Method and apparatus for calibration of laser three-dimensional measuring appliance

A laser three-dimensional measuring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unfavorable weight, large laser measuring head correction, unsuitable laser measuring head, large volume, etc., to overcome optical distortion, The effect of reducing calculation time and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

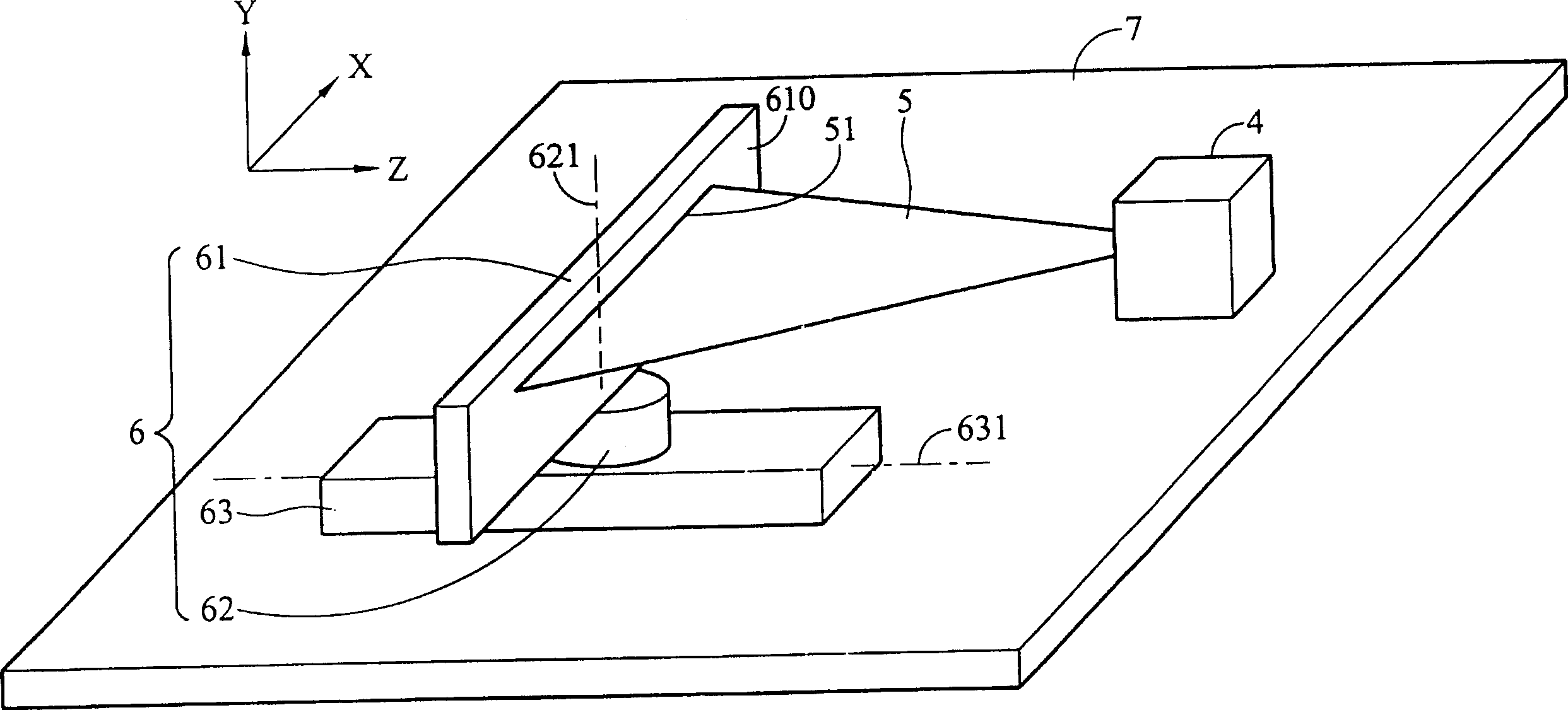

[0038] like figure 2 As shown, the figure shows a schematic diagram of the laser three-dimensional measuring device calibration device of the present invention, wherein the present invention mainly includes a laser measuring head 4 , a laser plane 5 , a calibration mechanism 6 , and a reference plane 7 .

[0039] As shown in the figure, this embodiment defines an X-axis, a Y-axis and a Z-axis of a Cartesian coordinate system in a three-dimensional space. The laser measuring head 4 can emit a laser plane 5, and the laser measuring head 4 and the calibration mechanism 6 are stably placed on the reference plane 7, and the reference plane 7 is parallel to the XZ plane as shown in the figure. .

[0040] In addition, the laser measuring head 4 has the function of sensing light, and can thereby generate a two-dimensional digital image 8 (such as Figure 3B shown); in general, the laser measuring head 4 can be connected to a computer (not shown) for storing digital image data and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com