Patents

Literature

89results about How to "Improve clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

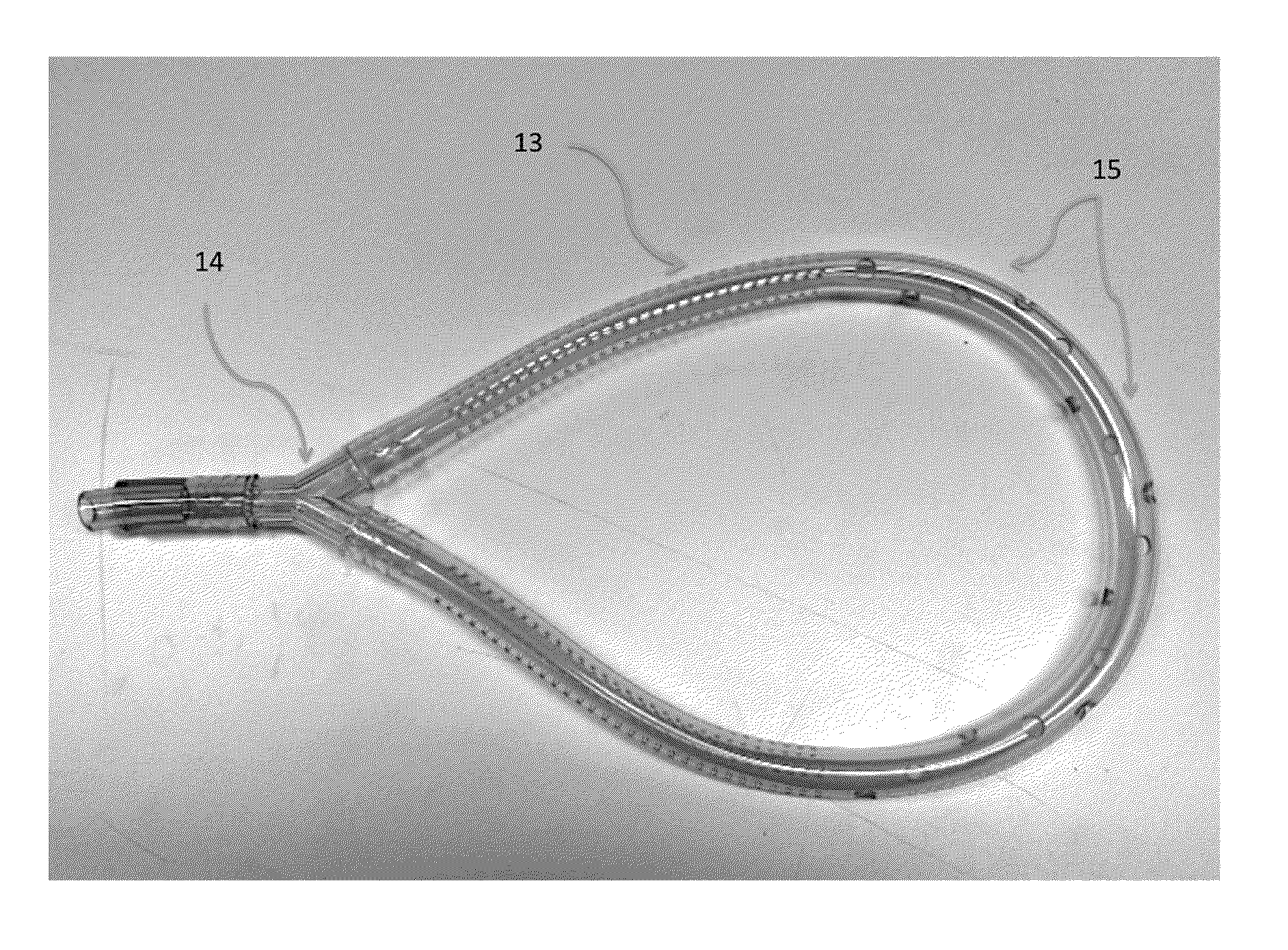

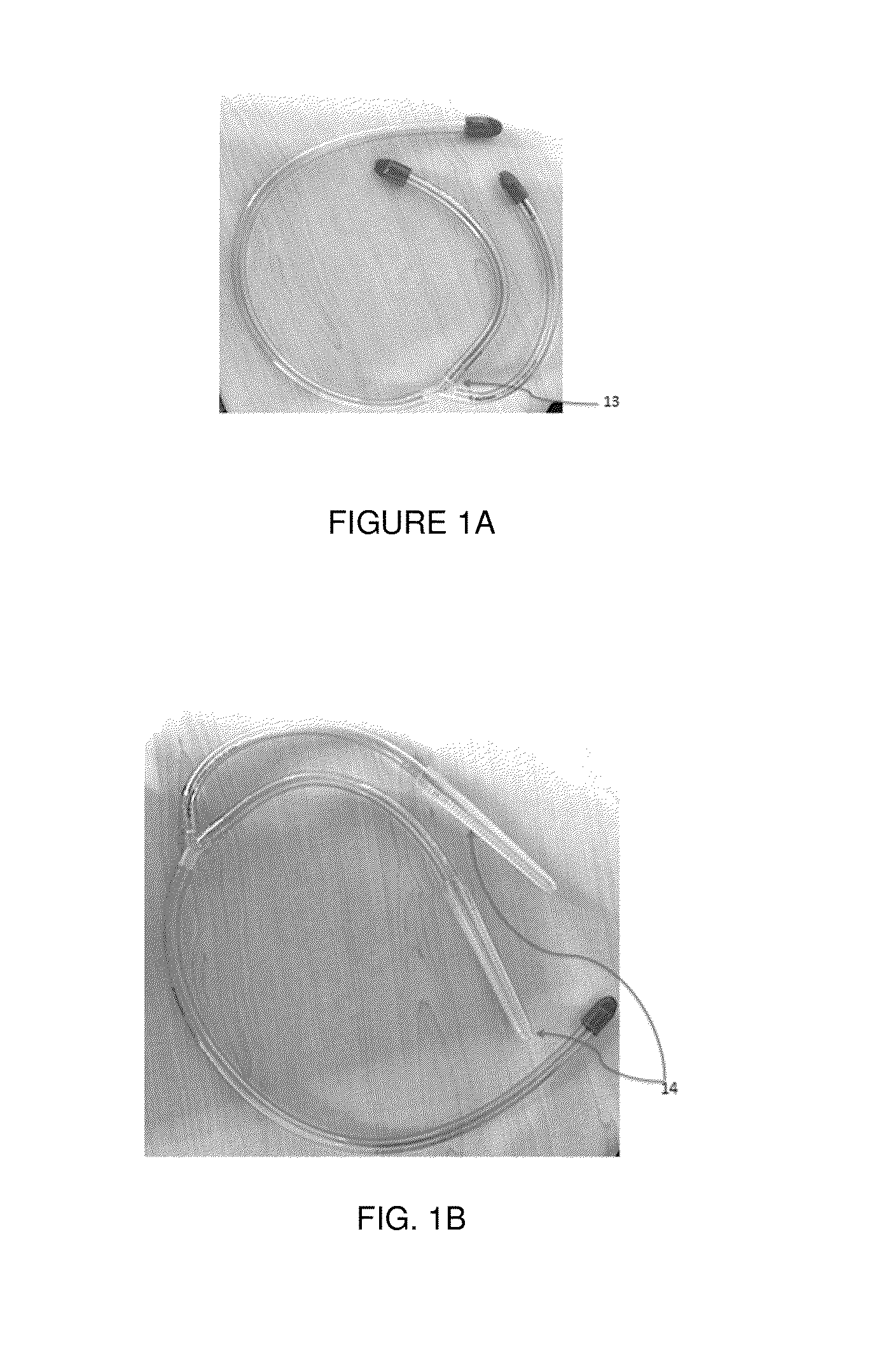

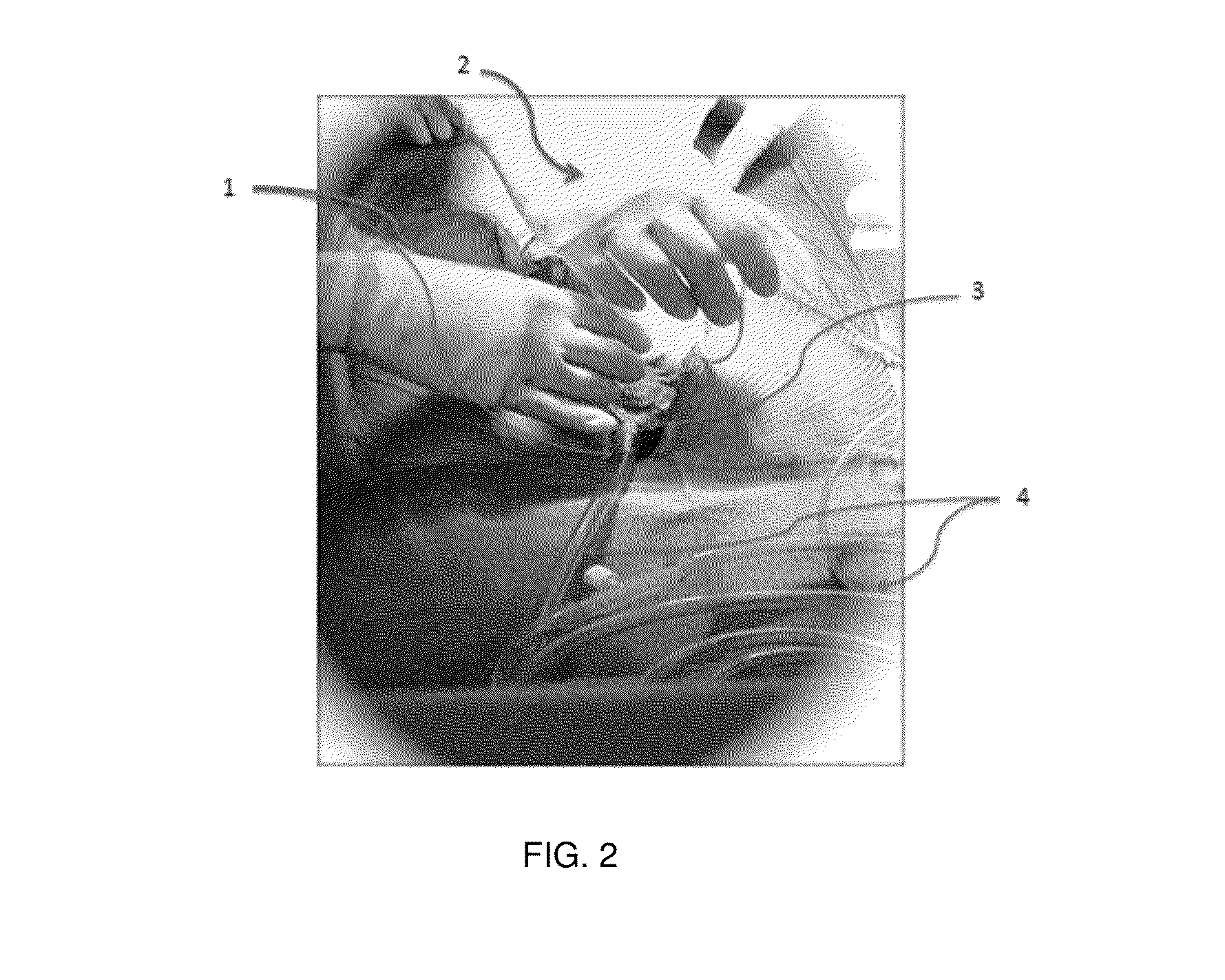

Body cavity drainage device and methods for using the same

InactiveUS20140228801A1Improve abilitiesPenetration of chemotherapeutic chemicals into the peritoneal cavity is veryWound drainsMedical devicesBiomedical engineeringDrain tube

The present invention provides a drainage tube and method that removes fluid from a peritoneal, abdominal, or other body site. The tube has a central internal passageway for the flow of fluids. The tubing has one or more crossholes that extend through the tubing material and provide fluid communication between the passageway of the drain tube and the peritoneal, abdominal, or other body site of a subject.

Owner:KEELING GARY

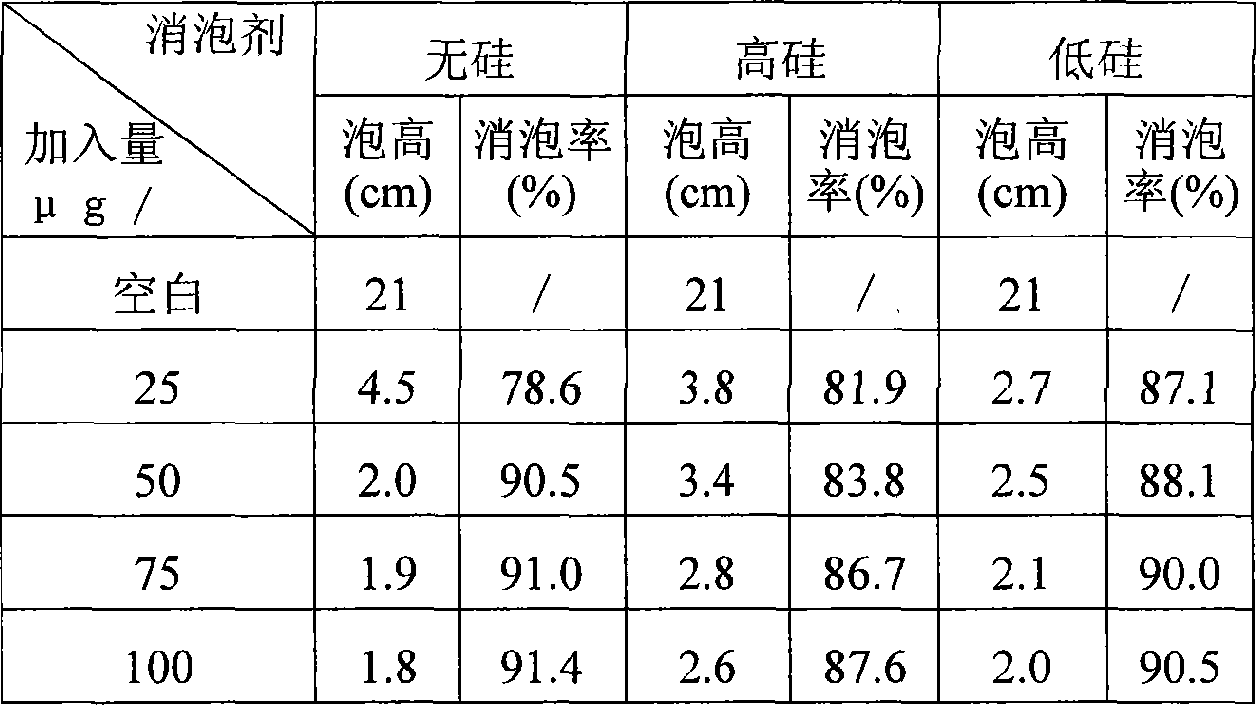

Additive for suppressing and delaying foam generation in coking reaction tower and its prepn process

InactiveCN101045880ASuppress and eliminate generationReduce entrainmentThermal non-catalytic crackingEpoxyHeptyl alcohol

The present invention is additive for suppressing and delaying foam generation in coking reaction tower and its preparation process, and relates to oil refining additive technology. The additive is prepared through compounding high molecular weight block polyether 30-50 wt%, fatty alcohol 20-40 wt% and solvent 20-40 wt%, where, the high molecular weight block polyether is block copolymer of ethylene glycol, epoxy ethane and epoxy propane of molecular weight 10,000-20,000, and the fatty alcohol is isocotanol or 3-enanthol, and the solvent is water solution of alcohol. The preparation process includes the first feeding solvent into reaction kettle and heating slowly to 40-60 deg.c, adding block polyether and fatty alcohol in the ratio via stirring to react for 1-2 hr, cooling and filtering off solid impurity to obtain the product. The additive can suppress and delay foam generation in coking reaction tower effectively.

Owner:SHENYANG POLYTECHNIC UNIV

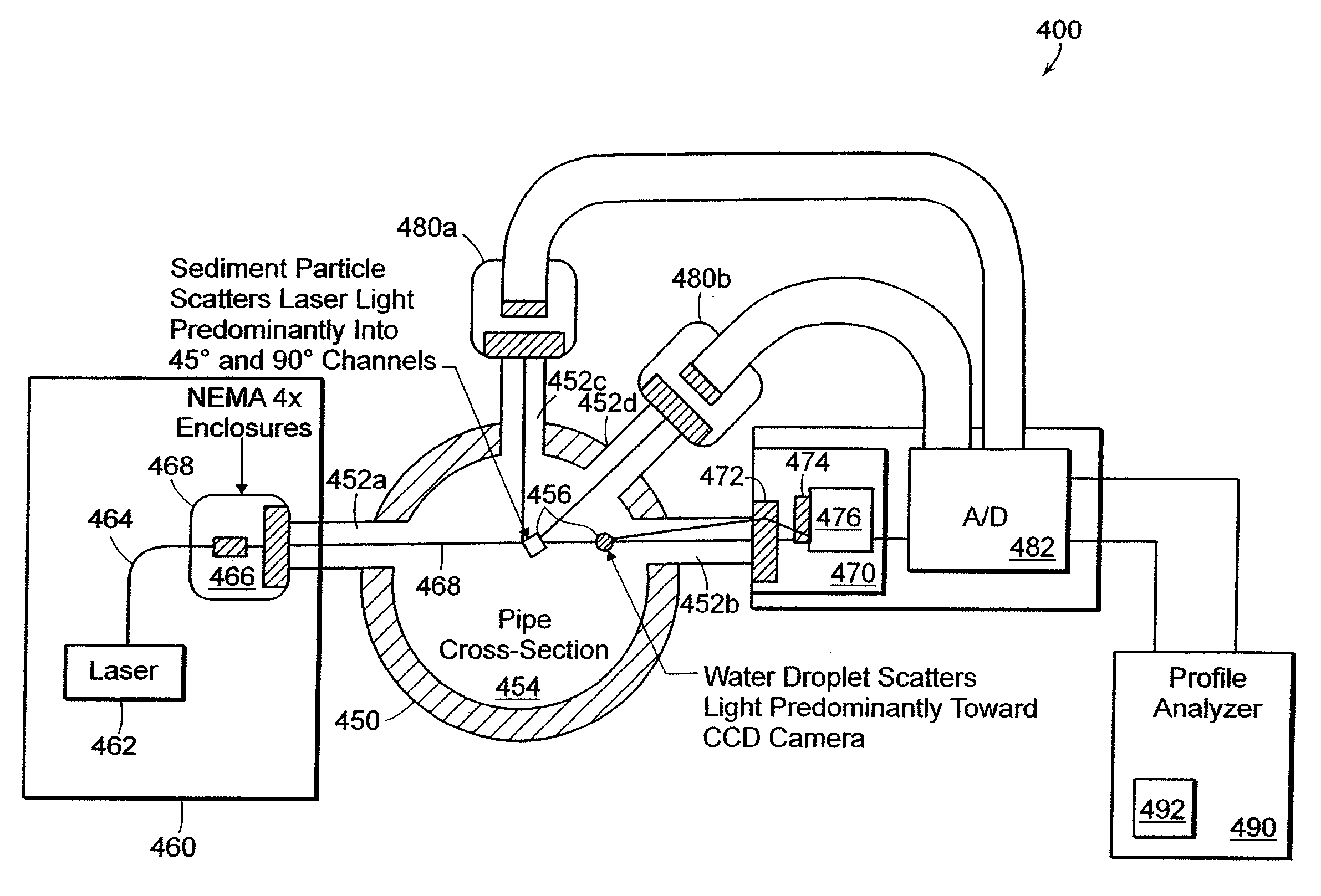

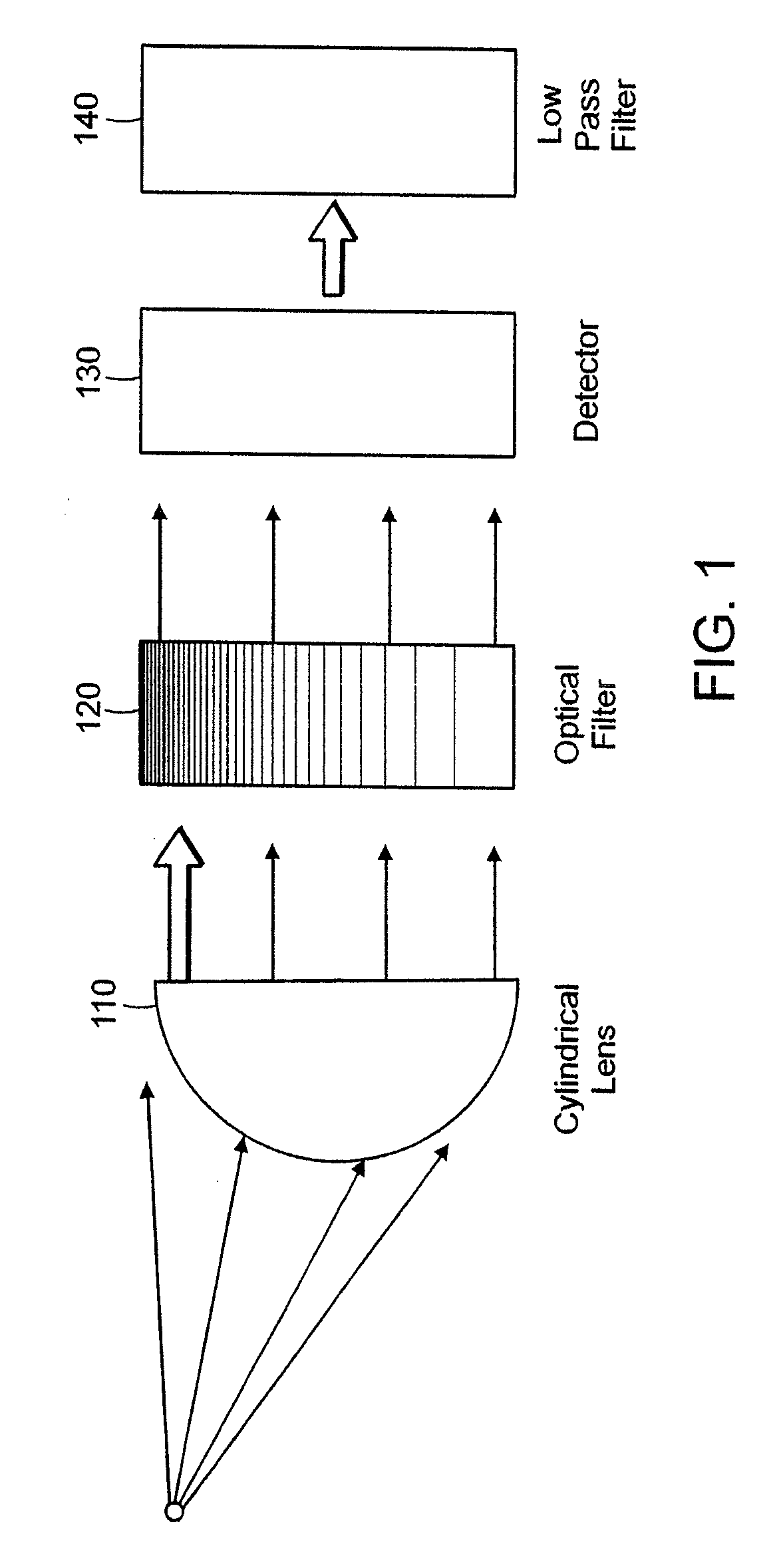

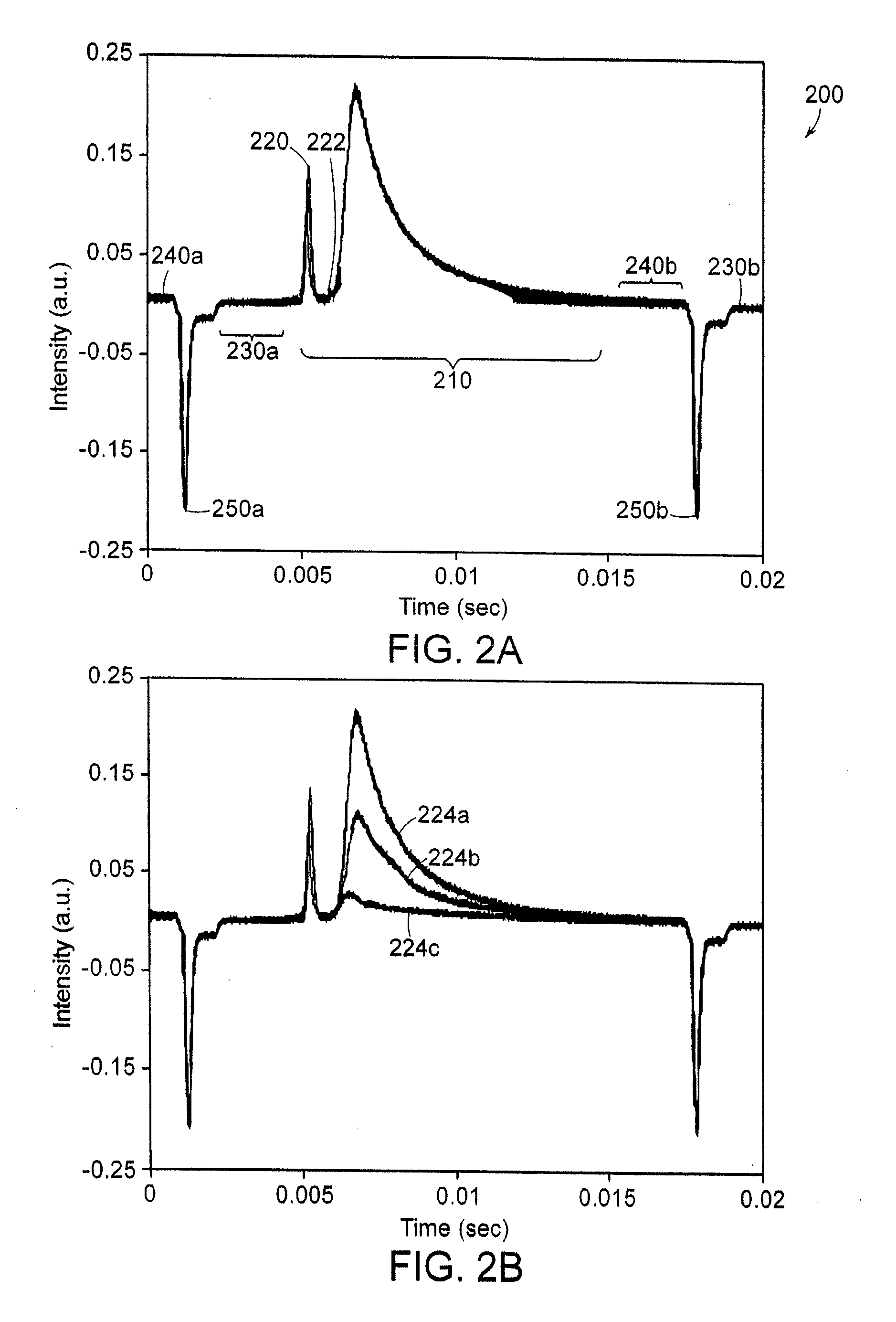

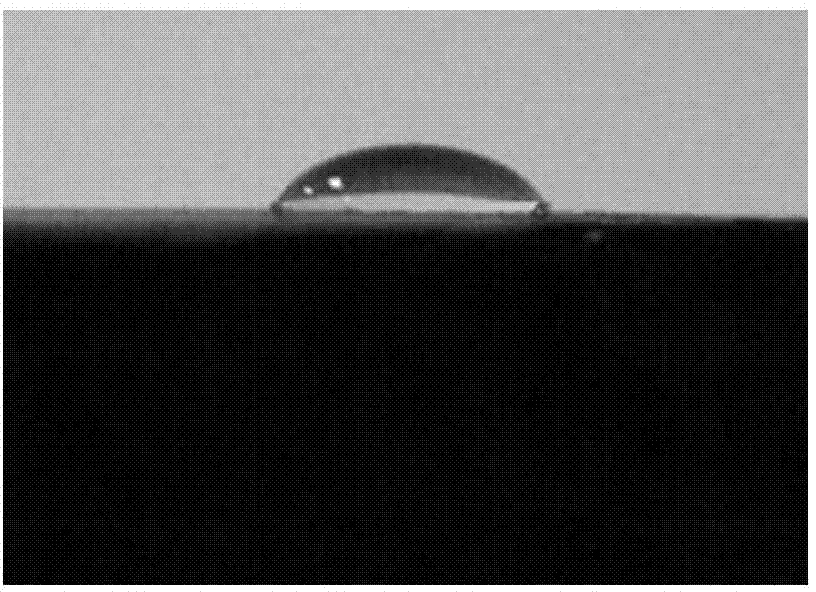

Cylindrical lens-based light sensor and use of the sensor in an automated method and apparatus for monitoring a target fluid for contaminants

InactiveUS20080002200A1Unnecessary workImprove cloggingScattering properties measurementsCylindrical lensLight scattering

A light scattering sensor is provided with a cylindrical lens focusing received light along substantially parallel lines, or bands, that correspond to a range of scattering angles and a linear detector that detects the light intensity along the substantially parallel lines. By using a cylindrical lens, the lens serves as an auto-collimator, whereby light scattered at a specific angle from the collimated light beam strikes the linear detector at a corresponding specific location regardless of the location from where the light was scattered. Embodiments of the cylindrical lens-based light sensor can be applied to a number of different applications and industries that analyze light scattering intensity as a function of scattering angle. For example, embodiments of the cylindrical lens-based light scattering sensor can be used for monitoring a target fluid for contaminants.

Owner:PHYSICAL SCI

Method for improving yield of coal-bed gas well by achieving coal-bed surface gas reverse wetting

InactiveCN103498650AImprove wettabilityImprove gas well productivityFluid removalDrilling compositionAlcoholProduct gas

The invention relates to a method for improving the yield of a coal-bed gas well by achieving coal-bed surface gas reverse wetting. The method includes the steps of adding a gas reverse wetting treating agent composed of perfluorooctanesulfonamide propyl amine oxide and a leveling agent O to a methyl alcohol solvent or an alcohol solvent to prepare a solution, or adding the gas reverse wetting treating agent to other fluid which enters the well, and pumping the solution into a coal bed. The coal-bed surface is thoroughly soaked into the solution containing the gas reverse wetting treating agent, and therefore liquid wetting property of the coal-bed surface can be effectively converted into gas wetting property, the method is easy and convenient to operate, coal-bed holes can be prevented from being blocked, the matrix can be prevented from being expanded, and the yield of the coal-bed gas well can be remarkably improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

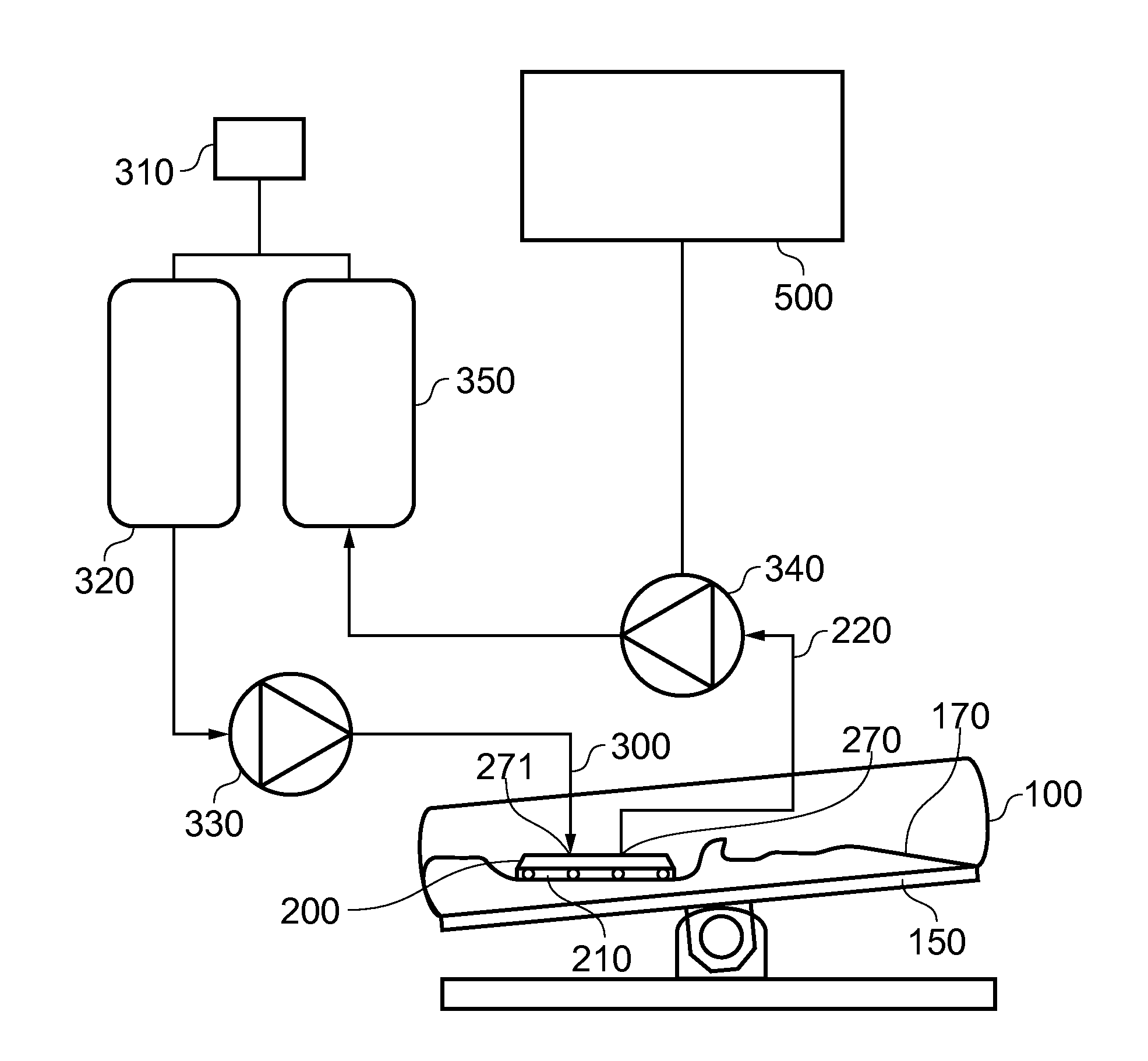

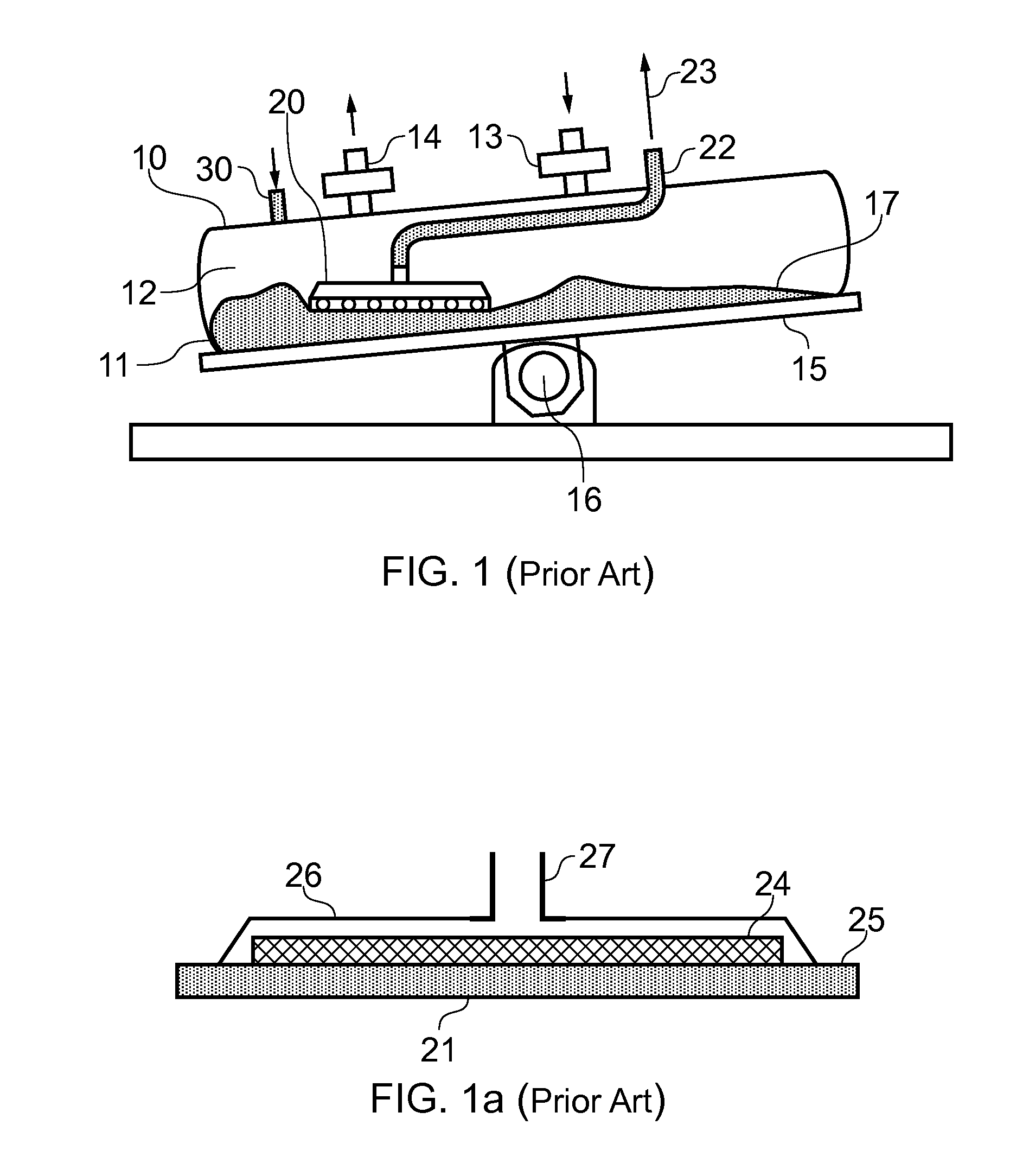

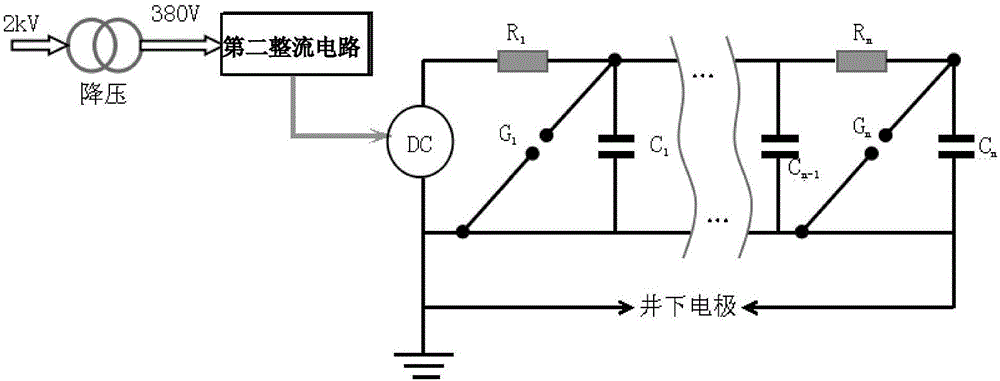

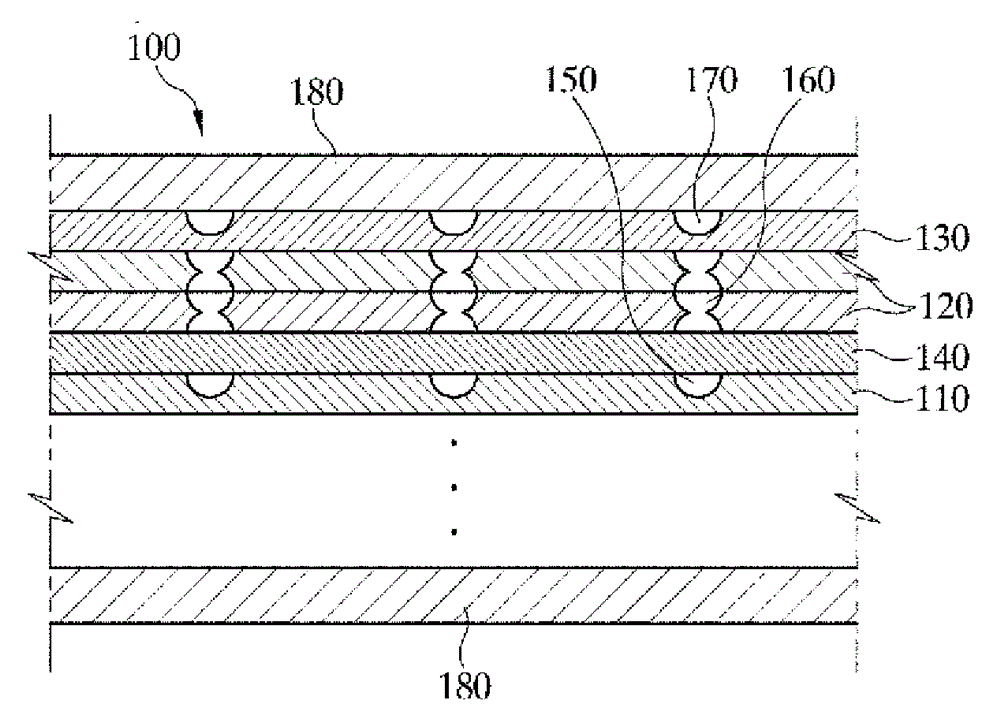

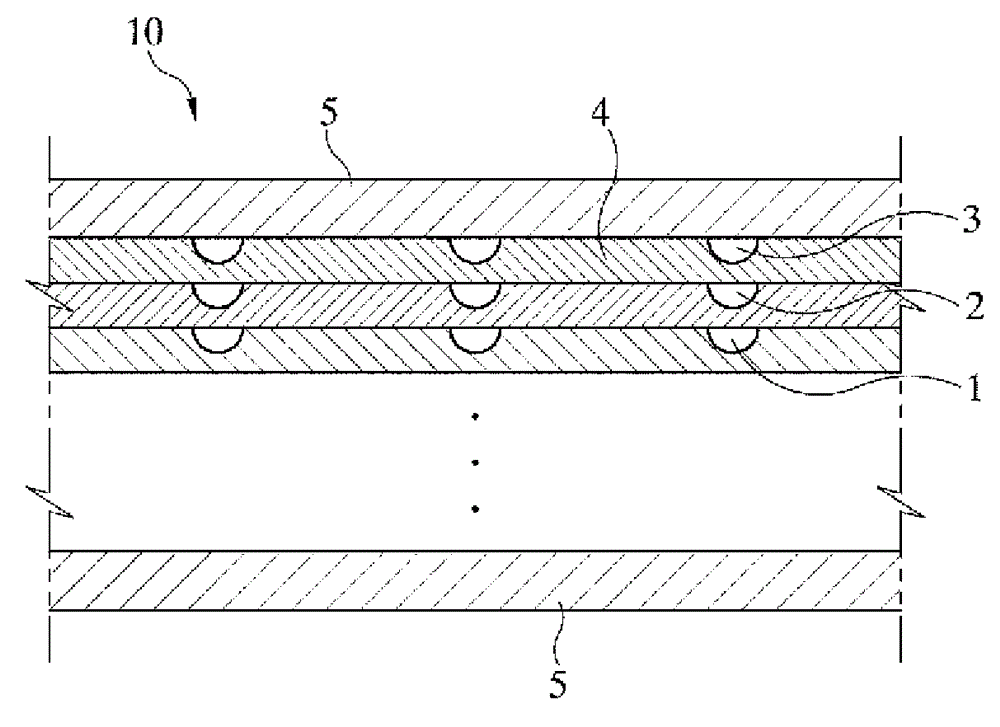

Bioreactor with feed and harvest flow through filter assembly

ActiveUS20130316396A1Improves durability of operationAvoid cloggingBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusionBioreactor

The present invention relates to a bioreactor and a method for operating a bioreactor which comprises a chamber (100) capable of receiving a liquid media, and a filter assembly (200) comprising a perfusion filter (210; 212; 214). The filter assembly (200) is disposed in the chamber (100) and the filter assembly (200) is free to move within the chamber (100). The filter assembly (200) comprises means for coupling a harvesting flow through said filter (210; 212; 214) and means for coupling a feed flow through said filter in an opposite direction compared to the harvesting flow. Through this arrangement, the clogging prevention of the perfusion filter can be improved.

Owner:CYTIVA SWEDEN AB

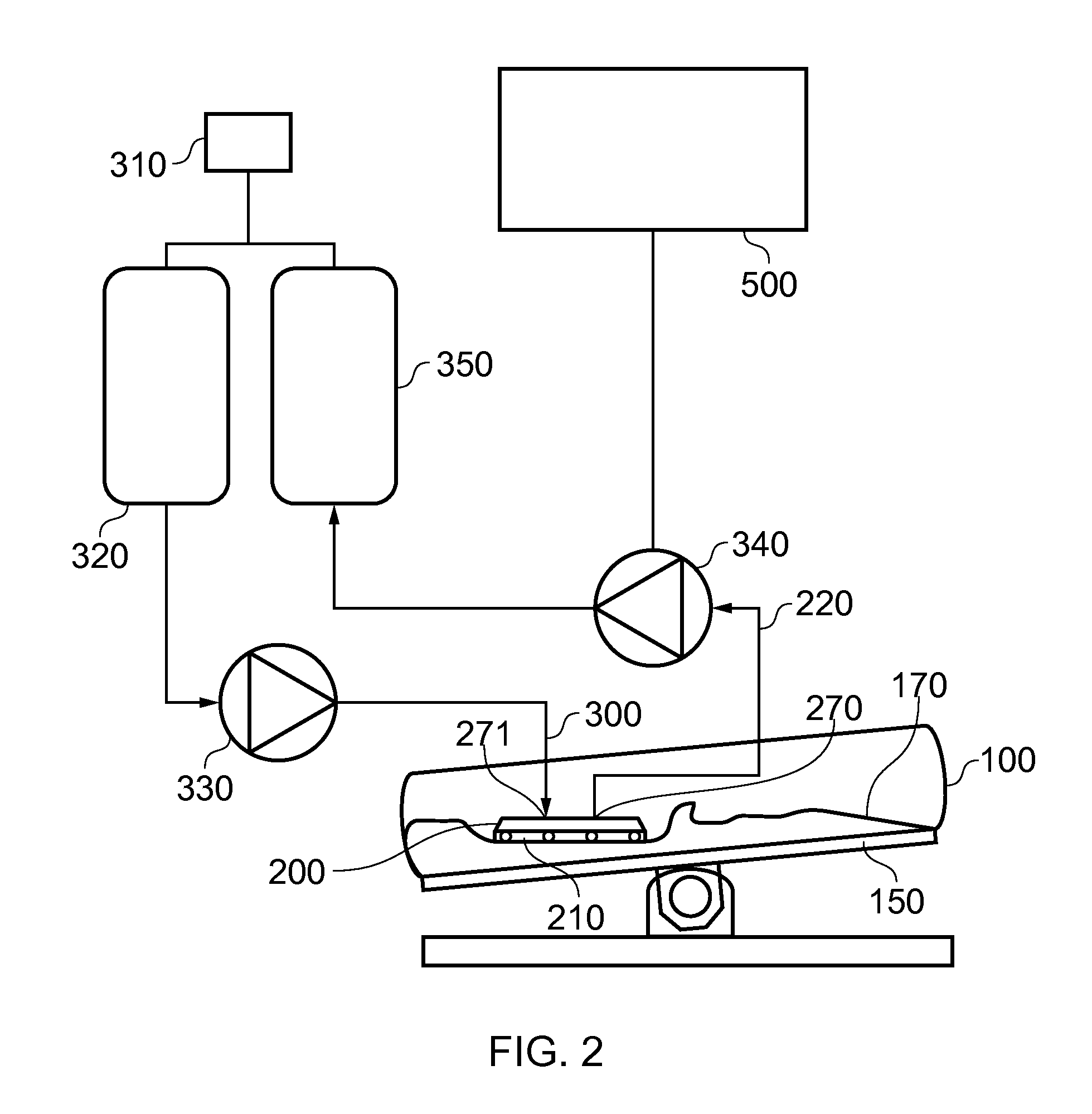

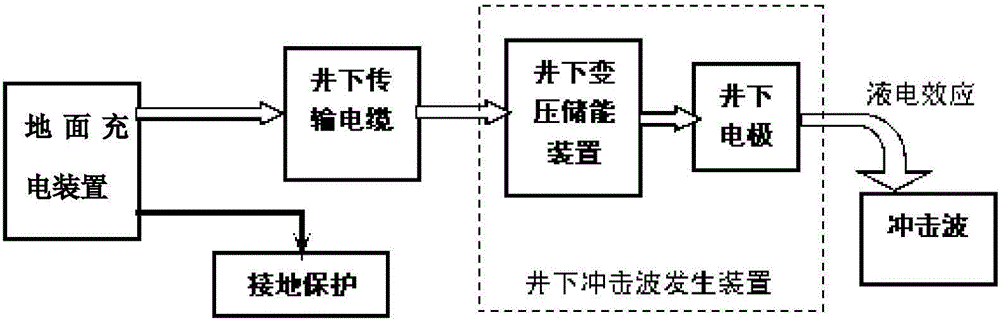

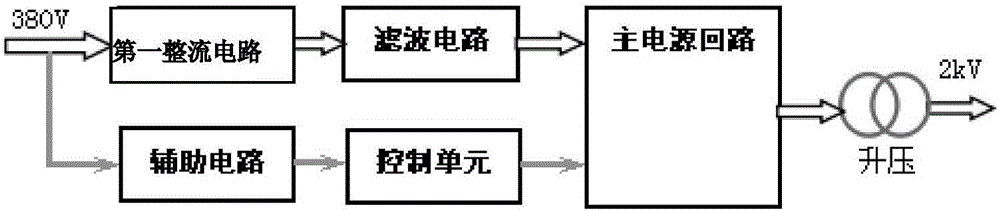

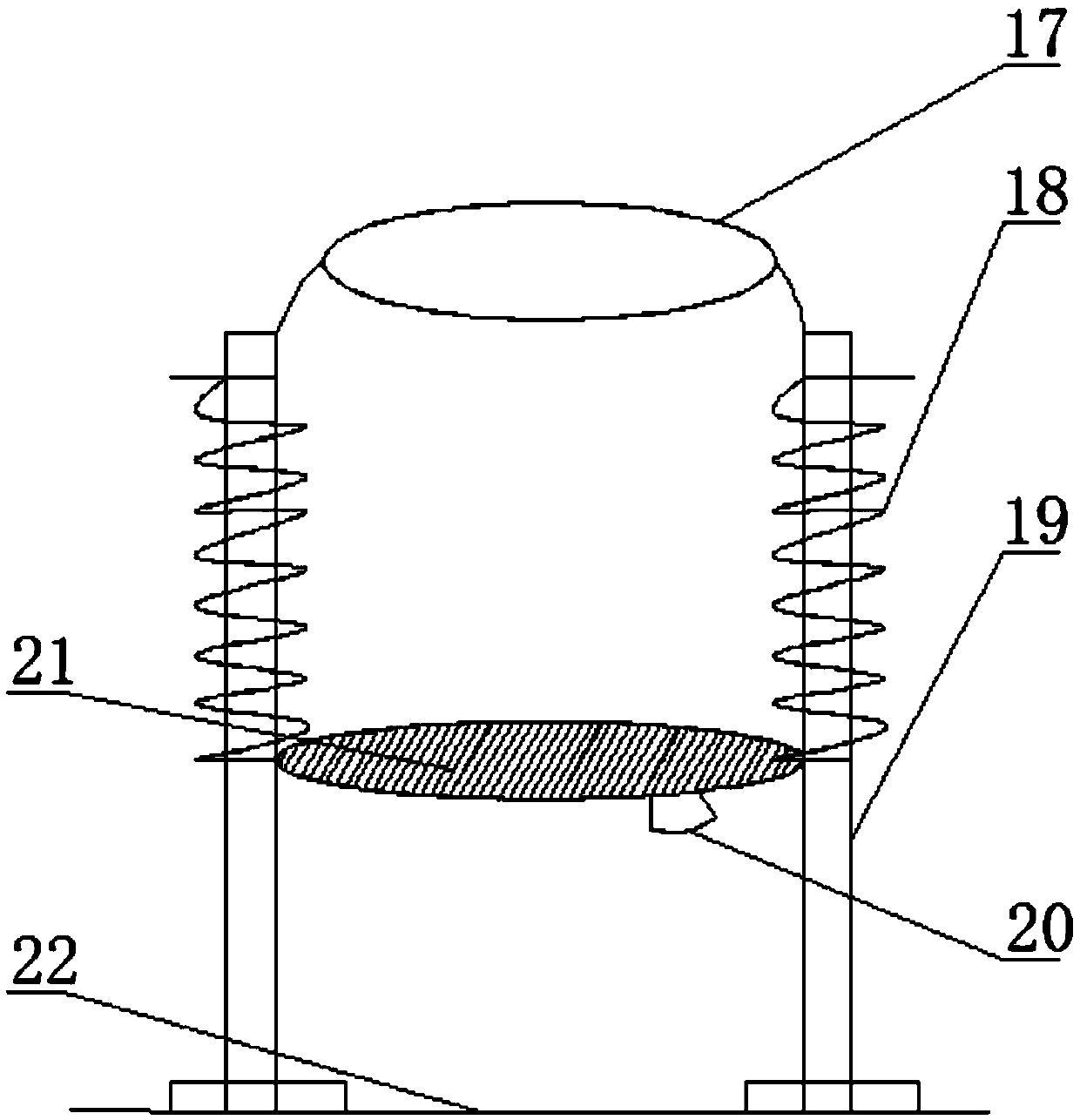

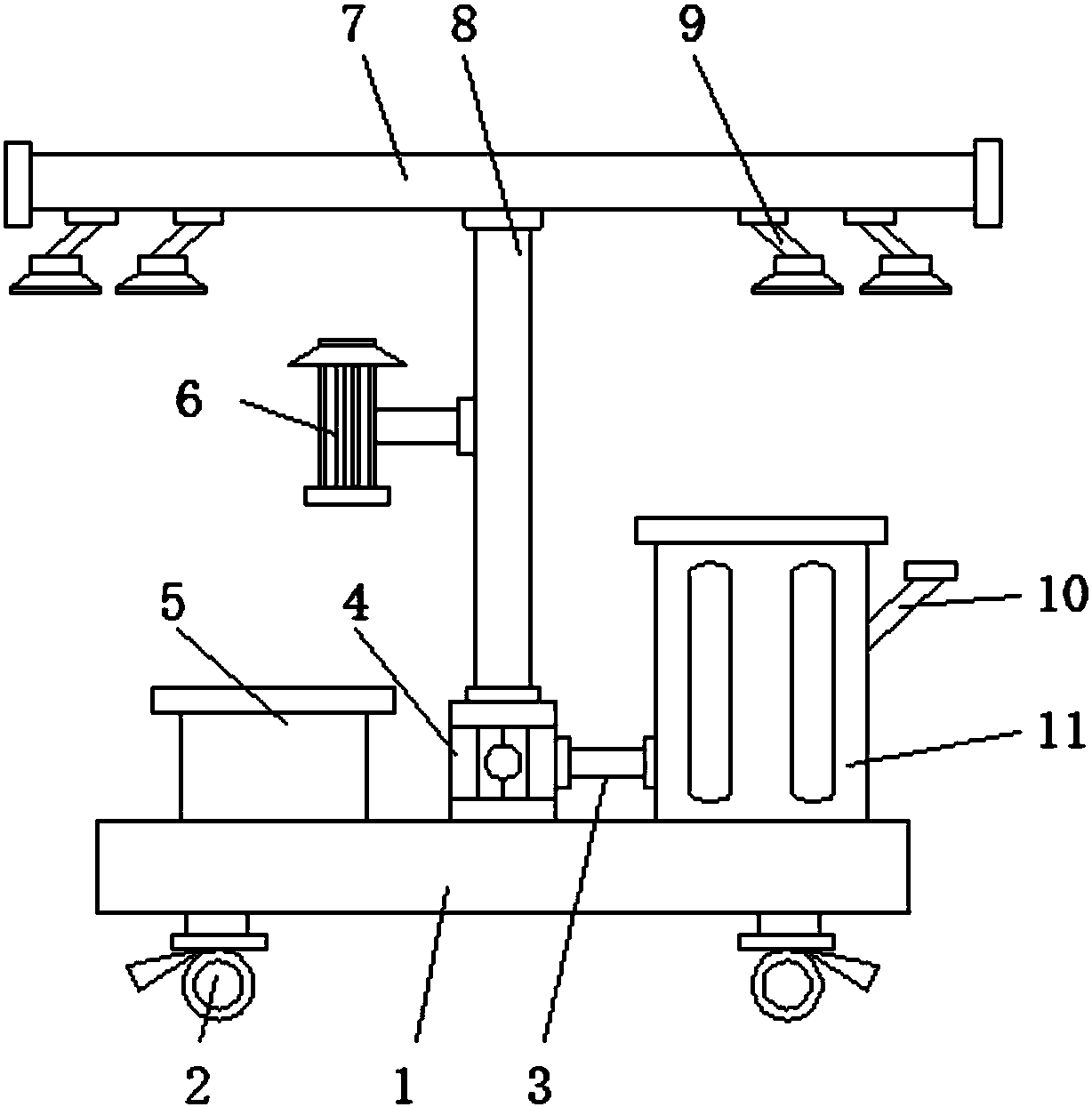

Oil and gas reservoir permeation-increasing and plugging-releasing device based on liquid-electric effect

The invention discloses an oil and gas reservoir permeation-increasing and plugging-releasing device based on a liquid-electric effect. The device includes a ground charging device which configured to transmit electric power to a downhole, a downhole device which is configured to store electric energy delivered by the ground charging device and capable of generating the liquid-electric effect to produce shock waves, and at least a downhole shock wave generating device, wherein the downhole shock wave generating device comprises a downhole variable pressure energy storage device and downhole electrodes, and is configured to lower the transmission voltage of the ground charging device to a charge voltage and then store the electric energy delivered by the ground charging device, accordingly, the charging voltage can be instantly increased by several times before being loaded to the downhole electrode to allow the downhole electrodes to generate the liquid-electric effect. The device is based on the electric spark explosion formed by the liquid-electric effect between downhole electrodes, and the periodic impact waves are excited to the surrounding strata, therefore, formation conditions can be improved, an oil permeation channel can be quickly dredged, and permeability of an oil well can be improved.

Owner:苏州峰极电磁科技有限公司

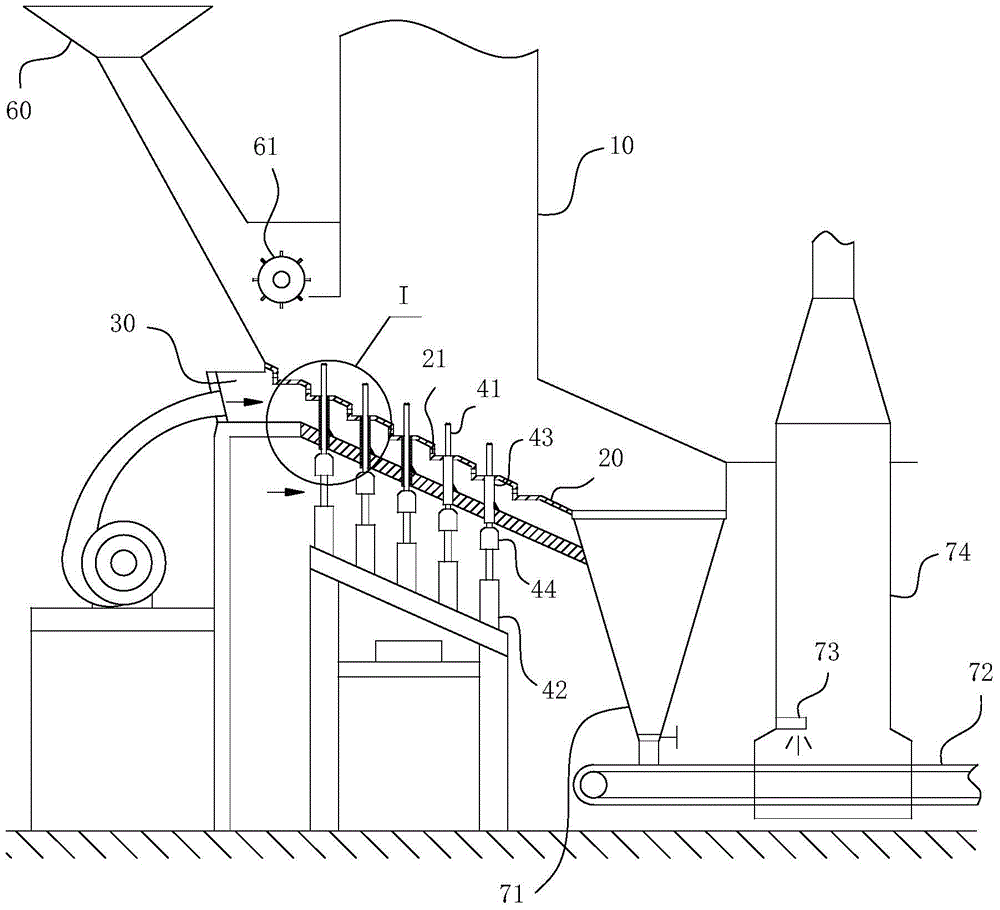

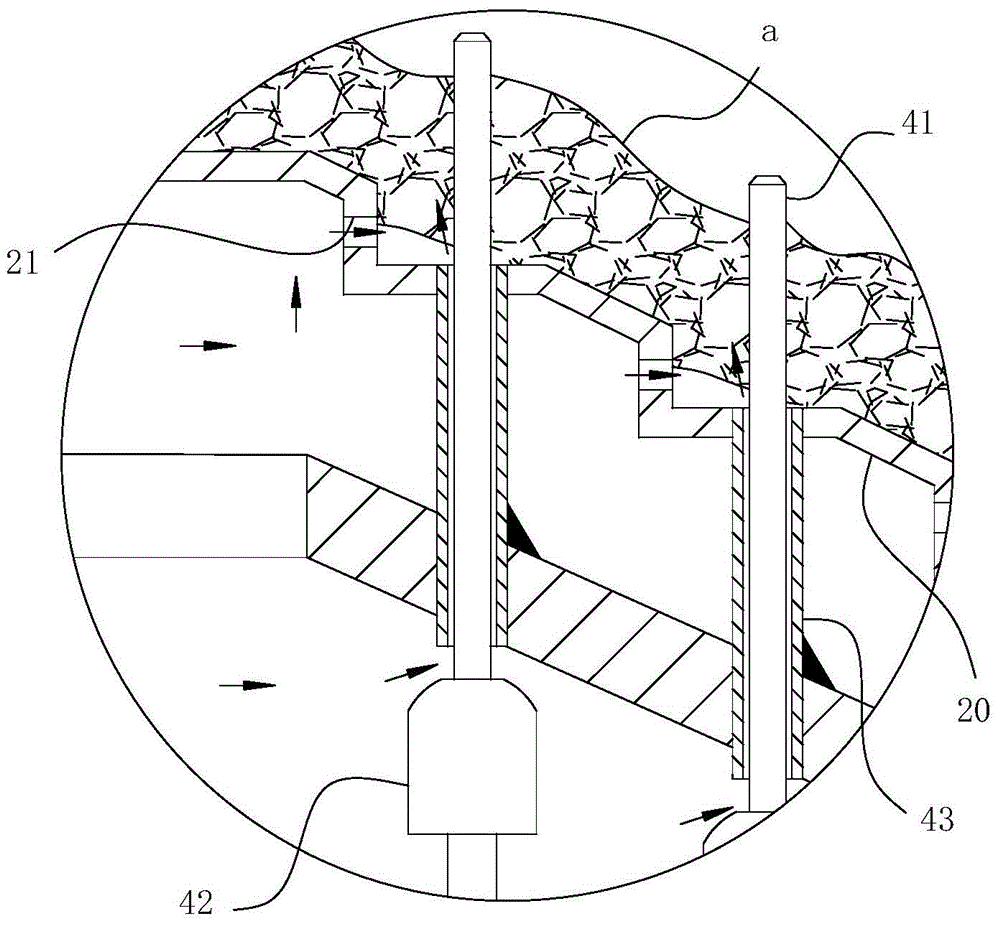

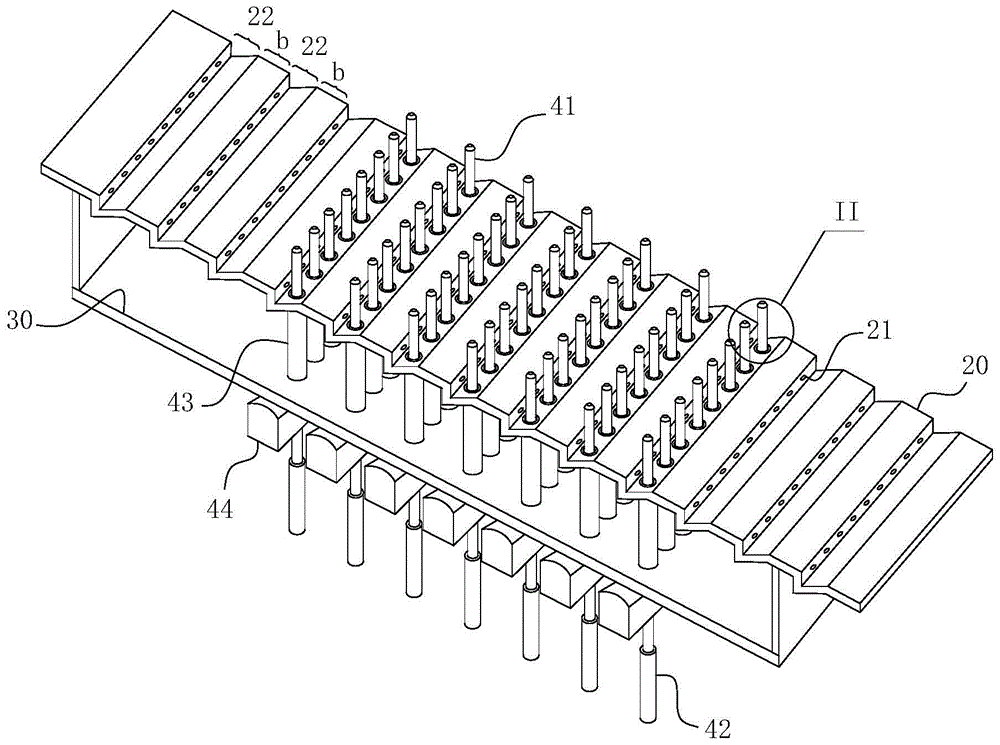

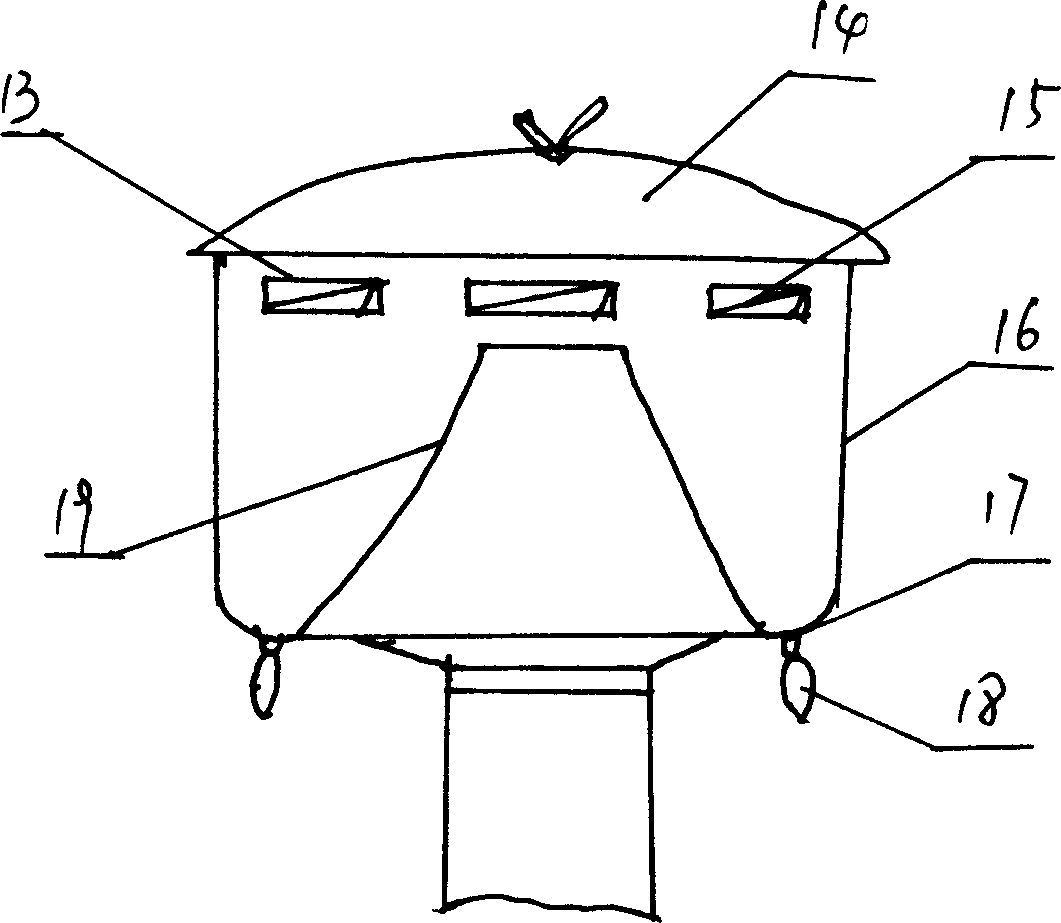

Fixed grate incinerator

InactiveCN104296148AAvoid subsequent continuous thermal expansion until it becomes soft and stuck.With self-cooling functionIncinerator apparatusCombustion chamberSlag

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate incinerator comprising a main combustion chamber and a fixed fire grate. The fixed fire grate is arranged obliquely, the higher end is provide with a material input end, the lower end is provided a slag outlet for slags after material combustion, and the slag outlet is communicated with a slag discharging component; a hot air chamber is arranged below the main combustion chamber; a hot air supply path penetrates the fixed fire grate; the fixed grate incinerator further comprises an ejecting rod and a power portion; the maximum lift of the ejecting rod penetrates the material layer of the fixed fire grate; an ejecting rod component further comprises a shaft sleeve with the preset length, one end of the shaft sleeve penetrates and is fixedly connected to the fixed fire grate along the moving direction of the ejecting rod, a vent gap allowing the air to penetrate is formed between the shaft sleeve and the ejecting rod, and the other end of the shaft sleeve is communicated with the outside and / or an air cooling chamber. The fixed grate incinerator has the advantages that material burning efficiency is high, the component operation reliability is high, and the service life is prolonged effectively.

Owner:安徽盛燃焚烧炉科技有限公司

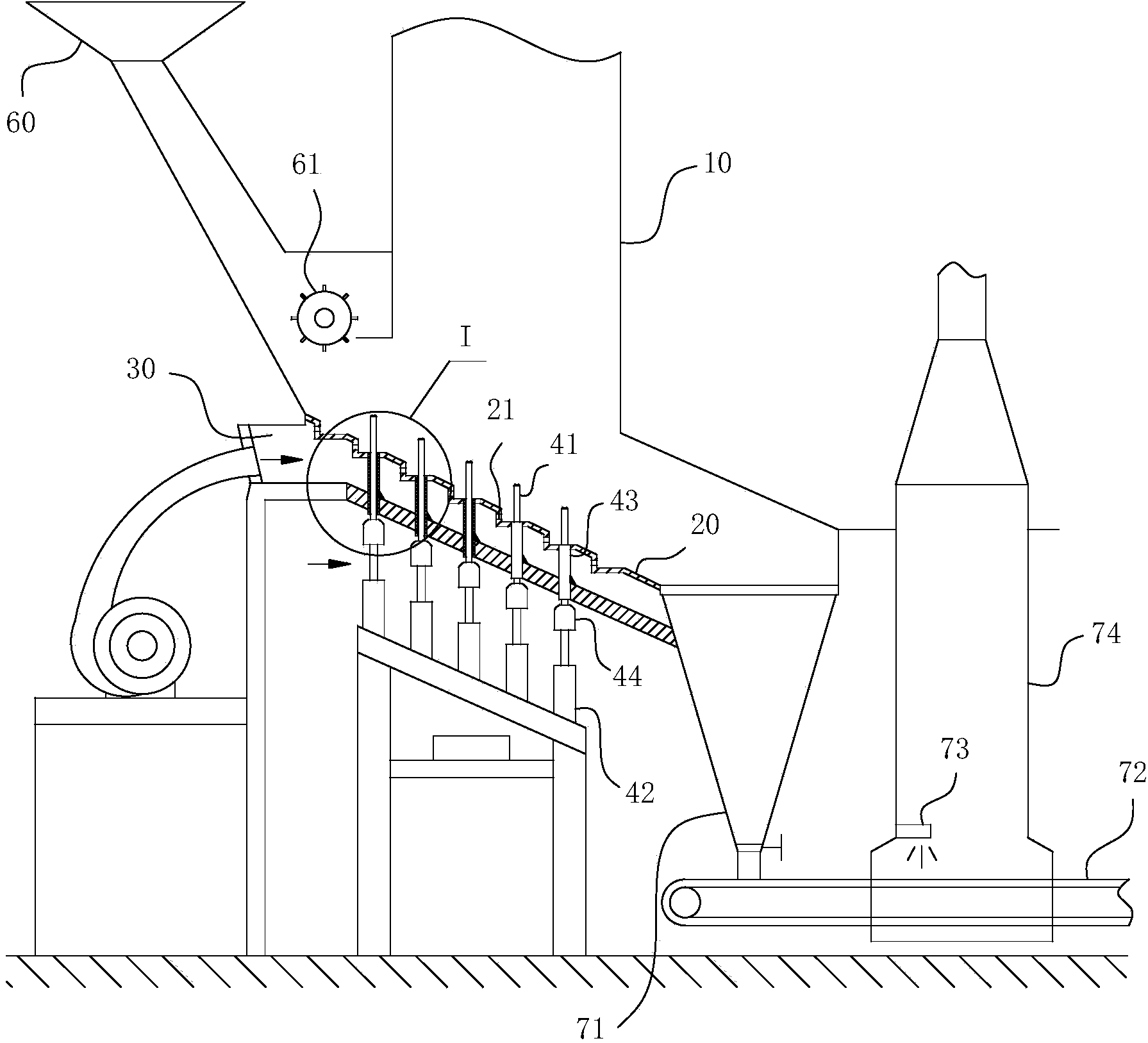

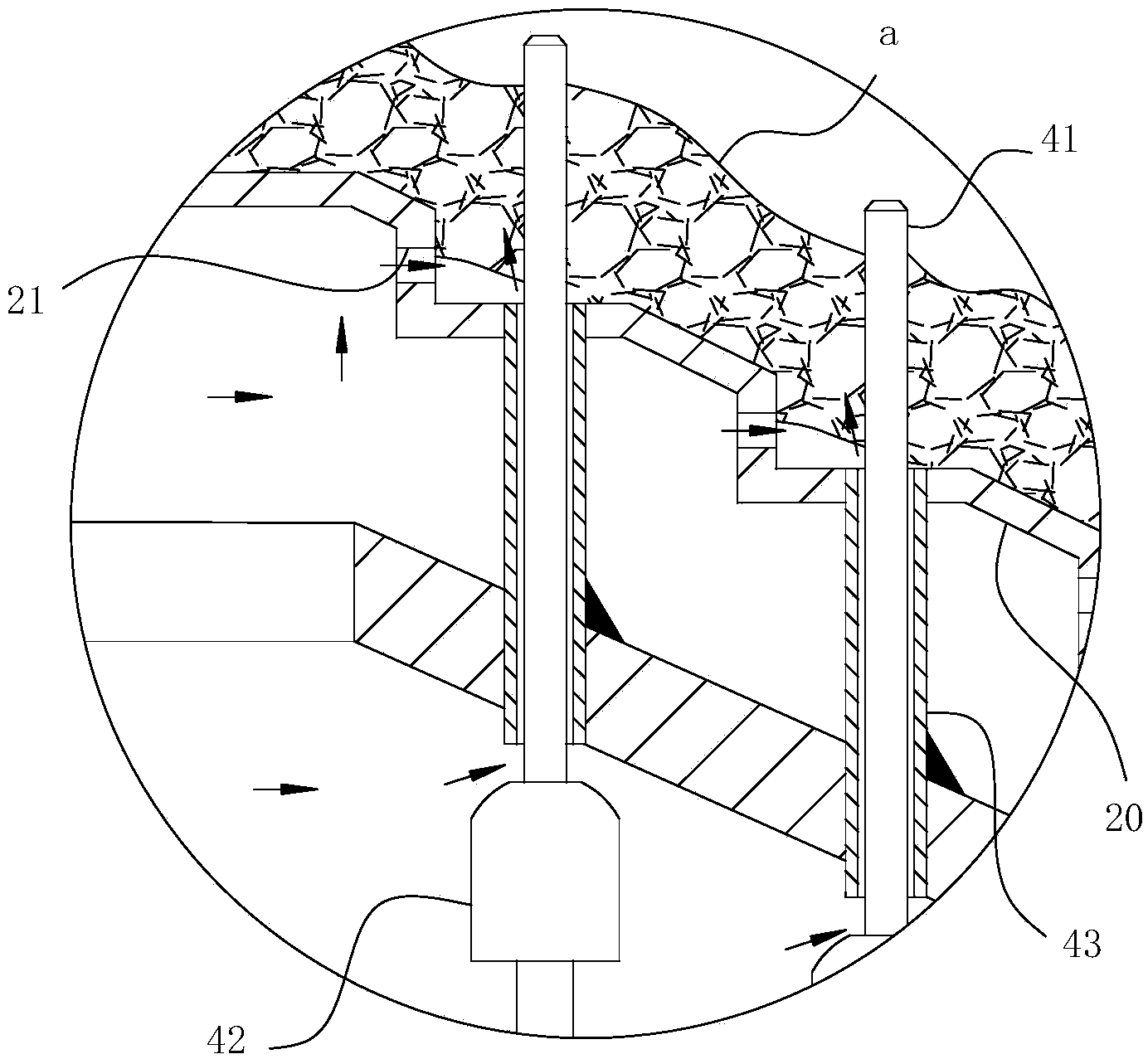

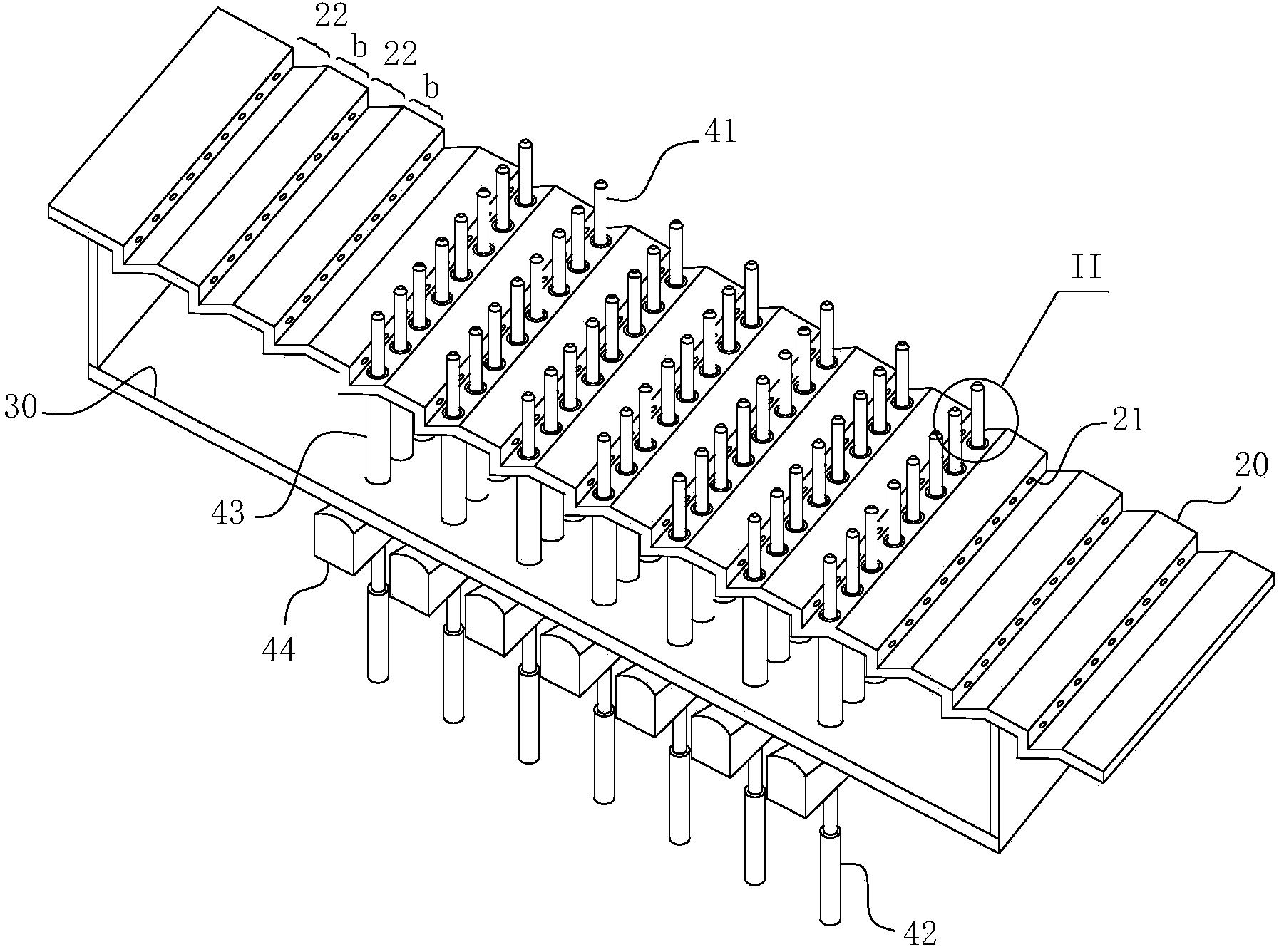

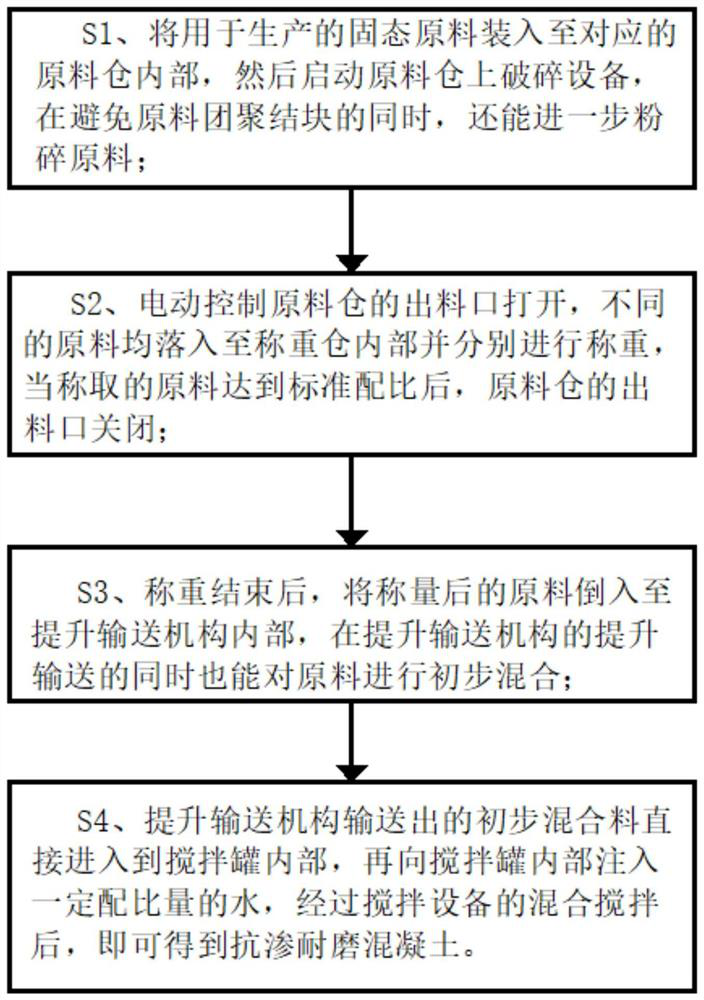

Impermeable wear-resistant concrete and preparation method thereof

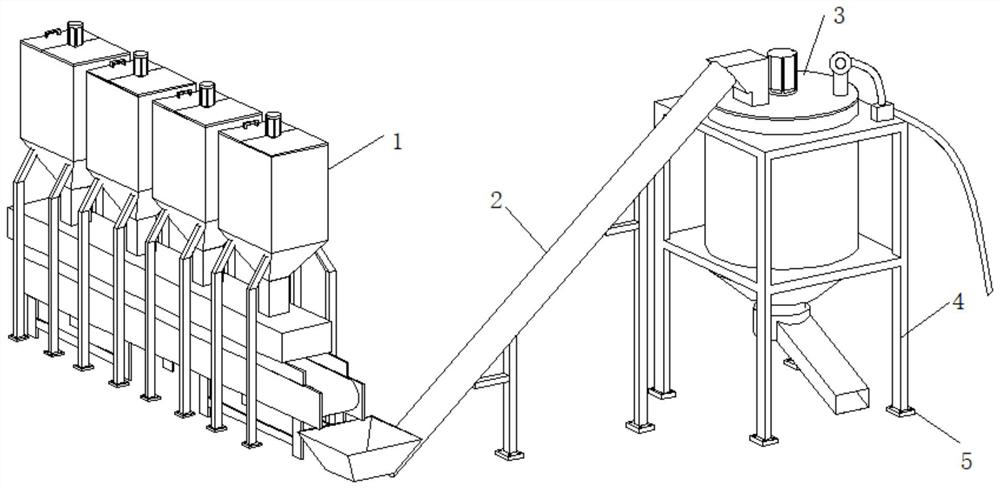

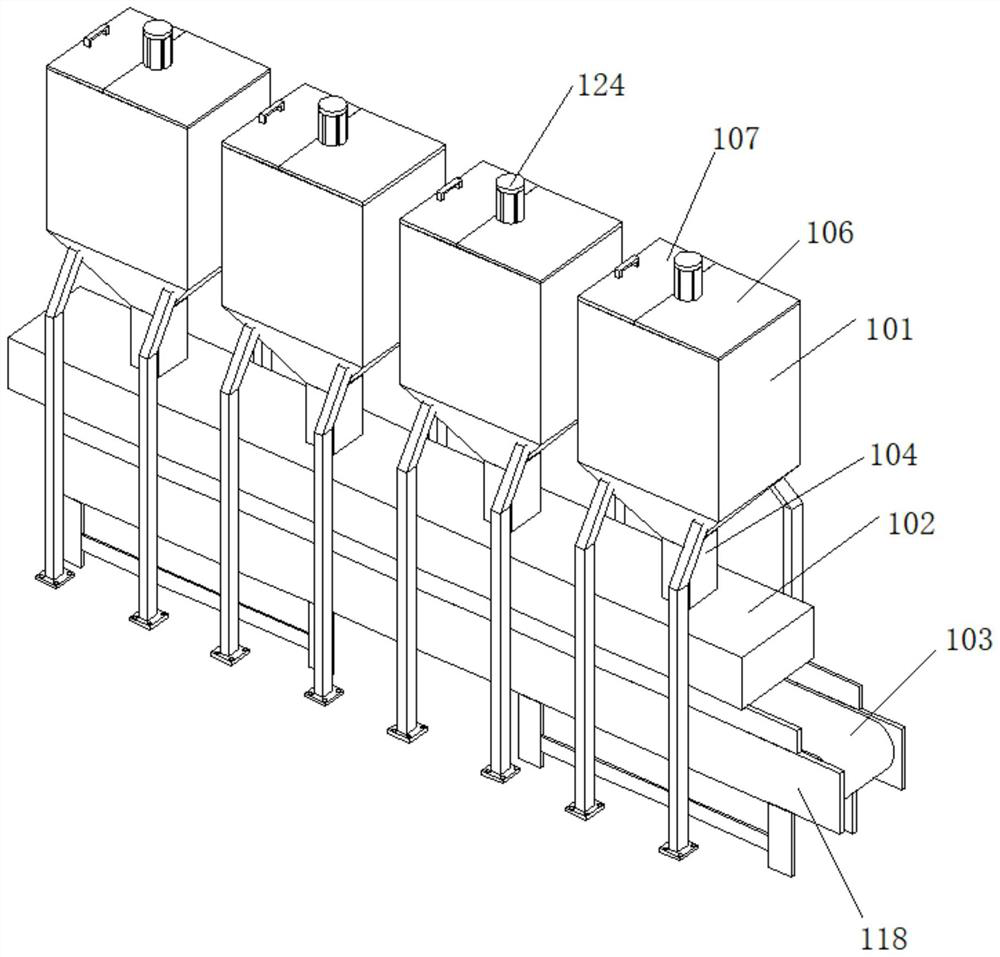

PendingCN112976303ANovel structureRealize automatic unloadingMixing operation control apparatusPretreatment controlFiberPolyvinyl alcohol

The invention discloses impermeable wear-resistant concrete and a preparation method thereof, and relates to the technical field of concrete preparation. The impermeable wear-resistant concrete comprises the following raw materials: cement, fly ash, blast furnace slag, quartz sand, broken stone, carbon black, a fiber filler, sodium alkyl benzene sulfonate, a water reducer, polyvinyl alcohol, an impermeable wear-resistant composition and water. The preparation device comprises a batching mechanism, a lifting and conveying mechanism and a mixing and stirring mechanism, wherein the discharging port end of the batching mechanism is connected with the feeding end of the lifting and conveying mechanism; and the discharging end of the lifting and conveying mechanism is connected with the discharging end of the mixing and stirring mechanism. According to the impermeable wear-resistant concrete and the preparation method thereof provided by the invention, prepared materials can be transferred at the same time, so that automatic unloading after weighing is realized; the inner wall of a lifting pipeline can be effectively prevented from being blocked while the materials are lifted and conveyed upwards; and the preparation method is simple, and the prepared concrete has the characteristics that the water-reducing rate is high, the workability and the fluidity of the road concrete are obviously improved, and the impermeability, the freezing resistance, the fracture resistance, the compression resistance, the wear resistance and the durability of the road concrete are improved.

Owner:李思颖

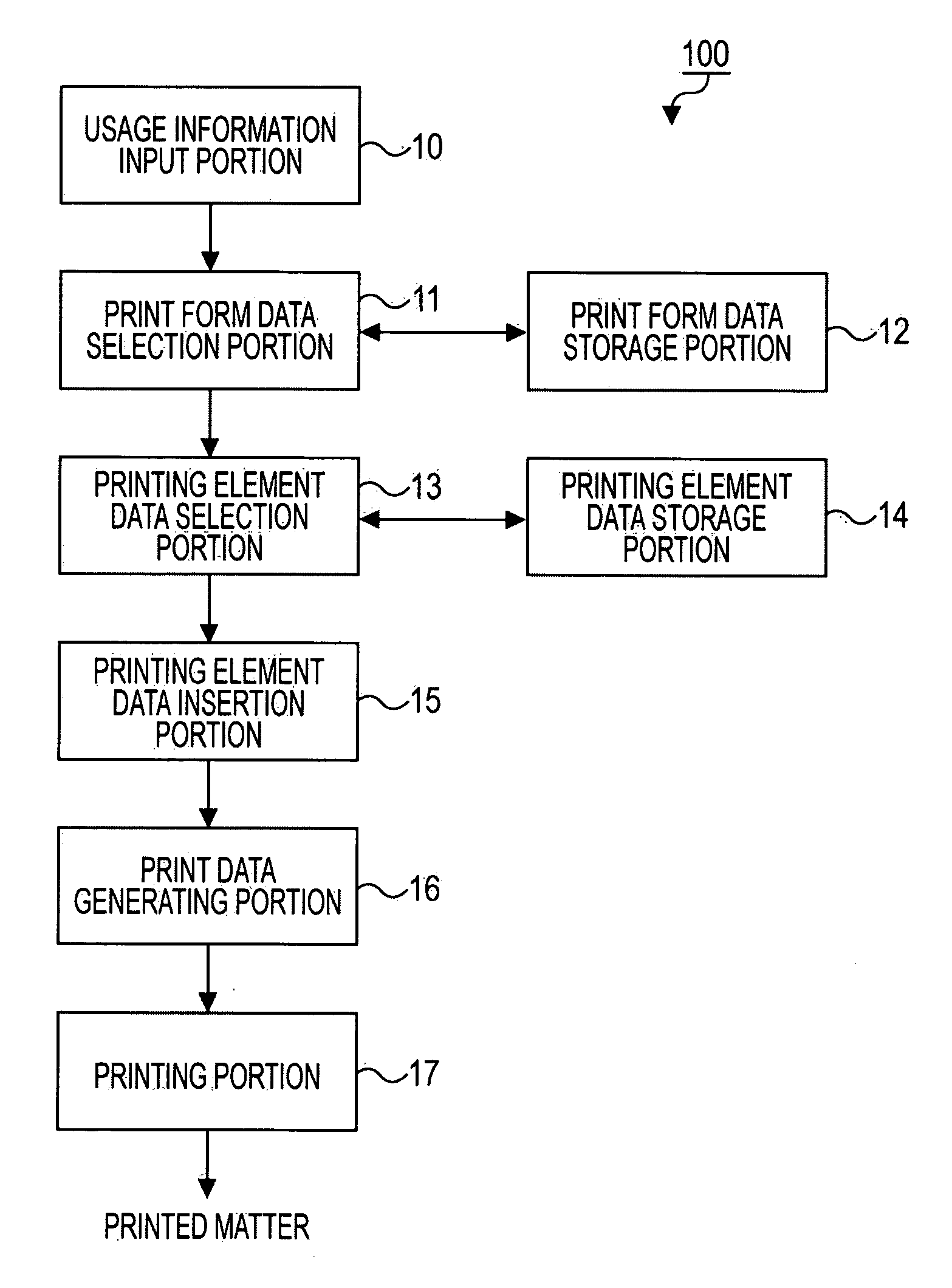

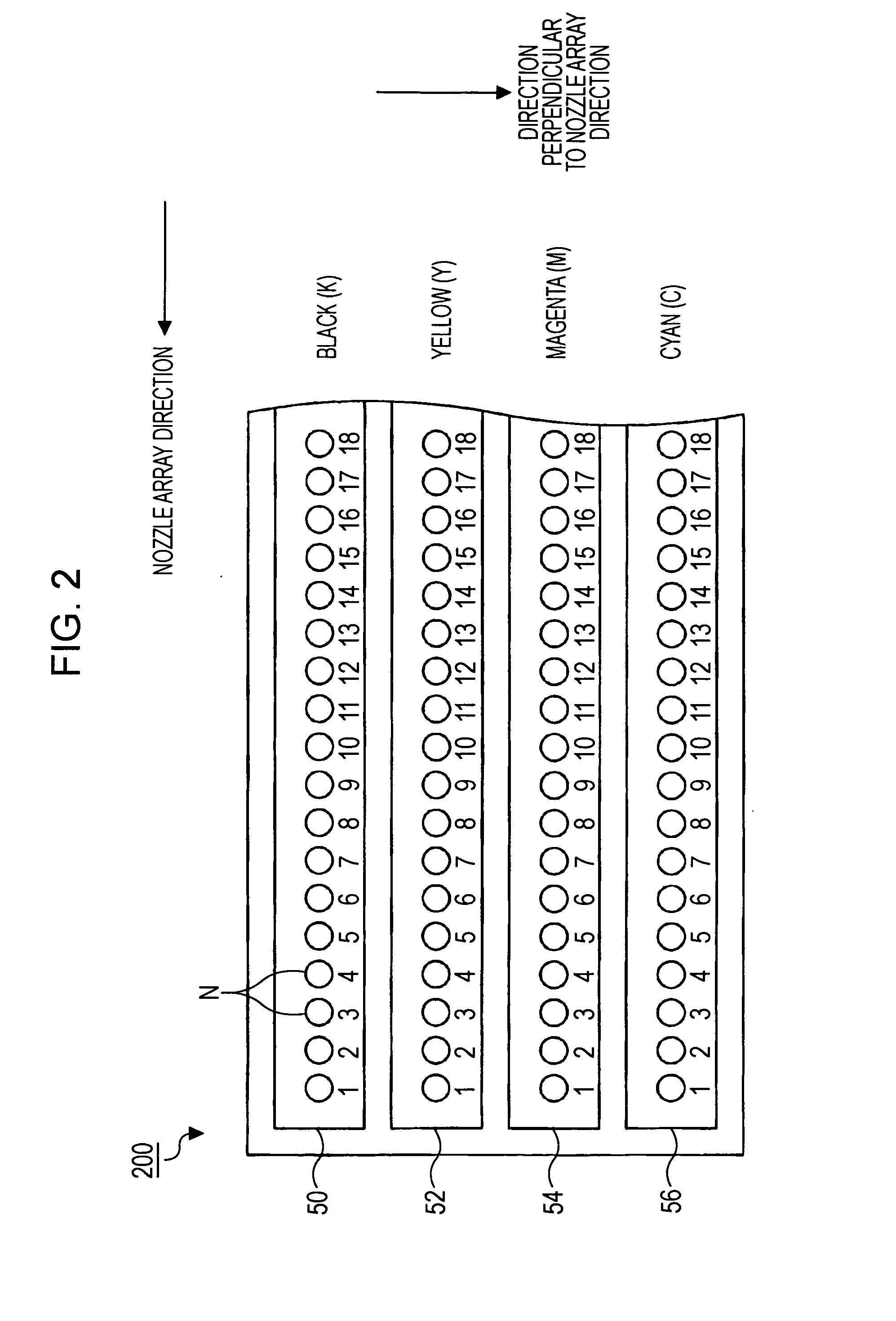

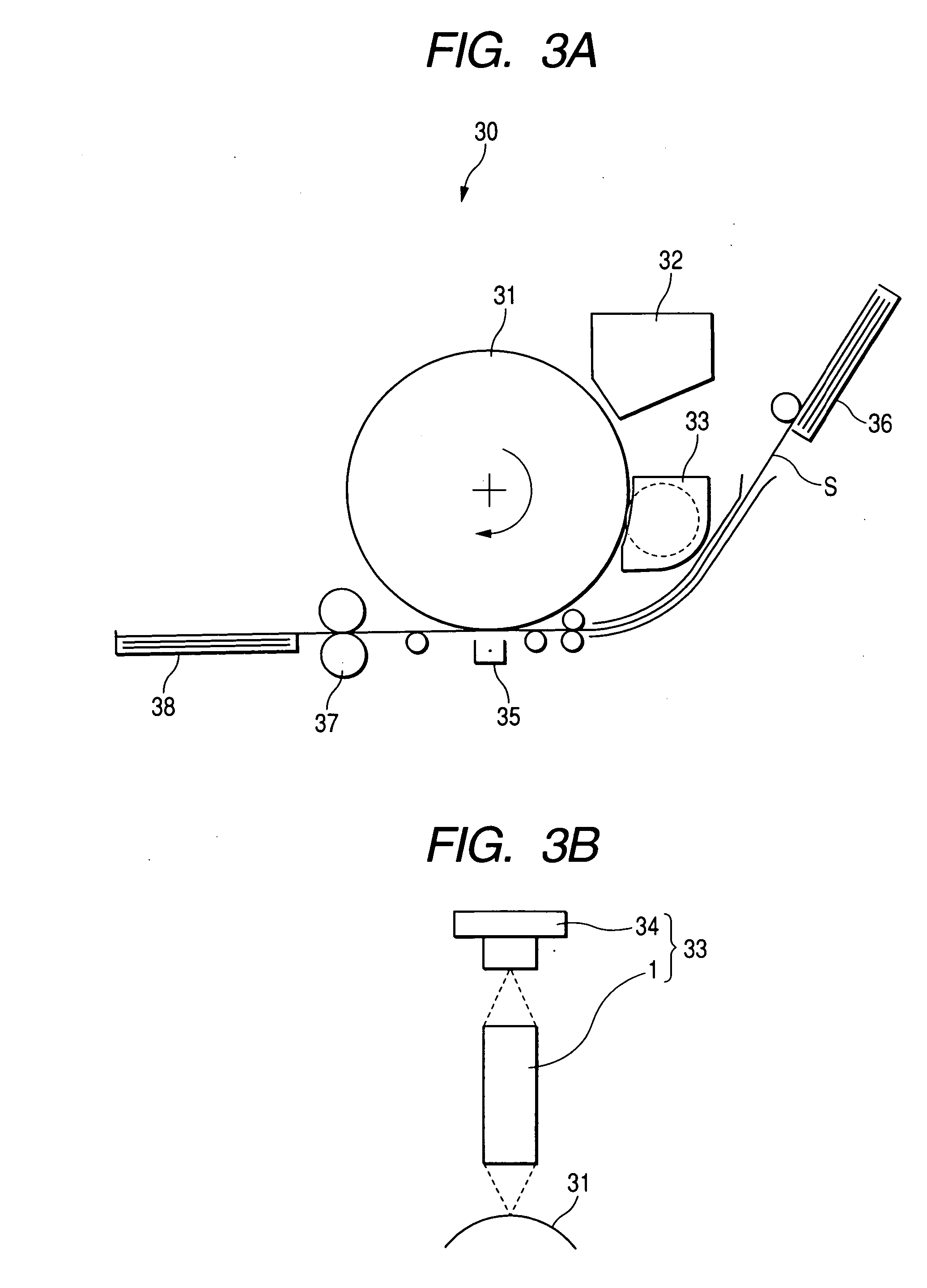

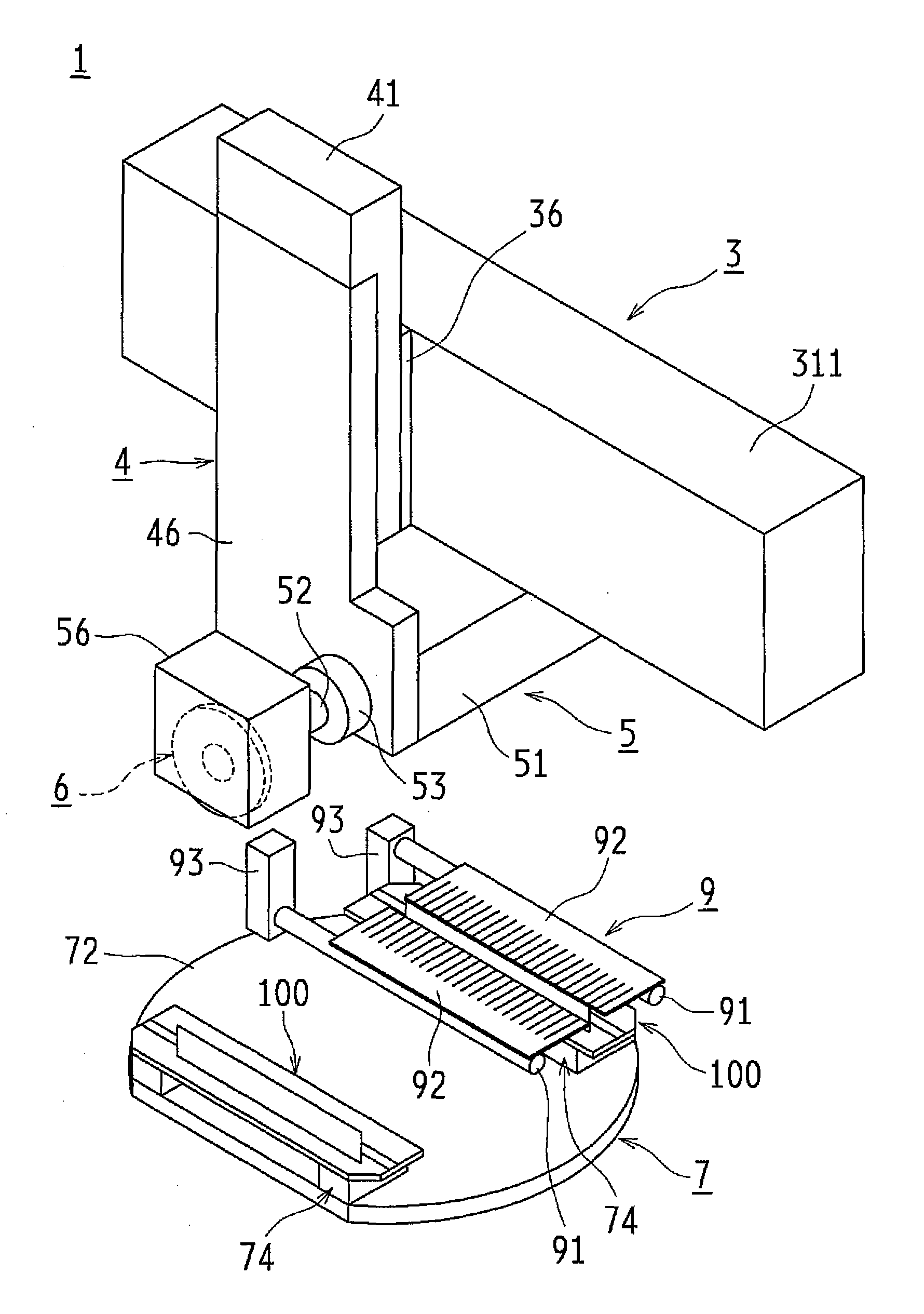

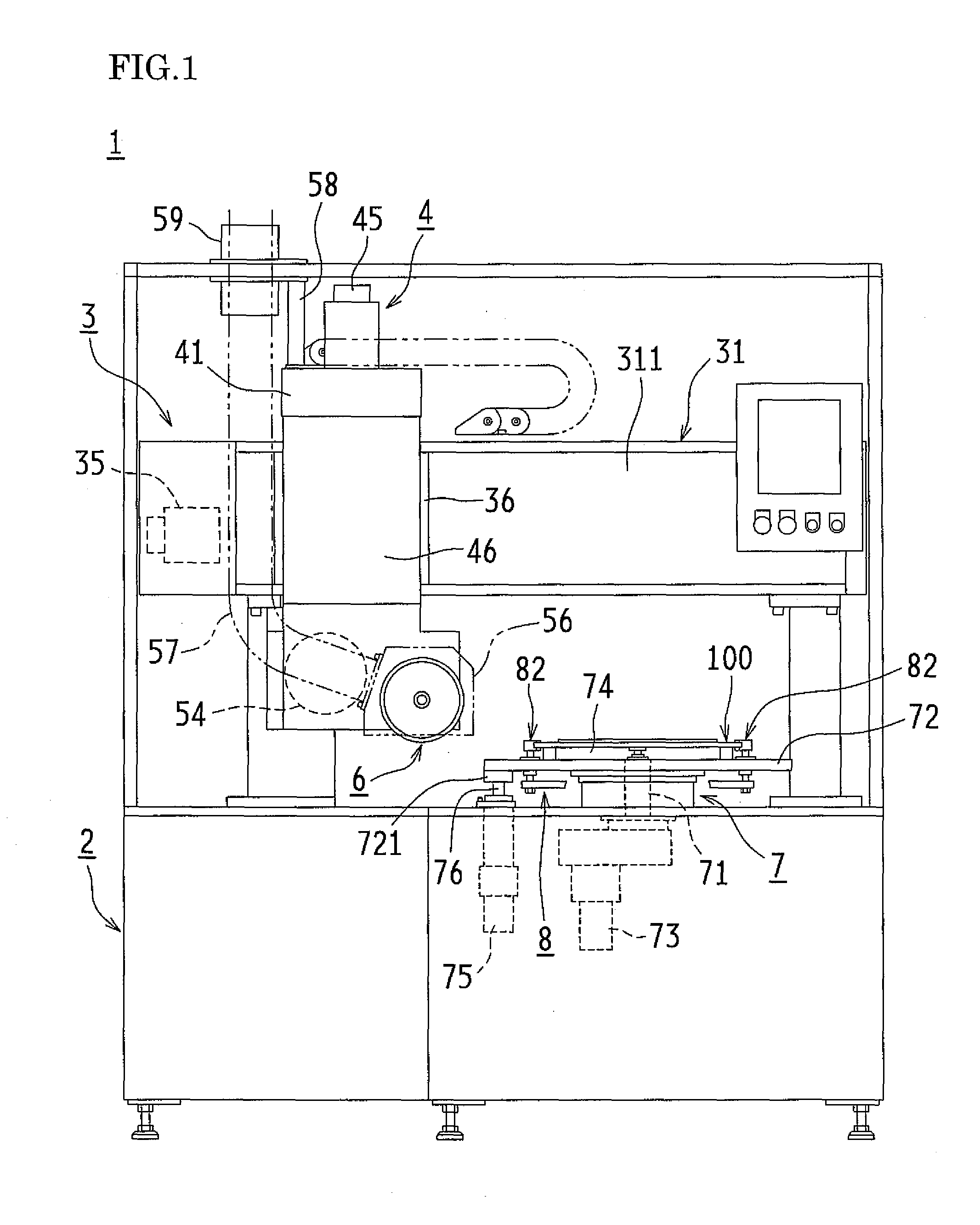

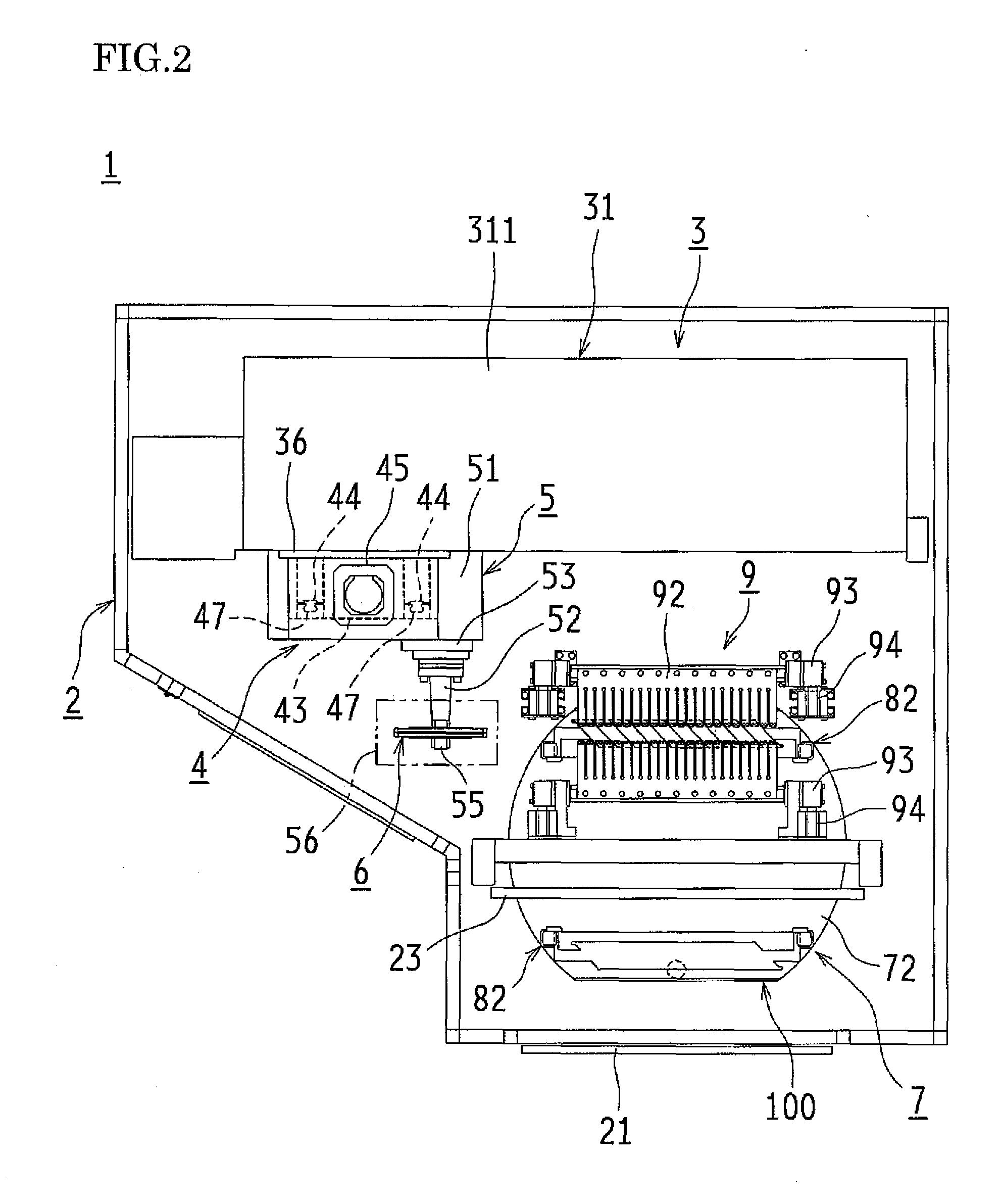

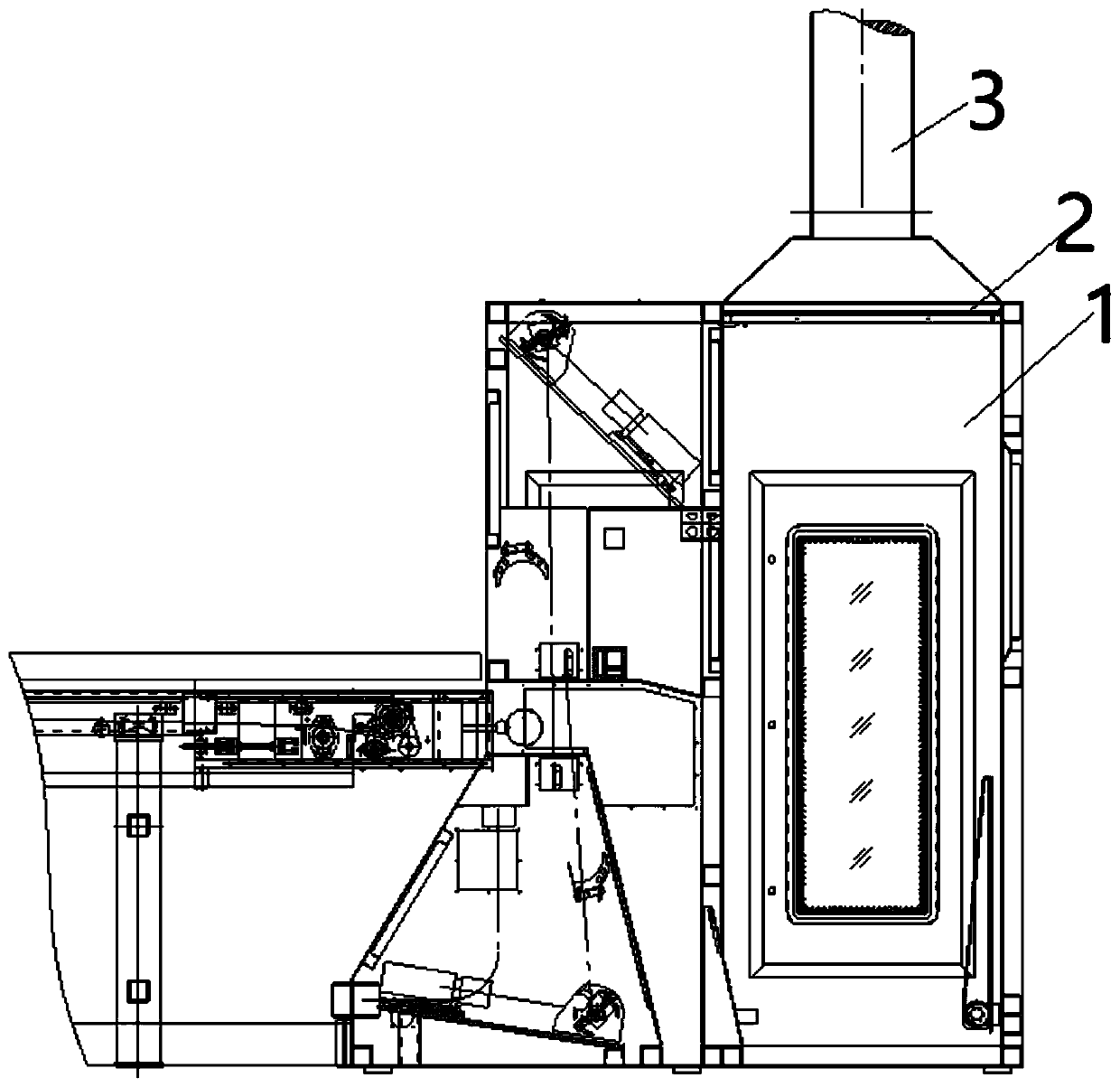

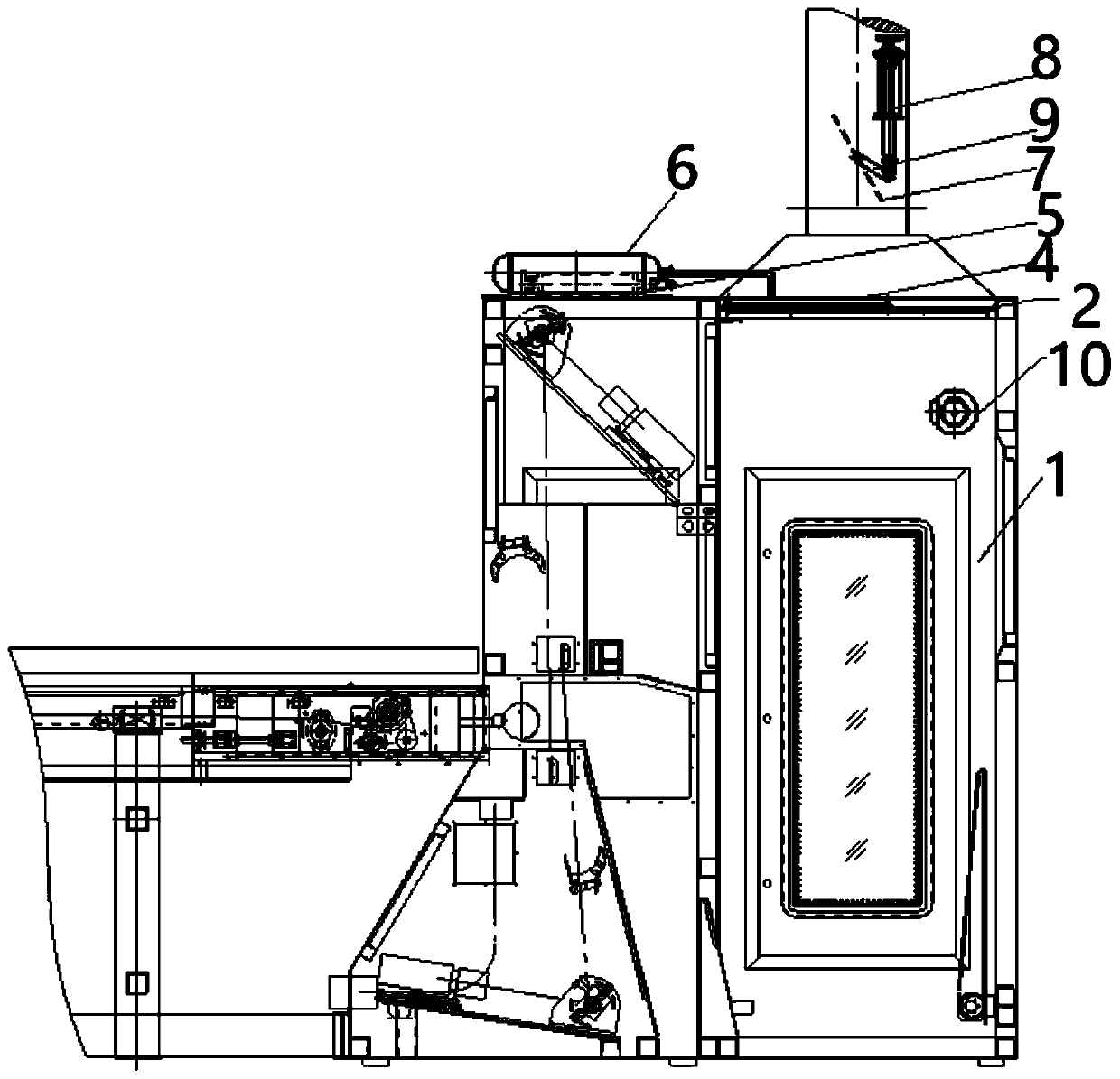

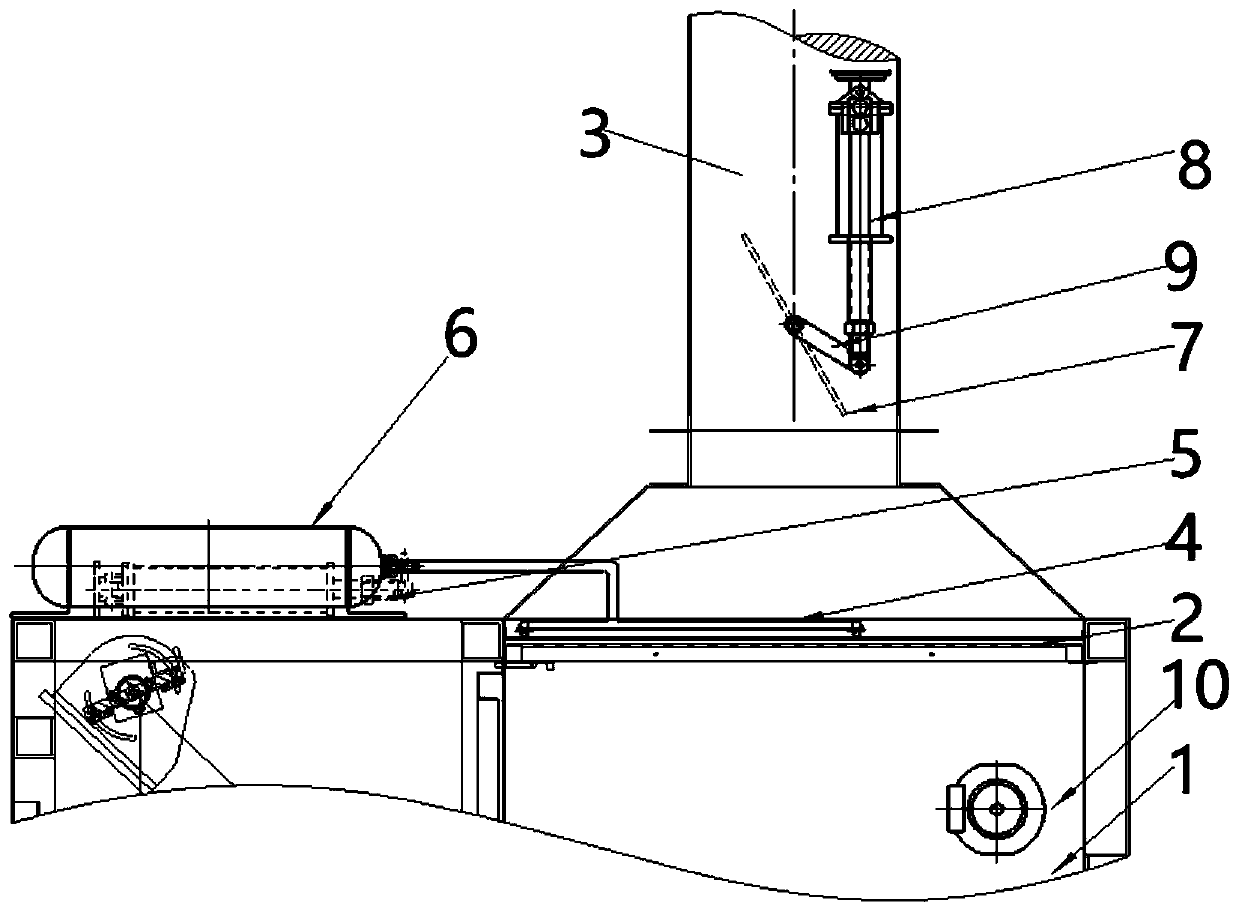

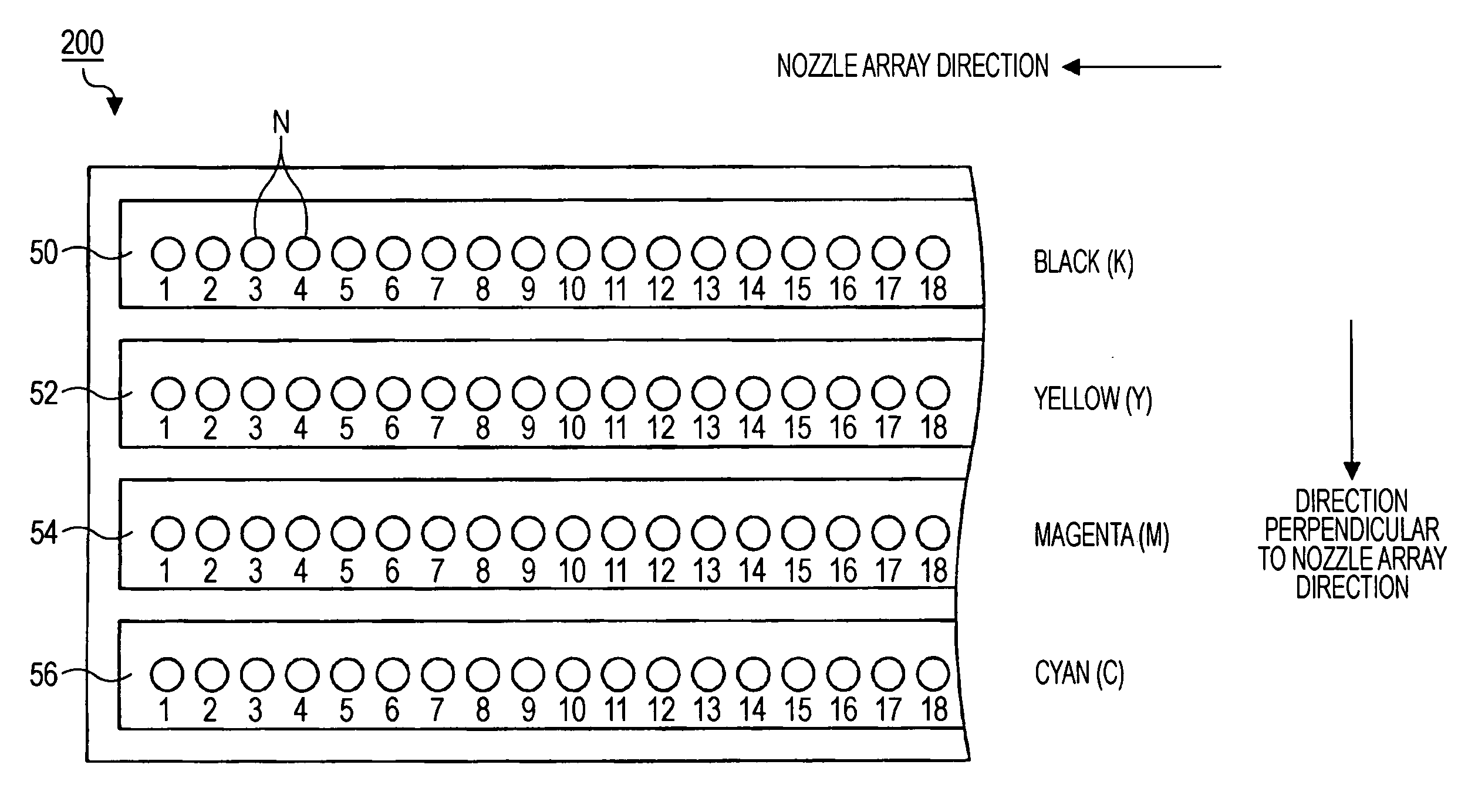

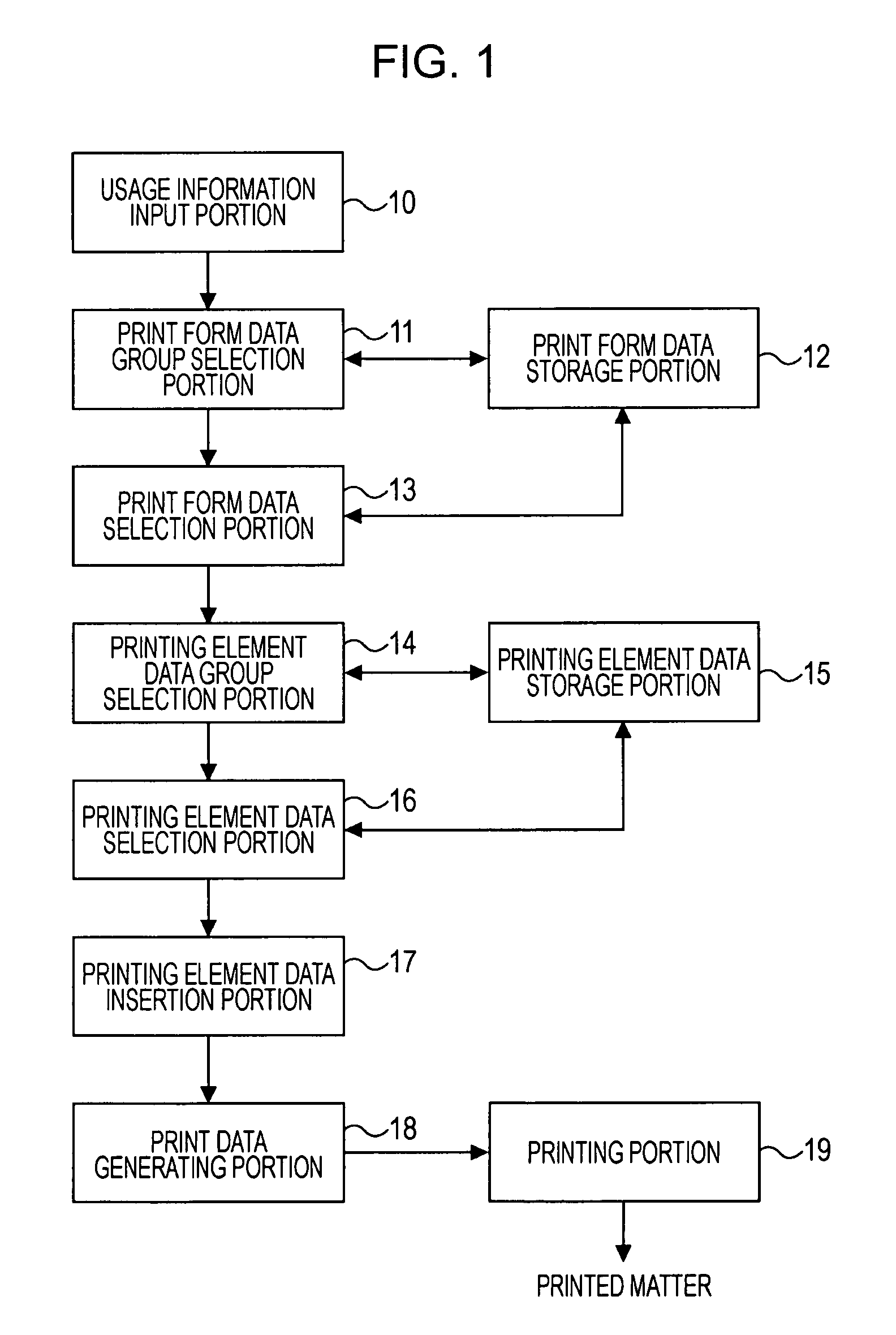

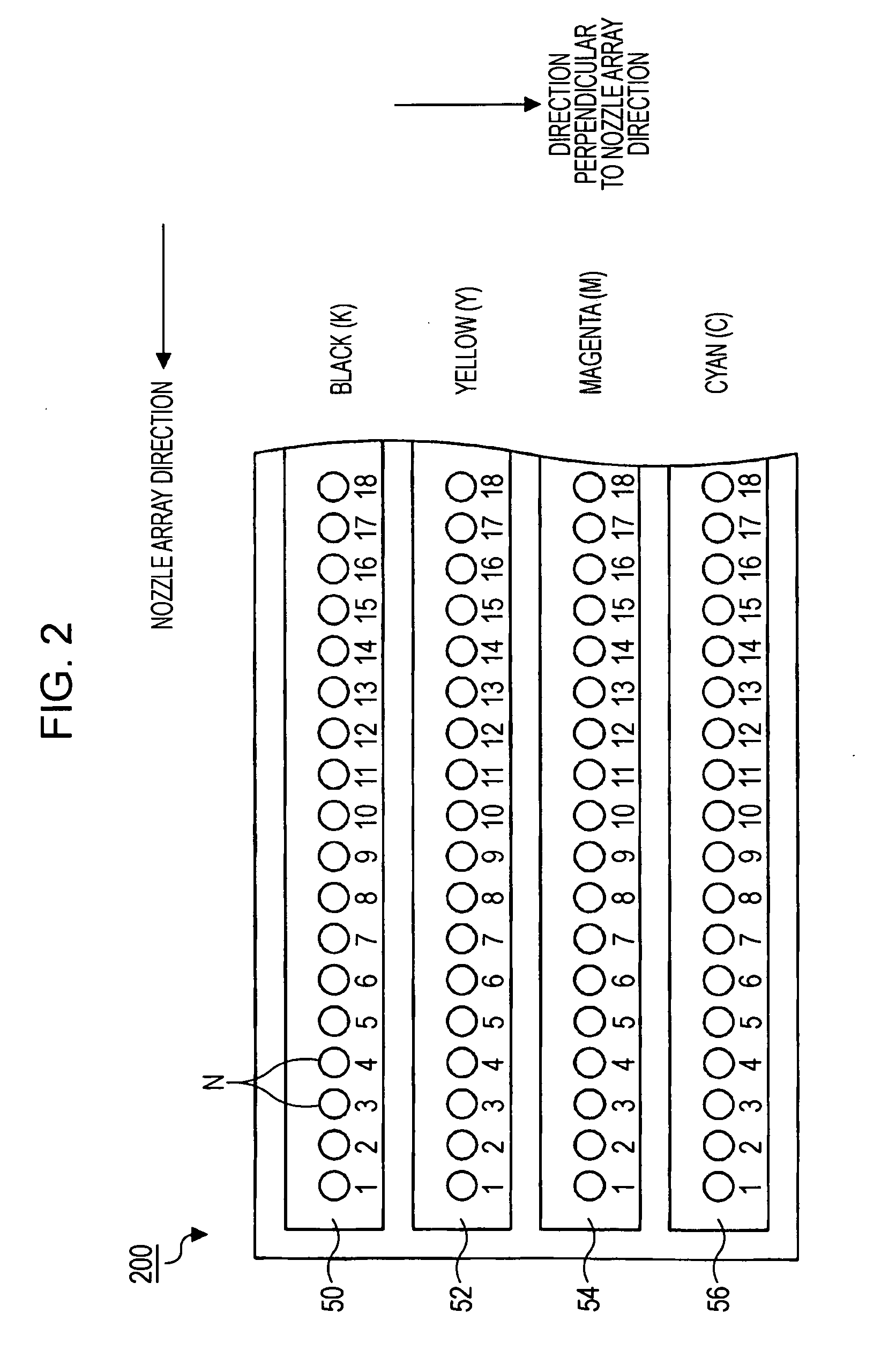

Printer, printing program, and printing method

ActiveUS20090066746A1Reduce in quantityChanging configurationInking apparatusVisual presentationData selectionEngineering

A printer includes a print head in which nozzles that form an image by discharging ink are arranged in a plurality of lines. The printer prints out an image on the basis of print form data in which information of layout contents of printing elements that form the content of print is set according to the attribute of each printing element. The printer includes a print form data storage unit, a printing element data storage unit, a print form data selection unit, a printing element data selection unit, and a printing element data insertion unit.

Owner:SEIKO EPSON CORP

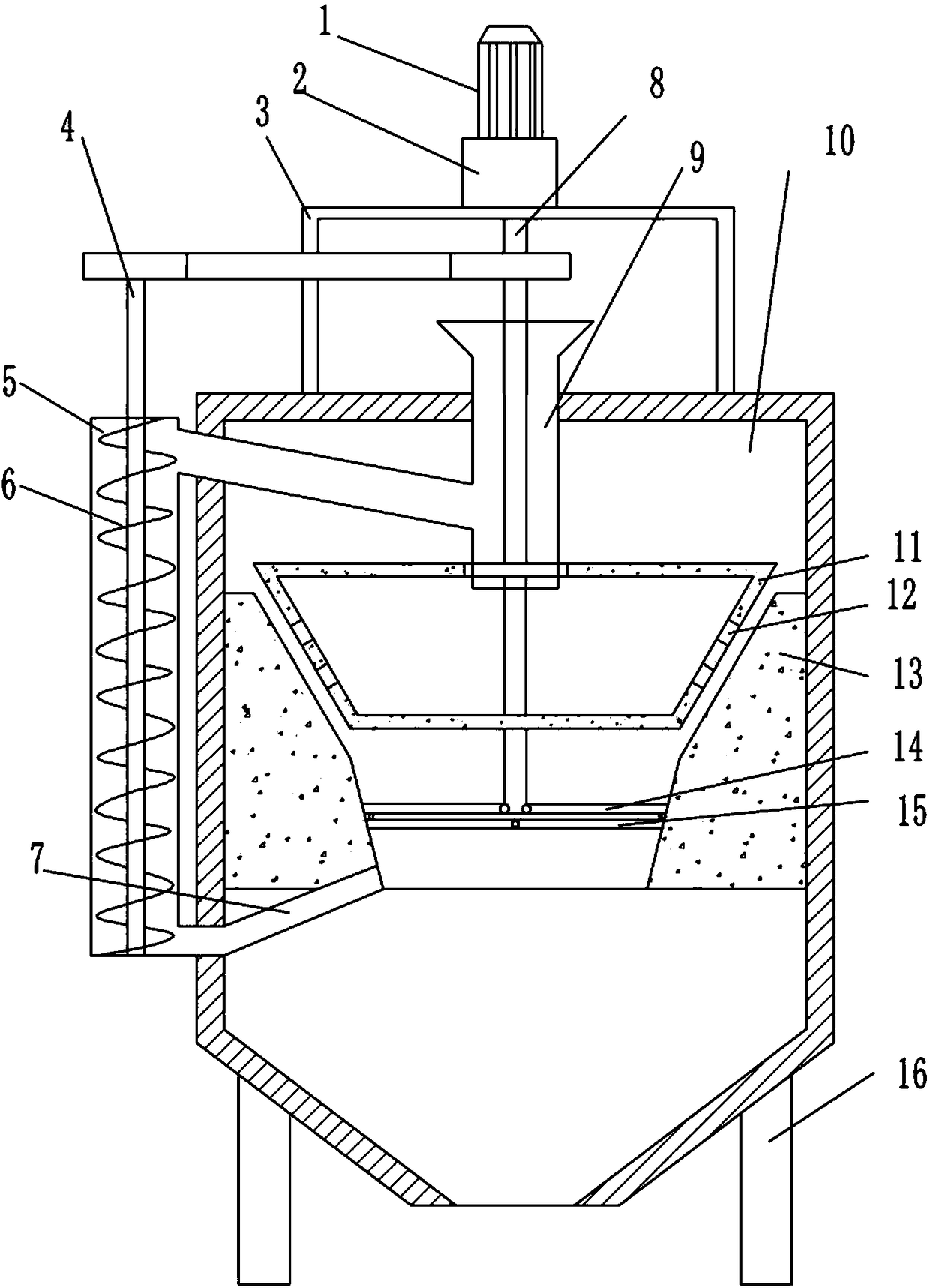

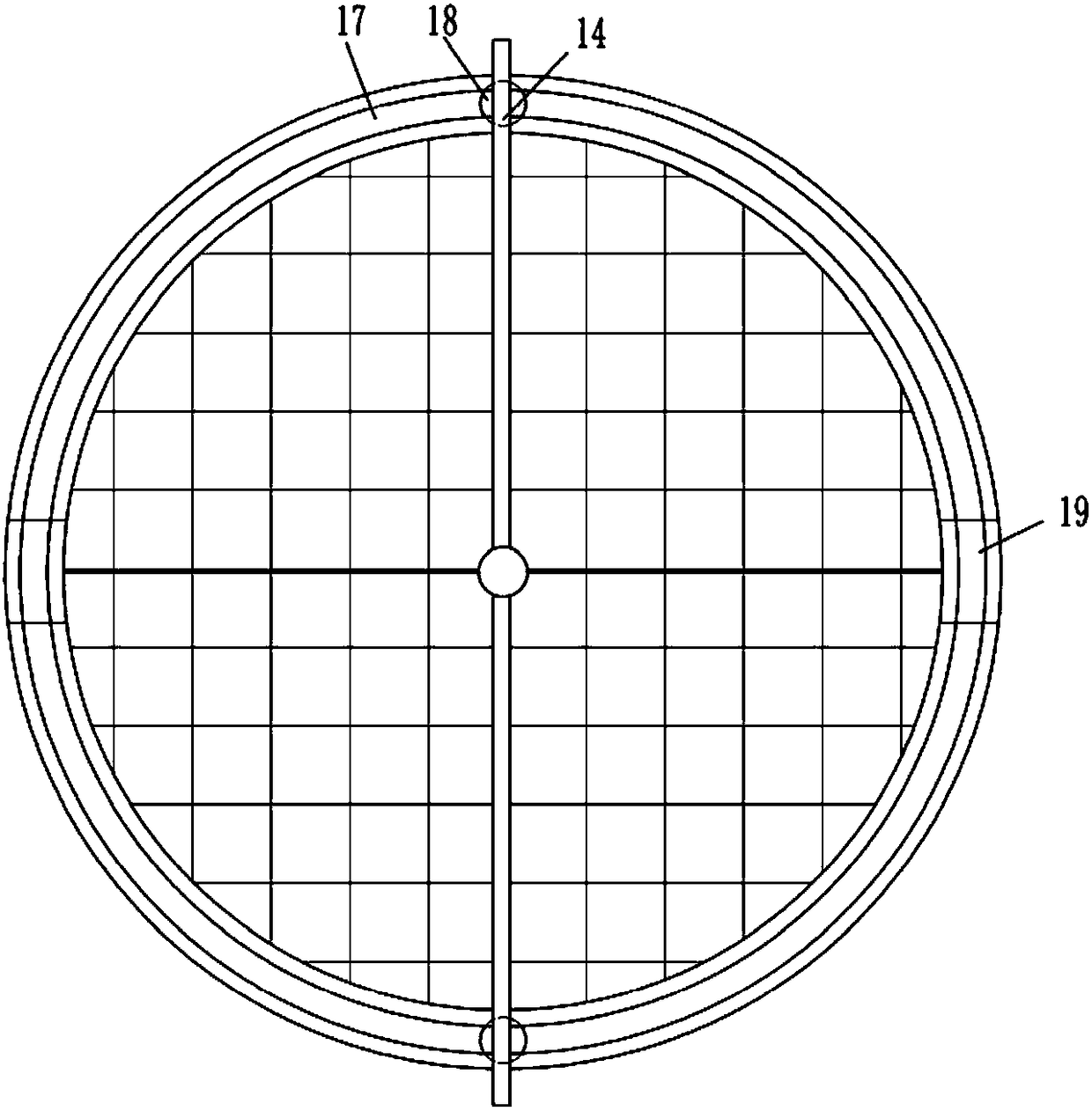

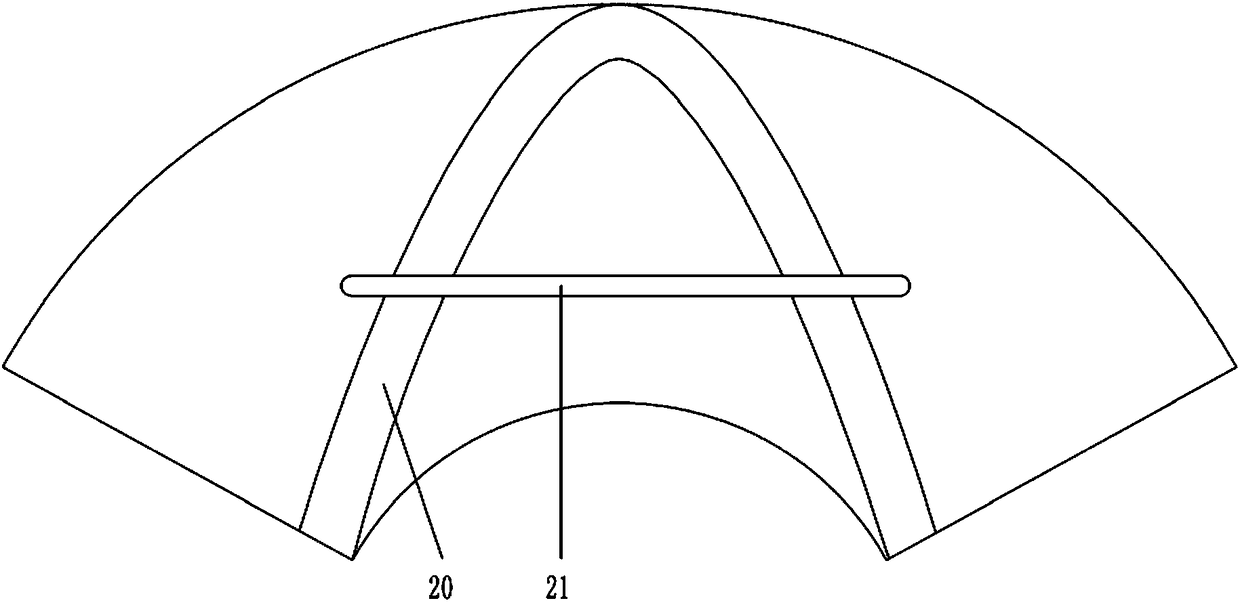

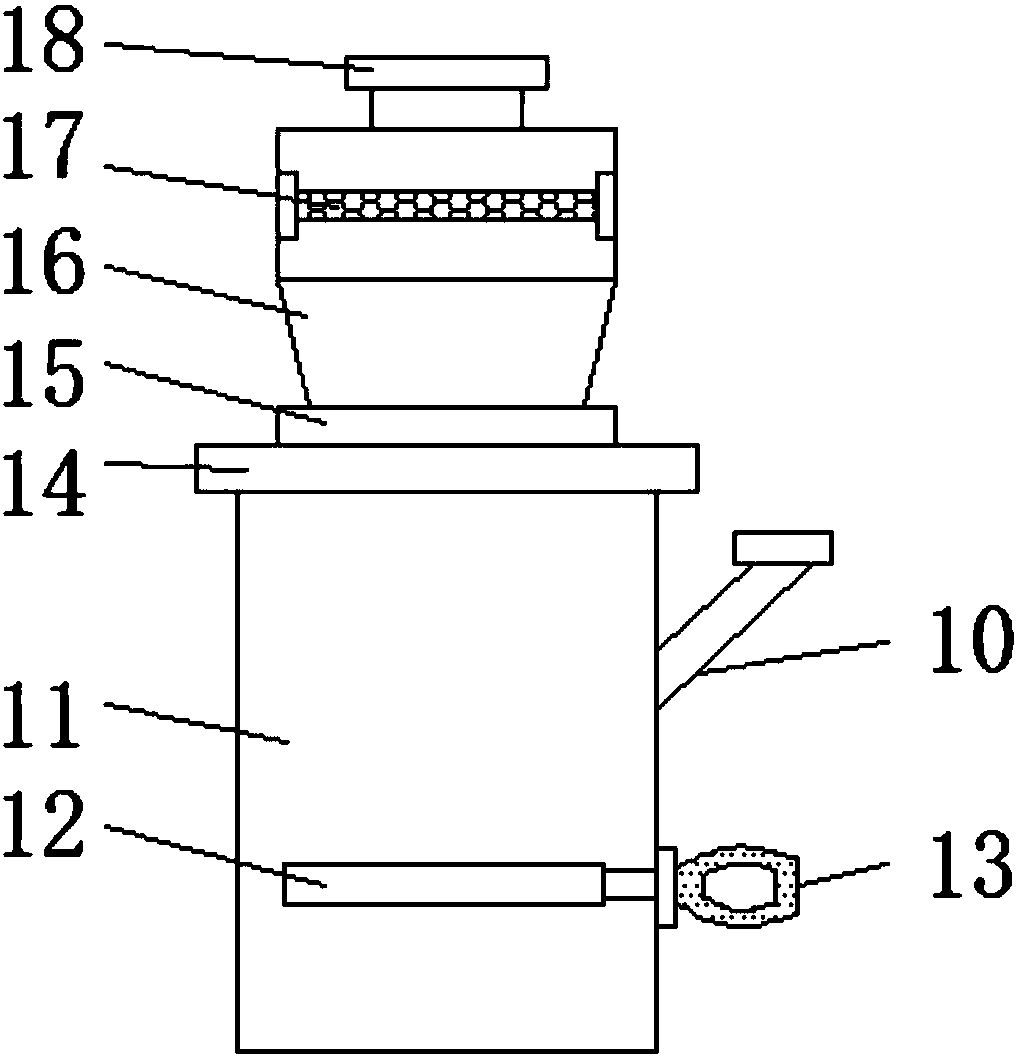

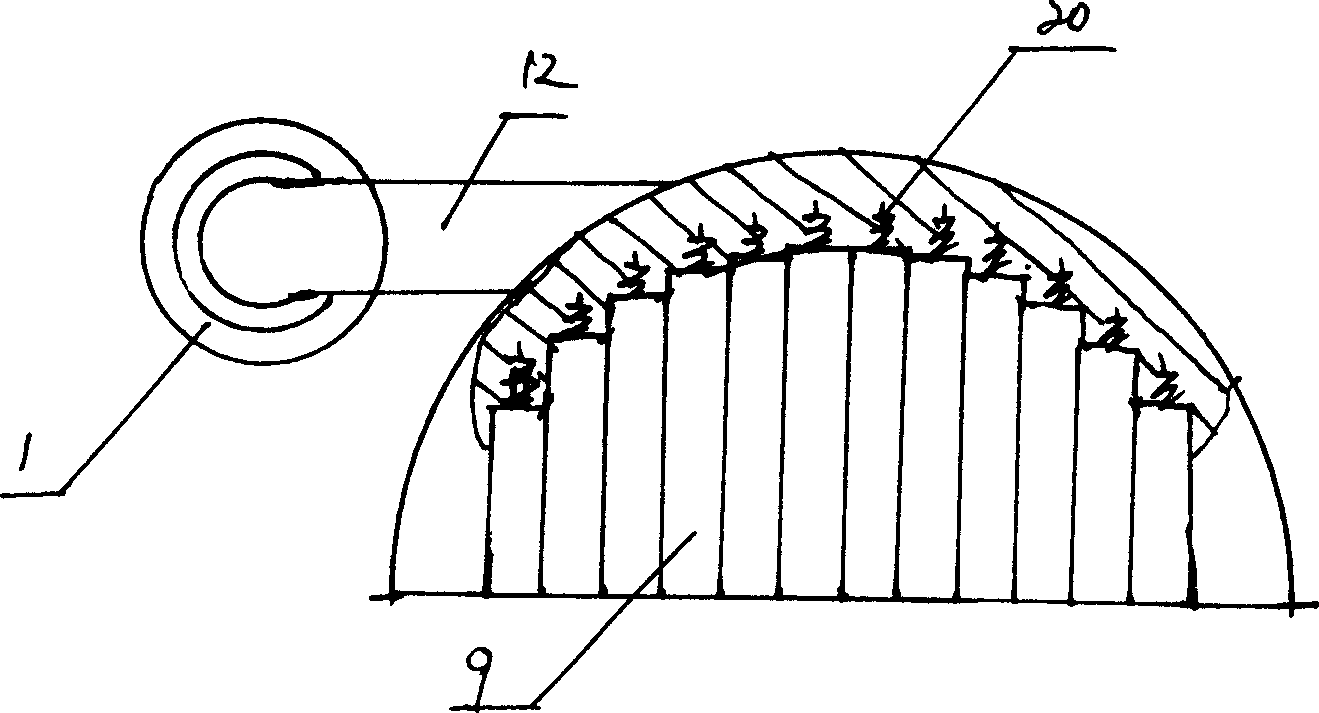

Powder grinding device for producing water-soluble coating

ActiveCN108160274AEfficient grindingImprove work efficiencyGrain treatmentsScrew conveyorFunnel shape

The invention belongs to the technical field of powder processing equipment, and particularly discloses a powder grinding device for producing a water-soluble coating. The powder grinding device comprises a processing barrel and a circulating barrel; a movable grinding block and a fixed grinding block which can be coordinated to grind powder are arranged in the processing barrel; the interior of the movable grinding block is hollow; sieve holes are formed in the side wall of the movable grinding block; a funnel-shaped channel is formed in the fixed grinding block; a fixed shaft is arranged onthe inner wall of the movable grinding block, and a closed curve sliding chute is formed in the inner wall of the movable grinding block; semicircular filter screens are hinged to the two sides of thefixed shaft; grooves are formed in the circumferential lines of the filter screens; a motor is arranged at the upper end of the processing barrel and is connected with a rotating shaft, and the rotating shaft can drive the movable grinding block to rotate; two movable rods are hinged to the bottom end of the rotating shaft and are connected in the sliding chute and the grooves in a sliding mode;a circulating material port is formed in the fixed grinding block; a spiral conveying mechanism is connected outside the circulating material port; and the upper end of the circulating barrel communicates with a feeding pipe. According to the scheme of the powder grinding device, the phenomenon that the filter screens are blocked after the powder is ground can be avoided, and unqualified powder can be circularly ground.

Owner:宁波隆锐机械制造有限公司

3-D channel gas heat exchanger

ActiveCN105102800AImprove cloggingReduce thermal stressInternal combustion piston enginesGas handling/storage effectsD channelEngineering

The present invention relates to a 3-d channel gas heat exchanger. The 3-D channel gas heat exchanger includes a plurality of heat exchange plates configured to have heating surface units for exchanging heat formed on one sides of the heat exchange plates and a plurality of passages and that are formed in between the plurality of heat exchange plates and wherein the plurality of passages comprise, first passages configured to convey a first fluid having a first temperature through the first passages, second passages configured to convey a second fluid through the second passages for transferring heat to the first fluid having the first temperature and third passages configured to prevent freezing in the second passages by transferring heat to at least some of the second passages when a temperature (T) of the second fluid is below a predetermined temperature value (Tref).

Owner:CORHEX CORP

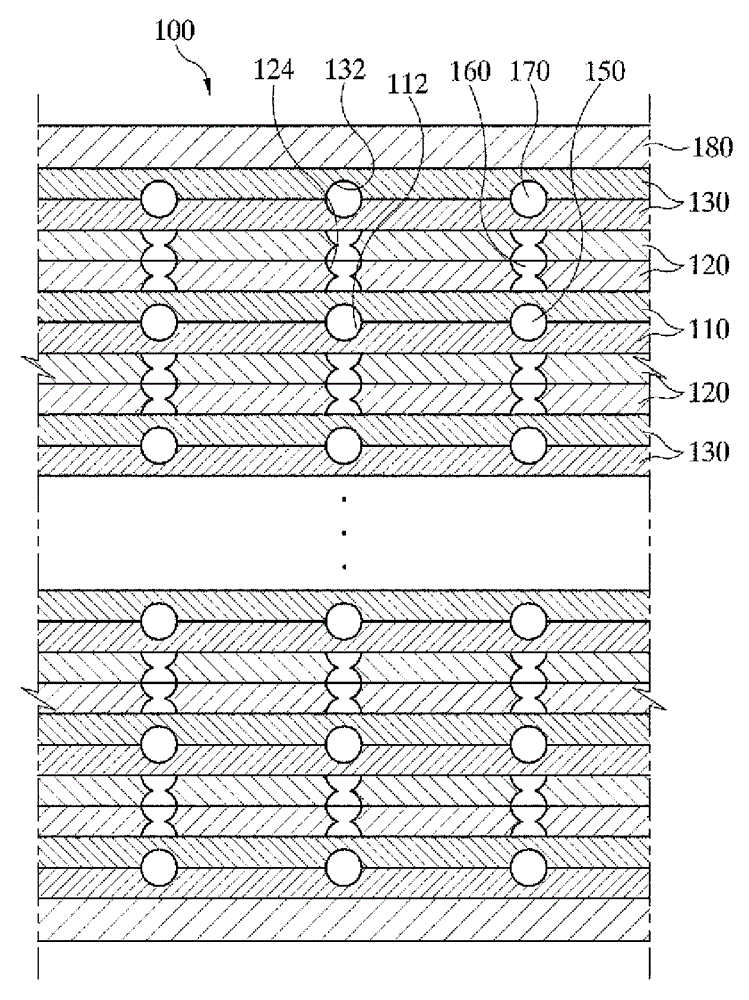

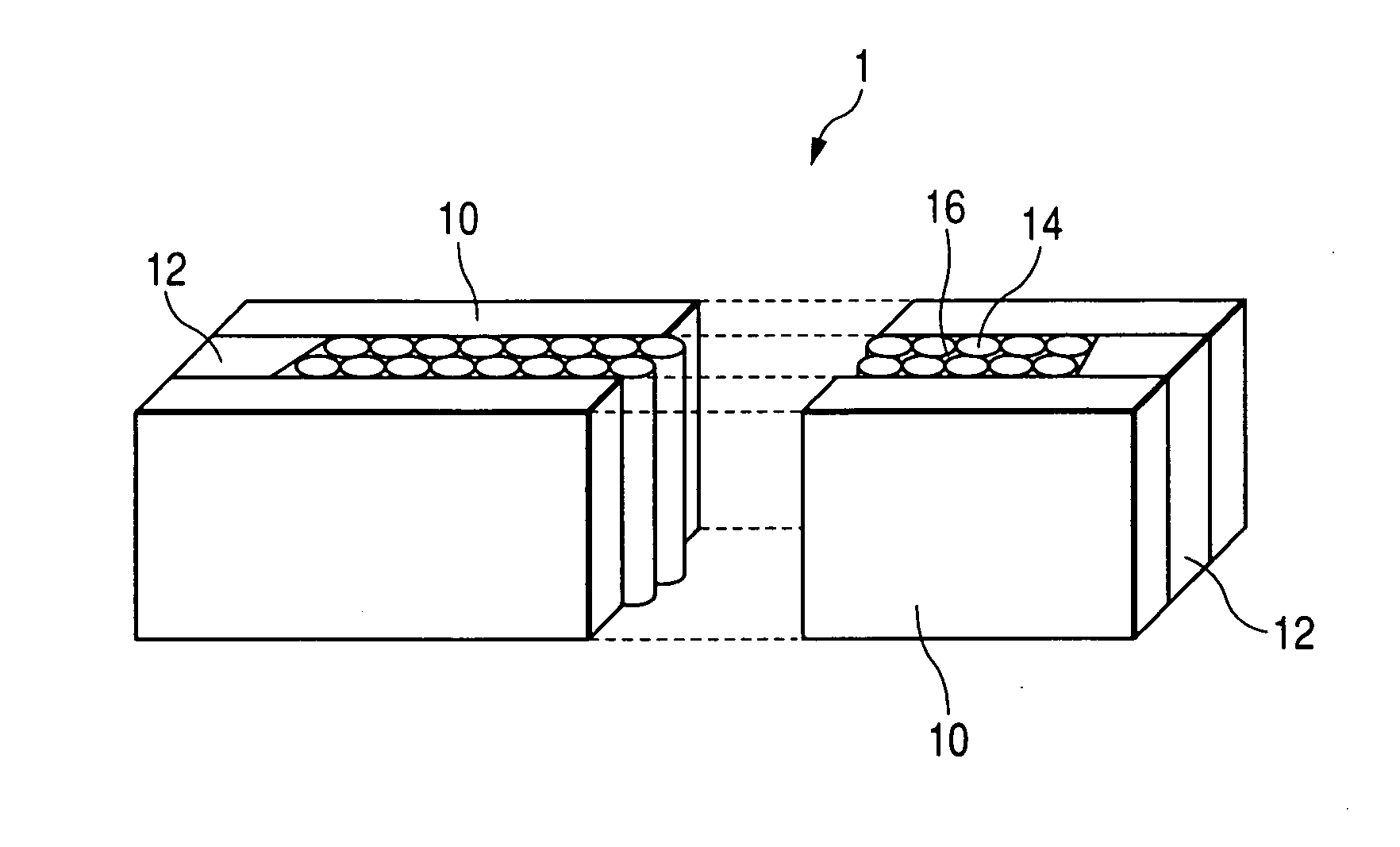

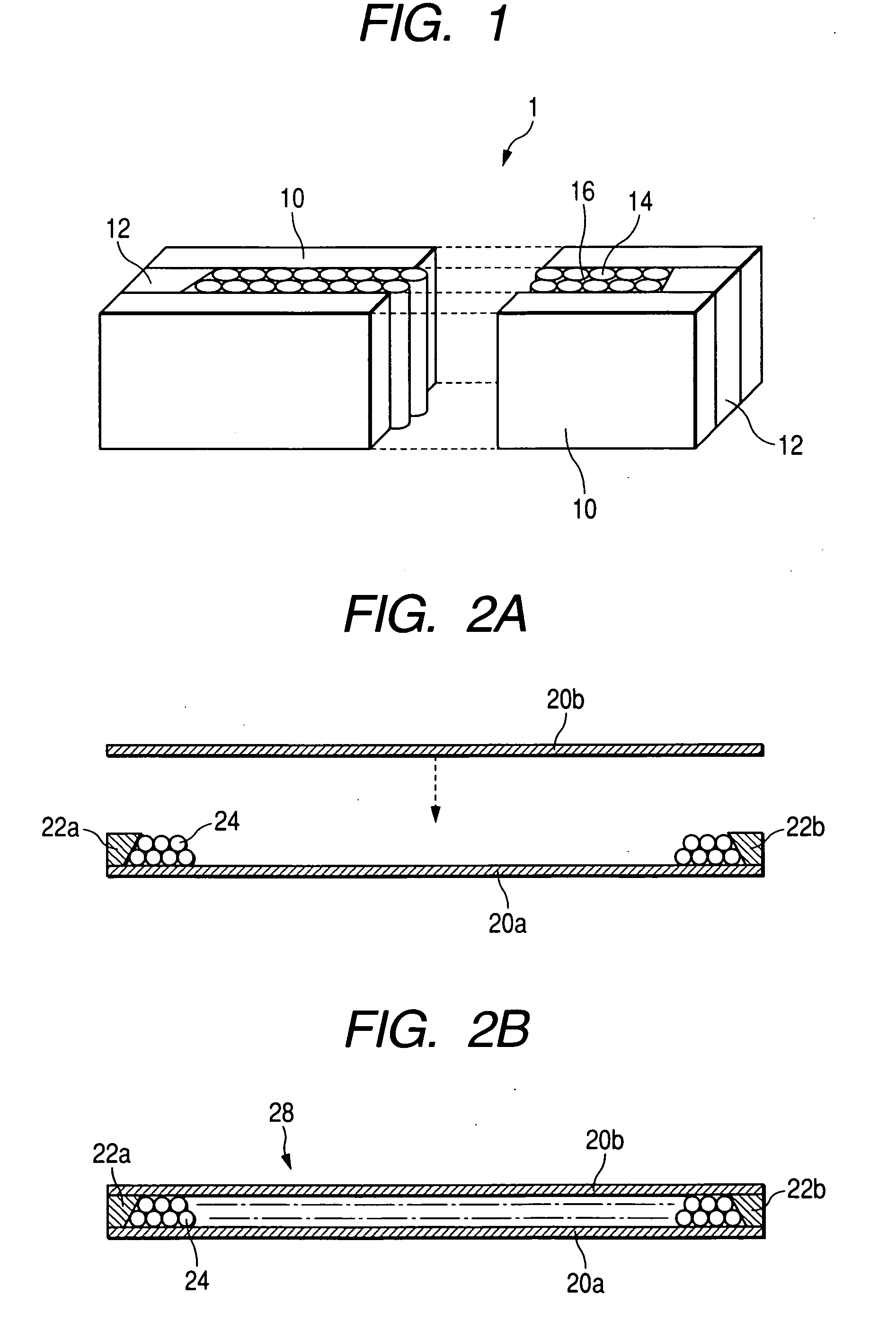

Rod lens array and method of manufacturing the same

In a rod lens array having a structure in which a plurality of rod lens elements are arranged between two side panels and a resin is filled and cured in spaces between the rod lens elements to be integrally formed, the side panels are made of a glass fiber reinforced epoxy resin and a phenol-based curing agent is used as a curing agent of the epoxy resin. In detail, the curing agent is exemplified by a phenol-based curing agent including a tris-hydroxyphenyl-methane skeleton.

Owner:NIPPON SHEET GLASS CO LTD

Groove machining apparatus for insulating spacer and groove machining method for the same

InactiveUS20130047815A1Reduce smoothnessImprove cloggingMilling cuttersInductances/transformers/magnets manufactureLeft directionHorizontal axis

A groove machining apparatus for an insulating spacer includes a cutting blade that is removably fixed to a rotation shaft rotatable around a horizontal axis and movable in a right-left direction and in an up-down direction and mounts for a cassette that are fixed in a loading / unloading position opposing an entrance through which the cassette can be loaded / unloaded and in a working position 180 degrees apart from the loading / unloading position and facing the cutting blade, respectively, on a rotary table. The apparatus includes positioning devices that are respectively located in the vicinity of the mounts to position and fix the cassette to the mounts, and a clamping device that corresponds to the cassette in the working position and presses opposing edges in a front-back direction of a plurality of insulating spacers aligned on the cassette.

Owner:IDEMITSU IND

Online blowing dust removal system and control method thereof

PendingCN111468402AIncrease dust removal intensityEffective dredgingSievingScreeningForeign matterThermodynamics

The invention discloses an online blowing dust removal system. The online blowing dust removal system comprises a foreign matter removal machine bin, a screen arranged above the foreign matter removalmachine bin and used for screening dust and blades, a dust removal device arranged above the screen and used for dust absorption, a movable blowing device used for blowing the screen downwards, an adjusting device used for adjusting the dust absorption strength of the dust removal device, a detection device used for detecting the inner pressure of the foreign matter removal machine bin and a control device. The blowing device, the detection device and the adjusting device are connected with the control device. The control device is used for receiving pressure signals of the detection device,used for controlling adjusting operation of the adjusting device and used for controlling moving and blowing of the blowing device. By means of the system, the phenomenon that the dust removal screenis blocked can be effectively reduced, the device dust removal effect can be improved, the impurity removal effect of the foreign matter removal machine bin can be improved, and the online blowing dust removal system is simple in device structure and convenient to use and can be used and popularized; and in addition, the invention provides a control method applied to the above online blowing dustremoval system.

Owner:JILIN TOBACCO IND

Method for reversing gas humidity on surface of rock core by using cationic fluorocarbon surfactant

The invention relates to a method for reversing gas humidity on the surface of a rock core by using cationic fluorocarbon surfactant. The humidity reserving treatment agent used by the method contains the cationic fluorocarbon surfactant, a quaternary ammonium salt surfactant and a polar fluid, preferably FC911, hexadecyl trimethyl ammonium bromide and water. The invention also provides a method for reversing the humidity on the surface of sandstone into gas humidity, which comprises: pumping a humidity reversing treatment agent which contains 0.1 to 1 weight percent of cationic fluorocarbon surfactant into a rock stratum of a gas oil well till the entire surface of the sandstone in the rock stratum is immersed in the humidity reversing treatment agent; and thus, realizing the reversion into the gas humidity on the surface of the rock core. The method can effectively reserve the liquid humidity on the surface of the sandstone into gas humidity. The method is simple, convenient and easy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

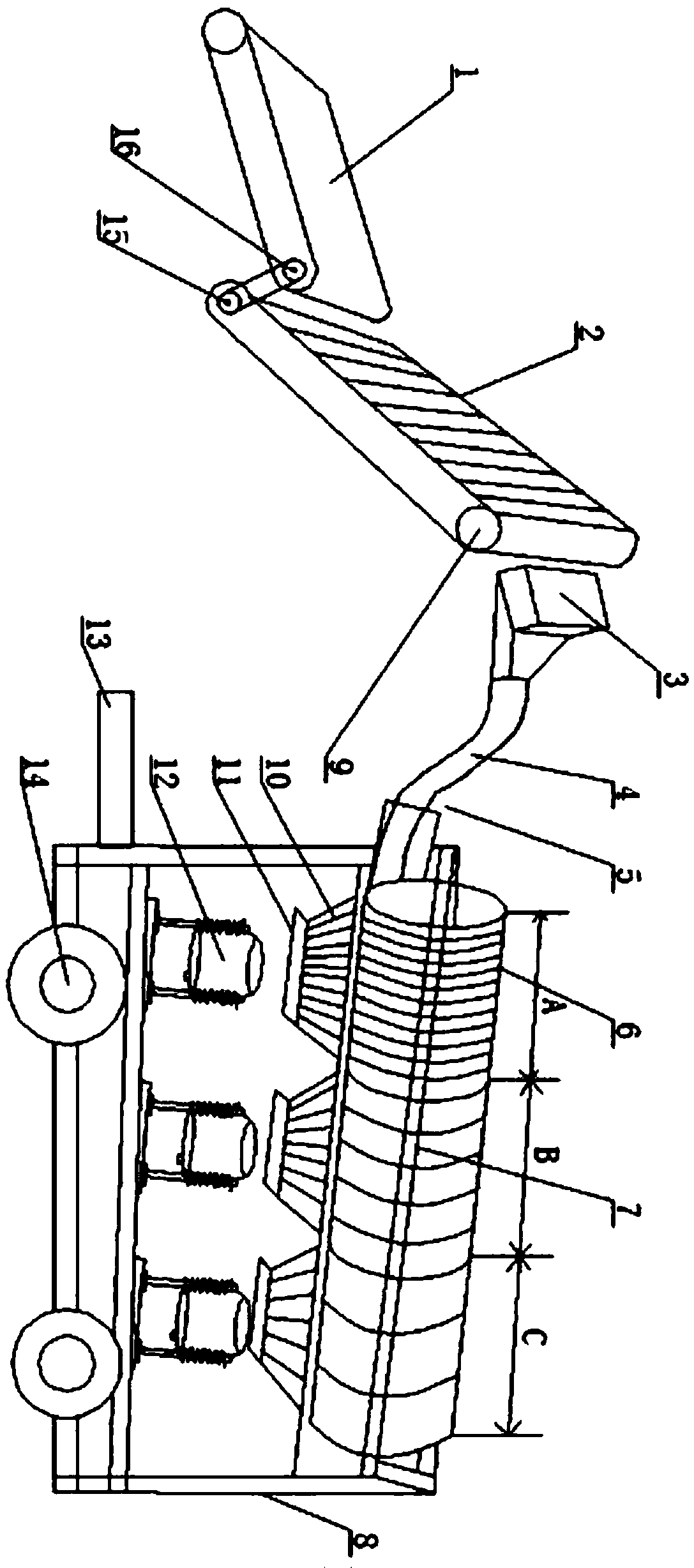

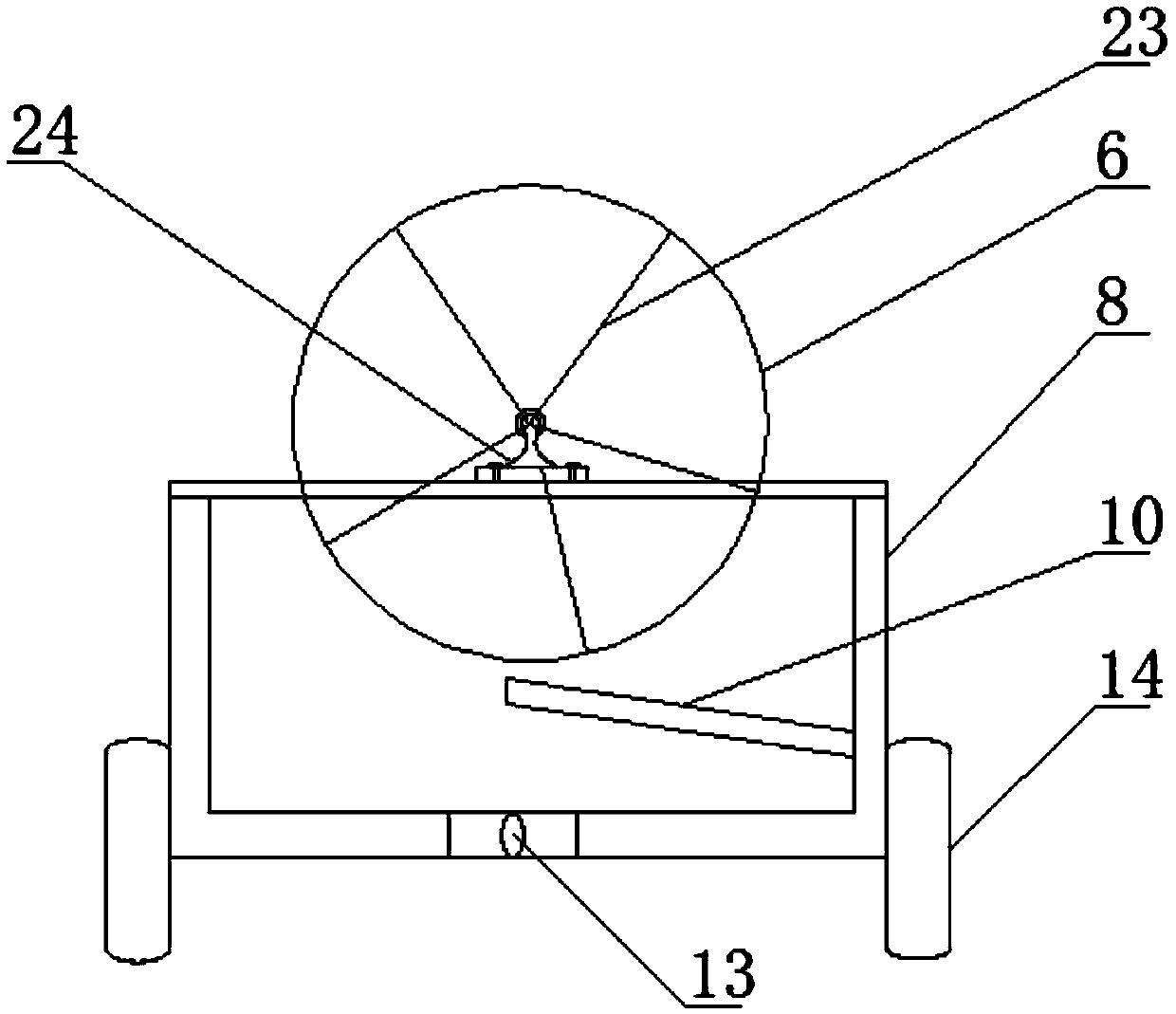

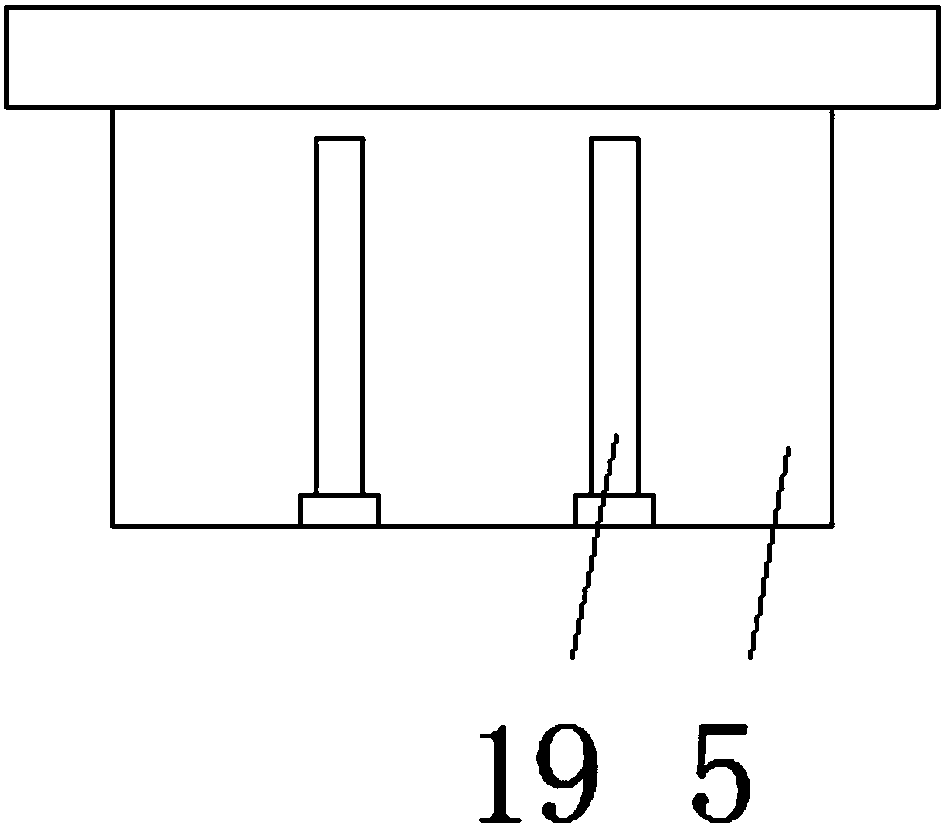

Potato classifying and bagging device

ActiveCN105363679AEasy to separateFunction increasePackaging fruits/vegetablesGradingEngineeringHollow cylinder

The invention discloses a potato classifying and bagging device. A rolling classifying screen is of a hollow cylinder structure formed by connecting annular classifying bars, the classifying bars are sequentially provided with a classifying area A, a classifying area B and a classifying area C from left to right in the order from small density to large density, and a fixed feed port is formed in higher end of the rolling classifying screen fixed to a machine frame. A lifting device is provided with an inclined transmitting scraper plate, a fixed receiving hopper is arranged at the upper end of the inclined transmitting scraper plate, the lower end of the fixed receiving hopper is connected with a receiving hose, and the receiving hose is communicated into the fixed feed port. A dropping hopper is arranged below the rolling classifying screen, and a receiving device is arranged below the end of the dropping hopper. The potato classifying and bagging device can convey, lift and automatically collect potatoes and separate the potatoes and soil, the rolling classifying screen is reliable in structure, practical and easy to operate, the potatoes and the soil can be fast separated, and the production efficiency is high.

Owner:侯文会

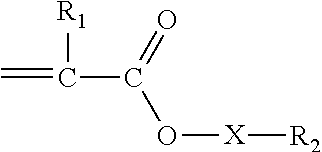

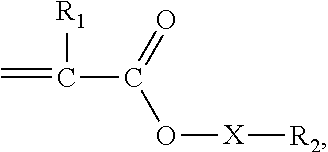

Aqueous emulsion paint with improved stain removal and anticlogging properties

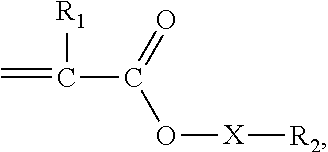

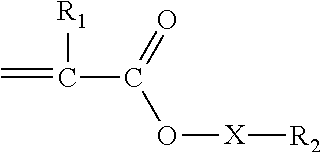

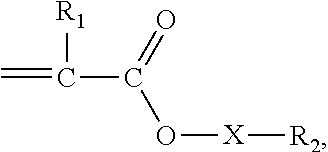

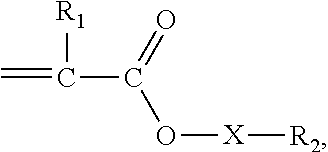

ActiveUS20170335116A1Obviates abilityImprove decontamination abilityEmulsion paintsPhosphateMethyl group

The present invention provides an aqueous composition for coating substrates comprising: one or more emulsion copolymer, the emulsion copolymer being a copolymerization product of a monomer mixture comprising a monomer of formula I,wherein R1 is hydrogen or methyl, X is a divalent organic alkylene oxide group, n is an integer ranging from 1 to 50 and R2 is hydrogen or an alphatic or aromatic hydrocarbon group having from 1 to 20 carbon atoms, and a phosphate surfactant. When incoroporated into a coating composition, the coating composition show both improved stain-resistance properties and anti-clogging properties.

Owner:DOW GLOBAL TECH LLC +1

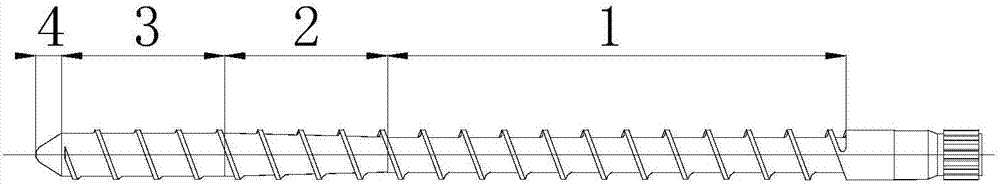

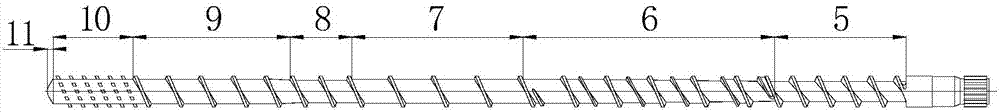

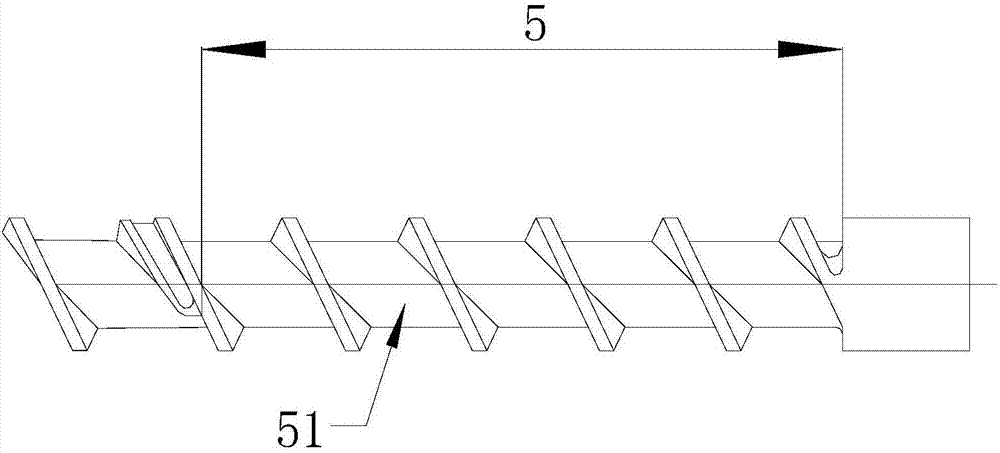

Special extrusion screw for polyethylene of raised temperature resistance and extrusion method of special extrusion screw

The invention discloses a special extrusion screw for polyethylene of raised temperature resistance (PE-RT) and an extrusion method of the special extrusion screw. The special extrusion screw comprises a feeding segment, a compression segment, a first metering segment, a pressure reducing segment, a second metering segment, a mixing segment and a screw head which are connected in sequence, wherein the feeding segment, the pressure reducing segment, the first metering segment and the second metering segment all adopt single-start thread structures; the compression segment adopts a double-start thread structure consisting of a main thread and an auxiliary thread; the auxiliary thread and the main thread intersect at one side of the feeding segment and do not intersect at one side of the first metering segment; and the mixing segment adopts a trapezoidal structure. The special extrusion screw for PE-RT is simple in structure, convenient to use, high in fusing efficiency, uniform in plasticization, high in conveying capability and high and stable in yield at a high rotational speed.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method for ultrathin glass

A manufacturing method for ultrathin glass includes the following steps: providing at least one glass; fixing the glass in an upright standing state; atomizing an etching solution to obtain an atomized etching solution; and conveying the atomized etching solution to at least one nozzle of at least one liquid guiding tube through the at least one liquid guiding tube, and sprinkling the atomized etching solution onto the surface of the glass through the at least one nozzle. The flat ultrathin glass can be manufactured through the method.

Owner:梁泽超

Agricultural spraying device and using method thereof

InactiveCN108925528AWide applicabilityIncreased versatilityInsect catchers and killersAgricultural engineeringWater pipe

The invention discloses an agricultural spraying device and a using method thereof. The device comprises a supporting floor; a tool box body, a water pump and a water collecting tank body are fixed onthe supporting floor, the water collecting tank body and the water pump are connected through a guide pipe, one side of the water collecting tank body is connected with a pesticide inlet pipe, and atop cover is installed on the top end of the water collecting tank body; a connecting member is fixed on the top cover, a filter tank is installed on the connecting member, and the top end of the filter tank is connected with a water inlet pipe; and the water pump is connected with a spray rod, the spray rod is connected with a water conveying pipe, and the water conveying pipe is connected with spray heads. According to the device disclosed by the invention, water in the water collecting tank body is uniformly sprayed out from the four spray heads arranged on the water conveying pipe by the water pump, and the spraying area is wider, so that the applicability of the spraying device is wider; and a moderate amount of pesticide liquid is conveyed to the water collecting tank body through the pesticide inlet pipe, a stirring handle is held by hands, so that the water and the pesticide liquid are fully and uniformly shaken and mixed by a stirrer, and pesticide spraying to crops is realized.

Owner:新昌县富侨农业有限公司

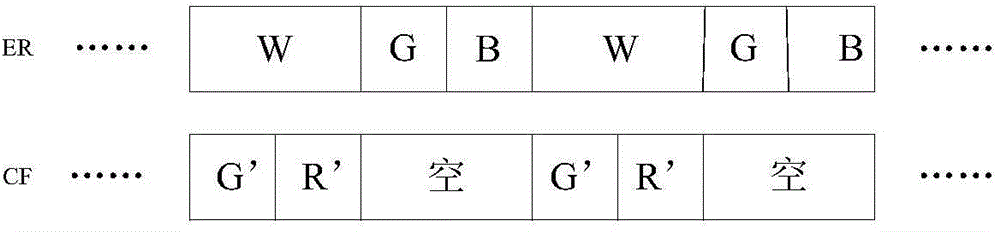

OLED display panel and manufacturing method thereof, and OLED display apparatus

ActiveCN104900679AReduce line defectsReduce color mixingSolid-state devicesSemiconductor/solid-state device manufacturingEconomic benefitsEvaporation

The invention provides an OLED display panel and a manufacturing method thereof, and an OLED display apparatus. The OLED display panel comprises a light-emitting layer containing white sub pixels and colorful sub pixels; and the dimension of one white sub pixel is equal to the sum of dimensions of at least two colorful sub pixels and the number of the colorful sub pixels is less than the number of primary colors forming colors. Besides, the OLED display panel also includes a color membrane containing colorful stop blocks matching the colorful sub pixels; and the colorful stop blocks are arranged at one side, facing the display side, of the light-emitting layer and are located at positions corresponding to the location of the white sub pixels. With the OLED display panel, the qualities of the OLED display panel and the display apparatus can be improved; and one mask and evaporation process can be reduced, thereby improving the production efficiency. Therefore, the economic benefits are increased.

Owner:BOE TECH GRP CO LTD +1

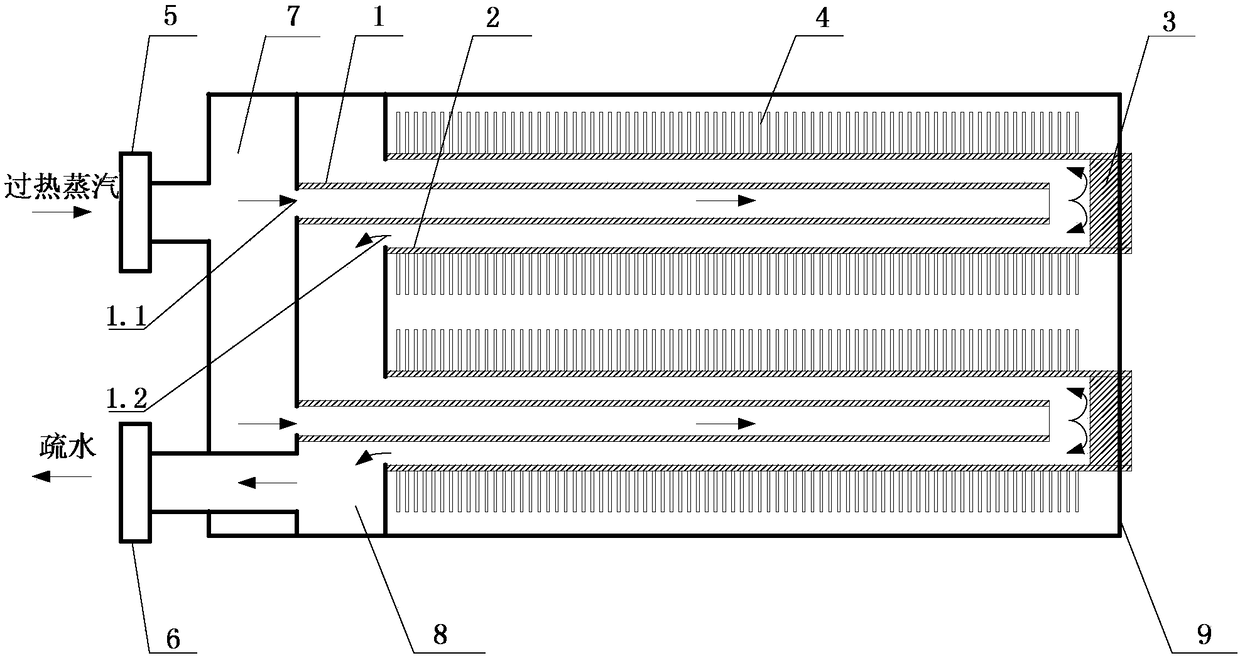

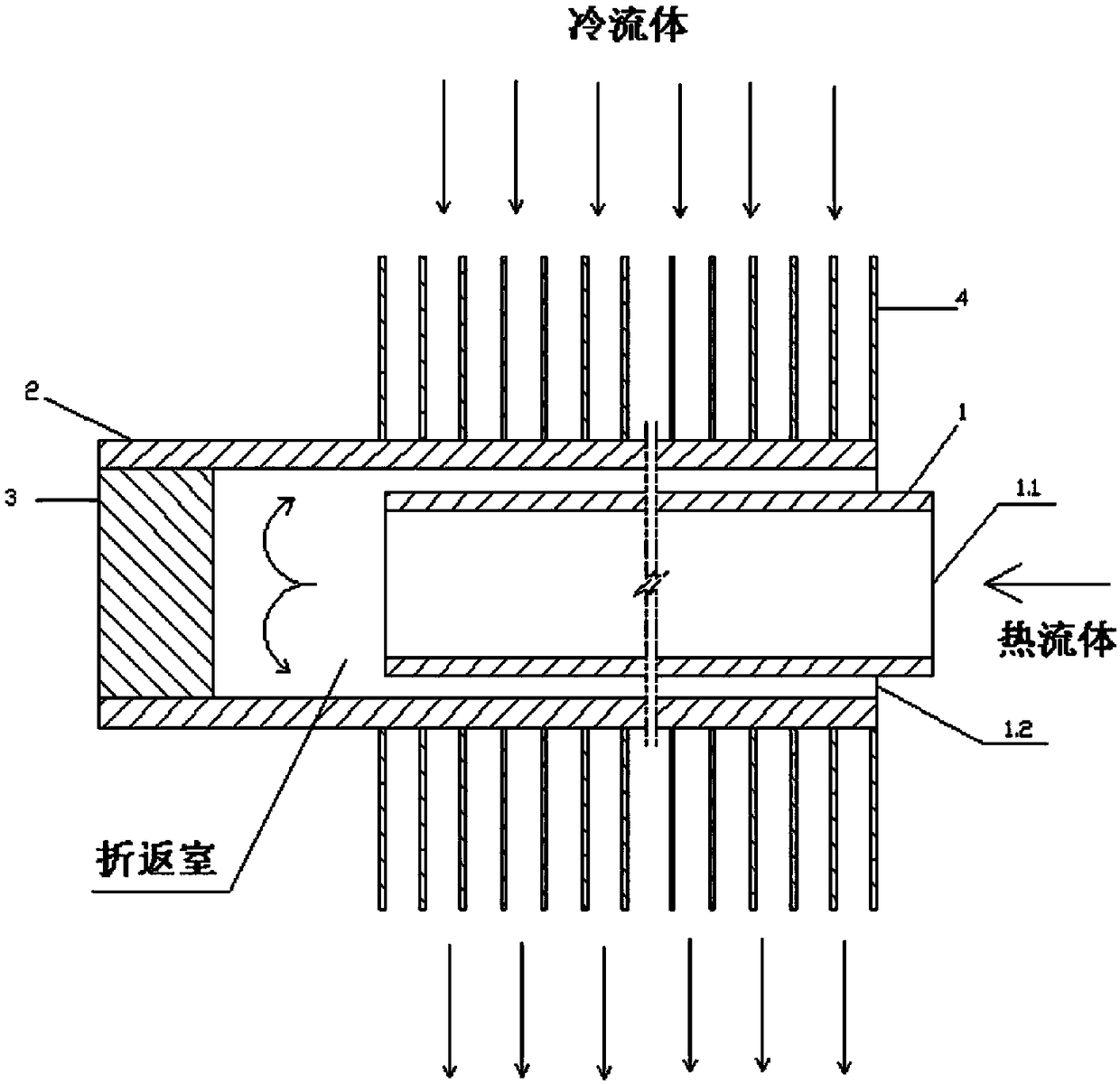

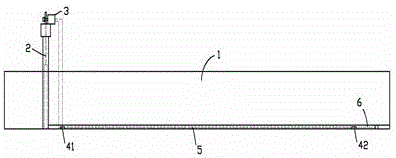

Efficient casing pipe type air heater device

InactiveCN108167857ANo washout leaksImprove cloggingCombustion processIndirect carbon-dioxide mitigationEngineeringAir heater

The invention relates to an efficient casing pipe type air heater device. The device is provided with a steam header (7) on the upper portion of one end in an outer frame (9); one end of the steam header (7) is connected with a steam inflow pipe (5); the other end of the steam header (7) is connected with an inner pipe (1); the exterior of the inner pipe (1) is sleeved with an outer pipe (2); oneend of the outer pipe (2) is closed by an outer pipe plug (3); fins (4) are wound on the outer wall of the outer pipe (2) to form a fin pipe: the lower portion of one end in the outer frame (9) is provided with a hydrophobic header (8); one end of the hydrophobic header (8) is connected with a hydrophobic pipe (6); and the other end of the hydrophobic header (8) is connected with an outer pipe (2). A coaxial type structure is adopted for the device, and fluid enters from the inner pope, returns through a folding back chamber, and returns through a sandwich layer channel between the outer pipeand the inner pipe. The temperature distribution of the outer wall of a whole casing pipe tends to be uniform in the pipe length direction, and the phenomena of hot expanding leakage, bend brushing leakage and outlet hydrophobic icing and the like can be well avoided. The efficient casing pipe type air heater device has the beneficial effects of being compact in structure, easy to machine, low incost, long in service life and the like.

Owner:SOUTHEAST UNIV

Automatic dredging sewage discharge ditch

ActiveCN105839596AReduce maintenance costsEasy to dredgeArtificial water canalsMotor controllerPressure difference

The invention provides an automatic dredging sewage discharge ditch. The automatic dredging sewage discharge ditch comprises a ditch body and an electric gate which is disposed at the head end of the ditch body. The electric gate is driven through a servo motor; a head end hydraulic pressure gauge is disposed at the bottom, on the rear side of the electric gate, of the ditch body, and a tail end hydraulic pressure gauge is disposed at the bottom of the tail end of the ditch body; the head end hydraulic pressure gauge and the tail end hydraulic pressure gauge are together coupled to a motor controller; and the motor controller controls the servo motor according to hydraulic pressure data which are sensed through the head end hydraulic pressure gauge and the tail end hydraulic pressure gauge. Specifically, when the situation that the pressure difference of the head end hydraulic pressure gauge and the tail end hydraulic pressure gauge is larger than a first set value occurs and the duration of the situation is longer than set time, the electric gate is closed; and when the pressure of the head end hydraulic pressure gauge and the pressure of the tail end hydraulic pressure gauge are smaller than a second set value, the electric gate is opened. The automatic dredging sewage discharge ditch can automatically detect whether the ditch is blocked or not and automatically perform cleaning to eliminate the blocking phenomenon so that the maintaining cost of the sewage discharge ditch can be greatly reduced.

Owner:JIANGSU HAIRONG THERMAL ANDENVIRONMENTAL ENG CO LTD

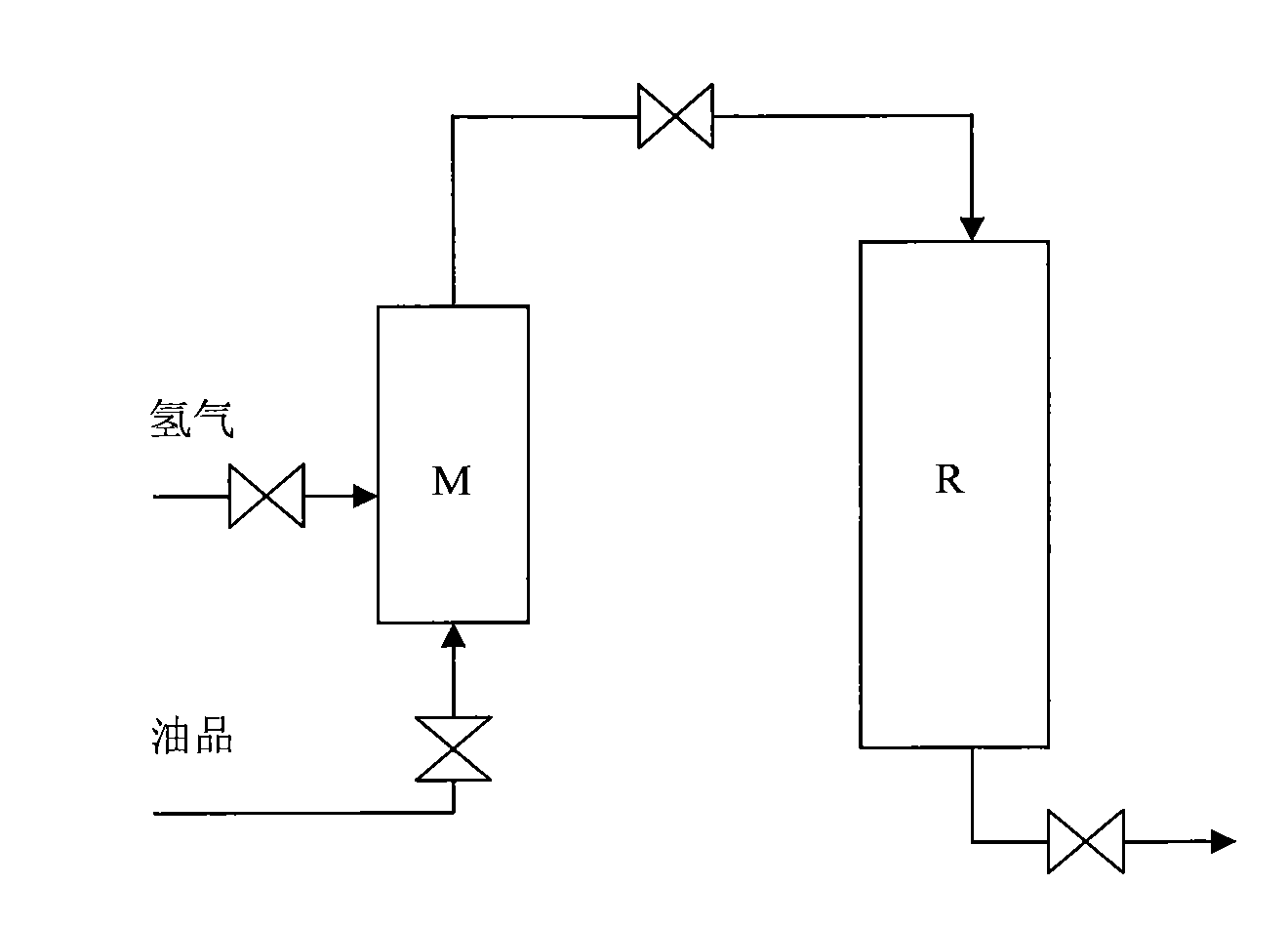

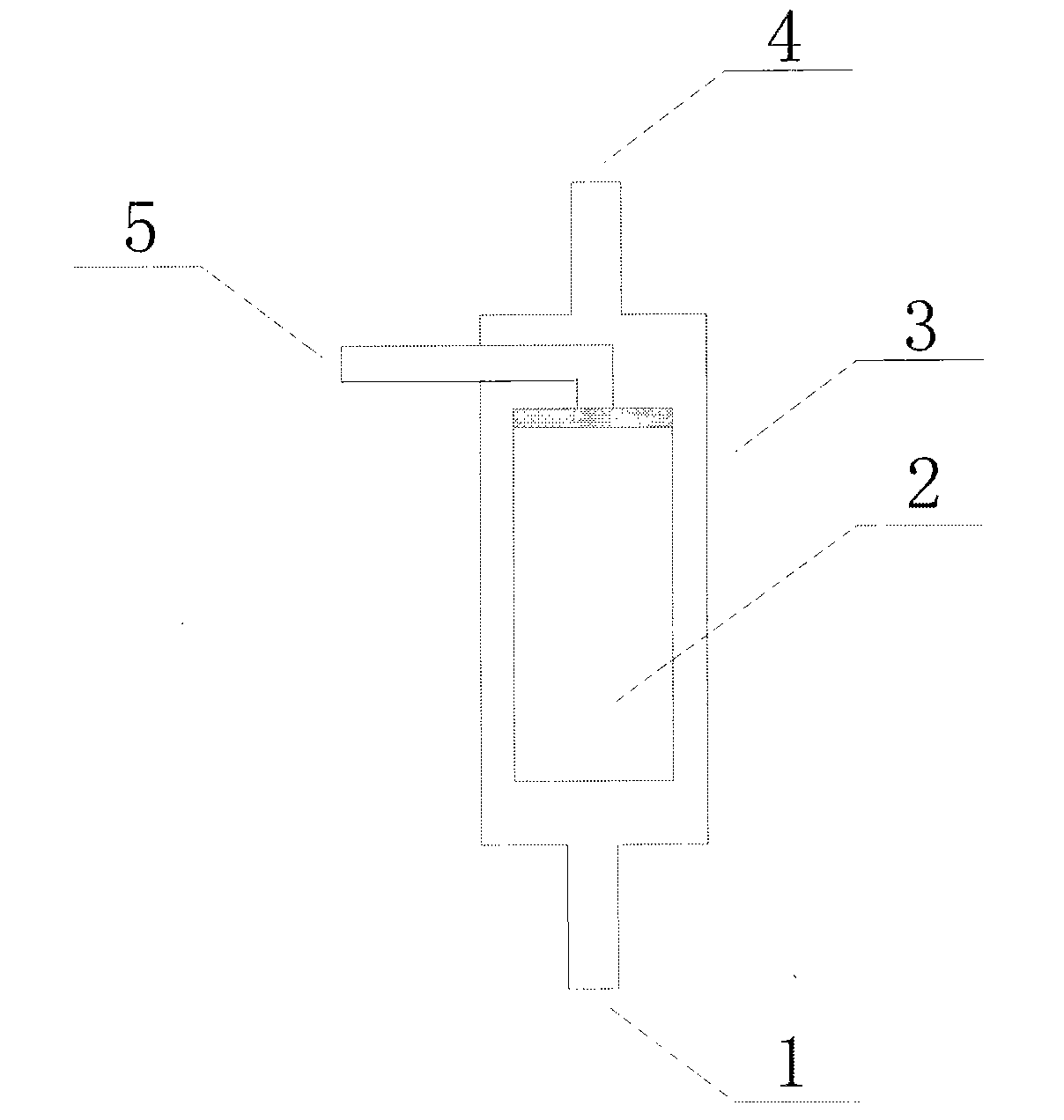

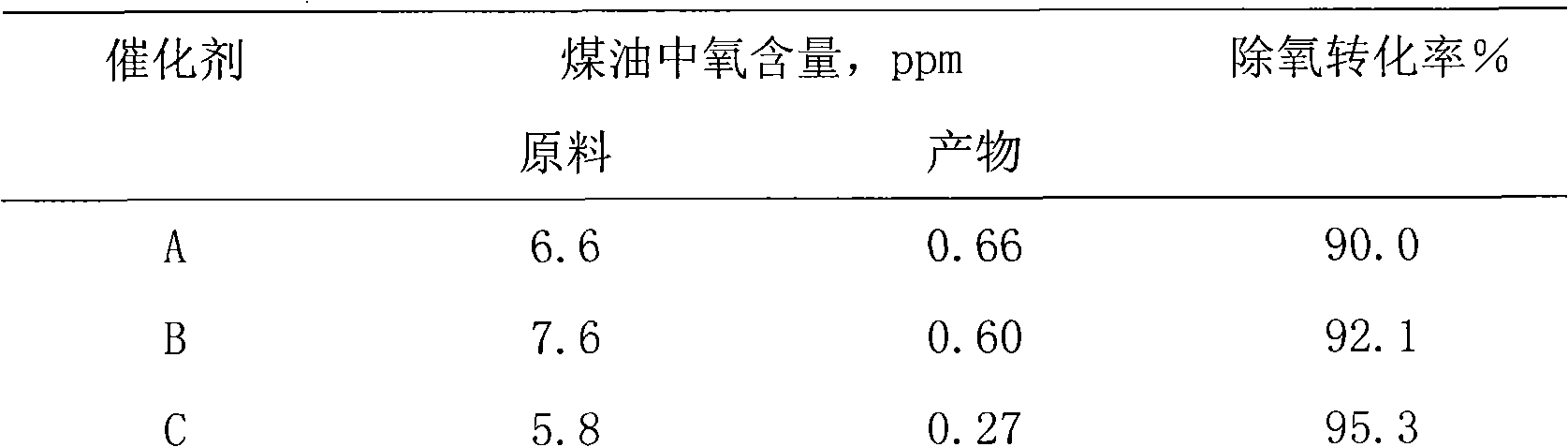

Deoxidation catalyst for oil product, preparation method thereof and catalytic hydrogenation method for removing dissolved oxygen in oil product by adopting catalyst

ActiveCN101612569AHigh strengthGood oxygen removal stabilityCatalyst activation/preparationHydrocarbon oils refiningHydrogenation reactionOxygen

The invention relates to a deoxidation catalyst for an oil product, a preparation method thereof and a catalytic hydrogenation method for removing dissolved oxygen in the oil product by adopting the catalyst. The deoxidation catalyst for the oil product takes gamma-alumina which has the specific surface area of between 50 and 300m<2> / g and the pore volume of between 0.2 and 2.0cm<3> / g as a carrier, palladium supported on the carrier as a main catalytic element, and one of silver, tin and lead as a co-catalytic element; and the preparation method thereof comprises two steps of the preparation of the alumina carrier and the preparation of the catalyst. The catalytic hydrogenation method for removing the dissolved oxygen in the oil product by adopting the catalyst comprises the following steps that: the oil product is fully mixed with hydrogen before the oil product enters a hydrogenation reactor; and then the mixed oil product enters the reactor and is contacted with the deoxidation catalyst. The catalyst has high strength and good deoxidation stability, can still have higher activity under lower temperature and pressure, can keep higher reaction activity for a long time, and ensure that the removal rate of trace oxygen in the oil product can reach over 90 percent.

Owner:CHINA PETROCHEMICAL CORP

Method for producing hydrogen peroxide

InactiveCN106458584AAvoid cloggingIncrease pressure dropPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesParticulatesHydrogen

The invention relates to a method for producing hydrogen peroxide by converting hydrogen and oxygen in the presence of a liquid reaction medium and a particulate noble metal support catalyst in a fixed-bed reactor, wherein the liquid reaction medium and a gas phase containing hydrogen and oxygen flow against the fixed bed from below. The fixed bed is arranged in the reactor such that the volume of the fixed bed expands by 1 to 10% in the operating state relative to a rest state without a flow against the fixed bed. As a result of the fixed bed expansion according to the invention, the fixed bed can be prevented from clogging due to abrasions on the catalyst.

Owner:EVONIK DEGUSSA GMBH

Fixed grate incinerator

InactiveCN104296148BAvoid subsequent continuous thermal expansion until it becomes soft and stuck.With self-cooling functionIncinerator apparatusCombustion chamberSlag

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate incinerator comprising a main combustion chamber and a fixed fire grate. The fixed fire grate is arranged obliquely, the higher end is provide with a material input end, the lower end is provided a slag outlet for slags after material combustion, and the slag outlet is communicated with a slag discharging component; a hot air chamber is arranged below the main combustion chamber; a hot air supply path penetrates the fixed fire grate; the fixed grate incinerator further comprises an ejecting rod and a power portion; the maximum lift of the ejecting rod penetrates the material layer of the fixed fire grate; an ejecting rod component further comprises a shaft sleeve with the preset length, one end of the shaft sleeve penetrates and is fixedly connected to the fixed fire grate along the moving direction of the ejecting rod, a vent gap allowing the air to penetrate is formed between the shaft sleeve and the ejecting rod, and the other end of the shaft sleeve is communicated with the outside and / or an air cooling chamber. The fixed grate incinerator has the advantages that material burning efficiency is high, the component operation reliability is high, and the service life is prolonged effectively.

Owner:安徽盛燃焚烧炉科技有限公司

Air dust remover without filter core of internal-combustion engine

InactiveCN1598283AImprove intake air qualityEnsure intake air qualityCombustion-air/fuel-air treatmentMachines/enginesAir filterCentrifugal force

The invention discloses a gas engine air dust catcher without filter core, the product is a dry type and direct discharging air dust catcher, the principle is; it uses the strong air flow generated when the air flows, through the separation to the air, the particle dust in the air is discharged through the eccentric force, at the same time, it uses speed adjustable dust discharging fan to increase a transverse dust eliminating force at the side surface, and the tiny dust in the air is cleaned out. The invention can be used matching with the gas engine directly; it also can be used matching with the air filter, in order to upgrade the air quality further. The advantages are economic, high dust eliminating effect, long service life and low cost.

Owner:唐开太

Printer, Printing program, and printing method

InactiveUS20080259368A1Easy to createUniform frequencyDigitally marking record carriersDigital computer detailsData selectionEngineering

A printer includes a print head in which nozzles that form an image by discharging ink are arranged in a plurality of lines. The printer prints out an image on the basis of print form data in which information of layout contents of printing elements that form the content of print is set according to the attribute of each printing element. The printer includes a print form data storage unit, a printing element data storage unit, a print form data selection unit, a printing element data selection unit, and a printing element data insertion unit. The print form data selection unit selects a piece of print form data, which is used for printing, from multiple pieces of print form data stored in the print form data storage unit in a specific sequence that is set so that, when the printing is continuously performed, the frequencies of use of the nozzles of the print head are uniform and are equal to or higher than a predetermined frequency.

Owner:SEIKO EPSON CORP

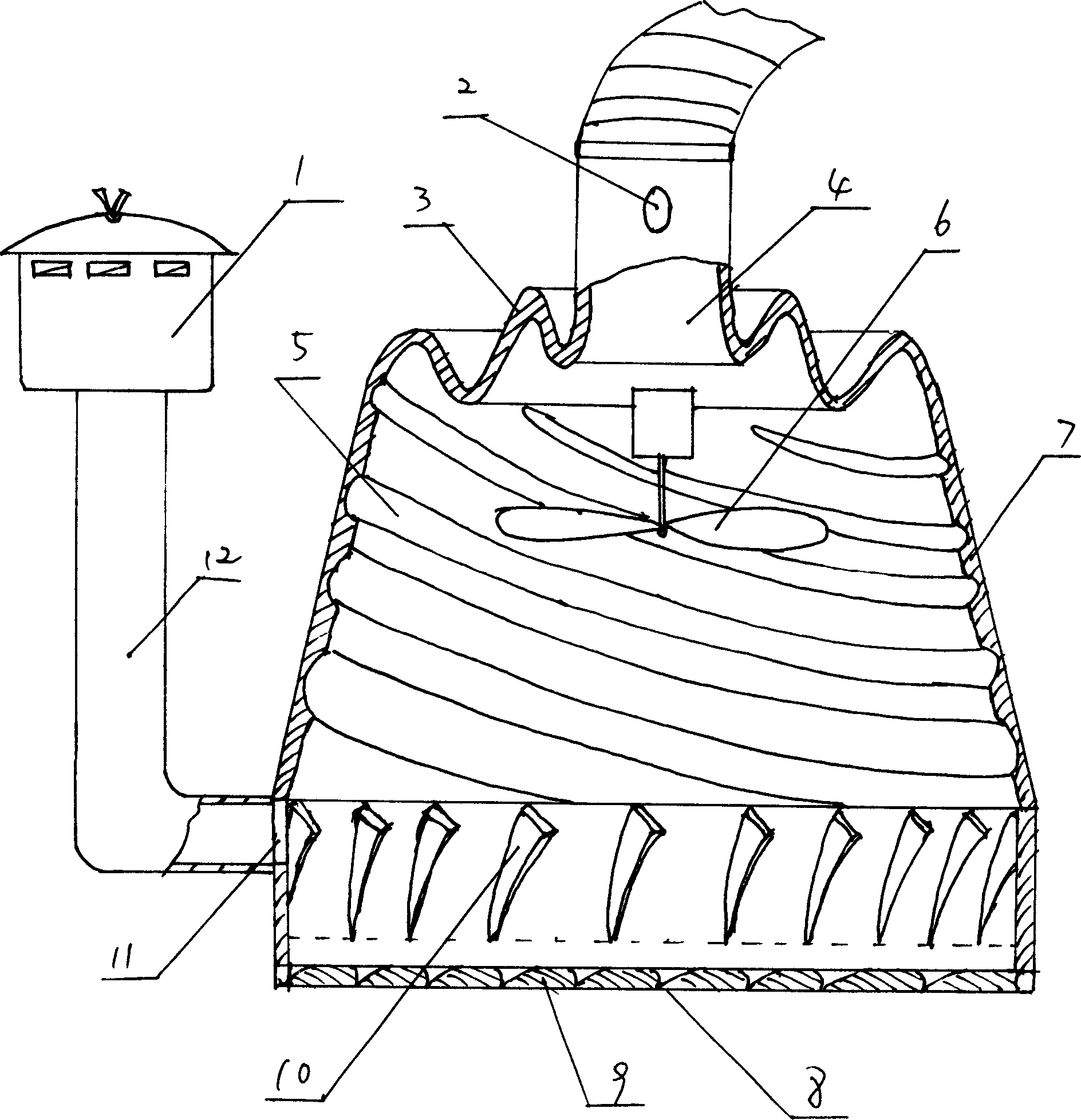

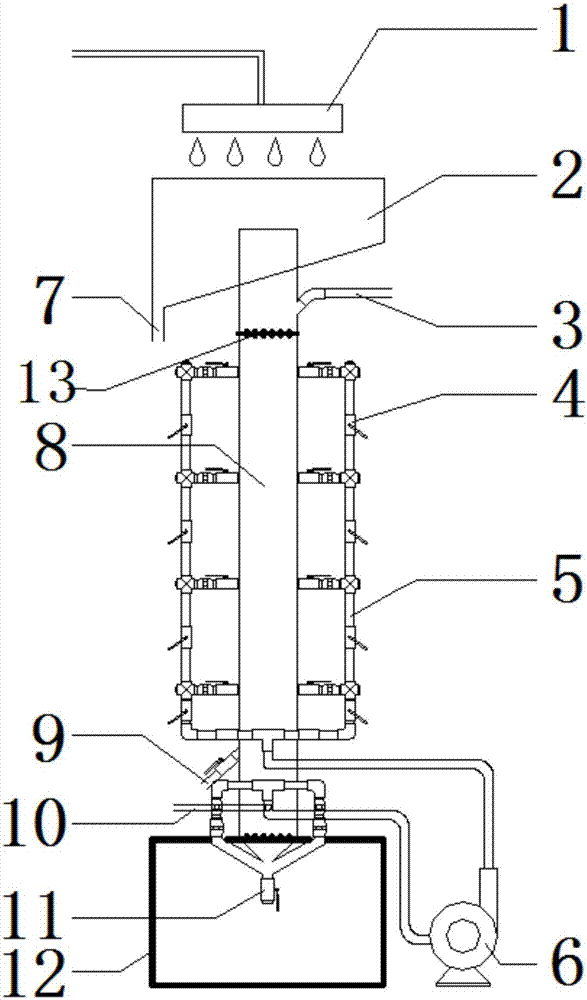

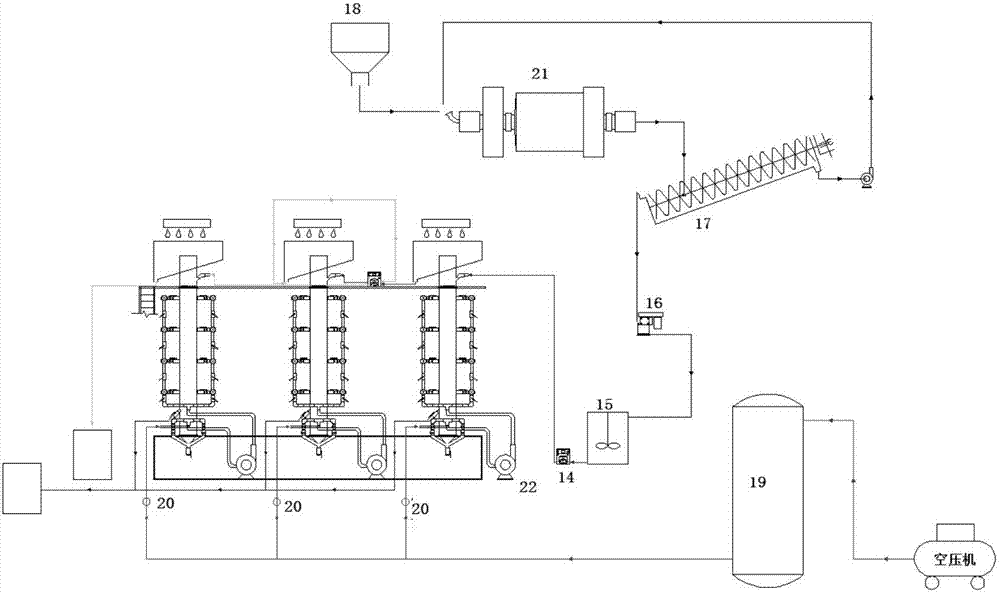

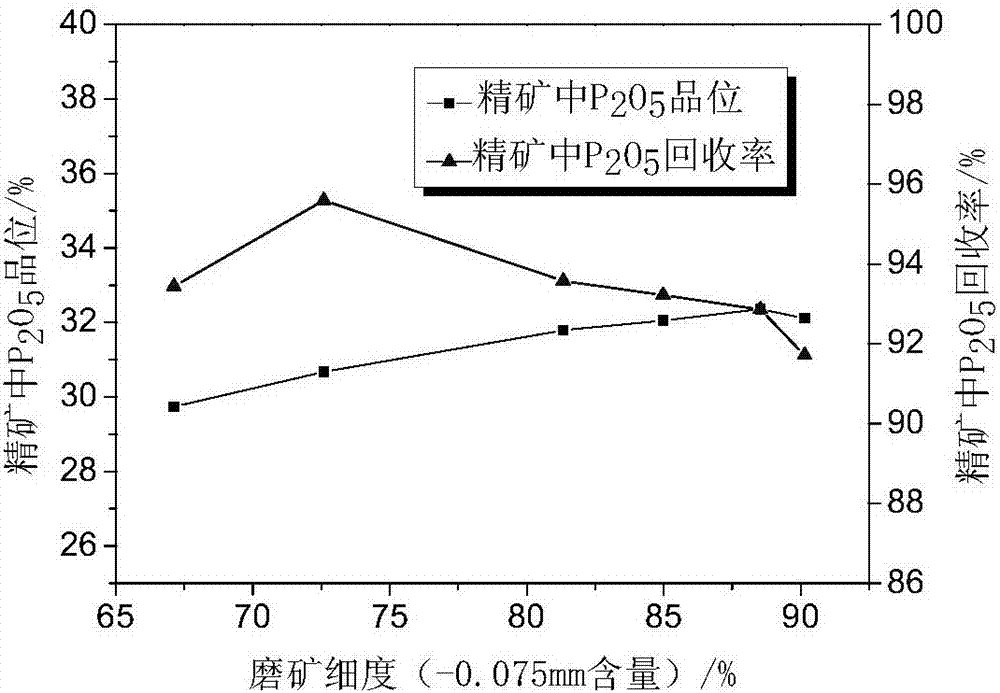

Floatation method and device for coarse-particle floatation column

The invention discloses a floatation method and device for a coarse-particle floatation column. When the coarse-particle floatation column works, pulp is led in the column from a feeding pipe which is located at the inlet of a column body, and declines gradually along the whole fracture section of the column body, and compressed air with certain pressure is inflated in the column through an air inflation device located on the lower portion of the column body; a large amount of tiny bubbles gradually rise along the whole fracture section of the column body, the pulp and the bubbles form convective motions, and mineral particles and the bubbles make contact with each other sufficiently; by symmetrically arranging cyclic pipelines on the two sides of the column body, the cyclic pipelines communicate with the air inflation device located at the bottom, by opening valves of a certain section of or several sections of cyclic pipelines, with assistance of floatation of the bubbles, floatable coarse particles attached to the bubbles can be conveyed to certain height through the pressure generated by a cyclic pump, and the coarse particles are carried by the bubbles to float to the surface of the pulp and form a foam layer, and the coarse particles automatically spill over as concentrates. Gangue minerals which cannot float falls in the lower portion of the column body, are collected by a cone body part, and then are discharged from a tailing pipe. The floatation device is simple in structure, obvious in effect and high in practicability.

Owner:GUIZHOU UNIV

Aqueous emulsion paint with improved stain removal and anticlogging properties

ActiveUS10800927B2Obviates abilityImprove decontamination abilityEmulsion paintsPolymer scienceActive agent

The present invention provides an aqueous composition for coating substrates comprising: one or more emulsion copolymer, the emulsion copolymer being a copolymerization product of a monomer mixture comprising a monomer of formula I,wherein R1 is hydrogen or methyl, X is a divalent organic alkylene oxide group, n is an integer ranging from 1 to 50 and R2 is hydrogen or an aliphatic or aromatic hydrocarbon group having from 1 to 20 carbon atoms, and a phosphate surfactant. When incorporated into a coating composition, the coating composition show both improved stain-resistance properties and anti-clogging properties.

Owner:DOW GLOBAL TECH LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com