Patents

Literature

996results about How to "Simplify the calibration process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

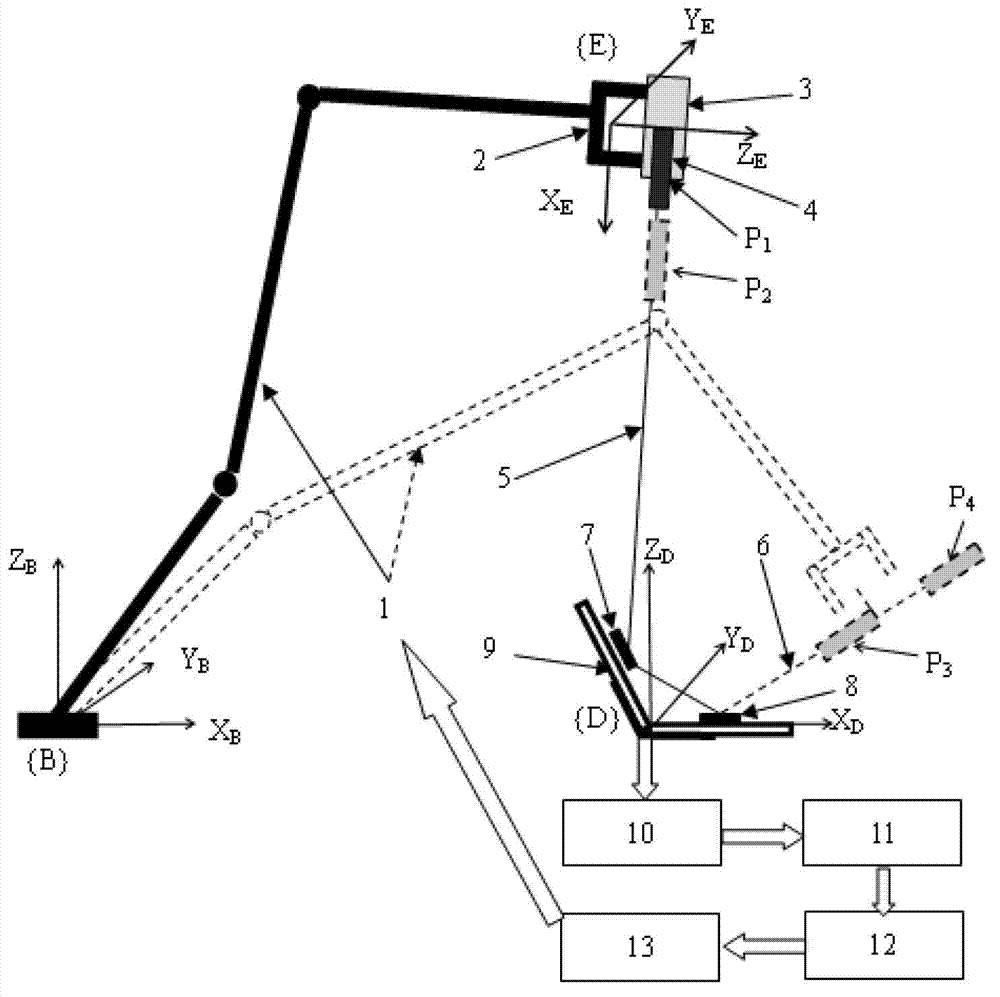

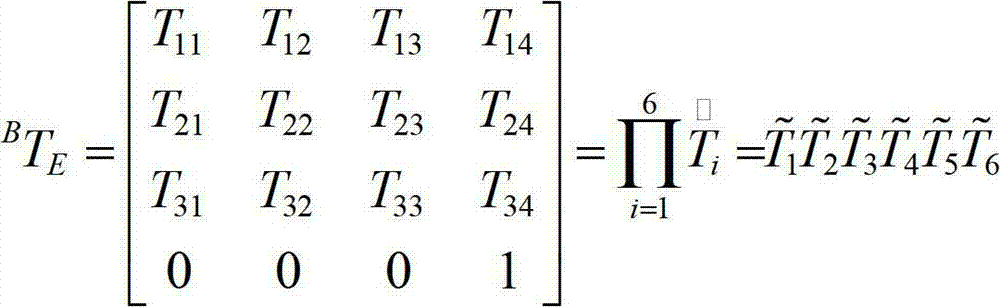

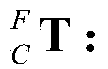

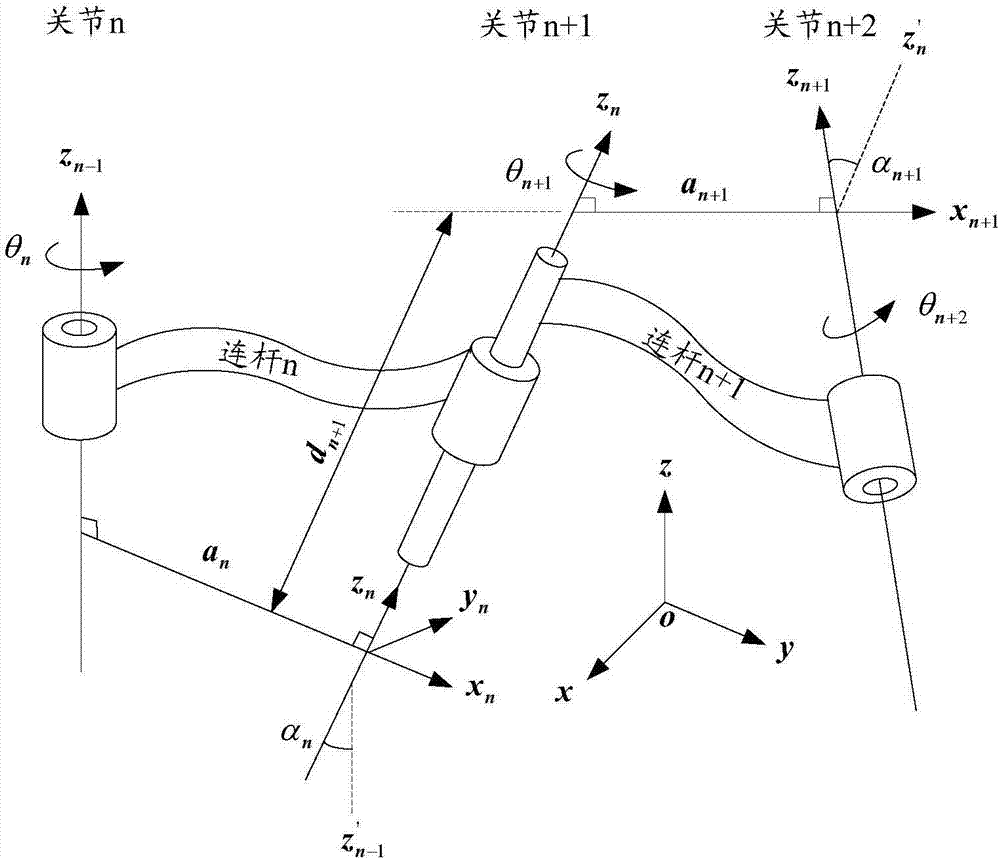

Automatic calibration apparatus for robot tool coordinate system based on laser tracking measurement and method thereof

InactiveCN102087096AAutomated calibration meetsSimplify the calibration processUsing optical meansSimulationCalibration result

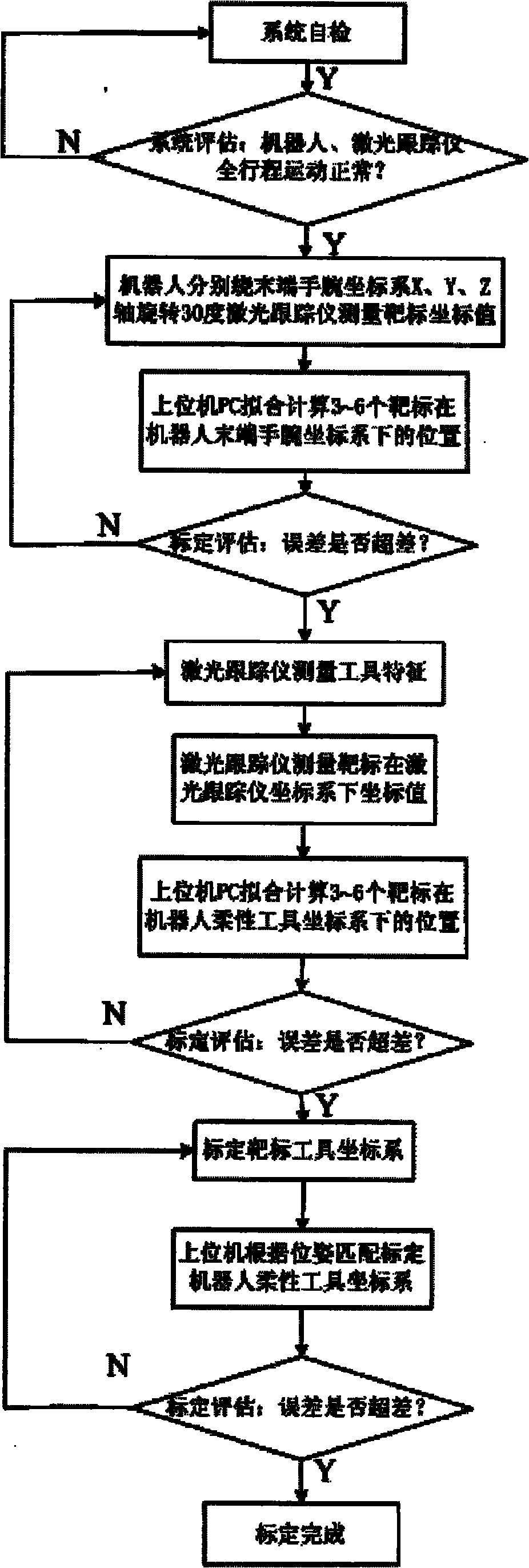

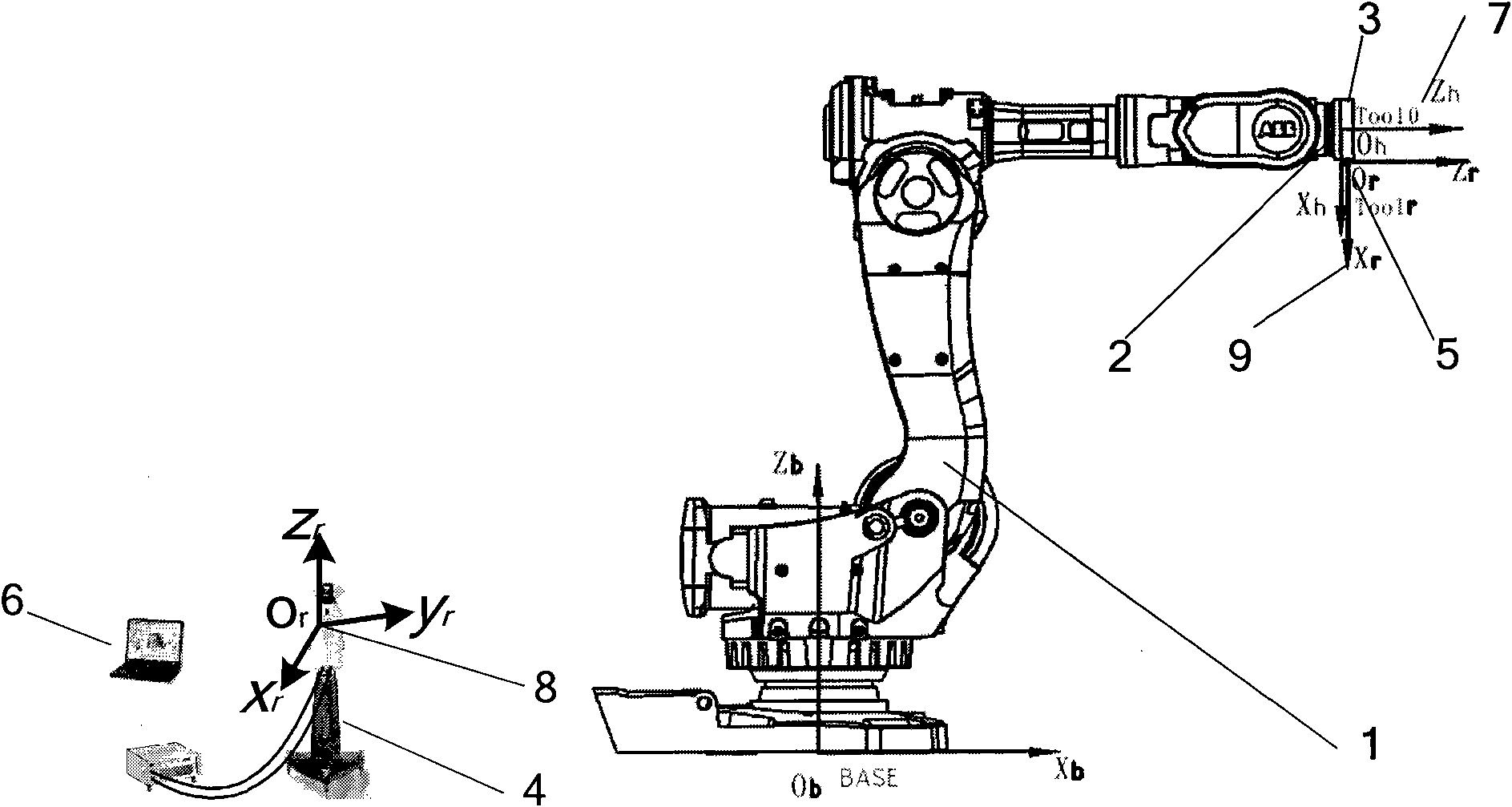

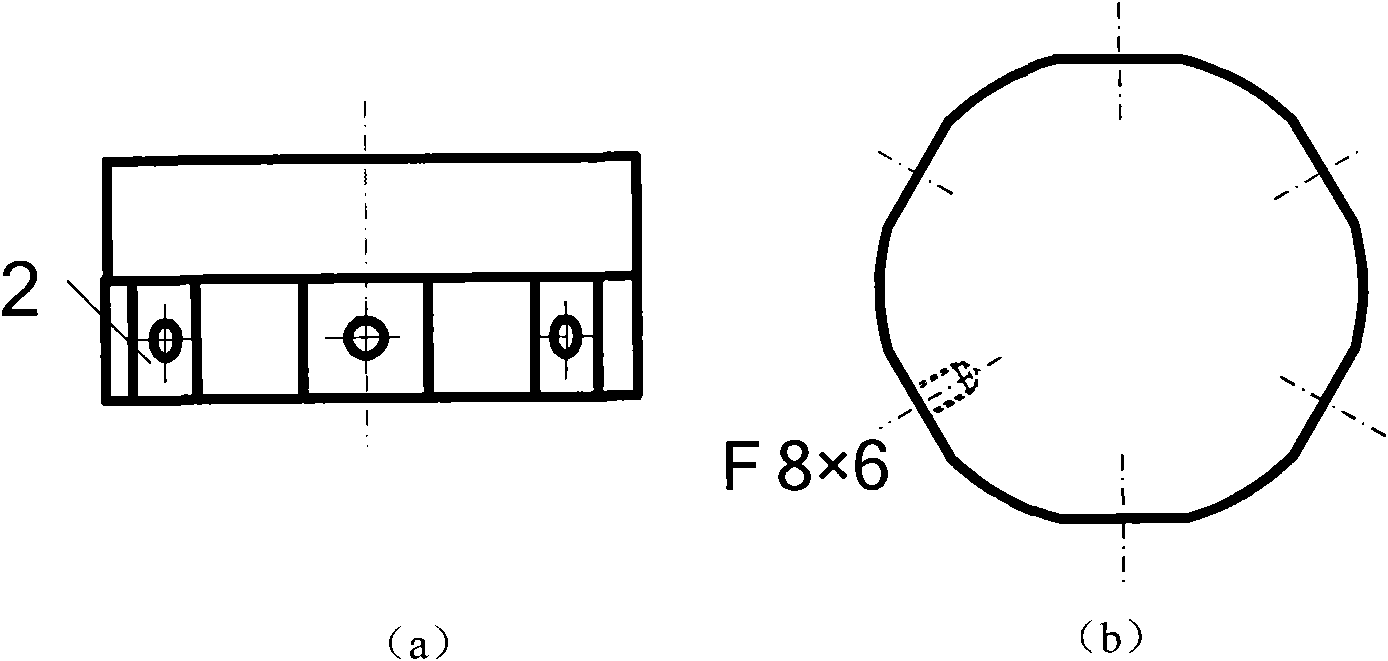

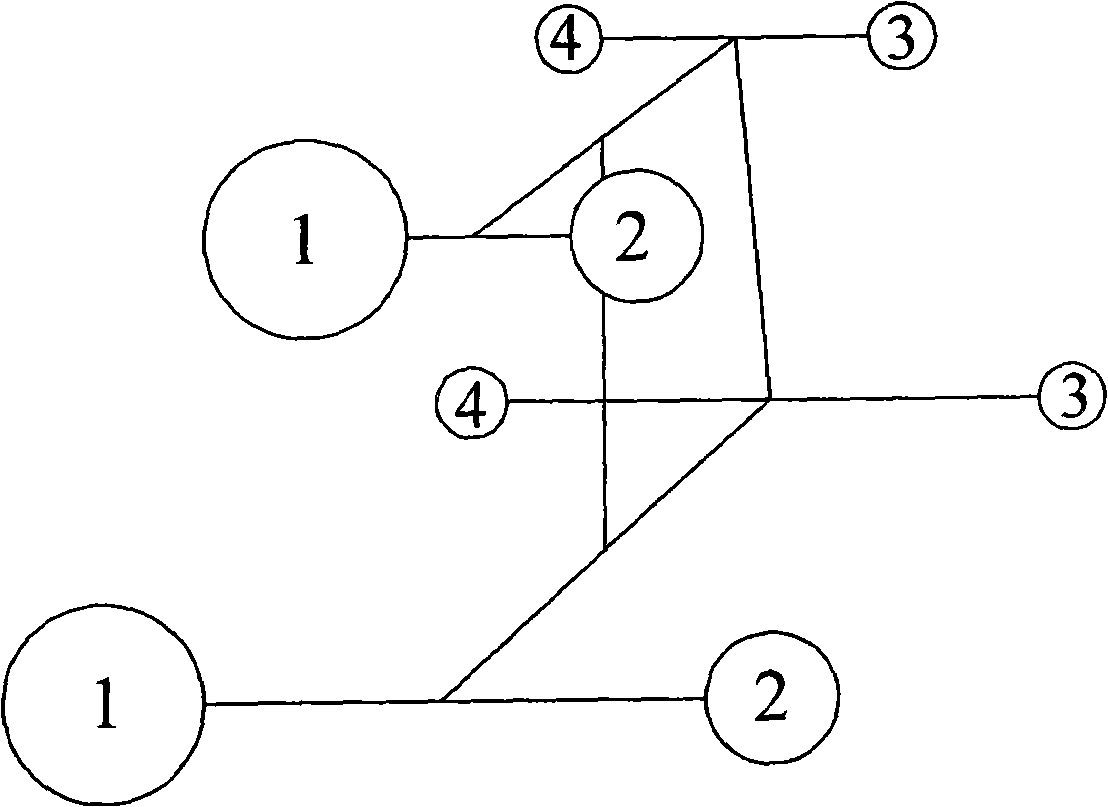

The invention discloses an automatic calibration apparatus for a robot tool coordinate system based on laser tracking measurement and a method thereof, wherein the apparatus comprises a robot, a target flange, target installing holes, a laser tracker, a tool and a host computer; the robot is provided with the target flange and the tool; the target flange is provided with six target installing holes; and the external side of the robot is provided with the laser tracker and the host computer. According to the method of the invention, the robot tool coordinate system is calibrated by matching, analyzing and calculating the position relations of three to six targets in a robot end wrist coordinate system and in the robot tool coordinate system. The apparatus and the method provided by the present invention have the advantages that the robot tool coordinate system can be automatically calibrated; calibration operation is simple and is high in precision and high efficiency; calibration results are reliable; and digitalized modeling and digitalized calibrating are realized and the tool possesses versatility when being replaced.

Owner:ZHEJIANG UNIV

Multiple video cameras synchronous quick calibration method in three-dimensional scanning system

A synchronous quick calibration method of a plurality of video cameras in a three-dimensional scanning system, which includes: (1) setting a regular truncated rectangular pyramid calibration object, setting eight calibration balls at the vertexes of the truncated rectangular pyramid, and respectively setting two reference calibration balls at the upper and lower planes; (2) using the video cameras to pick-up the calibration object, adopting the two-threshold segmentation method to respectively obtain the corresponding circles of the upper and lower planes, extracting centers of the circles, obtaining three groups of corresponding relationships between circle center points in the image and the centres of calibration ball in the space, solving the homography matrix to obtain the internal parameter matrix and external parameter matrix and obtaining the distortion coefficient, taking the solved video camera parameter as the initial values, and then using a non-linear optimization method to obtain the optimum solution of a single video camera parameter; (3) obtaining in sequence the external parameter matrix between a plurality of video cameras and a certain video camera in the space, using the polar curve geometric constraint relationship of the binocular stereo vision to establish an optimizing object function, and then adopting a non-linear optimization method to solve to get the optimum solution of the external parameter matrix between two video cameras.

Owner:NANTONG TONGYANG MECHANICAL & ELECTRICAL MFR +1

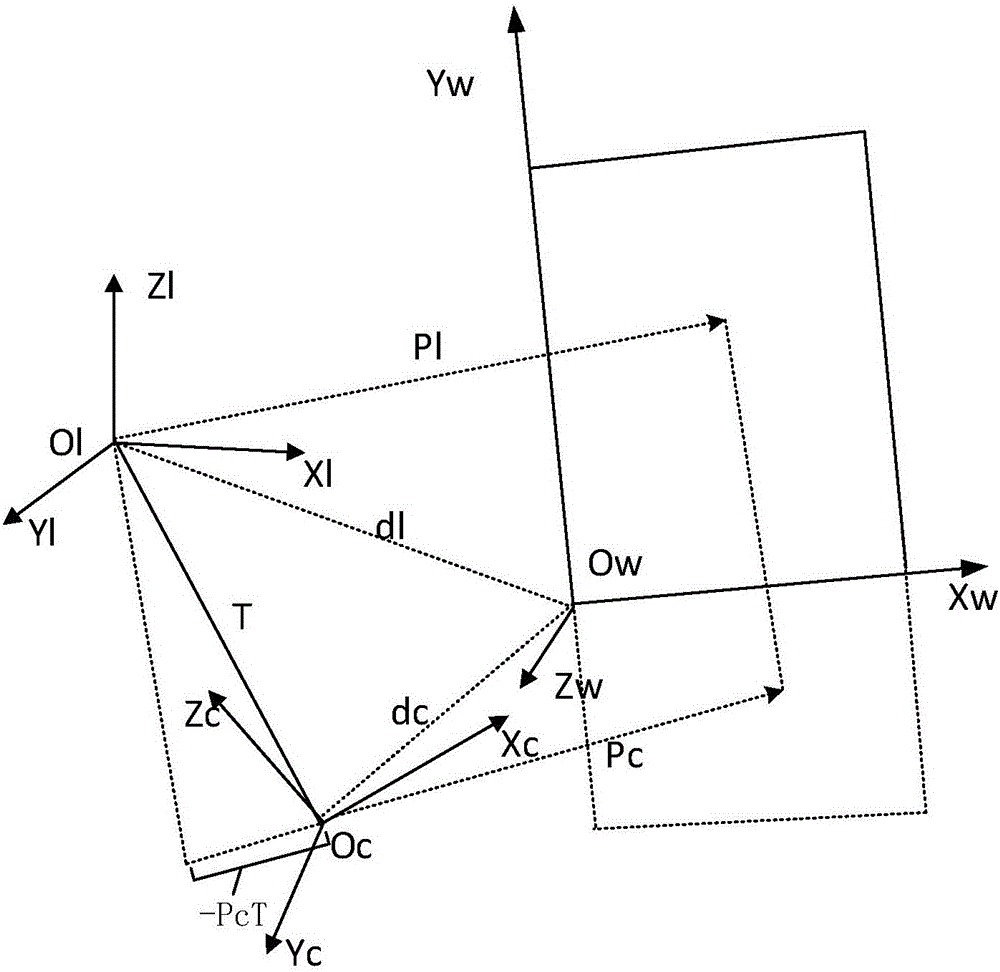

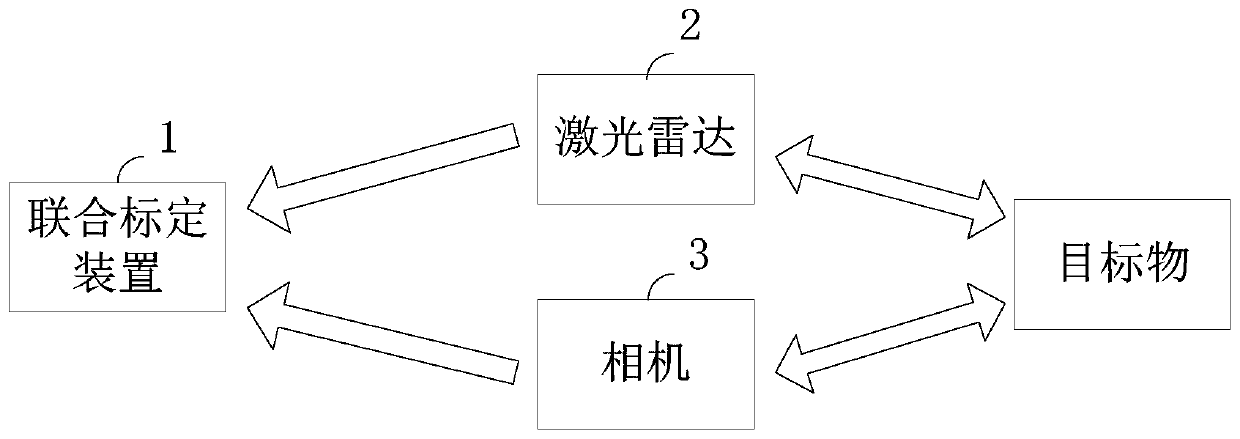

A joint calibration method of a 3D lidar and a monocular camera

InactiveCN106228537ASimplify the calibration processFast calibrationImage analysisCalibration resultCorrespondence principle

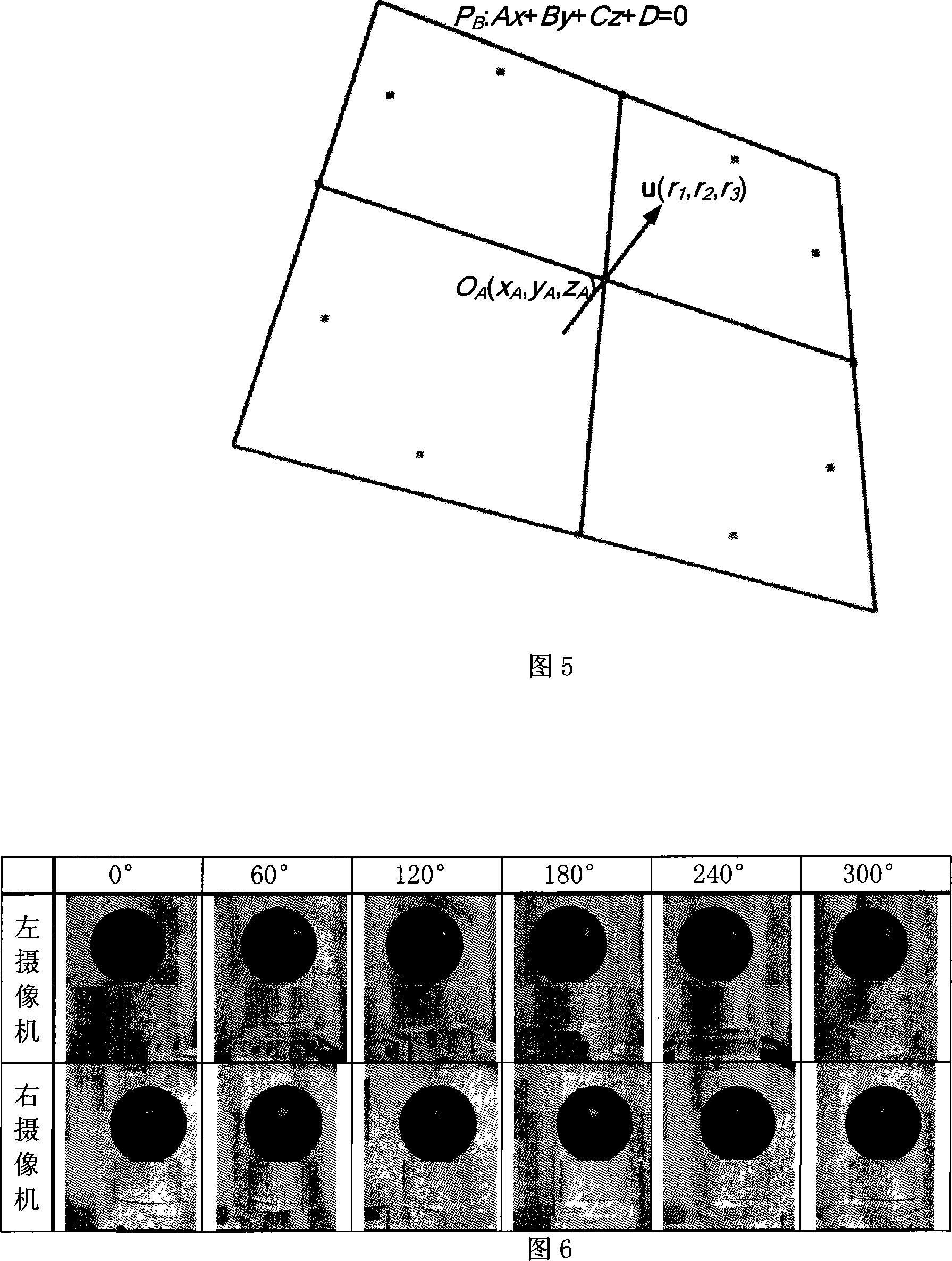

The invention relates to a joint calibration method of a 3D lidar and a monocular camera, and belongs to the field of information fusion. The invention aims at improving the calibration efficiency under the requirement of ensuring the joint calibration accuracy of multi-sensor information fusion. Firstly, the monocular camera is calibrated, and then a normal vector of a target calibration plate in a monocular camera coordinate system, the distance from the target calibration plate to the origin in the monocular camera coordinate system, a normal vector of a fitting plane in a 3D lidar coordinate system and the distance from the origin to the fitting plane in the 3D lidar coordinate system are respectively solved at each position. Then, the results of the joint calibration are solved by using the distance correspondence principle. Finally, the result of the joint calibration is taken as the initial value into an optimization objective function to obtain the optimal joint calibration result. The joint calibration method of the invention greatly reduces human participation, reduces random errors caused by complicated man-made operation, simplifies the process of multi-sensor joint calibration and improves the precision of the calibration.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

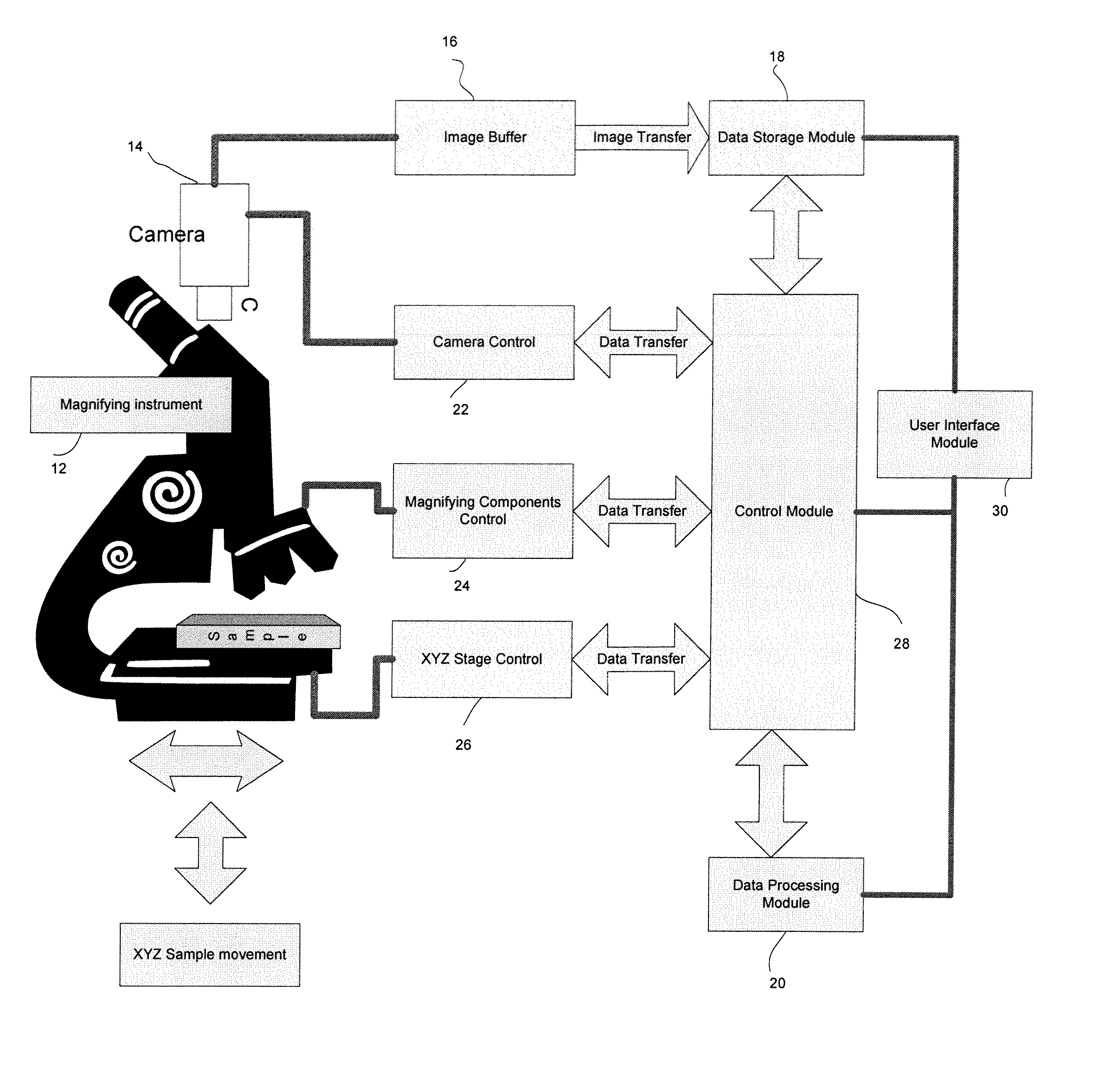

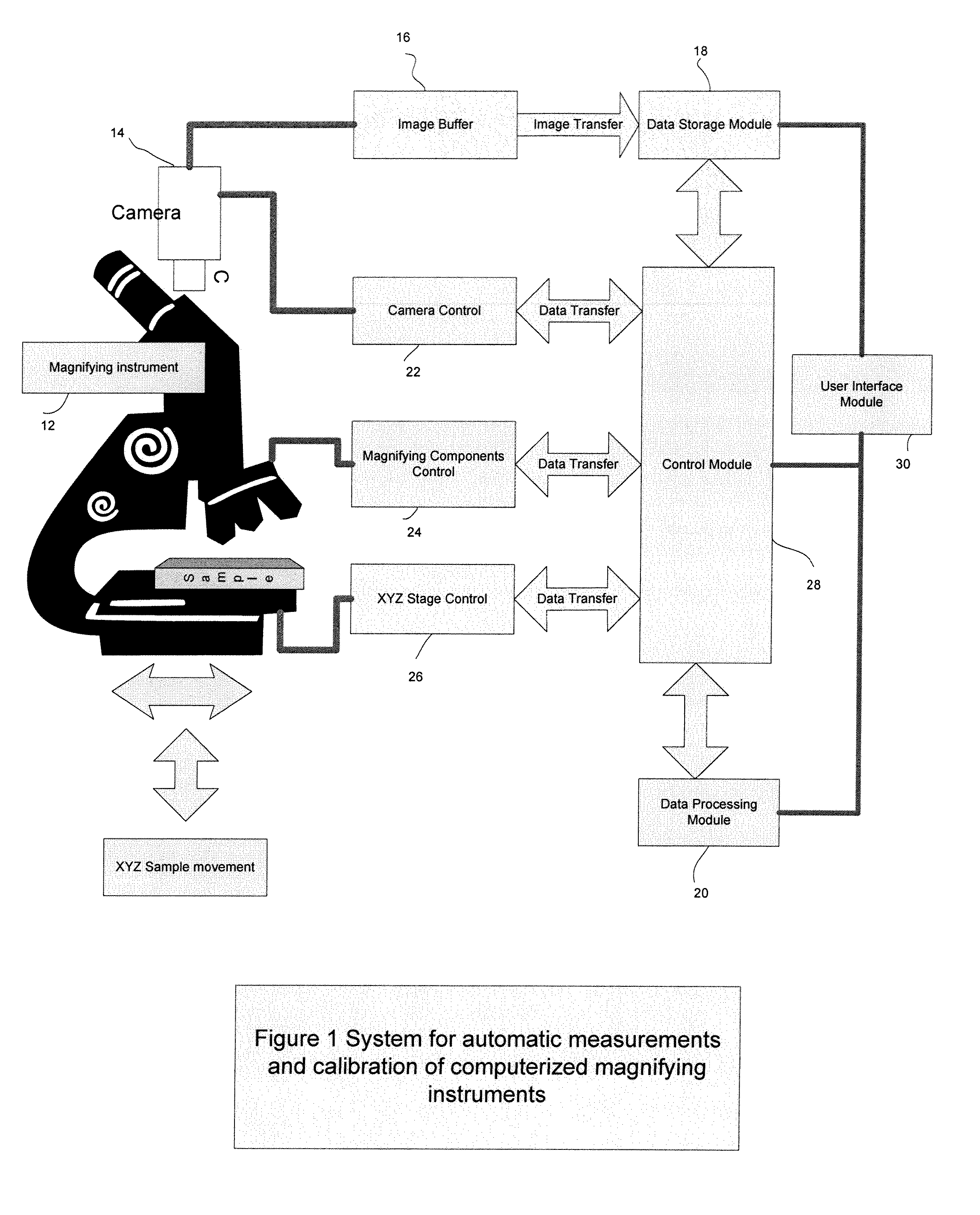

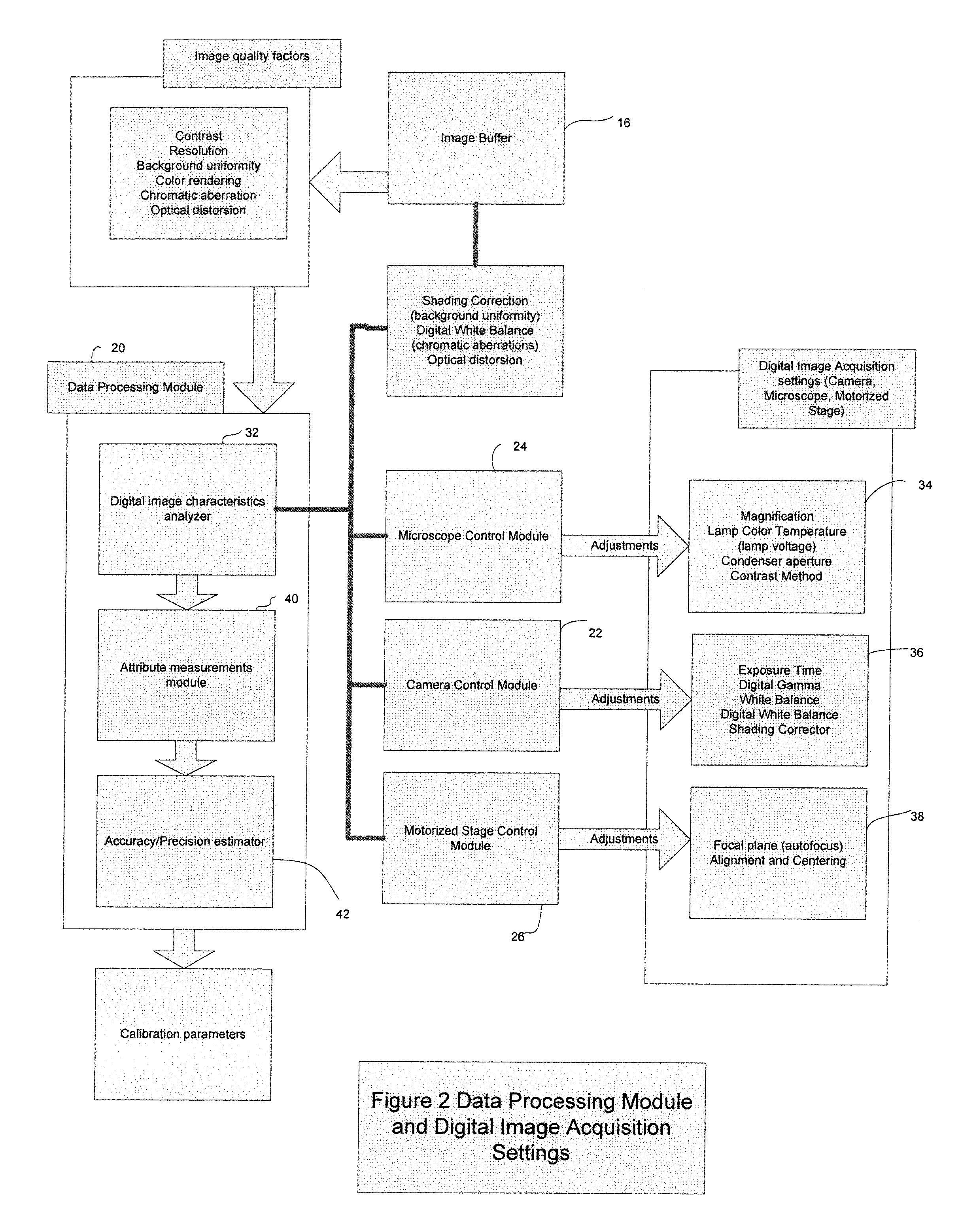

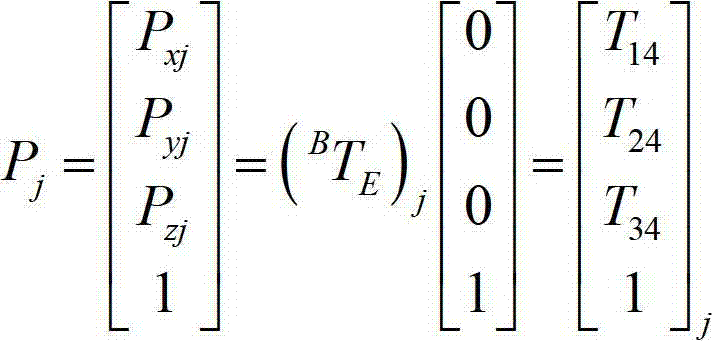

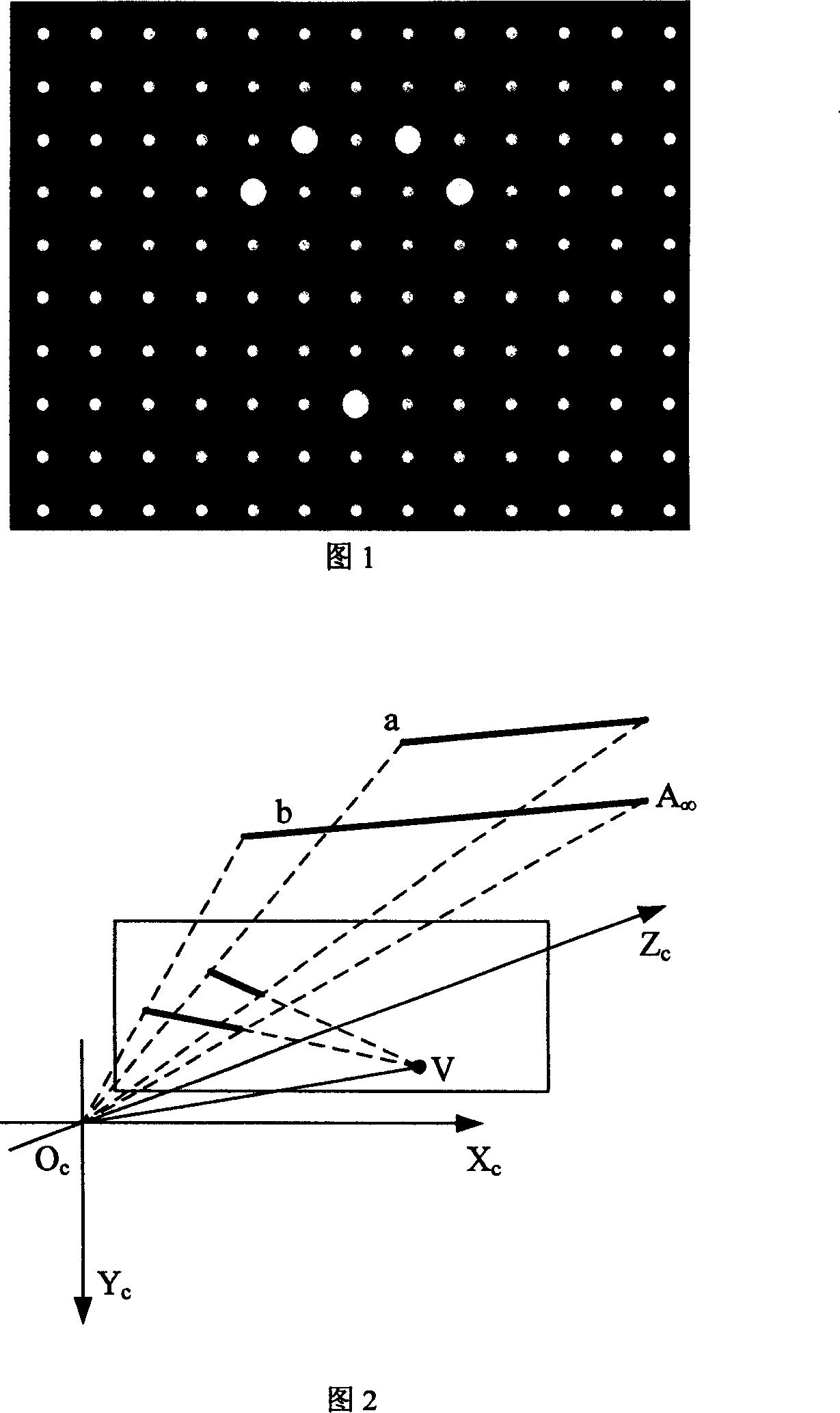

System and method for automatic measurements and calibration of computerized magnifying instruments

ActiveUS20070211243A1Not easy to make mistakesSimplify the calibration processImage enhancementPhotometry using reference valueIdentification deviceDigital image

The present invention relates to a system and method for automatic measurements and calibration of computerized magnifying instruments. More particularly, the method includes an automatic calibration aspect, which includes obtaining an optimized digital image of a reference object including at least one standardized landmark feature, and establishing calibration parameters based on one or more measured attributes of the landmark feature. The method further desribes a calibration aspect, which includes providing calibration parameters, obtaining a digital image including at least one known attribute, measuring the at least one known attribute and comparing the measured value with the known value. The method further includes an aspect of automatic measurement of an attribute of one or more object, which includes retrieving calibration parameters, acquiring a digital image and measuring the attribute. The system includes an object support, a reference object including one or more standardized landmark features, and an automatically readable identification means.

Owner:CLEMEX TECH

PSD (Position Sensitive Detector)-based industrial robot self-calibration method and device

InactiveCN102825602ASimple structureLow priceProgramme-controlled manipulatorUsing optical meansLight spotLaser beams

The invention discloses a PSD (Position Sensitive Detector)-based industrial robot self-calibration device, wherein two PSDs are arranged on two plates of a V-shaped clamp respectively; the V-shaped clamp is placed in an achievable range of a robot; when the robot is at different positions, a projection light spot and a reflection light spot of a laser beam emitted by a laser which is fixedly arranged at the tail end of the robot are positioned at positions of central points of the two PSDs respectively; and self-calibration of zero offset of the robot and self-calibration of a spatial posture are performed through two virtual constraint lines. The self-calibration device has a simple structure and is easy to mount and operate and high in positioning accuracy, and the self-calibration of the spatial posture and the zero offset of the robot can be simultaneously realized; and the invention also provides a PSD-based industrial robot self-calibration method.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

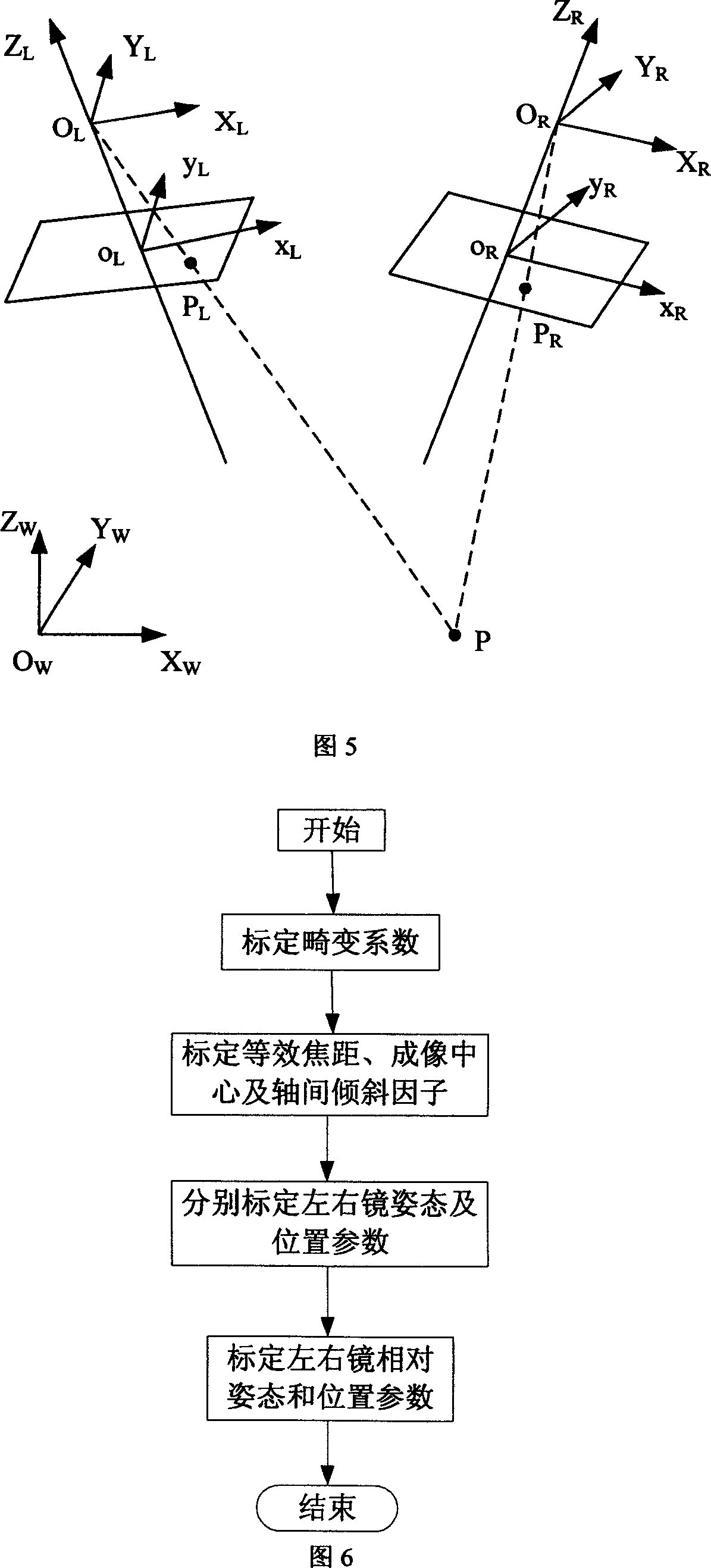

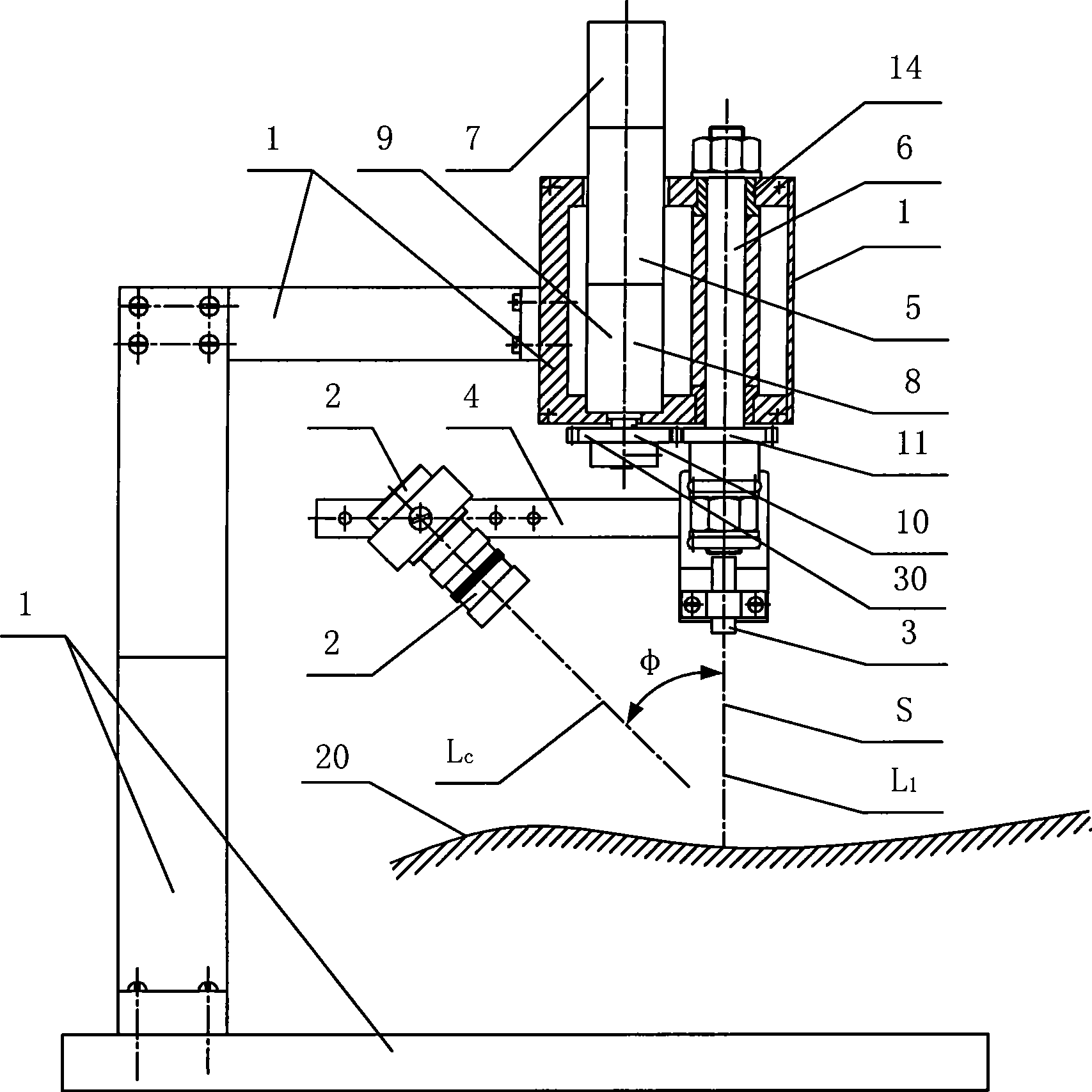

Double-camera calibrating method in three-dimensional scanning system

InactiveCN101021947AAchieve full linear calibrationHigh speedImage analysisTelevision systemsImage correctionVisual perception

This invention relates to a double-vidicon calibration method in a three-D scan system including: calibrating aberration coefficient first, then correcting the pick-up image utilizing the aberration coefficient to calibrate the internal parameter of the vidicon combined with an deal pinhole perspective model, and the parameter includes an imaging center, slant factors among axeses and equivalent focuses, finally calibrating the outside parameters of the right and left vidicons based on the internal parameter and further utilizing the outer model of the double vidicons to calibrate relative outside parameters of the two vidicons to get the internal and outside parameters.

Owner:海安江理工技术转移中心有限公司 +1

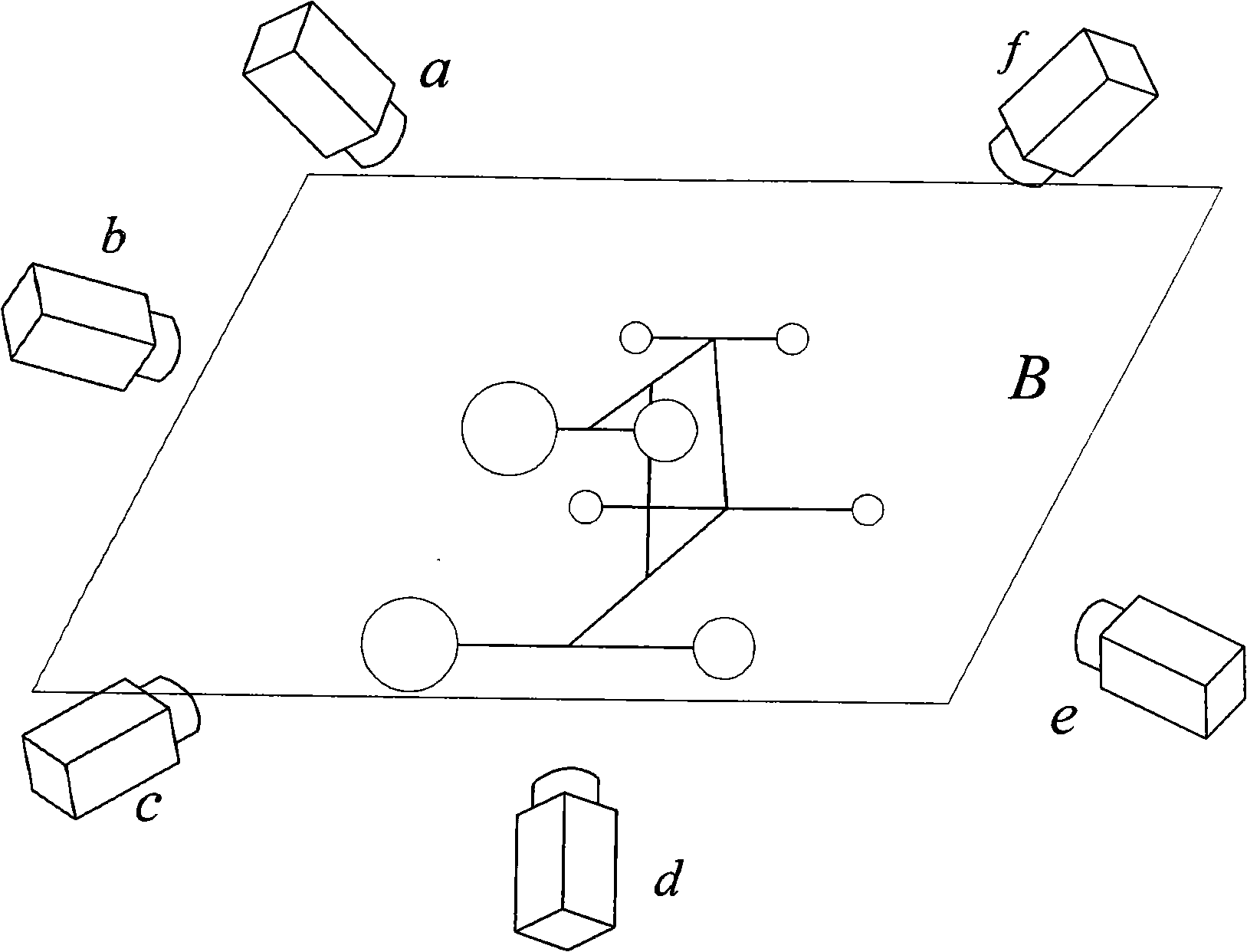

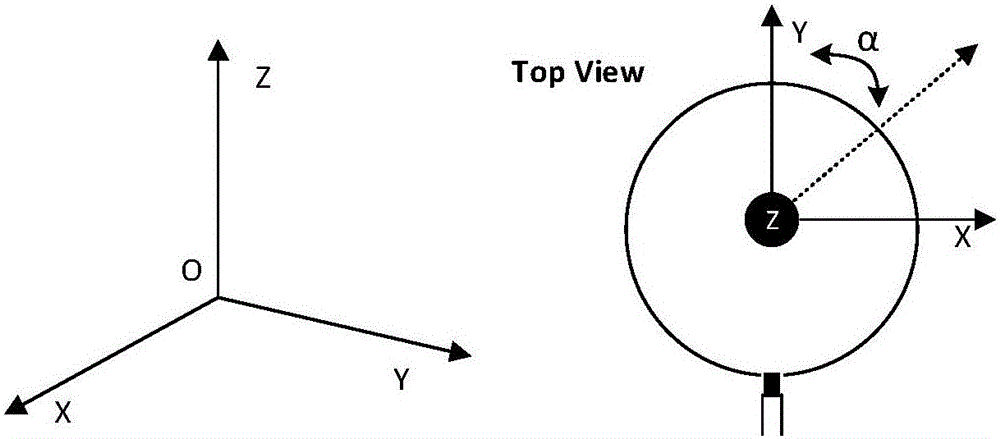

Line-shaped laser vertical rotation type three-dimensional appearance measuring apparatus and method thereof

InactiveCN101476881AAvoid inconvenienceHigh precisionUsing optical meansRotational axisMeasurement device

The invention relates to a device and a method for measuring a horizontal laser vertically rotary three-dimensional shape, and belongs to the technical field of computer vision measurement. The device comprises a base, a camera, a horizontal laser, a motor, a rotational axis, an angle measuring element, a driving circuit, a switching circuit and a controller, wherein the camera and the horizontal laser are fixedly connected with the rotational axis of which a central line is positioned in a laser plane of the horizontal laser; the included angle between an observation plane formed by the central line of the rotational axis and a focal center of a lens and the laser plane is between 80 and 100 DEG; and the included angle between the central line of the rotational axis and an optical axis of the lens is between 40 and 50 DEG. The device can detect edge information in various directions, realize high-precision measurement of the three-dimensional shape of object surfaces, and avoid the inconvenience caused by rotation of objects in the prior method, has a simple structure, low cost and high measurement precision, and is suitable for surface detection of the objects with various dimensions.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

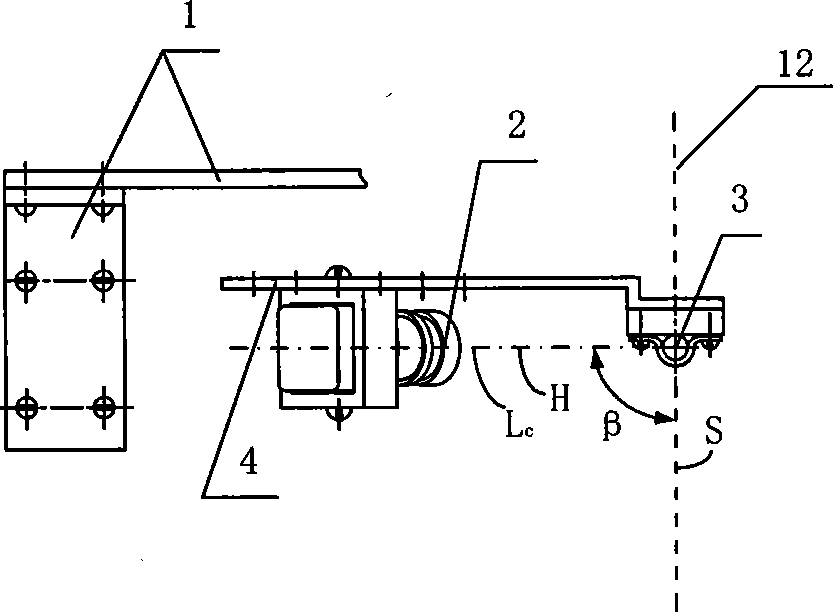

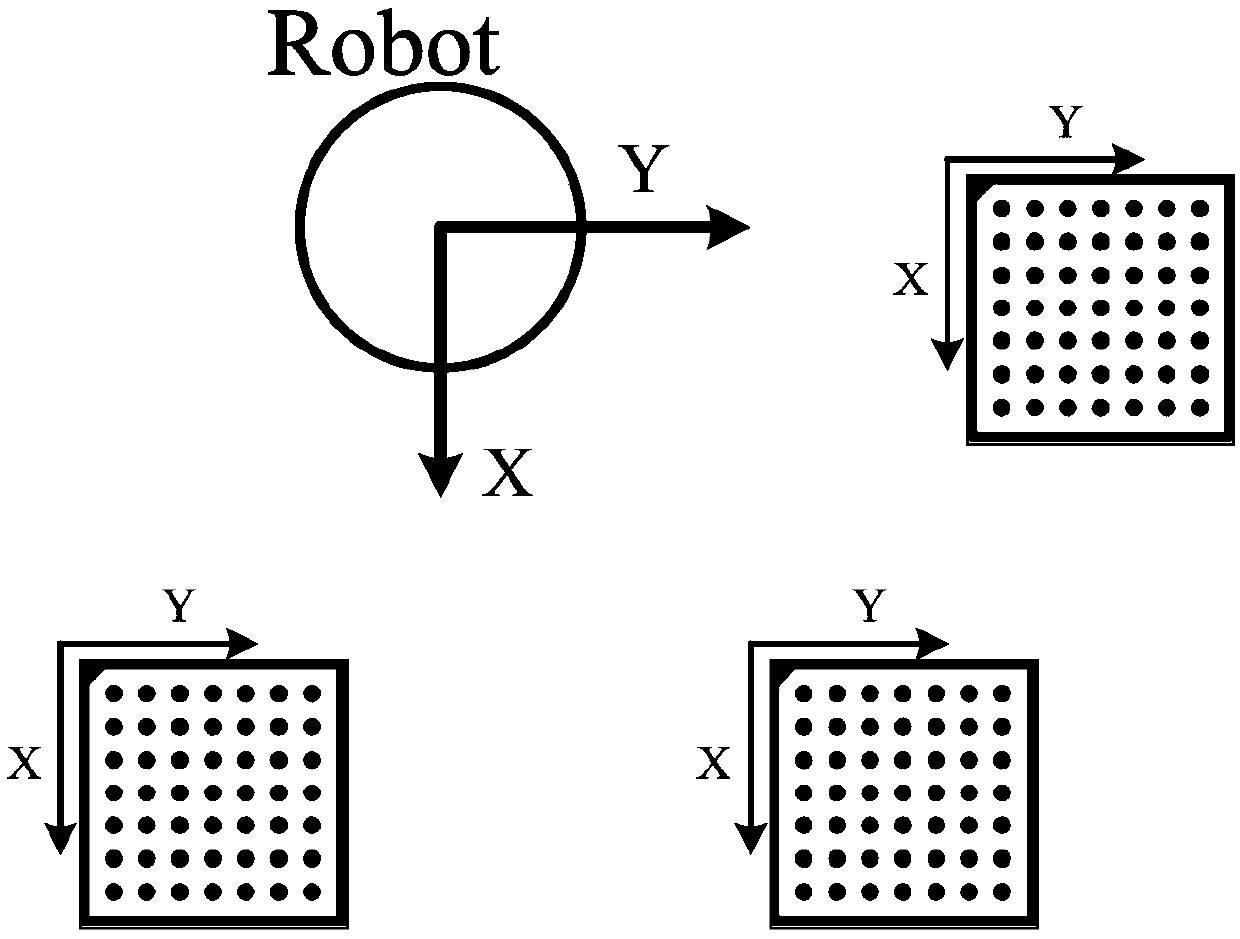

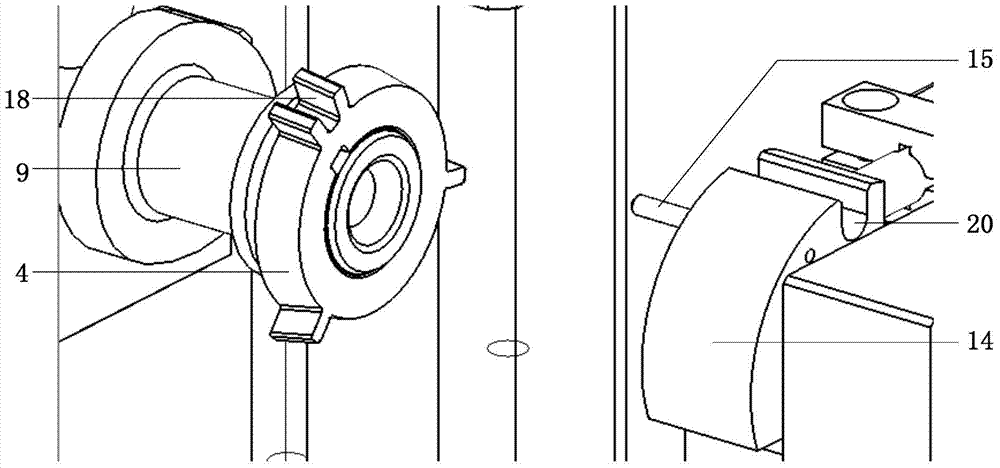

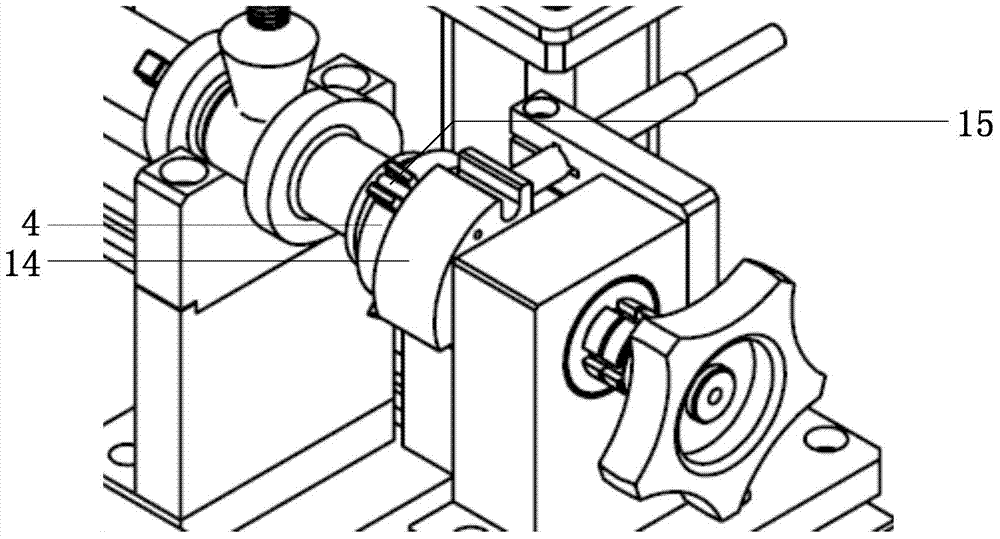

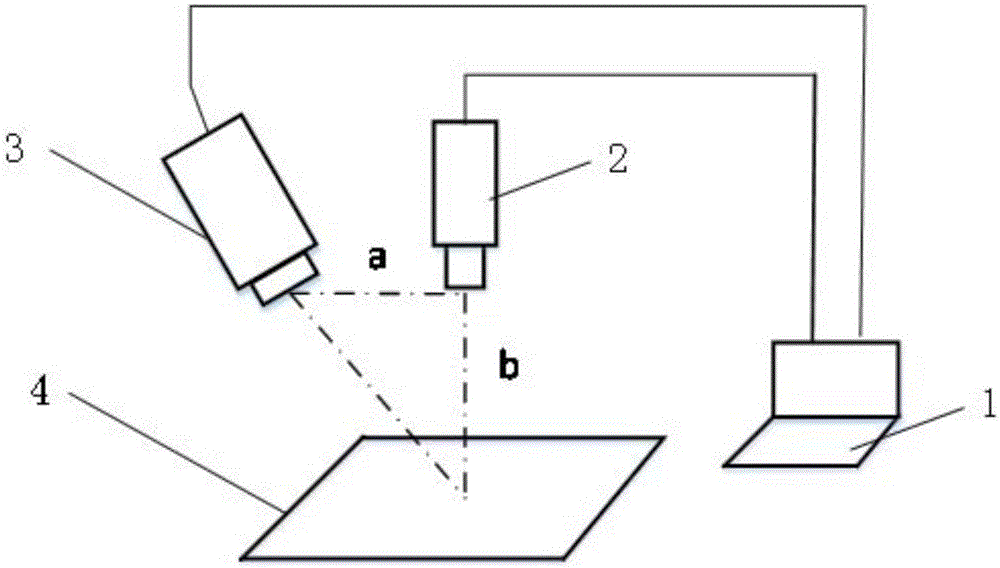

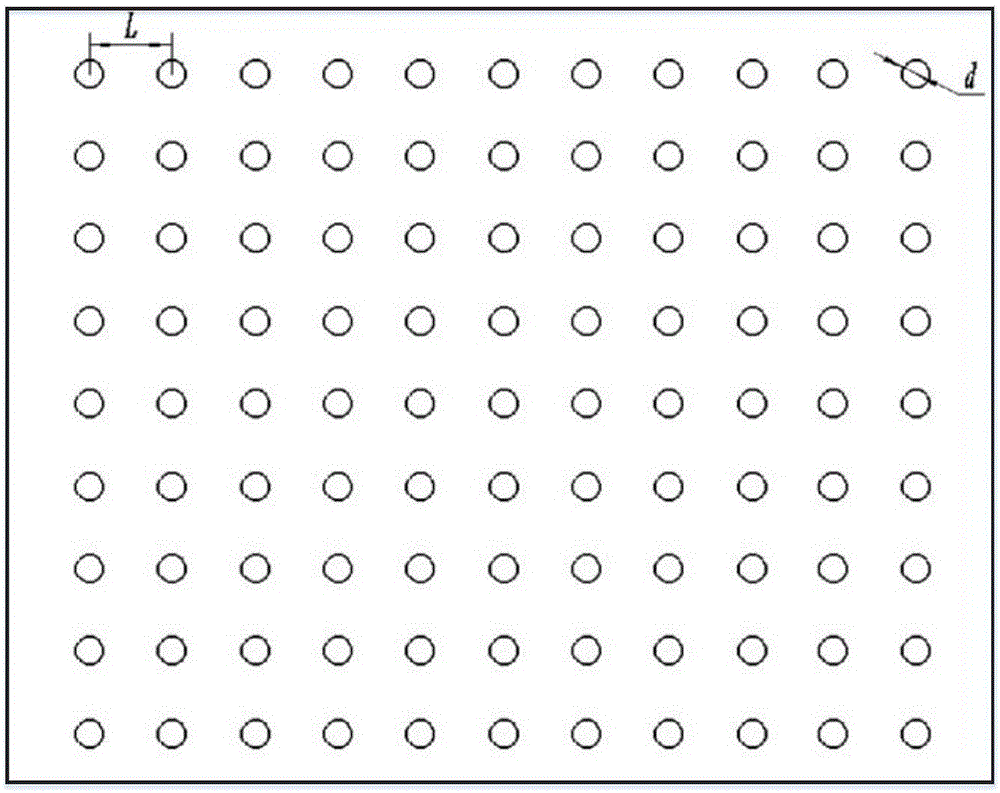

Calibration method and device for robot hole forming platform vision measurement system

ActiveCN103991006ASimple structureEasy to processAutomatic control devicesMeasurement/indication equipmentsIntrinsicsDepth direction

The invention discloses a calibration device for a robot hole forming platform vision measurement system, and further discloses a calibration method based on the calibration device. The method comprises the steps of building a calibration plate coordinate system and a tool coordinate system according to a calibration plate, building a two-dimensional transformation relation of the calibration plate coordinate system and the tool coordinate system on a calibration plate locking face according to the geometric positional relation of a middle hole and a spindle hole of a none-hole array, building a camera coordinate system on a calibration plate shooting face, conducting calibration on camera intrinsic parameters and calculation on camera external parameters according to a nine-hole array image shot by a camera, building a two-dimensional transformation relation of the camera coordinate system and the calibration plate coordinate system on the calibration plate locking face, thereby obtaining a two-dimensional hand-eye relation of the camera coordinate system and the tool coordinate system on the calibration plate locking face, and then obtaining a three-dimensional hand-eye relation between the camera coordinate system and the tool coordinate system by combining distance information, obtained through measurement of a camera coordinate system original point in the hole forming depth direction with distance information, obtained through measurement, of a tool coordinate system original point.

Owner:ZHEJIANG UNIV

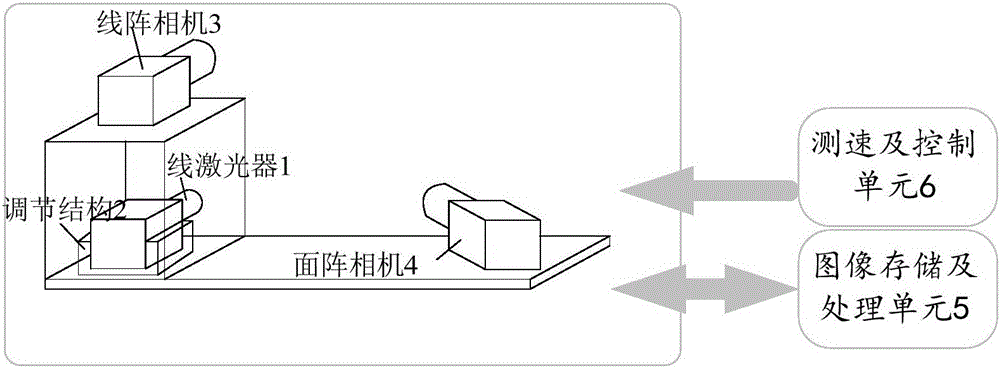

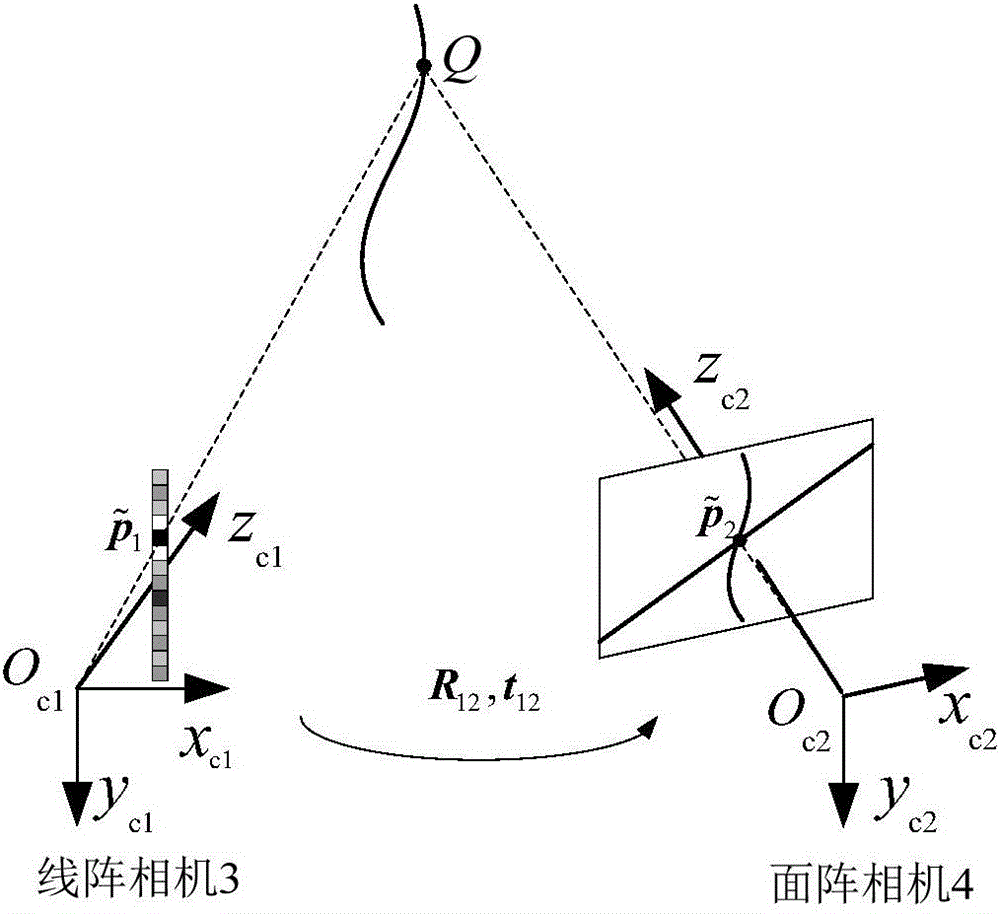

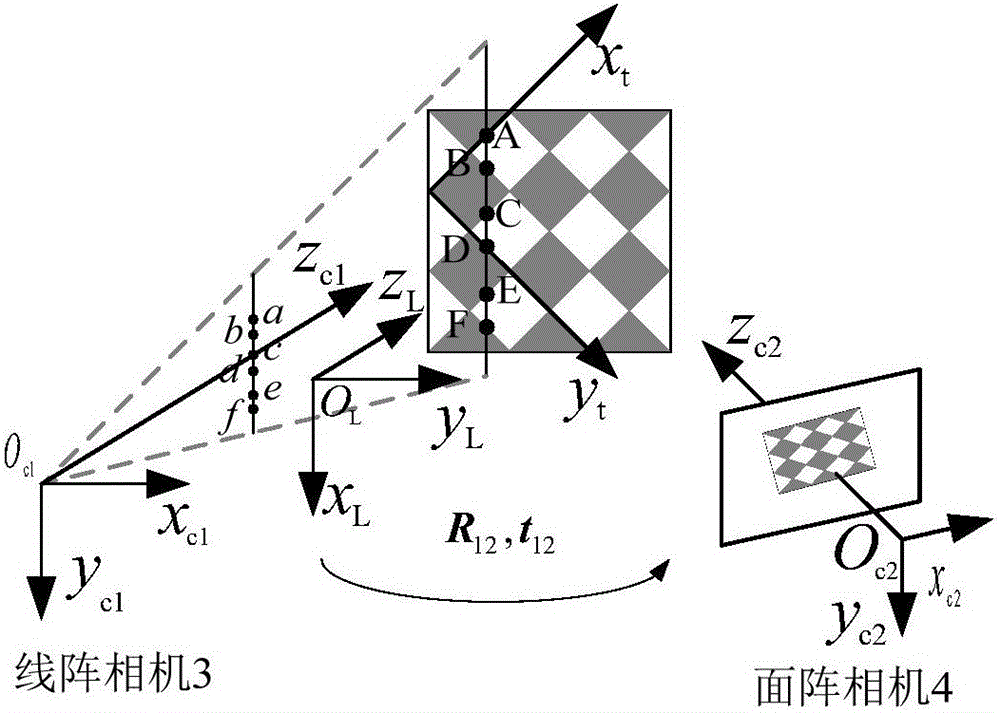

Stereo vision sensor integrates line array camera and area array camera and calibration method

ActiveCN106289106ARealize 3D reconstructionFast frame rateUsing optical meansObject detectionVision sensor

The invention discloses a stereo vision sensor integrates a line array camera and an area array camera and a calibration method. The vision sensor can synchronously acquire gray and depth information of an object image. The sensor mainly comprises the line array camera, the area array camera, a laser and other accessories. The line array camera acquires a clear image through line laser illumination, and forms the stereo vision sensor with the area array camera. The line laser is used as the feature of the area array camera image, matches an epipolar constraint to realize corresponding matching of the line array camera and the area array camera image. Three-dimensional coordinate reconstruction is realized through a stereo vision measurement model. The sensor can simultaneously acquire the image information of the object and the spatial depth information corresponding to each pixel in a push-scan manner. The stereo vision sensor provided by the invention can be widely applied to the fields of object recognition, fault diagnosis and the like.

Owner:BEIHANG UNIV

Joint calibration method and device, electronic equipment and storage medium

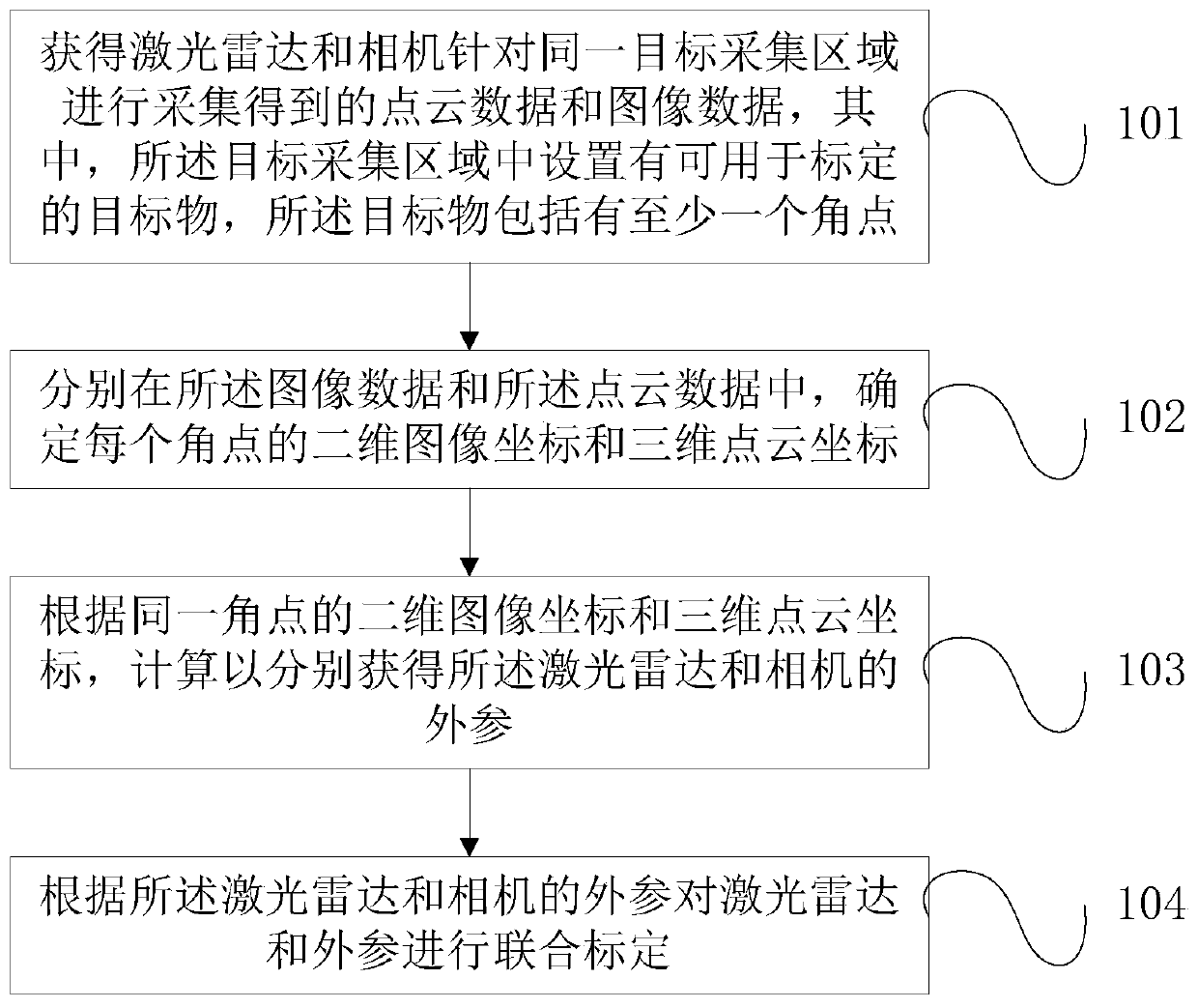

PendingCN111127563AGood for repeated calibrationImprove calibration efficiencyImage enhancementImage analysisPoint cloudEngineering

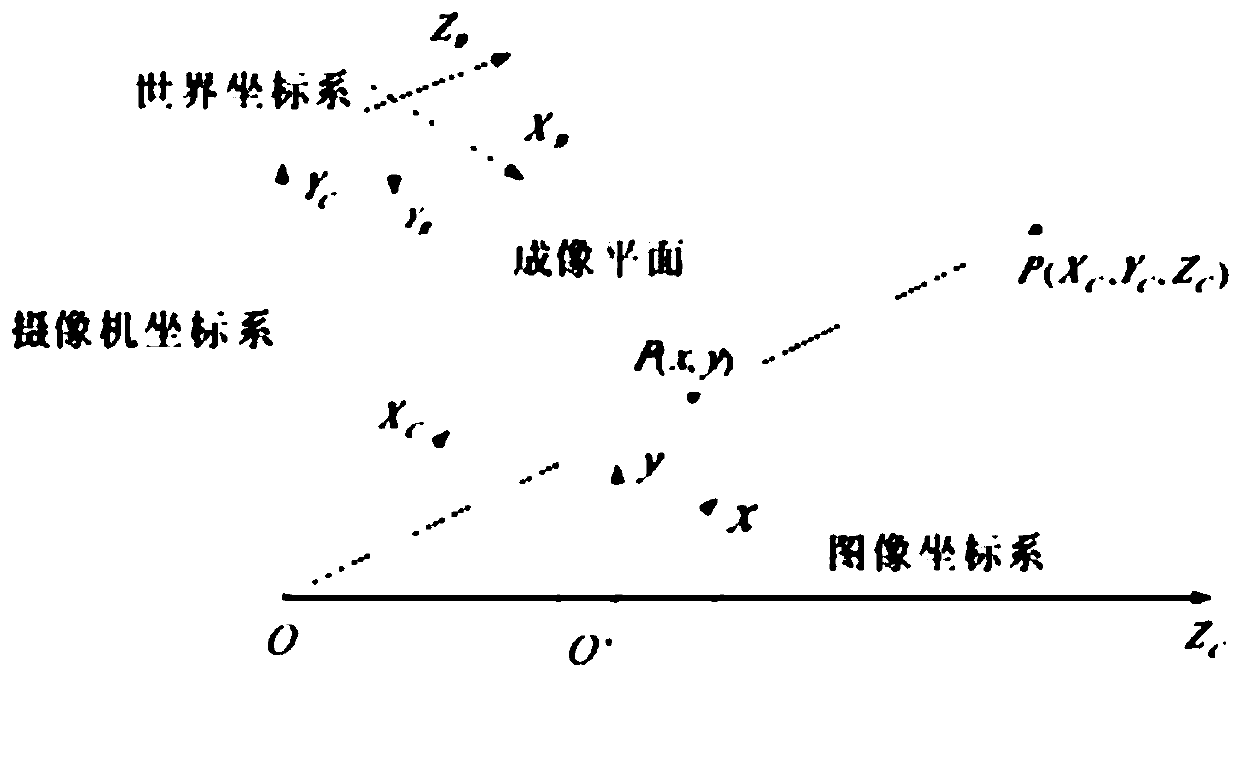

According to the joint calibration method and device, the electronic equipment and the storage medium provided by the invention, the method includes: acquiring the point cloud data and the image dataacquired by the laser radar and the camera for the same target acquisition area, wherein the target acquisition area is internally provided with the target object capable of being used for calibration, and the target object comprises at least one corner point; determining a two-dimensional image coordinate and a three-dimensional point cloud coordinate of each corner point in the image data and the point cloud data respectively; according to the two-dimensional image coordinates and the three-dimensional point cloud coordinates of the same angular point, performing calculating to respectivelyobtain external parameters of the laser radar and the camera; performing joint calibration on the laser radar and the external parameters according to the external parameters of the laser radar and the camera. Therefore, the calibration of the laser radar and the camera is not carried out by using a calibration plate; insteadly, the point cloud data and the image data acquired by the laser radar and the camera aiming at the target object in the same target acquisition area are directly calibrated, so that the calibration efficiency is improved, the calibration process is simplified, and repeated calibration of the laser radar and the camera is facilitated.

Owner:BEIJING WANJI TECH

Method for calibrating star sensor

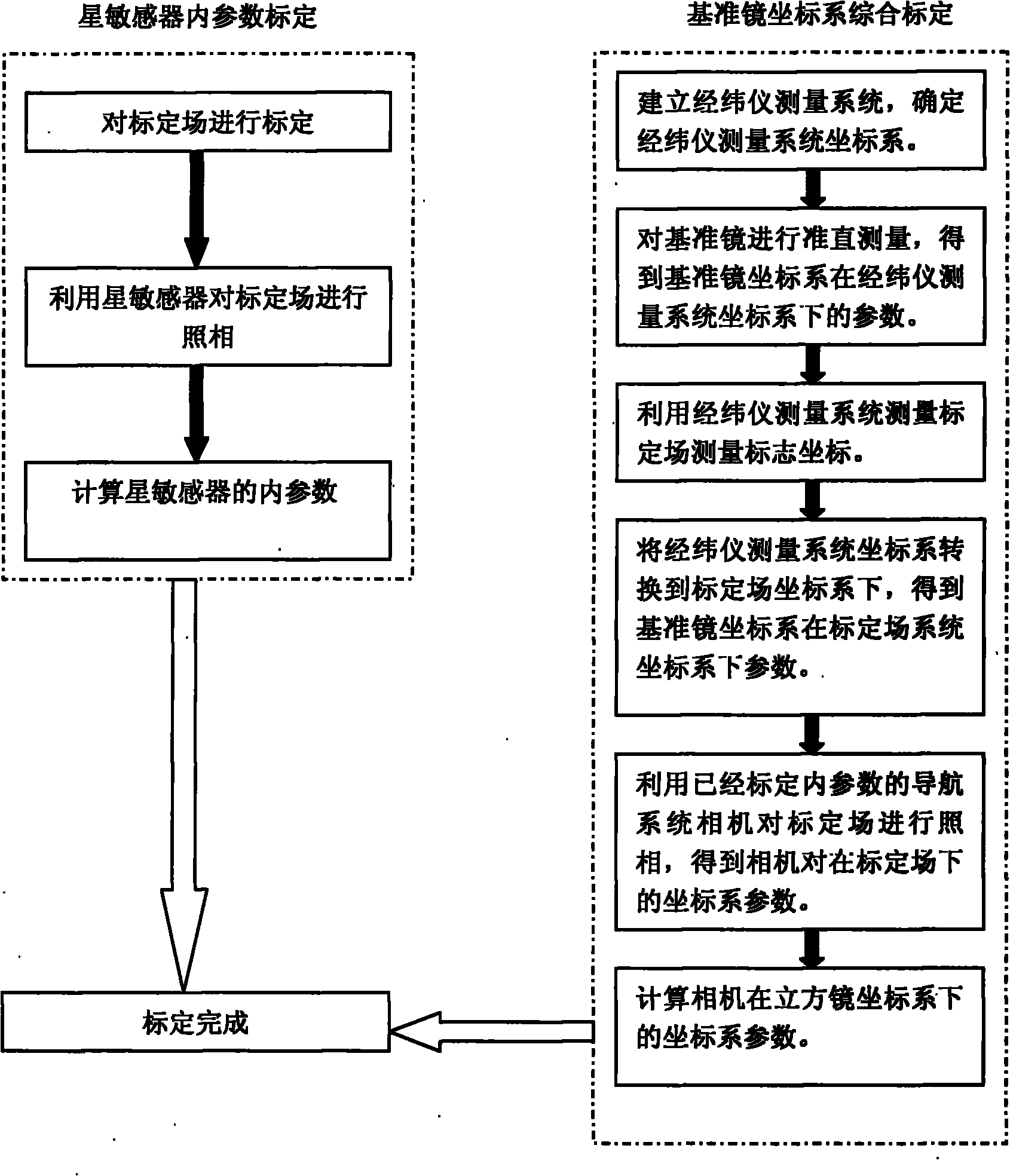

InactiveCN101858755ASimplify the calibration processReduce precisionMeasurement devicesTheodoliteImaging processing

The invention relates to a method for calibrating a star sensor, which can effectively solve the problems of low calibrating speed, low efficiency and high hardware requirements of the star sensor. The method comprises the following steps of: calibrating internal parameters of the star sensor to obtain a coordinate of a mark point in a coordinate system of a photogrammetric system; carrying out image processing on a picture and calculating internal parameters of cameras; establishing a transit surveying coordinate system; carrying out measurement on a manual surveying mark of a calibrating field by using a transit surveying system to obtain a three-dimensional coordinate of the manual surveying mark in the coordinate system of the transit surveying system; carrying out common point conversion by utilizing a three-dimensional coordinate value to obtain a conversion relation of the coordinate system of the calibrating field and the coordinate system of the transit surveying system and converting the coordinate system of the transit surveying system and a cubic prism coordinate system into the coordinate system of the calibrating field; and taking a picture of the calibrating field again to obtain a relation of the two cameras and the cubic prism coordinate system. The method for calibrating the star sensor of the invention has the advantages of simple calibrating process, low required precision for the hardware, high calibrating precision and high speed, greatly improves the working efficiency and is an innovation on the calibration of the star sensor.

Owner:BEIJING INST OF CONTROL ENG +1

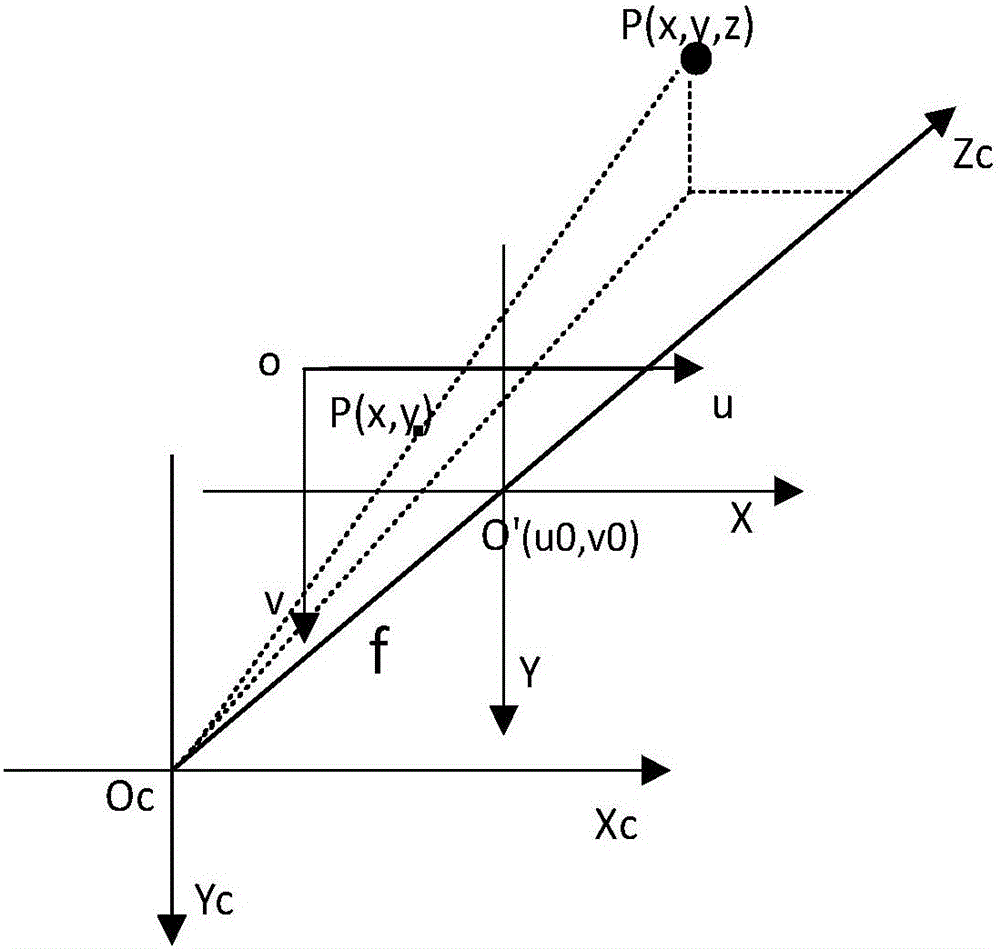

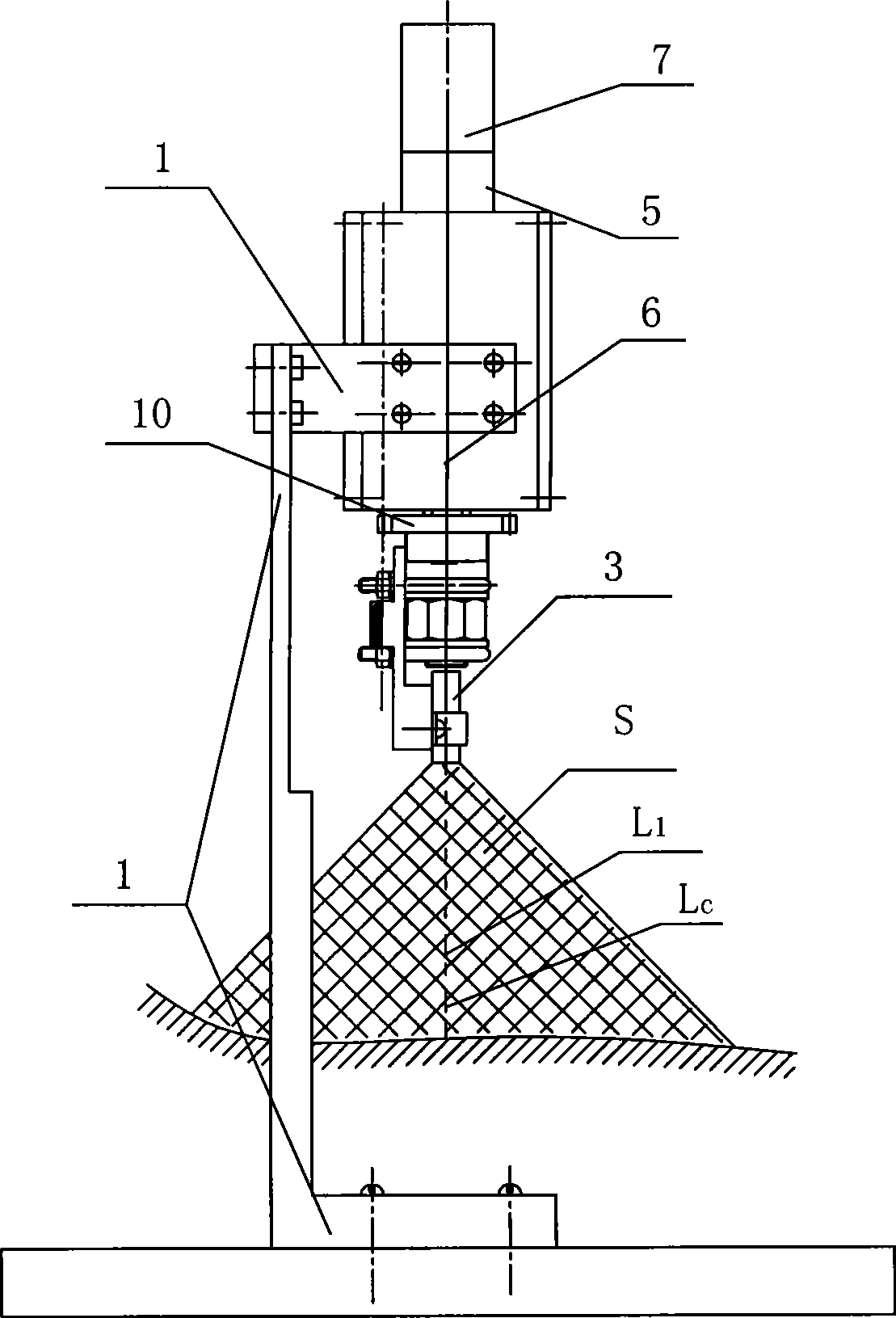

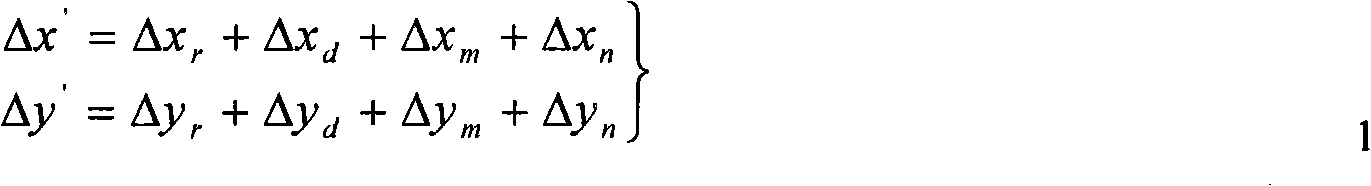

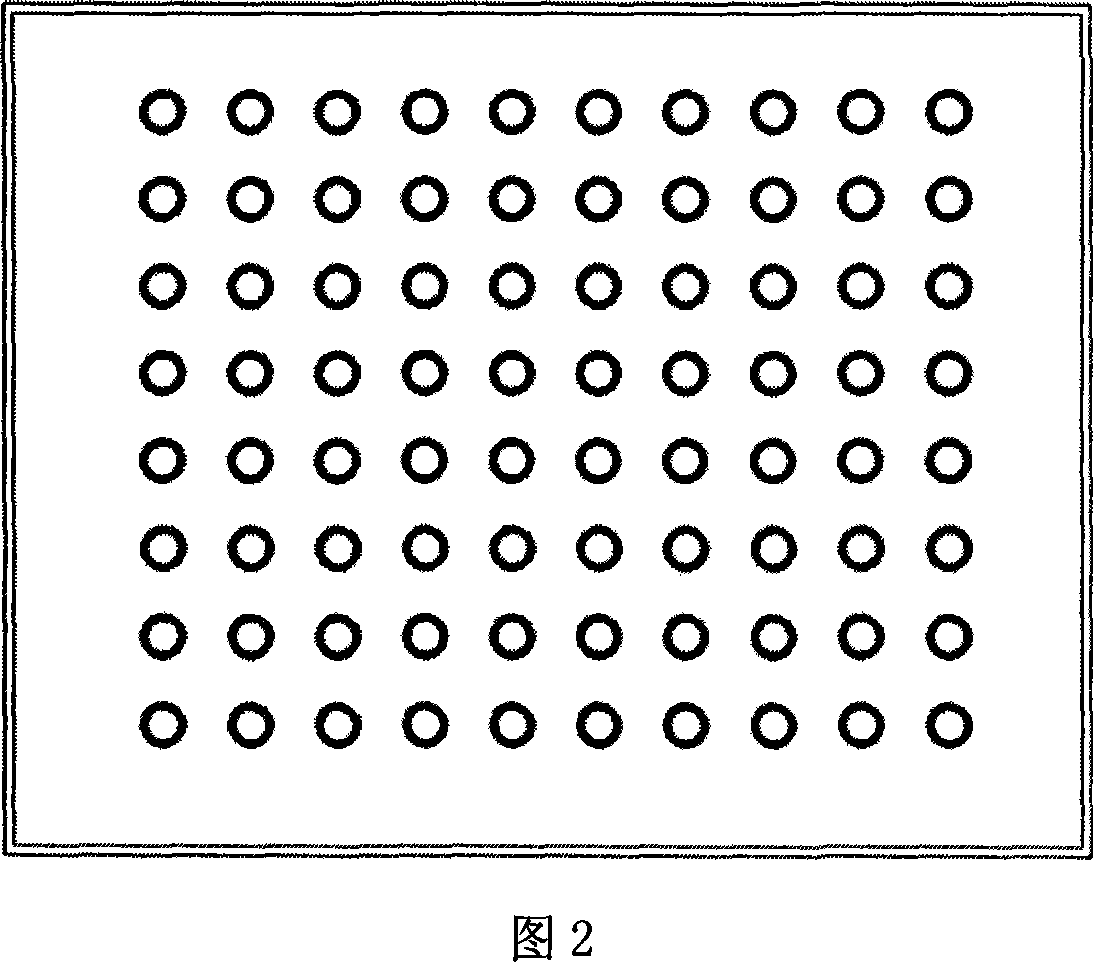

Method for measuring three-dimensional contour based on phase method

InactiveCN101074869AEasy to buildShorten the timePhotogrammetry/videogrammetryUsing optical meansField of viewSystem parameters

A 3-D outline measuring method based on phase includes calibrating internal parameter of video camera by applying nonlinear means, forming measurement system to cover required region of measured object by both projector and video camera simultaneously, setting up measurement relational expression (MRE) of formed measurement system, collecting sample points by placing calibration plate at 3-4 different positions in measurement scope, substituting obtained sample points into MRE to obtain system parameter, placing measured object in said measurement scope to obtain phase value being substituted in MRE and video camera model to obtain 3-D outline of object.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG +1

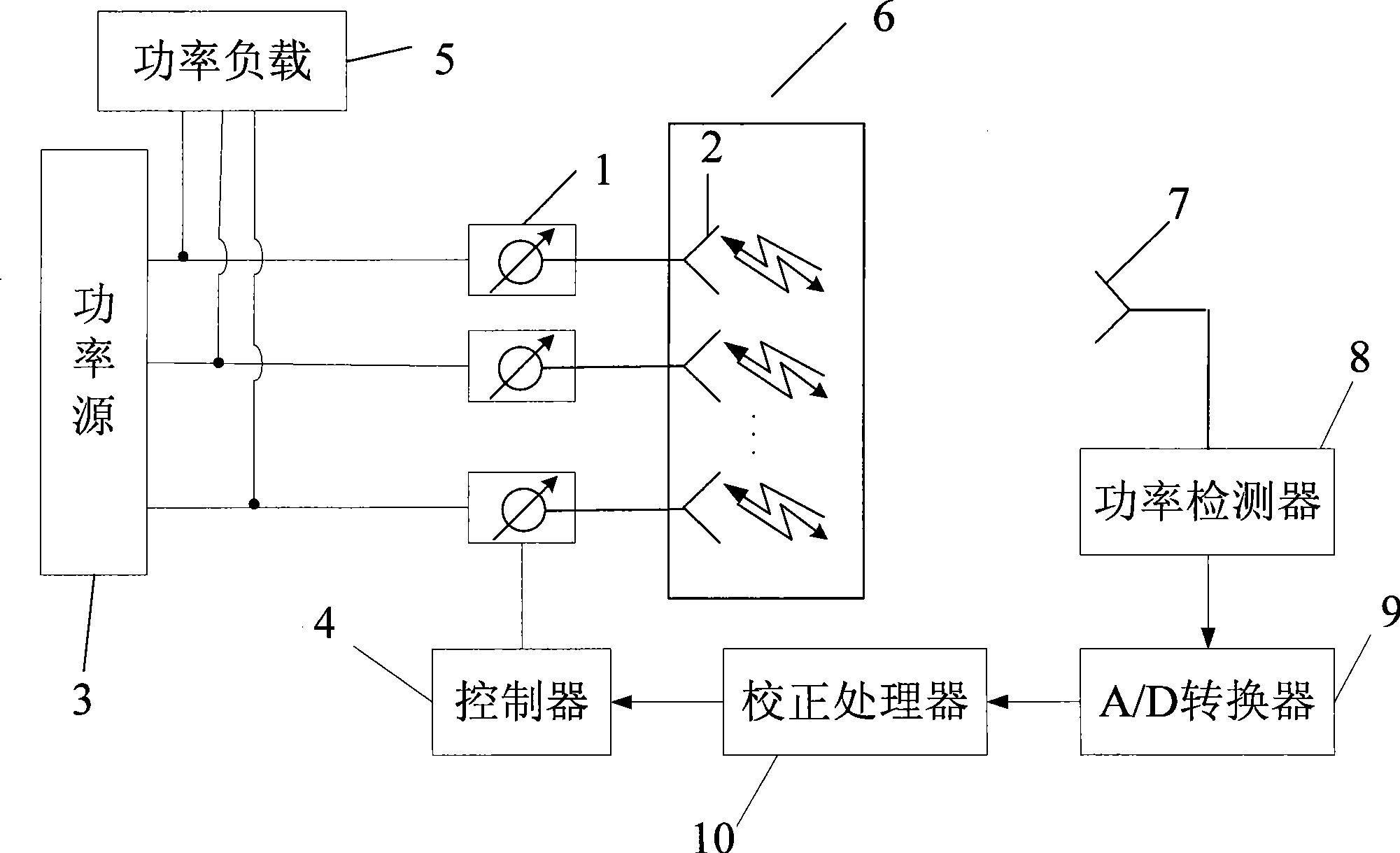

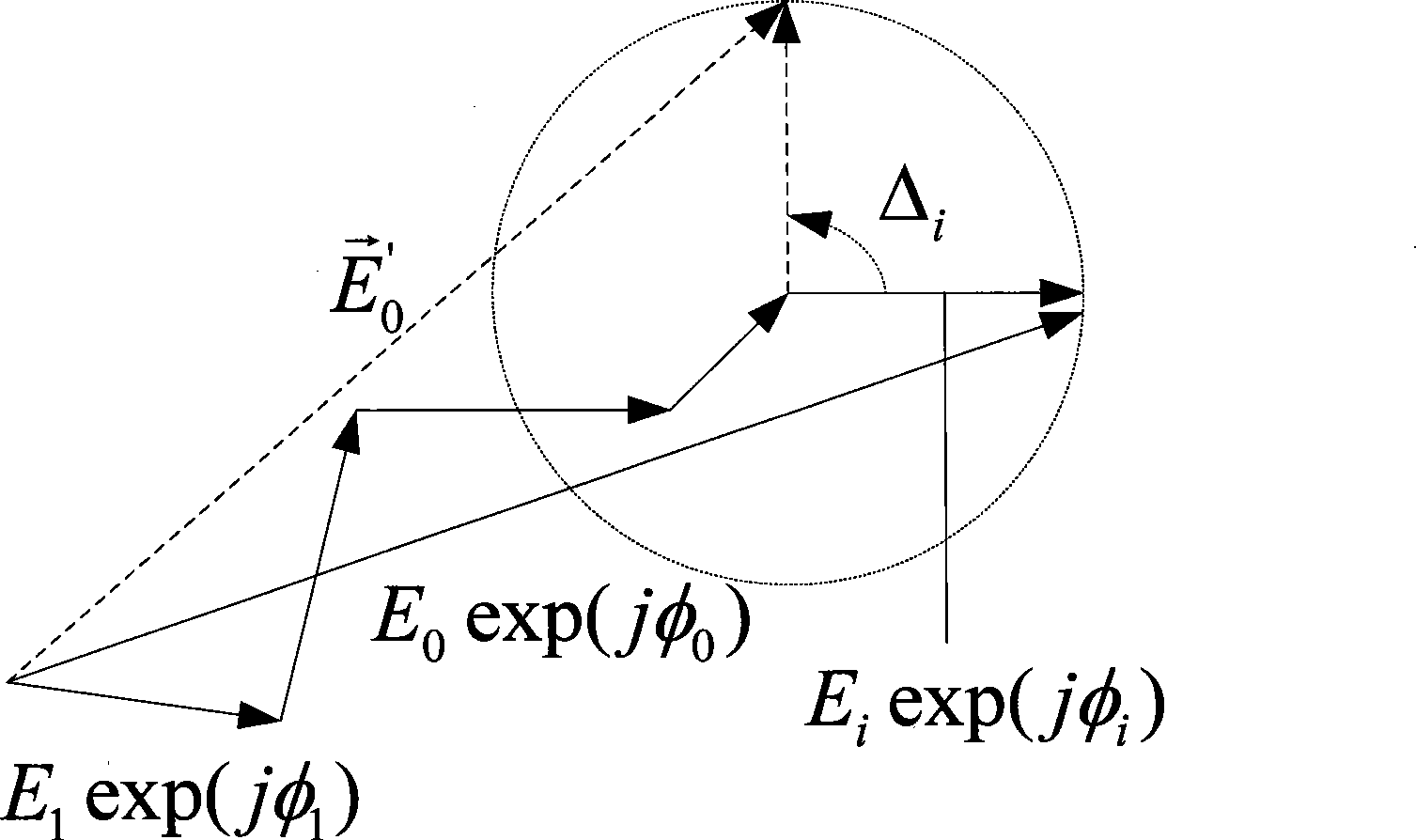

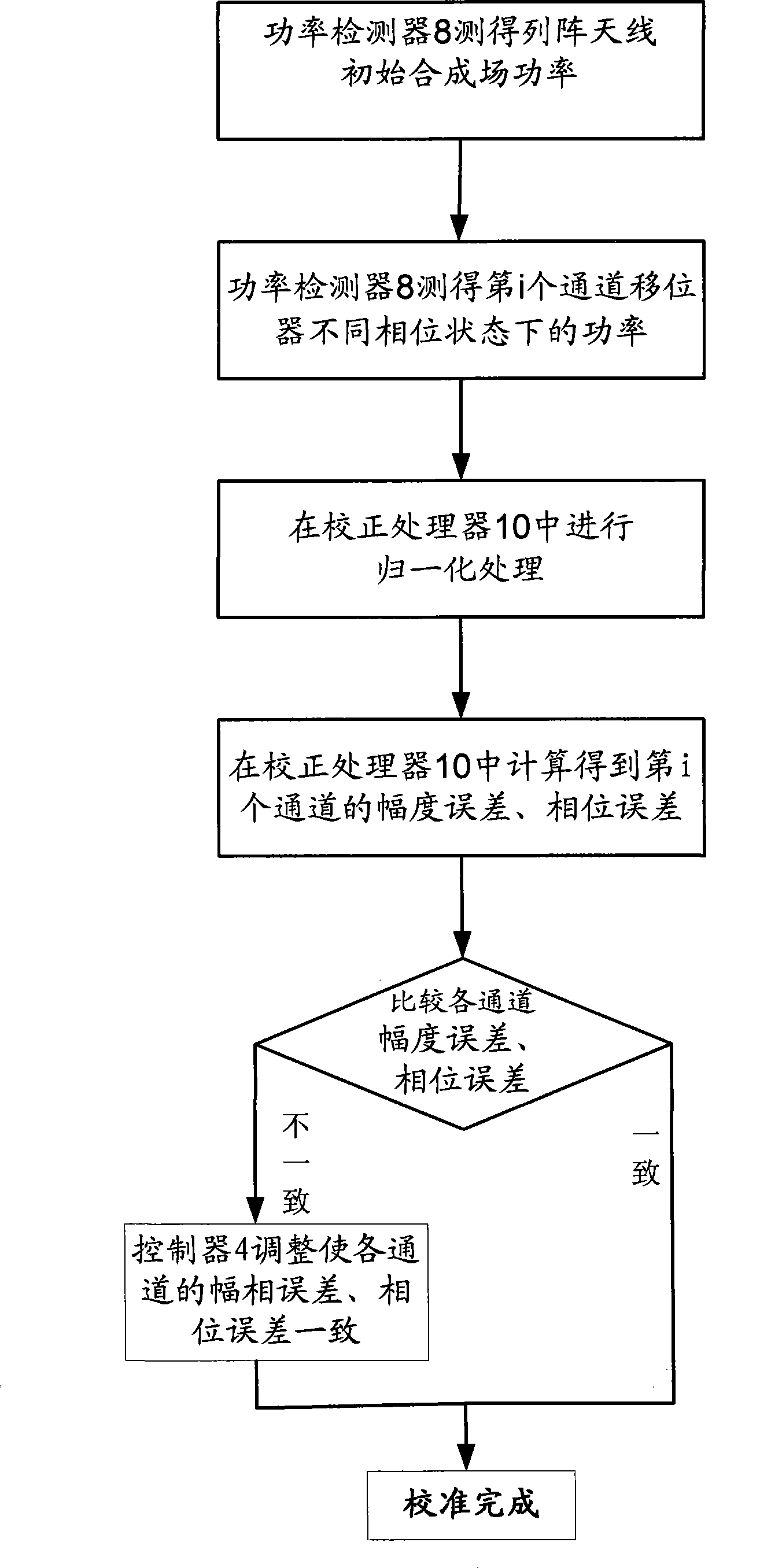

External calibration method for phase variable power detecting array antenna

ActiveCN101483274ACalibration process is simpleLow hardware environment requirementsAntennasCalibration algorithmPhysics

A phase alterable power detected array antenna external calibration method is an external calibration algorithm of an array antenna channel amplitude and phase consistency calibration. The array antenna comprises a plurality of antenna units, the phase of each antenna unit signal is controllable, and each antenna unit signal stacks and forms the array antenna signal. In order to realize the calibration of the array antenna, the invention alters the state of an alterable digital phase shifter connected with each antenna unit, obtains a response to the external calibration signal of the array antenna, forms a positive definite or overdetermined equation corresponding the response of a specific channel at multiple different states, obtains the relative amplitude and the relative phase corresponding to the reference signal of the channel by solving the equation, thus obtains an phase-amplitude consistency error of each channel of the array, thereby realizing calibration.

Owner:中国航天科技集团公司第五研究院第五〇四研究所

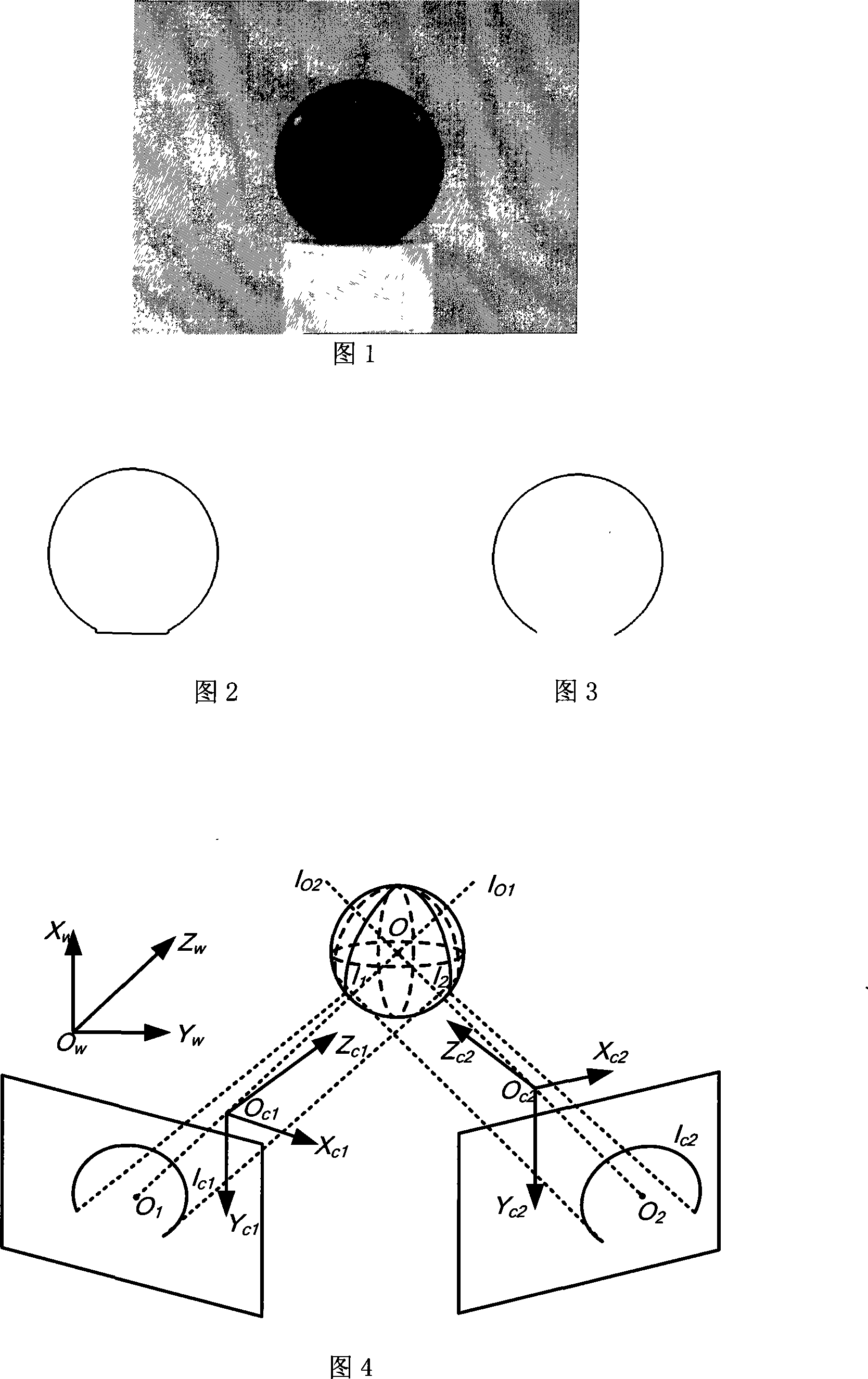

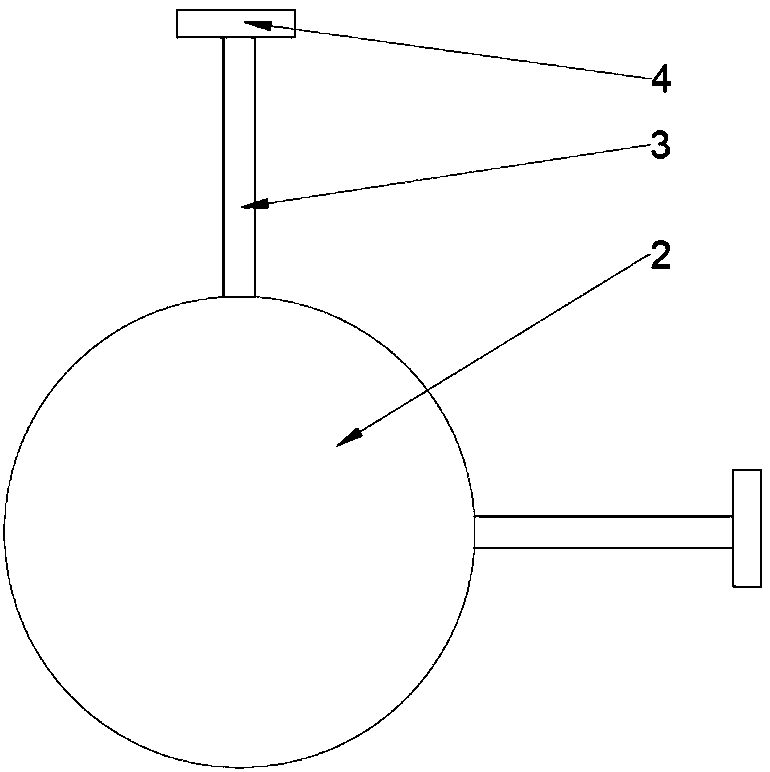

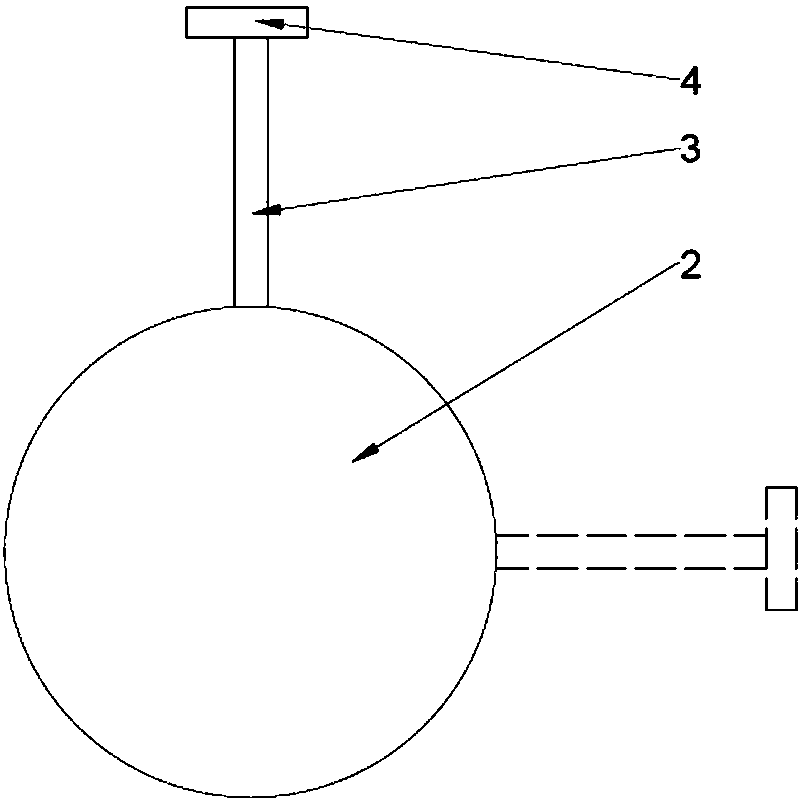

Binocular vision rotating axis calibration method

InactiveCN101216296ANo precision requiredEasy to operateImage analysisUsing optical meansVisual perceptionHuman eye

The invention belongs to detection techniques with visual principle, particularly relates to a method for calibrating rotating shaft by binocular vision with convenient operation and simple calibration process. The technical proposal of the invention includes that the method for calibrating rotating shaft by binocular vision comprises the following steps of: (1) obtaining edge of a spherical target; (2) calculating the coordinates of the spatial spherical center; and (3) calibrating and calculating parameters of the rotating shaft. The invention measures the spatial characteristic points mainly by using two cameras to simulate the structure of human eyes.

Owner:TIANJIN UNIV

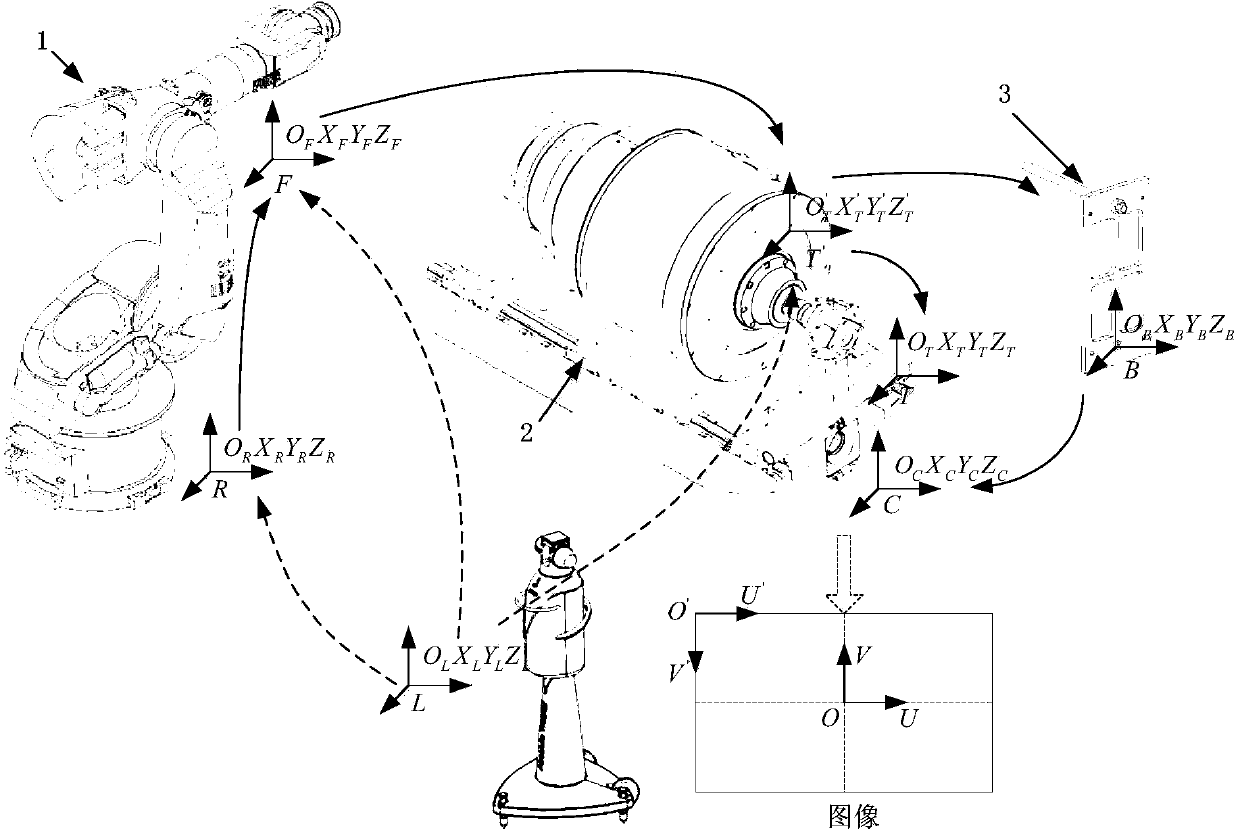

Automatic calibration method for line structured light visual system of arc welding robot

ActiveCN108717715AHigh precisionIncrease flexibilityImage analysisManipulatorEngineeringRobot workspace

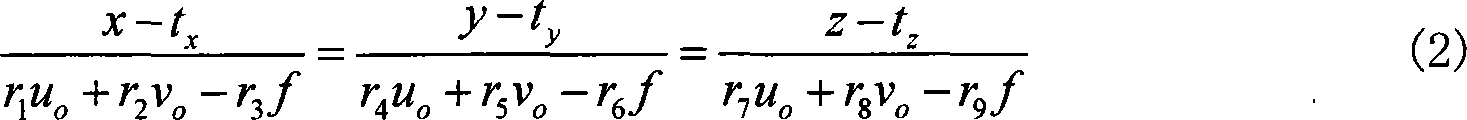

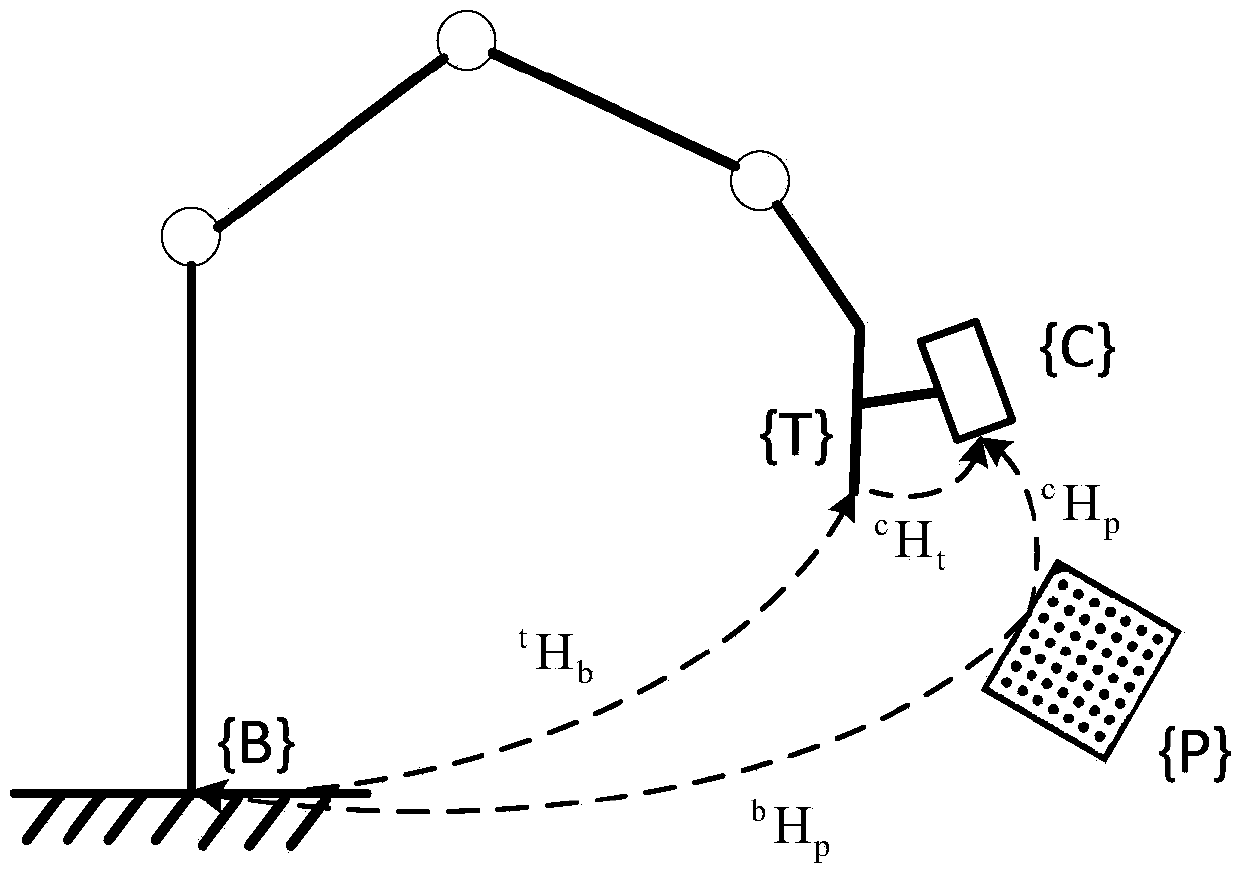

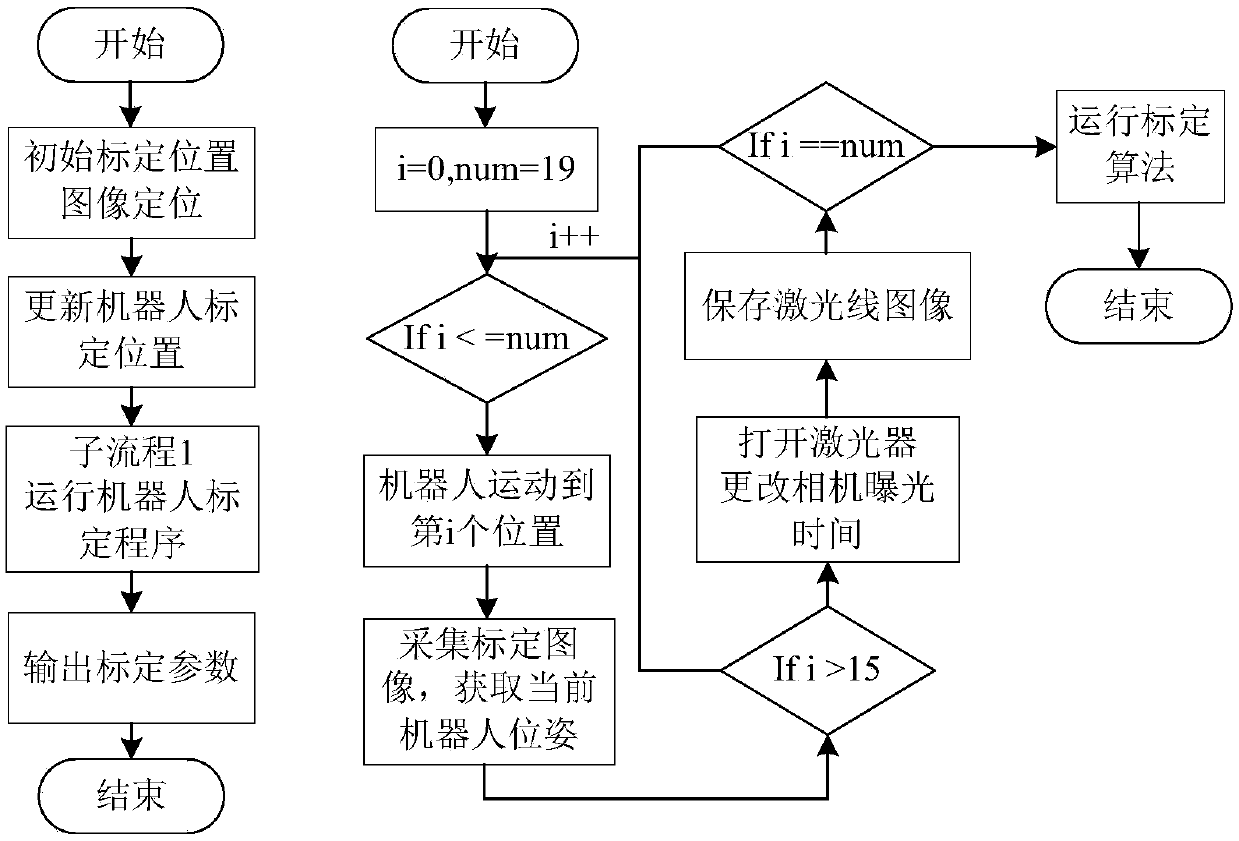

The invention discloses an automatic calibration method for a line structured optical visual system of an arc welding robot. The method comprises the steps of: 1, placing a calibration plate at any position in a working area of the robot according to a predetermined constraint limit; 2, manually manipulating the robot to ensure that the position of the calibration plate is in a rectangular frame in the middle of a collected image and updating the position component of each collection point in a robot calibration program on the basis; 3, collecting 15 calibration plate images in 15 positions and calibration plate images in other 4 positions and the corresponding laser stripe images; and 4, calculating internal parameters of a camera and hand-eye relationship parameters through the collectedprevious 15 images and calculating structured light plane parameters through the collected latter four images. The method disclosed by the invention has the advantages that image positioning is onlycarried out on the first collection position of the calibration plate and the subsequent positions are automatically updated through translation transformation with no need for human operation, so that the calibration method is convenient and quick, the flexibility and the rapidity are greatly increased and the method can meet the needs of actual production environments.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for controlling AT (automatic transmission) difference value gear shifting process

InactiveCN102102756ASimplify the calibration processGearing controlLoading factorAutomatic transmission

The invention discloses a method for controlling an AT (automatic transmission) difference value gear shifting process. A drive factor (Dr) which reacts driving requirement in real time and a loading factor (Ld) which reacts the loading condition in real time are added, a difference value of the driving factor and the loading factor among an economic gear shifting chart (pattern D), a motive gear shifting chart (pattern S) and a loading gear shifting chart (pattern L) is carried out, thus a power shifting map is changed as the changes of the driving factor and the loading factor in real time. Through adopting a difference value between Dr, Ld and the pattern D, the pattern S as well as the pattern L by the gear shifting process, a gear shifting line in the gear shifting map is regulated to be adaptive to the driving condition in real time according to the actual driving condition, the calibration is calibrated through calibrating the basic pattern D, pattern S and pattern L gear shifting charts and calibrating parameters which influence the Dr value and the Ld value by a calibration engineer, and the calibration process can be simplified.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

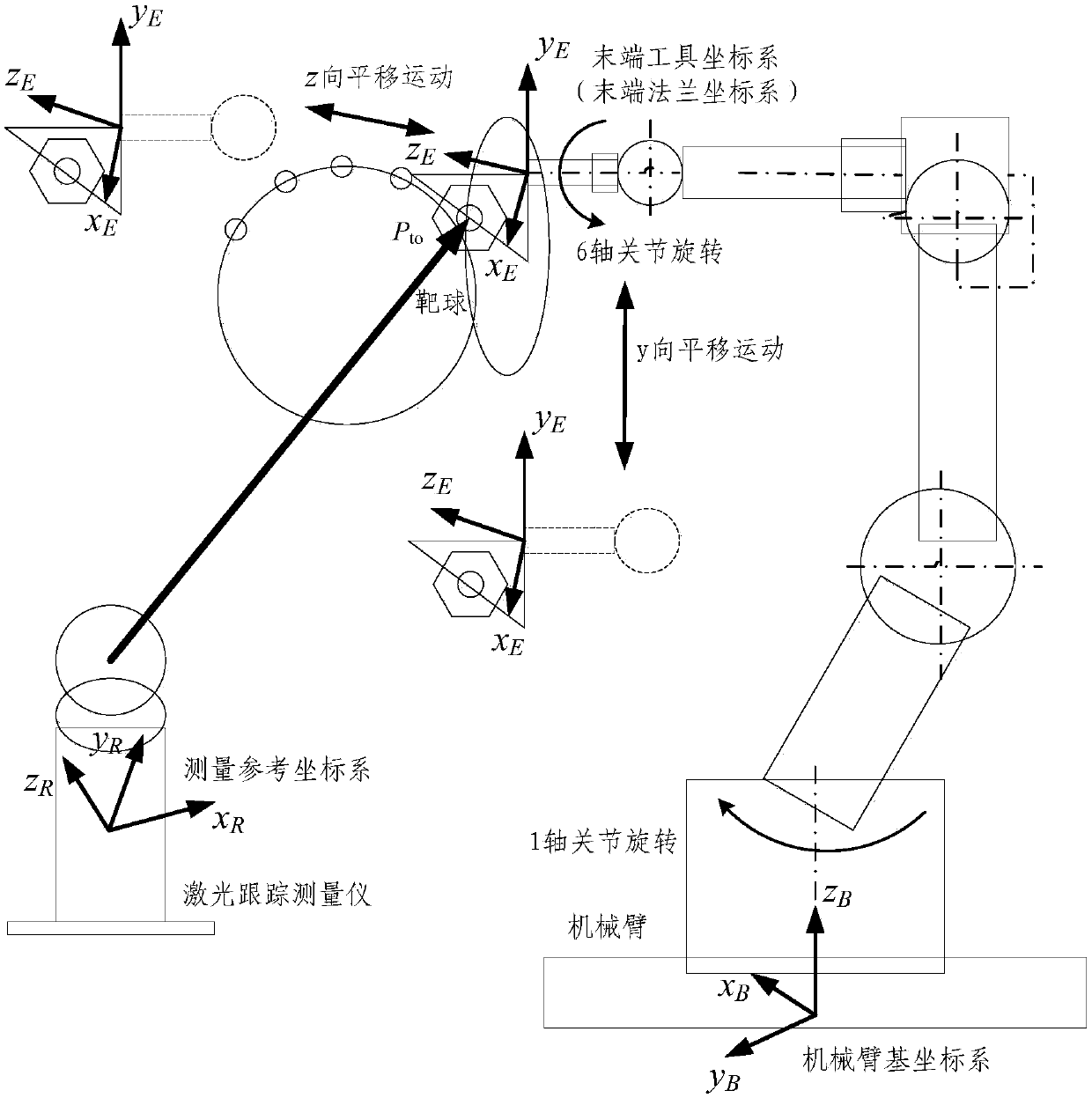

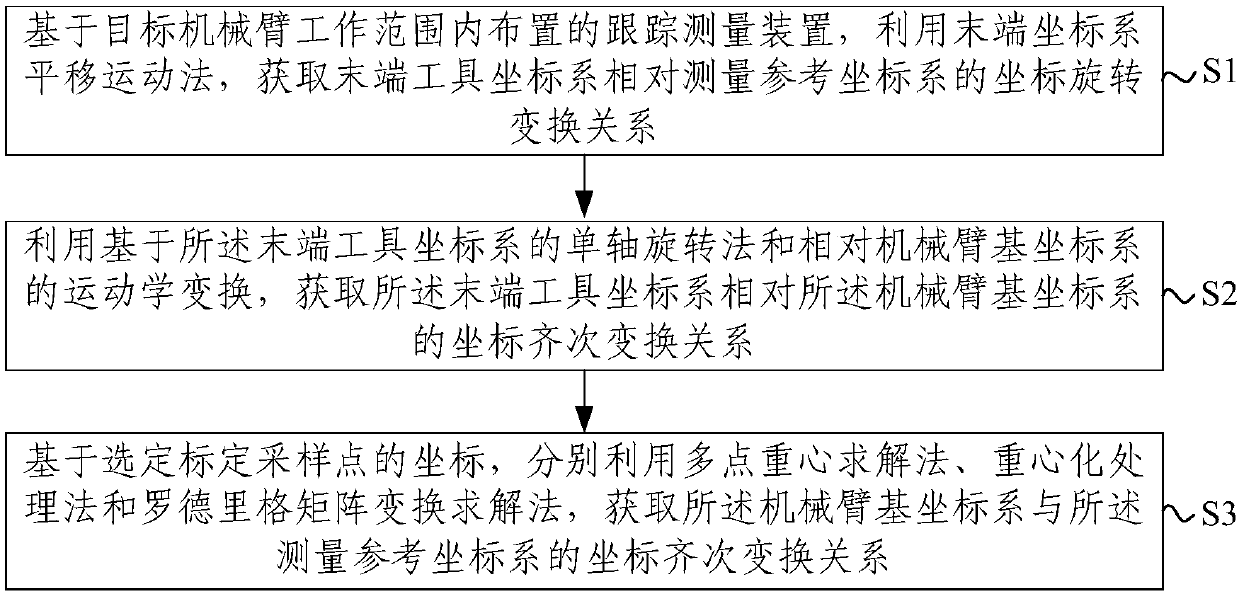

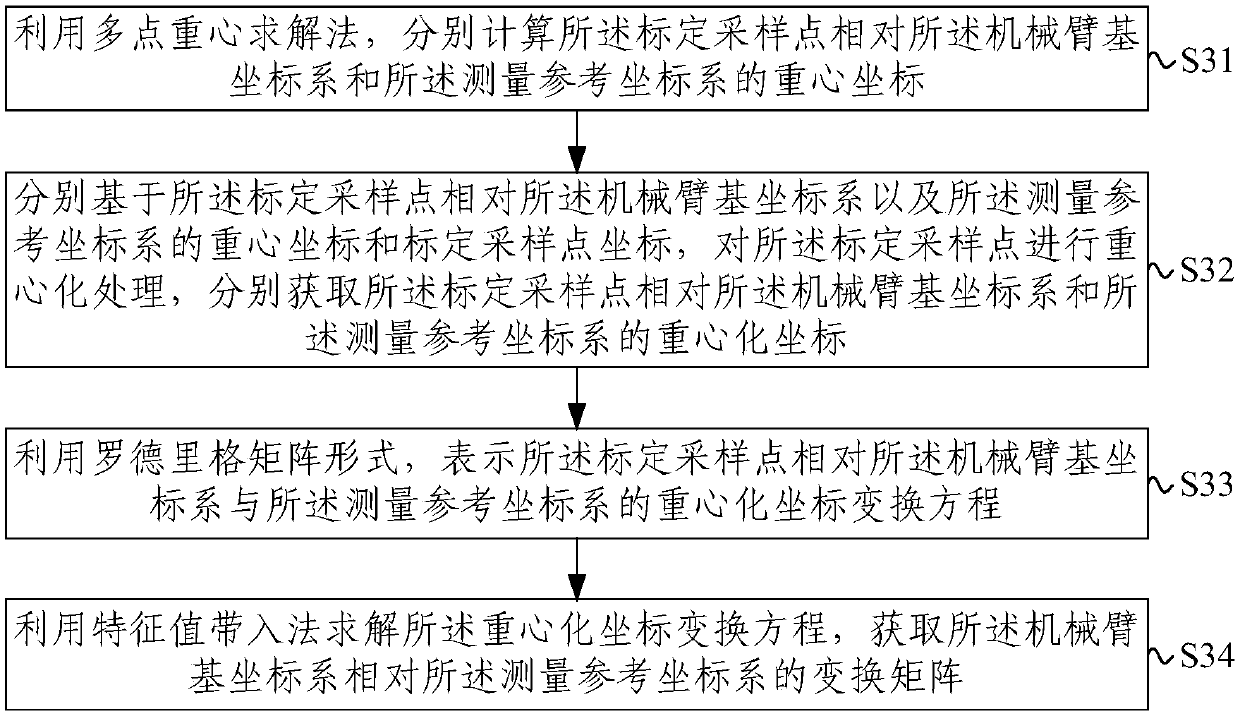

Transformation calibration method and system for mechanical arm coordinate system

ActiveCN107738254AReduce calibration timeImprove calibration accuracyProgramme-controlled manipulatorImage analysisMeasurement deviceGravity center

The invention provides a transformation calibration method and system for a mechanical arm coordinate system. The transformation calibration method comprises the steps that S1, based on a tracking measurement device arranged in the working range of a target mechanical arm, the coordinate rotation transformation relation of a tail end tool coordinate system relative to a measurement reference coordinate system is obtained through a tail end coordinate system translational movement method; S2, the coordinate homogeneous transformation relation of the tail end tool coordinate system relative to amechanical arm base coordinate system is obtained through a single-axial rotation method based on the tail end tool coordinate system and kinematic transformation relative to the mechanical arm basecoordinate system; and S3, based on coordinates of selected calibration sampling points, the coordinate homogeneous transformation relation of the mechanical arm base coordinate system and the measurement reference coordinate system is obtained through a multipoint gravity center solution method, a gravity center processing method and a Roderick matrix transformation solution method. The calibration procedure is simple, the calibration algorithm is free of the iterative process, the consumed time of coordinate calibration can be effectively reduced, and the calibration precision of the coordinate systems is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

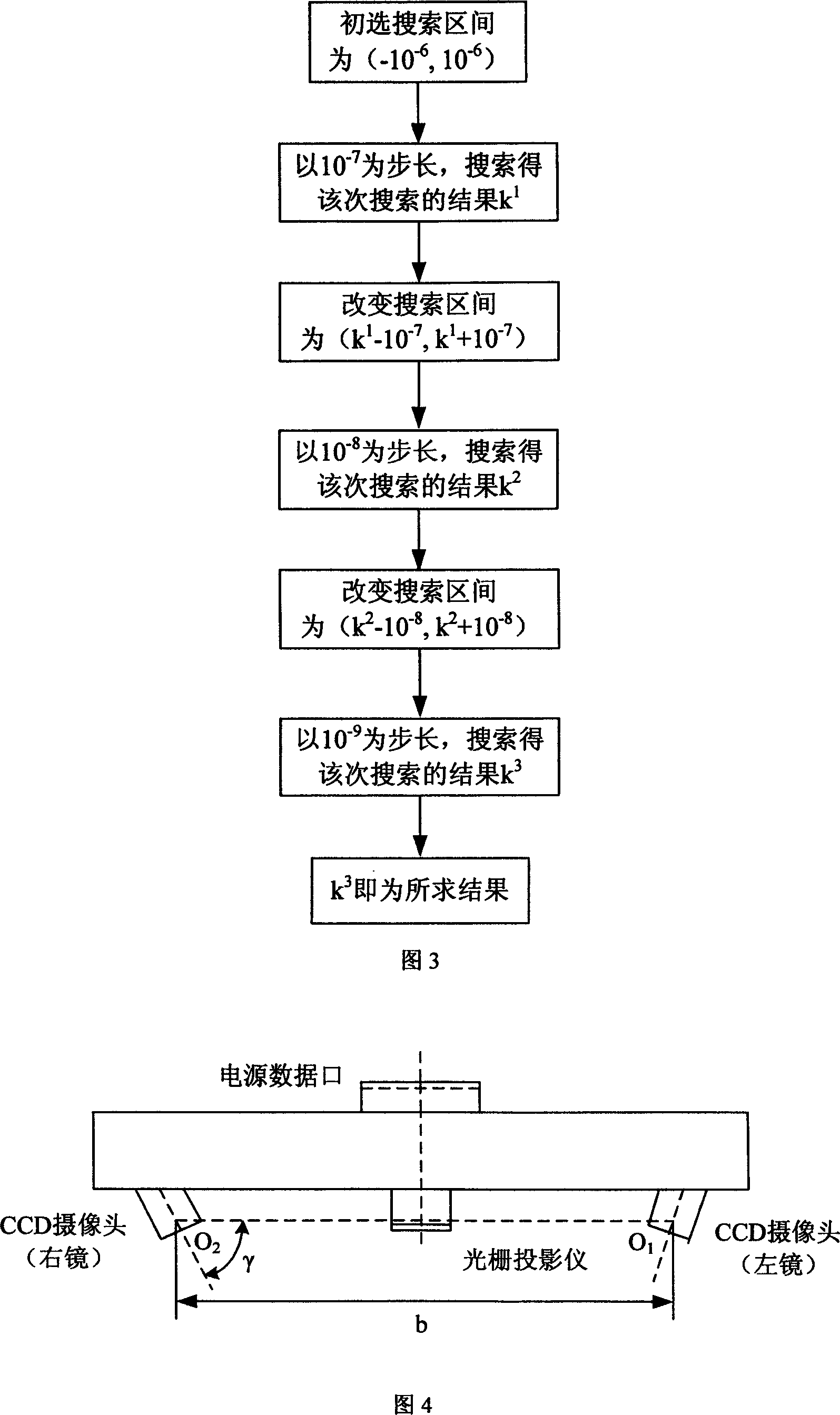

Calibrating method based on fixed parameters and variable parameters for three-dimensional scanning system

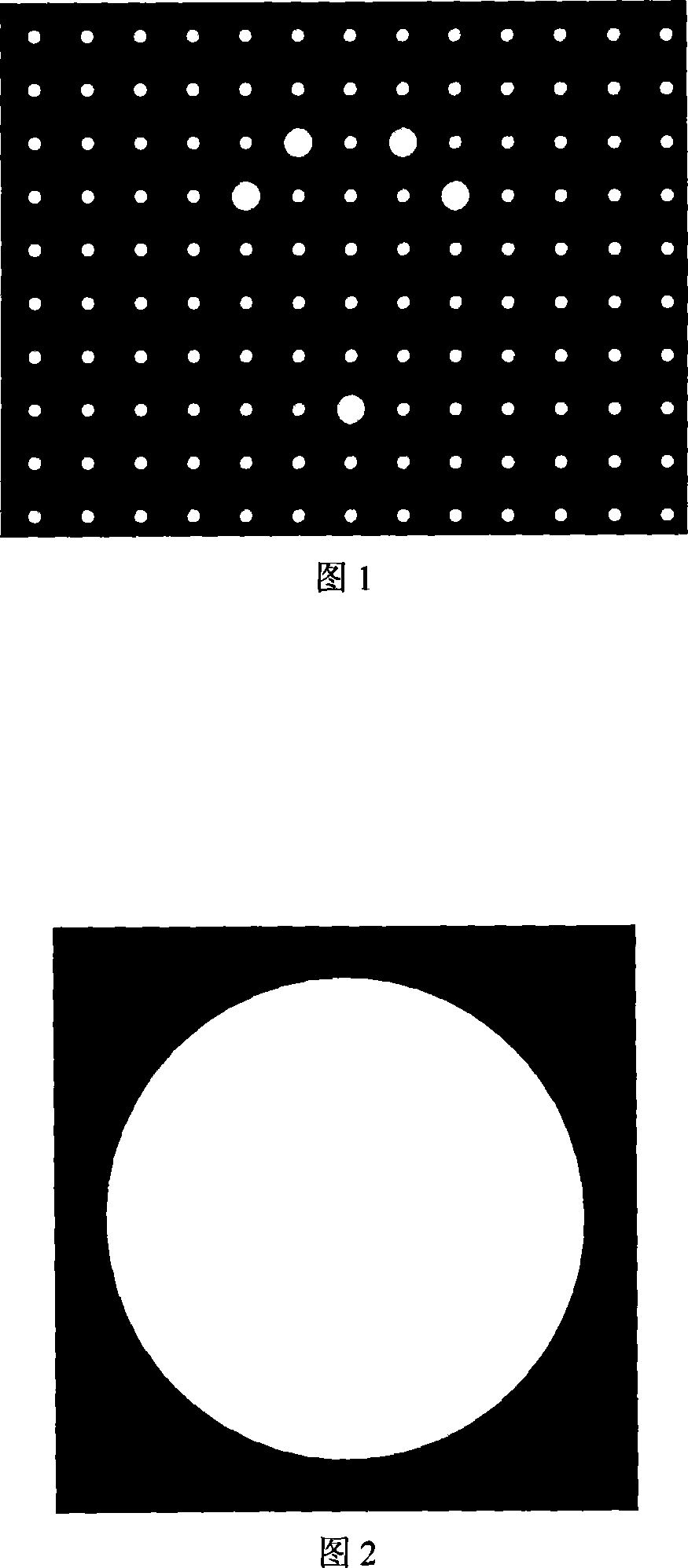

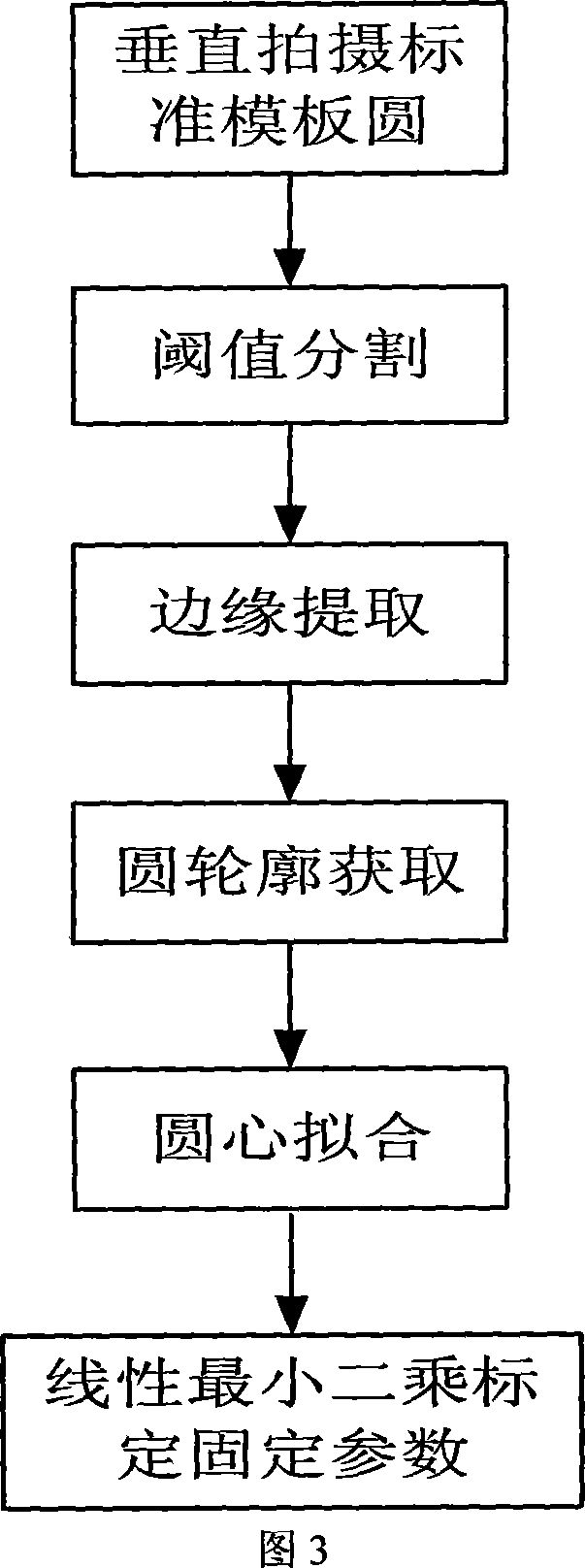

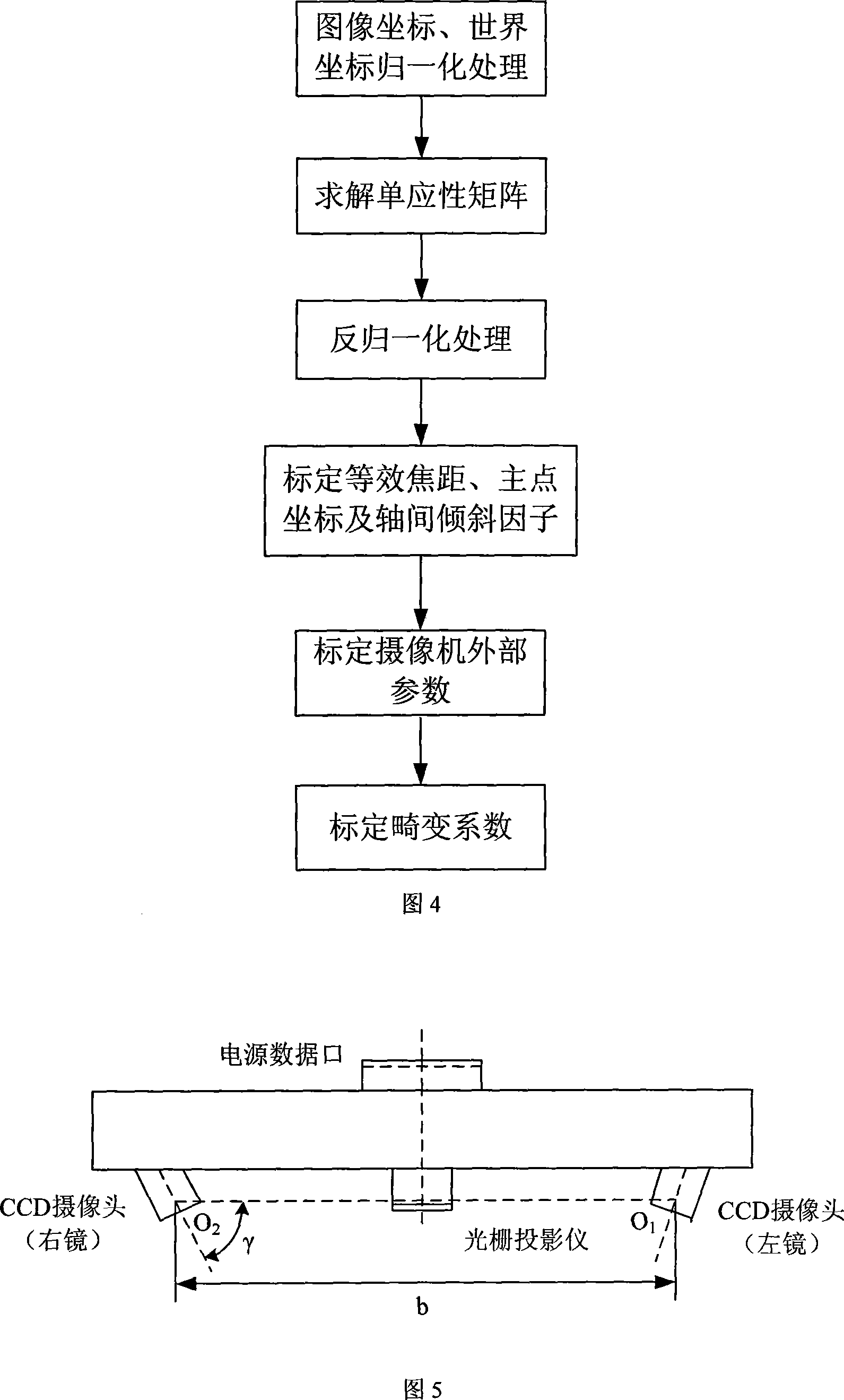

InactiveCN101025824ACompatible with practical engineering applicationsCalibration Distortion CoefficientImage analysisImaging processingModel parameters

A calibration method based on fixed and variable parameters in three-dimensional scanning system relates to the camera model parameter calibration in the visual system including the following steps: (1) fixed parameters calibration is primarily to acquire coordinates of sampling points on circular contour and heart in image coordinates through image processing techniques, and then use n sampling points to get aspect ratio through least squares method, (2) after obtaining the fixed parameters, it uses the image coordinates of image midpoint and the corresponding space coordinates of world midpoint to demarcate the initial value of variable parameters for the camera, including the equivalent focal length, main point coordinates, axis tilt factor, distortion factor and external parameters, (3) after demarcation, it takes fixed parameters as a constraint for nonlinear optimization objective function to establish a binding target function and get the optimal solution of variable parameters through the nonlinear optimization method.

Owner:南通鑫唐纺织印染有限公司 +1

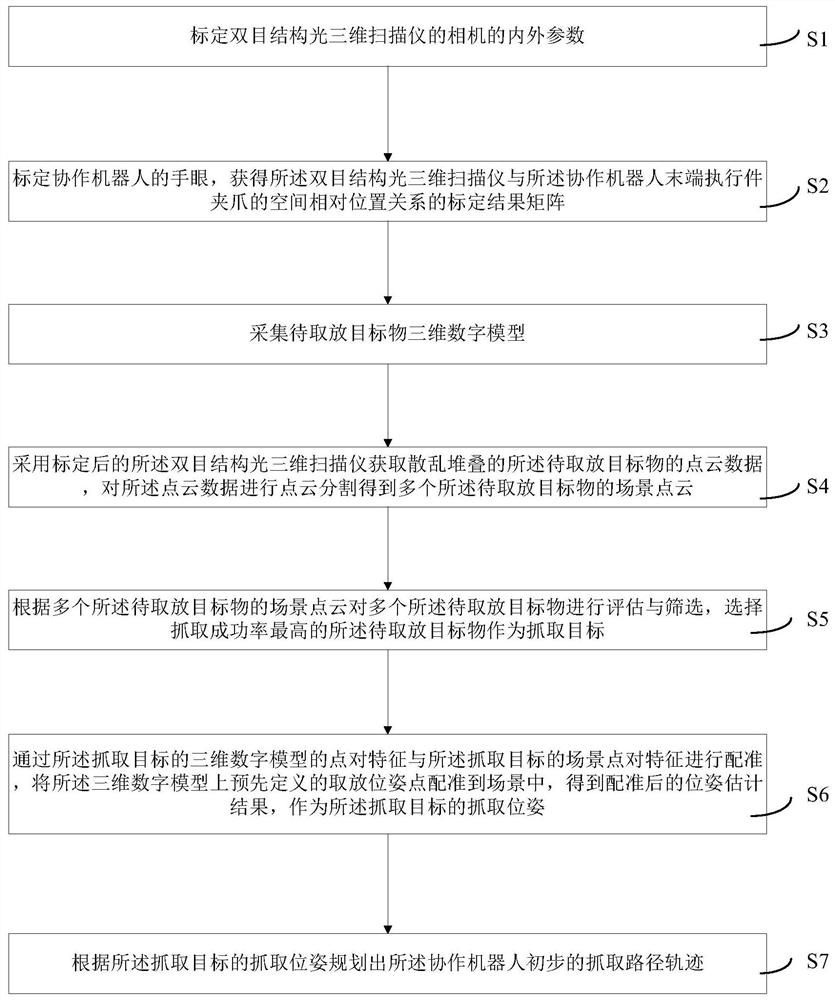

Visual 3D taking and placing method and system based on cooperative robot

ActiveCN112476434AImprove the quality of acquisitionGet fastProgramme-controlled manipulatorImage analysisPattern recognitionComputer graphics (images)

The invention provides a visual 3D taking and placing method and system based on a cooperative robot. The method comprises the steps that internal and external parameters of a camera of a binocular structured light three-dimensional scanner are calibrated; the hands and eyes of the cooperative robot are calibrated, and a calibration result matrix is obtained; a three-dimensional digital model of to-be-taken-and-placed target objects is collected; the calibrated binocular structured light three-dimensional scanner is adopted to obtain point cloud data of the to-be-taken-and-placed target objects which are stacked in a scattered mode, and the point cloud is segmented to obtain scene point clouds of the multiple to-be-taken-and-placed target objects; the to-be-taken-and-placed target object with the highest grabbing success rate is selected as a grabbing target according to the scene point clouds of the multiple to-be-taken-and-placed target objects; the three-dimensional digital model ofthe grabbing target and scene point pair features are registered, pre-defined taking and placing pose points are registered into a scene, and a registered pose estimation result is obtained and serves as a grabbing pose of the grabbing target; and a preliminary grabbing path track of the cooperative robot is planned. The target object can be accurately recognized, and the grabbing positioning precision is high.

Owner:新拓三维技术(深圳)有限公司

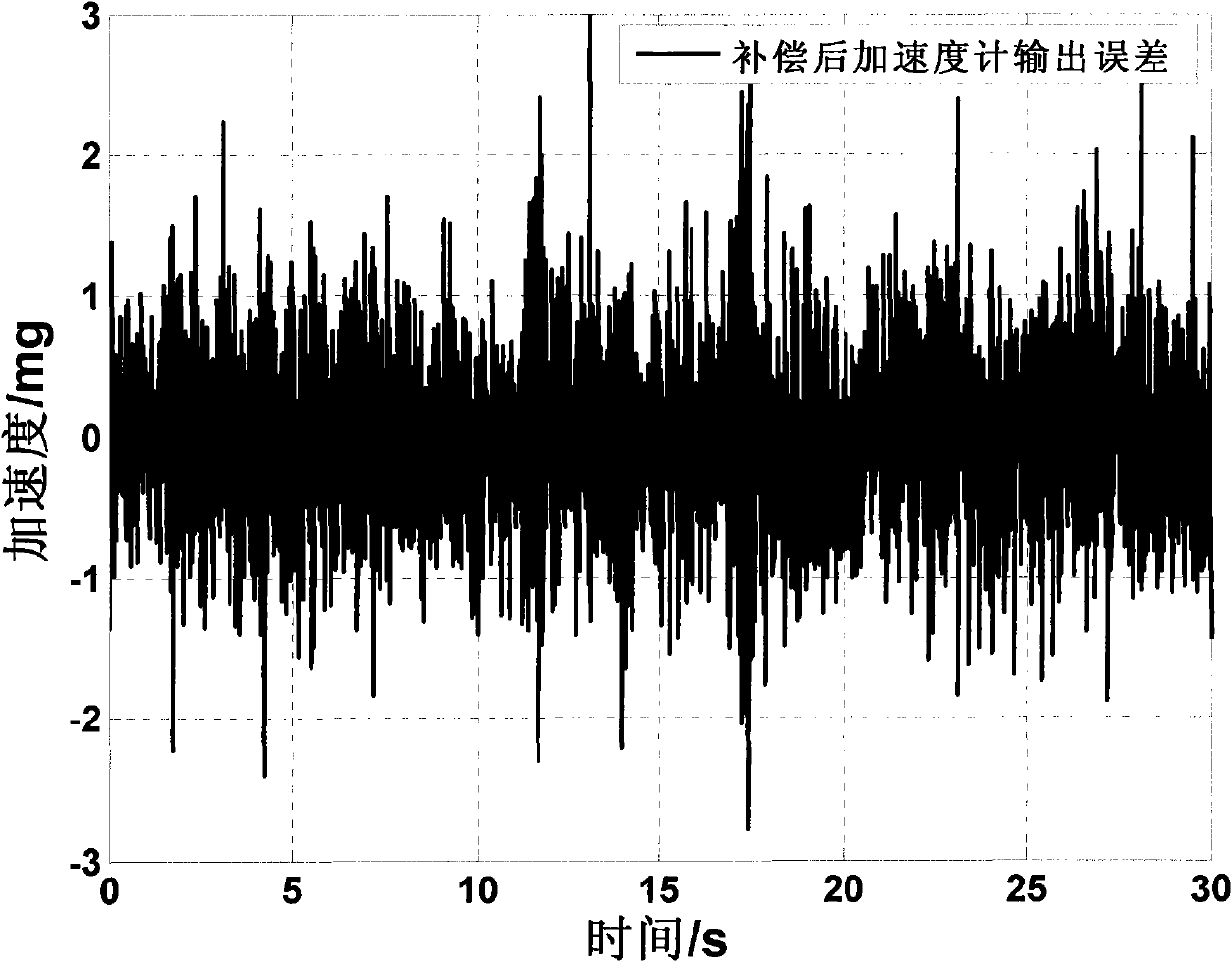

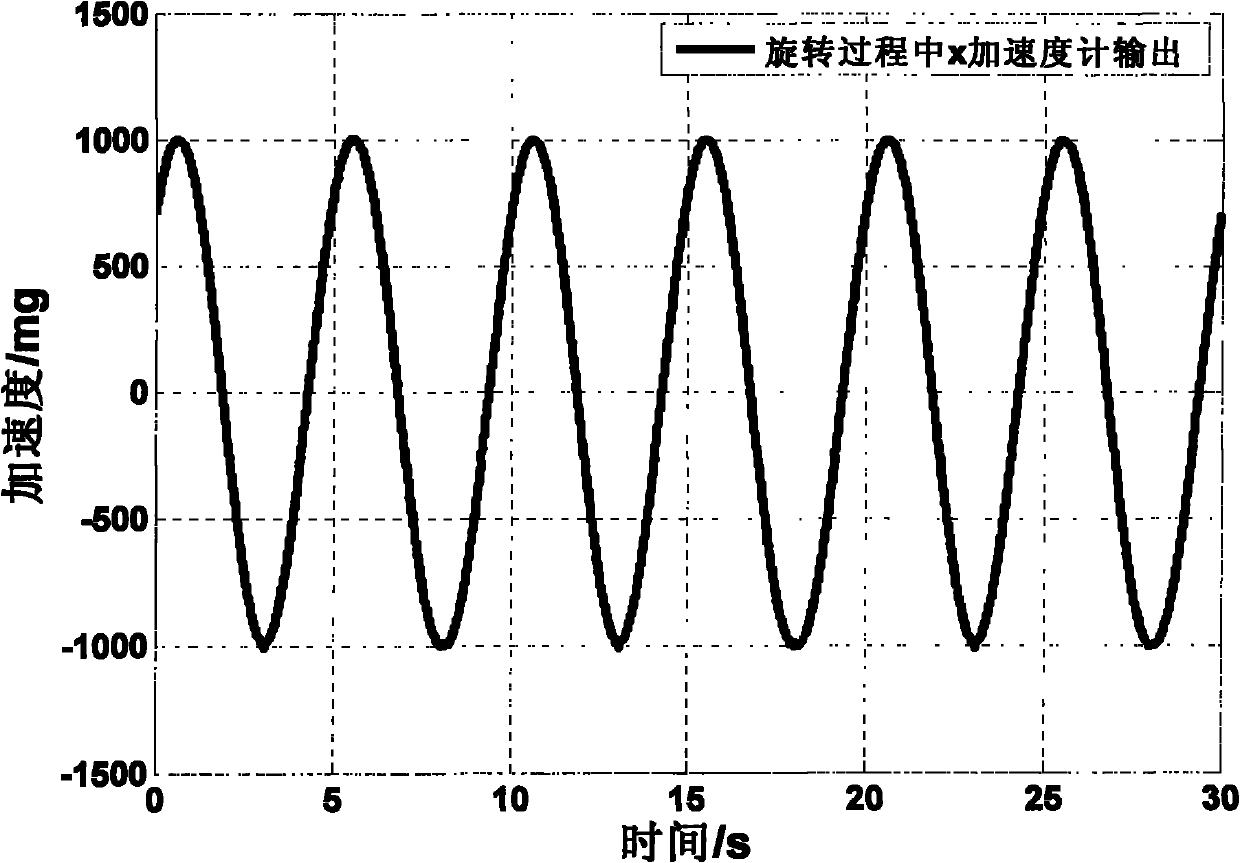

Accelerometer error calibration and compensation method based on rotary mechanism

InactiveCN101852818ASimplify the calibration processImprove estimation accuracyTesting/calibration of speed/acceleration/shock measurement devicesLeast squaresEngineering

The invention relates to an accelerometer error calibration and compensation method based on a rotary mechanism, which comprises the following steps that: an accelerator is arranged on the rotary mechanism according to a certain requirements; the relationship between the dynamic continuous output of the accelerator and the rotating angle of the rotary mechanism is obtained through the rotation of the rotary mechanism; and a least square method is used for estimating and obtaining the bias, the scale factor, the non-linear error coefficient of the scale factor, the cross-coupling error coefficient and the like of the accelerator. The method uses the rotary mechanism to estimate all error coefficients of the accelerator, and is characterized by accuracy, high efficiency, easy operation, high universality and the like. After the method estimates the error coefficients and carries out corresponding error compensation, the output precision of the accelerator can be greatly improved. The method is also applicable to the calibration of a gyroscope, and can greatly improve the precision in measuring the speed of a top.

Owner:BEIHANG UNIV

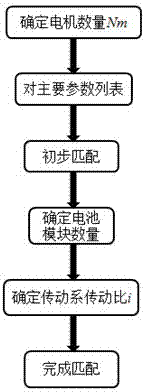

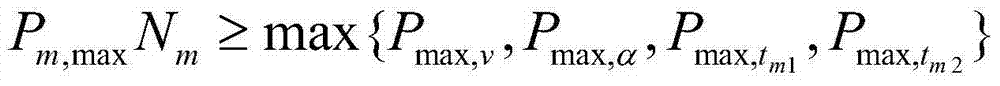

Power matching method applicable to electric vehicle

ActiveCN103568868ASimplify the calibration processPower matching is simple and effectiveSpeed controllerElectric energy managementElectric machineryEngineering

The invention discloses a power matching method applicable to a blade electric vehicle. The method comprises the steps as follows: firstly, the quantity of motors is determined according to a driving manner adopted by the vehicle type; then main parameters such as whole vehicle parameters, motor parameters and battery parameters are listed; initial power matching is performed according to the parameters in a list; and then the quantity of battery modules is determined according to an initial matching result, the transmission ratio of a transmission is determined later, and the power matching of the blade electric vehicle is completed. According to the power matching method, rapid and more accurate power matching can be performed aiming at blade electric vehicles with different vehicle type requirements and different power performance requirements, the matching time can be reduced, the matching expenses are saved, and the whole vehicle development period is shortened.

Owner:天津天海轮毂电机科技有限公司

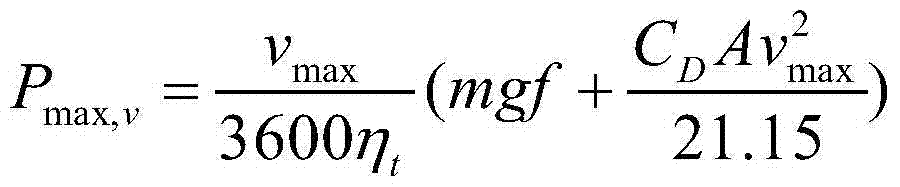

Camshaft signal panel angle detection gauge

InactiveCN104266628AGuaranteed detection accuracySimple structureMeasurement devicesEngineeringCamshaft

A camshaft signal panel angle detection gauge comprises a supporting base, a compressing mechanism, an angle positioning mechanism and a detecting mechanism. The compressing mechanism is installed on a supporting base and located on the outer side of the angle positioning mechanism. The angle positioning mechanism comprises a top base, a rear support and a front support, wherein the top base, the rear support and the front support are sequentially arranged on the supporting base. An angle positioning pin is installed on the top base. The detecting mechanism comprises a sliding rail, a detecting base and a displacement sensor. The sliding rail is installed on the supporting base. The detecting base is installed on the sliding rail. A detecting shaft is installed in the detecting base. An angle detecting block is installed at one end of the detecting shaft. An angle detecting pin, a reference groove and a reference surface are arranged on the angle detecting block. The displacement sensor is fixedly installed on one side of the detecting base. The displacement sensor makes contact with the reference surface of the angle detecting block. The camshaft signal panel angle detection gauge is simple in structure and easy and convenient to operate, calibration is easy, the detection precision of a camshaft is ensured, and the product percent of pass is improved.

Owner:济南易恒技术有限公司

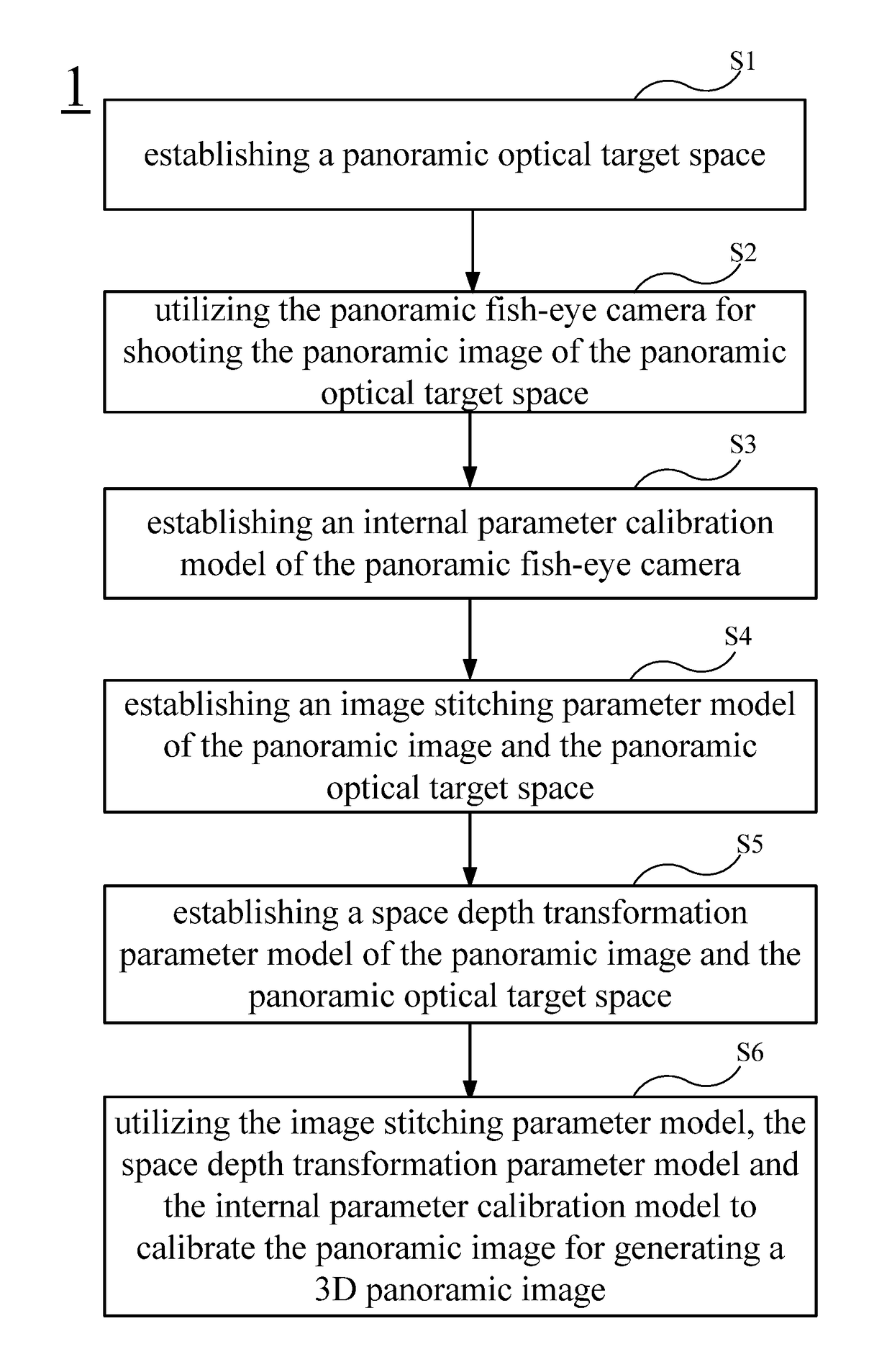

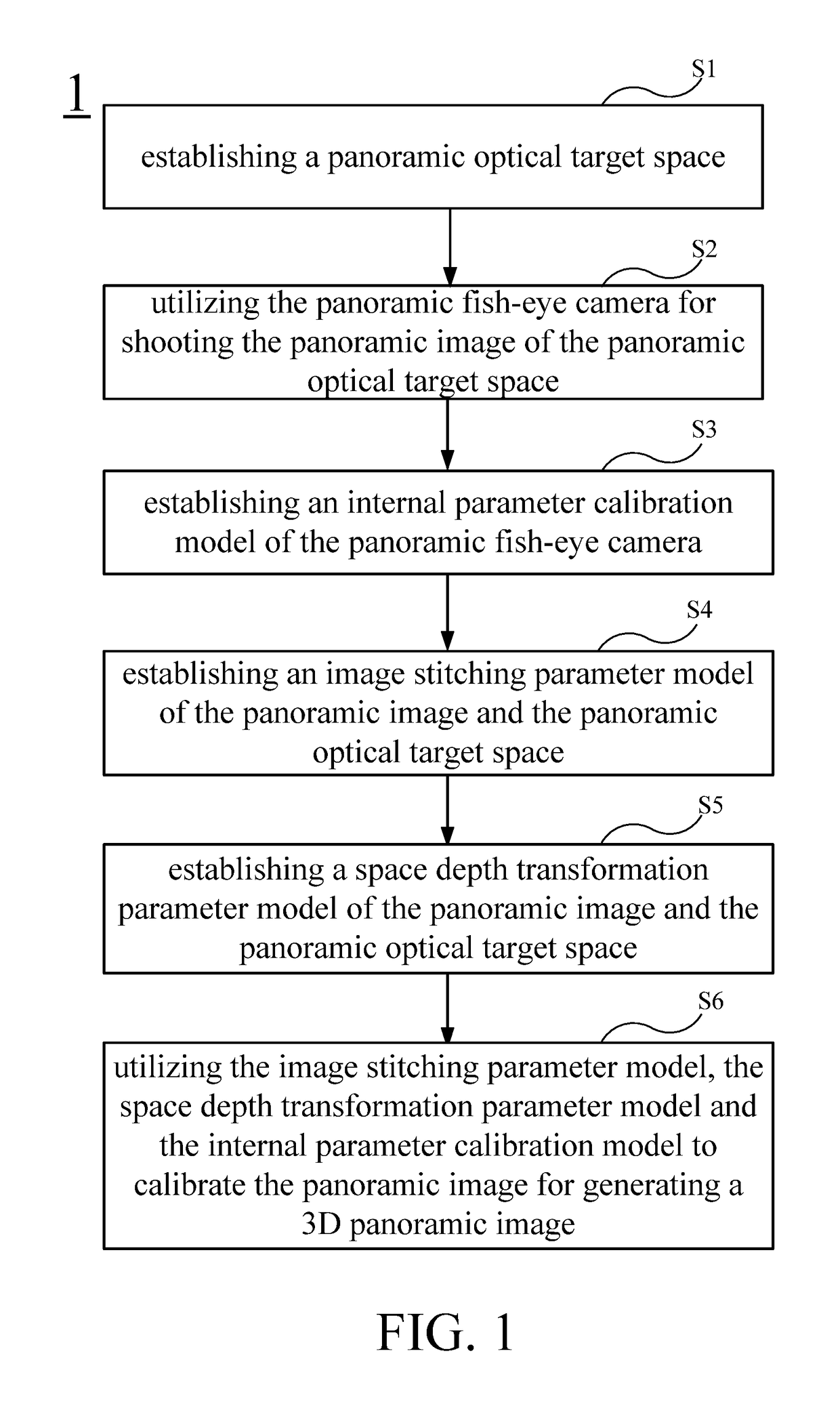

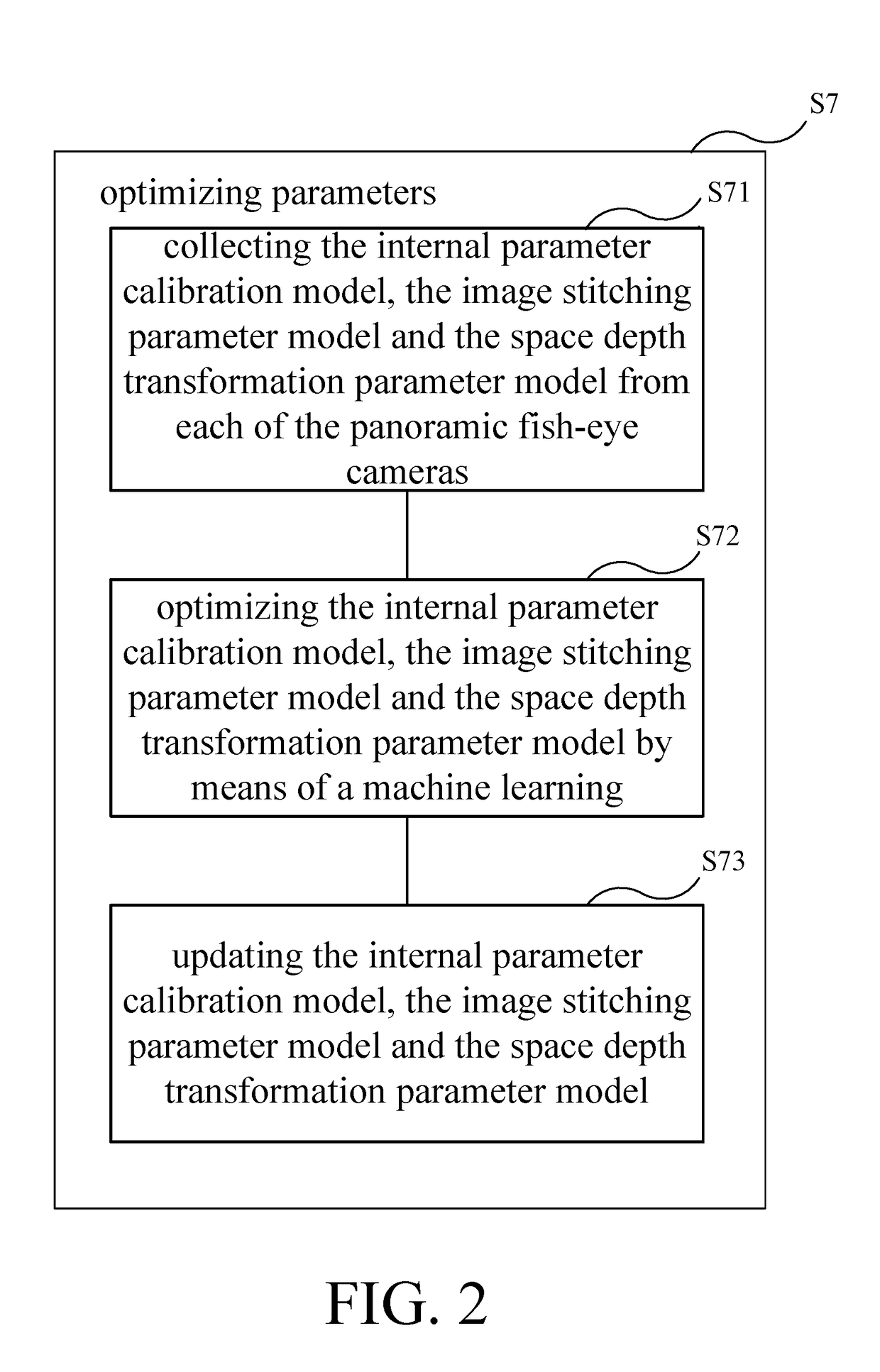

Image calibrating, stitching and depth rebuilding method of a panoramic fish-eye camera and a system thereof

InactiveUS20170127045A1Simple algorithmCalibrated instantly and portable convenientlyImage enhancementTelevision system detailsTransformation parameterComputer science

The present invention provides an image calibrating, stitching and depth rebuilding method of a panoramic fish-eye camera comprising the following steps of: establishing a panoramic optical target space; using the panoramic fish-eye camera for shooting the panoramic optical target space's panoramic image; establishing an internal parameter calibration model for the panoramic fish-eye camera; establishing an image stitching parameter model and a space depth transformation parameter model of the panoramic image and the panoramic optical target space; and using the internal parameter calibration model, the image stitching model and the depth transformation parameter model to calibrate the panoramic image for generating a 3D panoramic image. Compared to the prior art, the present invention can optimize the calibration parameters by accumulating all the camera data and executing a machine learning for increasing the computing efficiency.

Owner:HANGZHOU YUTU TECH CO LTD

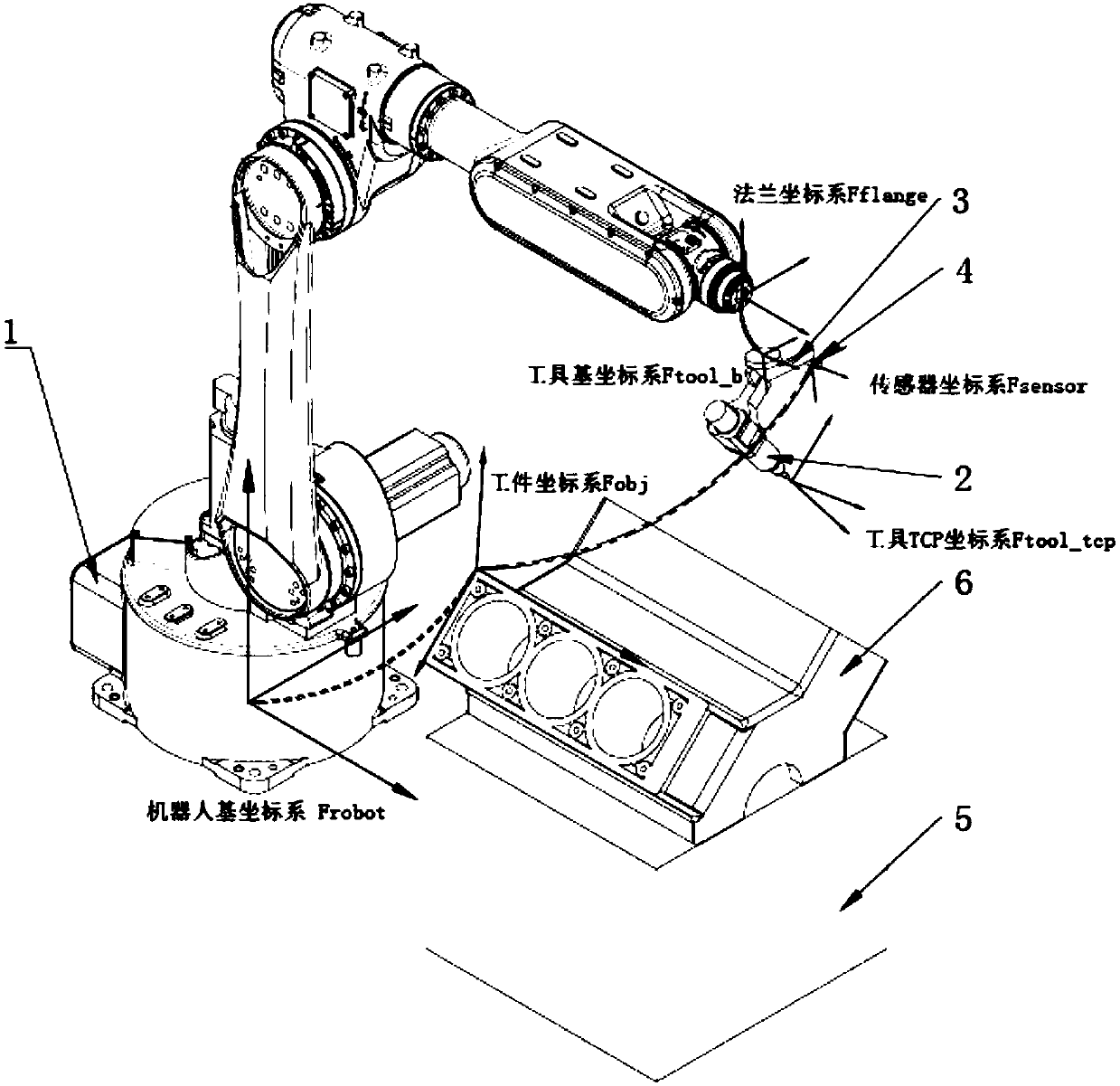

Calibration system and method of industrial robot workpiece coordinate system

InactiveCN107650144ASimplify the calibration processAvoid inaccurate measurementsManipulatorEngineeringRobot controller

The invention relates to a calibration system and method of an industrial robot workpiece coordinate system. The calibration system comprises an industrial robot, a robot controller, a robot ending tool, a sensor installation intermediate structural member, a calibration sensor assembly, a workpiece mounting table and a workpiece arranged on the workpiece mounting table. The calibration sensor assembly measures points on the workpiece, points on the characteristic curved boundary are detected, and a signal is output and then input into the robot controller; a trigger path is interrupted when the robot controller receives the signal, middle position data Fflange and displacement data Msensor in the height direction of a calibration sensor are recorded, and 6D data of the workpiece coordinate system is worked out by combining sensor mounting position data Fsensor. According to the calibration system and method of the industrial robot workpiece coordinate system, the calibration process is simple, the situation that measurement is not accurate due to the fact that a calibration plane is oblique can be avoided, the calibration precision is high, the calibration system can be applied tovarious workpiece occasions, the application cost of the calibration system is low, and achieving of large-range application and promotion is facilitated.

Owner:EFORT INTELLIGENT EQUIP CO LTD

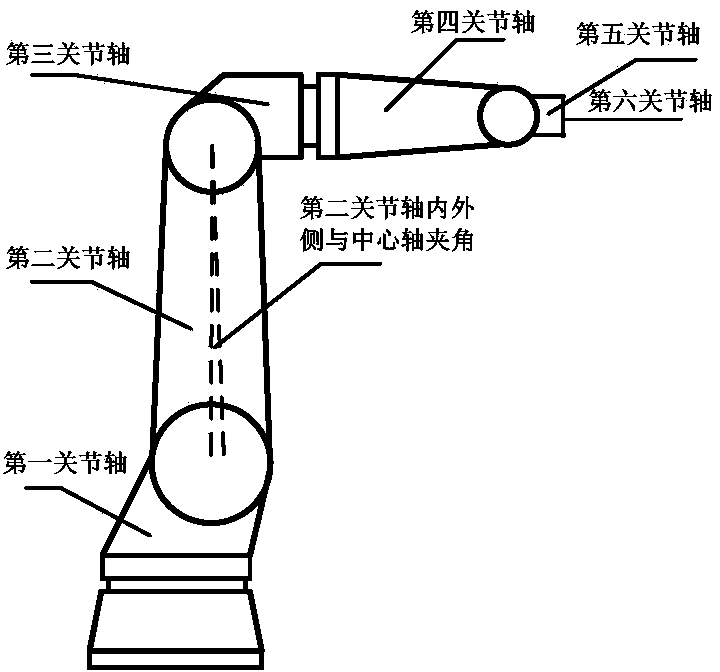

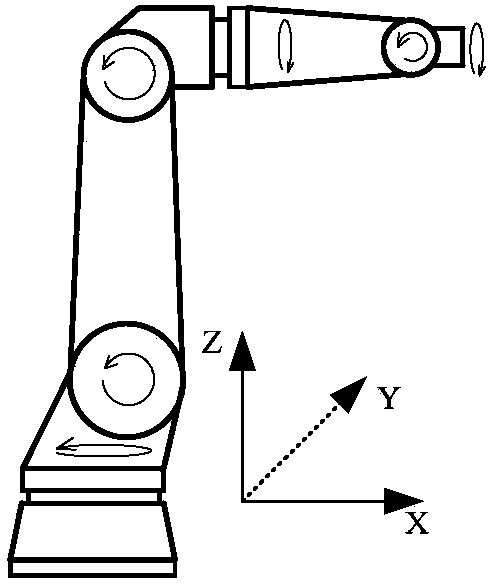

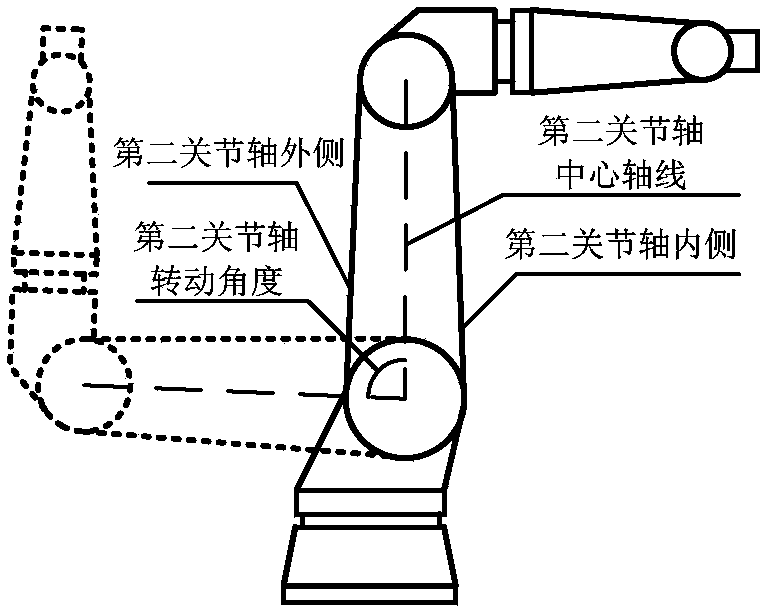

Zero calibration method of six-axis industrial robot

The invention discloses a zero calibration method of a six-axis industrial robot. The zero calibration method comprises the following steps that reference positions are selected and set as initial zeros; a first joint axis is rotated on the basis of the reference positions; a second joint axis is adjusted to allow the inner side of the second joint axis to be kept in a horizontal position; a group of positions, where a difference value of a rotation angle of the second joint axis is maximum, in various groups of positions where a difference value of a rotation angle of the first joint axis is 180 degrees is determined; the first joint axis is rotated to a position perpendicular to the group of positions, which is the zero position of the first joint axis; on this basis, the second joint axis to a sixth joint axis are calibrated horizontally or perpendicularly by a precise level gauge; the rotation angles of the joint axes are written down; and the zero positions of the joint axes, namely the zero positions of the six-axis industrial robot are acquired finally. According to the method, the scale-free six-axis industrial robot can acquire the zero positions easily and quickly under the condition that the zeros are lost, and the motion precision of the industrial robot is improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

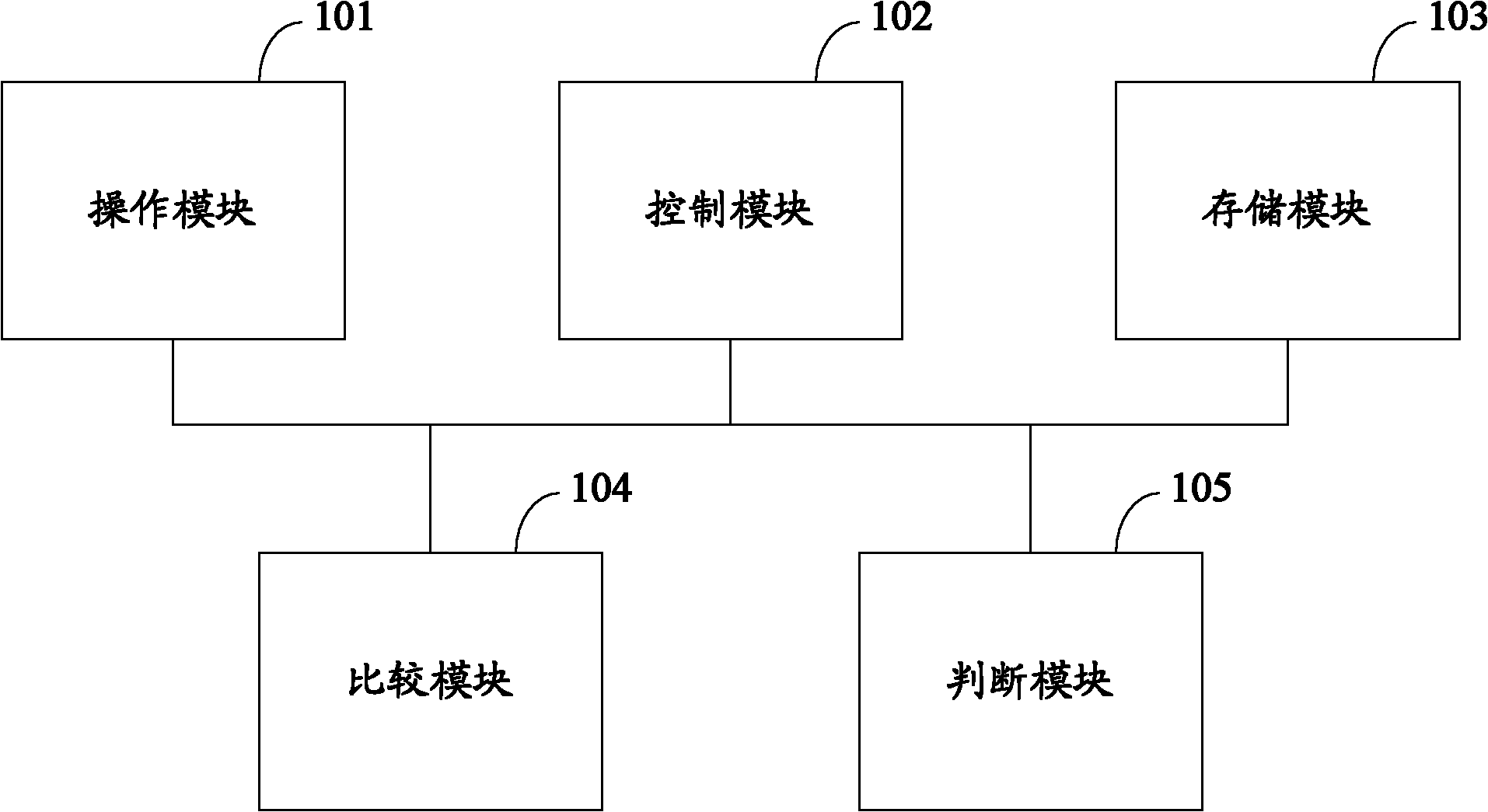

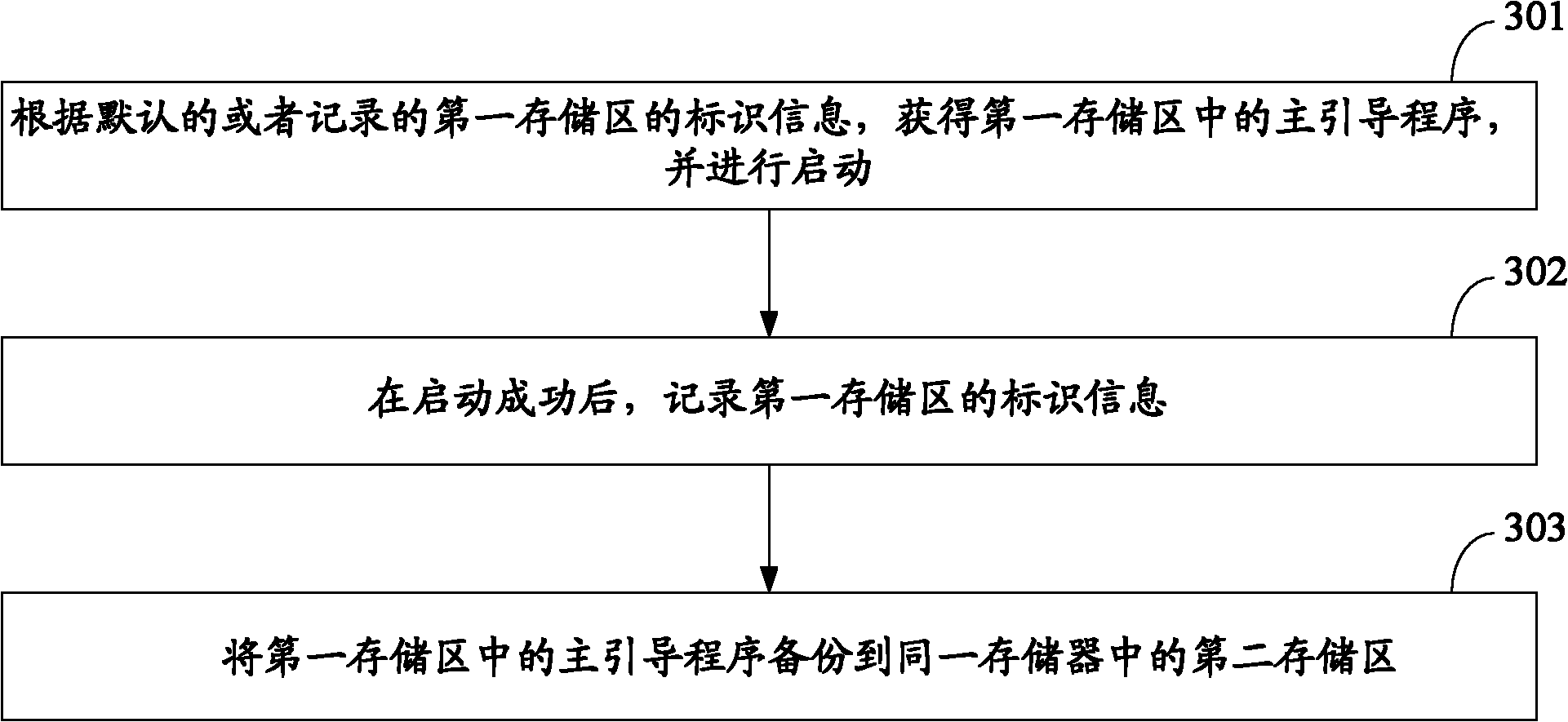

Method and device for backing up boot program

ActiveCN102023908AImplement backupGuaranteed correctnessProgram loading/initiatingRedundant operation error correctionBootingStart up

The invention discloses a method for backing up a boot program, which is used for realizing backup of the boot program and improving the reliability of system startup. The method comprises the following steps: obtaining a main boot program in a first memory area according to the default or recorded identification information in the first memory area, and starting up the main boot program, wherein the first memory area is the current memory area; after the main boot program is successfully started up, recording the identification information in the first memory area; and backing up the main boot program in the first memory area to a second memory area in the same memory. The invention also discloses a method for upgrading a boot program, which is used for realizing upgrading of the boot program. The method comprises the following steps: determining whether the boot program is needed to be upgraded after the main boot program in the first memory area is started up; if so, obtaining upgrading information; and upgrading the boot program backed up to the second memory area according to the obtained upgrading information. The invention also discloses a device for realizing the method.

Owner:ZTE CORP

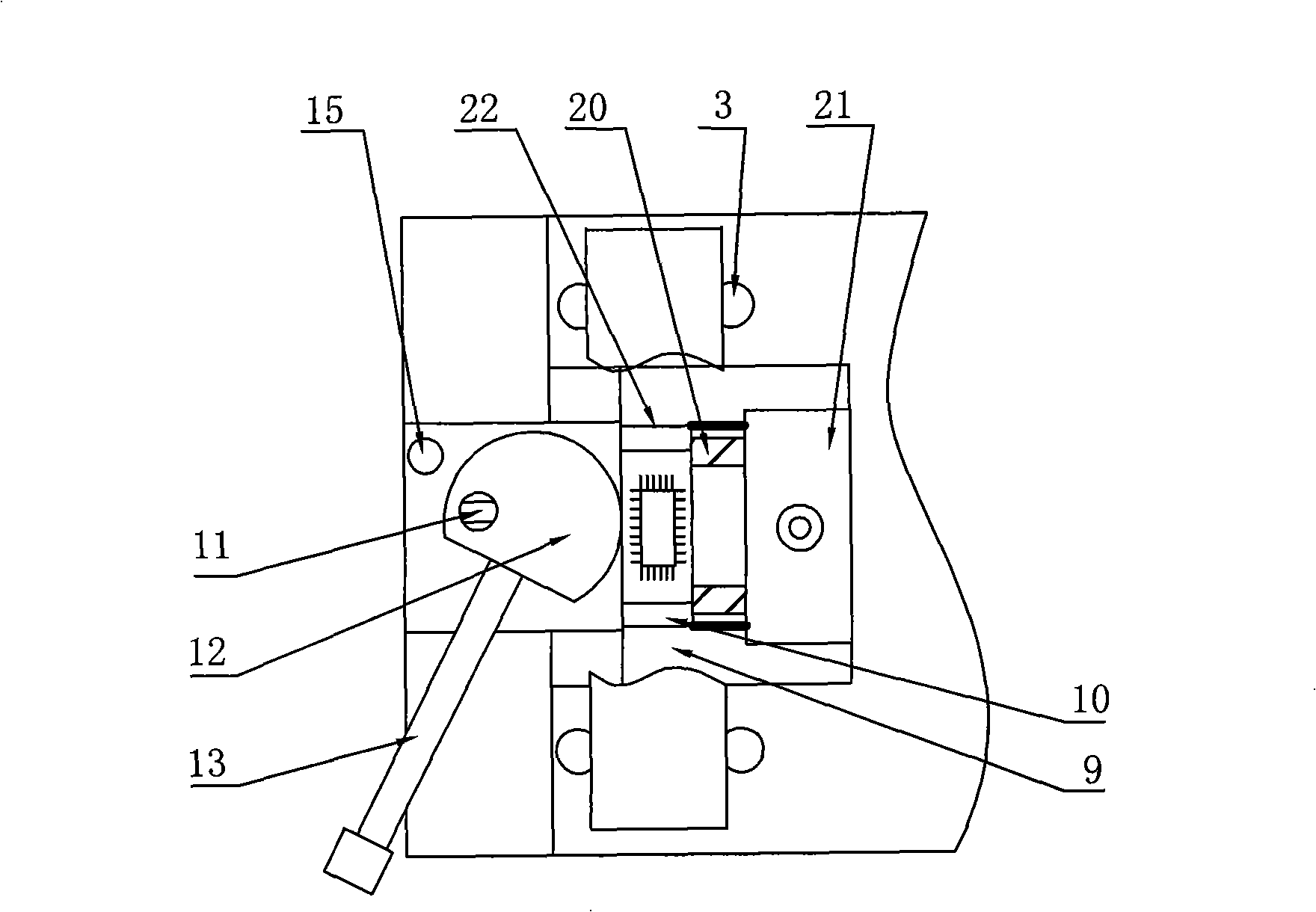

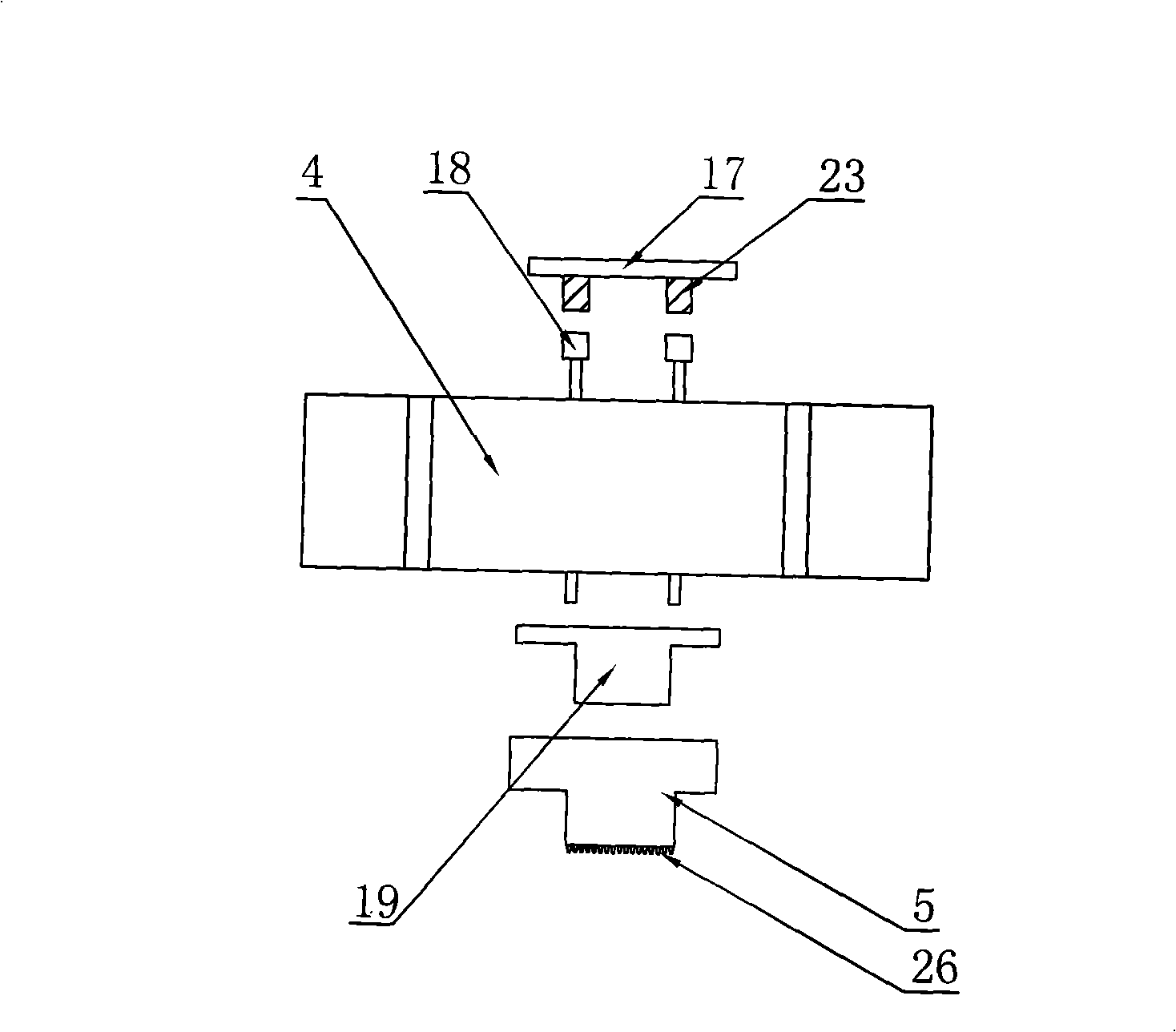

Pin shaping apparatus for integrated circuit and pin shaping method

InactiveCN101312641ASimplify the calibration processAccurate correctionPrinted circuit manufactureElectrical componentsPre treatmentMechanical engineering

An integrated circuit pin shaping device and a pin shaping method belong to the semi conductor device processing technical field, wherein the device comprises a base provided with a door type frame, the base under the door type frame is provided with a guide pillar and an upper module block capable of longitudinally moving along the guide pillar, the door type frame is provided with a first eccentric wheel unit capable of longitudinally moving the upper module block, the base under the door type frame is provided with a slide way, a lower module block capable of transversely moving along the slide way and a second eccentric wheel unit capable of transversely moving the lower module block, one end of the slide way is provided with a stop block. The upper and lower module blocks are detachably provided to make the correction of the pins simple and accurate, thereby satisfying the user demands and reducing price, production / maintenance cost. The corrected integrated circuit can pass the check of automatic checking devices and is applicable in patch production. The invention has wide application in the pin shaping of various integrated circuits and the preprocessing technical field of patch production.

Owner:上海允科自动化有限公司

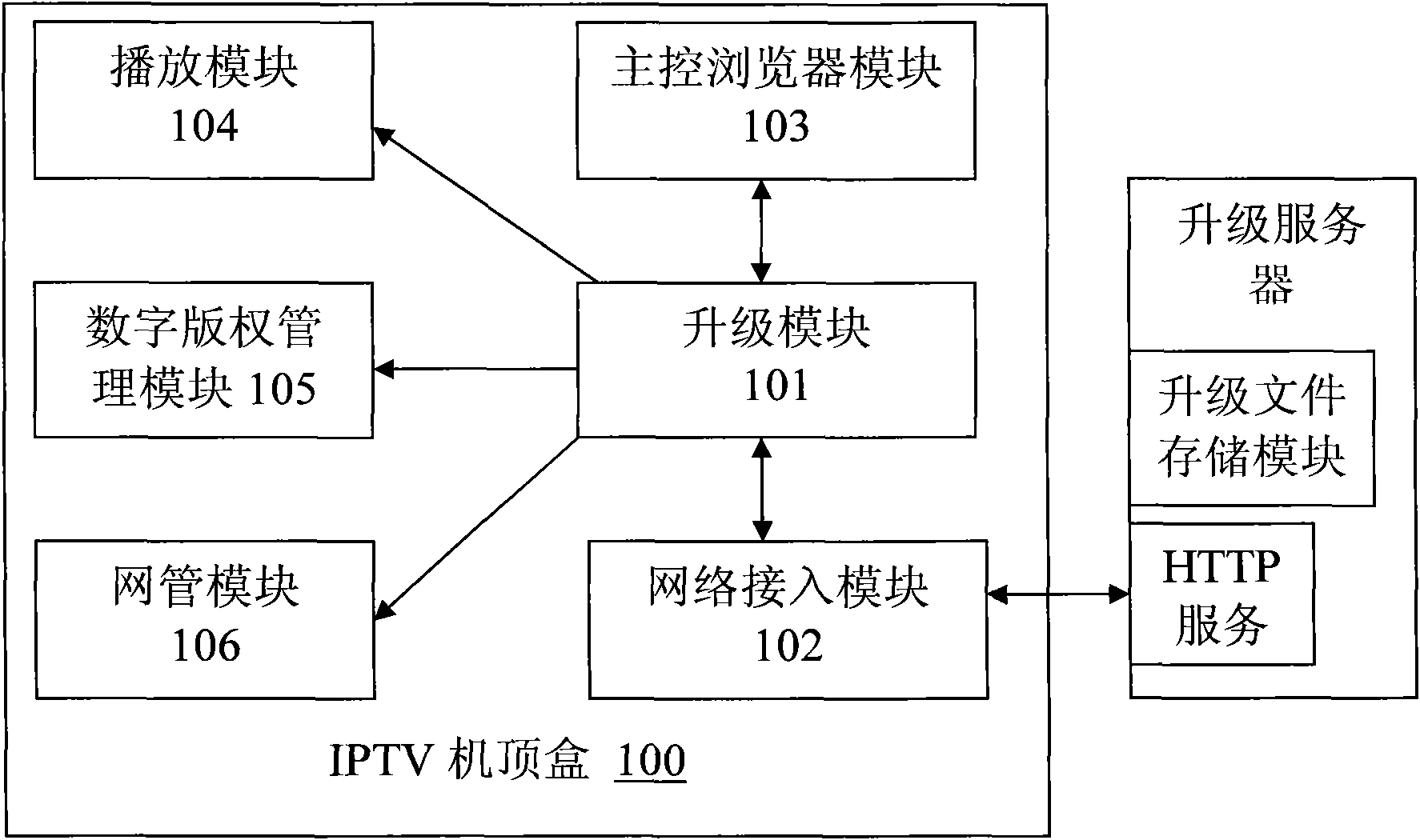

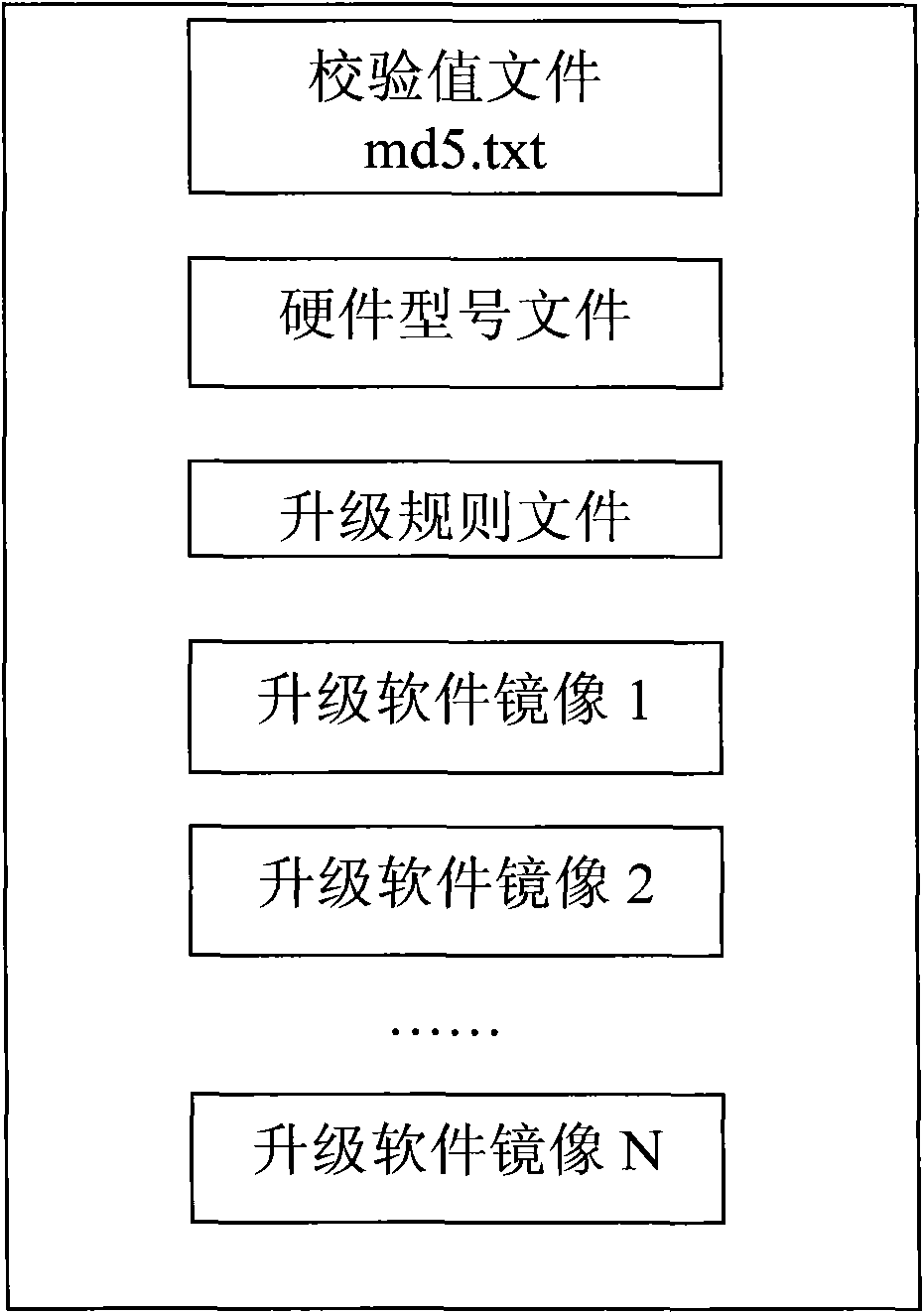

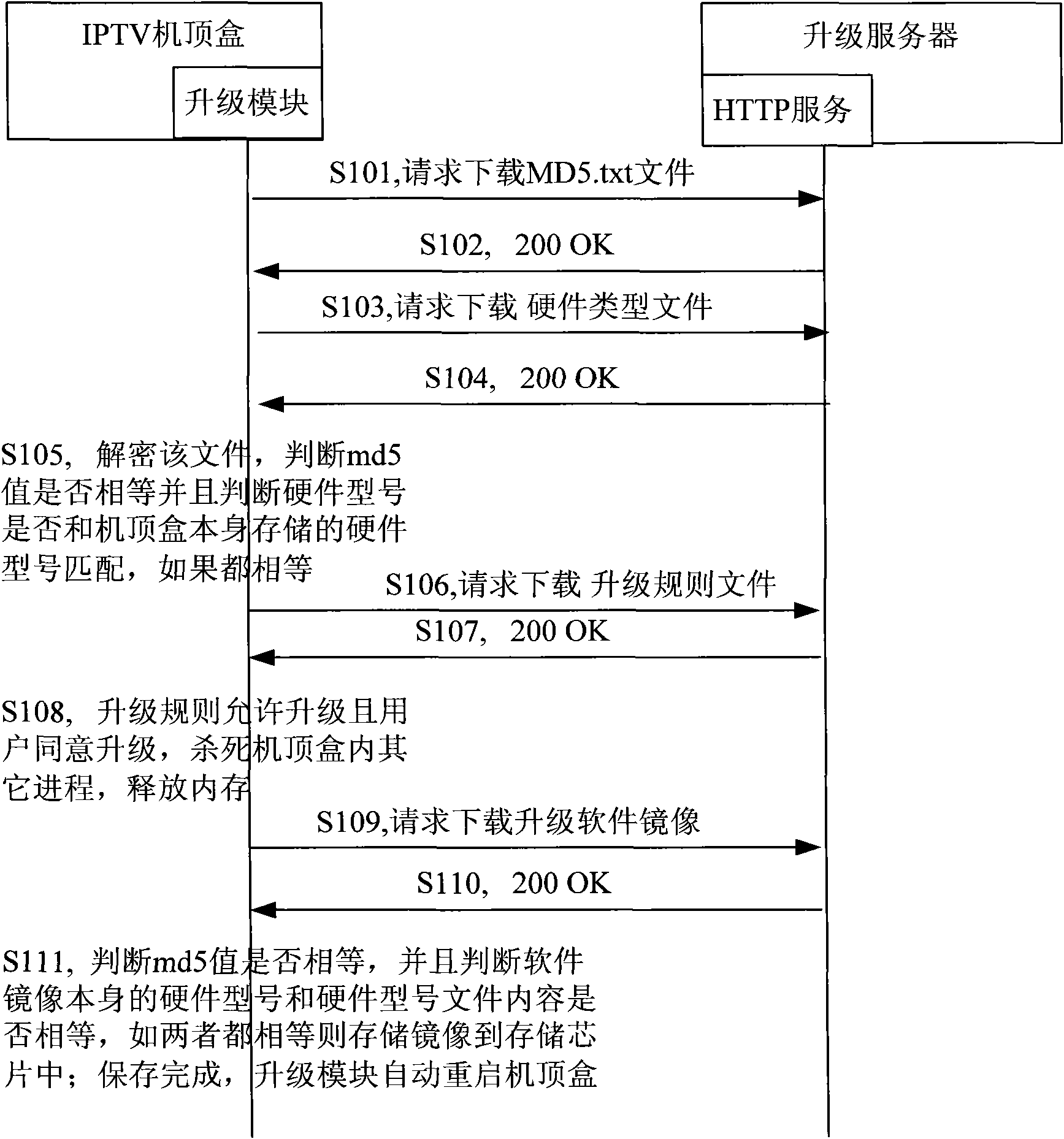

Method and system for upgrading interactive internet protocol television (IPTV) set top box (STB)

InactiveCN101867694ASimple planEasy to implementTelevision system detailsPulse modulation television signal transmissionUpgradeSoftware

The invention discloses a method and a system for upgrading an interactive internet protocol television (IPTV) set top box (STB). The upgrading method has the steps as follows: appointing a hardware model file and the hardware model of an upgrade software mirroring file by an upgrade server, and establishing an independent check value file; and downloading the proof test valve file by the IPTV STB, checking the downloaded hardware model file and the upgrade software mirroring file by using the check value, judging whether the hardware models of the STB, the hardware model file and the upgrade software mirroring file are consistent or not, and completing the upgrading process by the IPTV STB through the upgrade software mirroring file when the check is successful and the models thereof are consistent. The invention appoints the definitions of the hardware model file and the hardware model of the upgrade software mirroring, has simple checks on the hardware model and the upgrade software mirroring, can be compatible with upgrade of various hardware platforms, ensures upgrading safety, and has the characteristics of simple scheme, easy realization and good compatibility.

Owner:ZTE CORP

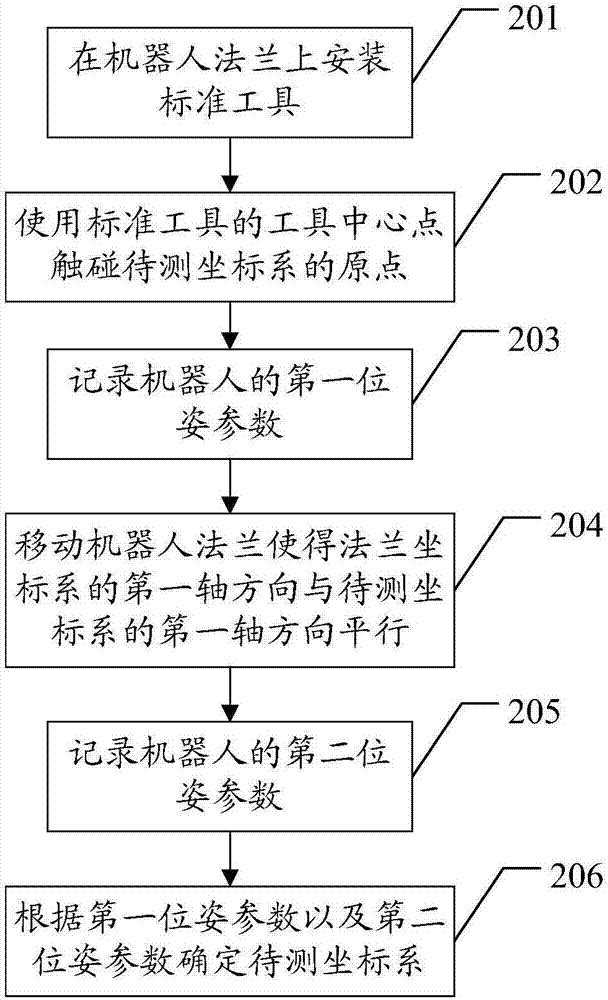

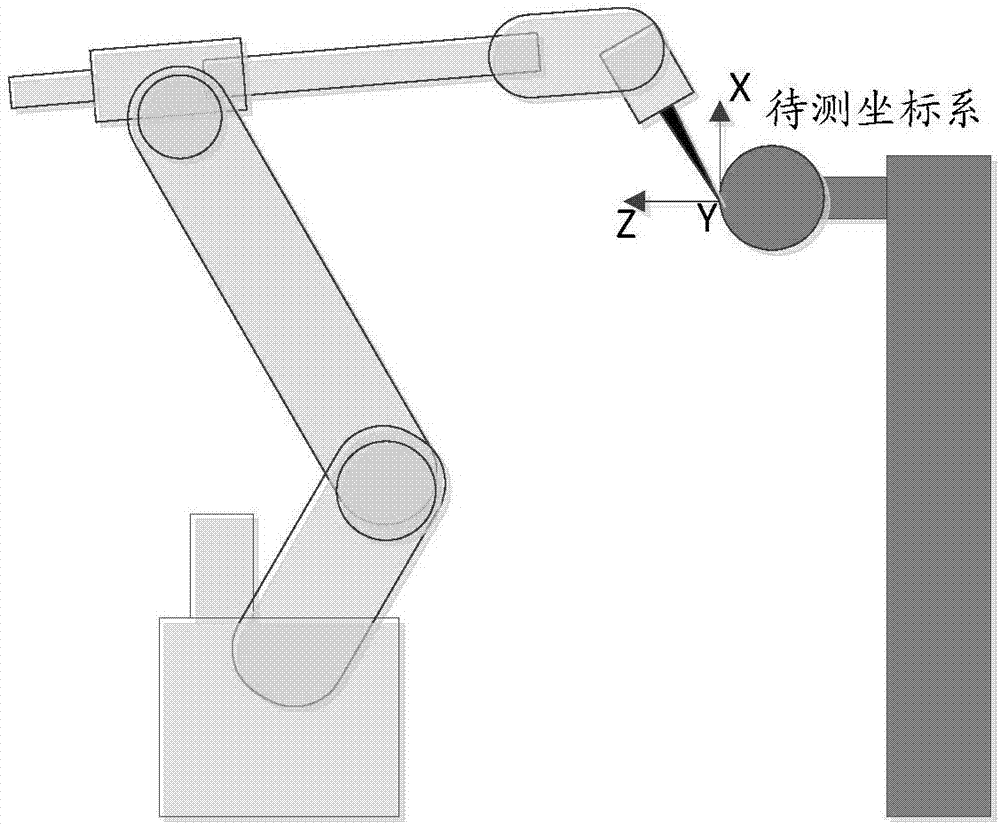

Method, system, and device for calibrating coordinate system

ActiveCN107995885ASimplify the calibration processProgramme-controlled manipulatorMeasurement devicesSystem under testComputer science

A method for calibrating a coordinate system is used to simplify a calibration process of a coordinate system under test. The method comprises: enabling a contact of a tool center point of a standardtool with an origin of a coordinate system under test (202); recording a first pose parameter of a robot when the tool center point contacts the origin (203); moving a robot flange, such that a firstaxis direction of a flange coordinate system of the robot flange is parallel to a first axis direction of the coordinate system under test (204); and recording a second pose parameter of the robot when the first axis direction of the flange coordinate system is parallel to the first axis direction of the coordinate system under test (205); and calculating, according to the first pose parameter andsecond pose parameter, a target calibration parameter of the coordinate system under test in a target coordinate system (206).

Owner:SHENZHEN A&E INTELLIGENT TECH INST CO LTD

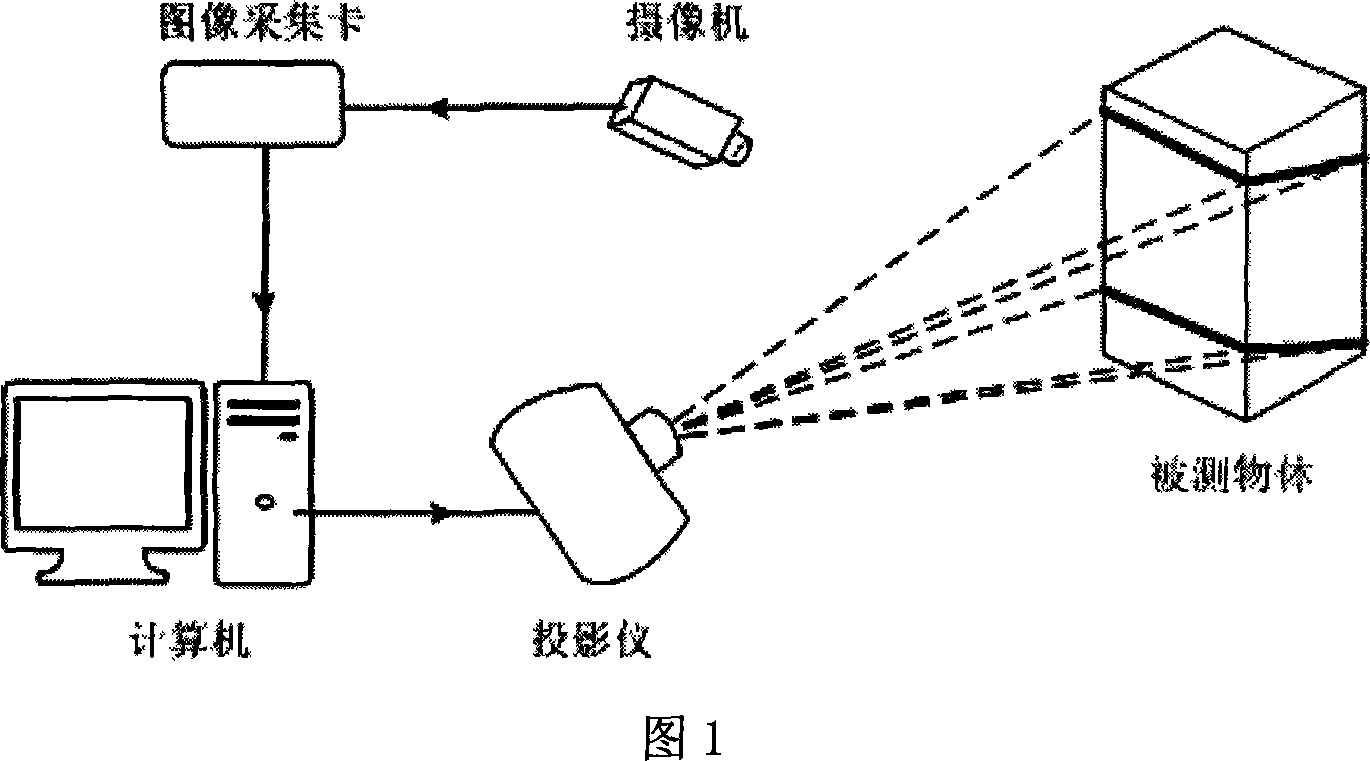

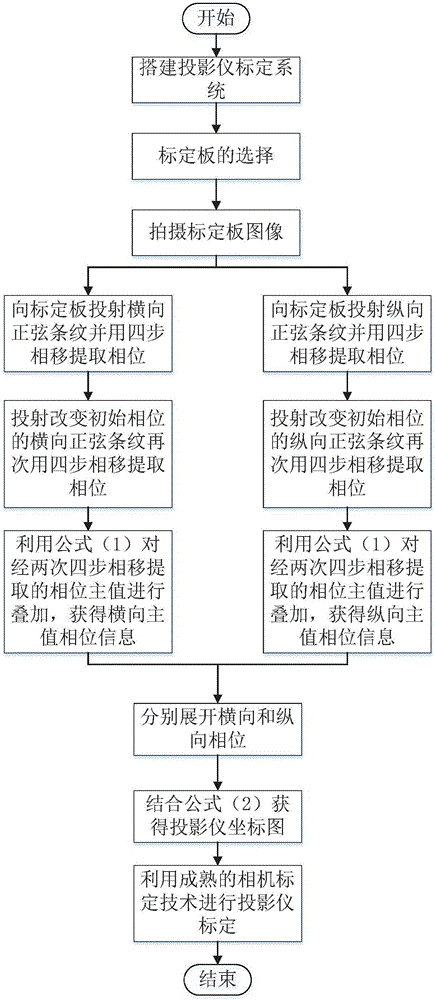

Projector calibration method based on double four-step phase shift

InactiveCN105091750AThe calibration process is simple and easy to operateImprove calibration accuracyUsing optical meansComputer visionPhase shifted

The invention relate to a projector calibration method based on double four-step phase shift. The method comprises the following steps that 1) a calibration board is selected; 2) a projector calibration system is established; 3) an image of the calibration board is shot by a camera; 4) a DLP projector projects horizontal and vertical sine stripes onto the calibration board, and images formed on the calibration board are shot; 5) the step 4) is repeated to obtain a group of 4 horizontal images and a group of 4 vertical images; 6) phase extraction is carried on the two groups of horizontal images and two groups of vertical images, obtained in the steps 4) and 5) respectively, in the four-step phase shift method to obtain two horizontal phase principal-value images and two vertical phase principal-value images, and every two principal-value images in the same direction are overlapped to obtain an overlapped phase principal-value image; 7) phase expansion is carried out on each overlapped phase principal-value image obtained in the same direction to obtain a phase expansion image; and 8) absolute horizontal and vertical phases are obtained via the phase expansion images, and a pixel coordinate (mu, theta) of a corresponding point in a projector pixel coordinate is obtained, and the projector is calibrated.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com