Patents

Literature

149results about How to "Improve gas quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

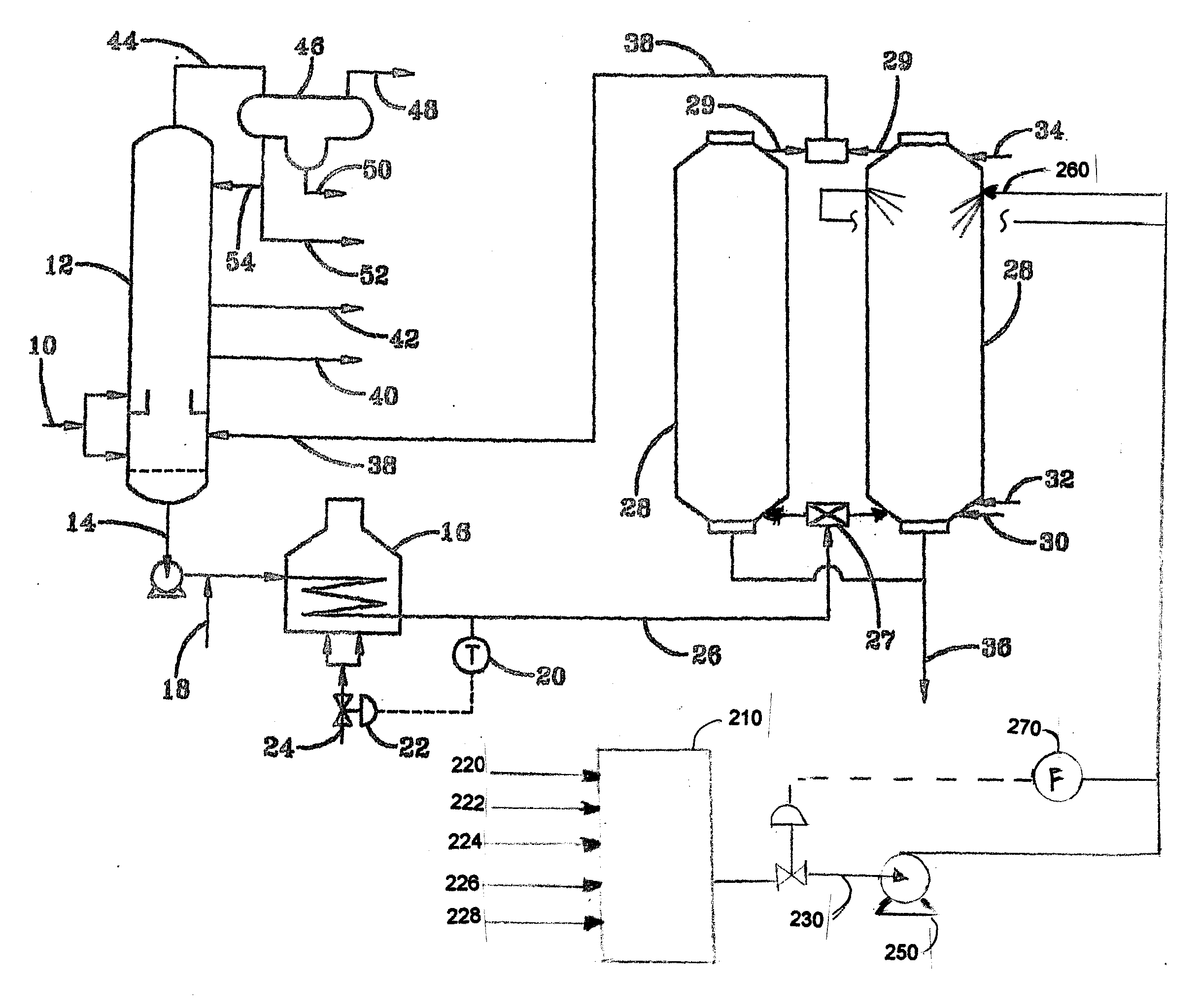

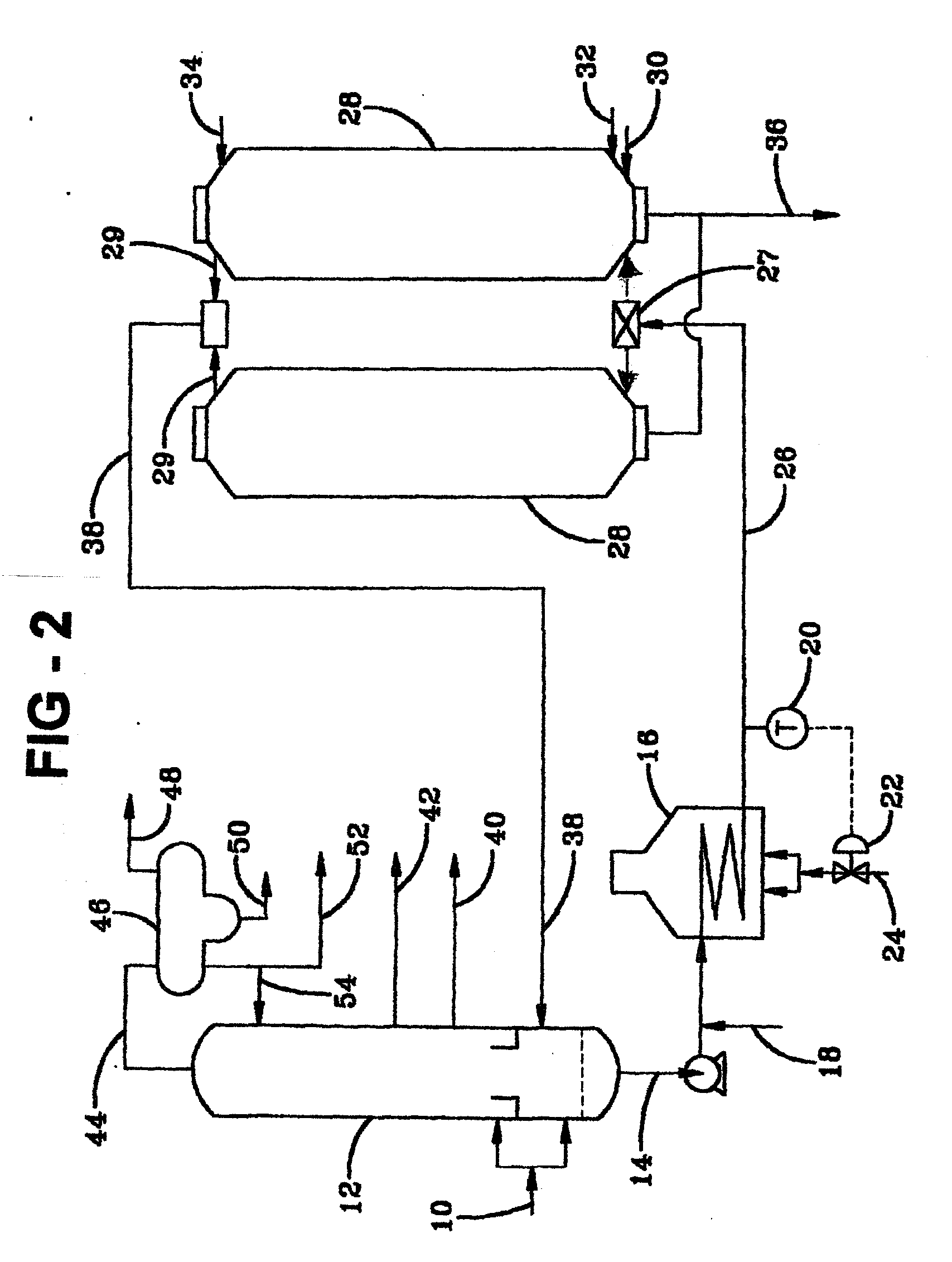

System and Method of Introducing an Additive with a Unique Catalyst to a Coking Process

InactiveUS20090209799A1High propensity to cokePromotes cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkyl transferNaphtha

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. Modifications of the catalysts in the additive improve performance for certain desired outcomes. One exemplary embodiment of the present invention uses the olefin production capabilities from newly developed catalysts to increase the production of light olefins (e.g. ethylene, propylenes, butylenes, pentenes) for alkylation process unit feed, the production of oxygenates, and petrochemical feedstocks, such as plastics manufacture. Another exemplary embodiment of the present invention is the use of the olefin production from newly developed catalysts to improve the coker naphtha quality. A third exemplary embodiment of the present invention uses the cracking characteristics of newly developed catalysts to optimize the production of light gas oils, naphtha, and gases from the coking process.

Owner:ETTER ROGER G +1

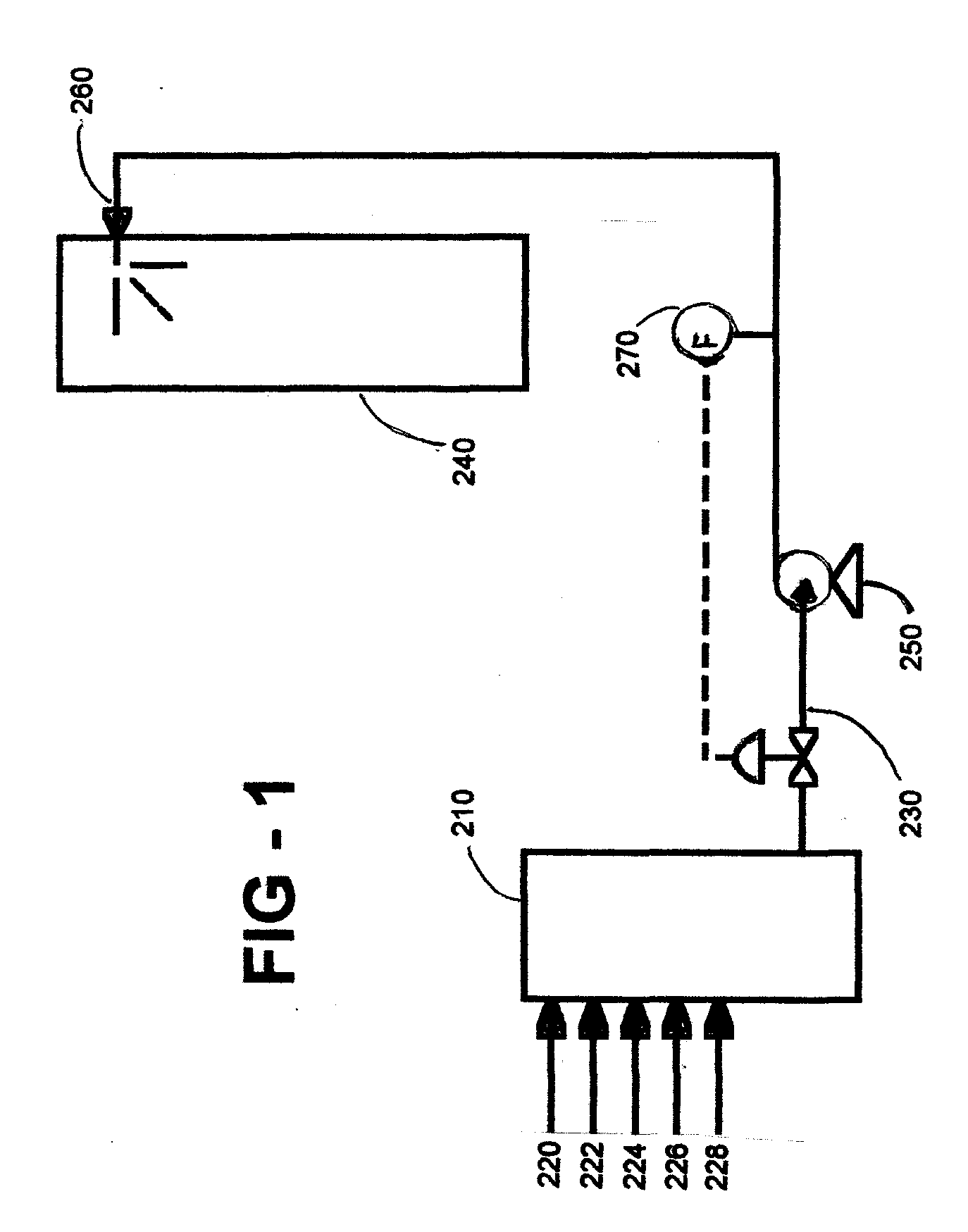

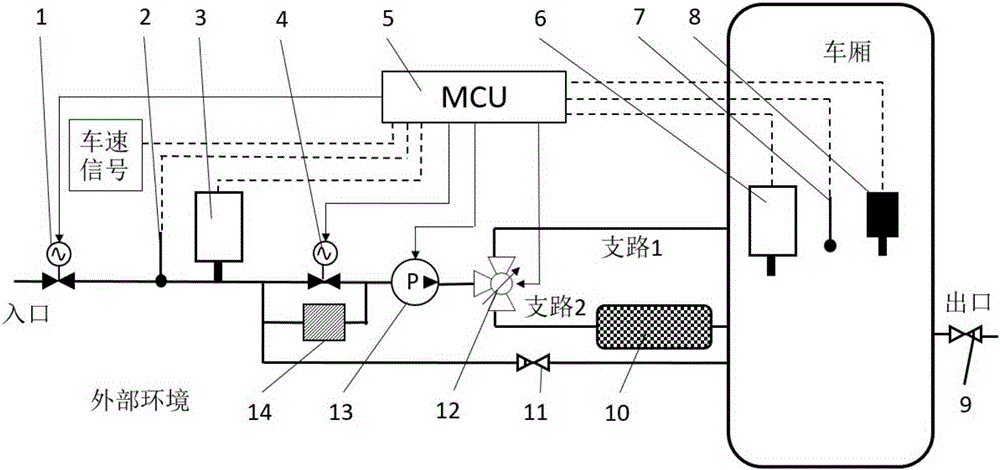

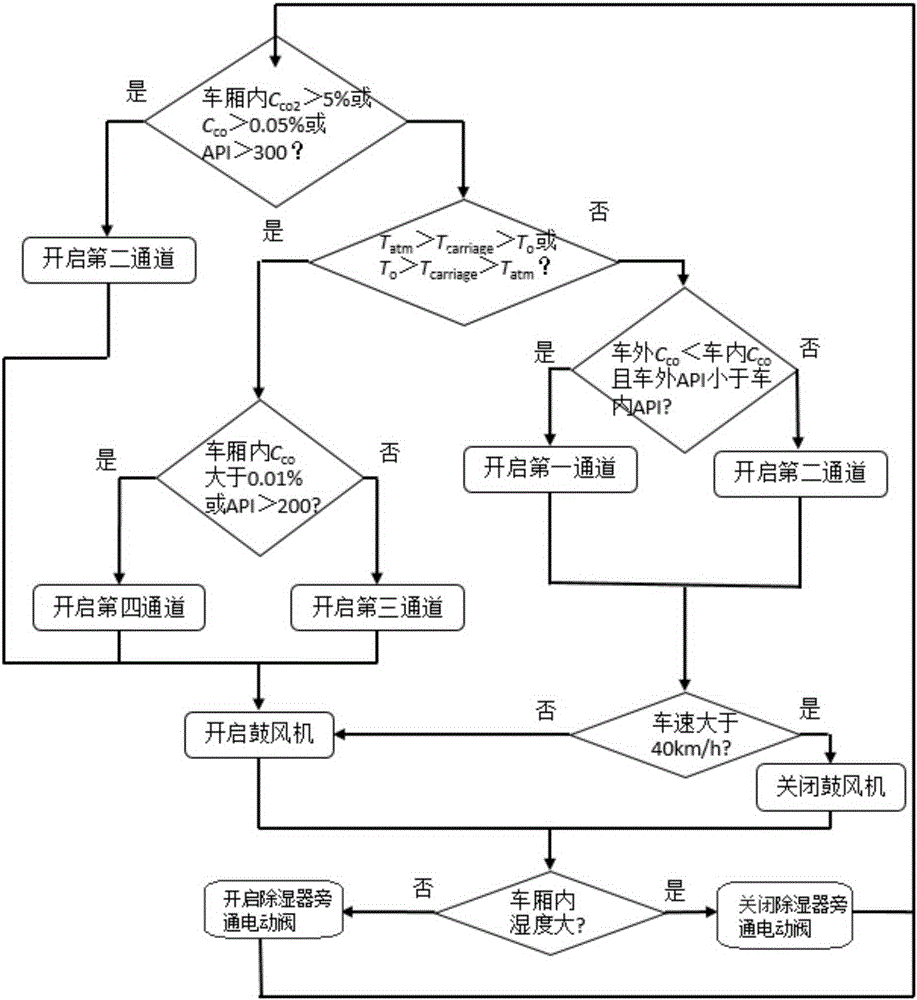

Automobile passenger compartment air conditioning apparatus based on air quality assessment and method thereof

ActiveCN105329069AIncrease humidityImprove gas qualityAir-treating devicesVehicle heating/cooling devicesAir cycleIndoor air quality

The invention discloses an automobile passenger compartment air conditioning apparatus based on air quality assessment and a method thereof. The apparatus comprises a temperature sensor, an air quality detector, a humidity sensor, an air purifier, an air blower, an electric valve and a microprocessor (MCU). The temperature sensor, the air quality detector, the humidity sensor and the air quality detector monitor the temperature, humidity and quality of air in a compartment in real time, and signals are sent to MCU, the MCU controls an electronic-control tee valve, the air blower and the electric valve according to the collected signals and the rules set in inner, so as to switch air circulation modes or air-flow channels. The apparatus can utilize the external environment to the most extent to maintain appropriate temperature and humidity of the air in the compartment and good air quality in an assisting manner, utilize a dehumidifier to effectively lower the air humidity in the compartment, utilize an air purifier to improve the air quality in the compartment in harsh environments, and the threat of life safety of passengers due to the deterioration of air quality in the compartment is prevented.

Owner:ZHEJIANG UNIV +1

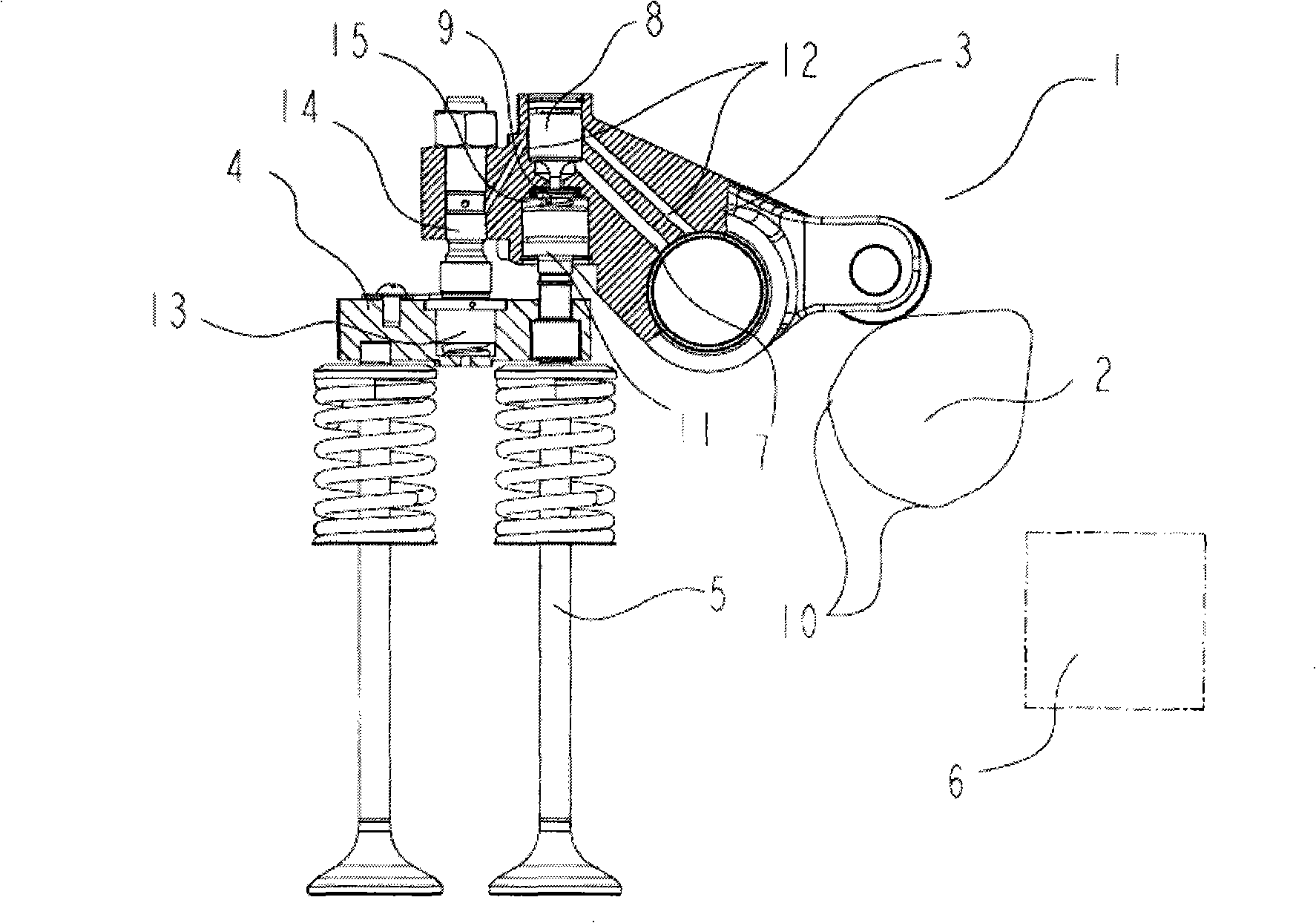

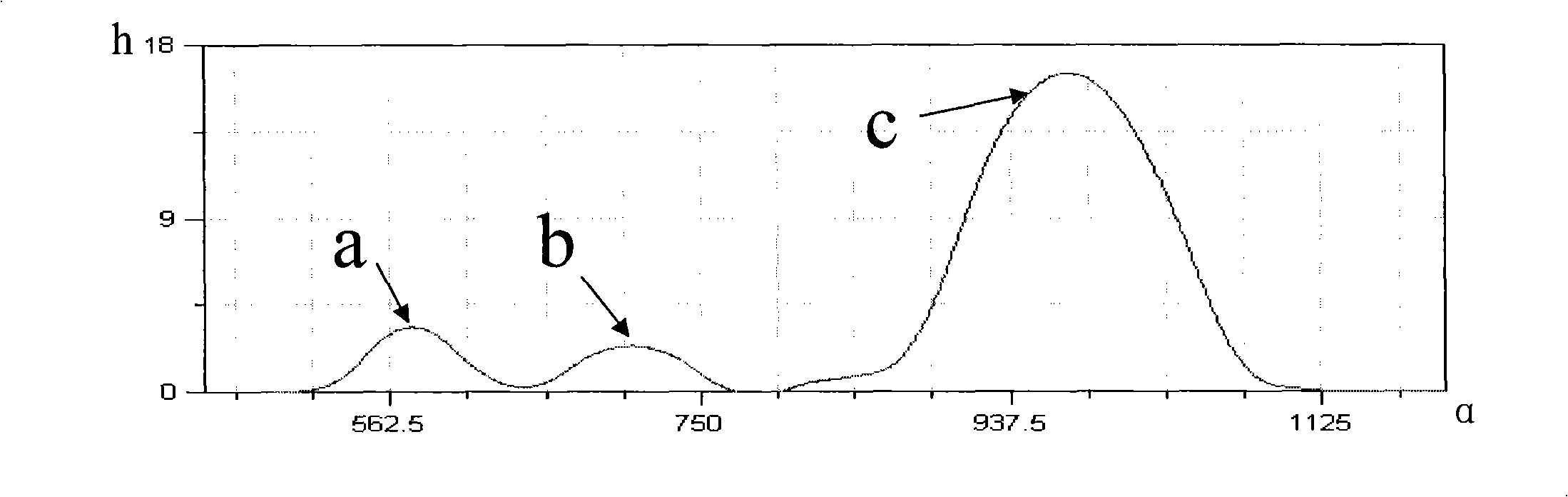

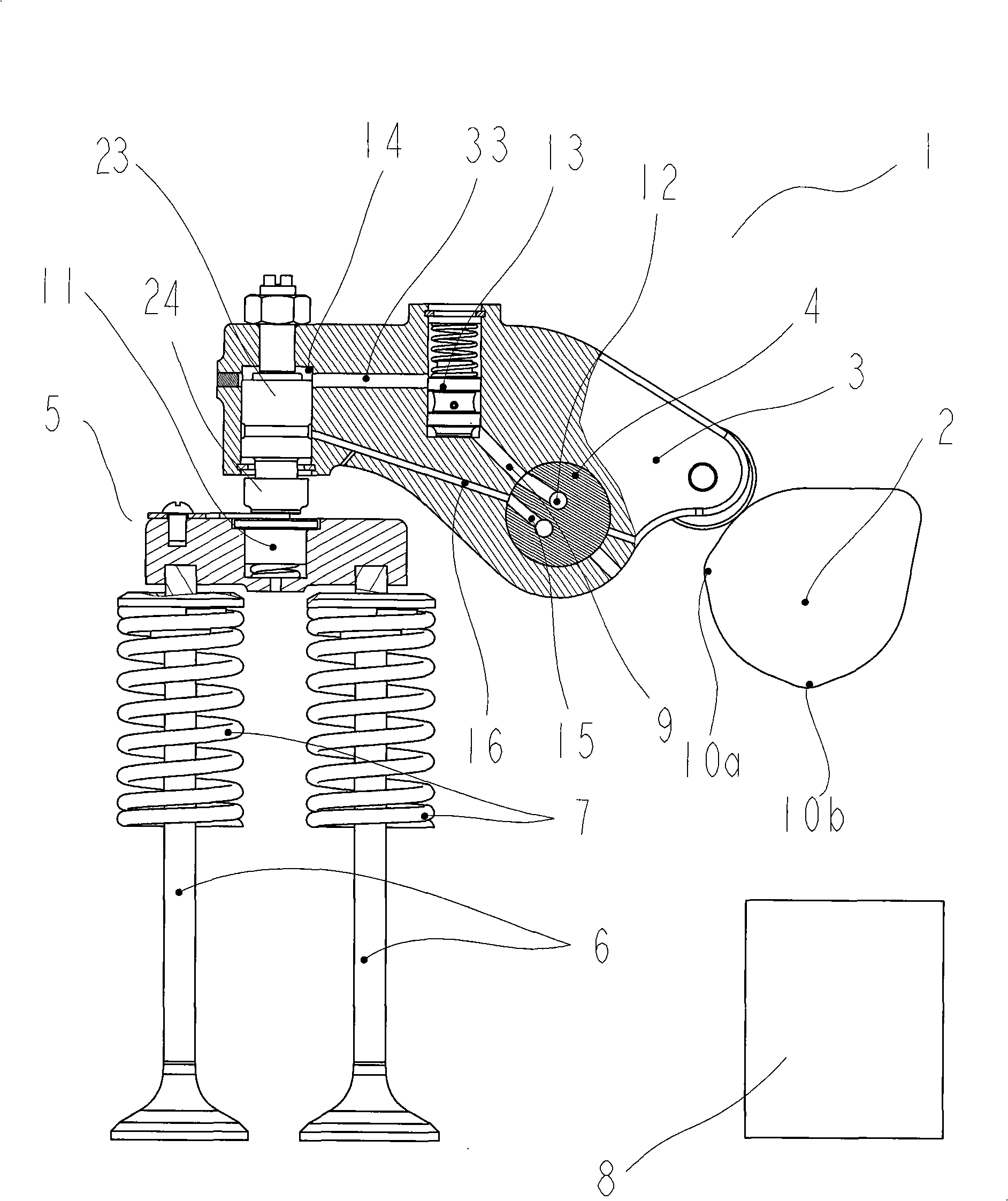

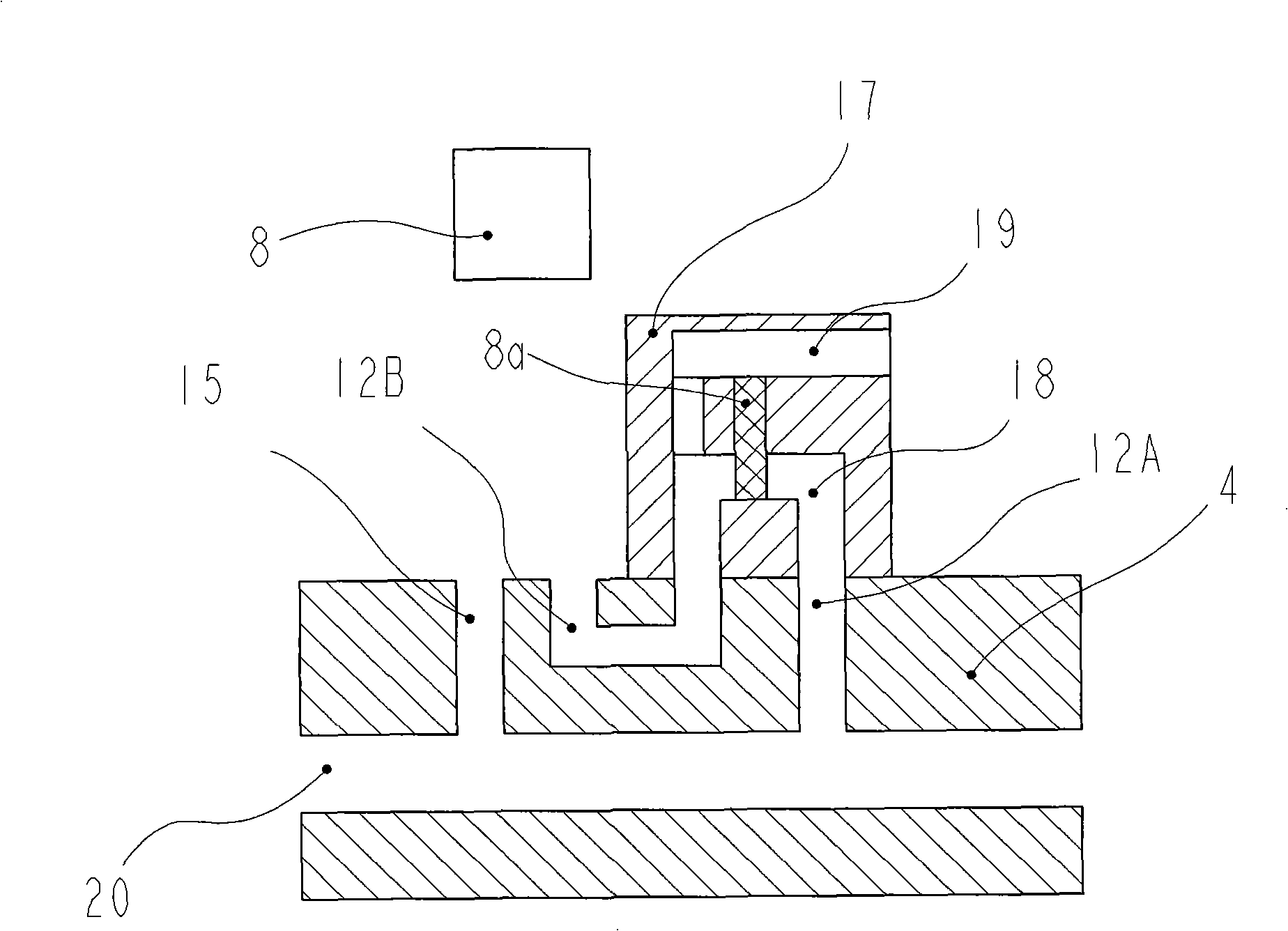

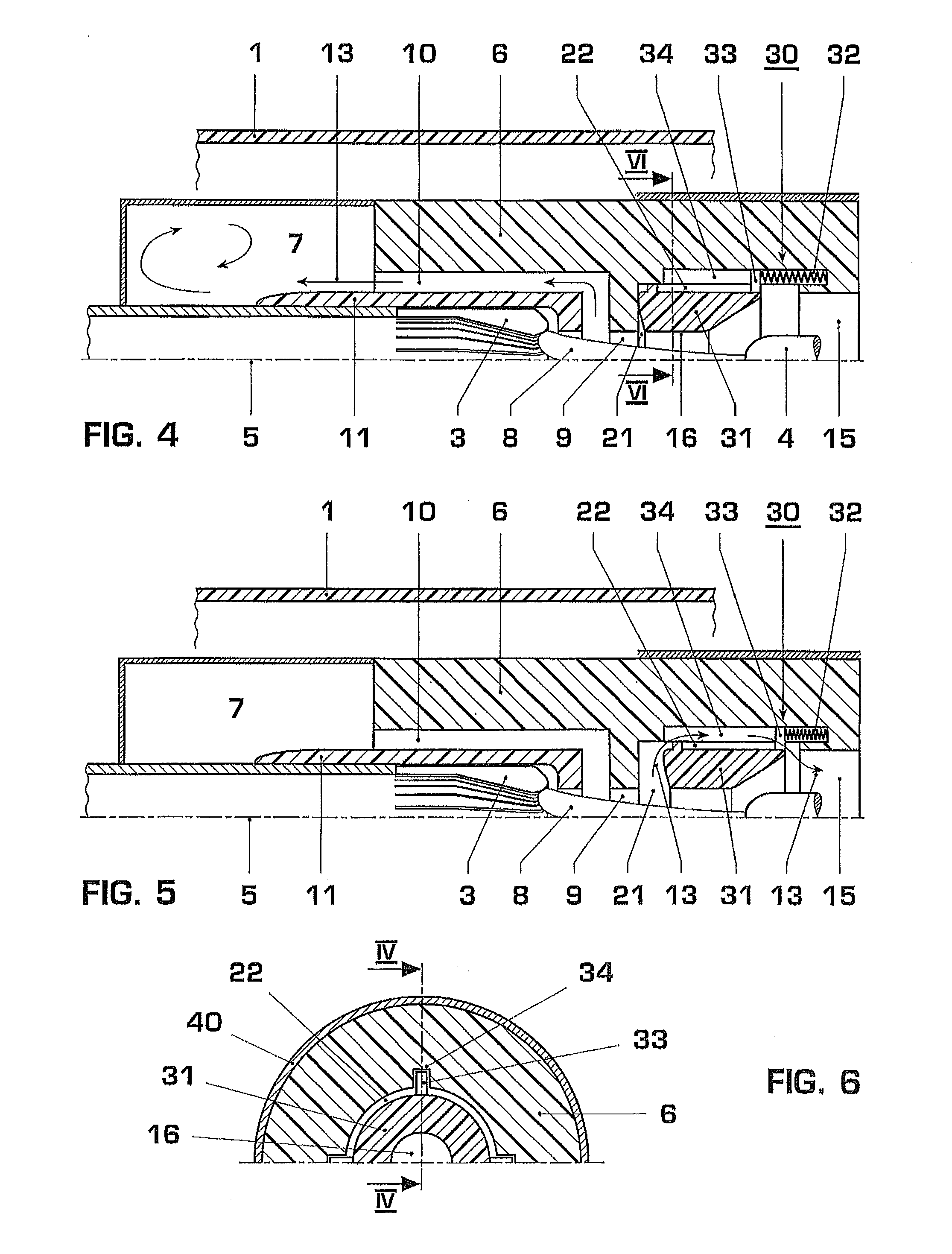

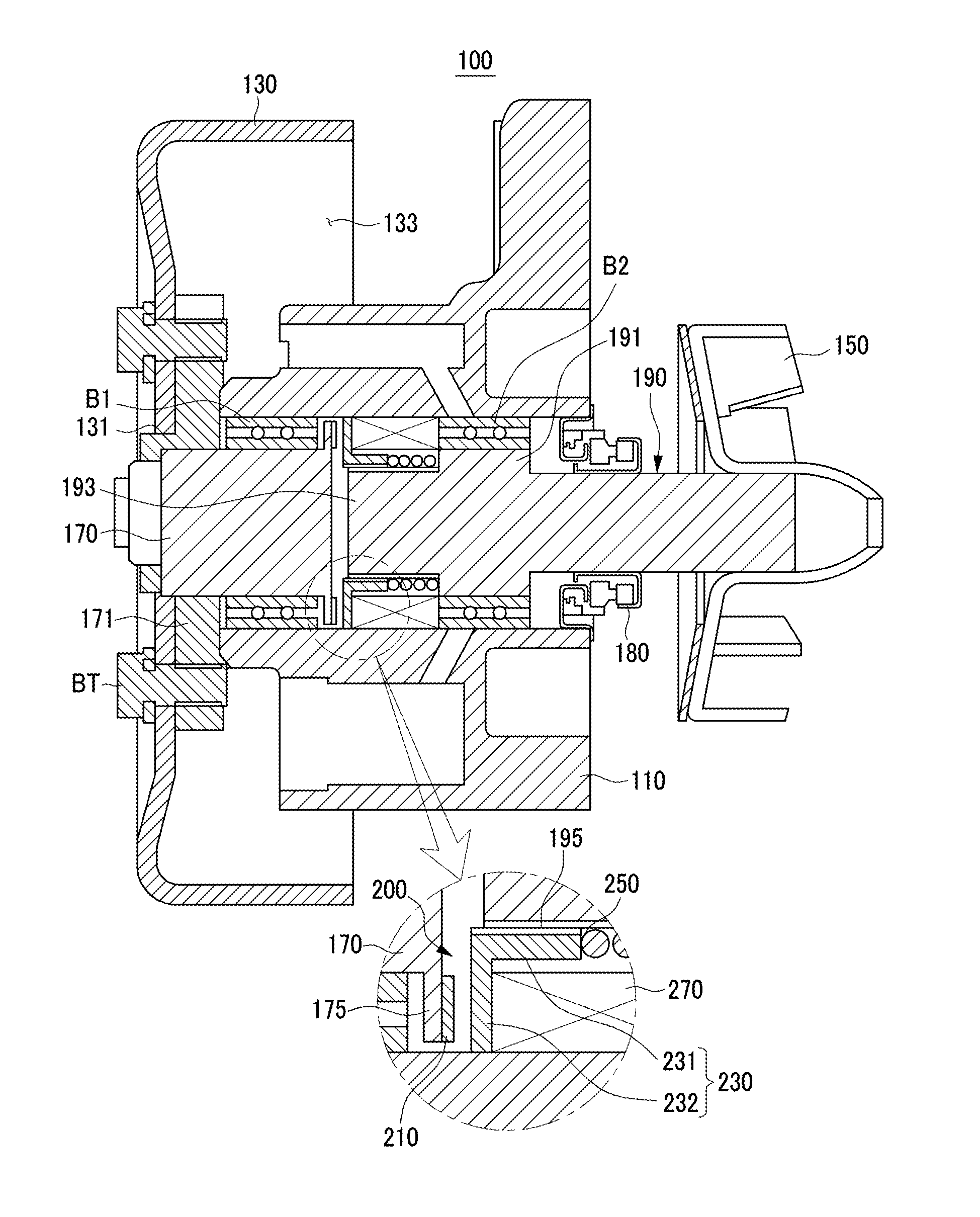

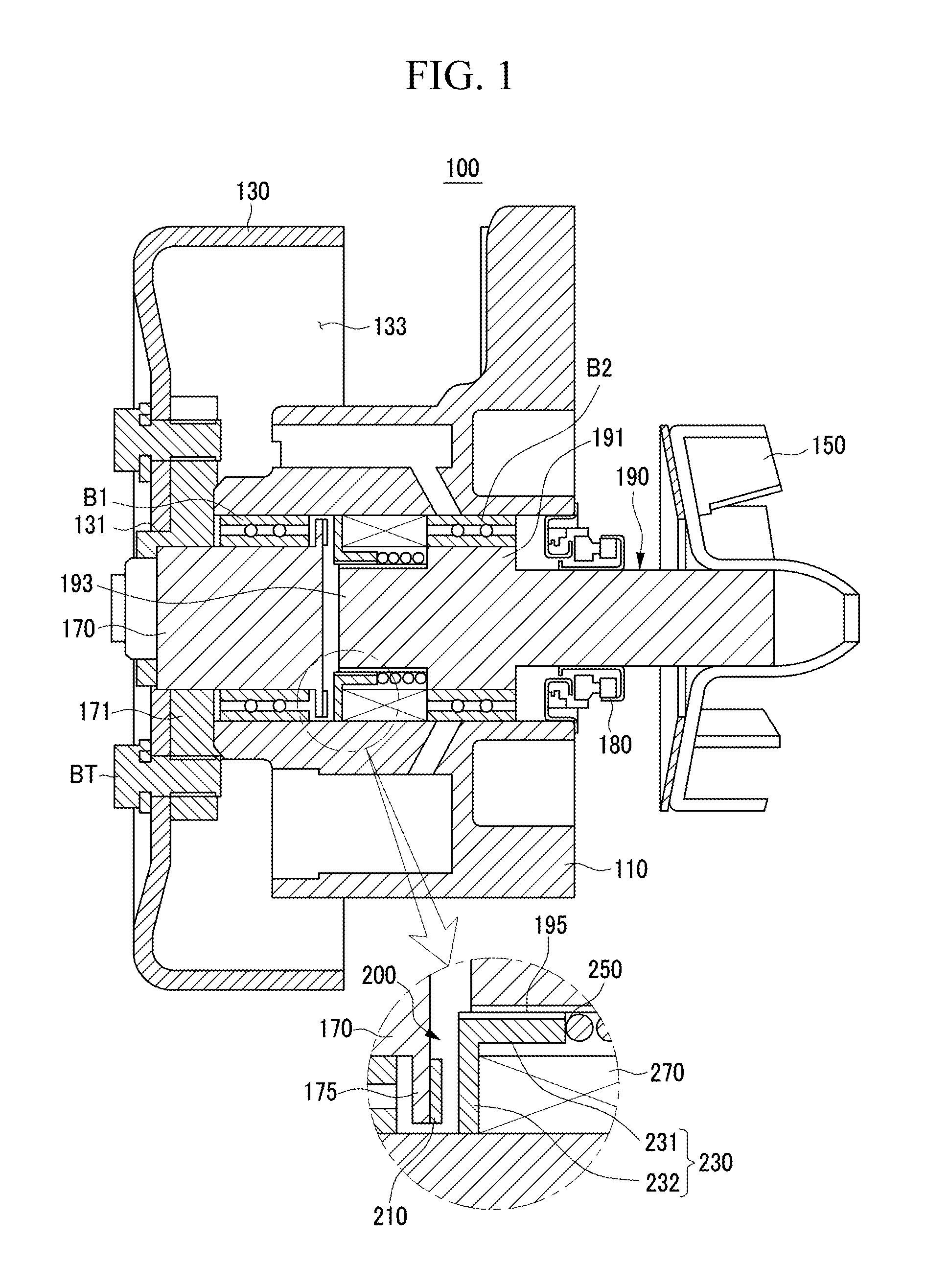

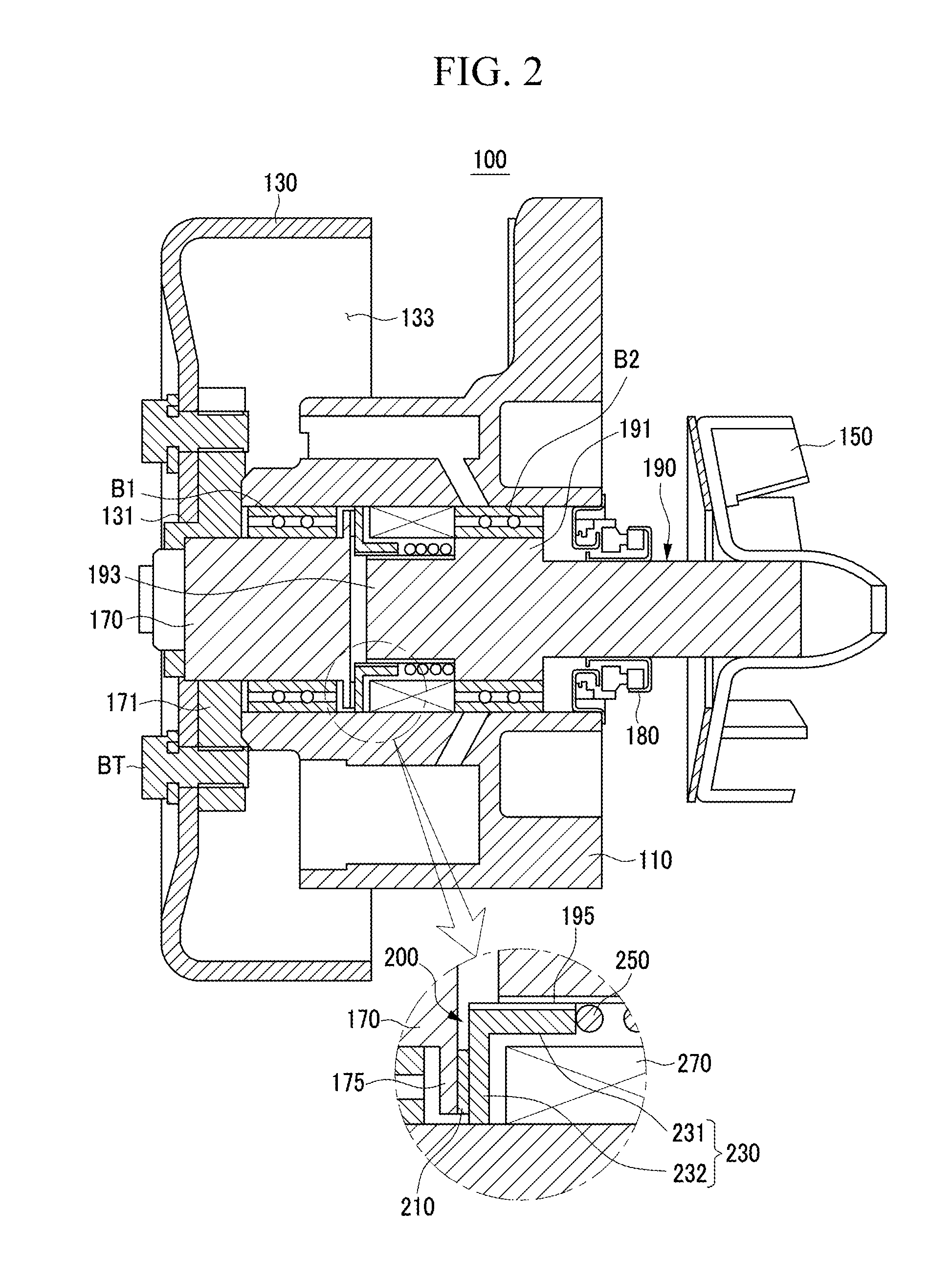

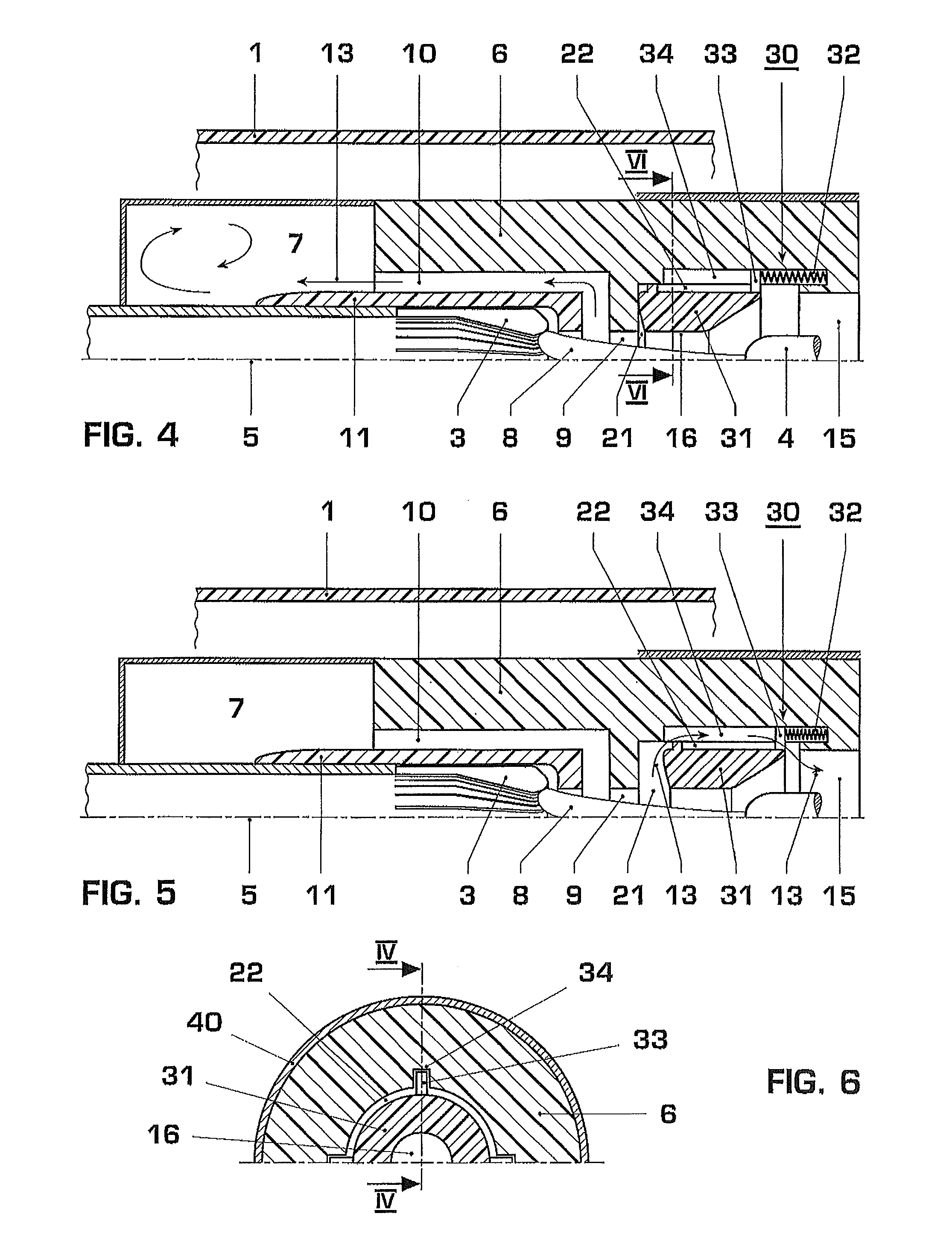

Rocker arm integrated type brake device of four-stroke internal combustion engine

InactiveCN101349178AIncrease stiffnessImprove balanceValve arrangementsOutput powerCombustionExhaust valve

The invention provides a rocker-integrating type braking device for four-stroke internal combustion engines. Control and check valve mechanisms (8 and 9) are integrated at one end of a valve of a rocker (3) and a clearance compensation mechanism (11); a plunger of the clearance compensation mechanism is always in contact with the upper end of an exhaust valve (5); a braking protrusion (10) is arranged on the molded line of an exhaust cam (2) of an engine; the control and check valve mechanisms are coaxial with the clearance compensation mechanism, and the control and check valve mechanisms and the exhaust valve are coaxially arranged in a cylindrical cavity on the rocker; and a plunger spring in the clearance compensation mechanism is a valve core spring, and a valve core cavity is a plunger cavity of the clearance compensation mechanism. Compared with the prior art, two functional mechanisms for compression and braking of a rocker-integrating type engine are not arranged in a disjoint and mutually perpendicular way but are arranged coaxially in the invention, thereby simplifying structure, reducing the difficulty of machining the exhaust rocker, raising the rigidity of the rocker, raising the reliability of gas distribution mechanisms and raising the accuracy and maneuverability of braking the clearance adjustment of a cam.

Owner:俞黎明

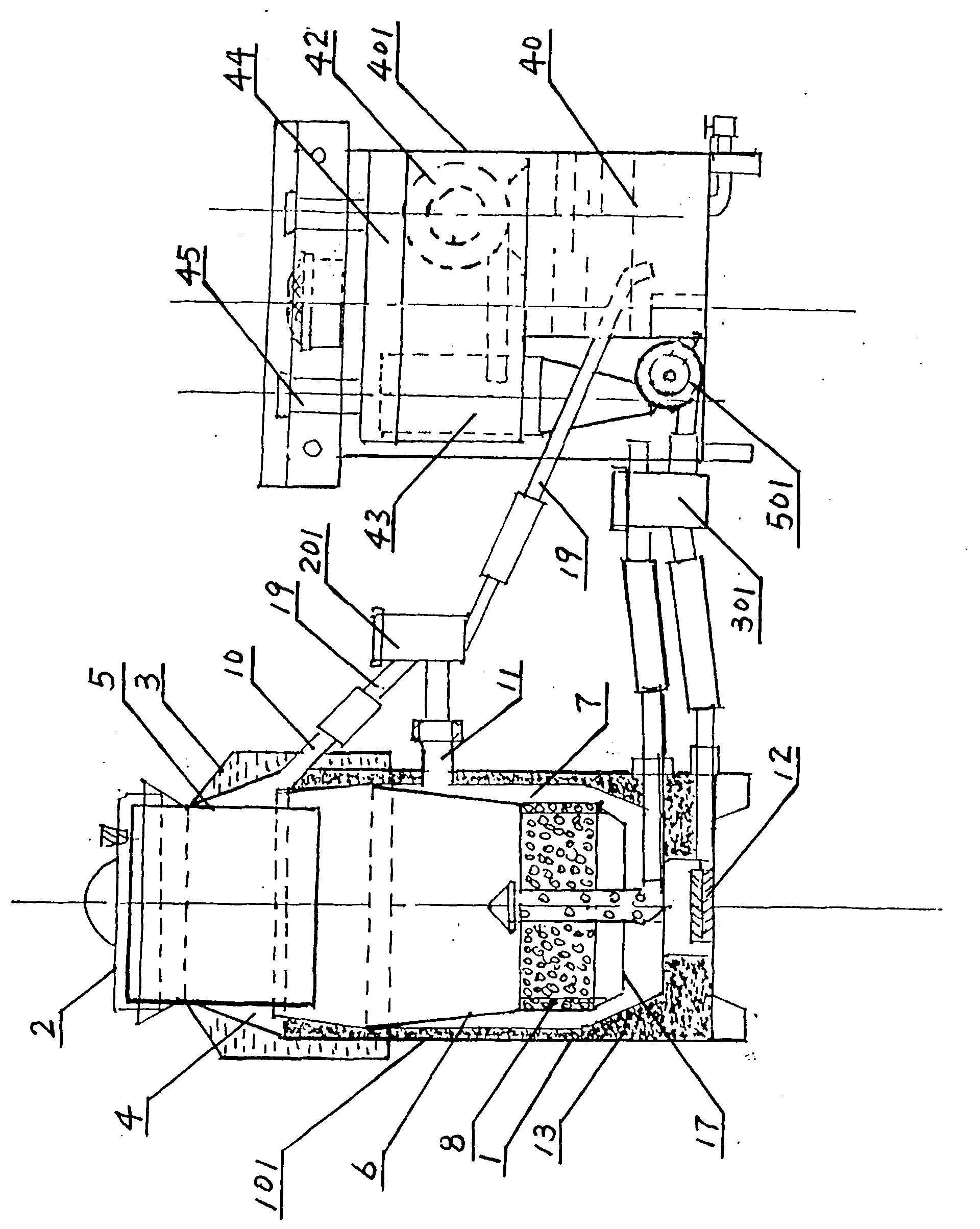

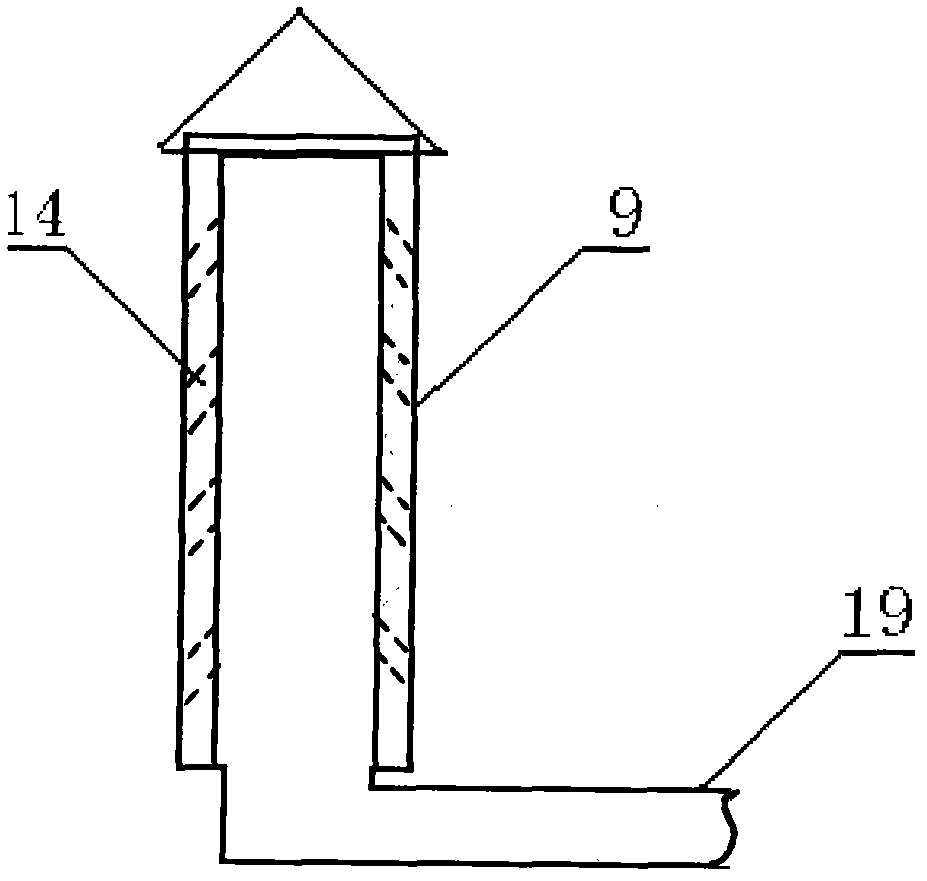

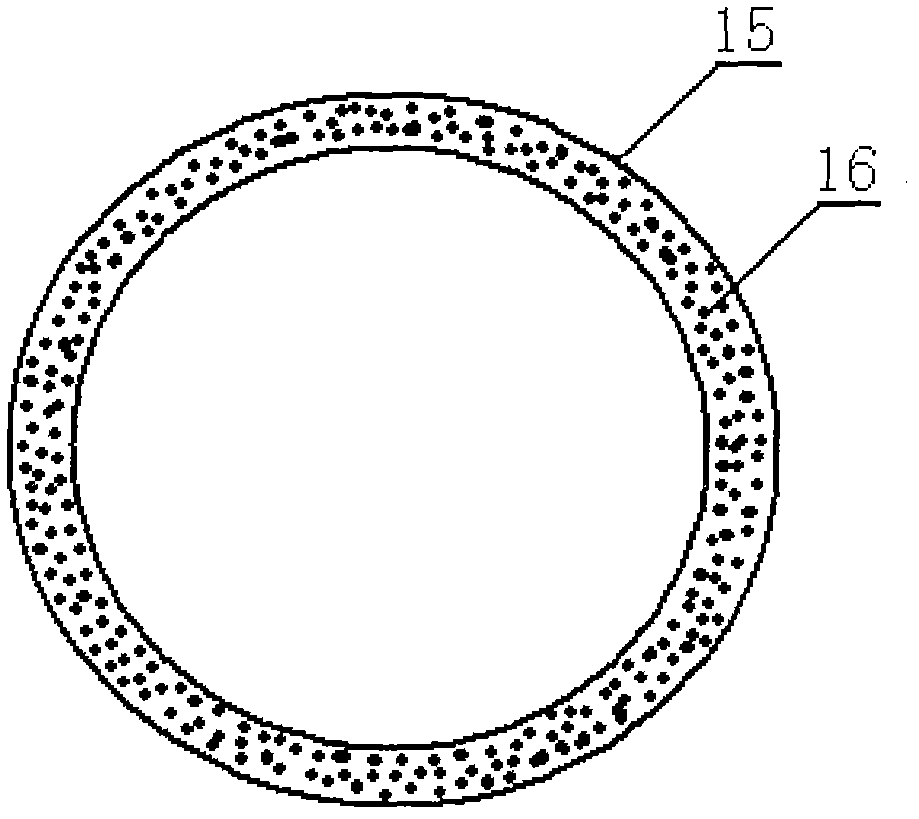

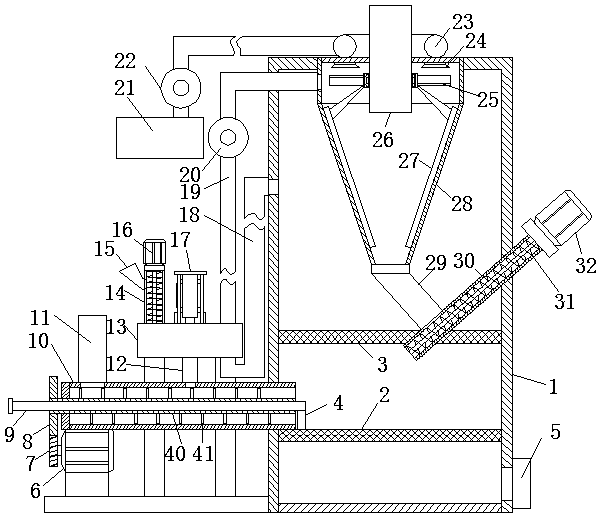

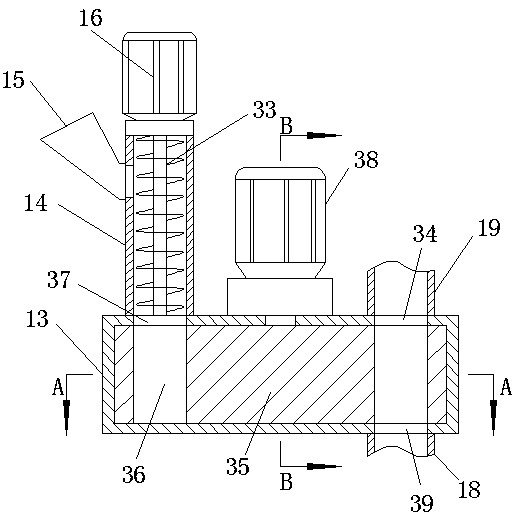

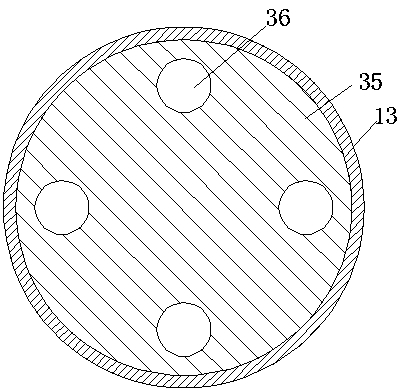

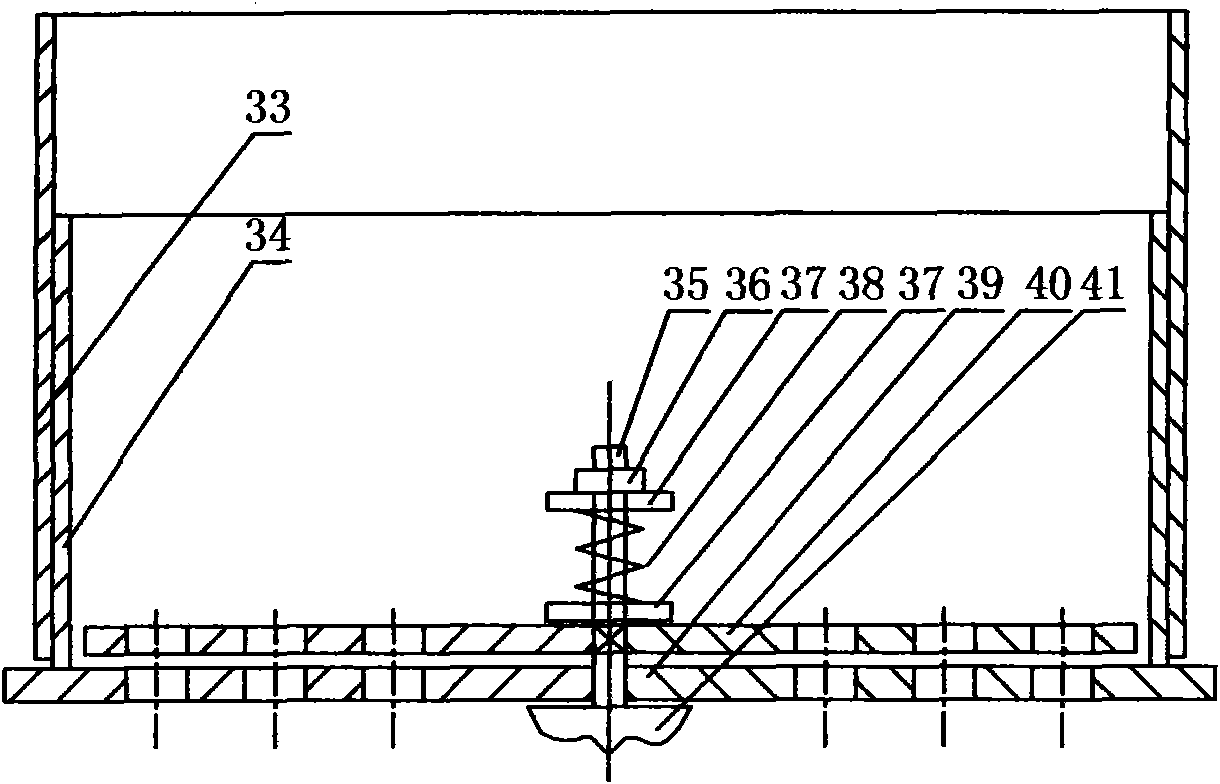

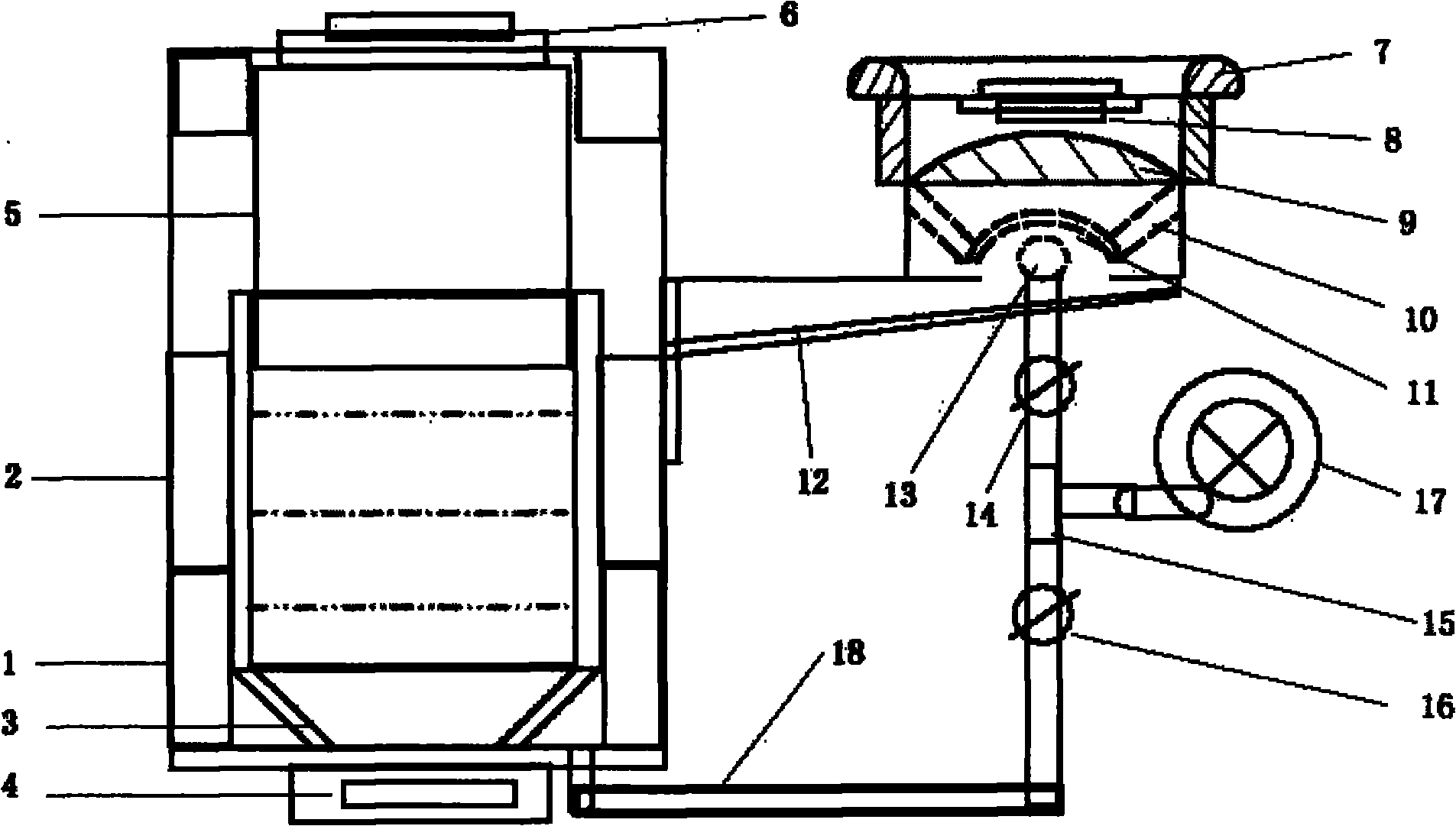

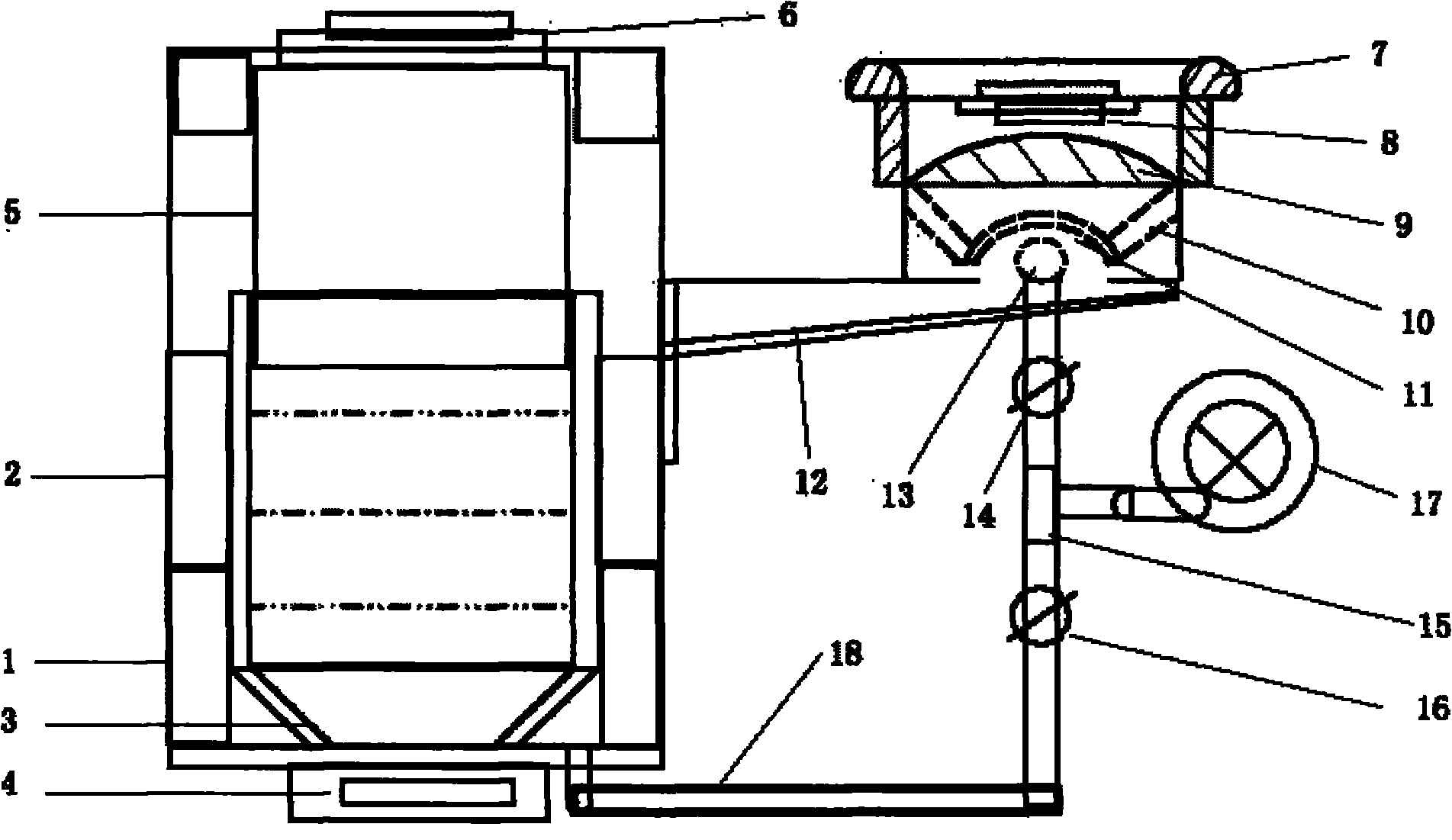

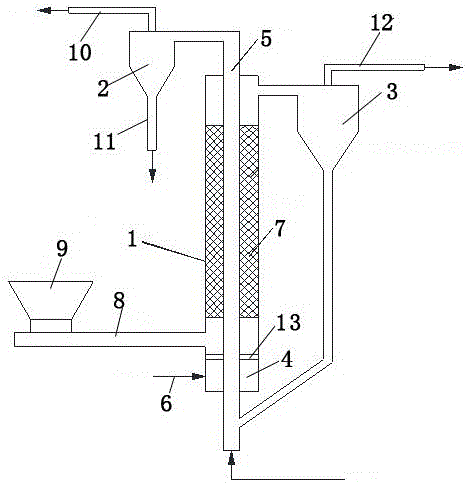

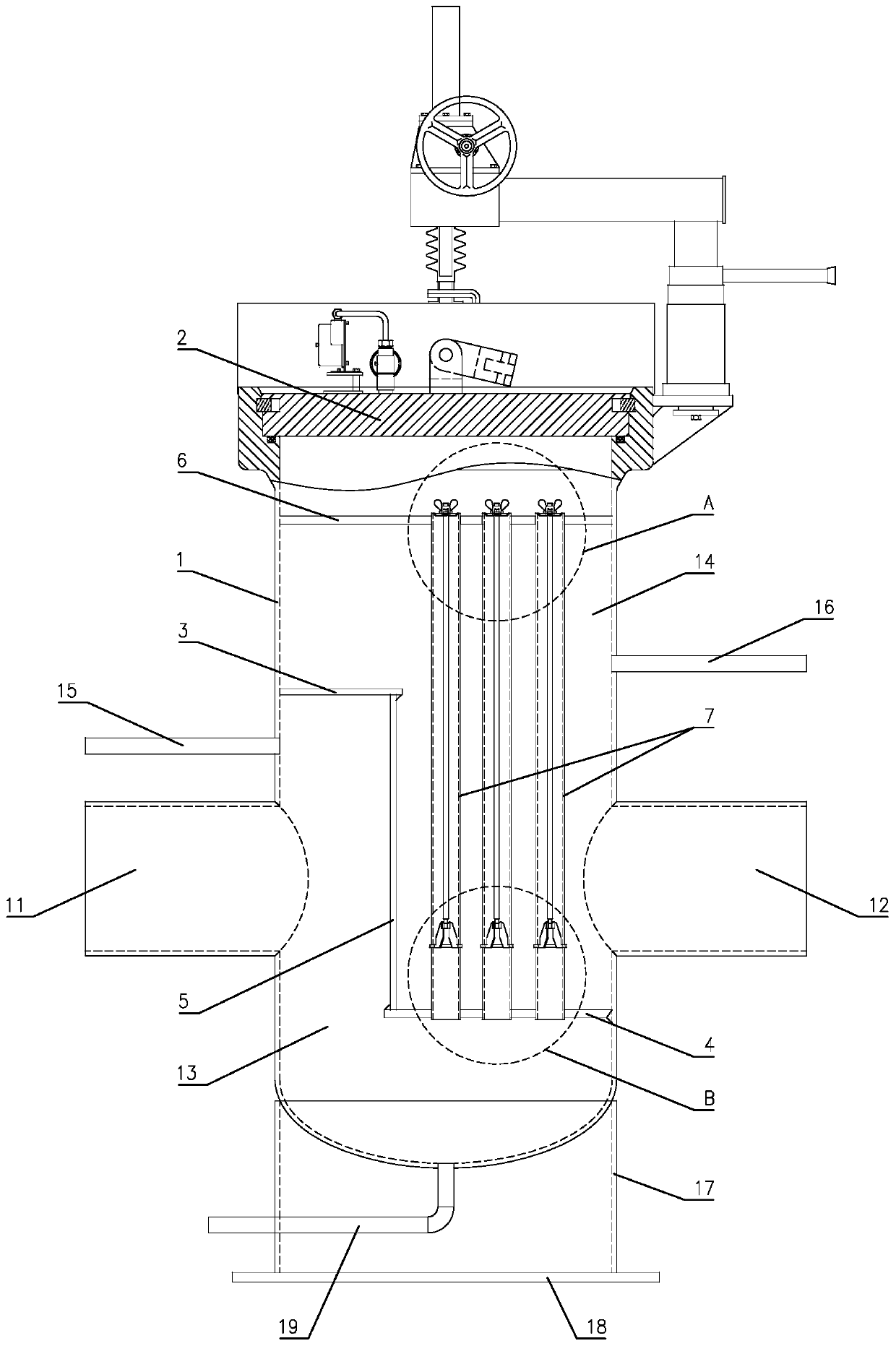

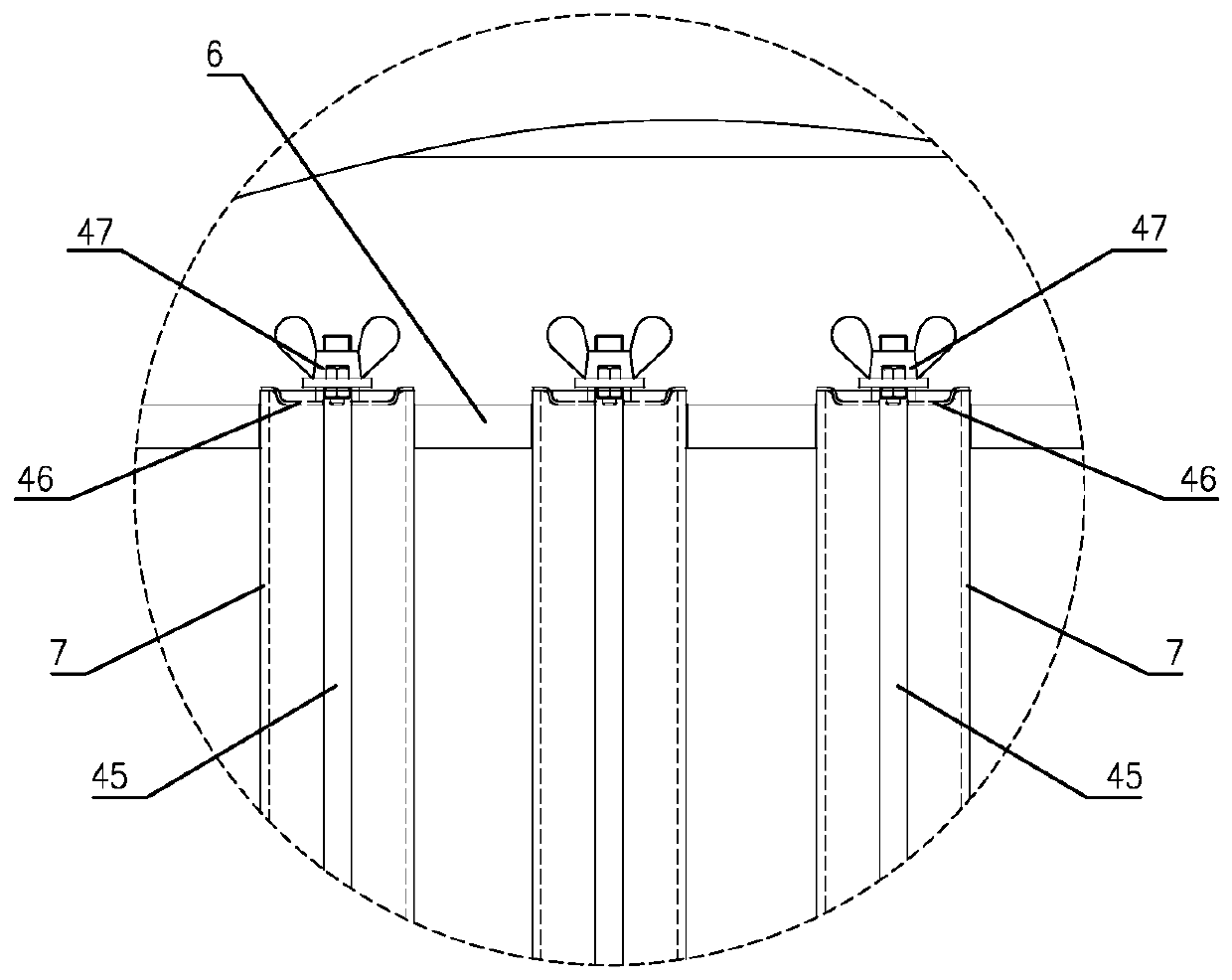

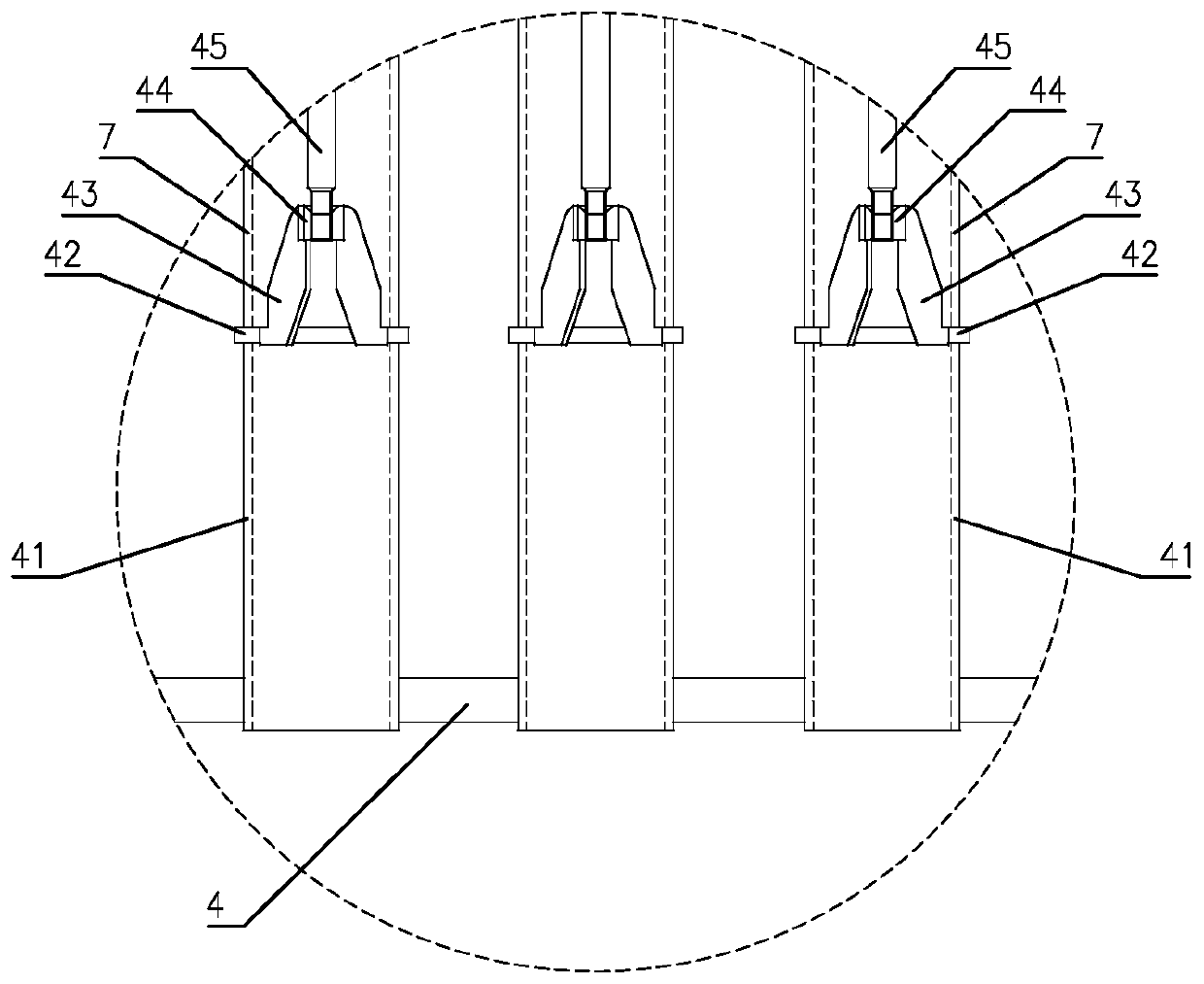

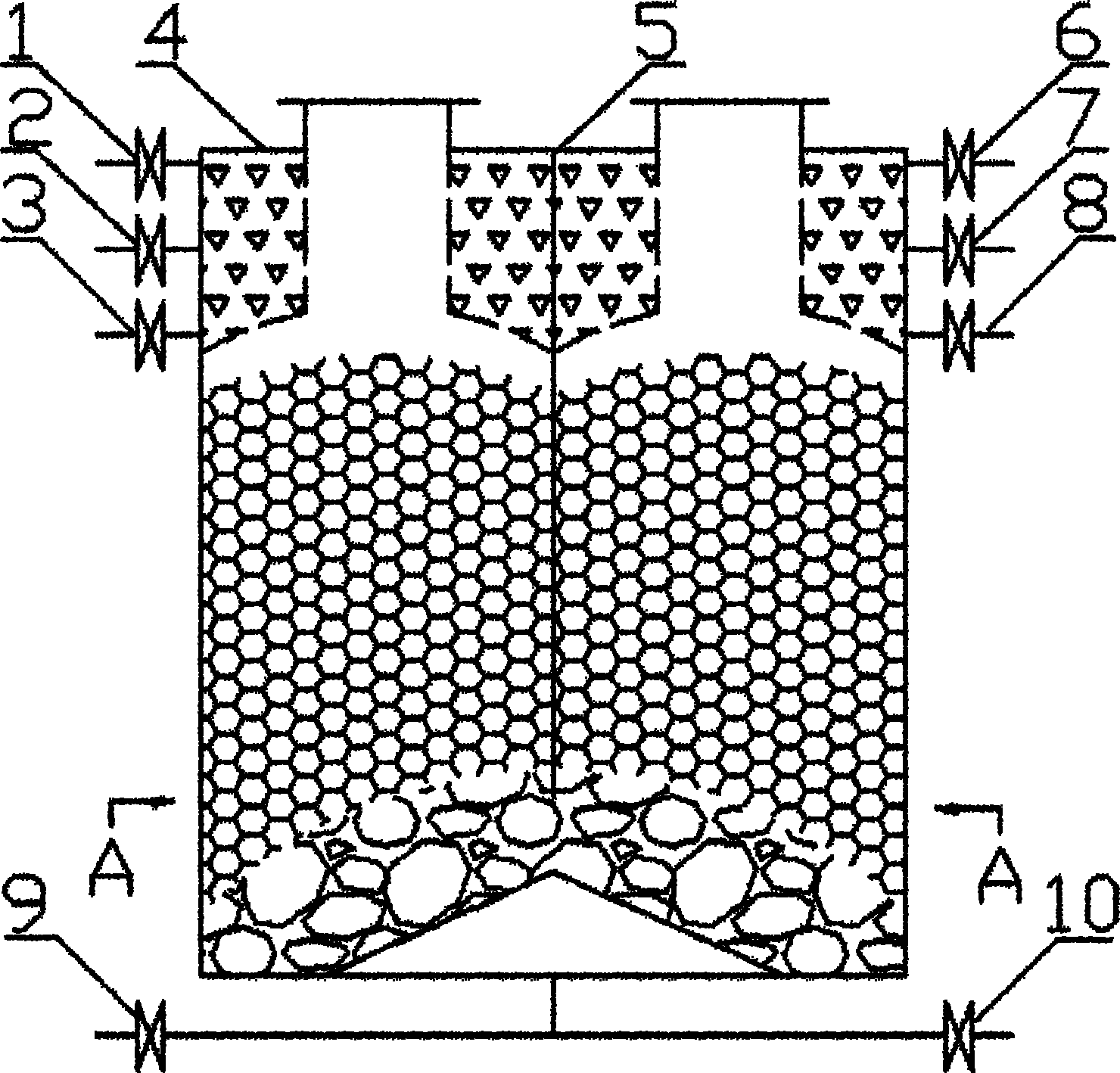

Double-flow biomass gasified gas purification device

InactiveCN102079998AHigh calorific valueIncrease contact areaBulk chemical productionCombustible gas productionReaction temperatureMoisture

The invention relates to a gasified gas purification device, in particular to a double-flow biomass gasified gas purification device, which solves the problems of low reaction temperature of a gasification furnace, abundant generated tar and wastewater, low gas-producing efficiency and abundant impurities and low heat value of output gas, resulted from unscientific structure of the gasification furnace. The gasified gas purification device comprises a gasification furnace, a gas flow control valve, a vortex flow oxidation-assisted control valve, a gas purifier and a fan. The gasified gas purification device provided by the invention has the advantages of increasing the reaction temperature of the furnace, wherein the temperature in oxidation, reduction and pyrolysis cylinders is between 1,300 and 1,600 DEG; increasing the gasification intensity; being capable of quickly separating moisture in biomass combustible gas so that gas quality is better; ensuring greatly reduced tar content in the combustible gas, less wastewater generated, high gas-producing efficiency and low environmental pollution due to the adoption of a mesh-type catalytic cracking device; and removing tar, moisture and ash in the gas through the gas purifier so that the heat value of the gas is improved. The gasified gas purification device is widely applied in industrial and civil fields.

Owner:林口信安建材板业有限公司

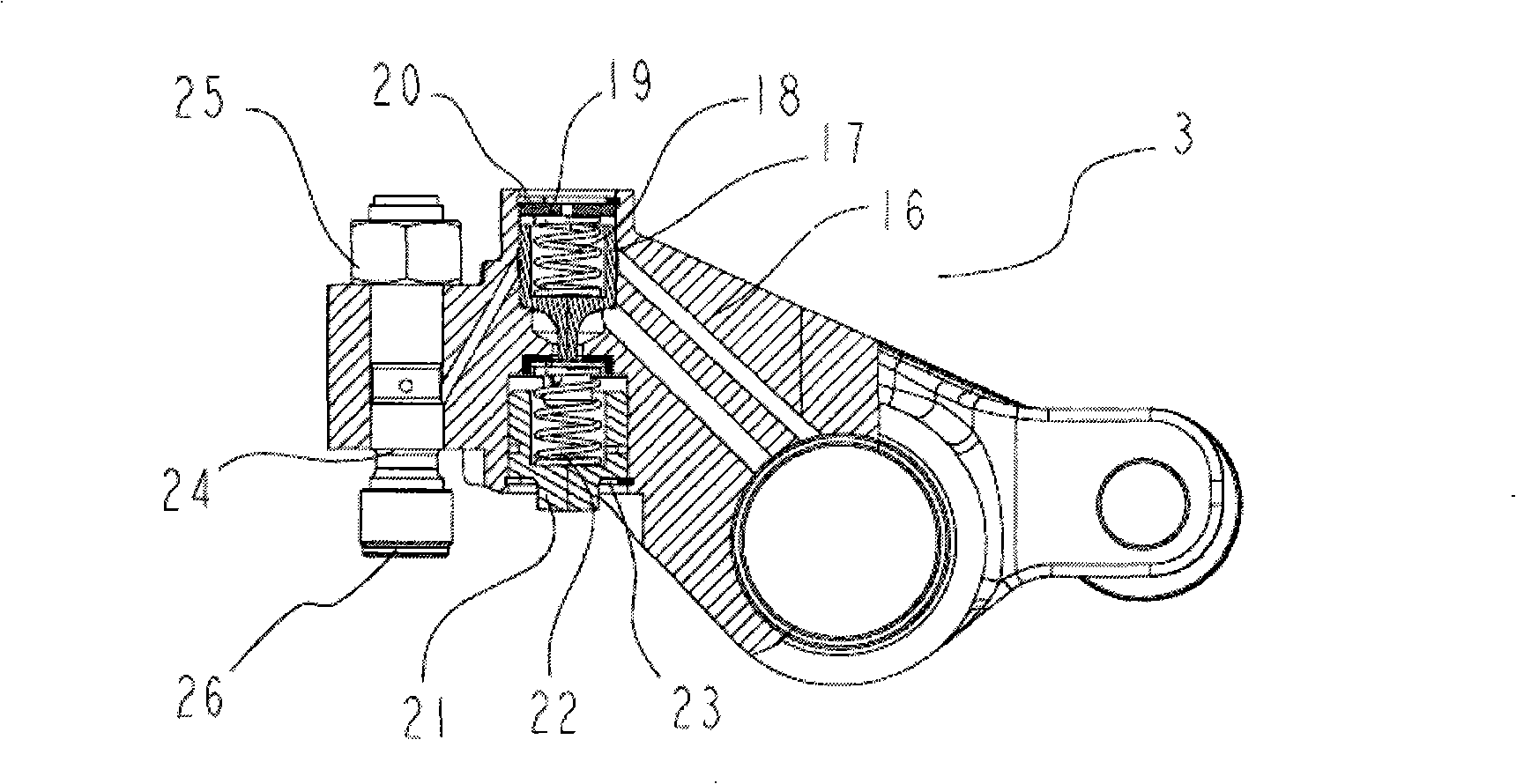

Compression braking device of four-stroke cycle internal combustion engine

ActiveCN101526018AImprove reliabilityImprove balanceValve arrangementsOutput powerRocker armOil pressure

The invention provides a compression braking device of a four-stroke cycle internal combustion engine. A control valve mechanism (13) and a clearance compensation mechanism (23) with the compensated clearance being the lift range of a braking projection are installed in parallel on one end of an amounting elephant feet of a rocker (3); a clearance compensation mechanism (11) with the compensated clearance being the lift range of a valve clearance is arranged in the midpoint of the connecting positions of an exhaust valve bridge (5) and two exhaust valves (6); the elephant feet (24) are coaxially connected below the lower end of the previous clearance compensation mechanism (23); the upper end of the next clearance compensation mechanism (11) is always in contact with the lower ends of the elephant feet; and the spring force of the clearance compensation mechanism is smaller than braking oil pressure and larger than dead weight of the elephant feet. Compared with the prior art, the compression braking device improves the reliability and the balance of a valve actuating mechanism, simplifies the structure, reduces the processing difficulty of the rocker, improves the rigidity of the rocker, and improves the accuracy and operability of the adjustment of the valve clearance. In addition, when the engine compresses and brakes, the two exhaust valves can be opened at the same time, thereby improving the braking effect of the engine.

Owner:ZHEJIANG LIMING INTELLIGENT MFG CO LTD

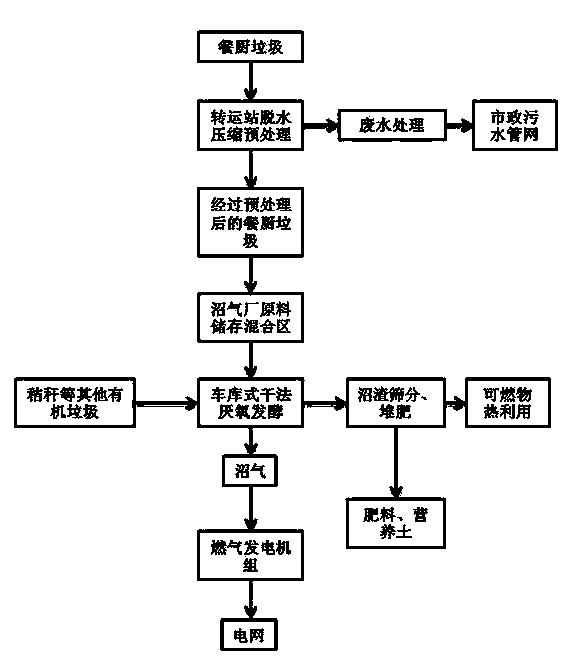

Garbage type dry fermentation comprehensive treatment method for kitchen wastes and organic wastes

InactiveCN103773809ASimple preprocessingReduce investment and operating costsBio-organic fraction processingEnergy inputSaw dustPre treatment

The invention discloses a garbage type dry fermentation comprehensive treatment method for kitchen wastes and organic wastes. The organic wastes are selected from garden wastes, sludge from sewage treatment plants, straws, animal wastes, wood flour, saw dust and the like. The method comprises the steps of carrying out dehydration and degreasing pretreatment on the collected kitchen wastes at a transfer station; mixing the pretreated kitchen wastes and organic wastes to carry out garbage type dry anaerobic fermentation, and the like. The method disclosed by the invention is characterized in that the fermentation raw materials are very simple in pretreatment; no stirring equipment is arranged in an anaerobic tank, and the fermentation raw materials do not need to be continuously stirred; feeding and discharging can be finished without the help of a pump; no any mobile mechanical equipment is arranged in the anaerobic tank. Therefore, organic raw materials with relatively high impurity contents can be fermented. Compared with a wet fermentation technology, the garbage type dry fermentation comprehensive treatment method has the effect of remarkably reducing the investment and operation costs.

Owner:徐蔚航

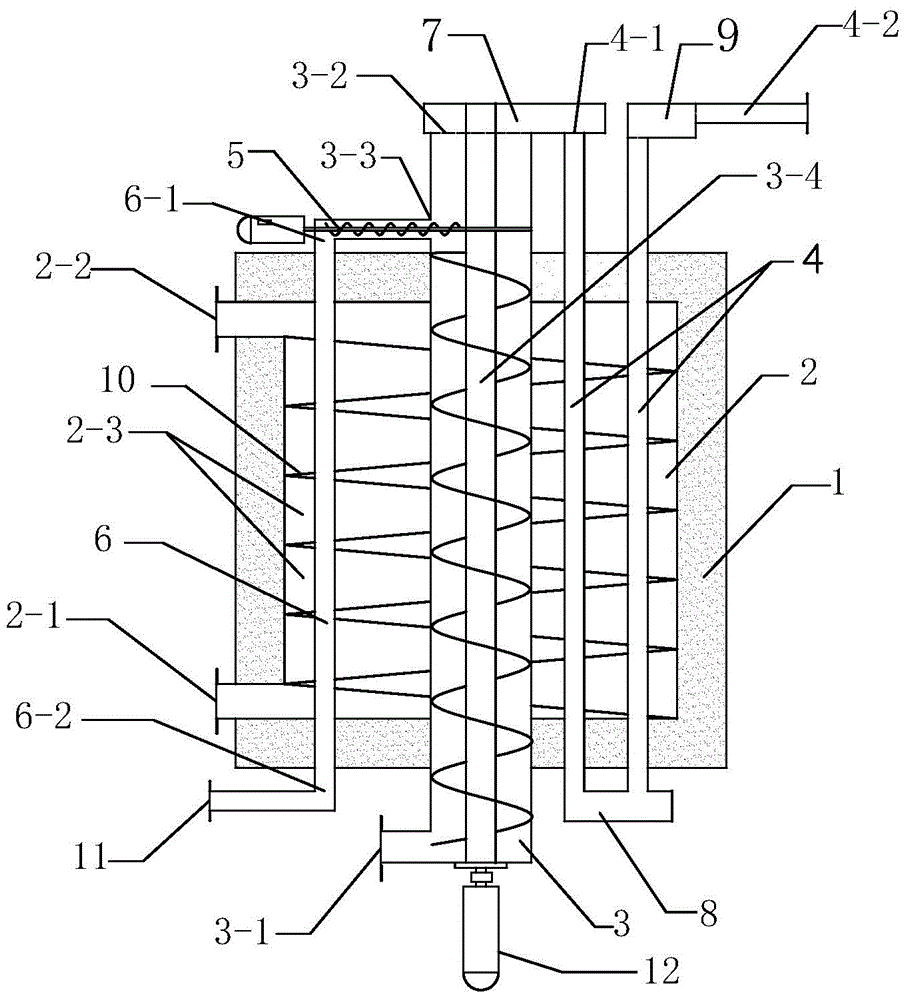

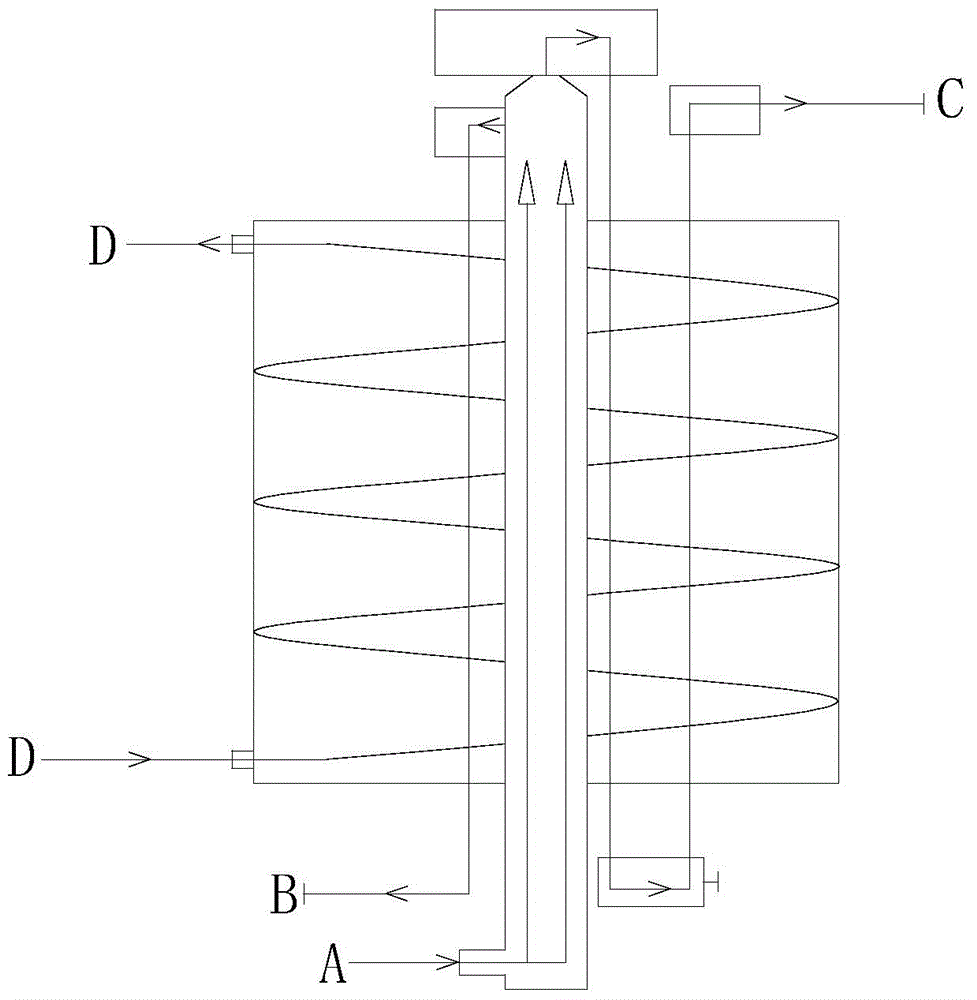

Continuous and overall biomass pyrolysis furnace

ActiveCN104099111AImprove heat utilizationReduce internal frictionBiofuelsIndirect heating destructive distillationThermal insulationFlue gas

The invention provides a continuous and overall biomass pyrolysis furnace which comprises a thermal insulation casing and a flue gas heat supply cavity, wherein a pyrolysis chamber is formed in the flue gas heat supply cavity. The biomass pyrolysis furnace is characterized in that a pyrolysis gas tar pyrolysis chamber and a semicoke calcination chamber are further formed in the flue gas heat supply cavity; the pyrolysis chamber, the pyrolysis gas tar pyrolysis chamber and the semicoke calcination chamber are vertically arranged in the flue gas heat supply cavity and penetrate through a spiral hot air channel, and upper ends and lower ends of the pyrolysis chamber, the pyrolysis gas tar pyrolysis chamber and the semicoke calcination chamber extend out of the flue gas heat supply cavity; and a material inlet is formed in the lower end of the pyrolysis chamber, a pyrolysis gas outlet and a semicoke outlet are formed in the upper end, the pyrolysis gas outlet in the upper end of the pyrolysis chamber is communicated with a pyrolysis gas inlet in the pyrolysis gas tar pyrolysis chamber, and the semicoke outlet is communicated with a semicoke inlet in the semicoke calcination chamber through a horizontal auger. According to the continuous and overall biomass pyrolysis furnace, three processes including pyrolysis, tar pyrolysis and semicoke calcination are implemented in a segmented manner in the same flue gas heat supply cavity, the whole reaction process is controlled effectively, the quality of charcoal and gas is improved, and the conversion efficiency is increased.

Owner:武汉海德天物新材料有限公司

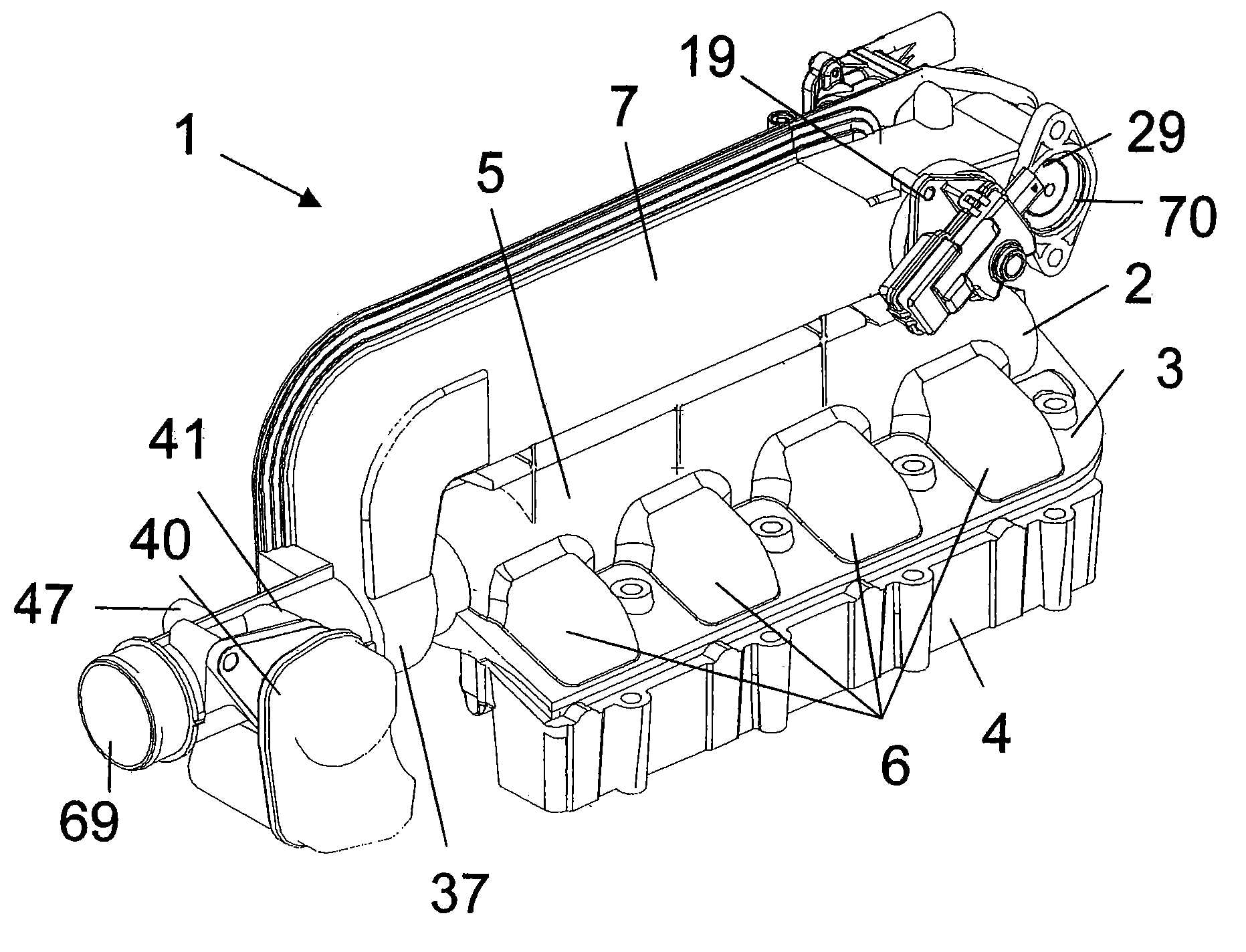

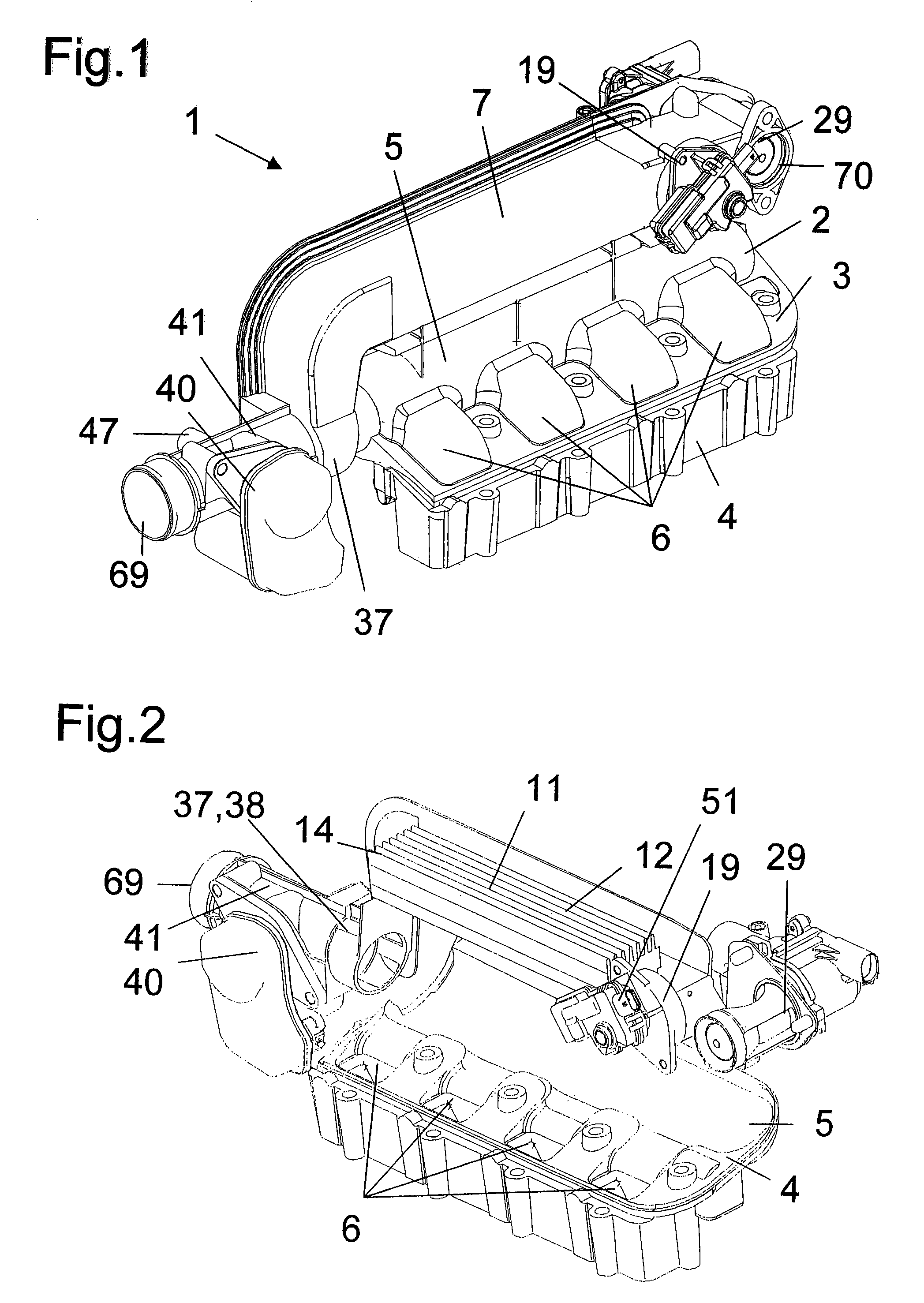

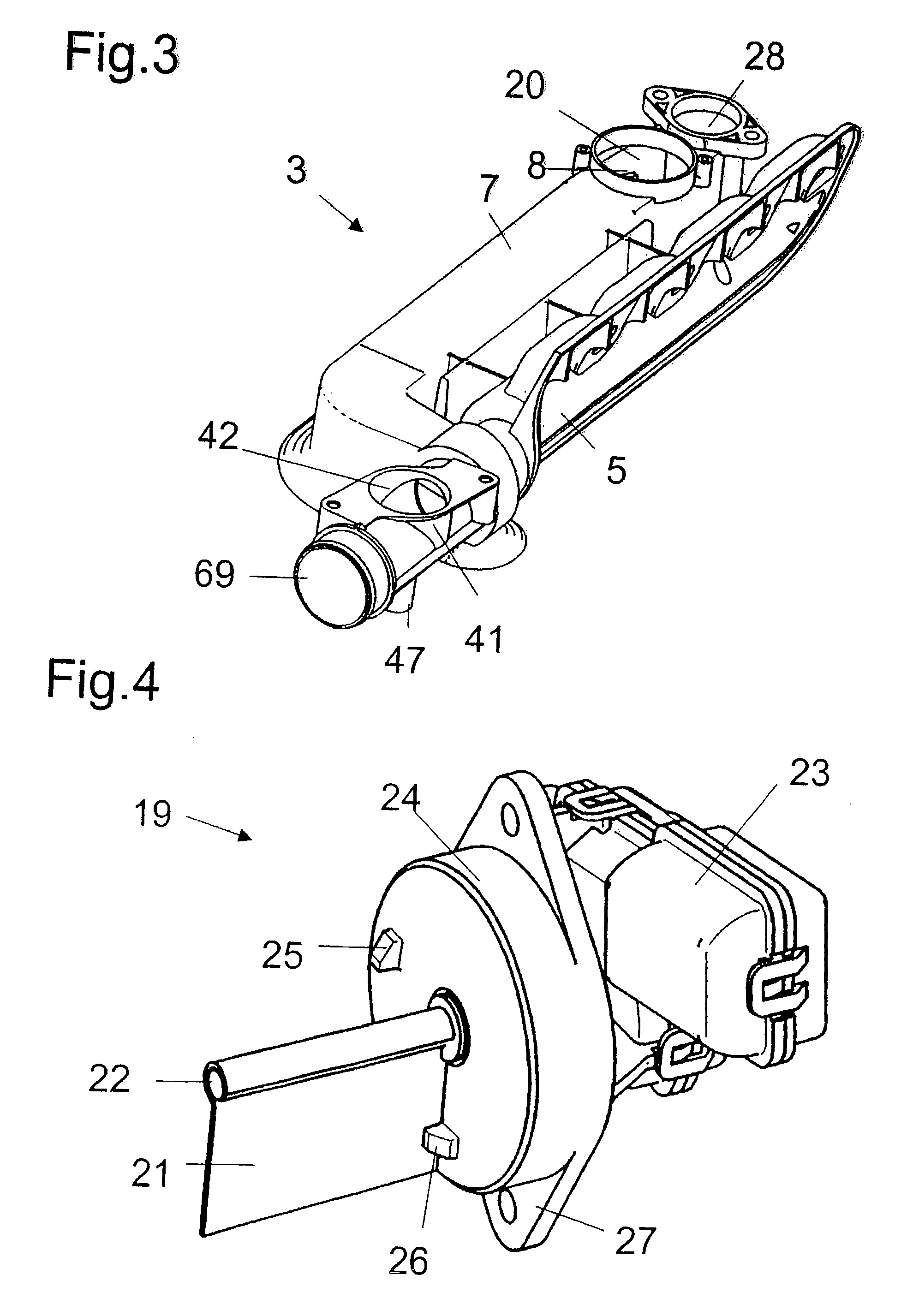

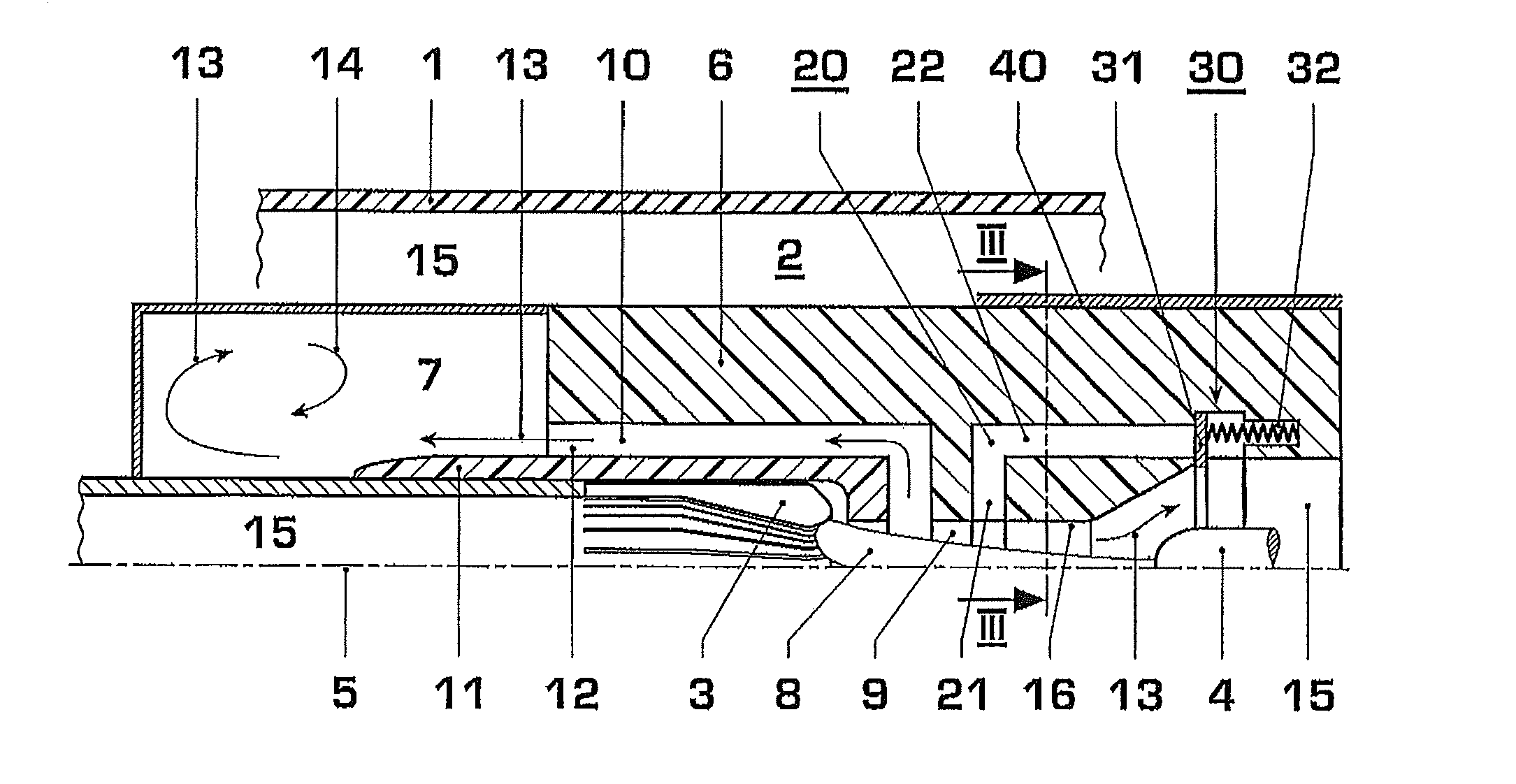

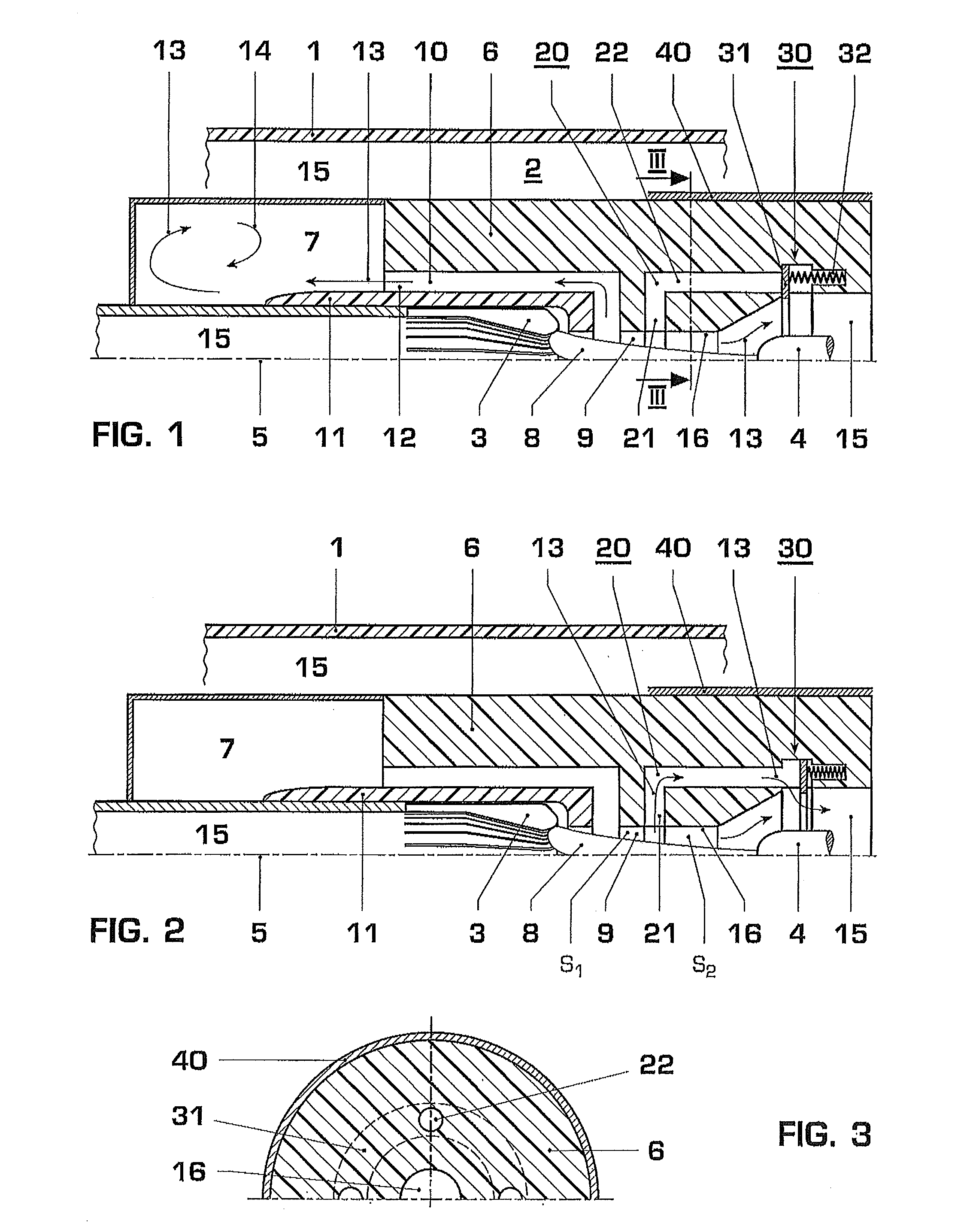

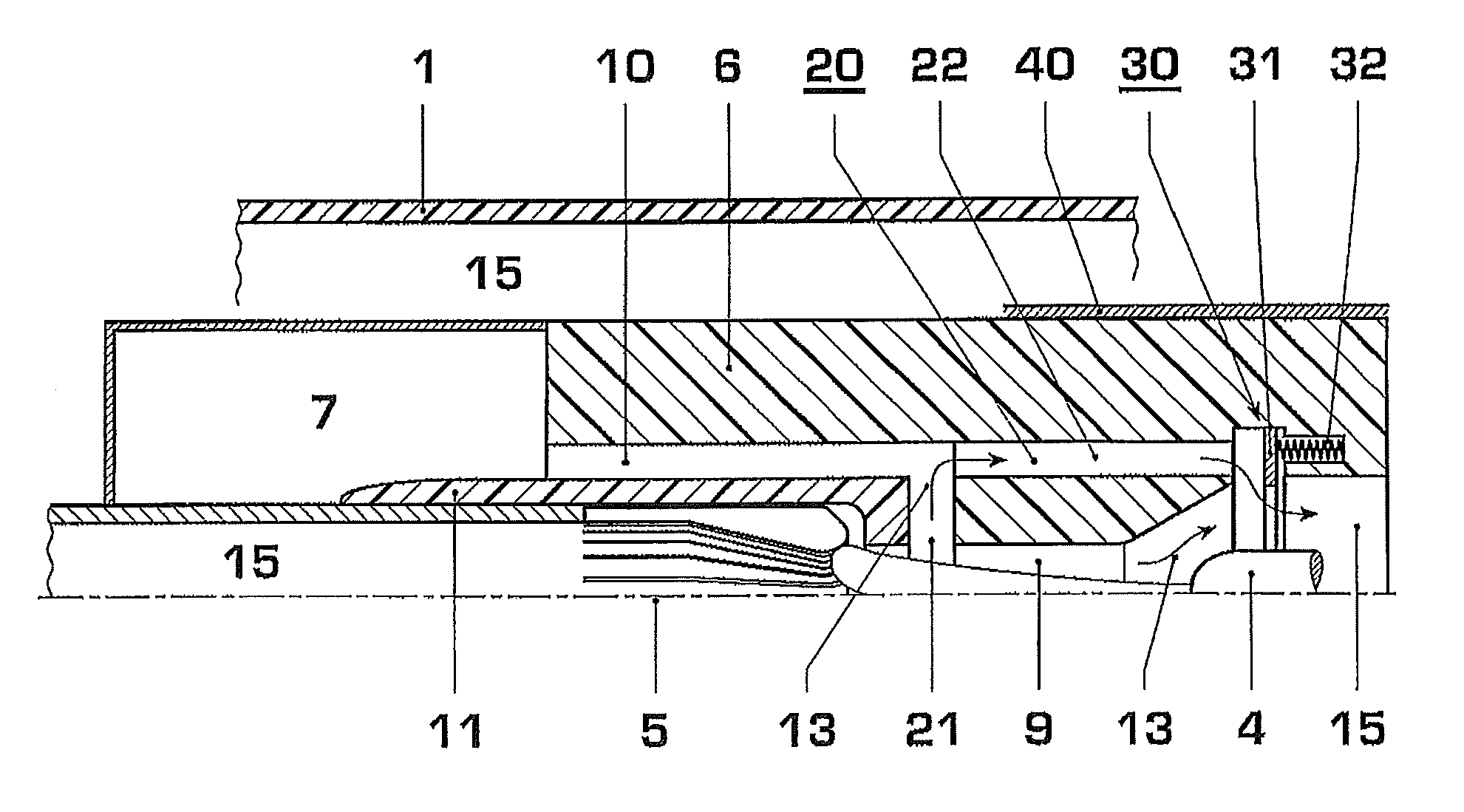

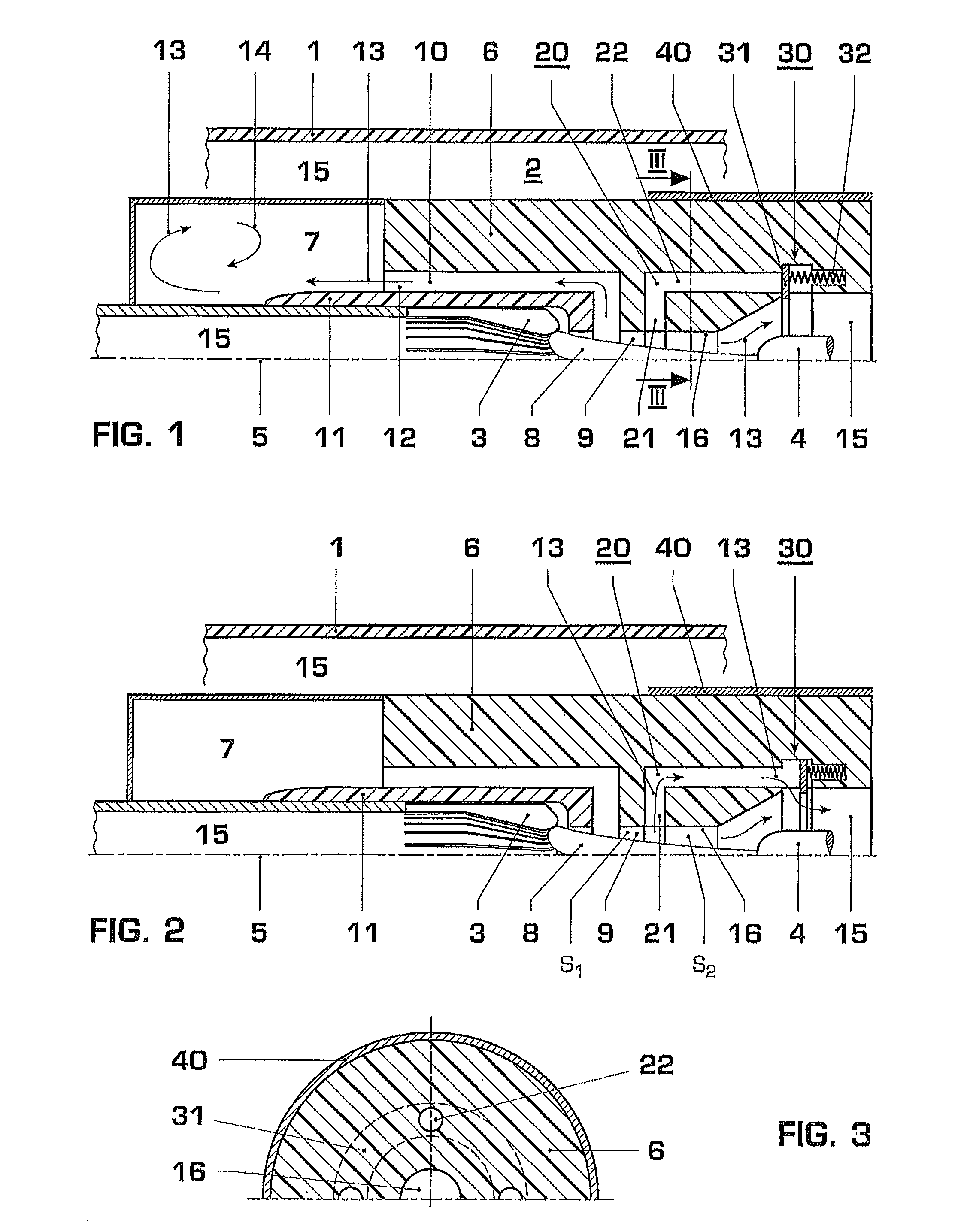

Air-intake duct system for a combustion engine

InactiveUS7207324B2Temperature optimizationCold start and warm-up periods of the engineInternal combustion piston enginesNon-fuel substance addition to fuelCombustionEngineering

The invention relates to an air-intake duct system (1) in which a throttle valve (40), an exhaust gas recirculating valve (29), a bypass valve (19), an exhaust gas cooler (11), against which exhaust gas flows via bypass valve (19), and, optionally, an air mass sensor are integrated. A complete intake unit for modern engines is hereby created, with which achieves a charging optimization and thus a reduction in fuel consumption as well as a reduction in pollutants by a corresponding thermal management in the engine by the exhaust gas cooler (11) that, together with a shell (3, 4) of the housing (2), is manufactured as a single piece. The individual add-on pieces (12, 19, 29, 40, 59) are optimally matched to one another and have, due to their designs, a low weight and a low finishing work requirement. This makes it possible to distinctly reduce assembly and manufacturing costs.

Owner:PIERBURG GMBH & CO KG NEUSS

Method for removing tar oil from gasified combustible gas by using waste rubber and plastic crack oil

InactiveCN101186836AImprove purification effectAdaptableLiquid hydrocarbon mixture productionGasoline stabilisationDistillationWaste rubber

The invention relates to a process for removing tar oil with gasification gas. At present, the operating cost and the maintenance cost of the present process for removing tar oil are high, and the second pollution of the waste water of tar oil is brought out. The concrete steps of the invention are that waste rubber and plastic used for schizolysis are conveyed to a schizolysis furnace and oil gas mixture and solid charcoal are generated after the heat schizolysis reaction, the oil gas mixture produced by the schizolysis reaction is separated via a rectifying tower and then oil products and gas are generated, and the distillate with the temperature of 200-350 DEG C is separated out as oil washing distillation cut which is employed to absorb the tar oil in the gasification gas which contains tar oil. Compared with the existing technology, the process for removing tar oil in gasification gas has high process reliability, increases the thermal value of the gas, reduces the operation cost , produces no waste water of tar oil, and promotes the added value of the tar product .

Owner:南京绿展能源有限公司

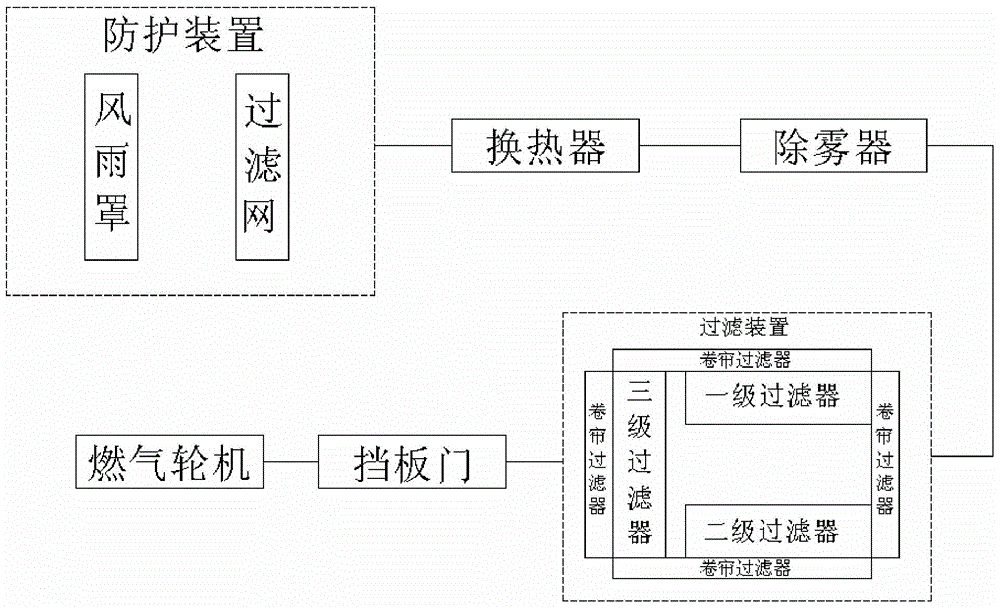

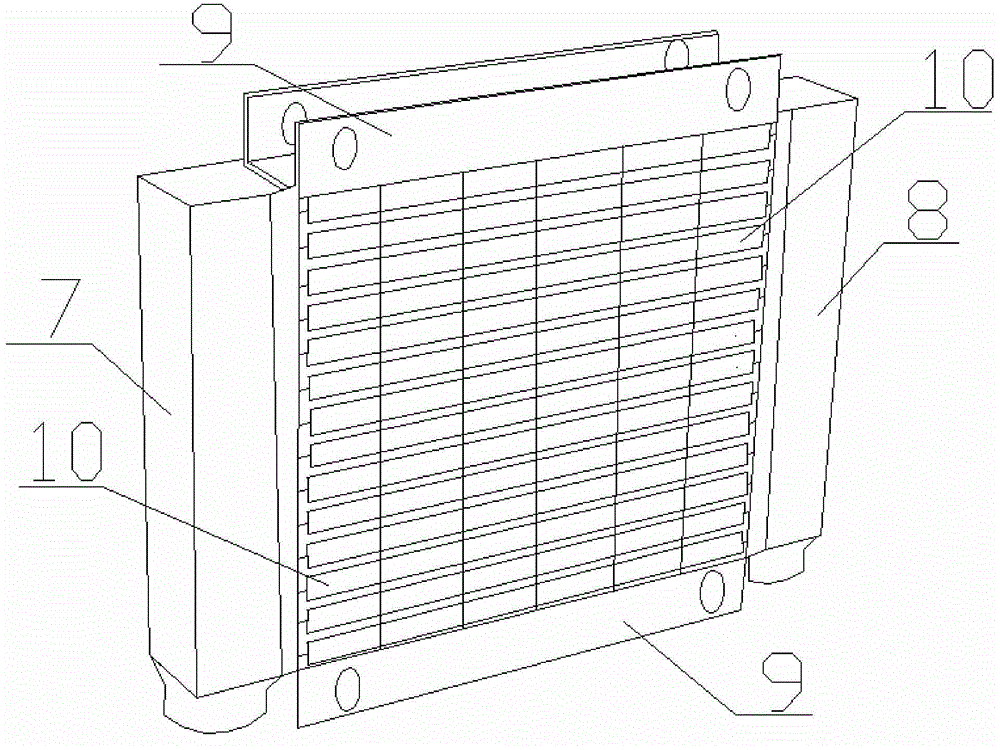

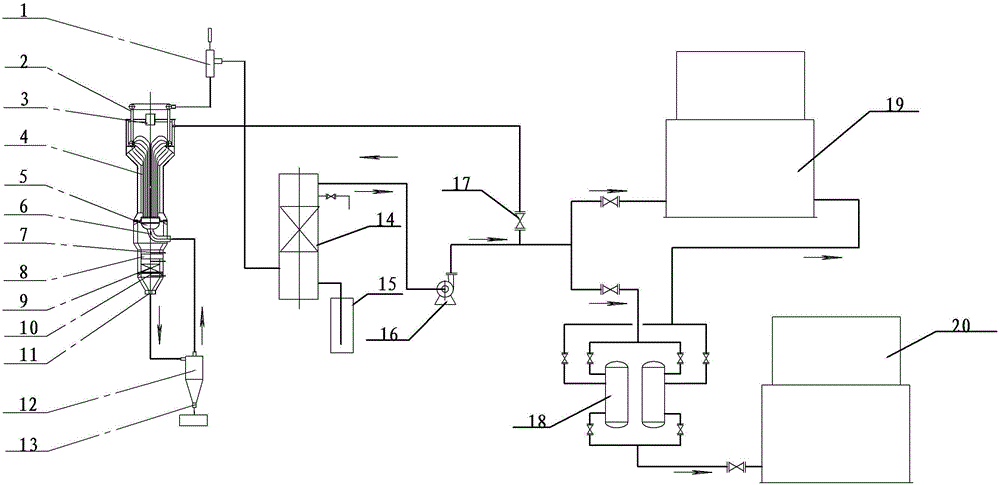

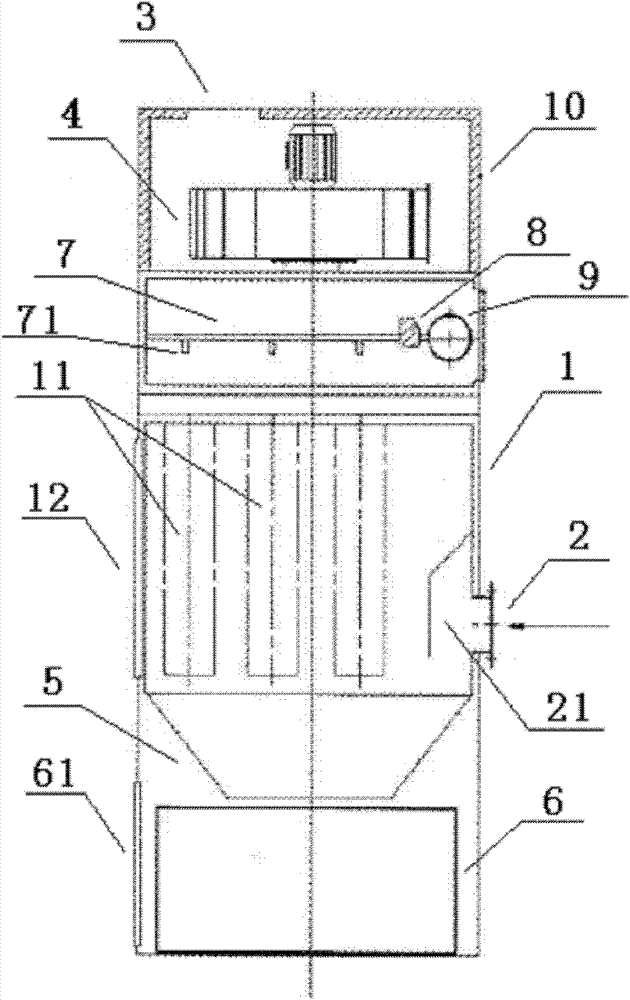

Air intake system and method for gas turbine

InactiveCN104895677AAvoid blockingDecrease productivityGas turbine plantsTurbine/propulsion air intakesRam-air intakeFiltration

The invention discloses an air intake system for a gas turbine. The air intake system comprises an air intake ducting connected with an air inlet of an internal-combustion engine, a protection device, a heat exchanger, a demister, a filter device and a baffle door, wherein the protection device, the heat exchanger, the demister, the filter device and the baffle door are connected through the air intake ducting; the protection device is connected with the heat exchanger; the heat exchanger is connected with the filter device; the demister is arranged between the heat exchanger and the filter device; a blast deflector is arranged at one end of the outlet of the filter device; and the baffle door is arranged at the outlet of the air intake ducting. The invention further discloses an air inlet method of the gas turbine. The air intake system of the gas turbine is simple in structure and performs multiple filtration on gas, so that the quality of the gas is ensured, and the service life of the gas turbine is prolonged. The air intake method of the gas turbine is simple and practicable to operate.

Owner:江苏华强新能源科技有限公司

Gas-insulated high-voltage circuit breaker with a relief duct which is controlled by an overflow valve

InactiveUS20100219161A1Control pressureLoad moreHigh-tension/heavy-dress switchesAir-break switchesEngineeringQuenching

A high-voltage circuit breaker includes two arcing contacts, which are capable of moving relative to one another along an axis, an insulating nozzle, a heating volume for accommodating quenching gas, a heating channel, and an overpressure valve. The pressure of the quenching gas is based on the energy of a switching arc, which is formed when the breaker opens and generates arcing gas, and the heating channel opens out, with axial alignment, into the heating volume. The heating channel connects an arc zone, and the overpressure valve limits the pressure of the quenching gas by opening a relief duct, which opens out into an expansion space. In high-current switching, the pressure of the arcing gases in the arc zone is limited, and the quality of the quenching gas stored in the heating volume is improved, due to the relief duct having an outflow section extending in the radial direction.

Owner:ABB RES LTD

Composite biomass staged gasification furnace

The invention relates to the technical field of gasification furnaces, and in particular to a composite biomass staged gasification furnace. The furnace comprises a furnace body; a fire grate is fixedon the side wall of the lower part in the furnace body; a space below the fire grate is a slag cavity; an ash discharge port is formed in the side wall of the furnace body corresponding to the slag cavity; a filter screen is also fixed on the inner wall of the furnace body; the filter screen is positioned above the fire grate; a fine filter is fixed to the top wall of the interior of the furnacebody, a feeding mechanism is fixed to the outer side of the furnace body, a primary filtering mechanism is fixed to the feeding mechanism and connected with the feeding mechanism through a feeding pipe, and the primary filtering mechanism is connected with the upper portion of the side wall of the furnace body and a fine filtering mechanism through a first air pipe and a second air pipe. Accordingto the composite biomass staged gasification furnace, the content of tar and smoke dust in fuel gas is greatly reduced, the fuel gas quality is improved, equipment is protected, the filtered tar is returned to the furnace again to be subjected to high-temperature cracking to generate small molecular fuel gas, then the fuel gas generation efficiency is improved again, and the tar generation amountis reduced.

Owner:HUNAN INSTITUTE OF ENGINEERING

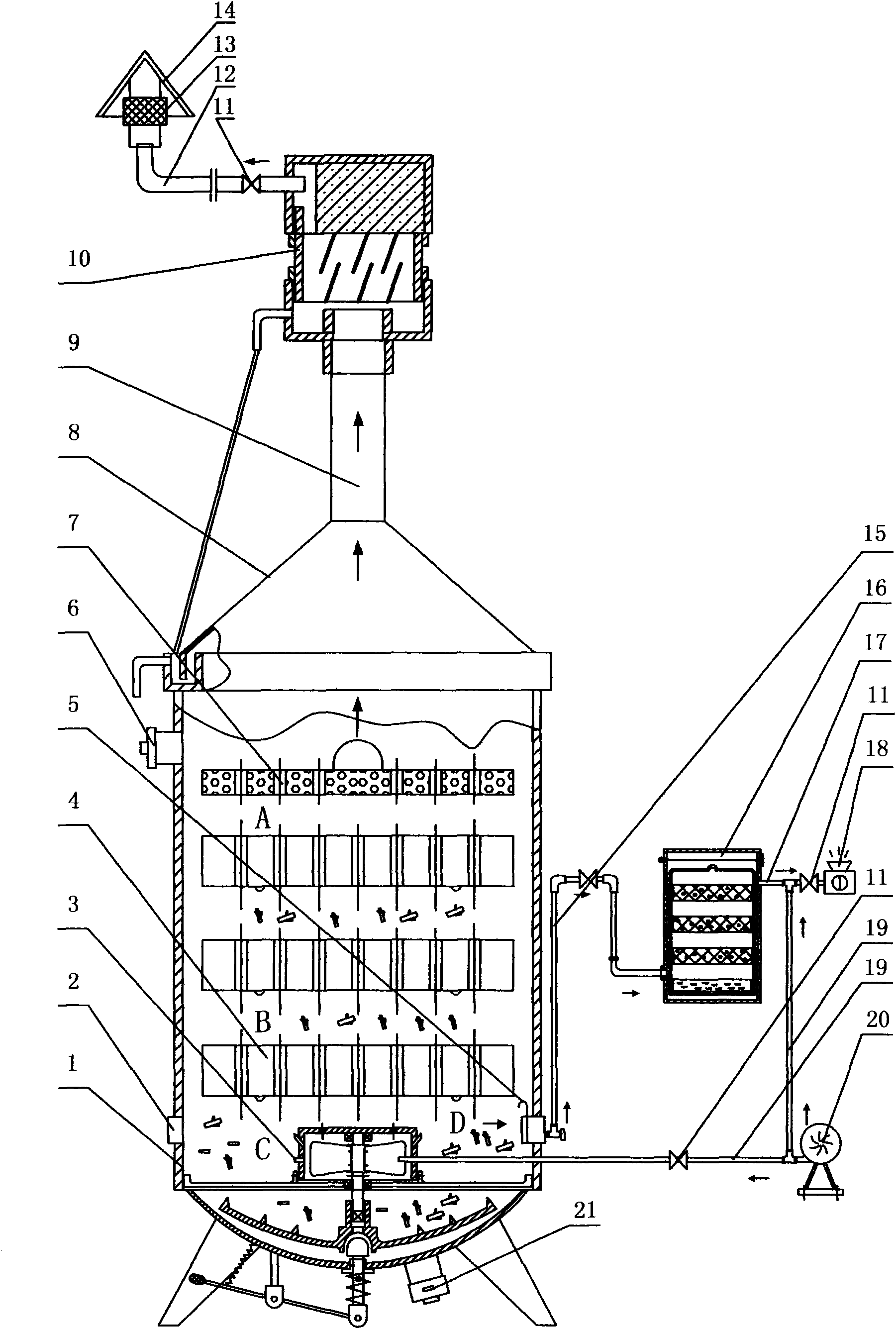

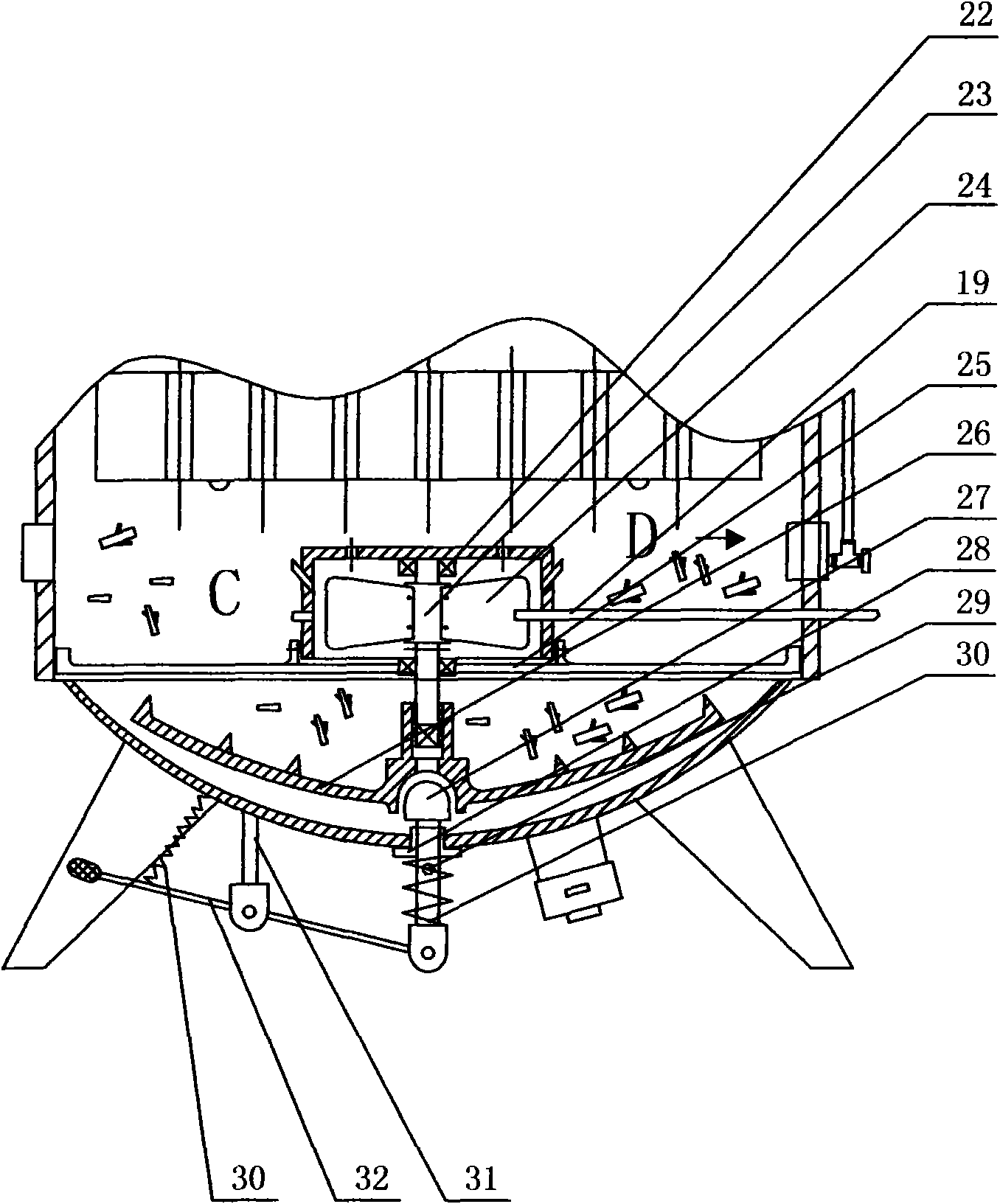

High-efficiency, energy-saving and environment-friendly stalk gasifier

InactiveCN101643653AFull simmering effectSolve technical problemsSpecial form destructive distillationDust controlEngineering

The invention relates to a high-efficiency, energy-saving and environment-friendly stalk gasifier. The stalk gasifier adopts the mechanical lever principle, pyrology, chemistry and environmental science, is provided with an exhaust stirring device, a cellular air door adjustment device, an air door adjustment cover, a smoke prevention and dust control filter and a coke tar filter device, and hermetically burns cellular stalk compressed cakes which are compressed from wheat and rice straws, weeds and melon vines, thereby effectively solving the long-term technical problems existing in the prior gasifier, fully and hermetically burning the stalks in the gasifier, effectively improving the quality of the generated gas, saving energy, cracking the tar discharged by the gasifier and effectively filtering and removing the smoke dust and the tar discharged by the stalks. Because a gas cooker is electronically and automatically ignited and a gasifier body adopts a corrosion-resistant and hightemperature-resistant coating, the service life of the stalk gasifier is strongly guaranteed. The discharge amount of the smoke dust and the tar meets the national environmental protection requirements. The main parts of the stalk gasifier are all assembled, so the stalk gasifier brings great convenience to the cleaning of the smoke dust and the tar and the maintenance, is safe in operation and can be used for supplying heat, bath and the like. The stalk gasifier saves a large amount of coal, oil and natural gas for the country, contributes to building a new socialist countryside for the country and brings social and economic benefits.

Owner:李云飞

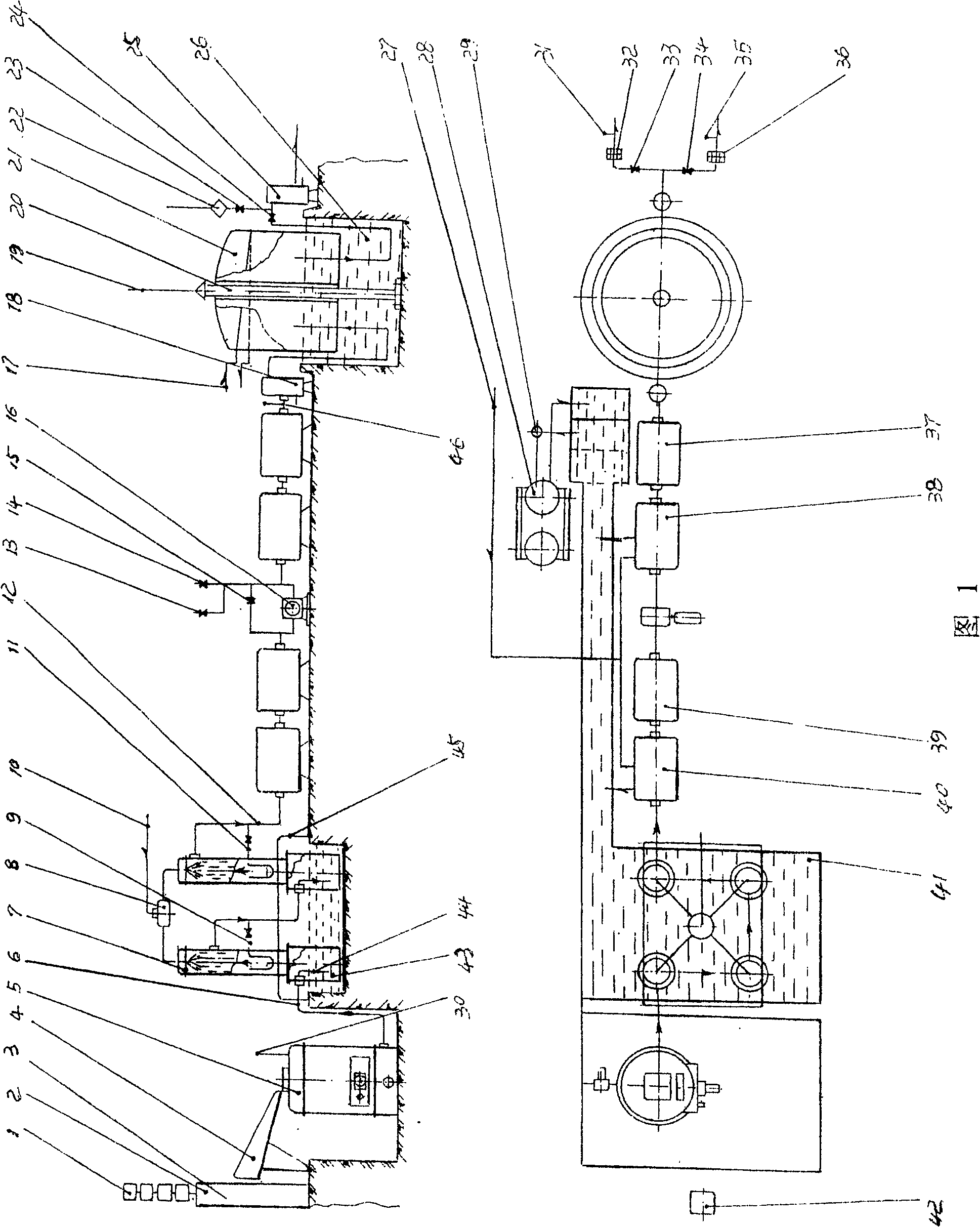

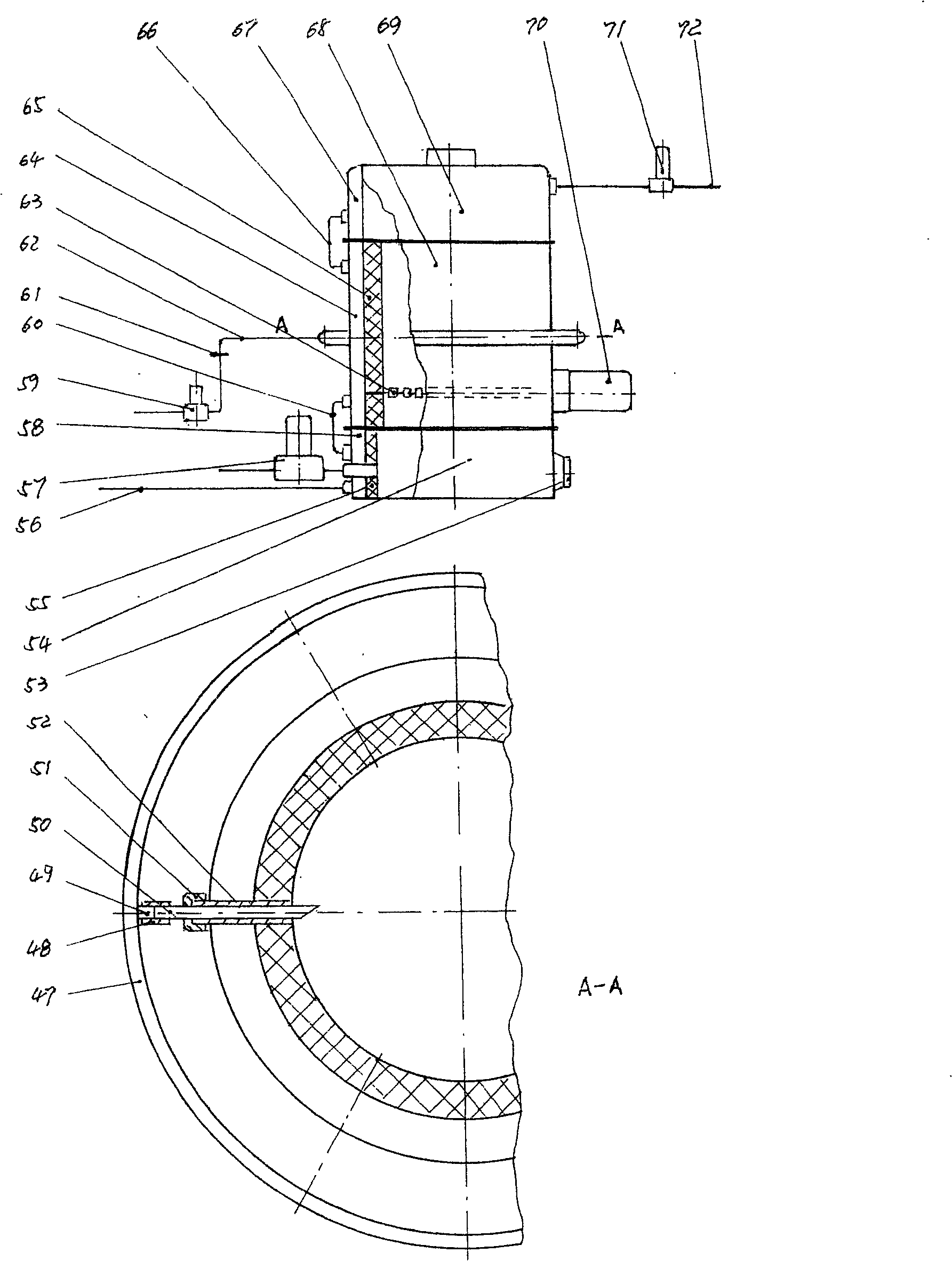

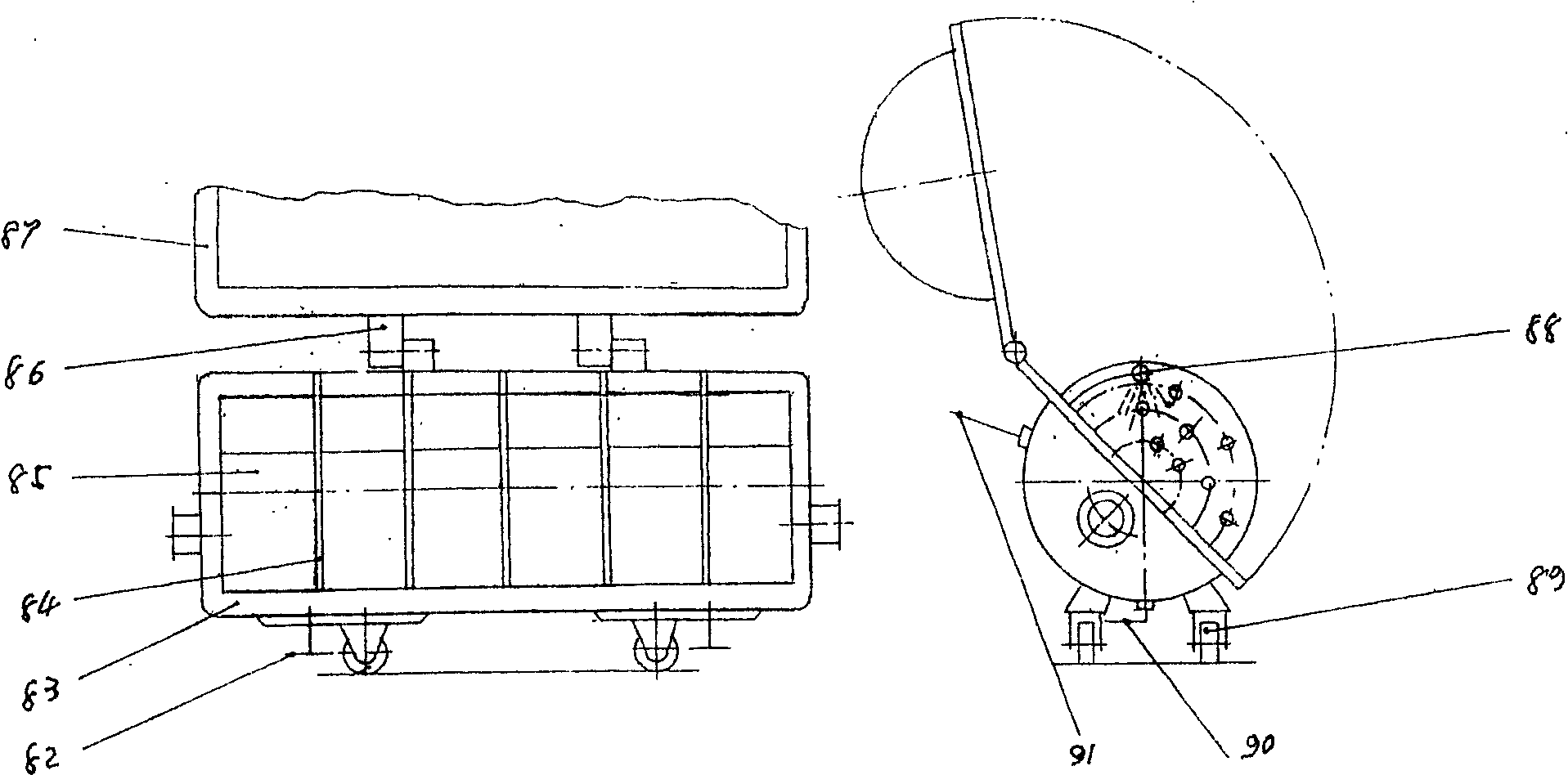

Water pump for vehicle

InactiveUS20110135444A1Stable exhaust gas qualityLow costPump componentsWind motor controlImpellerEngineering

A water pump for a vehicle, may include a first shaft fixed to a pulley to be rotated thereby, a second shaft fixed to an impeller for pumping, and clutch that is disposed between the first shaft and the second shaft to selectively connect the first and second shafts to transfer a rotation torque of the first shaft to the second shaft.

Owner:HYUNDAI MOTOR CO LTD +1

Novel tar-free stove integral gasifier

InactiveCN102252348AReduce contentNo emissionsDomestic stoves or rangesLighting and heating apparatusCatalytic pyrolysisTar

The invention relates to a novel tar-free stove integral gasifier, comprising an updraught gasifier body provided with a high temperature cracking burner and an annular tar cracking unit. The central portion of the updraught gasifier body is equipped with a blanker, the bottom of the updraught gasifier body is equipped with the annular tar cracking unit and a ventilation pipe II, and one side of the updraught gasifier body is equipped with an air inlet pipe. The annular tar cracking unit is communicated with the air inlet pipe, and is provided with a dried layer, a dolomite layer and a charcoal catalytic pyrolysis layer from top to bottom. The inner wall of a gas stove is arranged at the outboard of the high temperature cracking burner, a taper fire-resistant air distribution ring is arranged at the bottom of the high temperature cracking burner, and a trumpet-shaped air pipe is arranged at one side of the bottom of the high temperature cracking burner. The taper fire-resistant air distribution ring is provided with a stove core. An infrared screen and an exhaust pipe are arranged on the top of the stove core, and a fuel-air mixing chamber internally provided with a ventilation head is arranged vertically below the stove core. The ventilation head is communicated with the ventilation pipe II through a ventilation pipe I. According to the invention, the purpose of sustainable combustion by one charging and no discharge of tar can be achieved.

Owner:JIUQUAN LVJU ENERGY TECH DEV

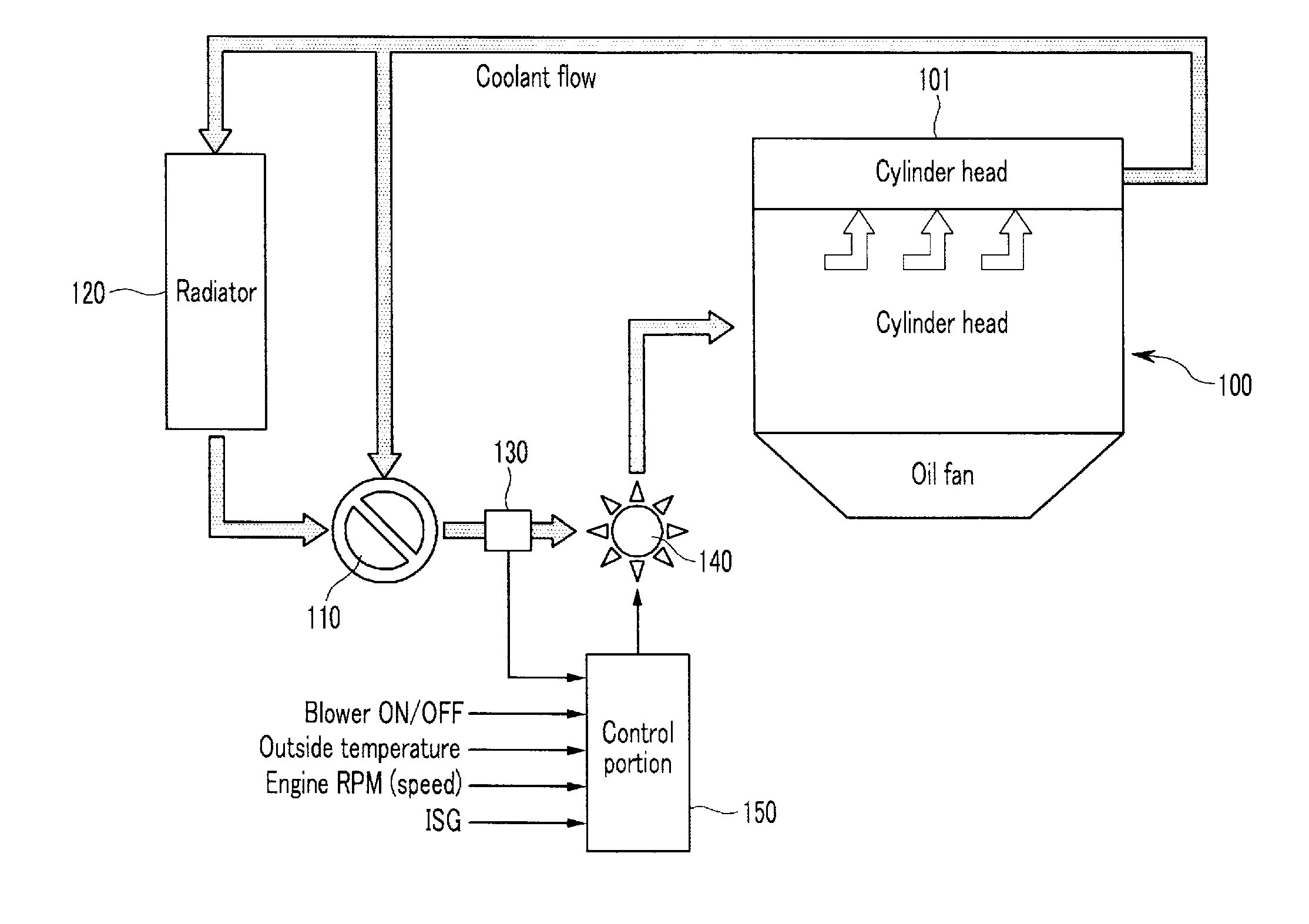

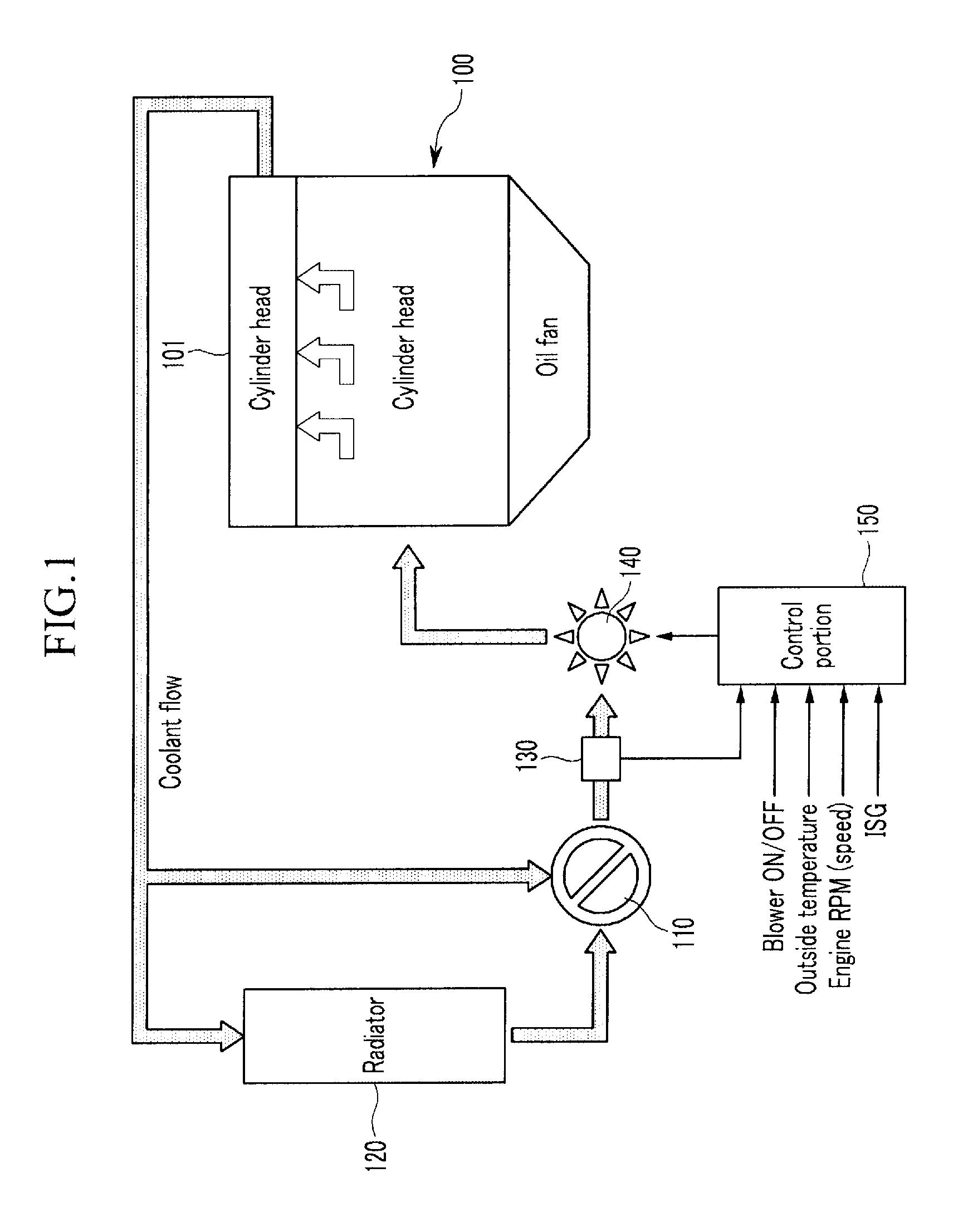

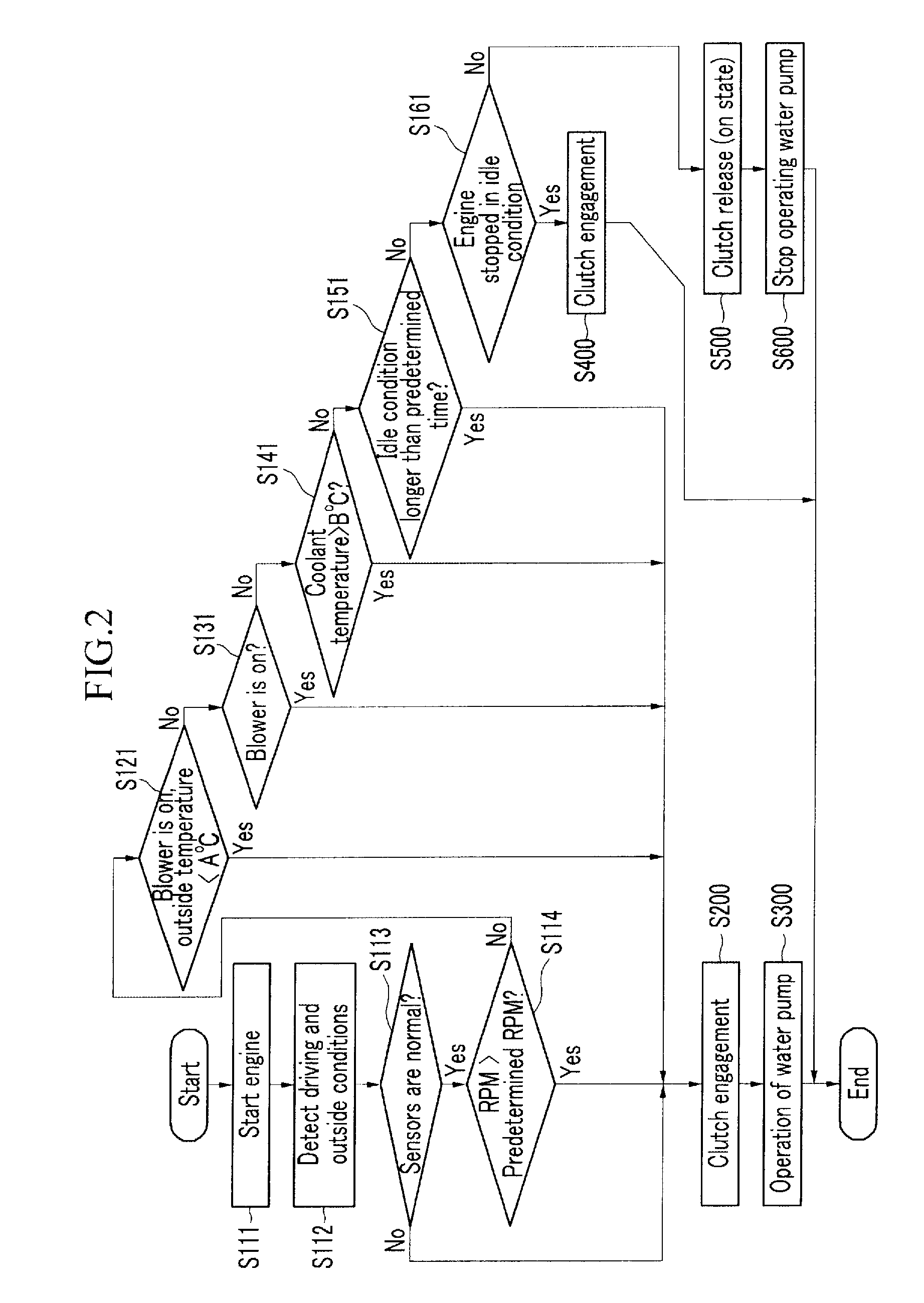

Variable water pump control system and the control method thereof

ActiveUS20110135508A1Increased durabilityImprove fuel efficiencyCoolant flow controlMotor parameterControl systemEngineering

A variable water pump control apparatus, may include a detecting portion detecting engine speed, operation of an idle stop and go system (ISG), coolant temperature, operation of a blower, and outside temperature, a variable water pump selectively circulating a coolant through an engine, and a control portion controlling the variable water pump according to the detected information including operating conditions and outside environmental factors, and a variable water pump control method may include detecting a driving condition and an environmental condition of a vehicle, and engaging or releasing a clutch of a variable water pump according to a detected condition so as to selectively circulate a coolant.

Owner:HYUNDAI MOTOR CO LTD +1

Biomass gasification centralized safety and early warning air supplying system

InactiveCN101319752AHarm reductionAdd new featuresContainer filling methodsContainer discharging methodsWater bathsTar

The invention relates to a biomass gasification concentrating safety and early-warning gas supply system, mainly comprising a feeding rack, a wind-controlled gasification furnace, grouped water spray towers, a horizontal spray filtering purification can, a double-tank tar retriever, a surplus heat utilization device and an underground wet gas reservoir. The invention mainly has the characteristics that 1) the pyrolysis, oxidation and reducing reaction in the gasification furnace can be actively controlled by wind to improve the gasification efficiency; 2) the tar in the system can be recycled, and the energy utilization rate is improved; 3) the gas has a long technical process, high quality and high purity; 4) the components of the gasification machine are easy to maintain independently; 5) the early-warning function has four levels, i.e. blue, yellow, orange and red, and the alarming mechanism can be used to control the system safety automatically. Therefore, the invention is capable of supplying biomass gas in a high efficient and safe manner.

Owner:曾自旺

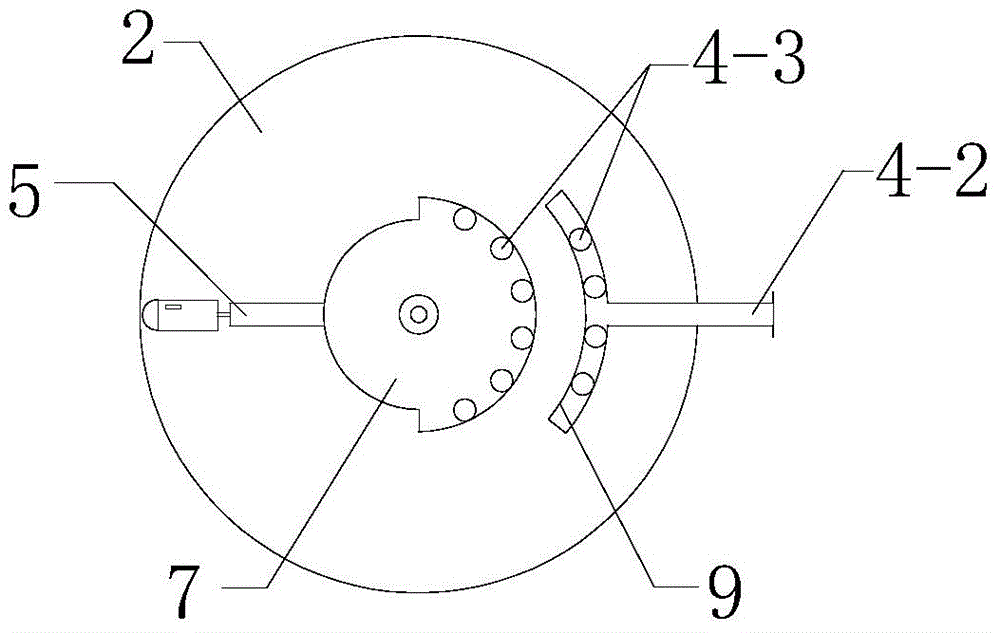

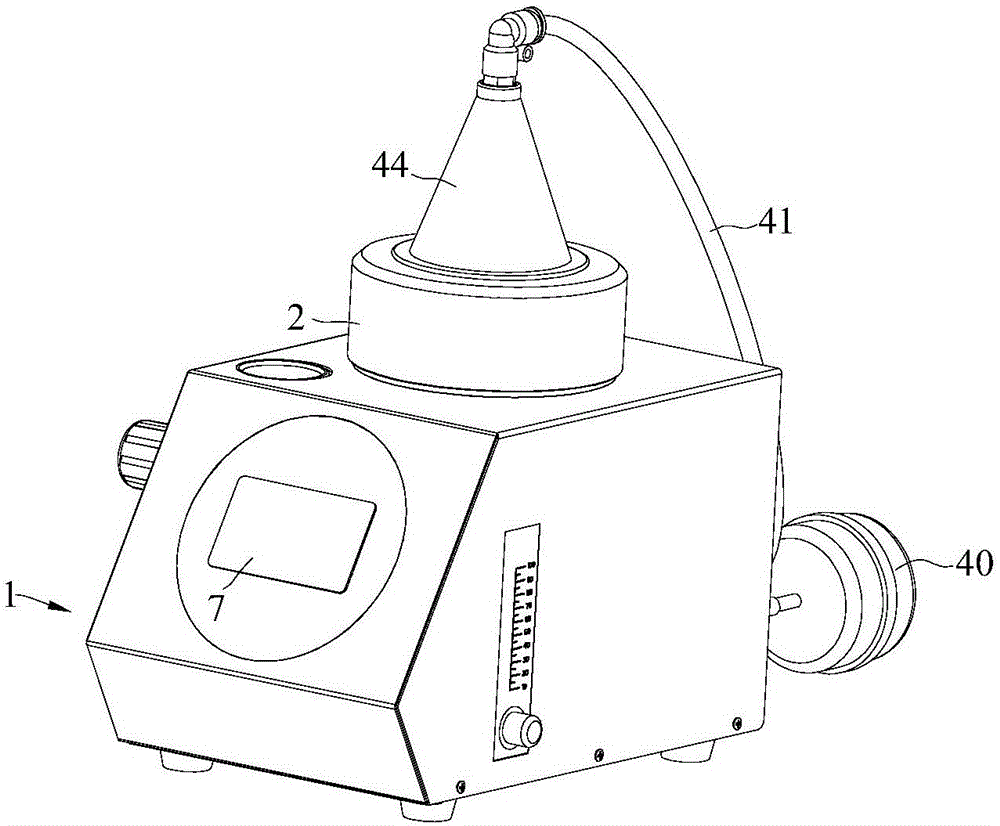

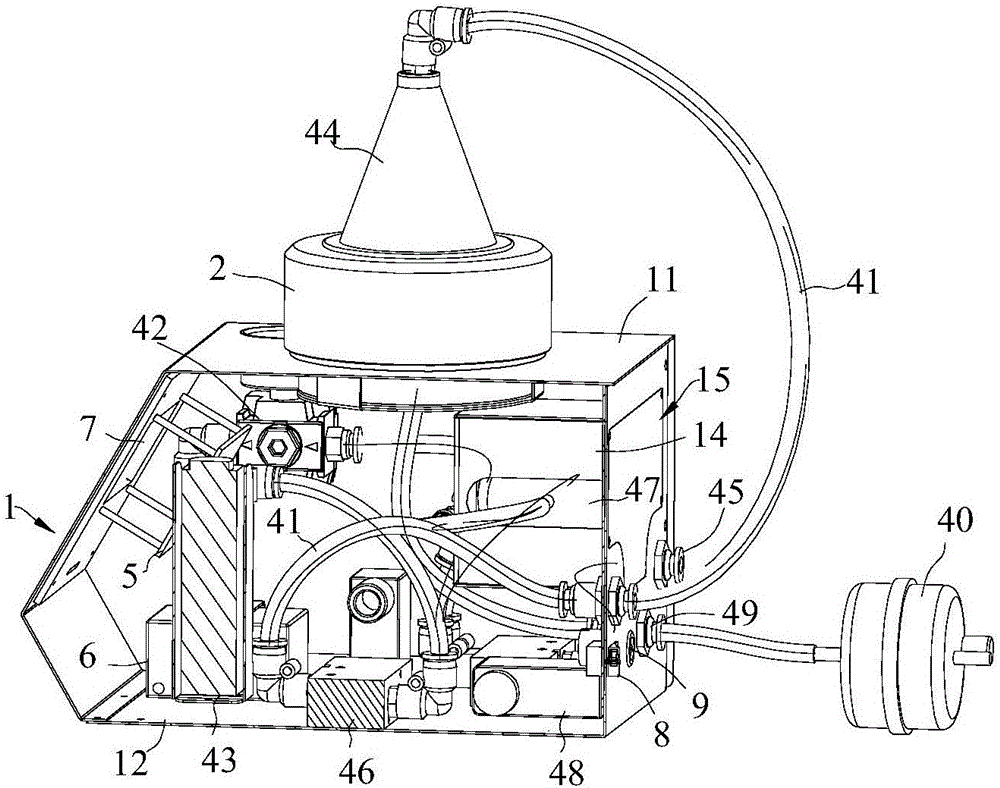

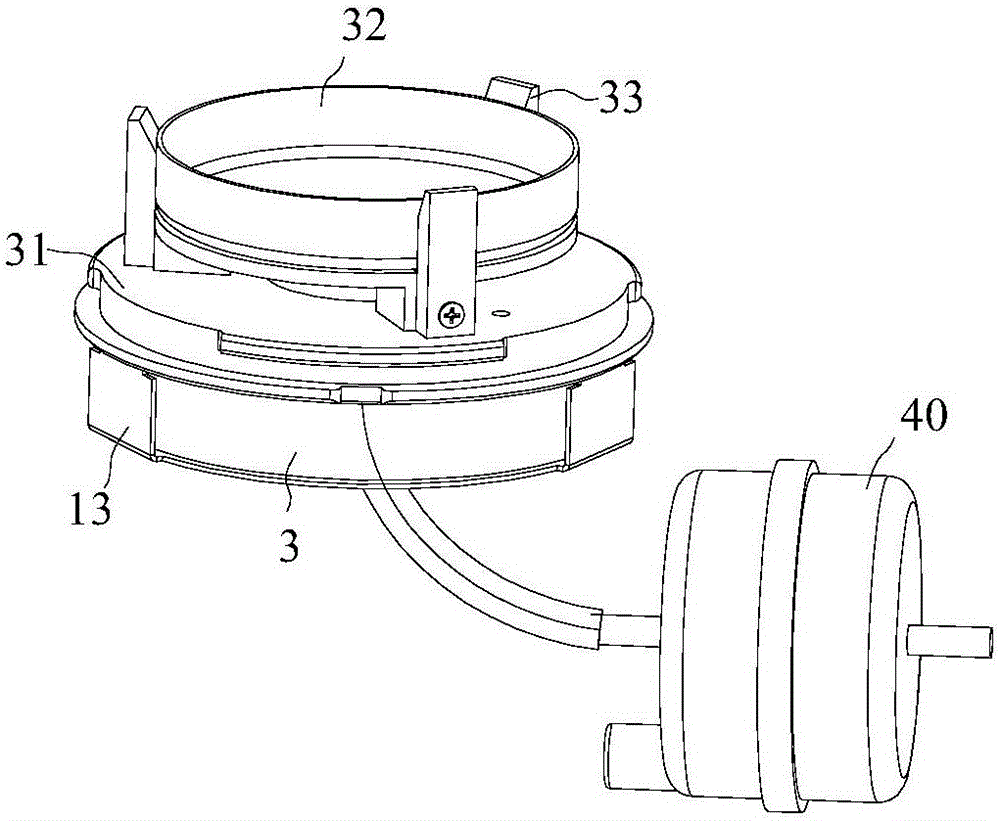

Flow-adjustable impact type compressed air microorganism sampler with sieve meshes

ActiveCN106479875AConstant sampling rateGuaranteed accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsInlet channelPerfect sampling

The invention discloses a flow-adjustable impact type compressed air microorganism sampler with sieve meshes, and is applied to the technical field of microorganism acquisition and quantity monitoring. The flow-adjustable impact type compressed air microorganism sampler comprises a shell, a sampling head and a controllable decompression gas circuit system. The sampling head is arranged on the top of the shell, the controllable decompression gas circuit system is arranged in the shell, an air inlet channel is arranged on the sampling head, a culture dish seat which directly faces the air inlet channel is arranged on the shell and is positioned below the sampling head, an air outlet channel is arranged on the culture dish seat, the controllable decompression gas circuit system comprises a gas circuit, a gas pressure regulating valve and a gas flow meter, the gas pressure regulating valve and the gas flow meter are arranged on the gas circuit, one end of the gas circuit on the shell is connected to a gas source connector, and the other end of the gas circuit is butted to the air inlet channel of the sampling head by a gas dispersing head. Compared with other treatment methods, the flow-adjustable impact type compressed air microorganism sampler has the advantages that the flow-adjustable impact type compressed air microorganism sampler is high in sampling speed and particle capture rate; the actual contents of bacteria in compressed air can be accurately expressed, and accordingly a perfect sampling method is proposed.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

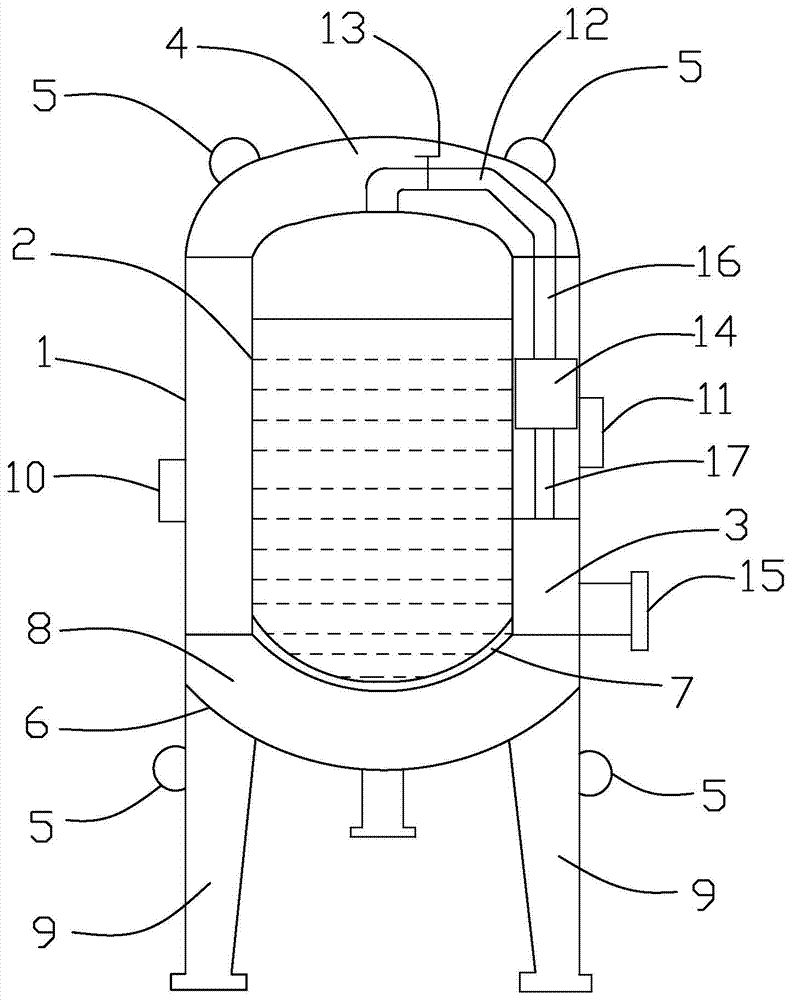

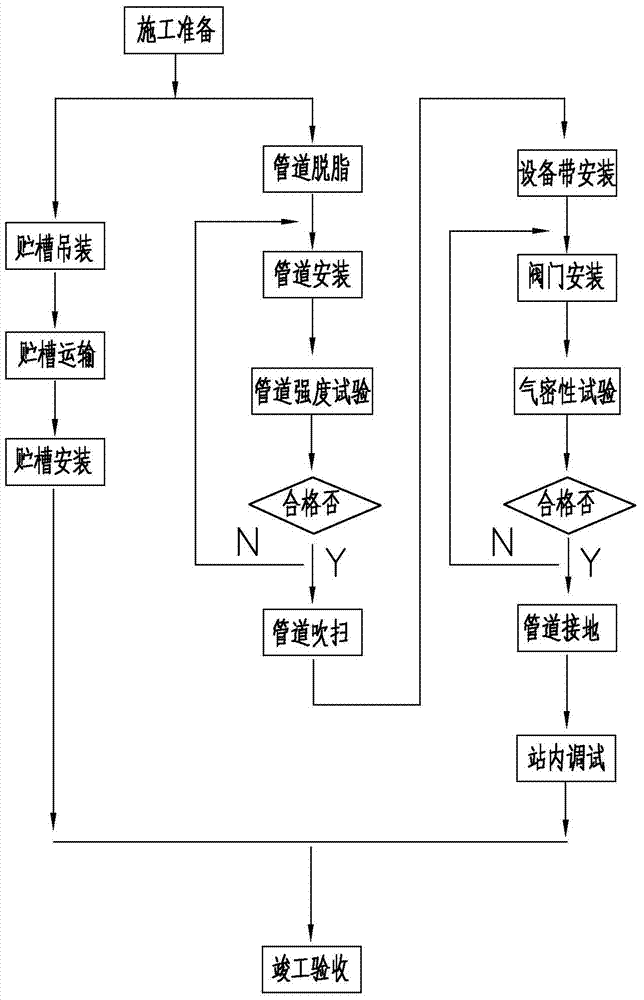

Construction method of centralized medical liquid oxygen supply system

InactiveCN103791227AImprove adsorption capacityAvoid enteringPipe laying and repairConnecting rodsEngineeringWorkload

The invention discloses a construction method of a centralized medical liquid oxygen supply system. The construction method comprises the following steps: (1) preparing for construction; (2) lifting a storage tank; (3) transporting the storage tank; (4) installing the storage tank; (5) degreasing pipelines; (6) installing the pipelines; (7) testing the intensity of the pipelines; (8) sweeping the pipelines; (9) installing equipment belts; (10) installing valves; (11) testing air tightness; (12) grounding the pipelines; (13) testing in station; and (14) finishing and inspecting. According to the invention, the technique and method are implemented accordingly in constructions of oxygen supply center parts in new construction, reconstruction and expanding construction projects of medical organizations, the gas storage amount is large, the construction method is safe and reliable and is convenient to operate, the cost is reduced, the gas product is high in quality, the economical benefit is remarkable and the daily maintenance workload is small; on one hand, the safe oxygen usage of a hospital is guaranteed, and on the other hand, the cost of the hospital is saved and the benefit of the hospital is improved; compared with a traditional construction method, the construction method disclosed by the invention has great advantages in terms of construction time, quality, safety and the like.

Owner:宁波奉天海供氧净化成套设备有限公司

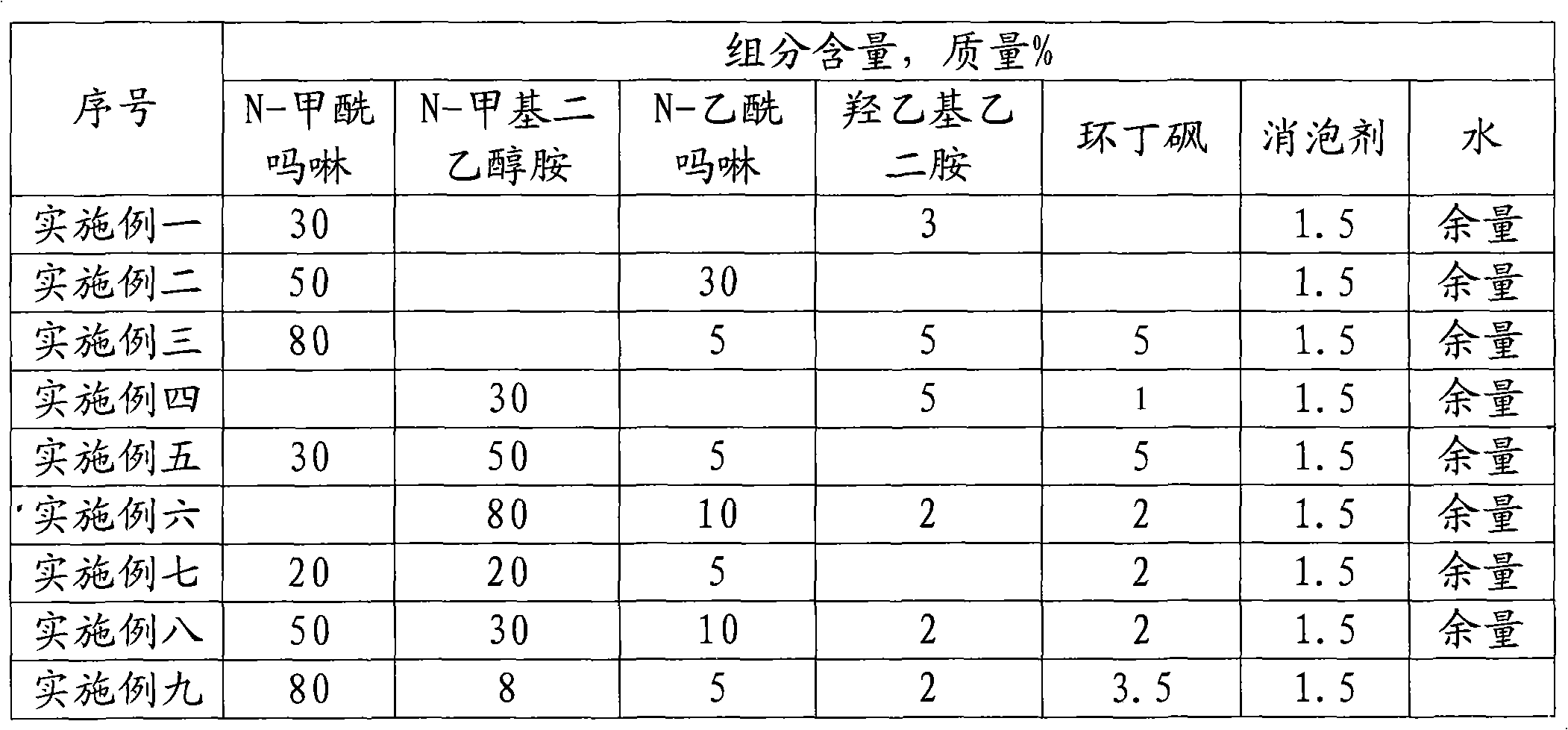

Treating agent for mixing acid components in mixed gases

InactiveCN104815525AEasy to handleImprove gas qualityDispersed particle separationRoom temperatureProduct gas

The invention relates to a treating agent for acid components in mixed gases. The treating agent comprises a composition containing hydramine and amide or a water solution. The treating agent is used for removing and purifying the acid components in the mixed gases, can be applied to the gas treatment processes in the fields such as natural gas extraction, chemical fertilizer gas synthesis, petrochemical production and room-temperature gas recovery.

Owner:DOT CHEM TECH R&D INC

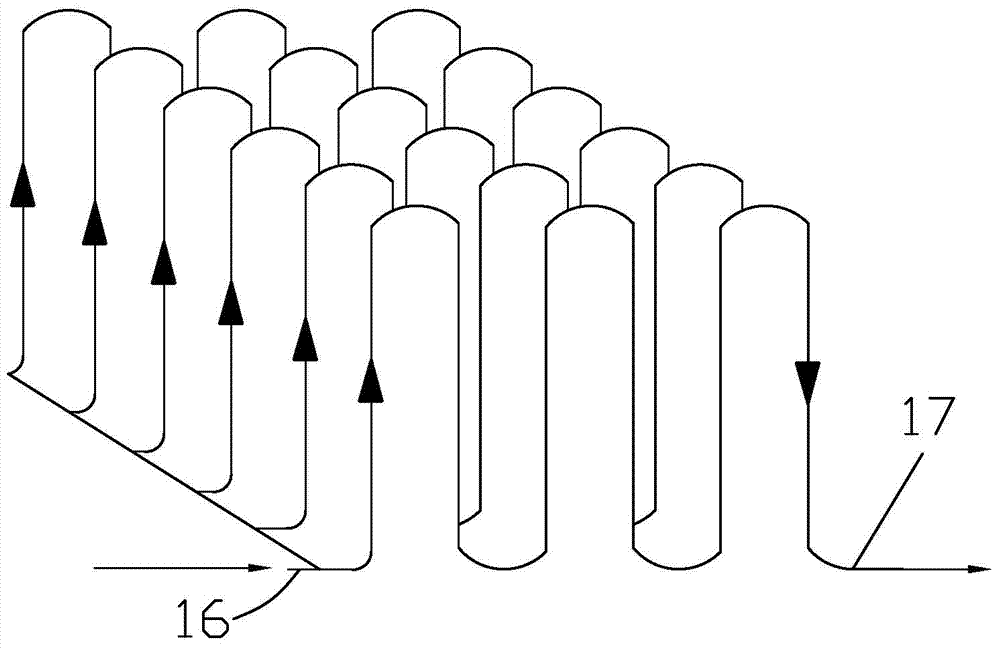

Method for preparing flue gas by using high-temperature cracking biomass

InactiveCN103980944AWill not cause secondary pollutionImprove unit qualityFixed-bed gasificationBiomass carbonSlag

The invention discloses a method for preparing flue gas by using high-temperature cracking biomass. A cracking gasification furnace is divided into an upper section and a lower section, wherein a heat exchanger used for cracking biomass is arranged in an upper-section furnace hearth; a heater and a catalyst which are used for performing catalytic cracking on tar are arranged in a lower-section furnace hearth; the upper-section furnace hearth is communicated with the lower-section furnace hearth; raw materials are continuously or intermittently fed from a furnace feeding port; because high-temperature cracking gas exists in a heat exchanger array tube in a furnace from bottom to top, the raw materials fed into the furnace are dried and cracked from top to bottom to generate cracking gas, biomass carbon and the tar; the generated cracking gas carries the biomass carbon and the tar to enter a lower-section tar cracking section; in the section, the cracking gas, the biomass carbon and the tar are heated to reach the tar catalytic cracking temperature by virtue of a heating device, wherein 99.5% of tar in the cracking gas is cracked into the flue gas and the biomass carbon; the biomass carbon and ash slag are separated from the cracking gas subjected to tar cracking, and then the cracking gas is introduced into an upper-section heat exchanger array tube pass, and is used for transferring the heat to the materials outside a tube for cracking. The flue gas prepared by the method disclosed by the invention is high in calorific value, and does not contain the tar.

Owner:程培胜

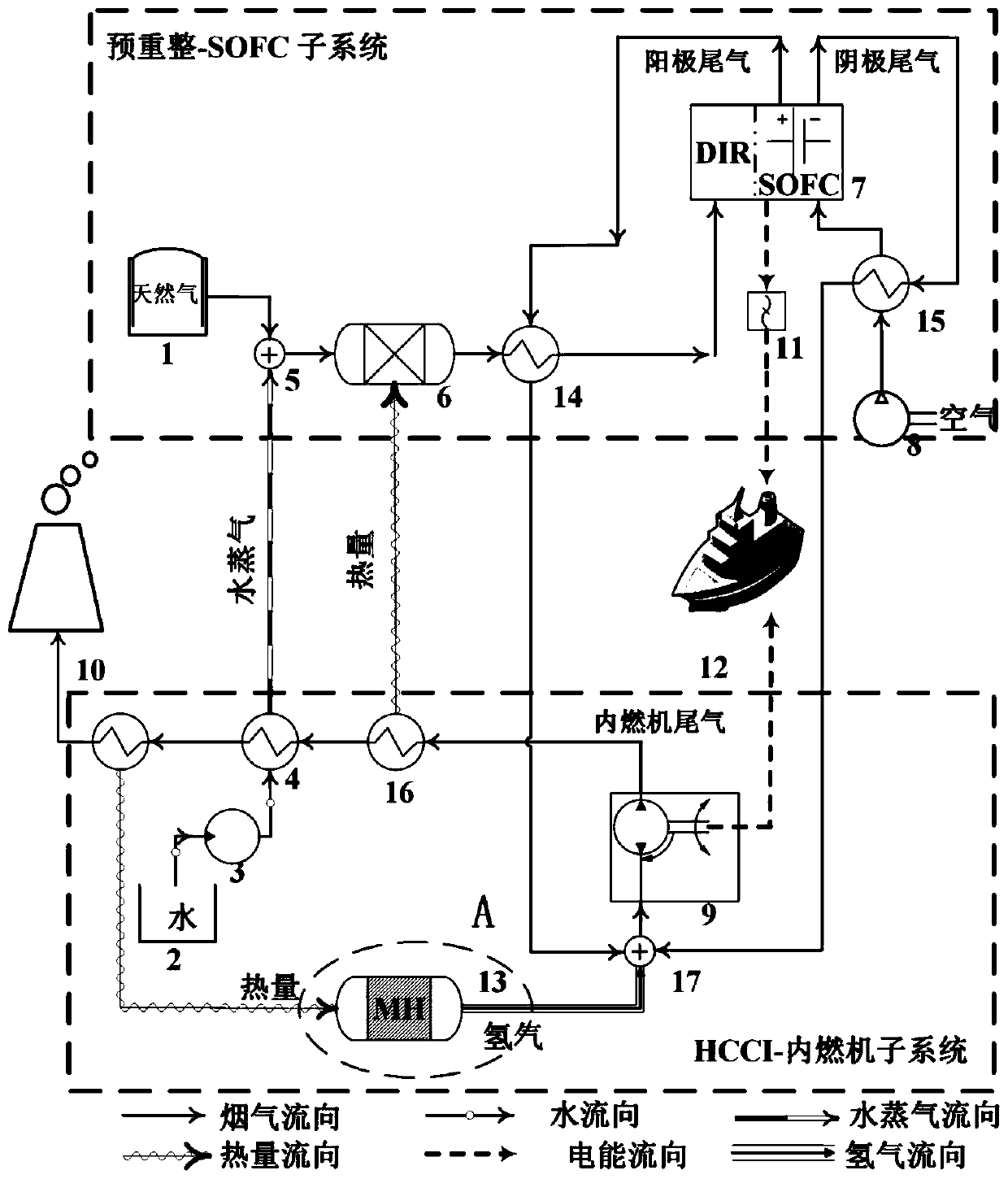

Solid oxide fuel cell and internal combustion engine combined power system and operation method thereof

ActiveCN110077221AIncrease profitReduce thermal waste heat emissionsHybrid vehiclesFuel cell heat exchangeHomogeneous charge compression ignitionChemical reaction

The invention discloses a solid oxide fuel cell and internal combustion engine combined power system and an operation method thereof. According to the system, a solid oxide fuel cell (SOFC) device anda homogeneous charge compression ignition (HCCI) internal combustion engine are combined together to form the combined power system, the HCCI internal combustion engine can generate electricity by utilizing exhaust of the SOFC device, energy in the fuel is used fully, exhaust heat and waste heat emissions are reduced, and an ideal way of comprehensive utilization of the energy is achieved. The HCCI internal combustion engine and the SOFC device are combined together. A pre-reforming reactor is placed in front of the SOFC device, the reforming reaction of fuel gas can be carried out in advance, the utilization rate of the fuel can be improved, and the electrochemical reaction inside the SOFC device is more complete. According to the solid oxide fuel cell and internal combustion engine combined power system, comprehensive use of the fuel is carried out, and the needs of various large power equipment can met; and compared with traditional energy supply equipment, the efficiency is higher, emission is less, and the economic value is higher.

Owner:XI AN JIAOTONG UNIV

Treatment agent of acidic components used for mixed gas

InactiveCN101780363AEasy to handleImprove gas qualityDispersed particle separationProduct gasPetrochemical

The invention relates to a treatment agent of acidic components used for mixed gas, which comprises a composite containing hydramine and amide or an aqueous solution. The treatment agent is used for removing and purifying the acidic components in the mixed gas and can be applied to the gas treatment process of the fields of natural gas exploitation, chemical fertilizer synthesis gas, petrochemical production, greenhouse gas recovery and the like.

Owner:JILIN TAINENG GASOLINEEUM & CHEM

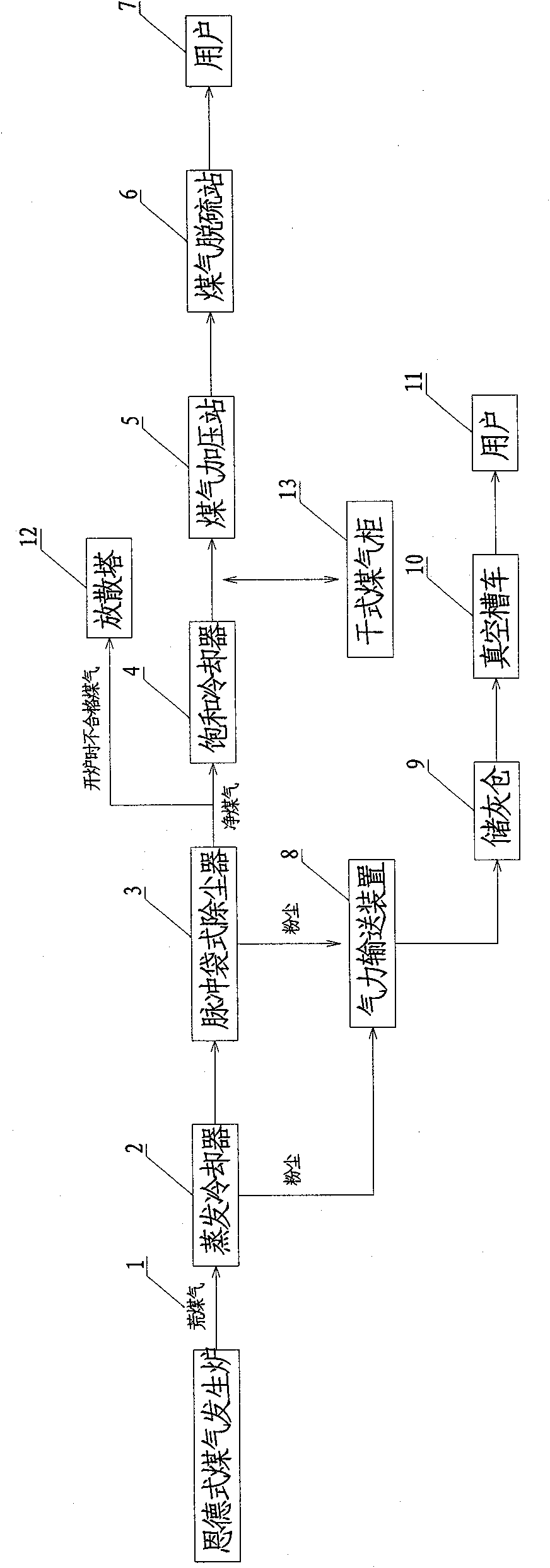

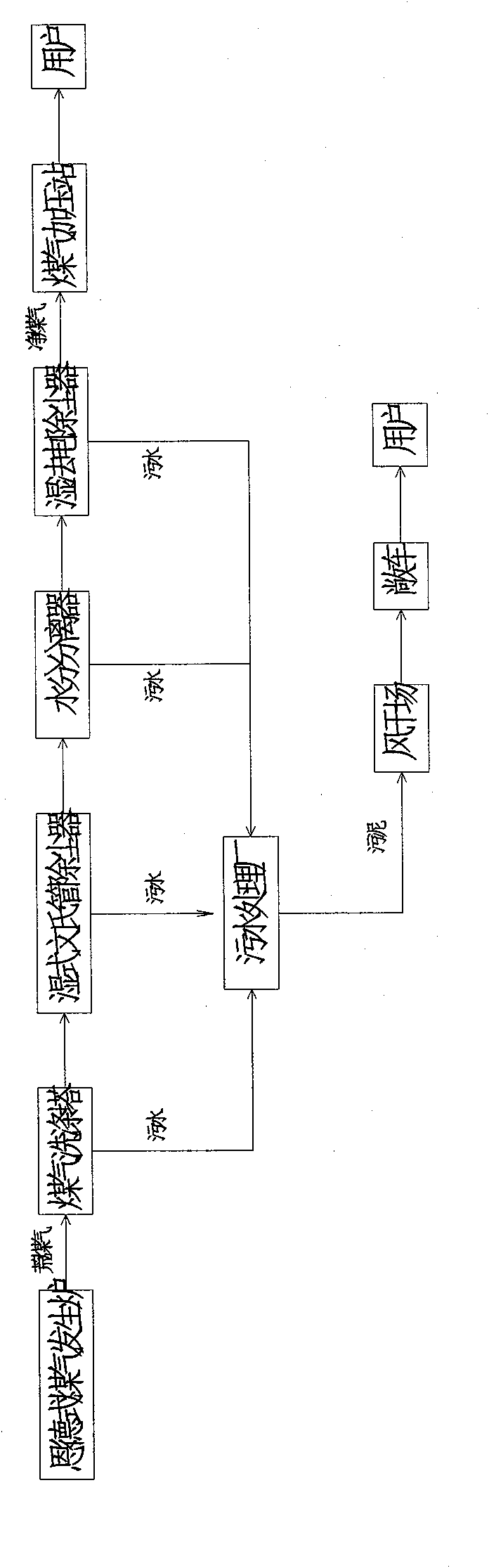

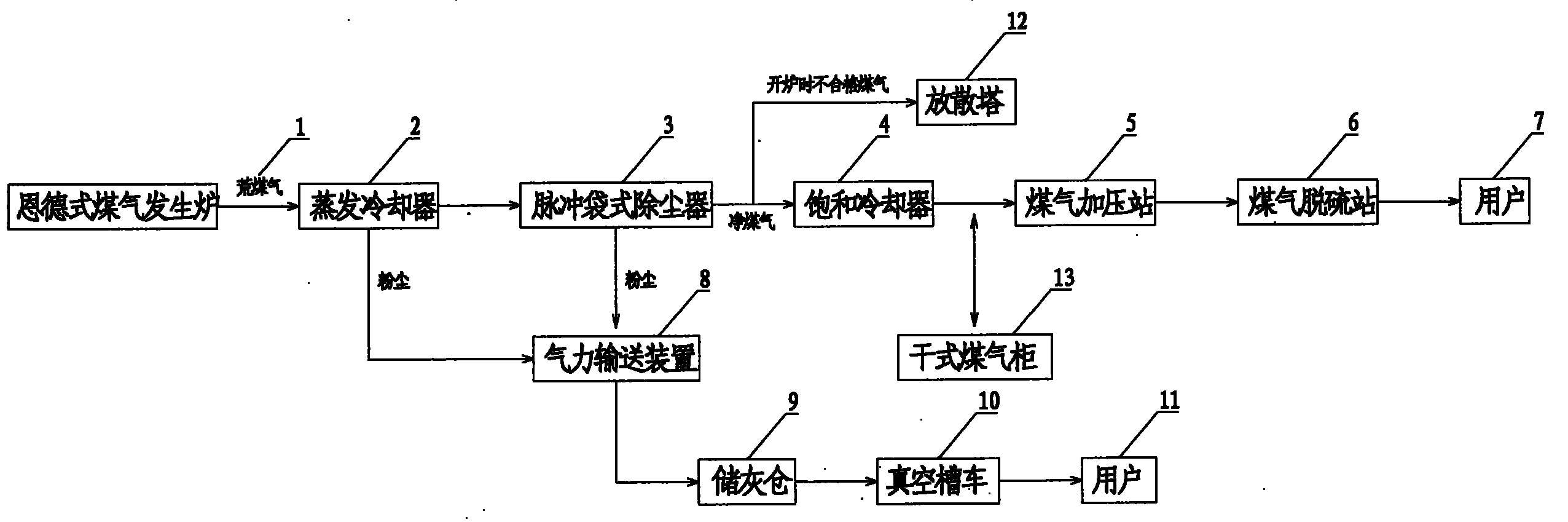

Process method for purifying raw coke oven gas from pulverized coal gasification furnace

InactiveCN101906328AExtended service lifeReduce maintenance workloadChemical industryGas purification by non-gaseous materials condensationEvaporative coolerProcess engineering

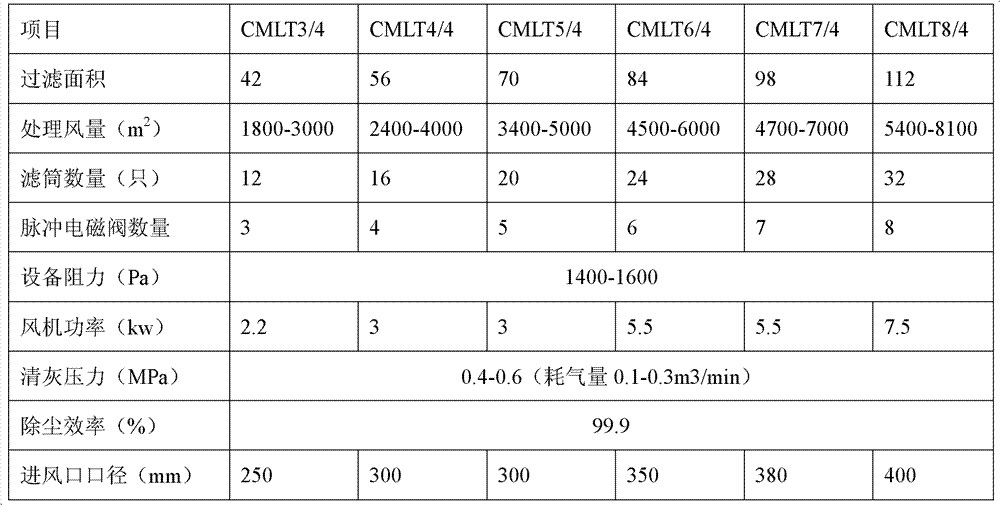

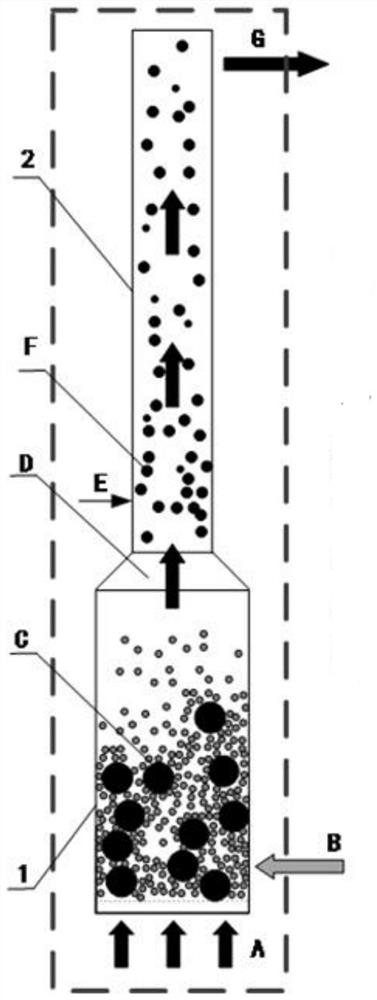

The invention discloses a process method for purifying raw coke oven gas from a pulverized coal gasification furnace, which is characterized by adopting a wet dedusting method. The process flow is untreated gases generated by the pulverized coal gasification furnace-devaporizer-pulse bag type dust remover-saturation cooler-gas cabinet-gas pumping station-gas desulfuration-gas users. In order not to pollute the environment, dust separated from the devaporizer and the pulse bag type dust remover is processed by the following process: dust-pneumatic conveyor-storage house-vacuum tank car-dust users. The invention has the advantages of simplifying and purifying system flows, reducing the construction investment and area occupied, improving the purifying efficiency, saving the energy consumption for purification, reducing the purifying cost, preventing the secondary pollution by dust and recycling the dry ash by means of measures such as unsaturated cooling, wet dedusting and wet ash discharging so as to realize the comprehensive effect of using the fly ash.

Owner:鞍钢集团工程技术有限公司 +1

Pyrolysis and biomass gas catalytic reforming reactor and application thereof

ActiveCN106367119APromote pyrolysisImprove gas qualityGas treatmentCombustible gas catalytic treatmentCatalytic reformingCyclone

The invention discloses a pyrolysis and biomass gas catalytic reforming reactor and application thereof. The reactor comprises a pyrolysis gasifier, a smoke cyclone separator, a pyrolysis gas cyclone separator and a feeder. The pyrolysis gasifier with novel characteristics can meet the pyrolysis gasifying treatment requirement for waste with complex physical properties well. A direct-fired type inner heating pipe and metal filler connected with the direct-fired type inner heating pipe are adopted and arranged in the pyrolysis gasifier, controllable temperature field reasonable in distribution can be set up in the pyrolysis gasifier, and beneficial reaction temperature conditions are set up for material pyrolysis in the pyrolysis gasifier. Meanwhile, the metal filler is coated with a catalyst in a segmented mode, pyrolysis of organic matter and reforming and detarring treatment on pyrolysis gas can be promoted, therefore, the pyrolysis gasifying conversion rate is overall increased, and the fuel gas quality of biomass gas serving as the pyrolysis product is overall improved.

Owner:NANJING UNIV

Gas-insulated high-voltage circuit breaker with a relief duct which is controlled by an overflow valve

InactiveUS8148660B2Load moreQuality improvementHigh-tension/heavy-dress switchesAir-break switchesEngineeringArc extinction

Owner:ABB RES LTD

Direct-buried gas filter

ActiveCN111389128ACompact structureAdaptableDispersed particle filtrationTransportation and packagingMechanical engineeringMechanics

The invention discloses a direct-buried fuel gas filter. The gas filter comprises a shell and a quick-opening blind plate mounted at an opening in the upper end of the shell, an air inlet and an air outlet are correspondingly formed in the left and right sides of the shell; an inner cavity of the shell is divided into an air inlet cavity and an air outlet cavity through a baffle assembly, the baffle assembly comprises a left baffle, a right baffle plate and a vertical baffle plate, the left baffle plate is horizontally arranged and located on the upper side of the air inlet, the right baffle plate is horizontally arranged and located on the lower side of the air outlet, and the upper end and the lower end of the vertical baffle plate are correspondingly connected with the left baffle plateand the right baffle plate. A support plate which is located on the upper side of the air outlet and is in a horizontal state is further arranged in the inner cavity of the shell, a plurality of vertical coalescence filter elements are arranged between the support plate and the right baffle plate, the lower ends of inner holes of a coalescence filter elements are communicated with the air inlet cavity, and the upper ends of inner holes of the coalescence filter elements are closed. The gas filter has the advantages of being compact in structure, high in adaptability and good in filtering effect, the burial depth and the installation difficulty can be effectively reduced, moisture in gas can be filtered out, and the safety and reliability of gas pipe network operation and the gas quality of the tail end are enhanced.

Owner:江苏盛伟燃气科技有限公司

Sterilizing inlet air deduster

InactiveCN102949902AExtended service lifeHas a buffering effectDispersed particle filtrationDeodrantsVertical filterWaste management

Owner:SHANGHAI KEYING ENVIRONMENTAL PROTECTION EQUIP

Method for two-stage preparation of methane gas from solid waste

ActiveCN113477190AImprove quality and increase productionAchieve reductionGaseous fuelsWaste based fuelPtru catalystMethanation

The invention discloses a method for two-stage preparation of methane gas from solid waste. The method comprises the following steps: step 10) in a first-stage methanation area, introducing water vapor from the bottom of the area, introducing solid waste and a modified calcium-based ore catalyst from a side edge, and under the action of the water vapor, mixing the solid waste and the modified calcium-based ore catalyst and allowing the mixture of the solid waste and the catalyst to ascend and undergo direct methanation reaction with water vapor to obtain crude methane gas; and step 20) discharging the crude methane gas from the top of the first-stage methanation area, feeding the crude methane gas into a second-stage methanation area, uniformly feeding hydrogen into the second-stage methanation area, pre-regulating the hydrogen-carbon ratio of the crude methane gas, carrying out catalytic methanation reaction on methane gas by using a catalytic methanation catalyst, and preparing high-quality methane gas via the catalytic methanation catalyst under the fluidization action of the hydrogen and the crude methane gas. The method can achieve the effects of high fuel utilization rate, high methane quality and low catalysis cost.

Owner:SOUTHEAST UNIV

Method for carrying out coal gasification regionally by fixed bed

ActiveCN102154026AQuality improvementSmall temperature fluctuationsChemical industryFixed-bed gasificationProduction rateSlag

The invention relates to a method for carrying out coal gasification regionally by a fixed bed. In the method, the middle upper part of a gas furnace is divided into two gasification regions by a partition wall; in the blowing phase, a blowing valve and a nitrogen adding valve at the bottom of the gas furnace are opened, two chimney valves at the middle upper part of the gas furnace are opened, other valves are closed, air enters the gas furnace to be burnt, the temperature of the gas furnace is raised, and generated blowing gas is sent to a post station from the chimney valves to be processed; in the gas preparation phase, the nitrogen adding valve at the bottom of the gas furnace is opened, gas valves and steam valves in the two regions at the middle upper part of the gas furnace are opened and closed alternately, one region is used for conveying gas outside while the other region is used for conveying steam inwards simultaneously, and other valves are all closed; the air added with nitrogen enters the gas furnace to be burnt, high temperature air gas is generated, and steam enters the furnace to react so as to generate high temperature water gas; and two streams of high temperature gas are transversely and longitudinally mixed and flow in a horizontal and vertical crossed mode between gasification layers to continuously perform a gasification reaction and finally is output outwards through the regions where the gas valves are opened. The method has high steam resolution ratio, high gas production rate, high gas quality, low carbon residue of slags and obvious effects of saving energy and reducing consumption.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com