Patents

Literature

272 results about "Ram-air intake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ram-air intake is any intake design which uses the dynamic air pressure created by vehicle motion to increase the static air pressure inside of the intake manifold on an internal combustion engine, thus allowing a greater massflow through the engine and hence increasing engine power.

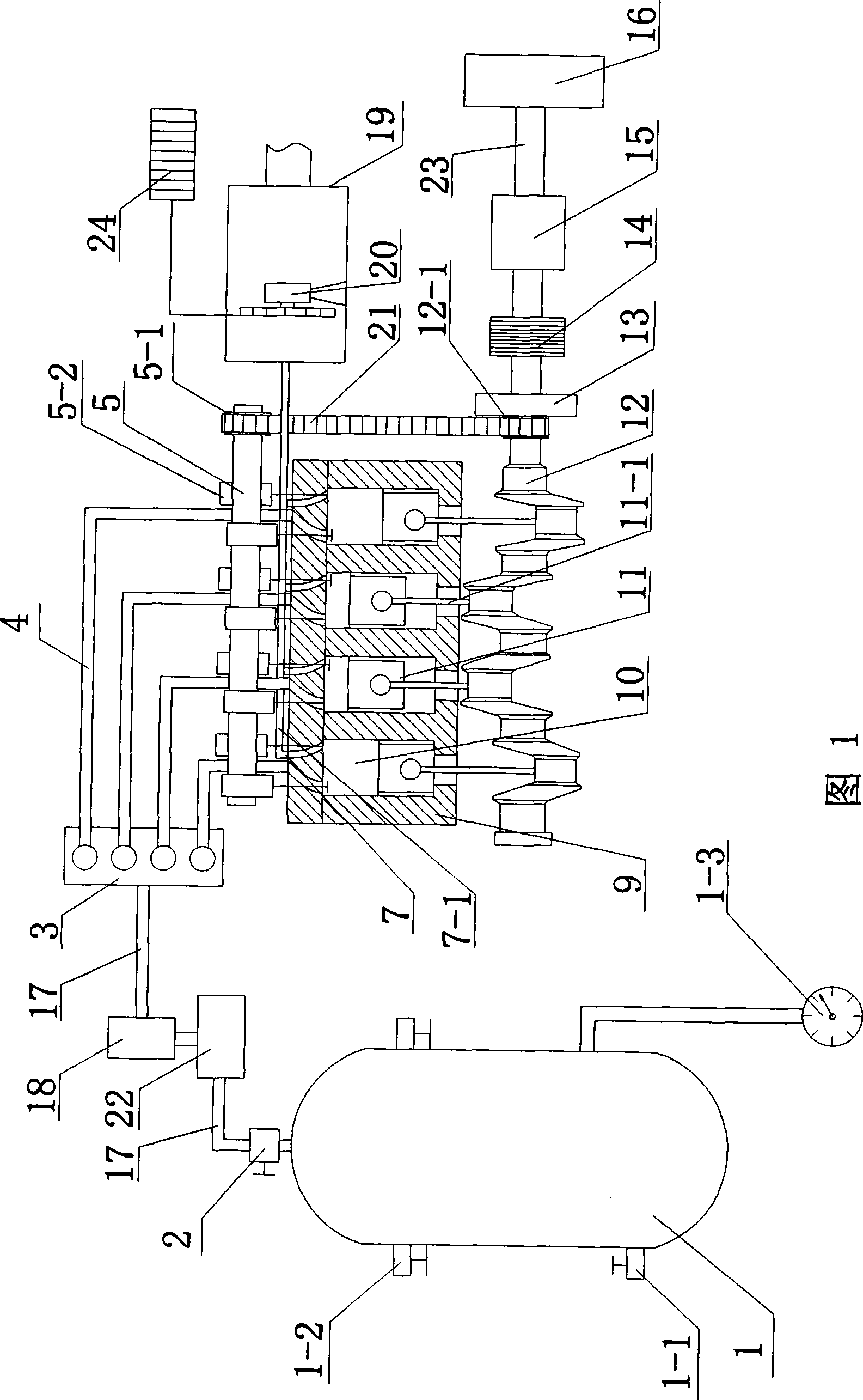

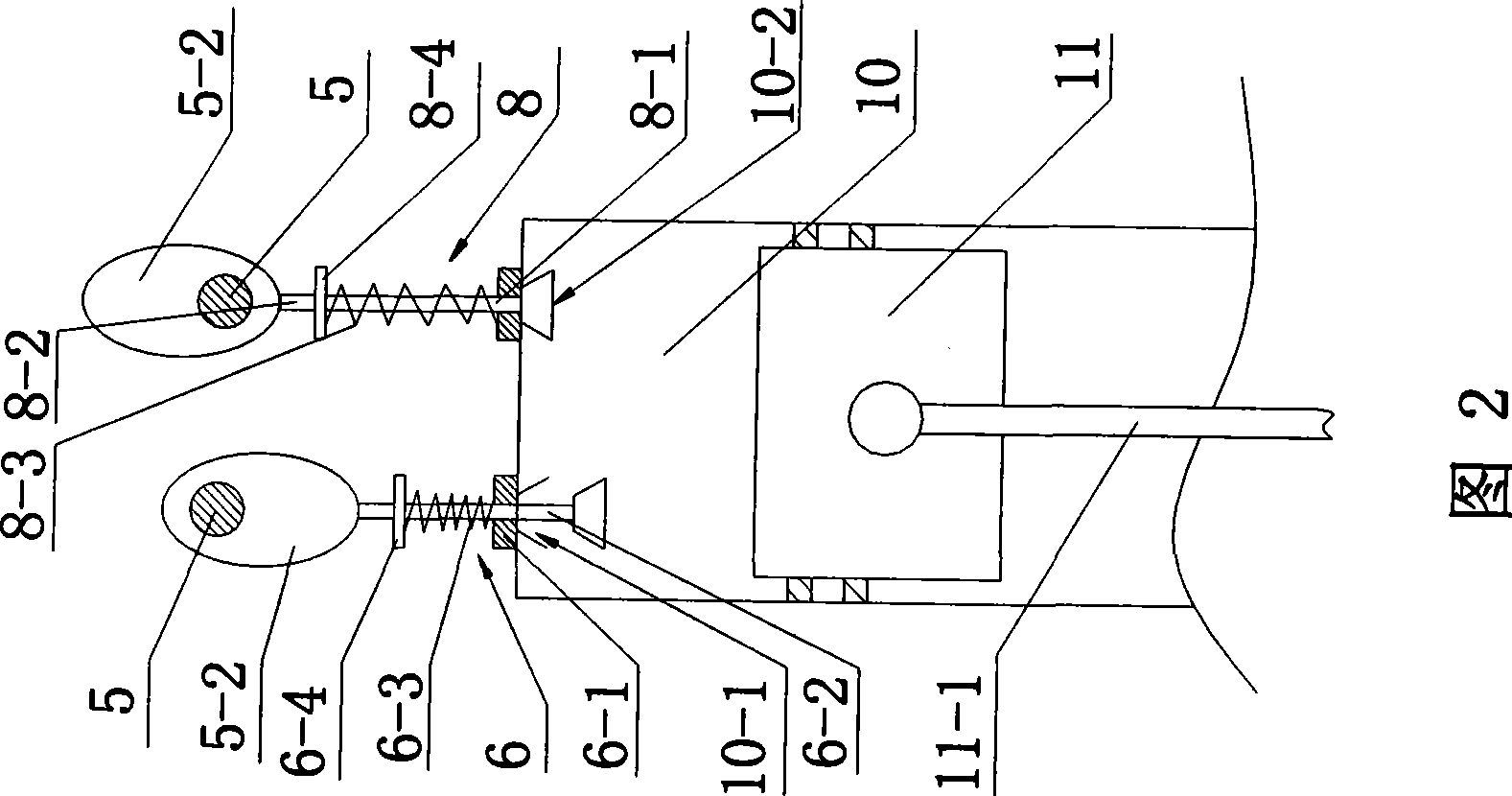

Air power engine assembly

InactiveCN101413403ALow costNo pollutionMechanical power devicesEngines characterised by uniflow principleDistributorPiston

The invention relates to an air-powered engine assembly, which comprises an air tank, an air valve, an air distributor, an intake pipe, camshafts, an intake duct, an exhaust control device, air cylinders, pistons, crankshafts, couplers, clutches, automatic gearboxes and differentials connected with the outside. The assembly is characterized in that the air valve, a constant pressure chamber and a pressure controller are arranged between the air tank and the air distributor; the air distributor is connected with a plurality of air cylinders on an air cylinder gasket; each air cylinder is connected with an exhaust chamber through an exhaust manifold; the exhaust chamber is provided with a turbine generator which is connected with a storage batter; the air cylinders are provided with the camshafts for controlling the air intake and exhaust of the air cylinders; the air cylinders are provided inside with the pistons for driving the crankshafts to rotate; the camshafts and the crankshafts are connected by chains; and the crankshafts are connected with the differentials through the couplers, the clutches and the gearboxes in turn. Therefore, doing work through air compression rather than fuel, the air-powered engine assembly has the advantages of avoiding waste gas discharge and air pollution, along with reliable operation, convenient operation, economical efficiency, practicality and so on. In addition, due to recycle of the waste gas for power generation, the air-powered engine assembly saves energy and reduces costs.

Owner:周登荣 +1

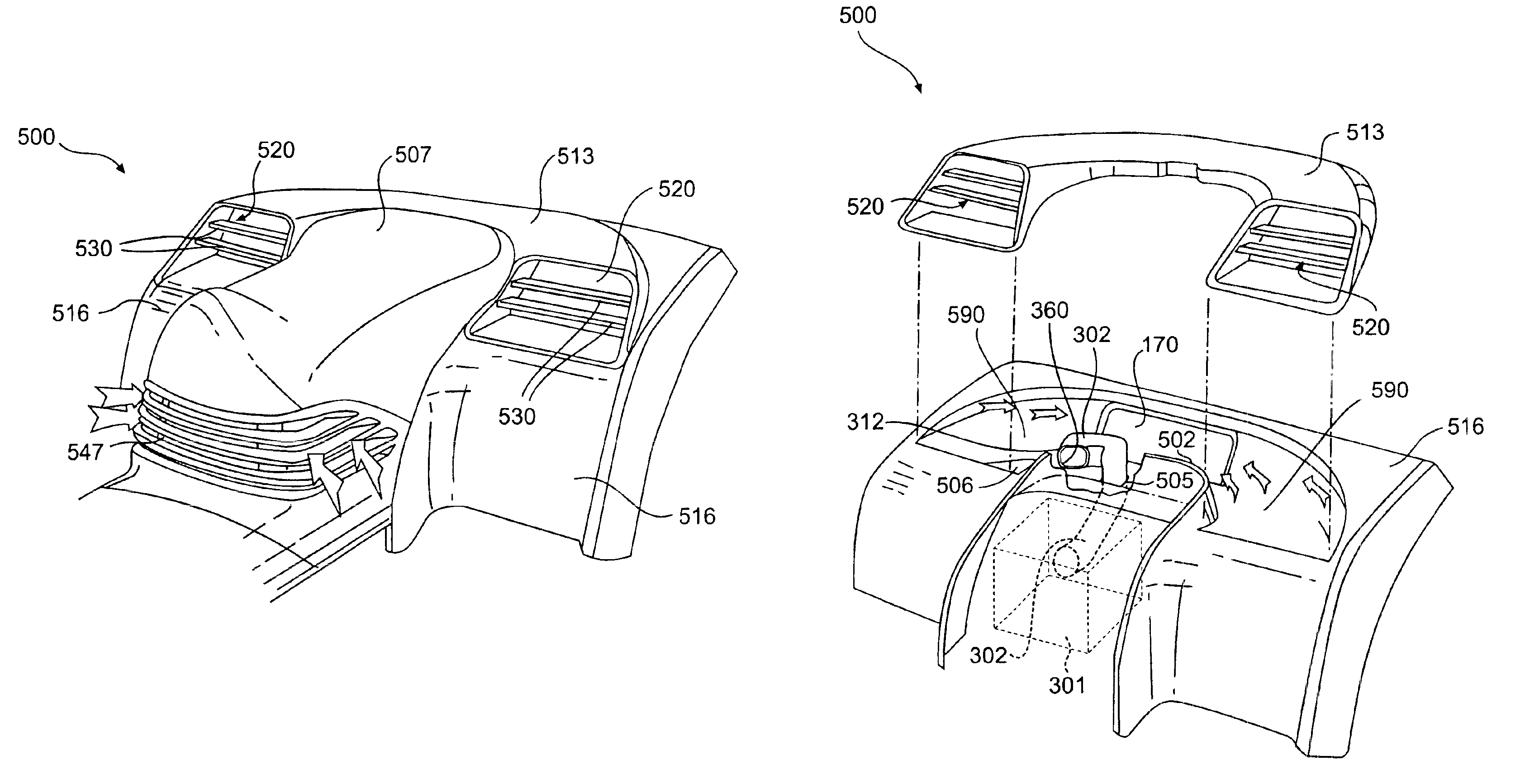

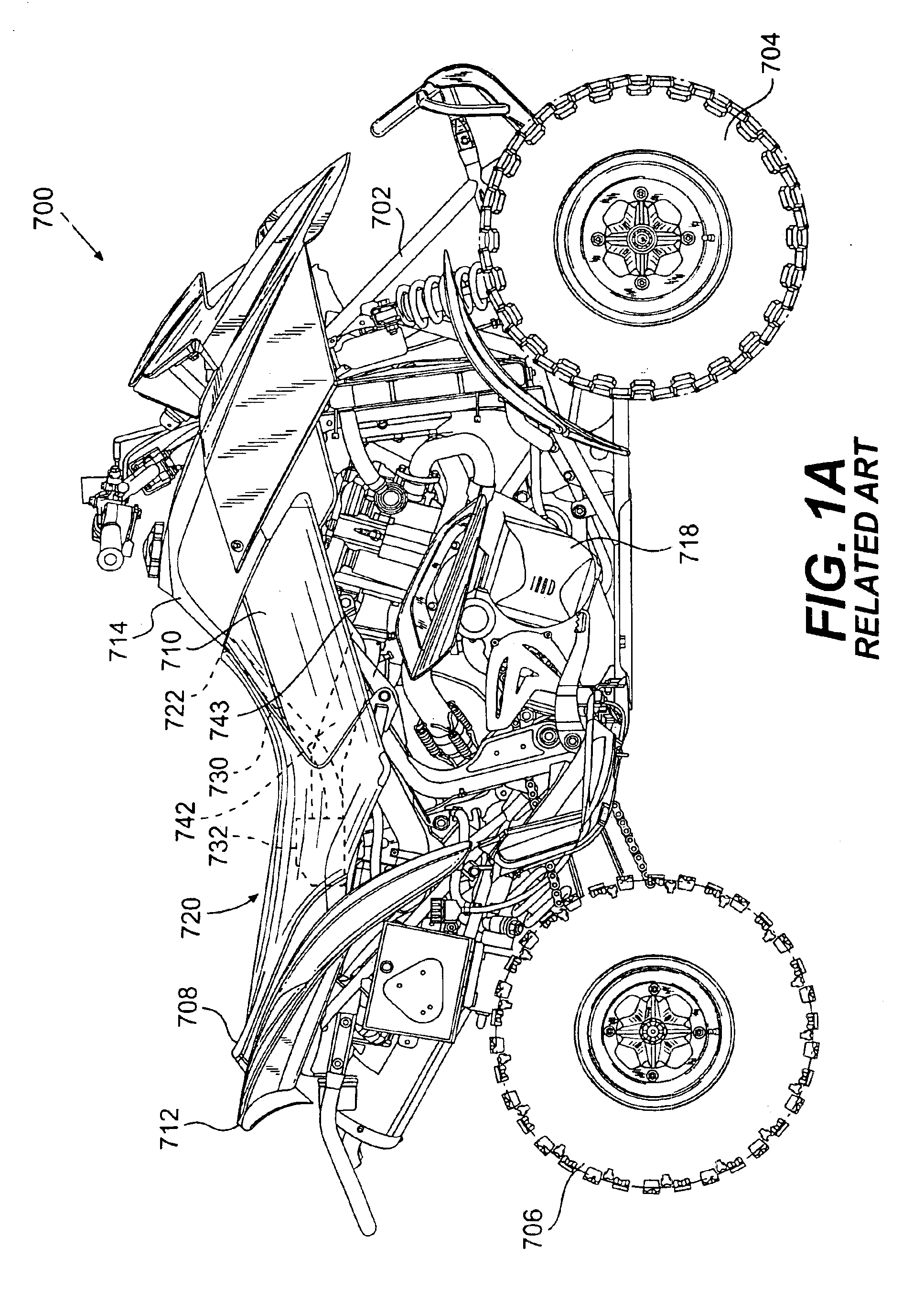

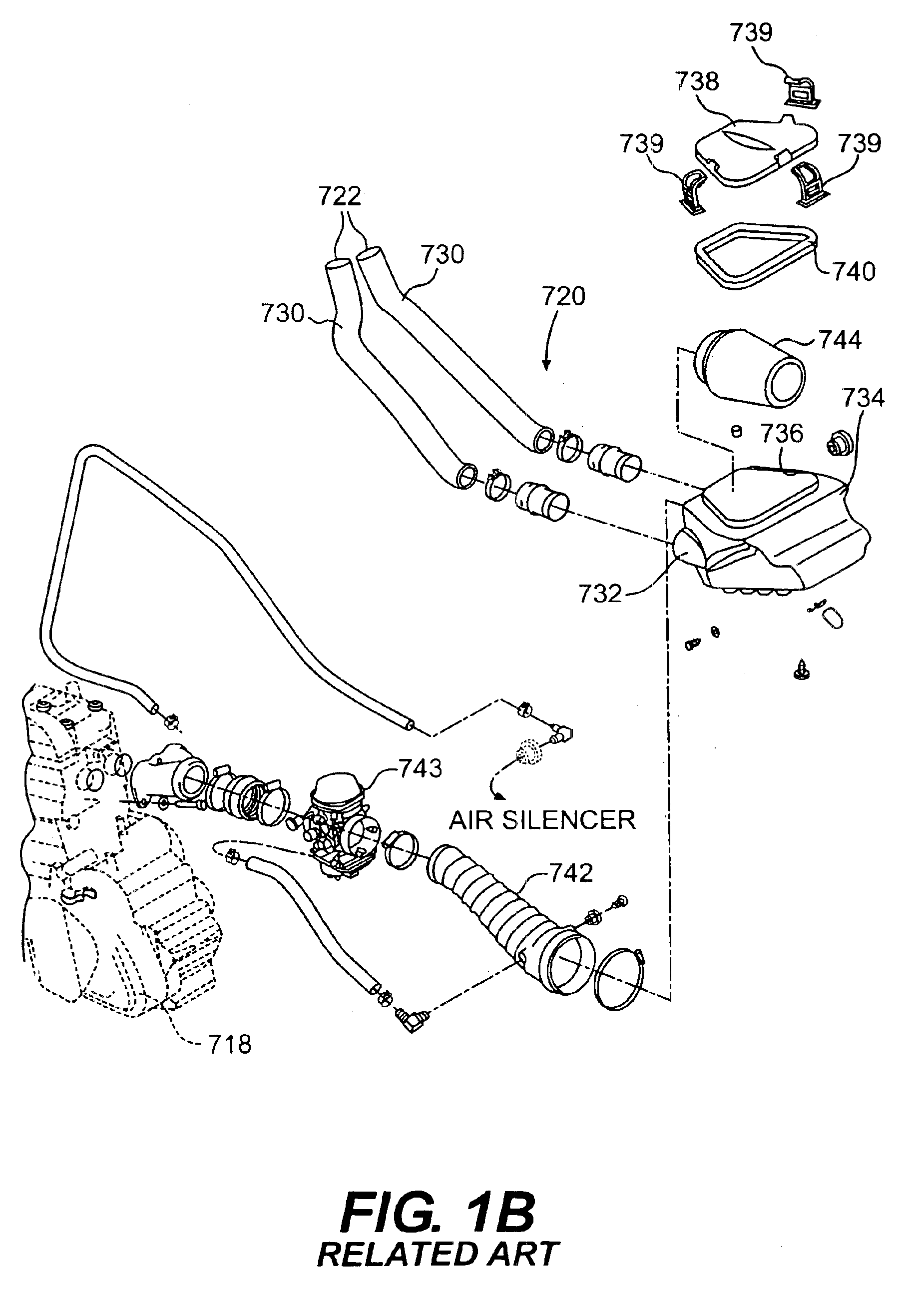

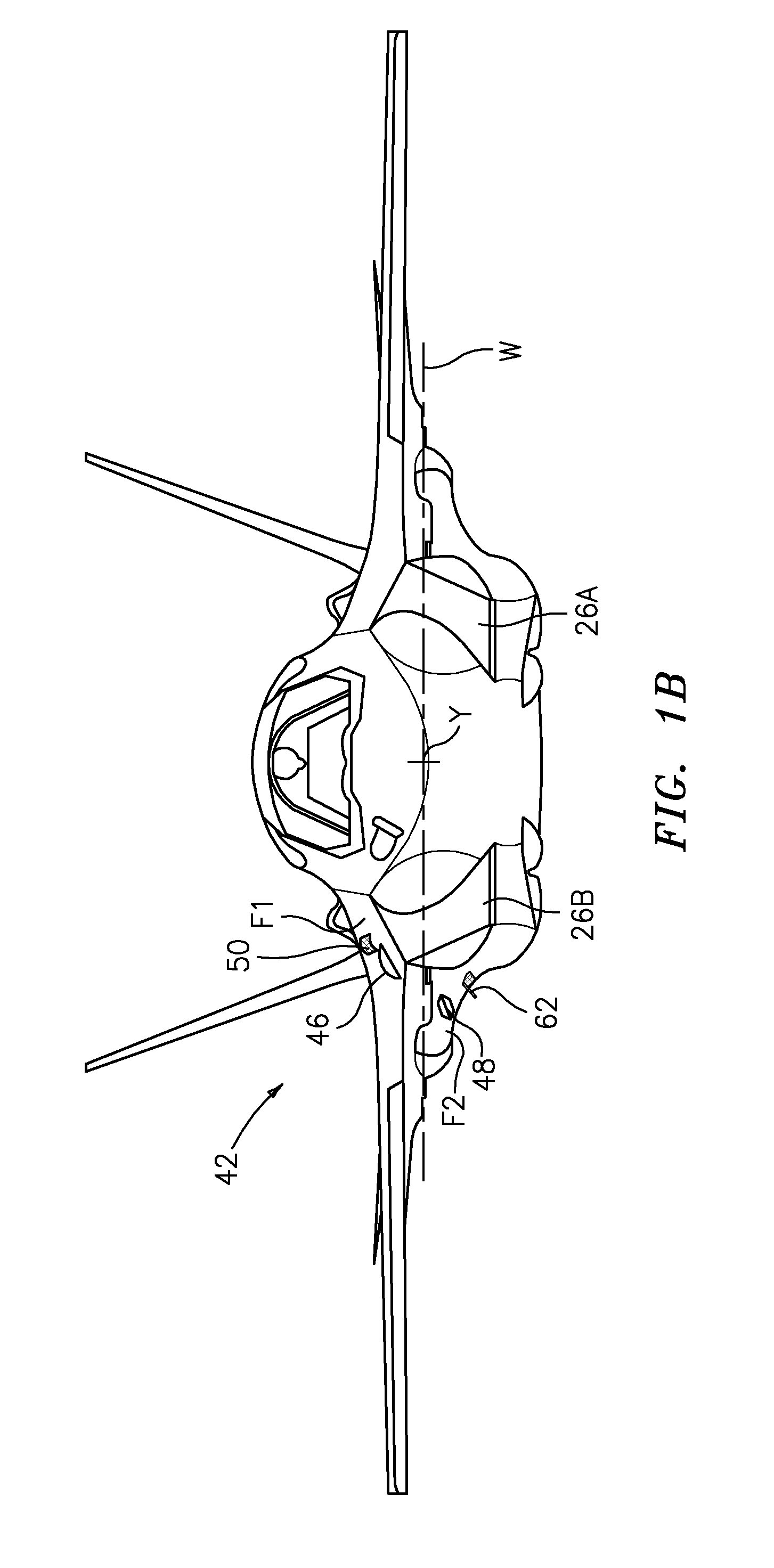

Air intake for a straddle-type all terrain vehicle

InactiveUS6892842B2Avoid disadvantagesAvoid vibrationCyclesInternal combustion piston enginesTerrainRam-air intake

An all terrain or straddle type vehicle is provided with an air intake system having an air intake pipe with reduced length thereby avoiding unnecessary vibration which may adversely affect the fuel-to-air ratio of the engine, thereby improving engine performance. Also an inlet end of the air intake pipe is positioned so that the vehicle's capability for traversing water of a predetermined depth is improved. The height of the inlet end of the intake pipe is greater than the predetermined depth of the water to protect against water entering the air intake pipe due to encountering a water wave created in front of the vehicle that has a depth greater than the predetermined depth of the water. Additionally, openings in rear fenders of the vehicle channel intake air to both a radiator / fan assembly and the air intake system.

Owner:BOMBARDIER RECREATIONAL PROD INC

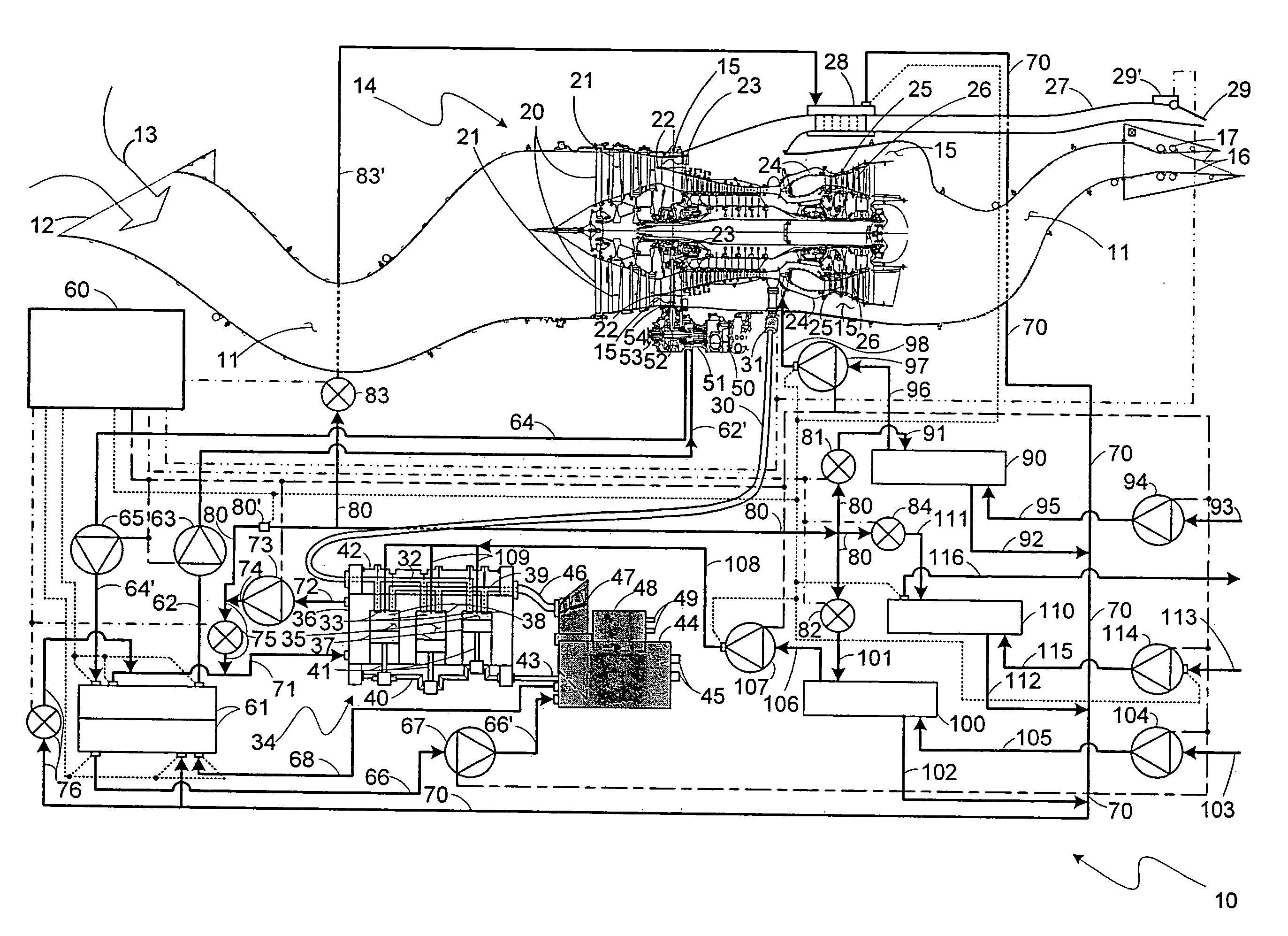

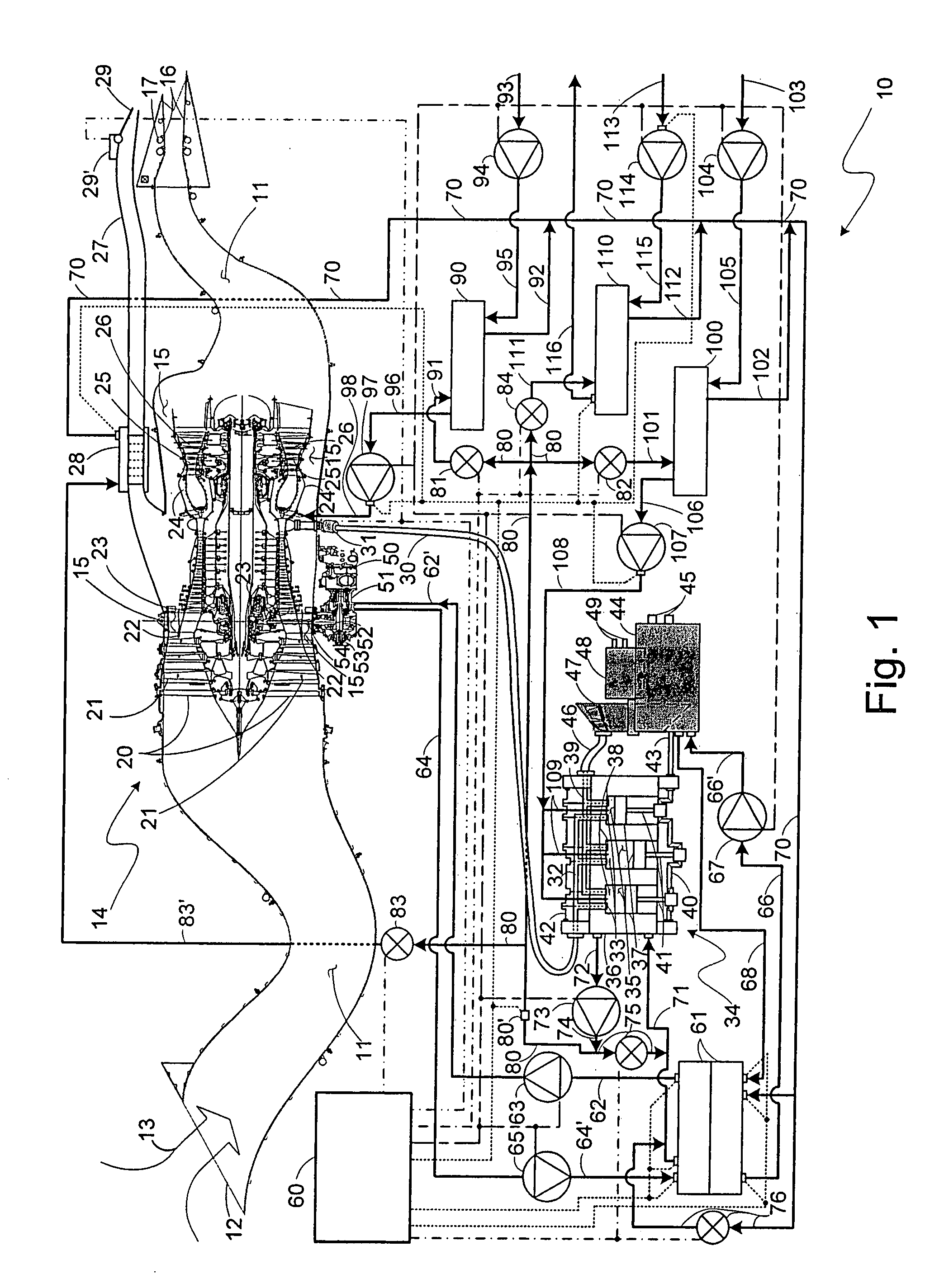

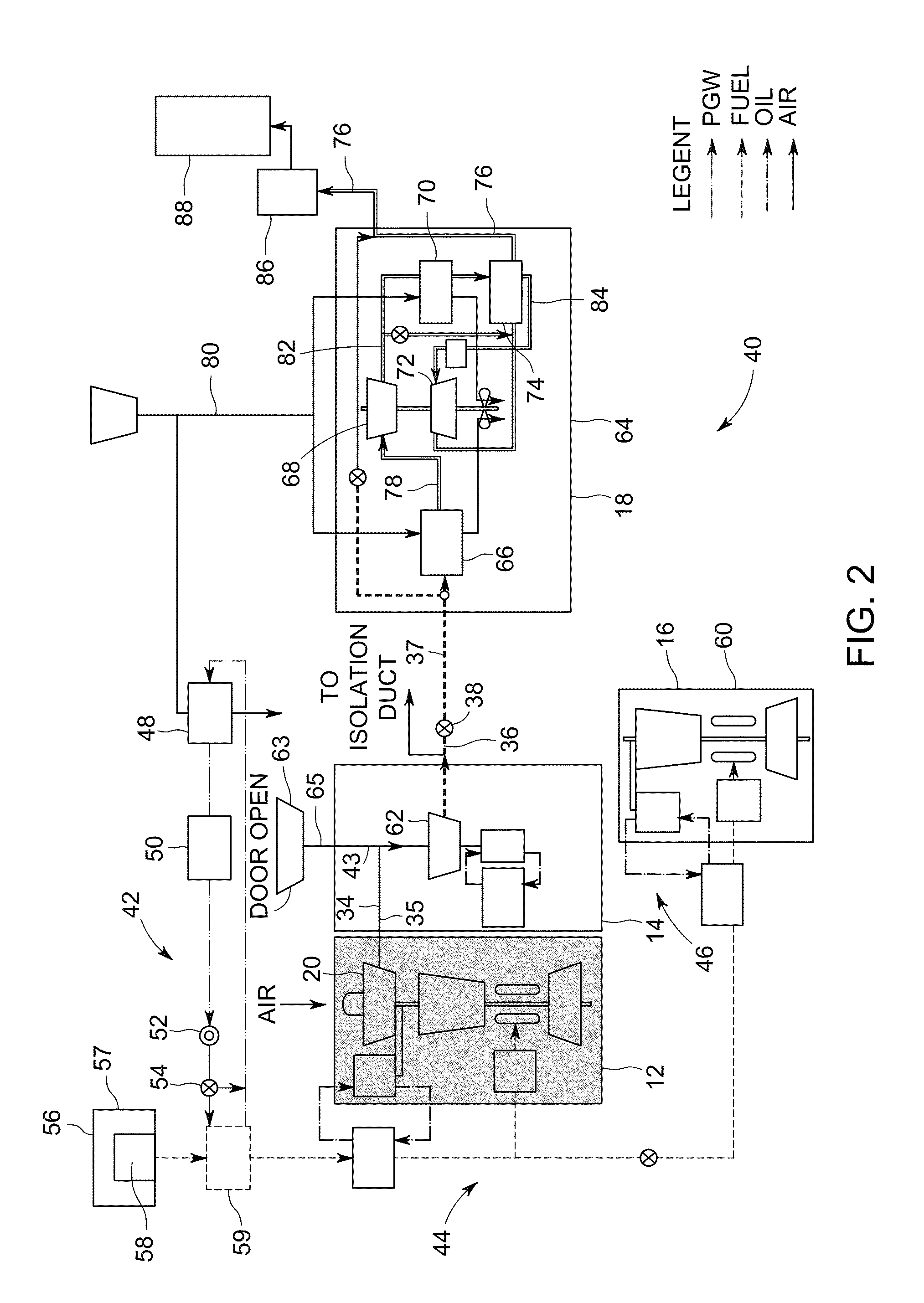

Aircraft combination engines thermal management system

InactiveUS20080314573A1Engine fuctionsCombination enginesExternal combustion engineThermal management system

An engine combination for generating forces with a gas turbine engine generating force that utilizes an engine lubricant for lubricating moving components in the turbofan engine, and an internal combustion engine provided in the combination as an intermittent combustion engine generating force that utilizes a coolant for transporting heat generated in the intermittent combustion engine away therefrom and having an air intake, there being an air transfer duct connected from a compressor in the gas turbine engine to the air intake to transfer compressed air thereto. A coupling heat exchanger is coupled to both the gas turbine engine and the intermittent combustion engine to have the engine lubricant and the coolant pass therethrough to thereby permit the coolant to transport heat in the engine lubricant away therefrom. A further cooling heat exchanger is coupled to both the coupling heat exchanger and the intermittent combustion engine to have a remote fluid from a source thereof and the coolant pass therethrough to permit the remote fluid to transport heat in the coolant away therefrom, and with the coolant also circulating through at least one of the coupling heat exchanger and the intermittent combustion engine.

Owner:RAYTHEON TECH CORP

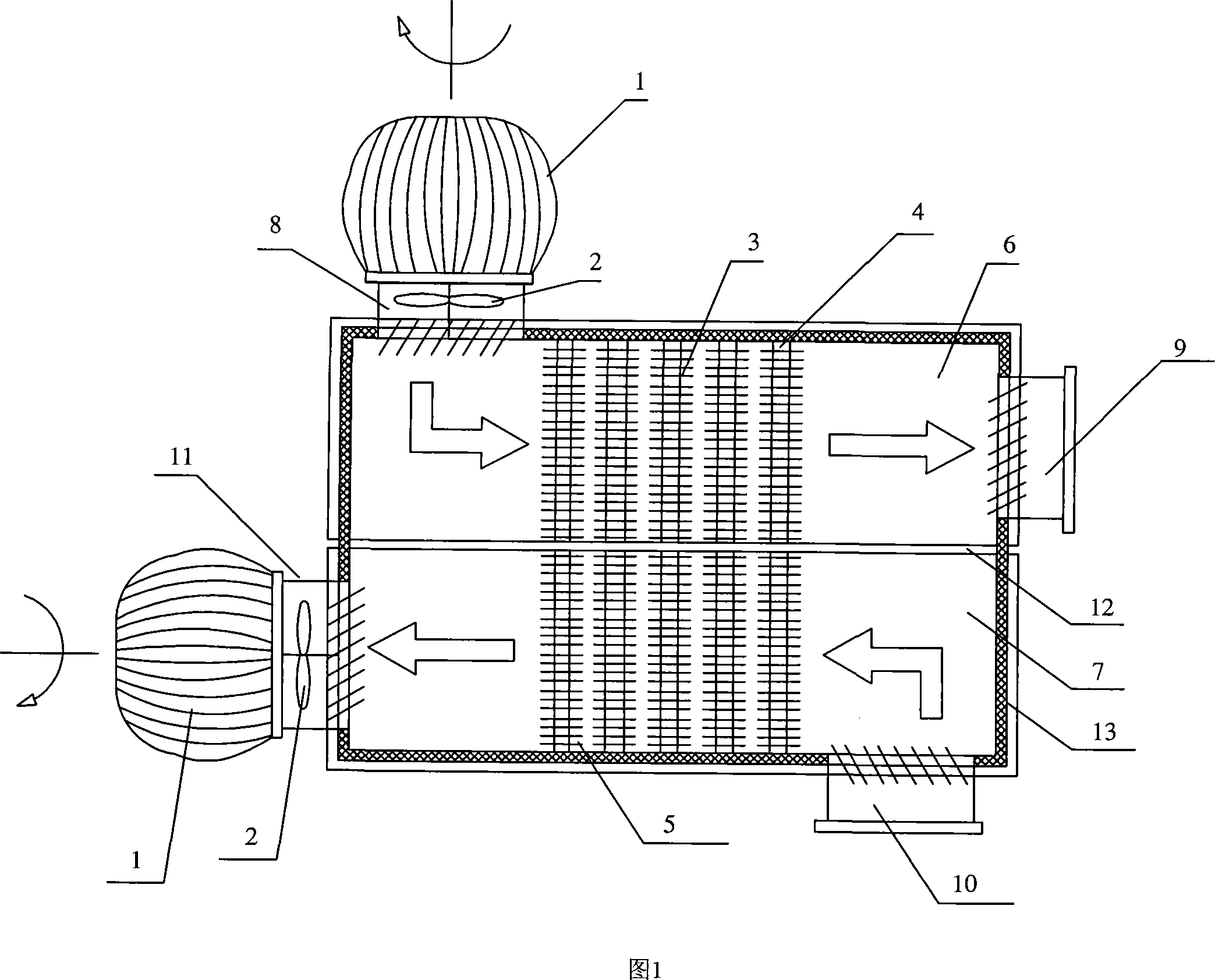

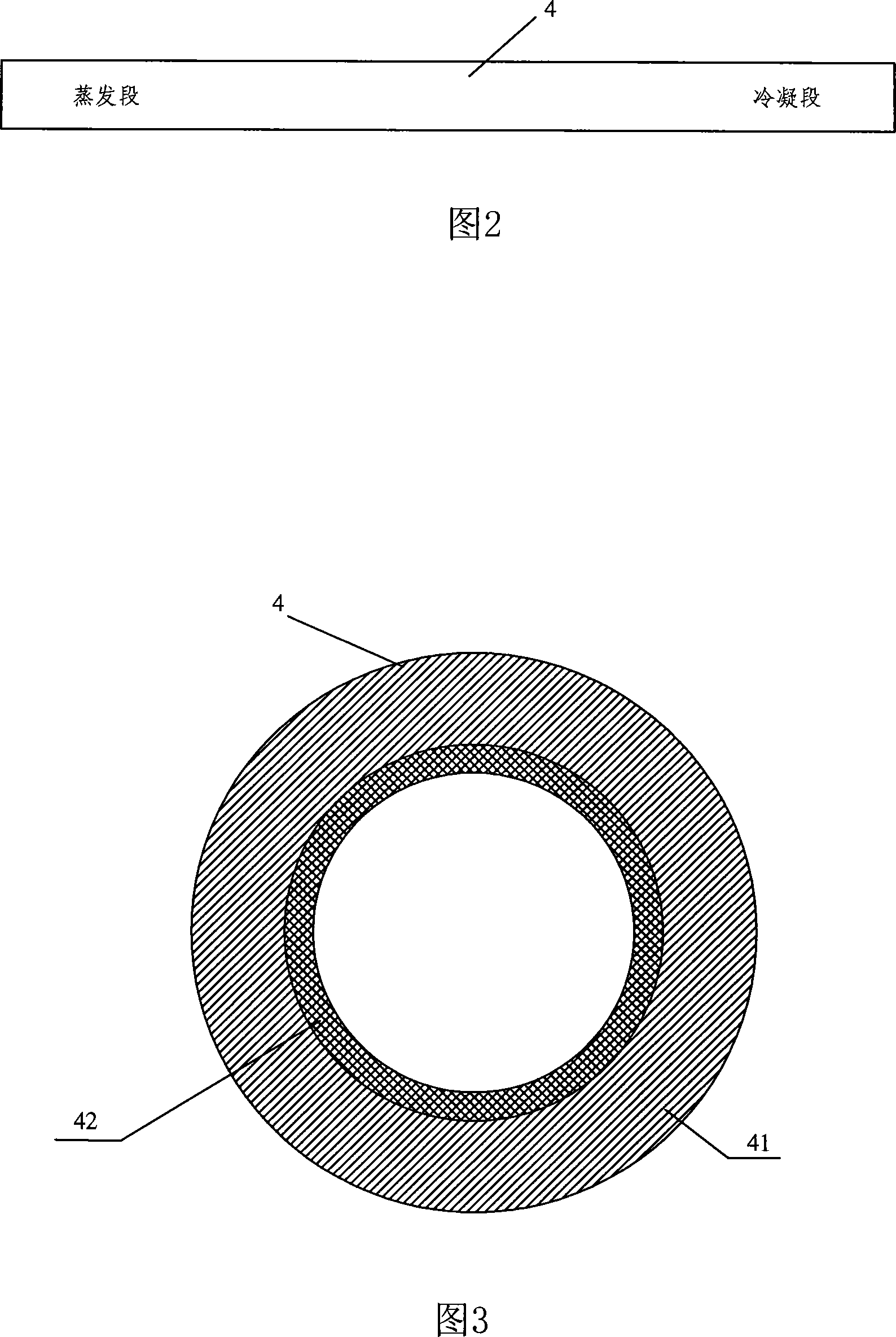

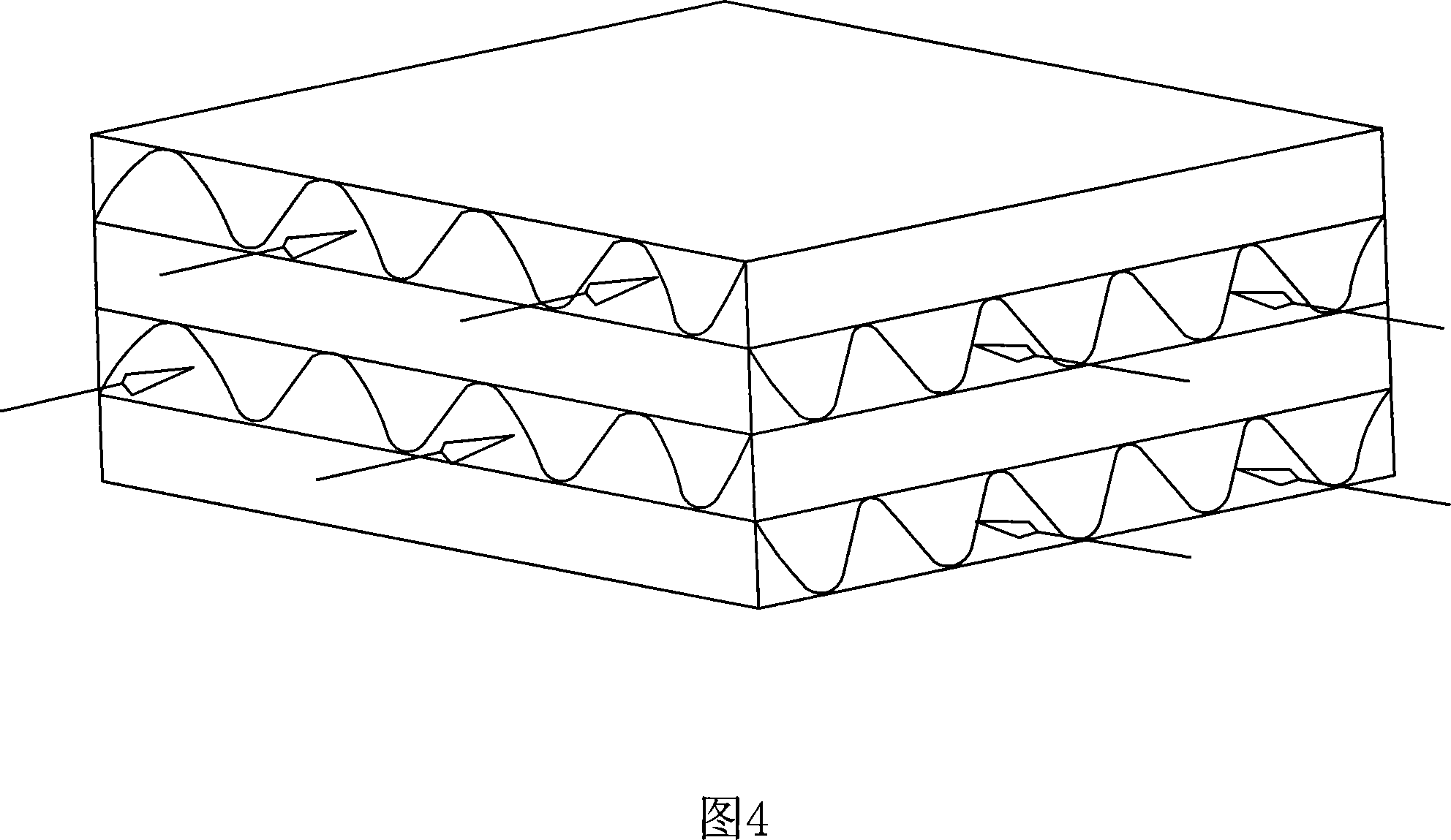

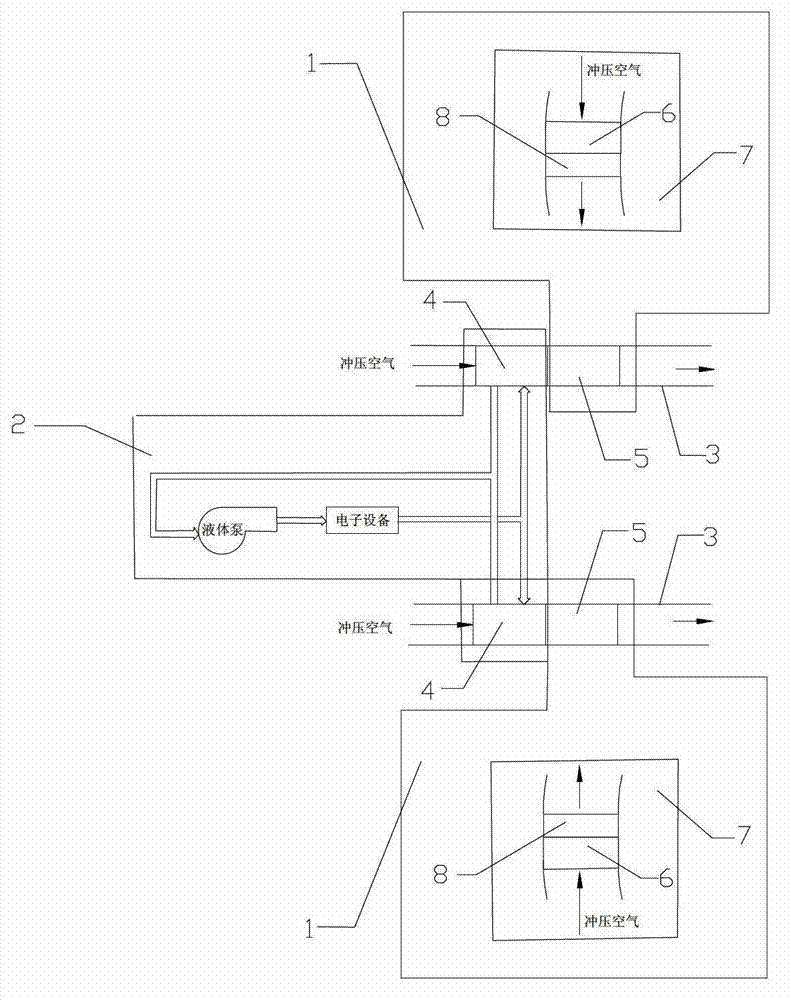

Unpowered type air heat recovery device

InactiveCN101169280ASimple structureEasy to processEnergy recovery in ventilation and heatingHeat recovery systemsRam-air intakeFresh air

The invention provides a powerless type air heat recollection device which is characterized in that the device at leased includes a fresh air channel used for bringing in fresh air and an air exhaustion channel to exhaust the indoor air, wherein, the two ends of the fresh air channel are respectively provided with an air inlet A communicated with the outside and an air outlet B communicated with the inside. The two ends of the air exhaustion channel are respectively provided with an air outlet A1 communicated with the outside and an air inlet B1 communicated with the inside; at least either of the air inlet A or air outlet A1 is provided with an air cap which includes a wind wheel and shaft, which are driven by the external wind power, and a fan which is driven by the shaft and can form a fixed air intake or exhaustion flow in the fresh air channel or the air exhaustion channel under the drive of the wind cap; the device also at least includes a heat exchanger which runs through the fresh air channel and the air exhaustion channel.

Owner:赵耀华

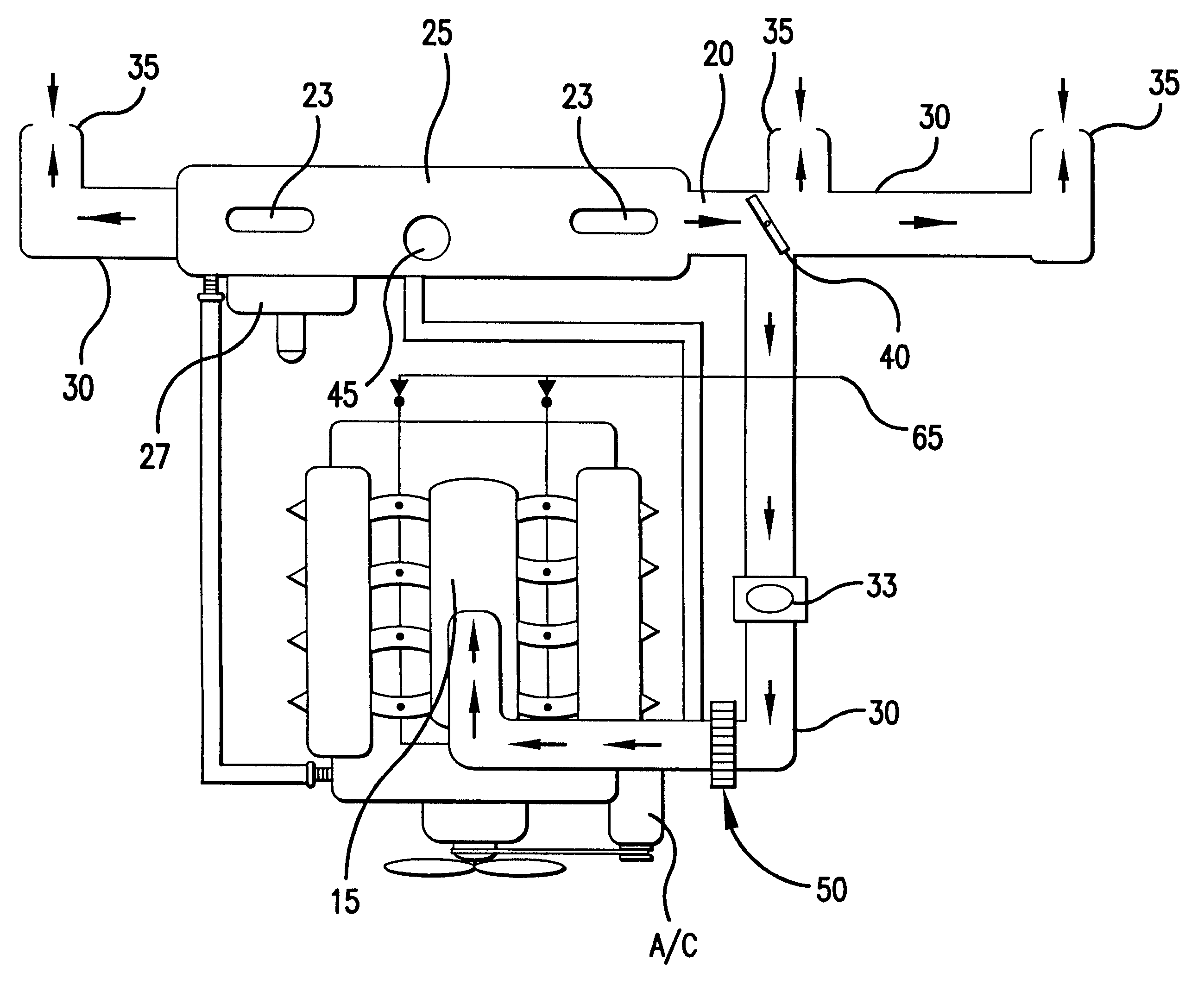

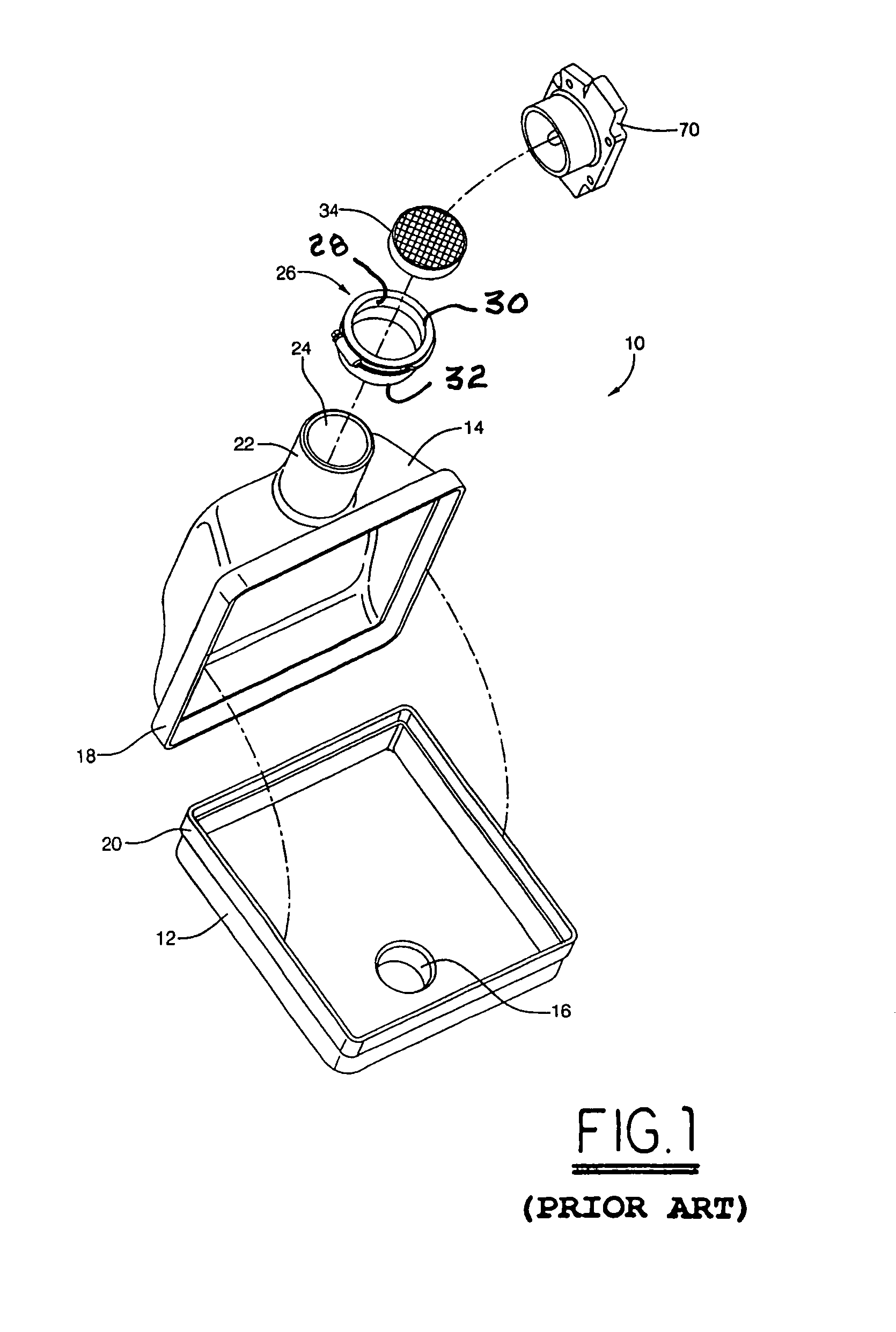

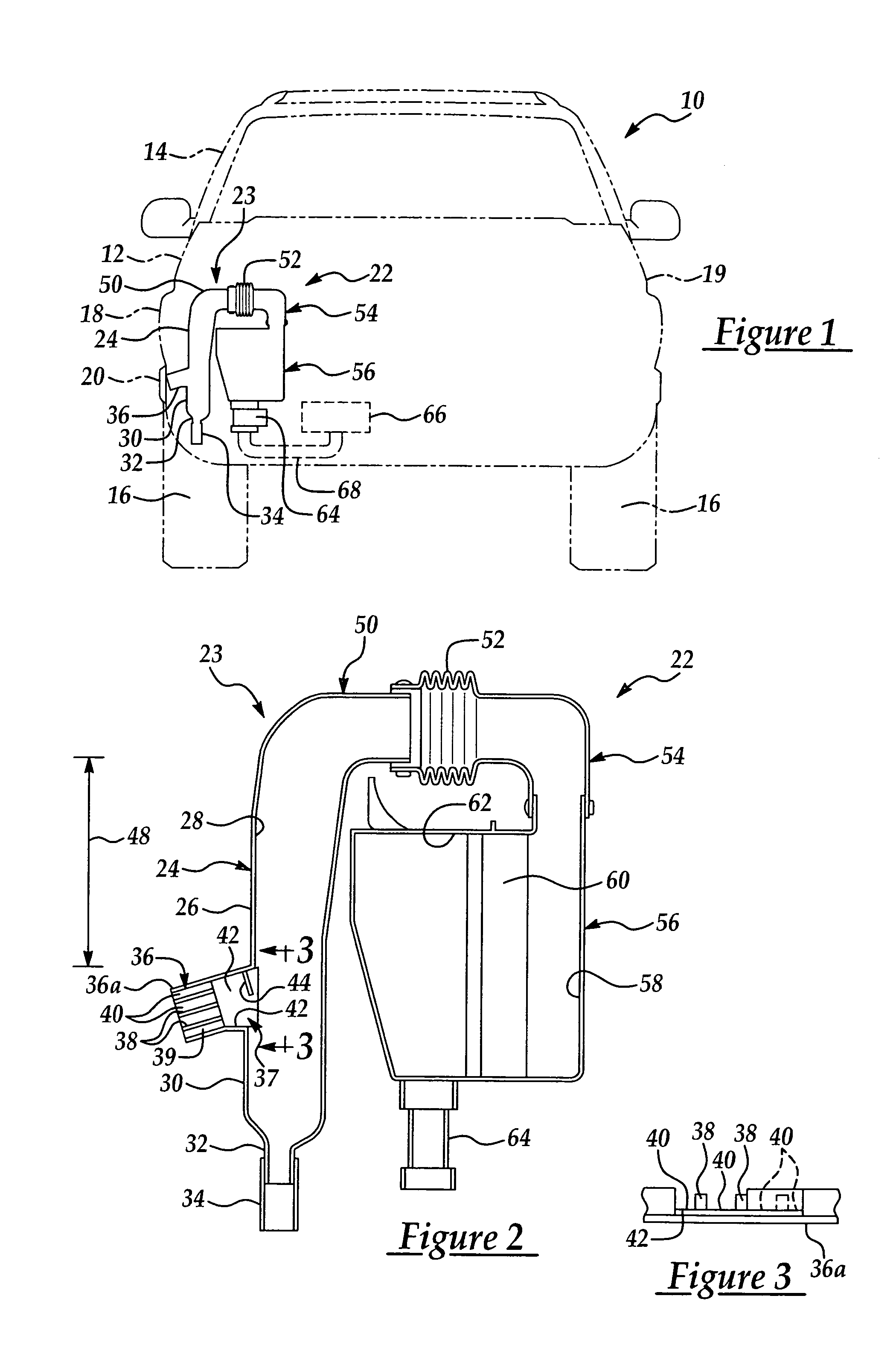

Vehicle air induction system

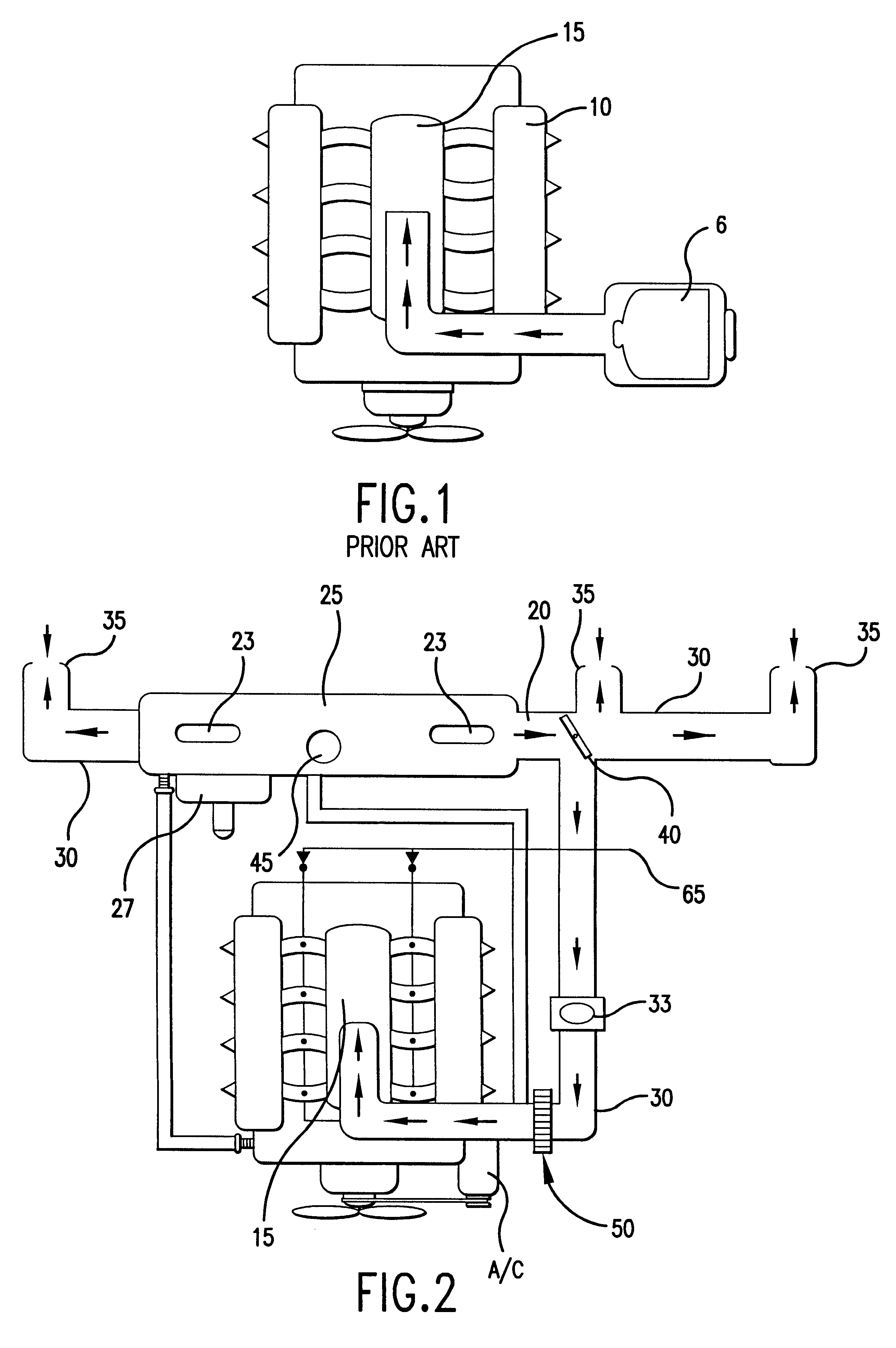

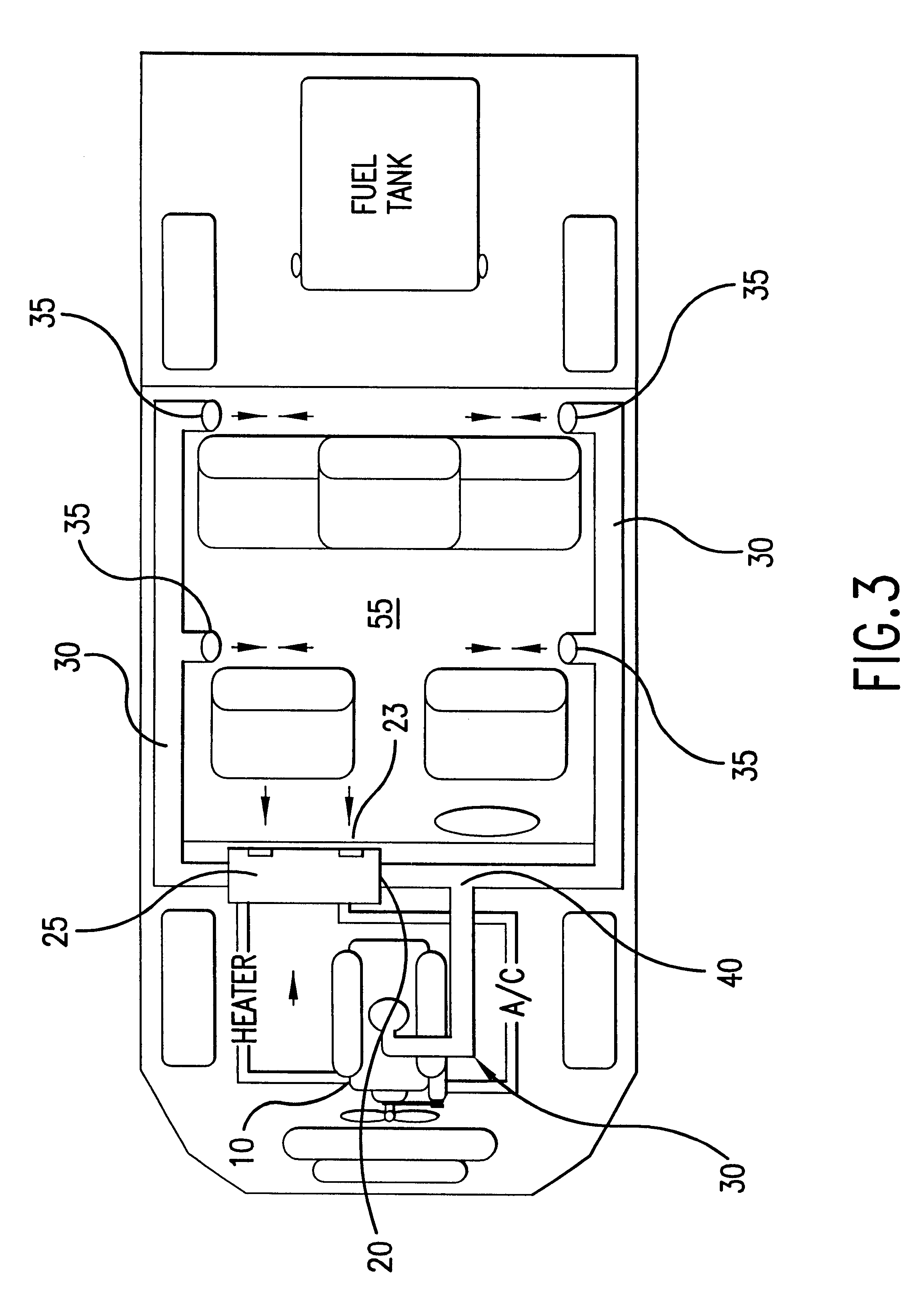

InactiveUS6314949B1Lower emission levelsImprove efficiencyInternal combustion piston enginesTemperatue controlRam-air intakeTemperature control

This invention is an air induction system that enables an enhanced flow of temperature-controlled, magnetically influenced forced air to the air intake of internal combustion, turbine-type, and other engines having an air intake manifold. An interior air inlet is positioned in communication with a passenger compartment of the vehicle. Additionally, or alternatively, a plenum outlet is positioned in an HVAC plenum of the vehicle. An air supply duct extends between the interior air inlet and / or the plenum outlet and the air intake manifold supplies conditioned air to the air intake manifold. Performance may be enhanced with the positioning of magnets and / or an air diverter valve into the system. As a result of the enhanced flow of magnetically influenced air and the more steady state of the temperature of the inducted air, fuel consumption and air emissions levels are reduced.

Owner:FUEL MANAGEMENT

Automated fresh air cooling system

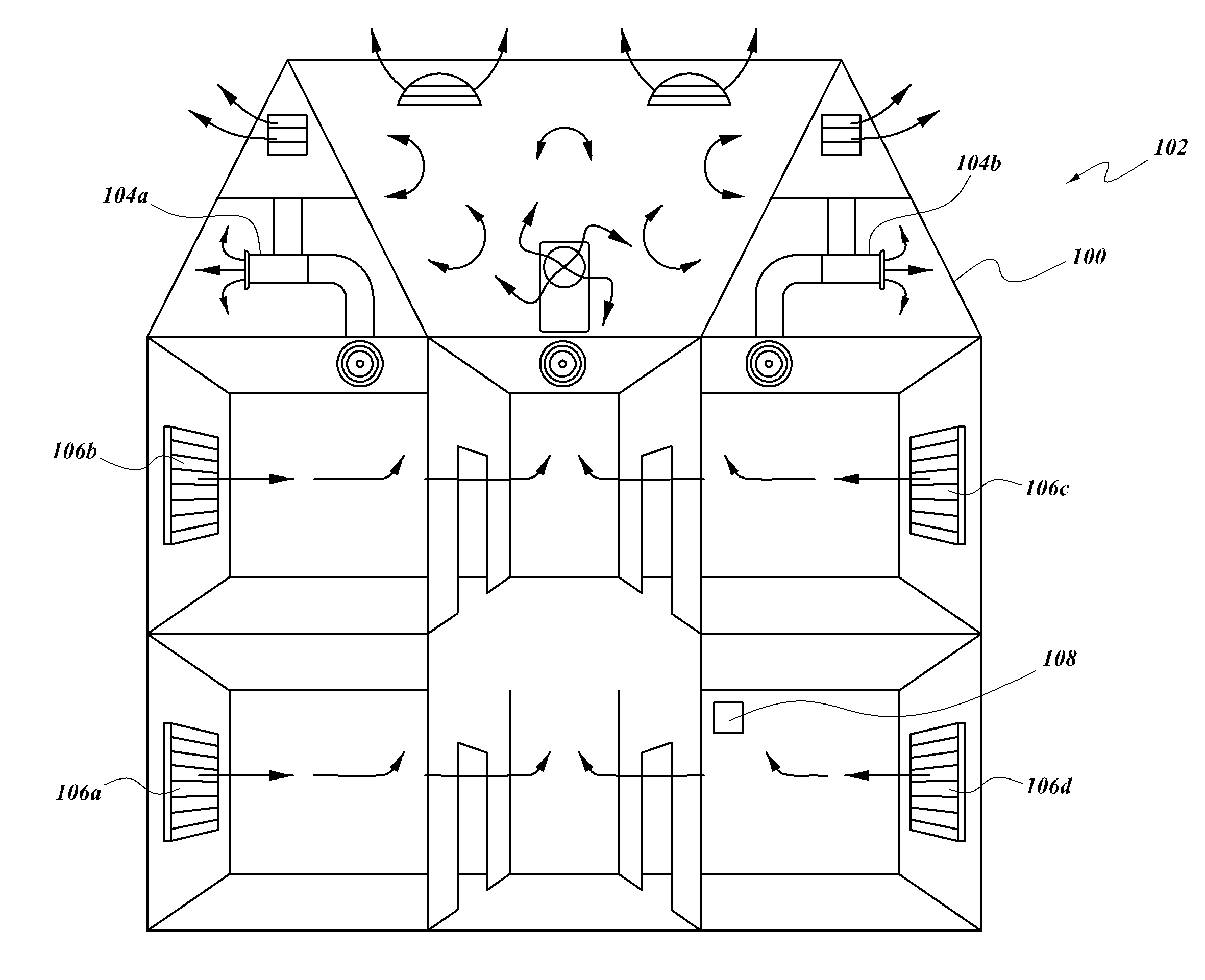

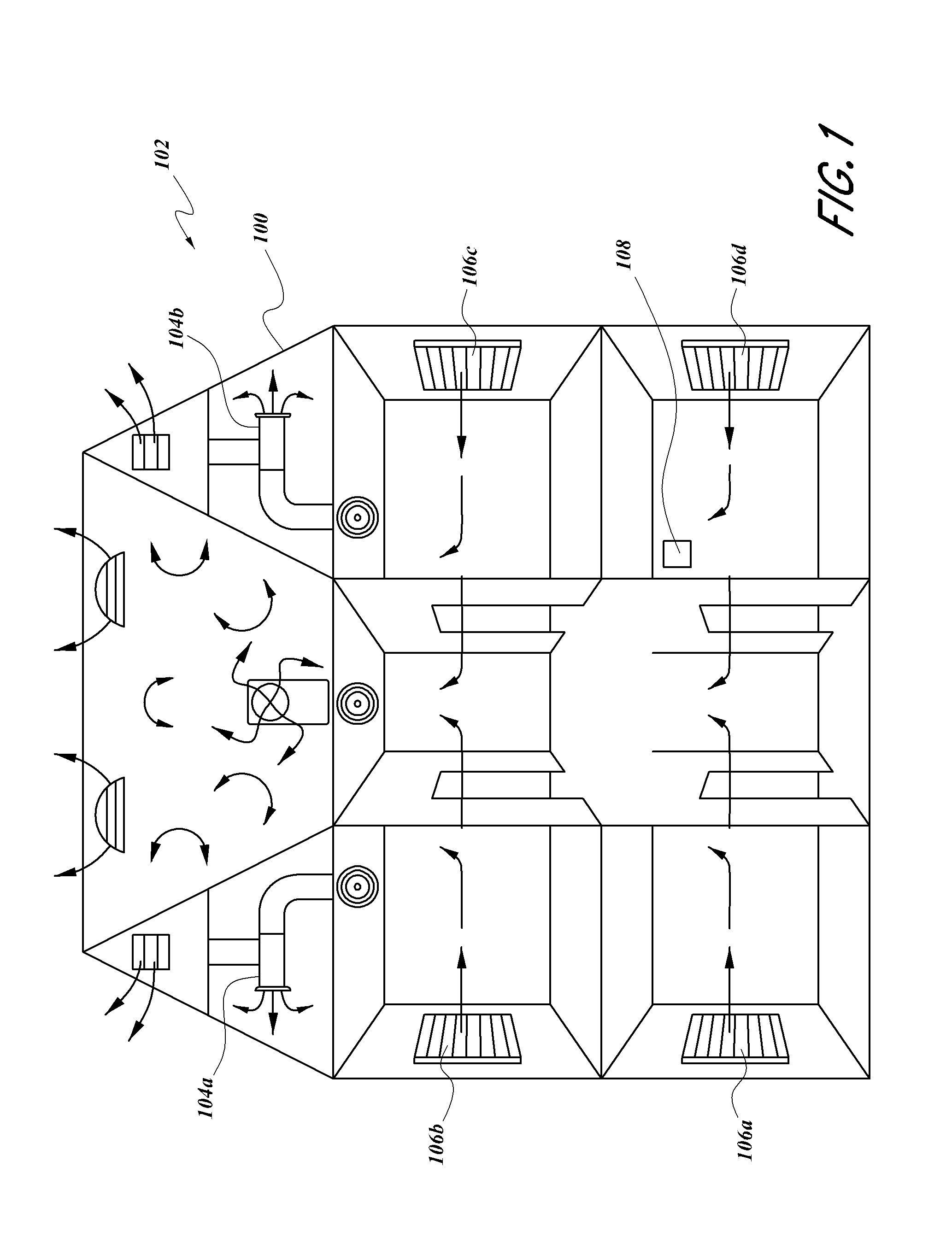

InactiveUS20140206278A1Mechanical apparatusSpace heating and ventilation safety systemsRam-air intakeUser input

Embodiments of the present disclosure are directed to an automated fresh air cooling system. The automated fresh air cooling system can include a whole house fan, an air intake, an air conditioner, and at least one controller. The controller can adjust the usage of the different components of the fresh air cooling system in order to reduce overall energy consumption as well as cost to a consumer. The system can be completely automated and no user input is required.

Owner:QC MFG

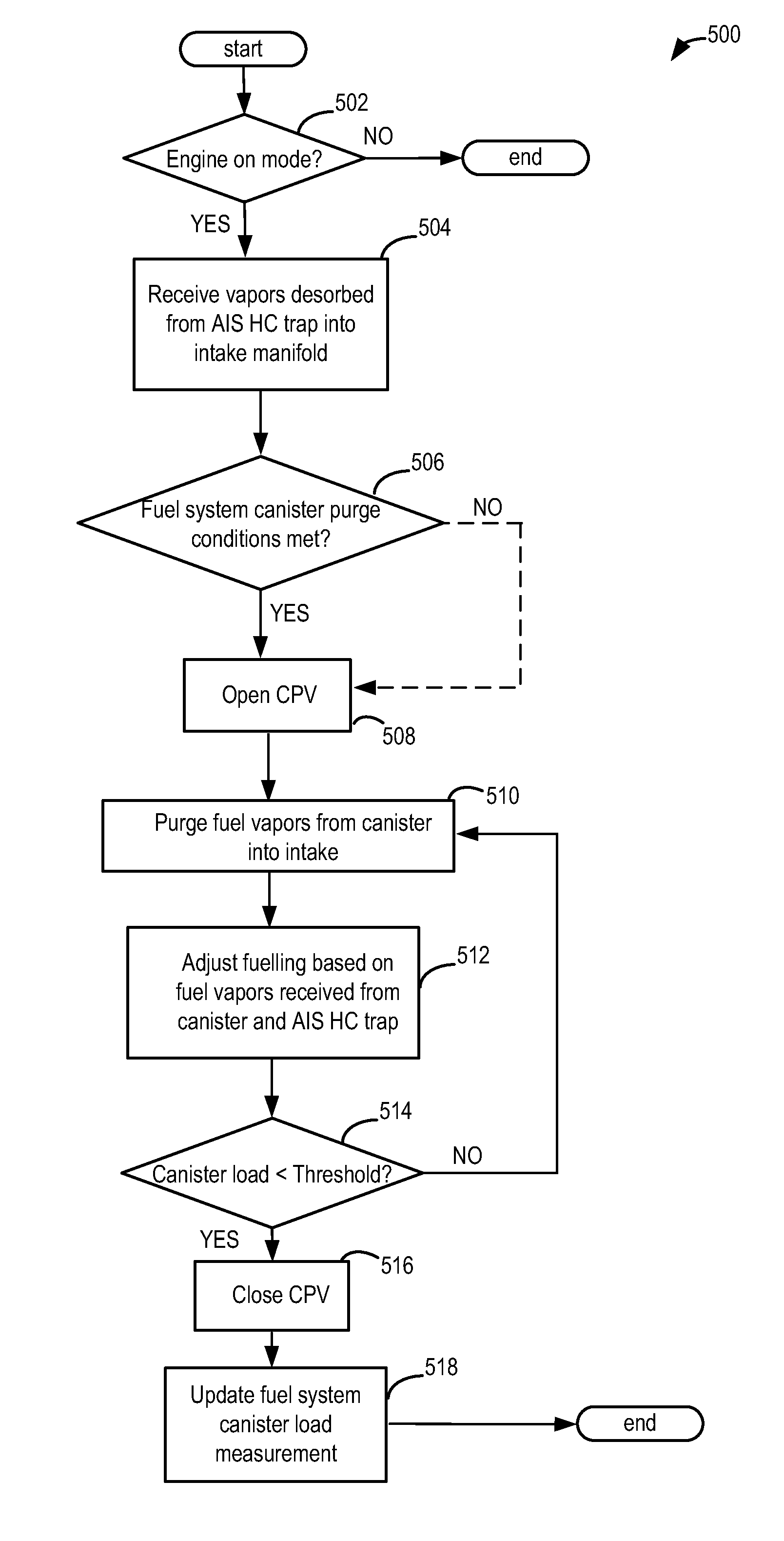

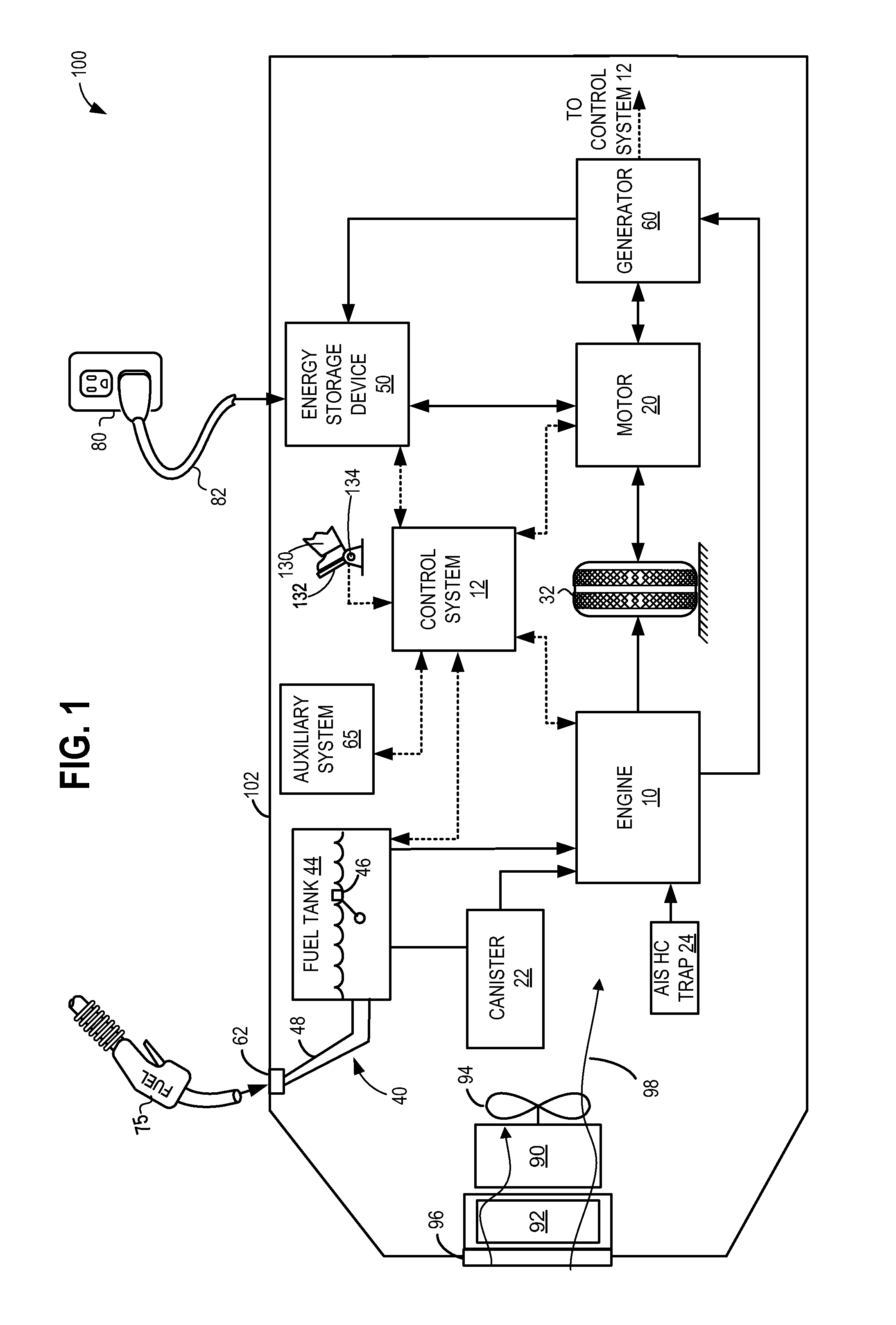

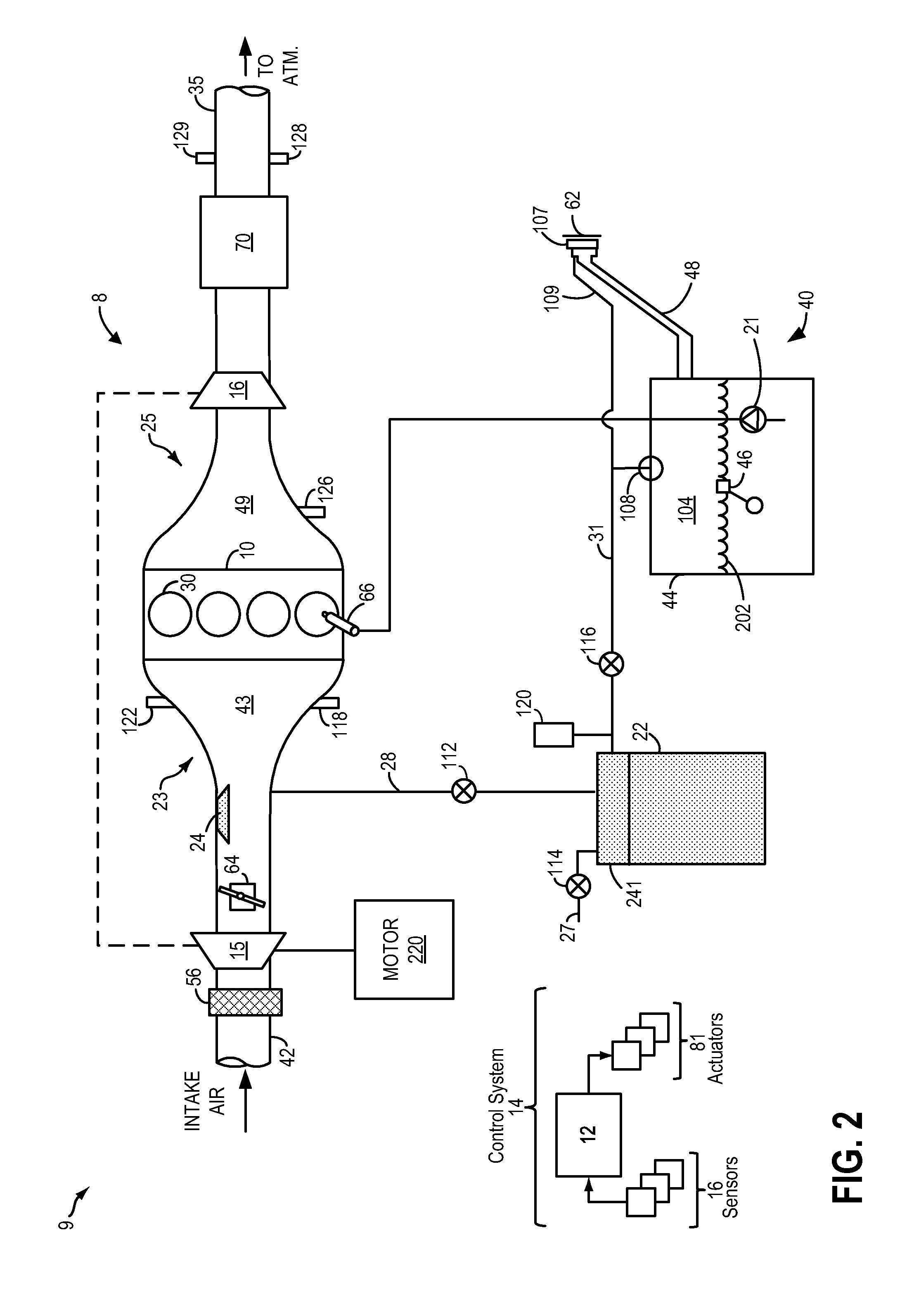

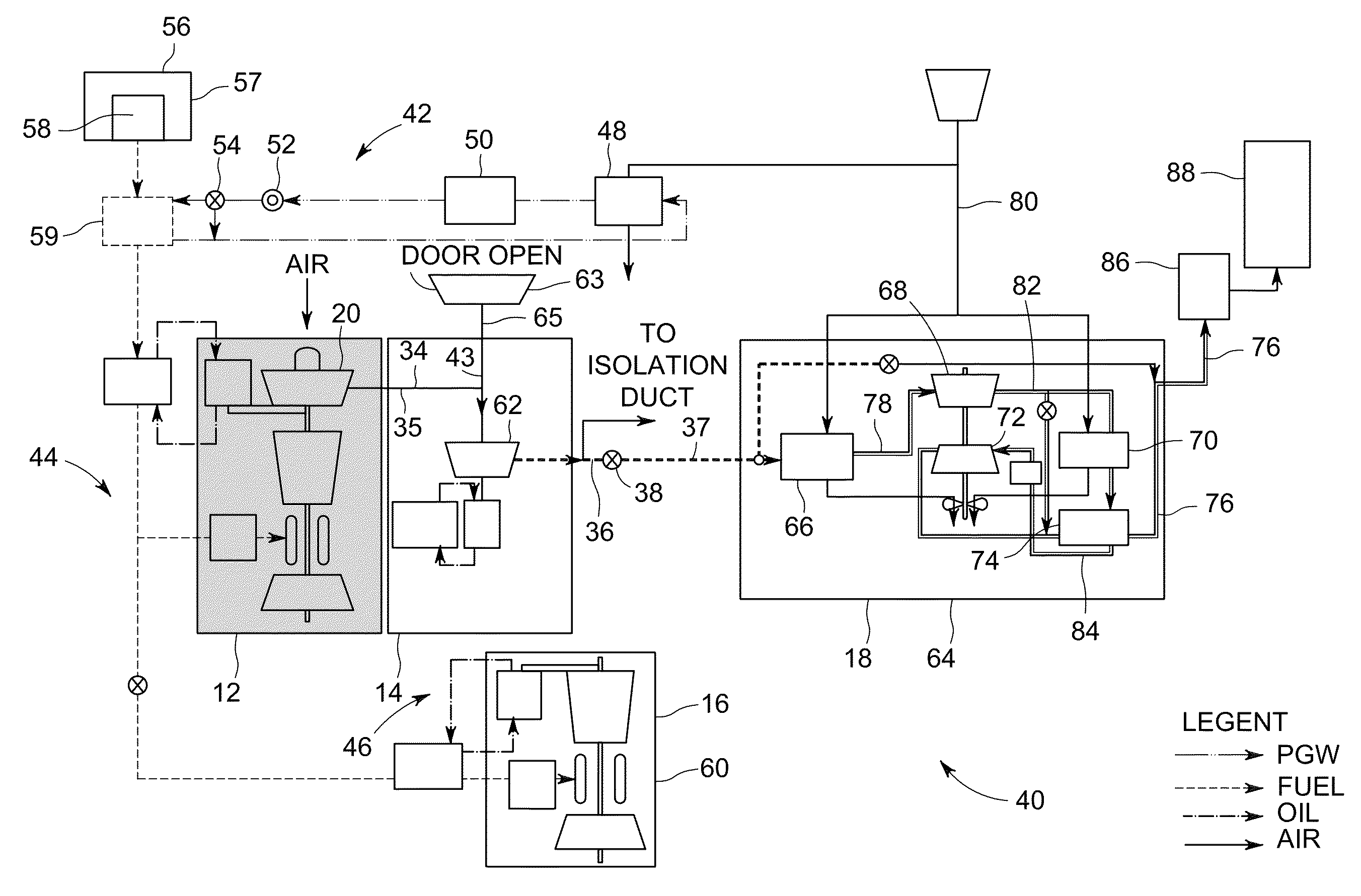

Method for purging of air intake system hydrocarbon trap

ActiveUS20150120108A1Increasing evaporative emissionAccelerate emissionsHybrid vehiclesElectrical controlRam-air intakeEngineering

Methods and systems are provided for improving air intake system hydrocarbon trap purging during engine-off time in a hybrid electric vehicle. One method includes opening the throttle during vehicle motion under battery operation and allowing airflow through the trap to purge its contents into the fuel canister via the canister purge valve. Upon transition into the engine-on mode, fuel vapors are released from the canister into the engine intake.

Owner:FORD GLOBAL TECH LLC

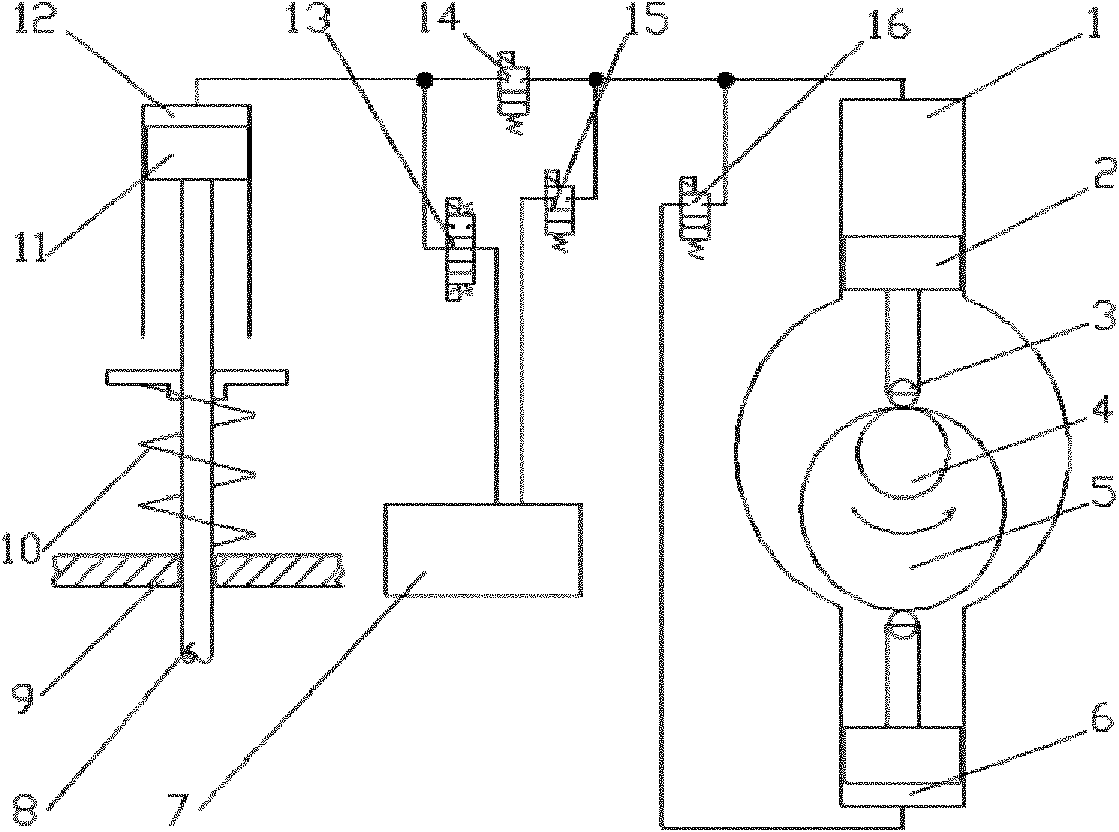

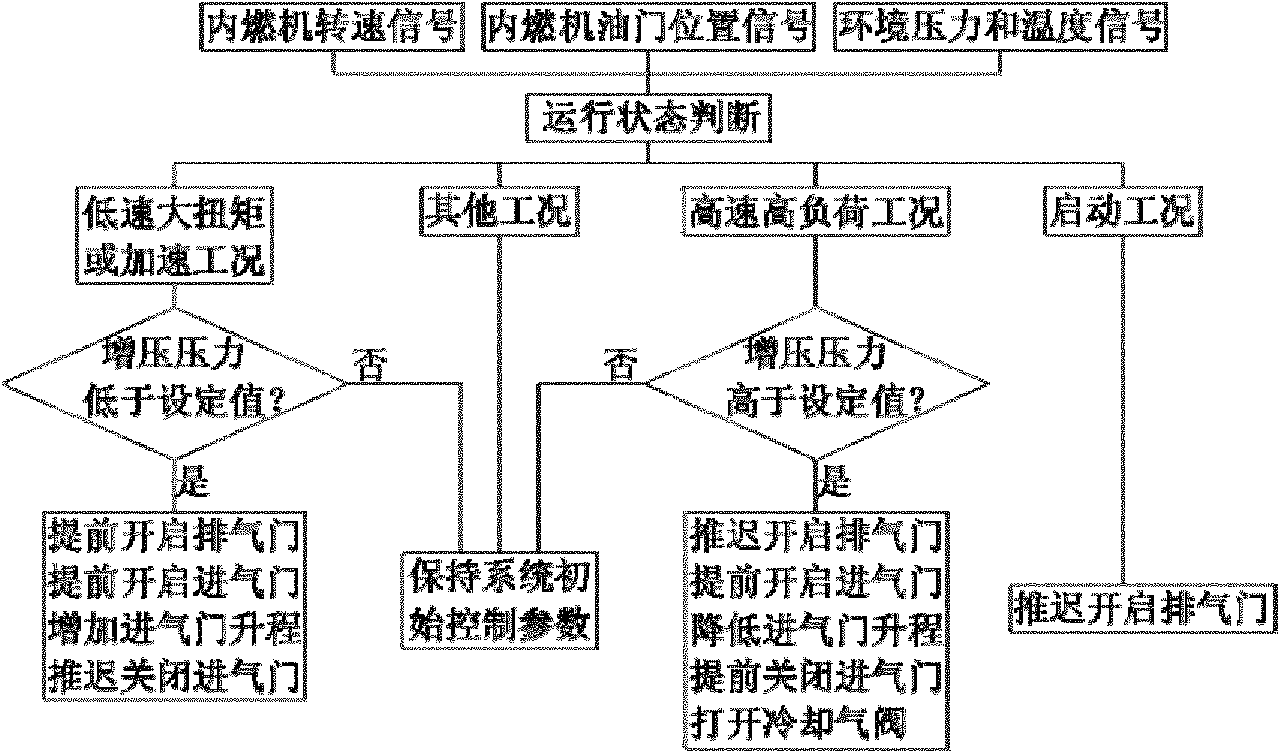

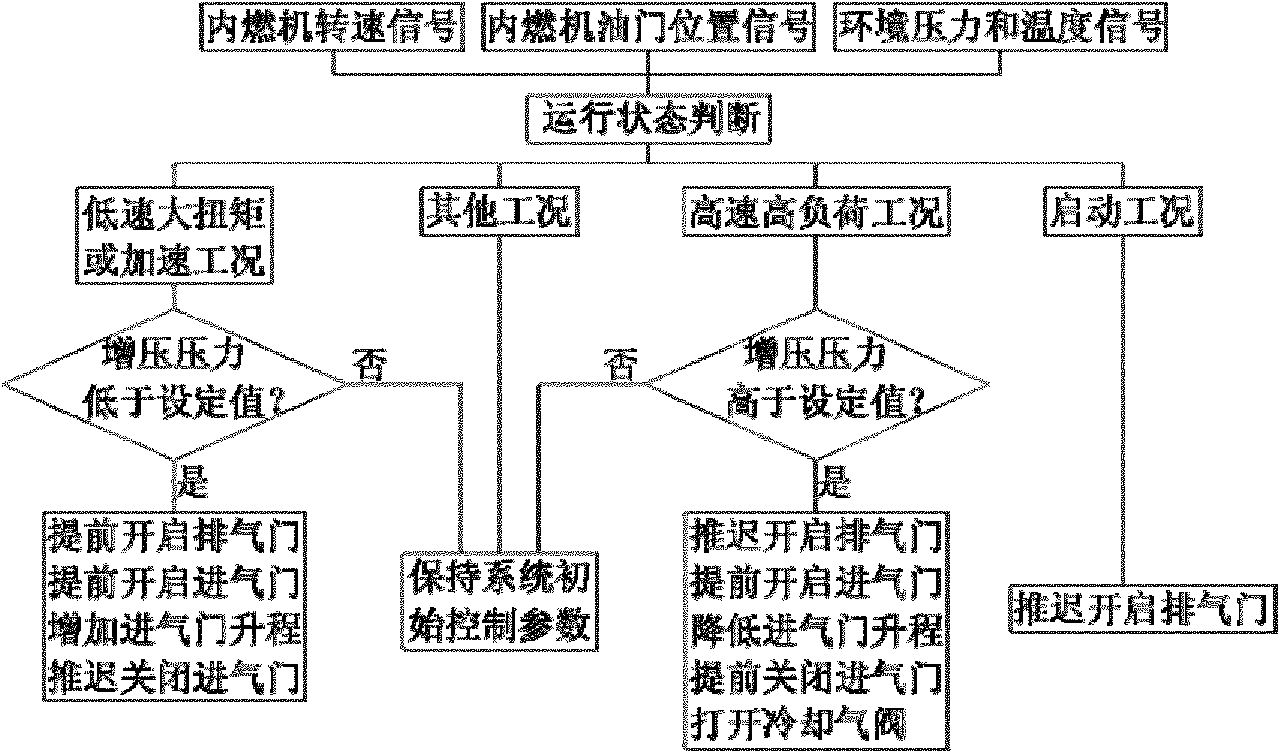

Control method of air intake and air exhaust valves of internal combustion engine

InactiveCN102022154AIncrease overlap angleReduce liftInternal combustion piston enginesOutput powerRam-air intakeLow speed

The invention provides a control method of air intake and air exhaust valves of an internal combustion engine, which belongs to the field of air intake and air exhaust systems of internal combustion engines. The control method of the air intake and air exhaust valves is based on thermodynamic cycle of high pneumatic compression ratio and low expansion ratio so as to ensure that the air exhaust valve is opened as soon as possible and the opening / closing time of the air intake valve is properly adjusted when a turbocharged internal combustion engine is under a low-speed and large-torque working condition, a highland operation working condition and an acceleration working condition, therefore, air intake flow is ensured to be increased as much as possible under the working conditions. Meanwhile, a passage is arranged between an air intake pipe behind a compressor and an air exhaust pipe before a turbocharger; air of low temperature is introduced into the air exhaust pipe to reduce exhaust temperature so as to protect the turbocharger; when cold start is carried out, the air exhaust valve is opened later to enhance compression temperature in a cylinder; and once the start is carried out, the air exhaust valve is opened early to increase the air intake quantity. The control method can largely enhance the dynamic property of the internal combustion engine under the low-speed and large-torque working condition and the highland working condition, improve the start performance and acceleration performance of the internal combustion engine and enable the internal combustion engine to obtain a better emission performance.

Owner:DALIAN UNIV OF TECH

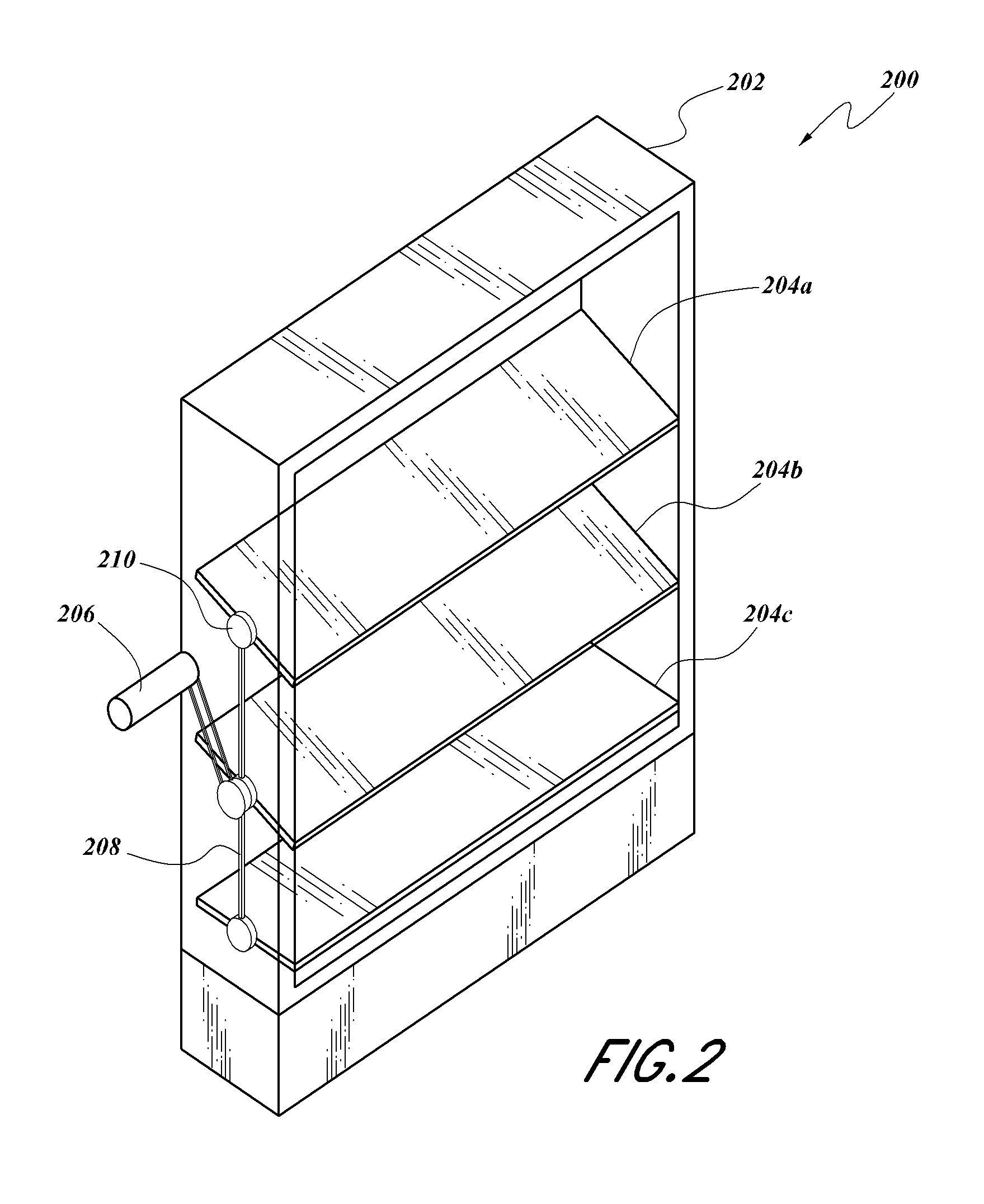

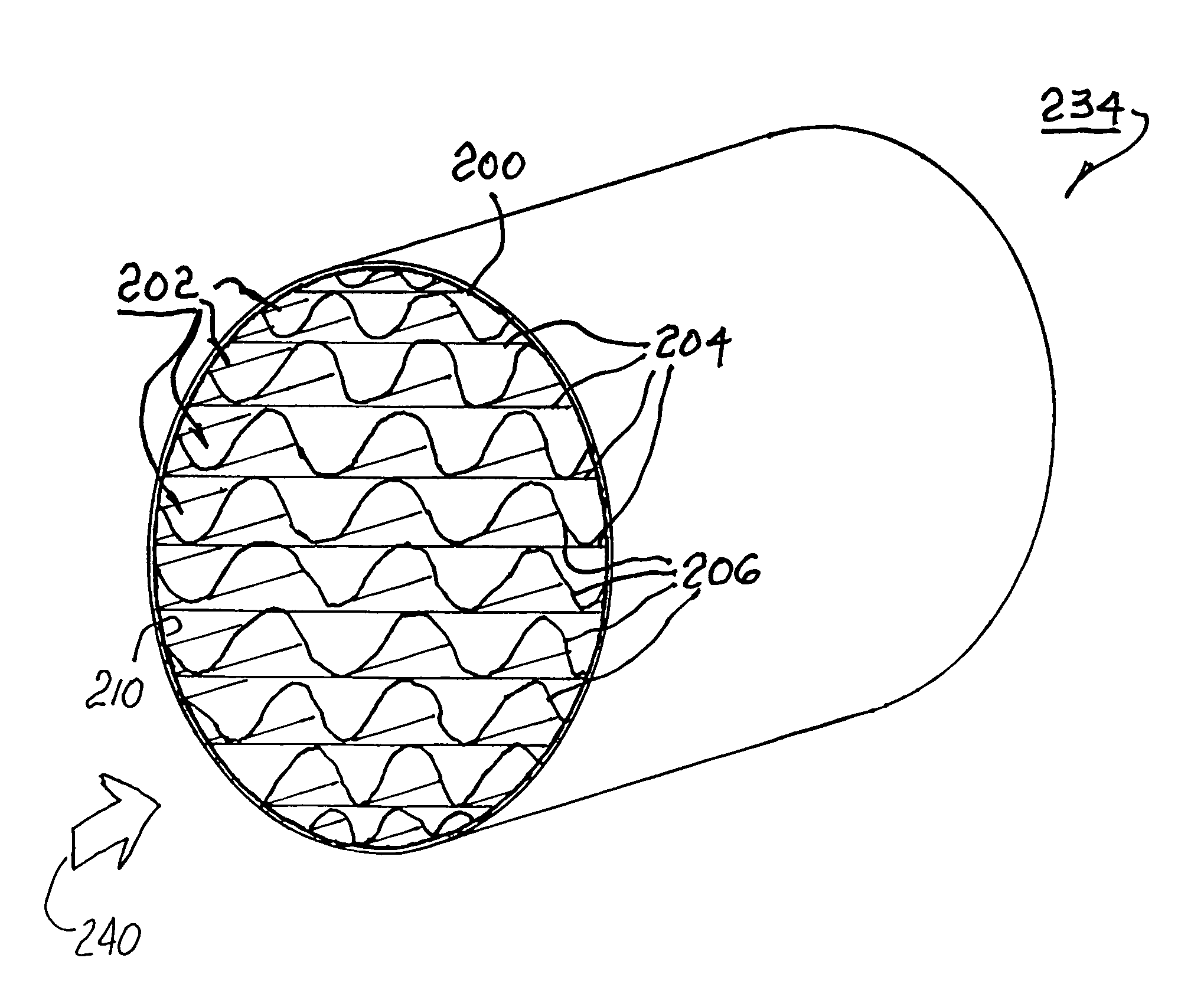

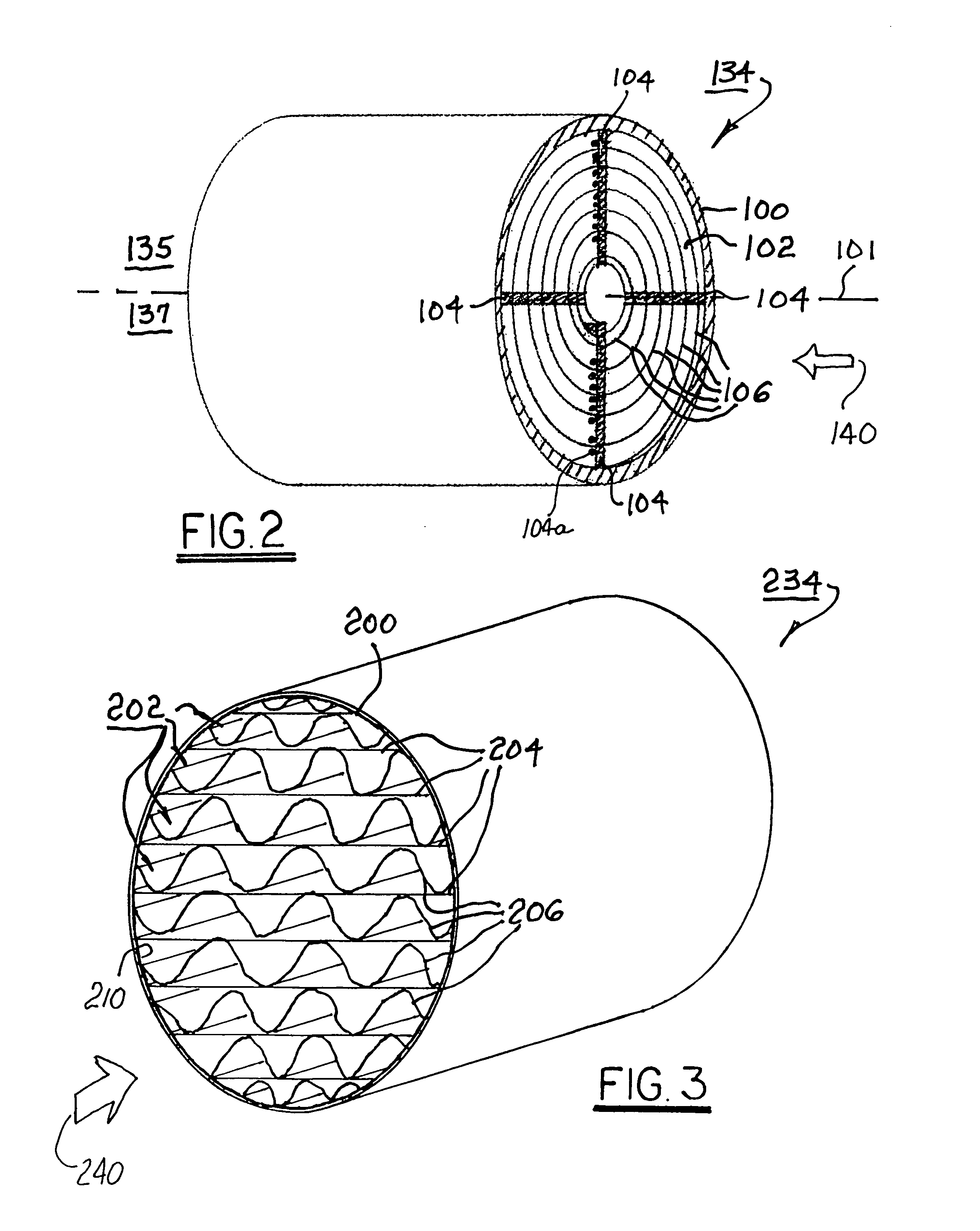

Low-resistance hydrocarbon adsorber cartridge for an air intake of an internal combustion engine

InactiveUS7222612B2Minimizing reduction in total open areaIncrease probabilityNon-fuel substance addition to fuelMachines/enginesActivated carbonRam-air intake

Owner:DELPHI TECH INC

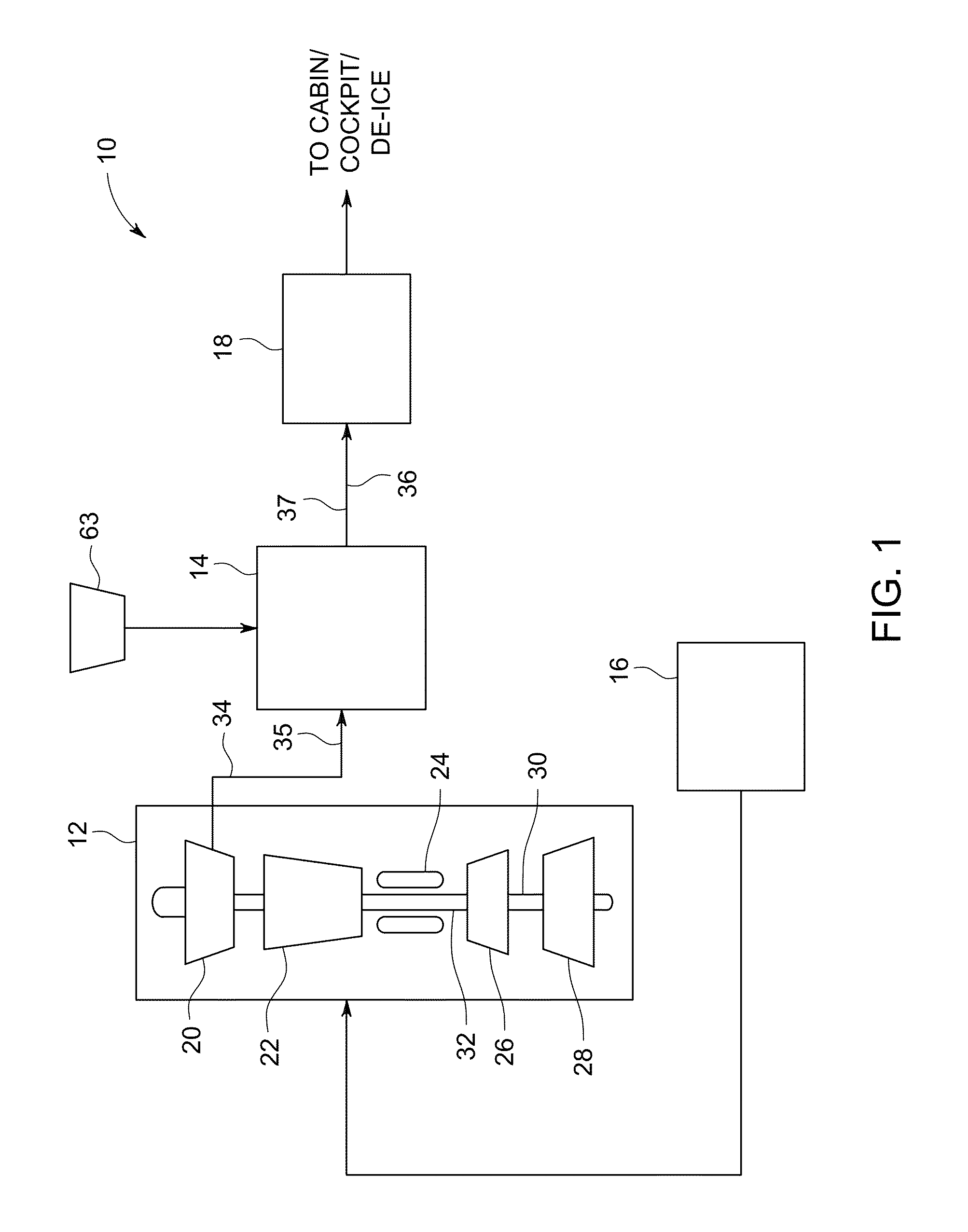

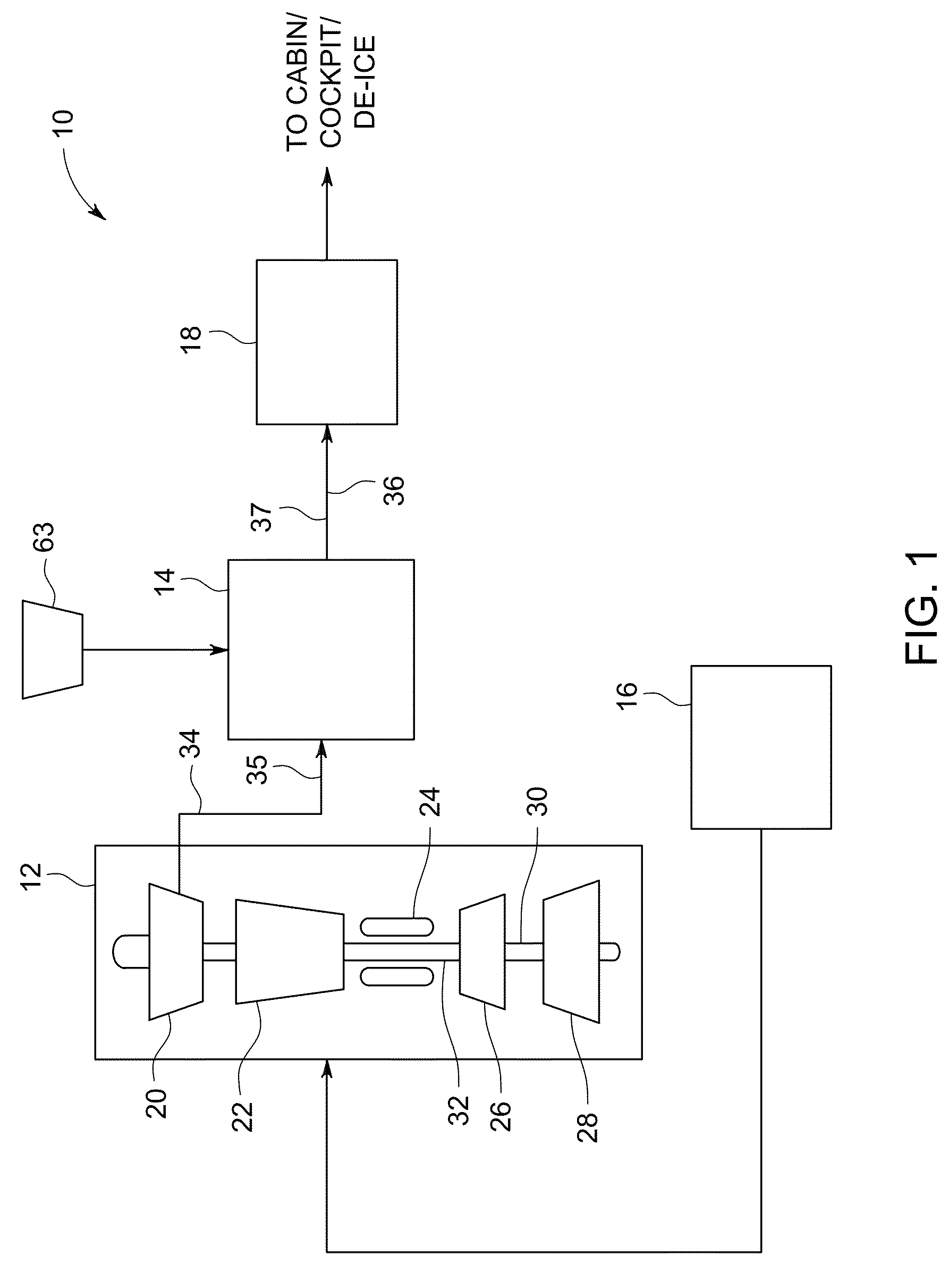

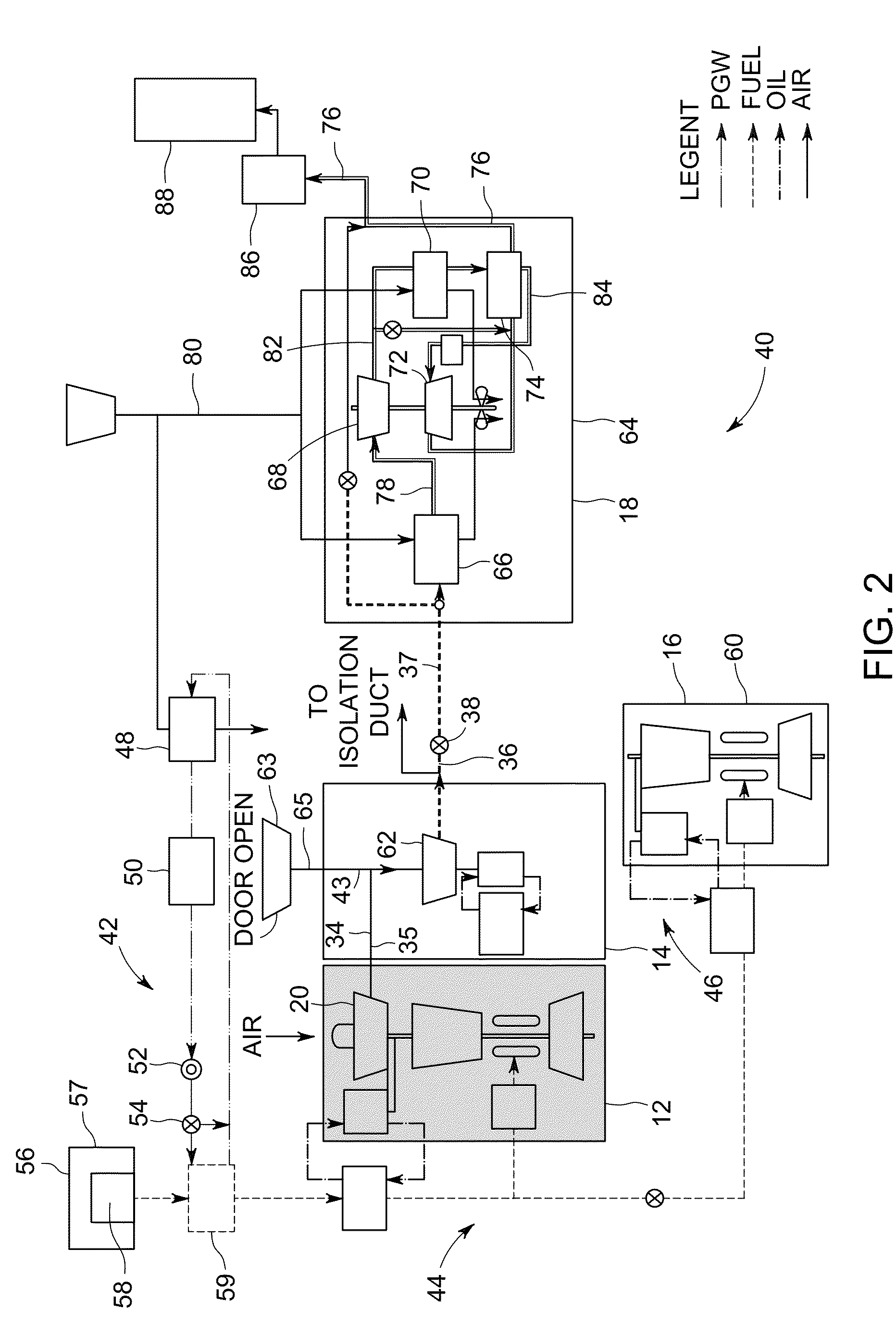

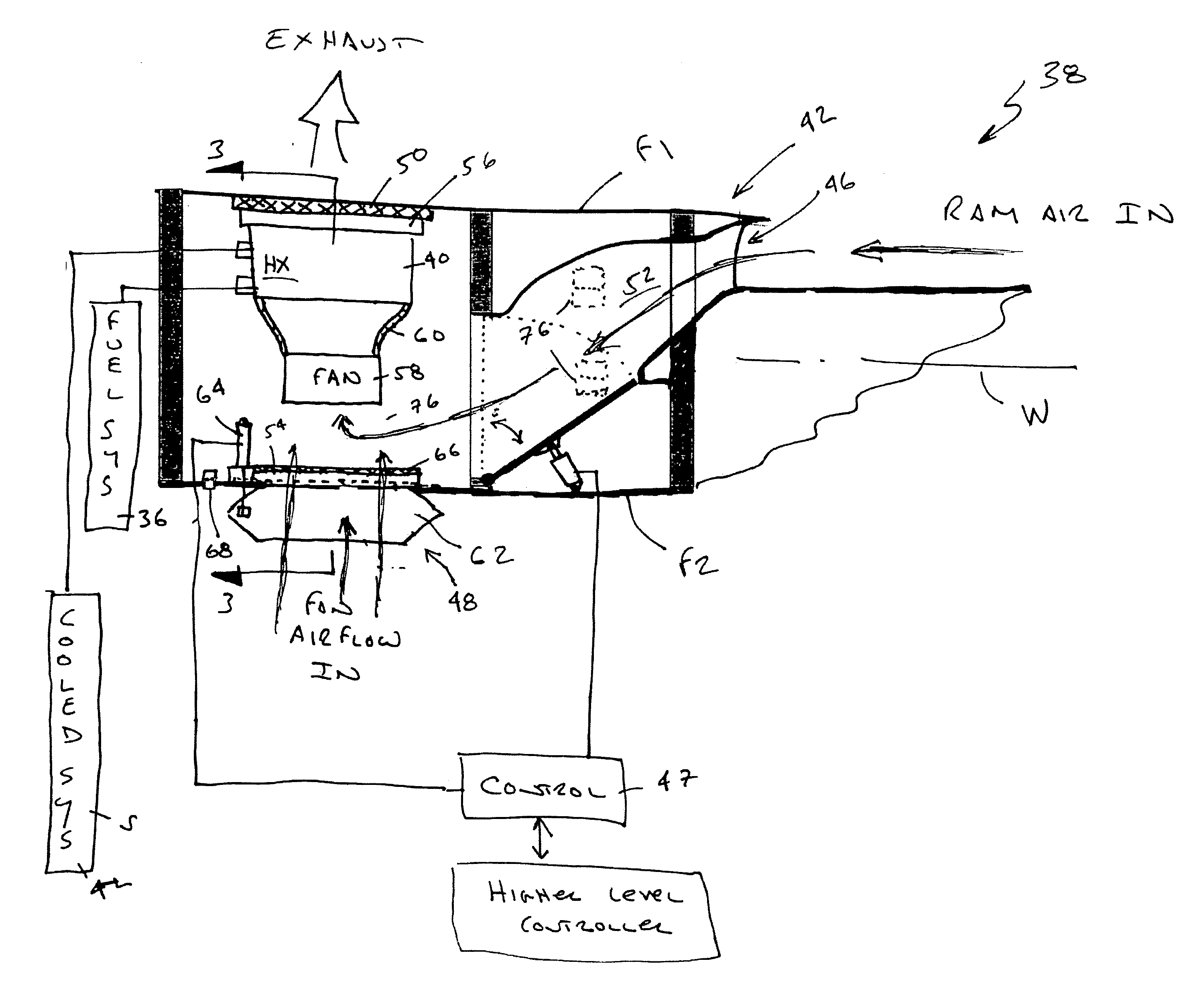

Aircraft energy management system including engine fan discharge air boosted environmental control system

ActiveUS20130318983A1Reduced ram air drag lossMinimizing overall aircraft weightAir-treatment apparatus arrangementsEnergy efficient board measuresRam-air intakeControl system

An aircraft energy management system including a cabin air compressor adapted to be coupled to a source of fan discharge air at a first pressure during an inflight operating mode and adapted to be coupled to a ram intake air during a ground operating mode. The system further including an environmental control system mechanically coupled to a compressor exit of the cabin air compressor. The aircraft energy management system configured to provide a conditioned fluid flow to an aircraft cabin, cockpit or de-icing system.

Owner:EMBRAER SA

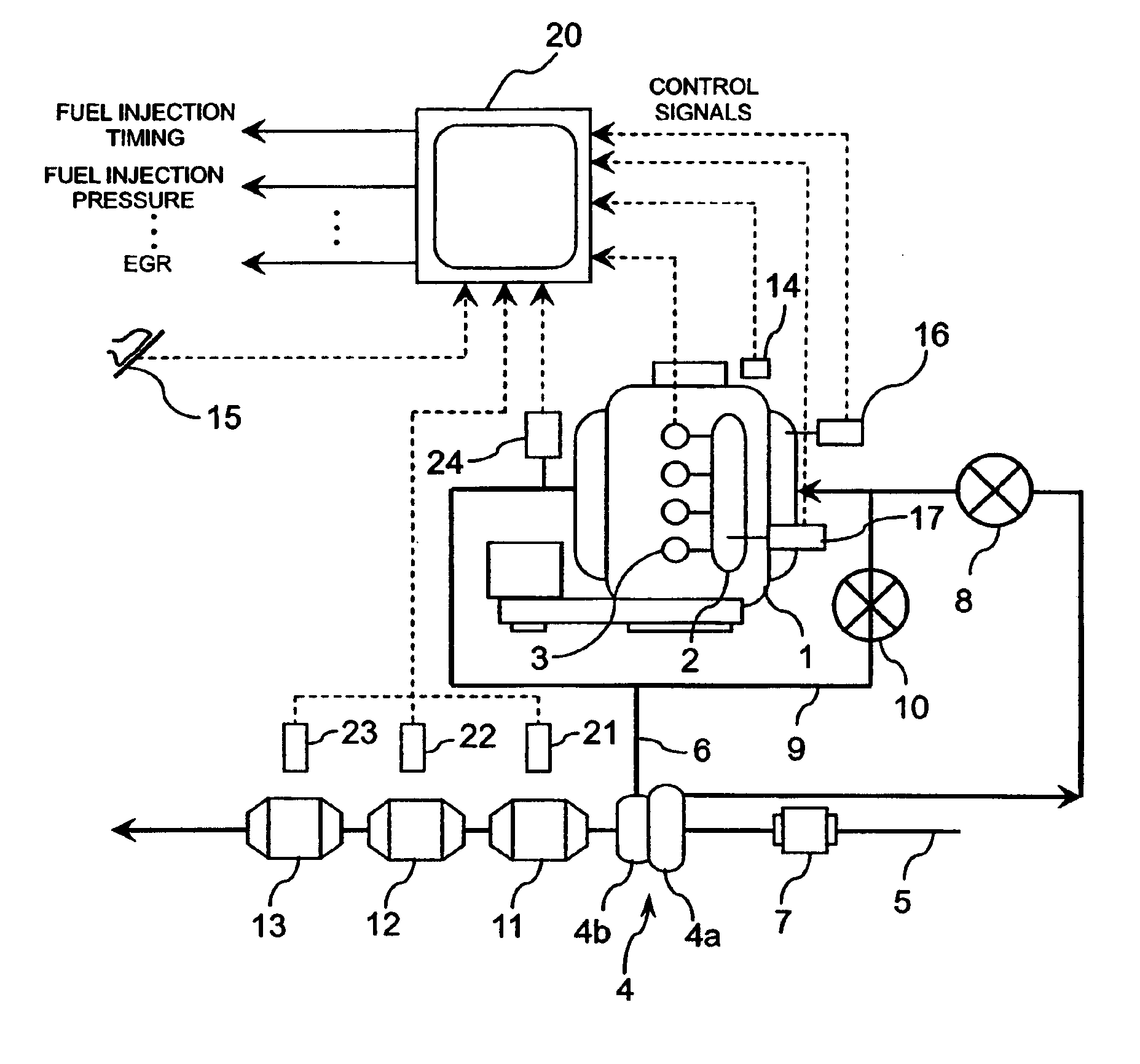

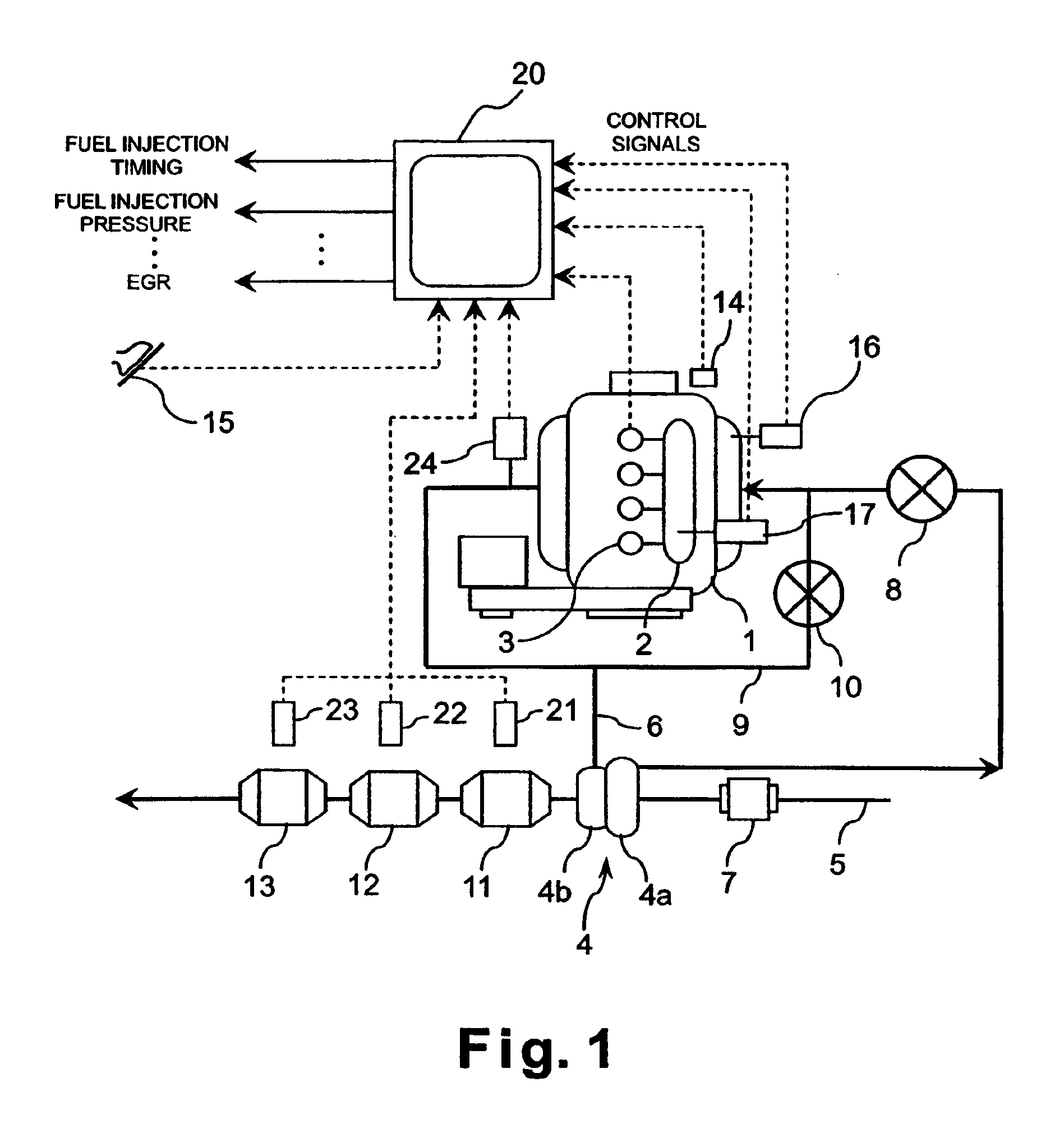

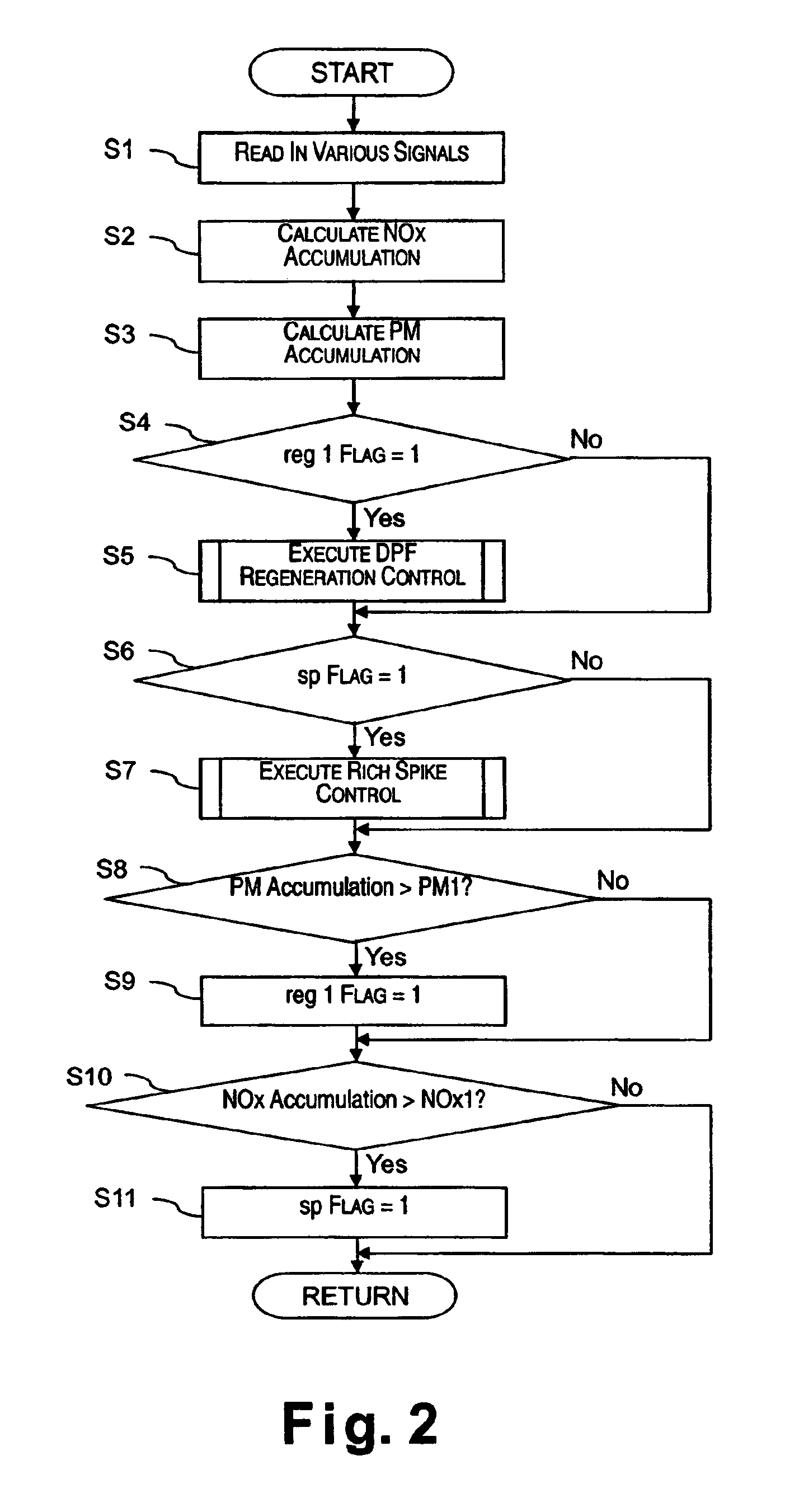

Exhaust gas recirculation control system

ActiveUS6957642B2Excess air ratio is reducedAvoid problemsElectrical controlInternal combustion piston enginesRam-air intakeControl system

Owner:NISSAN MOTOR CO LTD

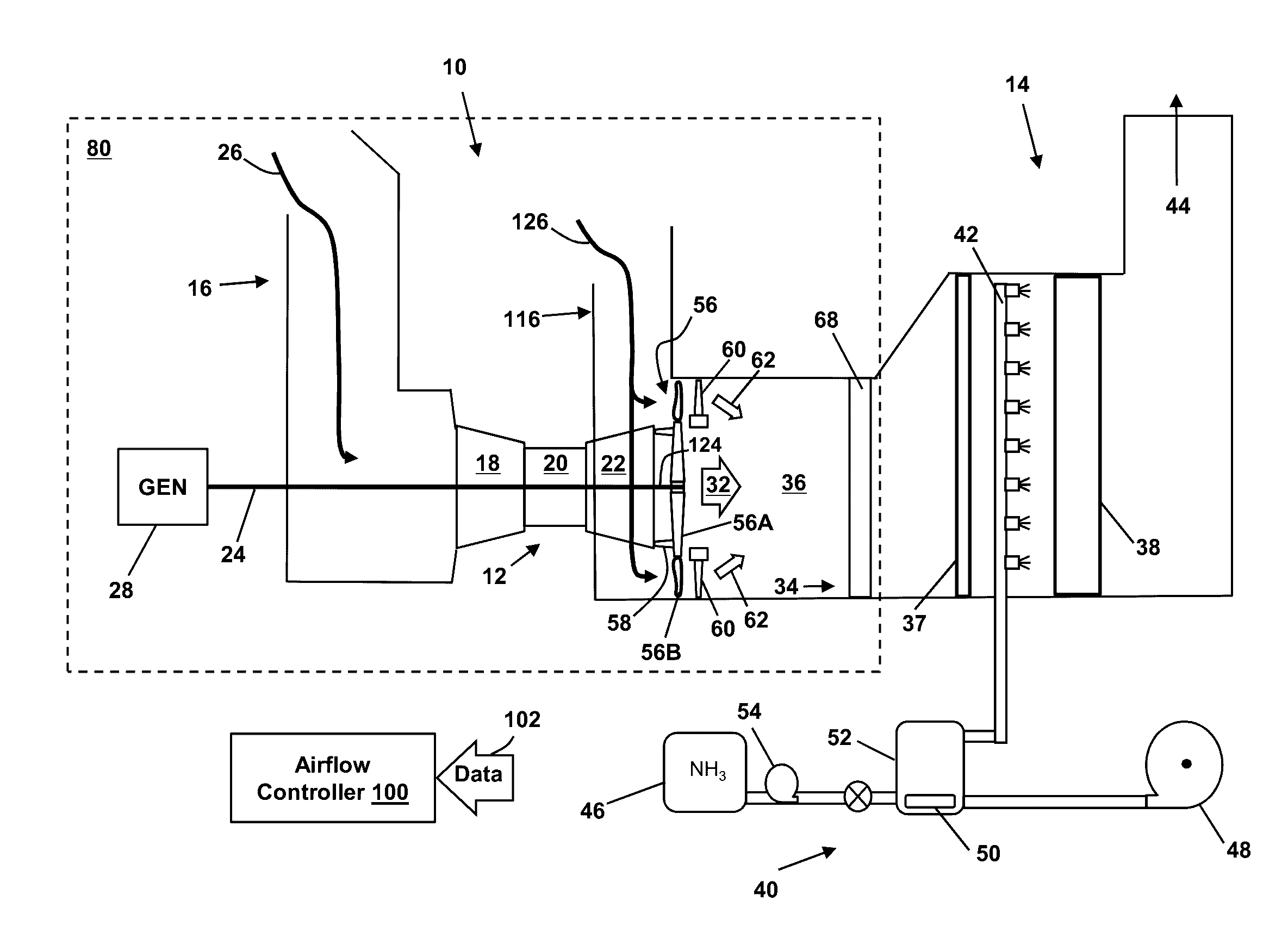

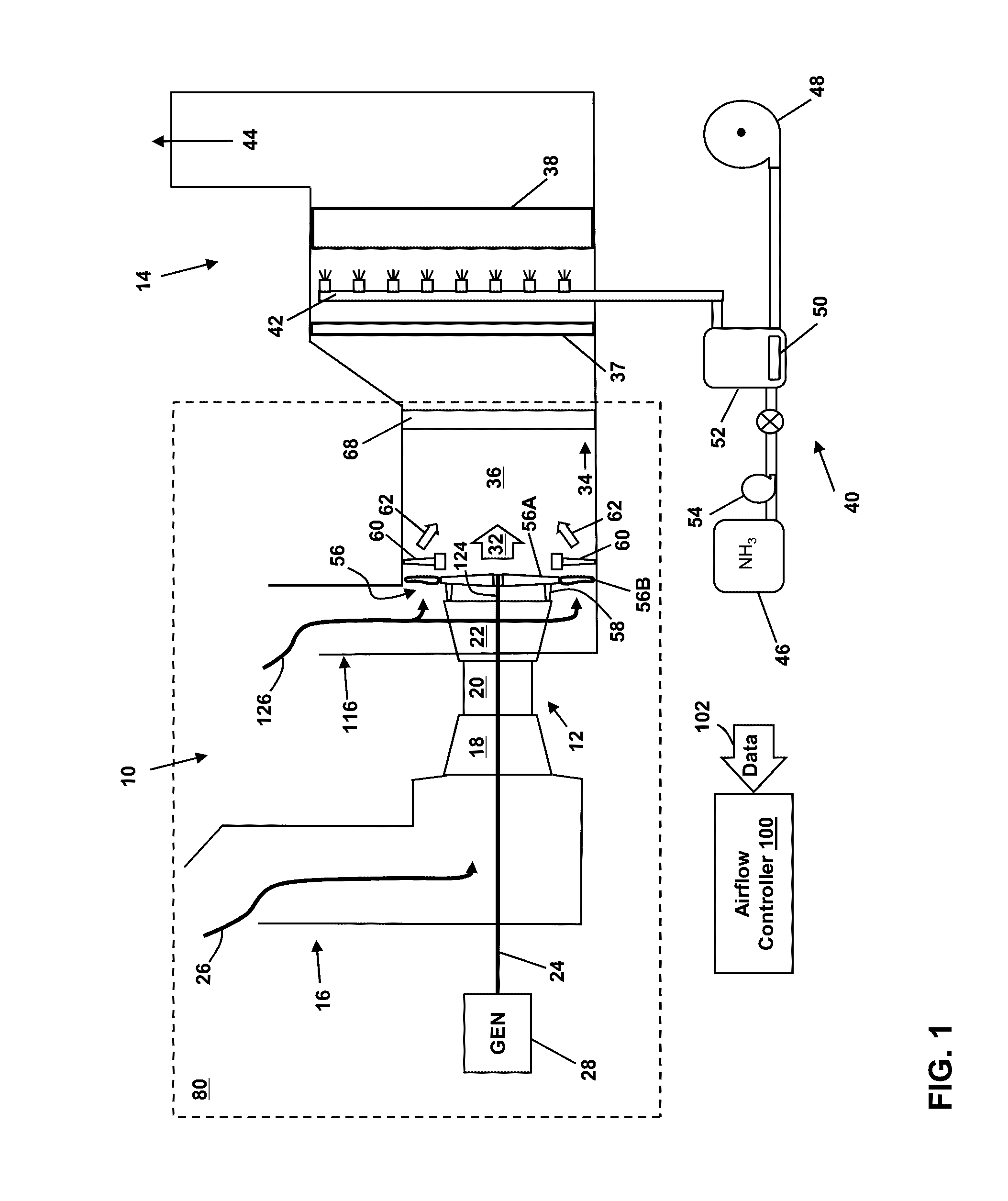

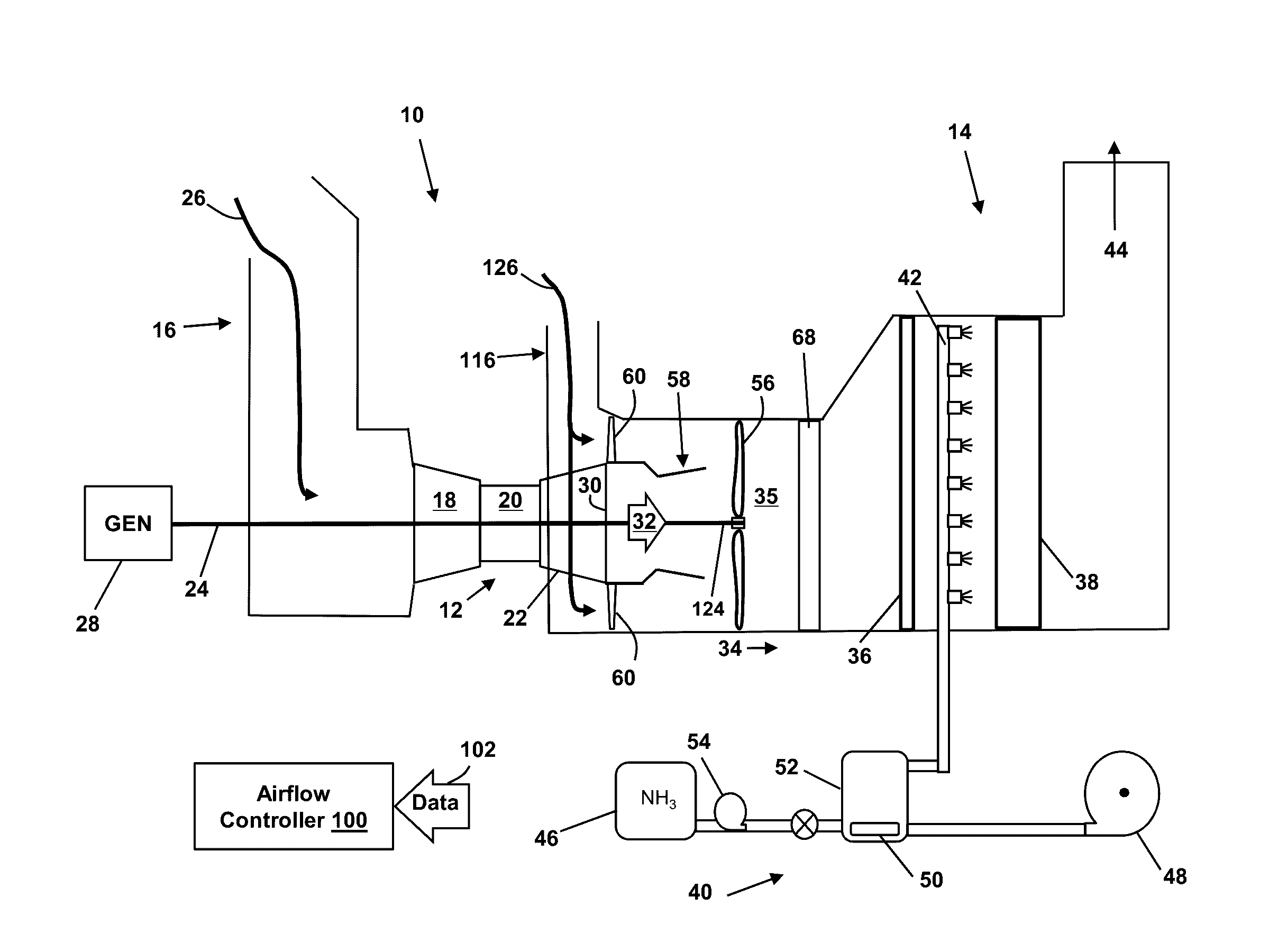

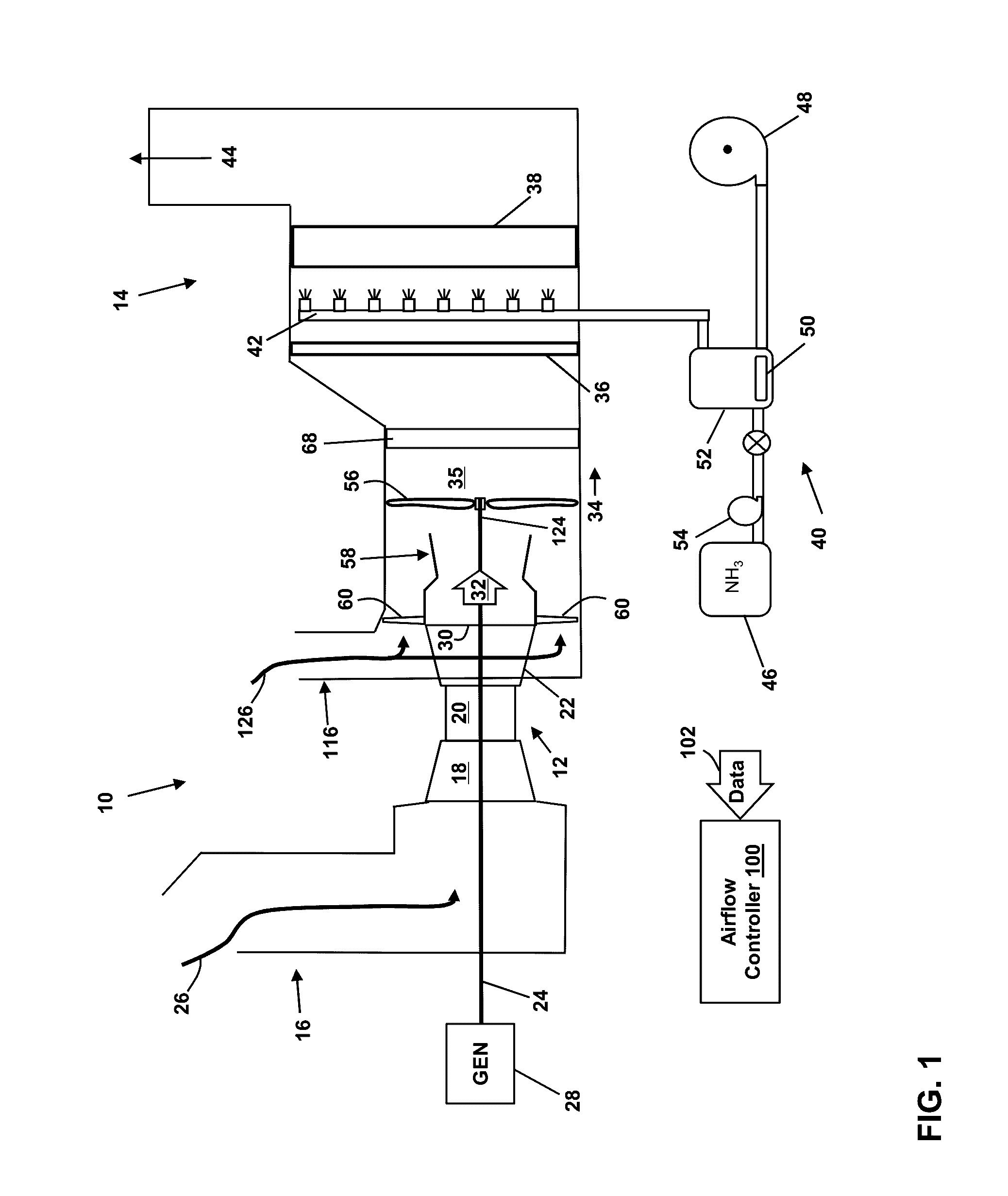

Power generation system exhaust cooling

ActiveUS20160376957A1Reduce the temperatureExhaust apparatusSilencing apparatusRam-air intakeCombustor

A power generation system according to an embodiment includes: a gas turbine system including a compressor component, a combustor component, and a turbine component; an airflow generation system coupled to an expander shaft downstream of the gas turbine system for drawing in a flow of ambient air through an air intake section; a mixing area for receiving an exhaust gas stream produced by the gas turbine system;a flow directing system for directing the flow of ambient air generated by the airflow generation system to the mixing area to reduce a temperature of the exhaust gas stream;and an exhaust processing system for processing the reduced temperature exhaust gas stream.

Owner:GENERAL ELECTRIC CO

Air intake system

ActiveUS7069893B2Reduce intakeShorten the progressCombination devicesInternal combustion piston enginesRam-air intakeFuel cells

A novel air intake system which is suitable for at least substantially reducing the inadvertent intake of water with ambient air into an air compressor or other operational component of a fuel cell or internal combustion engine is disclosed. The air intake system typically includes an elongated air flow conduit having a downwardly-angled air inlet arm that is typically fitted with multiple louver elements and a splash shield to deflect entering water downwardly into a drain or gullet chamber. The air intake system typically further includes a mechanism for gravity-mediated draining of water from the air flow conduit to prevent entering water from being drawn into the air compressor or other component.

Owner:FORD MOTOR CO

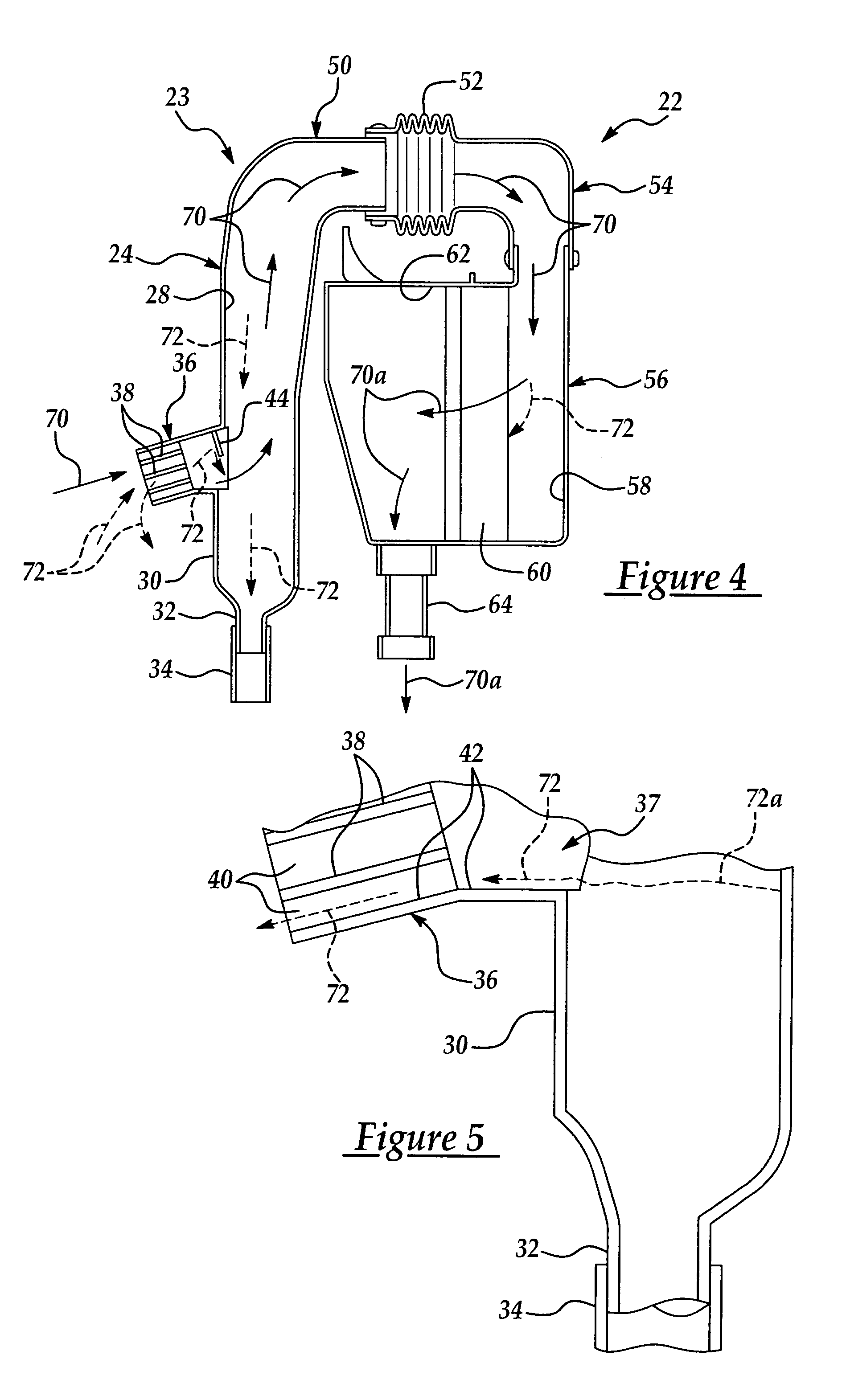

Stamping-turbine air injection composite aero-engine

ActiveCN105221295ASingle stage pressure ratio highReduce consumptionRam jet enginesComposite engine plantsRamjetAviation

The invention discloses a stamping-turbine air injection composite aero-engine and aims to solve the problems that the existing gas turbine engine is complicated in structure and limited in running speed range, and a ramjet engine cannot voluntarily start, cannot run at a low speed, is difficult in cooling, and has higher requirements for the high temperature resistance of a complete machine. The stamping-turbine air injection composite aero-engine comprises a stamping air inflow cone, an outer duct engine case, an inlet guide blade, a liquid oxygen regulating valve, a liquid nitrogen regulating valve, an inner duct engine case, a rectifying blade, a fuel oil regulating valve, a centrifugal compressor, a diffuser, a combustor, a concentric shaft, a worm wheel, an inner duct rectifying nozzle, a starting dynamo and the like. The stamping-turbine air injection composite aero-engine effectively utilizes the stamping effect and advantages of a turbojet engine, participates in precooling treatment, effectively solves the problems that the ramjet engine takes air in the starting and high-speed states, and the engine power is limited, is simple in structure, low in cost, high in efficiency, wide in running speed range and low in running speed of the complete machine, and has a better application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Aircraft energy management system including engine fan discharge air boosted environmental control system

ActiveUS9254920B2Reduced ram air drag lossesReduce weightAir-treatment apparatus arrangementsEnergy efficient board measuresRam-air intakeControl system

An aircraft energy management system including a cabin air compressor adapted to be coupled to a source of fan discharge air at a first pressure during an inflight operating mode and adapted to be coupled to a ram intake air during a ground operating mode. The system further including an environmental control system mechanically coupled to a compressor exit of the cabin air compressor. The aircraft energy management system configured to provide a conditioned fluid flow to an aircraft cabin, cockpit or de-icing system.

Owner:EMBRAER SA

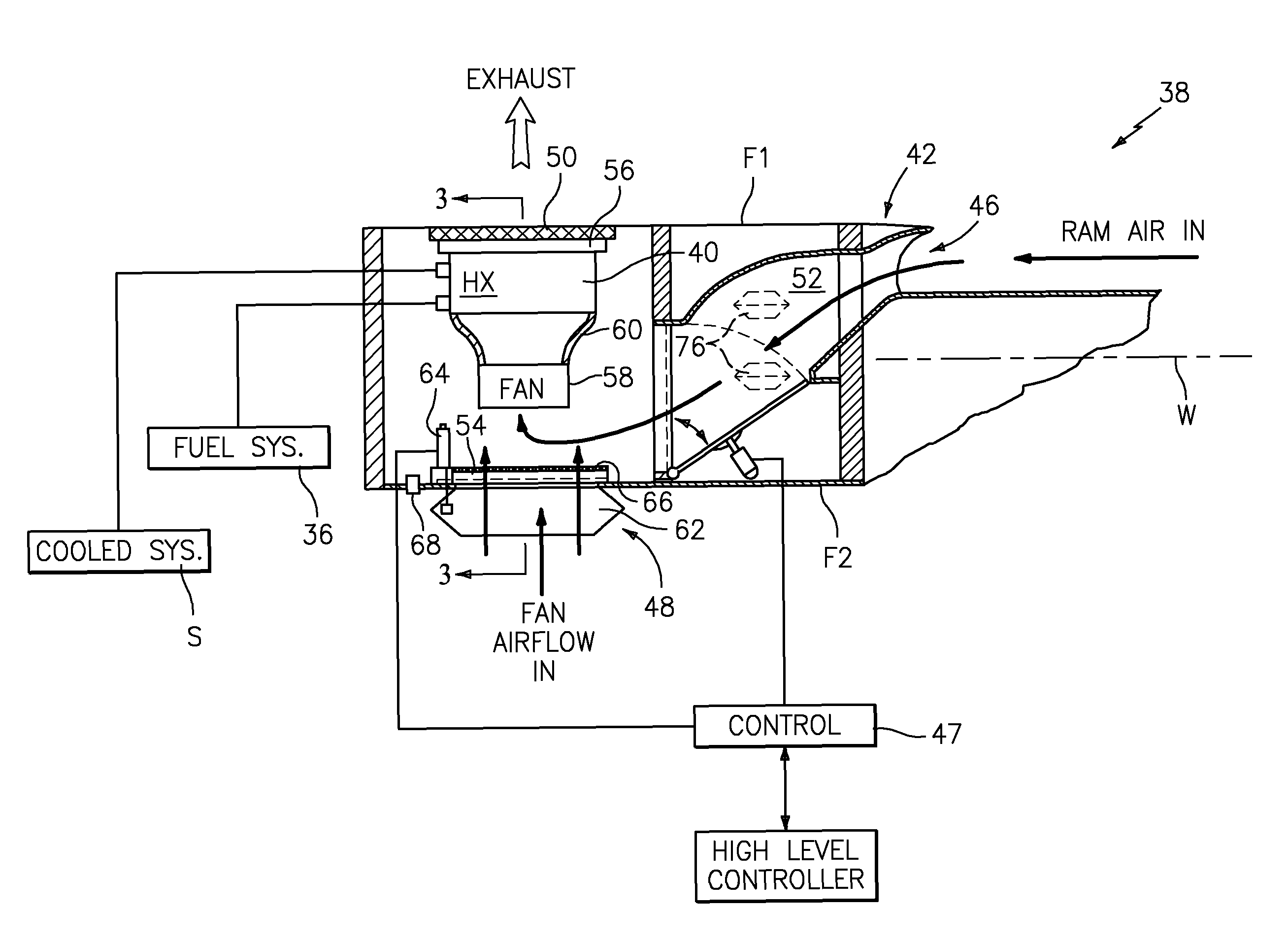

Aircraft thermal management system with reduced exhaust re-ingestion

InactiveUS7857257B2Minimize damageMinimize re-ingestion of heated exhaust airflowGas turbine plantsJet propulsion plantsRam-air intakeThermal management system

Owner:RTX CORP

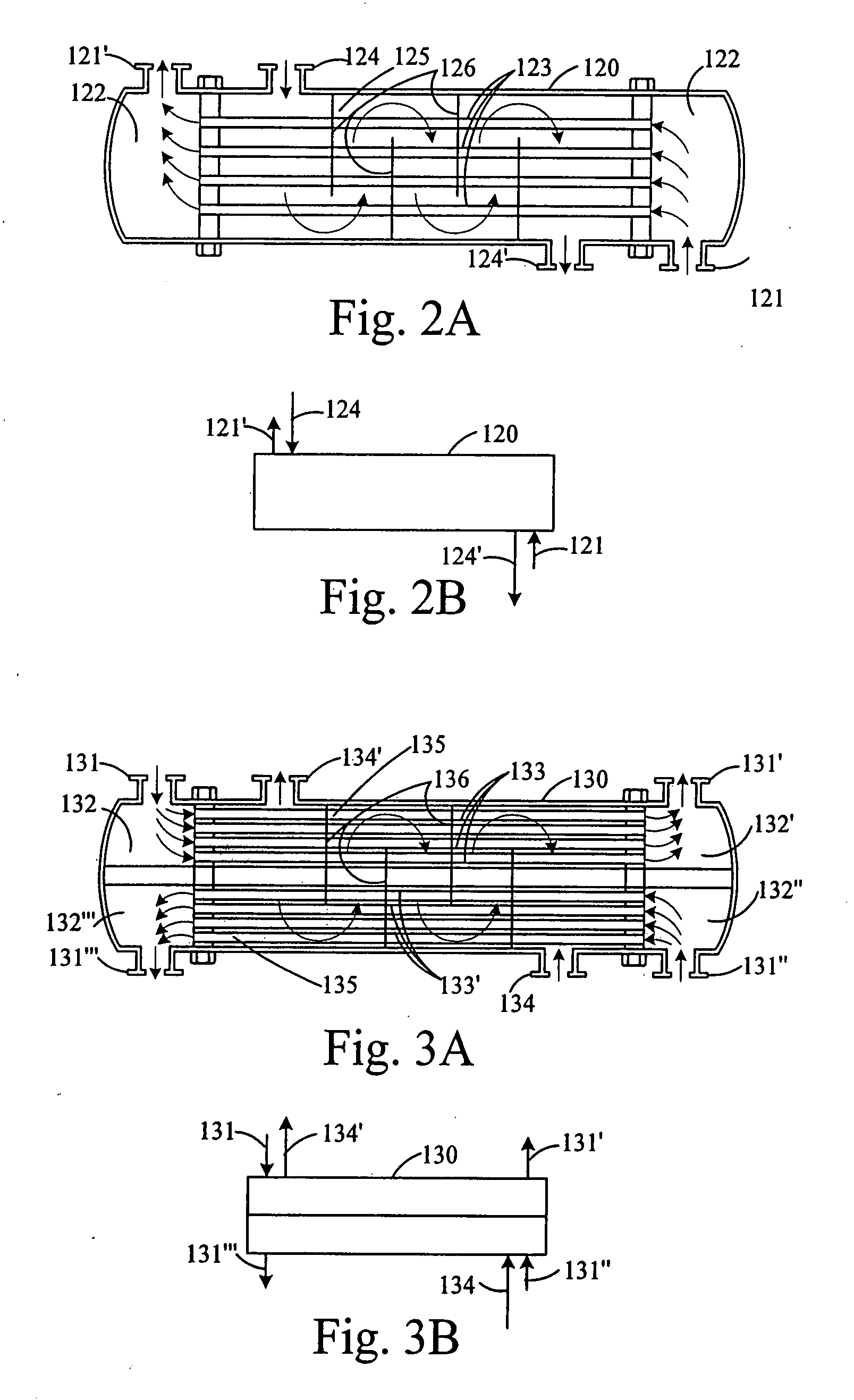

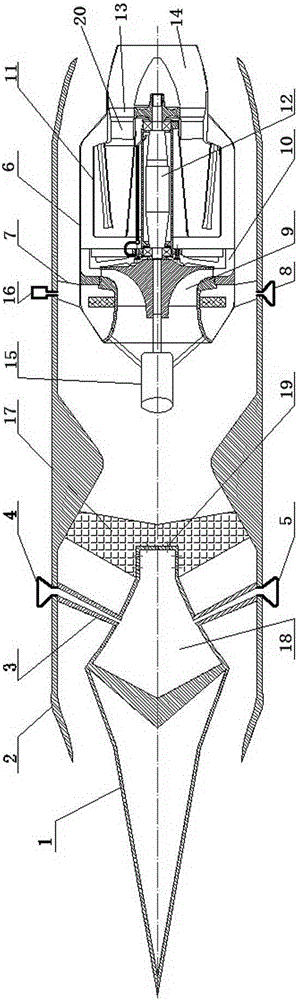

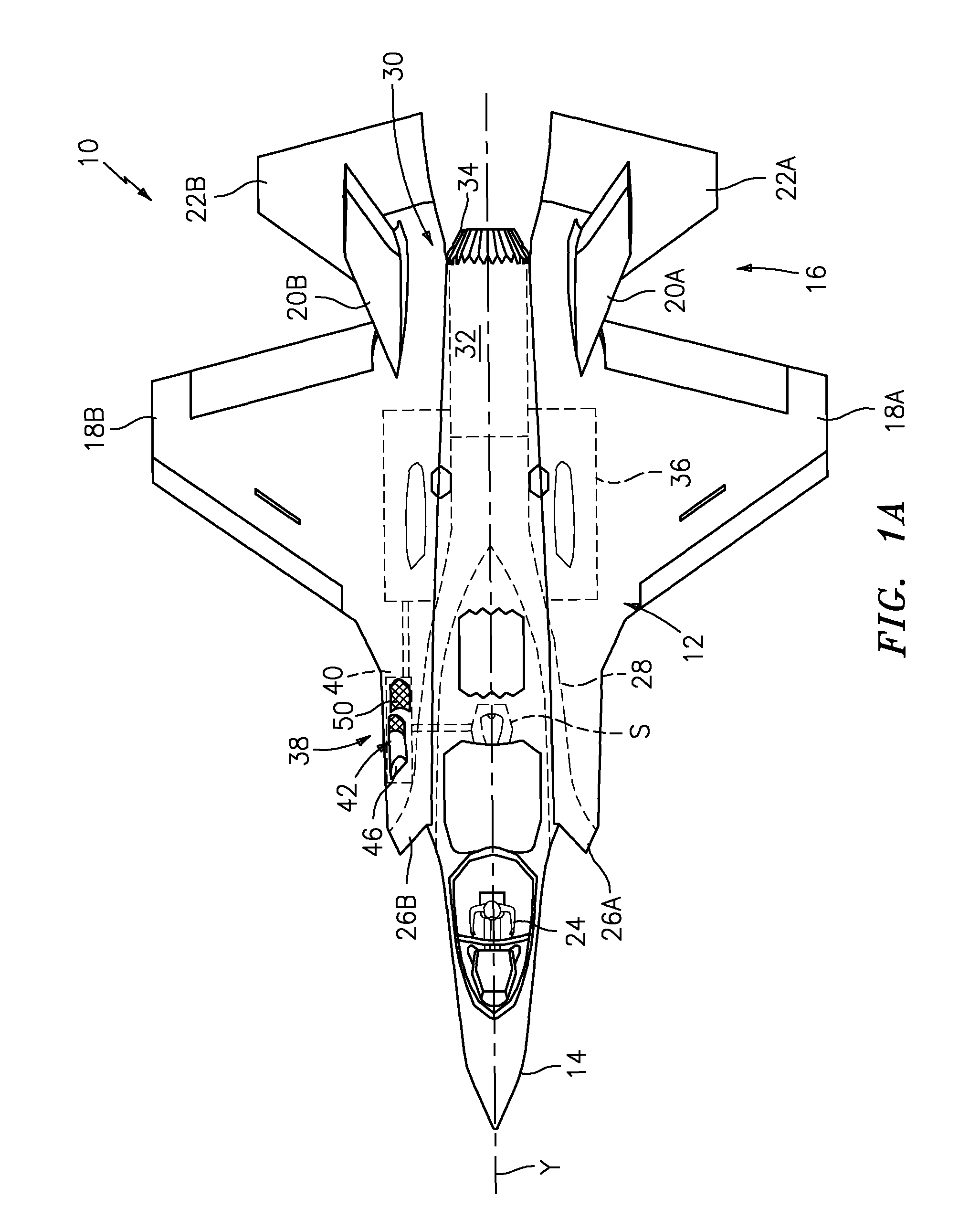

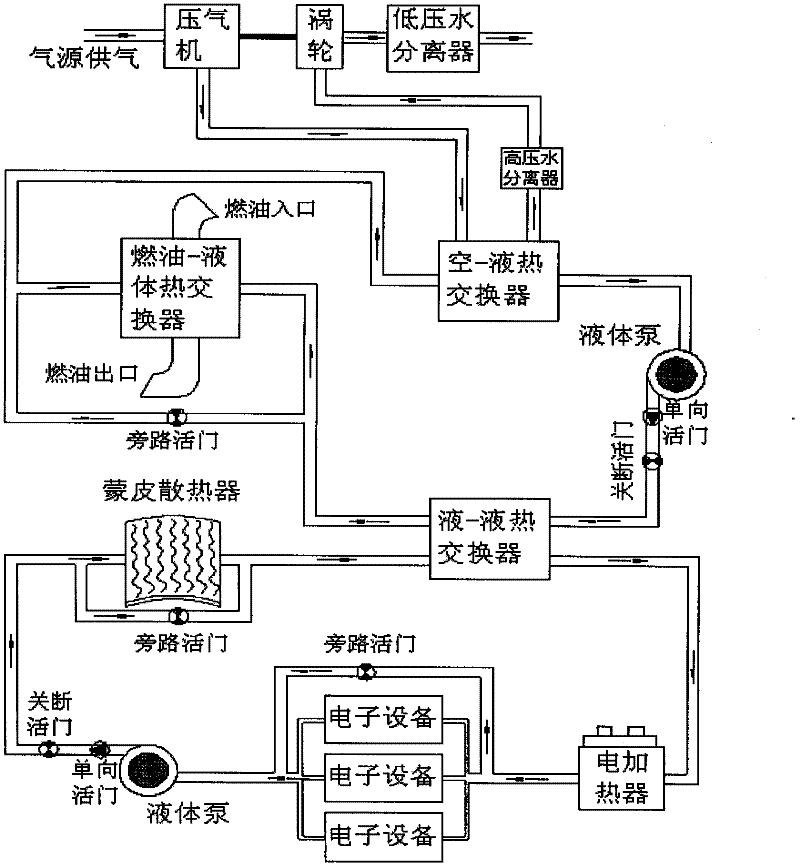

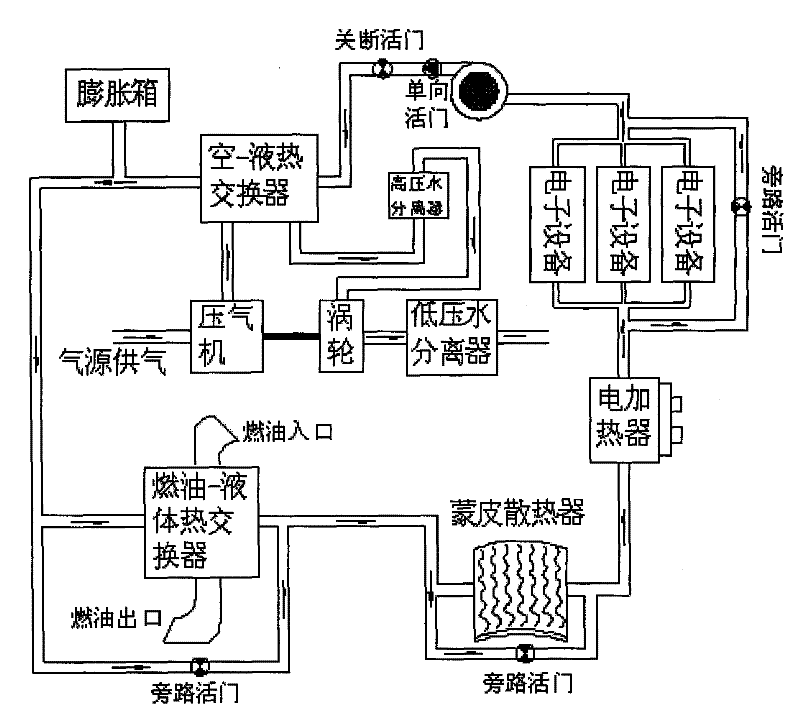

Comprehensive environmental control/liquid cold and heat energy management system for non-stamping air inlet duct

ActiveCN102381479AReduce compensatory lossesImprove water removal efficiencyAir-treatment apparatus arrangementsEnergy efficient board measuresFuel oilEngineering

The invention relates to a comprehensive environmental control / liquid cold and heat energy management system for a non-stamping air inlet duct, belonging to the field of aircraft-mounted equipment and in particular relating to an improved comprehensive environmental control / liquid cold and heat energy management system for the non-stamping air inlet duct. The system is composed of four parts of a two-wheel type high pressure water-removing refrigerating assembly, a liquid cooling system 1, a liquid cooling system 2 and a fuel oil system, wherein the high pressure water-removing refrigerating assembly and the liquid cooling system 1 are coupled through an air-liquid heat exchanger; and the air-liquid heat exchanger is located at the downstream of an air compressor outlet in the two-wheel type high pressure water-removing refrigerating assembly and is located between a fuel oil-liquid heat exchanger and a liquid pump in the liquid cooling system. The system reduces the compensation loss of the refrigerating system property, improves the water-removing and refrigerating efficiency of the refrigerating assembly, effectively reduces the influence on the flight performance of an aircraft, enhances the fuel oil efficiency of the aircraft and has good aircraft economy.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

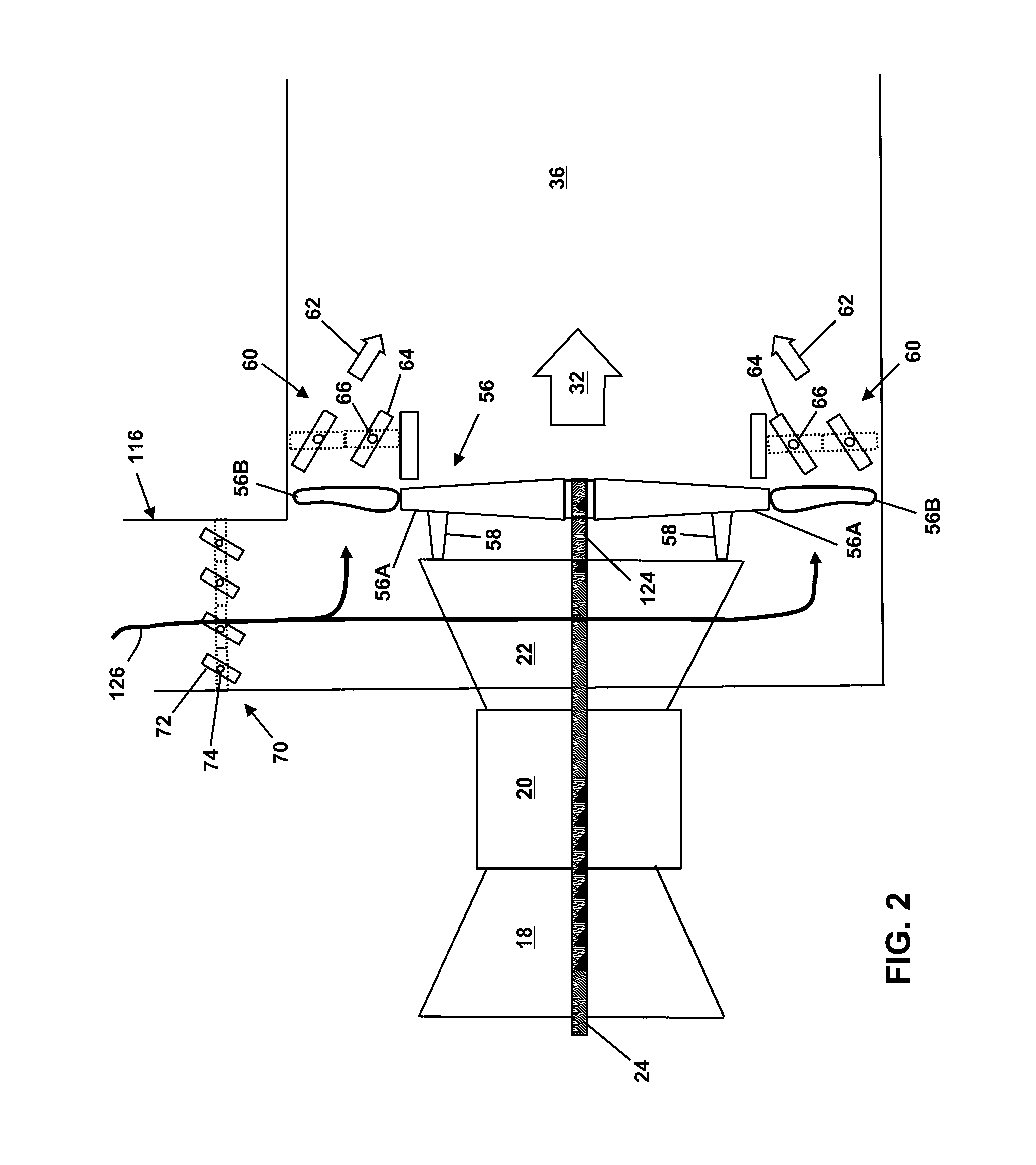

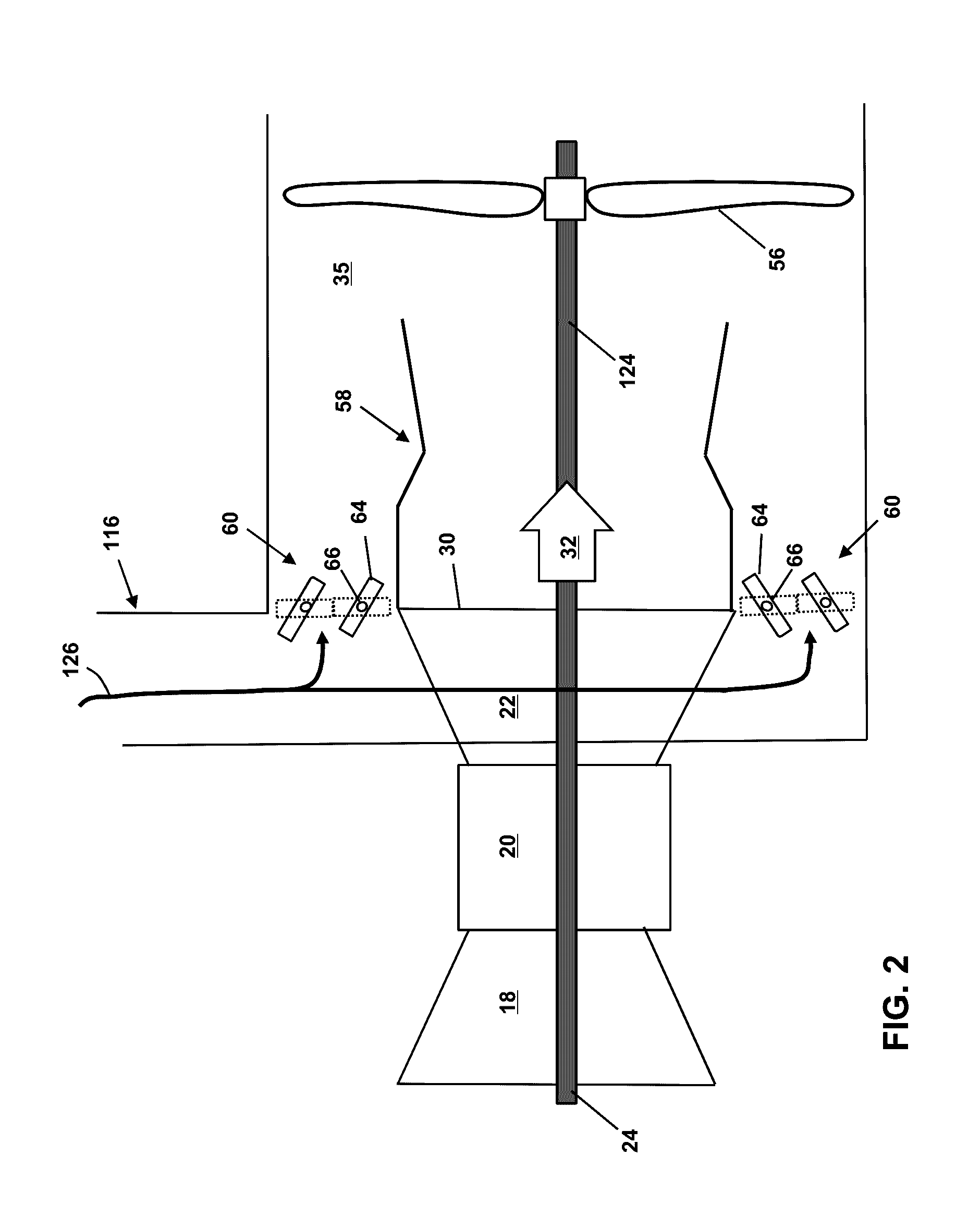

Power generation system exhaust cooling

ActiveUS20160376961A1Internal combustion piston enginesExhaust apparatusRam-air intakeControl system

An airflow control system for a gas turbine system according to an embodiment includes: an airflow generation system for attachment to a rotatable expander shaft of a gas turbine system, downstream of the gas turbine system, for drawing in a flow of ambient air through an air intake section into a mixing area; and an eductor nozzle for attachment to a downstream end of the turbine component for receiving an exhaust gas stream produced by the gas turbine system and for drawing in a flow of ambient air through the air intake section into the mixing area, the exhaust gas stream passing through the eductor nozzle into the mixing area; wherein, in the mixing area, the exhaust gas stream mixes with the flow of ambient air drawn in by the airflow generation system and the flow of ambient air drawn in by the eductor nozzle to reduce a temperature of the exhaust gas stream.

Owner:GENERAL ELECTRIC CO

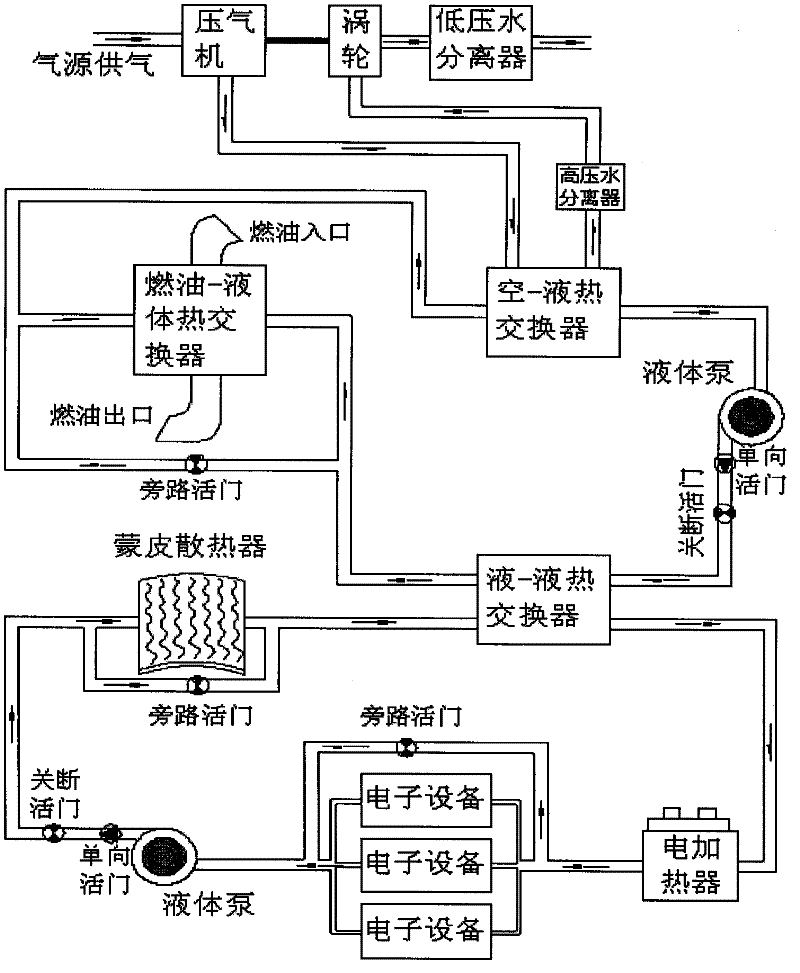

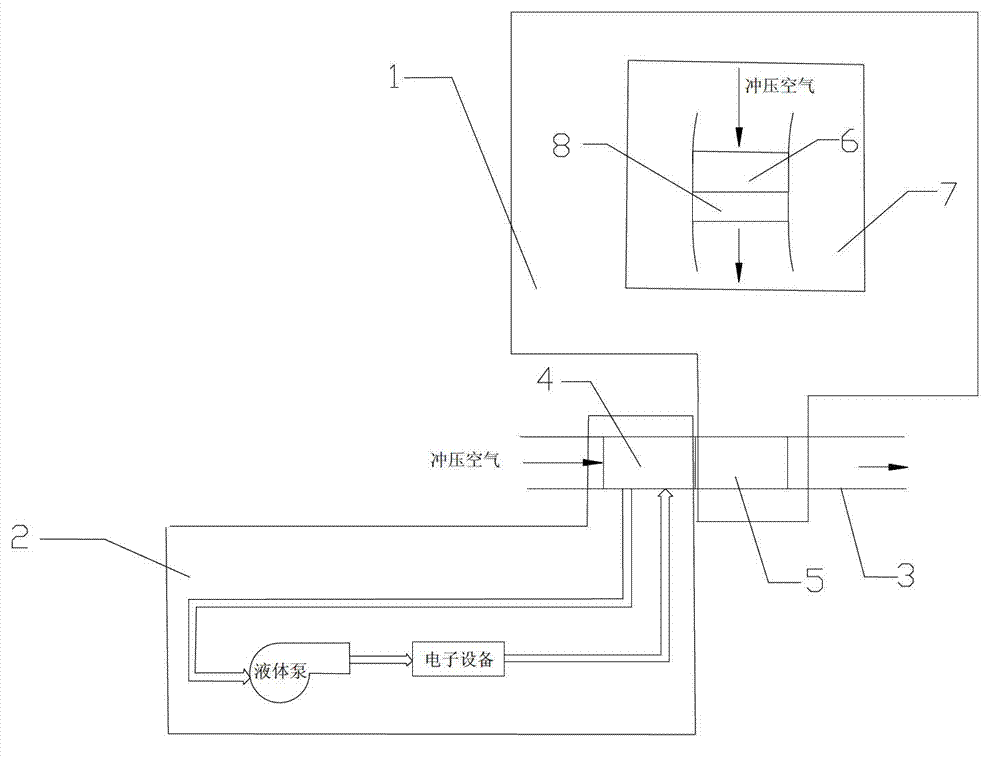

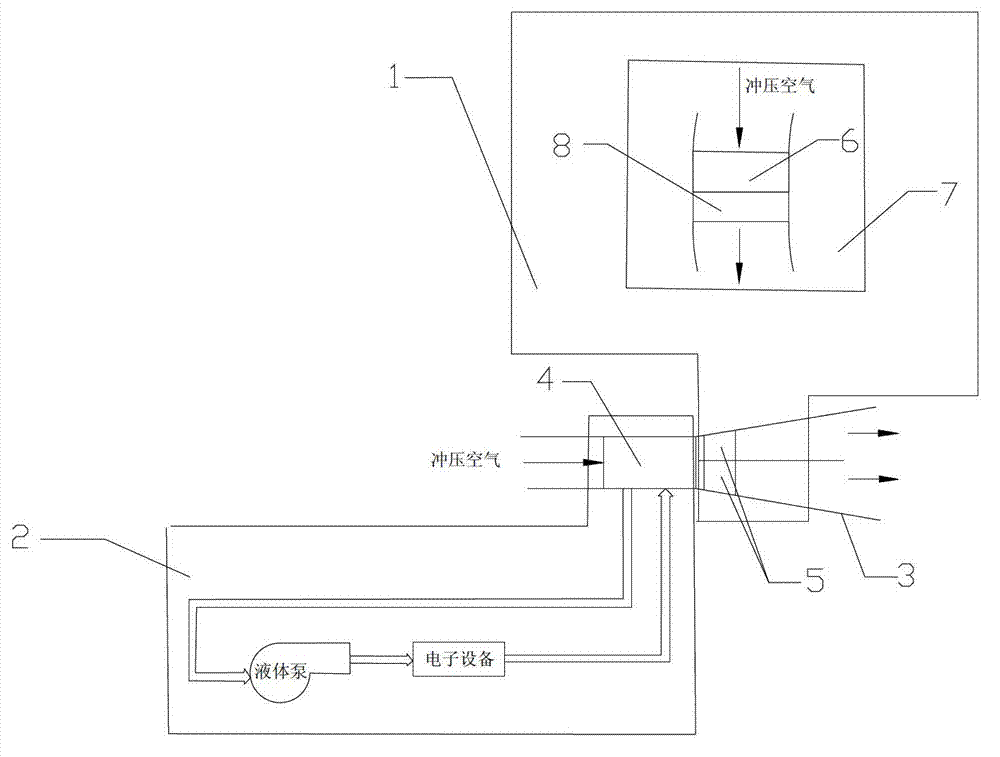

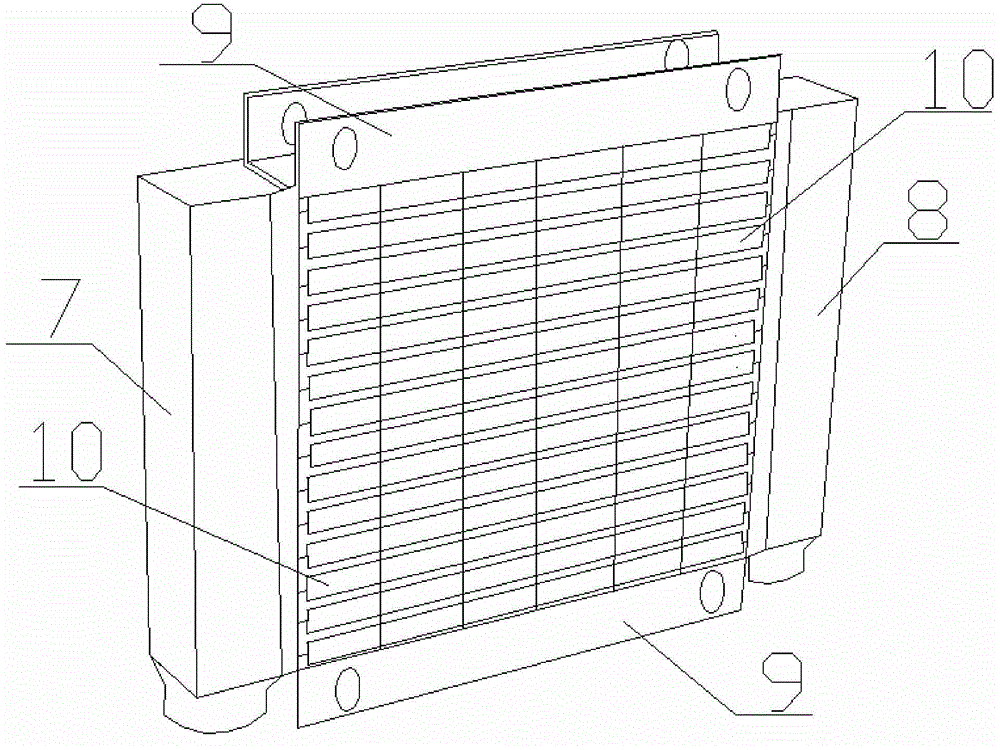

Structure and application method of punching air inlet channel shared by liquid cooling system and environmental control system of airplane

InactiveCN102756807AReduce total ram airReduce fuel compensation lossAir-treatment apparatus arrangementsJet aeroplaneNacelle

The invention relates to the field of airplane environment control, and is particularly applicable to comprehensive integrated design of a liquid cooling system and an environmental control system of an airplane. A structure of a punching air inlet channel shared by the liquid cooling system and the environmental control system of the airplane is formed by a liquid cooling system 1, an environmental control system 2 and a punching air inlet channel 3, wherein an air-liquid heat exchanger 4 of the liquid cooling system 1 is mounted at the front part of a secondary heat exchanger 5 of the environmental control system 2; a primary heat exchanger 6 of the environmental control system 2 is mounted in an engine nacelle 7 and in front of a pre-cooler 8; and the punching air inlet channel 3 is shared by the air-liquid heat exchanger 4 of the liquid cooling system 1 and the secondary heat exchanger 5 of the environmental control system 2. According to the structure disclosed by the invention, the total amount of punching air needed by the liquid cooling system and the environmental control system can be greatly reduced, so that the compensatory loss of fuel oil of the airplane is reduced, and endurance time is prolonged.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Invisible air intake system

InactiveCN102923309AImprove stealth performanceReduce intake air lossPower plant air intake arrangementsRam-air intakeExhaust valve

The invention relates to an air intake system which is used in an aircraft, and particularly relates to an invisible air intake system. A total main air intake channel of the invisible air intake system is designed into a bent S-like shape; an air intake bypass, an air accumulation cabin, an air path and an exhaust bypass are connected in sequence so as to form into an auxiliary air flow path; an air intake controller is installed on the air accumulation cabin; an exhaust valve is positioned at an outlet of the exhaust valve at the rear part of the auxiliary air flow path; when the air intake controller is at the opened state, the exhaust valve is at the closed state; and when the air intake controller is at the closed state, the exhaust valve is at the opened state. With the adoption of the air intake system, the influence of a boundary layer generated by a wing / body to an engine, and the requirements of the engine on the quantity and the quality of the air intake at different velocities / different engine states are met; and meanwhile, with the adoption of the air intake system, openings in the surface of the wing / body can be reduced with good invisibility performance.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

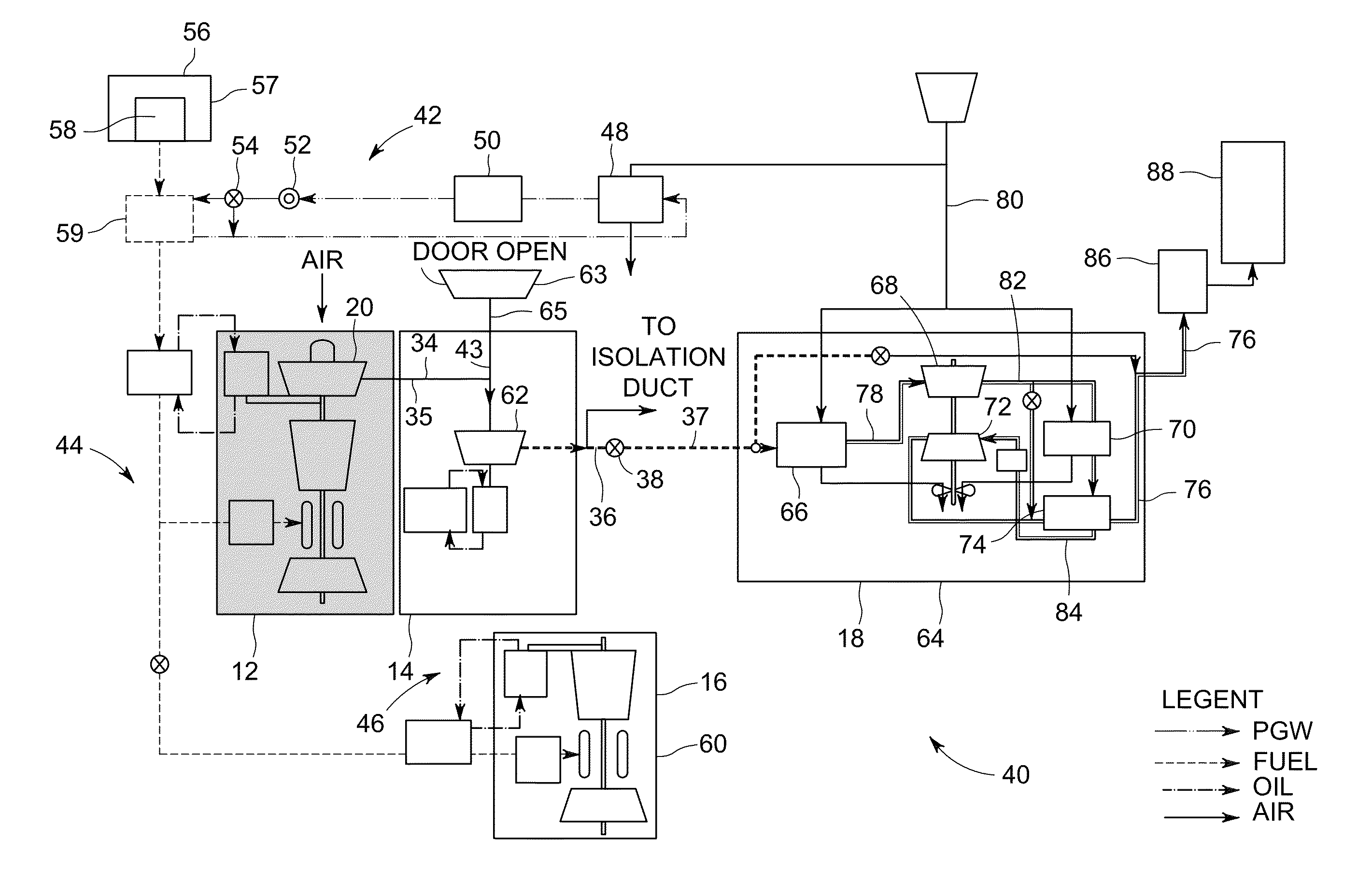

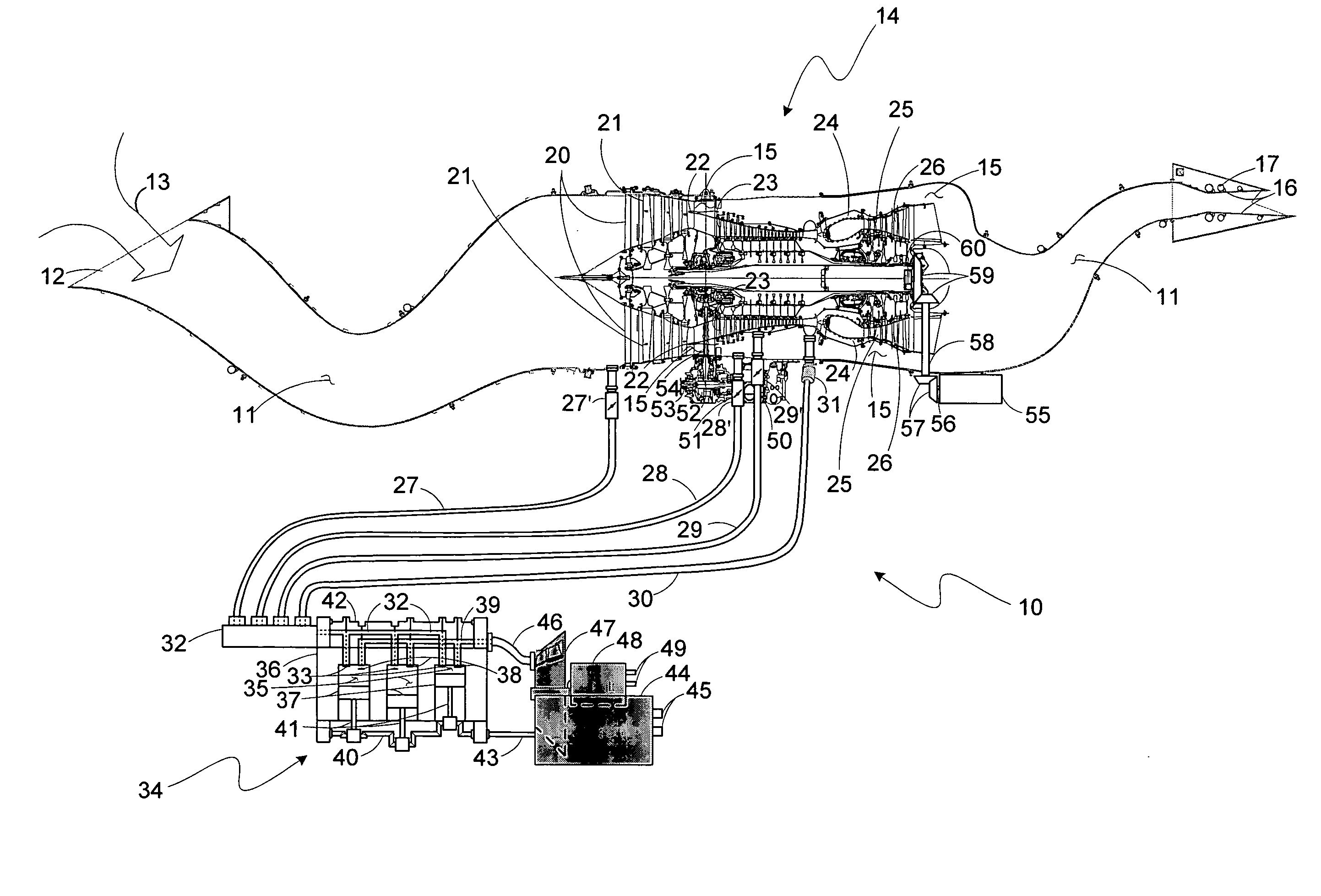

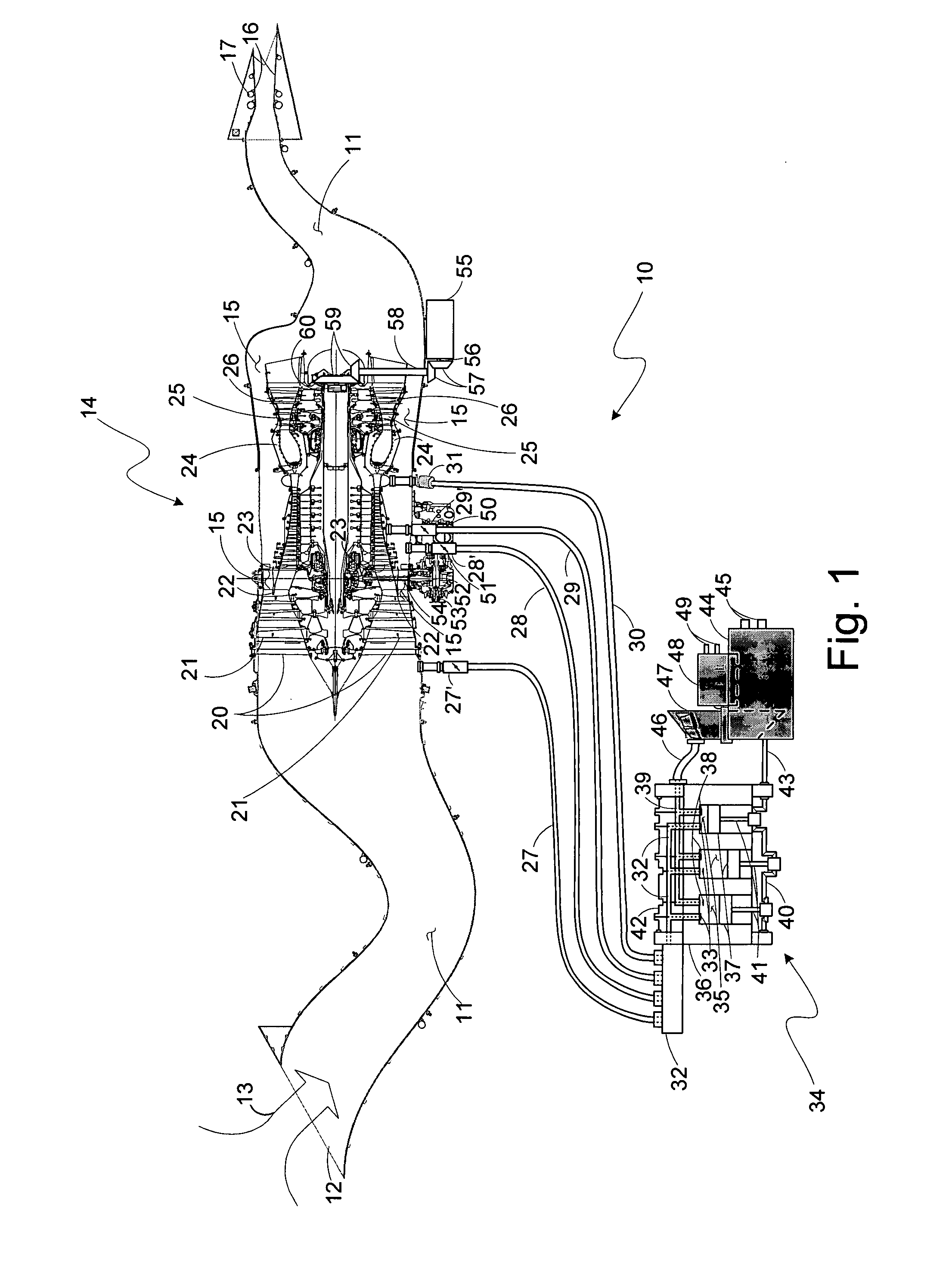

Aircraft combination engines plural airflow conveyances system

InactiveUS20100013242A1Reciprocating combination enginesCombination enginesRam-air intakeExternal combustion engine

An engine combination for generating forces with a gas turbine engine generating force, and an internal combustion engine provided in the combination as an intermittent combustion engine generating force having an air intake, there being a plurality of air transfer ducts each extending from a different location in the gas turbine engine so as to be capable to provide air in each of those air transfer ducts at one end thereof at pressures differing from one another and connected at the other end of each to the air intake to transfer air thereto.

Owner:UNITED TECH CORP

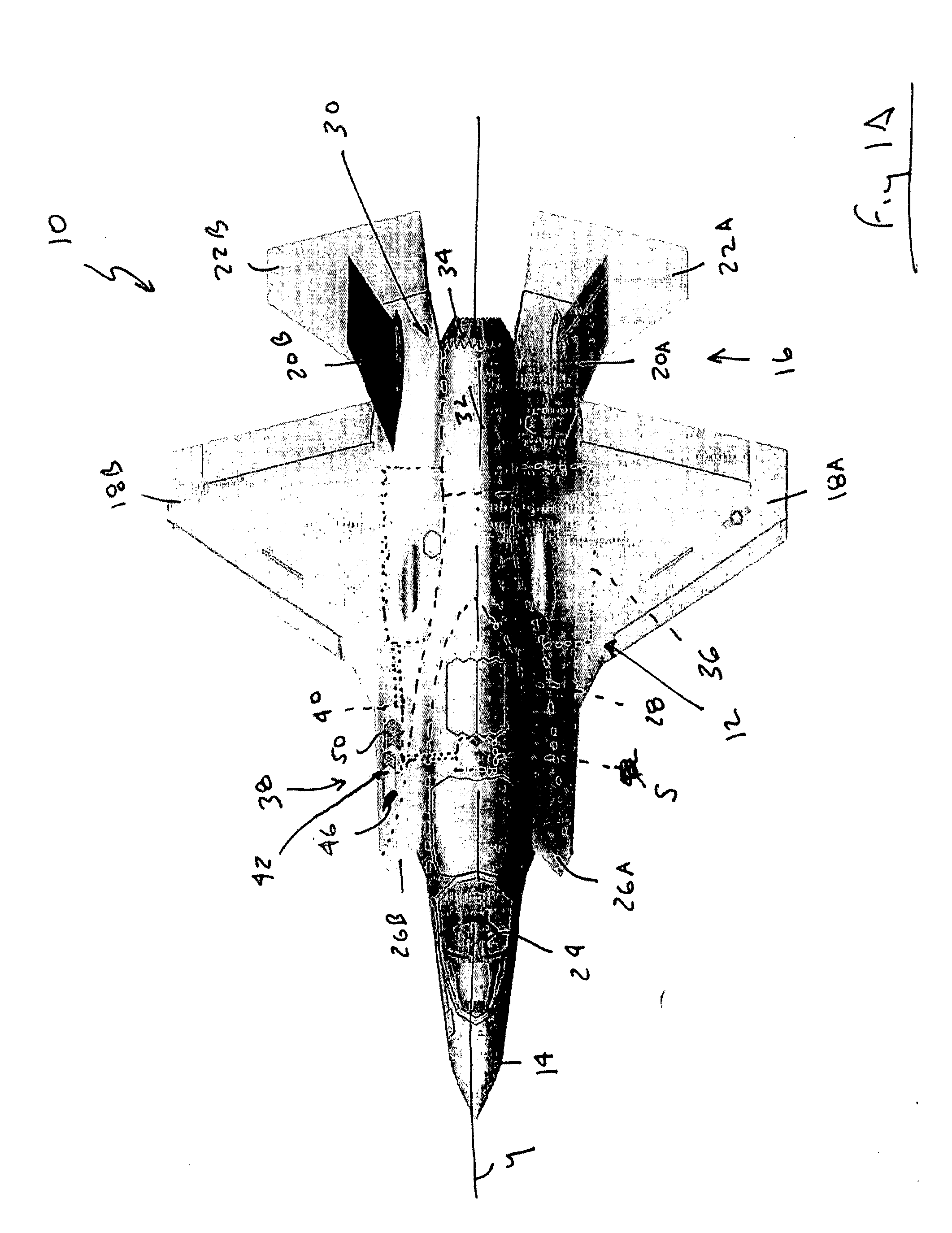

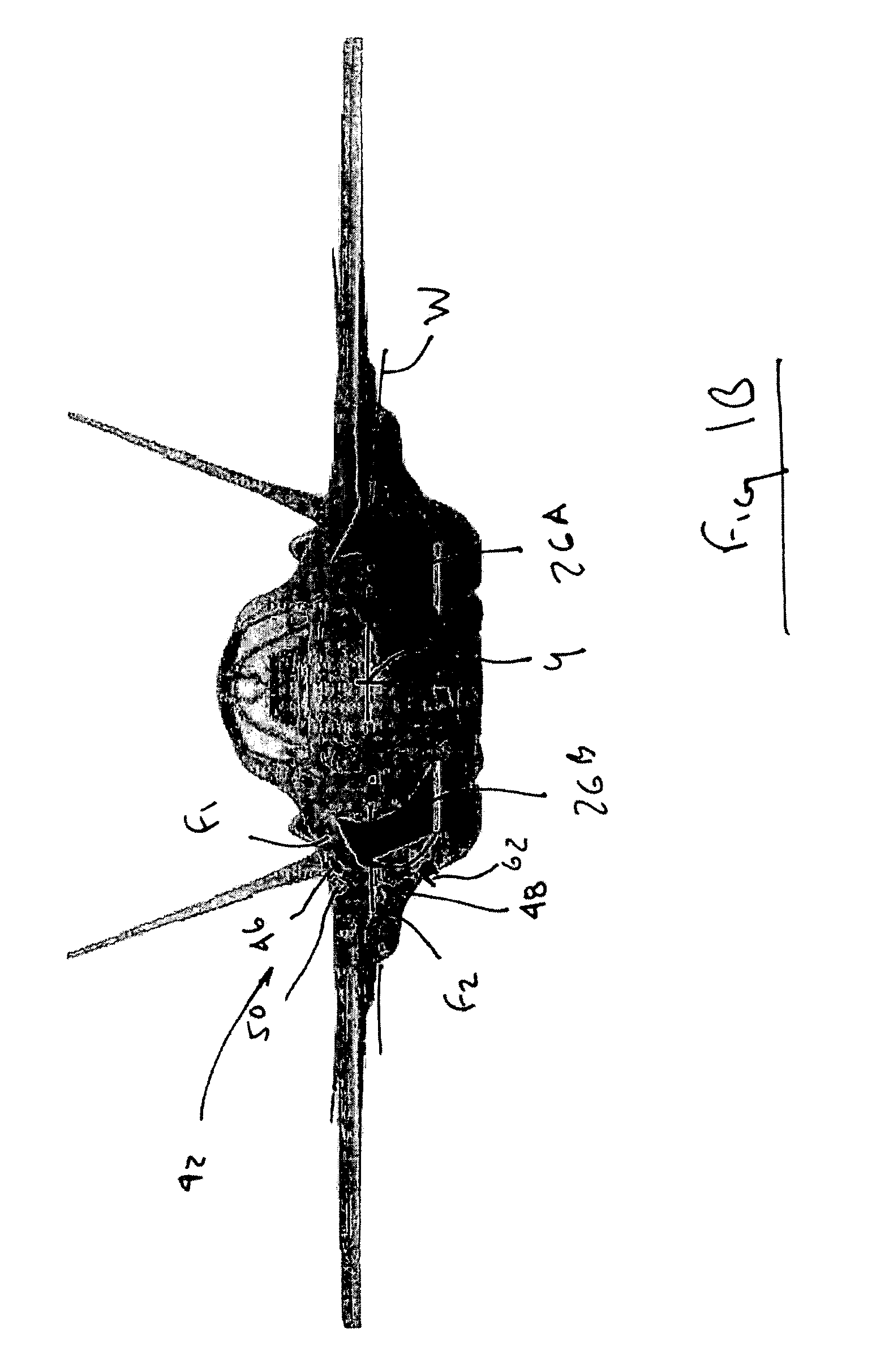

Aircraft thermal management system with reduced exhaust re-ingestion

InactiveUS20080053101A1Minimizes leakageMinimized pressure lossGas turbine plantsJet propulsion plantsRam-air intakeThermal management system

A thermal management system includes a cooling duct system that locates a ram air intake and an exhaust through a first aircraft surface above a second aircraft surface which locates a fan intake. During ground operations, an anti-re-ingestion door is open and a ram air door is closed such that the fan system may draw relatively cooler air from below the aircraft and exhaust the heated air above the aircraft to minimize re-ingestion of the heated exhaust. During flight operations, the anti-re-ingestion door is closed and the ram air door is open such that ram airflow communicates through the fan system prior to communication through the heat exchanger. Both the anti-re-ingestion door and the ram air door may also be operated in flight.

Owner:RAYTHEON TECH CORP

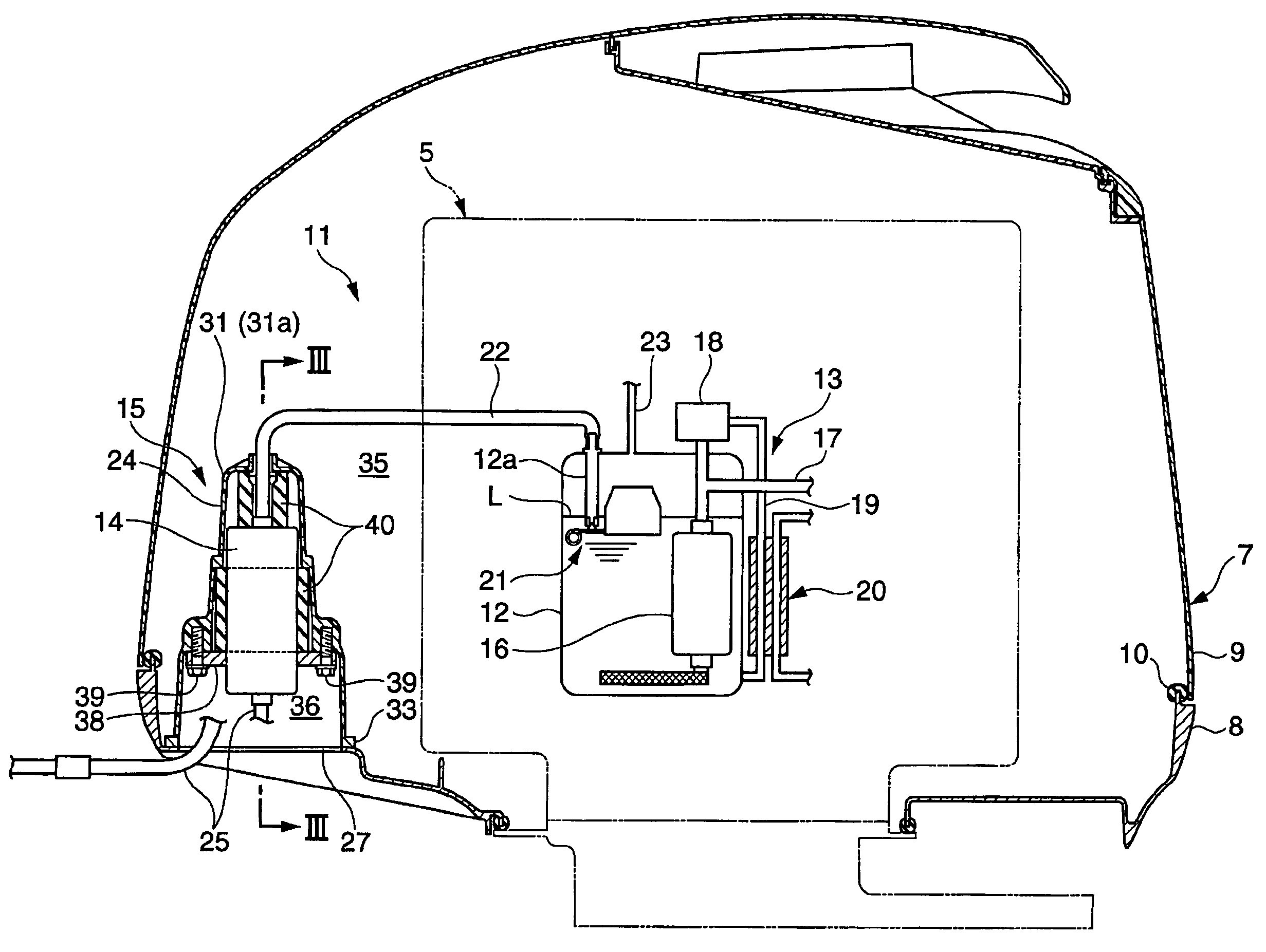

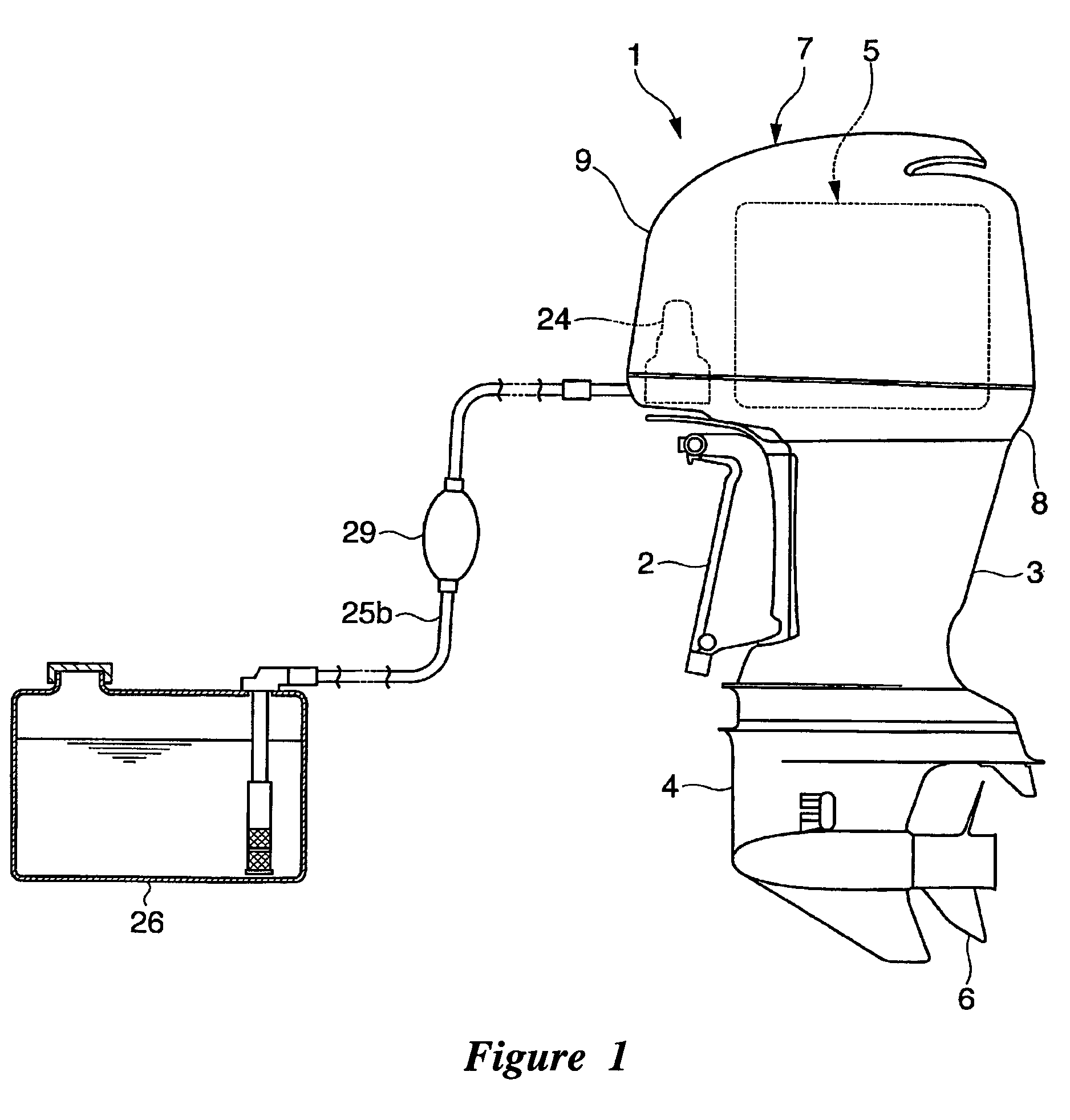

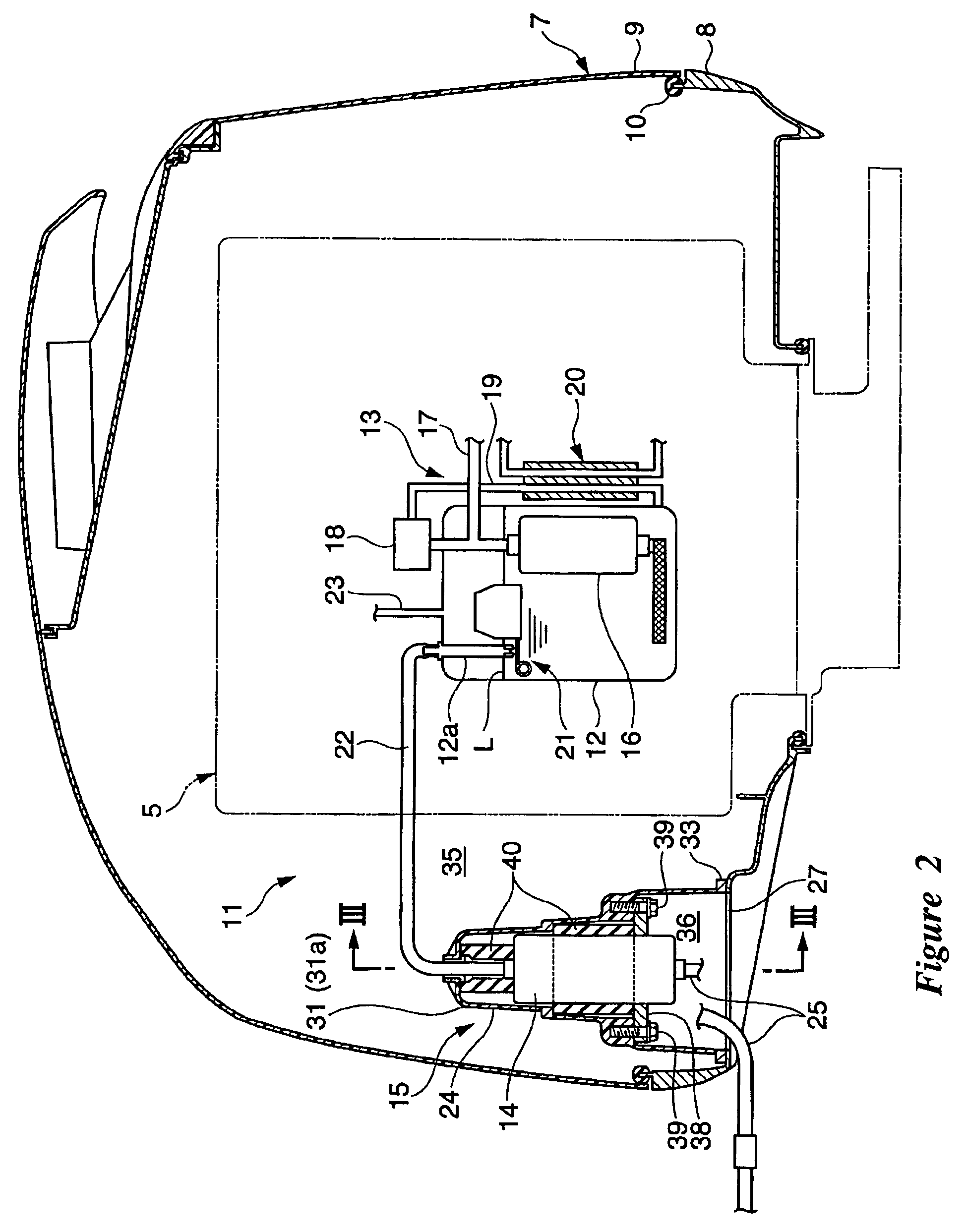

Outboard motor with forward air intake and air-cooled fuel pump

ActiveUS7401598B2Avoid problemsA large amountLiquid coolingPropulsion power plantsRam-air intakeFuel filter

An outboard motor can comprise a cowling for covering an engine, a high pressure fuel supply system, and a low pressure fuel supply system. The high pressure fuel supply system can have a vapor separator tank and a high pressure fuel pump. The low pressure fuel supply system can have a low pressure fuel pump. A heat insulating chamber, defined from a space for accommodating the engine, can be formed within the cowling. The heat insulating chamber houses the low pressure fuel pump and the fuel filter.

Owner:YAMAHA MARINE KK

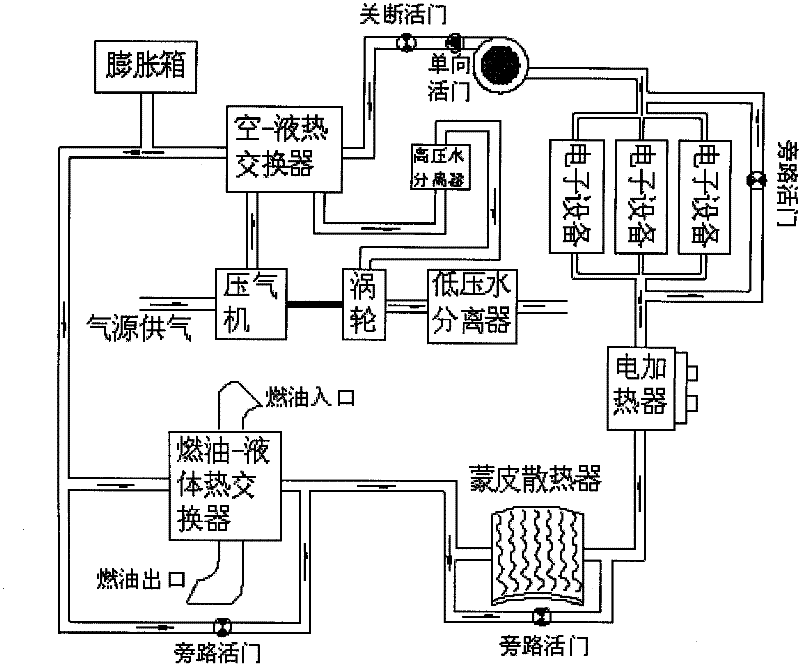

Comprehensive environmental control/liquid cooling heat energy management system without ramjet inlet

InactiveCN102390538AReduce compensatory lossesImprove water removal efficiencyAir-treatment apparatus arrangementsEnergy efficient board measuresRamjetFuel efficiency

The invention discloses a comprehensive environmental control / liquid cooling heat energy management system without a ramjet inlet, belongs to the field of aircraft-carried equipment, and particularly relates to improvement on the comprehensive environmental control / liquid cooling heat energy management system without the ramjet inlet. The system consists of a two-wheel type high-pressure dehydration and refrigeration component, a liquid cooling system and a fuel system, wherein the high-pressure dehydration and refrigeration component is coupled with the liquid cooling system through an air-liquid heat exchanger; the air-liquid heat exchanger is positioned on the downstream of an air compressor outlet in the high-pressure dehydration and refrigeration component and is positioned between a shut-off valve and an expansion box in the liquid cooling system; the liquid cooling system is coupled with the fuel system through a liquid-fuel heat exchanger; and the liquid-fuel heat exchanger is positioned between the expansion box and a skin radiator in the liquid cooling system. Through the system, the performance compensation loss of the refrigeration system is reduced, the dehydration and refrigeration efficiency of the refrigeration component is improved, the influence on the flight performance of an aircraft is effectively reduced, the aircraft fuel efficiency is increased, and the aircraft economy is good.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

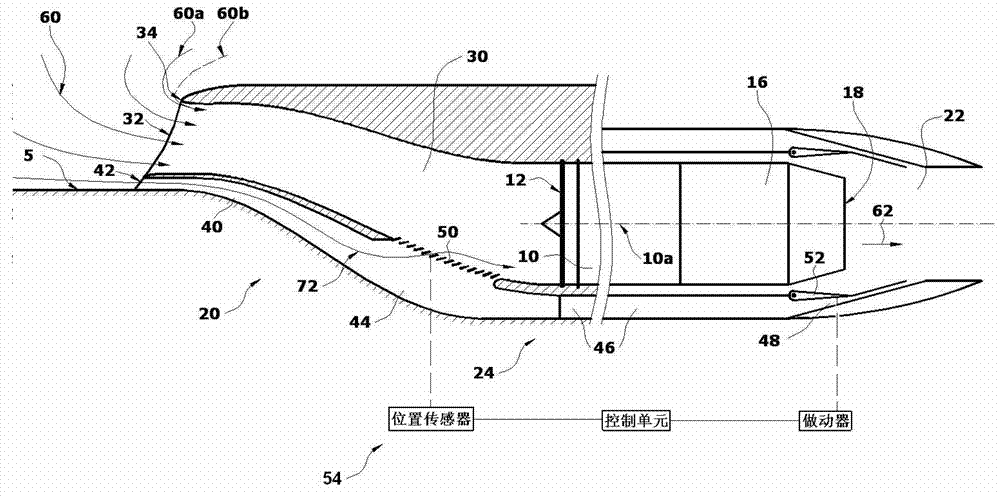

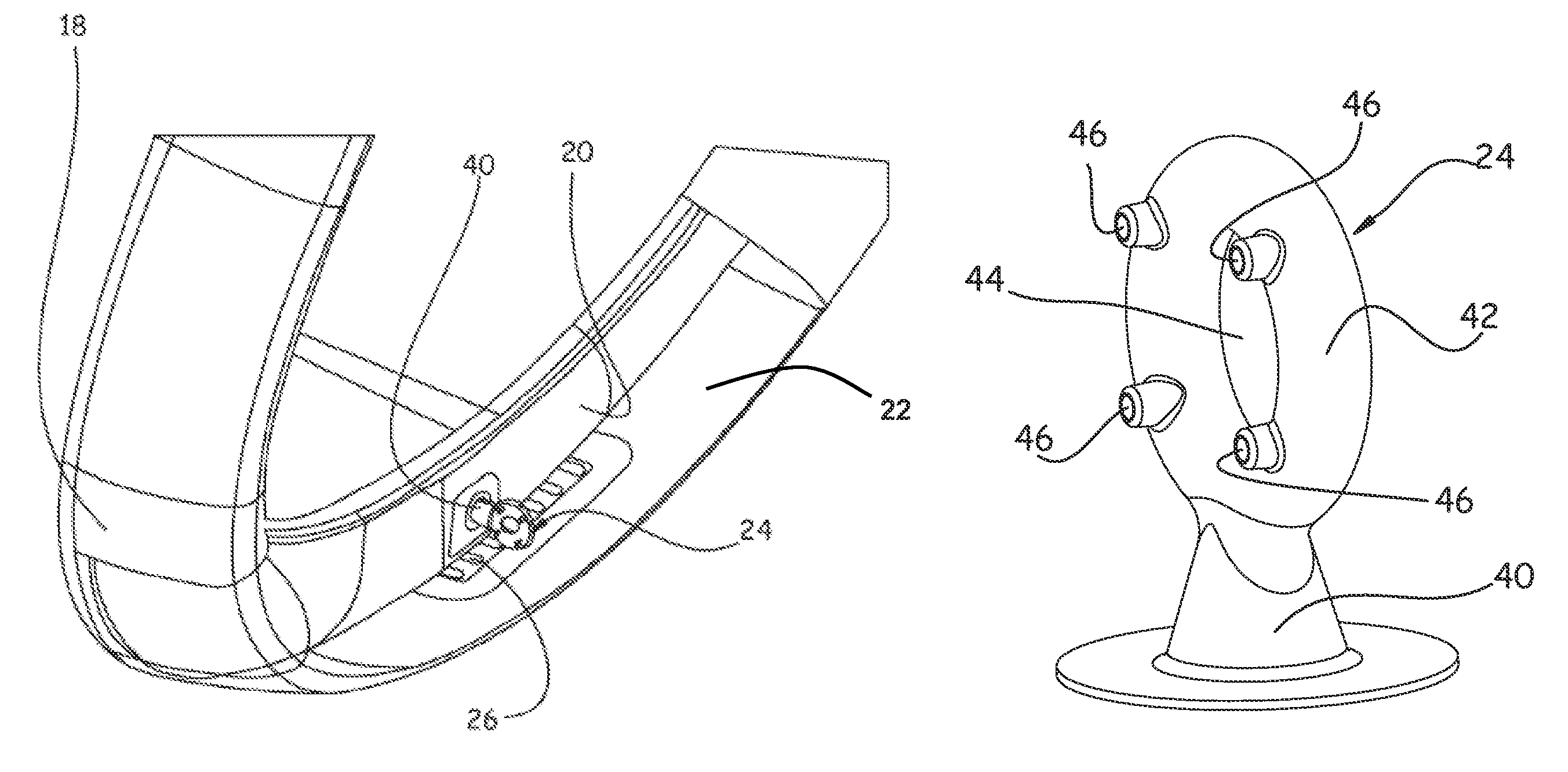

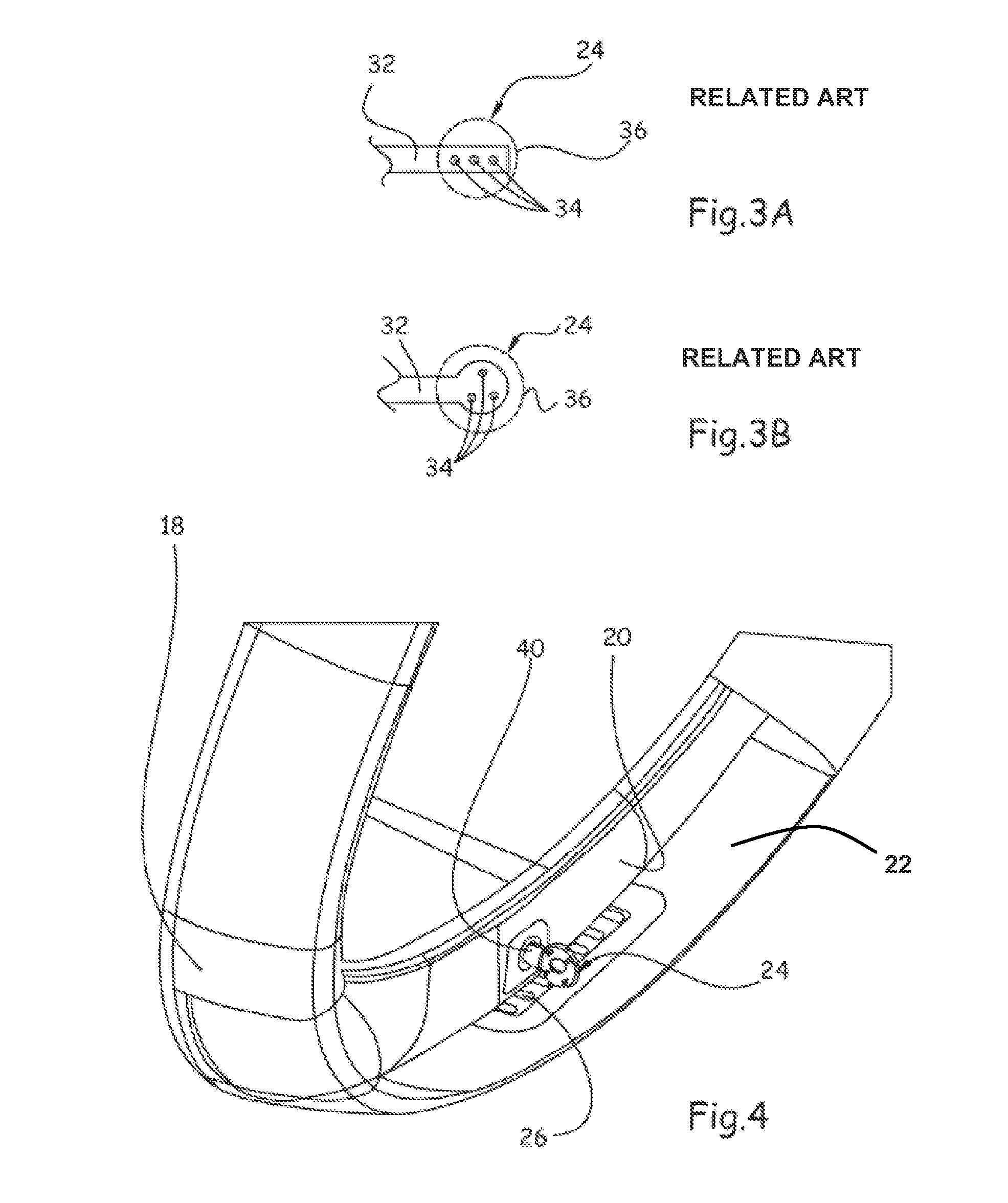

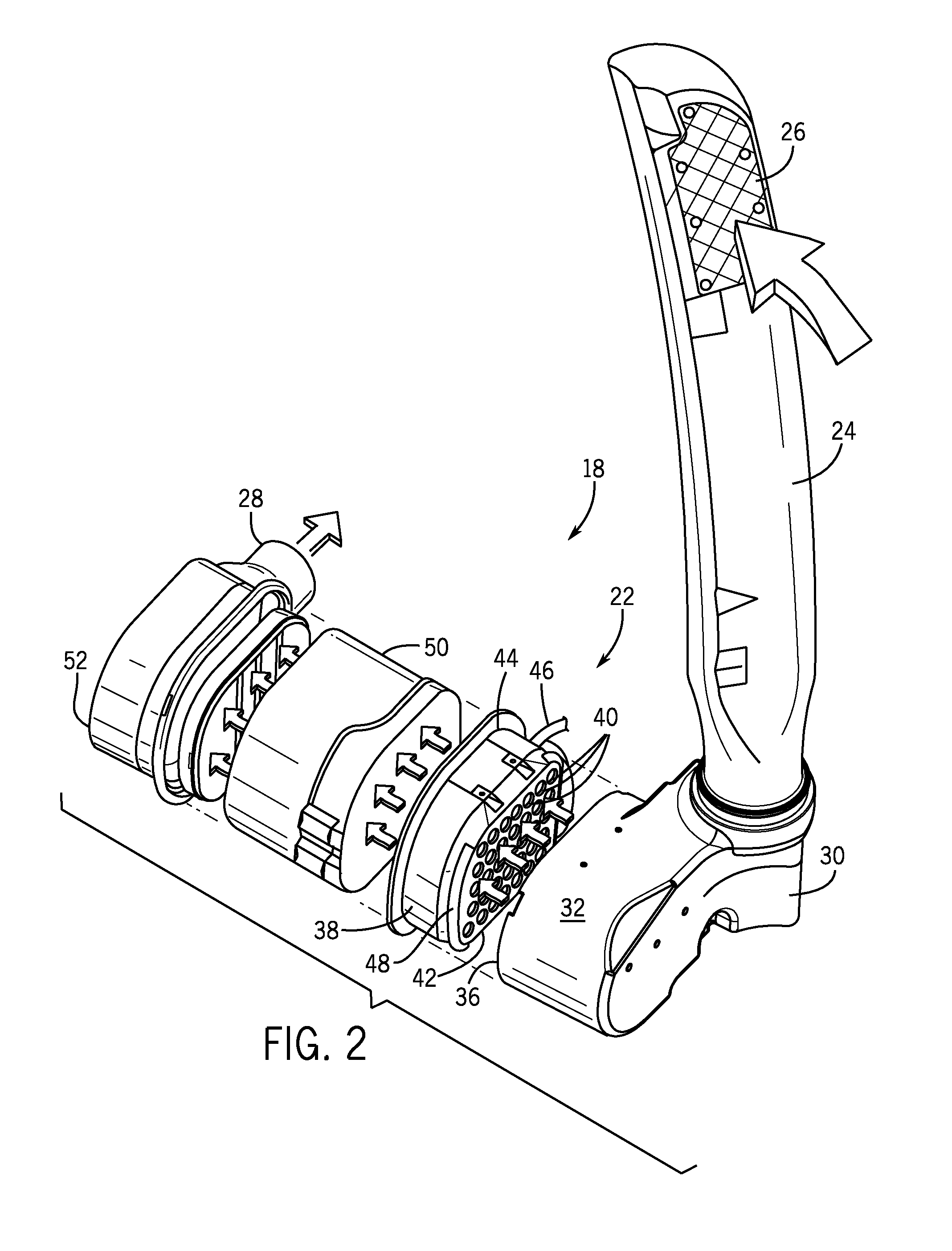

Aircraft nacelle air intake incorporating optimized ice-treatment hot air injection means

An aircraft nacelle air intake includes a duct extending around the circumference of the air intake and elements (24) for the localized injection of hot air into the duct to make the hot air circulate in the duct along its circumference, characterized in that the injection elements (24) include a collector tank in a plane secant with the direction of the stream of air flowing through the duct including at least one hole (44) allowing the air stream flowing in the duct to pass through it and a plurality of injection orifices (46) which are connected to a hot air supply and arranged around the passage hole or around and / or between the passage holes (44).

Owner:AIRBUS OPERATIONS (SAS)

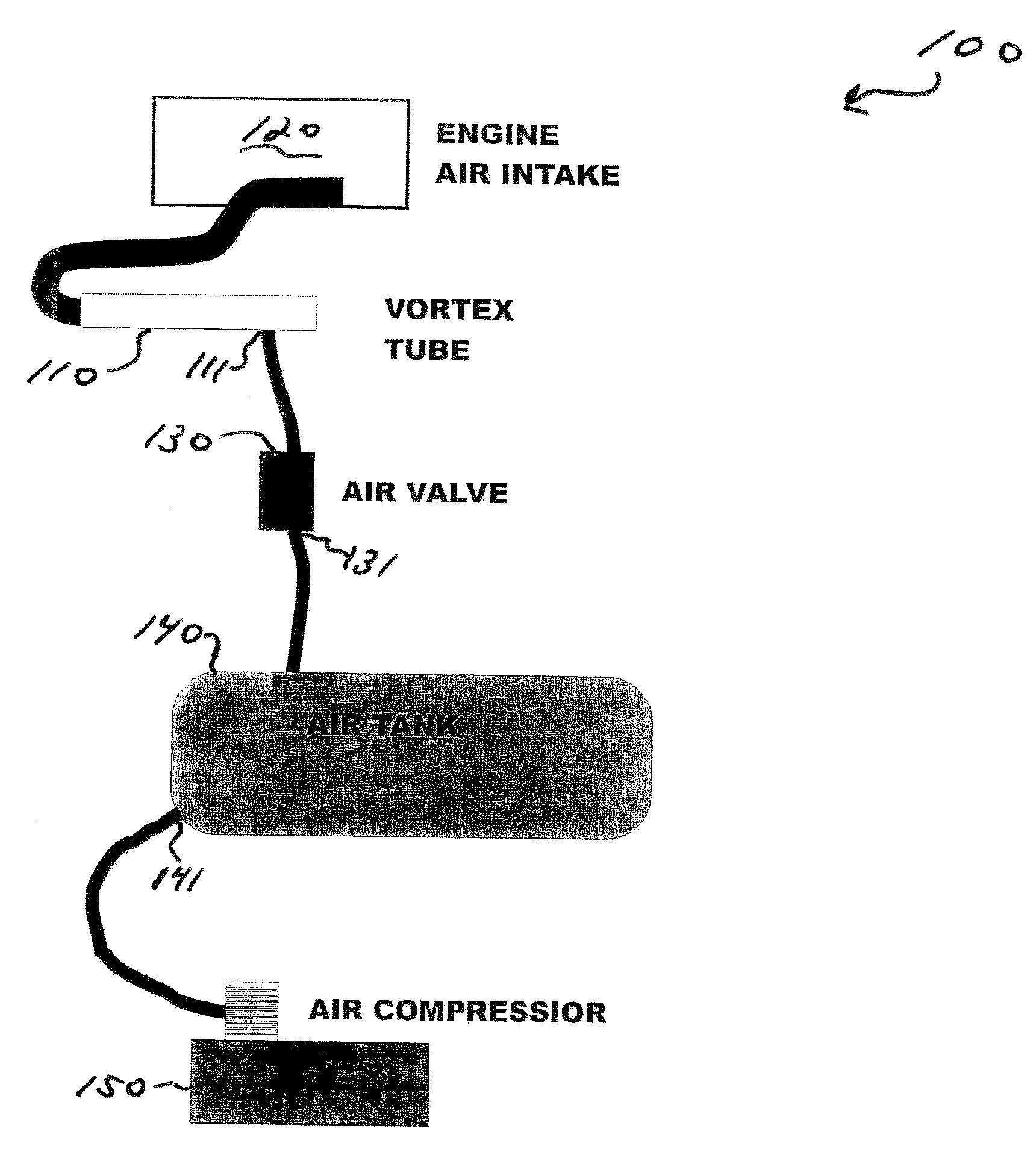

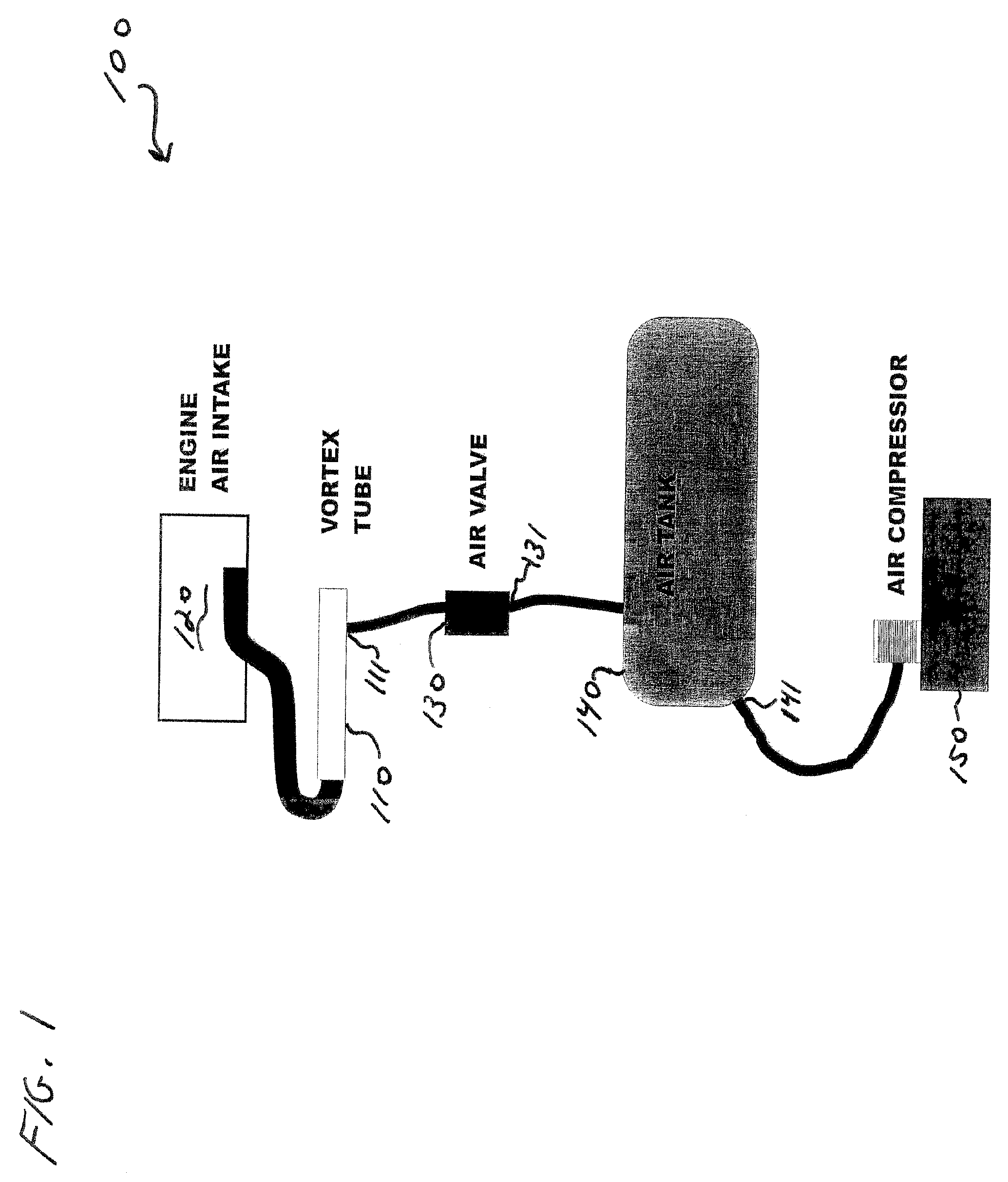

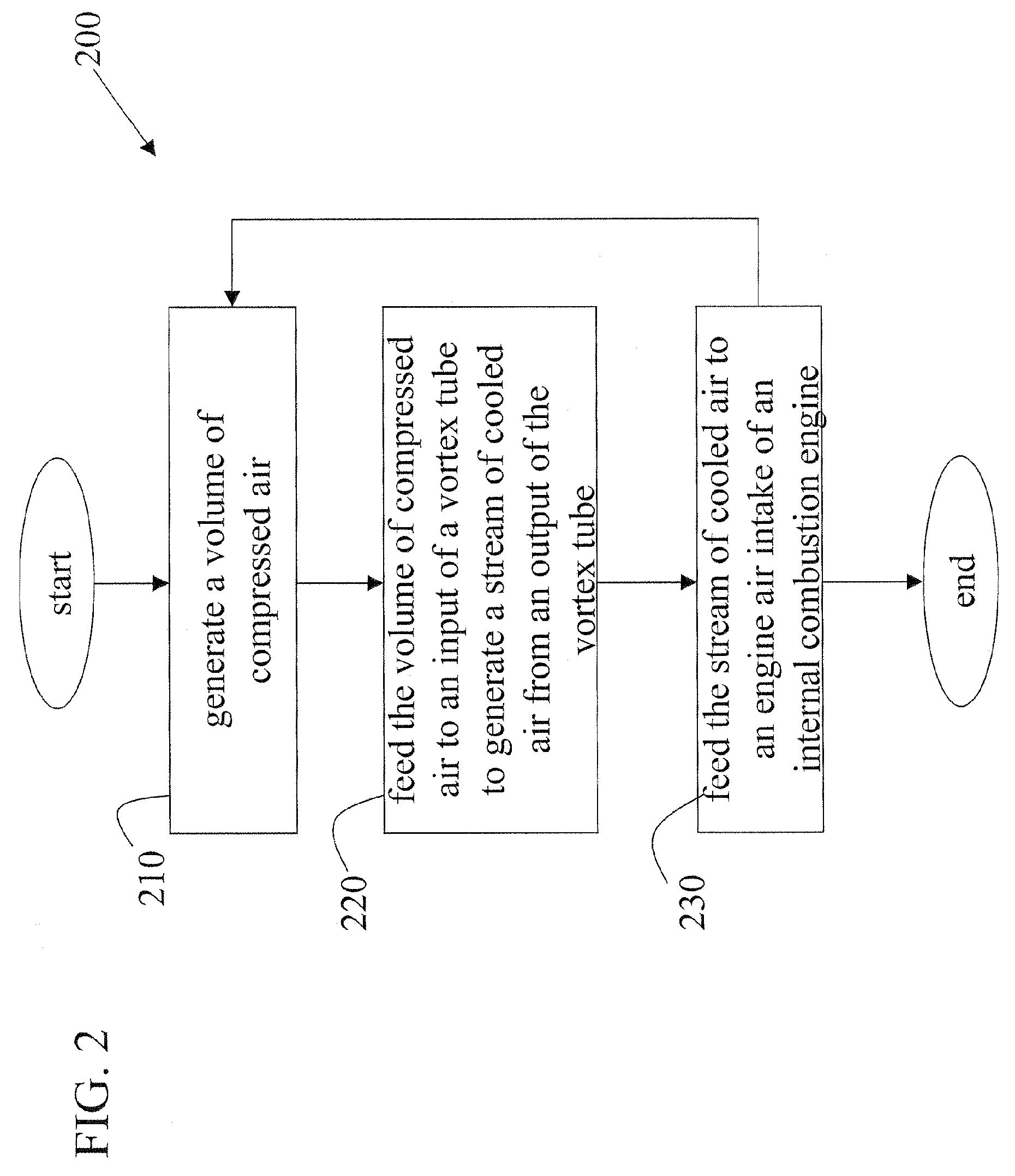

System and method for cooling air intake

InactiveUS7198036B2Internal combustion piston enginesThermal treatment of fuelRam-air intakeEngineering

A system and method for increasing the horsepower and torque provided by an internal combustion engine involve the use of a vortex tube to provide cooled air to the air intake of the engine. The system utilizes a source of compressed air such as provided by a compressor and air tank. The compressed air is injected into the vortex tube producing a heated stream of air and a cooled stream of air. The cooled stream of air is directed into the intake of the engine. The system enhances the air flow and drops the induction air temperature into the engine. An air valve may be used to control the flow of compressed air into the vortex tube.

Owner:THERMO TEC HIGH PERFORMANCE AUTOMOTIVE

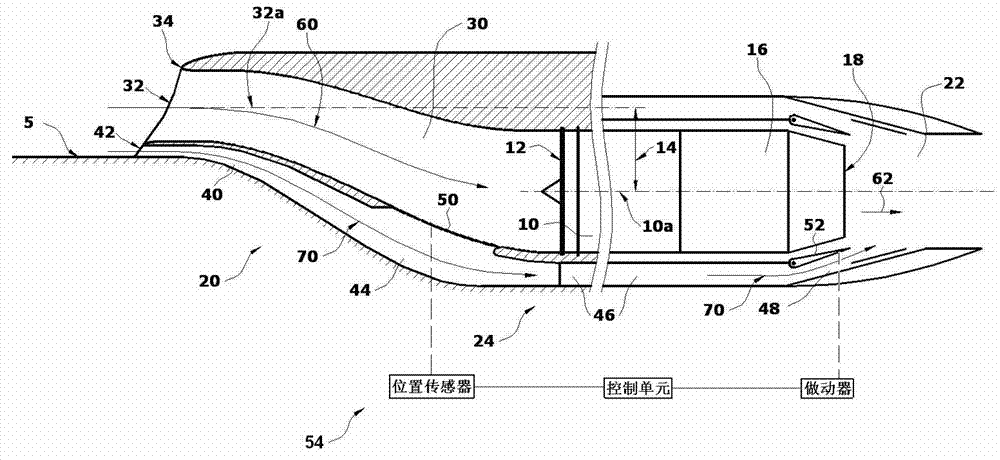

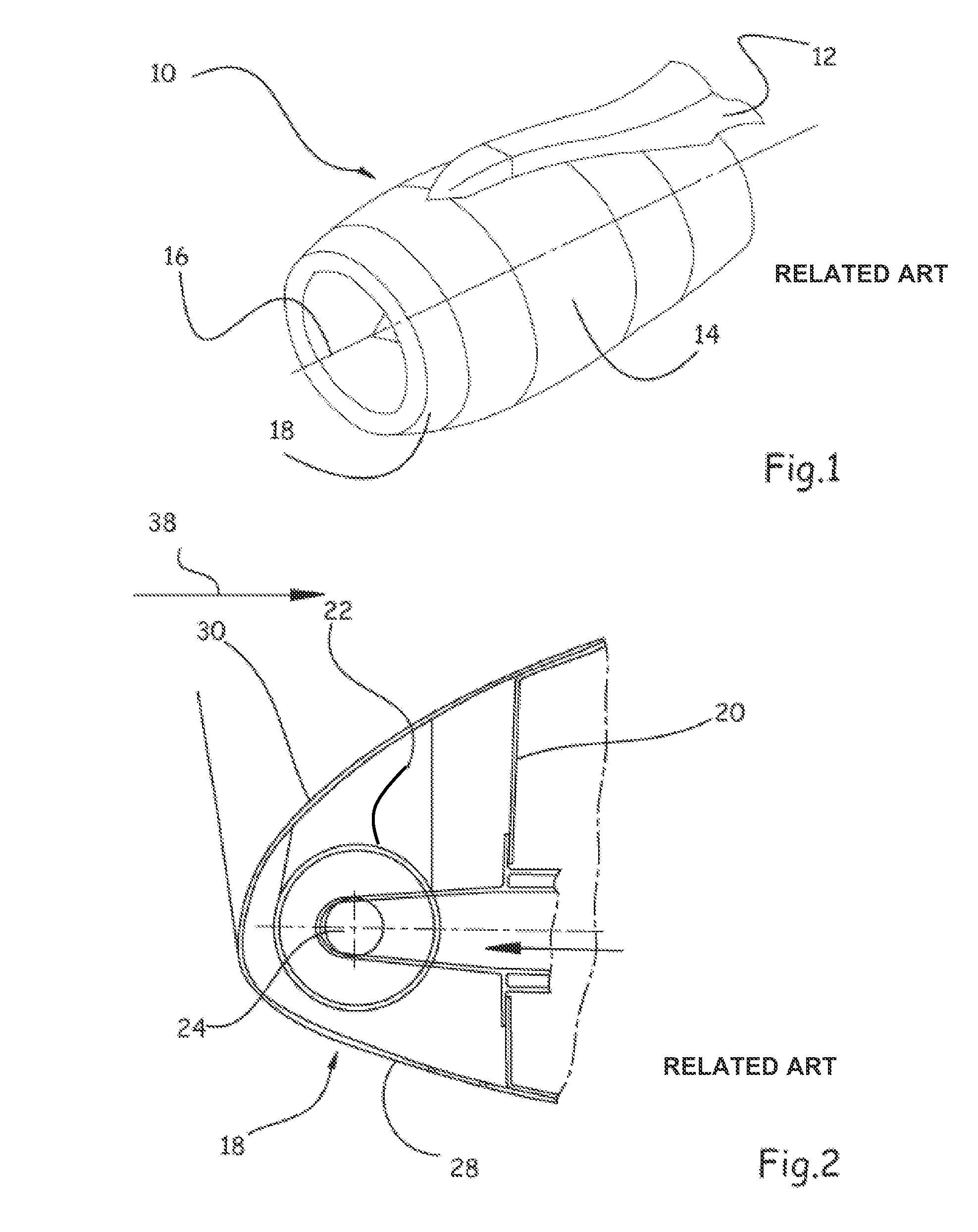

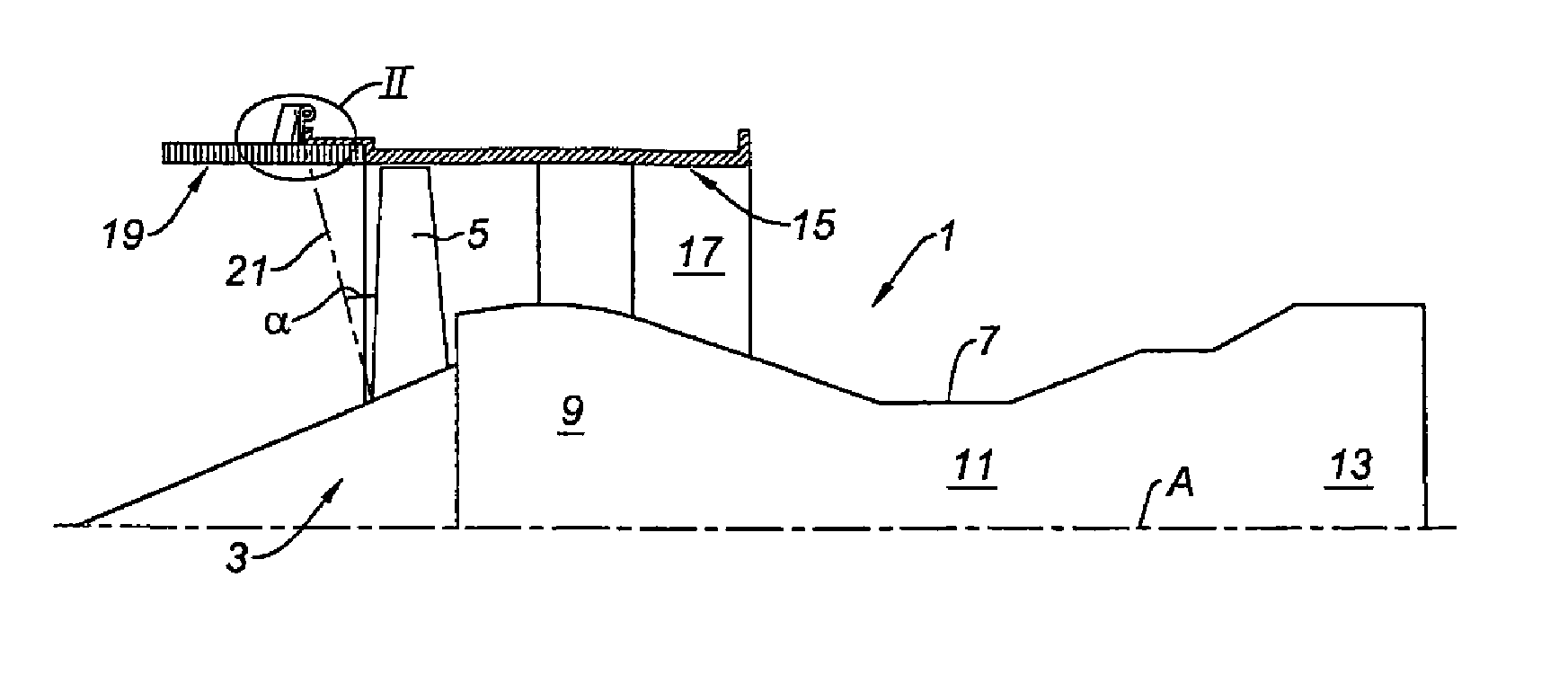

Air intake for aircraft nacelle, and propulsion assembly including such air intake

InactiveUS20100320316A1Controlling the riskReduce impactGas turbine plantsFuselage insulationRam-air intakeNacelle

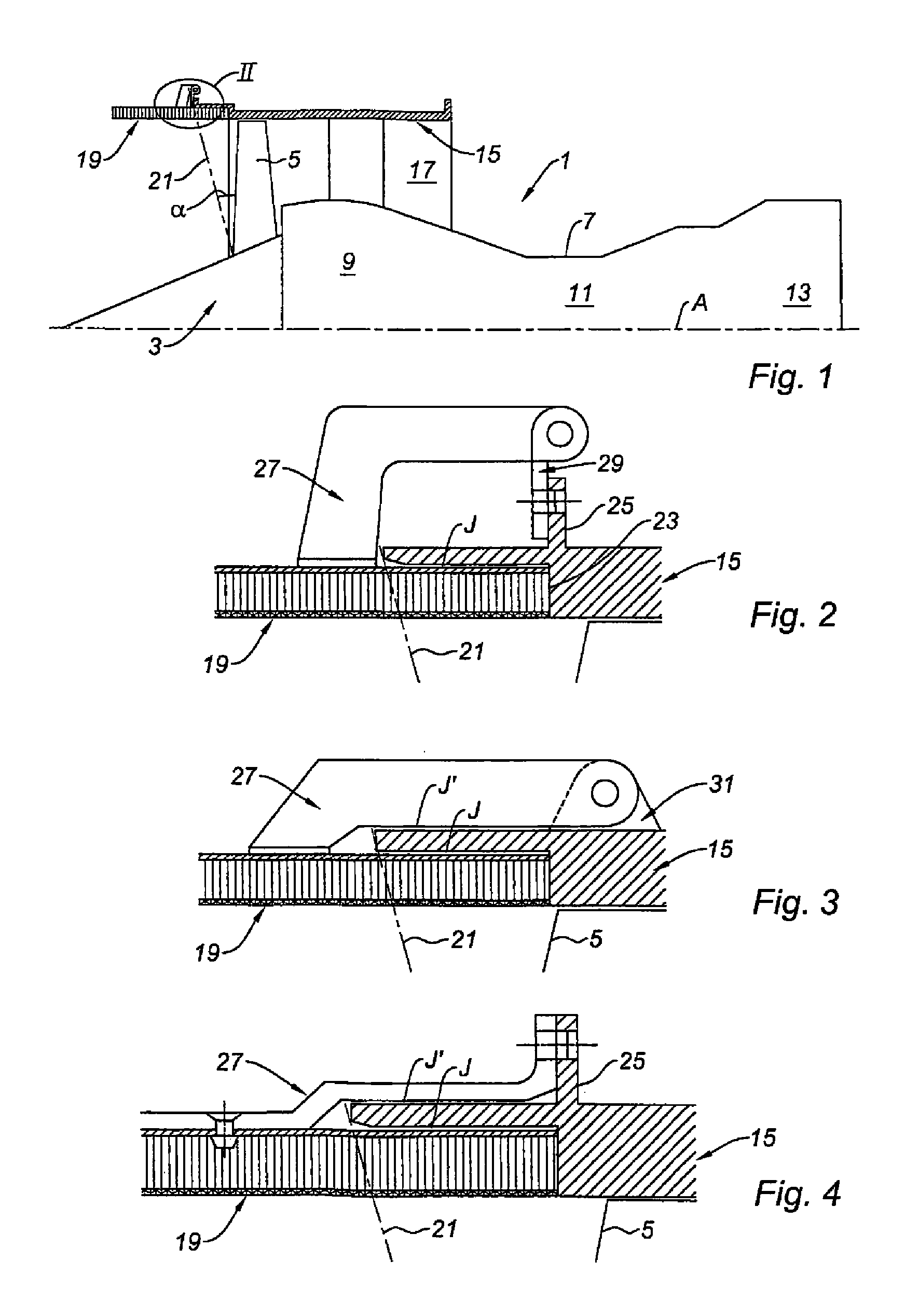

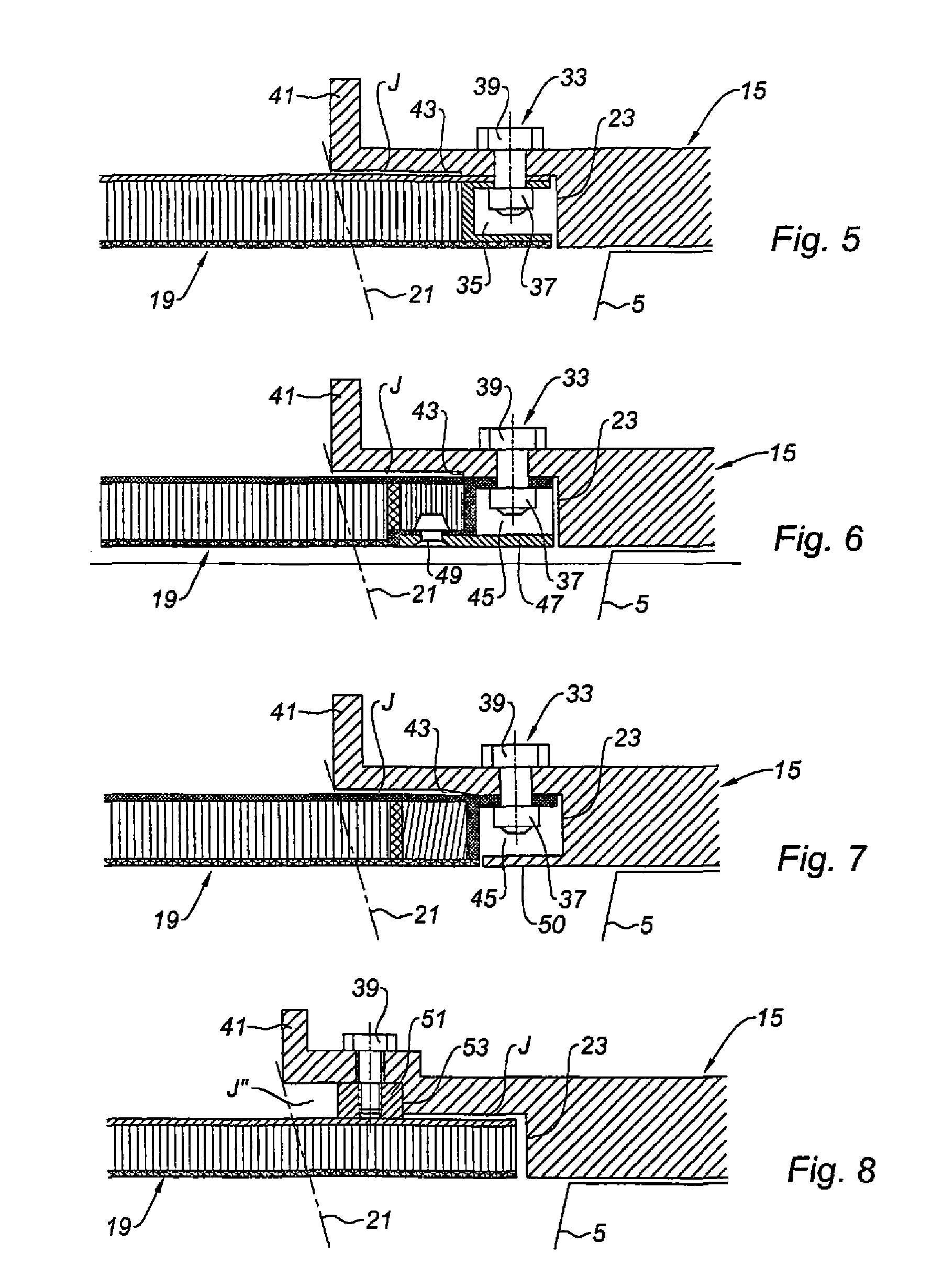

The invention relates to an air intake for an aircraft nacelle that comprises a shroud (19) that can be mounted on the fan casing (15) of a turbojet engine (1). The shroud (19) is sized so as to define a circumferential gap (J) relative to the casing (15). Punctual linking means (27, 33) between the shroud (19) and the casing (15) are discretely distributed at the periphery of said shroud (19).

Owner:SAFRAN NACELLES

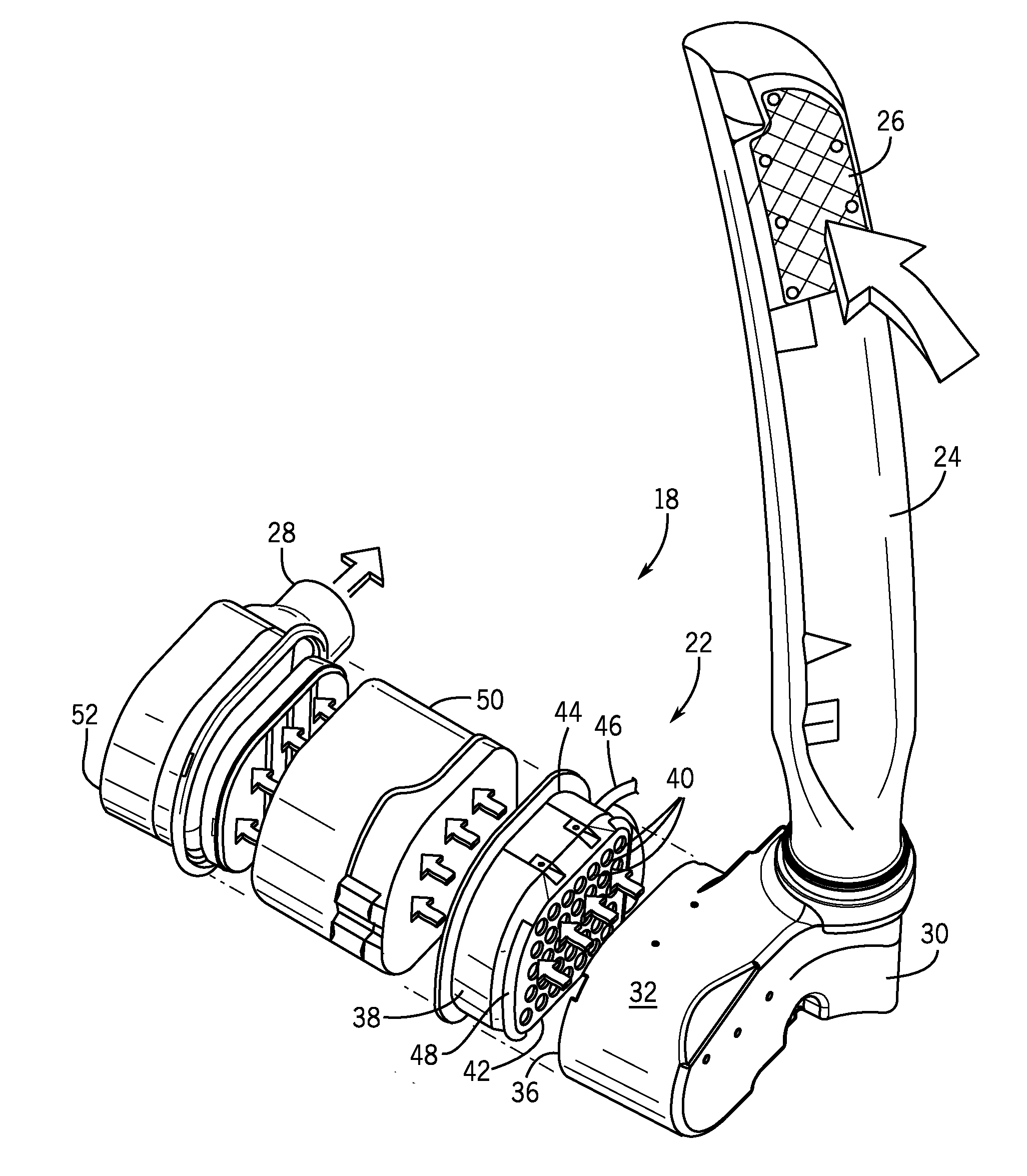

Air intake system for an off-road vehicle

An air intake system includes a pre-cleaner having a plurality of tubes configured to receive a flow of air, to filter particulate material from the flow of air, and to provide the flow of air to an engine of an off-road vehicle. The system also includes a controller configured to receive a first signal indicative of an air intake flow rate of the engine, to determine a target number of open tubes for the pre-cleaner based at least in part on the air intake flow rate and a desired air flow rate for each tube of the plurality of tubes, and to output a second signal to a component of the air intake system indicative of instructions to enable the flow of air to the target number of open tubes and to block the flow of air to the remainder of tubes of the plurality of tubes.

Owner:BLUE LEAF I P

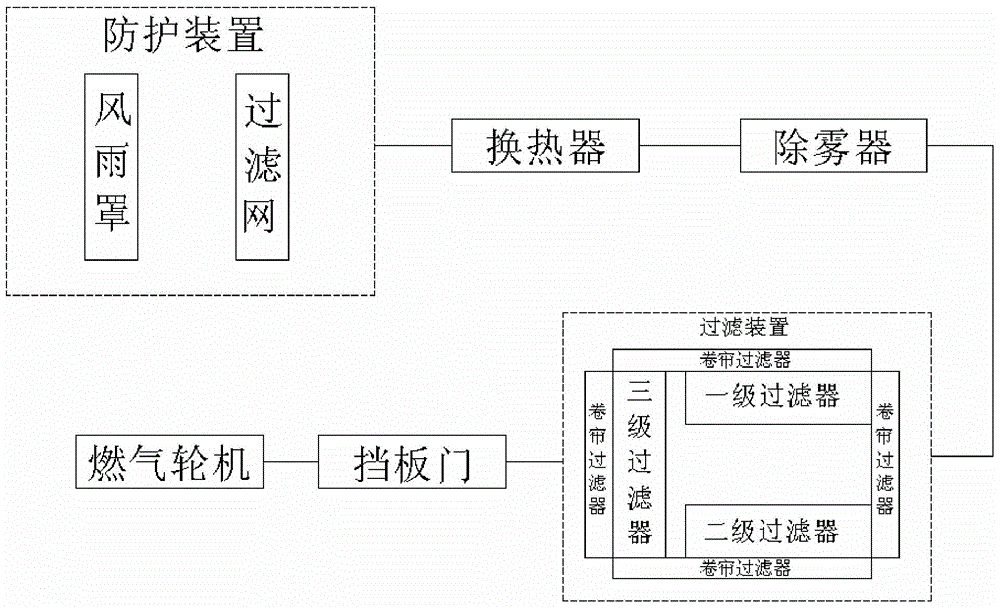

Air intake system and method for gas turbine

InactiveCN104895677AAvoid blockingDecrease productivityGas turbine plantsTurbine/propulsion air intakesRam-air intakeFiltration

The invention discloses an air intake system for a gas turbine. The air intake system comprises an air intake ducting connected with an air inlet of an internal-combustion engine, a protection device, a heat exchanger, a demister, a filter device and a baffle door, wherein the protection device, the heat exchanger, the demister, the filter device and the baffle door are connected through the air intake ducting; the protection device is connected with the heat exchanger; the heat exchanger is connected with the filter device; the demister is arranged between the heat exchanger and the filter device; a blast deflector is arranged at one end of the outlet of the filter device; and the baffle door is arranged at the outlet of the air intake ducting. The invention further discloses an air inlet method of the gas turbine. The air intake system of the gas turbine is simple in structure and performs multiple filtration on gas, so that the quality of the gas is ensured, and the service life of the gas turbine is prolonged. The air intake method of the gas turbine is simple and practicable to operate.

Owner:江苏华强新能源科技有限公司

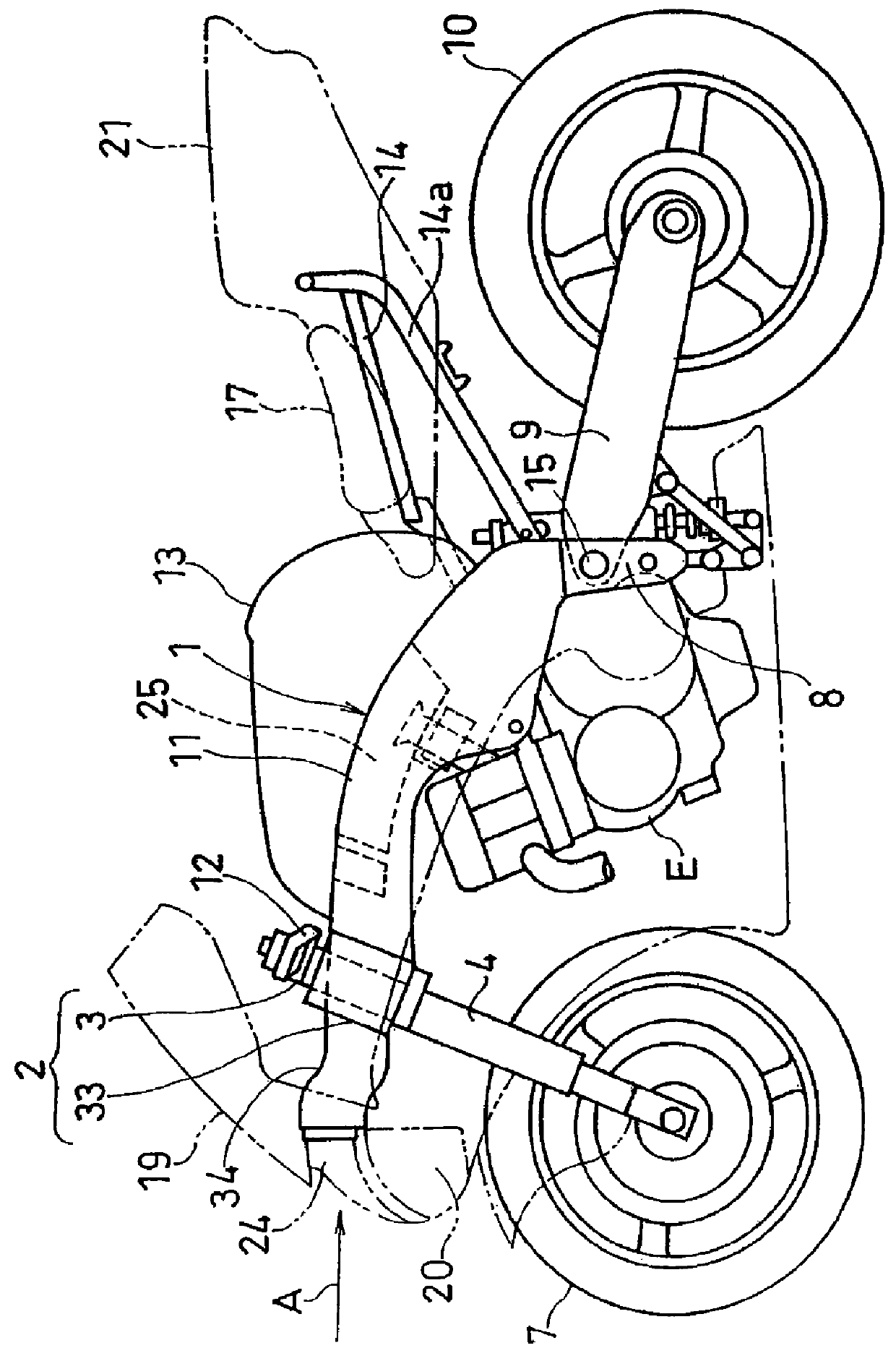

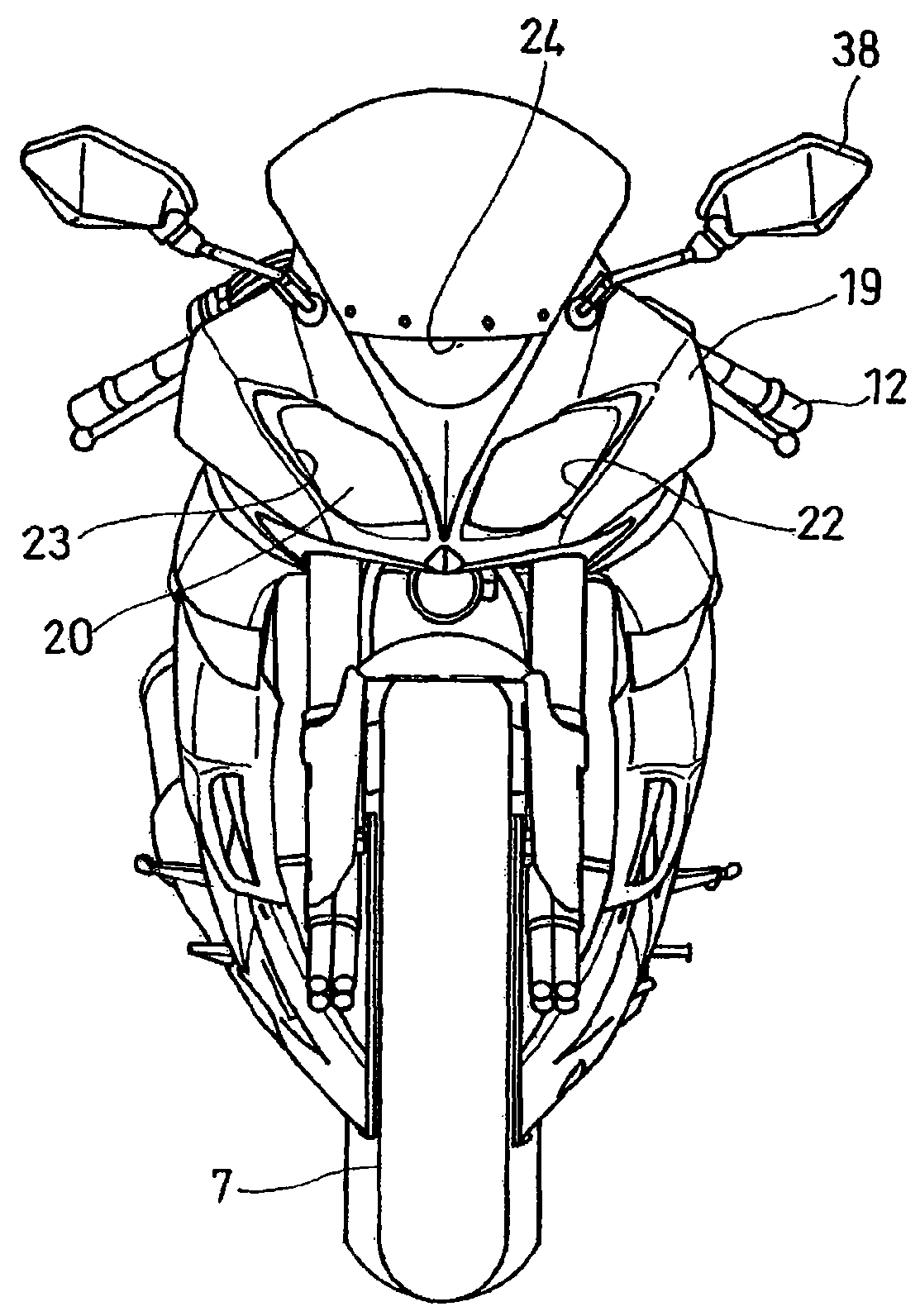

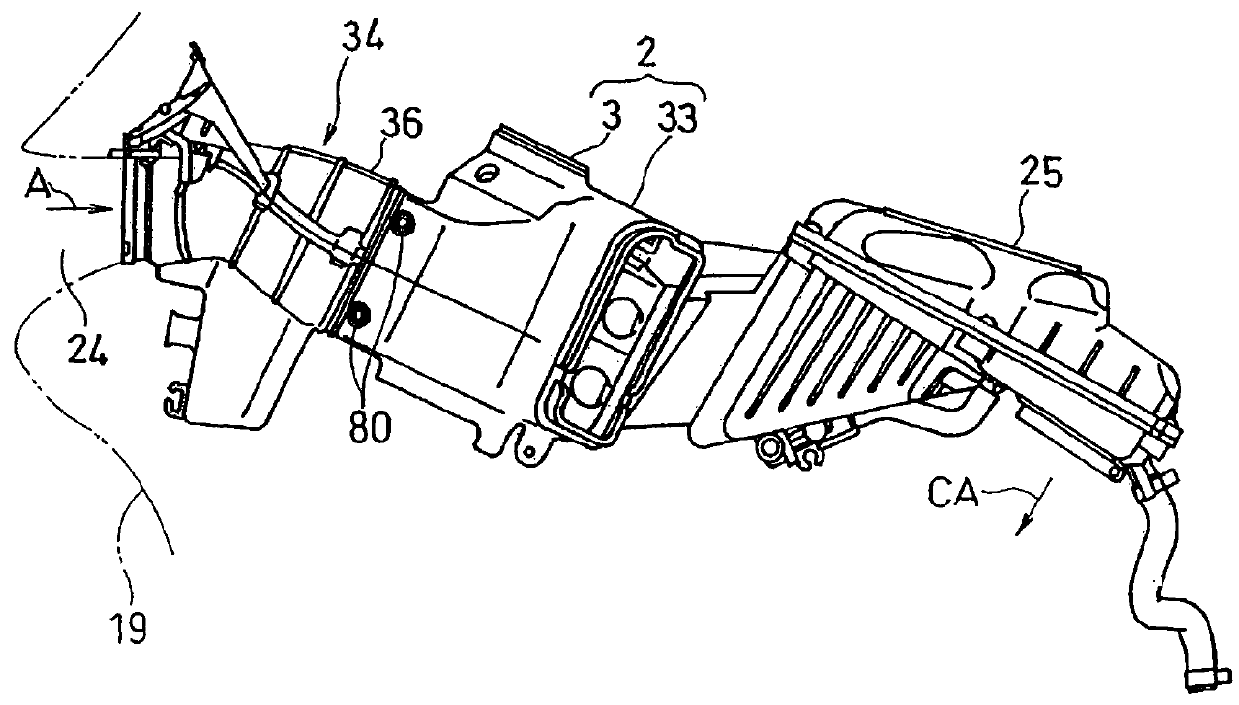

Ram intake unit having a sound absorbing structure

ActiveUS8162101B2Efficient removalPrevent removalNon-fuel substance addition to fuelExhaust apparatusRam-air intakeCombustion

A ram intake unit mounted on a front portion of a frame structure of a motorcycle includes an acoustic material disposed along an inner wall of a ram air intake duct for absorbing induction noises, which duct forms an induction system through which an incoming wind can be introduced towards a motorcycle combustion engine, and a holder disposed inwardly of the acoustic material for securing the acoustic material to the ram air intake duct.

Owner:KAWASAKI MOTORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com