Patents

Literature

275results about How to "Reduce random error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for point-of-interest attraction in digital images

InactiveUS20070116357A1Reduce random errorImage enhancementImage analysisDigital imageComputer science

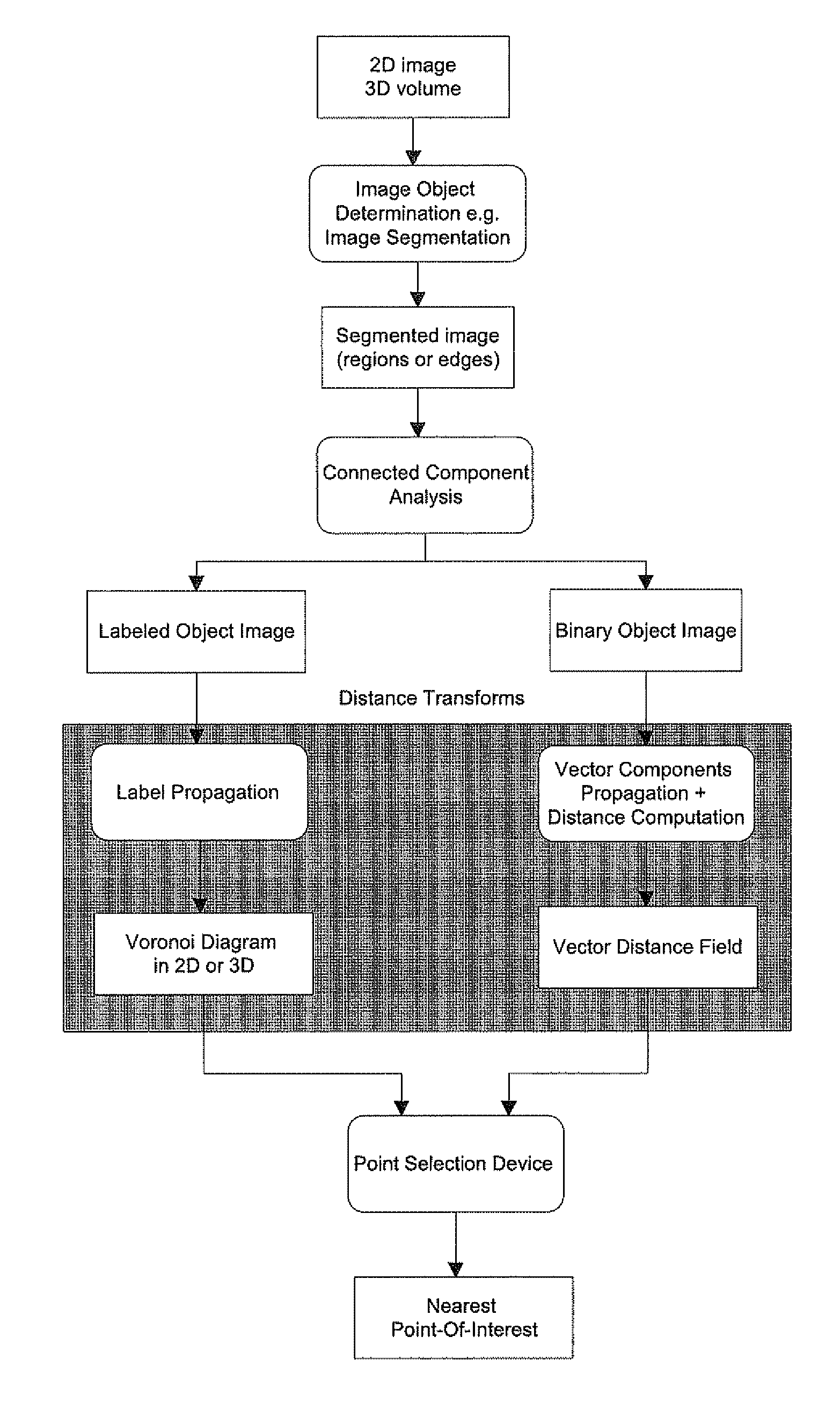

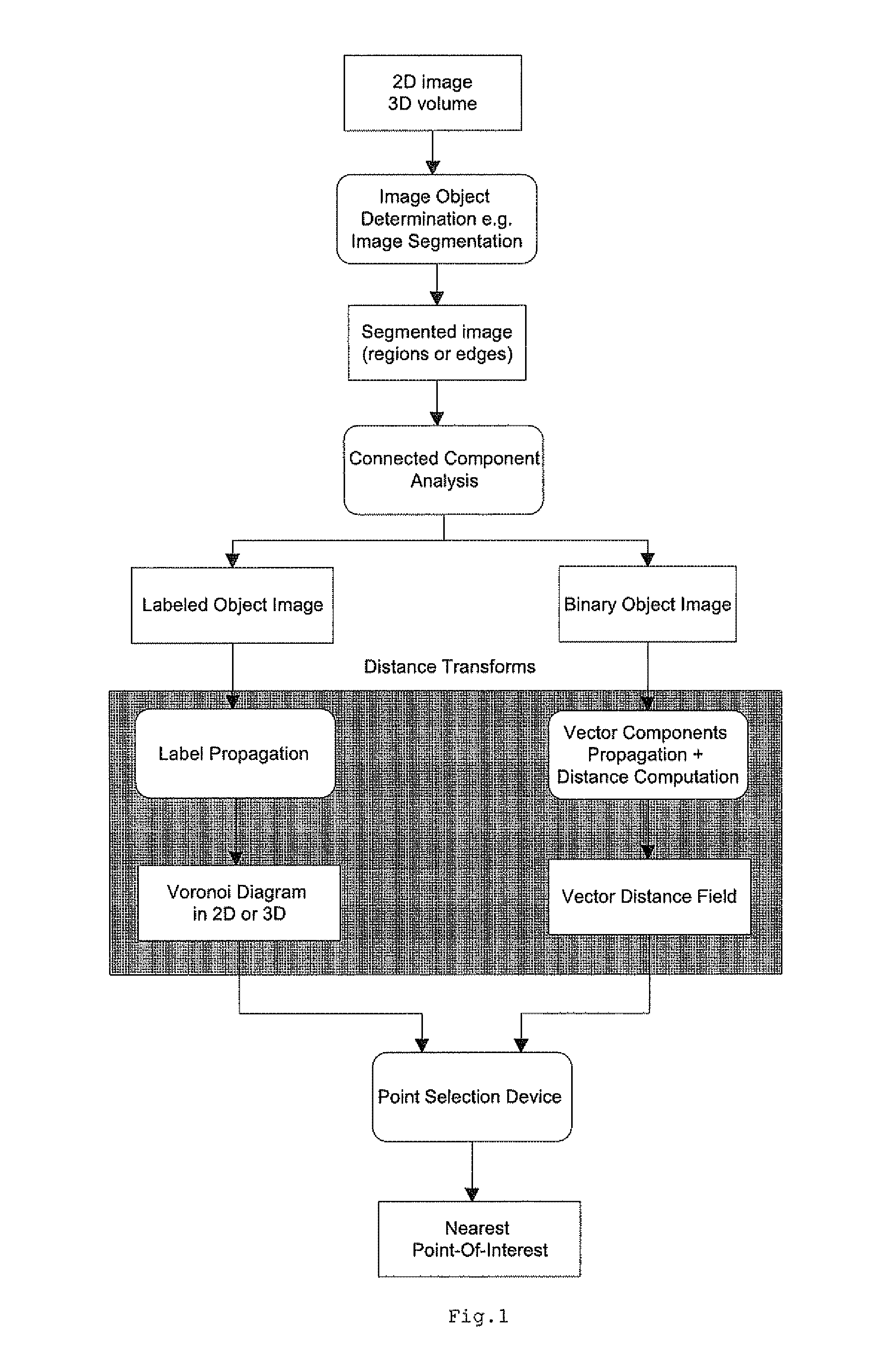

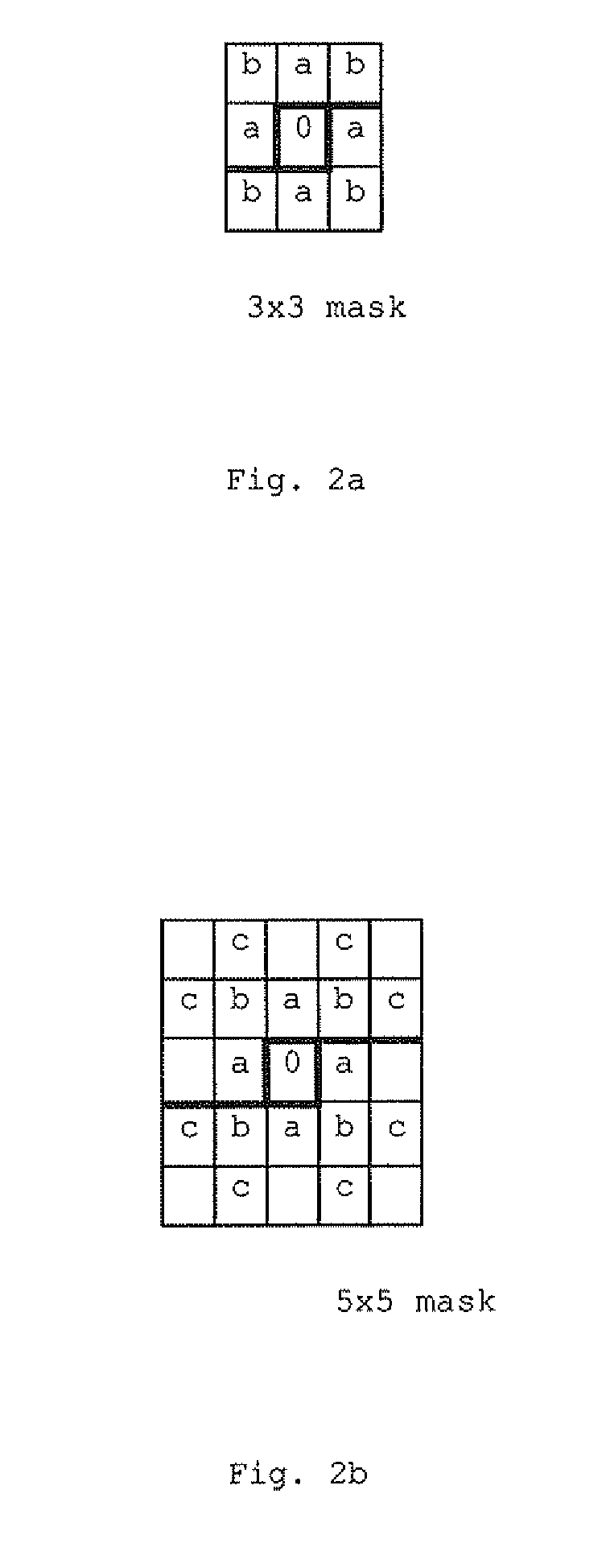

A method for point-of-interest attraction towards an object pixel in a digital image by first performing object segmentation resulting in a contour-based or a region-based representation of object pixels and background pixels of the image. Secondly a vector distance transform image is computed comprising a vector displacement of each background pixel towards the nearest of said object pixels and the nearest object pixel for a given background pixel is determined by adding the vector displacement to said background pixel. Finally the point-of-interest is attracted towards the determined nearest object pixel.

Owner:T2PHARMA GMBH

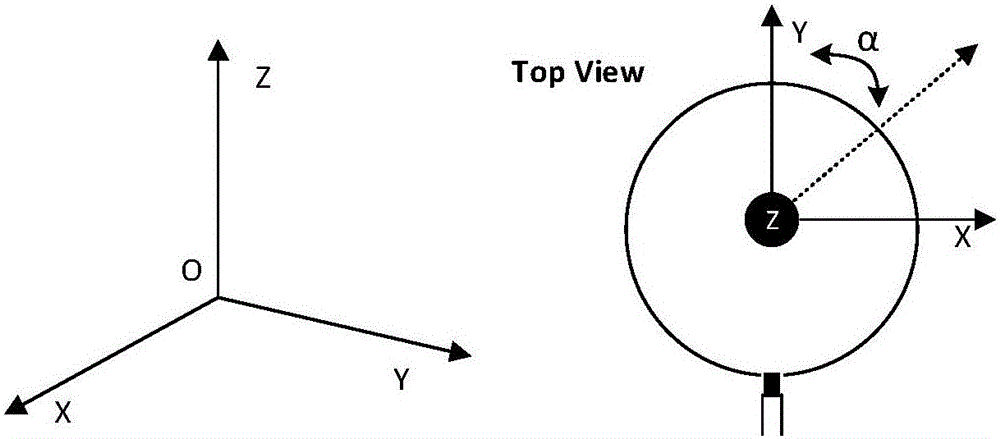

A joint calibration method of a 3D lidar and a monocular camera

InactiveCN106228537ASimplify the calibration processFast calibrationImage analysisCalibration resultCorrespondence principle

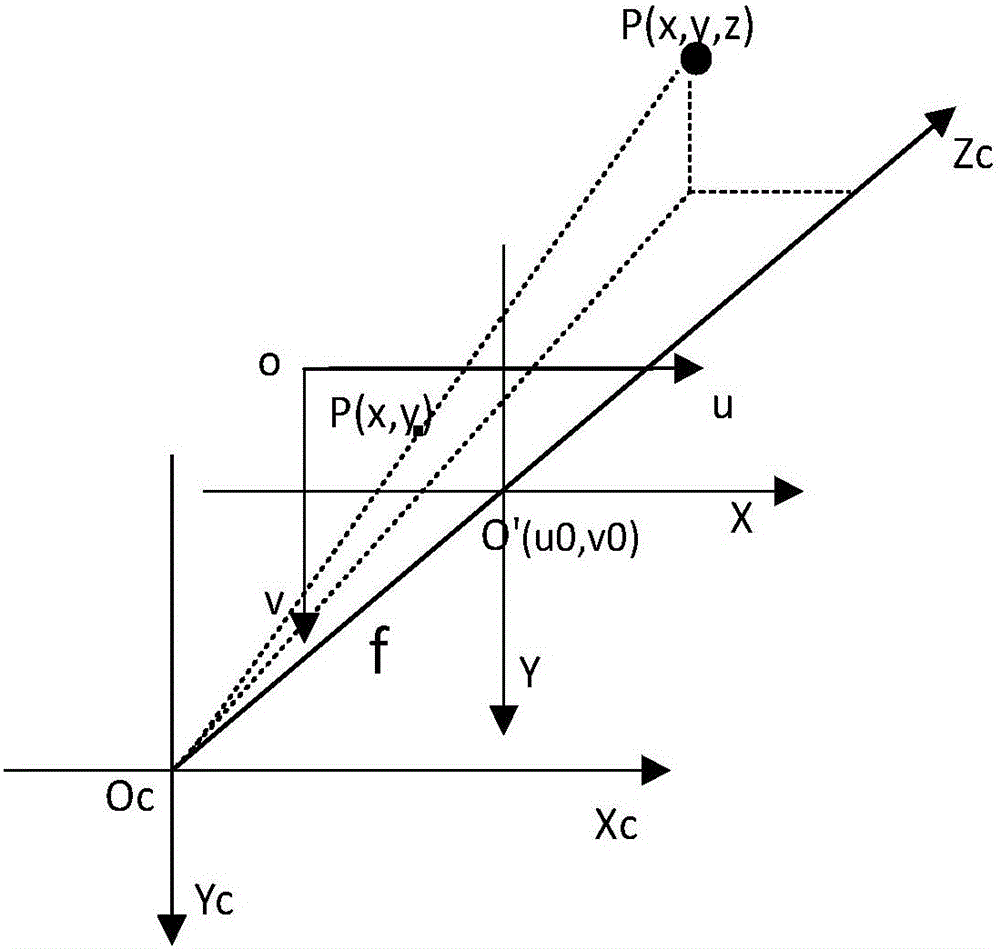

The invention relates to a joint calibration method of a 3D lidar and a monocular camera, and belongs to the field of information fusion. The invention aims at improving the calibration efficiency under the requirement of ensuring the joint calibration accuracy of multi-sensor information fusion. Firstly, the monocular camera is calibrated, and then a normal vector of a target calibration plate in a monocular camera coordinate system, the distance from the target calibration plate to the origin in the monocular camera coordinate system, a normal vector of a fitting plane in a 3D lidar coordinate system and the distance from the origin to the fitting plane in the 3D lidar coordinate system are respectively solved at each position. Then, the results of the joint calibration are solved by using the distance correspondence principle. Finally, the result of the joint calibration is taken as the initial value into an optimization objective function to obtain the optimal joint calibration result. The joint calibration method of the invention greatly reduces human participation, reduces random errors caused by complicated man-made operation, simplifies the process of multi-sensor joint calibration and improves the precision of the calibration.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

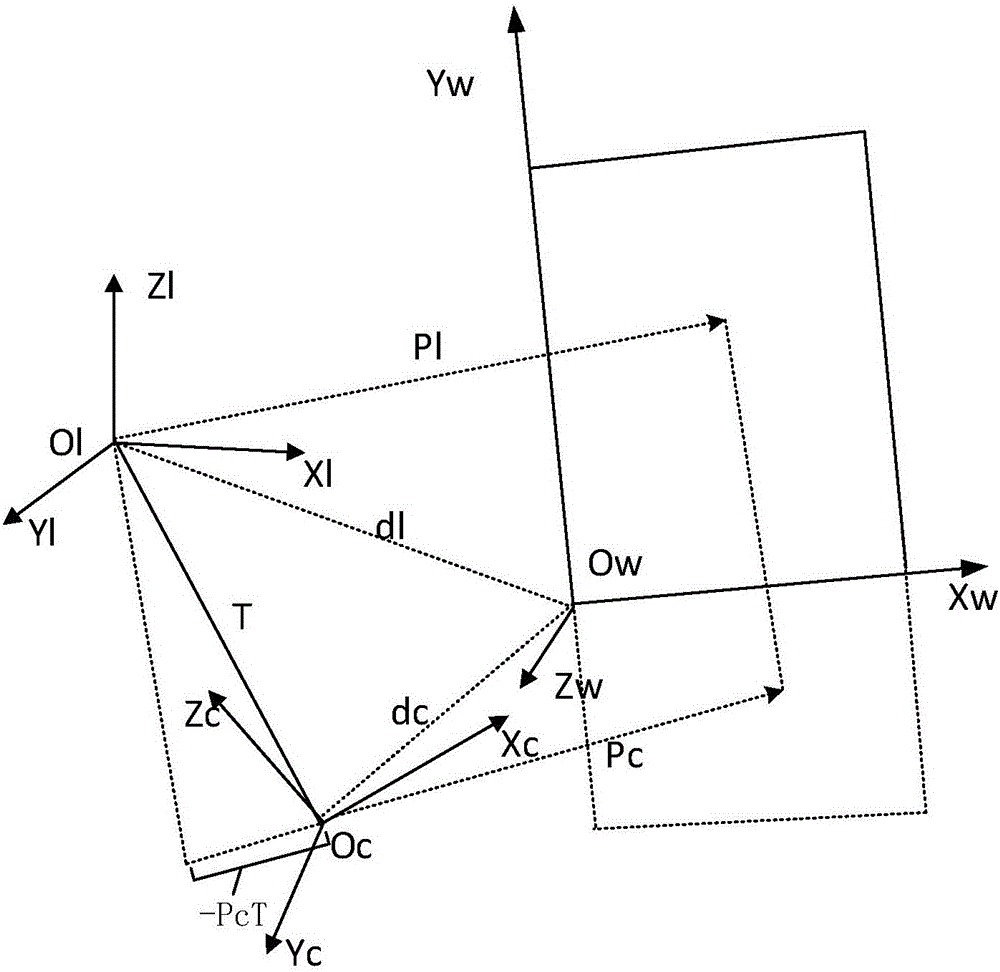

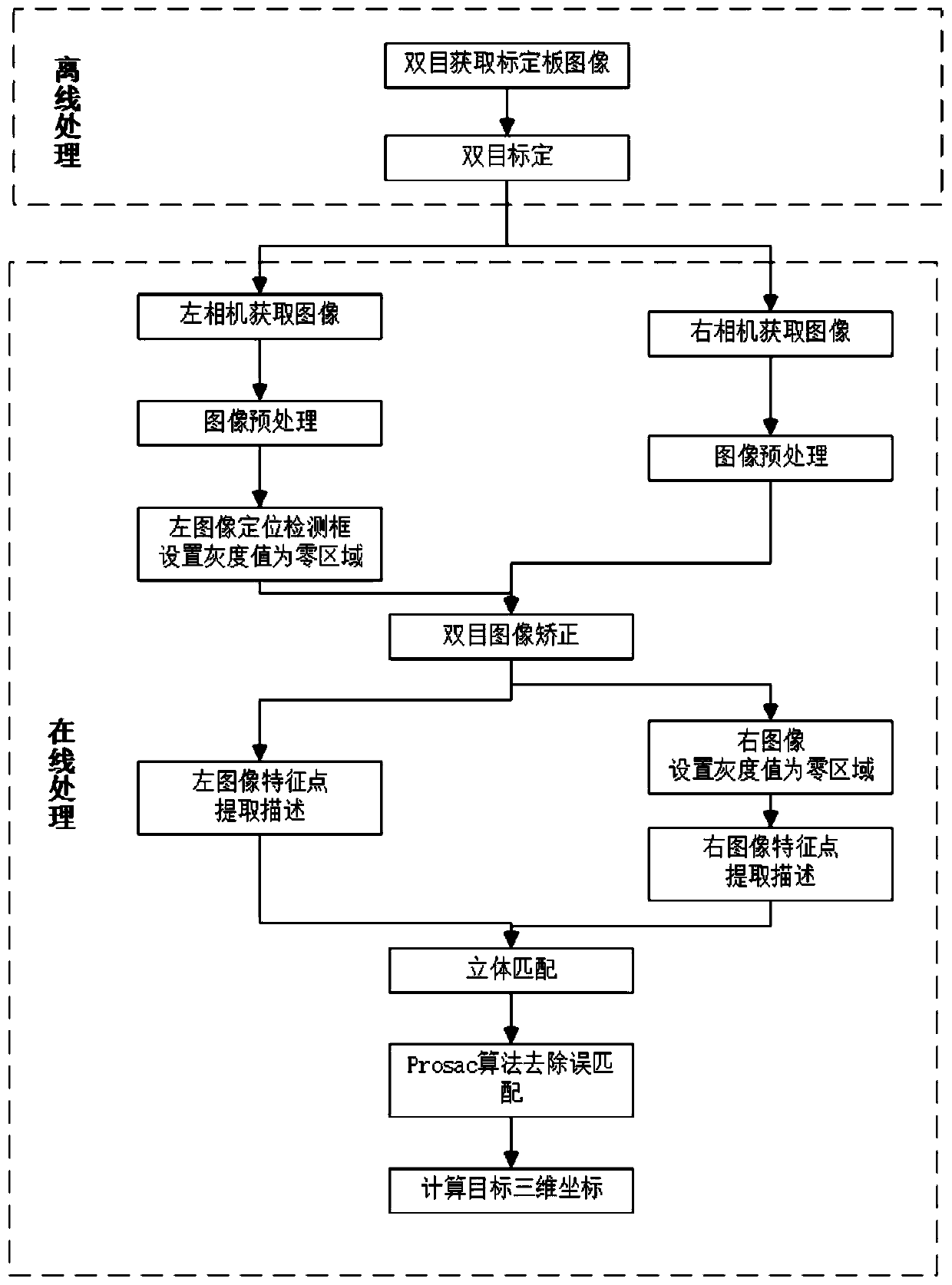

Binocular vision positioning method for target grabbing of underwater robot

ActiveCN111062990AMeet real-time requirementsReduce random errorImage enhancementImage analysisImage correctionBinocular stereo

The invention relates to a binocular vision positioning method for target grabbing of an underwater robot, and belongs to the field of computer vision. The method is mainly used for accurately acquiring three-dimensional information of a grabbed target when an underwater robot works. The method comprises the following steps: double-target positioning: calculating internal and external parameters of left and right cameras; target detection: positioning a target object detection frame; binocular image correction: carrying out distortion correction and stereo correction, and determining a right image target area; binocular image stereo matching: extracting image feature points, describing the feature points, performing stereo matching, and removing mismatching; and calculating the three-dimensional information of the target in the image under the left camera coordinate. According to the method, the accurate parallax value is obtained by extracting feature points, removing unstable featurepoints through non-maximum suppression, constructing a binary descriptor, matching the feature points and removing mismatching. Through the scheme, the binocular stereo matching robustness can be improved, and meanwhile, the three-dimensional information of the detection target can be accurately obtained, so that the real-time positioning requirement on the target when the underwater robot grabsthe target is met.

Owner:HARBIN ENG UNIV

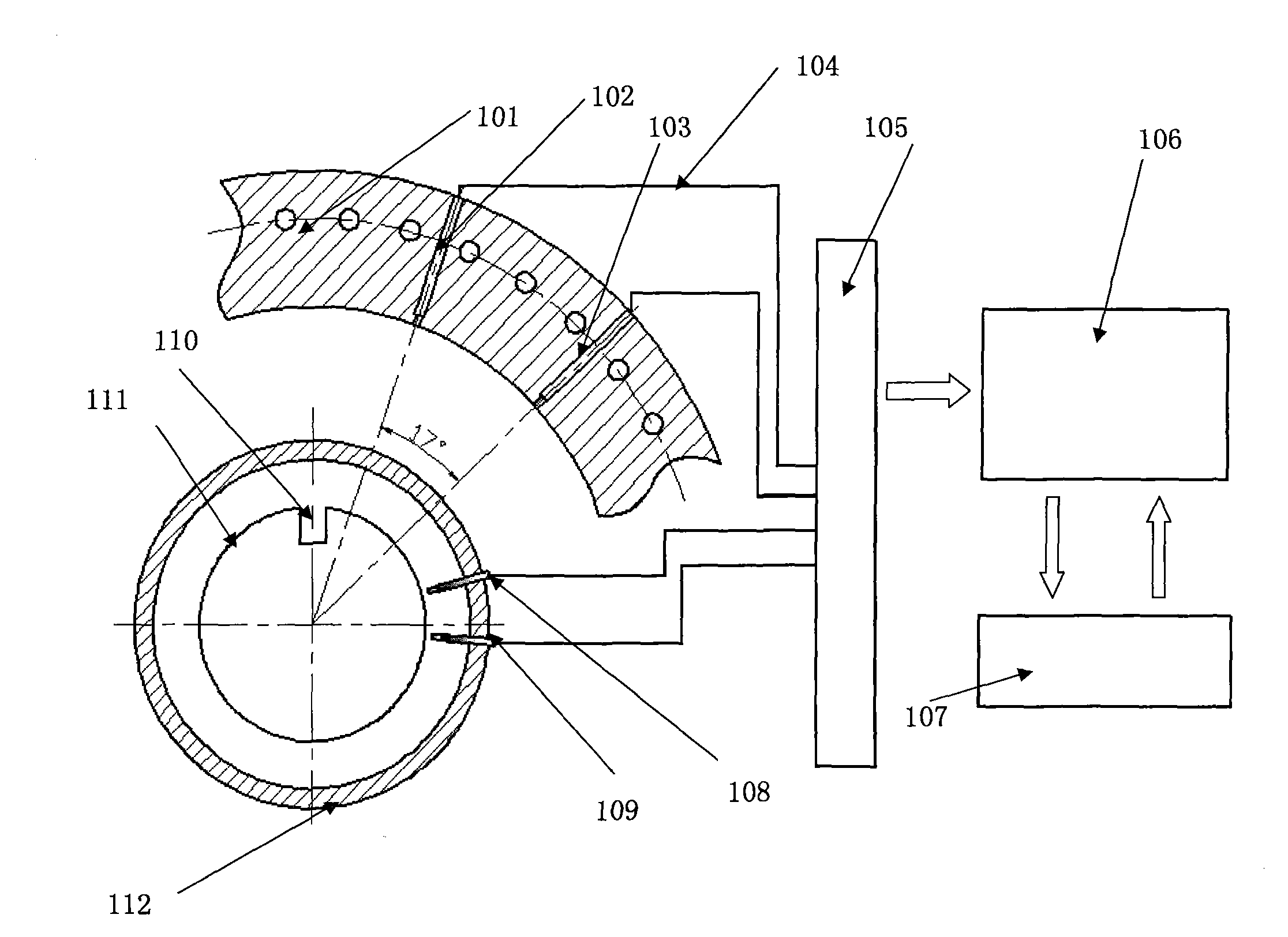

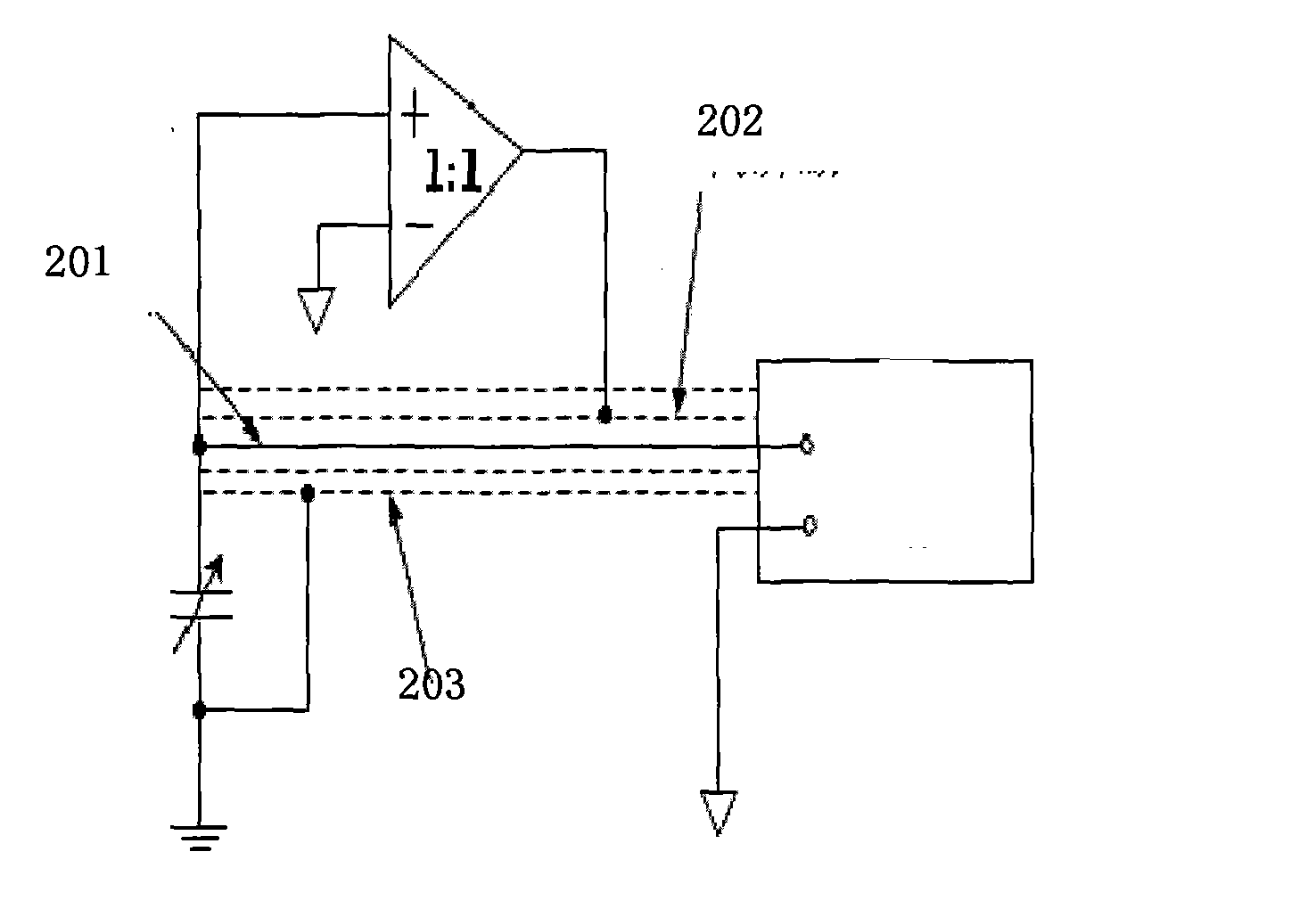

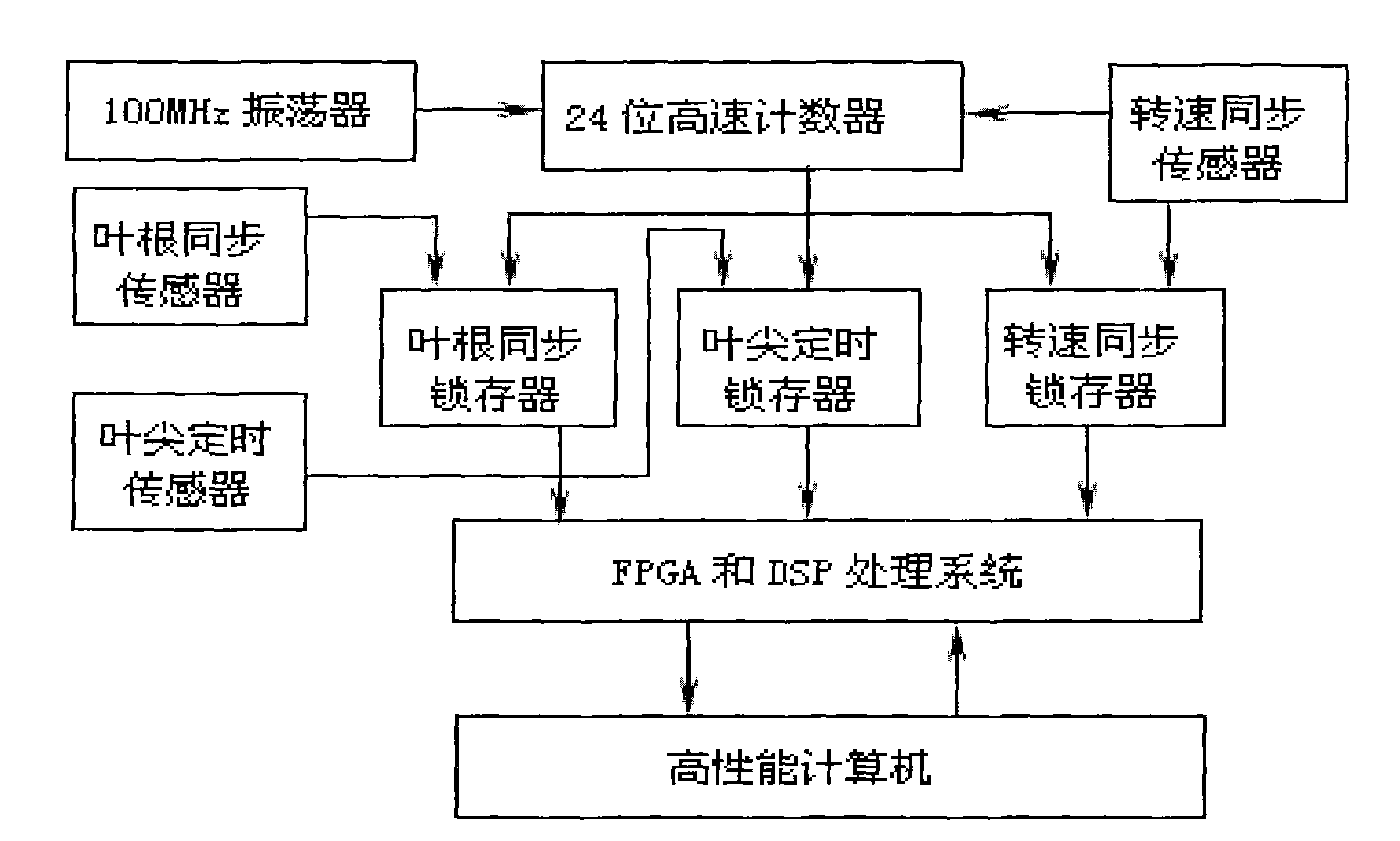

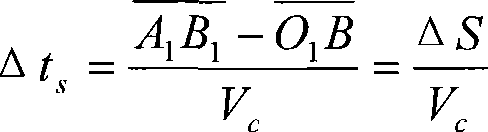

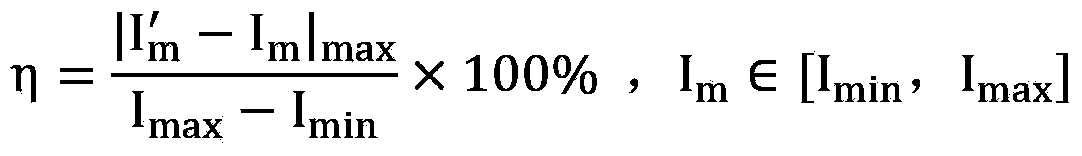

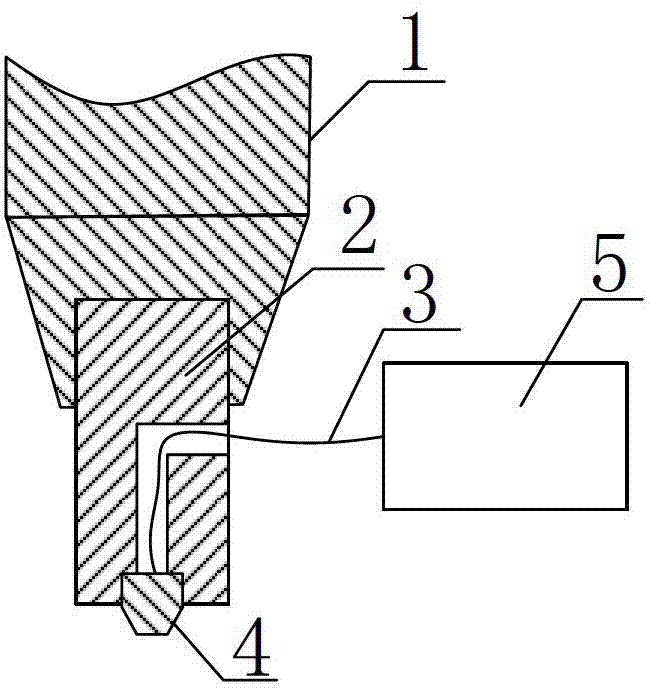

Real-time on-line monitoring apparatus of blade vibration of flue gas turbine

InactiveCN102735326AReal-time monitoring of vibrationHigh precisionSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCapacitanceFlue gas

The invention relates to a real-time on-line monitoring apparatus of blade vibration of a flue gas turbine. The monitoring apparatus comprises blade tip timing sensors, an angle reference sensor, a rotating speed synchronization sensor, a preprocessing system, a data integrated processing card, and a computer. The blade tip timing sensors, the angle reference sensor, and the rotating speed synchronization sensor are connected with the preprocessing system that is connected with the data integrated processing card; and the data integrated processing card is connected with the computer. According to the invention, the sensors employ double-shielded capacitance impulsers; single-core double-shielded wires are utilized as transmission lines of output signals; and a driving cable technology is utilized to effectively reduce a random error introduced by an environmental interference; and a charge amplification circuit is used to extract a capacitance pulse signal, thereby eliminating the system error basically and improving the measurement accuracy of the system.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

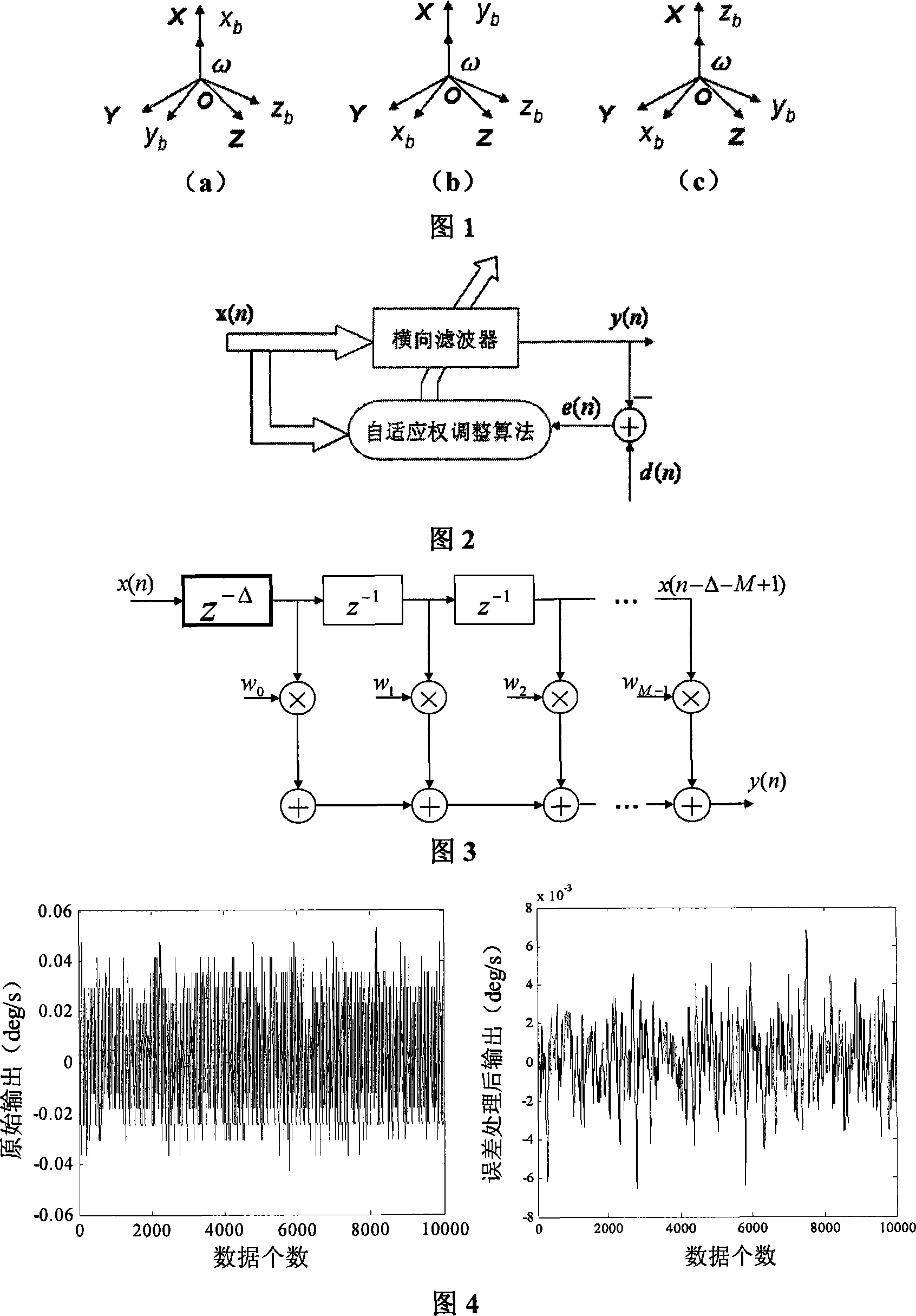

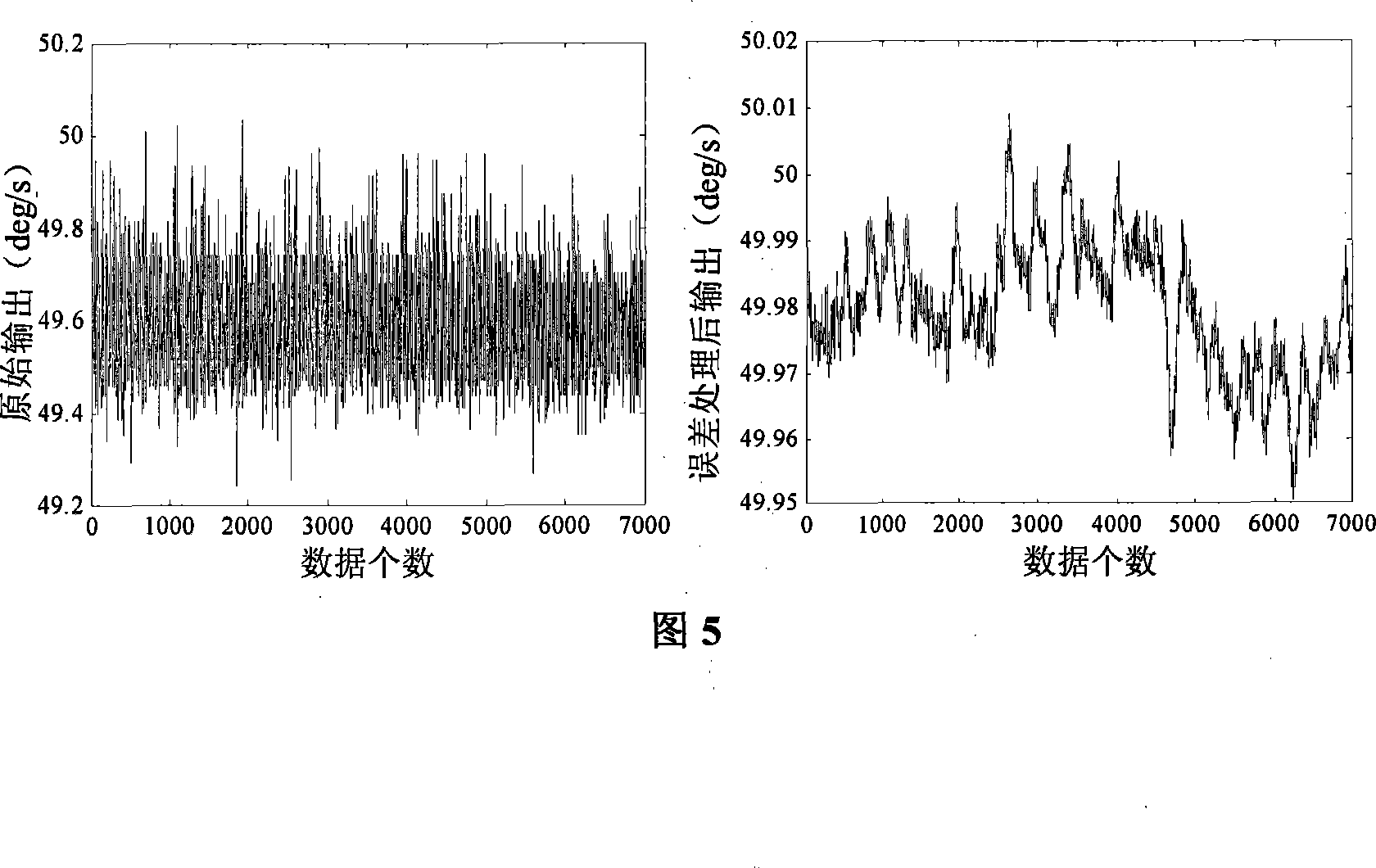

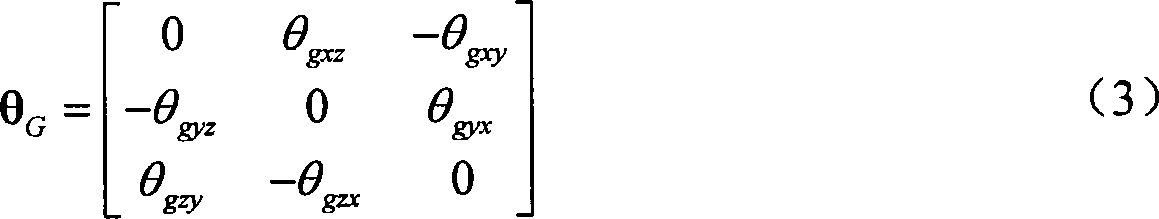

Error processing method for output signal of optic fiber gyroscope component

InactiveCN101221046AReduce random errorReduce zero offset driftAdaptive networkNavigation by speed/acceleration measurementsSelf adaptiveInertial navigation system

The invention discloses an error processing method of the output signal of an optical-fiber scopperil component and belongs to the error processing methods of the output signal of an optical-fiber scopperil component in an inertial navigation system. The concrete steps of the processing method are that: an output signal model of the optical-fiber scopperil component and an error model thereof are built; the marking and the compensation of the fixed error of the optical-fiber scopperil component are implemented; the self-adaptive filtering of the random error of the optical-fiber scopperil component is implemented. The processing method effectively reduces the zero-offset drift of the optical-fiber scopperil component which is caused by temperature changes, has high marking precision of the fixed error, high marking efficiency and good adaptability; furthermore, the processing method effectively reduces the random error of optical-fiber scopperil, has small amount of computation, and is suitable for real industrial applications.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

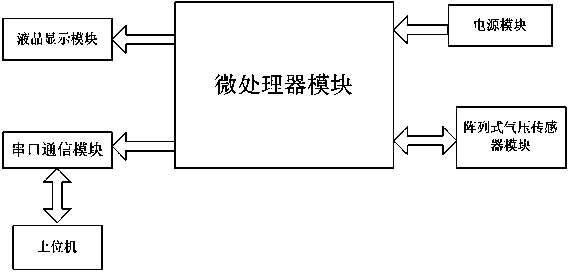

Relative height measuring device and method

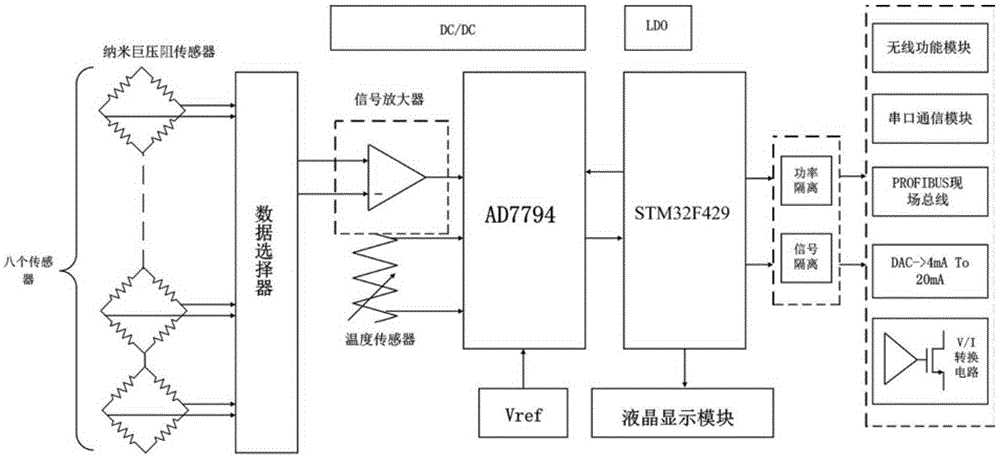

ActiveCN103712599AEliminate measurement errorsReduce random errorHeight/levelling measurementNeural learning methodsMeasurement deviceLiquid-crystal display

The invention discloses a relative height measuring device which comprises a host computer, a microprocessor module, as well as an array type gas pressure sensor module, a power supply module, a liquid crystal display module and a serial port communication module which are respectively connected with the microprocessor module. A measuring method employing the relative height measuring device comprises the following steps: accomplishing a genetic algorithm optimized BP (Back Propagation) neural network in a host computer, transmitting obtained weights, thresholds and relative height calculation equations to the microprocessor module, acquiring gas pressure and temperature through the array type gas pressure sensor module and transmitting the gas pressure and temperature to the microprocessor module, processing the received air pressure and temperature through the microprocessor module so as to obtain the relative height, and transmitting the result to the liquid crystal display module to be displayed and stored in the host computer. With the combination of software and hardware, noise can be suppressed, useful signals can be recovered, enhanced and extracted, and the great precision and stability are achieved.

Owner:广东华工工程建设监理有限公司

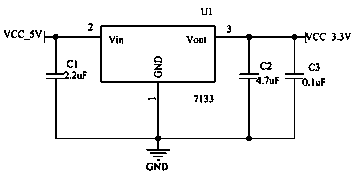

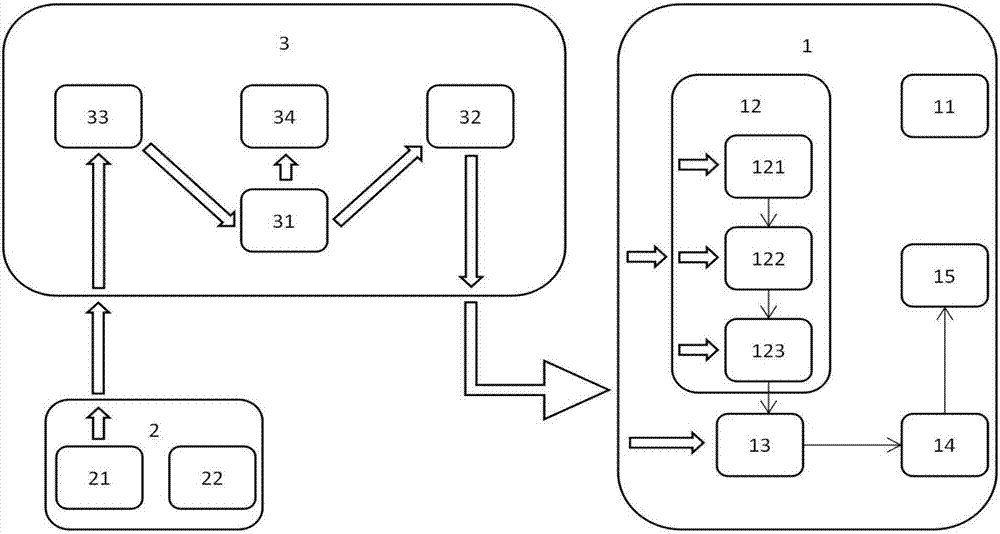

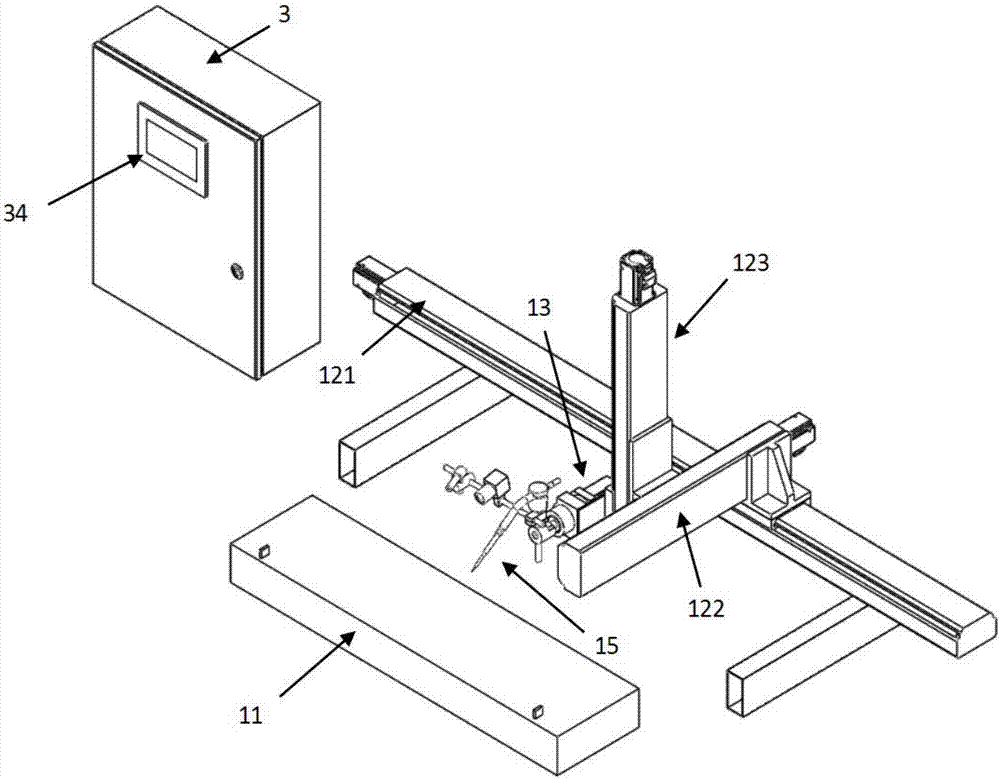

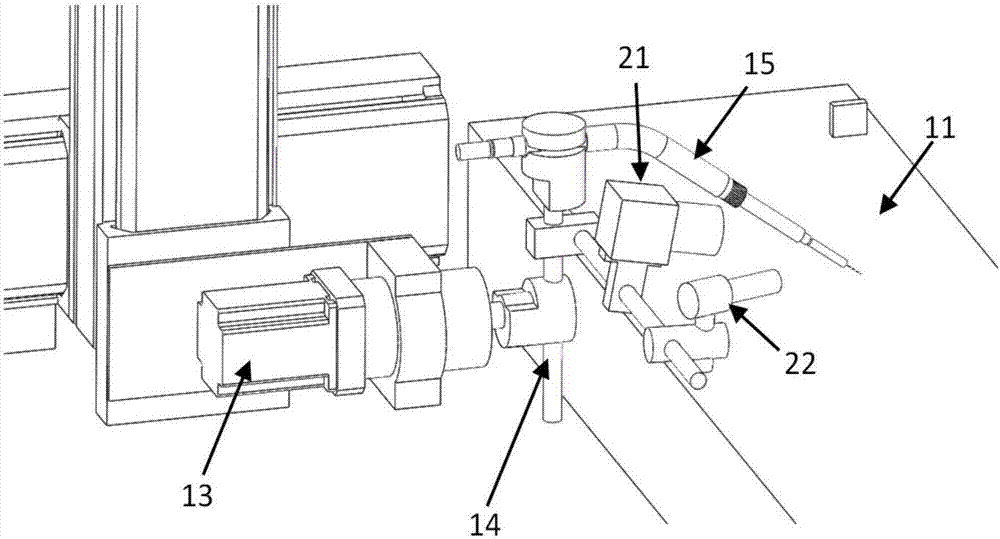

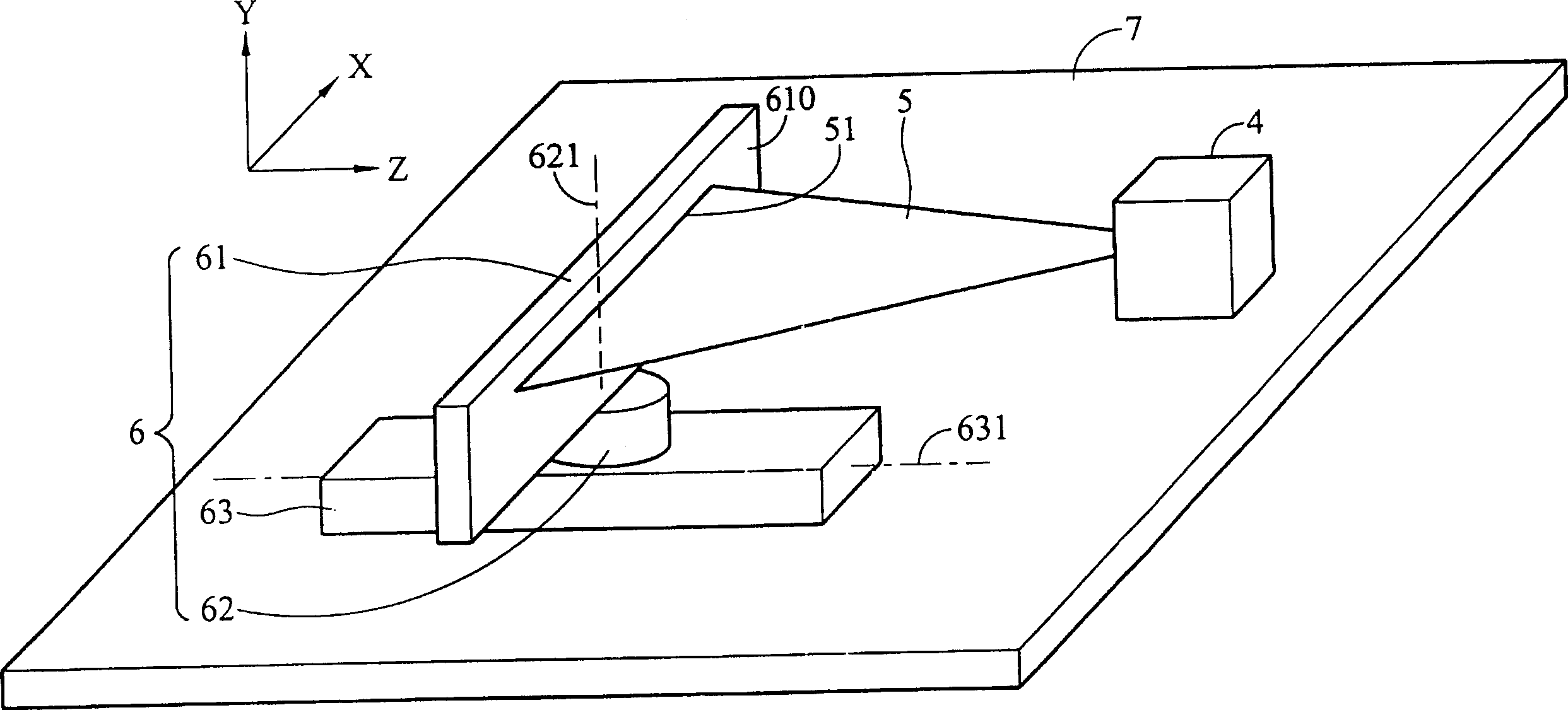

Welding seam tracking control device and method based on cross laser device

ActiveCN107414253AImprove detection accuracyReduce random errorWelding accessoriesEngineeringWeld seam

The invention discloses a welding seam tracking control device and method based on a cross laser device. The welding seam tracking control device is characterized by comprising a four-freedom-degree robot, a visual sensor and an integrated control cabinet; the four-freedom-degree robot comprises a working platform, a moving module, a Y-axis stepping motor, a bracket and a welding gun; the Y-axis stepping motor is fixed to a Z-axis slide table of a Z-axial moving module body, and a rotary shaft of the Y-axis stepping motor is parallel to the moving direction of a Y-axial moving module body; the bracket is used for fixing the visual sensor and the welding gun; the visual sensor comprises a camera and the cross laser device; and cross laser rays emitted by the cross laser device are irradiated on a to-be-welded workpiece and shot by the camera. The welding seam tracking control method is used for conducting vision measurement on fillet welding seams, three-dimensional position information of the welding seams, the inclined angle of the plane of the welded workpiece and the directions of the welding seams can be obtained accurately, and the welding gun can conduct high-precision self-adapting tracking control over the welding seams.

Owner:HEBEI UNIV OF TECH

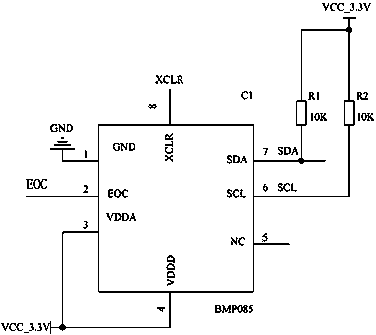

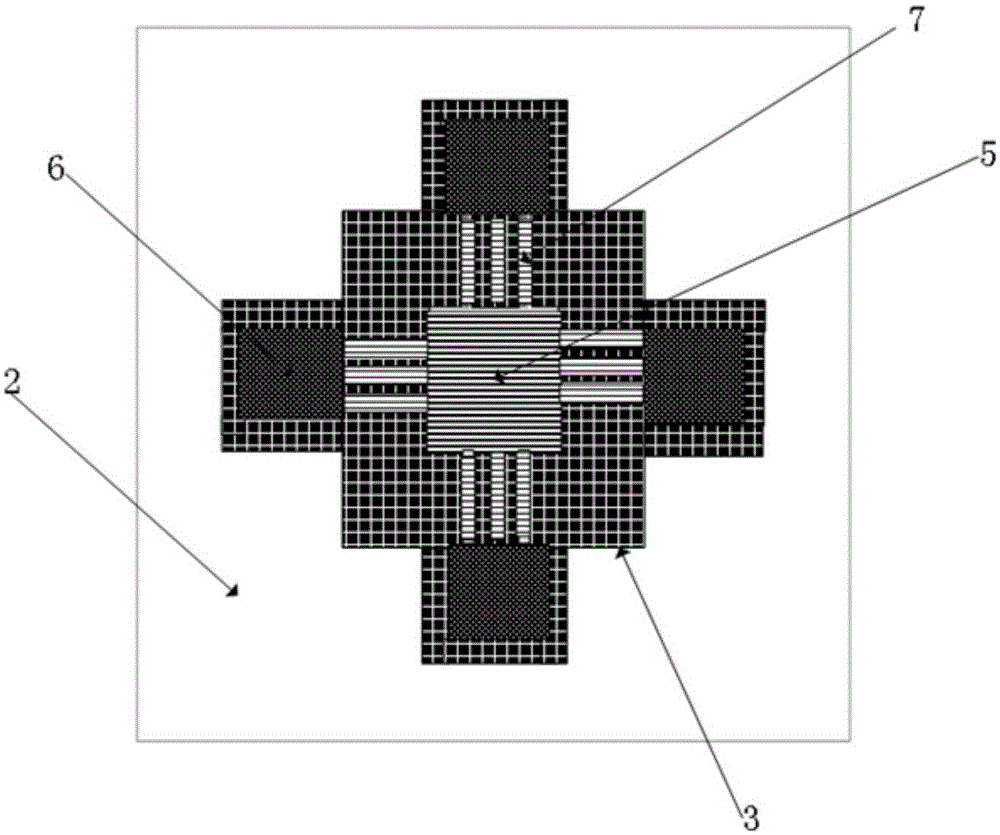

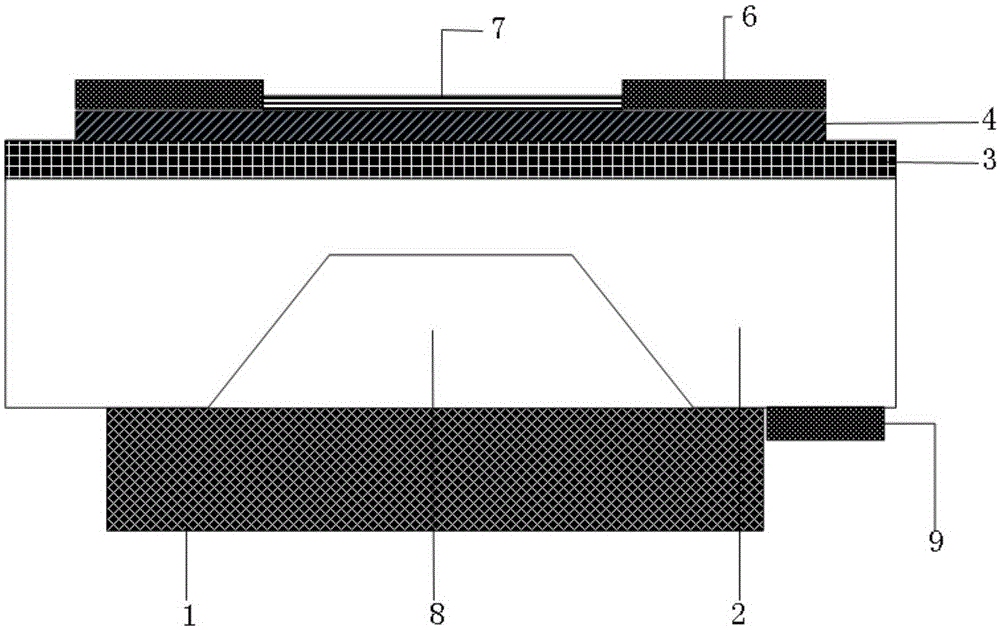

Array type air pressure measurement compensation device and method based on quantum particle swarm wavelet neural network

InactiveCN105258839AReduce distractionsHigh sensitivityFluid pressure measurement using ohmic-resistance variationBiological neural network modelsQuantum particleNon linearity

The invention discloses an array type air pressure measurement compensation device and method based on quantum particle swarm wavelet neural network. A micro-processing module is started to send instruction to a pressure sensor array and a temperature sensor, so that the air pressure and temperature are measured; measurement data is transmitted to the micro-processing module and a host computer respectively; the host computer establishes a wavelet neural network according to the received air pressure and temperature, and the wavelet neural network is optimized by utilizing the quantum particle swarm algorithm, the quantum particle swarm wavelet neural network is trained at the same time, and an obtained air pressure correction compensation formula is transmitted to the micro-processing module; the micro-processing module calculates the accurate air pressure value whose error is compensated; and the accurate air pressure value is transmitted to a display module and displayed. Retardation error of air pressure measured by arrays is compensated on the basis of the quantum particle swarm wavelet neural network, temperature drift and non-linearity are compensated, errors are reduced, effective signals are enhanced, air pressure measurement is more accurate, and requirements for meteorology measurement are met.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

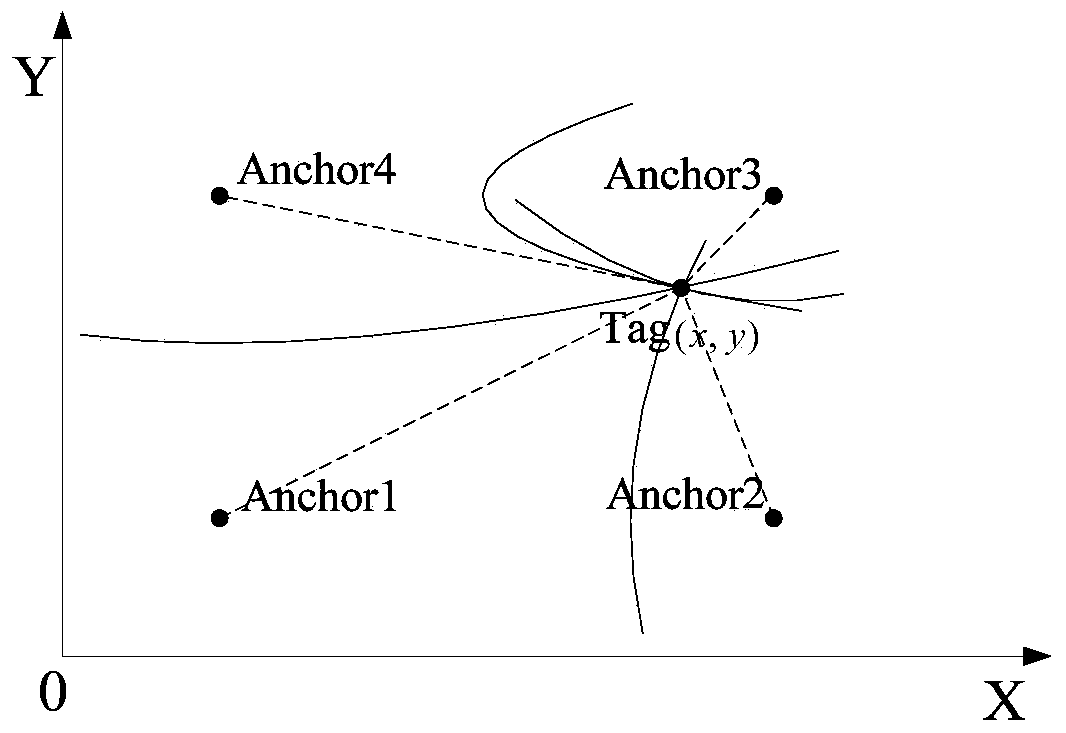

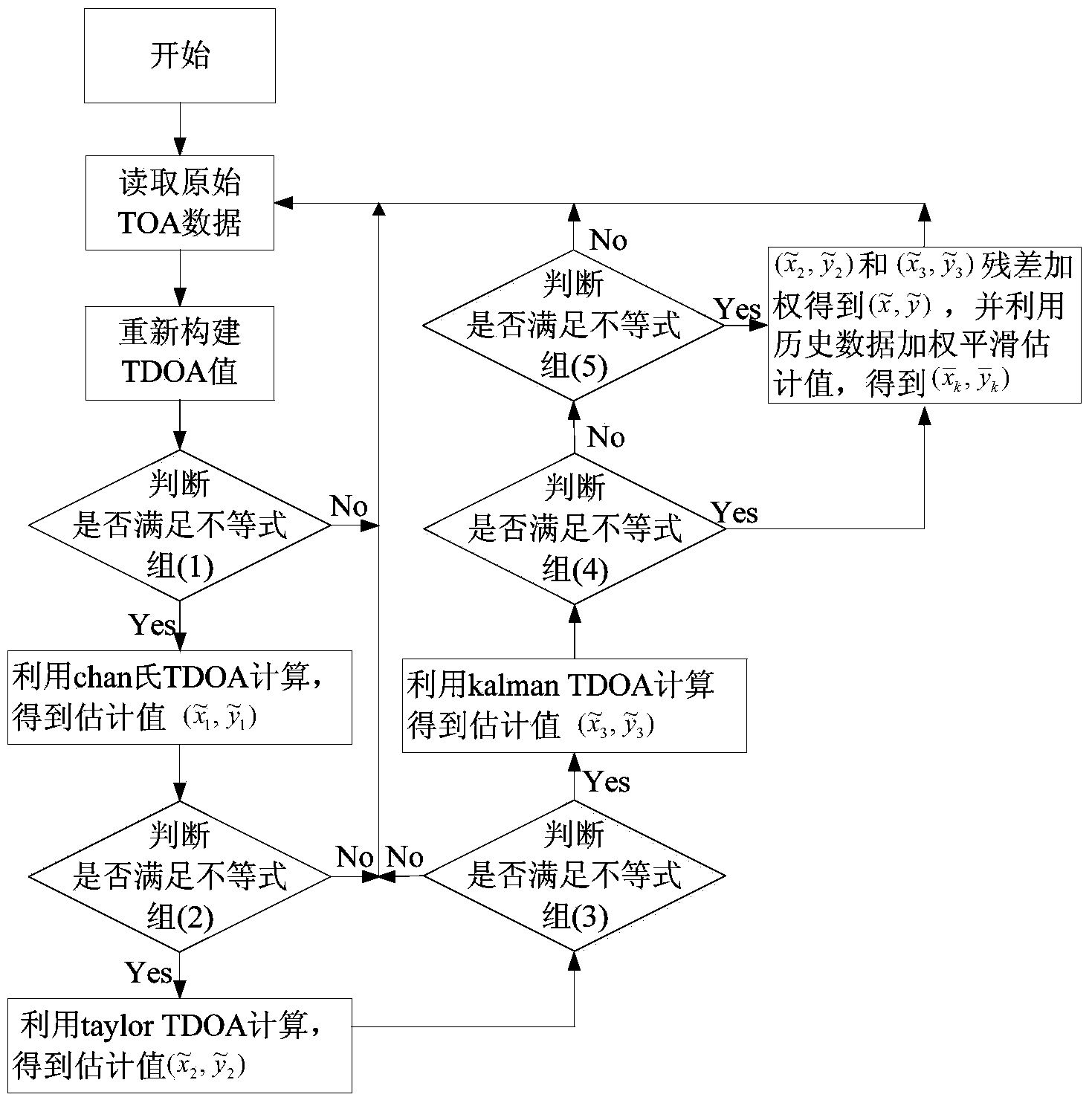

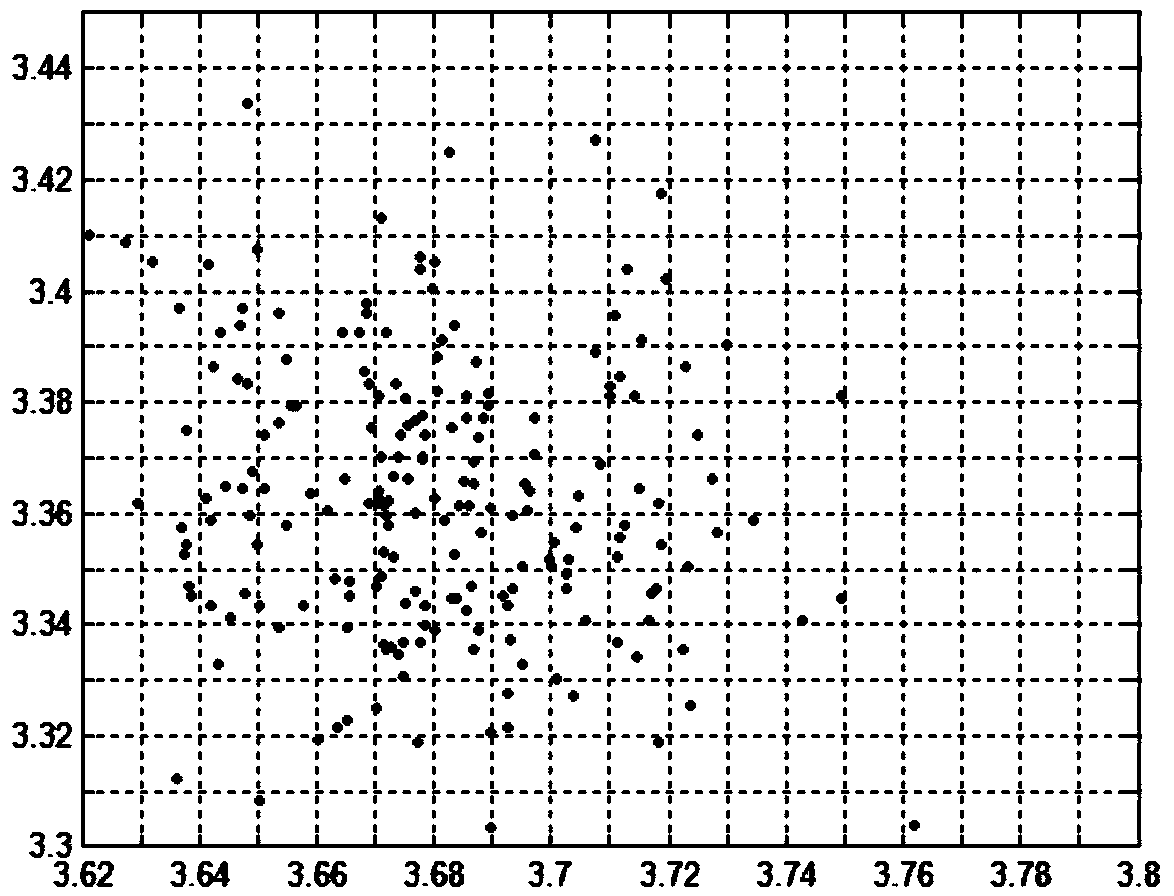

Indoor wireless sensor network positioning method based on TDOA

InactiveCN104080165APrecise positioningReduce random errorNetwork topologiesOriginal dataWireless sensor networking

The invention provides an indoor positioning method based on TDOA. According to the method, firstly, TOA original data are utilized to reconstruct TDOA data; secondly, on the basis of the characteristic that the geometric law and a TDOA measurement value have large influence on a Chan's TDOA method, whether the original data are obtained through measurement under the line-of-sight condition or under the condition that non-line-of-slight interference is not serious is judged; next, position coordinates of a target node are estimated respectively through a Taylor series expansion iteration method and an extension Kalman method; finally, a final estimation value is obtained through residual weighting and data smoothing. Due to the method, influences of random errors and NLOS errors can be effectively reduced, and the method can be applied to system positioning between wireless sensor network nodes.

Owner:HANGZHOU DIANZI UNIV

Tetramethylbenzidine (TMB) coloration solution and preparation method thereof

ActiveCN103063661AEasy to operateReduce random errorMaterial analysis by observing effect on chemical indicatorSolubilityHydrogen phosphate

The invention relates to a tetramethylbenzidine (TMB) coloration solution and a preparation method of the TMB coloration solution and belongs to the technical field of biological in-vitro diagnostic reagents. A solution and B solution are mixed in an isopyknic mode to obtain the TMB coloration solution, the A solution comprises, by molarity, citric acid 0.01-0.5 mol / L, sodium hydrogen phosphate 0.01-0.5 mol / L, hydrogen peroxide 0.01-0.5 mol / L and EDTA 0.1-1 mmol / L; the B solution comprises the TMB, hydrochloric acid and polyvinylpyrrolidone, wherein TMB 0.1-1 mmol / L, hydrochloric acid 0.01-0.5 mol / L and by weight percentage, polyvinylpyrrolidone 0.1-10%. The dissolving system of the TMB is adjusted to increase solubility of the TMB, and the polyvinylpyrrolidone enables the one-phase TMB solution to be capable of being stored for two years at the storage temperature of 2-8 DEG C.

Owner:杭州联科生物技术股份有限公司

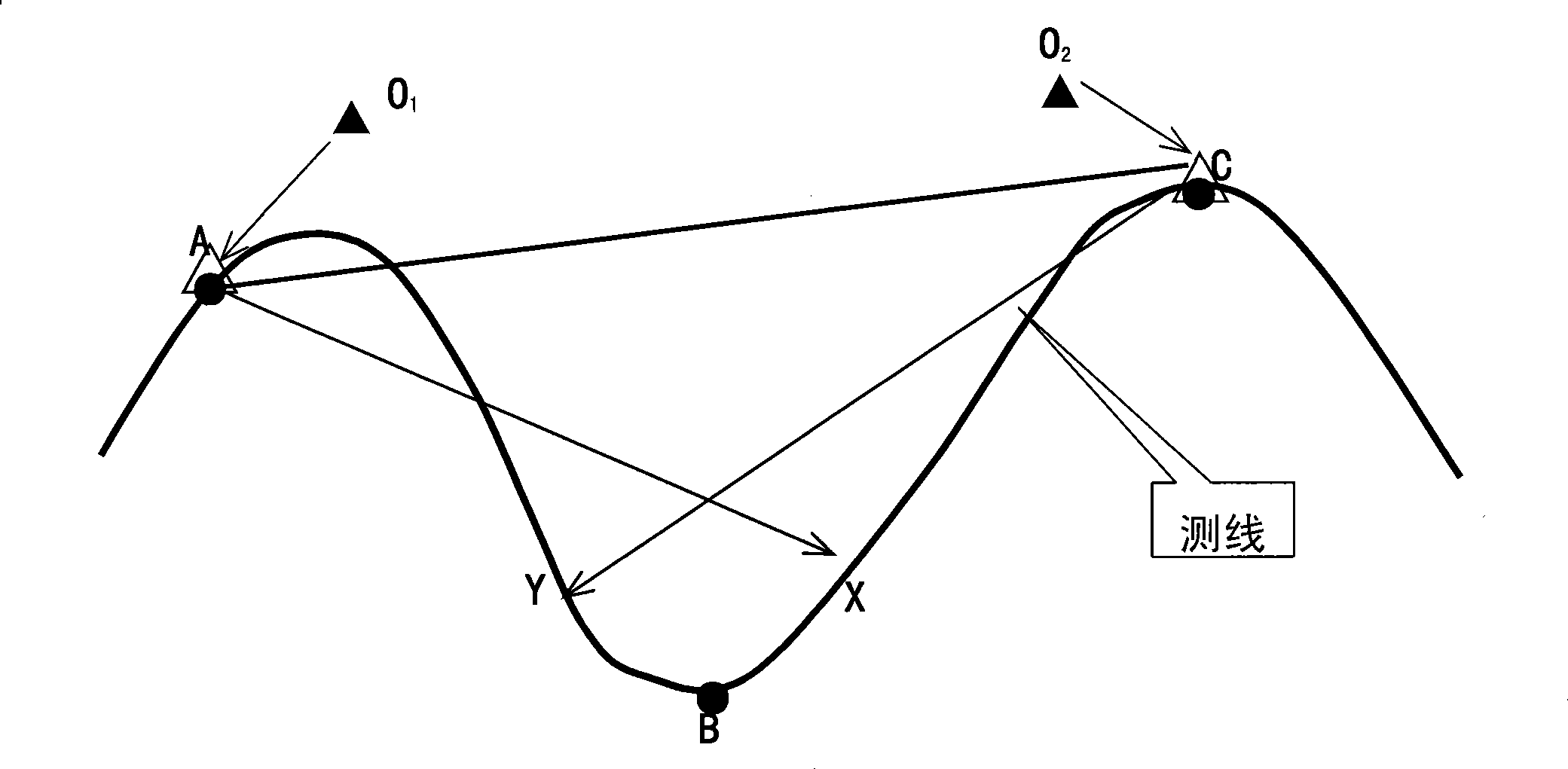

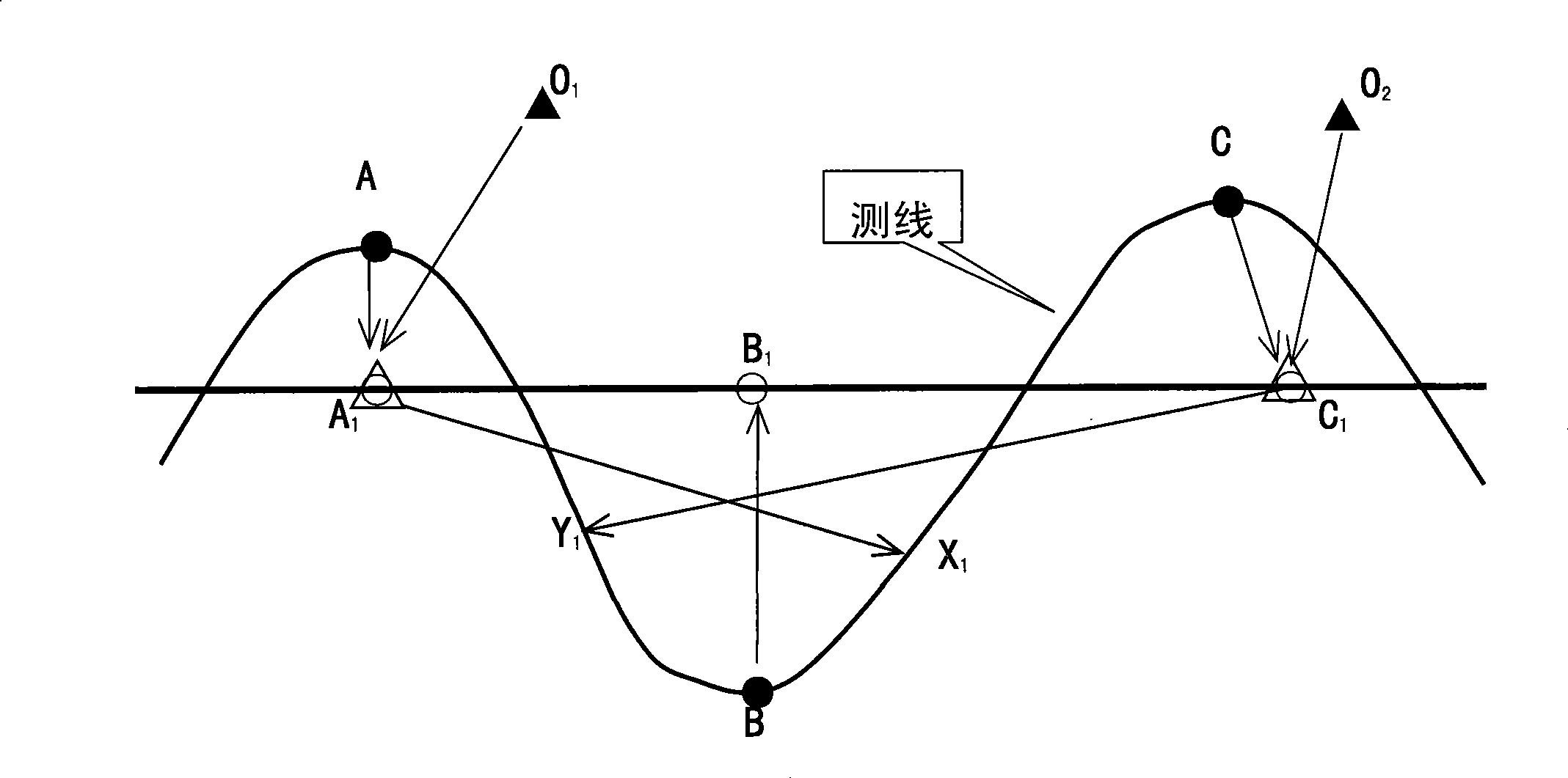

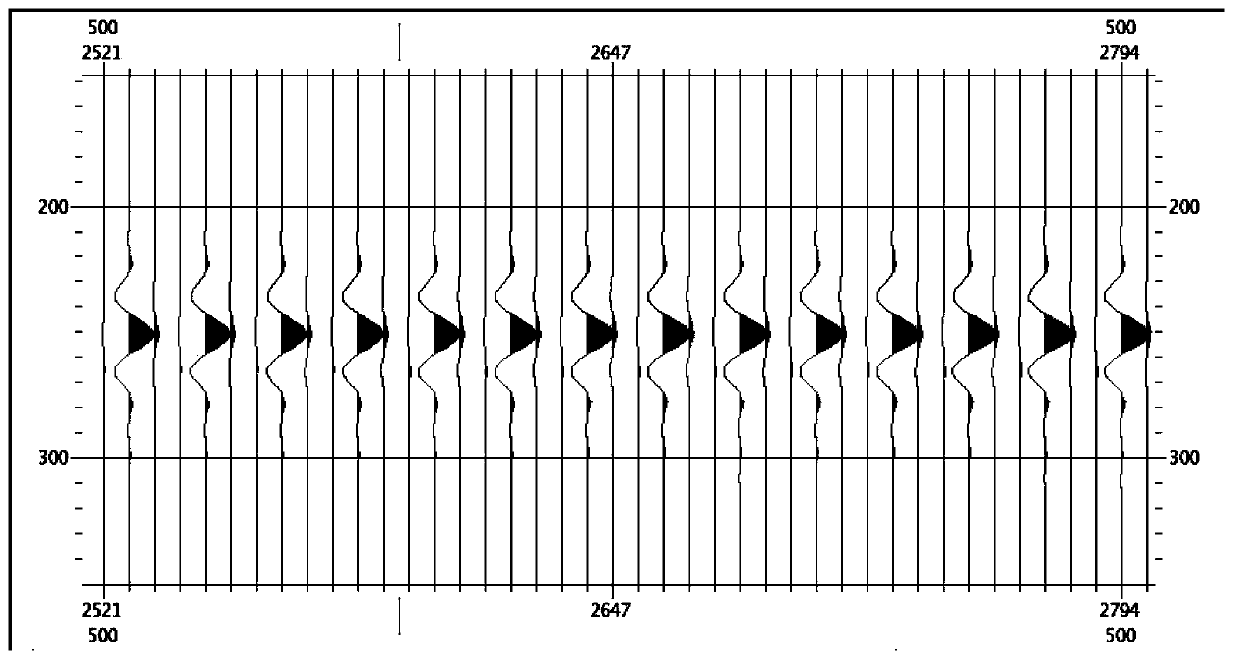

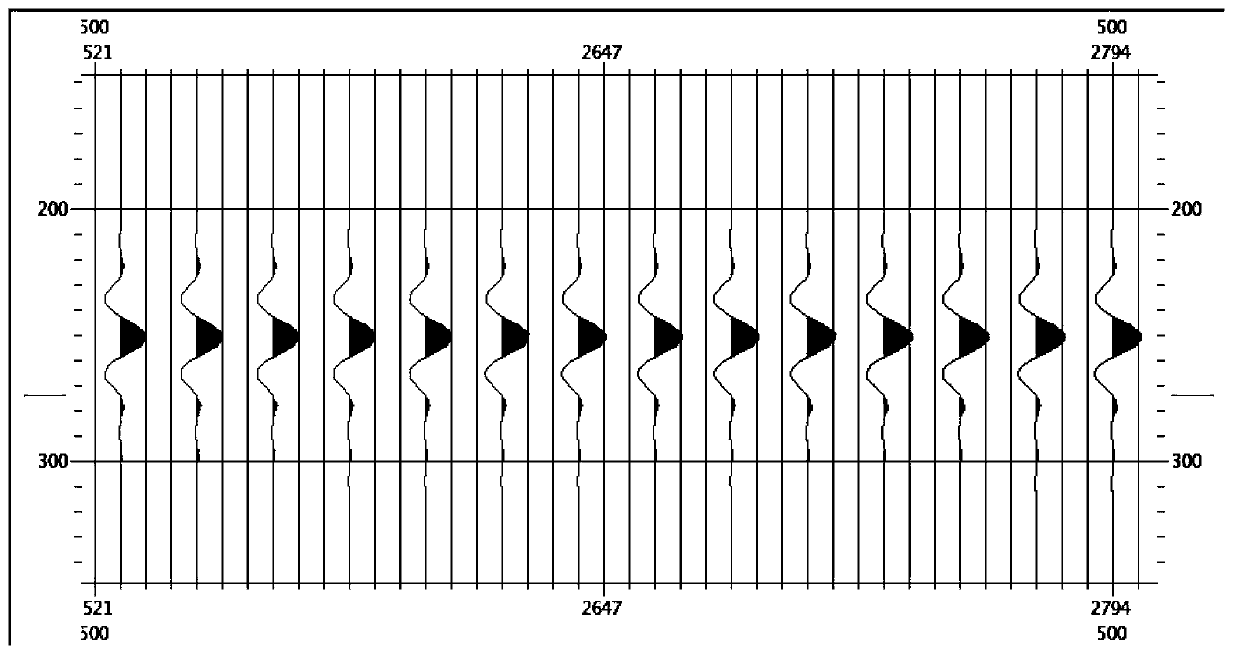

High precision refraction static correction data inversion method

InactiveCN101363916AHigh precisionRelaxation of application conditionsSeismic signal processingSurface structureComputer science

The invention relates to a geophysical prospecting method which is a high-precision refraction static correction data inversion method. The method comprises the steps: the production shot first arrival data of an earthquake work area are collected; the refraction wave delay time is calculated out through the following steps; and the data of micro logging control points and the information of refraction delay time are used for obtaining the time-depth curve of the low deceleration layer of the work area. Micro logging control points provide a target layer depth (HD), a refraction result offered delay time tD, a comprehensive tD(HD) curve and a conversion tD curve, thereby obtaining a reliable surface structure model and a high-precision low deceleration zone static correction result profile map. The invention has the advantages that the depth curve constrains and inverses the delay time when the high-precision low deceleration layer is used; the depth errors caused by the inaccurate velocity are eliminated; the application condition is wide; the adaptability is strong; and the result precision is finally improved.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

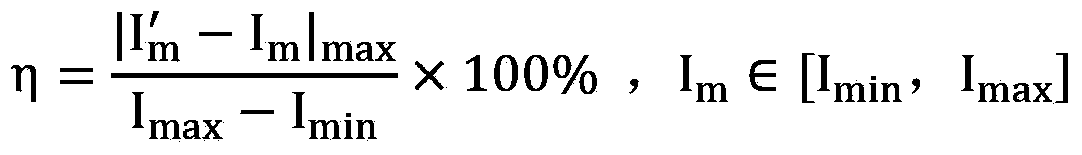

CCD camera nonlinearity degree calibration method based on structured light three-dimensional measurement system

InactiveCN103413309AIncrease the number ofSmall gray gradientImage analysisUsing optical meansThree dimensional measurementCalibration result

The invention provides a CCD camera nonlinearity degree calibration method based on a structured light three-dimensional measurement system. The method comprises the steps that according to the measurement processes of the structured light three-dimensional measurement system, on the basis that a series of standard images which are projected by a projector and accord with linear distribution are collected, a standard image gray scale-camera collected image gray scale distribution curve is drawn after certain data processing so as to further calculate the nonlinearity degree of a CCD camera; because gray scale gradient is small when the standard images are grouped, and the number of images collected by the CCD camera is large, random errors are reduced, and nonlinearity degree measurement precision is improved; the CCD camera nonlinearity degree calibration method based on the structured light three-dimensional measurement system accords with conditions of the structured light three-dimensional measurement system, and is simple in calibration process, less in middle link, and accurate in nonlinearity degree calibration result.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

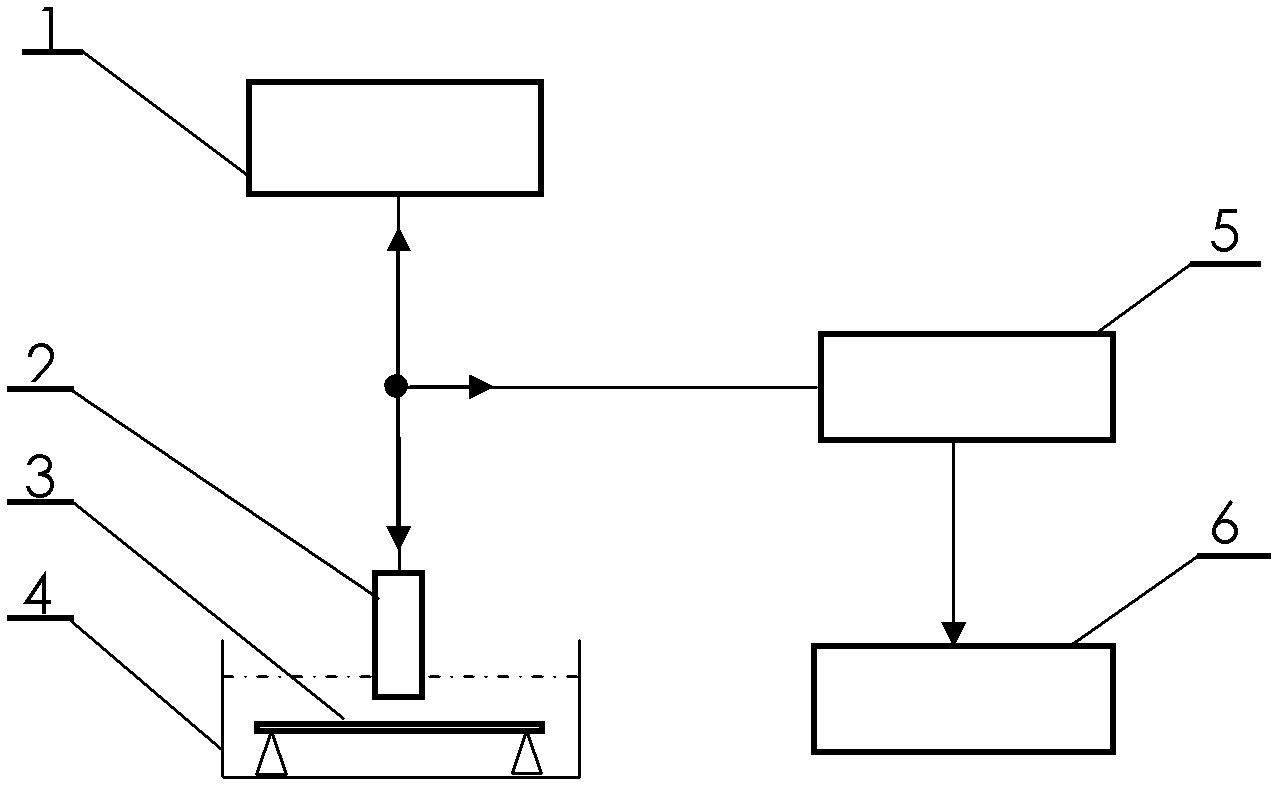

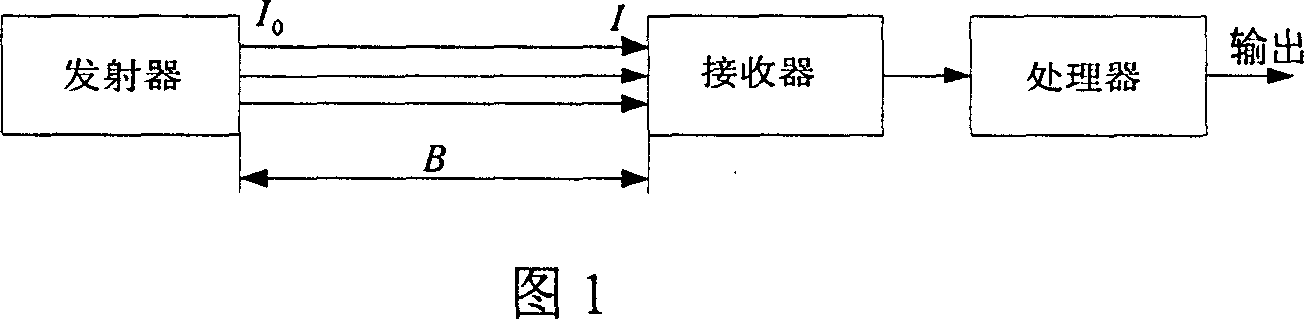

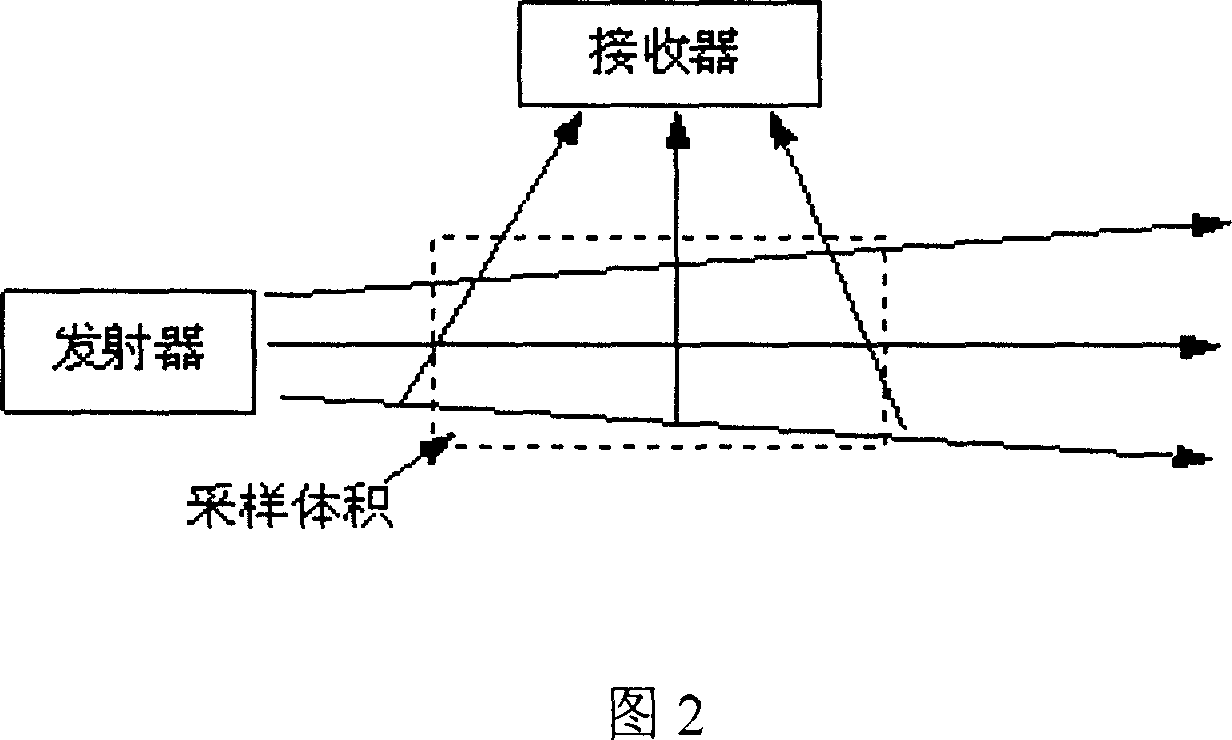

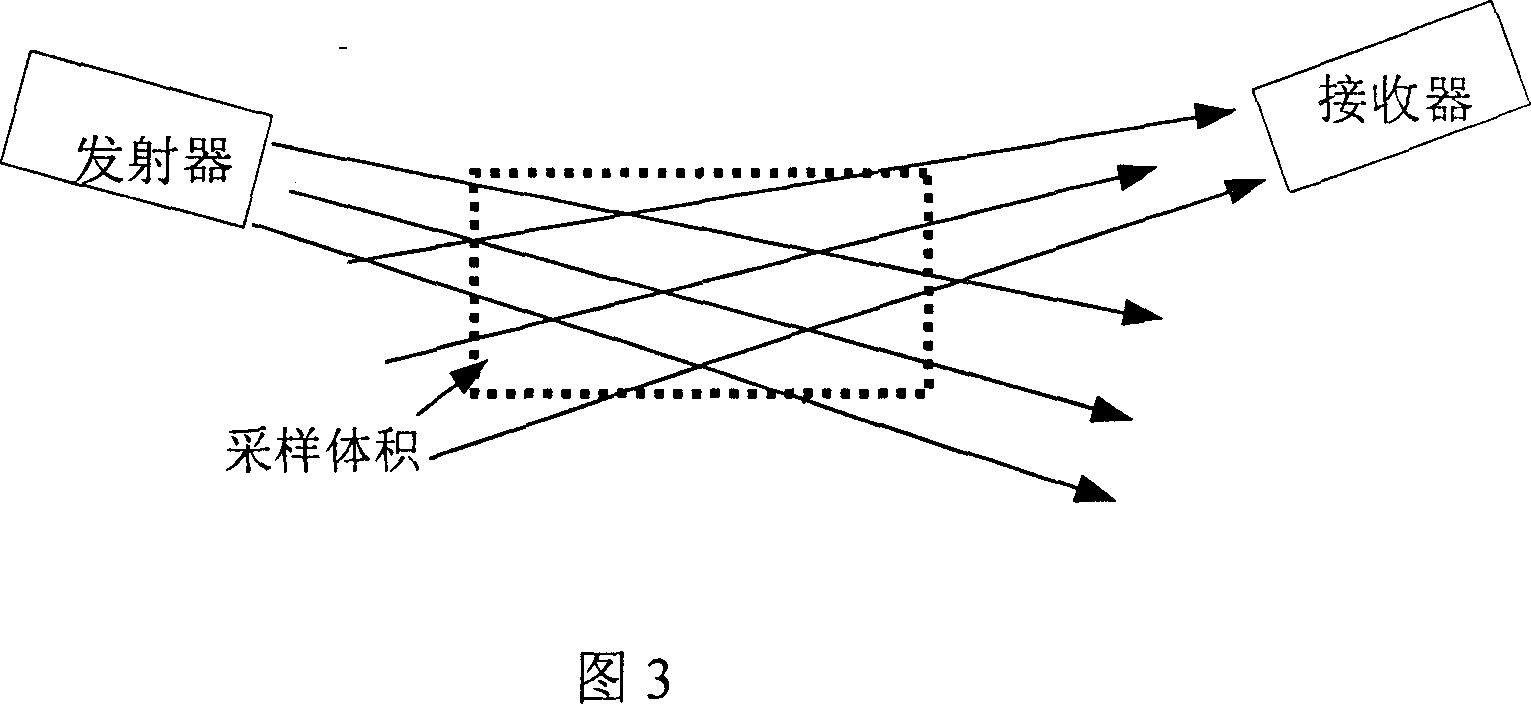

Method and device for measuring thickness of numerical control machining workpiece

ActiveCN102902232AImprove measurement efficiencyRealize online thickness testProgramme controlComputer controlPersonal computerData transmission

The invention discloses a method and a device for measuring thickness of a numerical control machining workpiece and is suitable for online thickness measurement in the numerical control machining process. The measuring method comprises the following steps of: manufacturing a circular groove for storing a coupling agent on a blank, setting detection points, extracting coordinates of the detection points, planning a detection path, and generating a numerical control program; transmitting the numerical control program to a numerically-controlled machine tool, controlling the machine tool to move, and automatically triggering an ultrasonic probe to measure through a terminal processor once the machine tool moves to a point; and finally, transmitting the measuring data to the terminal processor. The thickness measuring device consists of a knife handle connecting device, an ultrasonic probe, a data transmission line and a terminal processor, wherein one end of the knife handle connecting device is connected with the ultrasonic probe; the other end of the knife handle connecting device is connected with the knife handle of a machine tool spindle, so that numerical control motion of the probe is realized; and the terminal processor can be a personal computer (PC) of a numerical control system and can be connected with the PC of the numerical control system. By the method and the device, the thickness of the numerical control machining workpiece is automatically measured on line, and the thickness measuring efficiency is greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

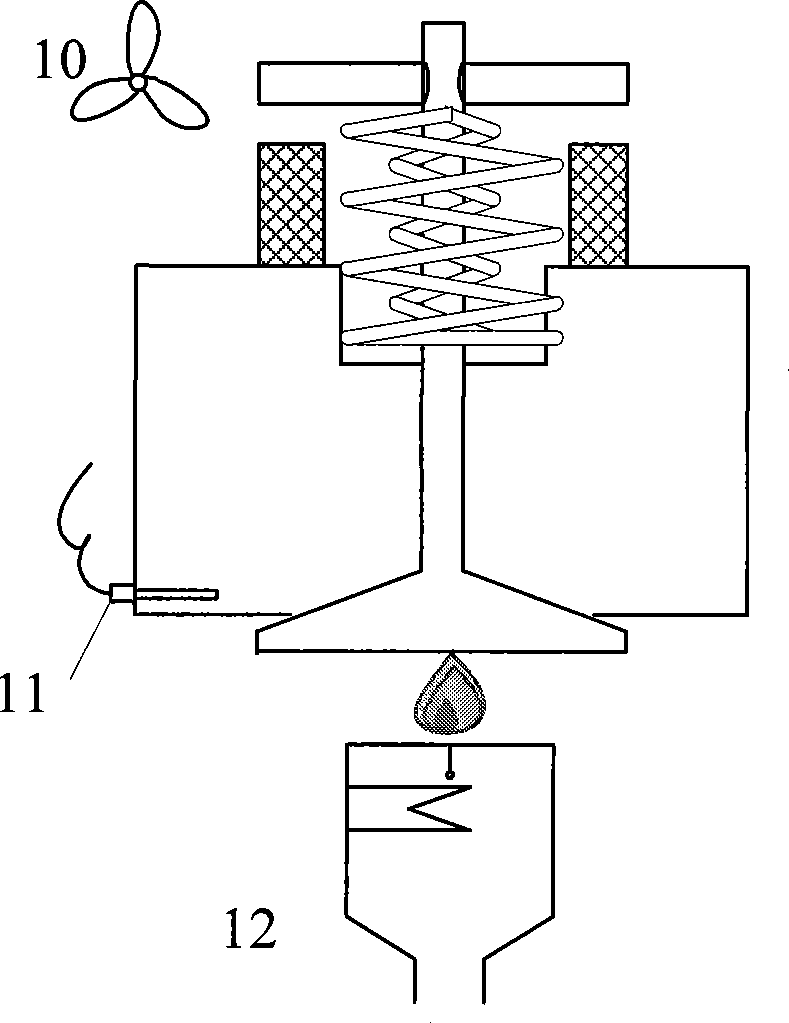

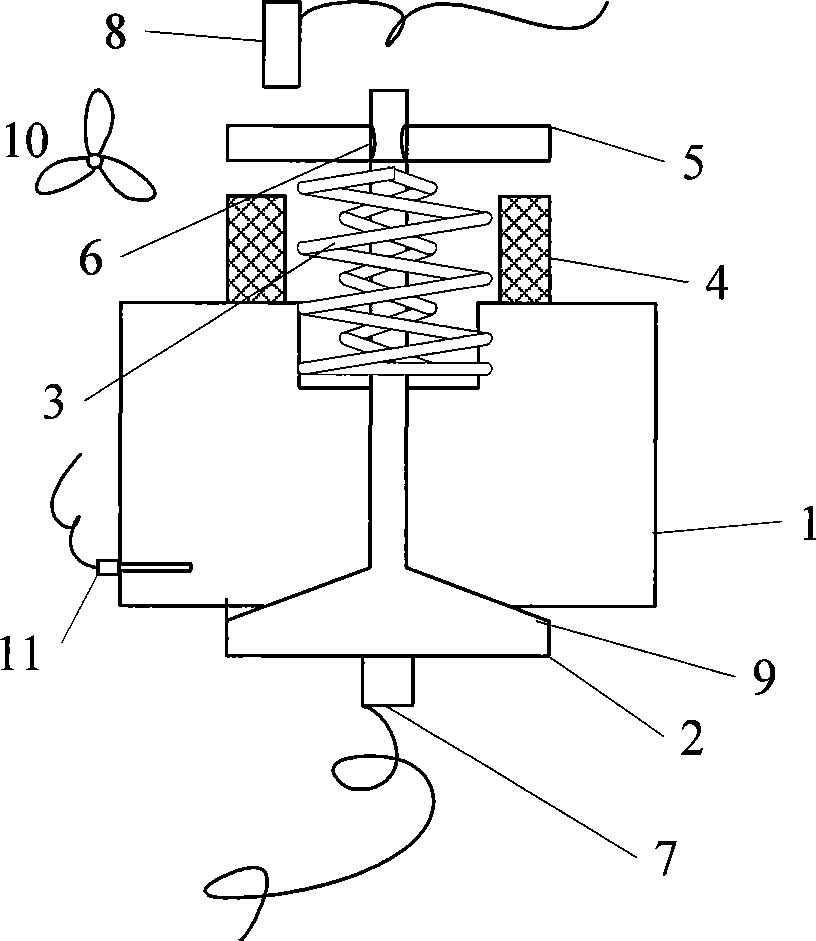

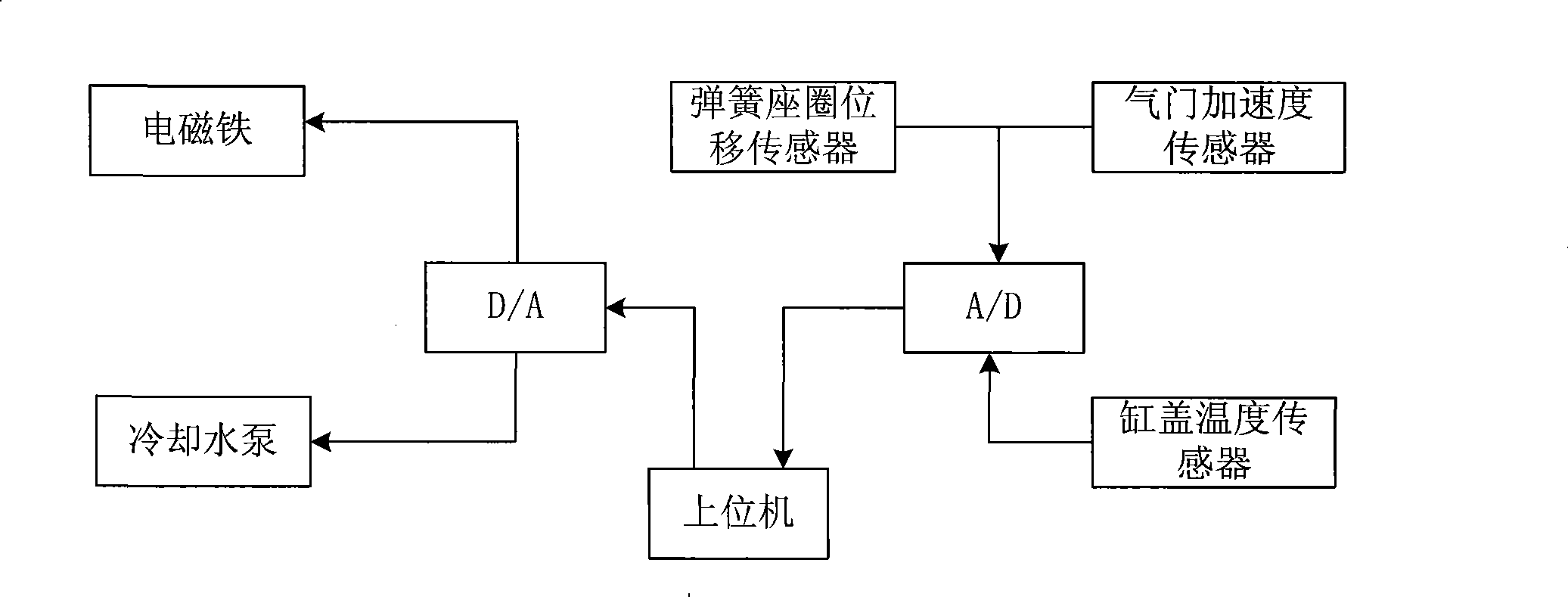

Abrasion test method of air valve and seat ring

InactiveCN101398358AHigh impact strengthGet rid of the bondageMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceCombustorControl engineering

The invention relates to a quick abrasion testing method in the field of power machinery technique, aiming at providing an abrasion testing method used for a valve and a seat ring which are used for an internal-combustion engine. The method comprises a calibration stage and a test stage; in the calibration stage, a valve base is provided with a valve acceleration sensor; a displacement sensor is arranged above a valve spring seat ring; an electromagnet coil gets the electricity; an upper bit machine records the dripping speed and distance of the valve and determines the power-on control strategy for the electromagnet; during the test stage, the valve is heated by an installed burner; and the upper bit machine determines the rotation speed control strategy of the cooling water pump of a water cooling system. The quick abrasion testing method can achieve extremely high impact frequency, and shorten the testing time; the dripping speed of the valve can be jointly determined by two different sensors and the accuracy of the test is improved; the temperature of the cylinder cover is kept at the temperature of the cylinder cover when the internal combustion machine works normally, thus ensuring the reliability of the testing conclusion. The parts are few, the structure is simple and the manufacture cost is low.

Owner:ZHEJIANG UNIV

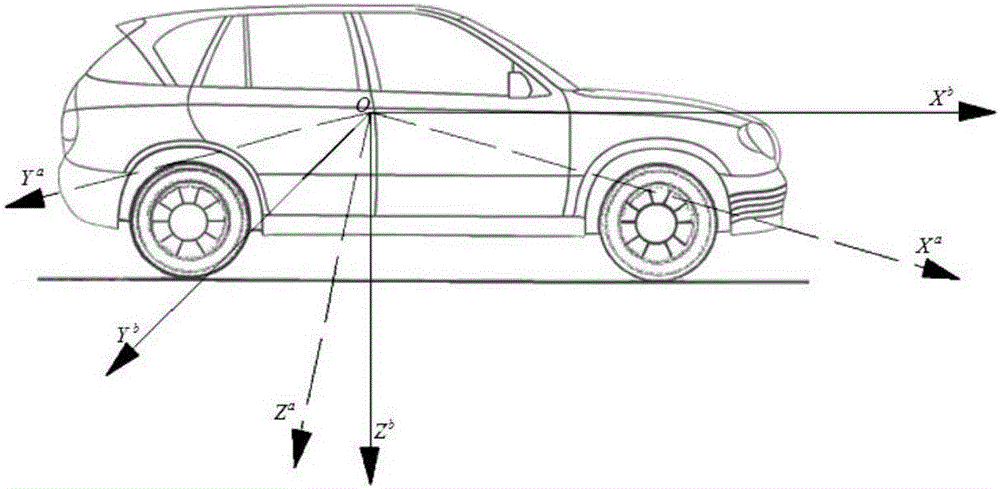

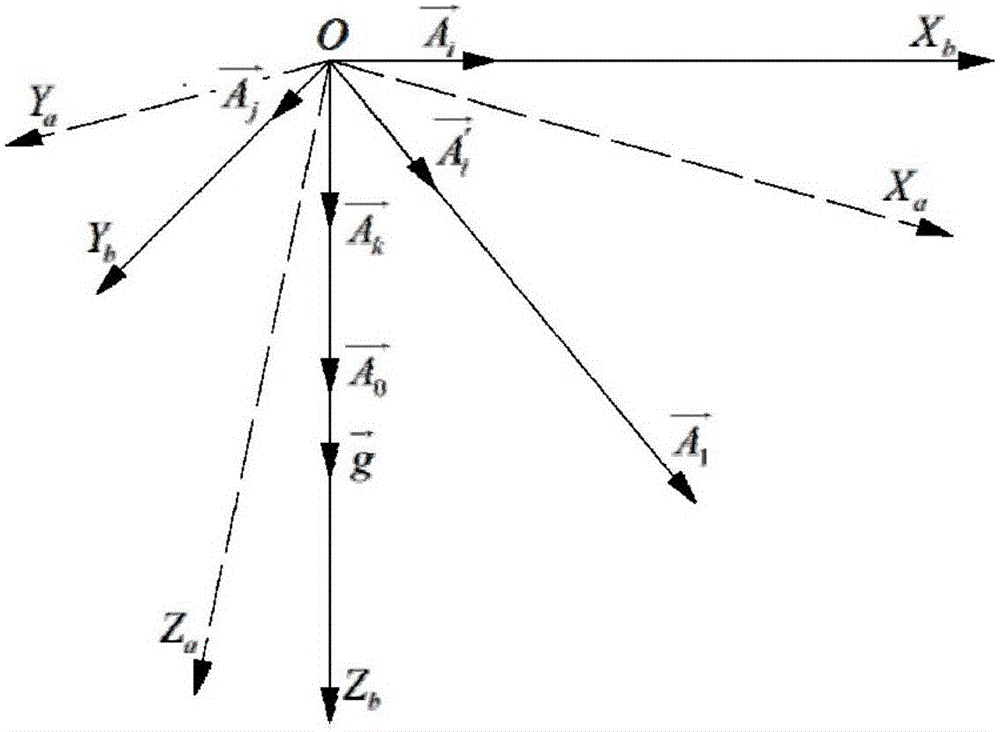

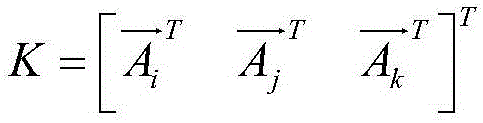

Three-axis acceleration sensor mounting error correcting method

ActiveCN105807095AEliminate errorsLow requirements for measurement conditionsTesting/calibration of speed/acceleration/shock measurement devicesClassical mechanicsAngular error

The invention relates to a three-axis acceleration sensor mounting error correcting method, and is used for correcting angle error between an acceleration sensor coordinate system and a vehicle coordinate system, so that a theoretical value of an acceleration sensor is obtained, the method is characterized in that, the method comprises the steps: the acceleration sensor is arranged on the vehicle, a measured value vector A0 of the acceleration sensor when the vehicle is static on a horizontal ground and a measured value vector A1 of the acceleration sensor when the vehicle acceleratedly moves on the horizontal ground are read, an error correction coefficient matrix K is calculated, wherein the K and other formulas are shown in the description, a theoretical value formula which is shown in the description of the acceleration sensor in the vehicle coordinate system is obtained, wherein vector Aa is a measured value of the acceleration sensor in a general condition. Compared with the technology in the prior art, the method considers vehicle pitch angle influence, the requirements of the measurement condition are low, the calculation method is simple, and the sensor coordinate axis error can be effectively eliminated.

Owner:TONGJI UNIV

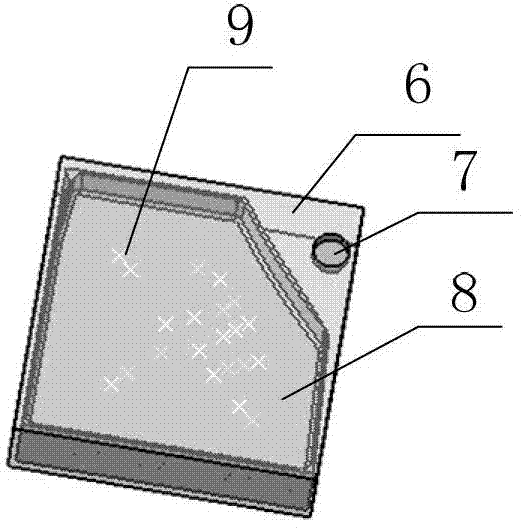

Calibration device and calibration method for joint calibration of laser radar and camera

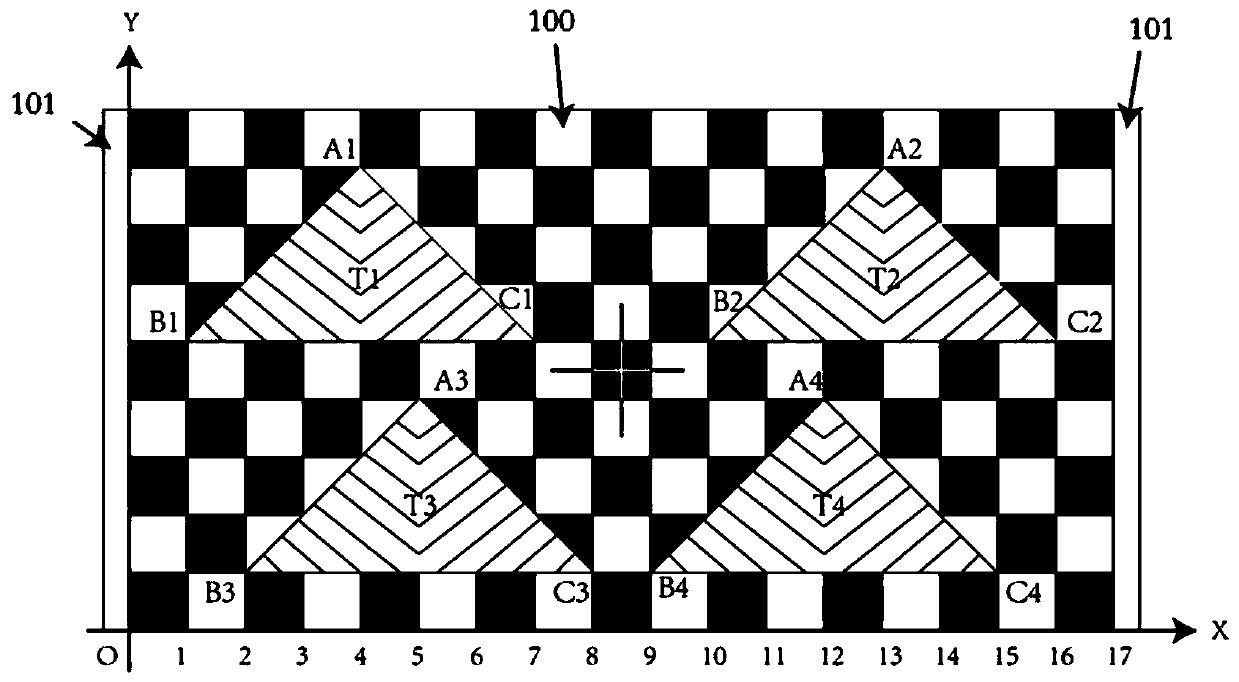

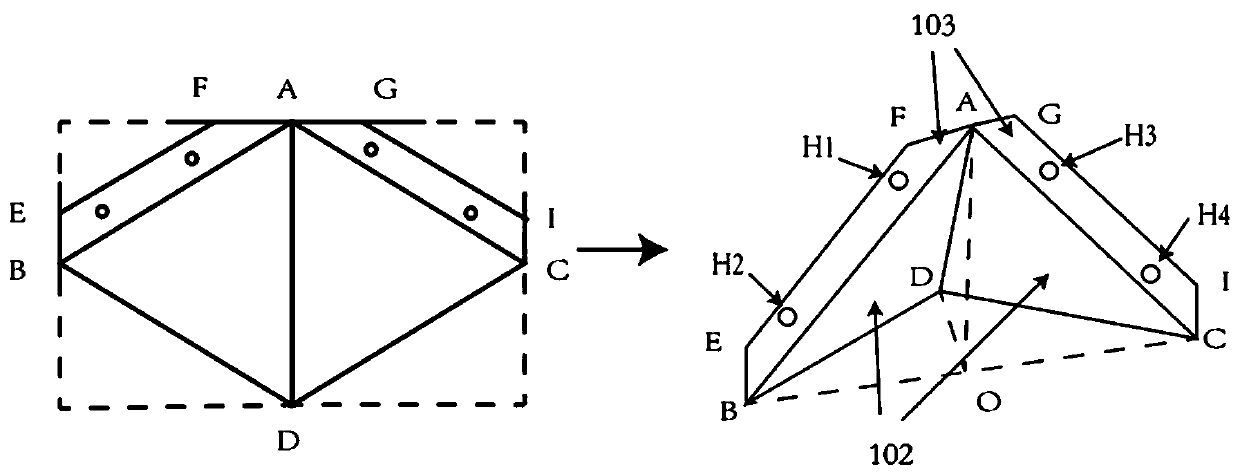

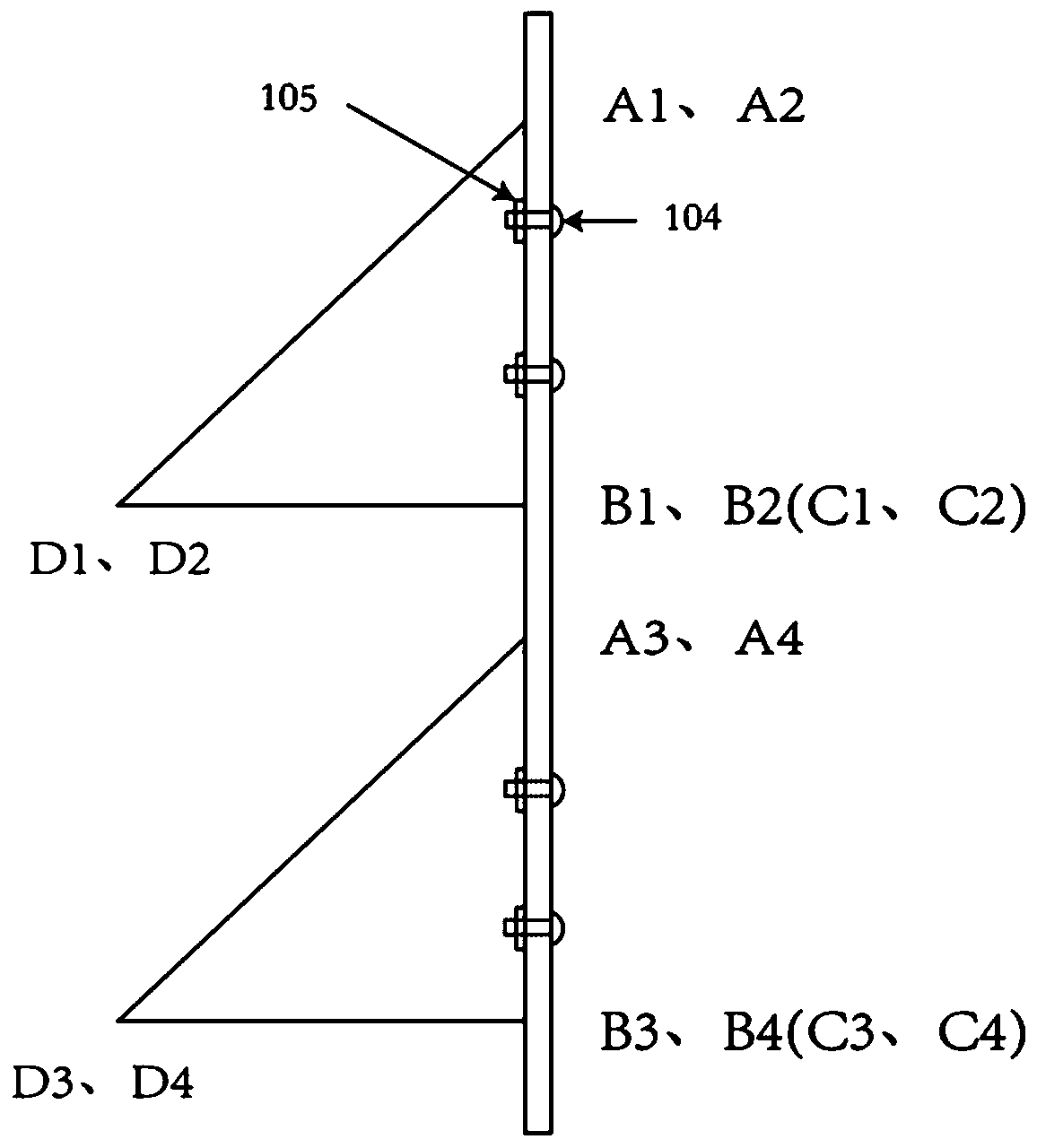

ActiveCN110322519AIncreased sensitivityImprove unityImage analysisWave based measurement systemsRight triangleRadar detection

The invention discloses a calibration device and a calibration method for joint calibration of a laser radar and a camera. The calibration device is composed of a calibration plate, a hollow tetrahedron baffle and a support. The calibration plate is a rectangular plate provided with a cross mark at the geometric center, and the length-width-height ratio is 1: 1:2 A square with the side length ofL is generated with the cross as the center is formed. 9 * 17 black-white square grids are generated through expansion with the square as the symmetric center. Four isosceles right triangles are arranged at specific positions and hollowed out, a specific hollow tetrahedron baffle is arranged behind a cavity, the bottom of the tetrahedron is matched with the cavity, so that the front-view calibration plate is free of the cavity, and L / 2 width vacancies are formed in the two sides of the calibration plate and fixed through a specific support. The calibration method comprises the following steps:calculating coordinates of feature points in a laser radar coordinate system and coordinates of camera pixel coordinate systems according to a fitting interpolation method provided by the invention by using a laser radar detection and camera shooting calibration device, obtaining enough feature point pairs, and substituting the feature point pairs into a coordinate conversion formula to obtain arelative position relationship between the two coordinate systems.

Owner:TIANJIN UNIV

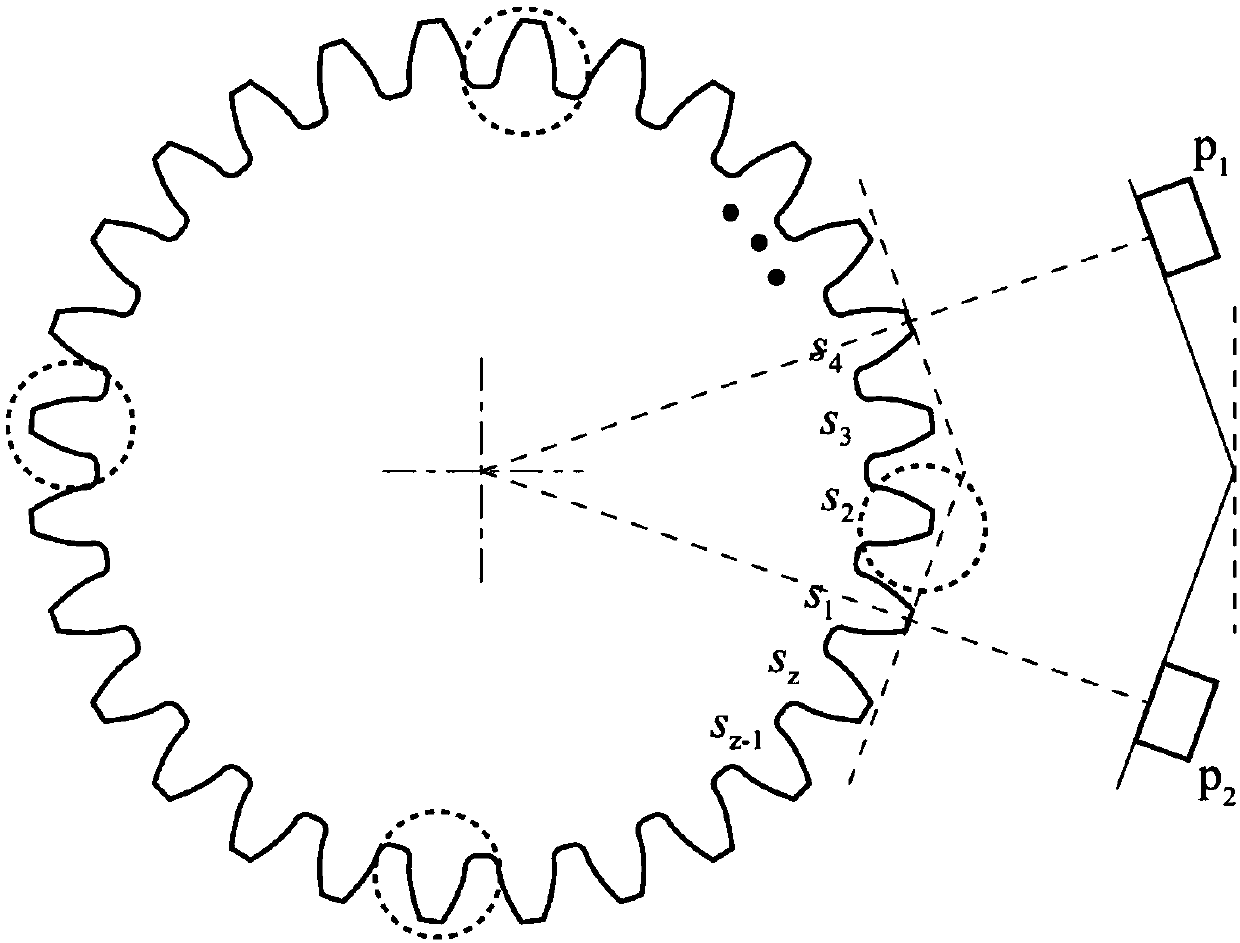

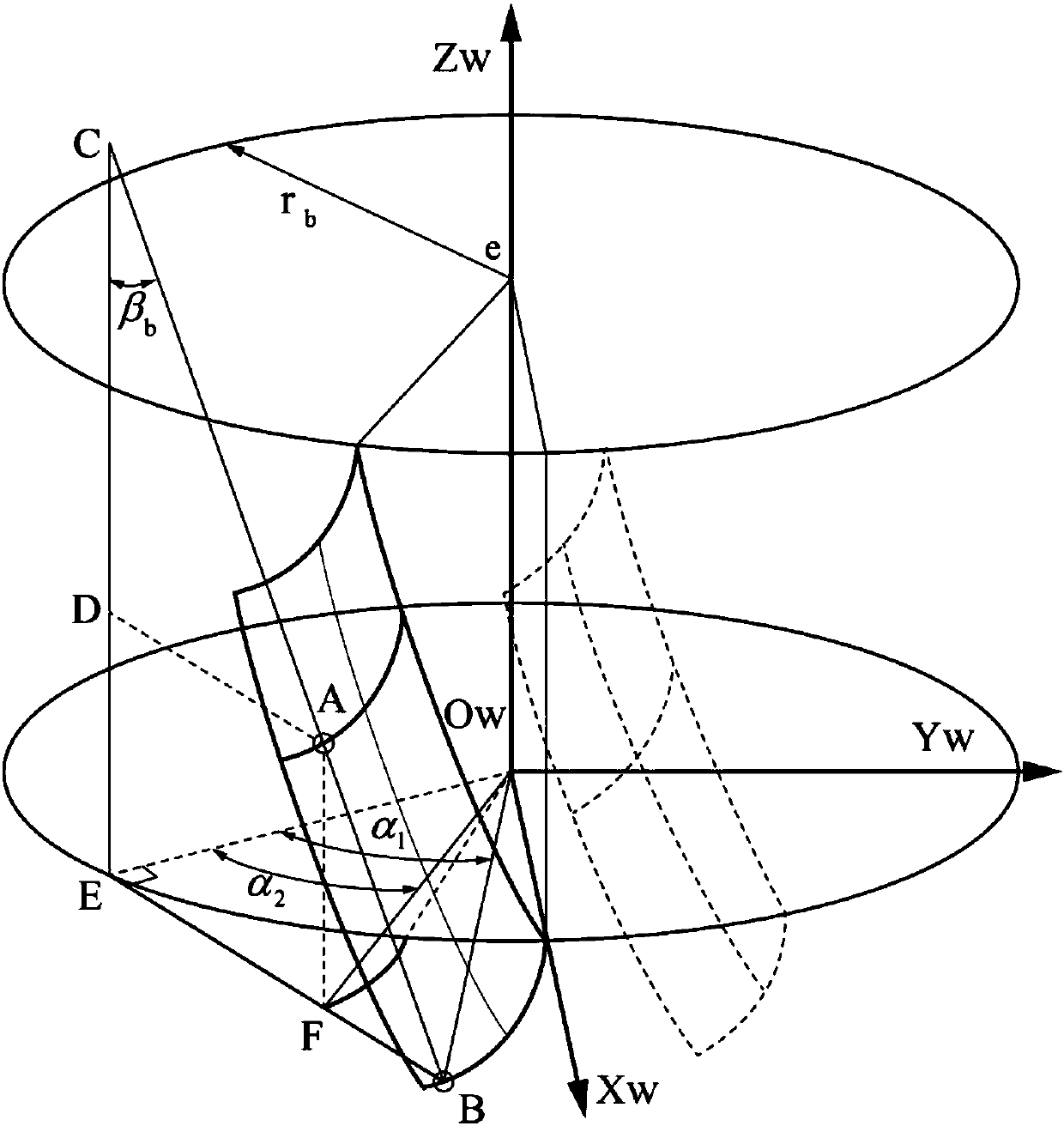

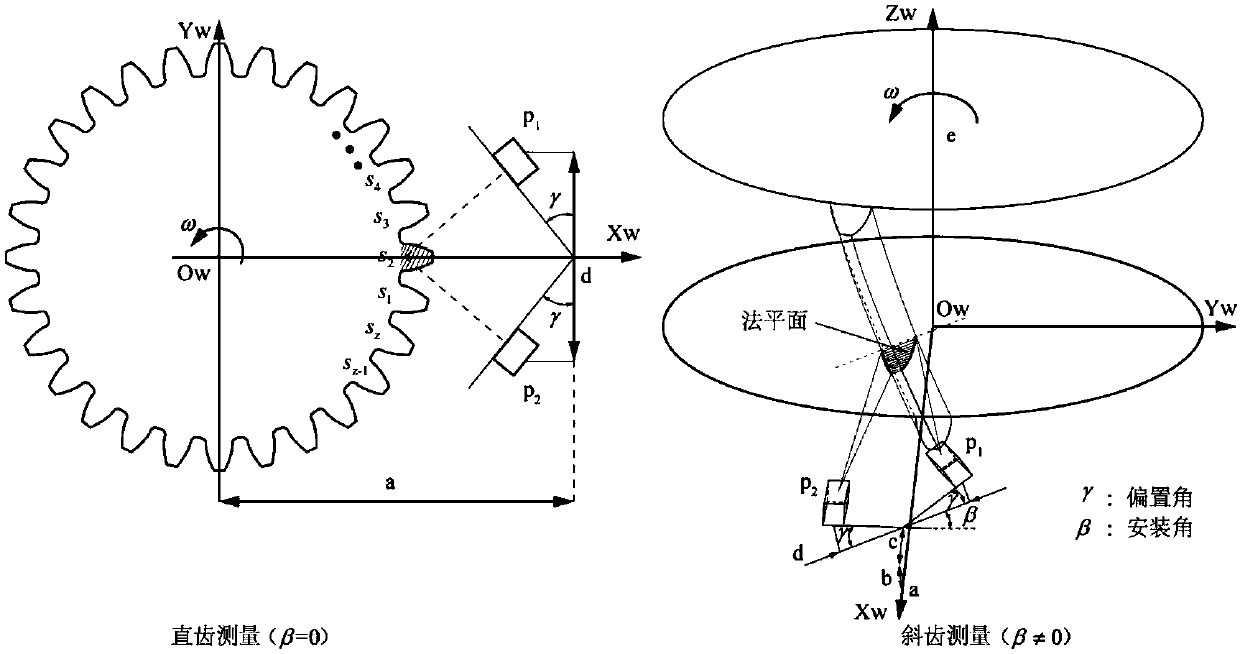

Gear teeth thickness measurement method based on line structured light

ActiveCN108050946AReduce the impactReduce adverse effectsUsing optical meansLaser probeData acquisition

The invention discloses a gear teeth thickness measurement method based on line structured light and belongs to the field of the precision test technology and instruments and the gear detection technology. After a detected gear is embedded, the center of a coordinate system is calibrated through a line laser probe, the design reference of the detected gear is selected as the reference for measurement, according to gear parameters, more than 4 gears uniformly distributed on the detected gear are selected, and three uniformly-distributed cross sections of each gear are taken as measurement positions; data acquisition, mounting parameters required by two probes and the relationship among the parameters are calculated according to the parameters of the detected gear, two line structured lightprobe coordinate systems are established, and data of two side surfaces of the detected gear is acquired; according to each mounting parameter and the measurement data, a space coordinate conversion formula for data acquisition is established, and each set of measurement values of the probe coordinate systems is converted to the gear design center. The method is advantaged in that a tooth thickness deviation mathematic model is established, and high precision measurement of tooth thickness deviation, string tooth thickness measurement and separate-tooth thickness average deviation is further realized.

Owner:BEIJING UNIV OF TECH

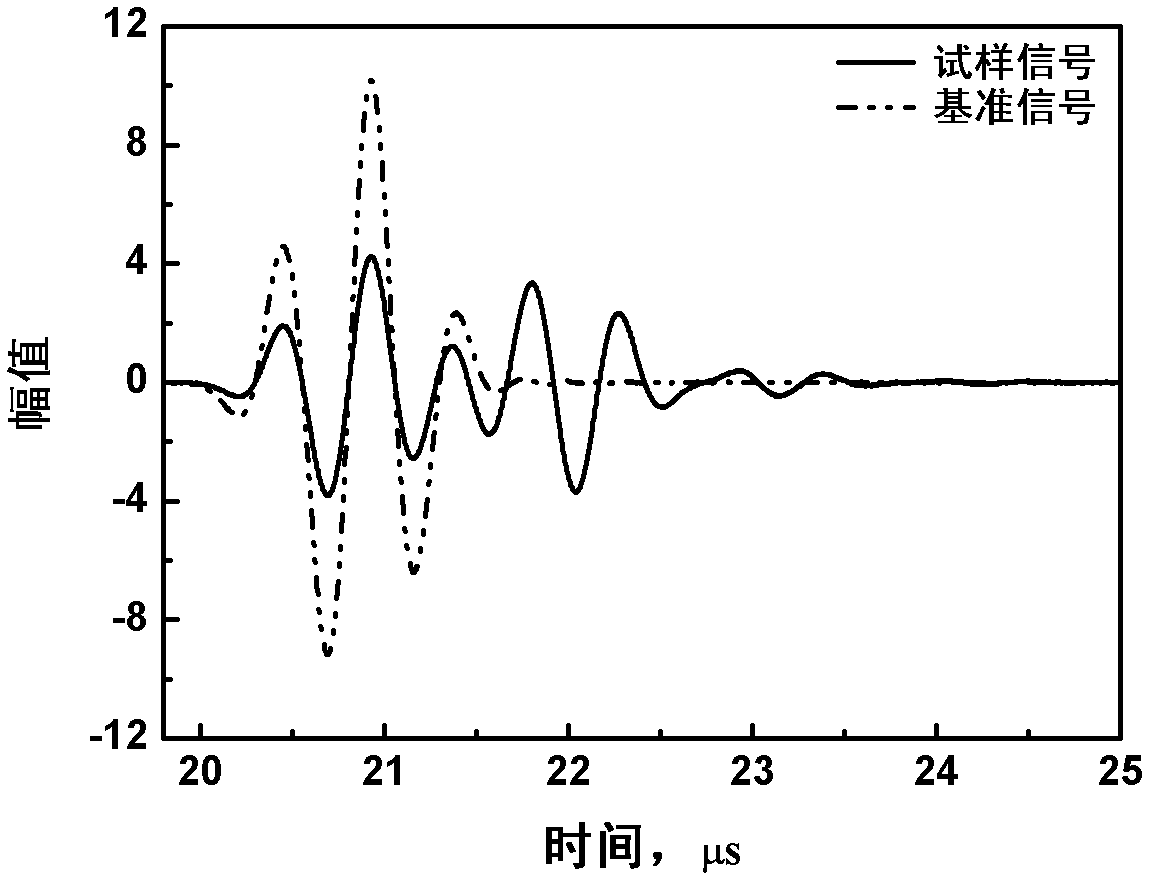

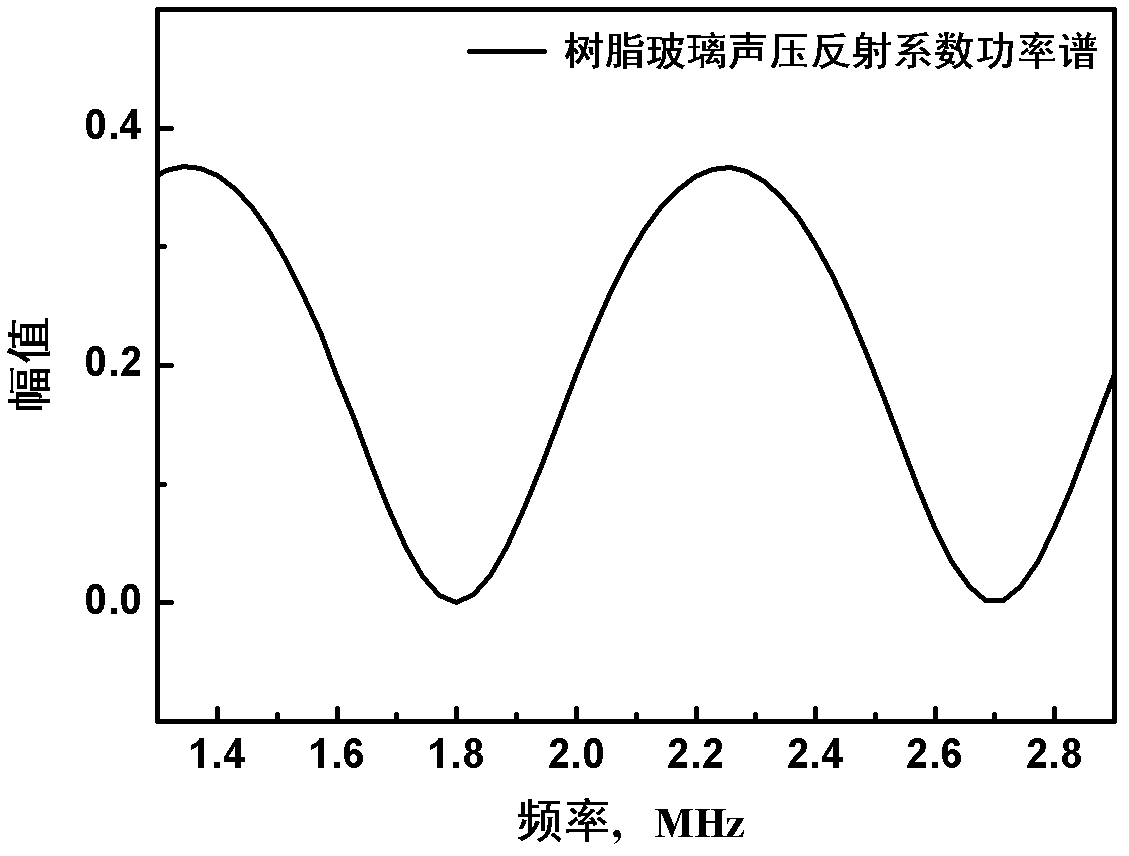

Method for measuring acoustic impedance and acoustic attenuation of thin layer based on sound pressure reflection coefficient power spectrum

ActiveCN102608212AReduce random errorHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesBandpass filteringSonification

The invention discloses a method for measuring the acoustic impedance of a thin layer based on a sound pressure reflection coefficient power spectrum, belonging to the technical field of ultrasonic nondestructive testing and evaluating of materials. The method comprises the steps of: acquiring aliasing signals formed by interface reflection echoes from water and an upper surface of the thin layer as well as from the water and a lower surface of the thin layer by using a pulsed ultrasound water logging echo system, acquiring an upper surface echo signal of a standard test block, performing FFT (Fast Fourier Transform) on the two signals respectively, and performing further processing to obtain the sound pressure reflection coefficient power spectrum; and then, performing low-pass filtering and band-pass filtering on the power spectrum to solve relevant coefficients in a power spectrum expression, and substituting the coefficients into an equation to solve the acoustic impedance of the thin layer. The method disclosed by the invention can be used for solving the acoustic impedance at the same time under the condition that any parameters of the thin layer are unknown, and the defect that part of parameters of the thin layer need to be known to obtain other parameters in the prior art is overcome.

Owner:DALIAN UNIV OF TECH

Based on laser rediffusion type atmospheric visibility testing method and testing instrument thereof

InactiveCN1948953AResolve errors due to atmospheric inhomogeneityAvoid errorsScattering properties measurementsColor/spectral properties measurementsExtinctionAtmospheric sciences

The invention relates to based on laser backscattering type atmospheric visibility measuring method and apparatus. It includes the following steps: respectively transmitting and receiving laser backscattering signal for five times as middle gain and high gain, sampling 400 points in each the received signal; respectively computing each fault extinction coefficient while sampling, computing its average extinction coefficient for five sets after removing the point with big error; computing whole relative extinction coefficient by data fusion algorithm; deducing the atmospheric visibility by relative extinction coefficient inversion. The invention has the advantages of high measuring precision, little volume, light weight, wide application range, and no collaboration object.

Owner:NAVAL UNIV OF ENG PLA

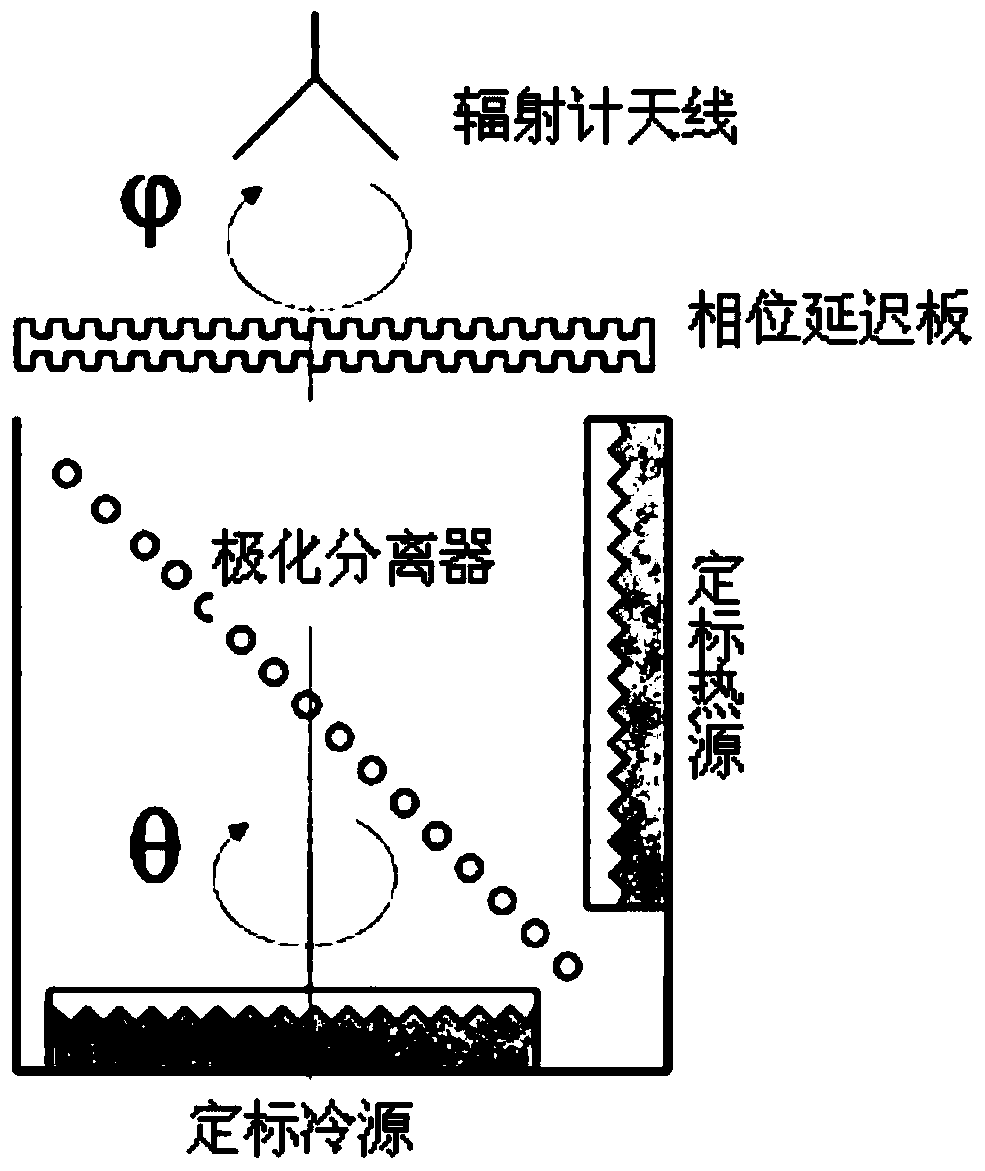

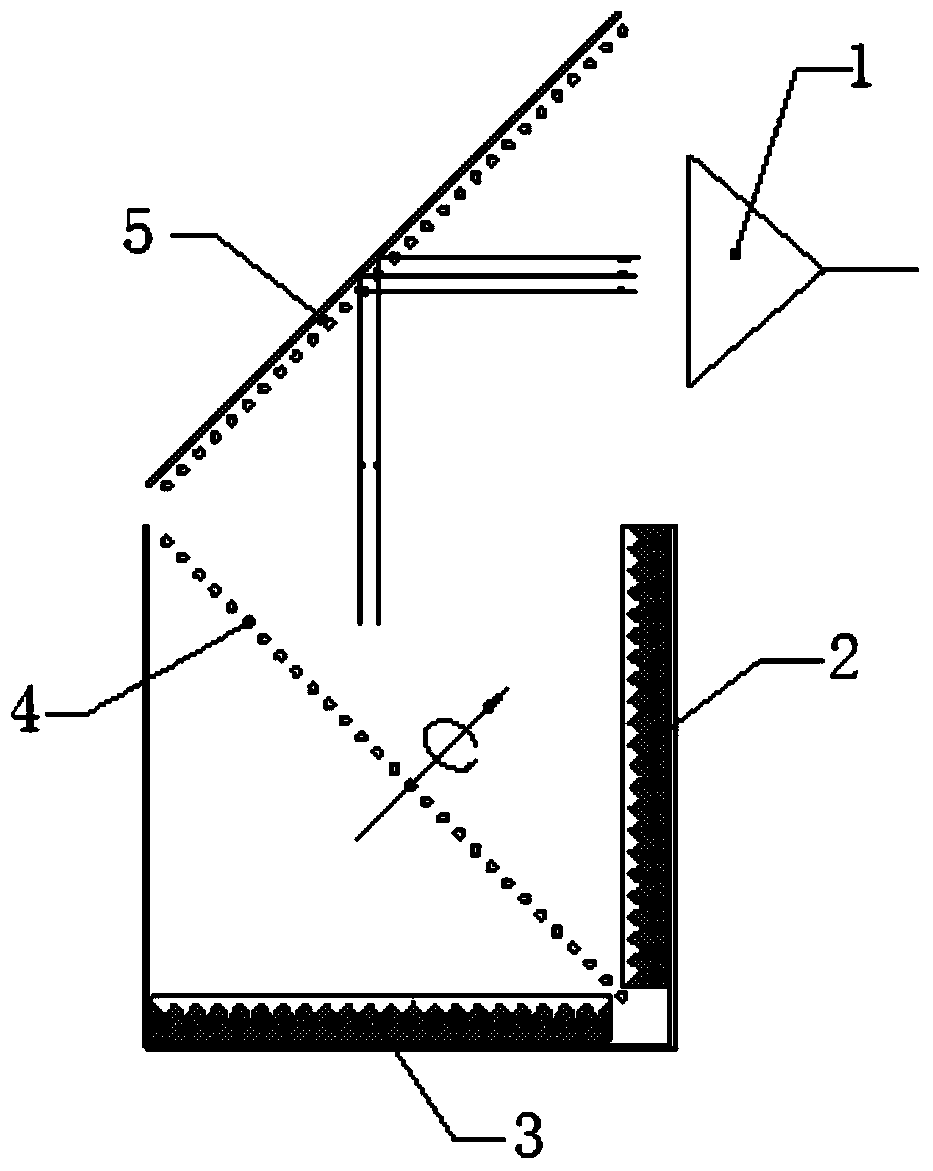

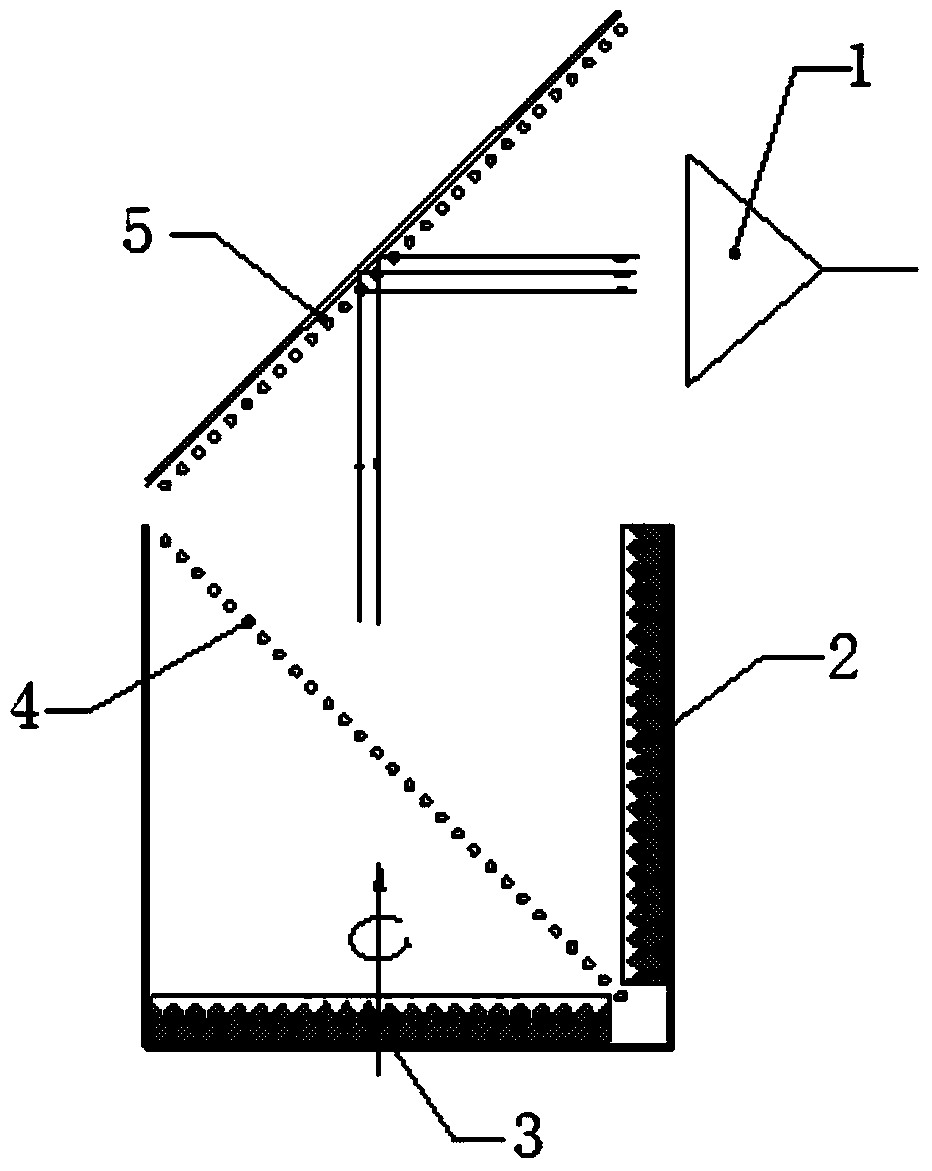

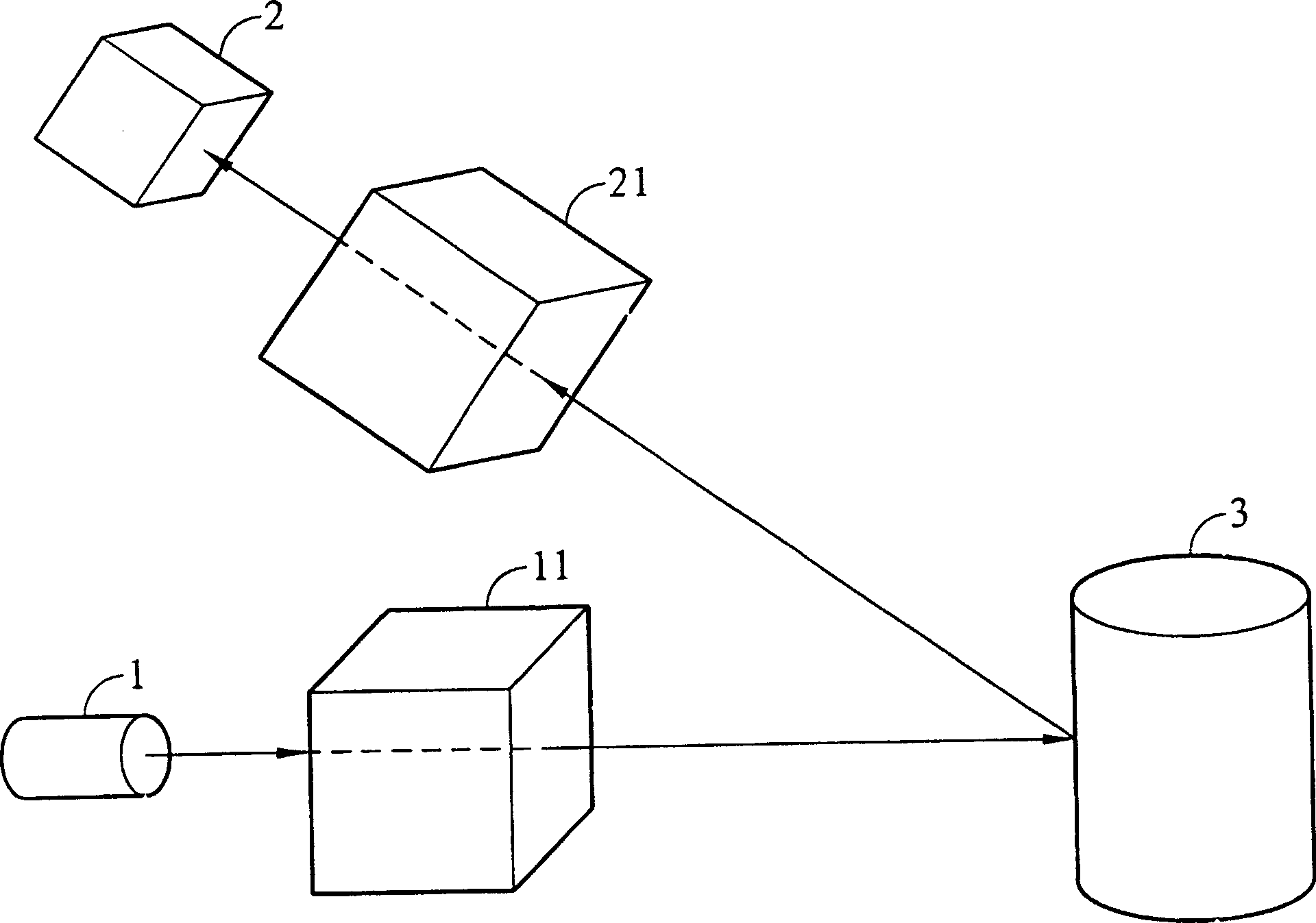

Complete-polarization microwave radiometer calibrating device and calibrating method thereof

The invention relates to a complete-polarization microwave radiometer calibrating device which comprises a calibrating hot source, a calibrating cold source, a polarization separator and a phase generator. The calibrating hot source is arranged on a horizontal plane or a vertical plane, the plane where the calibrating cold source is arranged is perpendicular to the plane where the calibrating hot source is arranged, the polarization separator is arranged between the calibrating cold source and the calibrating hot source, the polarization separator forms an 45-degree angle with the horizontal plane, and the plane where the phase generator is arranged forms a certain angle with the plane where the polarization separator is arranged. The complete-polarization microwave radiometer calibrating device effectively reduces system errors and random errors and greatly reduces calibrating uncertainty.

Owner:NAT SPACE SCI CENT CAS

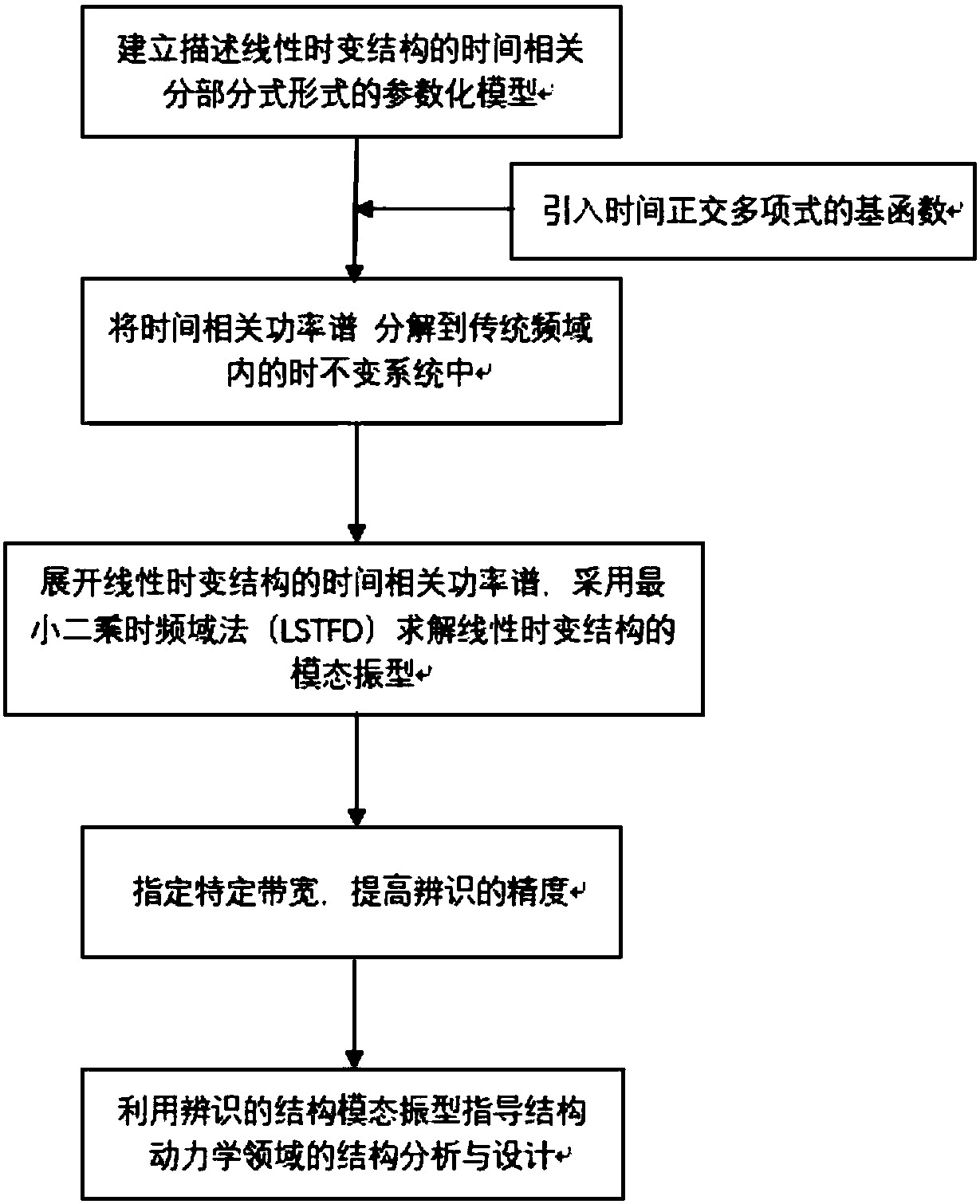

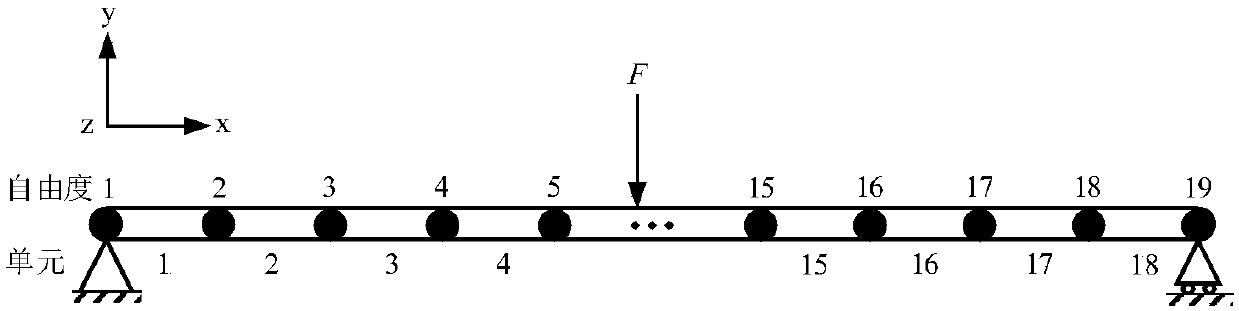

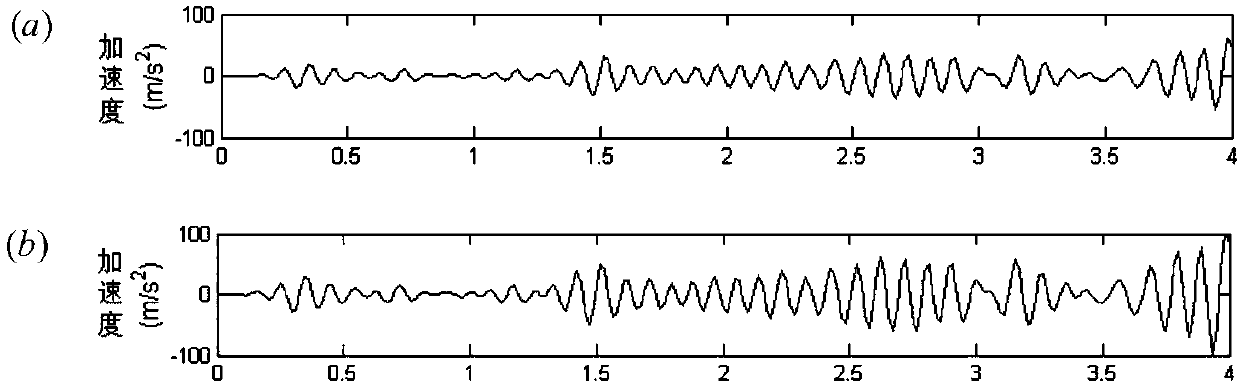

Linear time-varying structure modal shape identification method

InactiveCN108416141ASolve practical engineering technical problemsBroad application prospectsDesign optimisation/simulationSpecial data processing applicationsTime correlationStructural dynamics

The invention discloses a linear time-varying structure modal shape identification method, and belongs to the technical field of structural dynamics. On the condition that the linear time-varying structure model frequency and model damping are known, a parameterized model describing a time correlation time division form of a linear time-varying structure is built; a time orthogonal polynomial basefunction is introduced, the parameterized model is unfolded on the basis of the base function, and a time correlation power spectrum defined in the description is decomposed in a time-invariant system in the traditional frequency domain; the linear time-varying structure-based time correlation power spectrum is unfolded, and a parameter estimation method is adopted for solving the linear time-varying structure modal shape. The technical purpose of providing the method for integrally estimating the linear time-varying structure modal shape in the whole time within the time-frequency domain isachieved; in addition, the integrity of the model shape on a time shaft is improved, the identification effect is improved by assigning a bandwidth mode, multiple experiments can be conducted, a random error is reduced by taking the average value, and the identification capacity of the low-order model shape is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

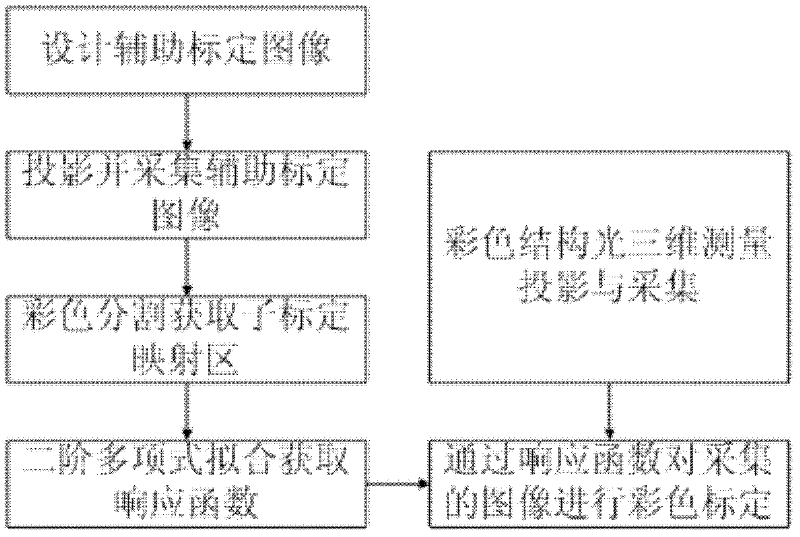

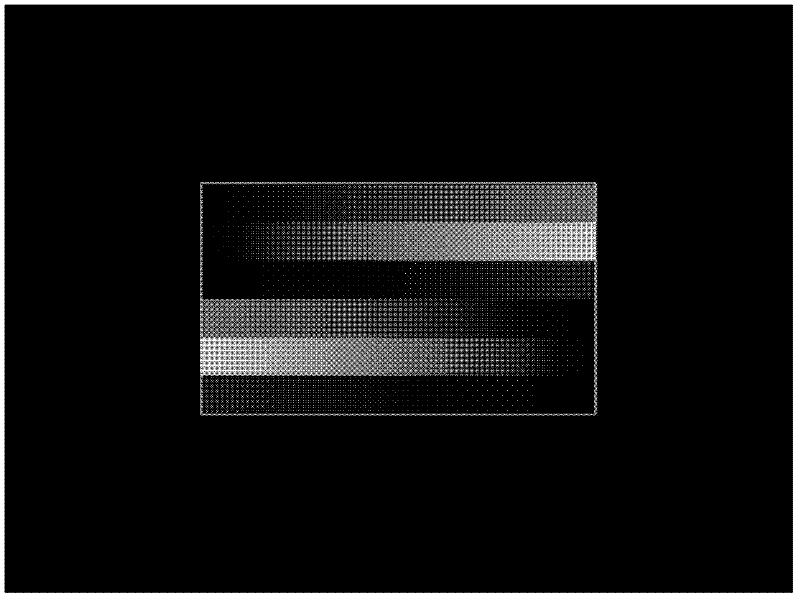

Color response calibration method in colored structure light three-dimensional measurement

InactiveCN102519395AImprove convenienceGuaranteed accuracyUsing optical meansColor imageThree dimensional measurement

The invention relates to a color response calibration method in a colored structure light three-dimensional measurement system, which comprises the following steps of: designing an auxiliary calibration image containing six sub-calibration areas, wherein the six sub-calibration areas comprise three basic pure colors, and each pure color has two brightness variation trends; turning the auxiliary calibration image into a white flat plate, carrying out color segmentation on the collected response image, and obtaining six sub-calibration mapping areas; carrying out average operation on the two sub-calibration mapping areas of each basic pure color according to the direction of the same variation trend; taking the result of the average operation as independent variable and ideal response curve as dependent variable for second-order polynomial fit, and obtaining the response function of color response calibration; and finally, according to the response function, calibrating the measurement colored image obtained in colored structure light three-dimensional measurement.

Owner:SOUTHEAST UNIV

Method for high-precision correction of embedding direction of three-component geophone

The invention provides a method for high-precision correction of the embedding direction of a three-component geophone by utilizing polarization characteristics of ground, multi-component seismic data. The method comprises the following steps: picking first arrival time; calculating a covariance matrix of a given first arrival time window of every three-component seismic record to find out an off diagonal element with a maximal absolute value and hence to determine a rotation angle; establishing a primary rotation matrix; ordering the three characteristic values of the covariance matrix from large to small; circularly calculating an included angle between the projection of every main characteristic vector in the X-Y plane and the axis X, as well as the included angle between the main characteristic vector and the Z-axis, and the azimuth angle of the main characteristic vector; calculating a deviation angle of the geophone; correcting the acquired three-component seismic data according to the deviation angle. The method has relatively high precision, effectively reduces random error, and improves result reliability and correcting computational efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

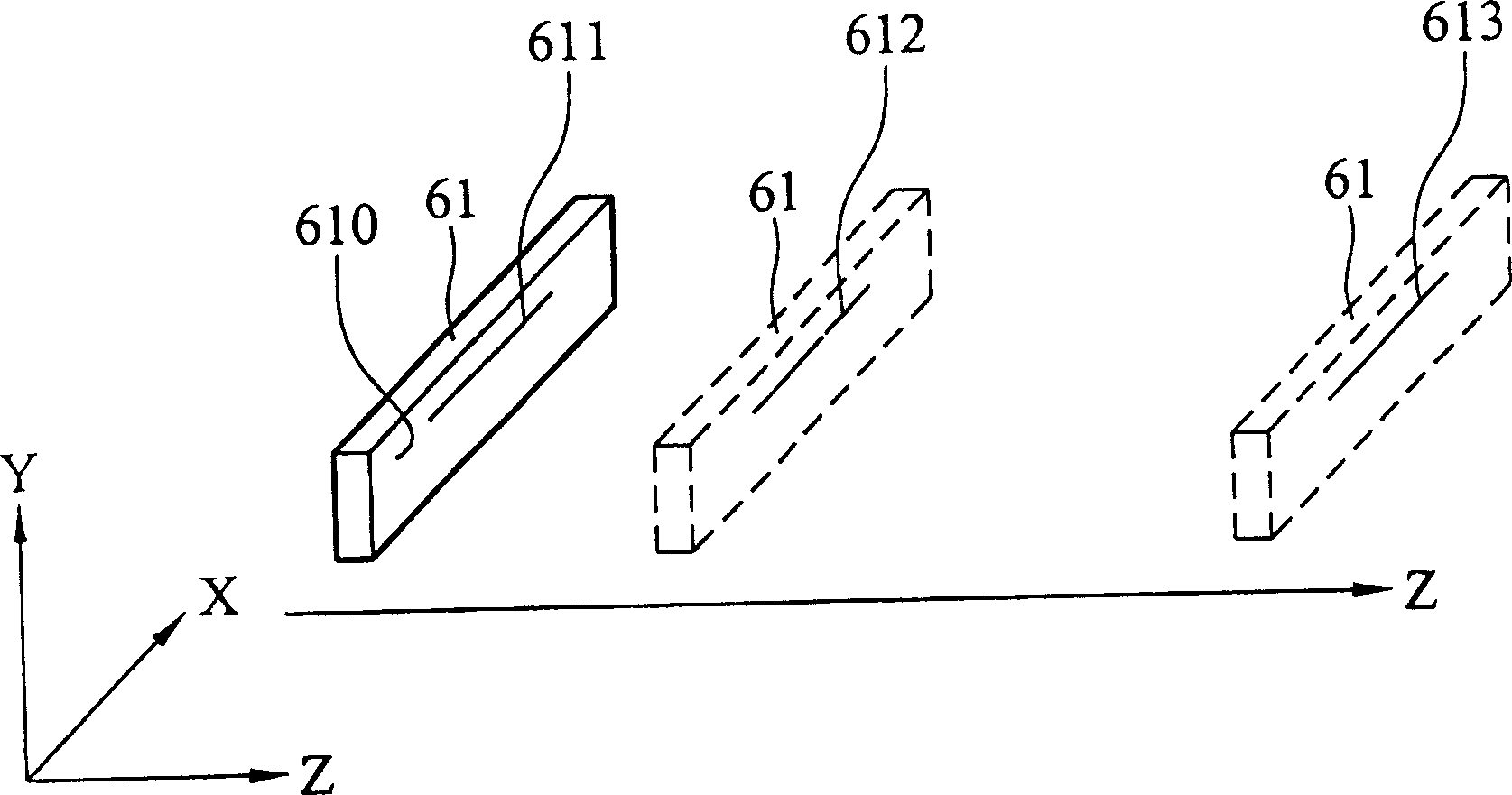

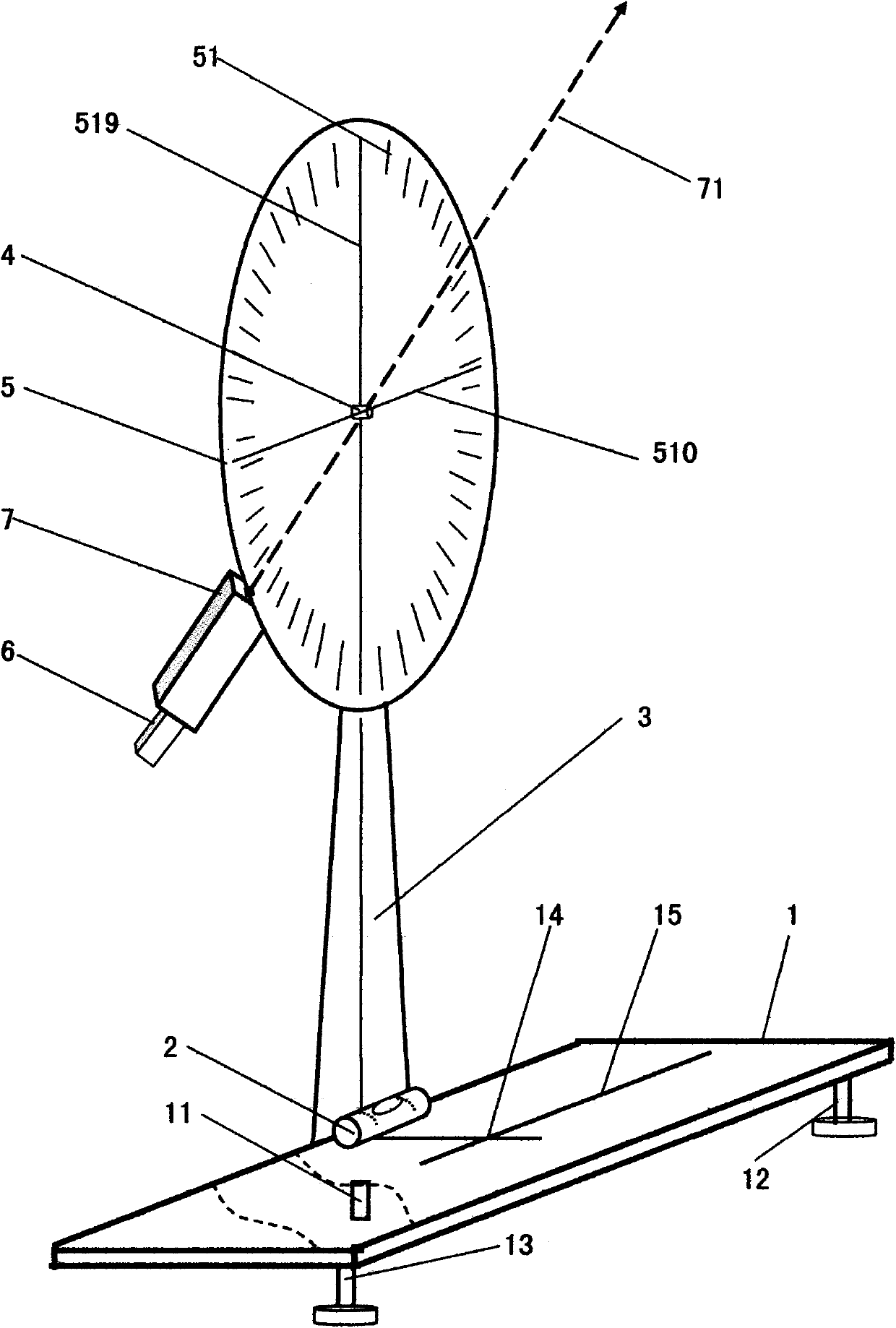

Method and apparatus for calibration of laser three-dimensional measuring appliance

The invention discloses a method and apparatus for calibration of laser three-dimensional measuring appliance, wherein the apparatus includes a base plane and a laser gauge pin arranged on base planeand able to set out a lasing plane, an aligning gear arranged on base plane, which includes a surface gauge, an adjusting plane is arranged on the surface gauge, and the correction method is, the laser gauge pin sending laser plane, projecting on the plane gauge, then the laser gauge pin can sense the reflected ray, and obtain a two-dimensional digital image.

Owner:IND TECH RES INST

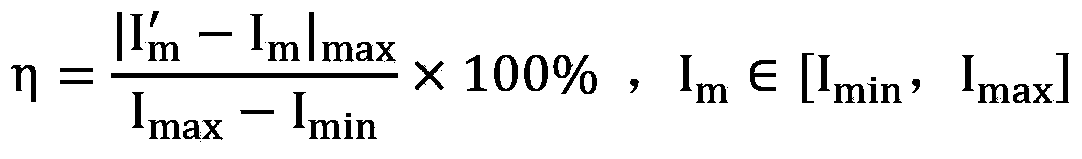

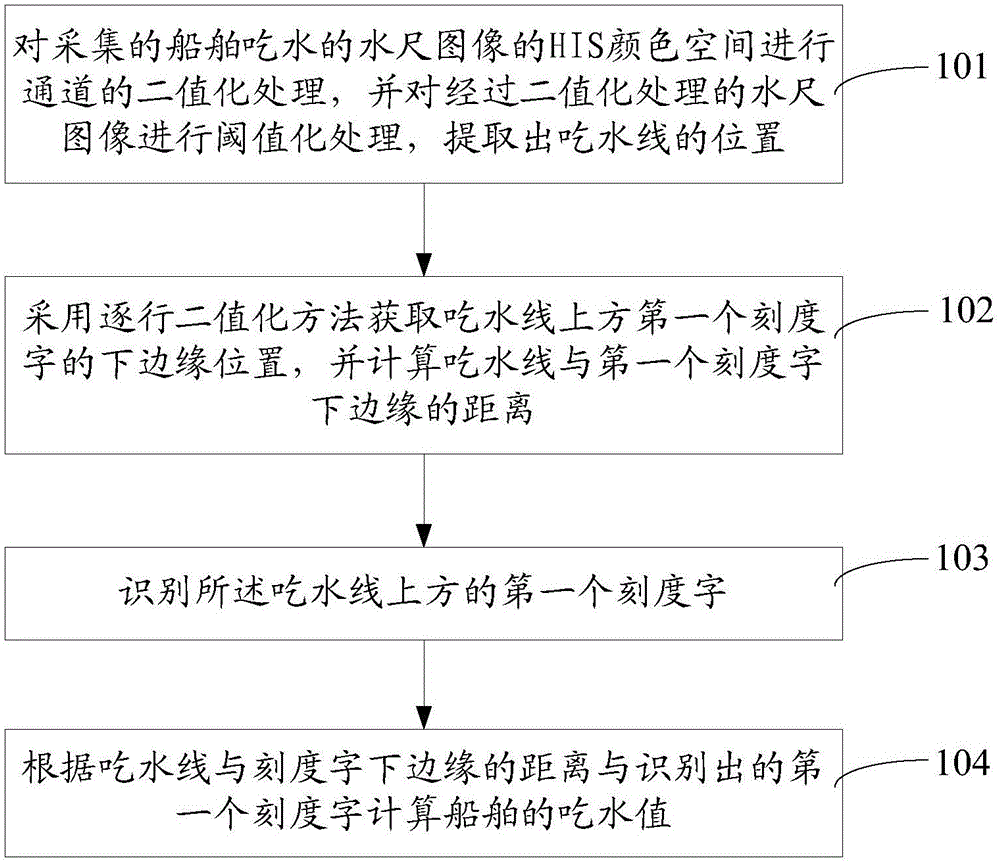

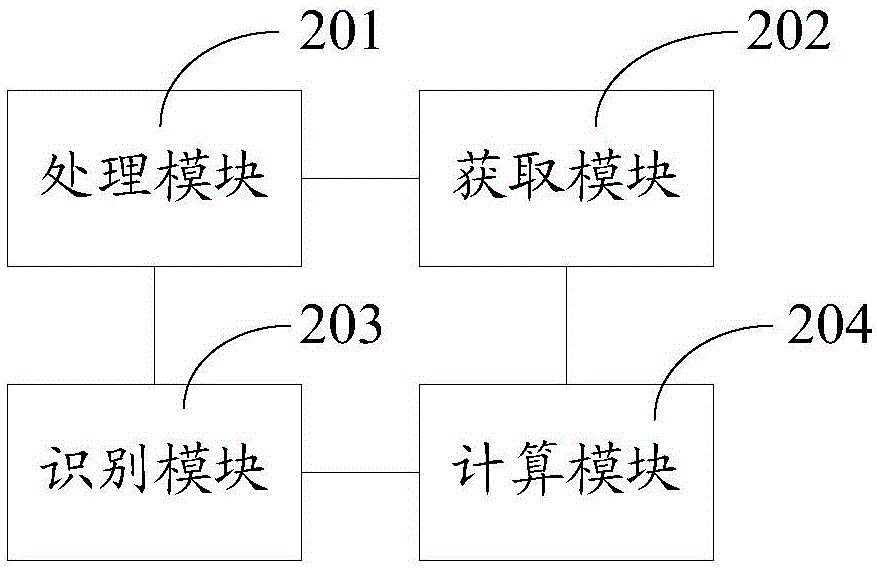

Water gauge image analysis method

InactiveCN105160288AReduce random errorReduce human errorCharacter and pattern recognitionImaging analysisSevere weather

The invention relates to a water gauge image analysis method, relates to the technical field of water gauge measurement, and solves a problem that the value of ship draught is difficult to measure precisely through naked eyes under severe weather conditions. The method comprises the steps: carrying out the channel binarization processing of an HIS color space of a collected water gauge image of ship draught, carrying out the thresholding processing of the water gauge image after binarization processing, and extracting the position of a waterline; obtaining the position of a lower edge of a first scale character above the waterline through employing a method of row-by-row binarization, and calculating the distance from the waterline to the lower edge of the first scale character; recognizing the first scale character above the waterline; and calculating the ship draught value according to the distance from the waterline to the lower edge of the first scale character and the recognized first scale character. The method can analyze the ship draught value conveniently, quickly and effectively under the severe weather conditions.

Owner:ZHEJIANG OCEAN UNIV

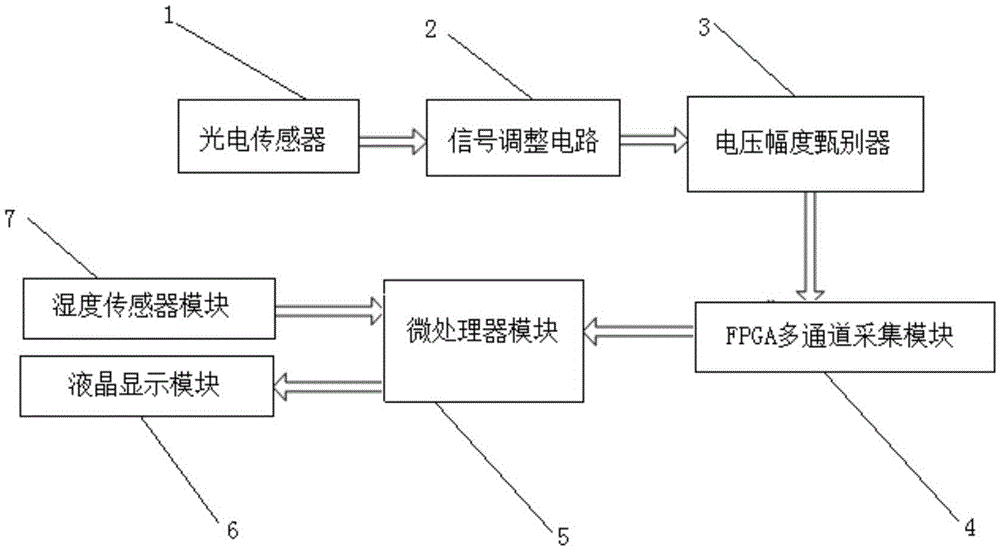

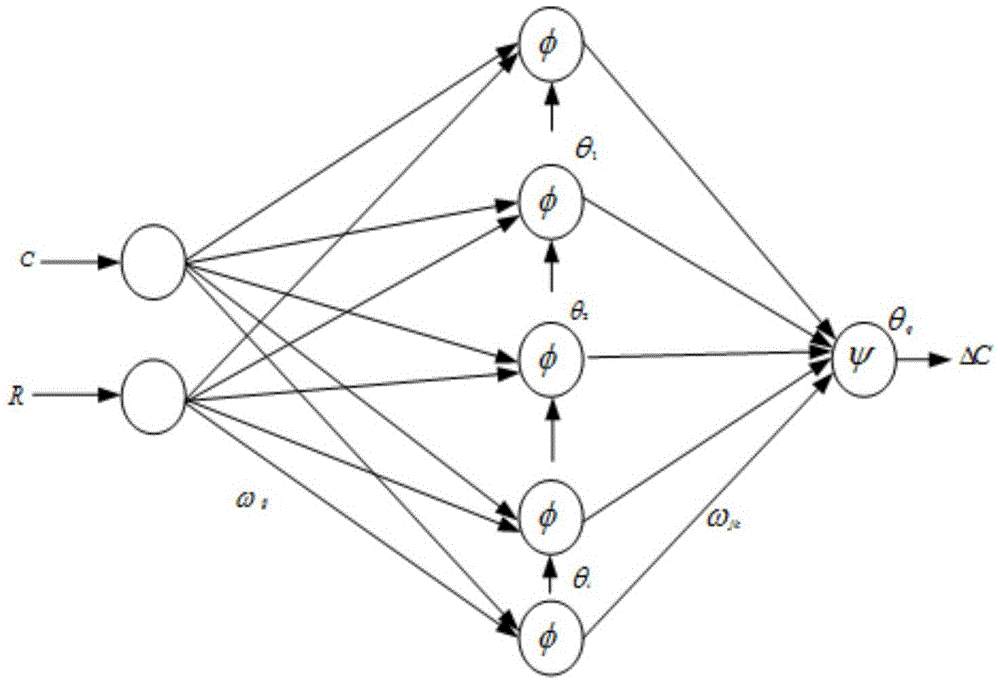

Suspended particulate matter mass concentration real-time detection device, and measuring method

ActiveCN105606499AReduce random errorEliminate measurement errorsParticle suspension analysisVoltage amplitudePhysics

The invention discloses a suspended particulate matter mass concentration real-time detection device. The suspended particulate matter mass concentration real-time detection device comprises a photoelectric sensor, a voltage amplitude discriminator, an FPGA multi-channel acquisition module, a microprocessor module, a liquid crystal display module, a humidity sensor module, and a power module; signals collected by the photoelectric sensor are transformed into voltage signals via a signal adjusting circuit, and the voltage signals are send to the voltage amplitude discriminator; the voltage amplitude discriminator is connected with the FPGA multi-channel acquisition module and the microprocessor module successively; the microprocessor module is connected with the liquid crystal display module and the humidity sensor module respectively. According to a measuring method using the suspended particulate matter mass concentration real-time detection device, after establishment of a BP neural network via particle swarm optimization, obtained weight values, threshold values, and a mass concentration calculation formula obtained via relative humidity correction are send to the microprocessor module; and the microprocessor module is used for humidity algorithm compensation of received measuring results based on the mass concentration calculation formula; so that influences of environment change on measuring results are avoided, and measuring data is optimized.

Owner:南京金海辉智控系统有限公司

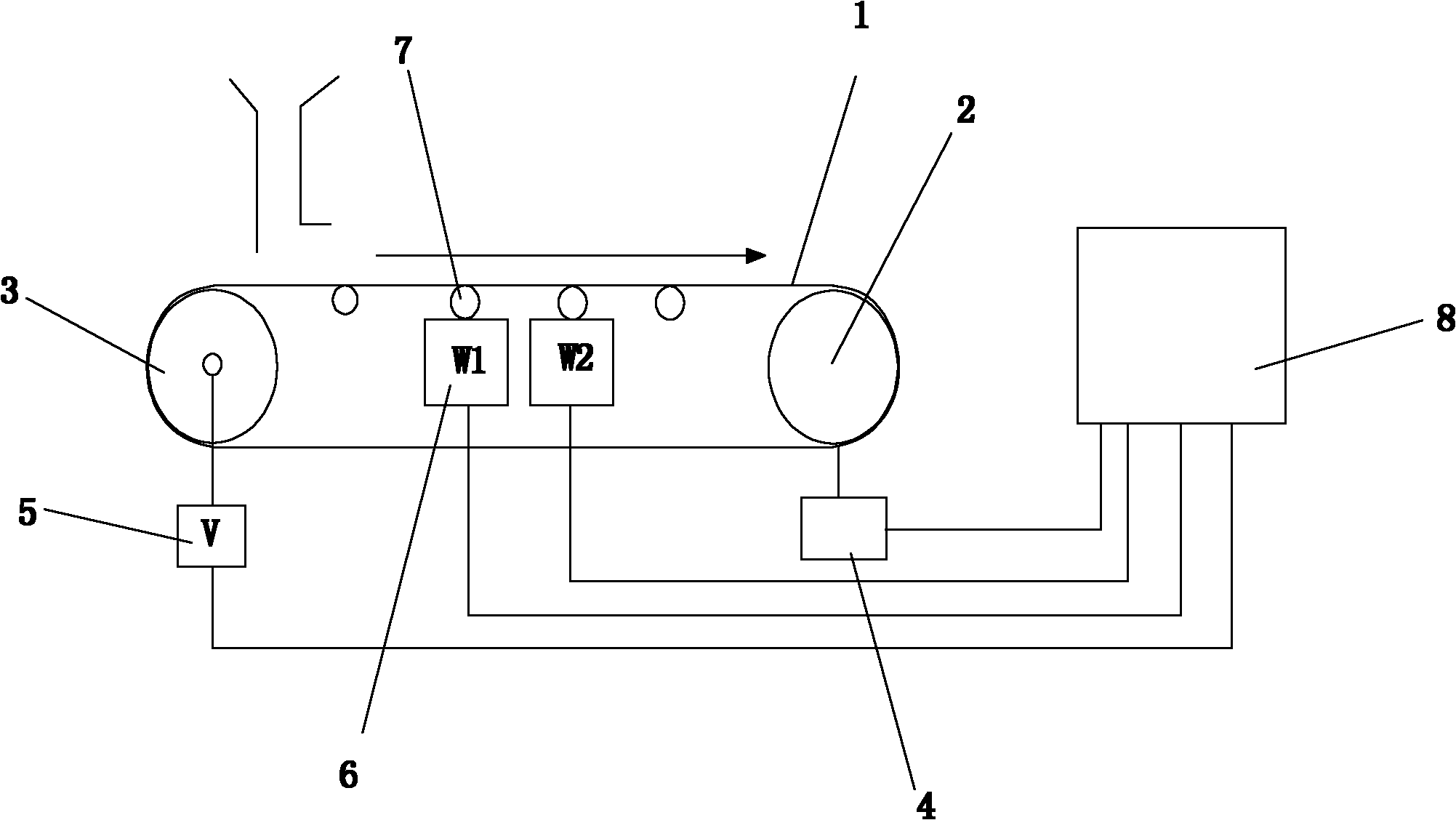

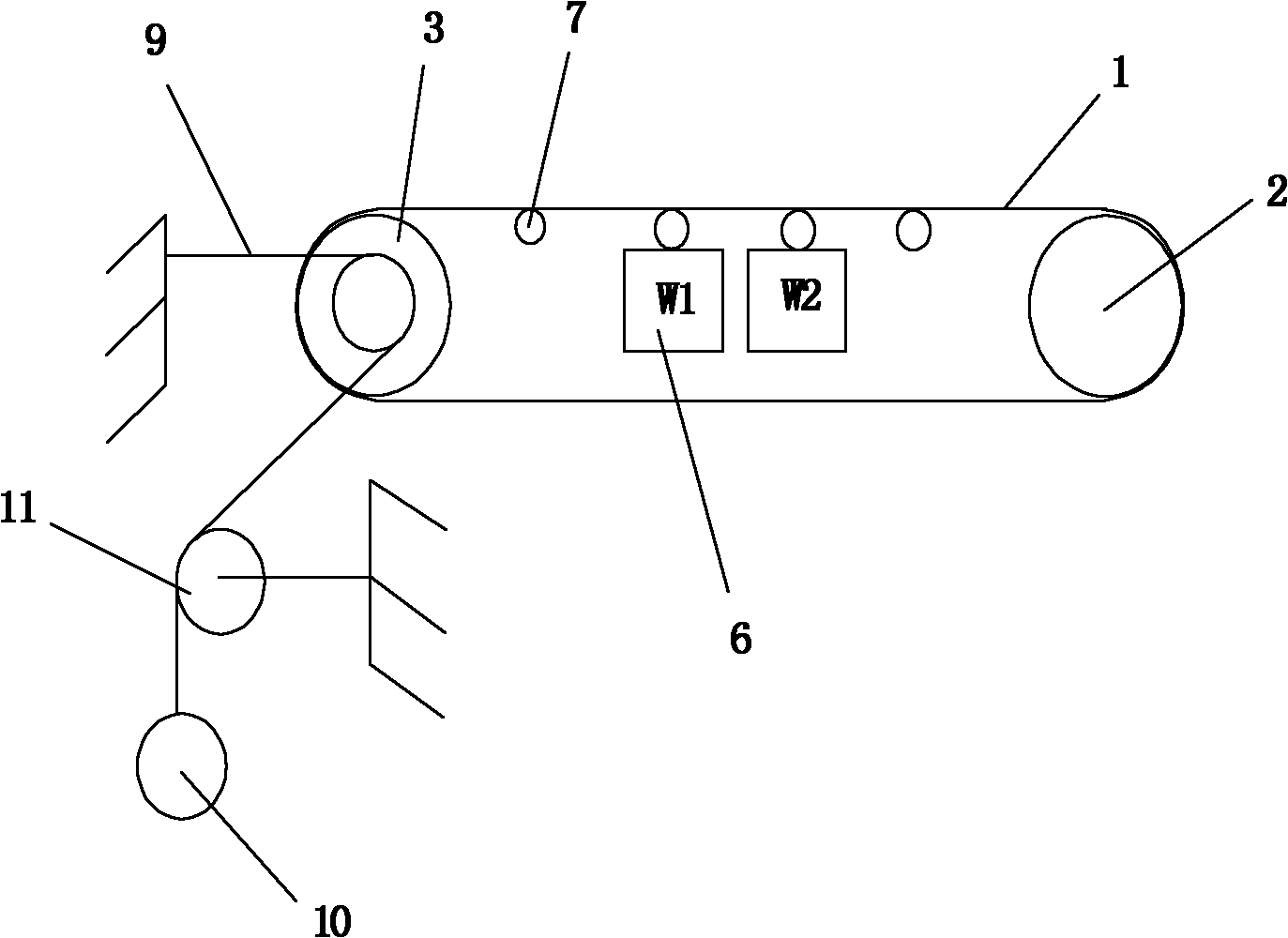

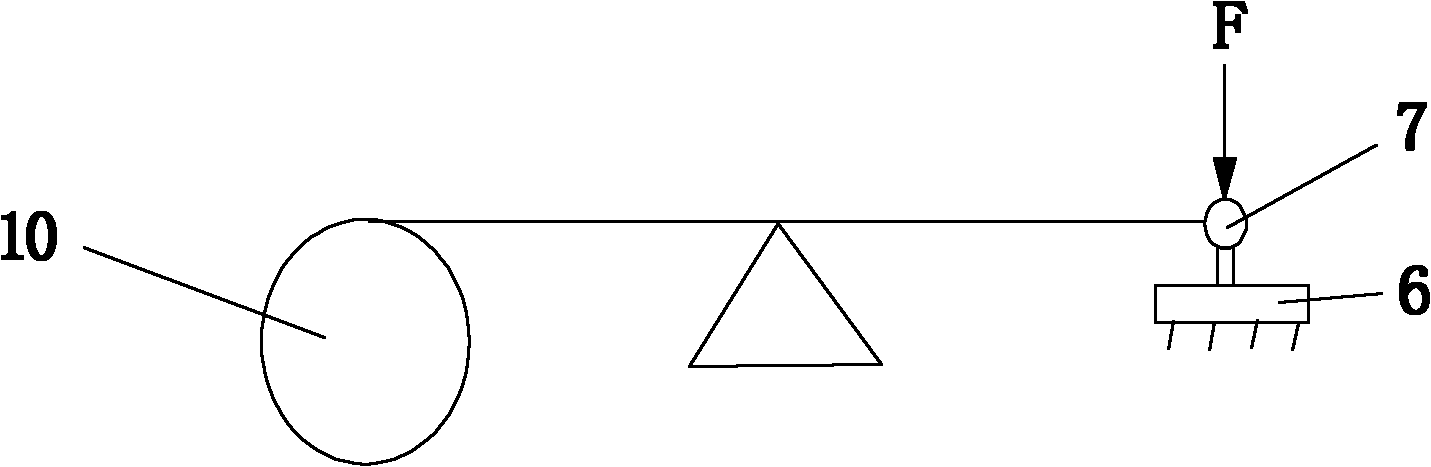

High-precision electronic belt scale and weighing algorithm of same

InactiveCN102322925AHigh sensitivityImprove calculation efficiencyWeighing apparatus for continuous material flowEngineeringLoad cell

The invention relates to a high-precision electronic belt scale and a weighing algorithm of the same. A tensioning structure of the traditional electronic belt scale cannot well maintain constant tension of a belt, and is easy to result in insensitive weighing. The high-precision electronic belt scale comprises a carrier roller, the belt and a motor which are arranged on a machine frame, and is characterized in that: the carrier roller comprises a weighing carrier roller, a primary carrier roller and a secondary carrier roller, the primary carrier roller and the secondary carrier roller are arranged at two ends of the belt, the primary carrier roller is connected with the motor, a speed sensor is connected at the outer part of the secondary carrier roller, a fixed rod is arranged at the lower part of the secondary carrier roller, a steel rope surrounds the secondary carrier roller and the fixed rod in sequence, and is connected with a counterweight block, one end of the steel rope is fixed, a weighing sensor is arranged at the lower part of the weighing carrier roller, and the weighing sensor, the motor and the speed sensor are connected with a controller. In the invention, the load of the weighing sensor can be adjusted to be zero through adjusting the counterweight block, so that the sensitivity of the electronic belt scale is increased; and the weighing sensor only receives a vertical force, and does not receive a tangential force produced during the operation of the belt.

Owner:杭州四五〇九机电设备有限公司

Direct-reading laser height measuring instrument

InactiveCN102889857ASimple structureGood for manufacturing costsOptical rangefindersUsing optical meansDirect readingHorizontal pitch

The invention provides a direct-reading laser height measuring instrument, belonging to height measuring instruments. The direct-reading laser height measuring instrument comprises a base and one fixing leg and two adjustable legs which are below the base as well as a bubble level at the center of a base panel, and is characterized by being provided with a stand column which is vertically fixed on the base; a spindle at the upper end of the stand column is movably sleeved on a dial on the spindle; a reading scale which is calibrated according to a horizontal spacing between the center of the dial and the bottom of a measured object is movably sleeved on a handle at the back of the dial and on the same spindle with the dial; and a laser emitter closing to an edge of the dial and fixed on the handle emits red laser beams in the radial direction of the dial, wherein the red laser beams is close to a dial surface. The reading scale is calibrated in accordance with an equation H=Ltan Alpha+H0, wherein H is a height value of a measured object point, L is the horizontal spacing between the center of the dial and the bottom of the measured object; Alpha is an included angle between a laser beam and a horizontal line, and H0 is a vertical height between the center of the dial and the bottom of the measured object. The trial result shows that the direct-reading laser height measuring instrument is simple, easy and practical, visualized and convenient, and higher in the correctness of a measuring result.

Owner:魏蓝天

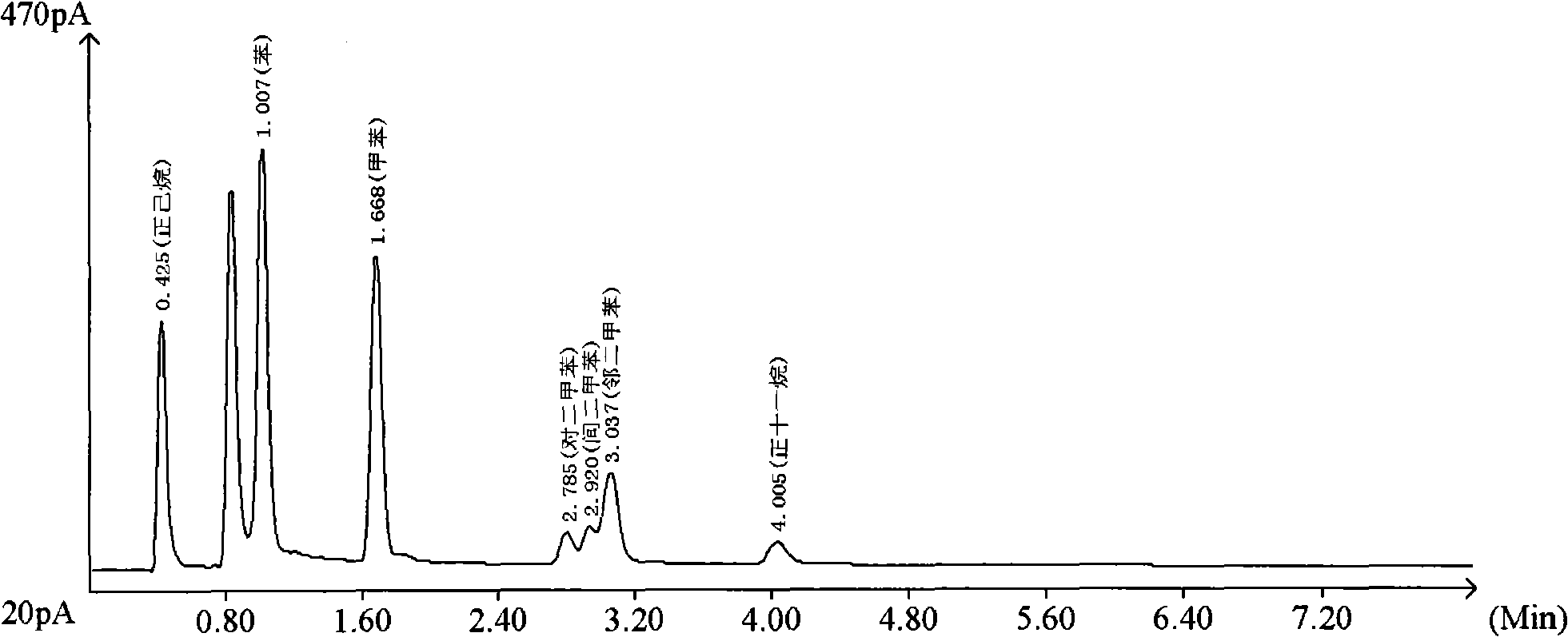

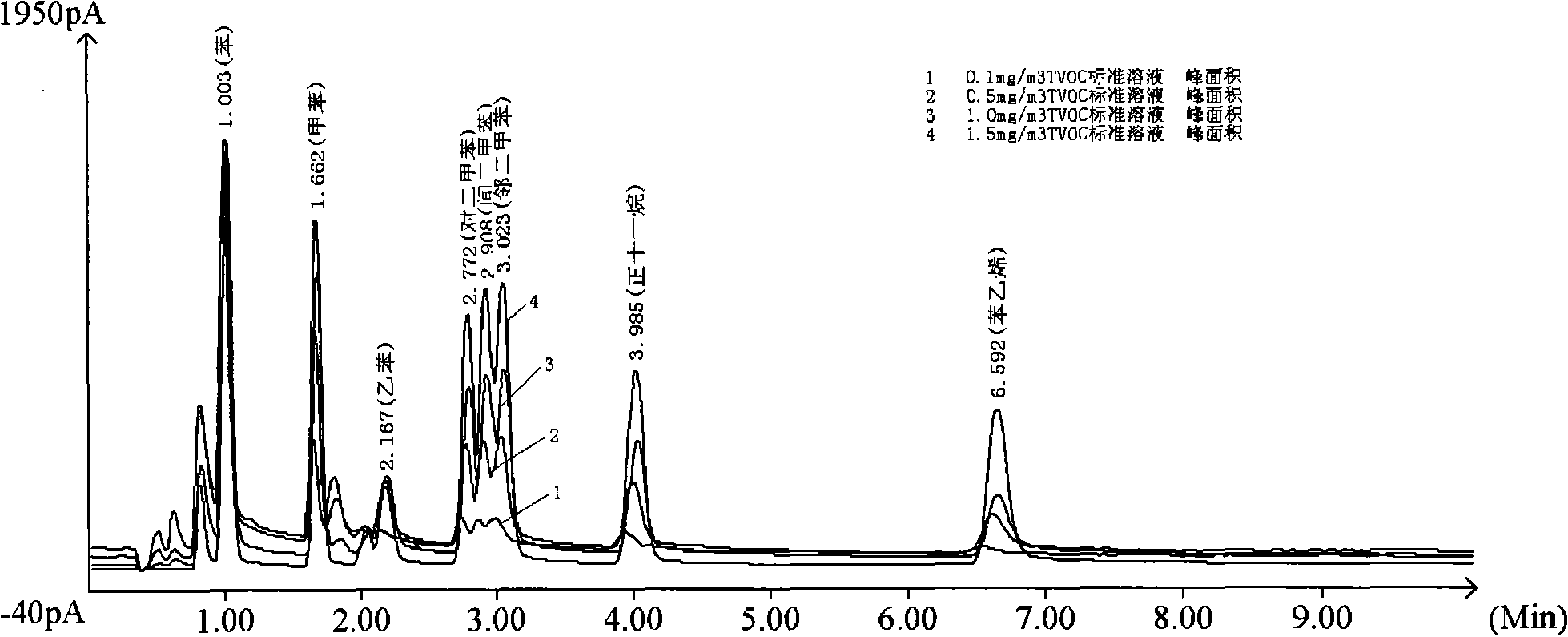

Photoionization gas chromatography detection method of organic volatile compounds in air

InactiveCN101539549AHigh detection sensitivityQuick responseComponent separationGas liquid chromatographicInternal standard

The invention relates to a photoionization (PID) gas chromatography detection method of organic volatile compounds in the air. The n-hexane internal standard method or the standard gas external standard method is used for detection. The detection method is characterized by fast response speed, high sensitivity and low detection limit (not more than 10ppb); the detection method can use a sampler for collecting gas and then directly inject a sample to a chromatograph for test and can also bring the chromatograph to the test site and complete the sampling from the environmental air, the sample injection and the test at one time. The detection method does not need to use a solid sorbent for concentration and does not need to carry out desorption by thermal desorption. Therefore, the detection method simplifies the detection procedure, reduces the system error and the random error caused during the absorption, the desorption and the extraction processes, greatly shortens the detection cycle and leads the detection result to be more accurate.

Owner:KUNMING UNIV OF SCI & TECH

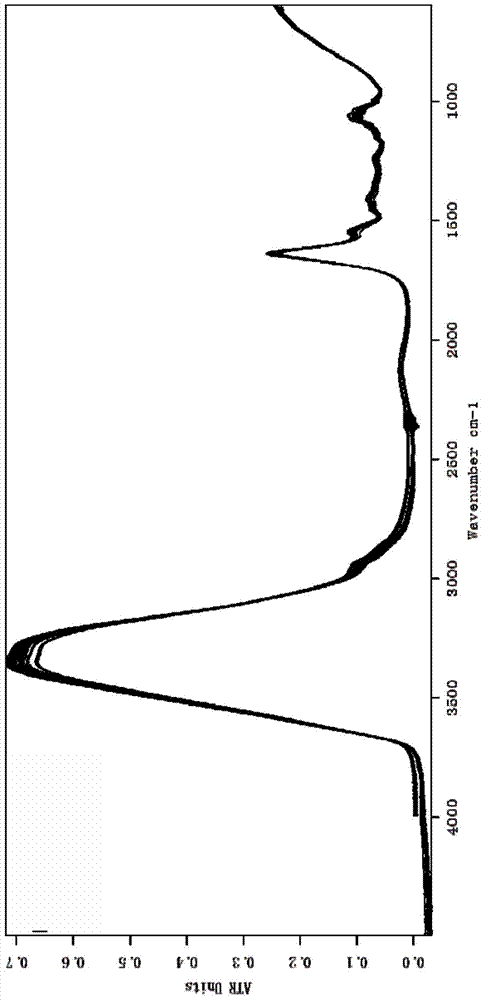

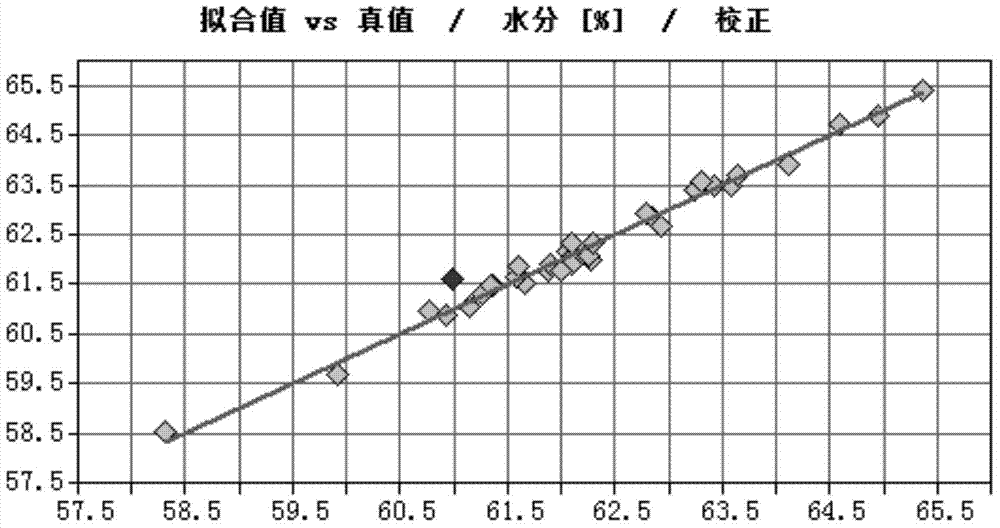

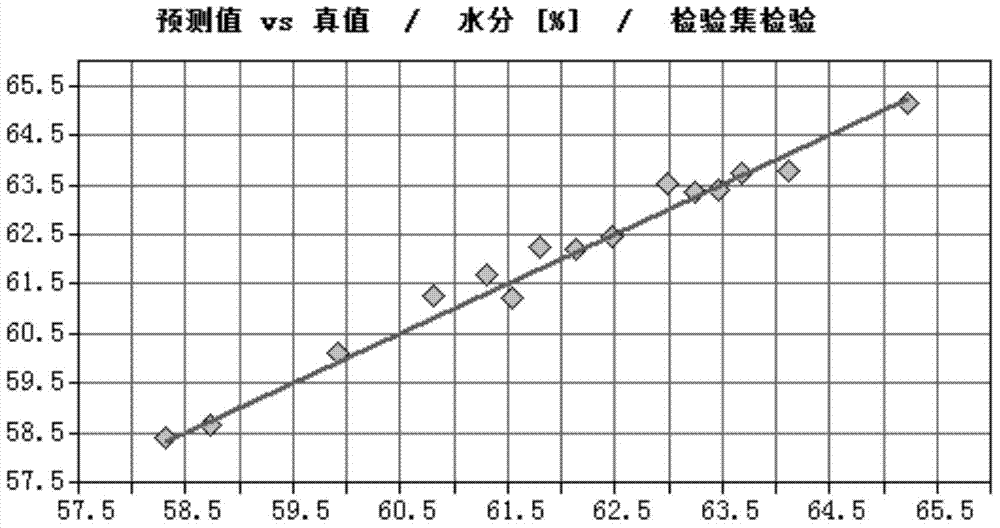

Method for rapid detection of contents of water and protein in royal jelly

ActiveCN104849232AReduce random errorHigh sensitivityMaterial analysis by optical meansPretreatment methodQuantitative model

The invention relates to a method for rapid detection of the contents of water and protein in royal jelly. The method comprises the following steps: 1, determination of the contents of water and protein in a royal jelly sample by using a conventional method; 2, establishment of an infrared spectrum database of the royal jelly sample: a step of scanning the royal jelly sample by using a Fourier transform infrared spectrometer, wherein each sample is scanned 3 times and an average value is taken; 3, selection of a spectral pretreatment method and an optimal modeling band; and 4, establishment of a quantitative model of the water and protein on the basis of optimal parameters. The method provided by the invention has simple operation and low cost and can quickly and reliably predict the contents of water and protein in the royal jelly on the premise that identification accuracy is ensured.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com