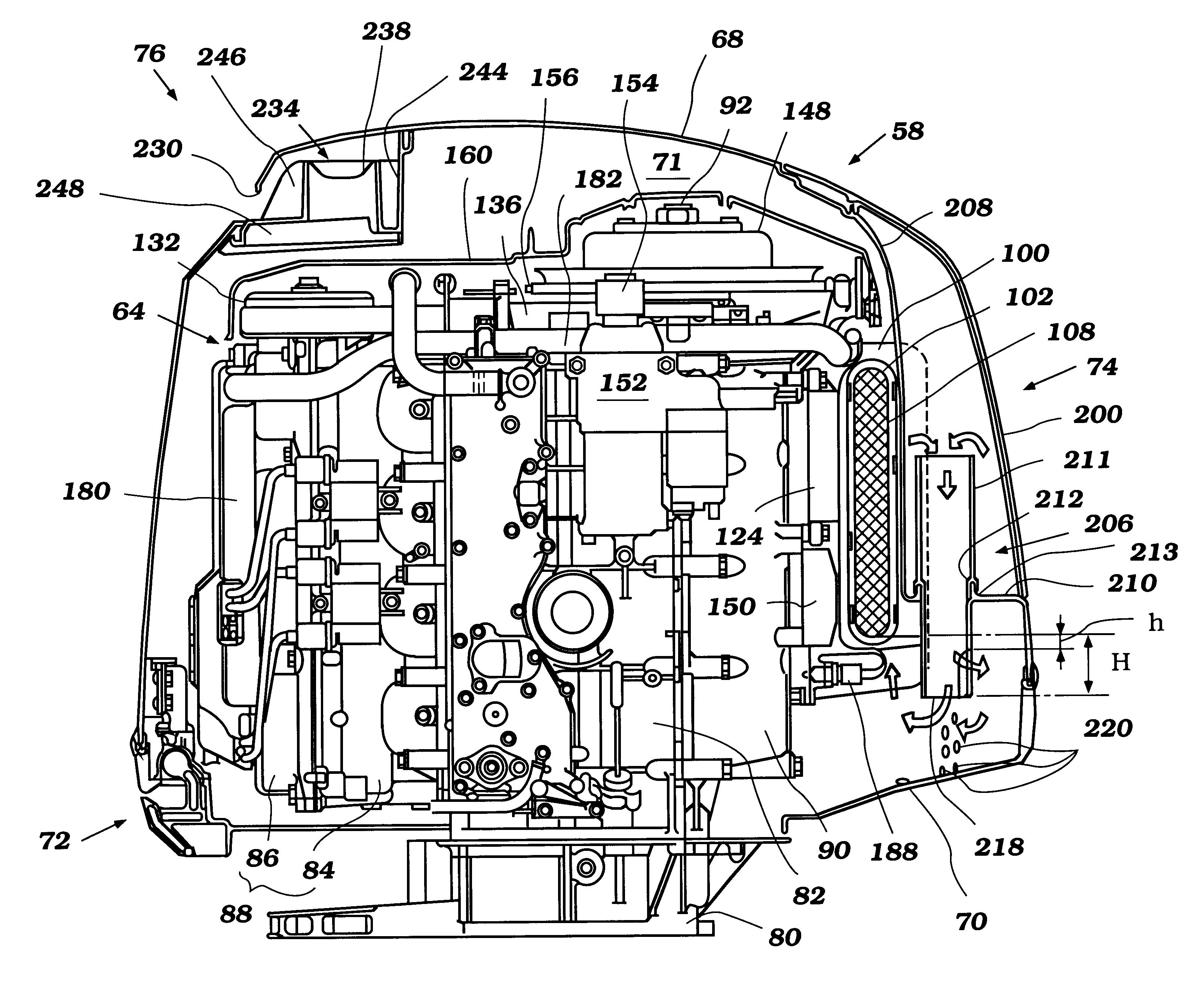

An engine for an outboard motor includes engine components disposed around the engine body. A cooling system includes a first water passage cooling the engine body and a second water passage branching off from the first water passage upstream the engine body and extending through the engine components. One engine component is generally positioned above the engine body. Two engine components are positioned on different sides of the engine body. The first and second water passages have separate discharge ports. The engine components are made of a metal material. The second water passage is defined by tubular members made of a corrosion-resistant material and the respective tubular members are embedded in the respective bodies of the engine components.

Owner:SANSHIN KOGYO CO LTD

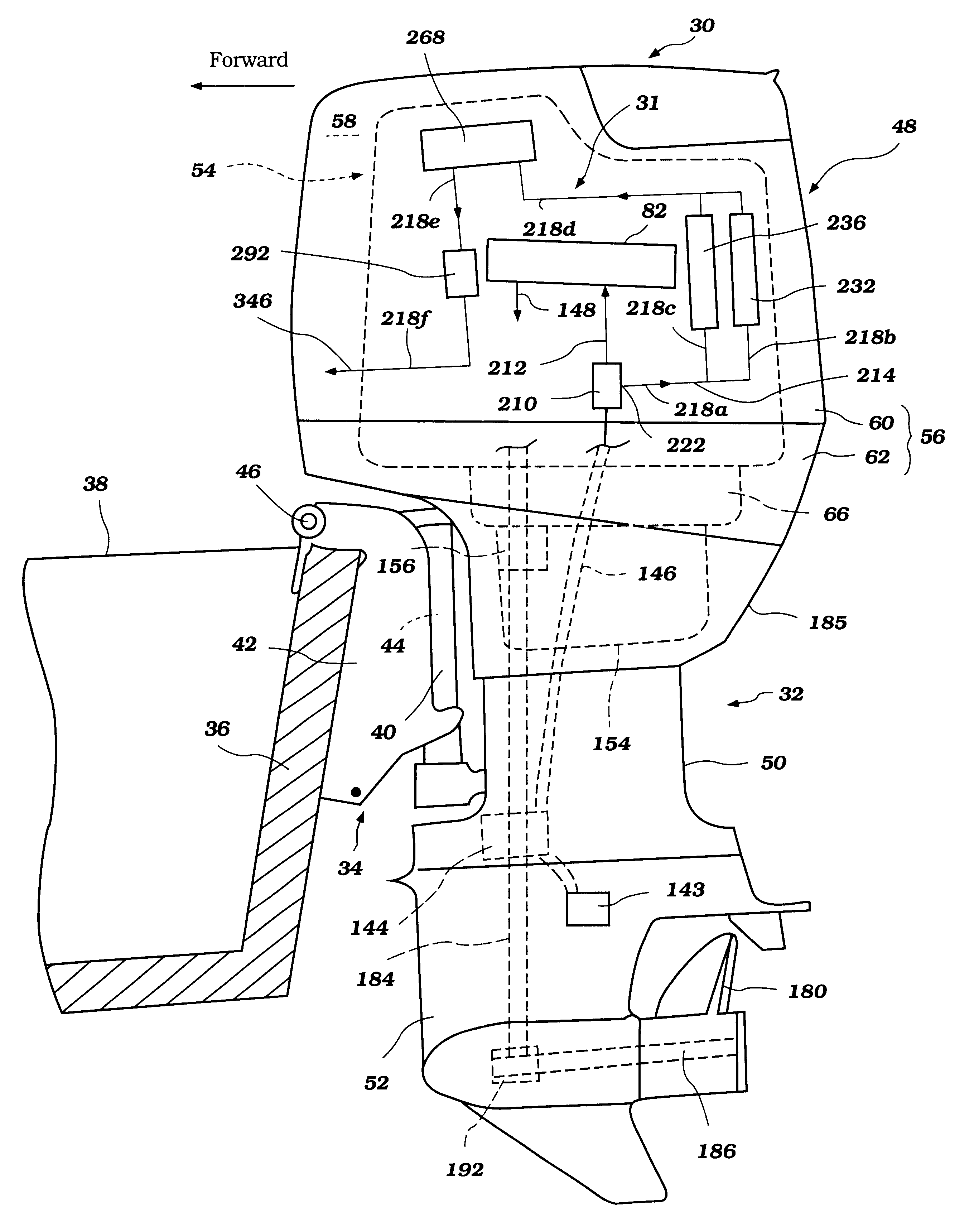

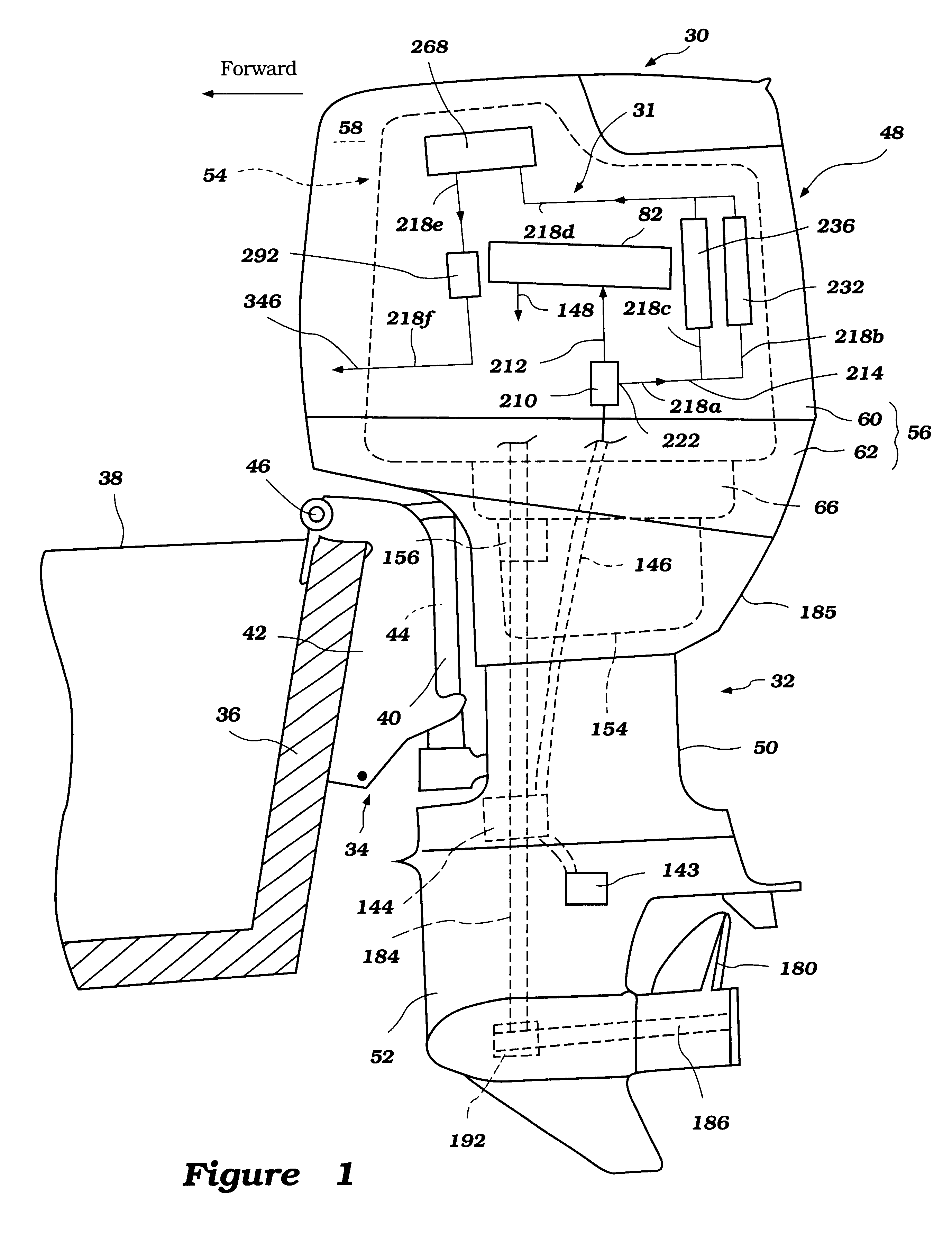

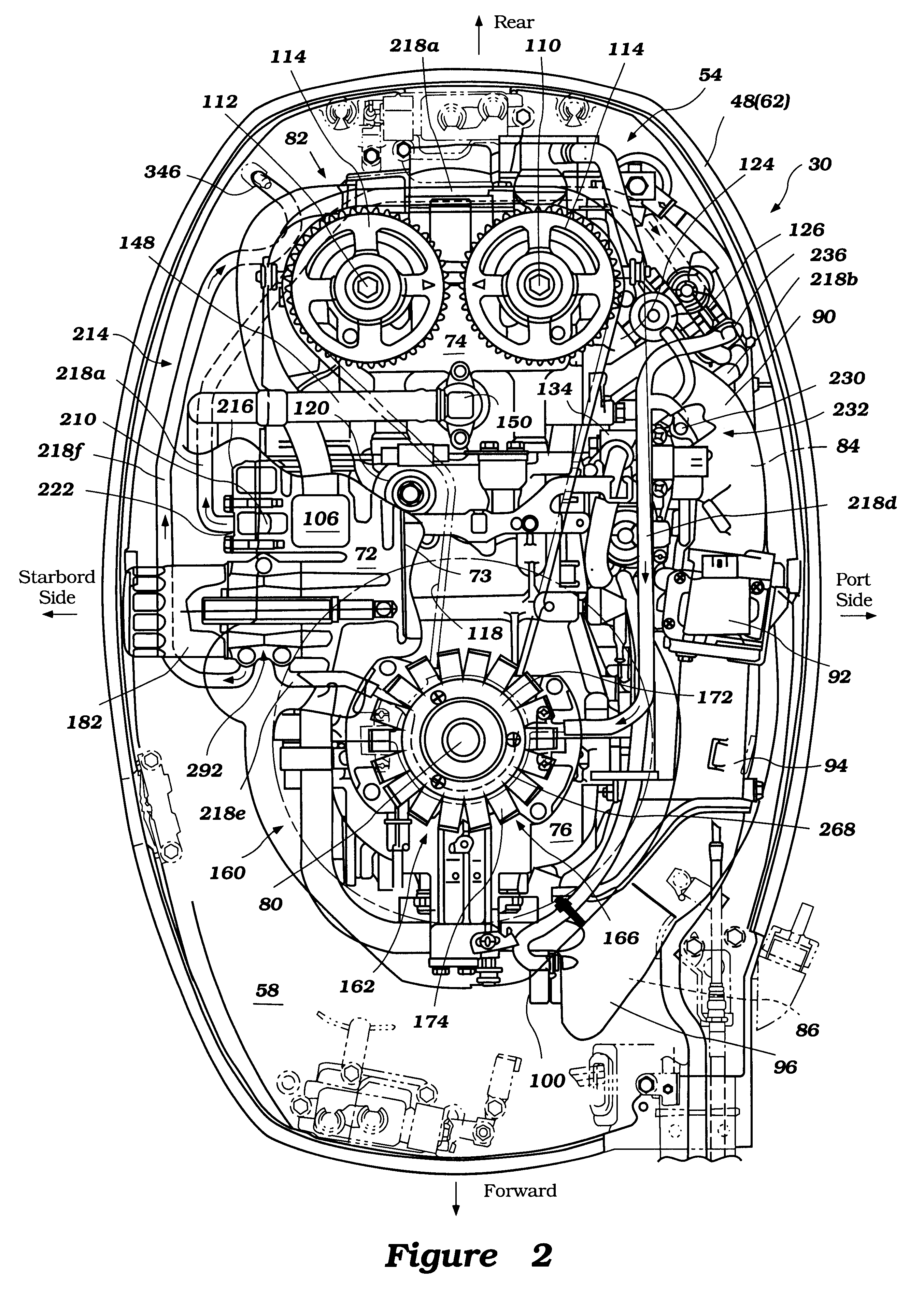

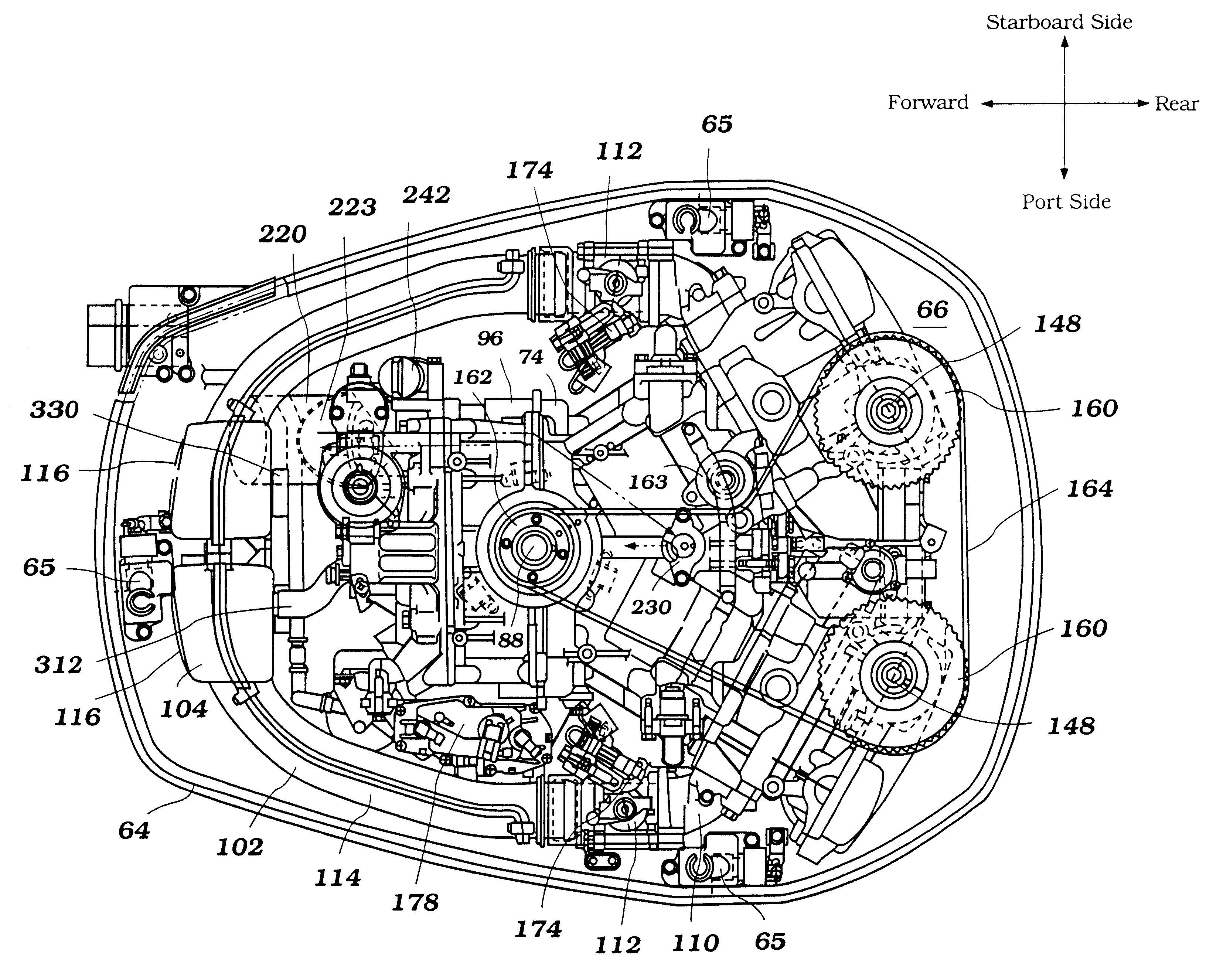

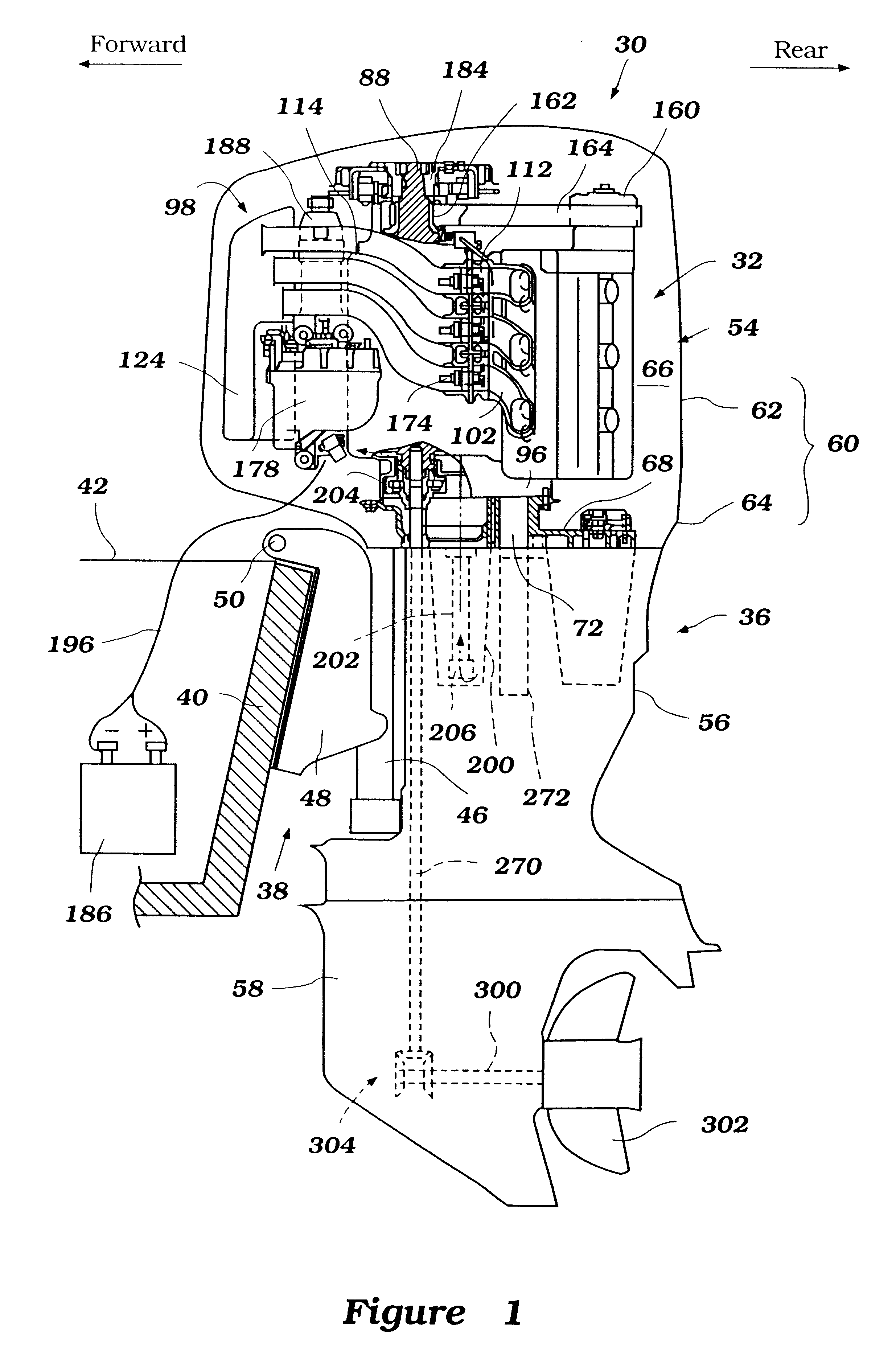

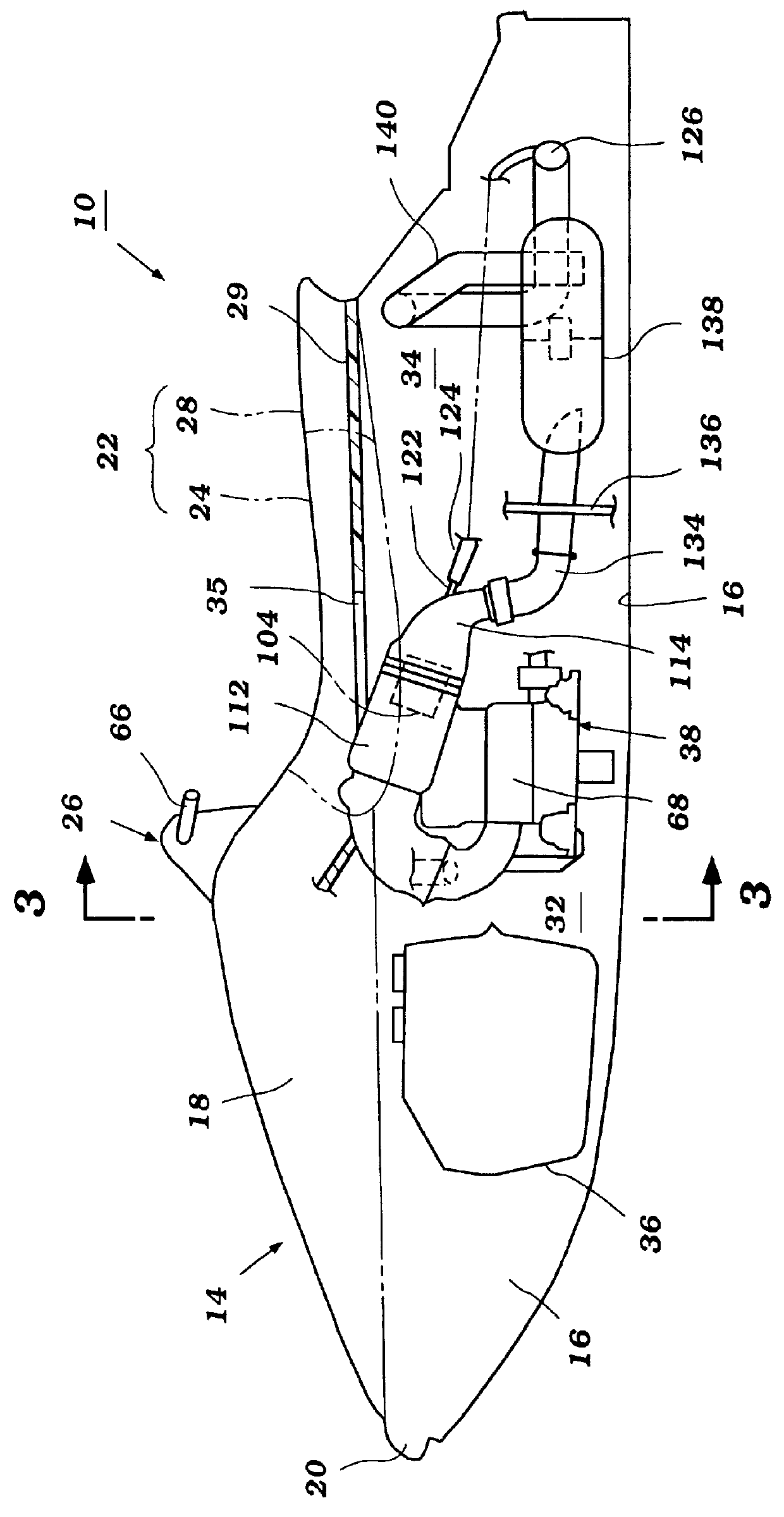

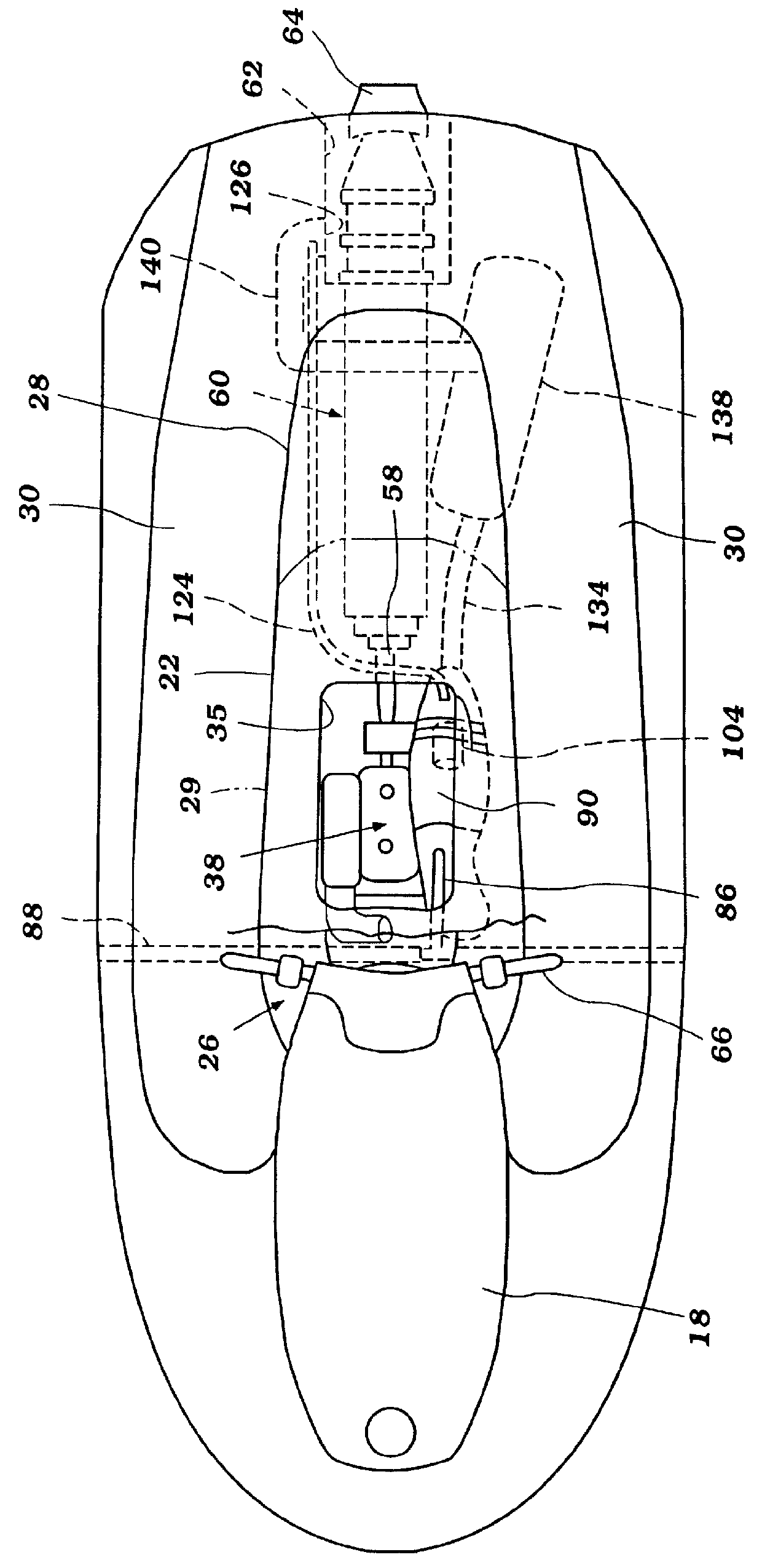

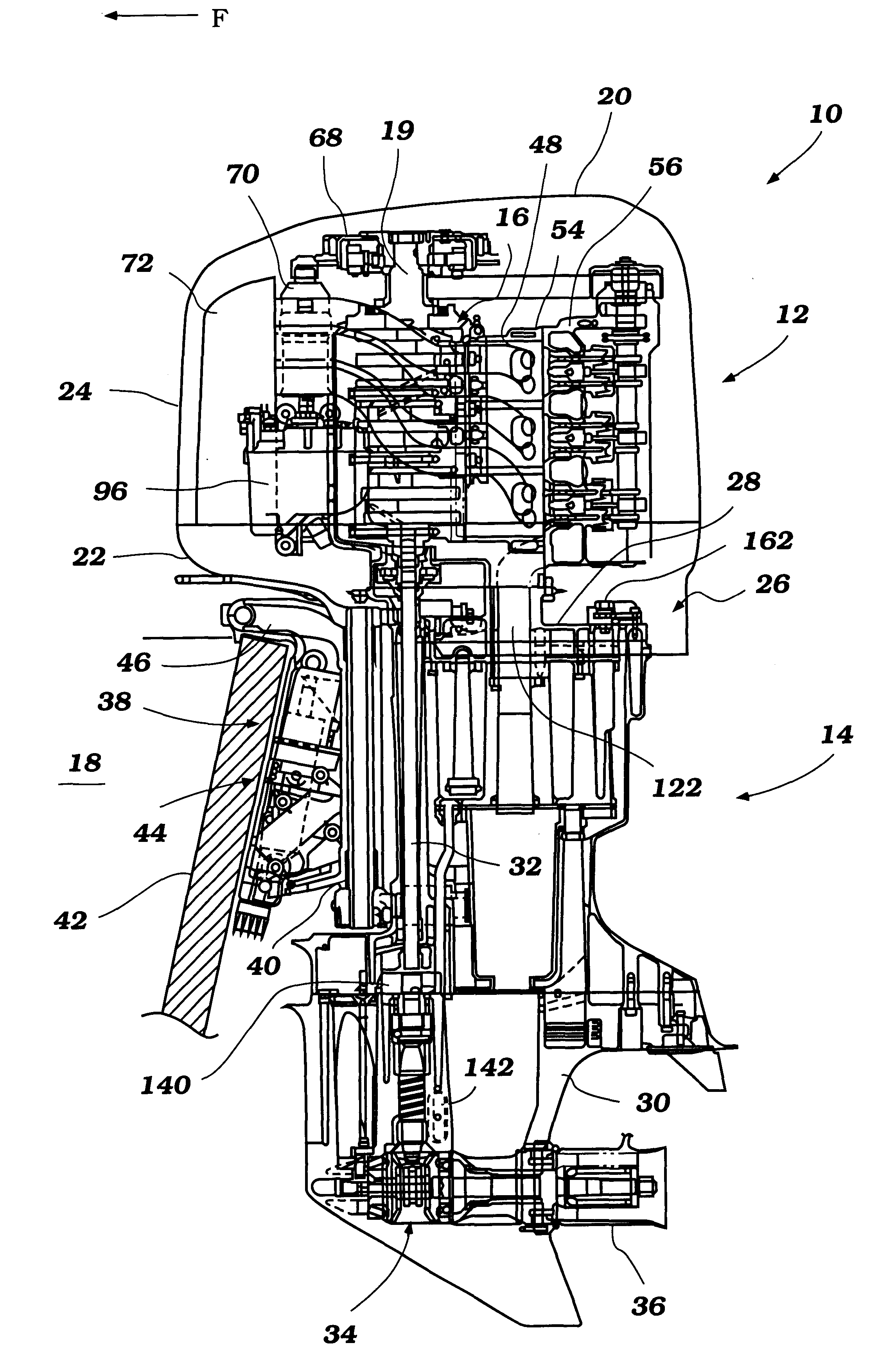

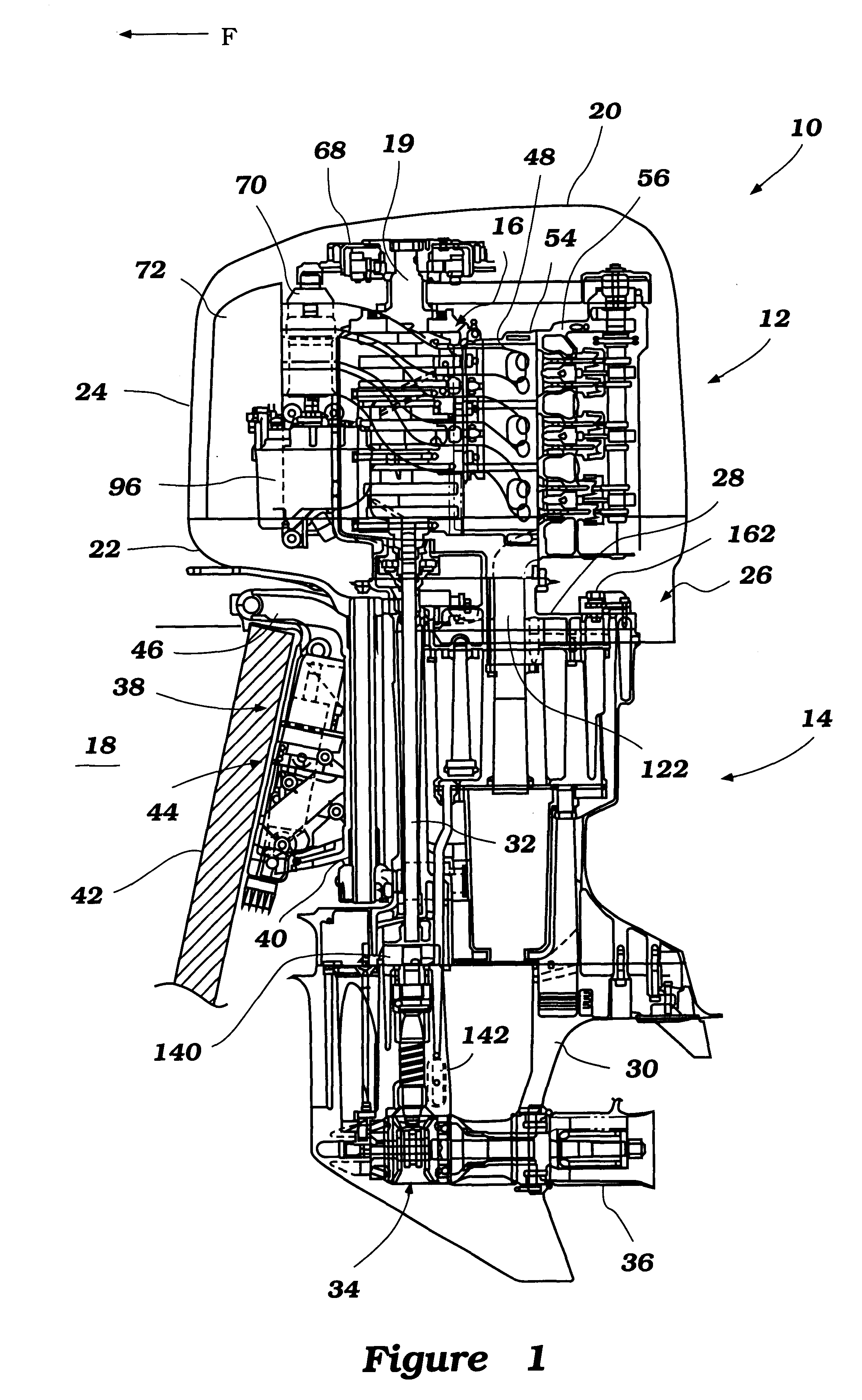

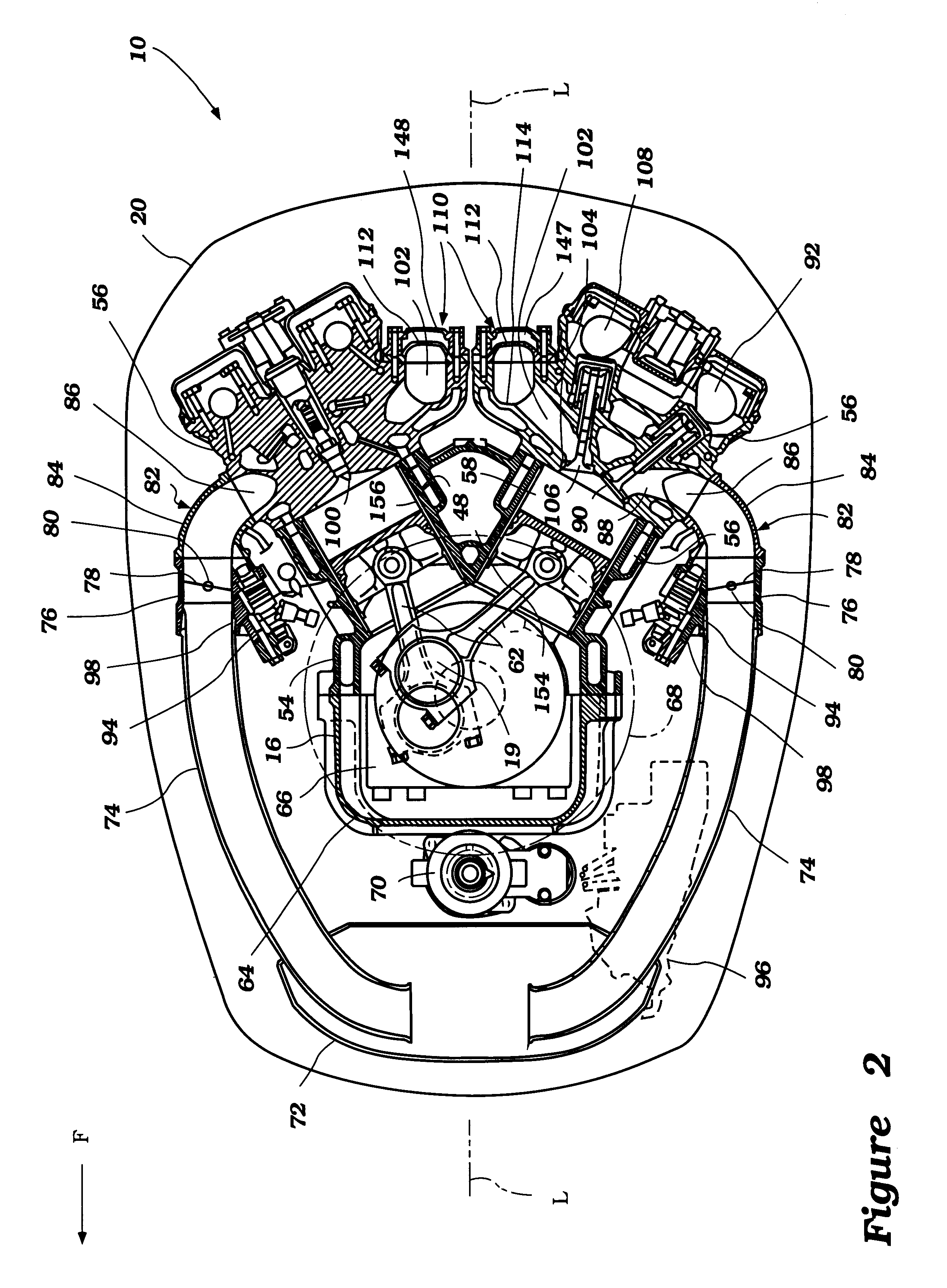

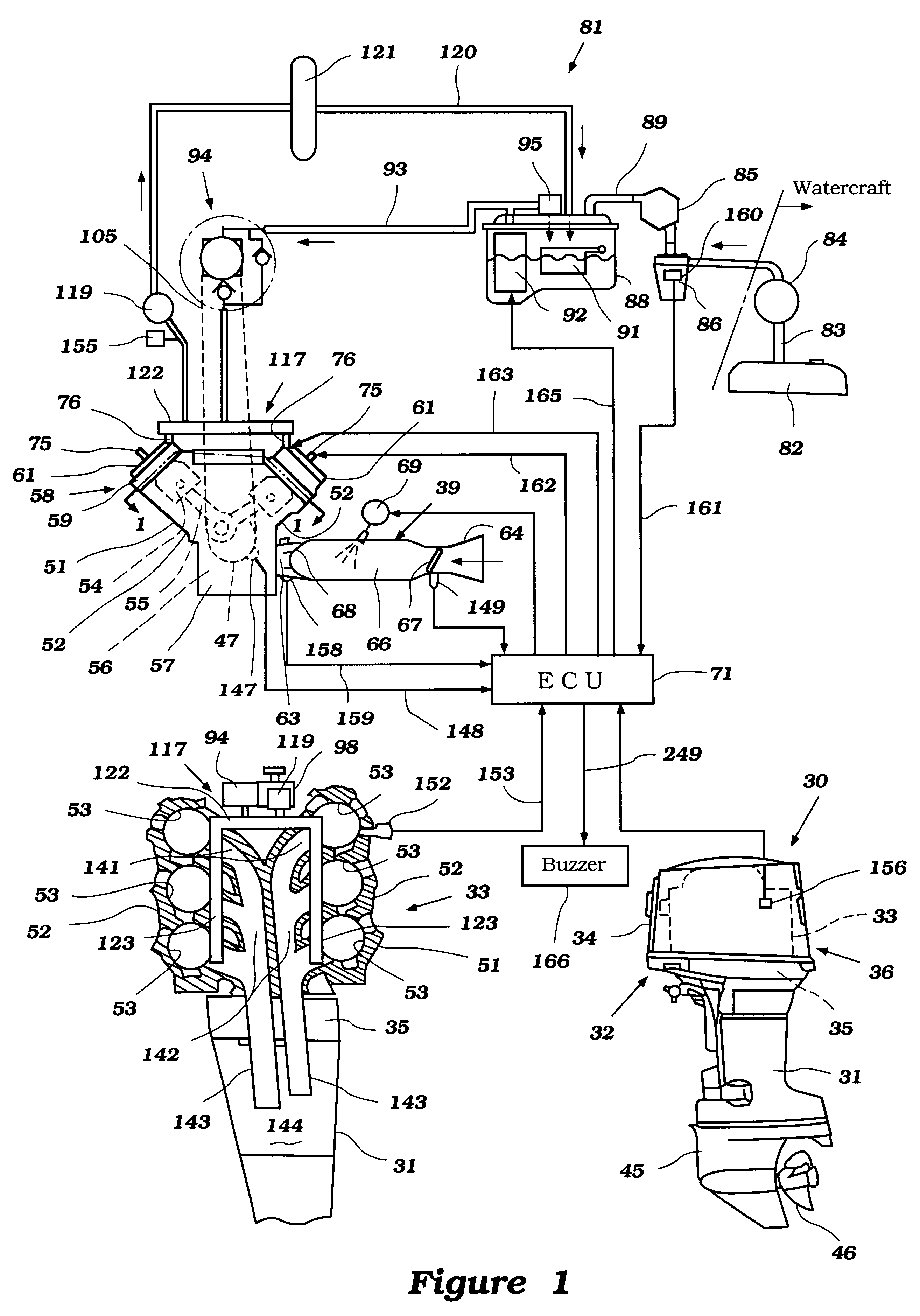

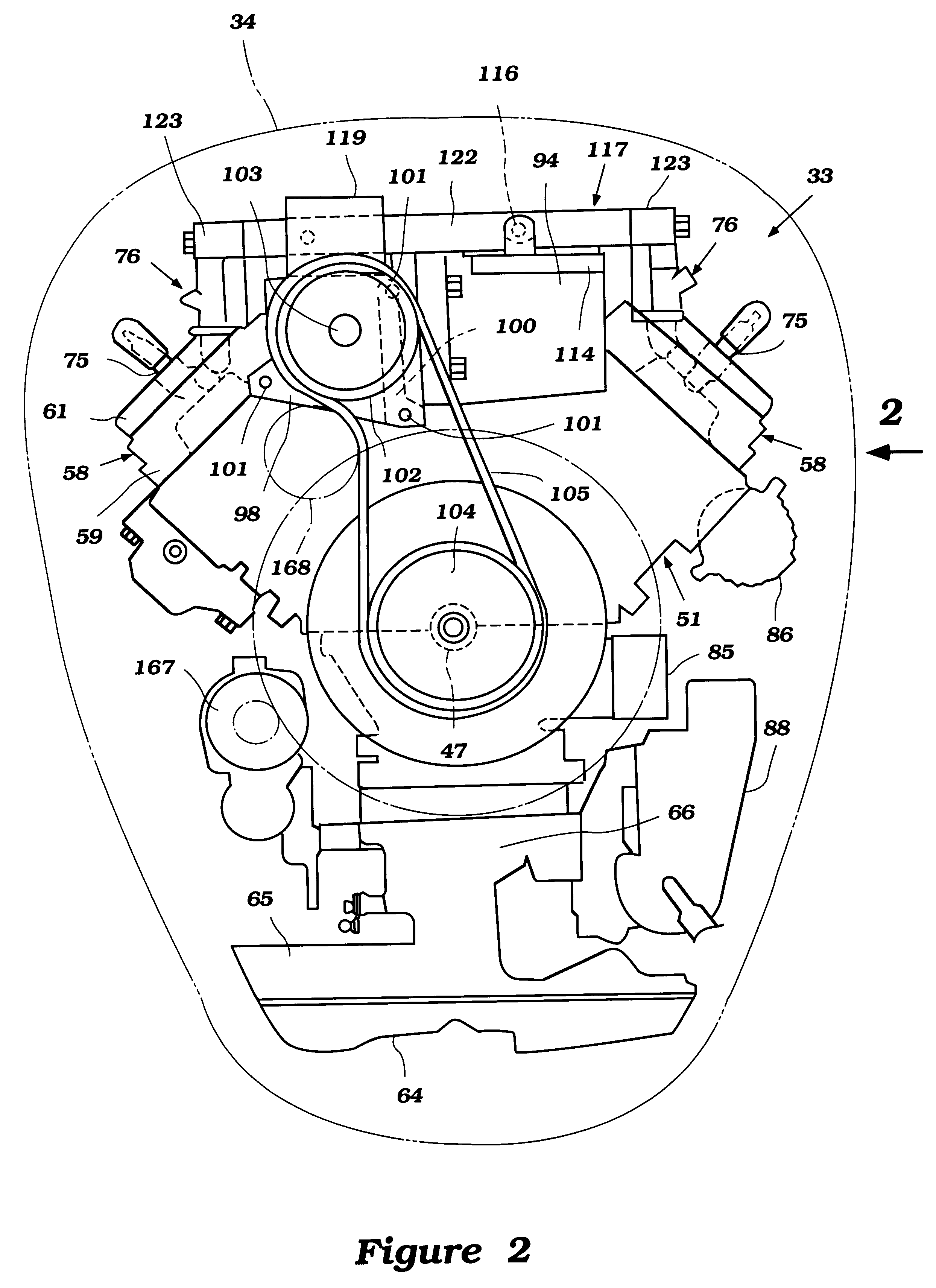

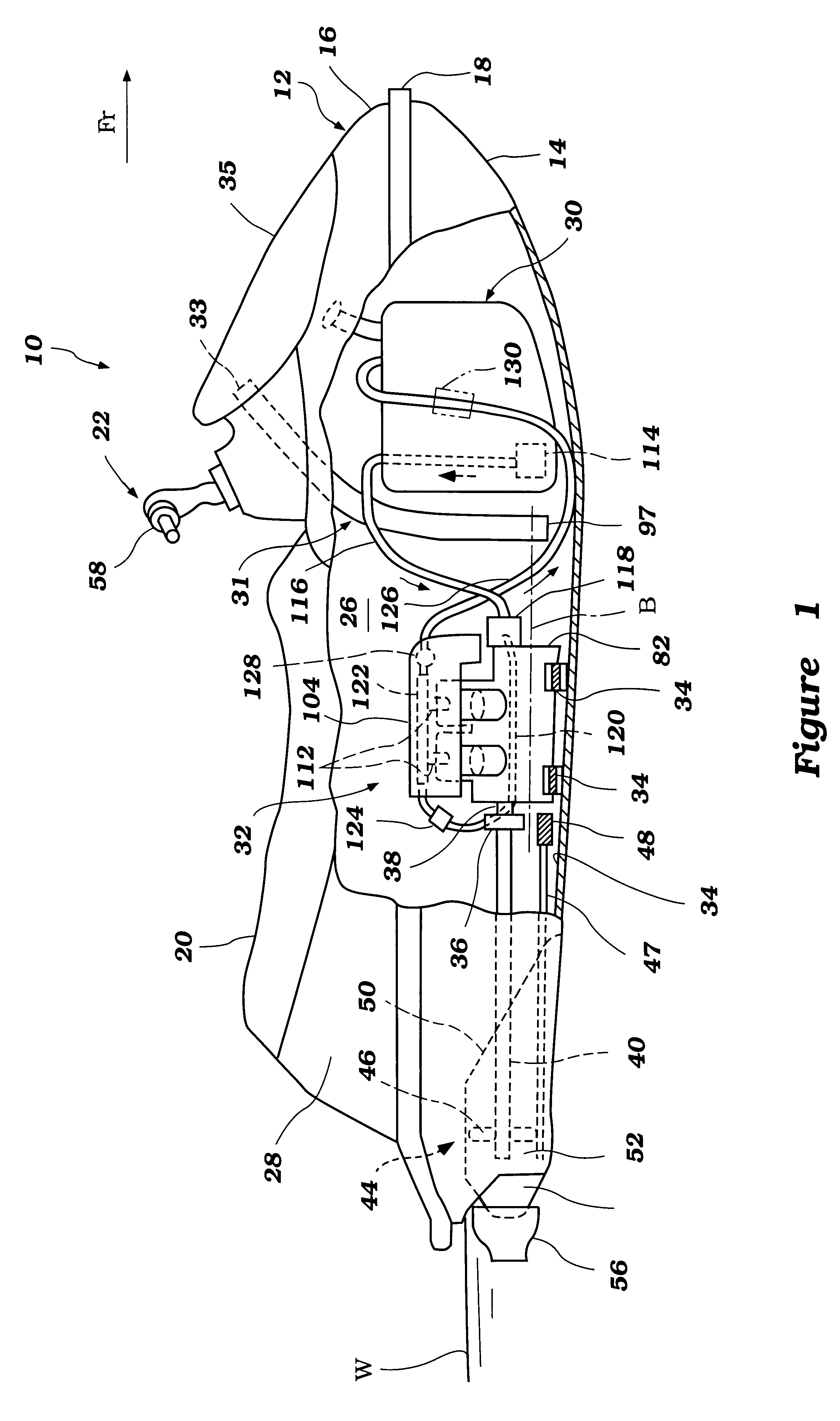

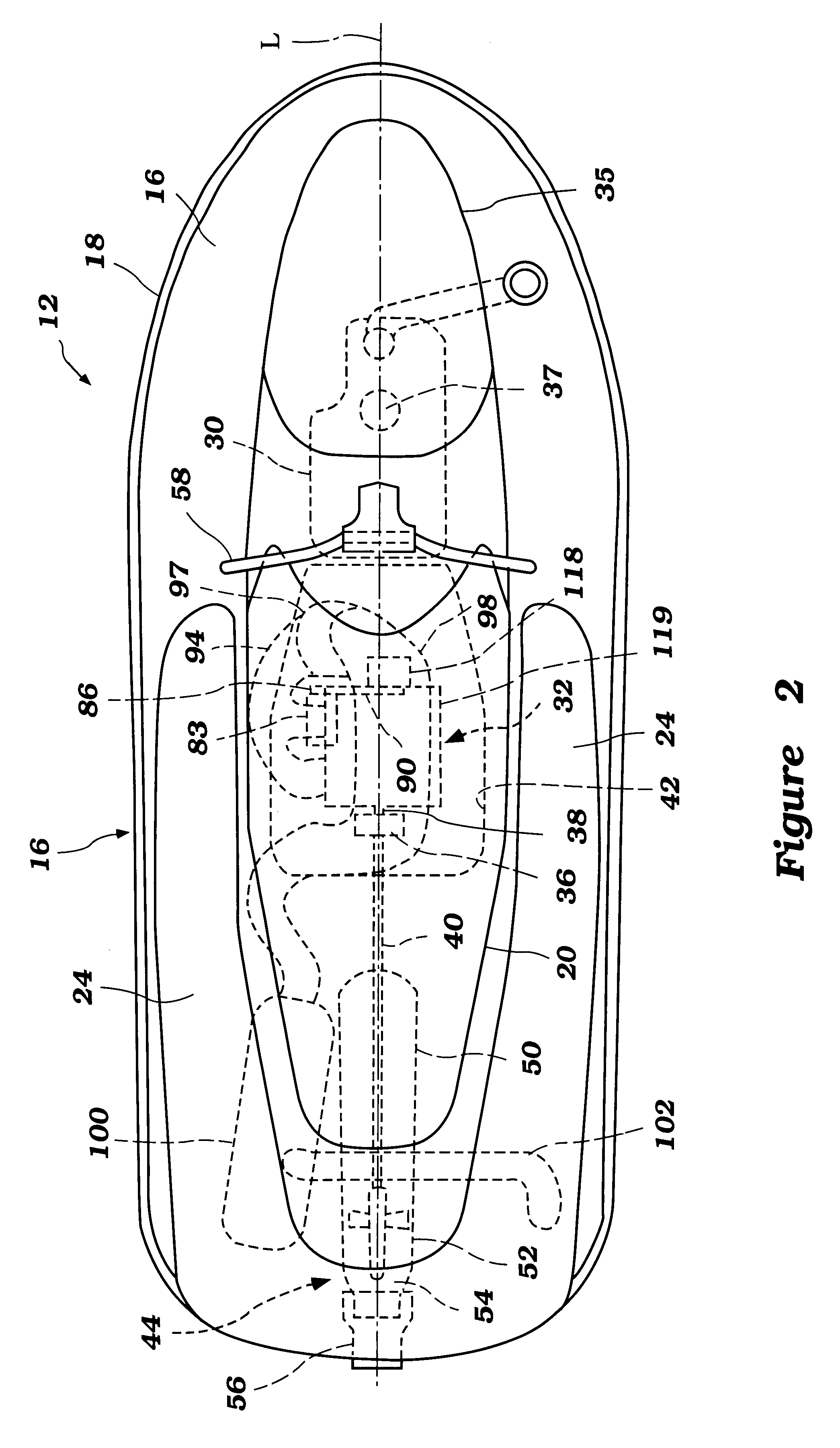

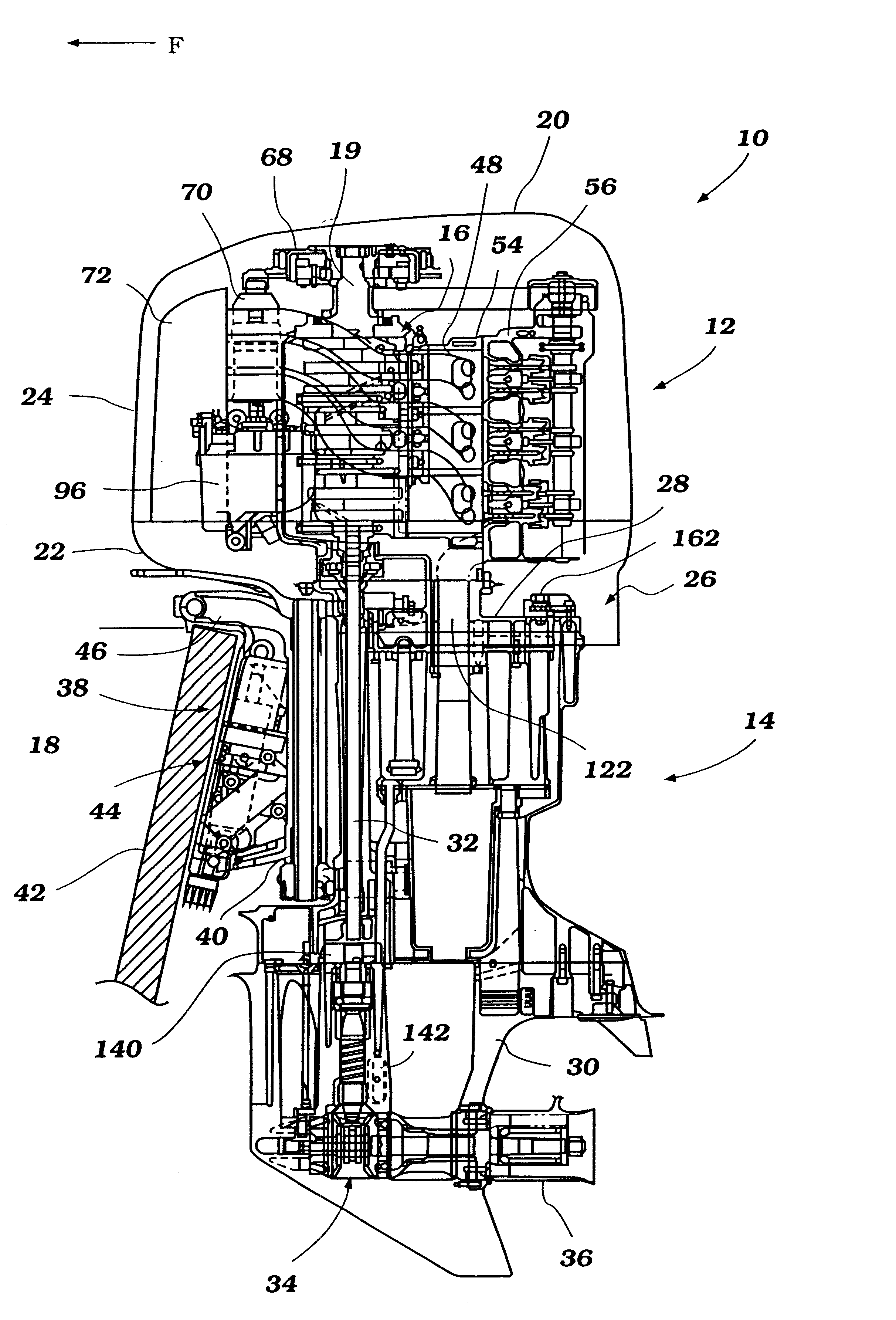

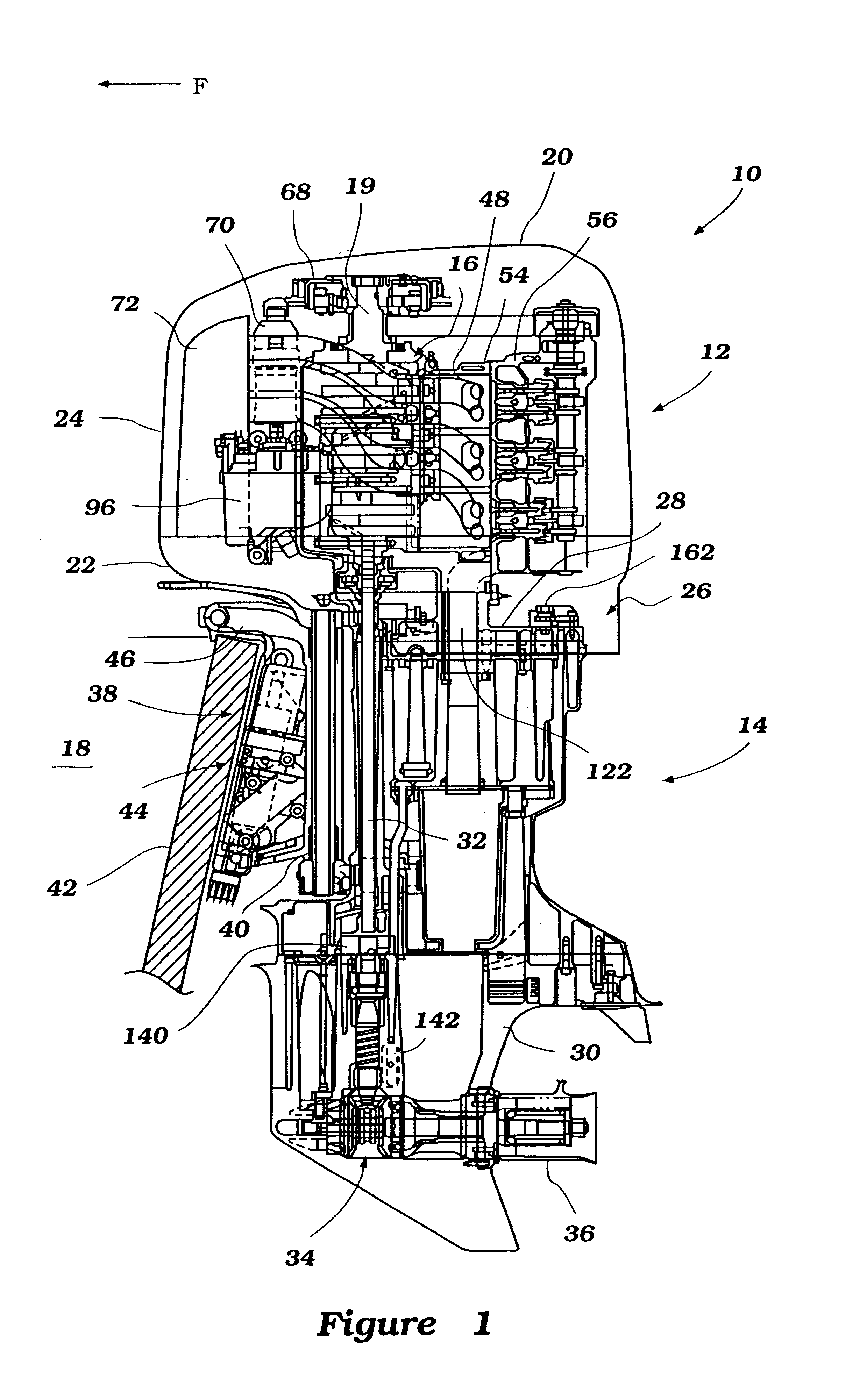

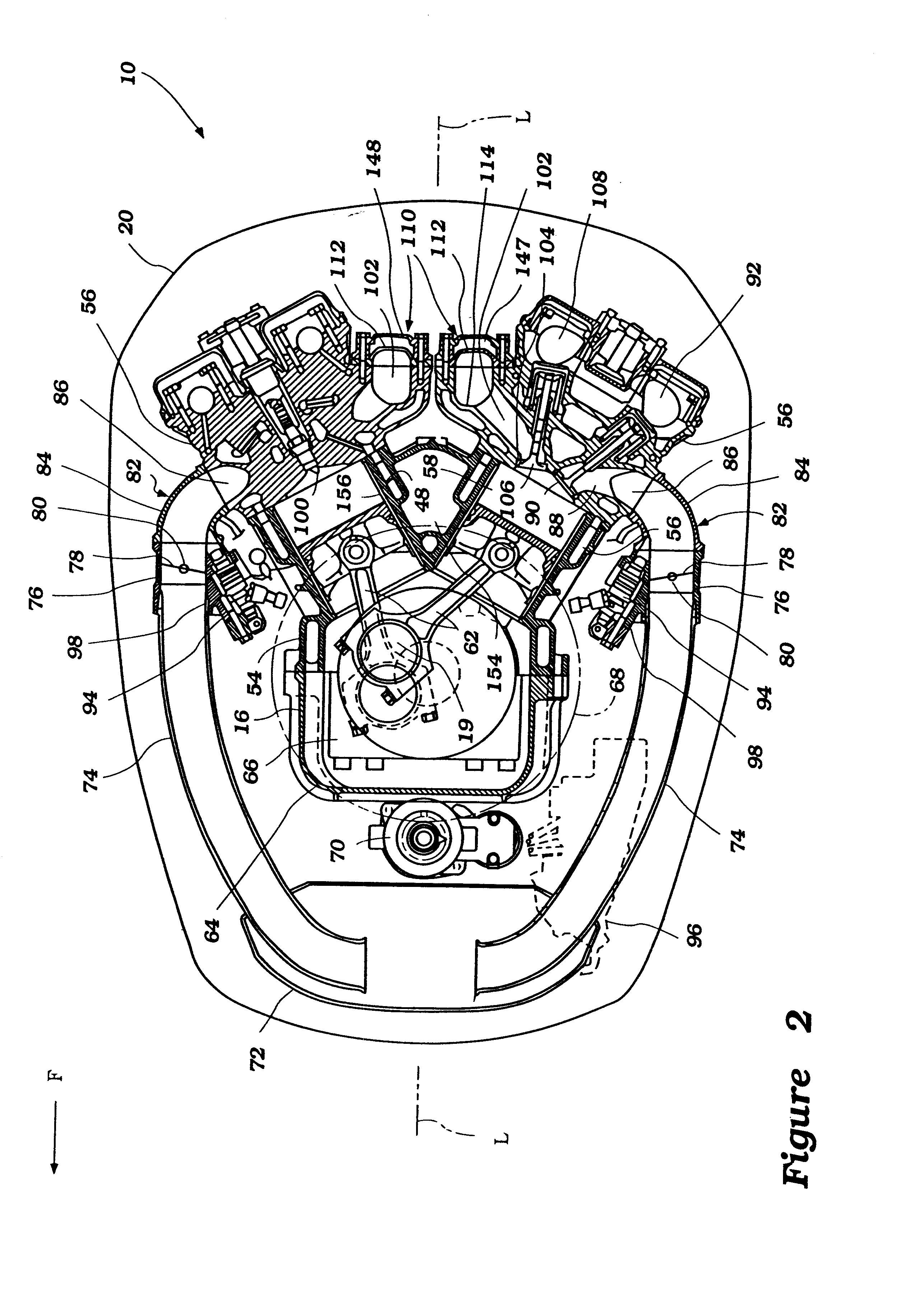

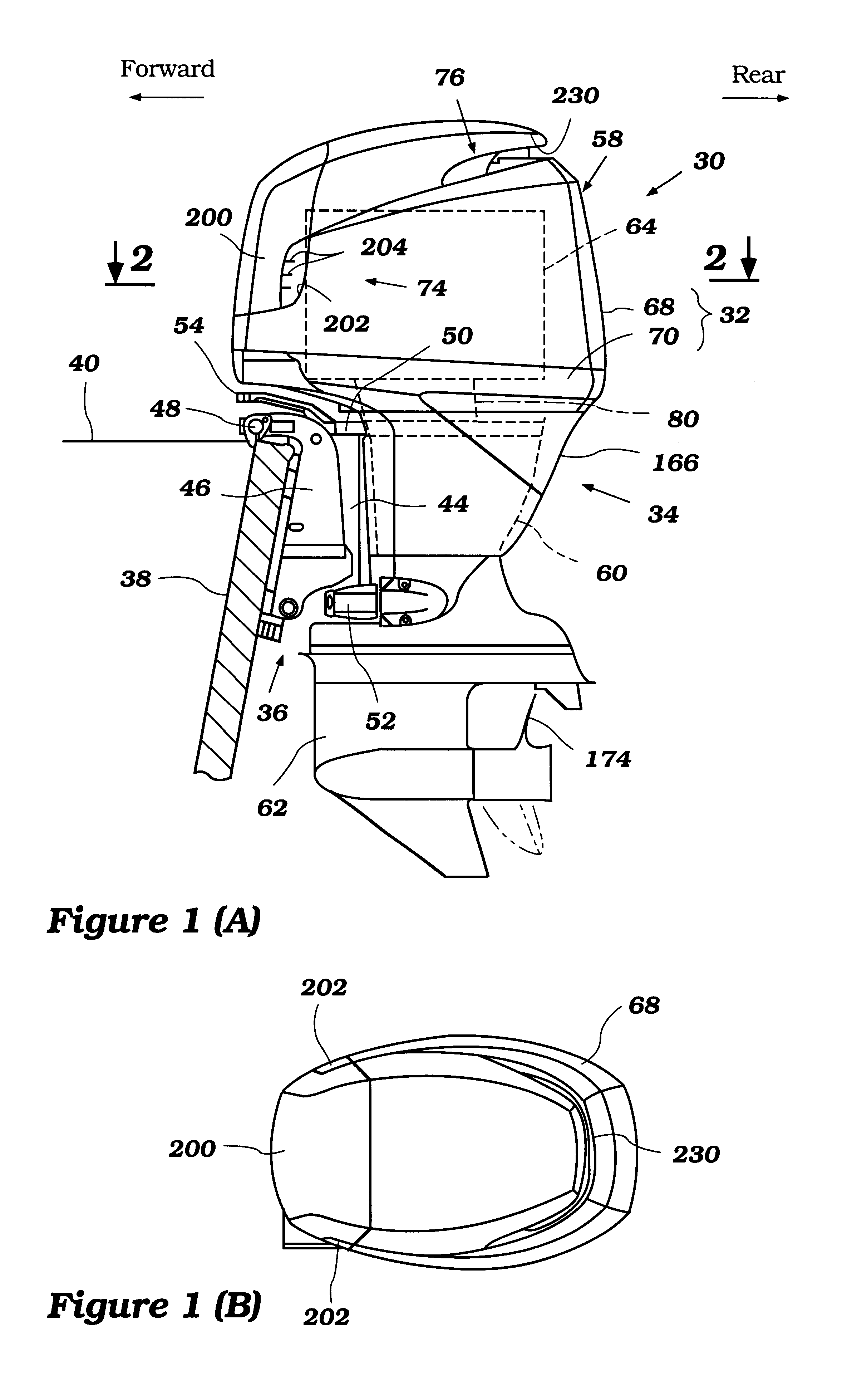

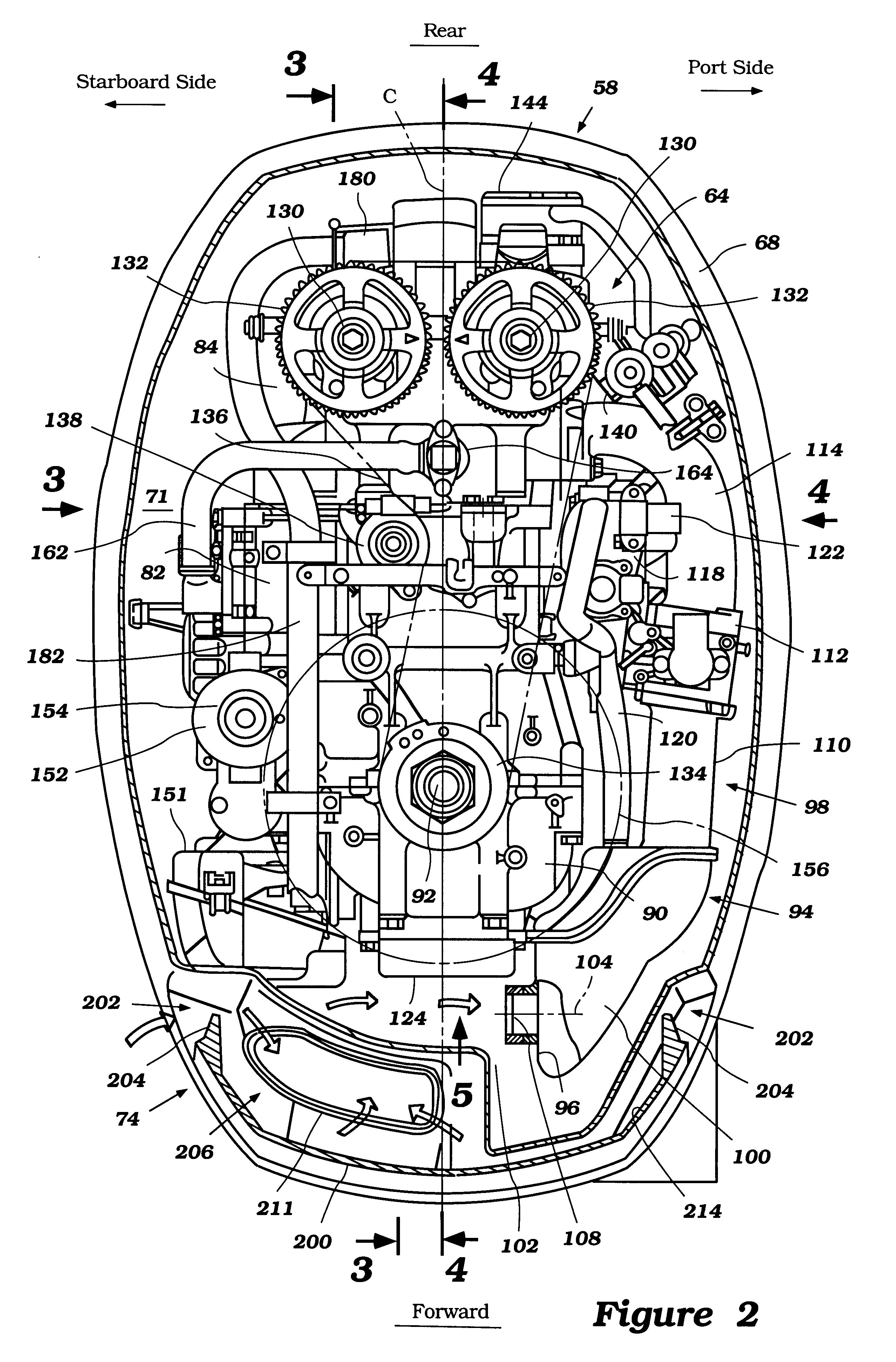

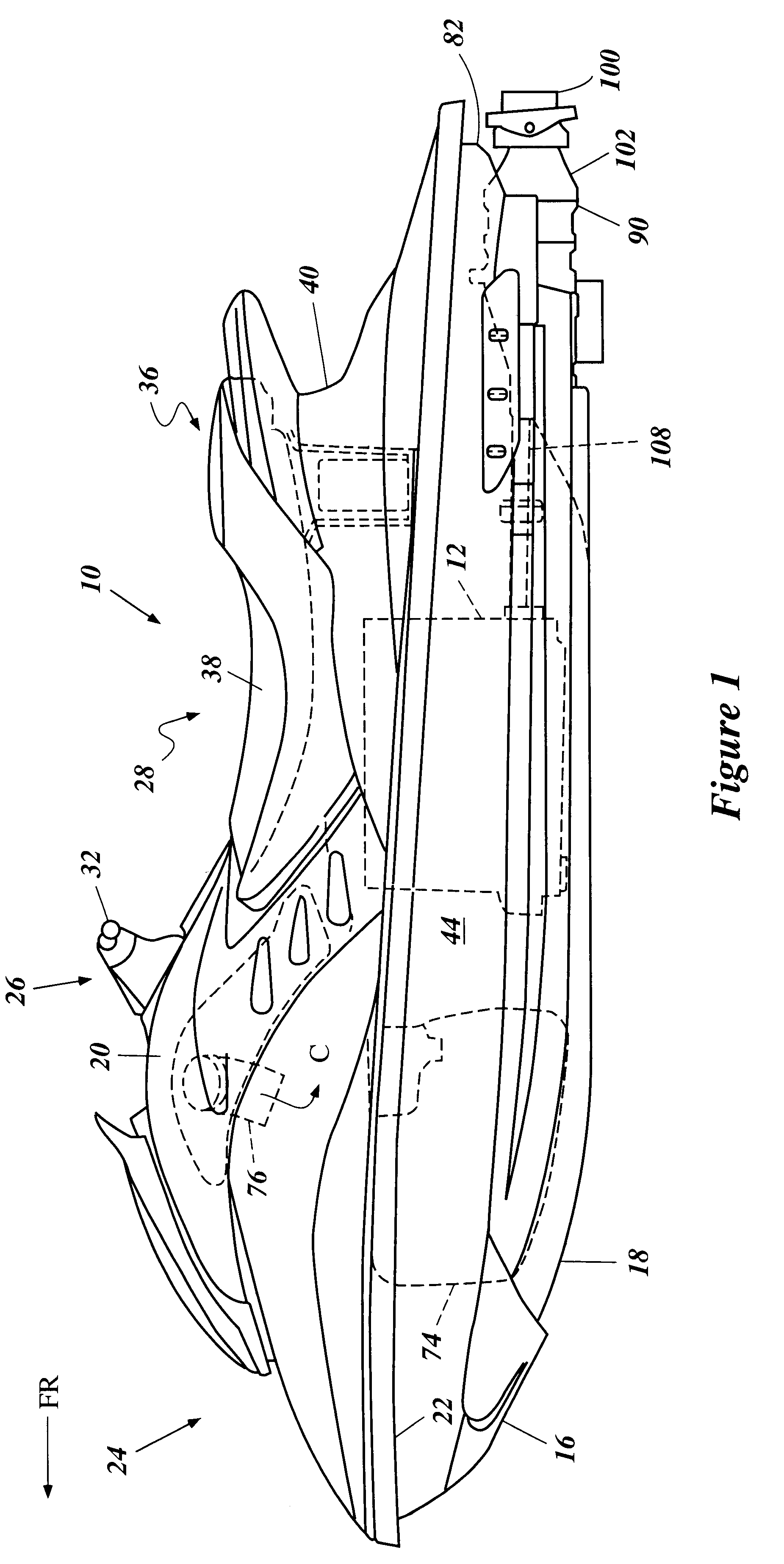

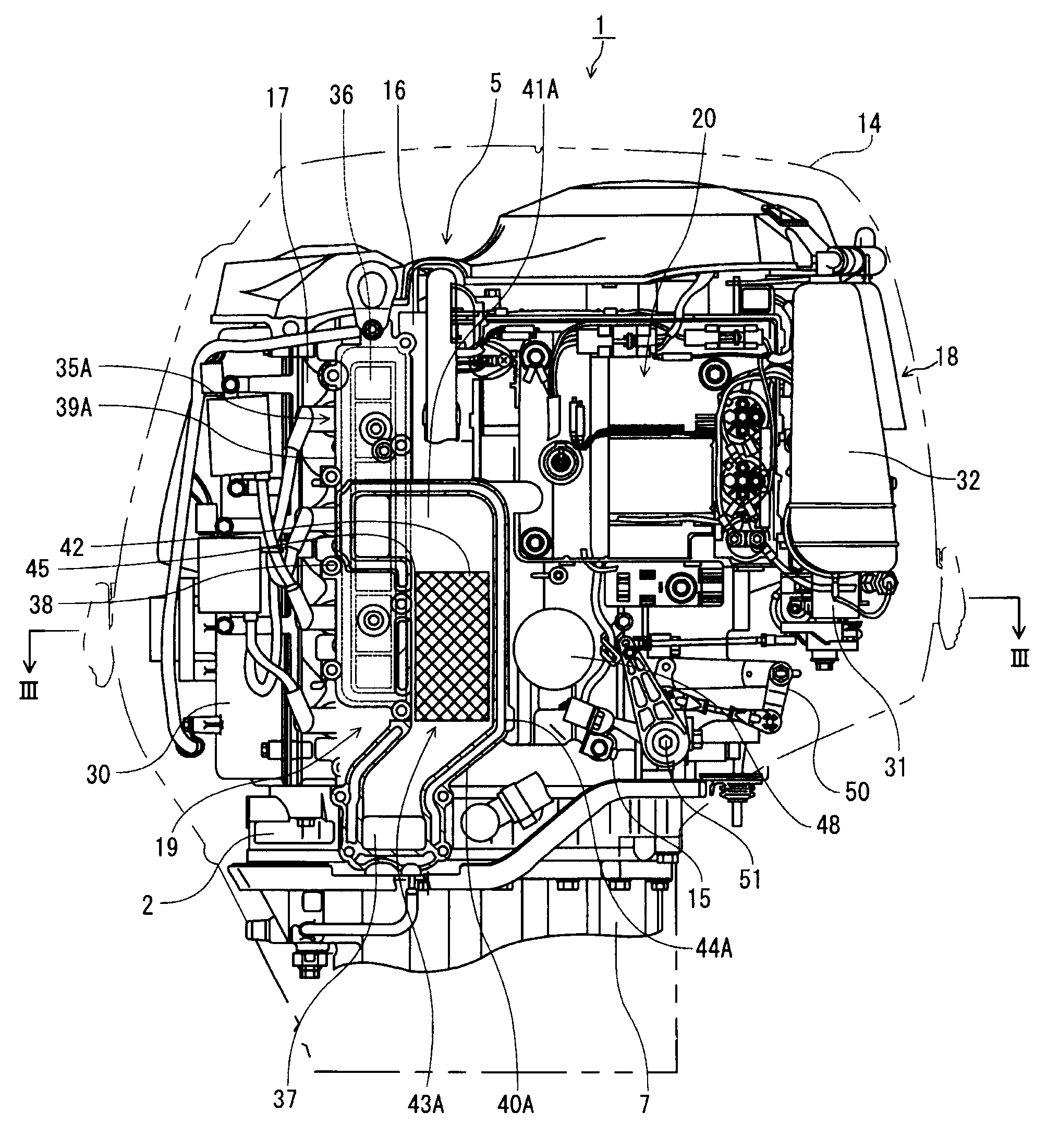

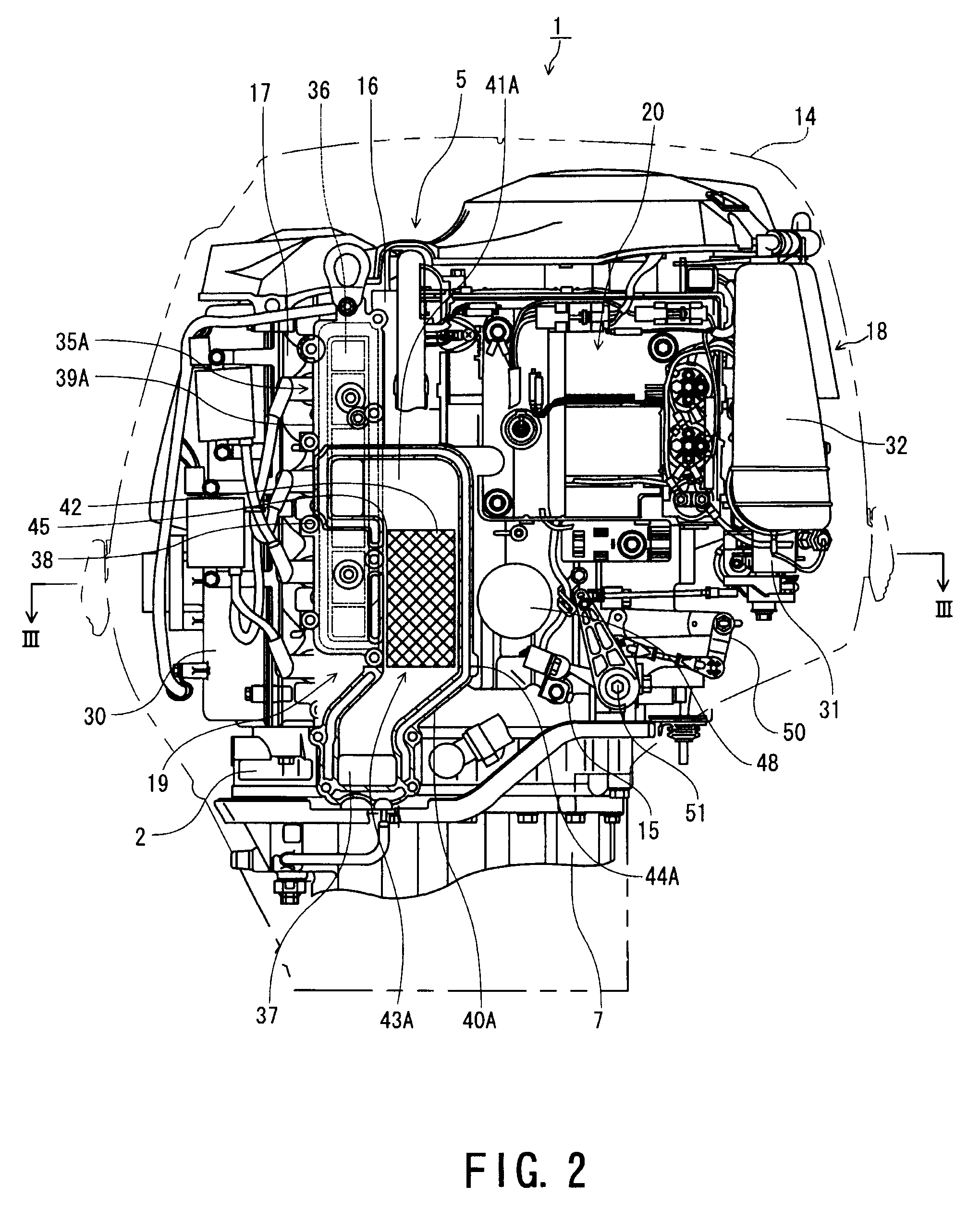

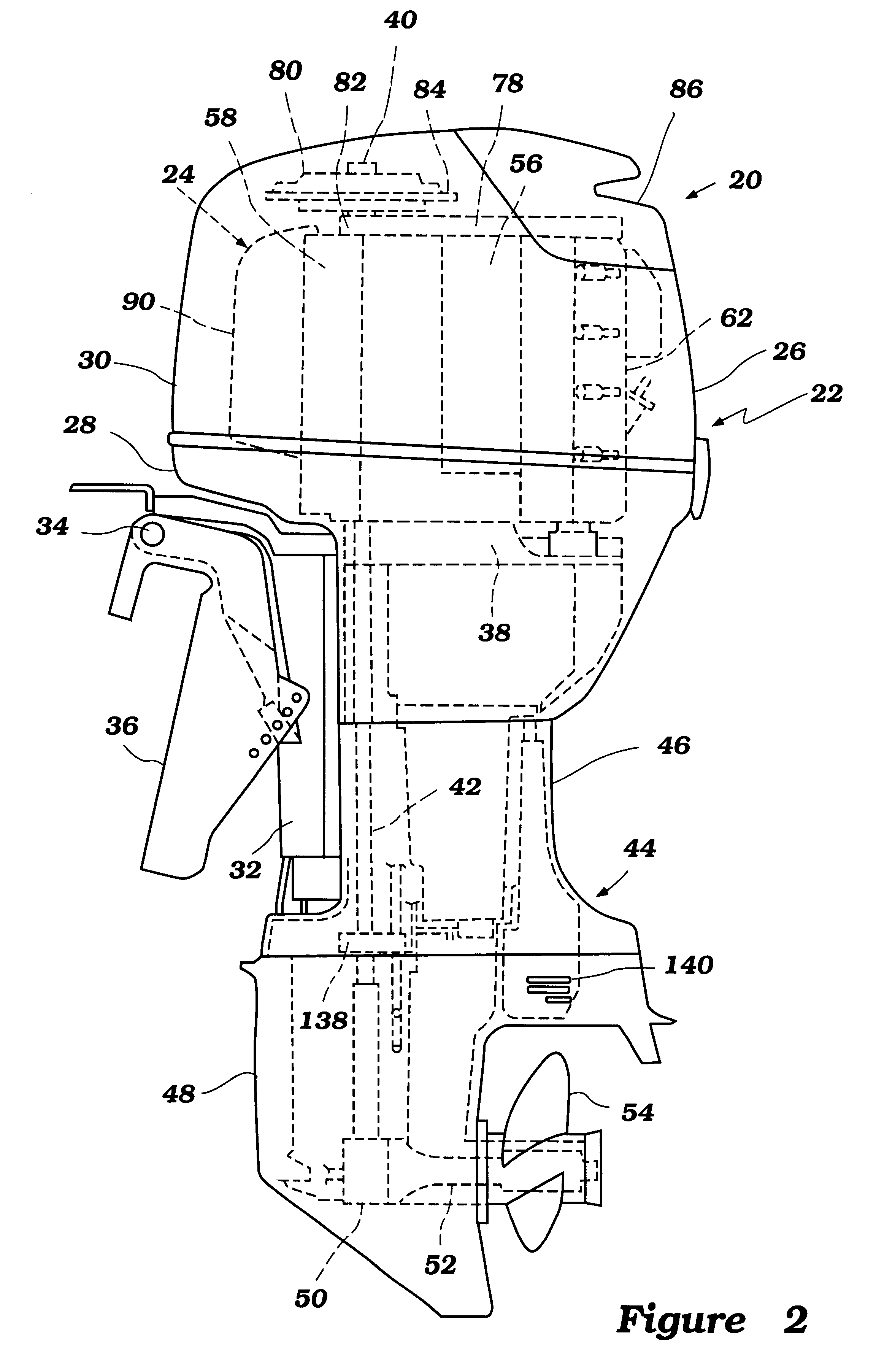

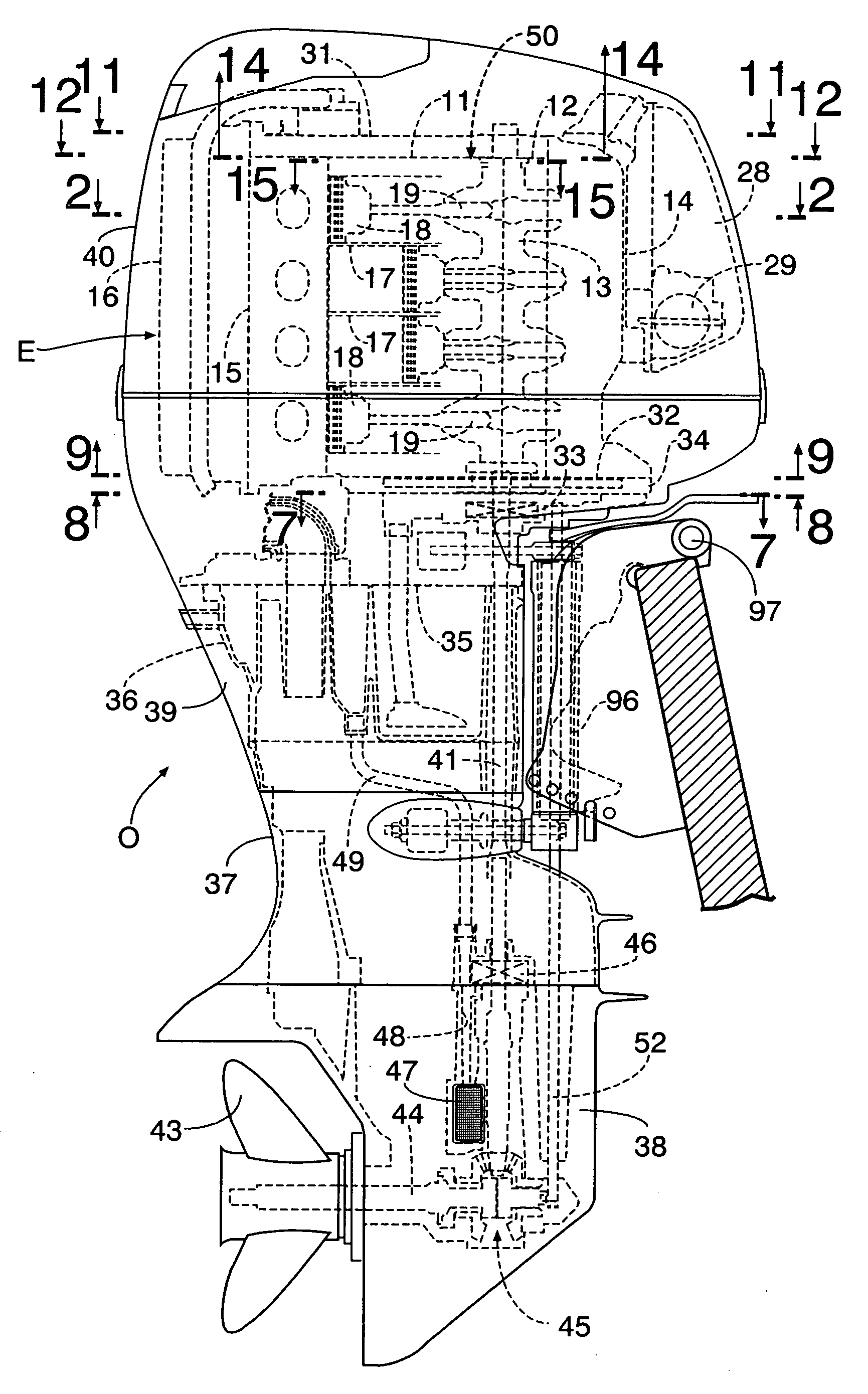

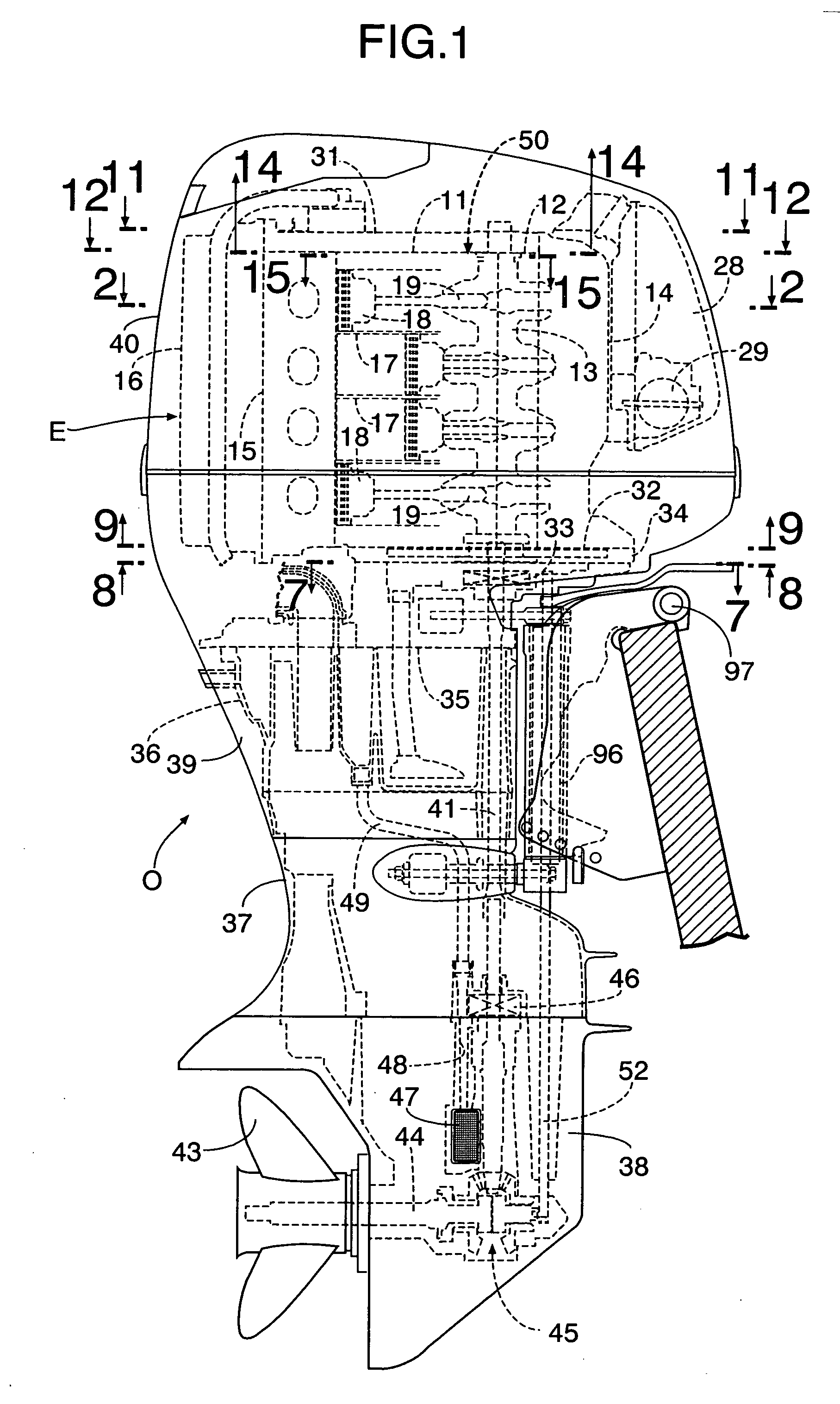

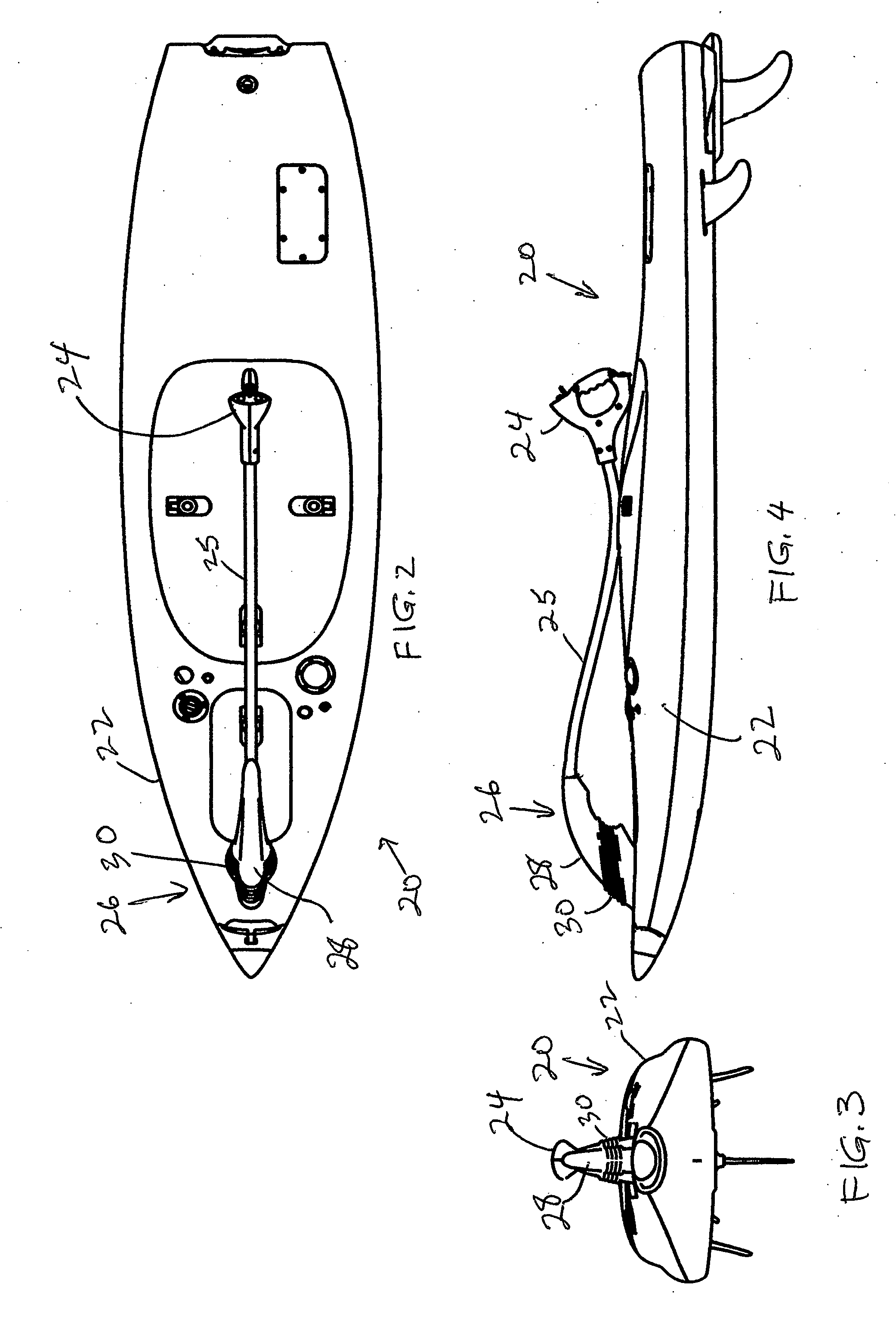

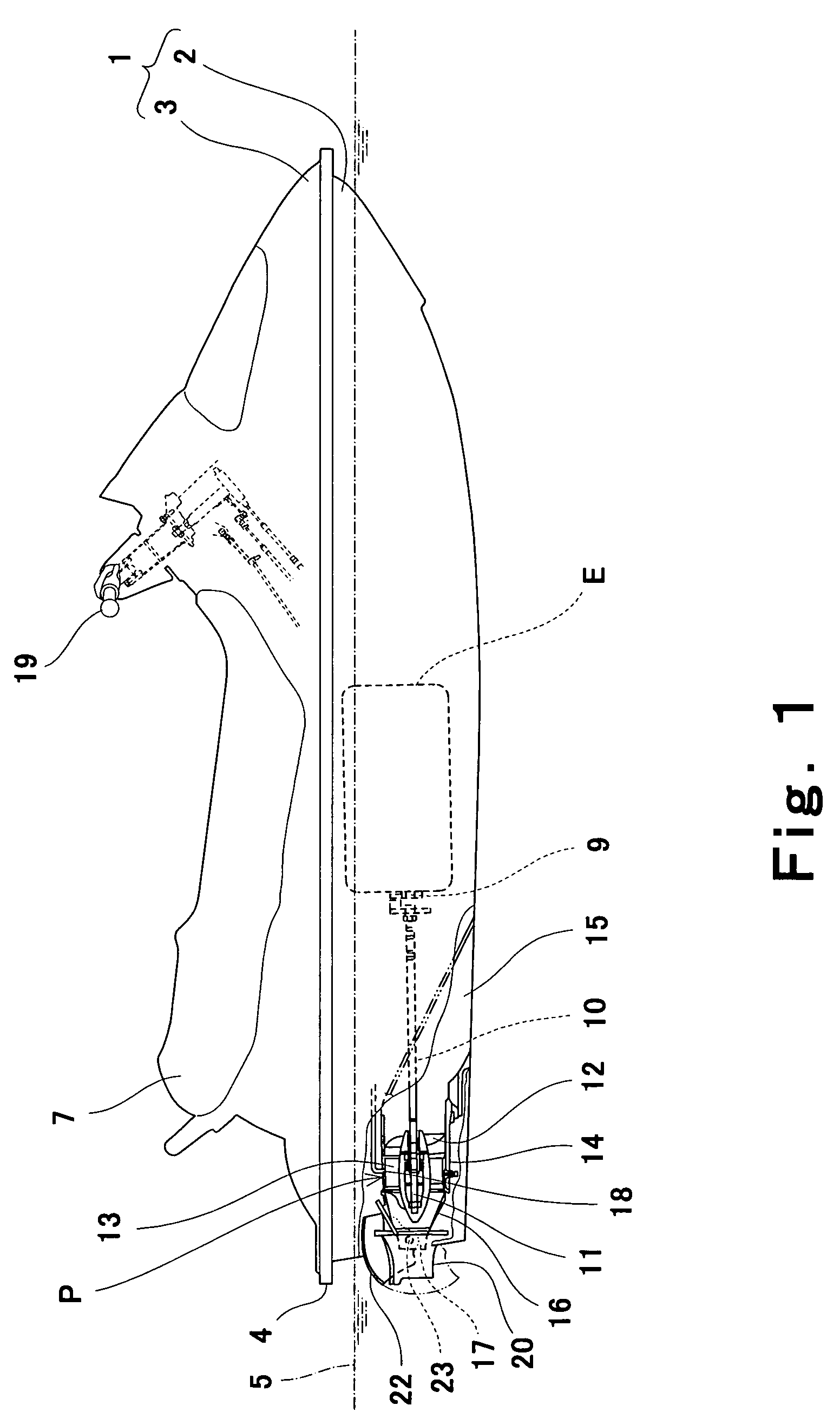

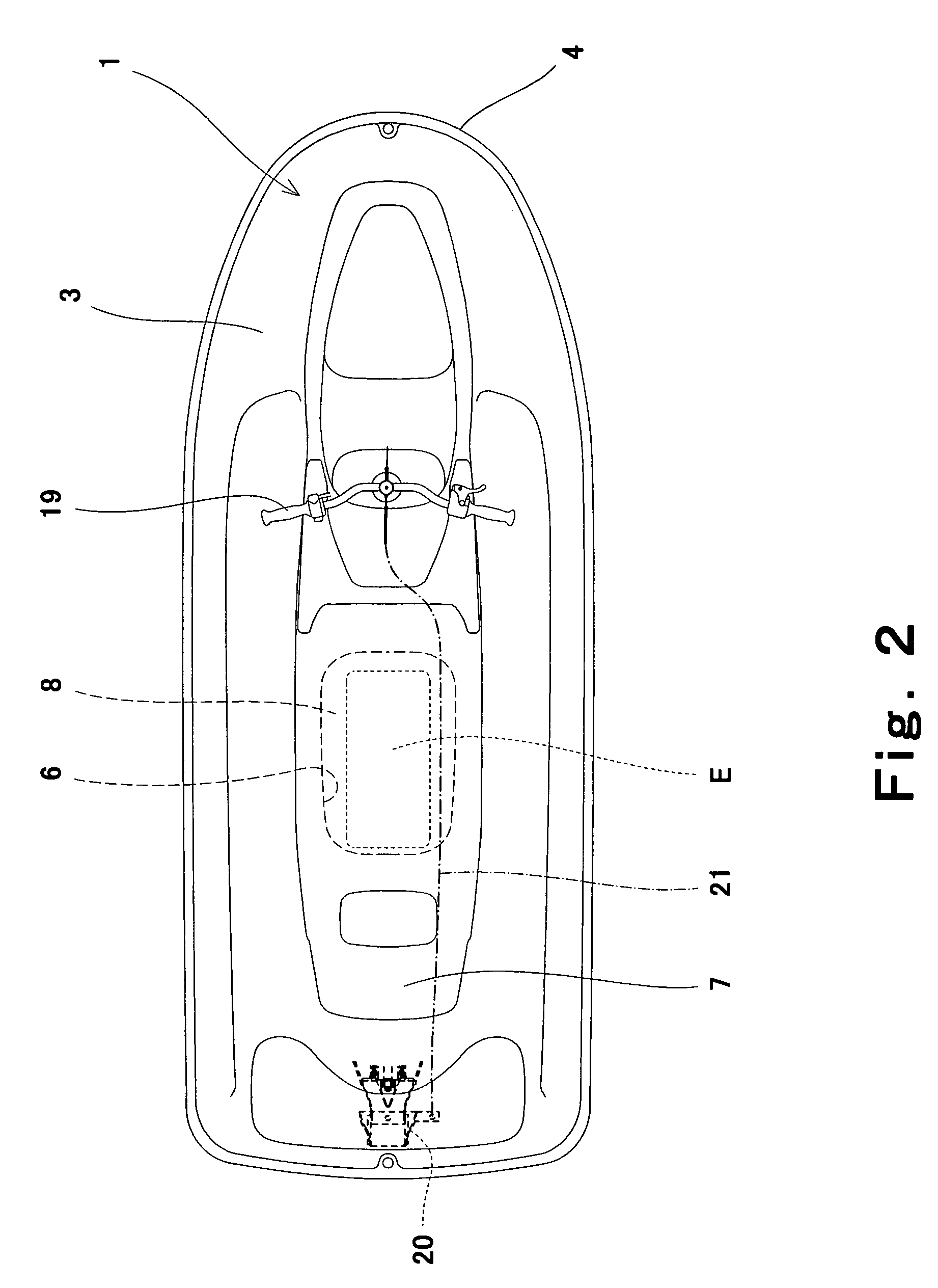

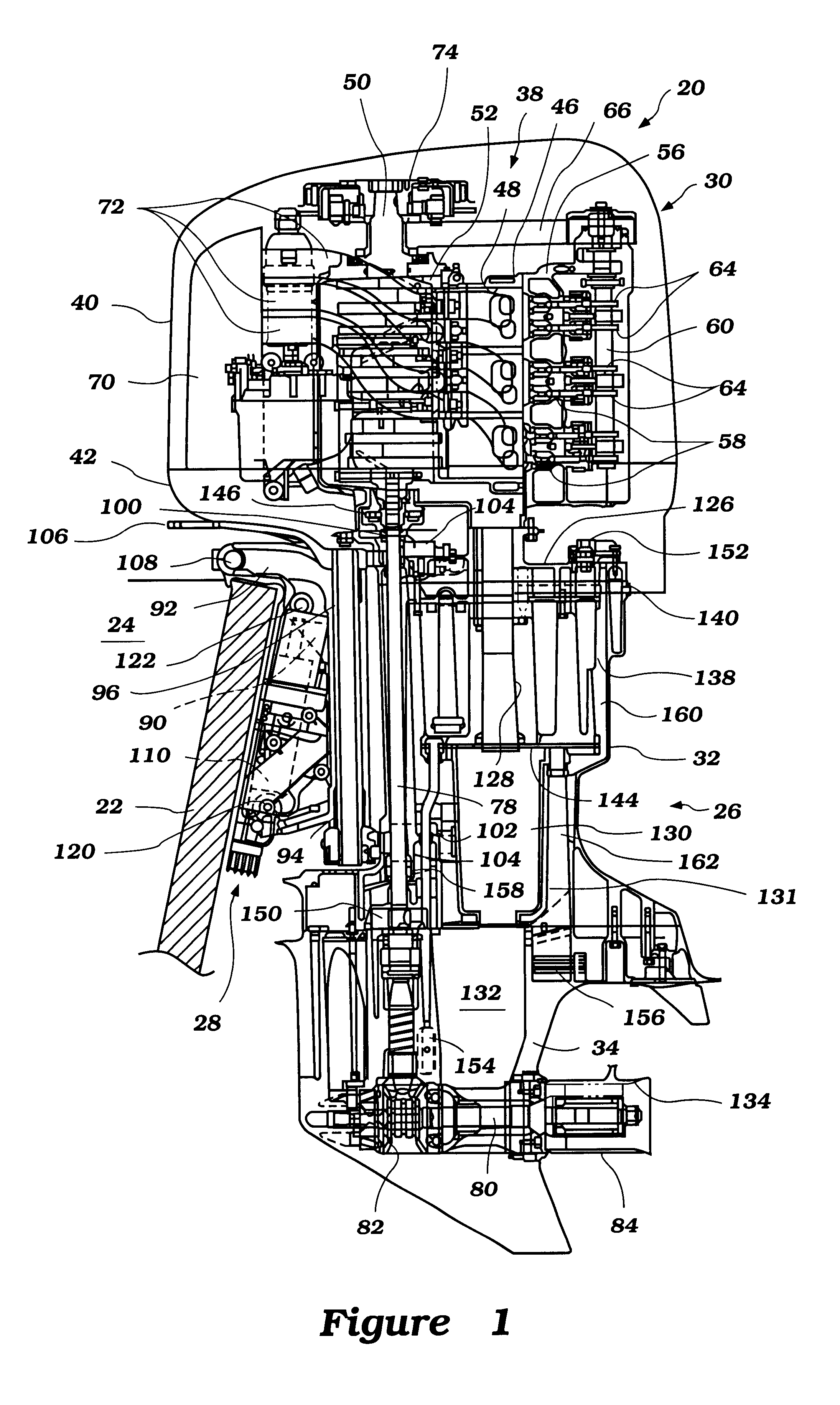

Arrangement for outboard motor

InactiveUS6346018B1Small sizeComponents is relatively effectivePower plants using condensersCasingsCombustion chamberCrankcase

An outboard motor comprises an internal combustion engine and a protective cowling that surrounds the engine. The cowling comprises at least an upper portion and a lower portion. The engine comprises a cylinder block that defines a cylinder bore. A cylinder head member is fixed at one end of the cylinder block and encloses one end of the cylinder bore. A crankcase member is fixed at the other end of the cylinder block and encloses the other end of the cylinder bore. The crankcase member forms a crankcase chamber. A piston is positioned within the cylinder bore. A crankshaft is rotably journaled in the crankcase chamber and is connected to the piston. The piston, the cylinder bore and the cylinder head together define a combustion chamber. The cylinder block, the cylinder head member and the crankcase member together defining an engine body. A first air intake conduit communicates with the engine and extends generally along a side of the engine body. The first air intake conduit communicates with an intake silencer located proximate the crankcase member. The engine further comprises a starter motor, an electronic control unit and a fuel supply system. The fuel supply system comprises a vapor separator and a fuel injector. The starter motor, the electronic control unit, the vapor separator and the fuel injectors are located in a space defined between the intake silencer, the first air intake conduit and the engine body.

Owner:SANSHIN KOGYO CO LTD

Turbocharger configuration for an outboard motor

A marine propulsion device is provided with a turbocharger that is located above all, or at least a majority of, the cylinders of an engine. The exhaust gases are directed to one side of the engine and the compressed air is directed to an opposite side of the engine. The turbocharger is located at a rear portion of the engine behind the crankshaft.

Owner:BRUNSWICK CORPORATION

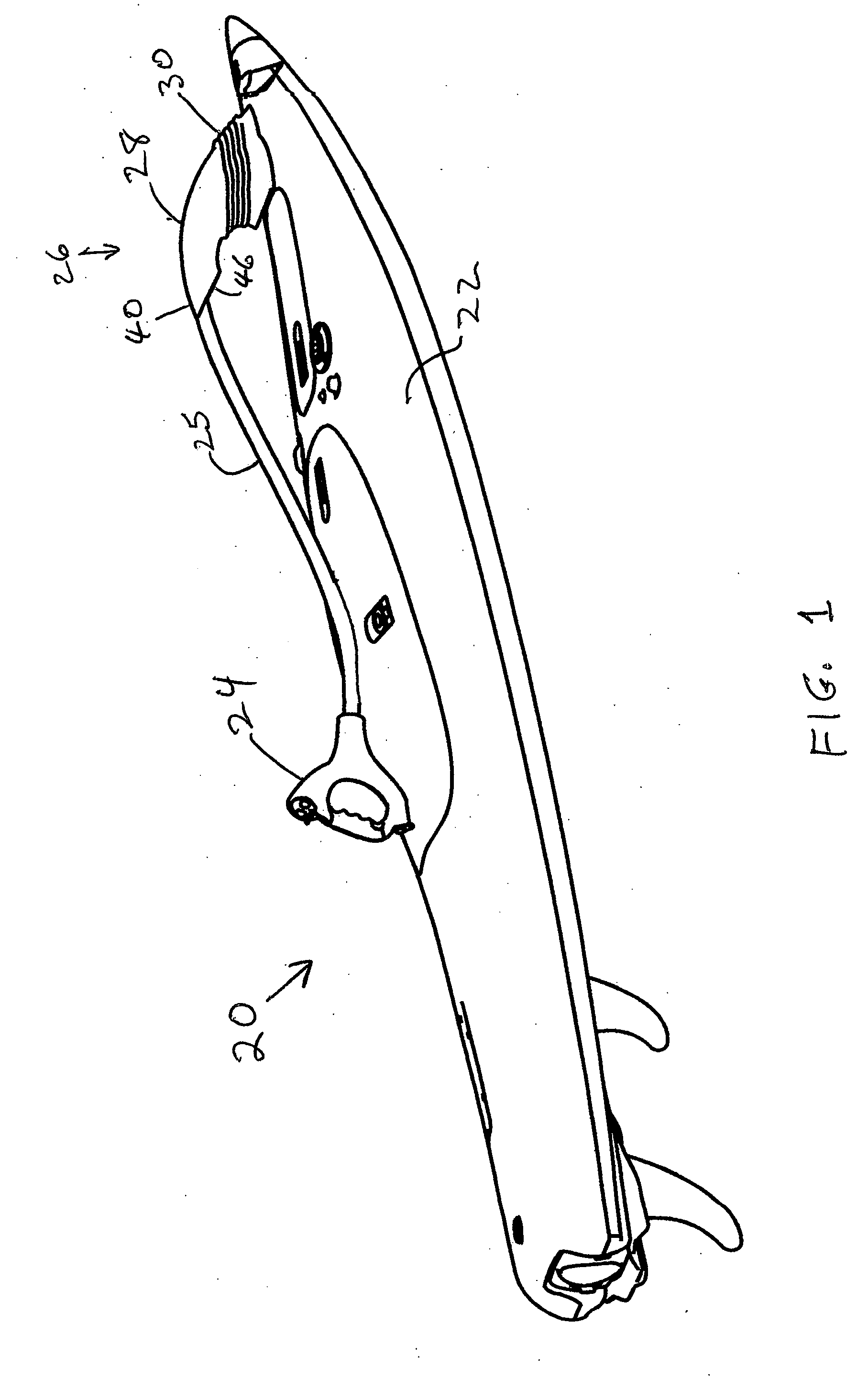

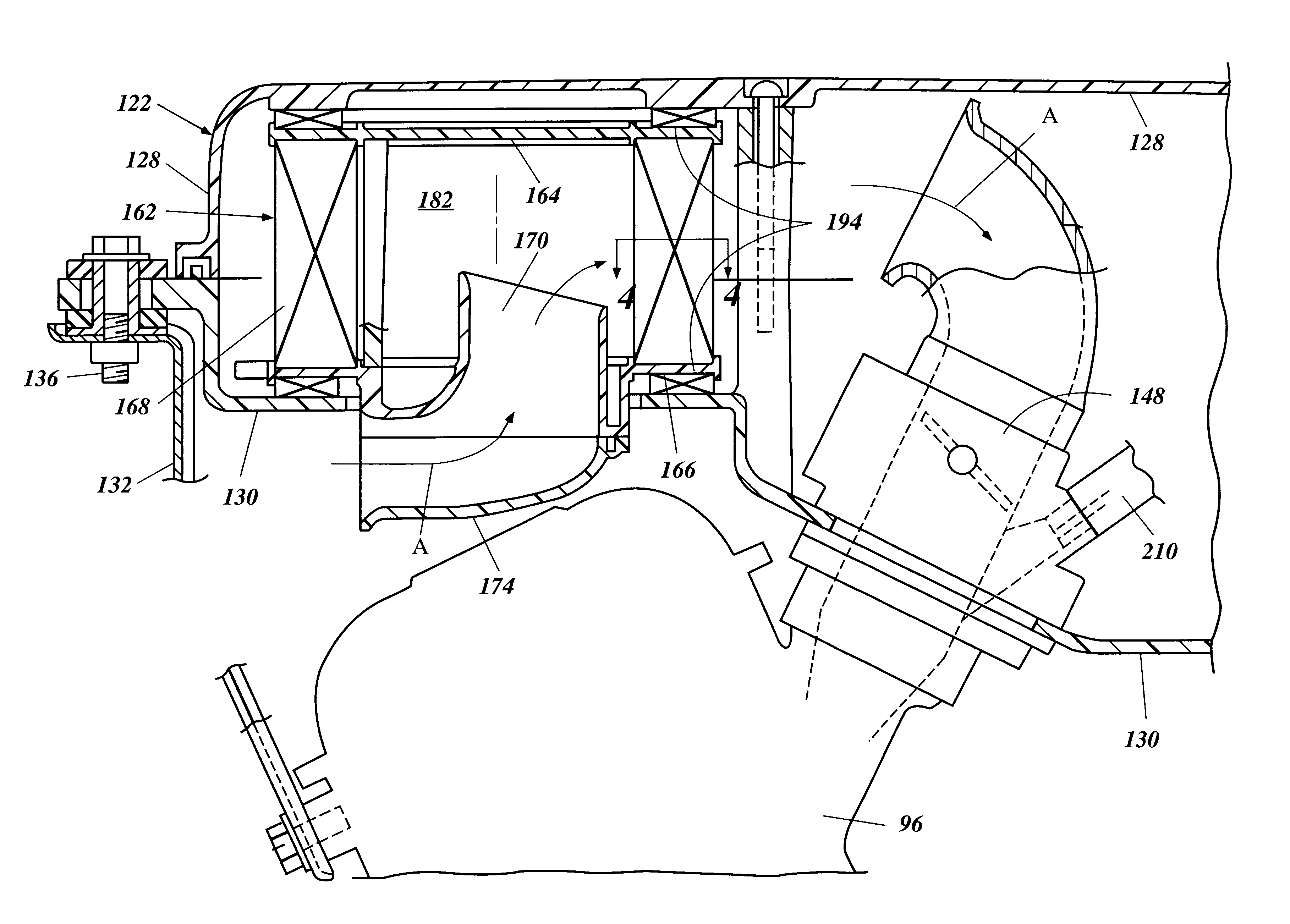

Catalytic exhaust system for watercraft

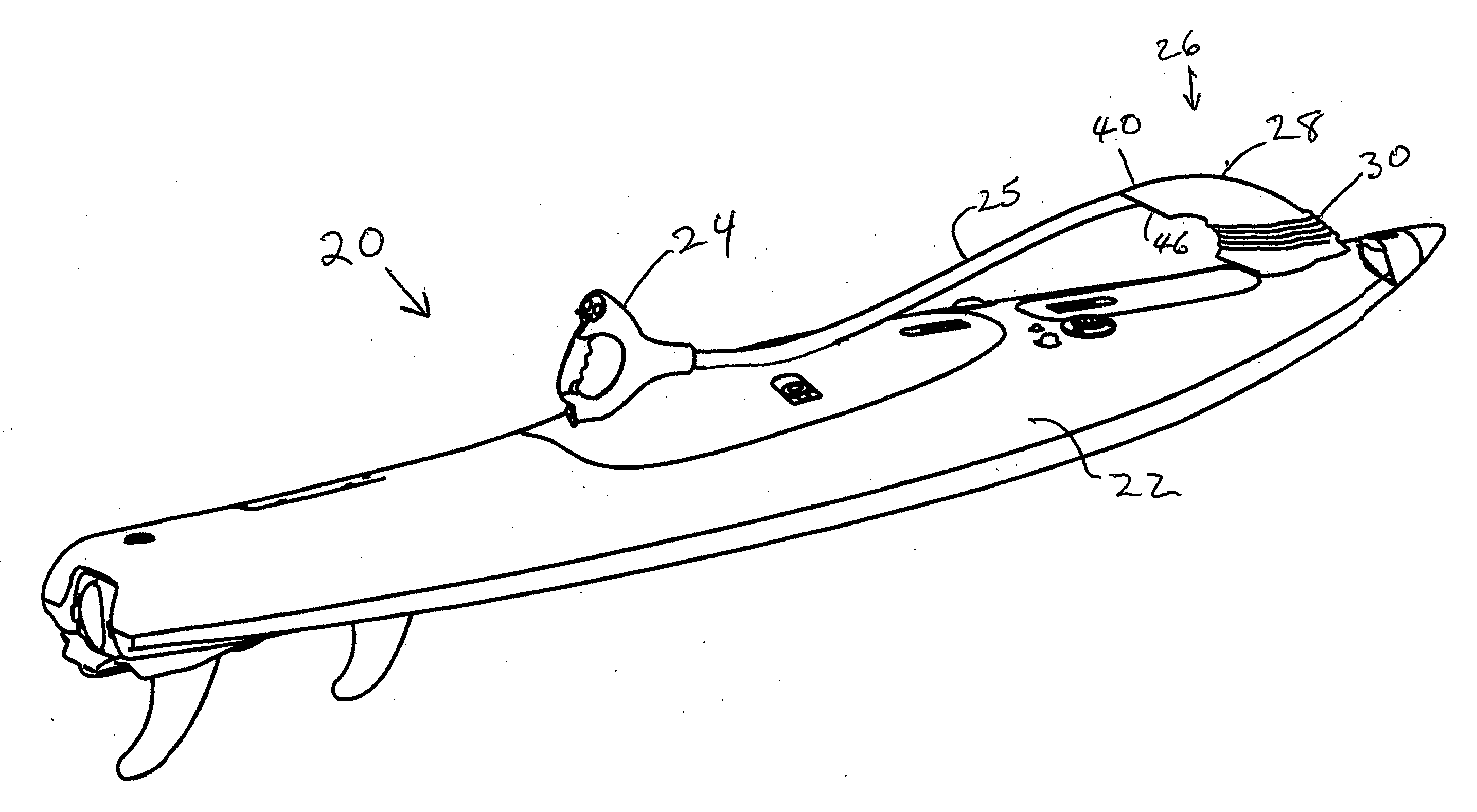

InactiveUS6120335APower plants using condensersInternal combustion piston enginesCombustion chamberWatercraft

A personal watercraft includes a catalytic exhaust system in order to reduce discharge of pollutants. The exhaust system includes an exhaust passage and a catalyzer that is located within an expansion chamber of the exhaust passage. A water jacket is provided adjacent the expansion chamber and a portion of water from the water jacket merges with the exhaust pipe at a merge point downstream from the catalyzer. The distance within the exhaust passage between an exhaust port of a combustion chamber and the front of the catalyzer and from the rear of the catalyzer to the coolant-exhaust merge point is such that a pressure wave from the combustion chamber reflects back from downstream of the catalyzer carries an exhaust / water mixture from the merge point upstream across the catalyst, thereby cooling the catalyzer. Also, an insertion port disposed in the exhaust system upstream of the catalyzer injects cooling water into the exhaust system, thus cooling the exhaust gases and the catalyzer.

Owner:YAMAHA MOTOR CO LTD

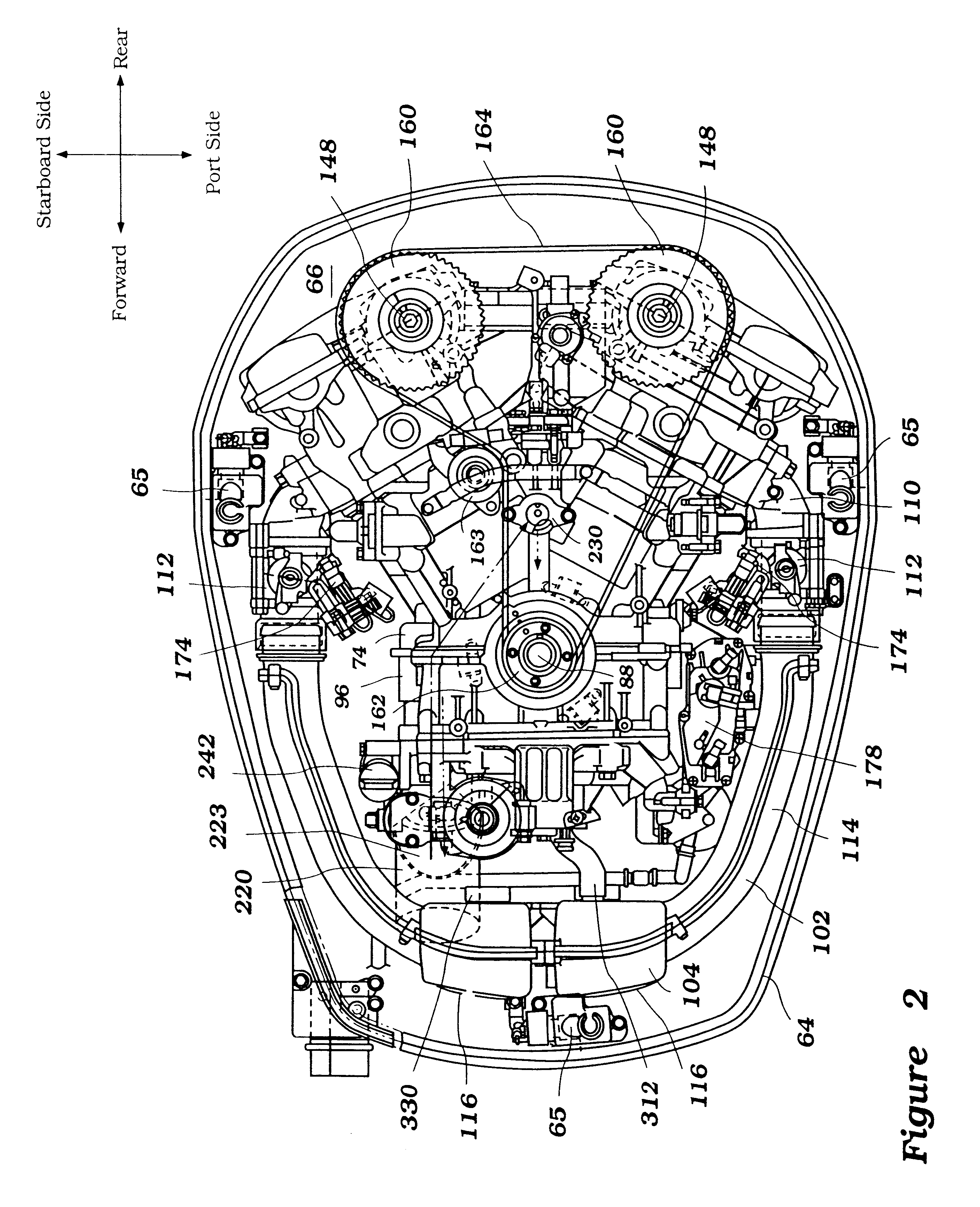

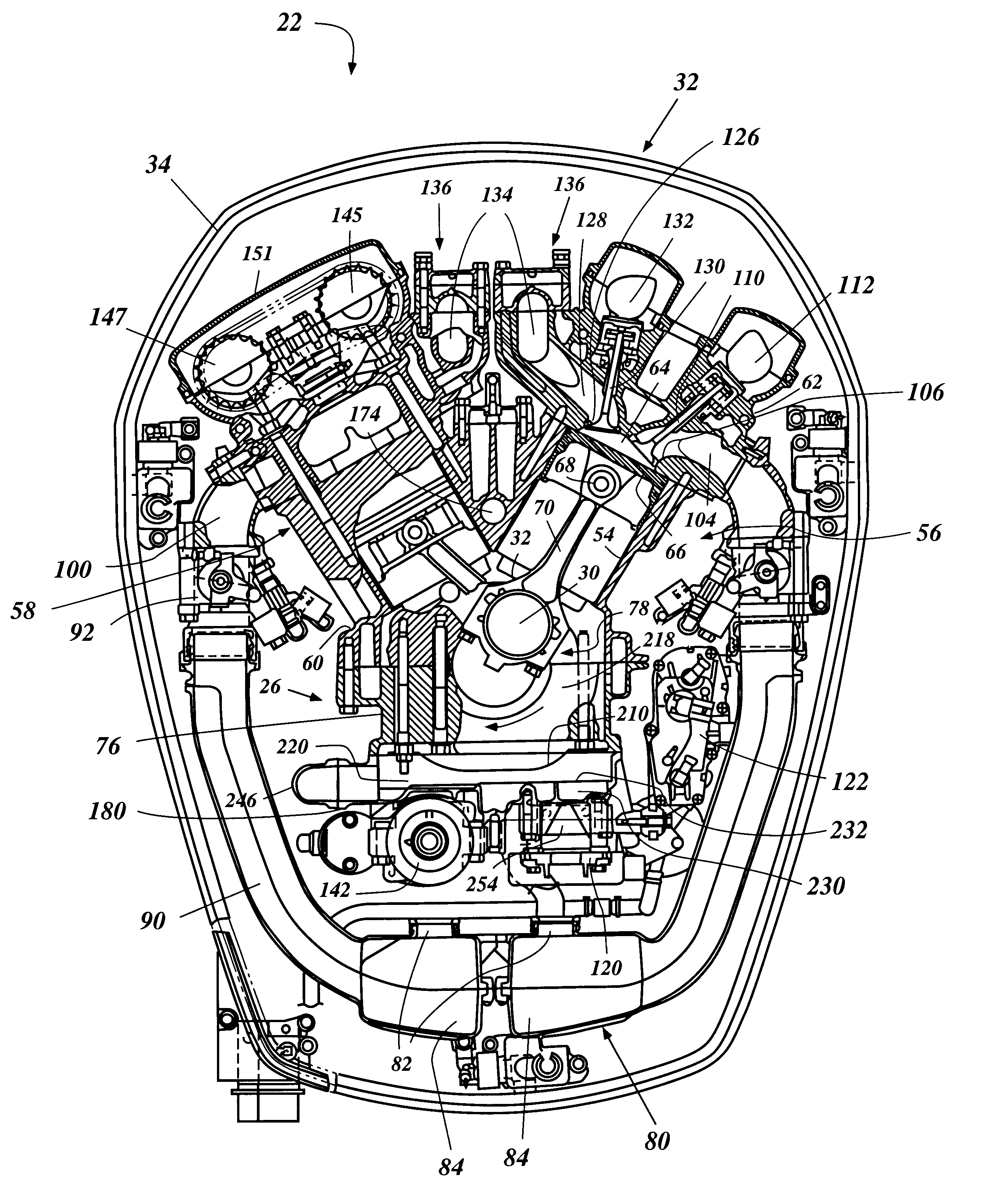

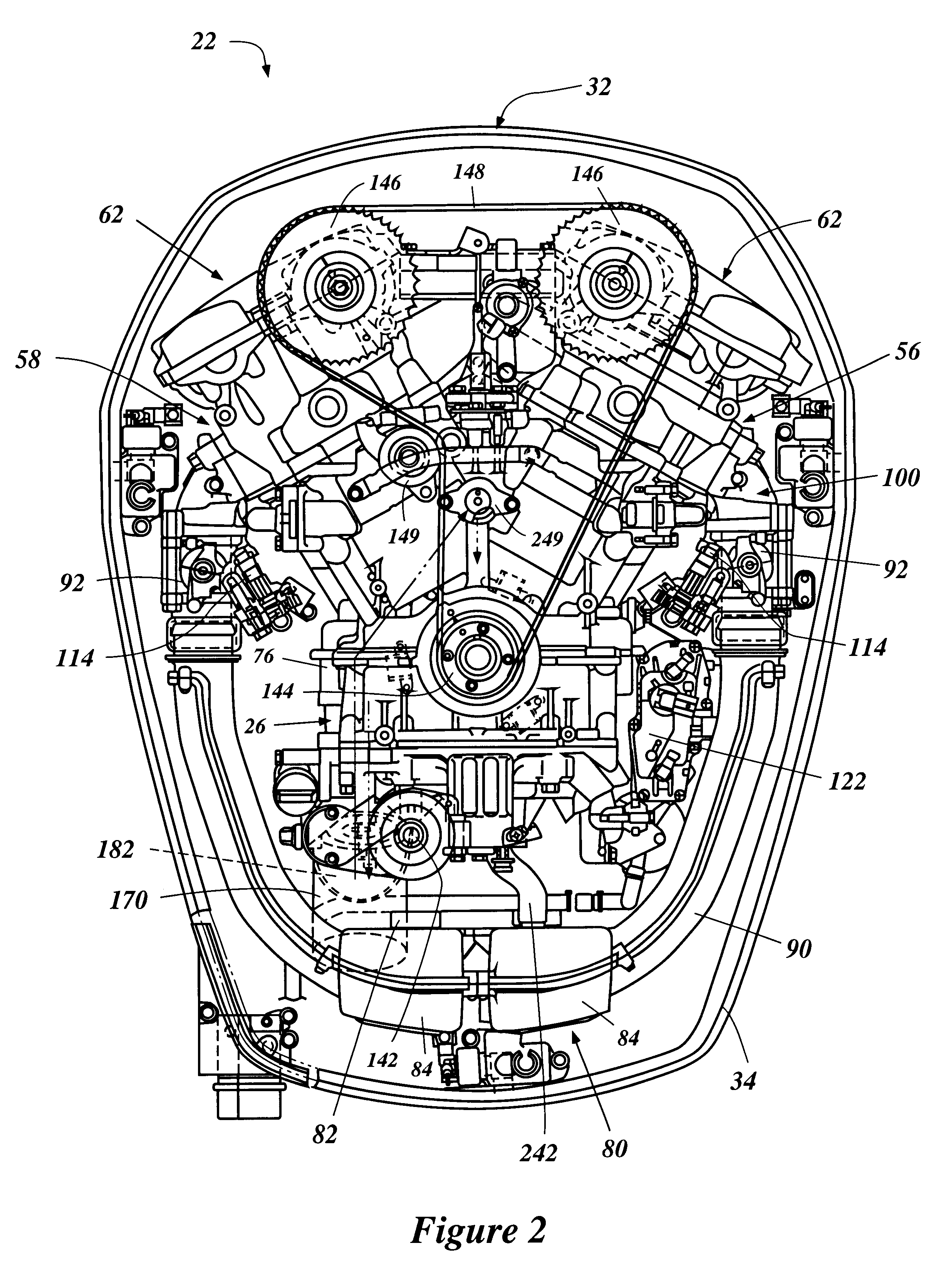

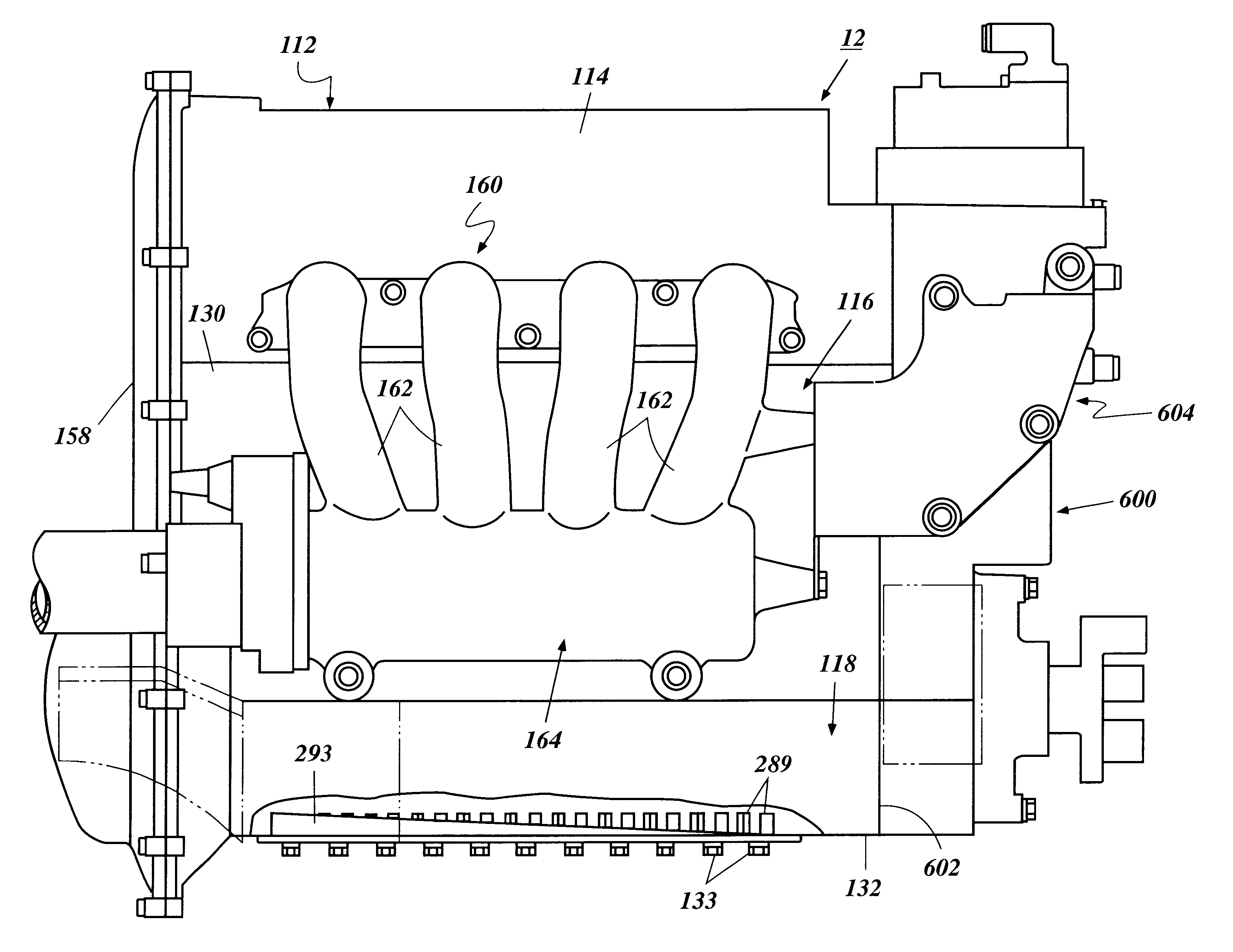

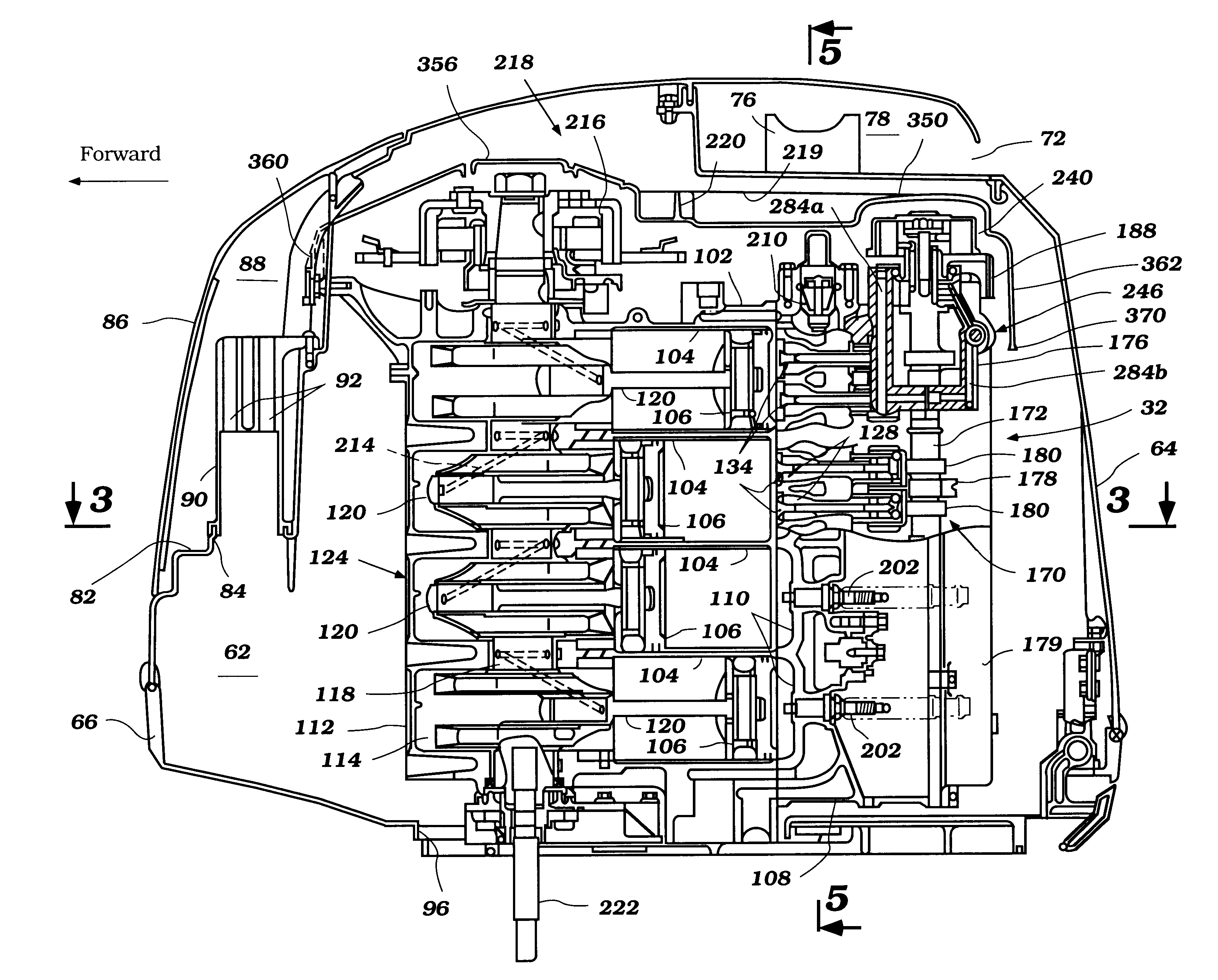

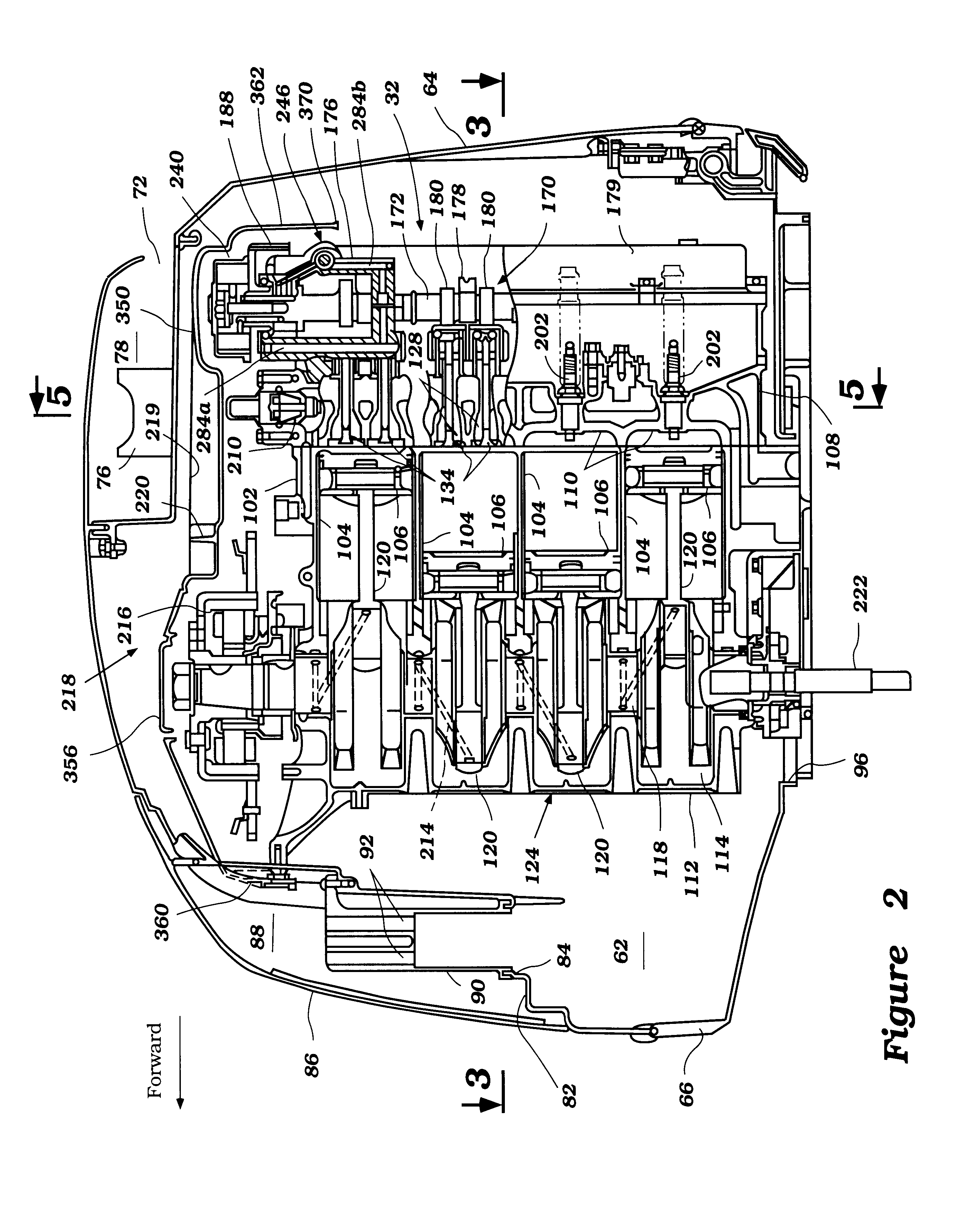

Outboard motor cooling and exhaust system

InactiveUS6302754B1Simplify the assembly processLiquid coolingPower plants using condensersCombustion chamberCylinder head

An outboard motor features a v-type internal combustion engine having a generally vertically extending crankshaft. Exhaust gases from combustion chambers are routed through a set of exhaust manifolds positioned within the valley defined by the two banks of cylinders. The exhaust flow is merged within a passage formed in the cylinder block prior to passing the exhaust flow into a passage formed within an exhaust guide plate to which the engine is mounted. The merged flow passage is positioned to allow a compact outboard motor construction. The motor also features a cooling pattern by which the exhaust manifold runners, the exhaust manifold, the cylinder head, the valley and the cylinders are cooled in that order.

Owner:SANSHIN KOGYO CO LTD

Fuel filter for engine

InactiveUS6224439B1Easy to checkAccurate inductionPower plants using condensersOutboard propulsion unitsFuel filterInternal combustion engine

A fuel filter for an internal combustion engine suitable for detecting water accumulated therein. The fuel filter has a holder that is mounted on the engine and holds a filter body. A vessel is detachably affixed to the holder. There is a space between the end of the filter body and the bottom of the vessel. An inlet and outlet are provided for inducing fuel into and discharging it from the vessel. The inlet and outlet are connected relative to each other through the filter body for admitting flow of the fuel. In one feature of this invention, a water detection mechanism is placed under the filter body in the vessel. In another feature of this invention, the vessel is made of a transparent material. In a further feature, the holder is mounted on the engine via a damping member.

Owner:SANSHIN KOGYO CO LTD

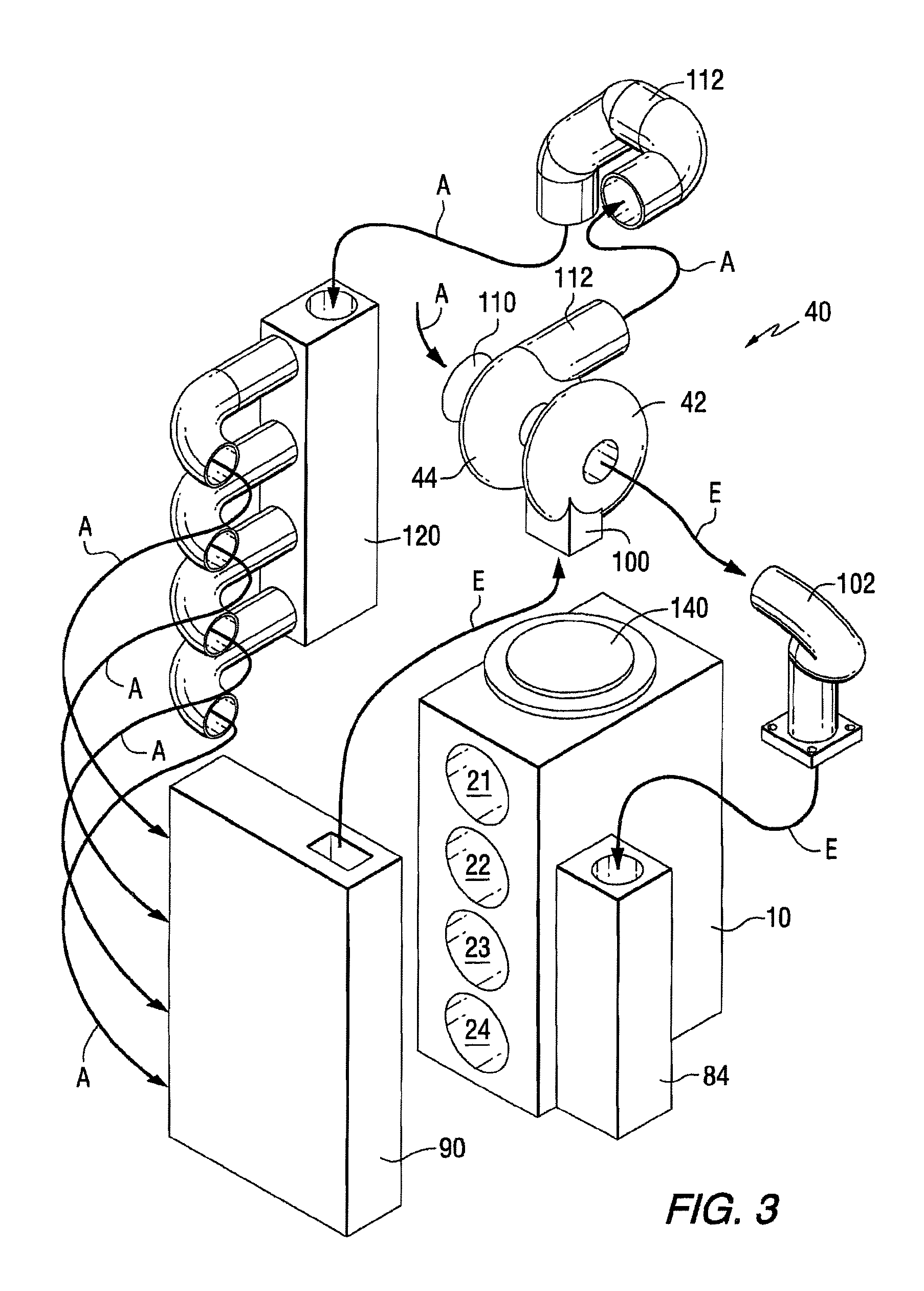

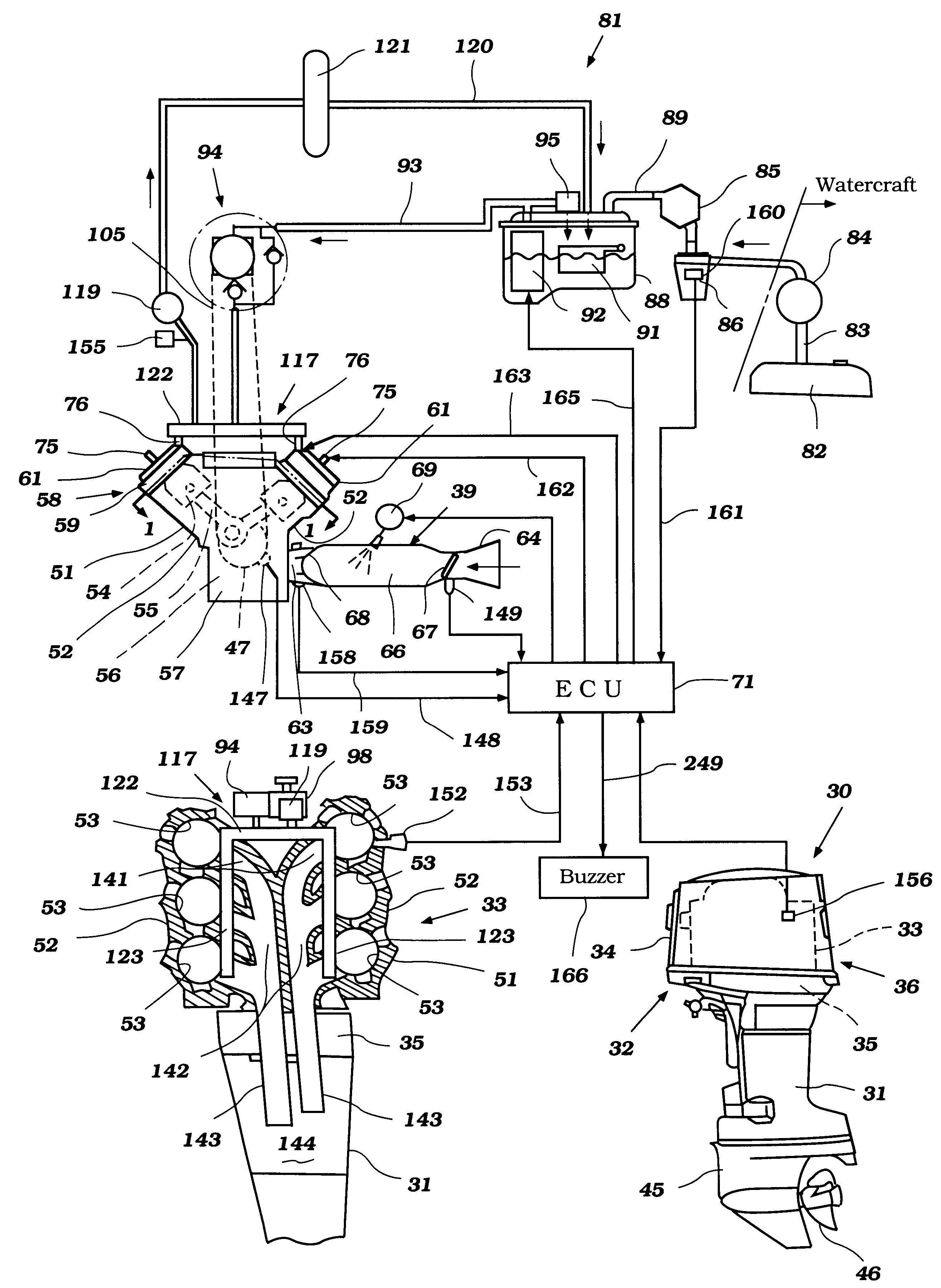

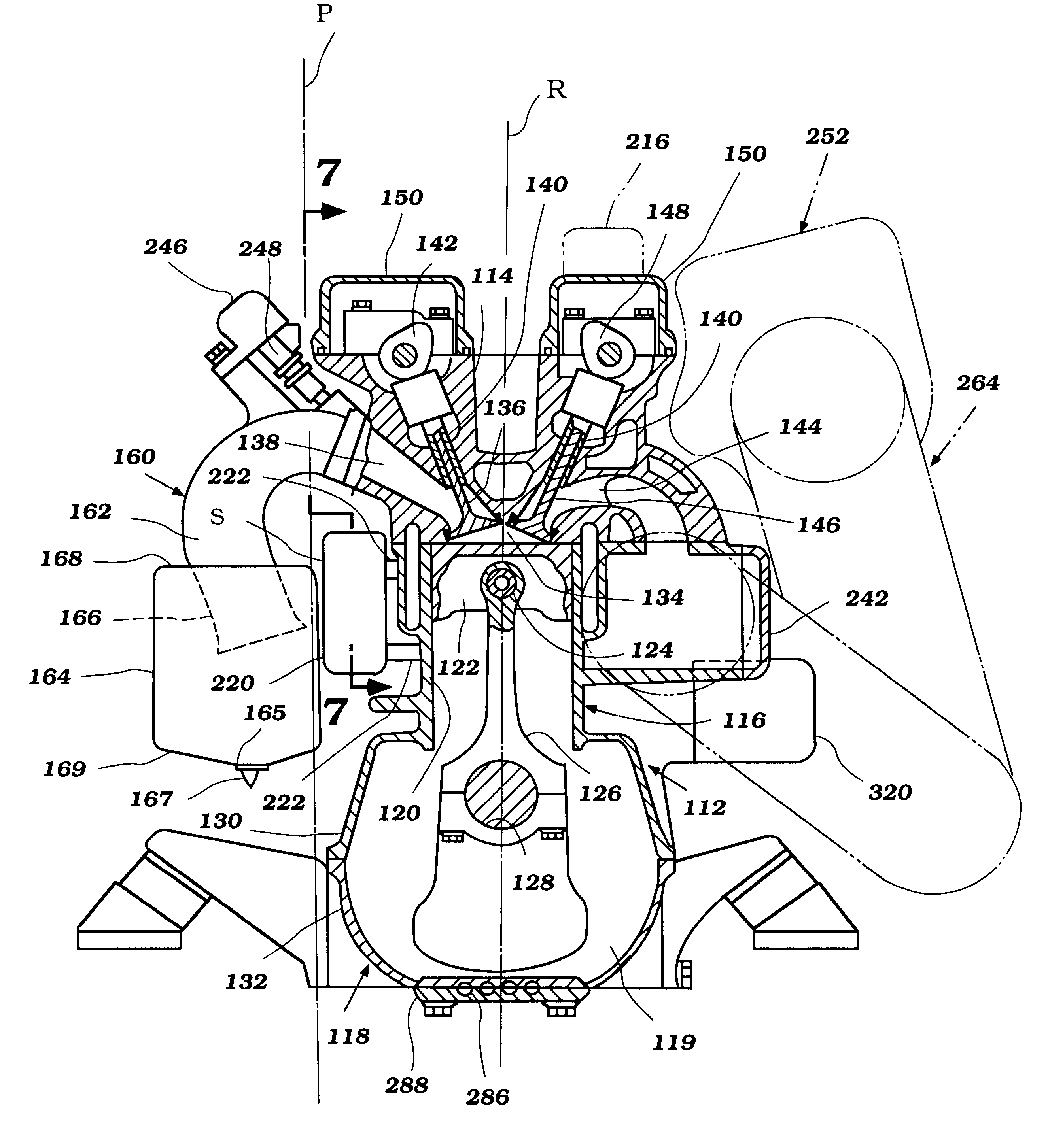

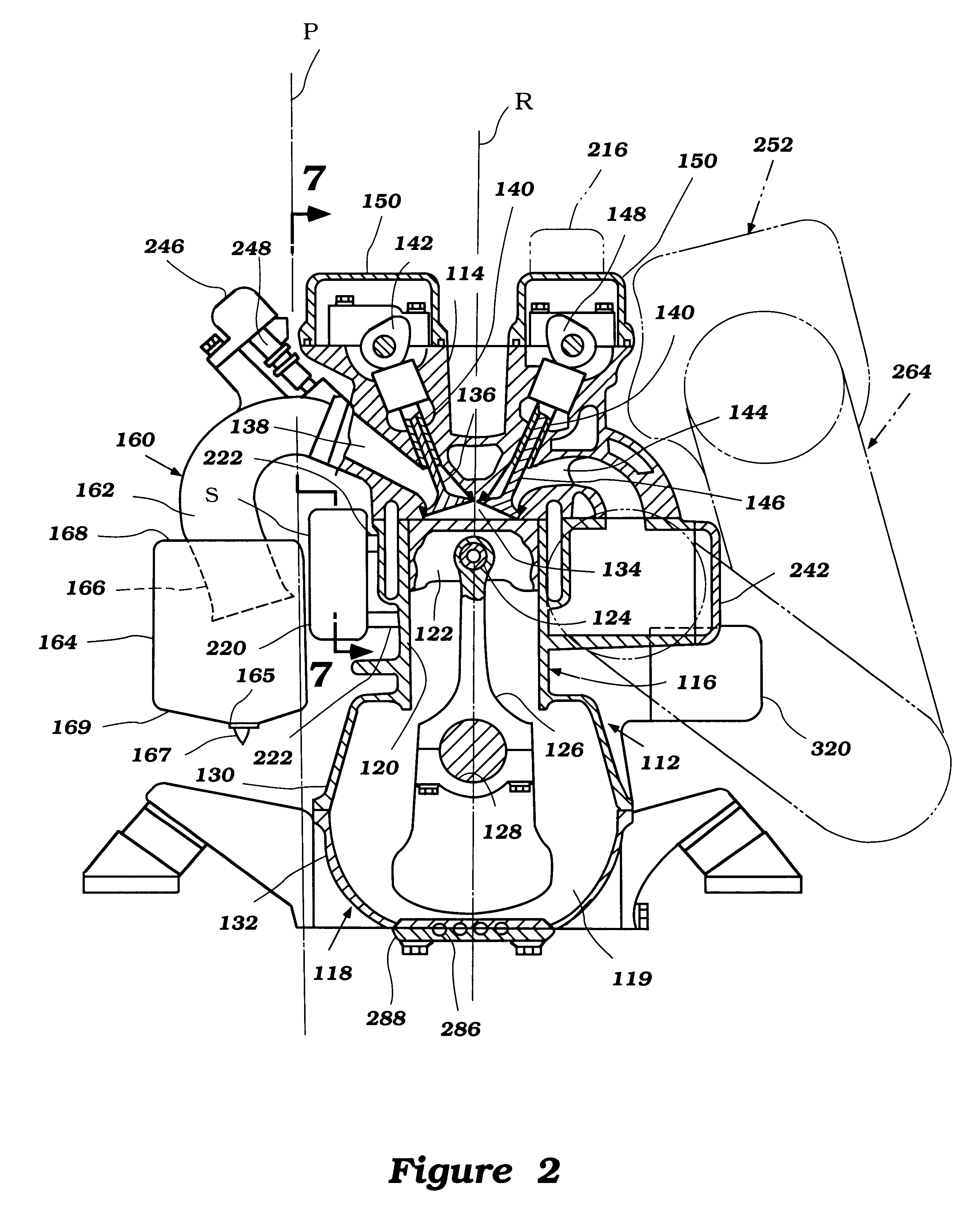

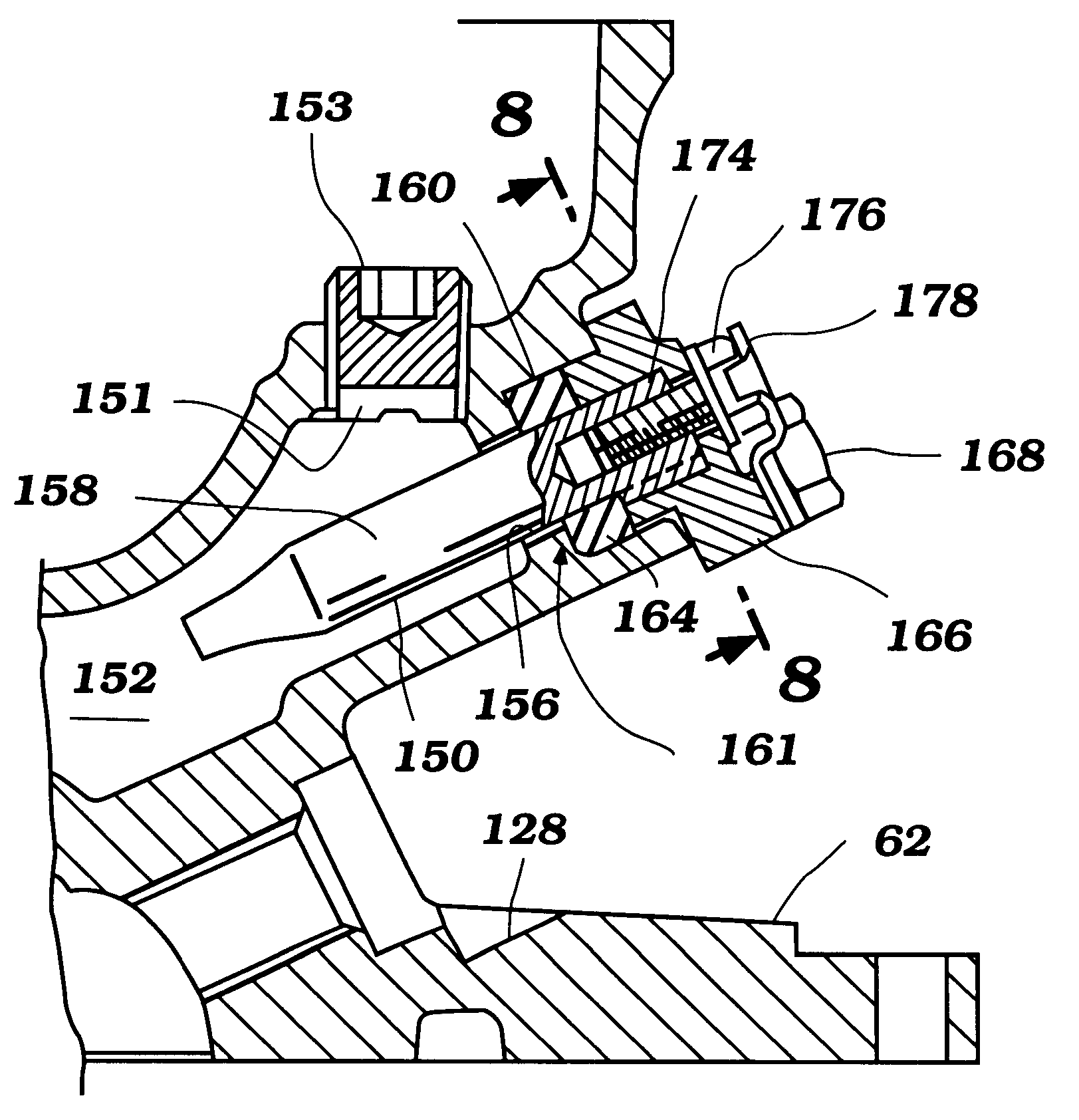

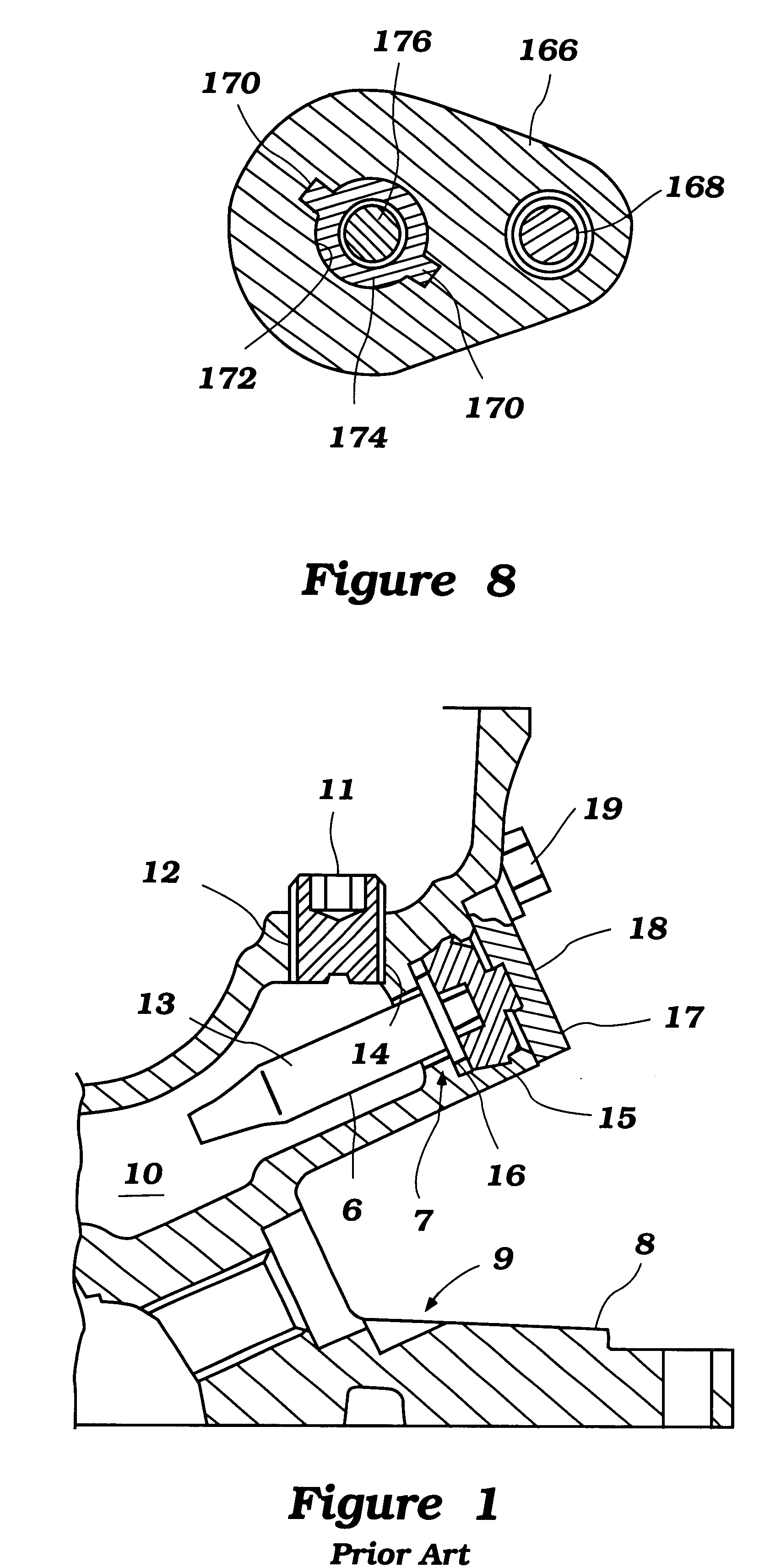

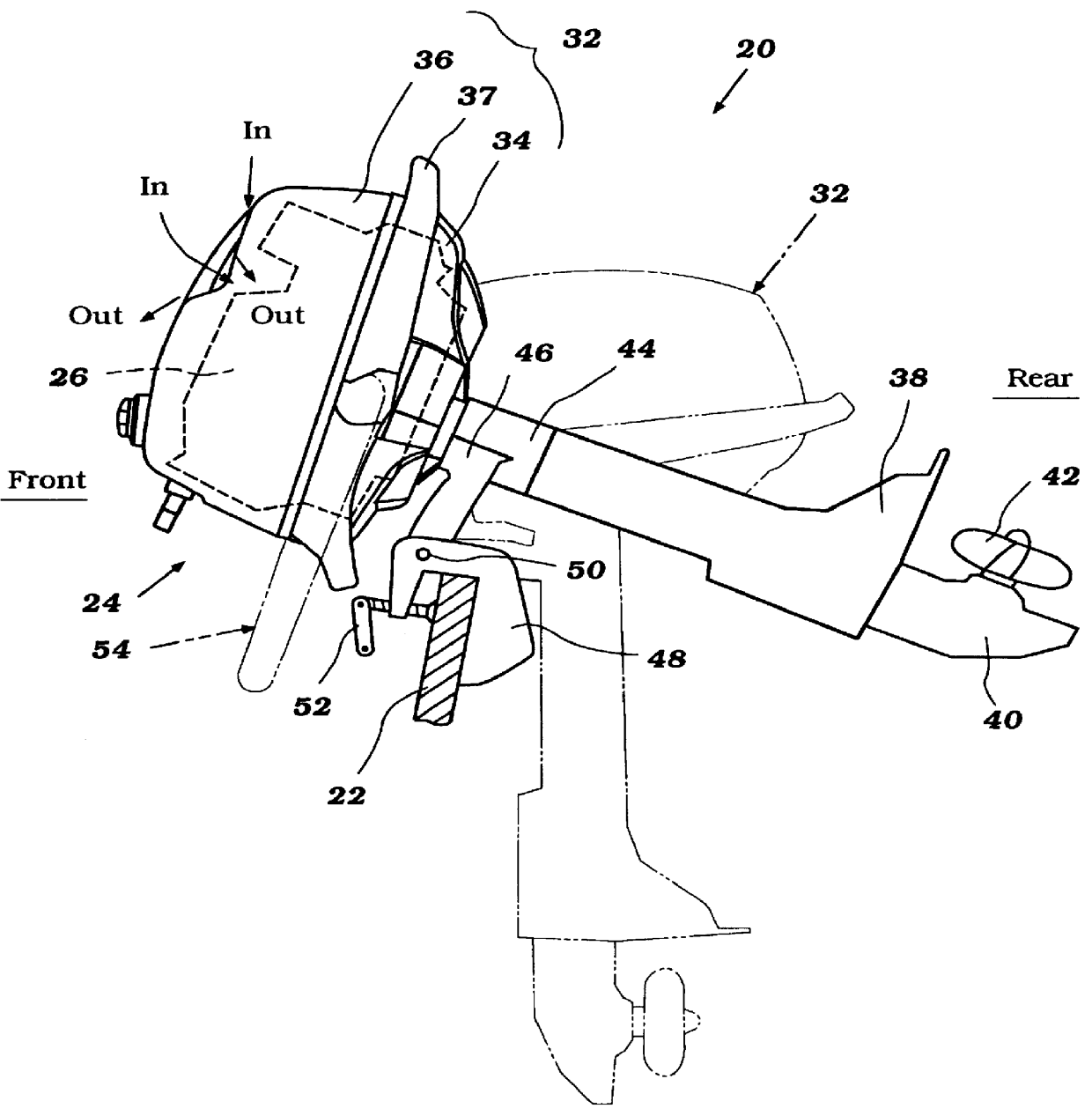

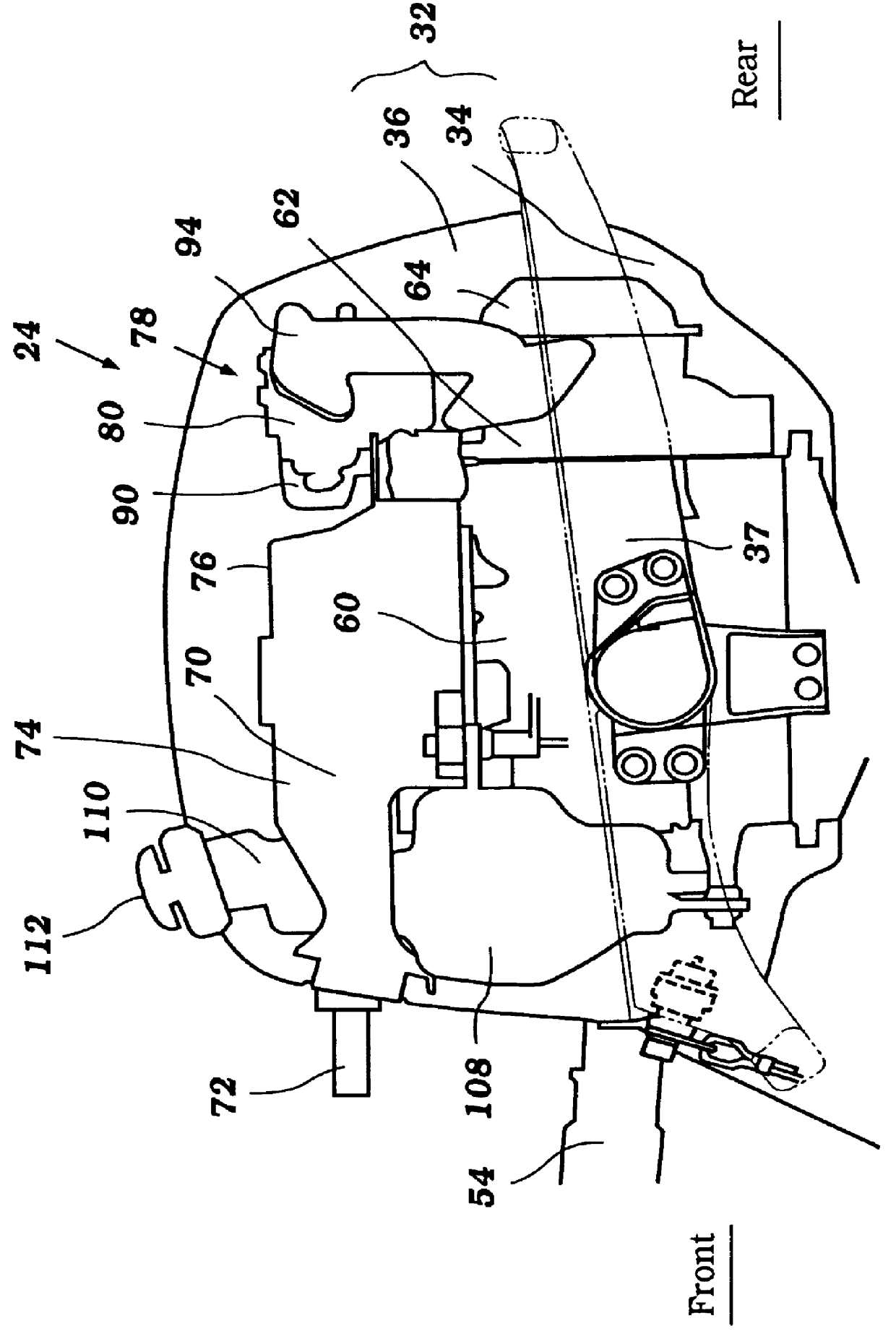

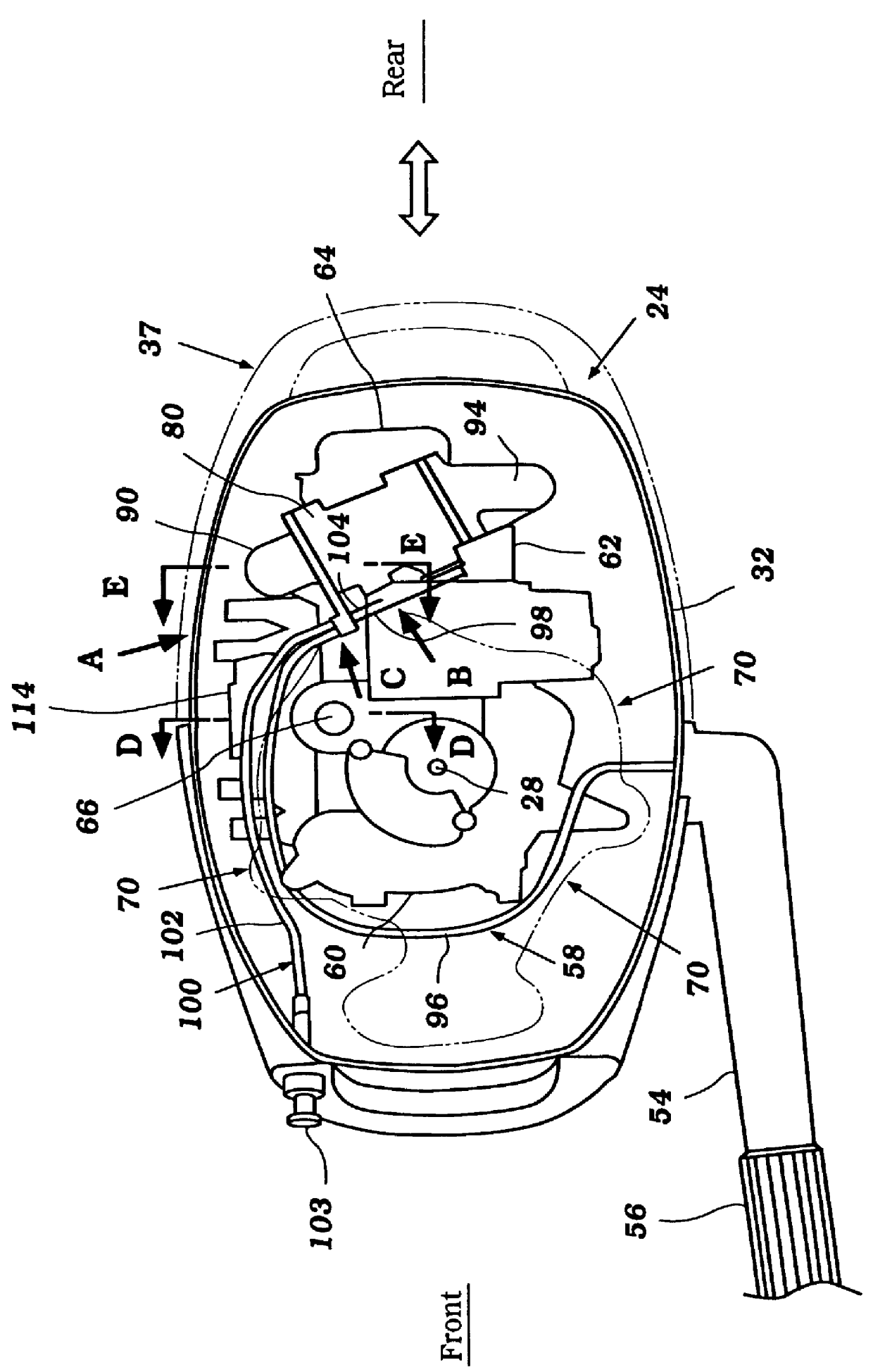

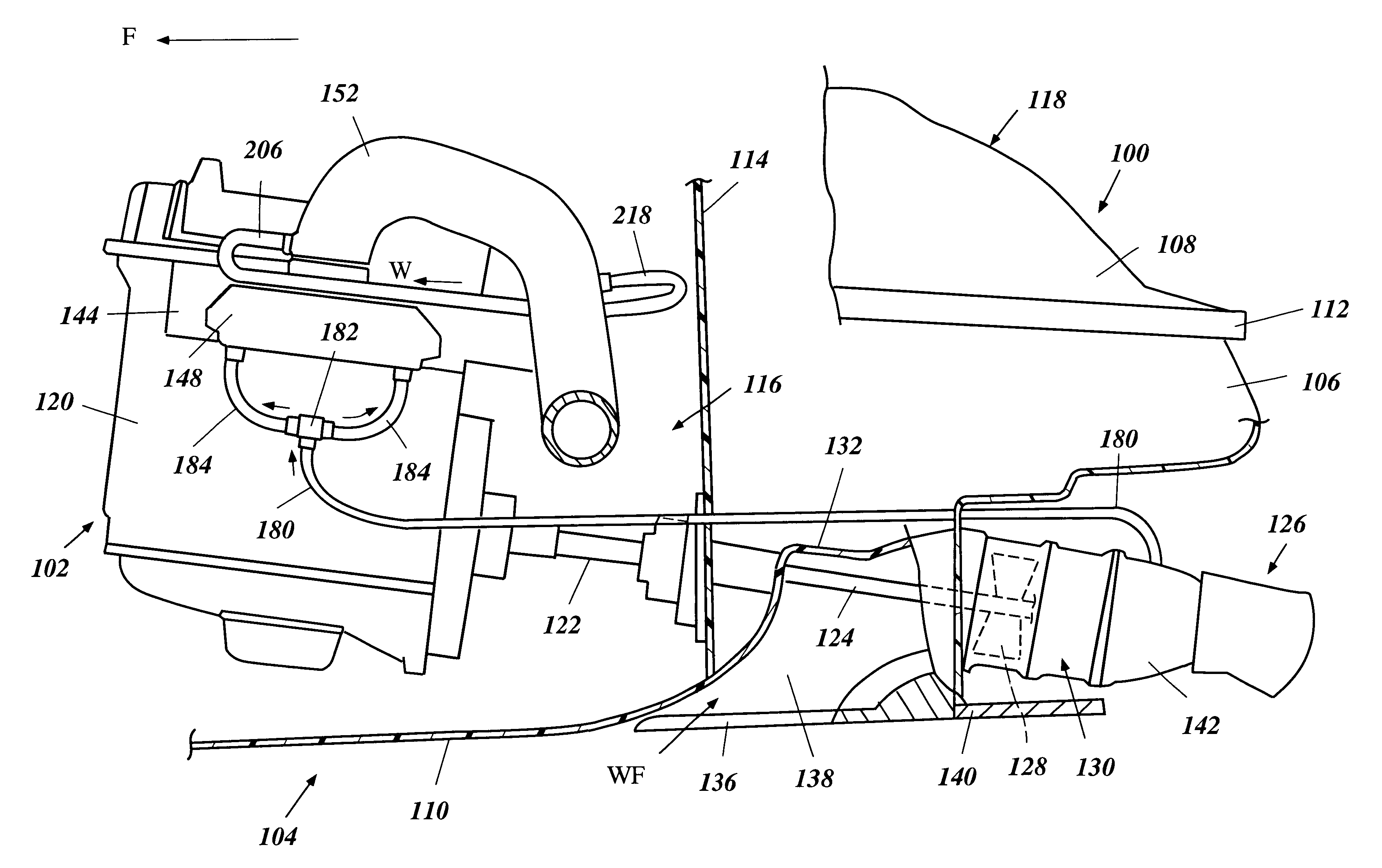

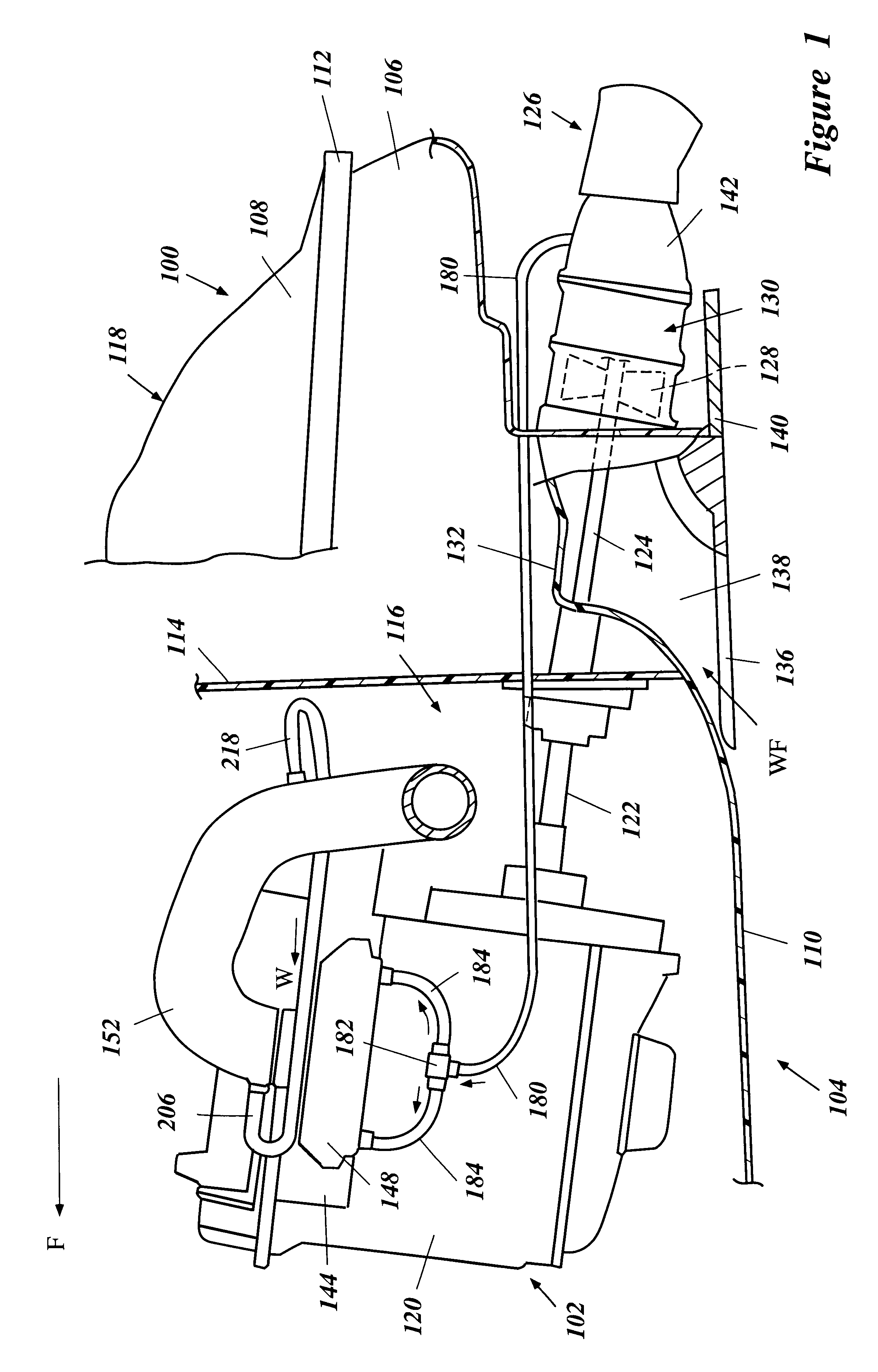

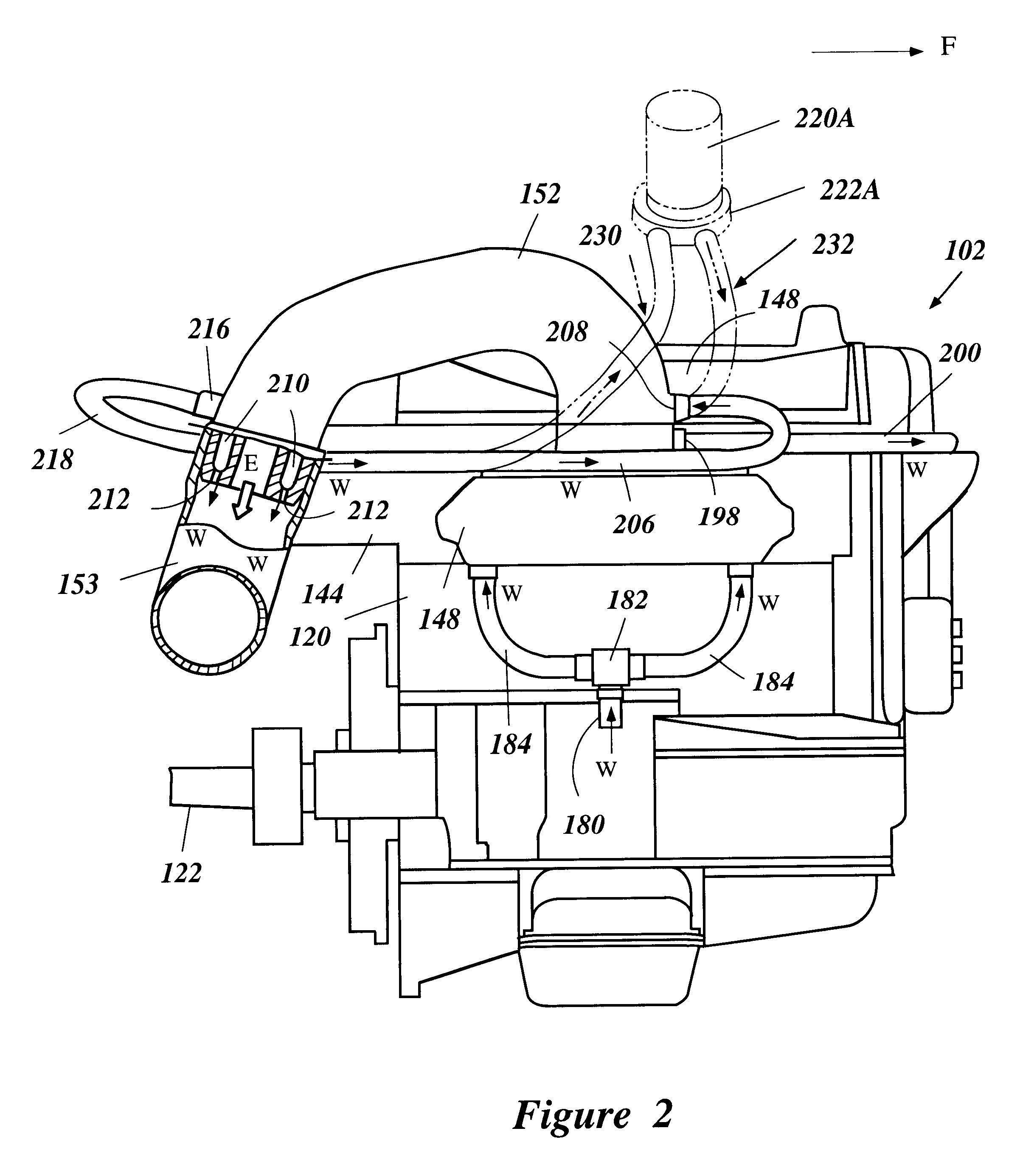

Engine component arrangement for outboard motor

InactiveUS6450847B1More compact motor constructionPower plants using condensersMachines/enginesWatercraftEngineering

An outboard motor has various electrical components mounted on a front side of the crankcase chamber. The crankcase chamber is connected by an electrical line to a negative terminal of a battery in an associated watercraft in order to ground the crankcase chamber. Thus, the electrical components are easily grounded by being connected to the crankcase chamber. An intake silencer of the engine induction system is positioned adjacent the crankcase chamber and at least one of the electrical components is disposed between the silencer and the crankcase member. An oil filter mount is also disposed on the front side of the crankcase chamber. The mount is adapted so that the oil filter can be installed thereon and is tilted along an inclined axis.

Owner:SANSHIN KOGYO CO LTD

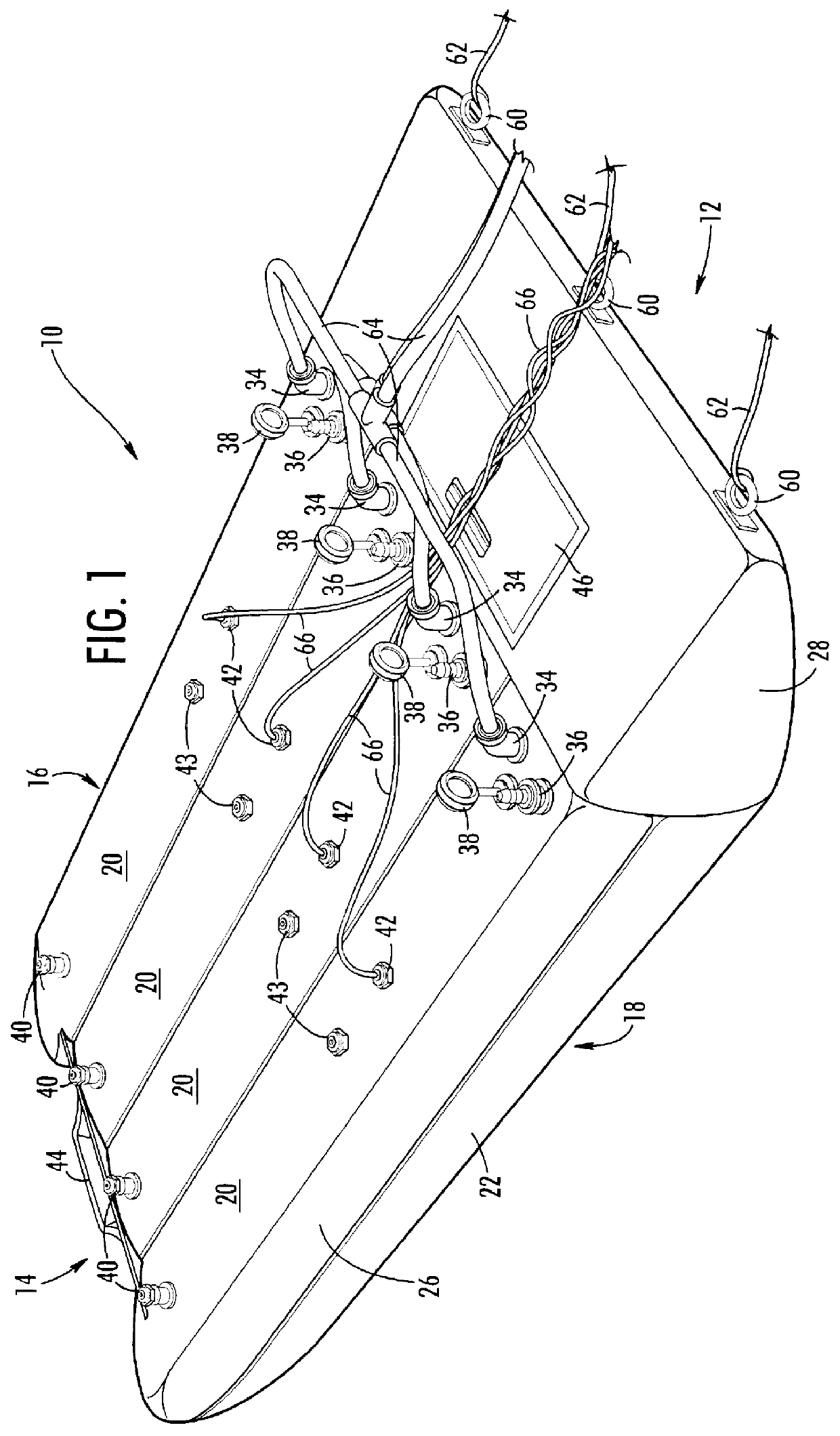

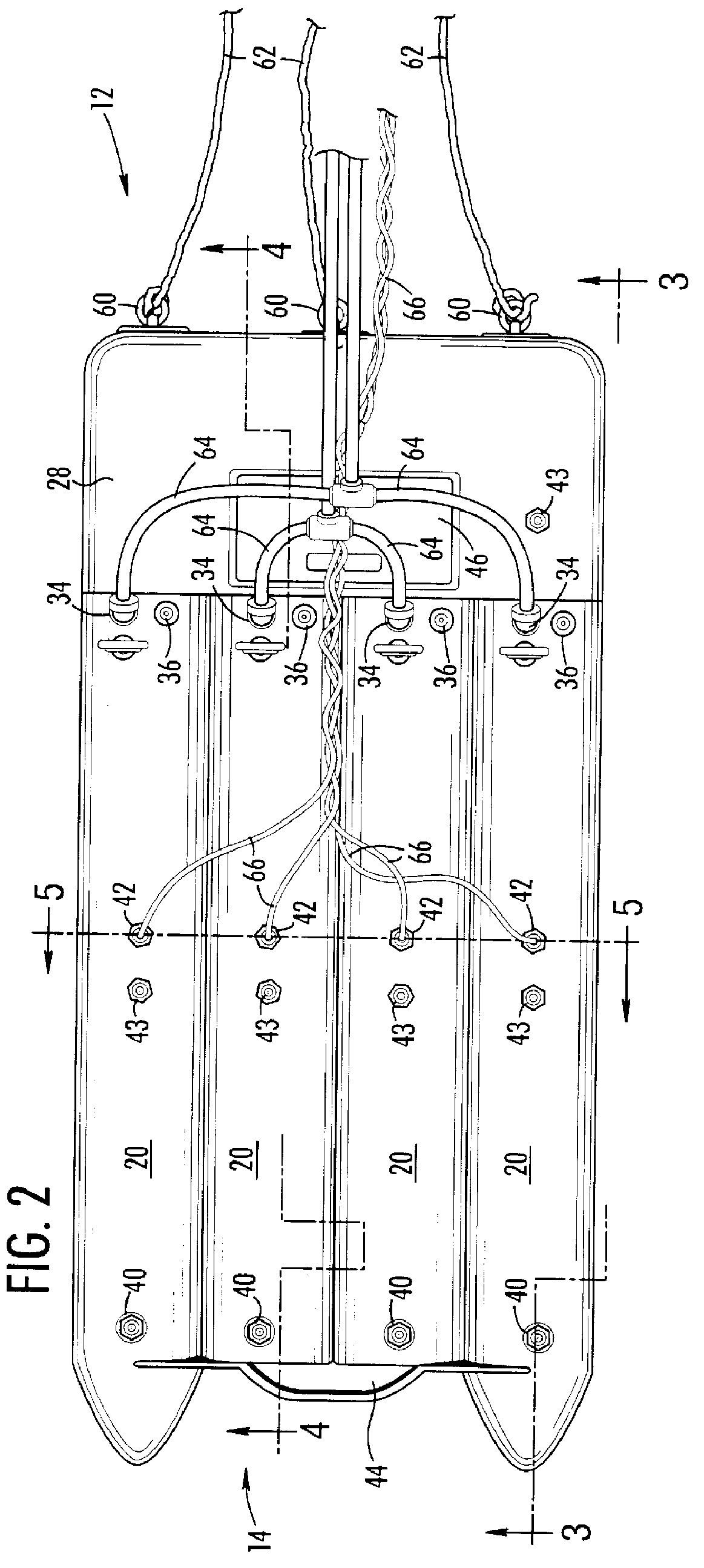

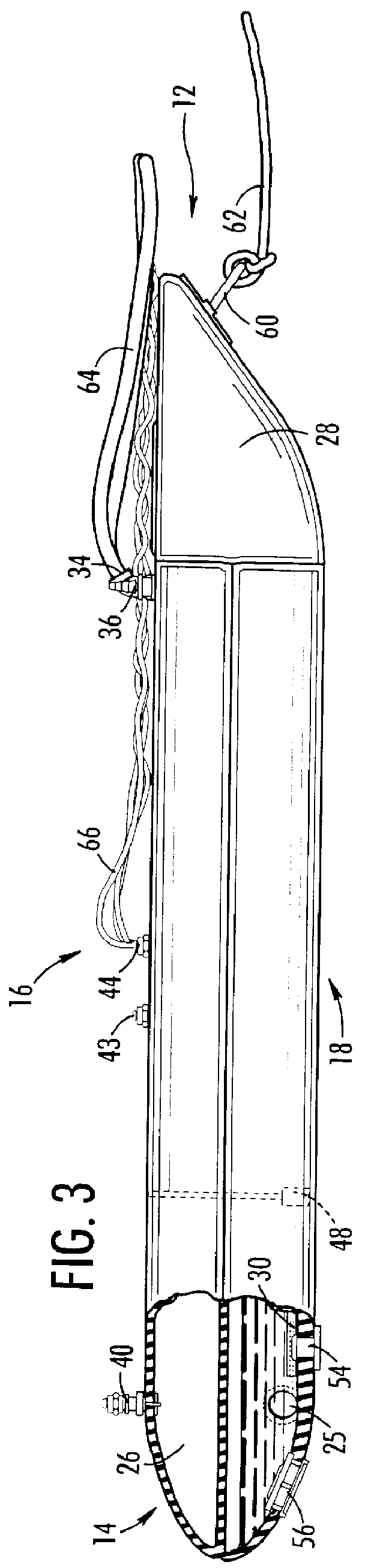

Floatable auxiliary fuel tank

A floatable fuel tank that is capable of serving as a barge or lifeboat / dingy. Tank comprises a plurality of bladders with each having a fuel chamber and air chamber running longitudinally from stern to a forward bladder. If used as a fuel storage device, tank is attached to boat using towing lines and fuel lines so boat consumes fuel held by fuel chambers. In emergency situations, tank is capable of use as a lifeboat by detaching towing lines, air lines and fuel lines and pumping fuel out of fuel chambers with air so that persons may reside on top of tank. Under normal conditions in this configuration, it could be used as a dingy for normal transportation to and from a boat at anchor.

Owner:LESESNE EDWARD R

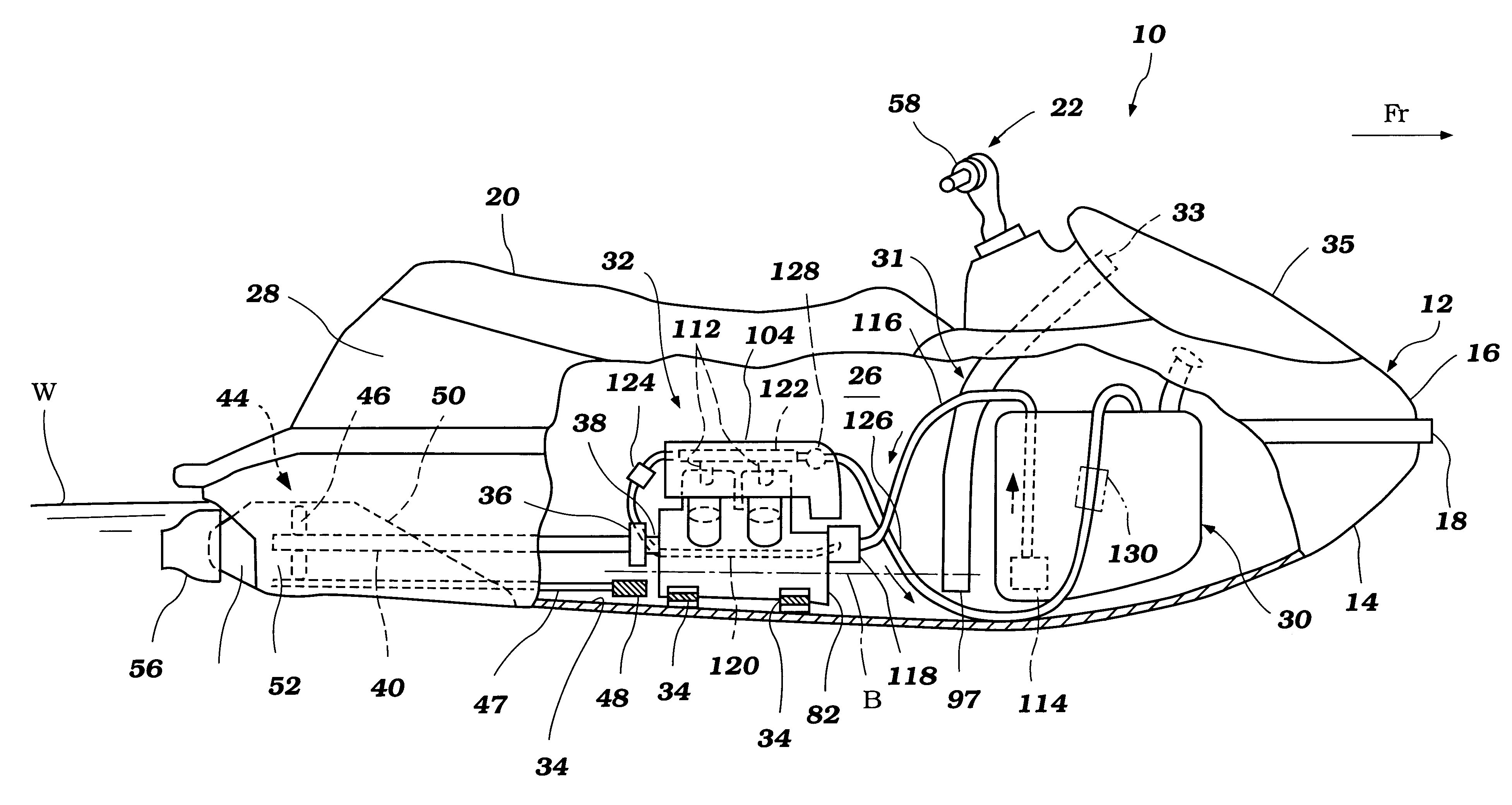

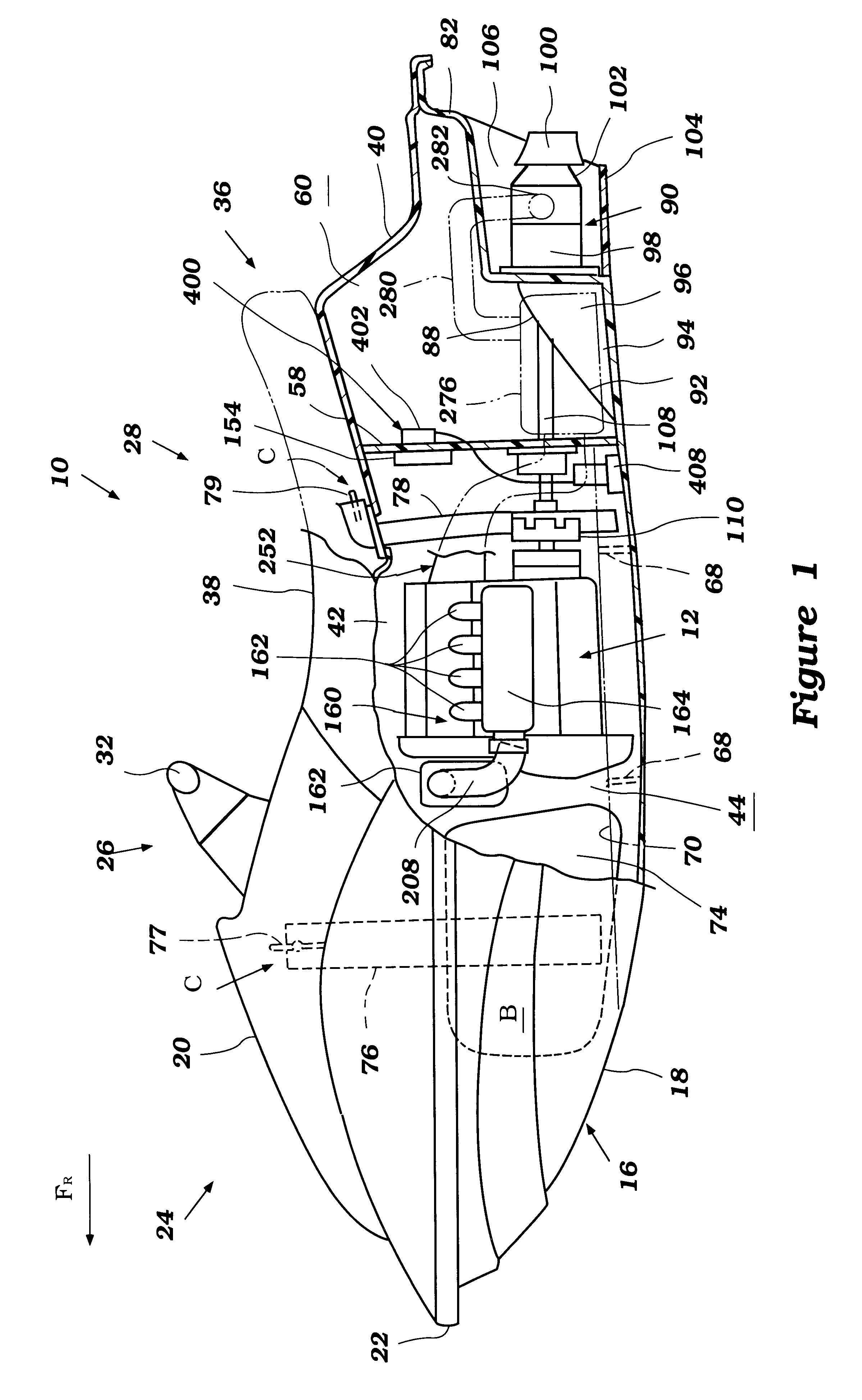

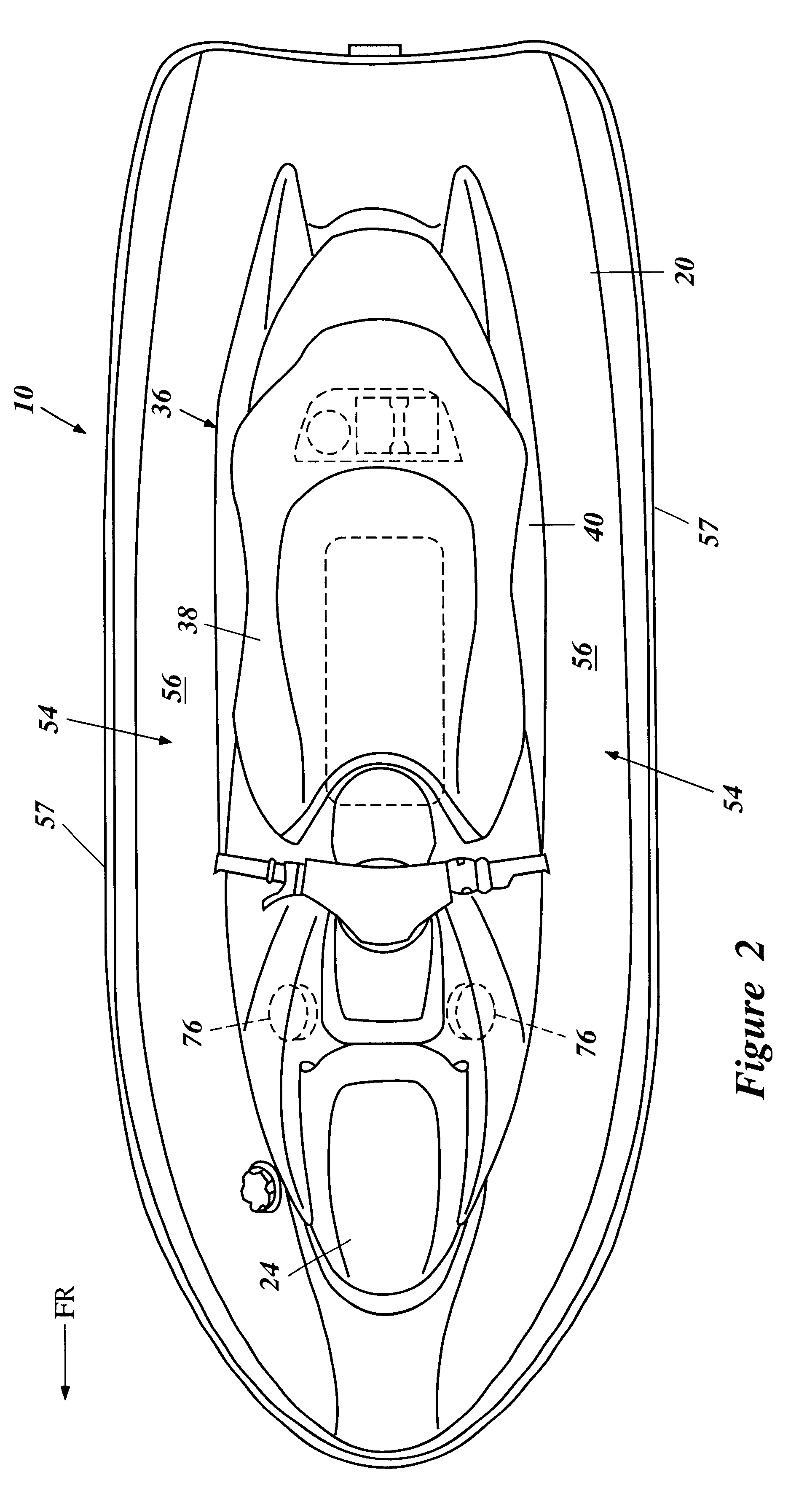

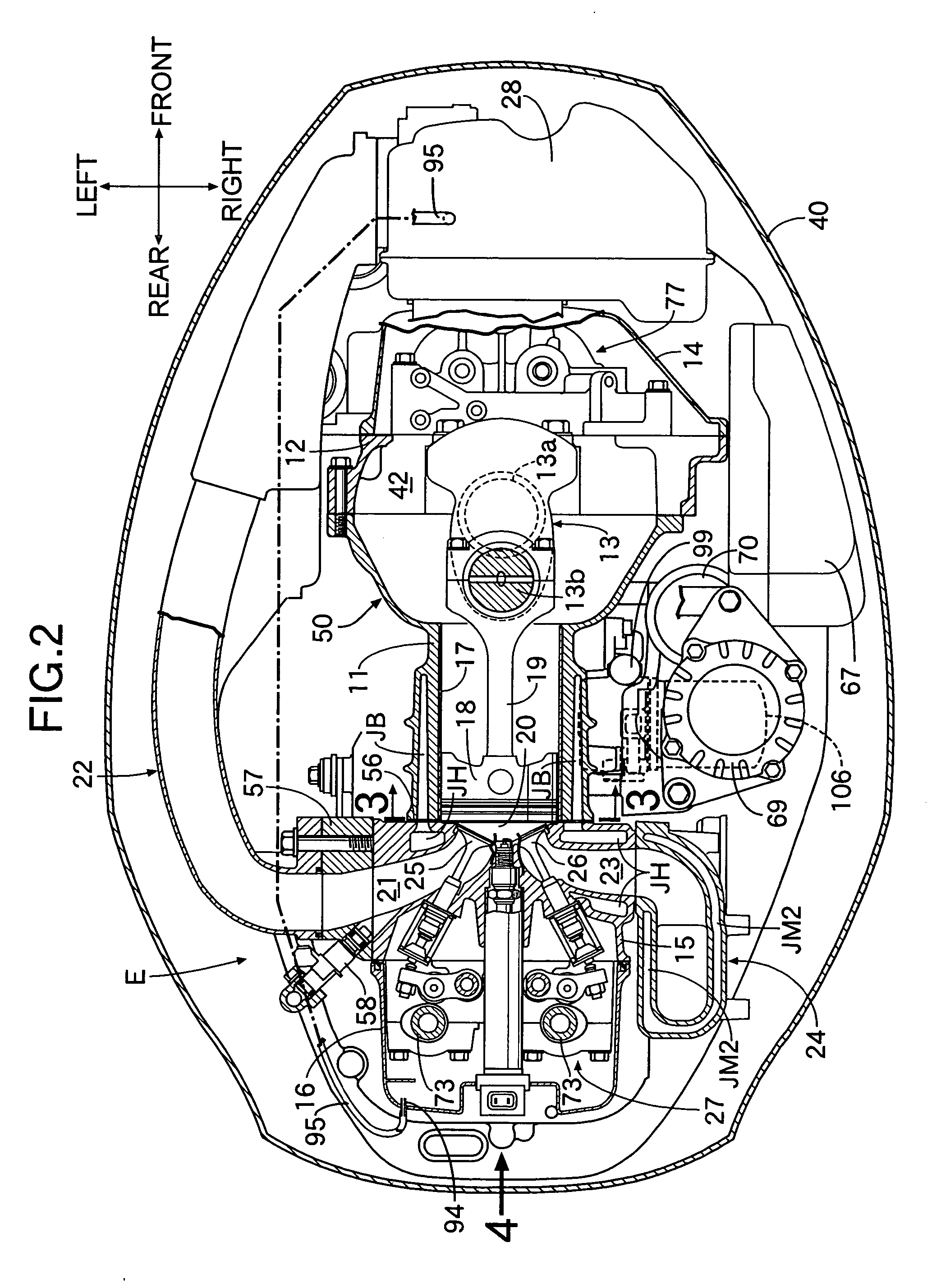

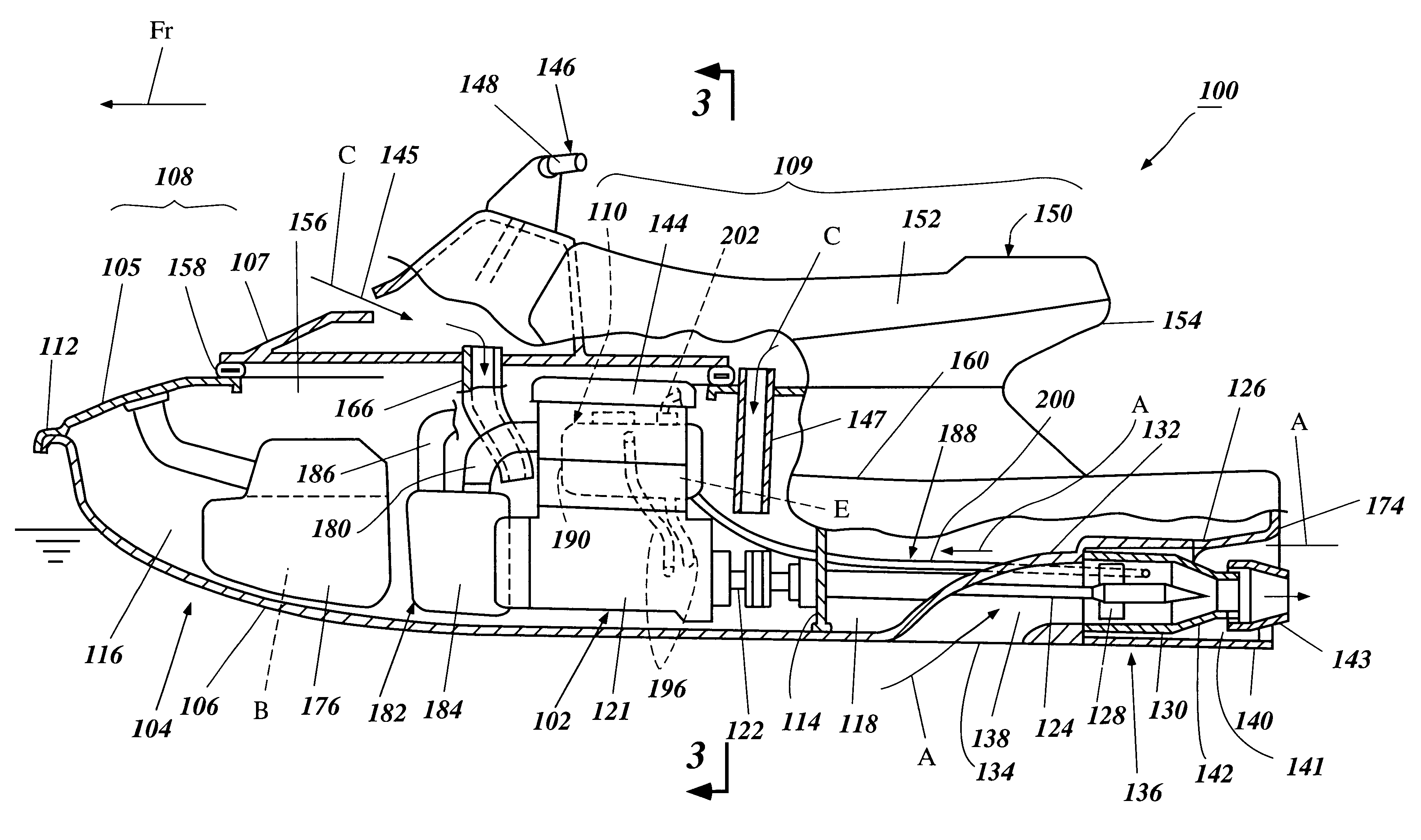

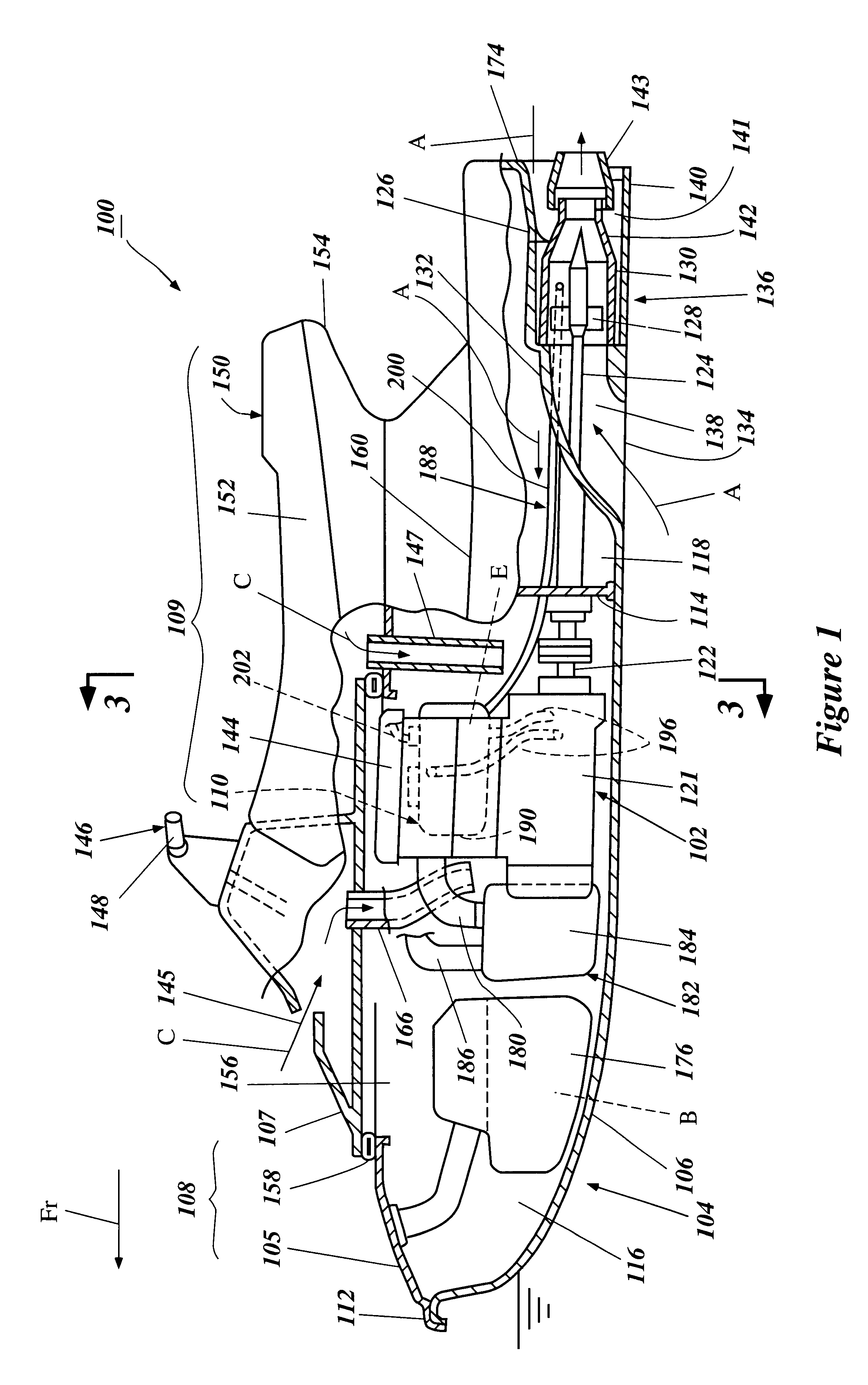

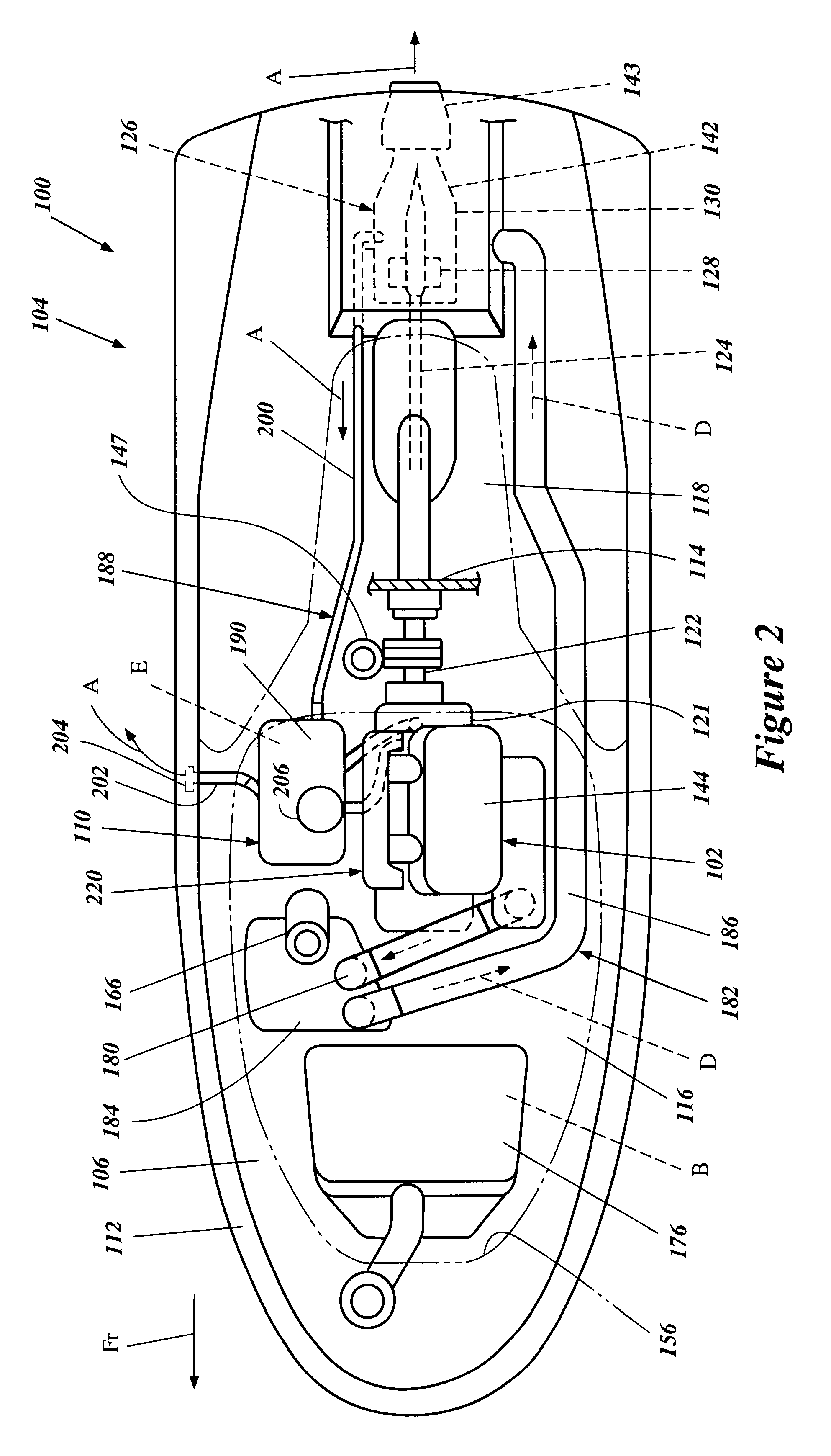

Engine and personal watercraft equipped with engine

InactiveUS6889651B2Efficient arrangementEfficiently dead spacePower plants using condensersLubrication of auxillariesCylinder headFuel tank

Owner:KAWASAKI MOTORS LTD

Fuel system and arrangement for small watercraft

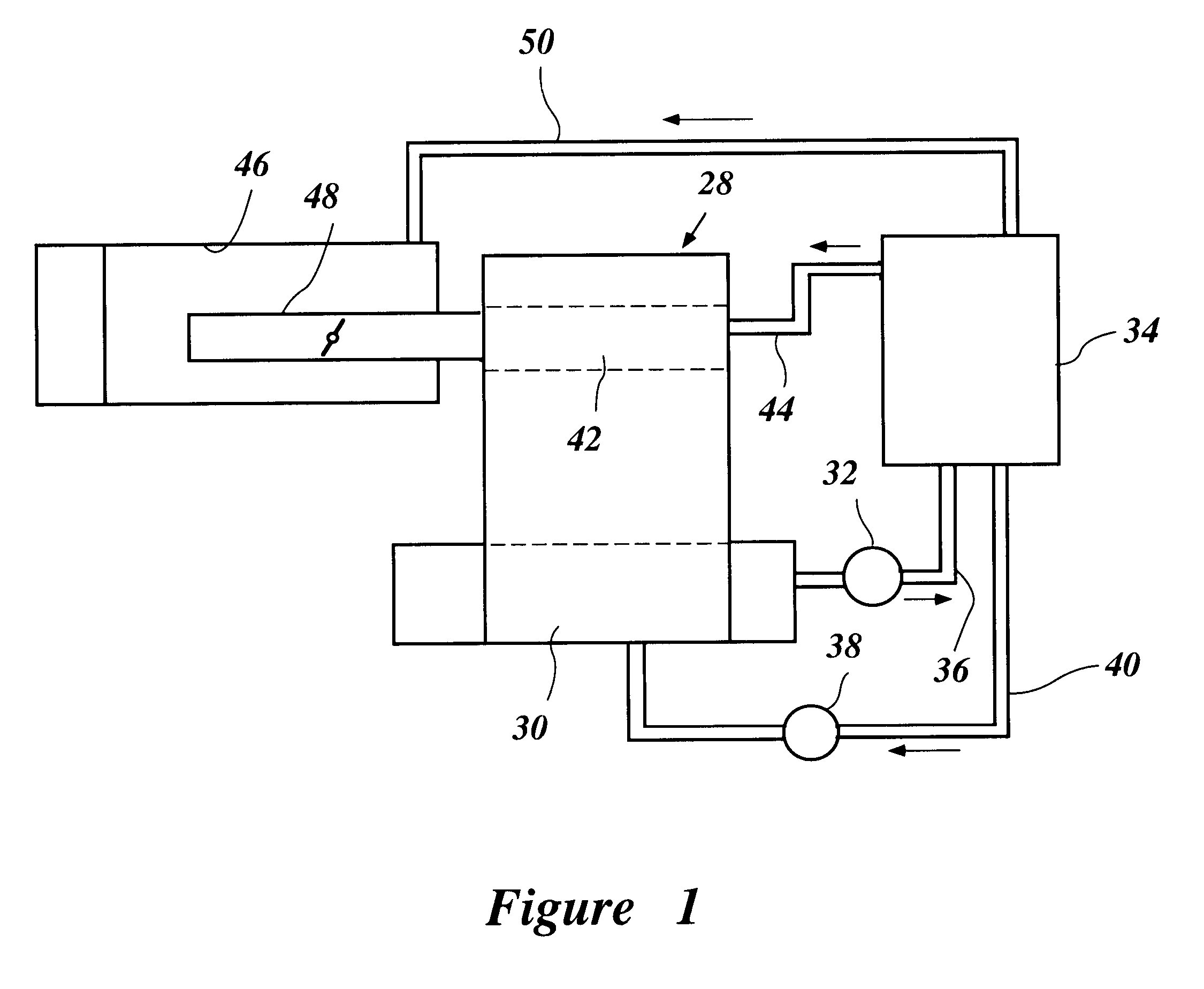

InactiveUS6244915B1Power plants using condensersInternal combustion piston enginesWatercraftOperating temperature

A small watercraft includes an improved fuel supply system that is configured and arranged to provide a compact engine design while promoting air cooling of at least a portion of the fuel supply system. In one mode, a fuel pump of the system is at least partially located within an air flow path between an outlet of an air duct and an inlet of the engine induction system. The air flow cools the fuel pump to reduce its operating temperature. As a result, the durability and performance of the fuel pump is improved despite the fuel pump lying in close proximity to the engine's exhaust system. Shock-absorbent mounts also couple at least a portion of the fuel supply system (e.g., the fuel pump and a fuel delivery rail) to the hull of the watercraft. These fuel system components consequently experience lessened impact when the watercraft skips over the body of water on which it is planing, and are thus less susceptible to breakage.

Owner:YAMAHA MOTOR CO LTD

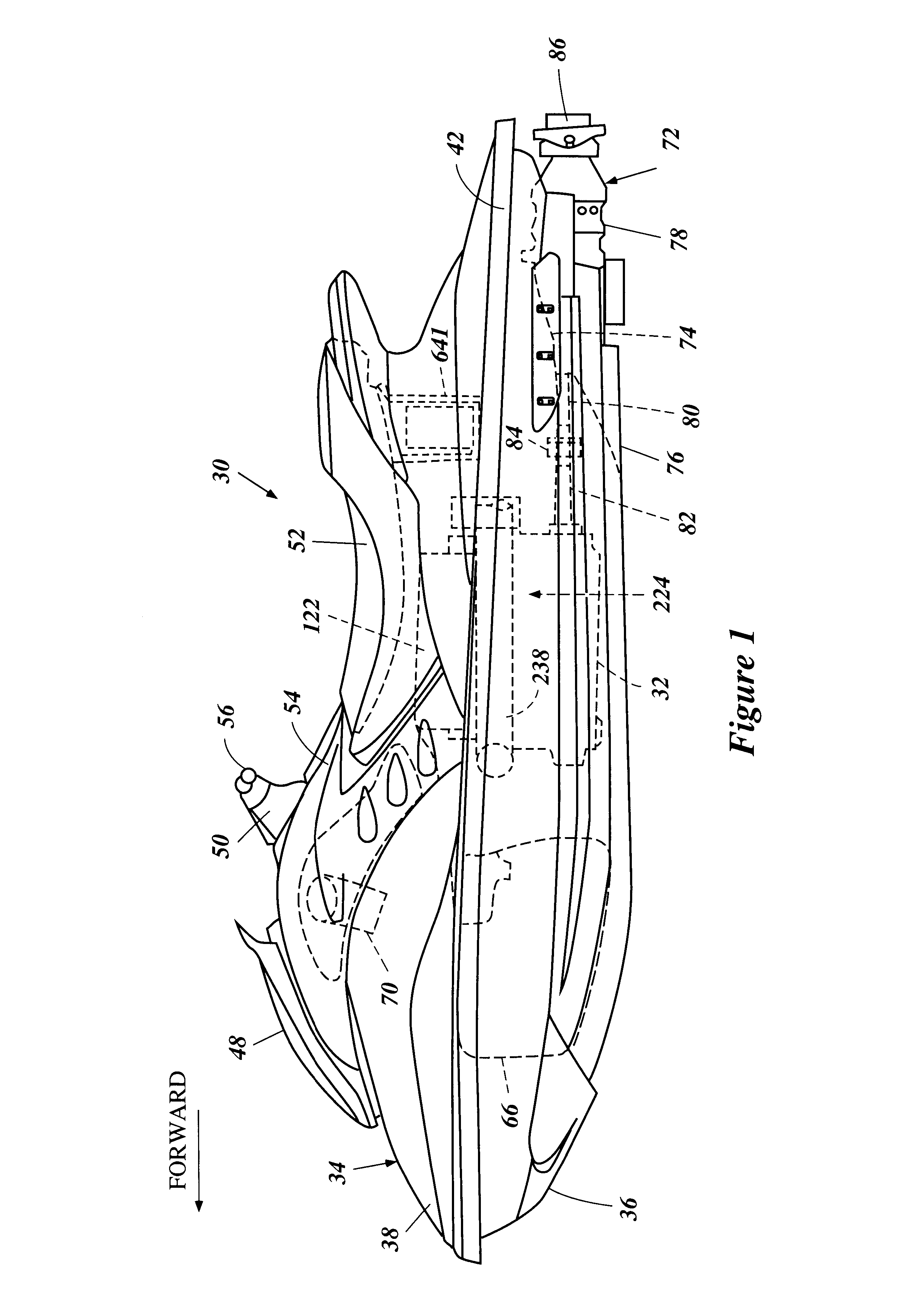

Vapor system arrangement for marine engine

A personal watercraft features a hull defining an engine compartment. An engine is mounted within the engine compartment. The engine comprises a cylinder head, a cylinder body and a crankcase. An induction system supplies air to the engine for combustion. The induction system comprising an intake box, an intake silencer, and a set of intake pipes that extend from the intake box to the engine. The intake pipes extend upward and inward toward the engine. A protective chamber is formed by an inside surface of the intake box, an outside surface of the engine and a lower surface of the pipes. A vapor separator is disposed within this protective chamber. The protective chamber can be augmented by an overhanging portion of the cylinder head, a protrusion from the cylinder body or other extensions from the intake box.

Owner:YAMAHA MOTOR CO LTD

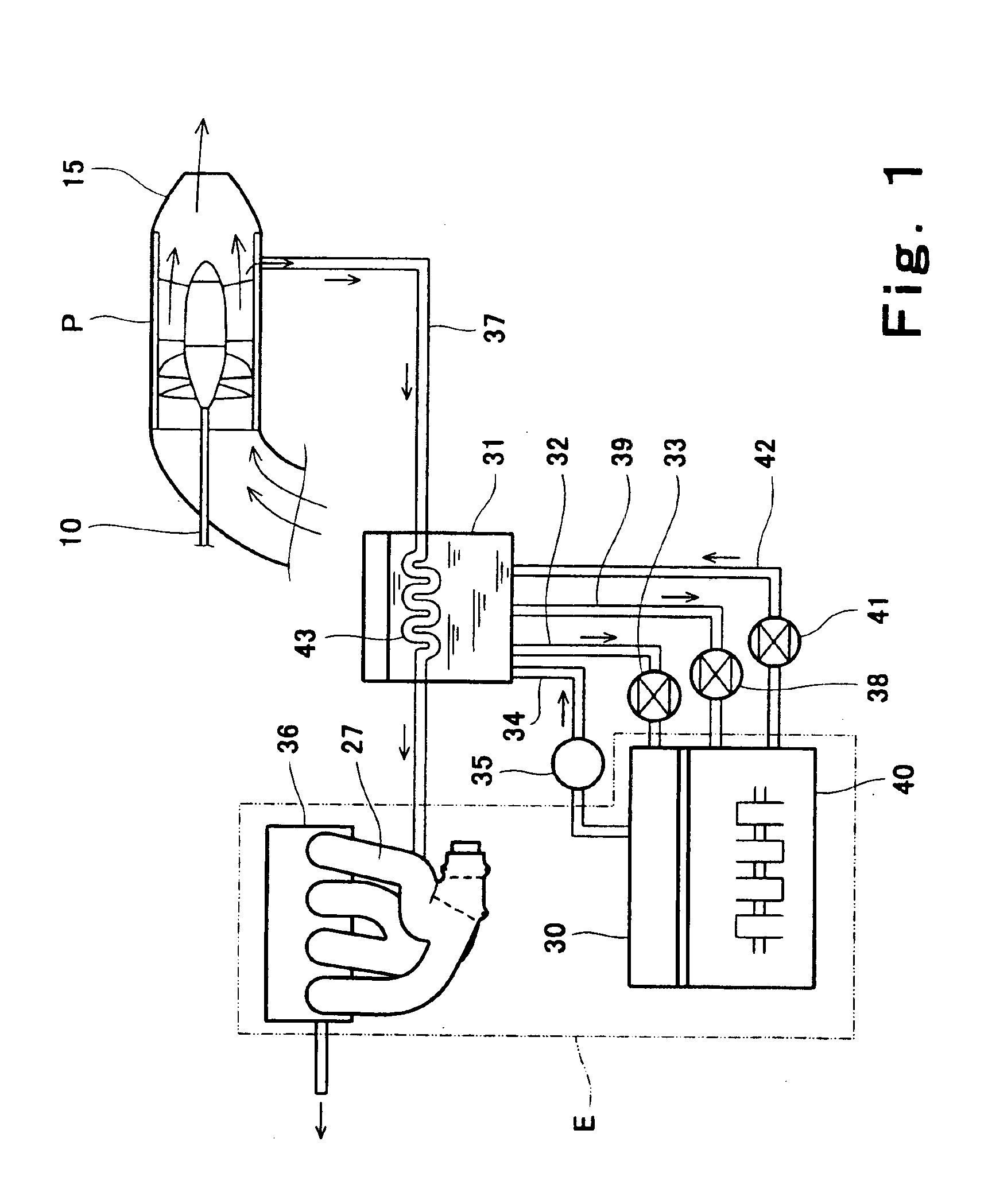

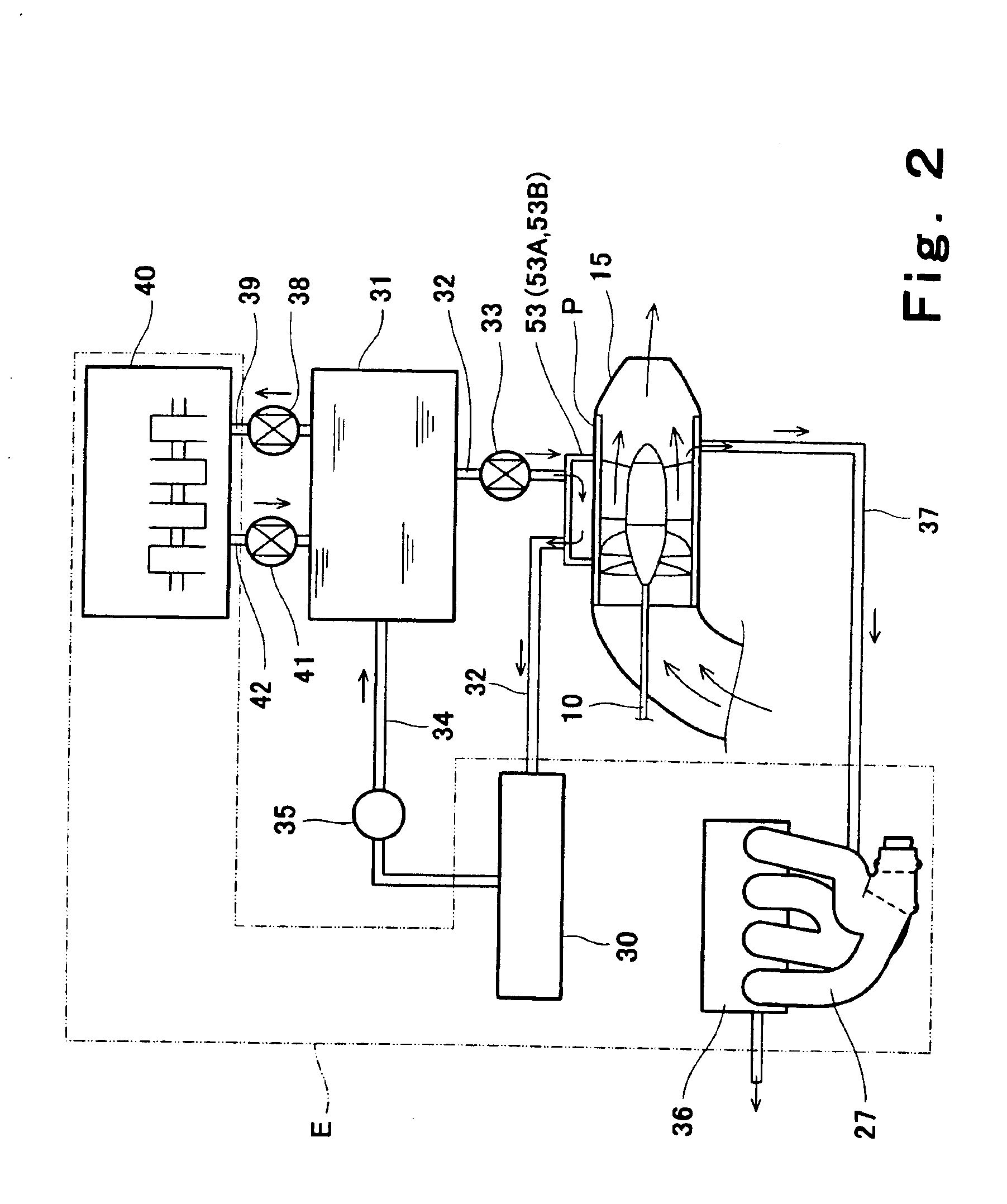

Outboard motor cooling and exhaust system

InactiveUS6471559B2Simplify the assembly processLiquid coolingPower plants using condensersCombustion chamberCylinder head

An outboard motor features a v-type internal combustion engine having a generally vertically extending crankshaft. Exhaust gases from combustion chambers are routed through a set of exhaust manifolds positioned within the valley defined by the two banks of cylinders. The exhaust flow is merged within a passage formed in the cylinder block prior to passing the exhaust flow into a passage formed within an exhaust guide plate to which the engine is mounted. The merged flow passage is positioned to allow a compact outboard motor construction. The motor also features a cooling pattern by which the exhaust manifold runners, the exhaust manifold, the cylinder head, the valley and the cylinders are cooled in that order.

Owner:SANSHIN KOGYO CO LTD

Cowling assembly for outboard motor

A cowling assembly for an outboard motor includes an improved construction that can supply relatively cool air containing little if no water to the induction device and that can also supply air to cool engine components without reducing the charging efficiency. The outboard motor has an engine that includes an air induction device and is enclosed by the cowling. The induction device has an air inlet opening. The cowling assembly defines a closed cavity in which the engine is contained and has an air intake duct that introduces air into the cavity. The intake duct adjoins the inlet opening and has an opening opened to the cavity and positioned lower than a lower end of the inlet opening. In one form, the cowling assembly has at least one front air intake opening formed on a side surface of its front portion. A rear air intake opening is also formed on a rear surface of its rear end portion. The cowling front air opening primarily supplies air to the induction system, while the cowling rear air opening primarily supplies a cooling air flow across the engine.

Owner:SANSHIN KOGYO CO LTD

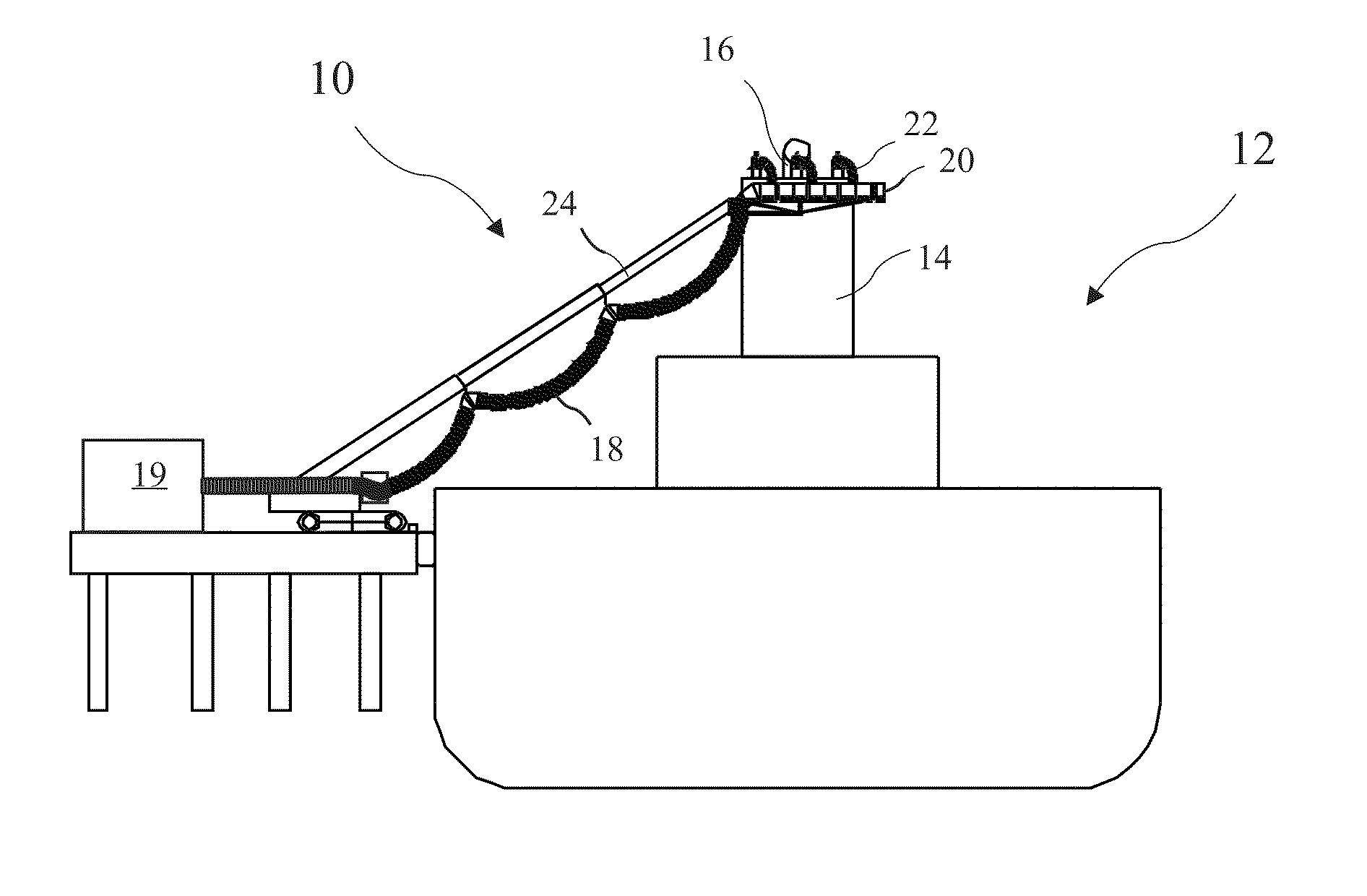

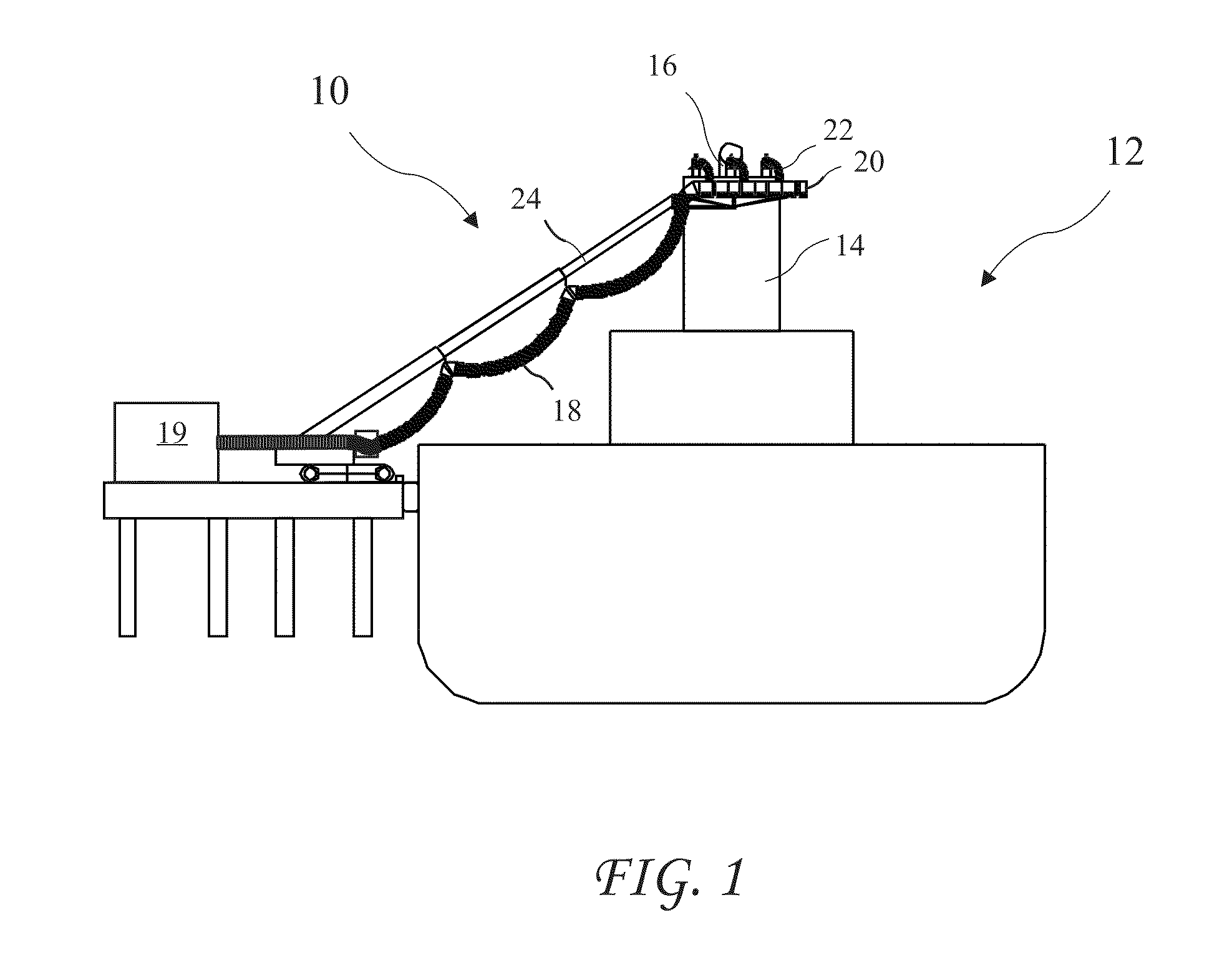

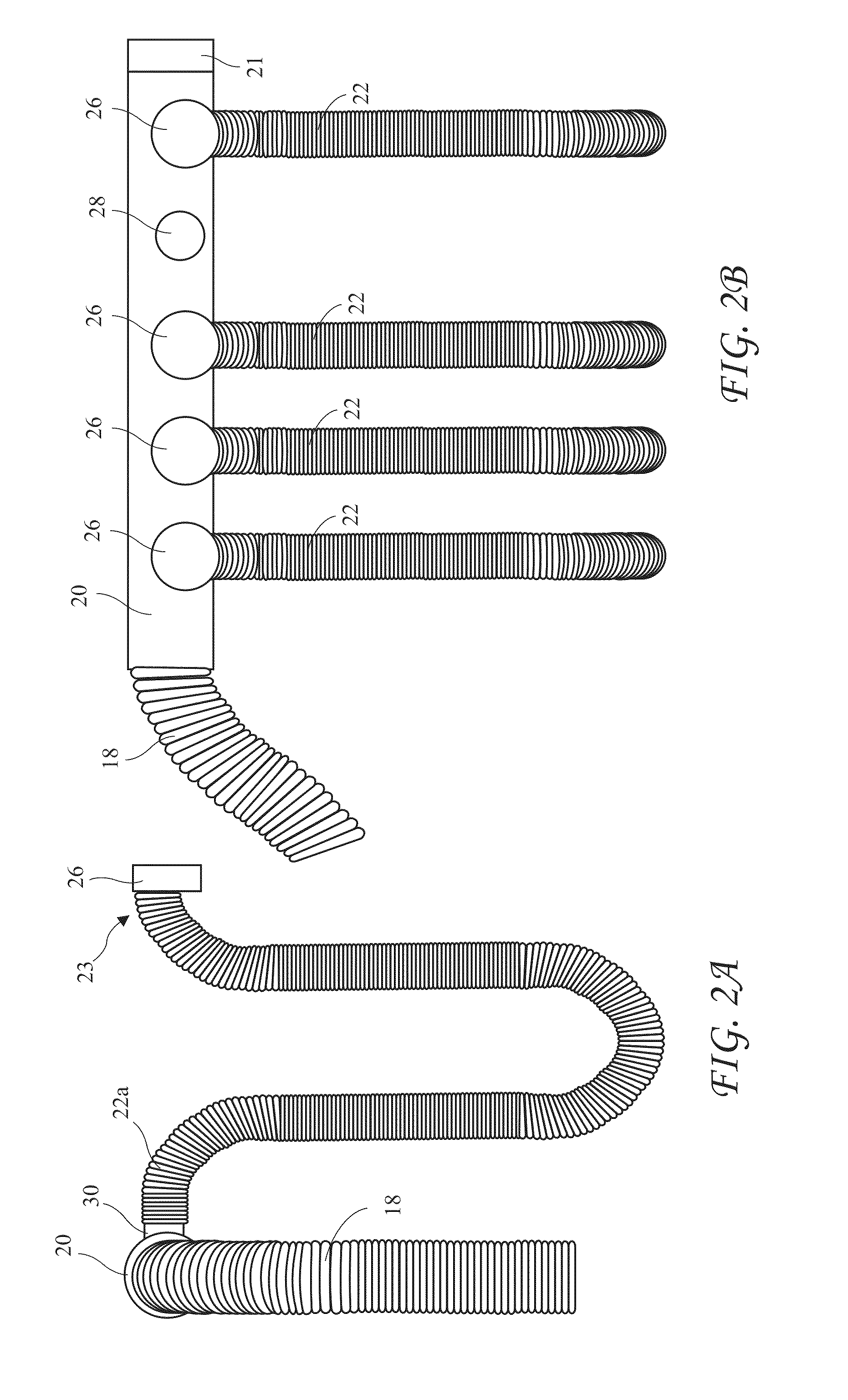

Exhaust gas capture system for ocean going vessels

ActiveUS8402746B2Reduce and eliminate leakage of gasSmall sizePower plants using condensersBarrels/casks fillingGreenhouseAir pollutants

An exhaust gas capture system for capturing the exhaust gas emitted by auxiliary engines, auxiliary boilers, and other sources on an Ocean Going Vessel (OGV) while at berth or at anchor so that these gases may be carried to an emissions treatment system for removal of air pollutants and or greenhouse gases. The exhaust gas capture system includes a manifold and a family of parallel-flow flexible ducts for connecting directly to individual OGV exhaust pipes. The exhaust gas capture system further includes apparatus for connecting the parallel-flow flexible ducts to the OGV exhaust pipes.

Owner:ADVANCED CLEANUP TECH +1

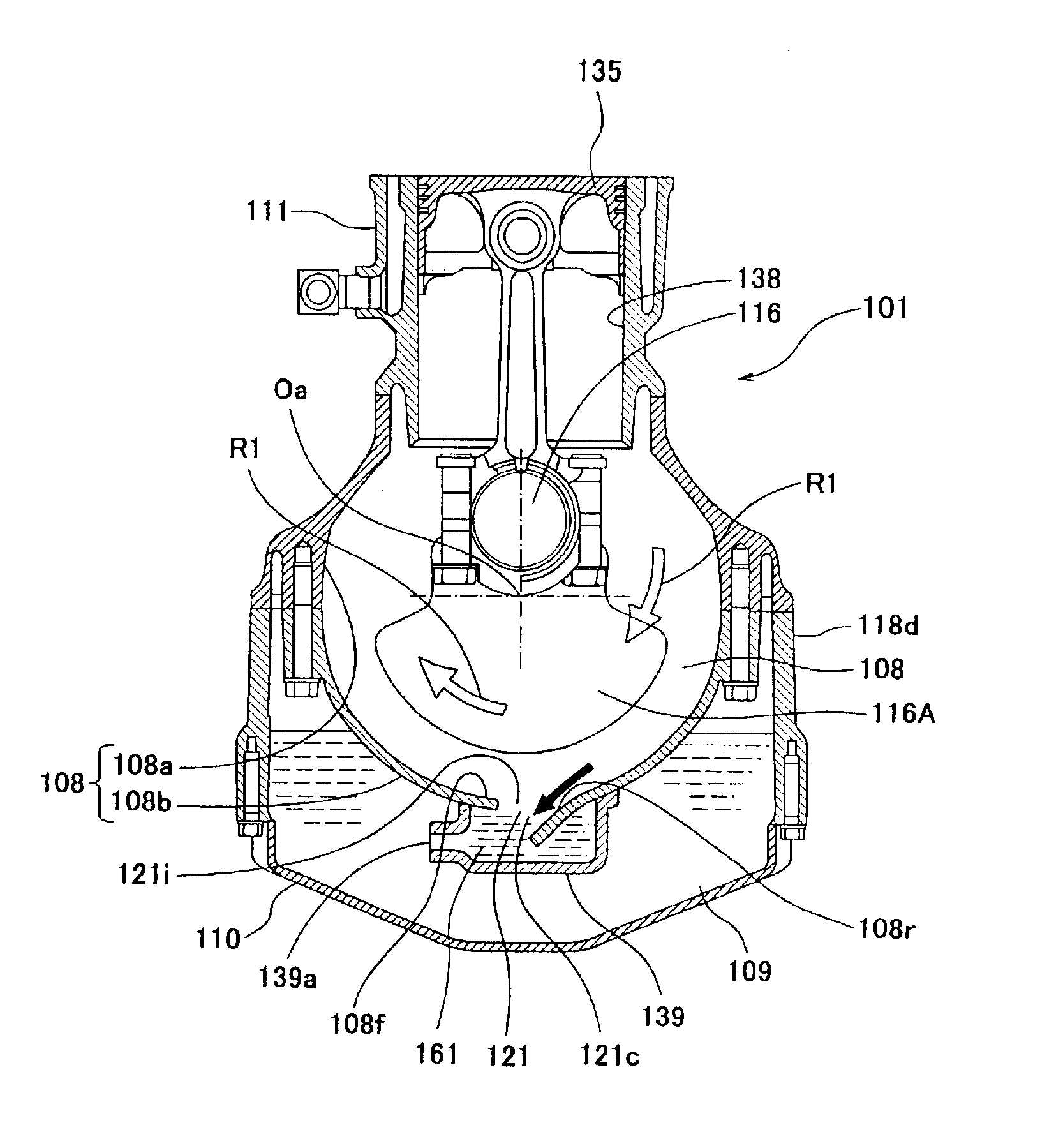

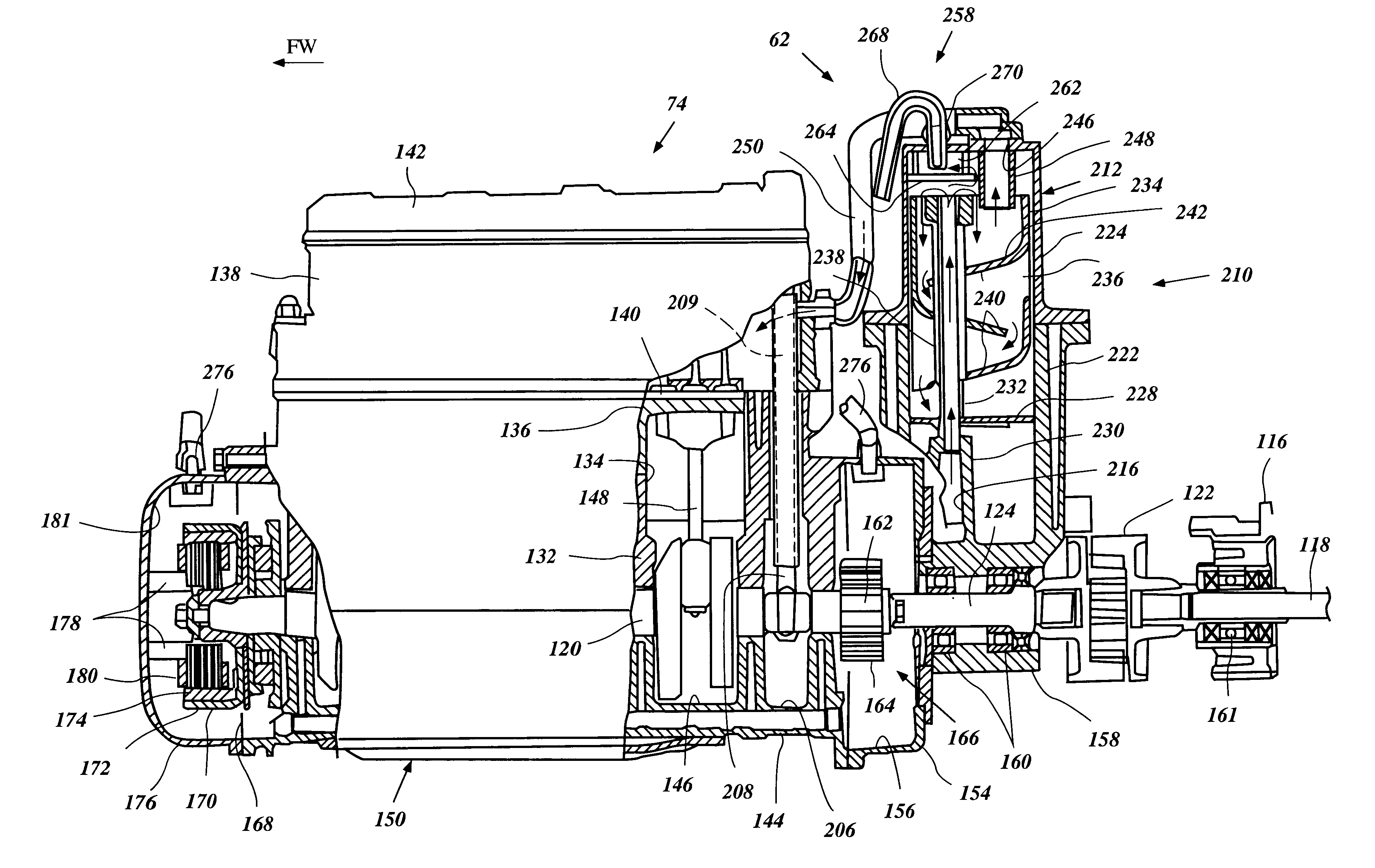

Lubrication system for 4-cycle engine of small watercraft

A watercraft includes a lubrication system having a lubricant pump assembly and a lubrication reservoir defined between a lower crankcase member and an oil cover. At least one oil passage connects a crankcase to the reservoir. The oil cover, or both the oil cover and the crankcase member may contain one or more baffles configured to impede a flow of oil away from the lubricant pump assembly. Additionally, the cover may include one or more projections securing one or more plugs within one or more countersink portions of the crankcase member.

Owner:SANSHIN KOGYO CO LTD

Exhaust system of outboard motor

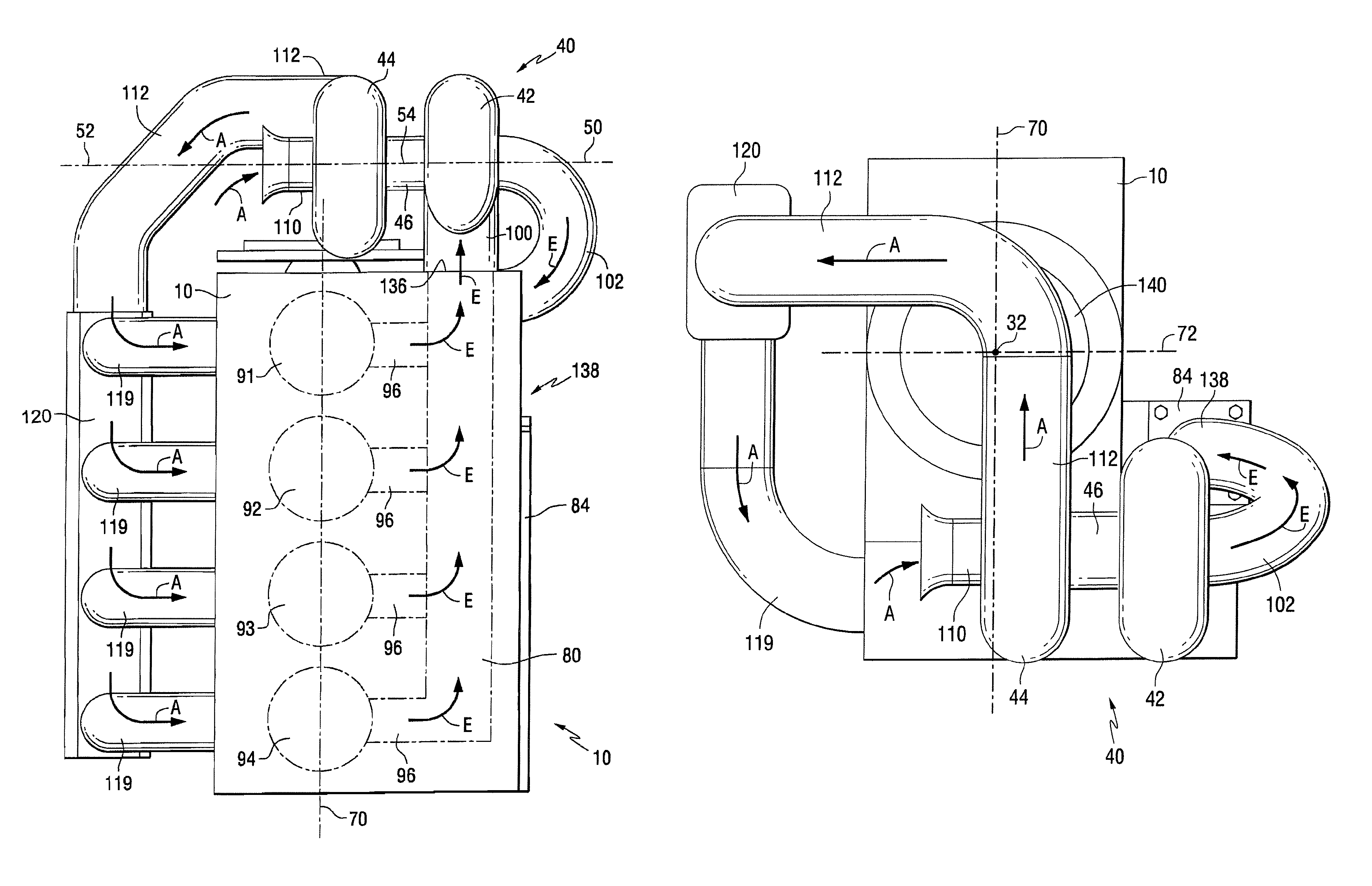

ActiveUS7704111B2Improve exhaust gas purification performanceSmall sizePower plants using condensersExhaust apparatusCylinder headCrankcase

An outboard motor includes a multi-cylinder engine which includes cylinders longitudinally oriented and vertically paralleled in a cylinder block, a cylinder head arranged at a rearward position of the cylinder blocks, and a crankcase arranged at a forward position of the cylinder block, the cylinder head having an outlet of an exhaust port at one side thereof. An exhaust system for the outboard motor includes an exhaust manifold which communicates the outlet of the exhaust port with an exhaust outlet opening, the exhaust manifold including a first exhaust gas passage extending in a vertical direction for gathering exhaust gas discharged from the outlet of each exhaust port and a second exhaust gas passage extending in a vertical direction adjacently to the first exhaust gas passage, and a catalyst unit is provided on the way of the second exhaust gas passage.

Owner:SUZUKI MOTOR CORP

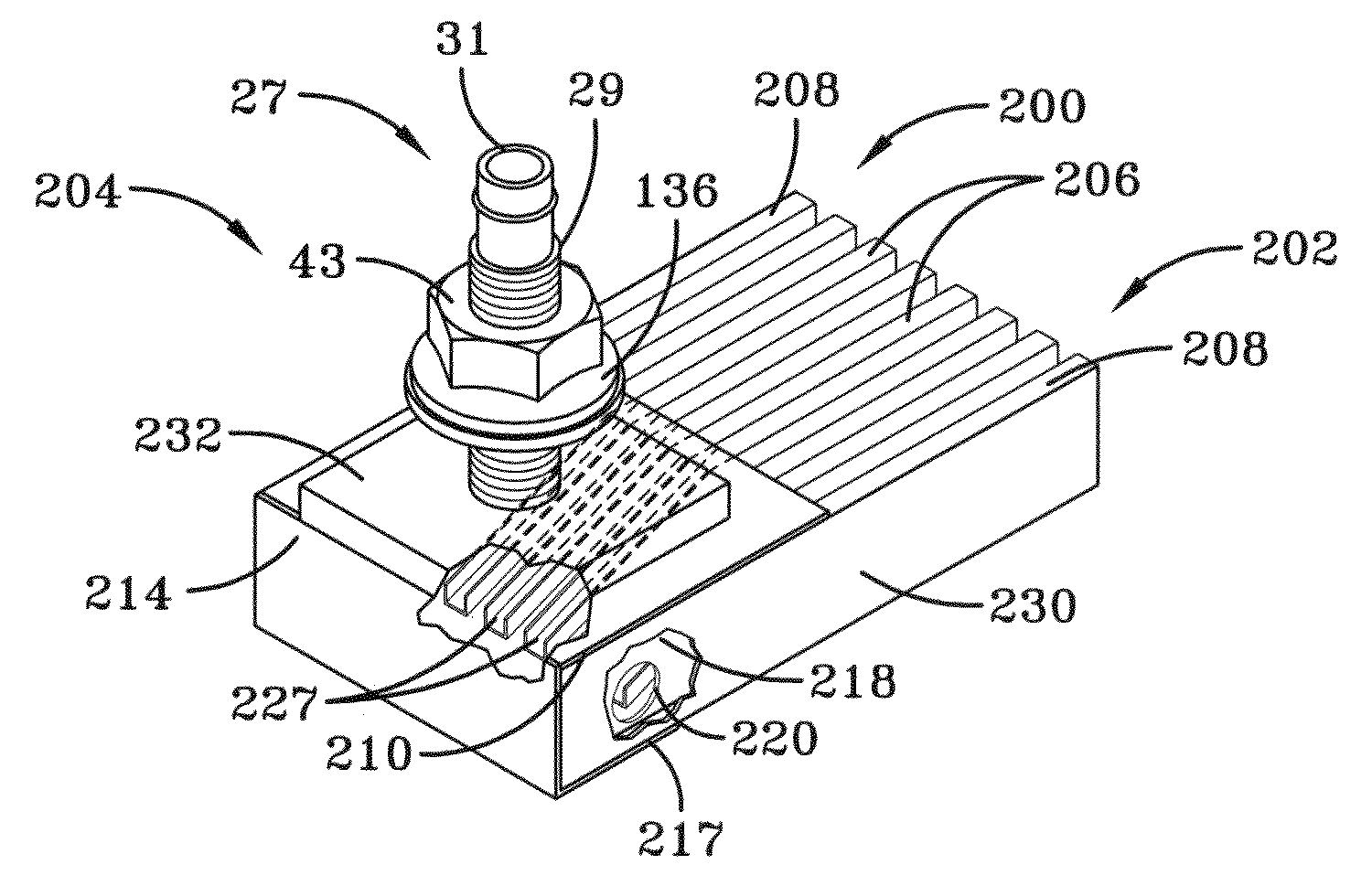

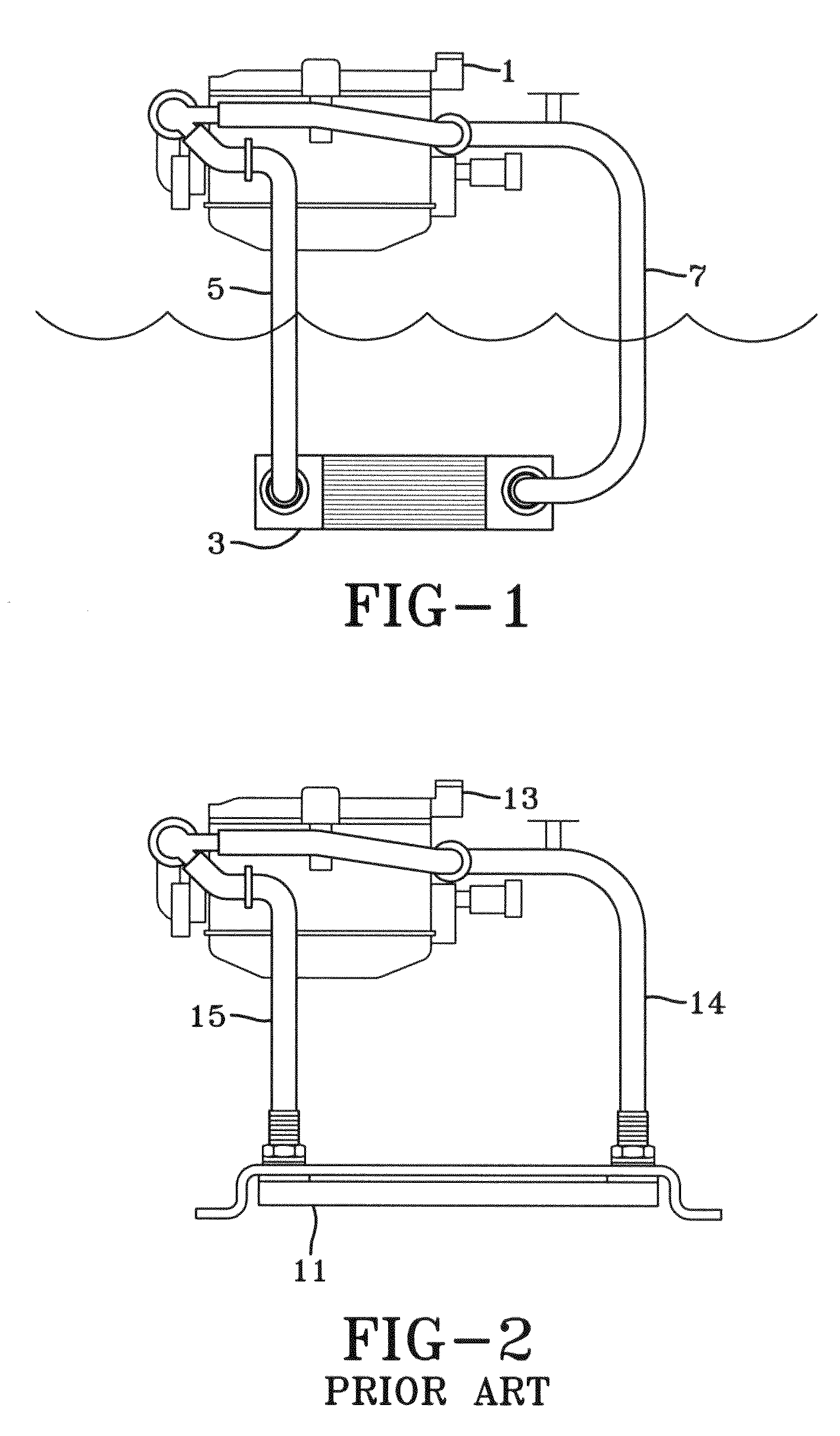

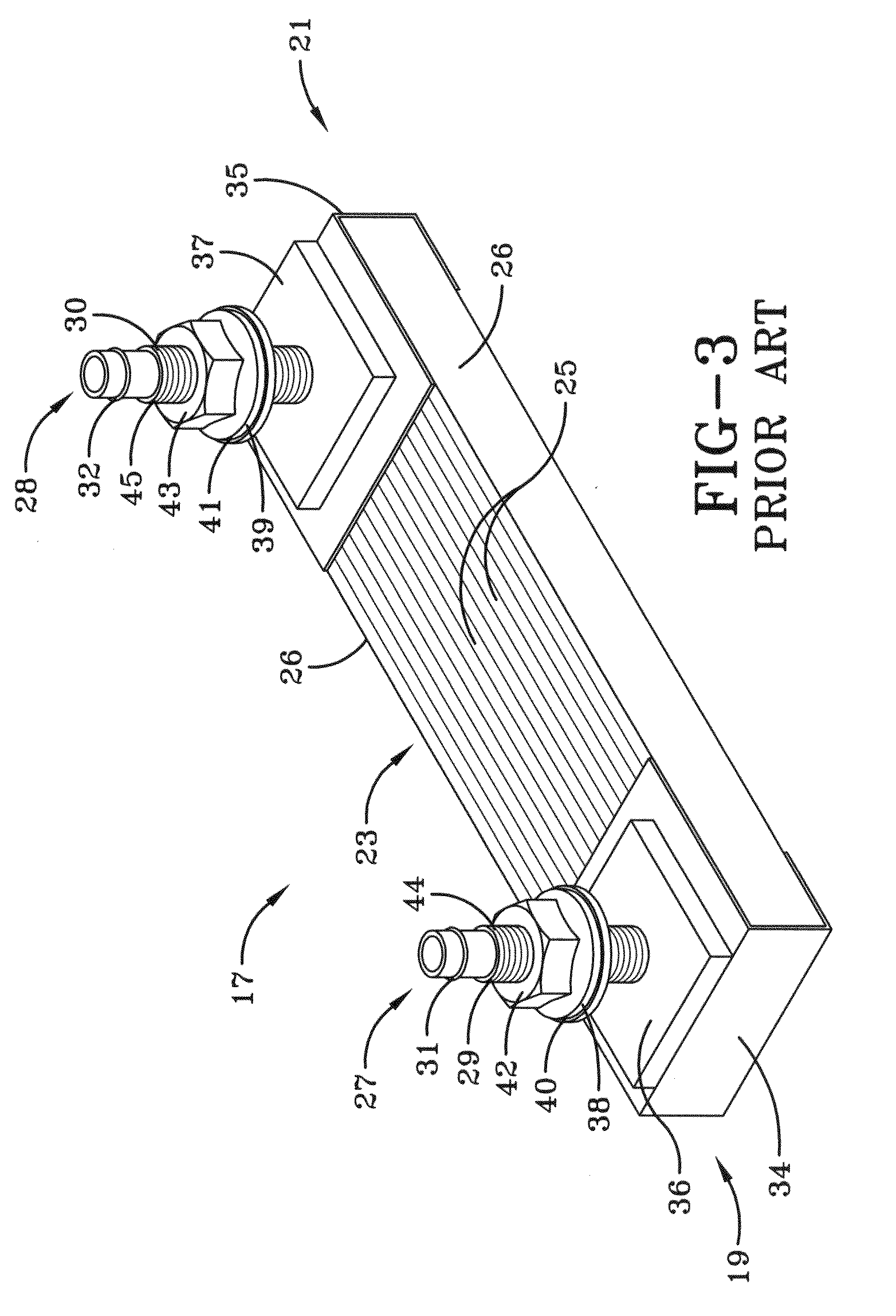

Keel cooler with fluid flow diverter

InactiveUS20090145591A1Enhances internal coolant flowEnhances subsequent heat transfer efficiencyPower plants using condensersAir-treating devicesCoolant flowKeel

A fluid flow diverter is provided in a standard rectangular header of a keel cooler for optimizing the coolant flow towards both the interior tubes and also towards the exterior tubes of the keel cooler. The improvement enhances the internal coolant flow and subsequent heat transfer efficiency similar to what has been realized with a non-rectangular header, for example, a header with a beveled wall.

Owner:DURAMAX MARINE

Ventilation system for watercraft engine

A ventilation system for a watercraft engine includes an improved construction that can inhibit oil in an oil container from flowing into an air induction system even if the watercraft capsizes. The engine includes an engine body and an air induction system that introduces air to combustion chambers. A lubrication system is arranged to lubricate at least a portion of the engine body with lubricant oil. The lubrication system includes an oil tank assembly out of the engine body. A ventilation system is arranged to separate a gaseous component from a liquid component. The ventilation system includes a separator configured to separate the gaseous component from the liquid component. A ventilation passage connects the separator with the air induction system. A return passage couples a bottom portion of the ventilation passage with inside of the engine body.

Owner:SANSHIN KOGYO CO LTD

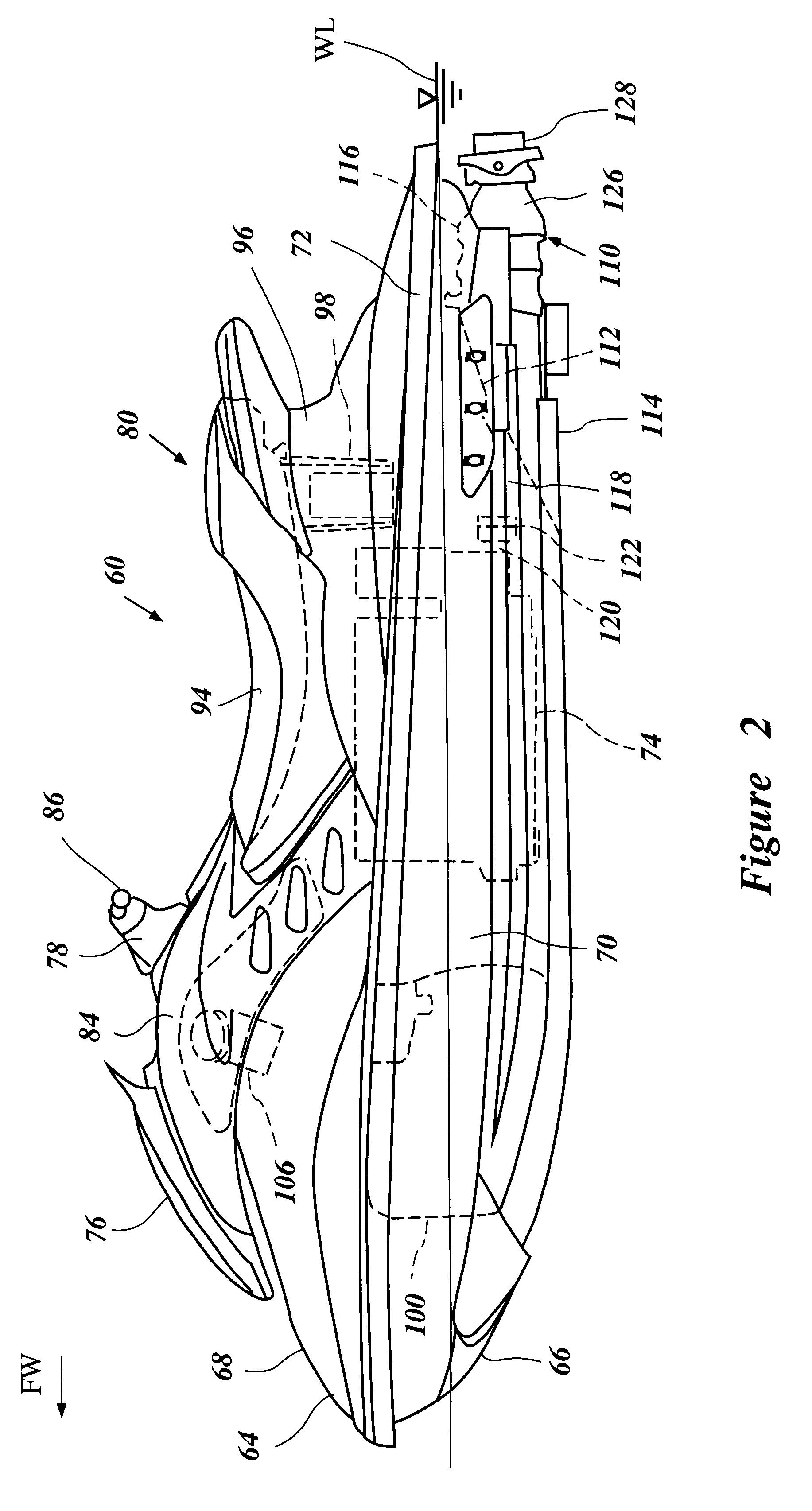

Outboard motor cooling and anode system

A mounting assembly for an anode of a corrosion protection system extends the useful life of the anode and hence the effectiveness of the system. The anode is mounted within an opening of an outboard motor engine. The engine also includes a coolant passage that extends through the engine and forms a portion of a cooling system. A biasing device biases the anode to contact the engine body. The anode also includes multiple contact surfaces which establish a plurality of electrical connections between the anode and the engine. In one mode, an electrically conductive cover links the anode to the engine at a point outside the opening. A seal is positioned between the opening and the cover to protect this electrical coupling. This outside connection thus ensures good electrical coupling between the anode and the engine body outside the presence of the coolant (e.g., salt water) flowing through the coolant passage.

Owner:SANSHIN KOGYO CO LTD

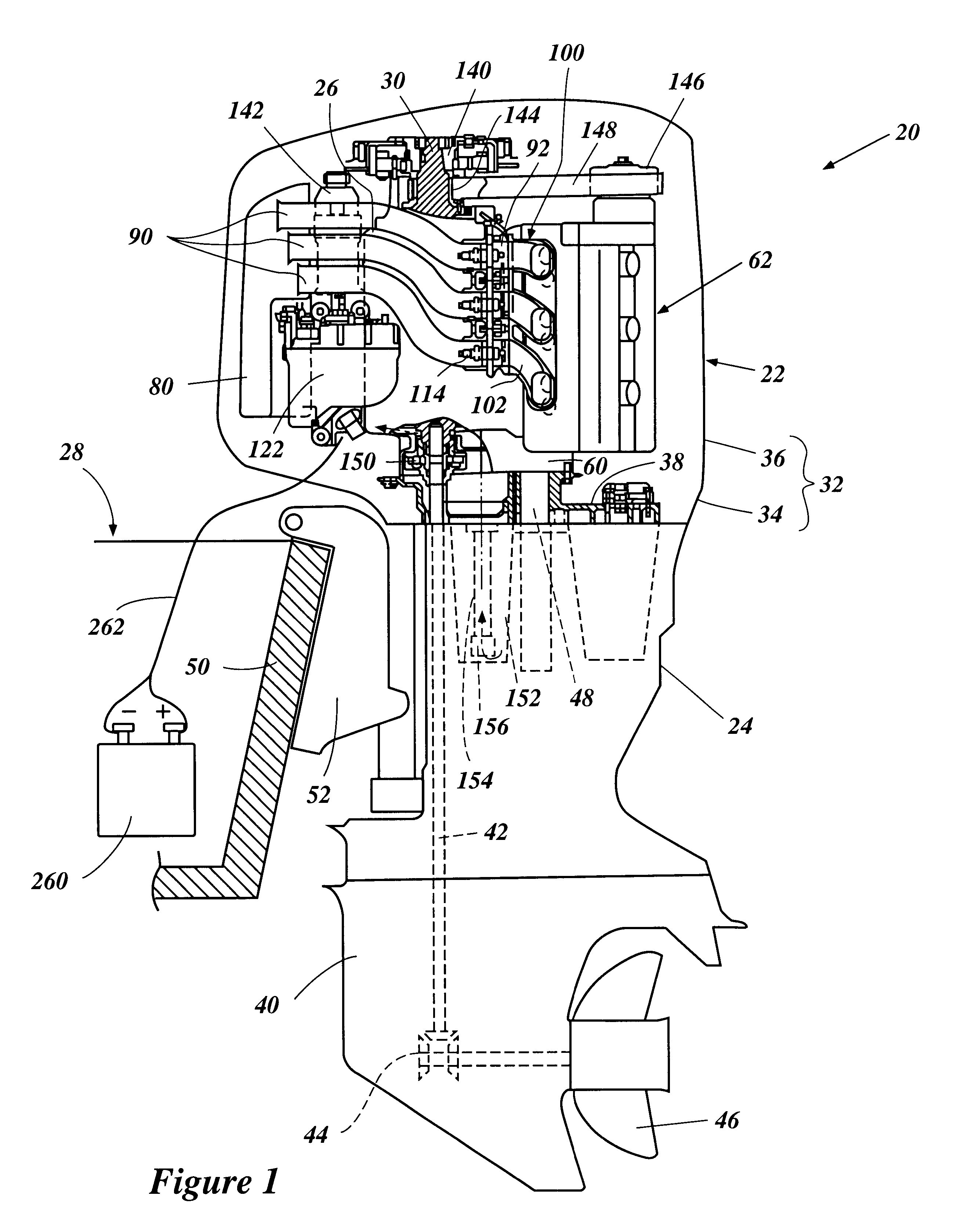

Outboard motor

An outboard motor includes an improved engine layout to provide a compact power head while simplifying the arrangement of components on the engine. In one mode, an induction system of the engine includes a carburetor that is arranged over a cylinder head. An intake pipe connects the carburetor to an intake port of the cylinder head. The pipe has generally a U-shape and loops around the upper side edge of the cylinder head. An air intake device is arranged upstream of the carburetor to supply air thereto. The air intake device includes a downward facing air intake opening that is located along a side of the engine below the upper end. This arrangement of the induction system that extends over the upper side of the engine produces a compact assembly without overly complicating the arrangement of other components on the engine, such as, for example, a manual starter device. With the present engine layout, the manual starter device is positioned on an upper side of the engine in front of the carburetor near a crankshaft of the engine. The air intake opening faces a lower air vent formed in a cowling below the engine. Cool air flows through the lower air vent and is drawn into the air intake opening for engine operation. This flow of cool air also cools the engine. The cowling also includes an upper vent to expel warm air from about the carburetor on the upper side of the cowling and to promote a current of air across the engine for cooling purposes.

Owner:SANSHIN KOGYO CO LTD

Vertical engine and outboard engine system

InactiveUS20050009420A1Increase freedomGood effectPower plants using condensersOutboard propulsion unitsCylinder blockOil filter

A base member mounted to a side of a cylinder block is formed with an inlet-side oil supply passage for supplying an oil to an oil filter, and an outlet-side oil supply passage for discharging the oil from the oil filter. As a result, it is unnecessary to increase the thickness of a wall of the cylinder block or to form a bulged portion in order to form the oil supply passages, thereby contributing to a decrease in weight of the cylinder block. Moreover, because the oil supply passages are formed in the base member, the layouts thereof can be determined freely without restrained by the shape of the cylinder block, thereby contributing an increase in degree of freedom for the design.

Owner:HONDA MOTOR CO LTD

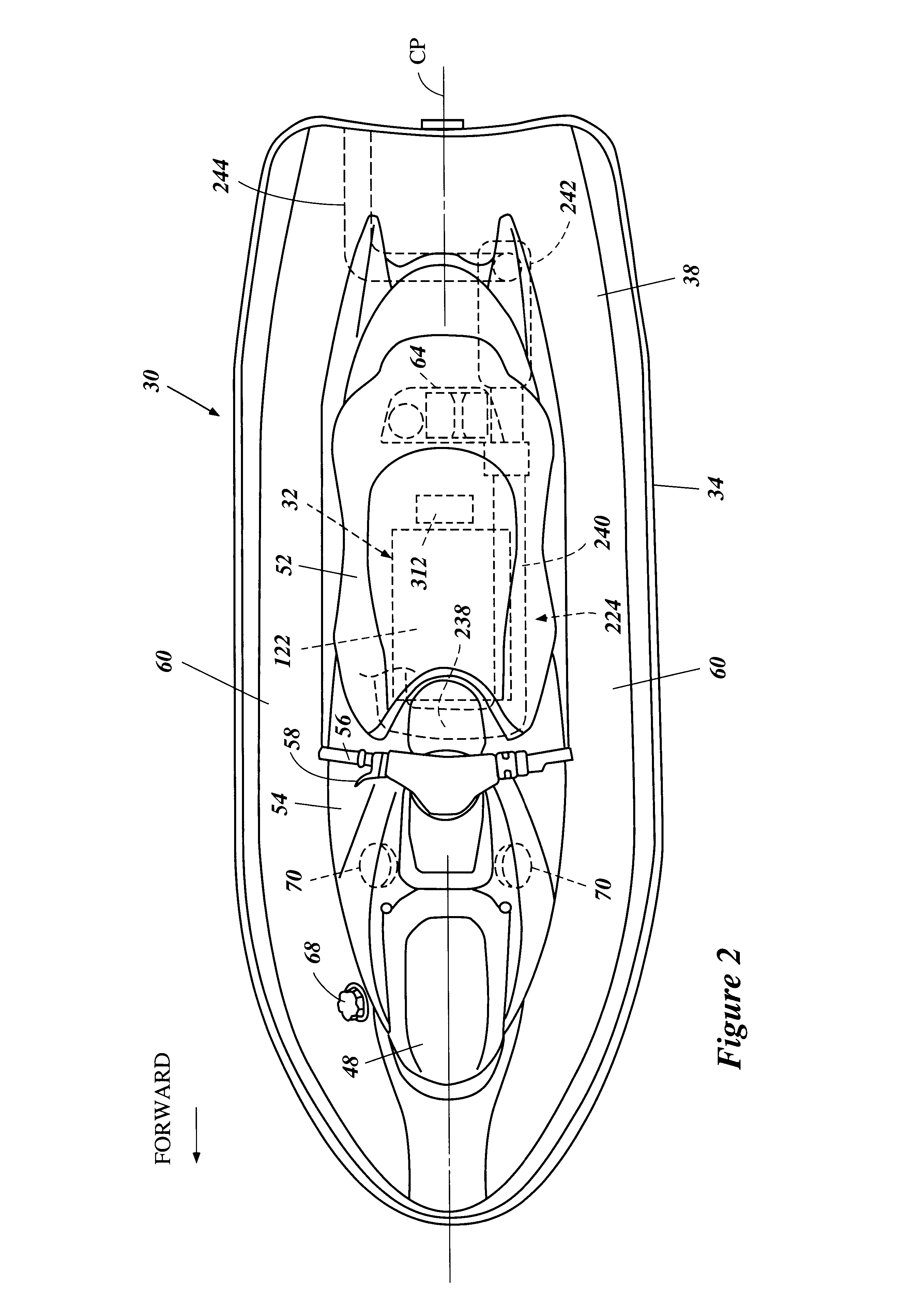

Personal watercraft air intake assembly

InactiveUS20050239352A1Improve performancePower plants using condensersWater sport boardsEngineeringWatercraft

An air intake assembly for a personal watercraft provides air to an internal combustion engine located within a hull cavity includes a housing having a generally horn-shaped configuration that includes a base and an outer end. The housing has an air passage that extends from a base to an outer end. An adaptor assembly connects the base to the hull and is arranged to form a seal around an opening in an upper portion of the hull. The adaptor assembly includes an opening aligned with the air passage. An air intake valve assembly is mounted in the opening with the valve assembly being arranged to be open to allow air flow into the hull when the upper portion of the housing points upward from a horizontal plane through the upper portion of the hull and being further arranged to close whenever the outer end of the housing has a downward pointing component.

Owner:MONTGOMERY ROBERT E

Cowling arrangement for outboard motor

An outboard motor includes a cowling substantially enclosing a four-cycle engine therein. The engine has an air induction device for introducing air to a combustion chamber, and an exhaust system for communicating exhaust products away from the combustion chamber. A pair of camshafts actuate intake and exhaust valves. A variable valve timing (VVT) mechanism is arranged at an upper end of at least one of the camshafts to set the camshaft to an angular position between advanced and delayed angular positions. The cowling includes an air intake, and an engine cover is positioned between the engine and the air intake. The engine cover covers the top and sides of the VVT mechanism so as to protect the VVT mechanism from contact with water that may enter the cowling through the air intake.

Owner:SANSHIN KOGYO CO LTD

Cooled oil reservoir for watercraft

A watercraft having a cooling system for the lubrication system of the engine, the cooling system including a reservoir, at least a portion of the reservoir being cooled by ambient water flowing through a cooling jacket in contact with the reservoir. Also disclosed is a watercraft having a cooling system for the lubrication system of the engine, the cooling system including a reservoir, at least a portion of the reservoir being cooled by direct and / or thermal contact with ambient water in which the watercraft floats.

Owner:YAMAHA MOTOR CO LTD

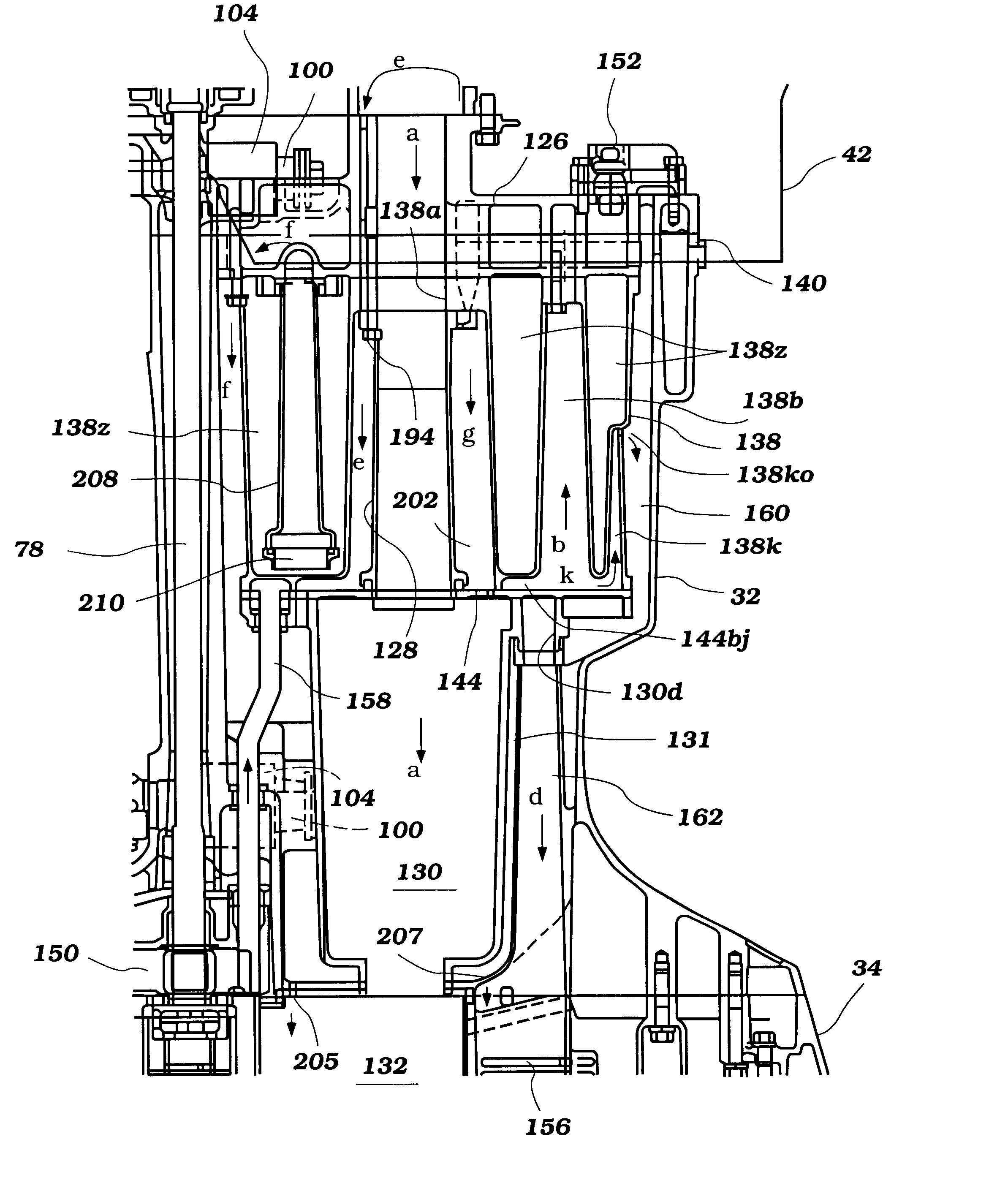

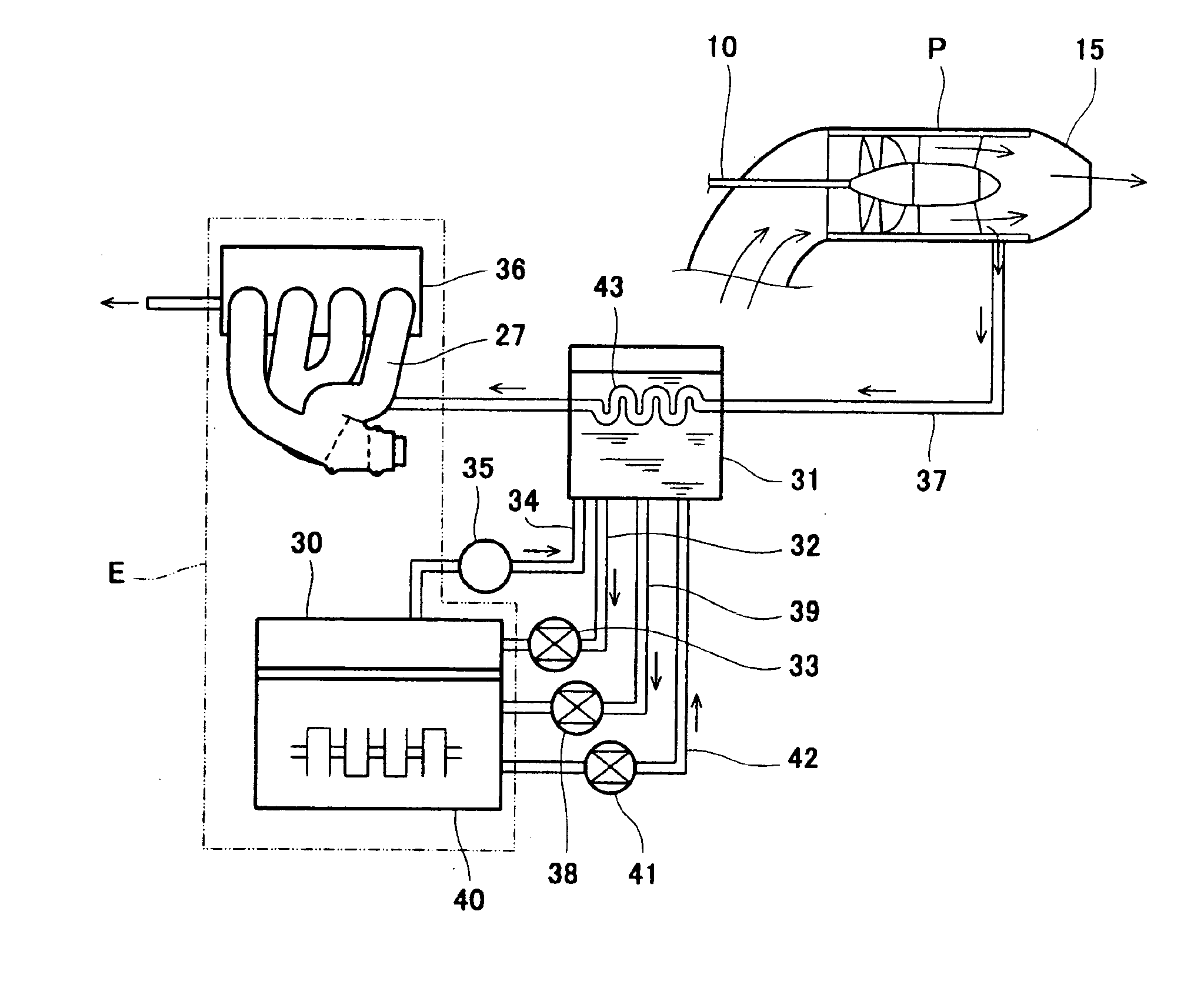

Cooling system for watercraft

InactiveUS6554664B1Power plants using condensersInternal combustion piston enginesCouplingWatercraft

An engine for a watercraft has a coupling plate interposed between a cylinder block and an exhaust manifold. The coupling plate comprises exhaust passages that complement the shapes of cylinder exhaust discharge ports and the exhaust manifold inlet ports. The coupling plate also includes a water jacket for use with a water cooling system. The cooling system can receive coolant from a pressure chamber within a jet pump unit of the watercraft. The cooling system also can include a lubricant cooler that receives coolant from an engine cooling jacket, an exhaust system cooling jacket or another cooling jacket.

Owner:YAMAHA MOTOR CO LTD

Oil cooler and small watercraft

InactiveUS6988919B2Simple piping configurationEasy maintenancePower plants using condensersLiquid coolingEngineeringWatercraft

An oil cooler of an engine for small watercraft. The oil cooler typically includes a mounting portion configured to mount the oil cooler on an outer wall face of an engine of the small watercraft, an oil passage configured to allow oil to flow therethrough and lead to outside of the oil cooler at the mounting portion, and a coolant passage through which coolant for cooling the oil flows, wherein the oil cooler is capable of being disassembled such that an inside of at least the coolant passage is exposed.

Owner:KAWASAKI MOTORS LTD

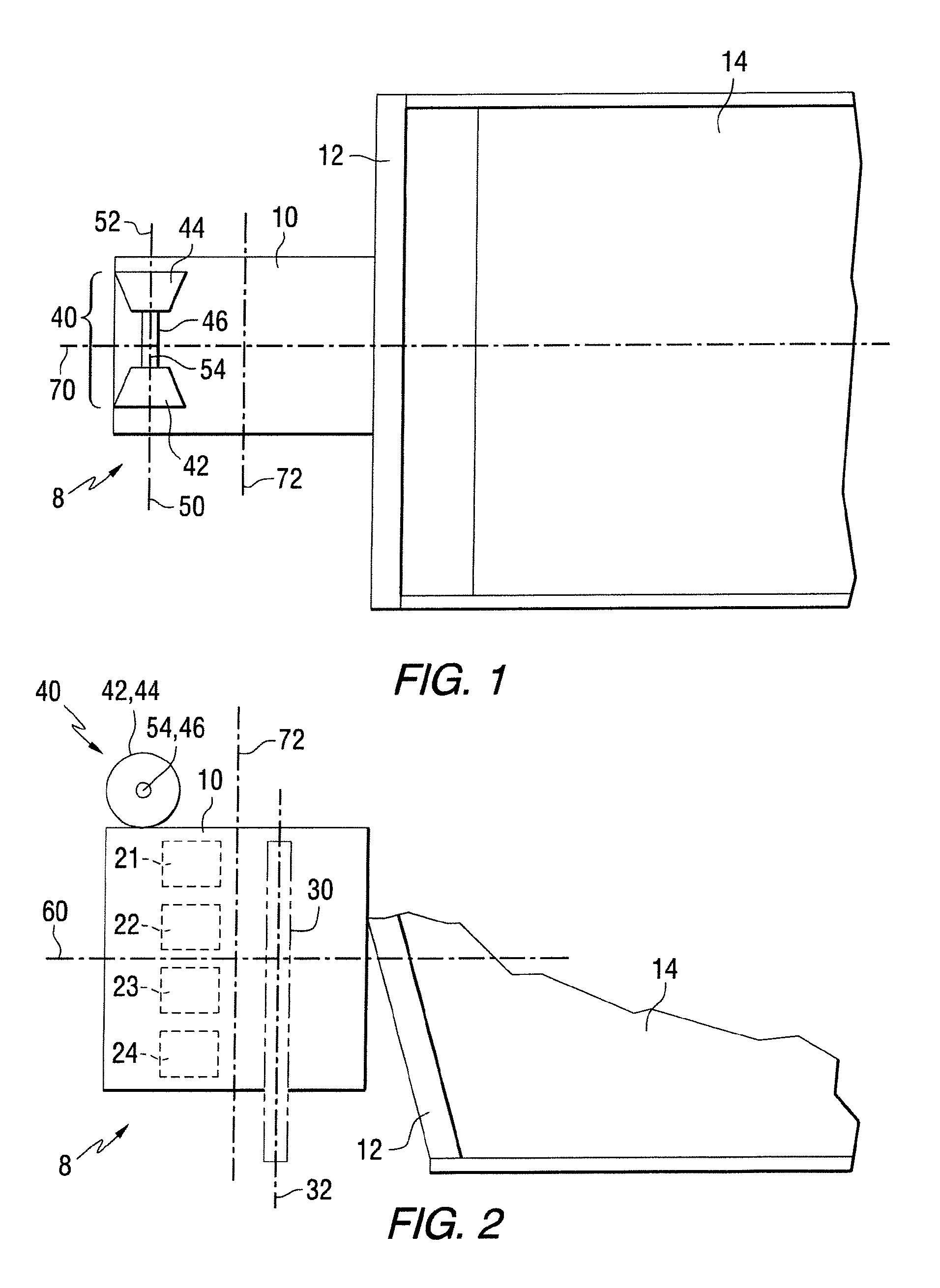

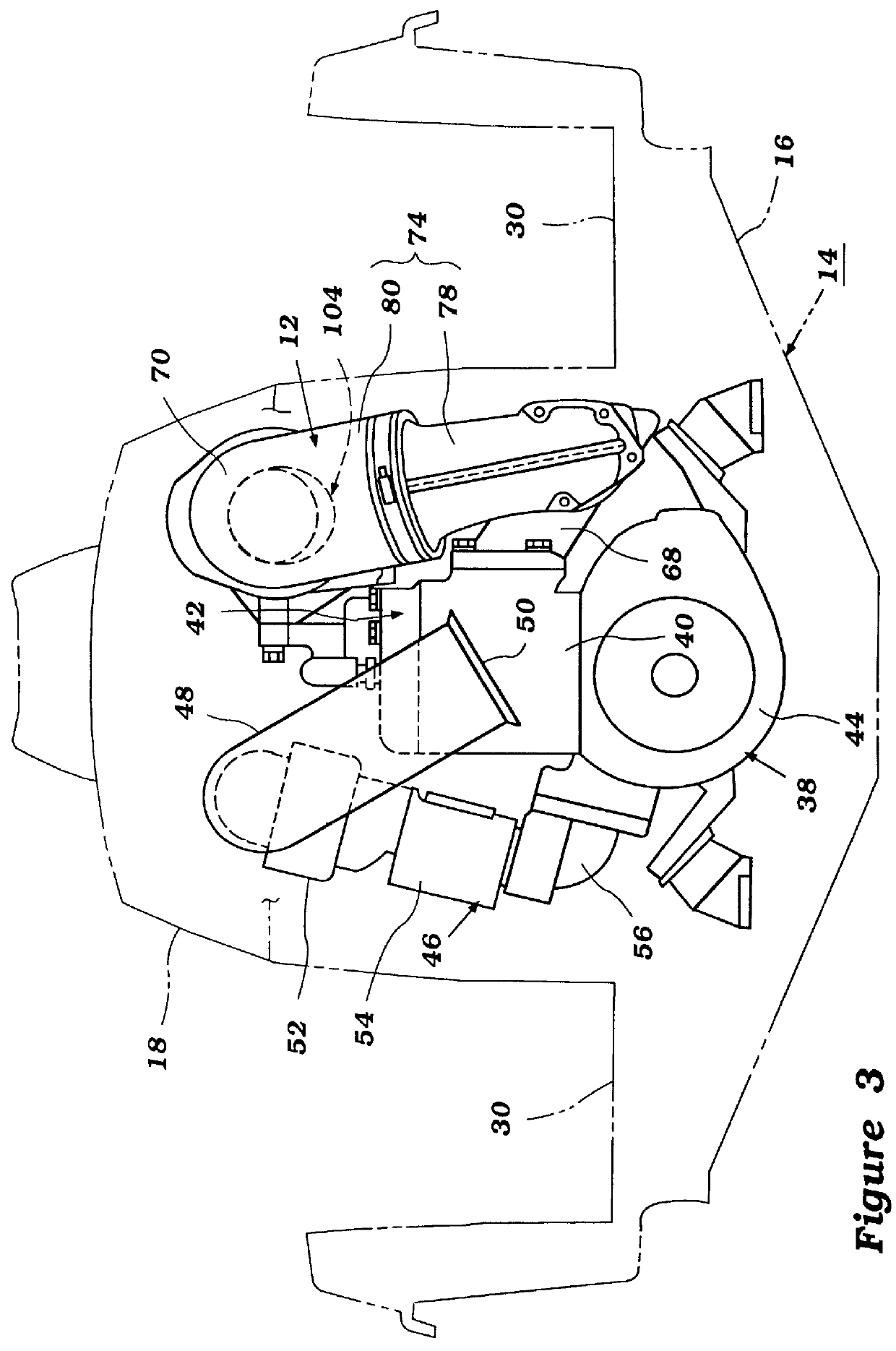

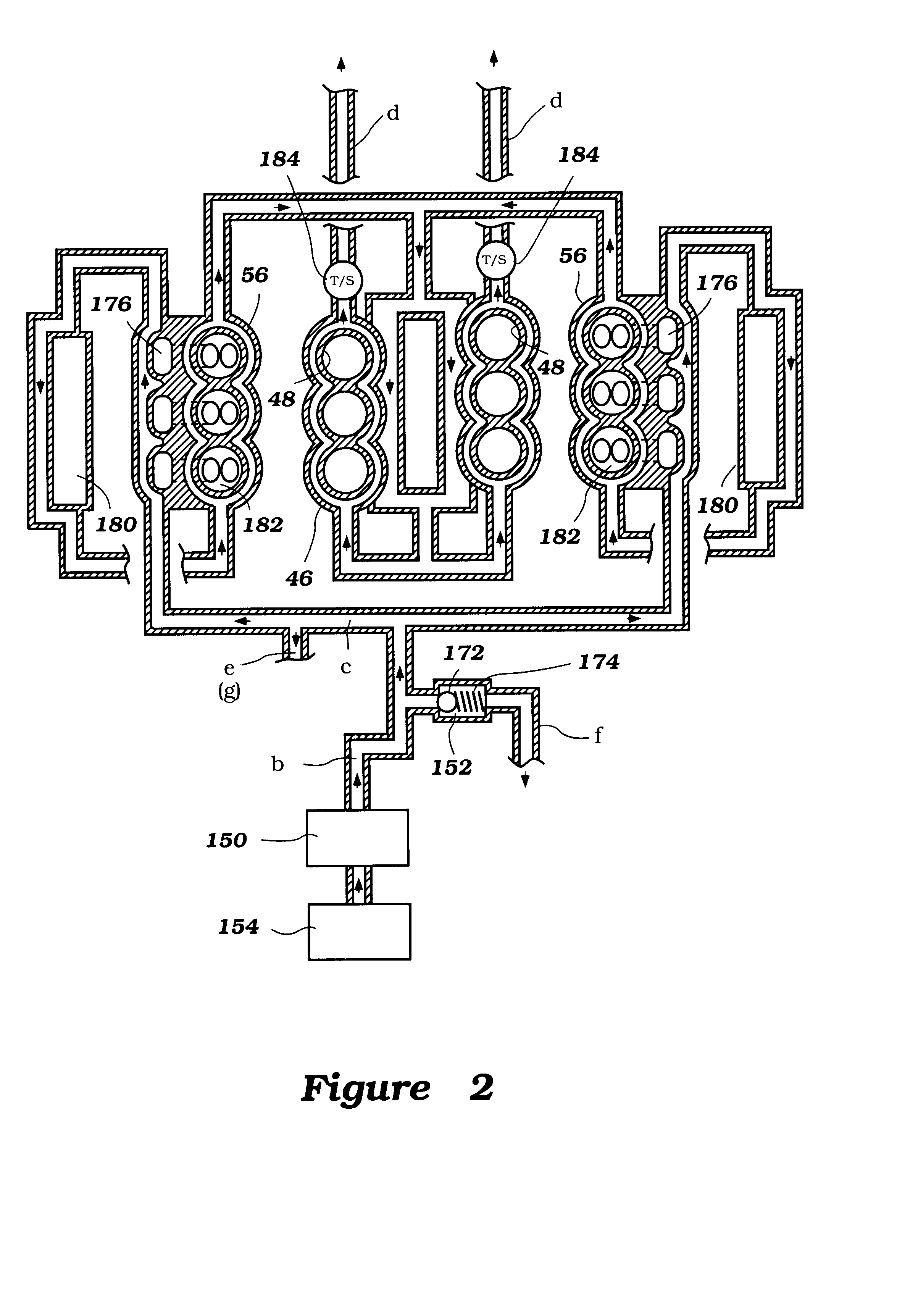

Induction system for 4-cycle engine of small watercraft

InactiveUS6672918B2Power plants using condensersOutboard propulsion unitsCombustion chamberFiltration

An induction system for a 4-cycle engine of a small watercraft includes an improved construction which can accommodate a large plenum chamber notwithstanding being placed in an engine compartment limited in size. The induction system includes improved filtration, and accessibility characteristics. The air induction system can include a plenum chamber member defining the plenum chamber. The air induction system can also include one or more throttle bodies within the plenum chamber to allow the construction of a large plenum chamber. The plenum chamber member is can comprise at least three parts with at least one part being disposed substantially above the spark plugs and being removable. The air induction system can also include an air filter having a water repellent element and an oil-resistant element arranged such that a flow of air entering the combustion chambers passes through both the water repellent and oil-resistant elements.

Owner:YAMAHA MARINE KK

Outboard motor cooling system

An outboard motor cooling system includes an improved construction to enhancing cooling of the lubrication system, and more particularly, an oil pan of the lubrication system. The oil pan depends from an engine of the outboard motor and into a driveshaft housing. A periphery coolant jacket is provided around the oil pan. A water pool is defined between the oil pan and the driveshaft housing. An exhaust manifold passes through in a hollow of the oil pan and a water curtain is defined between the hollow wall and the exhaust manifold. An upstanding water passage is also disposed through the oil pan. At least one of an upper and lower transverse water jacket extends transversely above or below the oil pan. No drain water from the engine flows through these jackets or passages. The oil pan therefore is sufficiently cooled. In addition, the upper transverse water jacket increases protection of engine components from heat deterioration.

Owner:SANSHIN KOGYO CO LTD

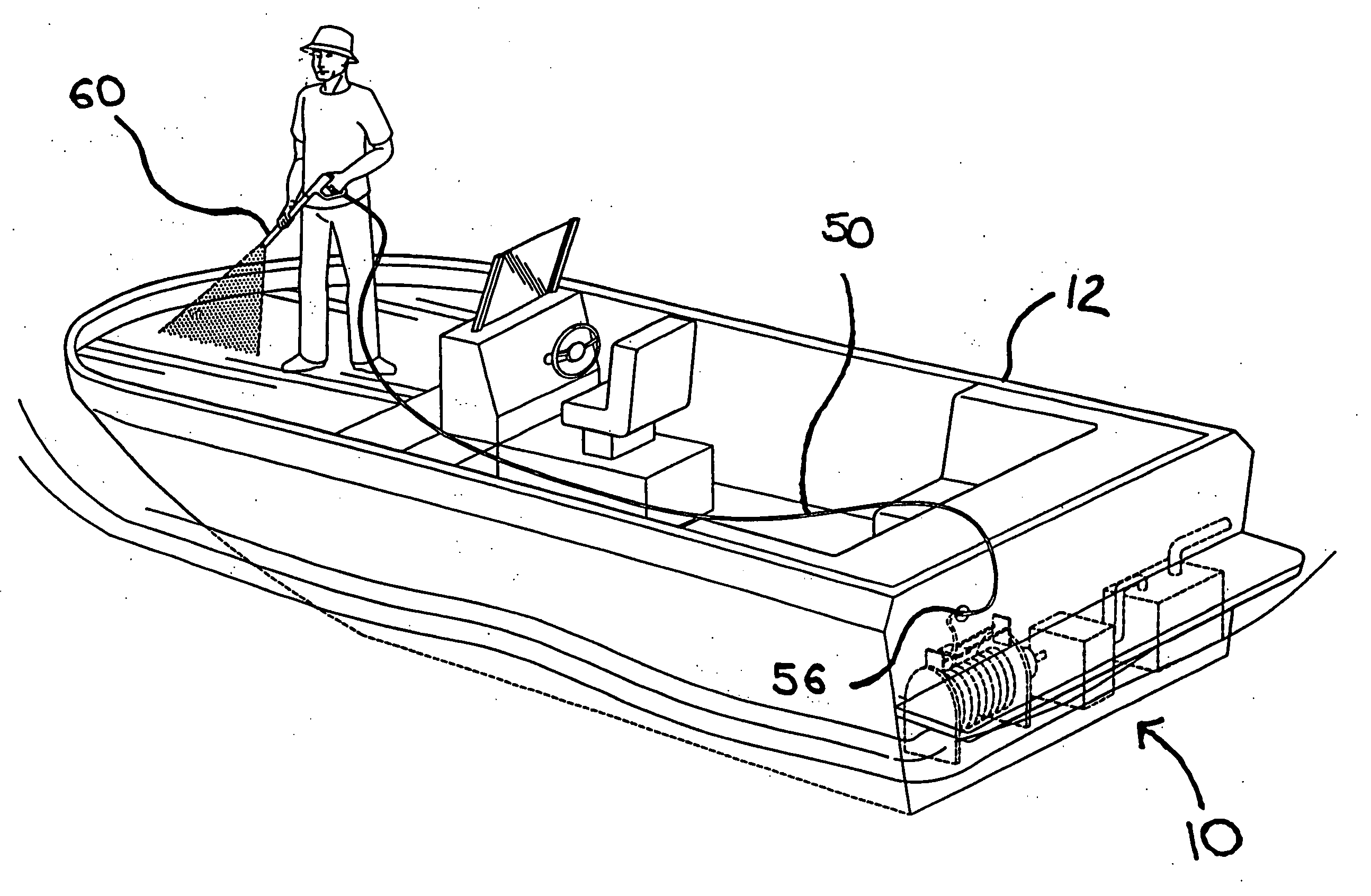

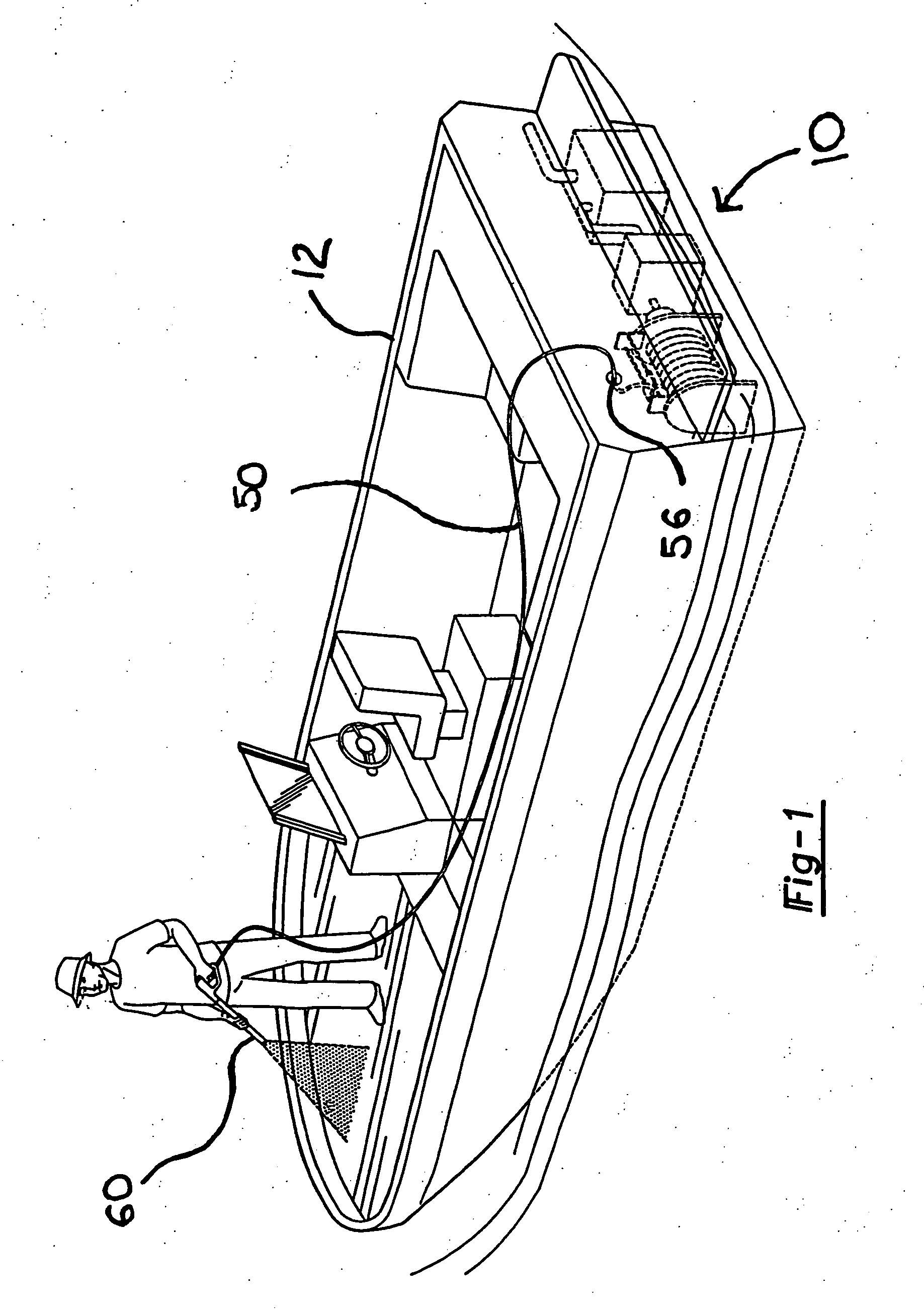

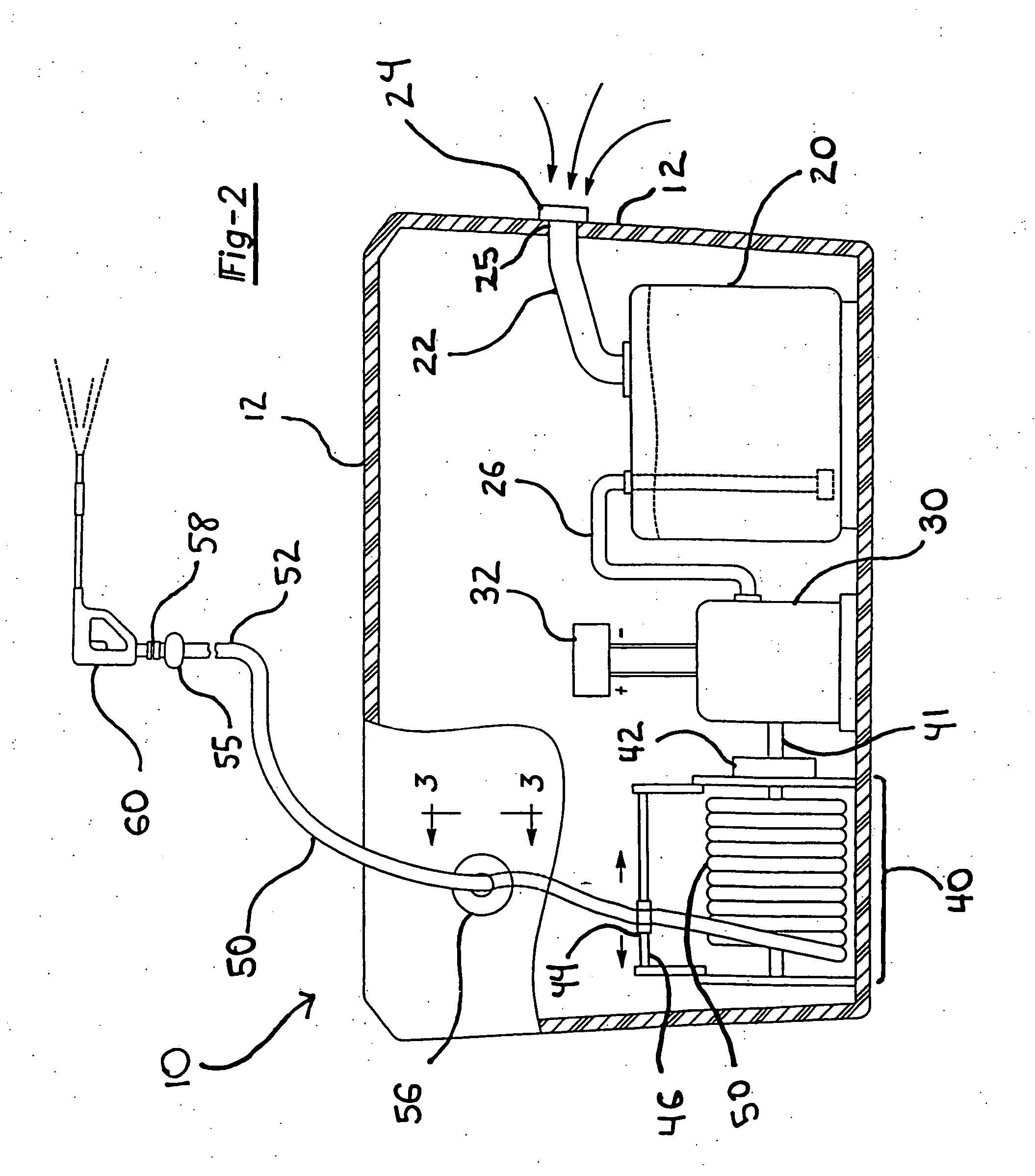

Boat/RV mounted pressure-wash system

InactiveUS20050156060A1Eliminate needEasy to storePower plants using condensersVessel cleaningBilgeHigh pressure

A boat or recreational vehicle (RV) mounted pressure washing system fully plumbed and integrated electrically with the boat or RV, and located remotely there within according to user's preferred mounting location such as the bilge, engine compartment or a supply cabinet. The system provides the user with a high pressure supply of water for washing, rinsing, etc. by means of a pump, water reservoir and fully retractably high pressure hose, to which a nozzle of choice may be quickly attached or removed when not in use. The pressure hose is of significant length to provide for the pressure washing of the entire vehicle and surrounding areas by the user, whereby when not in use is fully retractable into the boat or RV for storage.

Owner:ATTAR ROBERT A

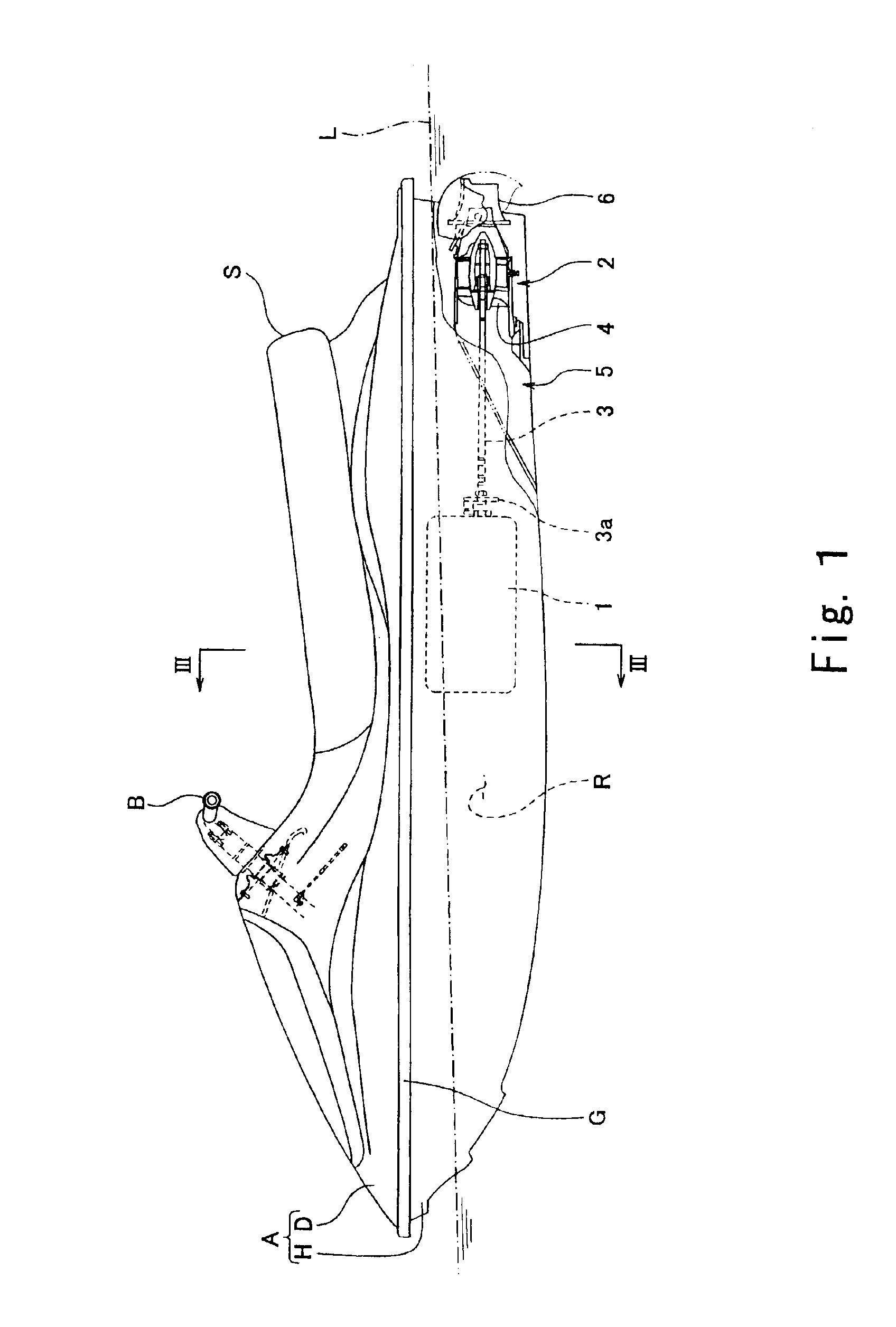

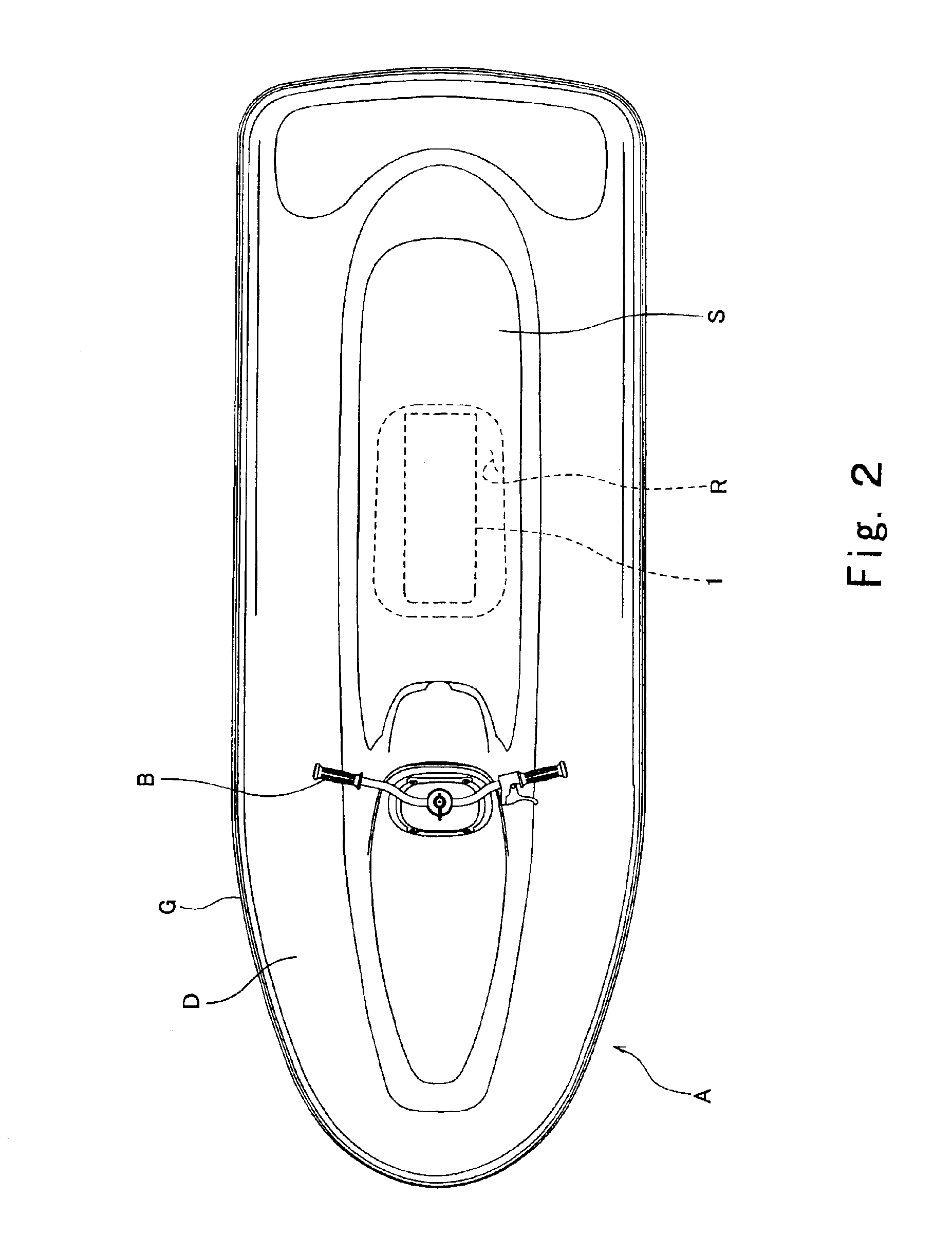

Small watercraft

InactiveUS6869324B2Variation in distributionVariation in temperature temperaturePower plants using condensersLiquid coolingWatercraftCylinder block

Disclosed is a small watercraft having an engine cooling system which can lessen variation in temperature and temperature distribution of the engine between the time when the engine is starting and when the watercraft is continuously driving with a throttle in a fully open or almost fully open position. The small watercraft adapted to be propelled by a water jet pump driven by an engine, comprises: a first cooling system for cooling a cylinder block of the engine, the first cooling system having an indirect cooling structure; and a second cooling system for cooling an exhaust system, the second cooling system having a direct cooling structure.

Owner:KAWASAKI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com