Patents

Literature

74results about How to "Improve coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

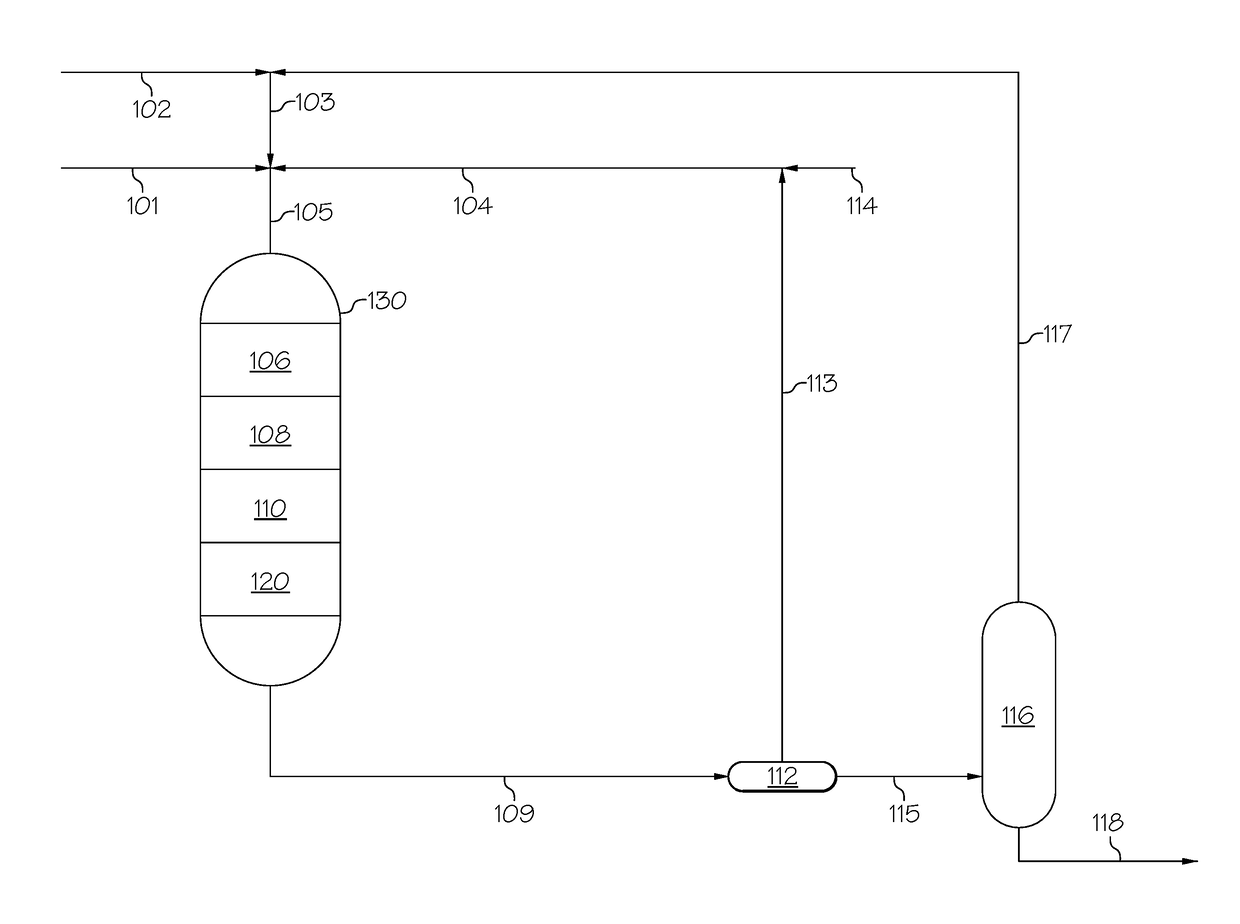

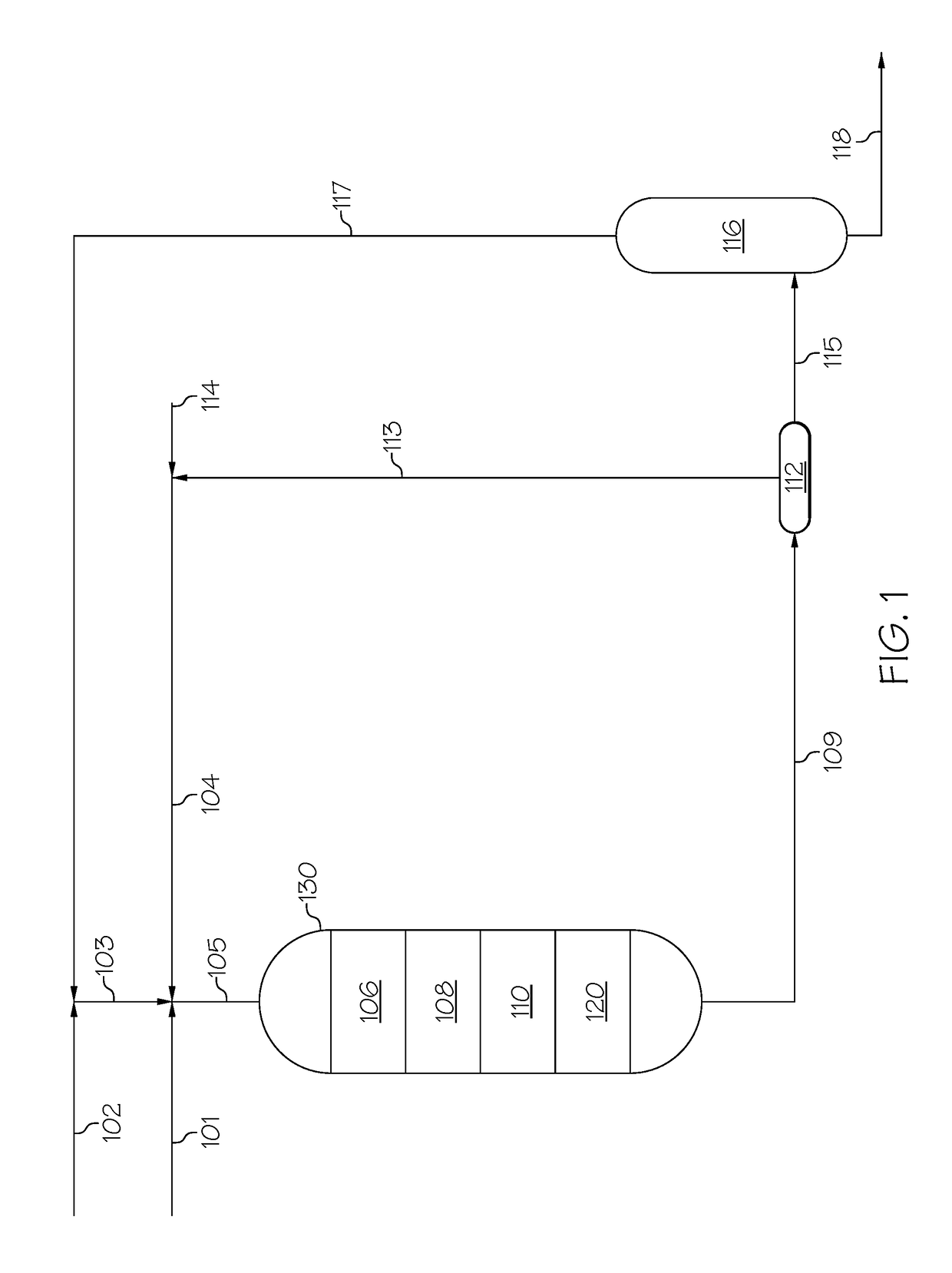

System and Method for Introducing an Additive into a Coking Process to Improve Quality and Yields of Coker Products

InactiveUS20090152165A1Promotes cokingImprove cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyBoiling pointTar

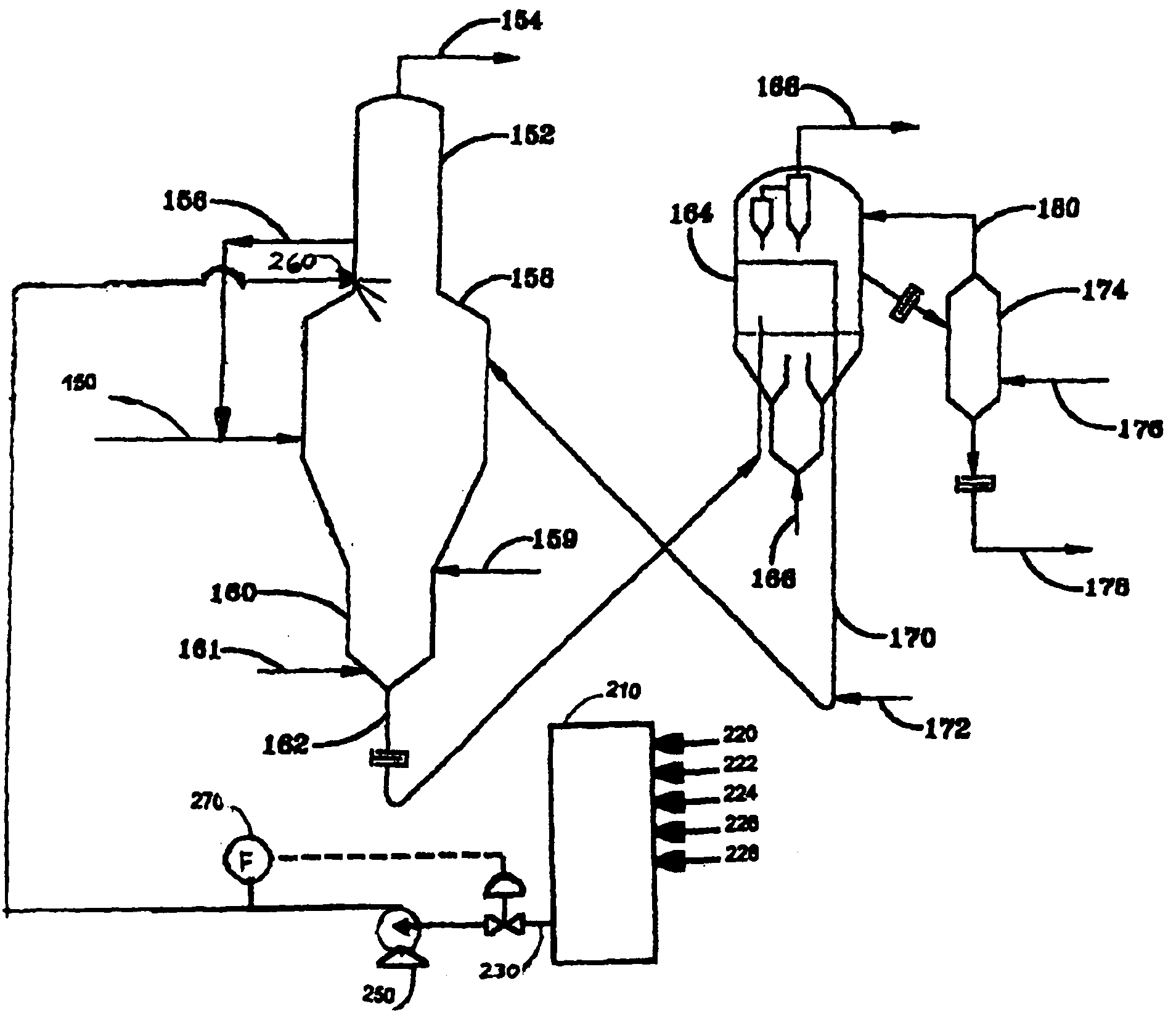

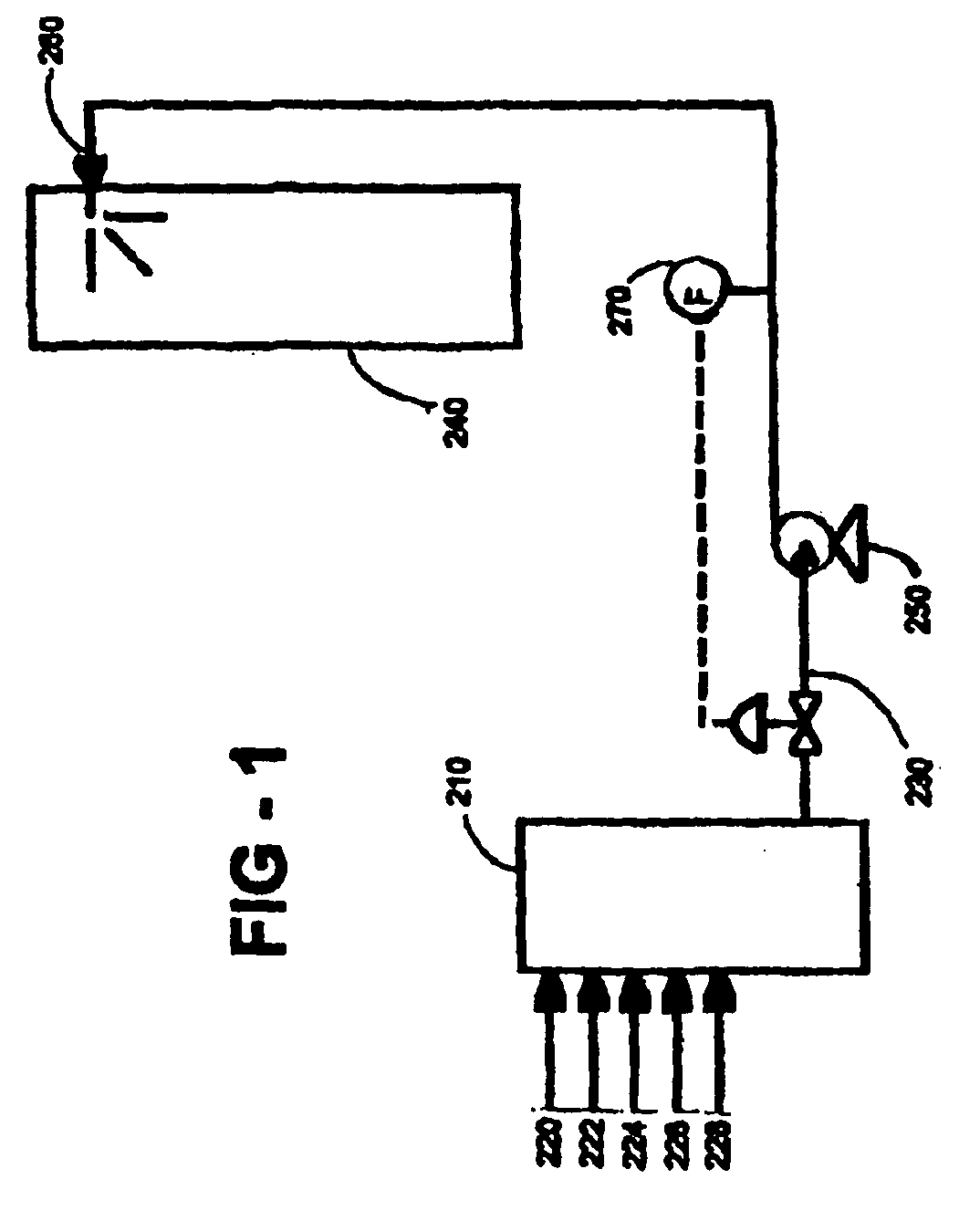

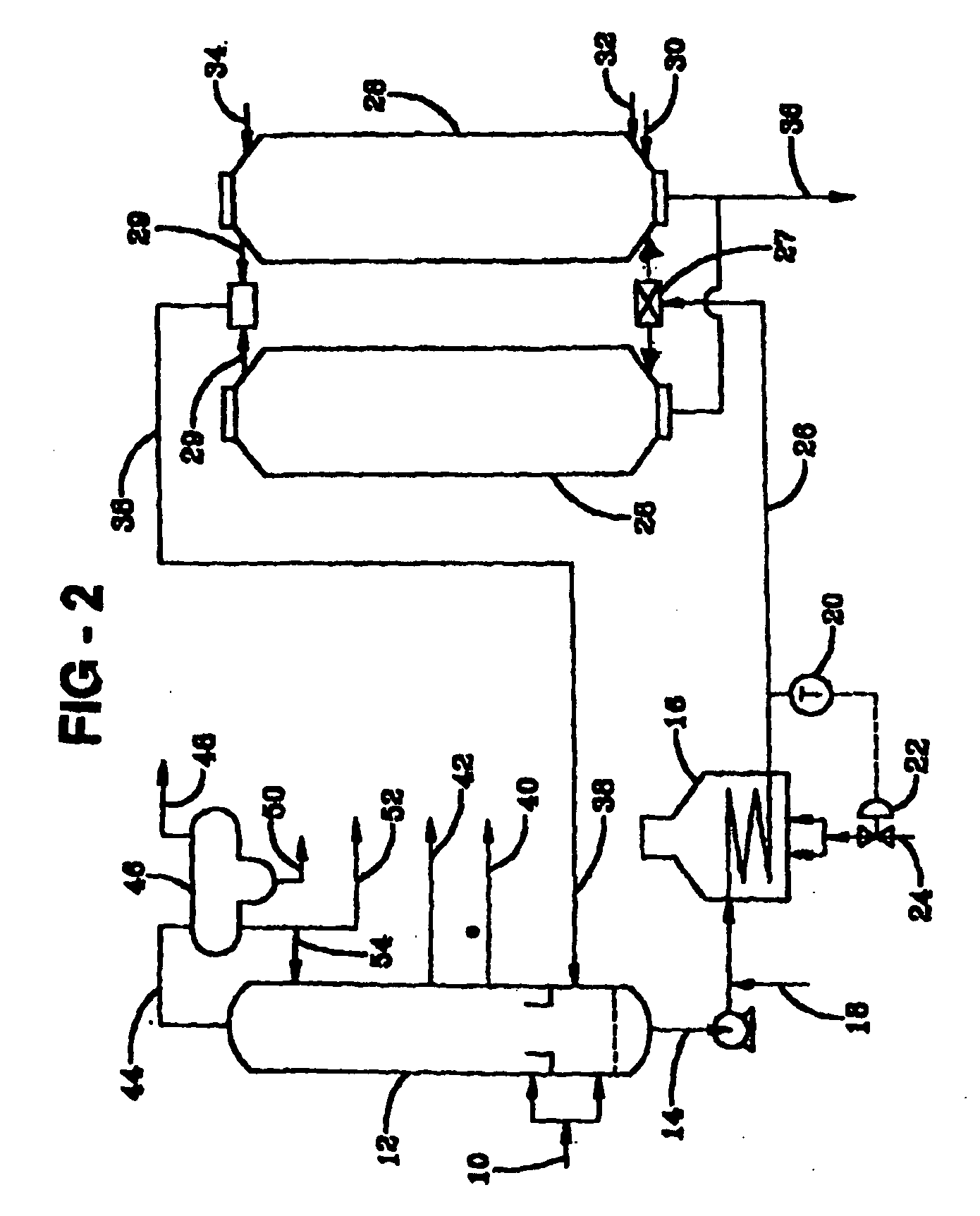

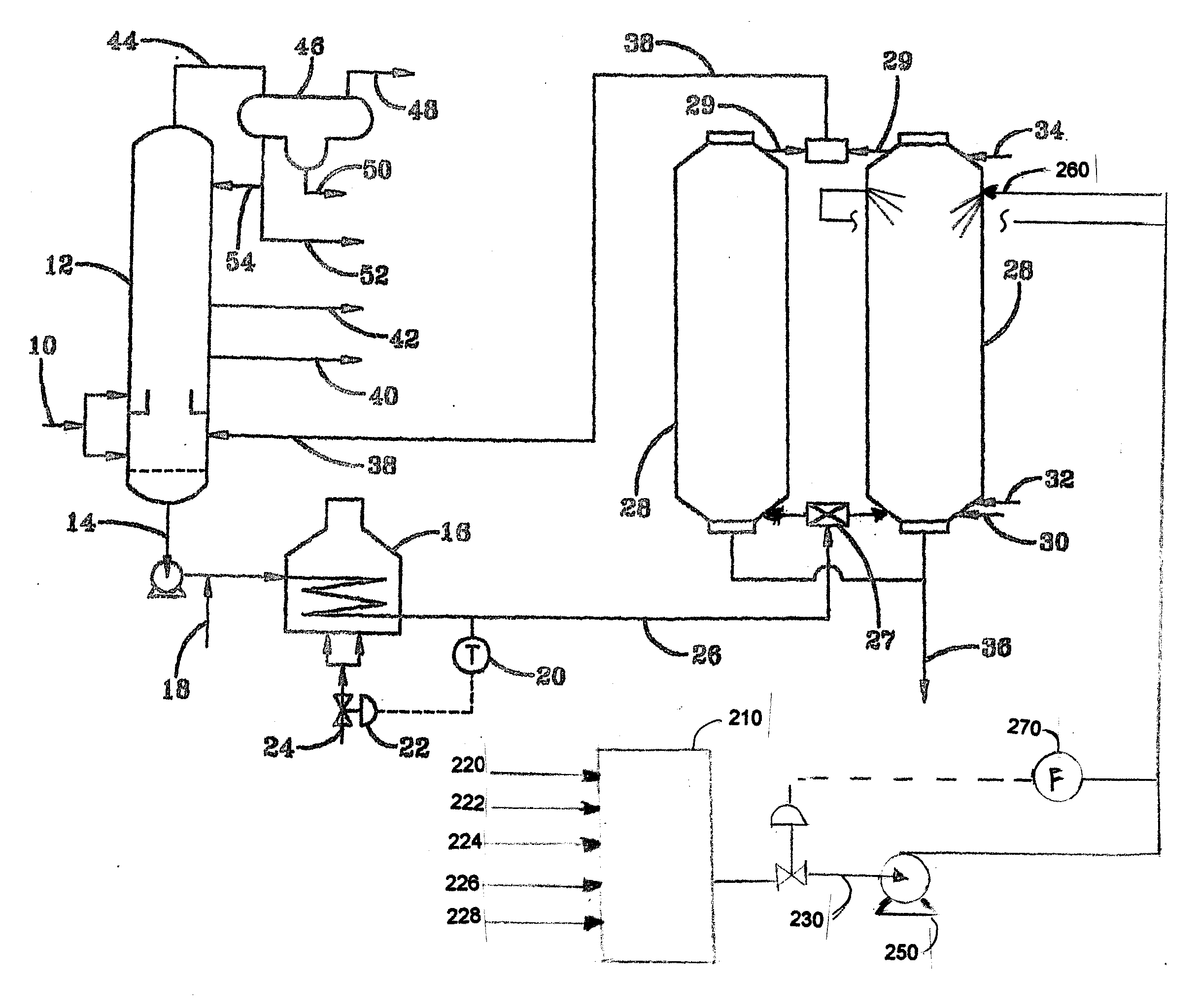

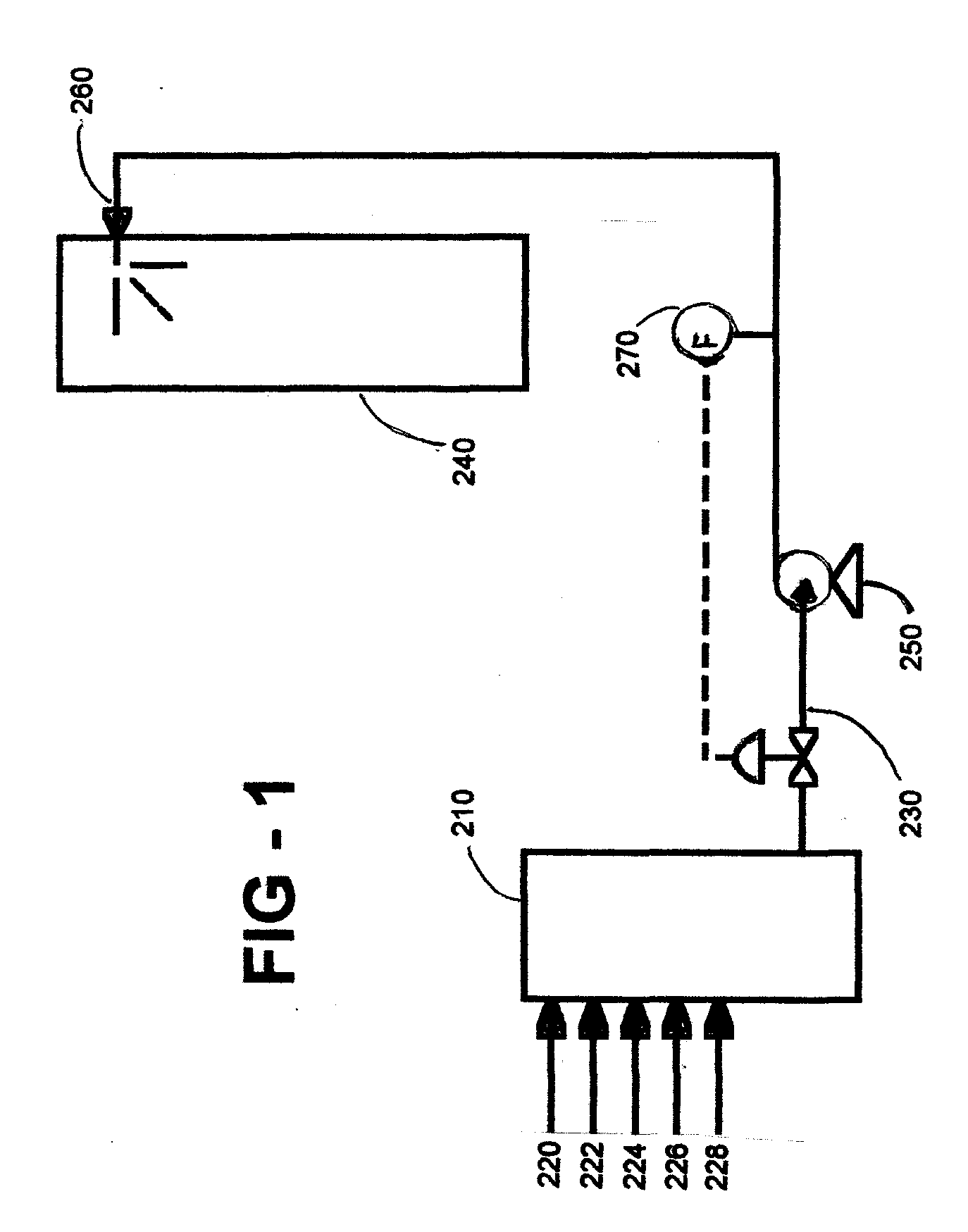

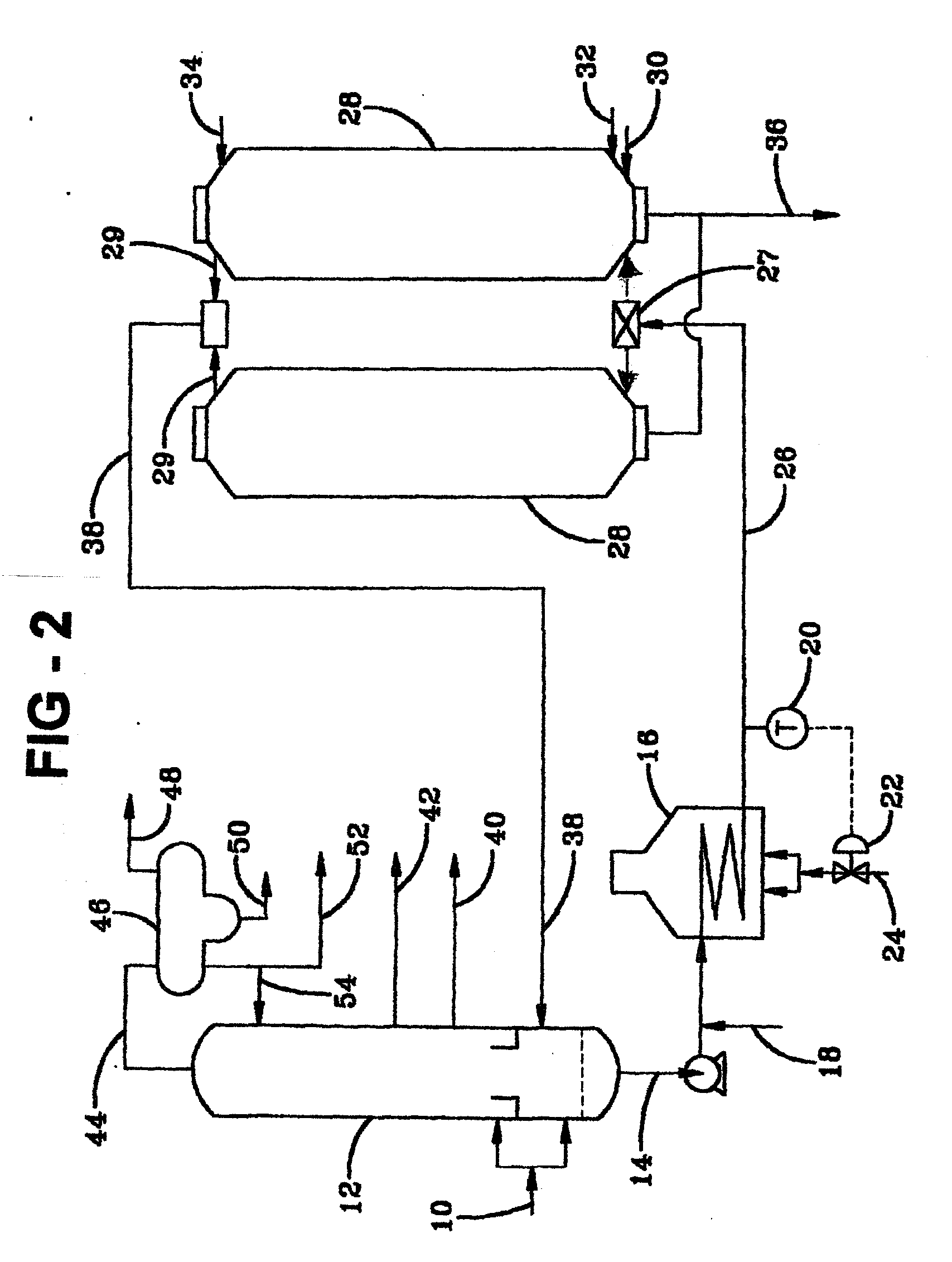

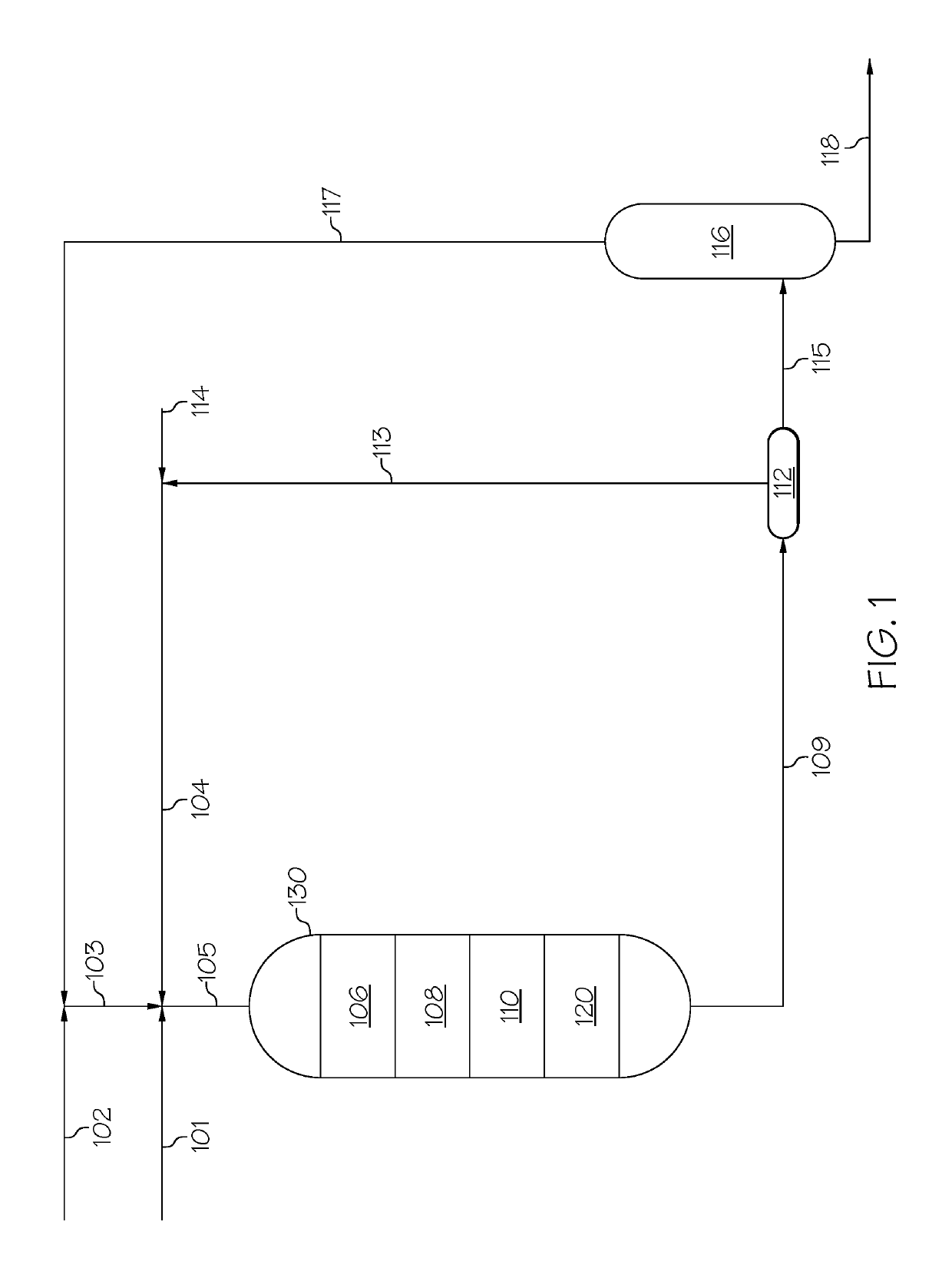

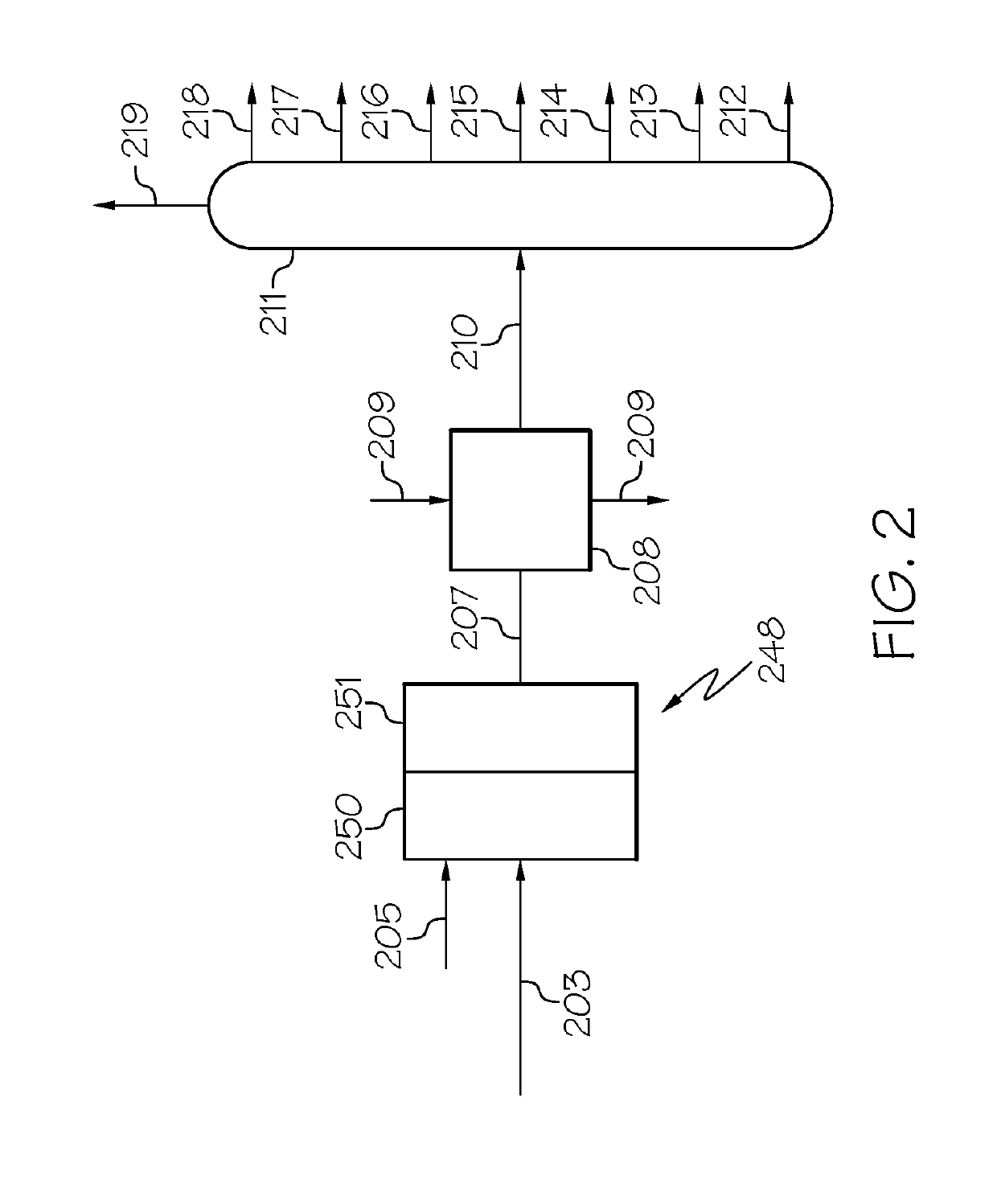

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. The quenching effect of the additive can be effectively used to condense the highest boiling point compounds onto the catalyst(s), thereby focusing the catalyst exposure to these target reactants. With a catalyst to crack these highest boiling point materials, this mechanism can effectively increase the catalyst's selectivity, thereby increasing its efficiency and reducing catalyst requirements and costs. Selective, catalytic conversion of the highest boiling point materials in the coking process product vapors (coker recycle and / or ‘heavy tail’ of the heavy coker gas oil) may be accomplished with an exemplary embodiment of the present invention in varying degrees. Exemplary embodiments of the present invention can also provide methods to control the (1) coke crystalline structure and (2) the quantity and quality of volatile combustible materials (VCMs) in the resulting coke. Pet coke from this process may have unique characteristics with substantial utility.

Owner:ETTER ROGER G

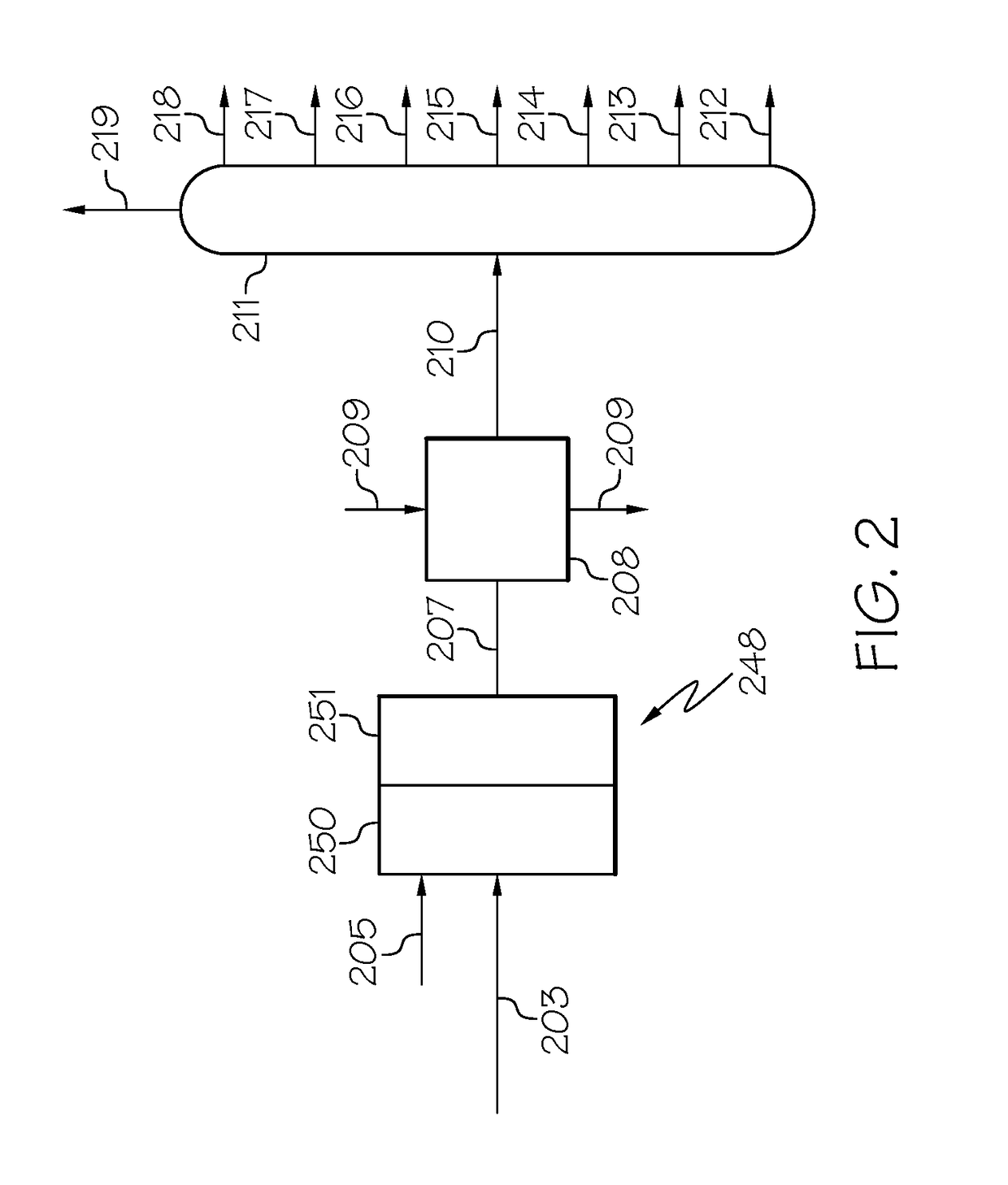

System and Method of Introducing an Additive with a Unique Catalyst to a Coking Process

InactiveUS20090209799A1High propensity to cokePromotes cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkyl transferNaphtha

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. Modifications of the catalysts in the additive improve performance for certain desired outcomes. One exemplary embodiment of the present invention uses the olefin production capabilities from newly developed catalysts to increase the production of light olefins (e.g. ethylene, propylenes, butylenes, pentenes) for alkylation process unit feed, the production of oxygenates, and petrochemical feedstocks, such as plastics manufacture. Another exemplary embodiment of the present invention is the use of the olefin production from newly developed catalysts to improve the coker naphtha quality. A third exemplary embodiment of the present invention uses the cracking characteristics of newly developed catalysts to optimize the production of light gas oils, naphtha, and gases from the coking process.

Owner:ETTER ROGER G +1

Zeolites, the production thereof, and their uses for upgrading heavy oils

ActiveUS20180333708A1Low costLess expensiveCatalytic crackingMolecular sieve catalystsFuel oilChemistry

According to one or more embodiments, a nano-sized, mesoporous zeolite particle may include a microporous framework comprising a plurality of micropores having diameters of less than or equal to 2 nm and a BEA framework type. The nano-sized, mesoporous zeolite particle may also include a plurality of mesopores having diameters of greater than 2 nm and less than or equal to 50 nm. The zeolite particles may be integrated into hydrocracking catalysts and utilized for the cracking of heavy oils in a pretreatment process.

Owner:SAUDI ARABIAN OIL CO

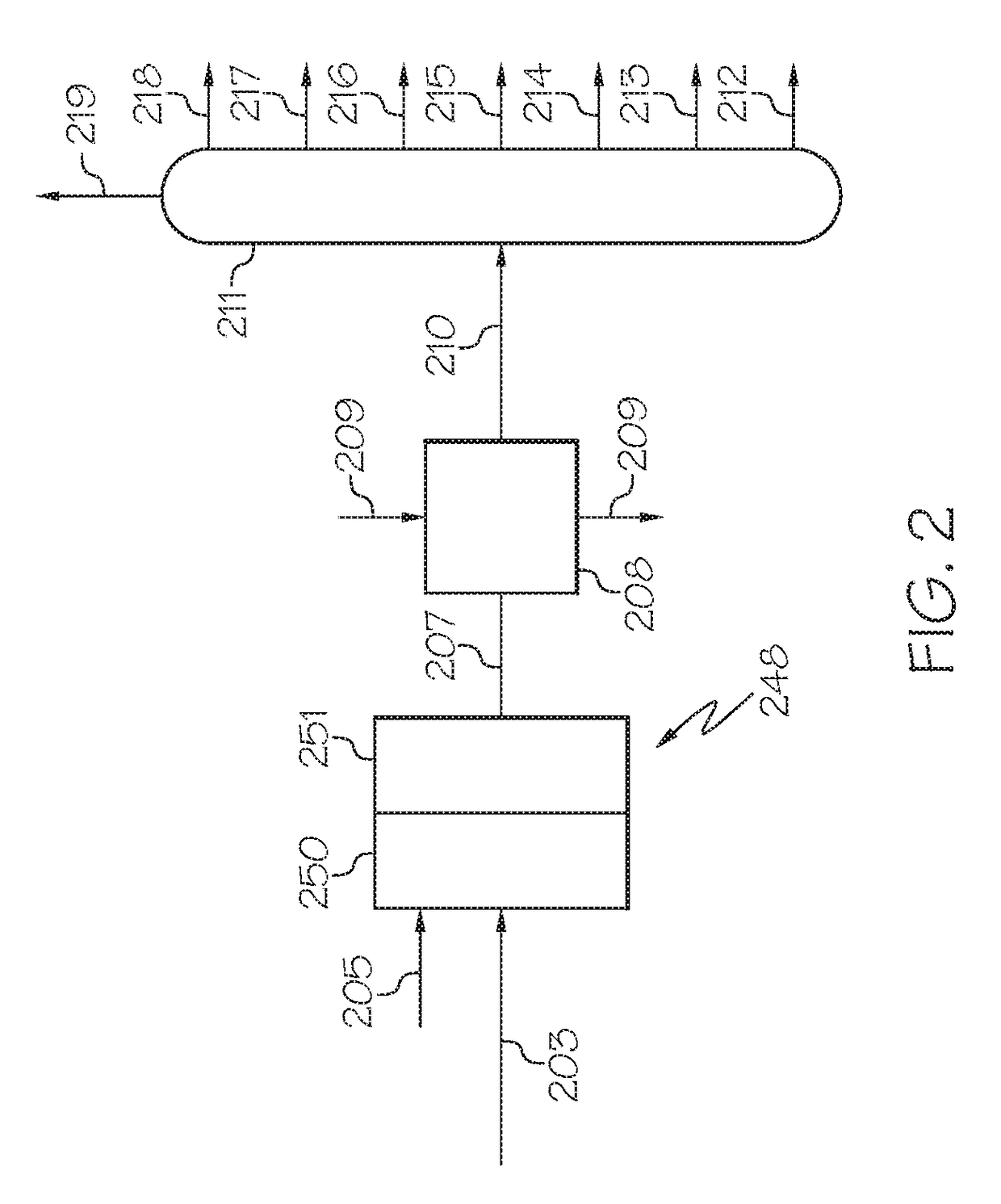

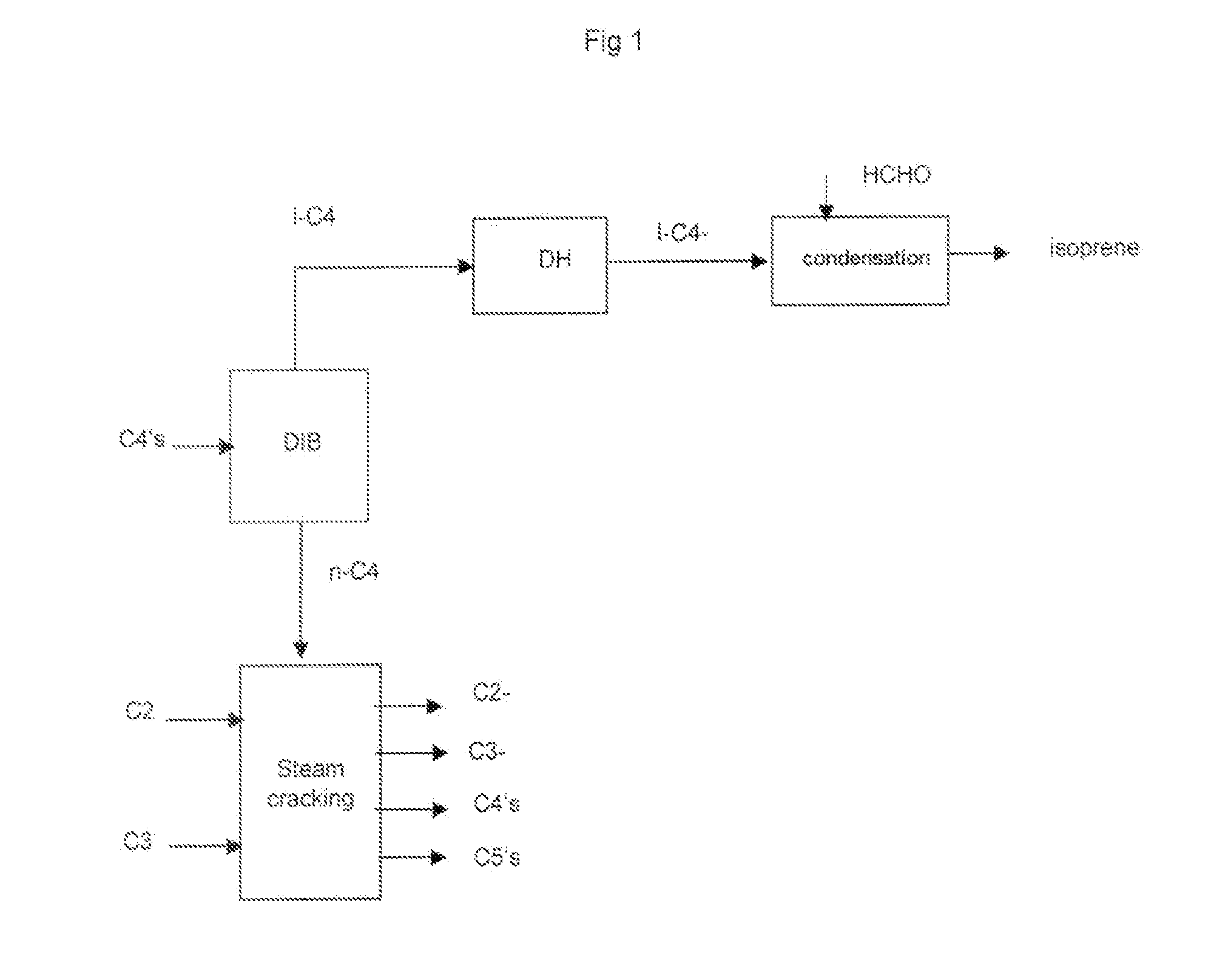

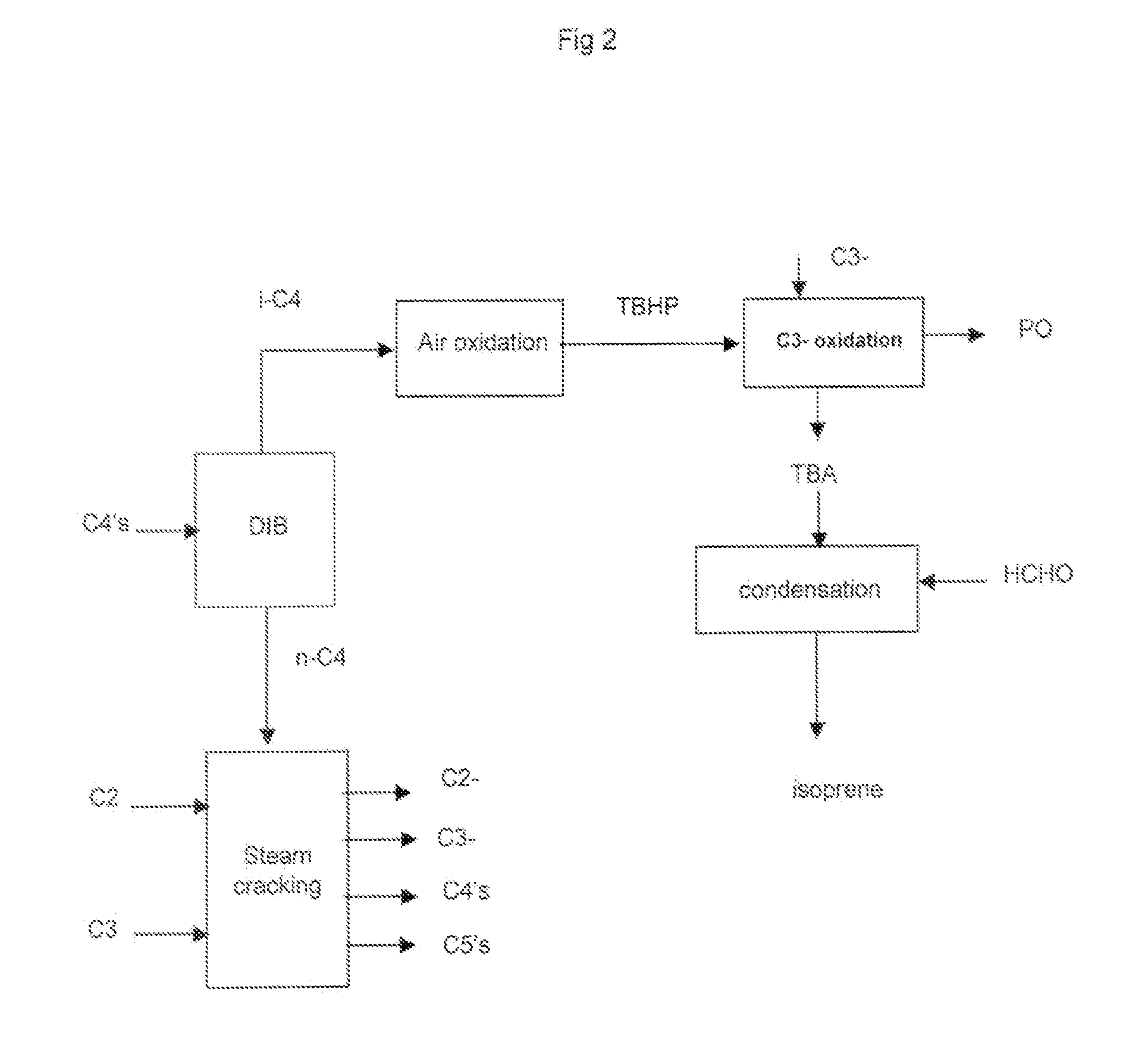

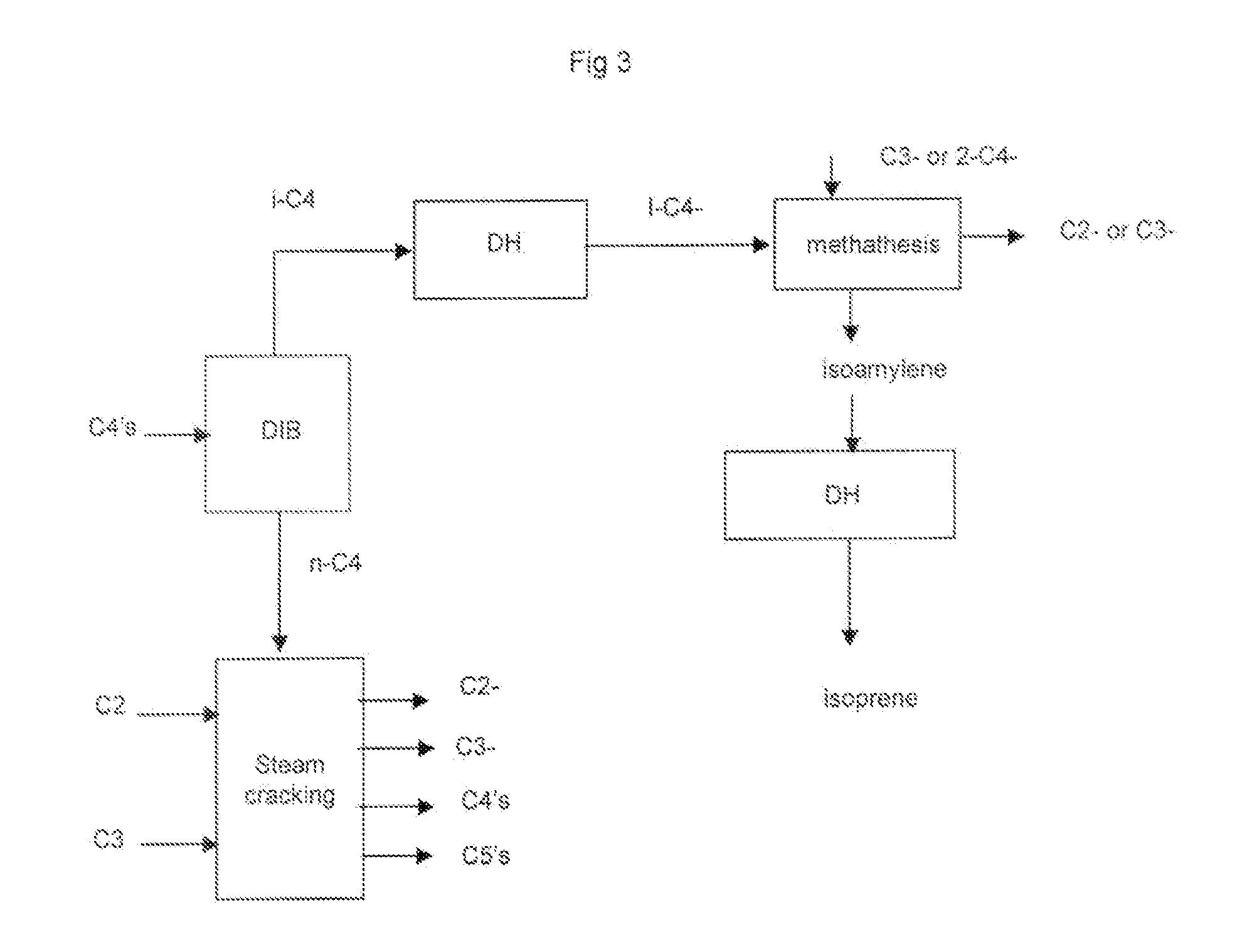

Production of Light Olefins and Isoprene from Butane

InactiveUS20110040133A1Increase valueImprove cokingOrganic compound preparationDistillation purification/separationButeneDehydrogenation

Process for the selective production of ethylene, propylene and isoprene from light hydrocarbons comprising: a) fractionating a butane fraction in a de-isobutanizer to obtain an enriched iso-butane fraction and an enriched normal-butane fraction, b) cracking said normal-butane fraction and optionally an ethane fraction, optionally a propane fraction, in a non-catalytic cracking zone to produce an olefin rich stream, c) treating said olefin rich stream in a separating section to recover: an ethylene stream, a propylene stream, d) transforming the recovered iso-butane of step a) into iso-butene or t-butyl hydroperoxide or partly into iso-butene and partly into t-butyl hydroperoxide, e) optionally reacting iso-butene of step d), if any, with formaldehyde to make isoprene, f) optionally reacting t-butyl hydroperoxide of step d), if any, with an olefin to give an epoxide and t-butanol and further separating t-butanol, or optionally having t-butyl hydroperoxide of step d), if any, decomposed to t-butanol and reacted with formaldehyde to give isoprene, or reacting a part of the t-butyl hydroperoxide of step d) with an olefin and having the remaining part decomposed to t-butanol and reacted with formaldehyde to give isoprene, g) dehydrating the t-butanol recovered at step f), if any, into iso-butene and reacting said iso-butane with formaldehyde to make isoprene, or reacting directly the t-butanol recovered at step f), if any, with formaldehyde to make isoprene, or dehydrating the t-butanol recovered at step f), if any, into iso-butene, hydrogenating said iso-butene to iso-butane and oxidizing said iso-butane into t-butyl hydroperoxide, and recycling said t-butyl hydroperoxide, or dehydrating the t-butanol recovered at step f), if any, into iso-butene, then disproportionating said iso-butene and propylene recovered at step c) (or 2-butene recovered at step c)), separating an isoamylene stream and converting the isoamylene into isoprene by dehydrogenation, or making any combination of above routes of said step g), h) optionally disproportionating iso-butene of step d), if any, and propylene recovered at step c) (or 2-butene recovered at step c)), separating an isoamylene stream and converting the isoamylene into isoprene by dehydrogenation, at least one of steps e), f) and h) is not optional.

Owner:TOTAL RES & TECH FELUY

High-temperature-resistant methanation catalyst as well as preparation method thereof

ActiveCN104399491AIncrease active siteLarge specific surface areaHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIncipient wetness impregnationOxide

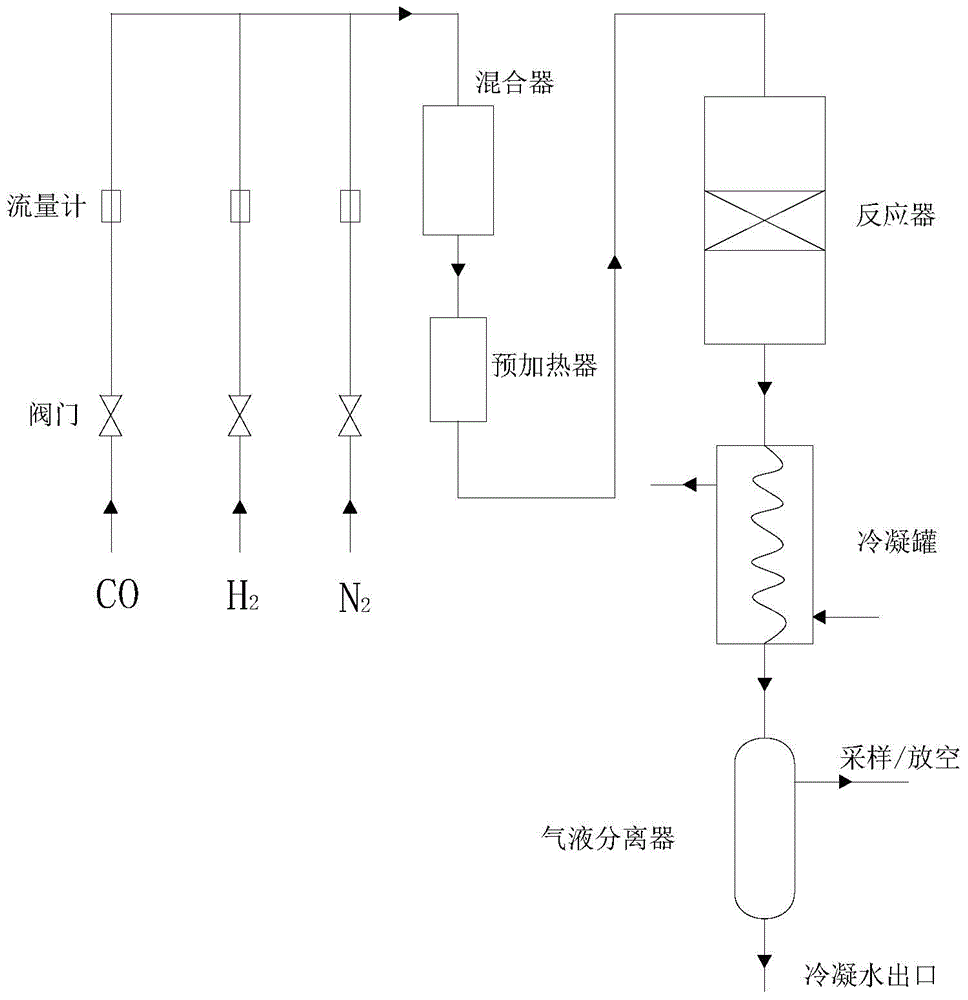

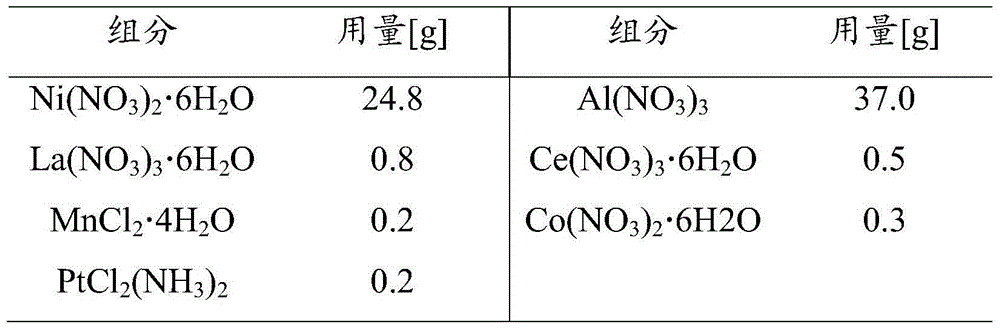

The invention discloses a high-temperature-resistant methanation catalyst as well as a preparation method thereof. According to the catalyst, Al2O3 is used as a carrier, Ni is used as a primary active component, La and Ce are used as secondary components, and metallic oxides of Mn, Co, Fe, W or Mg are used as other active auxiliaries; the preparation method of the catalyst comprises the following steps: carrying out ultrasonic dispersion and coprecipitation on the primary active component Ni and a PEG (polyethylene glycol)-aqueous solution of a carrier precursor, and separating, drying and roasting to obtain a NiO-Al2O3 catalyst; then, loading the secondary components La and Ce and precursors of the active auxiliaries to the NiO-Al2O3 catalyst by adopting an incipient-wetness impregnation method; finally, roasting and carrying out reduction activation to obtain the high-temperature-resistant methanation catalyst; the catalyst has high specific surface area, and can reduce carbon deposition reaction and improve the selectivity of methane. The high-temperature-resistant methanation catalyst can maintain relatively high methanation catalytic activity for a long time at high temperatures and can be widely applied to a methanation process under a high-temperature environment.

Owner:广东省瀚思尔科技有限公司

Additive for improving Zhundong coal combustion and coking characteristics and use method thereof

The invention relates to a Zhundong coal additive and provides an additive for improving Zhundong coal combustion and coking characteristics and a use method thereof. The additive comprises, by mass, 20-36% of SiO2, 8-18% of Al2O3, 12-28% of MnO2, 6-23% of Fe2O3, 4-10% of KMnO4, 5-15% of Fe(NO3)3, 1-5% of TiO2 and 2-4% of a waterproof adhesive. The additive of Zhundong coal can be prepared by simple processes, has a low cost, can be transported, stored and used conveniently, can well improve Zhundong coal combustion, coking, slag-bonding and dust deposition characteristics, can effectively improve a blending combustion ratio of Zhundong coal, and has no side effect on fire coal equipment, no damage on the human body and no pollution on the environment.

Owner:浙江百能科技有限公司 +1

Method for substituting cement kiln fuel with garbage derived overtails

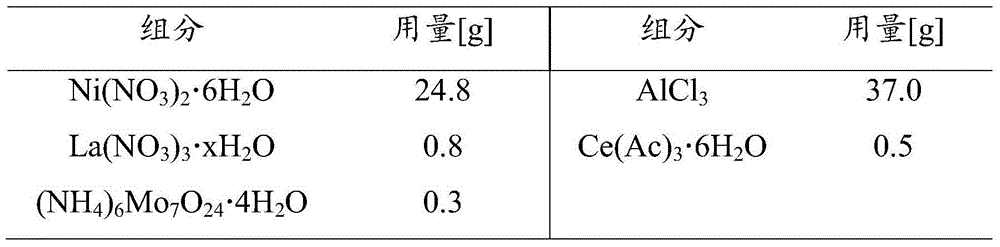

ActiveCN101173196AHigh calorific valueAvoid enteringBiofuelsSolid fuelsAlternative fuelsProcess engineering

The invention relates to a method for adopting waste derivative oversize material as substitute for cement kiln fuel, which is characterized in that the domestic waste in refuse reclamation station is separated and sorted, broken in packages, crushed and completely stirred and mixed, one part of the waste enters a precombustion furnace in the kiln tail of a cement kiln for combustion, while the other part of the waste enters the cement kiln from the kiln hood for combustion, thus the substitute fuel for cement production is produced. The invention has the advantages that the waste derivative oversize material having calorific value is adopted to substitute for industrial fuel in the cement kiln, thus resources of waste derivative oversize material are fully utilized, and coal energy resources are saved; simultaneously the cement kiln has the characteristics of high temperature, large carrying capacity, no residue after waste treatment and no secondary pollution, therefore the invention has the great advantages of energy saving and environmental protection.

Owner:LINGCHUAN JINYU CEMENT

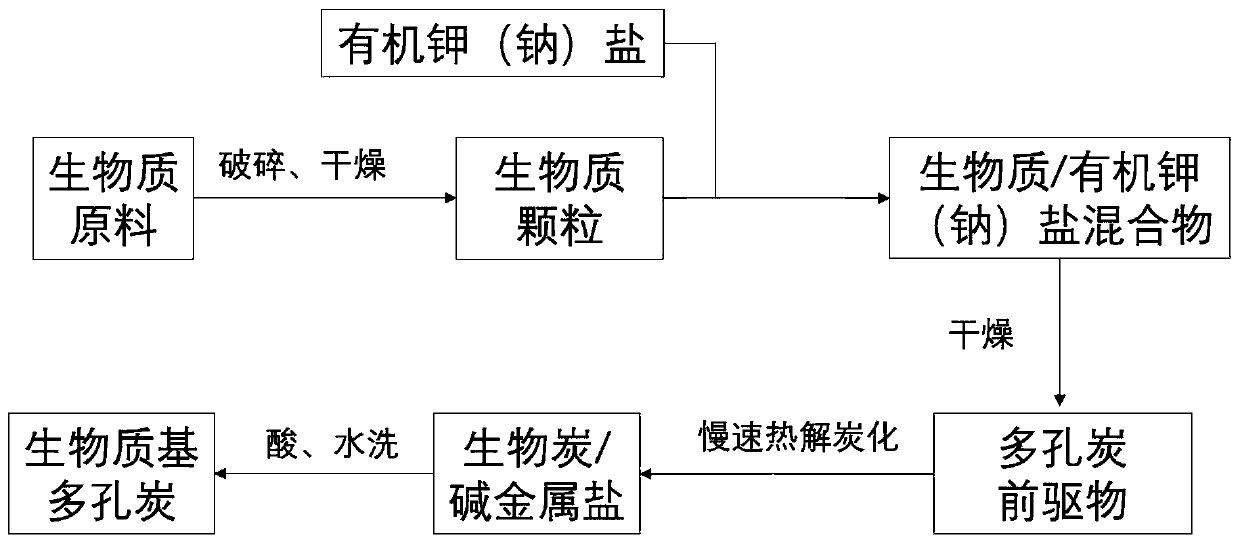

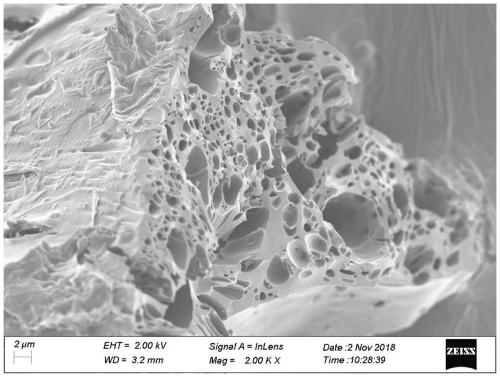

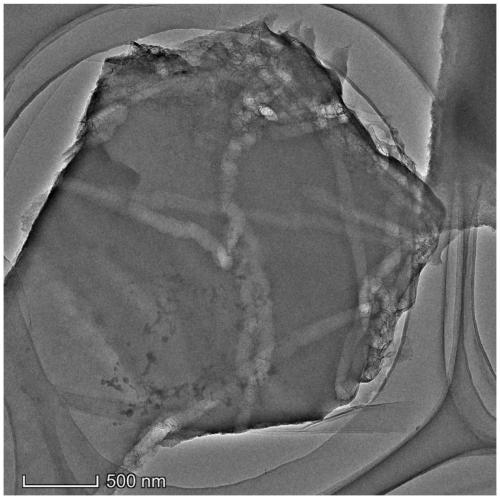

Preparation method of biomass-based porous carbon and product

The invention belongs to the field of biomass energy utilization, and discloses a preparation method of biomass-based porous carbon and a product. The method comprises the following steps: S1, mixingbiomass particles and an organic potassium salt or an organic sodium salt, heating and drying a mixture to obtain a porous carbon precursor; S2, heating, pyrolyzing and carbonizing the porous carbon precursor in an inert atmosphere, and then performing heat preservation; S3, performing acid pickling on the mixture, removing an alkali metal salt, then filtering and flushing the mixture with an excessive amount of deionized water till the filtrate is neutral, and performing drying to obtain the biomass-based porous carbon. The invention further discloses a corresponding product. According to thepreparation method, the preparation conditions are adjusted, the biomass is subjected to catalytic carbonization by adopting an activating agent, and the activating agent catalyzes the carbonizationand coking of the biomass, and is fully in contact with coke particles for further activation to generate micropores in order to obtain the biomass-based porous carbon with a large specific surface area. The method is simple, is a green and sustainable preparation method, and has wide applicablity for different saccharides and lignocellulose biomass raw materials.

Owner:HUAZHONG UNIV OF SCI & TECH

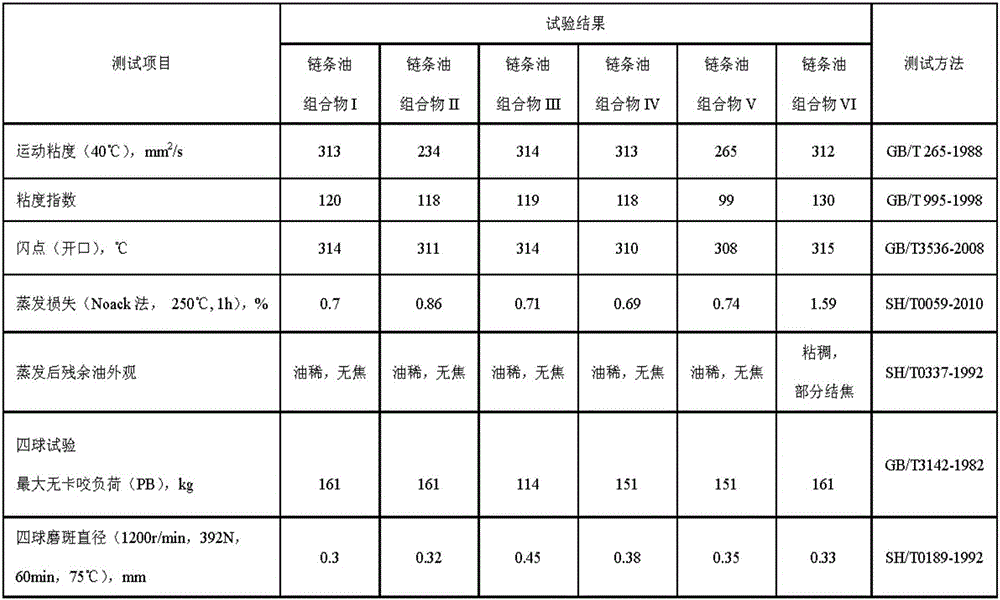

High-temperature chain oil composition and preparation method thereof

ActiveCN105838484AImprove high temperature performanceImprove wear resistanceAdditivesBase-materialsPentaerythritolPhosphate

The invention provides a high-temperature chain oil composition and a preparation method thereof. The high-temperature chain oil composition includes: (a) synthetic ester base oil; (b) alkoxy phosphate anti-wear reagent at extreme pressure; (c) oiliness agent; (d) viscosity index improver; (e) antioxygen; and (f) anticorrosive, wherein the (a) synthetic ester base oil is a mixture of dipentaerythritol ester and aromatic ester. The high-temperature chain oil composition is adapted to using at high temperature, has good high-temperature performance, has no carbon deposition residual working at high temperature for a long time, is without dripping, has good wear-resisting anti-attrition and corrosion resistant performances, and has low friction coefficient and small chain abrasion. Moreover, the high-temperature chain oil composition has low toxicity, is easy to decompose, and is environmentally friendly.

Owner:埃优诺特种新材料科技(山东)有限公司

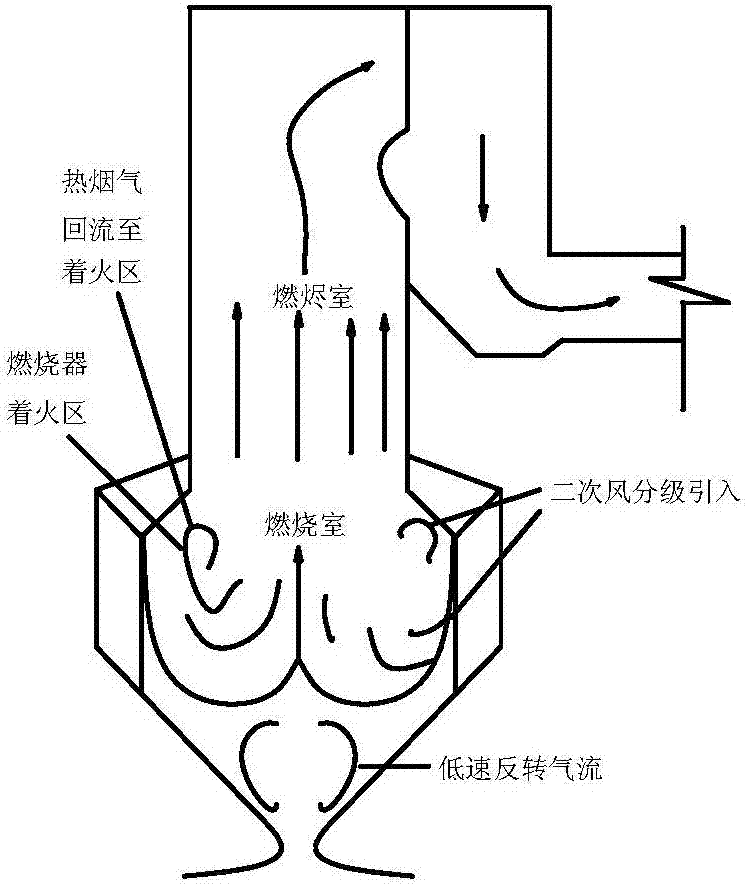

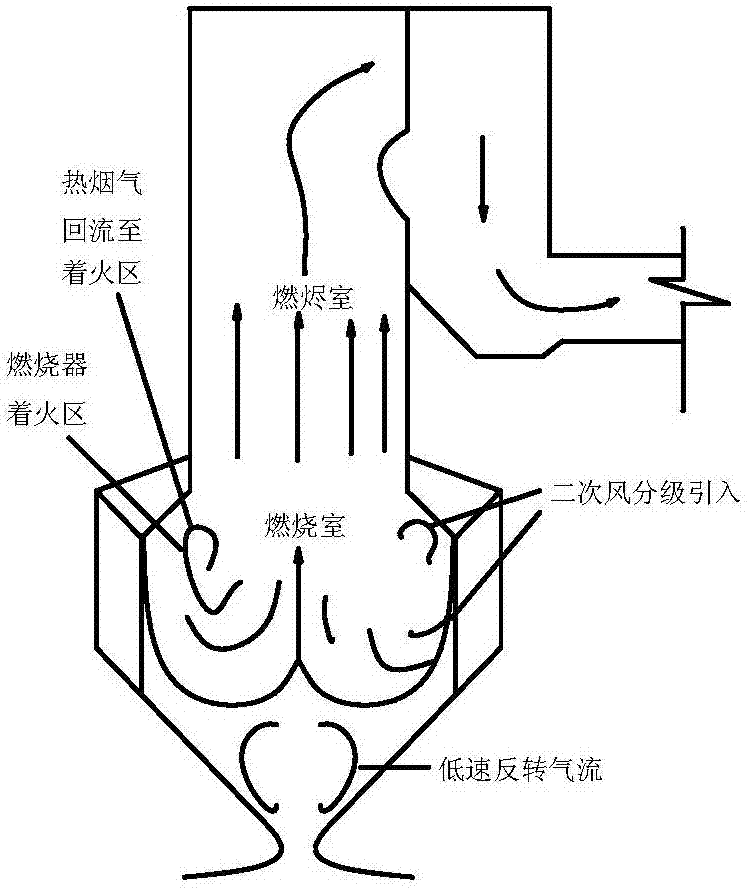

Method for reducing W-type flame boiler NOx emission

ActiveCN107355809AReduce generationIncrease contentCombustion using gaseous and pulverulent fuelAir supply regulationFlue gasProcess engineering

The invention relates to a method for reducing W-type flame boiler NOx emission. Fuel burns in a staged combustion manner, the method for reducing W-type flame boiler NOx emission specially comprises that free-burning coal and anthracite in a predetermined proportion are selected, the free-burning coal is employed to react with oxygen to form first stage combustion, wherein the free-burning coal is bituminous coal or a mixture of bituminous coal and meager coal; a high temperature flue gas atmosphere is formed in the first stage, being coerced by high temperature flue gas, the anthracite is ignited to form second stage combustion, the volatile component content of the free-burning coal is higher than of the anthracite, the volatile component content is larger than 25%, and the ratio of the bituminous coal to the anthracite is larger than 1:1; the dry ash-free basis volatile component content of as-fired coal keeps satisfying the formula: 15% < Vdaf < 20 %, the lower heating value of the as-fired coal keeps satisfying the formula: 20 MJ / kg < Qnet, ar < 22.5 MJ / kg, when the bituminous coal, the meager coal and the anthracite burn in a staged manner, Vdaf > 10 %. According to the invention, by employing a staged combustion control strategy, NOx generated by boiler combustion is reduced.

Owner:中国大唐集团科学技术研究总院有限公司

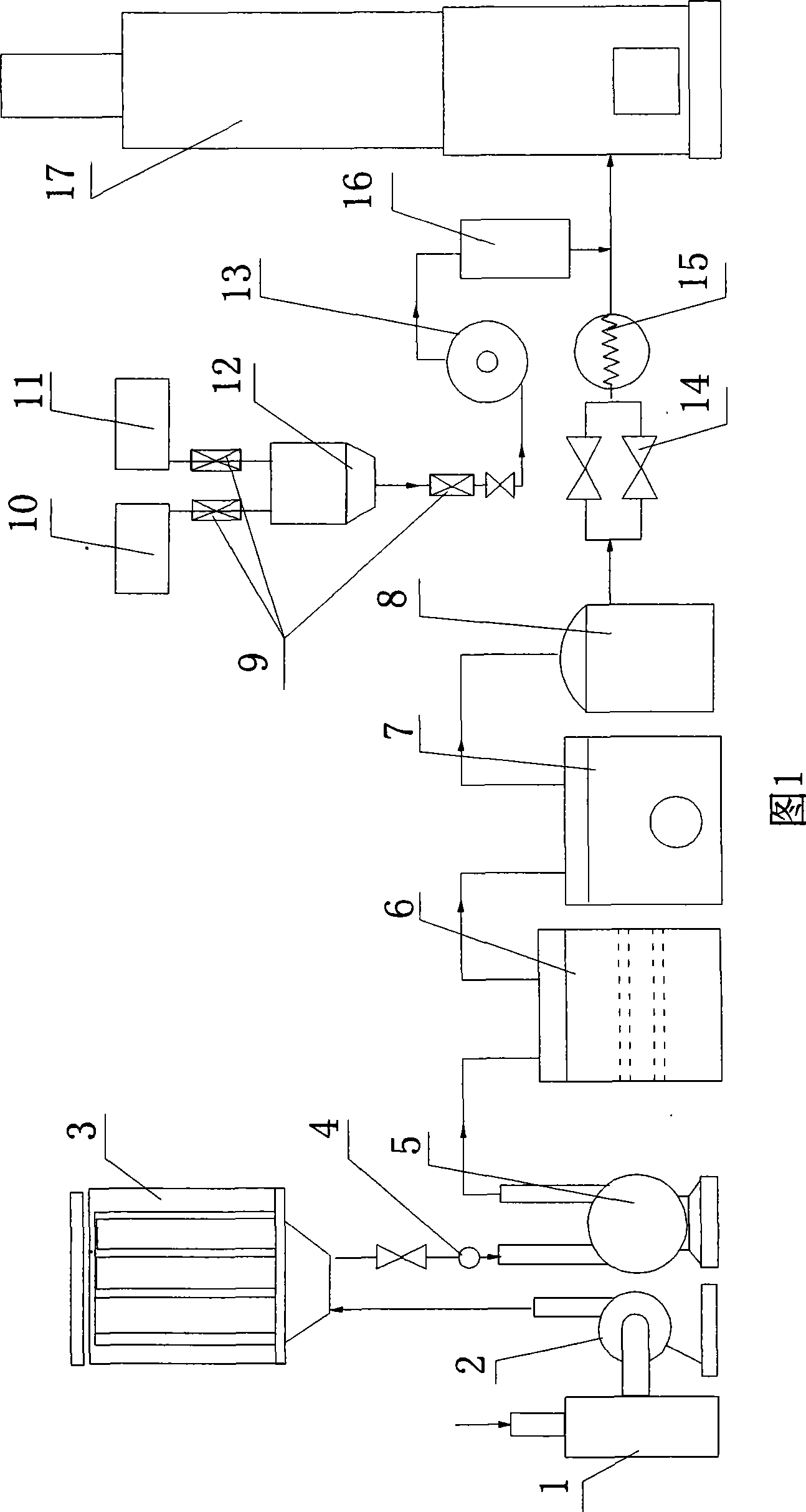

Oxygen-enriched air mixed blowing combustion adjuvant boiler energy-saving method and equipment used thereby

InactiveCN101413674AHigh flame temperatureLower the ignition temperatureSolid fuelsIndirect carbon-dioxide mitigationEngineeringKiln

The invention provides an energy-saving method of an oxygenized air mixed blowing supporter combustion boiler and equipment used by the method, belonging to an energy-saving and emission-reduction combustion technology of the boiler; the invention more particularly relates to an efficient energy-saving combustion technology combining oxygenized air technology and supporter combustion technology and equipment thereof; the effects of energy-saving and emission-reduction of the invention are different according to the different running situations and equipment of the boiler (kiln); the statistics obtained from the cases studies of dozens of boilers and kilns proves that the lowest coal-saving ratio is 5.7%, the highest coal-saving ratio is 25%, and the coal-saving ratio of a pulverized coal fired boiler of 670t / h in a thermal power plant is 8.34%, so that the statistical data shows that the effects of energy-saving and emission-reduction of the technical improvement measure are excellent, the technology can be widely popularized, and good social and economical benefits can be brought about.

Owner:张开军

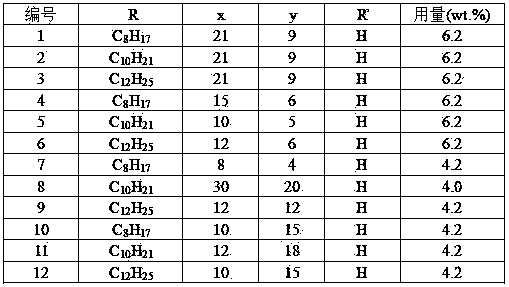

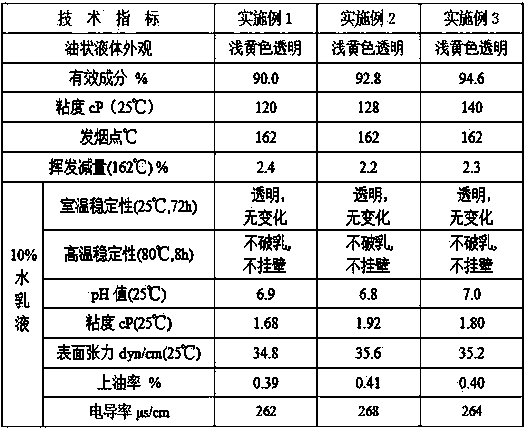

High-speed spinning oil used for polyester pre-oriented yarn (POY)

The invention relates to high-speed spinning oil used for polyester pre-oriented yarns (POY). The high-speed spinning oil used for the POY comprises a main part which contains more than twenty polyether type compounds of multiple components and multiple structures and accounts for 70-92% of the total mass, and the rest part is additive. A molecular structure of the polyether type compounds is RO[(EO)x / (PO)y]R', wherein end groups R and R' are H, or C1-C18 alkane, aryl, acyl or acylamino, or inorganic acid radical; [(EO)x / (PO)y] is a polyether chain segment composed of oxoethylene group and / or isopropoxy. The high-speed spinning oil used for the POY is applicable to polyester pre-oriented high-speed spinning and a subsequent textured yarn production technology and can give good smoothness and bundling property, overall viscosity-temperature-concentration characteristic and excellent thermal property to fibers, fewer broken filaments of the fibers are produced in the next drafting process, evenness and dyeing are uniform, little smoke is produced by a processing hot box, little white powder and coke are produced, a cleaning period is long, and product quality and stability are good.

Owner:江苏天音化工有限公司

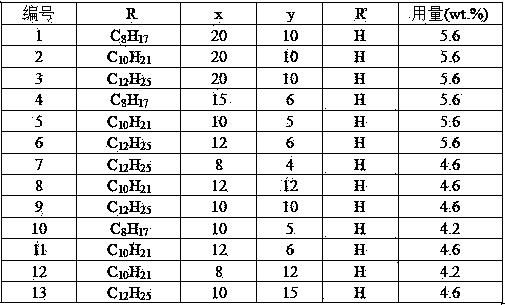

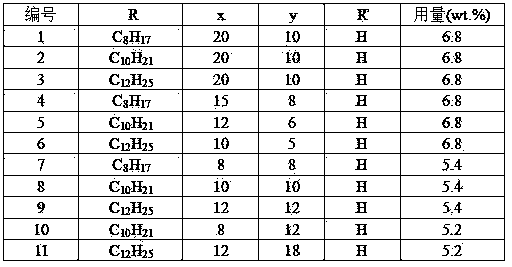

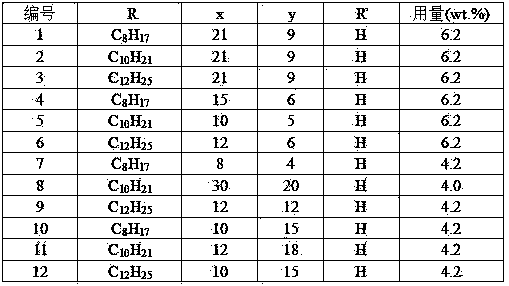

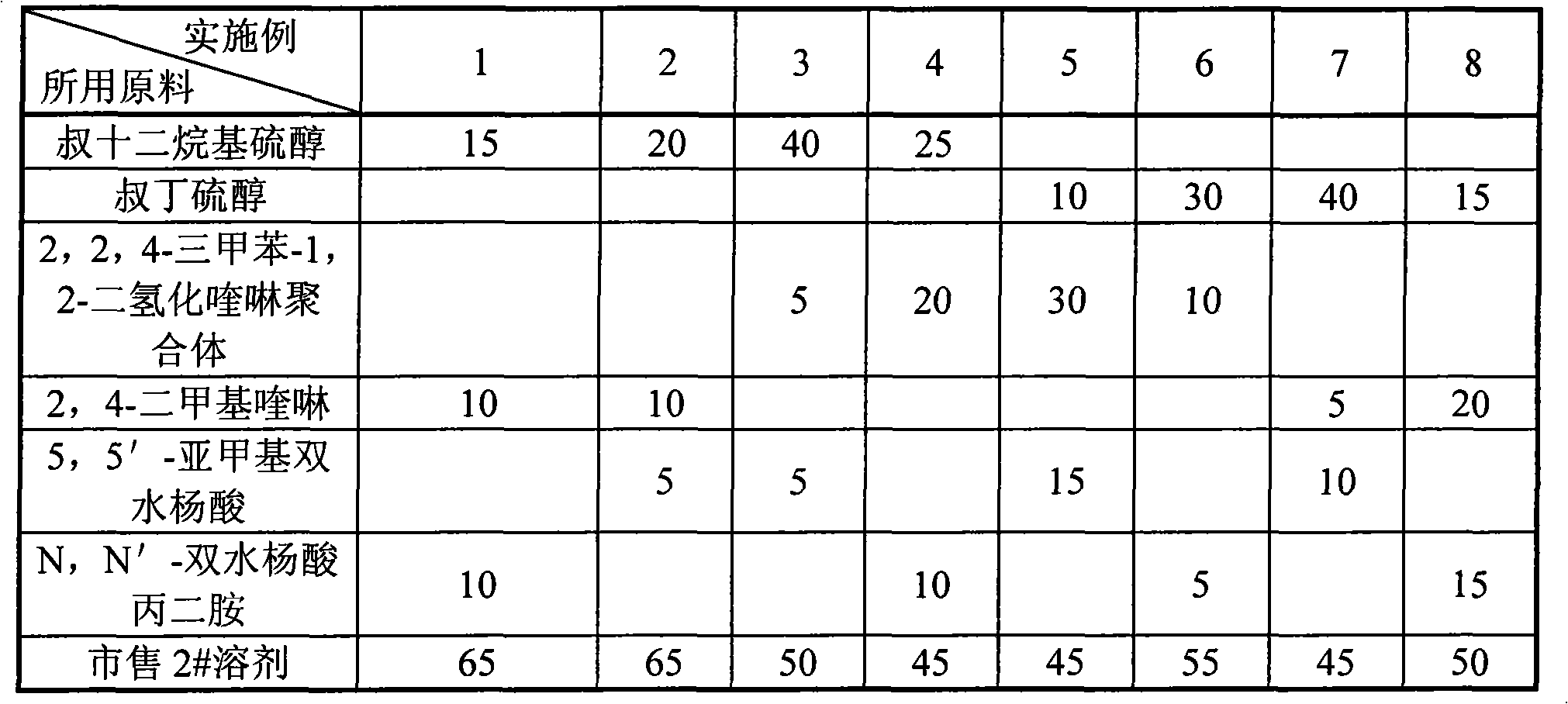

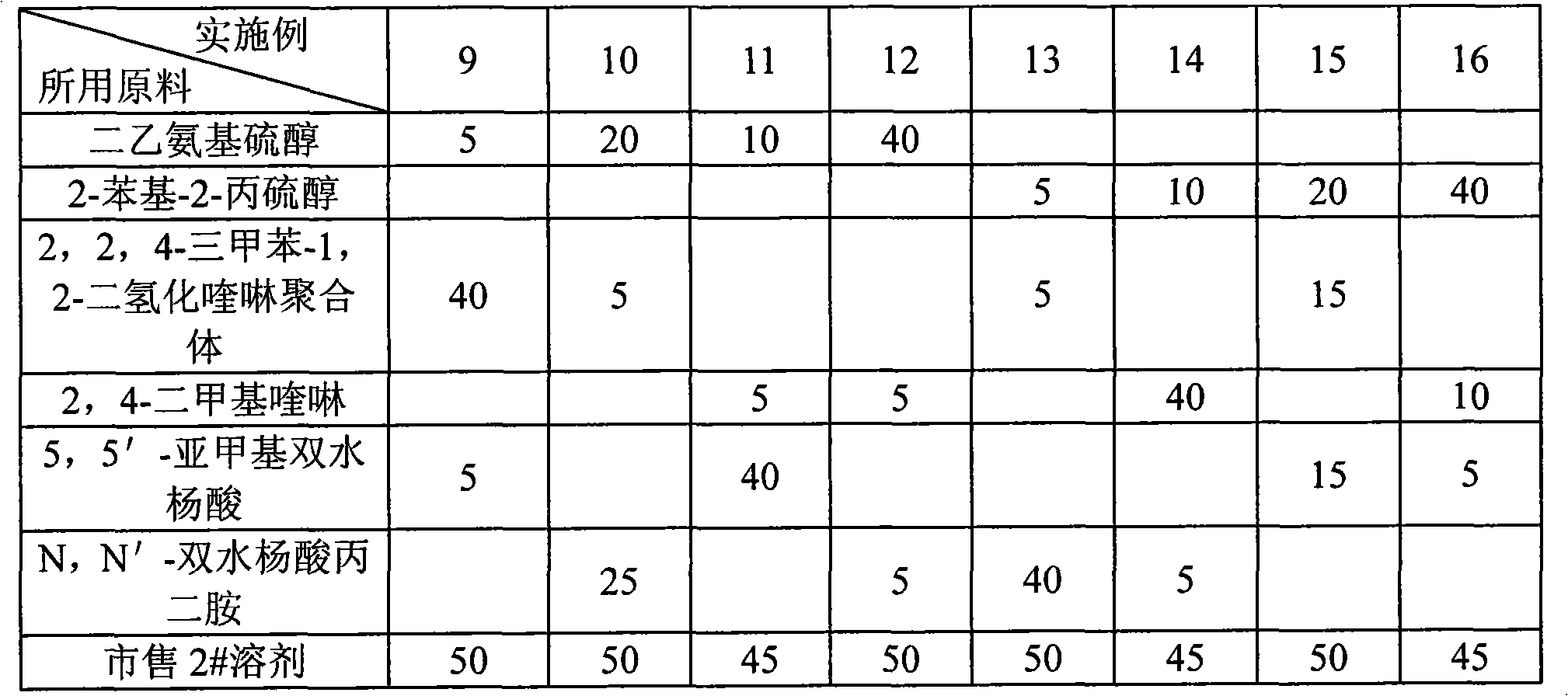

Ethylene cracking furnace coking restrainer and its use method

InactiveCN101318872APassivation of metal surfacesExtended service lifeThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingThiolOrganic solvent

The present invention relates to a coking depressor for an ethylene cracking furnace, and a method for using the same. The depressor consists of a thiol compound, a quinoline compound, a disalicylic acid compound and an organic solvent. The coking depressor not only overcomes the shortcomings in the prior depressor that the manufacturing cost is high, the injection operation is difficult, the distribution in the cracking furnace tube is uneven, and the depressor erodes the inner wall of the furnace tube, etc., but also effectively prolongs the service life of the cracking furnace and improves the yield of ethylene, the usage of the material and the load of an ethylene device. The producing amount of CO and CO2 is largely reduced, and thus the depressor is safe and environment-friendly.

Owner:北京斯伯乐科学技术研究院

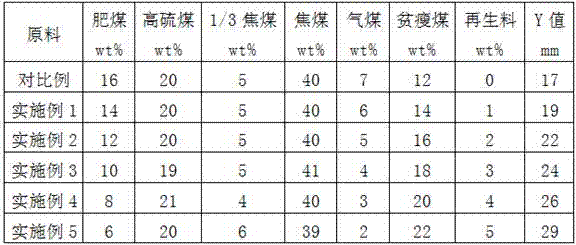

Coking mixed coal prepared via adding of reclaimed material, and coking coal blending method

The invention discloses a coking mixed coal prepared via adding of a reclaimed material, and a coking coal blending method. The coking mixed coal is composed of, by weight, (16-2N)% of fat coal, 19 to 21% of high-sulphur coal, 4 to 6% of 1 / 3 coking coal, 39 to 41% of coking coal, (7-N)% of meager lean coal, (12+2N)% of gas coal, and N% of the reclaimed material, wherein N<=5; the reclaimed material contains 21 to 24wt% of beta resin. According to the coking coal blending method, beta resin with adhesive effect is used for realizing combination of the coking mixed coal with coking coal blending technology, and is used for replacing a part of fat coal into coking coal to produce coke, so that coking coal source is widened, the using amount of expensive fat coal is reduced, and coal blending cost is reduced. The coking coal blending method is capable of widening the plastic temperature range of coking coal, realizing better connection of different kinds of coal, increasing cokeability in coking process, promoting anisotropic generation, ensuring that coke quality is capable of satisfying coke requirements of large blast furnaces, and at the same time increasing the using amount of low adhesive performance meager lean coal in coking coal blending, and reducing coal blending cost greatly.

Owner:宣化钢铁集团有限责任公司

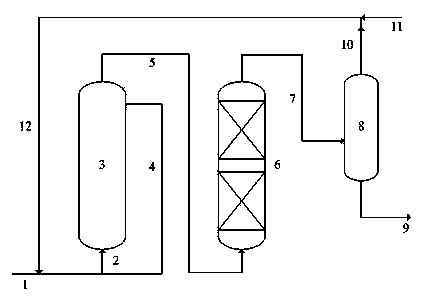

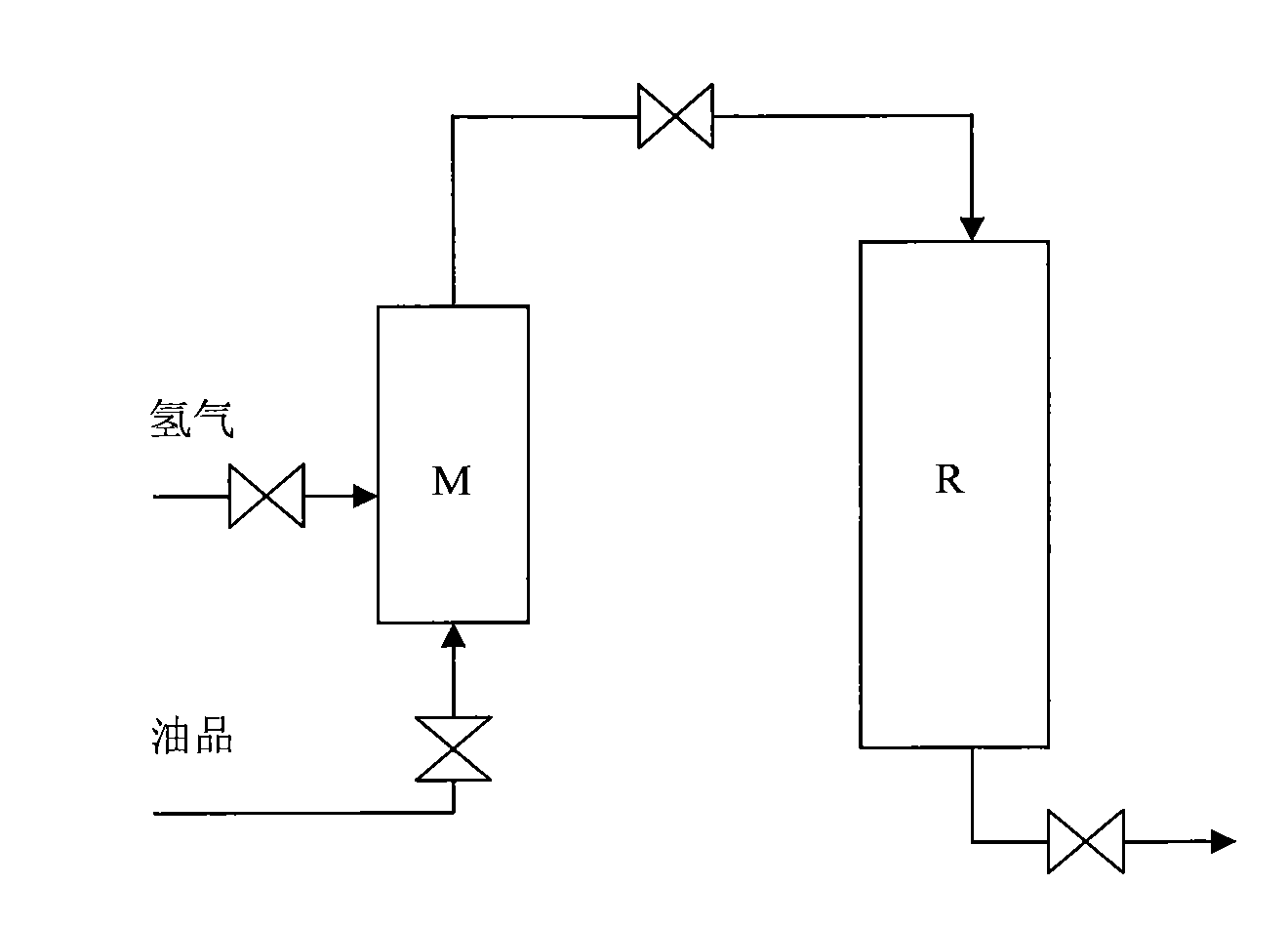

Hydrotreating method of inferior gasoline raw material

ActiveCN103805264AEfficient use ofAvoid abnormal downtimeTreatment with hydrotreatment processesHydrogenFluidized bed

The invention discloses a hydrotreating method of an inferior gasoline raw material. The method comprises the following steps: mixing inferior gasoline with thermal loaded oil and circulating hydrogen, allowing the mixture to enter a fluidized bed hydrogenation pretreatment reactor; separating the effluent of the hydrogenation pretreatment to obtain gas and liquid; returning the liquid as thermal loaded oil to the pretreatment reactor, allowing the gas to pass through a gasoline hydrotreating reactor in an upward flow manner; performing gas-liquid separation of the gasoline hydrogenation effluent in a low temperature low pressure separator, purifying the obtained hydrogen-rich gas for recycle, and performing gas stripping of the obtained liquid so as to be used as a gasoline blending component or a chemical raw material. The method of the invention greatly prolongs the running period of the inferior gasoline hydrotreating device.

Owner:CHINA PETROLEUM & CHEM CORP +1

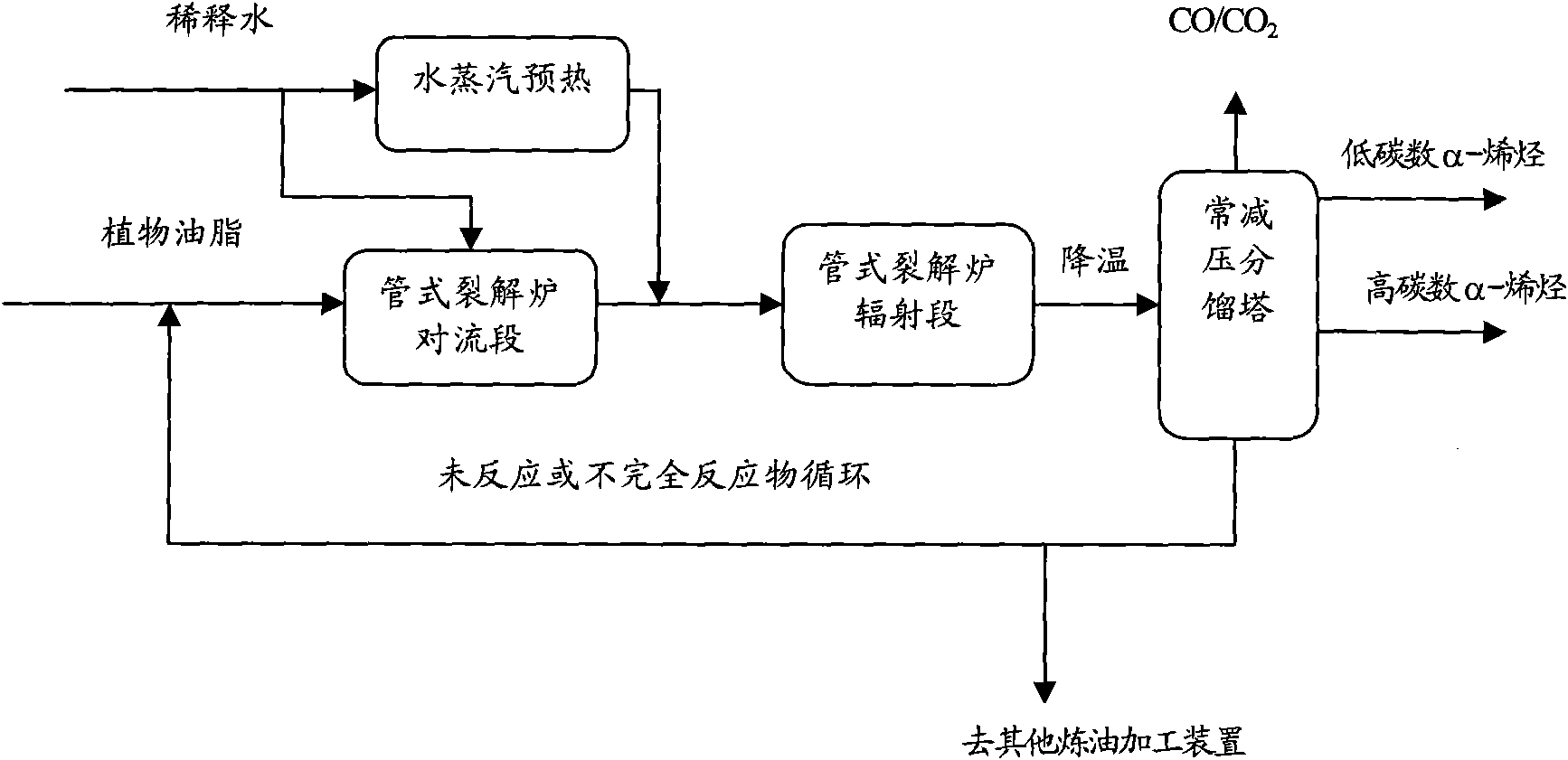

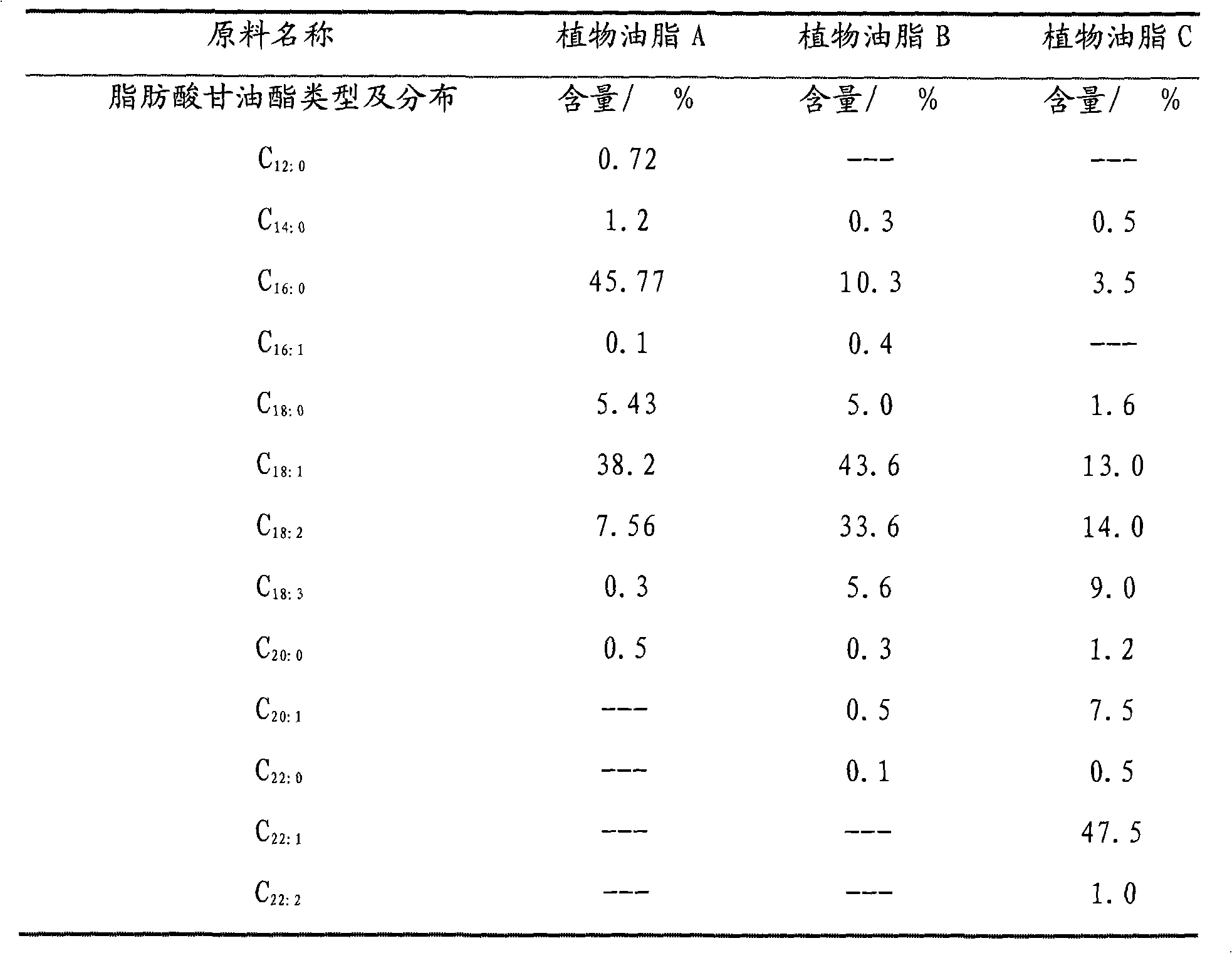

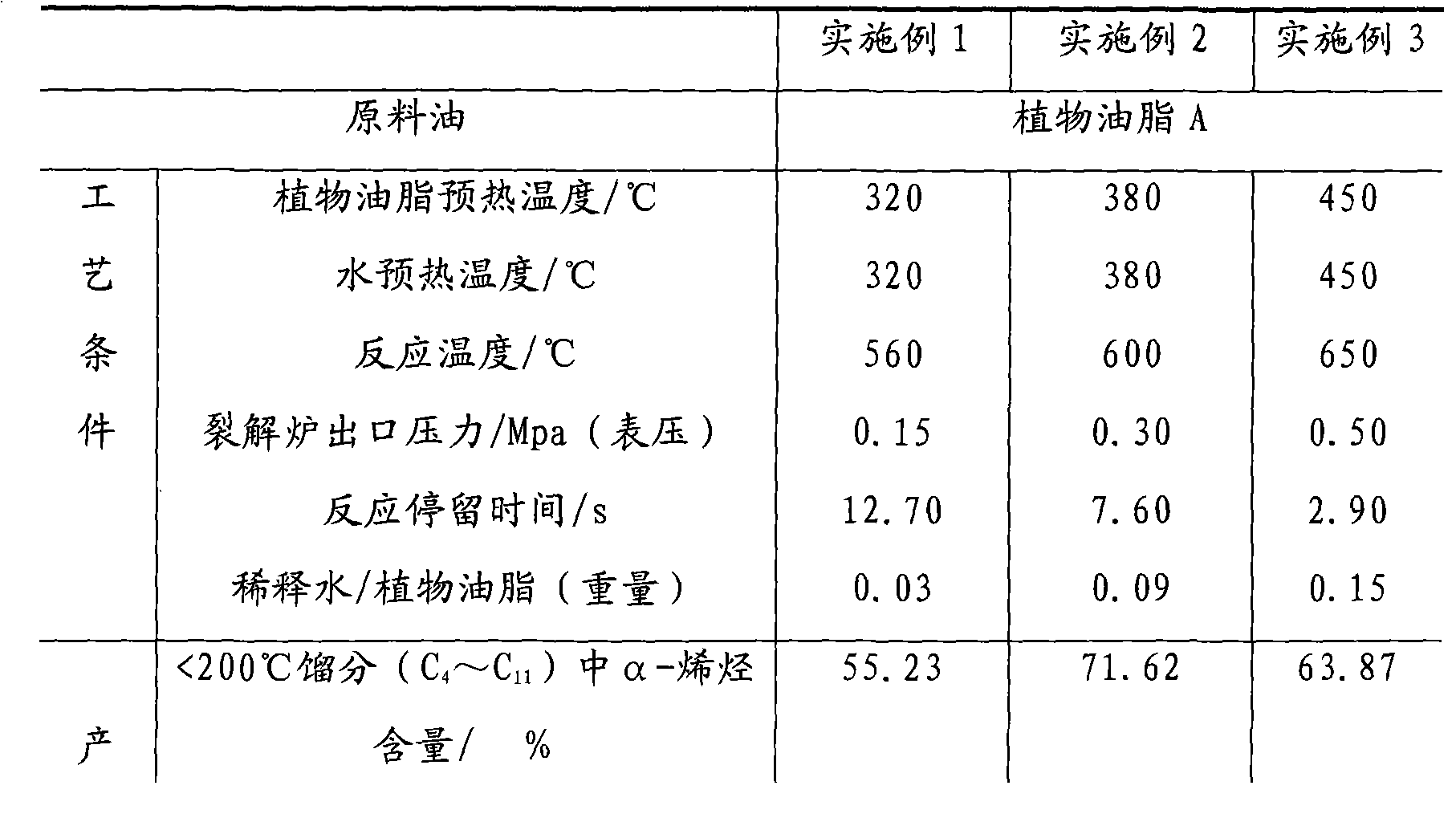

Method for preparing alpha-olefin from vegetable fat

ActiveCN102041025AHigh selectivityAlleviate the contradiction of tight supplyLiquid hydrocarbon mixture productionBio-feedstockAlpha-olefinRaw material

The invention relates to a method for preparing alpha-olefin from vegetable fat. The method comprises the following steps: inputting the vegetable fat and diluted water into a tubular cracking furnace; thermally cracking under a non-catalytic condition; and separating a product after the reacting product is cooled. In the method, the renewable vegetable fat is used for preparing the alpha-olefin,so that the sources of raw materials for preparing the alpha-olefin are widened, and the C6 to C12 alpha-olefin with high value can be conveniently produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

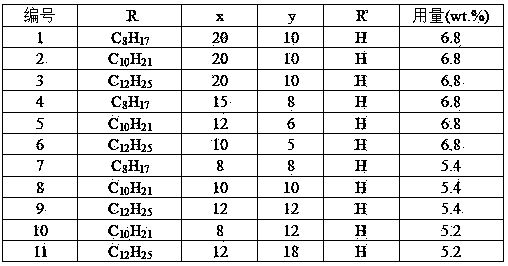

Preparation method of high-speed polyester POY (Pre-Oriented Yarn) spinning oil agent

The invention provides a preparation method of a high-speed polyester POY (Pre-Oriented Yarn) spinning oil agent. A pure oil agent except for water in the oil agent is composed of a main body part and an additive, wherein the main body part includes over 20 kinds of polyether compounds and the rest components belong to non-polyether additive. The preparation method comprises the following steps: firstly, metering the main body component of the oil agent, pumping the main body component into a reaction kettle in vacuum, stirring, heating to 50-70 DEG C, stirring, metering the additive components and water, and adding the metered additive components and water into the reaction kettle, stirring, heating to 70-80 DEG C, keeping the temperature for 40-50min, closely filter-pressing a product, and subpackaging the product after the product is checked to be qualified. The oil agent prepared by using the method provided by the invention is suitable for high-speed polyester POY spinning and a production process of a subsequent deform yarn; the oil agent endows the fiber good smoothness and bundling and favorable total viscosity-temperature and viscosity-concentration characteristics; the fiber is few in broken filament breaks, even and uniform in dyeing in the later drafting process; the smoke formation amount of a hot processing tank is small, generated white powder and coke amount are small and the cleaning period is long; a product is good in quality and stability.

Owner:江苏天音化工有限公司

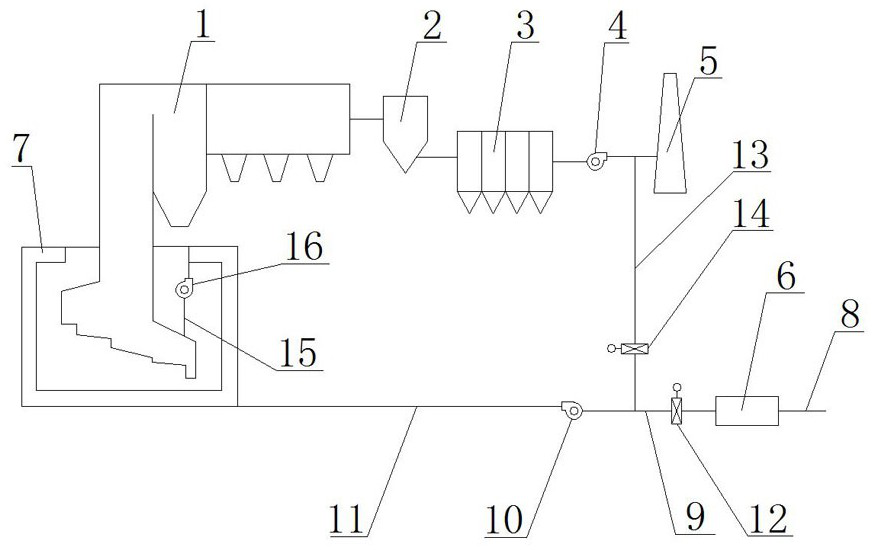

Flue gas recirculation system of household garbage incineration power plant

PendingCN113280351AIncreased inert gas contentSuppress generationEmission preventionIndirect carbon-dioxide mitigationAir preheaterInert gas

The invention discloses a flue gas recirculation system of a household garbage incineration power plant. The flue gas recirculation system comprises an incinerator, a reaction tower, a dust remover, an induced draft fan, a chimney and an air preheater, a flue gas outlet of the incinerator is connected with an inlet of the reaction tower, an outlet of the reaction tower is connected with one end of the dust remover, and the other end of the dust remover is connected with one end of the induced draft fan. The other end of the induced draft fan is connected with the chimney, air is introduced into one end of the air preheater, and the other end of the air preheater and the other end of the induced draft fan are connected with a secondary air chamber of the incinerator. According to the flue gas recirculation system of the household garbage incineration power plant, recycled flue gas replaces part of secondary air, so that the content of inert gas in a combustion area is increased, the flue gas absorbs heat, the concentration of oxygen is reduced, the flue gas and combustion-supporting air spread and combust in a high-temperature and low-oxygen atmosphere, the flame volume is multiplied, a local high-temperature area is reduced, temperature distribution is more uniform, generation of thermal NOx is inhibited, the coking problem of a hearth can be solved, and the heat efficiency and the generating capacity are improved.

Owner:CHINA TIANYING +1

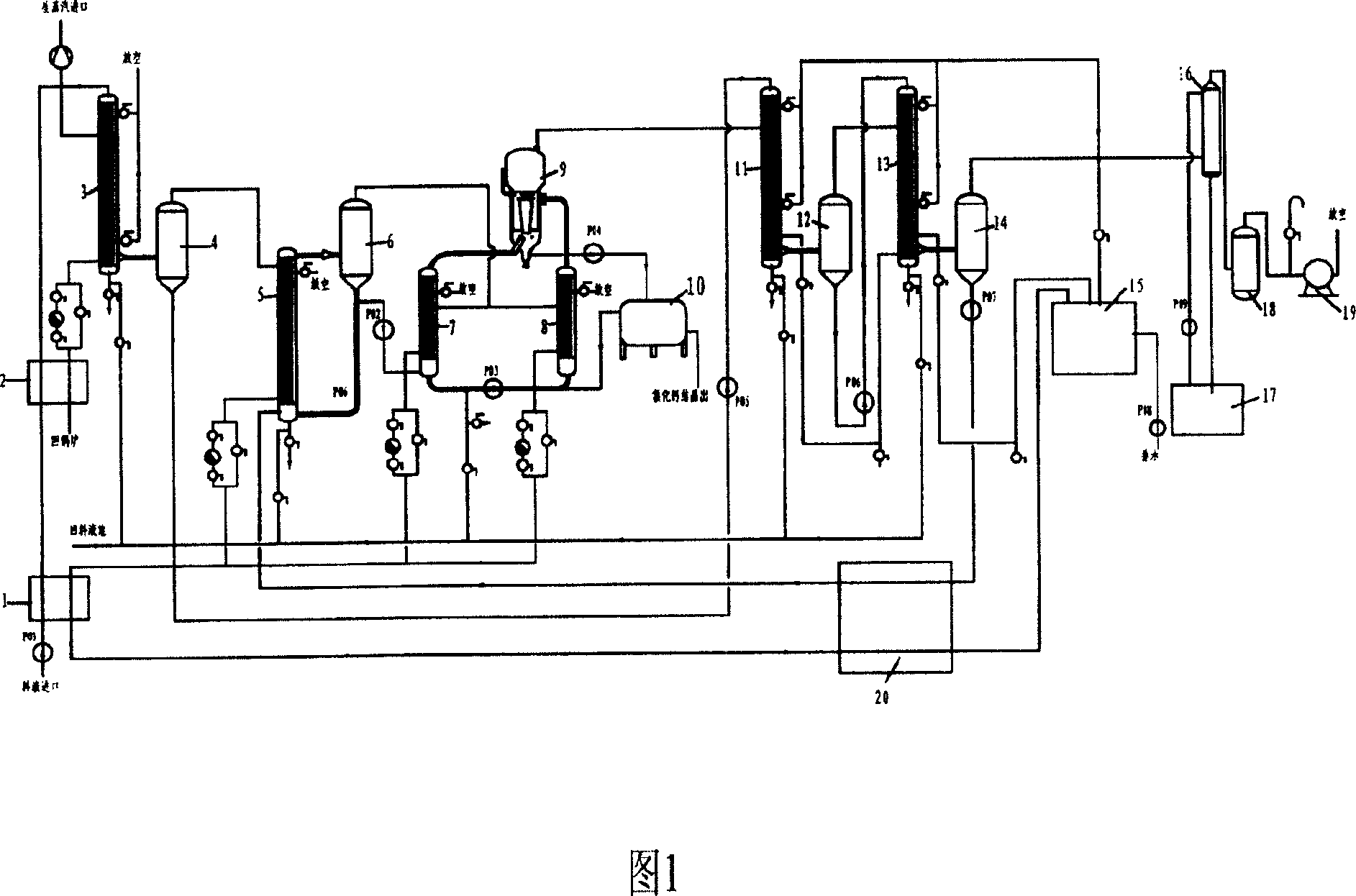

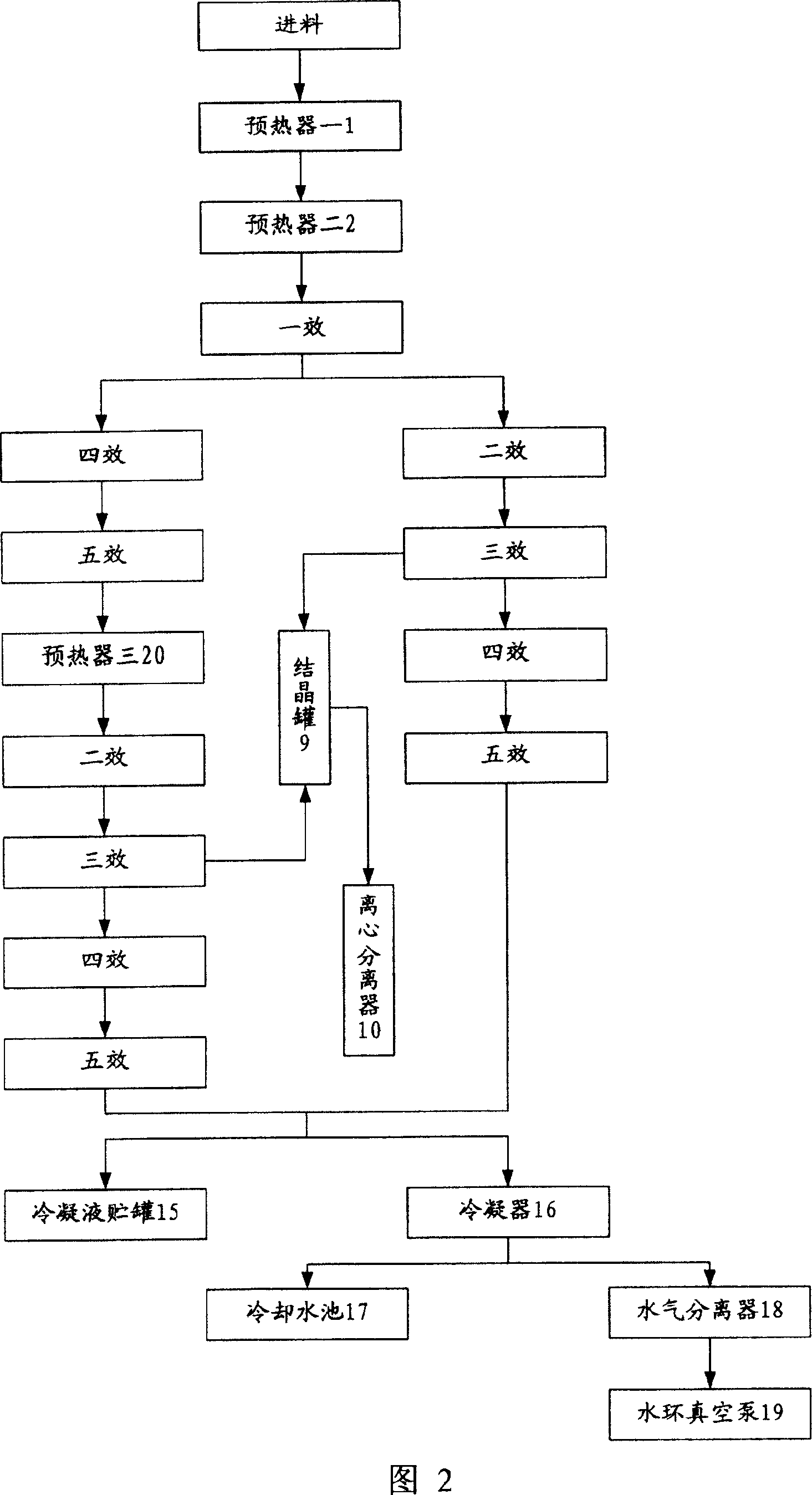

Waste water treating method and multi-effect evaporator for propylene oxide production

InactiveCN1321070CLow toxicityAvoid formingCalcium/strontium/barium chloridesDistillation in boilers/stillsChlorideMulti effect

The method of treating waste water from propylene oxide production adopts multi-effect evaporator and includes the following steps: multi-effect evaporating waste water to obtain concentrated waste water; crystallizing concentrated waste water to obtain calcium chloride crystal; centrifugally separating the calcium chloride crystal from waste water; and finally condensing to recover waste water steam. The present invention also discloses the structure of the multi-effect evaporator.

Owner:刘德沛

Method for improving thermal cracking of heavy oil in sub (ultra) critical water

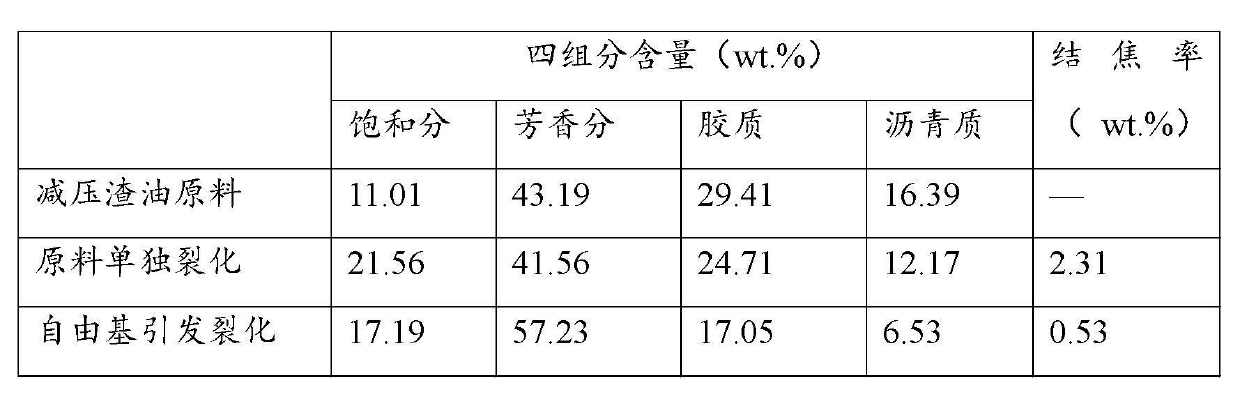

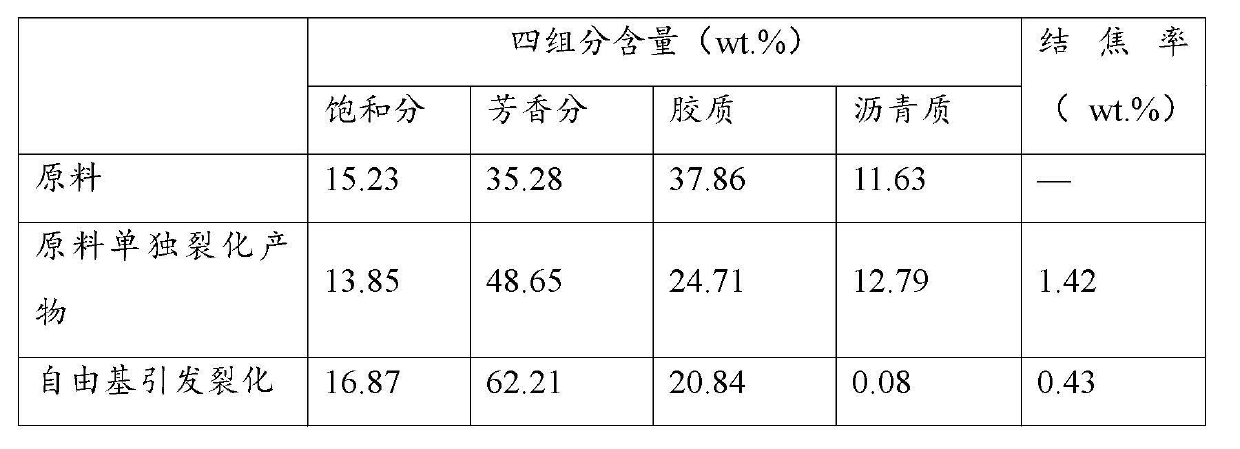

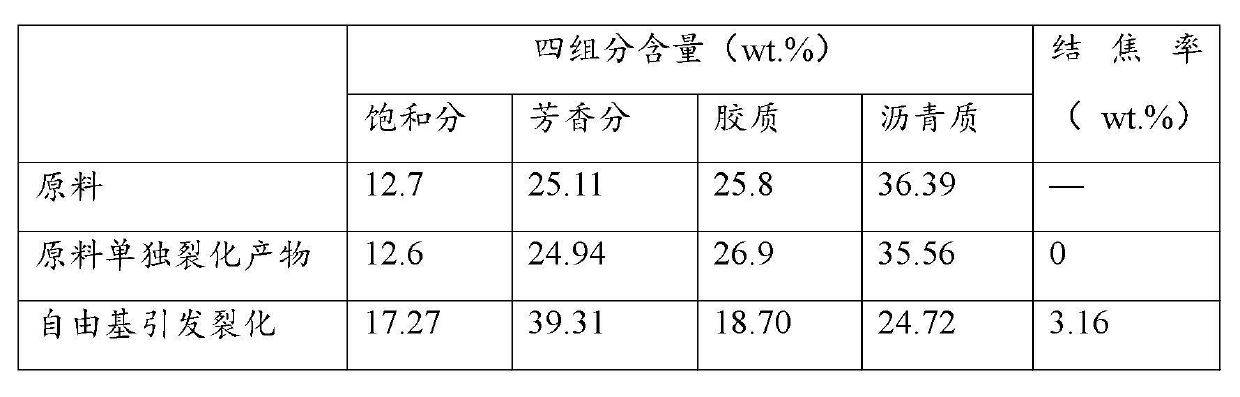

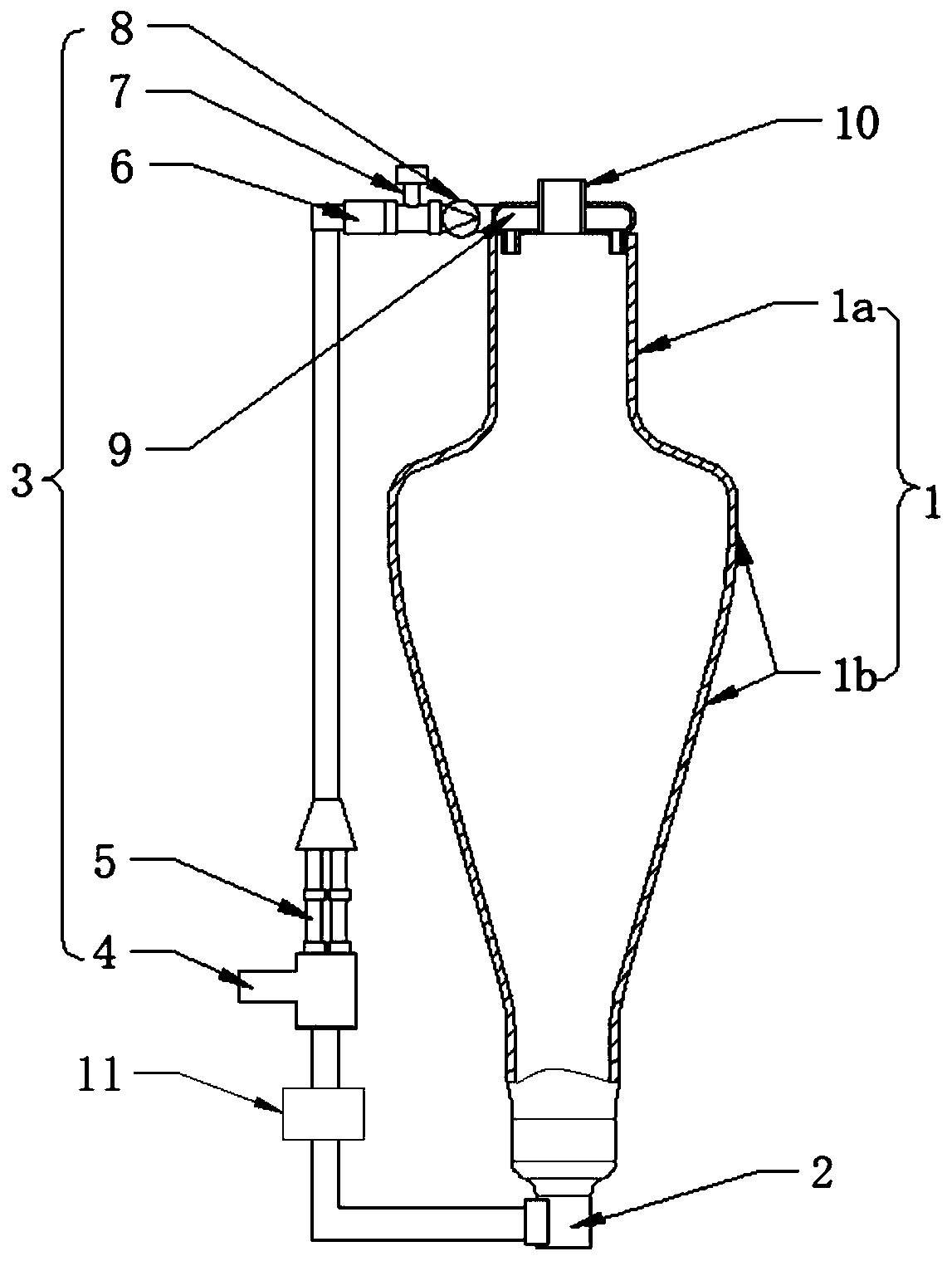

InactiveCN102676205AGood priming efficiencyUnique and ingenious ideaThermal non-catalytic crackingChemistryContinuous operation

The invention relates to a method for improving thermal cracking of heavy oil in sub (ultra) critical water. A radical initiator is introduced to improve the thermal cracking of heavy oil in the sub (ultra) critical water. Preferably, the heavy oil is selected from one or more of vacuum residuum, pitch and catalytic cracking slurry oil. The radical initiator is selected from one or more of elementary iodine, peroxide initiator and azo initiator. The thermal cracking temperature is 360-390 DEG C, the initial mass ratio of the heavy oil to the water is 2:1-1:4, the addition of the radical initiator is 5*10<-3>-20*10<-3> of the mass fraction of the heavy oil, and the thermal cracking is in intermittent or continuous operation mode. An ultrahigh reaction temperature threshold of the thermal cracking of the heavy oil at an induction period can be balanced, so that the thermal cracking of the heavy oil can be carried out under a mild condition, the distribution of cracked liquid phase products is improved, and at the same time coking is effectively suppressed. The operation is simple, the cost is greatly reduced, and the method is conductive to industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Feed method for coal tar hydrogenating unit

The invention relates to a feed method for coal tar. After the pressure of a coal tar raw material is boosted by a hydrogenation reaction raw material booster pump, the coal tar raw material enters a hydrogenation reactor without any indirect heat exchange; and before the pressure of the coal tar raw material is boosted, the coal tar raw material can be hot stream from a fractionating tower. The method can avoid a high-pressure heat-exchange temperature-rise process of the coal tar, eliminate the problem of fouling of high-pressure coal tar heat exchangers, reduce the hydrogenation catalyst bed pressure drop, slow down the coking, and prolong the operation cycle.

Owner:何巨堂

Method for improving coking on inner wall of furnace in acetylene carbon black cracking production

ActiveCN111569783AReduce heat loadIncrease production capacityPigmenting treatmentPyrolysis reactionsElectrically conductiveCarbon black

The invention belongs to the technical field of conductive carbon black materials and relates to a method for improving coking on the inner wall of an acetylene carbon black cracking furnace. The furnace body of the acetylene carbon black cracking furnace is divided into a reaction area and a cooling area from top to bottom; acetylene is subjected to a thermal cracking reaction in the reaction zone. According to the method of the invention, the discharging port of the cracking furnace is communicated with a gas reflux system, so that the gas reflux system refluxes hydrogen generated by cracking into the reaction zone, so that a gas curtain can be formed at a position close to the inner wall of the furnace, and therefore, the acetylene and cracking intermediate products can be prevented from coking on the inner wall of the reaction zone. According to the gas reflux system, the hydrogen generated by the cracking reaction of the acetylene can be utilized and re-sprayed to the inner wall surface of the reaction zone of the cracking furnace; and a protective gas isolation layer is formed between the furnace inner wall of the reaction zone of the cracking furnace and the acetylene atmosphere, so that the acetylene and the cracking intermediate products are prevented from contacting with the inner wall of the furnace body with relatively low temperature to form coking.

Owner:JIAOZUO CITY HEXING CHEMICAL INDUSTRY CO LTD

Zeolites, the production thereof, and their uses for upgrading heavy oils

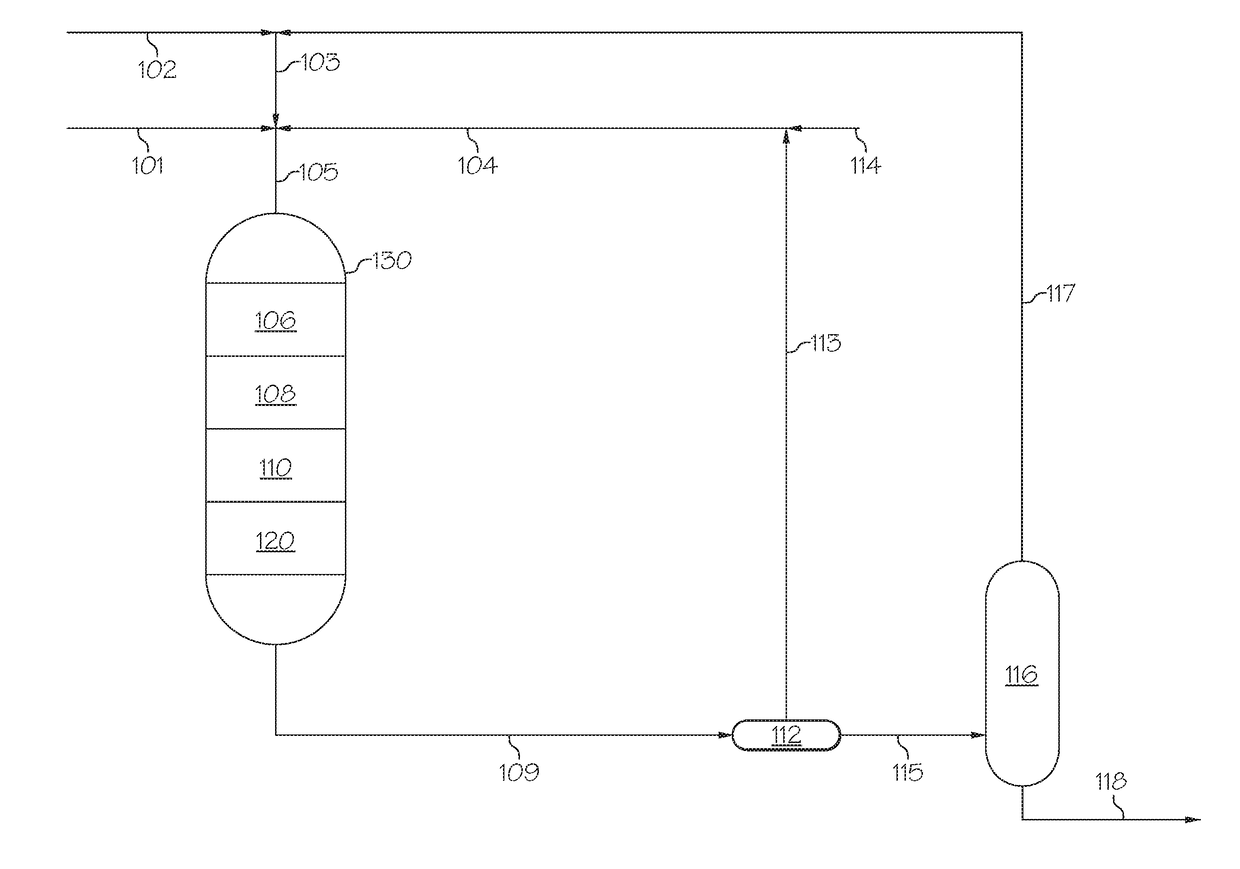

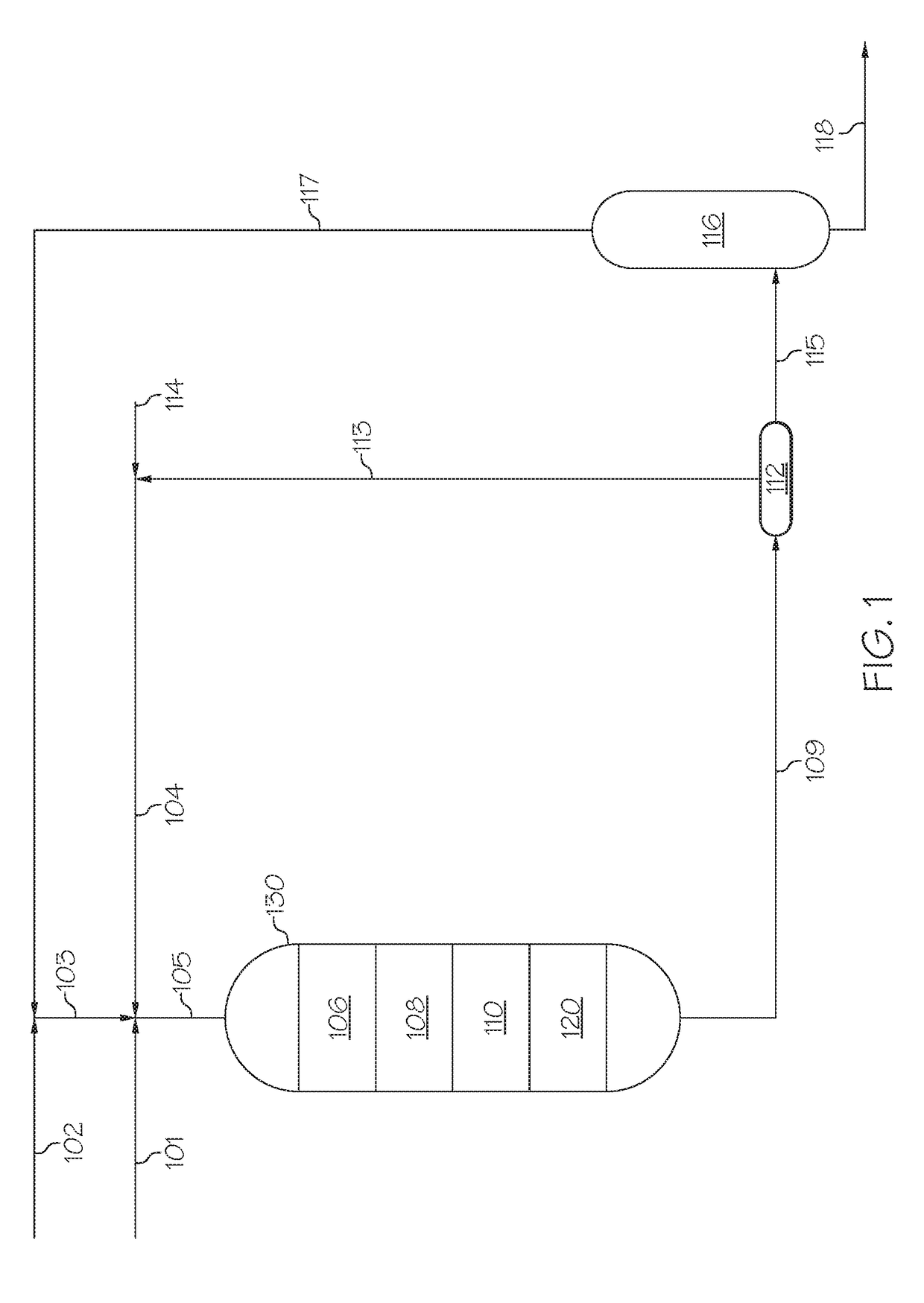

ActiveUS10407311B2Low costLess expensiveMolecular sieve catalystsCatalyst activation/preparationFuel oilModified zeolite

According to one or more embodiments disclosed herein, a mesoporous zeolite may be made by a method comprising contacting an initial zeolite material with ammonium hexafluorosilicate to modify the framework of the initial zeolite material, and forming mesopores in the framework-modified zeolite material. The contacting may form a framework-modified zeolite material. The mesoporous zeolites may be incorporated into catalysts.

Owner:SAUDI ARABIAN OIL CO

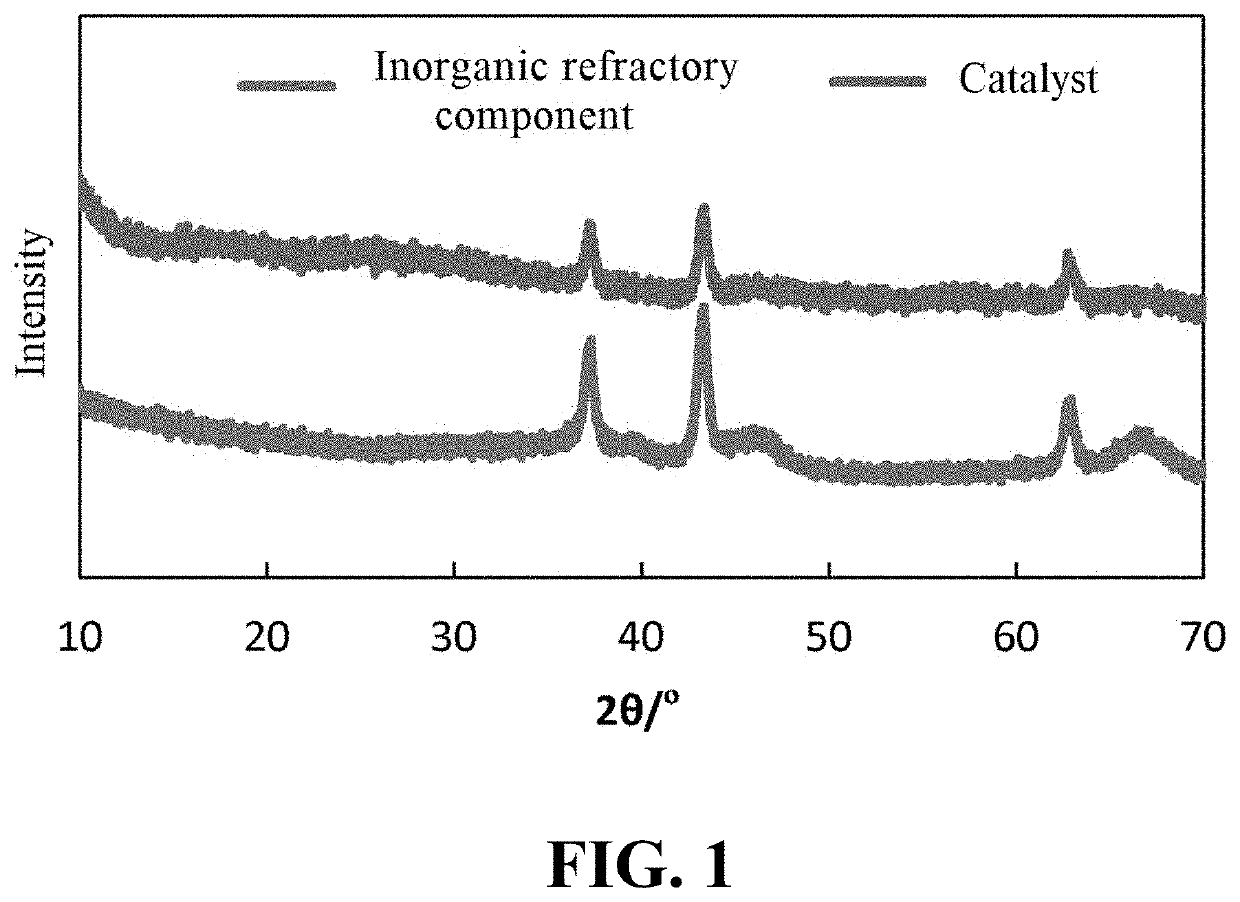

Hydrorefining catalyst, preparation method therefor and use thereof

ActiveUS20210094023A1Small sizeImprove catalytic performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrodesulfurization

Disclosed is a hydrofining catalyst comprising: an inorganic refractory component comprising a first hydrodesulfurization catalytically active component in a mixture with at least one oxide selected from the group consisting of alumina, silica, magnesia, calcium oxide, zirconia and titania; a second hydrodesulfurization catalytically active component; and an organic component comprising a carboxylic acid and optionally an alcohol. The hydrofining catalyst of the present application shows improved performance in the hydrofining of distillate oils. Also disclosed are a hydrofining catalyst system comprising the hydrofining catalyst, a method for preparing the catalyst and catalyst system, and a process for the hydrofining of distillate oils using the catalyst or catalyst system.

Owner:CHINA PETROCHEMICAL CORP +1

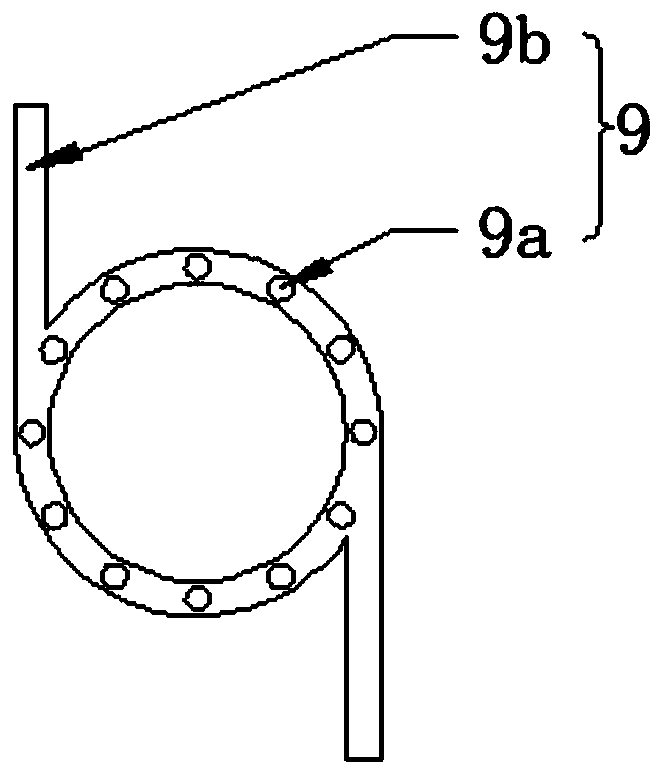

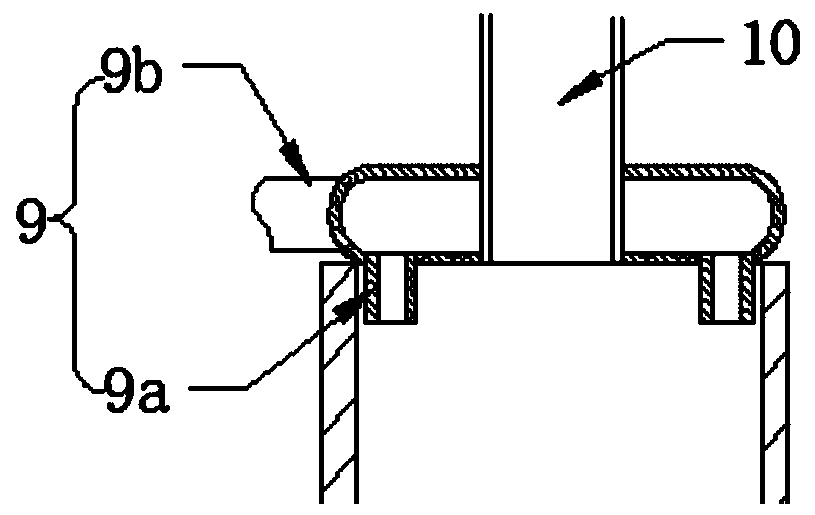

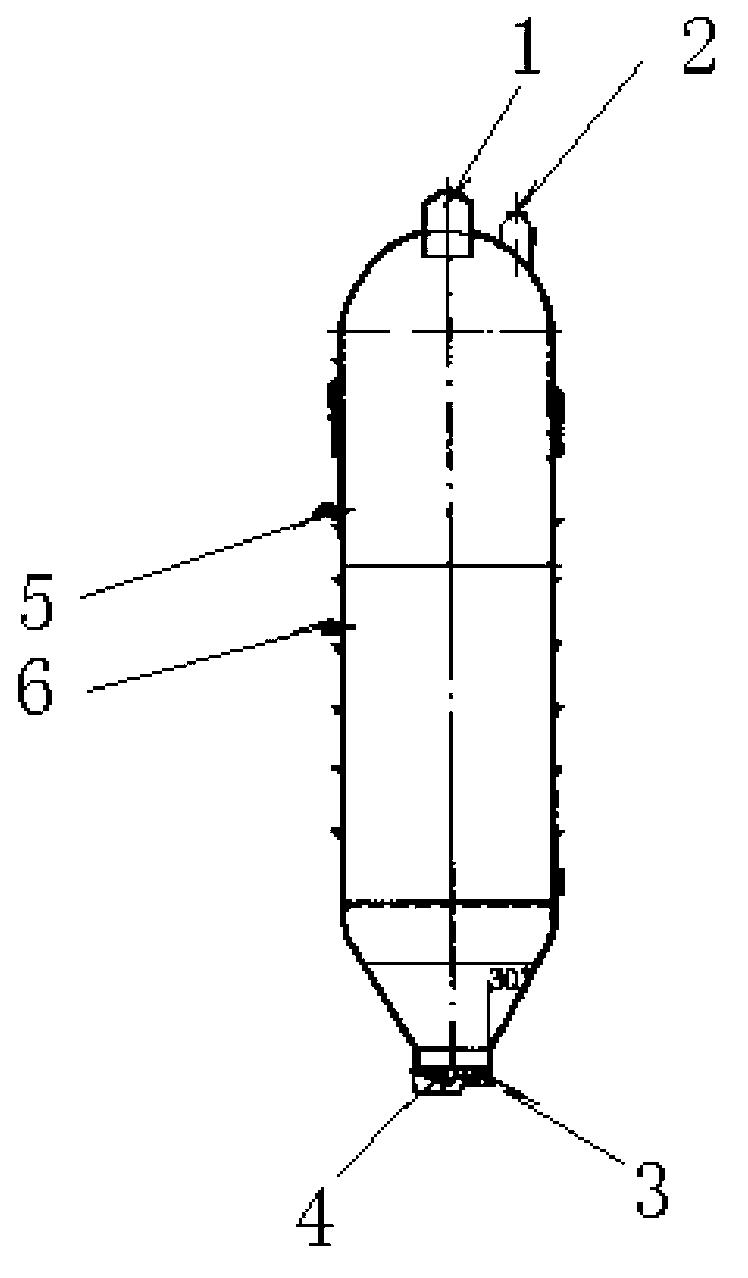

Horizontal reaction kettle delayed coking equipment and process thereof

ActiveCN103059887AIncrease heightNot easy to repairThermal non-catalytic crackingCoking carbonaceous materialsTotal investmentWorking environment

The invention discloses a piece of horizontal reaction kettle delayed coking equipment and a process thereof, which has small investment, convenience for operation, high security coefficient of work environment and wide application scope of raw material source. The horizontal reaction kettle saves complex corollary equipment and support equipment, and does not need foundation. The investment volume of the horizontal reaction kettle related in the invention is 3-4 hundred thousand yuan, and the total investment volume is greatly reduced relative to vertical reaction kettles, so that the financial burden of enterprises is reduced; the raw material is conveyed and fed via a raw material distribution valve, so that multiple horizontal reaction kettles can be connected; the reaction time and the time for shoving cokes can be arranged by a manner of feeding or discharging the raw material, so that the overall coking processing quantity is proportional to the number of single horizontal reaction kettle which is connected with the raw material; and because of the annular cavity of the raw material distribution valve, the raw material is under the clockwise or anticlockwise flow state, is not easy to coke, and is easy to operate.

Owner:TIANJIN DONGSHENG IND & TRADE

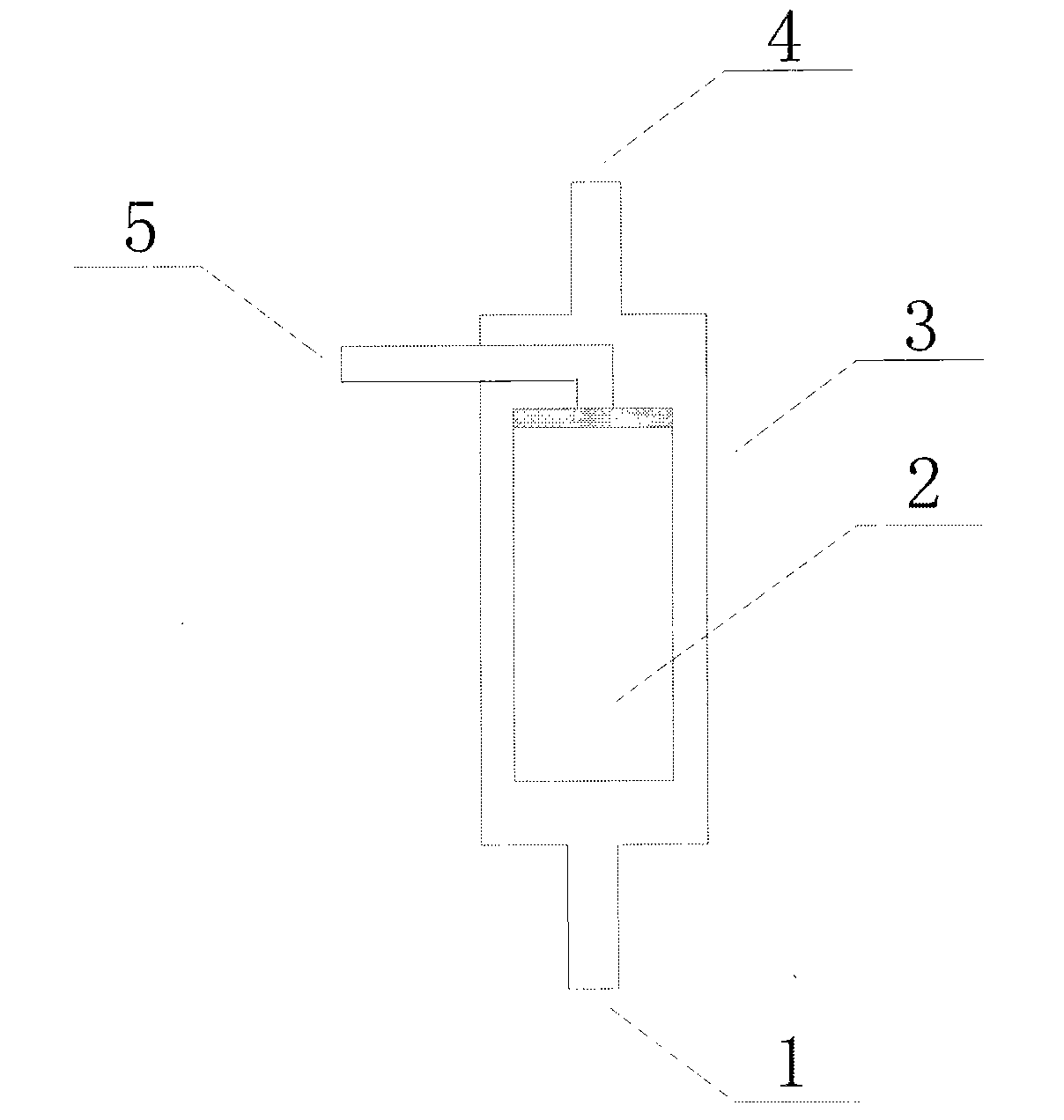

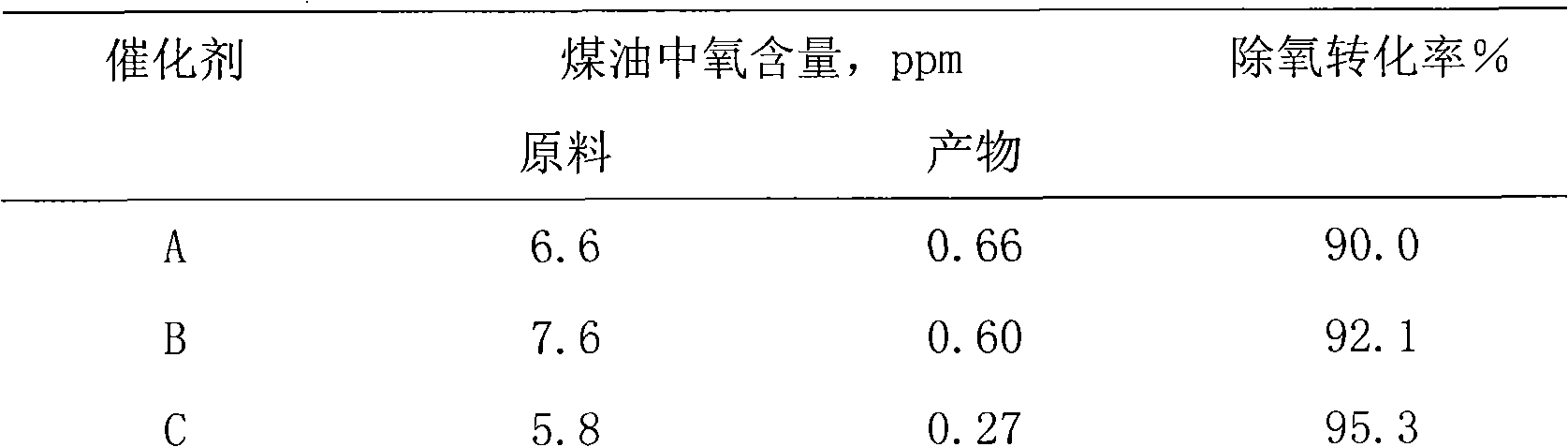

Deoxidation catalyst for oil product, preparation method thereof and catalytic hydrogenation method for removing dissolved oxygen in oil product by adopting catalyst

ActiveCN101612569AHigh strengthGood oxygen removal stabilityCatalyst activation/preparationHydrocarbon oils refiningHydrogenation reactionOxygen

The invention relates to a deoxidation catalyst for an oil product, a preparation method thereof and a catalytic hydrogenation method for removing dissolved oxygen in the oil product by adopting the catalyst. The deoxidation catalyst for the oil product takes gamma-alumina which has the specific surface area of between 50 and 300m<2> / g and the pore volume of between 0.2 and 2.0cm<3> / g as a carrier, palladium supported on the carrier as a main catalytic element, and one of silver, tin and lead as a co-catalytic element; and the preparation method thereof comprises two steps of the preparation of the alumina carrier and the preparation of the catalyst. The catalytic hydrogenation method for removing the dissolved oxygen in the oil product by adopting the catalyst comprises the following steps that: the oil product is fully mixed with hydrogen before the oil product enters a hydrogenation reactor; and then the mixed oil product enters the reactor and is contacted with the deoxidation catalyst. The catalyst has high strength and good deoxidation stability, can still have higher activity under lower temperature and pressure, can keep higher reaction activity for a long time, and ensure that the removal rate of trace oxygen in the oil product can reach over 90 percent.

Owner:CHINA PETROCHEMICAL CORP

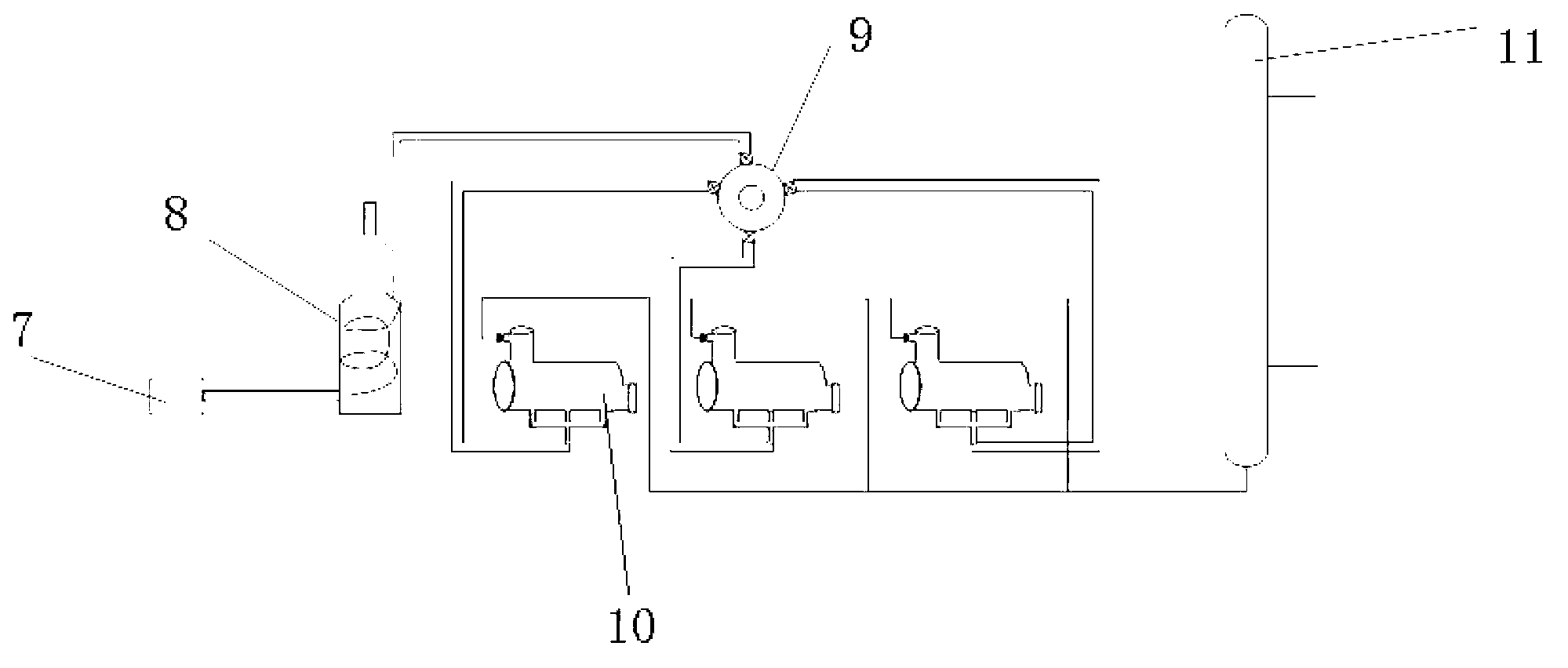

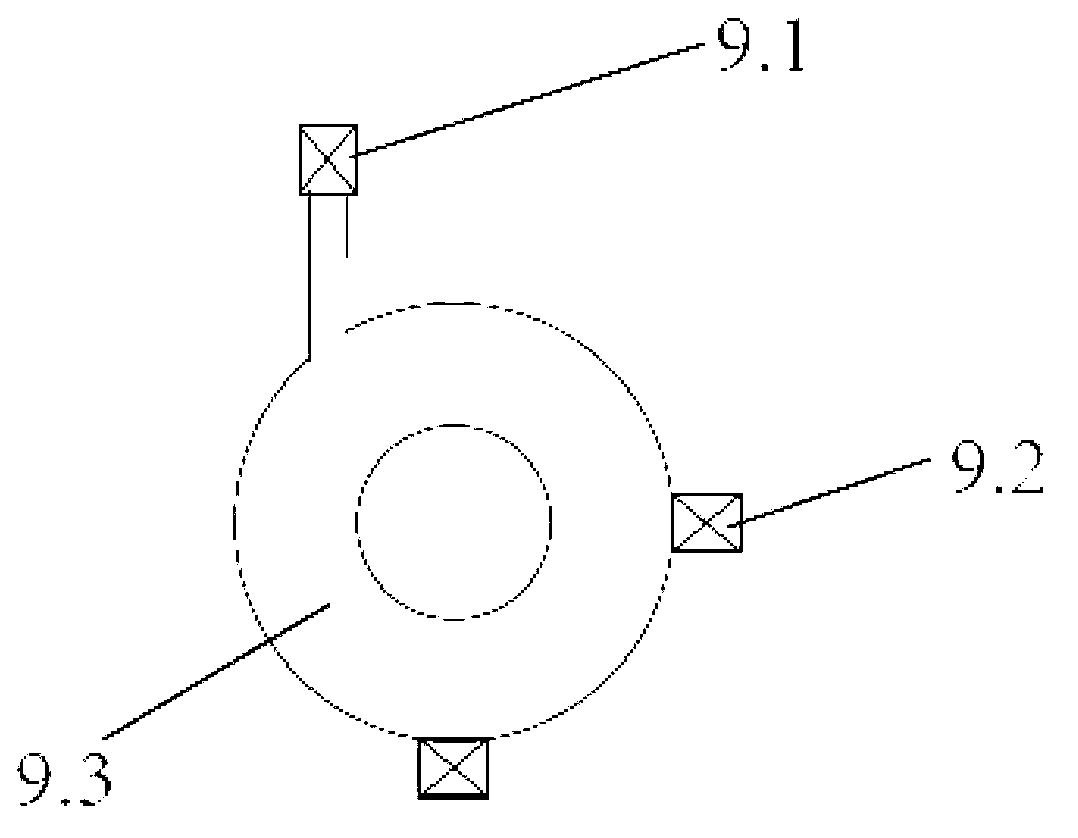

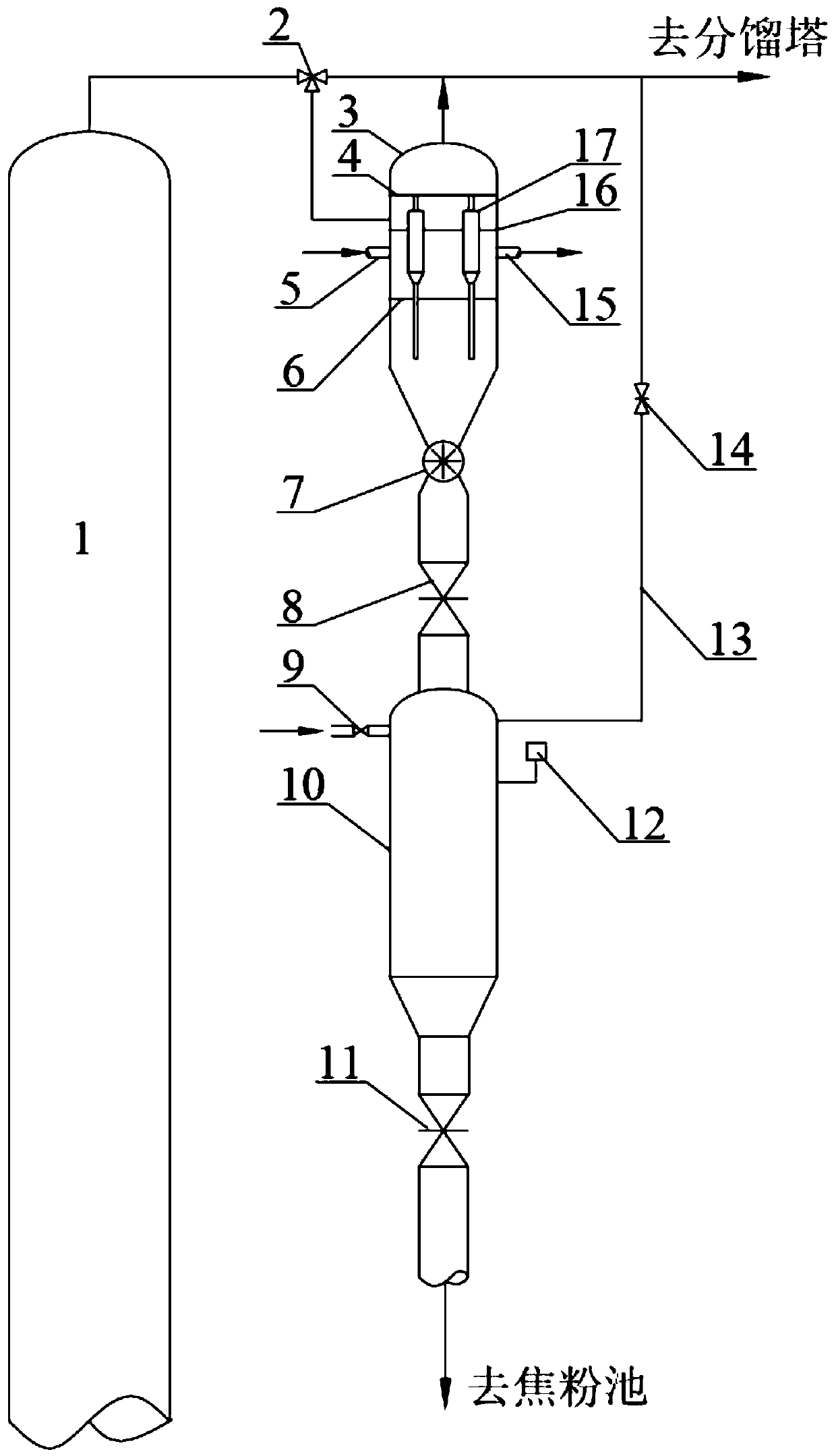

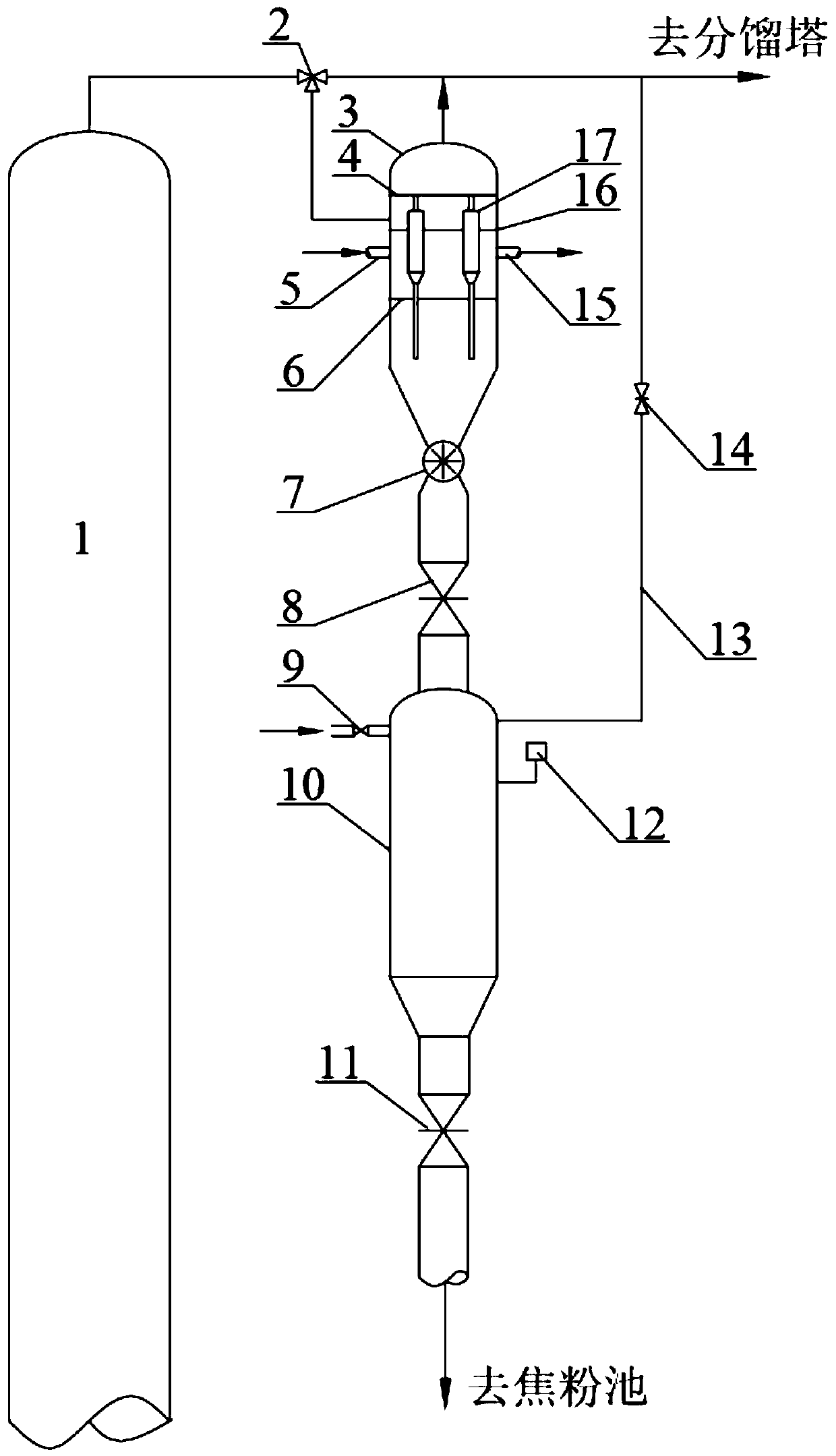

Delayed-coking tower-top oil gas online decoking device and method

ActiveCN111117684ACompact structureLower oil temperatureThermal non-catalytic crackingCatalytic crackingChemistryGas pipeline

The invention aims to provide a device and a method for online removal of coke powder from tower-top oil gas. The device and the method can effectively reduce the coke powder to enter a fractionatingtower and block a tower tray, and can avoid coking products from carrying the coke powder to enter a downstream device; thus, the catalyst activity of a downstream refining device and the long-periodoperation of the device are influenced. The device comprises a cyclone separator and a coke powder discharging system, wherein the cyclone separator comprises a separator tank body and a plurality ofcyclone single pipes; the plurality of cyclone single pipes are connected with and mounted in the separator tank body through supporting plates; the coke powder discharging system comprises a coke powder bin and a pressure balance pipe; the top part of the coke powder bin is connected with the bottom part of the cyclone separator through a star-shaped valve and a first gate valve; the pressure balance pipe is connected with the upper part of the coke powder bin, so the coke powder bin is connected with an oil-gas pipeline; the bottom part of the coke powder bin is connected with a discharge gate valve; and a pressurized gas inlet is also arranged at the upper part of the coke powder bin.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Zeolites, the production thereof, and their uses for upgrading heavy oils

ActiveUS20180334390A1Low costPromote conversionMolecular sieve catalystsCatalyst activation/preparationFuel oilModified zeolite

According to one or more embodiments disclosed herein, a mesoporous zeolite may be made by a method comprising contacting an initial zeolite material with ammonium hexafluorosilicate to modify the framework of the initial zeolite material, and forming mesopores in the framework-modified zeolite material. The contacting may form a framework-modified zeolite material. The mesoporous zeolites may be incorporated into catalysts.

Owner:SAUDI ARABIAN OIL CO

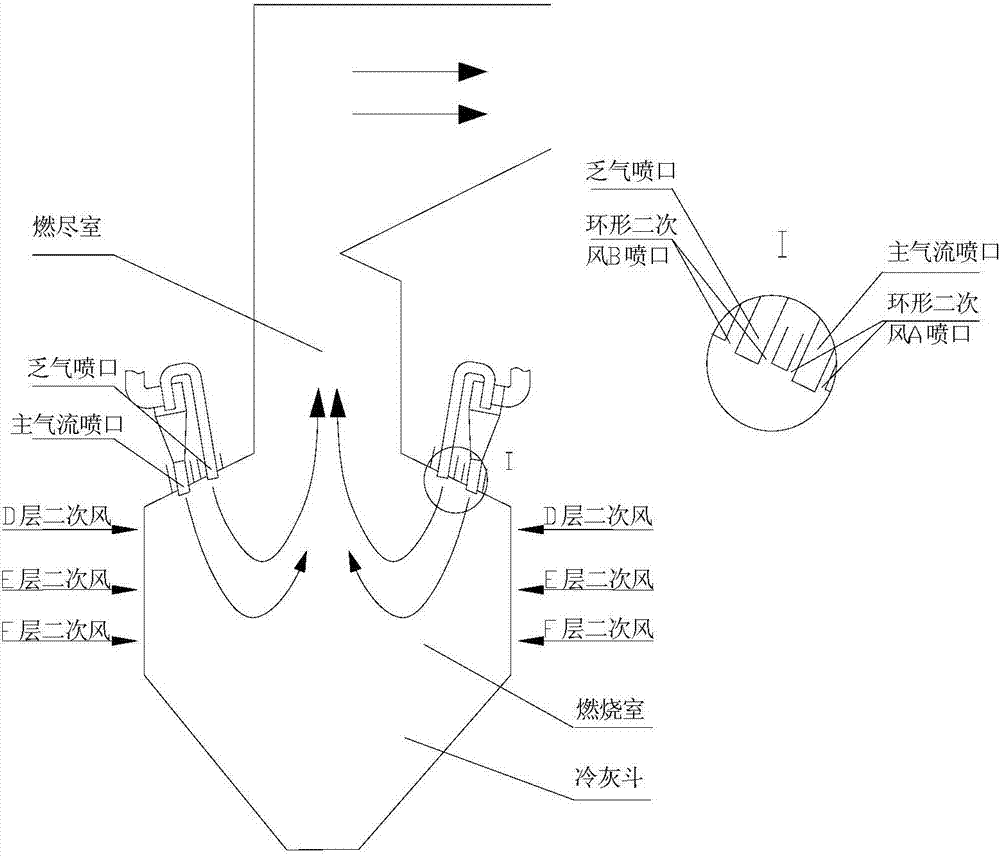

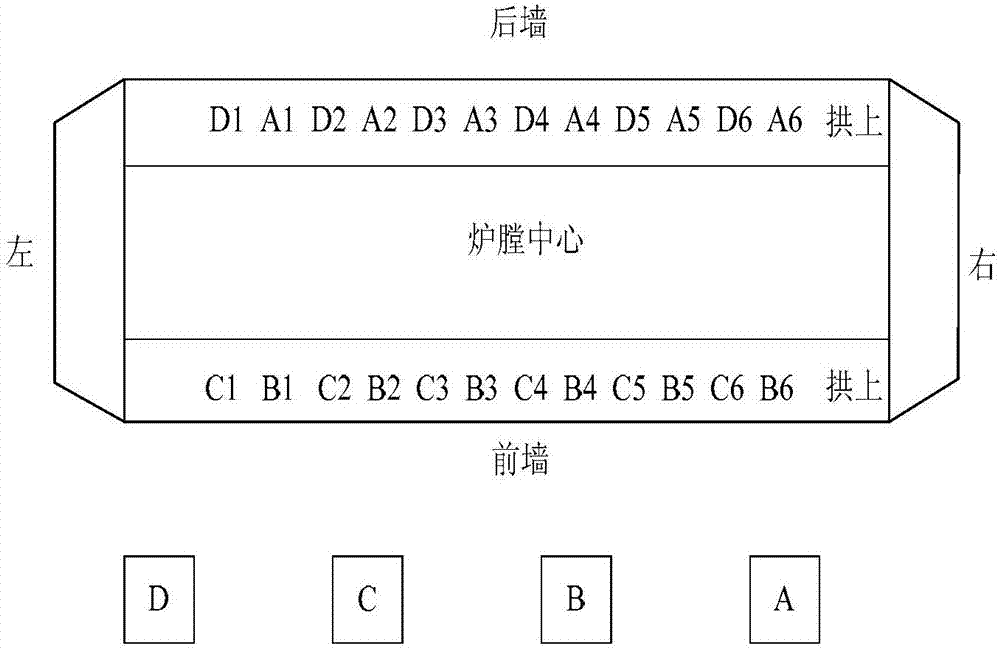

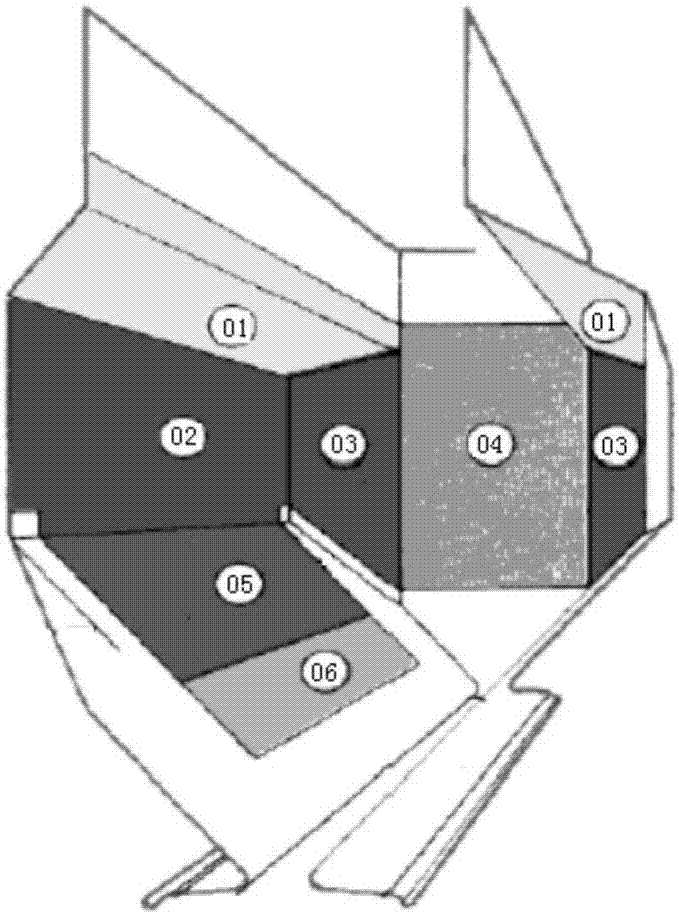

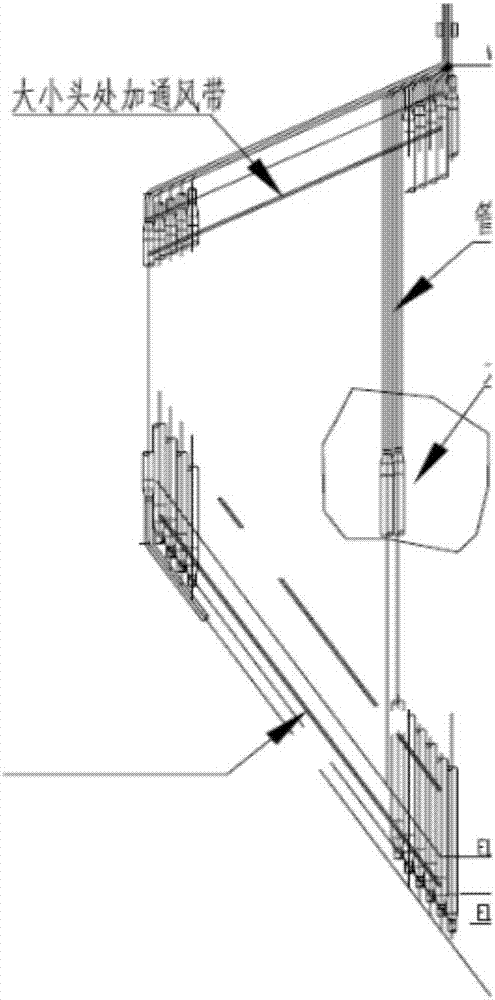

Boiler combustion optimization adjusting method

The invention relates to a boiler combustion optimization adjusting method. The boiler combustion optimization adjusting method comprises that a wing wall is vertically provided with four ventilation slits, secondary air is blown into the wing wall, water-wall tubes on the wing wall have the external diameter of 120.65 mm, the center distance of 146.4 mm and the tube spacing of 25.4 mm, and tubes on the upper and lower parts of the wing wall have the external diameter of 69.85 mm; in an original design, the water-wall tubes are connected with the tubes through reducer pipes, thick tubes on four ventilation bands needing ventilation are replaced by thin tubes, i.e., large and small heads on the upper portion are moved down, the tube spacing is 76.55 mm, the height of the ventilation bands are set to be the total length of the tubes of the wing wall or the ventilation bands are only arranged on the upper half part of the wing wall, and a refractory belt on a tube at each of the two sides of a ventilation slot is removed. According to the invention, the original wing wall no longer has large coke and only has loose coke the thickness of which is smaller than 50 mm, and has no threat to safe operation of a machine set. The coking conditions of the front and rear walls are greatly improved, and the coke thickness is obviously reduced. The NOx discharge amount is also reduced.

Owner:中国大唐集团科学技术研究总院有限公司

Catalyst for synthesis of acetonitrile by ammoniation of acetic acid and preparation method thereof

PendingCN113457661AImprove stabilityImprove cokingHeterogenous catalyst chemical elementsPreparation by ammonia-carboxylic acid reactionChemistryAluminium salts

The invention provides a catalyst for synthesis of acetonitrile by ammoniation of acetic acid and a preparation method thereof. The catalyst is porous spherical alumina containing transition metal or rare earth metal oxide, and the crystal form of alumina is a mixed crystal phase of one or two of gamma type or delta type. The preparation method comprises the following steps of: mixing powder prepared by neutralizing aluminum sulfate and sodium metaaluminate with pseudo-boehmite, then mixing the obtained mixture with transition metal, rare earth metal salts and a pore-enlarging agent, preparing small balls by using an oil ammonia column balling method, activating and roasting to obtain porous spherical aluminum oxide containing transition metal and rare earth metal oxide, and then hydrating the obtained aluminum oxide and drying to obtain the catalyst. A small amount of transition metal, rare earth metal and other auxiliaries are added in the preparation process of the catalyst, so that the stability of the catalyst is improved, the catalytic reaction temperature is greatly reduced, the coking condition of the catalyst is improved, the service life of the catalyst is prolonged, and the activity and selectivity of the catalyst are improved.

Owner:CHINA TIANCHEN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com