Patents

Literature

744results about "Intake silencers for fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Noise and vibration suppressors

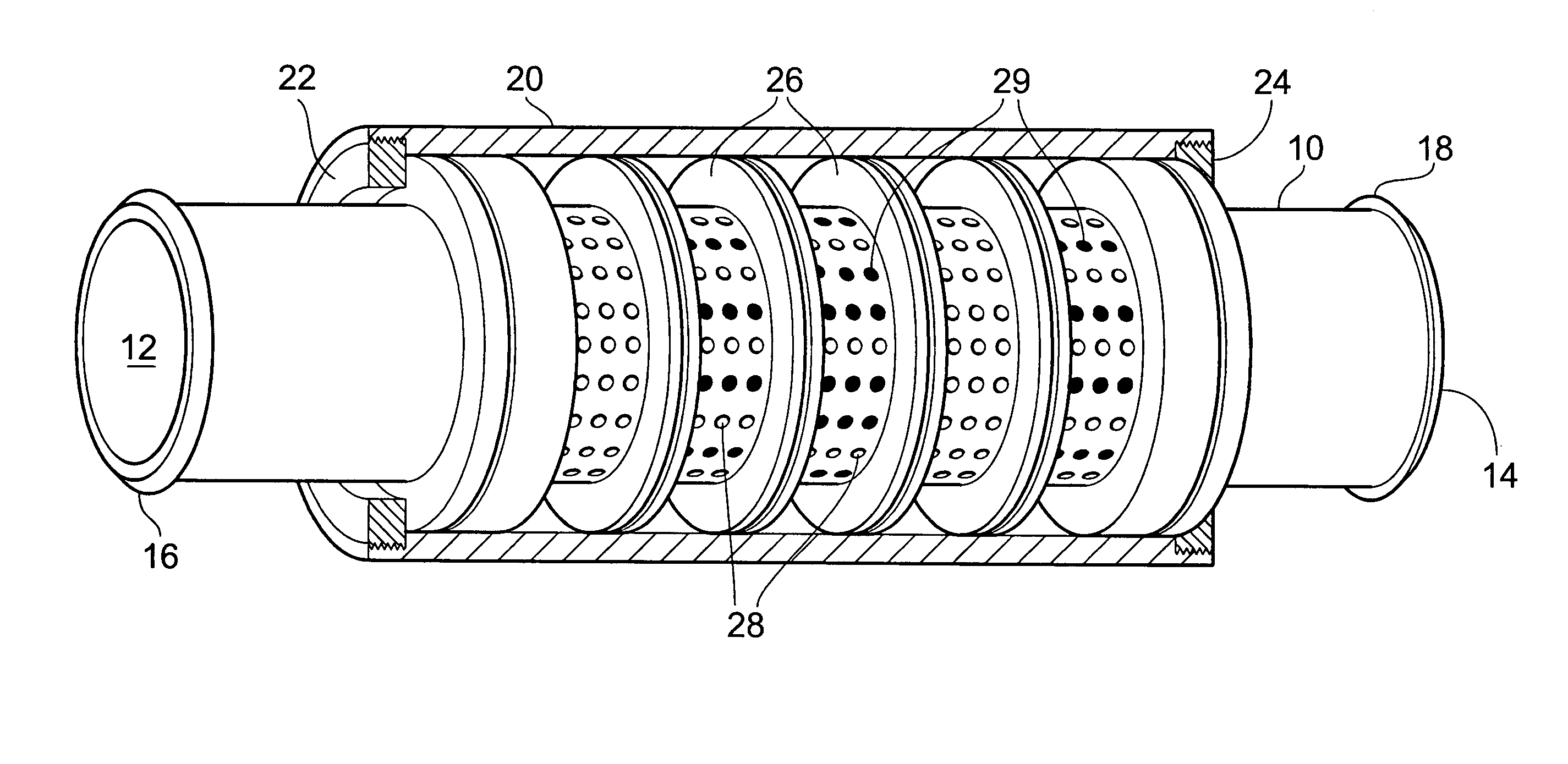

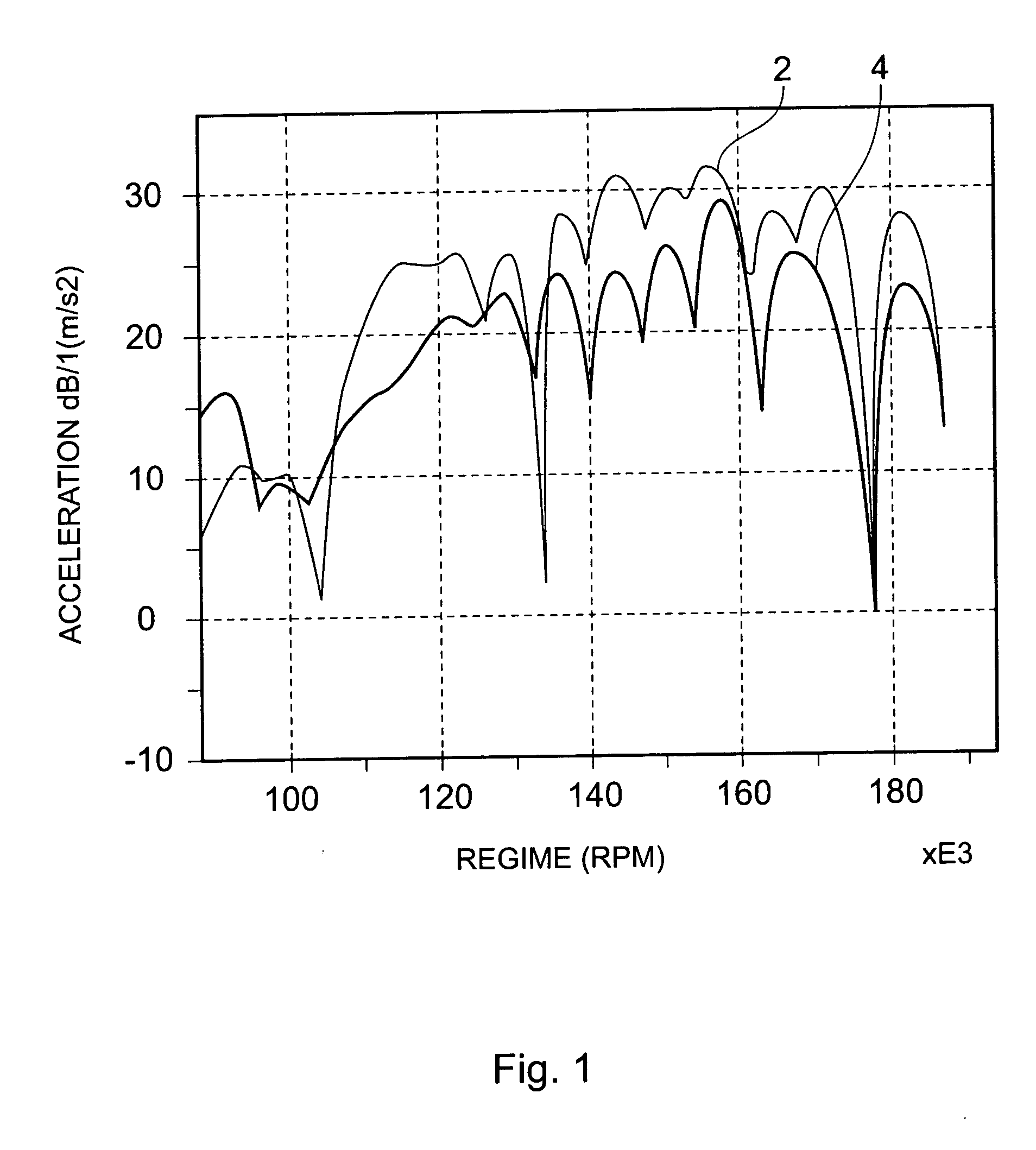

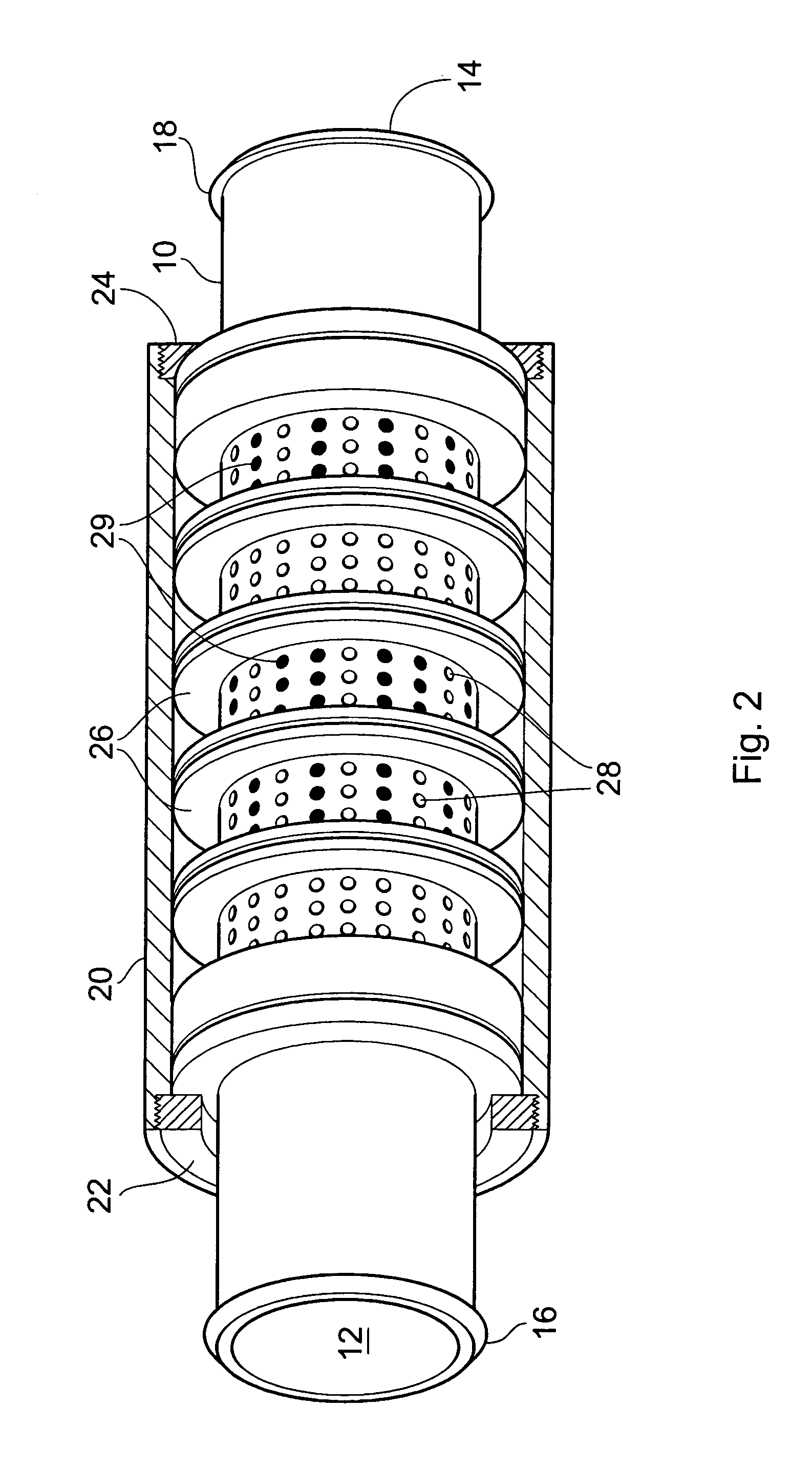

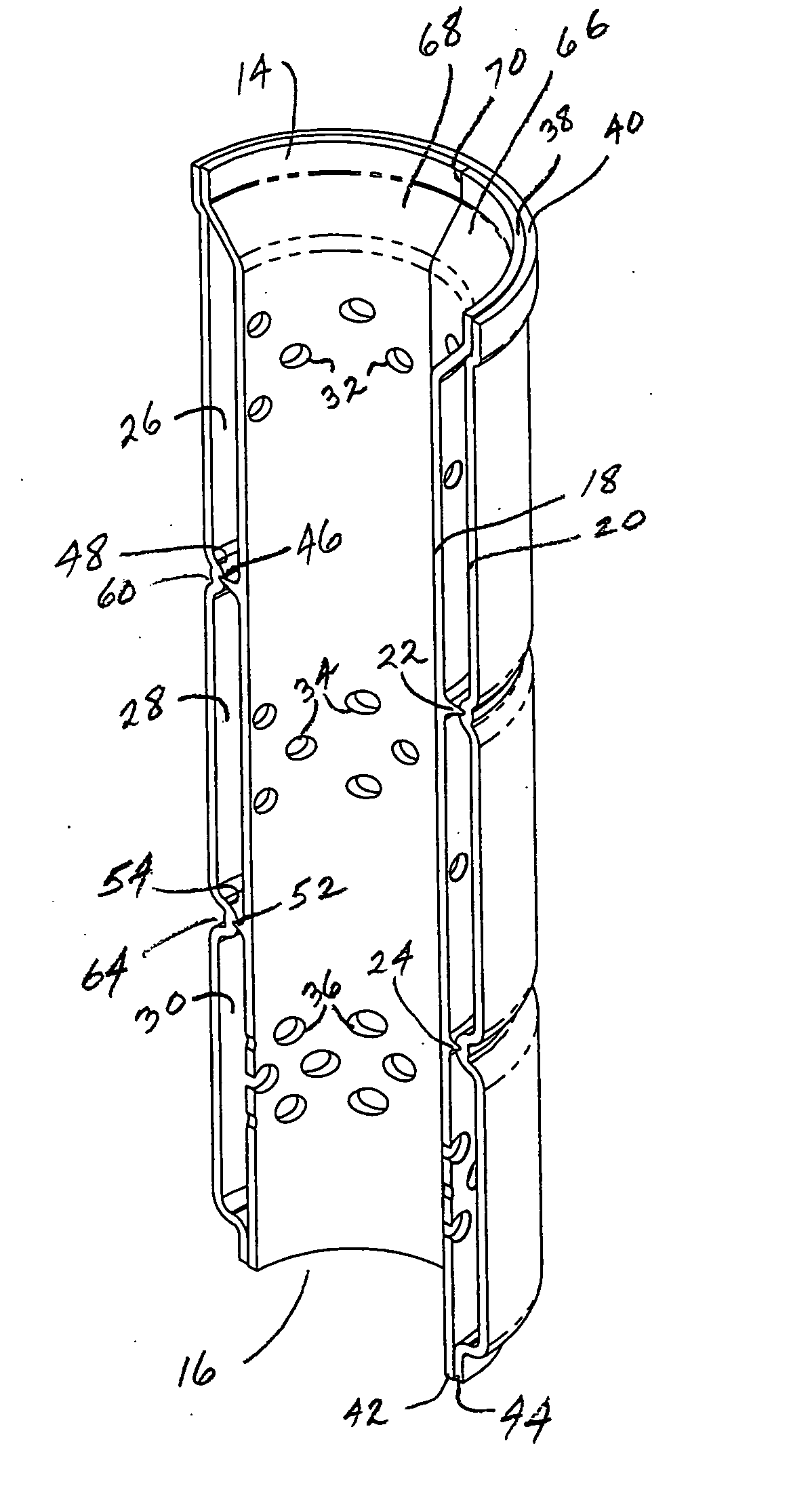

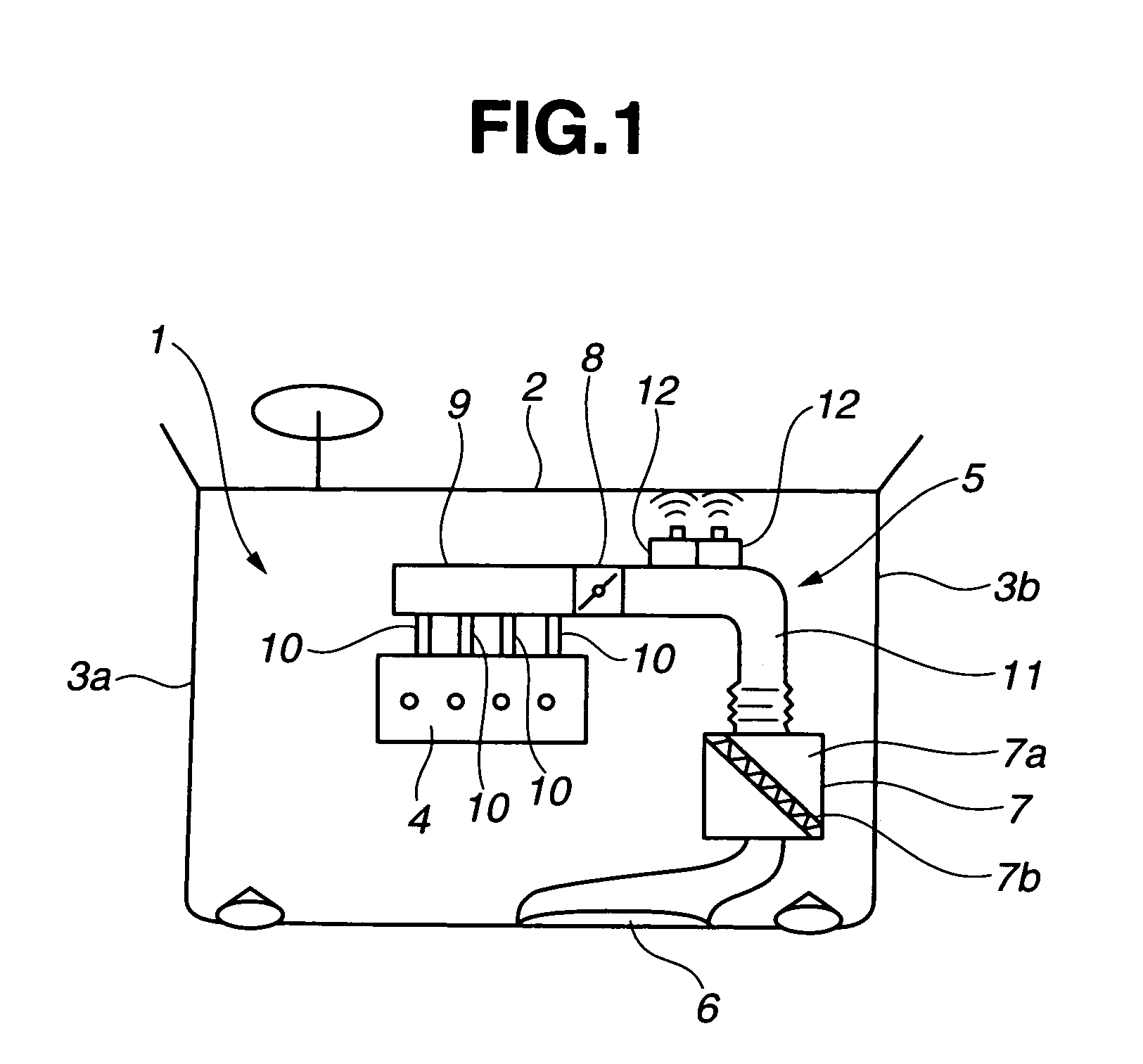

InactiveUS6983820B2Increase dampingSuppress noisePositive displacement pump componentsSilencing apparatusSuppressorModularity

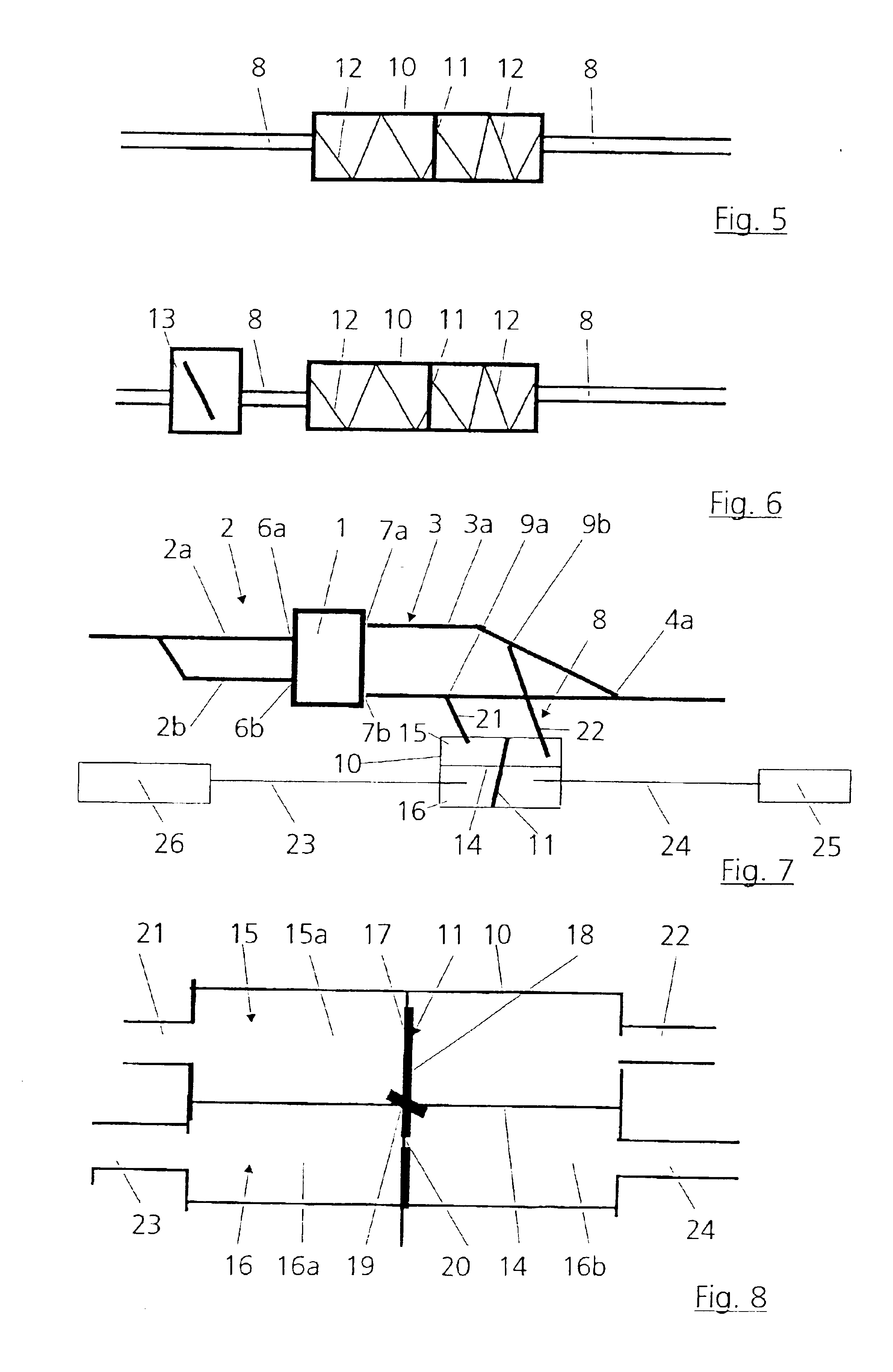

In order to form a noise suppressor in a hose of e.g. a motor vehicle, modular portions are connected in series to define suppression chambers with particular noise suppression characteristics. Those characteristics are due to the volume of each chamber, to the size of the apertures from the chambers to the central duct of the suppressor, and optionally due to spacers which are inserted into at least one aperture of the chambers to alter the effective open area of that aperture. Such spacers may also be used in which the noise suppressor is not modular. Where modular portions are used, it is preferable that each chamber is bounded by parts of two modular portions. A wall of one modular portion may then close the chamber in another modular portion, making the manufacture of the modular portions easier. Also disclosed is the use of a mass acting as a damper, which may be a noise suppressor as previously discussed, within a hose. The mass is connected to the hose by resilient means, e.g. electrometric material.

Owner:CADILLAC RUBBER & PLASTICS

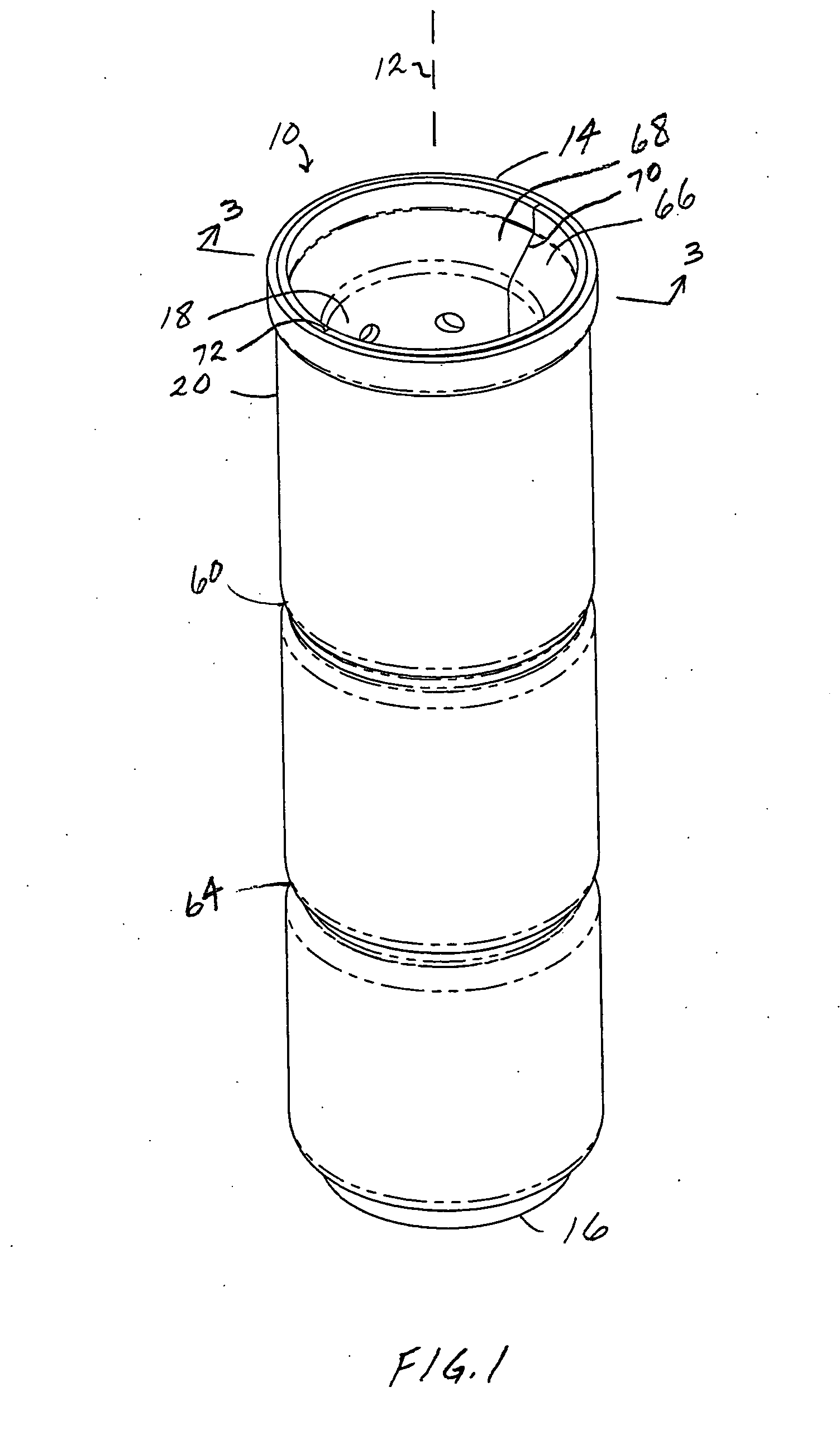

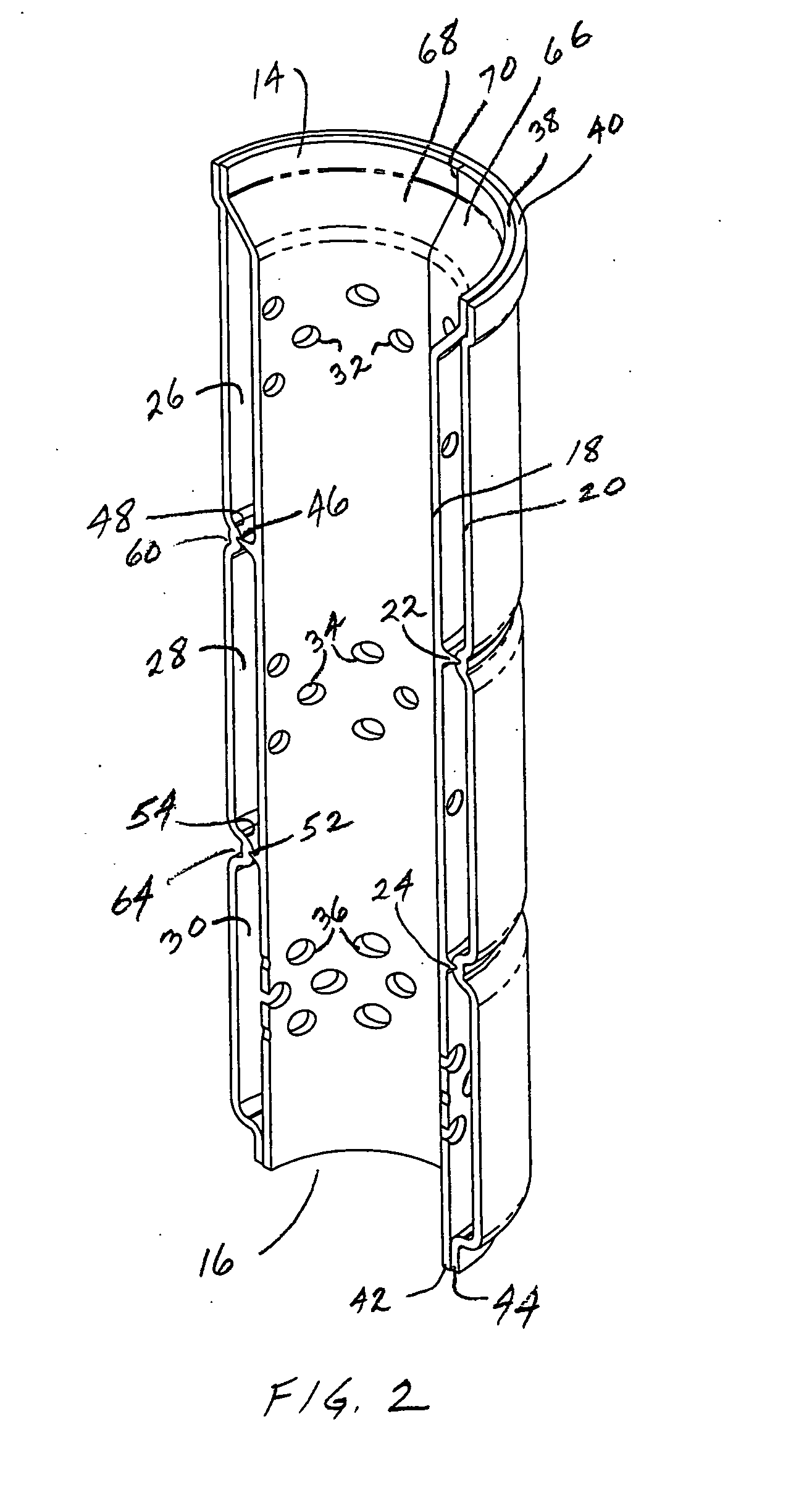

Resonator with retention ribs

InactiveUS20050150718A1Simple and cost-effectiveSilencing apparatusCombustion enginesEngineeringSecondary bonding

A resonator includes an inner perforated tube, an outer shell, and a plurality of annular ribs extending radially therebetween and defining resonant chambers. Progressive stepping of ribs and grooves enables axial insertion assembly with minimal cost. The need for welding or secondary bonding operations is eliminated.

Owner:FLEETGUARD INC

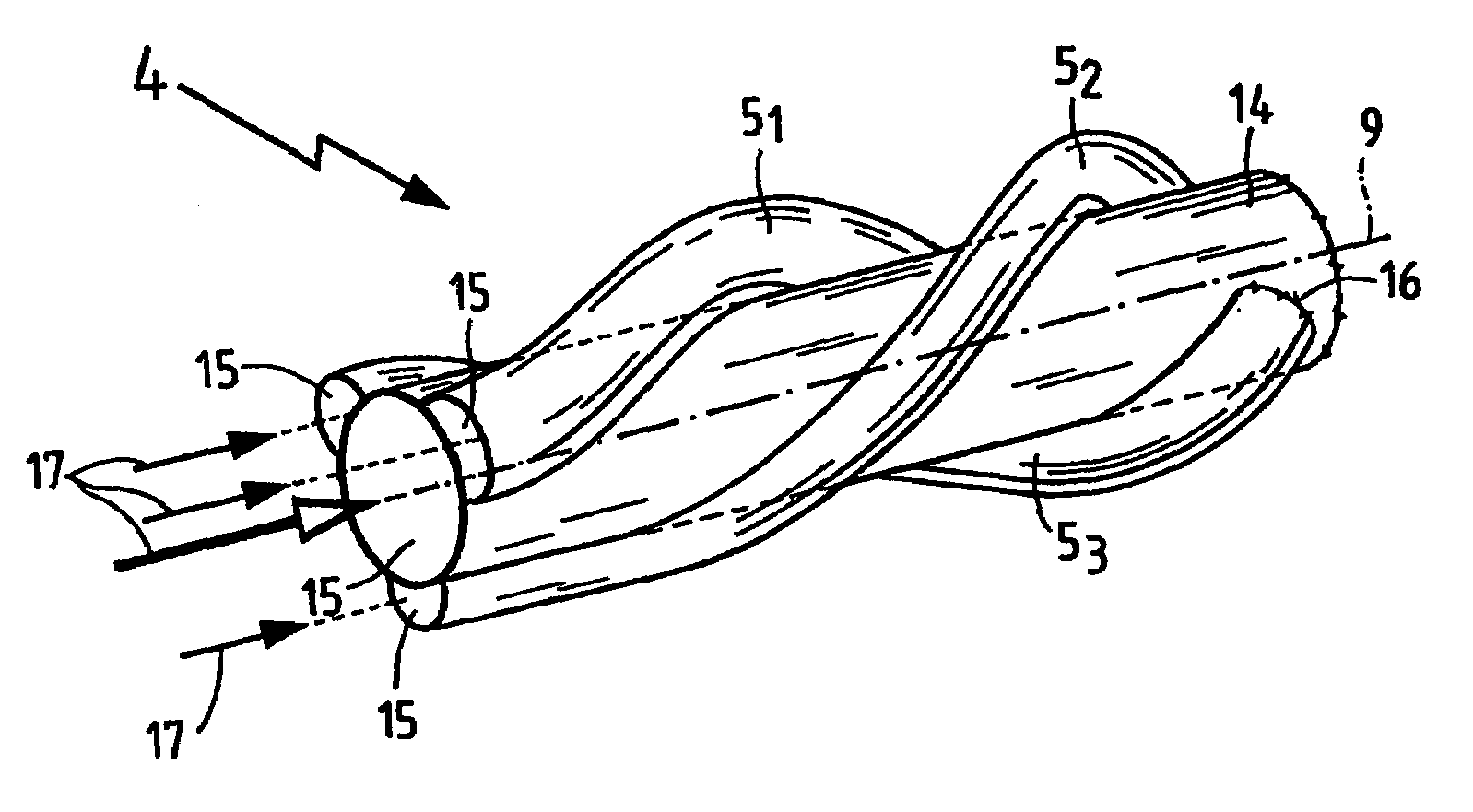

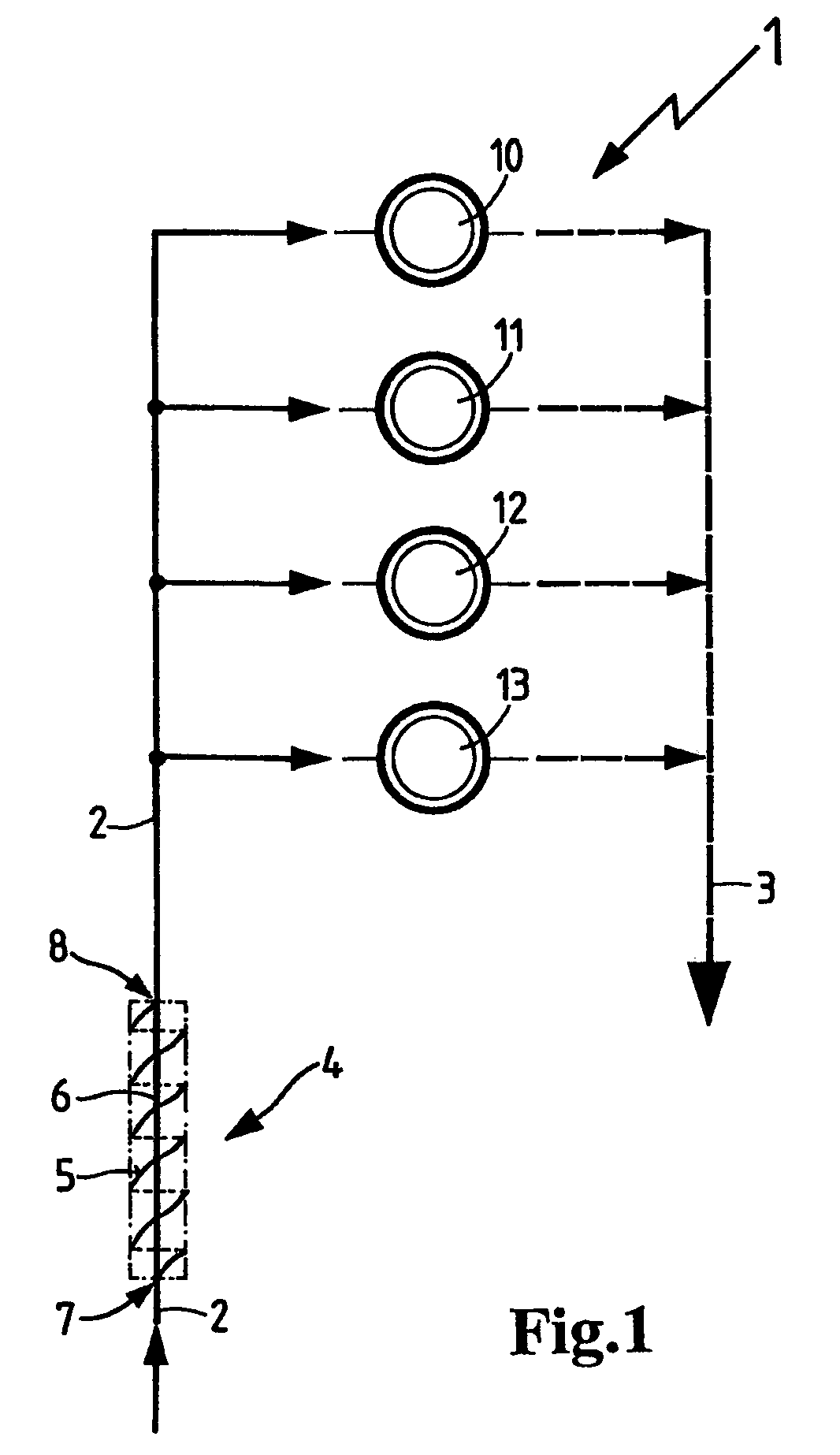

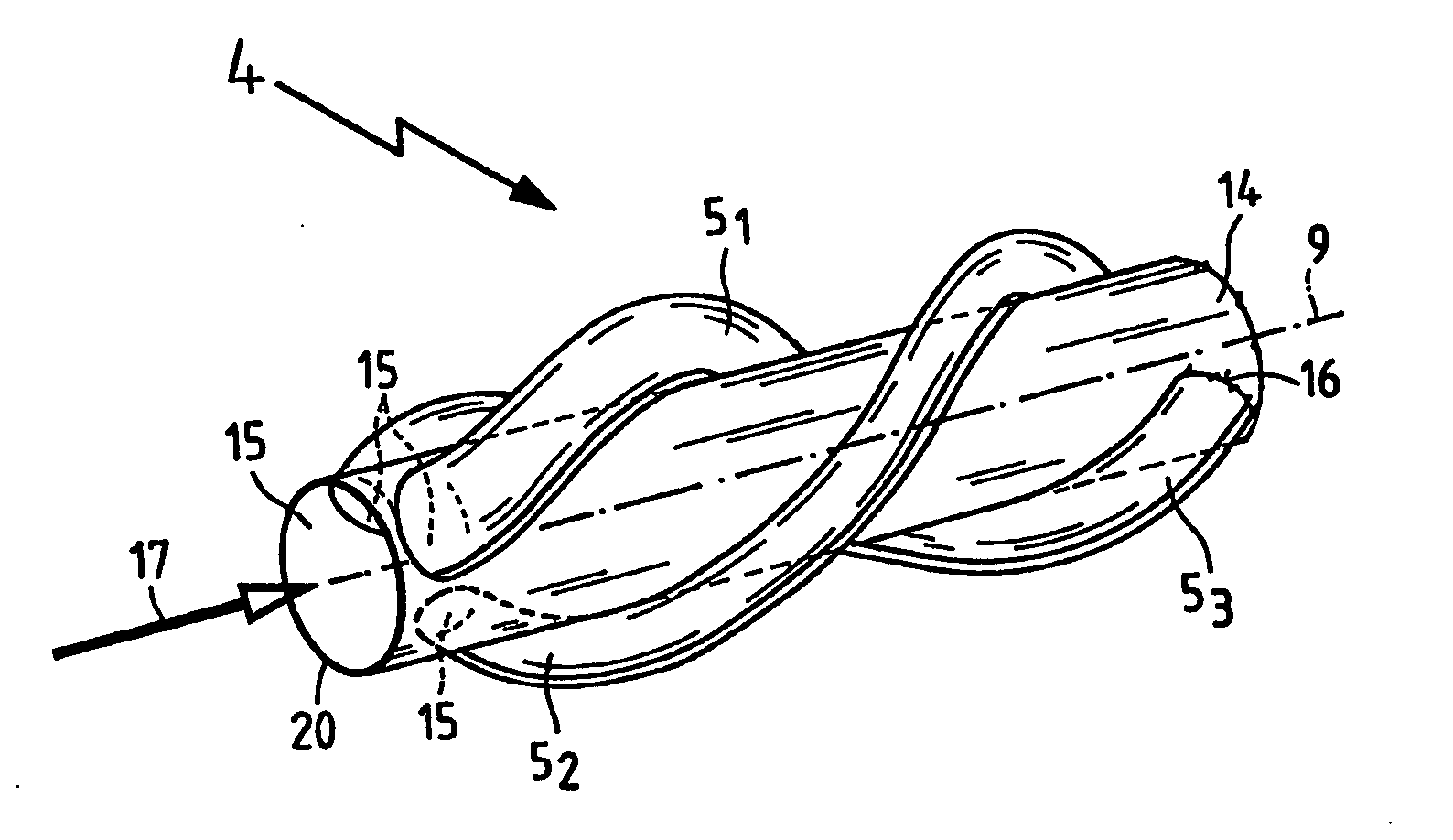

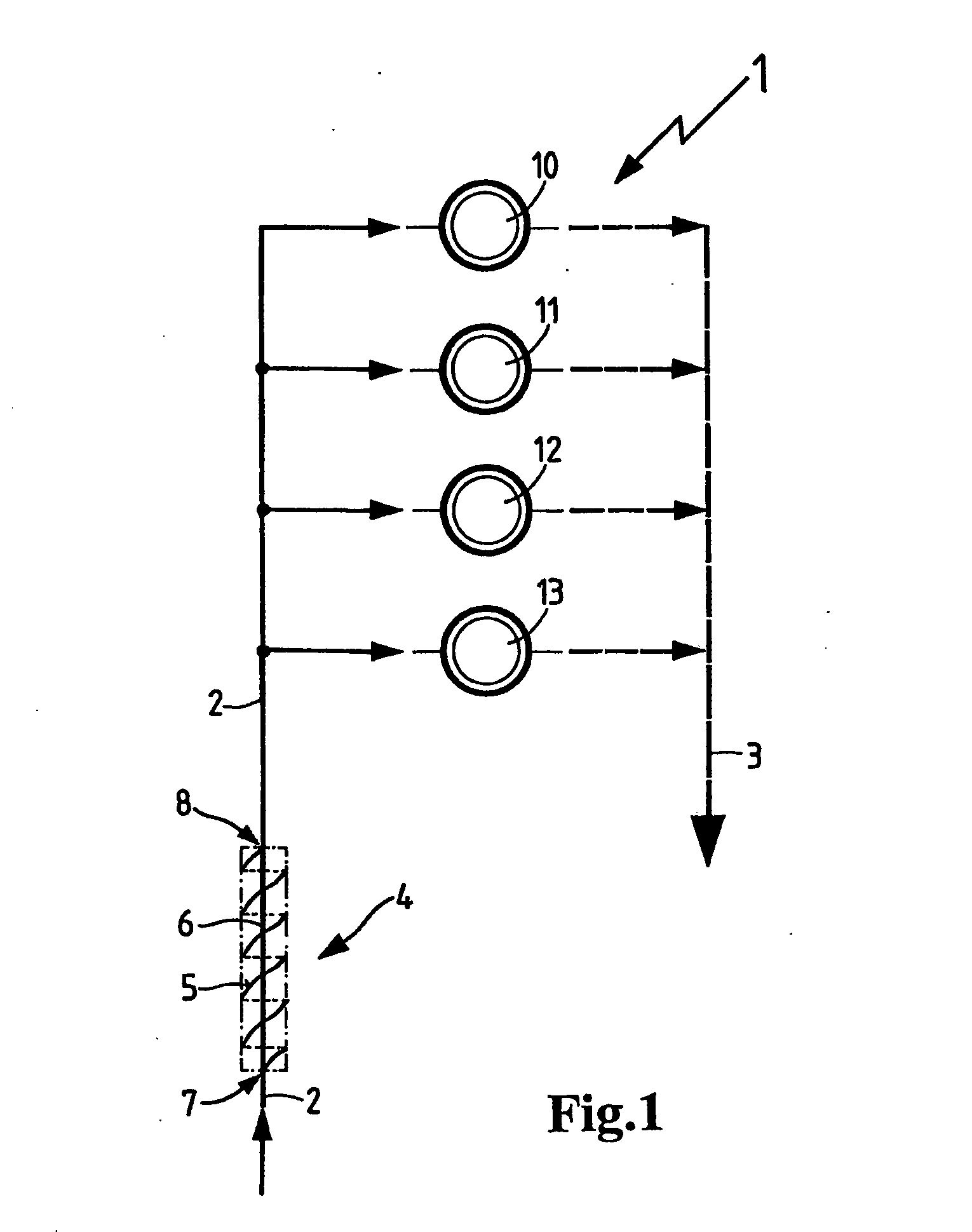

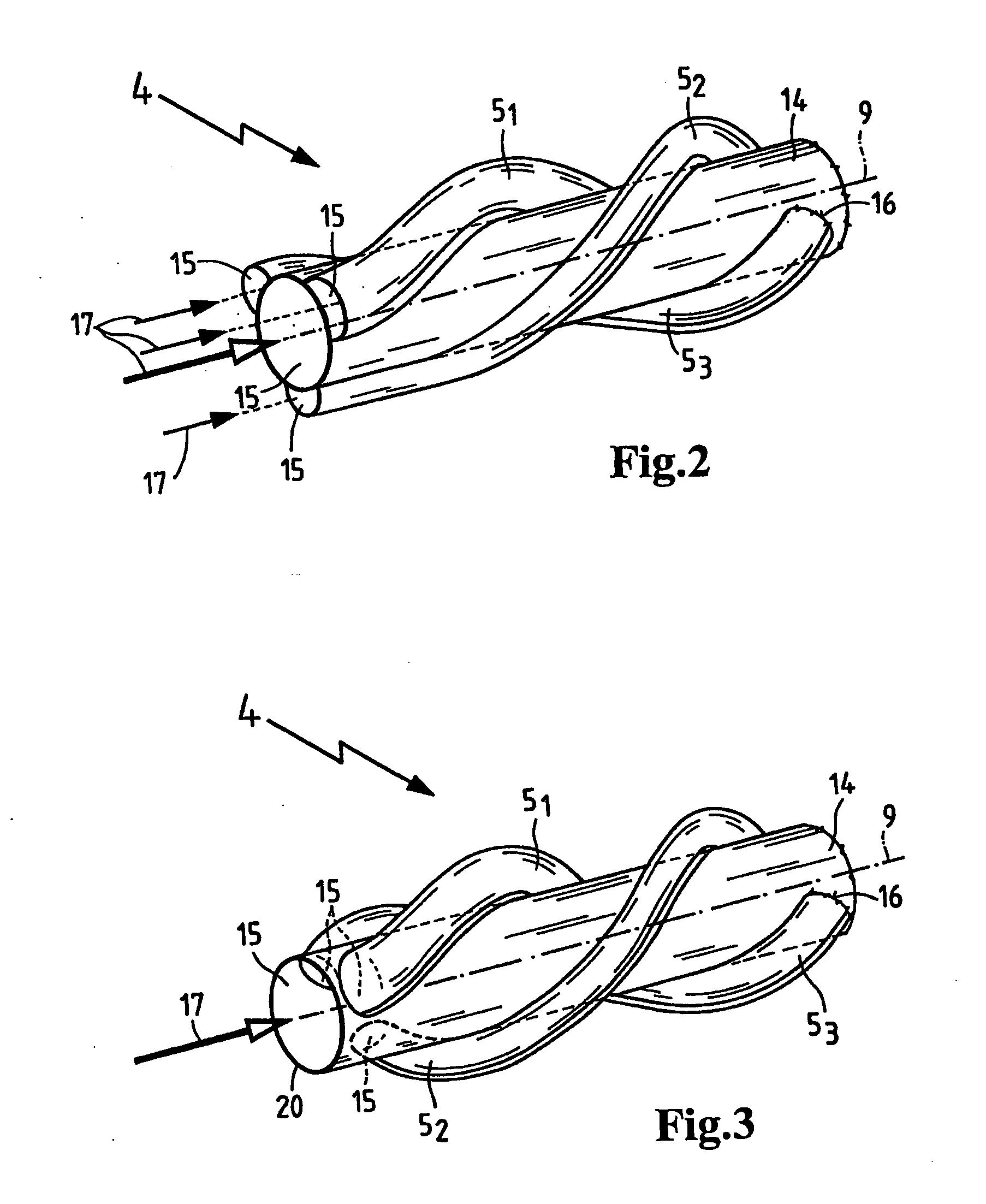

Noise suppressor apparatus for a gas duct

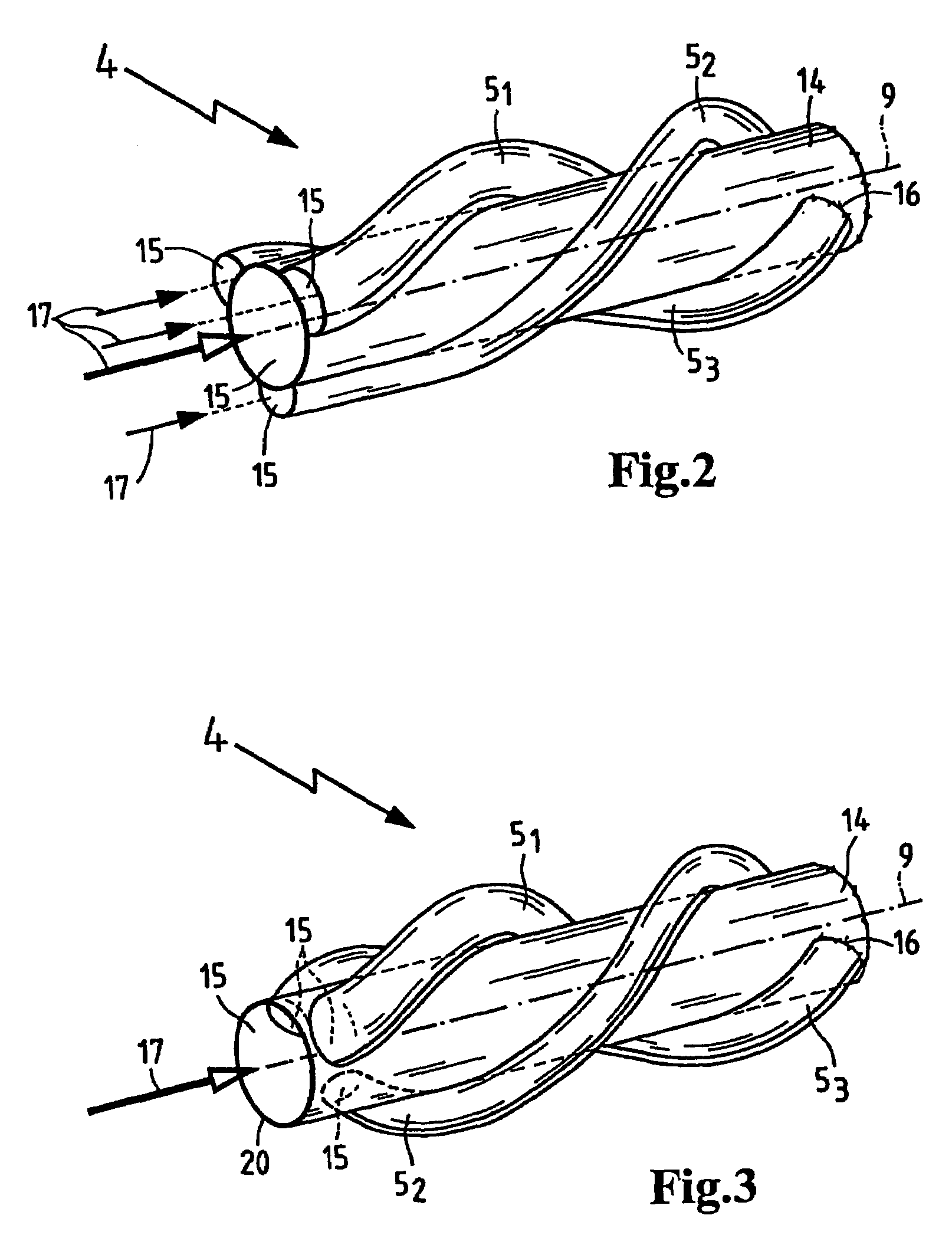

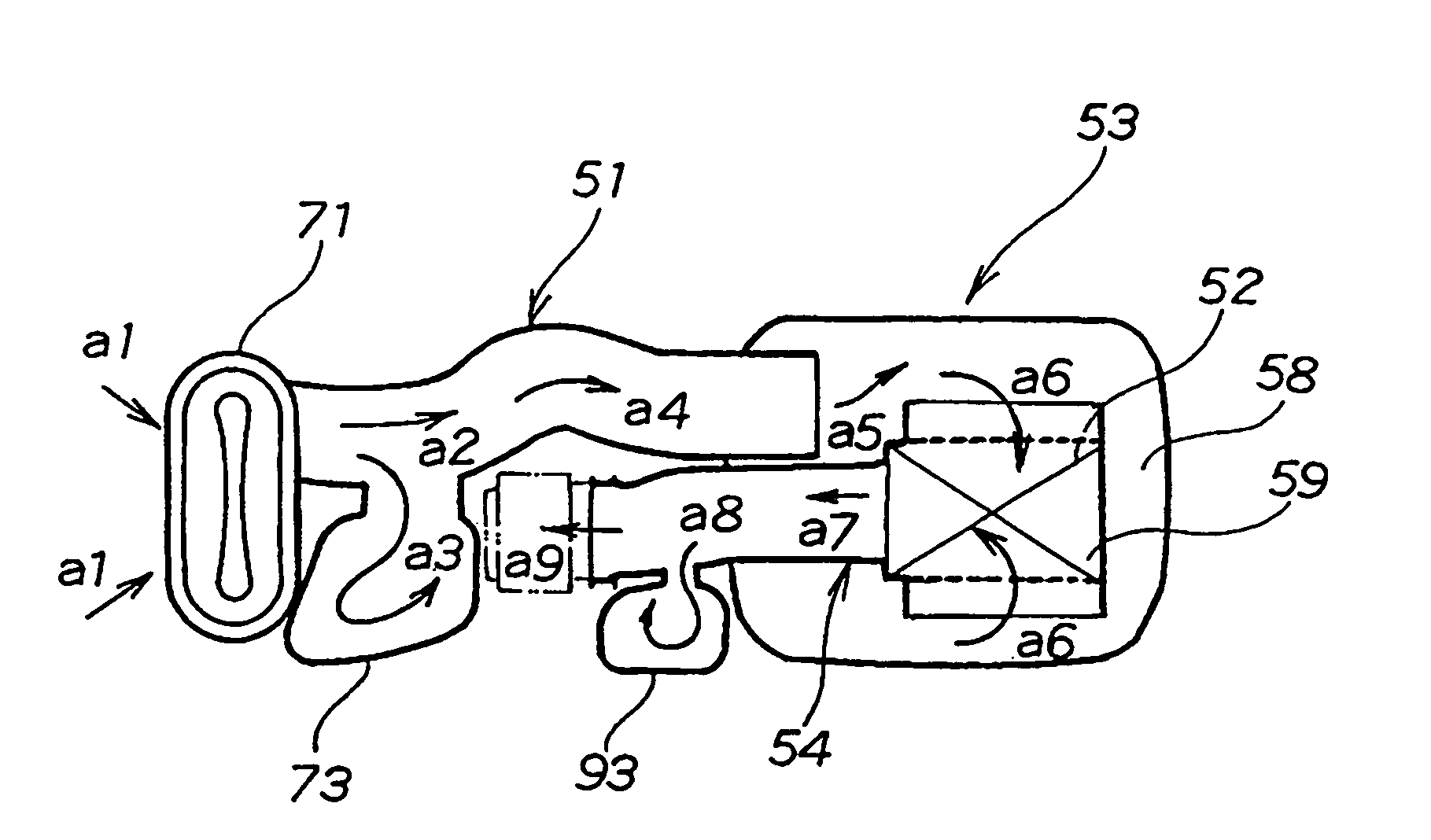

A sound damping device (4) for a tubular duct (2), particularly a gas transporting tract of an internal combustion engine (1) having a least one bypass channel (5) running parallel to a main duct (6) in a section of the duct (2). The bypass channel (5) is longer than the main duct (6) between a branching off point (7) and a re-entry inlet (8). The bypass duct according to the invention is configured as a spiral duct (5) which winds around the centrally disposed main duct (6) in order to decrease the installation space requirements for the noise suppressor (4).

Owner:MANN HUMMEL GMBH

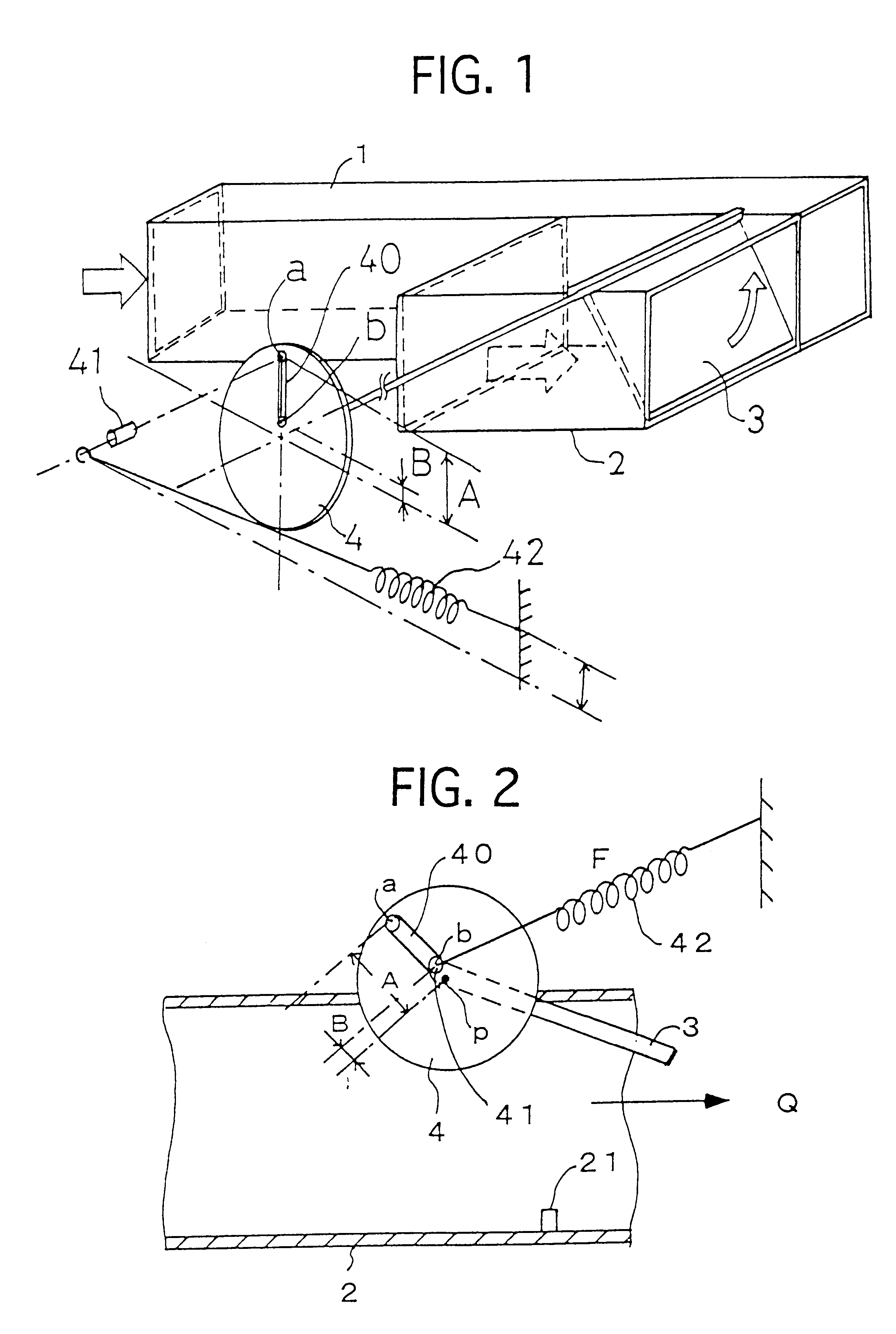

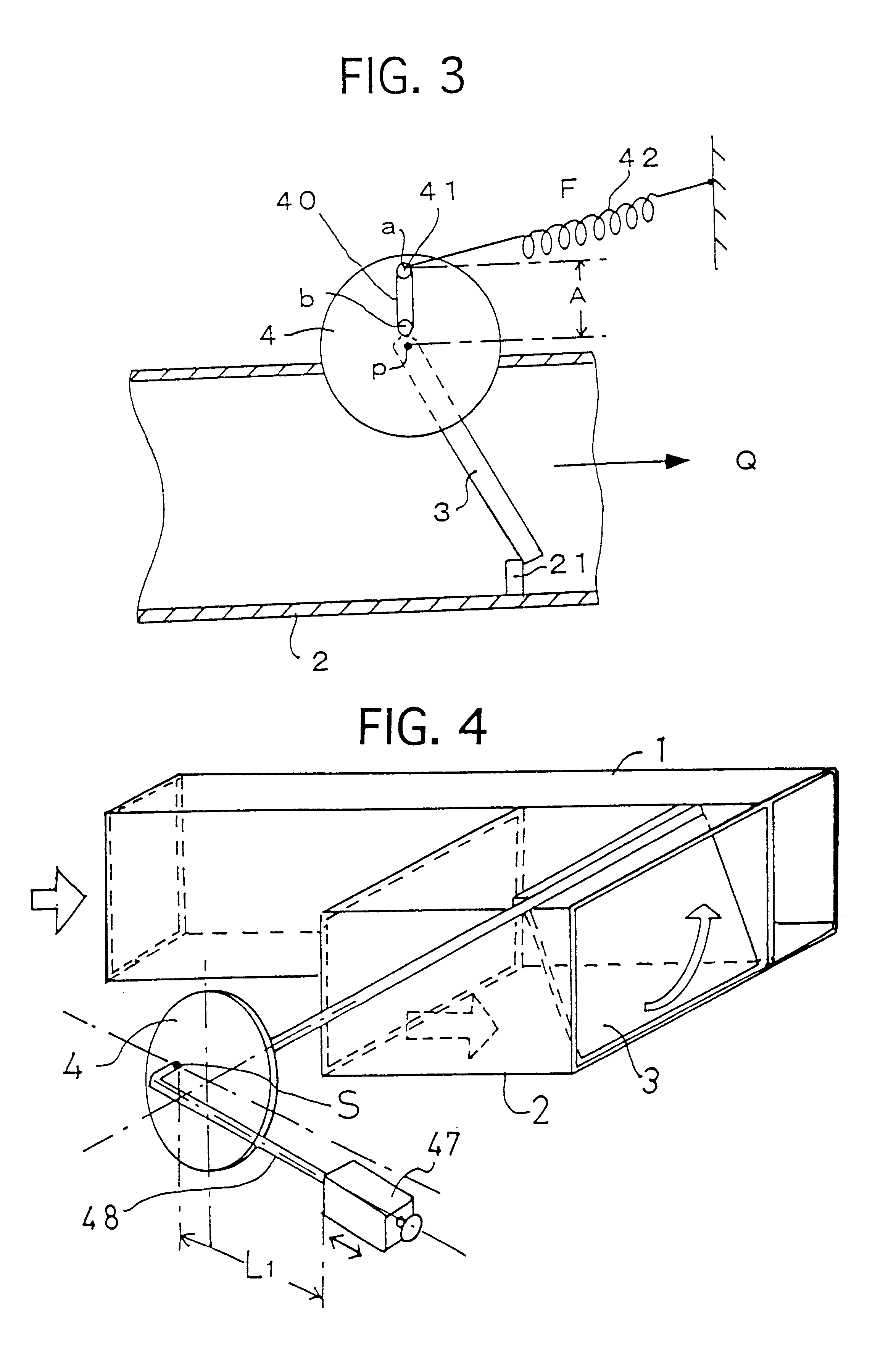

Intake air duct

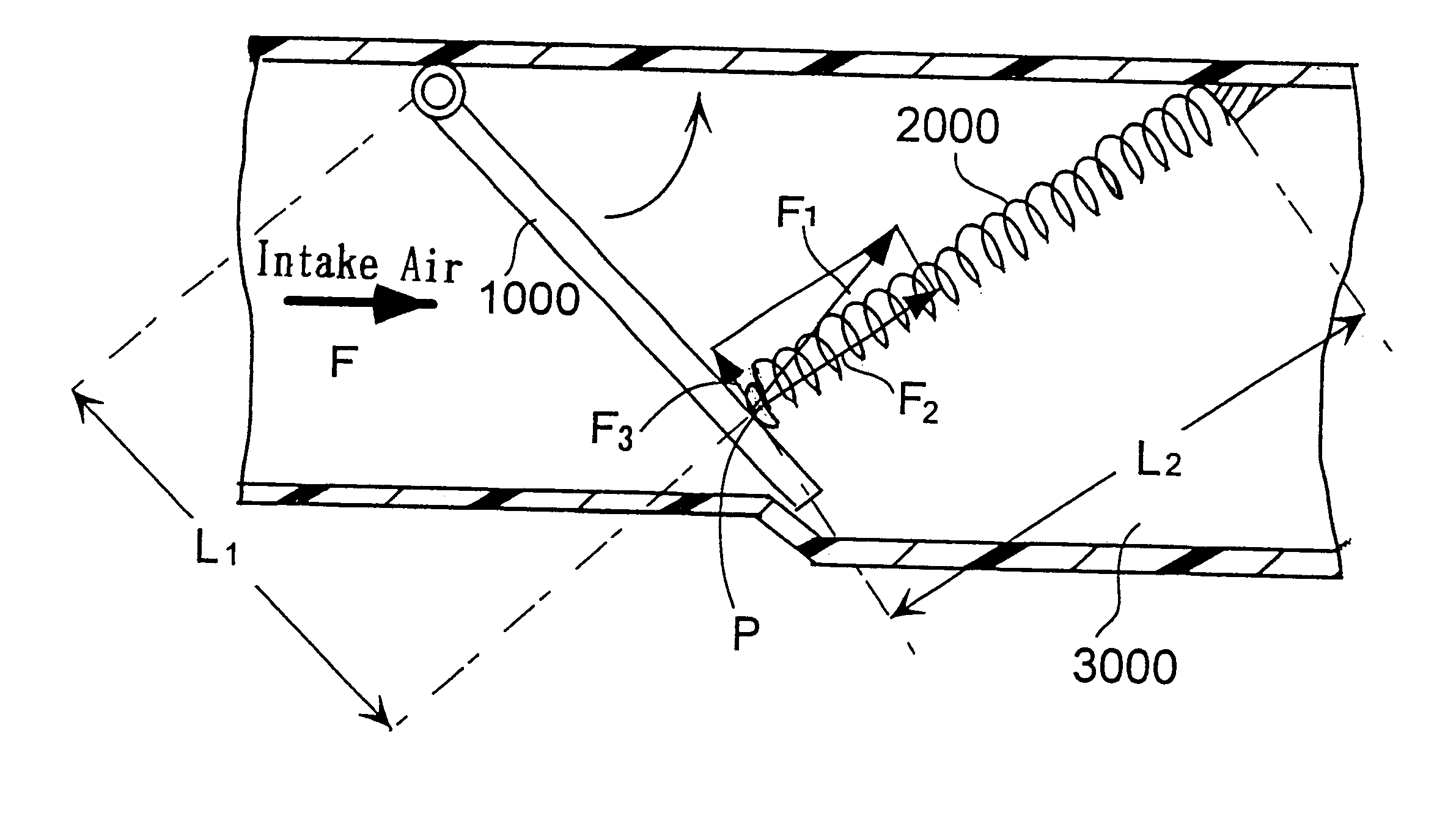

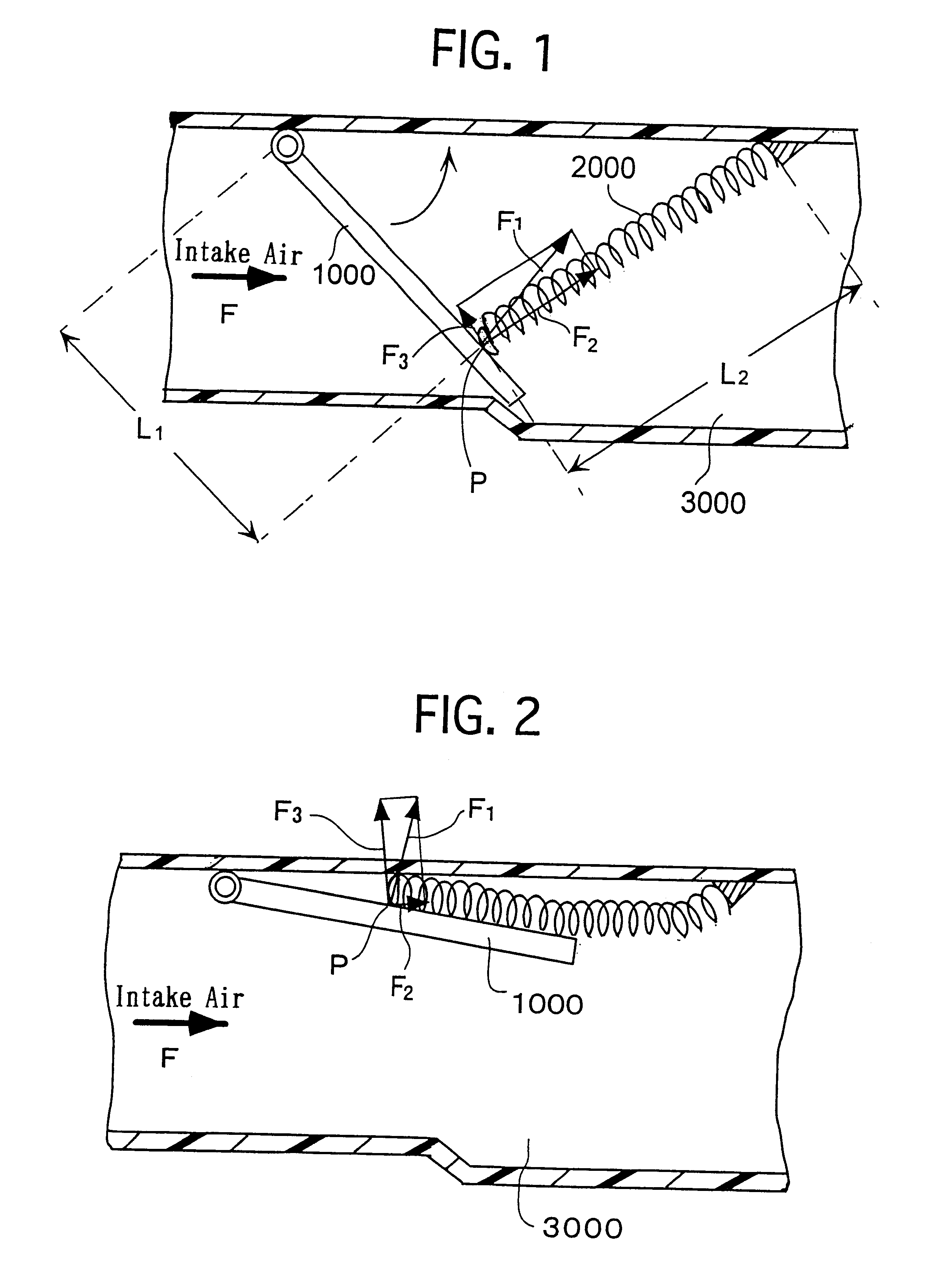

InactiveUS6332442B1Reduce intake noiseLow costInternal combustion piston enginesSilencing apparatusCoil springEngineering

An intake air duct serves as a passage for supplying air to an engine, and includes a first intake air passage, a second intake air passage, an opening-and-closing valve, an interlocking member and a coiled spring. The opening-and-closing valve is disposed swingably in the second intake air passage so as to open and close the second intake air passage. The interlocking member is disposed outside the first intake air passage or the second intake air passage, and swings by interlocking with the swinging of the opening-and-closing valve. The coiled spring is disposed swingably outside the first intake air passage or the second intake air passage, and has a swinging end, which is brought into contact with a surface of the interlocking member. The swinging end slides on a surface of the interlocking member as the swinging of the interlocking member. The second intake air passage is opened by the opening-and-closing valve when a first urging force, which acts onto the coiled spring while the interlocking member swings so as to interlock with the opening-and-closing valve being swung in an opening direction by a negative pressure exerted in the second intake air passage, is larger than a second urging force, which is exerted by a spring elasticity of the coiled spring. The second intake air passage is closed when the first urging force is smaller than the second urging force.

Owner:TOYODA GOSEI CO LTD

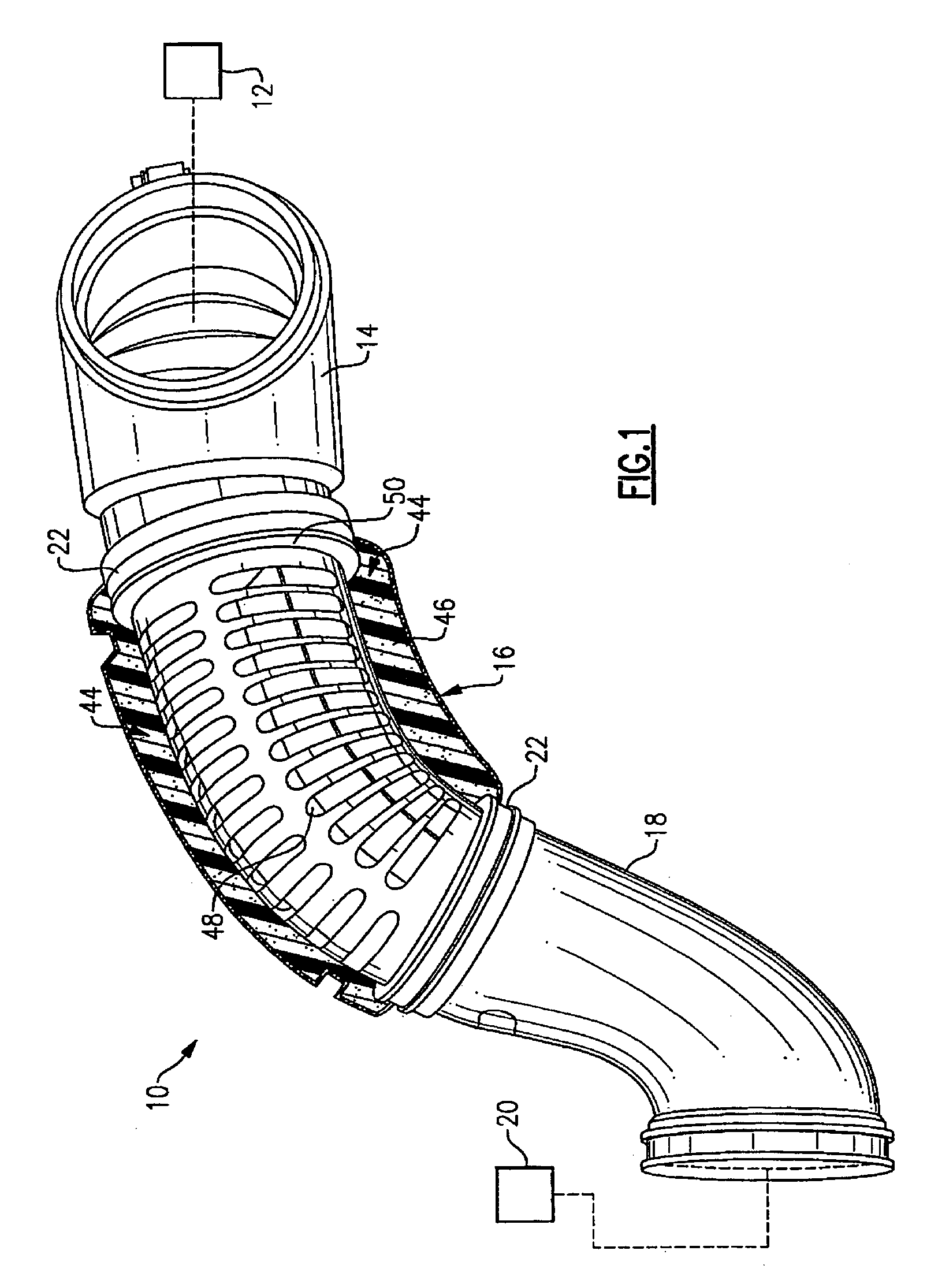

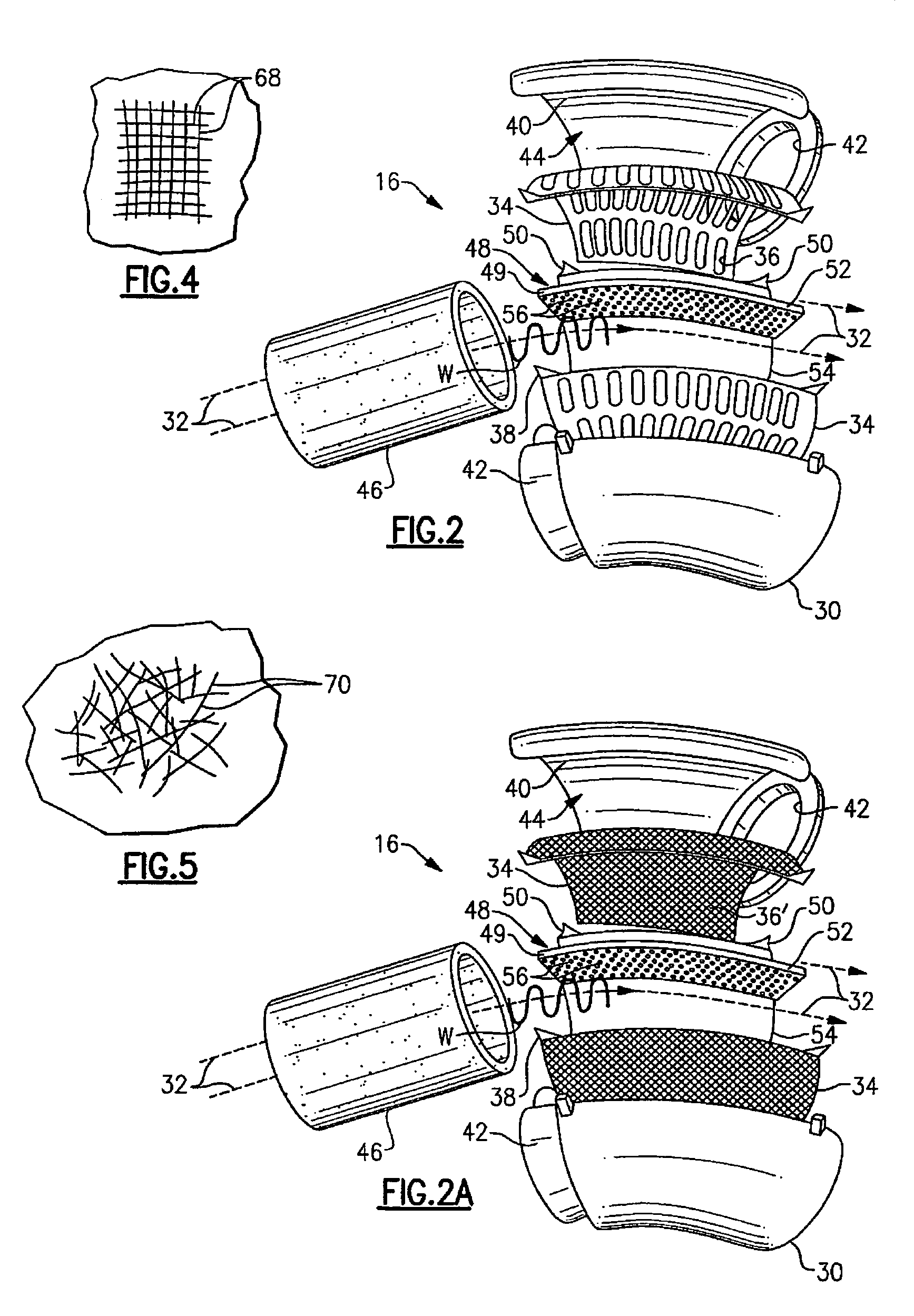

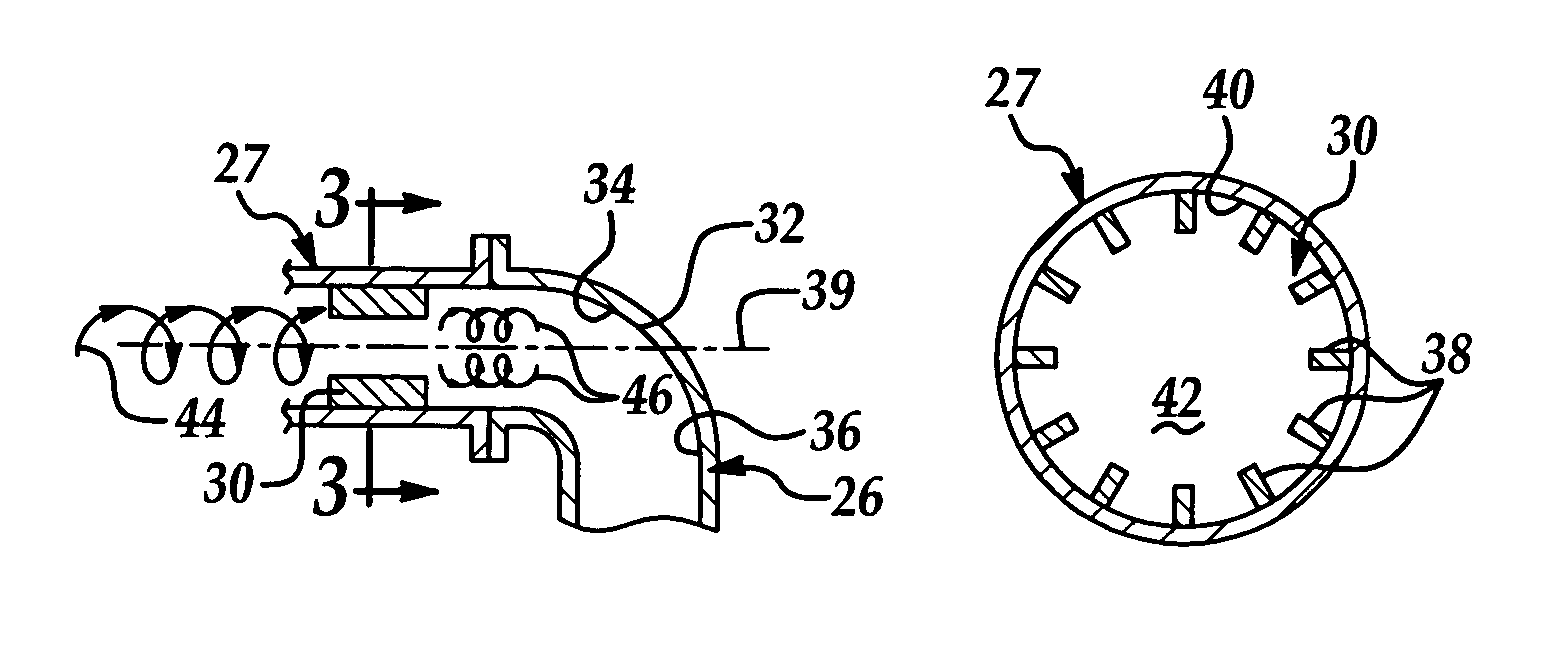

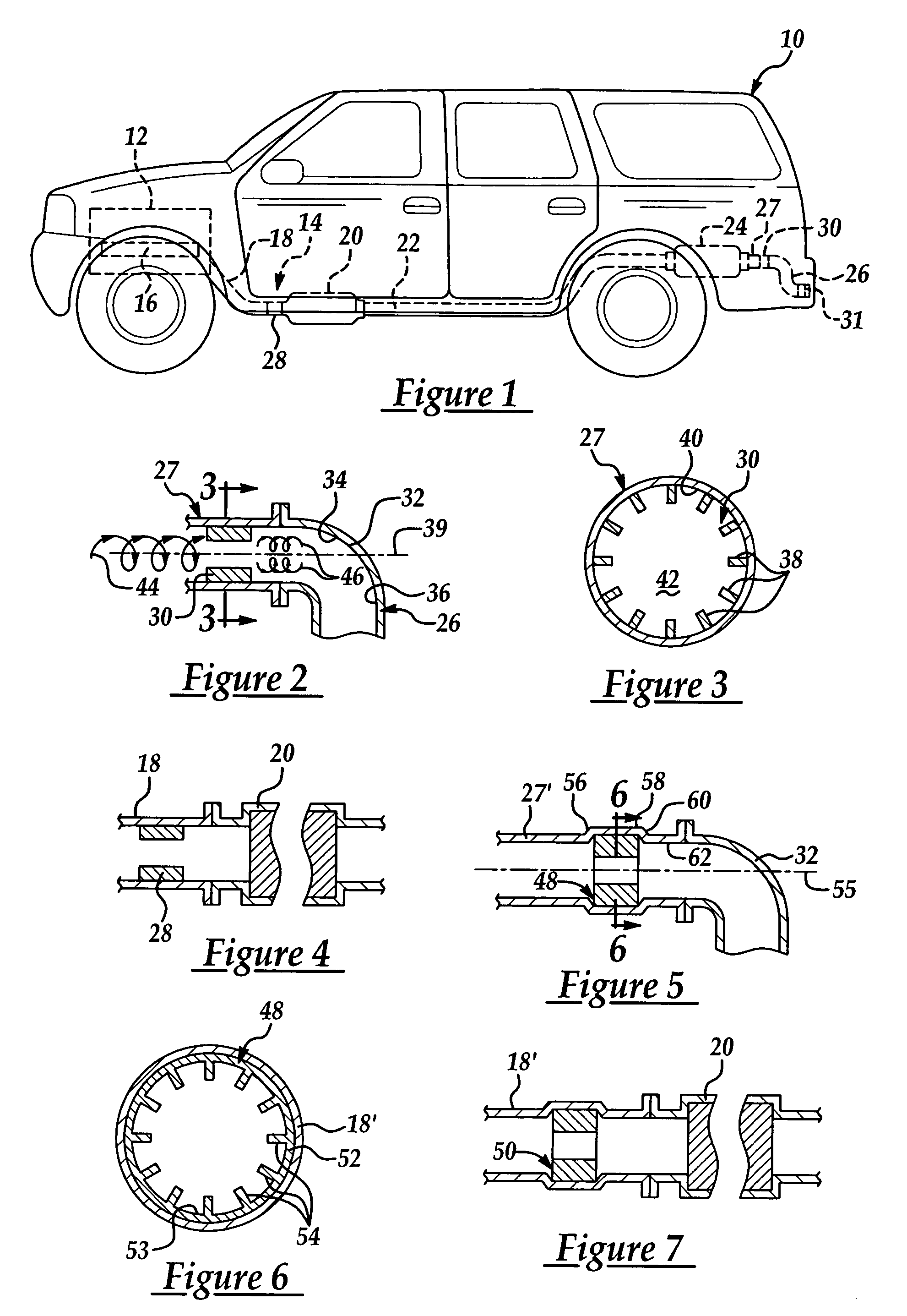

Silencer for air induction system and high flow articulated coupling

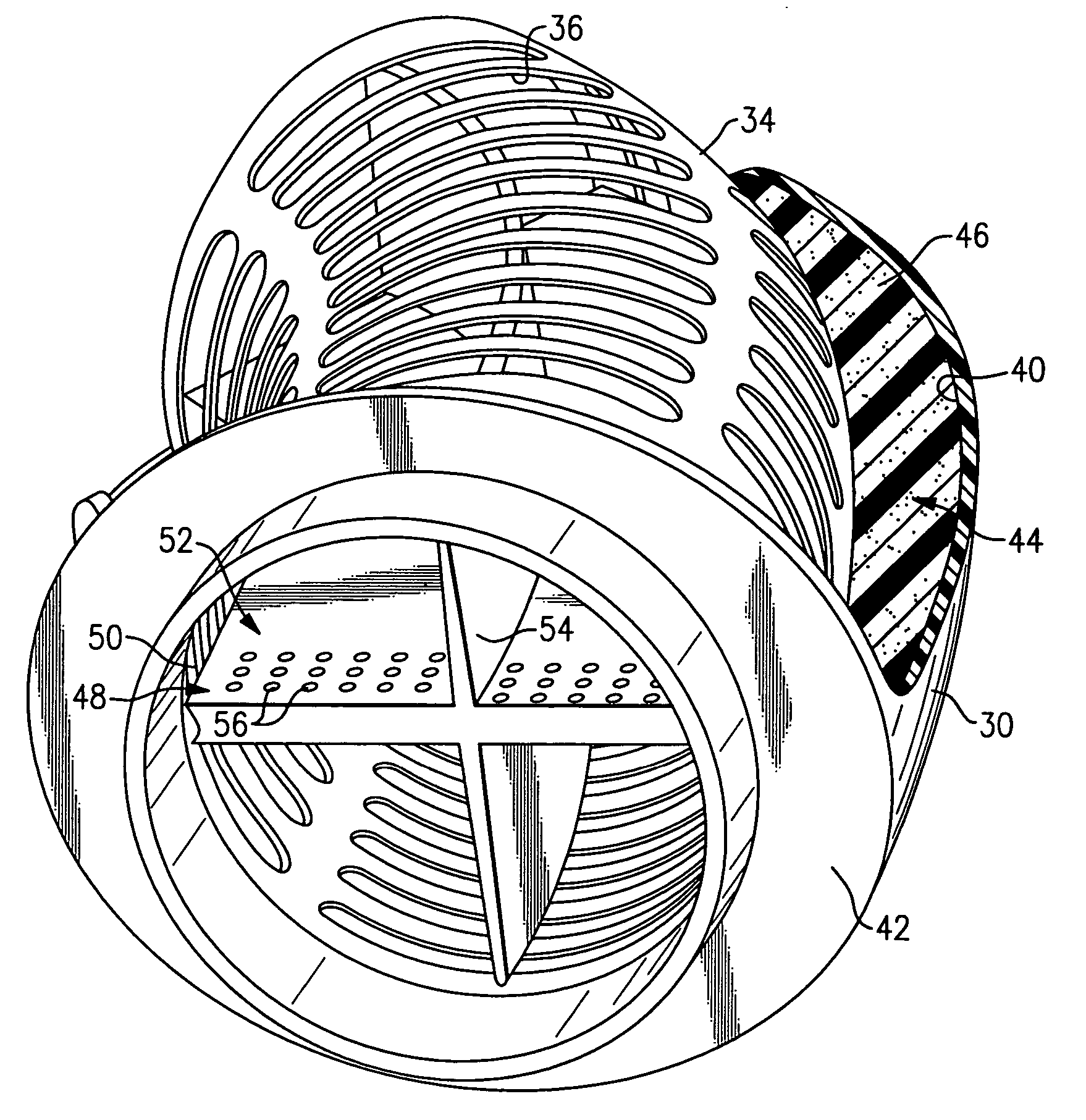

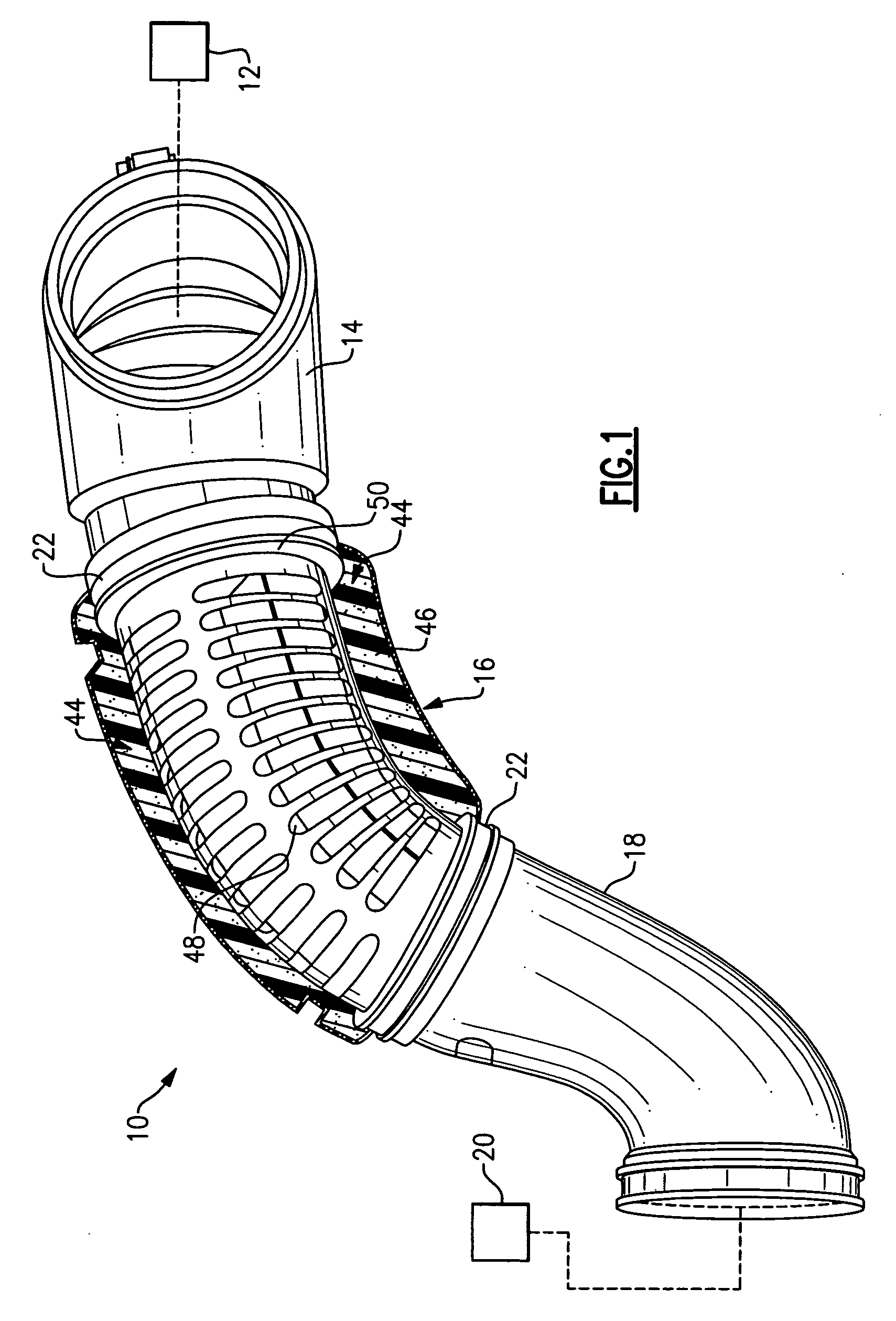

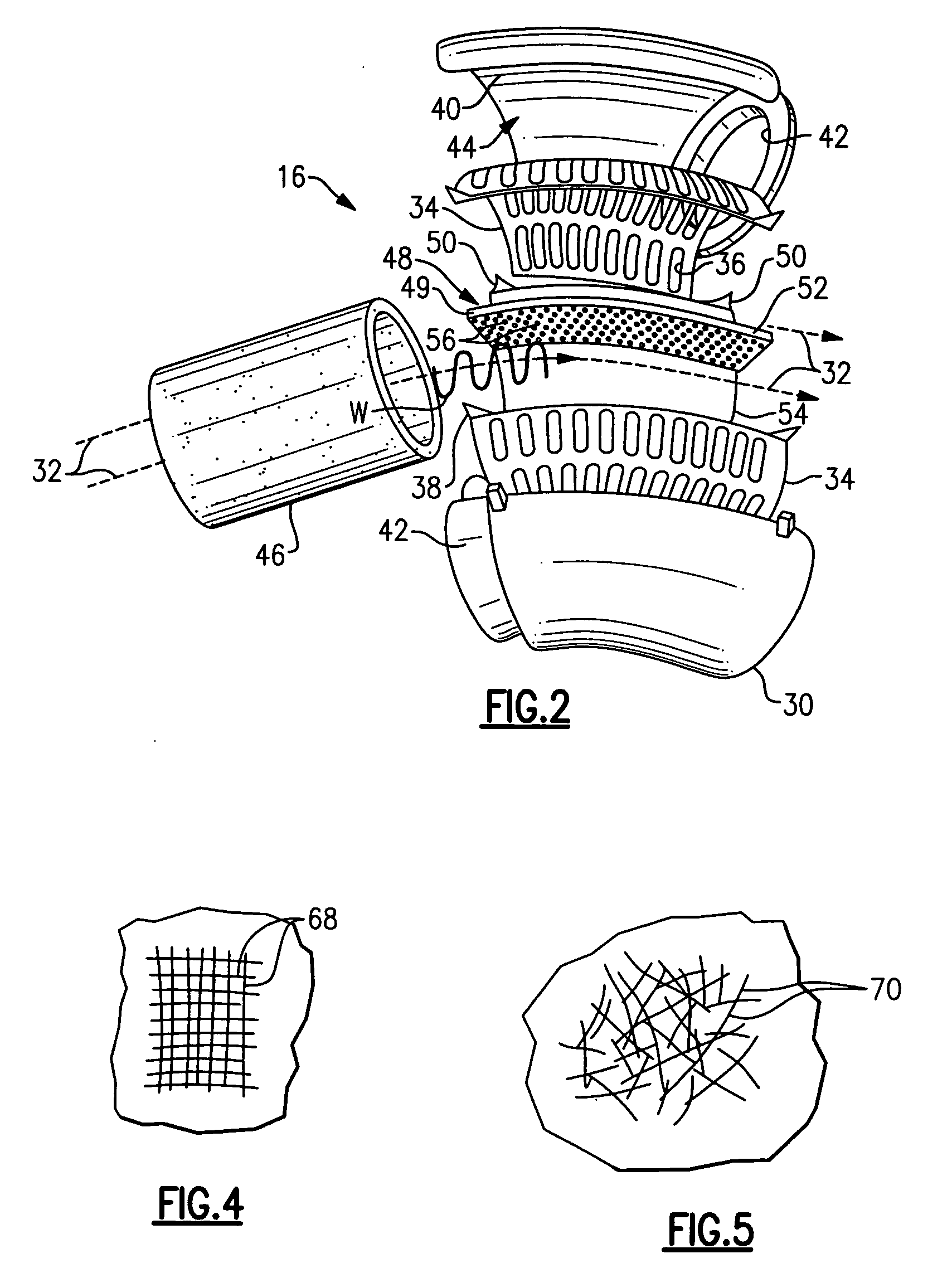

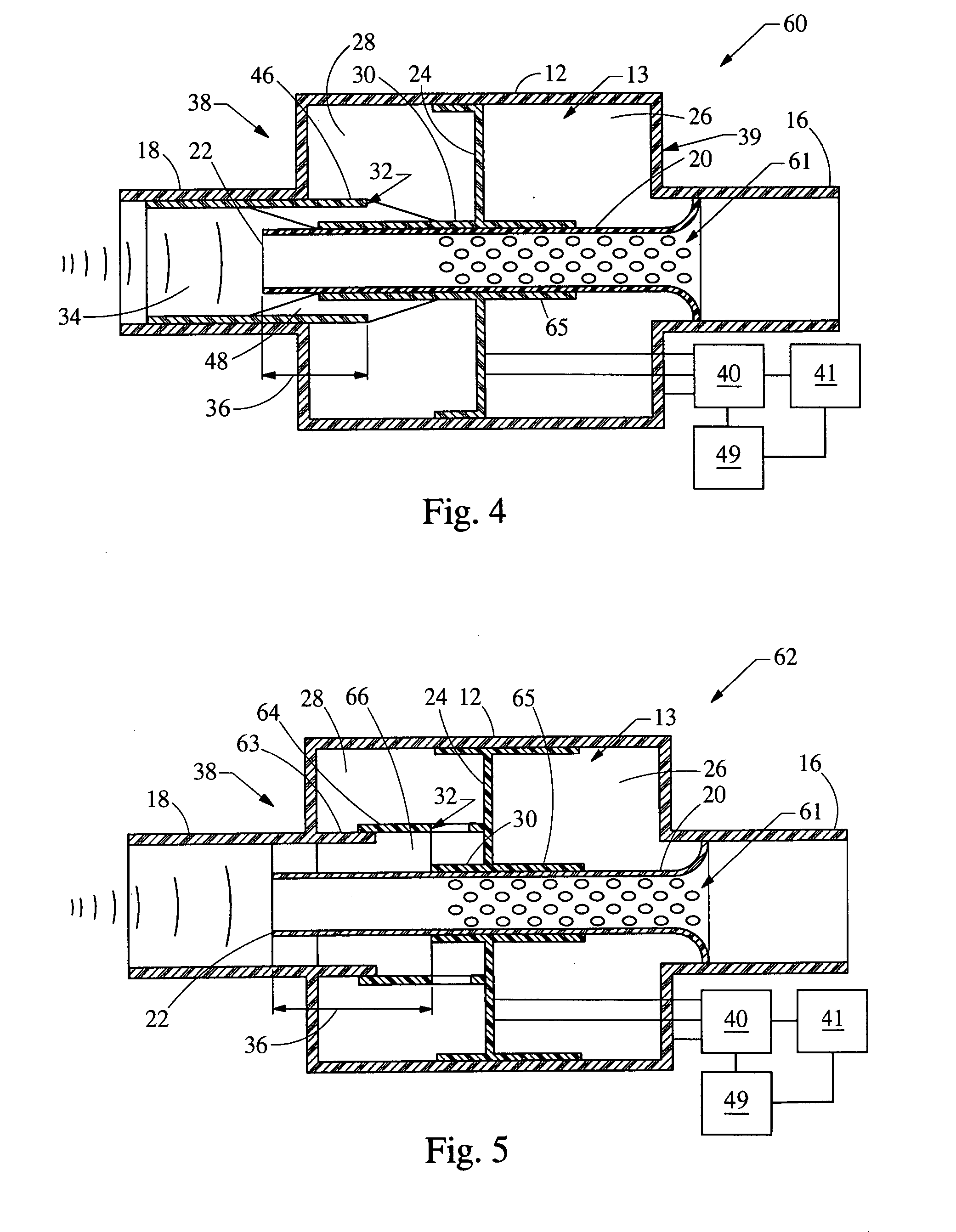

InactiveUS7631726B2Reduce flowReduce noise energySilencing apparatusMachines/enginesCouplingEngineering

An air induction silencer assembly includes an acoustic interference member disposed within a conduit. The acoustic interference member is tuned to acoustically cancel a selected noise energy frequency. An acoustic absorbing member is also disposed within the conduit. The acoustic absorbing member converts noise energy within the conduit into heat energy to attenuate noise energy within the air induction silencer assembly. The air induction silencer assembly connects to a flexible conduit that includes an inlet portion, an outlet portion, and a flexible joint that connects the inlet portion and the outlet portion together. The flexible joint includes a rolling lobe and a rolling surface. The rolling lobe moves along the rolling surface when the inlet portion moves relative to the outlet portion.

Owner:SIEMENS VDO AUTOMOTIVE INC

Compressor muffler

Owner:RIC INVESTMENTS LLC

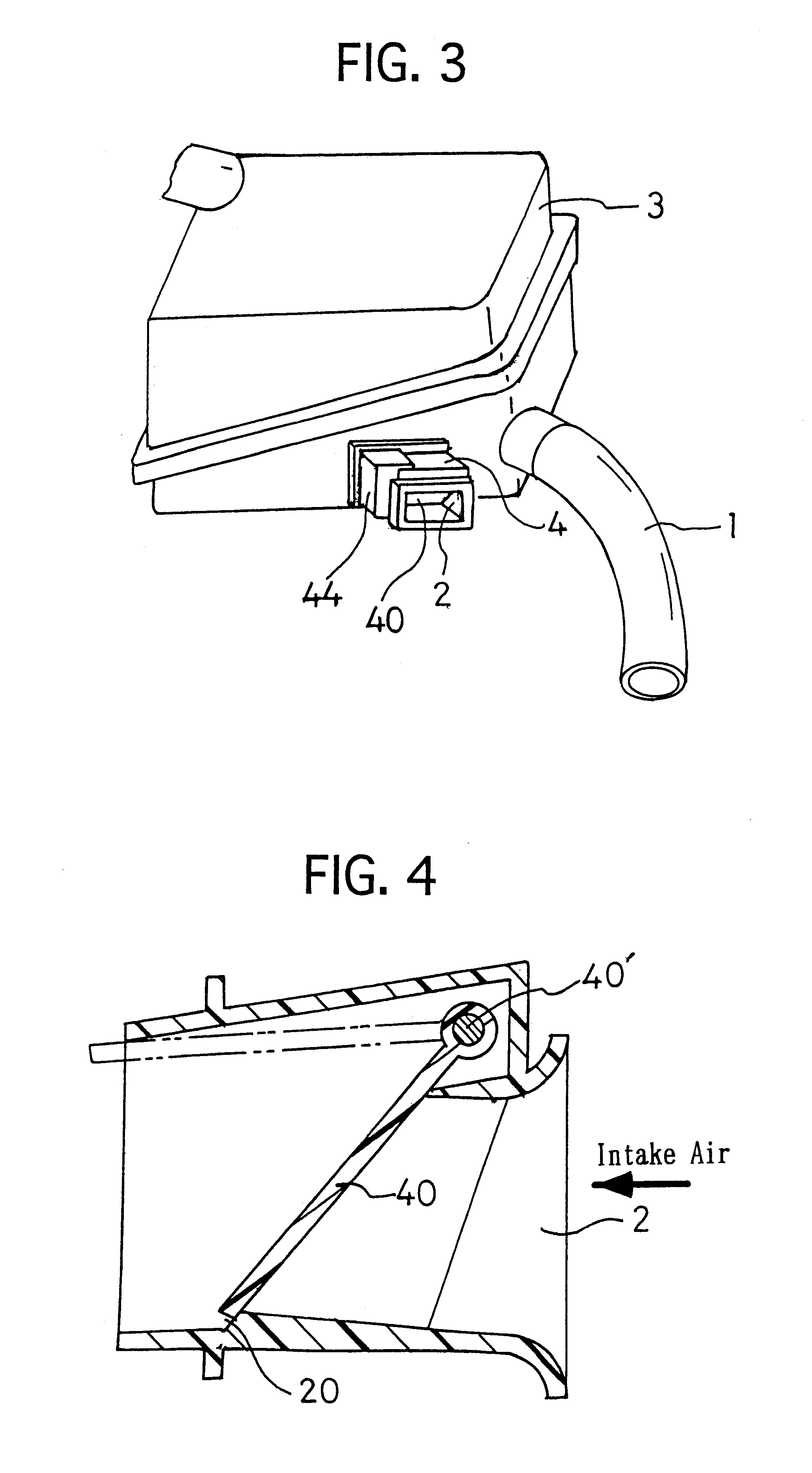

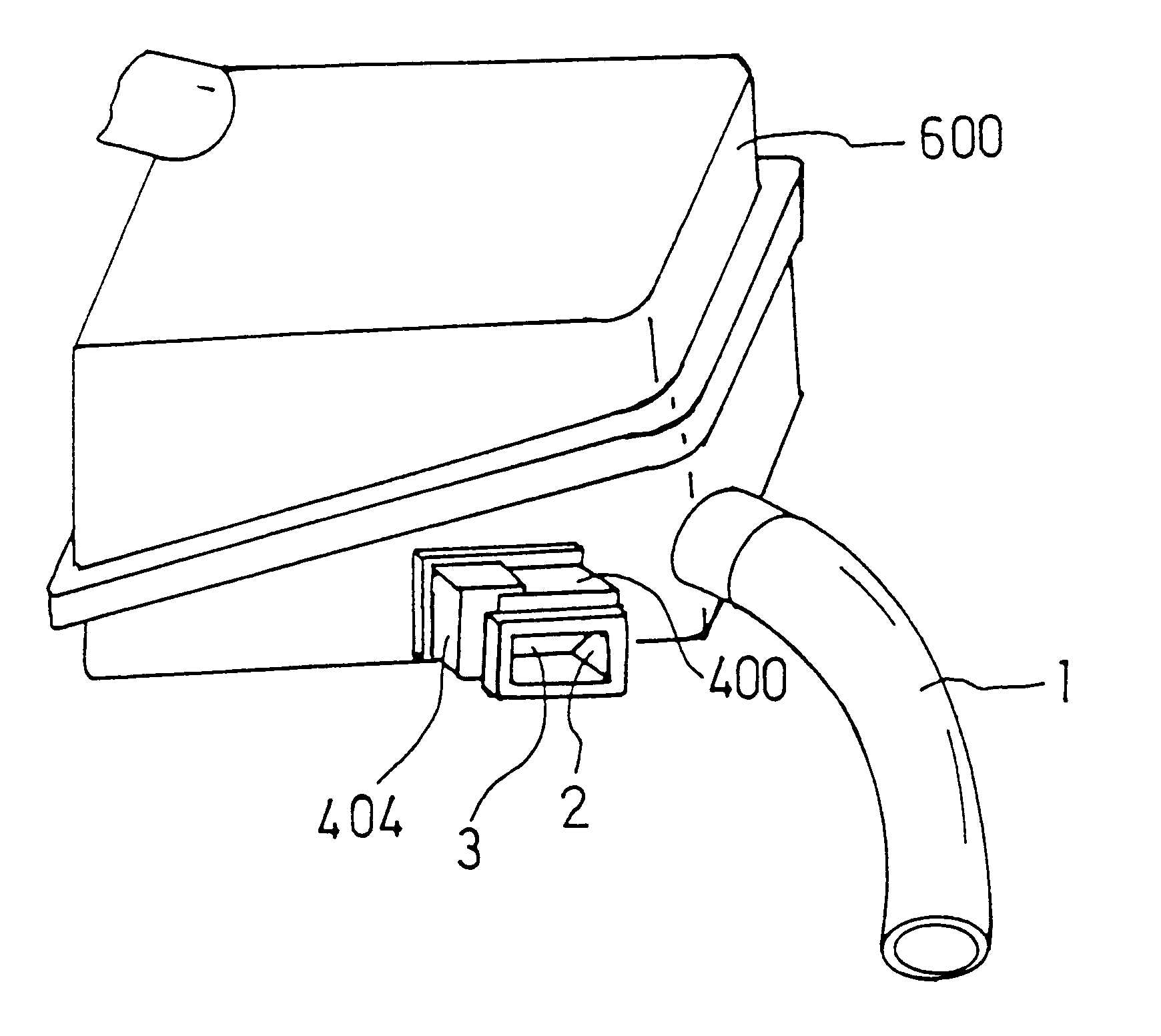

Air intake device

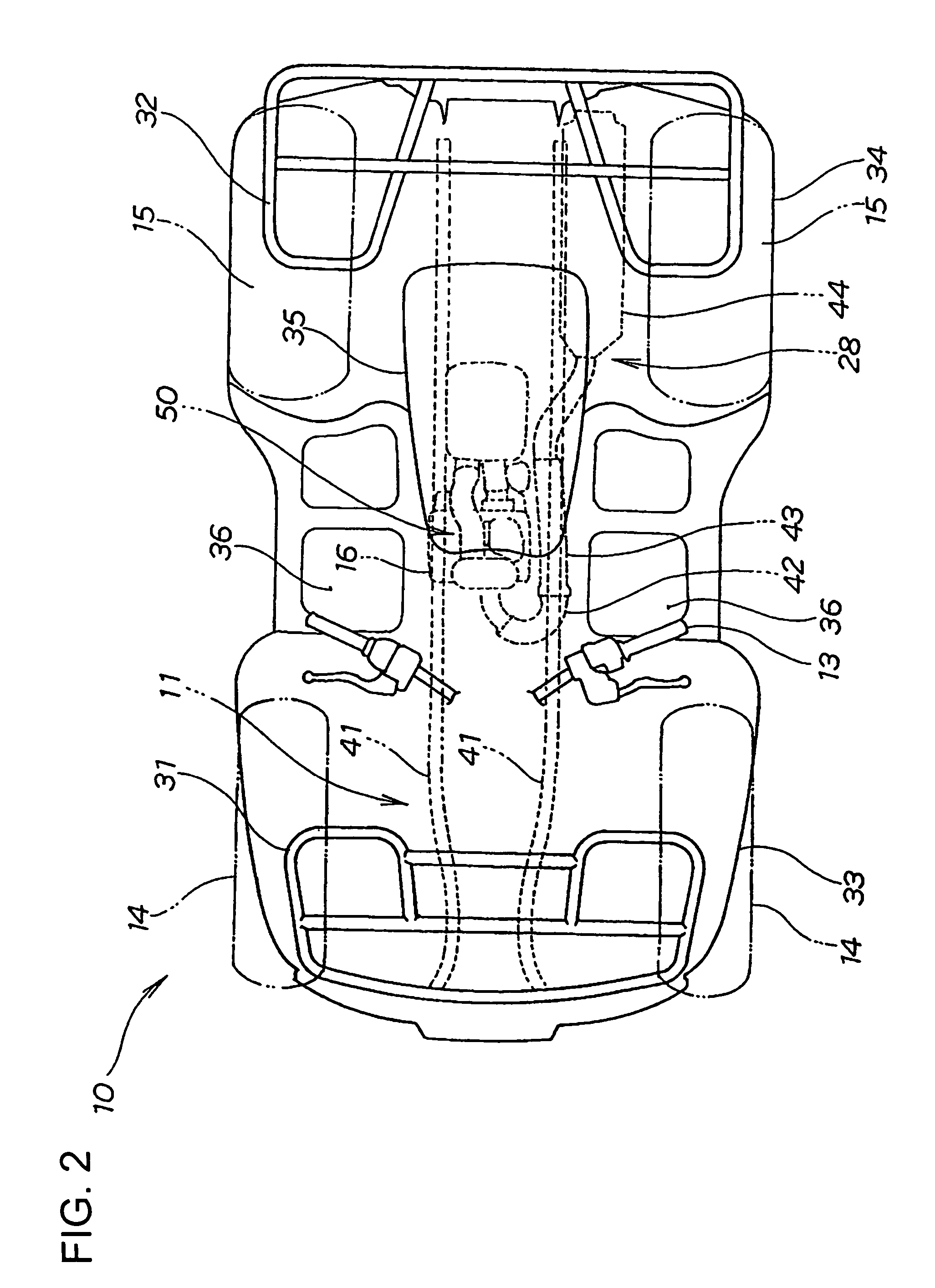

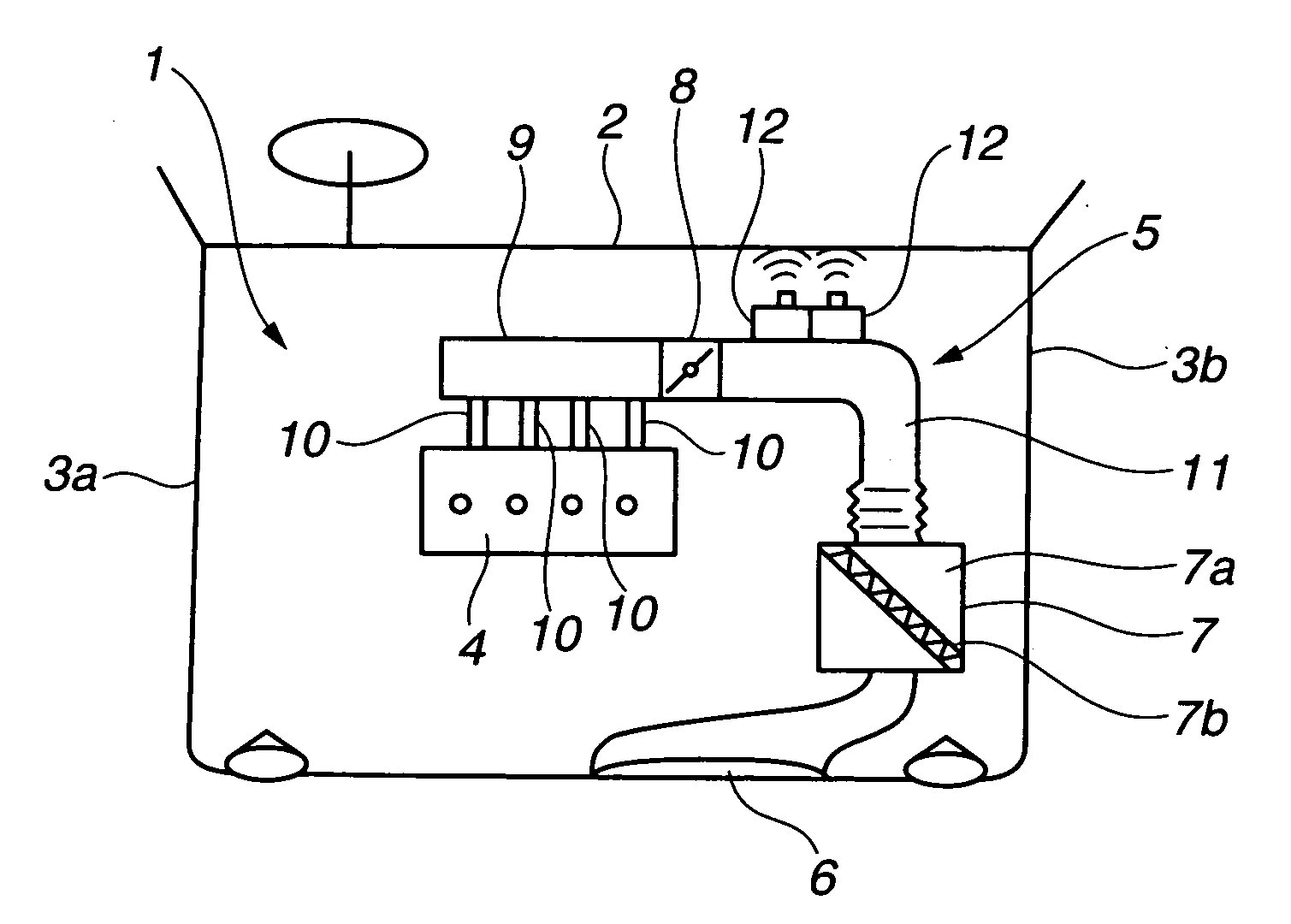

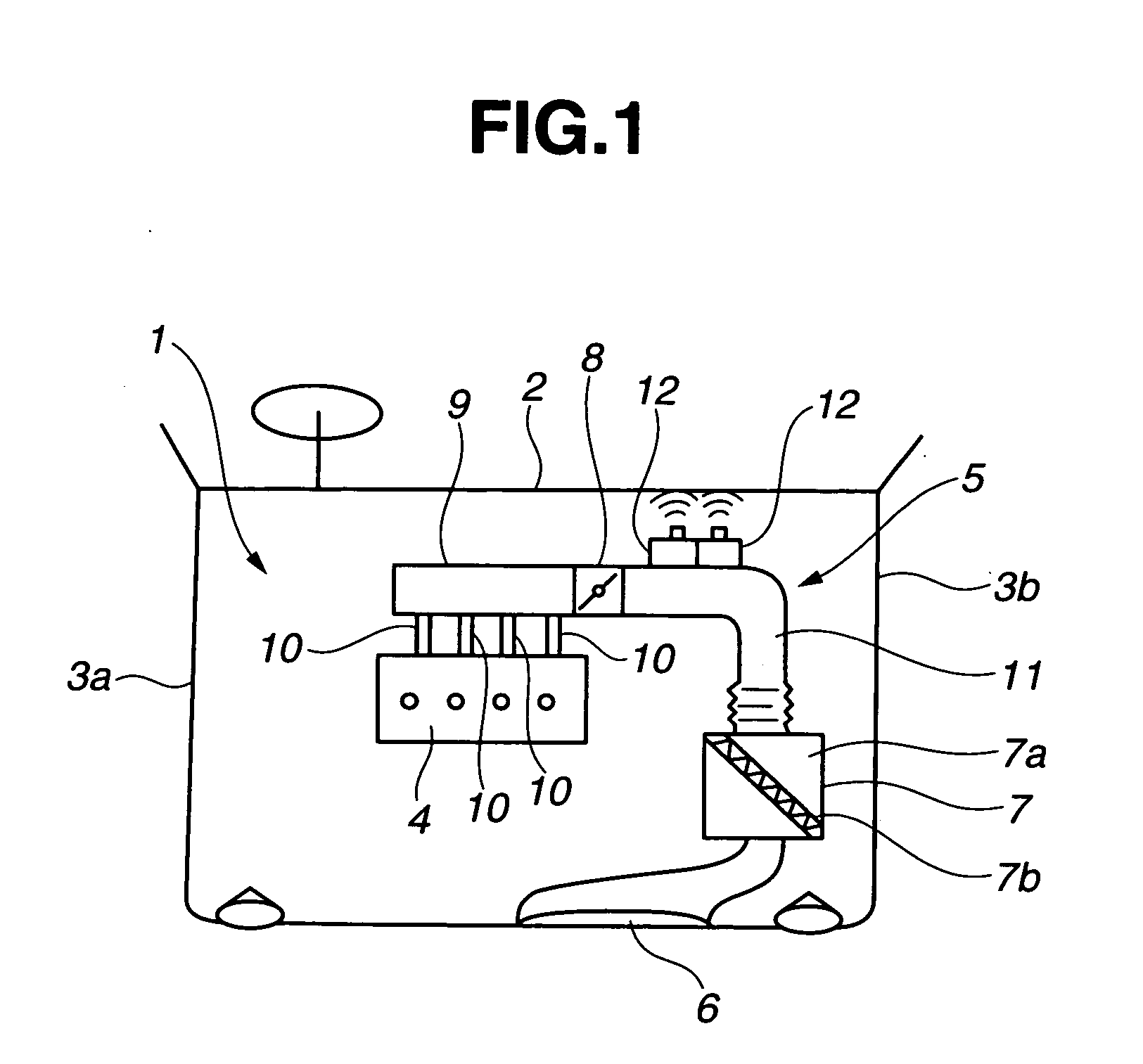

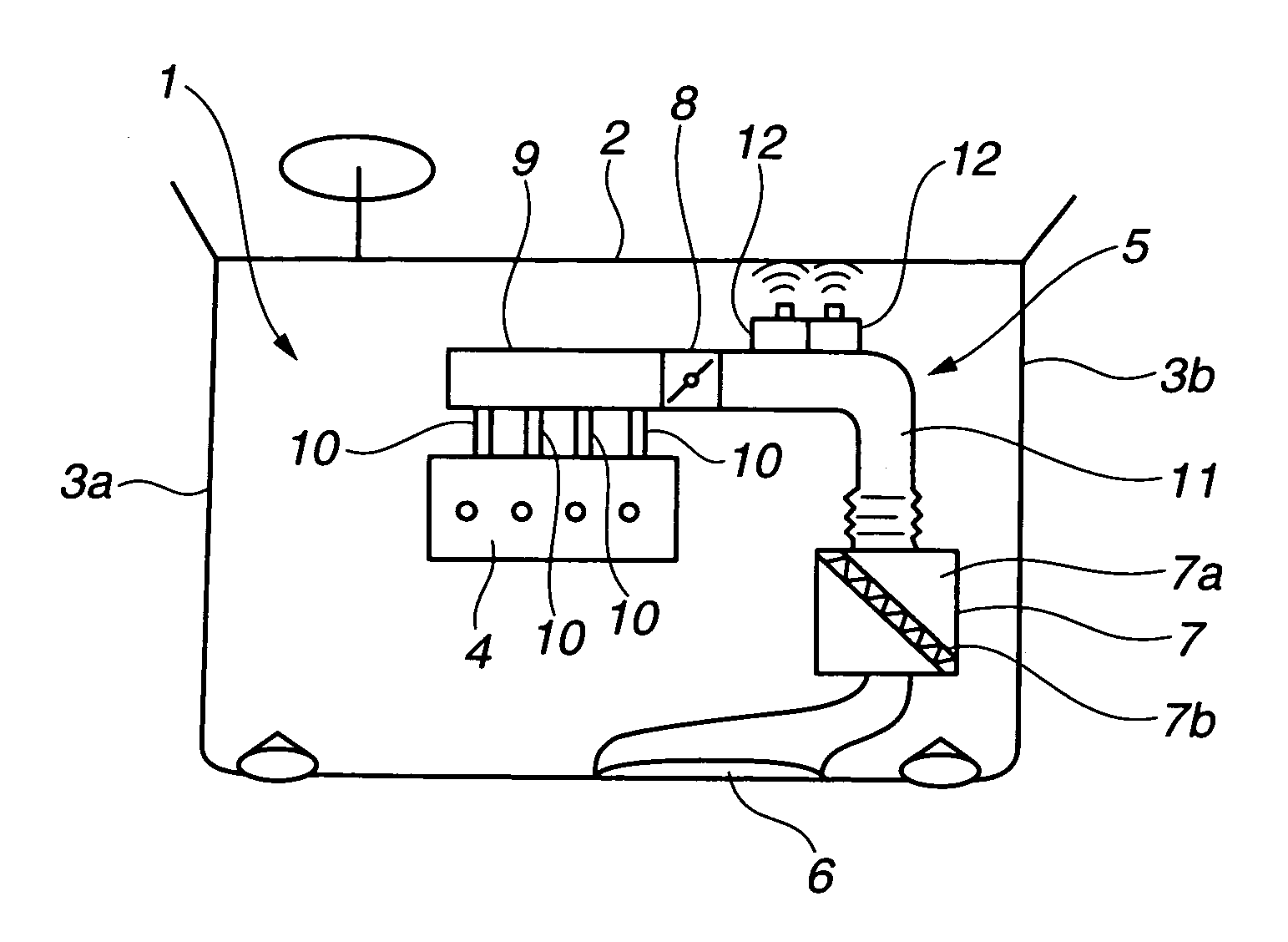

ActiveUS7159557B2Reducing intake sound levelReduce sound levelMachines/enginesAir intakes for fuelCarburetorEngineering

The present invention relates to a vehicle's air intake device. In an embodiment, the intake device comprises an intake pipe, an air cleaner case in fluid communication with the intake pipe, a connection pipe in fluid communication with the air cleaner case, a carburetor attached to the connection pipe, and a plurality of resonators. In an embodiment, the intake device comprises an intake pipe, an air cleaner case in fluid communication with the intake pipe, a connection pipe in fluid communication with the air cleaner case, a carburetor attached to the connection pipe, and means for reducing intake sound levels.

Owner:HONDA MOTOR CO LTD

Sound increase apparatus

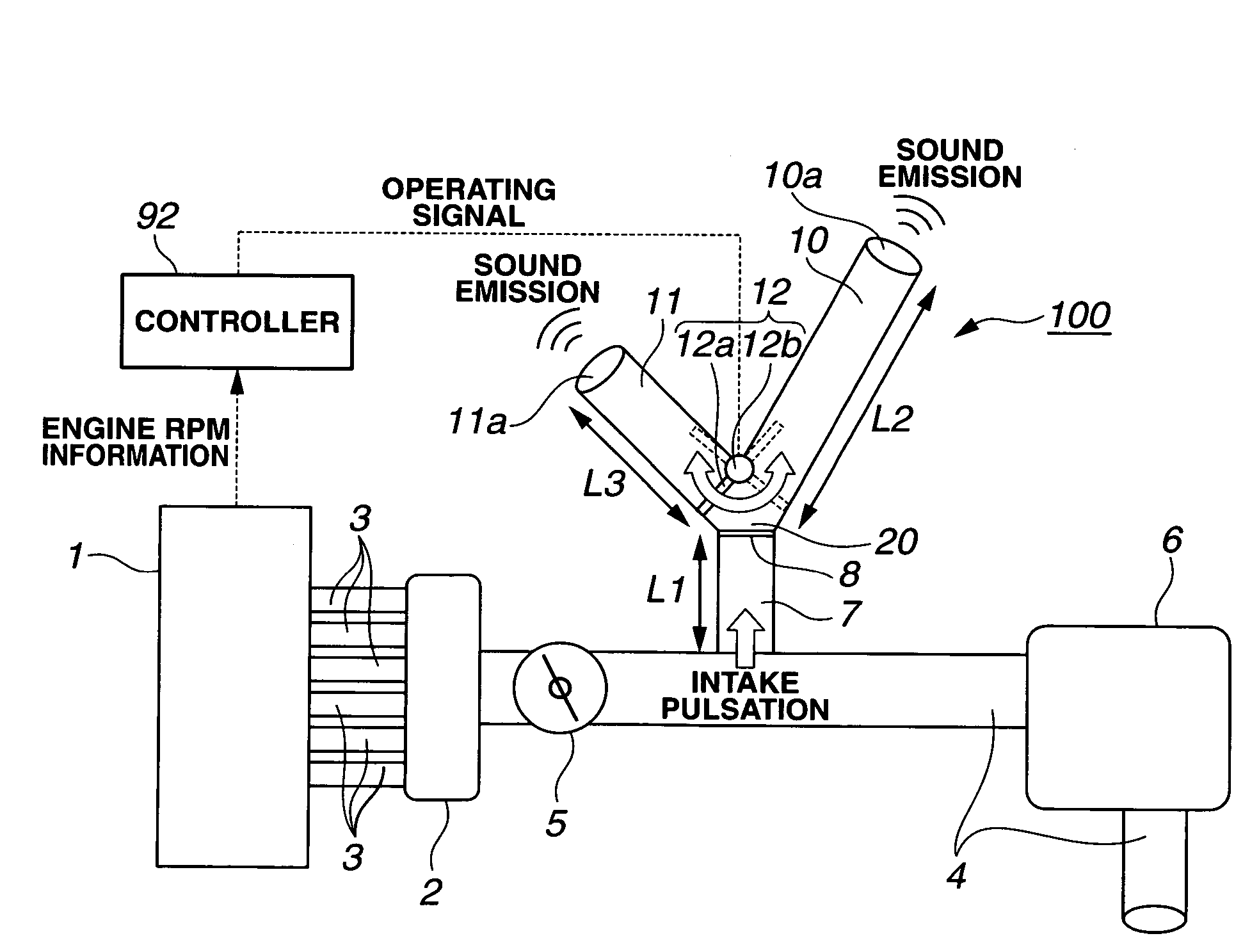

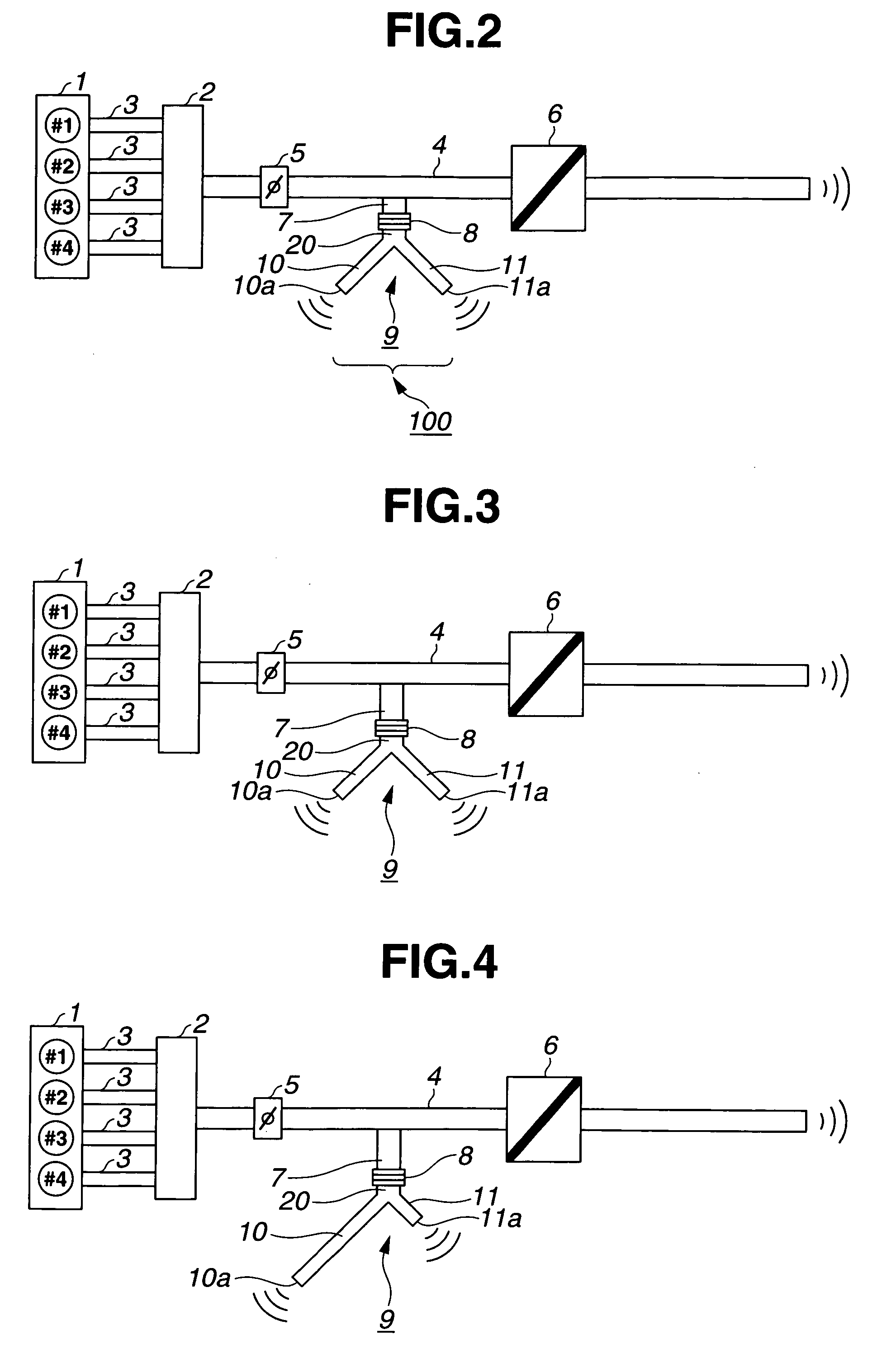

InactiveUS7353791B2Nice voiceMachines/enginesAir intakes for fuelExternal combustion engineEngineering

A sound increase apparatus includes a first hollow body member that communicates with an intake flow path of an internal combustion engine, a second hollow body member that communicates with the first hollow body member, and a vibration member capable of vibrating in an out-of-plane direction, which is inserted in a connection between the first and second hollow body members and closes a cross section of the connection. The second hollow body member has a plurality of opening portions, each of which communicates with the air.

Owner:NISSAN MOTOR CO LTD

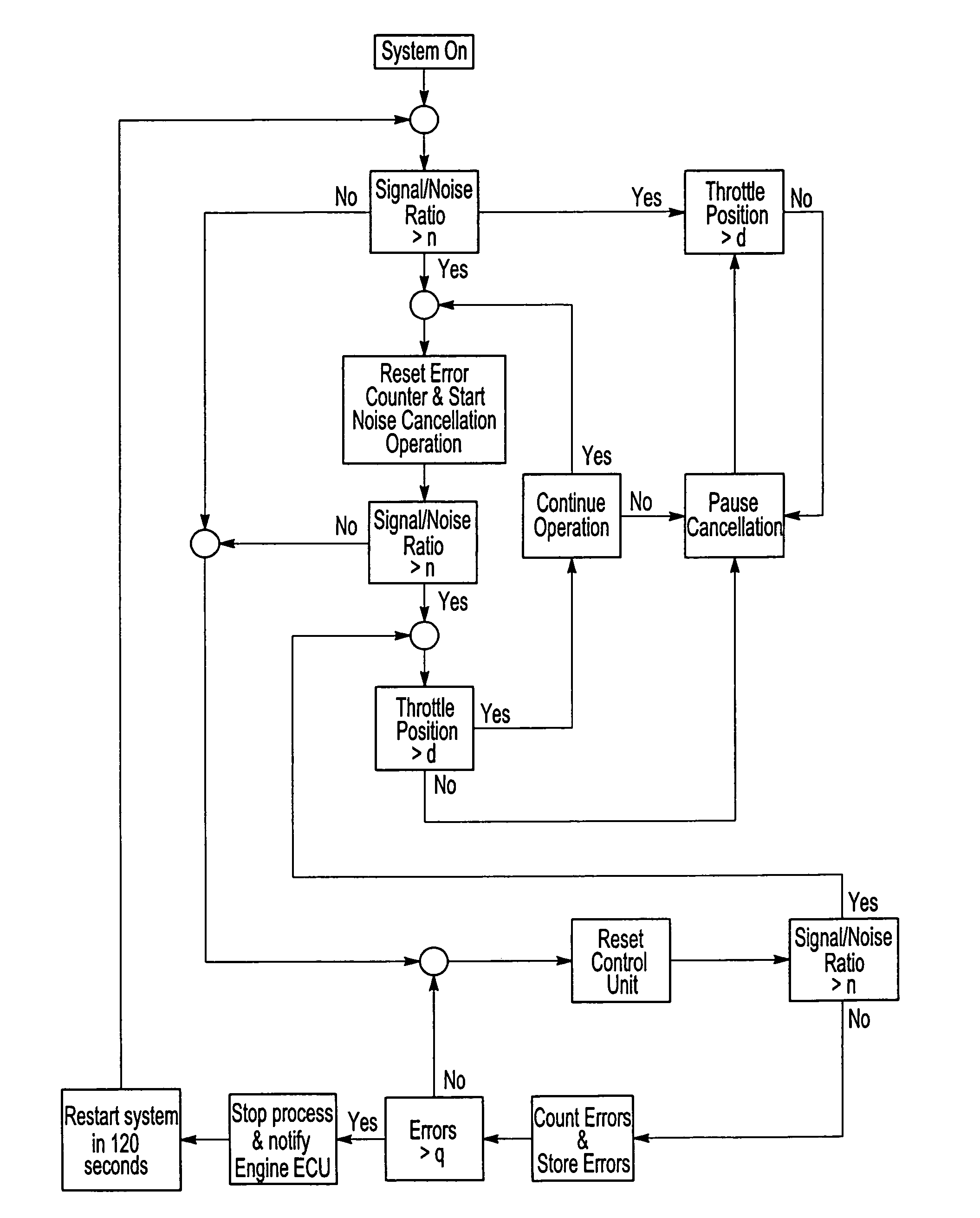

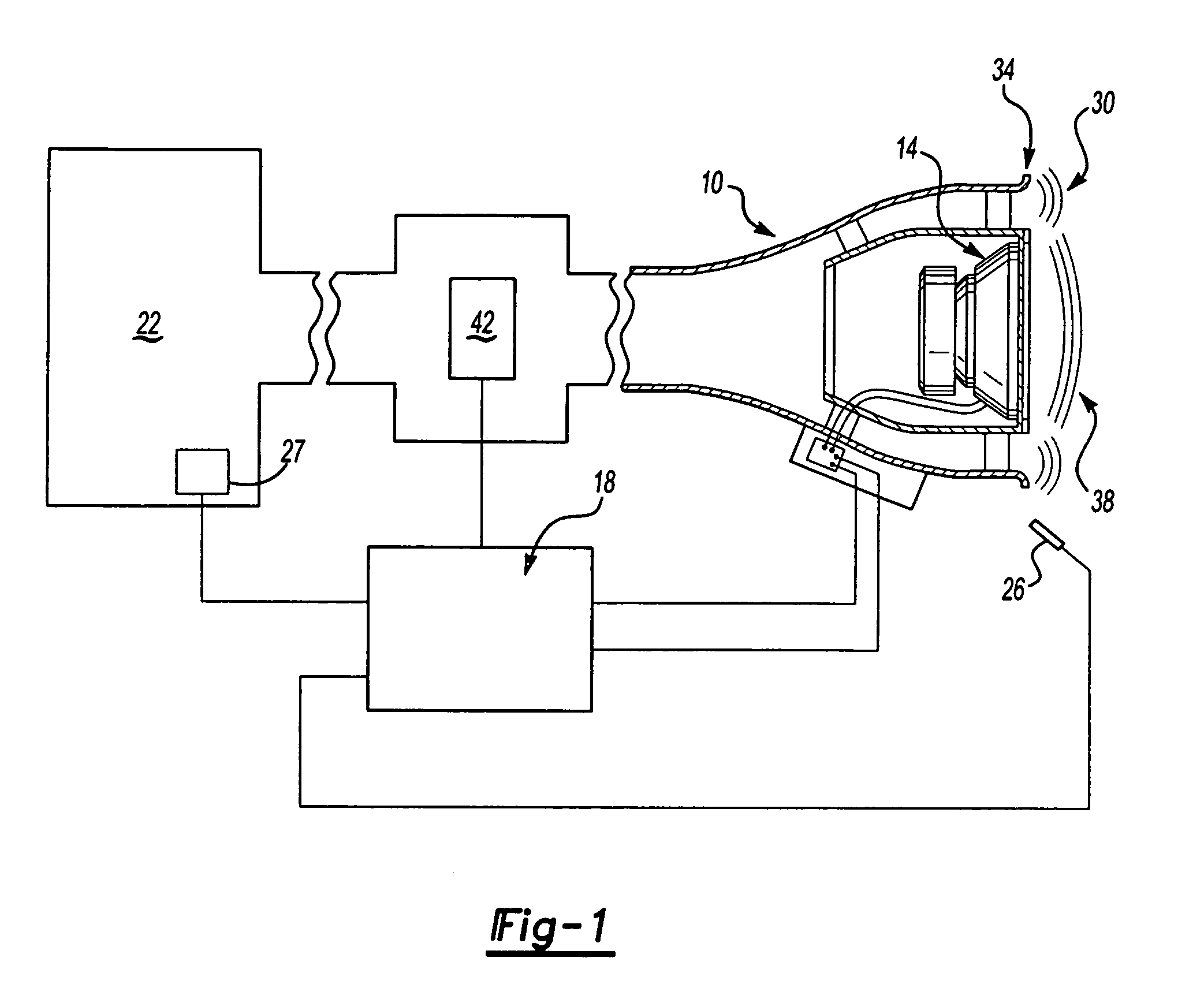

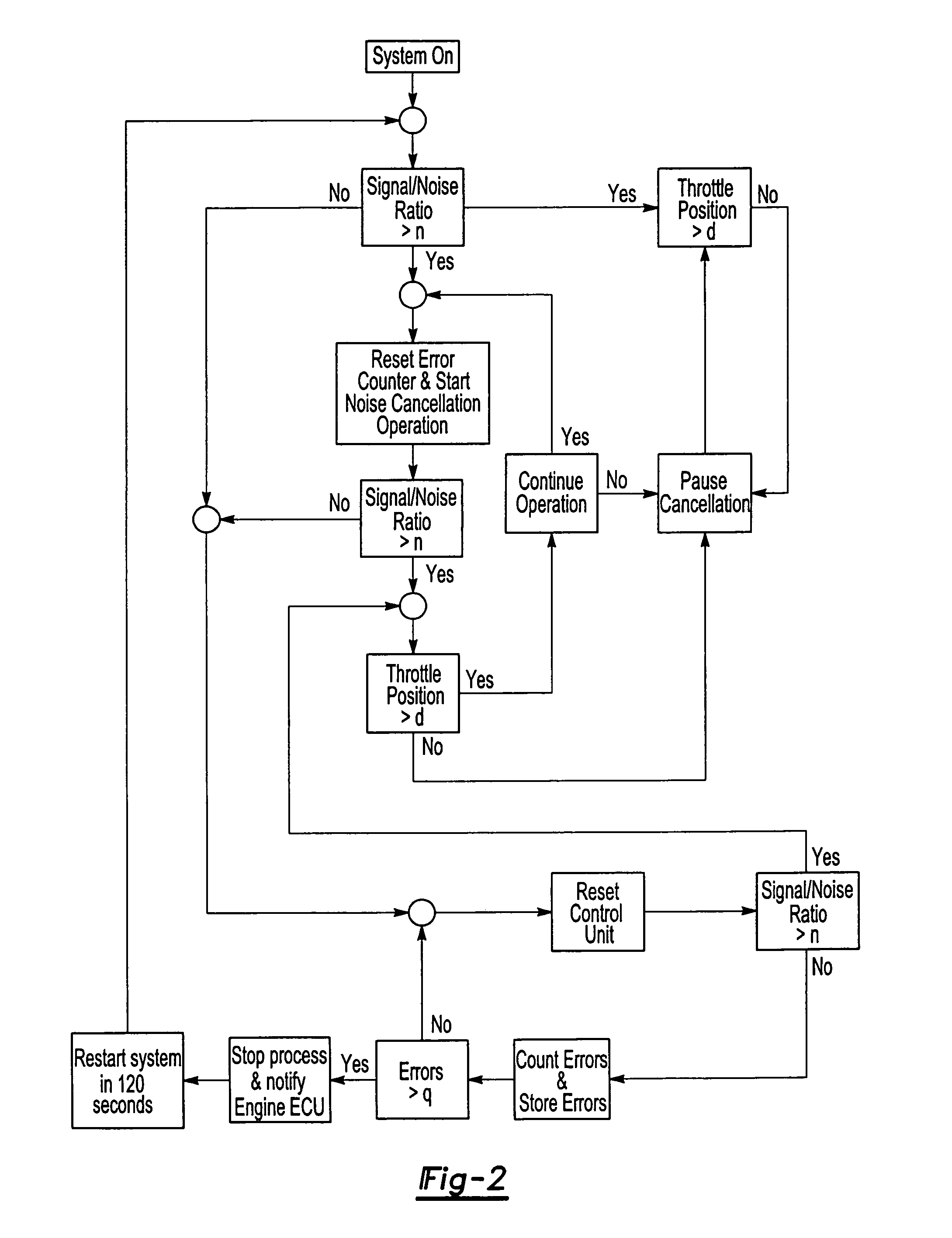

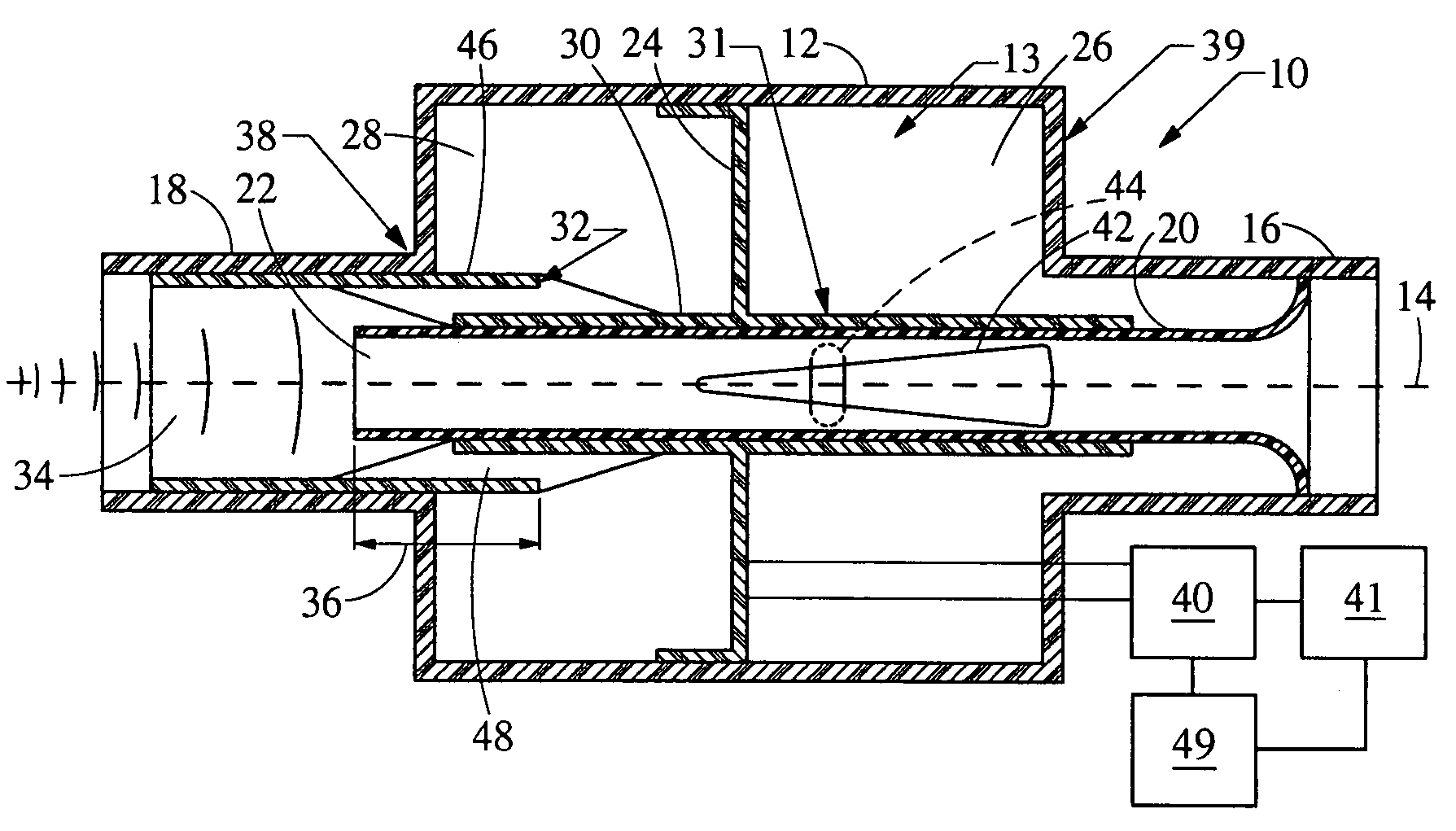

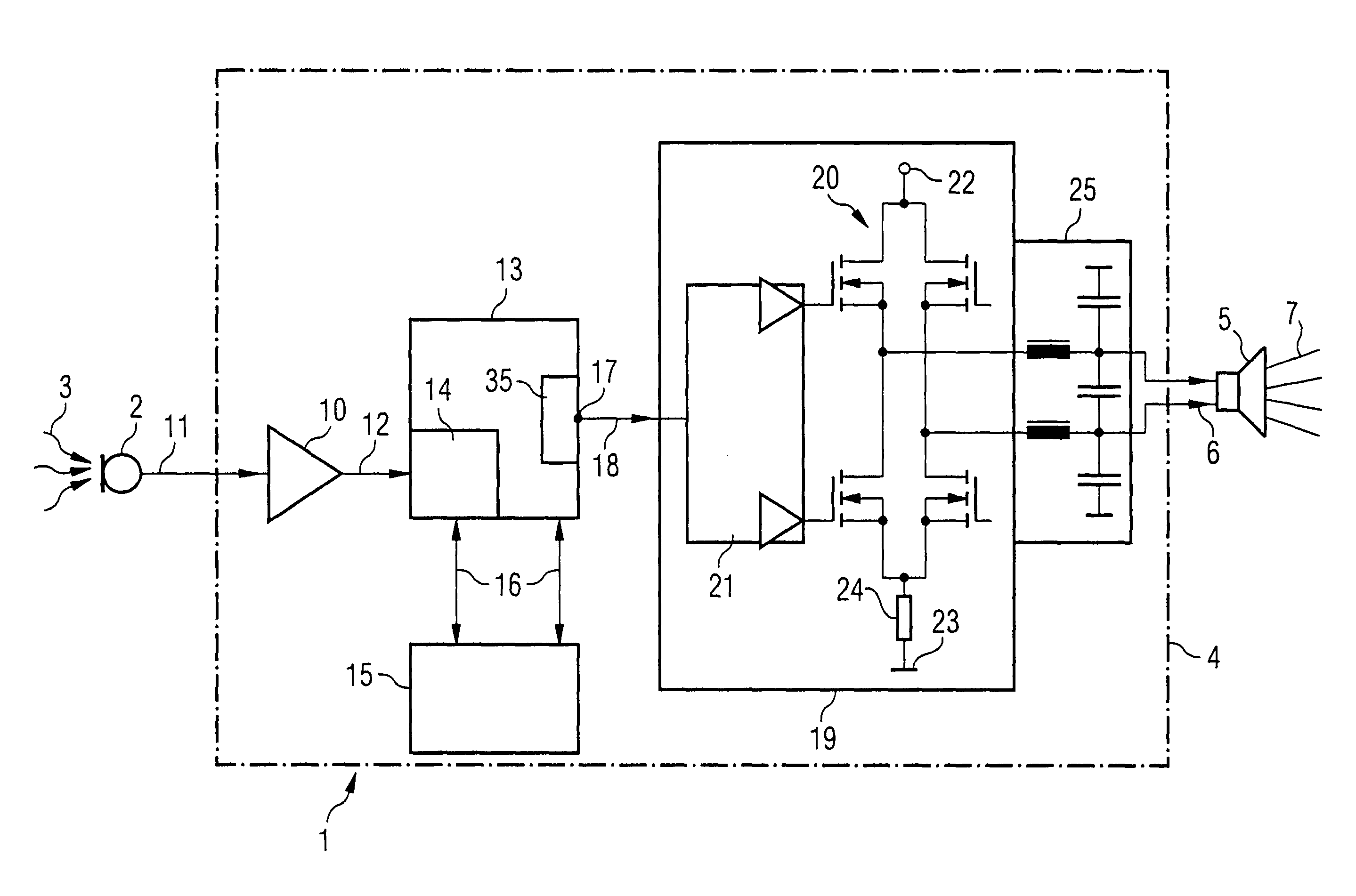

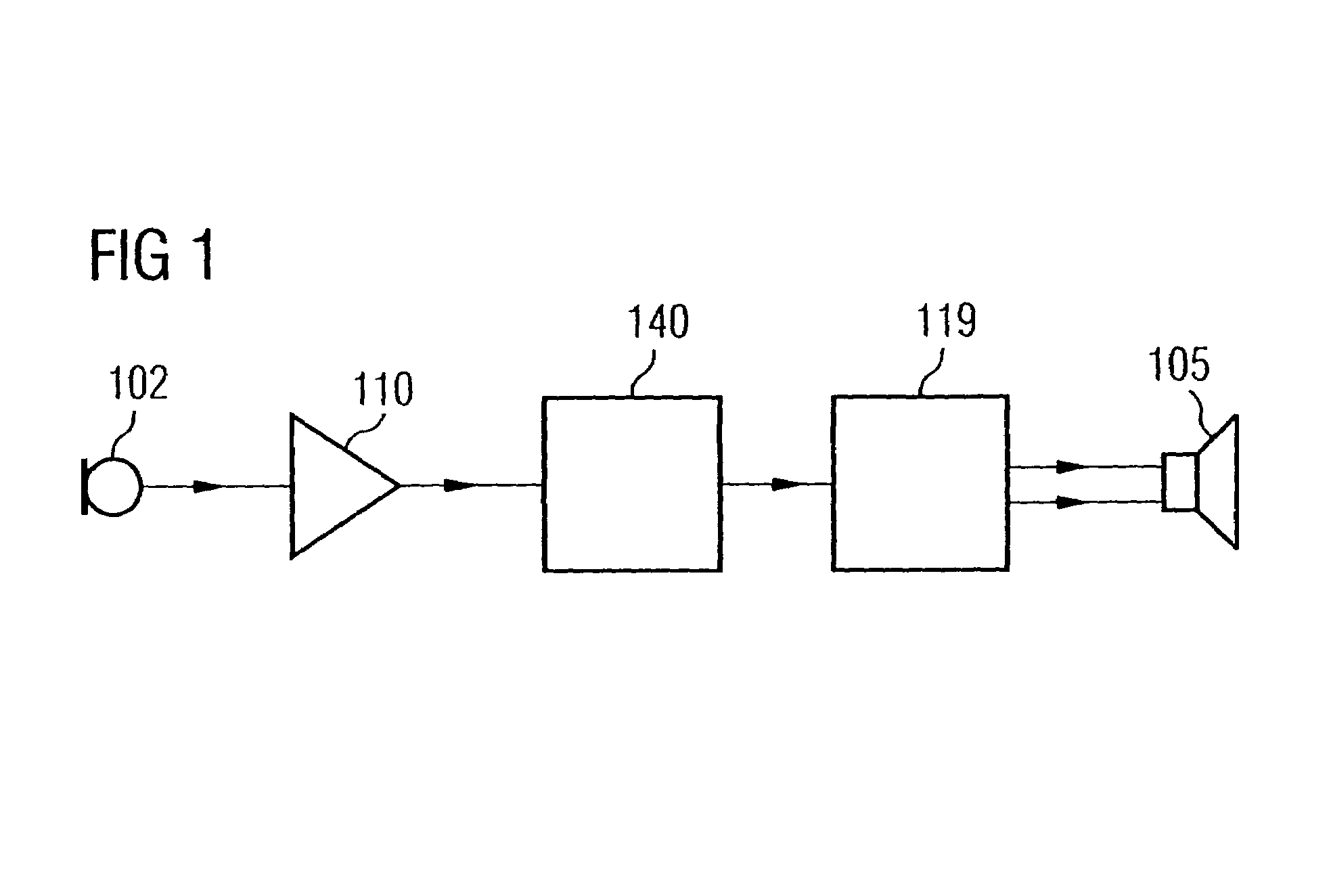

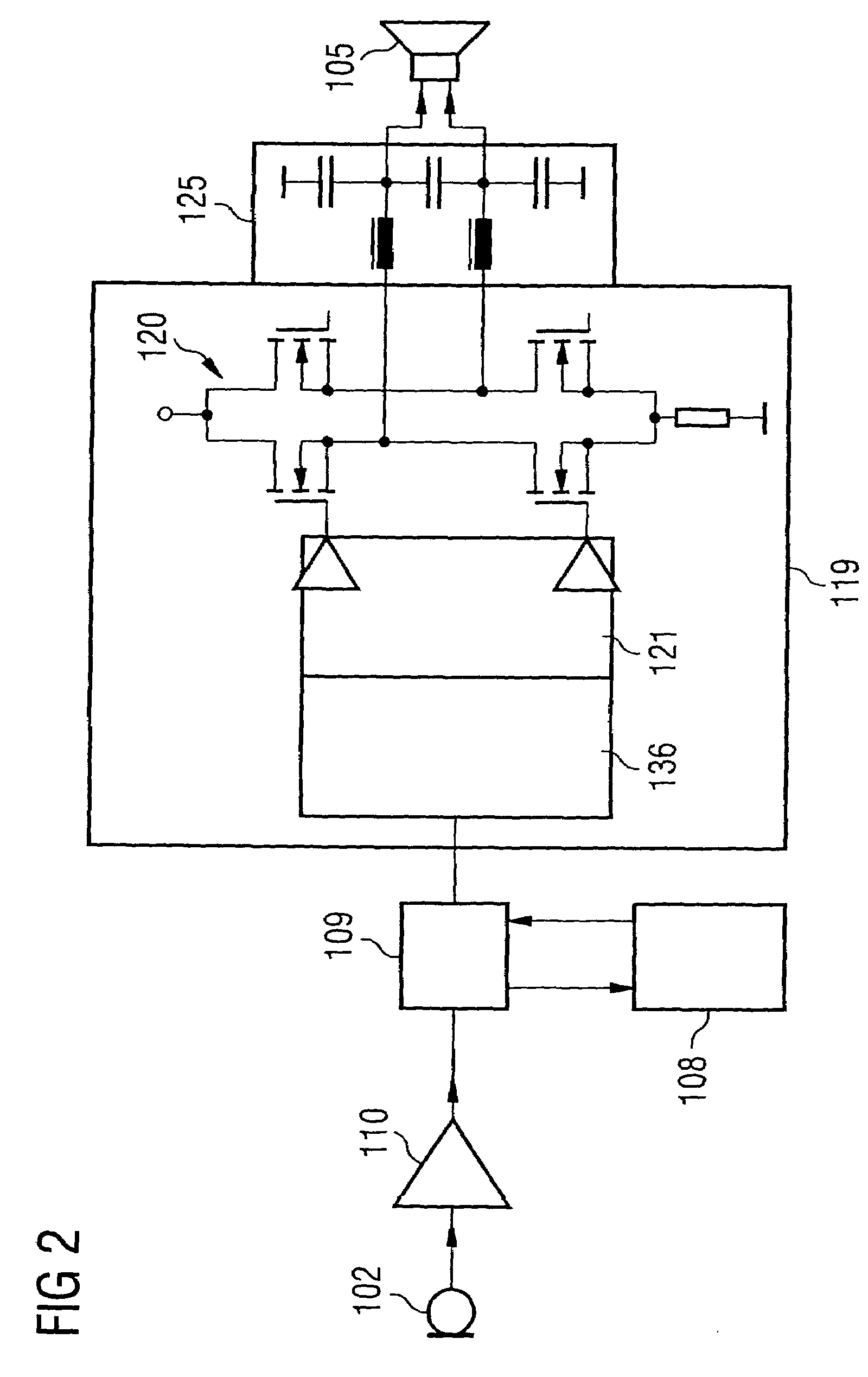

Active noise cancellation stability solution

ActiveUS7106866B2Reduce engine noiseControlling noise attenuationEar treatmentSilencing apparatusEngineeringLoudspeaker

The method of noise attenuation comprises the steps of generating a noise canceling signal, sensing for an system condition, and ceasing the generation of the noise canceling based upon the system condition. This method is embodied in a system that includes an air induction body, a speaker in proximity to the air induction body, a sensor for sensing a system condition, and a control unit with a noise cancellation feature. The control unit is in communication with both the speaker and the sensor. Based upon the sensed system condition, the control unit may disable the noise cancellation feature.

Owner:SIEMENS VDO AUTOMOTIVE CORP

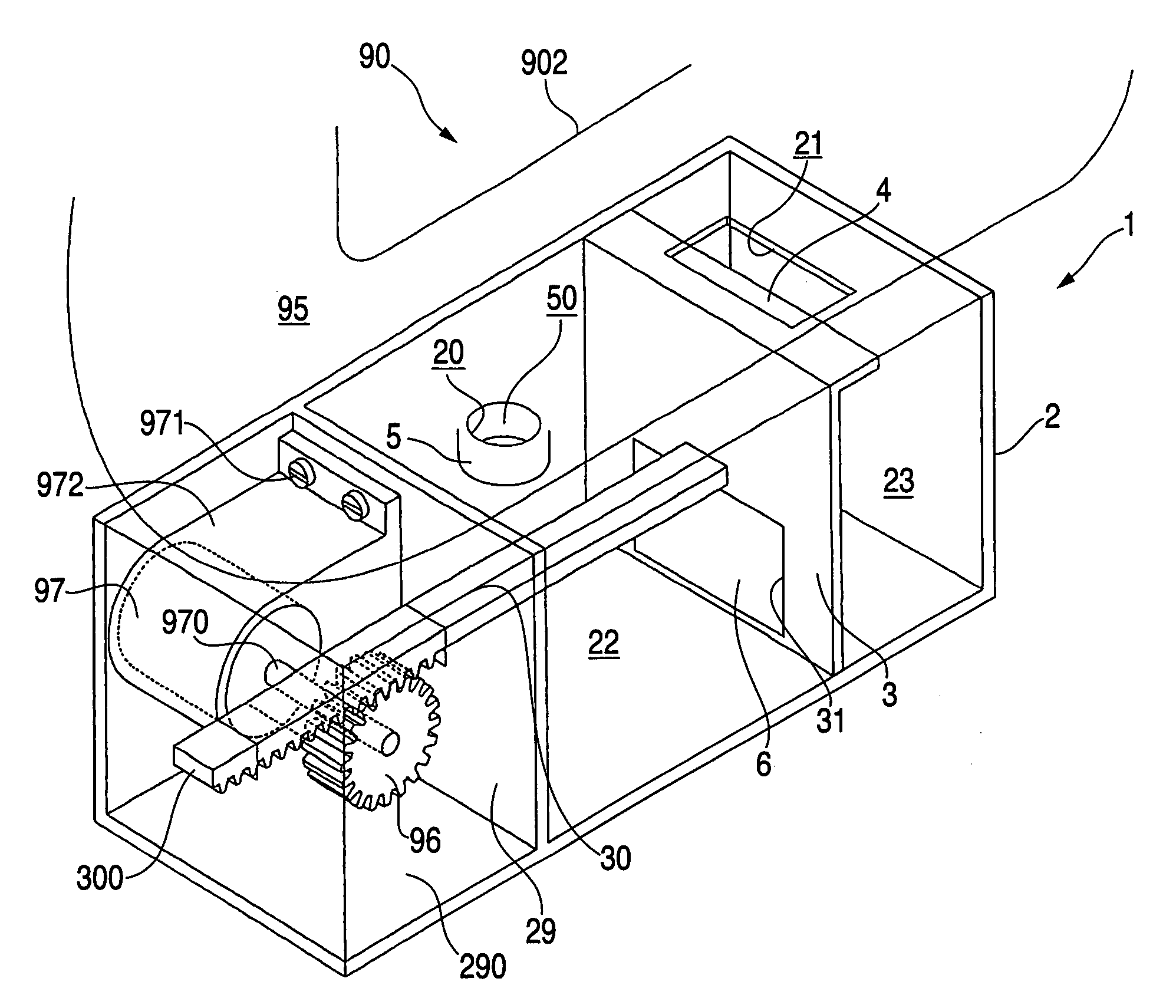

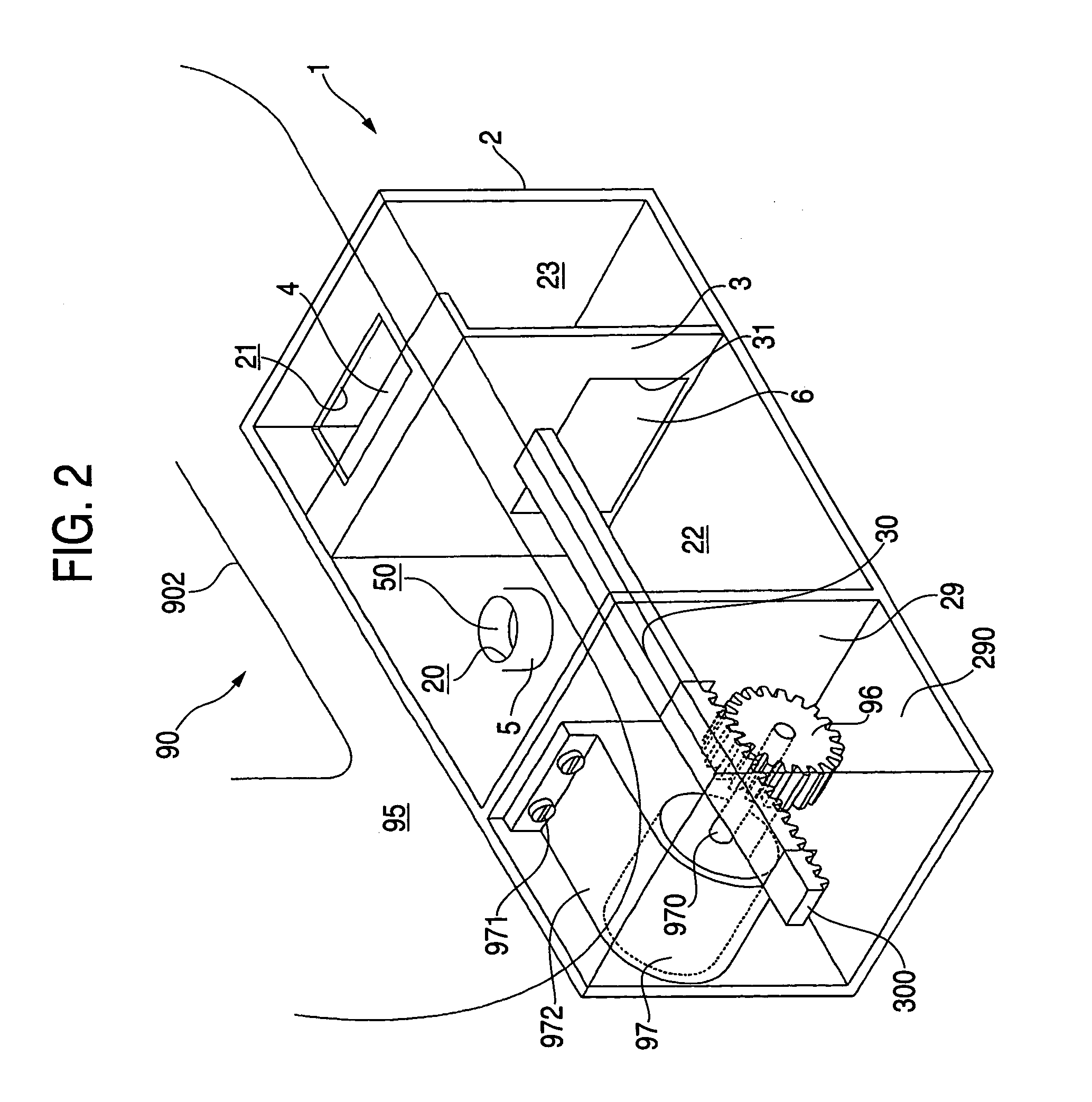

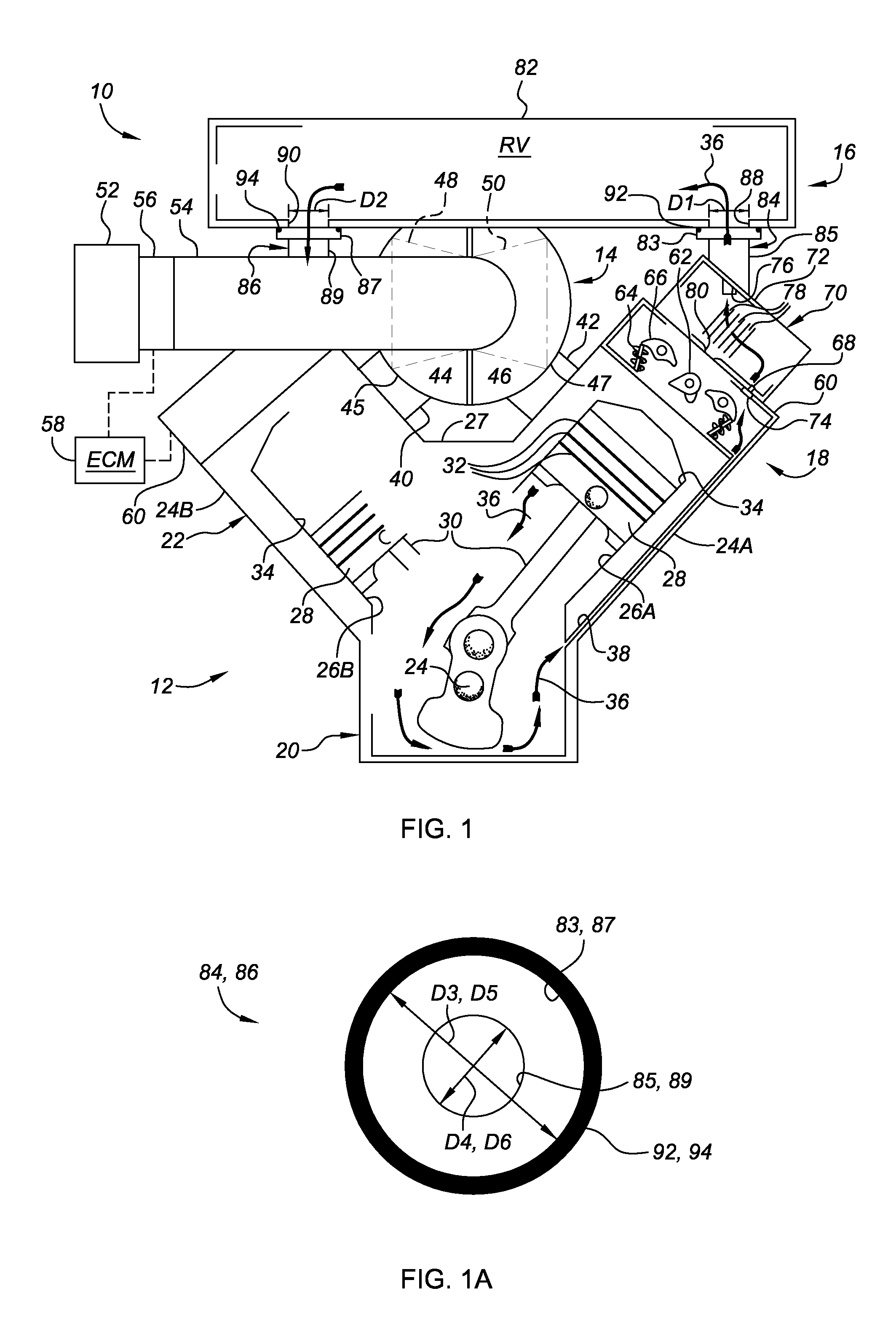

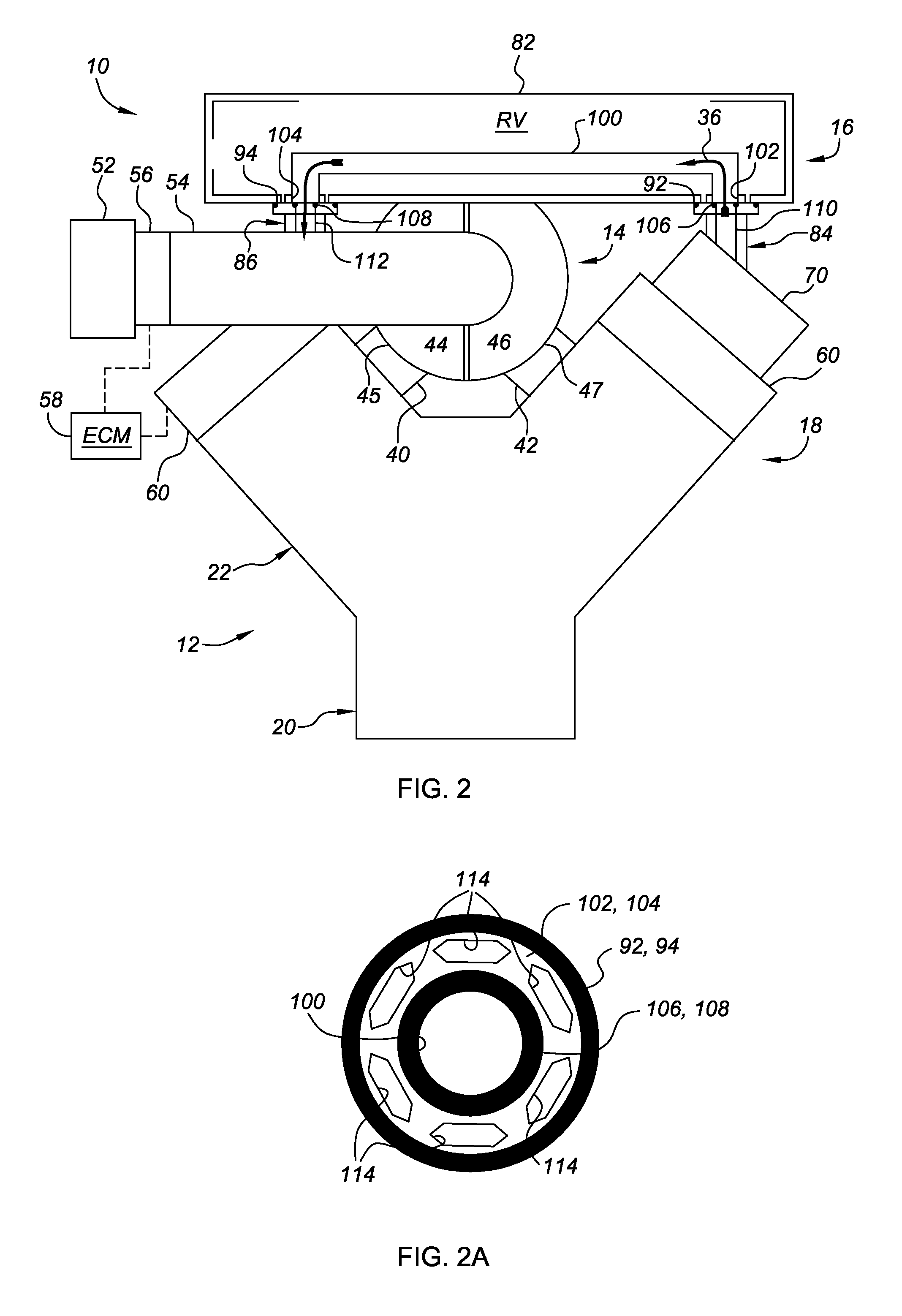

Electronically controlled dual chamber variable resonator

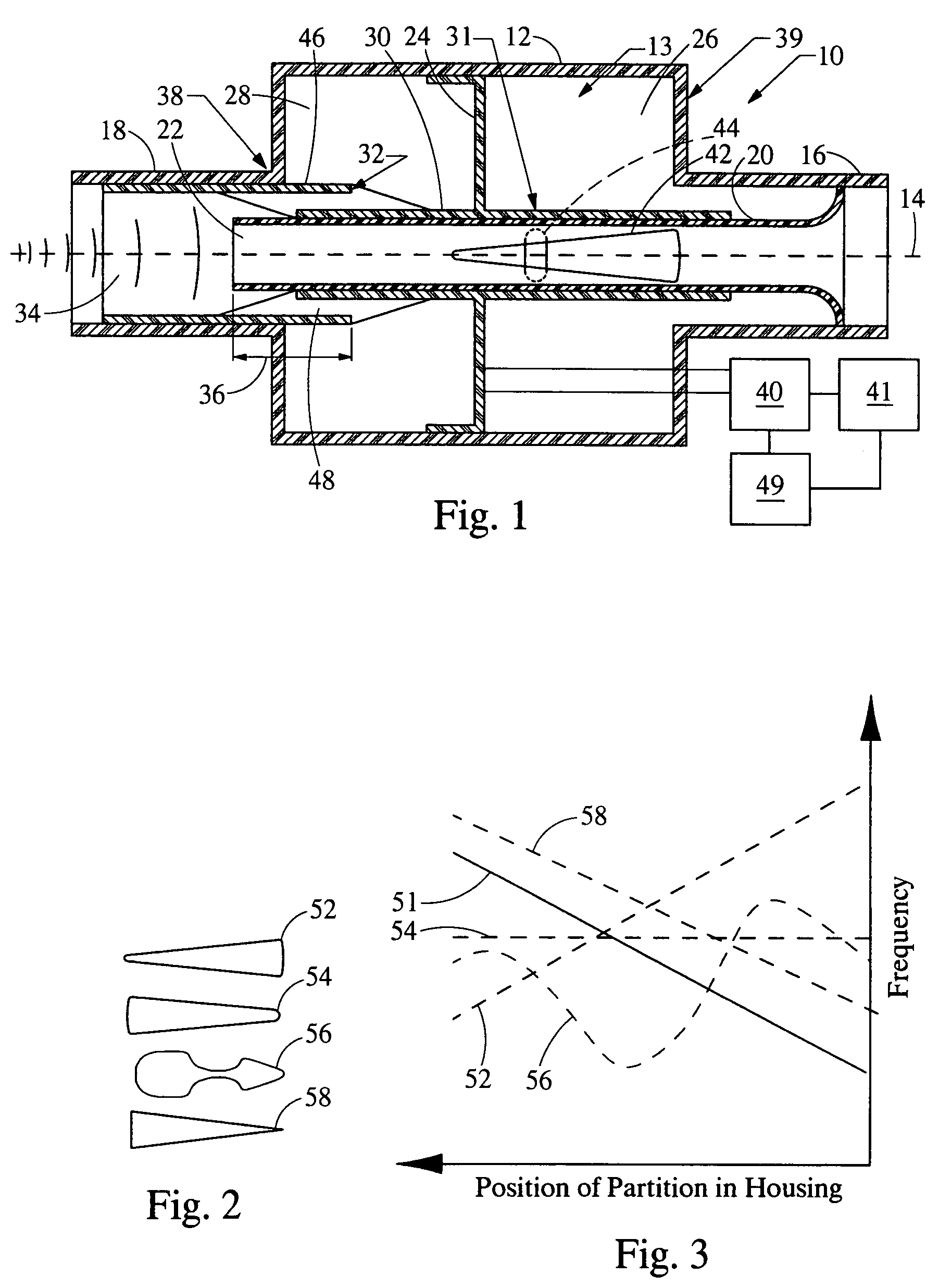

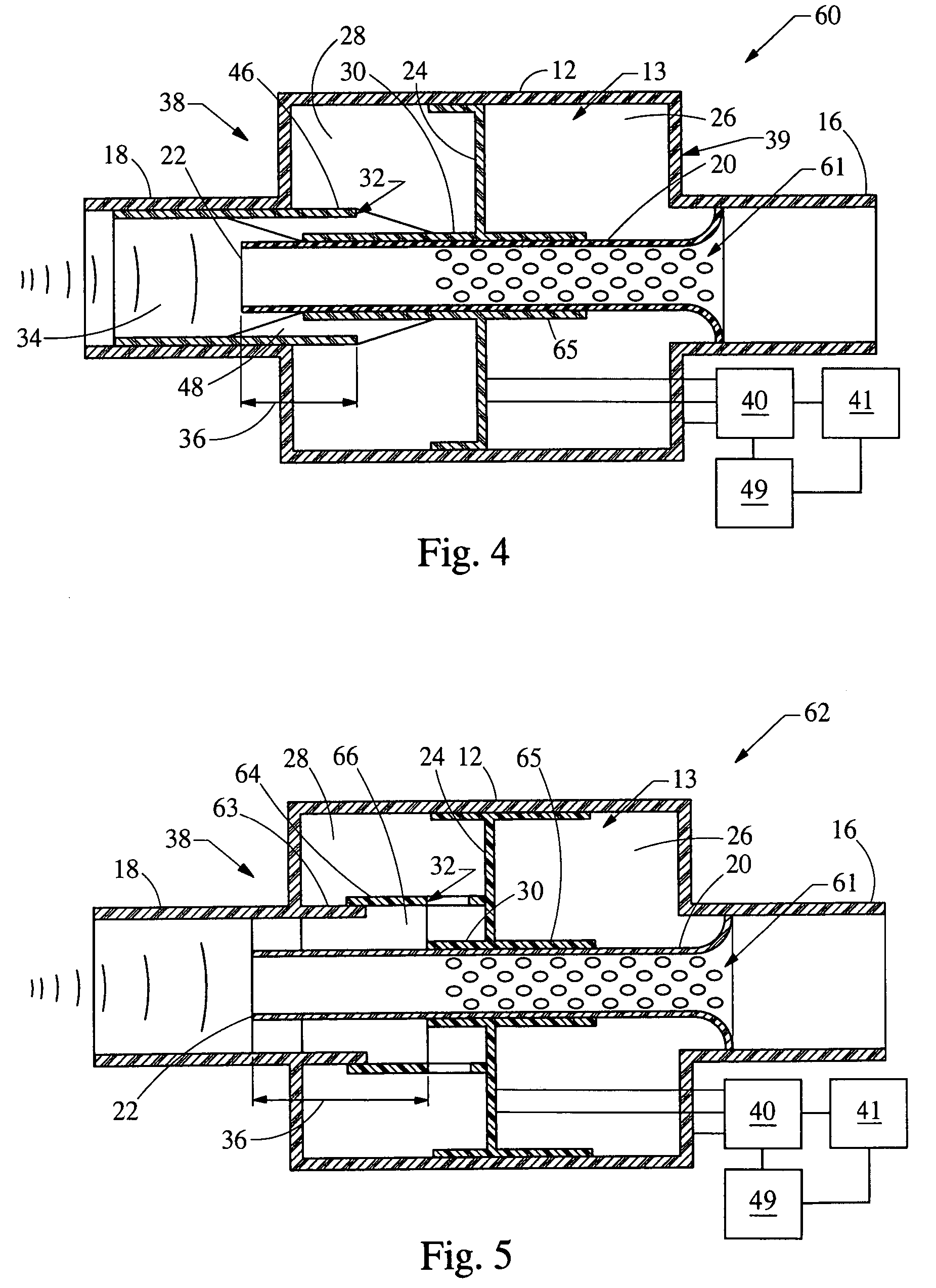

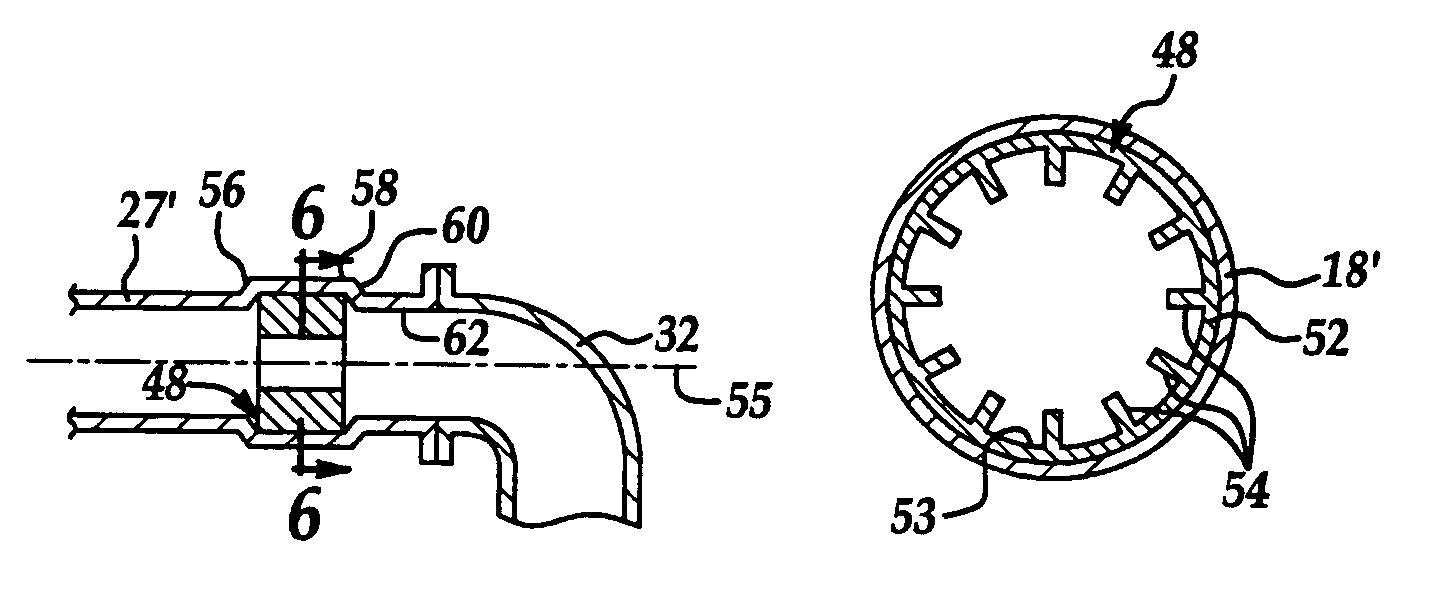

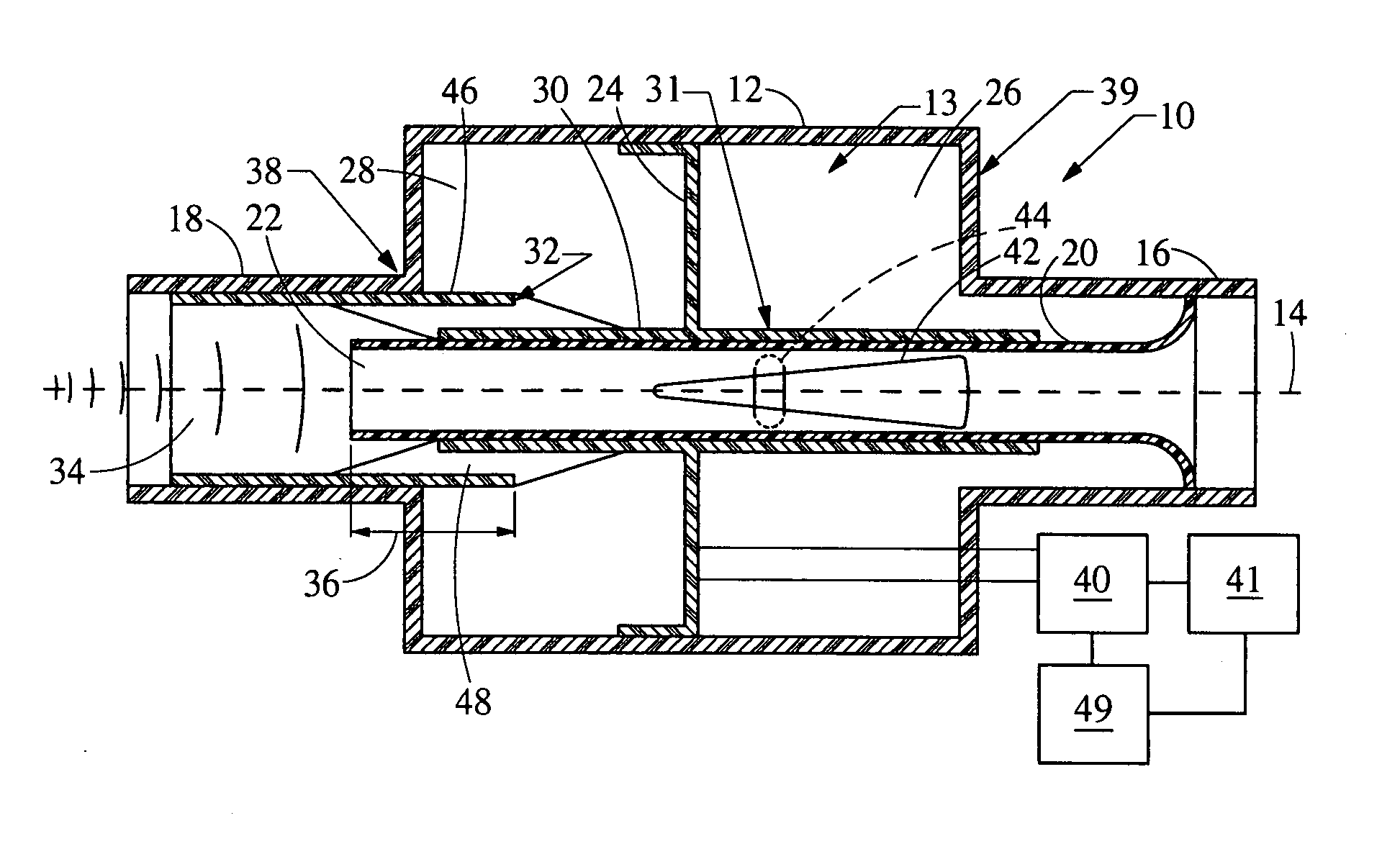

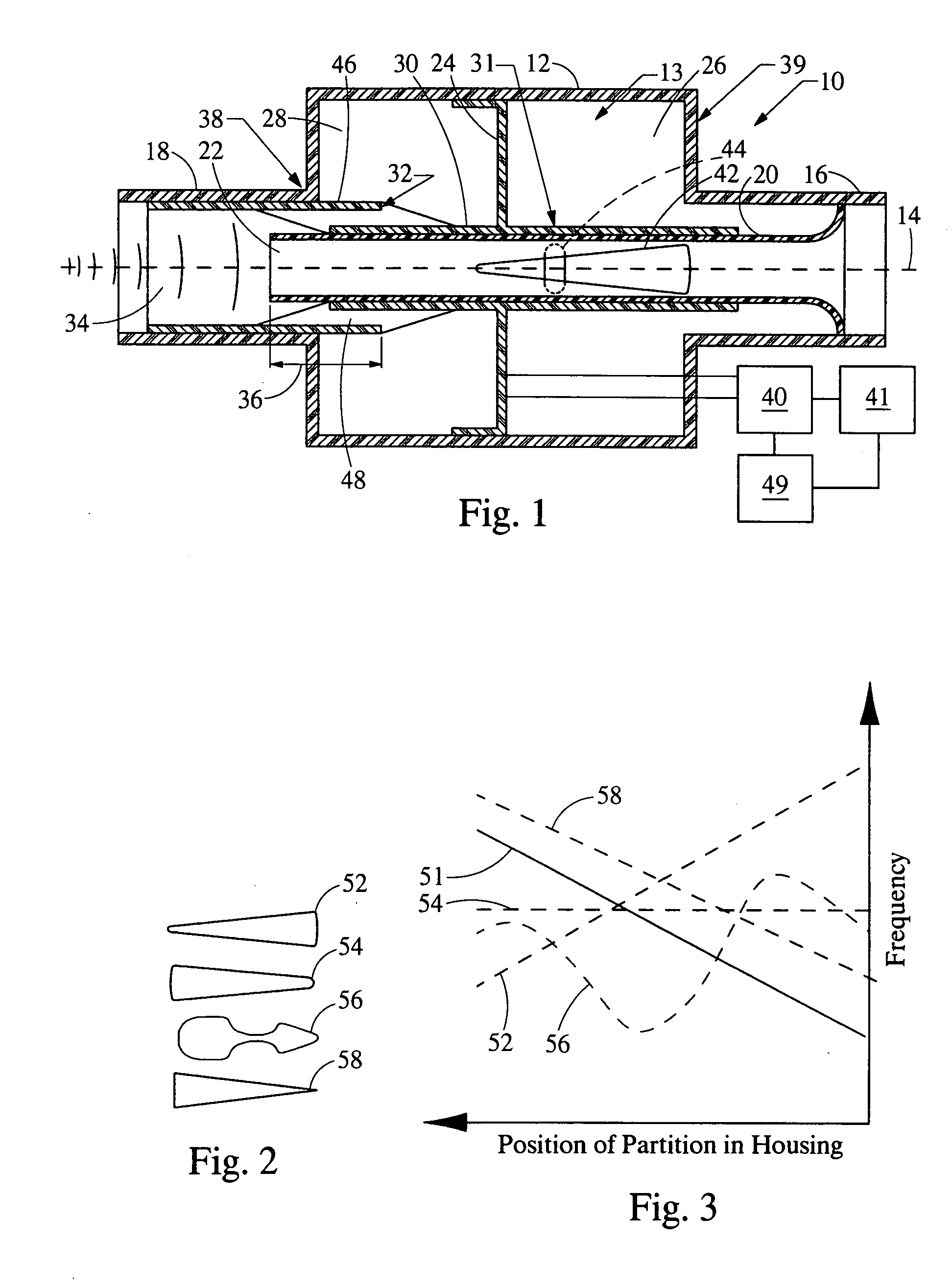

An in-line resonator for an air induction system of an internal combustion engine is provided. The system includes a resonator housing, an upstream duct, a downstream duct, a conduit, a partition, and a sleeve. The conduit extends through the resonator housing connecting the upstream duct and the downstream duct. The partition is moveable within the resonator housing and divides the housing into an upstream chamber and a downstream chamber. The downstream chamber, the conduit, and the downstream sleeve cooperate to form a first Helmholtz resonator that is in fluid communication with the downstream duct. The upstream chamber, the conduit, and the upstream sleeve cooperate to form a second Helmholtz resonator that is in fluid communication with the upstream duct. Further, a means is provided to axially move the partition to vary the volume of the chambers concurrently with the length and / or area of the passages.

Owner:HANON SYST

Noise attenuation device for a vehicle exhaust system

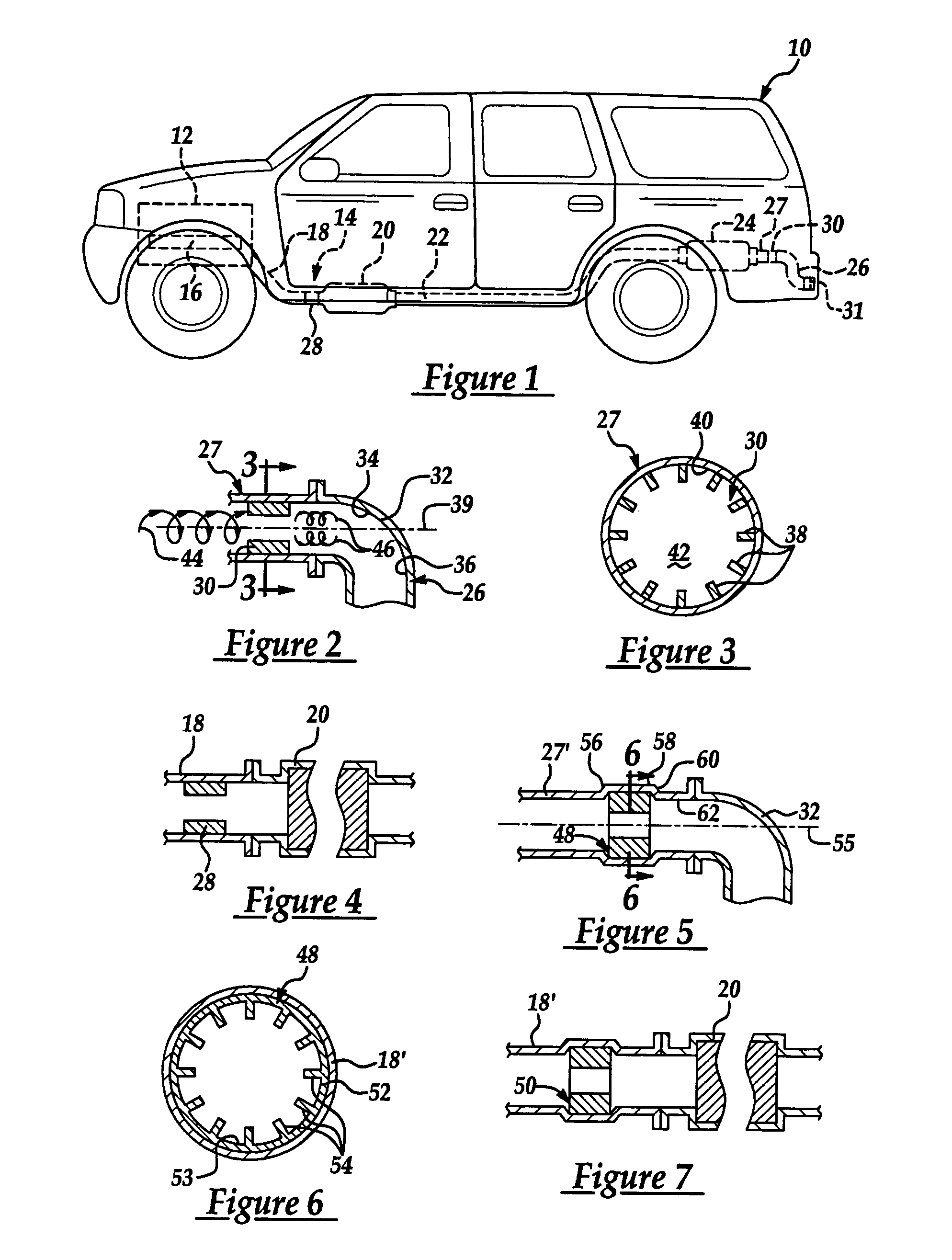

ActiveUS7131514B2Reduce turbulenceReduce noiseExhaust apparatusSilencing apparatusExhaust pipePulse flow

A noise attenuation device for a vehicle exhaust system is provided. The device includes an exhaust pipe having a passageway for receiving exhaust gas pulses from an engine. The device further includes a plurality of vanes extending from an inner surface of the passageway and spaced apart from one another. The vanes are configured to reduce turbulence in the exhaust gas pulses flowing past the vanes to reduce noise at a downstream outlet of the exhaust pipe.

Owner:FORD GLOBAL TECH LLC

Silencer for air induction system and high flow articulated coupling

InactiveUS20050284692A1Effective attenuationReduce flow of turbulent airSilencing apparatusMachines/enginesCouplingEngineering

An air induction silencer assembly includes an acoustic interference member disposed within a conduit. The acoustic interference member is tuned to acoustically cancel a selected noise energy frequency. An acoustic absorbing member is also disposed within the conduit. The acoustic absorbing member converts noise energy within the conduit into heat energy to attenuate noise energy within the air induction silencer assembly. The air induction silencer assembly connects to a flexible conduit that includes an inlet portion, an outlet portion, and a flexible joint that connects the inlet portion and the outlet portion together. The flexible joint includes a rolling lobe and a rolling surface. The rolling lobe moves along the rolling surface when the inlet portion moves relative to the outlet portion.

Owner:SIEMENS VDO AUTOMOTIVE CORP

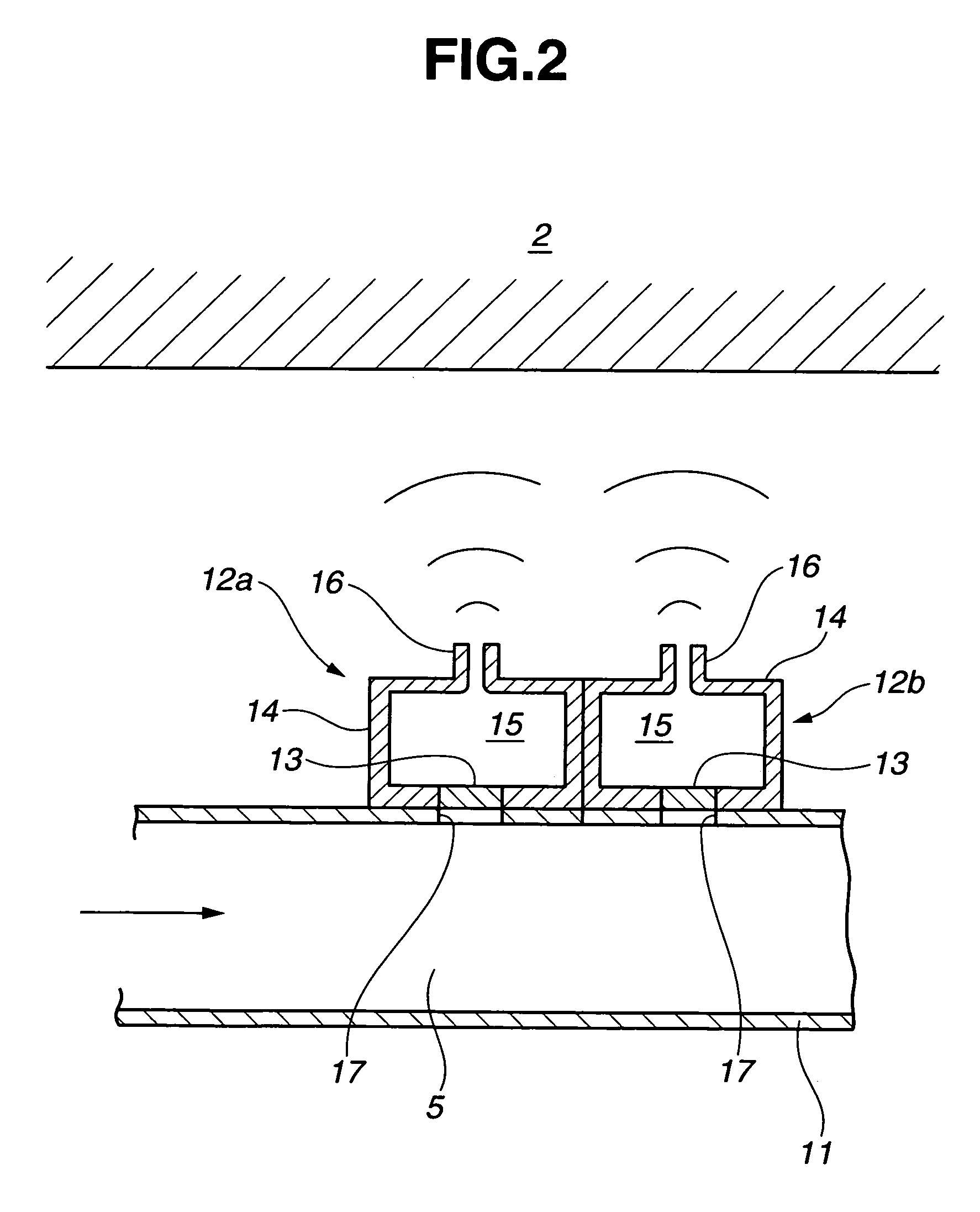

Intake device of internal combustion engine

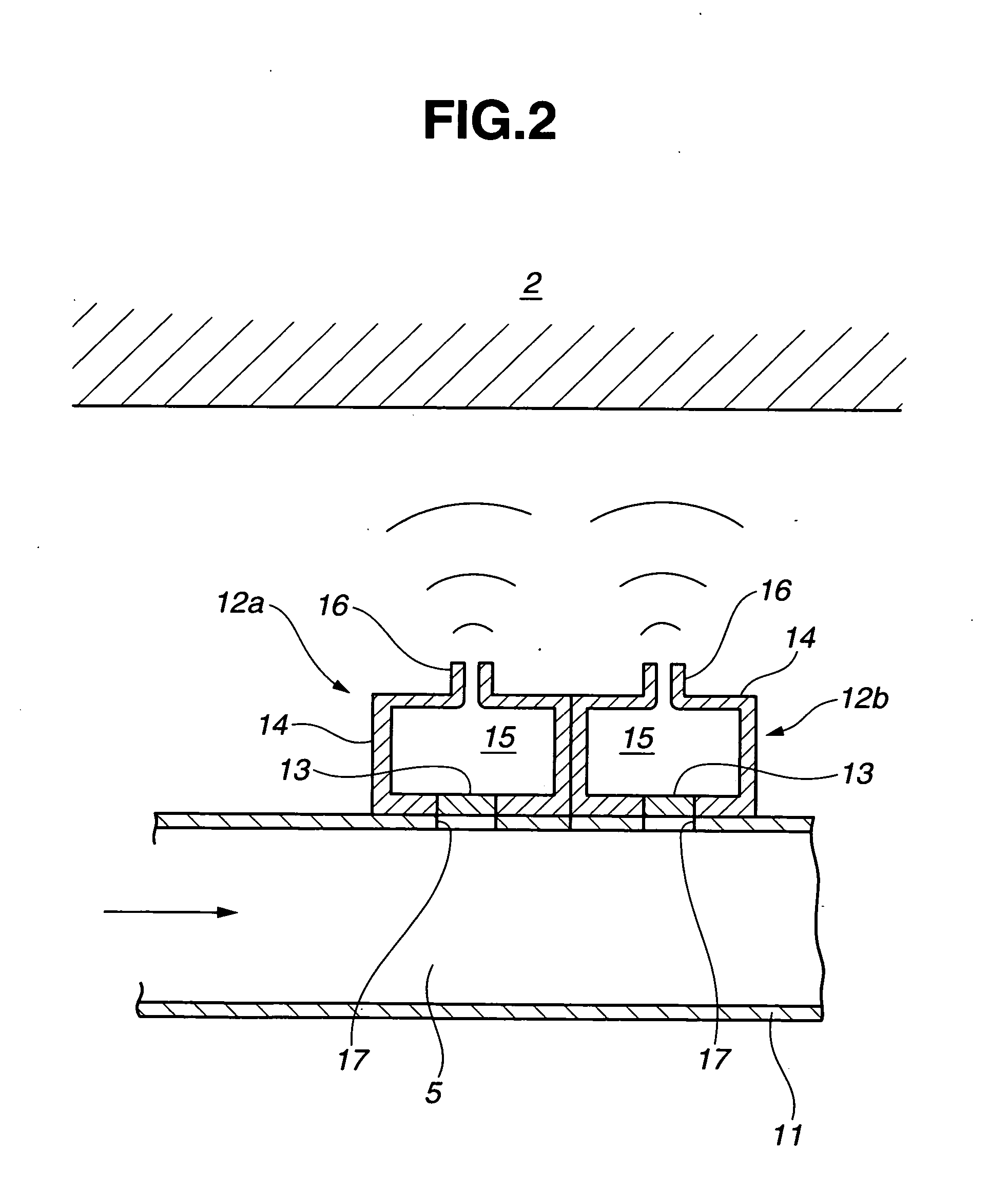

ActiveUS20070131189A1Reduce sound pressureExcellent toneInternal combustion piston enginesAir cleaners for fuelInterior spaceEngineering

A resonator 13 is provided including a resonating body 13 which is vibrated by intake air pulsation in an intake system 5, a volume chamber 14 connected through the resonating body 13 to the intake system 5, and a neck section 16 through which an interior space 15 of the volume chamber 14 is communicated with outside. The interior space 15 of the volume chamber 14 and interior of the intake system 5 are partitioned by the resonating body 13. The resonator is so set that a sound pressure in a certain frequency range is released from the neck section 16 to the outside under vibration of the resonating body 13. With this, the sound pressure characteristics of air intake sound can follow a rise in engine speed.

Owner:MAHLE JAPAN LTD

Intake device of internal combustion engine

ActiveUS7448353B2Increase air pressureIncrease engine speedInternal combustion piston enginesAir cleaners for fuelInterior spaceEngineering

A resonator 13 is provided including a resonating body 13 which is vibrated by intake air pulsation in an intake system 5, a volume chamber 14 connected through the resonating body 13 to the intake system 5, and a neck section 16 through which an interior space 15 of the volume chamber 14 is communicated with outside. The interior space 15 of the volume chamber 14 and interior of the intake system 5 are partitioned by the resonating body 13. The resonator is so set that a sound pressure in a certain frequency range is released from the neck section 16 to the outside under vibration of the resonating body 13. With this, the sound pressure characteristics of air intake sound can follow a rise in engine speed.

Owner:MAHLE JAPAN LTD

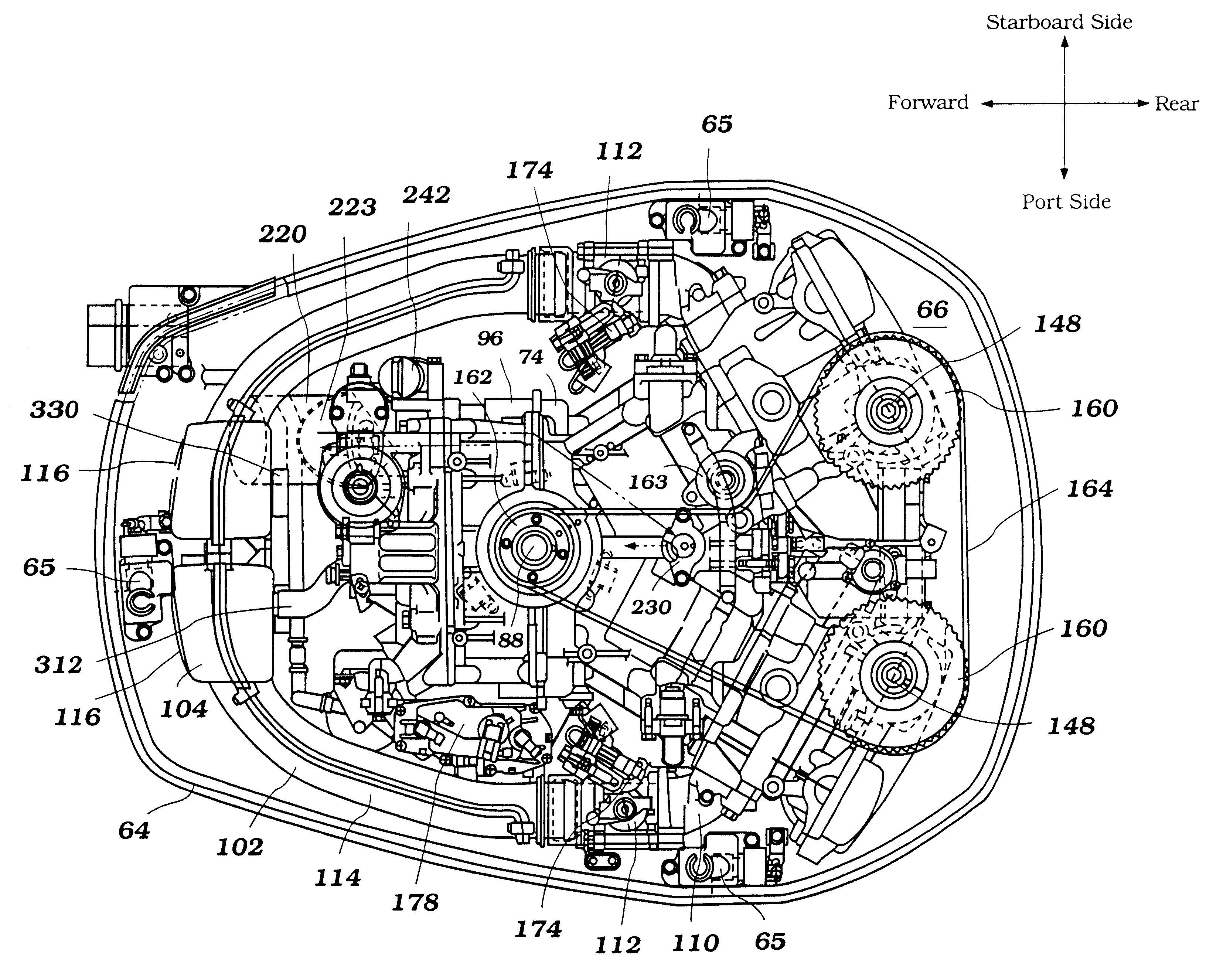

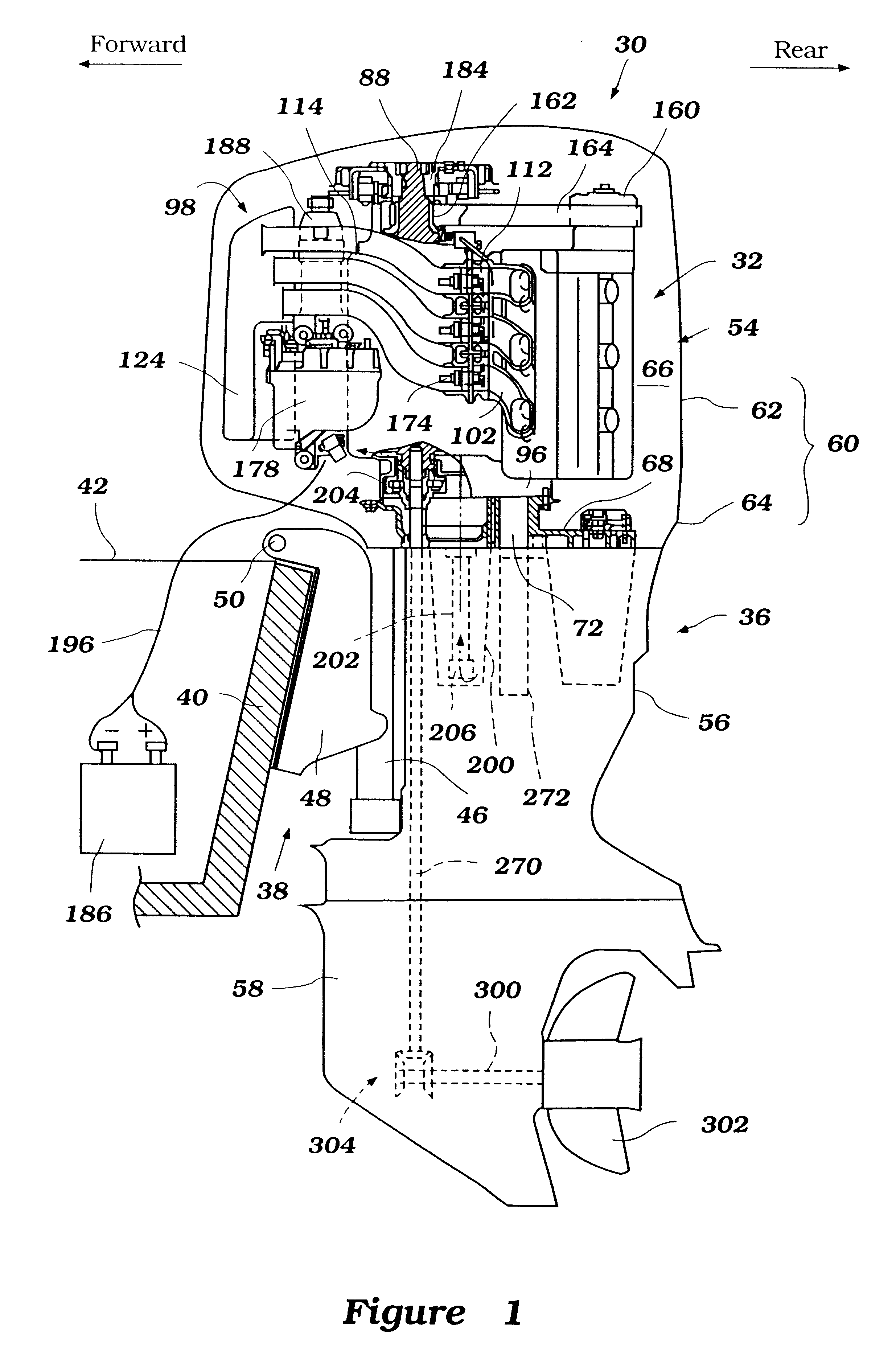

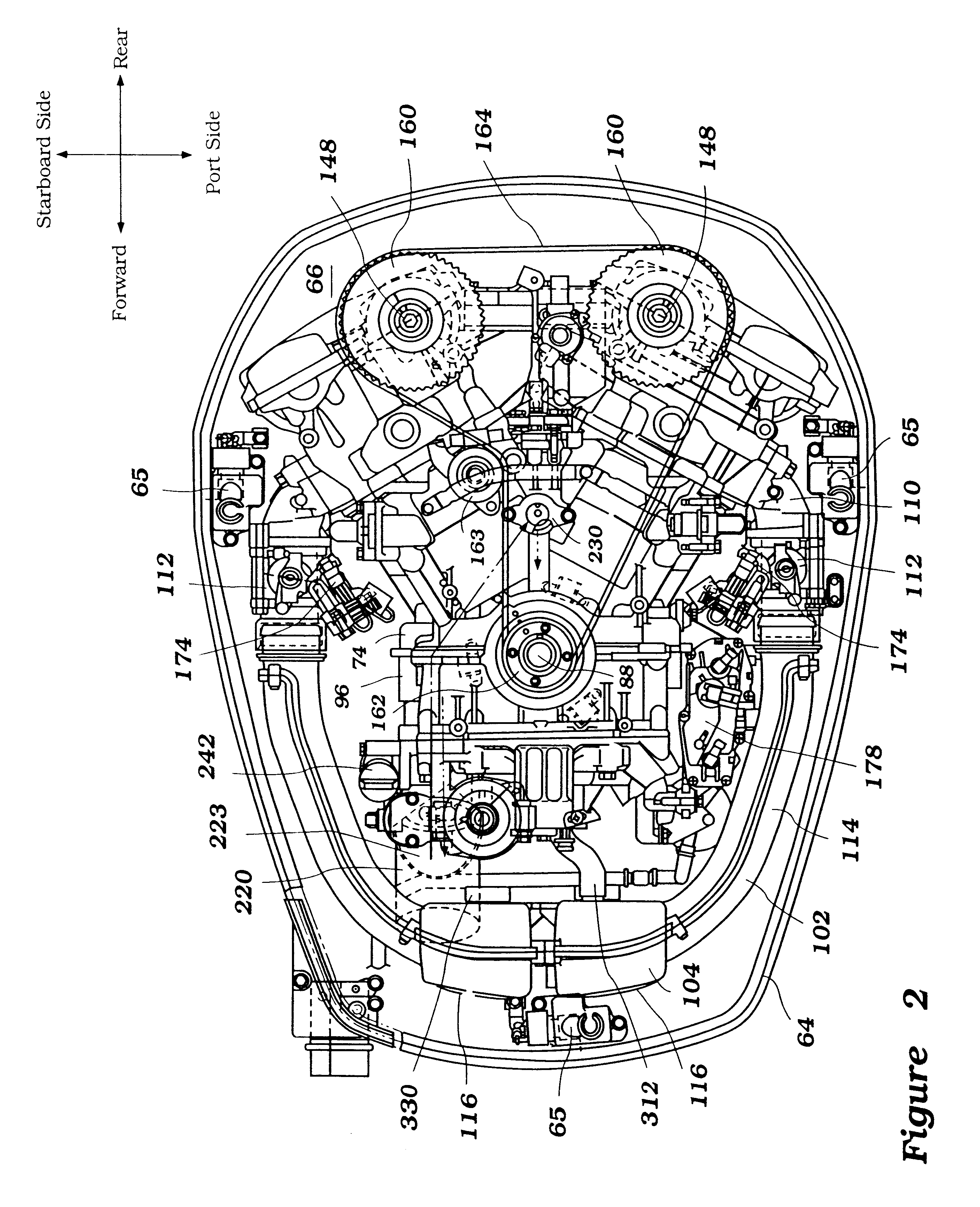

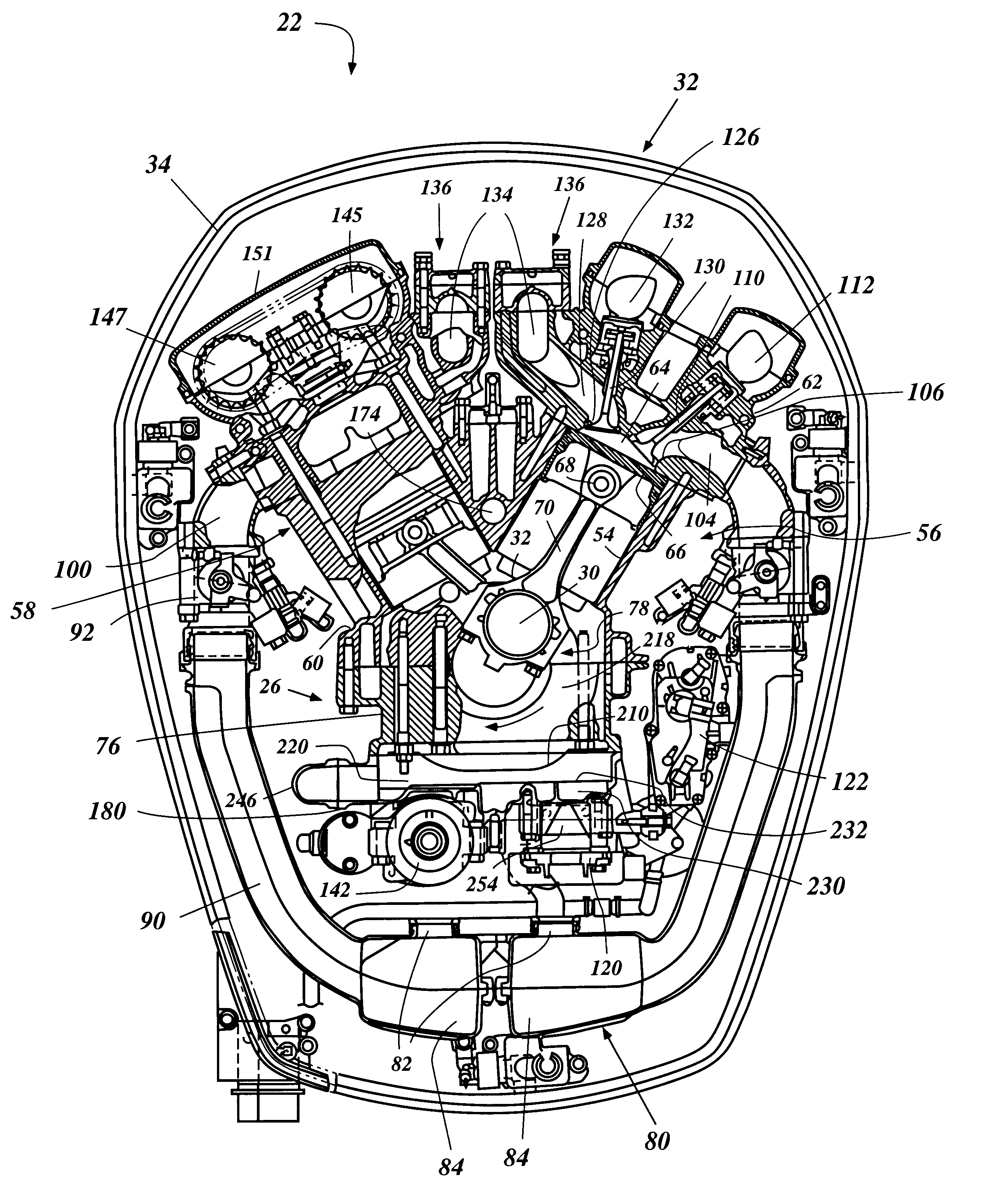

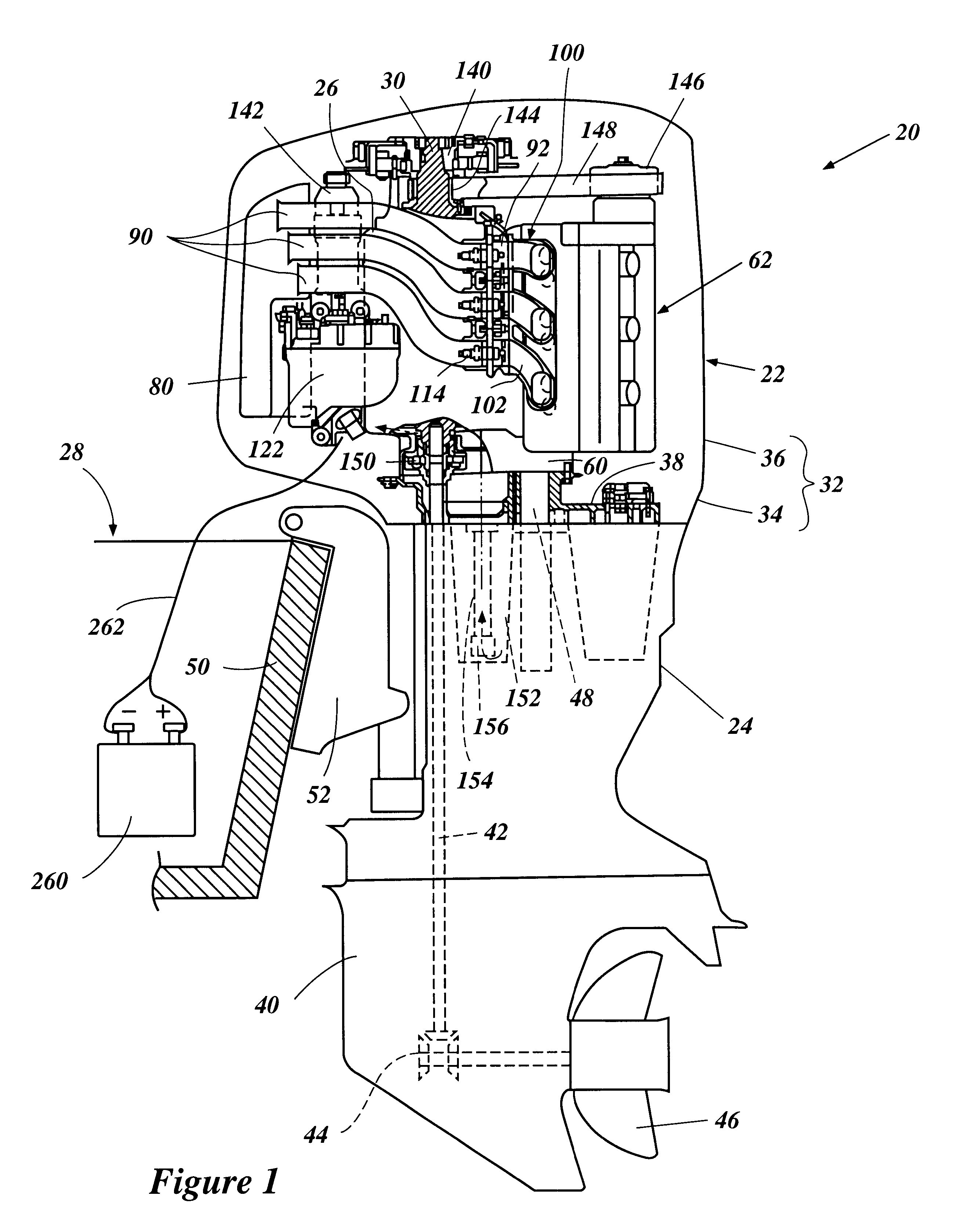

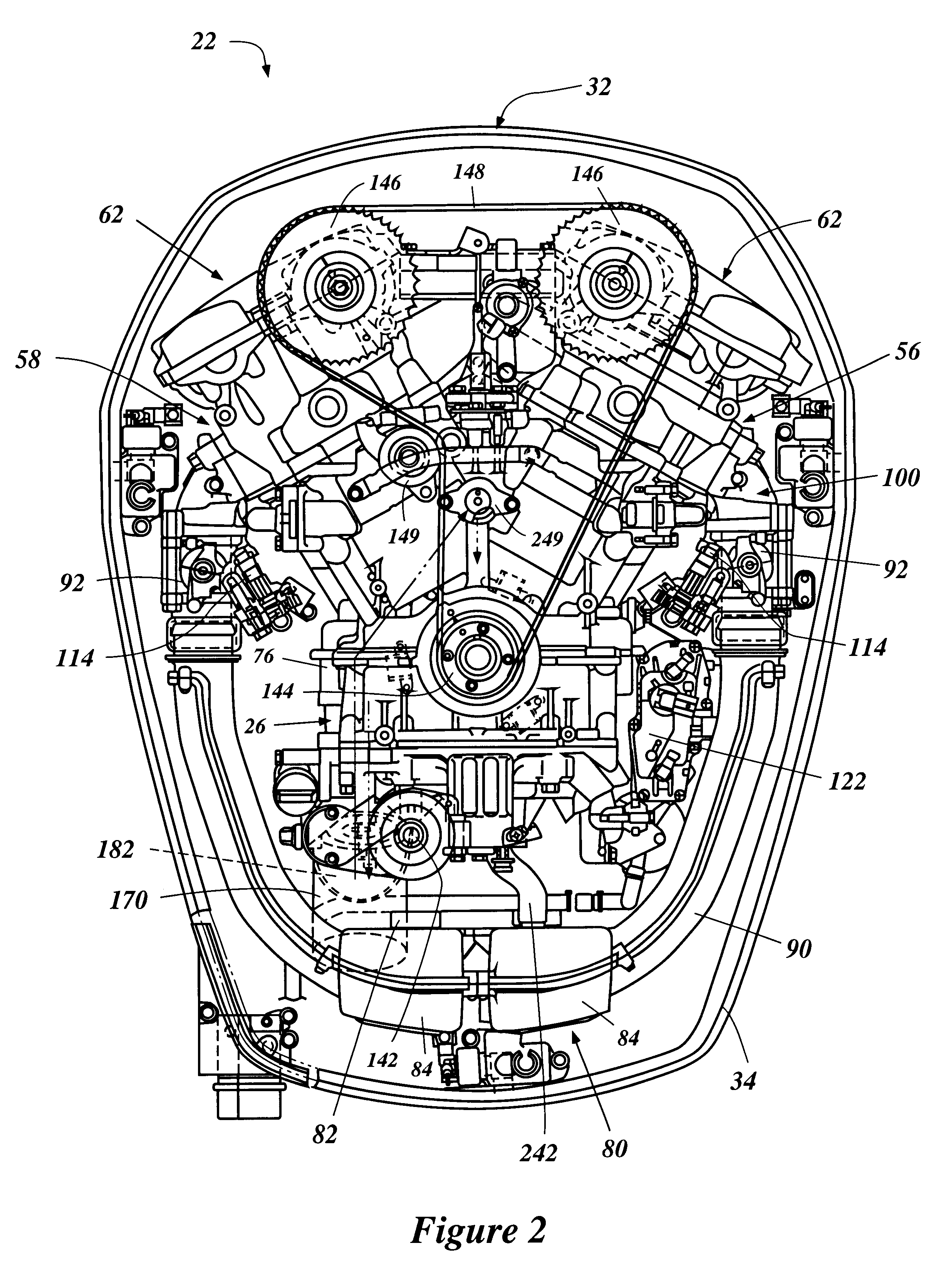

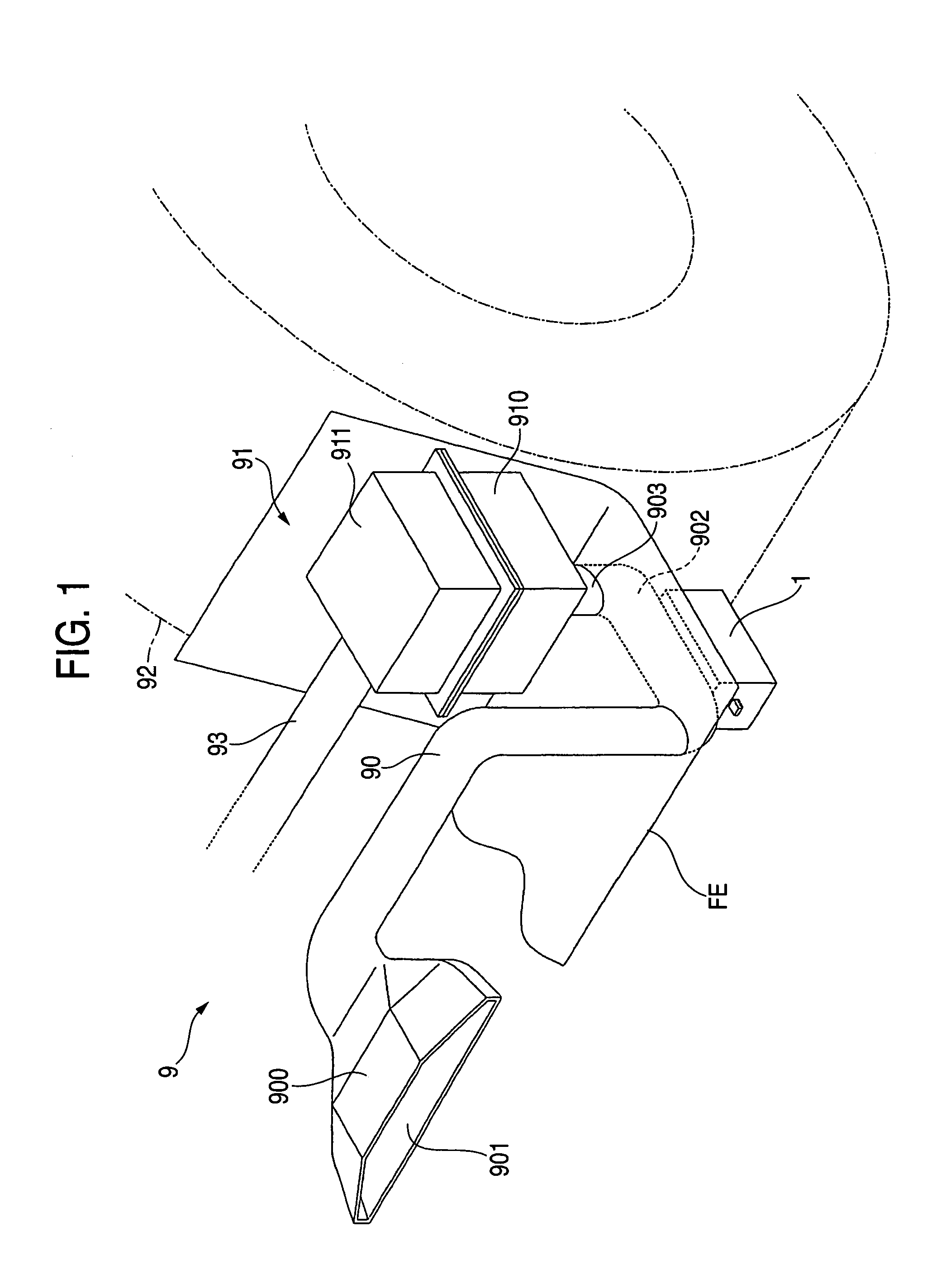

Arrangement for outboard motor

InactiveUS6346018B1Small sizeComponents is relatively effectivePower plants using condensersCasingsCombustion chamberCrankcase

An outboard motor comprises an internal combustion engine and a protective cowling that surrounds the engine. The cowling comprises at least an upper portion and a lower portion. The engine comprises a cylinder block that defines a cylinder bore. A cylinder head member is fixed at one end of the cylinder block and encloses one end of the cylinder bore. A crankcase member is fixed at the other end of the cylinder block and encloses the other end of the cylinder bore. The crankcase member forms a crankcase chamber. A piston is positioned within the cylinder bore. A crankshaft is rotably journaled in the crankcase chamber and is connected to the piston. The piston, the cylinder bore and the cylinder head together define a combustion chamber. The cylinder block, the cylinder head member and the crankcase member together defining an engine body. A first air intake conduit communicates with the engine and extends generally along a side of the engine body. The first air intake conduit communicates with an intake silencer located proximate the crankcase member. The engine further comprises a starter motor, an electronic control unit and a fuel supply system. The fuel supply system comprises a vapor separator and a fuel injector. The starter motor, the electronic control unit, the vapor separator and the fuel injectors are located in a space defined between the intake silencer, the first air intake conduit and the engine body.

Owner:SANSHIN KOGYO CO LTD

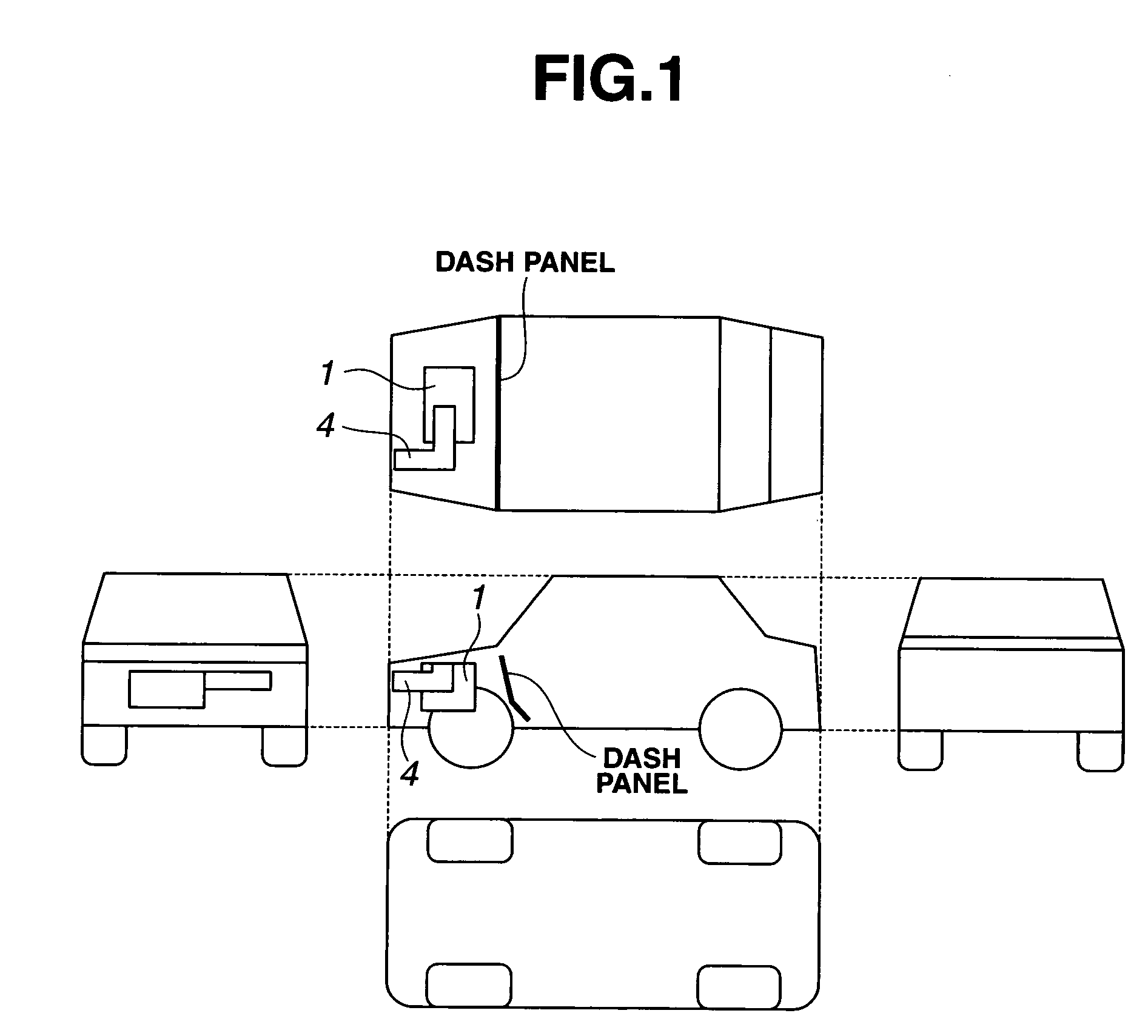

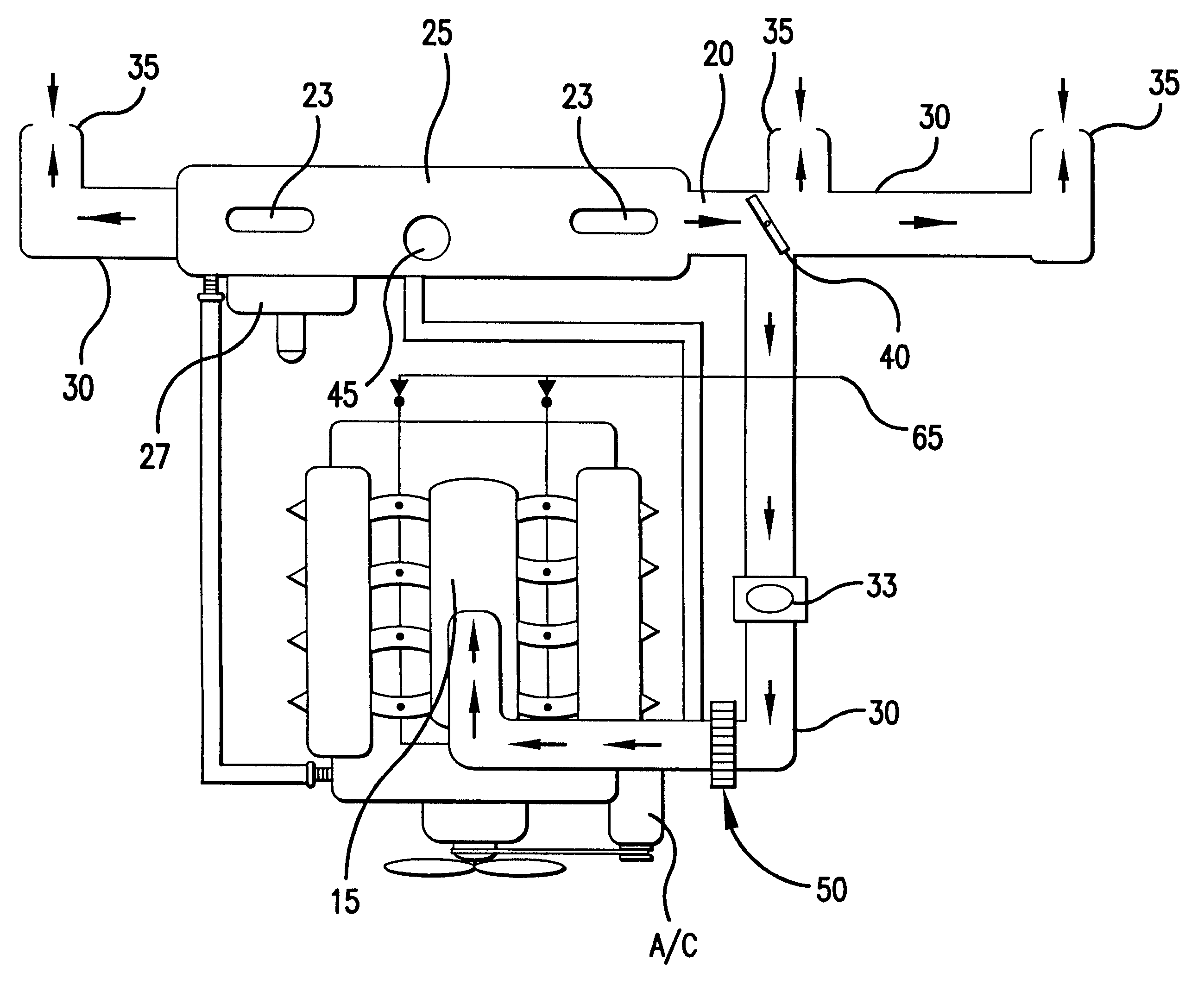

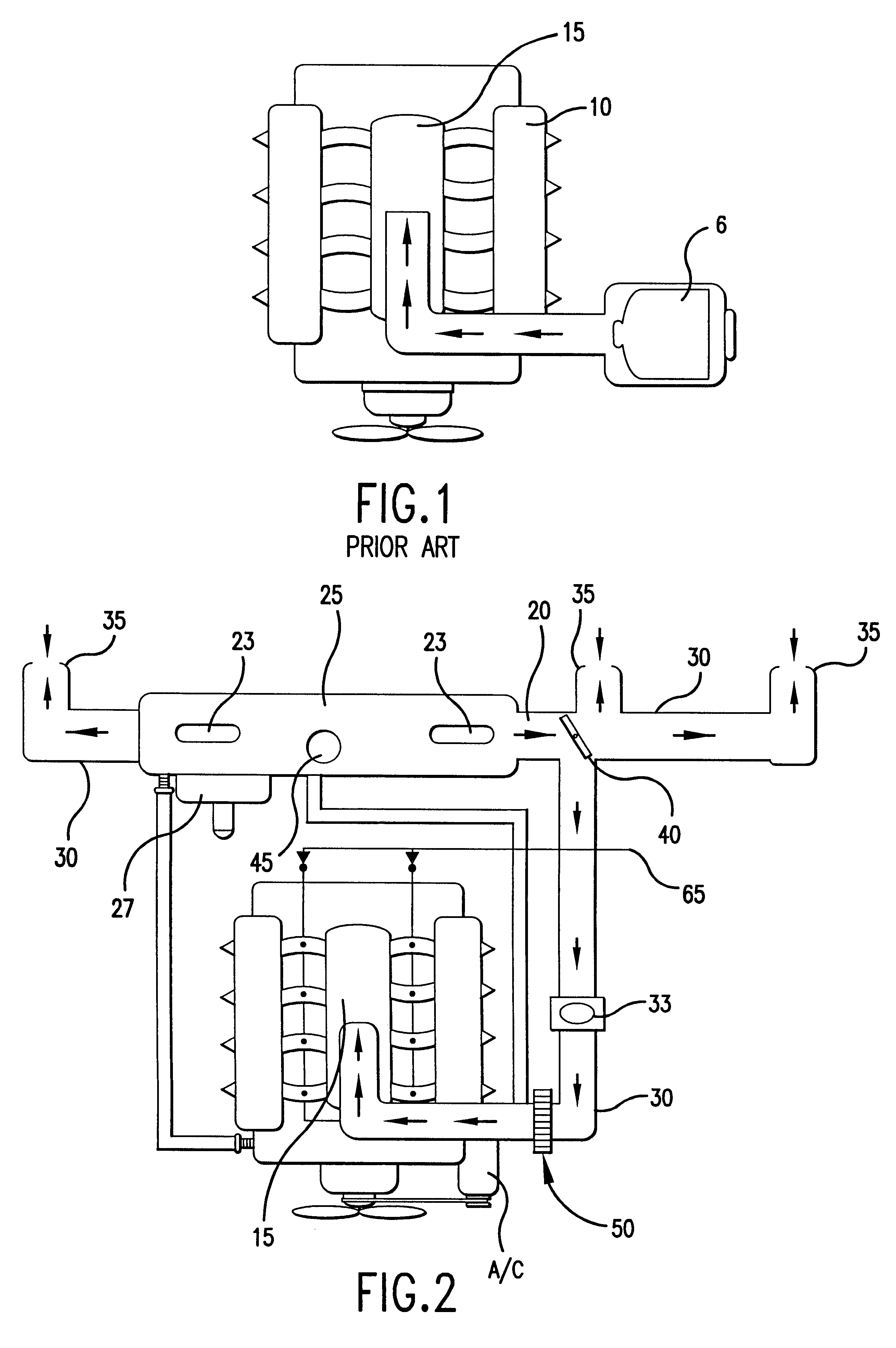

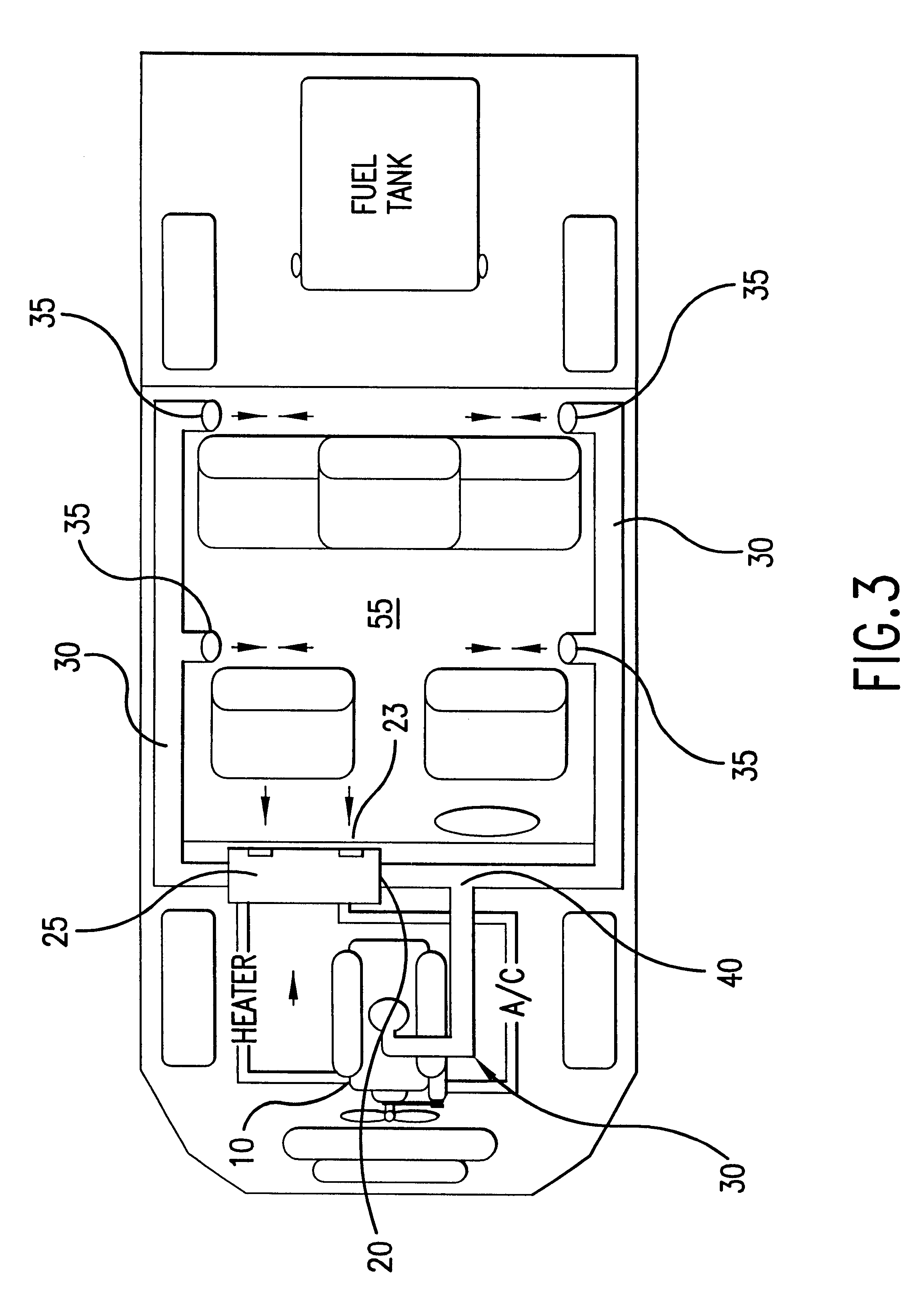

Vehicle air induction system

InactiveUS6314949B1Lower emission levelsImprove efficiencyInternal combustion piston enginesTemperatue controlRam-air intakeTemperature control

This invention is an air induction system that enables an enhanced flow of temperature-controlled, magnetically influenced forced air to the air intake of internal combustion, turbine-type, and other engines having an air intake manifold. An interior air inlet is positioned in communication with a passenger compartment of the vehicle. Additionally, or alternatively, a plenum outlet is positioned in an HVAC plenum of the vehicle. An air supply duct extends between the interior air inlet and / or the plenum outlet and the air intake manifold supplies conditioned air to the air intake manifold. Performance may be enhanced with the positioning of magnets and / or an air diverter valve into the system. As a result of the enhanced flow of magnetically influenced air and the more steady state of the temperature of the inducted air, fuel consumption and air emissions levels are reduced.

Owner:FUEL MANAGEMENT

Electronically controlled dual chamber variable resonator

ActiveUS20050252716A1Silencing apparatusSound producing devicesHelmholtz resonatorInternal combustion engine

An in-line resonator for an air induction system of an internal combustion engine is provided. The system includes a resonator housing, an upstream duct, a downstream duct, a conduit, a partition, and a sleeve. The conduit extends through the resonator housing connecting the upstream duct and the downstream duct. The partition is moveable within the resonator housing and divides the housing into an upstream chamber and a downstream chamber. The downstream chamber, the conduit, and the downstream sleeve cooperate to form a first Helmholtz resonator that is in fluid communication with the downstream duct. The upstream chamber, the conduit, and the upstream sleeve cooperate to form a second Helmholtz resonator that is in fluid communication with the upstream duct. Further, a means is provided to axially move the partition to vary the volume of the chambers concurrently with the length and / or area of the passages.

Owner:HANON SYST

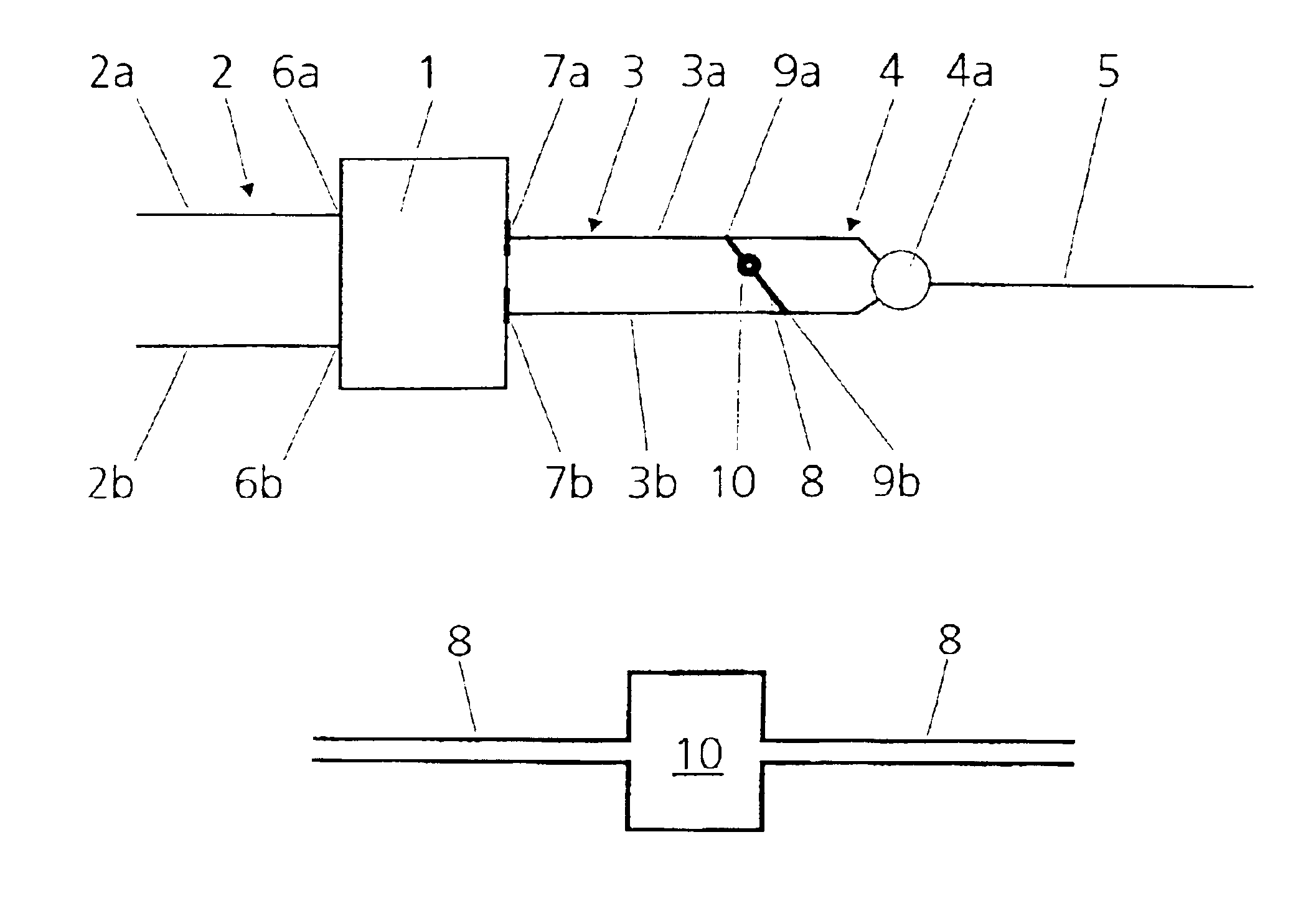

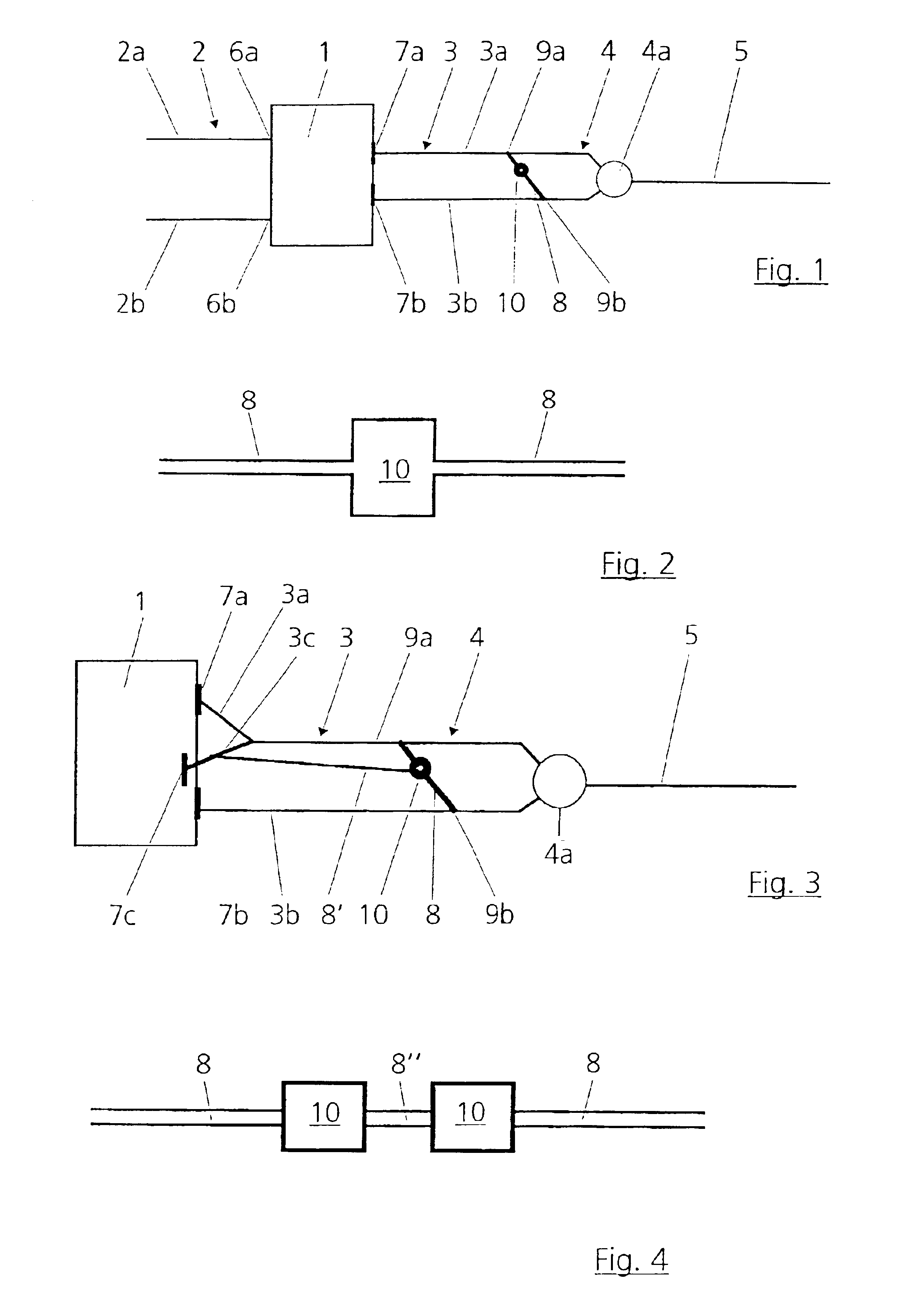

Noise suppressor apparatus for a gas duct

A sound damping device (4) for a tubular duct (2), particularly a gas transporting tract of an internal combustion engine (1) having a least one bypass channel (5) running parallel to a main duct (6) in a section of the duct (2). The bypass channel (5) is longer than the main duct (6) between a branching off point (7) and a re-entry inlet (8). The bypass duct according to the invention is configured as a spiral duct (5) which winds around the centrally disposed main duct (6) in order to decrease the installation space requirements for the noise suppressor (4).

Owner:MANN HUMMEL GMBH

Noise attenuation device for a vehicle exhaust system

ActiveUS7086498B2Reduce turbulenceReduce noiseExhaust apparatusSilencing apparatusExhaust fumesExhaust pipe

A noise attenuation device for a vehicle exhaust system is provided. The device includes an exhaust pipe having a passageway for receiving exhaust gas pulses from an engine. The device further includes a plurality of vanes extending from an inner surface of the passageway and spaced apart from one another and disposed upstream of a discontinuity in the exhaust pipe. The vanes reduce turbulence in the exhaust gas pulses flowing past the vanes to reduce noise at the exhaust pipe discontinuity.

Owner:FORD GLOBAL TECH LLC

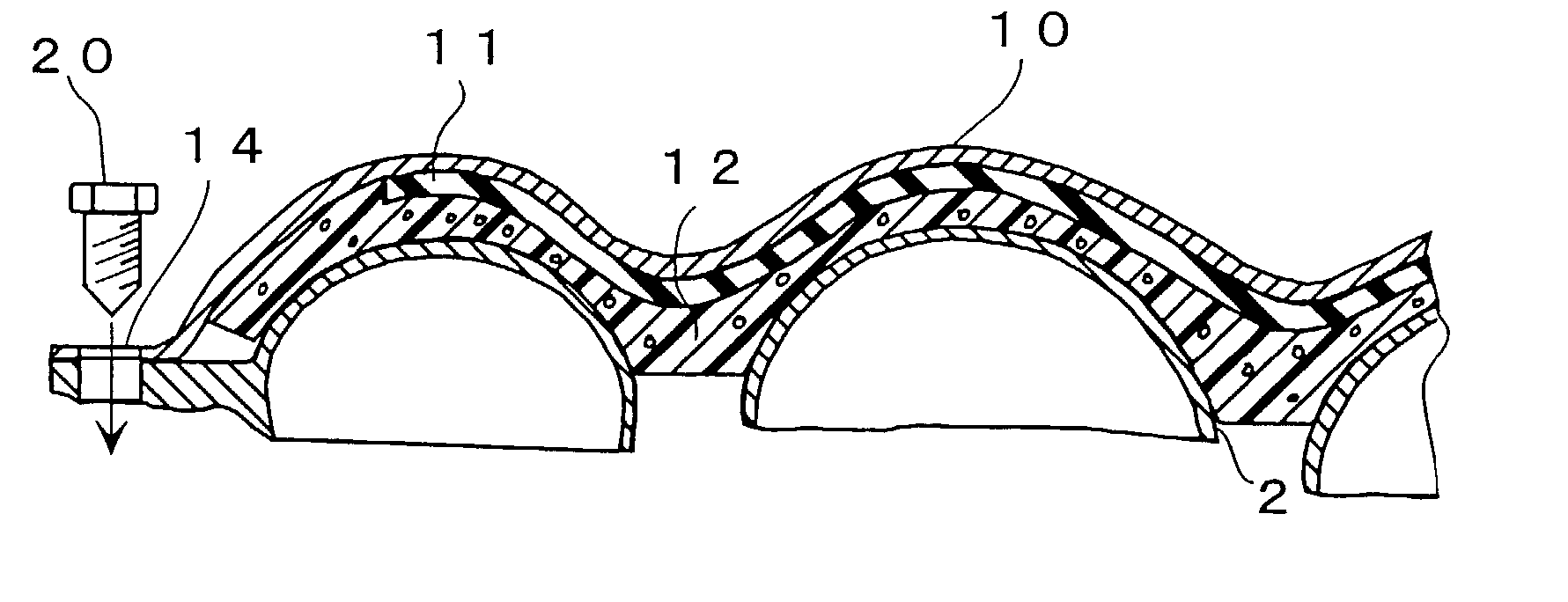

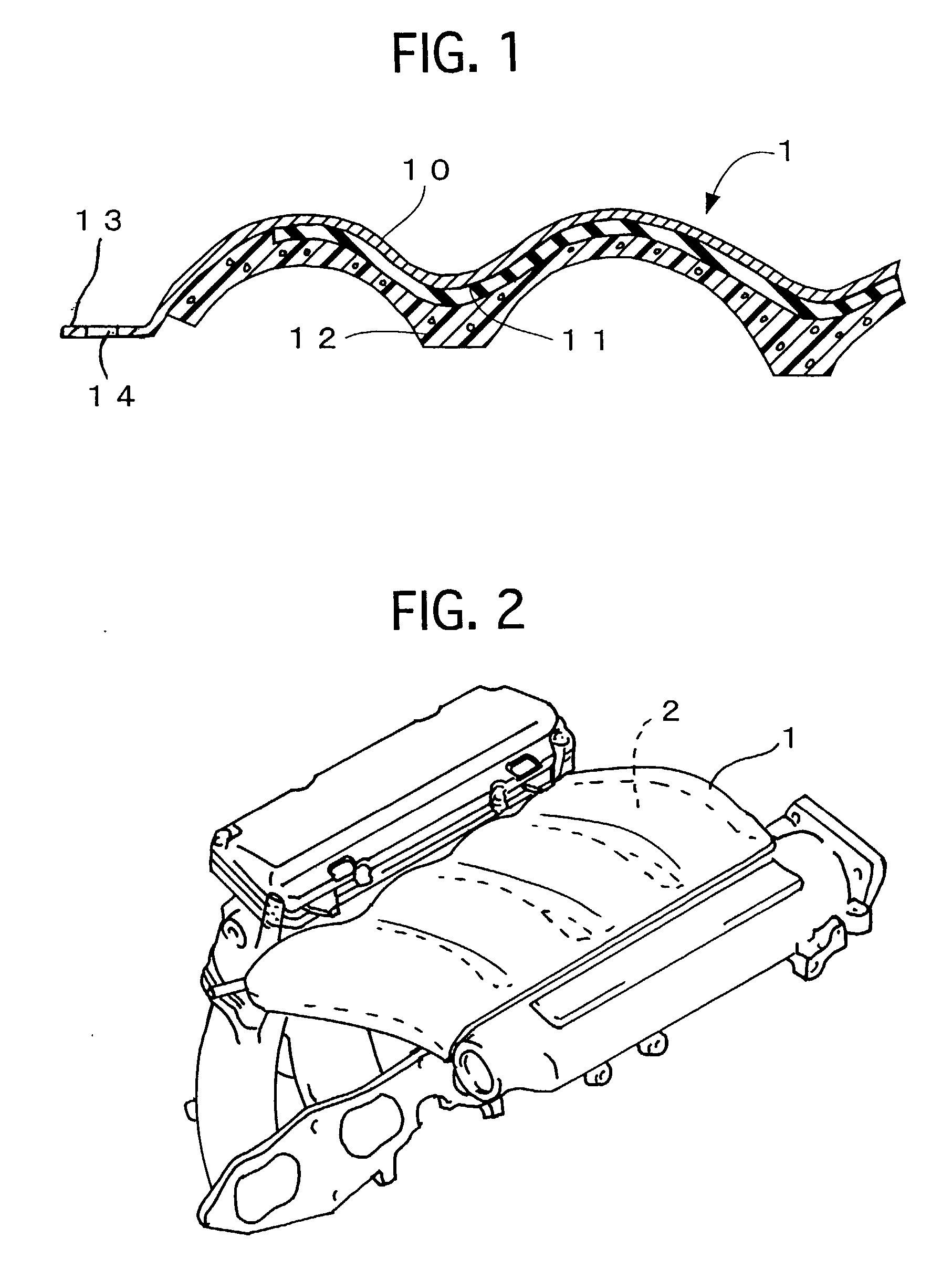

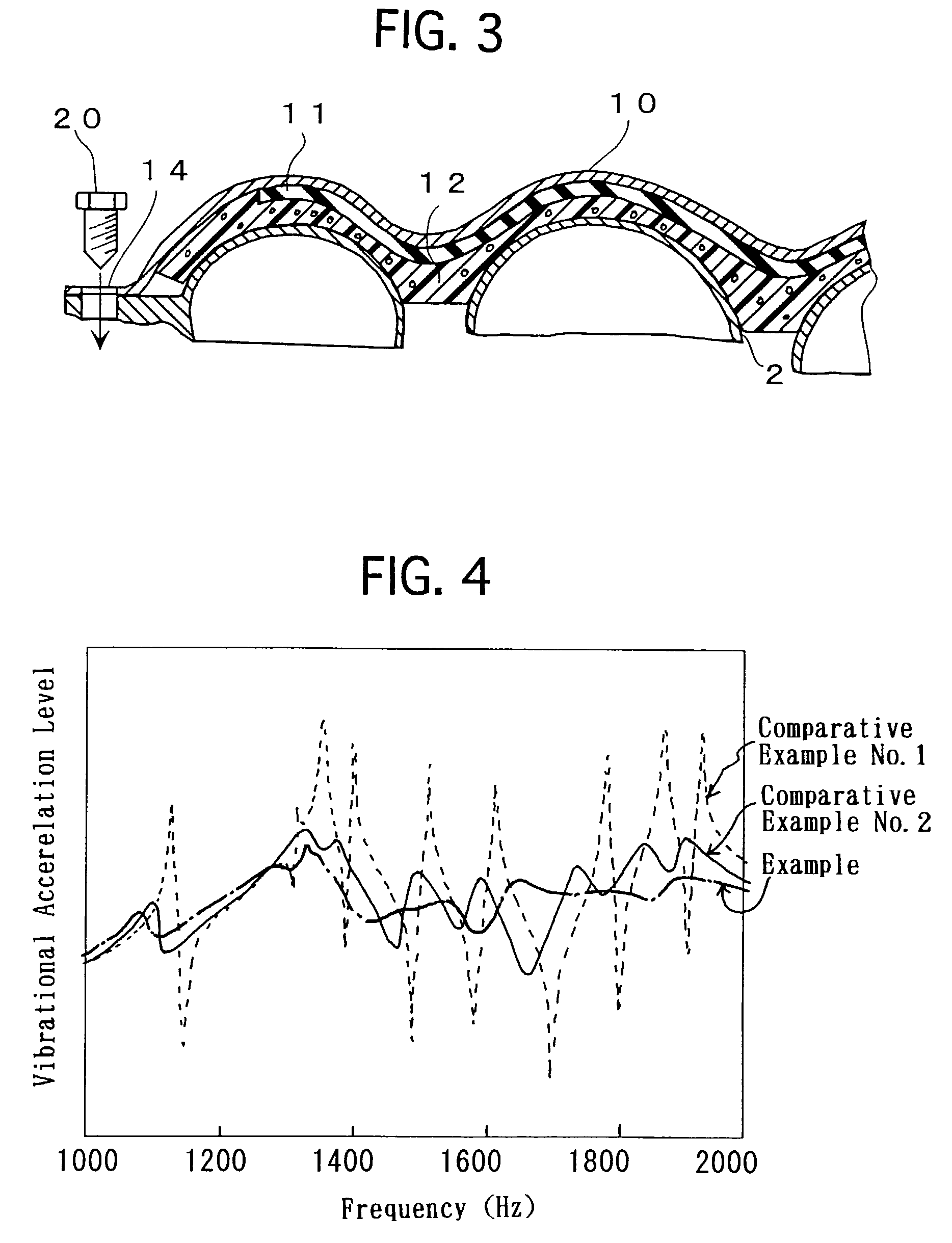

Soundproof cover

InactiveUS20030010566A1Avoid vibrationReduce in quantitySilencing apparatusMachines/enginesInsulation layerEngineering

A soundproof cover includes a sealing layer, a sound insulation layer, and a vibration inhibition layer. The sound insulation layer has a peripheral portion, is to be disposed so as to contact at least the peripheral portion with a noise source, and exhibits elasticity. The sound insulation layer is formed as a hard plate shape, has an installation portion to be fastened to the noise source, and is disposed so as to cover the sealing layer. The vibration inhibition layer is disposed on at least a part of an interface between the sealing layer and the sound insulation layer so as to adhere to the sound insulation layer, and inhibits the sound insulation layer from vibrating.

Owner:SUMITOMO RIKO CO LTD +1

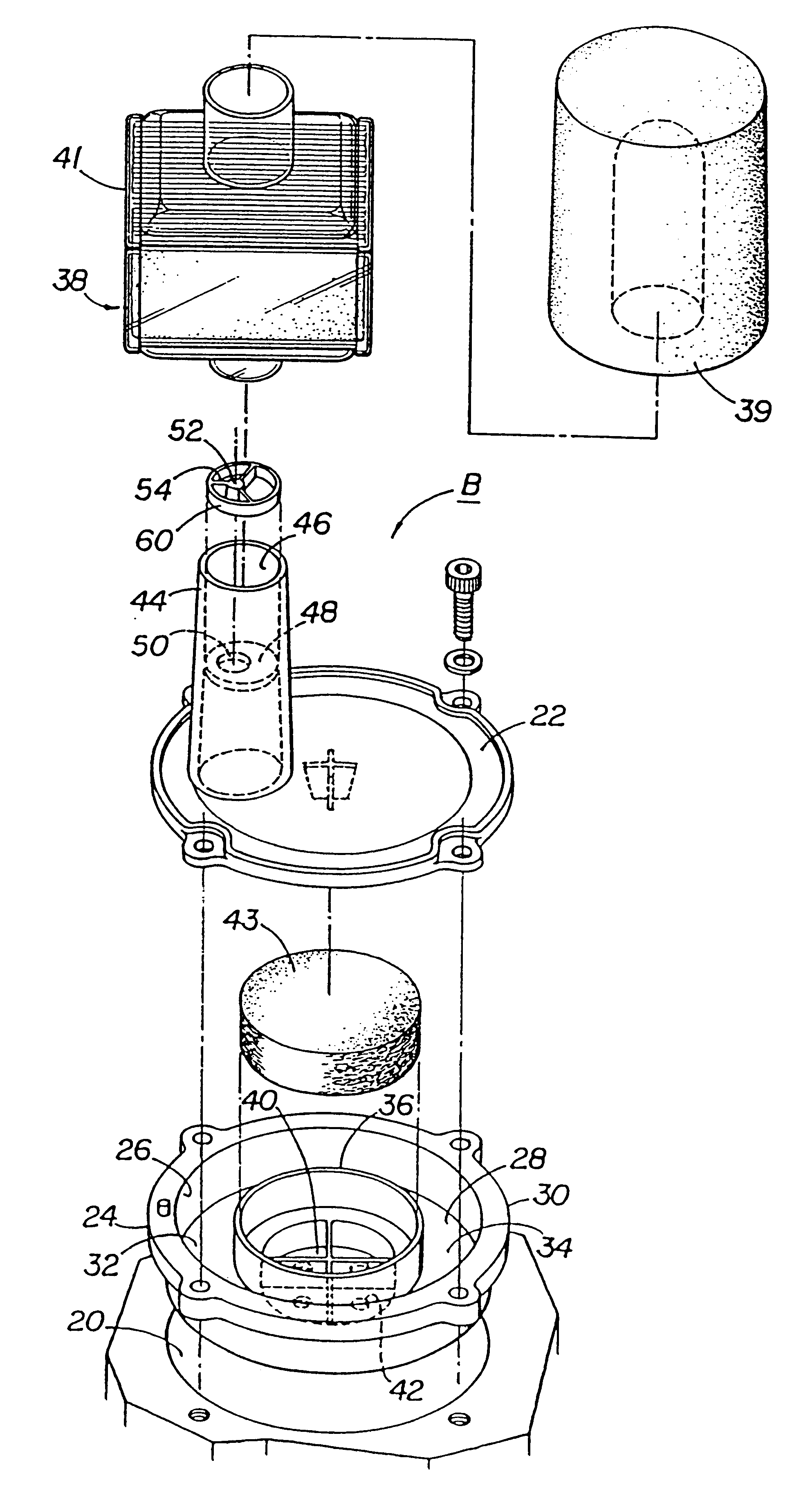

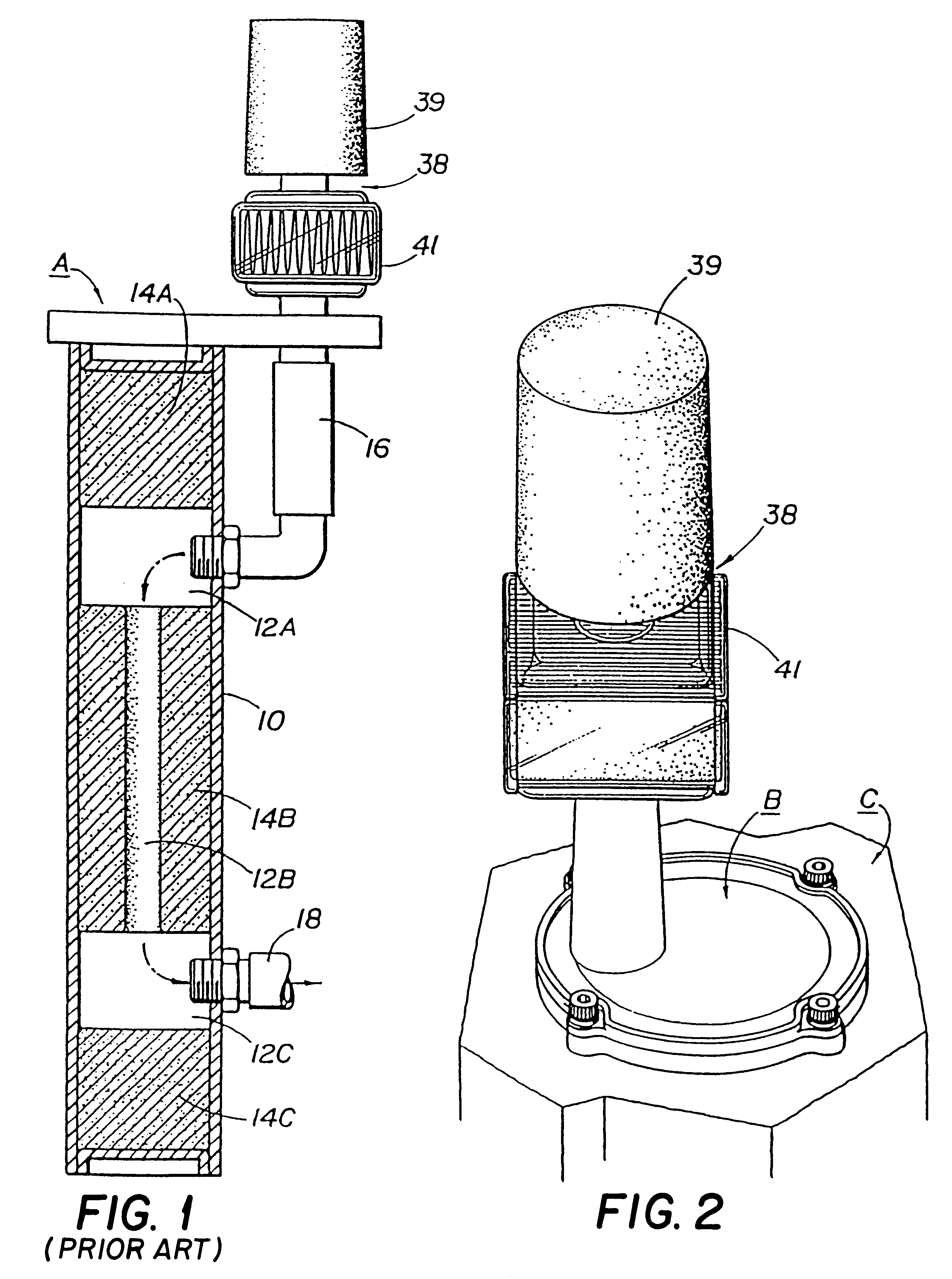

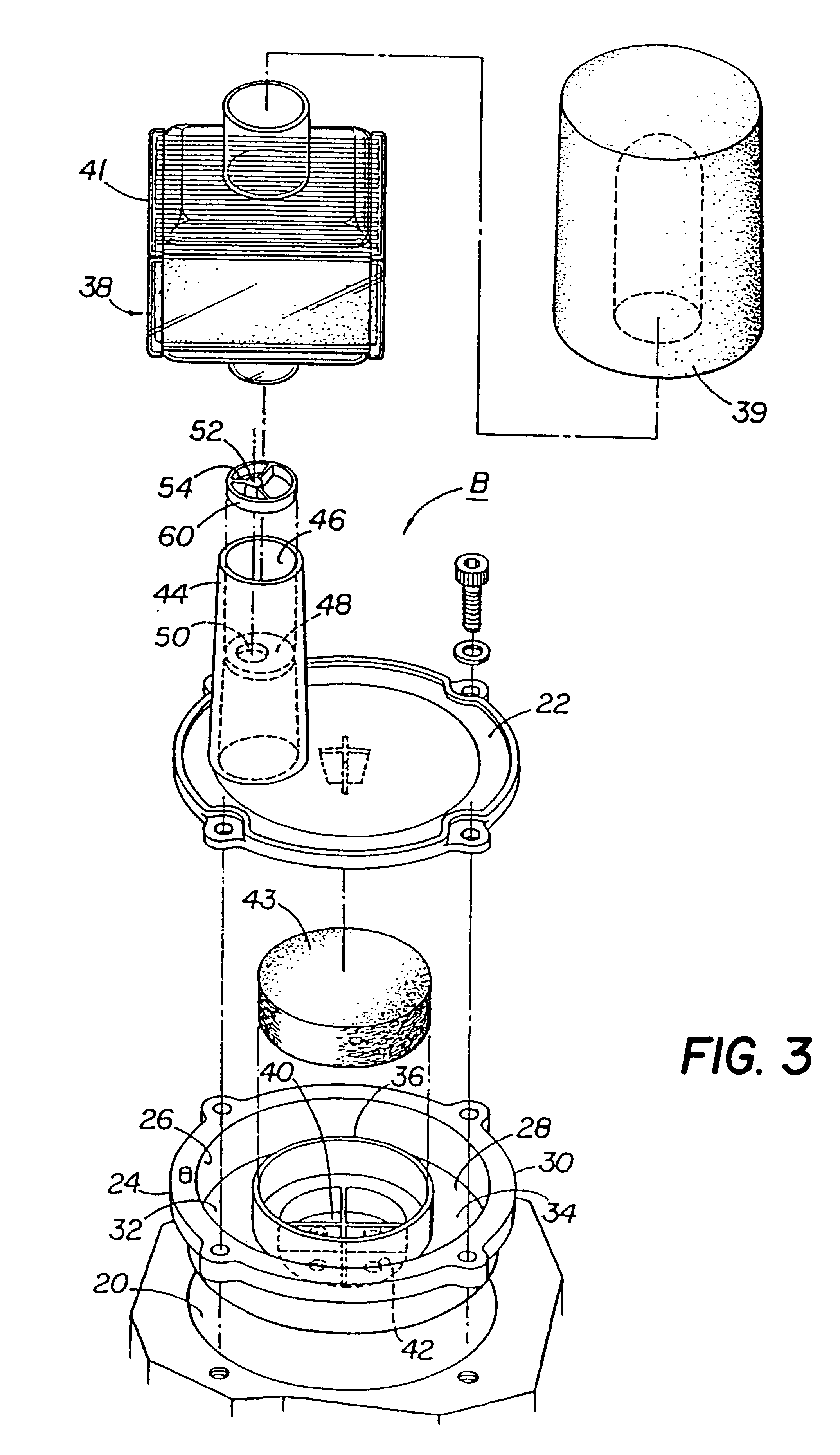

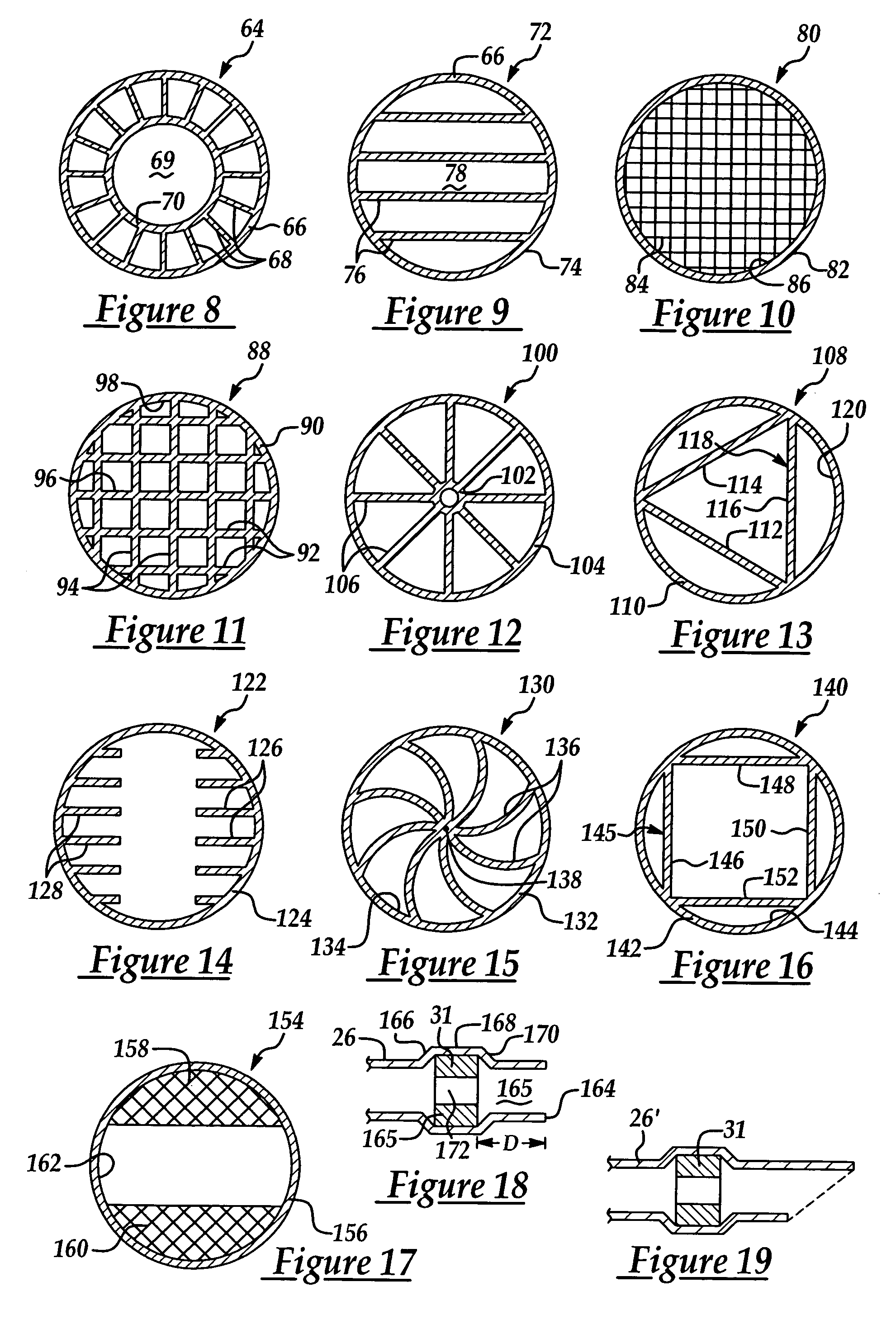

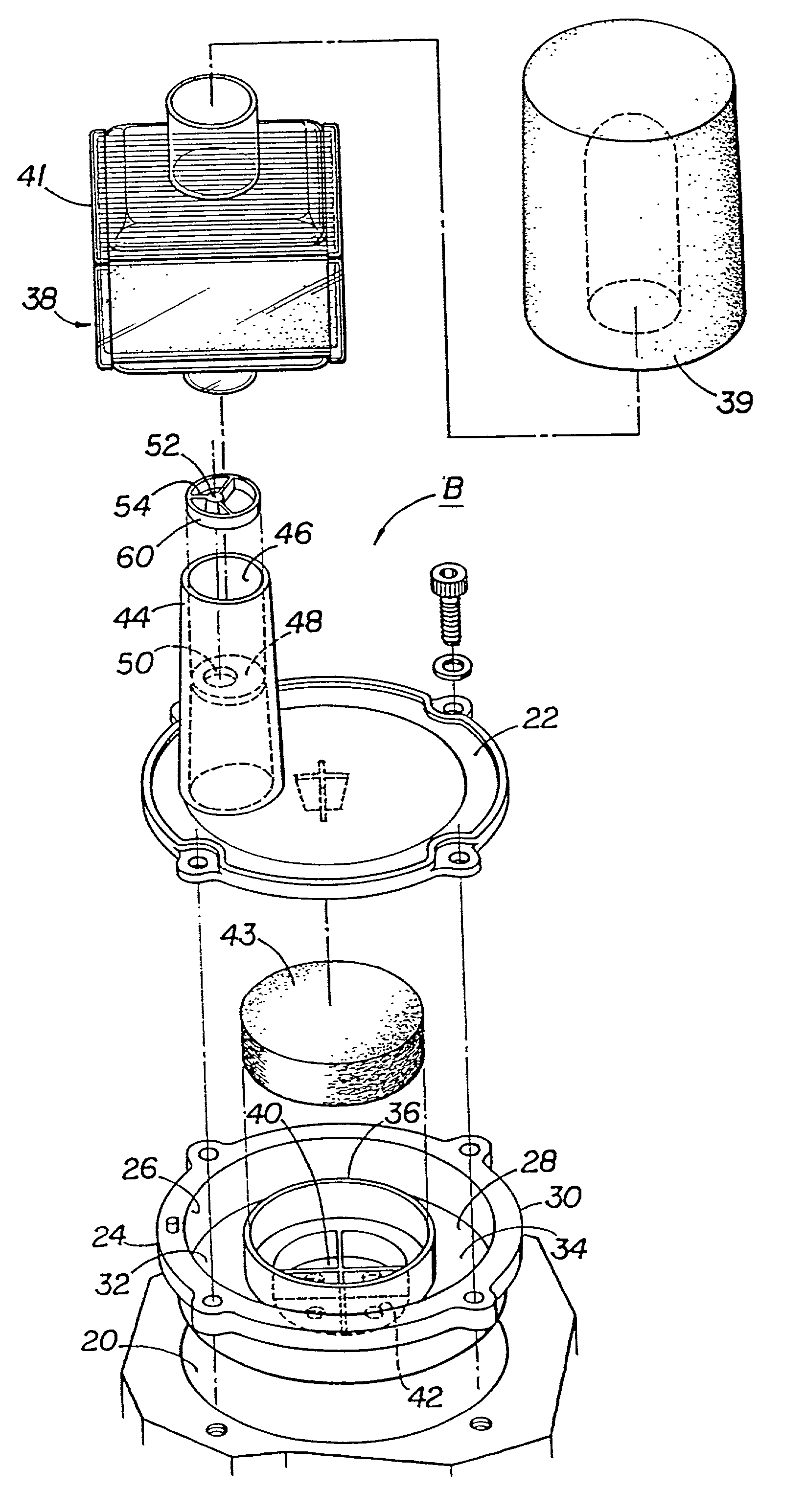

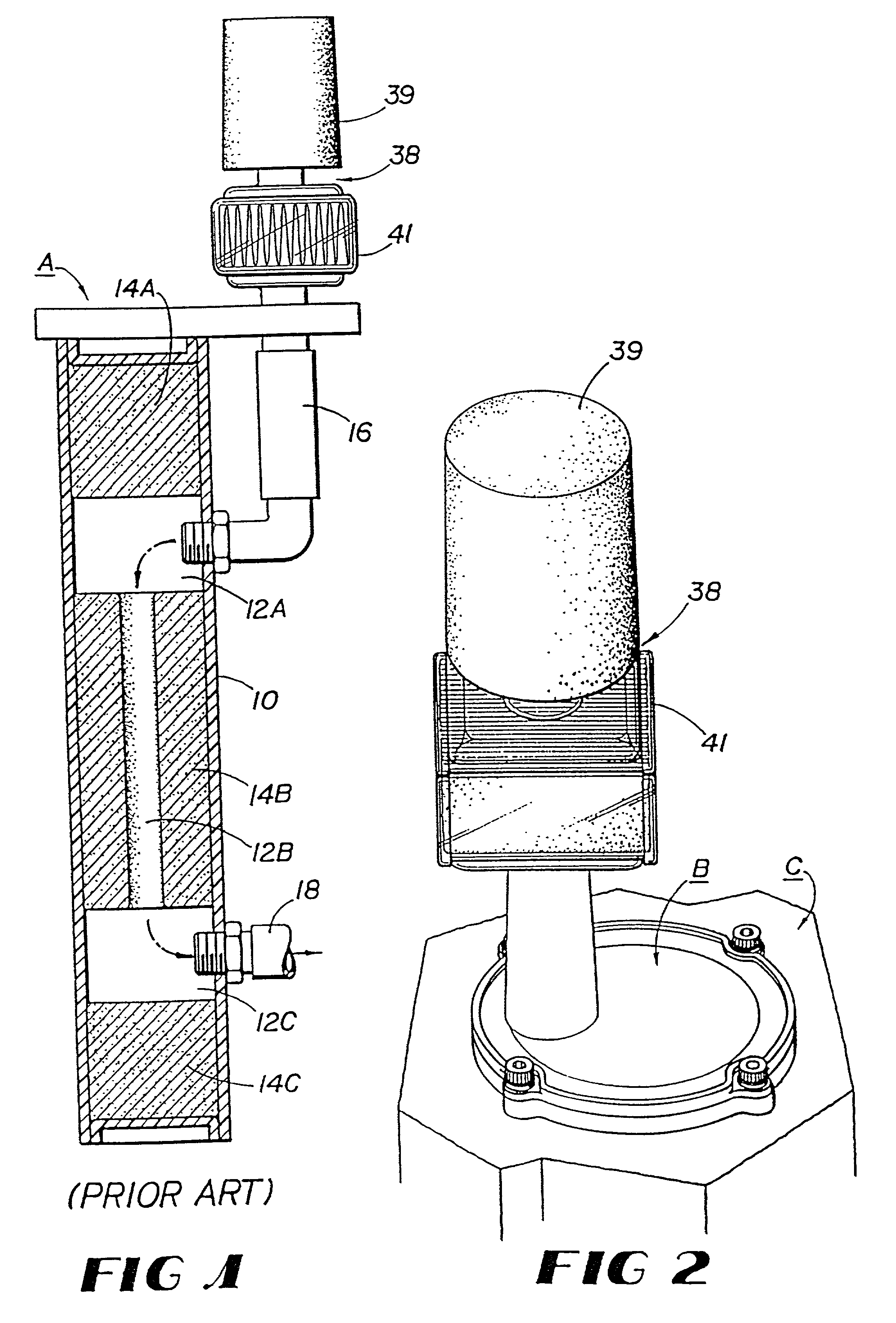

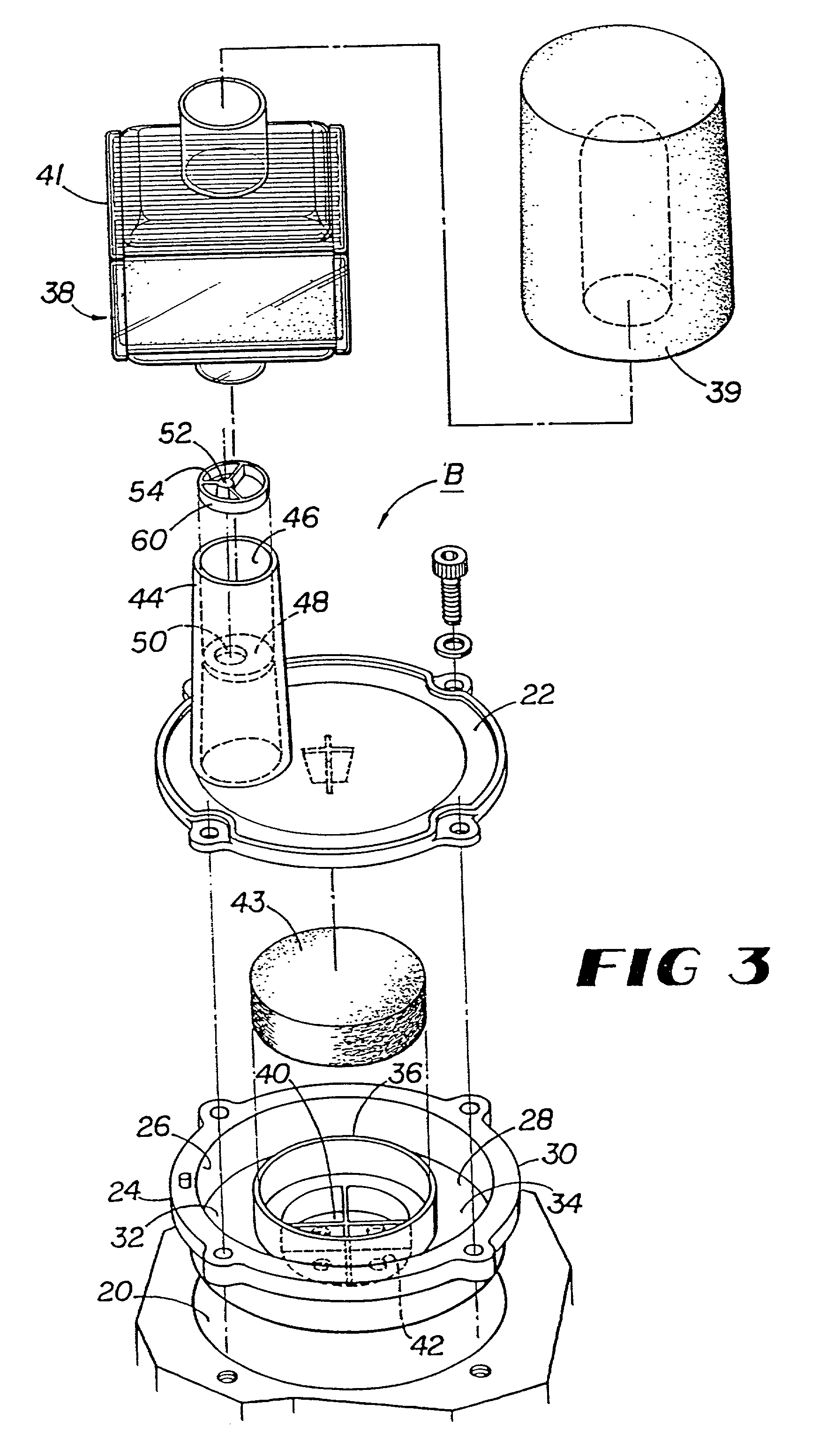

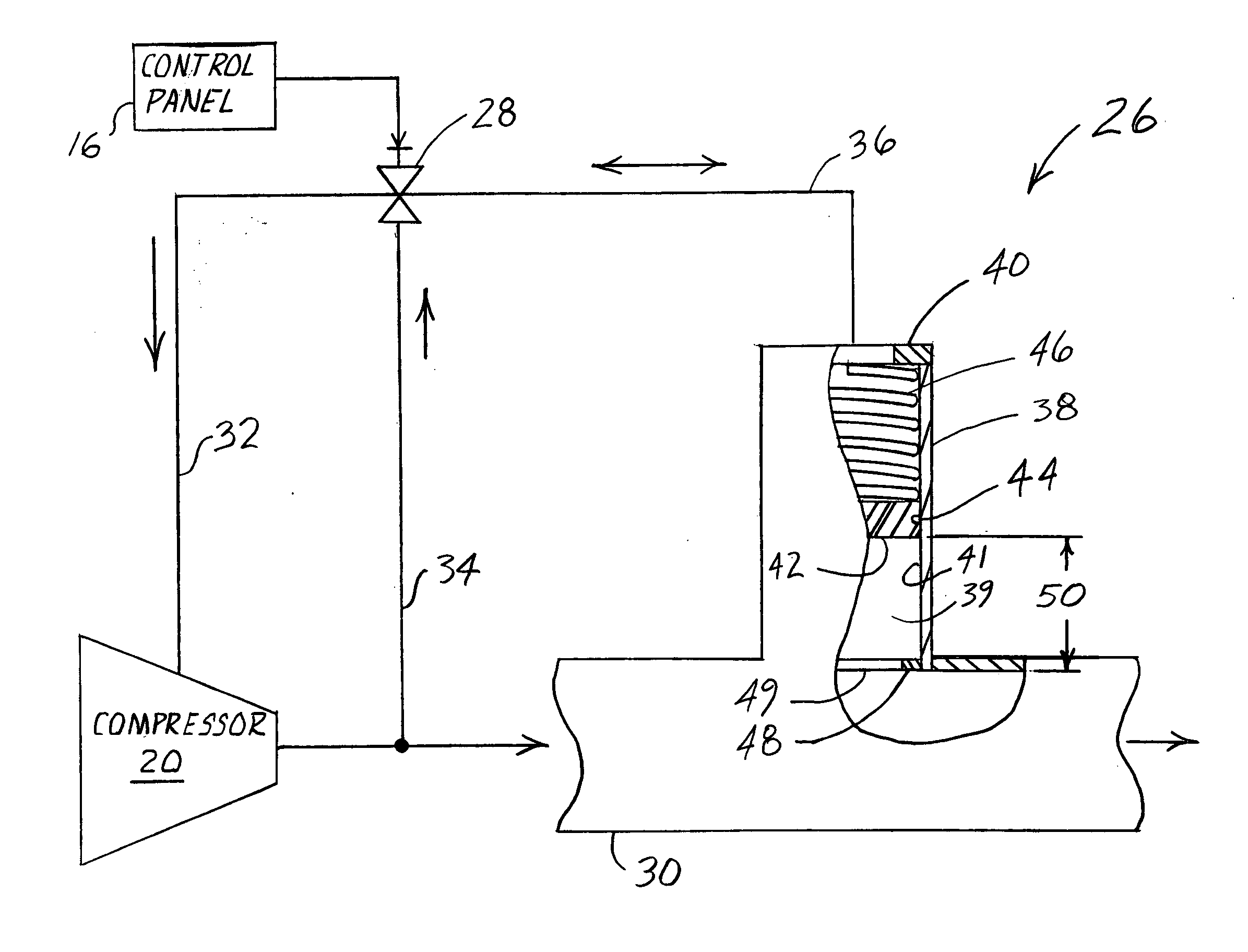

Compressor muffler

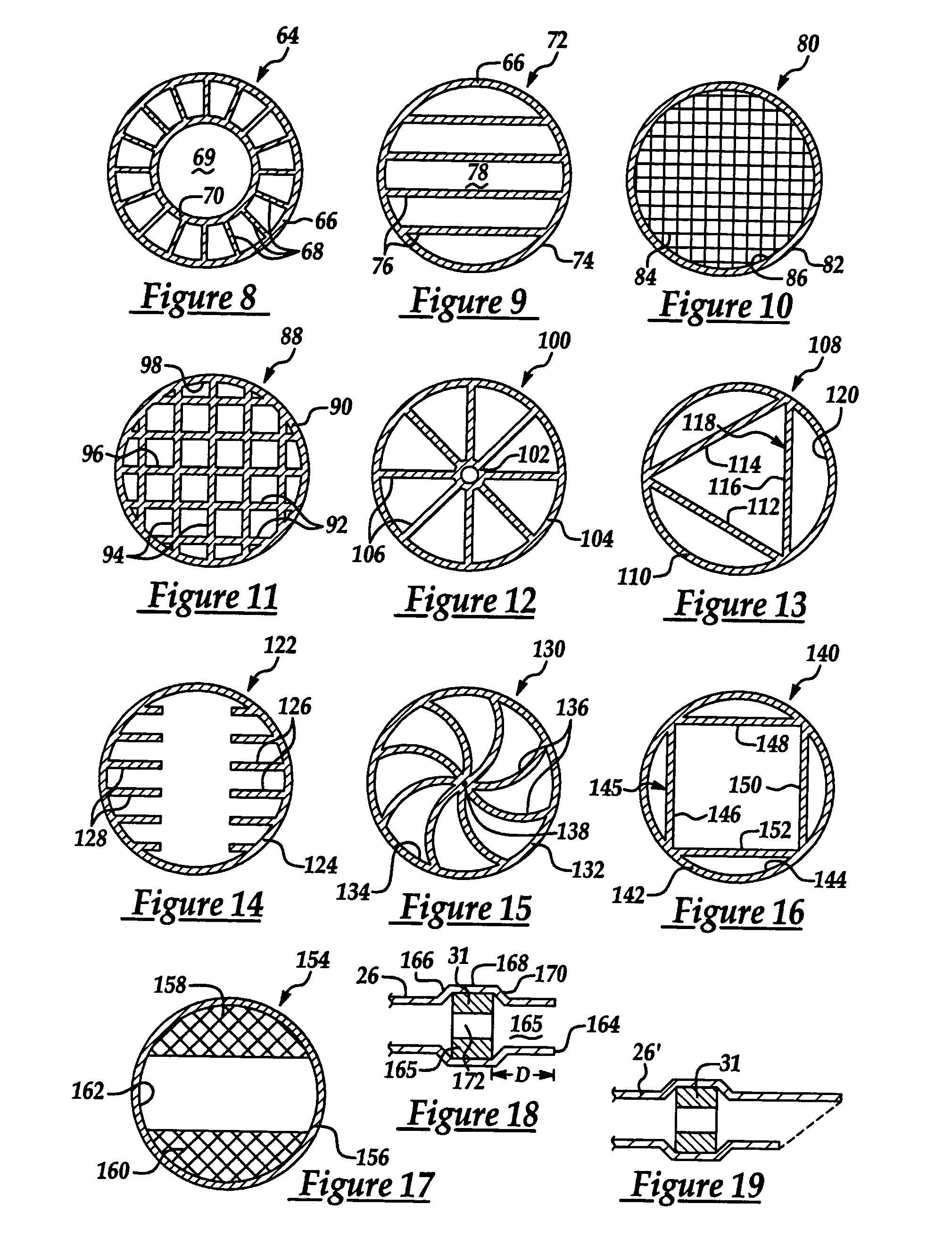

A muffler assembly for muffling noises associated with a compressor. The muffler assembly is mounted on the compressor such that the two move as a solid body. The muffler assembly includes an intake having a hollow interior adapted to receive a first flow of gas from the ambient environment. A baffle disposed in the hollow interior of the intake restricts the flow of gas through the intake. In one embodiment, the baffle defines at least a portion of a plurality of fluid portals that separate the first flow of gas into a plurality of flows of gas as the gas passes from a first side of the baffle to a second side of the baffle. As a result, the first flow of gas is disturbed and noise from the compressor is thereby attenuated. In another embodiment, a plurality of baffles are disposed in the hollow interior of the intake to define a tortuous path for the flow of gas through the intake for attenuating noise.

Owner:RIC INVESTMENTS LLC

Drive circuit, device, and method for suppressing noise, and use

InactiveUS7279964B2Good flexibilityLow costNegative-feedback-circuit arrangementsAmplifier modifications to reduce noise influenceMicrocontrollerNoise suppression

Owner:CONTINENTAL AUTOMOTIVE GMBH +1

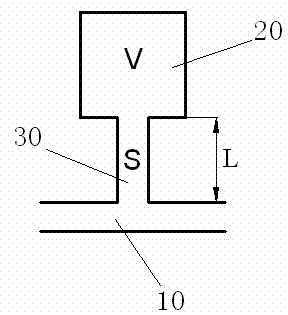

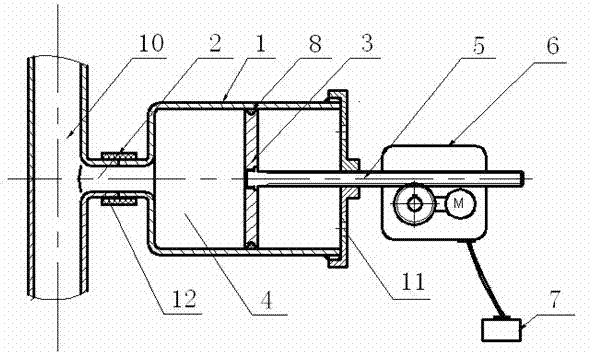

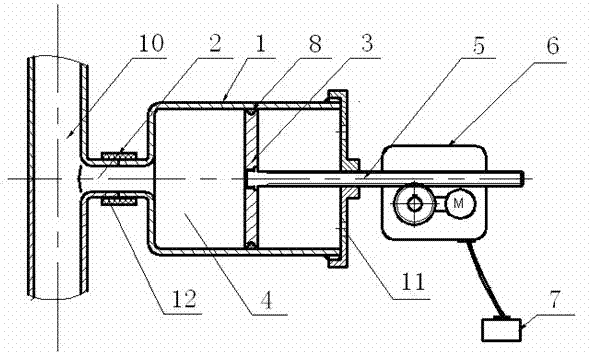

Resonance silencer with dynamically adjusted silencing frequency

InactiveCN102434337ASimple structureEasy to processIntake silencers for fuelEngineeringNoise reduction

The invention aims to provide a resonance silencer with a dynamically adjusted silencing frequency, which is applied to an engine to save space and improve noise reduction effect of the engine. The resonance silencer with the dynamically adjusted silencing frequency comprises a hollow housing; the housing is provided with a connecting hole used for being communicated with an engine air inlet pipeline; a resonance cavity communicated with the connecting hole is arranged in the housing; and the resonance cavity can be changed in volume under the control of an engine control unit. The resonance silencer with the dynamically adjusted silencing frequency is simple in structure, easy to manufacture and process and small in volume, and can save engine space. The volume of the resonance cavity is dynamically adjusted by the engine control unit to realize the aim of reducing induction noise at different rotation speeds.

Owner:CHERY AUTOMOBILE CO LTD

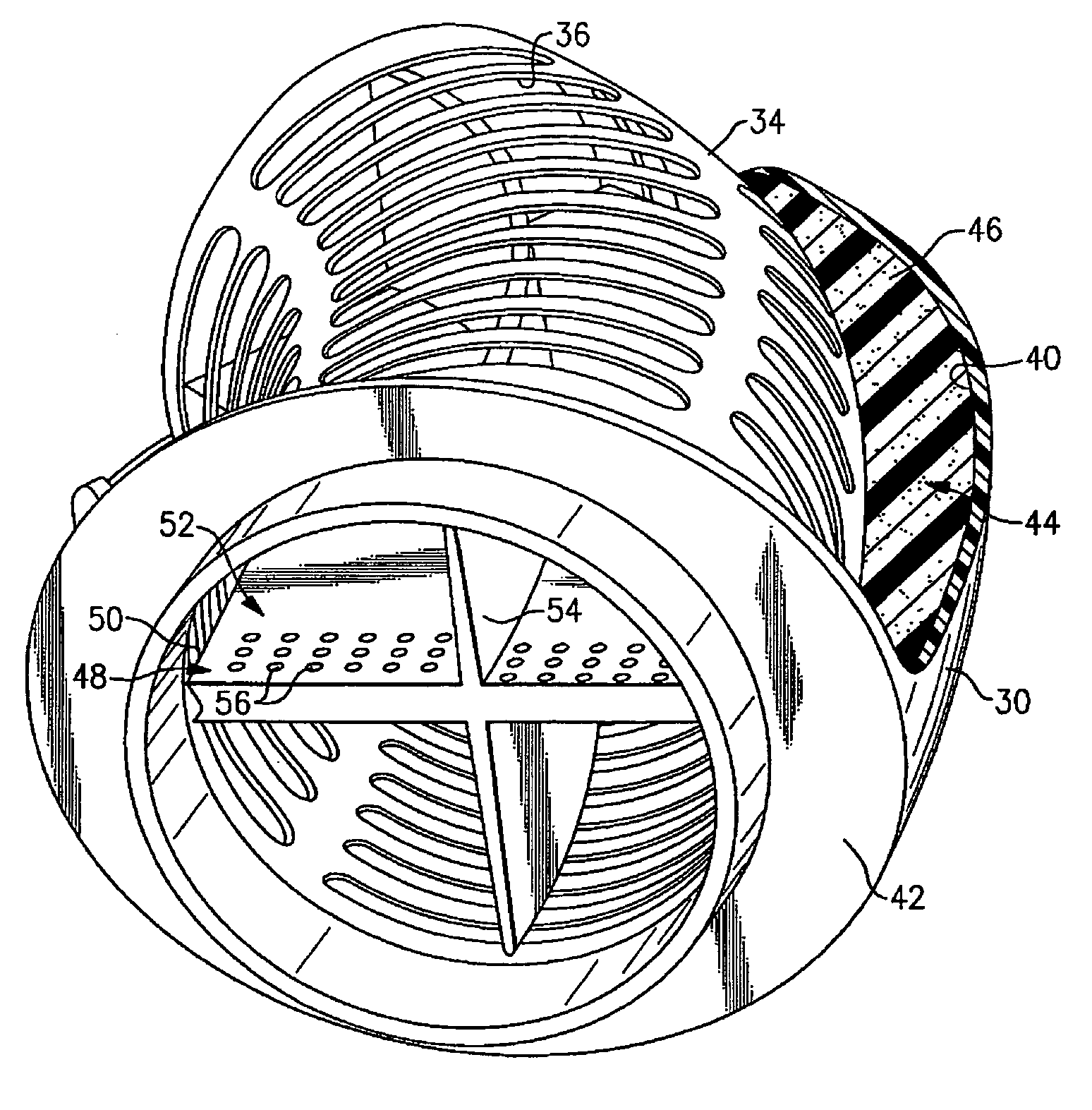

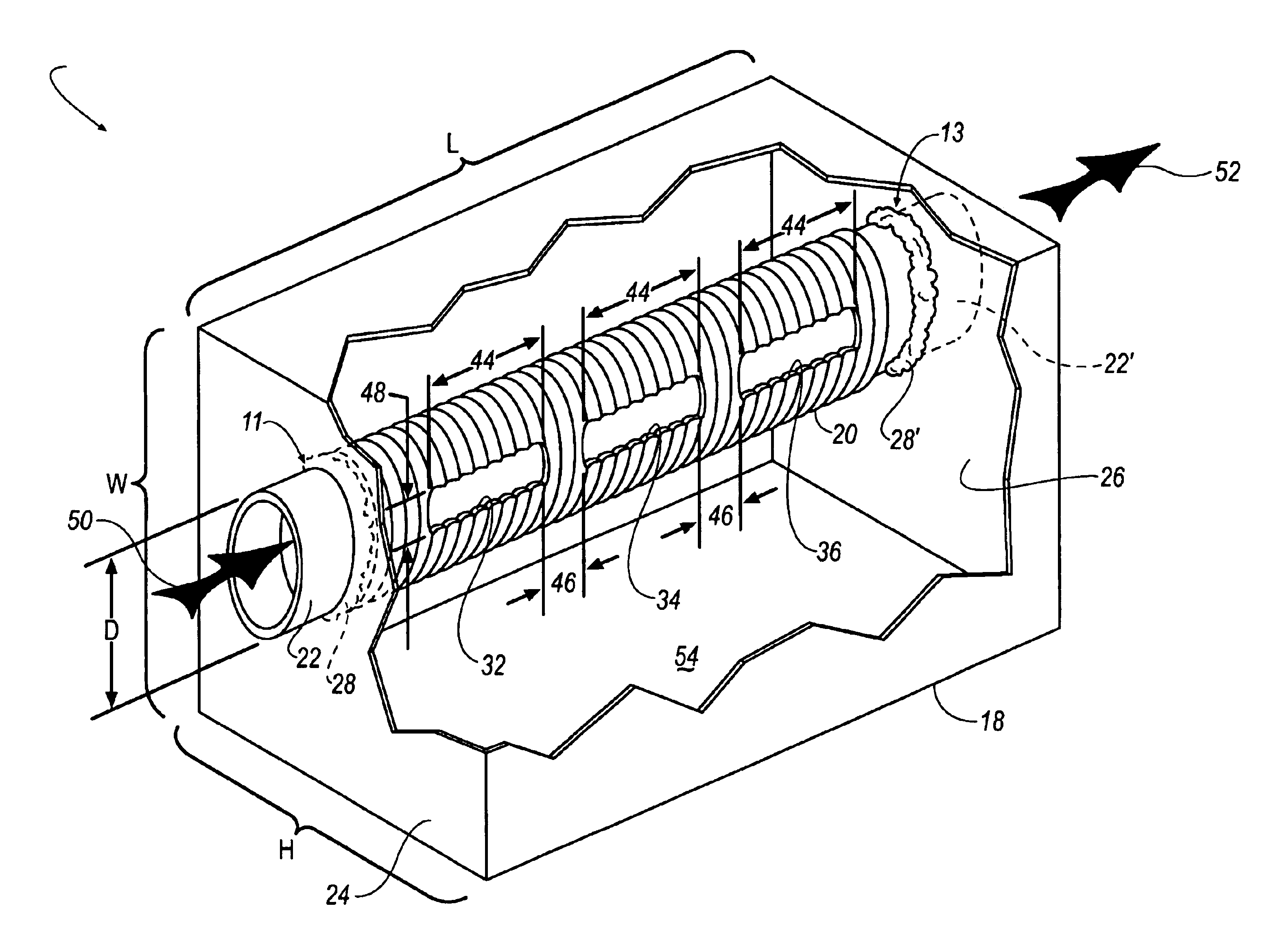

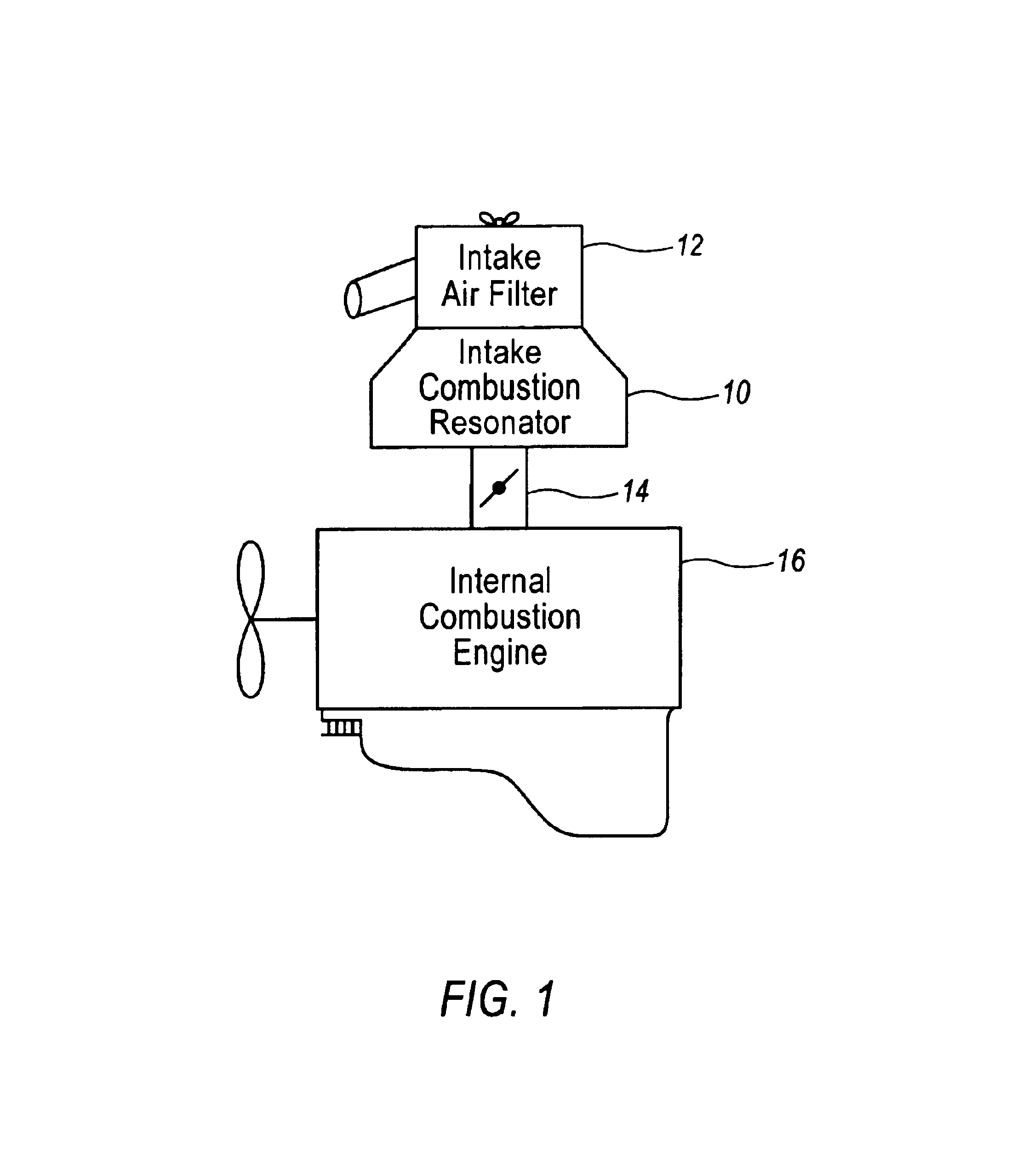

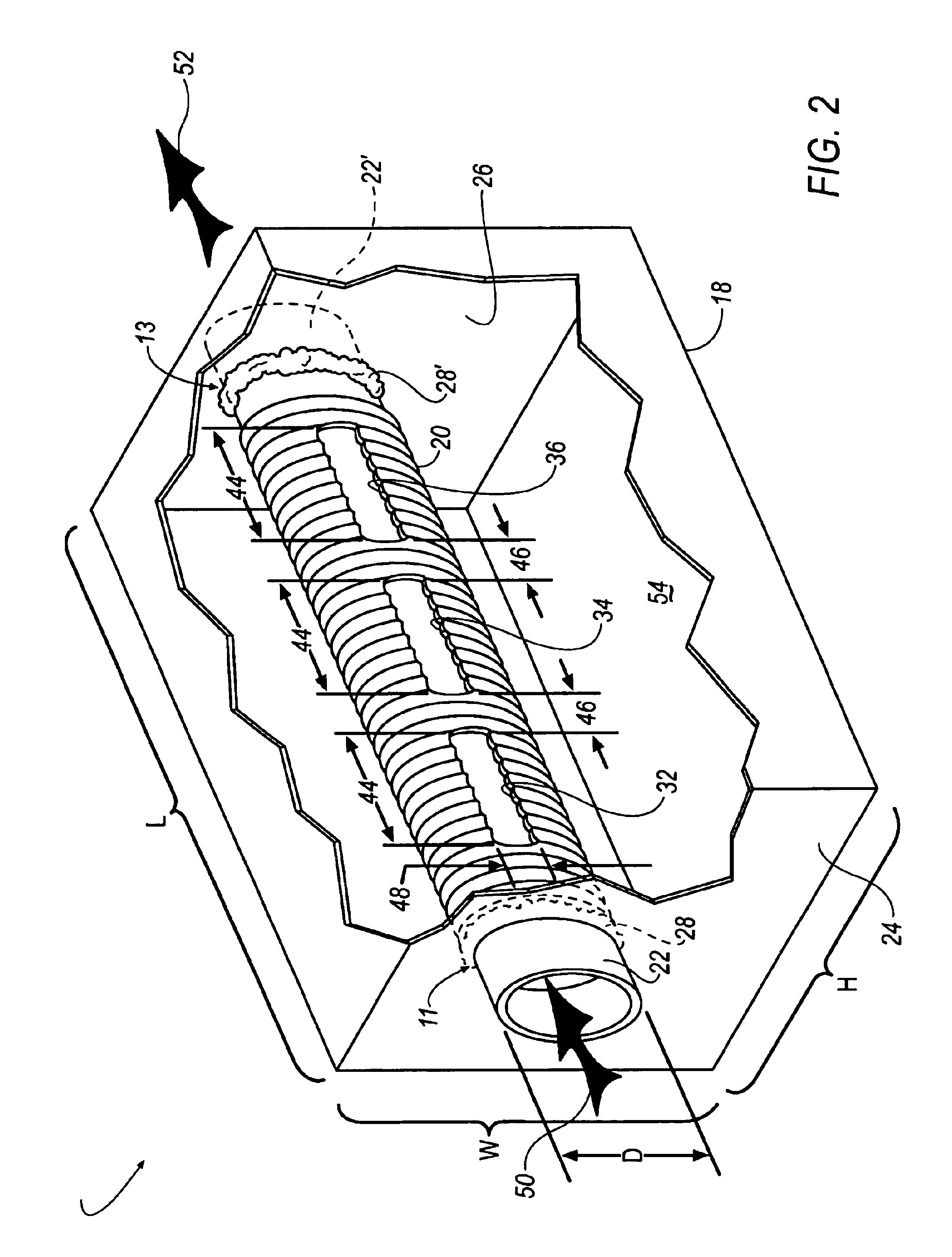

Combustion resonator

An intake combustion resonator including an enclosure which includes a resonator tube assembly passing through the enclosure. The resonator tube is formed from porous, undulated tube material and has openings formed in the tube walls. The openings serve as “tuned” passages through the porous tube walls. The resonator tube assembly is not centrally located within the enclosure but rather it is offset both in a height and a width orientation. The size, spacing, and orientation of the tube openings, porous, undulated sleeve material, the design of the enclosure, and the placement of the tube within the enclosure, all act in concert to give rise to the noise abatement properties of the present invention.

Owner:MAHLE TENNEX INDS

Intake duct

An intake duct capable of reducing intake noise when an engine runs at a low speed and supplying a sufficiently large amount of air when the engine runs at a high speed without using any electron control circuit or electromagnetic valve, which is produced at low costs. The intake duct includes valve adjusting means which restrains the movement of the valve member when the valve member brings a second intake passage from the closed state to the open state, and facilitates the movement of the valve member when the valve member brings the second intake passage from the open state to the closed state. When the second intake passage is brought to the open state from the closed state, the restraining force of the valve adjusting means is great to restrain the movement of the valve member, and when the second intake passage is brought to the closed state from the open state, the valve member readily pivots to open the second intake passage. Thus, the valve member is free from the half-closed state, and consequently, the generation of low-frequency booming noise can be prevented.

Owner:TOYODA GOSEI CO LTD

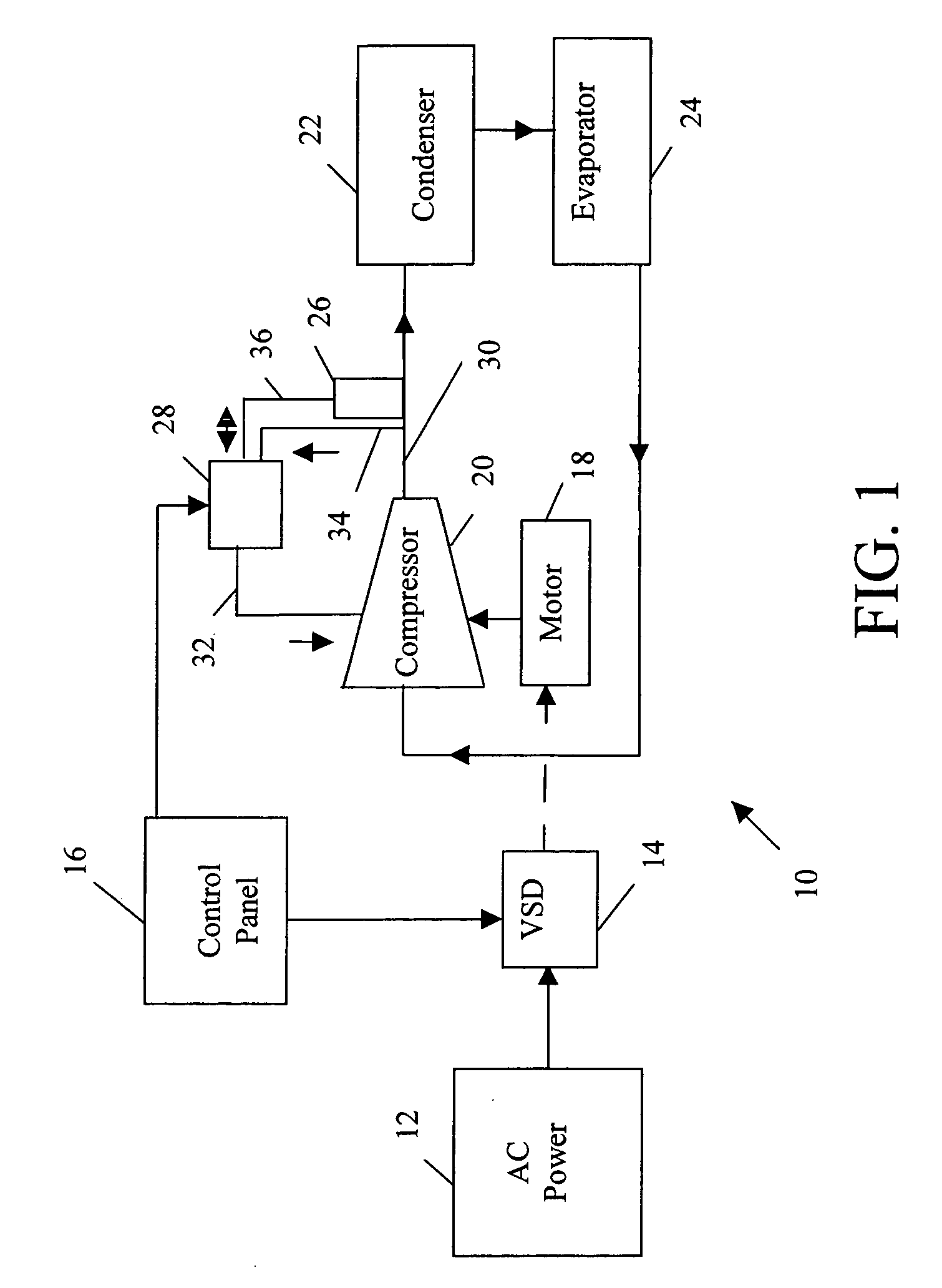

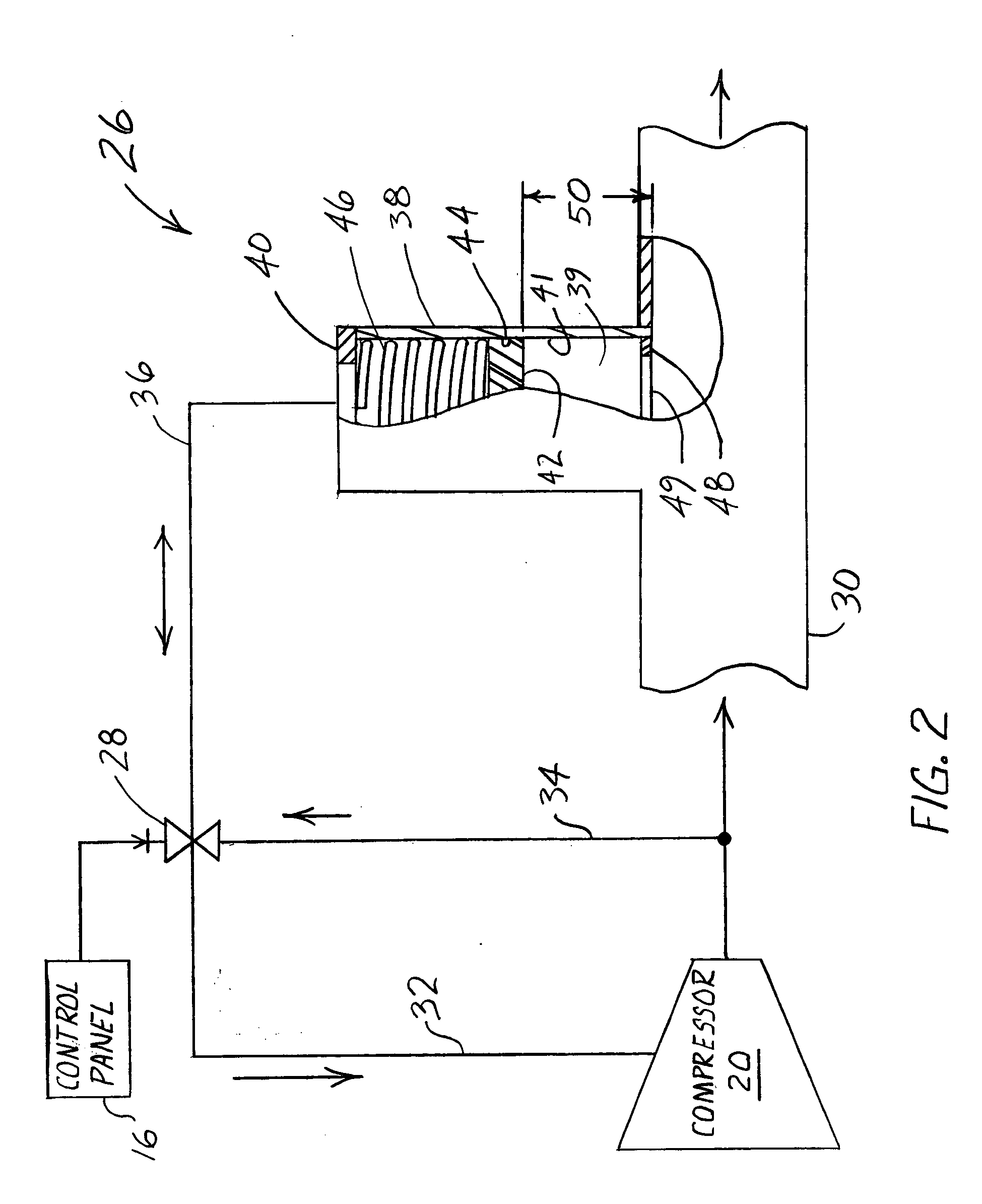

Apparatus and method of sound attenuation in a system employing a VSD and a quarter-wave resonator

InactiveUS20050194207A1Reduce noiseReduce manufacturing costAir-treating devicesCompression machines with non-reversible cycleUltrasound attenuationEngineering

A resonator in a closed fluid system includes a body having a passageway in communication with a closed fluid system wherein a piston is movable within the passageway. Each position of the piston within the passageway defines a noise attenuation frequency corresponding to a noise frequency generated by the closed fluid system. A device providing a pressurized fluid from the closed fluid system selectively moves the piston within the passageway to vary the noise attenuation frequency.

Owner:YORK INT

Device for noise structuring in a motor vehicle

A device for noise structuring in a motor vehicle has a plurality of gas-carrying lines connected to an internal combustion engine. At least two of the gas-carrying lines are acoustically linked together by at least one connection.

Owner:DAIMLER AG

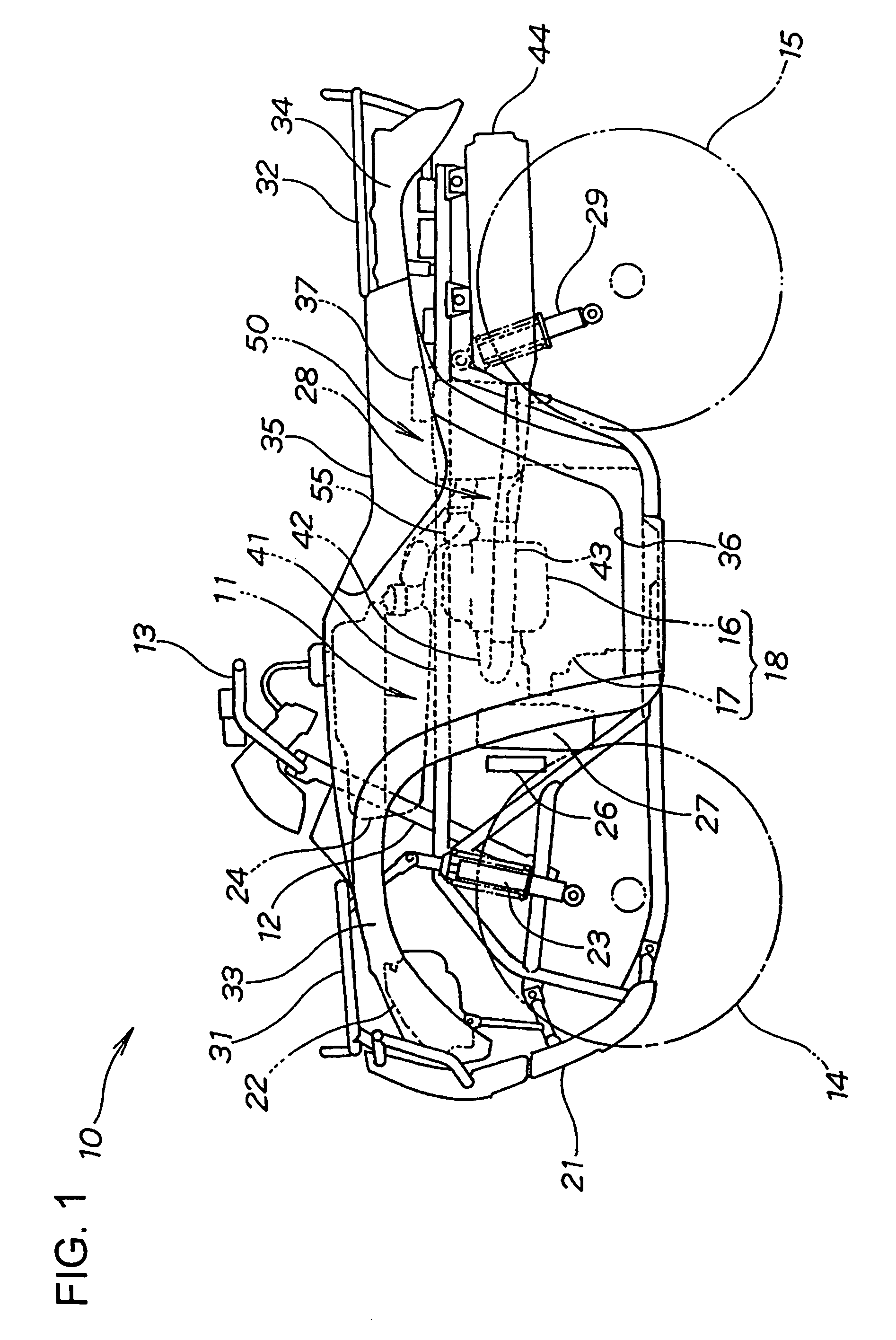

Engine component arrangement for outboard motor

InactiveUS6450847B1More compact motor constructionPower plants using condensersMachines/enginesWatercraftEngineering

An outboard motor has various electrical components mounted on a front side of the crankcase chamber. The crankcase chamber is connected by an electrical line to a negative terminal of a battery in an associated watercraft in order to ground the crankcase chamber. Thus, the electrical components are easily grounded by being connected to the crankcase chamber. An intake silencer of the engine induction system is positioned adjacent the crankcase chamber and at least one of the electrical components is disposed between the silencer and the crankcase member. An oil filter mount is also disposed on the front side of the crankcase chamber. The mount is adapted so that the oil filter can be installed thereon and is tilted along an inclined axis.

Owner:SANSHIN KOGYO CO LTD

Resonator

InactiveUS7089901B2Lower Level RequirementsIncrease/decrease the number of passagesMachines/enginesAir intakes for fuelEngineeringMechanical engineering

A resonator comprises a housing arranged in an intake member for defining an opening to communicate with an intake passage and a volume portion to communicate with the opening portion, a movable partition which can change the volume of the volume portion, and a movable cover associated with the movable partition for changing the opening area of the opening portion.

Owner:TOYODA GOSEI CO LTD

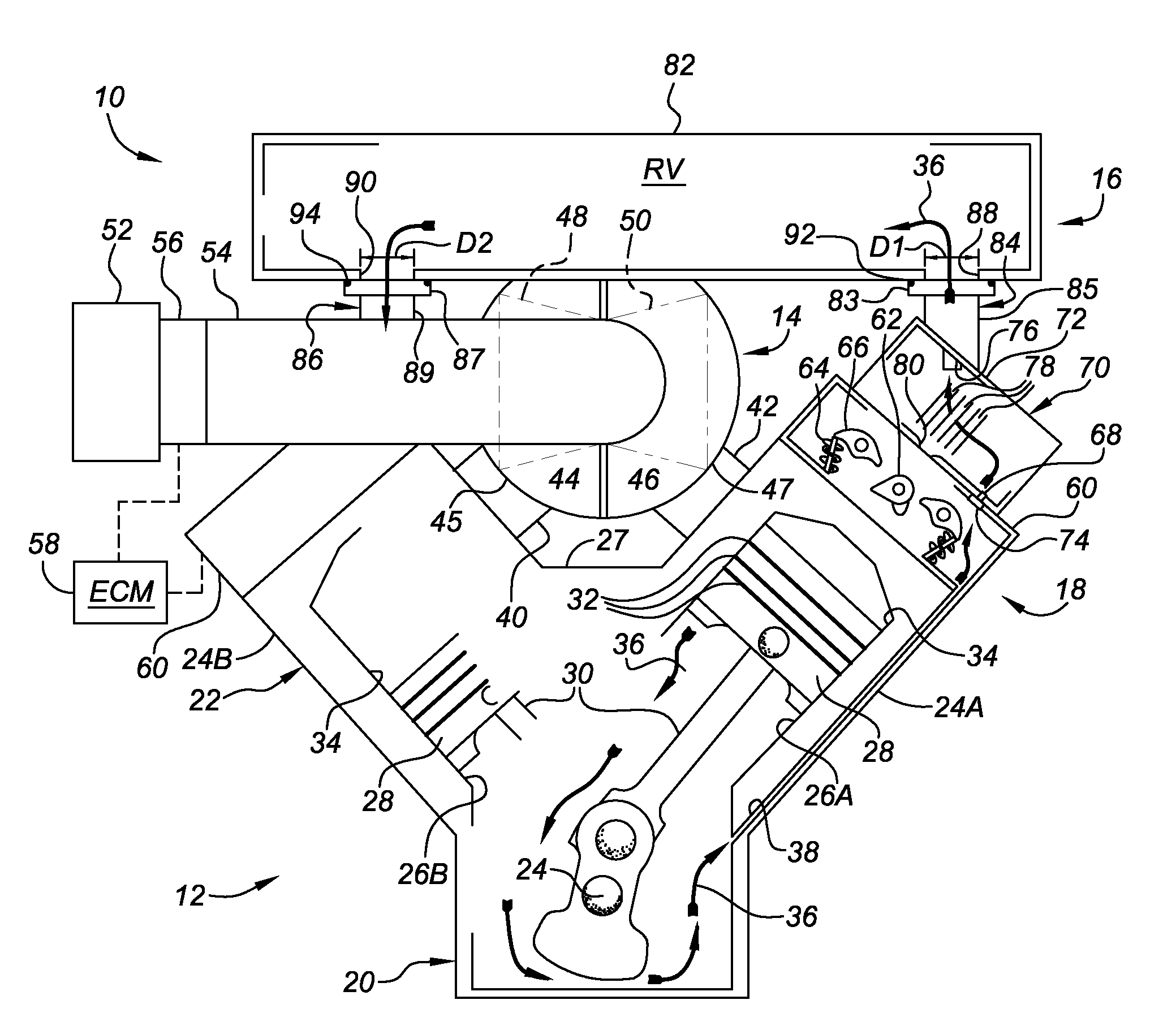

Resonator and crankcase ventilation system for internal combustion engine

ActiveUS20100071676A1Limit potential numberReduce the numberInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerMonobloc engine

The present invention provides a crankcase ventilation system and resonator for a turbocharged internal combustion engine assembly. The resonator, designed for intake noise reduction, is mounted to the engine. An oil separation unit, designed for passage of blowby gases, is mounted to a cam cover, sandwiched between the resonator and cam cover. The resonator has a resonator body defining a resonator volume therein. The resonator fluidly communicates the oil separation unit with the turbocharger air inlet pipe, whereby blowby gases are evacuated from the cam cover and delivered through the resonator volume for reintroduction to the engine's air intake system. Integration of the blowby passages into the resonator reduces the number of potential leak paths in the air induction system, and reduces overall engine mass, cost, and packaging size. The present design also offers improved On-board Diagnostics (OBD) by allowing only large flow areas to be disconnected.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com