Power matching method applicable to electric vehicle

A power matching, pure electric vehicle technology, applied in electric vehicles, control drive, power management and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

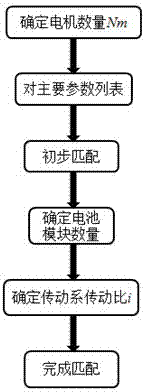

[0112] 1) Determine the number of motors N m : This embodiment selects the layout scheme of the power system independently driven by the rear two wheel hub motors, therefore, determine the number of motors N m for 2.

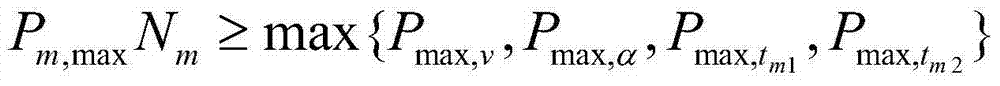

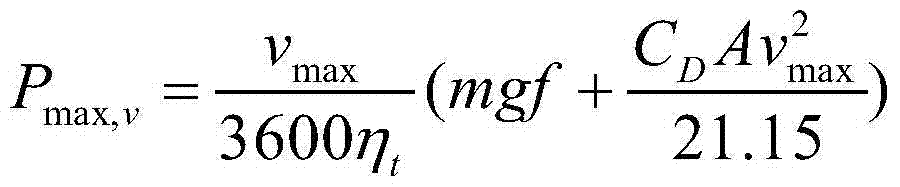

[0113] 2) List of main parameters: The list of main parameters is shown in Table 2, including vehicle parameters, motor parameters and battery parameters, among which vehicle parameters include vehicle full load weight, vehicle length, width and height, tire specifications, air resistance coefficient, transmission system Total efficiency, maximum vehicle speed, economical vehicle speed, maximum gradeability, maximum gradeability speed, acceleration time from 0-50km / h, acceleration time from 50-80km / h, driving range, conversion factor of rotating mass and acceleration of gravity; motor parameters include motor Type, motor efficiency, motor controller efficiency, rated operating voltage, minimum operating voltage and overload coefficient; battery parameters inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com