Patents

Literature

199results about How to "Reduce the probability of occurrence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

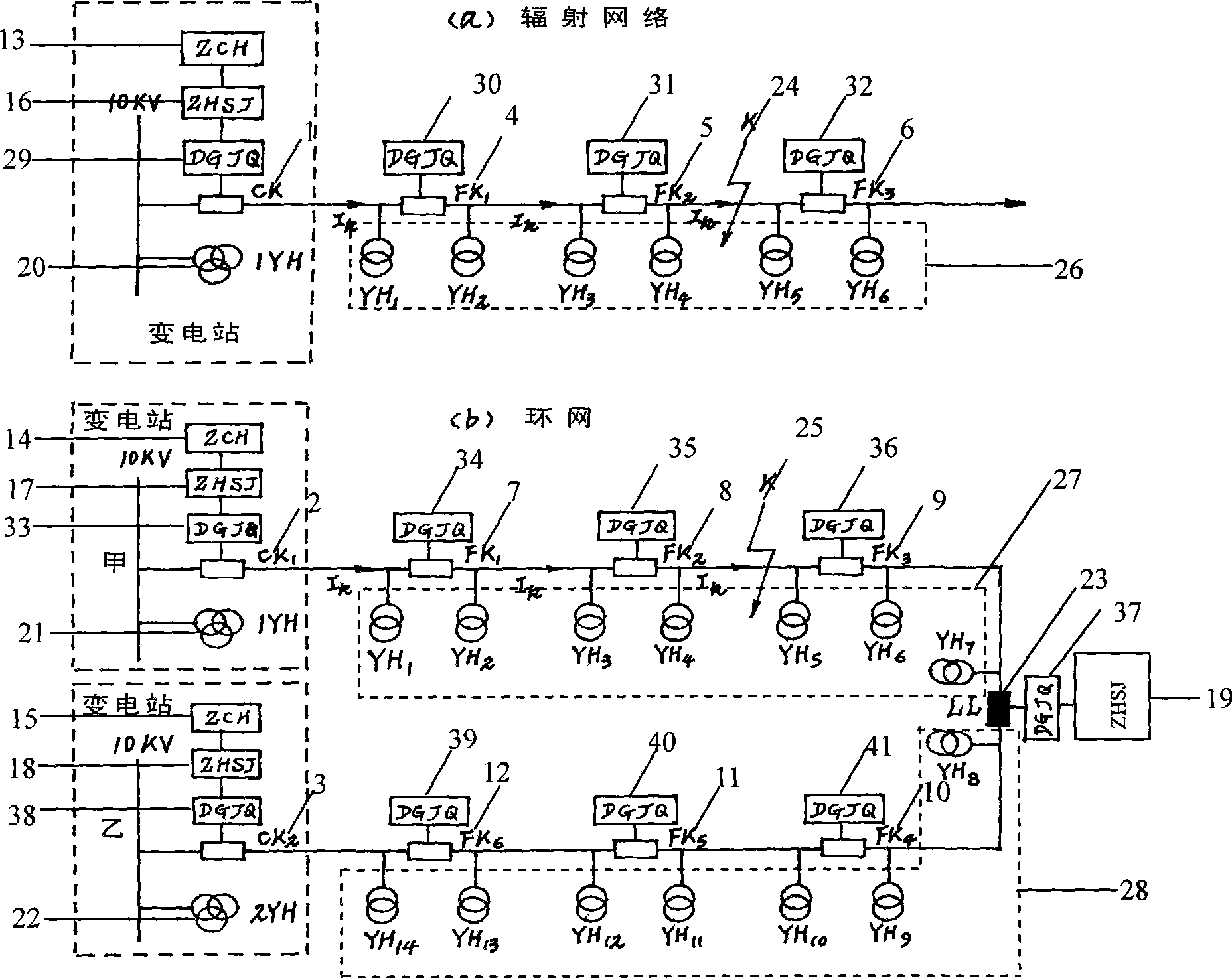

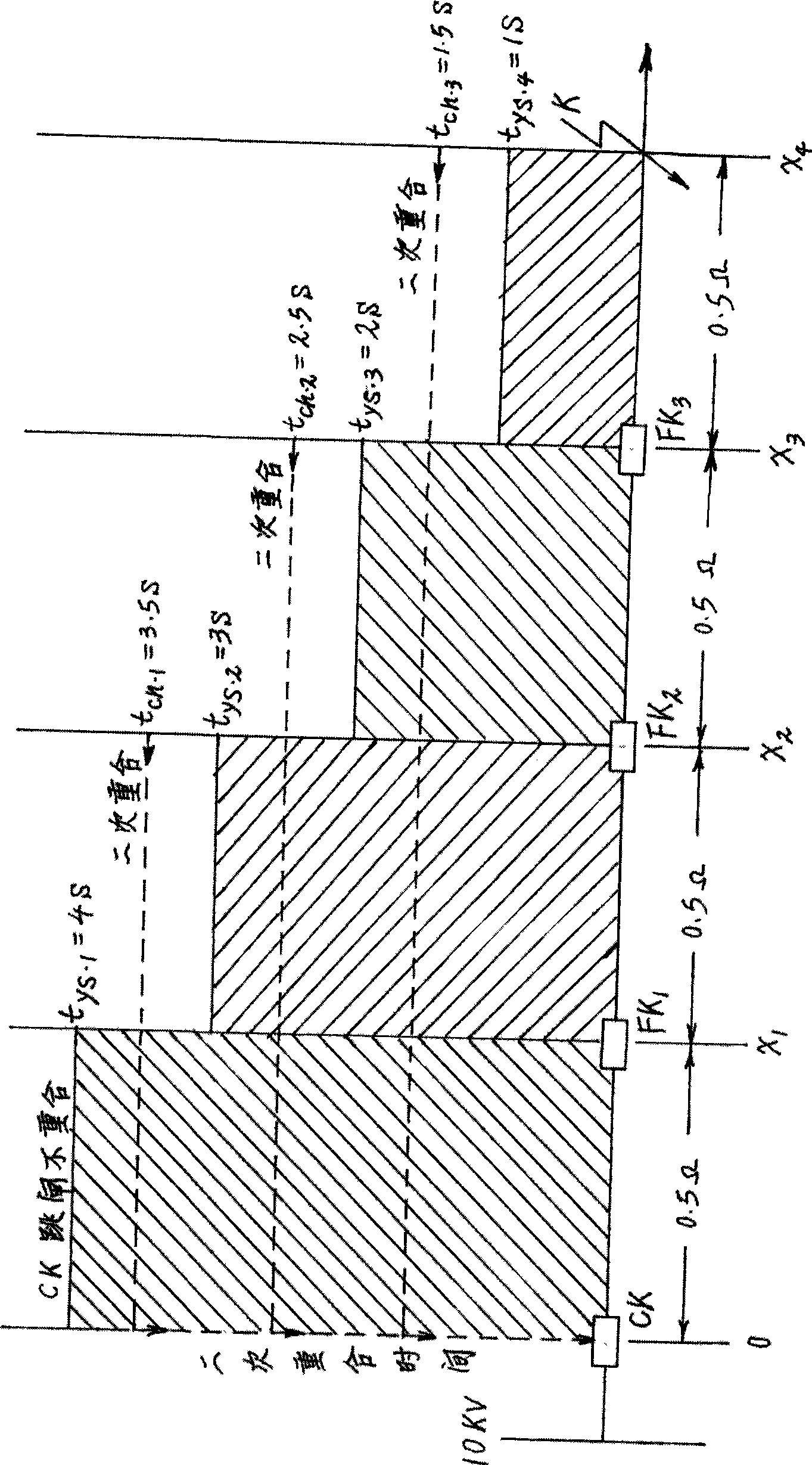

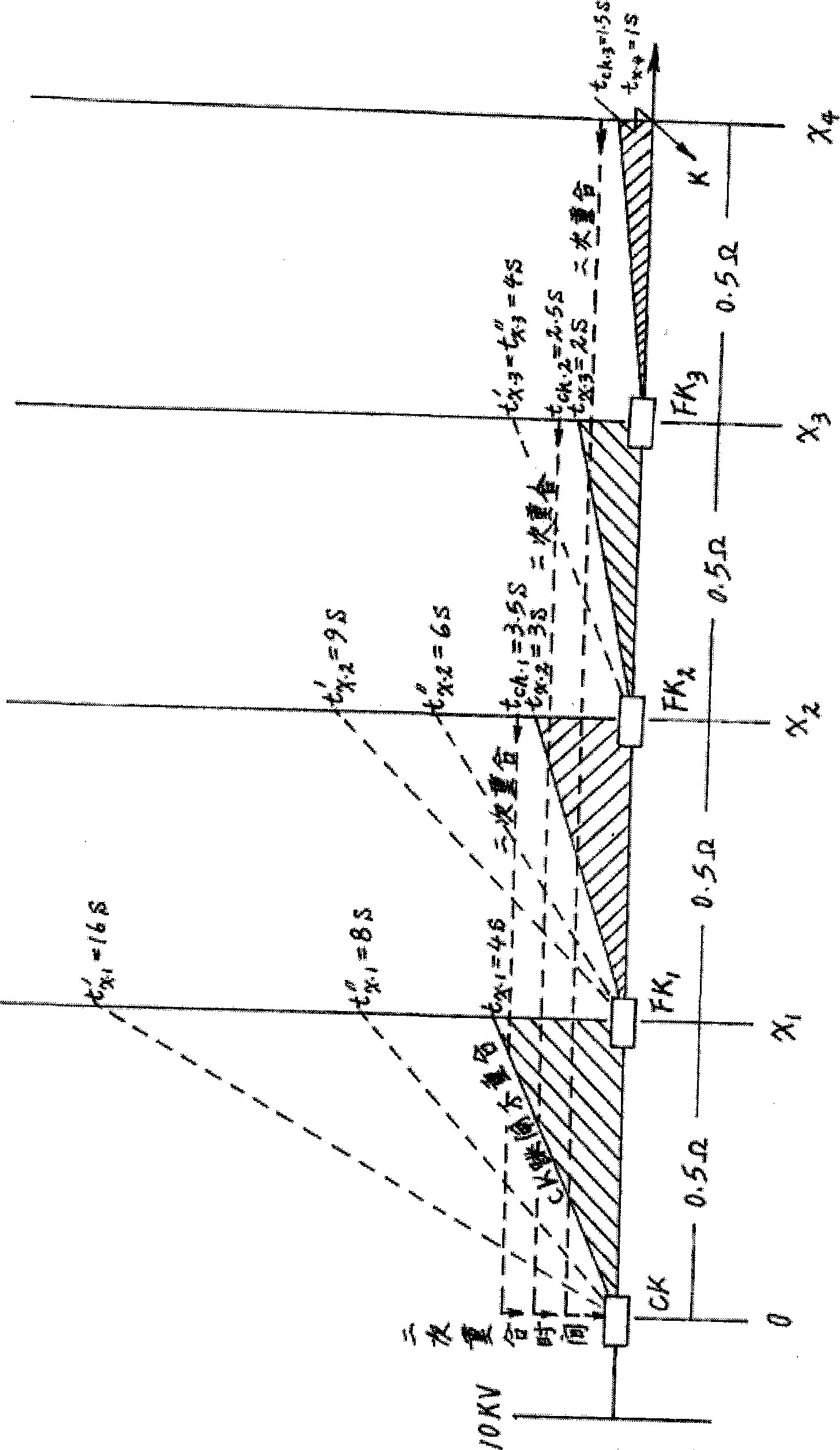

Method for detecting distribution network short circuit fault and restoring power supply in non-broken-down section

InactiveCN101534001AQuickly restore powerRestoration of power ensuresEmergency protective arrangements for automatic disconnectionFault locationElectricityThree-phase

The invention relates to a processing method for distribution network short circuit fault, in particular to a method for detecting the distribution network short circuit fault and restoring power supply in a non-broken-down section, and capable of achieving feeder line automatic local control. Short circuit fault detectors A (29) to M (41) are utilized for detecting the short circuit fault, and then reclosing time selection devices A (16), B (17), C (18) and D (19) are utilized for restoring power supply in the non-broken-down section. When short circuit happens, outlet switch A (1) or B (2) and C (2) protect the tripping in a relay way, and during permanent short circuit, the outlet switch A (1) or B (2) and C (3) protect the tripping of a second time in the relay way, a short circuit fault switch is pressed to achieve zero current tripping closedown, and a non-fault switch detects residual voltage cut-off and closedown for the second time. The outlet switch A (1) or B (2) and C (3) are coincided for the second time, so that the fault section is separated, the operation time limit of the non-fault switch is longer than the second reclosing time, three-phase normal voltage can be obtained, and the tripping no longer happens. As for the condition that the power is supplied by round network, one side of an interconnection switch (23) is deprived of electricity, non-fault switch for switching-on and tripping is delayed, and the voltage switching-on is detected in sequence.

Owner:江苏汉天星配电自动化科技有限公司

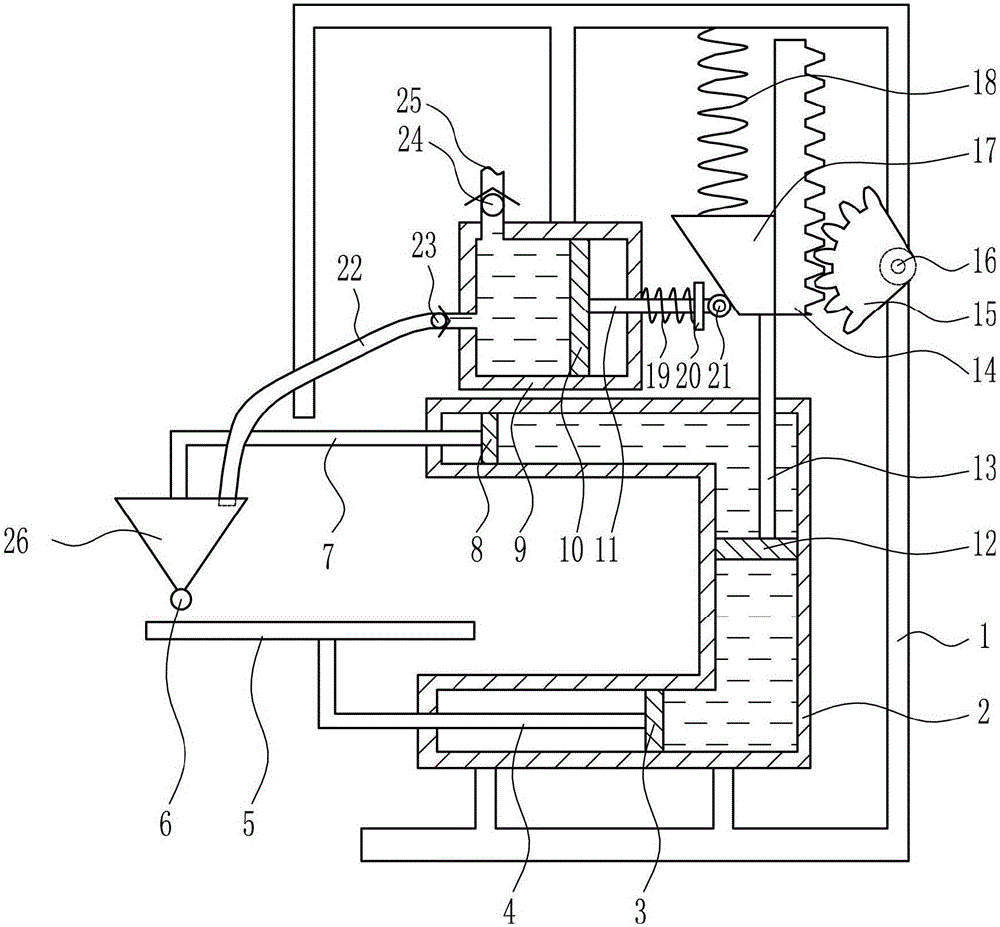

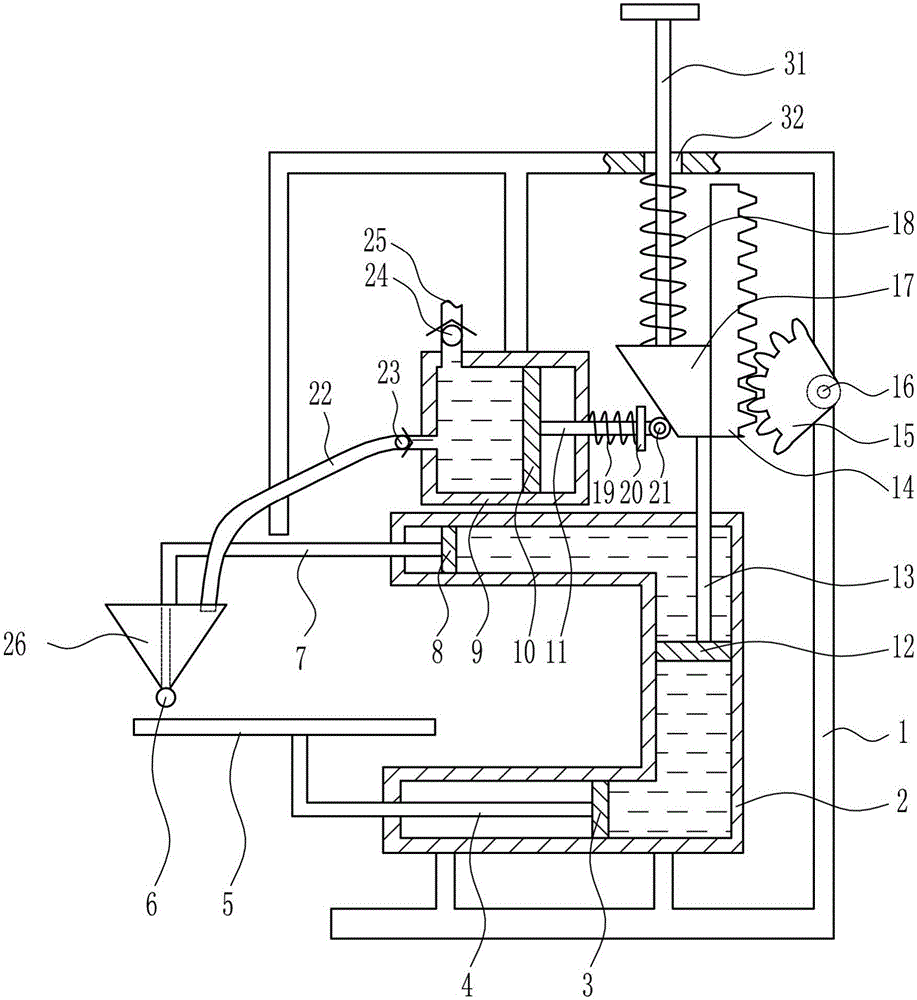

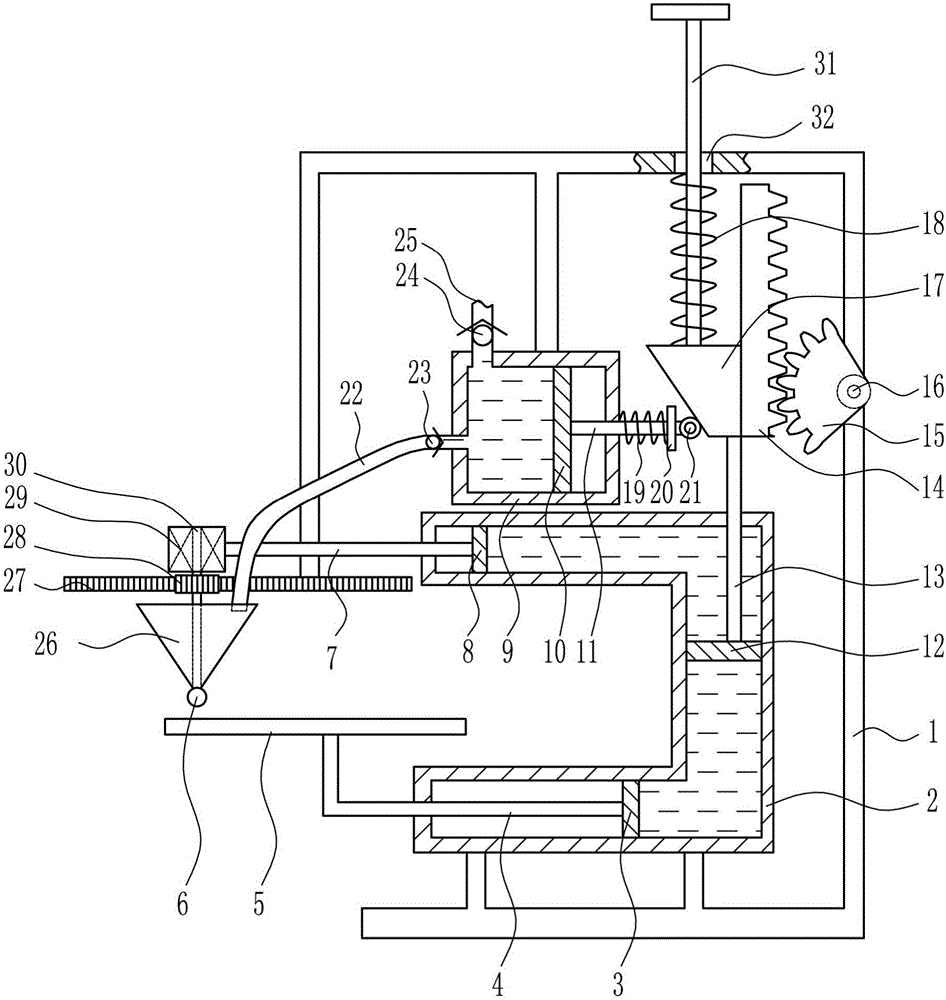

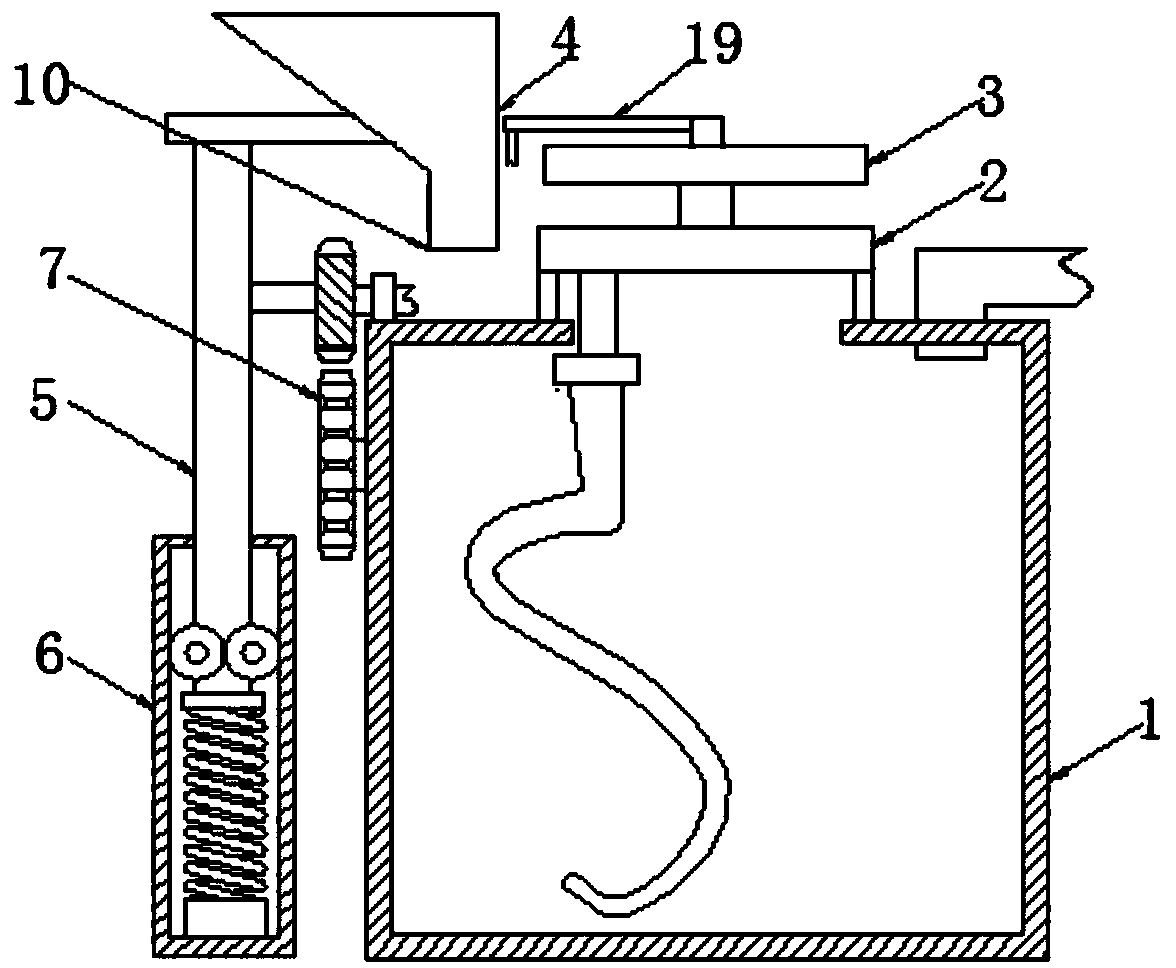

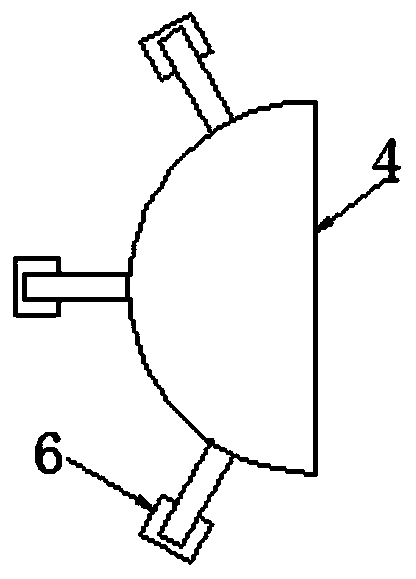

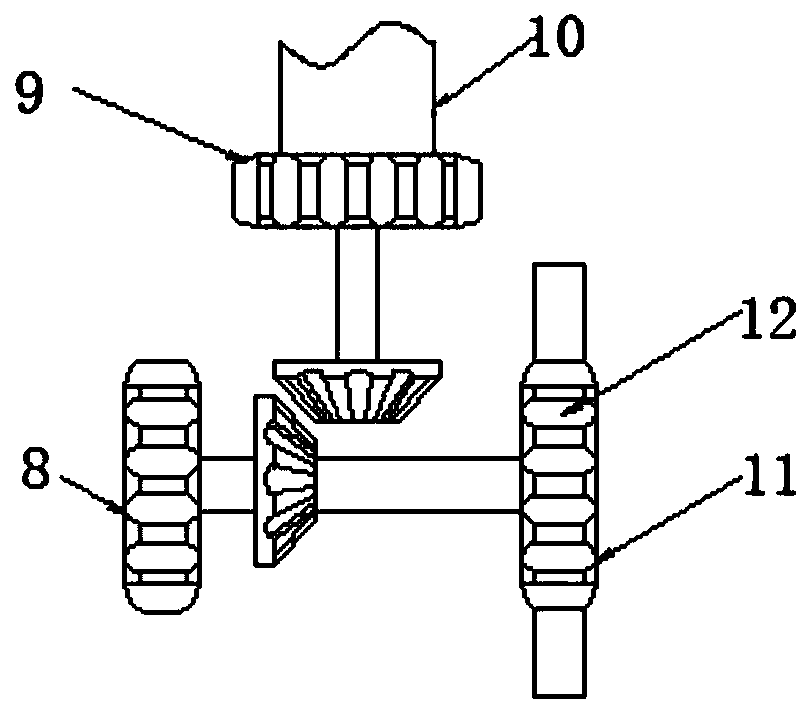

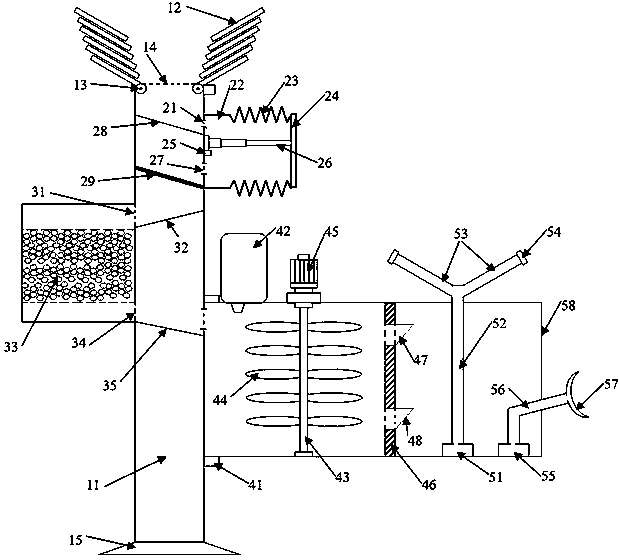

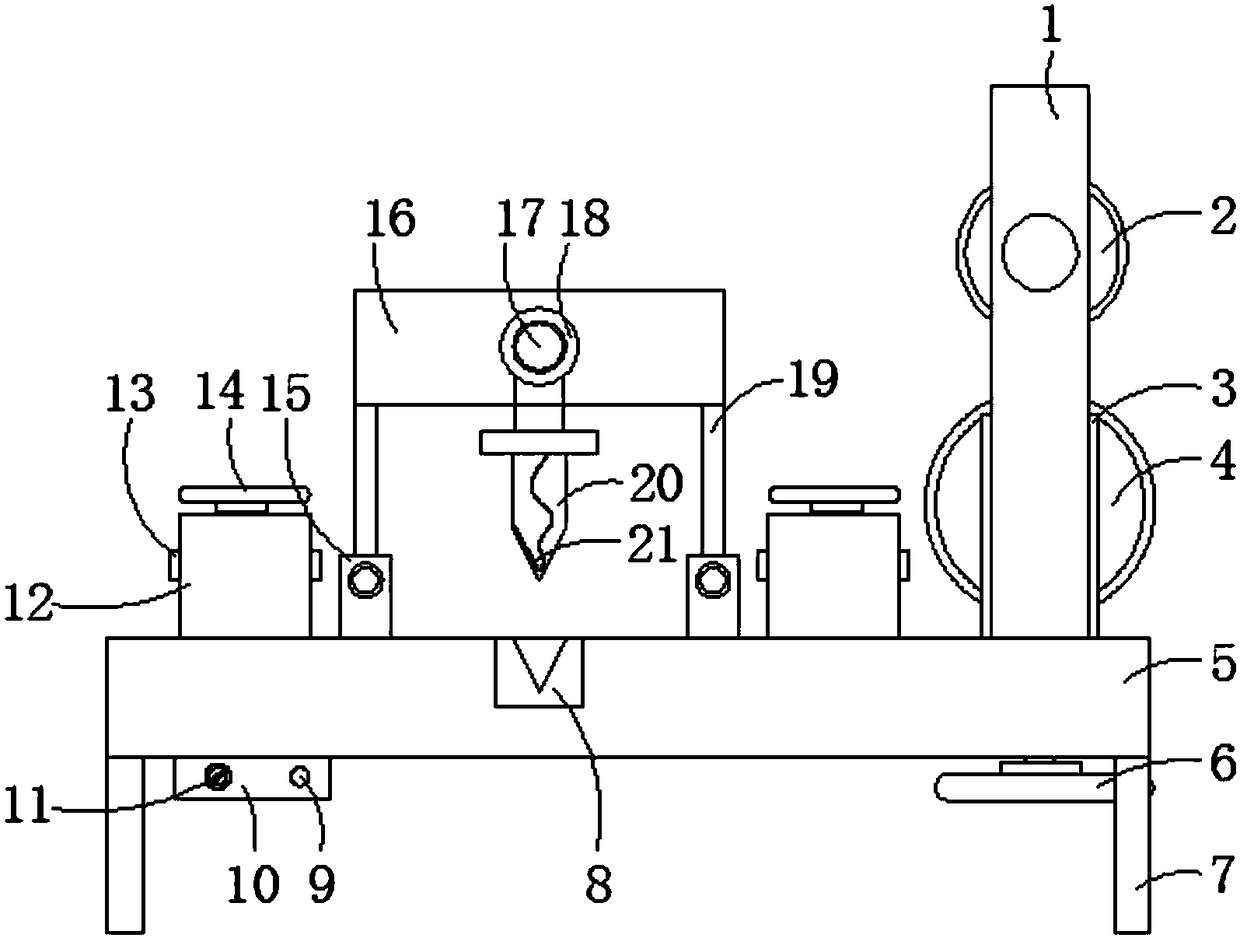

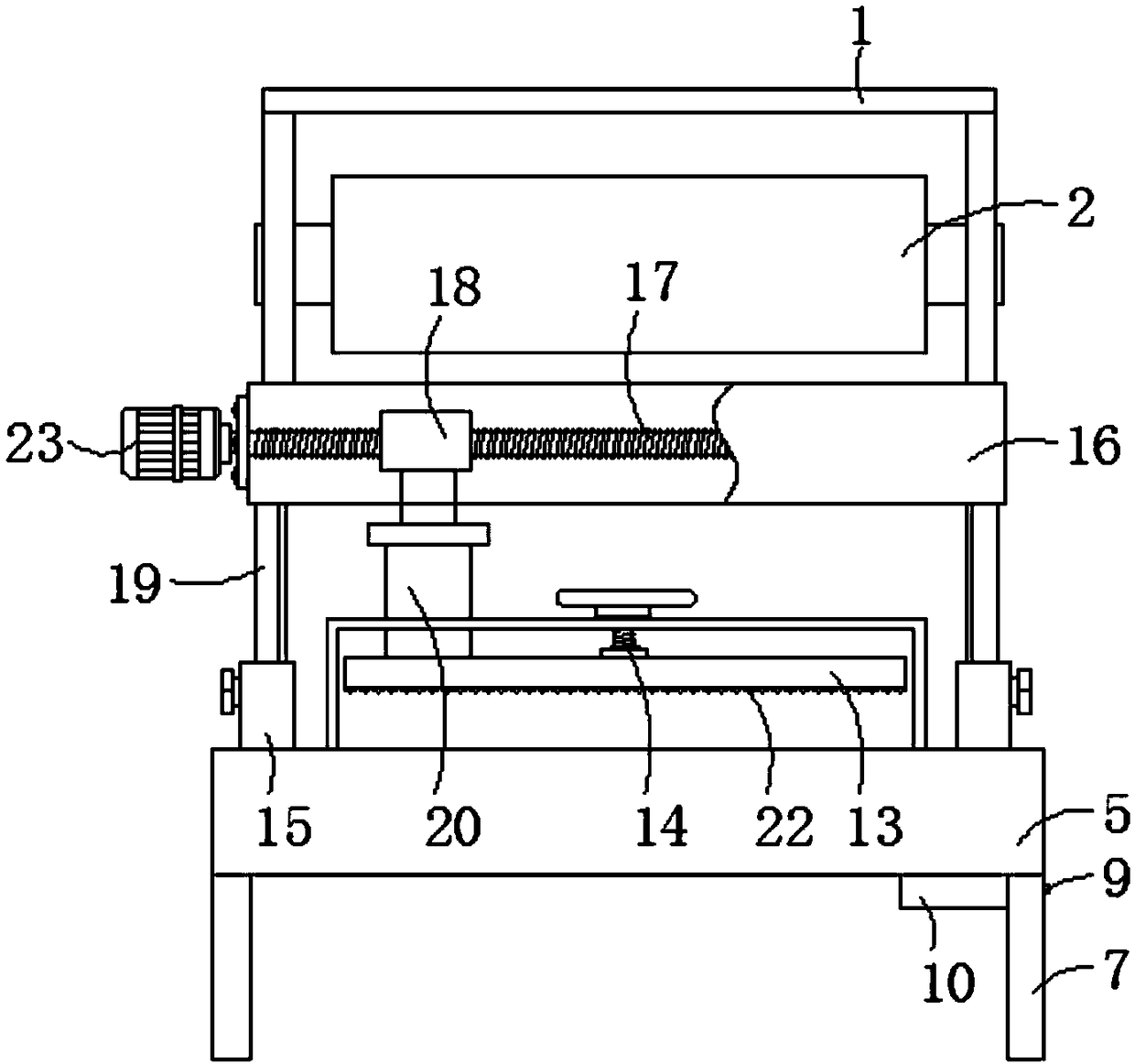

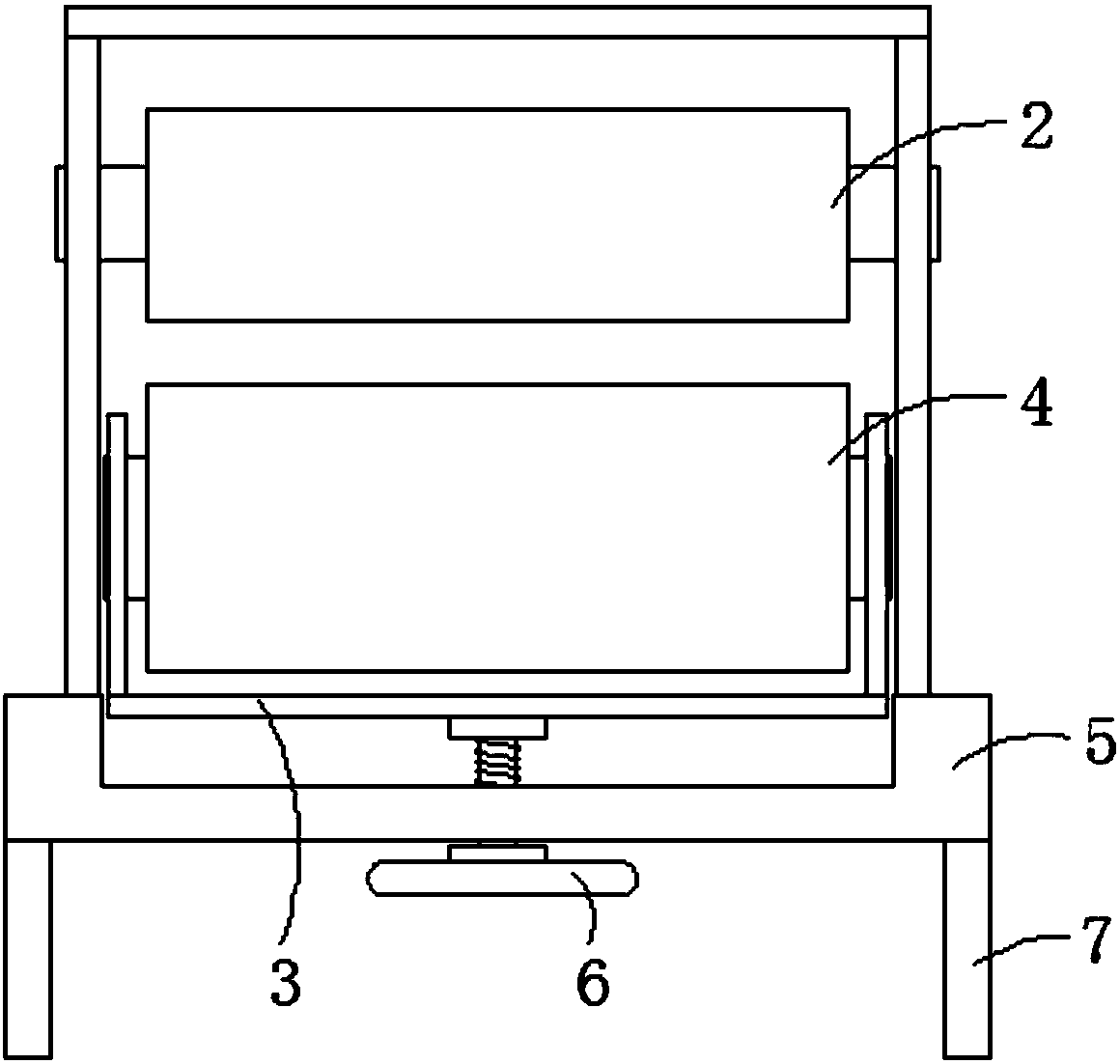

Efficient gluing equipment for shoemaking in shoe factories

InactiveCN106670056AApply glue evenlyDevice stableLiquid surface applicatorsCoatingsPistonFixed frame

The invention relates to gluing equipment, in particular to efficient gluing equipment for shoemaking in shoe factories. According to the efficient gluing equipment for shoemaking in the shoe factories, rapid gluing can be conducted, the gluing effect is good, and the gluing efficiency is high. The efficient gluing equipment for shoemaking in the shoe factories comprises a fixed frame, a U-shaped cylinder body, a first piston, a first left-right movement rod, a placing plate, a gluing head, a second left-right movement rod, a second piston, a small cylinder body and the like. The small cylinder body, a motor and the U-shaped cylinder body are arranged on the fixed frame in sequence from top to bottom. The motor is provided with a fan-shaped gear. The first piston is arranged in the lower portion of the U-shaped cylinder body in a matched mode. The first left-right movement rod is arranged on the left portion of the first piston. The efficient gluing equipment for shoemaking in the shoe factories achieves the effects of being good in gluing effect and high in gluing efficiency; a large number of gluing tasks can be rapidly completed through the efficient gluing equipment; in addition, a large amount of labor force is not needed; and a glued finished product is beautiful.

Owner:林永远

Perfect compound feed with low nitrogen and phosphorus emissions for feeding culter alburnus and preparation method of perfect compound

InactiveCN104381657ASufficient sourceScalable productionFood processingClimate change adaptationPhytaseVegetable oil

Owner:JIANGXI AGRICULTURAL UNIVERSITY

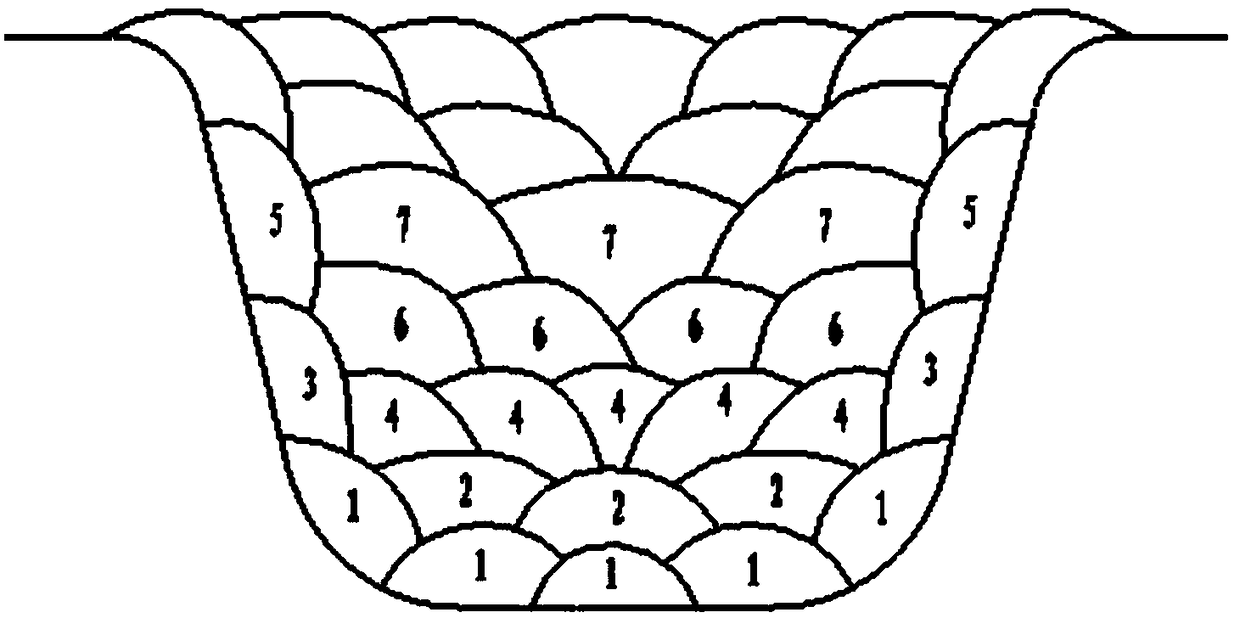

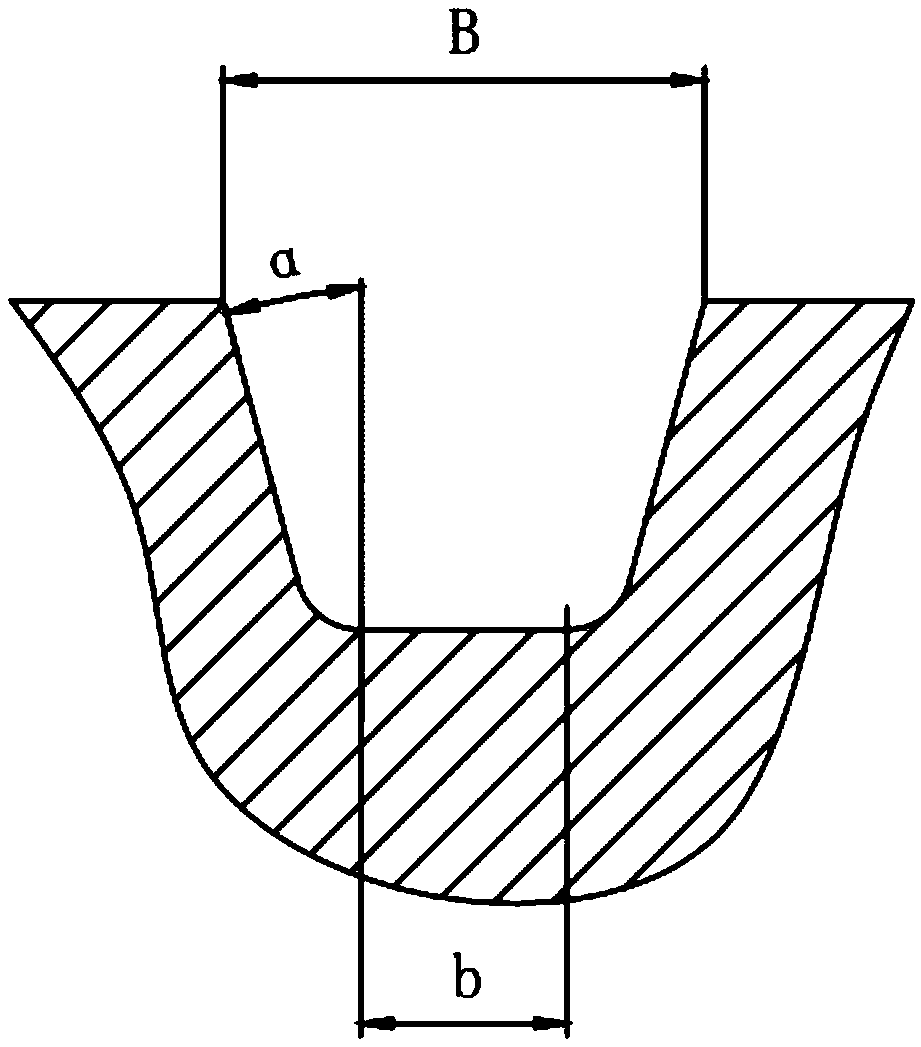

Casting defect eliminating method

The invention discloses a casting defect eliminating method which belongs to the field of casting treatment. The casting defect eliminating method provided by the invention comprises five steps: defect cleanup, bevel preparation, weld preheating, welding repair and postweld treatment, wherein the defect cleanup refers to eliminating common surface defects by grinding, and common crack defects andgreats defects are subjected to a next step; the bevel preparation refers to forming a U-shaped bevel in the defected position and the bevel surface is a smooth curved surface; the weld preheating refers to carrying out local preheating to the common defects and integral preheating to the great defects; the welding repair refers to carrying out 1-2 layers of resurfacing welding along the side surface of a bevel, further fully welding the concave part in the resurfacing welding position and repeating the step until the whole bevel is welded to be full completely; and the postweld treatment refers to carrying out dehydrogenation treatment to the common defects after being welded and annealing treatment to the great defects after being welded. By improving the welding method and optimizing the process parameters when repairing different defects, the invention greatly reduces the probability of adverse influencing factors occurring in defect repair process, saves the time spent in defect repair and achieves the effect of cost saving while ensuring the qualified rate of casting repair.

Owner:ANHUI MAGANG HEAVY MASCH MFG CO LTD

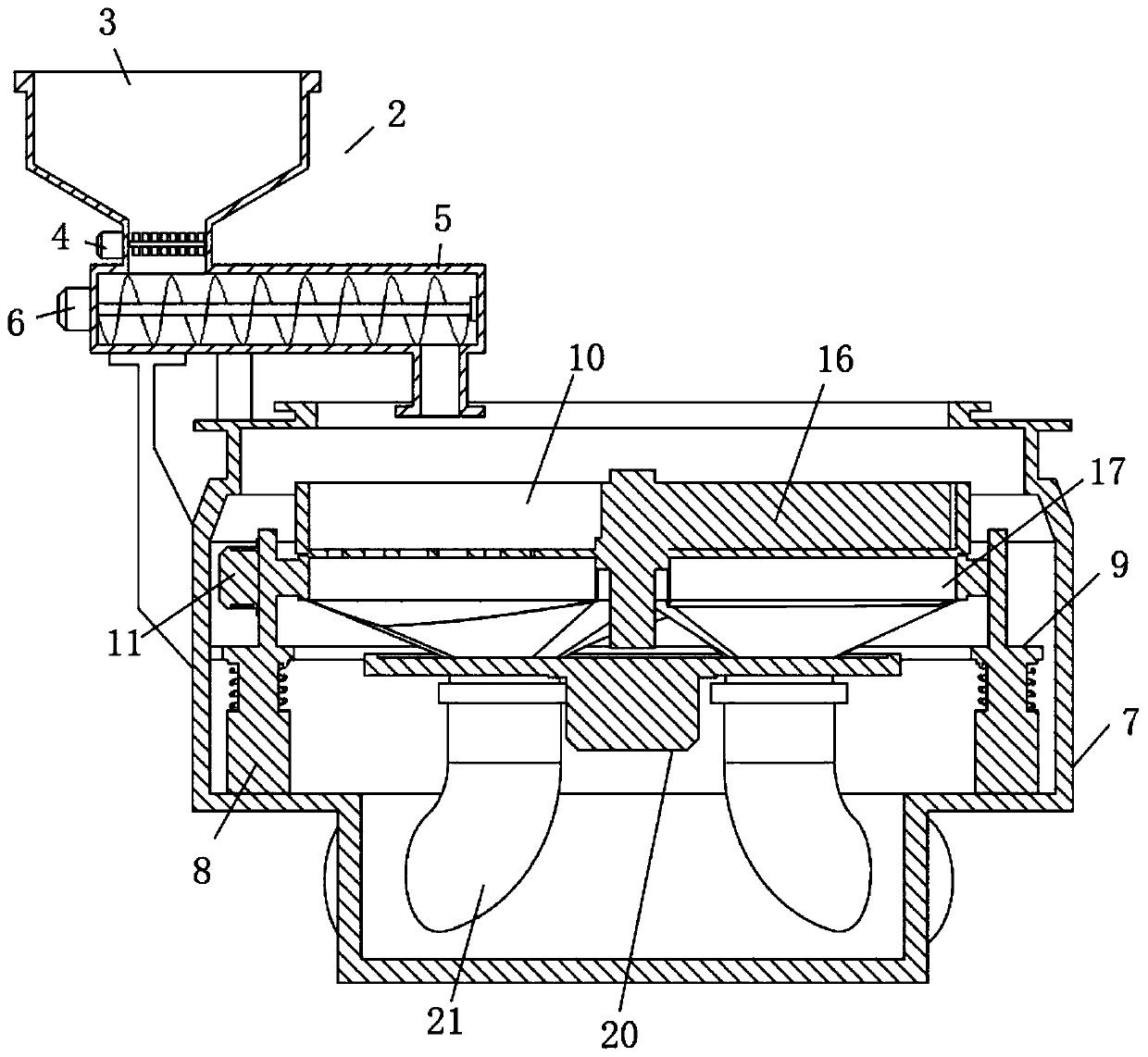

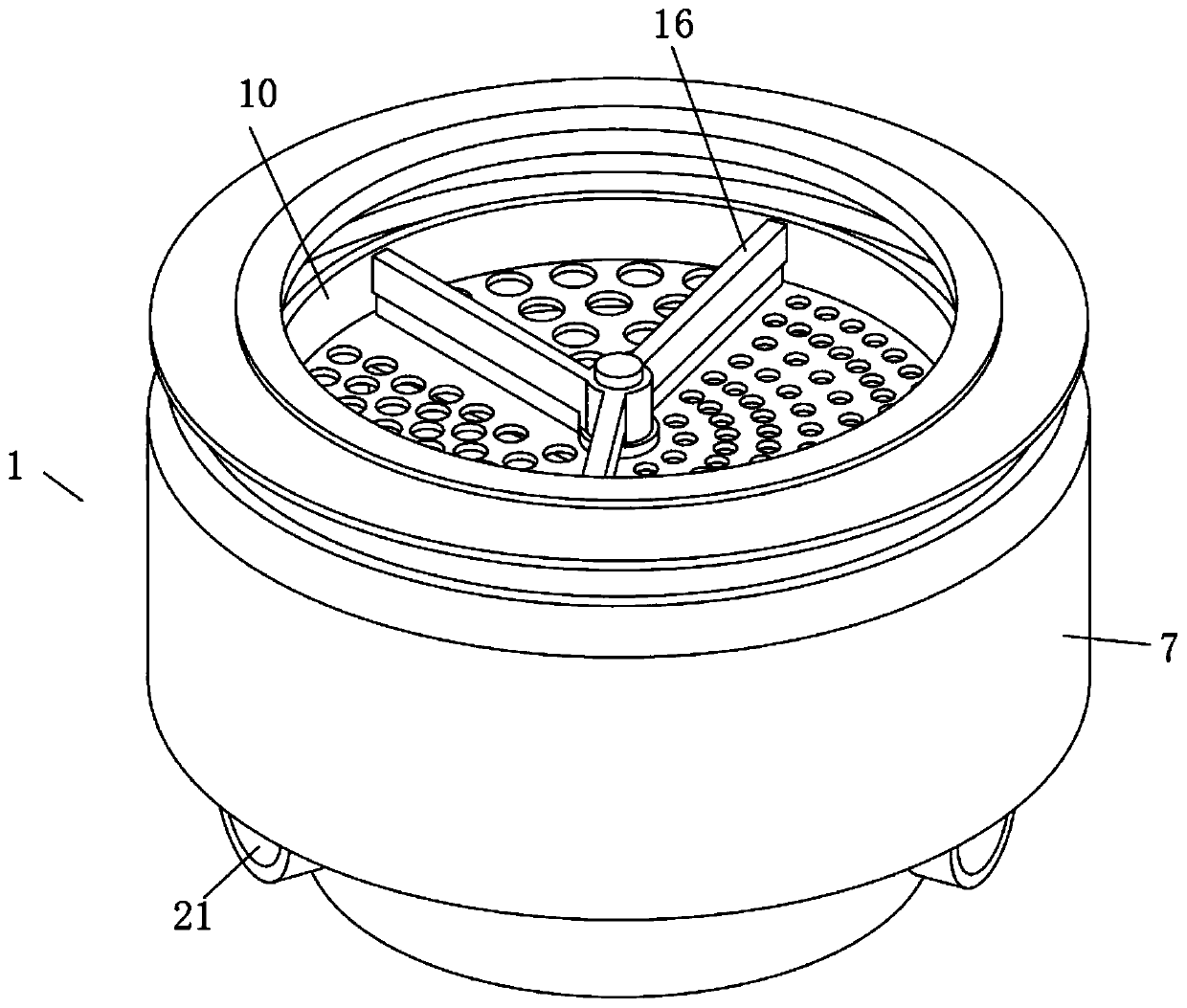

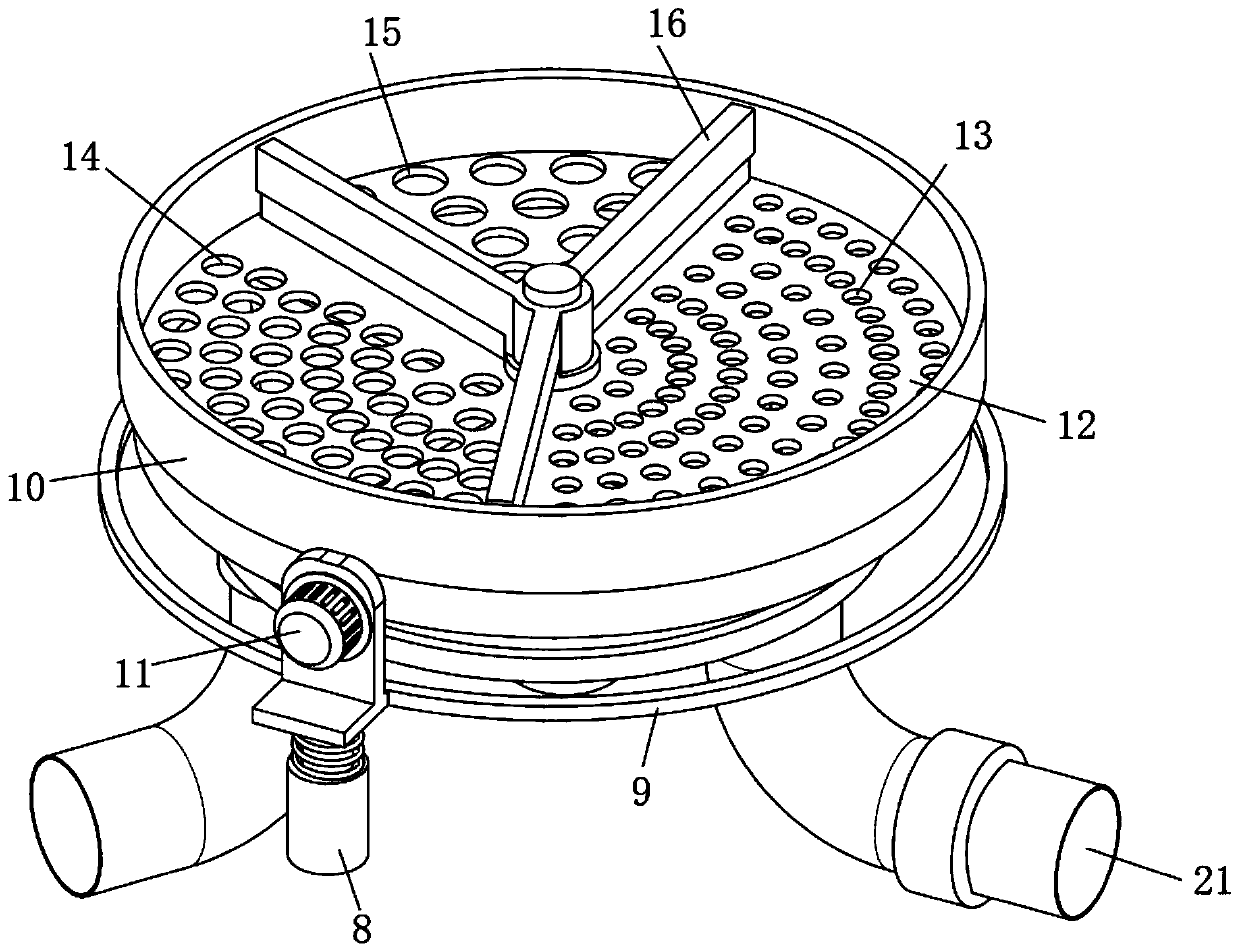

Flour detection equipment capable of quantitatively feeding and automatically stirring by utilizing gravity

InactiveCN110743412AExpand the mixing rangeFast formingTransportation and packagingRotary stirring mixersCircular discElectric machinery

The invention relates to the technical field of flour, and discloses flour detection equipment capable of quantitatively feeding and automatically stirring by utilizing gravity, wherein the flour detection equipment comprises a stirring bin, a rotating disc is movably connected above the stirring bin, and drives a stirring rod to rotate so as to stir flour, and the stirring rod is positioned at the eccentric position of the rotating disc. According to the invention, by increasing the stirring range of the stirring rod, the dough molding is accelerated, and the stirring rate is increased; a moving rod rotates to cause an arc block to approach a disc shell by using a support column as a rotating point, an arc strip synchronously moves, and is clamped with the disc shell to obstacle the rotation of the disc shell, and the rotating of the rotating disc is correspondingly stopped, so that the stirring operation is automatically suspended to conveniently take out the dough, and the reducingof the service life of the motor due to the repeated switching of the power supply is avoided; and a material receiving hopper moves downwards to open a material outlet, and the stirring rod rotates,so that the stirring is performed while the flour is discharged, the occurrence rate of the blocky flour dough is reduced, the stirring effect is good, the linkage among all structures is enhanced, and the operation is convenient and rapid.

Owner:杭州柯宏网络科技有限公司

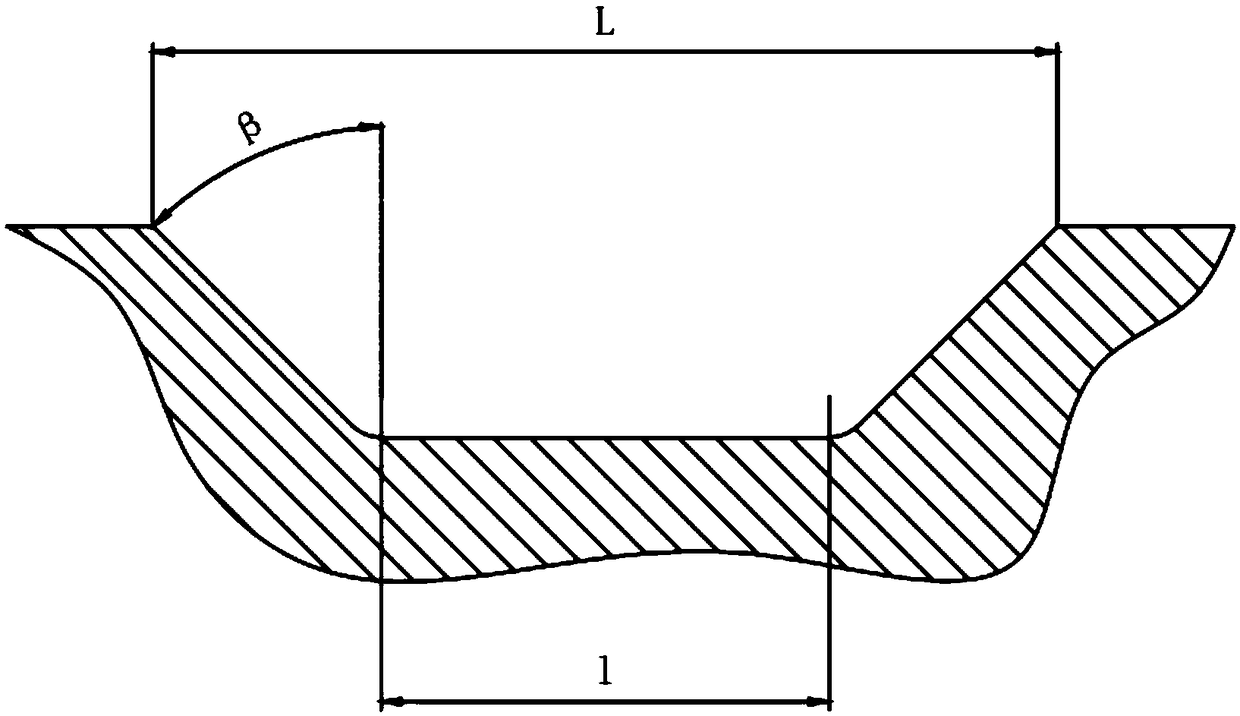

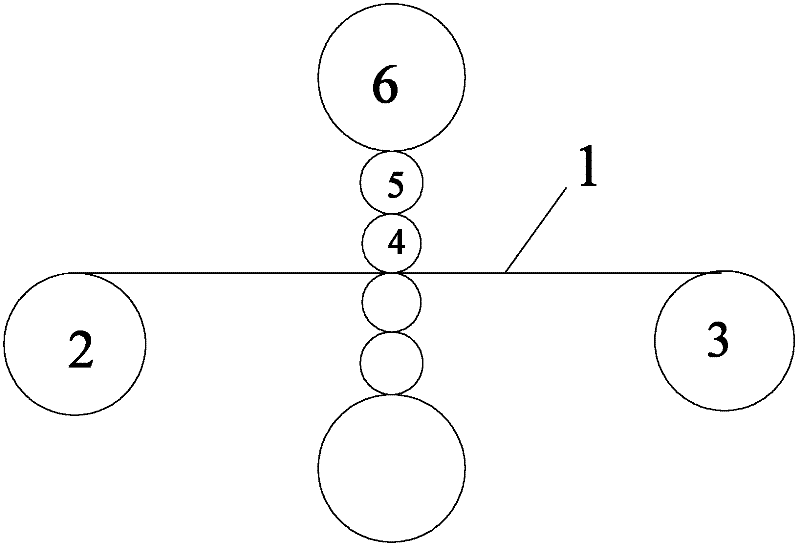

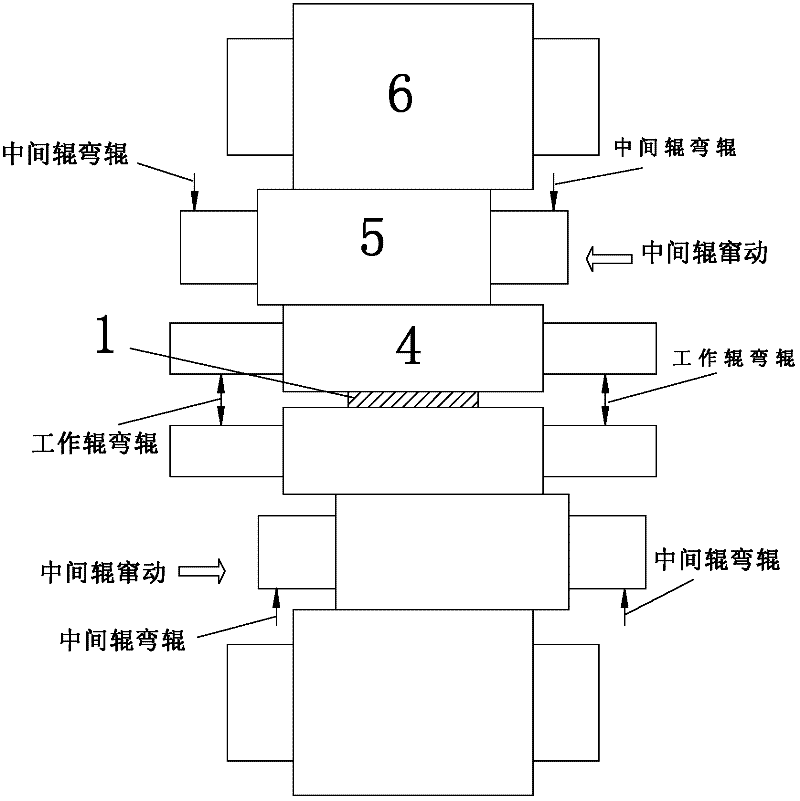

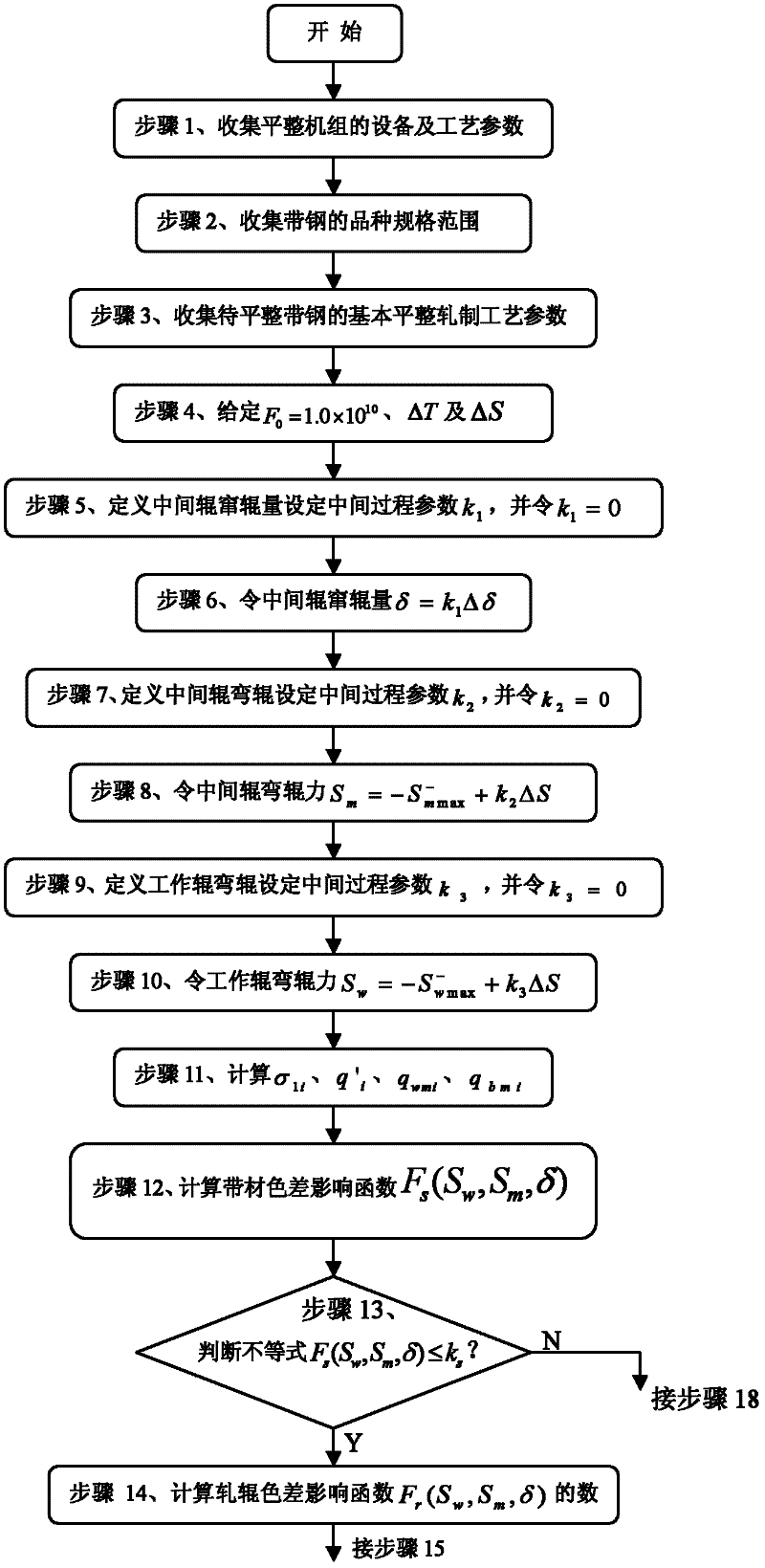

Roller parameter setting method for flatness and surface quality control of levelling unit

ActiveCN102266869AReduce color difference defects on strip steel surfaceReduce the probability of occurrenceProfile control deviceColor differenceQuality control

The invention discloses a roll system parameter setting method for a temper mill unit through strip shape and surface quality control, and belongs to the technical field of strip shape leveling production. In the method, roll system parameters are comprehensively optimized, equipment and process characteristics of a current voltage characteristic-6 (CVC-6) temper mill unit are considered, and a set of comprehensively optimized set model suitable for roll system parameters of a six-roll CVC-6 temper mill unit is established on the premise of fully exerting the potential of a control means of all roll system parameters of the unit. The invention has the advantages that: the equipment and process characteristics of the six-roll temper mill unit are fully considered in the rolling process, and a group of set values of optimal working roll bending force, intermediate roll bending force and intermediate roll movement of the temper mill are searched through a comparison method, so that transverse distribution values of rolling pressure, inter-roll pressure and forward pull are uniform in the process of rolling strips; therefore, the strip shape and surface quality of strip steel are considered, the probability of occurrence of color difference defects on the surface of the strip steel is reduced, and economic benefits are brought to the unit.

Owner:SHOUGANG CORPORATION

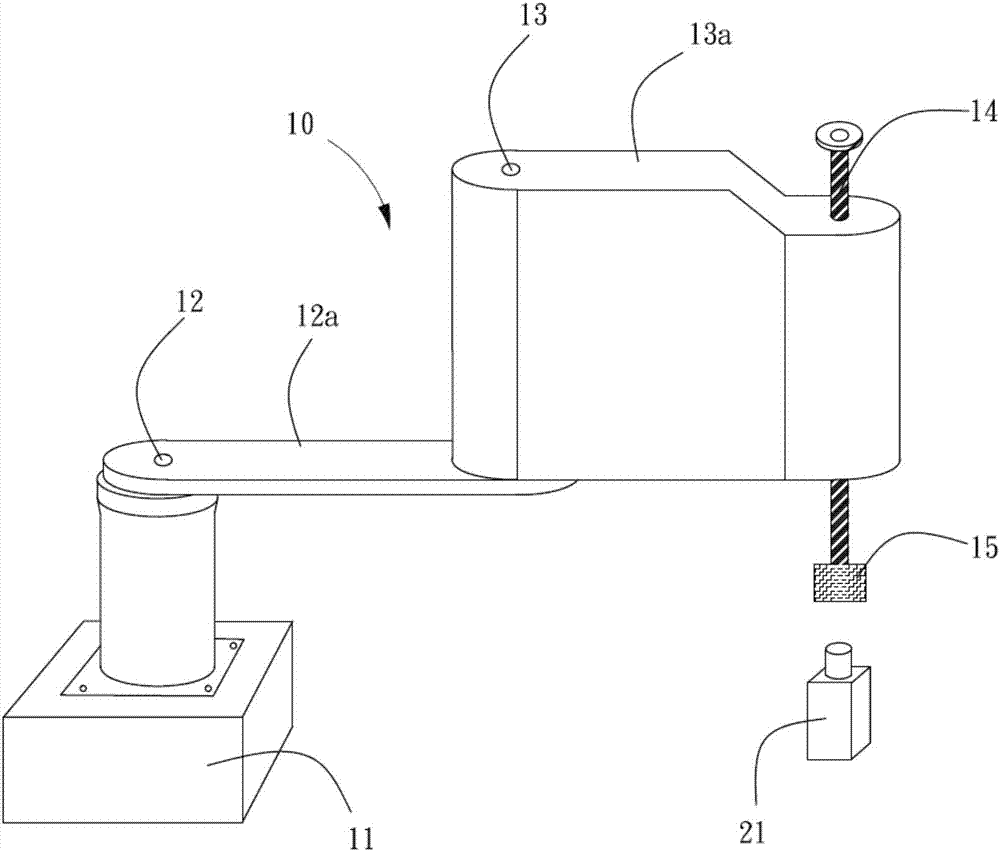

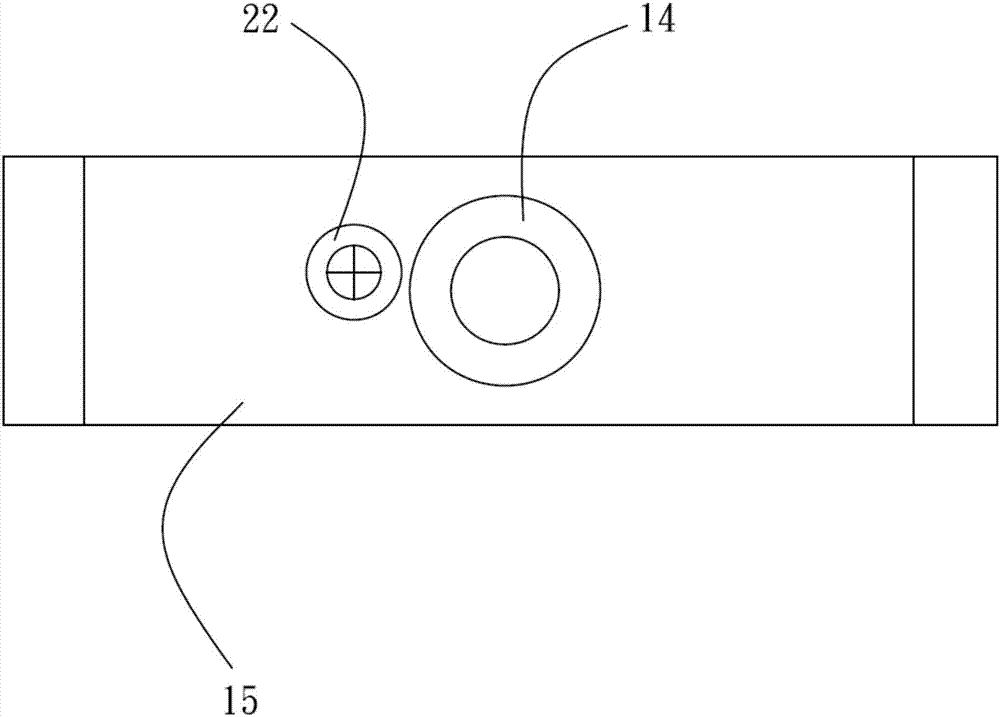

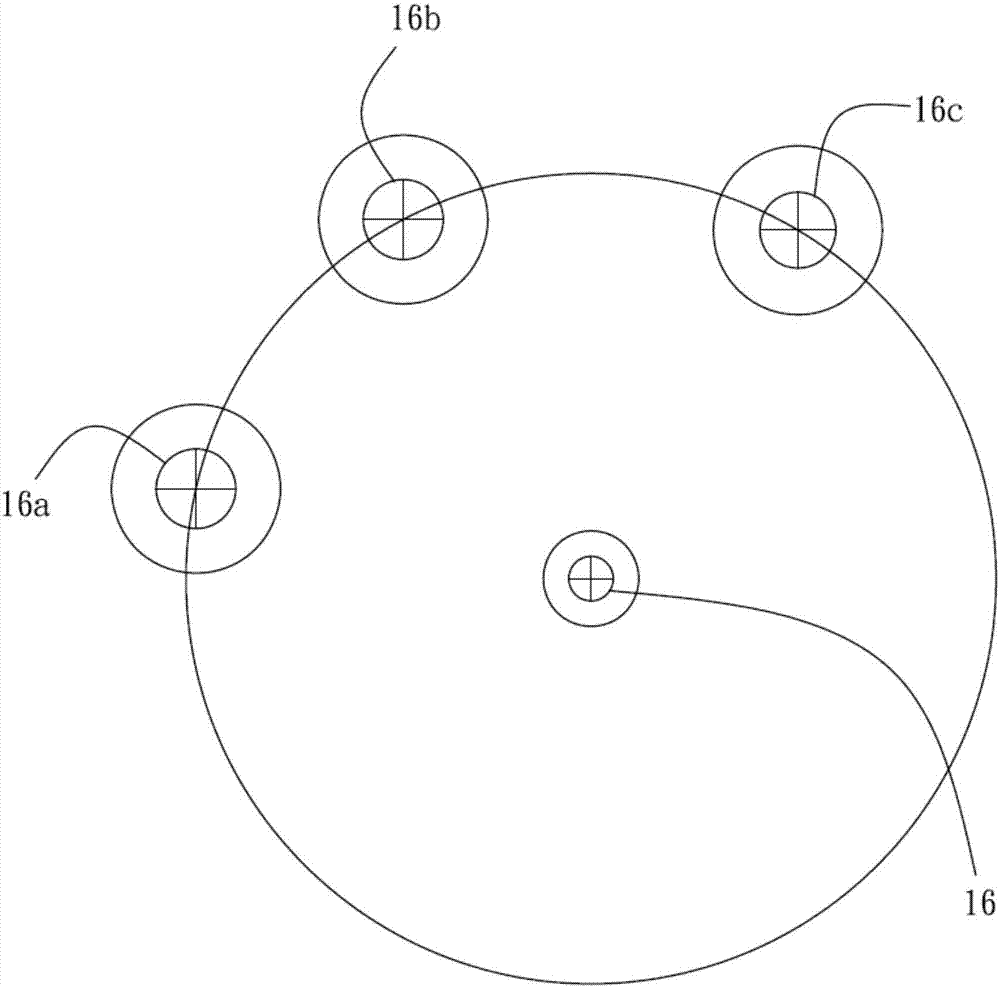

Coordinate labeling method for mechanical arm

InactiveCN107363823AReduce random errorReduce the probability of occurrenceProgramme-controlled manipulatorArm movingVisual system

The invention relates to a coordinate labeling method for a mechanical arm. The coordinate labeling method for the mechanical arm comprises the following steps that, a shaft arm moves towards the position of a camera till an original label is clear and visible in the shot view range of the camera, a visual system software records and treats the coordinate of the original label captured by the camera as a first coordinate; the shaft arm keeps the position unchangeable, after a end head rotates by a certain angle, the visual system software records and treats the coordinate of the original label captured by the camera as a second coordinate; after the end head rotates by a certain angle, the coordinate of the original label captured by the camera is recorded and treated as a third coordinate; and first circle centers of circles where the first coordinate, the second coordinate and the third coordinate are located are calculated, and a center coordinate A is obtained. Sampling and calculating in the measurement process are completed automatically, human eye aligning is not needed, the happening probability of random errors is reduced, the overlapping operation is conducted under a view where an image photographed by the camera is magnified for times, the accuracy is hundreds times of human eye aligning, the operation is simple, rapid and convenient, and the applicability and flexibility are high.

Owner:SHENZHEN HENGKETONG ROBOT

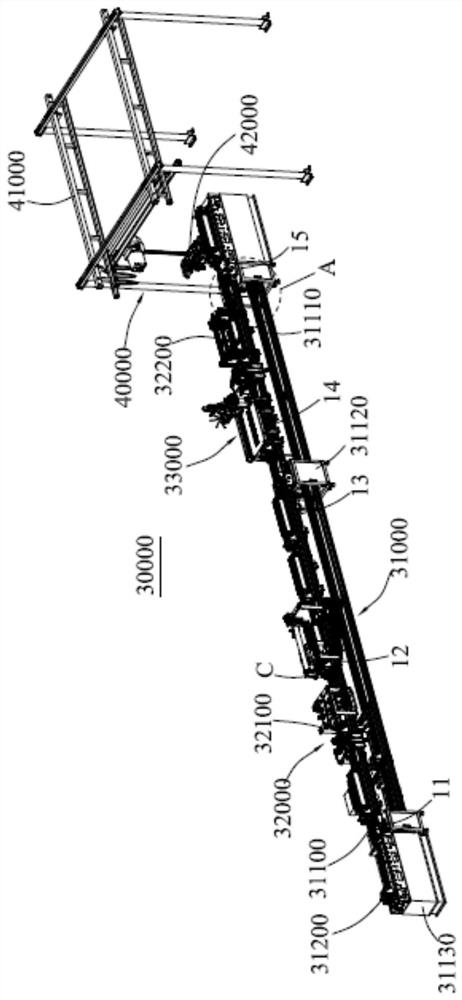

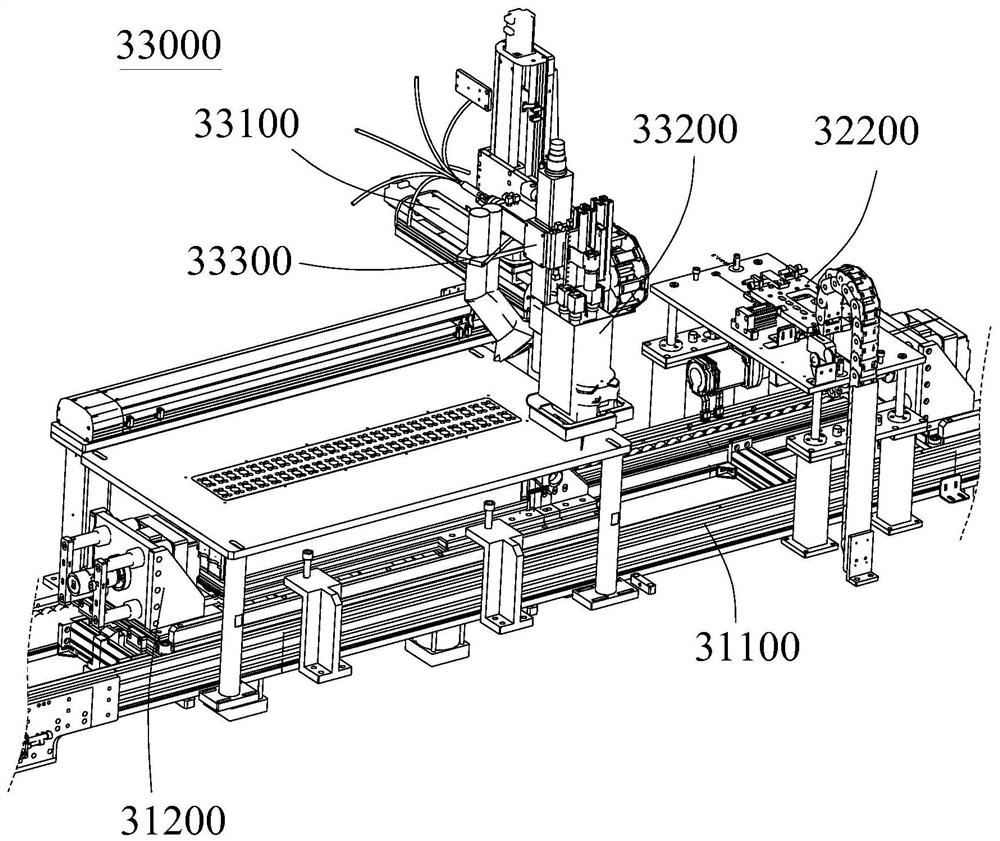

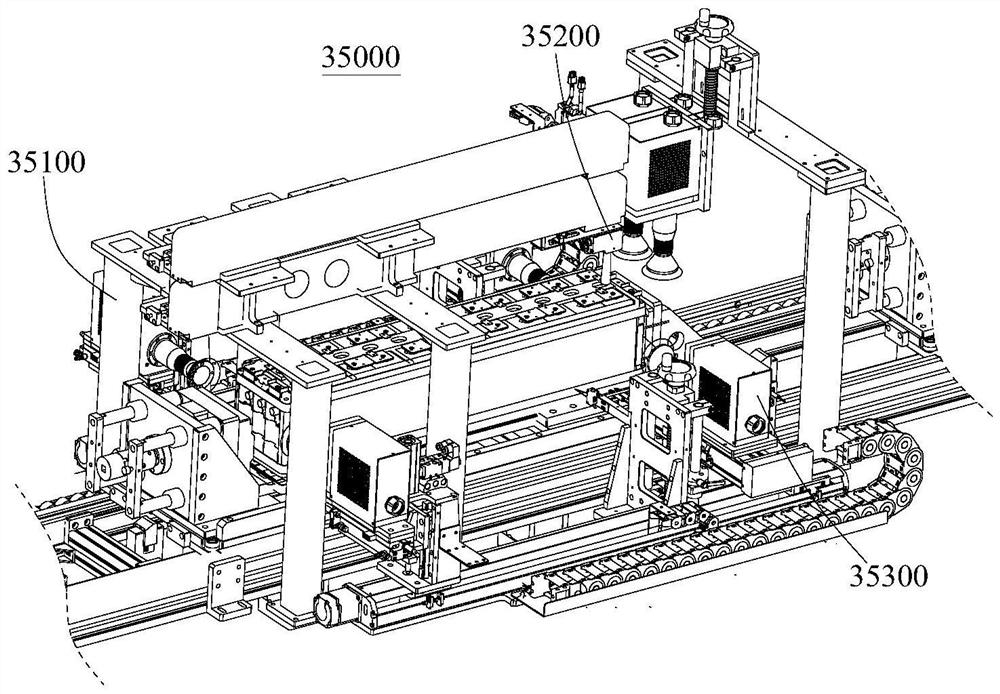

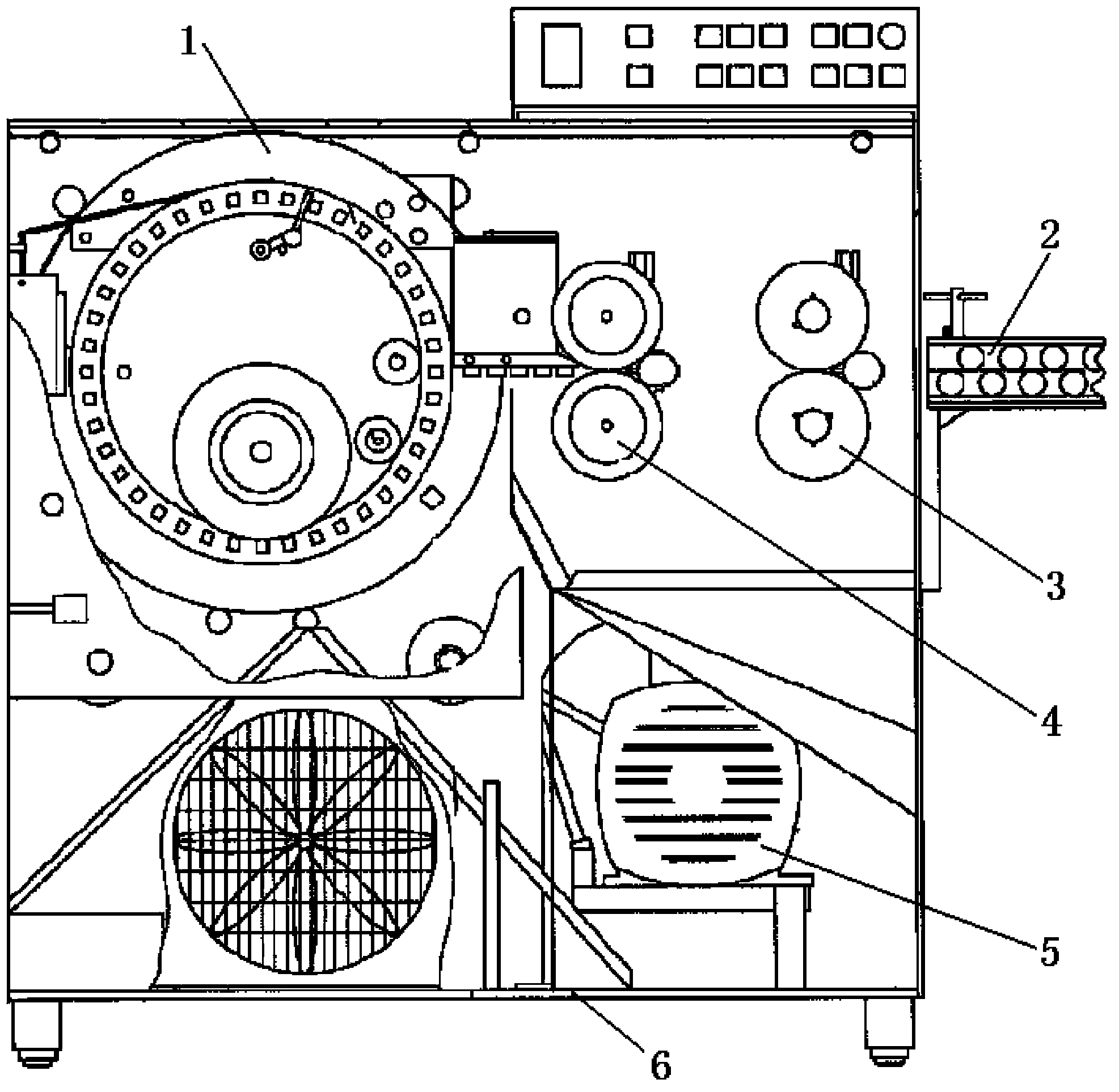

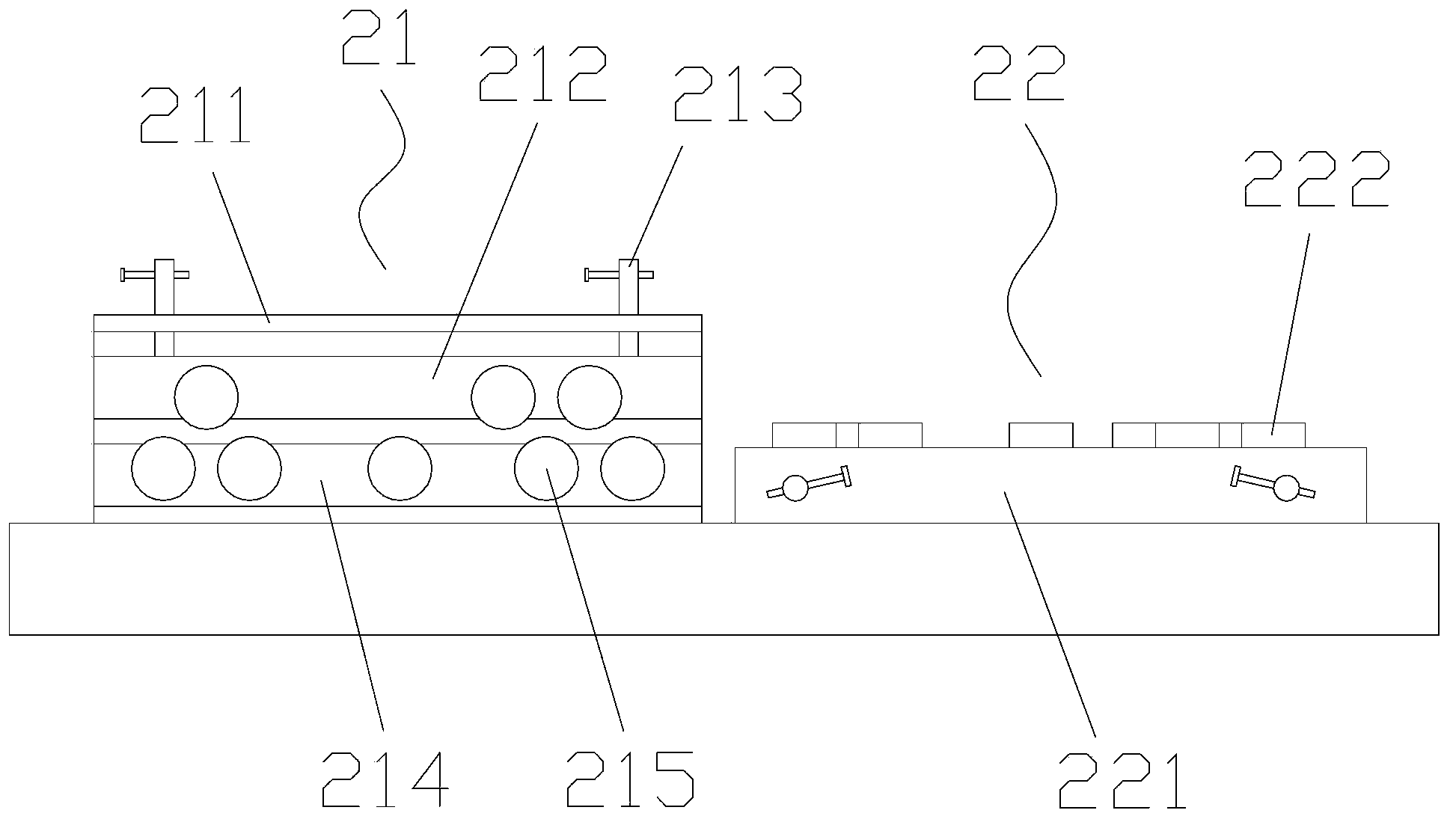

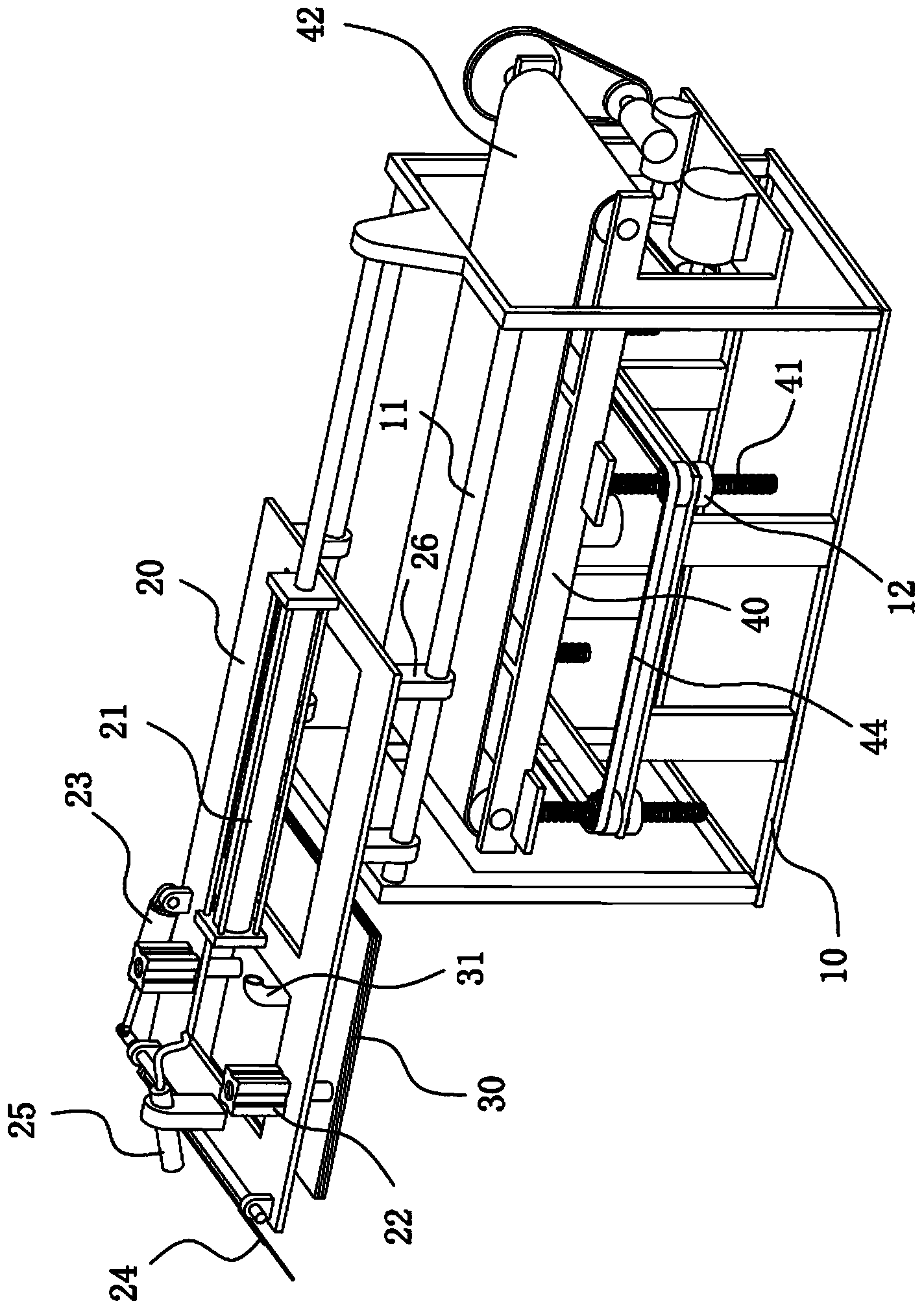

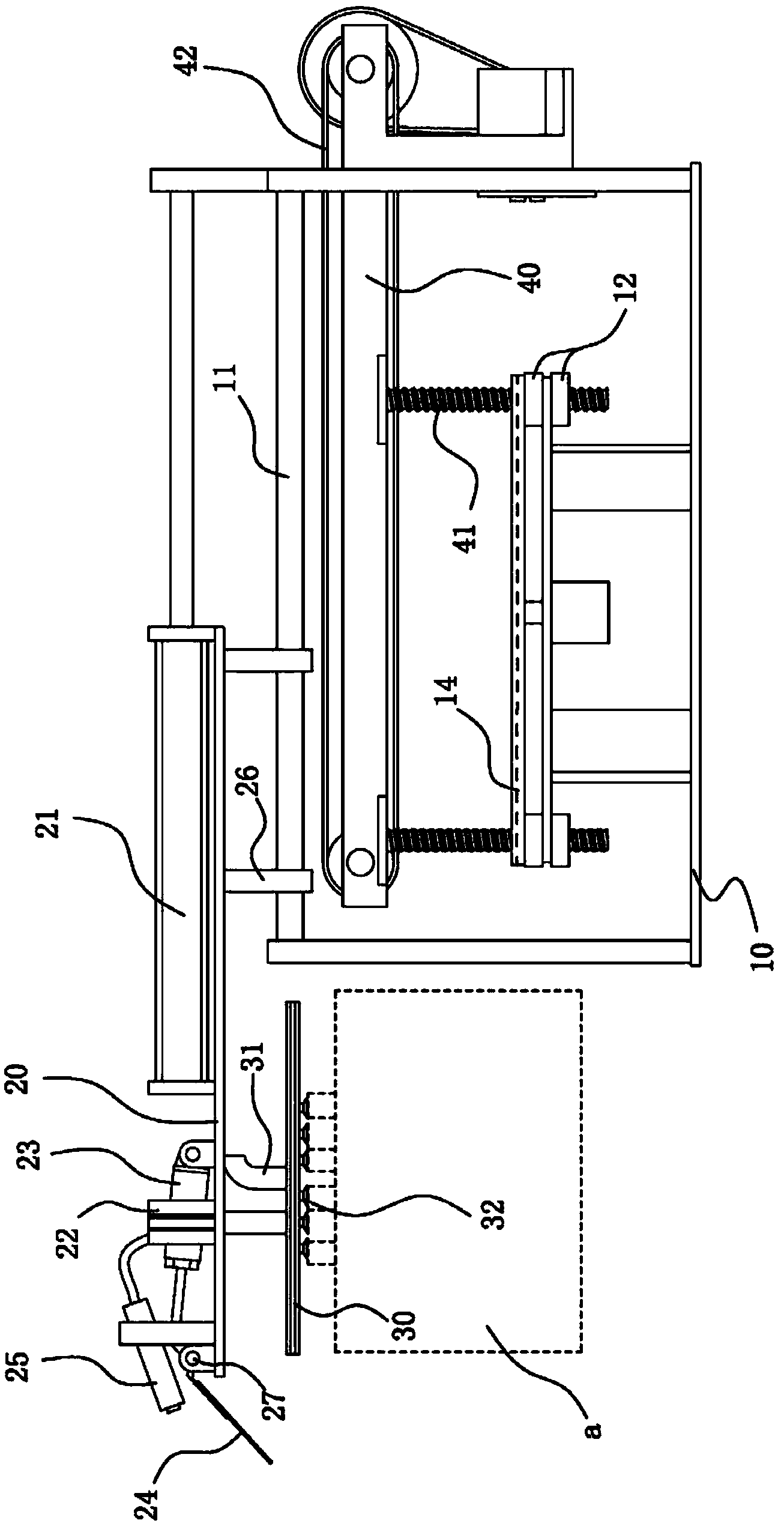

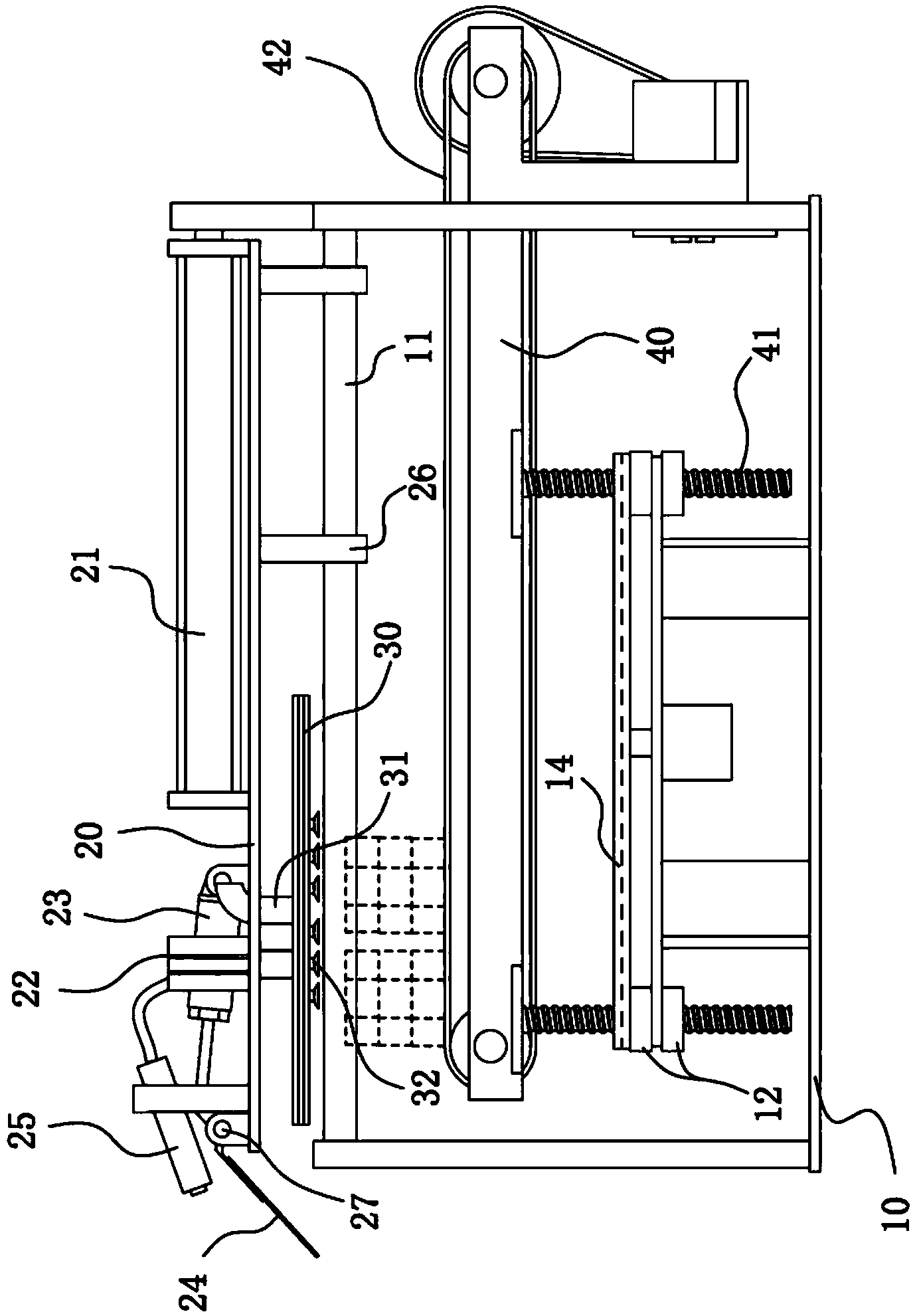

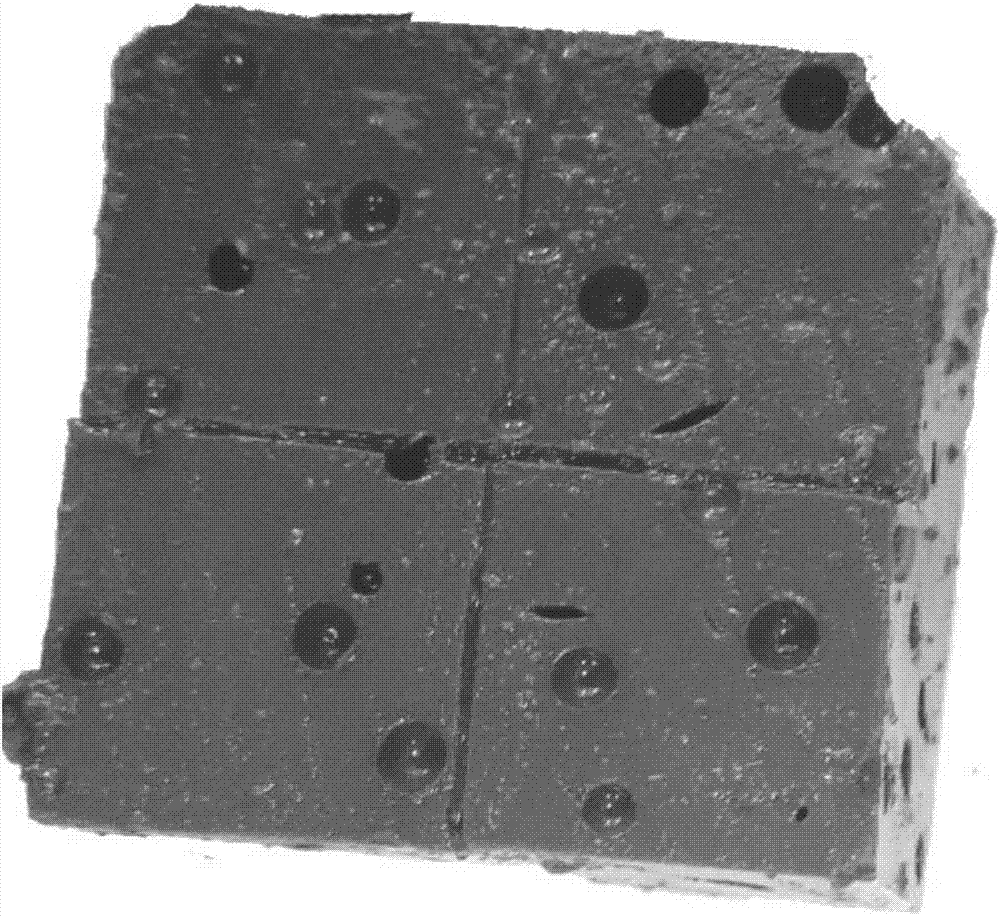

Battery module PACK production line and battery module

ActiveCN111682233AReduce the probability of occurrenceImprove assembly efficiencyPrimary cell manufactureFinal product manufactureForeign matterProcess engineering

The invention discloses a battery module PACK production line and a battery module. The battery module PACK production line comprises a pretreatment unit, a rubberizing unit, a battery pack assemblingunit and a finished product discharging unit. The pretreatment unit comprises a feeding testing device and a cleaning device, and the rubberizing unit is used for rubberizing single batteries. The battery pack assembling unit is used for assembling and welding a plurality of batteries into a battery module. The finished product discharging unit is used for taking out the battery modules in the battery pack assembling unit and moving the battery modules into the discharging conveying line. The pretreatment unit is used for testing and sorting the assembled single batteries, and the cleaning device is used for removing foreign matters attached to the single batteries, so that a foundation is laid for subsequent procedures, and the probability of defective products in the assembling processis reduced. The pretreatment unit, the rubberizing unit, the battery pack assembling unit and the finished product discharging unit are connected through the conveying belt, so that all stations do not work independently, and the assembling efficiency of the battery module is improved. Manual operation steps in the assembling process are reduced, the labor intensity of production personnel is reduced, and the production cost is saved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

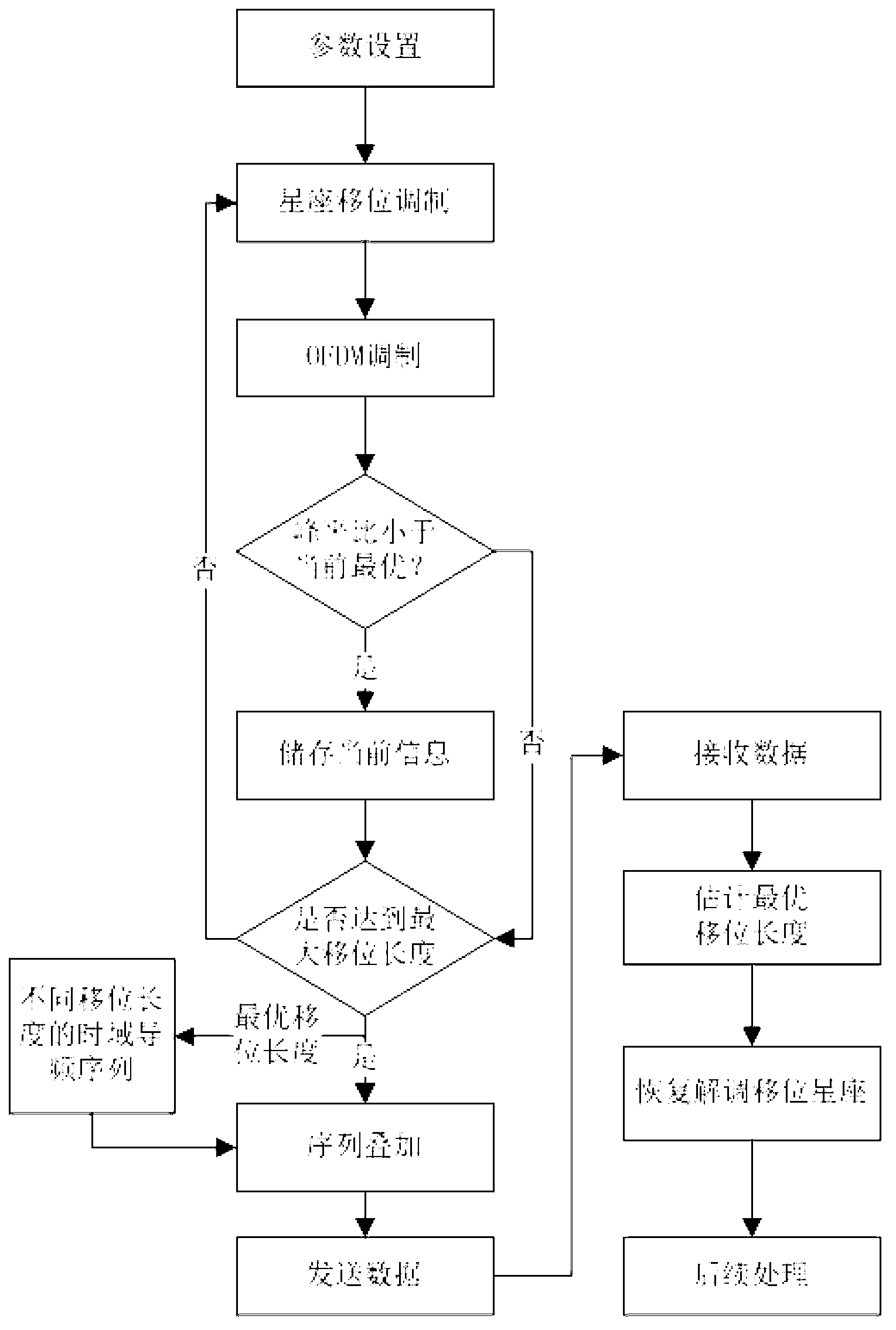

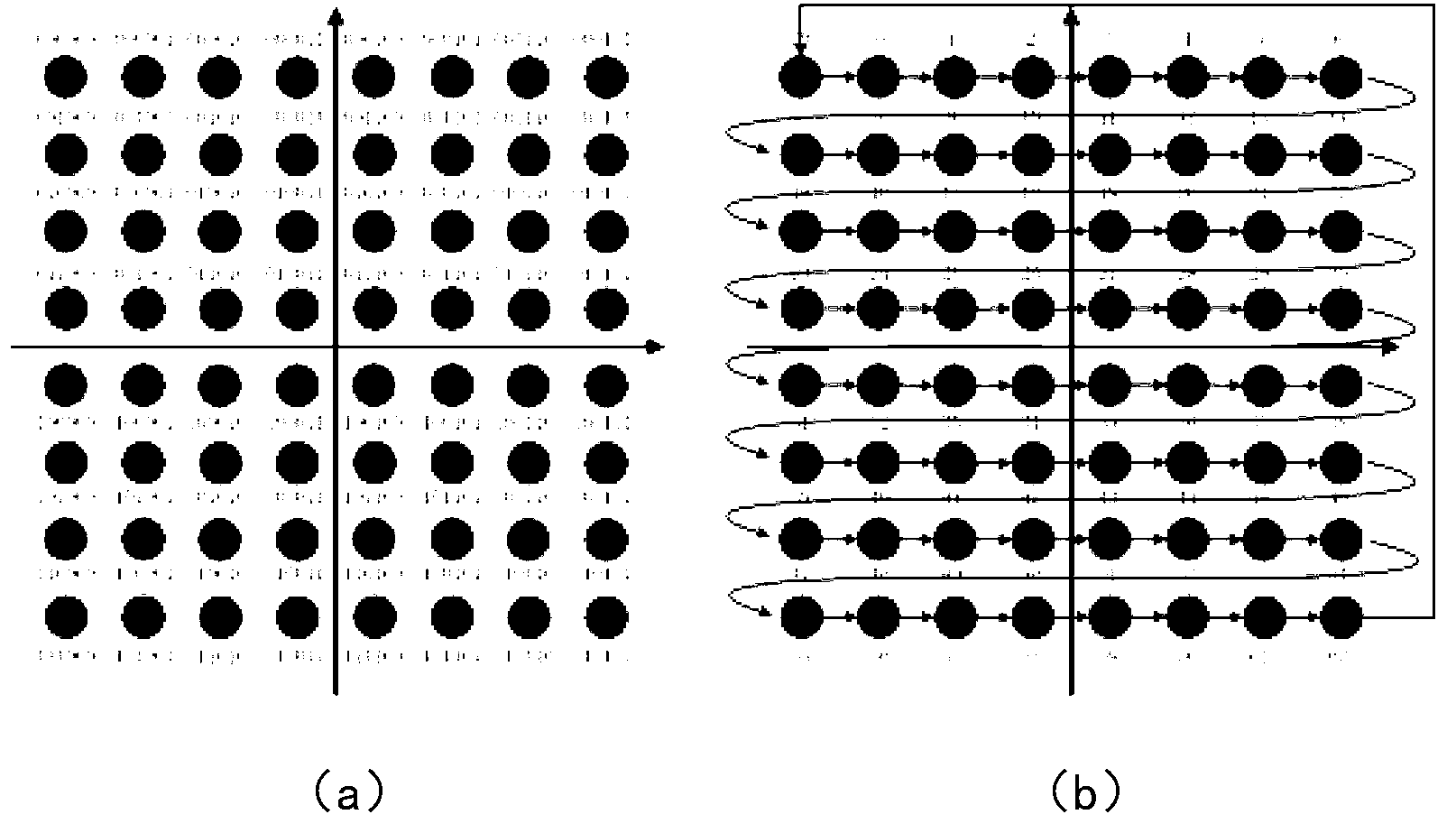

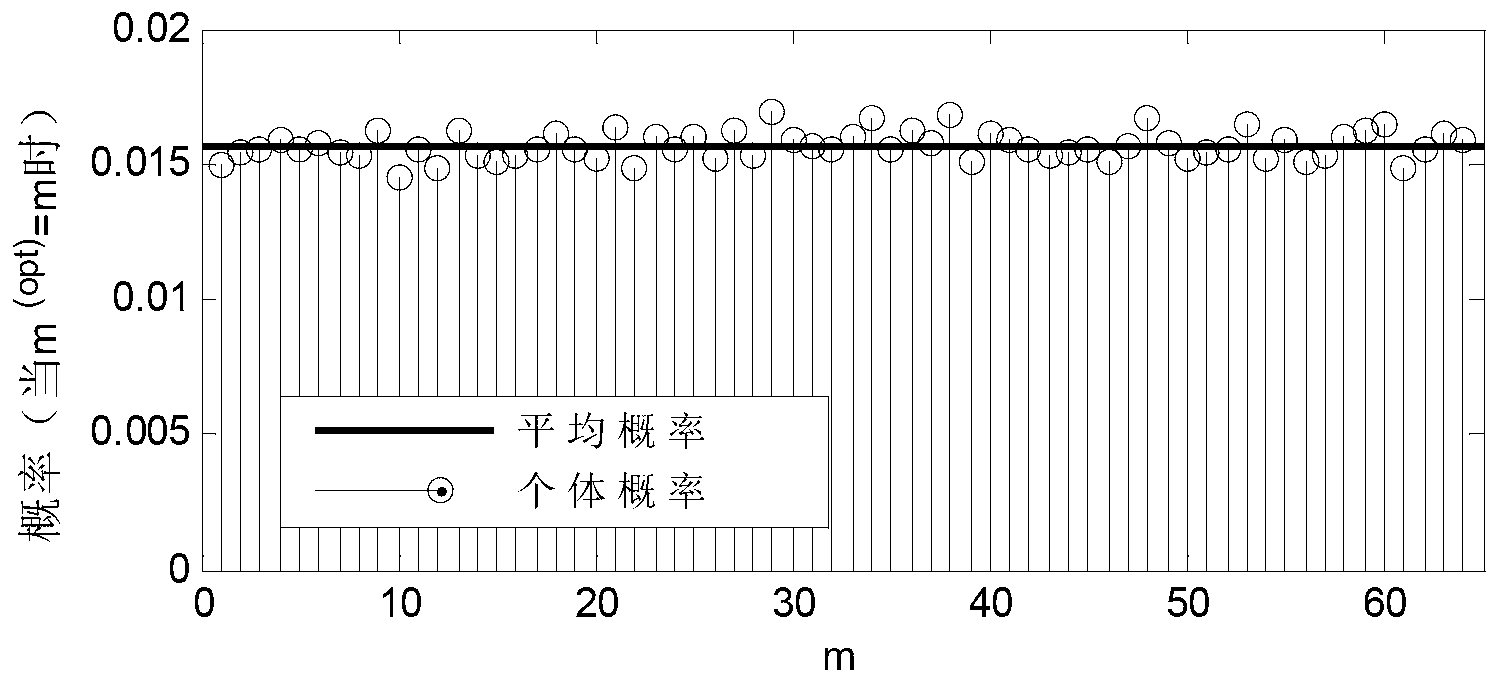

Peak-to-average power ratio suppression method based on cyclic constellation shift

InactiveCN103326987AReduce the probability of occurrenceEnhance non-correlationMulti-frequency code systemsQuadrature amplitude modulationConstellation

The invention discloses a peak-to-average power ratio suppression method based on cyclic constellation shift. The method comprises the following steps of: (1) setting initial quadrature amplitude modulation; (2) setting a maximum constellation shift length; (3) initializing an optimal solution; (4) determining an optimal constellation shift length depending on a minimum peak-to-average power ratio and transmitting data; (5) selecting a pilot frequency sequence corresponding to the optimal constellation shift length for superimposed transmission; (6) demodulating by a receiving end through a quadrature amplitude modulation constellation reduced and shifted by maximum likelihood estimation through information of pilot estimation. The method, in comparison with probability algorithms of the prior art, can be used for reducing the computation complexity, and meanwhile effectively reducing the peak-to-average power ratio on the premise of not affecting a bit error rate performance.

Owner:XIDIAN UNIV

Graphite-powder casting coating

InactiveCN104801662AImprove adhesionGood chemical stabilityFoundry mouldsFoundry coresAlcoholAcrylic resin

The invention discloses a graphite-powder casting coating, which is prepared from the following raw materials in parts by weight: 44 parts of graphite powder, 8 to 12 parts of diatomite, 9 to 11 parts of lauryl sodium sulfates, 1 to 4 parts of titanium dioxide, 6 to 8 parts of bonding agents, 5 to 10 parts of acrylic resin, 8 to 10 parts of stearic amides and 16 to 20 parts of ethyl alcohol, wherein the graphite powder and the titanium dioxide are enabled to pass through a 220-mesh screen. According to the graphite-powder casting coating, the graphite powder is mainly used as the main raw material; various additive materials are reasonably formulated by quantifying the graphite powder; the heat insulation effect is good; the diatomite, the lauryl sodium sulfates, the titanium dioxide, the biding agents, the acrylic resin and the stearic amides are added; various components interact; the adhesive force of the coating is improved; further, the coating is good in chemical stability; the occurrence rate of scour troughs in a production process is decreased; the sand fusion phenomenon of a cast part is avoided.

Owner:WUHU RONGCHUAN ELECTROMECHANICAL TECH

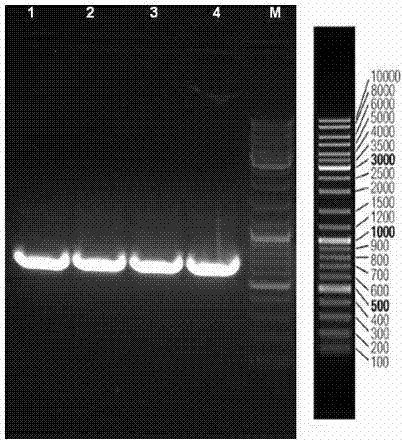

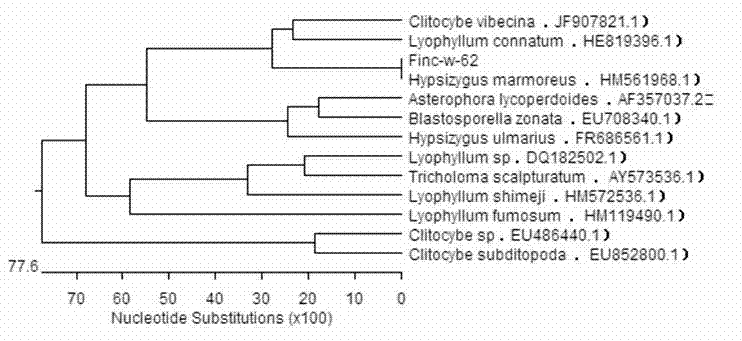

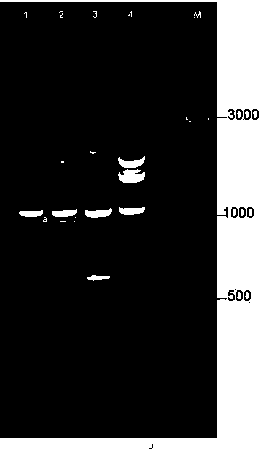

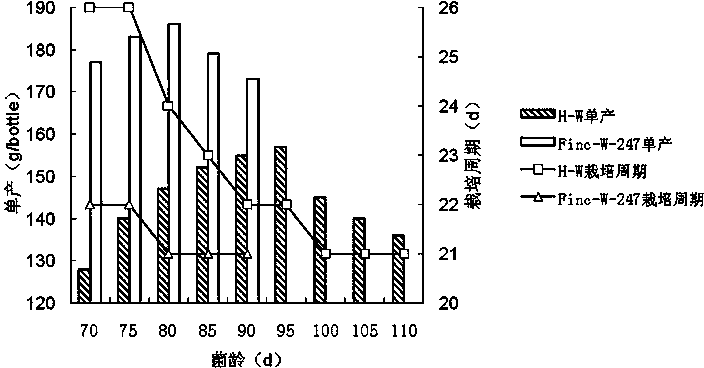

Pure white new hypsizigus marmoreus bacterial strain

ActiveCN103477993AShort training periodShort cultivation periodFungi productsLichen productsMicrobiologyBacterial strain

The invention provides a pure white new hypsizigus marmoreus bacterial strain Finc-W-62, and the preservation number of the bacterial strain is CCTCC NO: M 2012375. The culture and cultivation periods of Finc-W-62 are short, the production cost is low, pileus is not easy to open, tumor stropharia rugosannulata ratio is low, the appearance quality is improved and sporophore shelf life is long.

Owner:SHANGHAI FINC BIO TECH INC

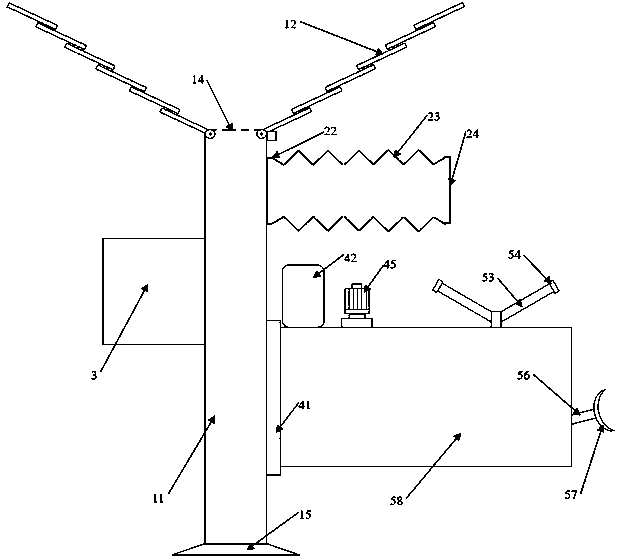

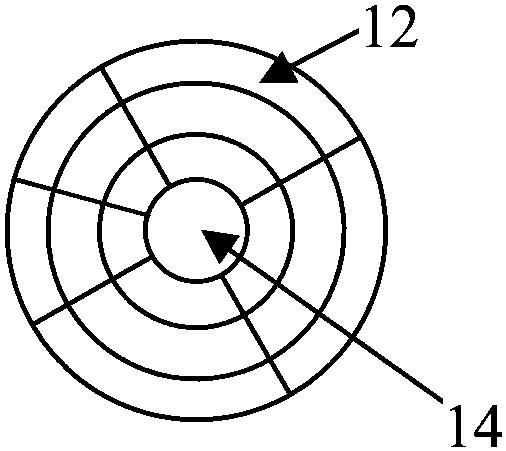

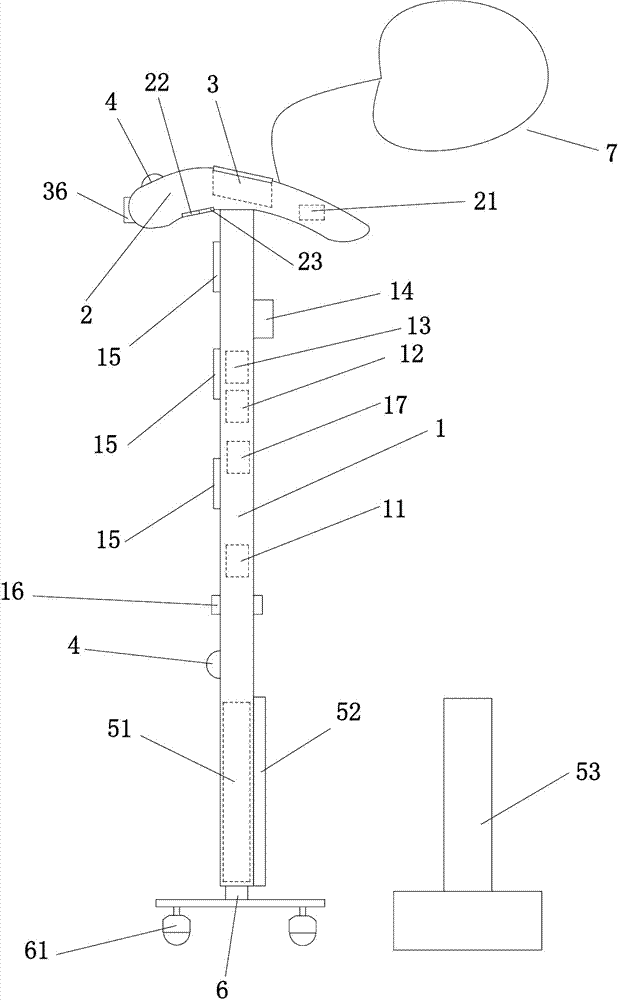

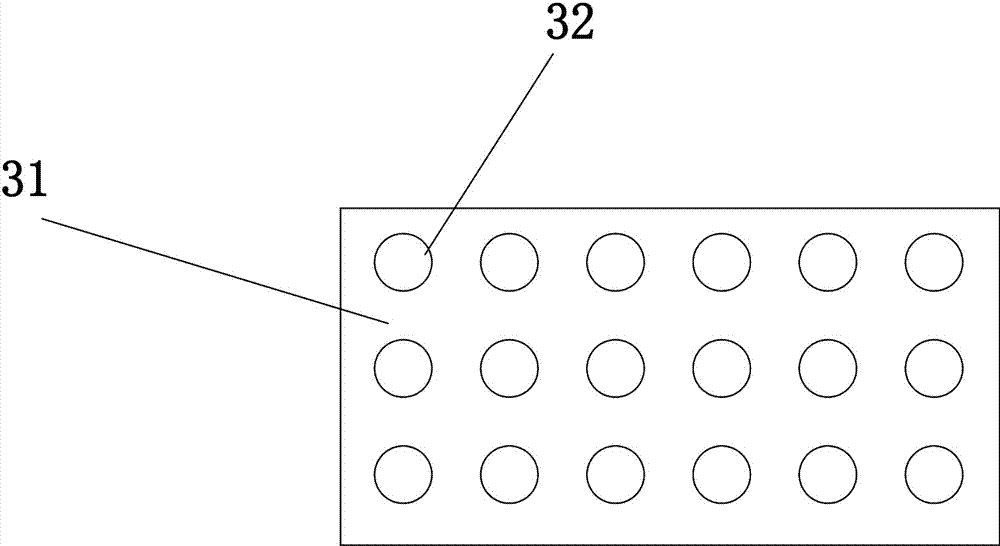

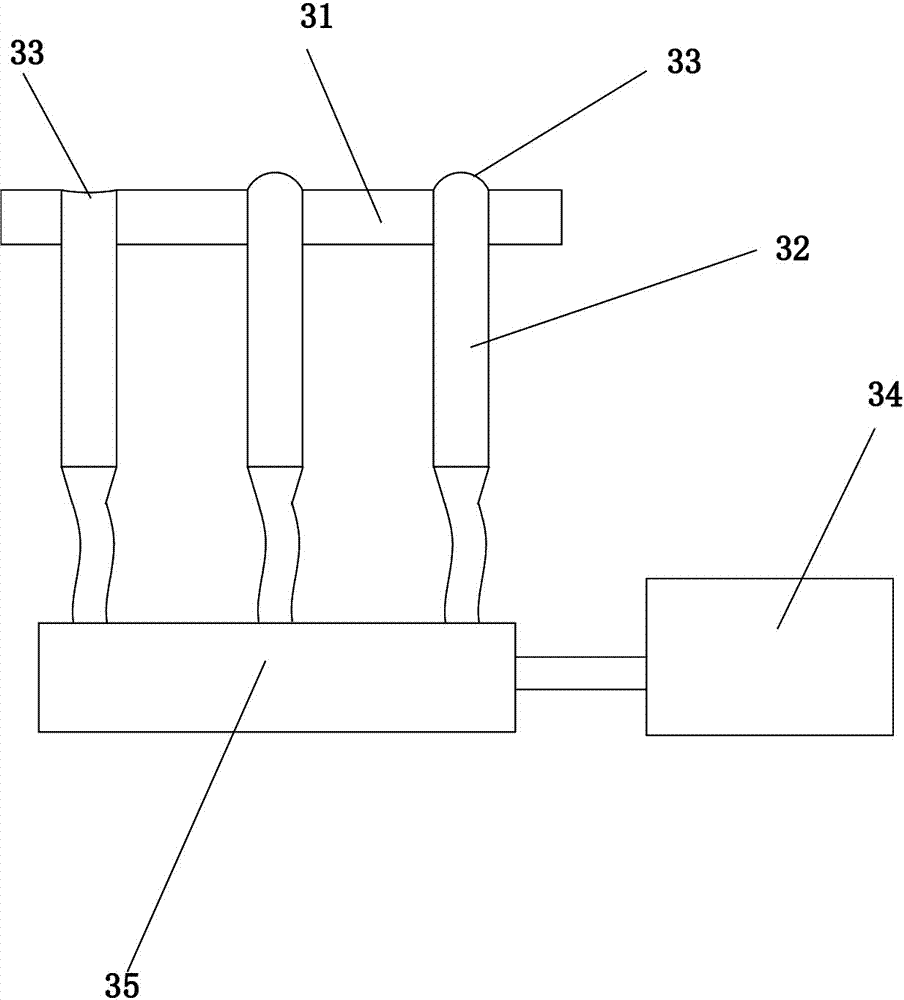

Intelligent delayed plant irrigation device

InactiveCN110447515AExpand the rainwater harvesting areaReduce the probability of occurrenceGeneral water supply conservationRotary stirring mixersStormwaterIrrigation

The invention belongs to the field of disaster reduction and prevention and smart cities, and particularly relates to an intelligent delayed plant irrigation device. The device comprises a rain collecting support part, a precipitation water storage part, a filtering adsorption part, a stirring part and a spraying part. This kind of devices are arranged in batches in a green belt or a park of a city. By collecting and treating rainwater and snow water and then carrying out irrigation on plants in rainless days, not only is rainwater stored in a centralized manner when the rainfall is large, butalso urban waterlogging caused by overlarge rainfall is avoided, and meanwhile, rainwater is stored and treated and then used for irrigation, so that the direct application of rainwater after primarycollection is achieved, and the increase of unnecessary treatment costs caused by retreatment after rainwater is mixed with other sewage is avoided.

Owner:朱赵伟

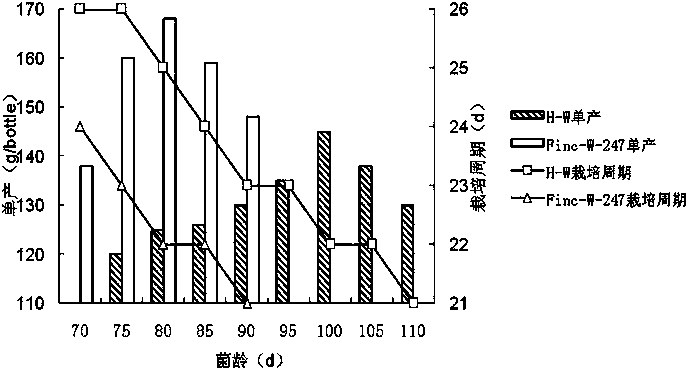

New pure white hypsizigus marmoreus strain

ActiveCN103503780AShort training periodShort cultivation periodFungi productsLichen productsBeta-glucanMicrobiology

The invention provides a pure white hypsizigus marmoreus strain Finc-W-247 of which the collection number is CCTCC NO:M2012378. The strain has the advantages of short cultivation and culture period, high single yield, high appearance uniformity among single plants and single sporophores in each single plant, low occurrence of cap mushroom tumors, high edibility, long preservation period, favorable mouthfeel, high beta-glucan content, high adaptability for culture media, and the like, and is suitable for large-area popularization and planting.

Owner:SHANGHAI FINC BIO TECH INC

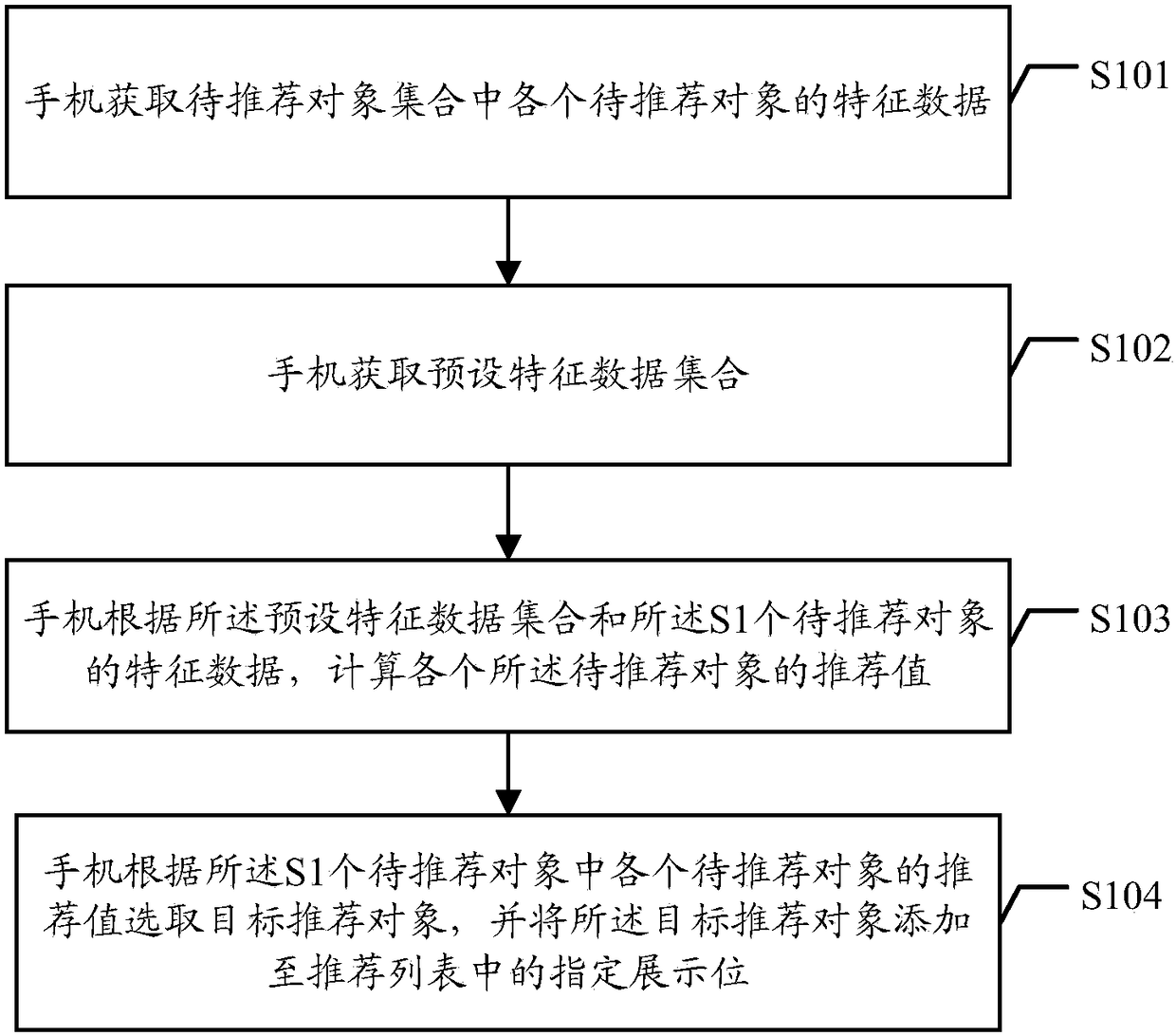

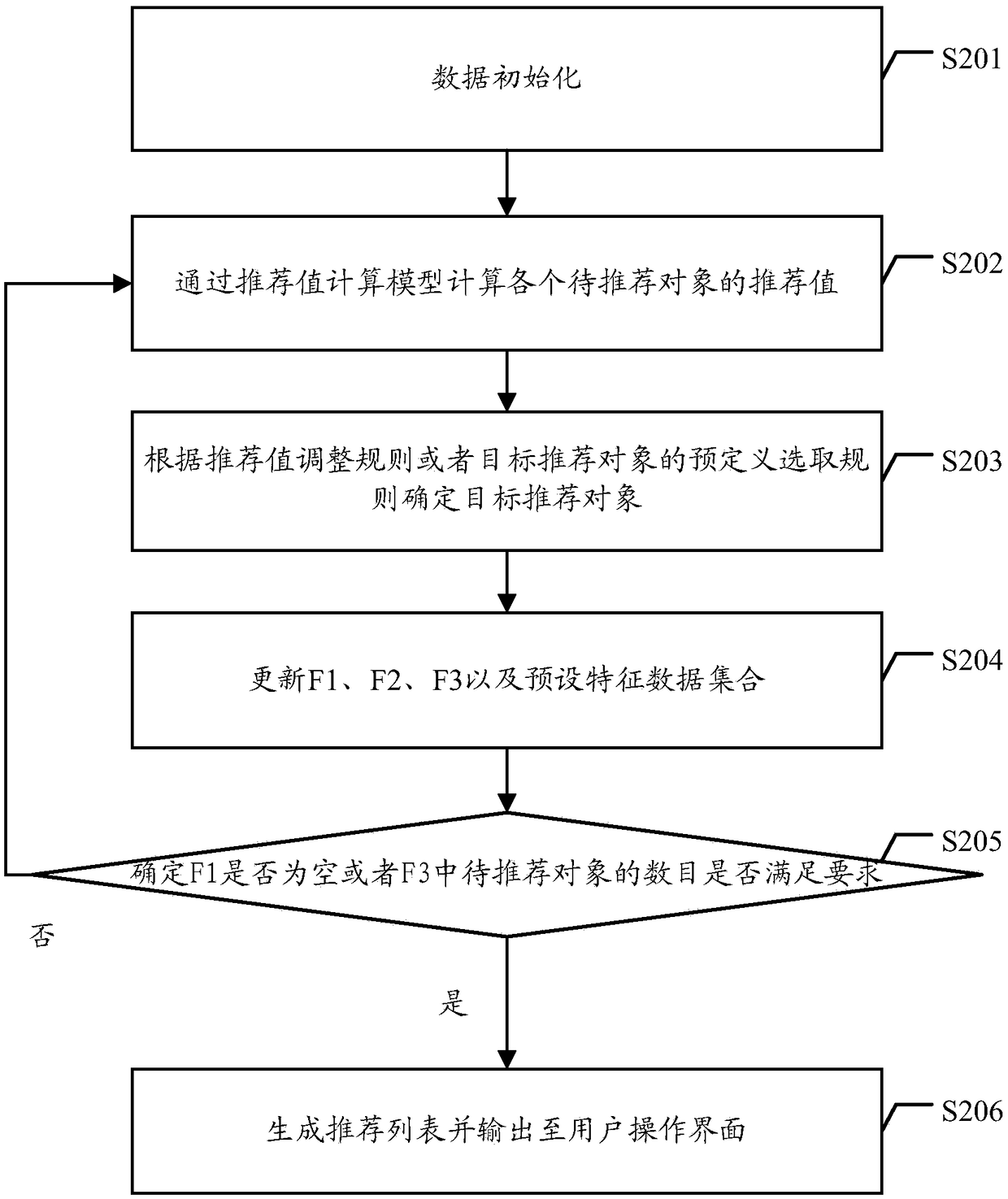

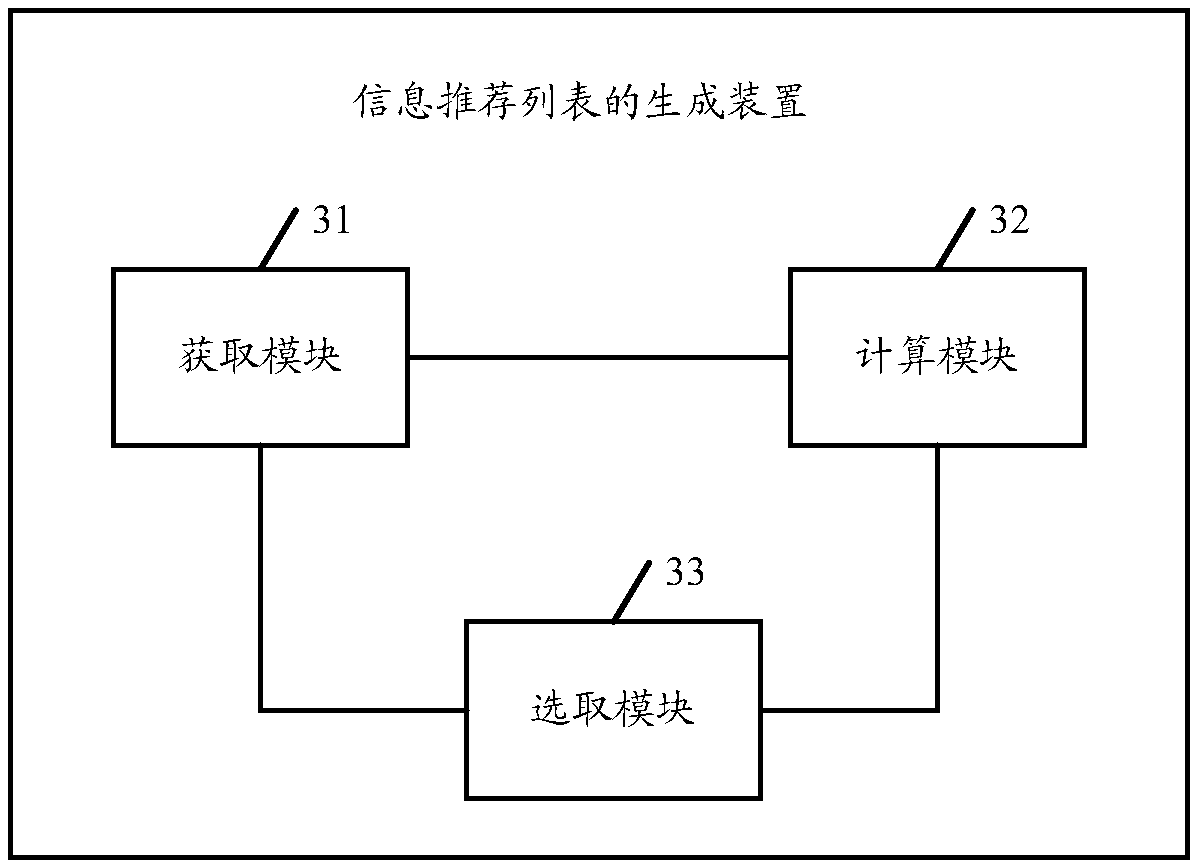

Information recommendation list generation method and device

ActiveCN108345419AControl dependenciesImprove calculation accuracySpecial data processing applicationsInput/output processes for data processingData setResource utilization

Embodiments of the invention disclose an information recommendation list generation method and device. The method comprises the following steps of: obtaining feature data of each to-be-recommended object in a to-be-recommended object set by a terminal, wherein the to-be-recommended object set comprises S1 to-be-recommended objects; obtaining a preset feature data set by the terminal, wherein the preset feature data set comprises feature data of S2 recommended objects, the feature data of the S2 recommended objects comprises feature data of an appointed recommended object, and S2 is smaller than or equal to S1; calculating a recommendation value of each to-be-recommended object by the terminal according to the preset feature data set and the feature data of the S1 to-be-recommended objects;and selecting a target recommended object by the terminal according to the recommendation value of each to-be-recommended object in the S1 to-be-recommended objects, and adding the target recommendedobject to an appointed display position in a recommendation list. By adoption of the method and device, the advantages of improving the recommended object selection correctness and improving the resource utilization rate of the recommendation list are provided.

Owner:HUAWEI TECH CO LTD

Blind-guiding stick capable of displaying braille alphabet

InactiveCN107080675AReduce the probability of occurrenceReduce incidenceWalking aidsHandrailHearing disorder

The invention relates to a blind-guiding stick capable of displaying a braille alphabet. The blind-guiding stick comprises a stick body, the top of the stick body is provided with a handrail, and the stick body is internally provided with a processor module, a wireless communication module, a voice receiving module, a voice processing module, an ultrasonic sensing module and a battery module, wherein a braille alphabet displaying module is arranged on the handrail. Compared with the prior art, outside information can be obtained through multiple sensors and communication equipment arranged in the blind-guiding stick, the information is converted into the braille alphabet so that blind people with hearing disorders can be informed and obtain outside environment information, the blind people with the hearing disorders are assisted in making a decision, and are assisted in going out, and thus the probability of occurrence of accidents is reduced.

Owner:张俊逸

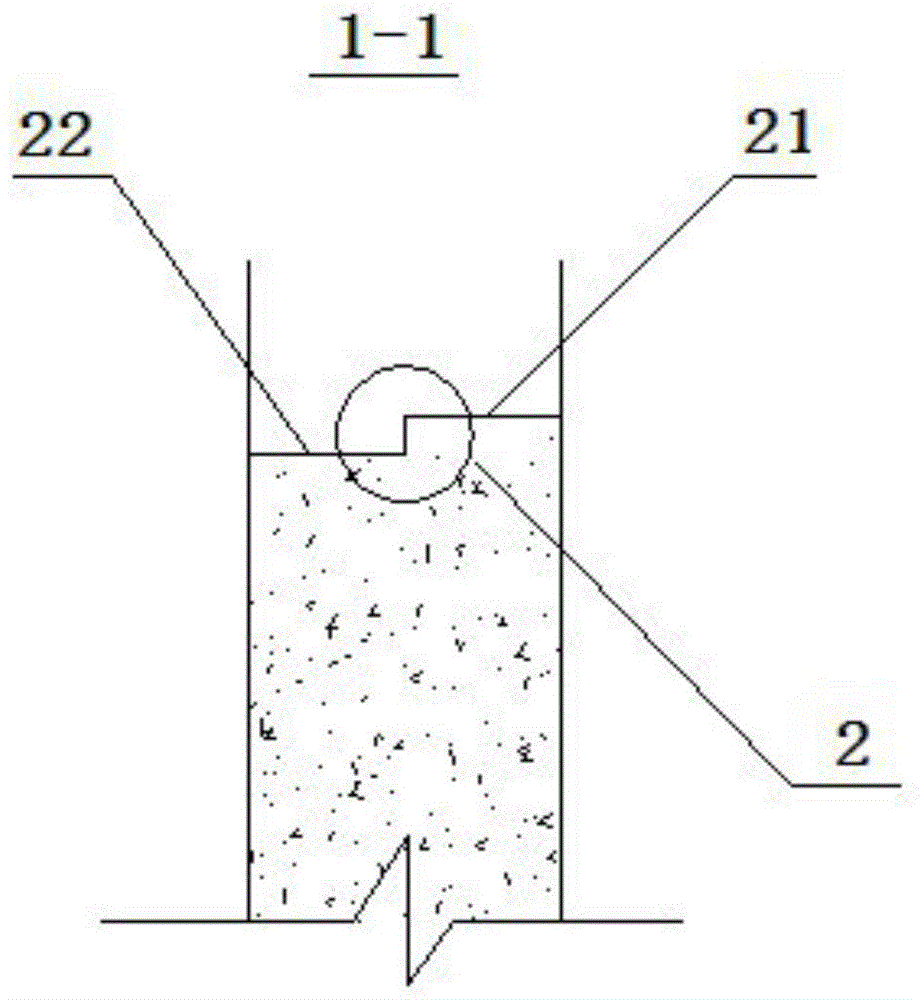

Outer-wall tongue groove capable of preventing water seepage of window and construction method of outer-wall tongue groove

InactiveCN104153485AReduce the probability of occurrenceReduce plaster thicknessWallsJoints tightening/coveringRebarWater seepage

Owner:TIANJIN 20 CONSTR

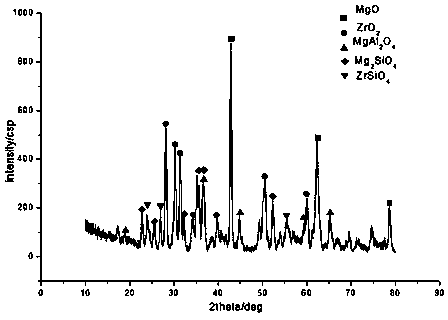

Refractory aggregate, stainless steel casting paint consisting of same and preparation method thereof

ActiveCN104209455AGood chemical stabilityReduce the probability of occurrenceFoundry mouldsFoundry coresLithiumPolyvinyl alcohol

The invention belongs to the technical field of casting materials, in particular relates to a refractory aggregate, a stainless steel casting paint consisting of the same and a preparation method thereof. The refractory aggregate consists of magnesia powder, emery powder and zircon powder, wherein the mass percentages of the components are as follows: 45-55% of magnesia powder, 15-20% of emery powder and 30-35% of zircon powder; the stainless steel casting paint consisting of the refractory aggregate comprises the following components in percentage by mass: 60-70% of ethanol, 2-3% of lithium-based bentonite, 2-3% of silica sol, 1.5-2.5% of polyvinyl butyral, 0.5-1.0% of phenolic resin, and the balance of the refractory aggregate; the preparation method of the paint comprises the following steps: firstly, the lithium-based bentonite is expanded, and is dispersed in the ethanol; then, the refractory aggregate is added to mix for 10-25 minutes; and then, the silica sol, the polyvinyl butyral and the phenolic resin are added in sequence, and the mixture is transferred into a high-speed rotating mixer for mixing to obtain the stainless steel casting paint. The aggregate and the paint can effectively improve the high-temperature strength and normal-temperature strength of castings, and largely reduce the occurrence rate of scabs and metal penetration in the production process.

Owner:SHIYAN LONGGANG CASTING

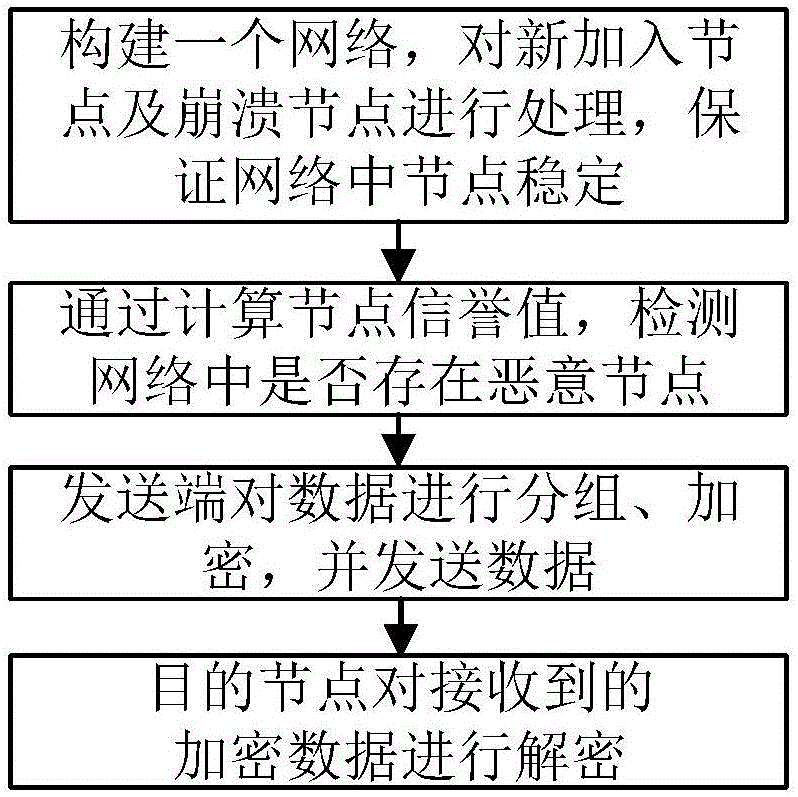

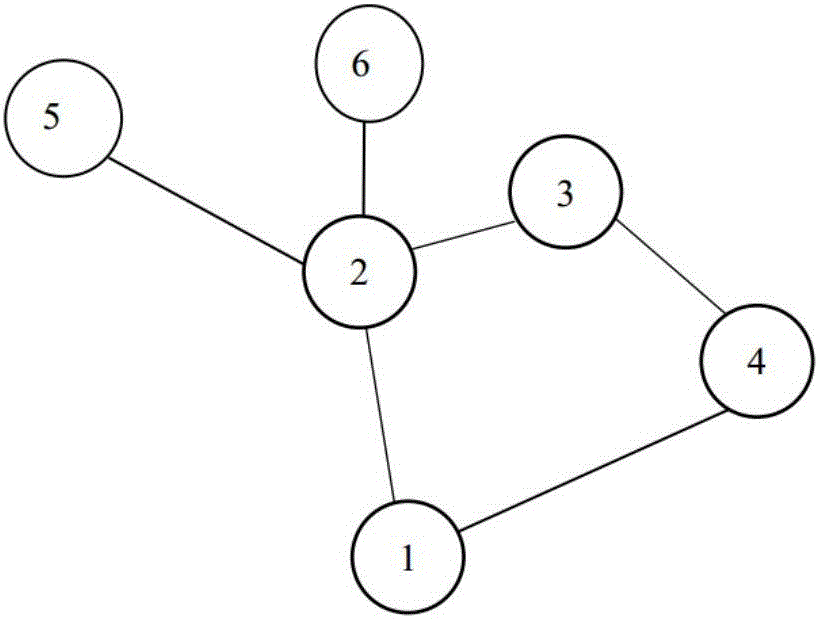

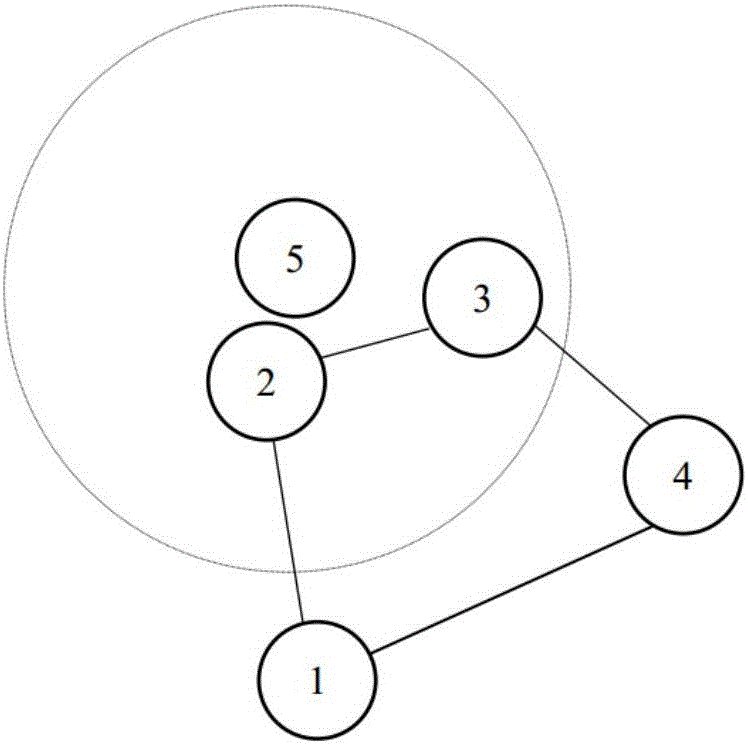

Secure ad-hoc network single-path routing data transmission method

ActiveCN106851630AReduce the probability of occurrenceSecurity arrangementHigh level techniquesData transmissionData security

The invention discloses a secure ad-hoc network single-path routing data transmission method for the problem that ad-hoc network data security is not sufficiently ensured. A stable network is established; under the condition that a new node joins the network and certain node in an original network is broken down, malicious node detection is carried out on the network; and a reputation evaluation formula parameter is updated in real time, thereby achieving a purpose of accurately detecting a malicious parameter. If a malicious node is detected, the node is processed as a breakdown node, and the security of the network is ensured. Data is encrypted through adoption of a key table, and the encrypted data is sent. In the original network, optimum path selection is carried out through a routing path hop count minimization rule and a link busy and idle rule between a sending node and a destination node. After a path is selected, the encrypted data is decrypted according to a corresponding key in the key table, and the original data information is restored.

Owner:陕西尚品信息科技有限公司

Spectacle frame processing method

The invention discloses a spectacle frame processing method. The spectacle frame processing method comprises injection molding, burring, polishing, assembling combination, examination and ink-jet printing. The spectacle frame processing method has a high automation degree and a low cost, is suitable for batch production, utilizes a liquid nitrogen refrigeration technology to freeze a product so that the product is embrittled, has a process of jetting polymer particles to burr of the product at a high rate so that high-efficiency high-quality burring is realized and product characteristics are not changed, utilizes a polishing process to make the spectacle frame flat and smooth so that good feel is obtained, utilizes the examination process to ensure if the spectacle frame size is qualified so that a rejection rate is reduced, and utilizes the ink-jet printing process for jet-printing spectacle frame specification and trademark on spectacle legs so that product postmarketing maintenance and spectacle frame brand publicity are promoted.

Owner:季叶俊

Garment fabric cutting equipment

InactiveCN108385362AHigh precisionReduce waste occurrenceSevering textilesEngineeringMechanical engineering

The invention discloses garment fabric cutting equipment. The cutting equipment comprises a working platform, a first supporting frame, a second supporting frame and pipe sleeves are welded to the topof the working platform, the pipe sleeves are located between the first supporting frame and the second supporting frame, a second threaded hand lever is connected to the top of the second supportingframe through threaded screwing, a press plate is mounted on one end of the second threaded hand lever, a soft rubber pad is mounted on the bottom of the press plate, and a first threaded hand leveris connected to the bottom of the working platform through threaded screwing. According to the cutting equipment, the problem that the cutting quality is affected by cutting position offset due to thefact that folds and positions of garment fabric are moved during the cutting process is avoided, the precision of cutting of the garment fabric is improved, and the occurrence rate of wastes is reduced; in addition, through a press roller and a smooth roll, the garment fabric can be tightened, on one hand, the garment fabric can be easily pulled and dragged to achieve fast loading and improve cutting efficiency, and on the other hand, the trouble of cutting due to the slacking of the fabric during the cutting is avoided.

Owner:长兴超特纺织有限公司

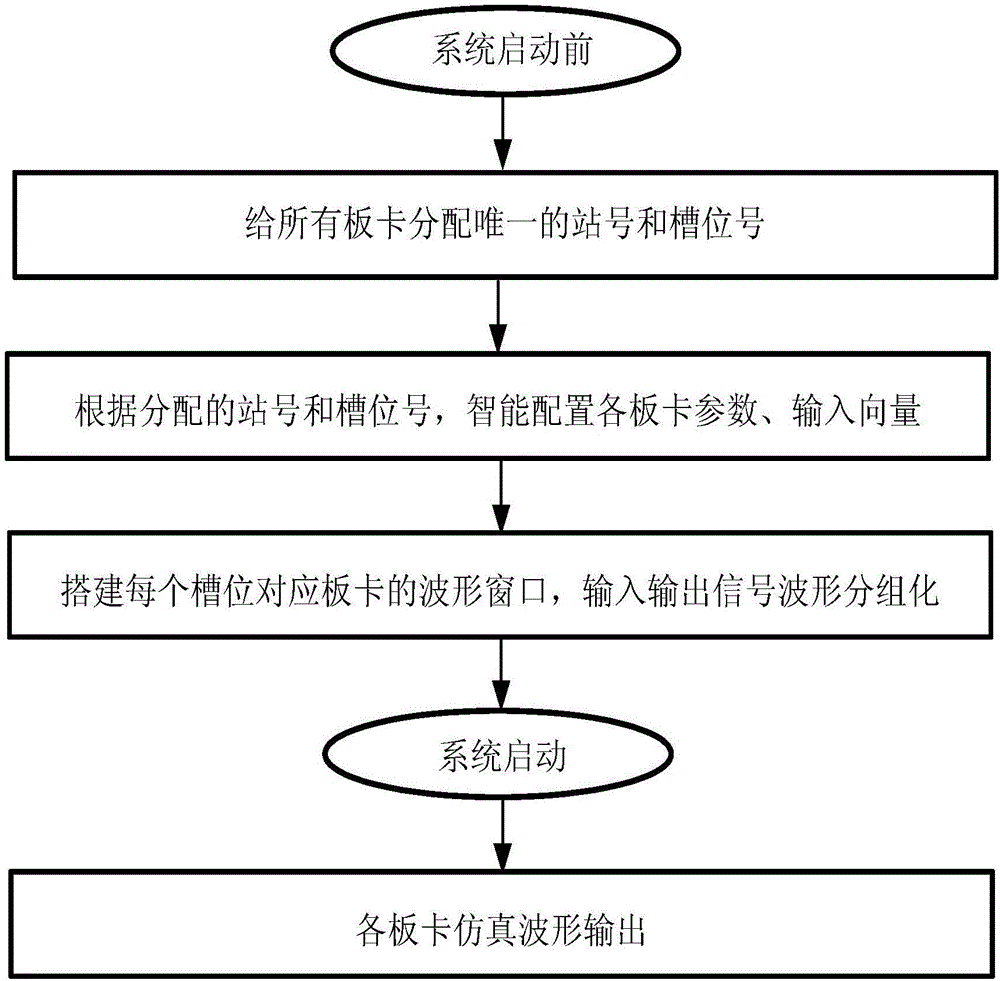

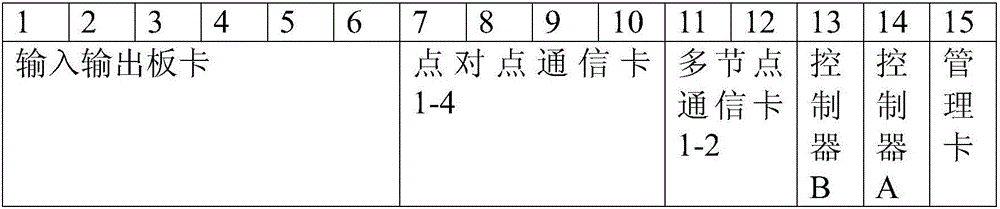

Realizing method for nuclear safety-level intelligent simulation verification platform based on FPGA technology

ActiveCN106773785AReduce the probability of occurrenceReduce probabilitySimulator controlComputer architectureNuclear power

The invention provides a realizing method for an intelligent simulation verification platform of a nuclear safety-level instrument control system based on an FPGA technology. The method comprises the following steps: step one: based on the FPGA technology, constructing the simulation verification platform according to hardware devices of the nuclear power station safety-level instrument control system, and distributing unique station number and slot position number to all hardware board cards; step two: according to the station number and the slot position number distributed to the board cards, configuring various board card parameters and input vectors, wherein the simulation verification platform is capable of simulating the situation of one or more board cards in the actual nuclear power station safety-level instrument control system; step three: constructing a waveform window of the board card corresponding to each slot position, grouping input-output signal waveforms, and forming a loop-locked simulation verification platform; and step four: starting the simulation verification platform to execute the verification. The method is capable of simulating the actual nuclear power station instrument control system really, the stability, reliability and safety can be satisfied, and the intelligent simulation verification can be realized.

Owner:CHINA NUCLEAR CONTROL SYST ENG

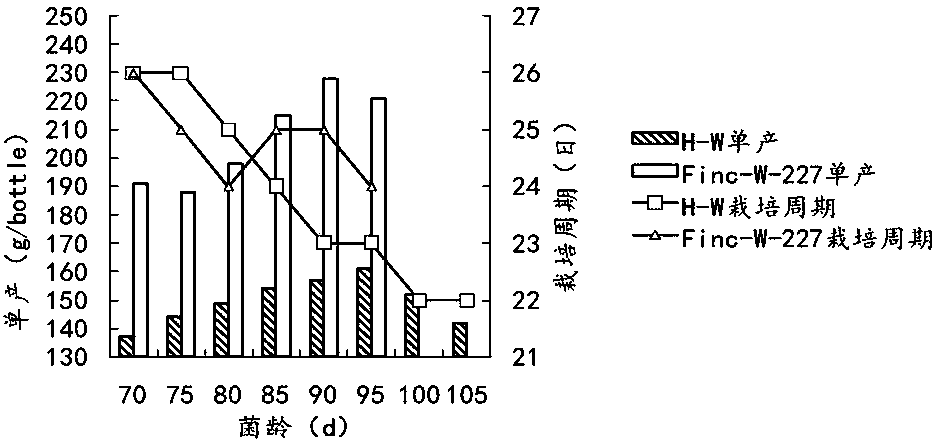

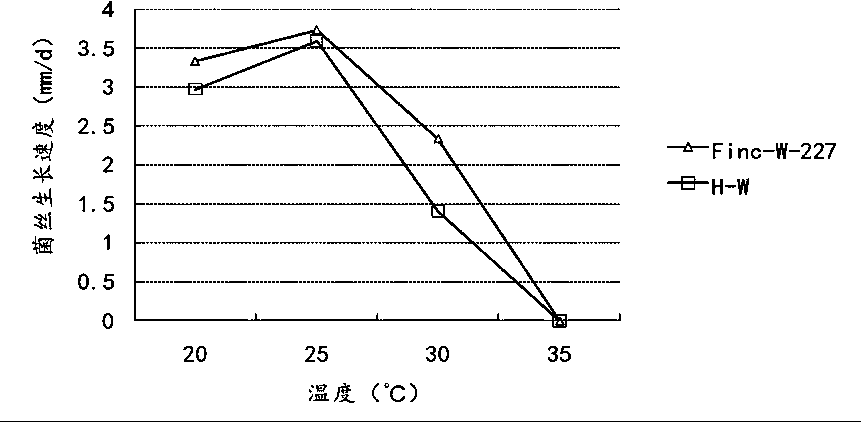

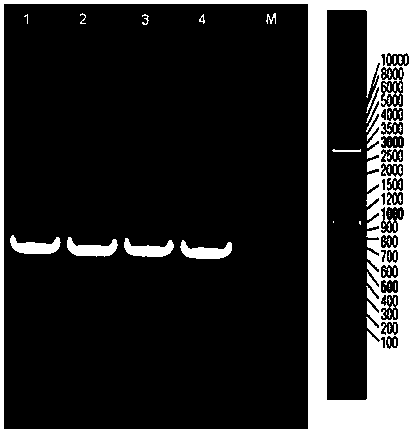

New pure white hypsizigus marmoreus strain

ActiveCN103503779AReduce the probability of occurrenceIncrease unit outputFungi productsLichen productsMicrobiologyMushroom

The invention provides a pure white hypsizigus marmoreus strain Finc-W-227 of which the collection number is CCTCC NO:M2012377. The pure white hypsizigus marmoreus strain Finc-W-227 has the advantages of low probability of occurrence of cap mushroom tumors, and high single yield, and is suitable for large-area popularization and planting.

Owner:SHANGHAI FINC BIO TECH INC

Grading beneficiation device for mining ore extraction

InactiveCN111545460AIncrease the number of passes through the sieveIncrease probabilitySievingScreeningMining engineeringElectric machinery

The invention discloses a grading beneficiation device for mining ore extraction, and relates to the technical field of ore processing. The grading beneficiation device comprises a sorting mechanism and a feeding mechanism, wherein one surface of the sorting mechanism is fixedly connected with the feeding mechanism; the feeding mechanism comprises a feeding hopper; the peripheral side surface of the feeding hopper is fixedly provided with a pre-scattering assembly; the bottom surface of the feeding hopper fixedly communicates with a material distributing pipe; the inner wall of the material distributing pipe is fixedly provided with a spiral conveying assembly; the sorting mechanism comprises a material screening shell; a group of symmetrically-arranged damping parts is fixedly connected with the inner wall of the material screening shell; and the top ends of the two damping parts are fixedly connected with supporting seats. According to the grading beneficiation device, through the design of the sorting mechanism and the feeding mechanism, the quantitative discharging and automatic grading screening process of materials can be completed in an automatic form; and meanwhile, throughthe vibrating design of a vibrating motor and the reciprocating swinging type design of a screening seat during screening, the frequency and probability of the materials flowing through screening holes can be effectively increased, and the faulty screening rate and the screening leakage rate of the materials are reduced.

Owner:合肥星研科技有限公司

Intelligent high-speed nail making machine

InactiveCN103350166AExtended service lifeReduce the probability of occurrencePinsNailsAgricultural engineeringAutomatic controller

The invention provides an intelligent high-speed nail making machine and relates to the field of nail making machines. The intelligent high-speed nail making machine comprises a rack, a straightening mechanism, a feeding mechanism, a cutting mechanism, a nail head forming device and a power driving device, and is characterized in that the straightening mechanism comprises a horizontal straightening component and a vertical straightening component, the horizontal straightening component comprises a horizontal roller frame horizontally fixed on a rack, a horizontal roller seat installed in the horizontal roller frame, and a horizontal straightening roller installed on the horizontal roller seat, and the vertical straightening component comprises a vertical roller frame vertically fixed on the rack, a vertical roller seat installed in the vertical roller frame and a vertical straightening roller installed on the vertical roller seat. The intelligent high-speed nail making machine adopts a rolling method, so that the noise is reduced, the service life of a die is prolonged due to the rolling use of a die ring, an electronic eye controller is used to reduce the occurrence rate of degraded products of the nail making machine, the equipment is automated owing to the design of an automatic controller, the continuous high-quality production of the nail making machine is guaranteed, the production efficiency is improved, the production cost is lowered, and better practical application value and social promotion value are obtained.

Owner:马鞍山市玉龙金属制品(集团)有限公司

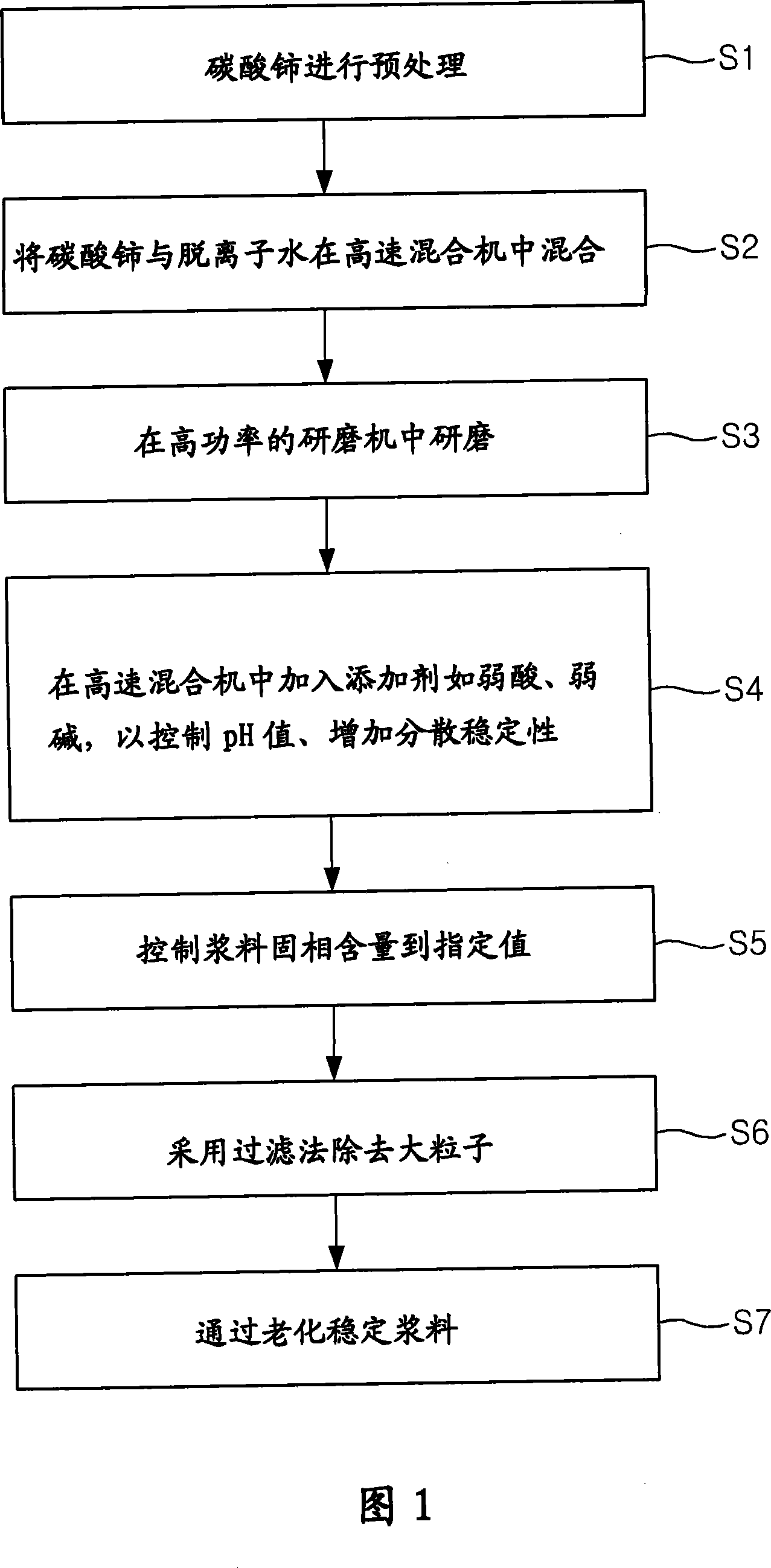

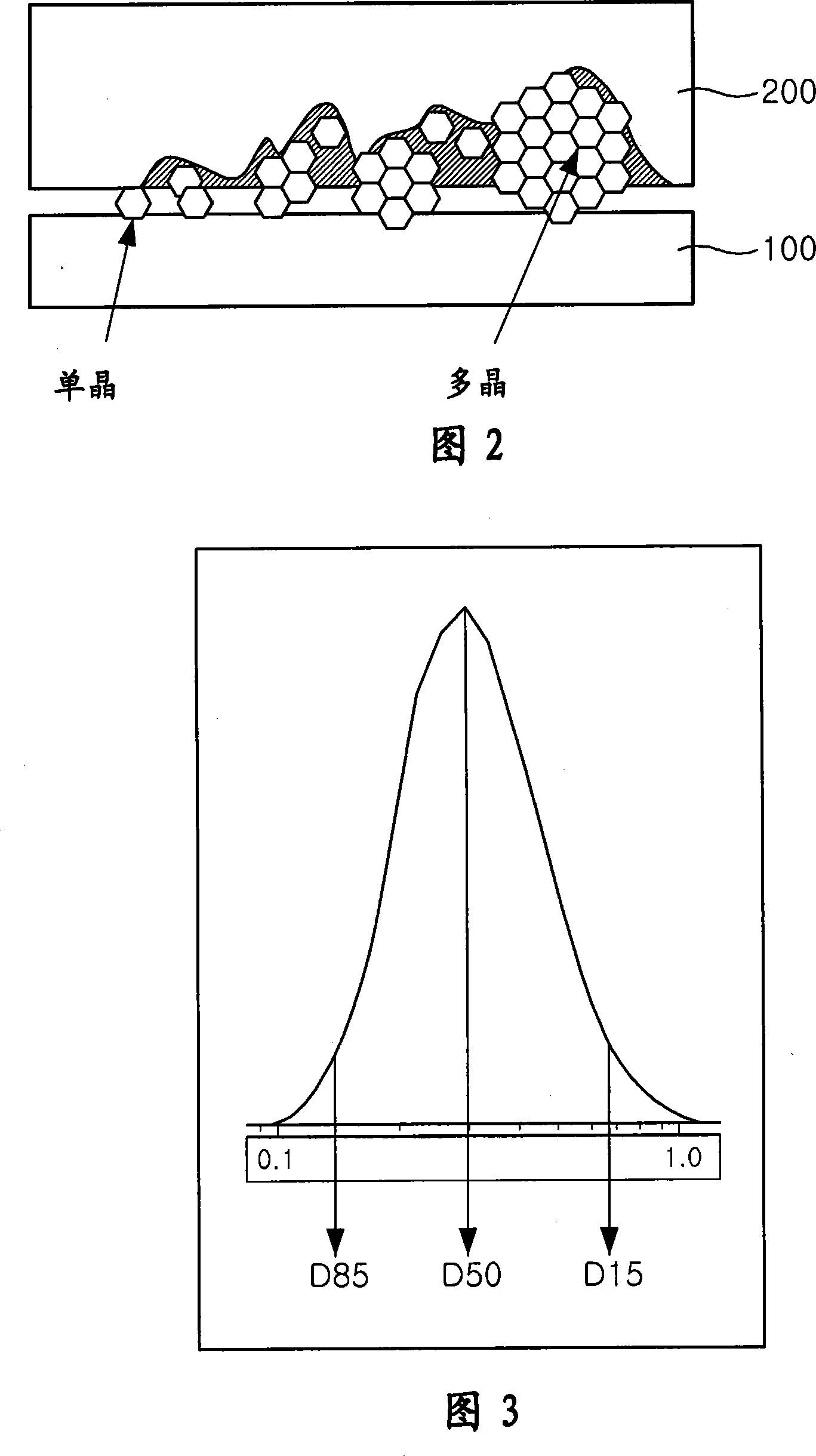

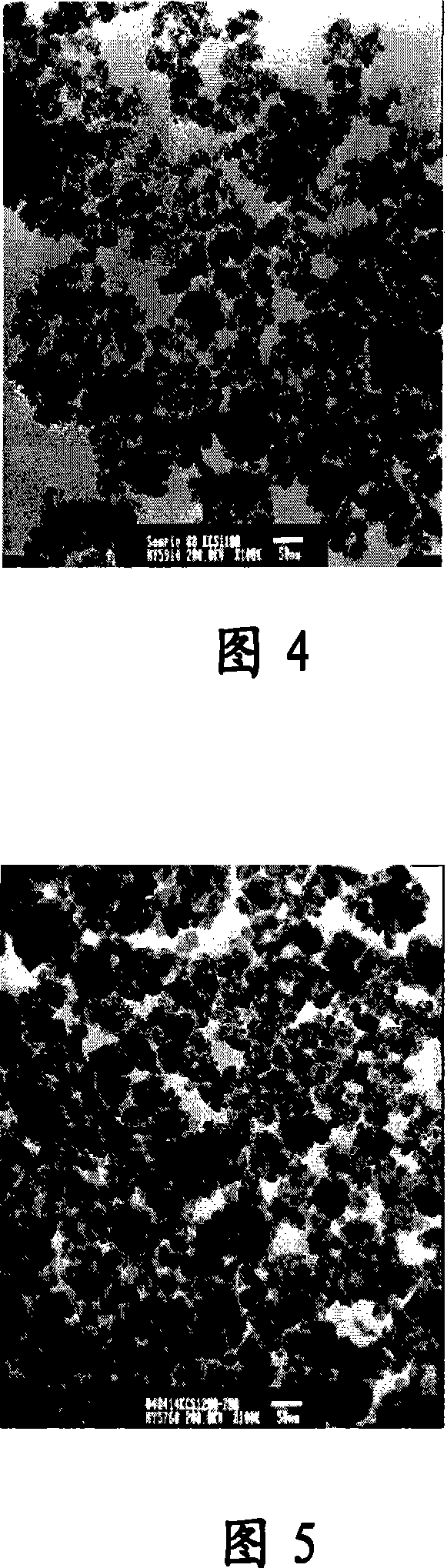

Polishing slurry, method of producing same, and method of polishing substrate

ActiveCN101092543ASmall sizeReduce the probability of occurrenceSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSlurryNitride

Disclosed is a polishing slurry, particularly, a slurry for chemical mechanical polishing, which is used in a chemical mechanical polishing process for flattening a semiconductor laminate. More particularly, the present invention provides a method of producing a slurry which has high removal selectivity to a nitride layer used as a barrier film in a shallow trench isolation CMP process needed to fabricate ultra highly integrated semiconductors of 256 mega D-RAM or more (Design rule of 0.13 mum or less) and which decreases the occurrence of scratches on a flattened surface, and a method of polishing a substrate using the same.

Owner:K C TECH +1

One-empty-in-two-ridge corn planting method

InactiveCN105325136AAchieving high-yield creation goalsGood ventilation and light transmissionFertilising methodsHorticultureControlled releaseRidge

The invention relates to a one-empty-in-two-ridge corn planting method. The method comprises the following steps: (1) preparing land; (2) selecting seeds; (3) performing coating; (4) sowing according to a one-empty-in-two-ridge method; (5) applying fertilizer, using BB fertilizer or slow / controlled-release fertilizer according to a detection result; (6) irrigating; (7) performing field management; (8) harvesting. Compared with the prior art, the beneficial effects of the method are that the method is characterized by simple, scientific, and rational, and the method effectively uses an empty ridge method to realize a marginal effect, so as to increase field ventilation and light penetrating amount and improve growing environment of corns, the method uses a high photosynthetic efficiency principle to realize a planting mode of ridges are border rows and plants are land, thereby improving utilization rate of illumination and accumulated temperature; since fertilizing amount is concentrated, being beneficial for corns to fully absorb intensively, thereby improving utilization rate of fertilizer, preventing problems of excessive or insufficient fertilization, improving corn yield and cultivated land quality, and the method has wide promotional value.

Owner:李振明

Reclaiming device of magnet forming equipment

InactiveCN103879747AReduce the probability of scrapped partsIncrease productivityConveyor partsTransfer mechanismMagnet

The invention belongs to the field of manufacturing of magnets and particularly relates to a reclaiming device of magnet forming equipment. The reclaiming device of the magnet forming equipment comprises a transfer mechanism and a conveying mechanism which are arranged on a base. The transfer mechanism is connected with the base in a sliding mode in the horizontal direction, the conveying mechanism is located on the sliding path of the transfer mechanism, and the conveying mechanism is located below the transfer mechanism. The reclaiming device of the magnet forming equipment has the technical effects that pressed magnets are transferred onto a conveying belt through the transfer mechanism to be stacked up in order, then, the magnets are conveyed to a pile-up place to be fired through the conveying mechanism, the probability of occurrence of scraped magnets is effectively reduced, and production efficiency is greatly improved.

Owner:黟县越驰科技电子有限公司

Selenium-rich chewing gum

InactiveCN103947816AInhibit synthesisInhibition of replicationChewing gumNormal peopleKappa-selenocarrageenan

The invention relates to a selenium-rich chewing gum. The selenium-rich chewing gum is characterized in that Kappa-selenocarrageenan is added into a chewing gum matrix to supplement 50-200mu g of organic selenium for normal people through chewing every day. According to the selenium-rich chewing gum provided by the invention, the chewing gum is taken as a carrier for supplementing selenium, the concept is novel, the mode of usually taking selenium-containing tablets and capsules by people is broken through, the selenium-rich chewing gum is very convenient to take and carry, Kappa-selenocarrageenan is added into the chewing gum matrix to prepare the selenium-rich chewing gum, Kappa-selenocarrageenan is slowly dissolved in saliva of the people and absorbed during the process that people chew the chewing gum and then, the selenium supplement for people is simple, convenient and direct; furthermore, the price is low and the selenium-rich chewing gum is easily accepted by the people.

Owner:柯志卫

Preparation method for improving blood curd texture

PendingCN107198132AImprove textureIncrease contentCheese manufactureFood ingredient functionsReduction treatmentAnticoagulant

The invention discloses a preparation method for improving the blood curd texture. The method comprises the following steps of collecting fresh blood of beasts and birds; mixing the blood with anticoagulants; 2, performing temperature reduction treatment and cold storage; 3, adding cooling water into the anticoagulation blood, wherein the temperature of the cooling water is 4 to 10 DEG C, and the mass percentage of the cooling water in the material liquid is 30 to 50 percent; 4, performing homogenate processing or ultrasonic processing, wherein the homogenate processing comprises the concrete parameters of the homogenate rotating speed being 3000 to 20000 rpm, the homogenate time being 3 to 20 min and the homogenate temperature being 4 to 10 DEG C; the ultrasonic processing comprises the concrete parameters of the ultrasonic power being 20 to 200 HZ, the ultrasonic time being 10 to 60 min, and the ultrasonic temperature being 4 to 15 DEG C; 5, performing post processing on the material liquid so as to prepare the blood curd. The blood curd prepared by the method has high quality, low hardness, good elasticity and good mouthfeel.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

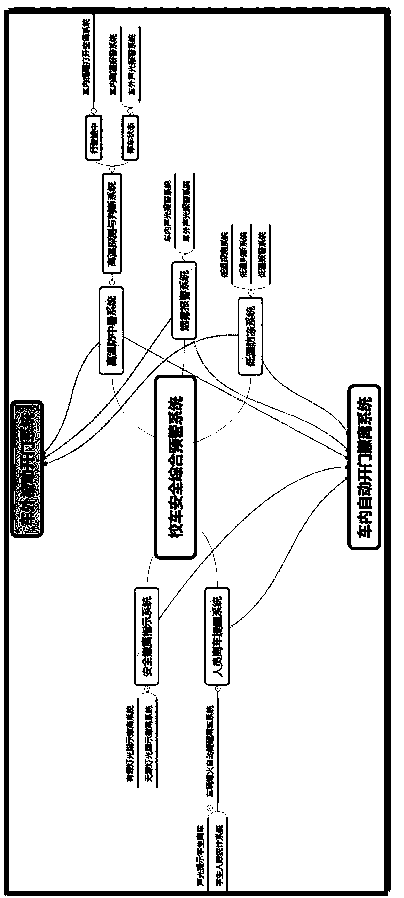

School bus safety comprehensive early warning system

InactiveCN108791052AImprove securityReduce the probability of occurrencePedestrian/occupant safety arrangementSignalling/lighting devicesIn vehicleSchool bus

A school bus safety comprehensive early warning system comprises a micro-control unit, a high-temperature heatstroke prevention system, a smog alarm system, a low-temperature anti-freezing system, a people off-vehicle reminding system, a safe evacuation indicating system, an in-vehicle automatic door opening evacuation system and an out-vehicle passive door opening evacuation system. The micro-control unit is connected with the high-temperature heatstroke prevention system, the smog alarm system, the low-temperature anti-freezing system, the people off-vehicle reminding system, the safe evacuation indicating system, the in-vehicle automatic evacuation system and the out-vehicle passive door opening evacuation system. The school bus safety comprehensive early warning system can achieve thedanger early warning and safety guarantee function under complex environments, and improve the safety factor of a school bus. The school bus safety comprehensive early warning system achieves the active and passive safety guarantees of danger sounding and early warning, and safe evacuation and warning, can effectively lower the occurrence probability of school bus related accidents, and provides asafety guarantee for safe traveling of masses of students.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com