Air dust remover without filter core of internal-combustion engine

A technology of dust collector and internal combustion engine, which is applied in the direction of combustion air/combustion-air treatment, machine/engine, mechanical equipment, etc. It can solve the problems of increased wear of internal parts, increased fuel consumption, increased exhaust gas pollution, etc., to ensure air intake Quality, prolong service life, improve the effect of intake air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

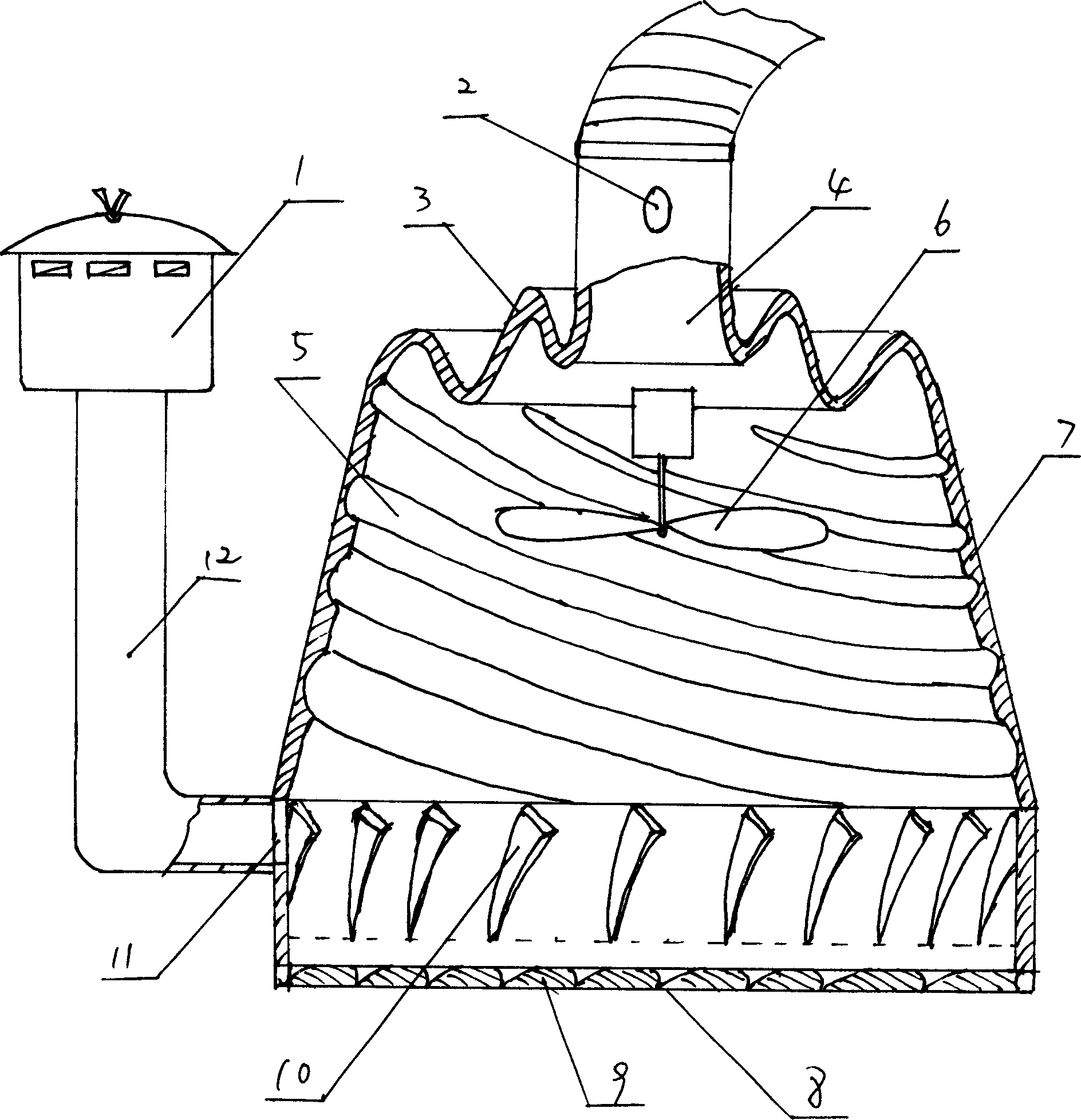

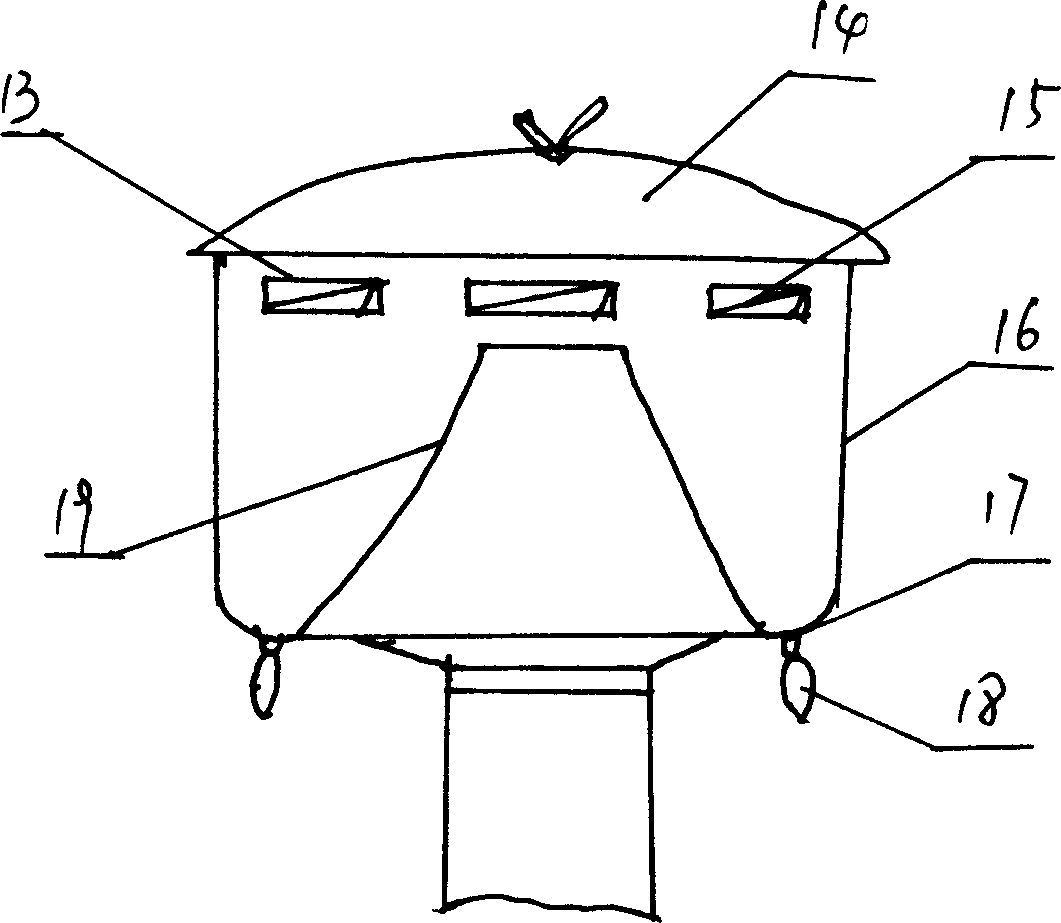

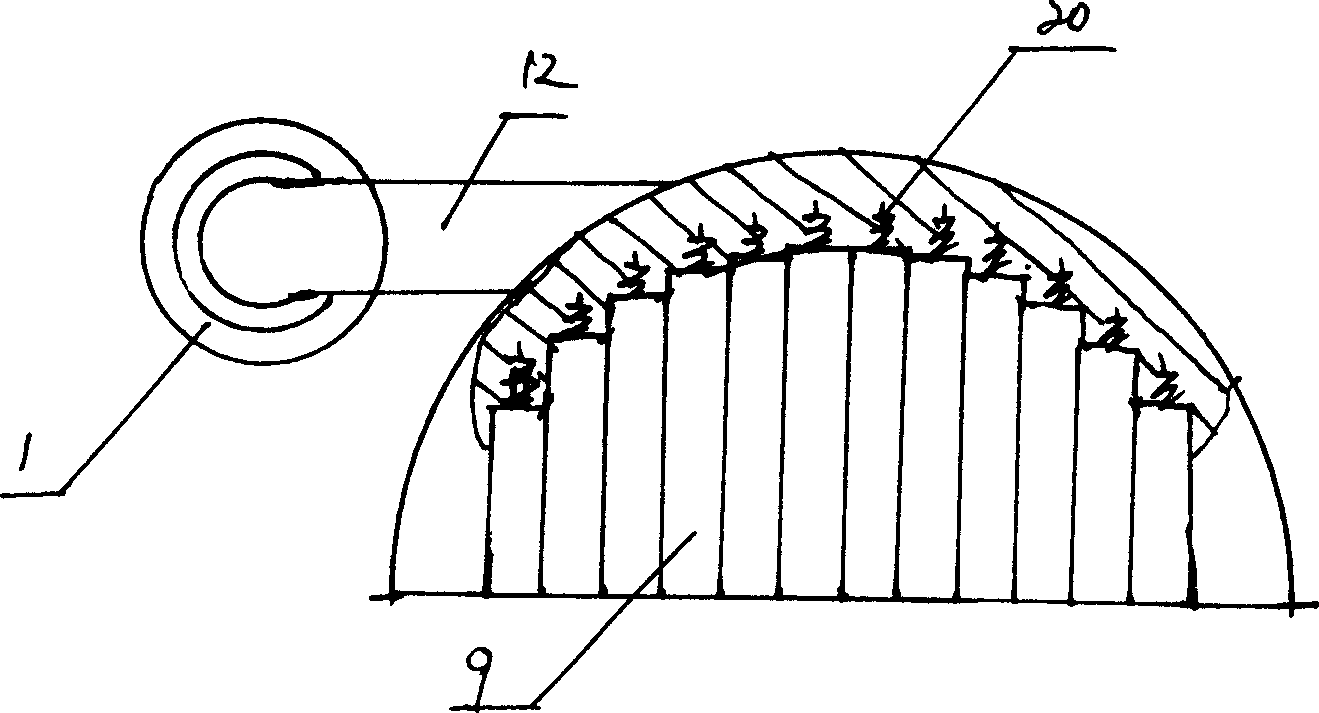

[0016] An air dust collector without a filter element for an internal combustion engine is provided with a dust removal box 7 with a circular cross section, and the shape of the dust removal box 7 is a cone with a small top and a big bottom. The top of the dust removal box 7 is provided with an air outlet 4, the bottom is provided with a dust outlet 8, and the side of the middle part is provided with an air inlet 11. The air inlet 11 is fixedly connected with an air inlet pipe 12, and the upper end of the air inlet pipe 12 is provided with A centrifugal dedusting air intake cap 1, the air intake channel formed by the air intake pipe 12 at the air inlet is tangent to the side wall of the dust removal box 7, that is, the air intake channel is tangent to the circular cross section of the box body 7, so that the gas After entering the dust removal box 7, a swirling flow is formed along the inner wall of the box body 7, and the inner wall of the dust removal box 7 below the upper ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com