Air intake system and method for gas turbine

A technology of gas turbine and air intake system, applied in the field of air intake system, which can solve the problems of gas turbine power and efficiency reduction, increase of intake pressure loss, and non-simultaneous occurrence, so as to ensure smooth flow, work efficiency, and use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

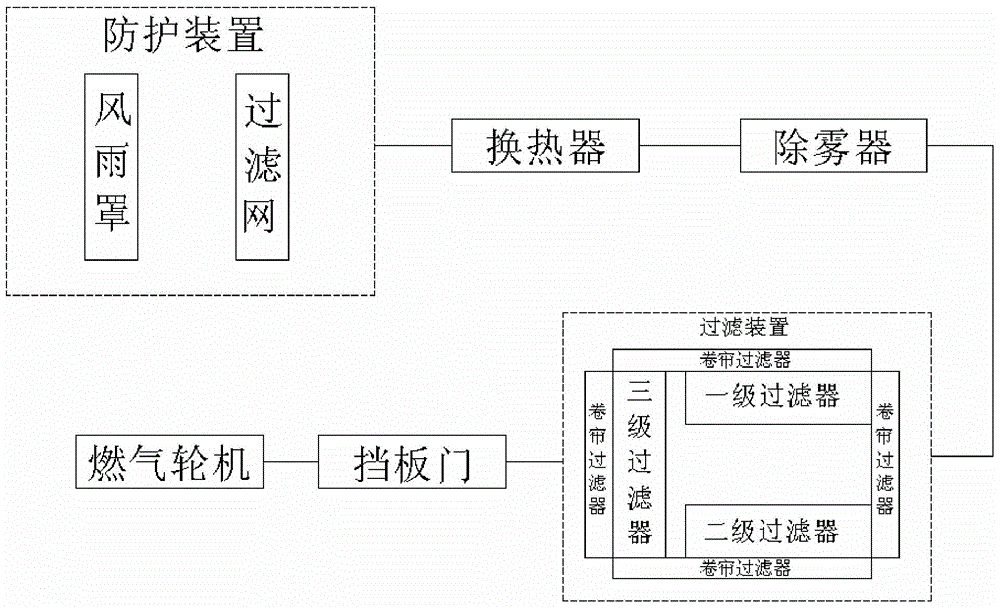

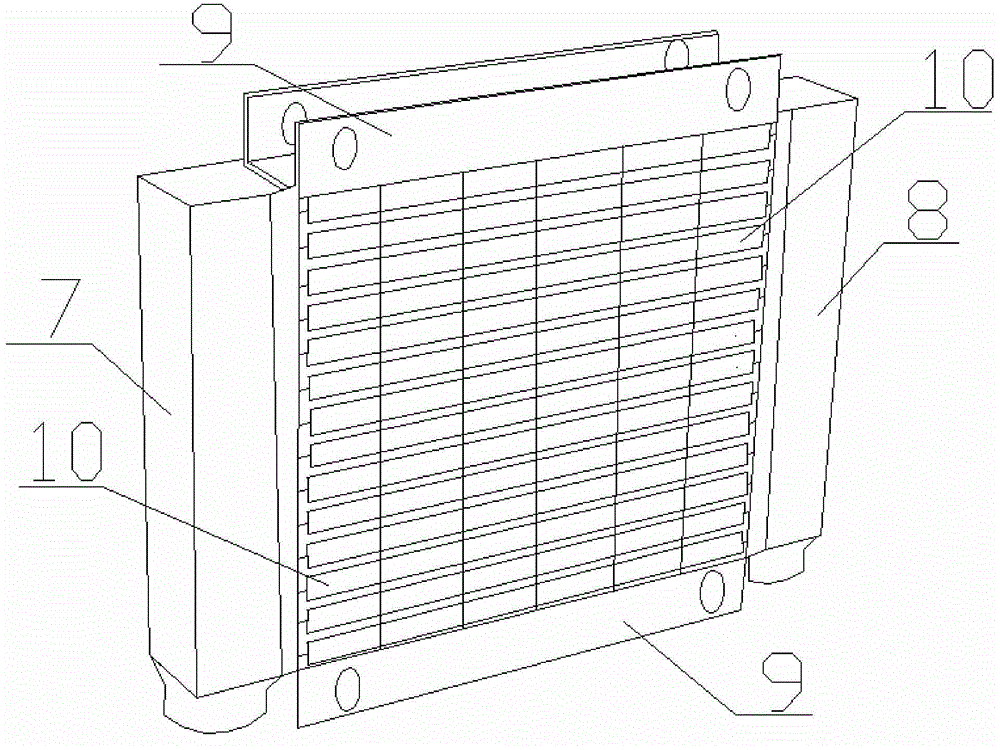

[0028] A gas turbine intake system provided in this embodiment has a structure such as Figure 1-4 As shown, it includes the intake pipe connected to the air intake of the internal combustion engine and the protective device connected through the intake pipe, heat exchanger, demister, filter device and baffle door, and the air intake pipe is also equipped with Pipeline muffler, the pipeline silencer is set between the deflector and the baffle door, the protective device is connected with the heat exchanger, the heat exchanger is connected with the filter device, and there is a demister between the heat exchanger and the filter, and the filter A diversion device is provided at one end of the outlet of the device, and a baffle door is provided at the outlet of the intake pipe, wherein:

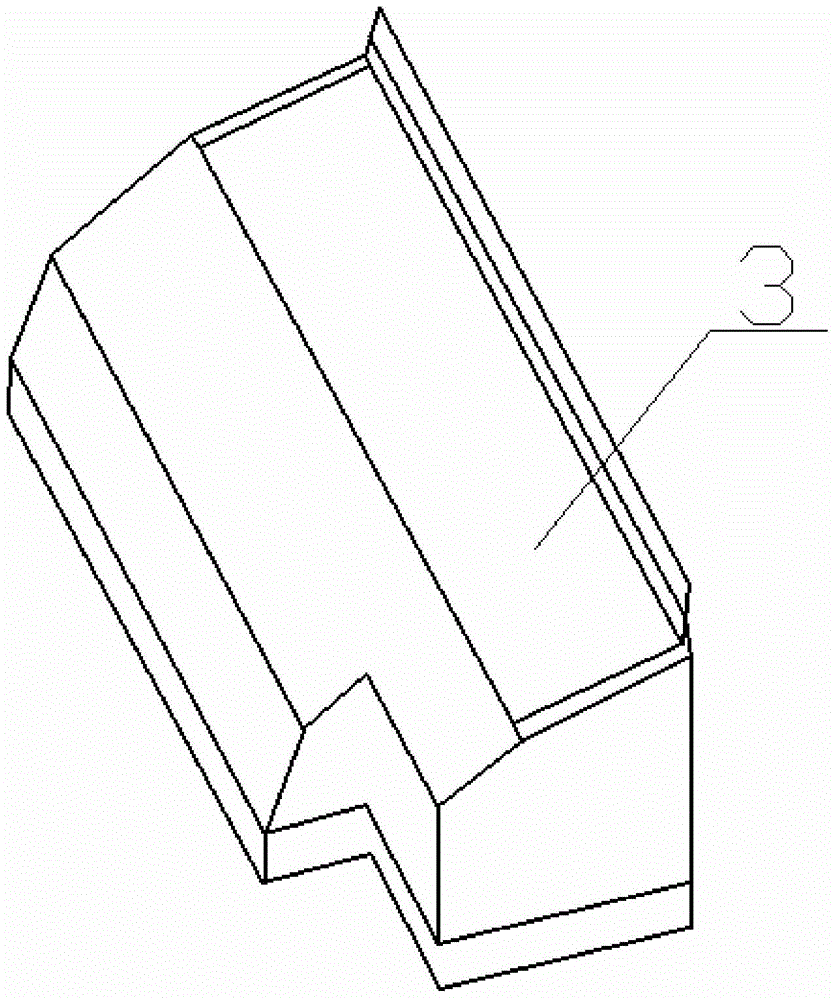

[0029] The protective device comprises a wind and rain cover 3 arranged at the entrance of the air intake duct and a filter screen arranged in the wind and rain cover 3,

[0030] The upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com