Deoxidation catalyst for oil product, preparation method thereof and catalytic hydrogenation method for removing dissolved oxygen in oil product by adopting catalyst

A technology of catalytic hydrogenation and oxygen catalyst, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problem of low oxygen removal efficiency and achieve stable oxygen removal Good performance, high activity, high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

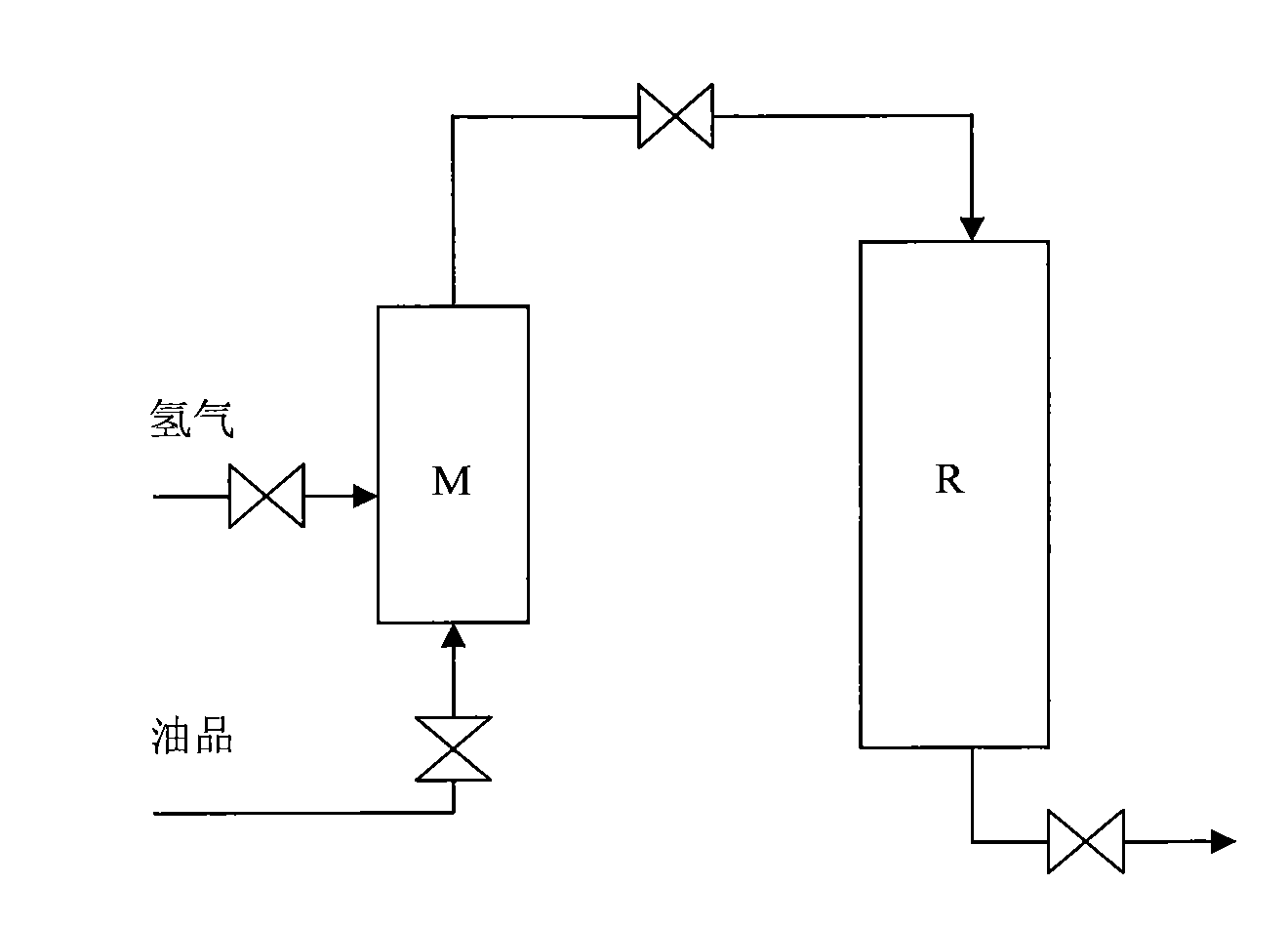

Method used

Image

Examples

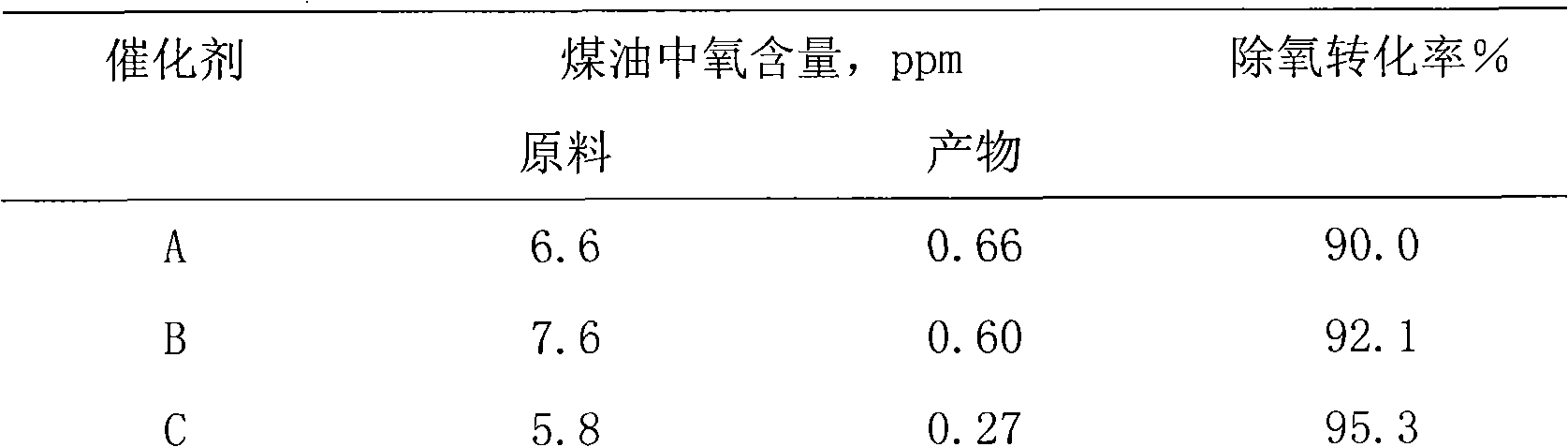

Embodiment 1

[0024] Take pseudo-boehmite powder and roll it into small balls of Φ1.5-2.5mm, dry at 150°C for 6 hours, and bake at 600°C for 4 hours to obtain a specific surface area of 210M 2 / g, pore volume 1.4Cm 3 / g γ-Al 2 o 3 Ball carrier.

[0025] The carrier was treated with 0.085N PdCl 2 Solution impregnation, drying at 120°C for 5 hours, and firing at 550°C for 3 hours. Catalyst A was prepared by reducing with hydrogen with a purity greater than 99% at 120° C. for 4 hours. The finished catalyst contains 0.6% palladium by weight.

Embodiment 2

[0027] The carrier among the embodiment 1 is first used the PdCl of 0.085N 2 Solution impregnation, drying at 120°C for 5 hours, and firing at 550°C for 3 hours. The calcined carrier was dechlorinated and treated with 0.5N SnCl 4 Solution impregnation, drying at 120°C for 5 hours, and baking at 550°C for 4 hours. Catalyst B was prepared by reducing with hydrogen with a purity greater than 99% at 120° C. for 4 hours. The finished catalyst contains 0.6% by weight of palladium and 1.2% by weight of tin.

Embodiment 3

[0029] Get pseudo-boehmite powder B preparation method as embodiment 1, make specific surface area 160M 2 / g, pore volume 0.9Cm 3 / g γ-Al 2 o 3 Ball carrier. First use 0.045N PdCl 2 Solution impregnation, drying at 120°C for 4 hours, and firing at 500°C for 2 hours. The calcined support was dechlorinated and treated with 0.8N Pb(NO 3 ) 2 Solution impregnated, dried at 120°C for 4 hours, and baked at 500°C for 4 hours. Catalyst C was prepared by reducing with hydrogen with a purity greater than 99% at 120° C. for 2 hours. The finished catalyst contains 0.1% by weight of palladium and 0.2% by weight of lead.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com