Patents

Literature

160results about How to "Guaranteed to block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carrier for exhaust-gas purification

InactiveCN101298057AIncrease contact areaGuaranteed to blockPhysical/chemical process catalystsInternal combustion piston enginesParticulatesHazardous substance

Owner:ACR

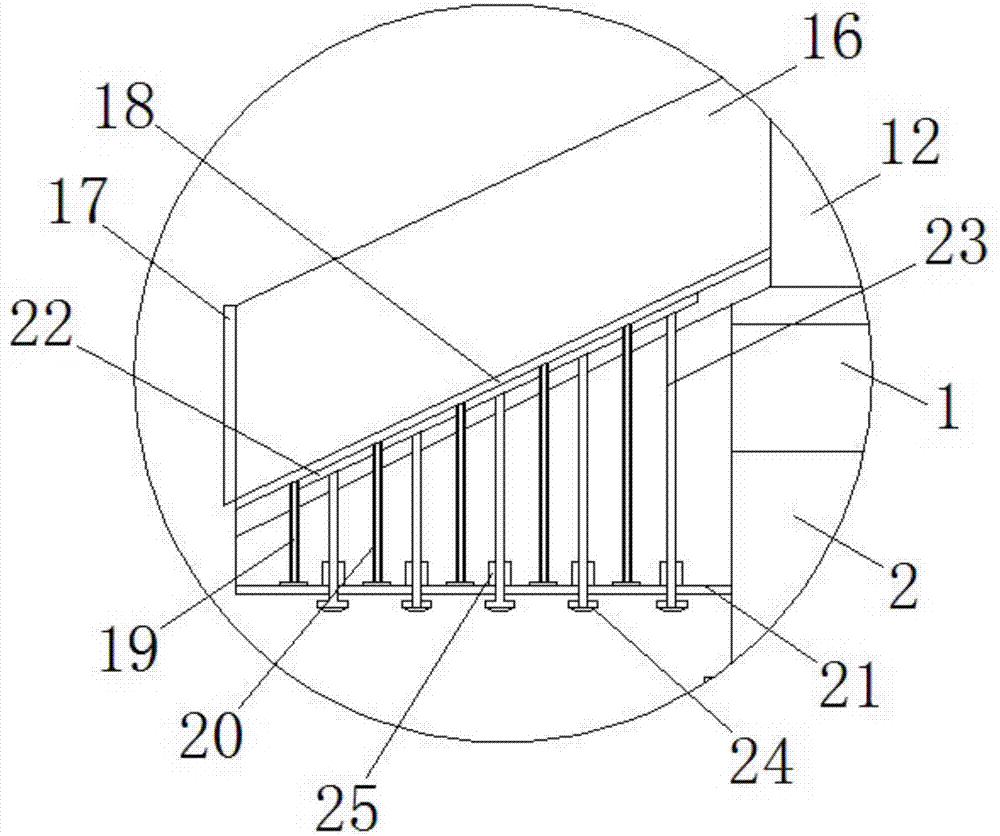

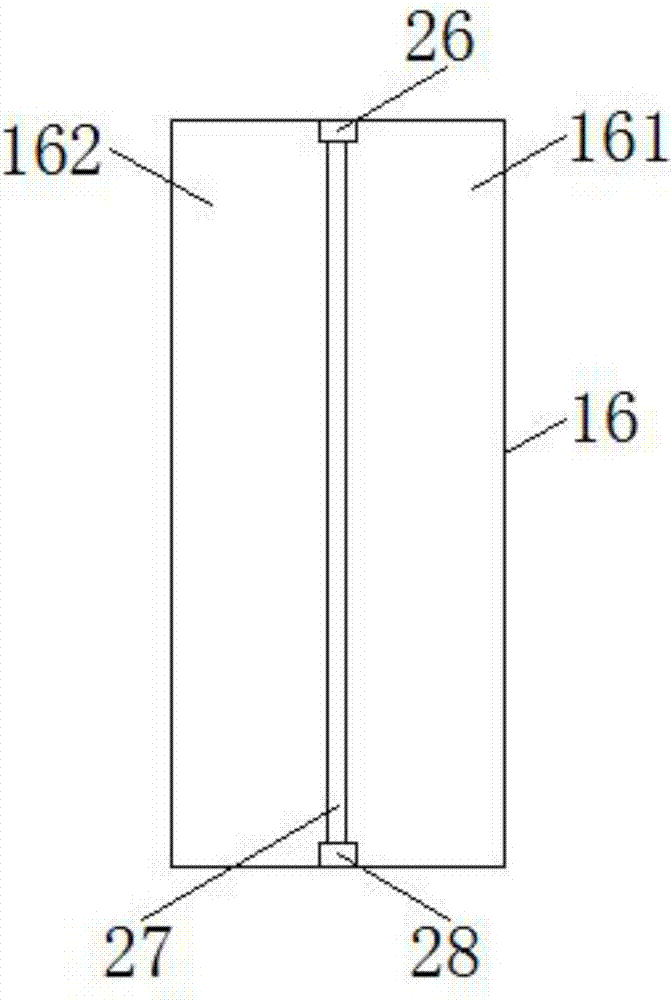

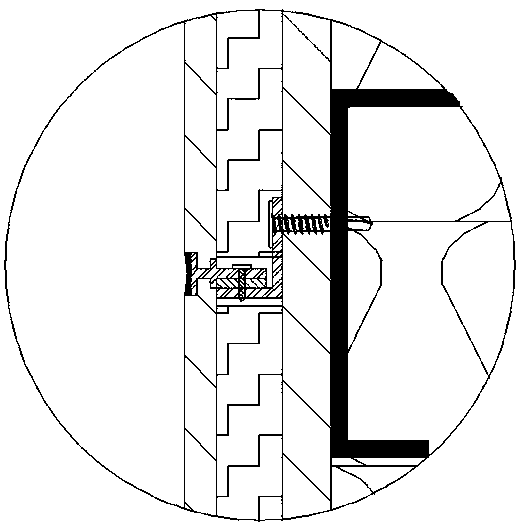

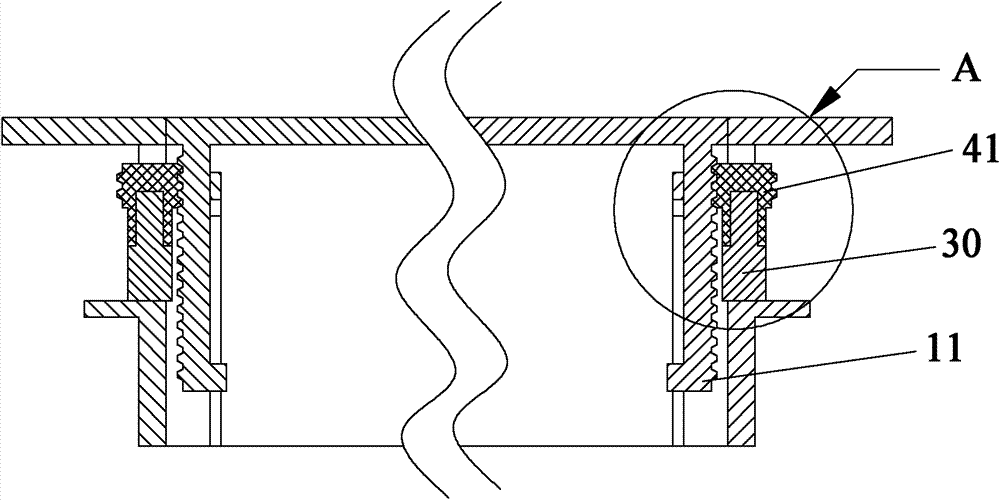

Outer-wall tongue groove capable of preventing water seepage of window and construction method of outer-wall tongue groove

InactiveCN104153485AReduce the probability of occurrenceReduce plaster thicknessWallsJoints tightening/coveringRebarWater seepage

Owner:TIANJIN 20 CONSTR

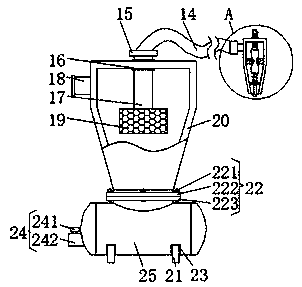

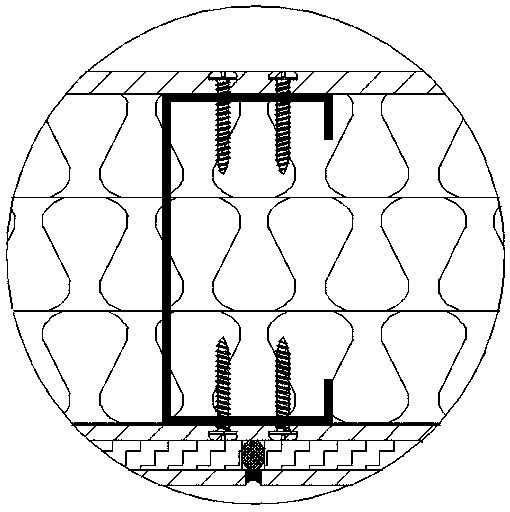

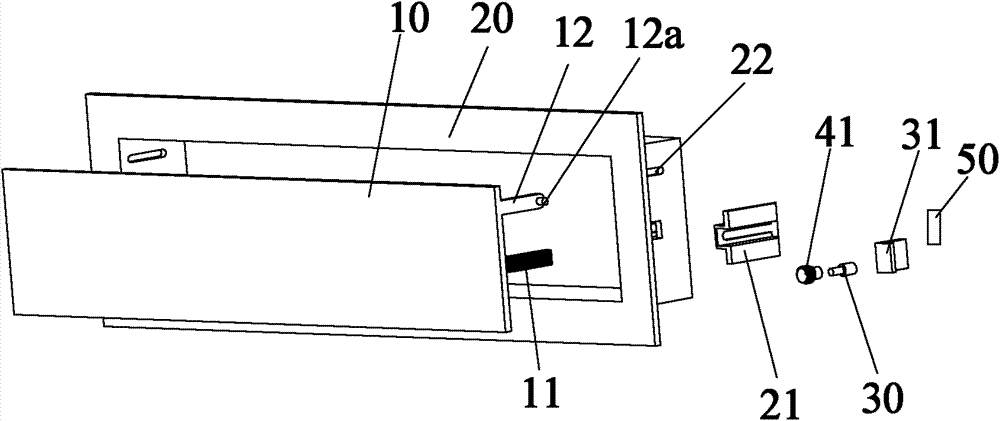

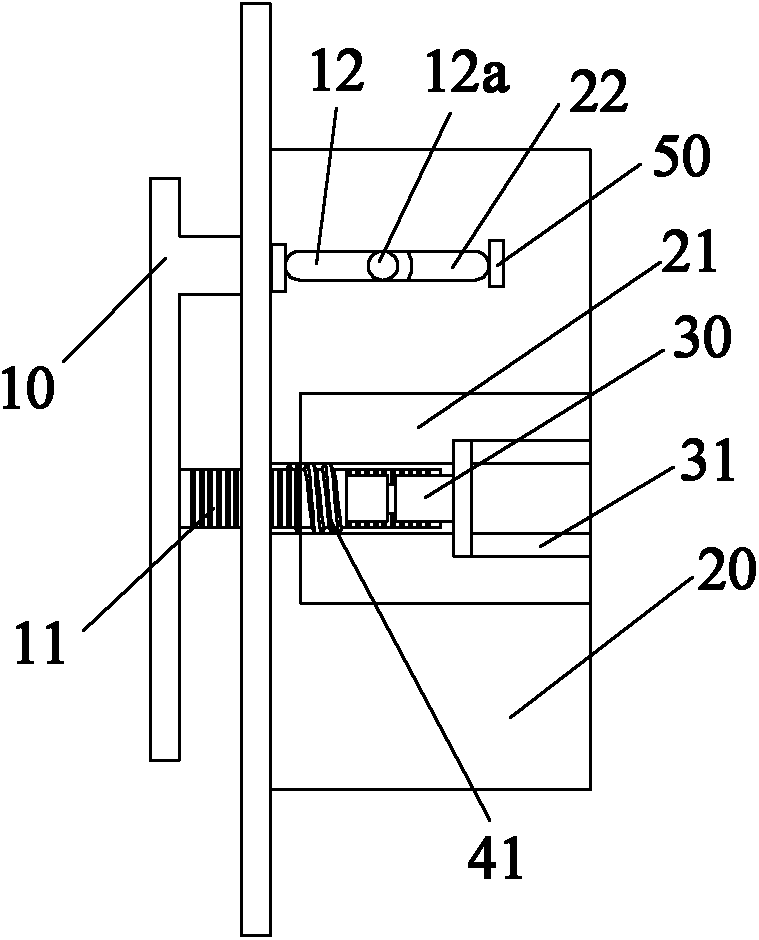

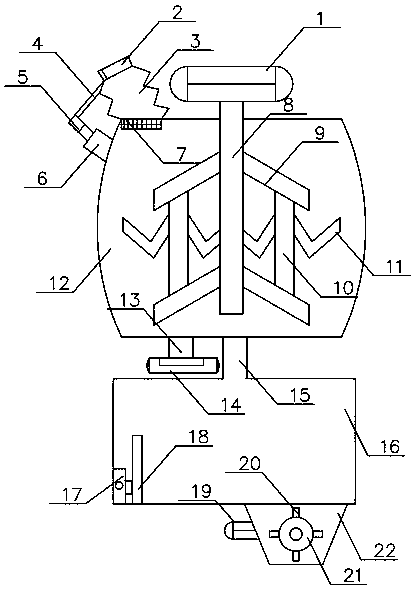

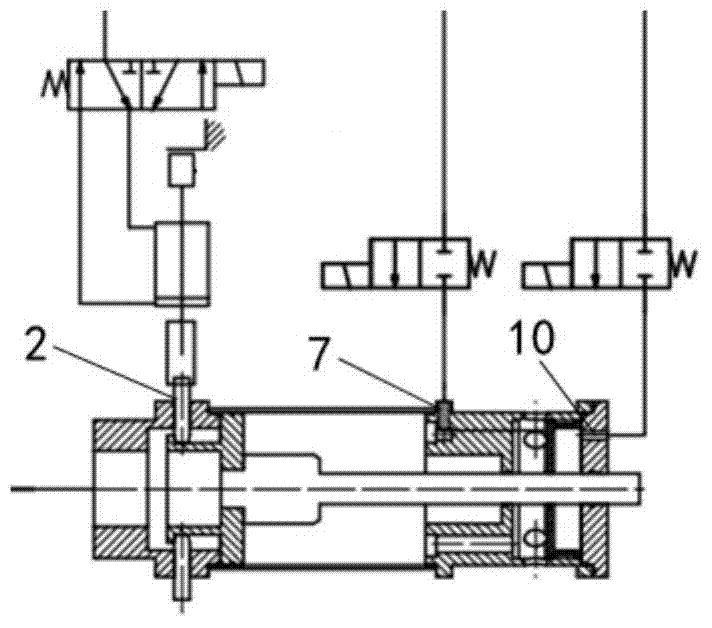

Sealing valve mounting structures and cleaning-free washing machine

ActiveCN110195333ASimple structureGood effectOperating means/releasing devices for valvesOther washing machinesEngineeringMechanical engineering

The invention relates to sealing valve mounting structures. Supporting plates installed on the inner side wall of an inner drum are involved, through holes corresponding to drainage ports formed in the side wall of the inner drum are formed in the middles of the supporting plates, and certain gaps are reserved between the supporting plates and the side wall of the inner drum, so that spaces for valve elements of sealing valves to up and down move in are formed; sleeve-shaped mounting sleeves are fixedly installed at the upper sides of the supporting plates, and through holes of the inner sidesof the mounting sleeves are coaxially opposite to the through holes in the supporting plates, so that the valve elements of the sealing valves are coaxially installed in the through holes of the inner sides in an up-down moving mode. The invention further provides a cleaning-free washing machine. The inner drum of the washing machine is a container of which an opening is buckled and then closed by a door cover, one or more drainage ports communicated with hollow parts of lifting ribs are formed in the side wall of the inner drum and provided with the sealing valves located in the lifting ribs, and the sealing valves are installed on the inner drum through the mounting structures.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +2

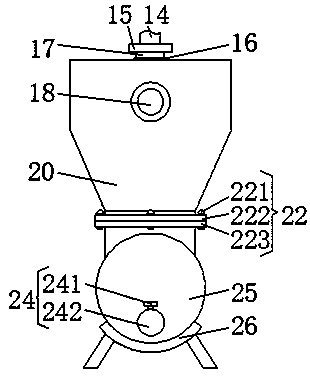

Anti-clogging drop irrigation device

InactiveCN108862659AImprove convenienceEasy to placeWater/sewage treatment by centrifugal separationRoot feedersIrrigationEngineering

The invention discloses an anti-clogging drop irrigation device. The anti-clogging drop irrigation device comprises a dropper and a centrifugal filter, the left side face and the right side face of the inner wall of the dropper are fixedly connected with the left side face and the right side face of a filter plate, a sliding sleeve is in clamping connection with the upper surface of the filter plate, a slide rod is slidably connected with the interior of the sliding sleeve, and the bottom end of the slide rod extends to the outer part of the dropper and is fixedly connected with the upper surface of a jacking head. The anti-clogging drop irrigation device is characterized in that, through mutual cooperation of a sealing block, a water leaking hole, the filter plate, a spring, the slide rod, the sliding sleeve, the jacking head, an extrusion device and the sealing block, when the dropper is inserted into the position of the soil where the plant root is located, the sealing block moves downwards to push the slide rod to slide downwards and extrude the spring to shrink, the jacking head moves downwards under driving of the slide rod to extrude the soil entering the dropper out, the filter plate can stop the soil from entering and clogging the water leaking hole, the mud on the filter plate is washed through the water flow, and thus the dropper is ensured to be always clear in theusing process.

Owner:王芳

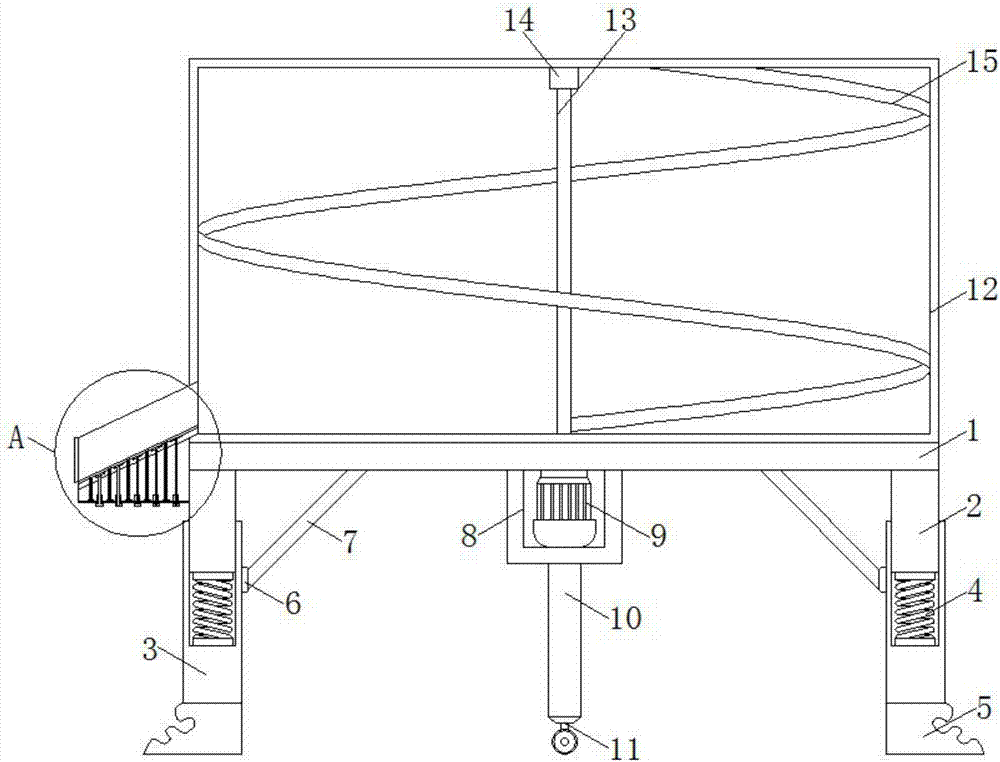

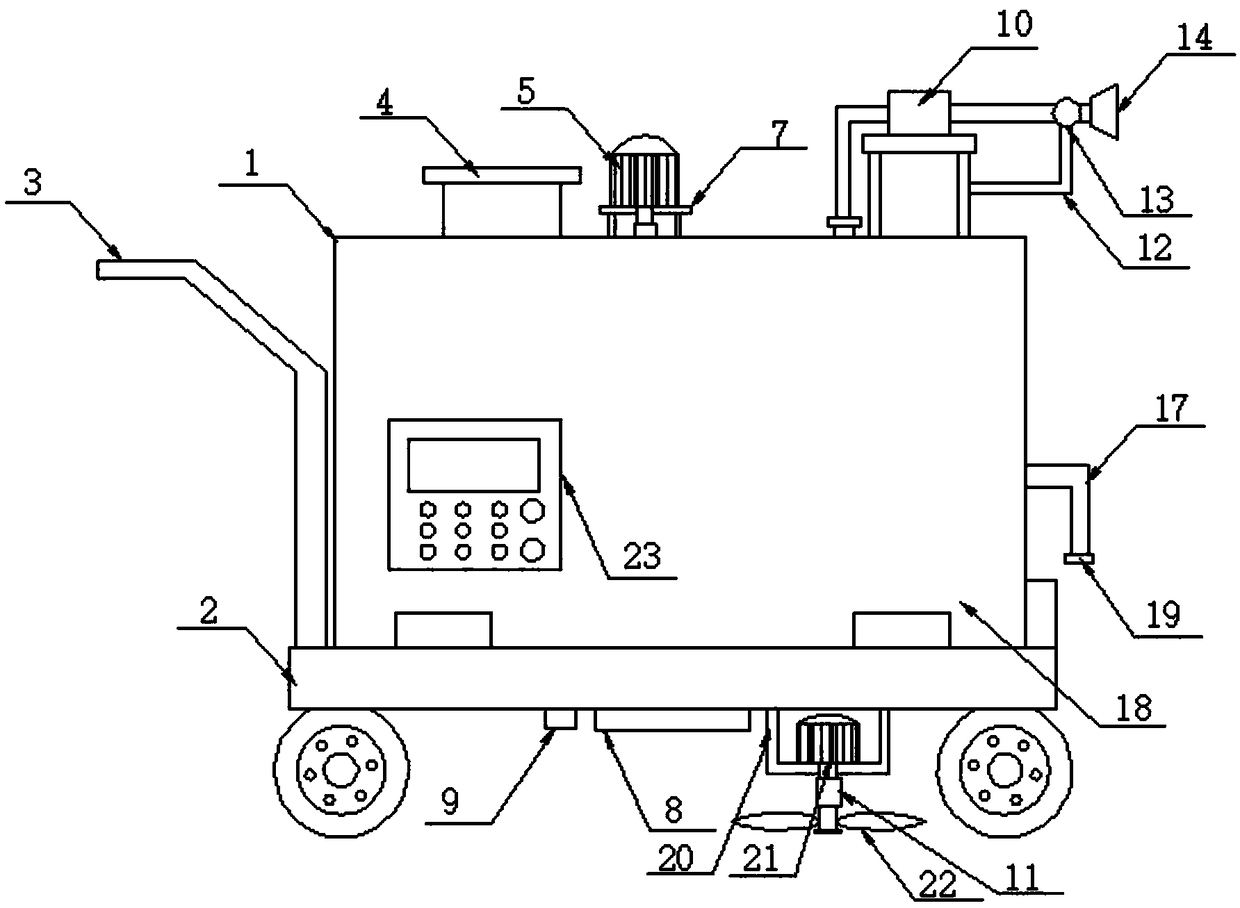

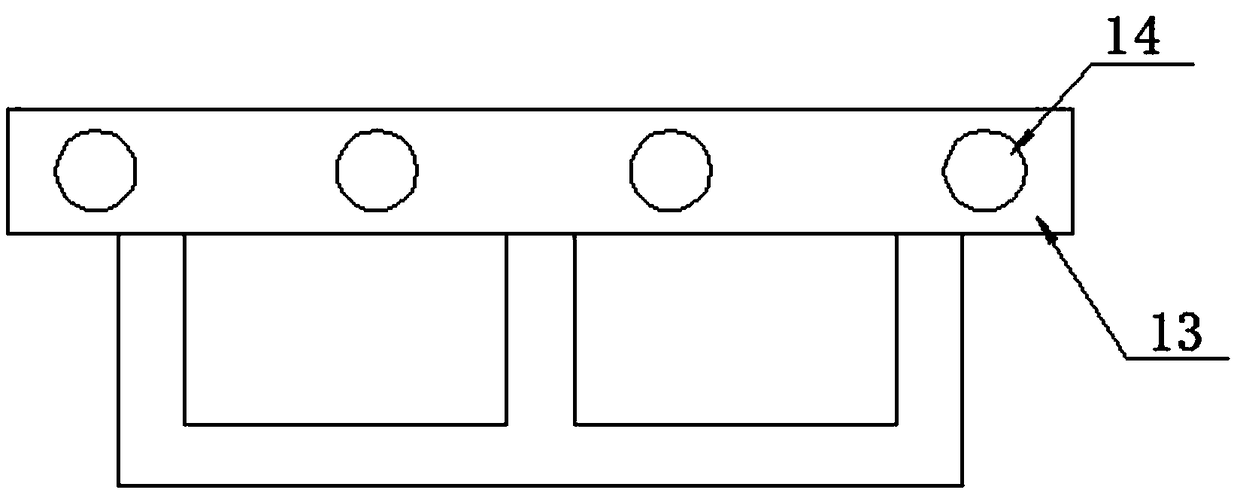

Concrete mixer capable of preventing material blockage and working stably for municipal administration

ActiveCN107310034AStable jobEffective blocking conditionDischarging apparatusCement mixing apparatusEngineeringBuilding construction

The invention relates to the technical field of municipal construction, and discloses a concrete mixer capable of preventing material blockage and working stably for municipal administration. The concrete mixer comprises a mounting base; lining columns are fixedly arranged at the bottom of the mounting base; the bottoms of the lining columns are connected with lower column sleeves in a sleeved mode; reciprocating springs located at the bottoms of the lining columns are fixedly arranged at the bottoms of inner cavities of the lower column sleeves; fixing support legs are fixedly arranged at the bottoms of the lower column sleeves; welding blocks are fixedly arranged on the inner sides of the lower column sleeves; inclined supporting frames located at the bottom of the mounting base are fixedly arranged on the inner sides of the welding blocks; and a motor mounting base located at the bottom of the mounting base is fixedly arranged on the inner sides of the inclined support frames. According to the concrete mixer capable of preventing the material blockage and working stably for the municipal administration, materials blocking a discharging slide way can be effectively jacked, dredging can be facilitated, the situation that the discharging slide way is blocked can be effectively avoided, and the stability of the overall work of the concrete mixer can be effectively guaranteed.

Owner:秦皇岛中燕机械设备有限公司

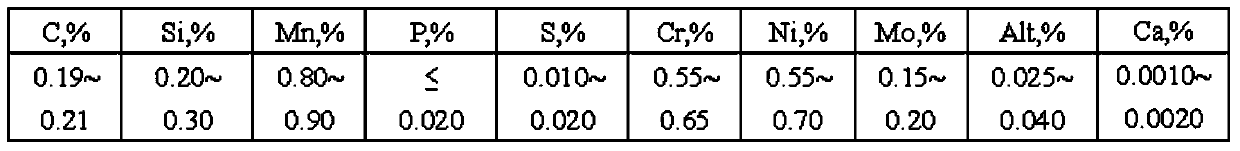

Method for preventing sulphureous gear steel SAE8620H from clogging nozzle

A method for preventing sulphureous gear steel SAE8620H from clogging a nozzle belongs to the technical field of thermodynamic equilibrium between molten steel and inclusions. During casting of the sulphureous gear steel AE8620H, the phenomenon of nozzle clogging can happen because of halfway denaturation of the inclusion Al2O3 and generation of CaS. The gear steel AE8620H belongs to aluminium killed steel, and the general way to prevent the inclusion Al2O3 from clogging the nozzle on a continuous caster is to conduct calcium line feeding treatment to make the inclusion Al2O3 denature to generate a low-melting-point compound, which is a liquid inclusion and can congregate, grow and float up by blowing argon into molten steel so as to be removed. The gear steel SAE8620H has a higher sulfur content, and if the addition of calcium is too high in the calcium line feeding treatment process, CaS can be generated, so the content of calcium added into the steel needs to be controlled to reduce the generation conditions of CaS to avoid the phenomenon that the submersed nozzle is clogged in a continuous casting process.

Owner:SHOUGANG CORPORATION

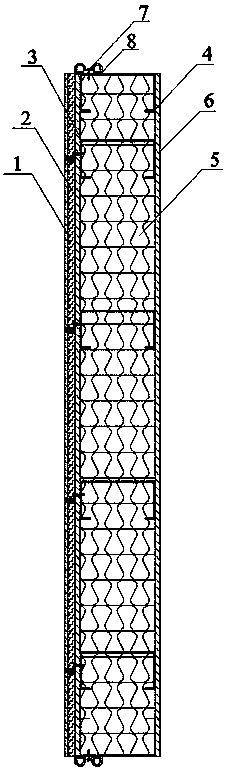

Fabricated external wall system and manufacturing and installation method thereof

PendingCN108589974AEffectively fixedImprove insulation effectWallsClimate change adaptationSurface layerKeel

The invention relates to a fabricated external wall system. The fabricated external wall system of a steel structure comprises an external decorative surface layer, a vacuum insulating plate layer, abase layer plate, a keel, a filling layer and an inner wall plate in sequence from outside to inside, the external decorative surface layer is fixed on the base layer plate, and the vacuum insulatingplate layer is arranged between the external decorative surface layer and the base layer plate. The base layer plate and the inner wall plate are separately fixed on the two sides of the keel. The filling layer is arranged in a cavity formed by surrounding of the base layer plate and the inner wall plate and separated by the keel, and the filling layer is a non-pouring filling material. Accordingto the fabricated external wall system of a steel structure, the base layer plate, the vacuum insulating plate or a STP heat preservation and decoration integrated plate can be effectively fixed through a set of elements; and mechanical connection is carried out on each layer, no hidden danger of shedding exists, the safety is improved, and the fabricated external wall system can be easily replaced when damaged.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

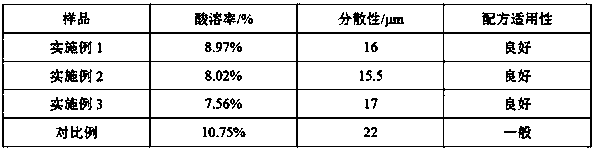

Air pipe air conditioning unit and air port part thereof

ActiveCN103090511AGuaranteed aestheticsSimple structureDucting arrangementsSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention provides an air pipe air conditioning unit and an air port part thereof. The air port part comprises an air outlet part and / or an air return part, a panel (10) is disposed on the air outlet part and / or the air return part in an extensible manner. The air port part is simple in structure. When the air conditioning unit is switched on, the panel (10) is opened simultaneously, and accordingly smoothness of an air outlet and / or an air return port is guaranteed. When the air conditioning unit is switched off, the panel (10) is closed simultaneously, and accordingly garbage or foreign objects cannot enter the air conditioning unit through the air outlet and / or the air return port. The problem that the air outlet part and / or the air return part are prone to dust accumulation is solved, and accordingly cleanness of indoor air can be maintained.

Owner:GREE ELECTRIC APPLIANCES INC

Stirring equipment for precious metal

PendingCN108543466AImprove stirring efficiencyGuaranteed to blockTransportation and packagingRotary stirring mixersPulp and paper industryEngineering

The invention relates to stirring equipment for precious metal and belongs to the technical field of precious metal crushing equipment. A feed port is formed in an upper stirring chamber, a cover is arranged at the upper end of the feed port, a filter screen is arranged at the junction of the feed port and the upper stirring chamber, and a motor is arranged on the upper stirring chamber and connected with main stirring blades through a rotating shaft, reinforcing ribs are arranged between the main stirring blades, each reinforcing rib and the corresponding main stirring blade form an I shape,and V-shaped auxiliary stirring blades are arranged on sides of the reinforcing ribs; a lower stirring chamber is arranged at the lower end of the upper stirring chamber and connected with the upper stirring chamber through a channel, a pusher is arranged at the inner bottom end of the lower stirring chamber and pushes the scraper to run along the bottom end of the lower stirring chamber, and a discharge port is formed in the lower end of the lower stirring chamber. A scraper is pushed by the pusher to drive noble metal to be stirred continuously, and stirring efficiency is improved.

Owner:NANJING DAMAI SCI&TECH IND CO LTD

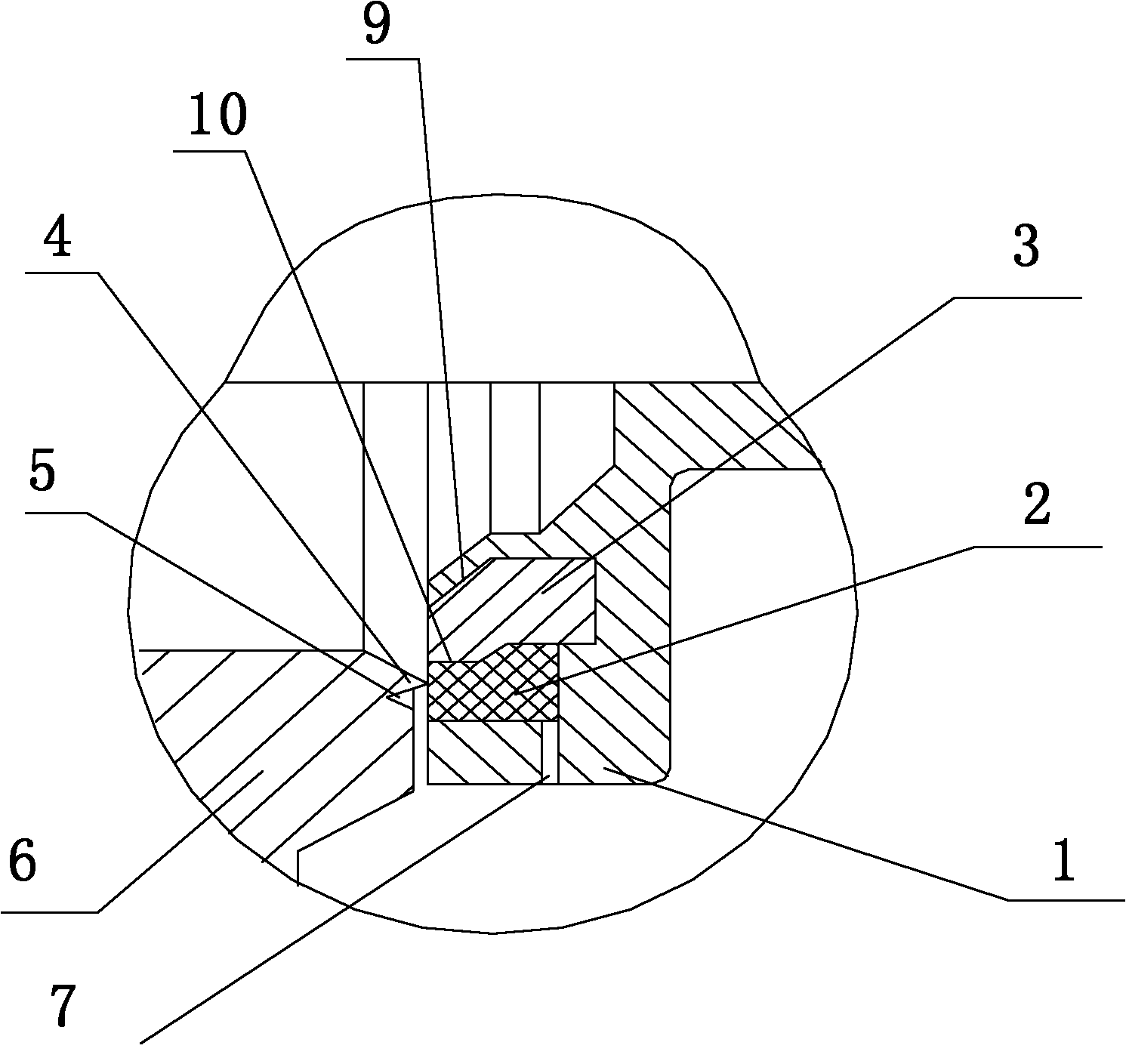

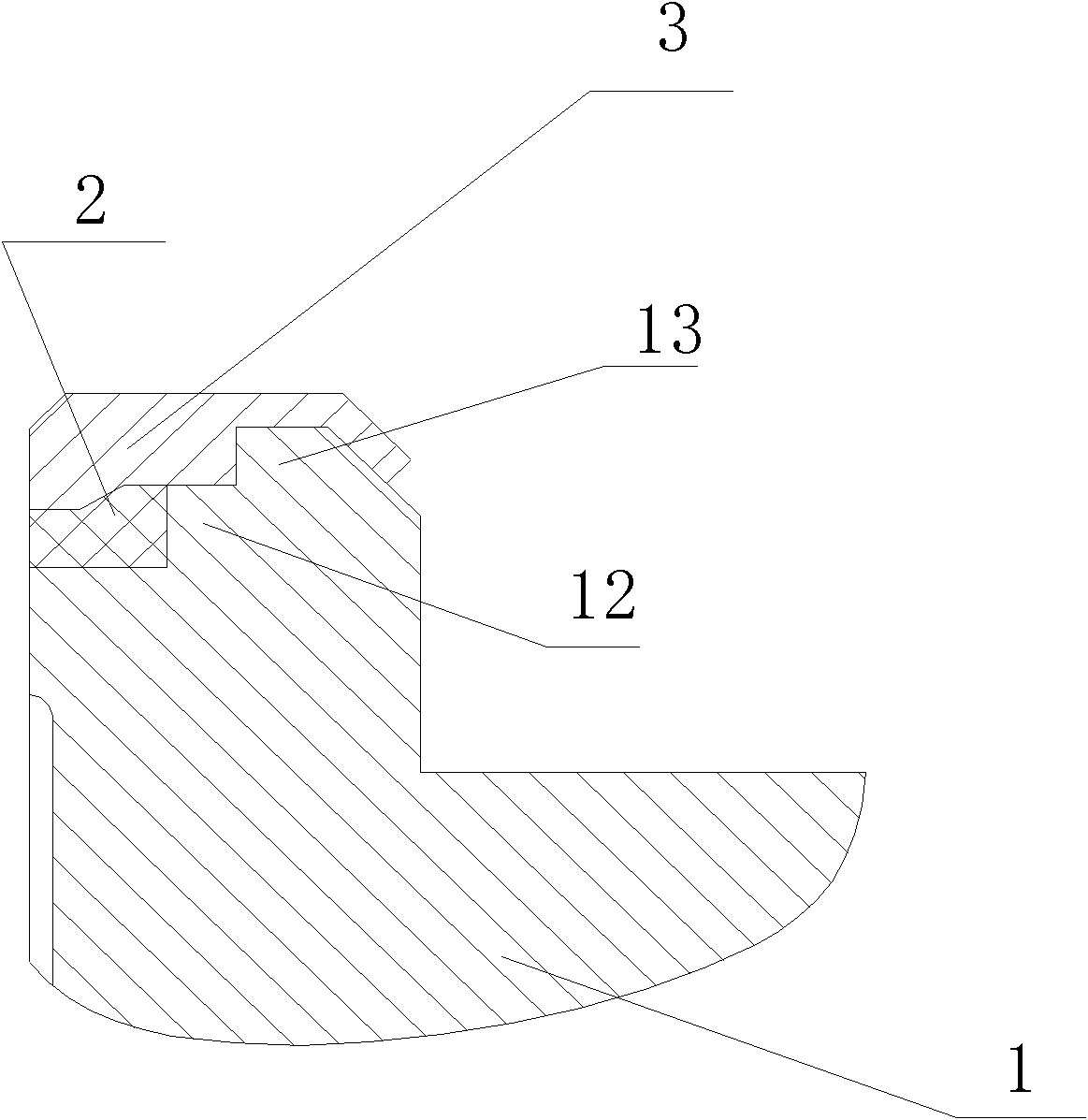

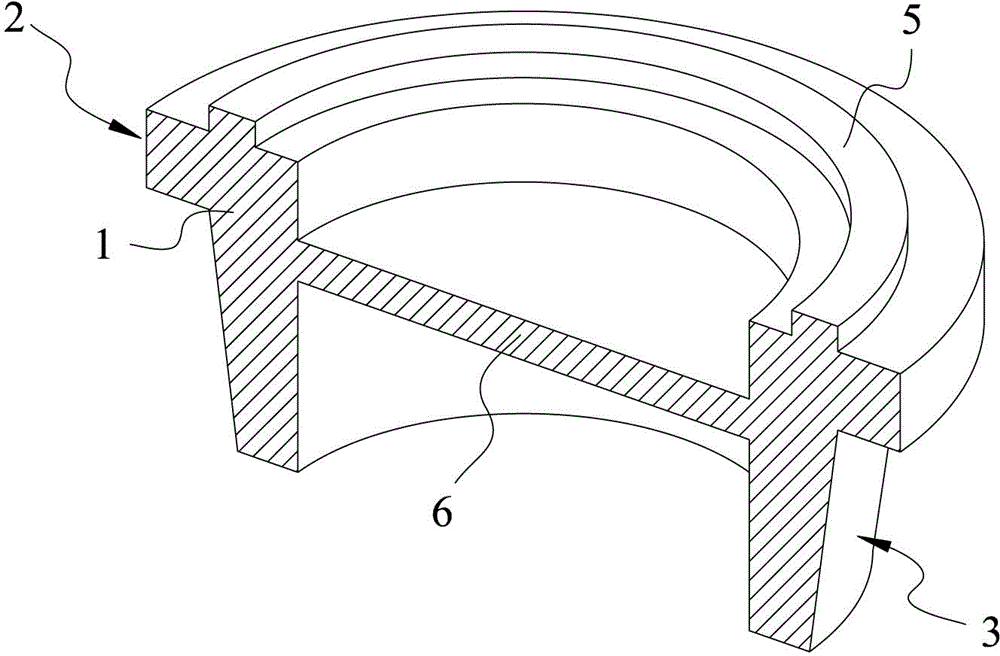

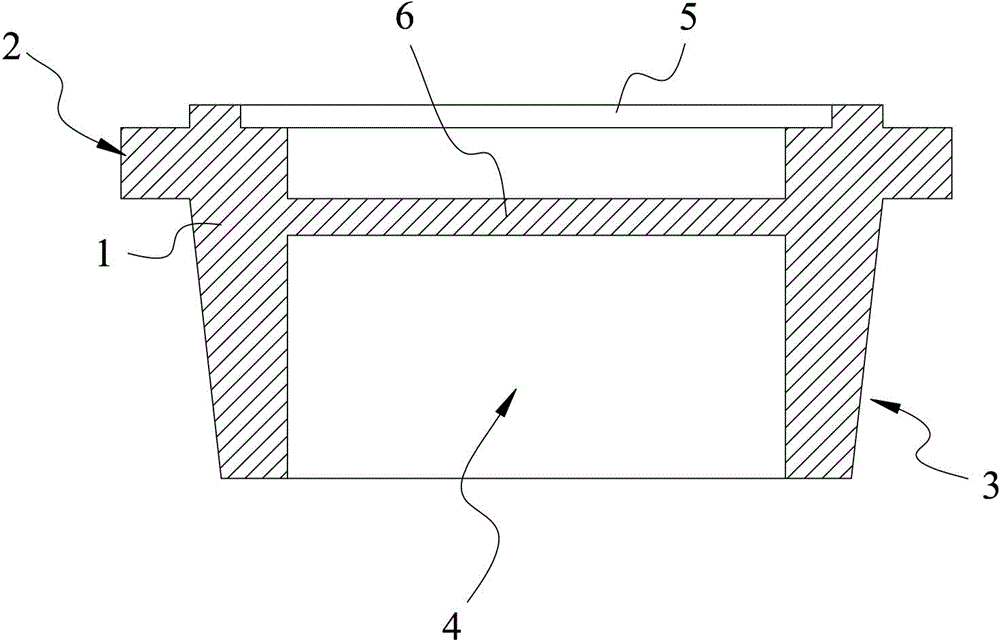

Composite split type high-pressure sealing pair

The invention relates to a composite split type high-pressure sealing pair, which comprises a valve seat, a valve spool base, a non-metal sealing ring and a metal fixing ring. An annular sealing groove is arranged on the valve spool base, and the non-metal sealing ring and the metal fixing ring are arranged in the annular sealing groove; a chamfer is arranged at one end, which is close to the valve seat, of the inner side surface of the metal fixing ring; an annular boss is disposed on the outer side surface of the metal fixing ring and corresponds to the chamfer; the outer diameter of the annular boss is slightly larger than the inner diameter of the non-metal sealing ring; the depth of the annular boss is smaller than that of the non-metal sealing ring; the inner wall of the annular sealing groove presses the chamfer of the metal fixing ring in an edge rolling manner; and an outwards protruded annular triangular step is arranged on the valve seat and is opposite to the non-metal sealing ring, and an inwards concave annular holding groove is arranged on the outer side of the triangular step. The composite split type high-pressure sealing pair can meet requirements of sealing of high-pressure media, and is reasonable in structure and reliable in performance.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

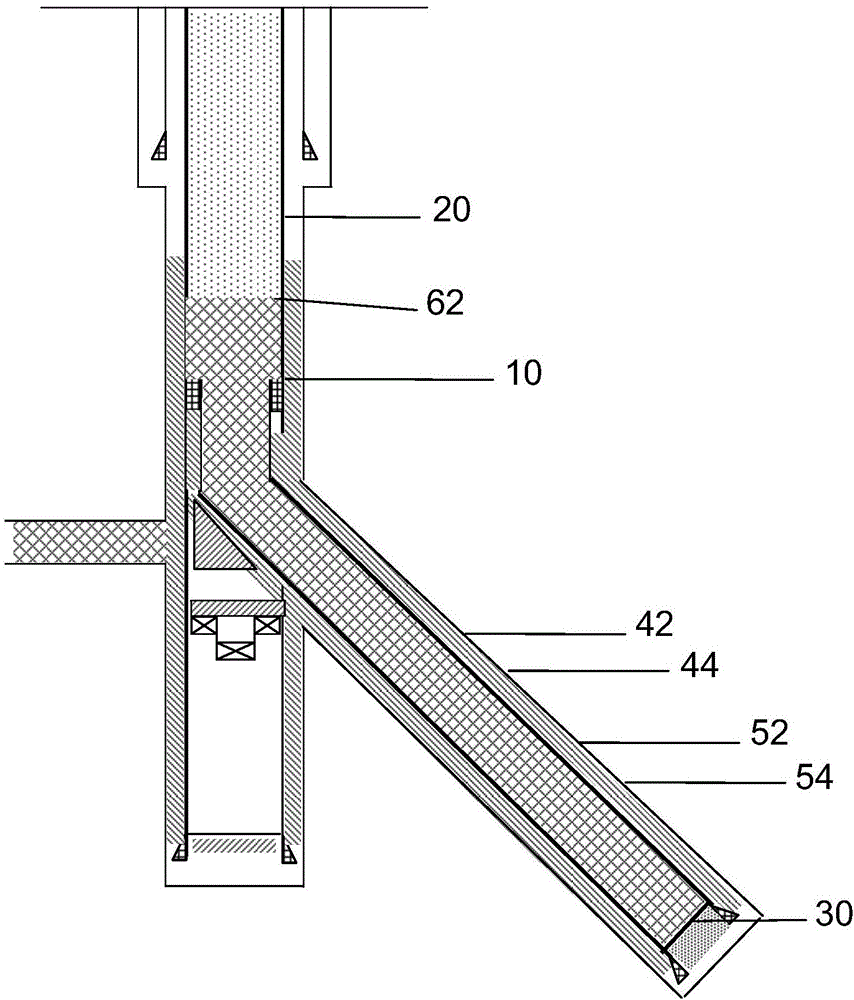

Auxiliary device for steel pipe machining

PendingCN113020640AAct as a barrierAchieving hindranceExpansion mandrelsChucksClassical mechanicsMachining

The invention discloses an auxiliary device for steel pipe machining, and relates to the technical field of auxiliary devices for steel pipe machining. The auxiliary device comprises a clamping tool and a conveying plate which are arranged side by side, the conveying plate inclines downwards in the direction close to the clamping tool, side protection plates are arranged on the two sides of the conveying plate, a through hole is formed in the lower end of the conveying plate in a penetrating mode, a first limiting rod capable of moving in a lifting mode is arranged in the through hole in a penetrating mode, a sliding groove is further formed in the conveying plate in a penetrating mode, a second limiting rod capable of moving in a lifting mode is arranged in the sliding groove in a penetrating mode, a fixing box is arranged at the lower end of the second limiting rod, a power assembly used for pushing the fixing box to move in the direction of the sliding groove is arranged on the outer wall of the fixing box, and a transferring assembly is further arranged between the clamping tool and the conveying plate. The auxiliary device has the advantages that steel pipes with different pipe diameters can be conveyed and discharged, it is guaranteed that one steel pipe is discharged at a time, the steel pipe carrying time is shortened, the clamping and fixing time of adjacent steel pipes is shortened, and the working efficiency is improved.

Owner:山西兴达通机电设备有限公司

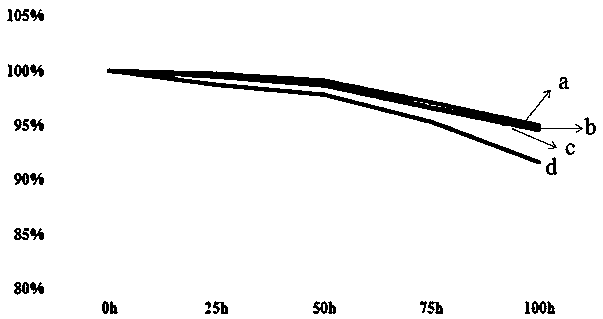

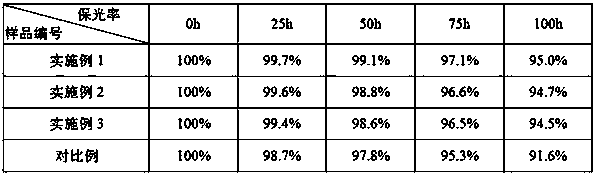

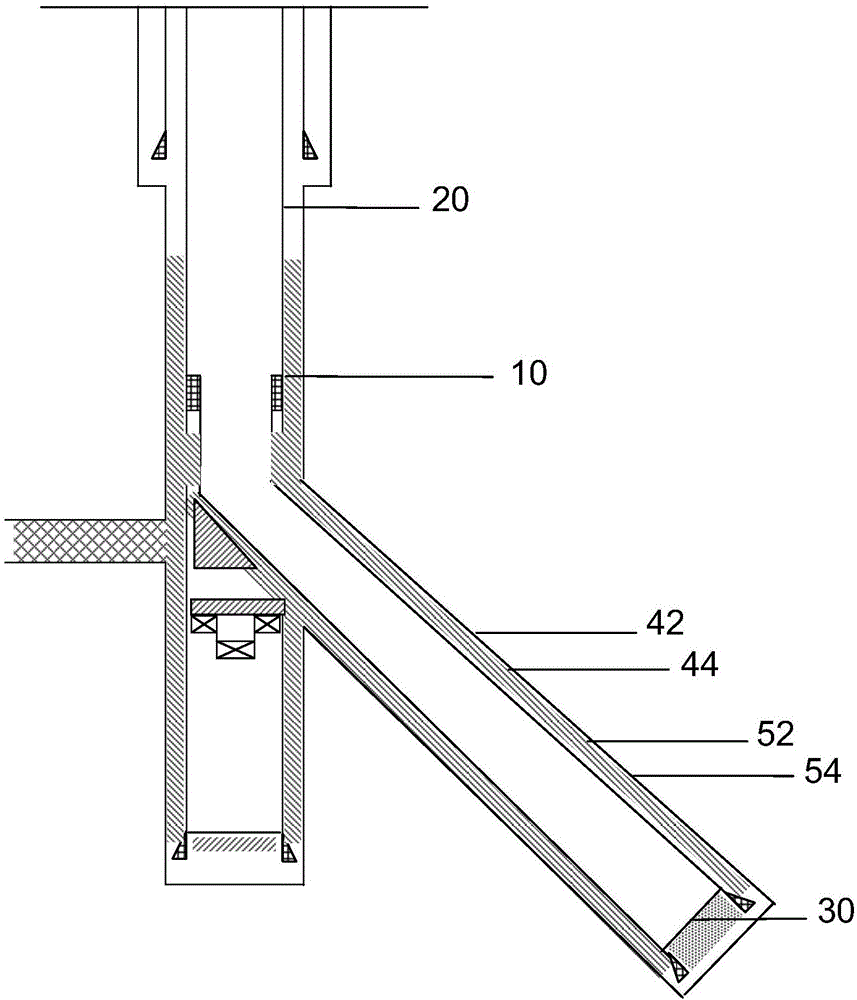

Special preparation method for improving weather fastness of titanium dioxide

ActiveCN110028812AAvoid reunionPrevent homogeneous nucleationInorganic pigment treatmentDispersityTitanium

The invention belongs to the technical field of preparation of titanium dioxide, and discloses a special preparation method for improving the weather fastness of titanium dioxide. The special preparation method comprises the following steps: 1) preparing a titanium dioxide slurry, adding a silicate solution, and coating a first layer of silicon film; 2) adjusting the pH value of the slurry coatedwith the silicon film to 2-4, homogenizing, adding a FeSO4 solution and a dilute alkali solution at the same time, maintaining the pH value of the slurry to 2-4, and then homogenizing; 3) then addingthe silicate solution, coating a second layer of silicon film; 4) adding an aluminum salt solution and the dilute a dilute acid solution or the alkali solution, coating an aluminum film; 5) washing with water the slurry coated with the aluminum film, flashing, and pulverizing with vapor to obtain a finished product of titanium dioxide. The prepared titanium dioxide is relatively high in weather fastness, and the dispersity and the formula applicability are comparatively excellent.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

Blocking method for perforation well sections of slim hole sidetracking well

ActiveCN106639969ASolve matching problemsGuaranteed to blockCleaning apparatusSealing/packingWell drillingBlock method

The invention provides a blocking method for perforation well sections of a slim hole sidetracking well. One of the blocking method comprises the step that S100, a wellhead well plugging device is opened, a workover fluid is filled in sleeves, and drafting process is conducted; S200, operation pipe columns are put in the well, blocking operation is successively conducted on each perforation well section from top to bottom, and the blocking operation is completed when the blocking operation is conducted on the lowermost perforation well section; and S300, the sleeves are cleaned through a drag bit to the position of an artificial well bottom, wherein the blocking operation comprises the steps that an impending cement plug is set in the position, below the corresponding perforation well section, of each operation pipe column; cement squeezing blocking operation is conducted; temporary cement plugs are formed above the impending cement plugs; the wellhead well plugging device is closed, and waiting on cement setting is conducted under pressure; and the wellhead well plugging device is opened, the downward-put drag bit successively drills through the temporary cement plugs and the impending cement plugs from top to bottom, and blocking operation is completed. The invention further provides the other blocking method for the perforation well sections of the slim hole sidetracking well. A packer is not needed, blocking is completed from top to bottom, the blocking method can be used for permanent well plugging or slim hole major repairing.

Owner:PETROCHINA CO LTD

Exhausting wave-resistant water stop device

ActiveCN105332779AReduce buoyancy resistanceImprove reliabilityExhaust apparatusSilencing apparatusEngineeringWaterstop

The invention provides an exhausting wave-resistant water stop device. The wave-resistant and water stop functions on an exhausting pipeline can be achieved and water can be prevented from entering equipment from the exhausting pipeline. The exhausting wave-resistant water stop device comprises an exhaust elbow, a wave-resistant shell, a hinge, a sliding mechanism, a water baffle and a floater, and peripheral equipment is an exhaust pipe. A mounting hole used for being connected with an exhaust port of the exhaust pipe is formed in the right side surface of a protective cover, an exhaust hole is formed in the arc surface, and one end of the exhaust hole is connected with the water baffle through the hinge. The floater and a guiding mechanism are located in the protective cover, and the end face of one side of the floater is tightly attached to the end face A of the protective cover. When water enters the protective cover from an opening in the bottom surface of the protective cover, the floater floats along the sliding mechanism so as to block off the exhaust port.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

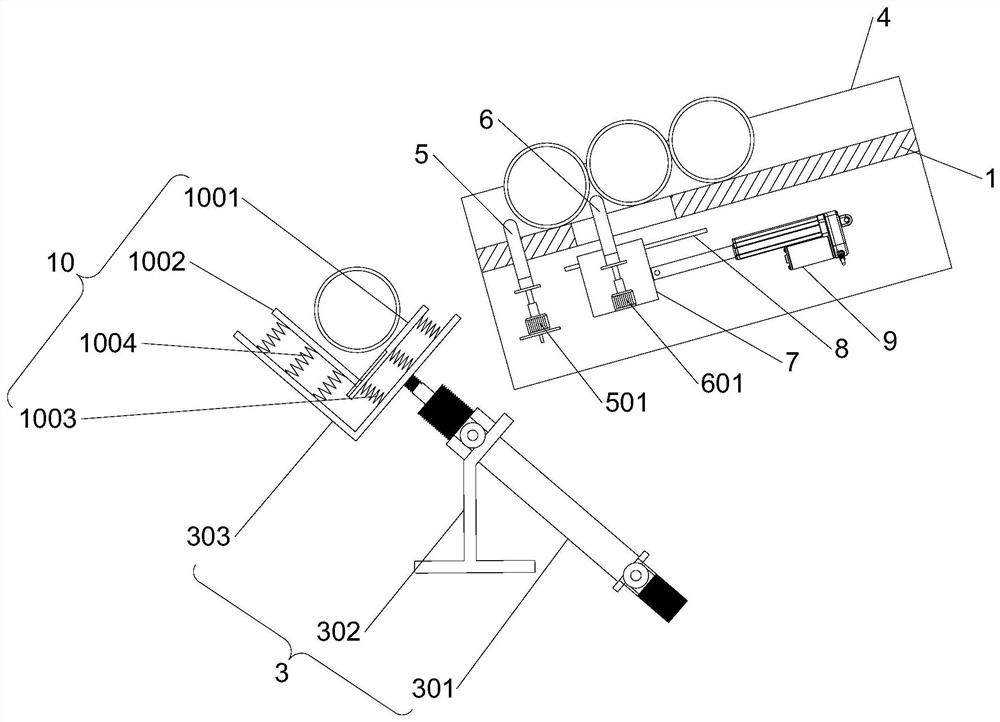

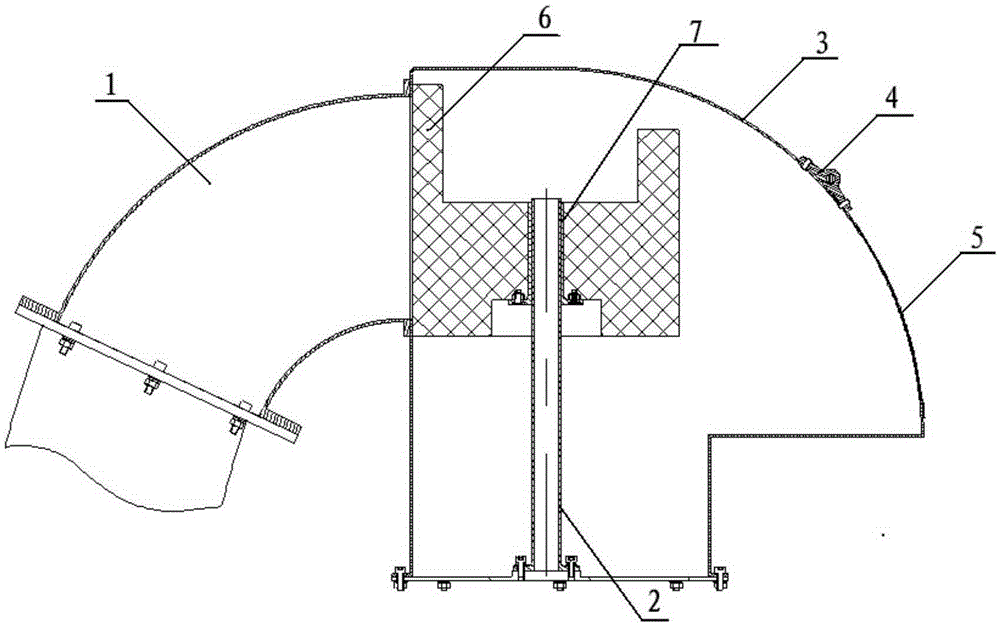

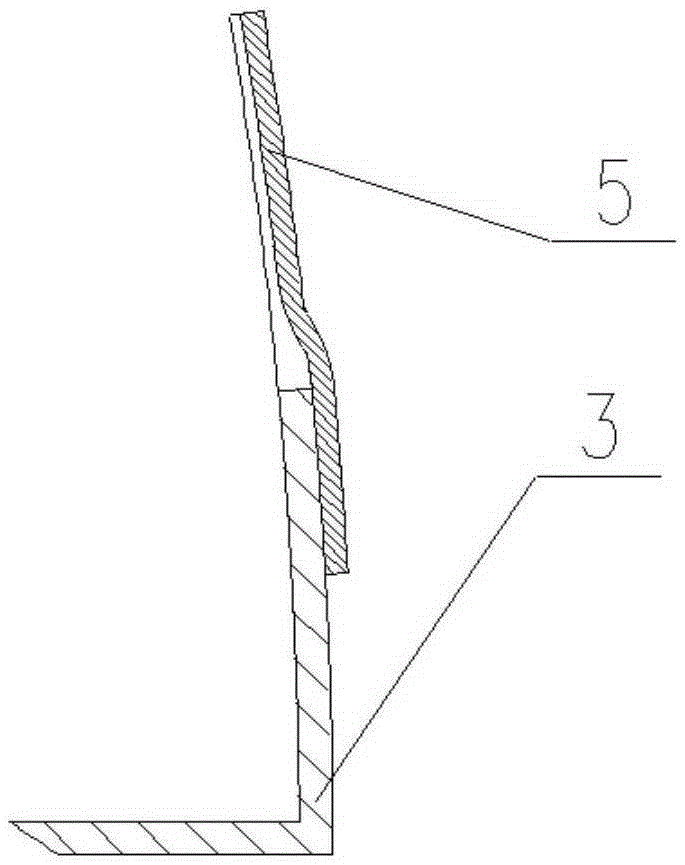

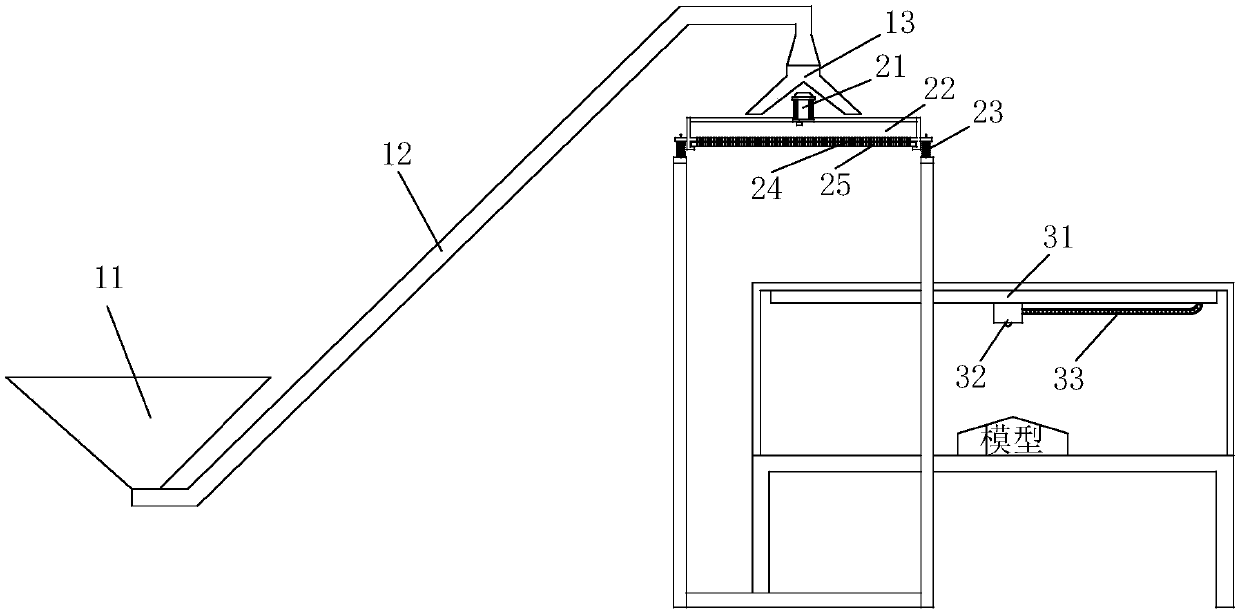

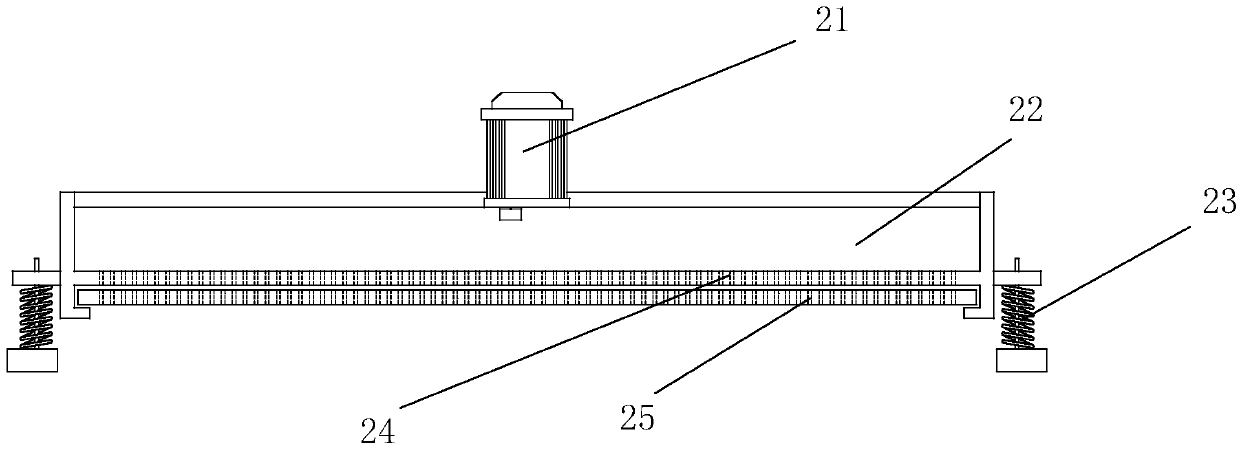

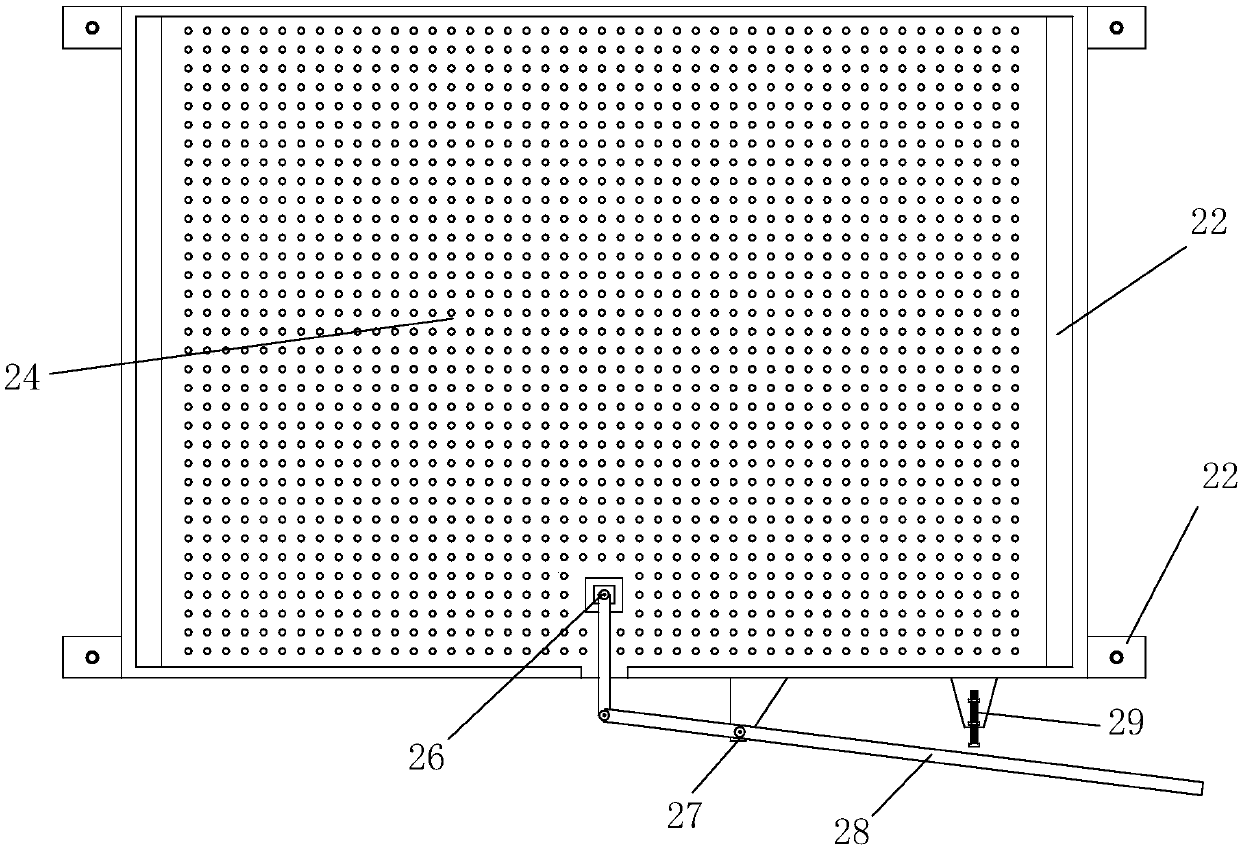

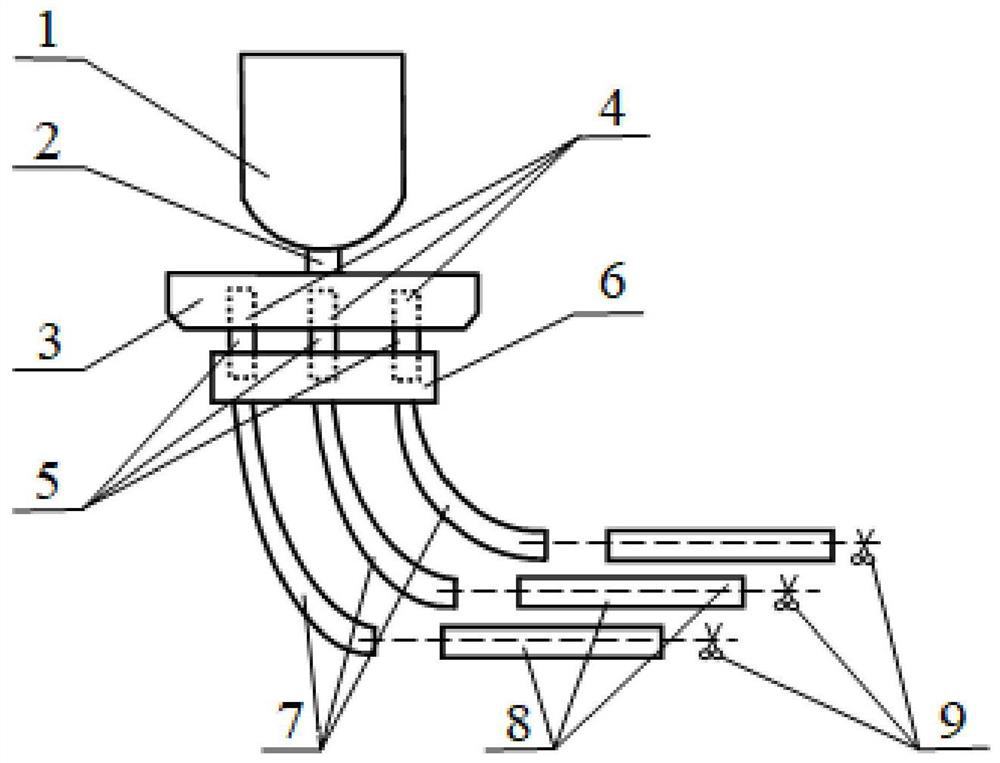

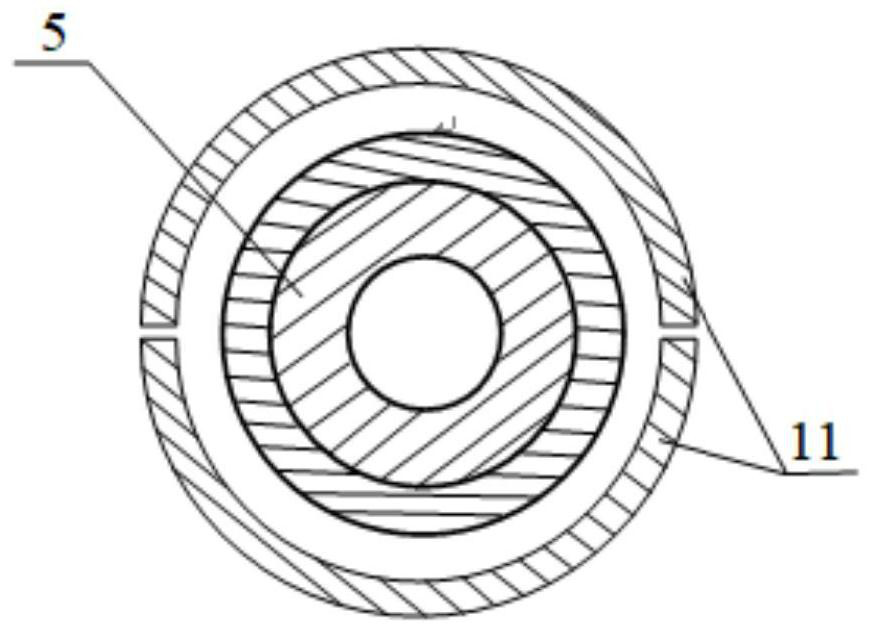

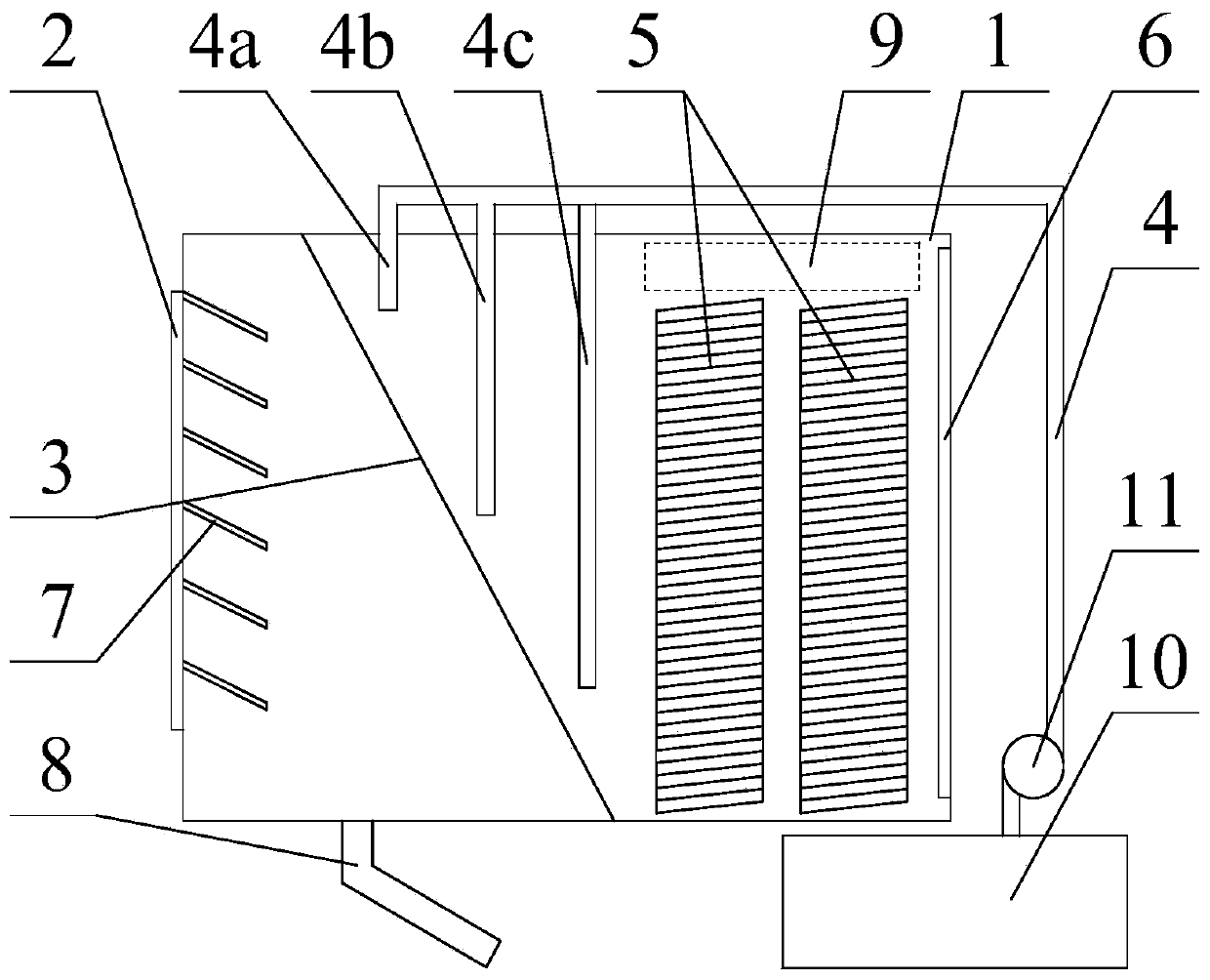

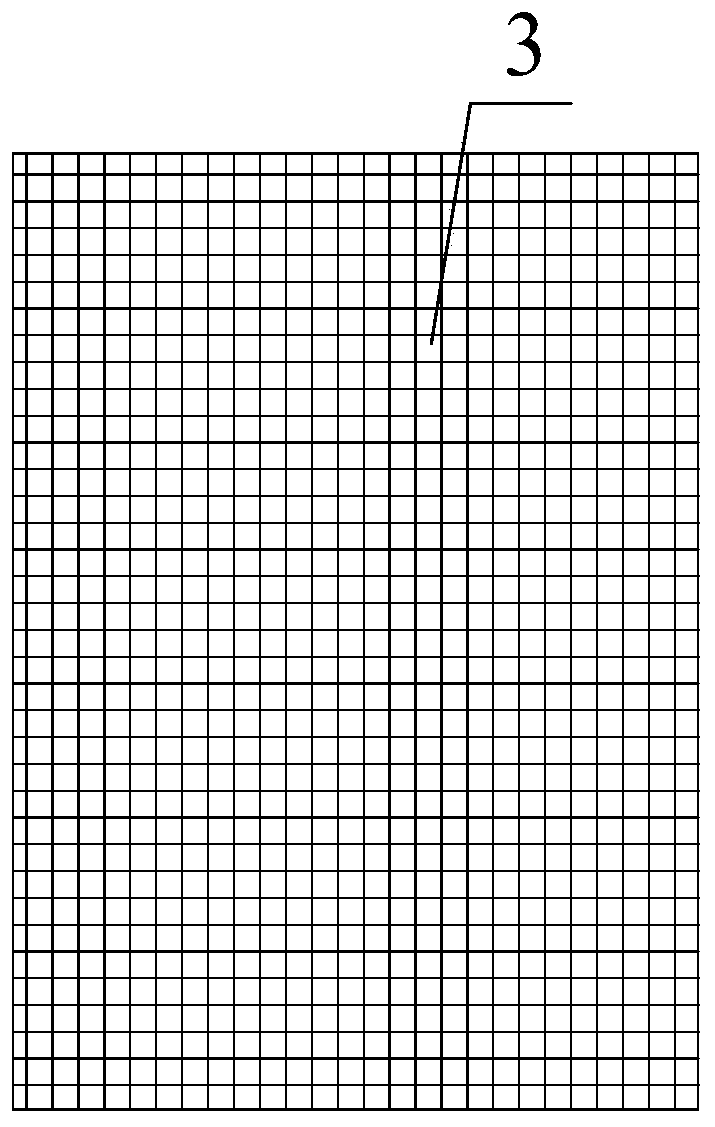

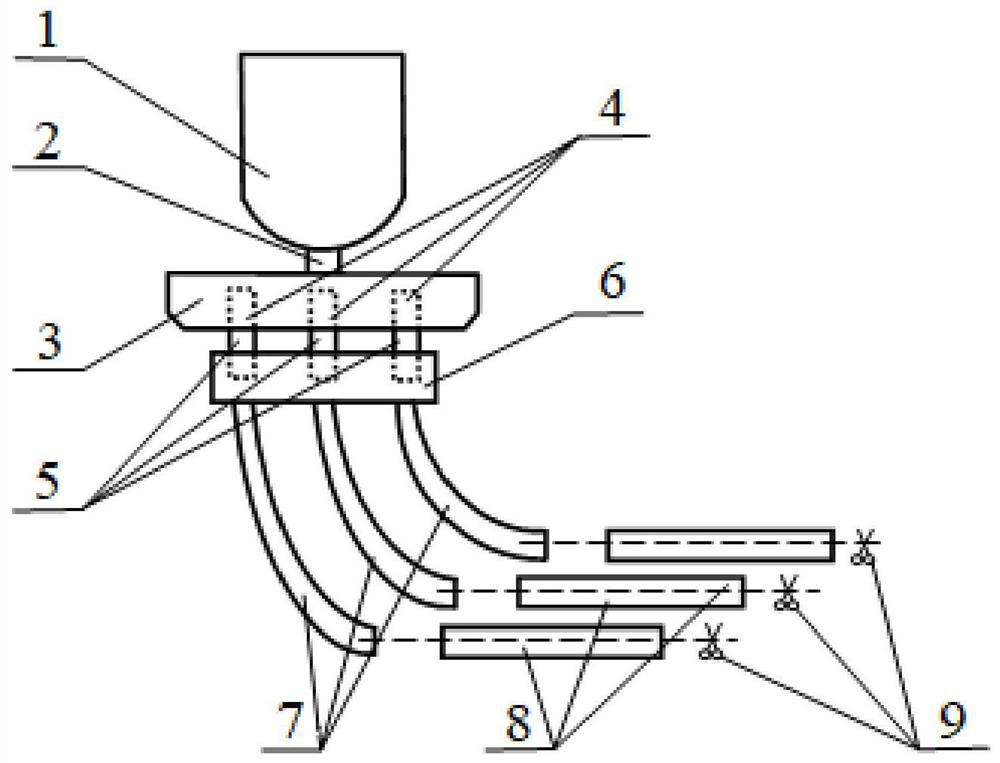

Snowfall simulating wind tunnel experiment device suitable for high fluidity particles

ActiveCN108036915AUniform stacking heightHigh simulation fidelityAerodynamic testingParticle packingMaterials science

The invention relates to a snowfall simulating wind tunnel experiment device suitable for high fluidity particles, and is suitable for the wind tunnel experiment of the particles of high fluidity likequartz sand. The device comprises a material feeding mechanism; a powder falling mechanism; and a shift measurement mechanism. The powder falling mechanism is composed of a support and a powder falling component which is arranged on the support. The powder falling component comprises a powder falling framework and an upper baseplate and a lower baseplate which are arranged on the powder falling framework and closely clung to each other. Mutually staggered powder falling holes are arranged on the upper baseplate and the lower baseplate. The upper baseplate and the powder falling framework arerelatively fixedly arranged and cooperated to form a powder falling tray for receiving the particles conveyed by the material feeding mechanism. The lower baseplate is connected by a driver and drivento move along the plane of the upper baseplate. The shift measurement mechanism is arranged beside the powder falling mechanism and used for measuring the particle packing height of the measurement area below the powder falling mechanism. Compared with the devices in the prior art, the device is simple in structure, low in test cost and high in simulation authenticity and can effectively guarantee uniform packing height of the particles in the test area.

Owner:TONGJI UNIV

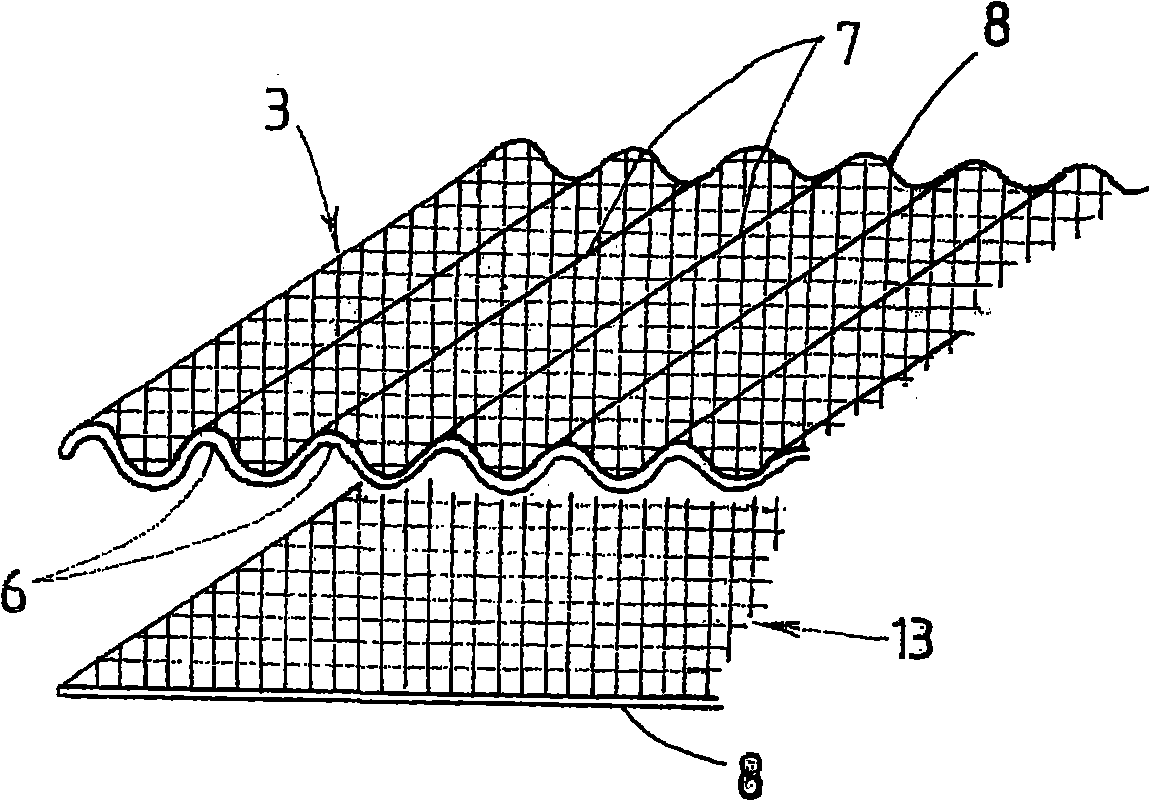

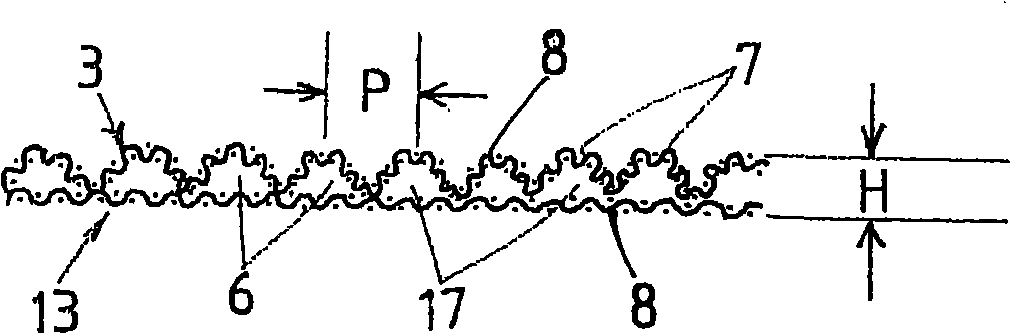

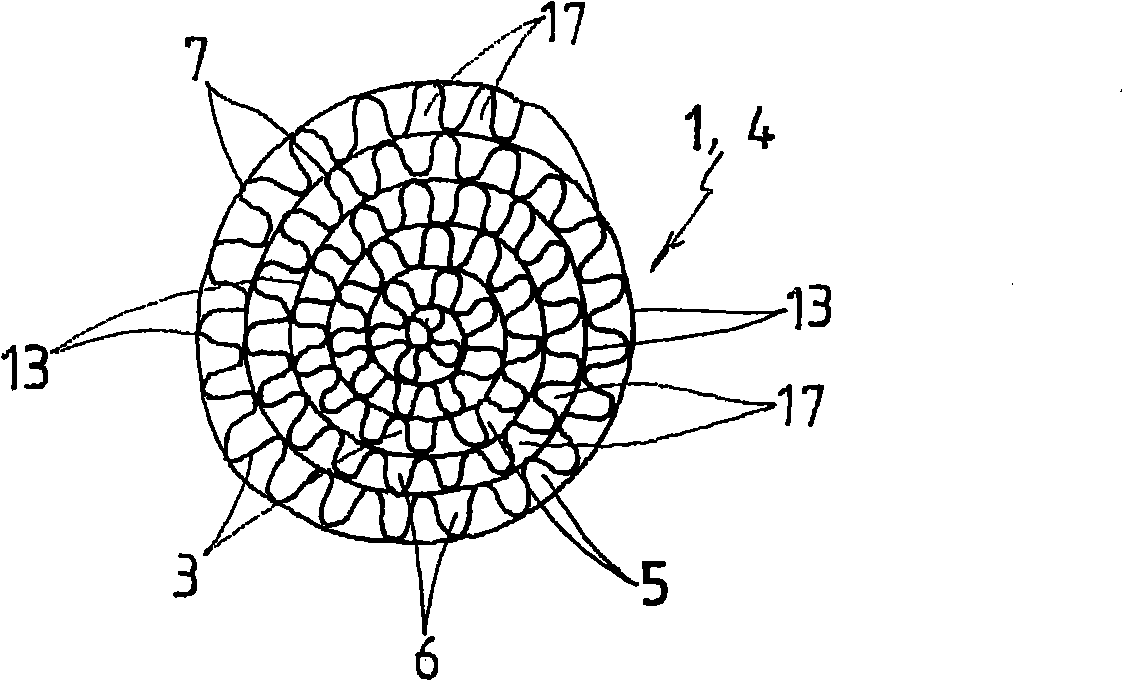

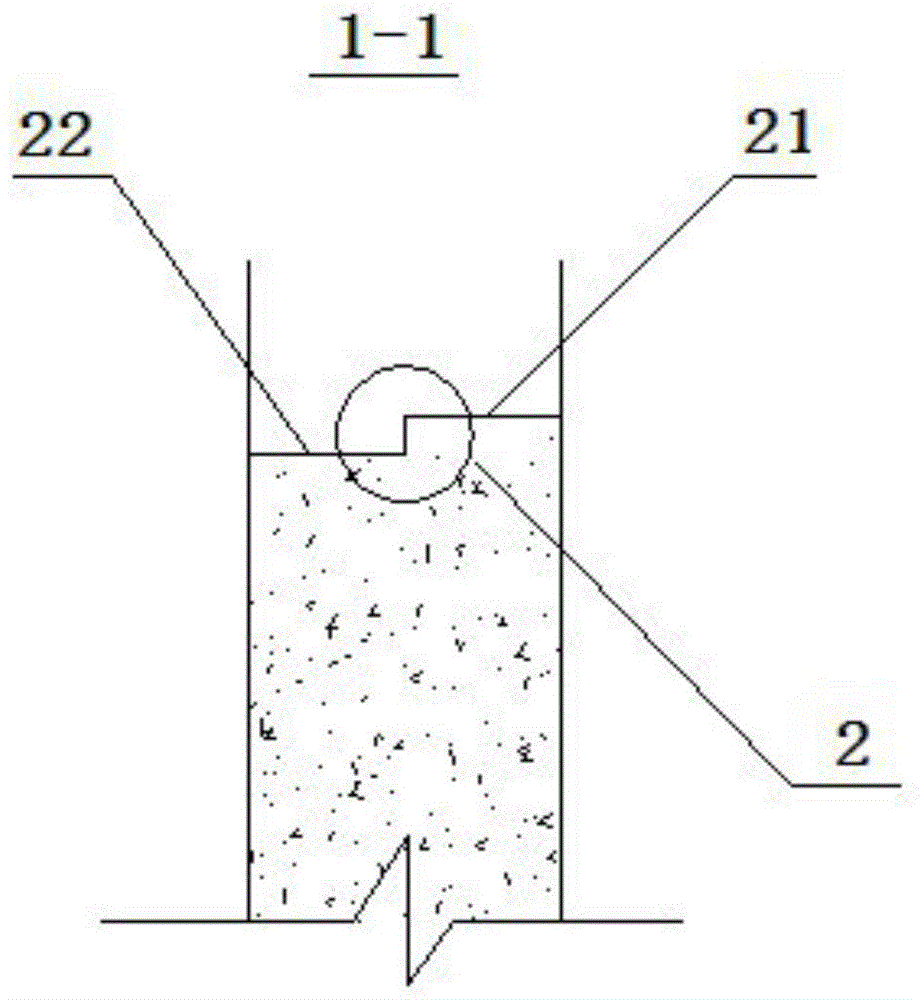

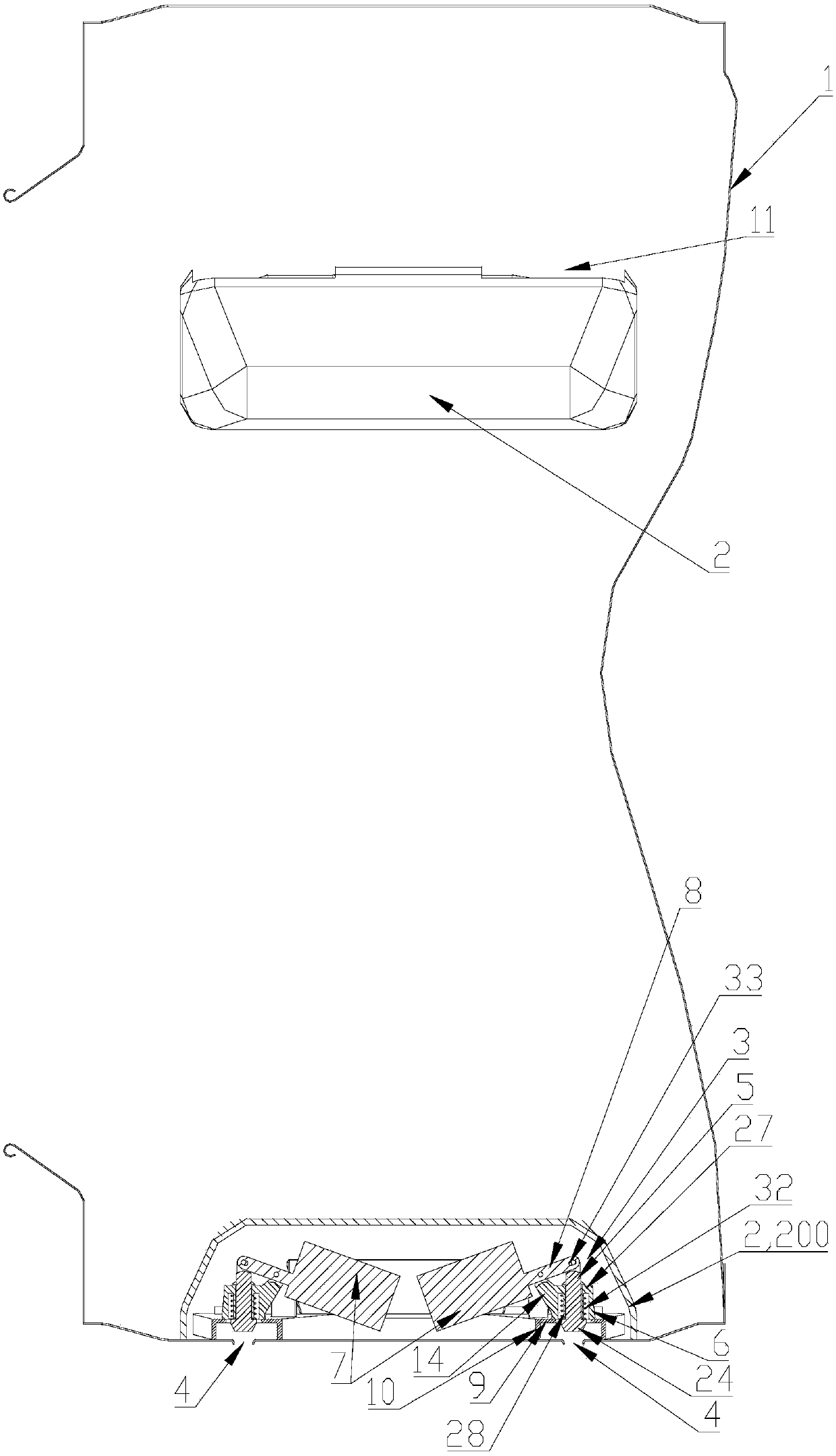

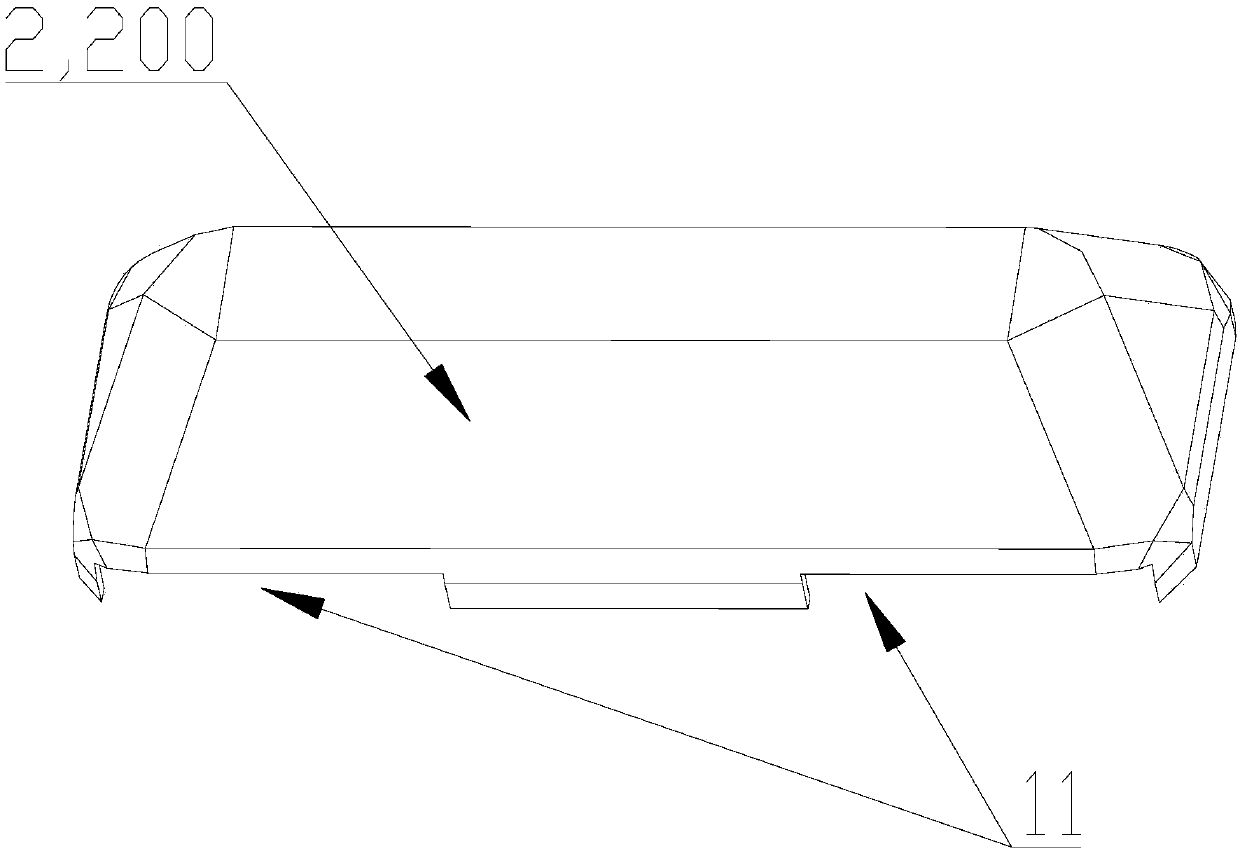

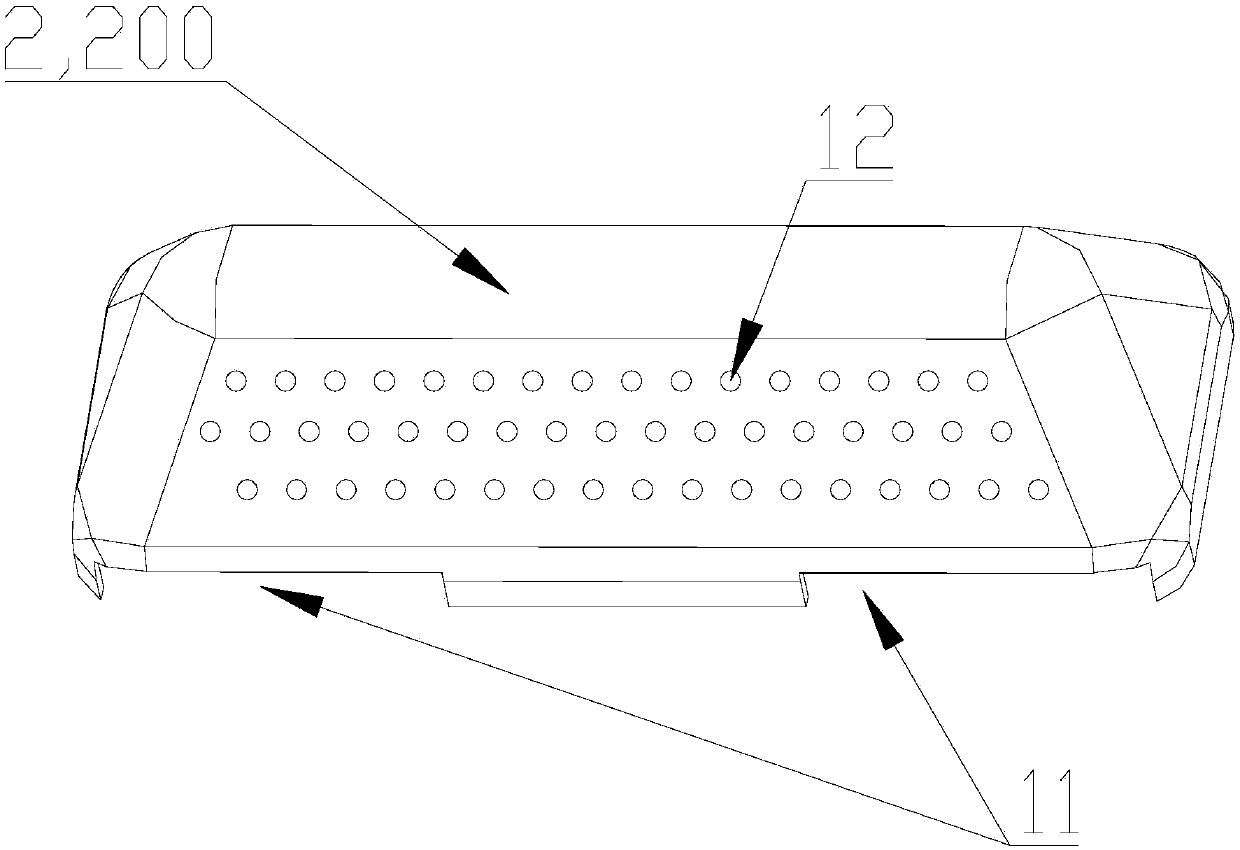

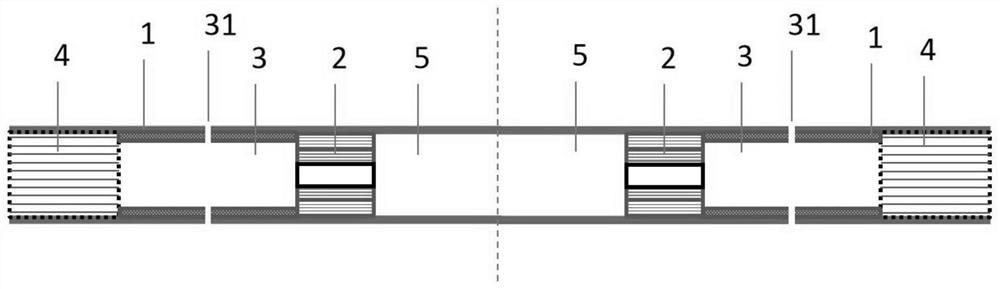

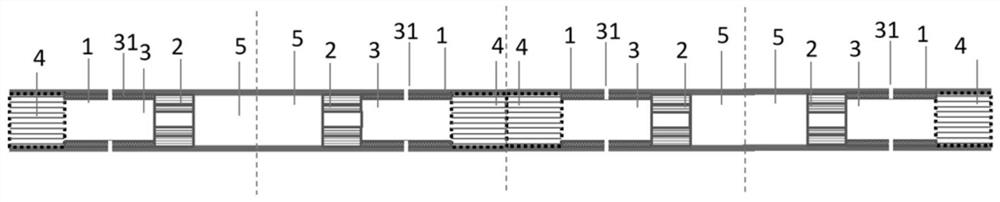

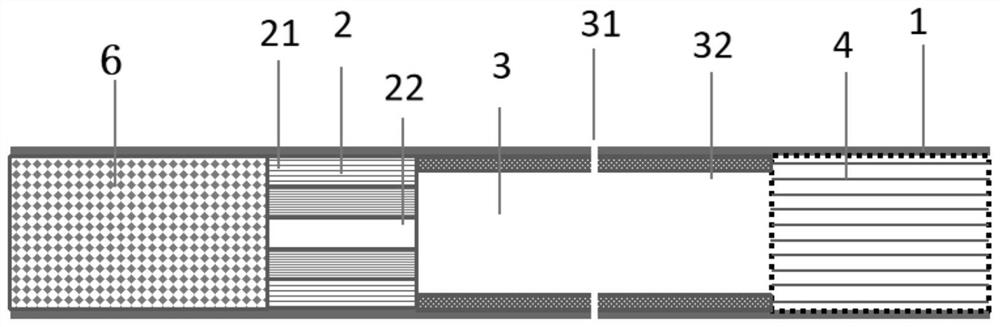

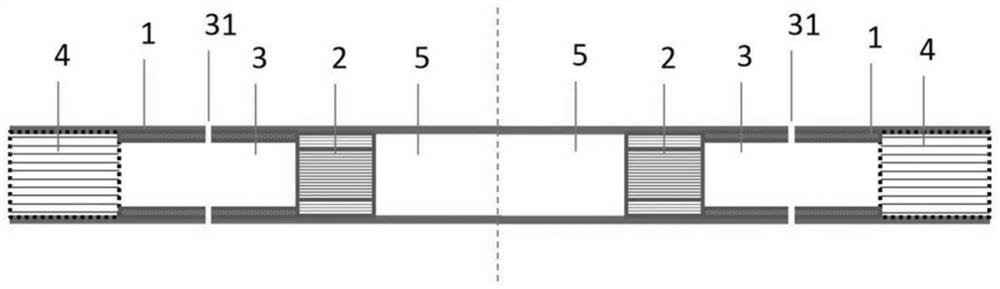

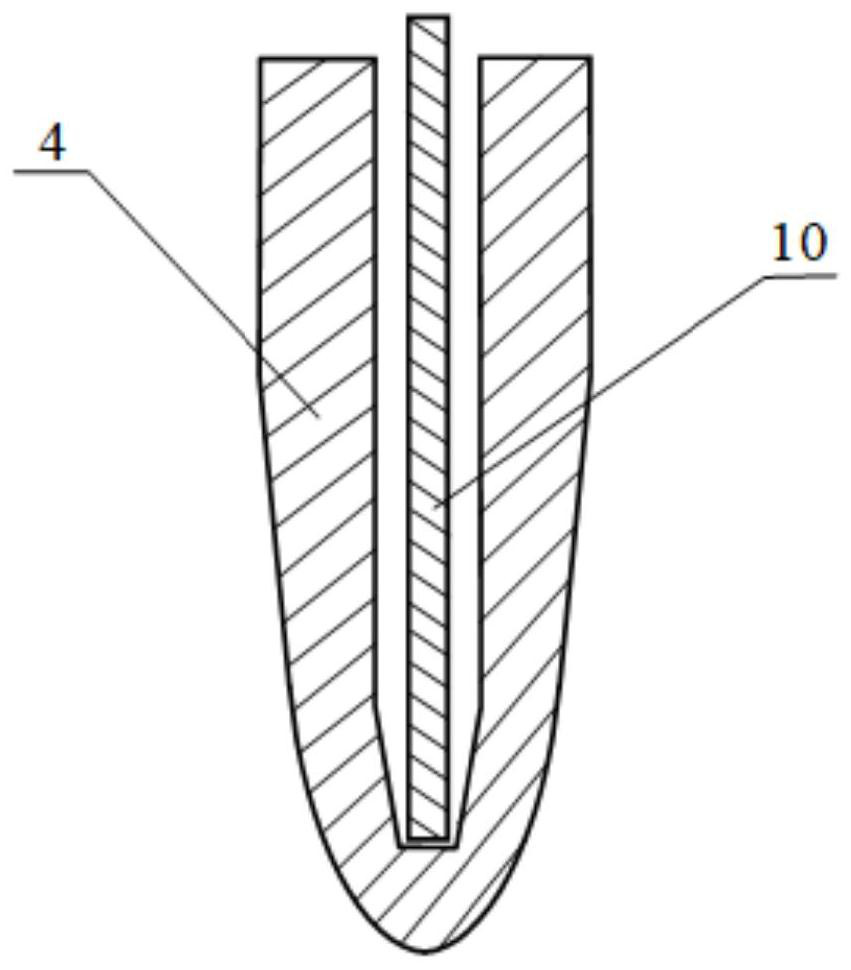

Aerosol generating product with multilayer groove corrugated structure

PendingCN114868960AIncrease the amount of smokeGuaranteed to blockTobacco treatmentCigar manufactureEngineeringMechanical engineering

The invention discloses an aerosol generating product with a multilayer groove corrugated structure. The aerosol generating product comprises an integrated outer tube (1), and an aerosol generating substrate (6), a plugging piece (2), a cavity structure (3) and a filtering piece (4) which are positioned in the outer tube (1), the plugging piece (2) comprises a pipe wall (21) and a pipe cavity (22), the pipe wall (21) is of a groove corrugated structure and comprises an outer layer (211), an inner layer (212) and a groove corrugated layer (213) located between the outer layer (211) and the inner layer (212), the outer surface of the plugging piece (2) is limited by the outer layer (211), and the pipe cavity (22) is limited by the inner layer (212); a plurality of groove corrugated layers (213) are arranged in the pipe cavity (22), and a spacing layer (221) is arranged between every two adjacent groove corrugated layers (213). The plugging piece comprises the multiple groove corrugated layers, the multiple groove corrugated layers support one another, and more airflow channels can be reserved as much as possible on the premise that it is guaranteed that the aerosol generating material is plugged.

Owner:CHINA TOBACCO YUNNAN IND

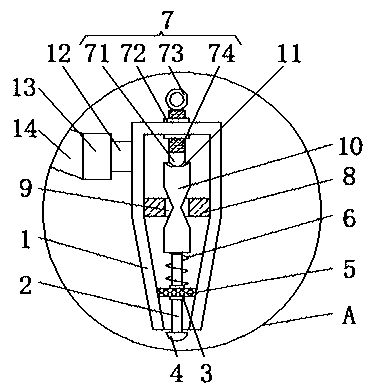

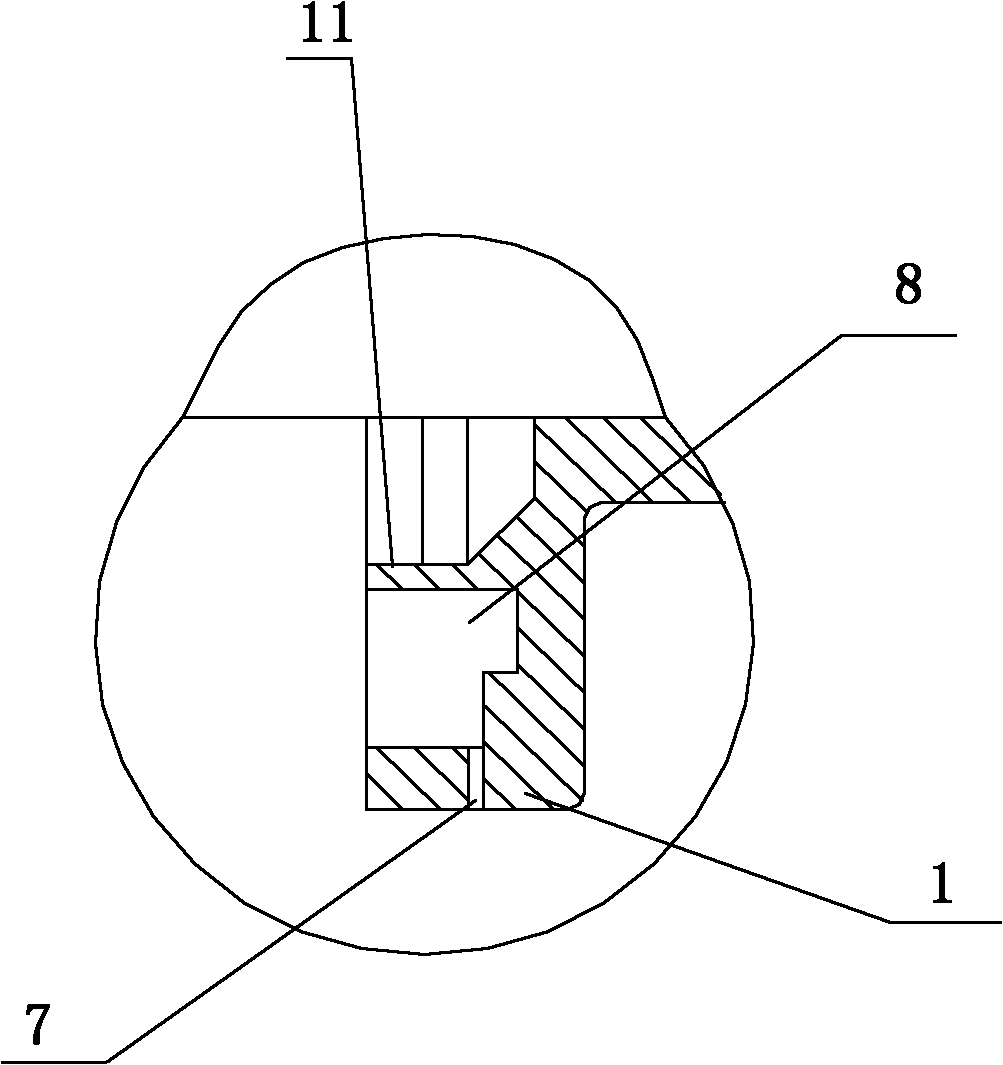

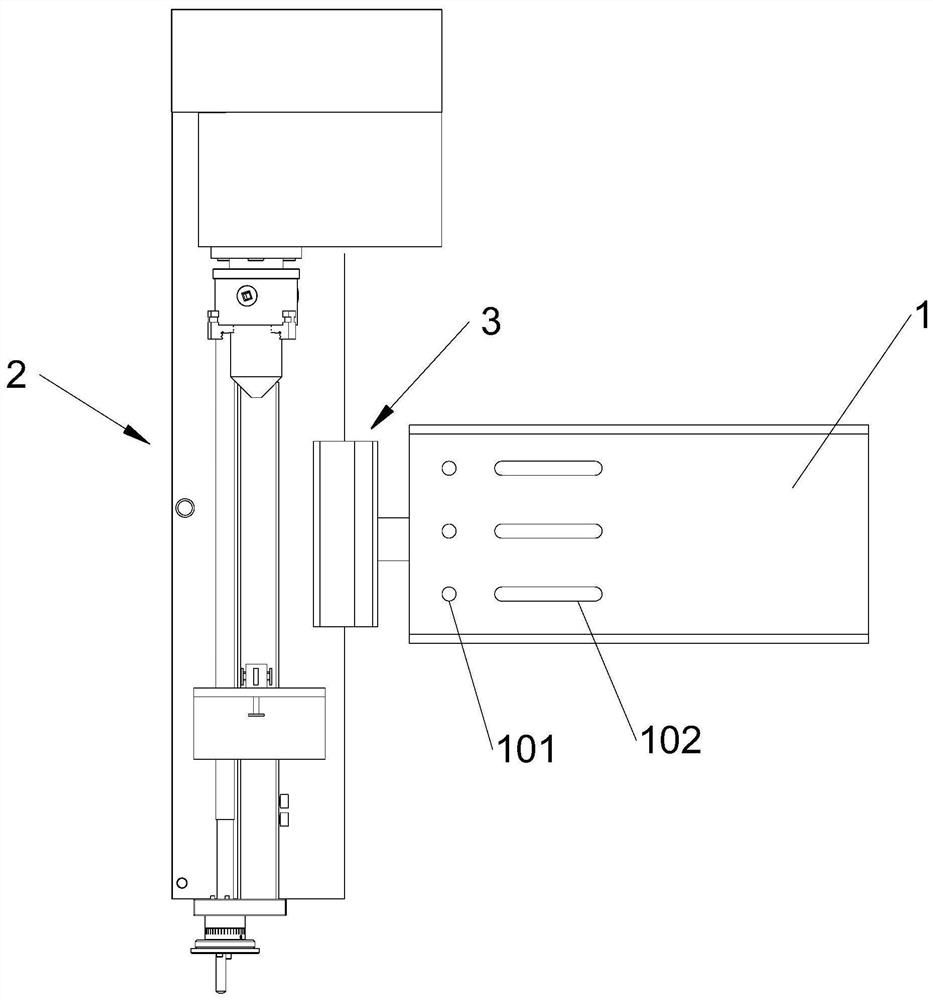

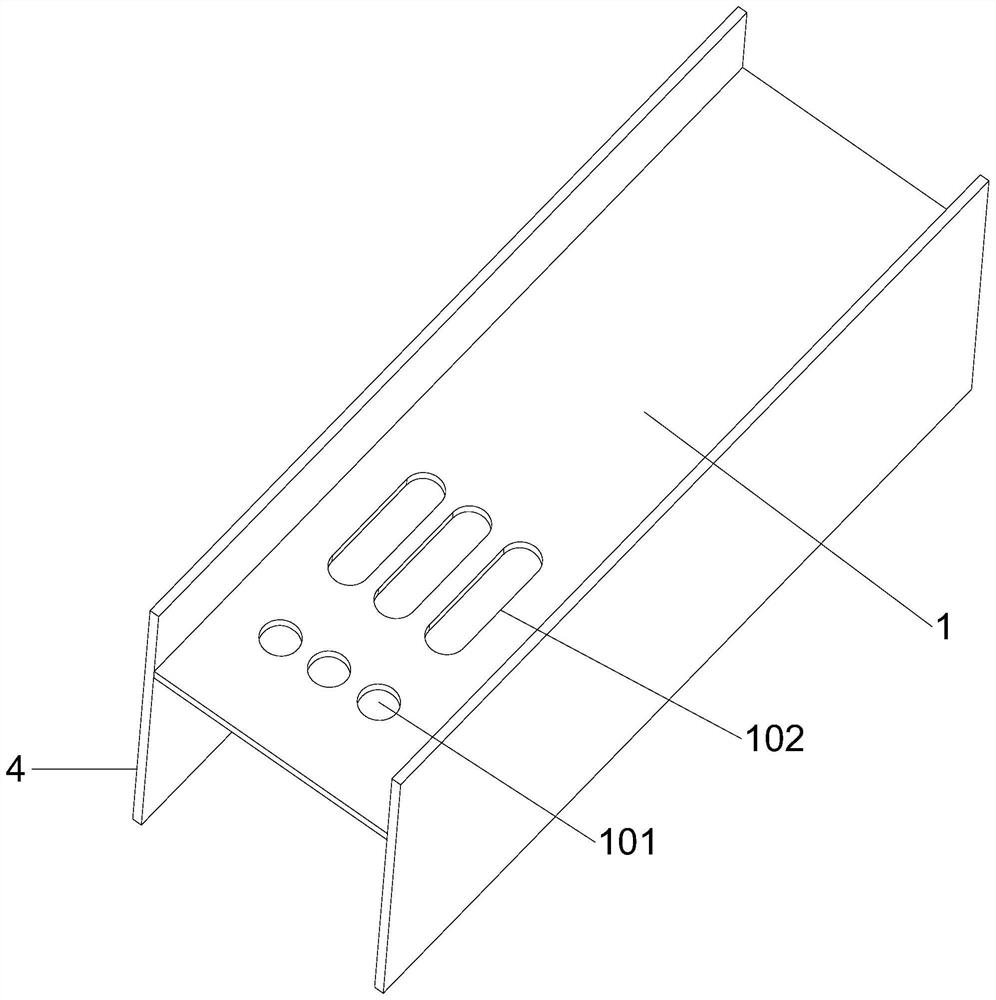

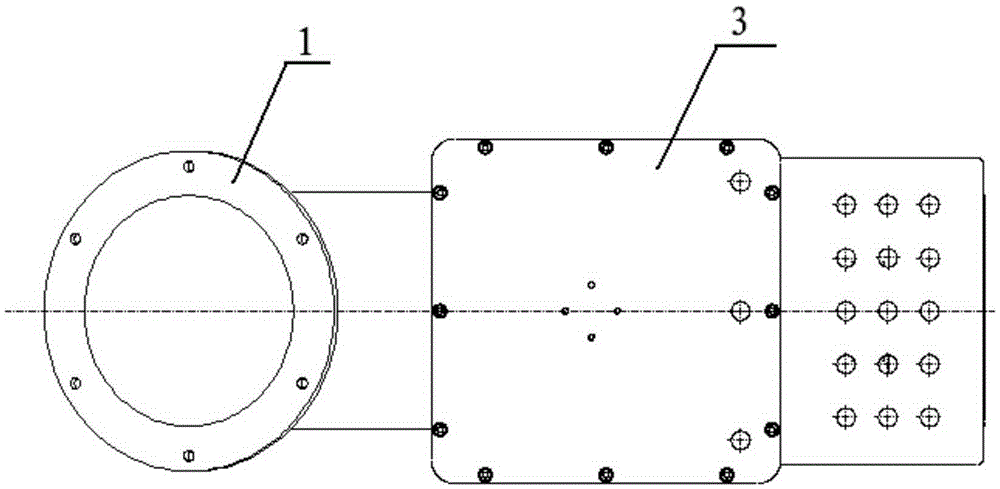

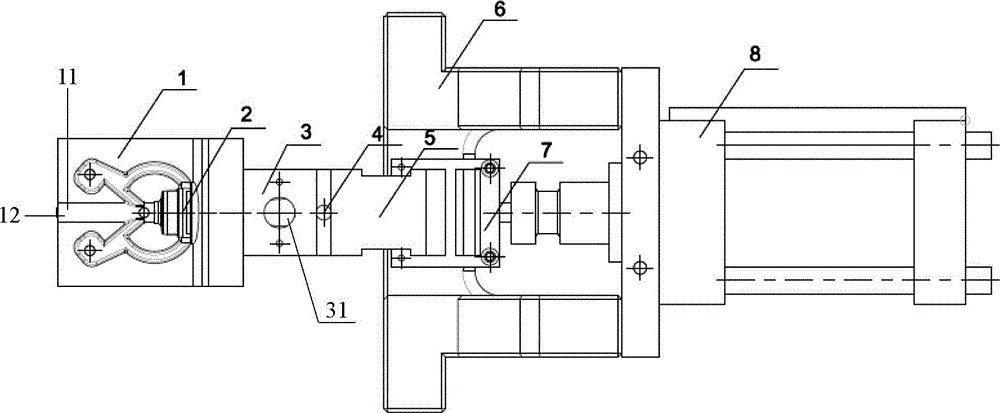

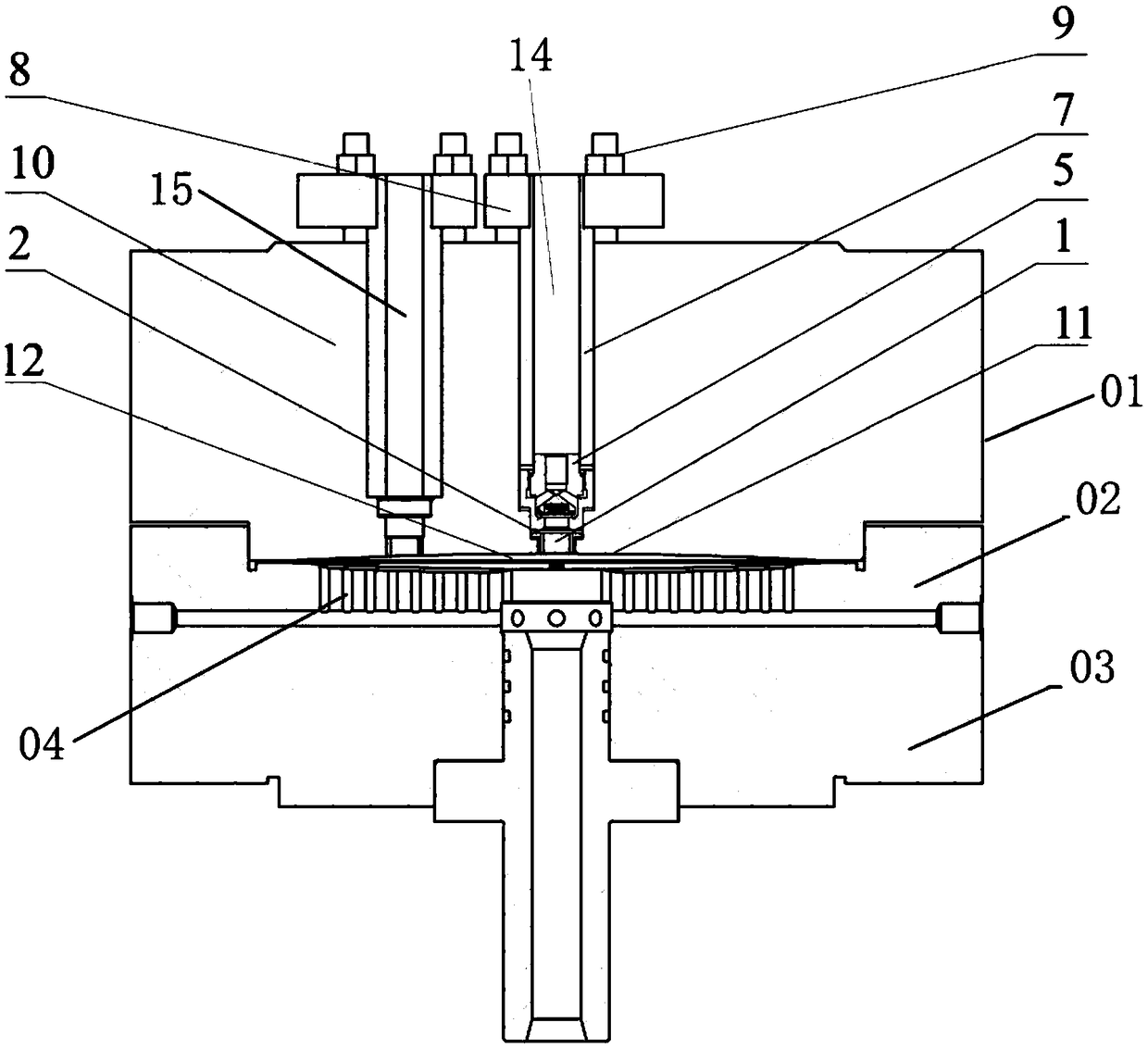

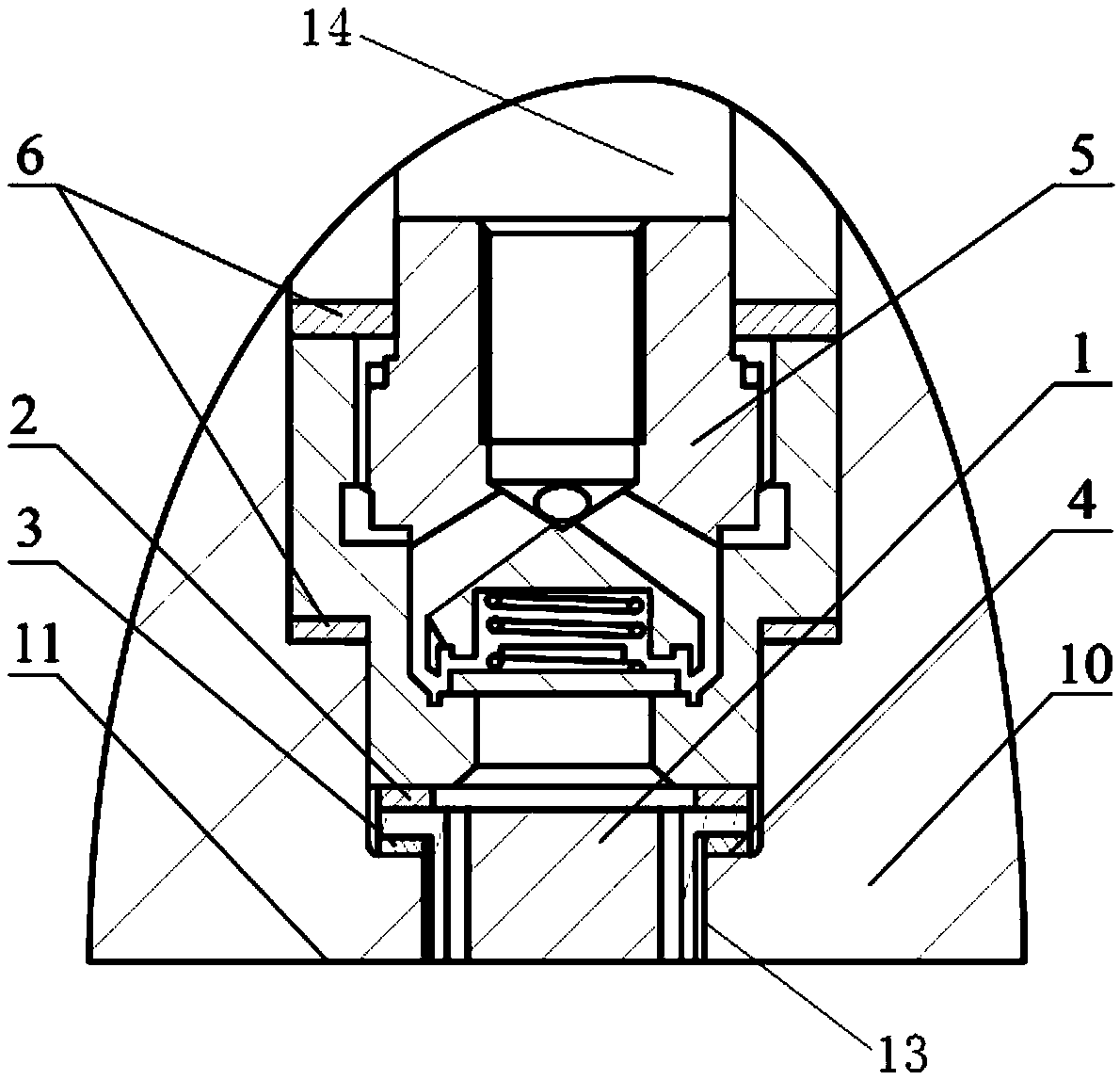

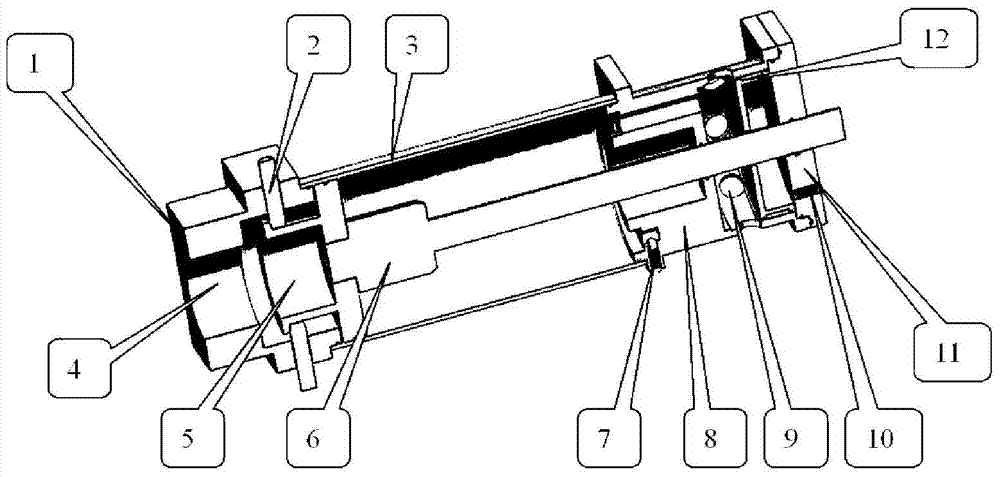

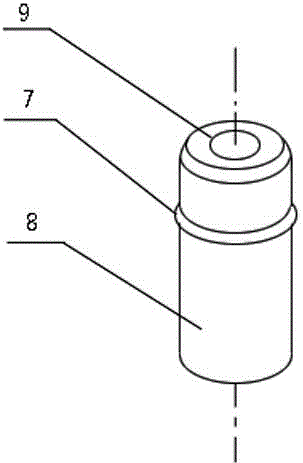

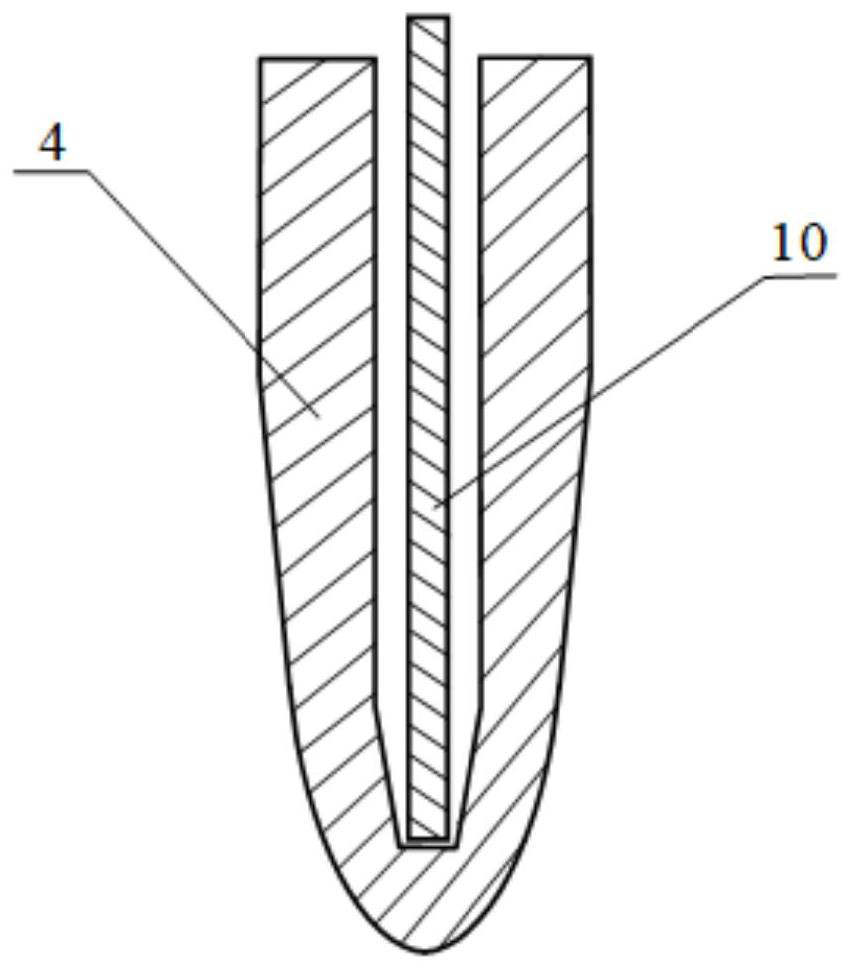

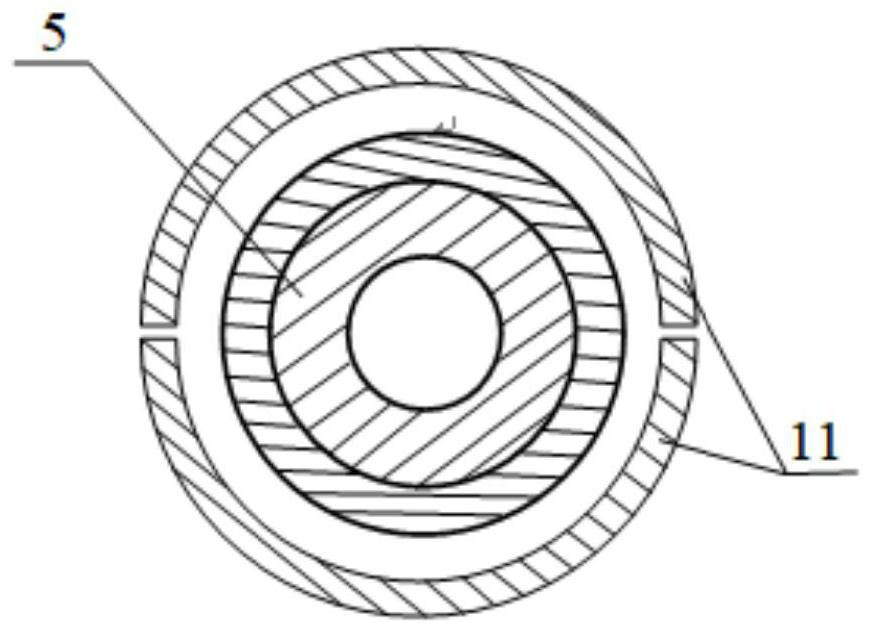

Core pulling vacuum valve for die casting and application method thereof

InactiveCN106286975AAchieve large displacement exhaustEliminate shrinkage defectsOperating means/releasing devices for valvesDie castingAlloy

The invention relates to the field of pressure casting of aluminum base alloys, in particular to a core pulling vacuum valve for die casting and an application method thereof. The core pulling vacuum valve for die casting comprises a movable module (1) and a valve rod (2), and is characterized by further comprising a valve head (3), a pressing block (4), a back base (5), an oil cylinder bracket (6), a connecting block (7) and an oil cylinder (8); the valve rod (2) is arranged in a pipe (11); the valve head (3) is provided with a connecting hole and an air extracting hole (31) communicating with the connecting hole; a back rod of the valve rod (2) is sleeved in the connecting hole of the valve head (3); a front rod of the valve rod (2) is provided with an exhaust port; and the back rod of the valve rod (2) is butted against the wall of the connecting hole of the valve head (3) through the pressing block (4). The application method of the core pulling vacuum valve for die casting is characterized by being performed according to the following steps: die casting preparation; pressing injection; cooling mold opening; and reuse. The core pulling vacuum valve for die casting is large in exhaust section area and high in casting quality.

Owner:SHANGHAI WANTAI AUTO PARTS

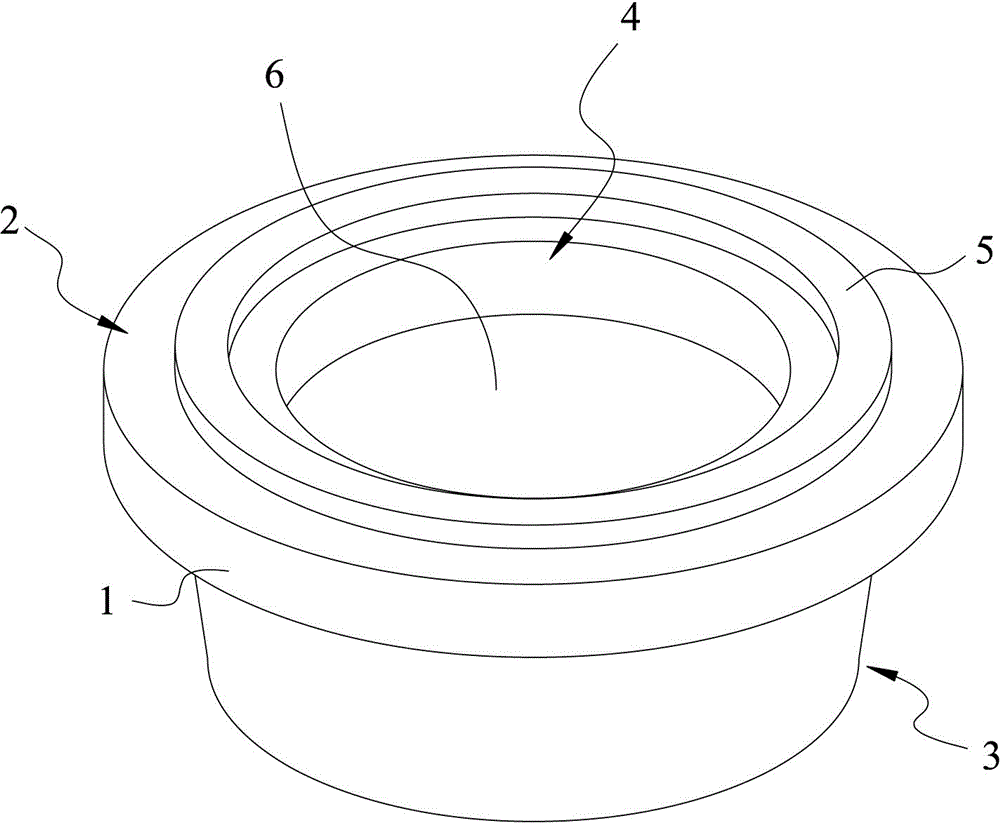

Cable tube bank plug

ActiveCN104092171ARealize blockingGuaranteed to blockCable installations in surface ductsCable installations in underground tubesEngineeringGasket

The invention relates to a cable tube bank plug. The cable tube bank plug comprises a ceramic body, wherein the ceramic body comprises a cylindrical outer edge part and a circular-truncated-cone-shaped plugging part, wherein the large-area bottom surface of the plugging part is connected to one end face of the outer edge part in a coplanar manner and the plugging part is coaxial to the outer edge part; the area of the large-area bottom surface of the plugging part is smaller than that of the end face of the outer edge part; the outer edge part and the plugging part are provided with a penetrating hole along the axis of the outer edge part and the plugging part; an end cover plate for blocking the cross section of the penetrating hole is arranged inside the penetrating hole; a stressed raised strip protruding along the axial direction of the outer edge part and surrounding the penetrating hole is arranged on the other end face of the outer edge part; the outer circumference of the stressed raised strip corresponds to that of the large-area bottom surface of the plugging part; a sealing gasket is arranged on the oblique side surface of the plugging part. The cable tube bank plug disclosed by the invention can be used for closely blocking the end opening of a tube bank, has certain strength by being provided with the stressed raised strip and made from a ceramic material, and can be crushed conveniently so as to be conveniently dismounted during dismounting.

Owner:STATE GRID CORP OF CHINA +3

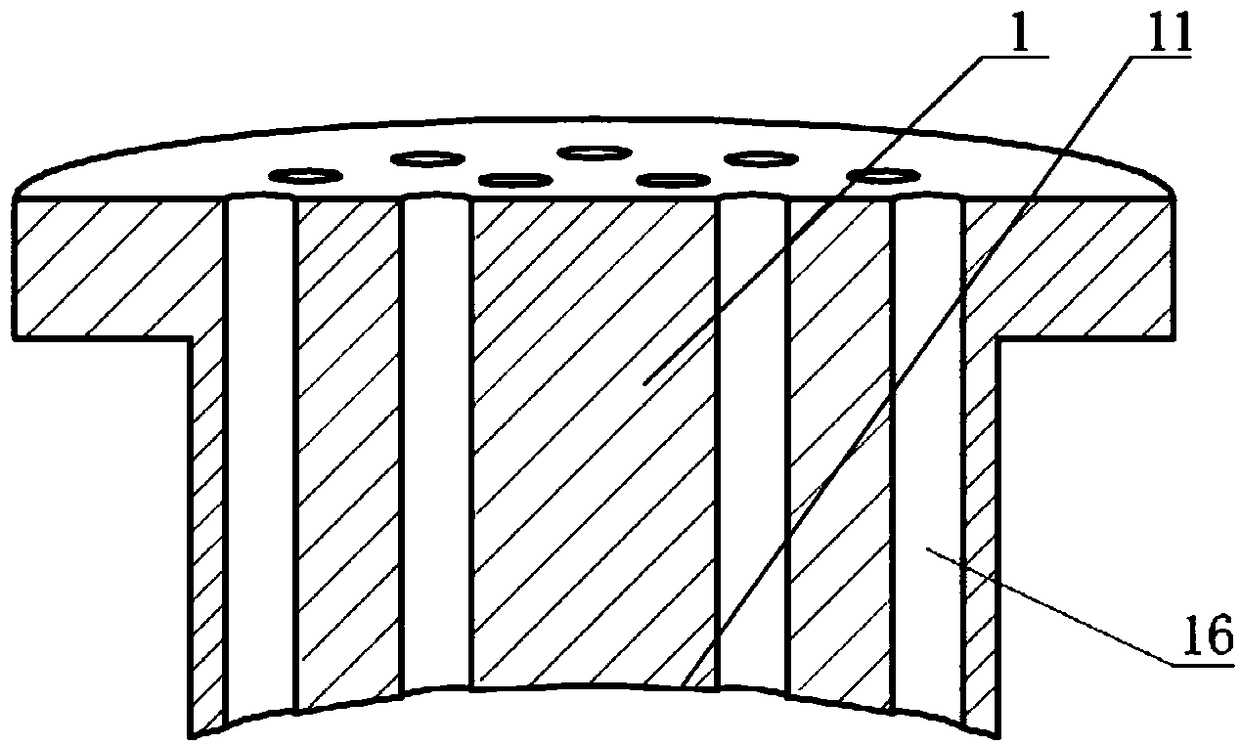

High-pressure diaphragm compressor, cylinder cover of high-pressure diaphragm compressor, and machining method of cylinder cover

ActiveCN109356822AHigh strengthDoes not affect normal operationPositive displacement pump componentsFlexible member pumpsExhaust valveEngineering

The invention discloses a high-pressure diaphragm compressor, a cylinder cover of a high-pressure diaphragm compressor and a machining method of the cylinder cover, and belongs to the field of diaphragm compressors. The cylinder cover of the high-pressure diaphragm compressor comprises a cylinder cover body, wherein cylinder cover body is provided with an exhaust valve, an exhaust hole blockage and an exhaust cavity, the area where exhaust holes are formed in the center of the cylinder cover is excavated to serve as the exhaust cavity, the exhaust hole blockage is independently installed in the exhaust cavity, a corrugated spring is arranged between the exhaust hole blockage and the exhaust valve, the exhaust hole blockage can be used for machining a diaphragm cavity profile of the diaphragm compressor together with the cylinder cover only after the cylinder cover is installed well, and the outer diameter of the exhaust hole blockage is smaller than the inner diameter of the exhaust cavity. According to the high-pressure diaphragm compressor, the cylinder cover of the high-pressure diaphragm compressor and the machining method of the cylinder cover, the problems that under the conditions of high temperature and high pressure, due to the structural limitation of the exhaust holes, the deformation of the exhaust holes is greatly constrained, full expansion cannot be achieved, andthen the thermal stress of the inner surfaces of small holes is quite large are solved, the thermal stress generated by the exhaust holes due to high temperature can be reduced, then the strength ofthe cylinder cover of the high-pressure diaphragm compressor is improved, and normal operation of the diaphragm compressor is not affected.

Owner:JIANGSU PERMANENT MACHINERY +1

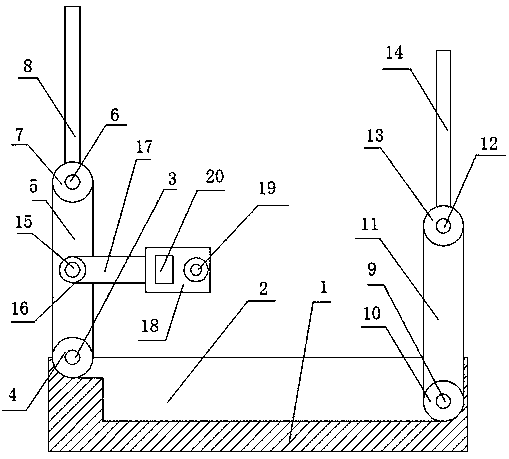

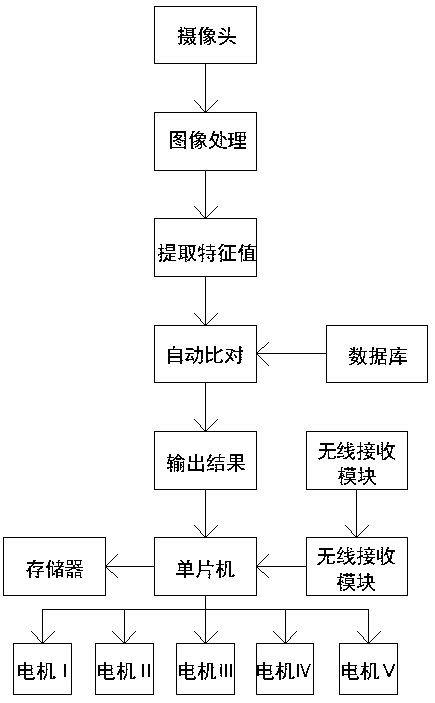

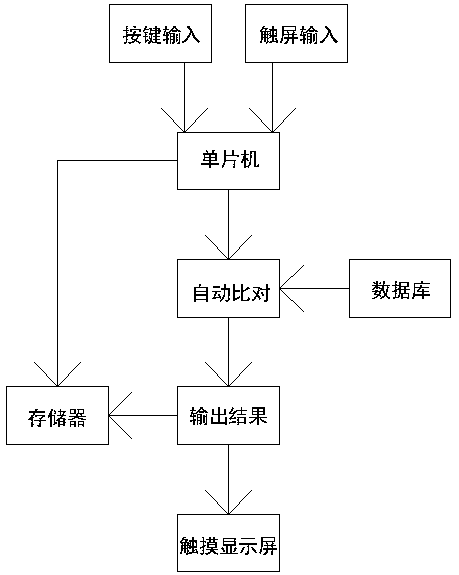

Automatic License Plate Recognition Parking Pile

InactiveCN109024364AEasy accessGuaranteed to blockTransmission systemsIndication of parksing free spacesParking spaceControl theory

The invention relates to a parking pile for automatically recognizing a vehicle license plate. The right end of the step groove (2) is provided with a motor (9), The output shaft of the motor III (9)is connected with the shaft sleeve III (10), the shaft sleeve III (10) is connected with the bottom end of the load-bearing rod II (11), the top end of the load-bearing rod II (11) is connected with the motor IV (12), the output shaft of the motor IV (12) is connected with the shaft sleeve IV (13), and the shaft sleeve IV (13) is connected with the gear rod II (14). The invention can judge whethera vehicle enters a parking space according to a license plate, and is suitable for a company special parking space or a personal special parking space.

Owner:芜湖挺优机电技术有限公司

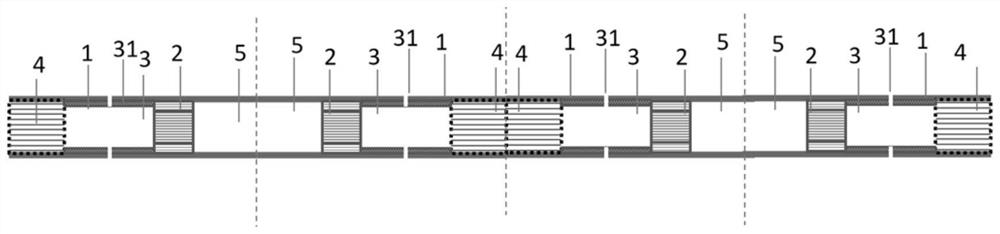

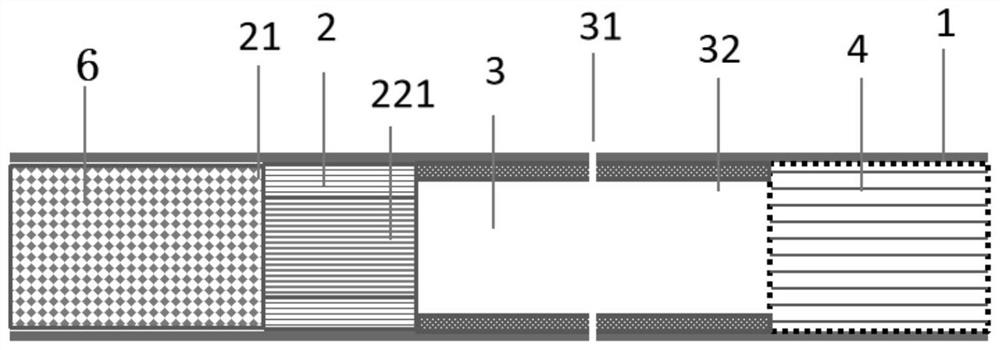

Aerosol generating product with composite form plugging piece

PendingCN114847543AImprove efficiencyIncrease the amount of smokeTobaccoCigar manufactureChemistryComposite material

The aerosol generating product comprises an integrated outer tube (1), and an aerosol generating substrate (6), a plugging piece (2), a cavity structure (3) and a filtering piece (4) which are positioned in the outer tube (1), the plugging piece (2) comprises a pipe wall (21) and a pipe cavity (22), the pipe wall (21) is of a groove corrugated structure and comprises an outer layer (211), an inner layer (212) and a groove corrugated layer (213) located between the outer layer (211) and the inner layer (212), the outer surface of the plugging piece (2) is limited by the outer layer (211), and the pipe cavity (22) is limited by the inner layer (212); a gathering sheet bar (221) is arranged in the pipe cavity (22). In the smoking process, the gathering sheet bar shrinks after being heated to block part of the middle airflow, so that more aerosol is in contact with aroma enhancing substances and / or fuming substances on the groove corrugated layer (213), and the effects of aerosol aroma supplementing and smoke amount increasing are further improved.

Owner:CHINA TOBACCO YUNNAN IND

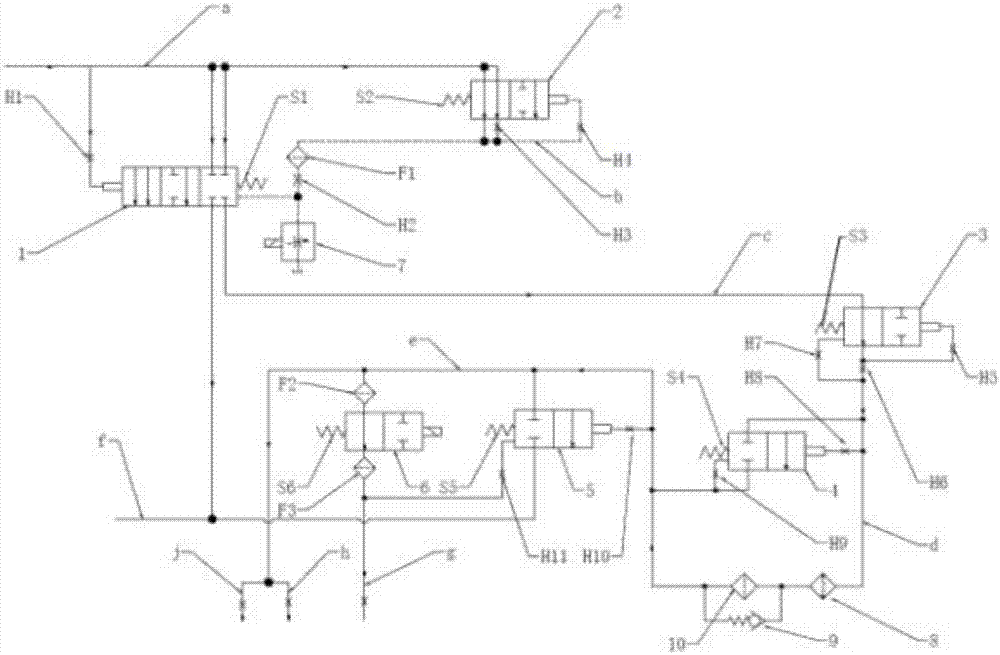

Gearbox lubricating and cooling system and gearbox

The invention discloses a gearbox lubricating and cooling system. The gearbox lubricating and cooling system comprises an oil tank, a main oil circuit, a main oil pressure control valve and a lubricating oil circuit. A lubricating and cooling oil circuit is divided into two oil circuit bodies which are used for clutch lubricating and gearbox inner bearing lubricating correspondingly. The output end of a lubricating flow control valve is connected with a residual stress control valve through an oil circuit. The lubricating and cooling oil circuit further communicates with an oil drainage oil circuit through the residual stress control valve. The output end of the oil drainage oil circuit leads to the oil tank. The output end of the lubricating flow control valve communicates with the spring end of the residual stress control valve. The gearbox lubricating and cooling system mainly has the beneficial effects that the effect that the lubricating and cooling system has stable pressure and flow is ensured through self feedback of the flow control valve and the dynamic balance between hydraulic oil and a spring; and the residual stress control valve is arranged, so that the maximum oil pressure of the lubricating and cooling system is limited, and the safety of the lubricating and cooling system is ensured.

Owner:捷孚传动科技有限公司

Method for preventing rare earth steel continuous casting nozzle from being blocked

The invention belongs to the technical field of continuous casting equipment, and particularly relates to a method for preventing a rare earth steel continuous casting nozzle from being blocked. The method comprises the following steps that 1, a stopper rod is heated at the beginning of continuous casting, and the heating temperature is kept higher than the temperature of tundish molten steel; meanwhile, a submersed nozzle is heated, and the heating temperature is kept higher than the temperature of tundish molten steel; 2, when the position of the stopper rod rises, namely, the nozzle is nodulated or blocked, the heating temperature of the stopper rod and the submersed nozzle is increased, and if the stopper rod continues rising, the heating temperature of the stopper rod and the submersed nozzle continues to be increased; and 3, after the stopper rod returns, the stopper rod and the submersed nozzle are cooled and adjusted back to the initial set temperature. According to the method,the easily-blocked parts of the nozzle and the stopper rod can be heated, the temperature of the parts is increased, the viscosity of rare earth inclusions is reduced, the fluidity of the rare earthinclusions is improved, and a good effect of improving nozzle nodulation and blockage is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

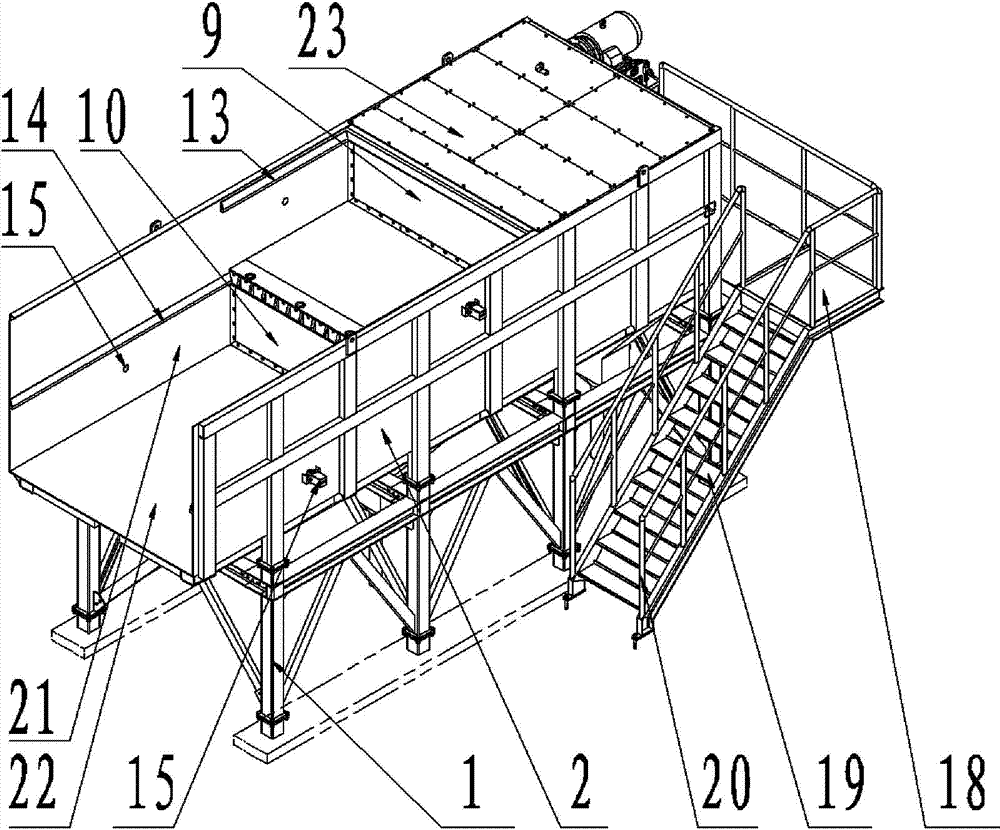

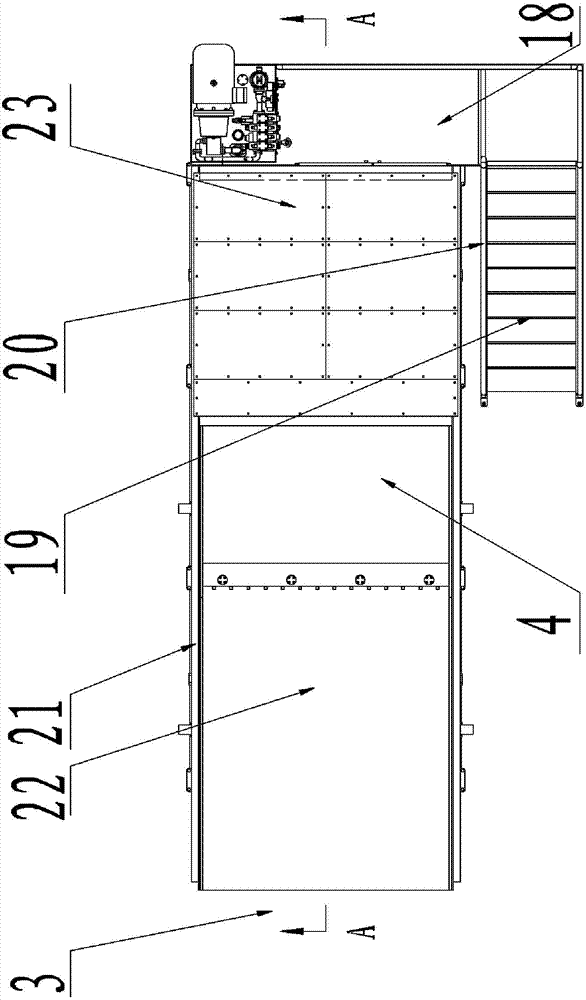

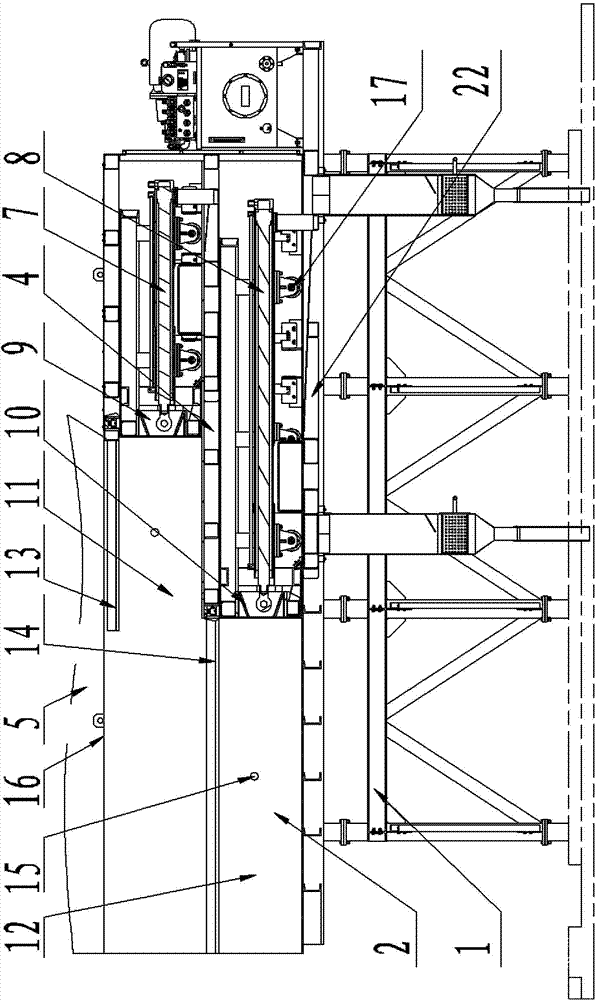

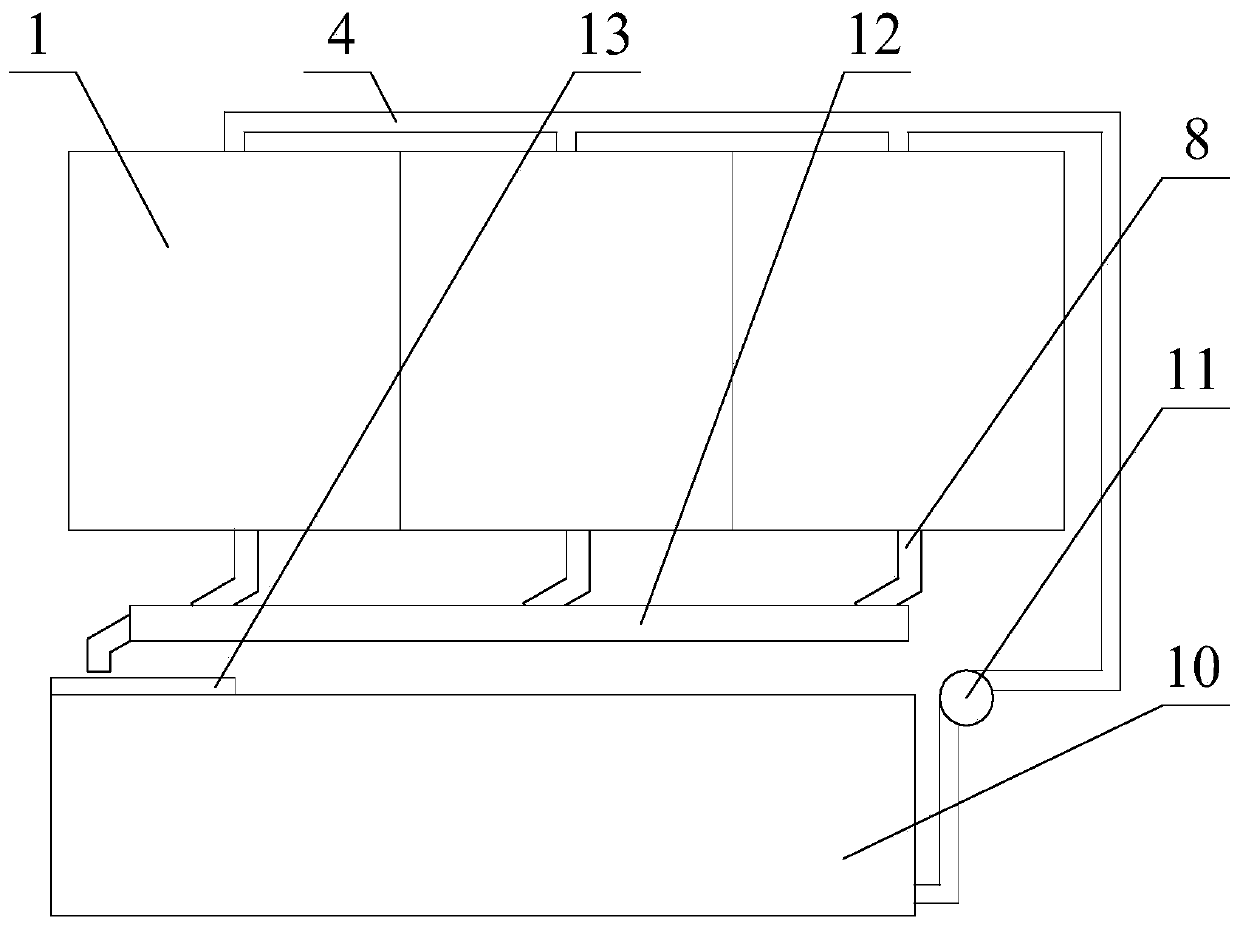

Material pushing device of waste transfer station

ActiveCN103466241BEasy to handleIncrease storage capacityRefuse receptaclesWaste collectionMechanical engineering

The invention discloses a material pushing device of a waste transfer station. The material pushing device of the waste transfer station comprises a rack, wherein a working framework is fixed to the top of the rack, a discharge chute is connected with the upper end of the working framework, material pushing oil cylinders are installed in the working framework, material pushing heads are installed on the material pushing oil cylinders, discharge chambers are arranged in front of the material pushing heads, the discharge chambers are communicated with the discharge chute, the material pushing heads comprise the upper material pushing head and the lower material pushing head, the upper material pushing head is arranged on the upper rear portion of the lower material pushing head, the discharge chambers comprise the upper discharge chamber and the lower discharge chamber, an upper pushing head guide rail is arranged on the portion, corresponding to the upper material pushing head, of the side wall of the upper discharge chamber, a lower pushing head guide rail is arranged on the portion, corresponding to the lower material pushing head, of the side wall of the lower discharge chamber, the material pushing oil cylinders comprise the upper material pushing oil cylinder and the lower material pushing oil cylinder, a piston rod of the upper material pushing oil cylinder is connected with the upper material pushing head, and a piston rod of the lower material pushing oil cylinder is connected with the lower material pushing head. The material pushing device of the waste transfer station is good in waste treatment and storage capacity, the requirement of material dumping of various waste collection vehicles can be met, the phenomenon that the waste collection vehicles block up is avoided, the labor time and labor intensity of workers are reduced, normal operation of the waste transfer station is ensured, the required covered area is small, and manufacturing cost and maintenance cost are low.

Owner:CHONGQING ENDURANCE & SHINMAYWA IND

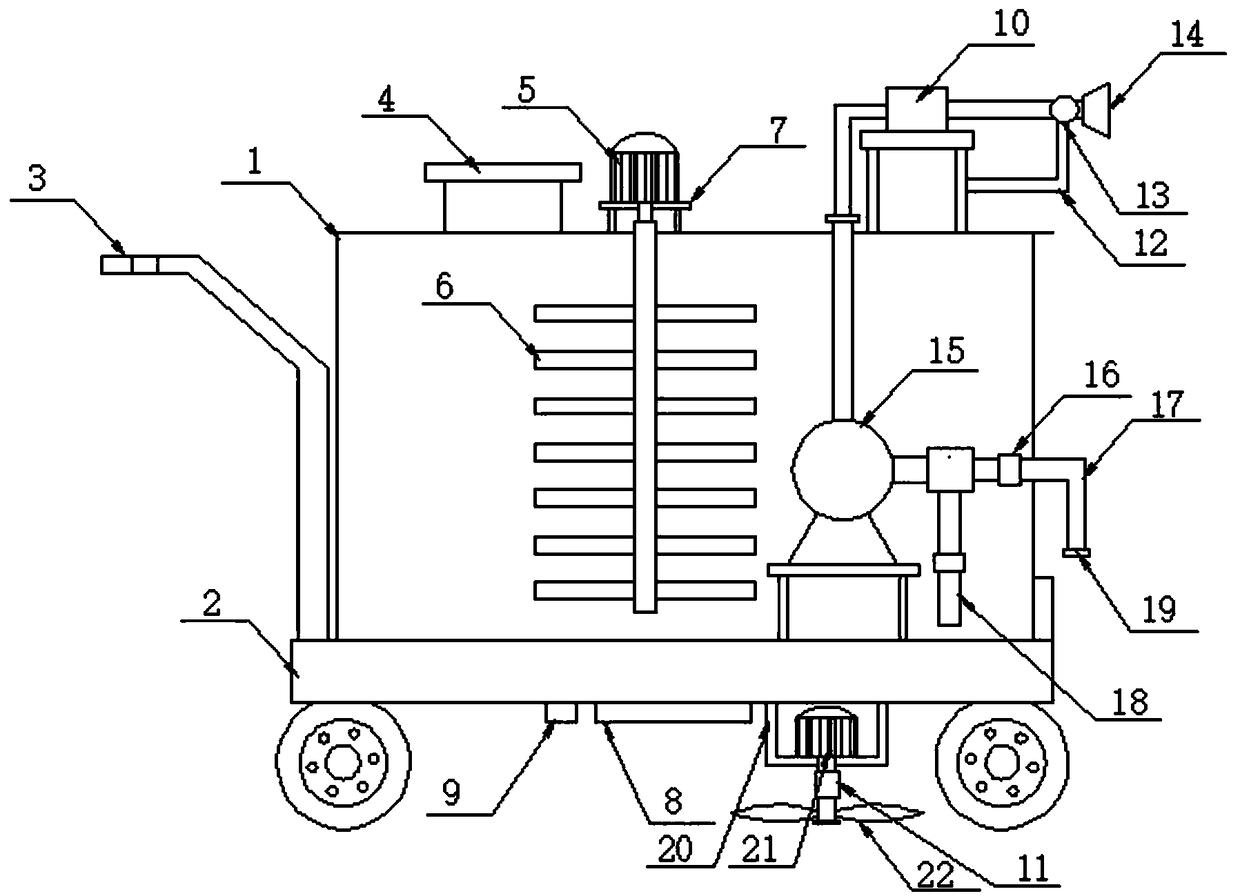

Livestock and poultry breeding house waste gas treatment device and waste gas treatment system formed by waste gas treatment device

PendingCN110327722AShorten the lengthSave spaceCombination devicesGas treatmentParticulatesWater filter

The invention relates to a livestock and poultry breeding house waste gas treatment device which comprises a device shell and a filter screen, wherein the device shell is of a sealing structure; one side of the device shell is provided with an air inlet. The side, opposite to the air inlet, of the device shell is provided with an air outlet; and a water baffle which is obliquely arranged is fixedly arranged on the air inlet. The back side of the air inlet is sequentially and fixedly provided with the filter screen and a spray pipe connected with inletting water to form a dust removal and deodorization assembly, the filter screen is obliquely arranged, and the spray pipe is provided with spray branch pipes along the arrangement direction of the filter screen, so that the filter screen is positioned in the spray range of the spray branch pipes. The waste gas treatment device also comprises a water filtering component which is fixedly arranged at the rear side of the spray branch pipes, and a drain pipe is arranged at the bottom of the device shell. According to the invention, waste gases, animal hairs and other fine particles in a breeding house can be discharged after being treated,and the environment is effectively protected.

Owner:曹梅君

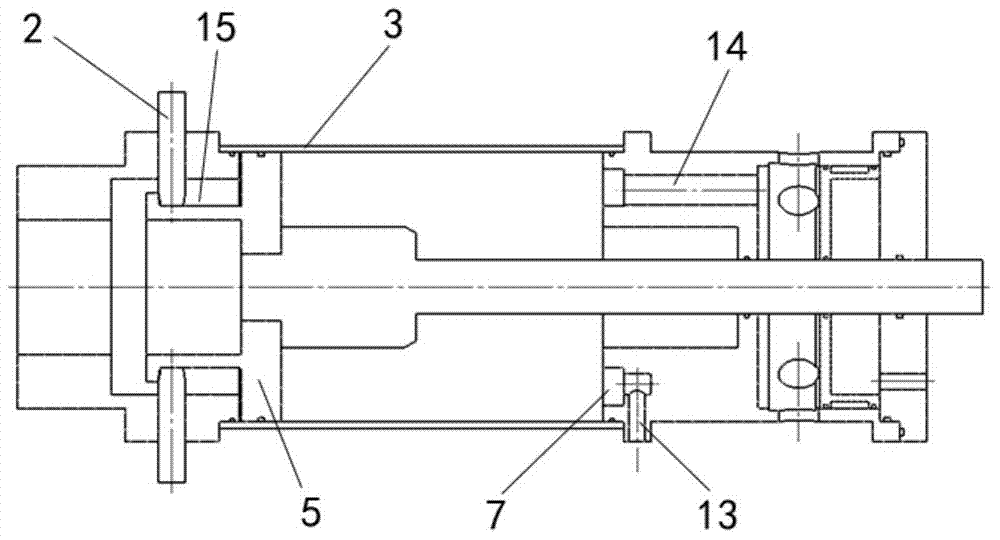

High-speed cylinder with buffer device

ActiveCN104712610AIncrease pressure differenceAchieve high thrustFluid-pressure actuatorsEngineeringMechanical engineering

The invention relates to a high-speed cylinder with a buffer device. The high-speed cylinder with the buffer device comprises a cylinder body, a piston component, a piston rod, a rear end cover and a front end cover. The rear end cover and the front end cover are arranged at the rear end and the front end of the cylinder body respectively, the rear end cover is provided with an air inlet, and the front end cover is provided with a hole. The piston component is arranged in the cylinder body, one end of the piston rod is connected with the piston component, and the other end of the piston rod penetrates out of the hole in the front end cover. A buffer piston is further arranged in the cylinder body and located between the piston component and the front end cover, and the buffer piston is provided with a hole for the piston rod to penetrate through. Exhaust outlets are formed in the cylinder body and located between the buffer piston and the front end cover. A vent hole enabling the front side and the rear side of the buffer piston to be communicated is formed in the buffer piston. The cylinder is provided with the buffer device, and the piston component of the cylinder can be effectively prevented from directly impacting the cylinder end covers.

Owner:AEROSPACE LIFE SUPPORT IND LTD

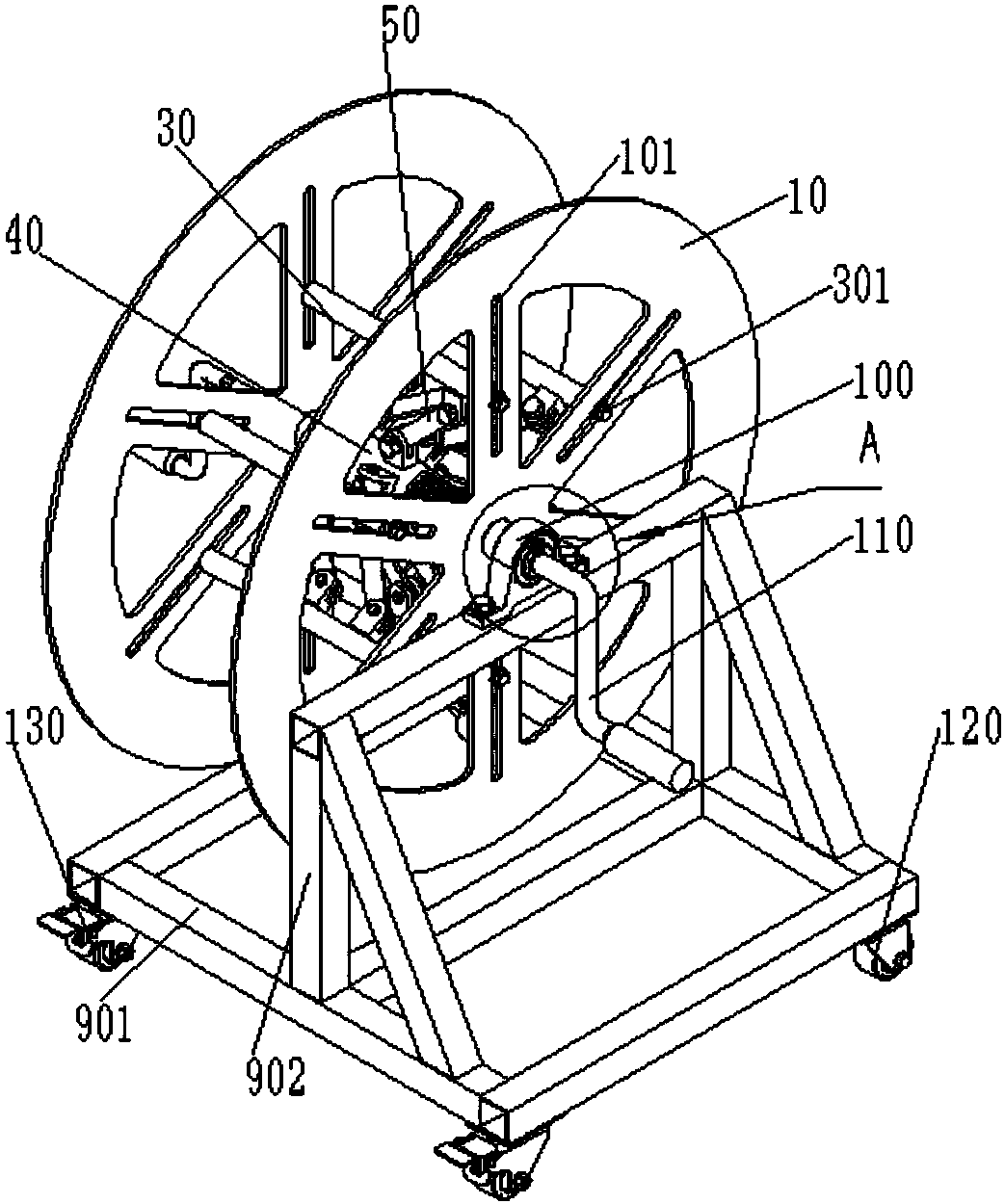

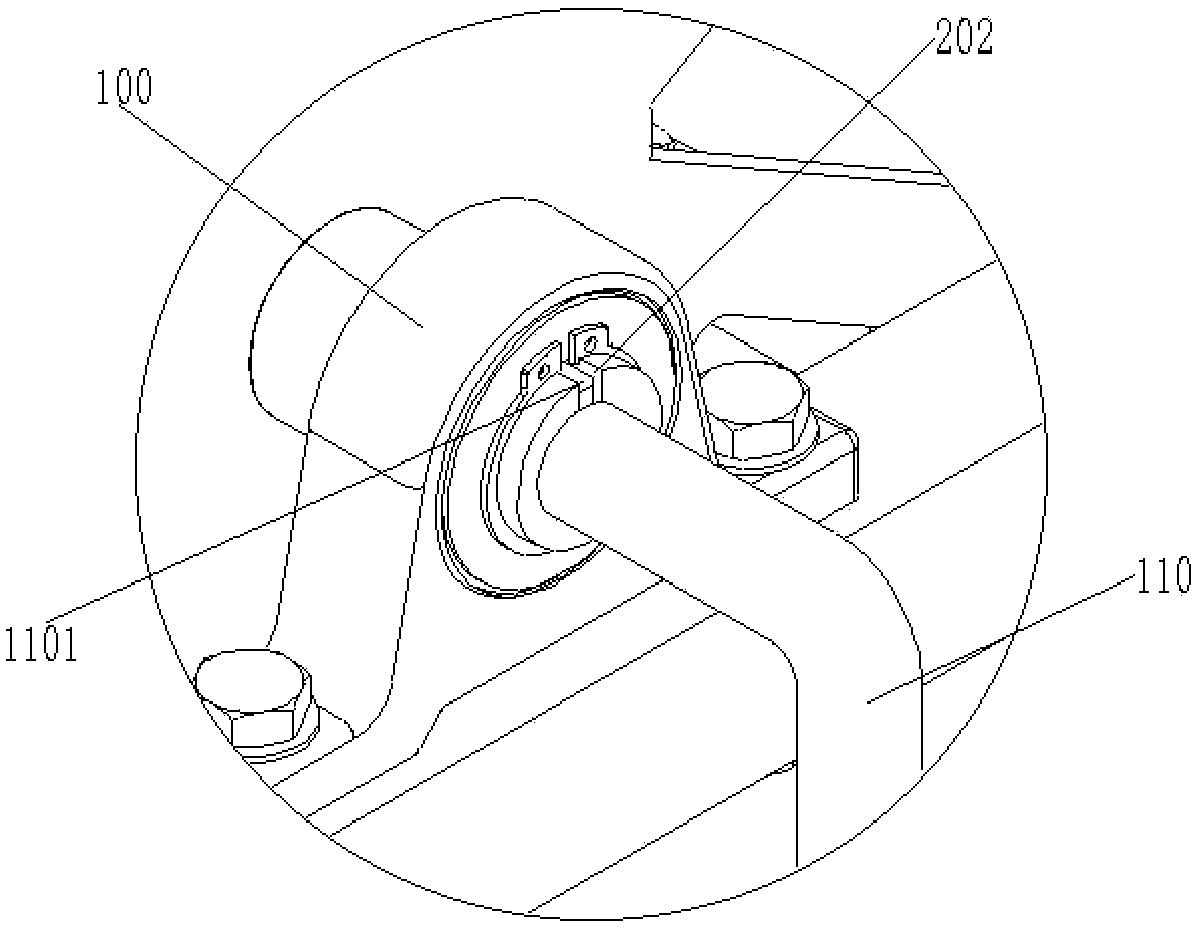

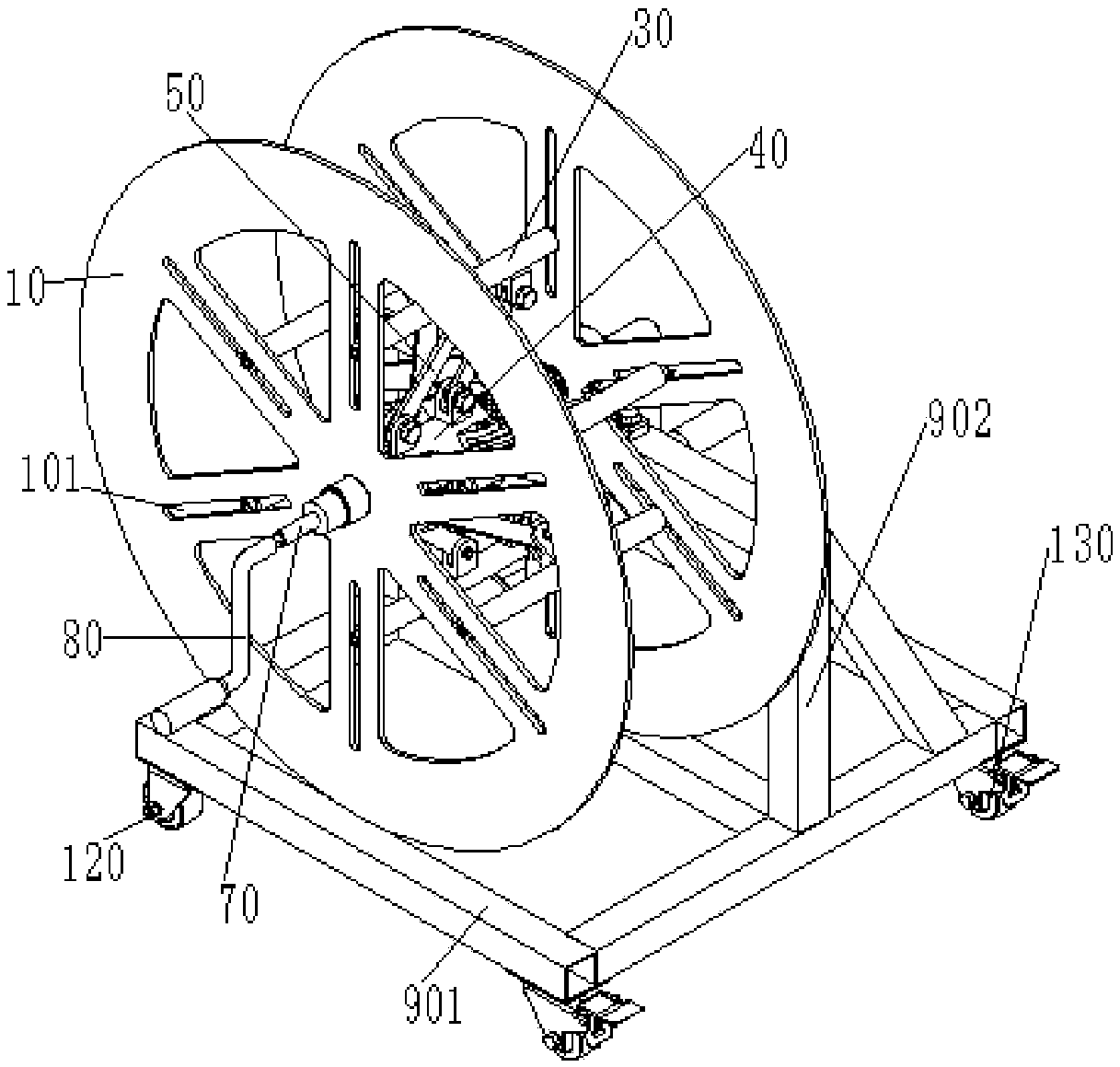

Power wire winding and unwinding device with adjustable inner diameter

The invention provides a power wire winding and unwinding device with the adjustable inner diameter, and relates to the technical field of power equipment. The power wire winding and unwinding devicewith the adjustable inner diameter comprises a support, wire blocking plates, a spindle, adjusting rods and a telescopic assembly, the two wire blocking plates are arranged and are fixedly connected with the spindle, the spindle is in pivot joint with the support, multiple first sliding grooves are circumferentially formed in the wire blocking plates in a manner of surrounding the rotating center,the length direction of the first sliding grooves faces the rotating center of the wire blocking plate, the first sliding grooves in the two wire blocking plates are in one-to-one correspondence, andthe two ends of the adjusting rods are in sliding fit with two first sliding grooves, in one to one correspondence, on the two wire blocking plates; the telescopic assembly is in drive connection with the adjusting rods, and enables all the adjusting rods to slide along the corresponding first sliding grooves at the same time. The technical problems that in the prior art, manual wire winding andunwinding waste time and labor, efficiency is low, injuries are easily caused, other potential safety hazards are caused, wire bundles formed through winding wires with different wire diameters are scattered and inconsistent, and the transport is affected are solved.

Owner:GUANGDONG POWER GRID CO LTD +1

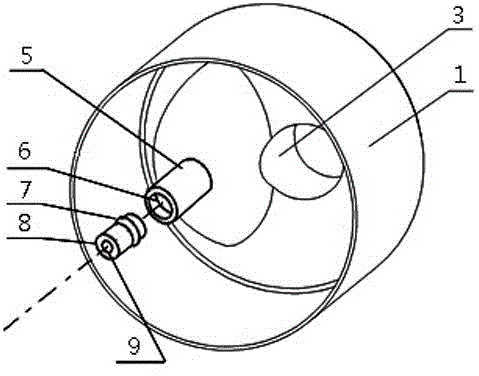

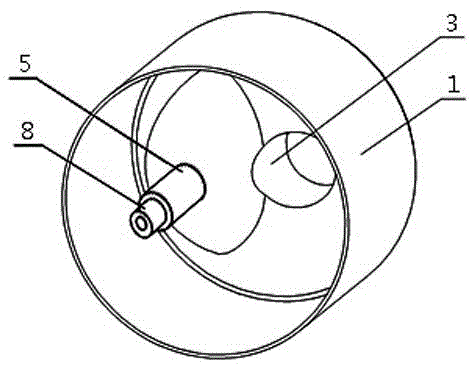

Automatic movable irrigation device and utilization method thereof

ActiveCN108967142AGuaranteed to blockReduce work intensityTransportation and packagingRotary stirring mixersWater storage tankEngineering

The invention discloses an automatic movable irrigation device, which comprises a water storage tank, an electric cart and a traction rod. The electric cart is arranged at the bottom of the water storage tank, the traction rod is obliquely arranged at one end of the top of the electric cart, the top of the water storage tank is provided with a water inlet, and a stirring motor is arranged on one side of the water inlet. A rotating shaft is in rotational connection with the stirring motor through a motor shaft of the stirring motor, and a plurality of stirring shafts are welded to the rotatingshaft. An alarm is arranged on one side of a weight detector which is arranged at the bottom of the electric cart, and a water pump is arranged in the water storage tank. A water inlet in one end of the water pump is connected with a first pumping pipe and a second pumping pipe through pipelines, the first pumping pipe and the second pumping pipe are provided with electromagnetic valves respectively, and the first pumping pipe is arranged outside the water storage tank. The automatic movable irrigation device has advantages that all-directional automatic irrigation is realized, work intensityis relieved, and irrigation efficiency is improved.

Owner:安徽启伦农业科技有限公司

Practical bottle neck

Owner:DONGGUAN JINGYUZUI ENVIRONMENTAL PROTECTION TECH

A method for preventing nozzle clogging of rare earth steel continuous casting

The invention belongs to the technical field of continuous casting equipment, and specifically relates to a method for preventing the clogging of the rare earth steel continuous casting nozzle, which includes the following steps: Step 1: when the continuous casting starts, the stopper rod is heated, and the heating temperature is kept higher than that of the tundish The temperature of the molten steel; at the same time, heat the submerged nozzle to keep the heating temperature higher than the temperature of the molten steel in the tundish; Step 2: When the position of the stopper rises, that is, nodules or blockages occur at the nozzle, then increase the pressure on the stopper and the submerged nozzle. The heating temperature of the nozzle, if the stopper rod continues to rise, continue to increase the heating temperature of the stopper rod and the submerged nozzle; Step 3: After the stopper rod returns to its original position, lower the temperature of the stopper rod and the submerged nozzle to the initial setting temperature. The method can heat the nozzle and the easily blocked part of the stopper rod, increase the temperature of the part, reduce the viscosity of the rare earth inclusions, improve their fluidity, and obtain a good effect of improving nozzle nodules and blockage.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com